Patents

Literature

5331results about How to "Advanced technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

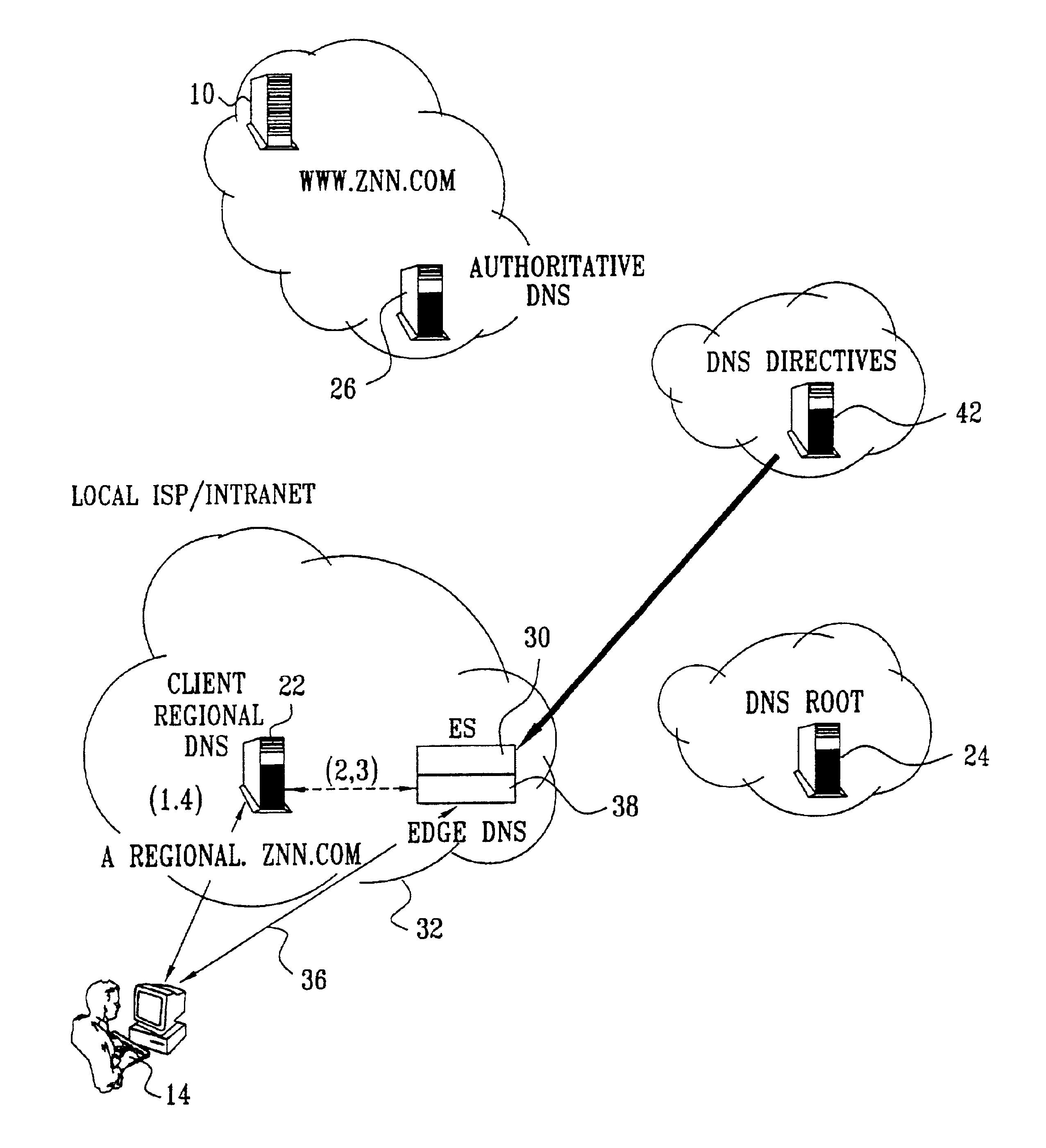

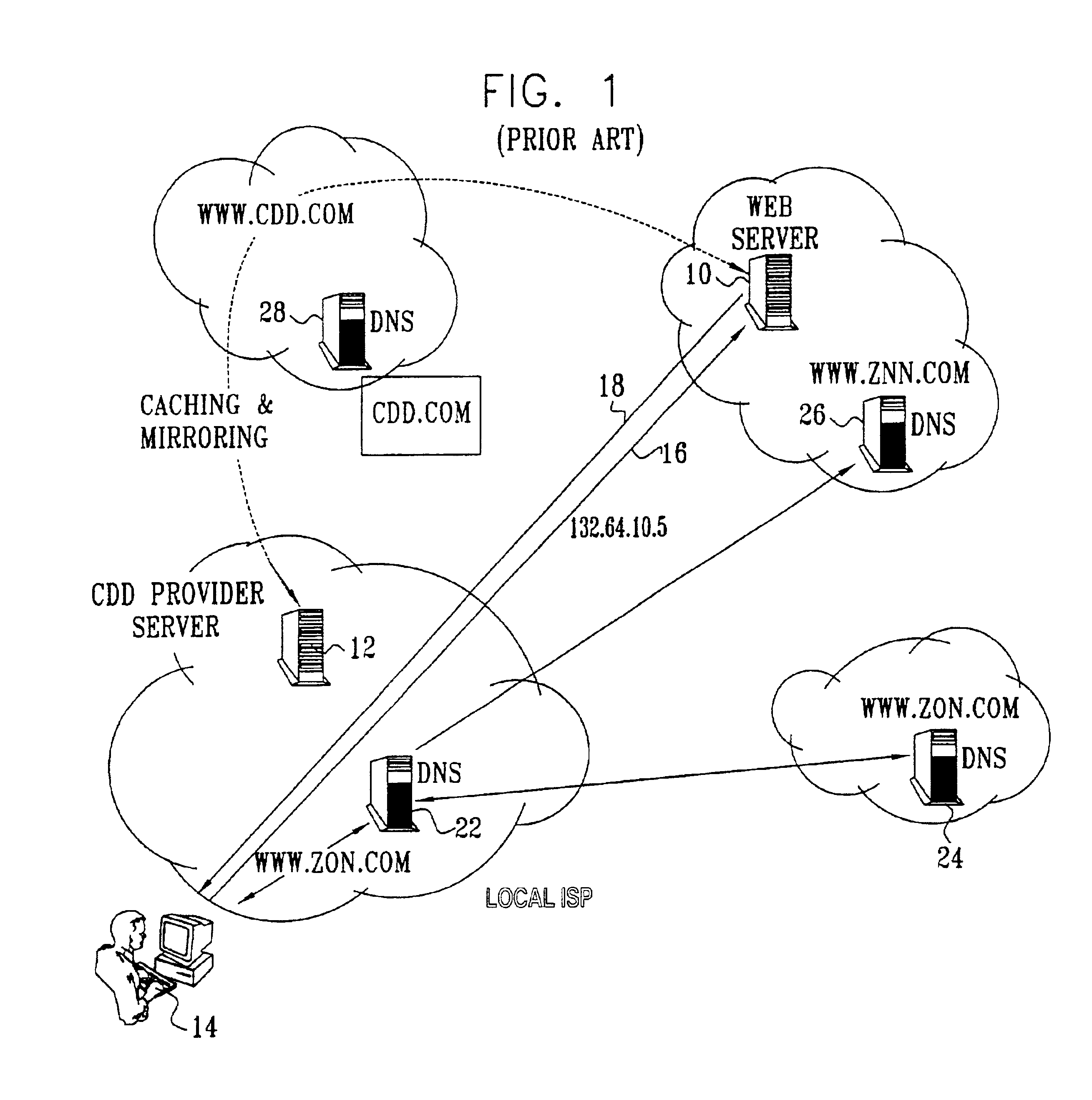

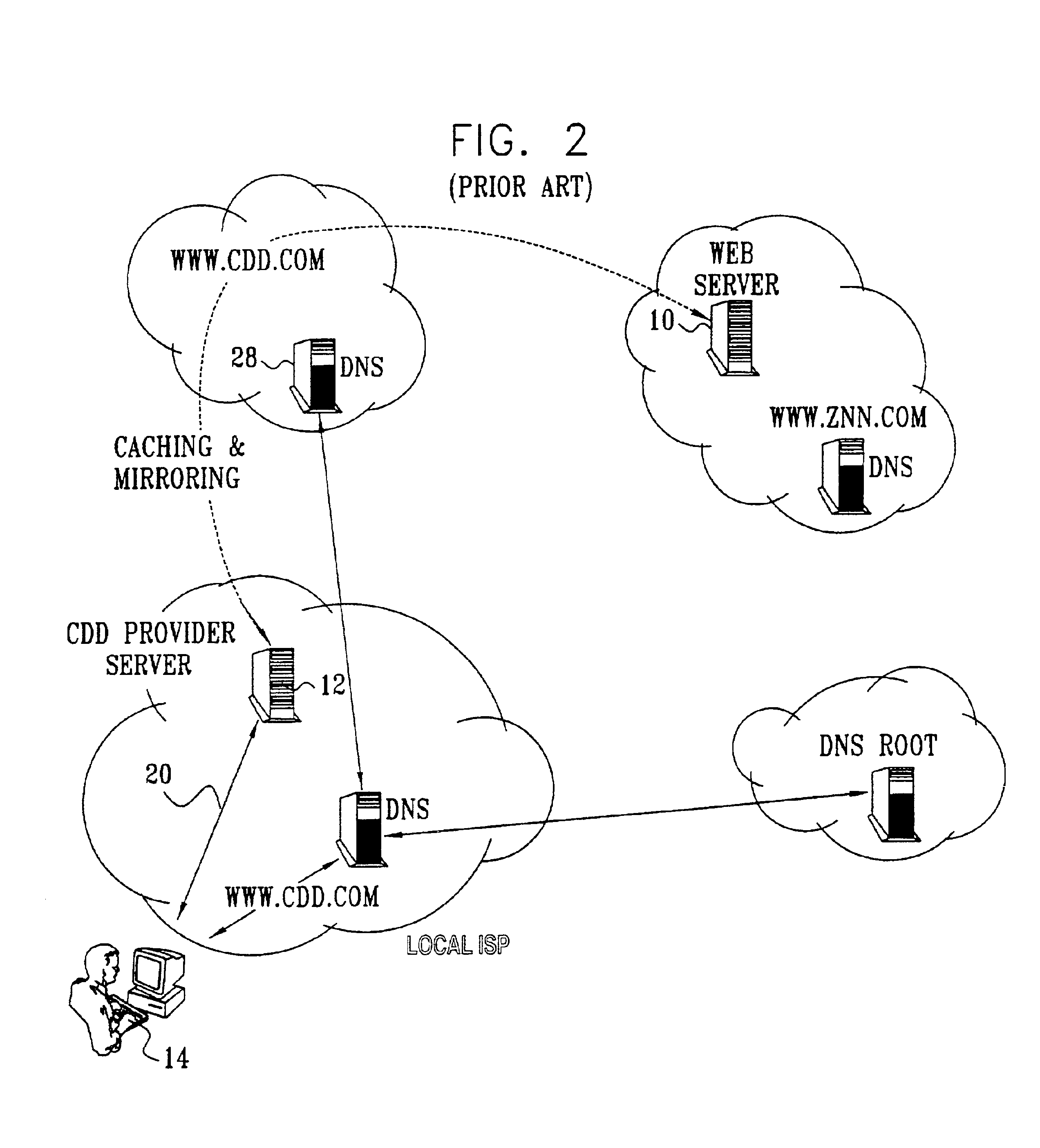

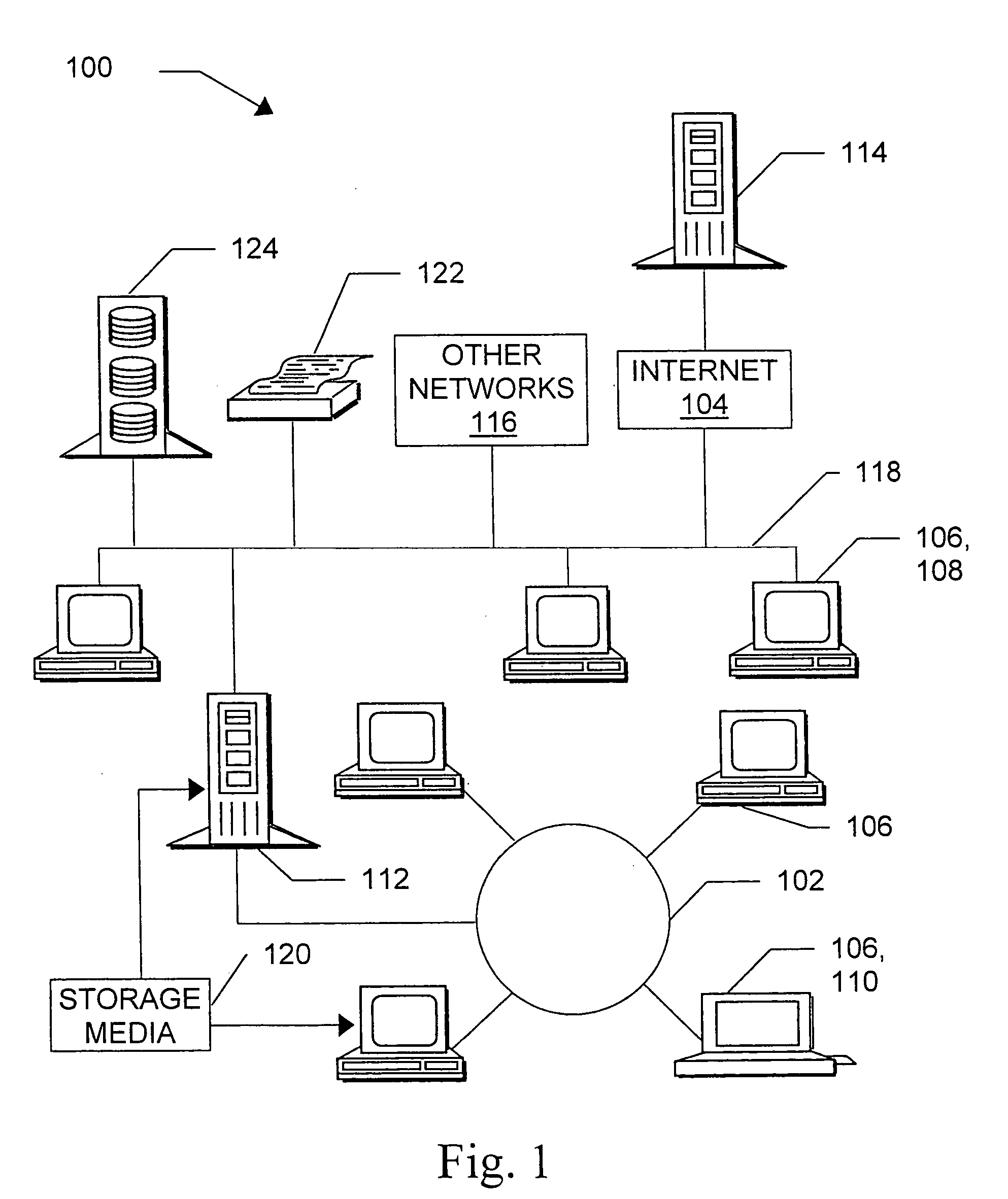

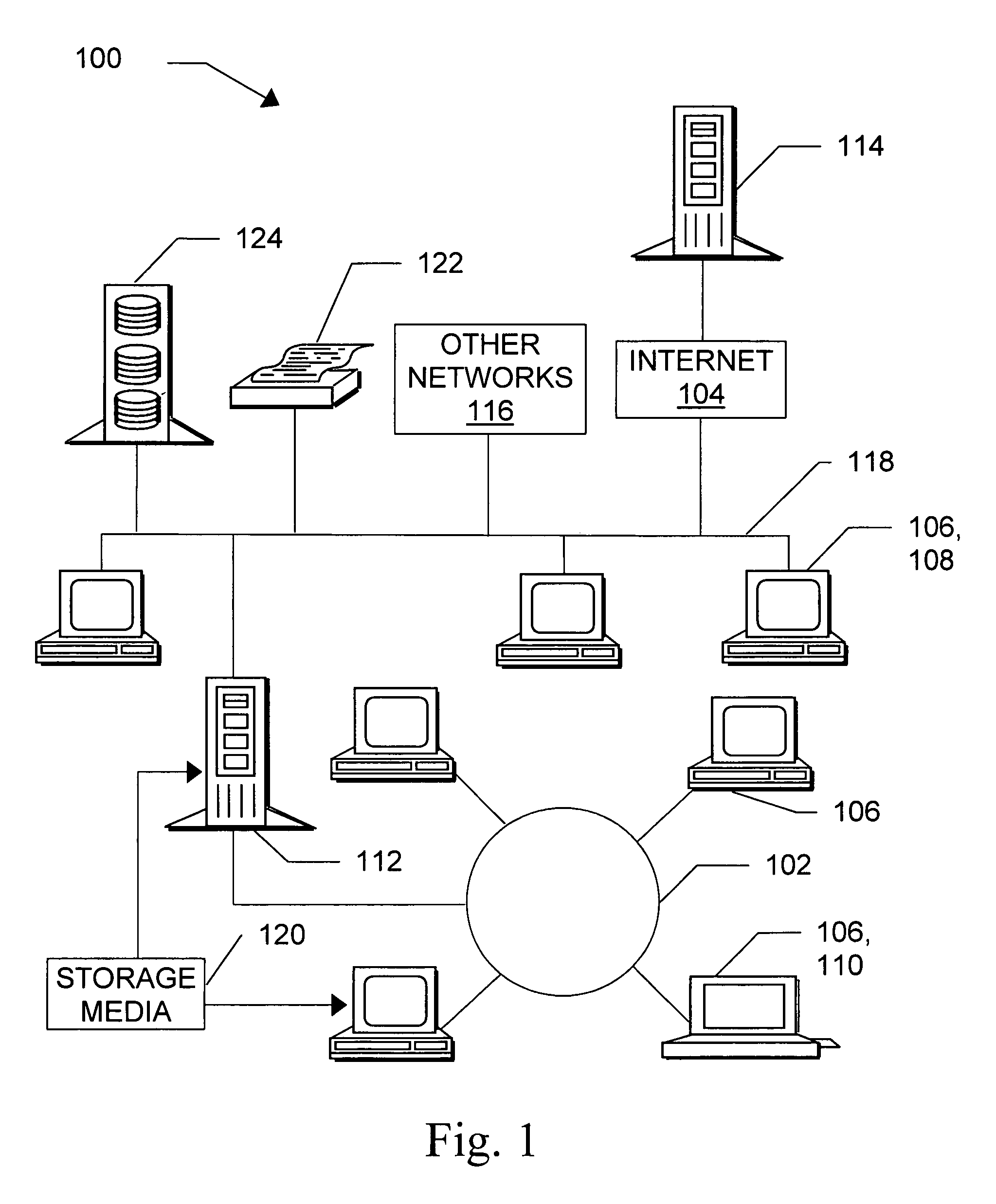

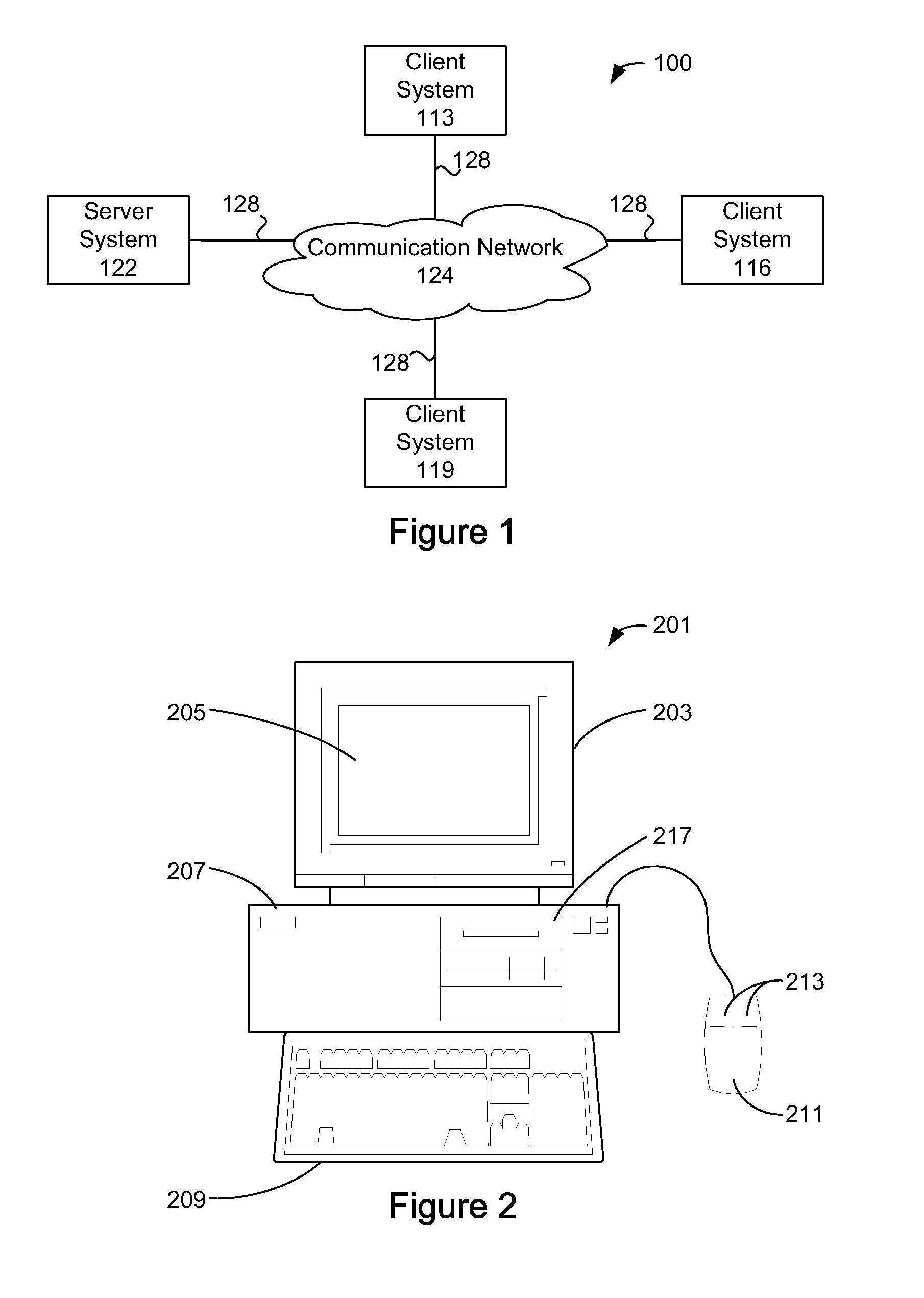

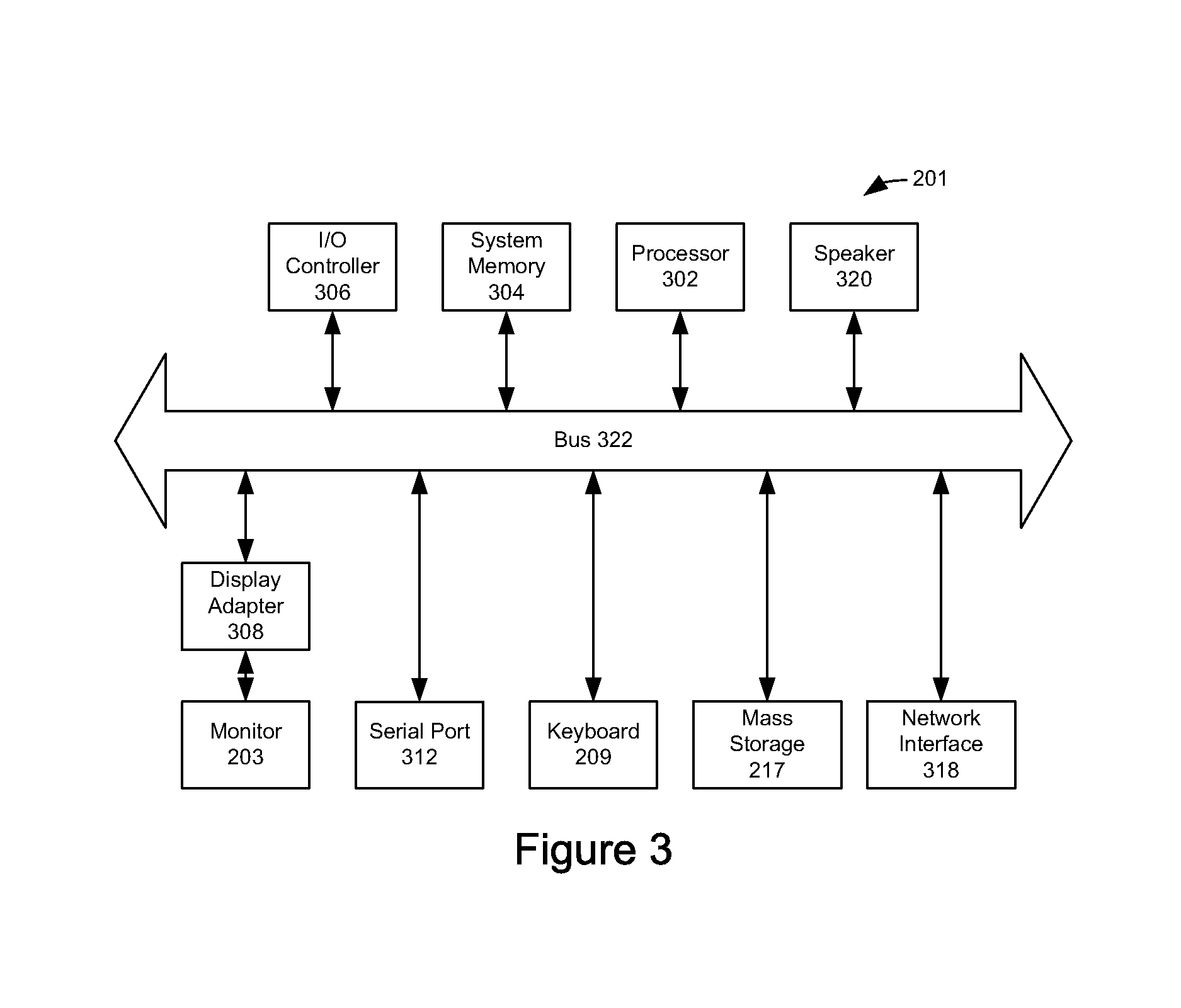

Differentiated content and application delivery via internet

InactiveUS6976090B2Decentralized and differentiatedAdvanced technologyMultiple digital computer combinationsWebsite content managementScalable systemEdge server

Owner:CISCO TECH INC

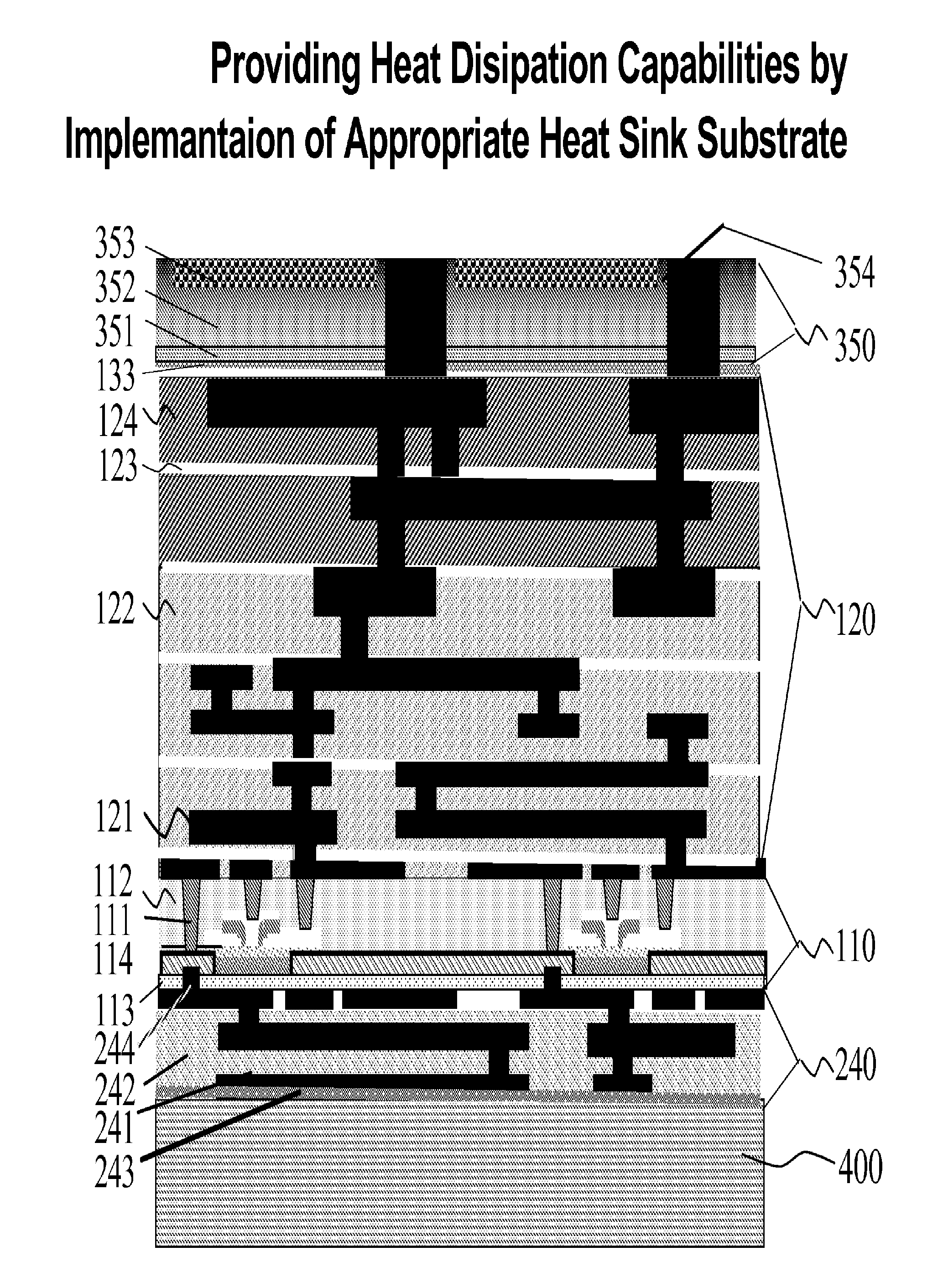

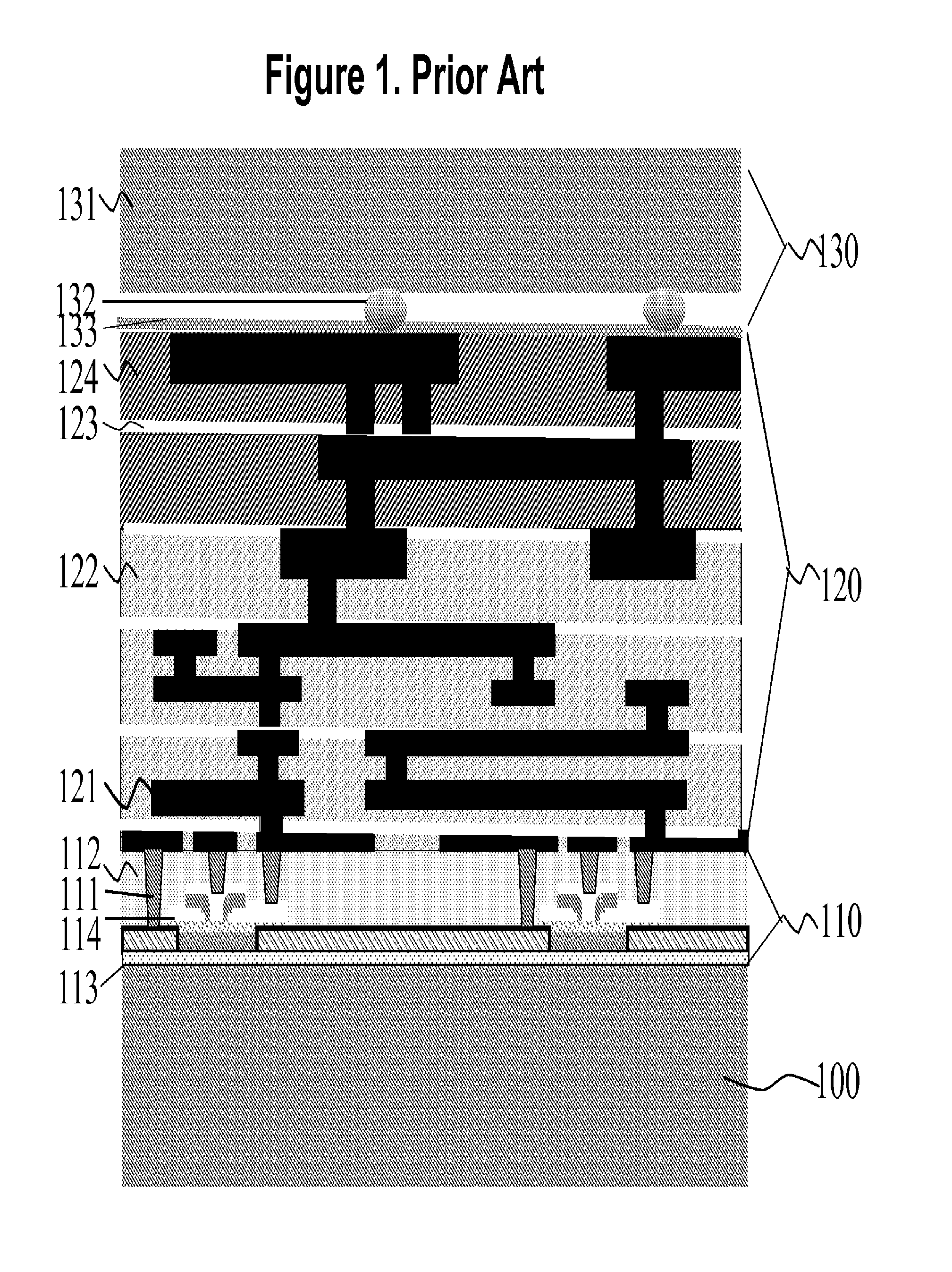

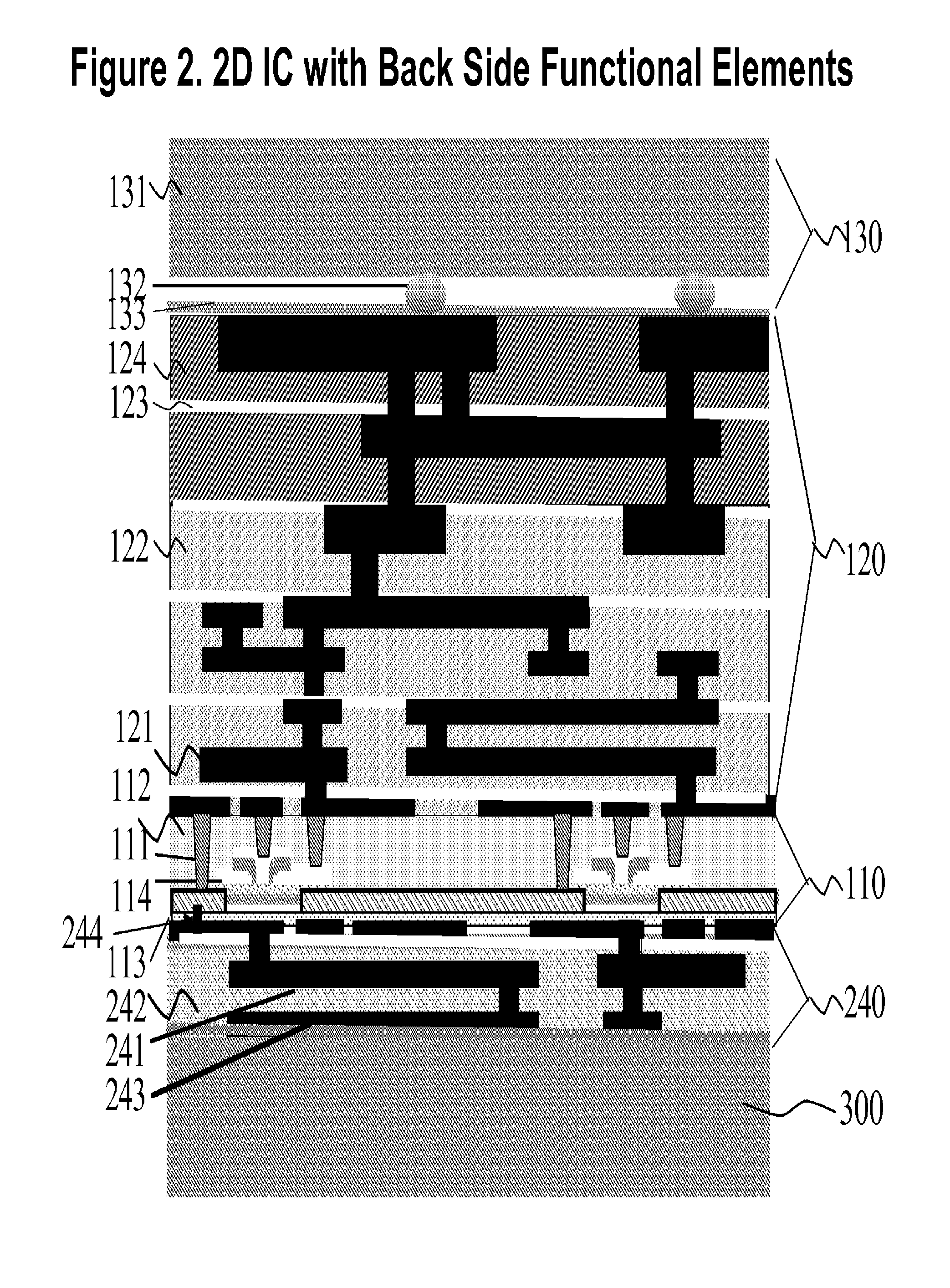

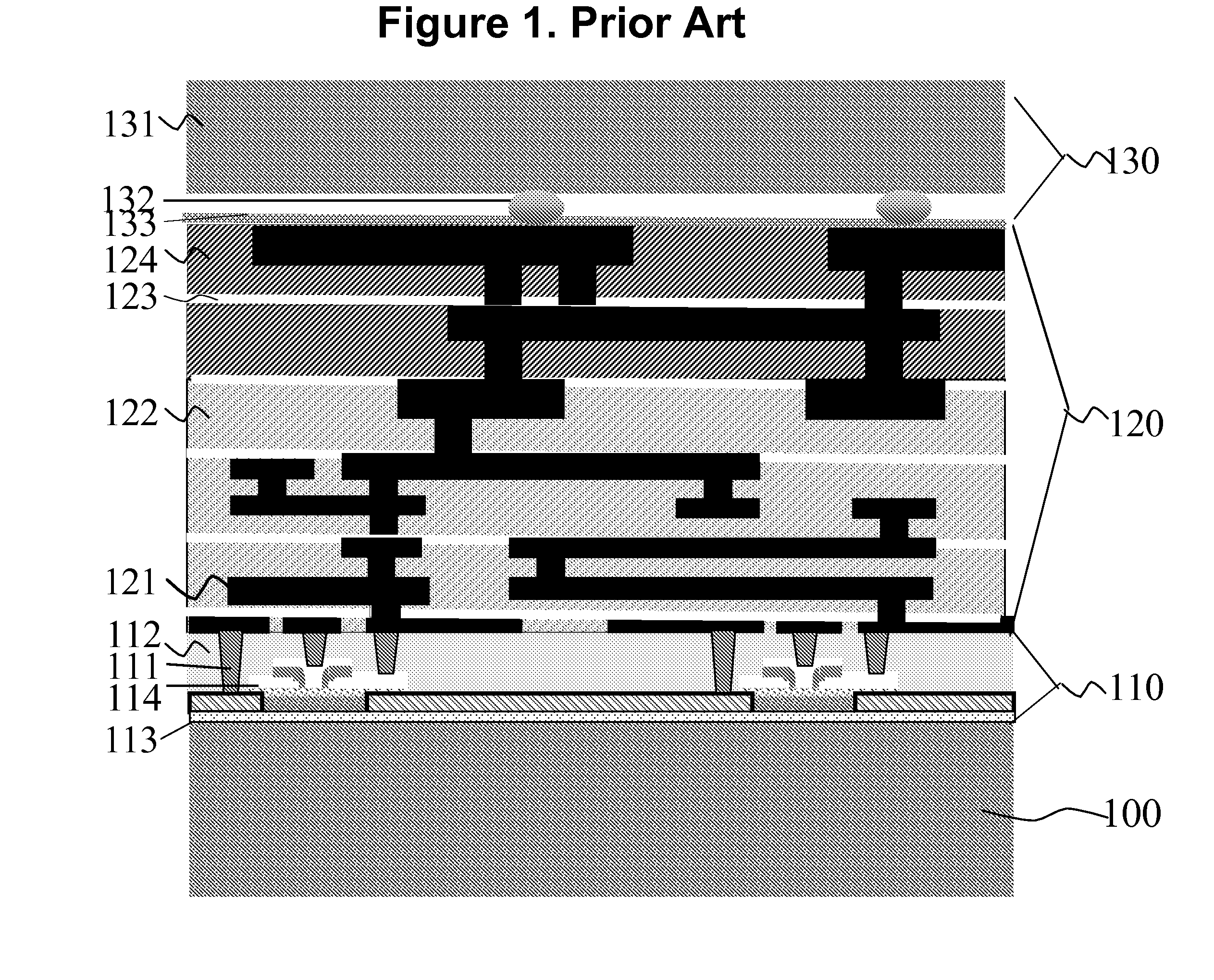

Layer transfer process and functionally enhanced integrated circuits produced thereby

InactiveUS20100081232A1Low costFunction increaseSemiconductor/solid-state device detailsSolid-state devicesEngineeringIntegrated circuit

A structure for a semiconductor components is provided having a device layer sandwiched on both sides by other active, passive, and interconnecting components. A wafer-level layer transfer process is used to create this planar (2D) IC structure with added functional enhancements.

Owner:LINKEDIN

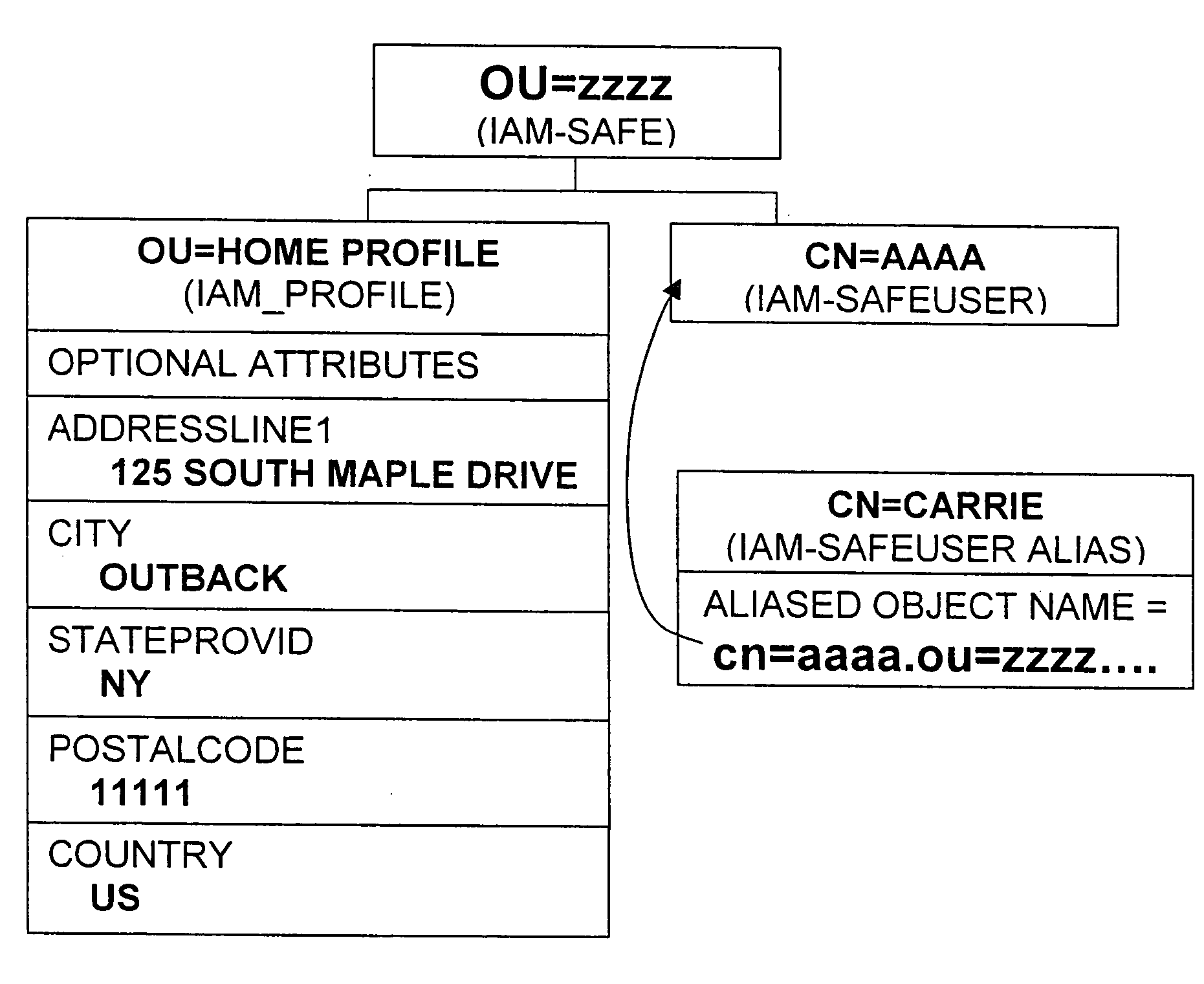

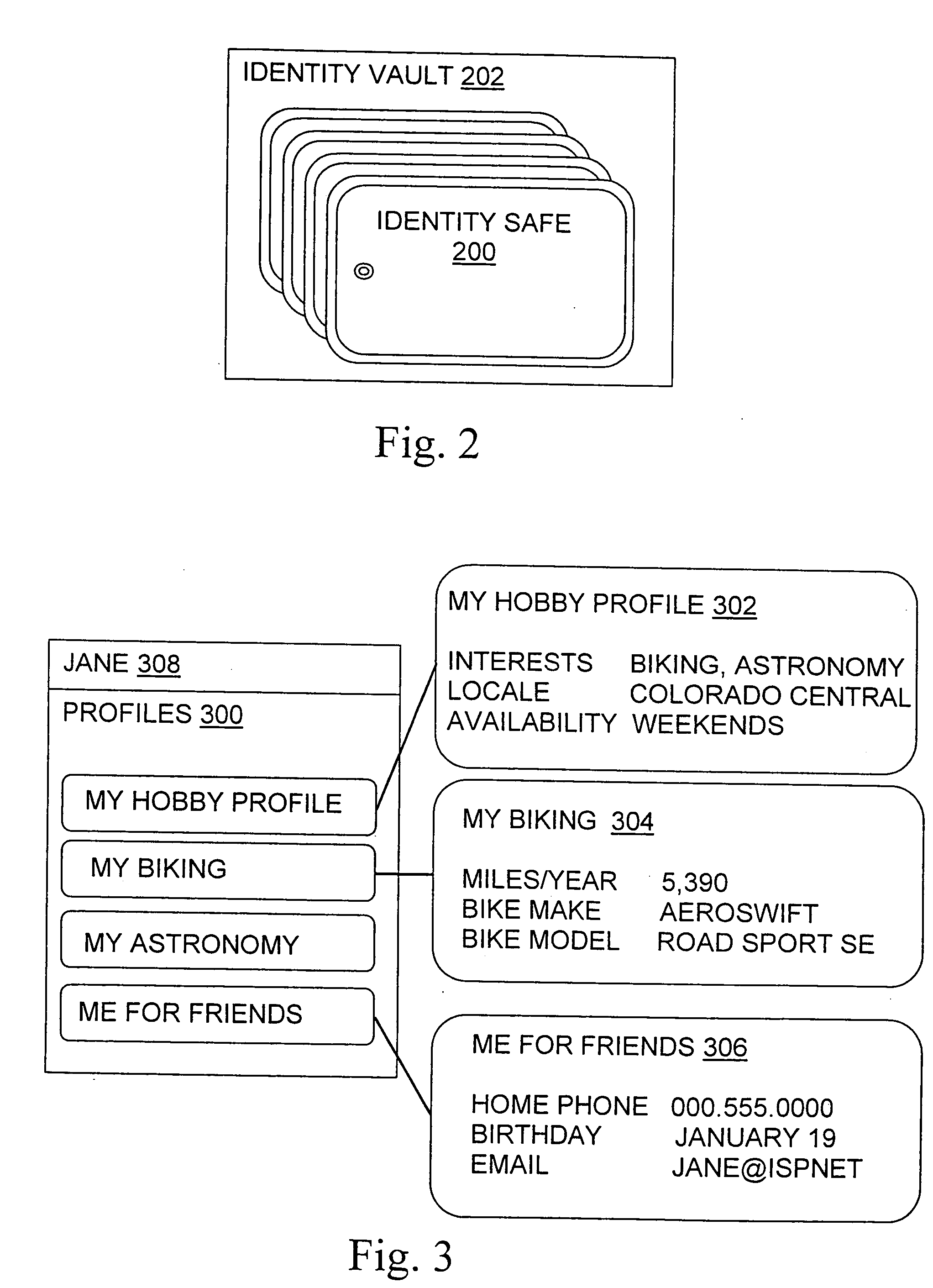

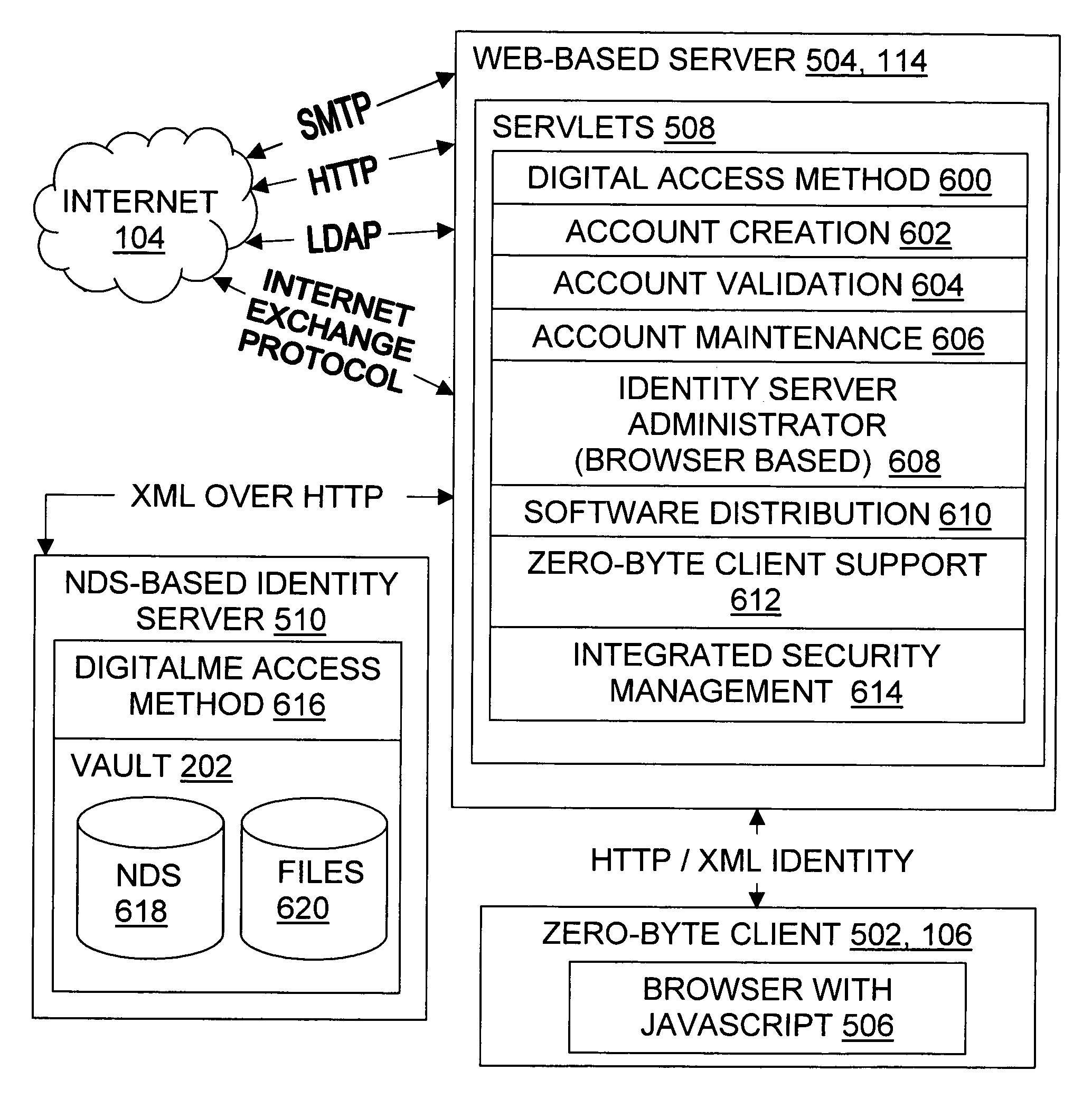

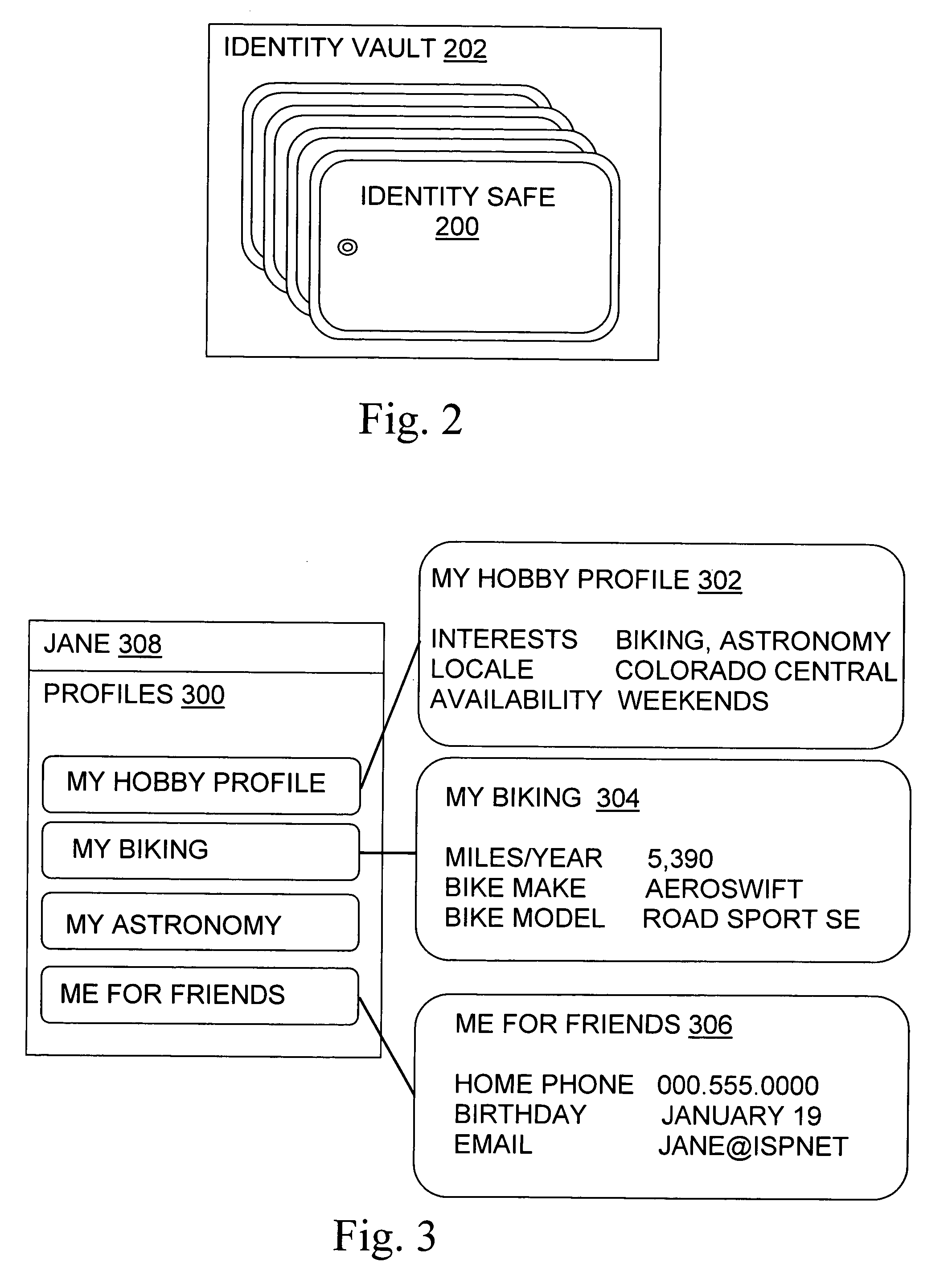

Managing digital identity information

ActiveUS20050044423A1Maintain the integrity of relationshipsAdvanced technologyDigital data processing detailsMultiple digital computer combinationsDigital identityPassword

A basic architecture for managing digital identity information in a network such as the World Wide Web is provided. A user of the architecture can organize his or her information into one or more profiles which reflect the nature of different relationships between the user and other entities, and grant or deny each entity access to a given profile. Various enhancements which may be provided through the architecture are also described, including tools for filtering email, controlling access to user web pages, locating other users and making one's own location known, browsing or mailing anonymously, filling in web forms automatically with information already provided once by hand, logging in automatically, securely logging in to multiple sites with a single password and doing so from any machine on the network, and other enhancements.

Owner:EMC IP HLDG CO LLC

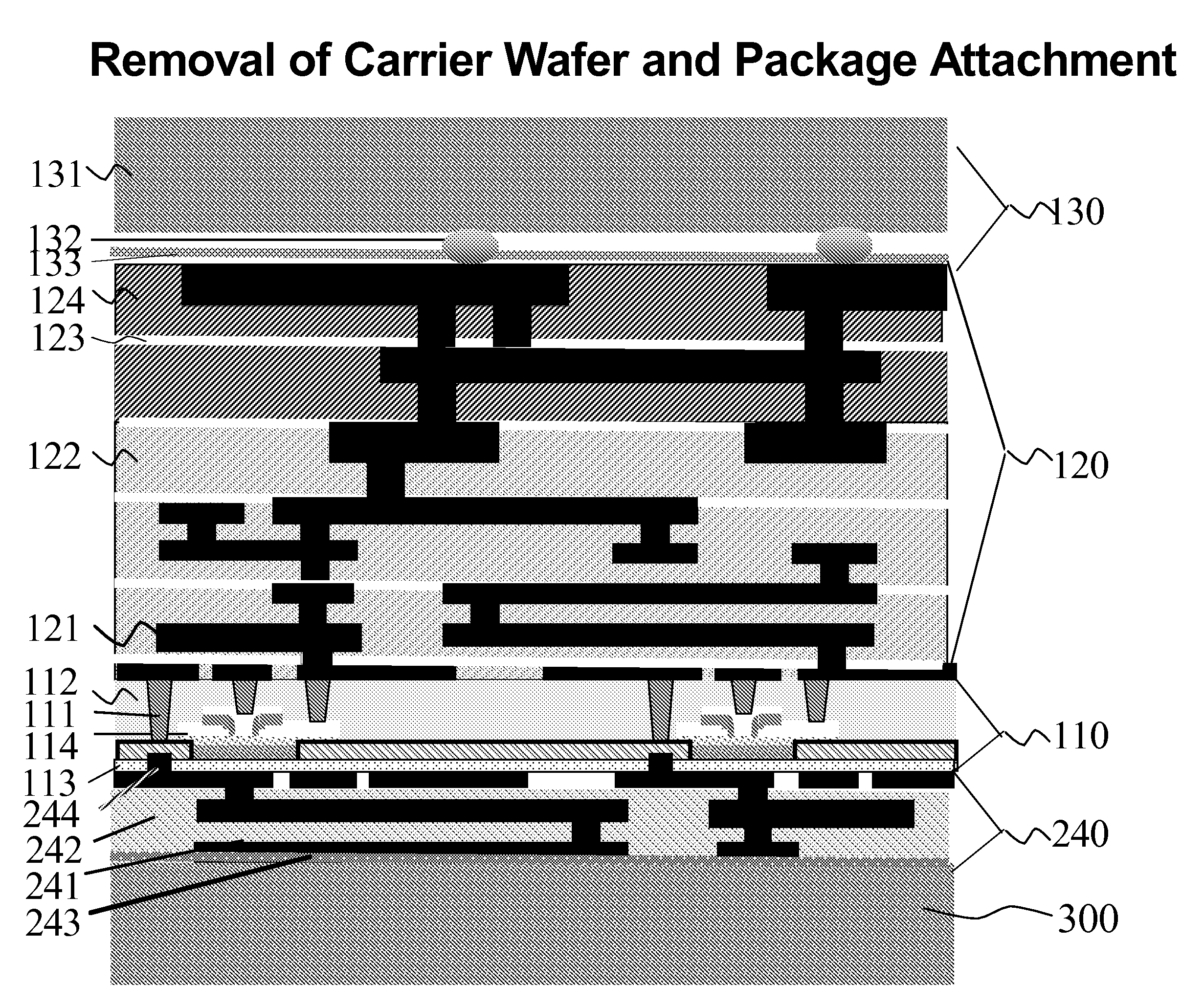

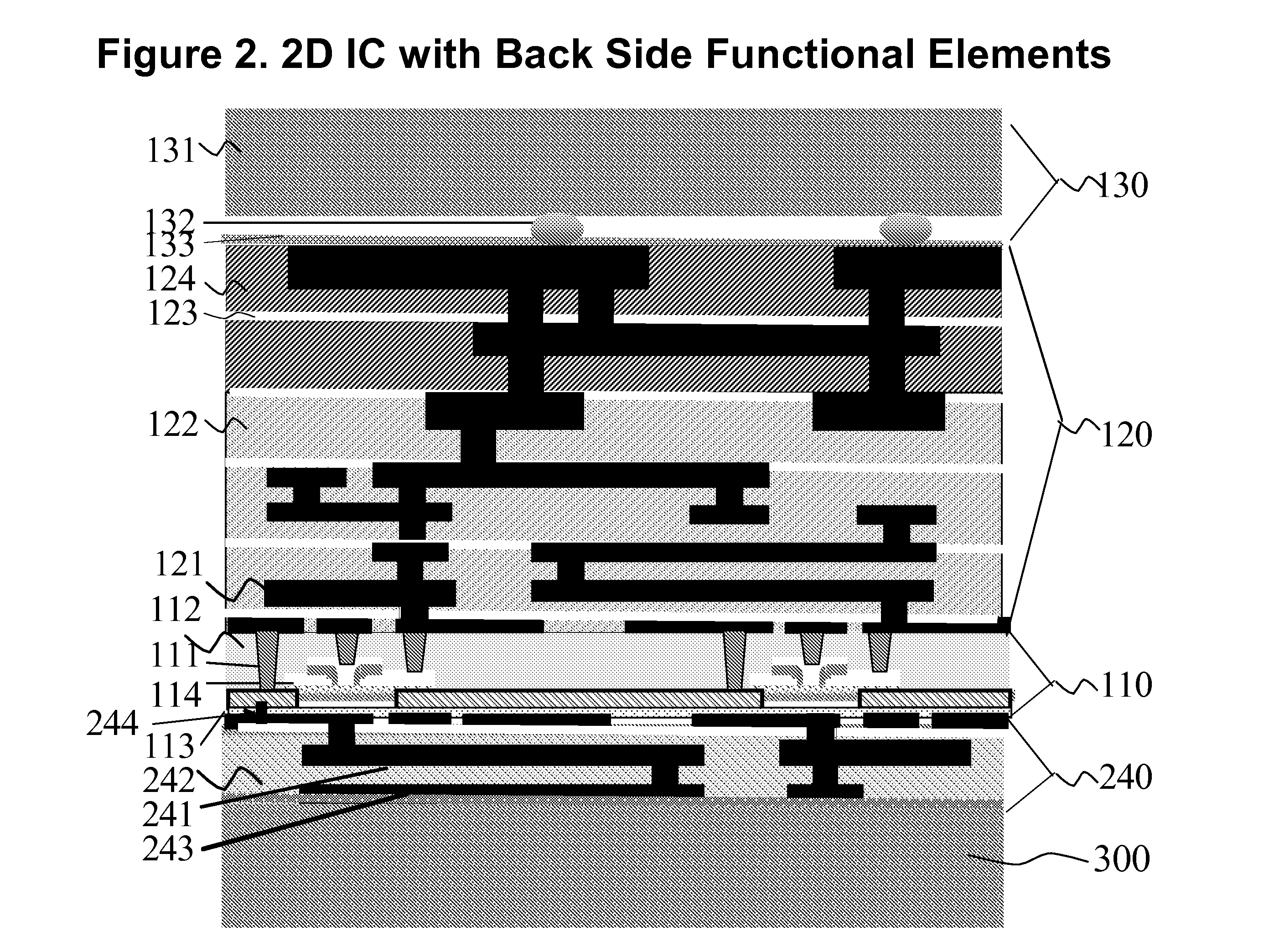

Layer Transfer Process and Functionally Enhanced Integrated Circuits Products Thereby

InactiveUS20080277778A1Low costFunction increaseSemiconductor/solid-state device detailsSolid-state devicesTransfer procedureEngineering

A structure for a semiconductor components is provided having a device layer sandwiched on both sides by other active, passive, and interconnecting components. A wafer-level layer transfer process is used to create this planar (2D) IC structure with added functional enhancements.

Owner:GLOBALFOUNDRIES INC

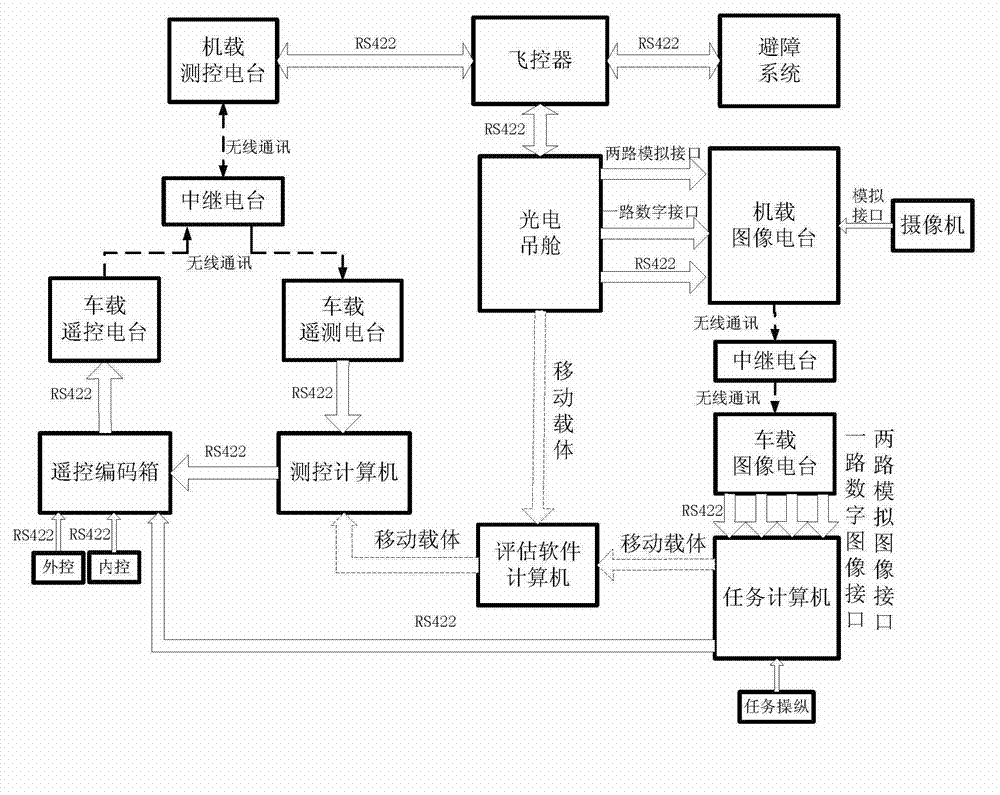

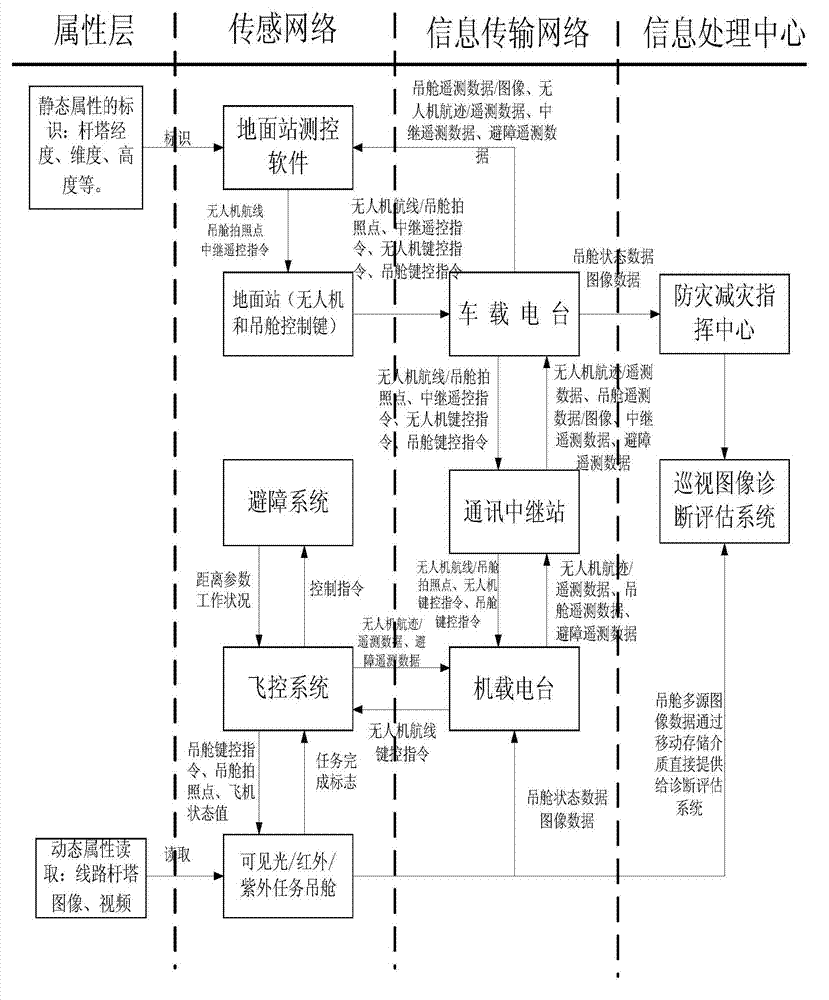

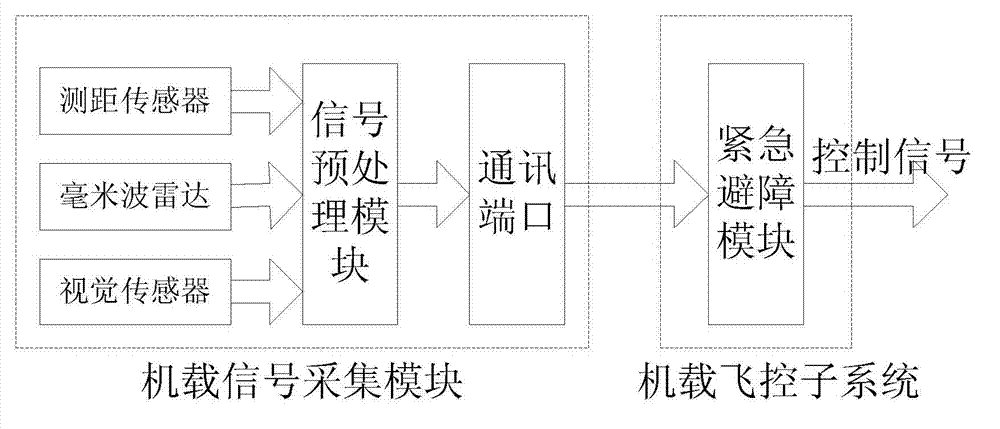

Special unmanned helicopter system suitable for routing inspection on power grid in mountain area

ActiveCN103078673AReduce grid failure rateReduce grid operating costsRadio transmissionTerrainGeographic information system

The invention discloses a special unmanned helicopter system suitable for routing inspection on a power grid in a mountain area, which comprises a sensor network, an information transmission network and an information processing center. According to the special unmanned helicopter system suitable for routing inspection on the power grid in the mountain area, which is disclosed by the invention, in the complex terrain environment of the mountain area and under the complex weather conditions of the mountain area, a medium-sized special unmanned helicopter system suitable for routing inspection on the power grid in the mountain area and an application method thereof can be provided. According to the invention, effective fusion of cutting-edge advanced technologies such as an unmanned aerial vehicle platform technology, a data chain communication technology, a GIS (Geographic Information System) technology, a visible light / infrared / ultraviolet high definition shooting, storage and transmission technology, a distance measuring and sensing technology and an image diagnostic evaluation technology is sufficiently utilized to implement daily routing inspection on a power transmission line.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

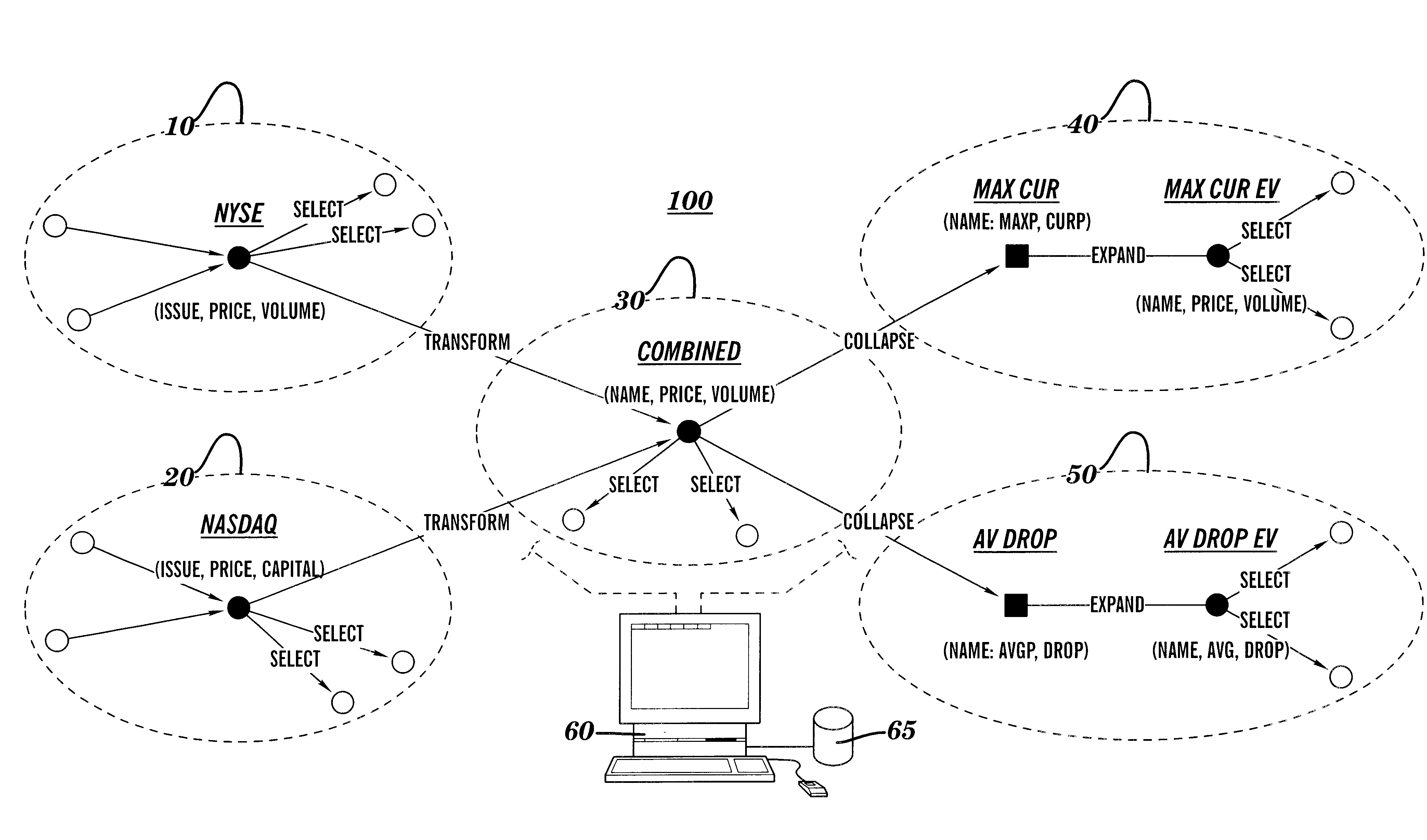

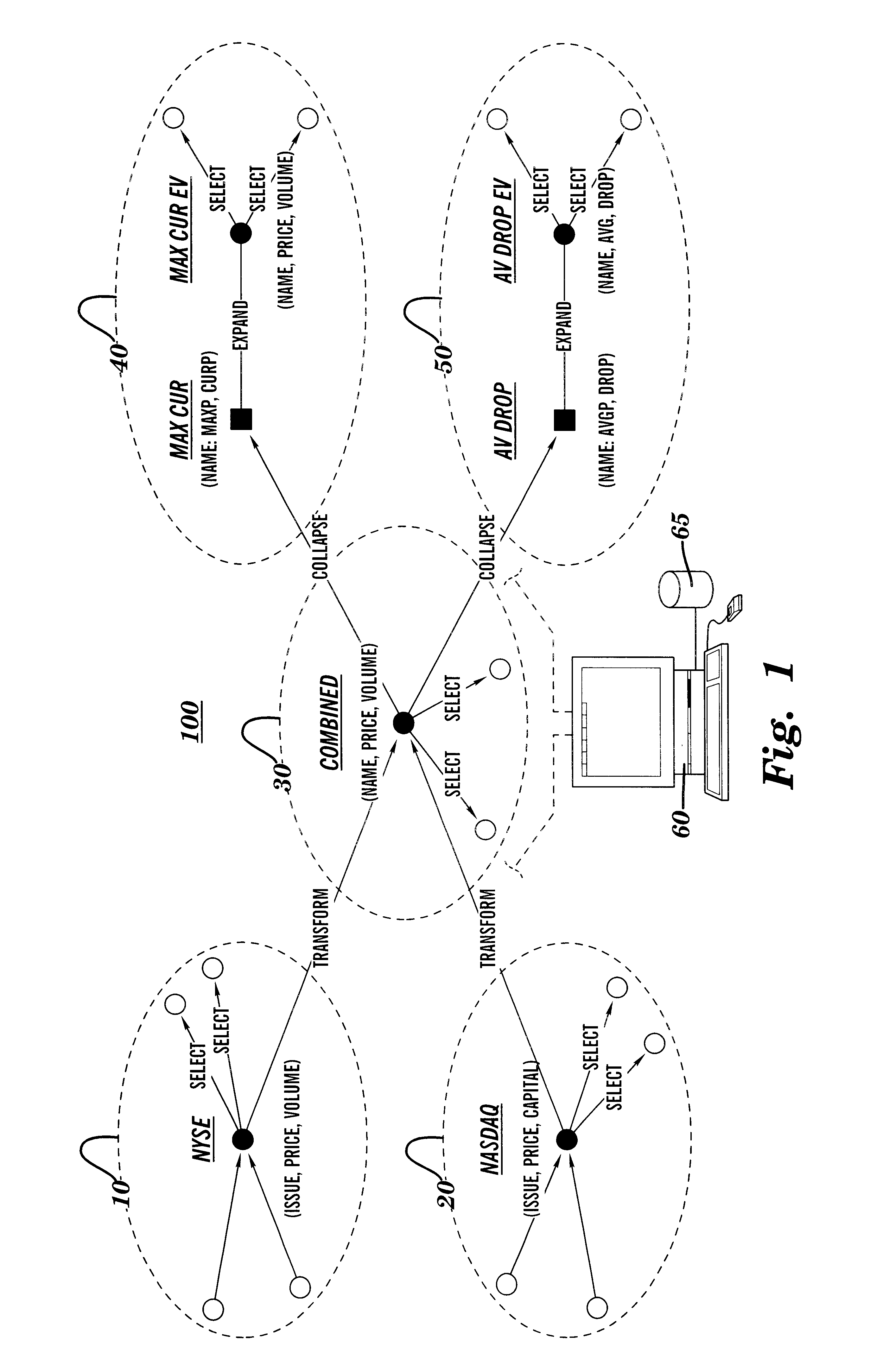

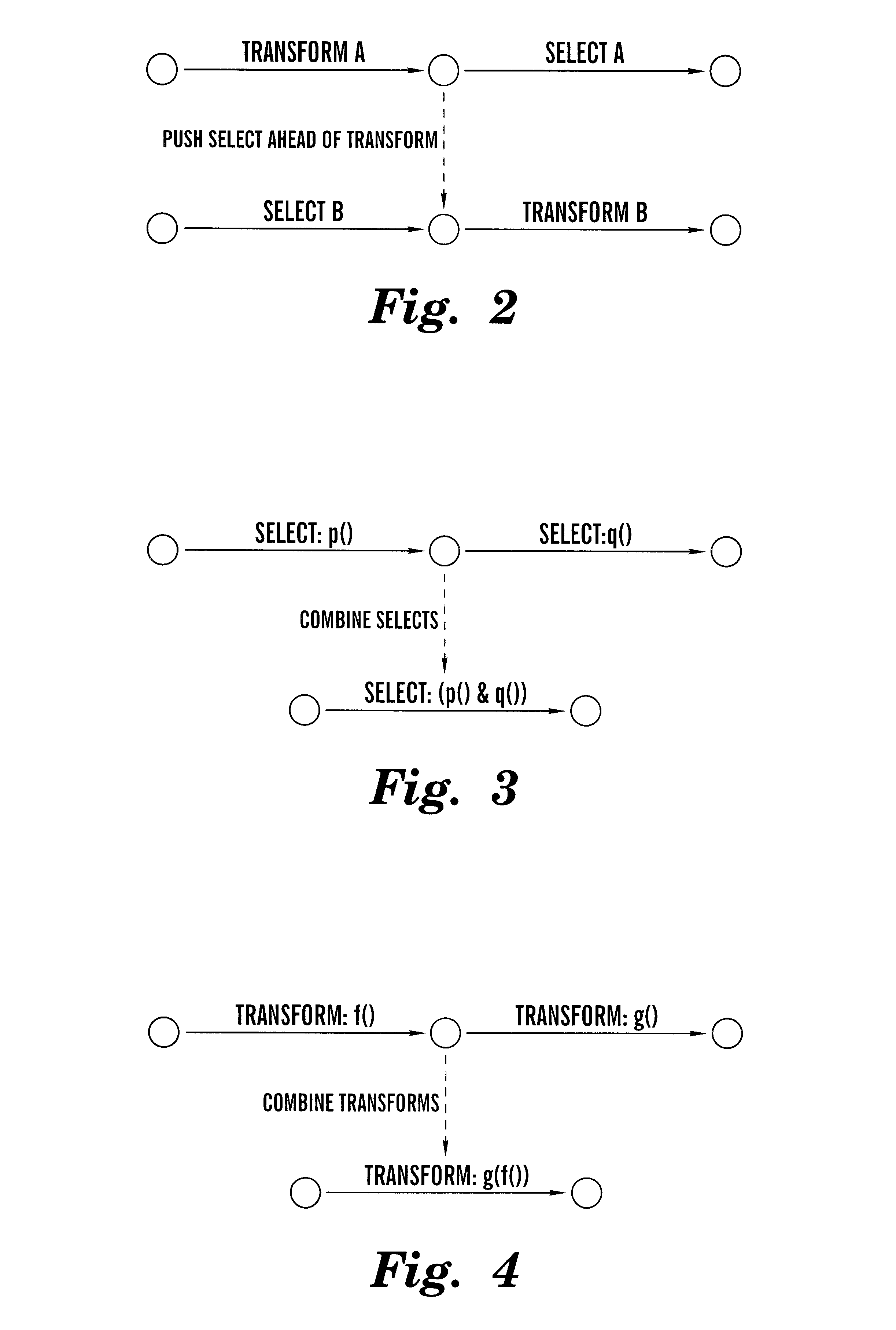

Reduction and optimization of operational expressions applied to information spaces between nodes in a publish/subscribe system

InactiveUS6681220B1Advanced technologyEfficient implementationData processing applicationsDigital data processing detailsInformation processingInformation space

Techniques for arranging operations performable on information in an information processing system are provided. In a system having a plurality of information producers and a plurality of information subscribers, paths are identified over which information traverses, and within which the information is subject to select and / or transform operations. The present invention optimizes the system by reorganizing the sequence of select and transform operations so that transforms follow select operations; and by combining multiple select and transform operations into single select and transform operations, respectively. Using these optimizations, the processing resources of the system can be reorganized, and / or information flow graphs describing the system can be designed, so that the select operations are "pushed" toward the producers, and transform operations are "pushed" toward the subscribers. Efficient content-based routing systems can then be used to implement the select operations.

Owner:IBM CORP

Managing digital identity information

ActiveUS7680819B1Maintain the integrity of relationshipsAdvanced technologyDigital data processing detailsMultiple digital computer combinationsDigital identityPassword

A basic architecture for managing digital identity information in a network such as the World Wide Web is provided. A user of the architecture can organize his or her information into one or more profiles which reflect the nature of different relationships between the user and other entities, and grant or deny each entity access to a given profile. Various enhancements which may be provided through the architecture are also described, including tools for filtering email, controlling access to user web pages, locating other users and making one's own location known, browsing or mailing anonymously, filling in web forms automatically with information already provided once by hand, logging in automatically, securely logging in to multiple sites with a single password and doing so from any machine on the network, and other enhancements.

Owner:EMC IP HLDG CO LLC

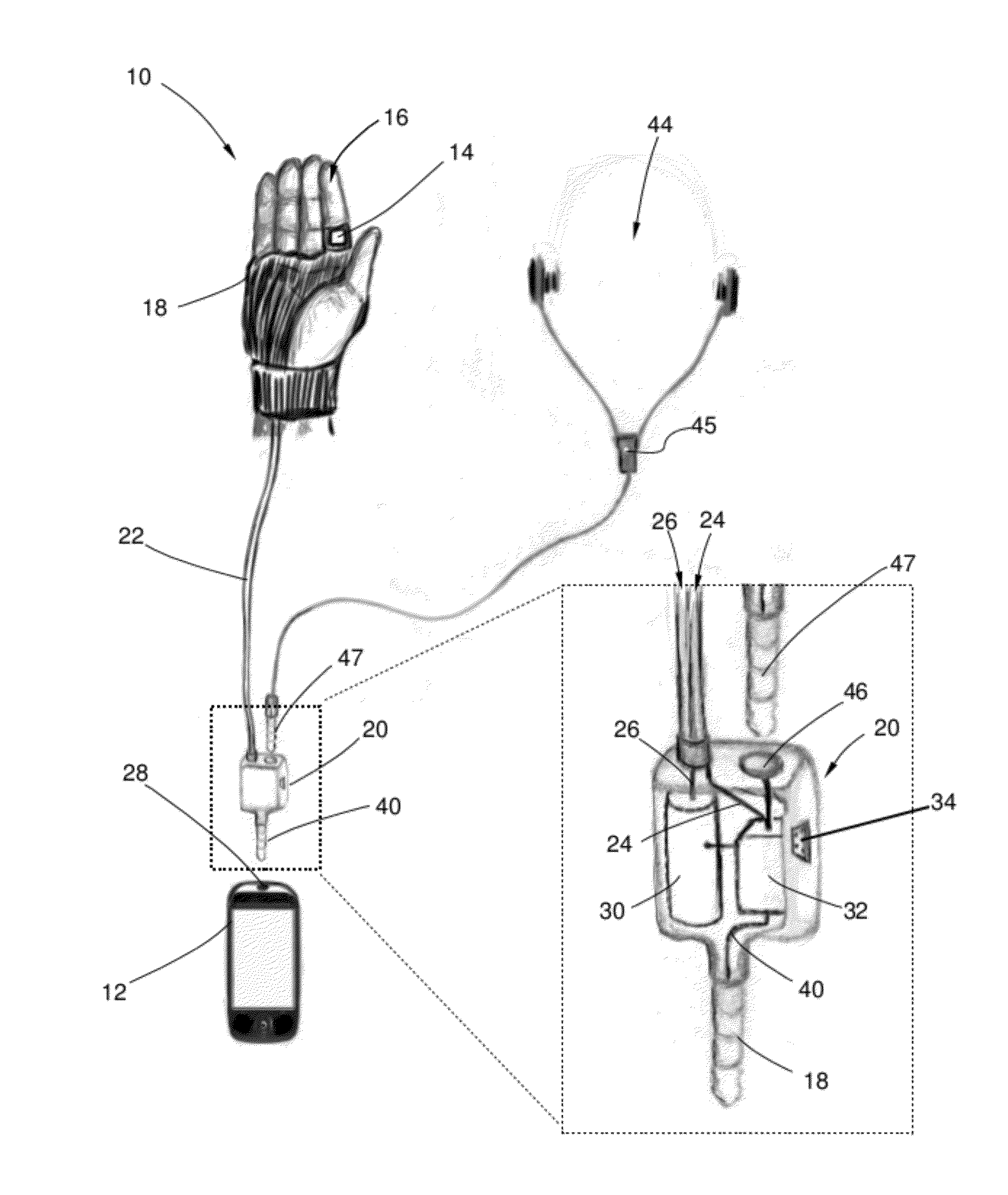

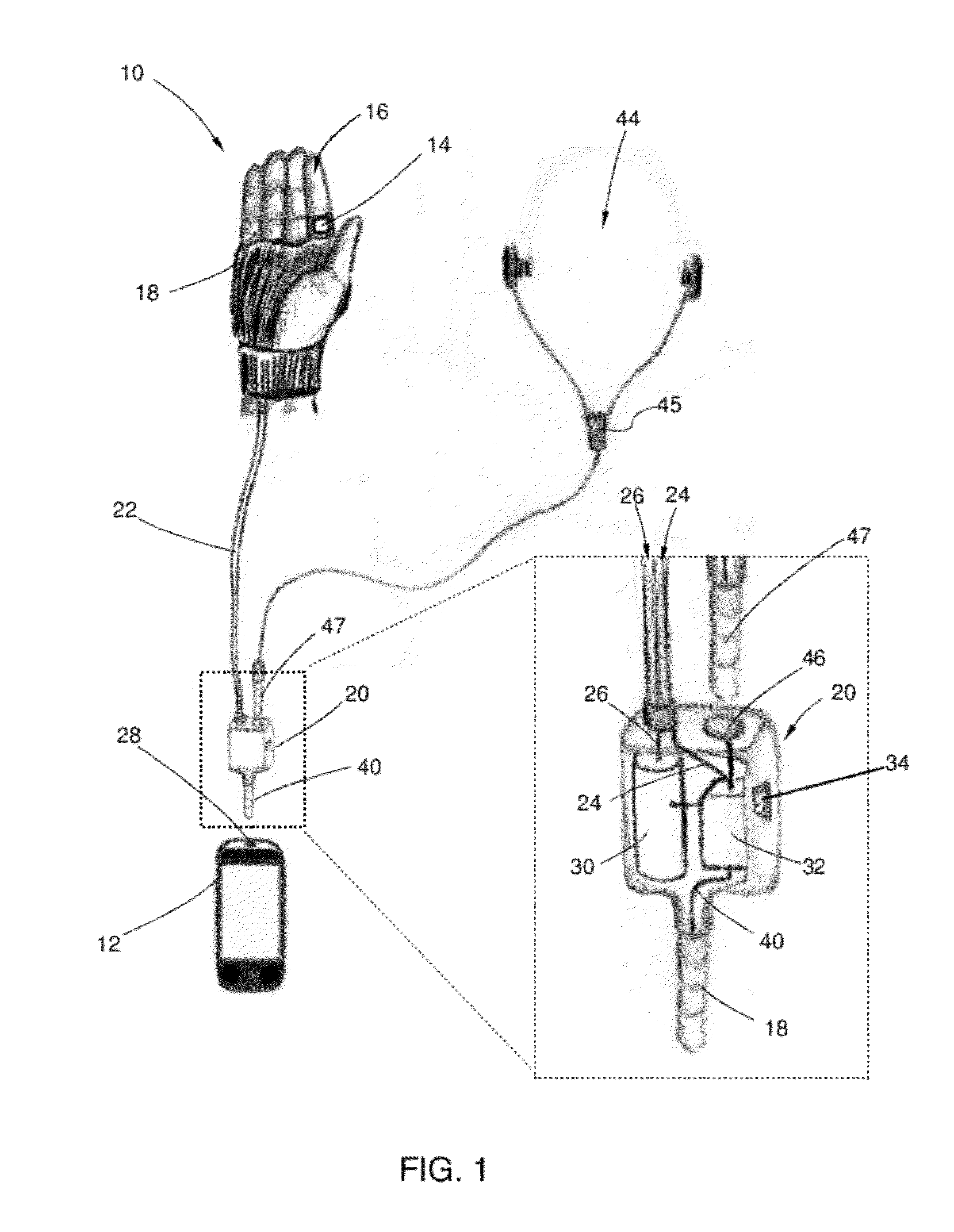

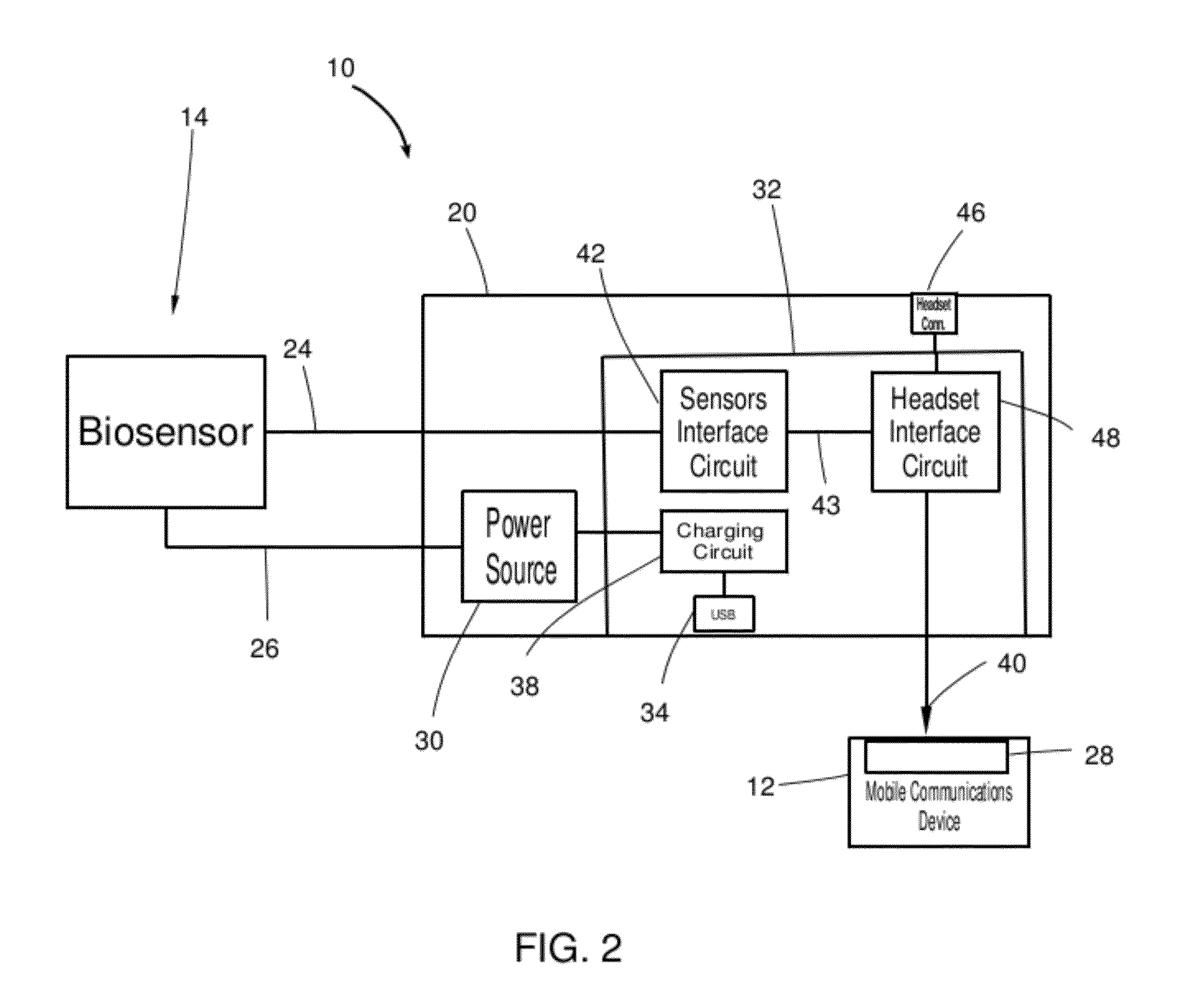

Biosensor Interface Apparatus for a Mobile Communication Device

ActiveUS20120156933A1Advanced technologySimple and inexpensiveSecuring/insulating coupling contact membersCouplings bases/casesElectricityElectrical connector

A bio sensor interface apparatus that utilizes pre-existing or standard electrical connectors of mobile devices such as smart phones, mobile media players, and tablets. The interface device transforms the input bio sensor signals to compatible electrical signals for input to one or more of the mobile's connectors. That signals are then conducted via one or more input conductors in the connectors to the mobile's microprocessor, which may display or transmit the biosensor signals and derive further measurements from them.

Owner:KALLOWS ENG INDIA PVT

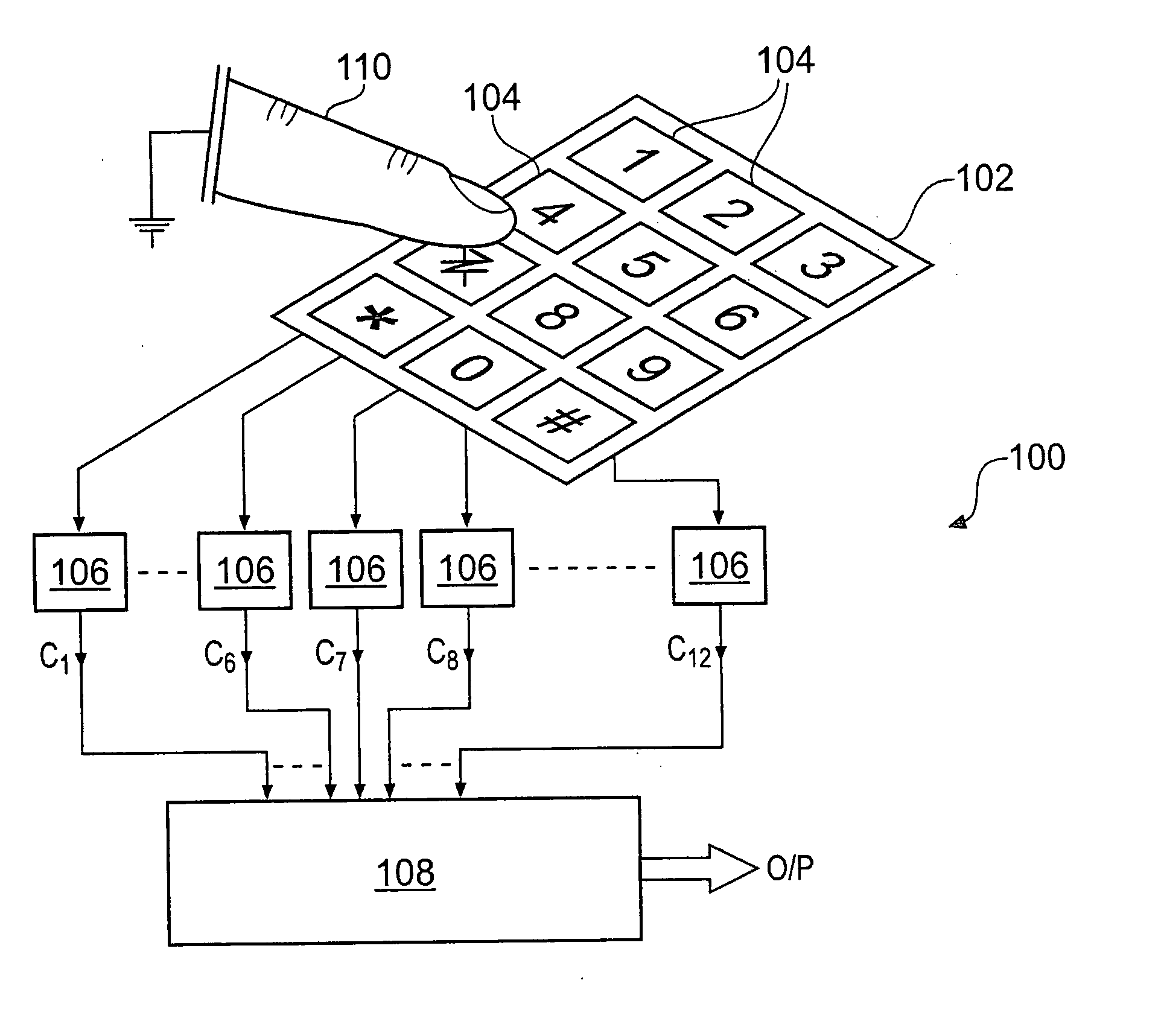

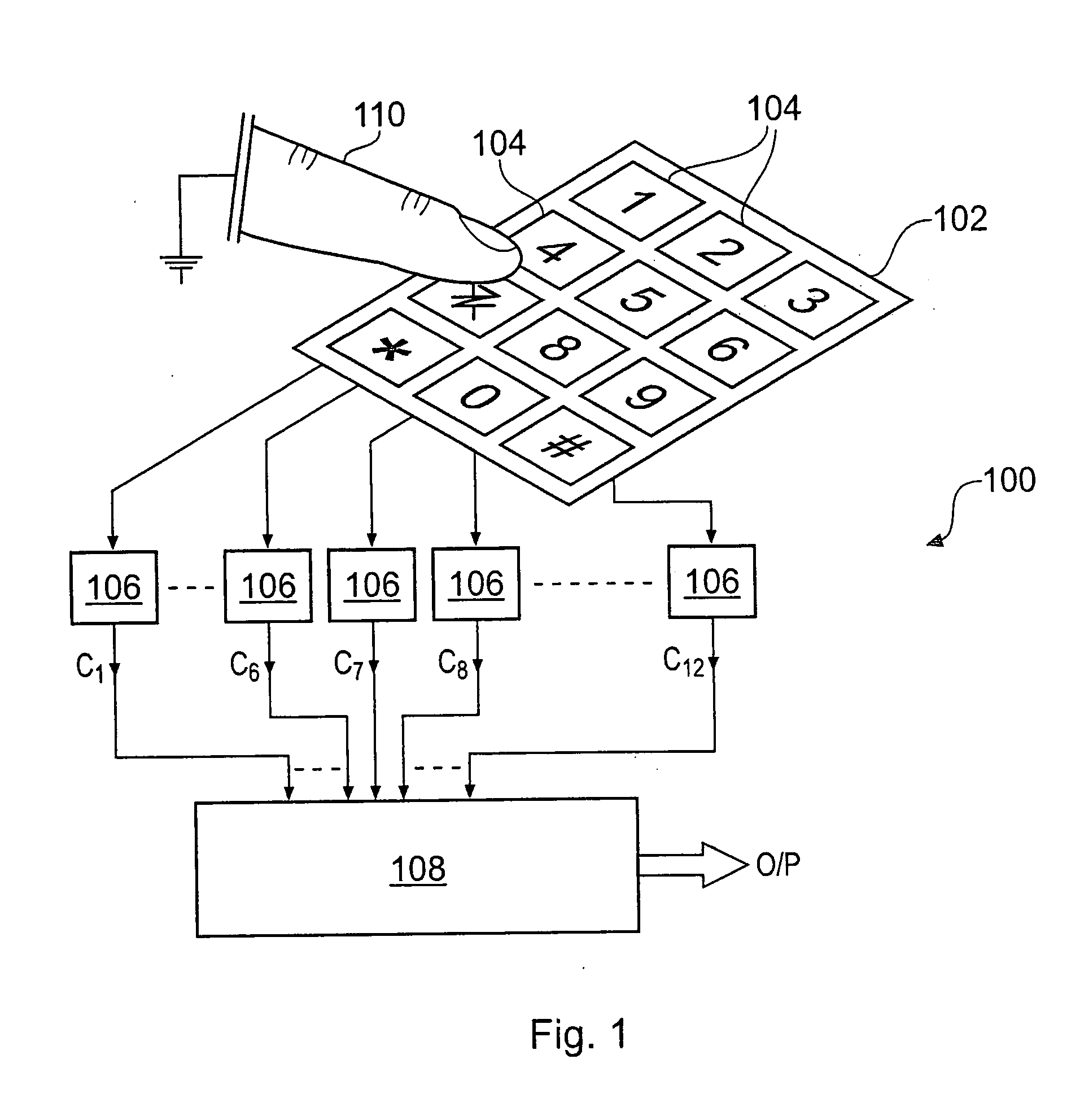

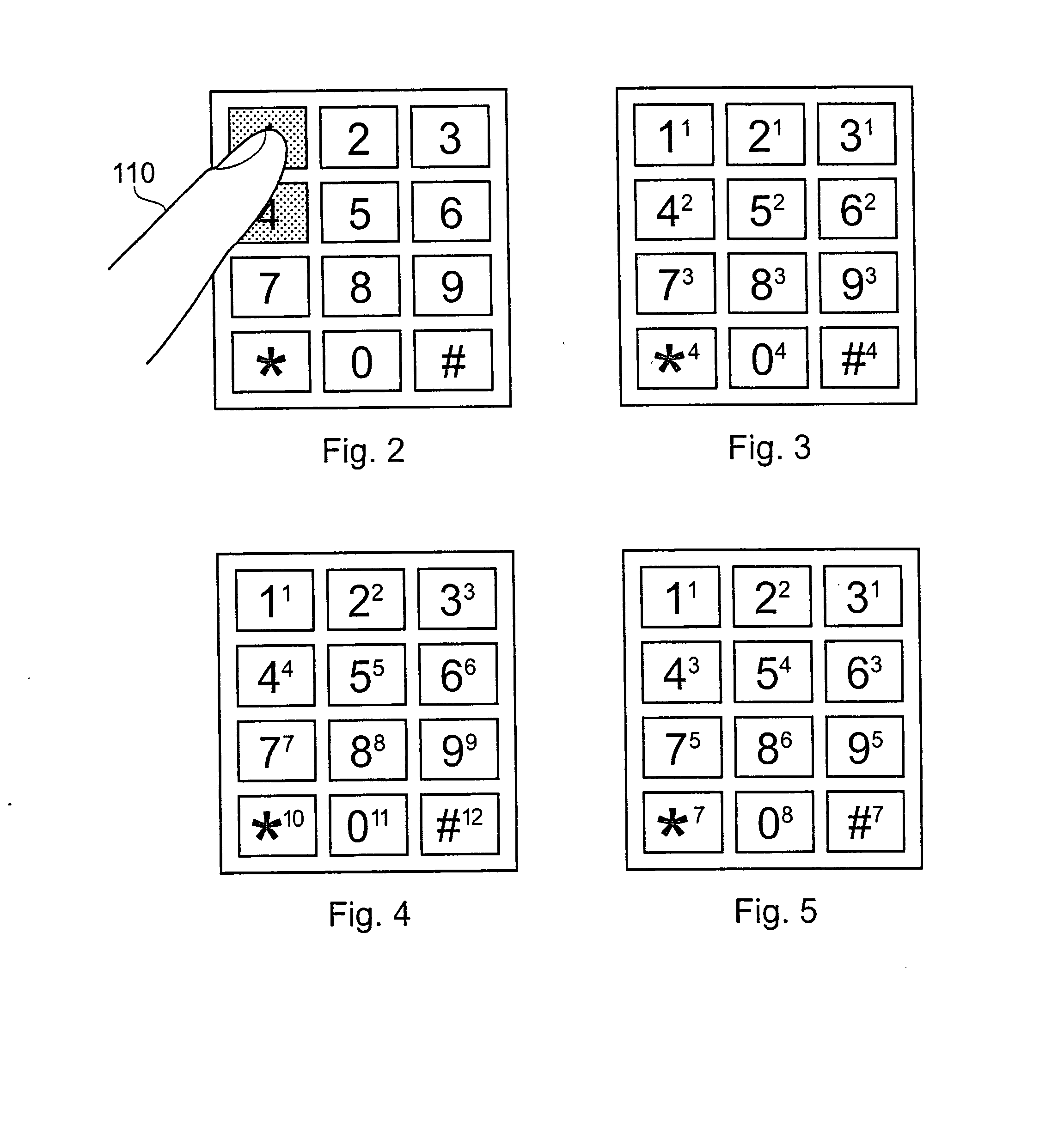

Capacitive Keyboard with Position Dependent Reduced Keying Ambiguity

InactiveUS20070273561A1Reduce ambiguitySignal strength value can be enhancedElectronic switchingInput/output processes for data processingHuman–computer interactionCapacitance transducer

Owner:NEODRON LTD

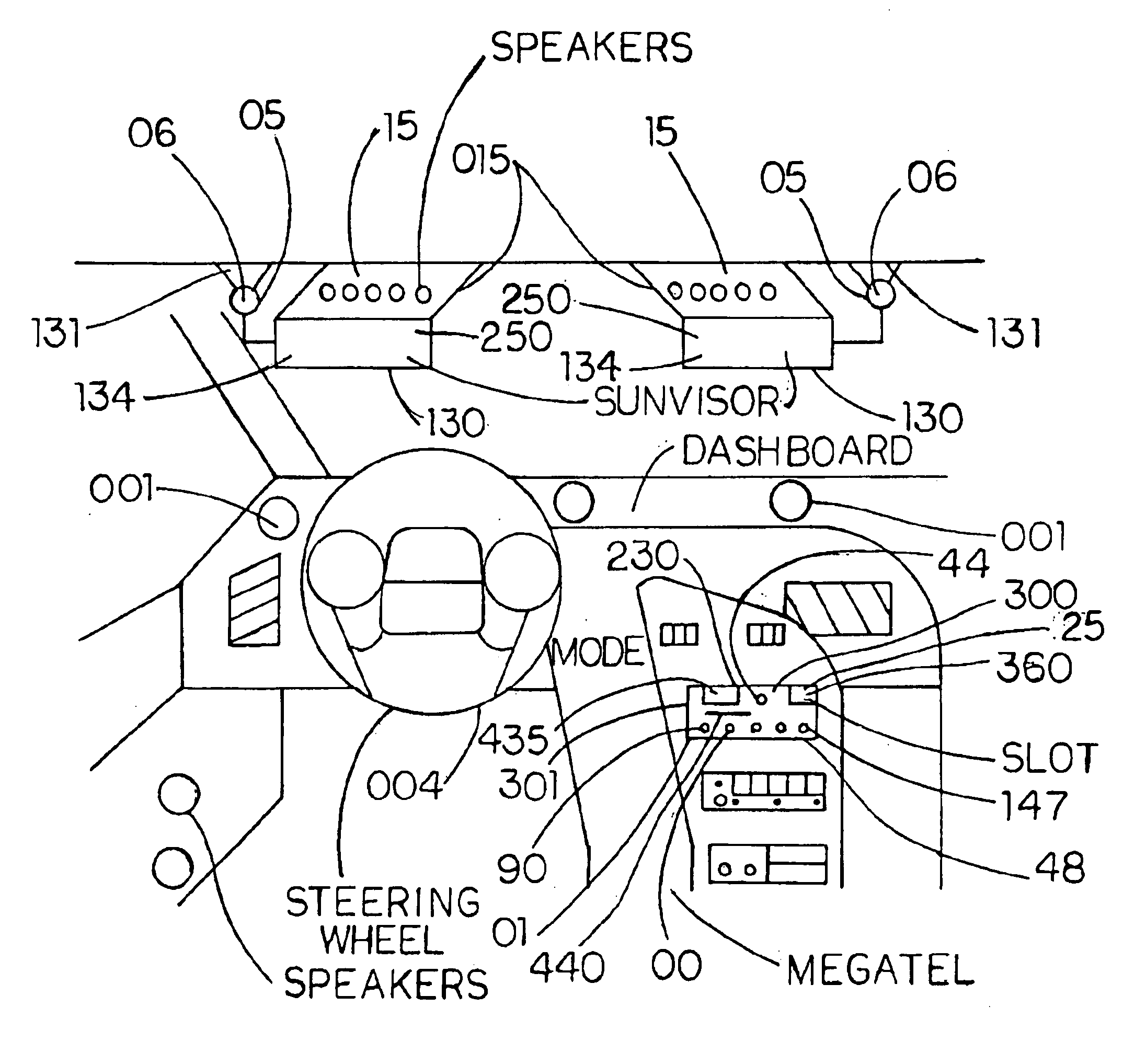

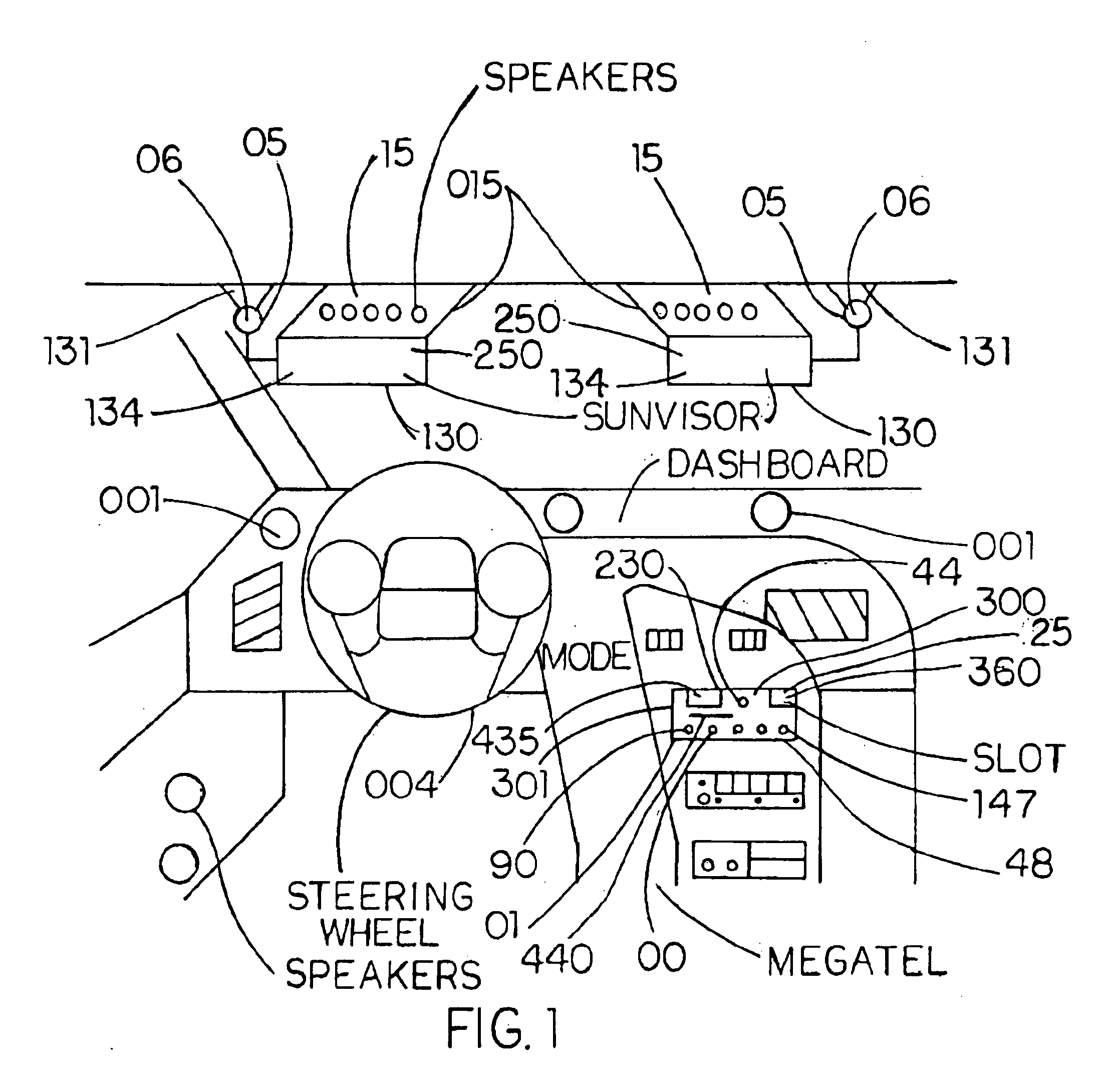

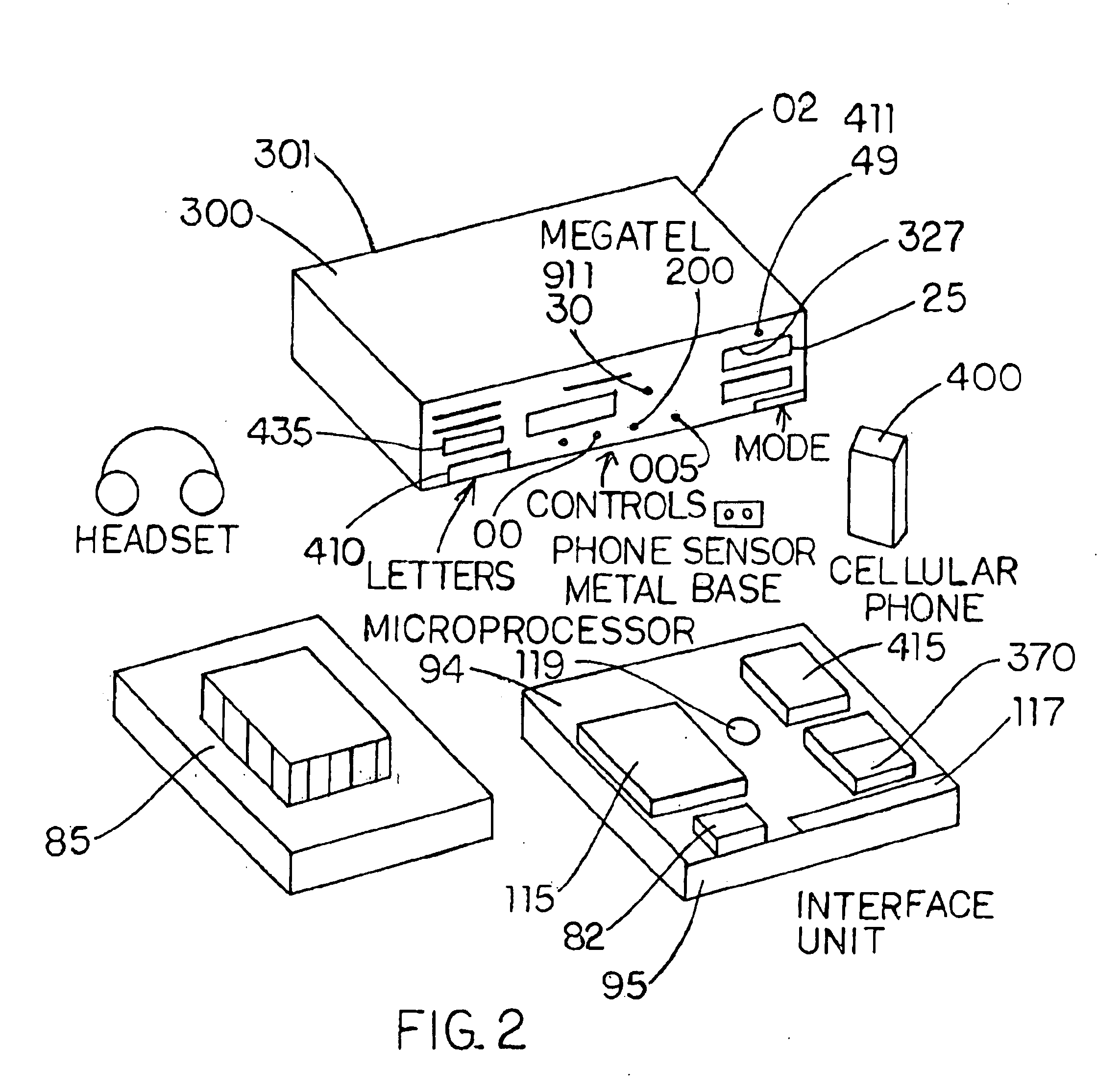

Megatel communication information system

InactiveUS6782240B1Reduction of pressure effectEnhanced informationSubstation speech amplifiersRadio transmissionThe InternetHands free

An entertainment device for vehicles adaptable to include various telecommunication and Internet applications, a sunviser monitoring screen for viewing, with an electronic screen protector for protecting the screen. The device, which is referred to as megatel, incorporates receivers and transmitters to enable cell phone and Internet transmission via the radio wave of an entertainment device radiated towards the antenna to the megatel body and output to the CPU. The signal to the CPU is controlled by the controller so that transmissions for the radio, the cell phone, and the Internet is separated and output to the monitoring screen and the speakers of the entertainment device so as to allow hands free communication while driving.

Owner:TABE JOSEPH A

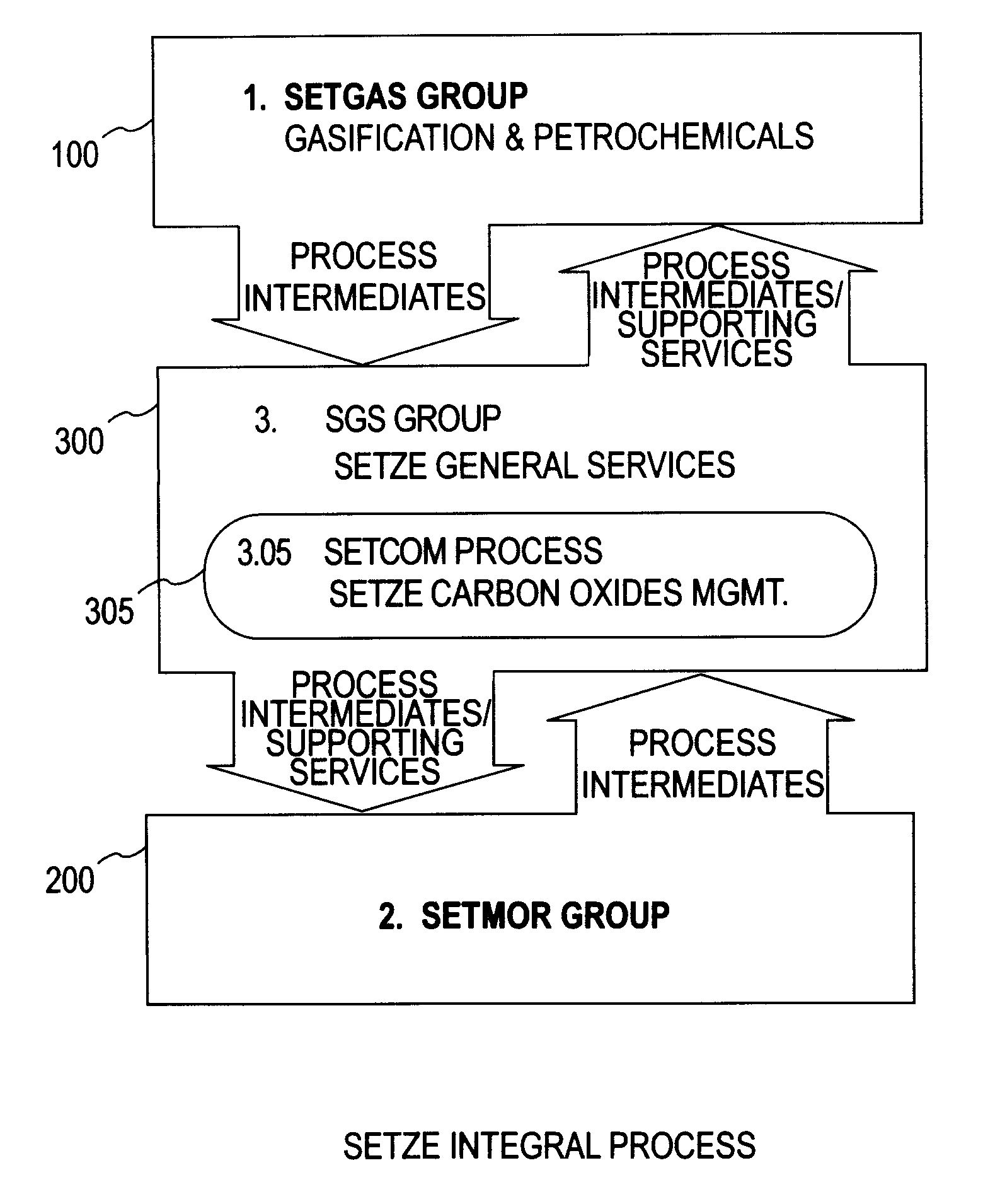

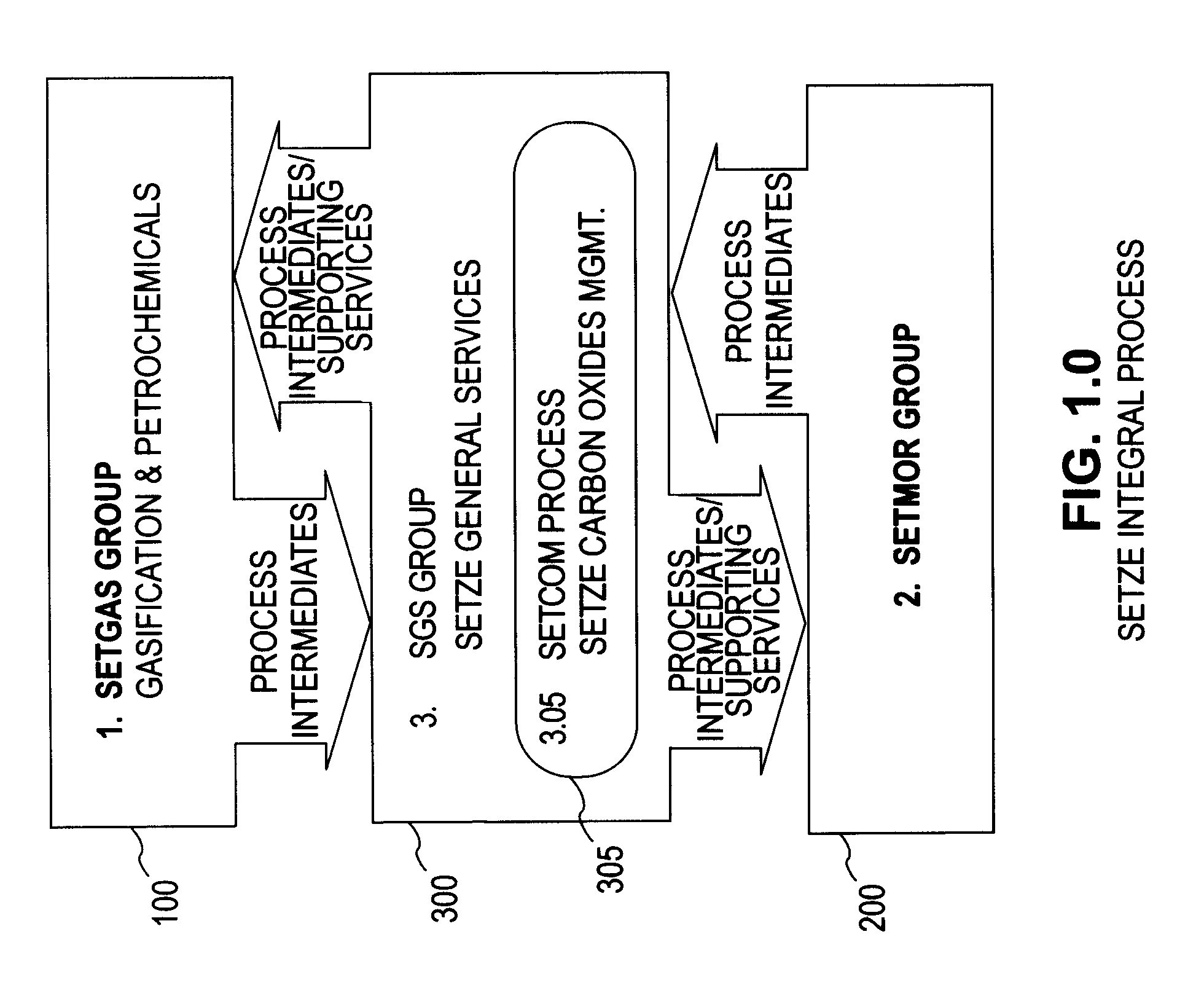

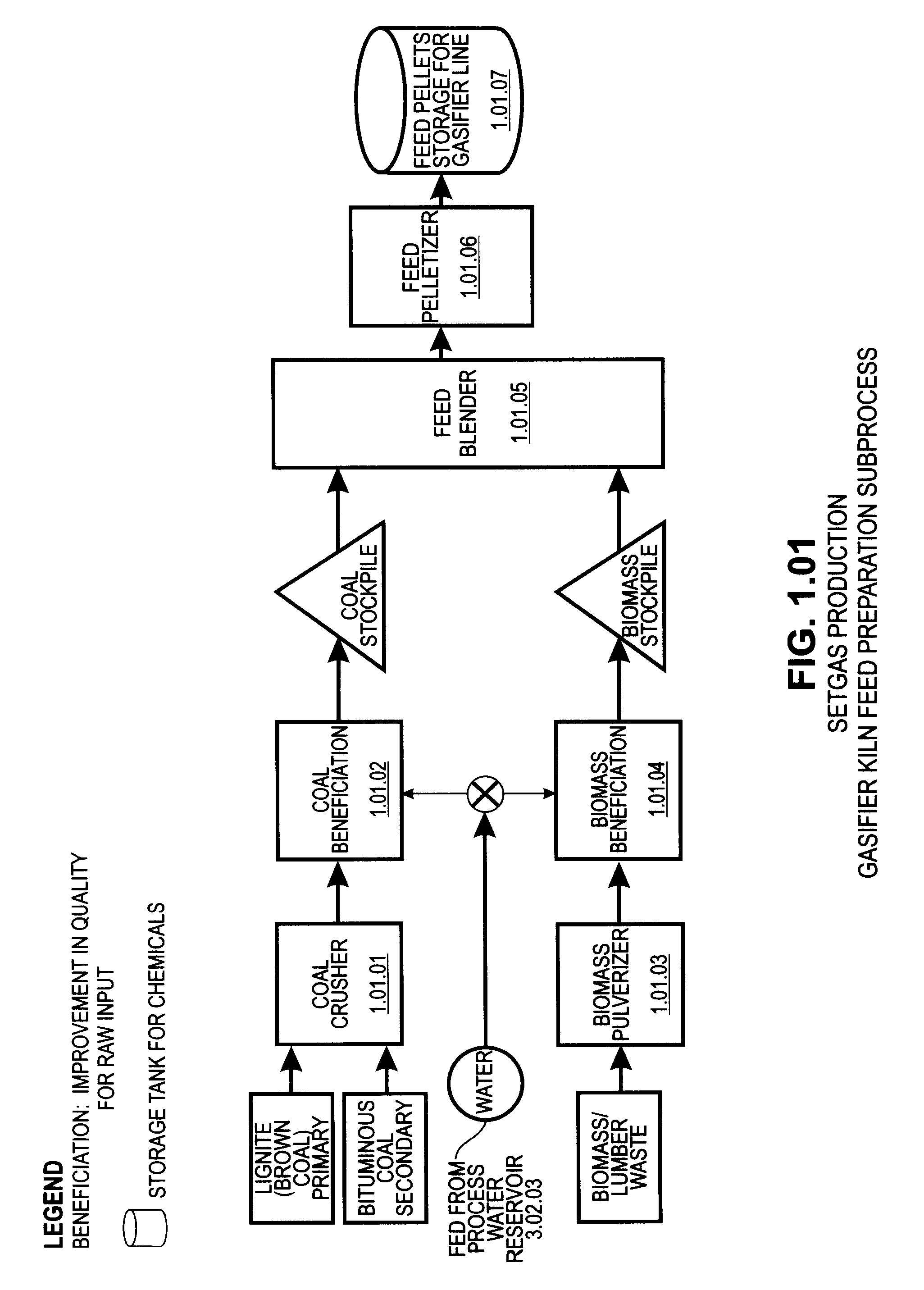

Zero emission gasification, power generation, carbon oxides management and metallurgical reduction processes, apparatus, systems, and integration thereof

ActiveUS7674443B1Improvement in individual technology componentEnhances economic performanceUsing liquid separation agentBiofuelsCyclonic separationOxygen

A system involving a two-step gasification of a carbonaceous source to produce bulk hydrogen that avoids the early formation of CO2 and obviates the traditional water gas shift (WGSR) step, carbochlorination of a metallic ore the production of metals found in the ore that utilizes carbon monoxide as an oxygen sink, rather than the traditional coke, and carbon oxides management that eliminates major impediments to emission-neutral power generation and the reduction of major metals. The gasification uses a rotary kiln reactor and gas-gas cyclonic separation process to separate synthesis gas into purified hydrogen and purified carbon monoxide. Purified bulk carbon monoxide issued in metallurgical reduction, and purified bulk hydrogen as fuel for an emission-neutral hydrogen combined cycle (HCC) turbine power generation station. The carbochlorination is integrated with: a) the concurrent separation and purification of all metal-chlorides (metchlors) and capture of CO2 for passage to the carbon oxides management system; b) the direct reduction of metchlors to nanoscale metallurgical powders and / or to dendritically-shaped particles, including metchlor reduction for the ultrahigh-performance semiconductor metals of the III-V group; and, c) the reforming of metal-oxides with improved crystalline structure from metchlors. The carbon oxides management collects, stores and directs to points of usage, carbon oxides that arise in various processes of the integrated system, and captures carbon monoxide for process enhancement and economic uses and captures carbon dioxide as a process intermediate and for economic uses.

Owner:DAVIS OLUMIJI B +1

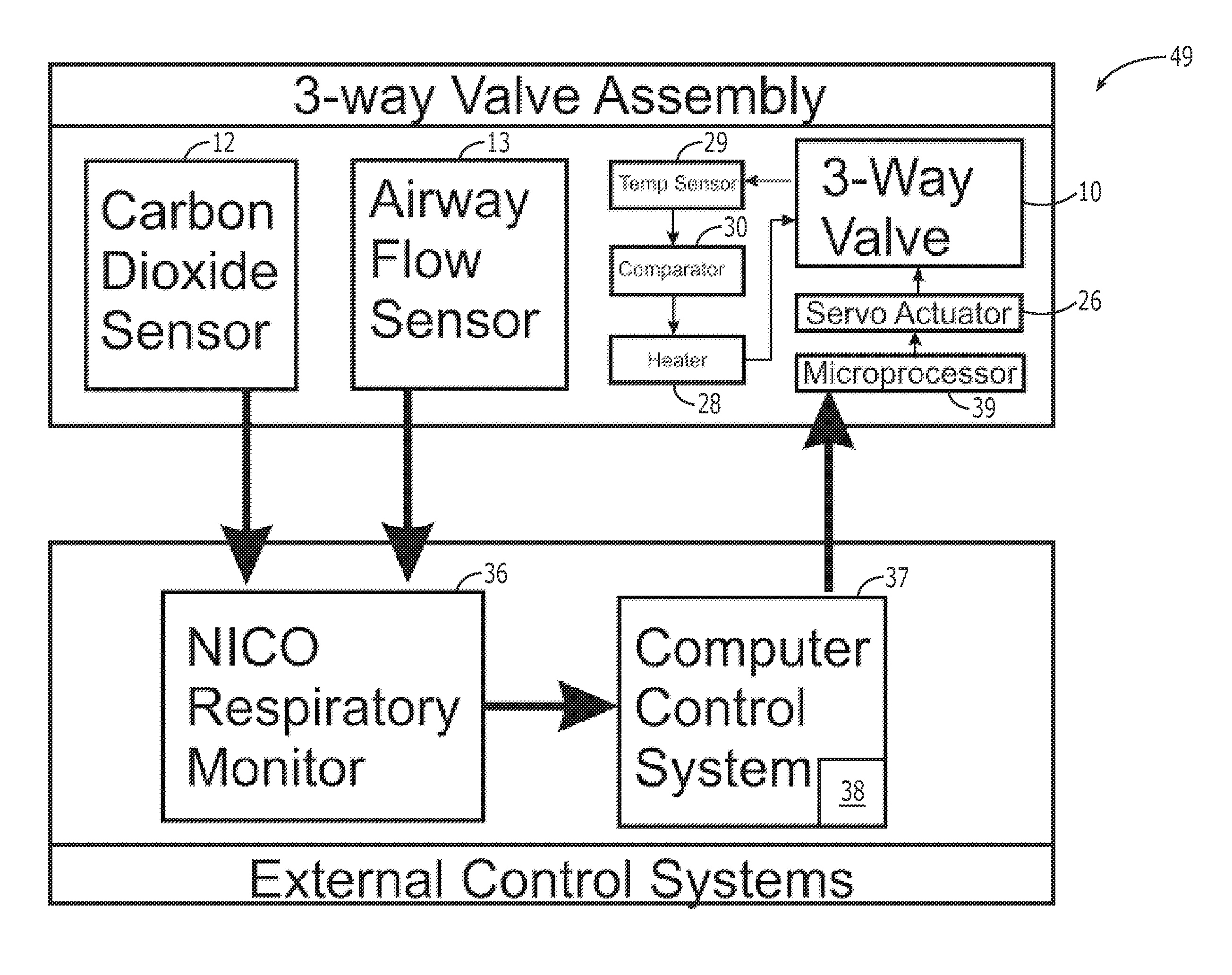

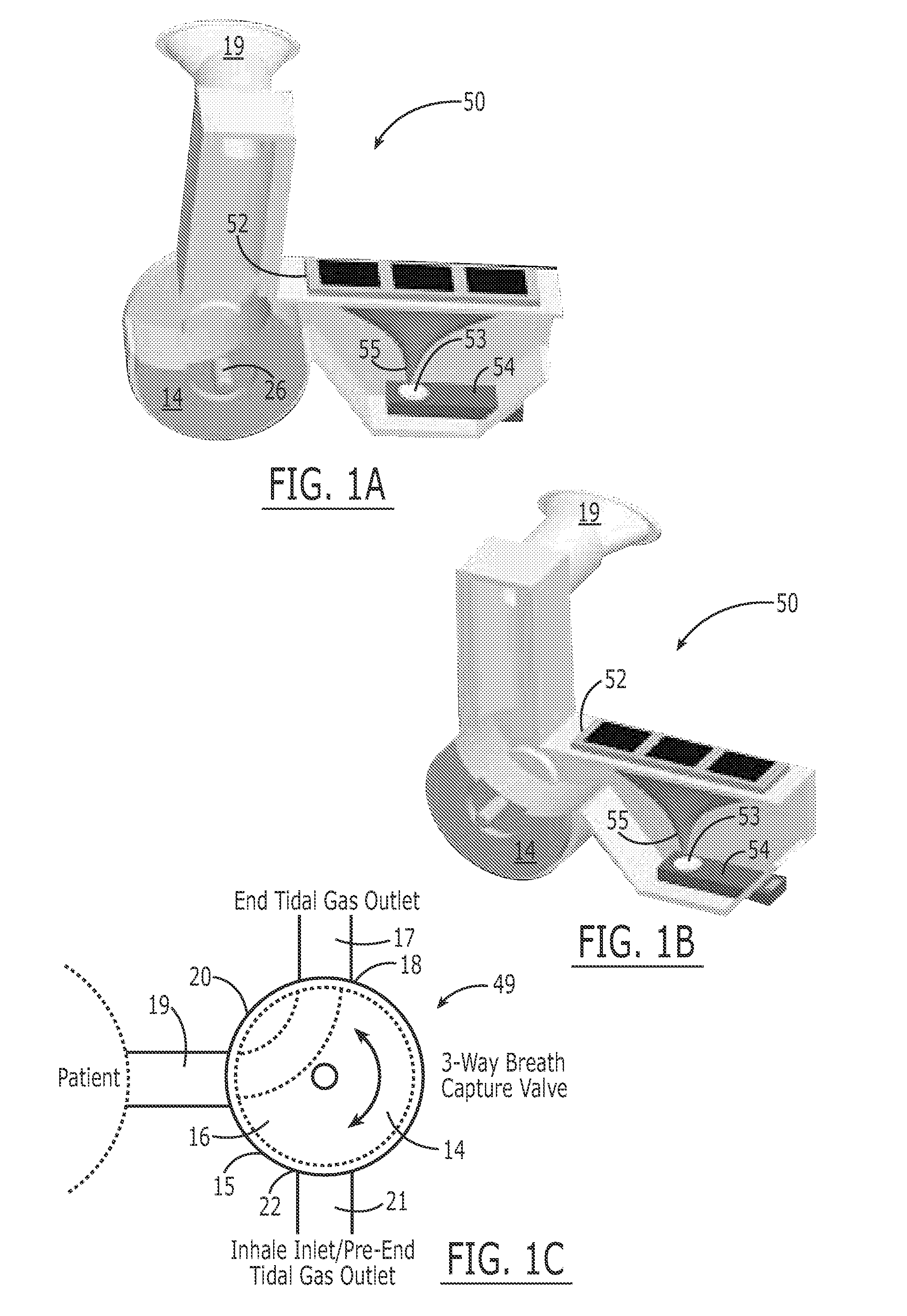

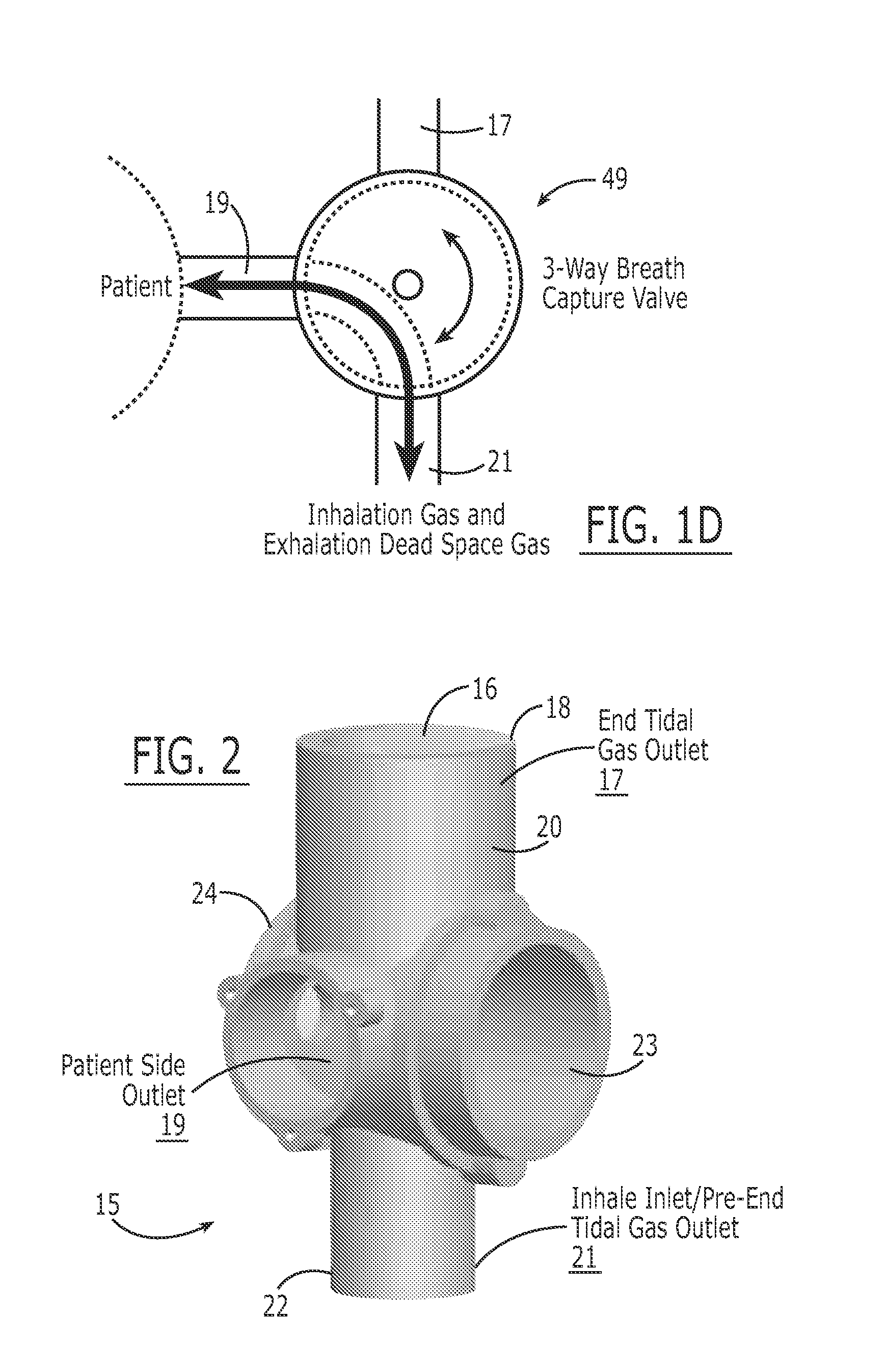

Breath and Breath Condensate Analysis System and Associated Methods

InactiveUS20070173731A1Accelerates and simplifies breath condensate analysisEconomical to useRespiratory organ evaluationSensorsInterior spaceProduct gas

A system for collecting an exhaled breath sample and exhaled breath aerosol from a subject includes a condensation chamber having an outerwall defining an interior space. The outer wall has an inlet port and an outlet port therethrough in fluid communication with the interior space. The inlet port is placeable in fluid communication with an exhaled breath sample of the subject. A condensation element is positioned within the condensation chamber interior space and has a shape tapering downwardly toward a bottom tip thereof. A condensation of fluid on the condensation element is enhanced through various elements. A collection area is positioned within the condensation chamber's interior space beneath the condensation element bottom tip. The collection area is for collecting condensate accumulating on an outer surface of the condensation element and dropping from the tip thereof.

Owner:EULIANO NEIL R

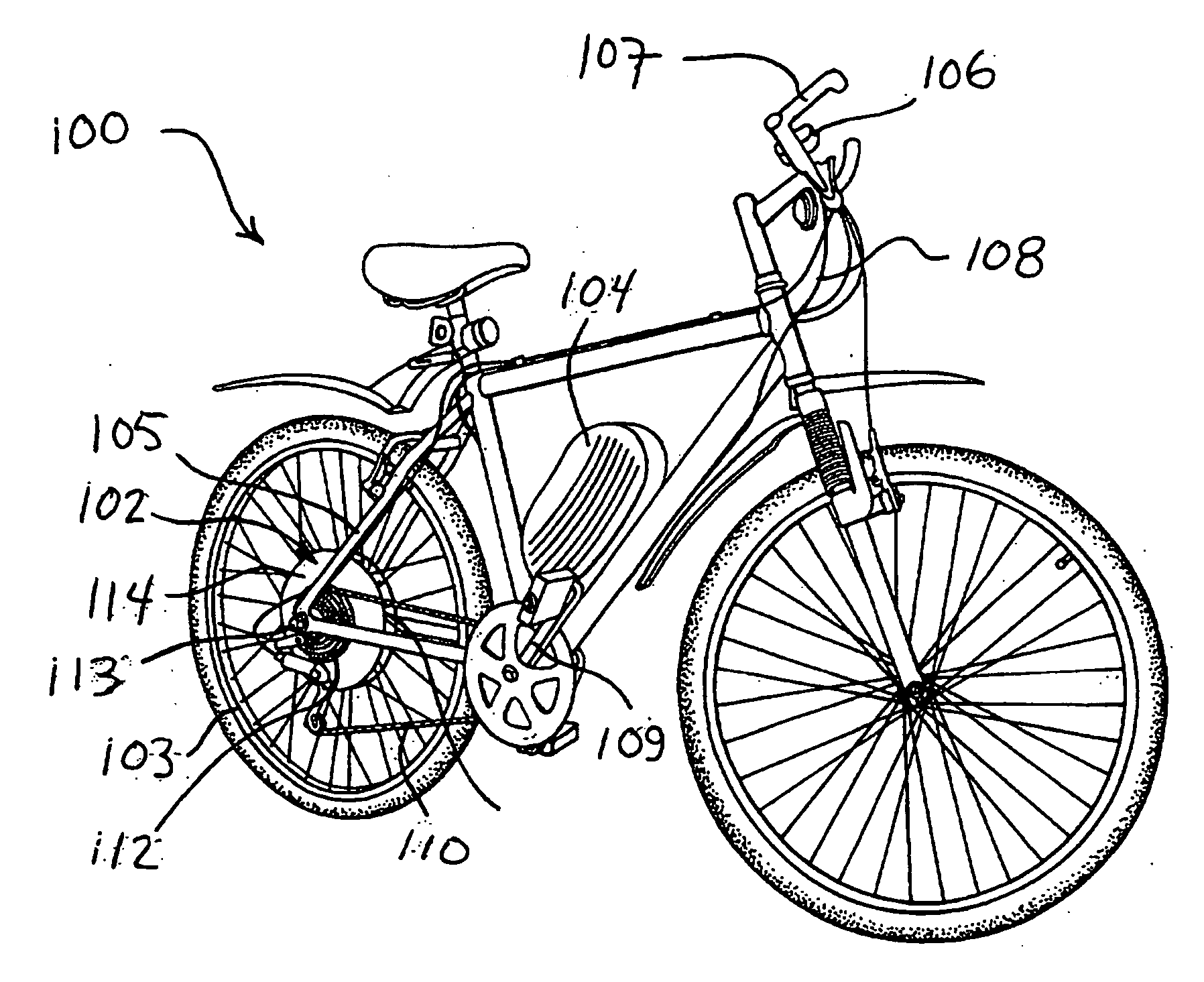

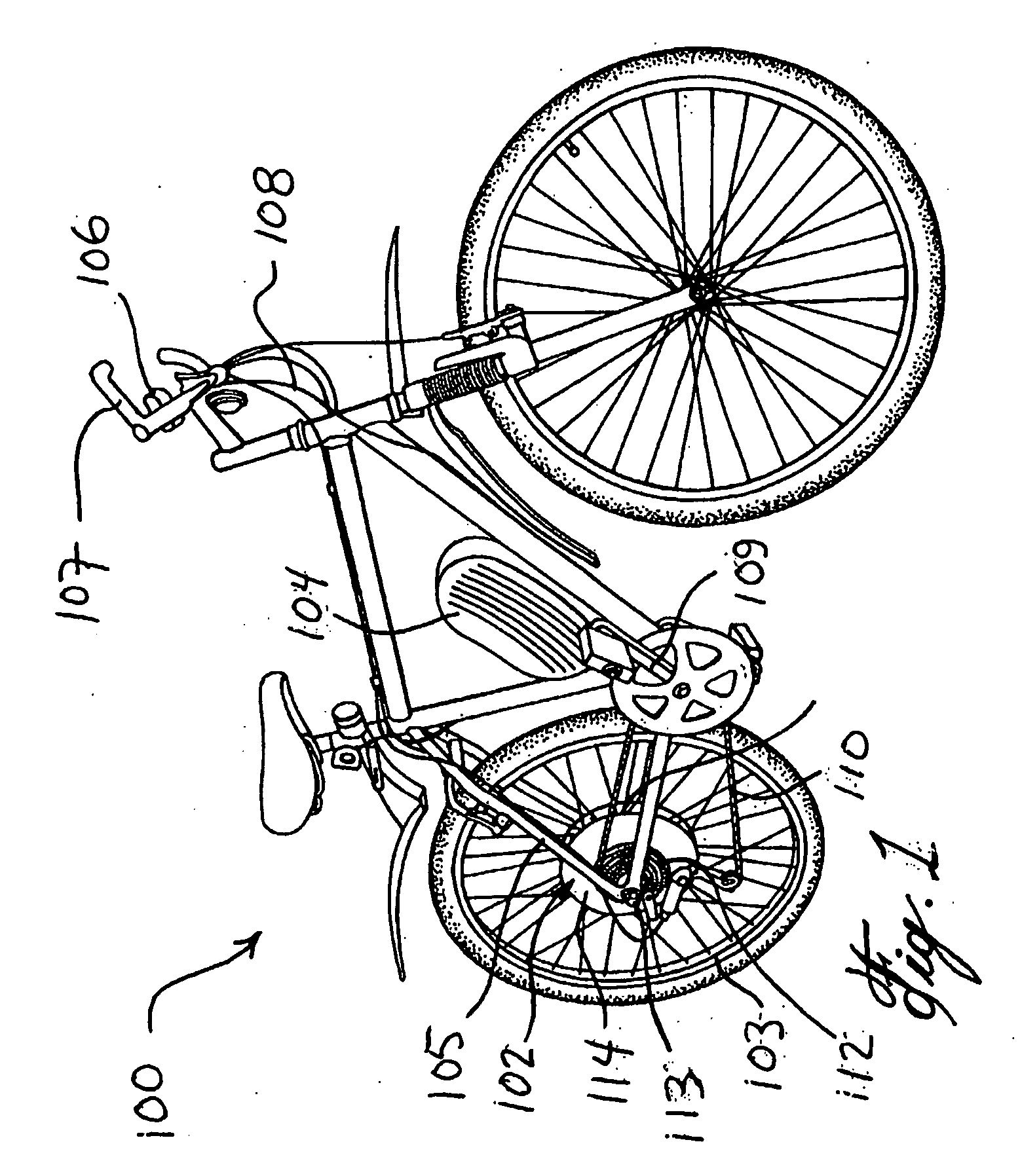

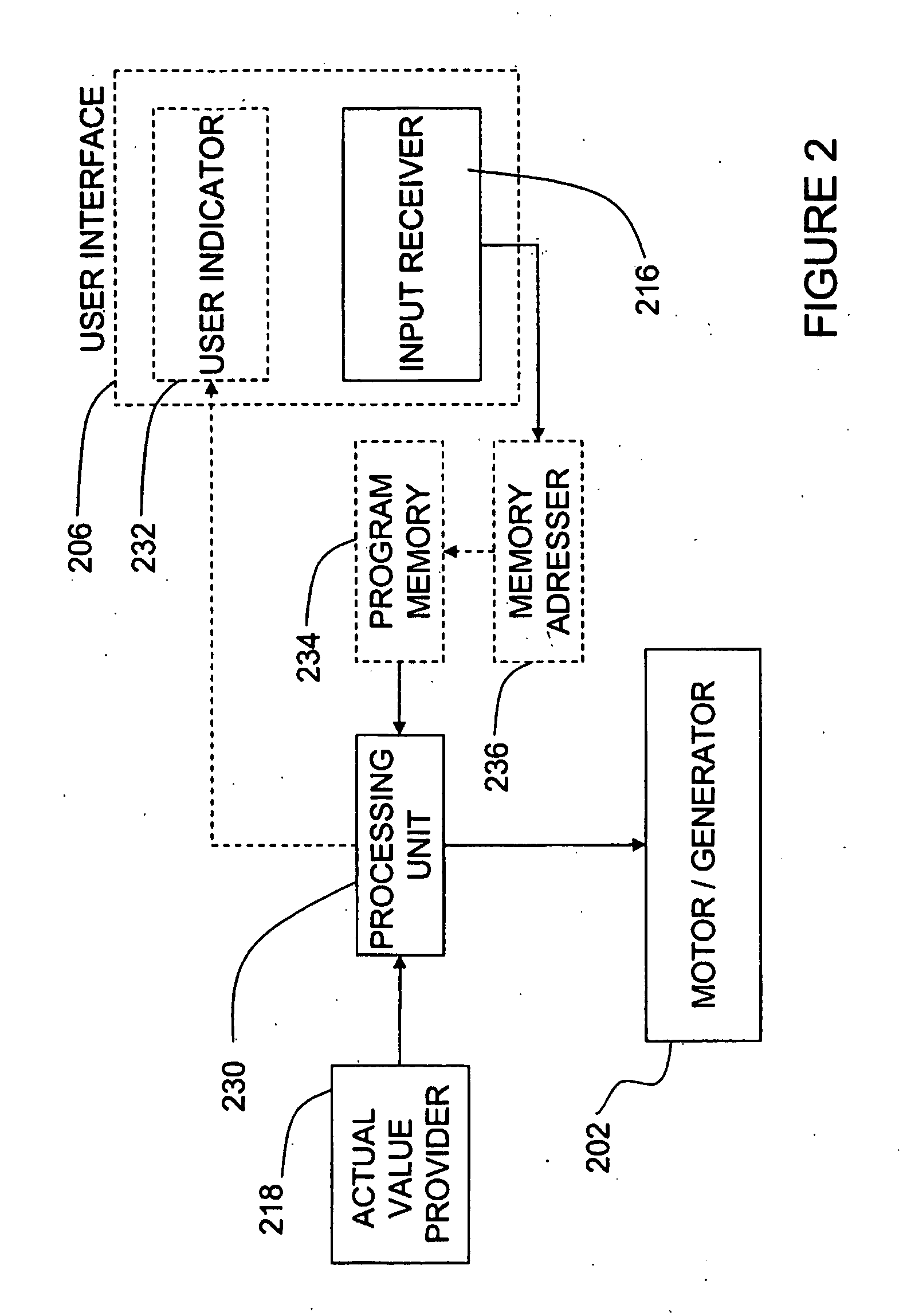

Energy Management System for Motor-Assisted User-Propelled Vehicles

InactiveUS20080071436A1Battery energy to longerComfortable rideVehicle testingVehicle fittingsUser inputMotor commands

An energy management system for a motor-assisted user-propelled vehicle comprising a motor capable of assisting in propelling the vehicle and a rechargeable power supply for supplying energy to the motor. The system comprises: a user input for providing a desired value for each of at least one control parameter related to the user; a sensor for each control parameter for obtaining an actual value of the control parameter; a value comparator for receiving the desired value and the actual value of each control parameter and comparing them to generate a comparison signal for each control parameter; a command generator for generating a motor command using at least one comparison signal; and a motor controller for operating the motor, using the motor command, either to assist in propelling the vehicle, or act to recharge the power supply, in a way to bring the actual value closer to the desired value.

Owner:9141 7030 QUEBEC +2

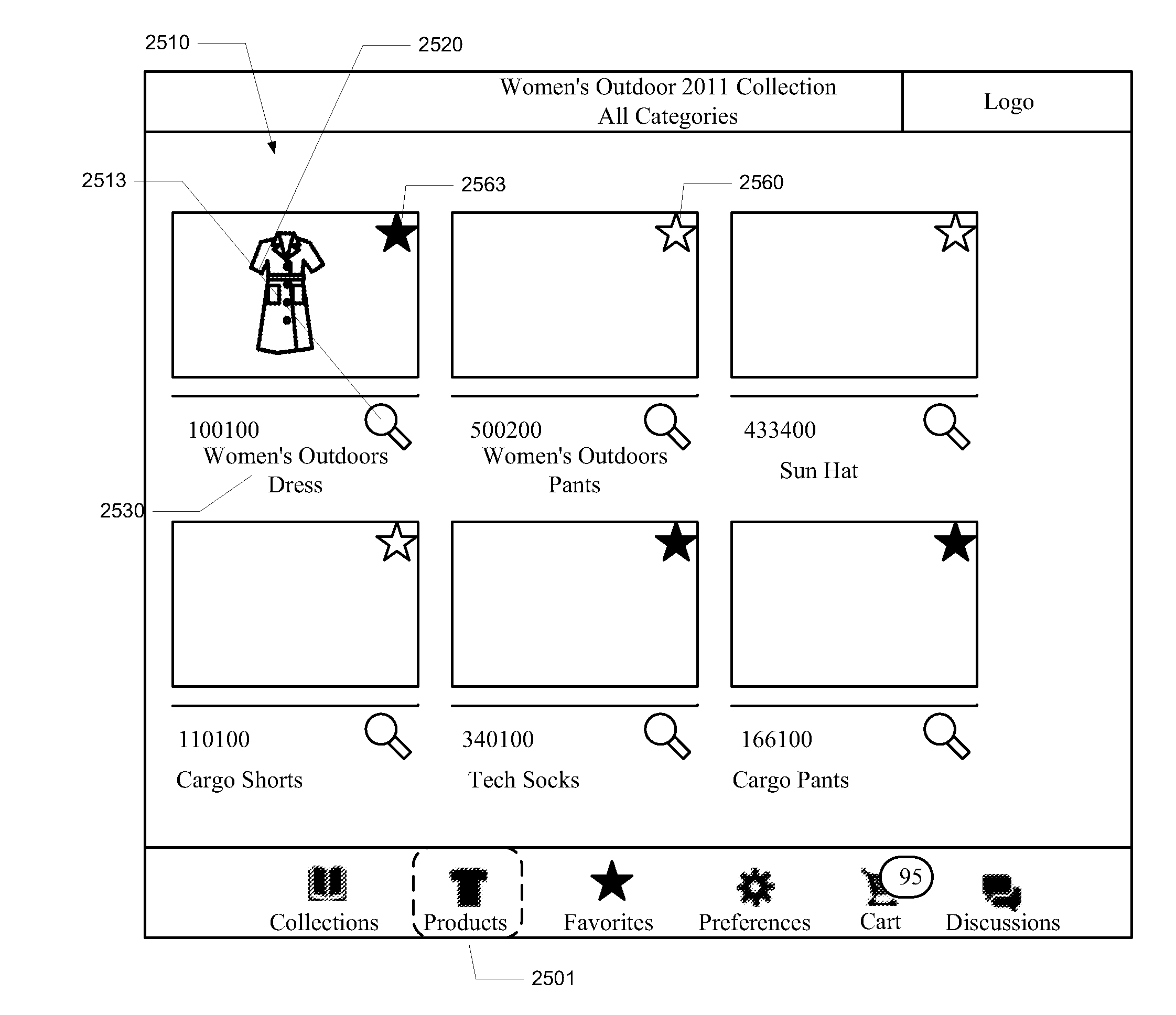

Interactive Collection Book for Mobile Devices

ActiveUS20120265644A1Drive more salesGood choiceService provisioningNear-field transmissionMobile deviceHuman–computer interaction

A software-based interactive collection book for mobile devices provides the users a way to connect their customers to products while the products are still being developed. This will allow a user to engage with their customers earlier to drive more sales. This will result in their products being more successful in the market at the time of launch.

Owner:CENTRIC SOFTWARE

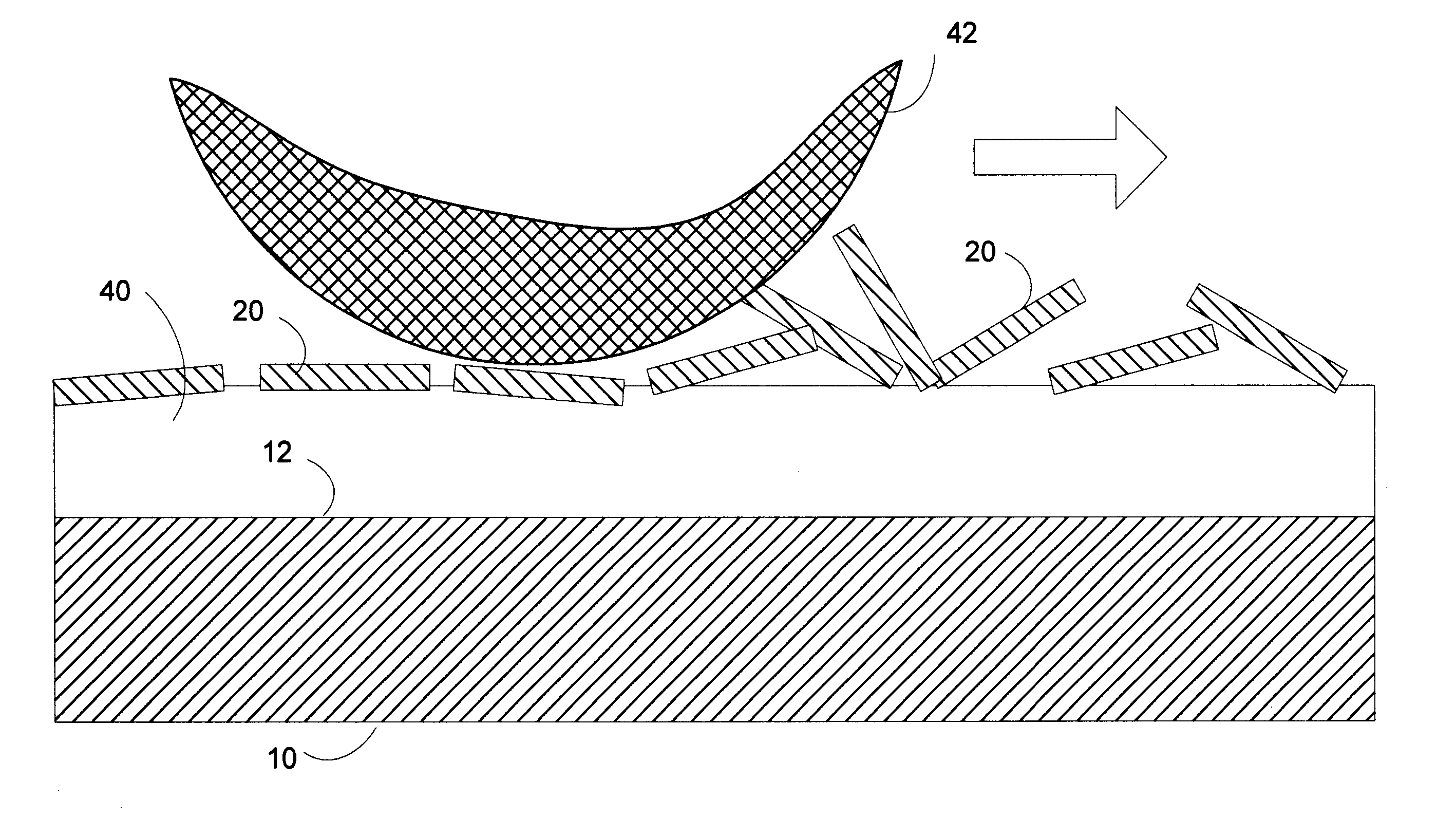

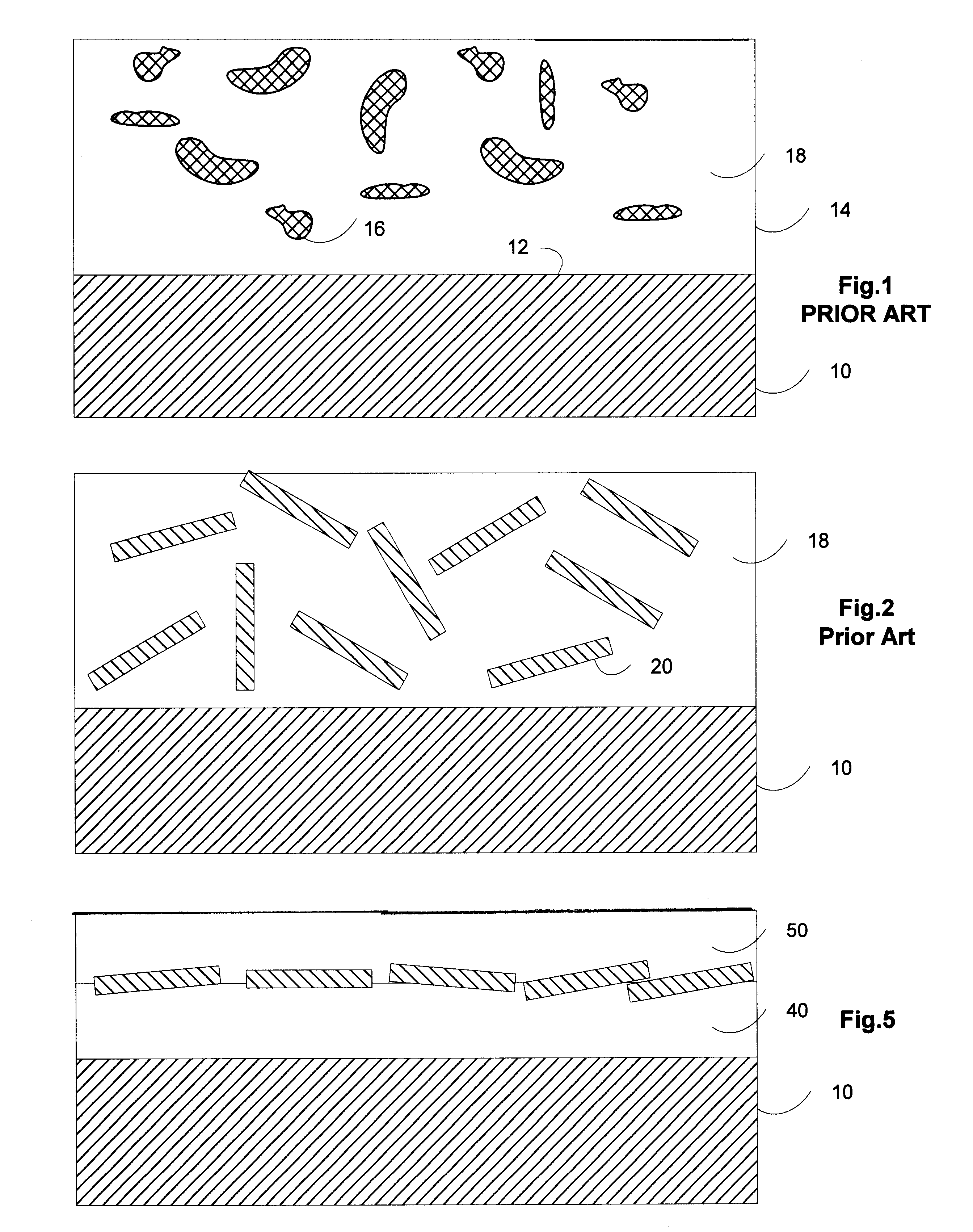

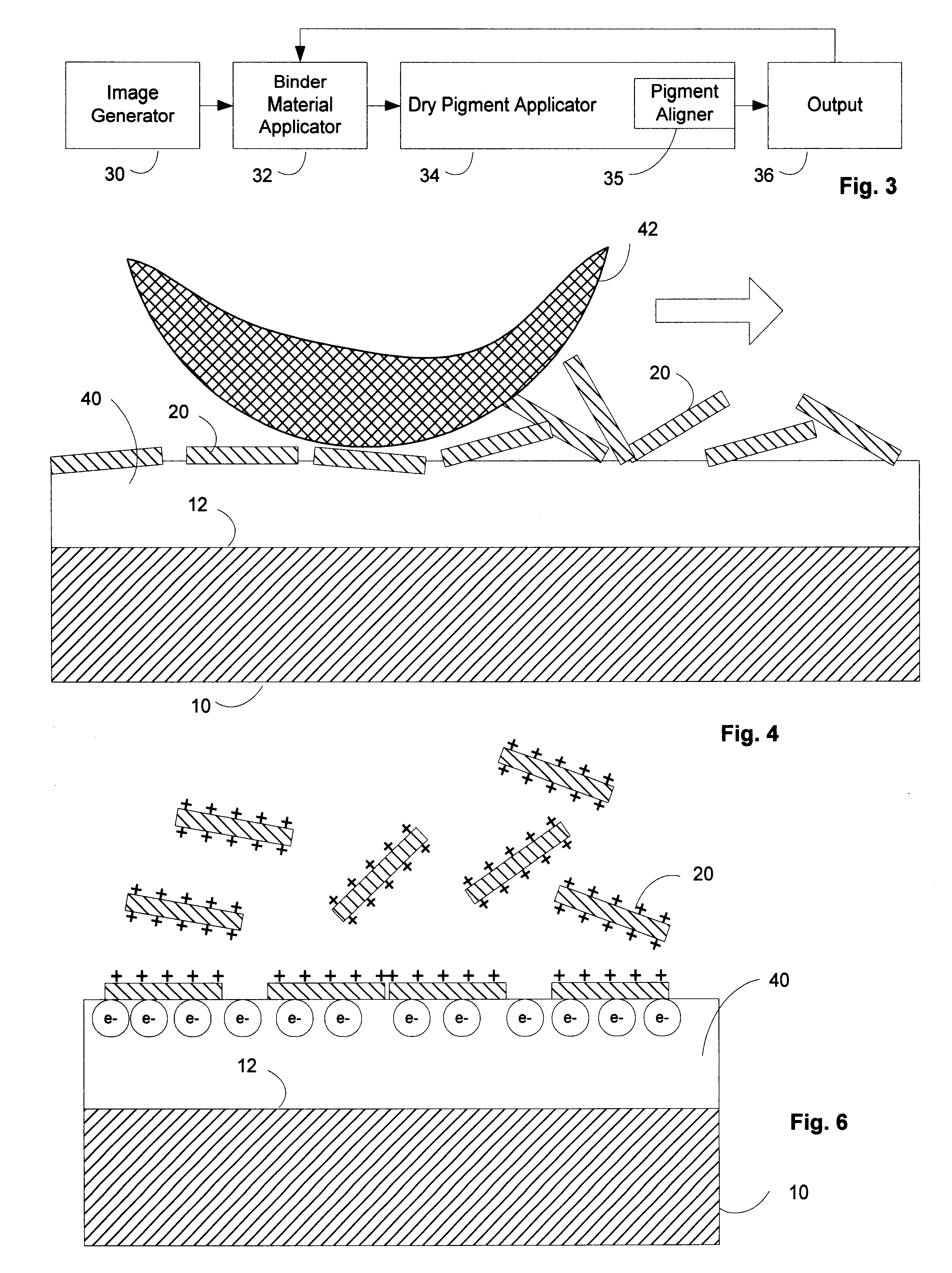

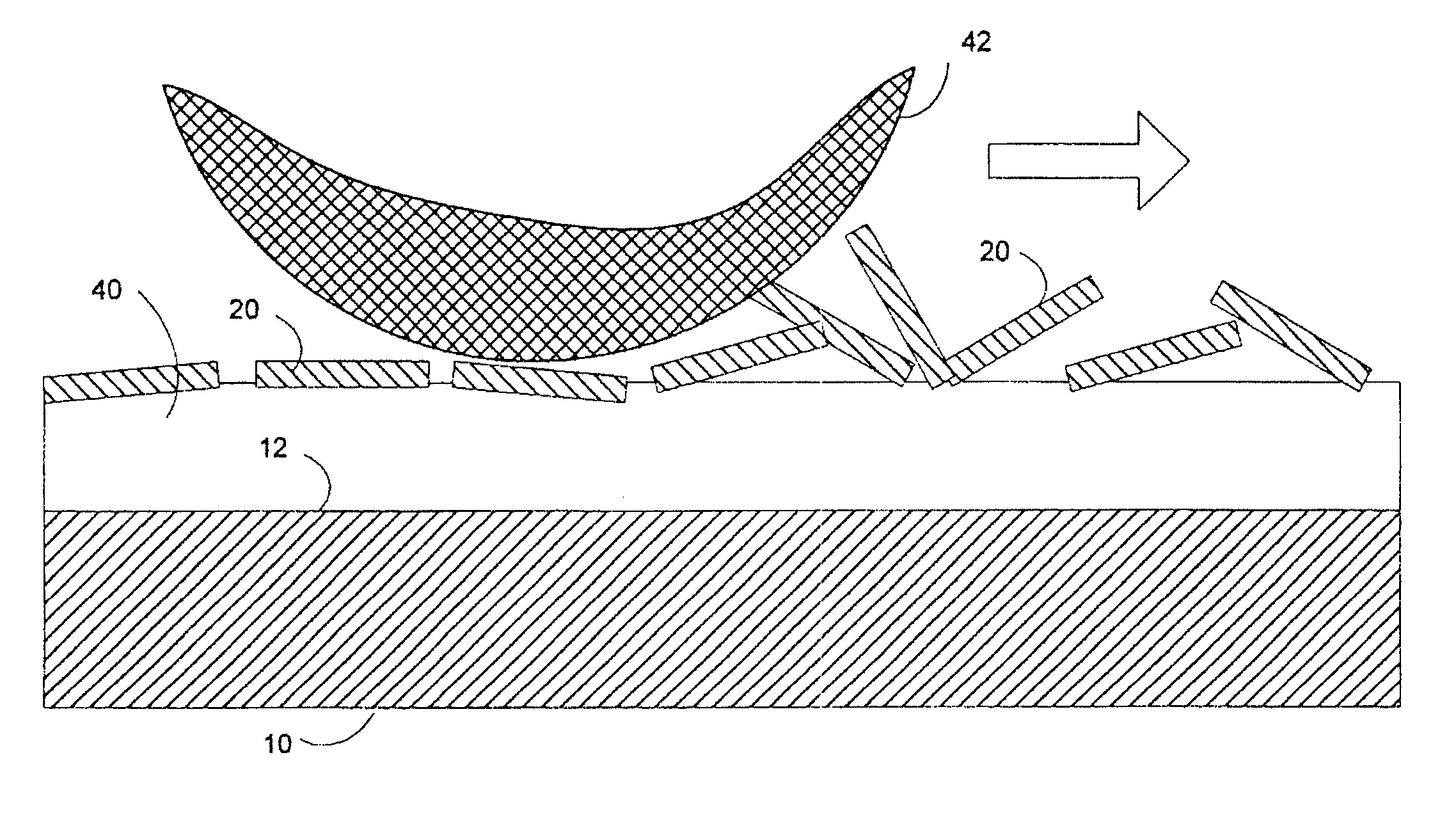

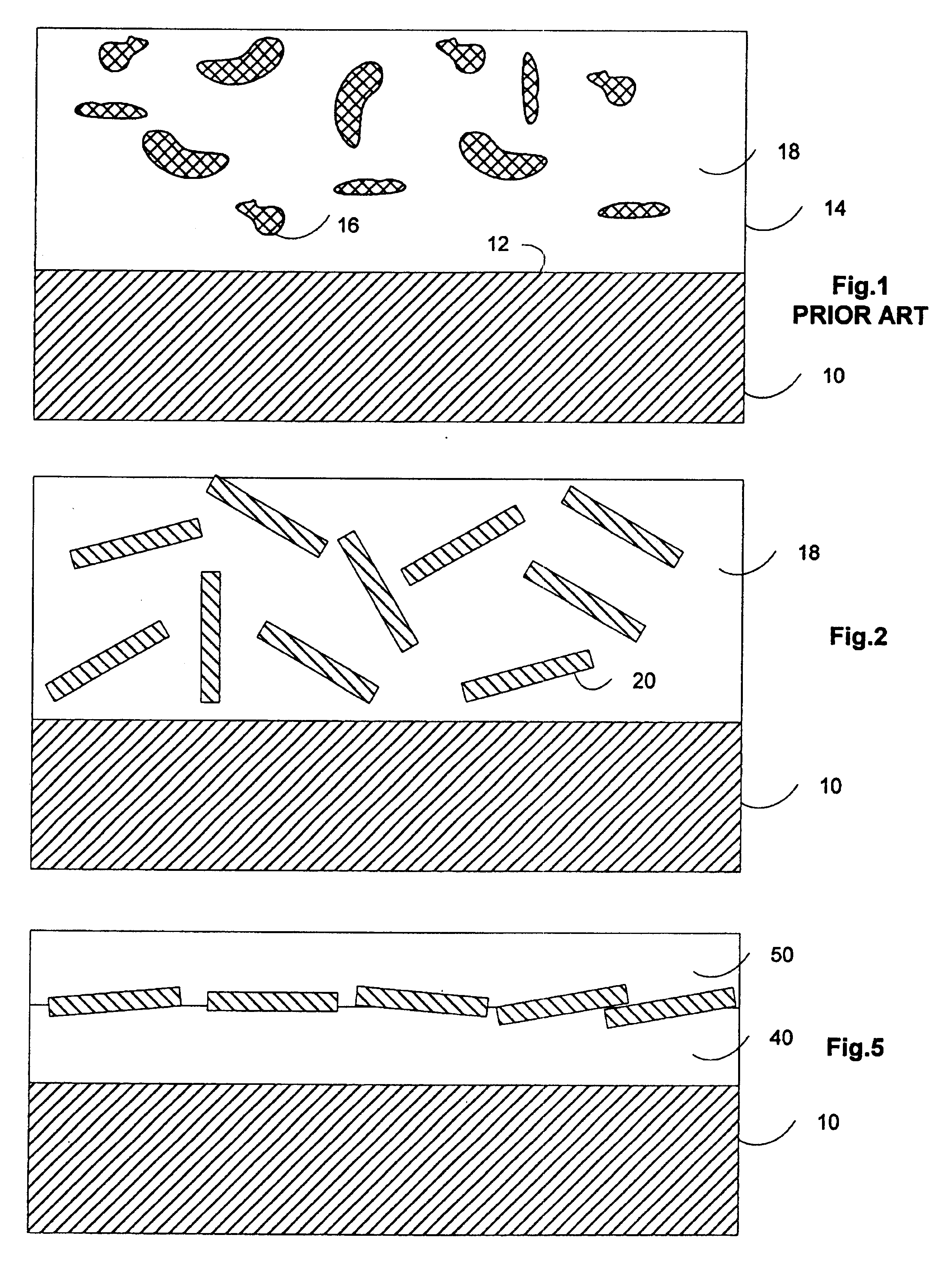

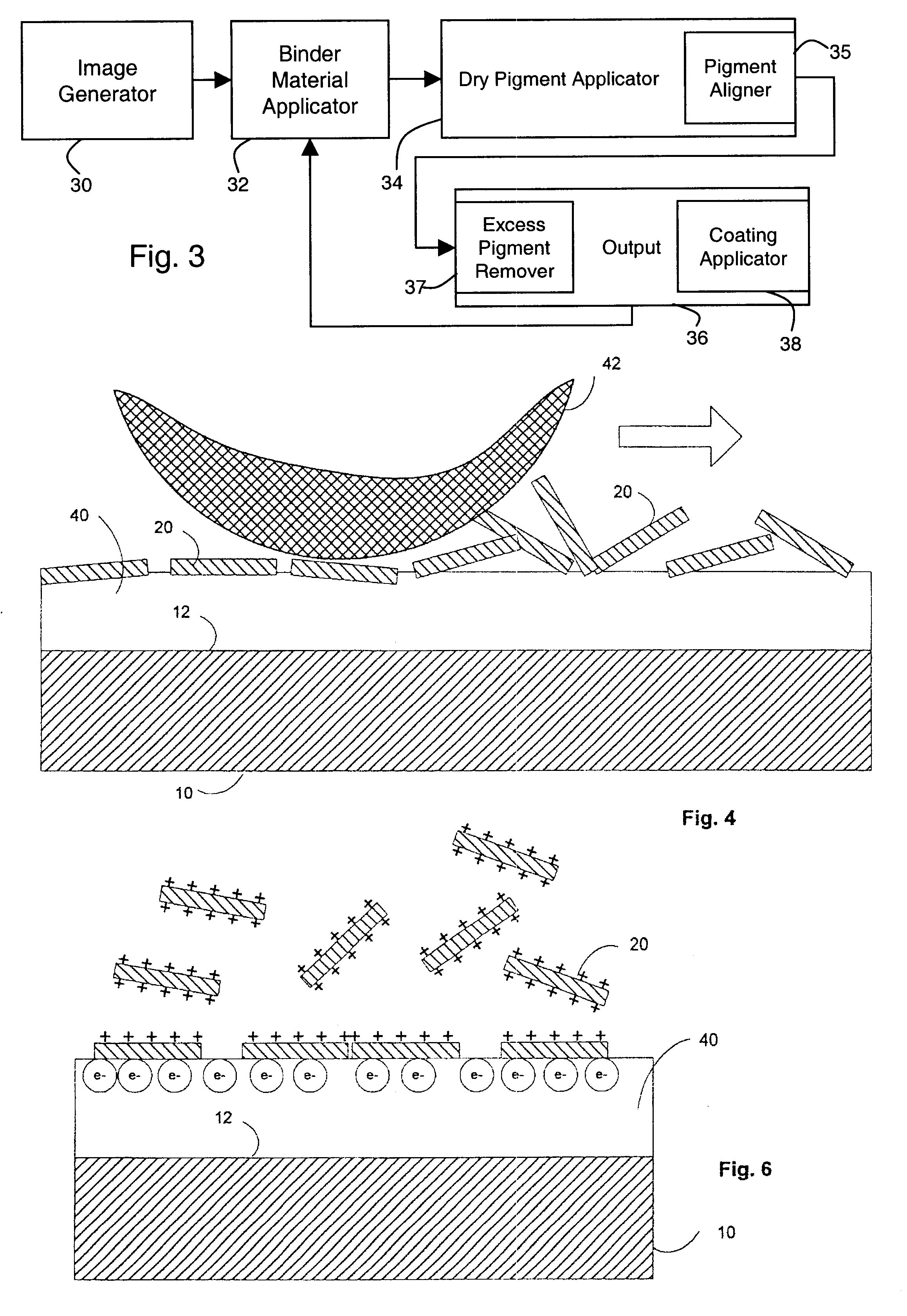

Method of dry printing and painting

InactiveUS6387457B1Function increaseAvoid less flexibilityPretreated surfacesPattern printingMaterials sciencePigment

A method of printing using dry pigments is introduced, wherein a binder material is applied to the surface of an object uniformly or in a pattern, and then dry pigment is applied to the binder material in a pattern or uniformly. The dry pigment sticks to the patterned binder, or the patterned pigment may be bound to the uniform binder, to produce a pattern.

Owner:REVEO

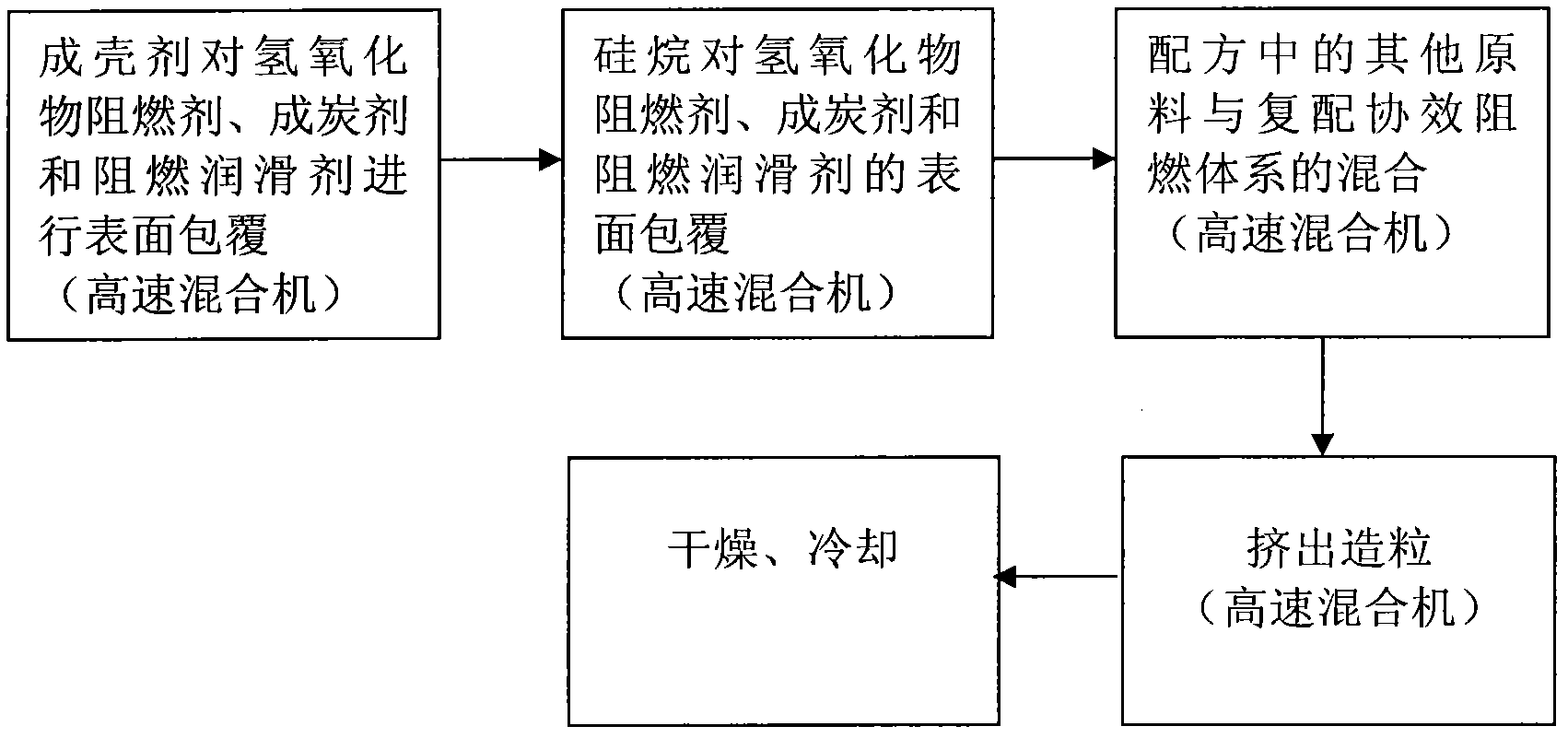

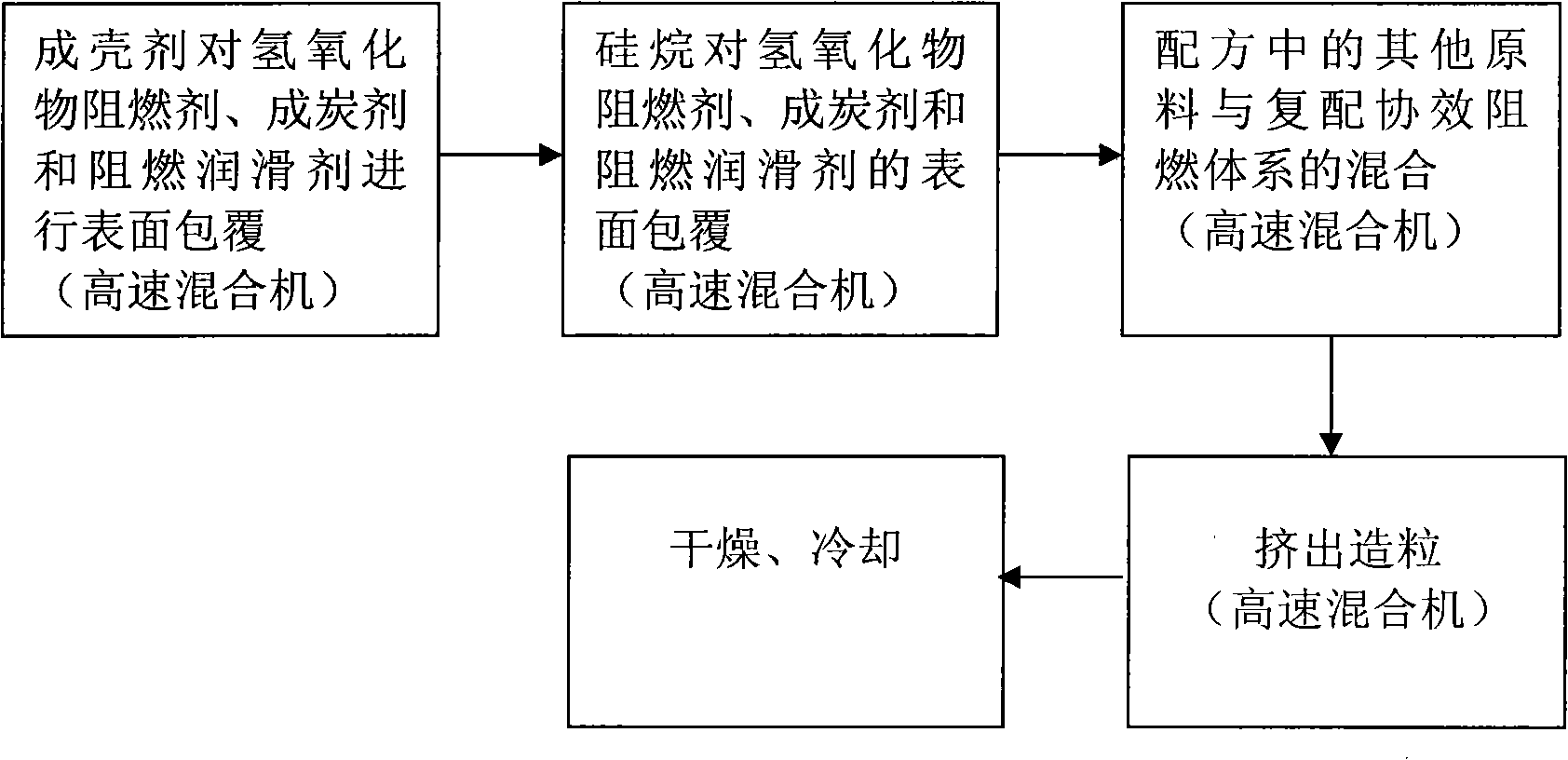

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

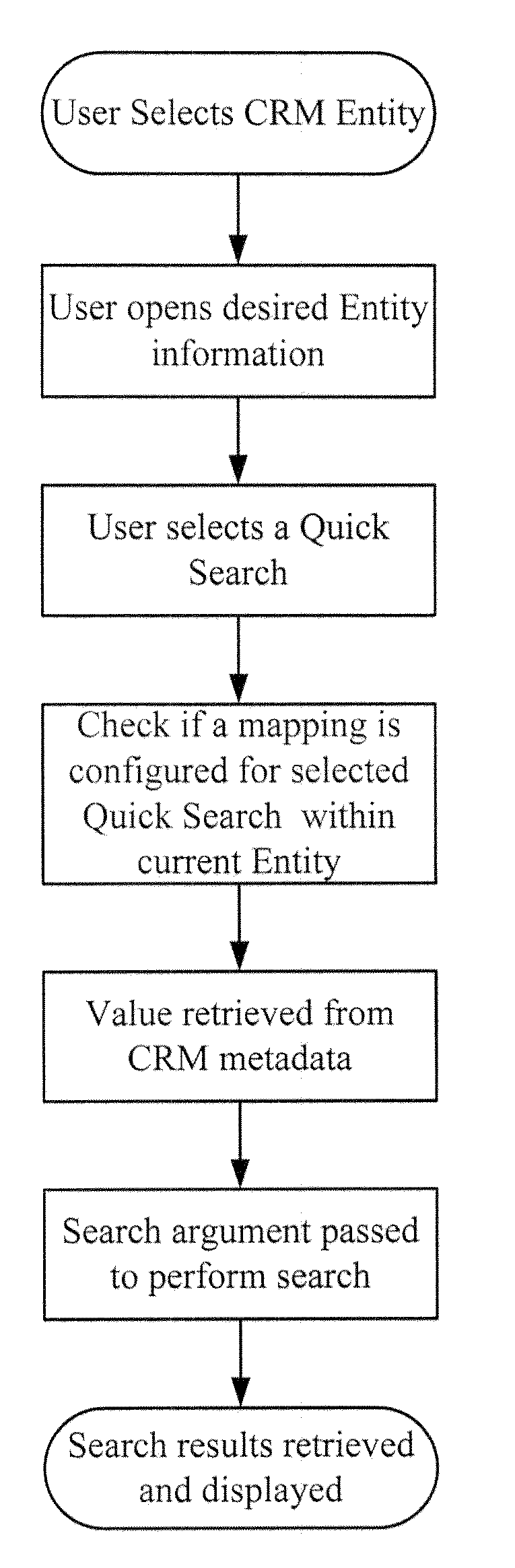

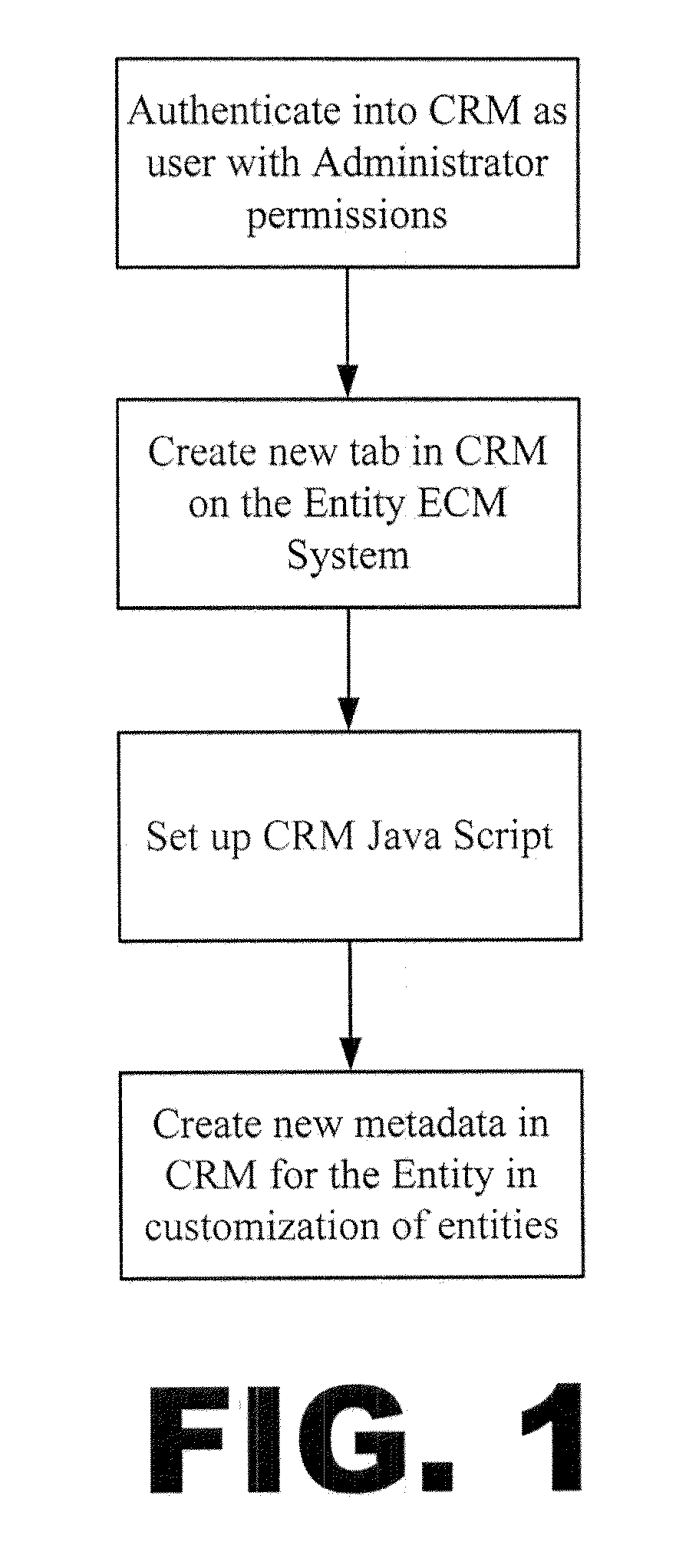

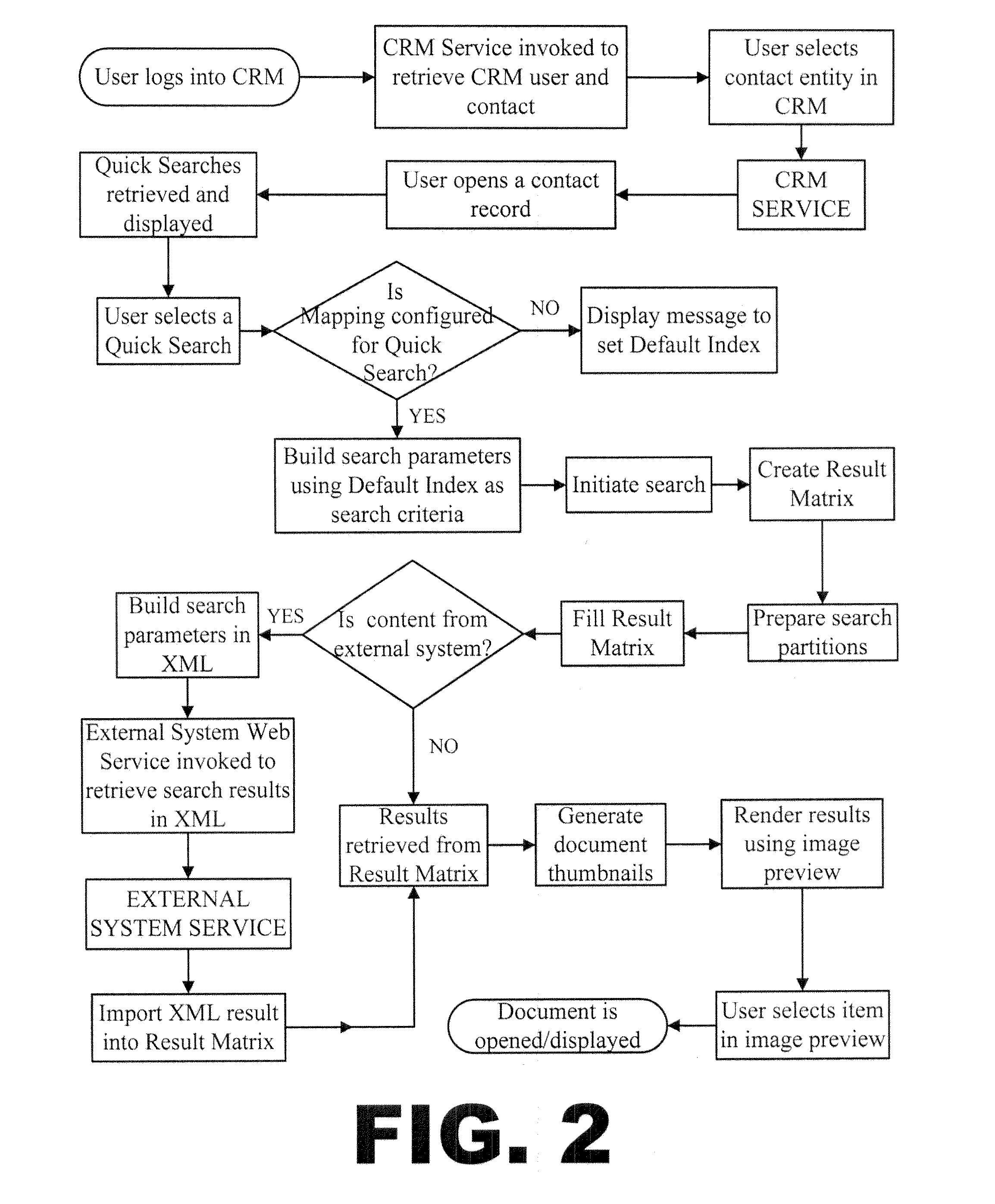

Relationship and Content Management Application

InactiveUS20120072436A1Easy retrievalEliminate needDigital data processing detailsOffice automationNetwork management applicationInternal documentation

A web-based Relationship and Content Management Application combining an organization's CRM and ECM systems by integrating CRM's contacts with an ECM system's key features and functionality. The user of such is able to efficiently store and retrieve a combination of information for a relationship from CRM as well as from ECM, avoiding human error and providing data centralization. Users may store and retrieve content from both internal document repositories within an ECM system as well as external document repositories in the user's system. The major features consist of the ease of use and data consistency, plus the leverages of CRM as the centralization of data.

Owner:WALL STREET NETWORK

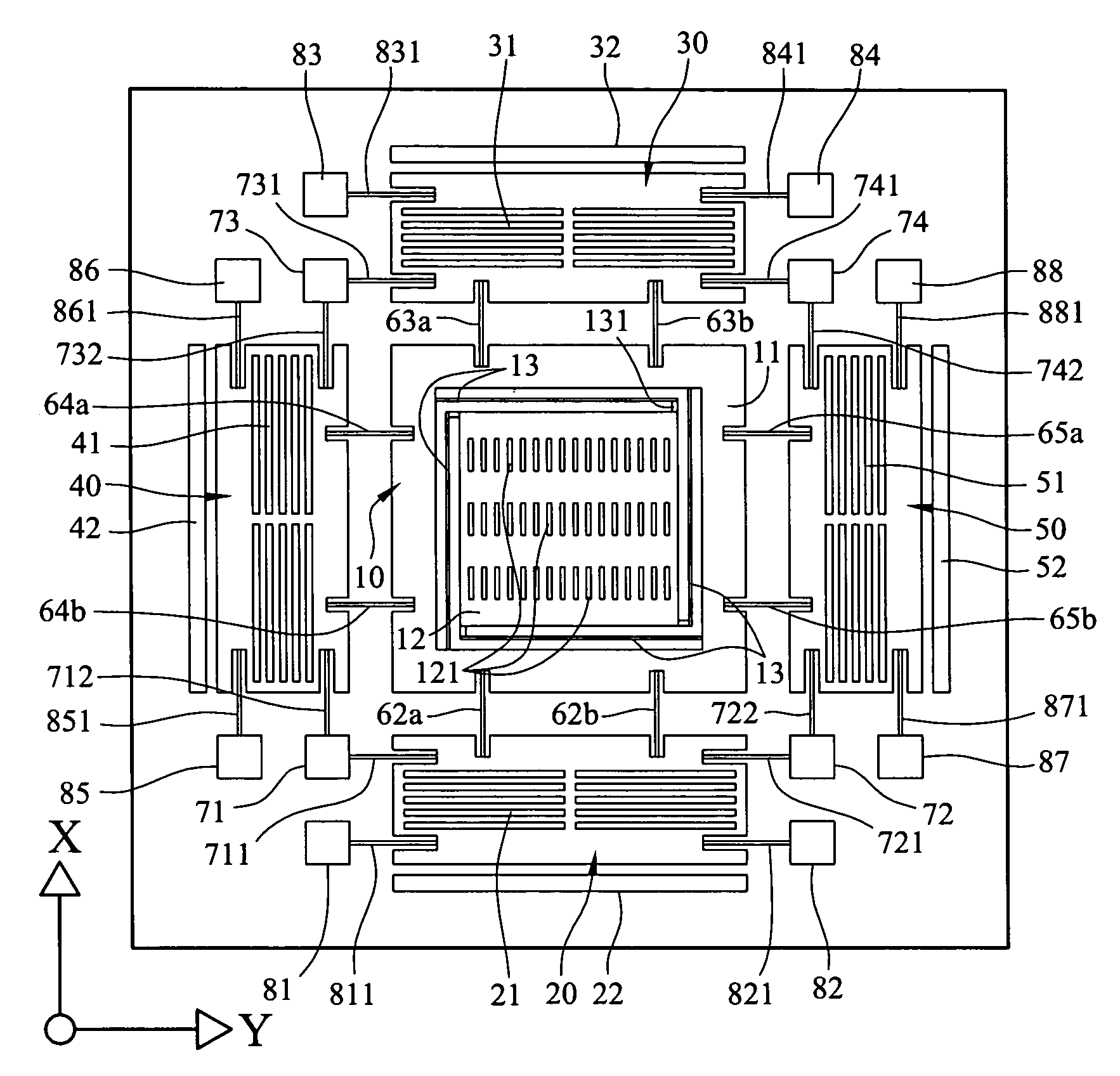

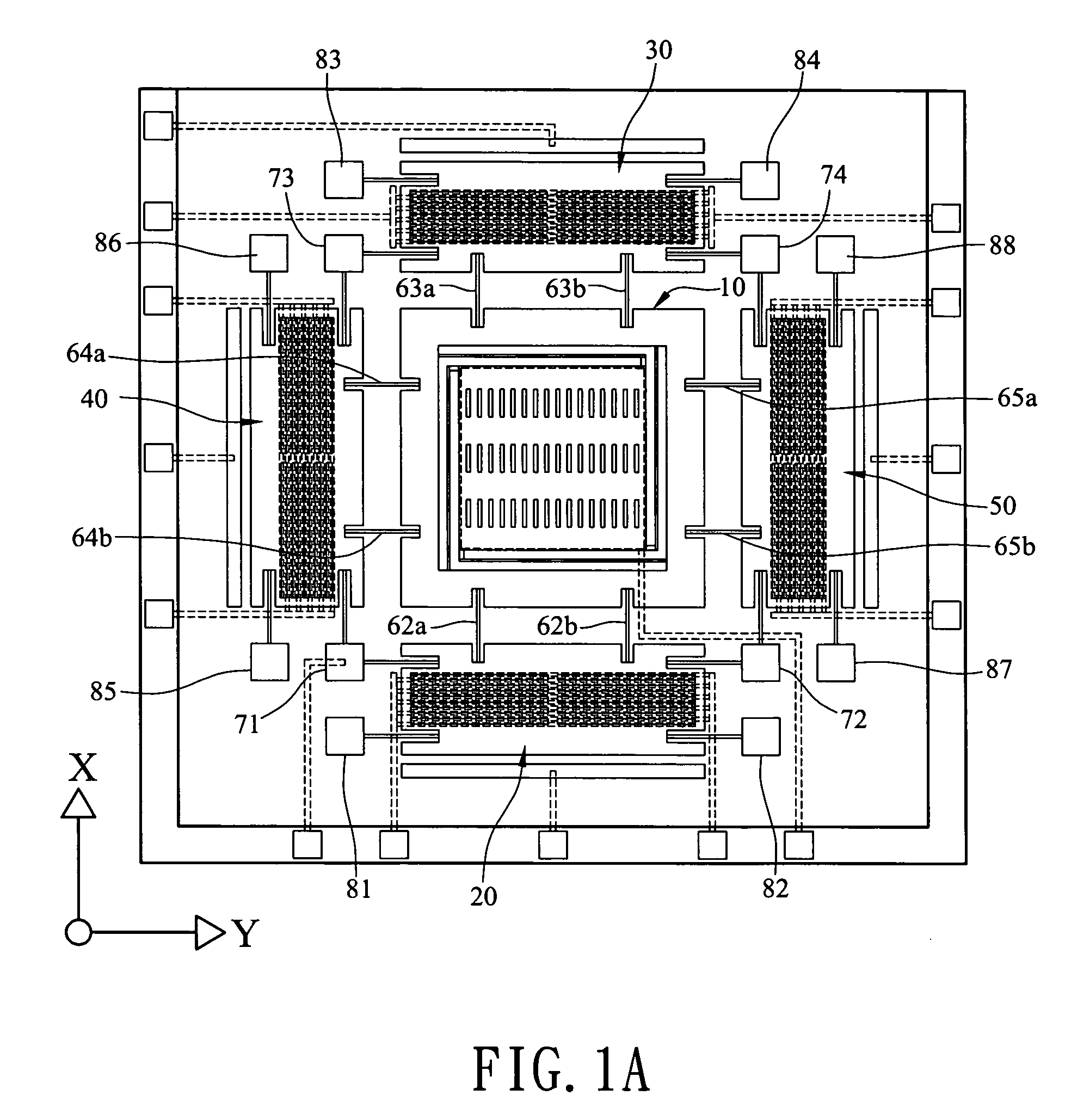

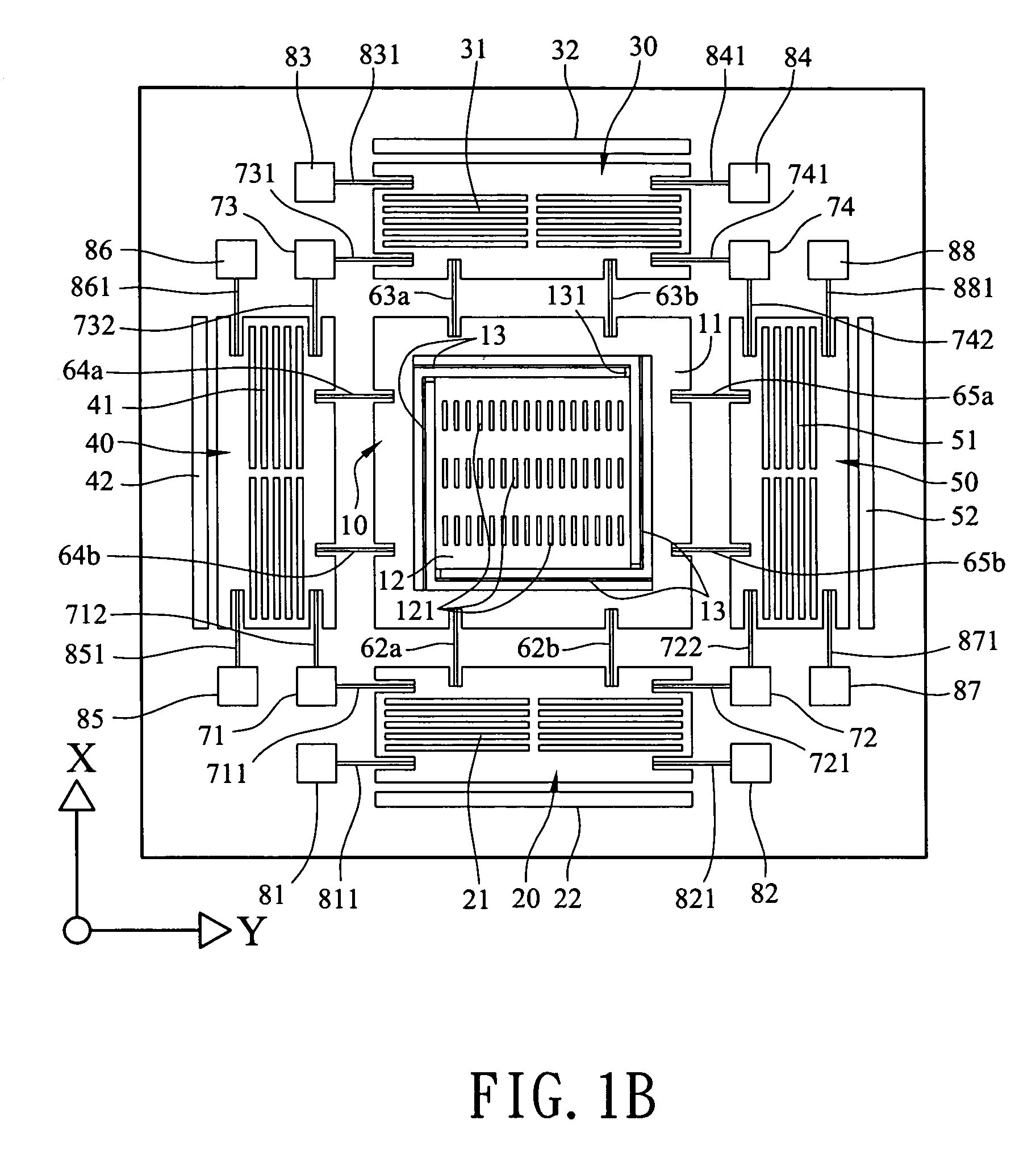

Micro accelerometer

ActiveUS7210351B2Performance is not affectedAdvanced technologyAcceleration measurement using interia forcesDevices characerised by mechanical meansAccelerometerManufacturing technology

A micro accelerometer including a plurality of proof masses is provided to detect the acceleration of the first axis, the second axis and the third axis. The disclosed micro accelerometer has the advantages of close loop control, mechanical decoupling, and not relying on high aspect ratio manufacturing technology.

Owner:NAT CHUNG SHAN INST SCI & TECH +1

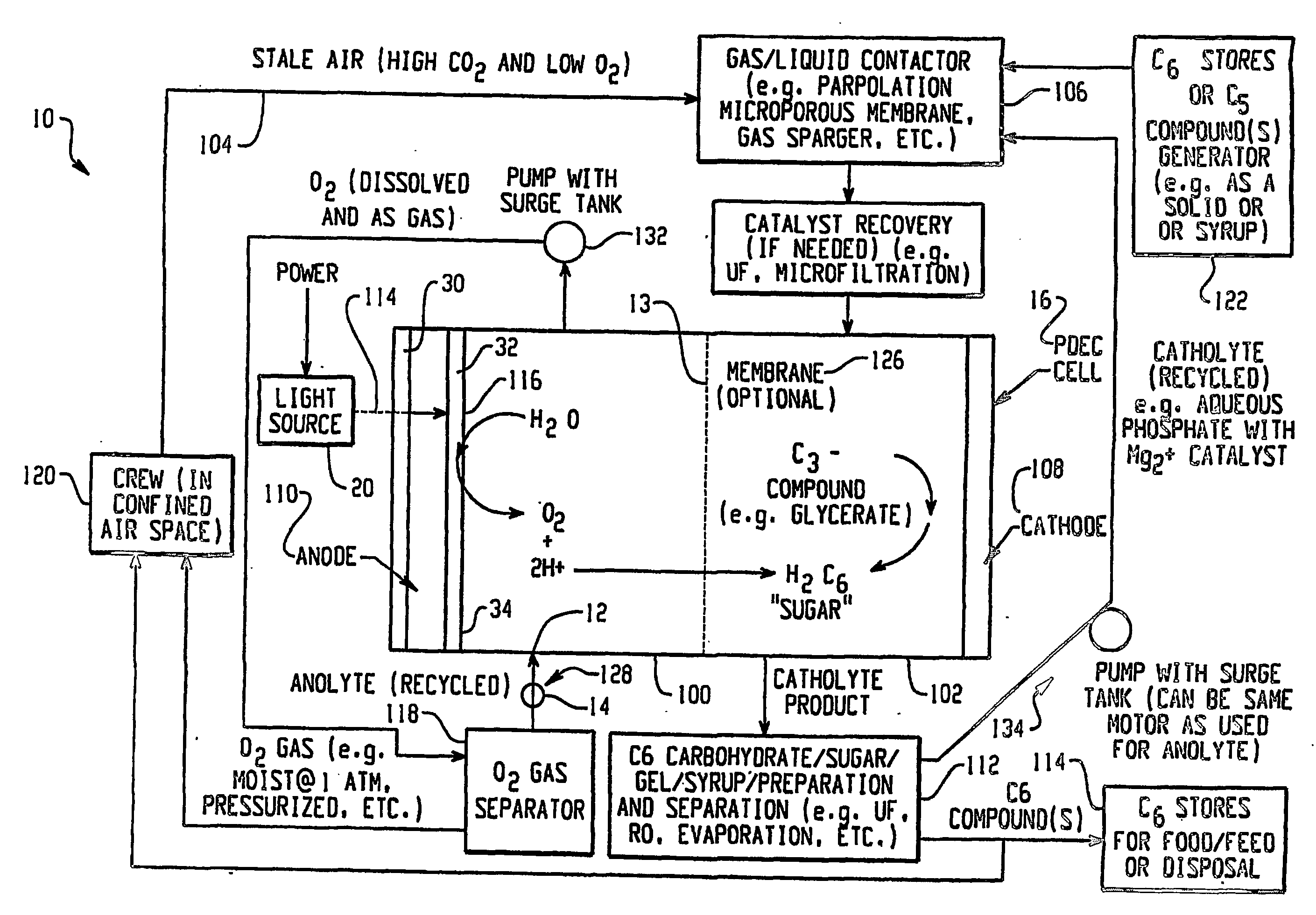

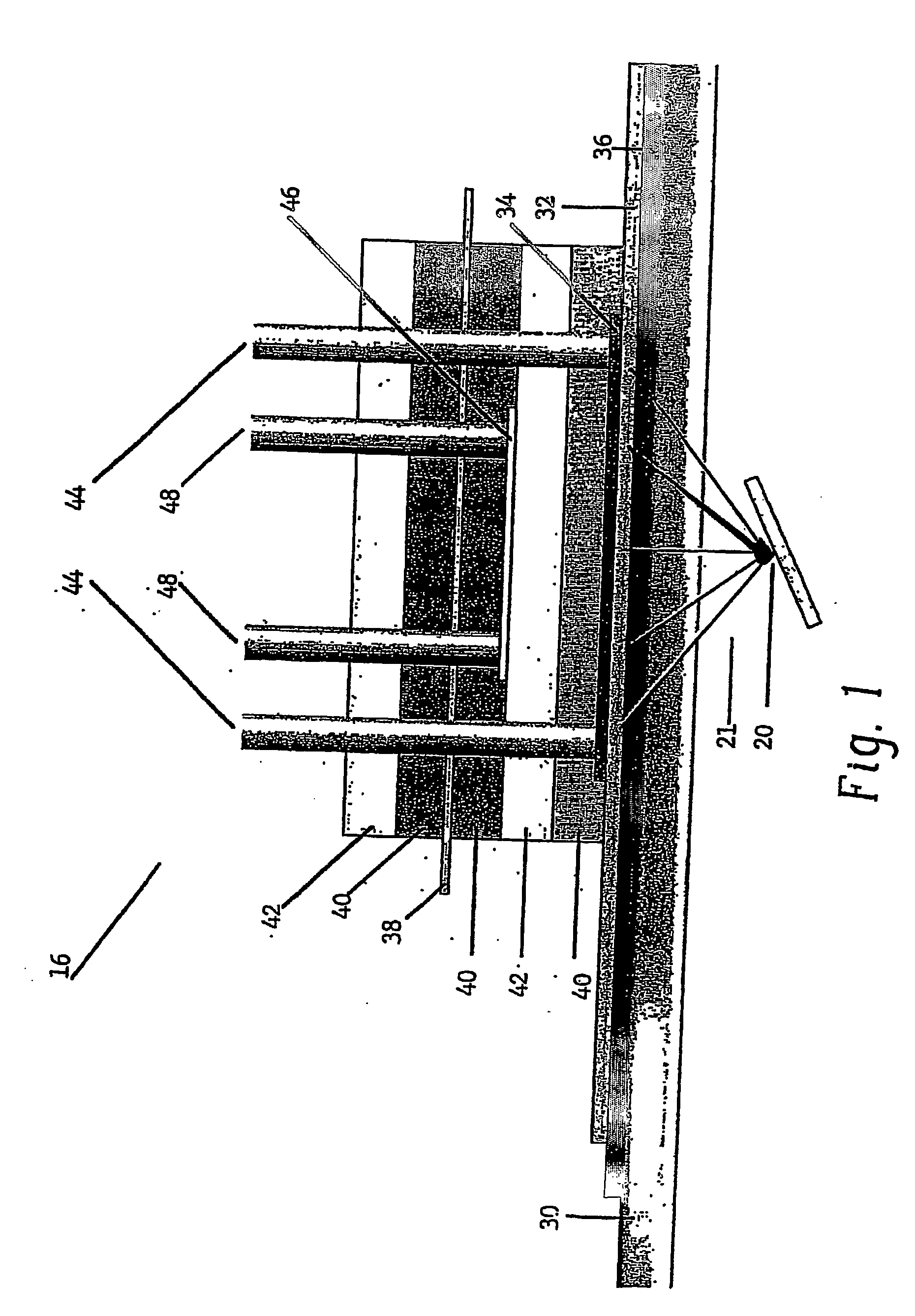

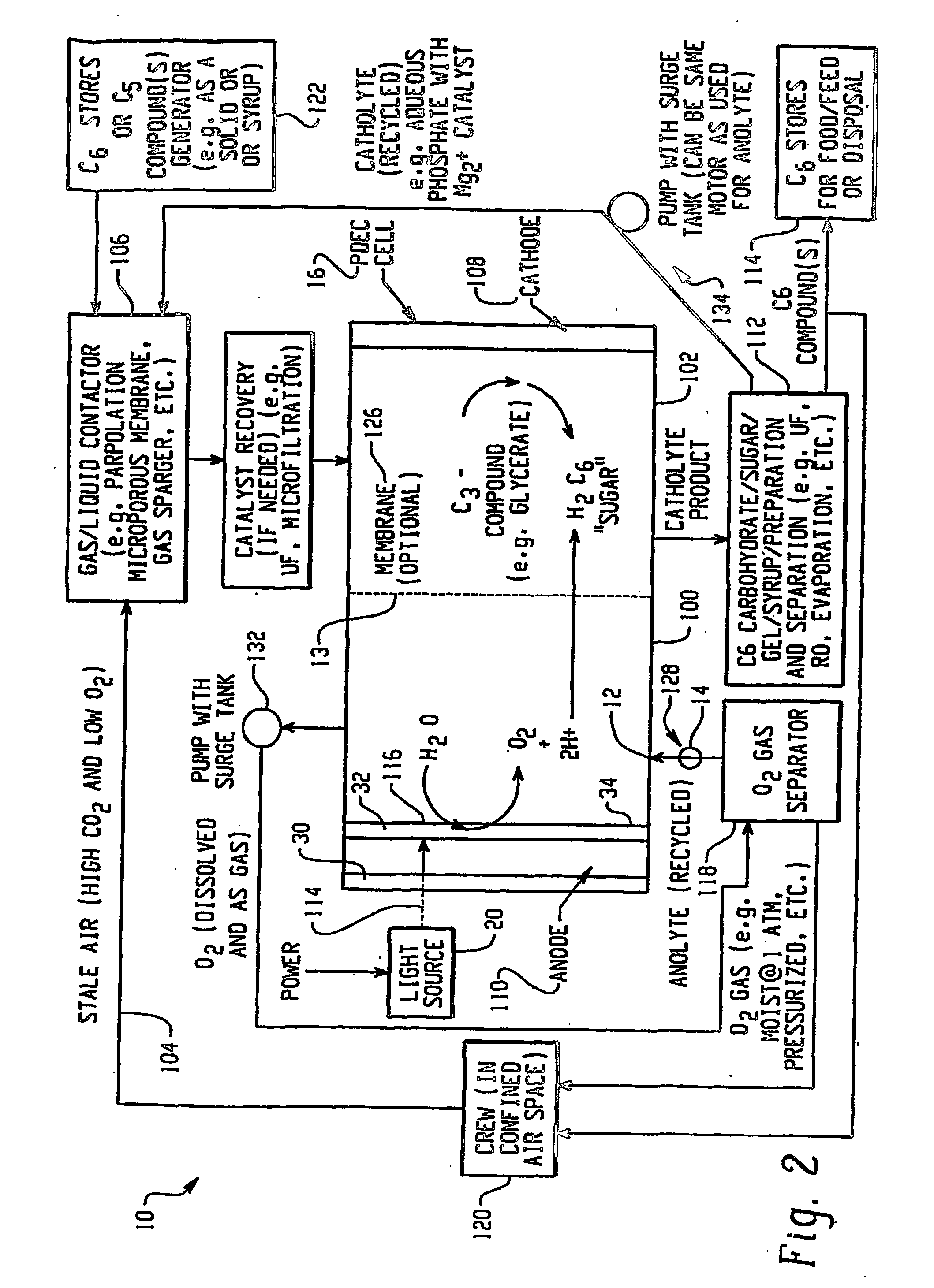

Photolytic oxygenator with carbon dioxide and/or hydrogen separation and fixation

Apparatus for oxygenating an enclosed space as well as removing carbon dioxide from the enclosed space. The apparatus comprises a photolytic cell (16) having an anode compartment with a photo-active surface having the ability to convert water to oxygen; a cathode compartment having the ability to convert carbon dioxide and hydrogen to a solid or liquid medium; and a light source (20) for providing light photons (21) to said photolytic cell and activating the photo-reactive surface.

Owner:BATTELLE MEMORIAL INST

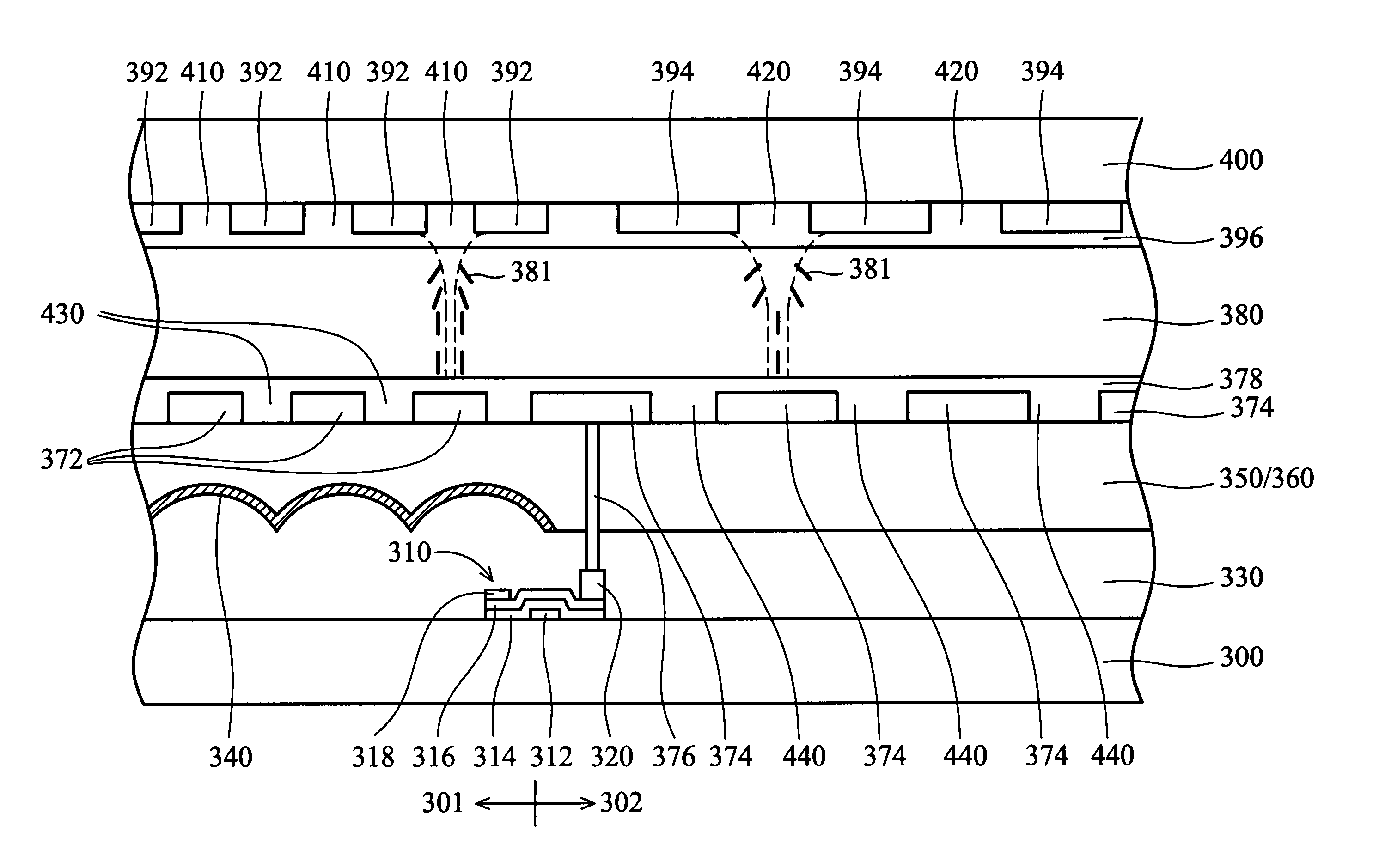

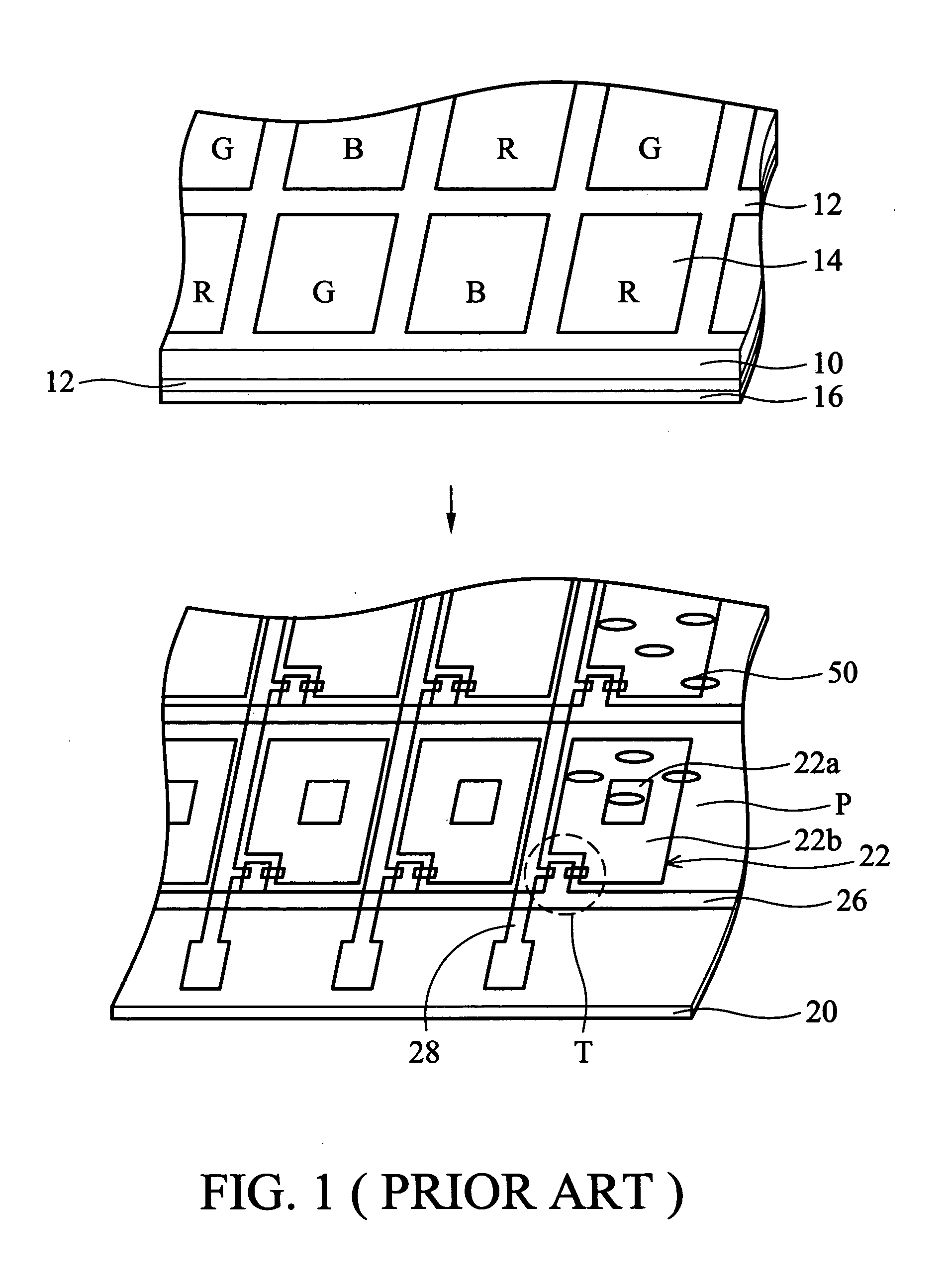

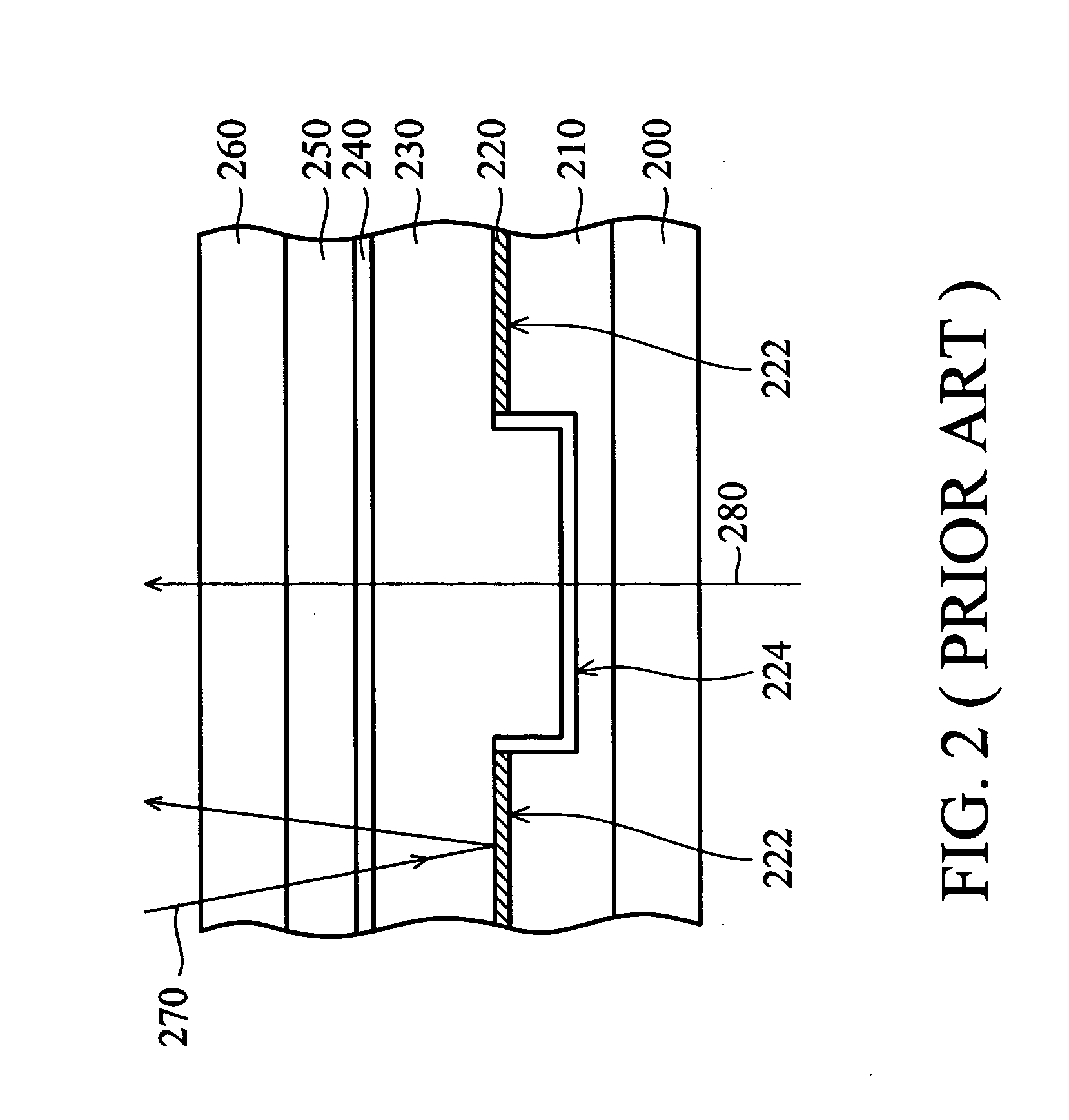

Transflective liquid crystal display device and fabrication method thereof

ActiveUS20050001959A1Maximum light efficiencyImprove disadvantagesNon-linear opticsElectrical batteryLiquid crystal

A transflective LCD device with a single cell gap. First and second pixel electrodes are formed on the lower substrate. First and second common electrodes are formed on an inner surface of the upper substrate. The first pixel electrodes and the first common electrodes are located in the reflective region. The second pixel electrodes and the second common electrodes are located in the transmissive region. A first orientation control window having a slit width “Src” is formed between the first common electrodes in an area corresponding to each first pixel electrode. A second orientation control window having a slit width “Stc” is formed between the second common electrodes, satisfying Src<Stc. The second orientation control window is in an area corresponding to each second pixel electrode. Accordingly, maximum light efficiency can be achieved in both reflective and transmissive modes.

Owner:HANNSTAR DISPLAY CORPORATION

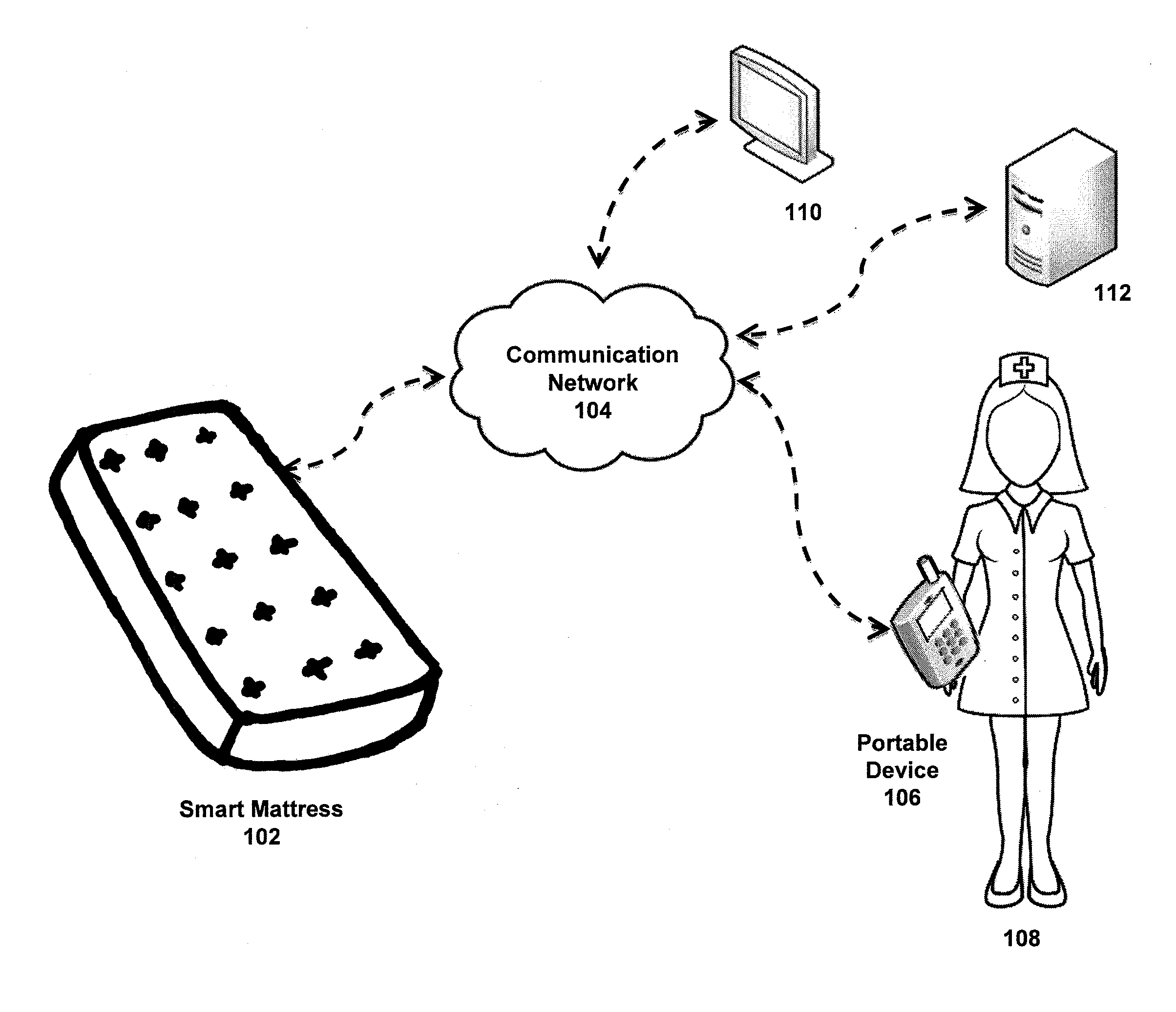

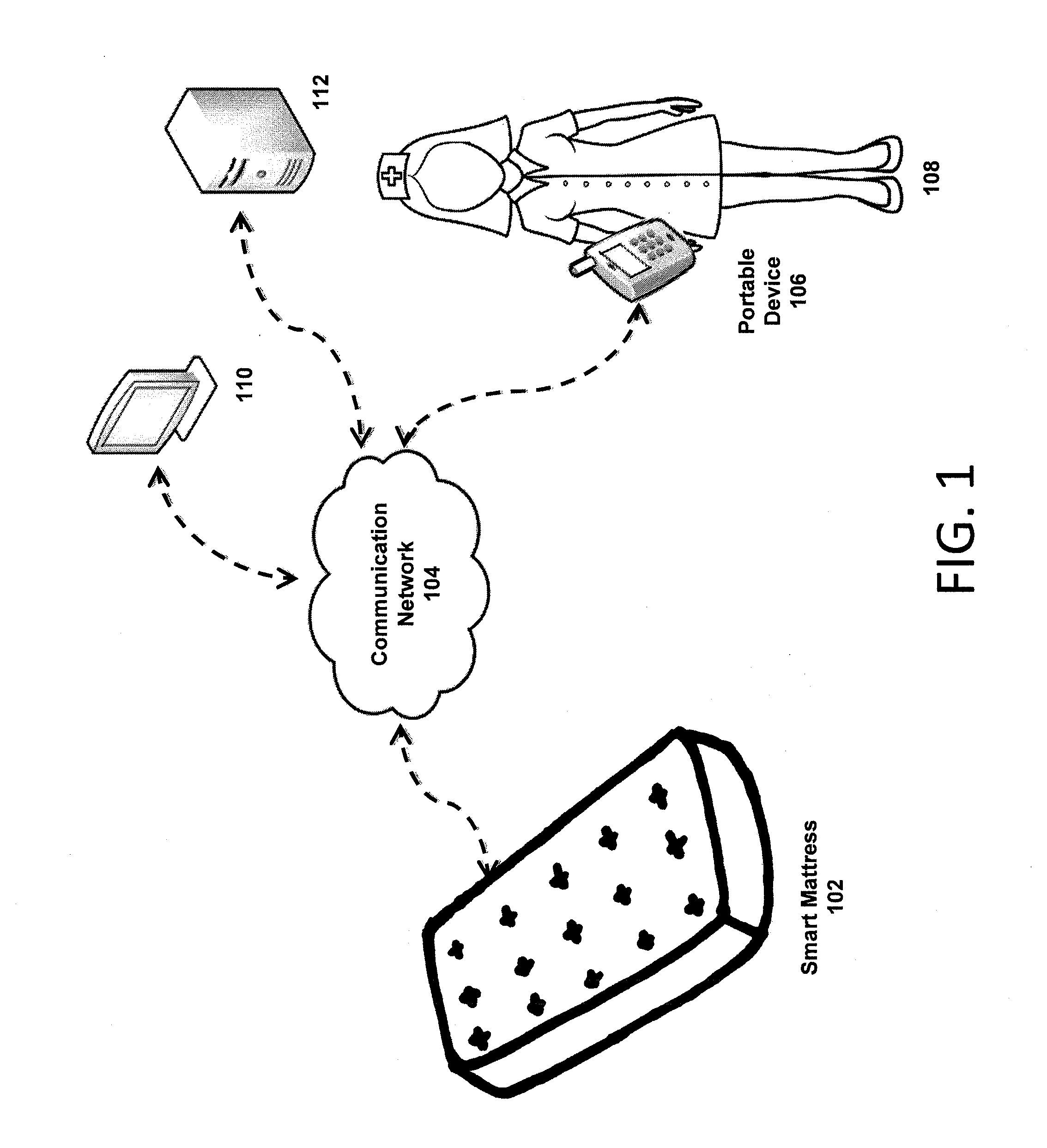

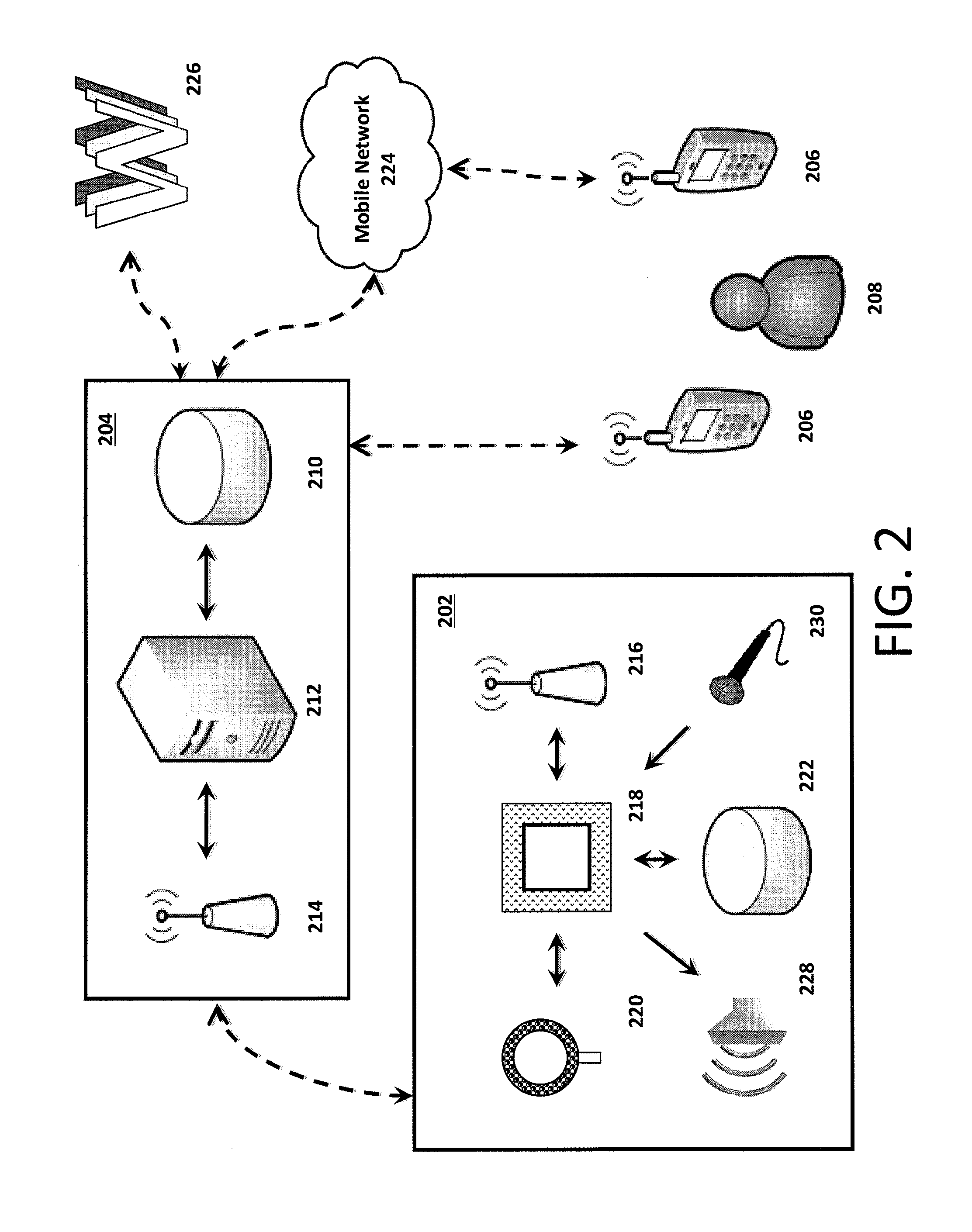

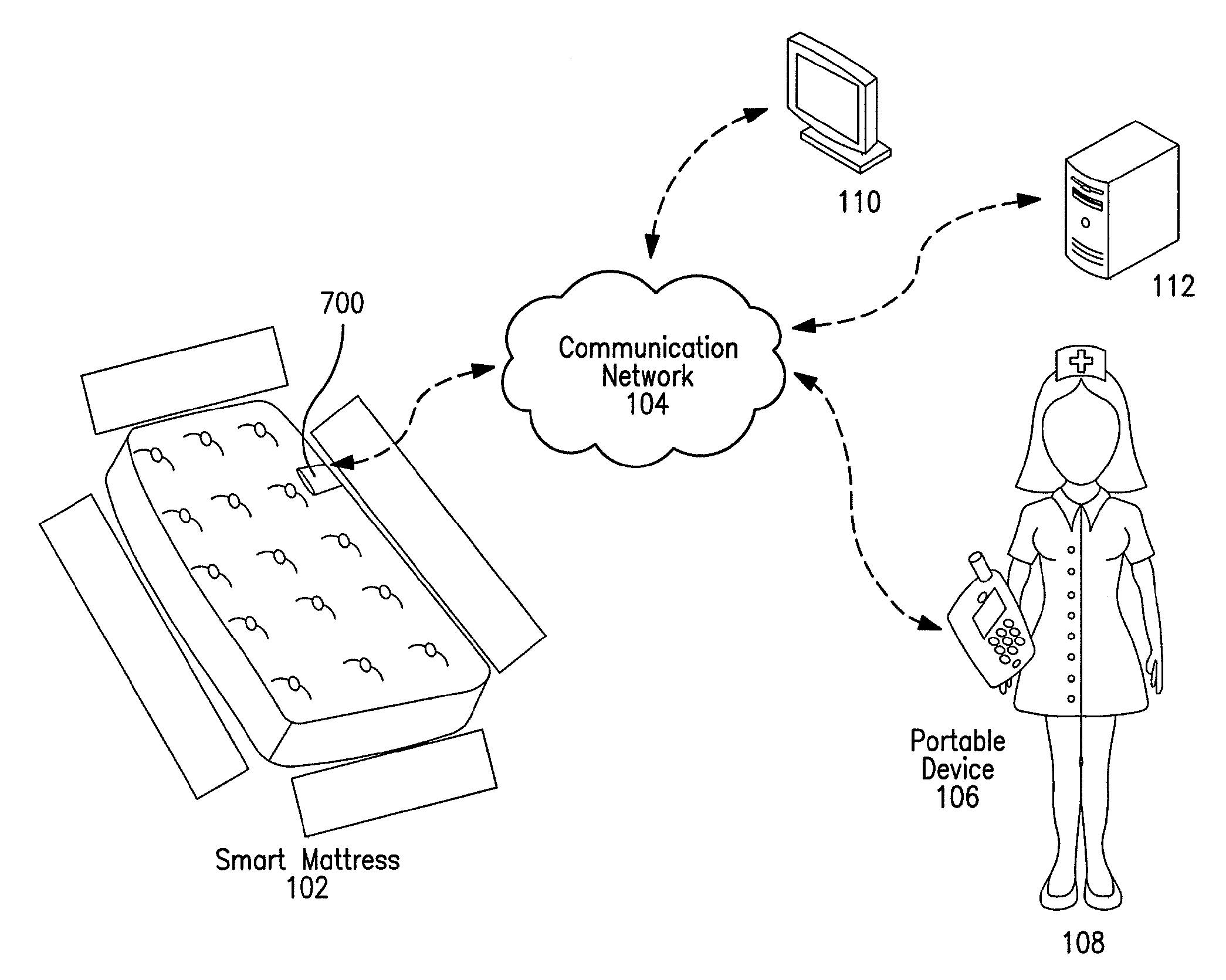

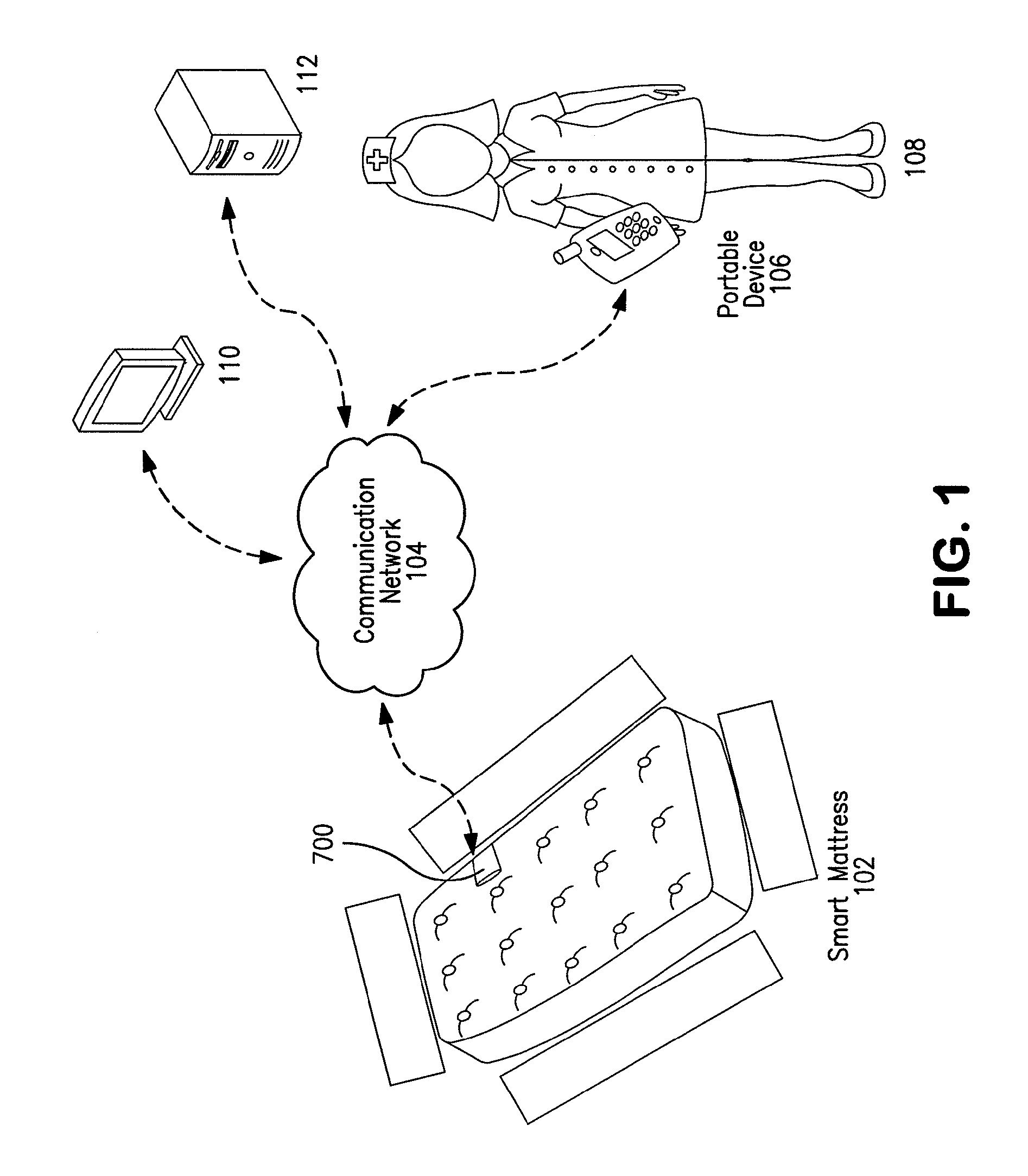

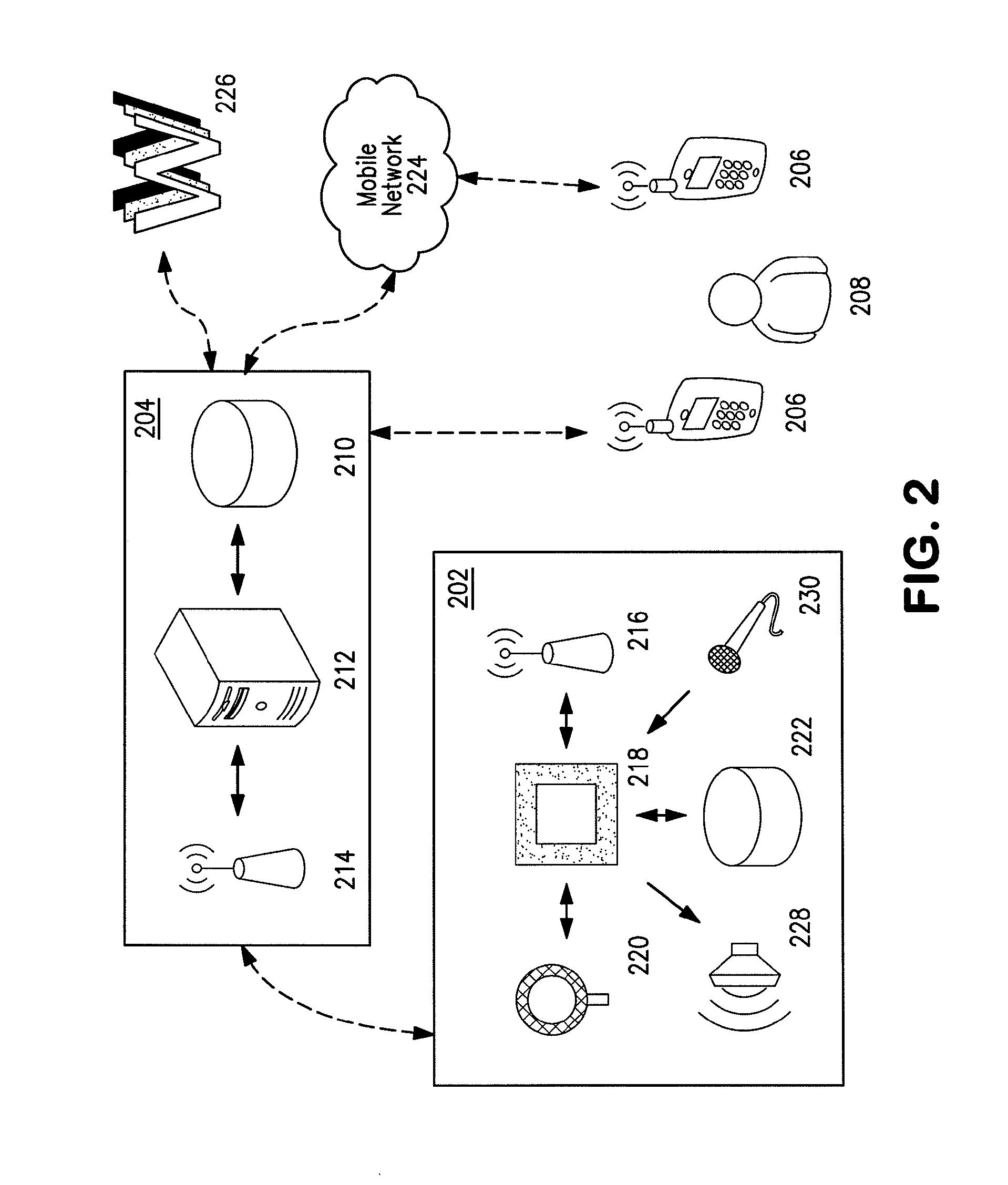

Smart mattress

InactiveUS20120053423A1Good flexibilityAdvanced technologyChildren furnitureDiagnostic recording/measuringBed-riddenCare giver

Systems and methods are disclosed for a self-contained Smart Mattress which is capable of monitoring the vital statistics of a patient in real time, analyzing the data using an embedded processor, storing patient identification and information, producing an electronic medical report and communicating any data to the caregiver or computer server using wireless technology, such as Bluetooth® Technology. Due to the self-contained nature of the mattress, it is also ideal for use as an emergency evacuation mattress for bed-ridden patients.

Owner:EVACUSLED

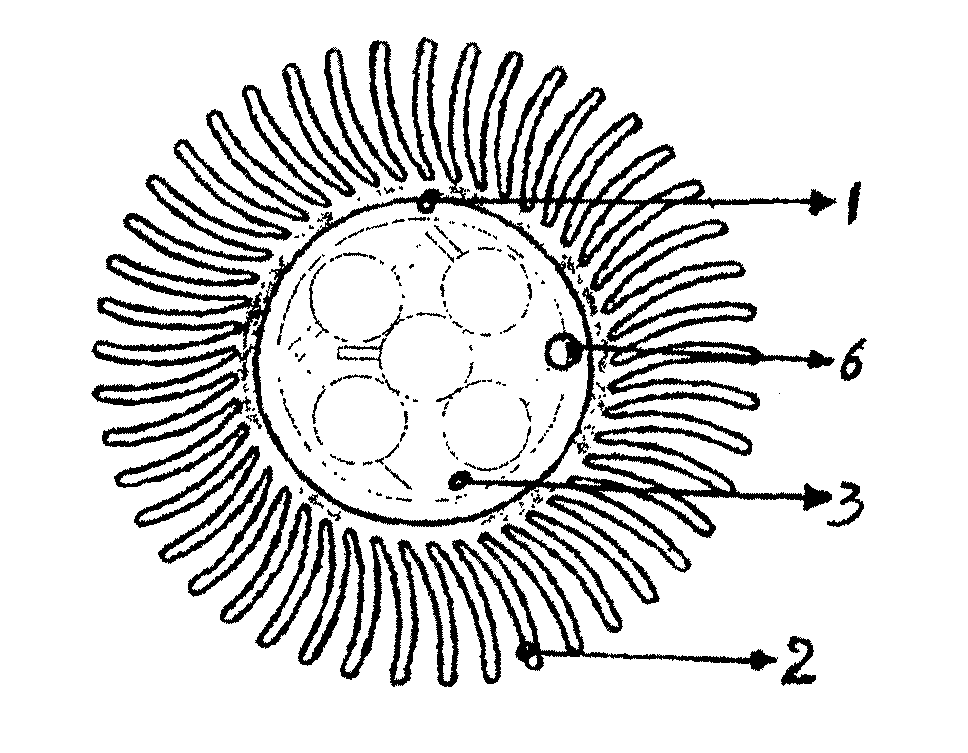

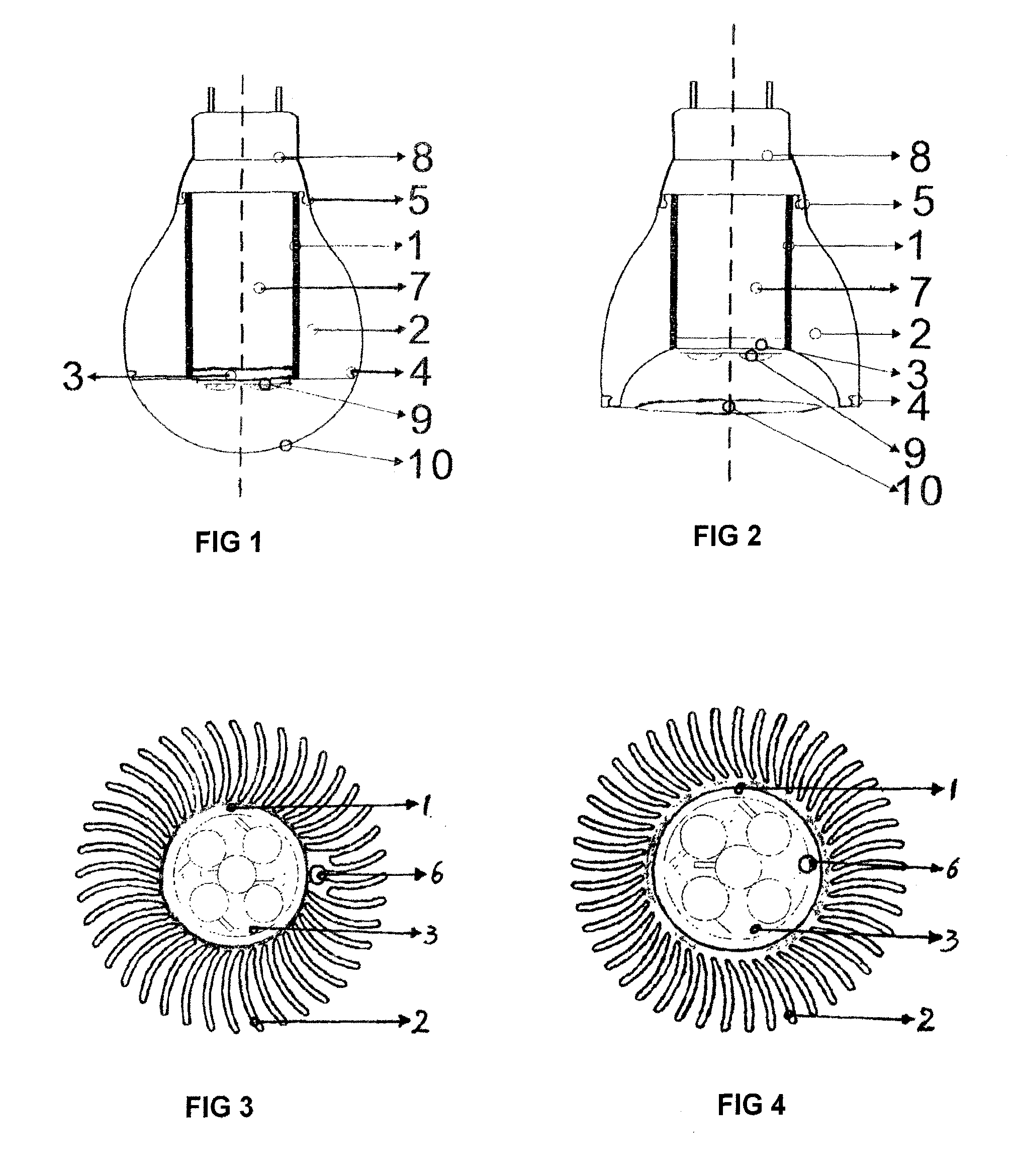

Built-in Heat Diffusion Lamp Body for LED Lamp

InactiveUS20090016063A1Simple materialSimple structurePoint-like light sourceElectric circuit arrangementsDiffusionInterference fit

A built in beat diffusion lamp body for LED lamp was invented. The purpose of the invention is to solve the difficulties of poor heat conduction and diffusion caused by the small heat diffusion surface of the material of a conventional LED lamp. The lamp body is made of a set of heat diffusion vanes encircling the heat diffusion complex. The vanes and heat diffusion complex are made from Aluminum alloy in a single process of extrusion moulding. The transverse section of the heat diffusion body is volute shaped. The bottom of the heat diffusion complex is fixed to an aluminum board or an aluminum circuit: board by interference fit. The heat generated by the LED elements can be absorbed and diffused by the board, the heat diffusion complex and the surrounding diffusion element. The outward appearance of the heat diffusion lamp body may be shaped into cup, ladder, or cylinder likeness to satisfy the application requirement. The advantages of current invention are: efficient heat absorption, conduction, and diffusion, low cost for manufacturing, and aesthetic appearance.

Owner:HU KAI

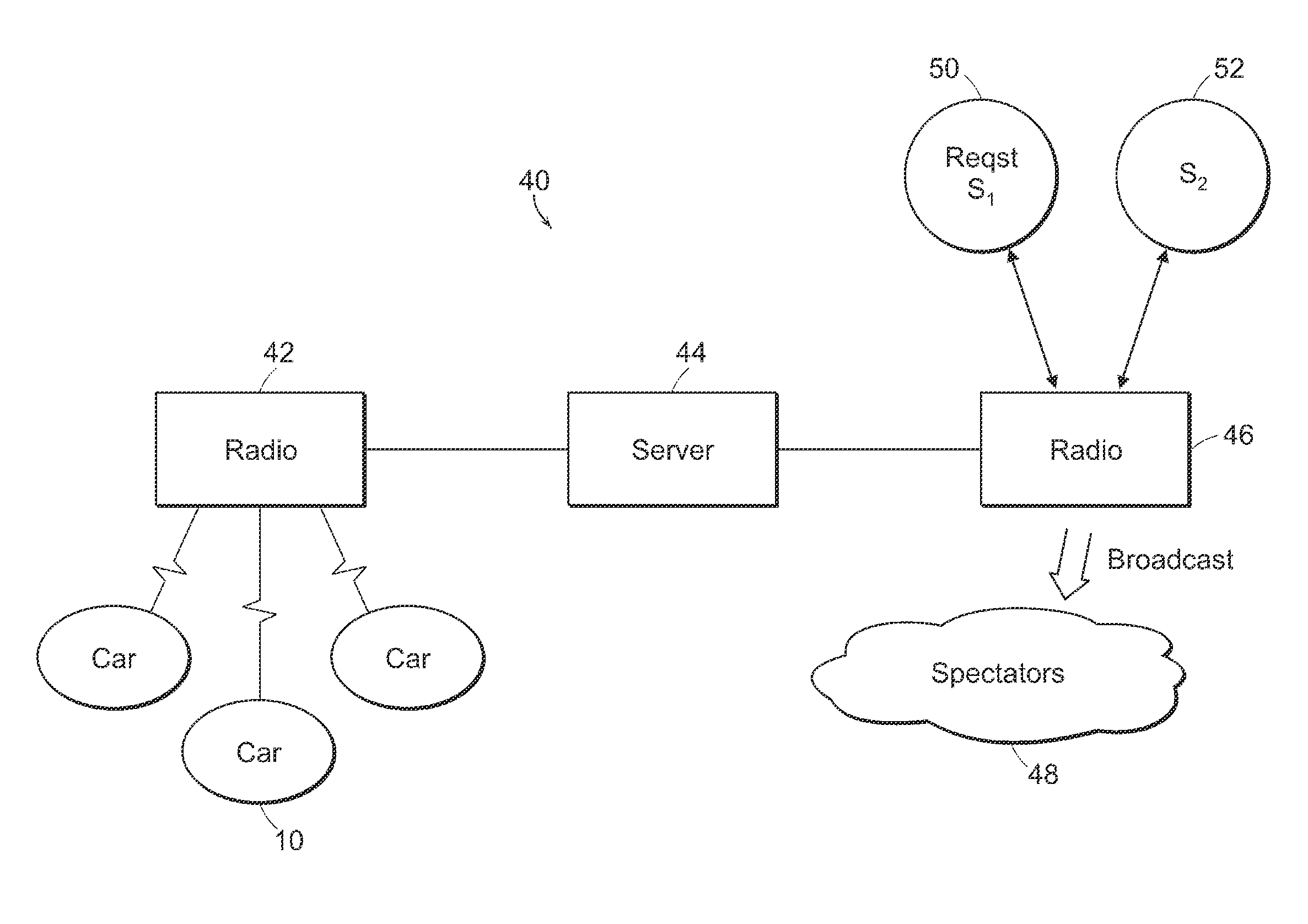

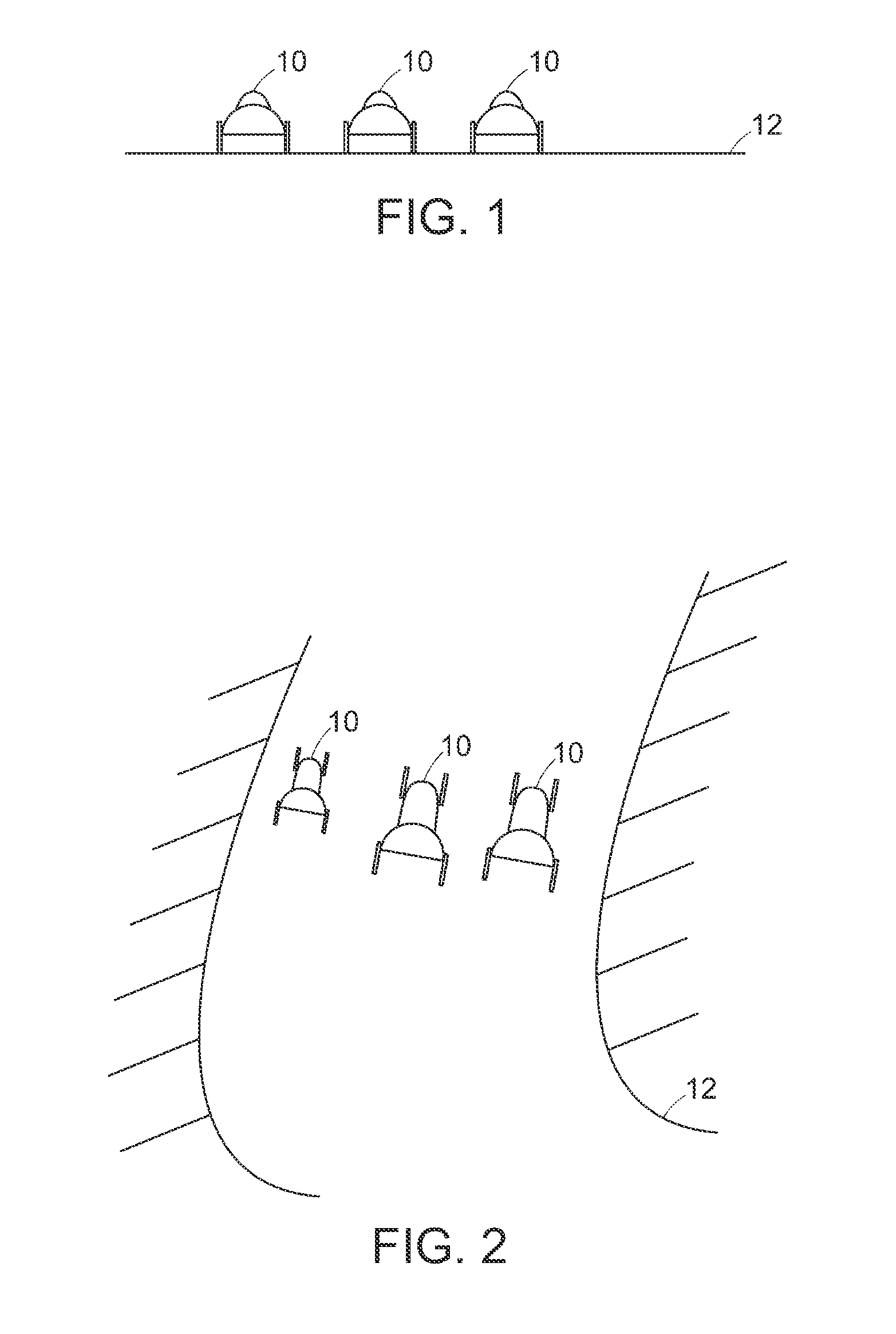

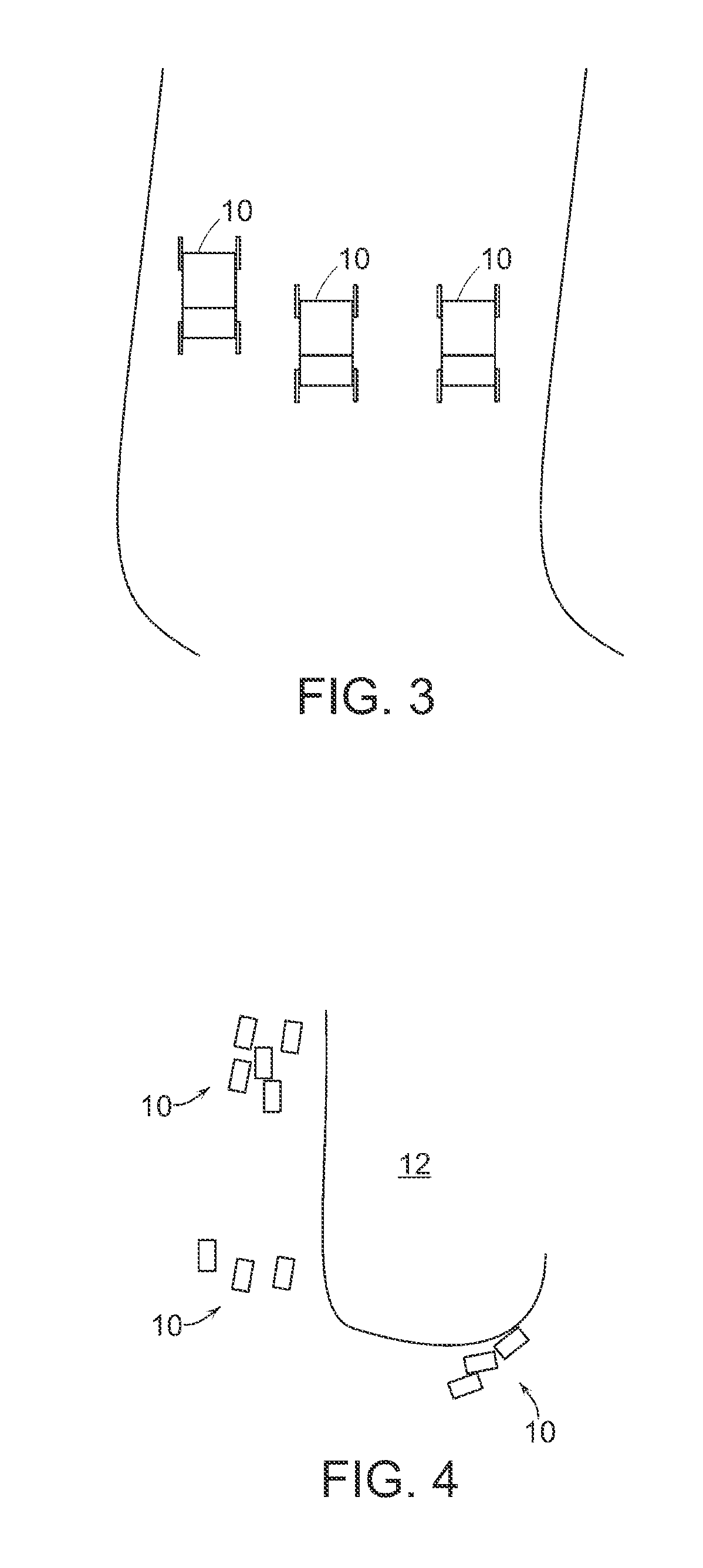

GPS Based Spectator and Participant Sport System and Method

ActiveUS20070015586A1Improve accuracyAchieve accuracyTelevision system detailsGymnastic exercisingMovement systemComputer science

A spectator sport system and method that displays different views of a sporting event and, in particular, uses the spectator's GPS position to assist in displaying a view from the spectator's position. The spectator, using a personal device, can zoom, pan, tilt and change the view, as well as change the view to another position, such as a finish line, goal, or a participant position. Vital information on the sporting event or a participant can be appended to the view. In some forms, augmented reality can be used, such as a finish line or goal, to enhance the experience. Additional service requests can be made from the personal device.

Owner:SPATIAL REALITY LLC

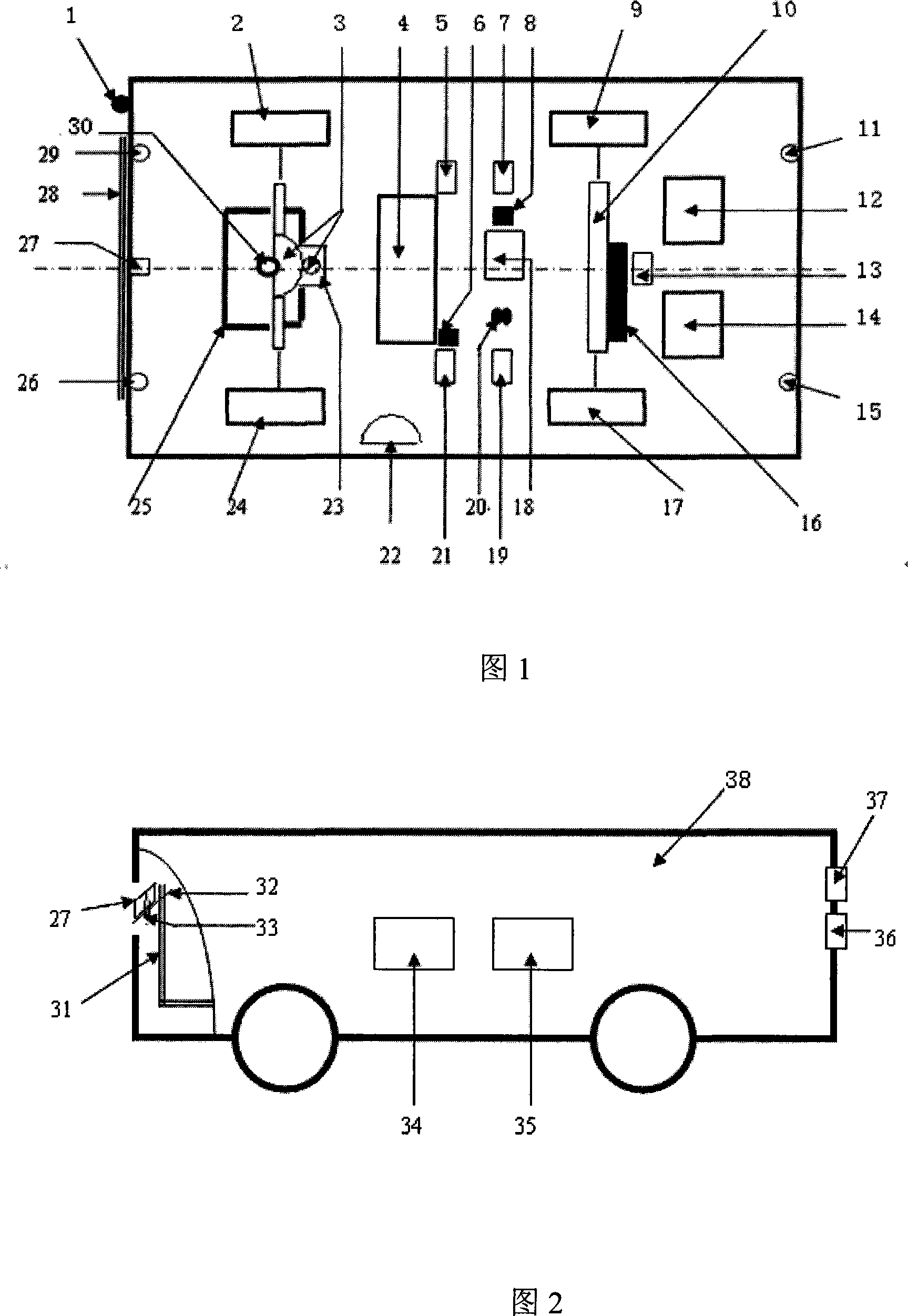

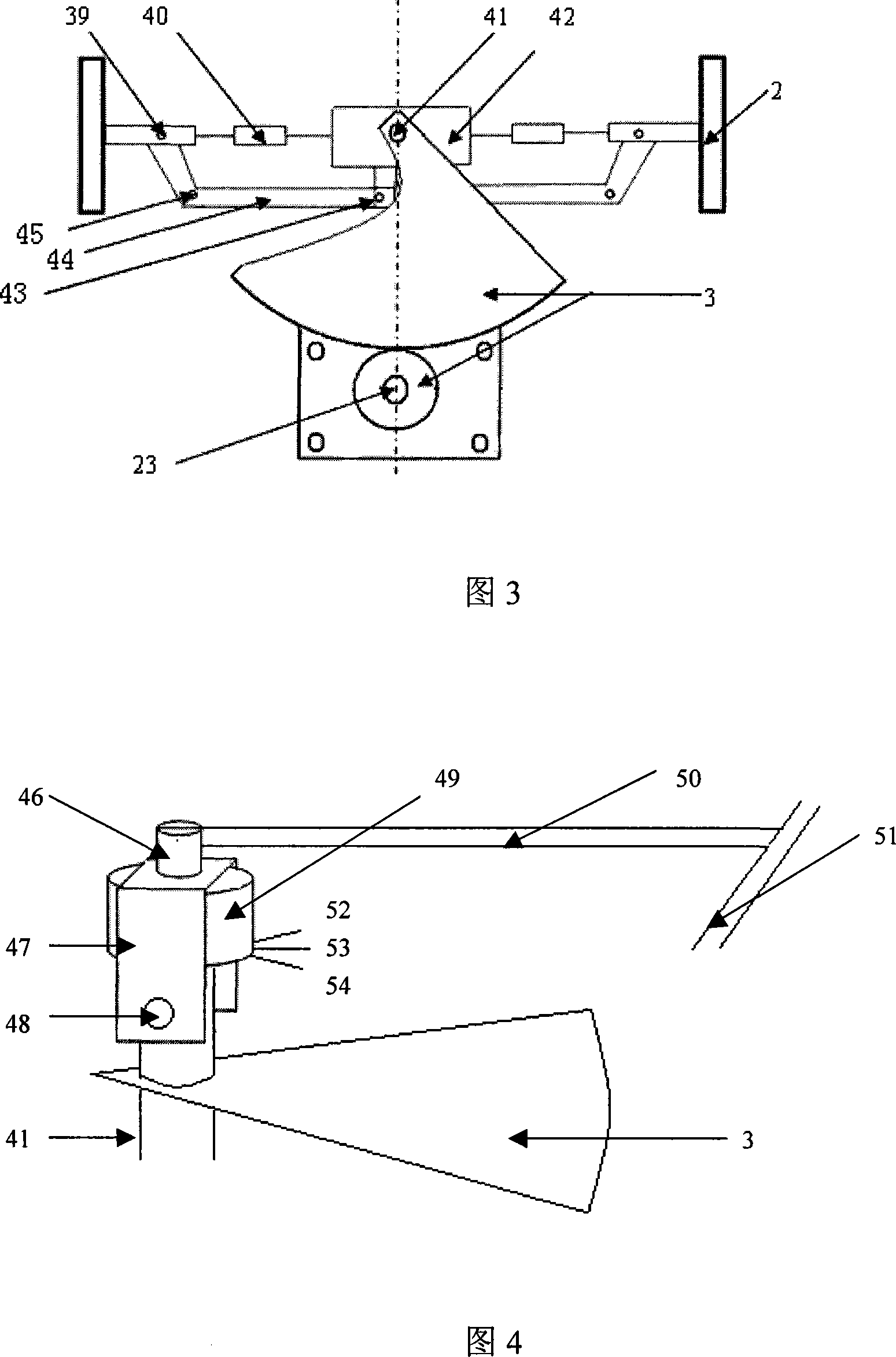

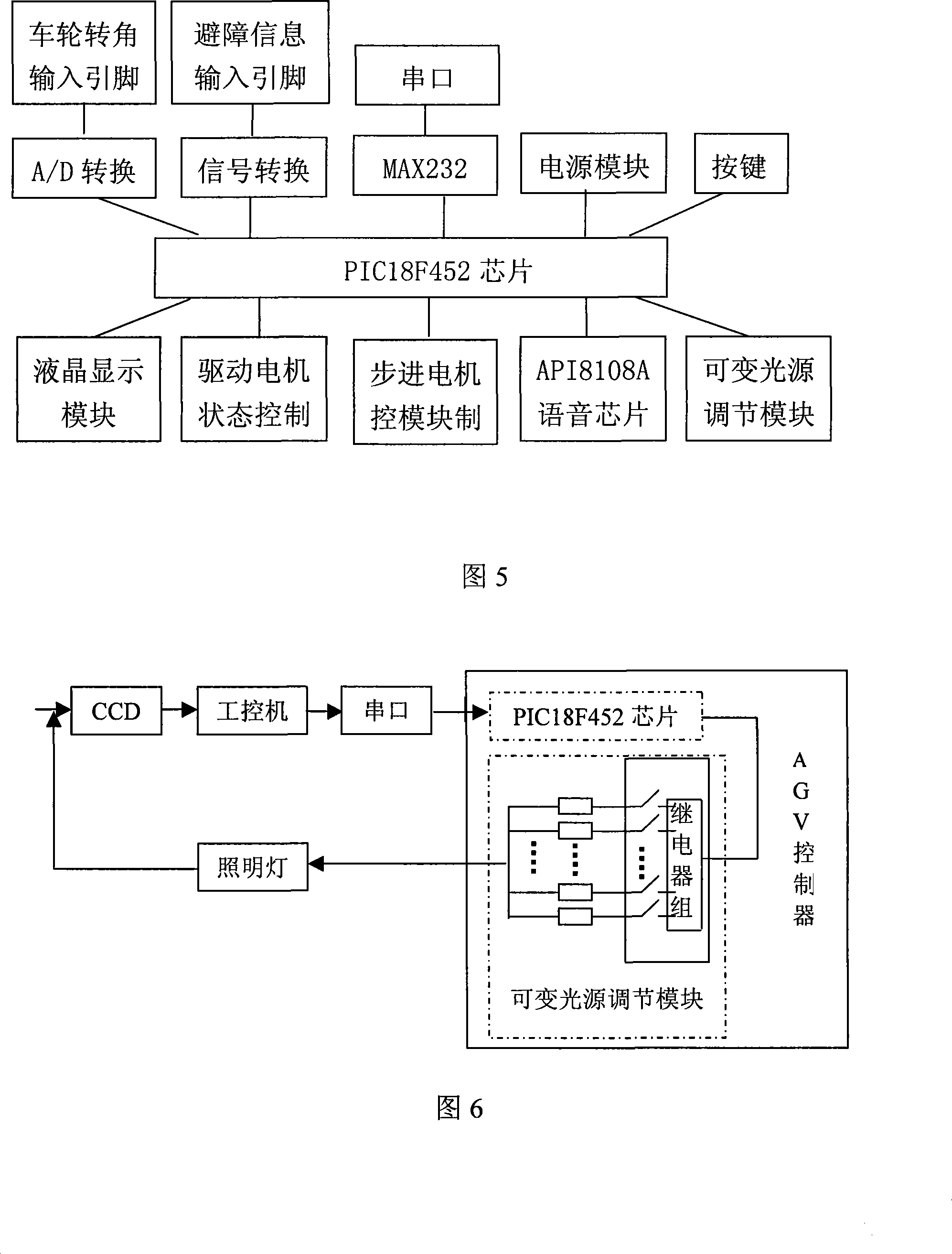

Automatic guidance system based on radio frequency identification tag and vision and method thereof

InactiveCN101183265AImprove stabilityLarge information capacityCo-operative working arrangementsCharacter and pattern recognitionWireless transceiverControl signal

The invention discloses an automatic guidance system based on radio frequency identification labels and vision, and the method of the automatic guidance system. The invention is characterized in adopting a four-wheel structure, wherein two front wheels are used for steering and two rear wheels are used for driving; a direct current motor is used as the travelling and driving device, which is driven to steer by a stepping motor; the invention is provided with a wheel steering angle positioning device, so the invention has relatively high dynamic response ability; a black and white parallel guide belt is adopted as a guide path, with the radio frequency identification labels discontinuously laid below, and red work station characters arranged at both sides; CCD collects road surface information, and the brightness of light source adaptive controls according to image gray information; characters are extracted by utilizing color differences; straight lines are rapidly HOUGH transformed and identified; a control signal is sent to AGV controller after processed by an industrial control computer, and the direct current motor and the stepping motor are controlled. In order to effectively realize the communication dispatch between AGVS in real time, radio frequency identification labels are adopted for positioning, and a wireless transceiver module is adopted for communication between AGVS and a host. The invention has the advantages of good environmental adaptability and navigation precision, and lower cost.

Owner:ZHEJIANG UNIV

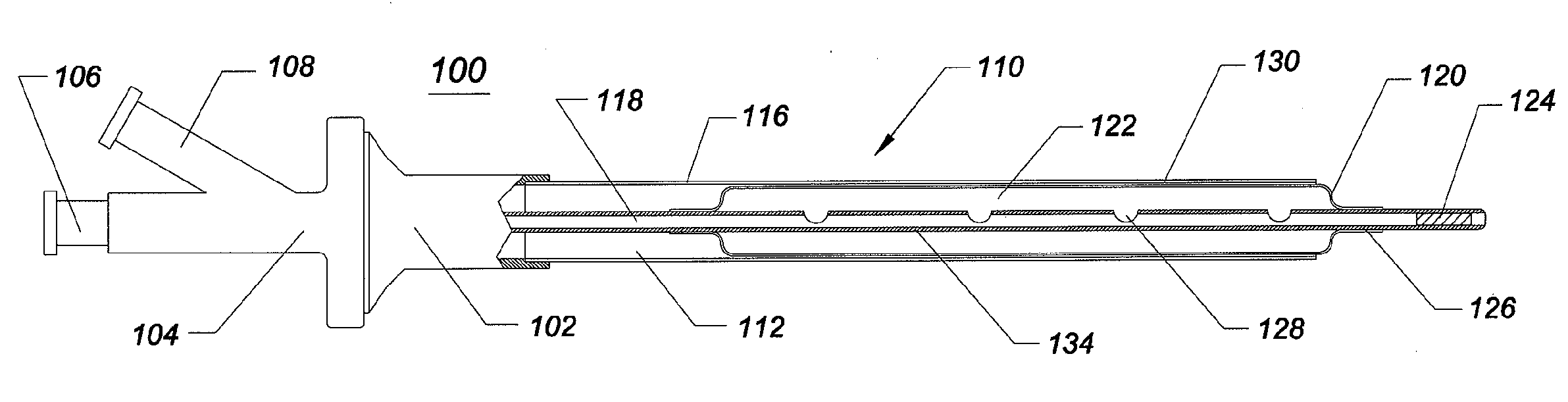

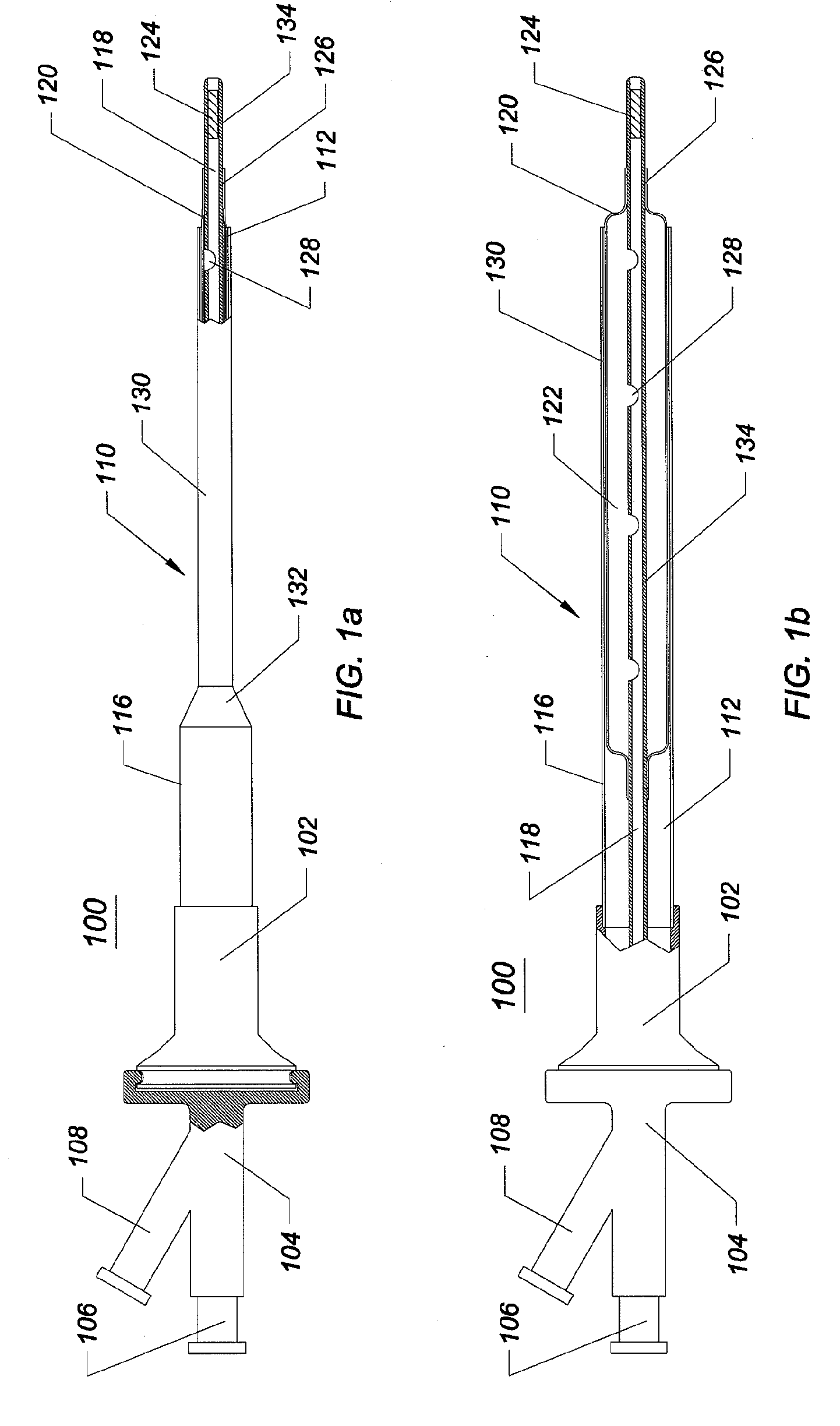

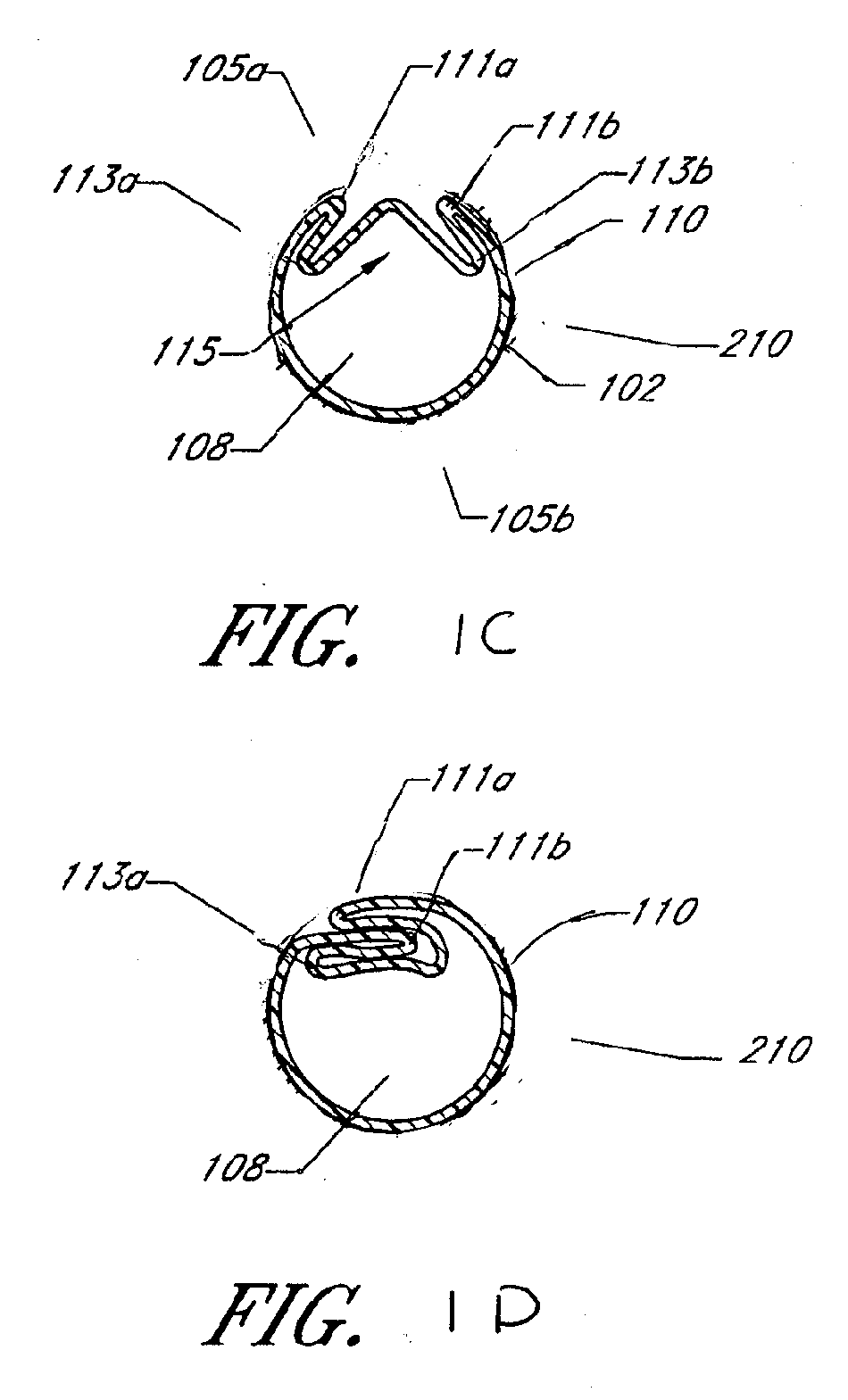

Expandable medical access sheath

An expandable medical sheath is configured to be introduced into a body in a first, low cross-sectional area configuration, and expanded to a second, enlarged cross-sectional configuration. The sheath is maintained in the first, low cross-sectional configuration by structures or elements within the sheath wall that maintain a collapsed shape. Upon expansion with a dilator, the sheath maintains a second, enlarged cross-sectional configuration by elements or structures within the sheath tubing wall that resist re-collapse. The sheath includes a nose cone or tapered fairing to deflect tissue from entering the collapsed distal end of the sheath during introduction. The fairing collapses following expansion and subsequent deflation of the dilator, thus allowing the tapered fairing to be withdrawn proximally through the central lumen of the sheath. In one application, the sheath is utilized to provide access for a diagnostic or therapeutic procedure such as percutaneous nephrostomy or urinary bladder access.

Owner:ONSET MEDICAL CORP

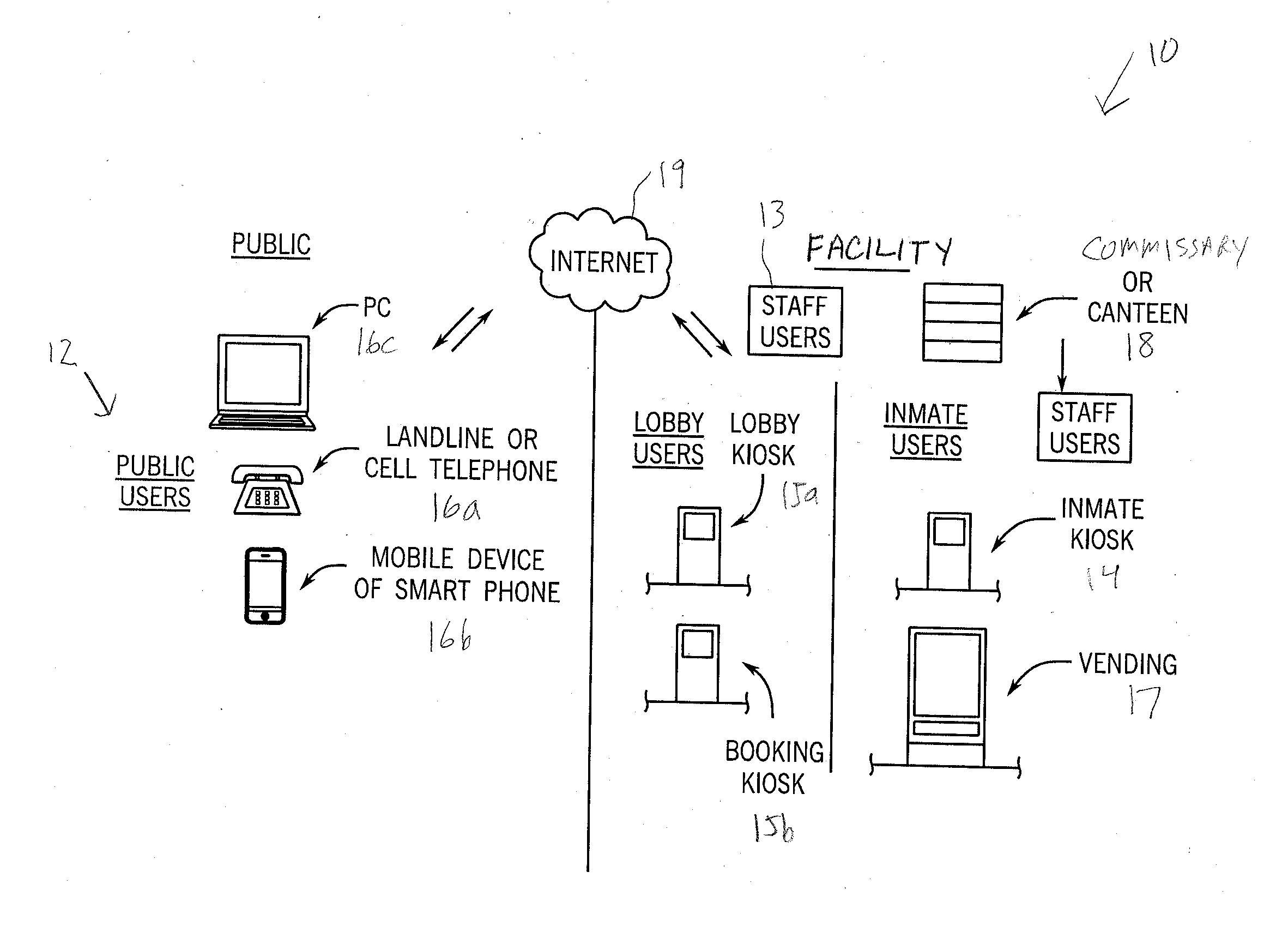

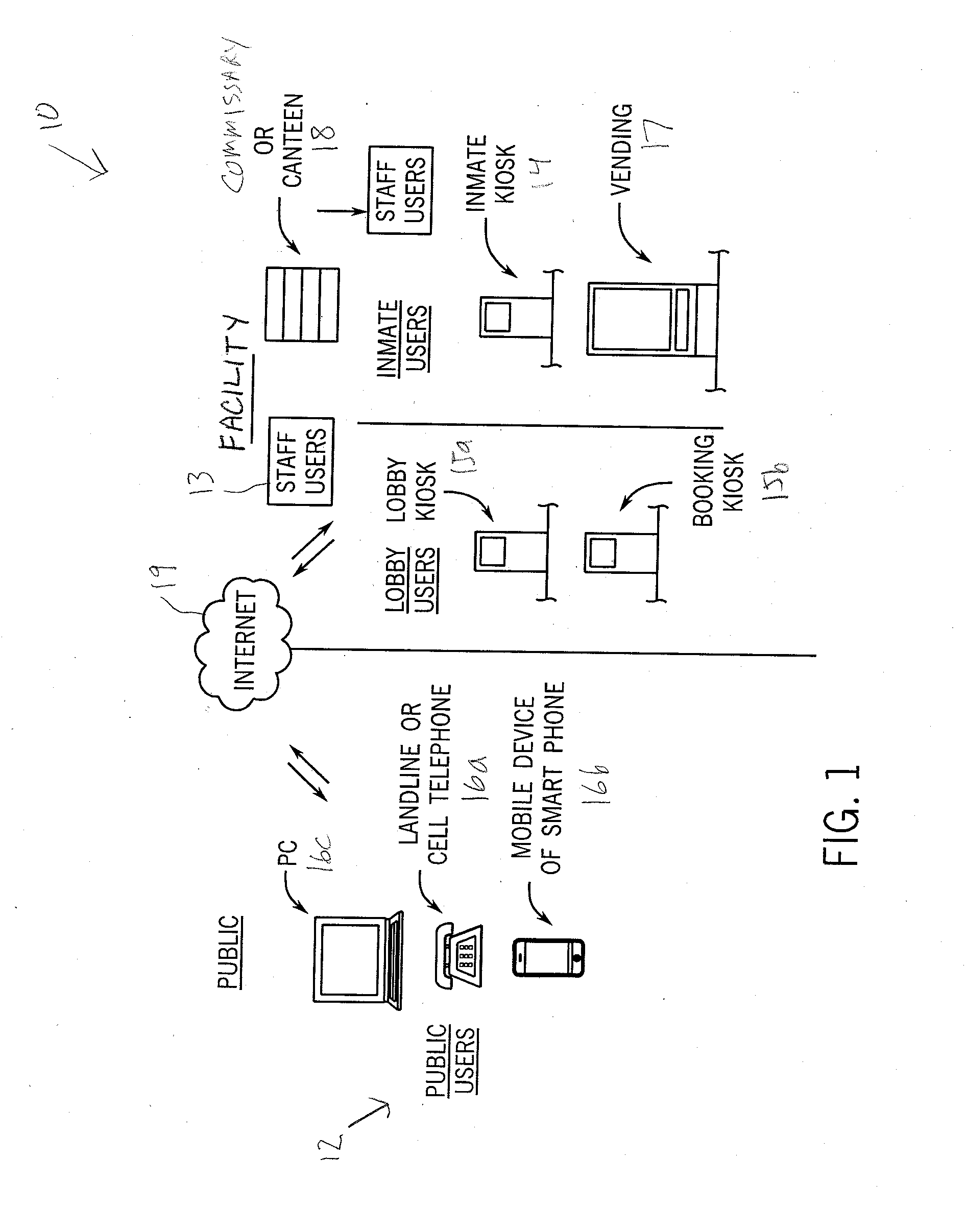

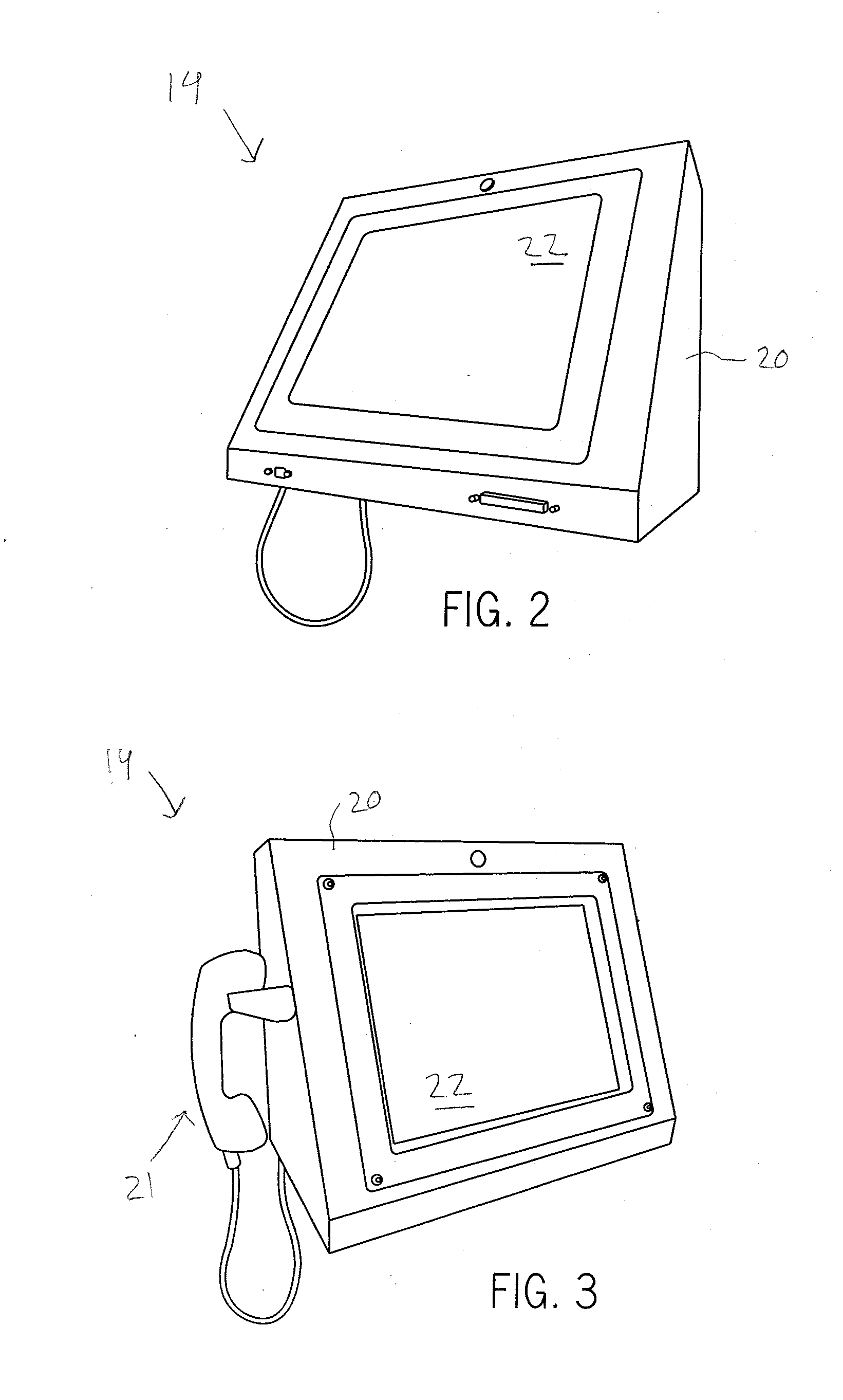

Audio-video remote visitation telecommunications technology

ActiveUS20140218466A1Practical and reliable and secure and accurate and efficientAdvanced technologyData processing applicationsTelevision conference systemsService provisionElectronic mail

A telecommunications system for use in a secure facility such as a jail, prison or the like. The systems, devices and methods disclosed provide telecommunications, email, other messaging, financial services, vending, and commissary or canteen services for inmates of a secure facility with respect to family, friends and others. The system also includes a system for video visitation via audio-visual communication. The system includes a phone server adapted to be communicatively connected to an external service provider; a monitoring station communicatively connected to the phone server, an account manager server communicatively connected to the phone server, and at least one telecommunications device disposed at the secure facility for use by the inmate and which is communicatively connected to the phone server. A method of telecommunicating, including video visitation, via the system is also disclosed.

Owner:TW VENDING

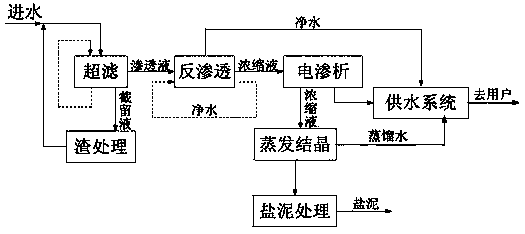

Membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater

ActiveCN103508602AAchieving zero emissionsReduce energy consumptionDispersed particle separationWater/sewage treatment bu osmosis/dialysisFiltrationUltrafiltration

The invention relates to a membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater. The process is as below: carrying out ultrafiltration pretreatment on industrial wastewater and sending the wastewater to a reverse osmosis process through a high-pressure pump; reusing lateral infiltration water; conducting electrodialysis treatment on a concentrate subjected to several times of filtration; evaporating and crystallizing the materials obtained from electrodialysis concentration to obtain salt slurry and water; carry outing posttreatment on the salt slurry; and reusing condensed water. The process provided by the invention couples membrane and evaporation crystallization, not only can recover high quality purified water from industrial wastewater with high salinity but also can realize zero discharge of wastewater with high salinity, and has the characteristics of low energy consumption, low production cost and advanced process.

Owner:NANJING JIUSI HIGH TECH +1

Apparatus for producing multi-color images on substrates using dry multi-colored cholesteric liquid crystal (CLC) pigment materials

InactiveUS6394595B1Function increaseAvoid less flexibilityLiquid crystal compositionsDuplicating/marking methodsColor imageComputer control system

A computer-controlled system for producing a multi-color image on a substrate using multi-colored cholesteric liquid crystal (CLC) pigment materials made from CLC flakes tuned to predetermined bands of color. An image generator automatically generates an image specifying a pattern over which binder material is to be applied to a substrate by a binder material applicator. A plurality of CLC pigment applicators automatically apply patterns of different-color CLC pigment material to the pattern of binder material, which binds thereto as the binder material dries according to its drying characteristics. An output device is used to automatically return the substrate to a different one of CLC pigment applicators after each application of a pattern of different-color CLC pigment material to the pattern of binder material. The output device automatically repeats the return of the substrate to the CLC pigment applicators until all bands of color in the multi-color image are rendered.

Owner:REVEO

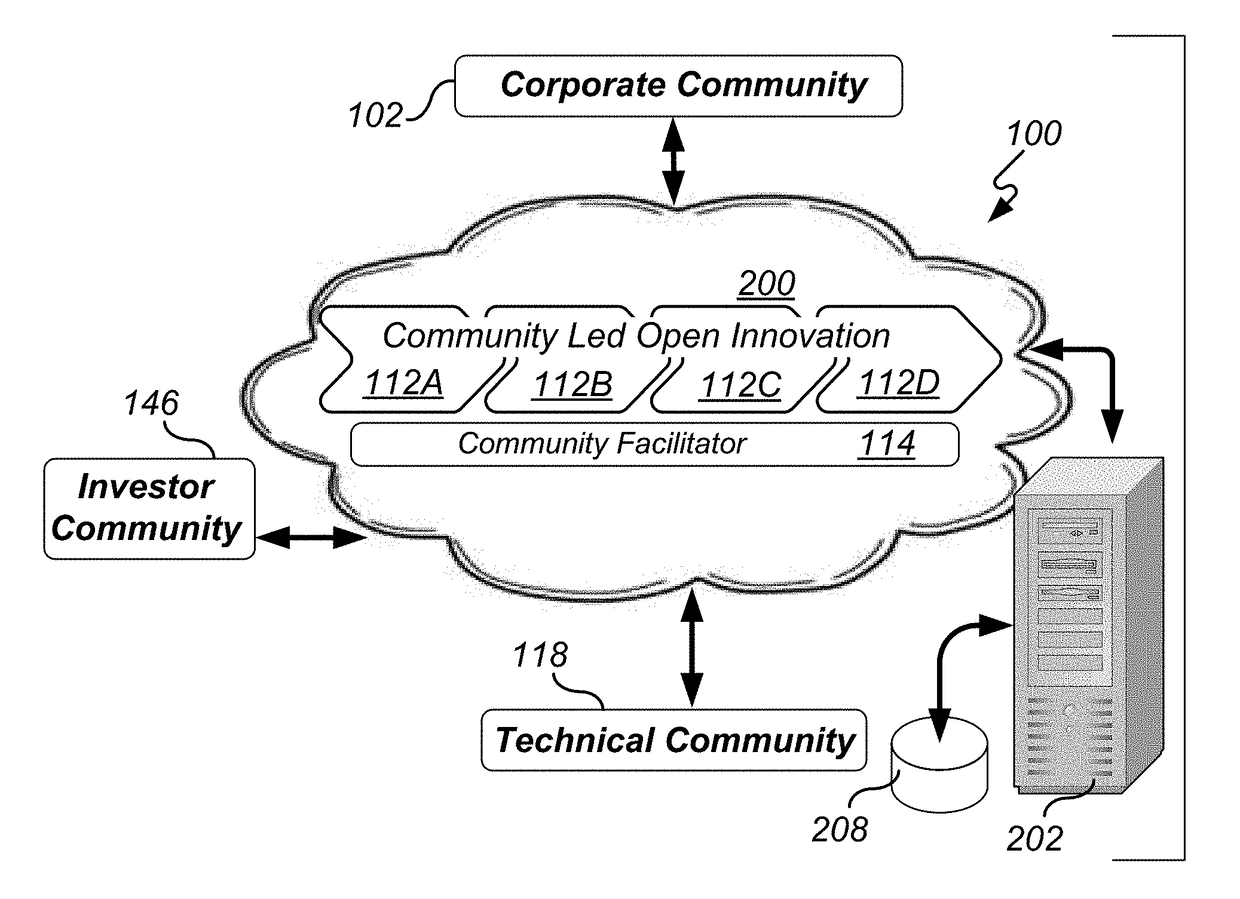

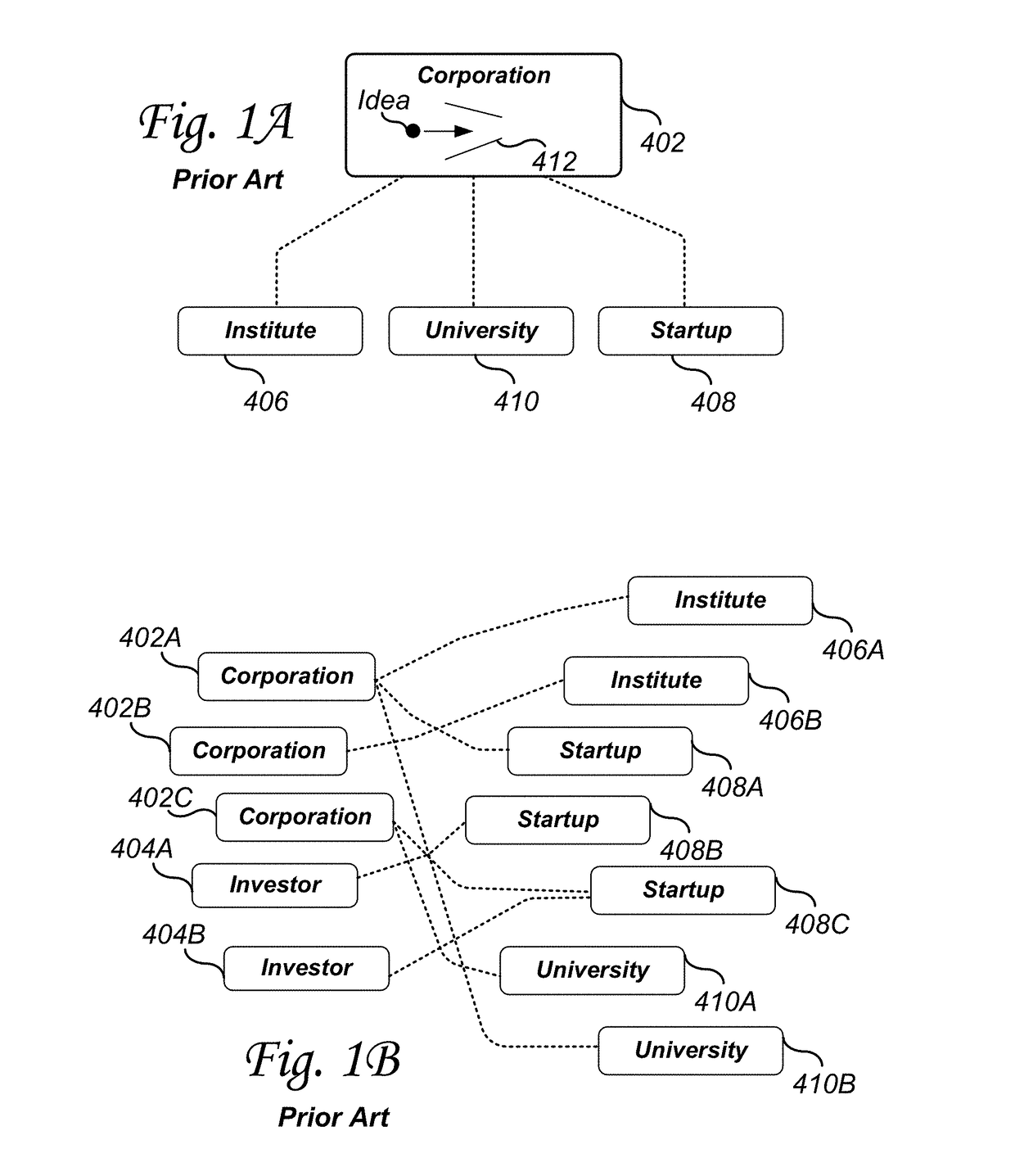

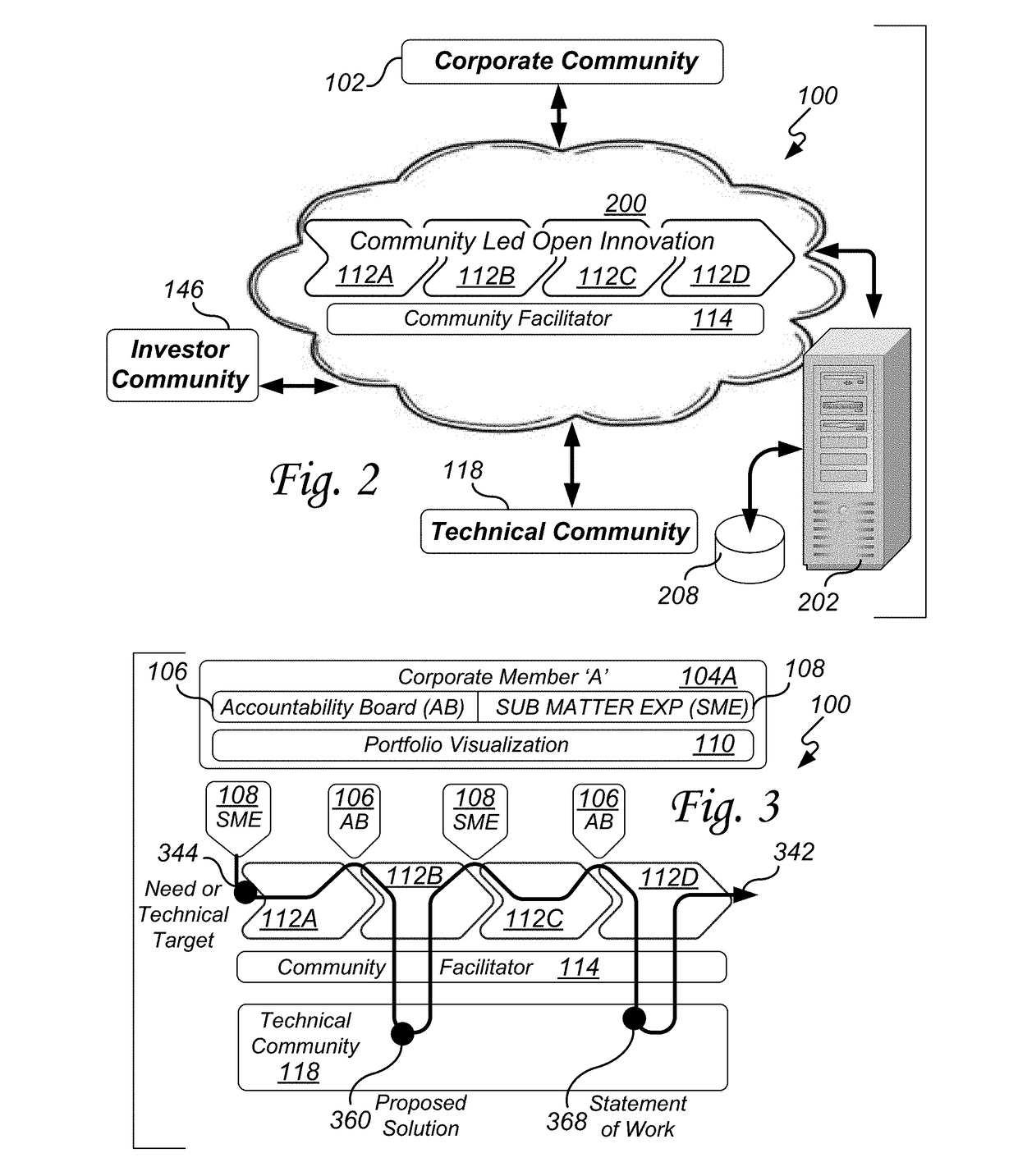

Community Led Open Innovation

InactiveUS20170262807A1Increase transfer rateConvenient introductionOffice automationOpen innovationGlobal network

The present invention relates to a community led open innovation system and method, operated over a global network, in an online community format that engenders increase in the technology transfer rate of technologies, technical resources, and technical capabilities to a CORPORATE COMMUNITY from a TECHNICAL COMMUNITY, comprising the steps of creating a TECHNICAL TARGET based on a NEED from a CORPORATE MEMBER, sharing the TECHNICAL TARGET with the TECHNICAL COMMUNITY, routing to the CORPORATE MEMBER a PROPOSED SOLUTION to the TECHNICAL TARGET, the PROPOSED SOLUTION being initiated by the TECHNICAL COMMUNITY MEMBER, and facilitating an introduction, related to the PROPOSED SOLUTION, by way of a transitory digital communication between the CORPORATE MEMBER and the TECHNICAL COMMUNITY MEMBER.

Owner:KOLLS H BROCK

Smart mattress

InactiveUS8672842B2Good flexibilityAdvanced technologyStuffed mattressesInflated body pressure measurementPhysical therapyData store

A mattress has a sensor pad affixed on a top surface thereof. The sensor pad has (i) a matrix array of plural pressure sensors, (ii) plural row conductors, and (iii) plural column conductors. Each intersecting row and column conductor provides an electrical signal from a corresponding sensor when pressure is applied thereto. The sensor pad has plural through-holes therein disposed between the plural row conductors the plural column conductors, respectively. Preferably, at least one patient-mounted physiological sensor is configured to provide an output signal corresponding to a patient physiological parameter. An electronic unit is mounted inside the mattress and is configured to receive signals from the sensor pad. The electronic unit has a data storage unit preferably storing (i) patient identification information, (ii) patient physiological information, and (iii) mattress information. A wireless transmitter is coupled to the electronic unit and is configured to wirelessly communicate at least the stored patient physiological information to an off-mattress device.

Owner:EVACUSLED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com