Deformed cylindrical section straightening device

A barrel section and arc-shaped technology, which is applied in the field of correction devices, can solve the problems that the roundness and the concentricity requirements of the two barrel sections cannot be guaranteed, the oil circuit of the annular fixed ring is complicated, and the barrel section rotation cannot be realized, so as to improve the assembly Alignment and welding quality, avoiding driving safety accidents and economic losses, and improving the efficiency of correcting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

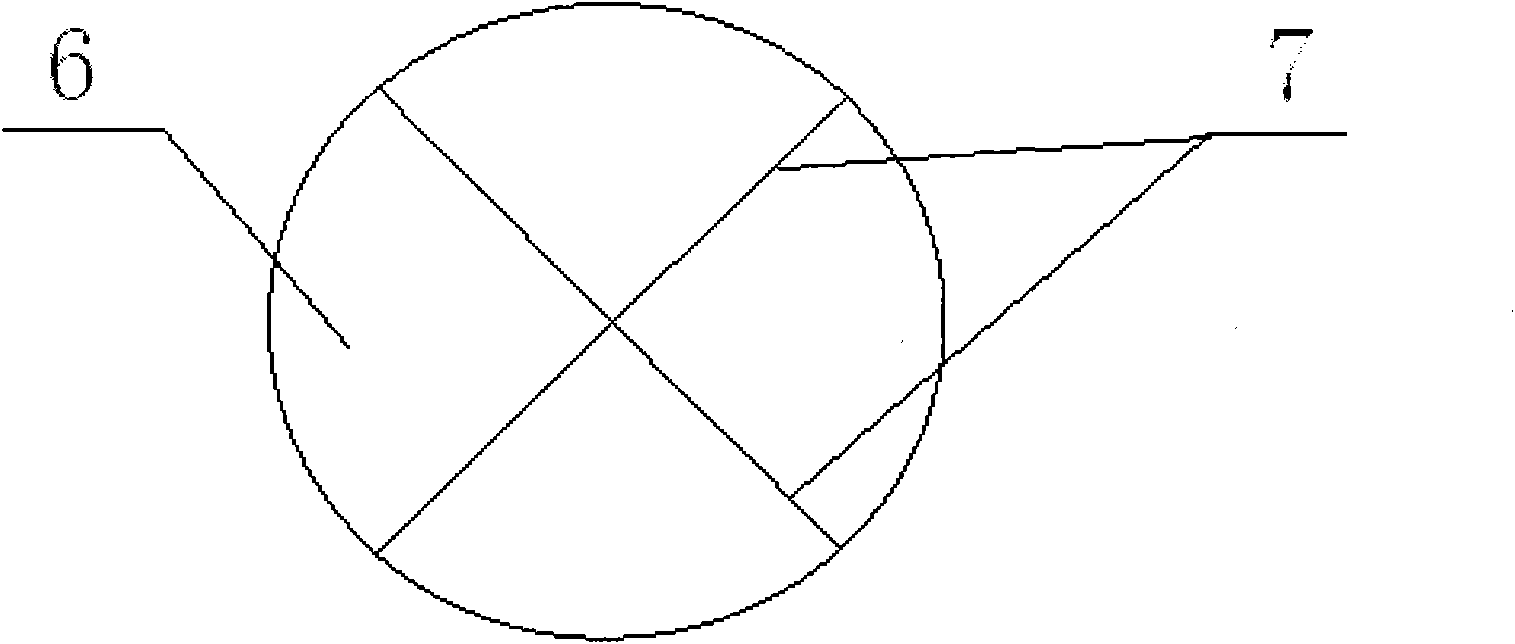

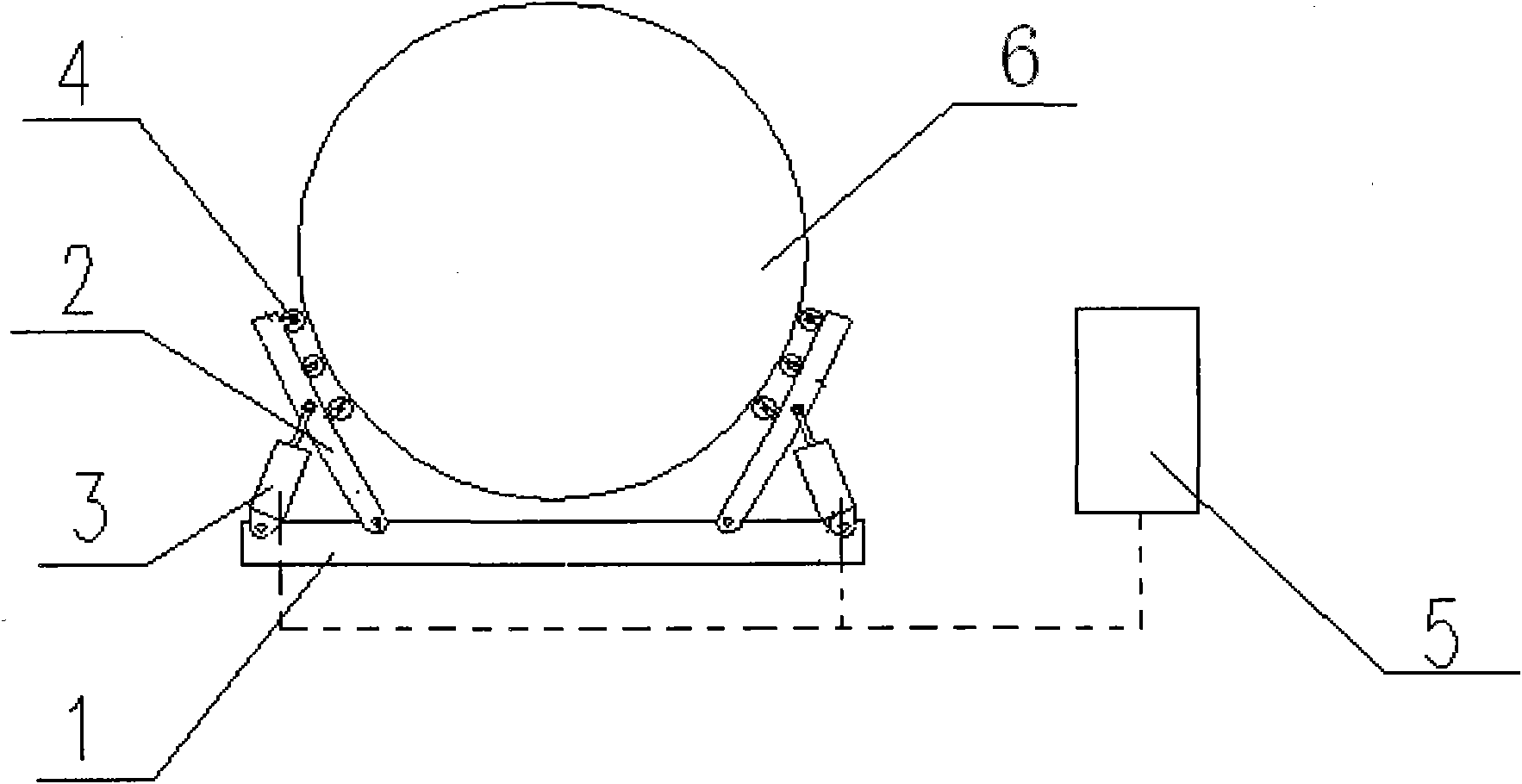

[0026] figure 2 It is a schematic diagram of the use state of the tube section deformation correction device provided in the first embodiment of the present invention. The tube section deformation correction device provided in this embodiment includes a frame 1, a lead frame 2, a hydraulic cylinder 3, and an electrical connection with the hydraulic cylinder 3. control system 5.

[0027] As shown in the specific embodiment shown in the figure, in the tube section deformation correction device, two guide frames 2 are hinged on the frame 1 to form mirror symmetry. The rectified cylinder section 6; the pedestal frame is a panel with a certain radian, and the surface of the pedestal frame 2 toward the rectified cylinder section 6 is an arc shape matching the outer circle of the cylinder section, and the pedestal frame with different radians can be used according to the diameter of the workpiece; A guide roller 4 is fixed on the side of the guide frame 2 facing the straightened ba...

Embodiment 2

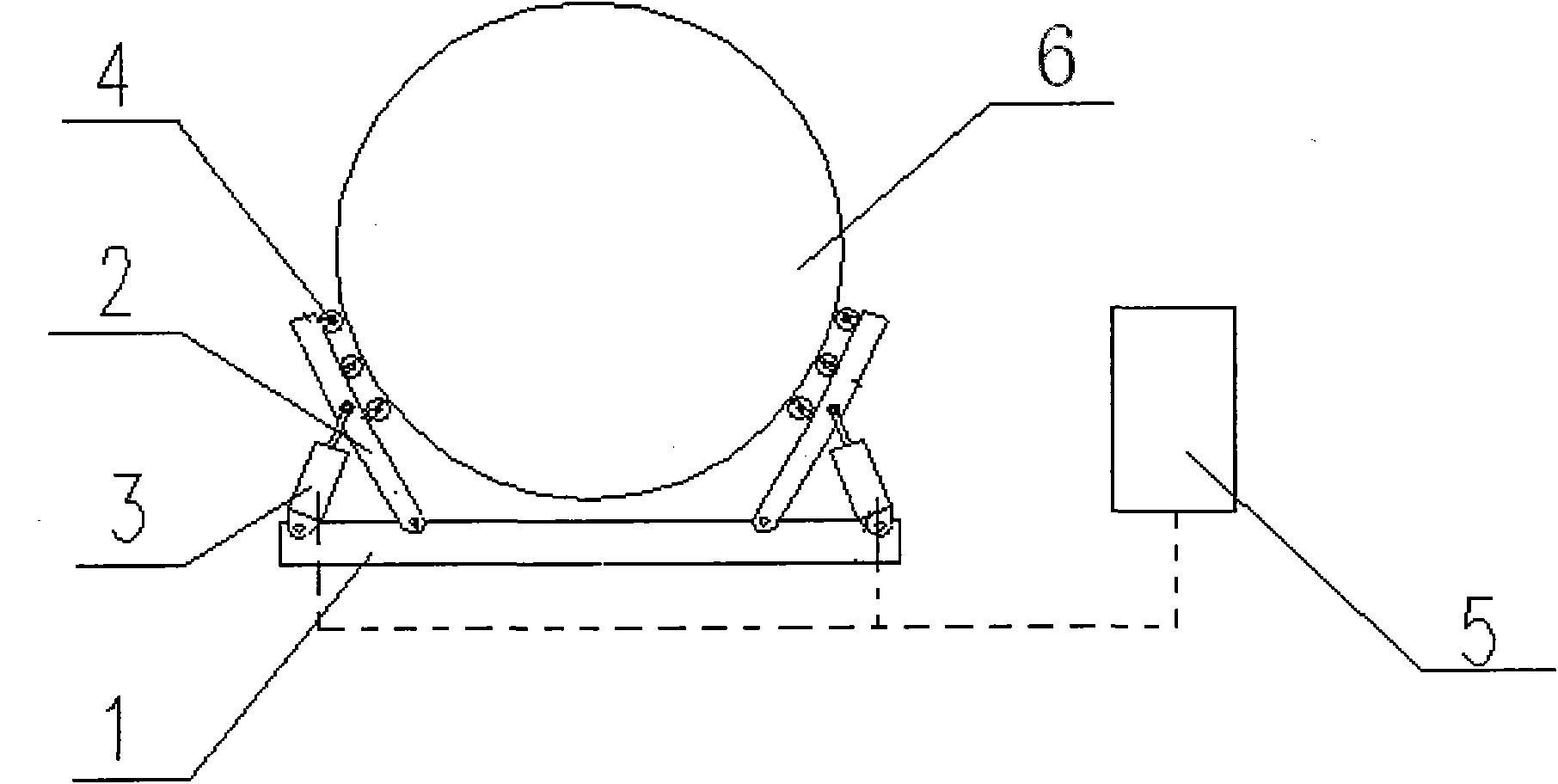

[0030] The difference between this embodiment and the first embodiment is that an air cylinder is used instead of a hydraulic cylinder to drive the expansion or reduction of the opening formed by the two guide frames. At the same time, a universal guide ball is provided on the side of the guide frame facing the straightened cylinder section, which is used to replace the guide roller in the first embodiment, so as to assist the circumferential rotation and longitudinal movement of the cylinder section. Solve the defect that other methods of correcting the roundness of the barrel section cannot be welded and rotated, and can assist the rotation of the barrel section to meet the needs of welding automation.

[0031] When correcting, first place the straightened cylinder section between the two guide frames; the operator starts the control system, drives the cylinder electrically connected to the start-up control system, and as the pressure of the cylinder increases or decreases, t...

Embodiment 3

[0033] The third embodiment of the present invention provides a device for correcting the deformation of a tube section, which includes a frame, two correction components and a control system. The two correction components are mirror-symmetrically arranged, and each correction component includes a guide frame and a driving cylinder; one end of each guide frame It is hinged on the frame; the surface of the guide frame facing the cylinder section to be corrected is an arc shape that matches the outer circle of the cylinder section; one end of the driving cylinder is hinged on the frame, and the other end of the driving cylinder is hinged on the guide frame away from the cylinder section to be corrected. side; the control system is electrically connected to the drive cylinder respectively.

[0034]When correcting, first place the deformed part of the straightened cylinder section between the two lead frames; the operator starts the control system and drives the drive cylinder that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com