MES system based on intelligent manufacturing management

An intelligent manufacturing and intelligent technology, applied in the field of MES system based on intelligent manufacturing management, can solve the problems of increasing production cost, material integration, ineffective classification management, and prolonging labor time of workers, etc., to achieve intelligent control, improve performance, Highly intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

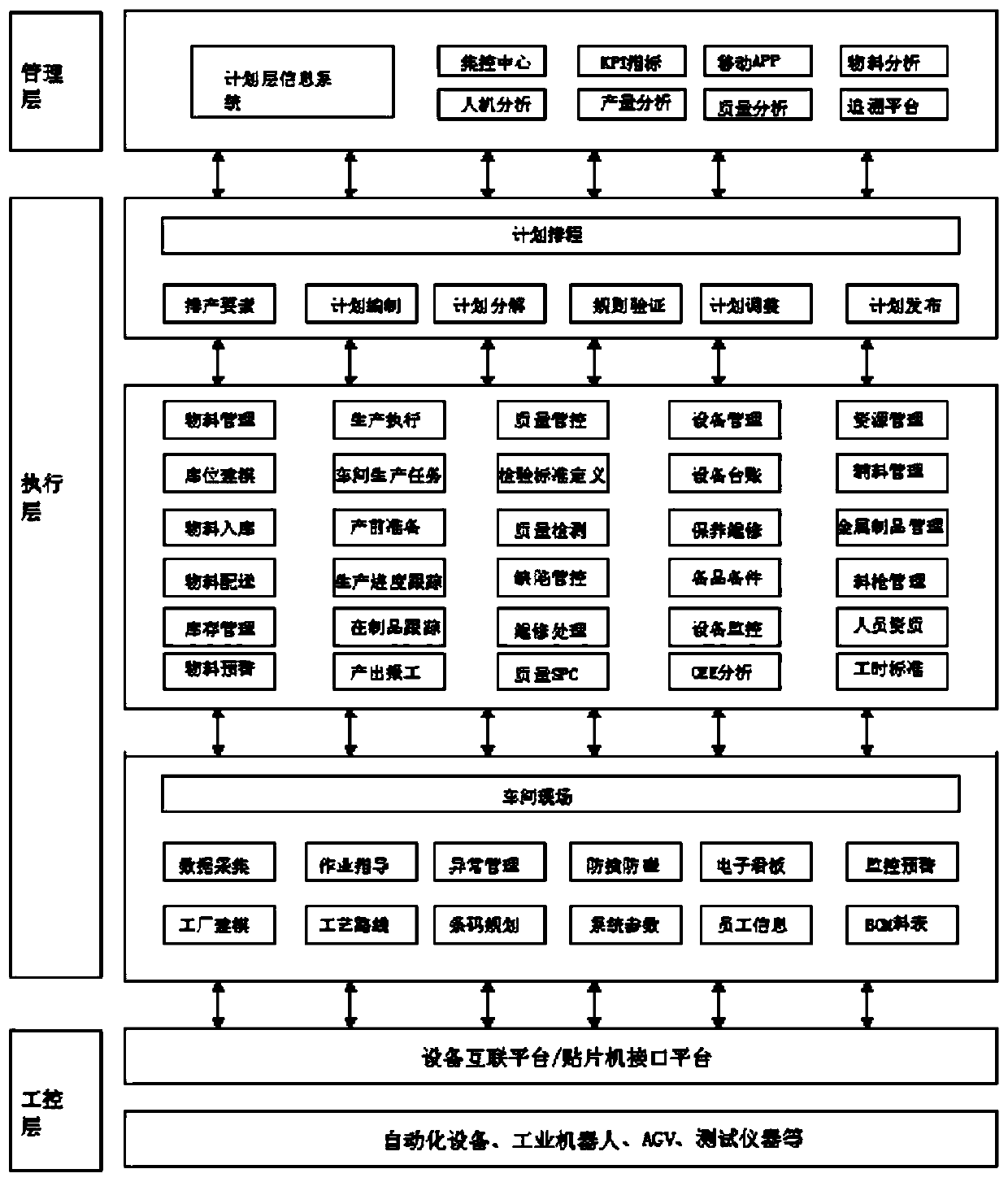

[0022] Refer to attached figure 1 , a MES system based on intelligent manufacturing management, including a management layer, an execution layer and an industrial control layer, the output end of the management layer is connected to the industrial control layer through the execution layer, wherein,

[0023] The management includes planning layer information system, centralized control center for information integration, KPI indicators for internal management of the organization, mobile APP for information viewing, recording and management, material analysis, man-machine analysis, output analysis and retrieval A traceability platform at the output end of the data source;

[0024] The execution layer includes planning and scheduling, and the planning and scheduling elements, planning, planning decomposition, rule verification, plan adjustment and plan release are respectively set in the planning and scheduling, and the output of the planning and scheduling is respectively equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com