Patents

Literature

192 results about "Manufacturing management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

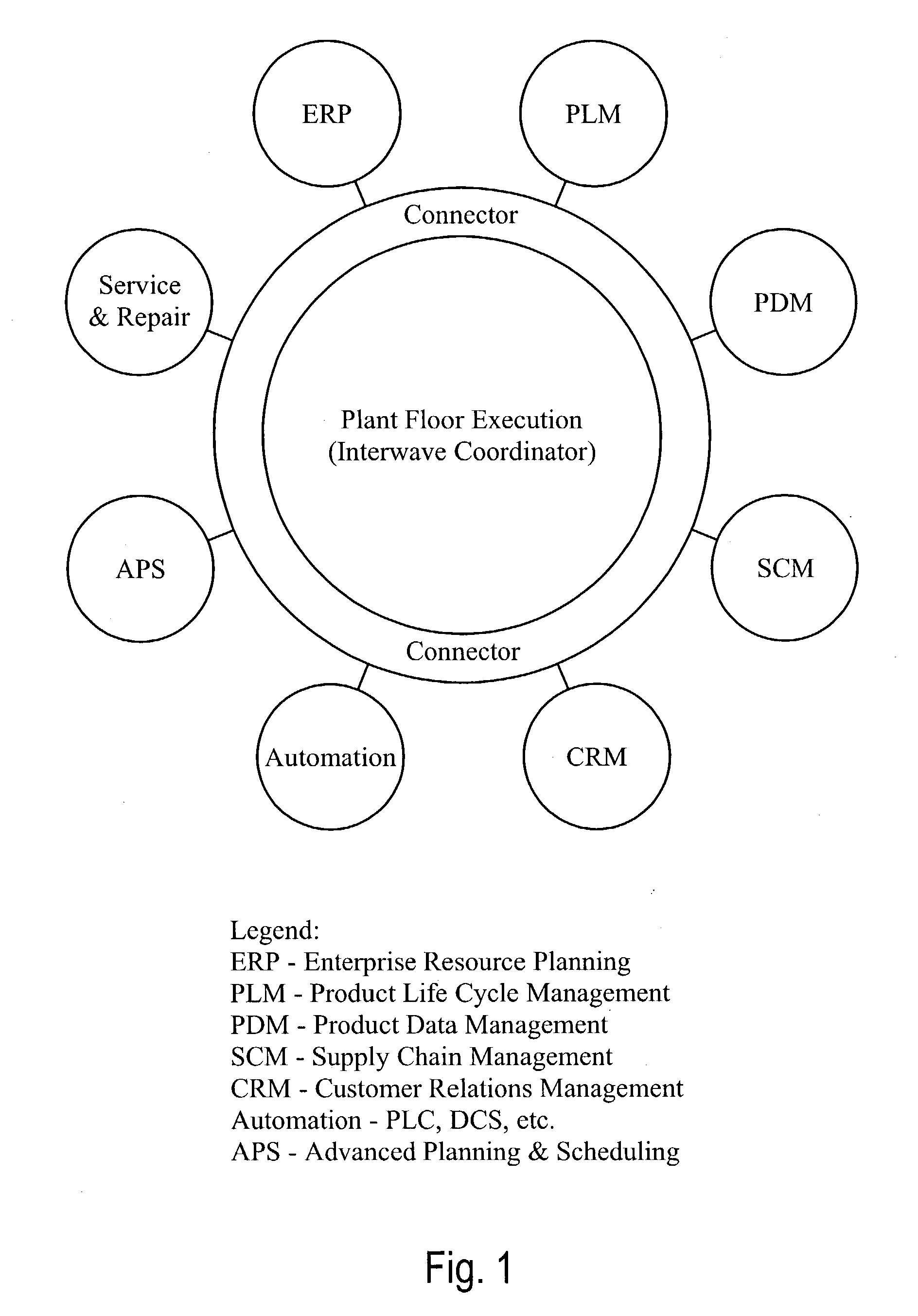

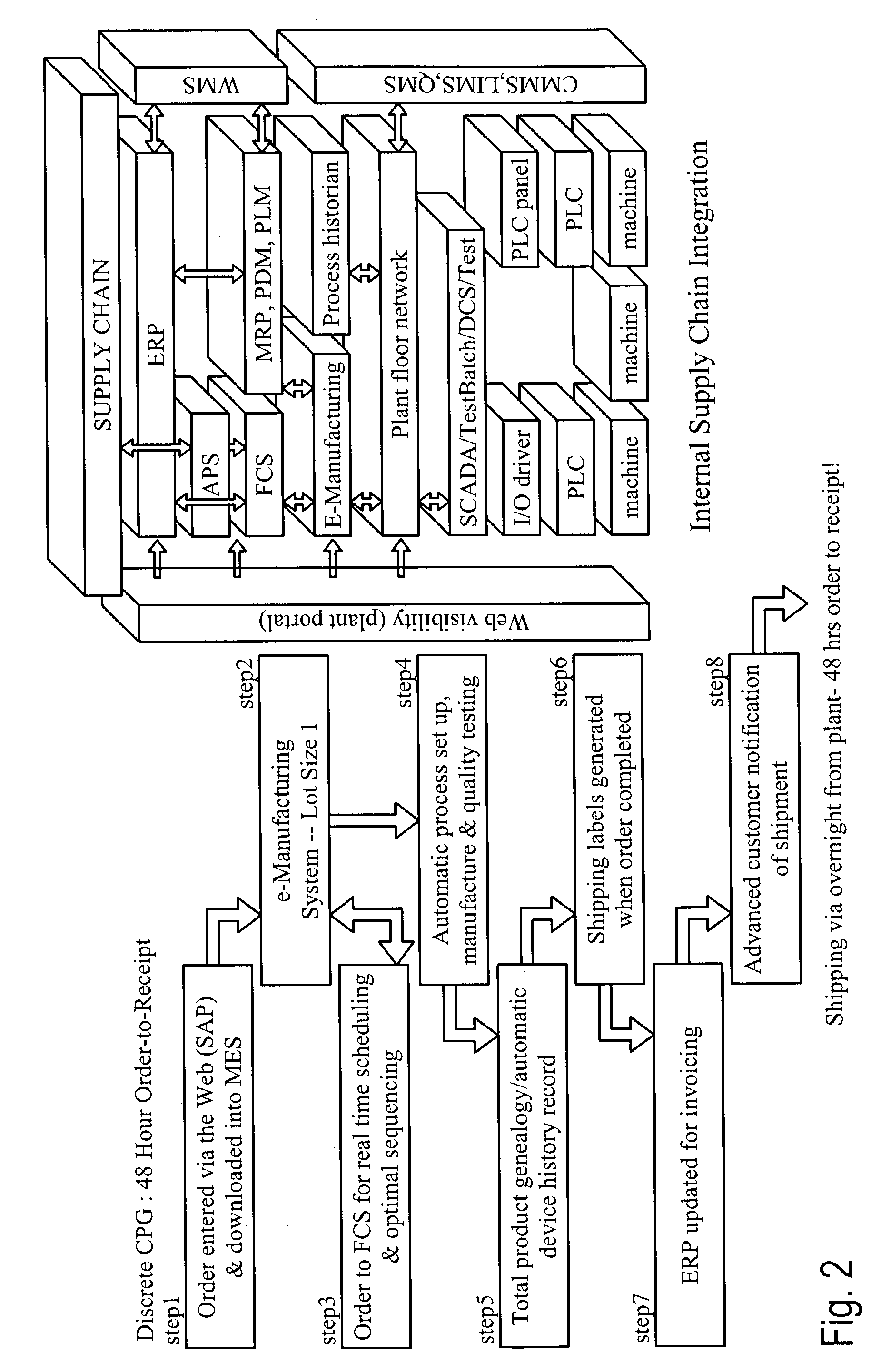

Suite of configurable supply chain infrastructure modules for deploying collaborative e-manufacturing solutions

ActiveUS20030200130A1ResourcesSpecial data processing applicationsManufacturing execution systemE-commerce

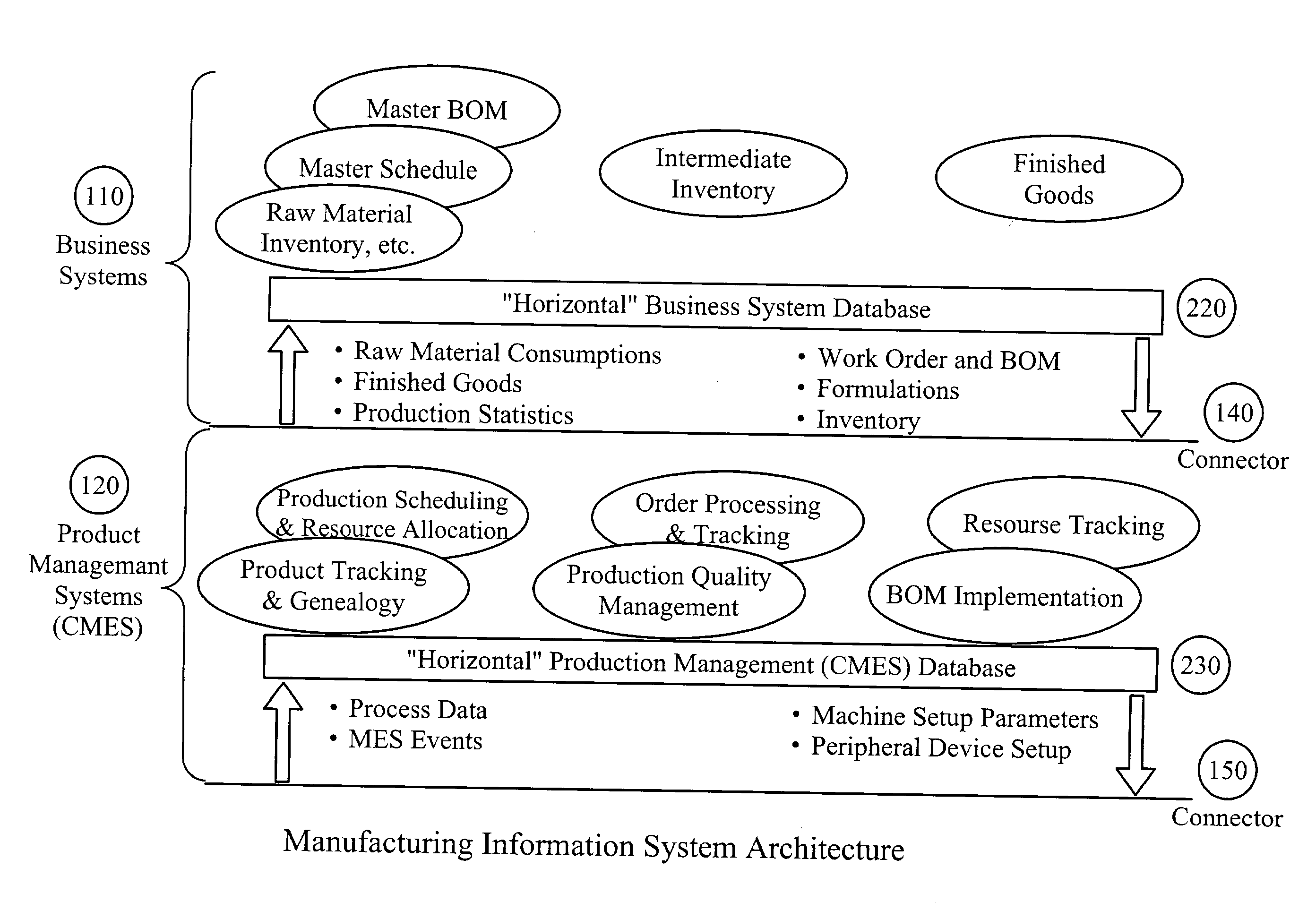

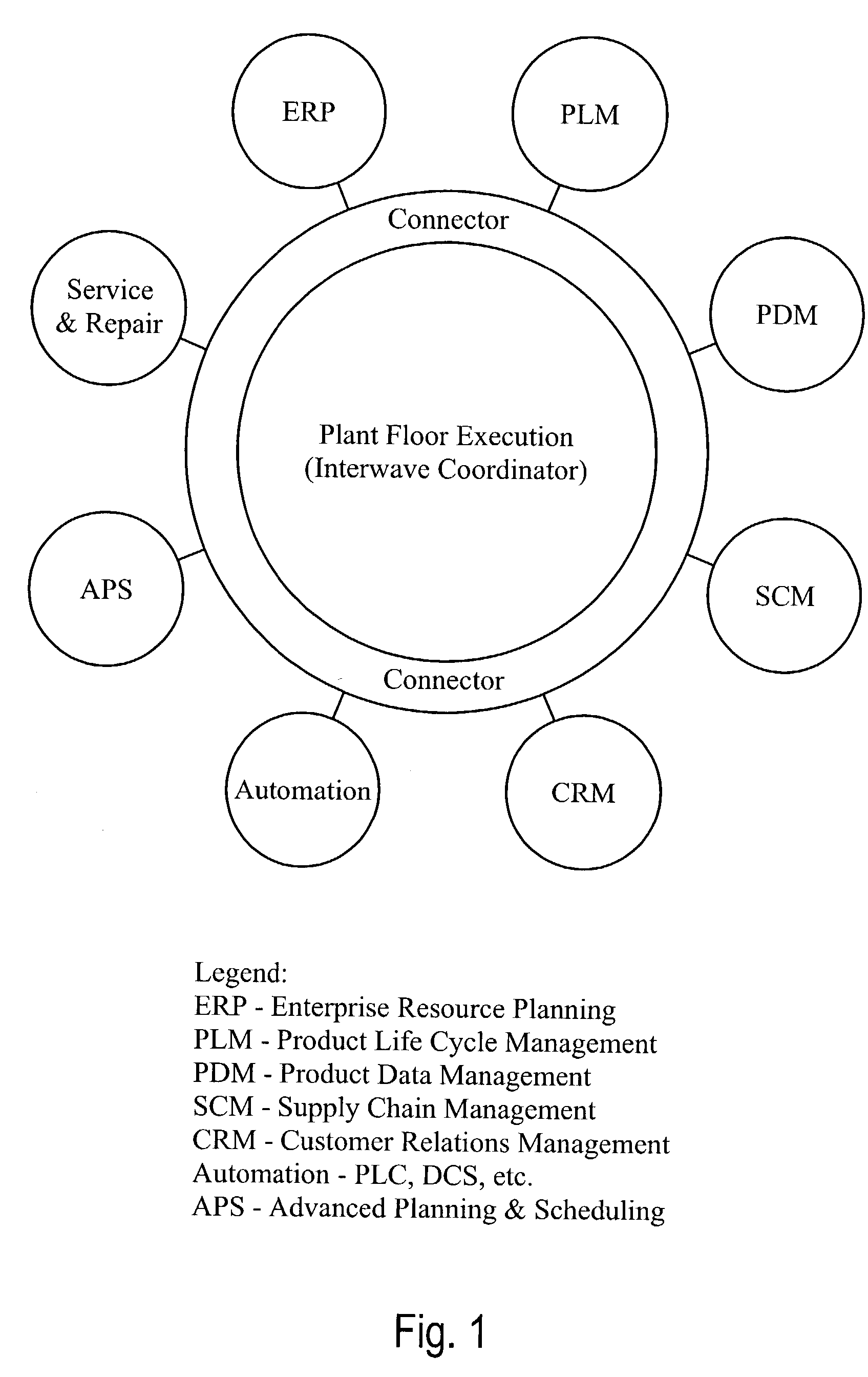

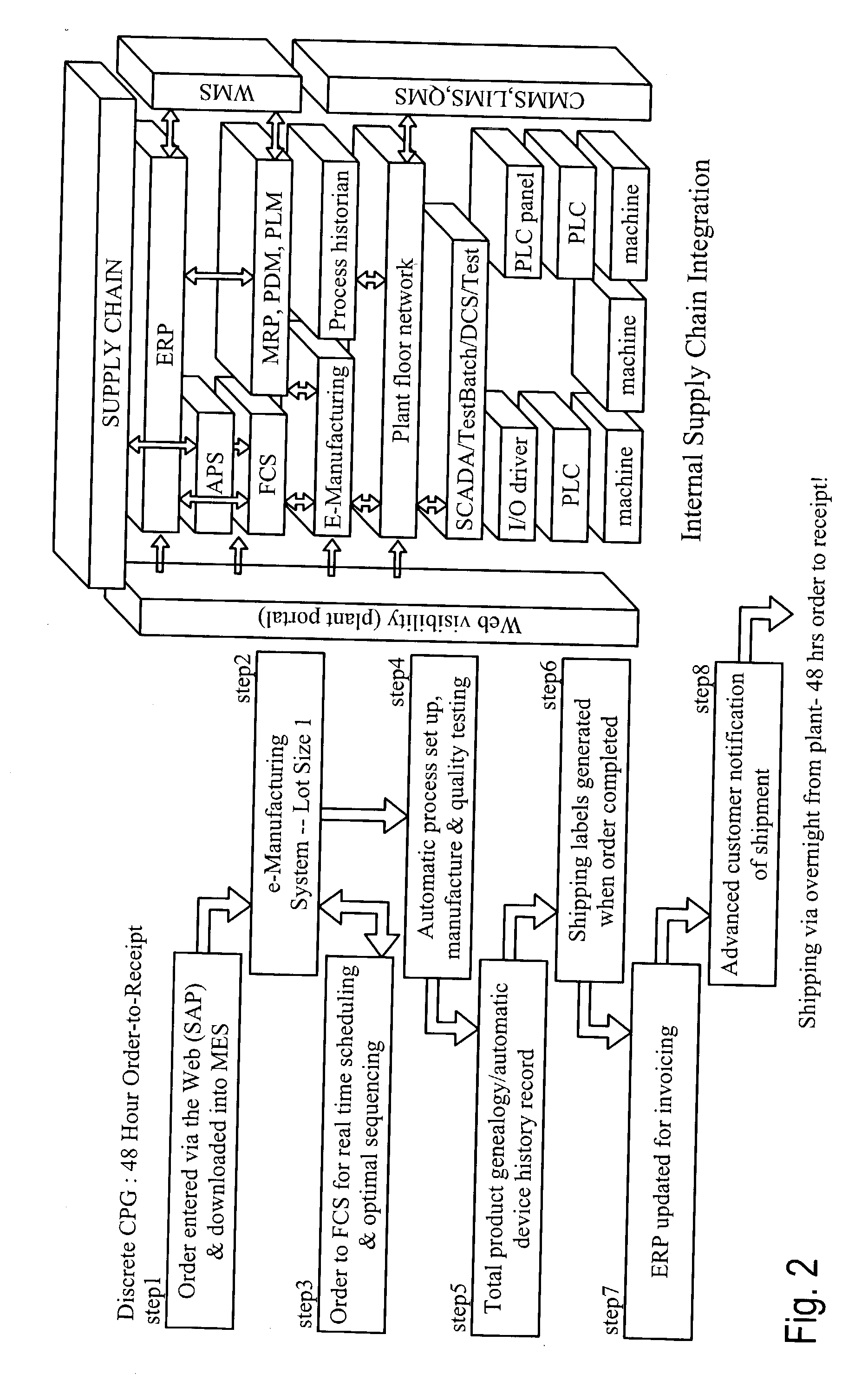

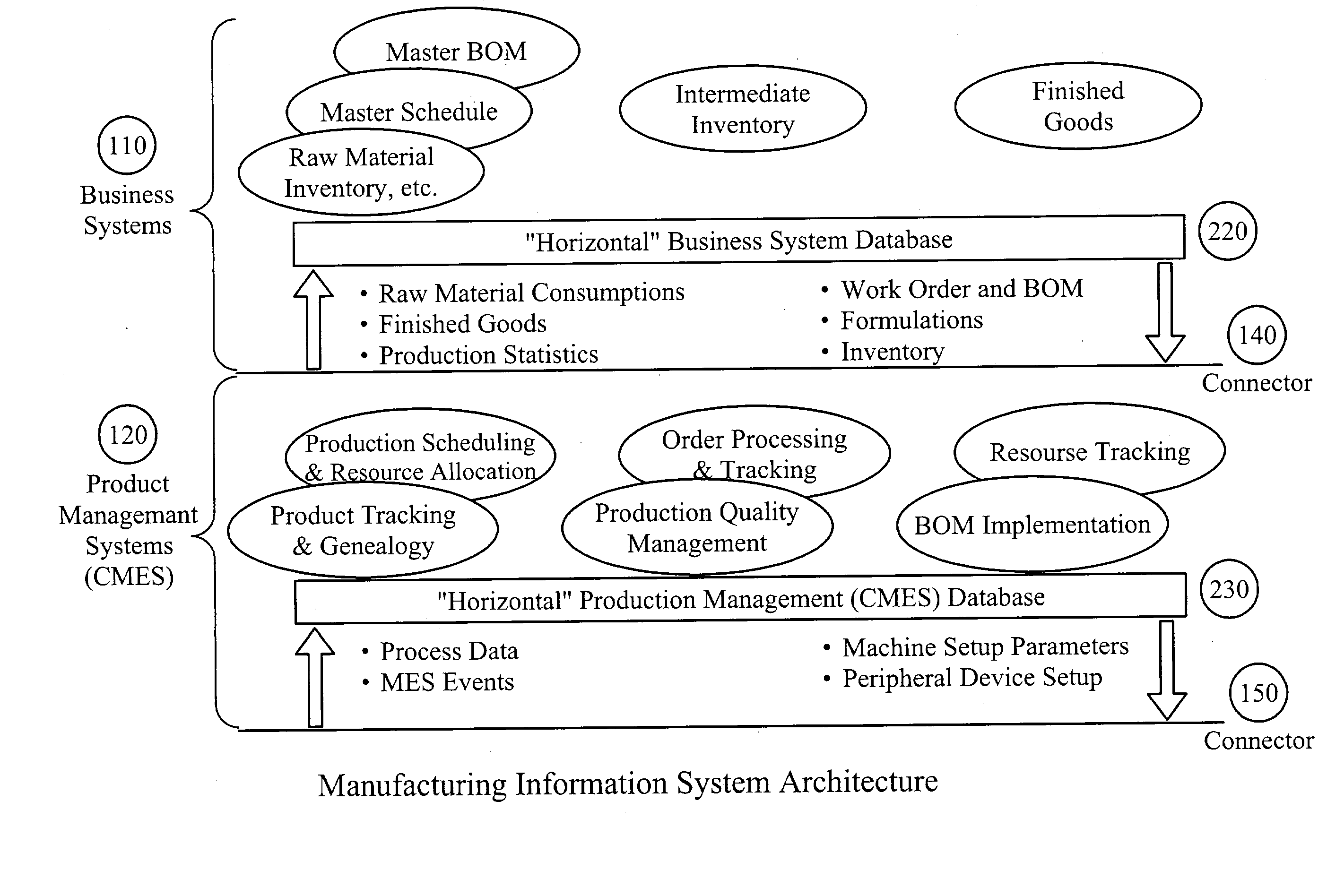

A suite of configurable supply chain infrastructure modules provides the "collective manufacturing management infrastructure" necessary to support a high velocity e-business initiative. At the core of the collaboration scheme is the Business Process Modeling Module. The Business Modeling Module consists of two components: Business Process Event Coordinator, and Business Process Modeler. To further support the collaborative scheme, a suite of highly configurable application templates and pre-configured industry applications provide an interface or wrapper around the business rules. The application templates are designed to be used as stand-alone components, or can be assembled / configured into a cohesive solution to provide a basic foundation layer for a Collaborative Manufacturing Execution System (CMES). To address the connectivity of the CMES layer to the business layer and the shop floor automation layer, an Extensible Markup Language (XML) Business Connector and Optical Photo Conductor (OPC) Shop Floor Connector fulfill the interface needs required to support a collaborative infrastructure.

Owner:ROCKWELL AUTOMATION TECH

Suite of configurable supply chain infrastructure modules for deploying collaborative e-manufacturing solutions

InactiveUS20030149608A1ResourcesSpecial data processing applicationsManufacturing execution systemApplication software

A suite of configurable supply chain infrastructure modules provides the "collective manufacturing management infrastructure" necessary to support a high velocity e-business initiative. At the core of the collaboration scheme is the Business Process Modeling Module. The Business Modeling Module consists of two components: Business Process Event Coordinator, and Business Process Modeler. To further support the collaborative scheme, a suite of highly configurable application templates and pre-configured industry applications provide an interface or wrapper around the business rules. The application templates are designed to be used as stand-alone components, or can be assembled / configured into a cohesive solution to provide a basic foundation layer for a Collaborative Manufacturing Execution System (CMES). To address the connectivity of the CMES layer to the business layer and the shop floor automation layer, an Extensible Markup Language (XML) Business Connector and Optical Photo Conductor (OPC) Shop Floor Connector fulfill the interface needs required to support a collaborative infrastructure.

Owner:ROCKWELL AUTOMATION

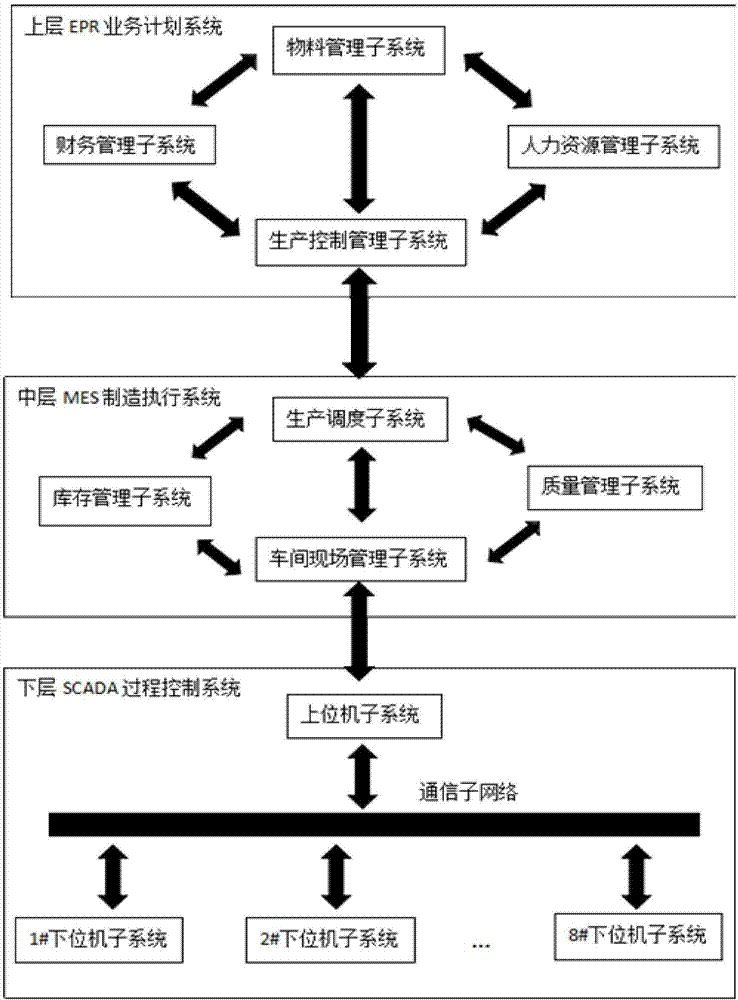

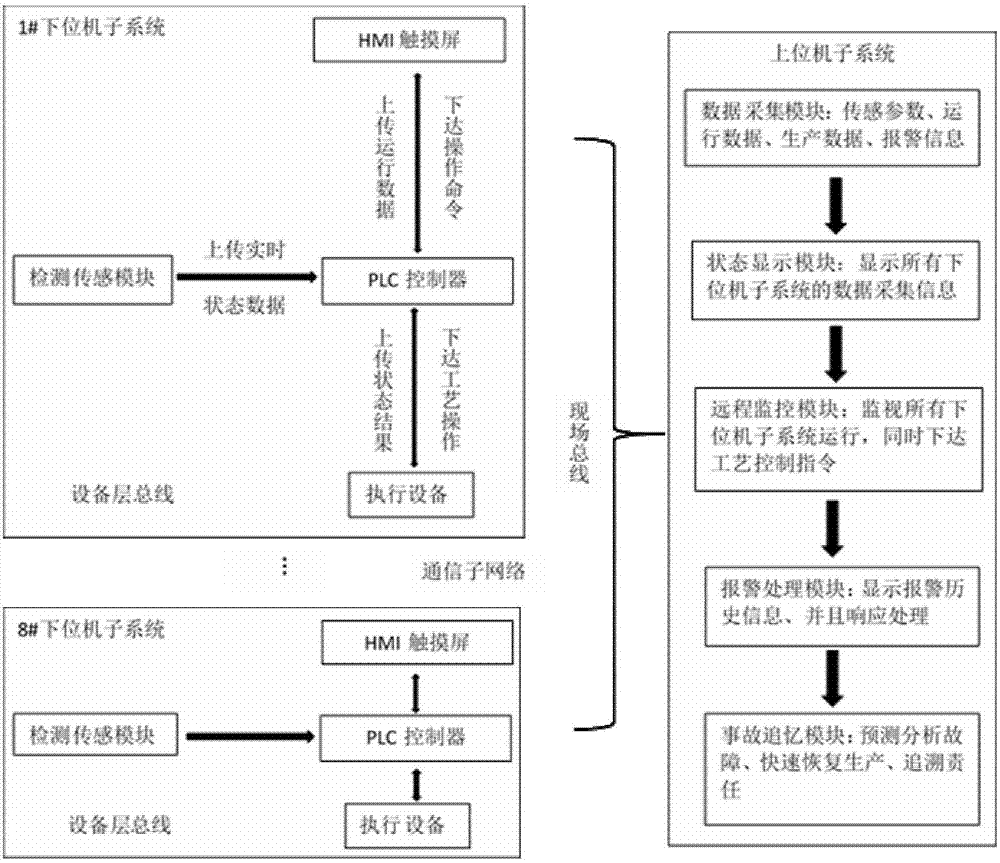

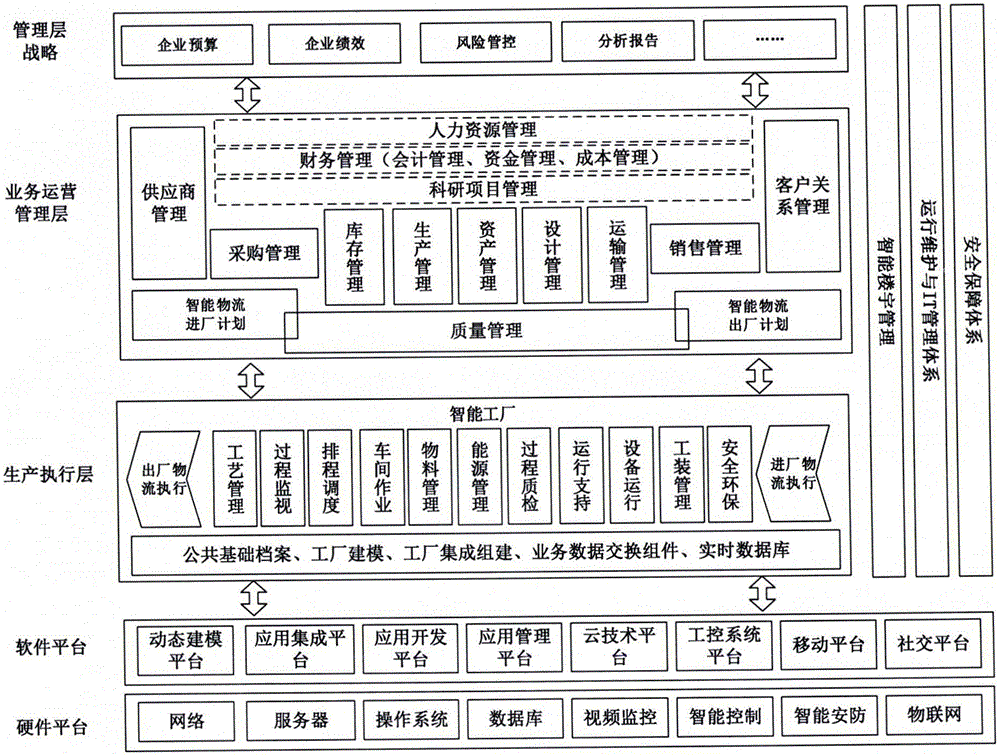

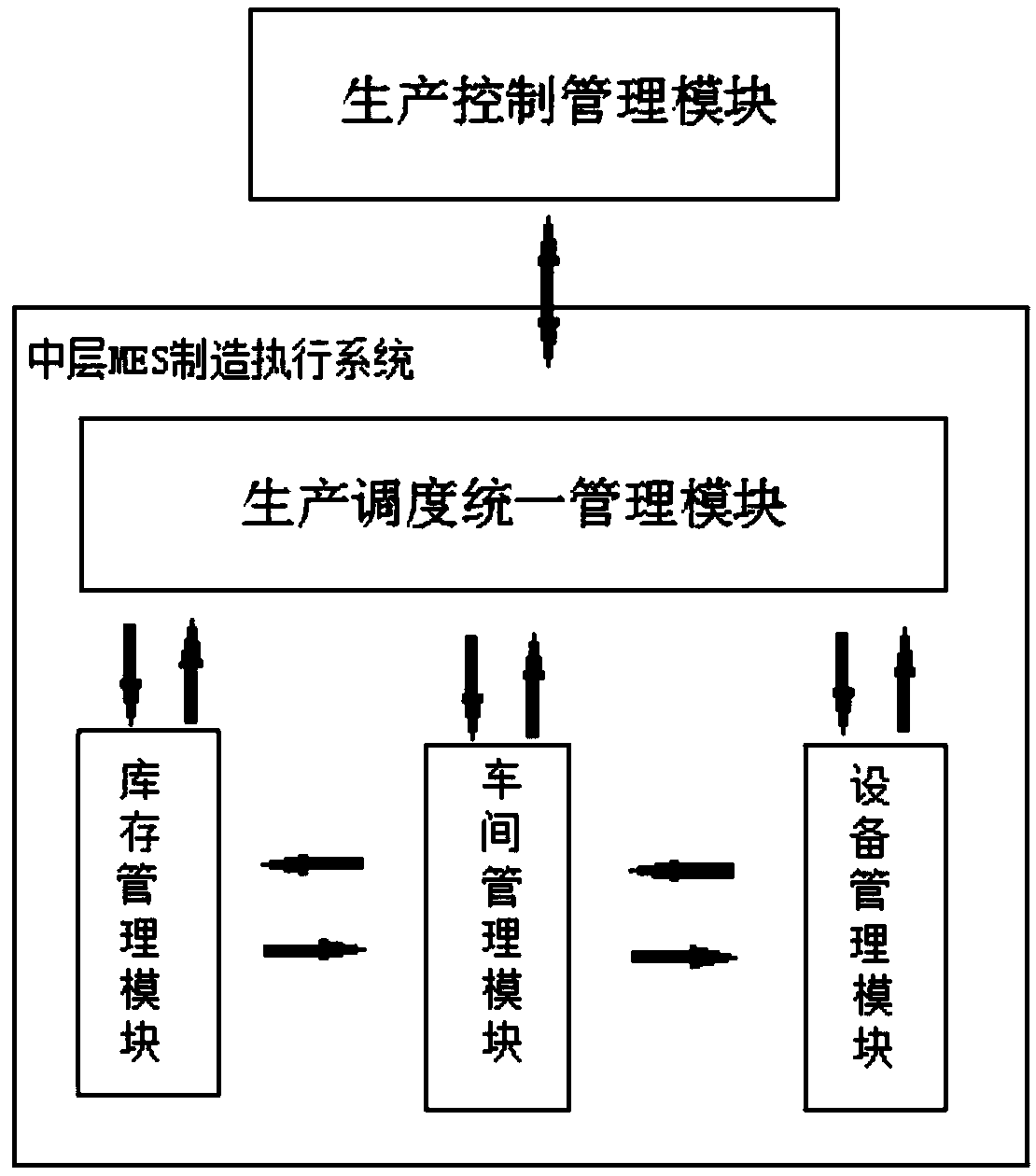

Intelligent factory system based on internet of things technology and industrial big data

InactiveCN107272629AIncrease productionReduce energy consumptionTechnology managementTotal factory controlManufacture execution systemReal time analysis

The invention relates to the field of intelligent production and manufacturing management technology, particularly to an intelligent factory system based on the internet of things technology and industrial big data. The intelligent factory system comprises a lower SCADA process control system, an intermediate MES manufacturing execution system, and an upper ERP business planning system. Therefore, problems of difficult real-time analysis and calculation, difficult accident tracing and restoration, high non-planned parking frequency, low work production efficiency, difficult non-transparent decision-making and difficult cooperation among the regional personnel are solved so as to improve the product output, reduce energy consumption and reduce the cost; the a humanized intelligent factory with equipment intelligence, modern management, and information computerization is established truly; and the core competitiveness of enterprise is enhanced.

Owner:科睿特软件集团股份有限公司

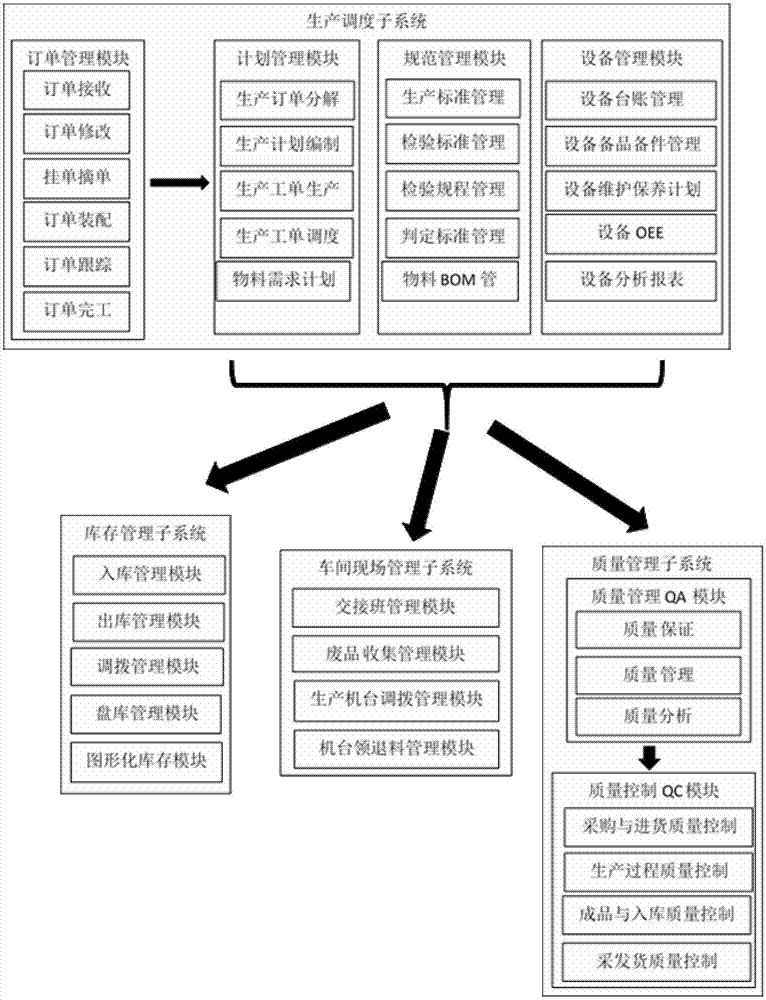

aps/mes lean manufacturing management system

InactiveCN102262757AImprove reaction speedImprove reaction efficiencyInstrumentsSoftware systemHand held

APS / MES lean manufacturing management system, including system hardware and system software, the software in the hardware is integrated in the main system software, and is seamlessly connected with the main system; the system hardware includes: industrial touch all-in-one machine connected to the host server and LED electronic kanban and The RFID card reader used to read the RFID card, the wireless receiving and transmitting device is connected with the host server, the handheld terminal and the terminal touch screen through the sensor, and the host server is also connected with the host of the logistics distribution center and the host of the delivery center; the system software includes: Supply chain management, sales management, procurement management, warehouse management, subcontract processing, production order, process route, workshop scheduling plan, handheld terminal module, terminal touch screen, material distribution, LED electronic kanban control system software module; system software The management module is divided into: basic data module, supply chain management module, equipment management module, production management module, and handheld terminal module; each module is composed of its corresponding sub-modules.

Owner:王圣亮

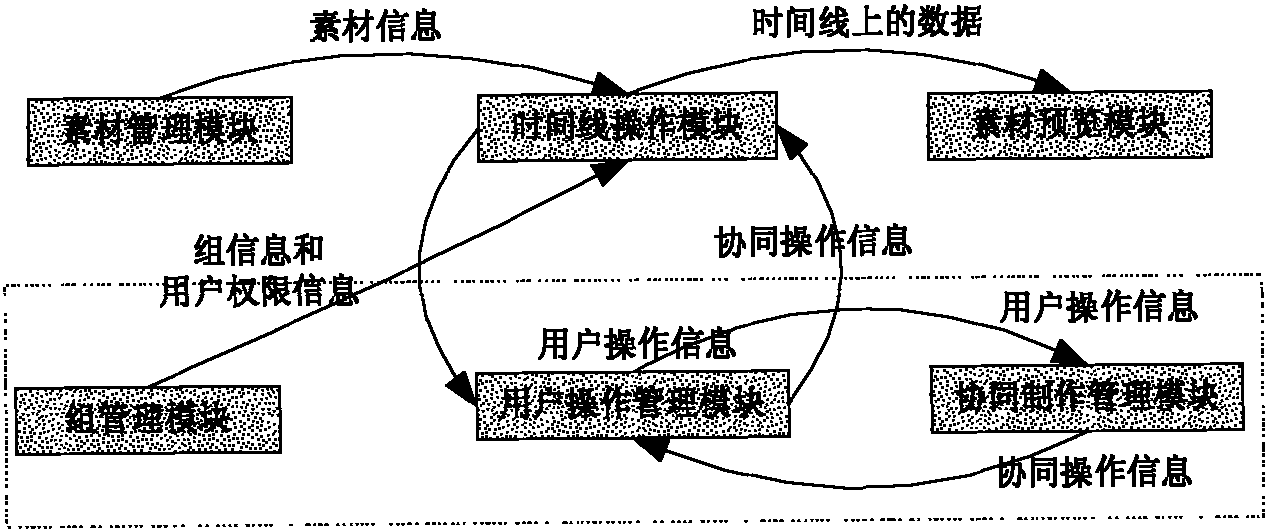

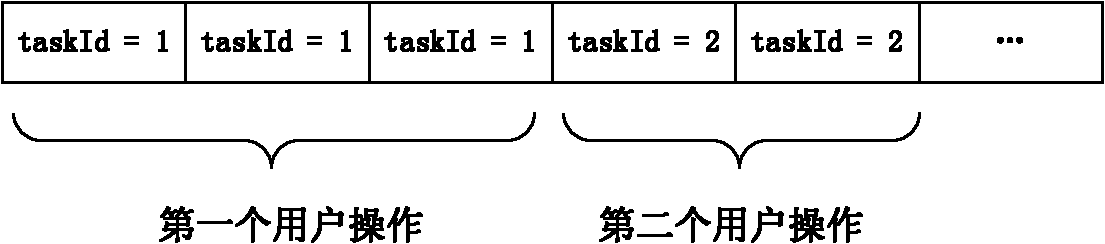

On-line collaborative nolinear editing system

ActiveCN102081946AAchieve sharingSolve the problem of collaborative editing and productionTelevision system detailsCarrier editingInformation processingTeam management

The invention discloses an on-line collaborative nolinear editing system belonging to the technical field of Internet media information processing. The on-line collaborative nolinear editing system comprises a manufacture team management module, a material management module, a timeline operation module, a material previewing module, a user operation management module and a collaborative manufacture management module. Edition operation for respective video of each person is shared by the on-line collaborative nolinear editing system to realize the on-line collaborative nolinear edition system for more people, the efficiency on collaborative edition manufacture of the on-line video program is improved, and the collaborative edition manufacture for more people under different environments can be realized.

Owner:SHANGHAI NAT ENG RES CENT OF DIGITAL TELEVISION

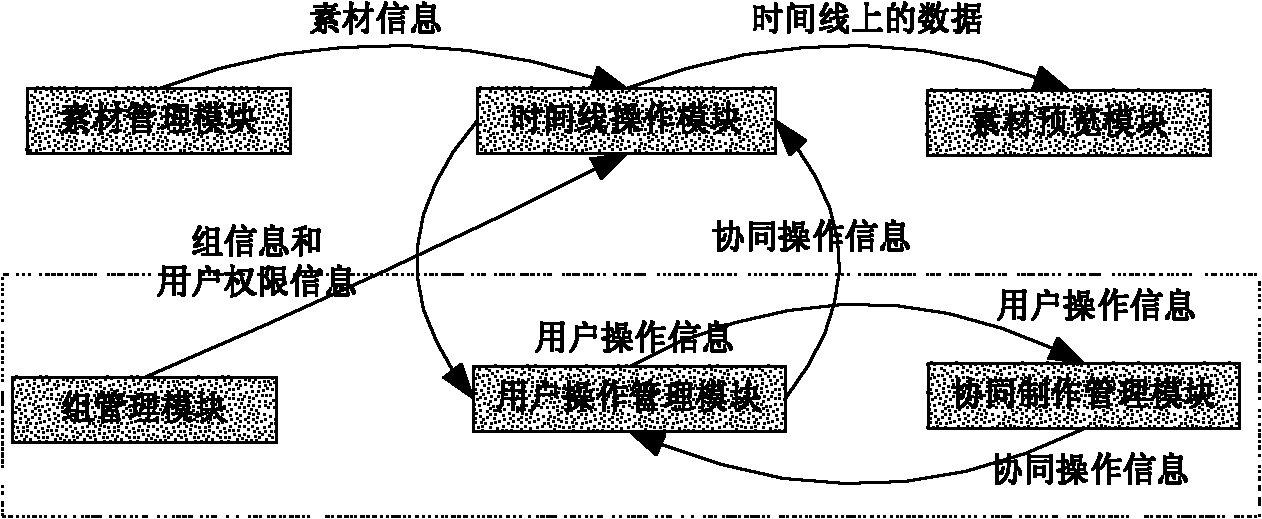

Internet + industrial 4.0 intelligent manufacturing management method and system

InactiveCN105427055AAddress changing needsQuick responseResourcesManufacturing computing systemsInformation resourceThe Internet

The invention discloses an Internet + industrial 4.0 intelligent manufacturing management method and a system. The Internet + industrial 4.0 intelligent manufacturing management method and the system are used to provide a comprehensive information resource service for system exploitation, testing and operation deployment. The method and system are characterized in that the Internet + industrial 4.0 intelligent manufacturing management method and the system comprise five layers of service frameworks, two safety systems and intelligent building management; the five layers of frameworks are a hardware platform layer, a software platform layer, a production manufacturing execution layer, a service operation management layer and a strategy management layer from bottom to top respectively; through the intelligent building management and a series of guarantee support auxiliary of the two systems of an operation maintenance and IT management system and safety guarantee, sensors which are located everywhere, an embedded terminal system, an intelligent control system and communication facilities form one intelligent network through a CPS. People and people, people and machine, machine and machine, and server and server can be interconnected so that transverse, vertical and end-to-end high integration is realized. A production network is constructed. Perfect fusion of virtual and real worlds is achieved and an industrial 4.0 mode of information physics fusion system construction and application is constructed.

Owner:北京中科云集科技有限公司

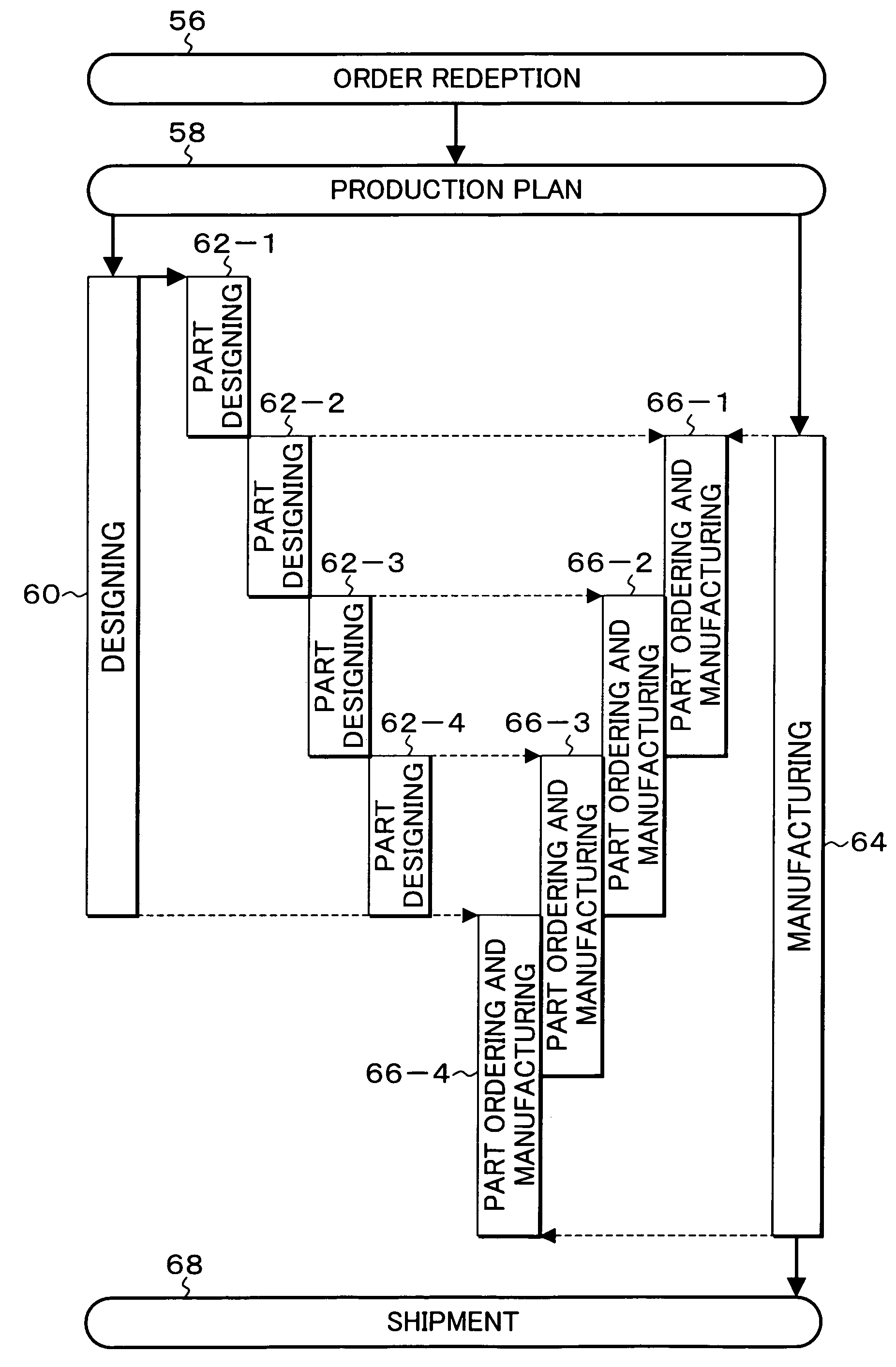

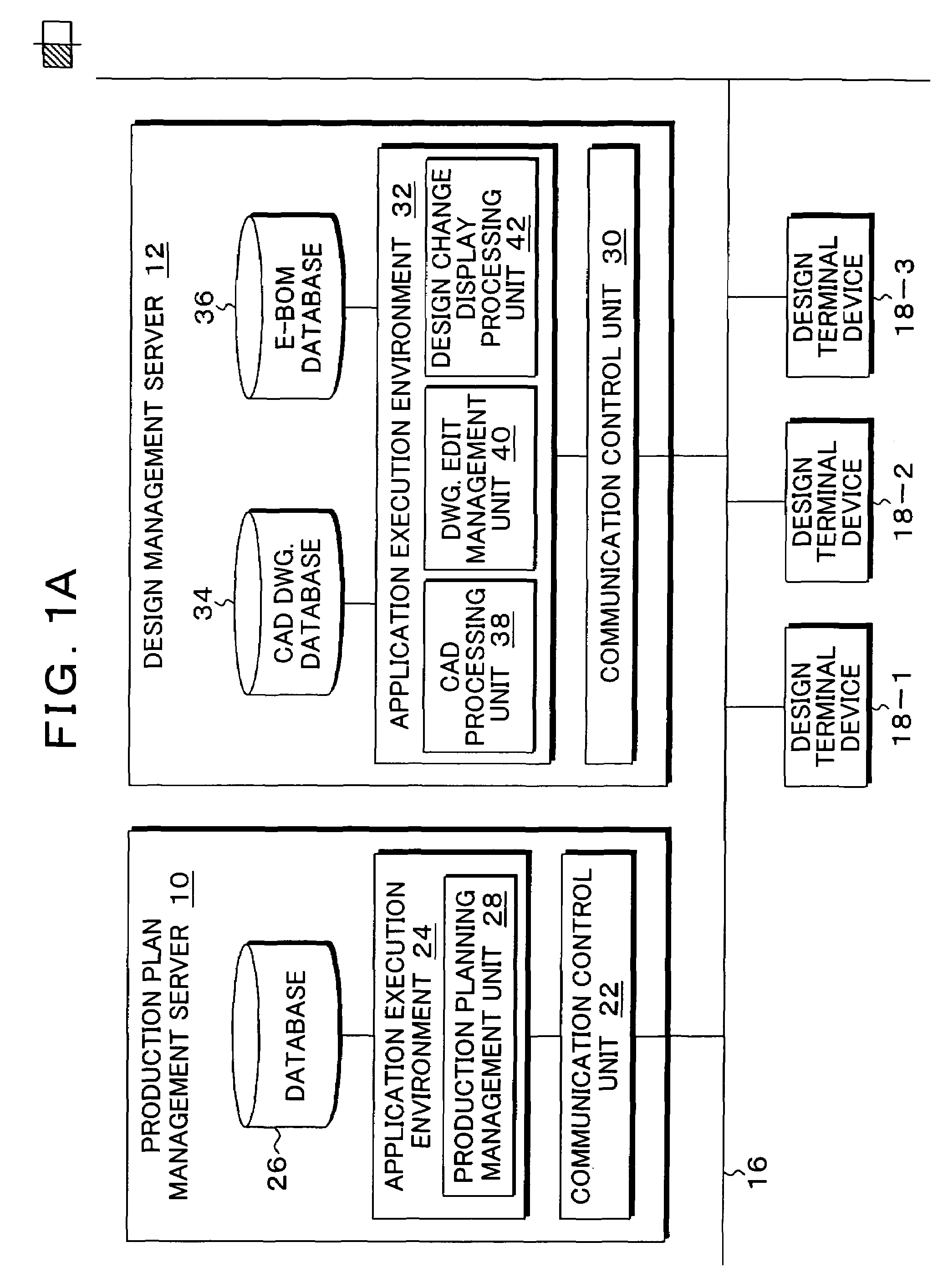

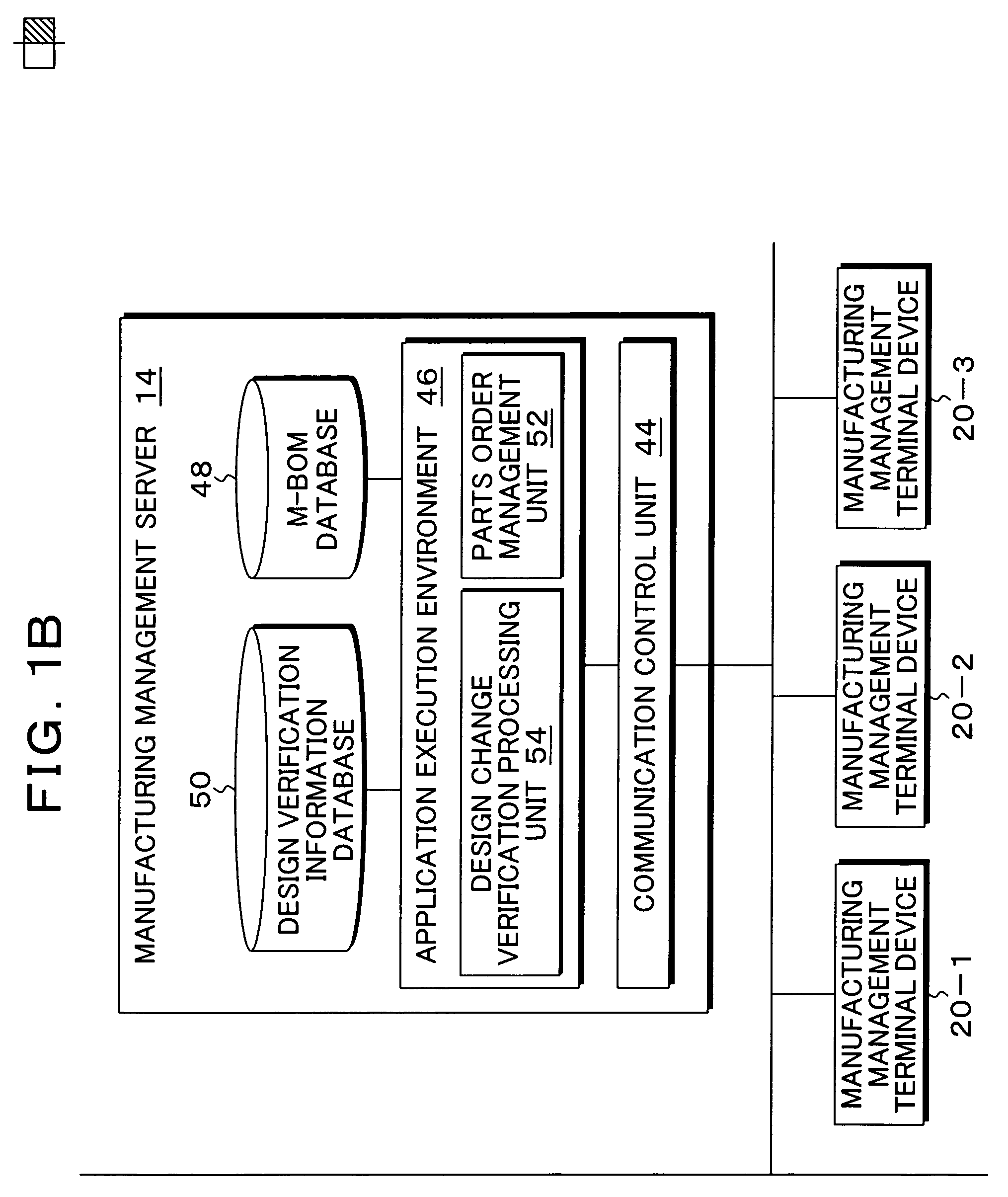

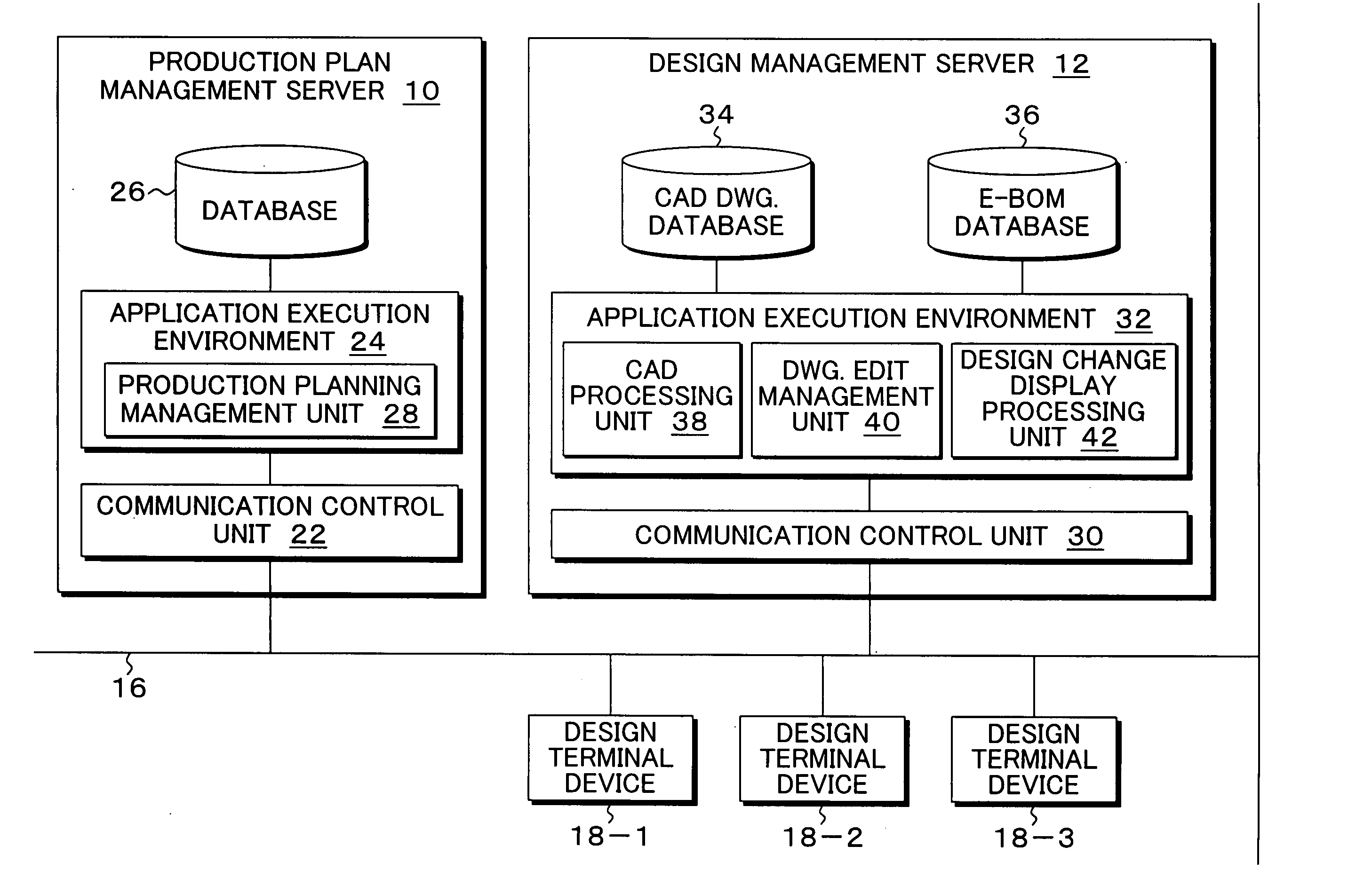

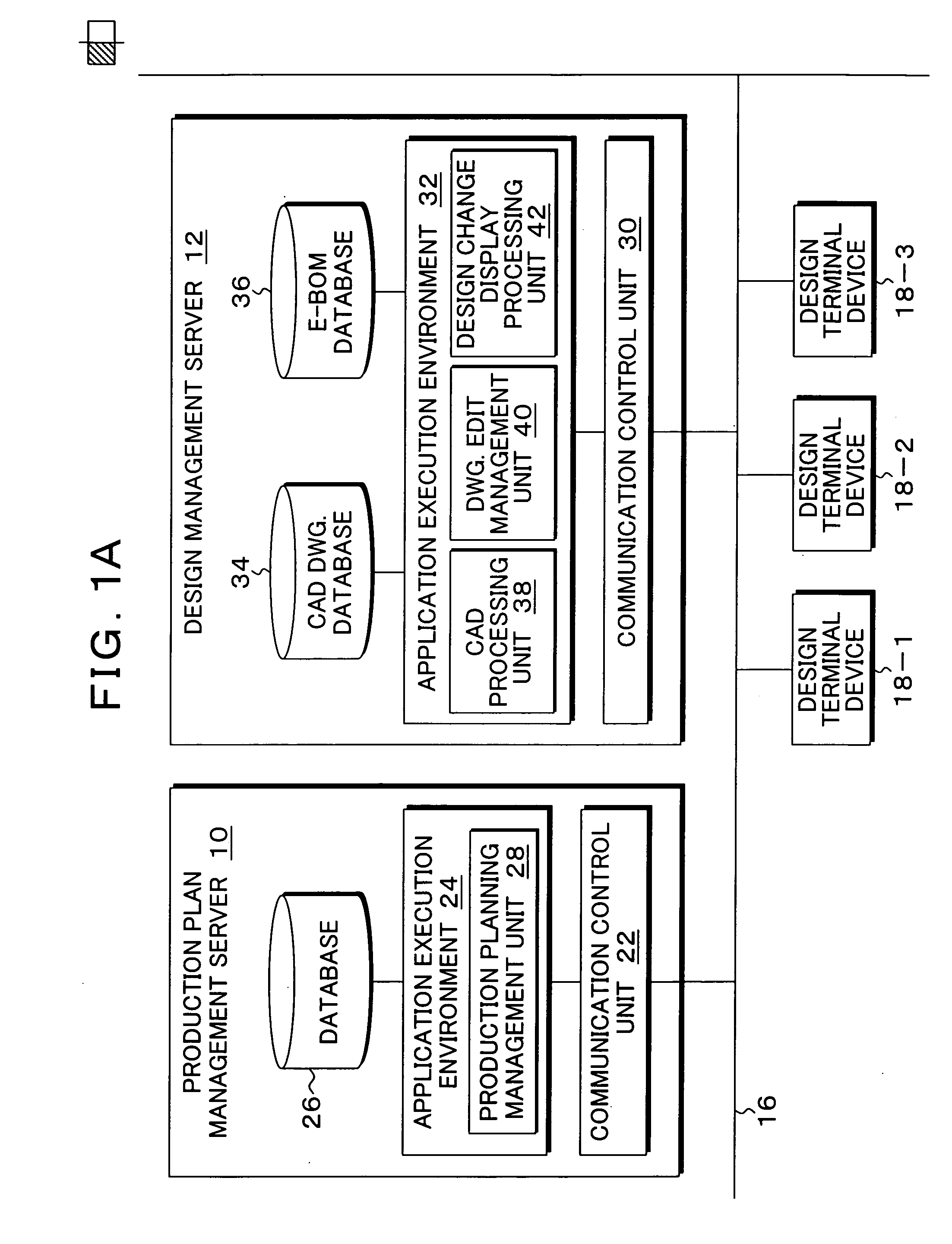

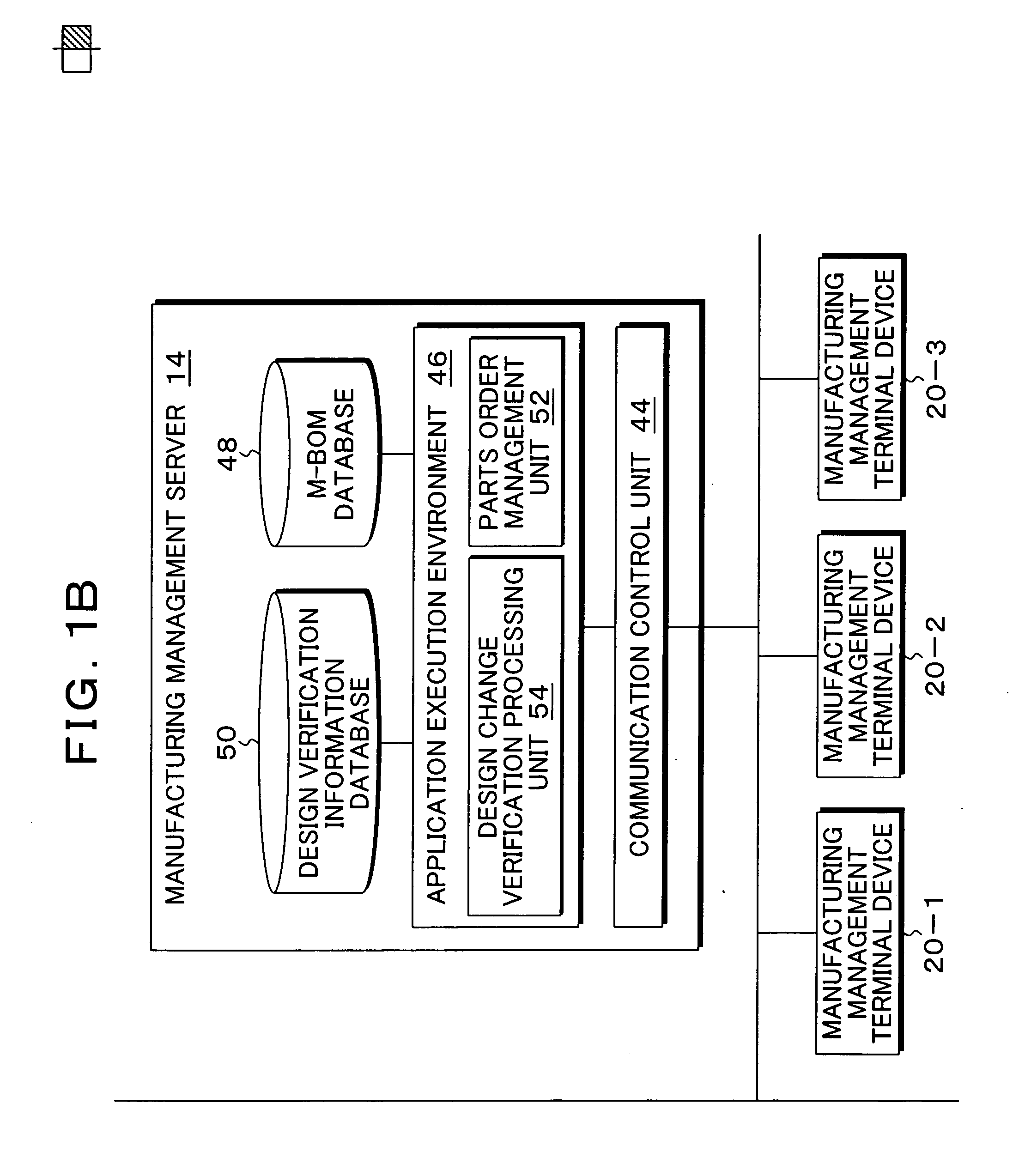

Design and manufacturing management system, method, and program

InactiveUS7606628B2Improve processing efficiencyApplied load reductionData processing applicationsComputer aided designManagement unitManufacturing management

Owner:FUJITSU LTD

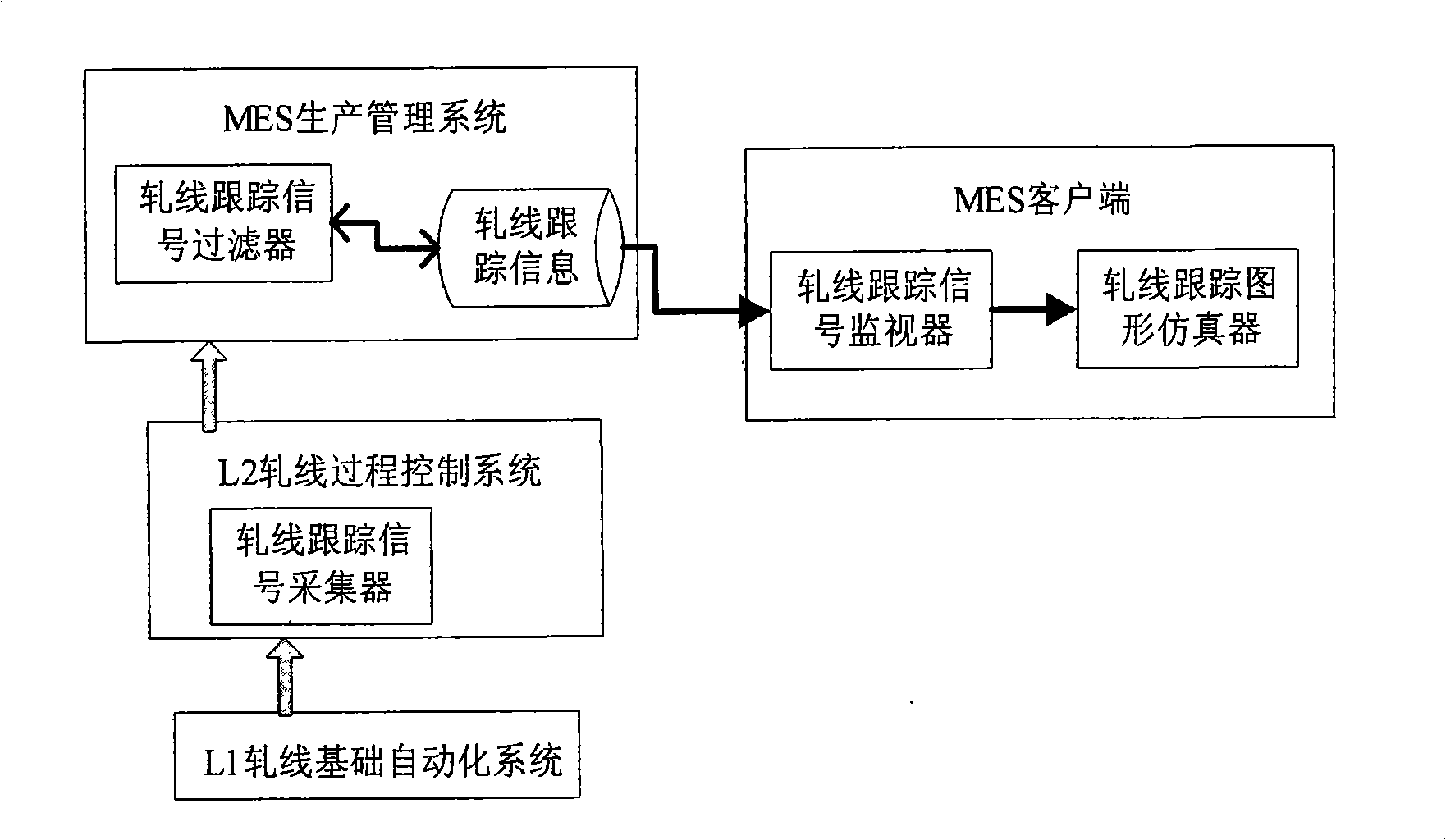

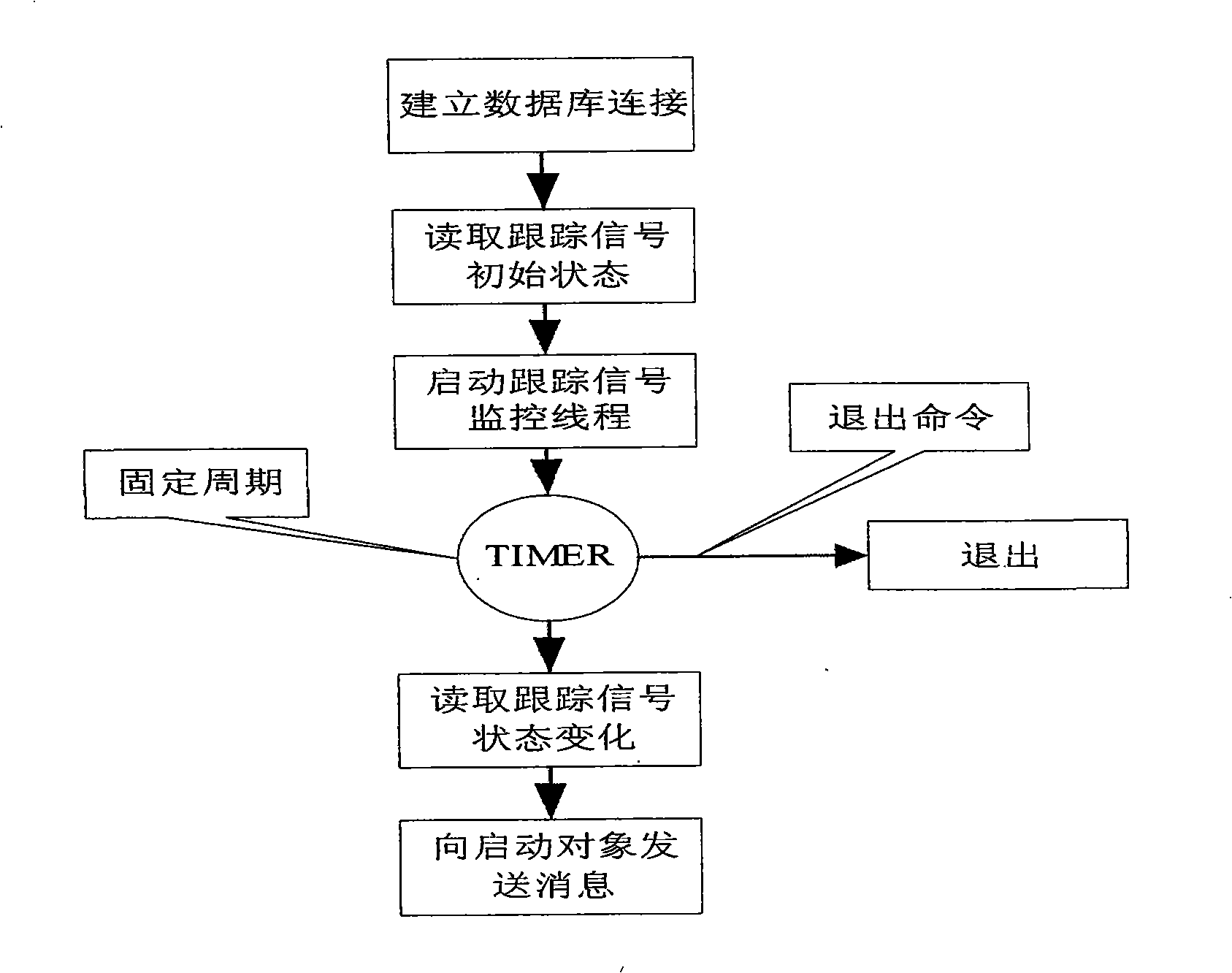

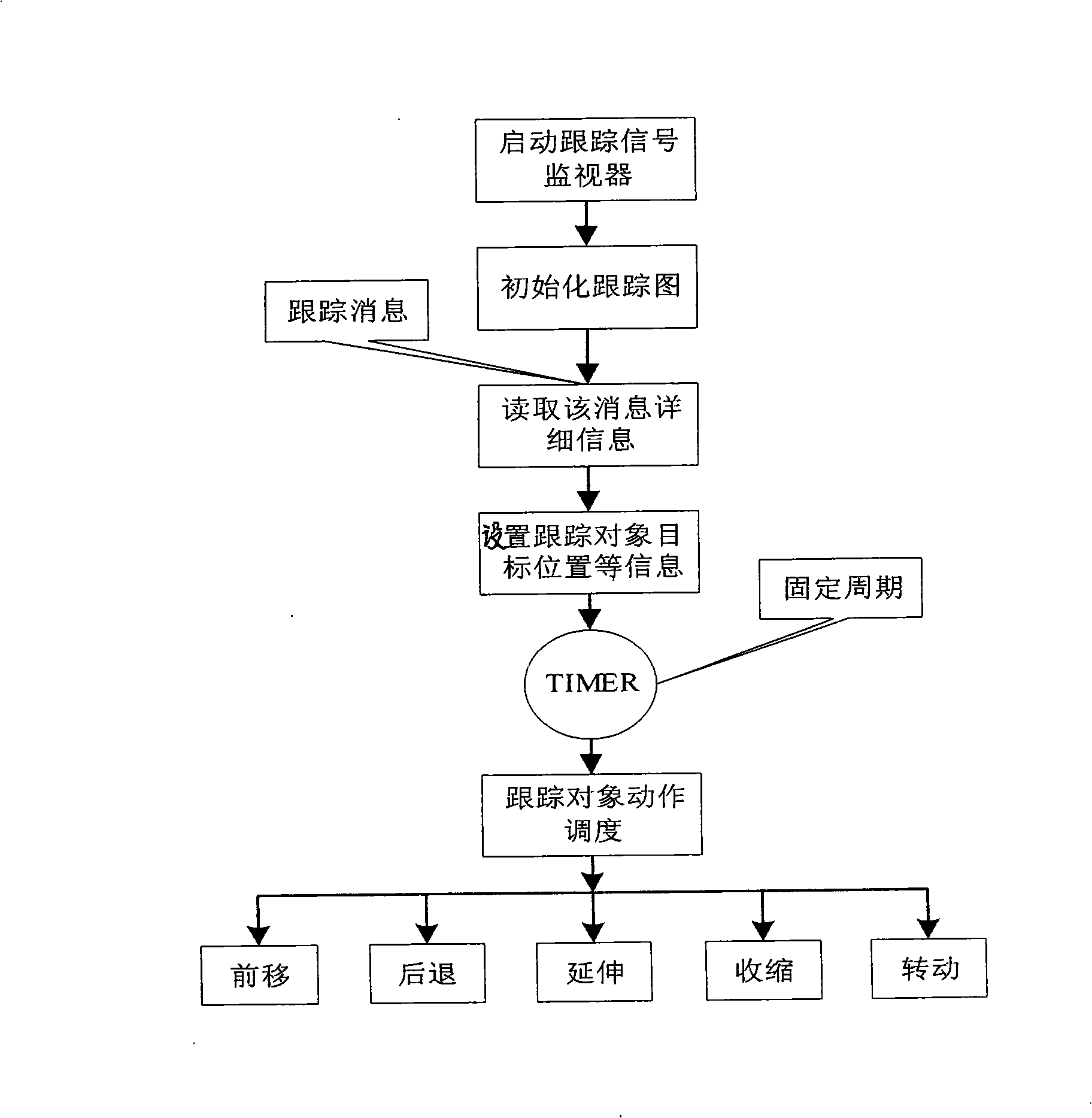

Method for tracking hot rolling production management level graphic rolling line material

InactiveCN101408757AMonitor productivityMonitor device statusProgramme controlComputer controlCommunications softwareSignal tracking

The invention relates to a hot rolling manufacturing management level graphical rolling line material tracking method, which mainly solves the technical problem that a manufacturing manager can not remotely monitor hot rolling line production and equipment status. The method has the technical proposal that the hot rolling manufacturing management level graphical rolling line material tracking method comprises the following steps: a. a rolling line signal tracking step: tracking signal data of the key position from an export of a heating furnace to the end of coiling is collected by a rolling line tracking signal collector, and then is transmitted to a MES by communication software; b. a rolling line signal filtrating step: the received tracking signal is analyzed and treated by a rolling line tracking signal filter, and the efficient tracking signal is stored in a database; c. a rolling line signal monitoring and graphical simulation step: tracking signal change information collected by a rolling line tracking signal monitor is input into a rolling line tracking graphical emulator; a band steel action graph is drawn out in real time at a client of the MES; field actual rolling process is simulated; the position of the band steel and the equipment state of a rolling mill are reflected in real time. The method mainly realizes real time tracking and dynamic mapping a track view on the material position during rolling process on the MES.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Design and manufacturing management system, method, and program

InactiveUS20060155407A1Improve processing efficiencyApplied load reductionData processing applicationsComputer aided designManagement unitManufacturing management

A drawing edit management unit of a design management server manages an E-BOM created from a CAD design drawing by storing the E-BOM in a E-BOM database, and notifies a manufacturing management server of design completion. A design change display processing unit causes design change permitted ranges and forbidden ranges to be displayed, upon design change, in accordance with design change verification information of a design change verification database. A parts order management unit of the manufacturing management server requests confirmation when receiving the design completion notice, and manages a M-BOM, to which preparation information including order instructions and manufacturing instructions of a part is added and which has been created from the E-BOM after confirmation, by storing the M-BOM in a M-BOM database. A design change verification processing unit manages design change verification information created from the preparation information of the M-BOM by storing the design change verification information in a design verification database.

Owner:FUJITSU LTD

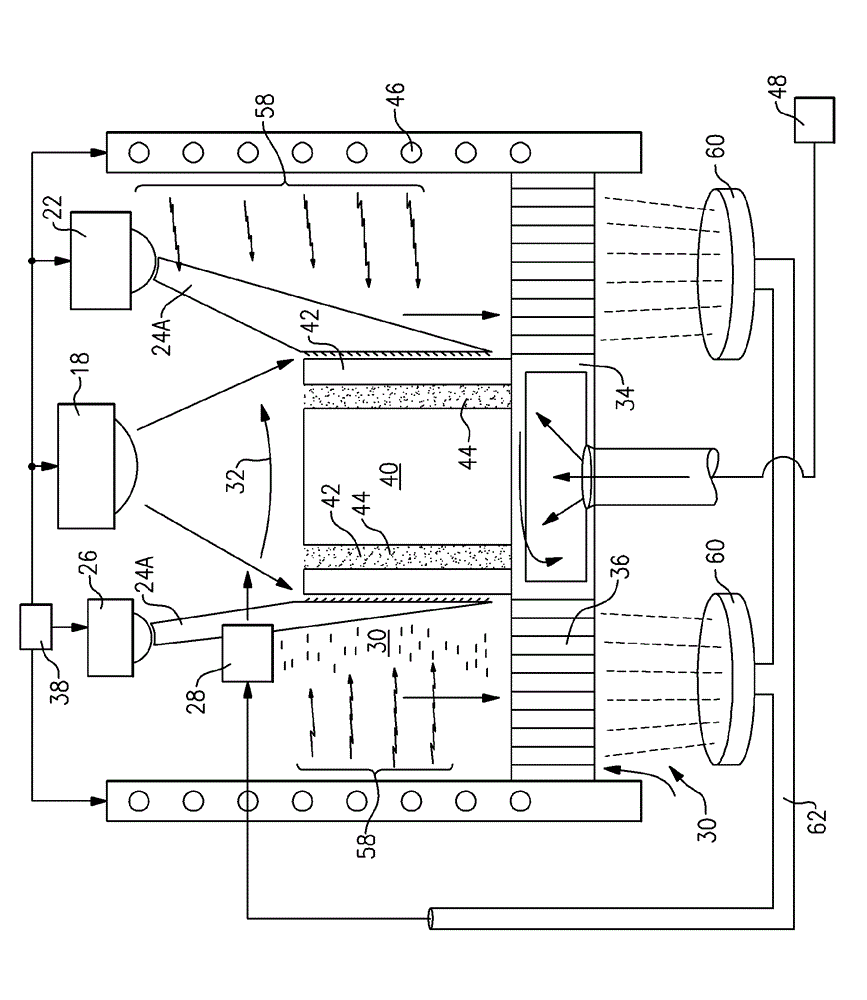

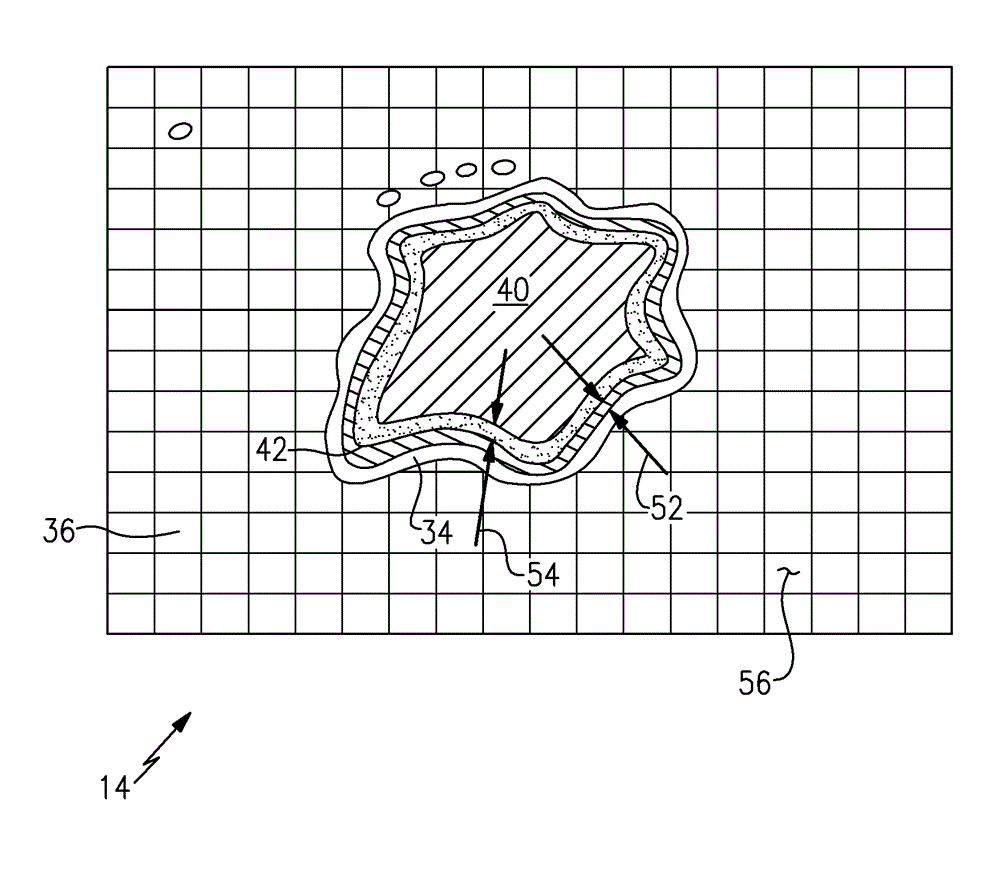

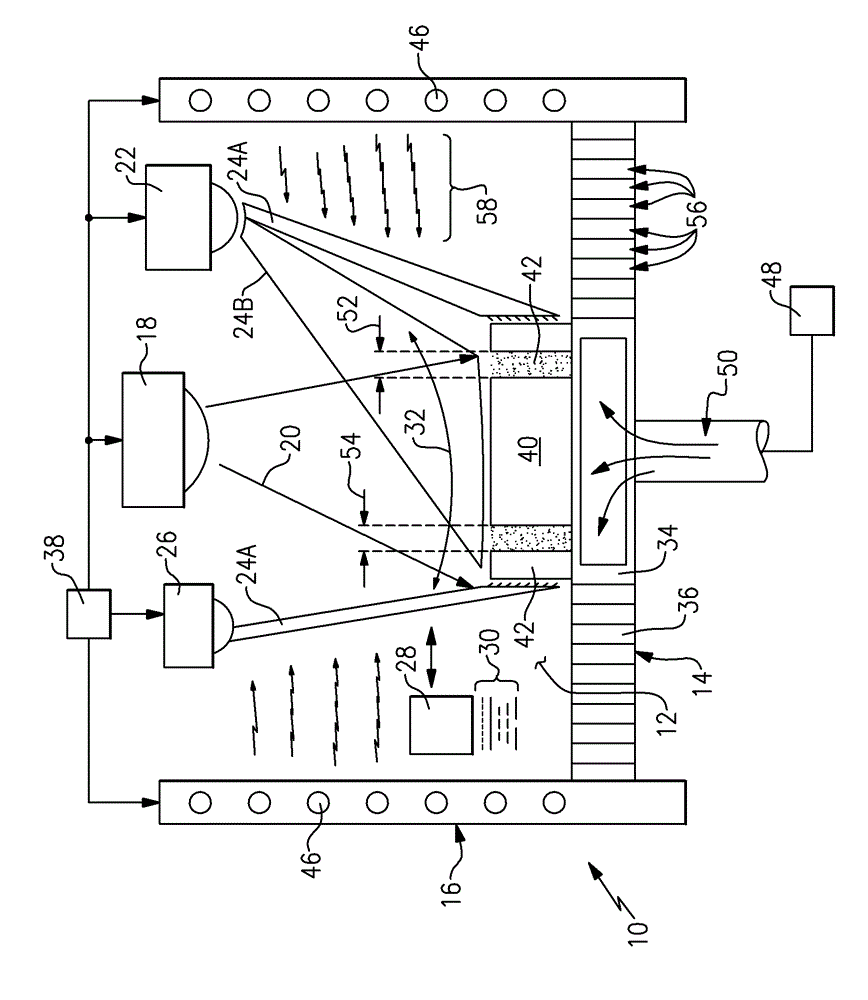

Additive manufacturing management of large part build mass

ActiveCN103056365AAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringManufacturing management

An additive manufacturing machine includes a base plate for supporting fabrication of a desired part geometry. The base plate includes a support portion defined based on the desired part geometry and an open region that includes a plurality of openings surrounding the support portion. A material applicator deposits material onto the base plate and an energy directing device directs energy to form the deposited material into a desired part geometry. The additive manufacturing machine manages large amounts of material required for fabricating the part by defining a boundary surrounding a periphery of a desired part geometry and forming a retaining wall along the defined boundary and the desired part geometry to retain excess material between the formed wall and the part. Excess material outside of the retaining wall falls through the open area below the base plate and is reclaimed for reuse.

Owner:UNITED TECH CORP

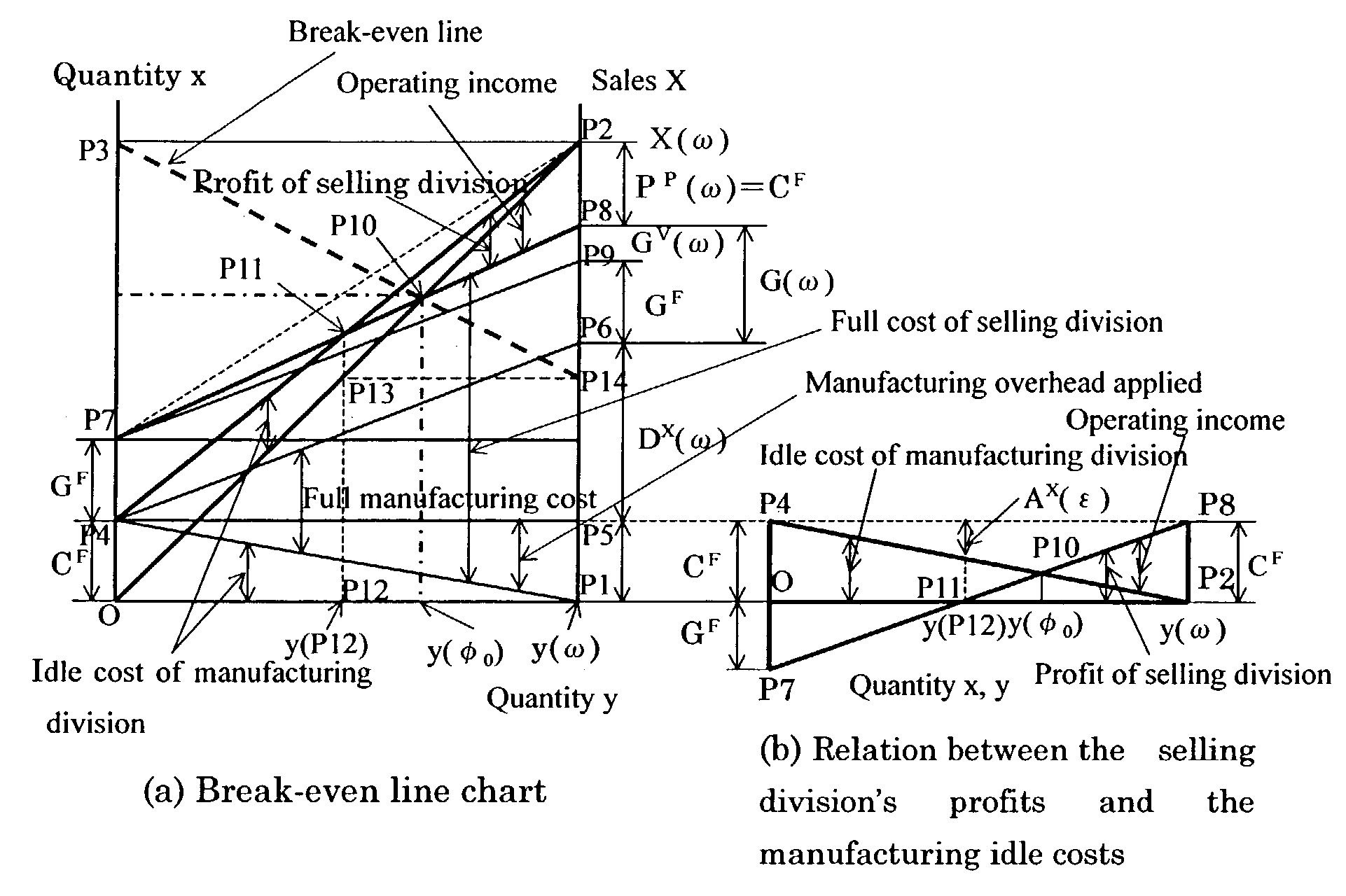

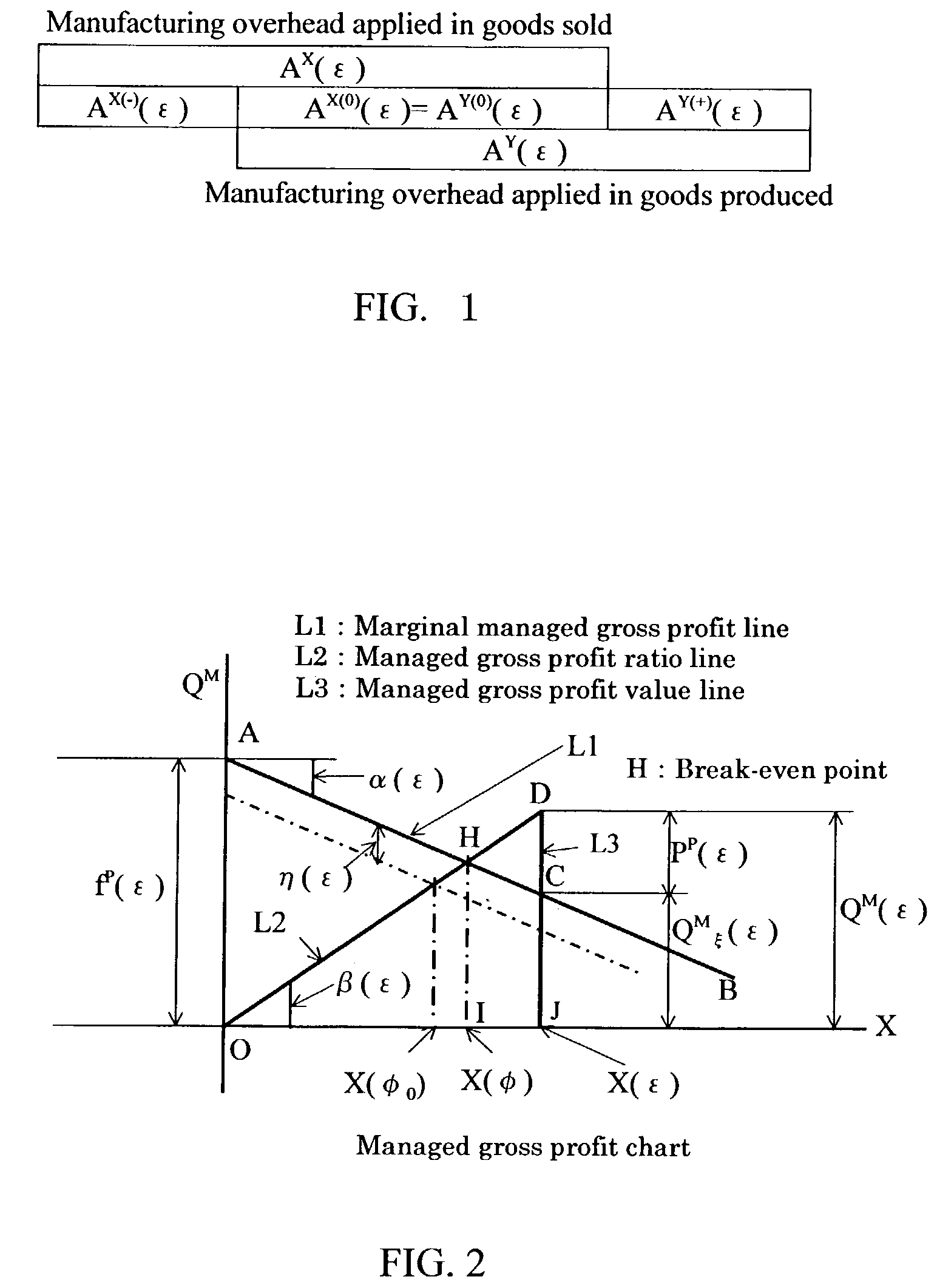

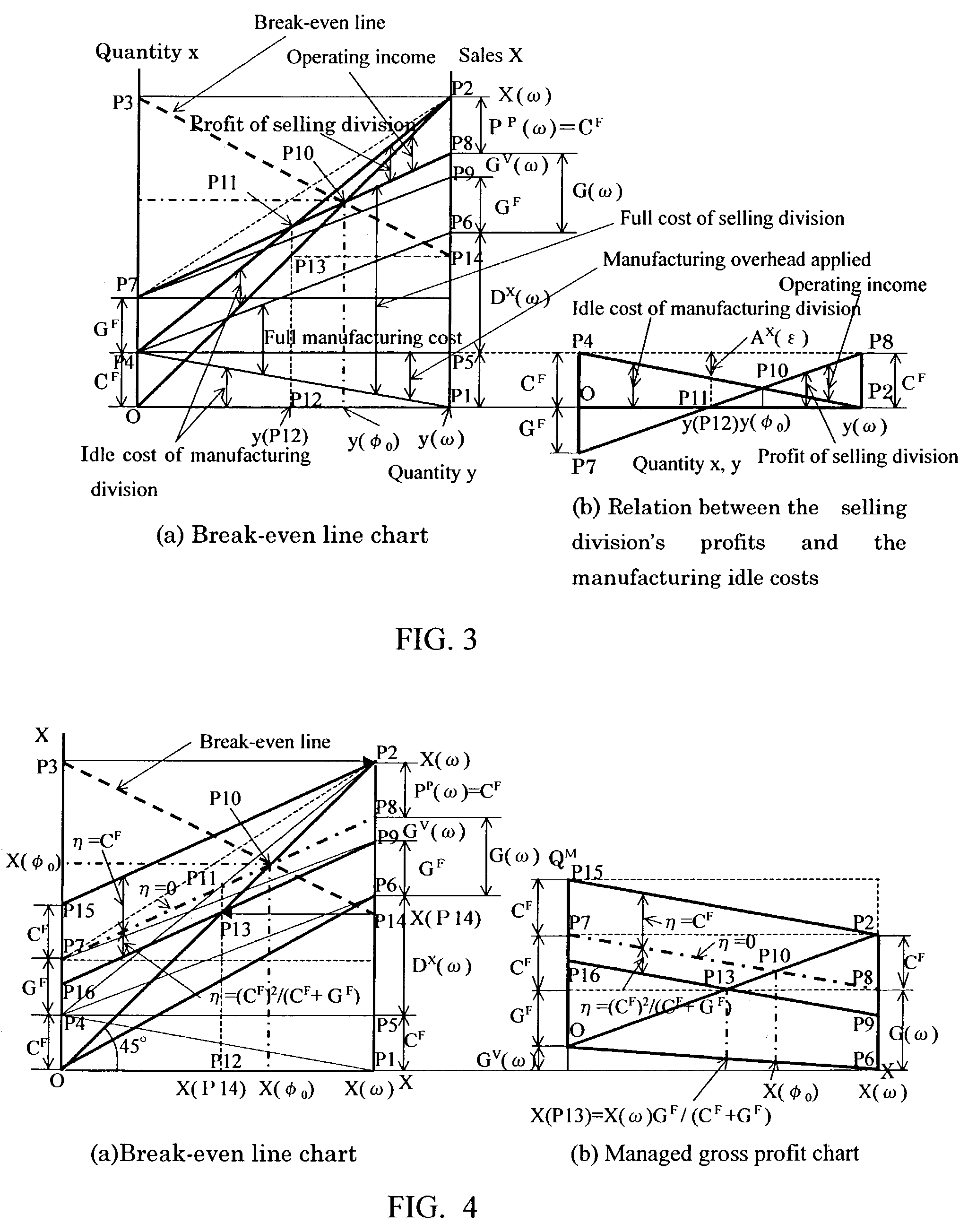

Accounting system for absorption costing

ActiveUS7302409B2Easy to understandComplete banking machinesFinanceInformation networksManufacturing management

An accounting system for an income statement under absorption costing (full costing), with a means for identifying the break even point in a break-even chart, using a 45-degree line, defining η=the net carryover manufacturing overhead applied in inventories, treating η as an additive constant to the other constants in a conventional break-even chart and identifying the break-even point as the intersection between the variable cost line added on the constant line and the 45-degree line. The system further includes a means for identifying the individual break-even point for each individual income statement of manufacturing management accounting departments in the company aiming at the managed gross profit chart previously originated by the applicant; for disclosing the break-even charts for concerned company personnel over a computer information network; and for advisors' advising system to send said break even charts over the information network to company clients.

Owner:HAYASHI YUICHIRO

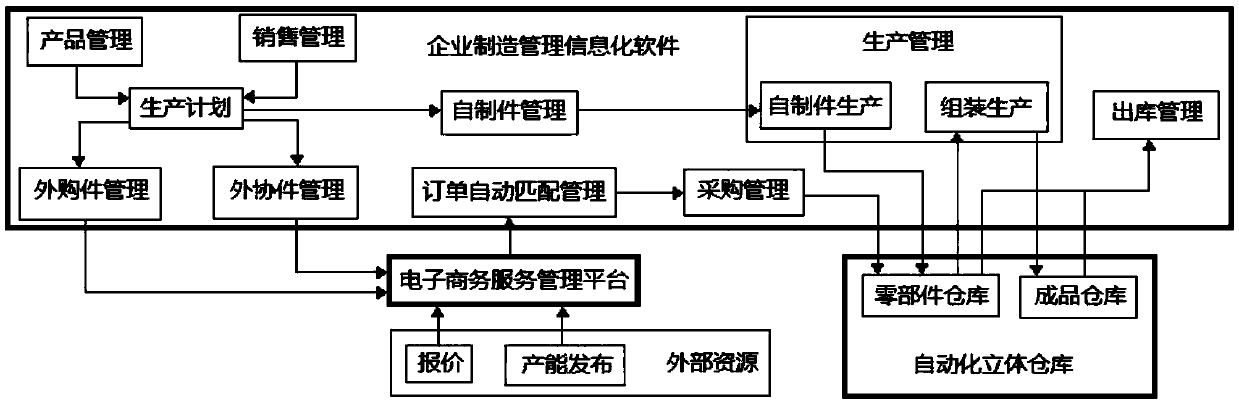

An enterprise manufacturing management and procurement integration platform

InactiveCN109523108AEfficient and convenient scientific managementQuick response to demandForecastingBuying/selling/leasing transactionsManufacture execution systemEnterprise resource planning

A manufacture management and purchasing integrate platform of enterprise is disclosed, including e-commerce service management platform, Sales management module, Production management module, Procurement management module, product management module, Production planning module, outsourcing component management module, Outsourcing part management module, homemade part management module, order automatic matching management module, issue management module and automated warehouse. The functional modules cover product life cycle management (PLM), enterprise resource planning (ERP), manufacturing execution system (MES), warehouse management system (WMS) and other aspects in enterprise management. And the information tools are streamlined, and then integrated with the e-commerce service platform as an integrated platform, so as to effectively improve the production and manufacturing management process in the interconnection of each link, and ultimately achieve the improvement of enterprise production efficiency and product quality.

Owner:SAIMO ELECTRIC

Big data based intelligent factory manufacturing management system

InactiveCN109634229AConvenient to get nearbyTimely feedback processingElectric/hybrid propulsionTotal factory controlNumerical controlMachine parts

The invention belongs to the technical field of big data, and discloses a big data based intelligent factory manufacturing management system. The big data based intelligent factory manufacturing management system comprises an integrated control system, a material transmission system, a data acquisition analysis and monitoring system, a communication system, a workshop central management and control system. According to the system, the relevant conditions can be conveniently acquired by workers, timely feeding back and processing can be carried out, the management quality of a production and manufacturing enterprise can be effectively improved, the production cost is reduced, and the serial processes among the operation processes of original equipment are changed into parallel processes among the operation processes, the full-process management of numerical control machining is realized, the efficiency and the rhythm of each preparation link are determined before the numerical control equipment is used for machining parts as well, and the abnormality and the delay situation of execution of a program in the production preparation process can be quickly positioned; and when a system judges that the machining plan condition is met, the machining program, a process document, the tool list information can be automatically sent to a station, the on-time production is realized, and theproduction efficiency of the machinery manufacturing enterprise is obviously improved.

Owner:DONGGUAN UNIV OF TECH

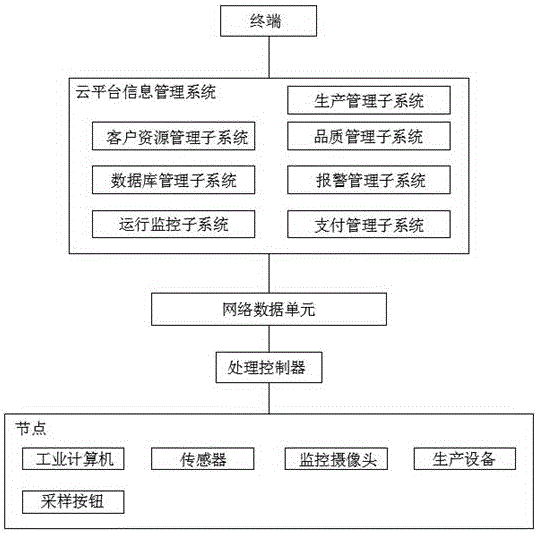

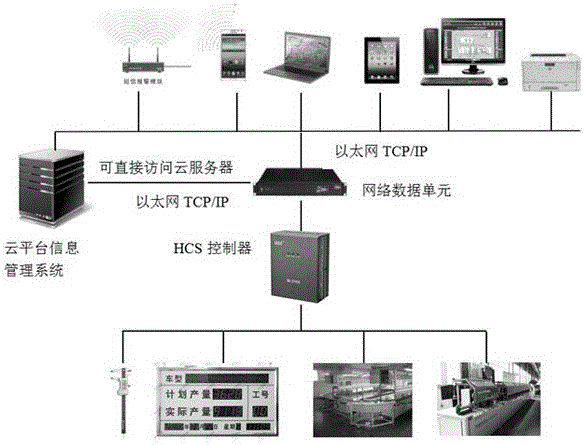

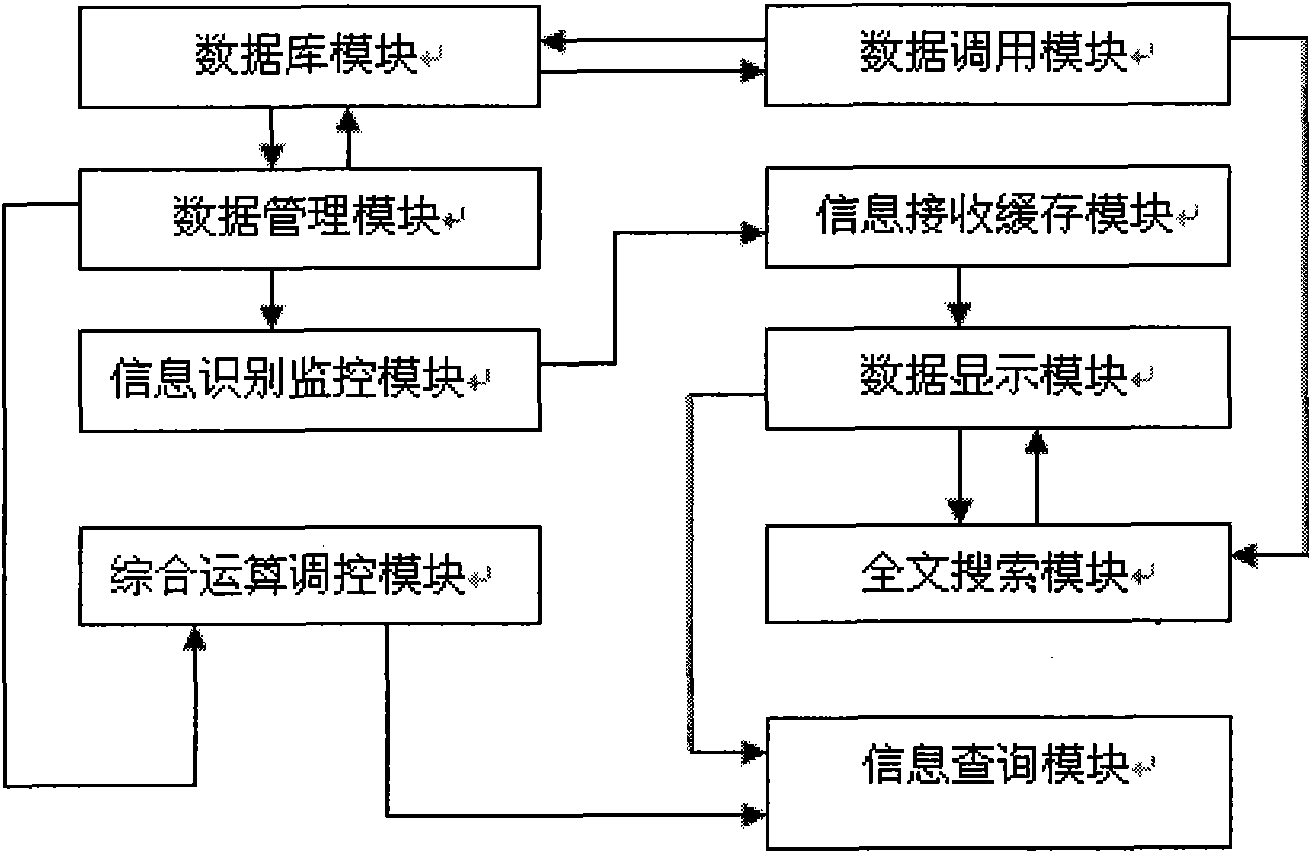

Intelligent manufacturing management information system

InactiveCN105956756AEfficient improvementGuaranteed qualityTechnology managementResourcesThe InternetAlarm management

The present invention provides an intelligent manufacturing management information system, which comprises a cloud platform information system, a network data unit, a processing controller, a terminal and a plurality of nodes. The cloud platform information system includes a customer resource management subsystem, a production management subsystem, a quality management subsystem, a database management subsystem, an alarm management subsystem and an operation monitoring subsystem. The network data unit is connected with the cloud platform information system through the Internet to give feedback on the data of a production site. The processing controller is connected with the network data unit and has a data processing and transferring capability to obtain production status data generated by and returned from the nodes of the production site; the nodes include sensing devices arranged at each working position, production equipment, and sampling buttons. All these nodes have their unique ID code. The system of the invention aims at providing information acquisition, analysis, processing, inquiry, real-time display, real-time function configuration and serving as an alarm platform for the manufacturing department of an enterprise.

Owner:珠海昊星自动化系统有限公司

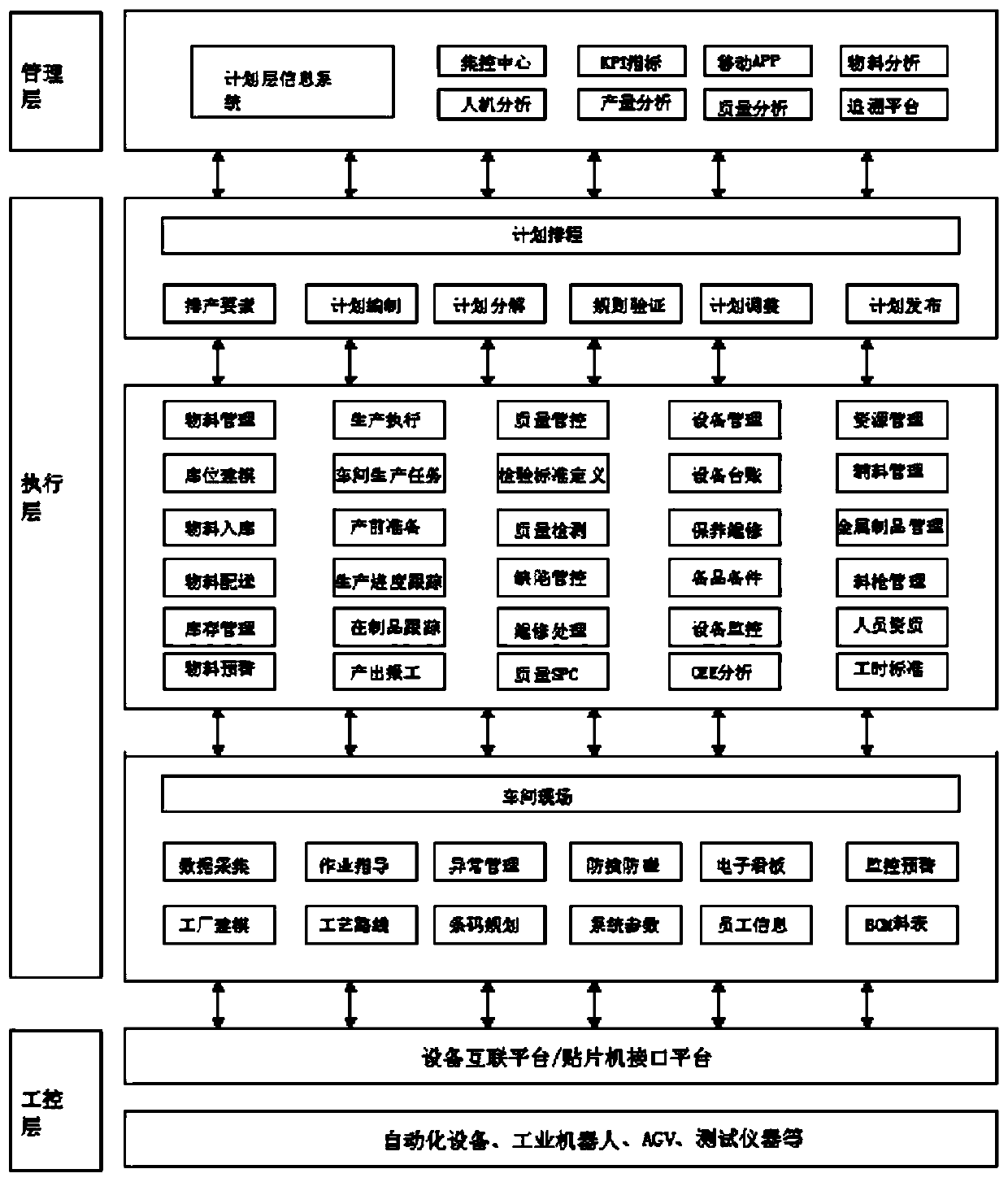

MES system based on intelligent manufacturing management

PendingCN110705814AEasy to useHigh degree of intelligenceResourcesLogisticsMobile appsTime information

The invention relates to an MES system based on intelligent manufacturing management. The system comprises a management layer, an execution layer and an industrial control layer, the management layercomprises a planning layer information system, a centralized control center used for integrating information, KPI indexes used for organization internal management, a mobile APP used for information watching, recording and management, a material analysis platform, a man-machine analysis platform, a yield analysis platform and a tracing platform used for retrieving the output end of a data source.The execution layer comprises a plan schedule; production scheduling elements, plan making, plan decomposition, rule verification, plan adjustment and plan release are arranged in the plan schedule, the output end of the plan schedule is provided with material management, production execution, quality control, equipment management and resource management, and the material management is correspondingly provided with warehouse location modeling for building a storage place according to the production capacity. The system has the advantages that advanced visual monitoring is achieved, real-time information of a warehouse and a factory is reflected in time, field equipment is connected to the Internet to achieve intelligent control, and the system is simple and efficient.

Owner:合肥东优电子科技有限公司

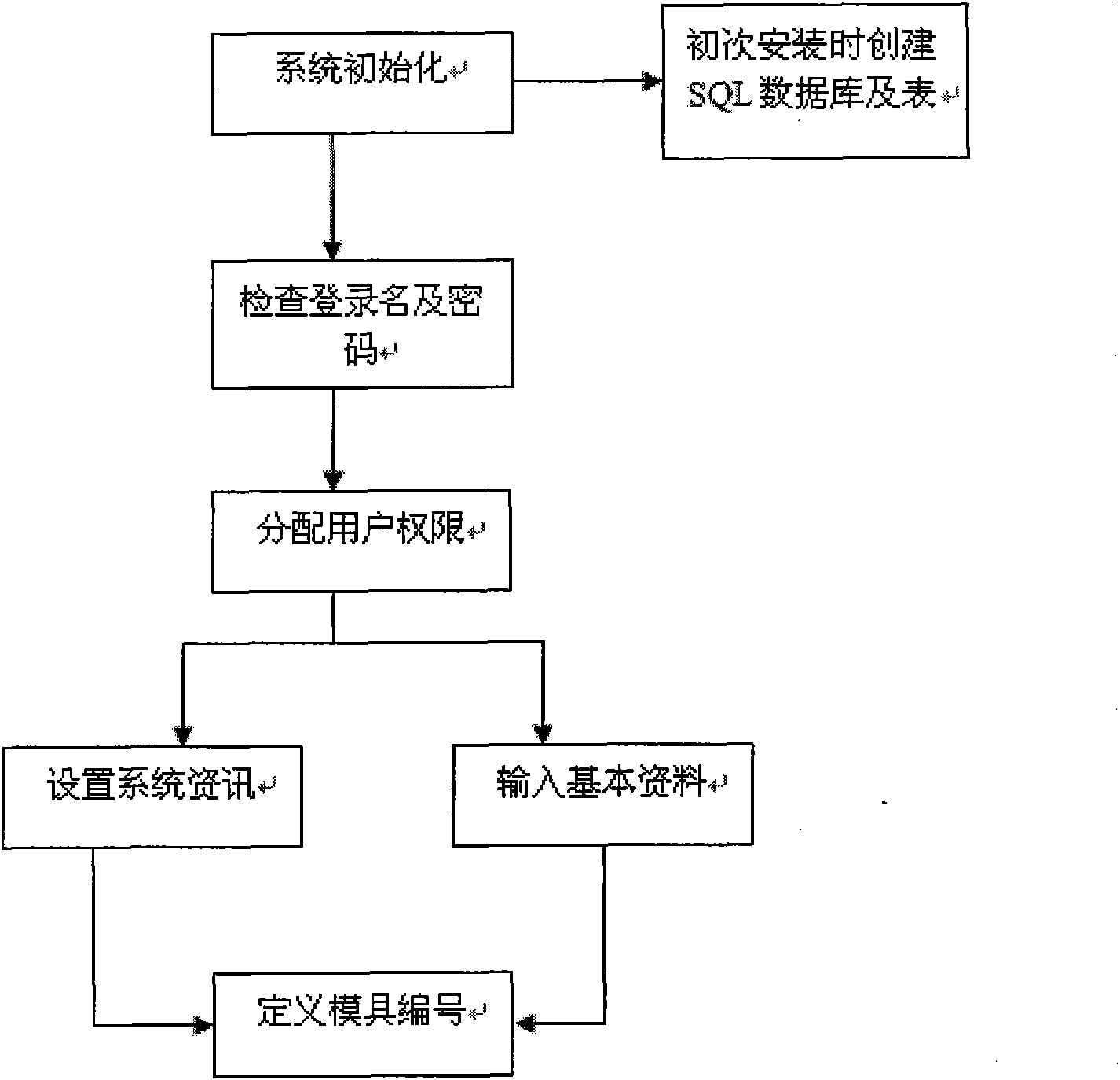

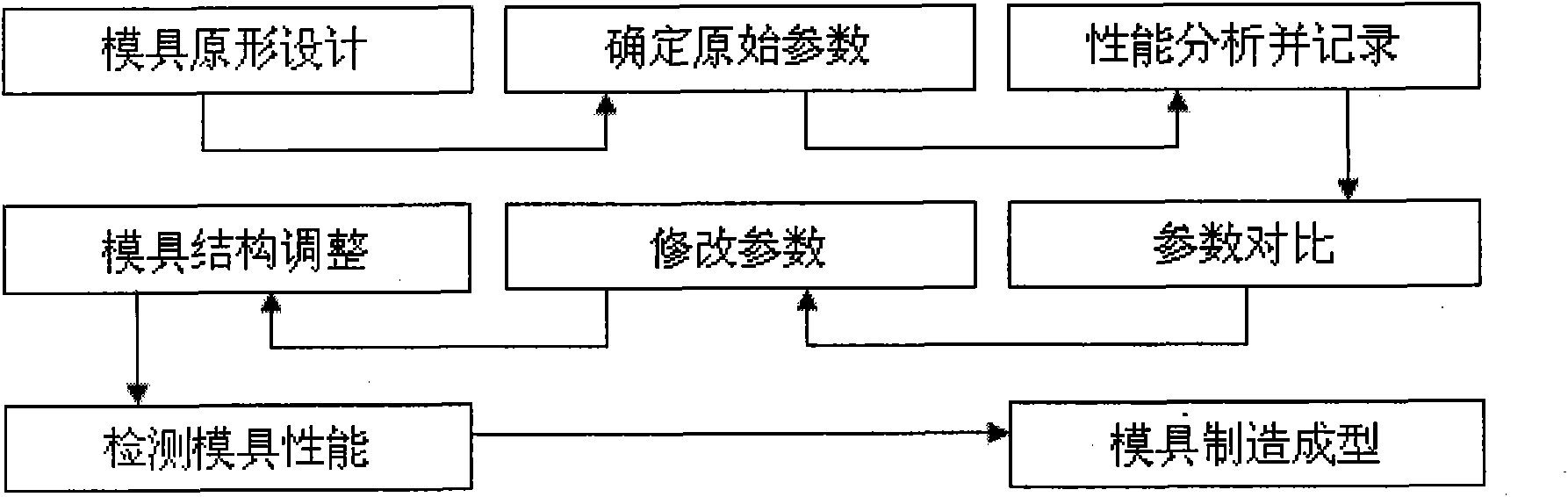

High-accuracy mold design method and mold manufacturing management system

InactiveCN102073762AQuality improvementRealize unified managementSpecial data processing applicationsComputer Aided DesignDesign software

The invention discloses a high-accuracy mold design method, which comprises the following steps of: (1) setting a computer aided design tool and optimizing the accuracy parameter of a tool comprehensive processing mold by using a mold design integrated mold; (2) designing a mold, namely manufacturing an original mold structure by using the computer aided design tool and determining the original performance parameter of the designed mold; (3) analyzing the mold accuracy, namely analyzing the comprehensive performance of the designed mold by using mold design software and recording a data value; and (4) optimizing mold accuracy, namely modifying the unreasonable structure and unqualified performance parameter of the mold in comparison to the original performance parameter of the mold by using the mold optimization tool, and determining the mold structure by detection. The invention also provides a mold manufacturing management system for implementing the method.

Owner:DONGGUAN GUANHUI HARDWARE

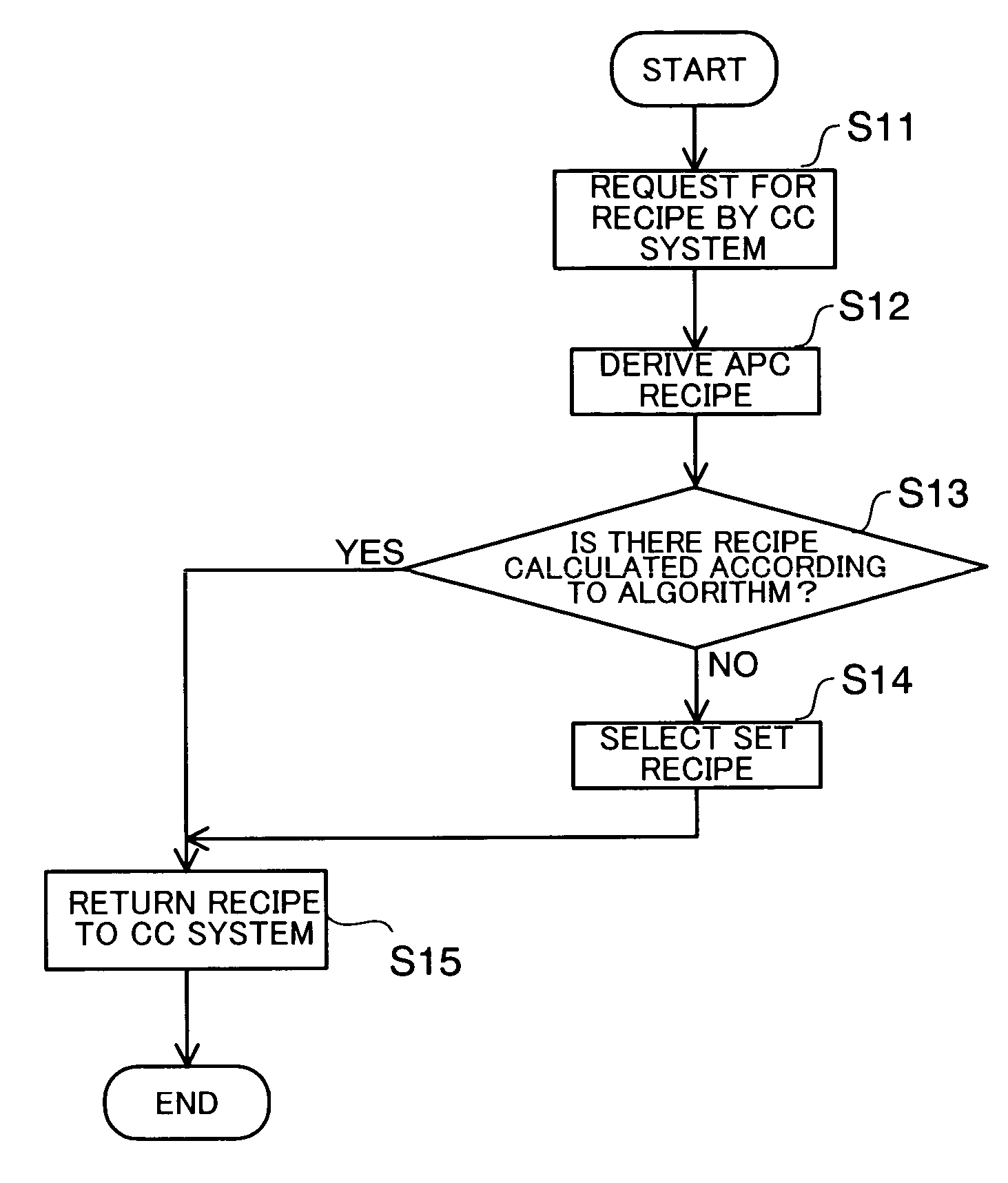

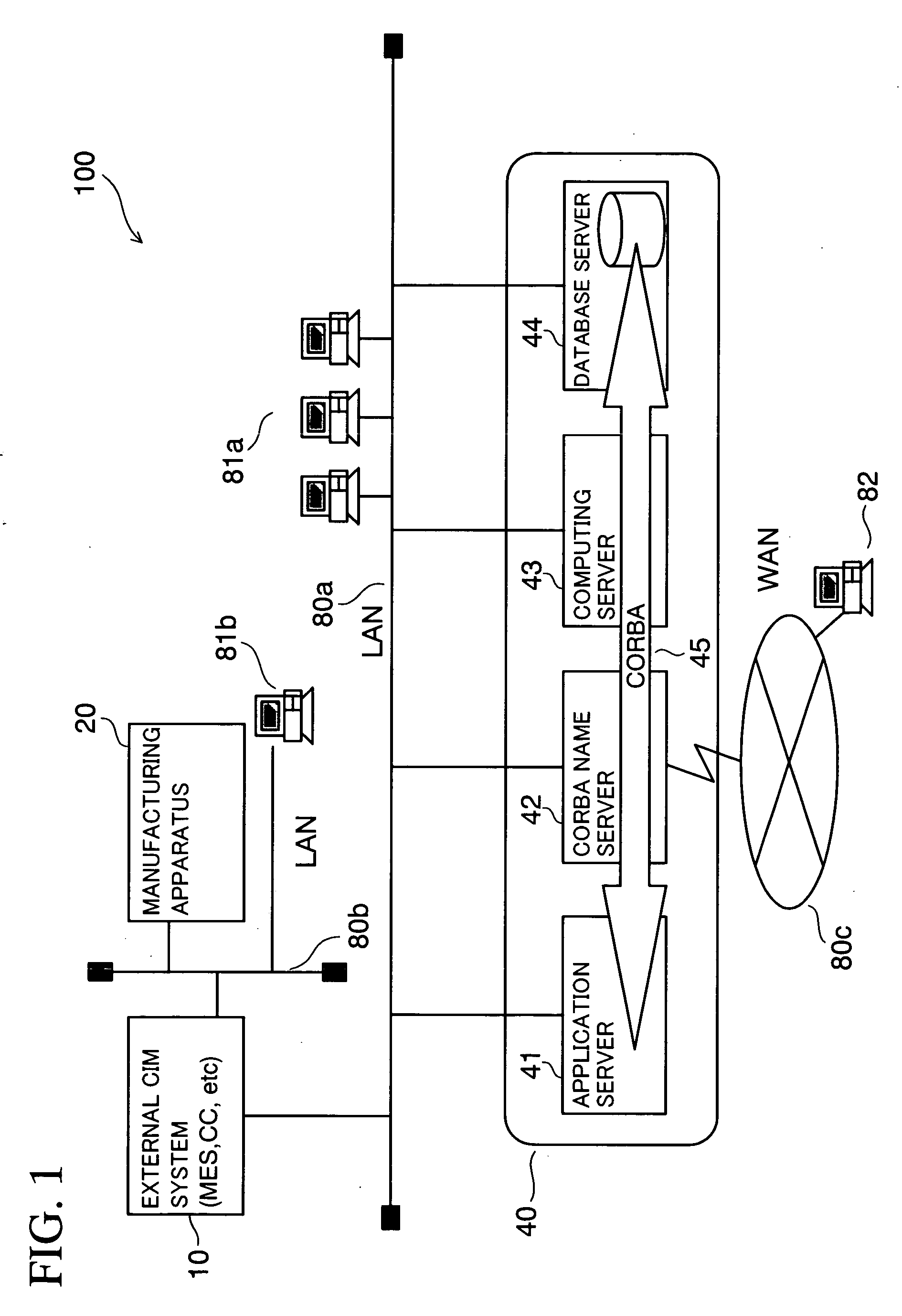

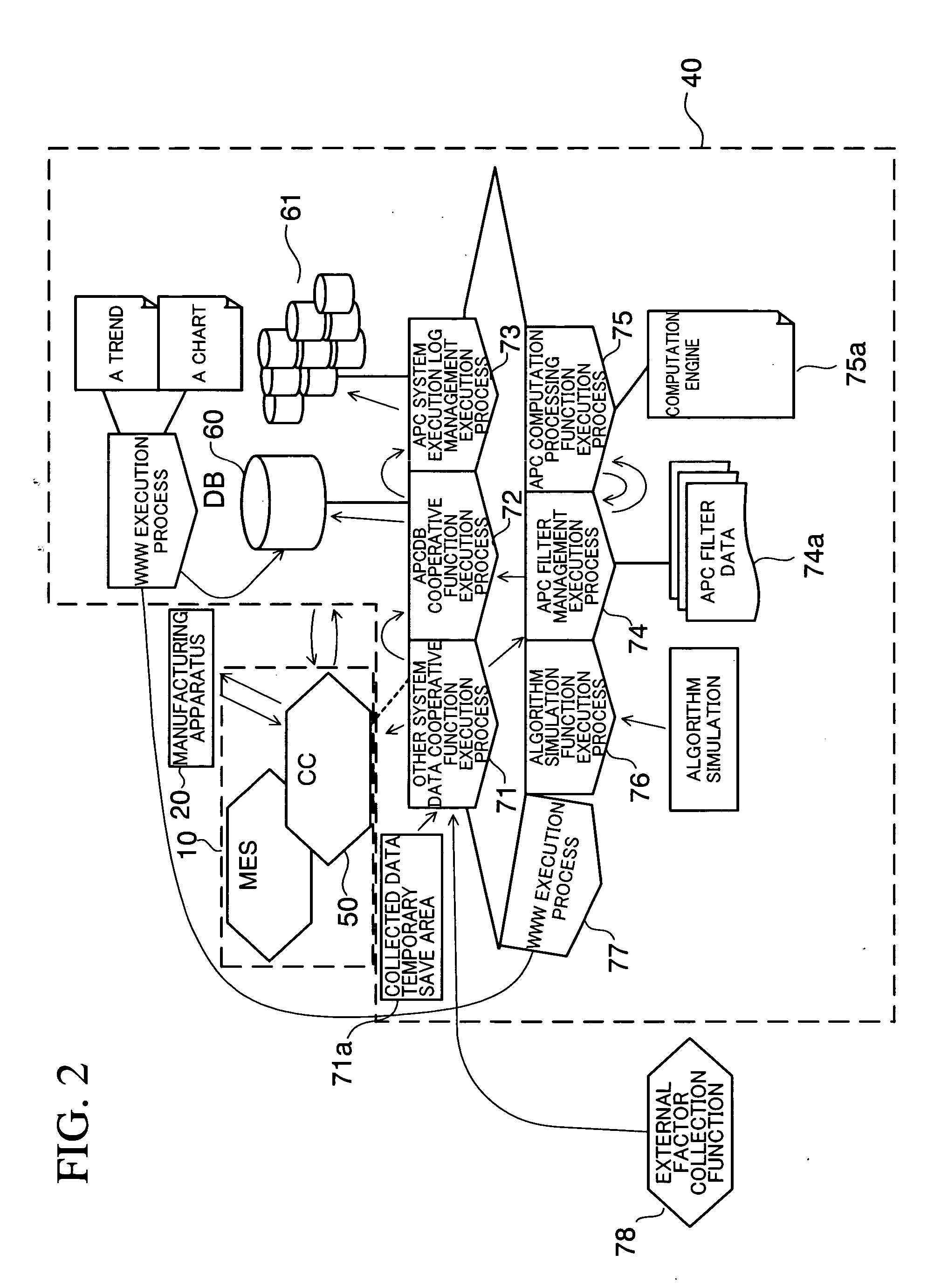

System for controlling semiconductor device manufacturing process and method of controlling semiconductor device manufacturing process

InactiveUS20070129839A1Programme controlSemiconductor/solid-state device manufacturingManufactured apparatusManufacturing data

In a system for controlling a semiconductor device manufacturing process, a recipe indicating a control condition for controlling processing in a semiconductor manufacturing apparatus is calculated by a computation performed using manufacturing data obtained in the semiconductor device manufacturing process and a predetermined algorithm, and when the recipe cannot be derived, an alternative recipe prepared beforehand is transmitted to a manufacturing management system for managing the semiconductor manufacturing apparatus. The alternative recipe may be derived using the predetermined algorithm by a recomputation in which input conditions are changed. When a recipe cannot be derived by the recomputation, a planned recipe with which semiconductor devices processed by the manufacturing process fall within specification values may be used as the alternative recipe.

Owner:FUJITSU LTD

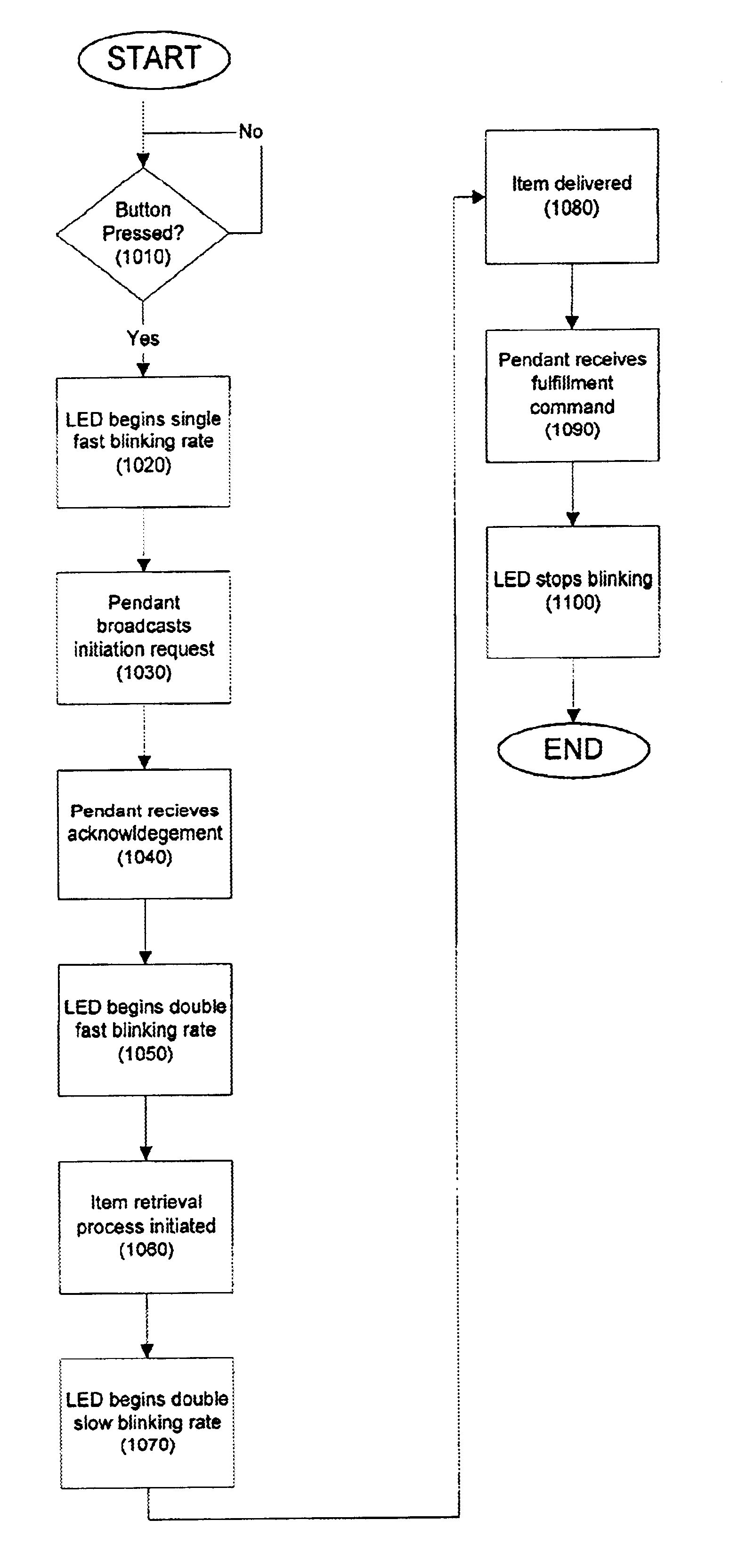

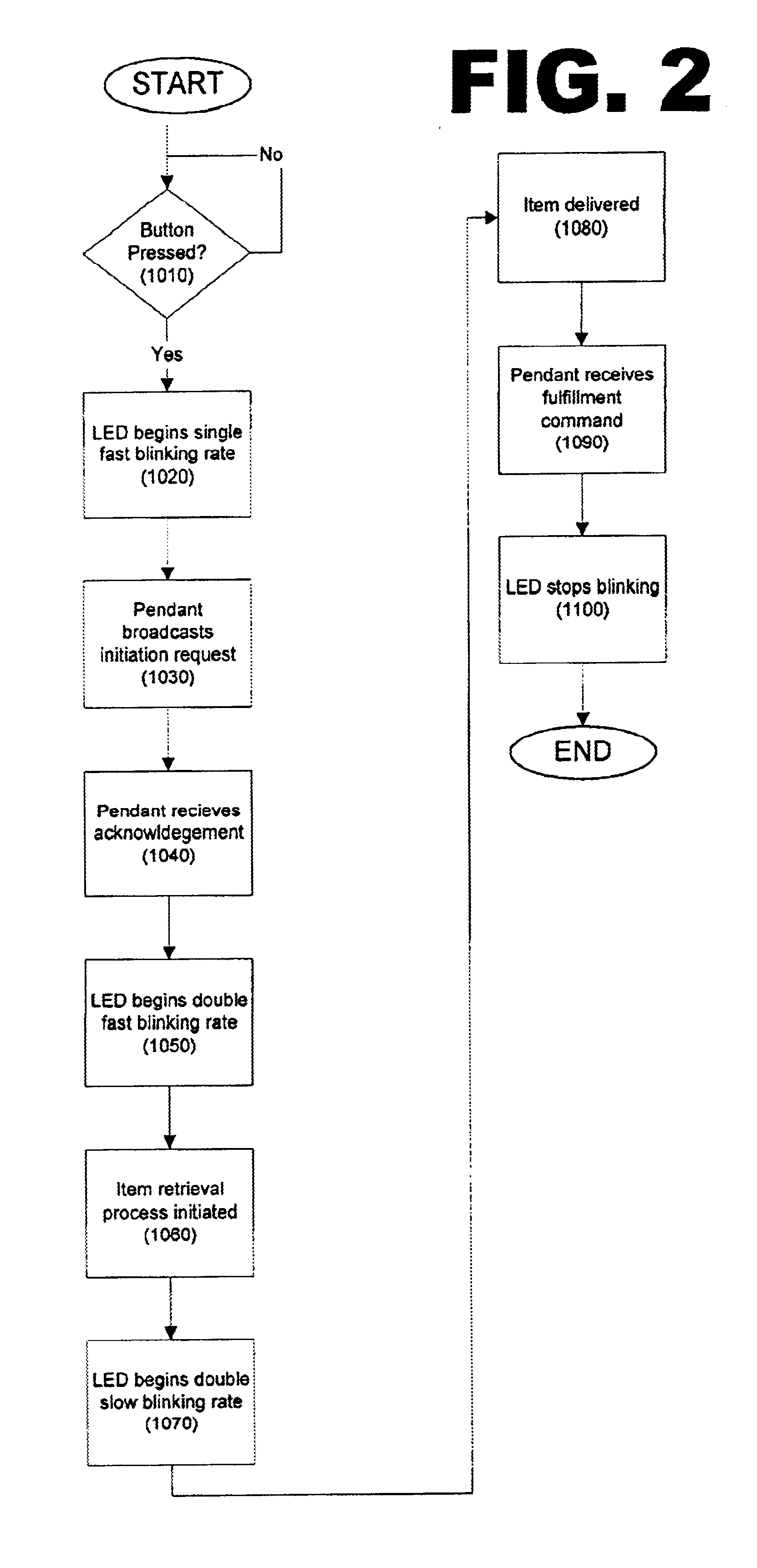

Apparatus for manufacturing management using a wireless device

InactiveUS6838977B2Easy to reconfigureEasy to makeDigital data processing detailsPayment architectureTransceiverComputer network

A method of inventory management is described. Upon activation of a button on a wireless device, the wireless device having a light source and a transceiver with a unique media address corresponding to a unique product, the device broadcasts a first signal including an order command and the unique media address by the transceiver via a wireless medium. A central controller then receives the first signal, identifies the unique media address included in the first signal, and using a database, identifies the unique product associated with the unique media address.

Owner:SYMBOL TECH LLC

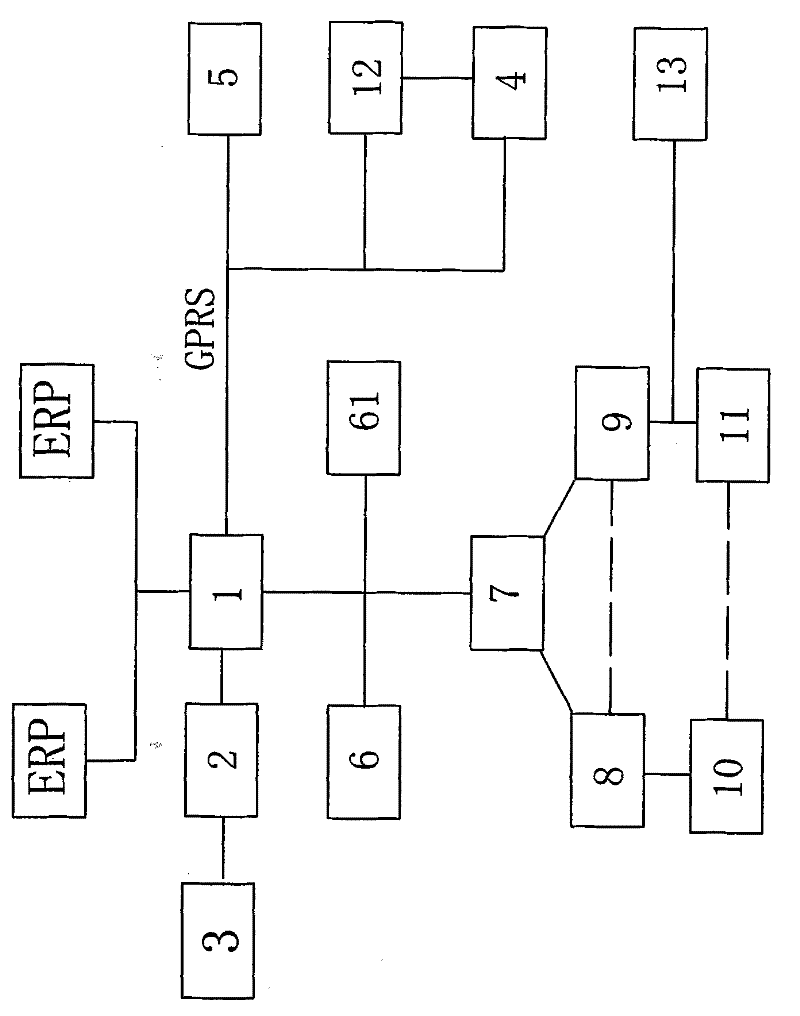

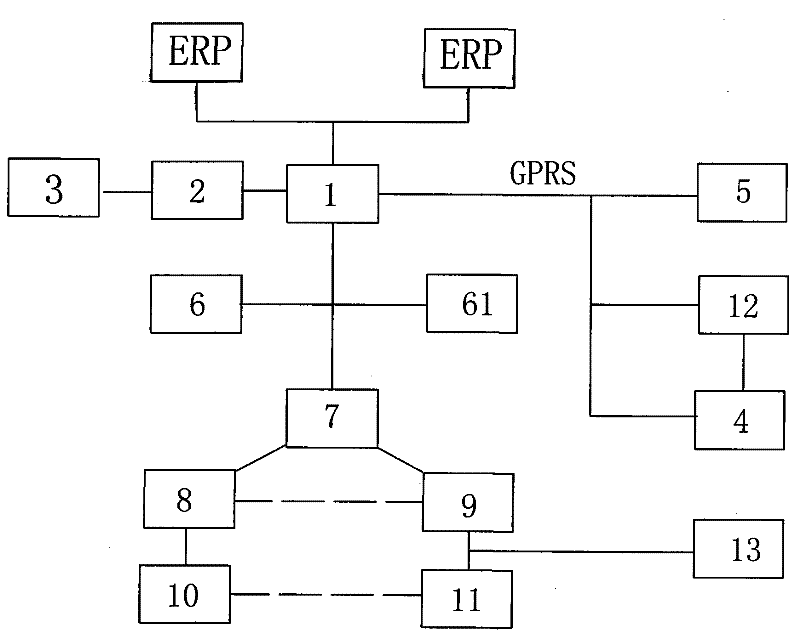

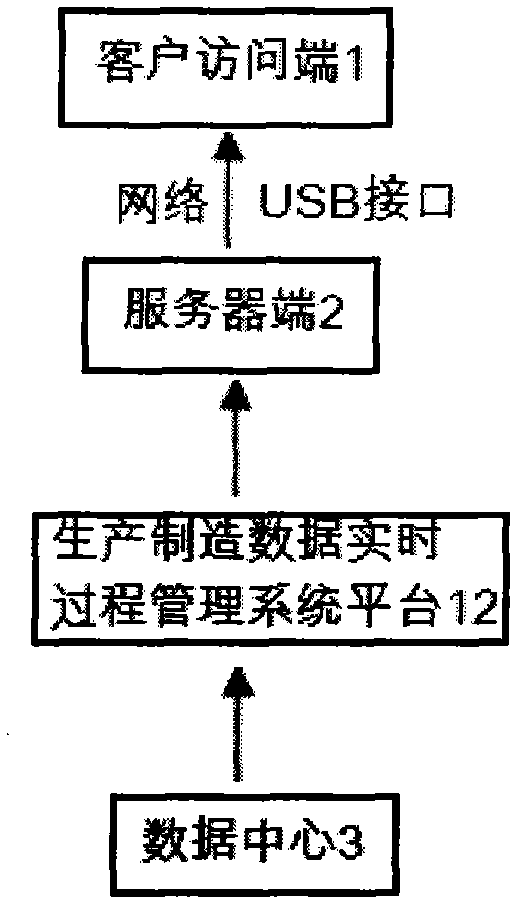

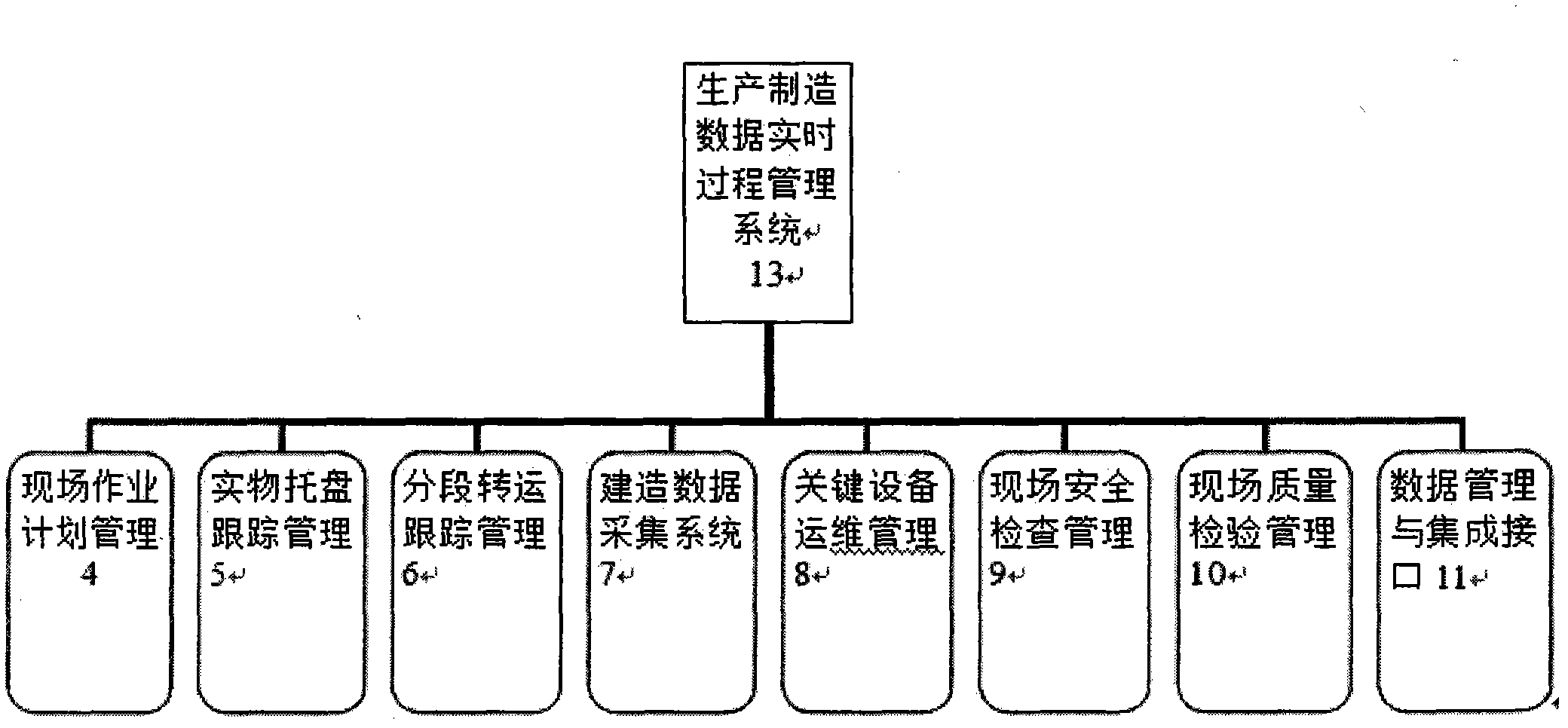

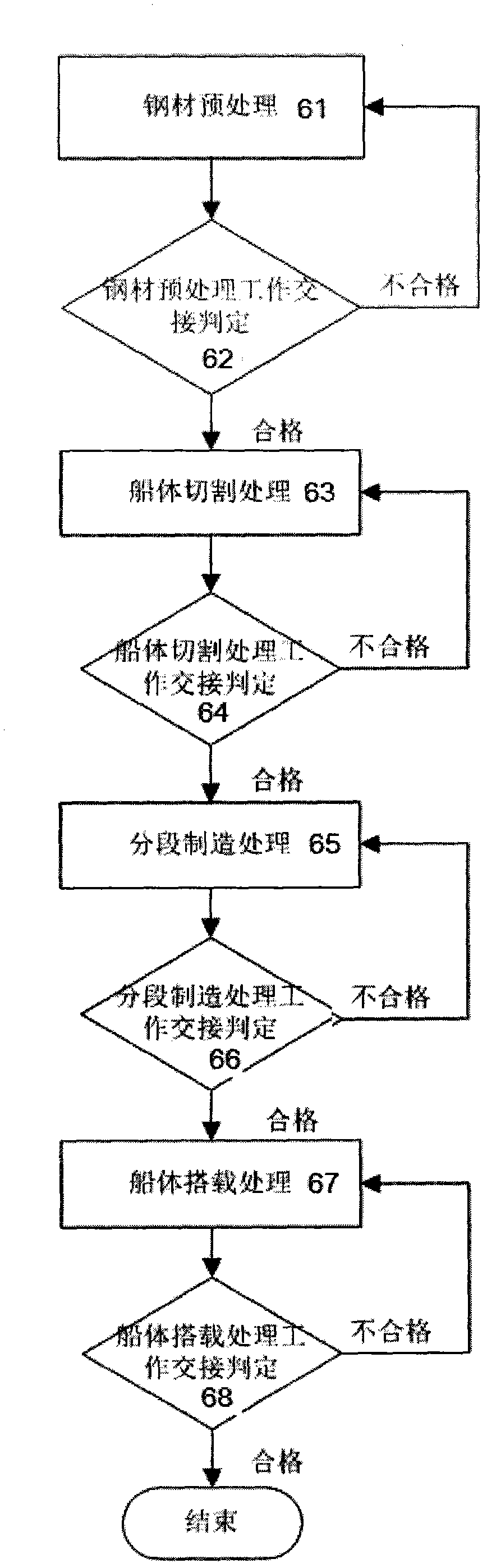

Multi-network-based manufacturing data real-time process management system and management method in ship manufacturing industry

InactiveCN102646220AReal-timeImplement feedbackResourcesManufacturing computing systemsData centerManufacturing enterprises

The invention discloses a multi-network-based manufacturing data real-time process management system and management method in a ship manufacturing industry. The manufacturing data real-time process management system is divided into a client access terminal, a manufacturing data real-time process management system platform, server terminals and a data center. The data center is respectively connected with the server terminals through a field operation plan management system, a real object tray tracing management system, a subsection transfer tracing management system, a construction data collecting system, a key equipment operation and maintenance management system, a field security examination management system, a field quality examination management system and a data management system. After the server terminals are optimized, the data center is linked with a PDA (Personal Digital Assistant) handheld terminal or a PC (Personnel Computer) client terminal through a multi-network module or a USB (Universal Serial Bus) port. According to the multi-network-based manufacturing data real-time process management system provided by the invention, the production executing efficiency is further improved, so as to bring about transformational influences on manufacturing management for ship manufacturing enterprises. With the development of the ship manufacturing industry in China, the project has the advantages of strong market demands and very wide industrialization prospect.

Owner:NANTONG WAIN SOFTWARE

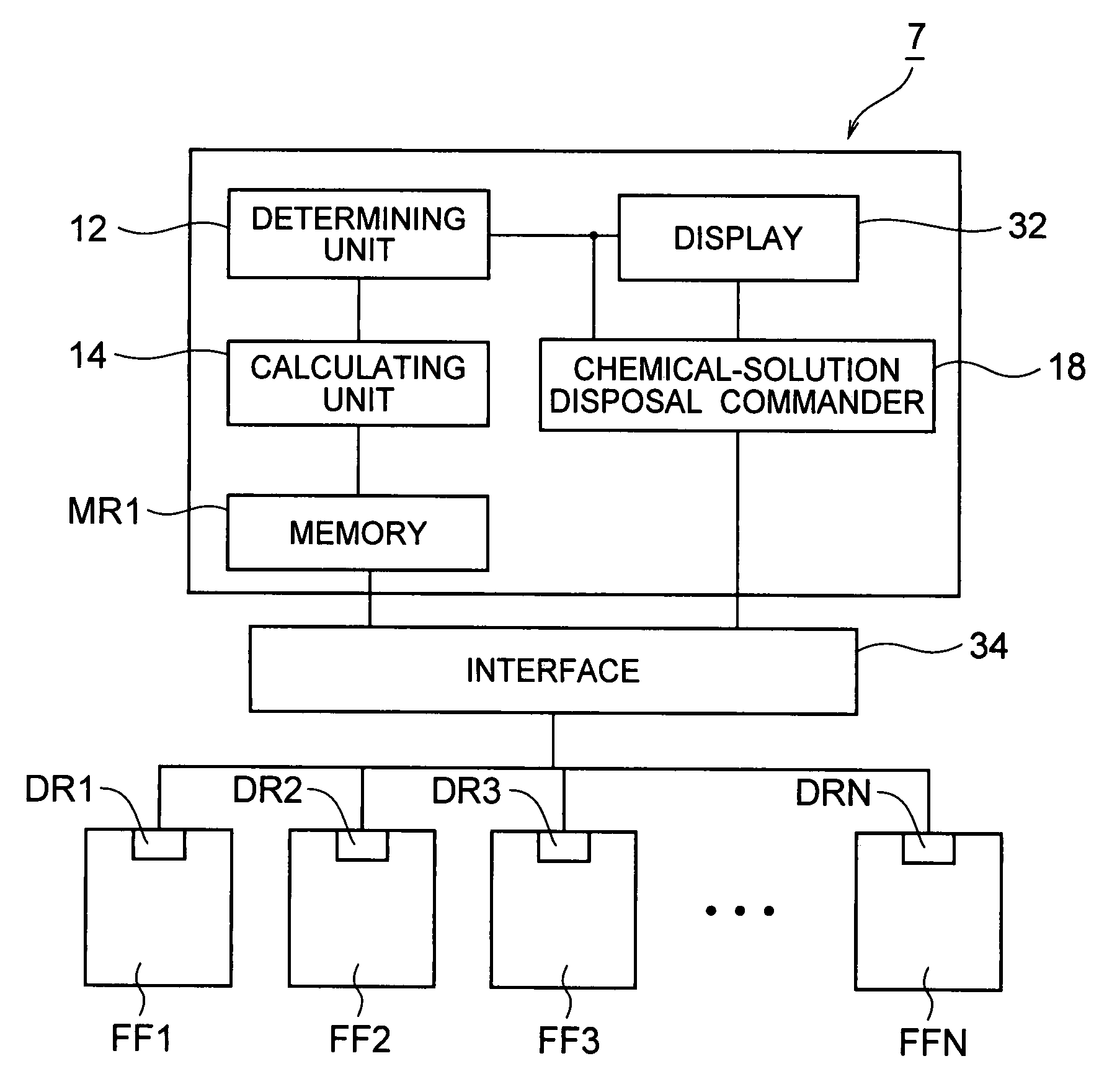

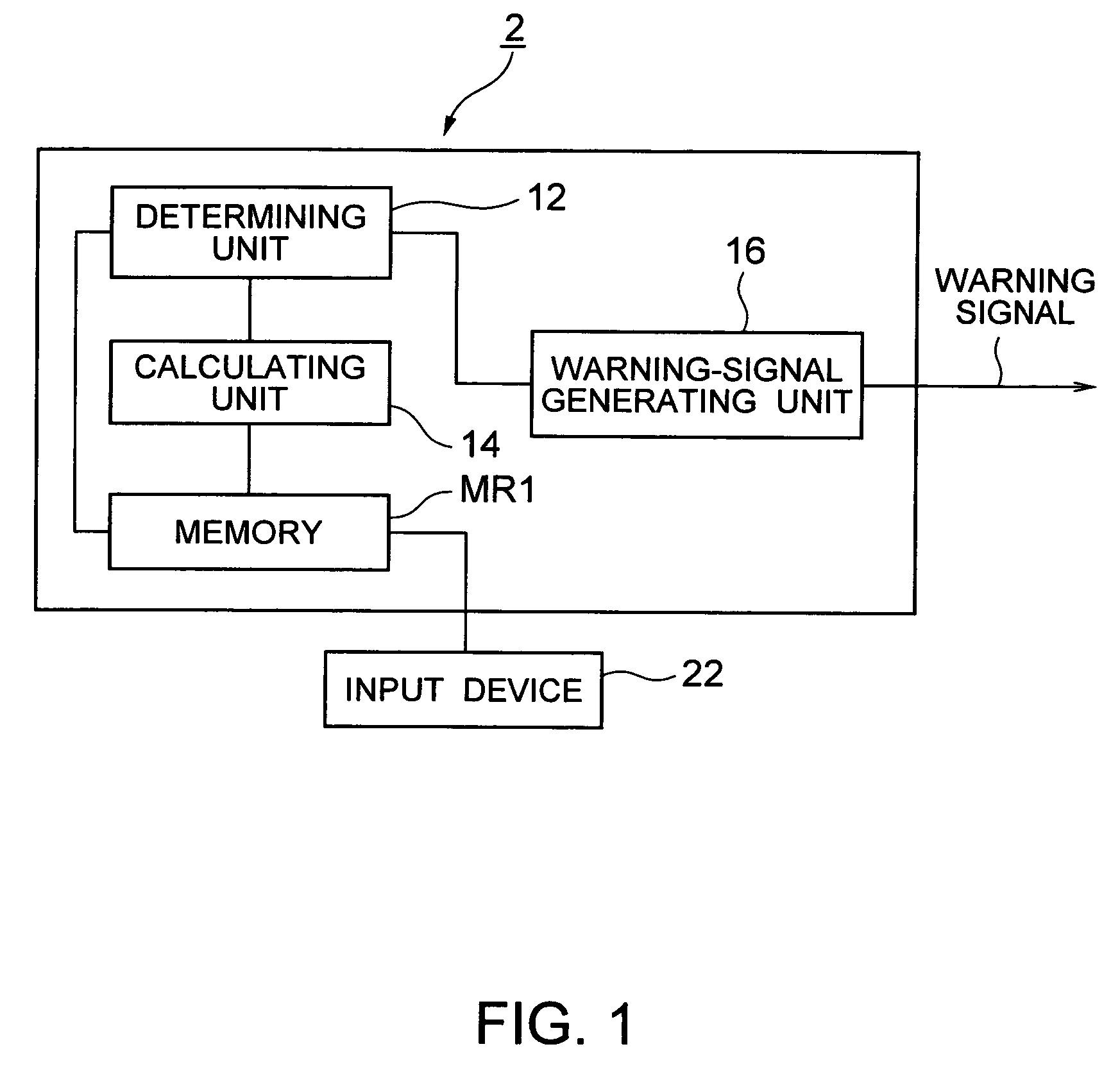

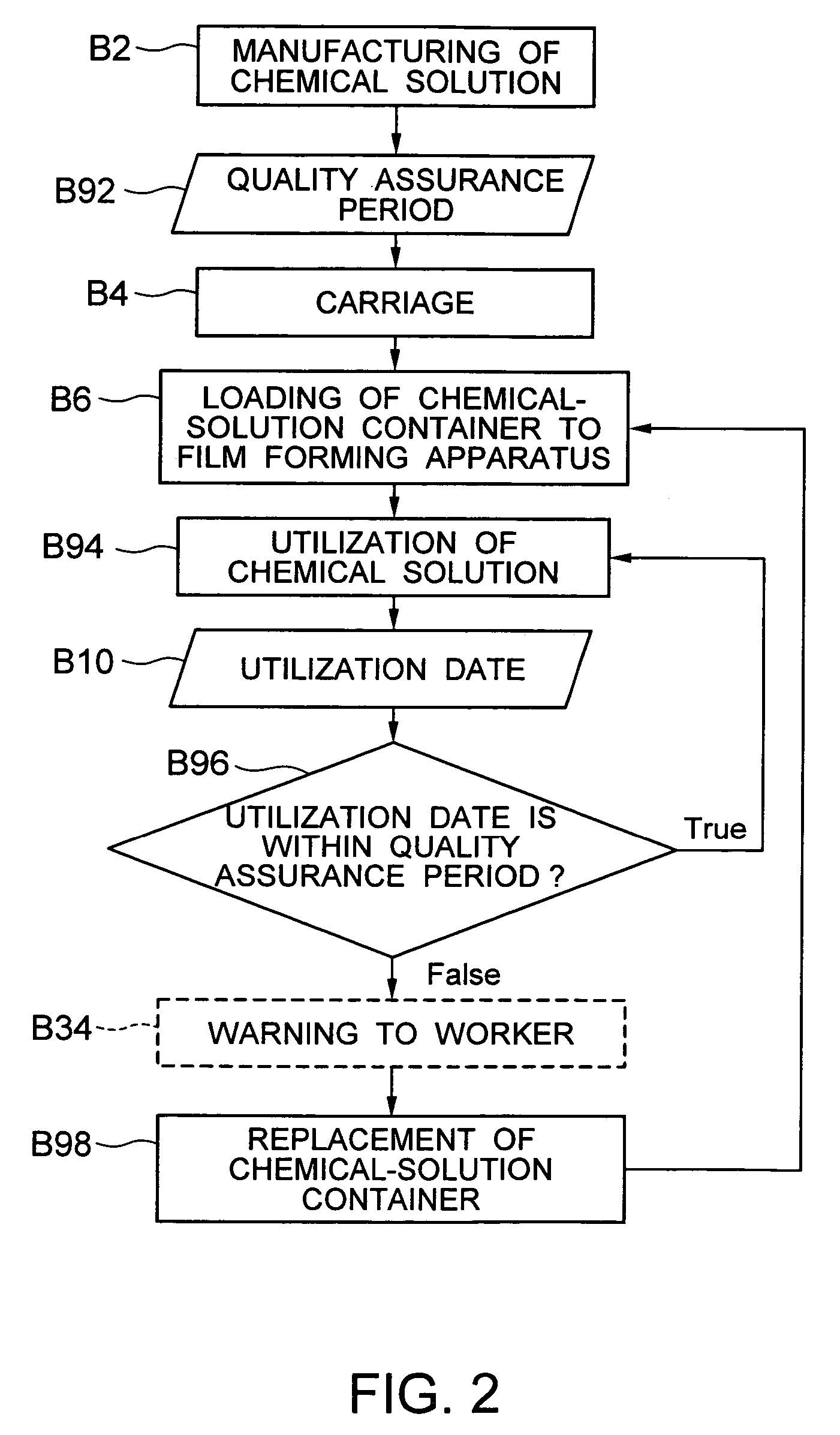

Film forming apparatus, manufacturing management system and method of manufacturing semiconductor devices

A film forming apparatus which forms a film on a substrate by utilizing a chemical solution, including: a correlation data creating unit which creates a correlation data that is related to the quality of a chemical solution, from data that is related to the properties of the chemical solution including at least one of data on storage temperature for the chemical solution to be loaded and data on pressure applied to the chemical solution to be loaded; and a determining unit which determines whether or not the chemical solution holds expected quality thereof on the bases of the correlation data.

Owner:KK TOSHIBA

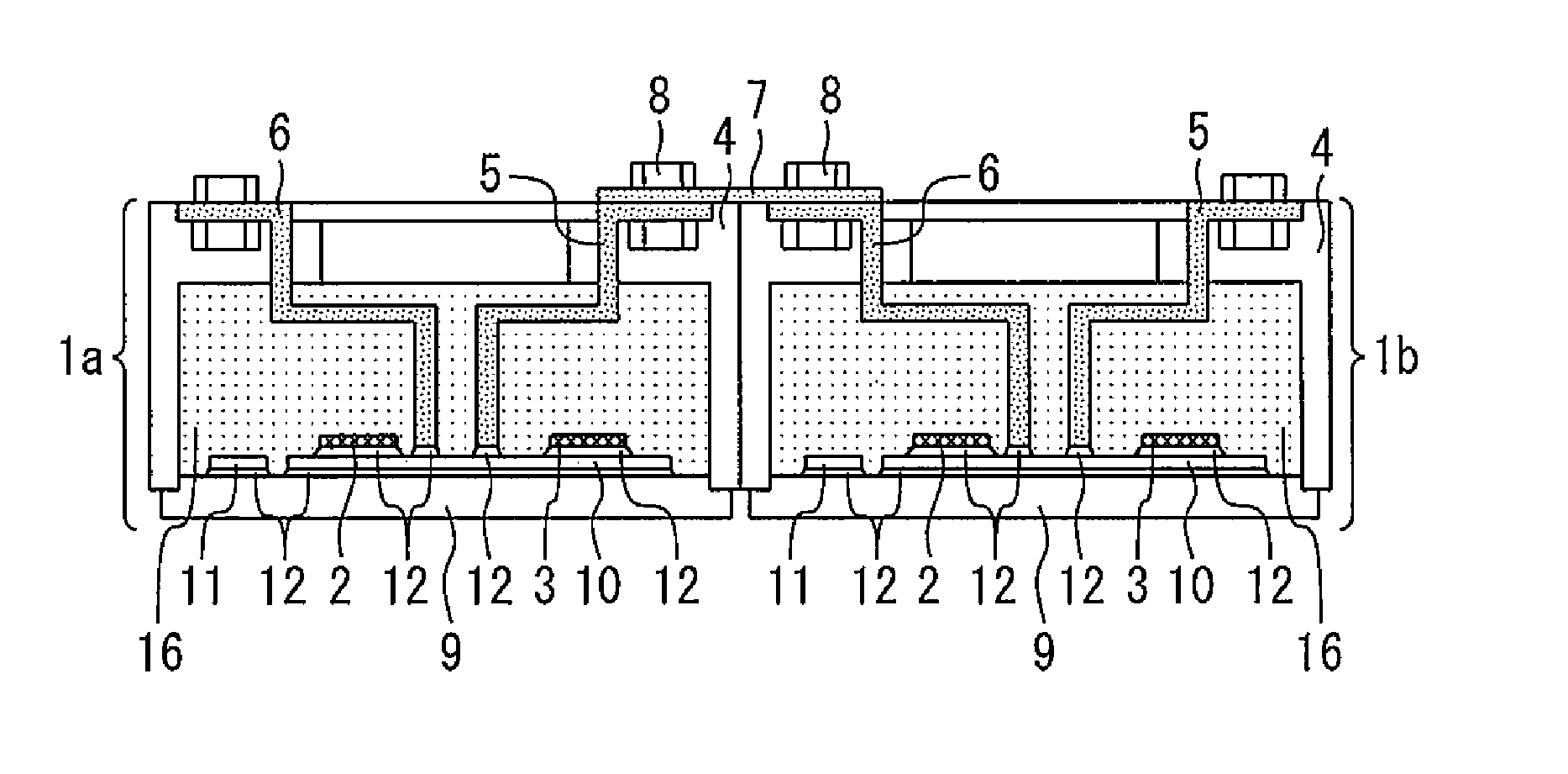

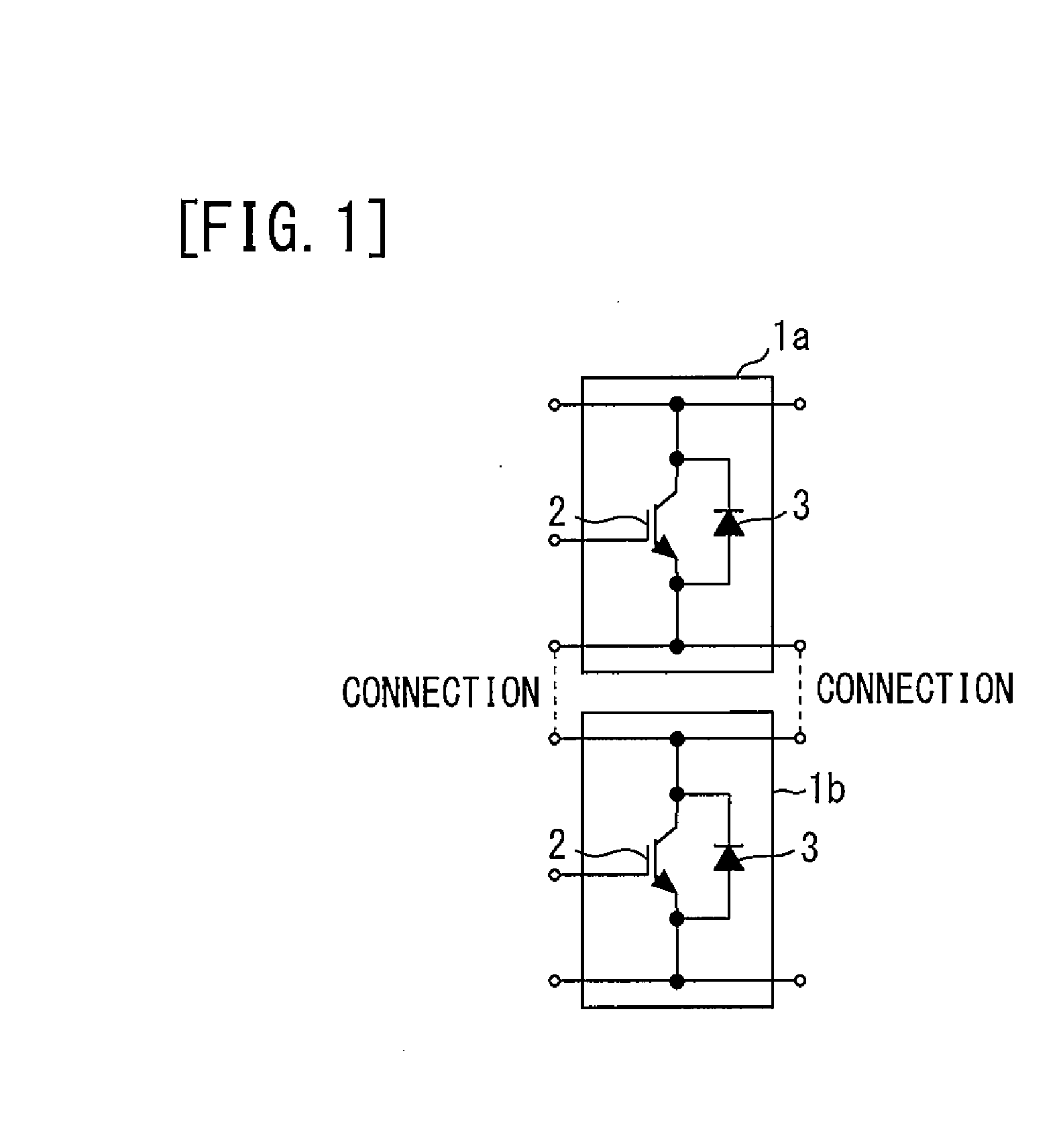

Semiconductor device

ActiveUS20150138733A1Low costReduce the numberSemiconductor/solid-state device detailsCircuit arrangements on support structuresSemiconductor chipManufacturing management

Each of semiconductor module includes a semiconductor chip, a case surrounding the semiconductor chip, and a main electrode connected to the semiconductor chip and led out to an upper surface of case. A connecting electrode is connected and fixed to the main electrodes of the adjacent semiconductor modules. The connecting electrode is formed only of a metal plate. The rated current, the rated voltage and the circuit configuration can easily be changed by changing the connection using the connecting electrode, thus enabling reduction of the design time and facilitating manufacture management. Only a malfunctioning one of the semiconductor modules may be replaced. There is, therefore, no need to replace the entire device. The connecting electrode is formed of an electrically conductive plate and, therefore, enables reduction of the number of component parts and reduction of the device in size in comparison with the conventional wiring bus bar.

Owner:MITSUBISHI ELECTRIC CORP

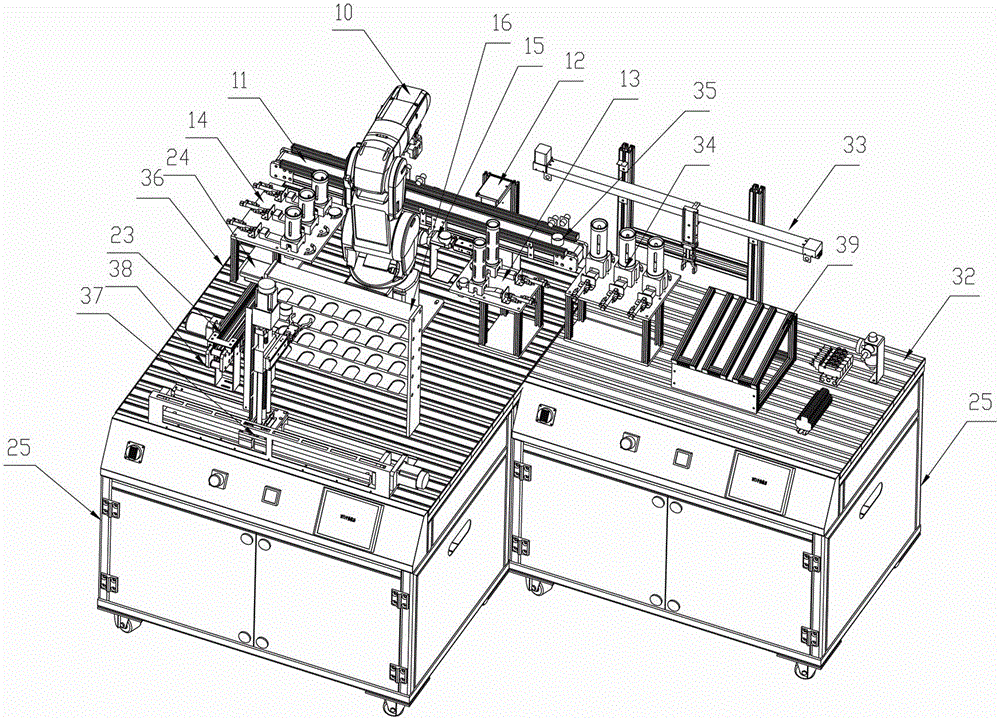

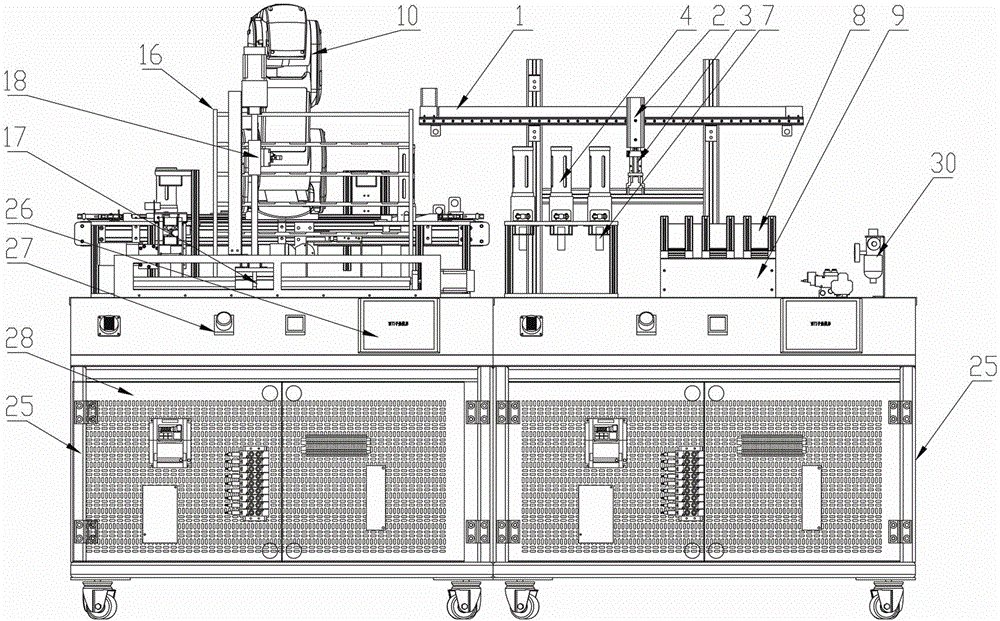

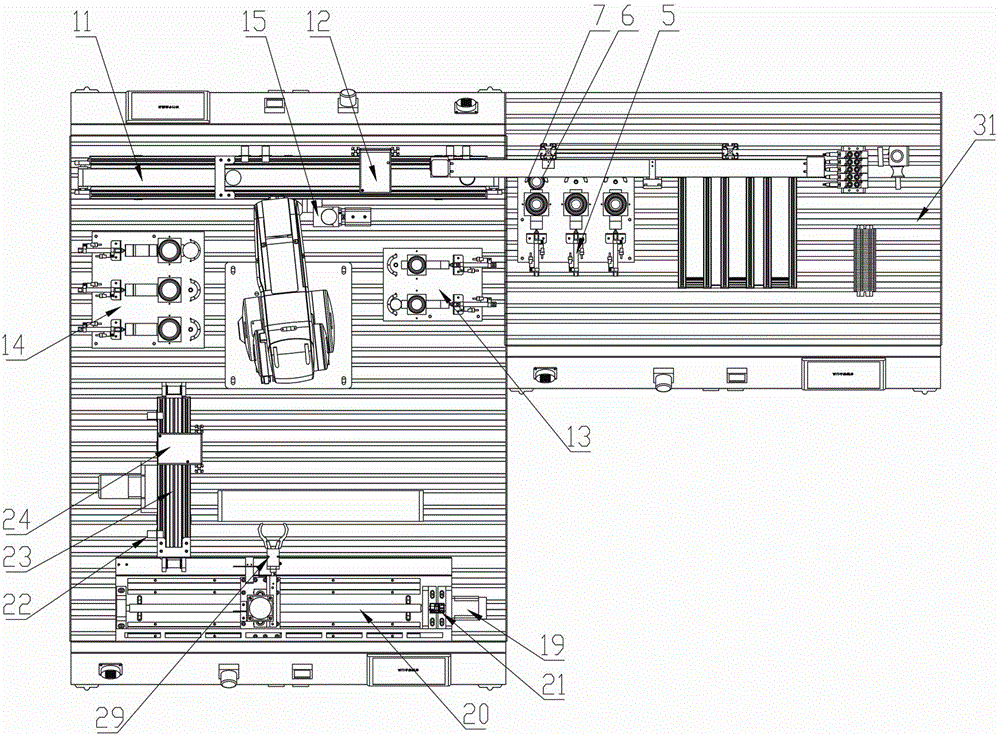

Production line information integration and control practice platform of intelligent manufacture

The invention relates to a production line information integration and control practice platform of intelligent manufacture. The practice platform is characterized by comprising a feeding and sorting integrated workstation, an industrial robot workstation, a multifunctional storage workstation and an intelligent production and manufacture management system. According to the technical scheme provided by the invention, the practical platform enables students to follow the development trends in intelligent manufacture and application of new technology, convenience is provided for optimization of teaching schemes, the platform can also help students develop learning interests and develop thinking, and thus, high-quality skill-orientated talents suitable for production line information integration and control, urgently needed by enterprises, and meeting requirements for intelligent factories and intelligent production in China manufacture 2025 plans in industry 4.0 can be cultivated.

Owner:ZHEJIANG TIANHUANG TECH INDAL

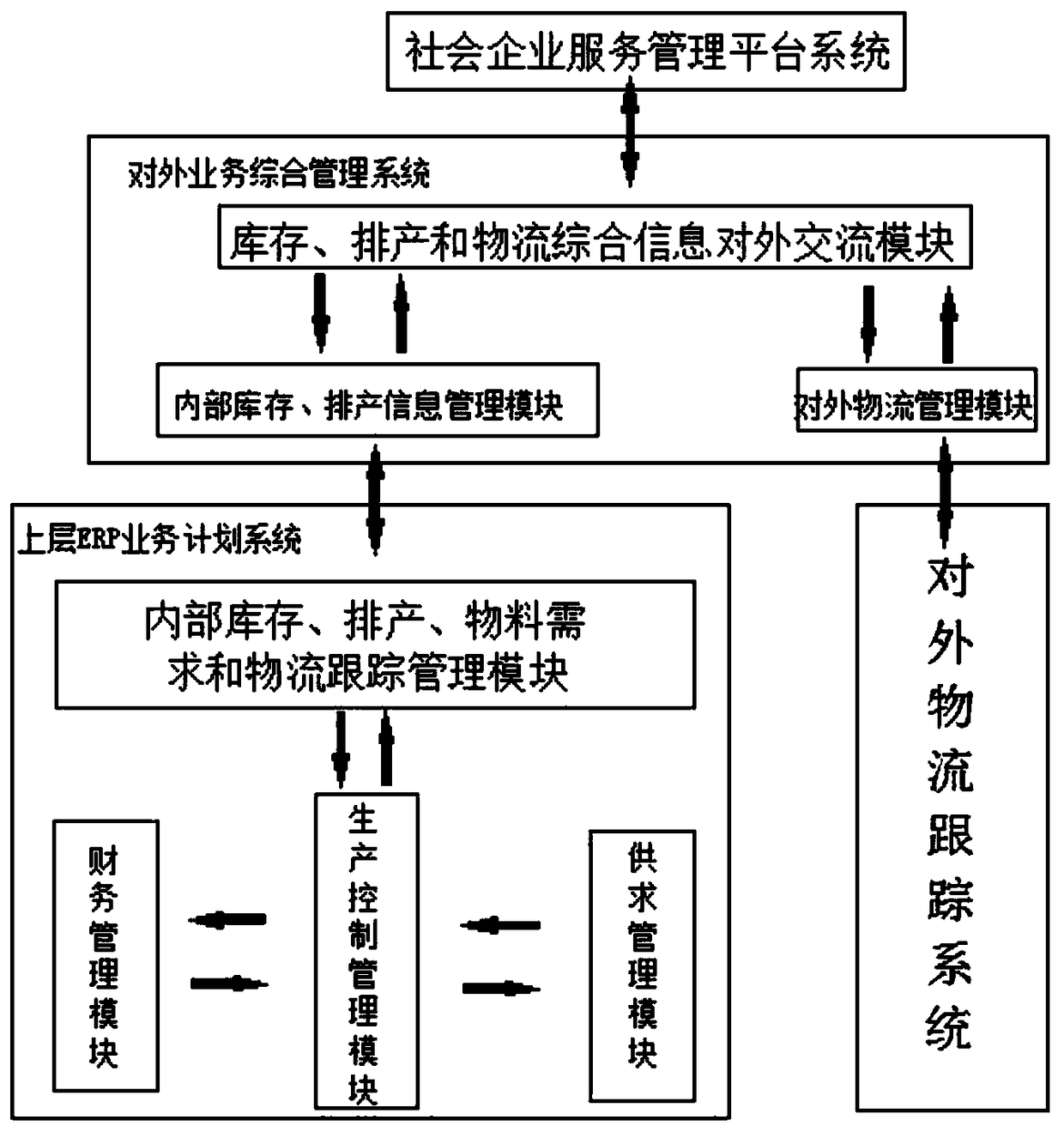

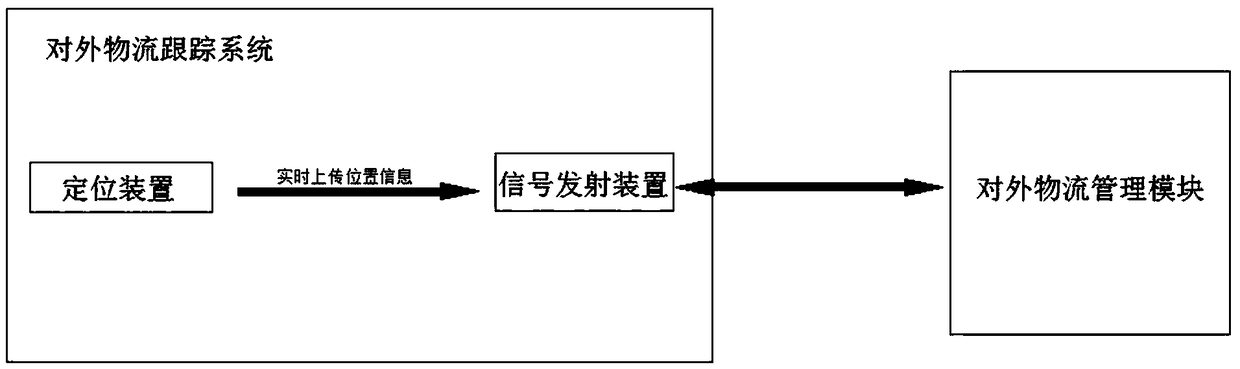

Internet of things technology and industrial big data-based intelligent factory system and method

InactiveCN108805451AAchieve transparencyProtect interestsResourcesLogisticsManufacture execution systemProgram planning

The invention discloses an Internet of things technology and industrial big data-based intelligent factory system and method, and belongs to the technical field of intelligent production, manufacturing and management. The Internet of things technology and industrial big data-based intelligent factory system comprises a lower-layer MES (Manufacturing Execution System), an upper-layer ERP (Enterprise Resource Planning) system, an outward service comprehensive management system and a social enterprise service management platform system. According to the Internet of things technology and industrial big data-based intelligent factory system disclosed by the invention, by taking the social enterprise service management platform system as a center, all companies perform information communicationwith the social enterprise service management platform system through the outward service comprehensive management system, so that the whole society is used as a super intelligent factory; and therefore, the problem of difficulty in coordination of all enterprises is solved, and the productivity of the industry is further optimized.

Owner:刁川川

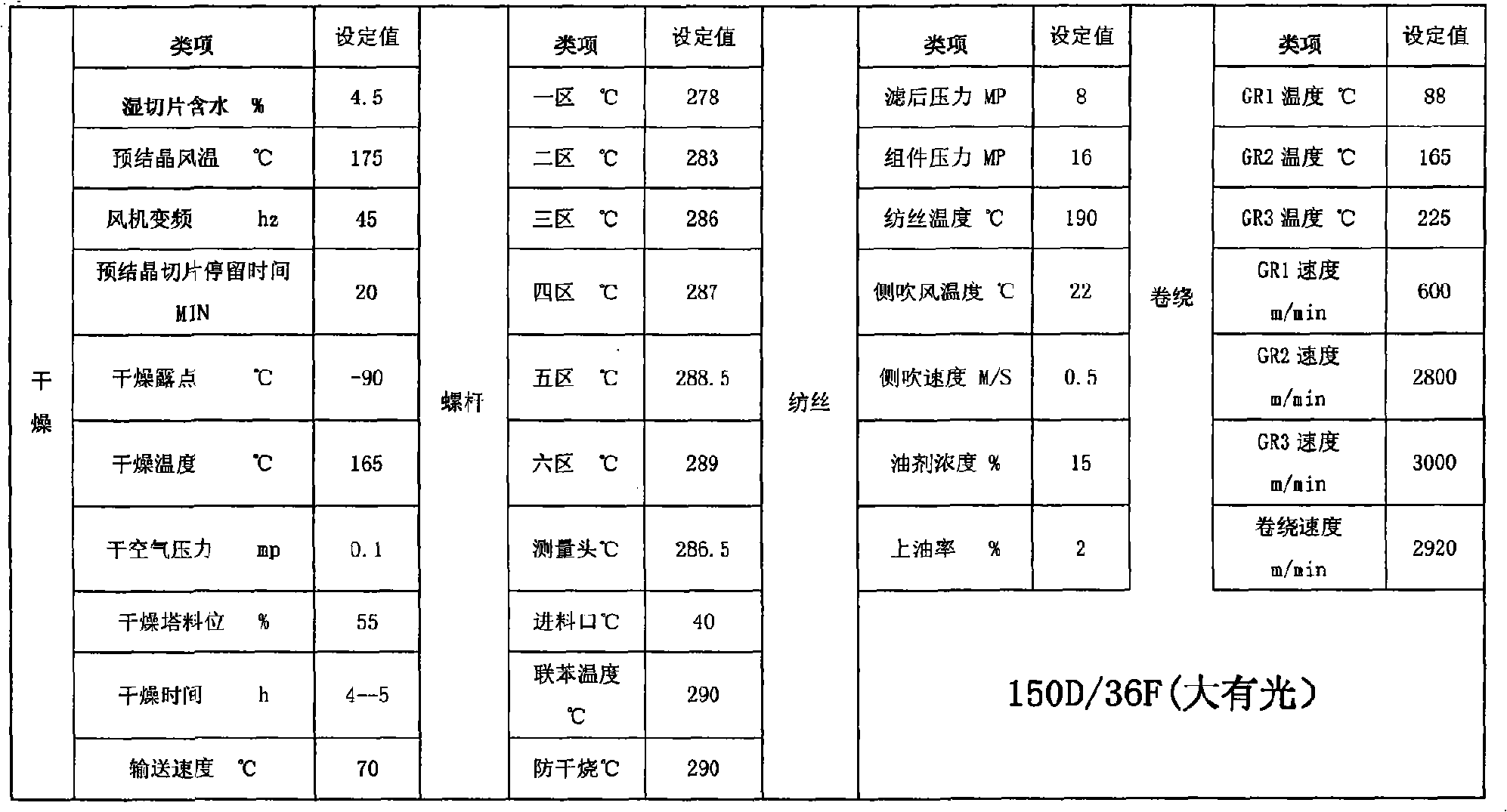

Preparation method for fine denier polyester industrial yarn

InactiveCN101275300ASimplify the 4-level stretching linkBig investmentMelt spinning methodsFilament-forming treatmentYarnPolyester

The invention provides a dawn terylene industry silk production method, including slice conveying, pre-crystallization, drying, screw rod squeezing, metering, filtering, spinning, bundling and oil applying, drafting, coiling, exterior checking, dyeing, and packaging, which is characterized in that a two stage stretching is adopted, a four stage of stretching step for producing the industry silk, the existing FDY production facility are used. Thereby the invention has small equipment increased investment, high added value products, few equipment investment, ripe technology, not quite difficult manufacturing management, strong producing stability and considerable products profit; the invention can produce high performance sewing thread in the same technological condition.

Owner:CHANGSHU FEITENG CHEM FIBER

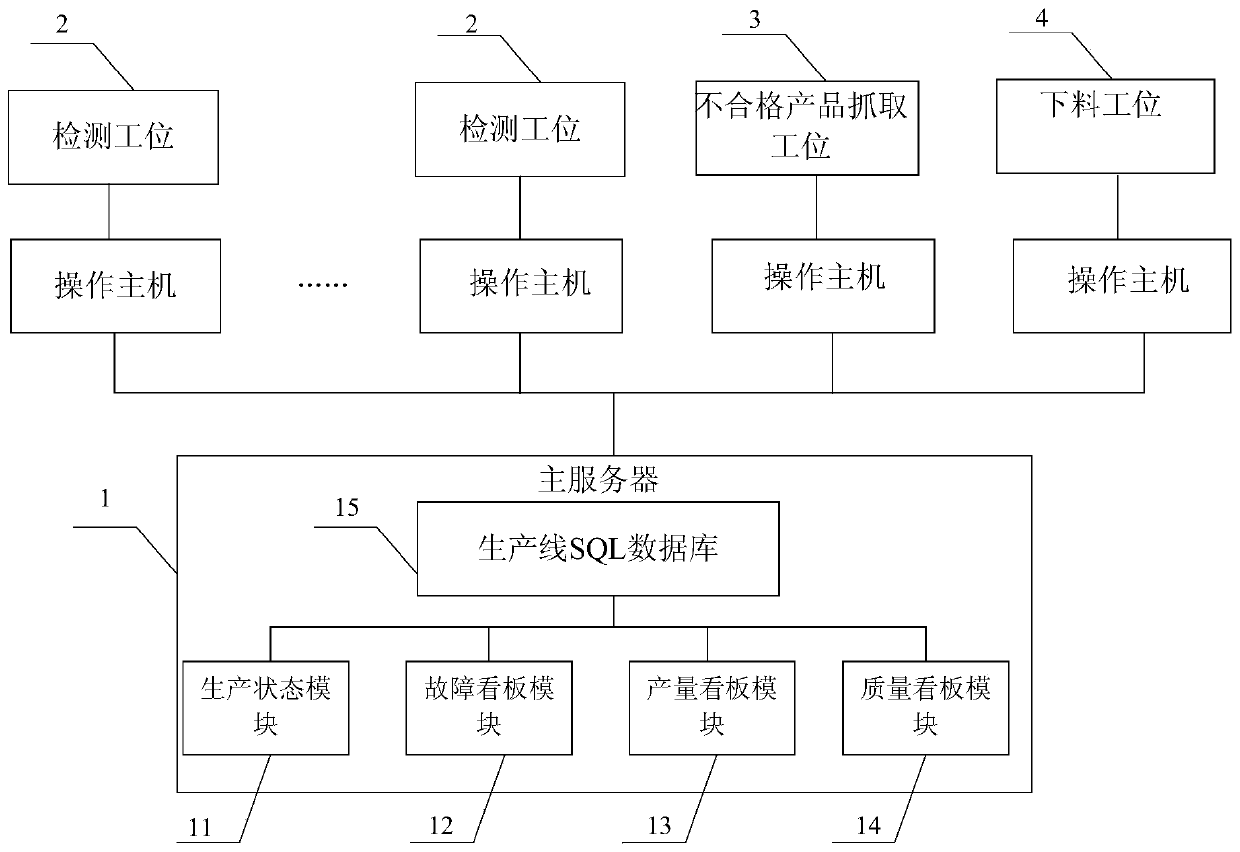

Intelligent management system for production line

InactiveCN110989521AAchieve positioningAvoid confusion and slow response to abnormal informationTotal factory controlProgramme total factory controlIndustrial engineeringServer

An intelligent management system for a production line belongs to the technical field of production and manufacturing management. To resolve the problems of disordered production equipment management,poor product quality management and control performance, disordered duties of operators, low production efficiency and long abnormal information response time of an existing production line, a main server and an operation host connected with each station of the production line are connected through a network cable to form a local area network. N detection stations, an unqualified product grabbingstation and a discharging station recognize products in a two-dimensional code scanning mode. Two-dimensional codes of the identified products and the product information detected by the station of the products are sent to the main server at the same time. The main server comprises a production line SQL database, a production state module, a fault billboard module, a yield billboard module and aquality billboard module. The system is used for production line management.

Owner:AEROSPACE HI TECH HLDG GROUP

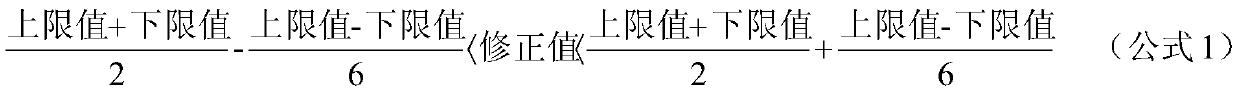

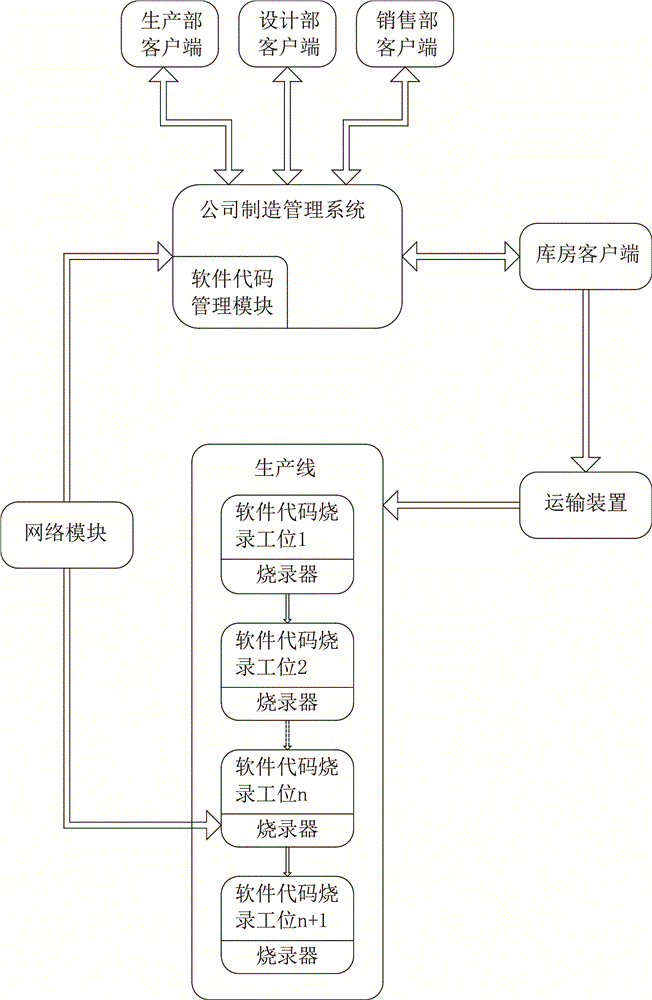

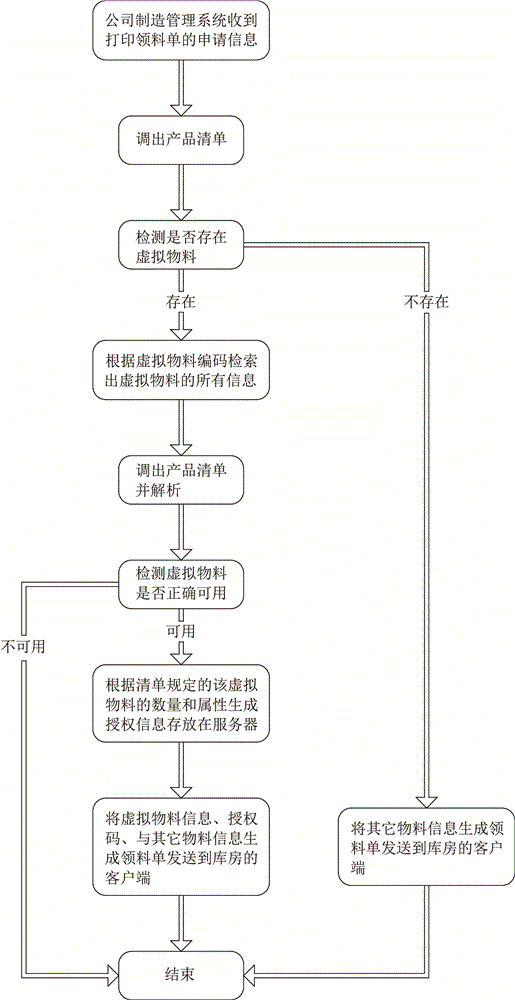

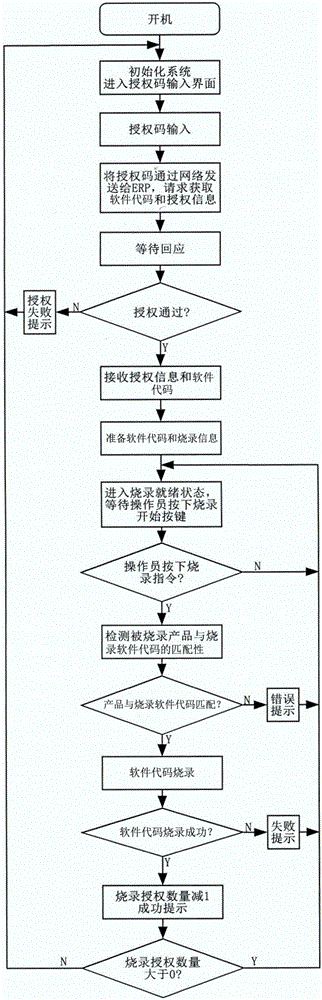

Control method for software burn in electronic product production

InactiveCN105159735AEnsure safetyUniqueness guaranteedProgram loading/initiatingSoftware engineeringManufacturing management

The invention discloses a control method for software burn in electronic product production. A software code is considered as a virtual material and is stored and managed together with a solid material, and the software code and the solid material are managed and controlled by a software code management module of an enterprise manufacture management system, so that the software code is taken, burned, destroyed and recorded in production and burn, and the software code becomes a material. Software of other versions or other products is prevented from being burned in currently produced product, burned chips are recorded and counted so as to prevent repeatedly burning and burning missing, and the software code is destroyed after burning so as to guarantee the security and uniqueness of the software code.

Owner:NINGBO JIANGBEI GOFRONT HERONG ELECTRIC

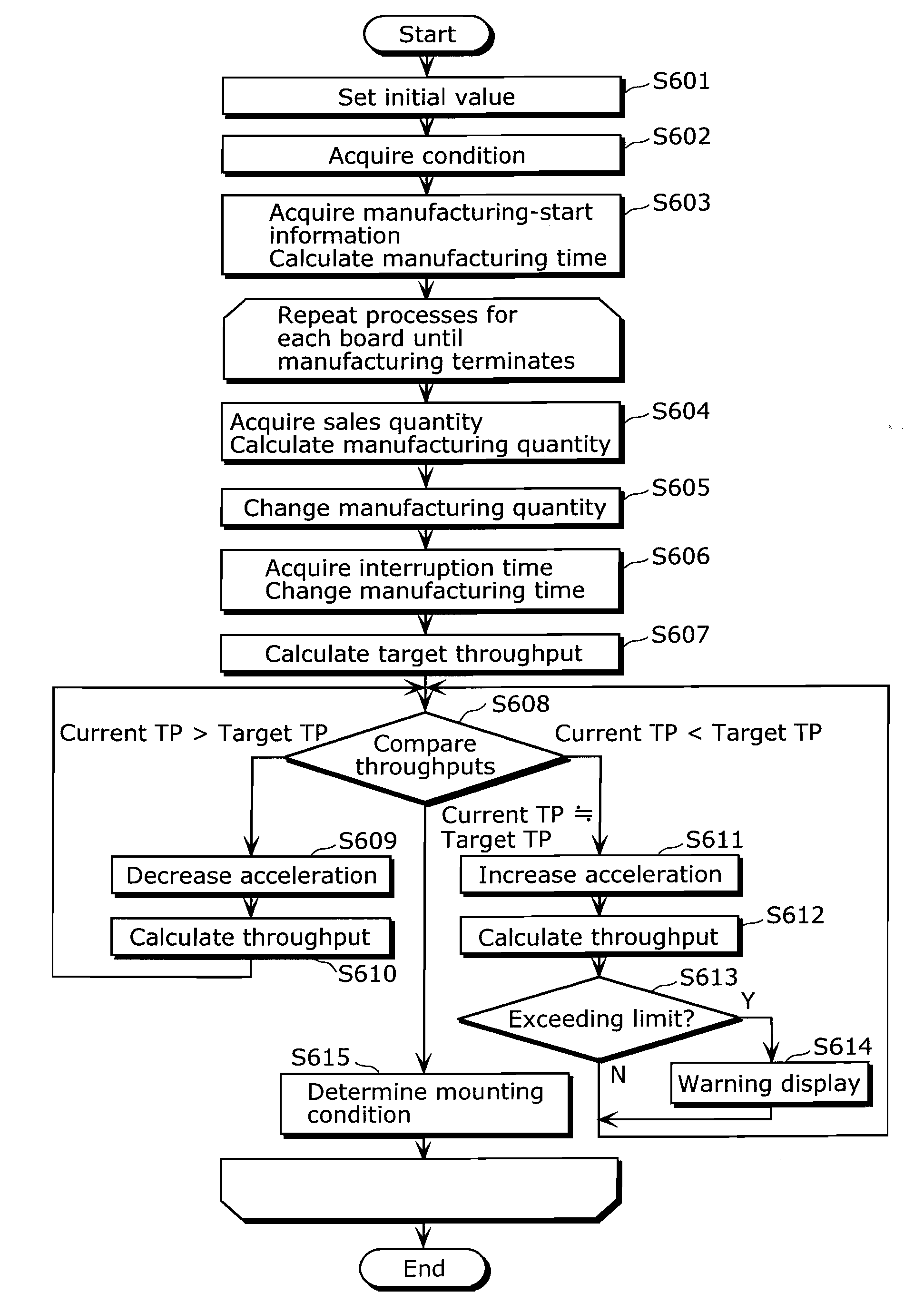

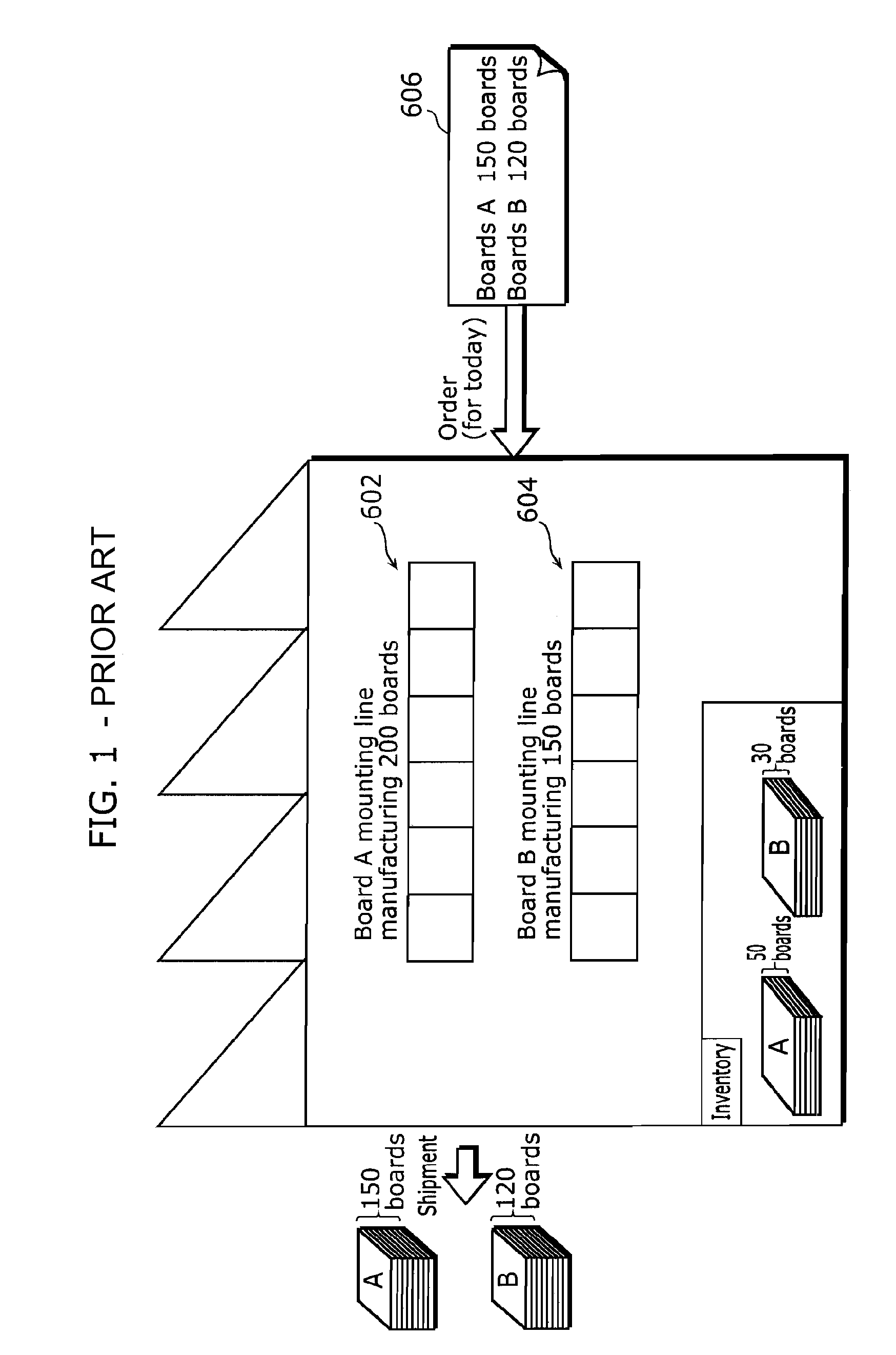

Manufacturing management method, manufacturing management apparatus, and mounter

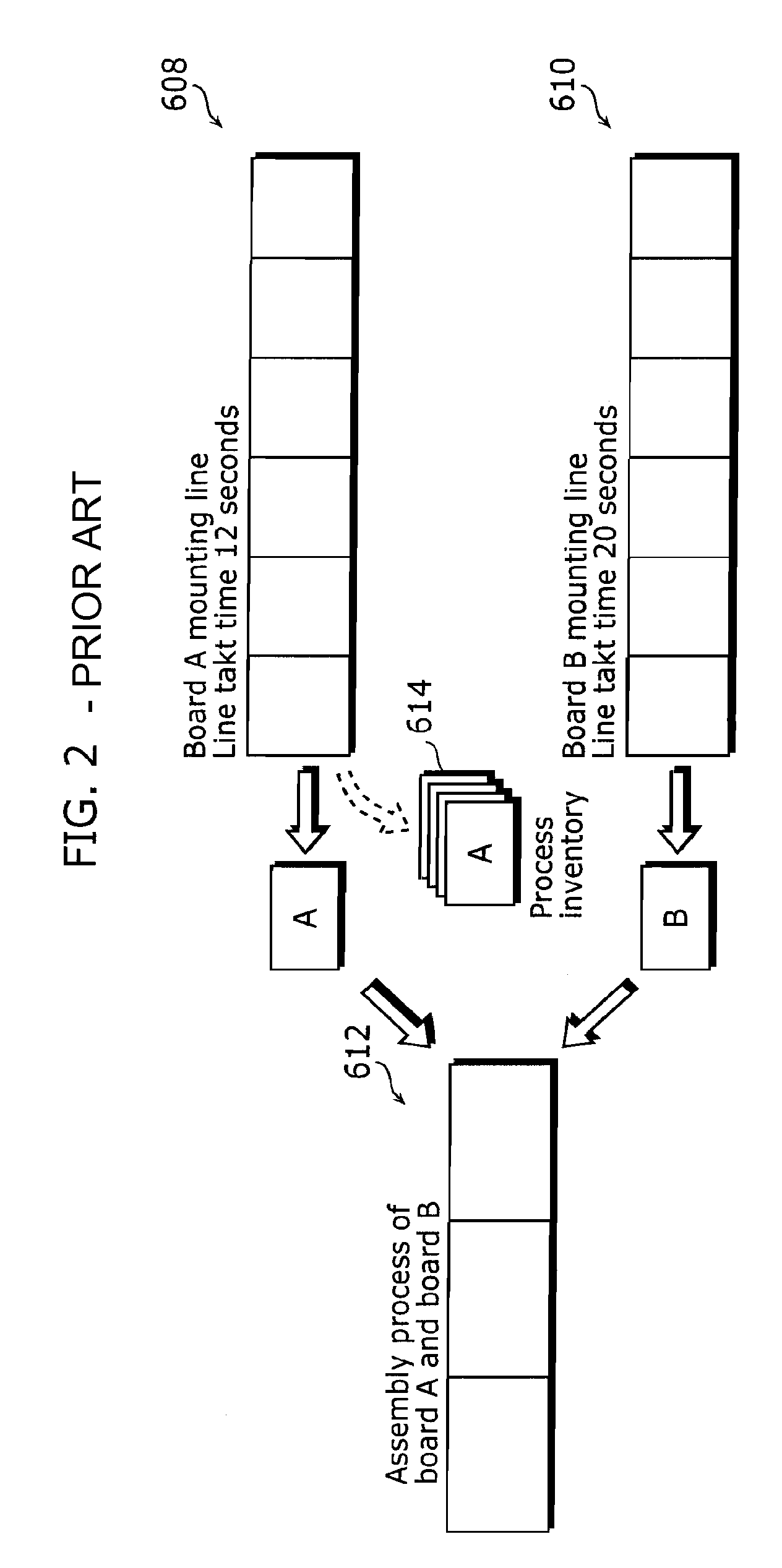

InactiveUS7801634B2Reduce cost lossExtended production timeProgramme controlDigital computer detailsManufacturing planningManufacturing management

A mounter for a manufacturing management method suppresses an occurrence of inventory shortage or excess inventory as much as possible, and provides energy savings when manufacturing is not performed at full capacity. A throughput determining step acquires manufacturing information included in a manufacturing plan while manufacturing equipment is manufacturing mounted boards and determines a throughput of the manufacturing equipment for the mounted boards based on the manufacturing information while the manufacturing equipment is manufacturing a sequence of the mounted boards. A manufacturing condition determining step determines a manufacturing condition for decreasing power consumption of the manufacturing equipment within a range of throughput not lower than the determined throughput in the case where the throughput determined in the throughput determining step is equal to or lower than a current throughput of the manufacturing equipment.

Owner:GK BRIDGE 1

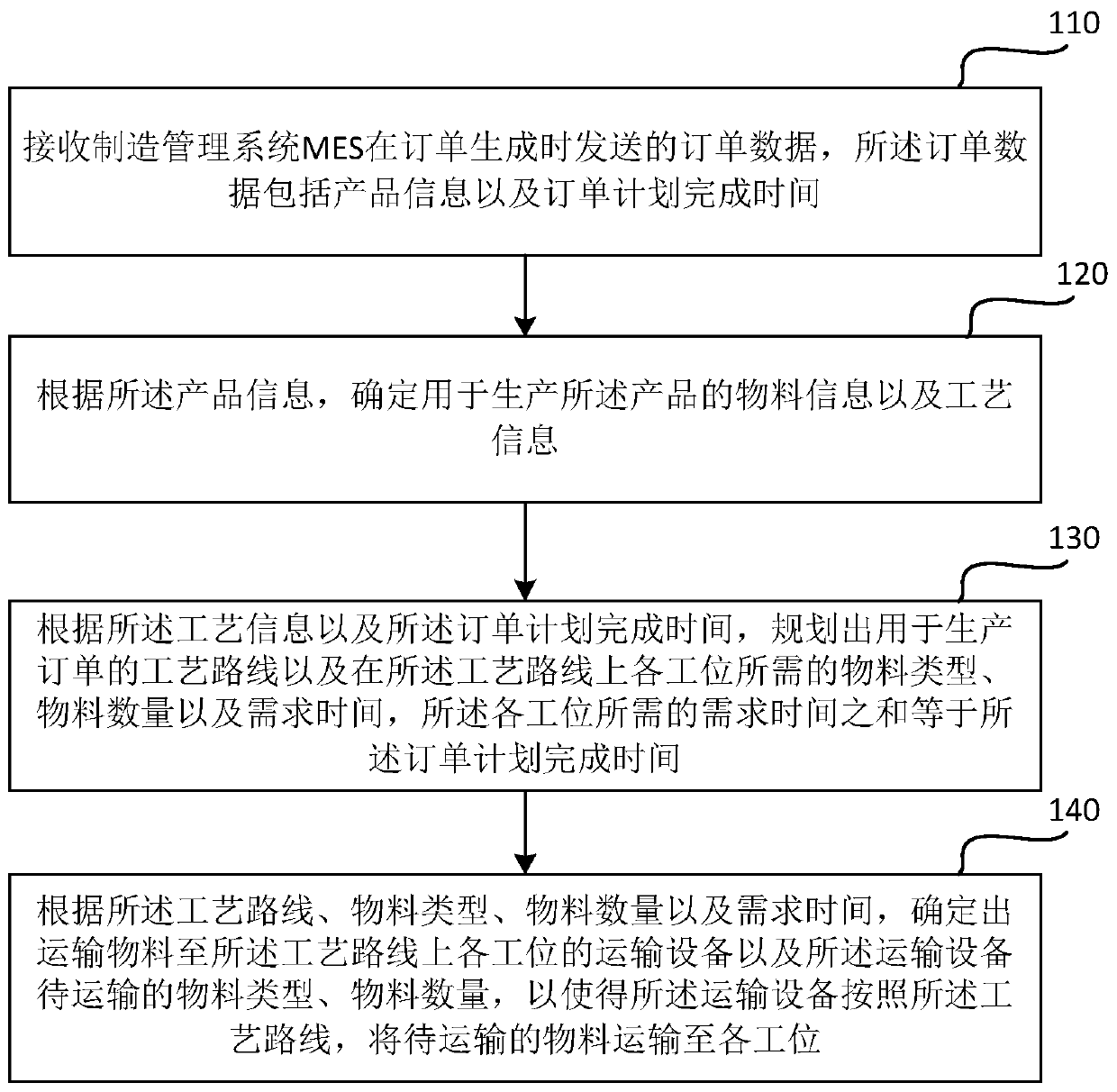

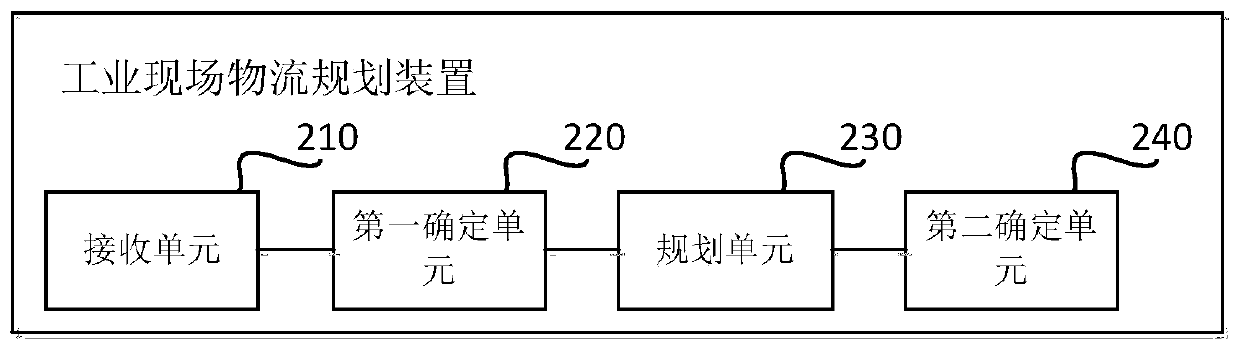

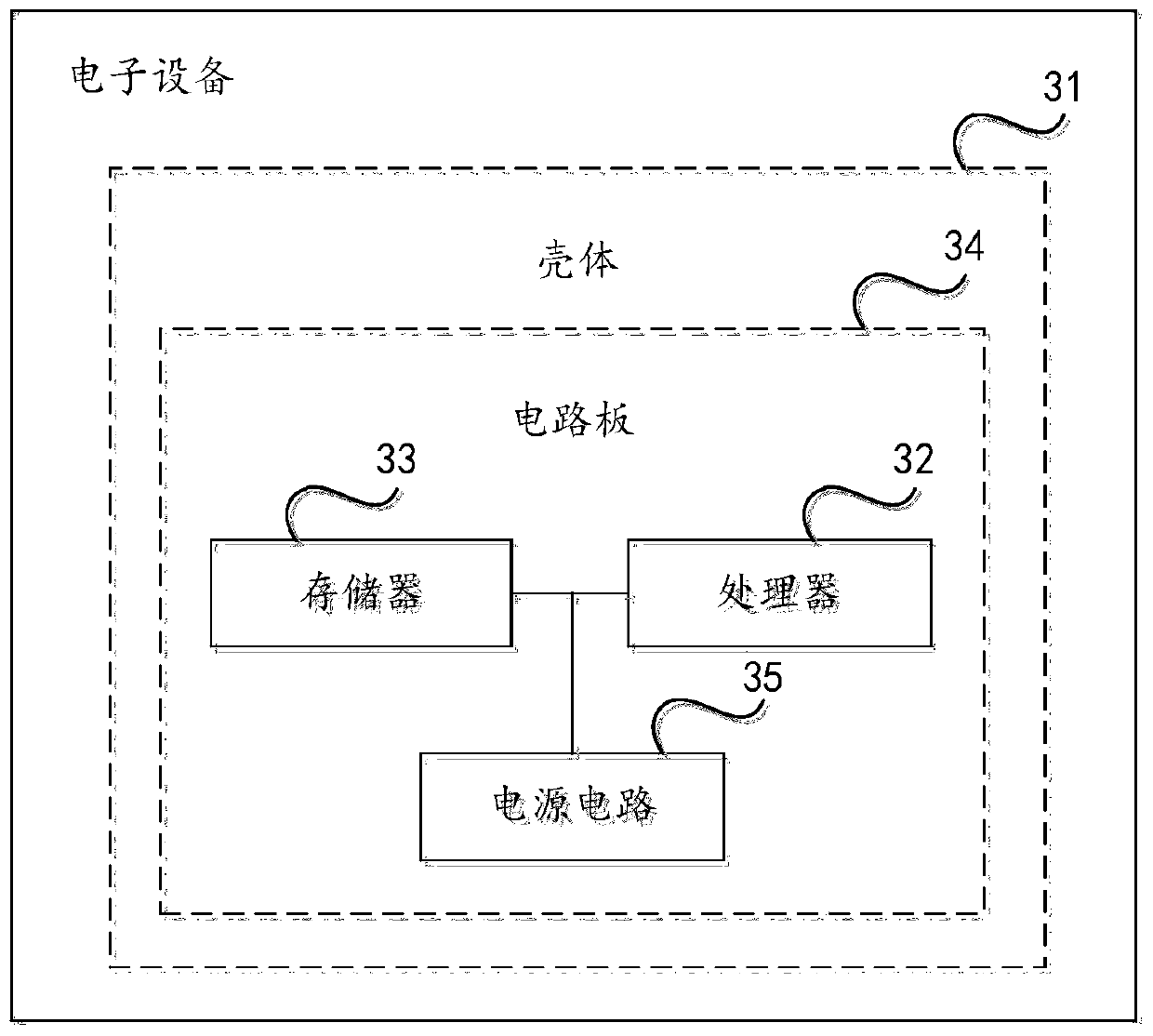

An industrial field logistics planning method and device

The embodiment of the invention discloses an industrial field logistics planning method and device, and relates to the technical field of information management. The method comprises the following steps: receiving order data sent by a manufacturing management system (MES) when an order is generated, wherein the order data comprises product information and order plan completion time; Determining material information and process information for producing products according to the product information; According to the process information and the order plan completion time, planning a process route for order production and the material type, the material quantity and the demand time required by each station on the process route, and enabling the sum of the demand time required by each stationto be equal to the order plan completion time; And according to the process route, the material type, the material quantity and the required time, determining the transportation equipment for transporting the materials to each station on the process route and the type and the quantity of the materials to be transported by the transportation equipment, so that the transportation equipment transports the materials to be transported to each station according to the process route.

Owner:北京航天智造科技发展有限公司

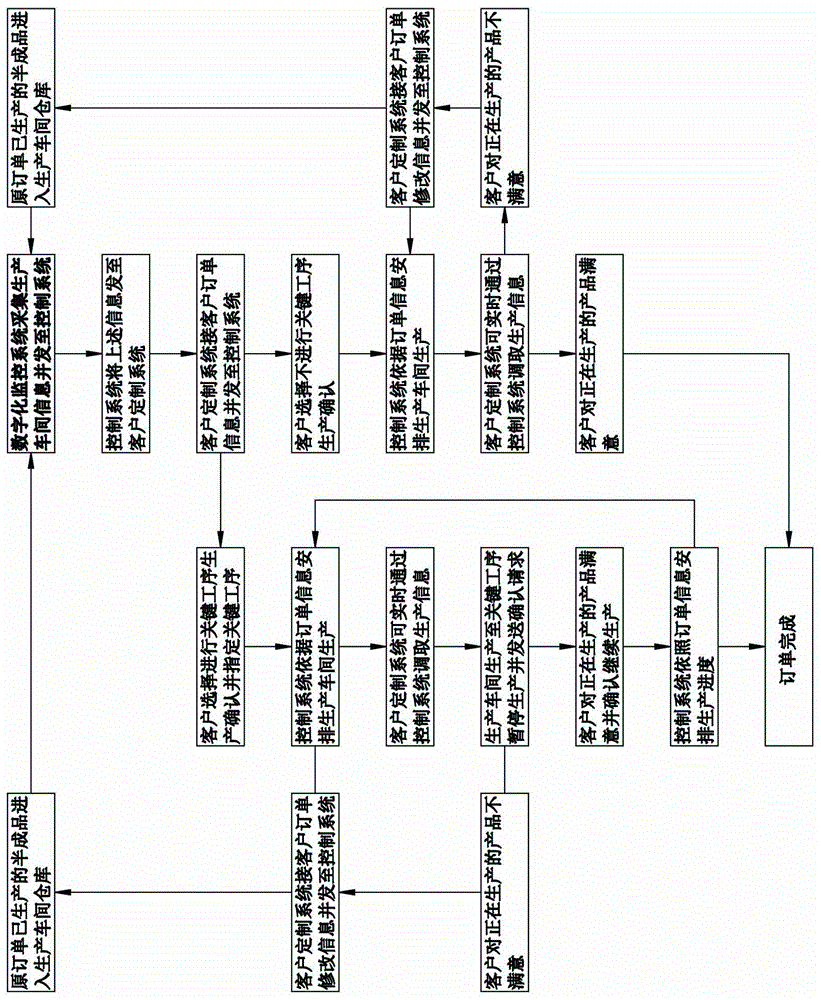

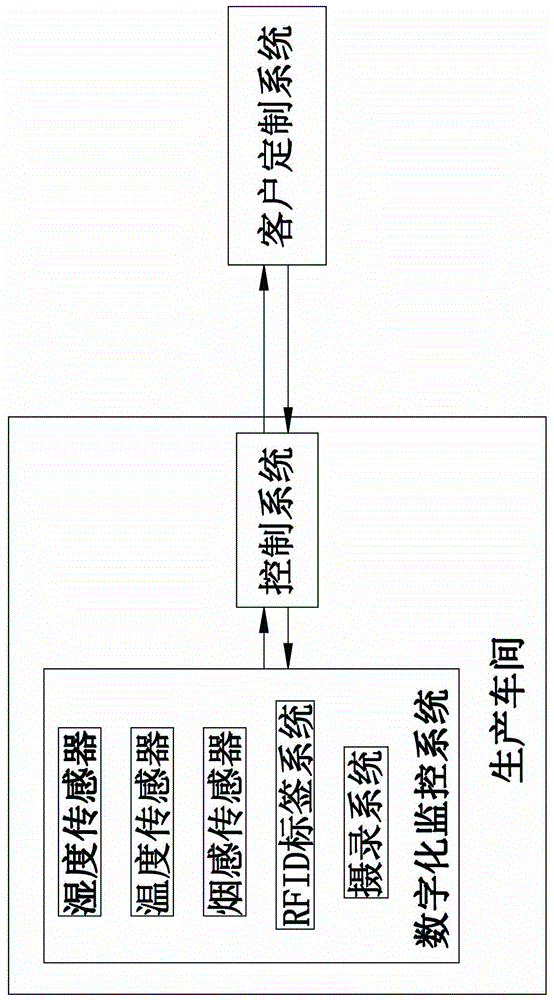

Customization manufacture method and system based on digital monitoring

InactiveCN105844436AUnderstand intuitiveReduce waste of resourcesBuying/selling/leasing transactionsLogisticsControl systemMonitoring system

The invention relates to a customization manufacture method and system based on digital monitoring. The customization manufacture method based on digital monitoring comprises steps of i) establishing a digital monitoring system of a manufacturing shop; ii) establishing a client customization system; iii) transmitting information collected by a digitalized monitoring system of a manufacturing shop in the step i to the client customization system in the step ii by a control system, authorizing the client customization system to control the manufacturing shop and generating a manufacture pre-control order; iv) transmitting the manufacture pre-control order generated by the step iii to a manufacture management department to perform regulation and optimization and arranging manufacture by the control system at regular intervals; and v) pushing the production process of the cargo which is customized for the client to the client customization system by the control system. The customization manufacture method and system based on digital monitoring enable the client to participate in the manufacture process and reduces the waste of the source.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

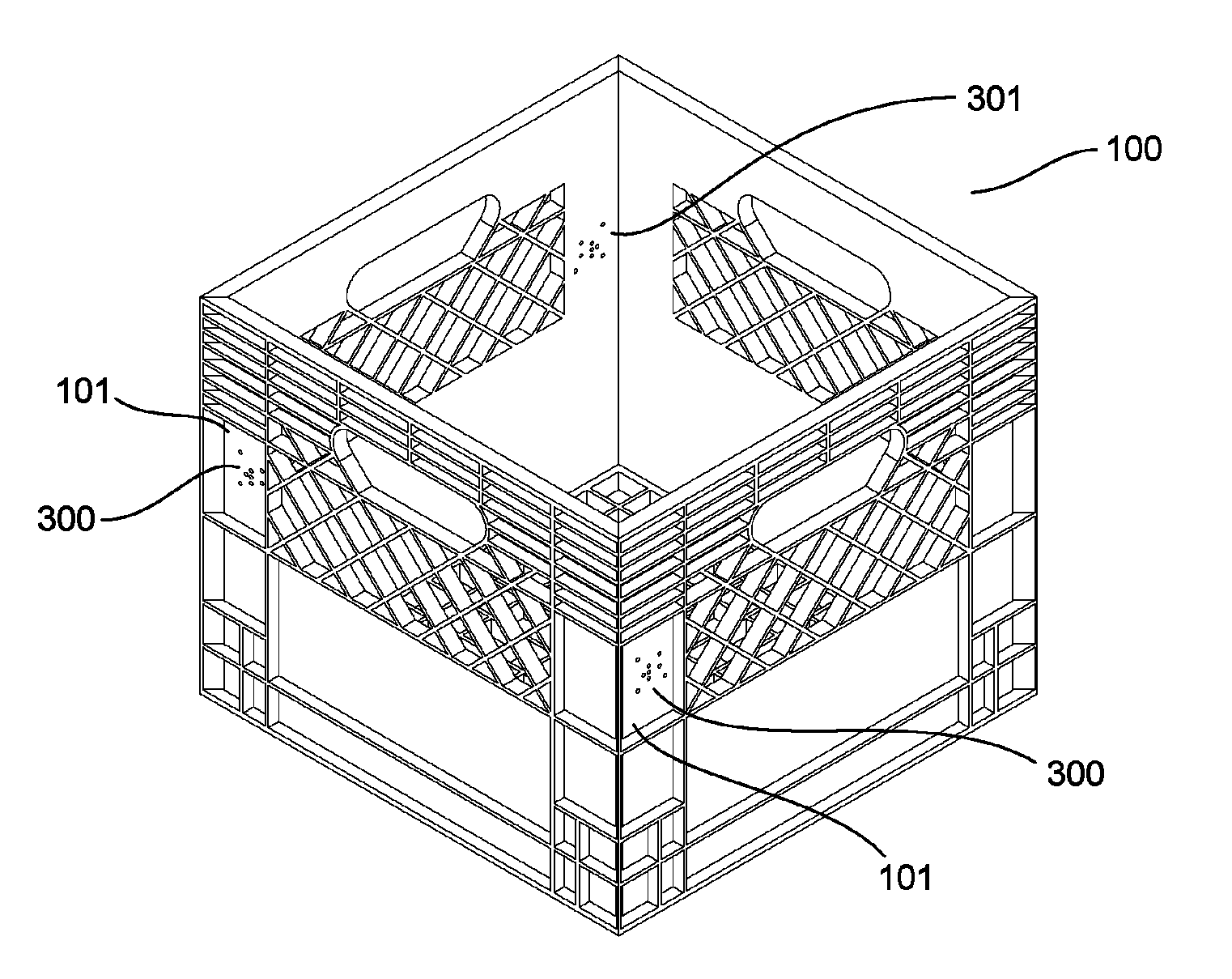

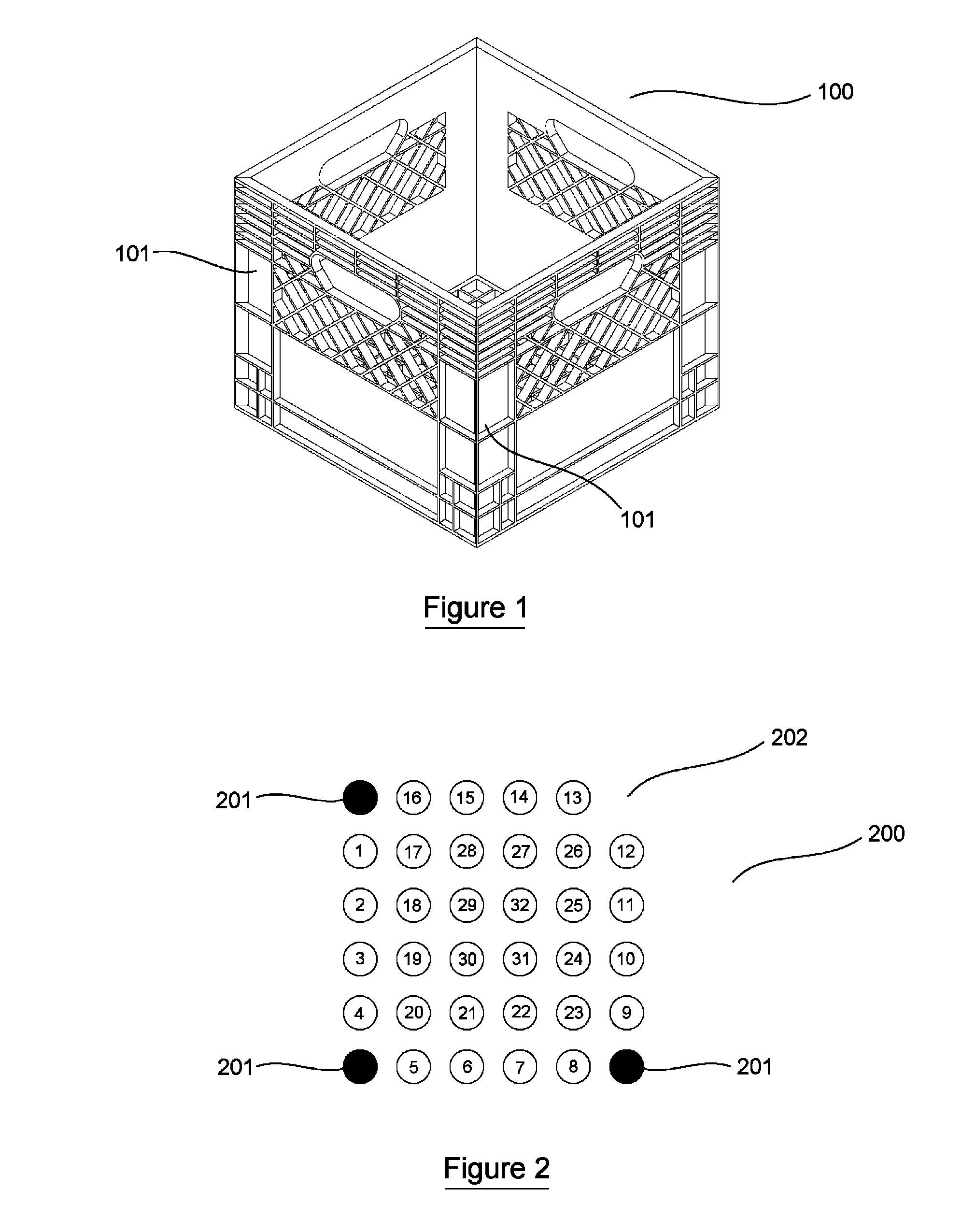

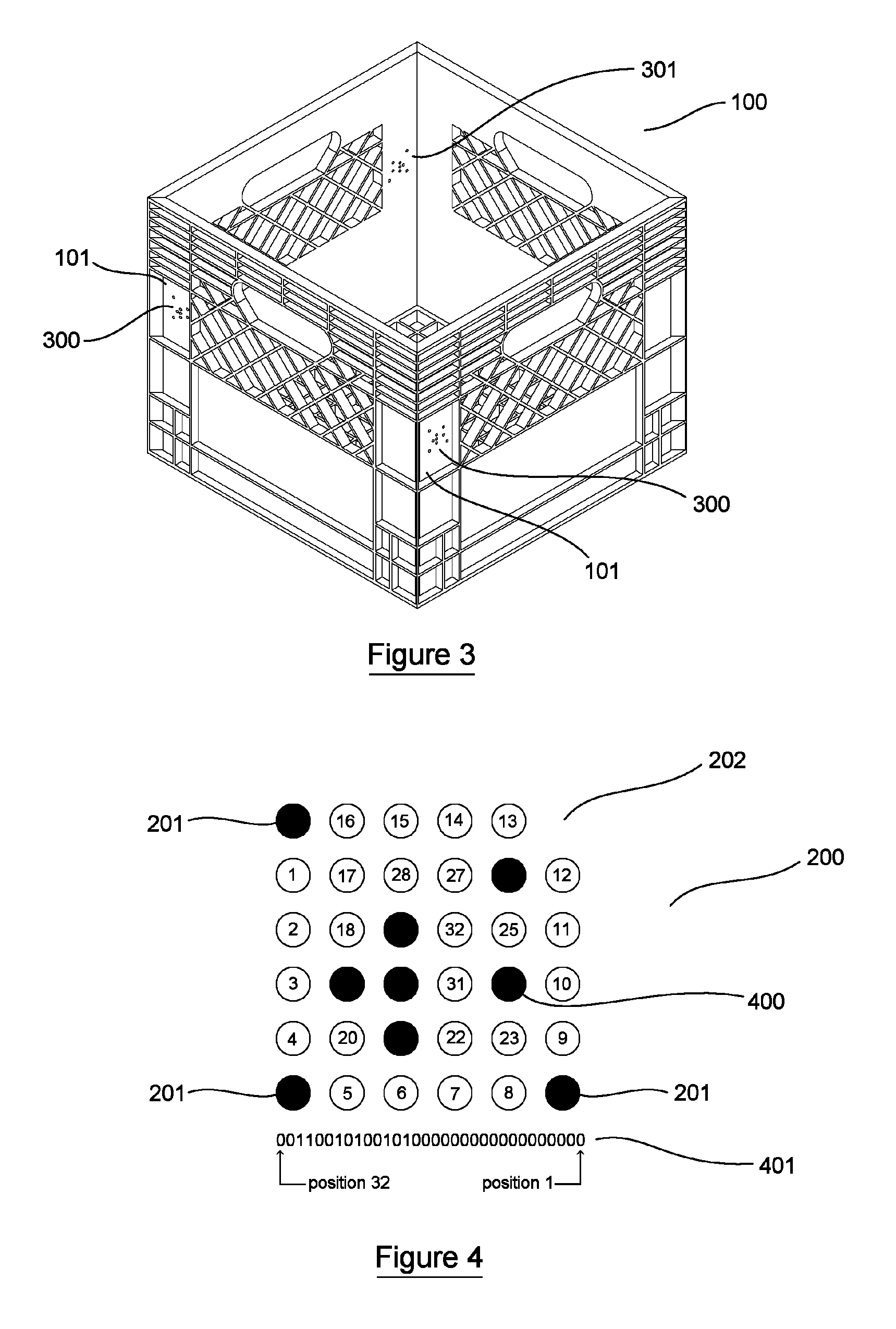

Method and system for identifying and tracking reusable packing crates

InactiveUS8418914B2Reduce material costsEliminates visible contrast limitationComplete banking machinesPackage recyclingBarcodeManufacturing management

A method and system is provided for permanently and visibly marking reusable packing crates with a unique mark and using the mark to identify and track the crate in a manufacturing environment. The mark can include a two-dimensional barcode comprised of holes drilled through one or more sidewalls of the crate to produce a unique and permanent pattern for identification. The code can be used to identify a crate uniquely and to assign waypoint data, process management data and content data that can be stored in a computer database. The data can be used for tracking information capabilities and business intelligence in and for manufacturing management systems.

Owner:CORMACK CAMERON LANNING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com