Pipeline construction straddle carrier and straddling method

A technology for pipeline construction and straddle carrier, which is used in pipeline laying and maintenance, transportation and packaging, and trolley cranes, etc. It can solve the problem that the equipment does not have power, cannot meet the needs of long-distance pipeline transportation, and cannot be hoisted with ordinary pipelines for handling and hoisting. equipment and other issues to achieve the effect of improving the level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

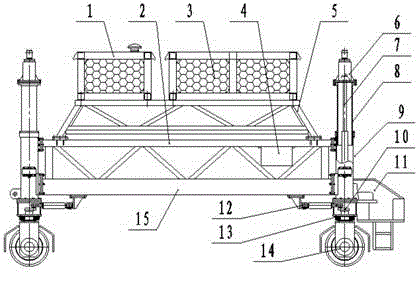

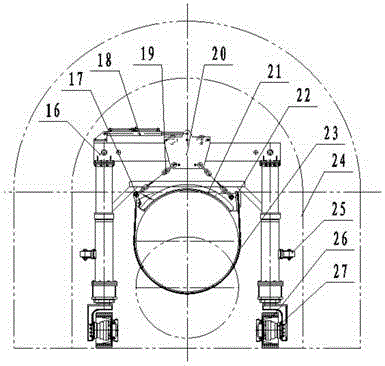

[0024] Example: such as figure 1 and figure 2 As shown; the frame includes two trusses, the two trusses have the same structure, now only one of the trusses is described, the truss 2 is a rectangular welded structure, the outer frame of the truss 2 is a rectangular square tube, and the abdomen is connected by section steel to enhance the overall rigidity , the left and right ends of the truss 2 are respectively connected with the column outer casing 9 by flanges, and the straddle carrier of the present invention is combined into a cuboid frame structure by 2 trusses, 4 columns, and 2 hanging beams, and becomes a rigid whole. The front of the platform 5 is ladder-shaped, and the side is a figure-eight saddle structure. The outer frame of the platform 5 is a rectangular square tube, and the abdomen is connected by a steel section. The power module 1 and the hydraulic transmission module 3 are respectively installed on the upper part of the frame 5. The power module 1 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com