Patents

Literature

125 results about "Material applicator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

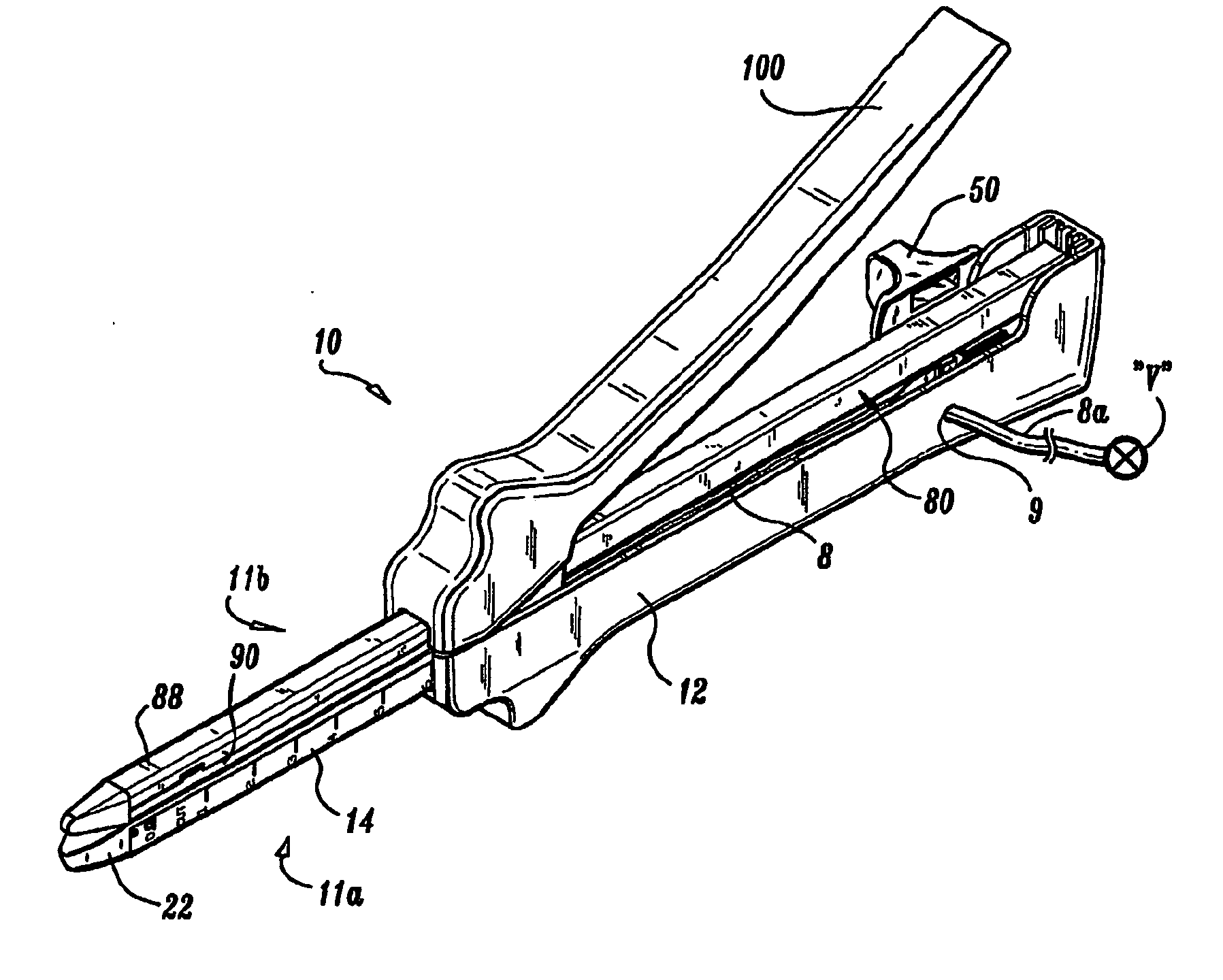

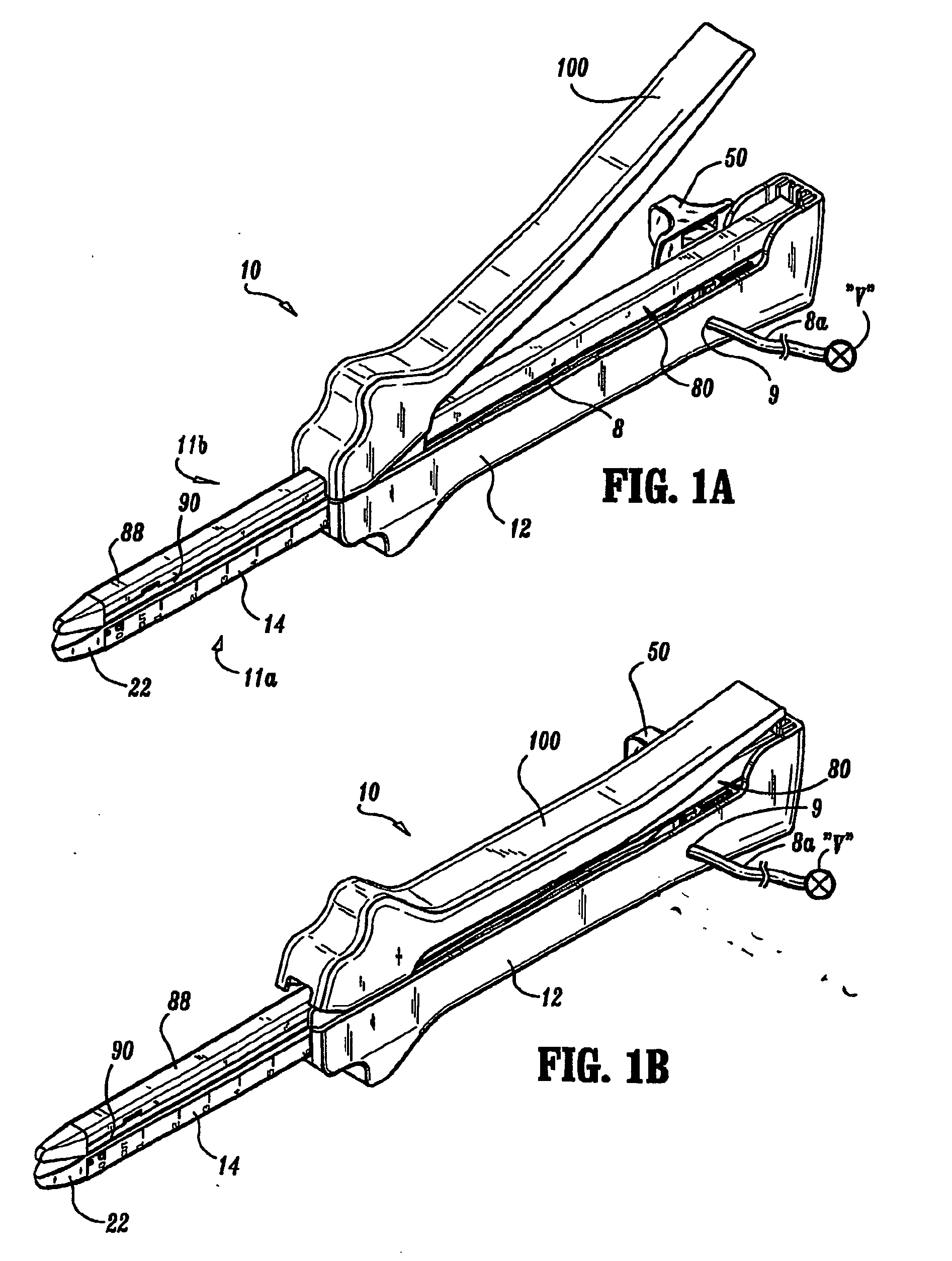

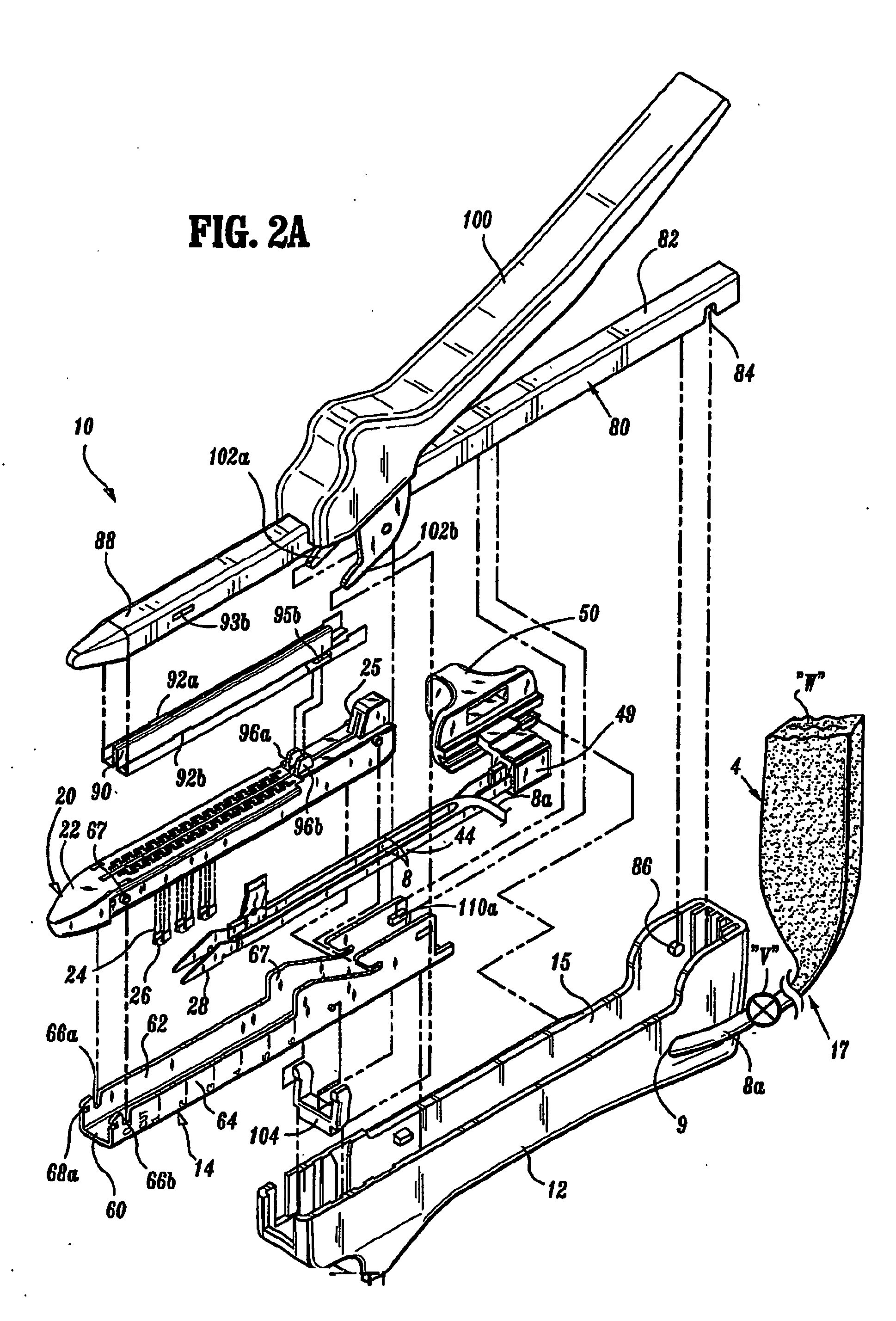

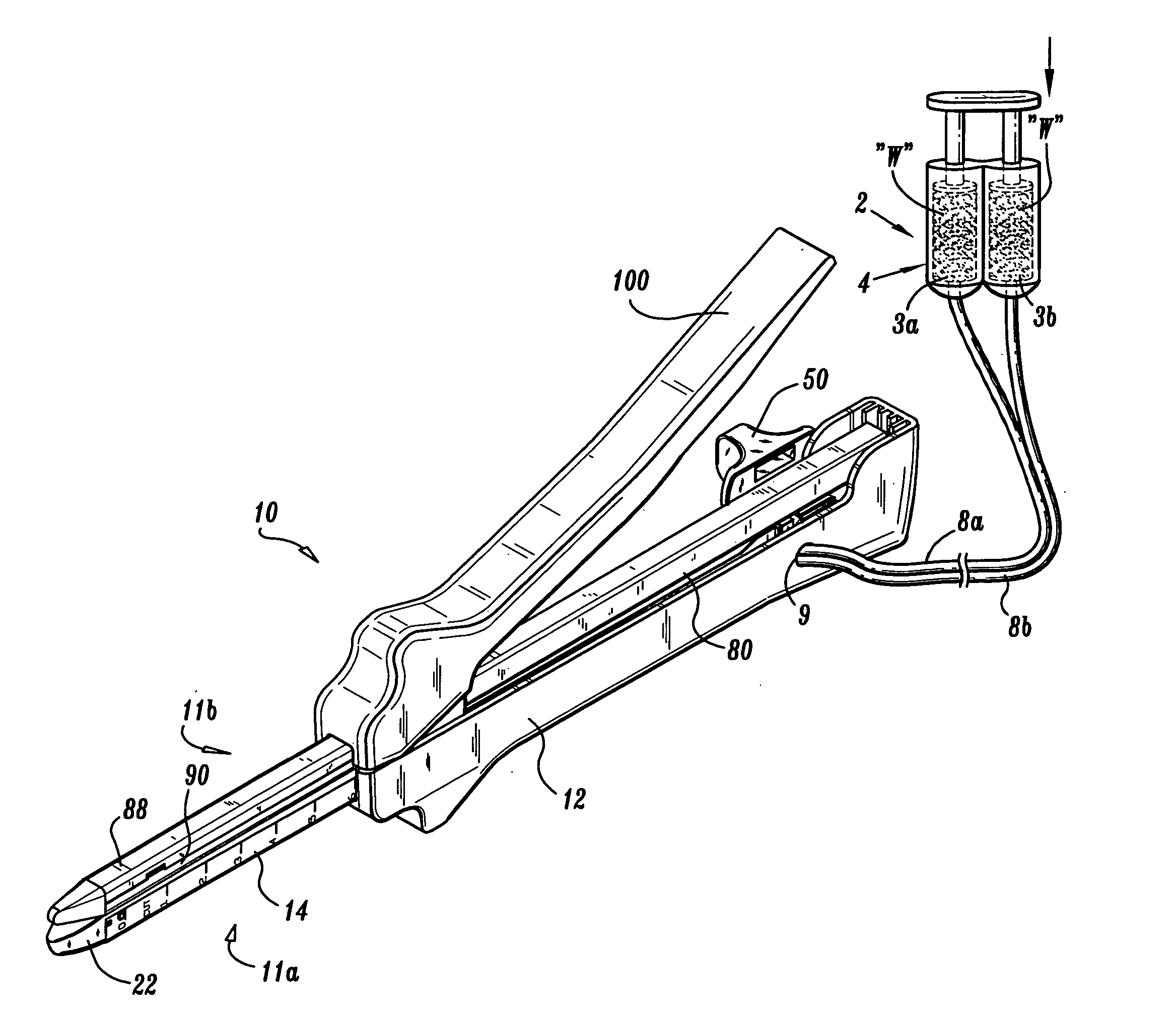

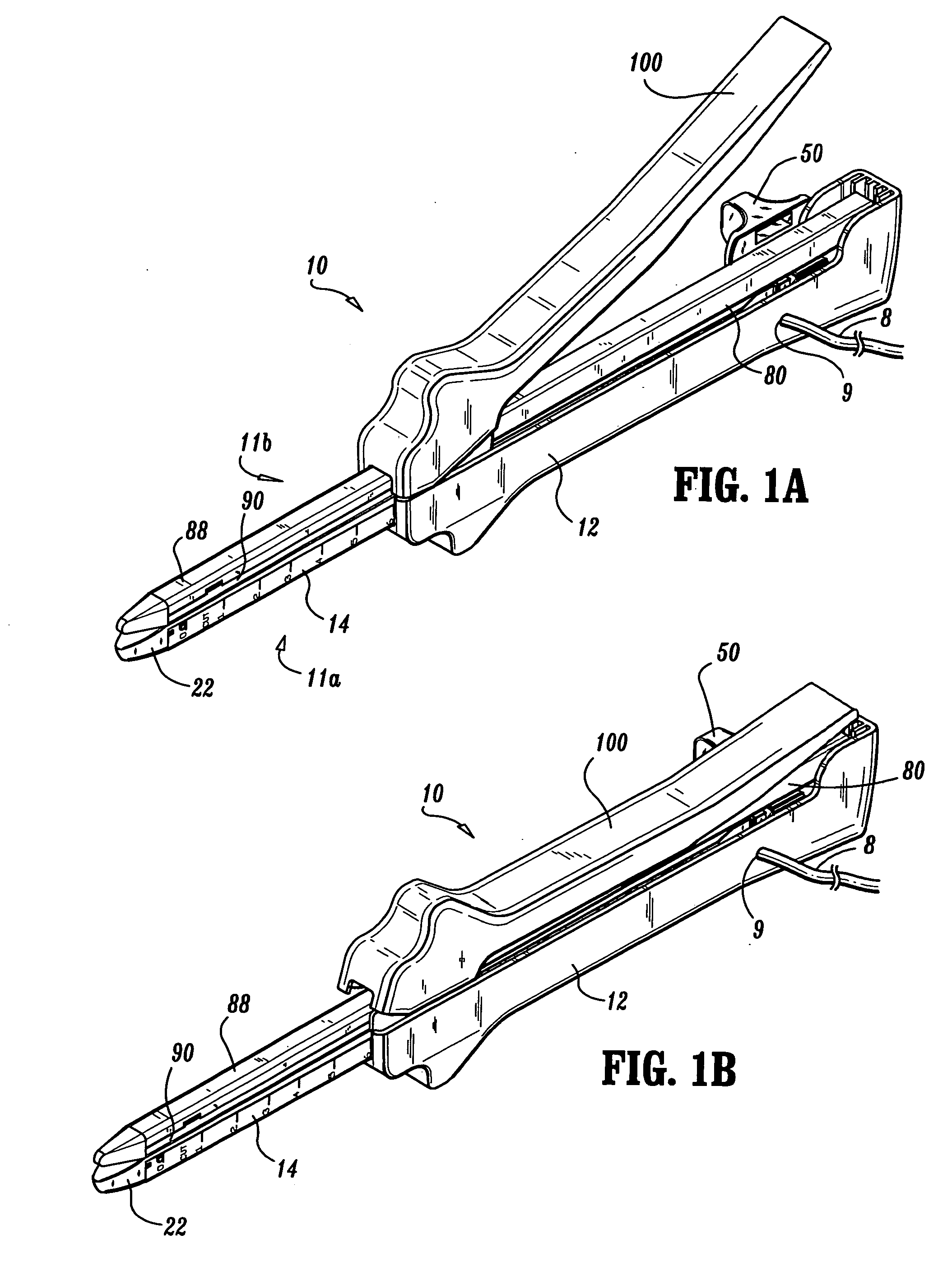

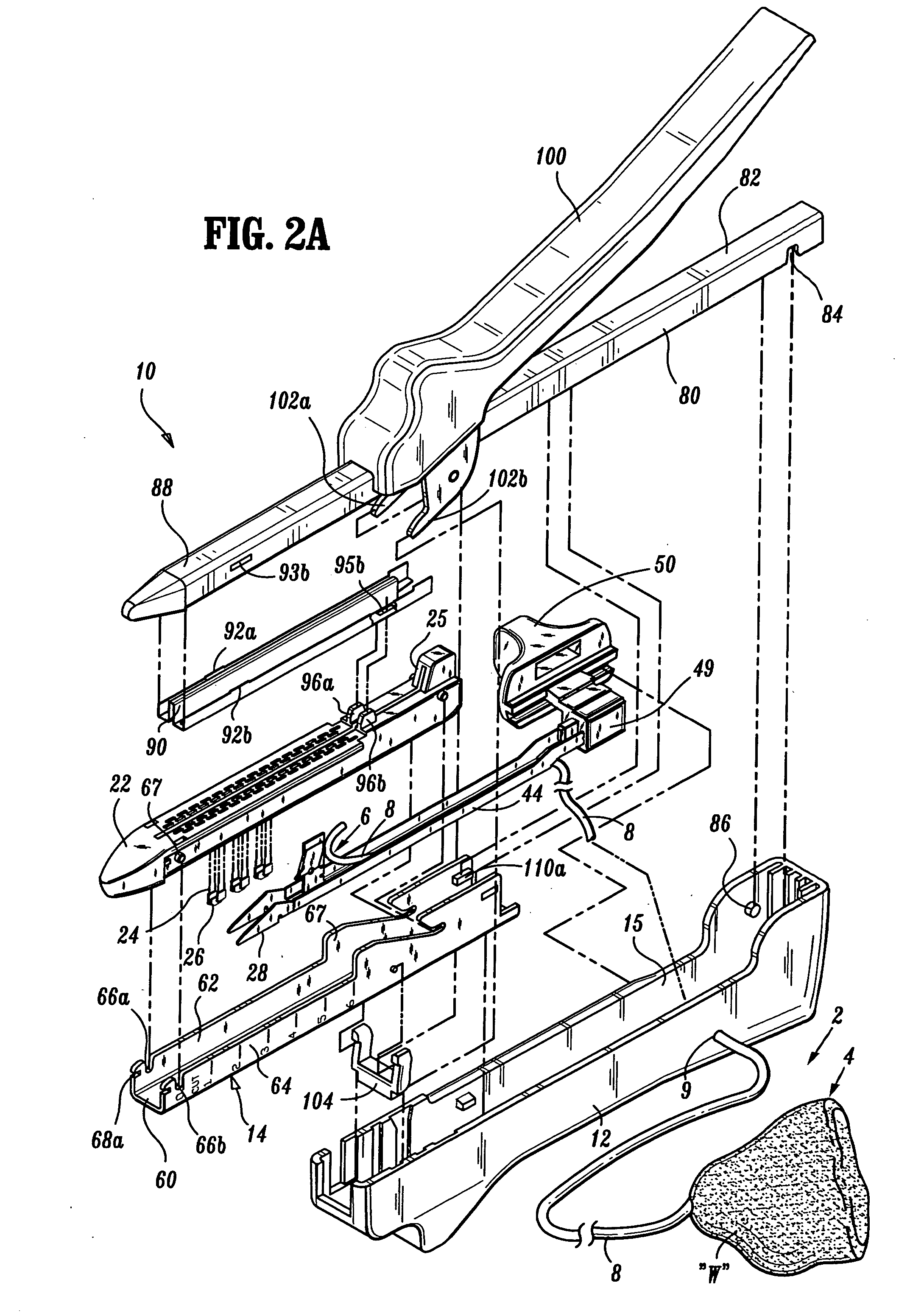

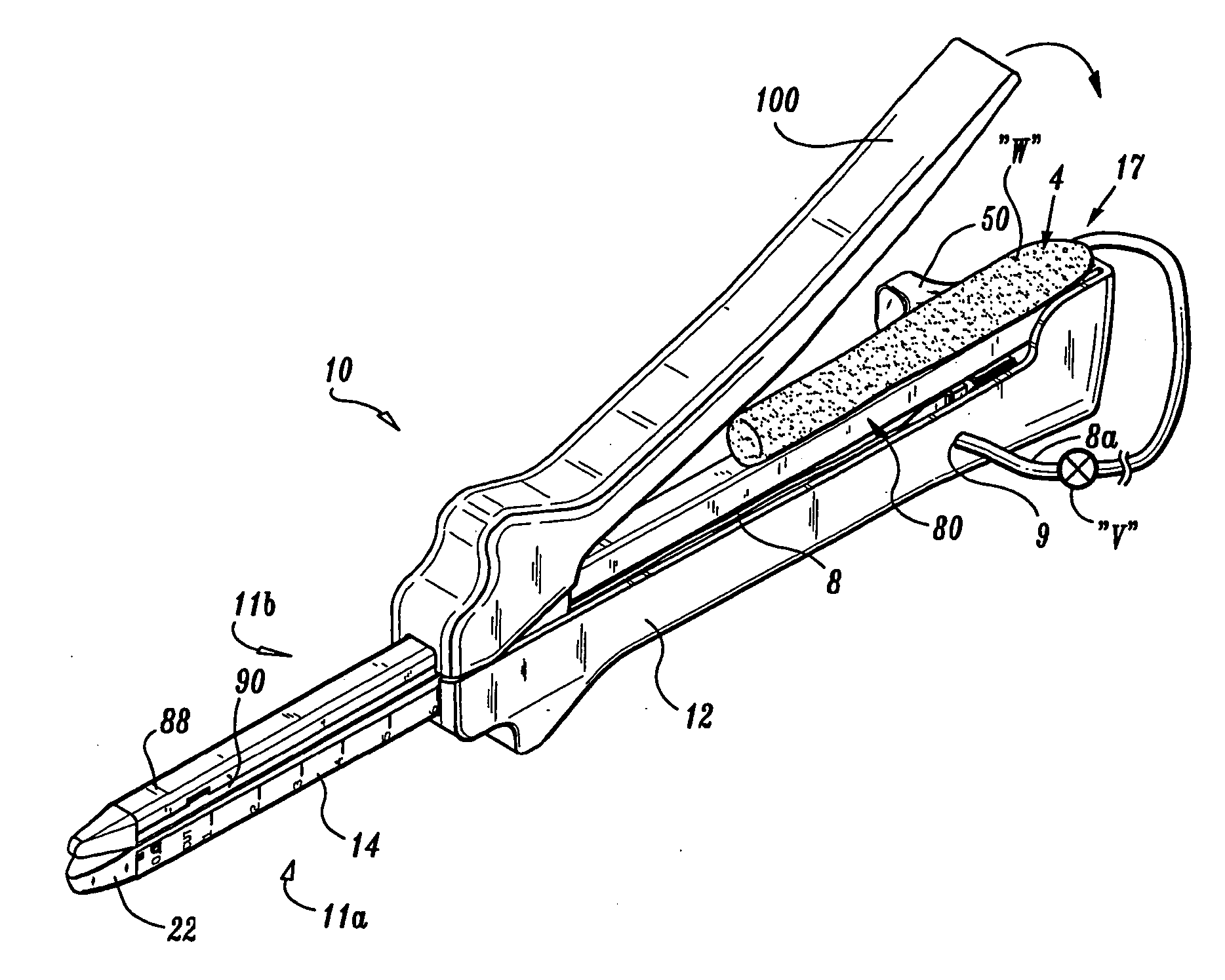

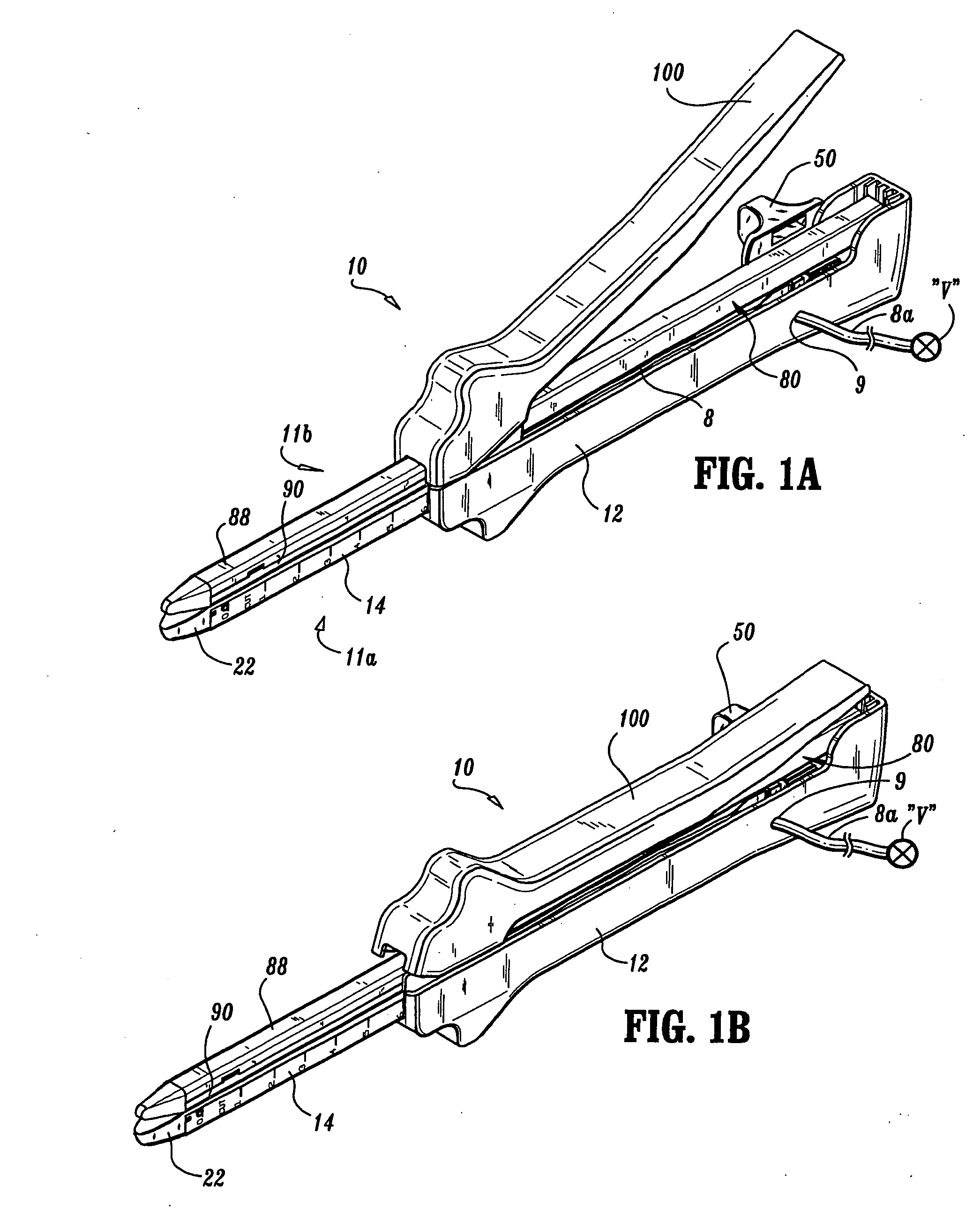

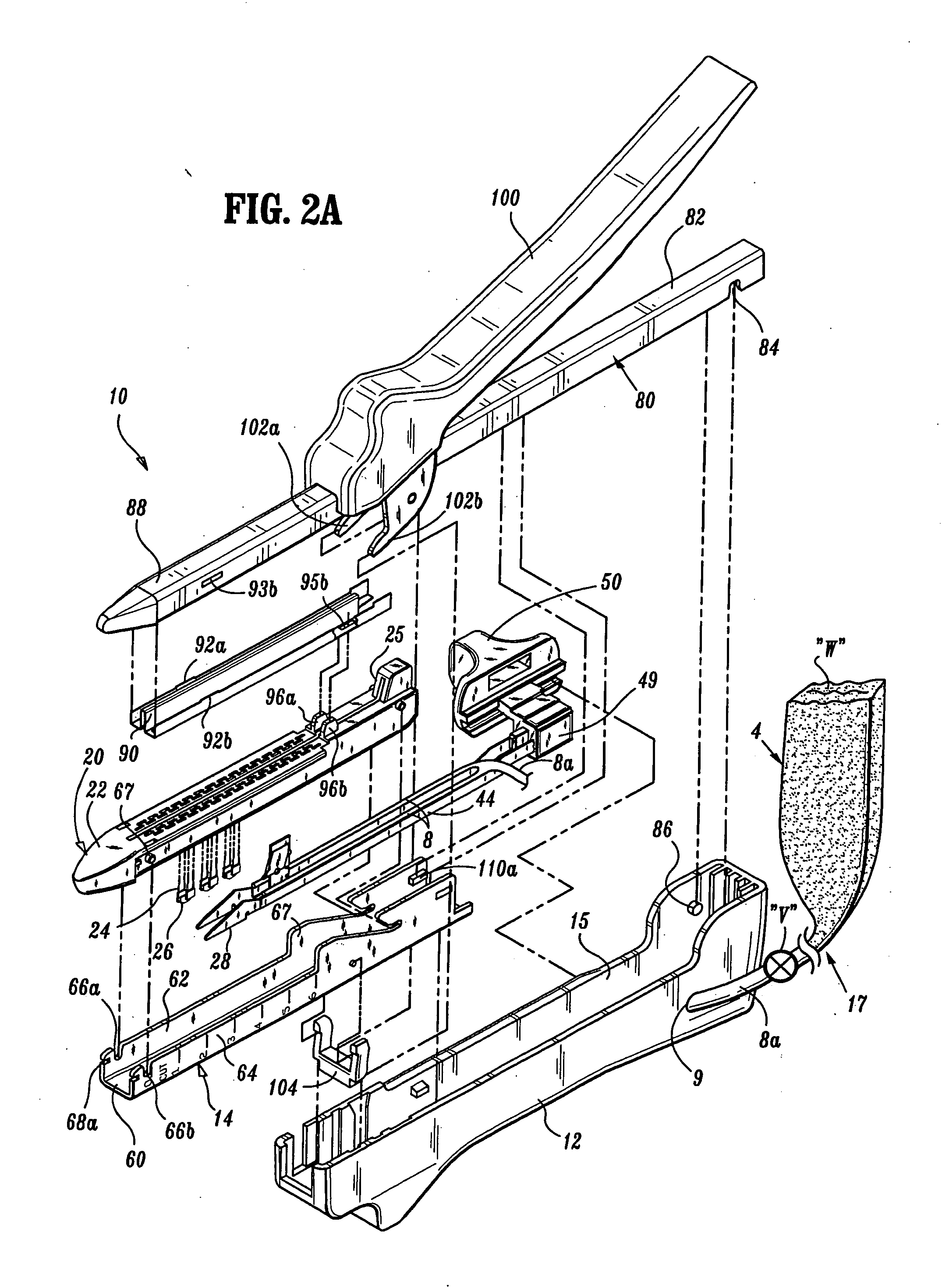

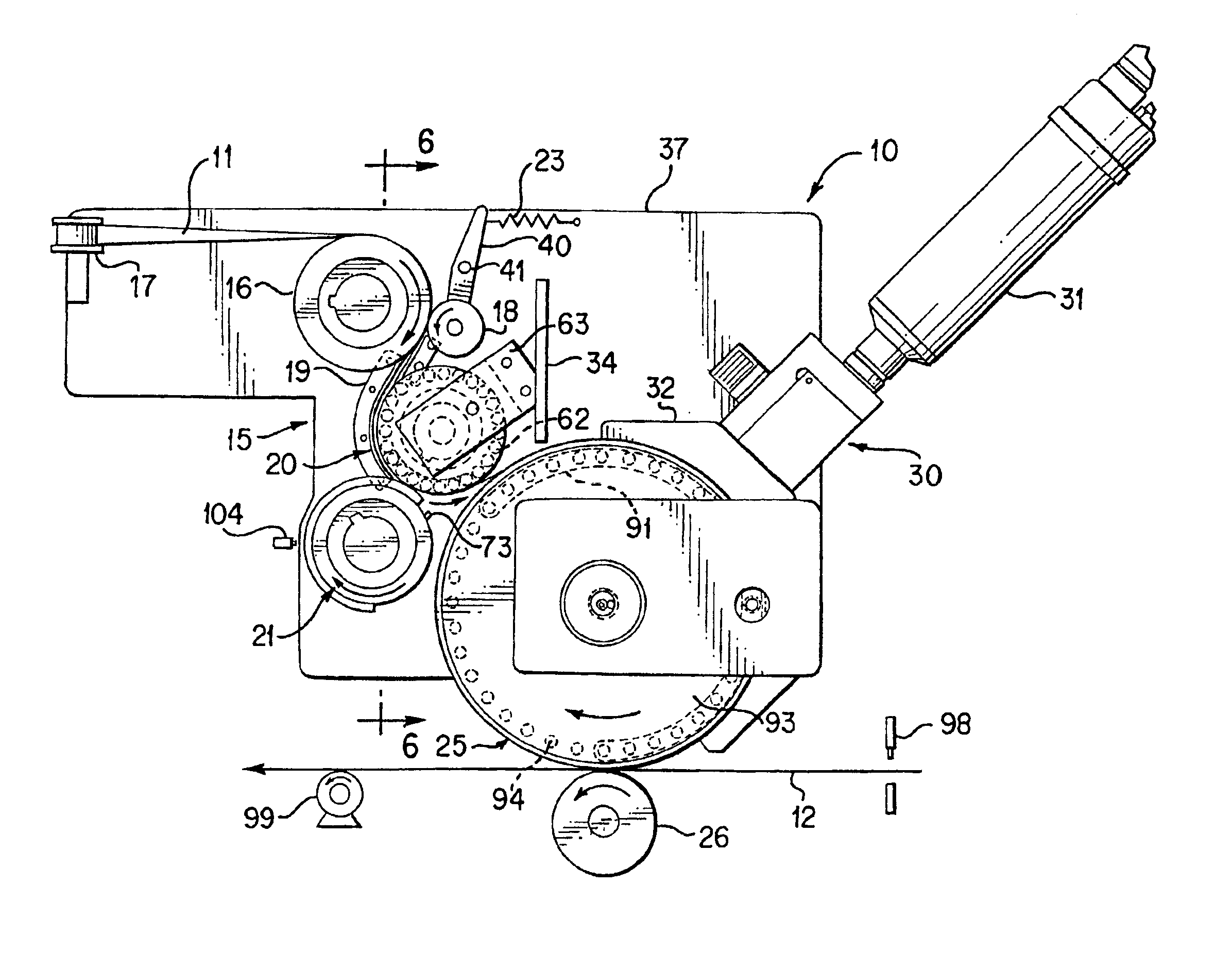

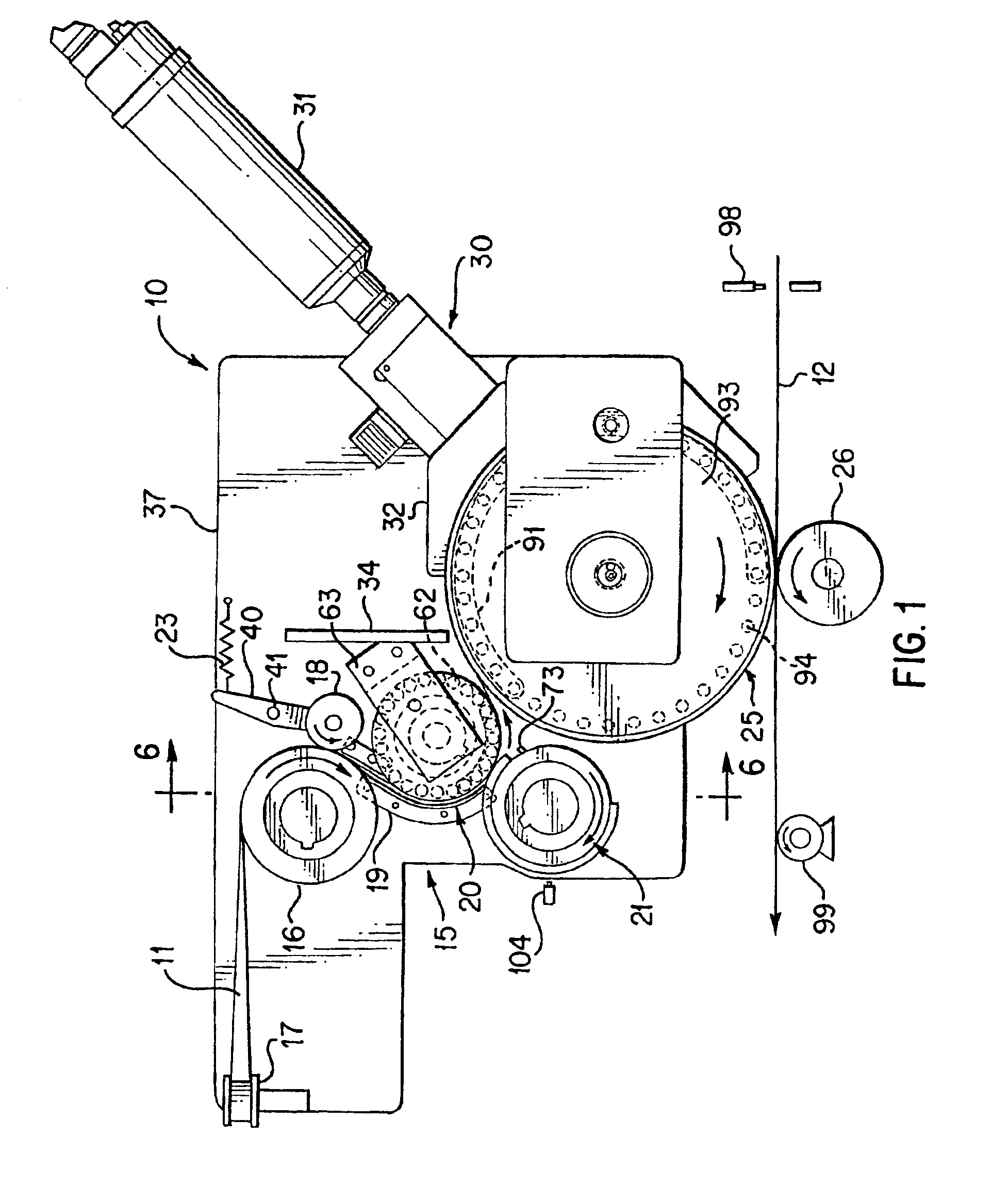

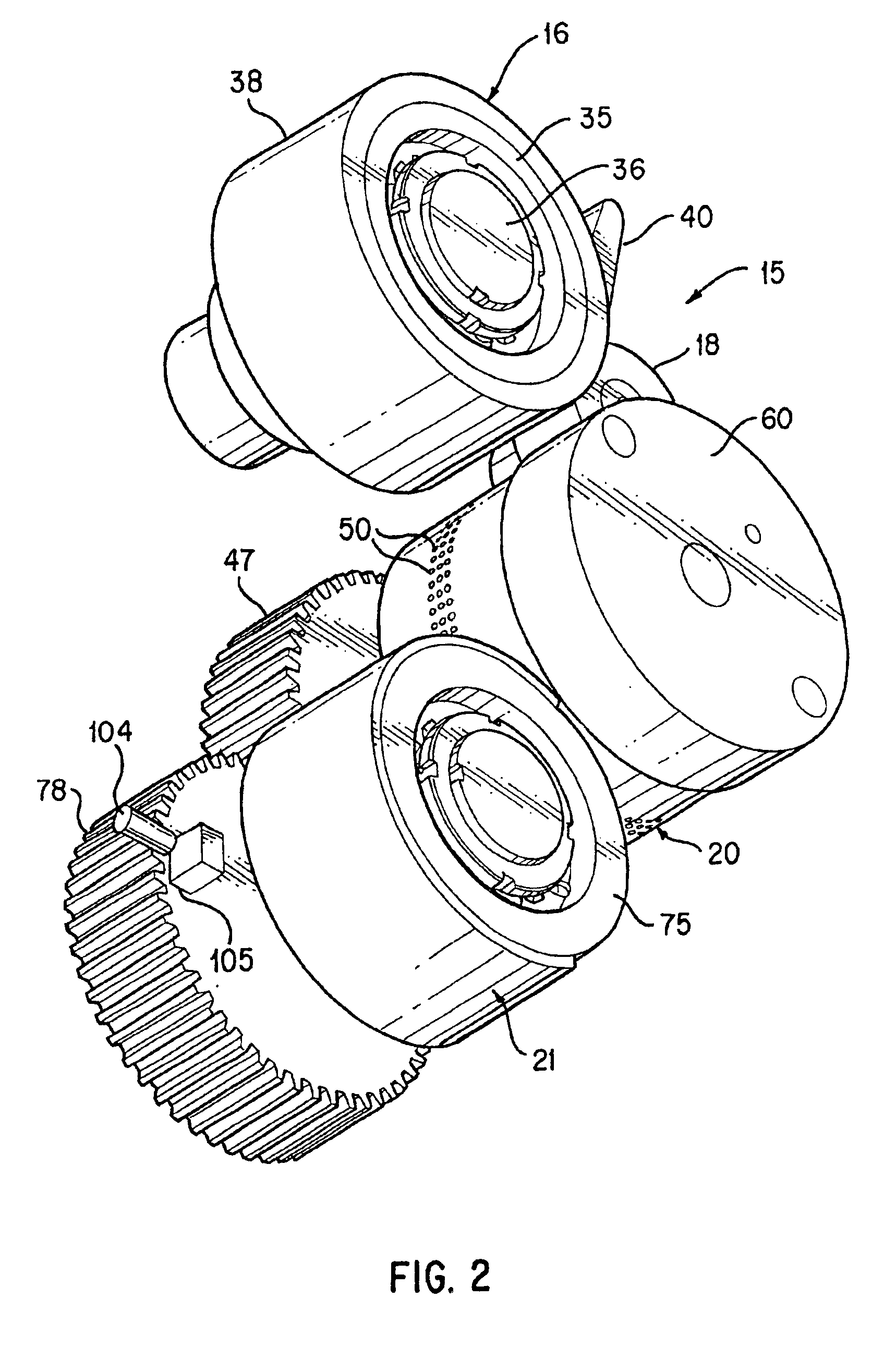

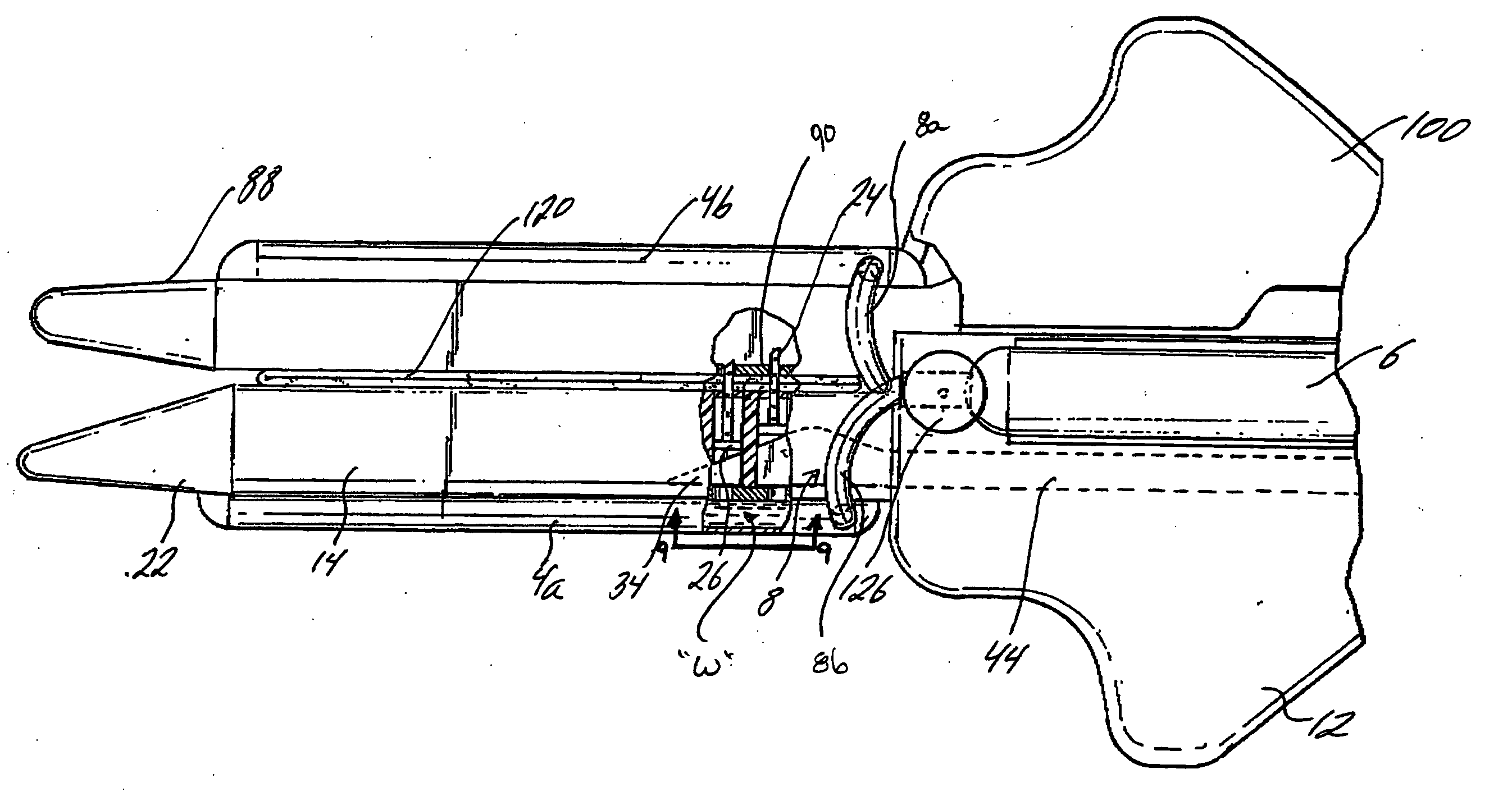

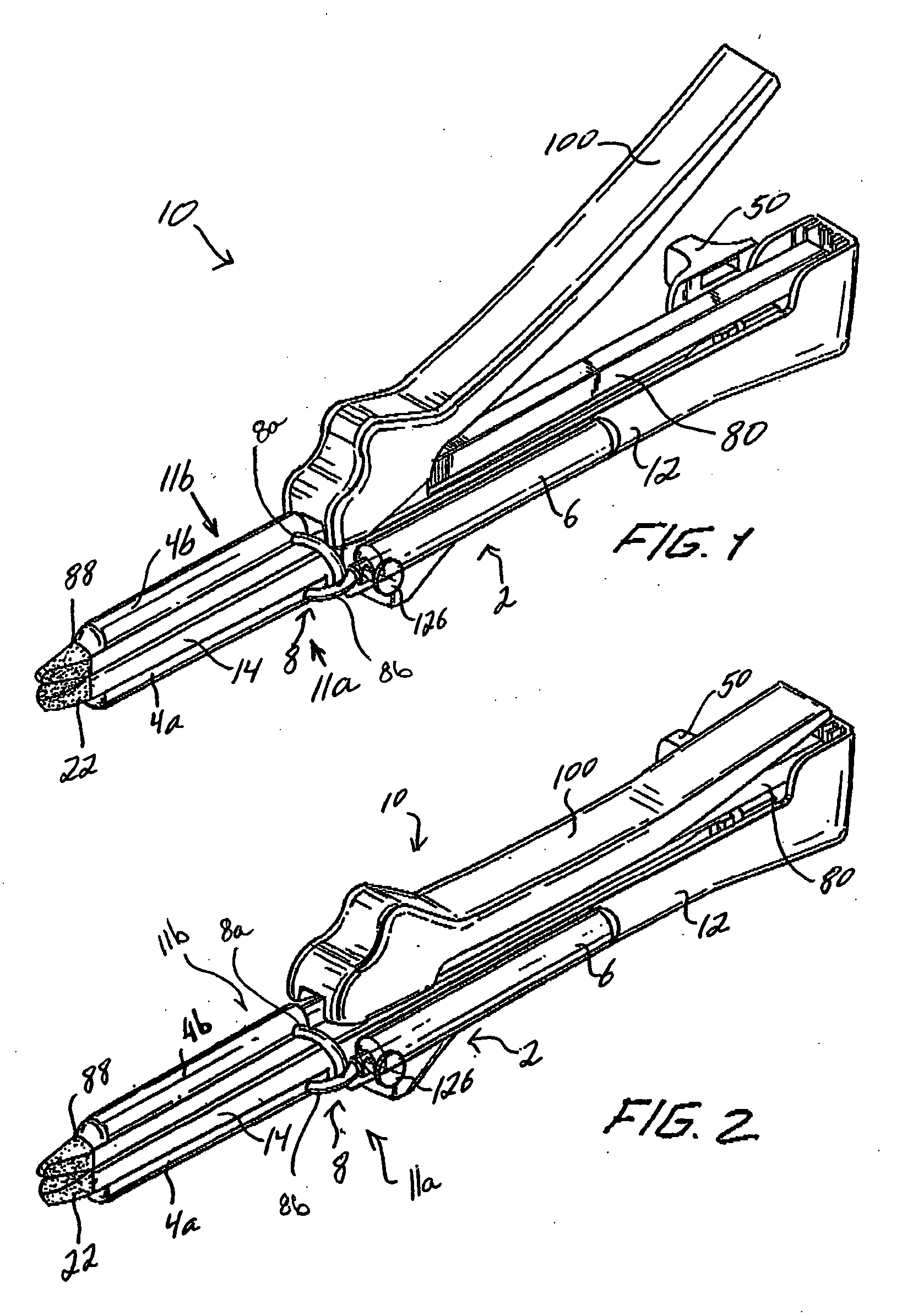

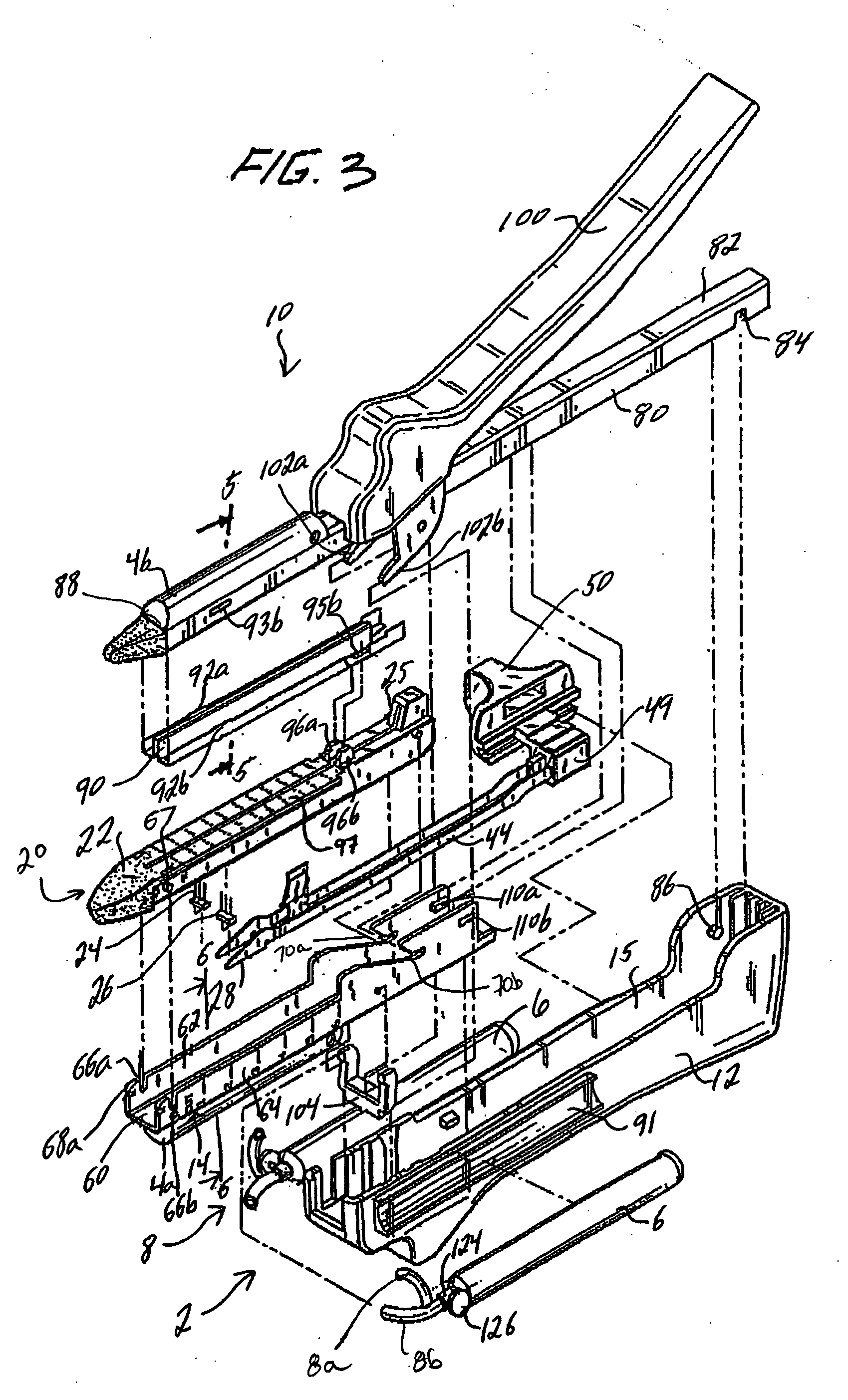

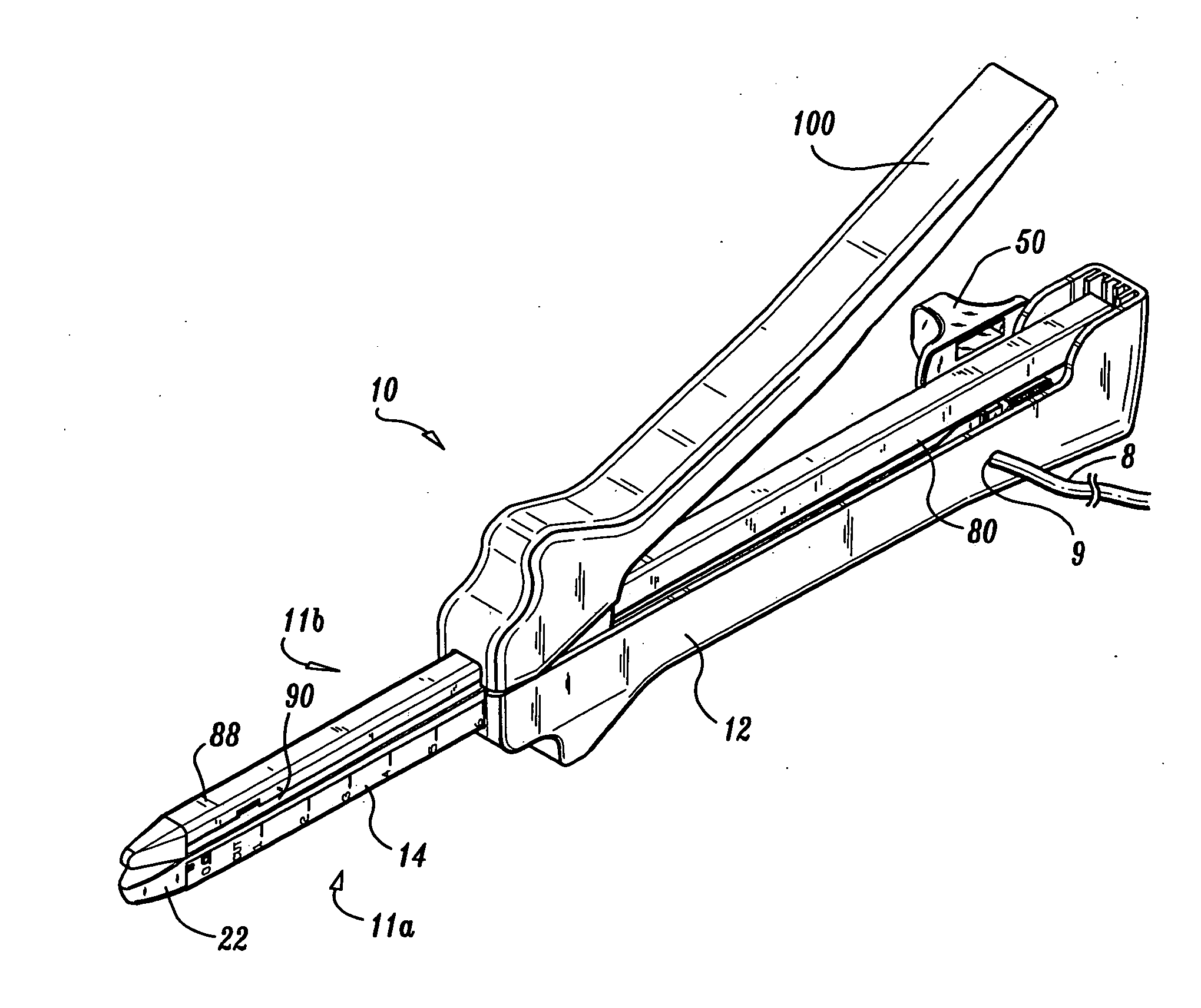

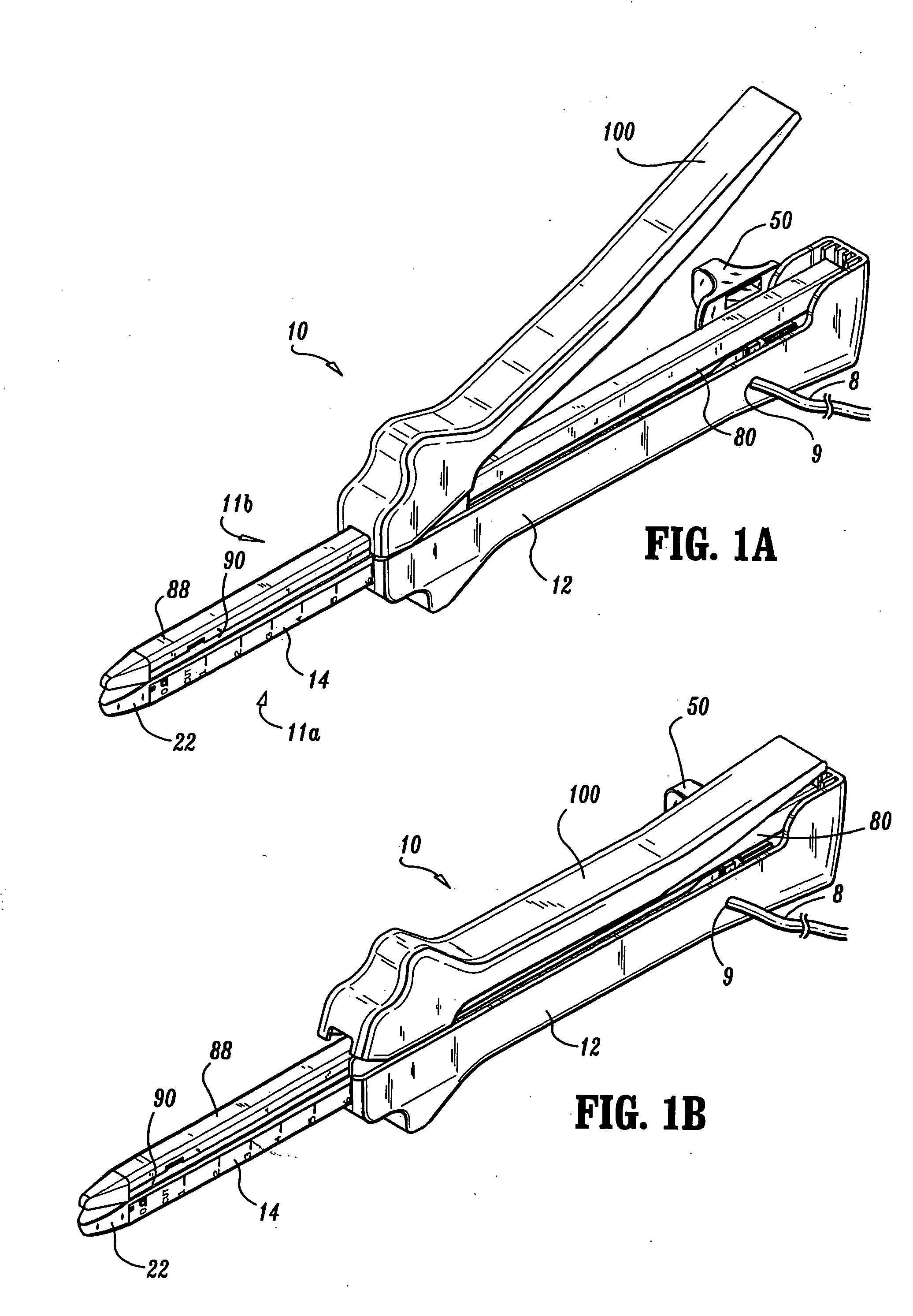

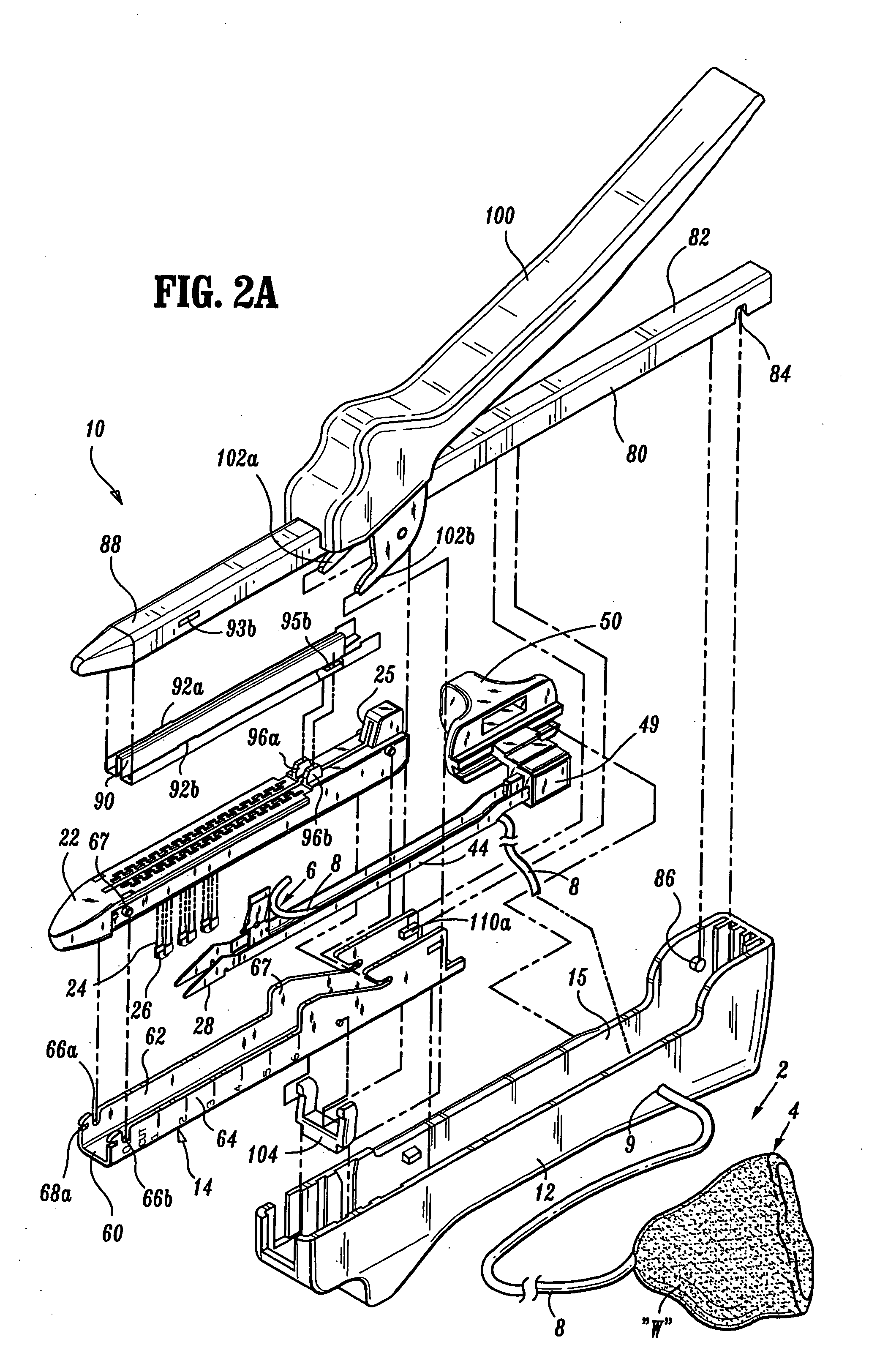

Surgical stapling apparatus having a wound closure material applicator assembly

ActiveUS20050145671A1Prevent staple line linePrevent line knife cut line bleedingSuture equipmentsStapling toolsSurgical stapleCatheter

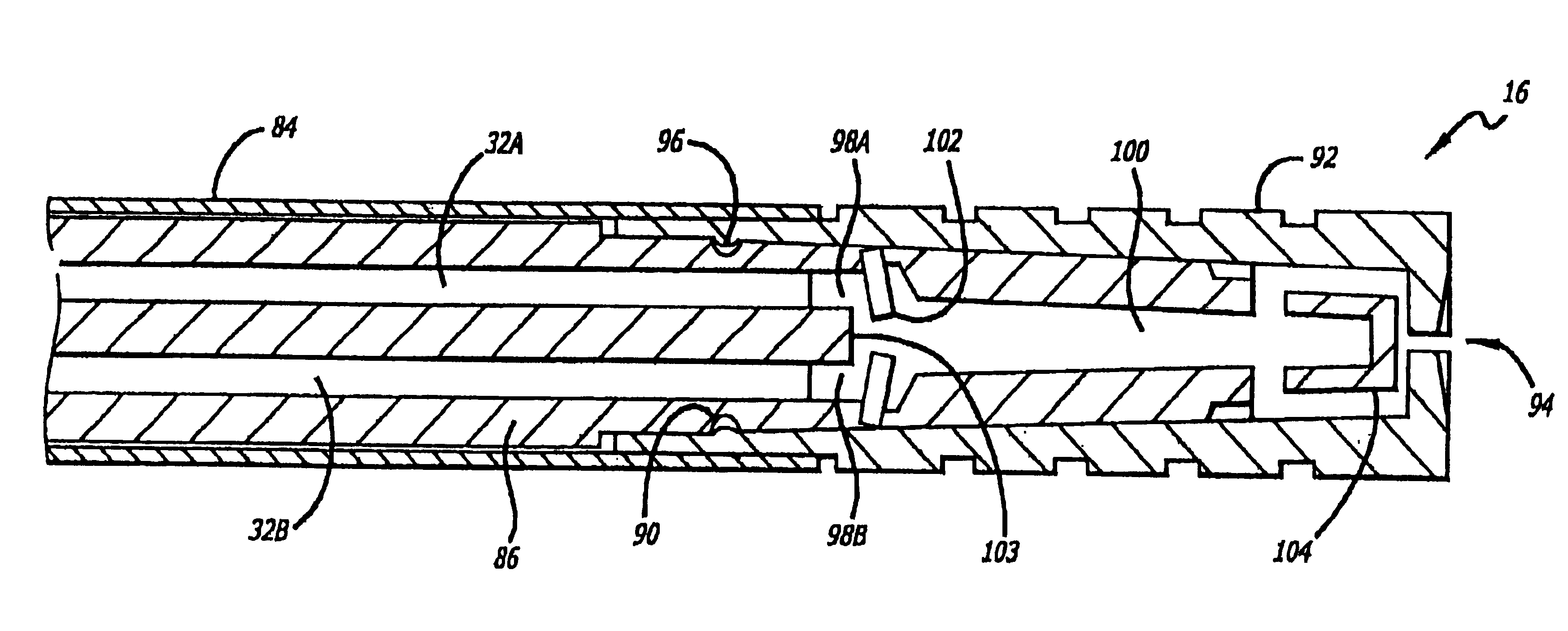

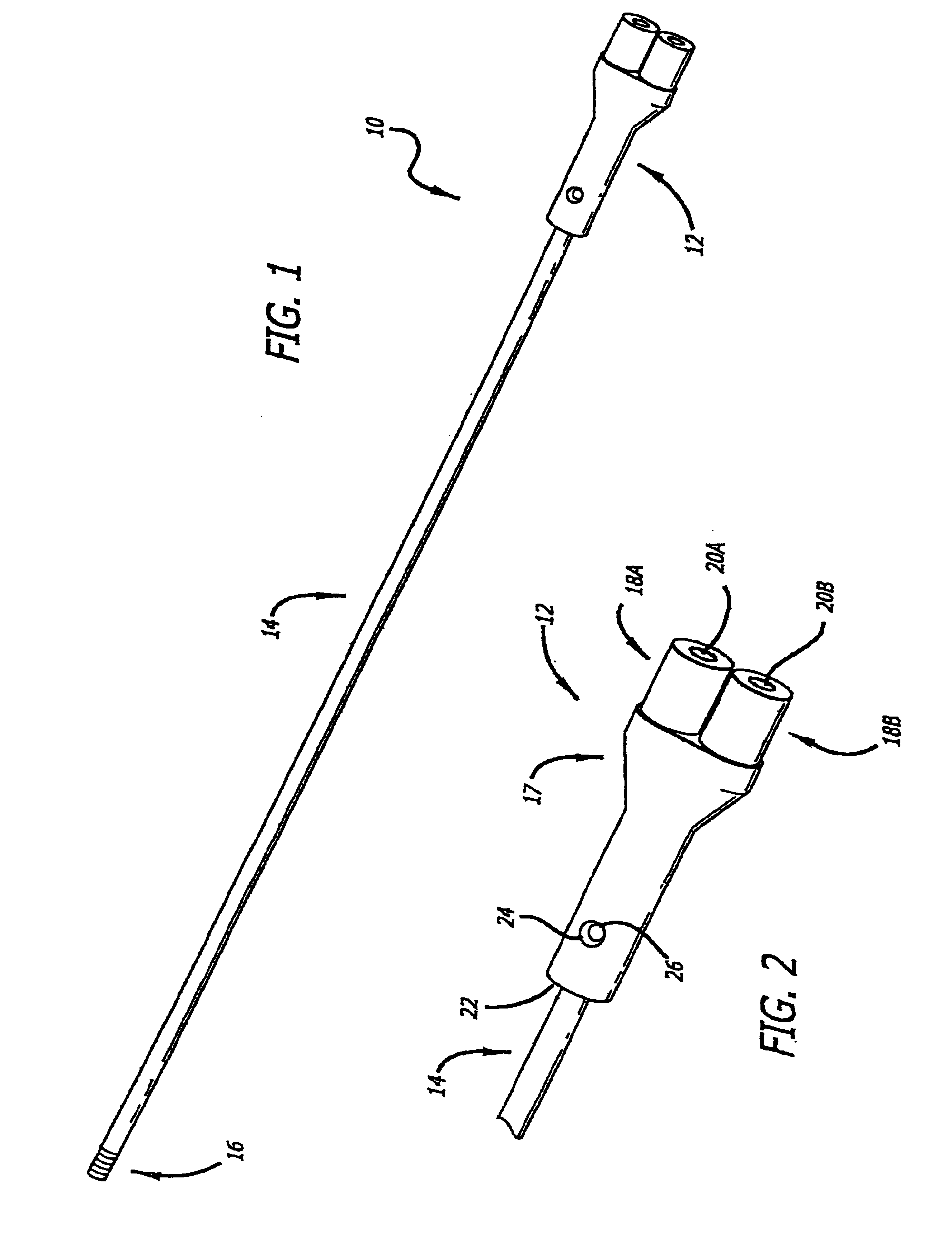

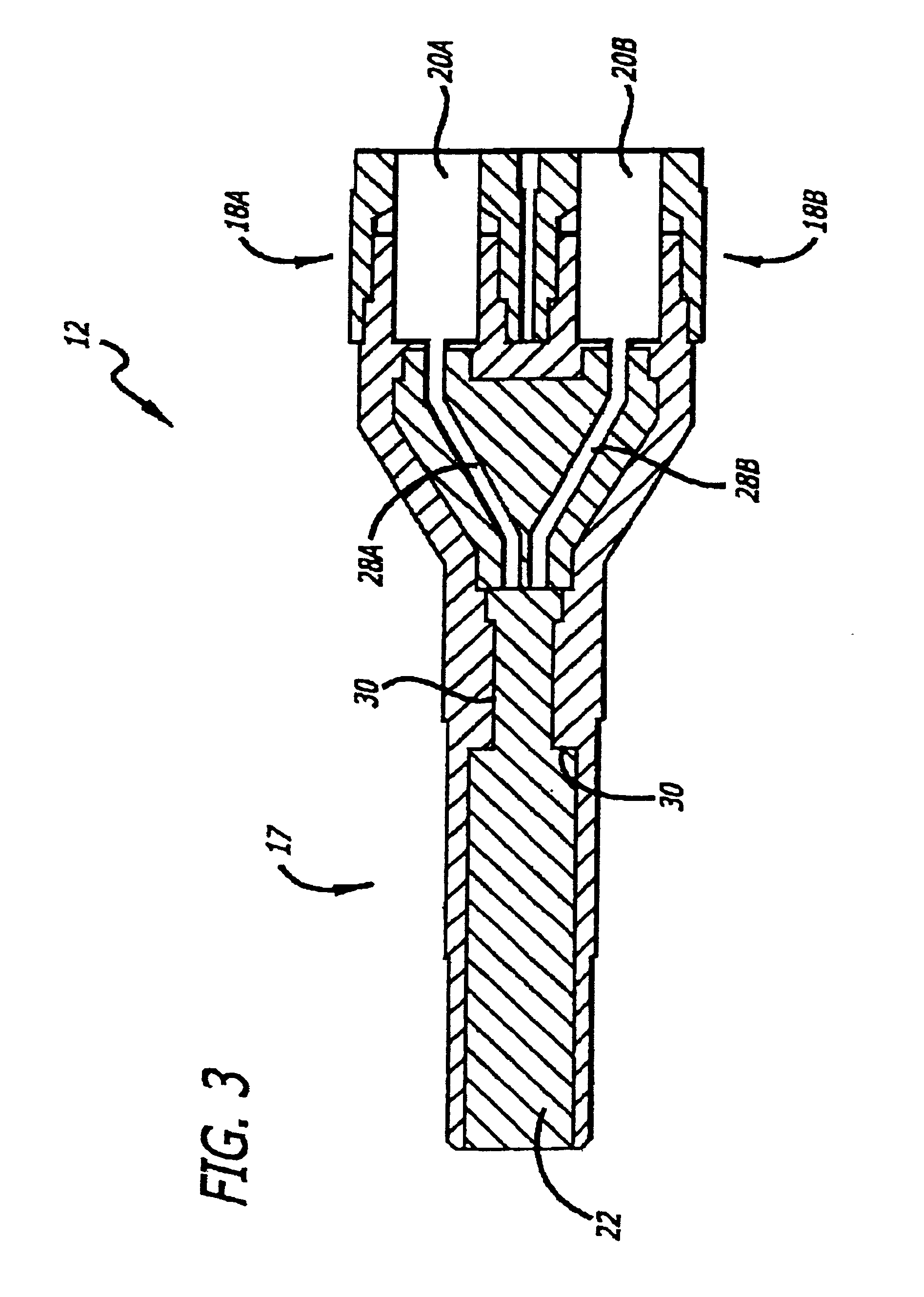

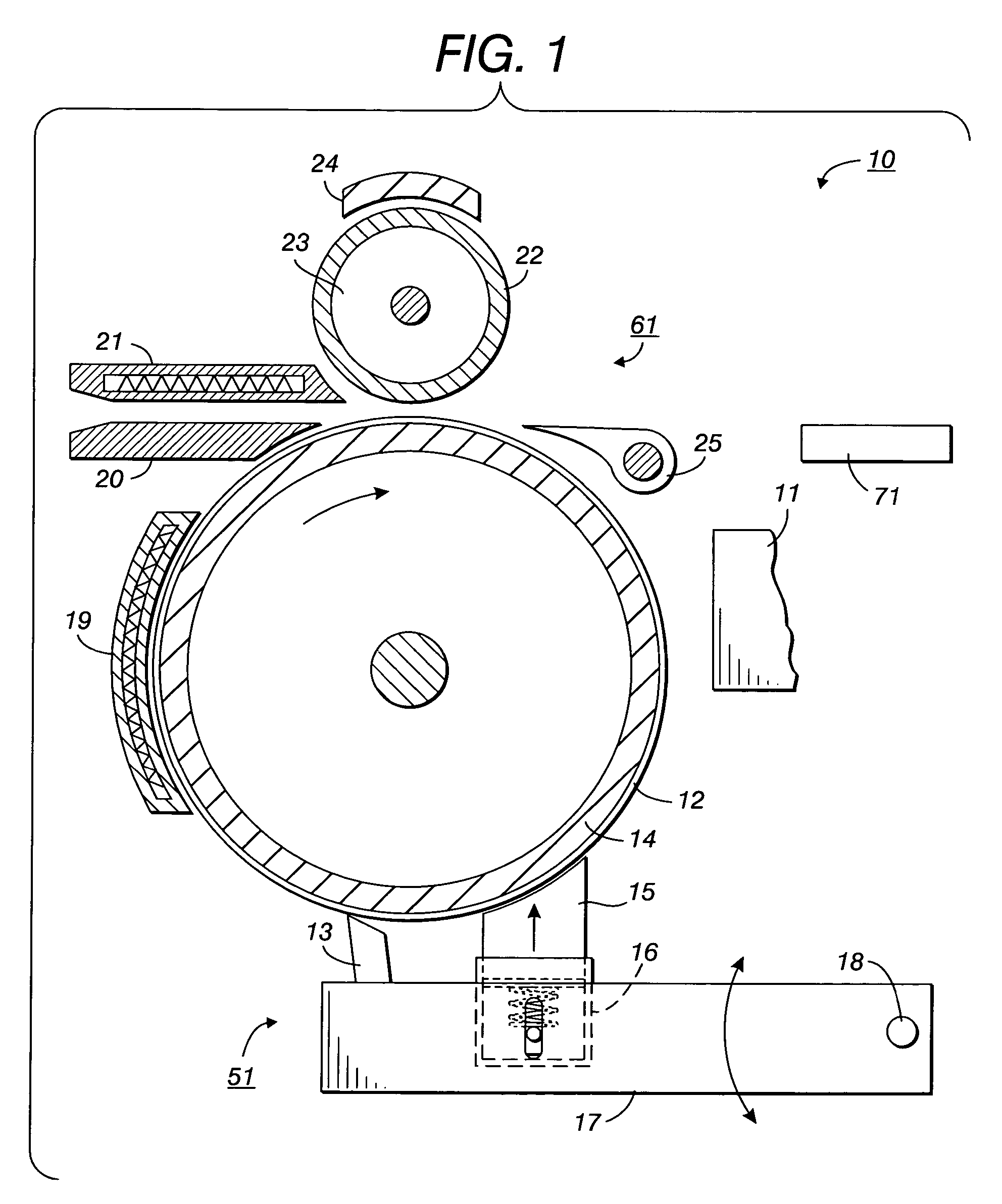

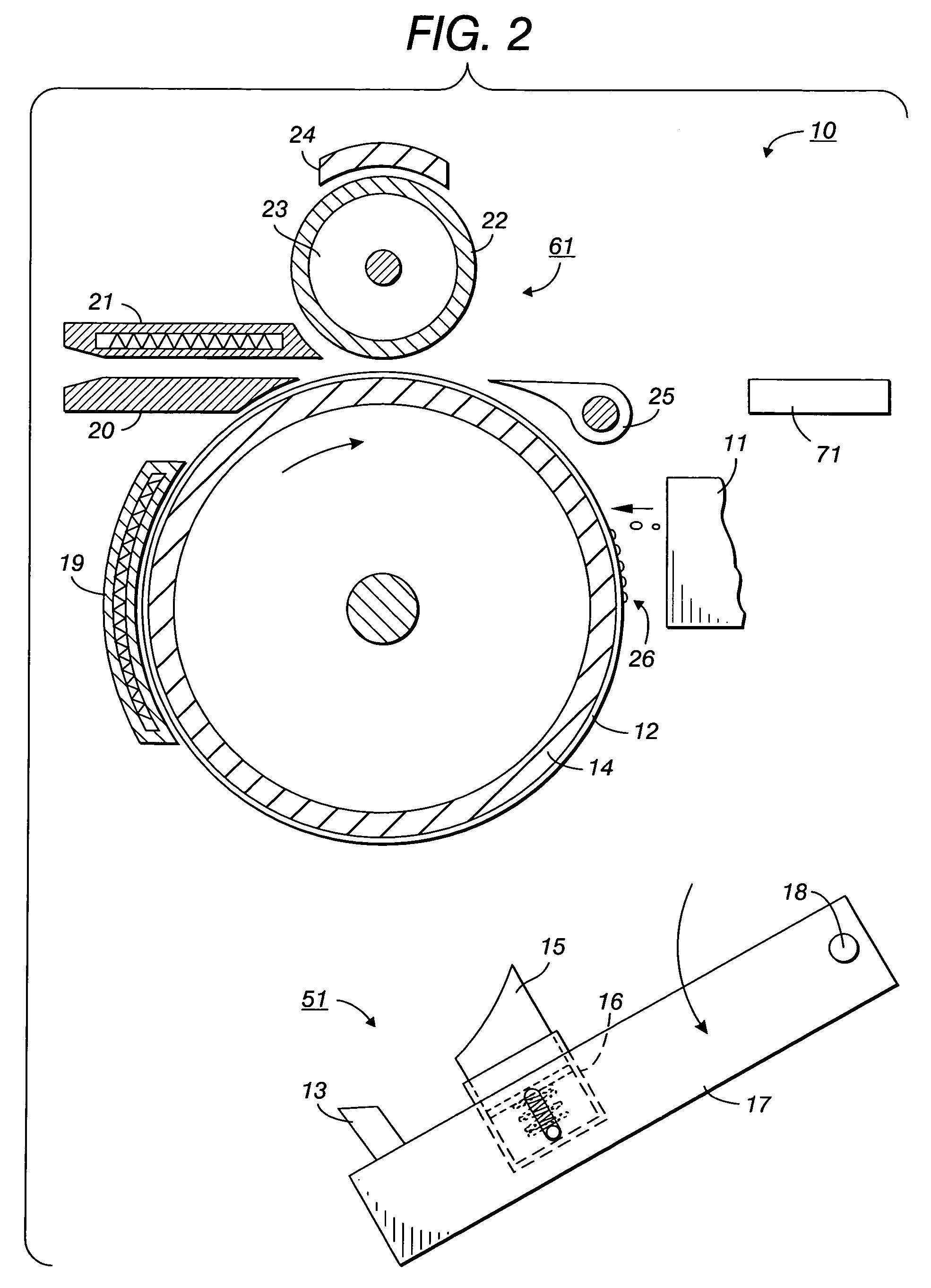

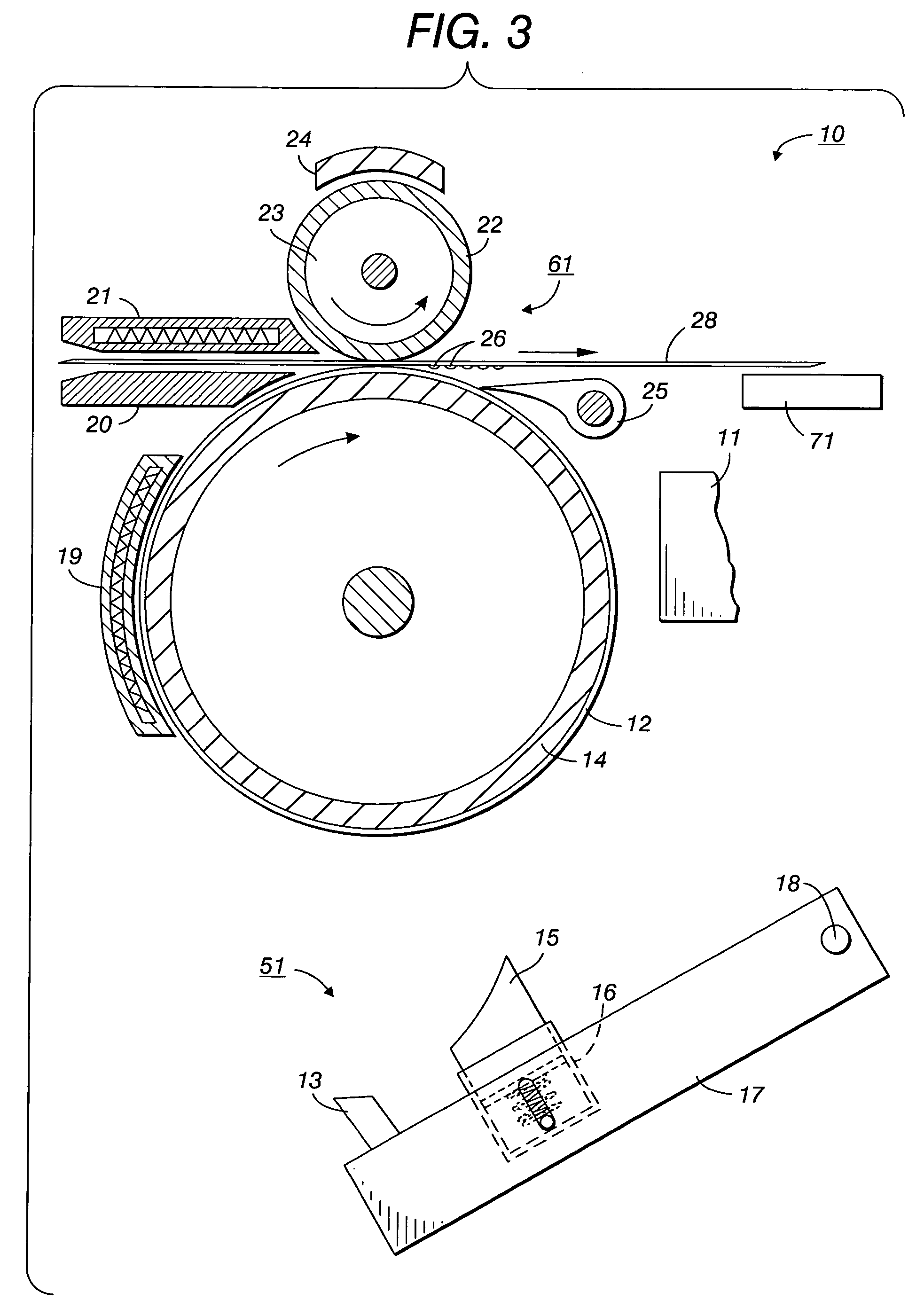

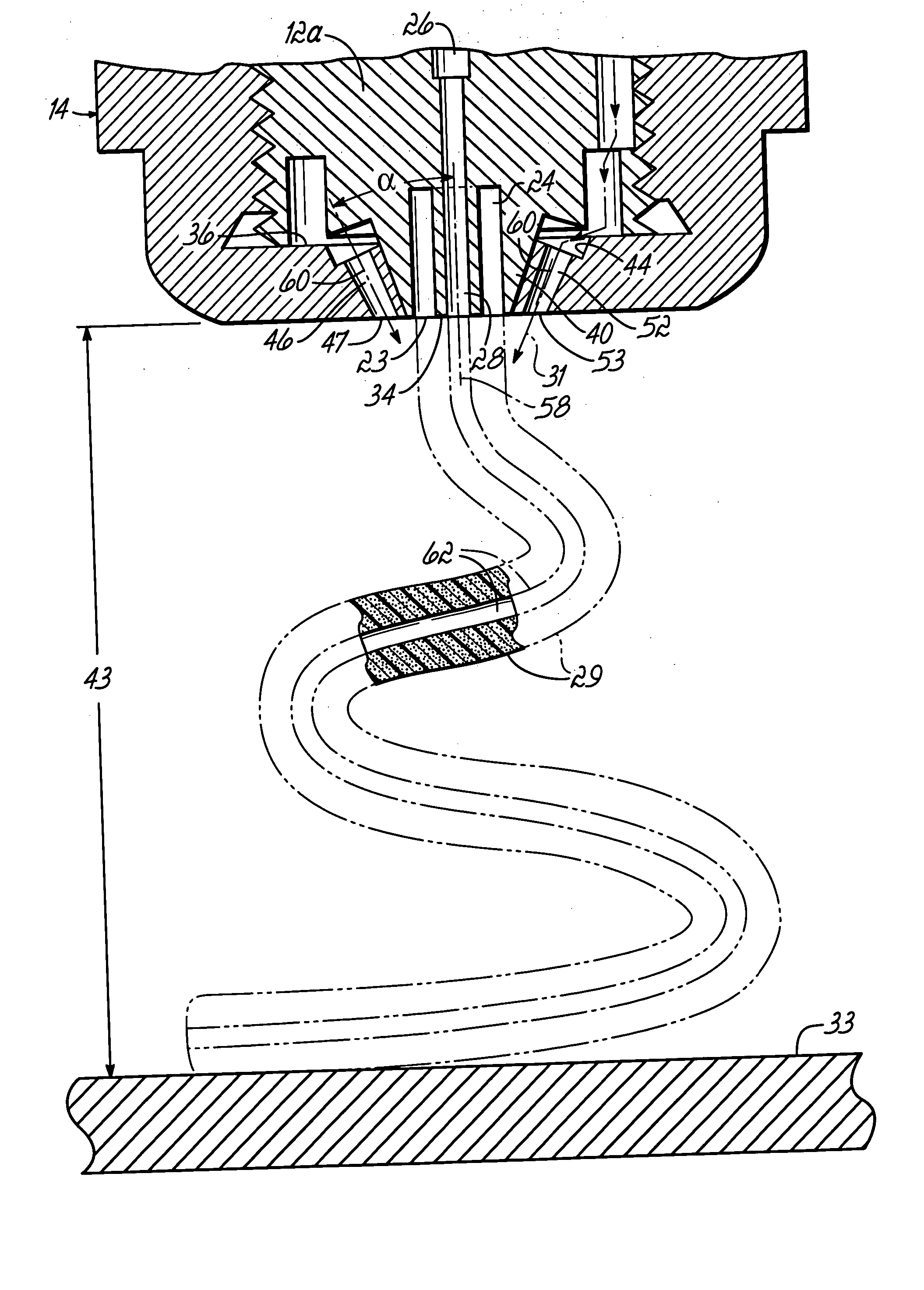

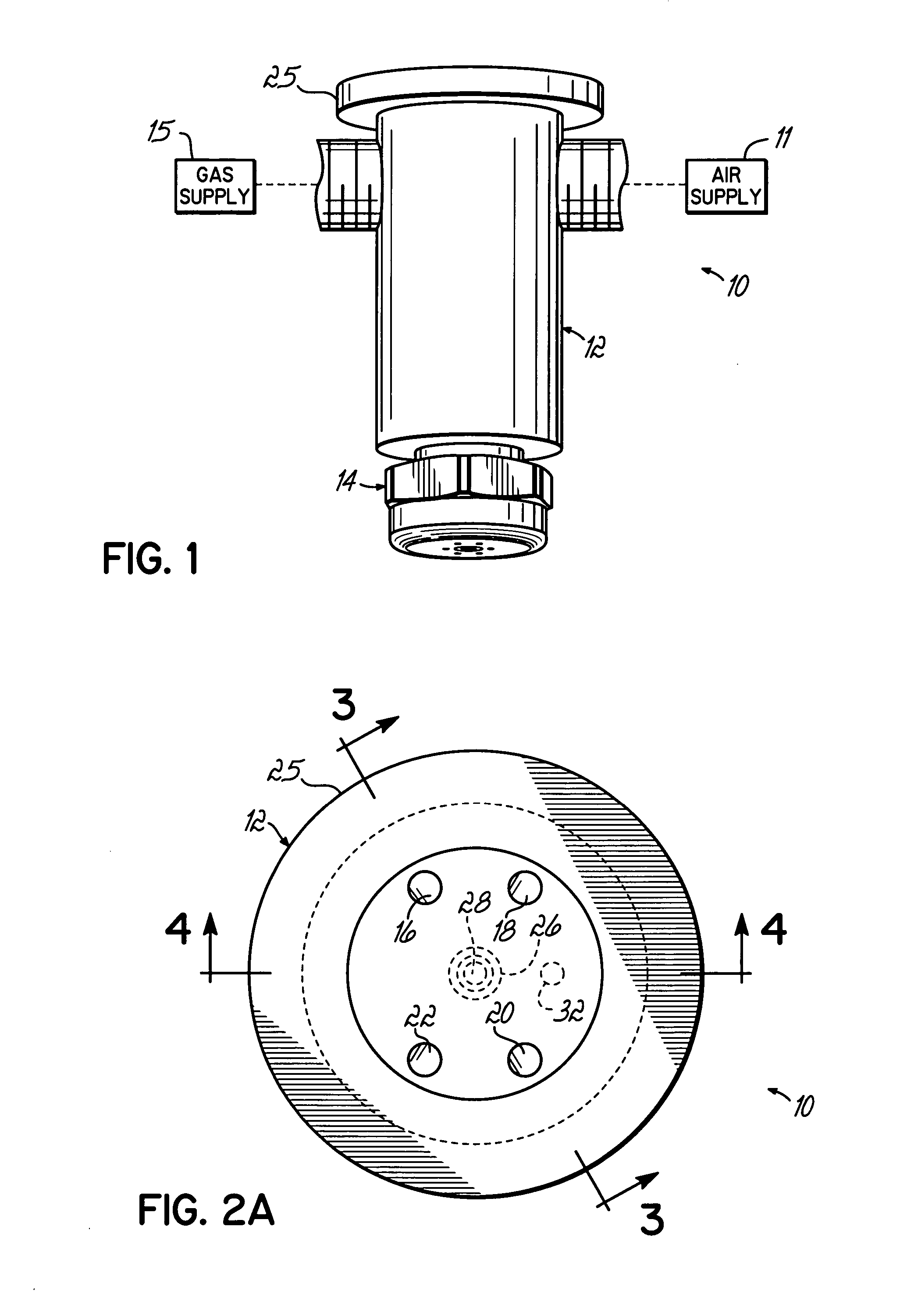

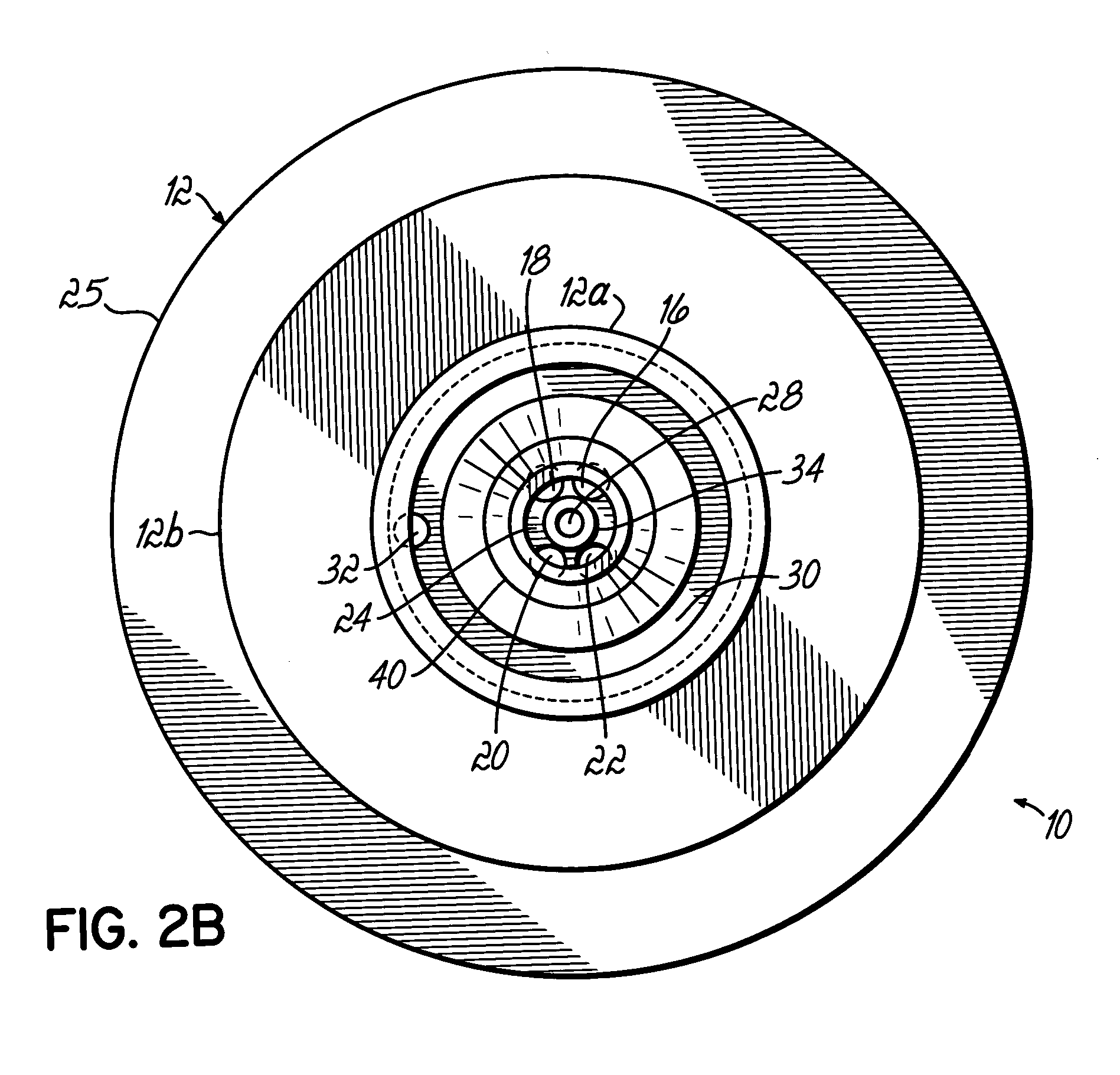

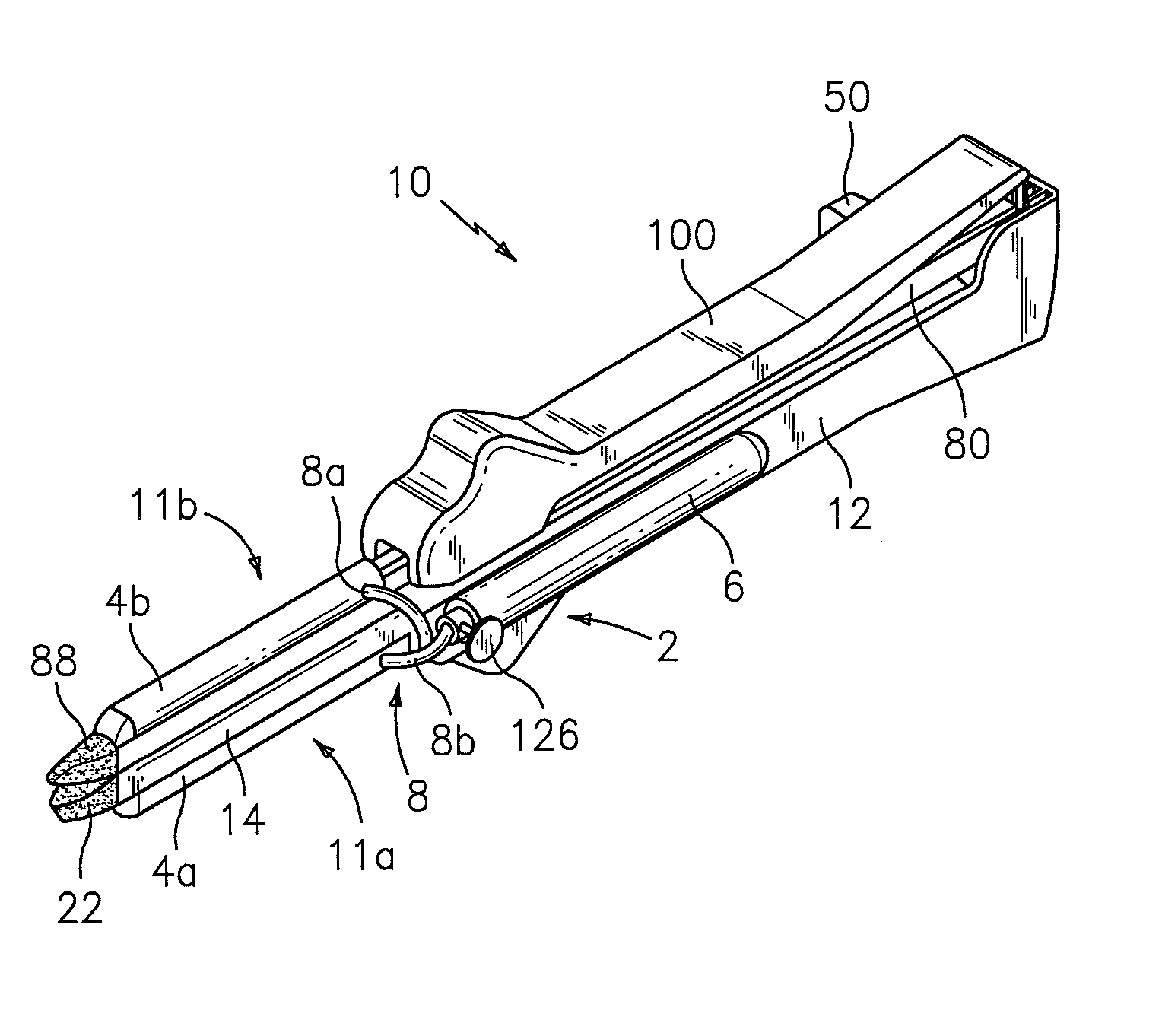

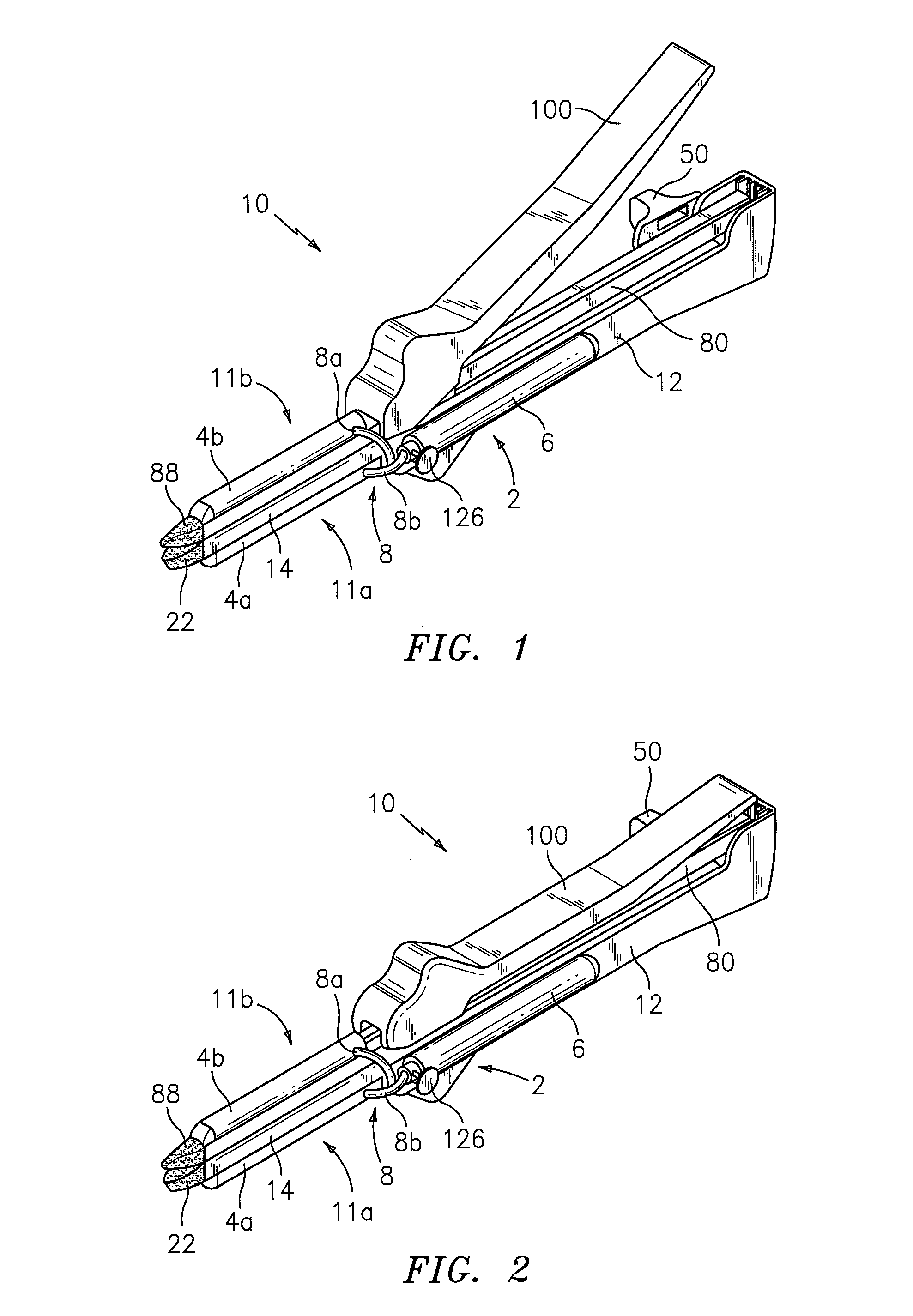

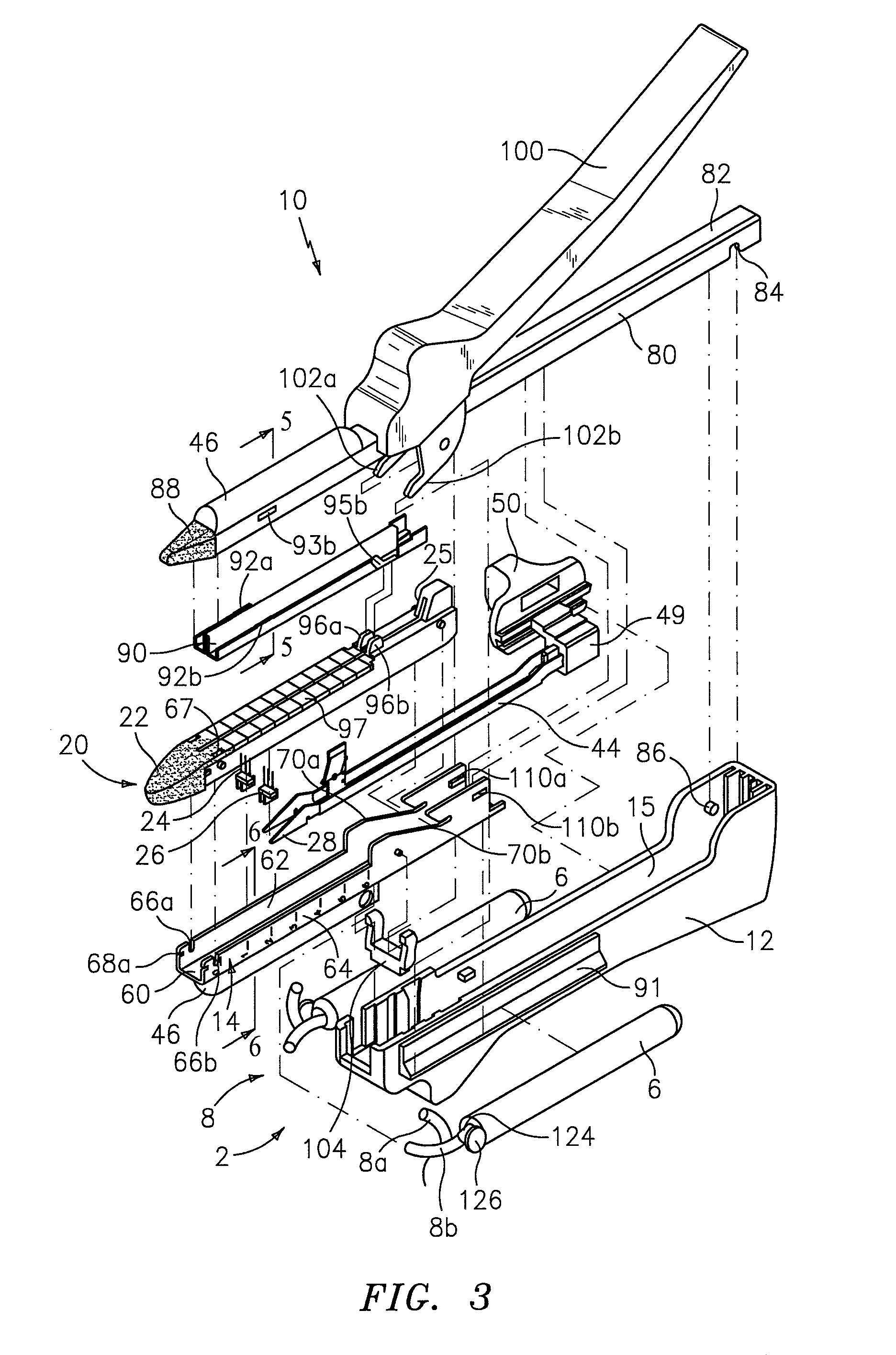

This disclosure relates to surgical stapling apparatus for enhancing one or more properties of body tissue that is or is to be repaired or joined. The apparatus includes a staple anvil, a staple cartridge, a driving member for driving the surgical staples from individual staple slots in the staple cartridge and against the staple anvil, and a wound closure material applicator assembly. The applicator assembly includes at least one conduit extending along at least a length of the driving member, anvil and / or cartridge and at least one reservoir in fluid communication with the at least one conduit, the reservoir containing a wound closure material therein. The staples can be coated with a wound closure material.

Owner:TYCO HEALTHCARE GRP LP

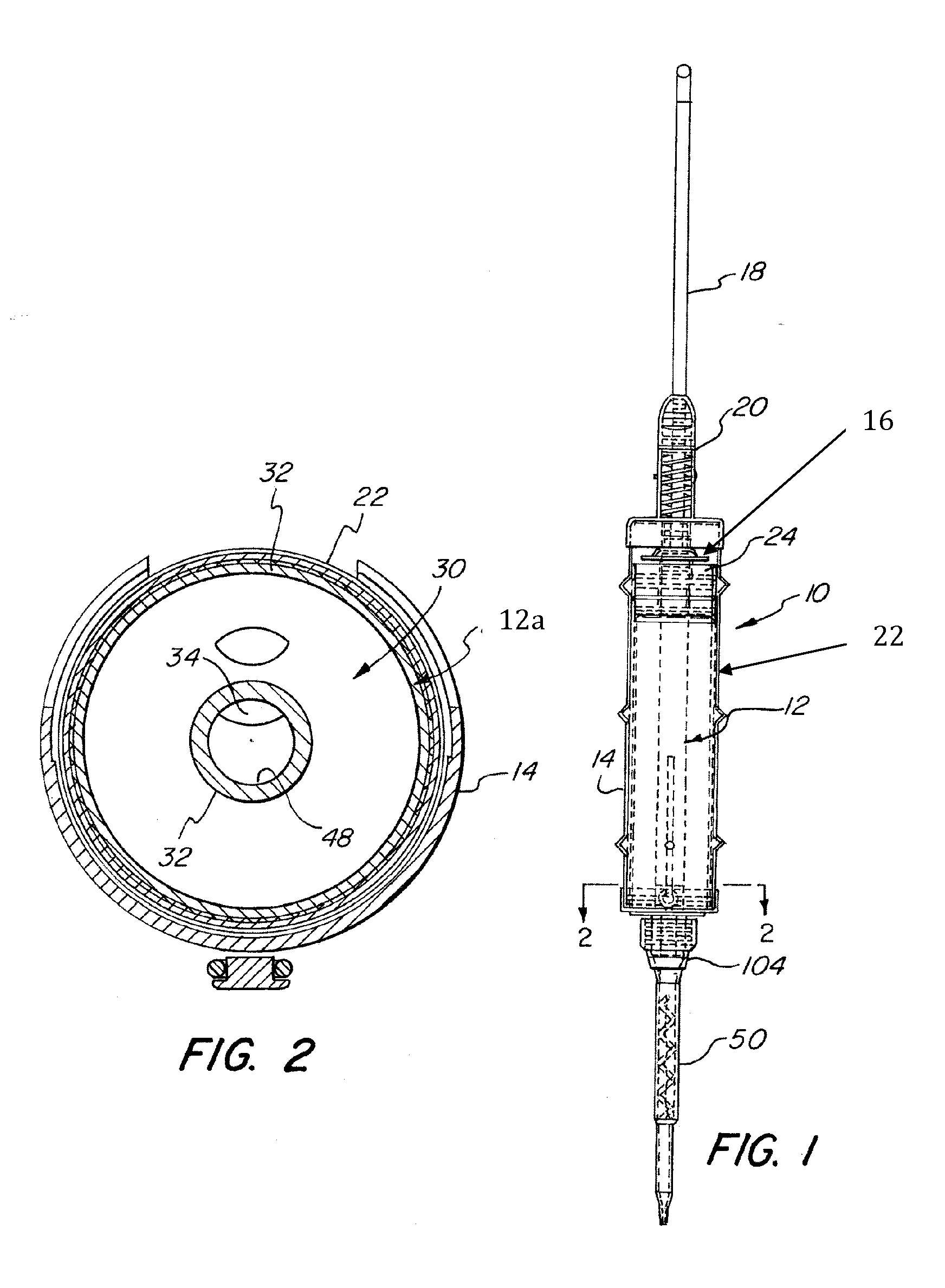

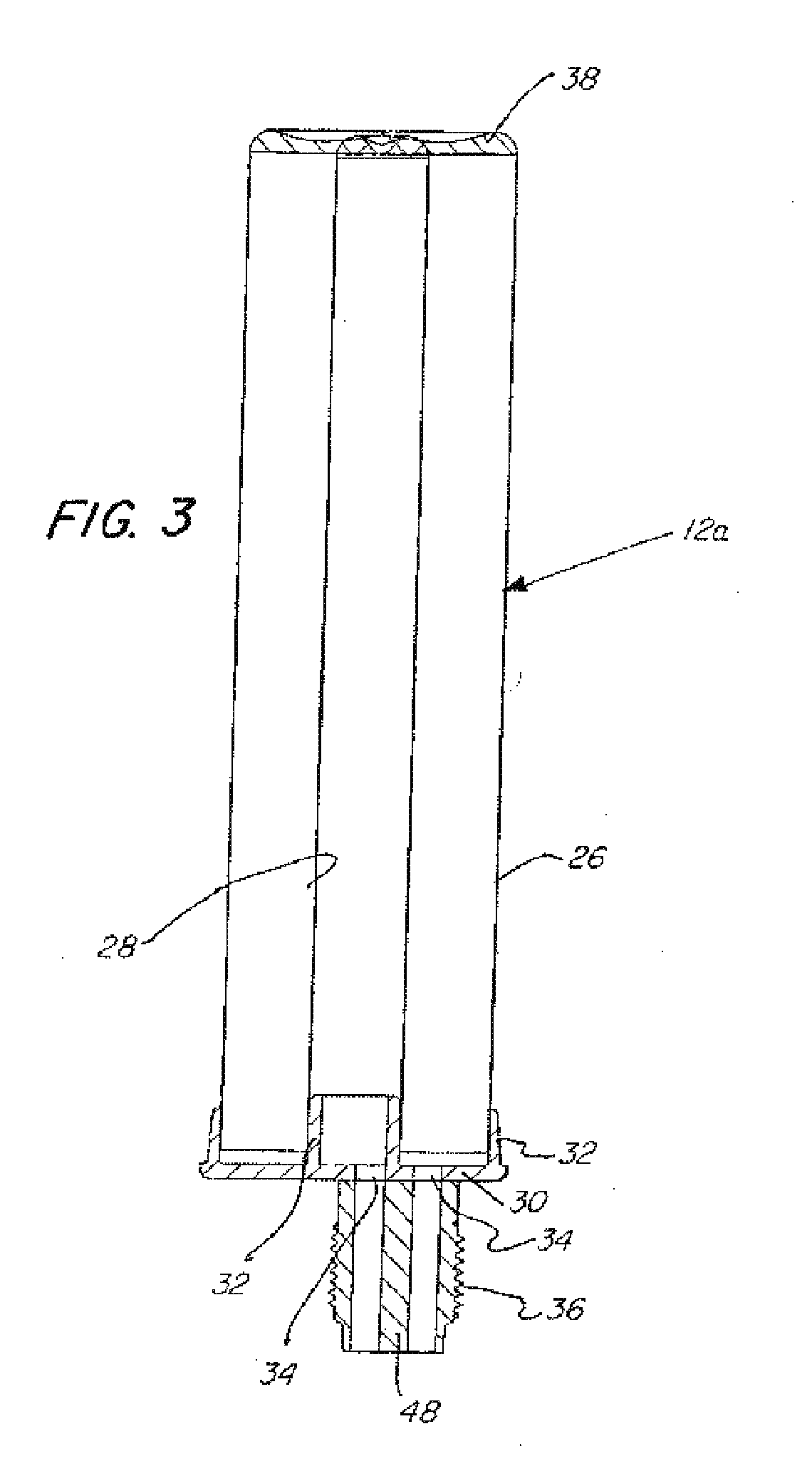

Wound closure material applicator and stapler

A surgical stapling apparatus includes a staple anvil and a staple cartridge having a working surface, one or more rows of individual staple slots formed in the working surface, a knife track formed along a length of the working surface, and a plurality of surgical staples individually disposed within the individual staple slots. The apparatus further includes an actuation sled having a knife and being configured and adapted to movably position the knife axially within the knife track. The apparatus also includes a wound closure material applicator assembly having a needle secured to the knife to dispense a quantity of wound closure material along a length of the knife track as the actuation sled and knife are moved therealong.

Owner:TYCO HEALTHCARE GRP LP

Surgical stapling apparatus having a wound closure material applicator assembly

InactiveUS20050192628A1Prevent staple line and knife cut line bleedingSuture equipmentsStapling toolsSurgical stapleCatheter

Owner:TYCO HEALTHCARE GRP LP

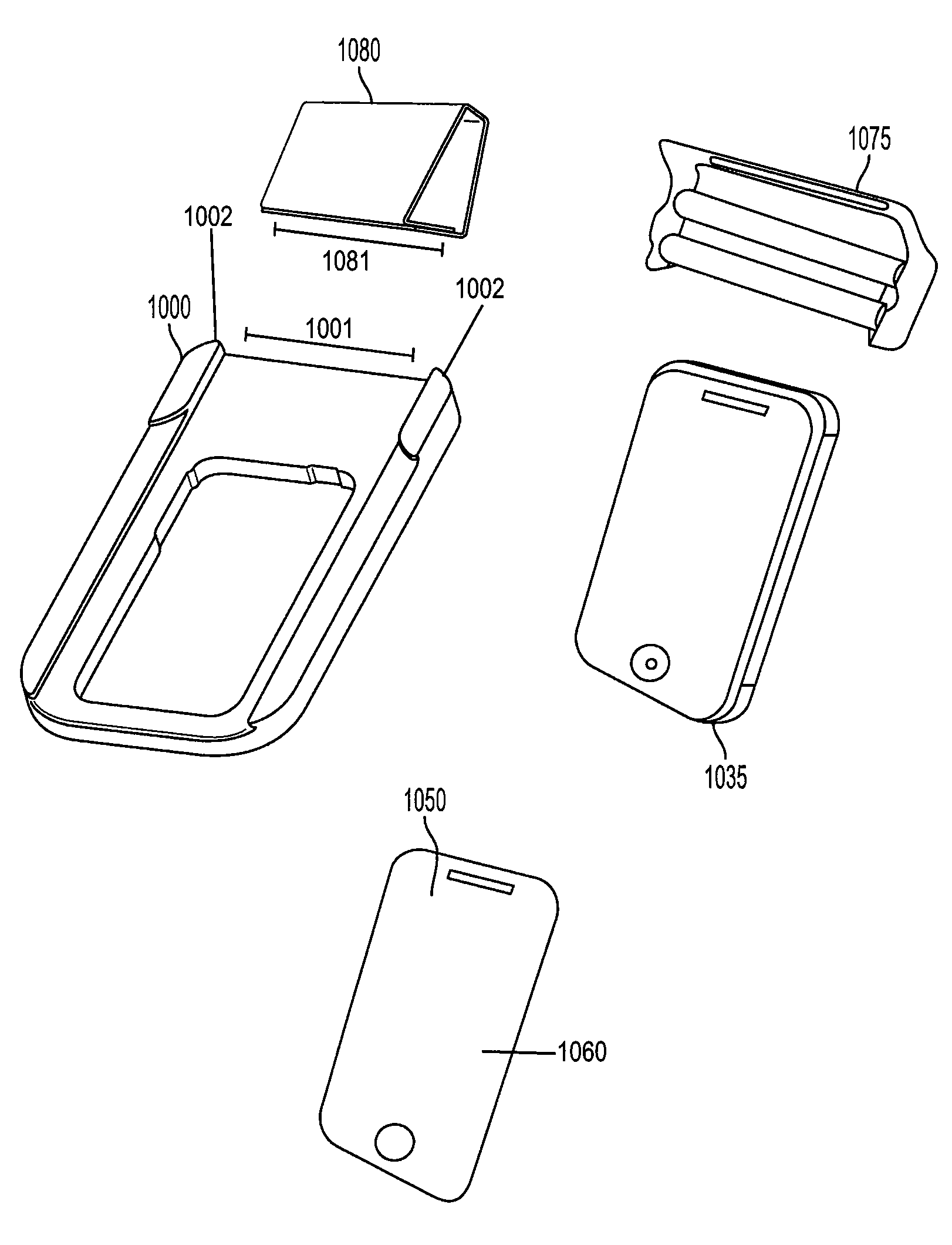

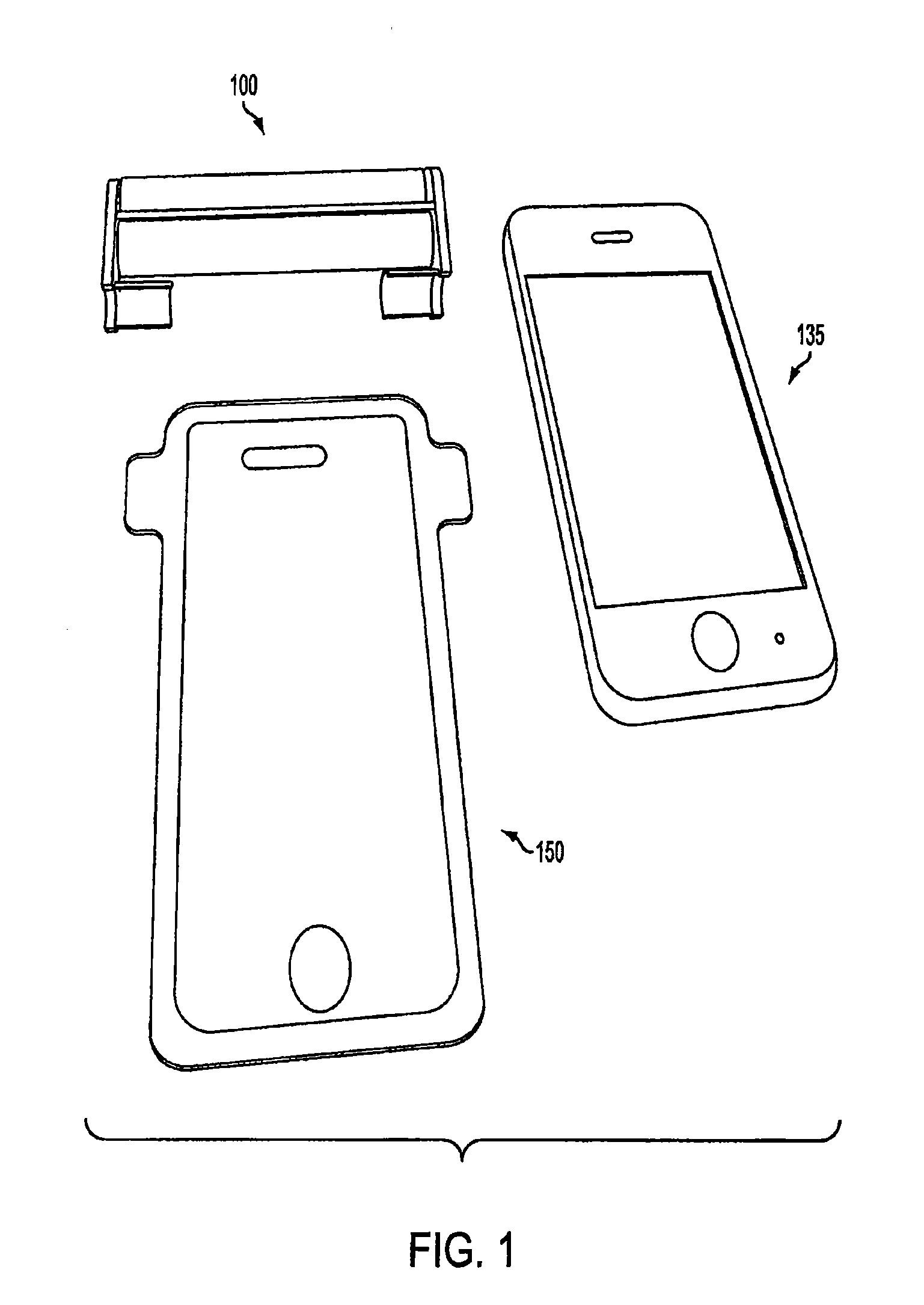

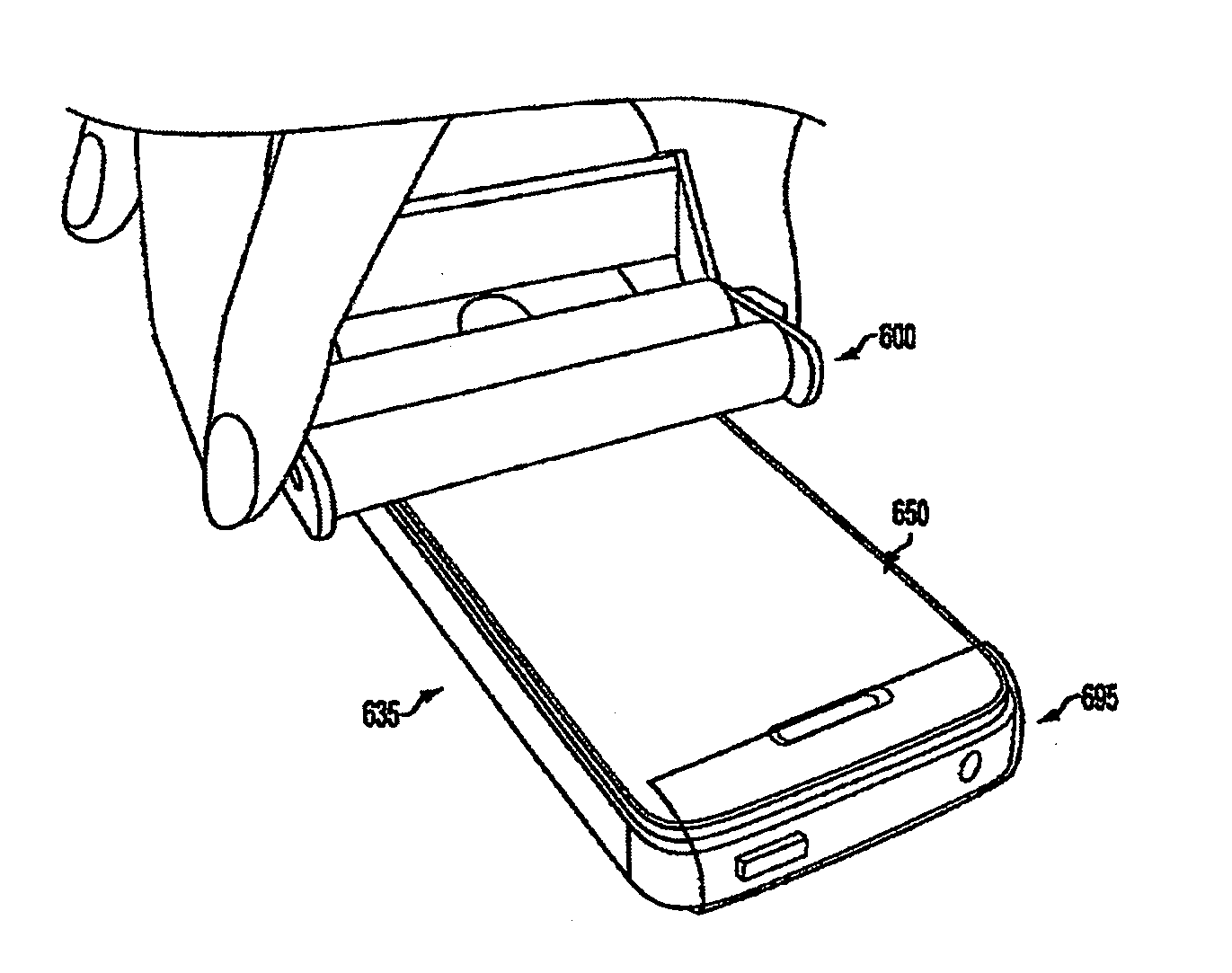

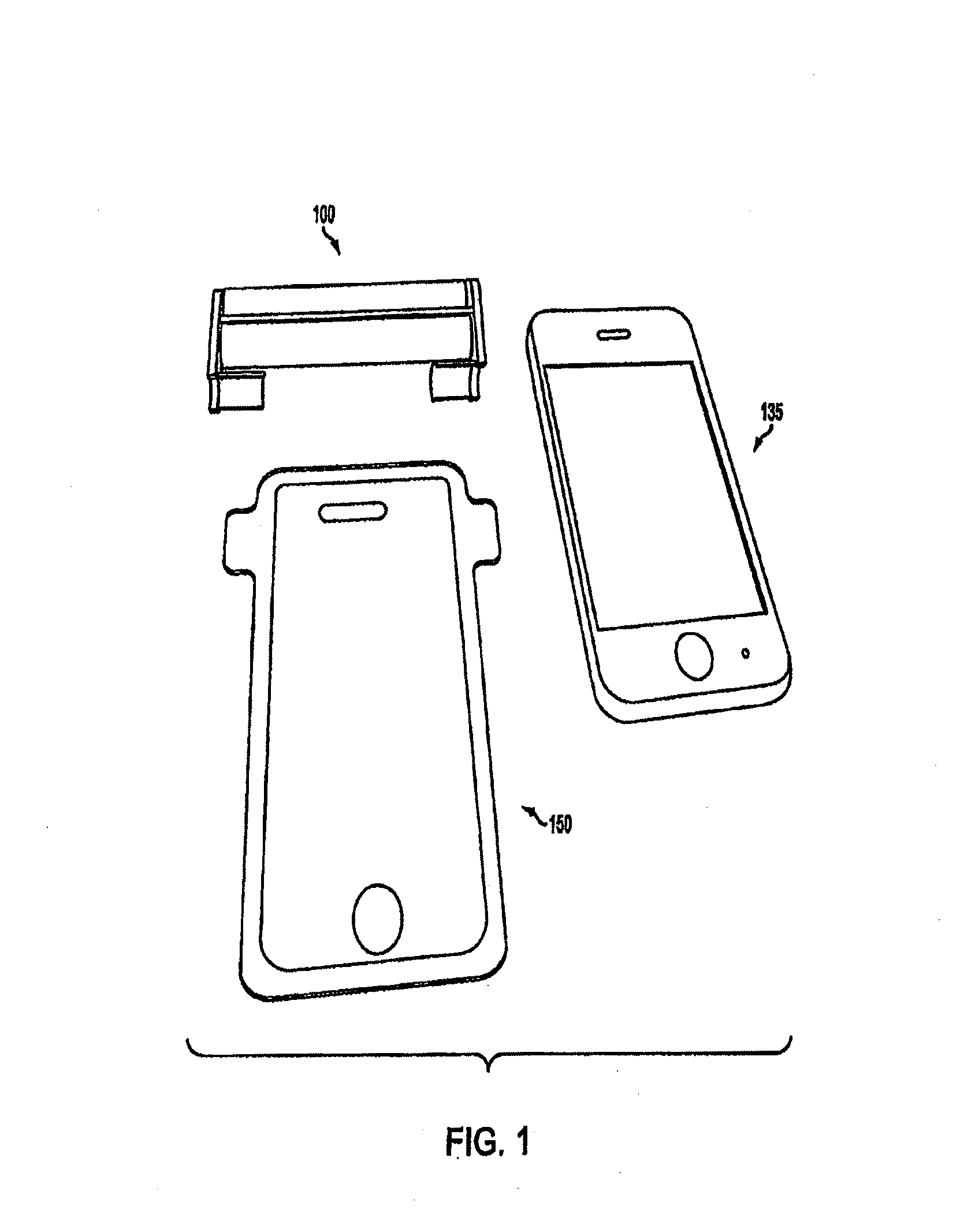

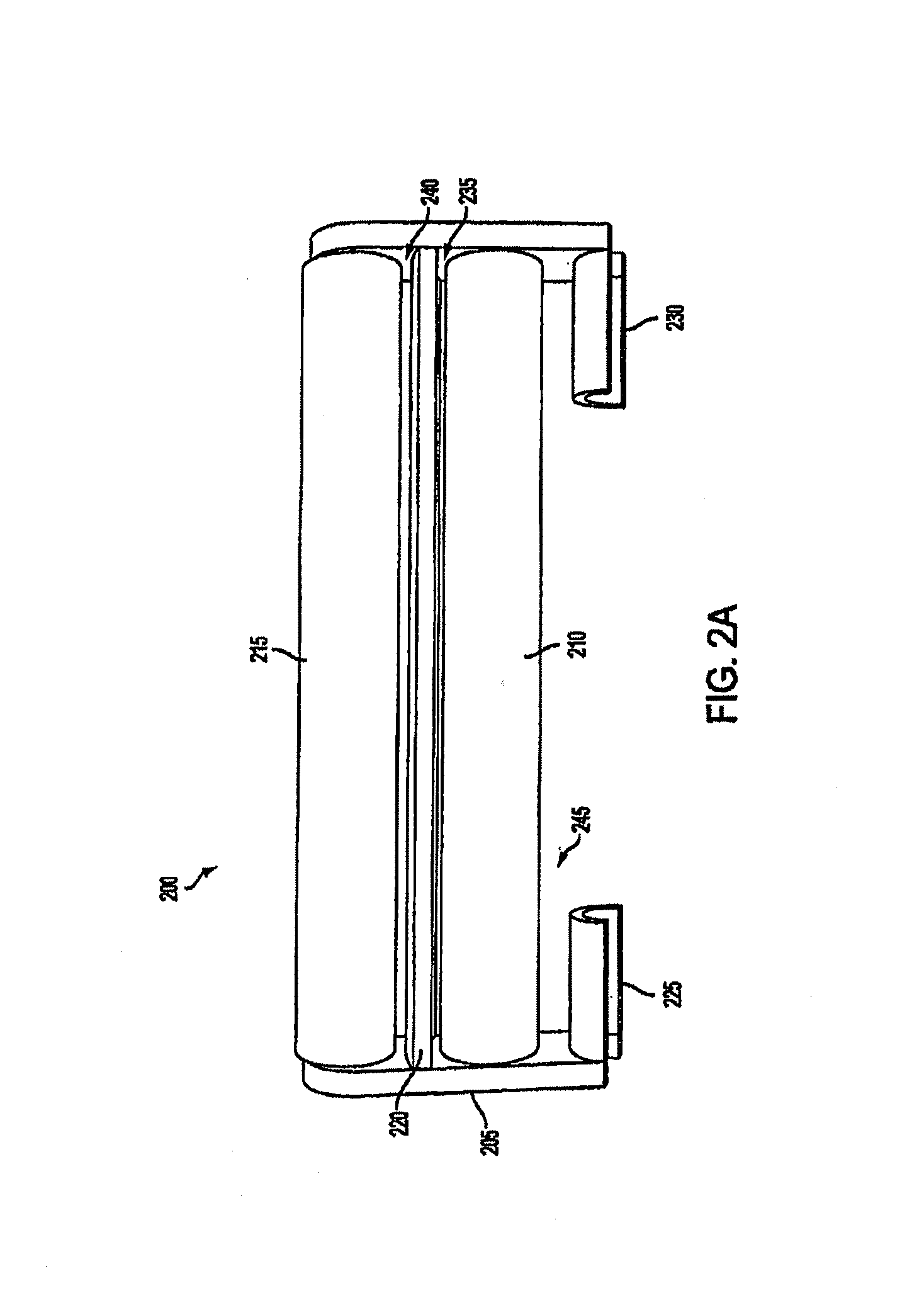

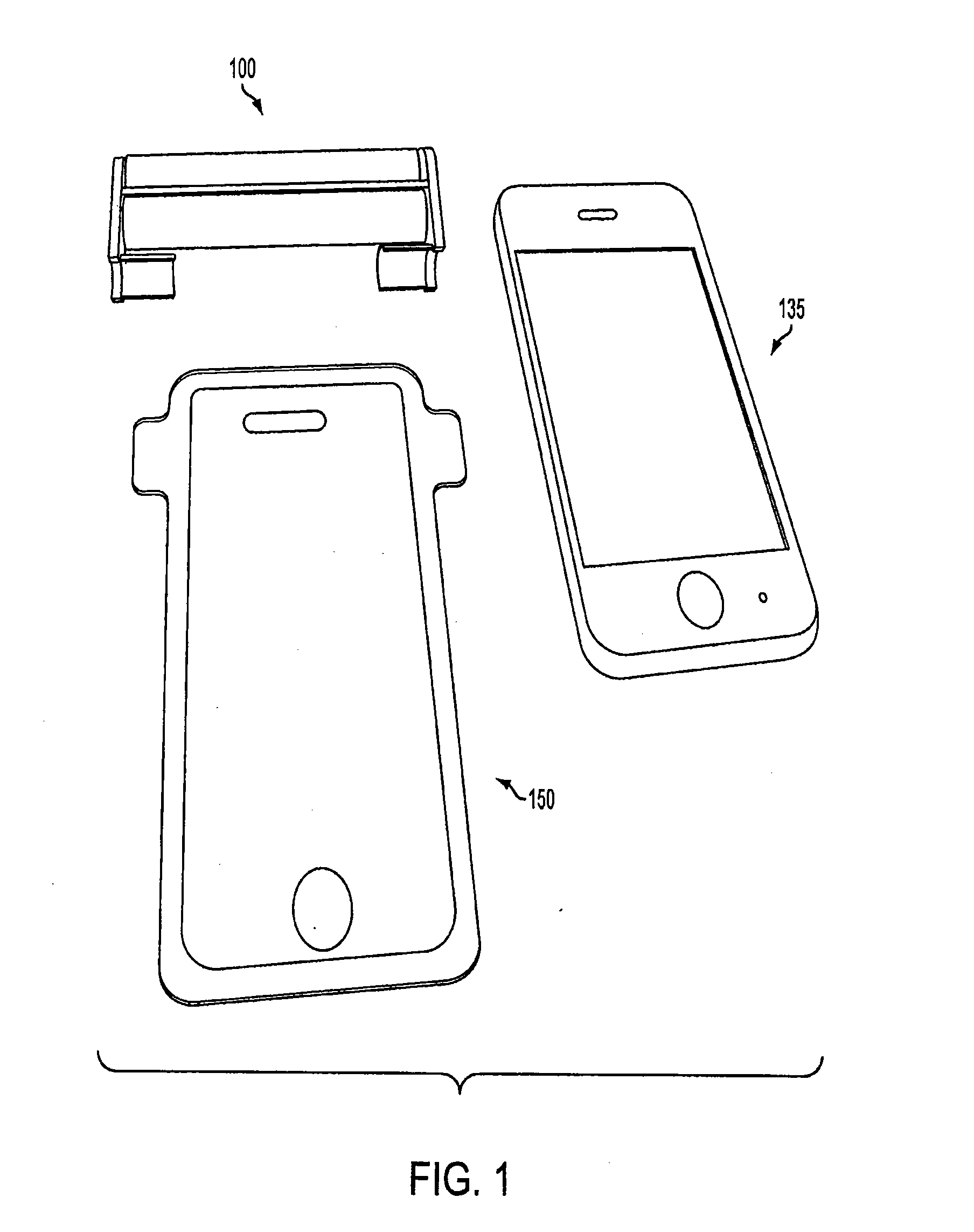

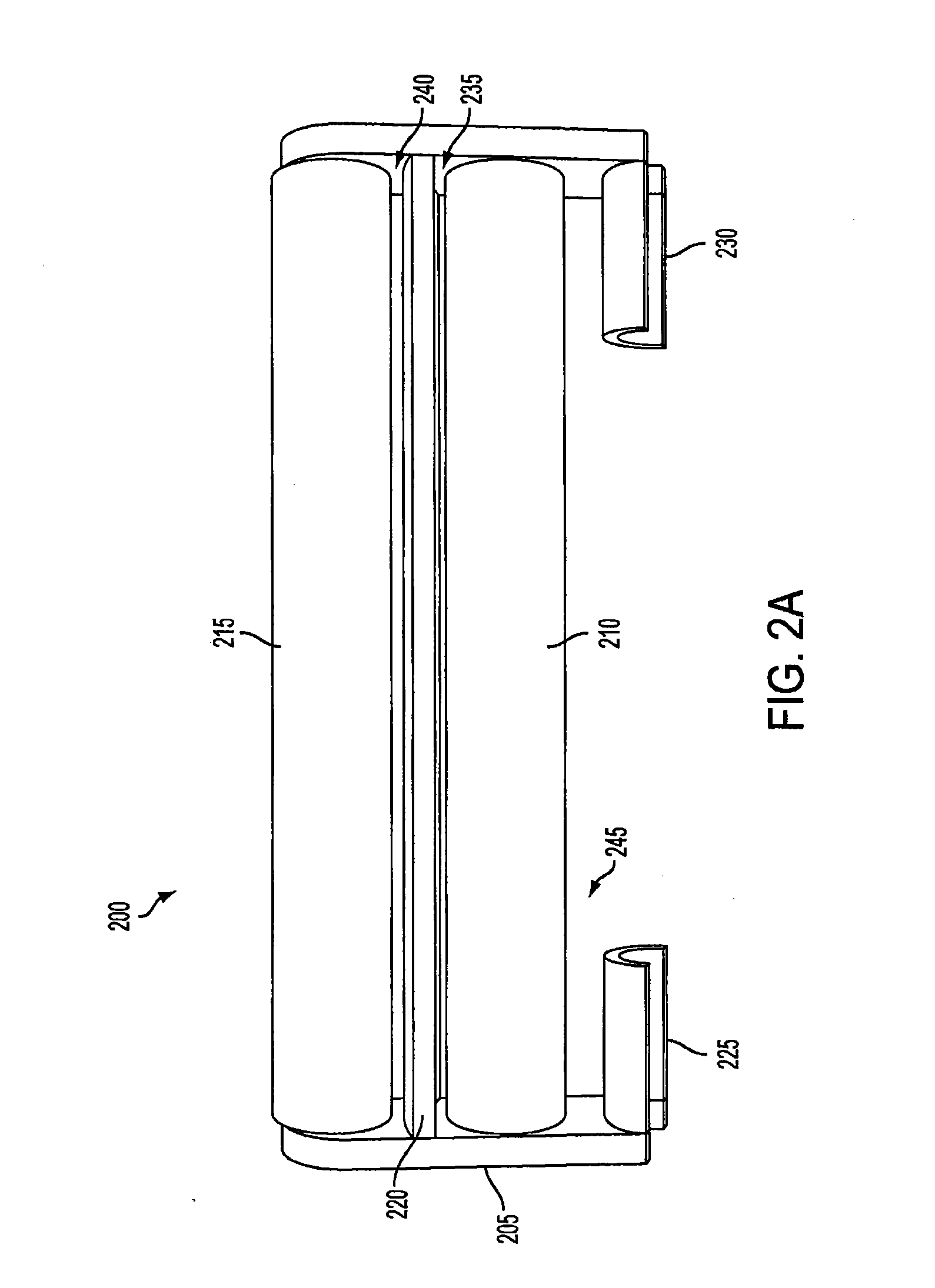

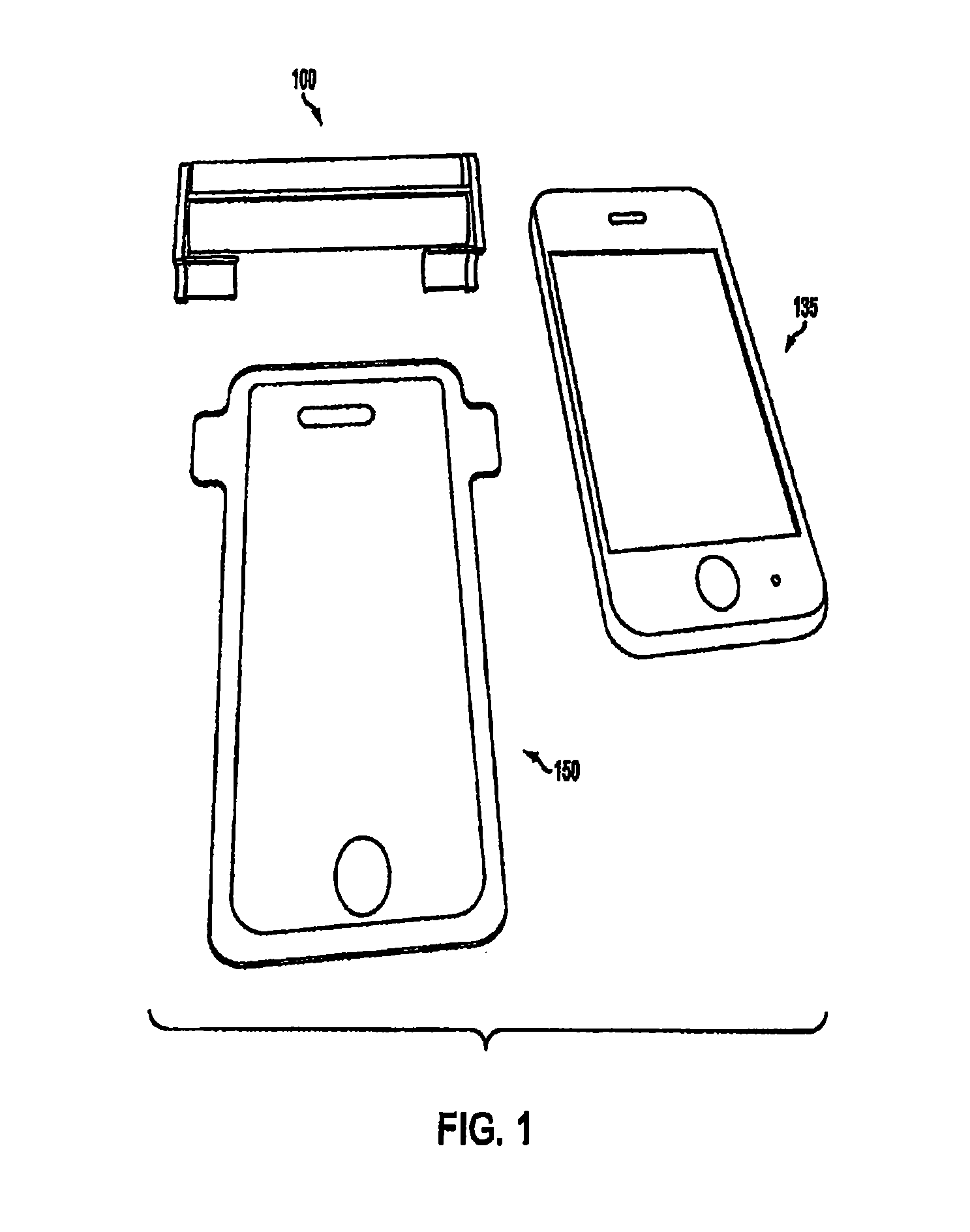

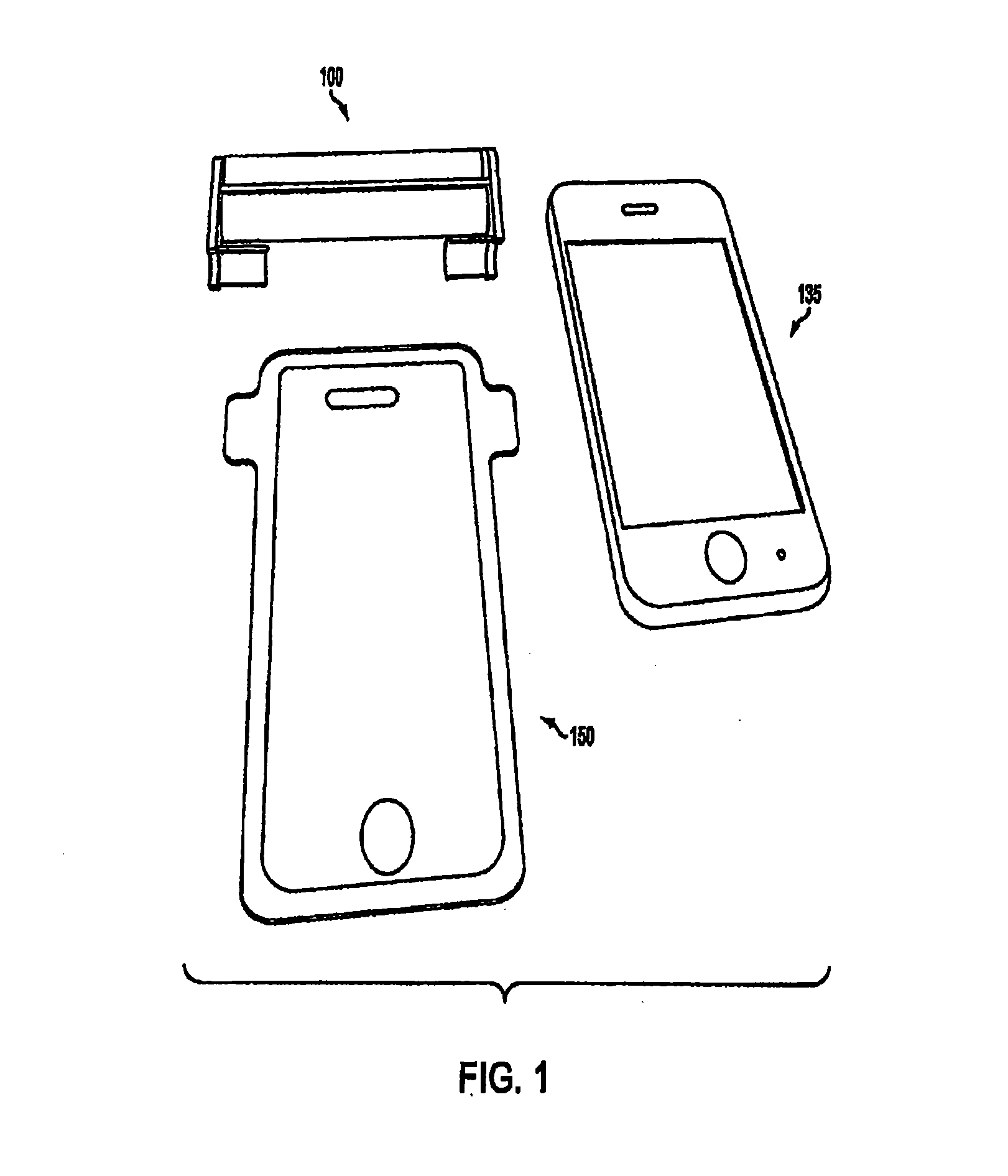

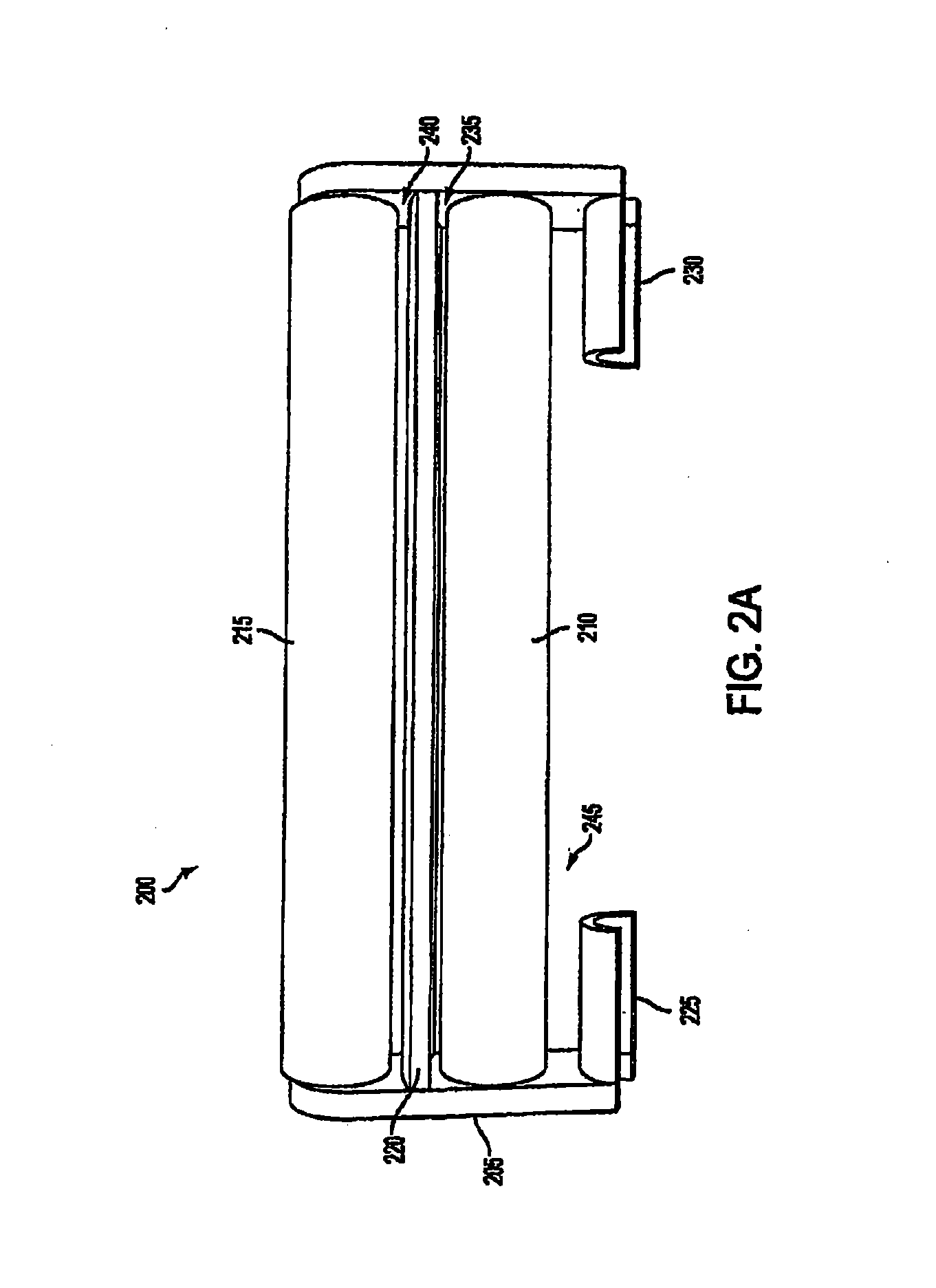

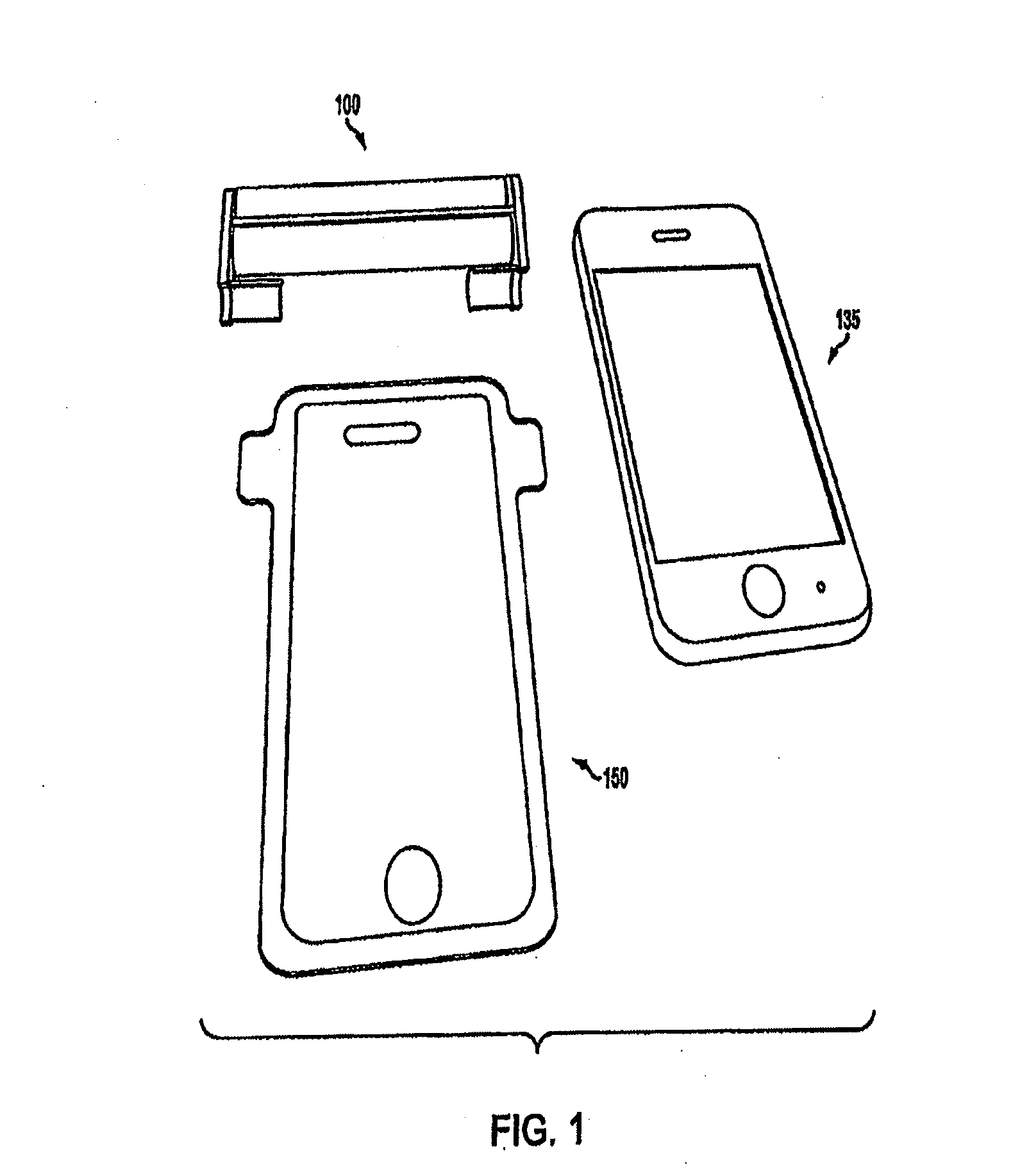

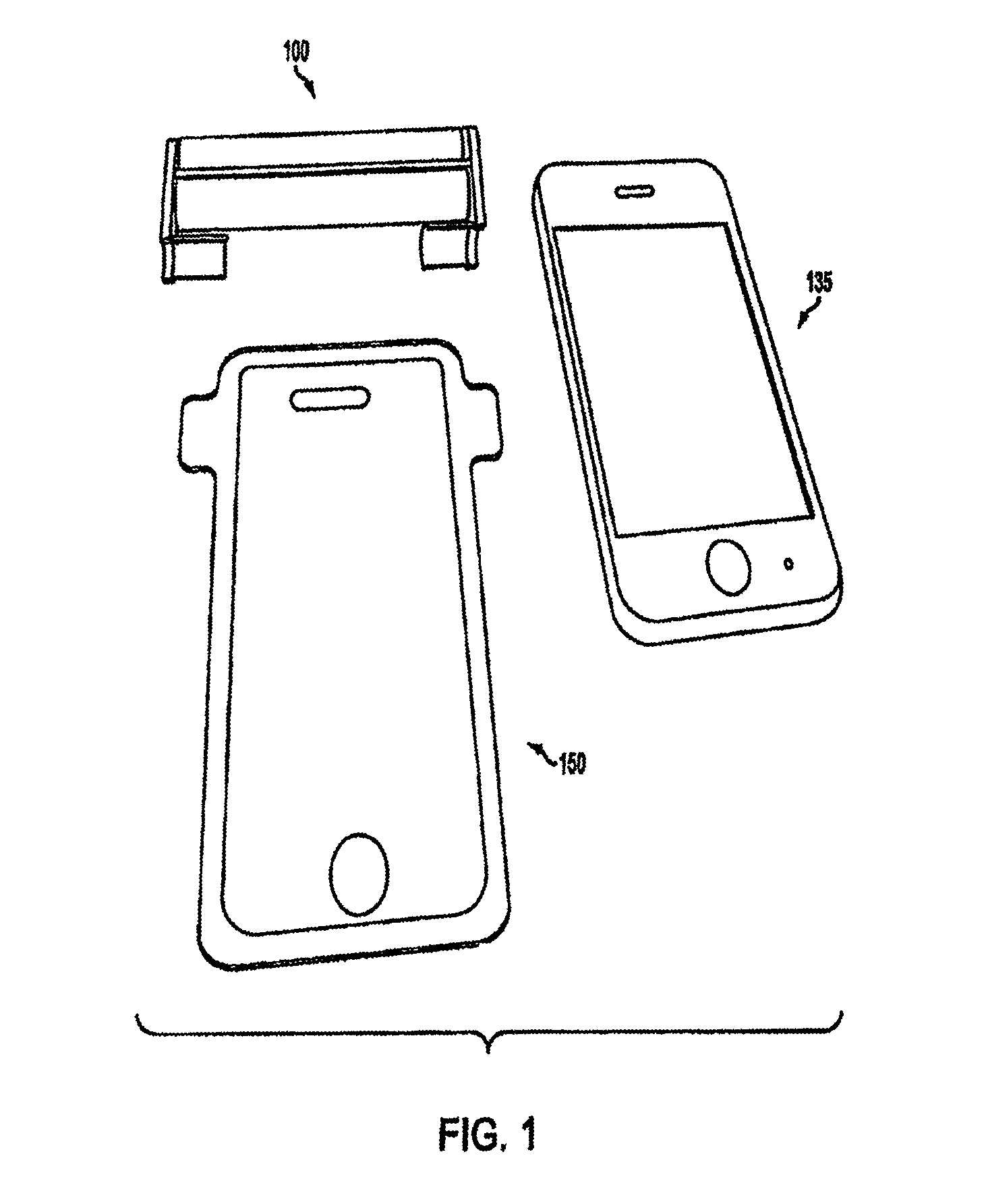

Protective material applicator device

ActiveUS8393377B2Reduces or eliminates air bubblesEliminate waiting timeLamination ancillary operationsLaminationTectorial membraneFluid solution

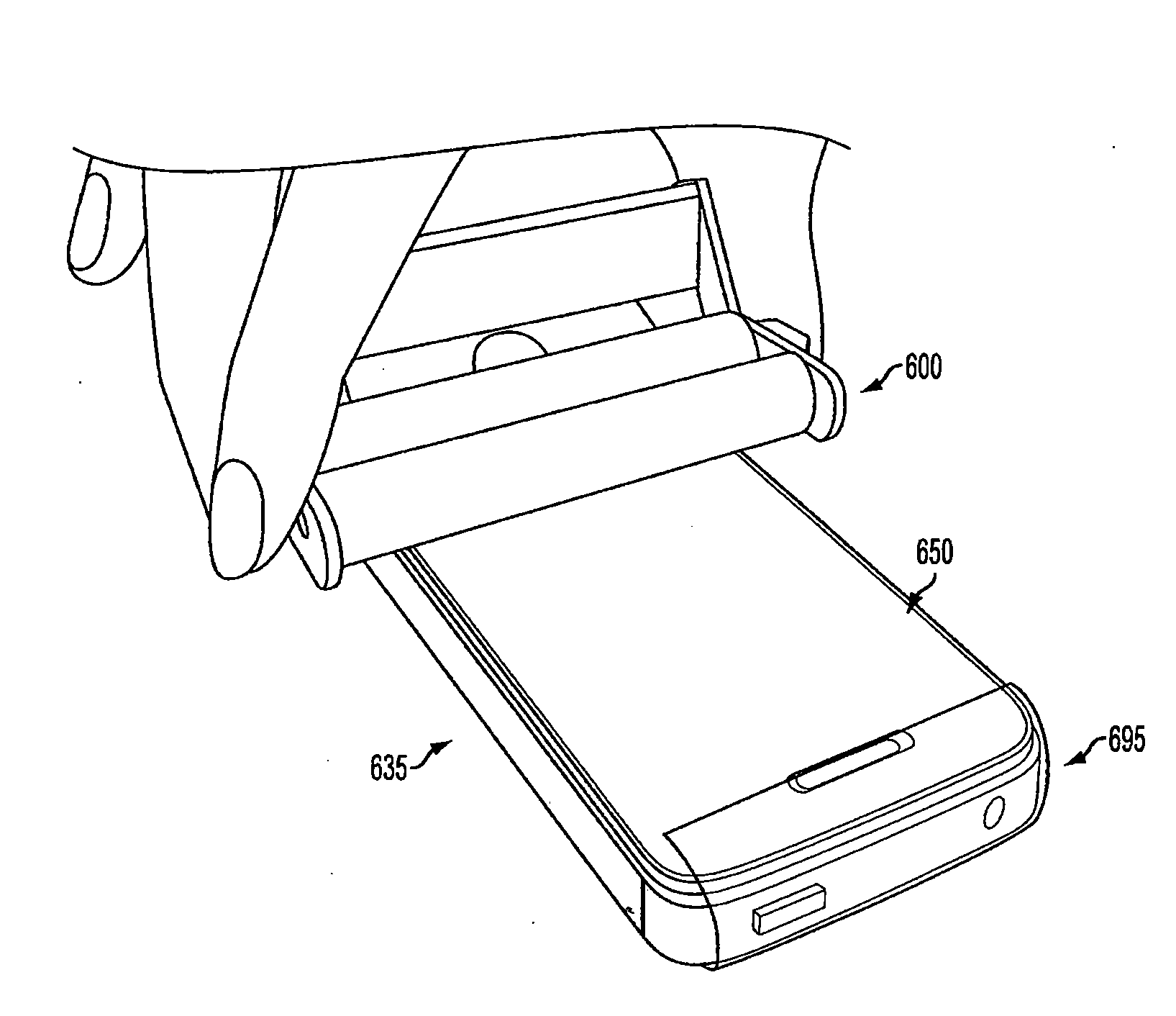

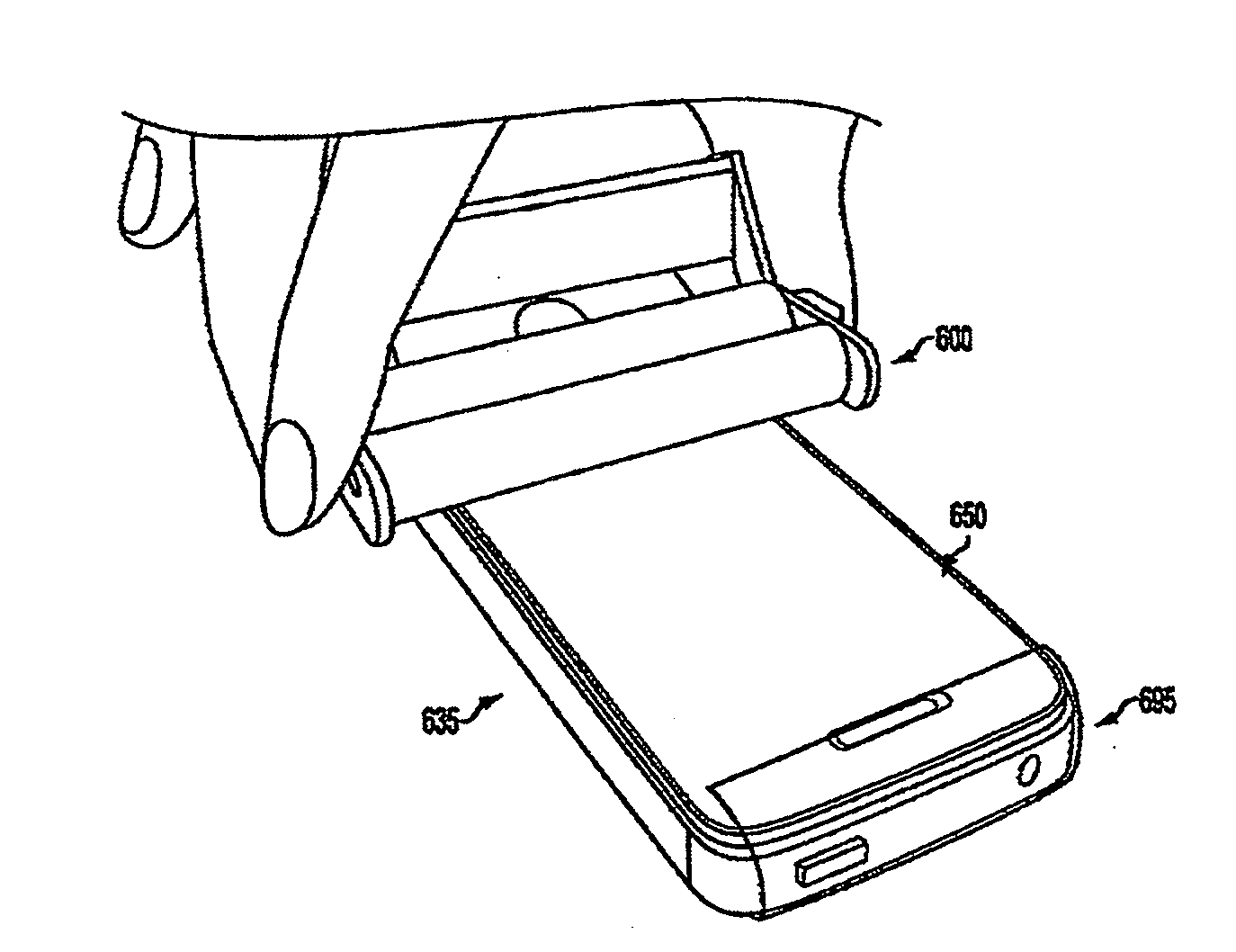

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a roller device may include a carriage or housing and one or more rollers coupled or integrated with the housing, configured to apply a protective material to a surface of the electronic device in a first orientation, and configured to function as a device stand in a second orientation. In addition or alternatively, a roller guide apparatus and / or a wedge may be utilized to assist the roller device in applying the protective material to the surface of the electronic device.

Owner:SUPERIOR COMM

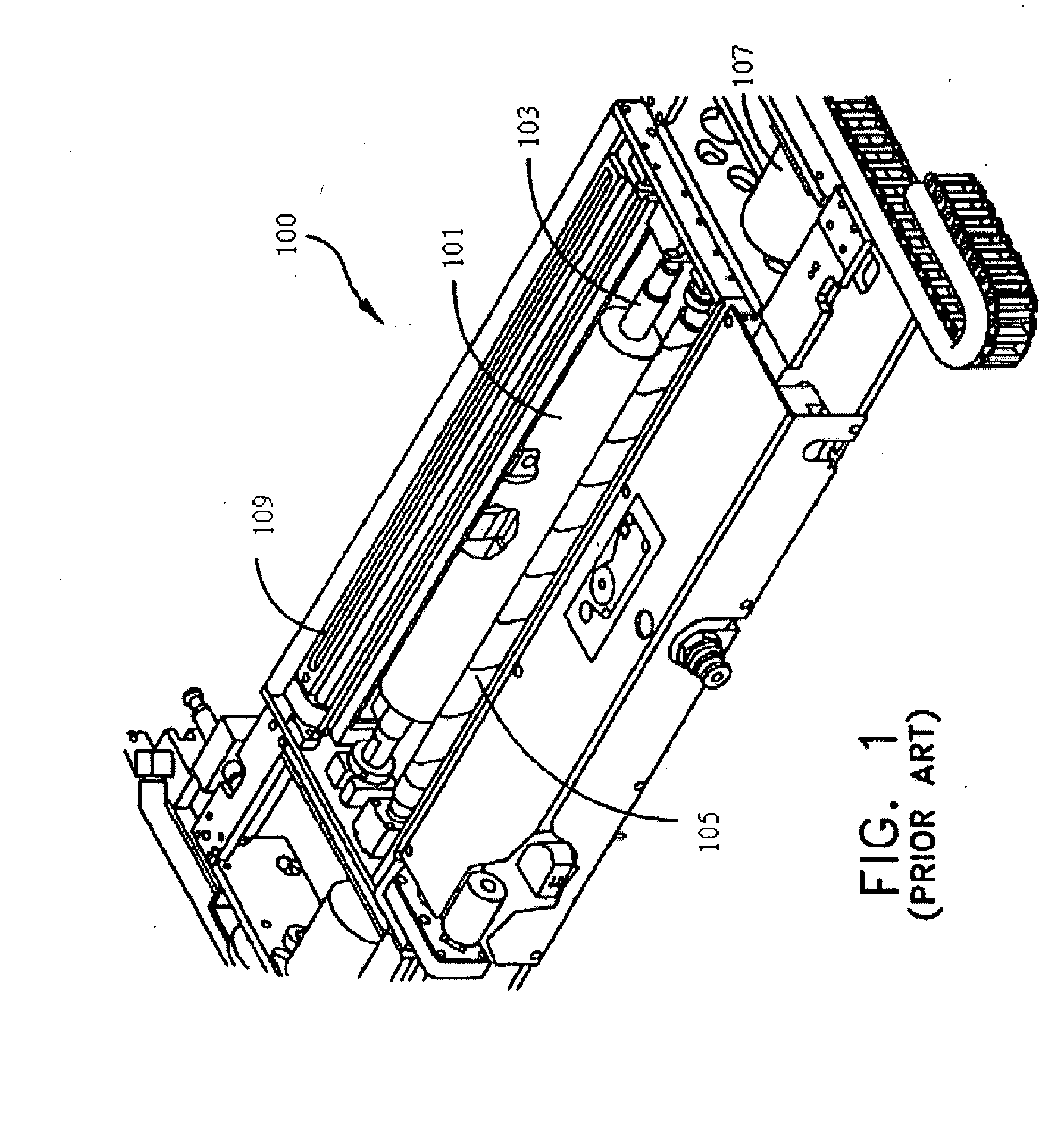

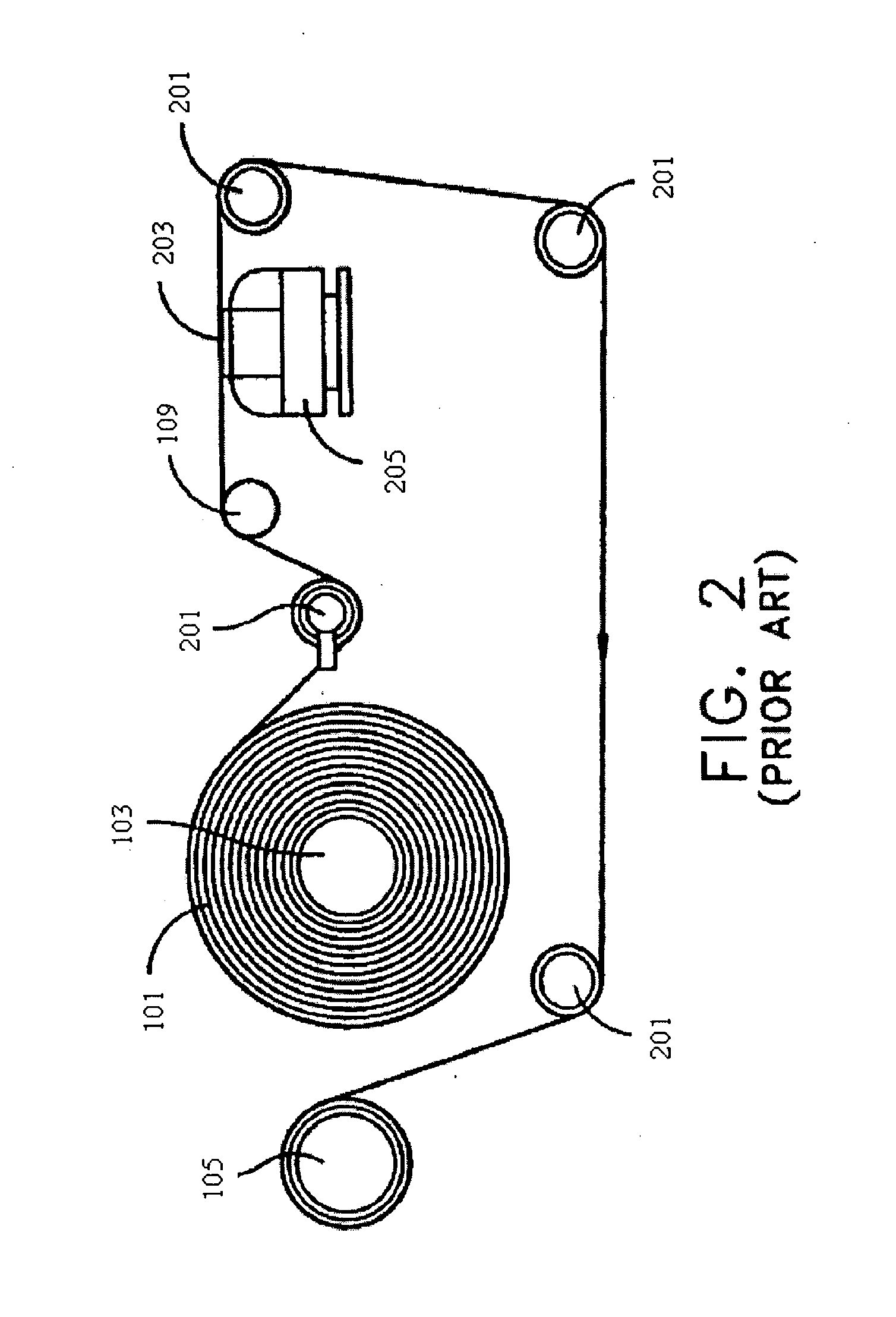

Web material advance system for web material applicator

InactiveUS6893528B2Easy to changeMechanical working/deformationBoxes/cartons making machineryEngineeringSide band

Owner:ADALIS

Protective material applicator device

ActiveUS20140124146A1Reduce eliminateEliminate waiting timeLamination ancillary operationsCasings/cabinets/drawers detailsTectorial membraneEngineering

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a flange may be configured to couple to the protective film. The flange may aid in the accurate application of the protective film to the electronic device.

Owner:SUPERIOR COMM

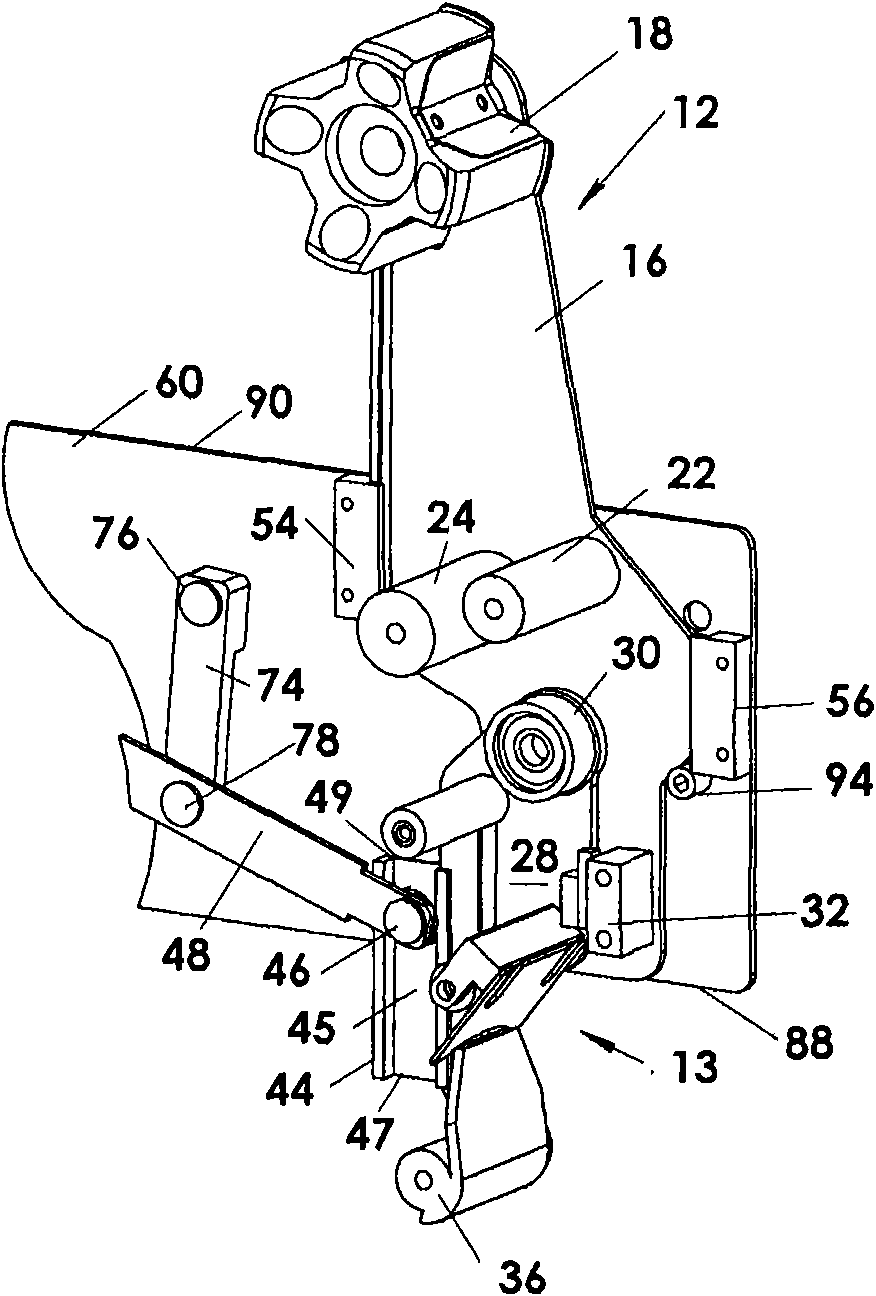

Apparatus for applying wound treatment material using tissue-penetrating needles

A surgical apparatus is provided including a disposable loading unit selectively operatively engagable within a distal end of a first half-section; and a wound treatment material applicator assembly for delivering wound treatment material to the target surgical site. The disposable loading unit includes a cartridge; a plurality of deployable needles supported within the cartridge, wherein each needle includes a lumen extending therethrough and at least one hole formed in an outer periphery thereof; and an actuation member translatably disposed within the cartridge for delivering a driving force to each needle to deploy the needles from the cartridge. The applicator assembly includes a first and second reservoir supported on the distal end of a respective first and second half-section; and a source of wound treatment material in fluid communication with each reservoir.

Owner:TYCO HEALTHCARE GRP LP

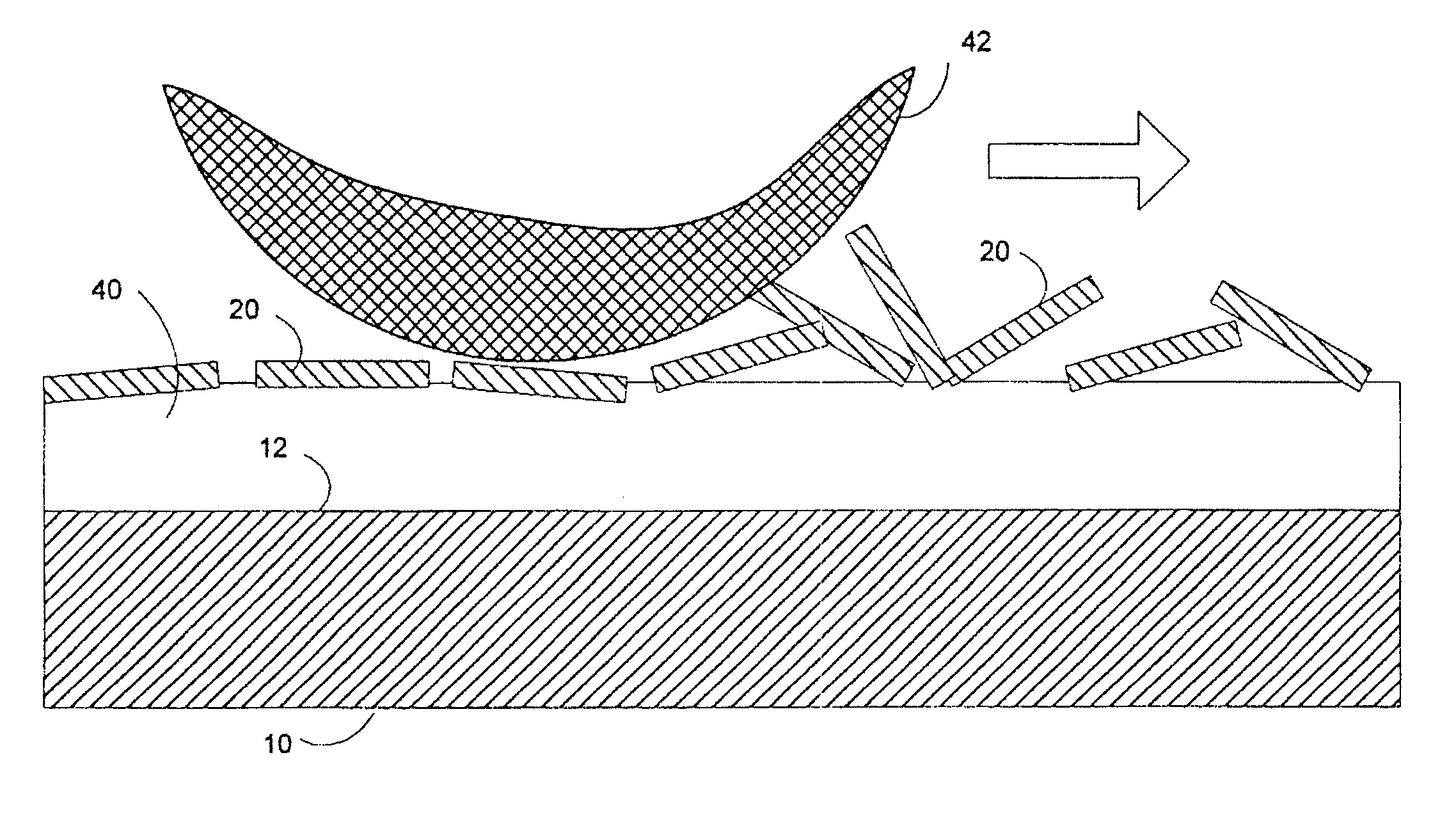

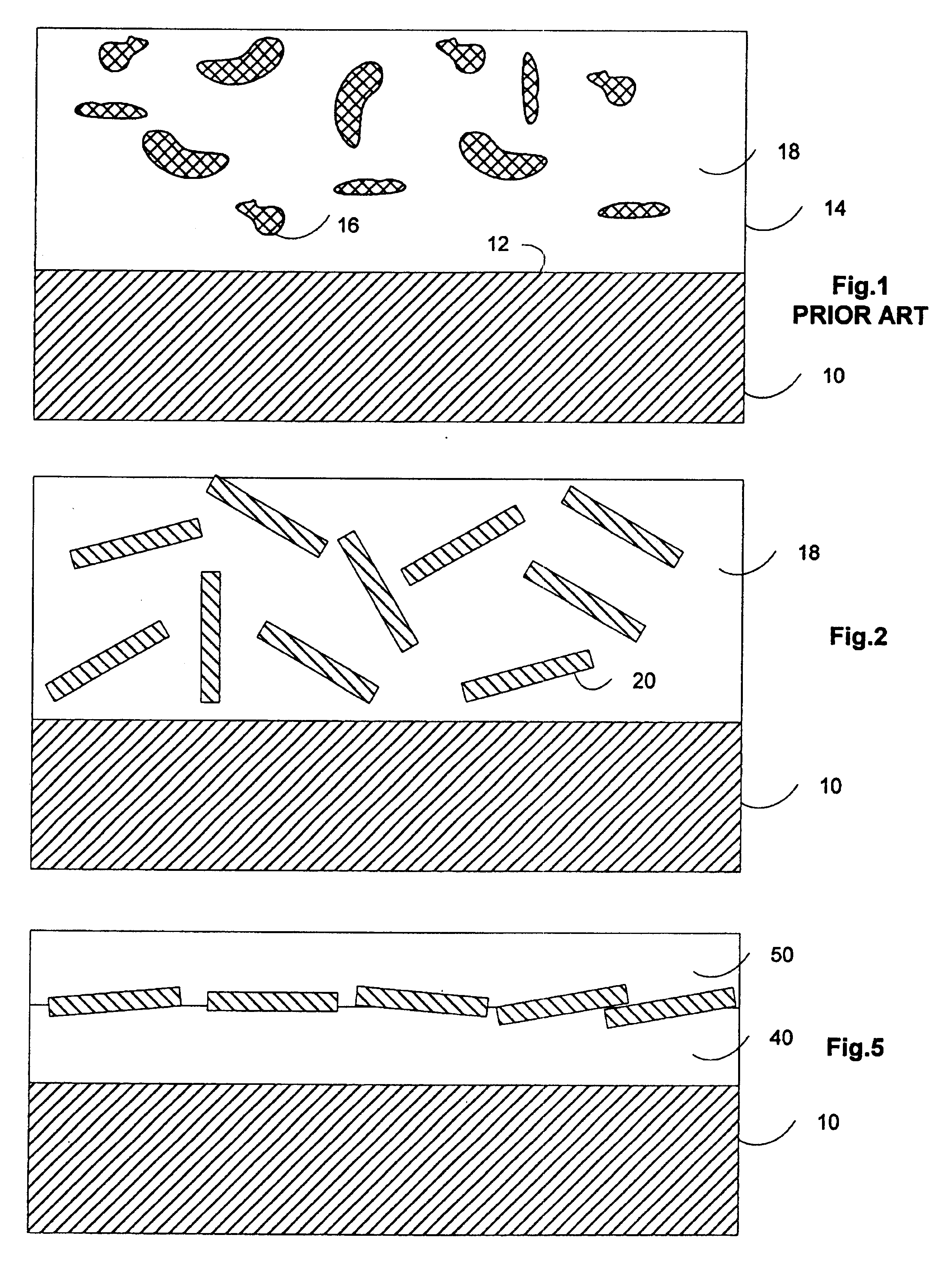

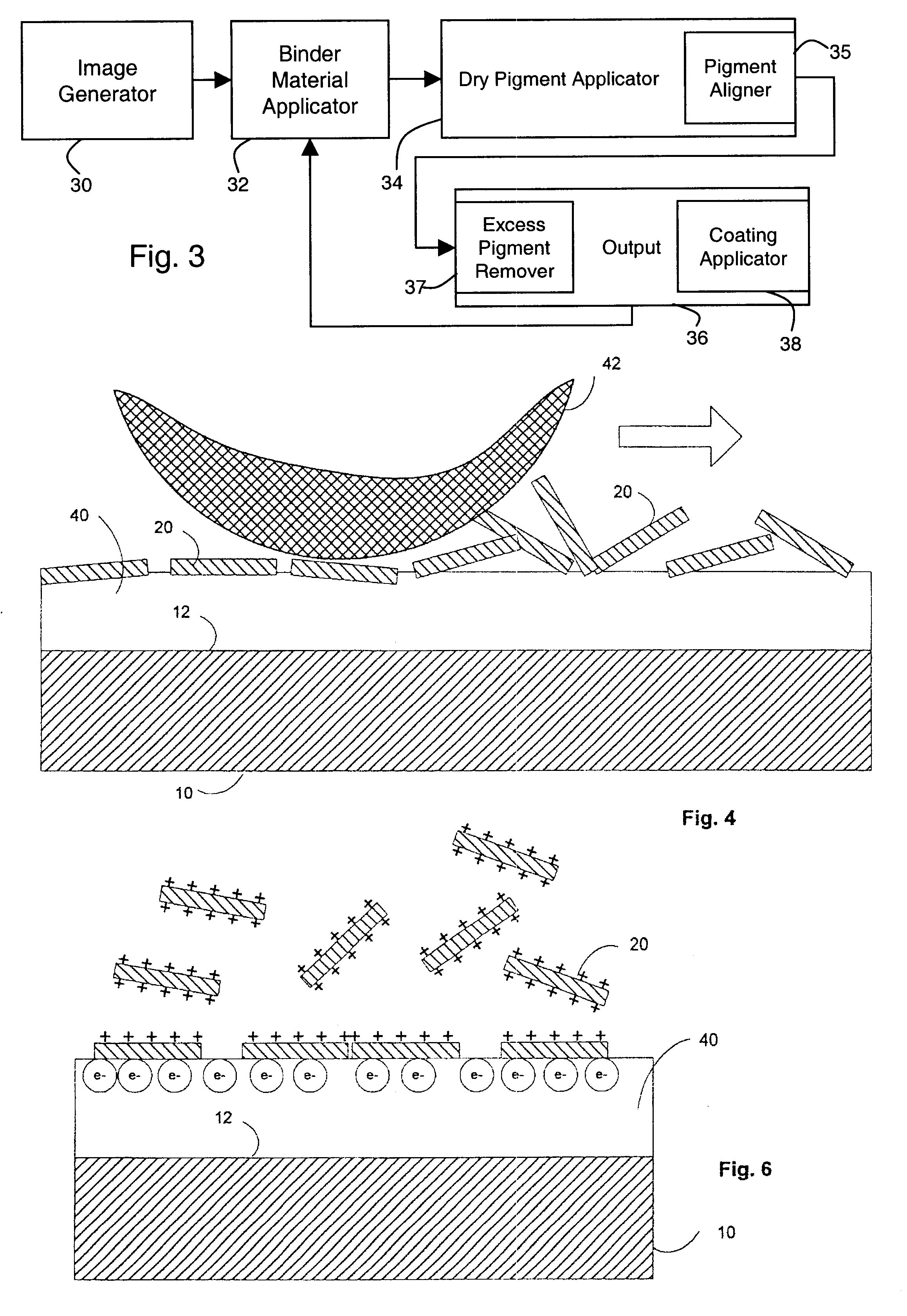

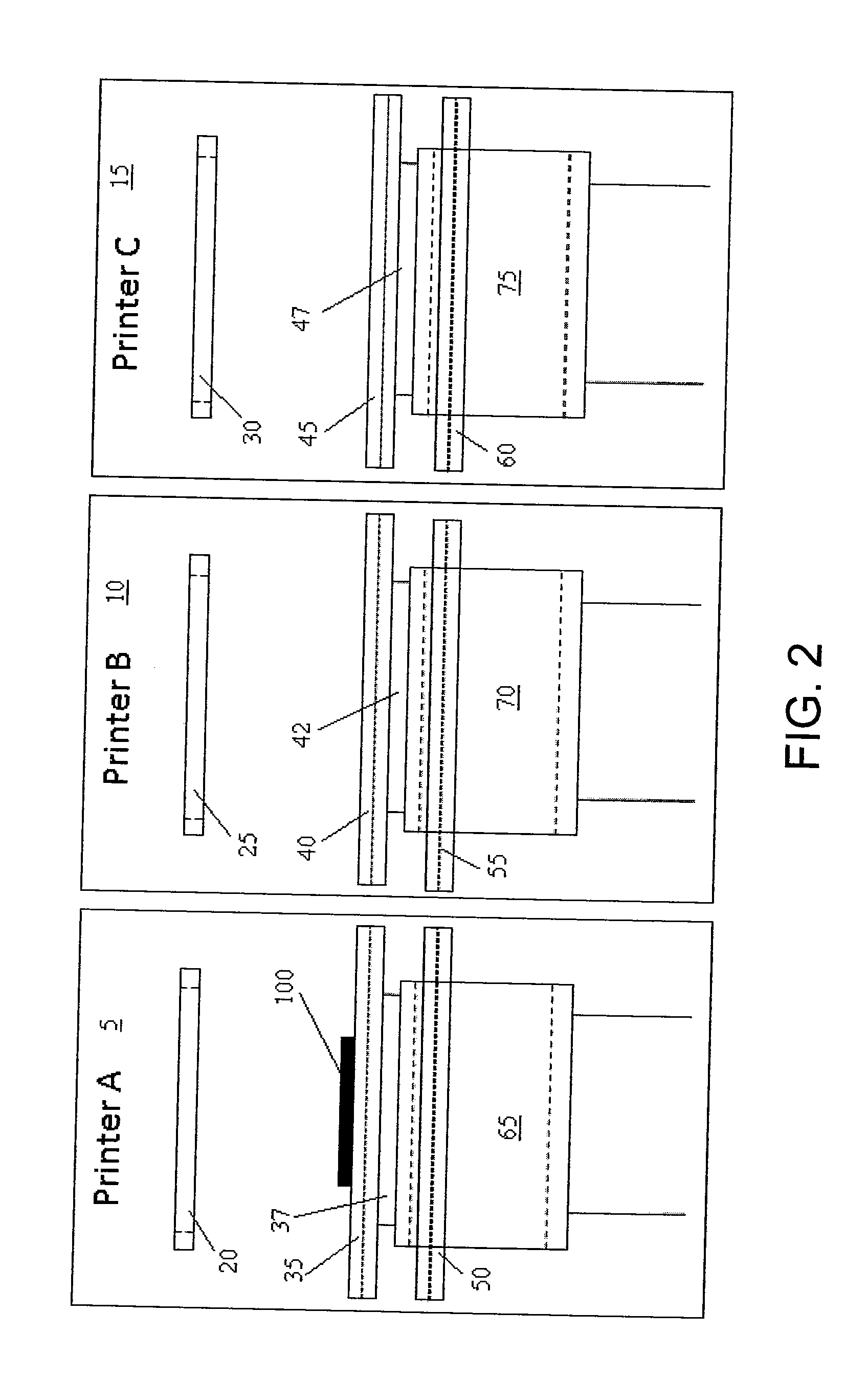

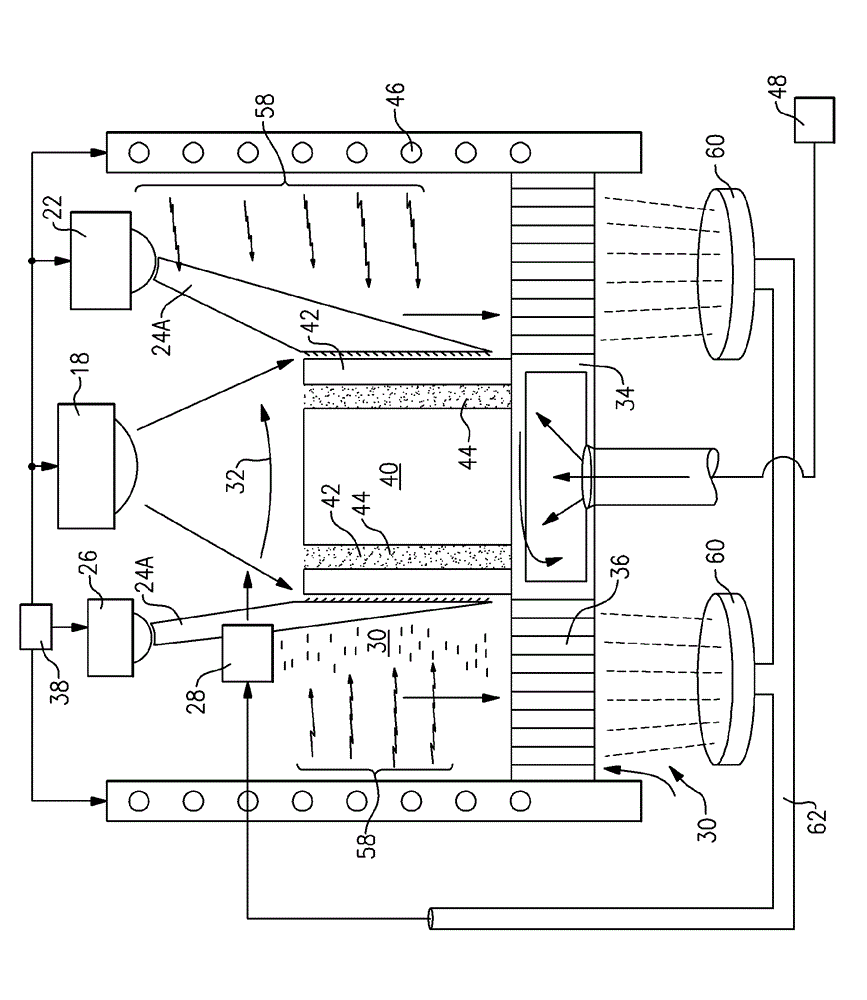

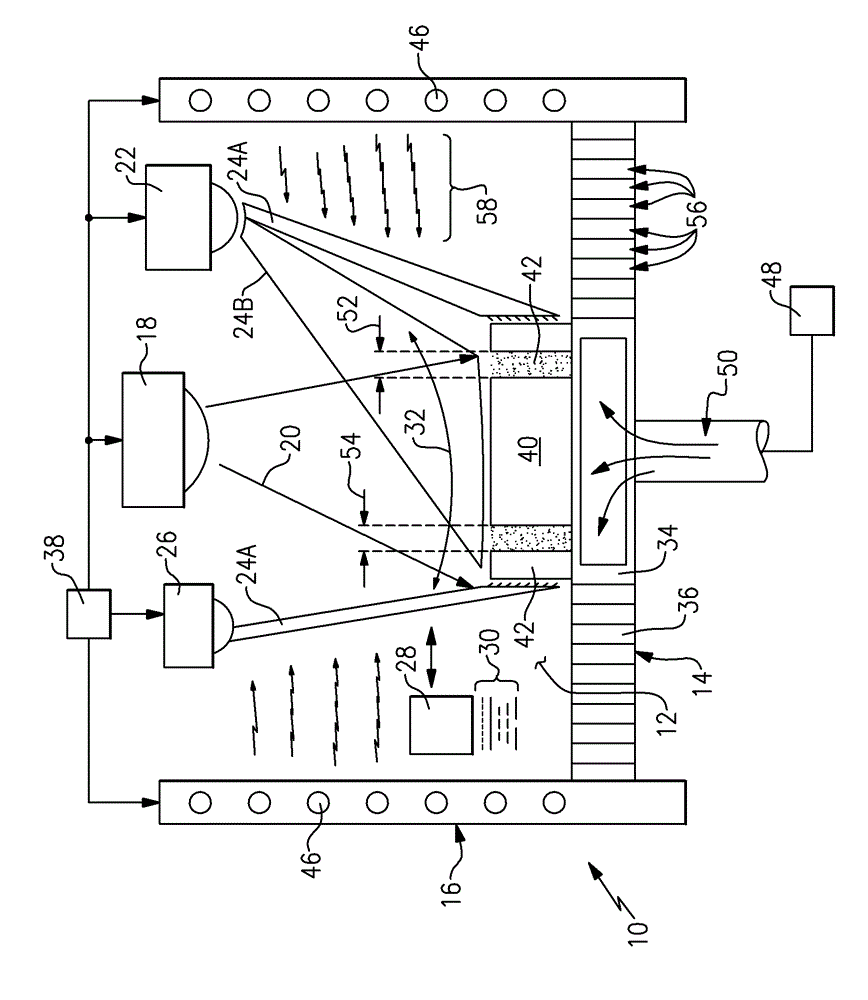

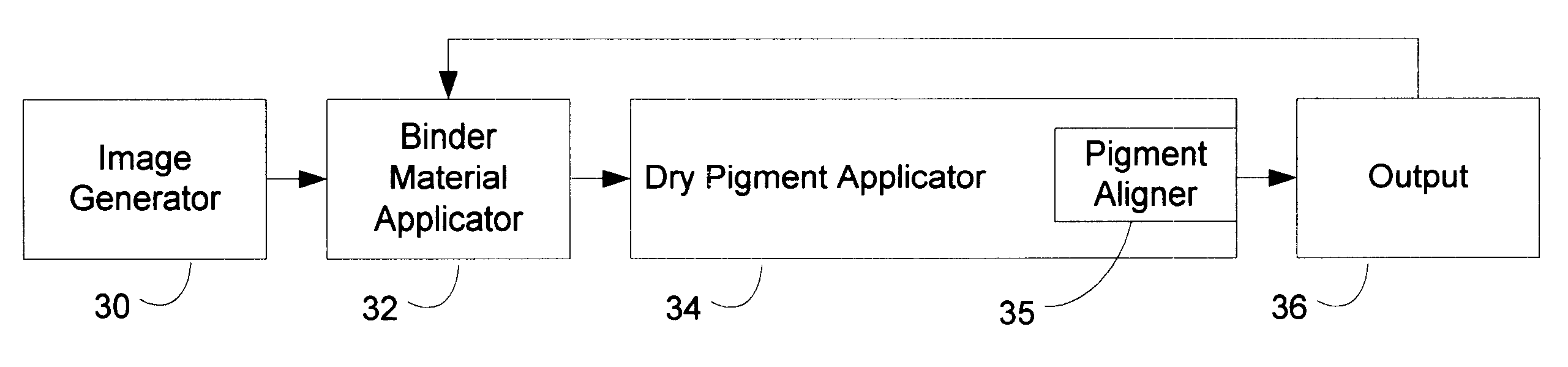

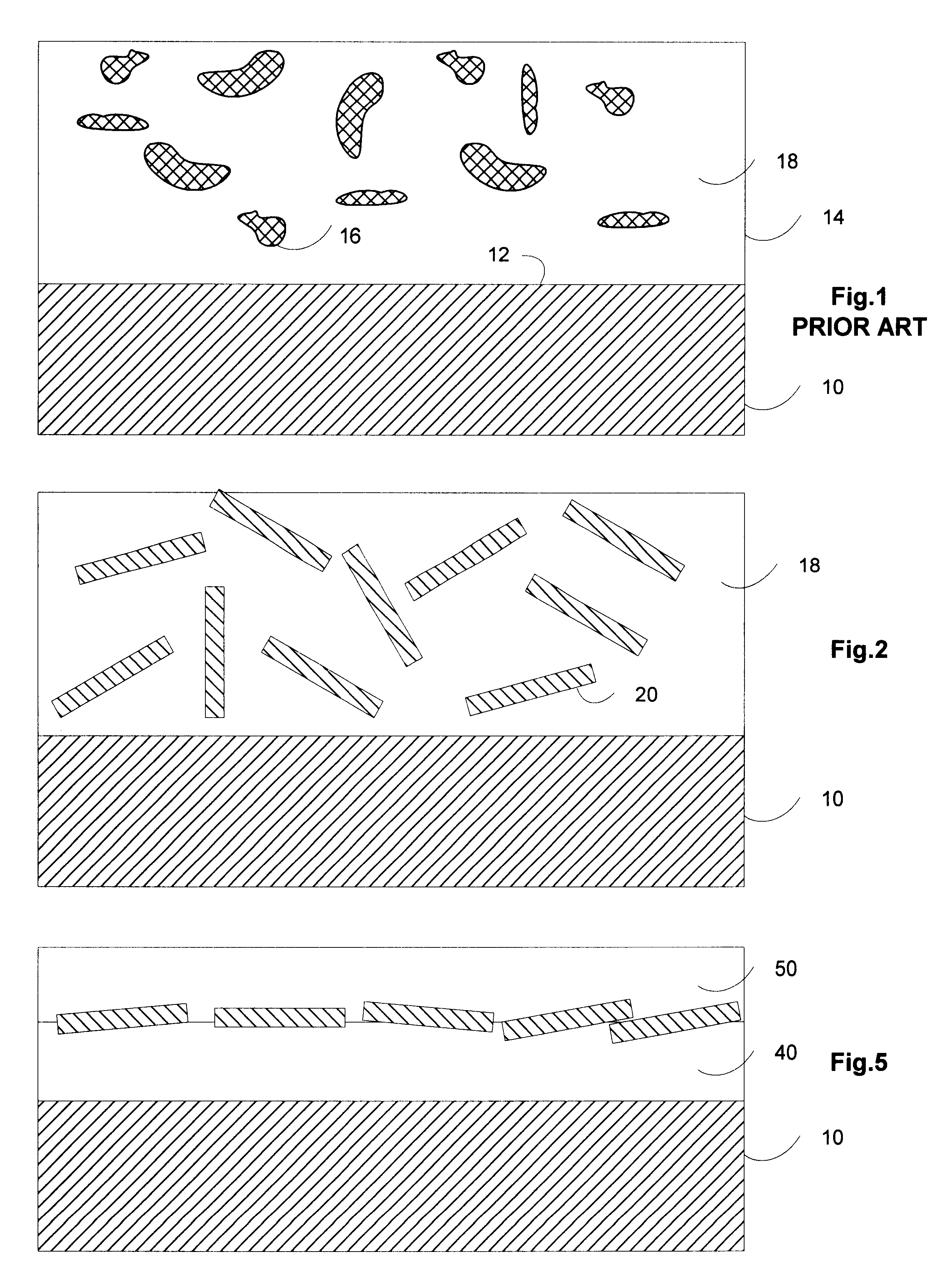

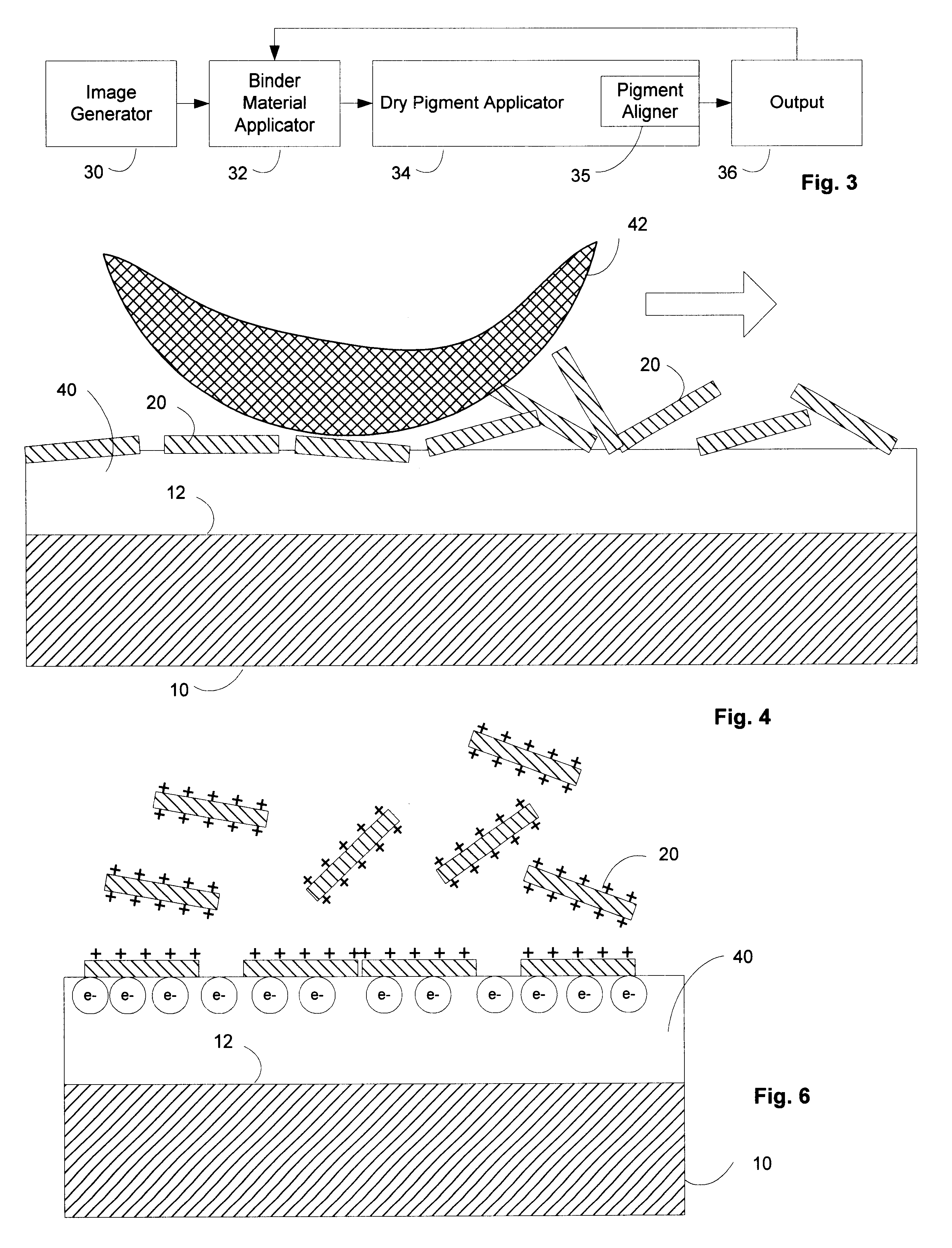

Apparatus for producing multi-color images on substrates using dry multi-colored cholesteric liquid crystal (CLC) pigment materials

InactiveUS6394595B1Function increaseAvoid less flexibilityLiquid crystal compositionsDuplicating/marking methodsColor imageComputer control system

A computer-controlled system for producing a multi-color image on a substrate using multi-colored cholesteric liquid crystal (CLC) pigment materials made from CLC flakes tuned to predetermined bands of color. An image generator automatically generates an image specifying a pattern over which binder material is to be applied to a substrate by a binder material applicator. A plurality of CLC pigment applicators automatically apply patterns of different-color CLC pigment material to the pattern of binder material, which binds thereto as the binder material dries according to its drying characteristics. An output device is used to automatically return the substrate to a different one of CLC pigment applicators after each application of a pattern of different-color CLC pigment material to the pattern of binder material. The output device automatically repeats the return of the substrate to the CLC pigment applicators until all bands of color in the multi-color image are rendered.

Owner:REVEO

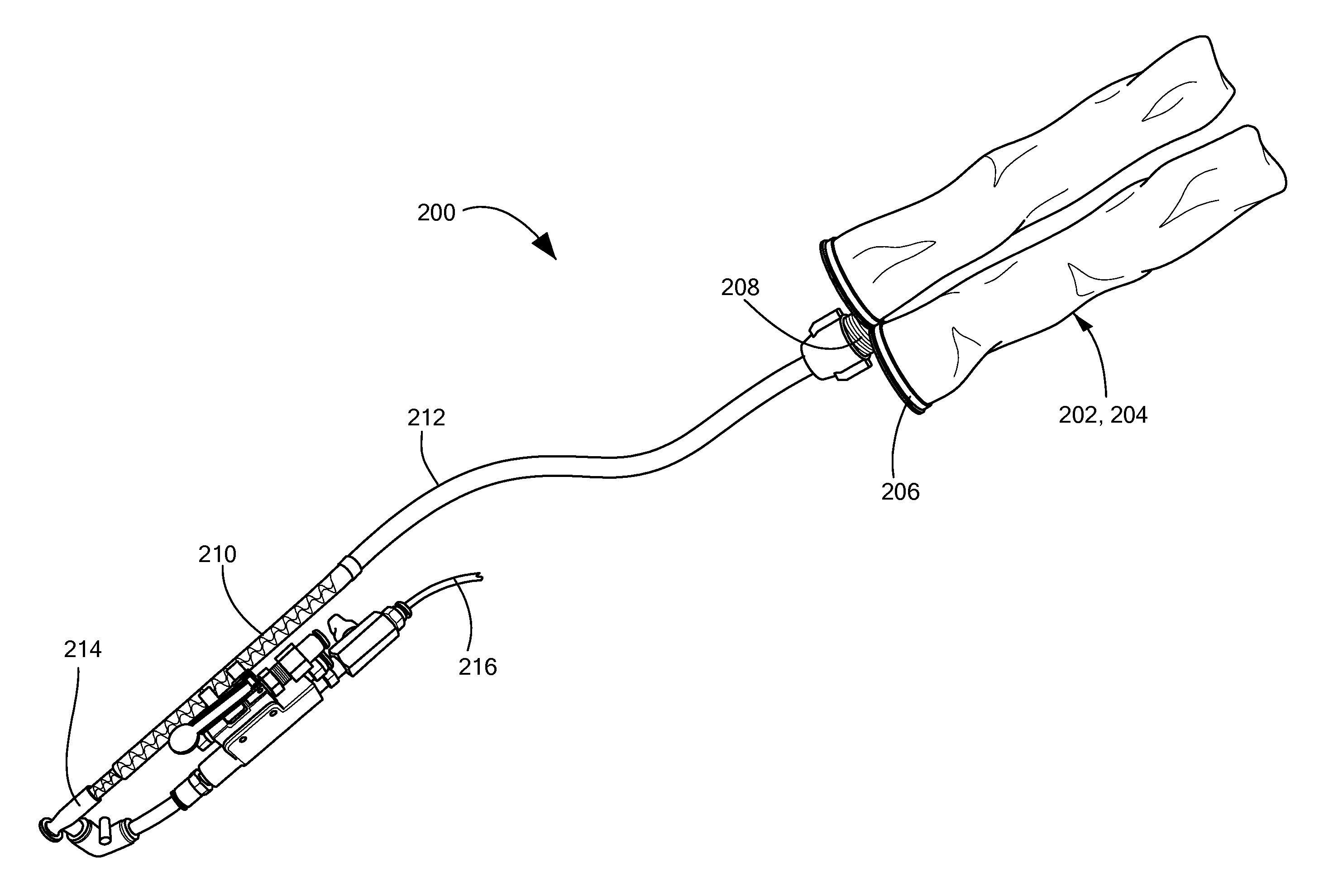

Laparoscopic spray device and method of use

InactiveUS6921381B2Efficient deliveryPrevent backflowLiquid surface applicatorsMedical devicesSurgical siteEngineering

A laparoscopic spray device for selectively applying a multiple component material dispensed from a multiple component material applicator to a surgical site in vivo is disclosed. The device comprises an interface member capable of engaging a multiple component applicator, a body having at least two lumens therein, and a detachable spray tip in fluid communication with the body. The detachable spray tip includes a mixing chamber having at least one flexible mixing member positioned therein which is capable of creating a turbulent flow within a mixing chamber. In addition, the at least one mixing member prevents a back flow of material from the mixing chamber to the at least two lumens. The present invention is particularly useful in remotely applying multiple component tissue adhesives to an internal incision.

Owner:BAXTER INT INC +1

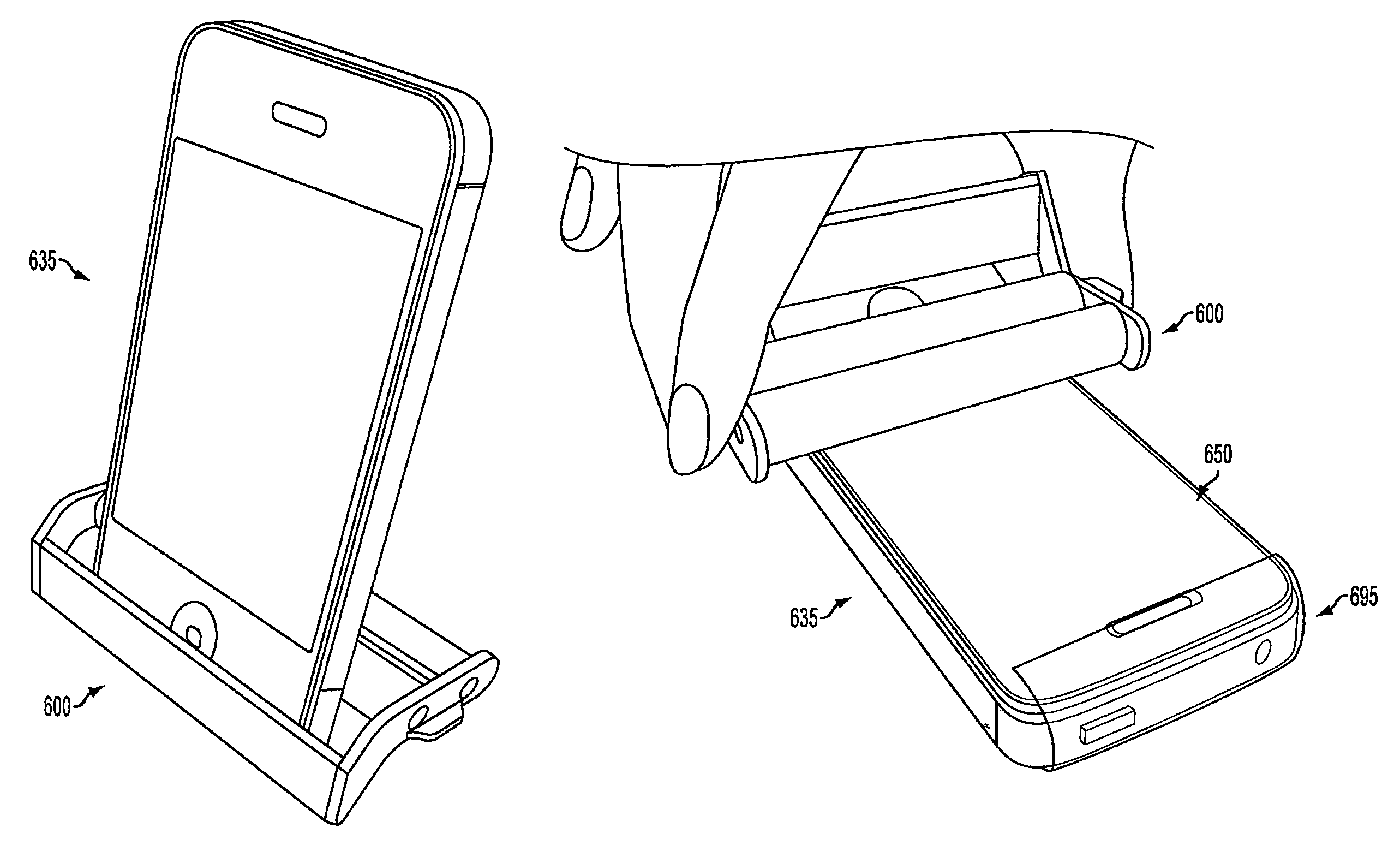

Protective material applicator device

ActiveUS20120211170A1Precise applicationReduces or eliminates air bubblesLaminationLamination apparatusTectorial membraneEngineering

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device instantly reducing air bubbles and eliminating the waiting time usually required when using a wet fluid solution. In one embodiment, a roller device may include a carriage or housing and one or more rollers coupled or integrated with the housing, configured to apply a protective material to a surface of the electronic device in a first orientation, and configured to function as a device stand in a second orientation.

Owner:SUPERIOR COMM

Surgical stapling apparatus having a wound closure material applicator assembly

A surgical stapling apparatus includes a staple anvil and a staple cartridge having a working surface, one or more rows of individual staple slots formed in the working surface, a knife track formed along a length of the working surface, and a plurality of surgical staples individually disposed within the individual staple slots. The apparatus further includes an actuation sled having a knife and being configured and adapted to movably position the knife axially within the knife track. The apparatus also includes a wound closure material applicator assembly having a needle secured to the knife to dispense a quantity of wound closure material along a length of the knife track as the actuation sled and knife are moved therealong.

Owner:TYCO HEALTHCARE GRP LP

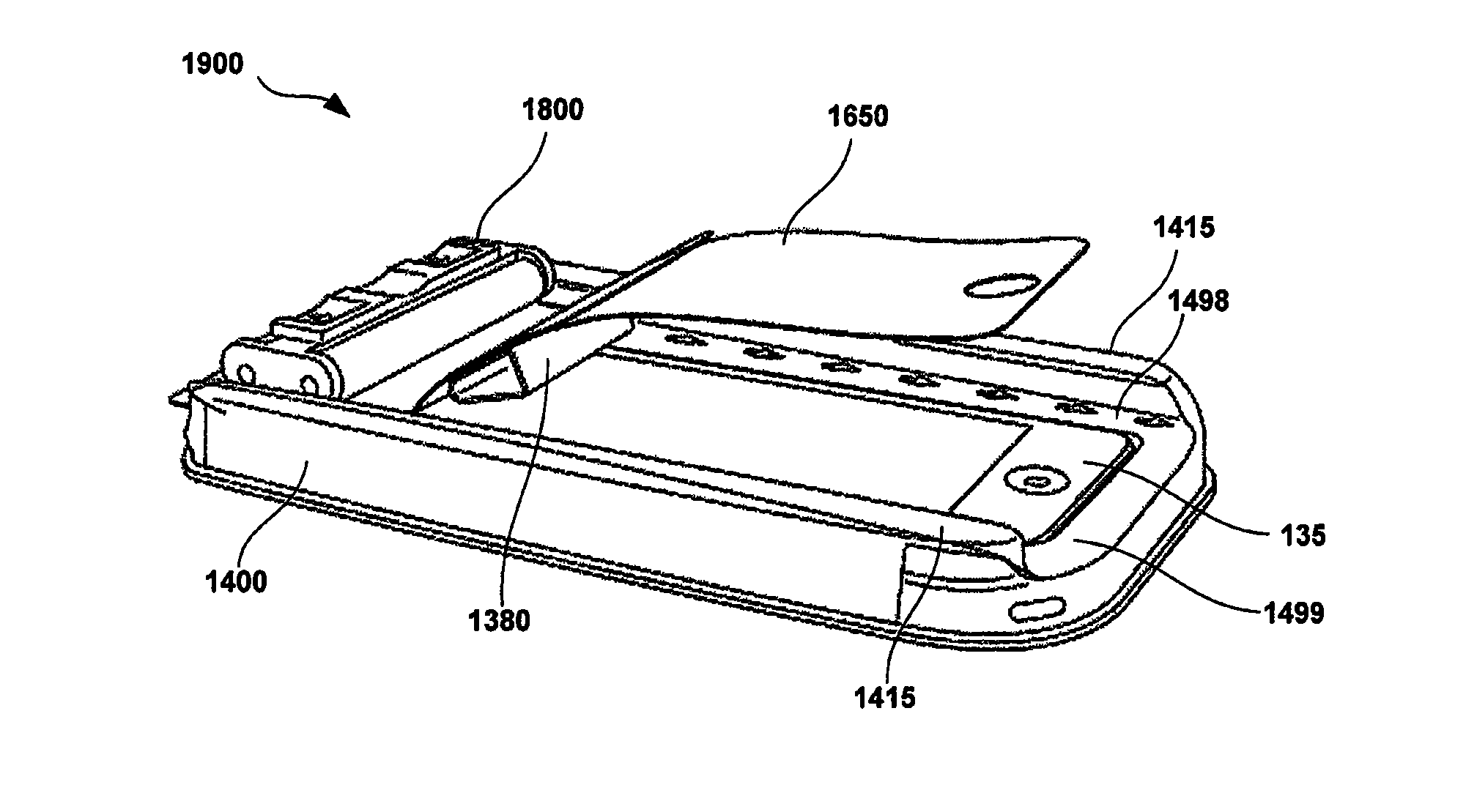

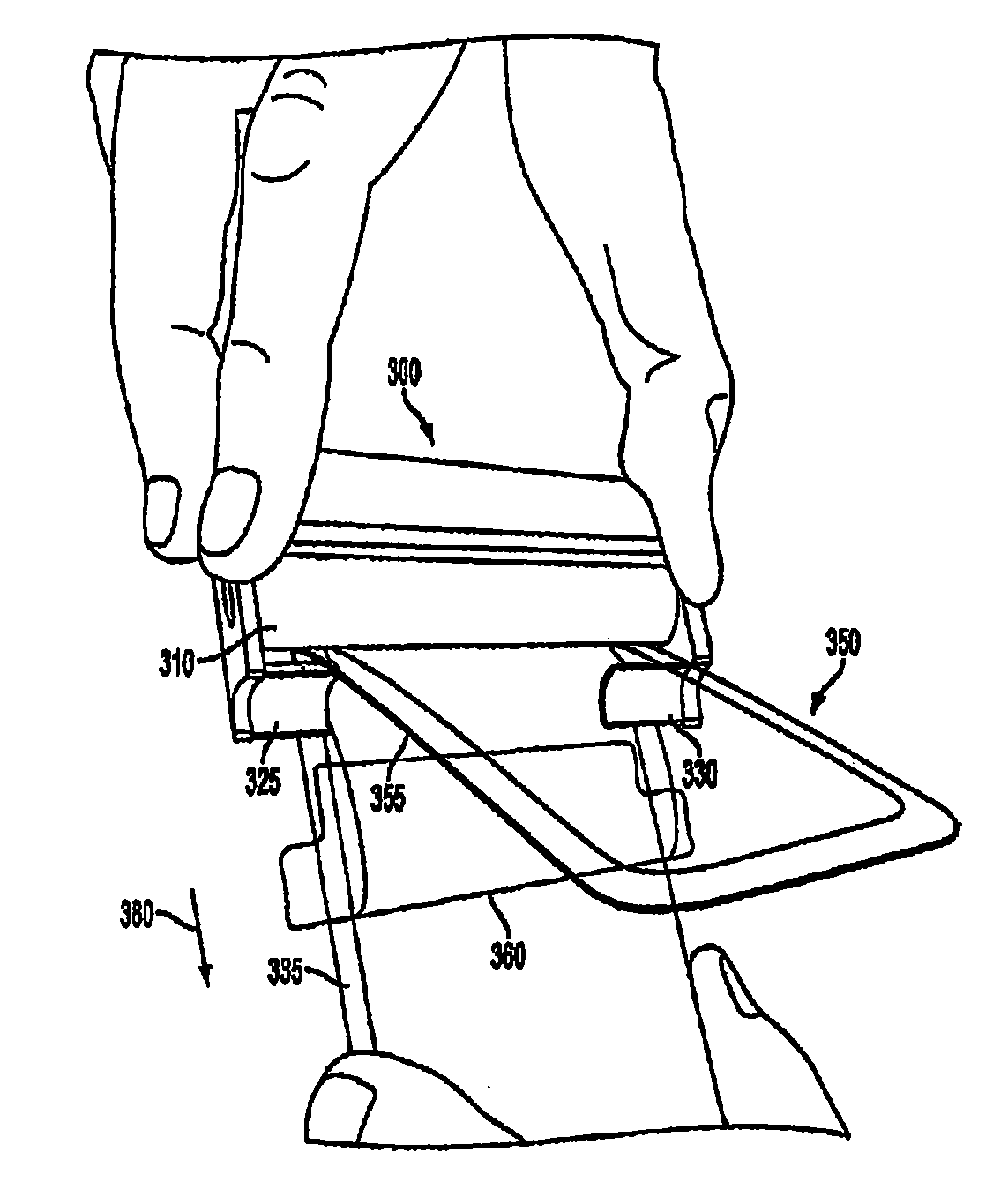

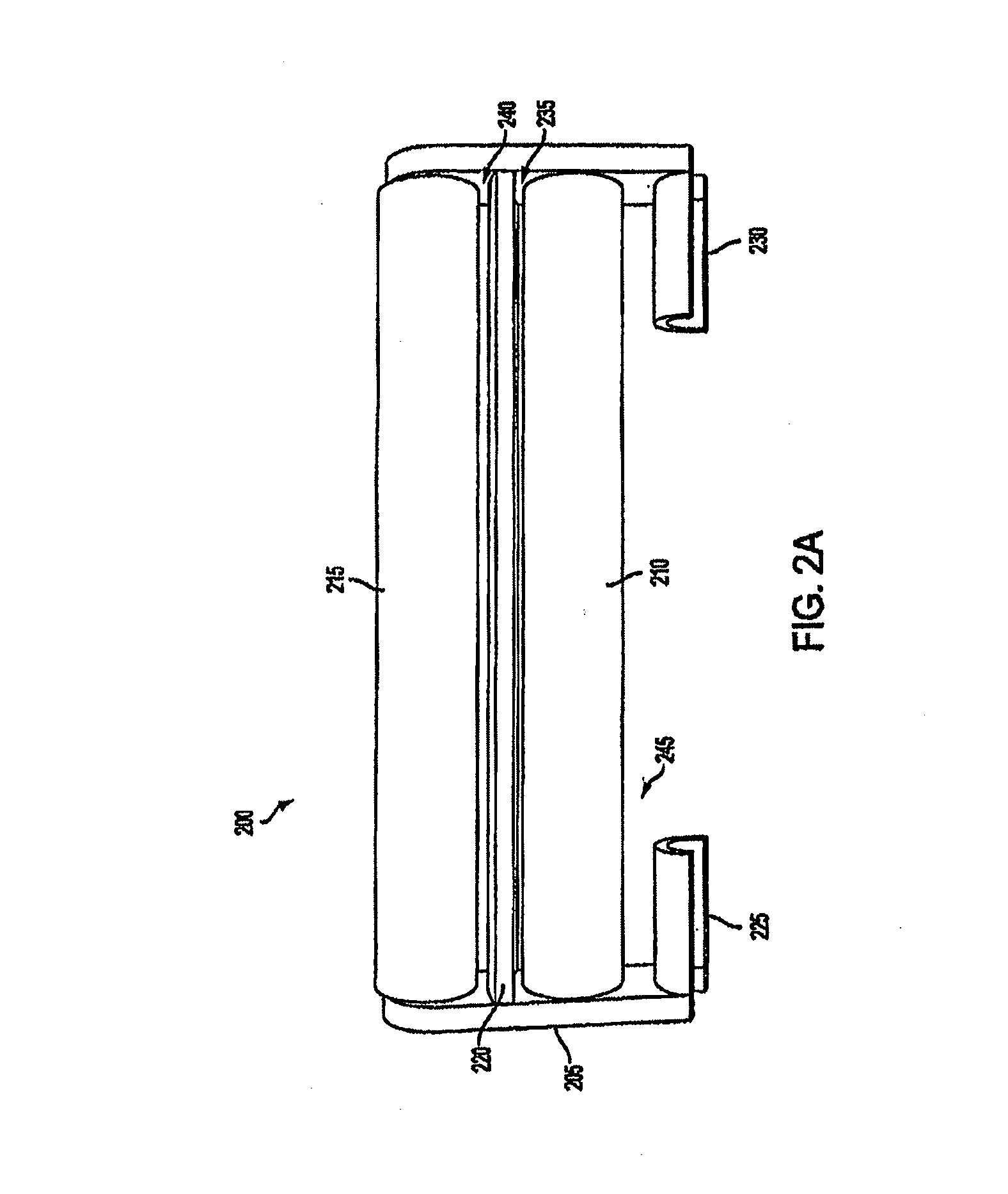

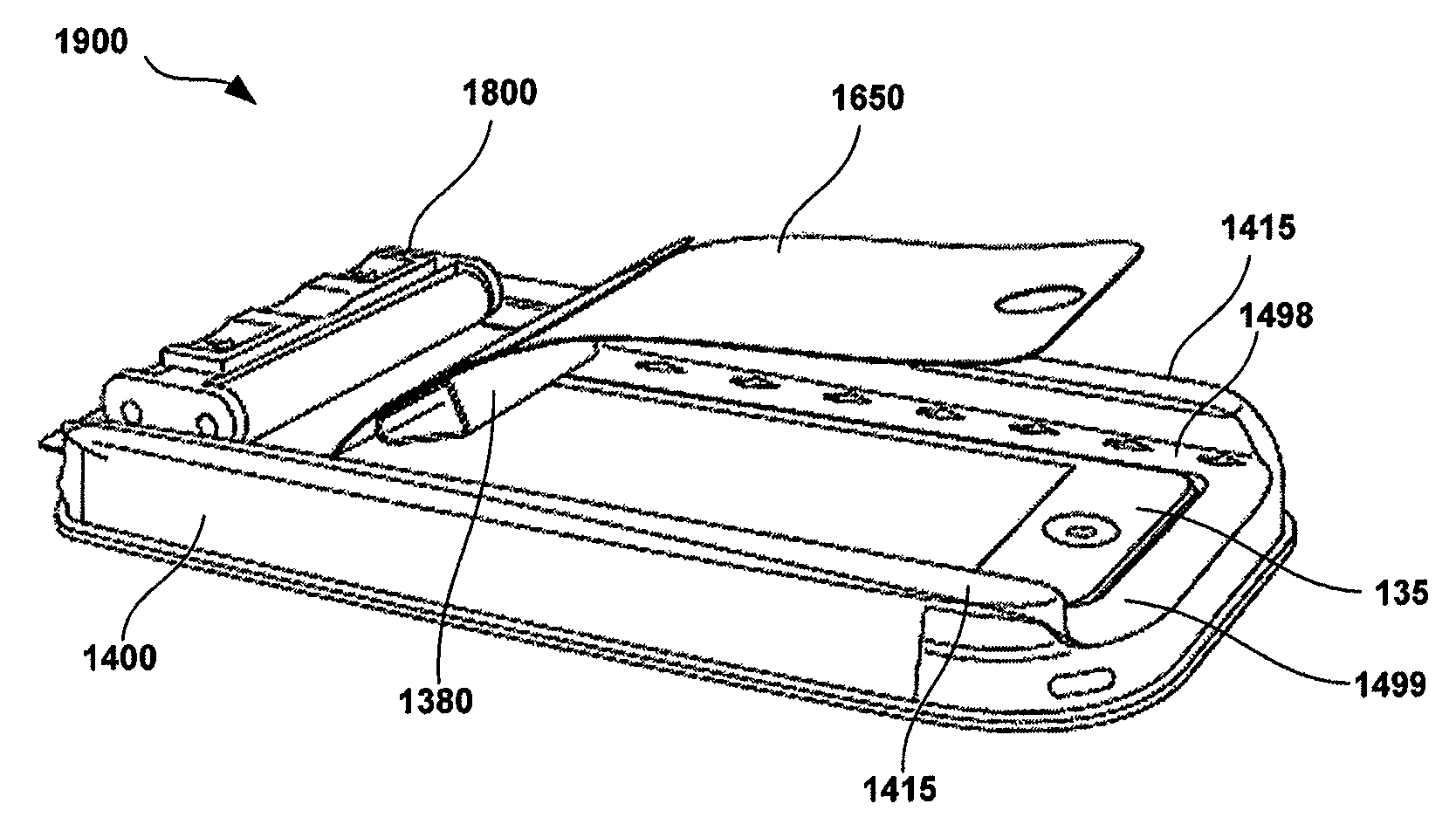

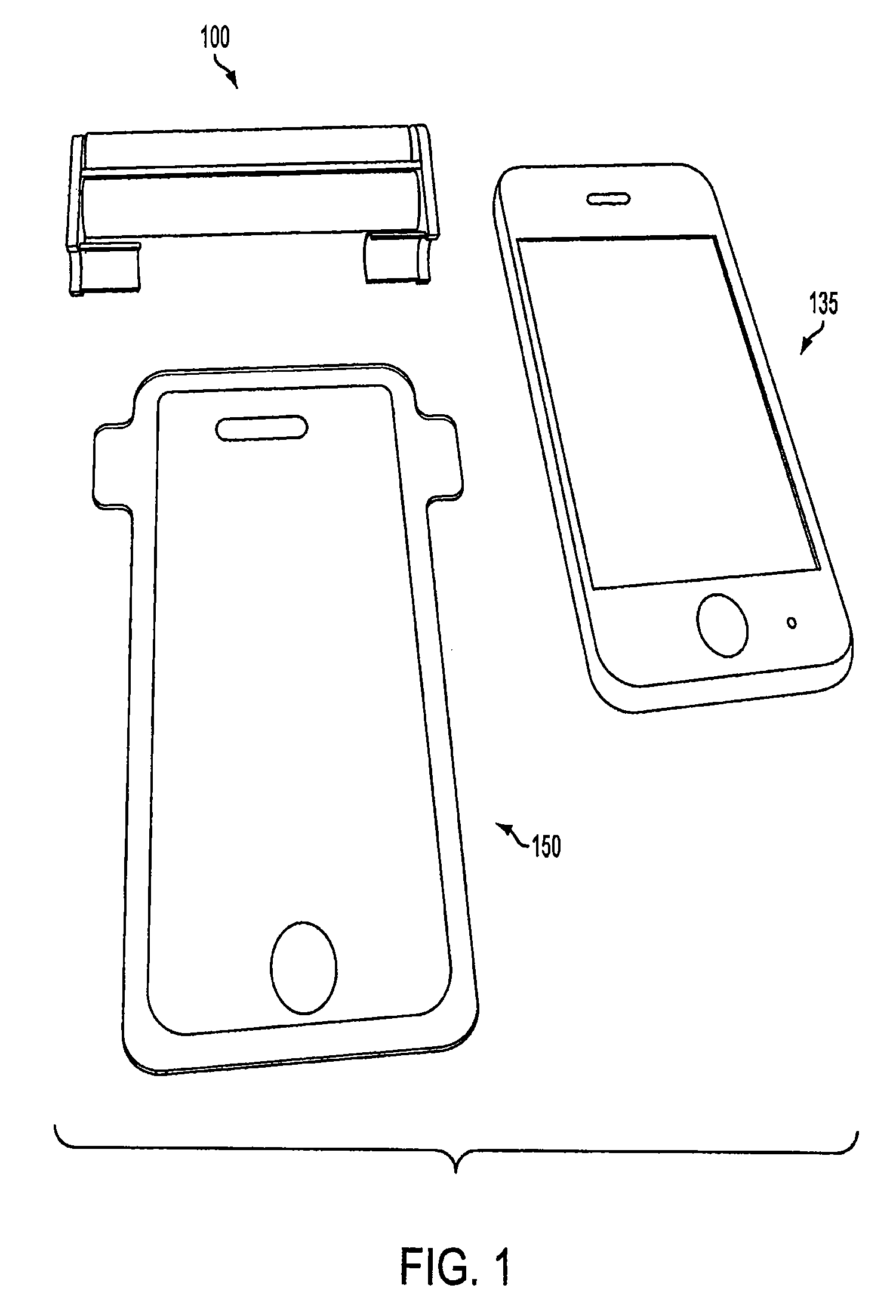

Protective material applicator device

ActiveUS9010396B2Reduces or eliminates air bubblesEliminate waiting timeLamination ancillary operationsCasings/cabinets/drawers detailsTectorial membraneProtection layer

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a well apparatus graspable by a user's hand for receiving any of a plurality of mobile communication device inserts is provided. Each of the plurality of mobile communication device inserts may have a mobile communication device receiving cavity of a different shape or size configured to receive a mobile communication device of a particular shape and size. After inserting a mobile communication device insert into the well apparatus, a user may insert a mobile communication device into the receiving cavity and apply a protective layer with a roller.

Owner:SUPERIOR COMM

Protective material applicator device

ActiveUS20120211171A1Reduce eliminateEliminate waiting timeLamination ancillary operationsCasings/cabinets/drawers detailsTectorial membraneEngineering

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a well apparatus graspable by a user's hand for receiving any of a plurality of mobile communication device inserts is provided. Each of the plurality of mobile communication device inserts may have a mobile communication device receiving cavity of a different shape or size configured to receive a mobile communication device of a particular shape and size. After inserting a mobile communication device insert into the well apparatus, a user may insert a mobile communication device into the receiving cavity and apply a protective layer with a roller.

Owner:SUPERIOR COMM

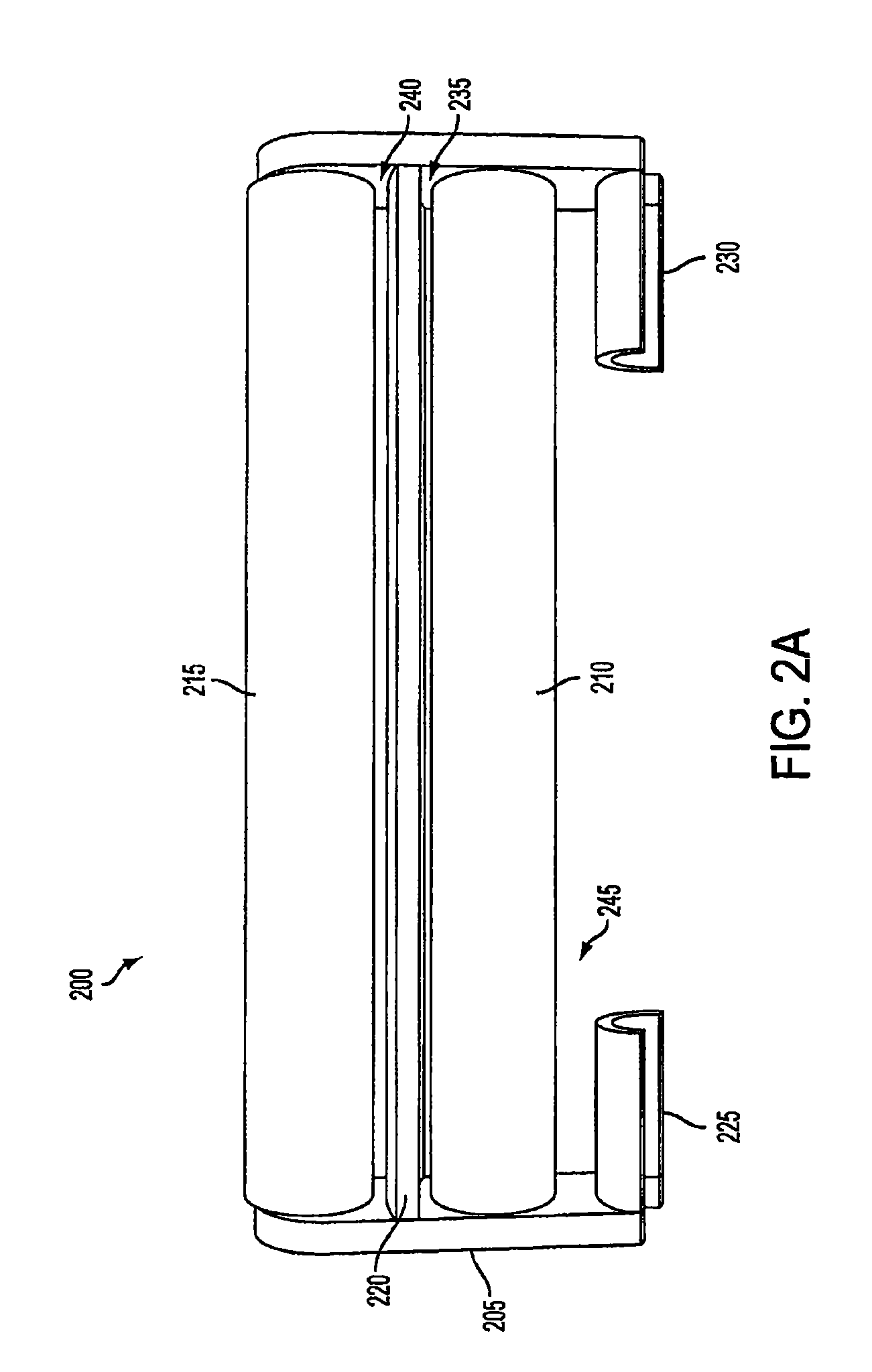

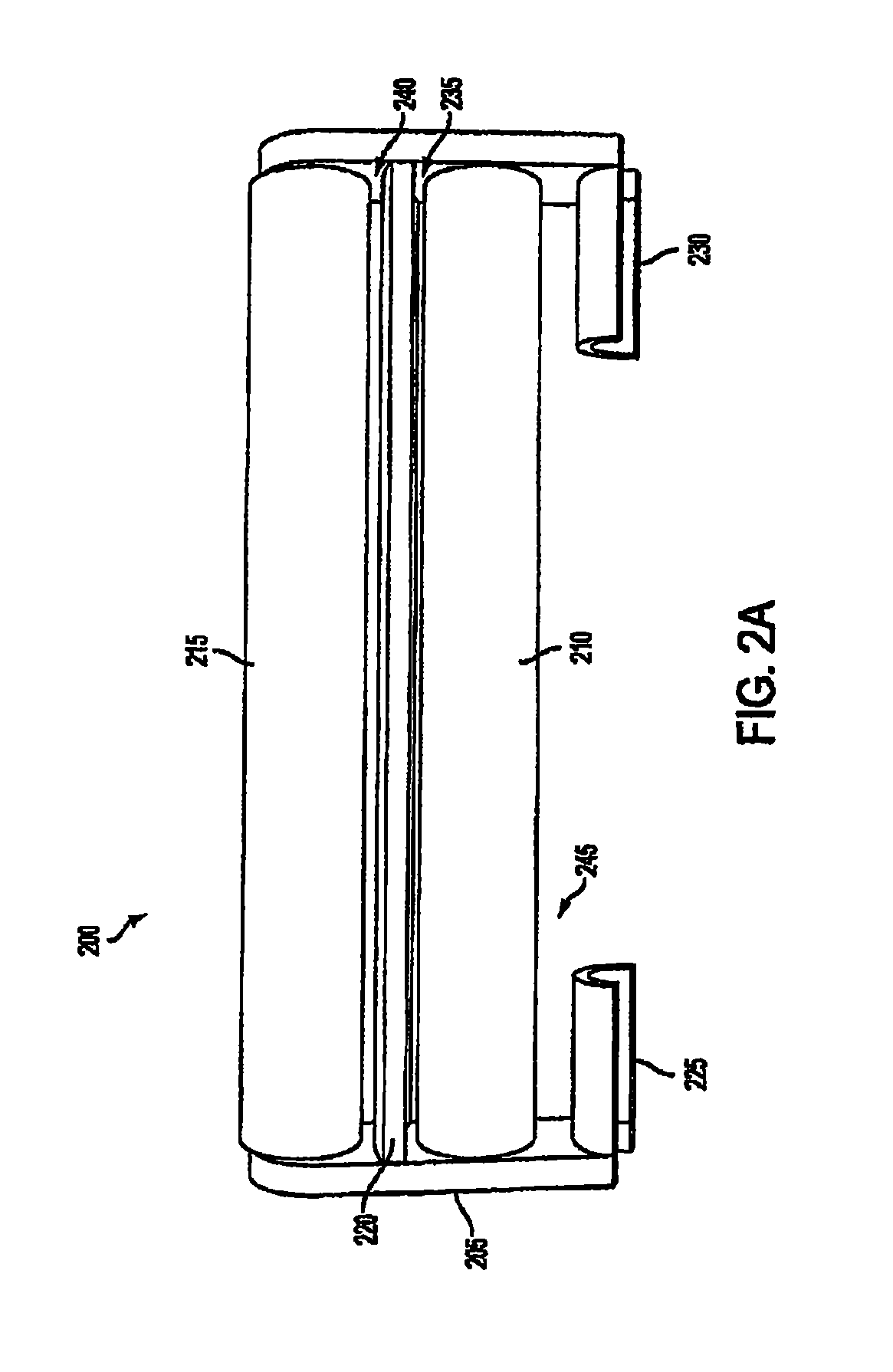

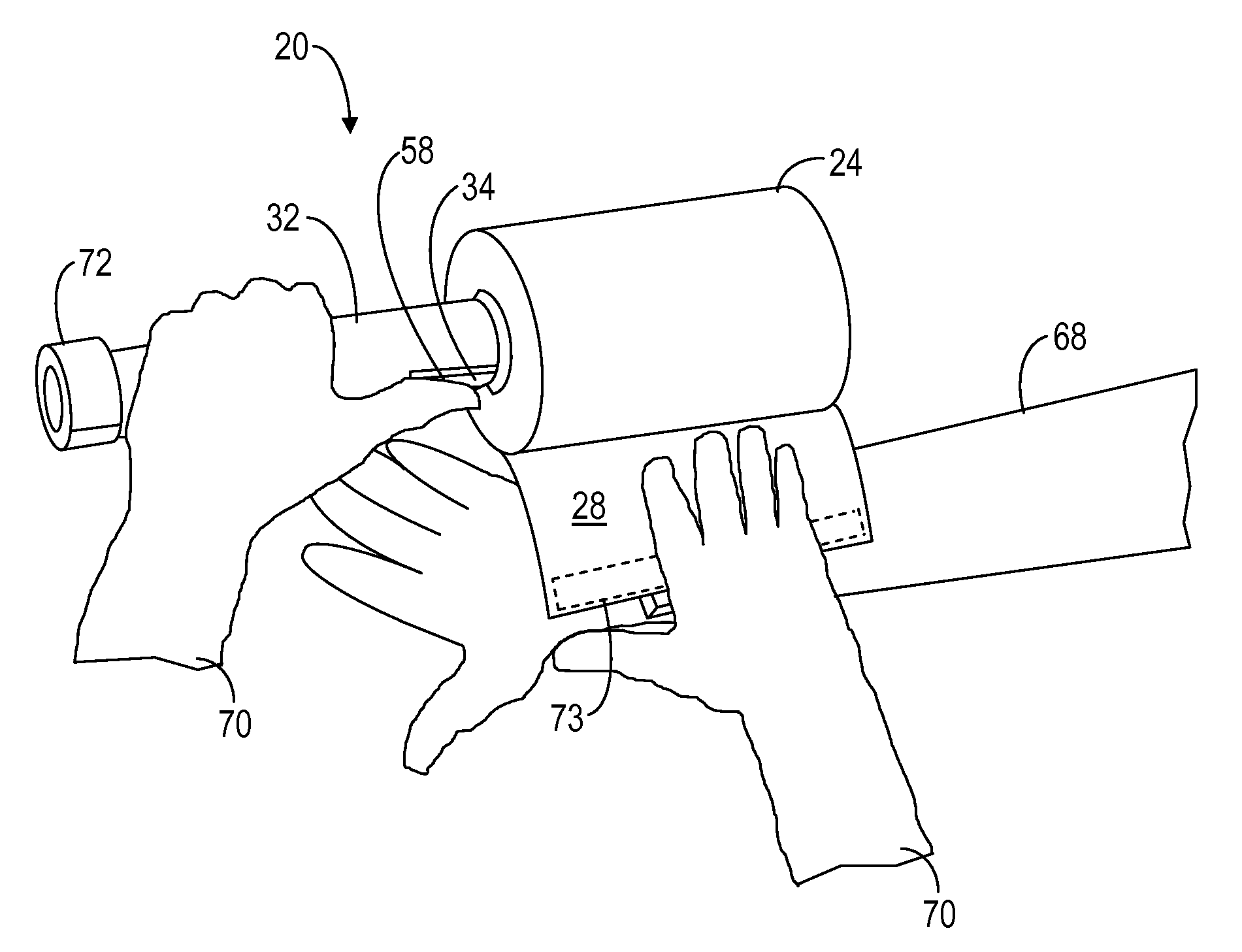

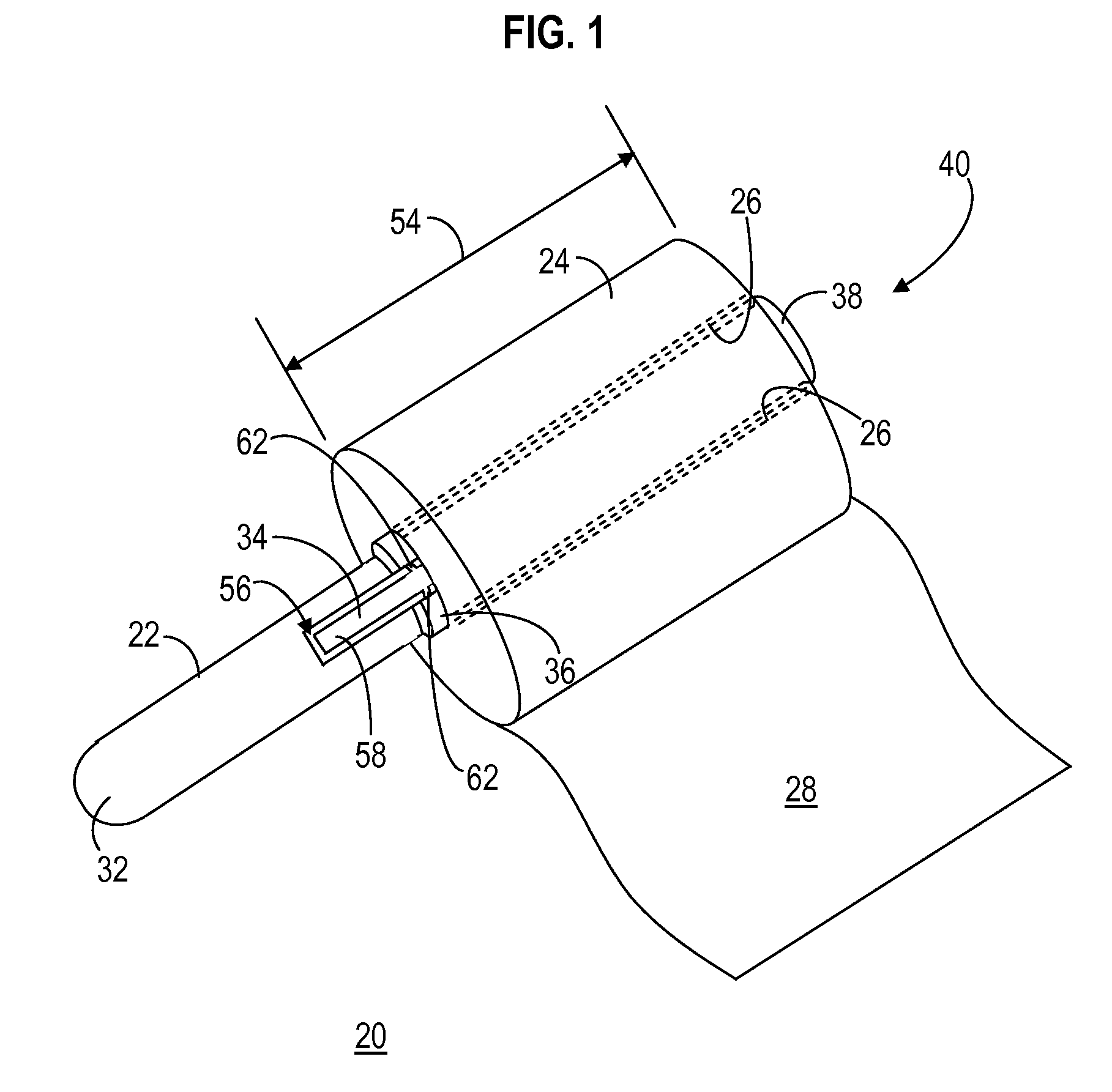

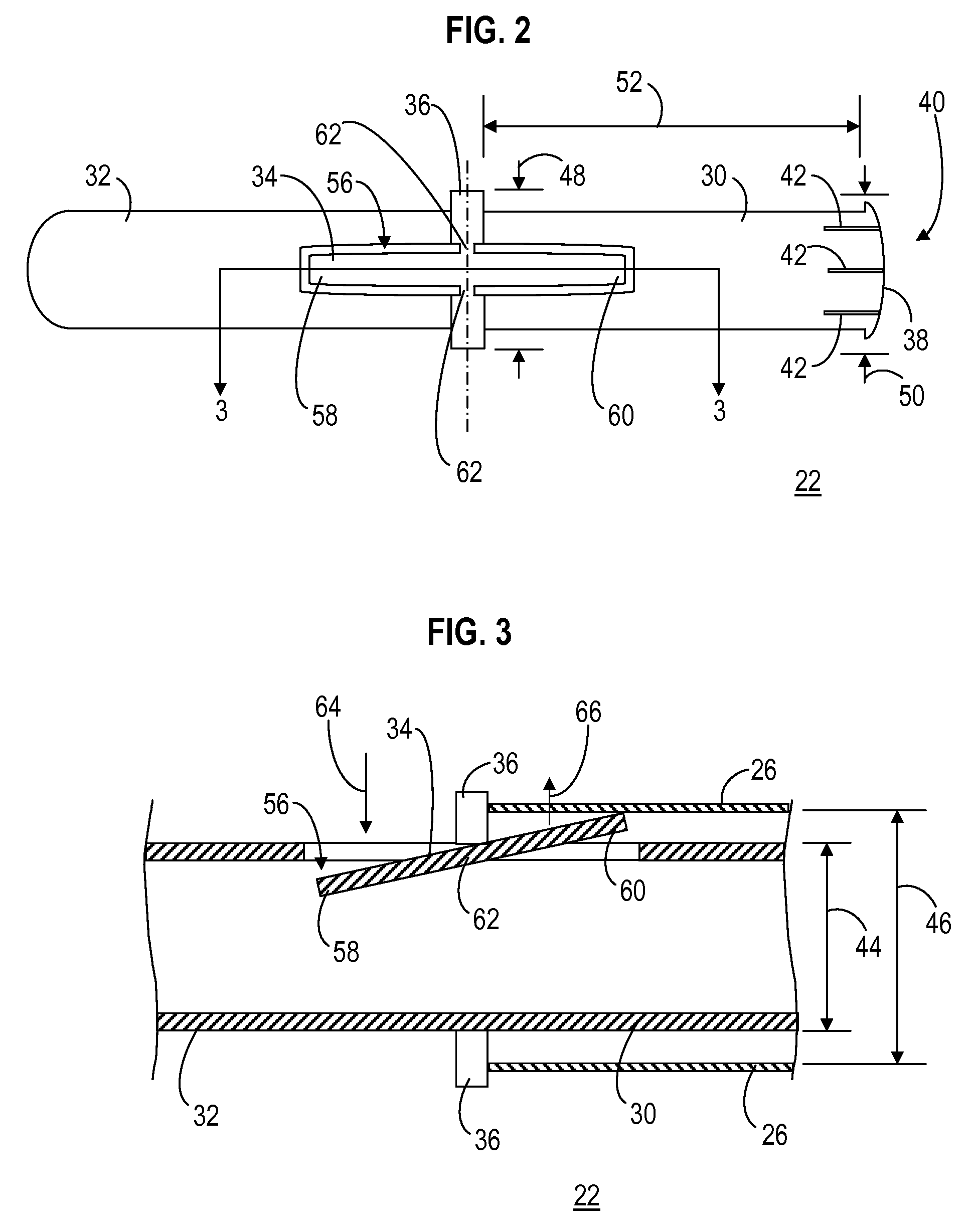

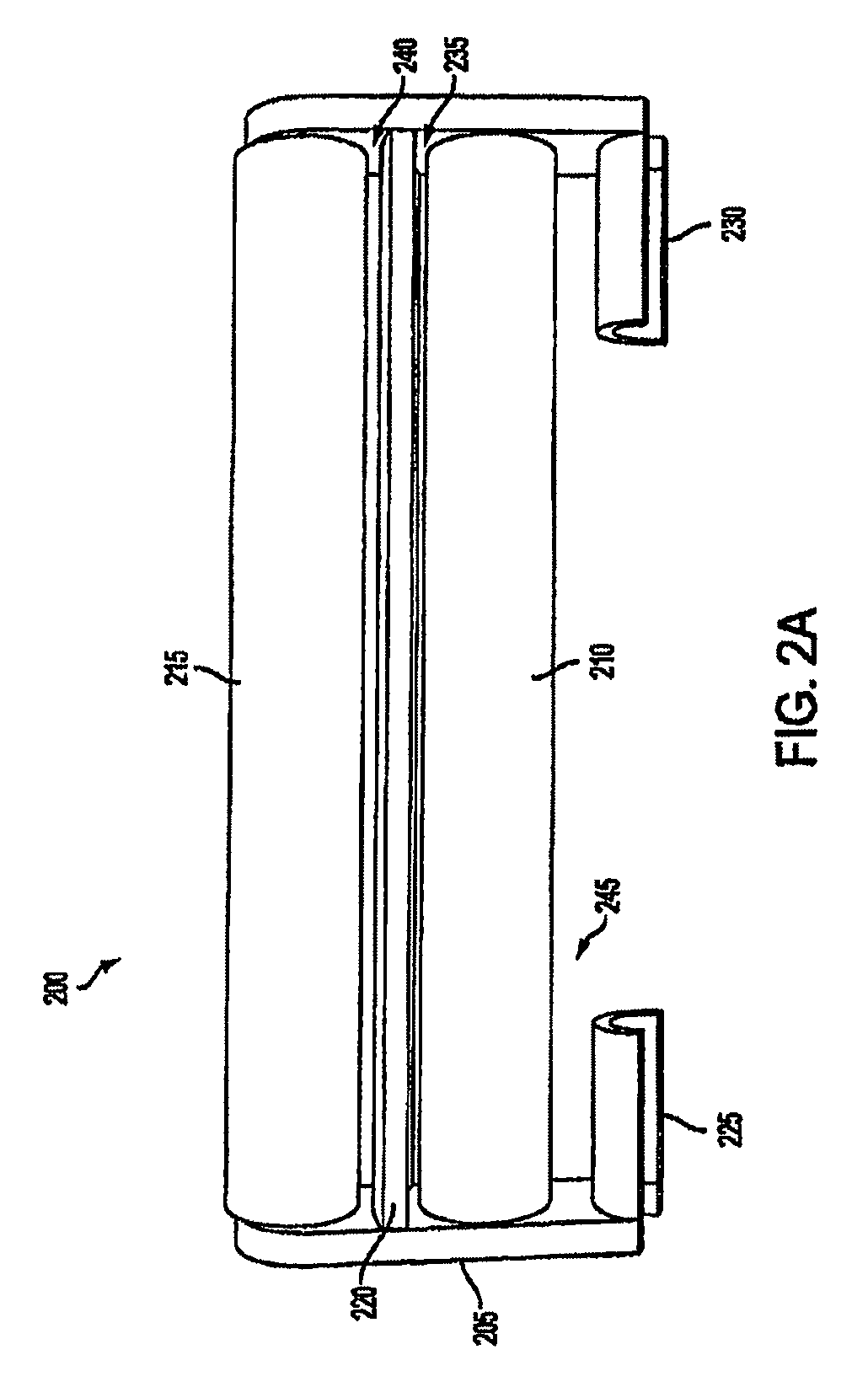

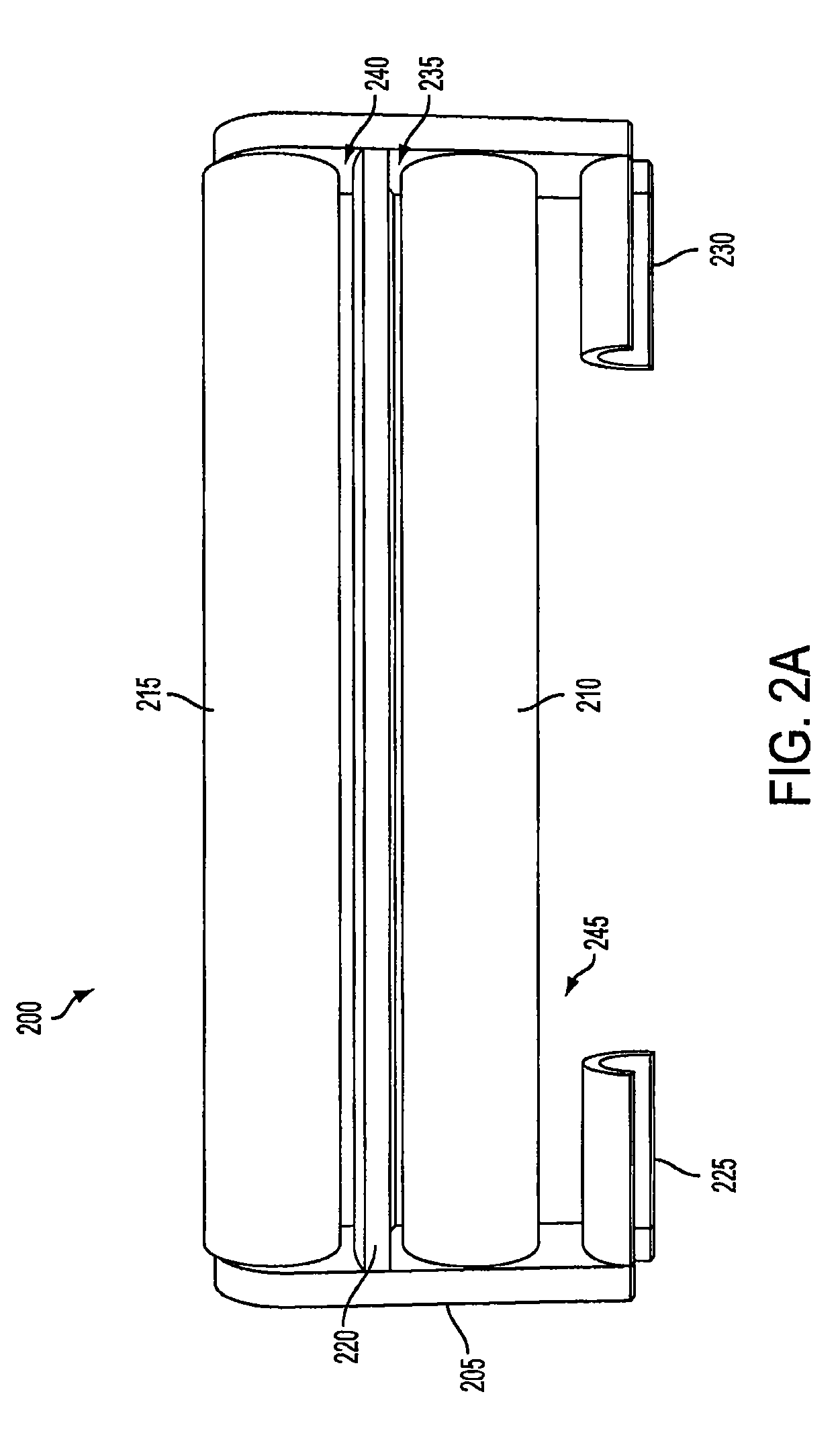

Rolled material applicator

An applicator for applying a rolled material to a body includes a spindle configured to hold the rolled material. A length of the spindle is at least equivalent to the width of the rolled material. A handle is coupled to the spindle, and a brake mechanism is integral with the handle for controlling a tension of the rolled material as it is applied to the body. The rolled material may be pre-wound on a spool that rotates around the spindle. Actuation of the braking mechanism increases pressure on the rotating spool in order to increase tension on the rolled material. Alternatively, the spindle rotates in conjunction with a shaft within the handle. The braking mechanism applies pressure against the rotating shaft to increase tension in the elongated material. Pre-wound cartridges of rolled material may be successively loaded on to the applicator's spindle for repeated usage of the applicator.

Owner:TRAUMAKWIK SOLUTIONS

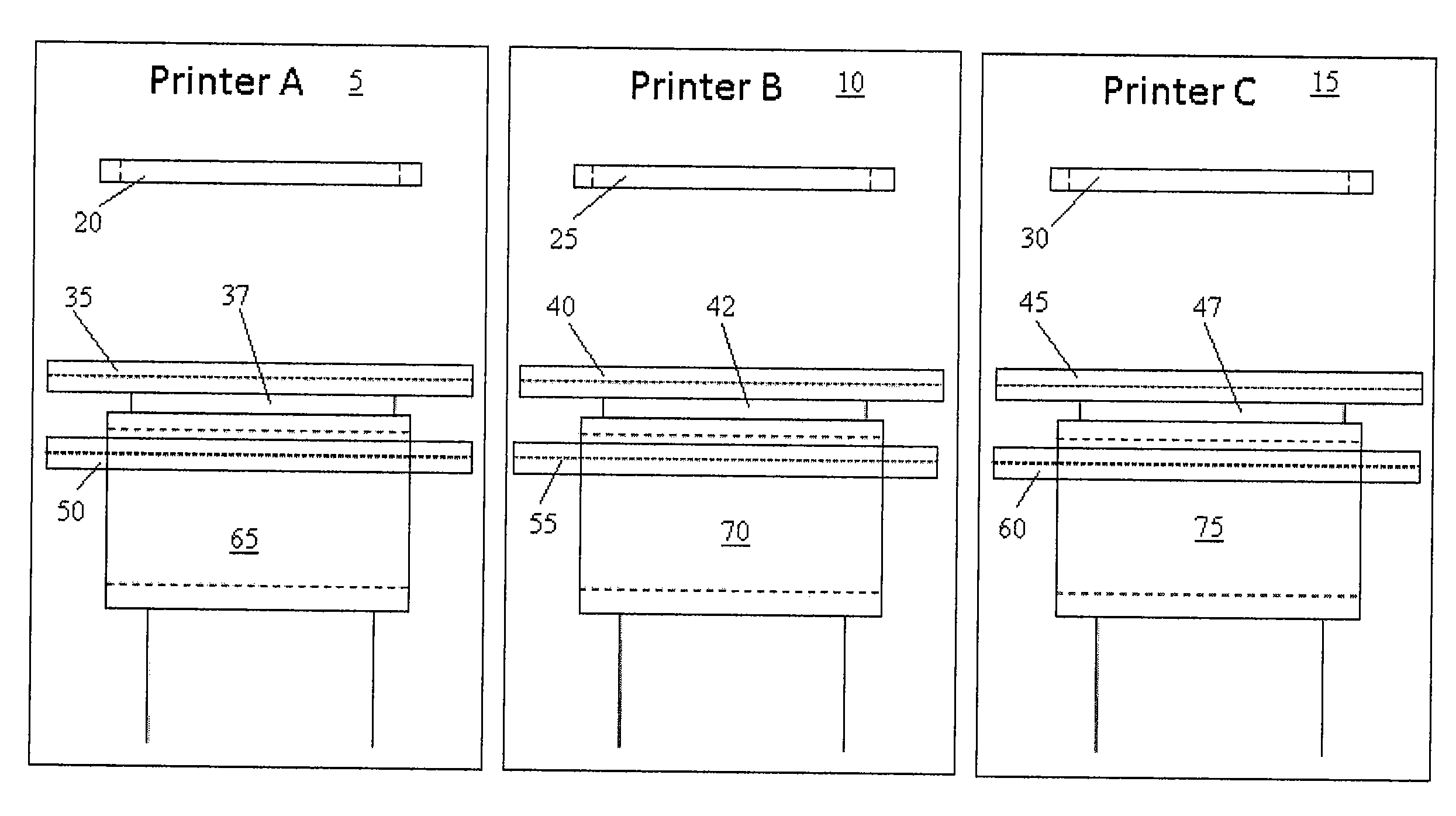

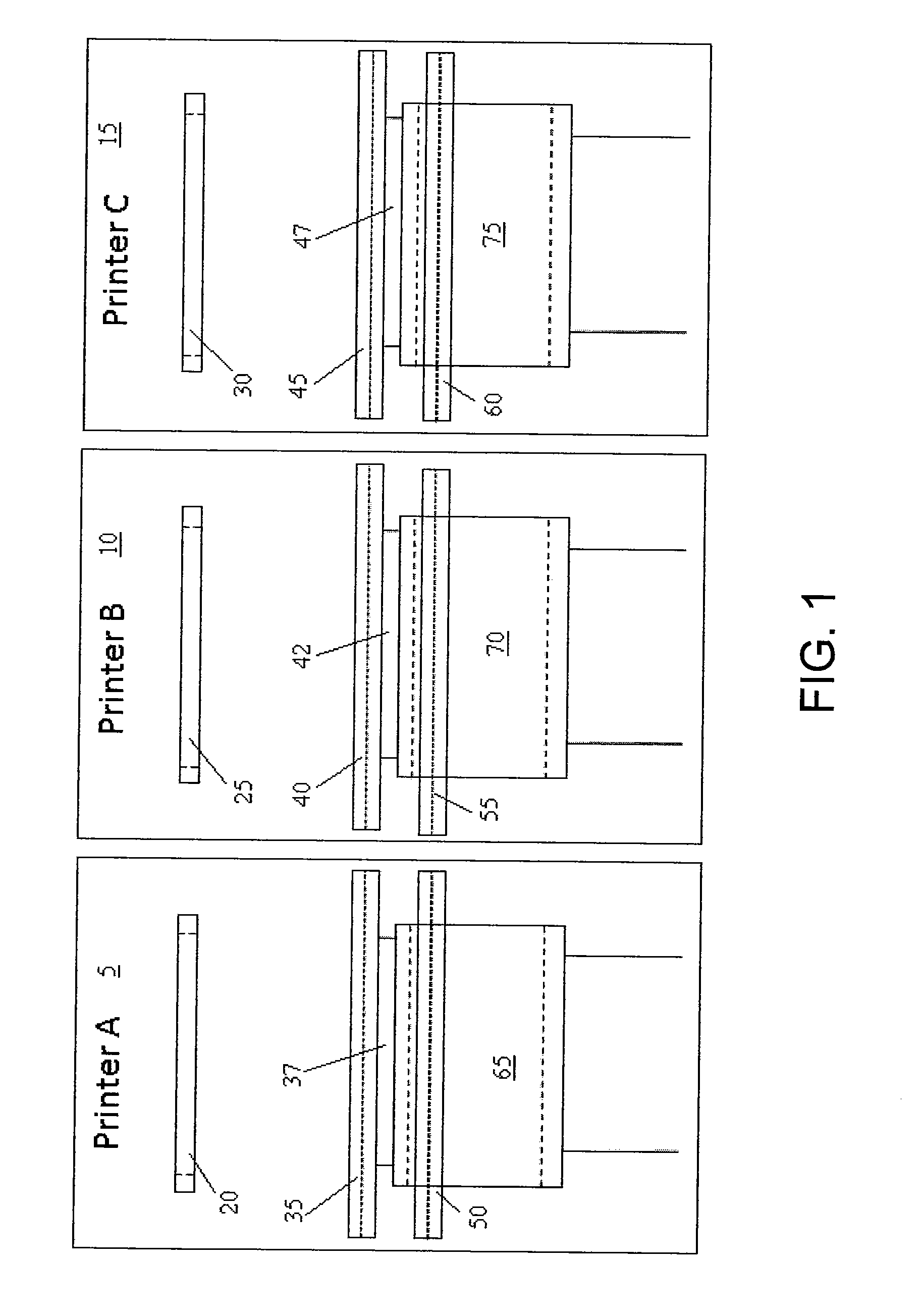

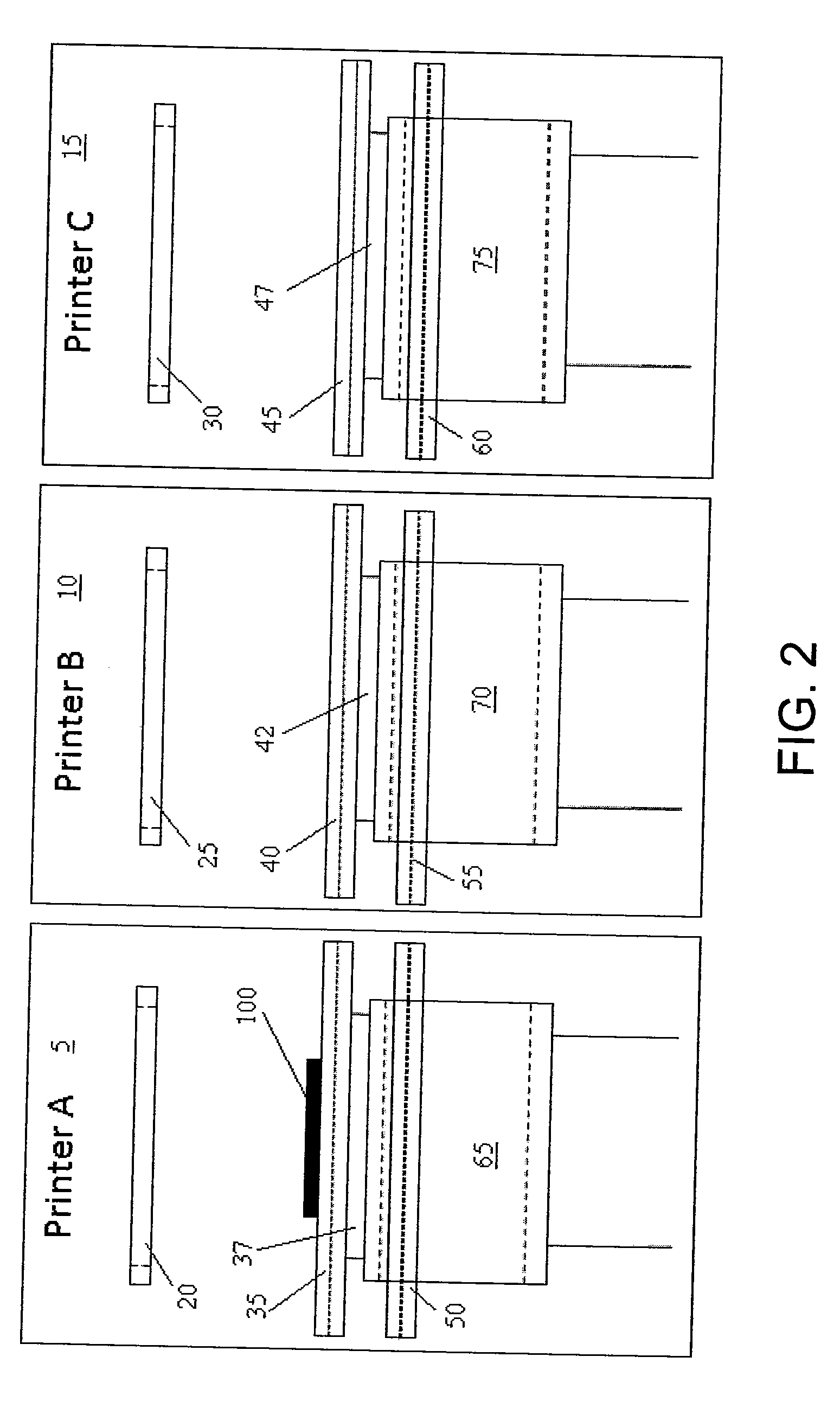

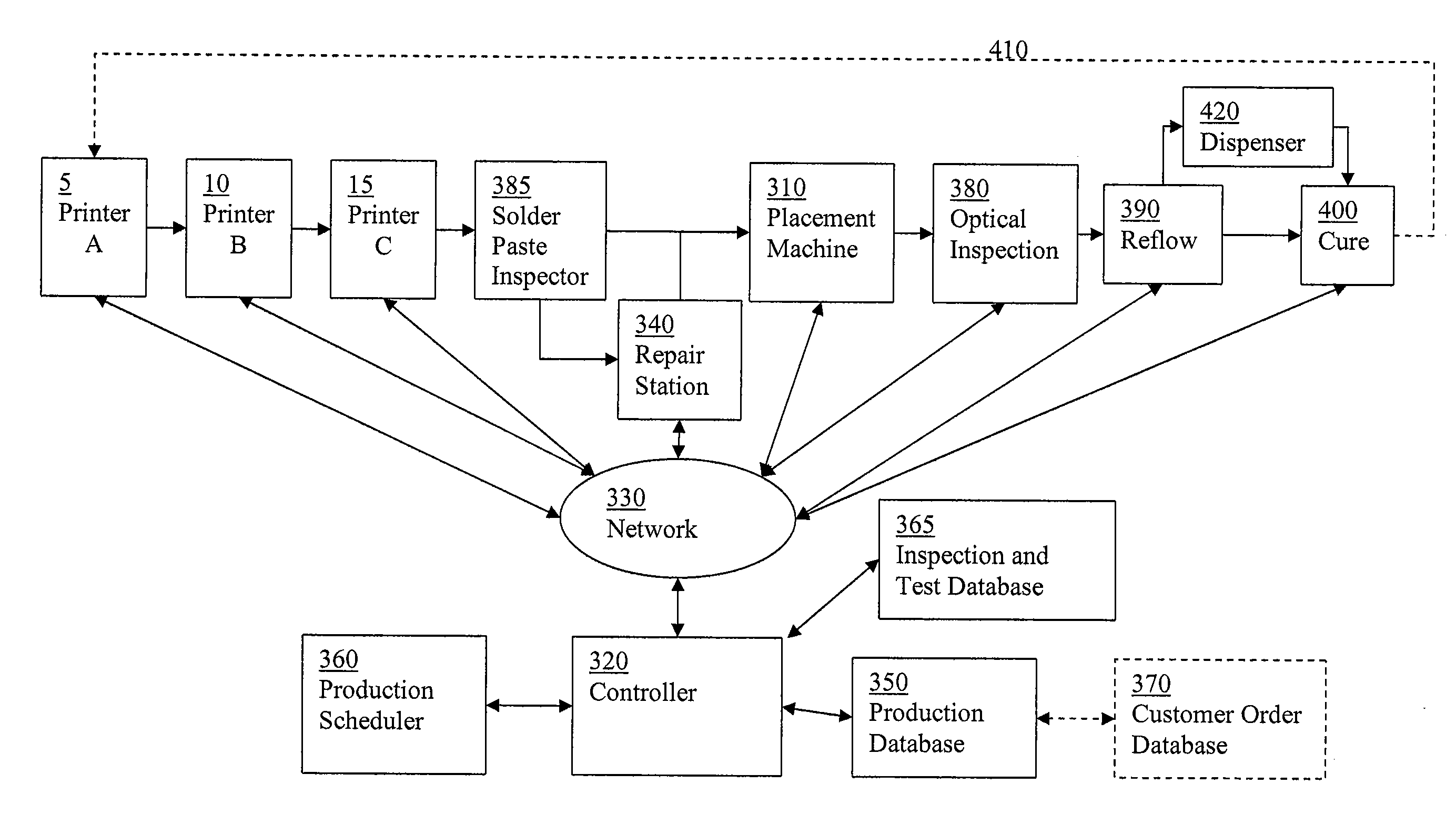

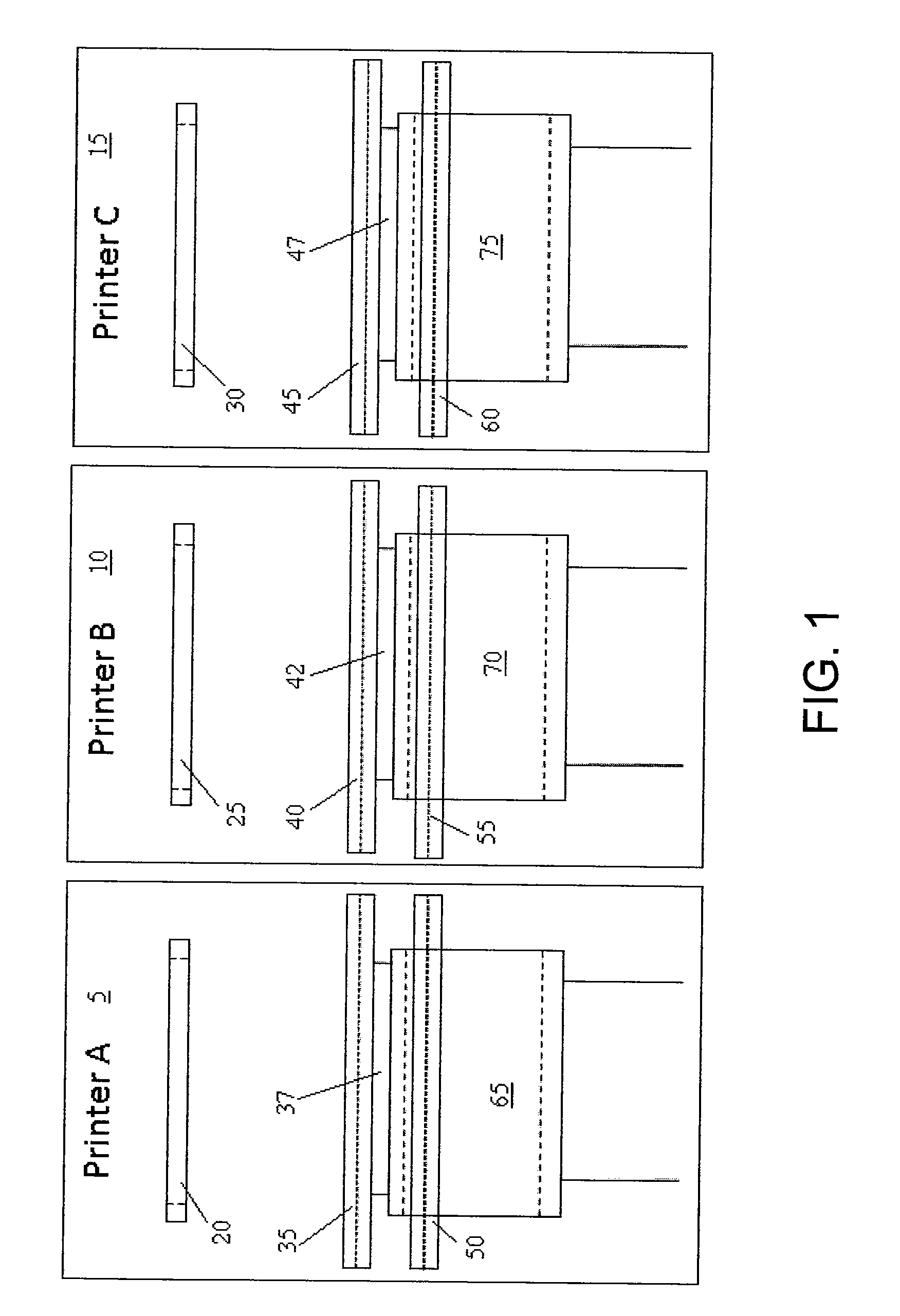

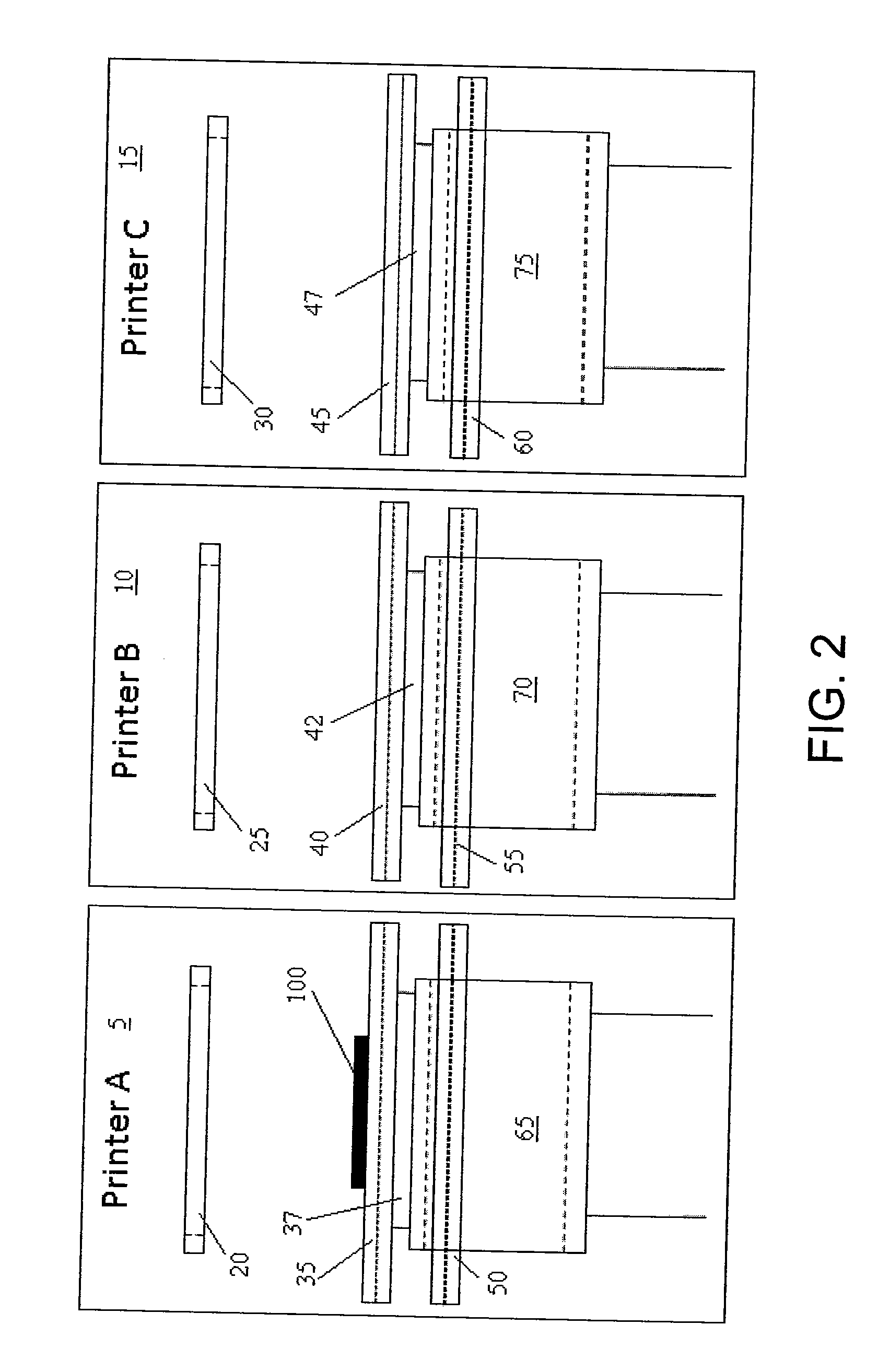

Vertically separated pass through conveyor system and method in surface mount technology process equipment

InactiveUS20100122633A1Printed circuit assemblingLiquid surface applicatorsProcess equipmentTransport system

Disclosed herein is an apparatus for depositing viscous material on an electronic substrate. The apparatus comprises a frame, an assembly material applicator coupled to the frame and configured to apply assembly material to the electronic substrate, a substrate support assembly, coupled to the frame, configured to support and secure the electronic substrate in a material application position, and a transport system, coupled to the frame, to shuttle electronic substrates to and from the substrate support assembly, the transport system including an upper track and a lower track disposed below the upper track.

Owner:ILLINOIS TOOL WORKS INC

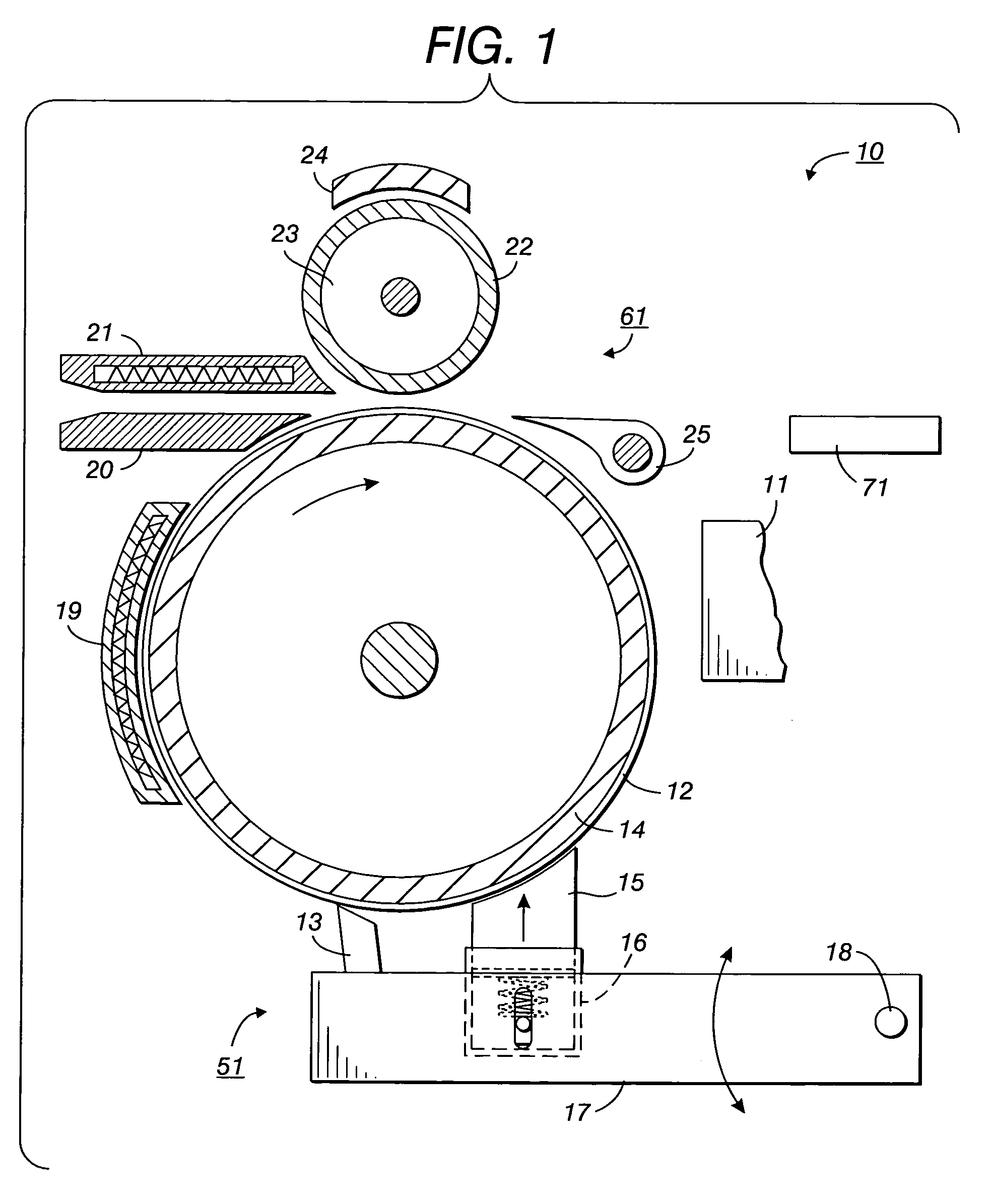

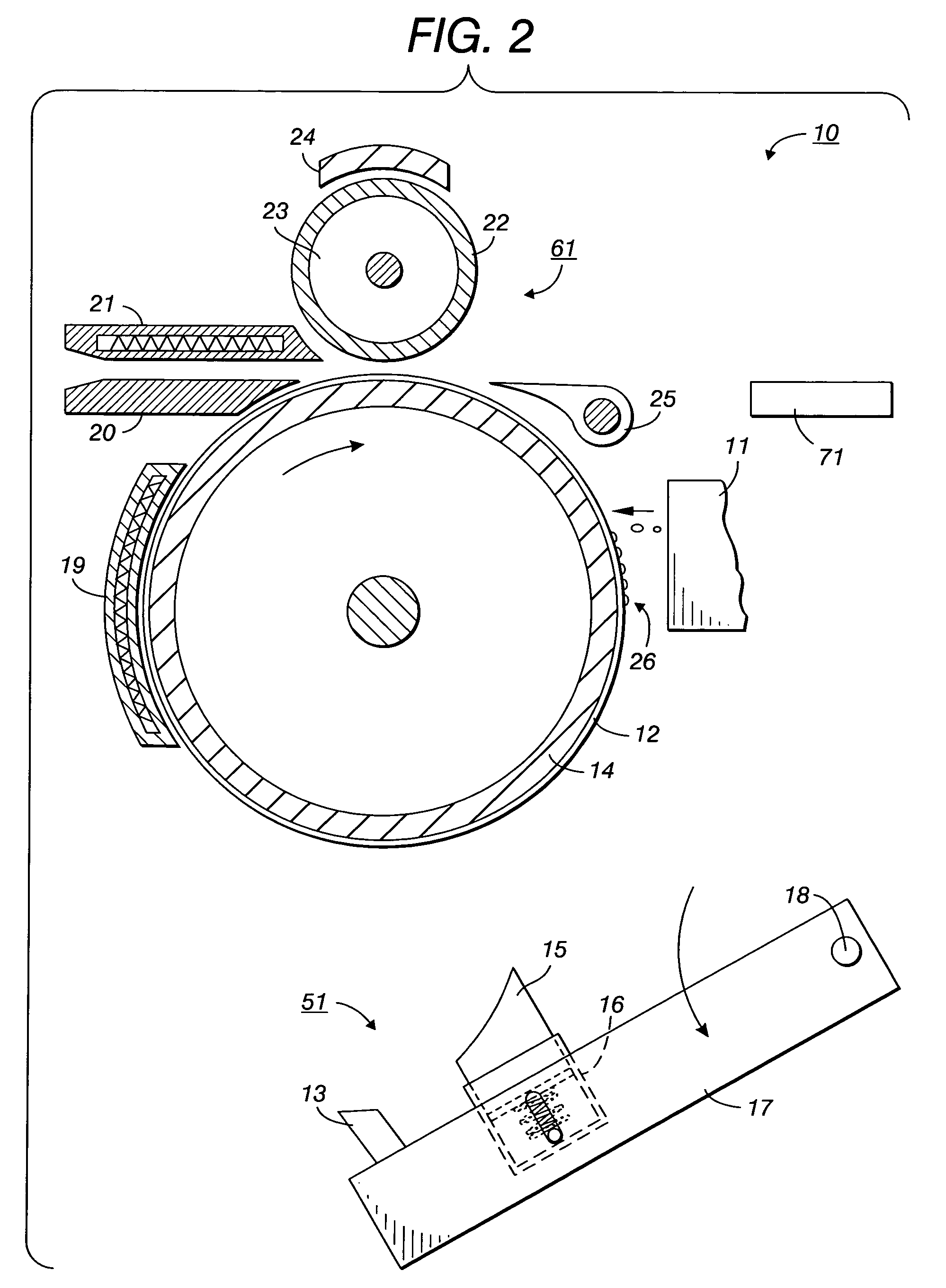

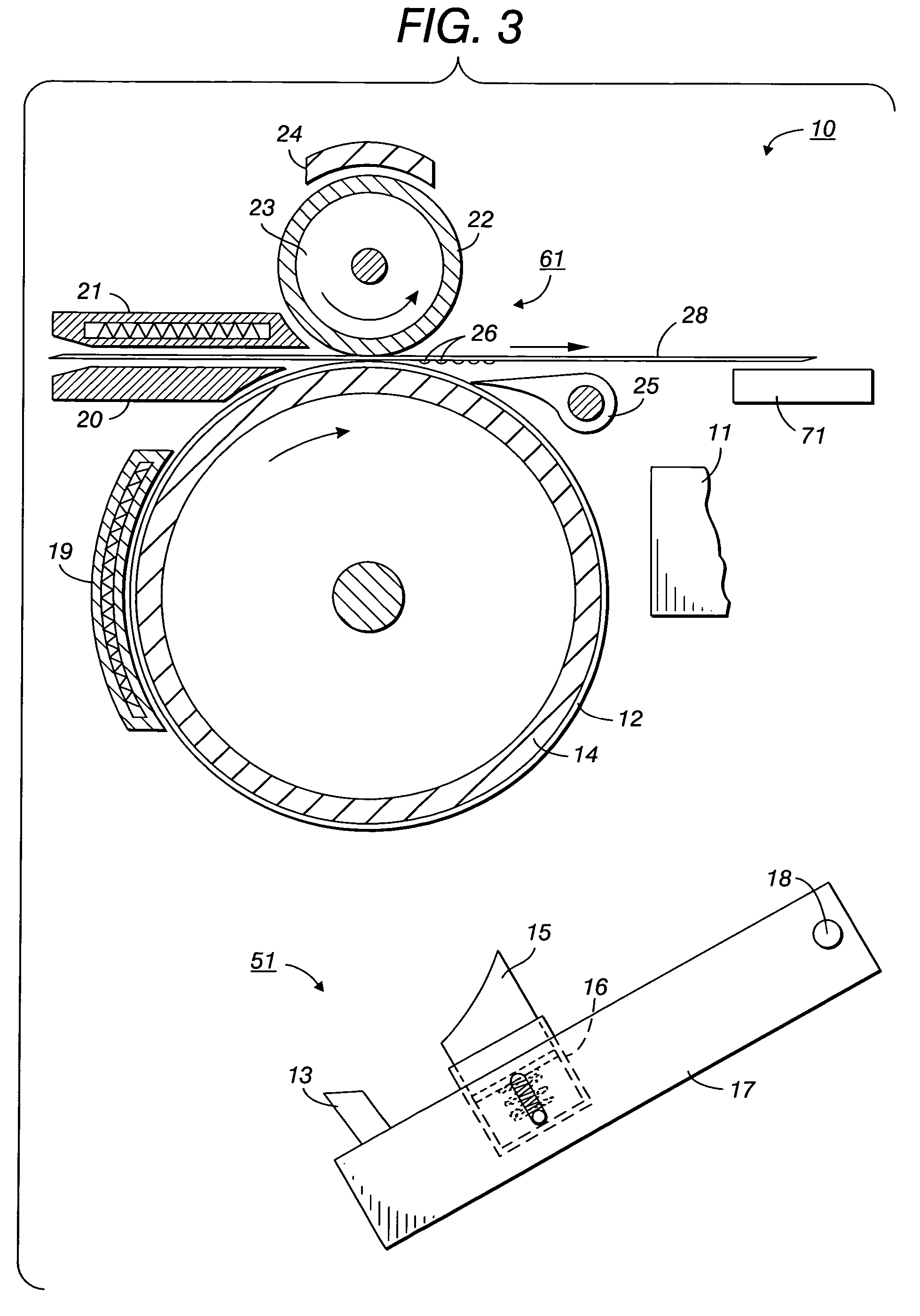

Printing apparatus and processes employing intermediate transfer with molten intermediate transfer materials

InactiveUS20050074260A1Electrographic process apparatusOther printing apparatusMetallurgyMaterial applicator

A printing apparatus for applying a marking material to a final substrate, said printing apparatus comprising an intermediate transfer member; an intermediate transfer material applicator for transferring intermediate transfer material from a solid block of intermediate transfer material to form a molten layer of intermediate transfer material on the intermediate transfer member; a marking material applicator situated to apply marking material in an imagewise pattern to the molten layer of intermediate transfer material on the intermediate transfer member; and a transferring apparatus to transfer the imagewise pattern of marking material to a final recording substrate.

Owner:XEROX CORP

Printing processes employing intermediate transfer with molten intermediate transfer materials

A block of intermediate transfer material for use in a printing apparatus having an intermediate transfer member, said intermediate transfer member being equipped with a heater to heat said intermediate transfer member to a temperature of at least about 40° C., said intermediate transfer member having a surface with a first shape, a marking material applicator situated to apply marking material in an imagewise pattern to the intermediate transfer member, and a transferring apparatus to transfer the imagewise pattern of marking material to a final recording substrate, said block of intermediate transfer material comprising a silicone polymer containing monomers of the formula wherein R1, R2, R3, R4, R5, x, y, and z are as defined herein, wherein the monomers can be directly bonded to each other or bonded through spacer groups, said block of intermediate transfer material having a surface with a second shape substantially the complement of the first shape.

Owner:XEROX CORP

Protective material applicator device

ActiveUS20140230988A1Reduce eliminateEliminate waiting timeLaminationLamination apparatusTectorial membraneEngineering

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a roller apparatus may be used to apply the protective film on the surface of the electronic device. The roller apparatus may include an opening for receiving a display peg.

Owner:SUPERIOR COMM

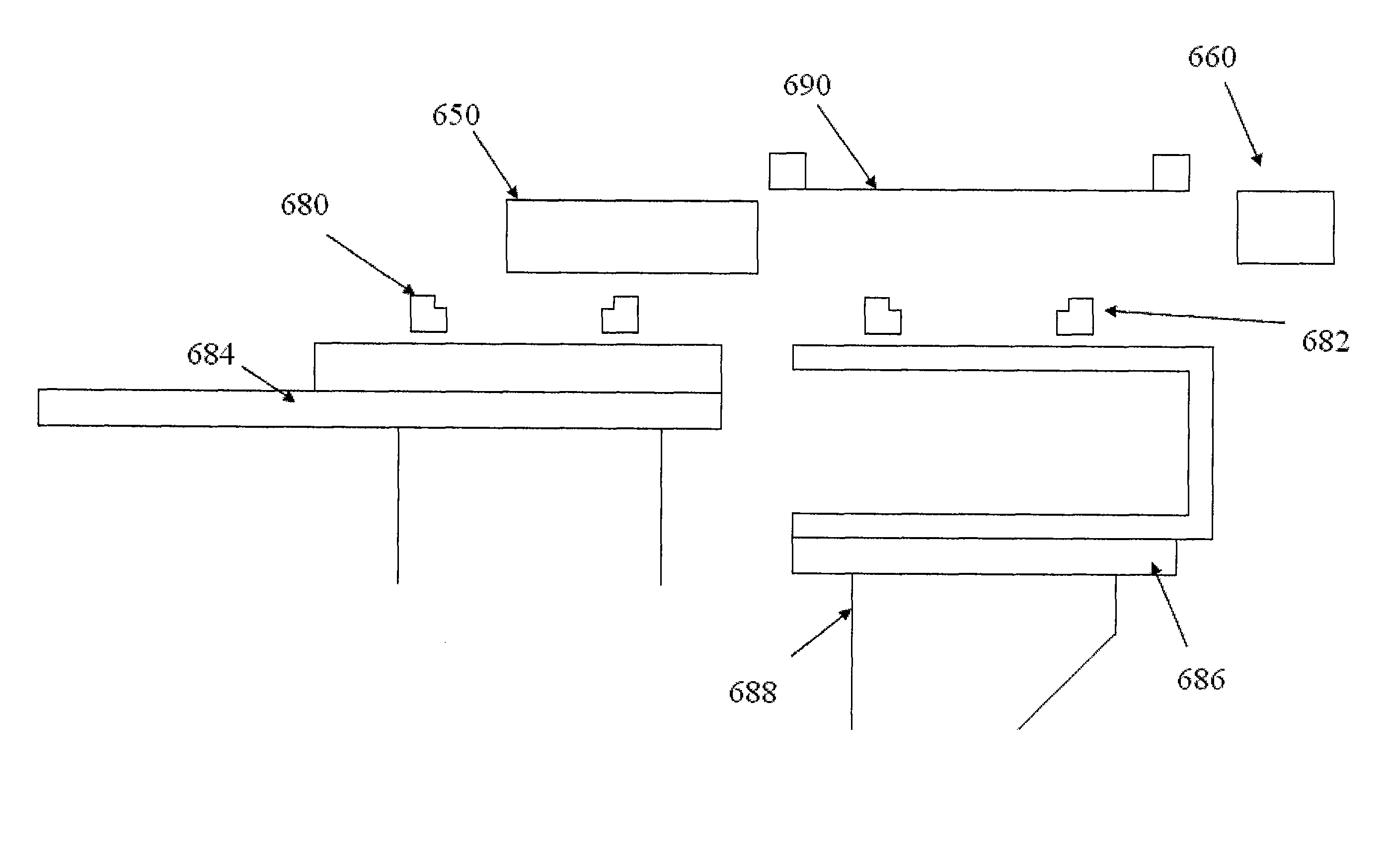

Strip material applicator of case sealer

ActiveCN101804924AReduce downtimeReduce riskWrapper twisting/gatheringArticle deliveryEngineeringMaterial applicator

The invention relates to a strip material applicator of a case sealer. The strip material applicator or a strip supplying head is formed by the combination of two separated devices, that is to say, the strip material applicator or the strip supplying head comprises a detachable unit and a fixing unit, wherein the detachable unit is positioned at the front part of the strip material applicator; the fixing unit is positioned at the rear part of the strip material applicator; and the detachable unit is jointed with the fixing unit through a padlock positioned between the detachable unit and the fixing unit so as to obtain the interactive action of the traditional strip material applicator, that is to say, the strip material applicator separates the traditional strip material applicator into two separated parts so as to obtain the capability of fast replacing strip materials 26 and reduce safety risks.

Owner:LAMUS ENTERPRISES

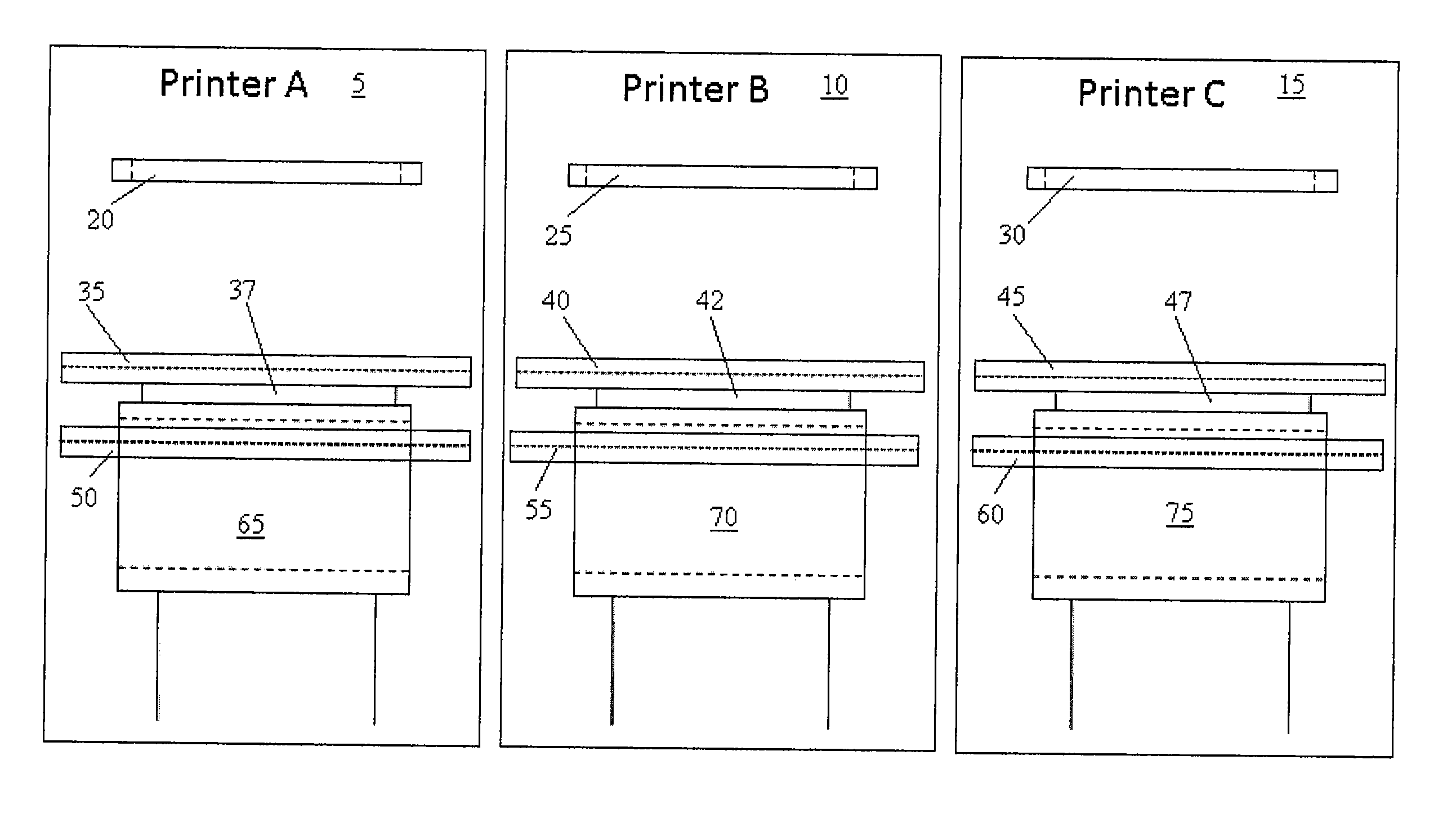

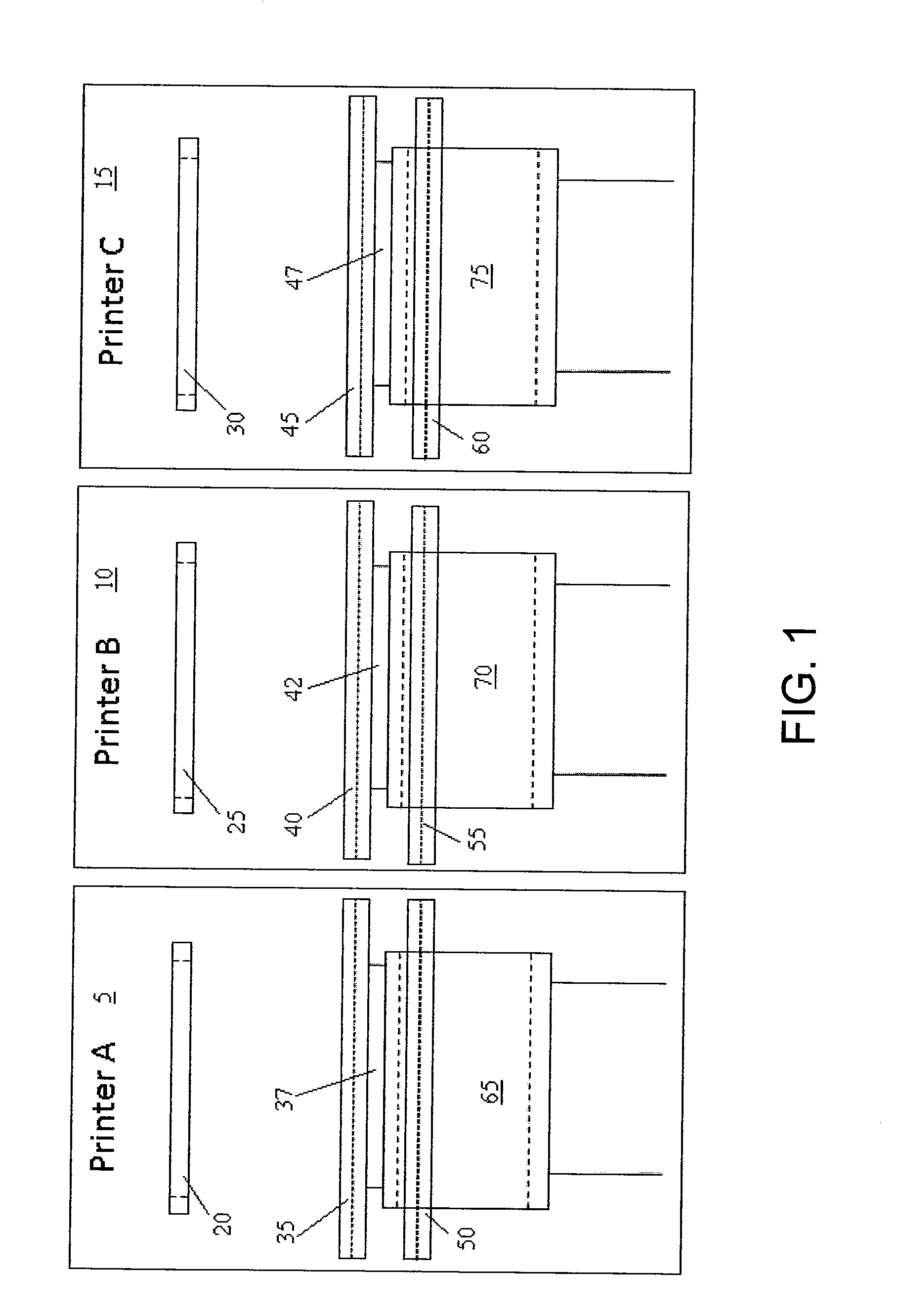

Vertically separated pass through conveyor system and method in surface mount technology process equipment

InactiveUS20100122634A1Printed circuit assemblingLiquid surface applicatorsTransport systemProcess equipment

Disclosed herein is an apparatus for depositing viscous material on an electronic substrate. The apparatus comprises a frame, an assembly material applicator coupled to the frame and configured to apply assembly material to the electronic substrate, a substrate support assembly, coupled to the frame, configured to support and secure the electronic substrate in a print position, and a transport system, coupled to the frame, to shuttle electronic substrates to and from the substrate support assembly, the transport system including a first track and a second track, the first track being mounted on a first displacement mechanism and the second track being mounted on a second displacement mechanism configured to laterally move the second track relative to the first track, the second displacement mechanism configured to raise the first track relative to the second track.

Owner:ILLINOIS TOOL WORKS INC

Applicators and methods for dispensing a liquid material

InactiveUS20070102841A1Increase surface areaLarge widthLiquid surface applicatorsConfectioneryBiomedical engineeringMaterial applicator

Applicators configured to dispense a hollow or shaped filament and methods of dispensing in which the hollow or shaped filament is impinged with gas jets. The applicator includes a dispenser body configured to discharge the hollow or shaped filament and a plurality of gas outlets arranged to impinge the filament in the space between the dispenser and the substrate.

Owner:NORDSON CORP

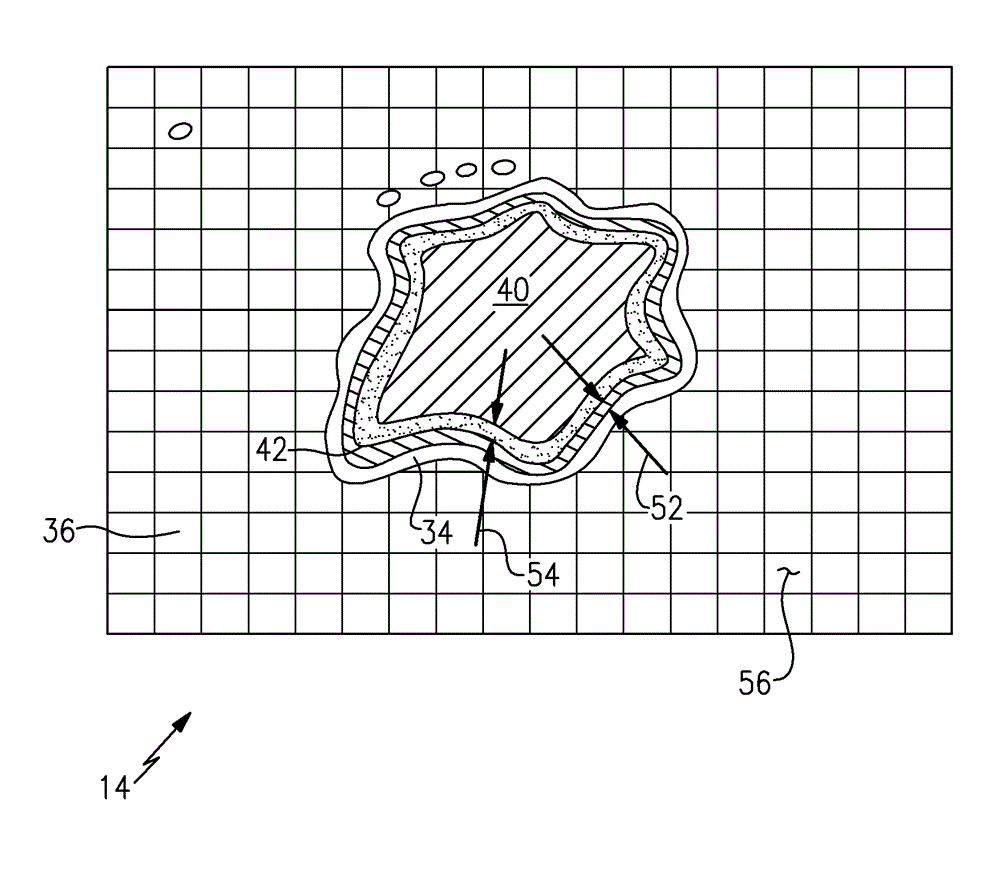

Additive manufacturing management of large part build mass

ActiveCN103056365AAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringManufacturing management

An additive manufacturing machine includes a base plate for supporting fabrication of a desired part geometry. The base plate includes a support portion defined based on the desired part geometry and an open region that includes a plurality of openings surrounding the support portion. A material applicator deposits material onto the base plate and an energy directing device directs energy to form the deposited material into a desired part geometry. The additive manufacturing machine manages large amounts of material required for fabricating the part by defining a boundary surrounding a periphery of a desired part geometry and forming a retaining wall along the defined boundary and the desired part geometry to retain excess material between the formed wall and the part. Excess material outside of the retaining wall falls through the open area below the base plate and is reclaimed for reuse.

Owner:UNITED TECH CORP

Protective material applicator device

ActiveUS9033019B2Reduces or eliminates air bubblesEliminate waiting timeLamination ancillary operationsCasings/cabinets/drawers detailsTectorial membraneEngineering

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device that instantly reduces air bubbles and eliminates the waiting time usually required when using a wet fluid solution. In one embodiment, a flange may be configured to couple to the protective film. The flange may aid in the accurate application of the protective film to the electronic device.

Owner:SUPERIOR COMM

Vertically separated pass through conveyor system and method in surface mount technology process equipment

InactiveUS20100125357A1Printed circuit assemblingMetal working apparatusTransport systemProcess equipment

Disclosed herein is a modular system for manufacturing printed circuit boards. The system comprises a plurality of pieces of processing equipment including at least one assembly material applicator, and at least one electronic component placement machine, and a transport system configured to transport circuit boards from the at least one stencil printer to the at least one electronic component placement machine, the system including an upper track and a lower track disposed below the upper track.

Owner:ILLINOIS TOOL WORKS INC

Vertically separated pass through conveyor system and method in surface mount technology process equipment

Disclosed herein is an apparatus for depositing viscous material on an electronic substrate. The apparatus comprises a frame, an assembly material applicator coupled to the frame and configured to apply assembly material to the electronic substrate, a substrate support assembly, coupled to the frame, configured to support and secure the electronic substrate in a print position, and a transport system, coupled to the frame, to shuttle electronic substrates to and from the substrate support assembly, the transport system including a first track and a second track, the first track being mounted on a first displacement mechanism and the second track being mounted on a second displacement mechanism configured to laterally move the second track relative to the first track, the second displacement mechanism configured to raise the first track relative to the second track.

Owner:ILLINOIS TOOL WORKS INC

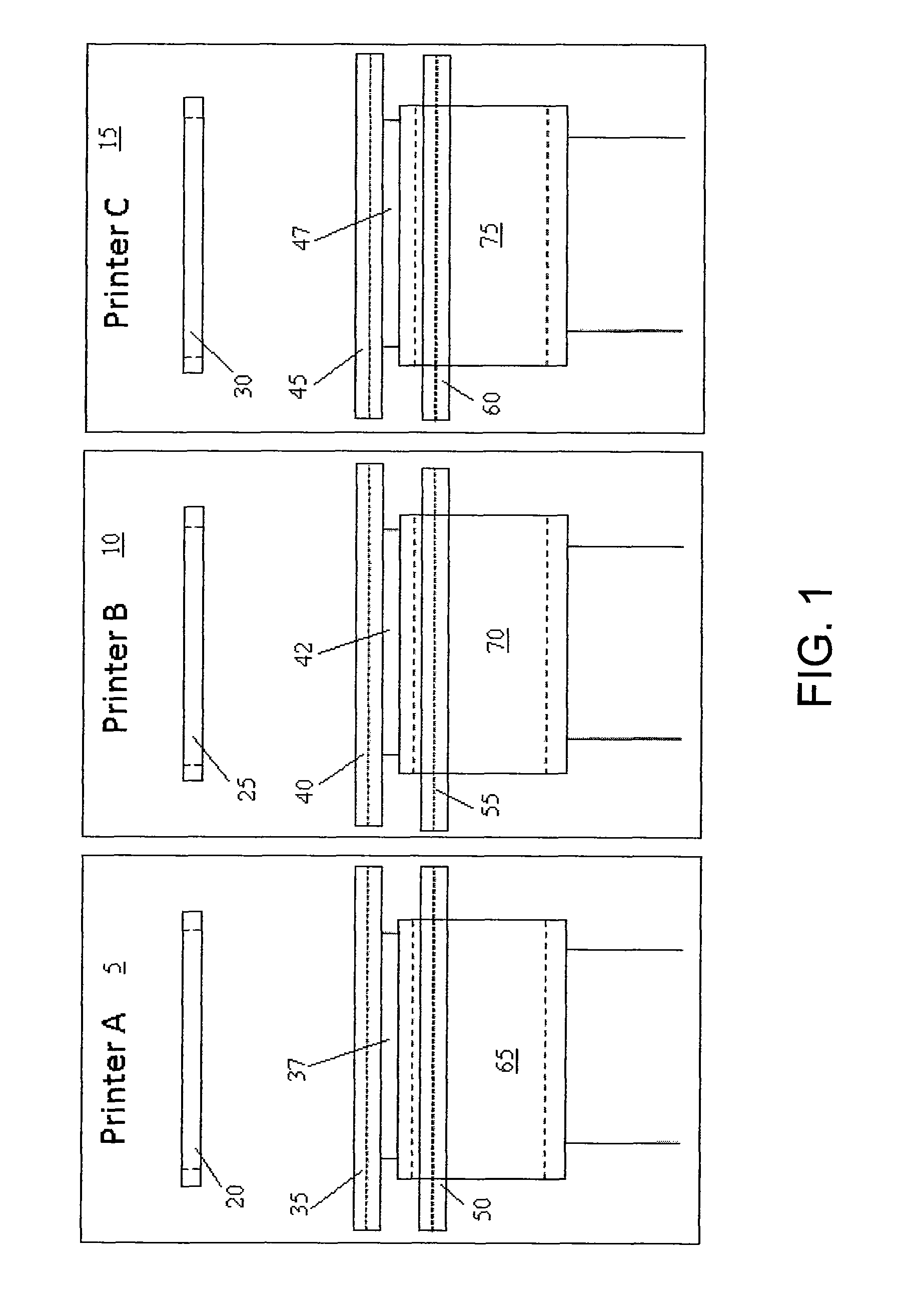

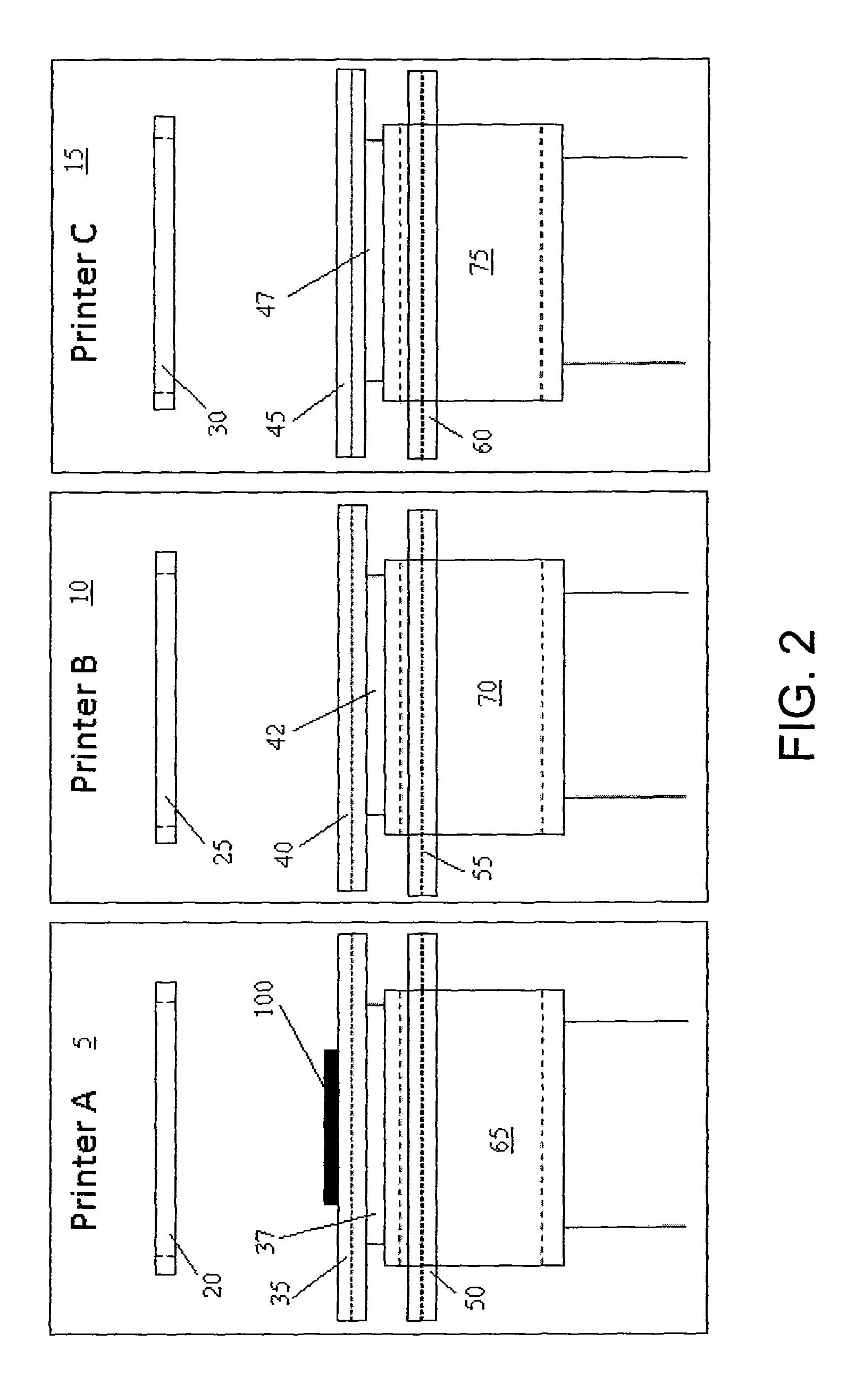

Computer-based system for producing multi-color multilayer images on substrates using dry multi-colored cholesteric liquid crystal (CLC) pigment materials applied to binder material patterns

InactiveUS6515717B1Function increaseAvoid less flexibilityLiquid surface applicatorsLayered productsOutput deviceOptoelectronics

A computer-based system for producing a multi-color multilayer image on a substrate using multi-colored cholesteric liquid crystal (CLC) pigment materials made from CLC flakes tuned to predetermined bands of color. A computer-controlled image generator automatically generates an image specifying a pattern over which binder material is to be applied to a substrate by a binder material applicator. A plurality of CLC pigment applicators automatically apply patterns of different-color CLC pigment material to a pattern of binder material applied to the substrate, binding thereto as the binder material dries. An output device is used to automatically return the substrate to a different one of CLC pigment applicators after each application of a pattern of different-color CLC pigment material to the pattern of binder material. The output device automatically repeats the return of the substrate to the CLC pigment applicators until all bands of color in the multi-color multilayer image are rendered and the multi-color multilayer image is produced.

Owner:REVEO

Protective material applicator device

ActiveUS8905107B2Reduces or eliminates air bubblesEliminate waiting timeWelding/cutting auxillary devicesAbrasion apparatusTectorial membraneEngineering

Devices, methods and systems disclosed herein relate to the application of a protective film on a surface of an electronic device instantly reducing air bubbles and eliminating the waiting time usually required when using a wet fluid solution. In one embodiment, a roller device may include a carriage or housing and one or more rollers coupled or integrated with the housing, configured to apply a protective material to a surface of the electronic device in a first orientation, and configured to function as a device stand in a second orientation.

Owner:SUPERIOR COMM

Component delivery system utilizing film bags

ActiveUS20160045928A1Easy to reachLiquid surface applicatorsCoatingsDelivery systemMaterial applicator

A dispensing apparatus includes two cylindrical sleeves, two shuttles slidingly disposed in the sleeves, push rods disposed in operable communication with the shuttles, and a piston, driven by pressurized gas, disposed in operable communication with the push rods. The cylindrical sleeves receive film pack bags having a common face plate that has an integrally formed discharge nosepiece having an internal partition that maintains separate flow streams from the film pack bags. A holder is disposed proximate a front end of the sleeves and configured to restrain the face plate during dispensing. A mixer is disposed in fluid communication with the film pack bags. A material applicator is disposed in fluid communication with the mixer. A first flexible tube is disposed upstream of and in fluid communication with the mixer. A second flexible tube is disposed in fluid communication with the material applicator for supplying atomization air to the material applicator.

Owner:NORDSON CORP

Apparatus for Applying Wound Treatment Material Using Tissue-Penetrating Needles

A surgical apparatus is provided including a disposable loading unit selectively operatively engagable within a distal end of a first half-section; and a wound treatment material applicator assembly for delivering wound treatment material to the target surgical site. The disposable loading unit includes a cartridge; a plurality of deployable needles supported within the cartridge, wherein each needle includes a lumen extending therethrough and at least one hole formed in an outer periphery thereof; and an actuation member translatably disposed within the cartridge for delivering a driving force to each needle to deploy the needles from the cartridge. The applicator assembly includes a first and second reservoir supported on the distal end of a respective first and second half-section; and a source of wound treatment material in fluid communication with each reservoir.

Owner:TYCO HEALTHCARE GRP LP

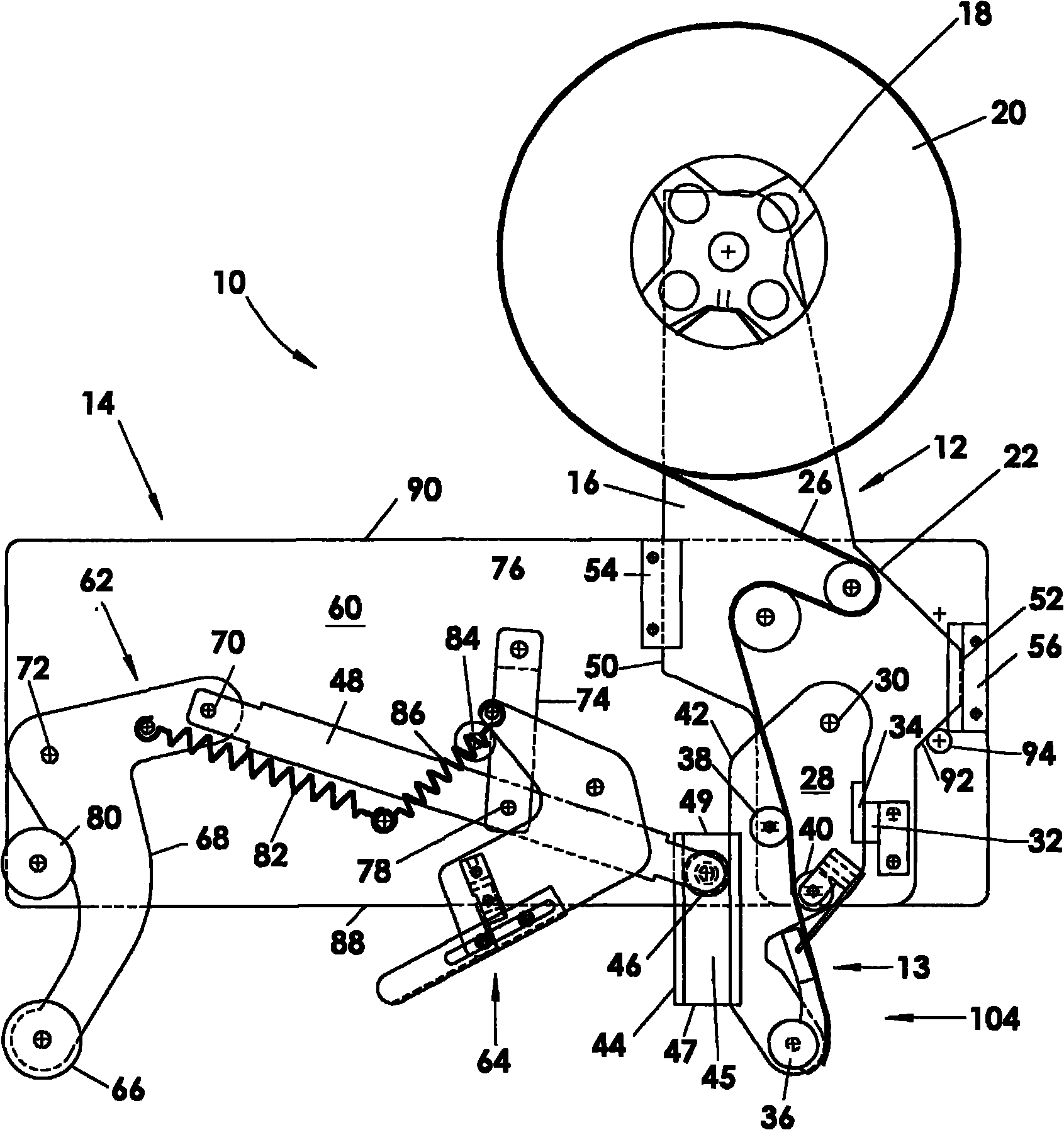

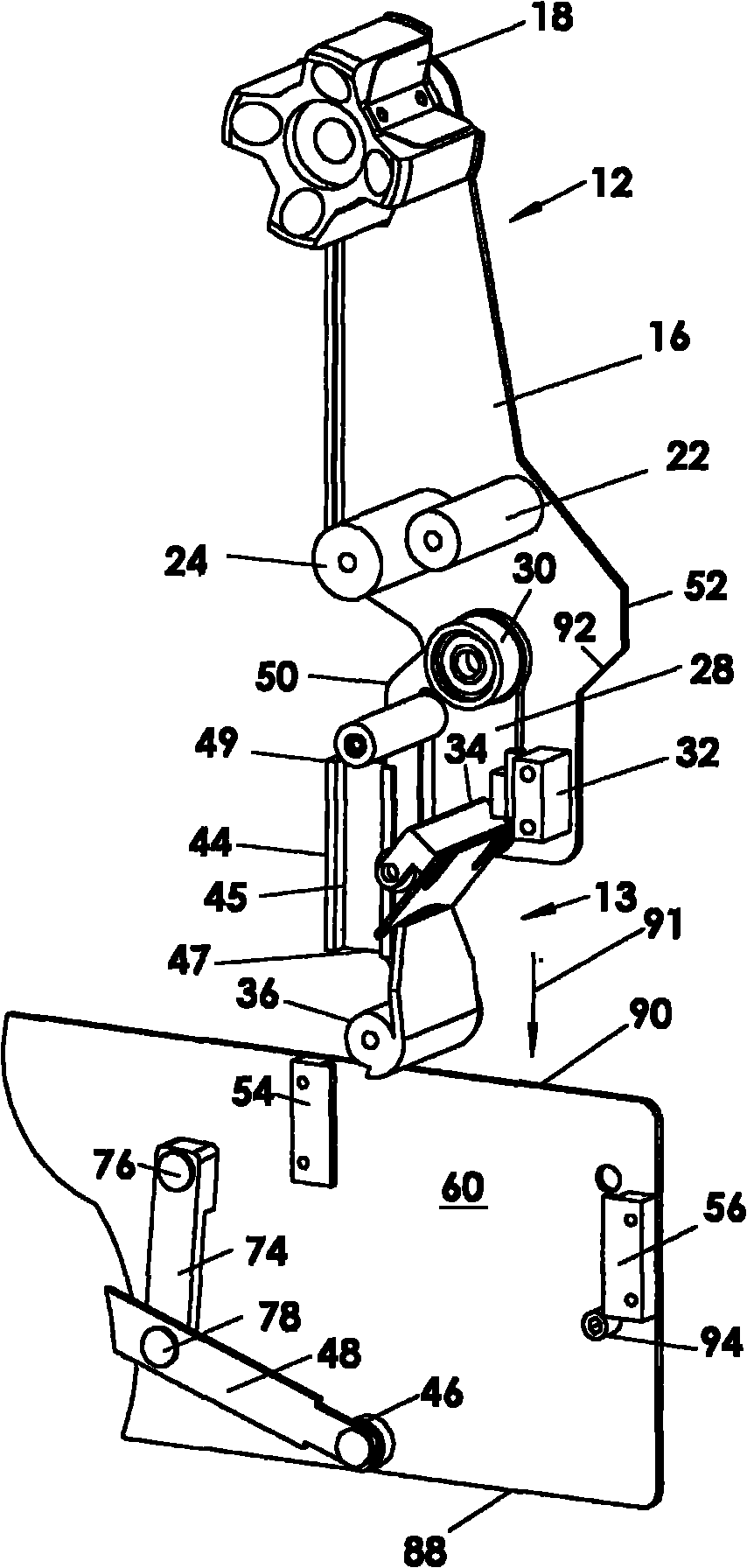

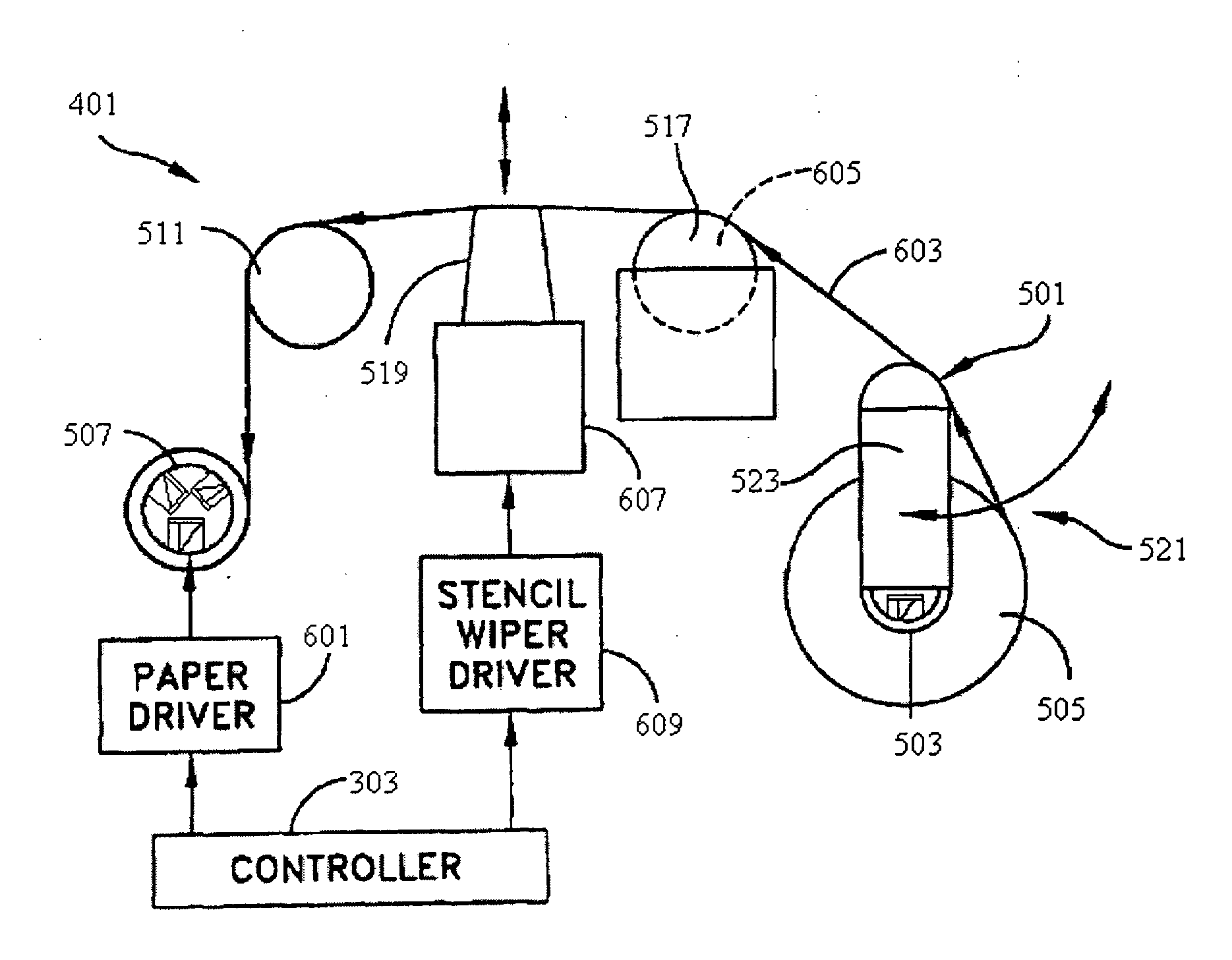

Methods and apparatus for engaging web-material cores

ActiveUS20080223233A1Reduce effective diameterPlaten pressesStencilling apparatusEngineeringPrinting press

A stencil printer apparatus is provided. The stencil printer apparatus may include a stencil, a material applicator to apply material on the stencil, a supply roller configured to receive a roll of web-material, the supply roller comprising a first shaft, a take-up roller to receive used web-material, the take-up roller comprising a second shaft, at least one spring-loaded protrusion element associated with one of the first shaft and the second shaft, and a drive configured to move web-material across the stencil between the supply roller and the take-up roller, and a frame to support the supply roller, the take-up roller and the drive. The at least one spring-loaded protrusion element may be configured and arranged on the at least one of the first shaft and the second shaft to resiliently engage at least one web-material core around which web-material may be disposed. Other embodiments and methods are provided.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com