Patents

Literature

309results about How to "Increase the level of mechanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

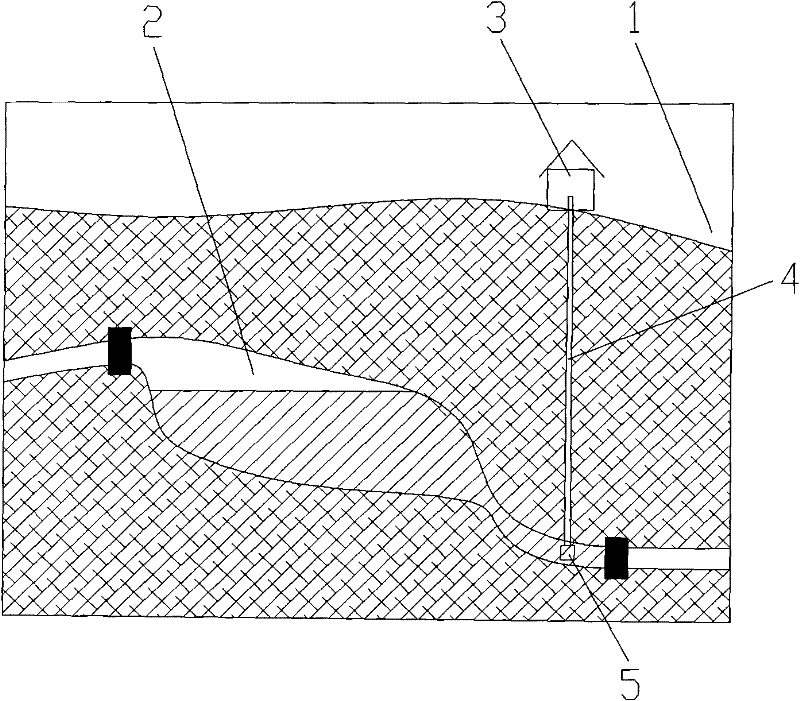

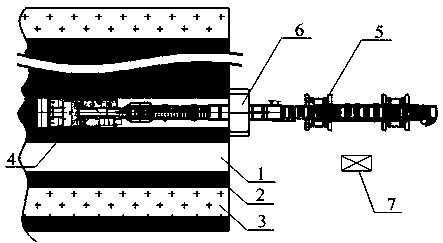

Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

InactiveCN102493838AIncrease the level of mechanizationReduce labor intensityUnderground miningSurface miningStopped workEngineering

The invention provides a method for fully mechanized continuously-filling coal mining of steeply pitching coal seams, which comprises the following steps: a stoping face is arranged as per the method of long-wall mining along the strike, and fully mechanized mining equipment for the steeply pitching coal seam is adopted; an air cushion and a working face filling pipeline are arranged on a base on the side of a mined out space of rear pillars of a fully mechanized mining support; whenever the working face advances for every 1.4 to 1.8 meters and after the support is moved, the working face filling pipeline is connected with an upper gateway filling main pipeline; the air cushion is filled with air, and auxiliary separation is arranged; paste is conveyed to a filling pipe branch sequentially from low to high so as to ensure filling and compacting, and finally the paste is conveyed to a supplementary filling pipe of the upper gateway; after the paste is coagulated, a portion of air in the air cushion is released, and the working face advances forward continuously; the steps are repeated until the stopping work for the whole working face and the filling work for the mined out space are finished. The method provided by the invention is convenient to operate and simple to carry out, can improve the mechanization level for mining the steeply pitching coal seams under buildings, railways and water bodies, improves the output of the working face, efficiently reduces the roof subsidence and the ground deformation, and realizes coal mining without the pillars and achieves Y type ventilation.

Owner:HUNAN UNIV OF SCI & TECH

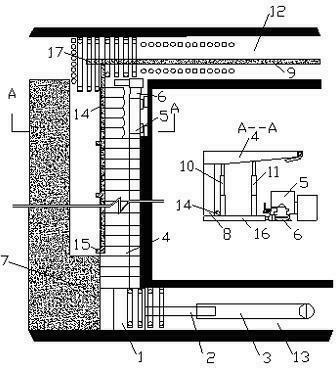

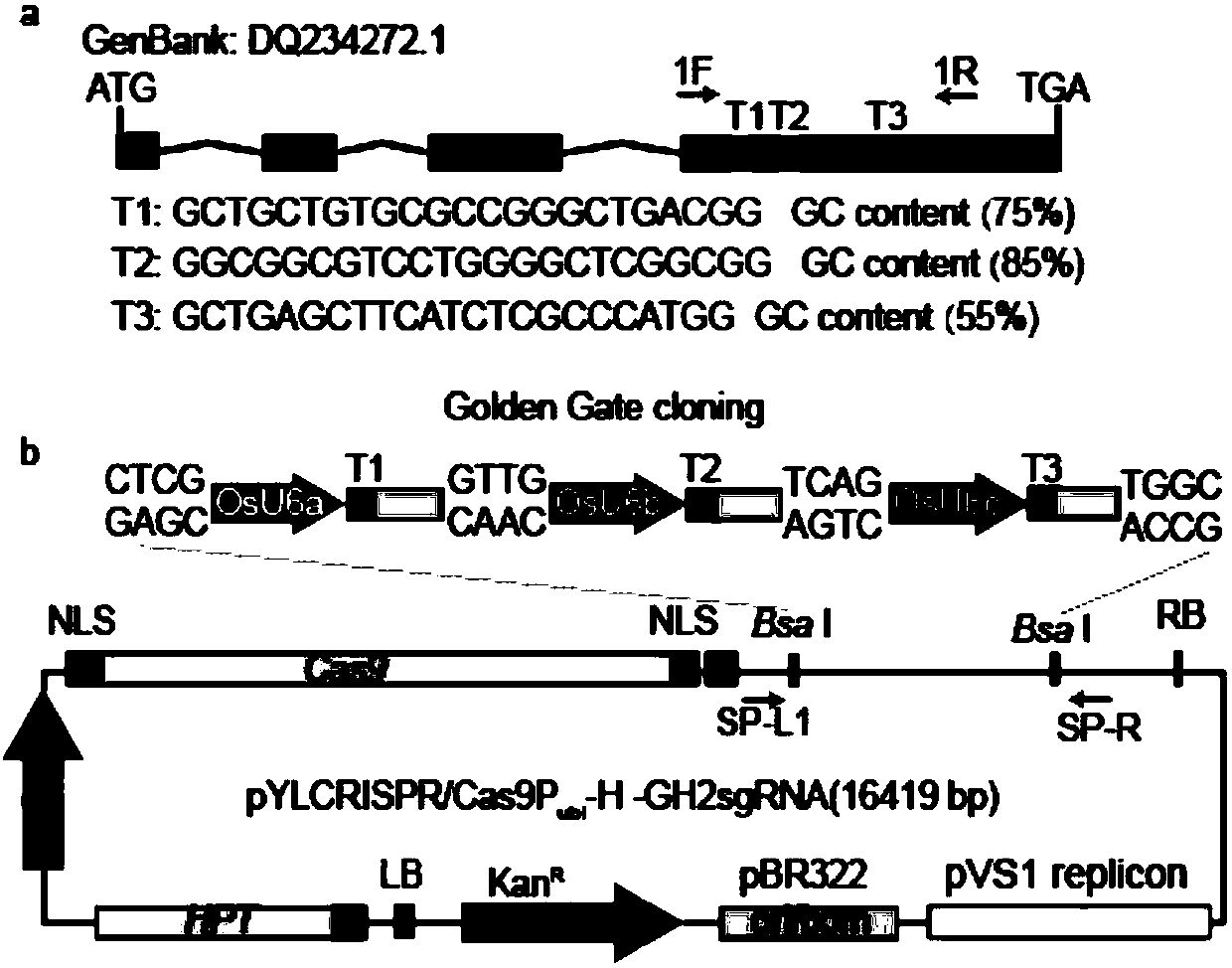

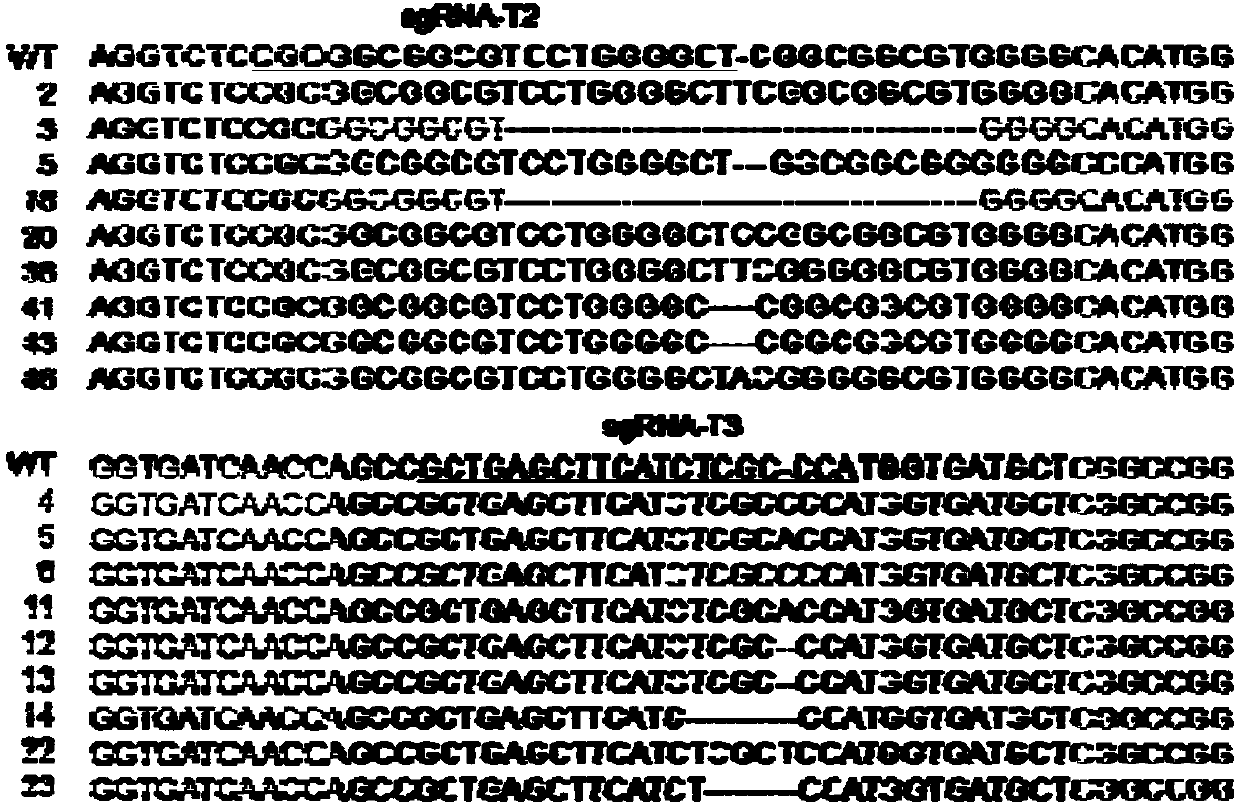

Vector sgRNA CRISPR/Cas9 relevant with character of rice reddish brown glume, vector construction and application

InactiveCN108034656AThe method is efficientSave time and costMicrobiological testing/measurementHorticulture methodsAlleleExon

The invention discloses a vector sgRNA CRISPR / Cas9 relevant with character of rice reddish brown glume, vector construction and application, for overcoming the defect that rice with reddish brown glume can be acquired only on the condition of mutation of two alleles OsCHi. The invention provides an sgRNA segment which comprises a gRNA of which specificity is targeted to the fifth exon of cinnamylalcohol dehydrogenase(CAD) gene of rice; the sgRNA refers to T1, T2 and T3 specifically. The invention further provides a CRISPR / Cas9 gene editing vector comprising the sgRNA and a construction methodof the vector. The vector can edit cinnamyl alcohol dehydrogenase(CAD) gene of rice. Besides, application of the segments and the vector in acquiring rice having characters of reddish brown glume andstem earing, and primer sequence for detecting CRISPR / Cas9-CAD gene reconstruction are also provided. According to the invention, conventional breeding cost can be reduced, mechanization level of hybrid rice seed production can be improved, and seeding cycle can be shortened.

Owner:SAAS BIOTECH & NUCLEAR TECH RES INST

Method for producing crimpy type high-grade green tea

InactiveCN102246866AResolution timeSolve quality problemsPre-extraction tea treatmentProduction rateGreen tea

The invention discloses a method for producing crimpy type high-grade green tea, which comprises the following sequence of operations: tedding fresh leaves, removing water in rollers, rolling to deblock, performing secondary water-removing, performing third water-removing, tedding to cool, shaping and rubbing, performing secondary tedding to cool and fragrance-extracting, wherein the secondary water-removing means that deblocked tea leaves are put in a 40 type well-known tea water remover for 20-25 seconds at the temperature of 130-140 DEG C; and the third water-removing means that the tea leaves after the secondary water-removing are returned back to a roller and are subjected to another time of water-removing for 15-22 seconds. The method for producing the crimpy type high-grade green tea has the advantages that the problem of long-time baking in a baking machine and many factors causing quality change can be completely solved, the occurrence of damage to tea leaves during warming up or stewing caused by slow manual stir-frying, and uneven stir-frying or not-required temperature at some time is prevented, so that the quality of the tea leaves is unified and is obviously improved; the labor force is reduced, and the yield is enhanced; the production rate is effectively increased, the tea leave dust is reduced, and the color and the luster are stable; and the method is convenient to operate and has little cost for machinery.

Owner:句容市春城馨香园茶场

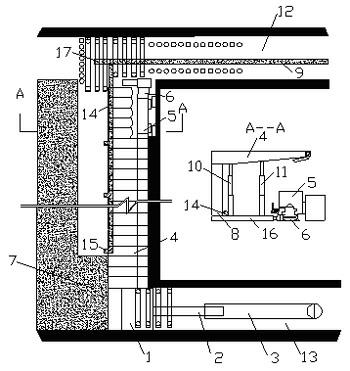

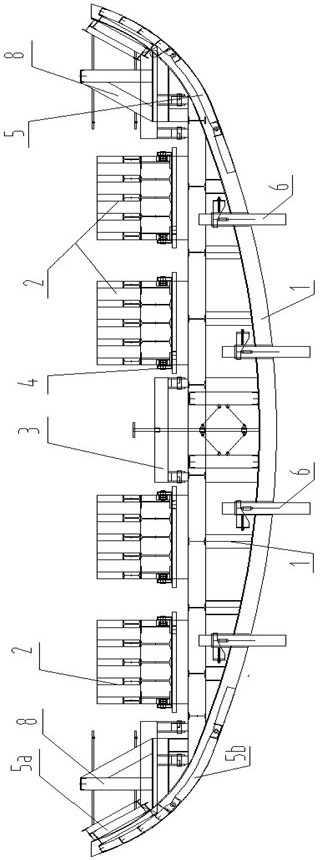

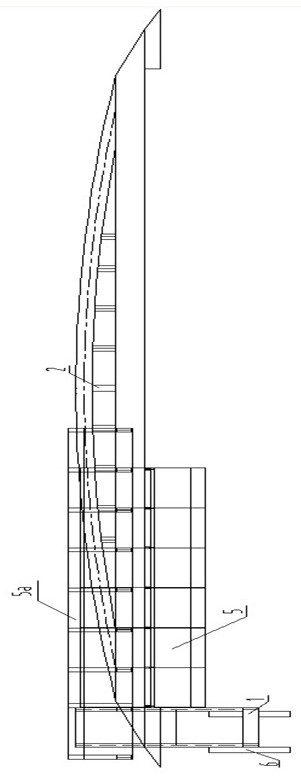

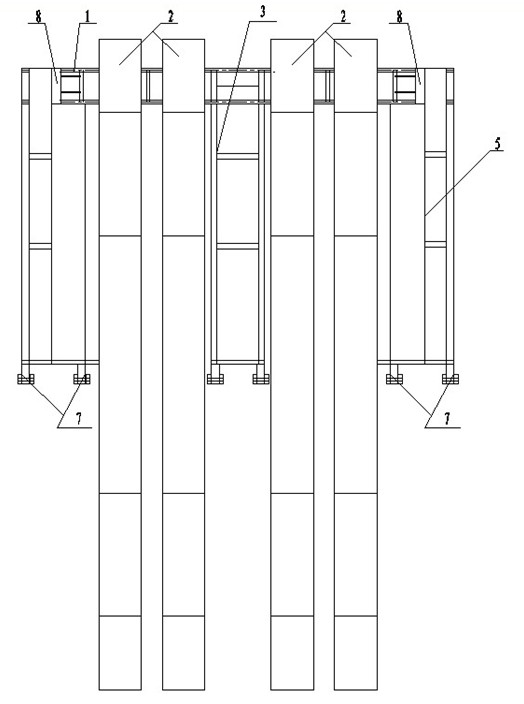

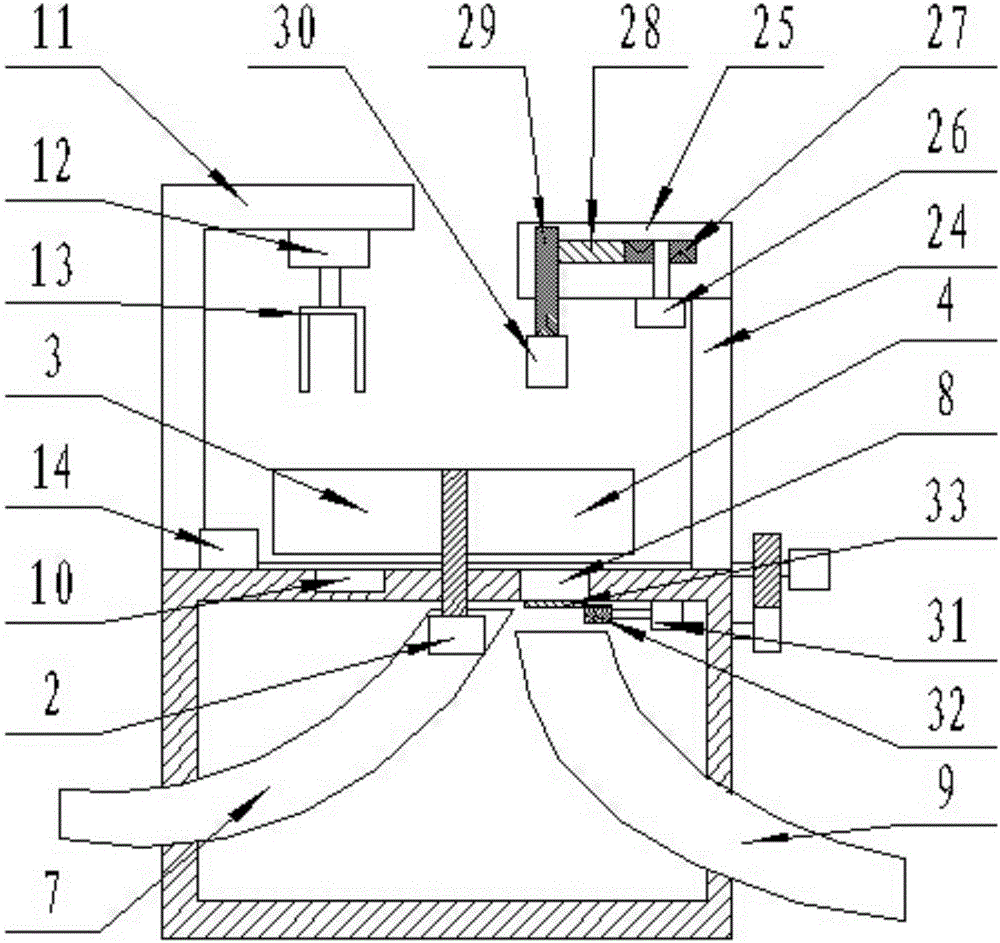

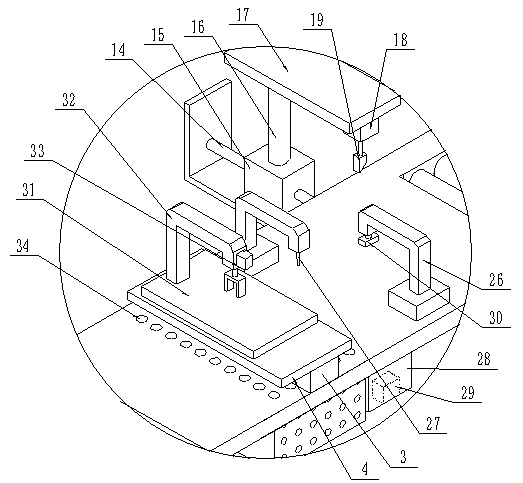

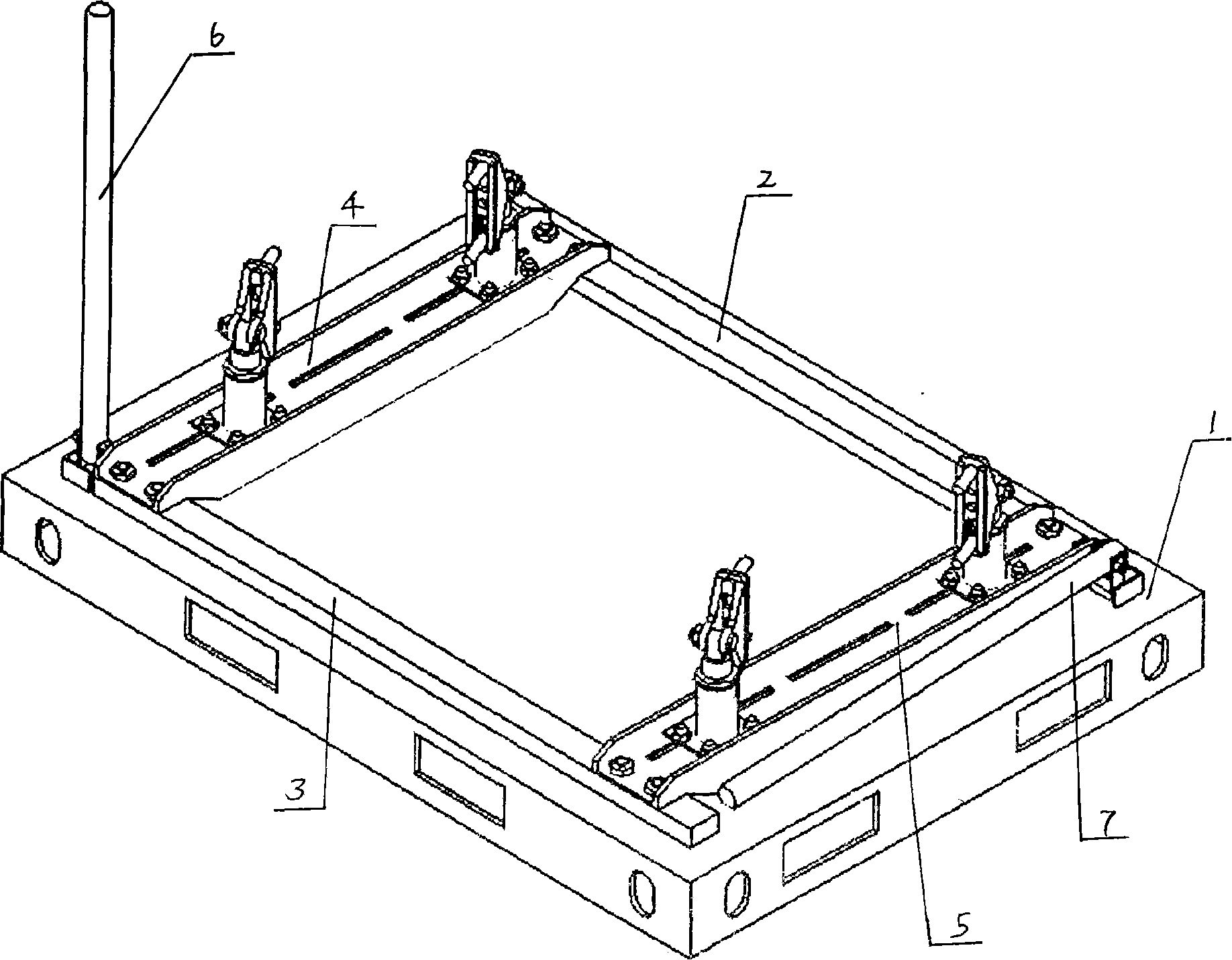

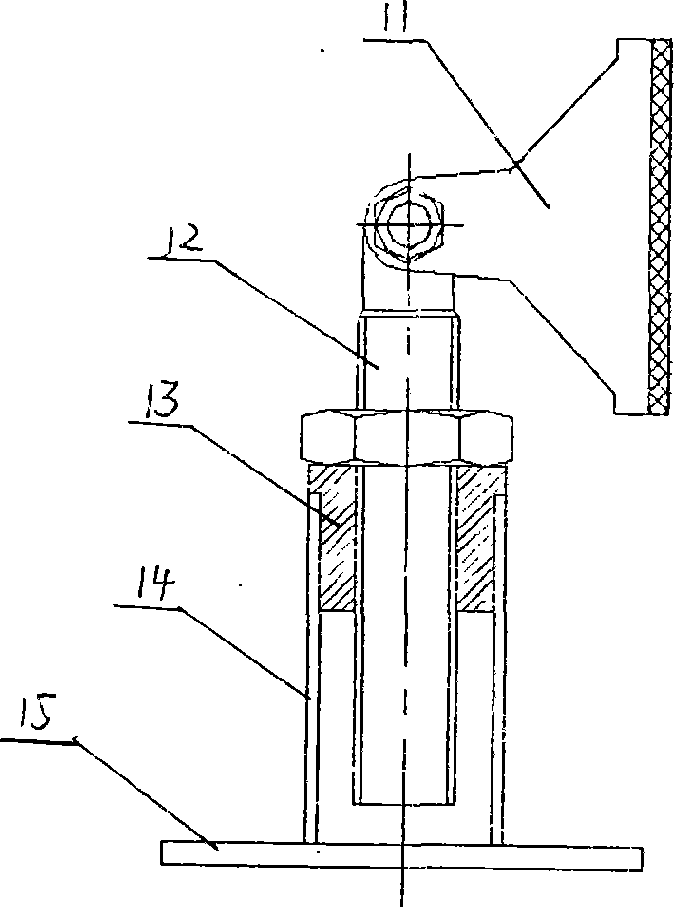

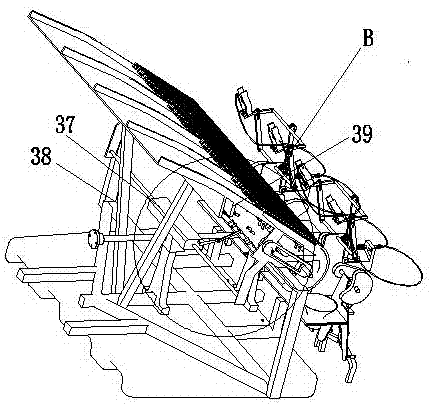

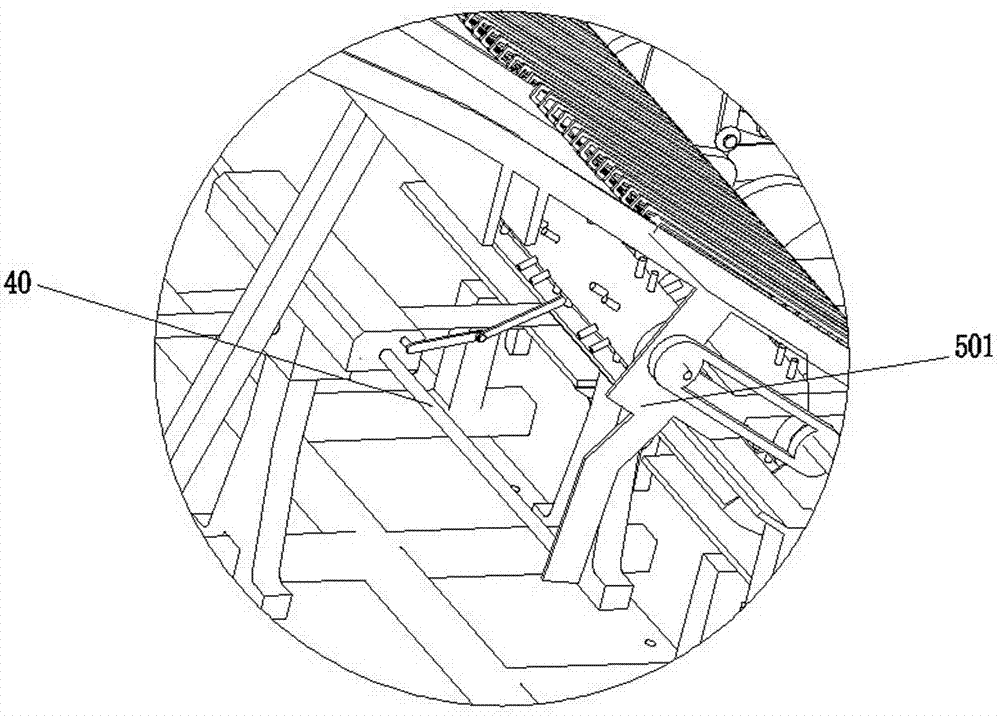

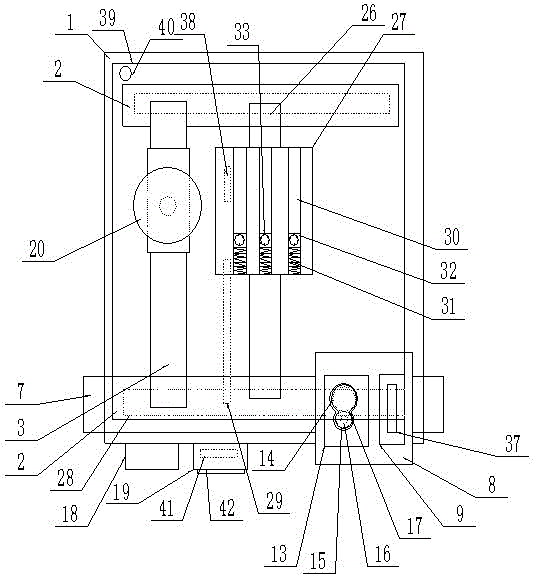

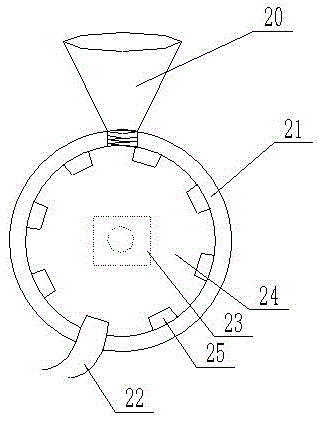

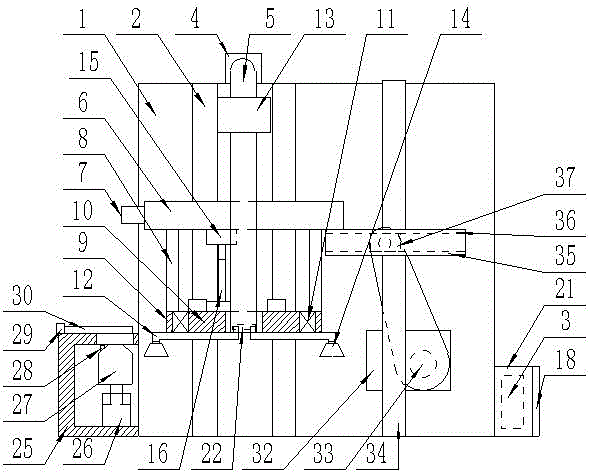

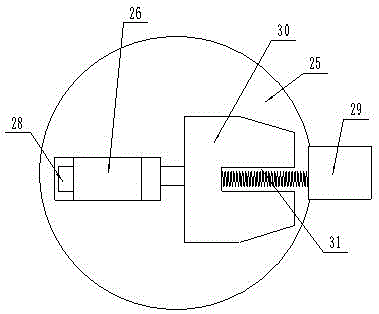

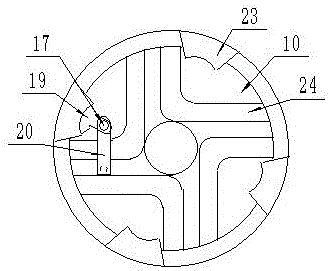

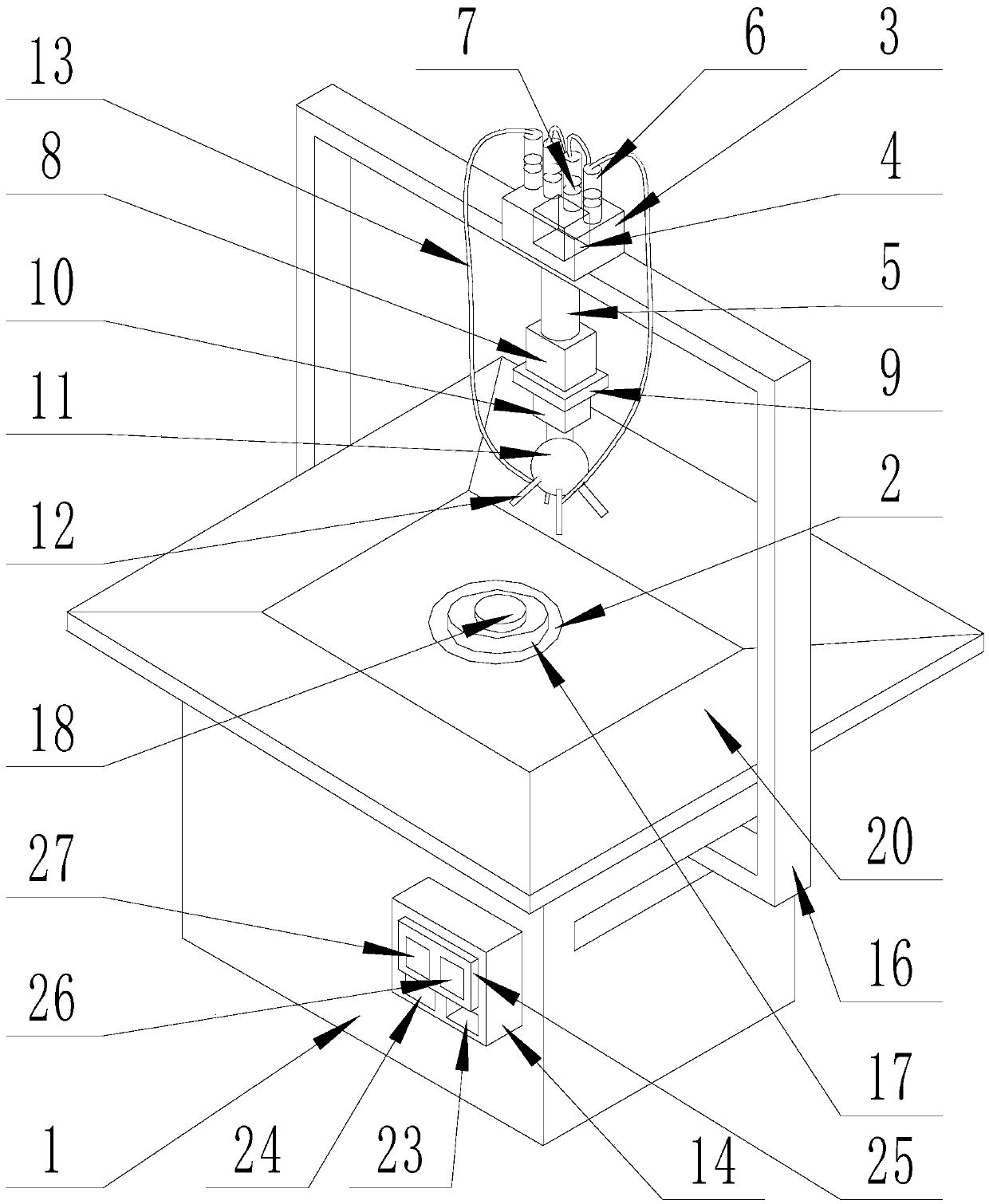

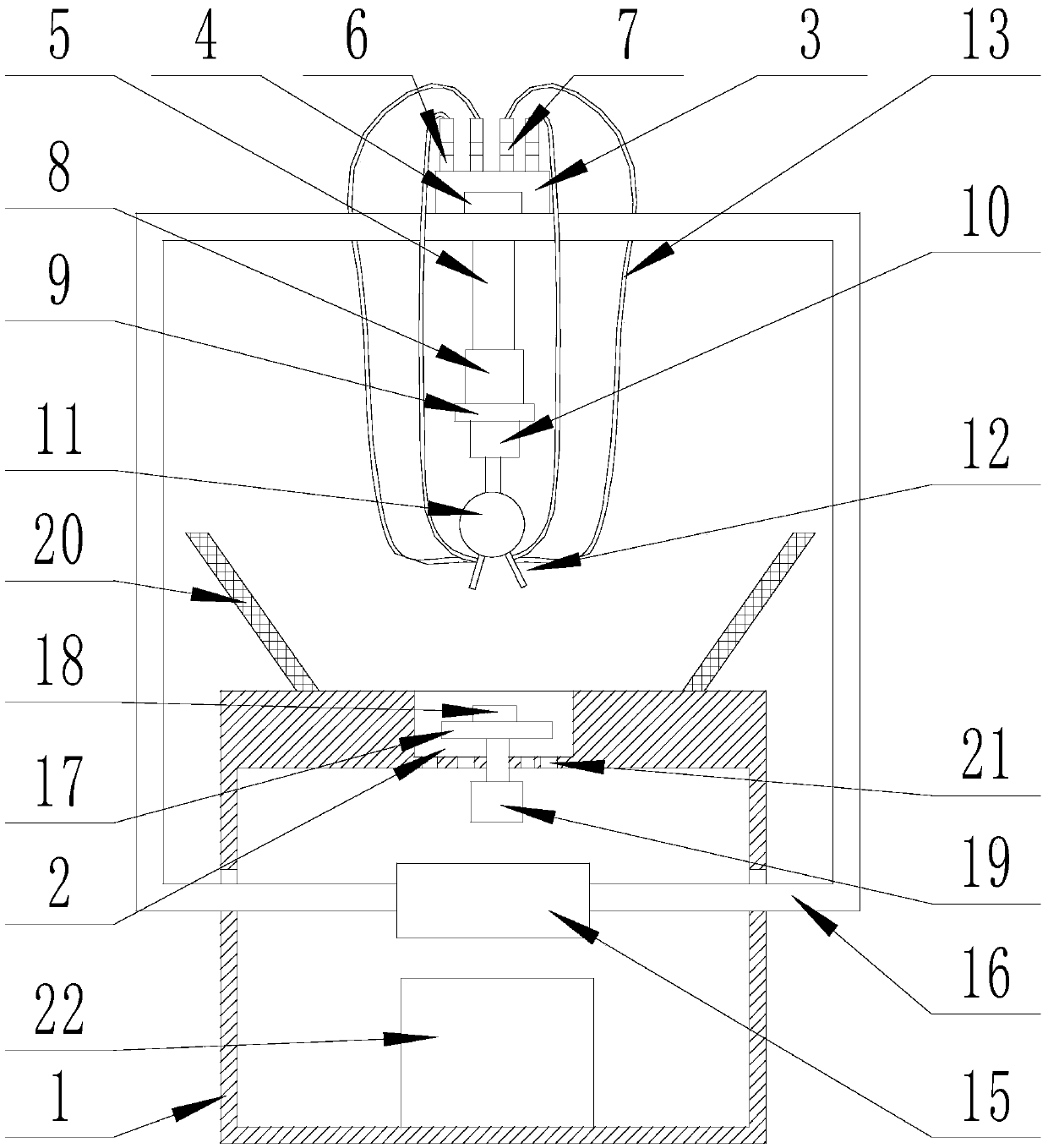

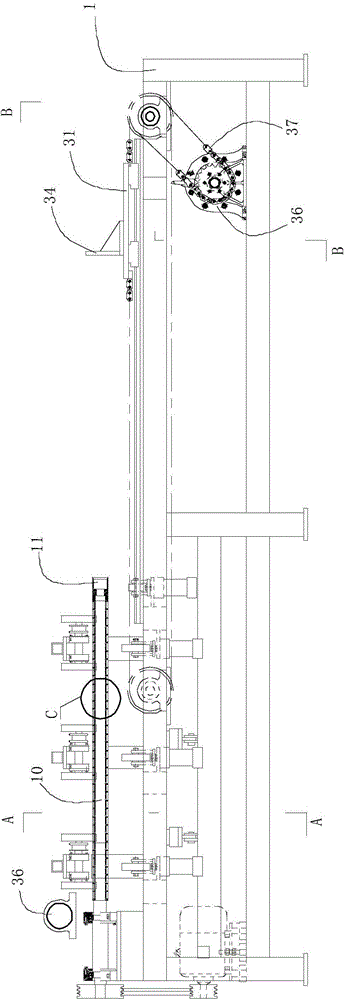

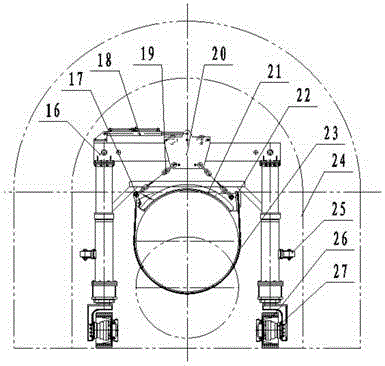

Construction equipment for inverted arch of two-track tunnel of high-speed railway

ActiveCN102146799AIncrease the level of mechanizationPrecise positioningUnderground chambersTunnel liningUltimate tensile strengthMechanization

The invention relates to construction equipment for the inverted arch of a two-track tunnel of a high-speed railway, belonging to the technical field of tunnel construction equipment. In the invention, the construction equipment for the inverted arch of the two-track tunnel of the high-speed railway comprises a trestle, an inverted arch mould frame and a terminal beam, wherein the terminal beam is connected with the inverted arch mould frame to form into a whole; the terminal beam and / or the inverted arch mould frame are / is connected to the trestle; and the terminal beam and the inverted archmould frame autonomously move on the trestle. In the invention, the construction equipment for the inverted arch of the two-track tunnel of the high-speed railway can position accurately, move in place fast and convenient, and has the advantages of high mechanization level, low article labor intensity and low construction cost; the construction equipment can complete the inverted arch through one-time monolithic casting with high construction efficiency and high construction quality, and can provide guarantee for quick tunneling; construction organization and work procedure partition in the tunnel are optimized, thereby being beneficial to standardized operation and safe and civil construction; and the construction operation is convenient and fast, breaks through the traditional inverted arch construction technology and ensures the continuous construction quality of the inverted arch, thus being in favor of popularization and application.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

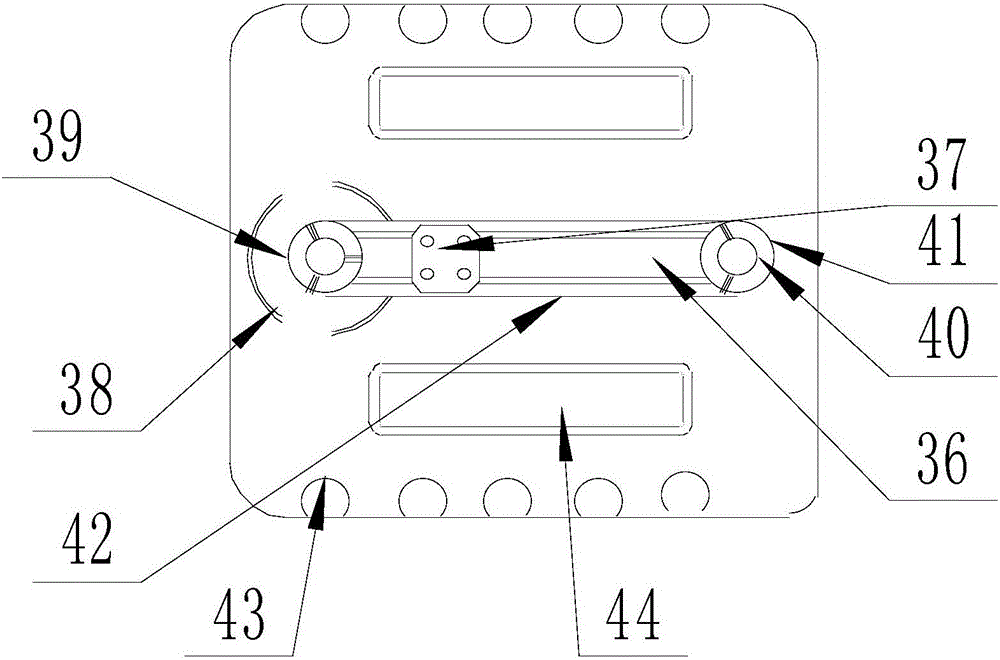

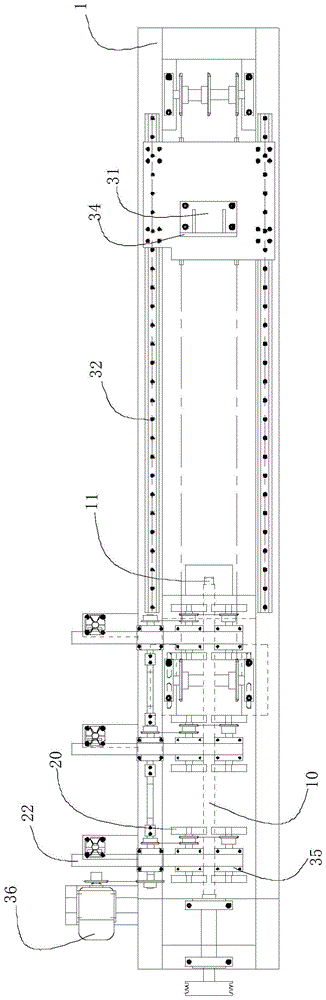

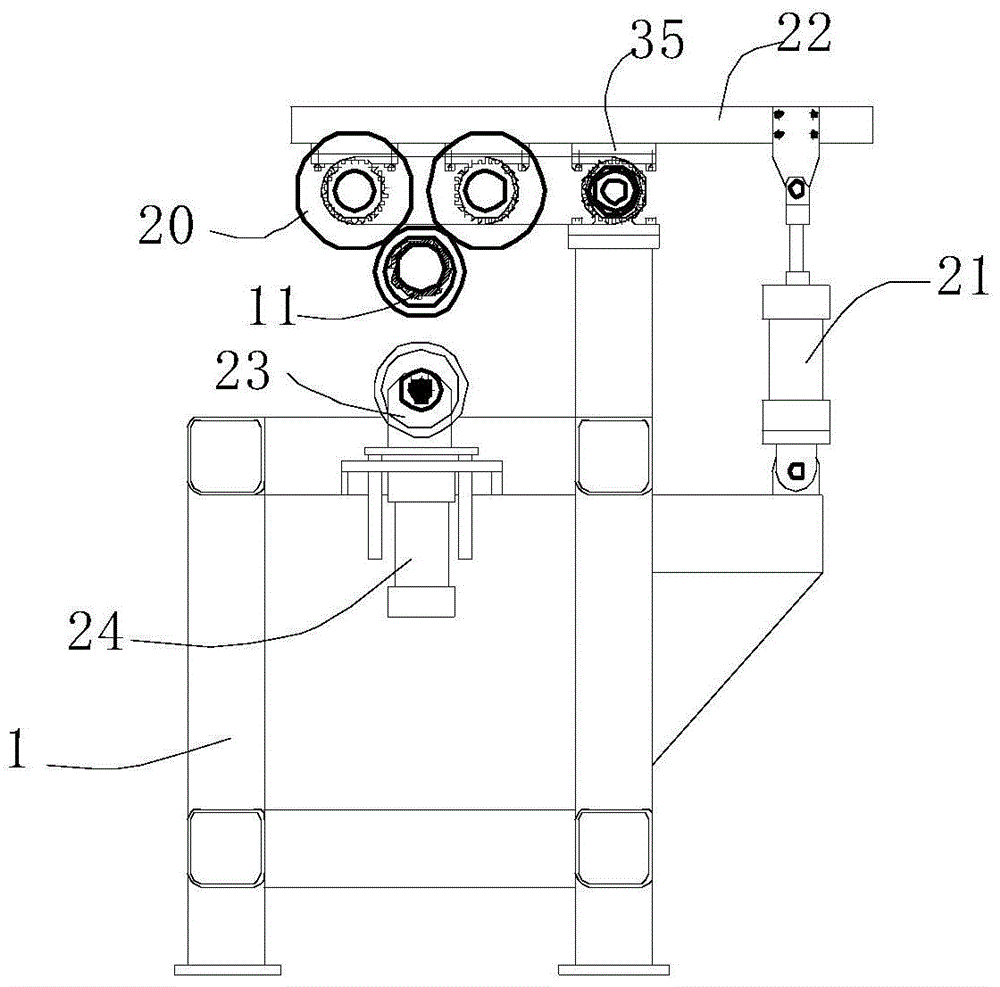

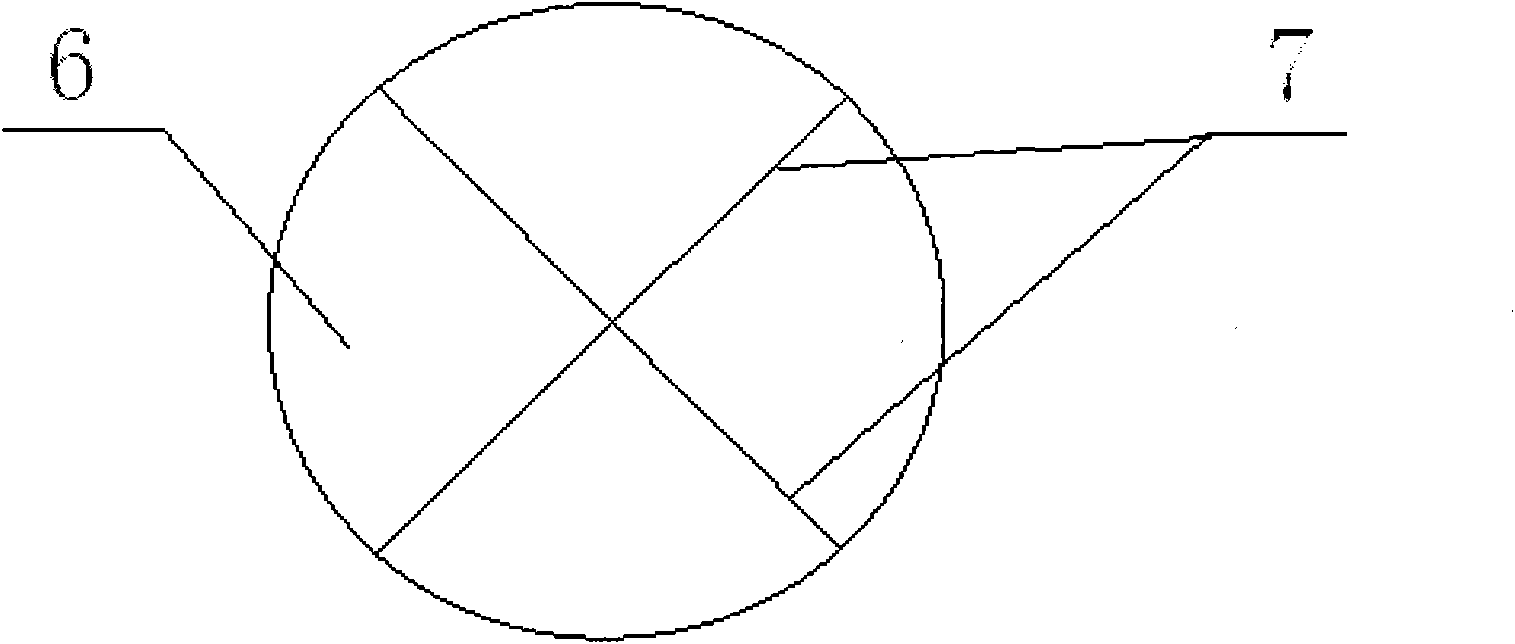

Apple grading and sorting device

InactiveCN106179968AIncrease the level of mechanizationImprove detection efficiencySortingGradingButt jointEngineering

The invention discloses an apple grading and sorting device. The apple grading and sorting device comprises a worktable which is of a cavity structure. The worktable is provided with a rectangular opening communicating with the inside of the cavity structure. A feeding unit is arranged at the upper end of the rectangular opening. A conveying unit is arranged on the worktable. The worktable is provided with a sorting unit in butt joint with the conveying unit. The worktable is provided with a labeling unit. An opening-closing door is arranged at a superior product inlet. The worktable is provided with a control box which is electrically connected with the feeding unit, the conveying unit, the labeling unit, a first rotary motor, a first linear motor, a clamping arm, an image collecting camera and the opening-closing door. The apple grading and sorting device has the beneficial effects of being simple in structure and high in practicability.

Owner:甘肃贡禾食品有限责任公司

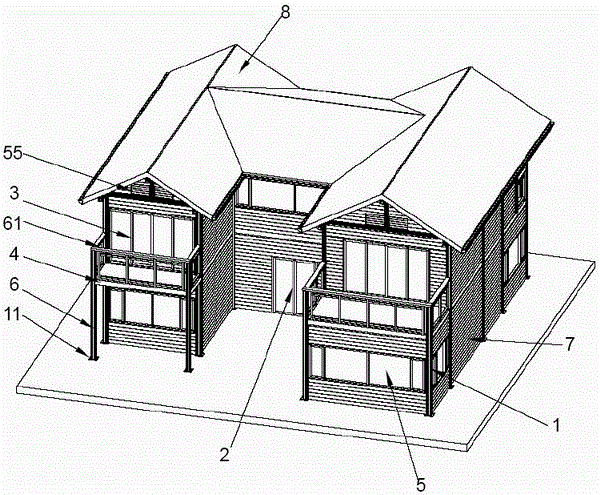

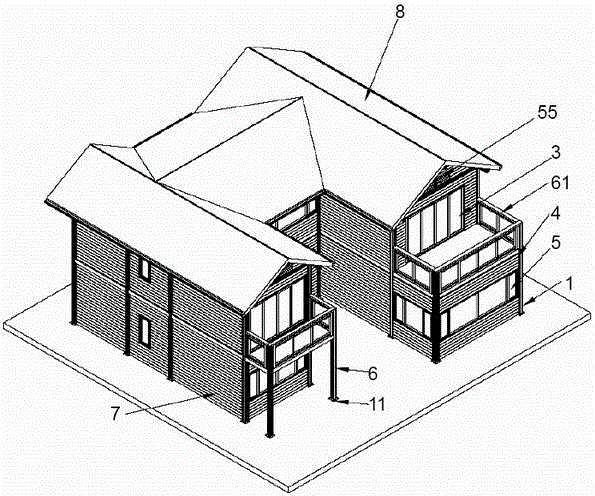

Aluminum alloy house

ActiveCN105040812AFirmly connectedShort design and manufacturing cycleBuilding roofsFloorsSection planeUltimate tensile strength

The invention relates to an aluminum alloy house. Aluminum alloy stand columns are arranged on the periphery and the inner ring of the house at intervals. Aluminum alloy beams are connected to the middle positions, in the height direction, of the aluminum alloy beams on the periphery and the inner ring of the house in a longitudinal and transverse segmented mode to form structures of the bottom layer and the second layer of the aluminum alloy house. Roof supporting columns are arranged on the aluminum alloy beams of the second layer. A roof is arranged on the roof supporting columns and the aluminum alloy stand columns. Three inwards-concave vertical face aluminum alloy combined wall plates are arranged in the middle of the aluminum alloy house in the foresight direction. An aluminum alloy gate is arranged in the middle of the front vertical face aluminum alloy combined wall plate, and therefore an inwards-concave space is formed in the aluminum alloy gate. Reverse Y-shaped sectional structures are arranged on the two sides of the roof. The front portion and the rear portion of the middle part of the roof are each in a slope shape. The two ends of each slope shape are connected with the middle rear portions of the reverse Y shapes on the two sides respectively. The aluminum alloy house is simple and firm in arrangement and connection structure, short in construction period, convenient to install, high in roof bearing strength and excellent in anti-seismic property.

Owner:ALUHOUSE TECHGD CO LTD

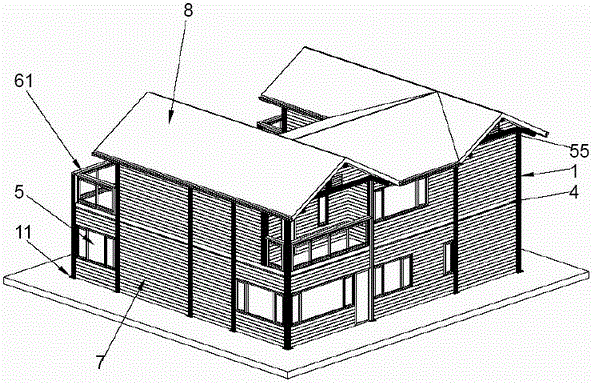

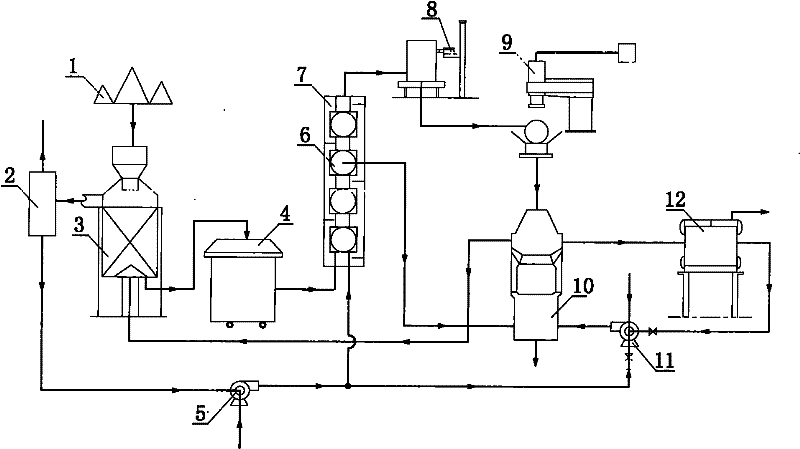

Technology and device for recycling waste heat of electrically fused magnesia smelted block

InactiveCN102345983AAchieve mechanical propertiesAchieve brokenIncreasing energy efficiencyWaste heat treatmentCold airCold blast

The invention relates to a technology and a device for recycling waste heat of an electrically fused magnesia melted block, which are characterized in that after a high-temperature magnesia melted block smelted in an electrically fused magnesia processing technique is entirely cooled in a tunnel heat exchange chamber, magnesia crystal crystallization and solidification are quickly completed, and hot air with medium-low temperature being preheated to be 200-300 DEG C is simultaneously obtained. The solidified magnesia melted block is hulled and cracked at high temperature to produce a high-temperature block. Cold air and the hot air with the medium-low temperature from the tunnel heat exchange chamber are fed into a high-temperature heat exchange tower to carry out heat exchange with the high-temperature block through a circulation air cooling method, hot air with high temperature being more than 1000 DEG C is generated to be fed into a mineral aggregate preheating tower, and magnesite is preheated to be more than 500 DEG C, so that the charging of hot materials is realized.

Owner:SHENYANG DONGDA IND FURNACE +1

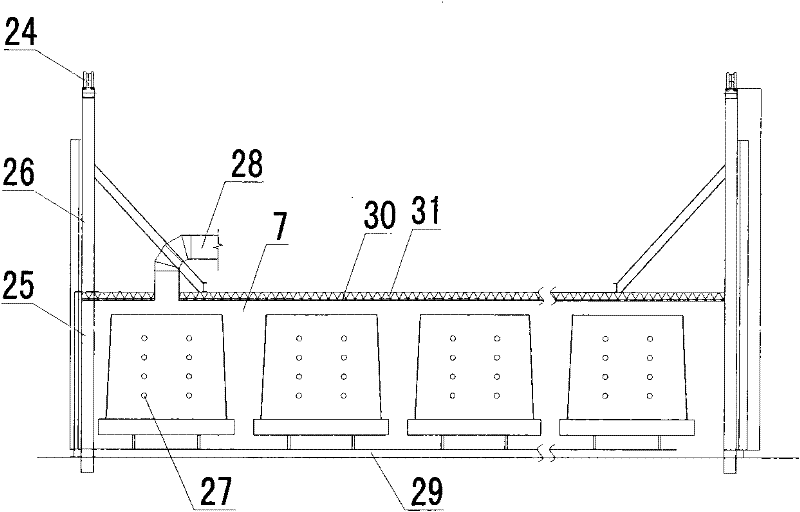

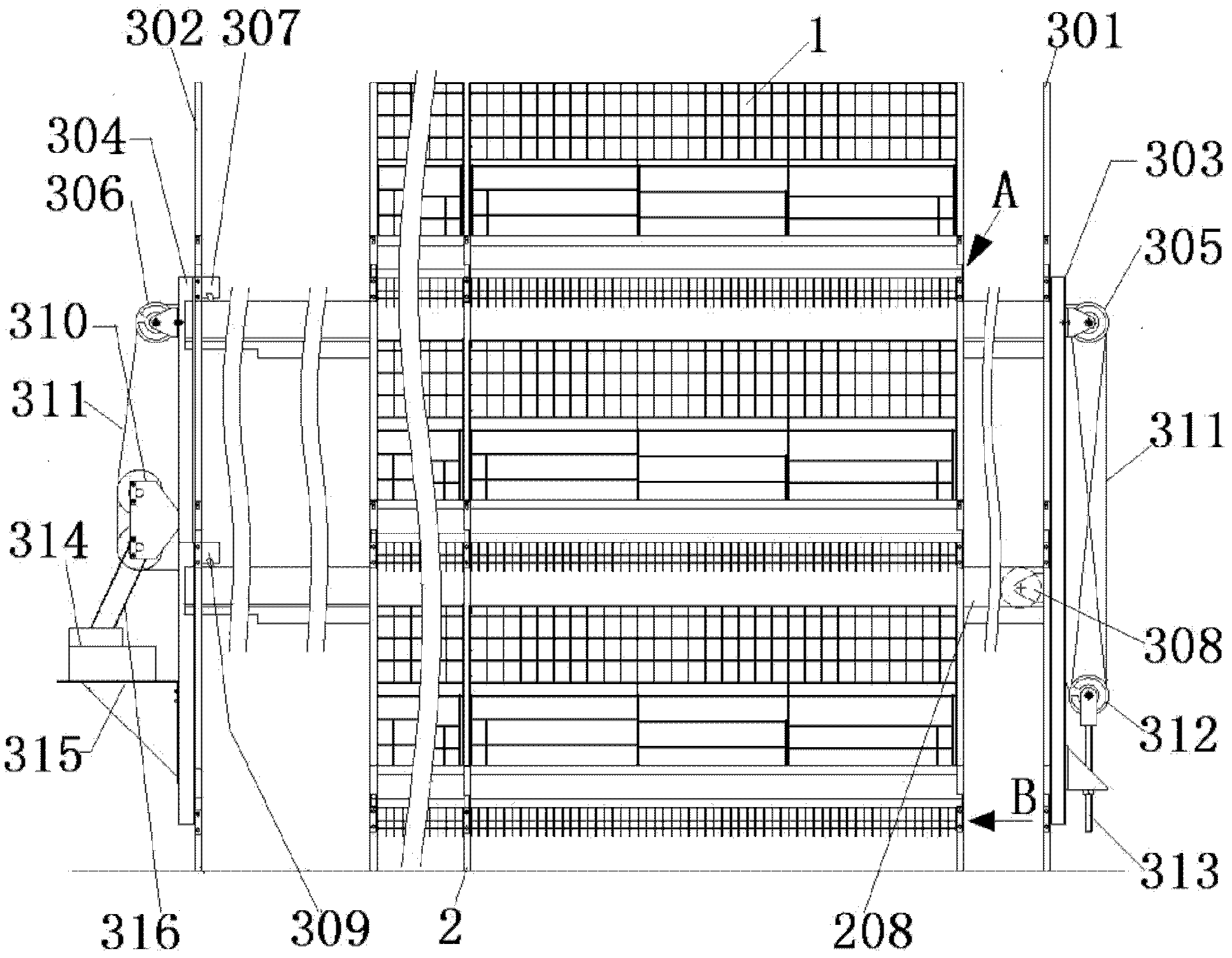

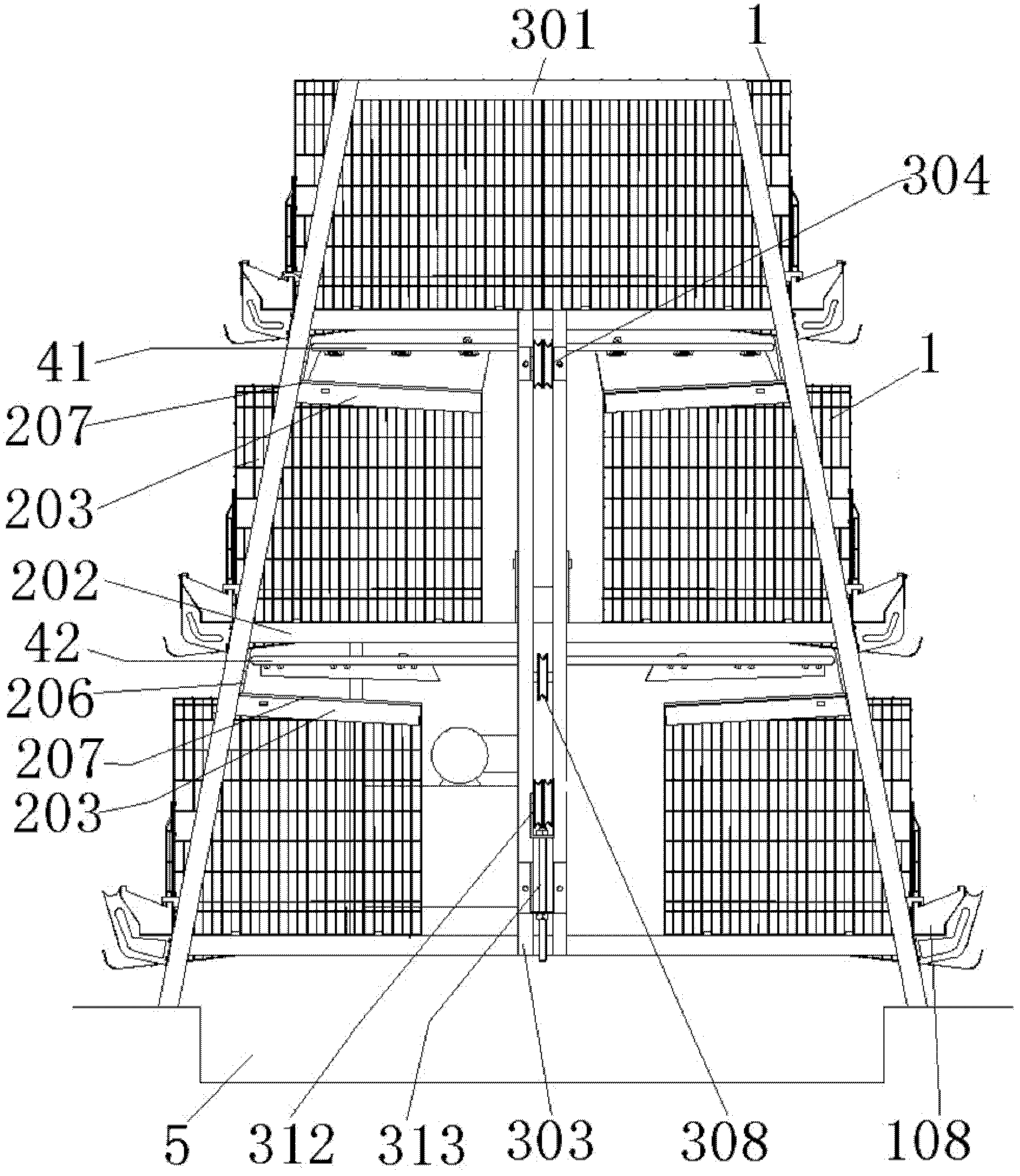

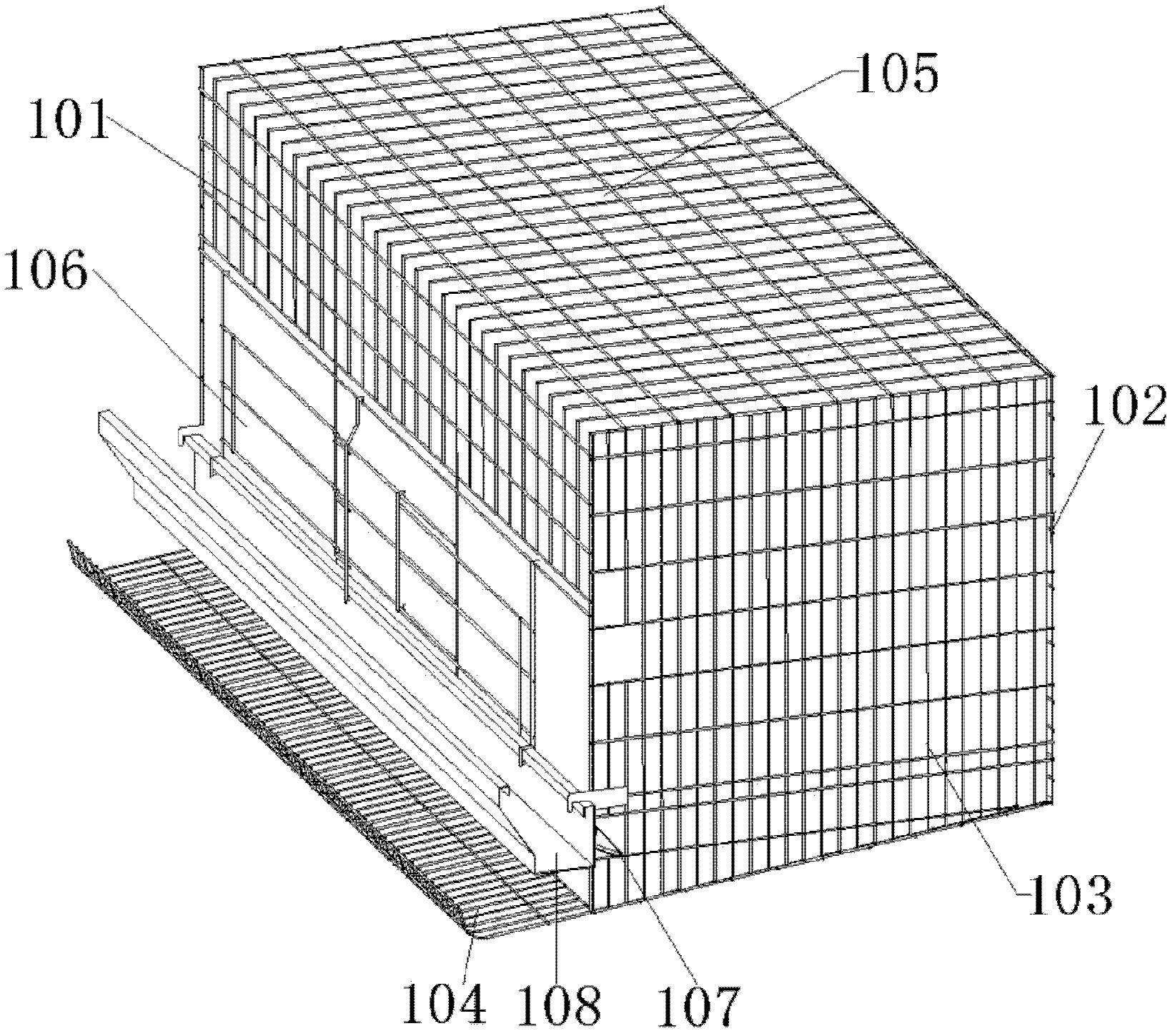

Small stepped type natural mating breeding equipment for breeding poultry

ActiveCN102422819AGuaranteed ventilation effectGuaranteed lighting effectsBird housingsMatingEnvironmental standard

The invention belongs to the technical field of stockbreeding machines, relating to small stepped type natural mating breeding equipment for breeding poultry. The small stepped type natural mating breeding equipment comprises a small stepped type natural mating cage and a manure removing device, wherein the small stepped type natural mating cage is formed by combining small stepped type natural mating cage units comprising six chicken cages and two three-layer trapezoid cage frames; every two adjacent stepped type natural mating cage units form a feeding unit; a top-layer chicken cage rear net is opened up and side nets of each layer of two adjacent chicken cages are opened up; and all cage tools of the whole cage groups respectively form a two-in-one large cage. The manure removing device comprises a manure removing machine driving mechanism and two manure removing machines which are respectively arranged below a bottom net of the top-layer chicken cage and bottom nets of two layers of chicken cages; and the manure removing machine driving mechanism can be used for simultaneously driving the two manure removing machines to alternatively carry out manure removing progress and manure removing return, so that the manure removing operation at the top of the cage is implemented. According to the small stepped type natural mating breeding equipment disclosed by the invention, the requirements of welfare breeding of the poultry and natural mating of the breeding poultry can be met; and the small stepped type natural mating breeding equipment is matched with feeding, drinking, trench manure removing and egg collecting systems and is suitable for large-scale intensive breeding poultry farms having high requirement on environmental standard.

Owner:CHINA AGRI UNIV

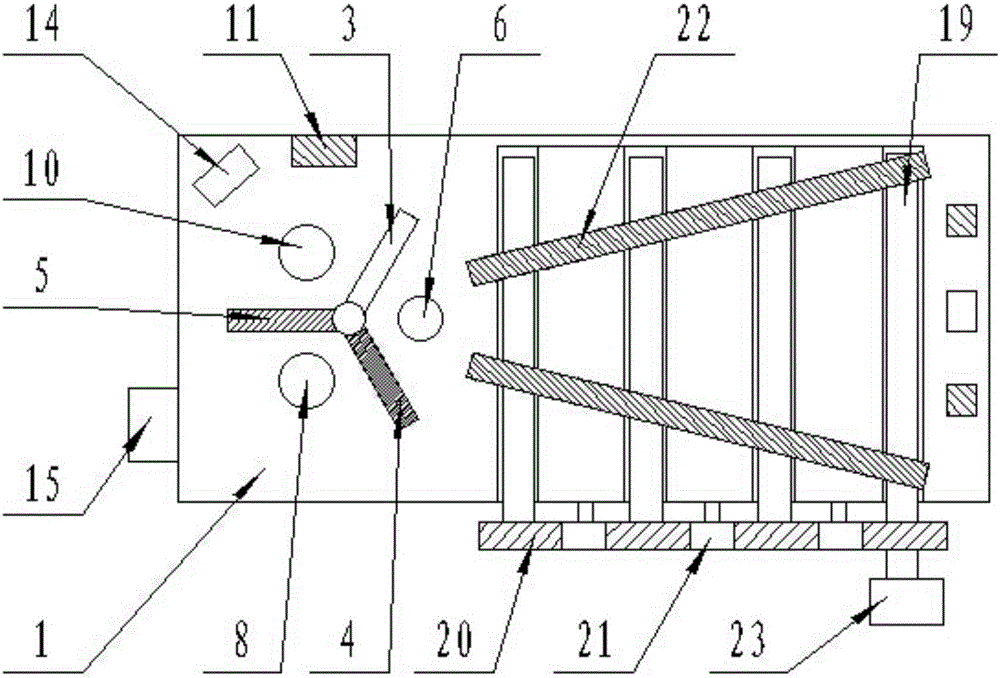

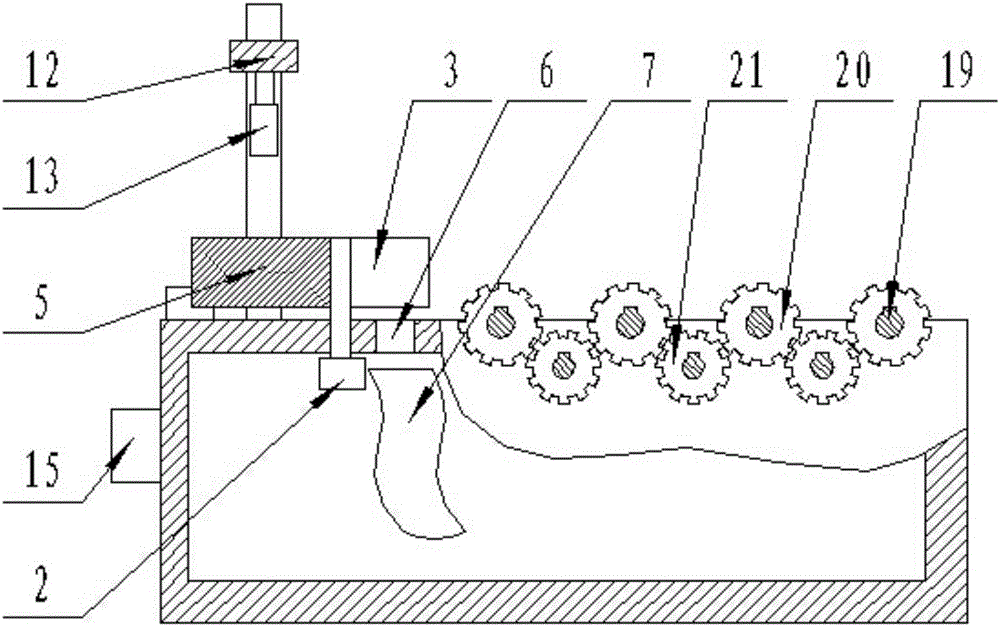

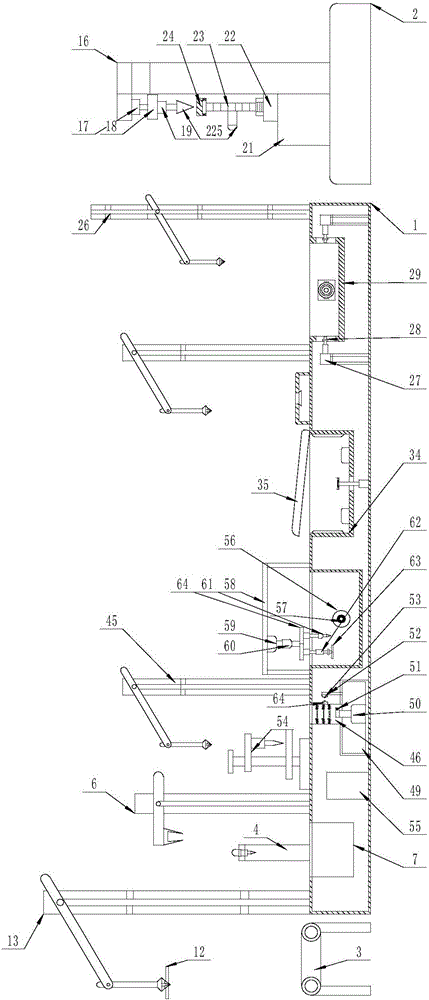

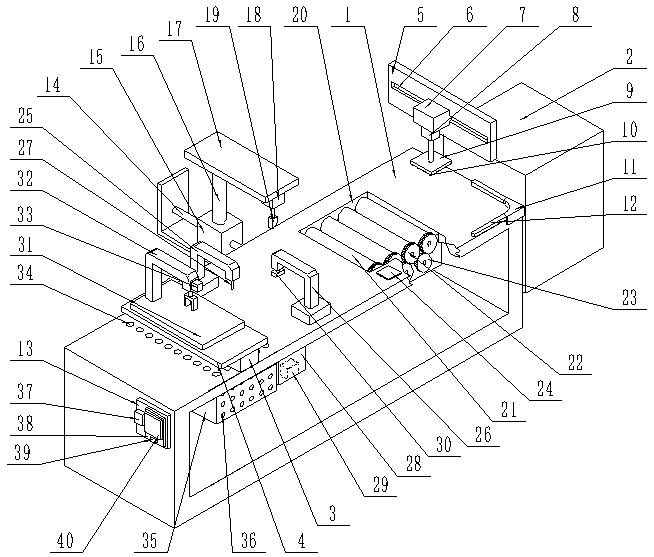

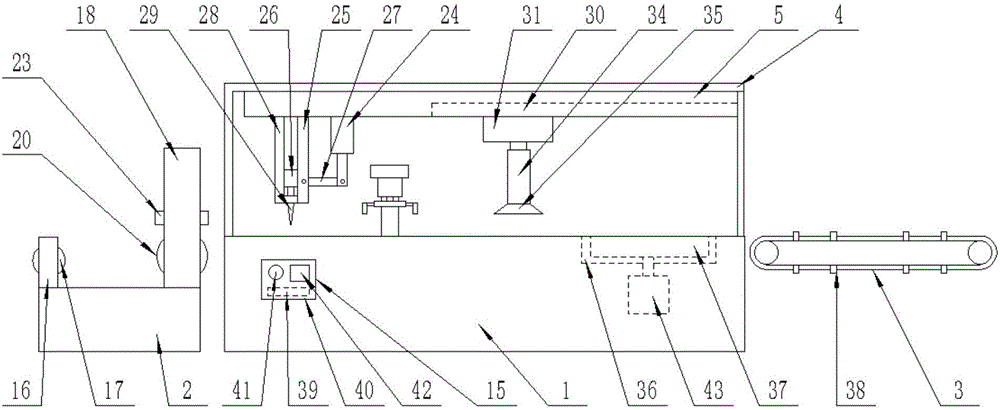

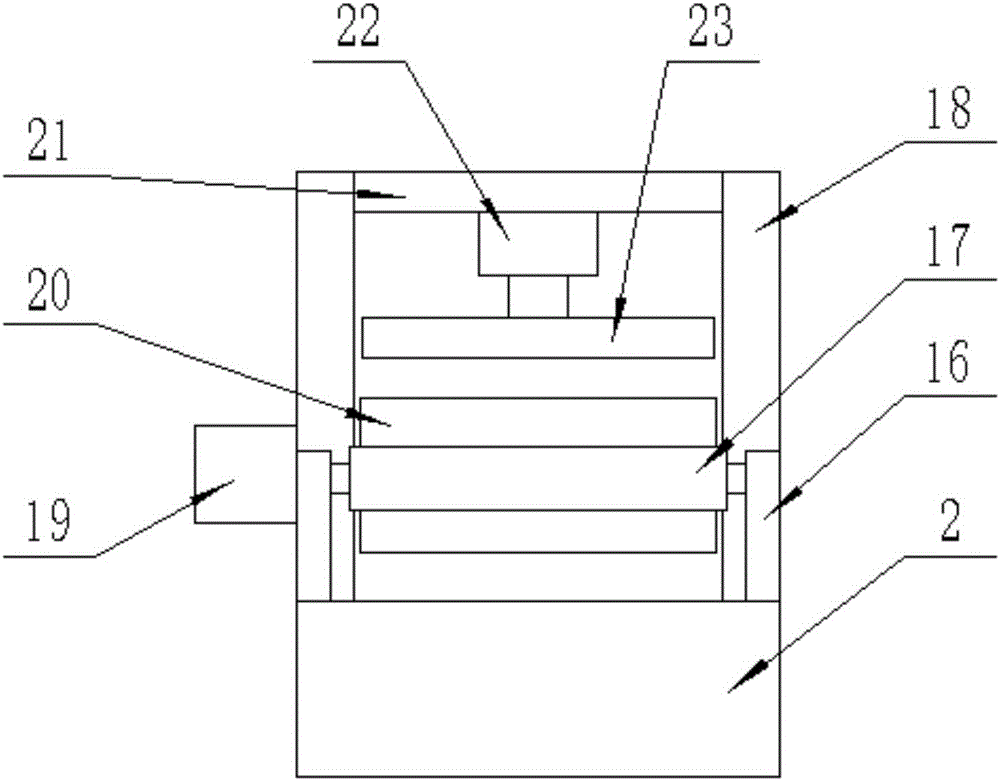

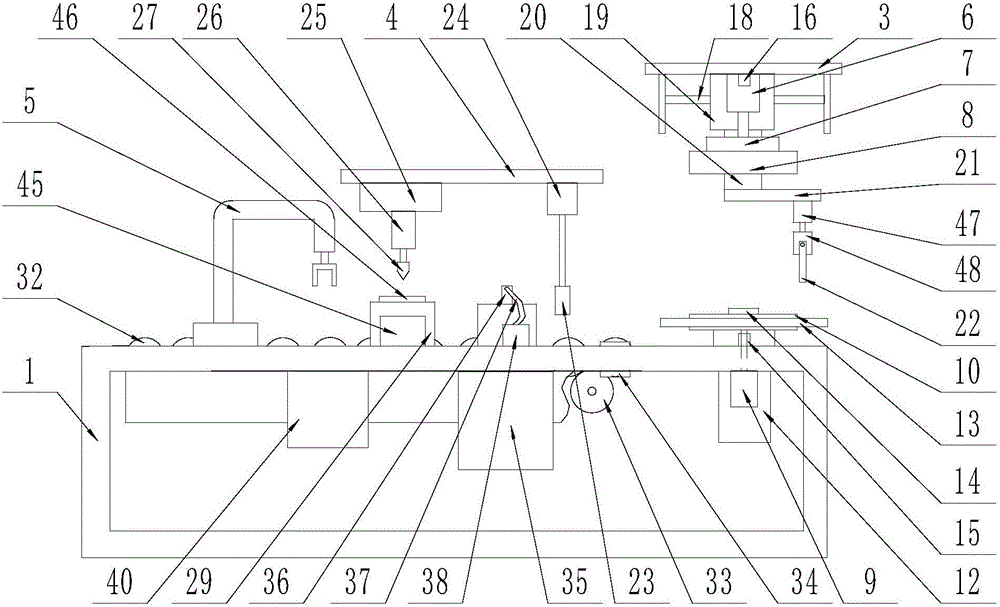

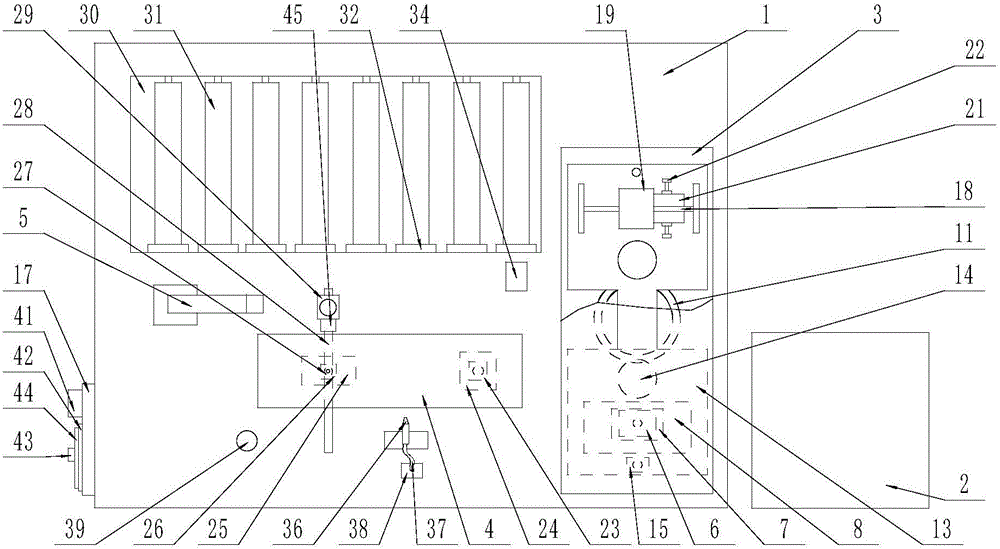

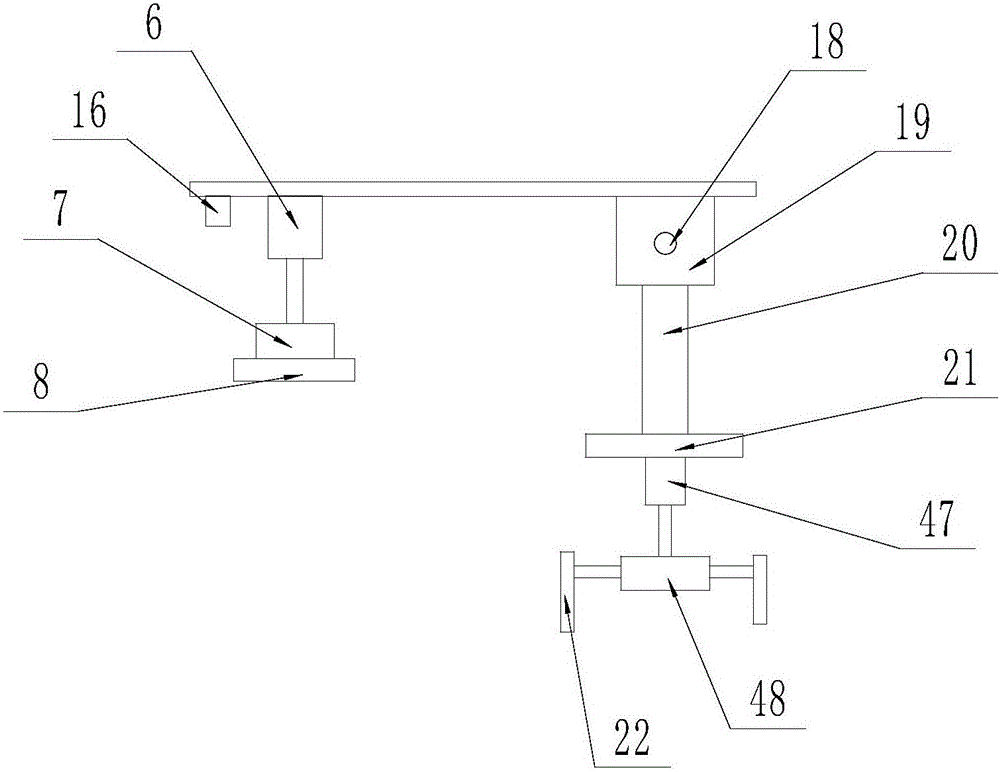

Automatic processing production line for heat-retaining cribs

ActiveCN105904564AIncrease the level of mechanizationMeet actual needsCradleMulti-purpose machinesAutomatic processingPlough

The invention discloses an automatic processing production line for heat-retaining cribs. The automatic processing production line for heat-retaining cribs comprises a workbench, a base arranged on one side of the workbench, and a conveyor belt arranged on the other side of the workbench and used for conveying a heater. The interior of the workbench is of a cavity structure. A vertical arm is arranged on one side of the main workbench, and a mounting plate is arranged on the vertical arm. A pair of fourth mechanical arms are arranged on the workbench. A fixing groove is formed in the surface of the workbench. A sliding rail is arranged on the mounting plate, and a connection body capable of moving back and forth in the length direction of the sliding rail is embedded in the sliding rail. A third linear motor is arranged on the connection body. A plough is arranged at the extension end of the third linear motor. The workbench is provided with a fifth mechanical arm used for clamping the heater. A fourth linear motor is arranged on the mounting plate, and an adhesive sprayer is arranged at the extension end of the fourth linear motor. The automatic processing production line for heat-retaining cribs has the beneficial effects that the structure is simple and practicability is high.

Owner:乳山市佳利制衣股份有限公司

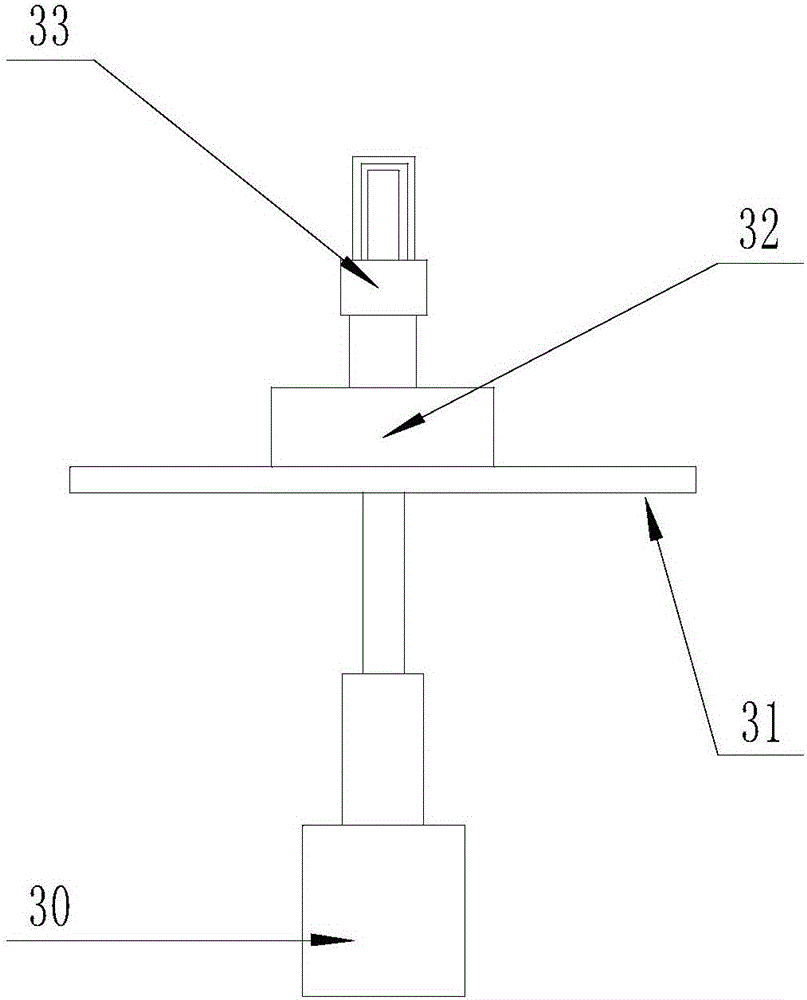

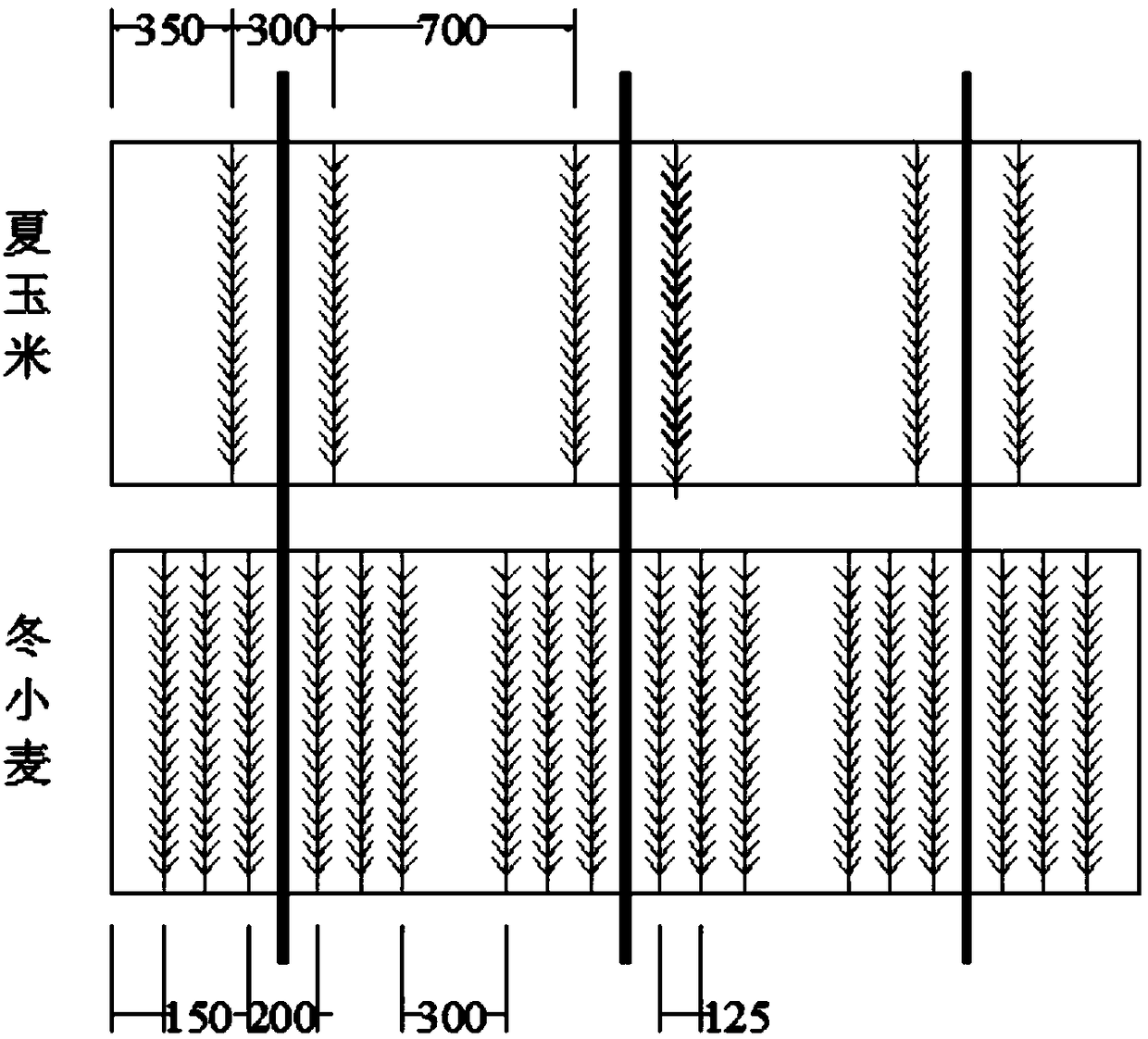

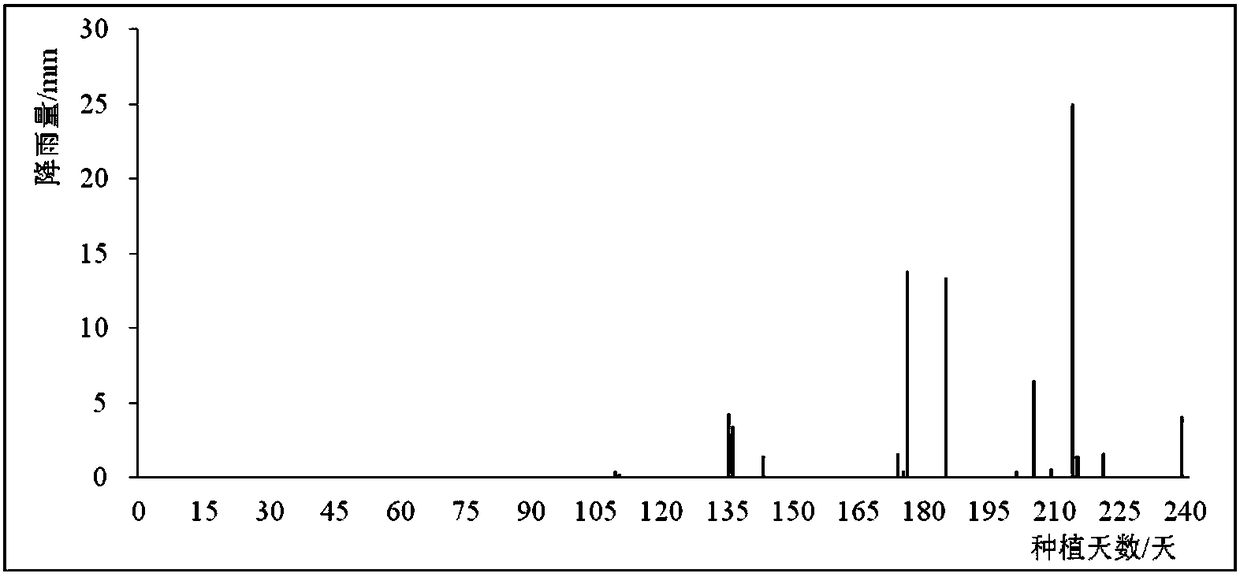

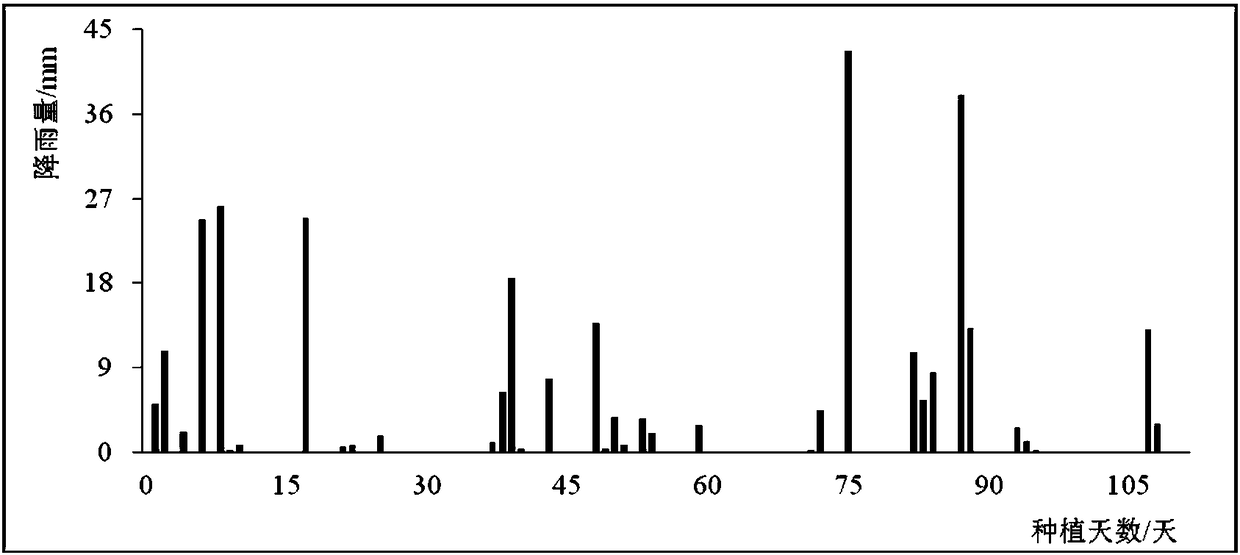

Environment-friendly drop irrigation water-saving cultivation method for winter wheat/summer maize crop rotation system

ActiveCN108142226AReduce the amount of layingReduce investmentClimate change adaptationWatering devicesWater savingAutomatic control

The invention relates to an environment-friendly drop irrigation water-saving cultivation method for a winter wheat / summer maize crop rotation system. A winter wheat / summer maize planting spacing anddrop irrigation belt arrangement mode is developed, a water and fertilizer integrated implementation scheme for water conservation and fertilizer saving of the winter wheat / summer maize crop rotationsystem is built, and different agricultural water saving methods, drop irrigation platform automatic control systems, precise positioning tractors and multifunctional all-in-one machines are also used, so that an environment-friendly drop irrigation water-saving cultivation technology for the winter wheat / summer maize crop rotation system suitable for north China plain is formed. The water and fertilizer utilization efficiency is improved, the irrigation cost is reduced, and the effects of increasing the yield and improving the efficiency are achieved.

Owner:CHINA AGRI UNIV

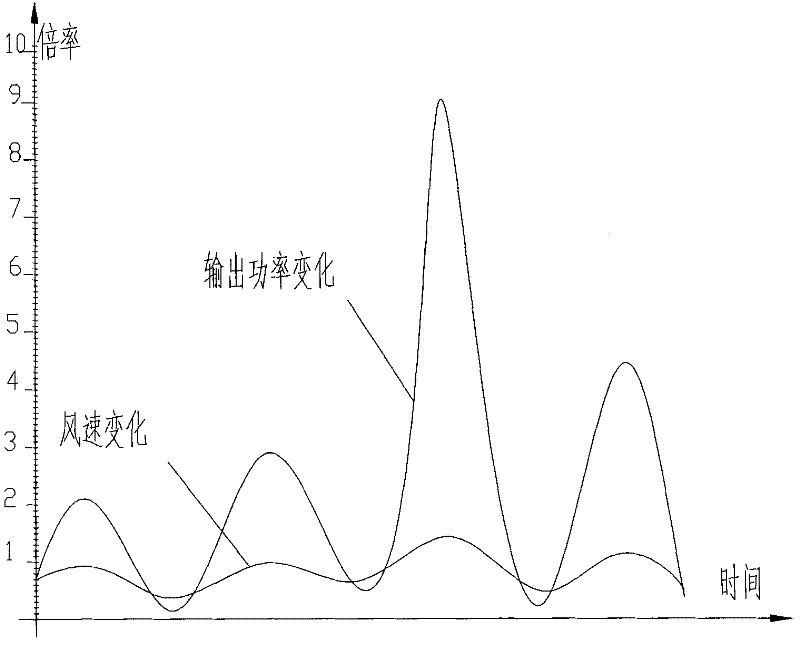

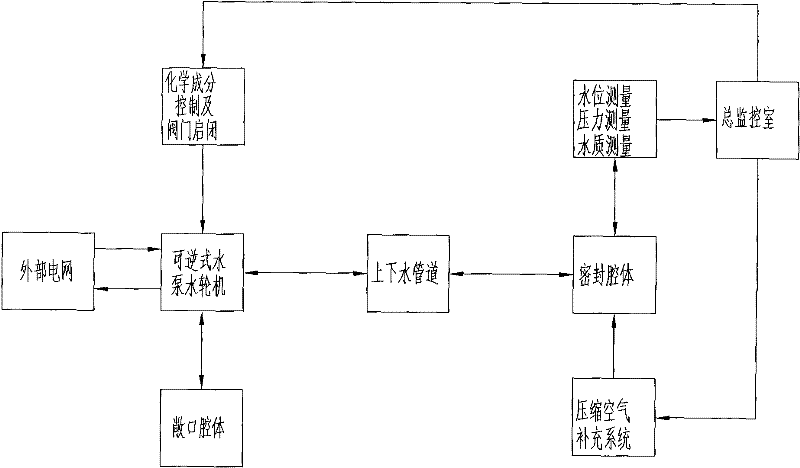

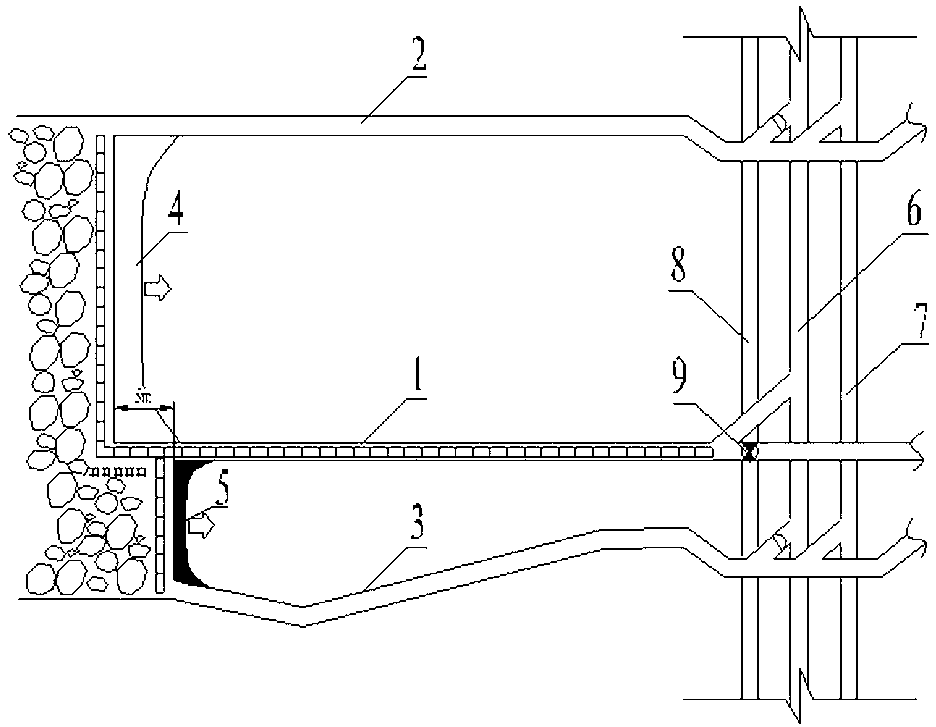

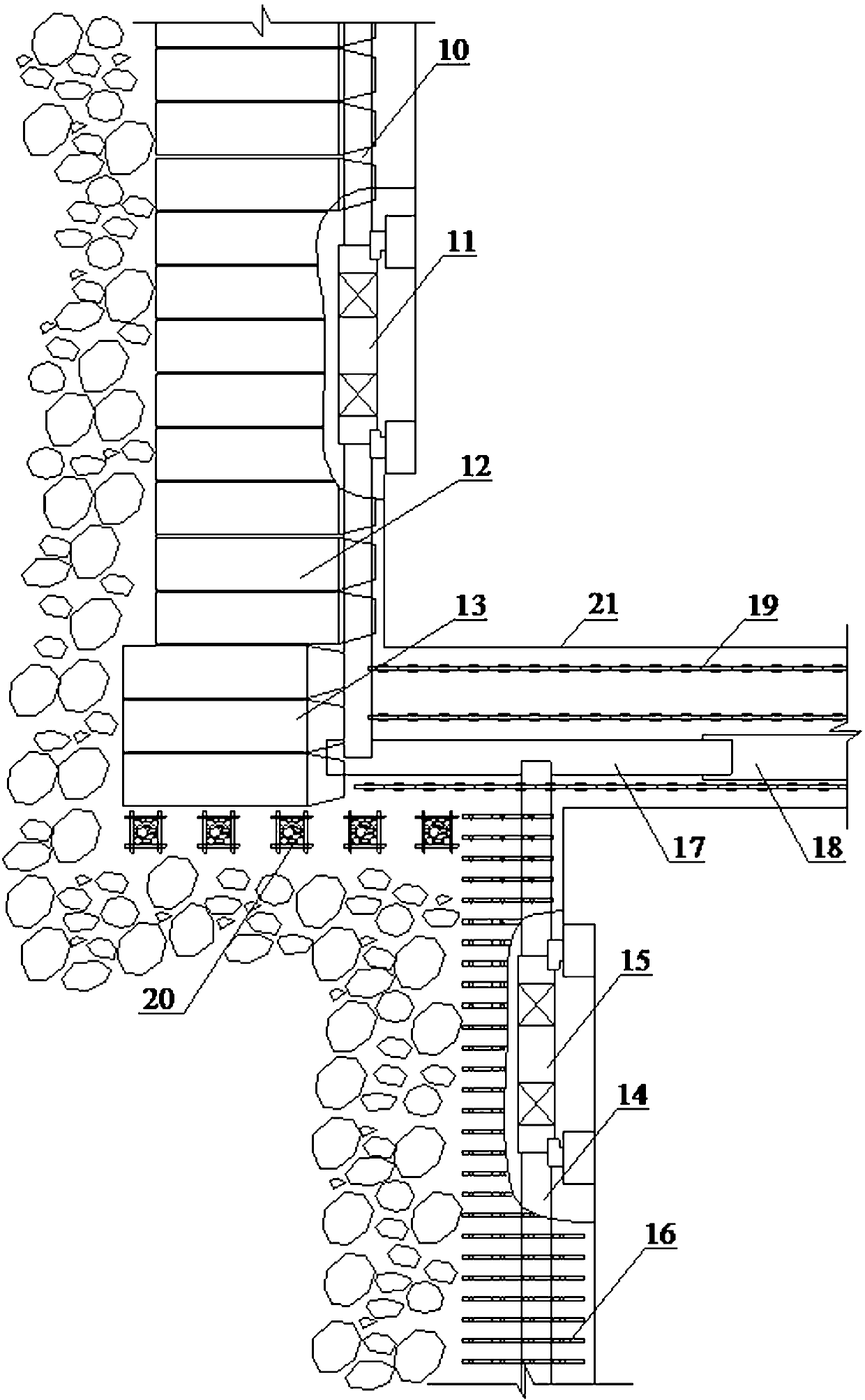

A method of using underground mines for energy storage and power generation

InactiveCN102261299ABalance power resourcesAchieve storageReaction enginesEngine componentsWater dischargeHigh energy

The invention relates to a method for energy storage and power generation by using an underground mine. At present, there is no method for energy storage and power generation with low equipment investment and high energy conversion rate. The present invention includes the steps of energy storage and power generation. In the energy storage step, the reversible pump-turbine is driven by the electric energy of the external power grid when the power grid is rich in the process of smoothing the peak and valley power, and the water in the open cavity is injected into the sealed cavity. , when the reversible water pump turbine stops running, adjust the air pressure in the sealed cavity to the design set value between 1-30 MPa; in the power generation step, the water in the sealed cavity is in the sealed cavity Under the action of air pressure, it is discharged into the open cavity through the upper and lower water pipes, and the discharged water drives the reversible water pump turbine to generate electricity, and the electric energy generated by the reversible water pump turbine is incorporated into the external grid that lacks power. The equipment of the invention has the advantages of low investment, simple operation, high energy conversion rate, and can effectively utilize the peak and valley power and wind power of the power grid.

Owner:陈汉保

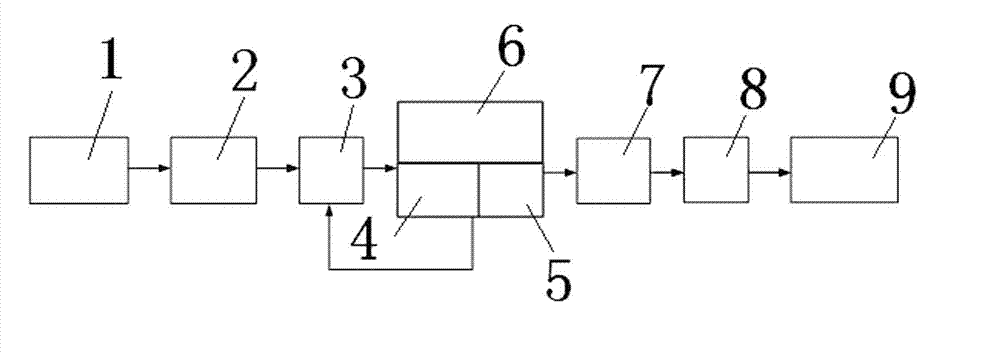

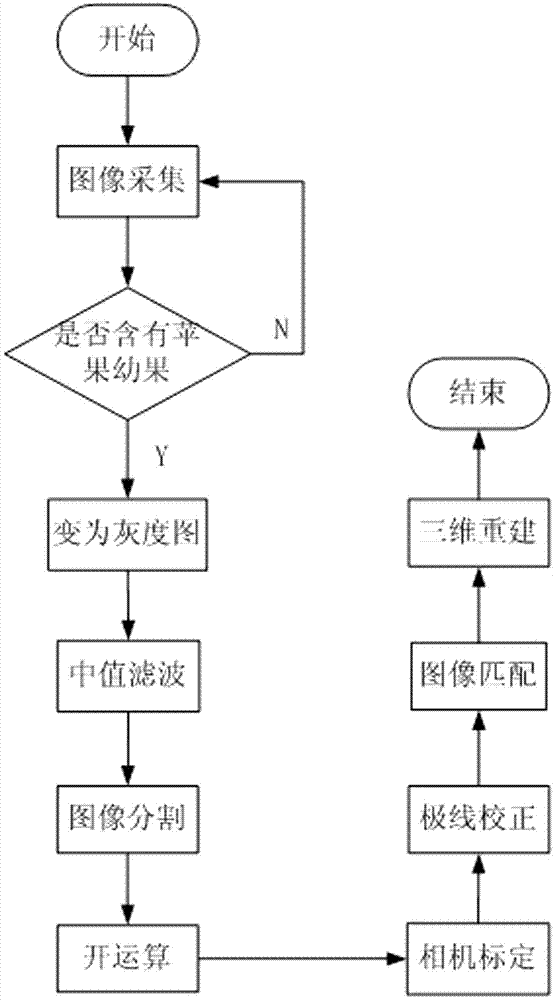

Apple fruitlet bagging robot visual positioning method

InactiveCN103198477AIncrease the level of mechanizationSimple hardware compositionImage analysisUsing optical meansImage intensificationImaging processing

The invention relates to a visual positioning method using an apple fruitlet bagging robot, in particular to an apple fruitlet bagging robot visual positioning system based on machine vision. The method is capable of carrying out accurate image processing and analysis on apple fruitlets, positioning the apple fruitlets accurately and fast through algorithms, determining accurate positions of the fruitlets, and guiding a mechanical arm to accomplish the bagging work. The method comprises a hardware part and a software part, wherein the hardware part comprises an image collecting device, a storage device, a processor and a controller, and the software part comprises an image processing program and a positioning program. The apple fruitlet bagging robot visual positioning method is achieved by ROI extraction, graying, image intensification, image segmentation, camera calibration, image epipolar line calibration, image feature extraction and matching, and image three-dimensional reconstruction.

Owner:SHENYANG LIGONG UNIV

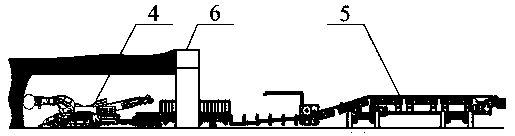

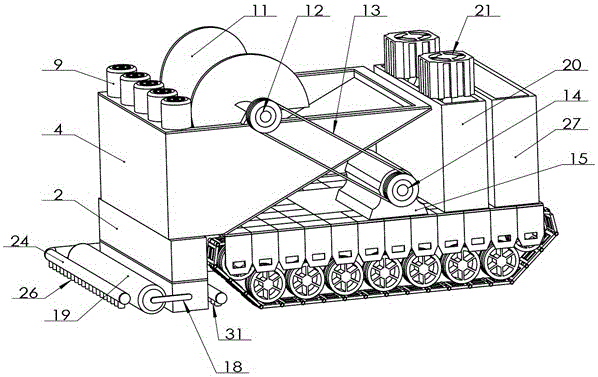

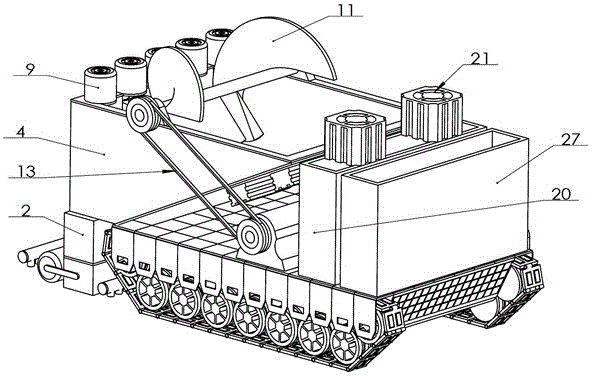

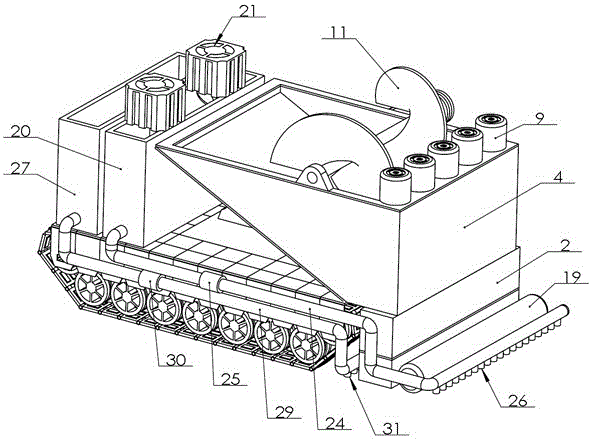

End slope mining method by using open-air end slope ore continuous miner

ActiveCN108194084AMeet the requirements of mechanized miningIncrease the level of mechanizationUnderground miningSurface miningEngineeringMechanization

The invention belongs to the technical field of application of coal mining equipment and coal mining methods, and particularly relates to an end slope mining process by using an open-air end slope orecontinuous miner. The end slope mining process comprises the following steps that 101, a mining face is arranged; 102, an equipment mounting and preparation area is arranged; 103, equipment is arranged and mounted; 104, a ventilation system is arranged; and 105, mining is conducted by using the continuous miner. The end slope mining process adopts continuous miner complete set mining equipment, the requirement of mechanized mining of end slope ore is met, the mechanization level of mining of the end slope ore is improved, the production efficiency is greatly improved, the labor intensity of workers is reduced, the stripping volume of rock and soil is reduced, and damage and disturbance to the environment is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

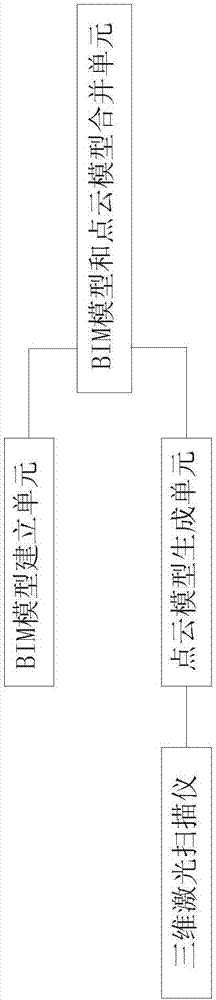

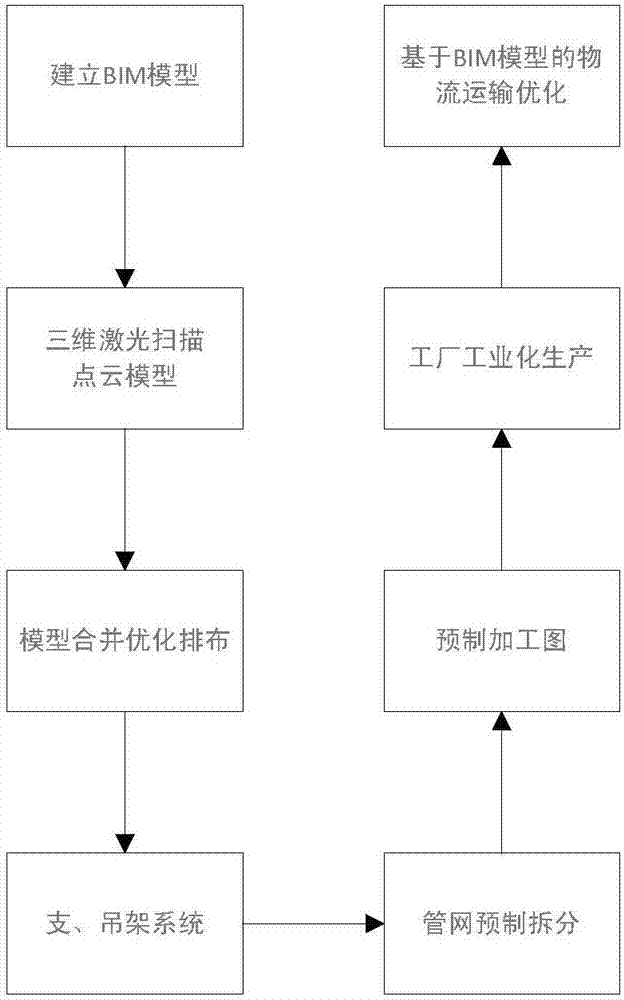

System and method for carrying out prefabrication and field assembly in electromechanical pipe network factory based on building information modeling (BIM)

PendingCN107133431ASatisfy the structural conditionsLow environmental requirementsGeometric CADDetails involving processing stepsPoint cloudLaser scanning

The invention discloses a system and a method for carrying out prefabrication and field assembly in an electromechanical pipe network factory based on building information modeling (BIM). The system comprises a BIM model establishment unit, a three-dimensional laser scanner, a point cloud model generation unit, a BIM model and point cloud model merging unit; the method mainly comprises the steps of establishing a BIM model, carrying out three-dimensional laser scanning to obtain a point cloud model, carrying out merging and optimized configuration on the BIM model and the point cloud model, designing a supporting and hanging bracket system, carrying out prefabricated disassembly on a pipe network and outputting a prefabrication manufacturing drawing, enabling a factory to produce a pipe network according to the prefabrication manufacturing drawing, and transporting the pipe network to the field for assembling. The system and the method help to greatly improve the construction efficiency while meeting the structure conditions of prefabrication manufacturing.

Owner:广州市镒辰智造科技有限公司

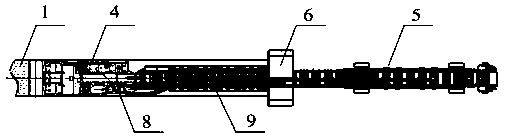

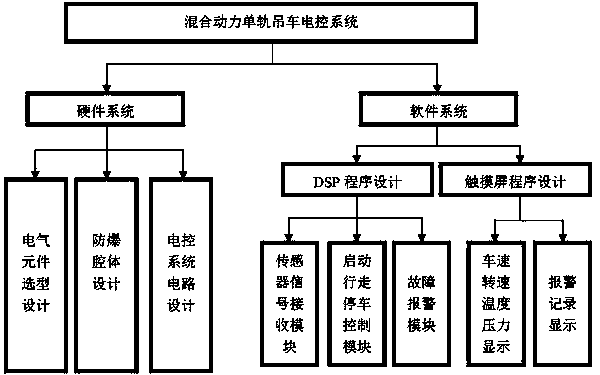

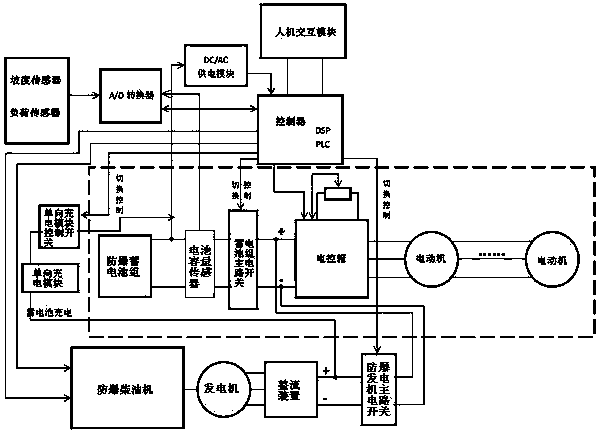

Oil-electricity hybrid powered monorail crane locomotive and power output control method thereof

The invention discloses an oil-electricity hybrid powered monorail crane locomotive and a power output control method thereof, and relates to the technical field of underground coal mine subsidiary transportation. The oil-electricity hybrid powered monorail crane locomotive comprises a monorail crane locomotive body, wherein an explosion-proof diesel engine, an explosion-proof accumulator battery, a motor and a controller are arranged on the locomotive body; the controller controls the explosion-proof diesel engine to provide power for the motor through an electric generator according to signals acquired by a sensor, so as to drive the locomotive to move, or controls the accumulator battery to provide power for the motor to drive the locomotive to move, or controls the explosion-proof diesel engine to provide power for the motor through the electric generator, and meanwhile controls the electric generator to charge the accumulator storage, so as to drive the locomotive to move. The monorail crane locomotive orderly hybridizes the power of the accumulator battery and the diesel engine, so that the locomotive is driven by the accumulator battery mainly in the routine running situation, and by the diesel engine under heavy load and the large slope working condition, so as to prolong the duration of the accumulator battery and reduce environment pollution.

Owner:HEBEI COAL SCI RES INST

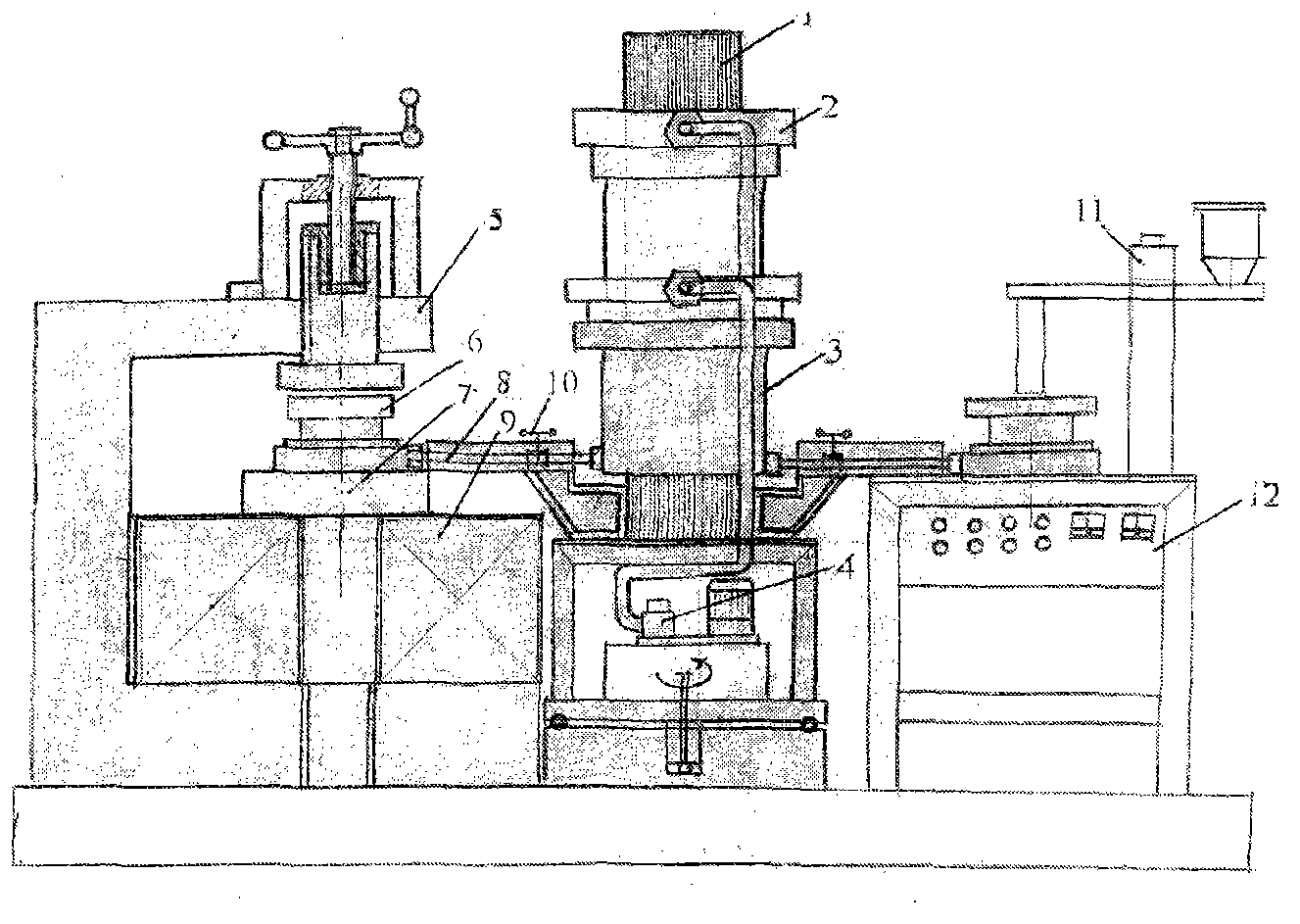

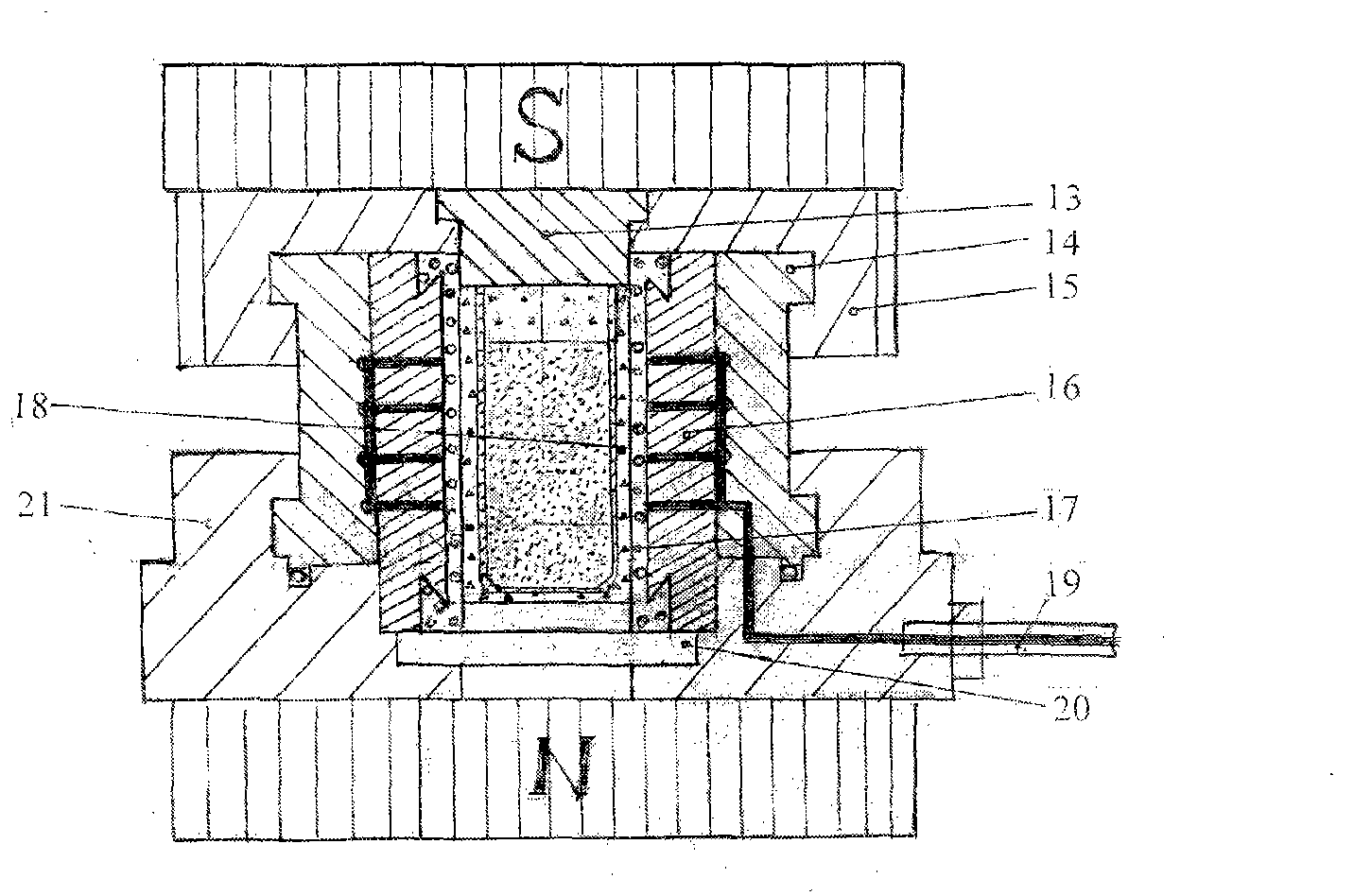

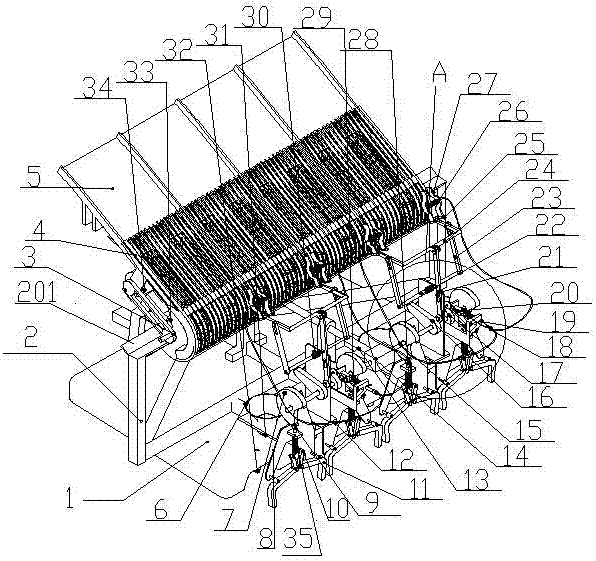

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

InactiveCN103878368AImprove automationIncrease the level of mechanizationInorganic material magnetismInductances/transformers/magnets manufactureResource utilizationMagnetic poles

The invention belongs to the field of technologies for manufacturing magnetic materials, and provides a technology and a device for forming dry bag quick isostatic pressing in oriented magnetic fields. The technology and the device have the advantages that an oriented magnetic field technology is ingeniously and organically combined with the technology and the device for forming dry bag isostatic pressing by the aid of a novel design concept, so that dry bag isostatic pressing can be formed in the oriented magnetic fields which have optional directions and optional magnetic field intensities by the aid of the novel technology and the novel device; orientation degrees of products can be obviously upgraded; two necessary working procedures in existing neodymium, iron and boron magnet production can be combined with each other to form one working procedure by the novel technology and the novel device, and the automation and mechanization levels are high; powder is not in contact with pressing blanks and oil in production procedures, and accordingly a latex sheath for binding the corresponding pressing blank can be omitted; the pressing blanks are quite uniform in density distribution and internal stress distribution; the pressing blanks can be machined, and original powder can be recycled; single-hole and multi-hole thin-walled pipes, sleeves and multi-magnetic-pole products which are heavy and are in complicated shapes or have large length-diameter (L / d) ratios can be produced by the aid of the technology and the device, the rare earth mineral resource utilization rate can be greatly increased, and the neodymium, iron and boron magnet industrial production level of China can be upgraded to the world leading level.

Owner:吴庆华 +2

Comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions

InactiveCN103104260AImprove mining efficiencyHigh recovery rateUnderground miningSurface miningCoal briquetteLength variation

The invention provides a comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions. Directed at mining of coal resources in irregular sections under complicated geological conditions, the method includes: arranging an equal length comprehensive mechanical mining face on the upper part of a coal briquette in a section, arranging an unequal length conventional mechanical mining face on the lower part of the coal briquette according to the remaining coal briquette shape in the section, making use of three section drifts to prepare two stope faces so as to form a double unit mining form between the equal length comprehensive mechanical mining face and the unequal length conventional mechanical mining face, advancing the two faces in a coordinated way, and always keeping the conventional mechanical mining face ahead of the comprehensive mechanical mining face by 5m, and when the length of the conventional mechanical mining face varies, increasing or decreasing the number of single hydraulic props and articulated roof beams in the conventional mechanical mining face or properly adjusting the prop space based on required support density so as to adapt to the face length variation. The method provided in the invention achieves arrangement of the equal length comprehensive mechanical mining face during irregular coal briquette mining under complicated geological conditions, simultaneously recovers coal resources to the utmost, and improves the mechanization level of coal mining under complicated geological conditions.

Owner:HUNAN UNIV OF SCI & TECH

Model toy processing device

ActiveCN105499998AIncrease the level of mechanizationIncrease productivityOther manufacturing equipments/toolsMetal working apparatusButt jointEngineering

The invention discloses a model toy processing device which comprises a worktable and a conveying belt arranged at the front end of the worktable and used for conveying toy parts. An edge and corner cutting unit is arranged at one end of the worktable. A hole milling unit is arranged on the rear side of the worktable. A conveying mechanism is arranged above the portion, between the hole milling unit and the edge and corner cutting unit, of the worktable. The interior of the worktable is of a cavity structure. A gluing unit is arranged on the upper surface of the worktable, a drying unit is disposed at the other end of the worktable, a controller is arranged on the worktable, and the controller is electrically connected with the hole milling unit, the conveying mechanism, the gluing unit, a butt joint adhesion unit, a drying unit electric trolley, a first rotary motor, a vacuum sucker and a cutting mechanism. The model toy processing device has the advantages of being simple in structure and high in practicality.

Owner:中山市宝晖塑胶制品有限公司

Automobile engine assembly transfer case

InactiveCN101164837ARealize universal adjustableImprove versatilityPackaging vehiclesContainers for machinesTransfer caseEngineering

The present invention discloses an automobile engine assembly epicyclic box applicable to several models. The invented automobile engine assembly epicyclic box includes pallet assembly, supporting head assembly and box cover. The pallet assembly is formed from pallet, slideways and buckle latches, on the pallet two fixed slideways are set, said two fixed slideways are parallelly-arranged, two ends of two mobile slideways are respectively fixed on the tracks of said two fixed slideways, in the front of pallet and in the back of pallet are respectively set two buckle latches; the box cover is connected with pallet by means of buckle latch; the supporting head assembly includes fixed seat, threaded rod, swivel nut, steel tube and base seat, the fixed seat is connected with the threaded rod by means of pin shaft, the upper and lower two sides of bearing surface of said fixed seat are respectively equipped with hole, the swivel nut is placed outside of said threaded rod, the swivel nut exterior is equipped with said steel tube, the swivel nut, steel tube and base seat are welded into one body, and the base seat is fixed on the mobile slideway.

Owner:MILITARY TRANSPORTATION RES INST OF PLA GENERAL LOGISTICS DEPT

Step type rice potted seedling transplanter

ActiveCN106888641AAchieve transplantingRealize transplanting in rows and holesTransplantingFurrow making/coveringAgricultural engineeringMechanical engineering

The invention discloses a step type rice potted seedling transplanter, comprising a body connection fixture, a furrowing ridging device, a potted seedling conveyer, a plurality of potted seedling picking devices, seedling conveying funnels, a plurality of potted seedling centralizers and a power input device, wherein the furrowing ridging device is arranged at the bottom of the body connection fixture, the potted seedling conveyer is slidably mounted on a slide channel guide of the body connection fixture, seedling picker claws of the potted seedling picking devices are arranged at an outlet end of the potted seedling conveyer side by side, one seedling conveying funnel is arranged below the seedling picker claw of the corresponding potted seedling picking device, and the potted seedling centralizers are arranged at the tail end of the transplanter side by side. The step type rice potted seedling transplanter is provided based on a traveling and seedling-transferring power assembly of an existing step type seedling transplanter in accordance with the characteristic that the prior rice seedling transplanter has high requirement on seedling growth, potted seedlings can be transplanted in lines and holes, and the requirement for mechanized rice planting in southern hilly areas can be met.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Cap sealing production line for tablet canning

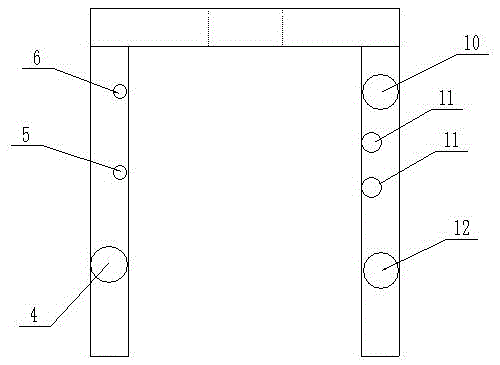

InactiveCN105523203ASimple structureIncrease the level of mechanizationPackage sterilisationSolid materialPlastic packagingPortal frame

The invention discloses a cap sealing production line for tablet canning. The production line comprises a workbench and a pair of portal frames arranged on the workbench, wherein the inside of one portal frame adopts a cavity structure; a transverse plate is arranged on the pair of portal frames; a counting and tablet discharging unit is arranged on the transverse plate; a conveying unit is arranged on the workbench; a stamping unit is arranged in the cavity structure of the portal frame and comprises a mold roll, an auxiliary rotating shaft and a driving clamping and conveying roller which are arranged in one supporting leg of the portal frames, an opening formed in the upper surface of a cross beam of the portal frames, a guide frame arranged on the cross beam of the portal frames, an air valve box which is arranged on the guide frame and can move in the length direction of the guide frame, a stamping mechanism and a plastic packaging machine which are arranged on the air valve box, a supporting shaft, a pair of tensioning rollers and a film winding roller which are arranged in the other supporting leg of the portal frames as well as a push mechanism arranged on one supporting leg of the portal frames. The production line has the beneficial effects of simple structure and high practicability.

Owner:ZHEJIANG AOTUOKANG PHARMA GROUP

Production line for machining temperature-sensitive decorative plates

InactiveCN106312577AIncrease the level of mechanizationEasy to operateOther manufacturing equipments/toolsProduction linePunching

The invention discloses a production line for machining temperature-sensitive decorative plates. The production line comprises a workbench, an auxiliary conveying platform and a conveying belt, wherein the auxiliary conveying platform is arranged at one side of the workbench, and the conveying belt is arranged at the other side of the workbench. A film pressing unit is arranged above the auxiliary conveying belt. A punching-carving integrated unit is arranged at the rear side of the workbench. A cross beam is arranged on the upper surface of the workbench. A carrying plate is arranged on the cross beam. A cutting unit and a clamping and delivering unit are arranged on the carrying plate. A deburring unit is arranged on the surface of the side, far away from the auxiliary conveying platform, of the workbench. The production line for machining the temperature-sensitive decorative plates has the beneficial effects of being simple in structure and great in practicability.

Owner:王杨

Special intelligent water conservancy irrigation device for agricultural greenhouses

ActiveCN105830873AIncrease the level of mechanizationReduce water consumptionWatering devicesCultivating equipmentsGreenhouseButt joint

The invention discloses a special intelligent water conservancy irrigation device for agricultural greenhouses. The device comprises a base frame and a humidity monitoring unit arranged on the base frame, wherein multiple parallel slides are arranged on the base frame, lifting units are arranged on the slides, rotary spraying units are arranged on the lifting units, multiple water pipe casings are arranged on the base frame, a main water guide pipe with one end butt-jointed with the corresponding rotary spraying unit is arranged in each water pipe casing, and a control box is arranged on the base frame. The device has the benefits that the structure is simple and the practicability is high.

Owner:广东卓越景观设计工程有限公司

Paint spraying device for artworks

ActiveCN105499031ASimple structureIncrease the level of mechanizationSpraying apparatusEngineeringMachine tool

The invention discloses a paint spraying device for artworks. The paint spraying device comprises a machine tool body, the machine tool body is internally of a cavity structure, and a groove is formed in the machine tool body and internally provided with a rotating support table; a movable gantry is arranged on the machine tool body and provided with a moving box capable of moving in the length direction of a cross beam of the movable gantry, a moving box X-phase moving motor is arranged in the moving box, a stand column is arranged on the moving box and provided with a spraying unit, and a control box is arranged on the machine tool body and is electrically connected with the movable gantry, the moving box X-phase moving motor, hydraulic columns and a Y-phase driving motor. The paint spraying device has the advantages of being simple in structure and high in practicability.

Owner:汕头市新凯纳科教玩具有限公司

Small floor grout spreading all-in-one machine

ActiveCN106193559AReduce labor intensityImprove efficiencyBuilding constructionsVehicle frameEngineering

The invention relates to a small floor grout spreading all-in-one machine. The small floor grout spreading all-in-one machine comprises a track type chassis, a front vehicle frame, a round through hole, a hopper, a feeding plate, an extrusion motor fixing seat, a conveying barrel, a bearing with a seat, an extrusion motor, an extrusion auger, a stirring auger, a driven belt wheel, a belt, a driving belt wheel, a motor, an extruder, a taped through hole, a connecting rod, a roller barrel, a grout box, a stirring motor, a stirrer, a grout outlet, a grout conveying pipe, a grout conveying pipe control valve, a grout spraying opening, a water tank, a water outlet, a water conveying pipe, a water conveying pipe control valve, a water spraying opening and a vibration motor. The small floor grout spreading all-in-one machine is reliable in structure, capable of relieving labor intensity of constructors and meanwhile greatly improving the floor grout spreading efficiency and quality, and beneficial to improving the mechanical level of floor grout spreading operation, and realizes rapid and efficient conduction of floor grout spreading operation.

Owner:嘉兴久珥科技有限公司

Inner section removal machine for bamboo

ActiveCN104908116AIncrease the level of mechanizationGuarantee the quality of bamboo expansionCane mechanical workingIrregularity removal devicesEngineeringMachining

The invention relates to an inner section removal machine for bamboo. The inner section removal machine comprises a frame and also comprises an inner section removal cutting tool assembly, an axial bamboo feeding mechanism and a radial bamboo positioning mechanism which are fixedly arranged on the frame; the axial bamboo feeding mechanism is corresponding to the inner section removal cutting tool assembly; the radial bamboo positioning mechanism is located on the periphery of the inner section removal cutting tool assembly; the inner section removal cutting tool assembly comprises a cutter shaft, a section breaking cutter, a plurality of scrapers and a plurality of positioning rings; the cutter shaft is driven by a main motor to rotate; the section breaking cutter is arranged at the front end of the cutter shaft; the plurality of scrapers are used for polishing the inner section of the bamboo; the plurality of positioning rings are used for preventing the excessive polishing; the plurality of scrapers and the plurality of positioning rings sleeve the cutter shaft; every positioning ring is arranged between the two corresponding adjacent scrapers. According to the inner section removal machine for the bamboo, the process of the inner section removal of the bamboo is mechanized, the efficiency of the machining link of the inner section removal is improved, and the quality can be effectively guaranteed.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

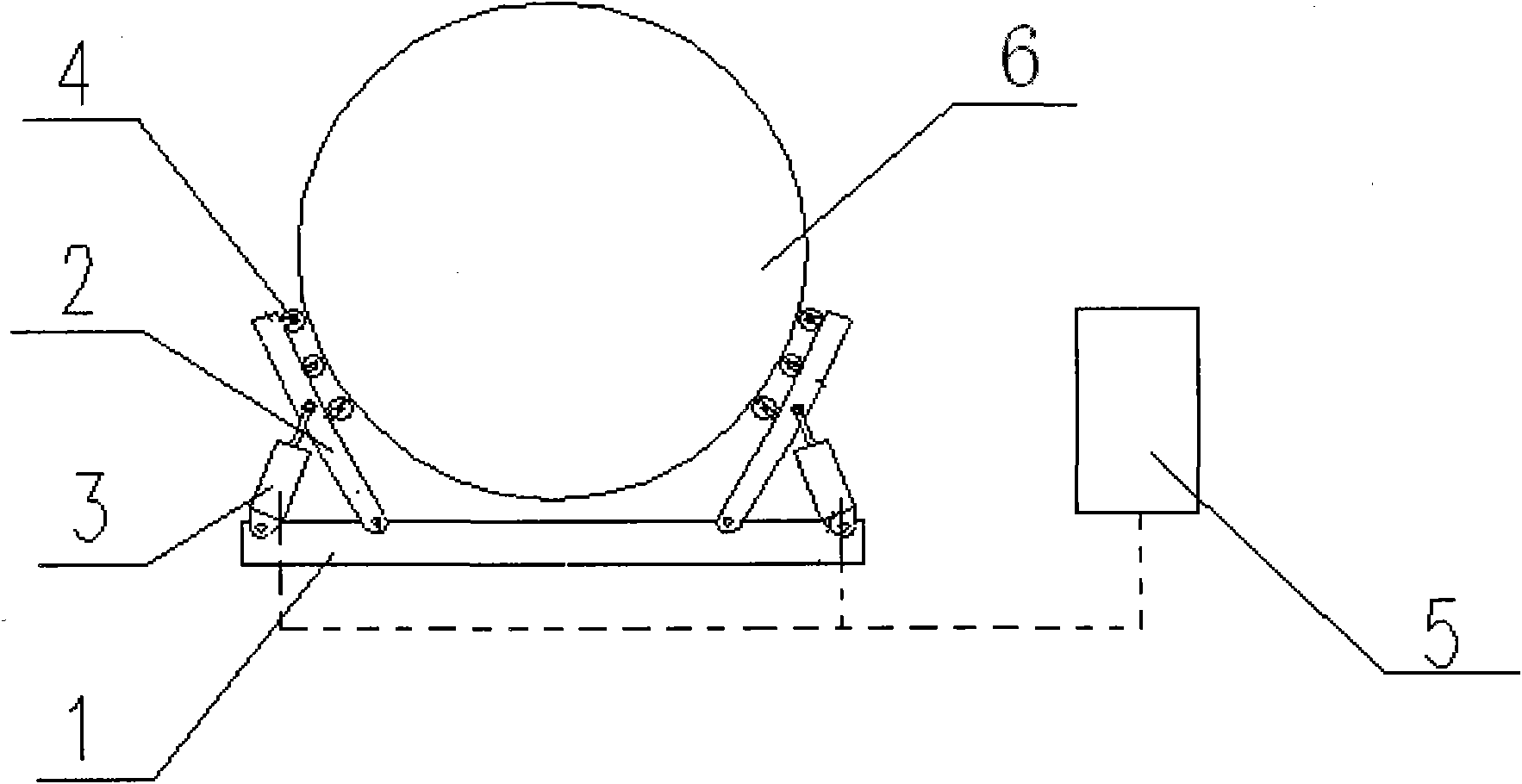

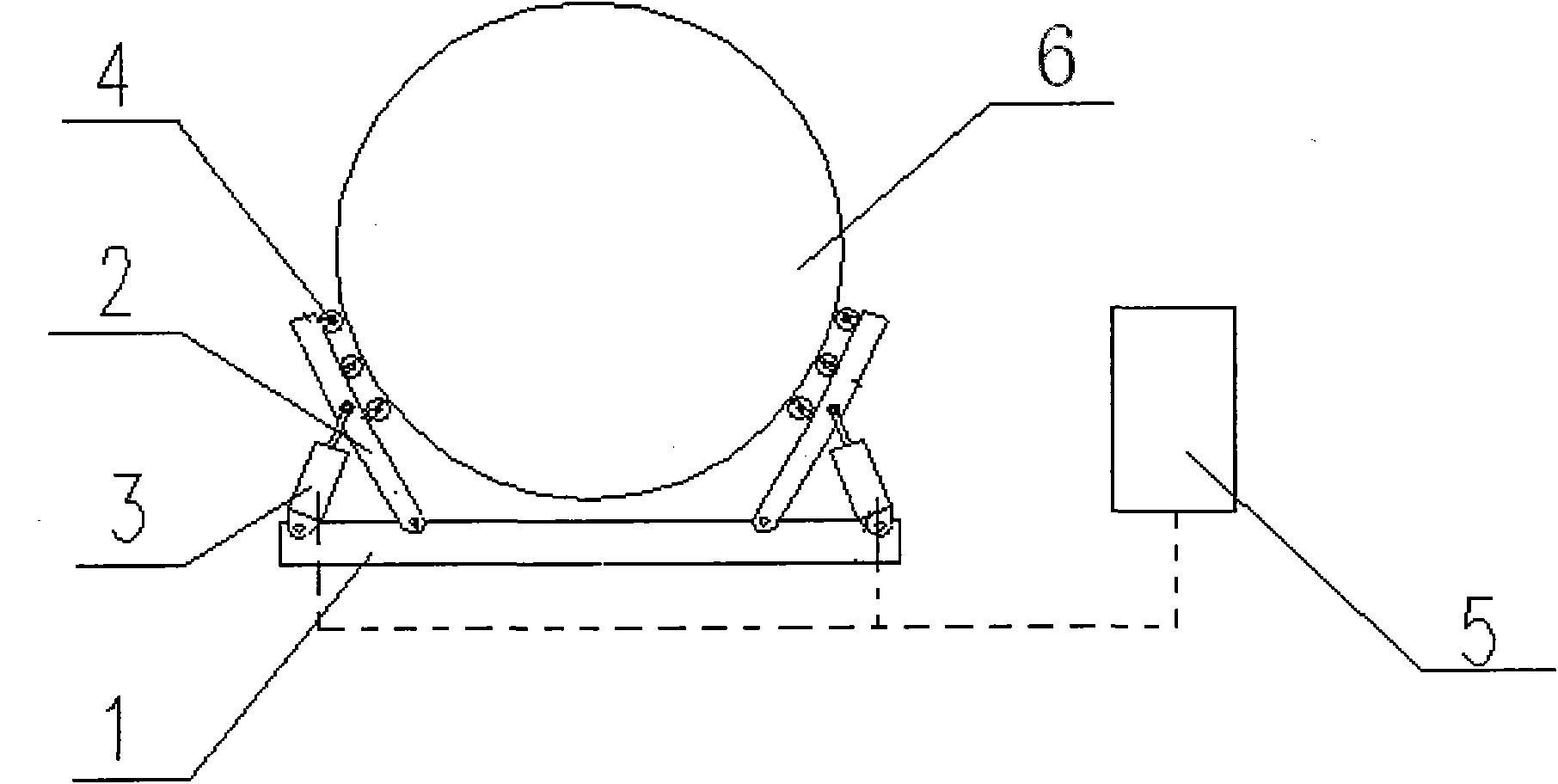

Deformed cylindrical section straightening device

The invention discloses a deformed cylindrical section straightening device which comprises a frame, two correction components and a control system, wherein the two correction components are in the mirror symmetry, and each correction component comprises a guiding frame and a driving cylinder; one end of each guiding frame is hinged on the frame; the surface facing to a corrected deformed cylindrical section, of each guiding frame, is an arc surface matched with the excircle of the deformed cylindrical section; one end of each driving cylinder is hinged with the frame, and the other end of the driving cylinder is hinged with one side far away from the corrected cylinder joint, of the guiding frame; and the control system is electrically connected with the driving cylinders respectively. The deformed cylindrical section straightening device has simple, reasonable and compact structure, overcomes many disadvantages of the prior art and realizes the mechanical adjustment of the roundness of the deformed cylindrical section; and by adopting the deformed cylindrical section straightening device, the degree of automation of the equipment and the adjustment precision of the roundness of the cylinder joint can be increased, the working efficiency of correction can be increased, and wastes can be reduced.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

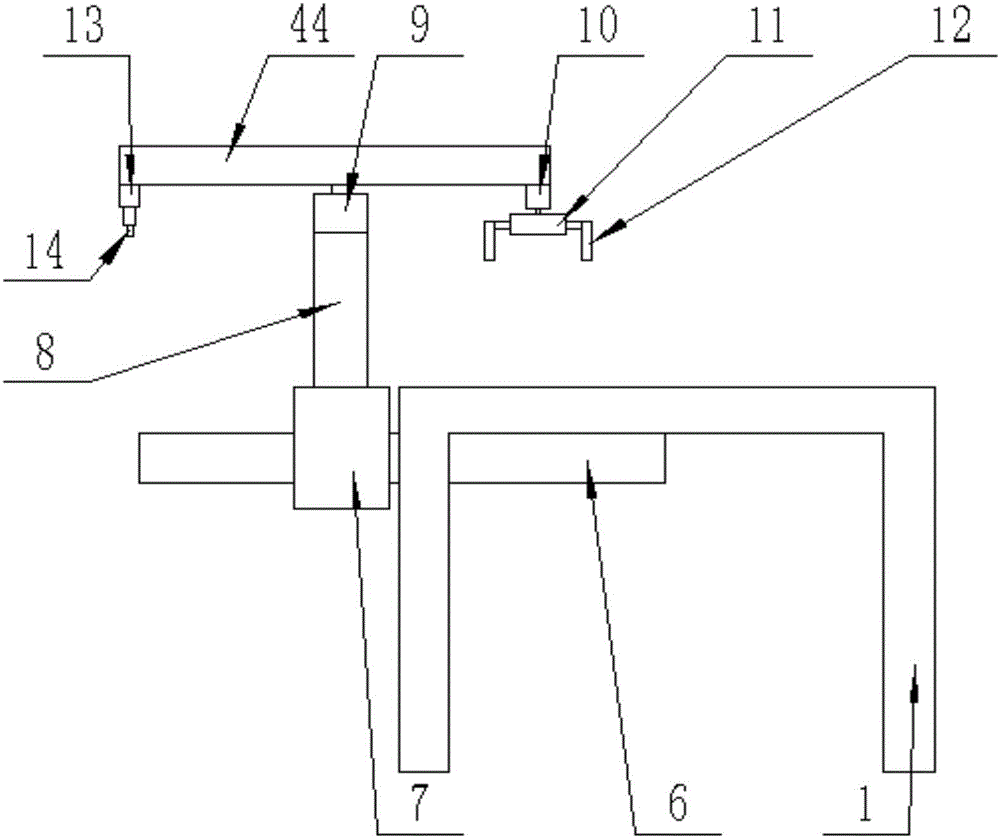

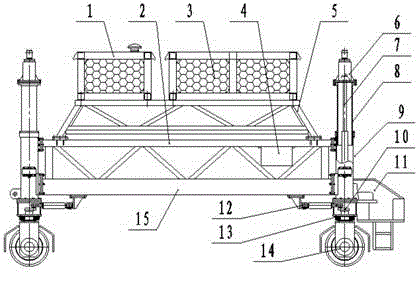

Pipeline construction straddle carrier and straddling method

InactiveCN105084218AIncrease the level of mechanizationFlexible walking and steeringPipe laying and repairBase supporting structuresVehicle framePipeline transport

The invention discloses a pipeline construction straddle carrier and a straddling method, and relates to the technical fields of hoisting, off-road transportation, and pipeline system. The straddle carrier comprises a frame, a door type elevating and hoisting system, which is symmetrically arranged front-to-rear, and a moving system; the frame comprises two trusses and one rack; two ends of each truss are respectively connected to the external column sleeves of the door type elevating and hoisting system; the front surface of the rack is in a trapezoid shape, and the side surface is in a splayed saddle structure. The upper parts of two trusses are both provided with flanges and fixed to the base of the rack through bolts. The door type elevating and hoisting system comprises two columns, a hoist beam, and a hoisting tool. The moving system is installed on the bottoms of the external sleeves of the columns. The provided straddle carrier can bear a maximal weight of 13 tons, can be applied to construction of pipelines with a diameter of 1422 millimeters or less in a tunnel, and integrates the functions of pipeline transportation, hoisting, and assembly together.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Painting color palette machining device

ActiveCN106002298AIncrease the level of mechanizationLow costOther manufacturing equipments/toolsOther artistic work equipmentsPunchingEngineering

The invention discloses a painting color palette machining device. The painting color palette machining device comprises a workbench and a conveying table arranged on one side of the workbench and used for conveying panels. The interior of the workbench is of a cavity structure. An installing plate is arranged above the end, close to the conveying table, of the workbench and provided with a cutting unit and a carving unit. A support is arranged above the workbench and sequentially provided with a punching unit and a hole milling unit. The workbench is provided with a mechanical arm used for transferring the panels. A conveying unit is arranged at the rear end of the upper surface of the workbench. The workbench is provided with a controller. The controller is electrically connected with the conveying table, the carving unit, the punching unit, the hole milling unit, the conveying unit, the mechanical arm, an air cylinder, a first linear motor, a first rotation motor and a pair of vacuum suction cups. The painting color palette machining device has the beneficial effects of being simple in structure and high in practicability.

Owner:天长市倍彩文化用品有限公司

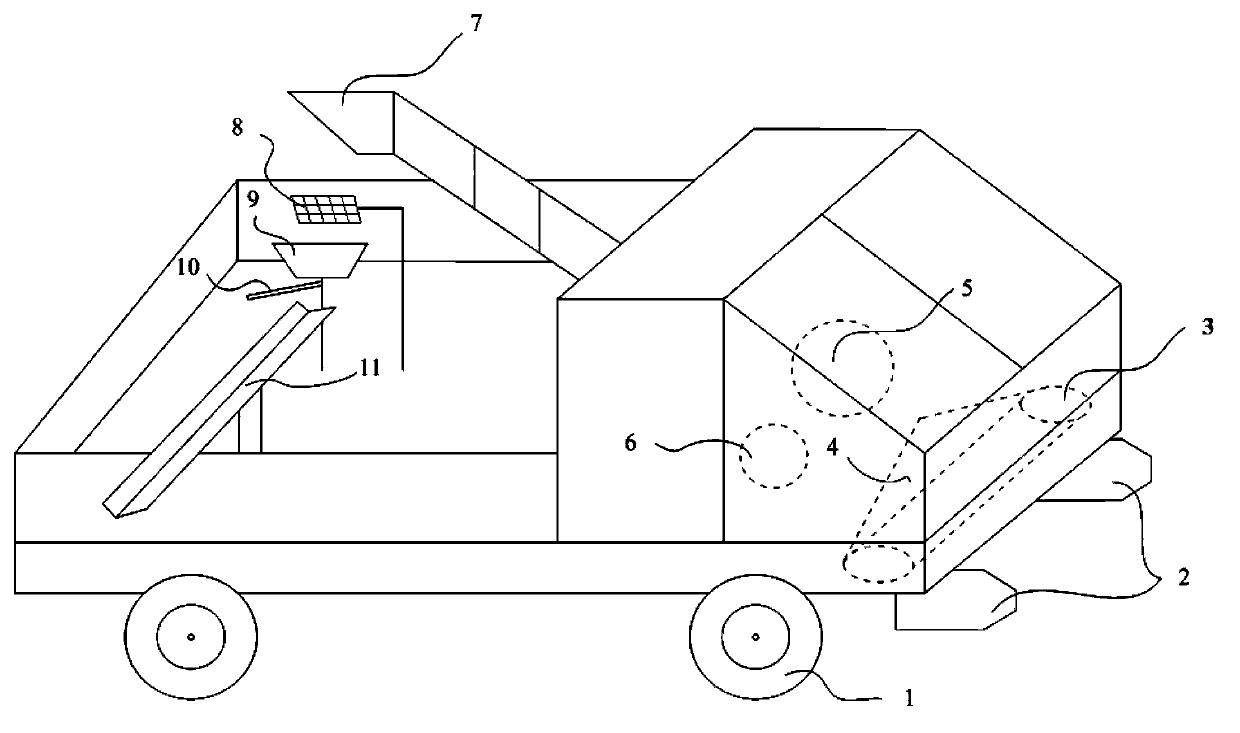

Grain collector

InactiveCN103964217AIncrease the level of mechanizationReduce lossesLoading/unloadingAgricultural engineeringTime cost

The invention discloses a grain collector which comprises a vehicle, a grain sucking device, a grain conveying device, a grain collecting device and a control device. The grain sucking device, the grain conveying device, the grain collecting device and the control device are fixed onto the vehicle, the grain sucking device, the grain conveying device and the grain collecting device are sequentially electrically connected with one another, and the control device is electrically connected with the grain sucking device, the grain conveying device and the grain collecting device and is used for controlling the grain sucking device, the grain conveying device and the grain collecting device. The grain collector has the advantages that grain collecting operation can be mechanically carried out in agricultural production, accordingly, grains can be mechanically, quickly and automatically collected, and the labor cost and the time cost can be greatly saved.

Owner:华东师范大学附属枫泾中学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com