Patents

Literature

891 results about "Quality management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality management ensures that an organization, product or service is consistent. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only on product and service quality, but also on the means to achieve it. Quality management, therefore, uses quality assurance and control of processes as well as products to achieve more consistent quality. What a customer wants and is willing to pay for it determines quality. It is written or unwritten commitment to a known or unknown consumer in the market. Thus, quality can be defined as fitness for intended use or, in other words, how well the product performs its intended function.

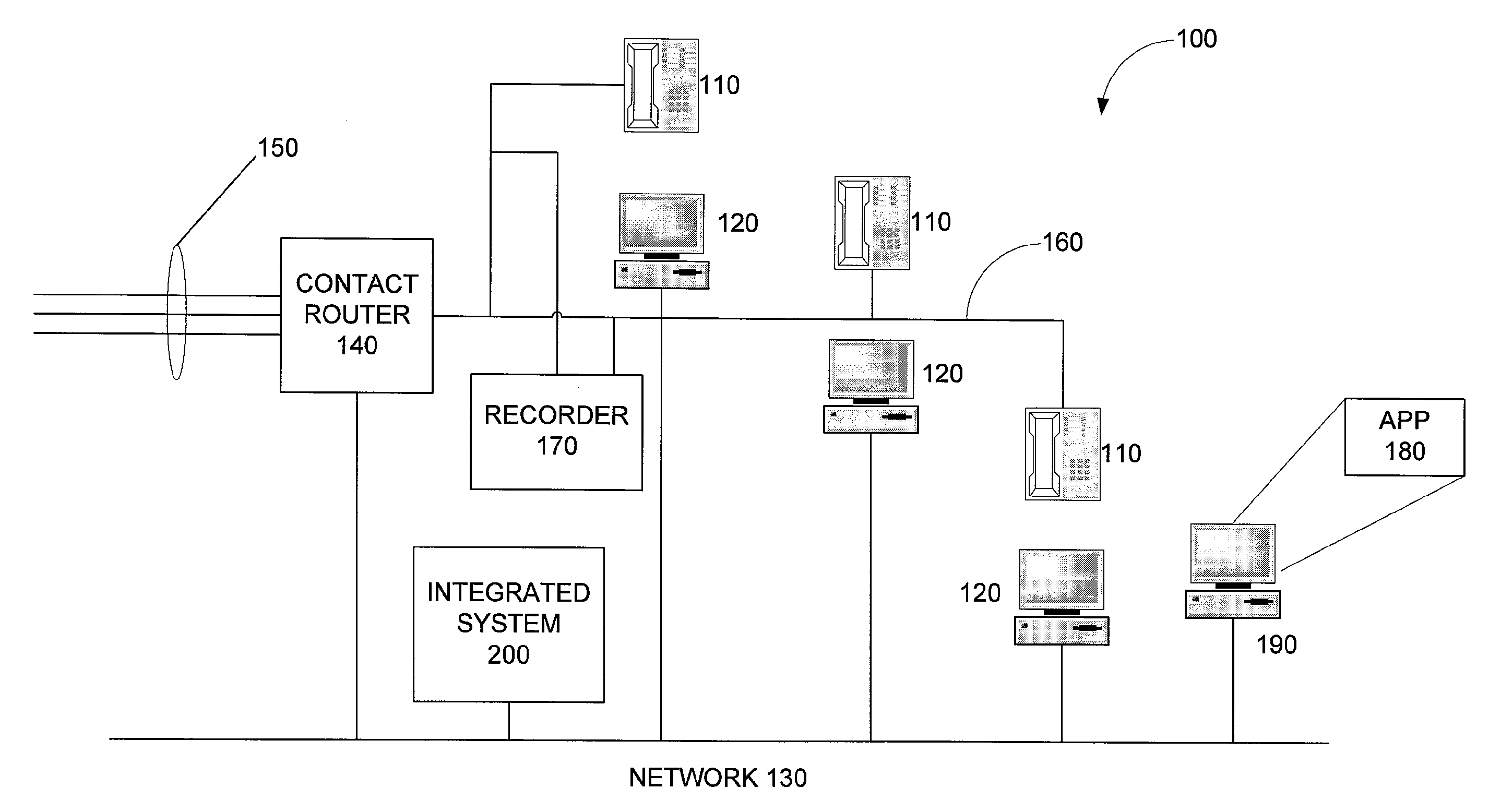

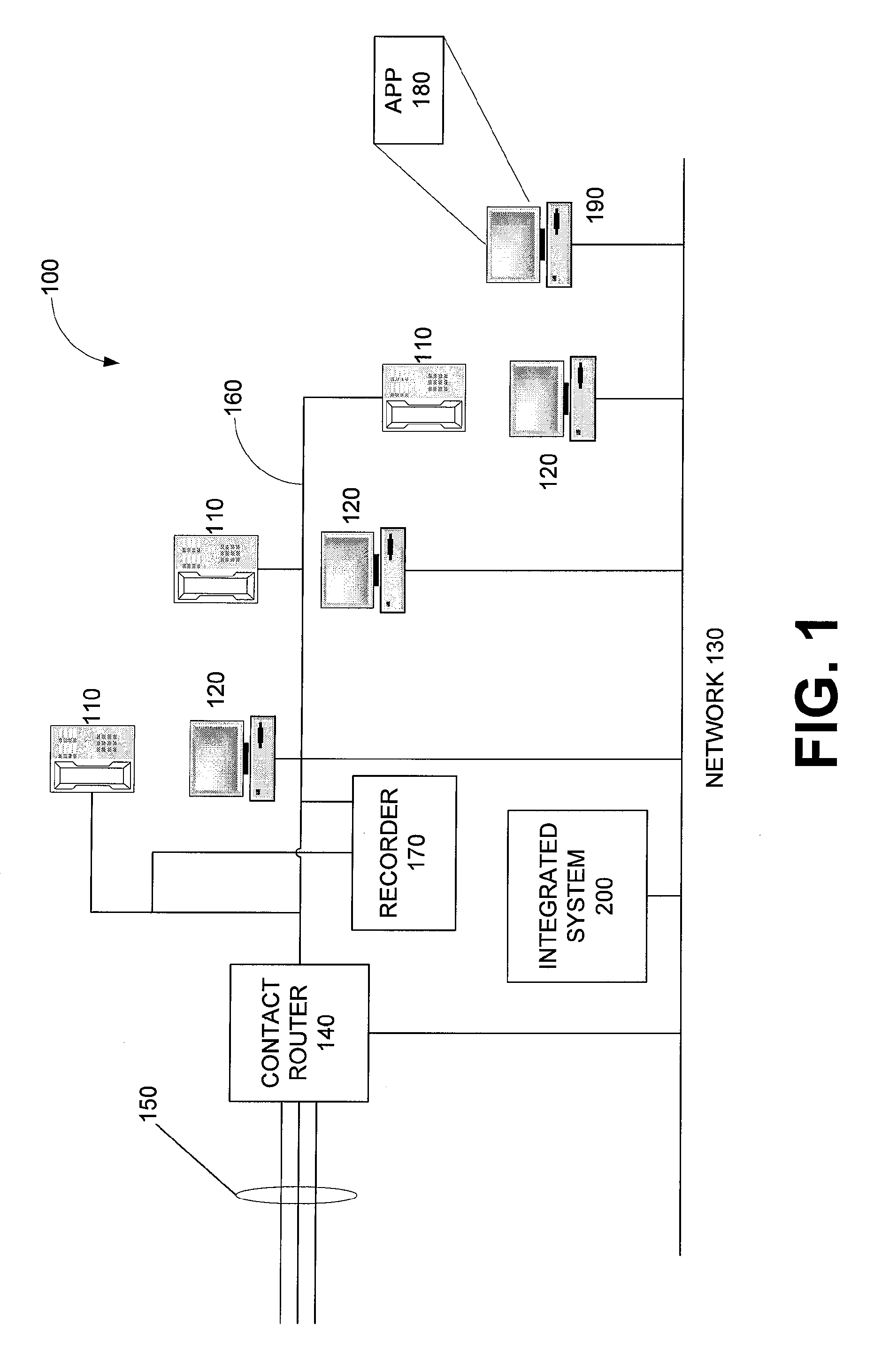

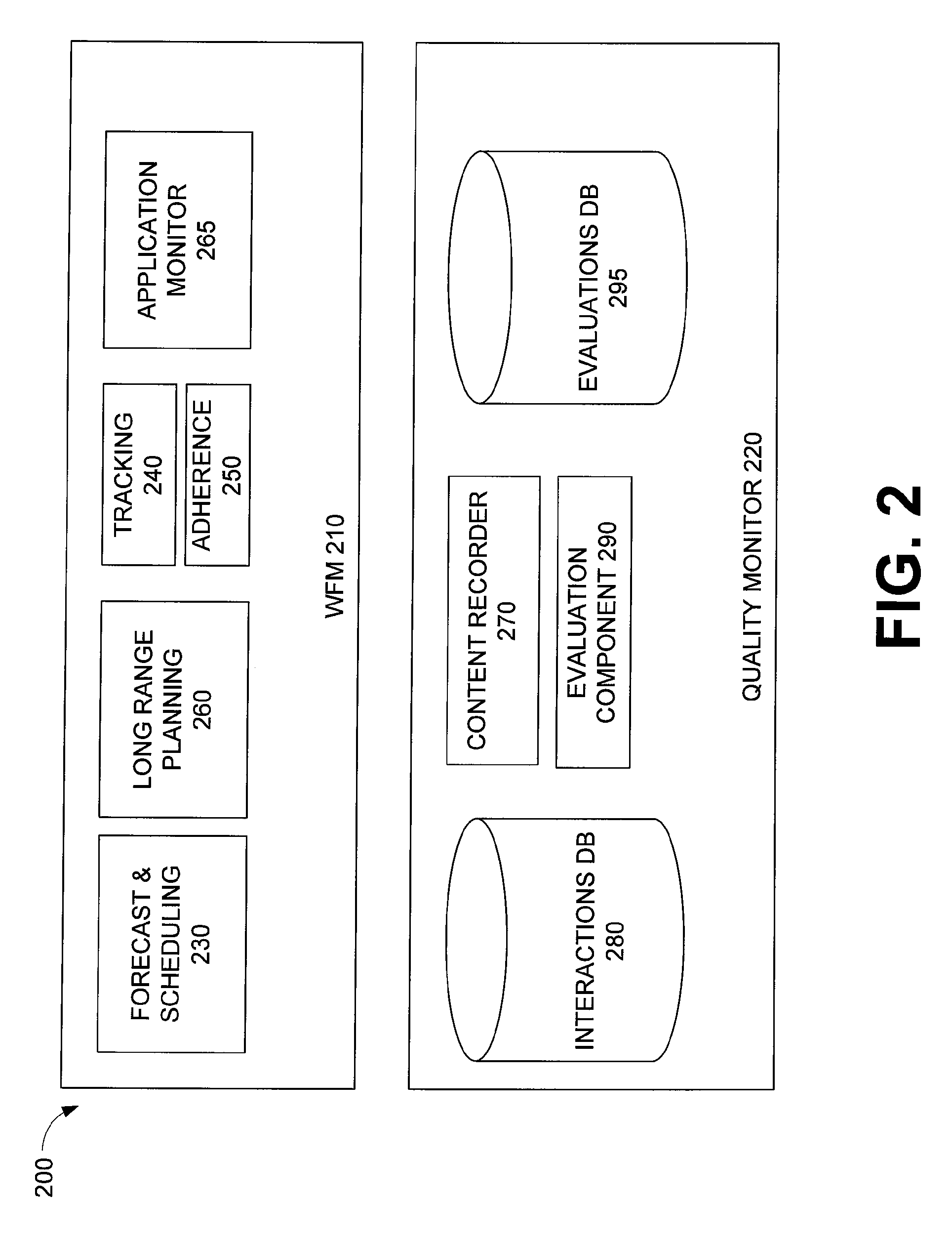

System and Method for Integrated Workforce and Quality Management

Methods and systems are presented for integrating workforce management and quality monitoring. In one embodiment, the method comprises the steps of: receiving information about a skill; capturing a plurality of contacts made by an agent; receiving an evaluation of the contacts; and updating the skill information based on the evaluation. The skill is associated with an agent, and the evaluation measures the agent skill. In another embodiment, the method comprises the steps of: receiving information about a skill; capturing a plurality of contacts made by an agent; receiving an evaluation form for the contacts; and updating the form based on the skill information. The skill is associated with an agent, and the form produces a measurement of the agent skill.

Owner:VERINT AMERICAS

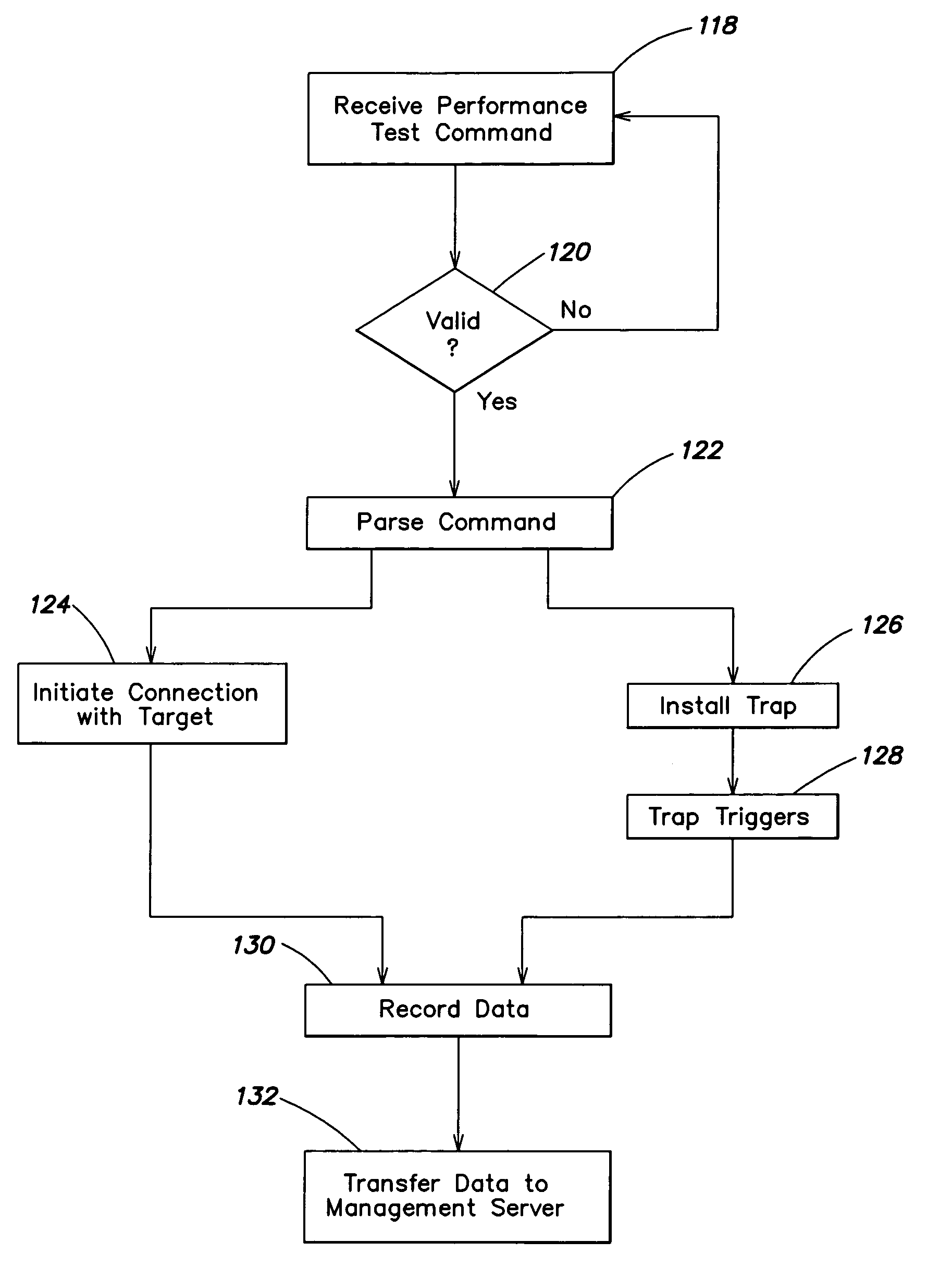

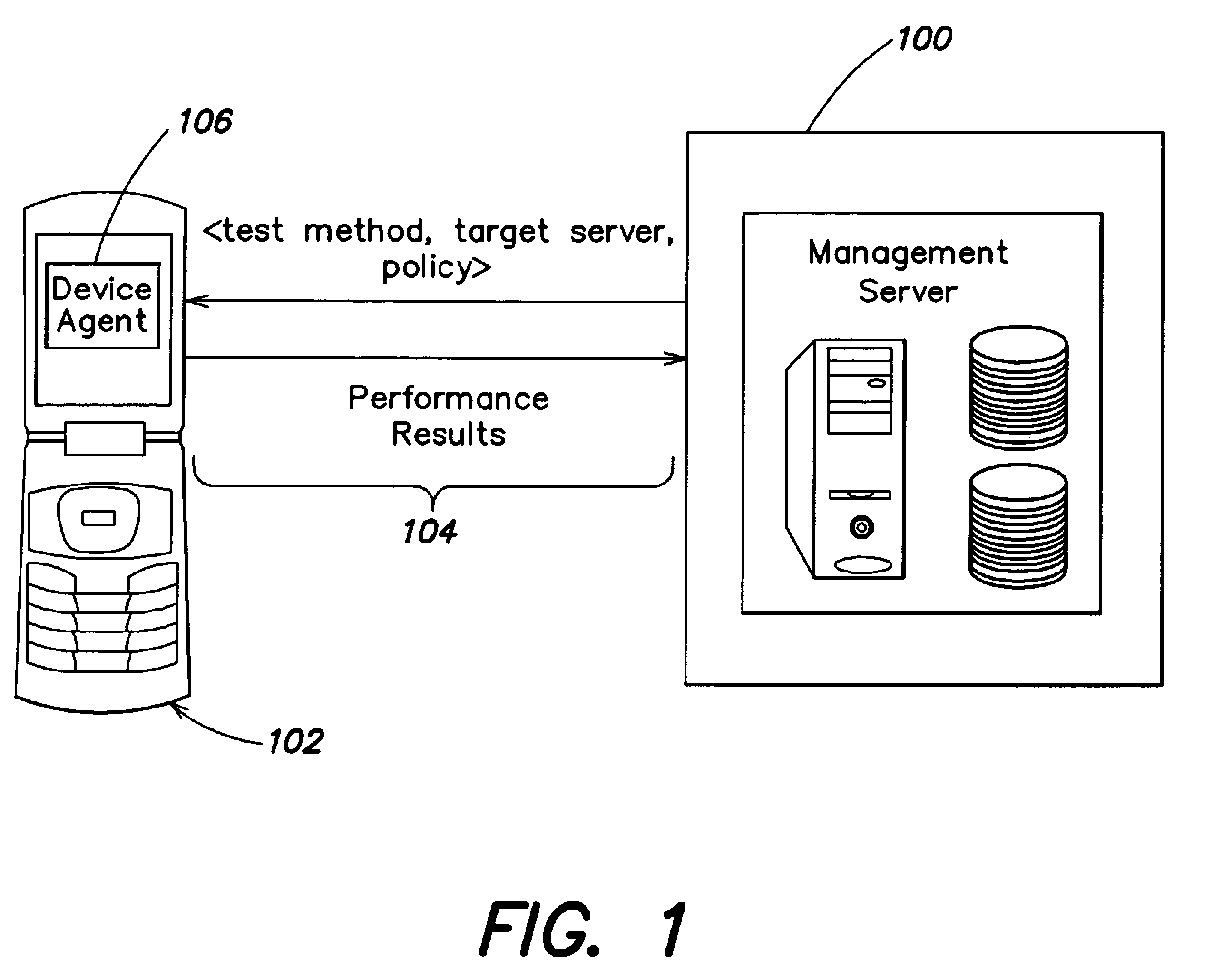

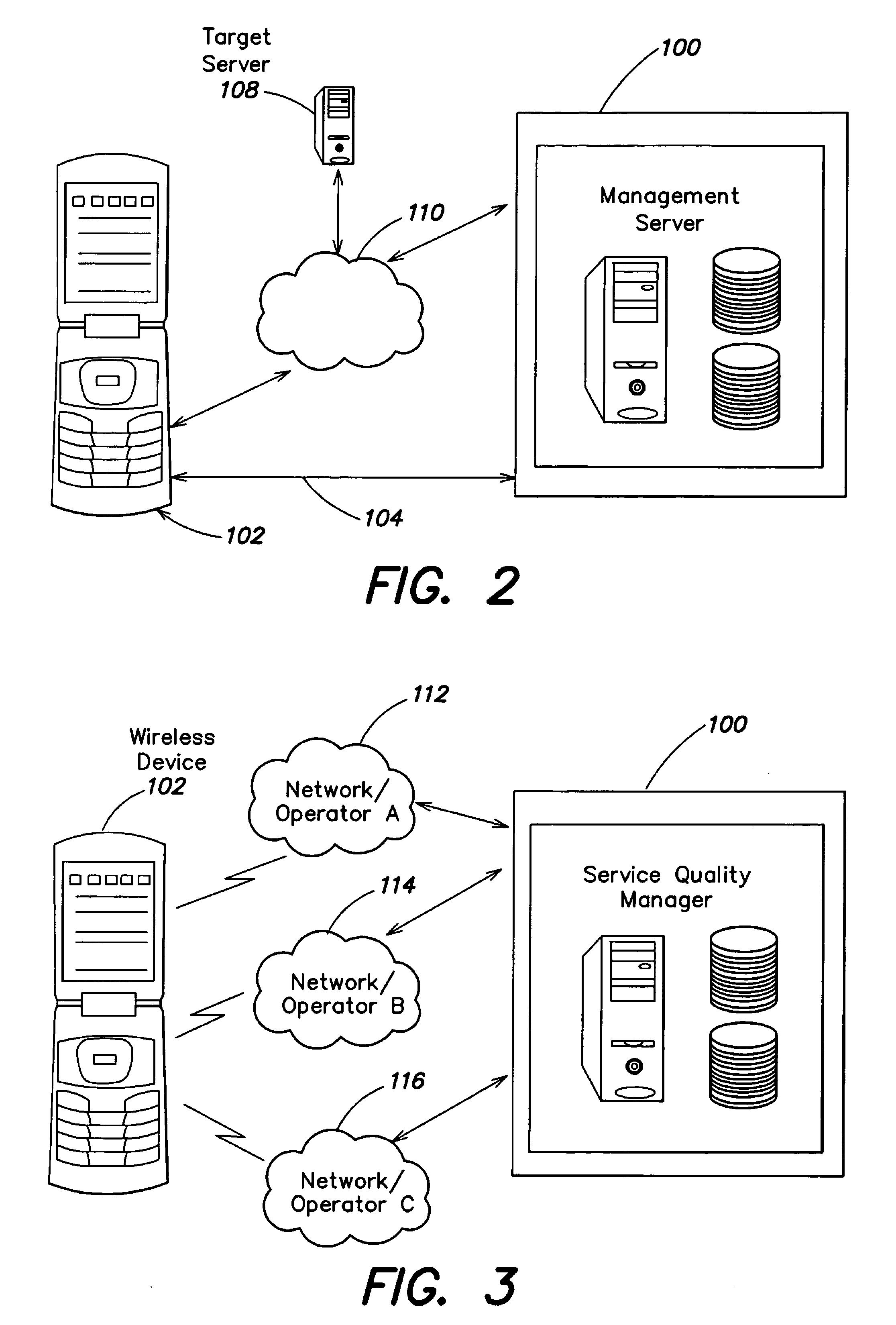

System and method for service quality management for wireless devices

ActiveUS7925740B2Monitor qualityTelephonic communicationMultiple digital computer combinationsQuality of serviceQuality management

A system and method for detecting and recording events related to the quality of service experienced by a wireless device in a wireless network. In one example, these events may be detected and recorded by the wireless device, without support from the network. Performance monitoring tests may be initiated by the wireless device at the direction of a management server, independent of the network in which the device may be operating. The wireless device may store the results of these tests and report the results to the management server.

Owner:MFORMATION +1

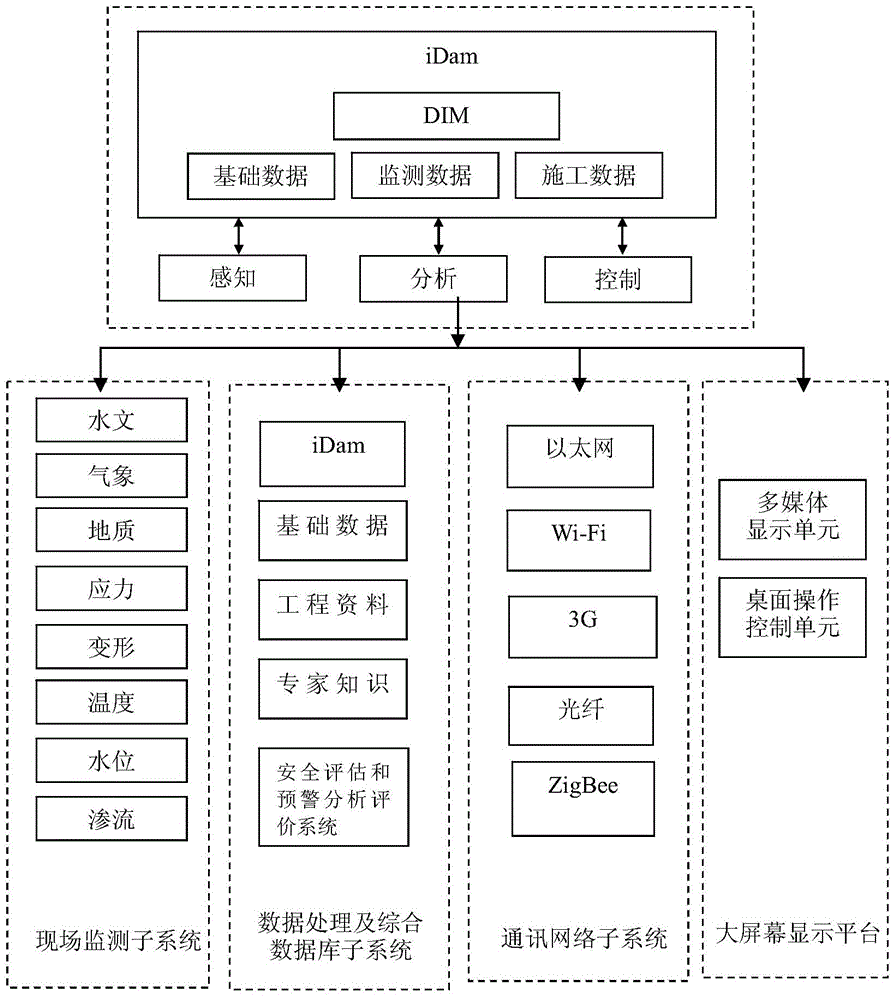

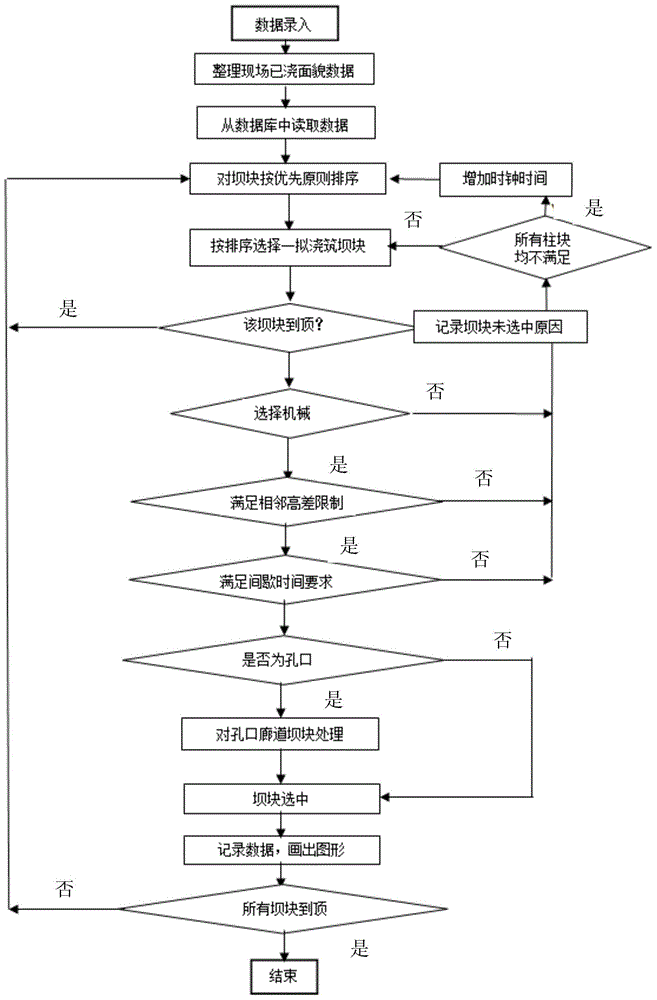

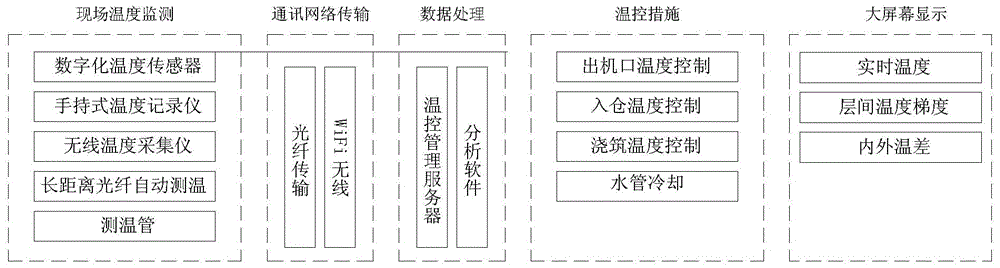

Dam safety intelligent monitoring and pre-warning system based on full life circle and method thereof

InactiveCN104678954ARealize full life cycle monitoringRealize evaluationProgramme total factory controlHigh archesDesign stage

The invention relates to a dam safety intelligent monitoring and pre-warning system based on full life circle and a method thereof, and belongs to the intelligent monitoring and pre-warning field of hydraulic and hydro-power engineering safety. By taking the full life circle of a high arch dam as a main line, a three-dimensional digital technology as a foundation and a building information model as a core, a full dam information model (DIM) including an overall three-dimensional structure of high arch dam concrete and foundation and construction process information are established, and an intelligent technology is applied by an intelligent high arch dam construction information platform for quality management and dynamic analysis control based on DIM development, so that the high arch dam construction such as application of essential data in the design period, full-process monitoring in the construction period and all-around monitoring and safety assessment and pre-warning analysis evaluation in the operation and management period of the high arch dam is realized, refine management and control on the high arch dam are realized, a foundation is provided for the safety management of the high arch dam, and safe operation in the whole life circle of the high arch dam is guaranteed.

Owner:CHINA THREE GORGES CORPORATION

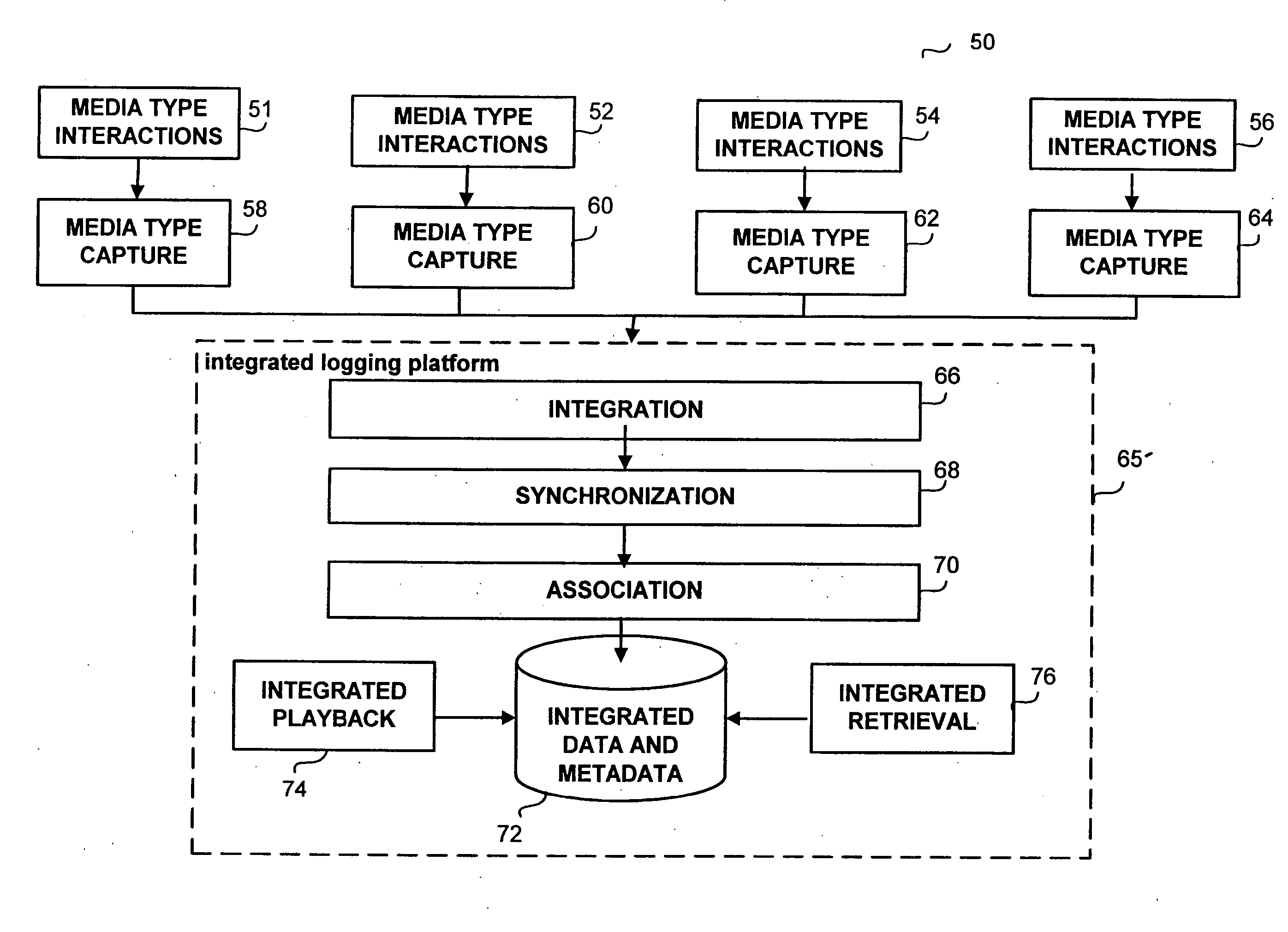

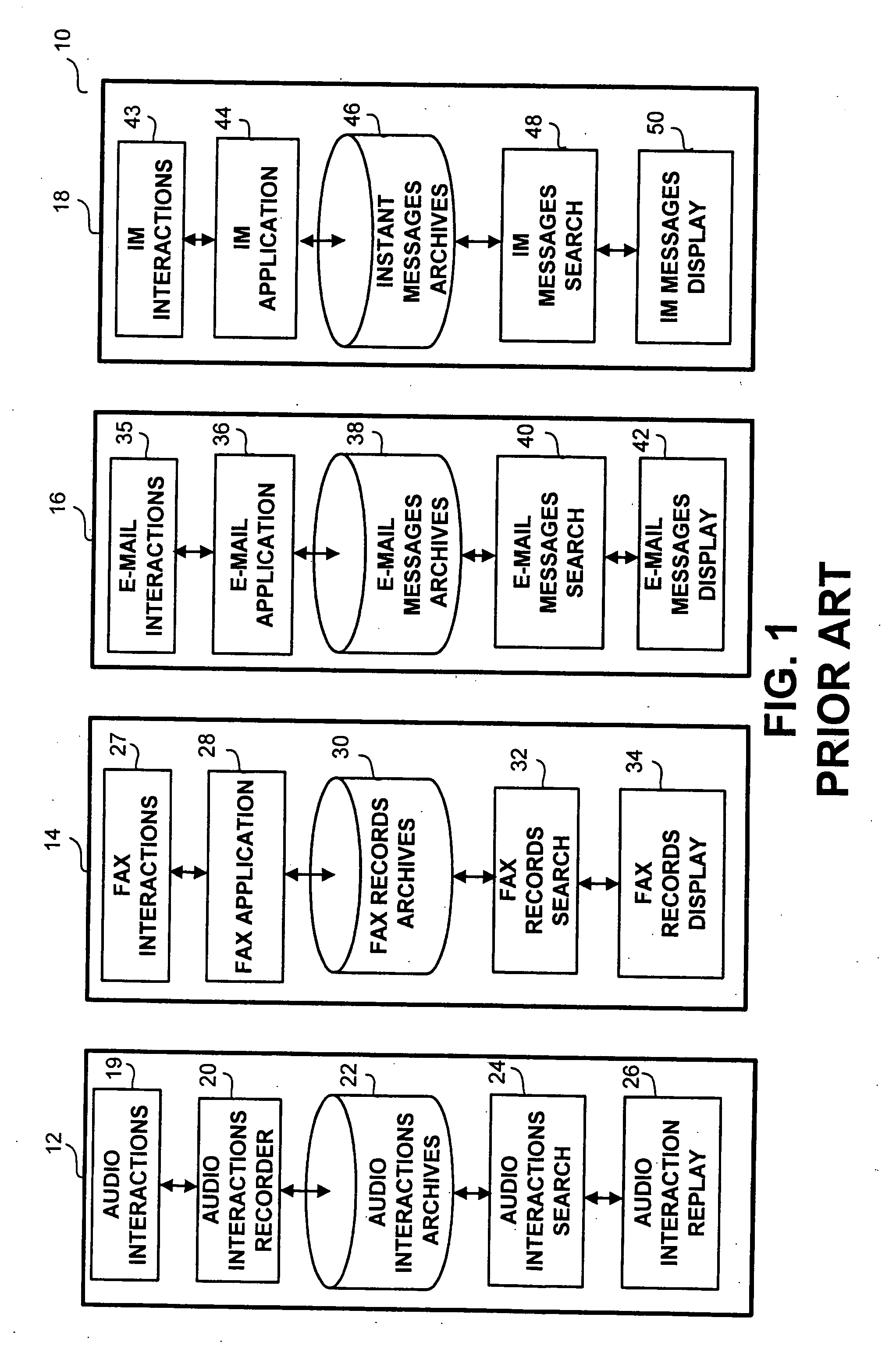

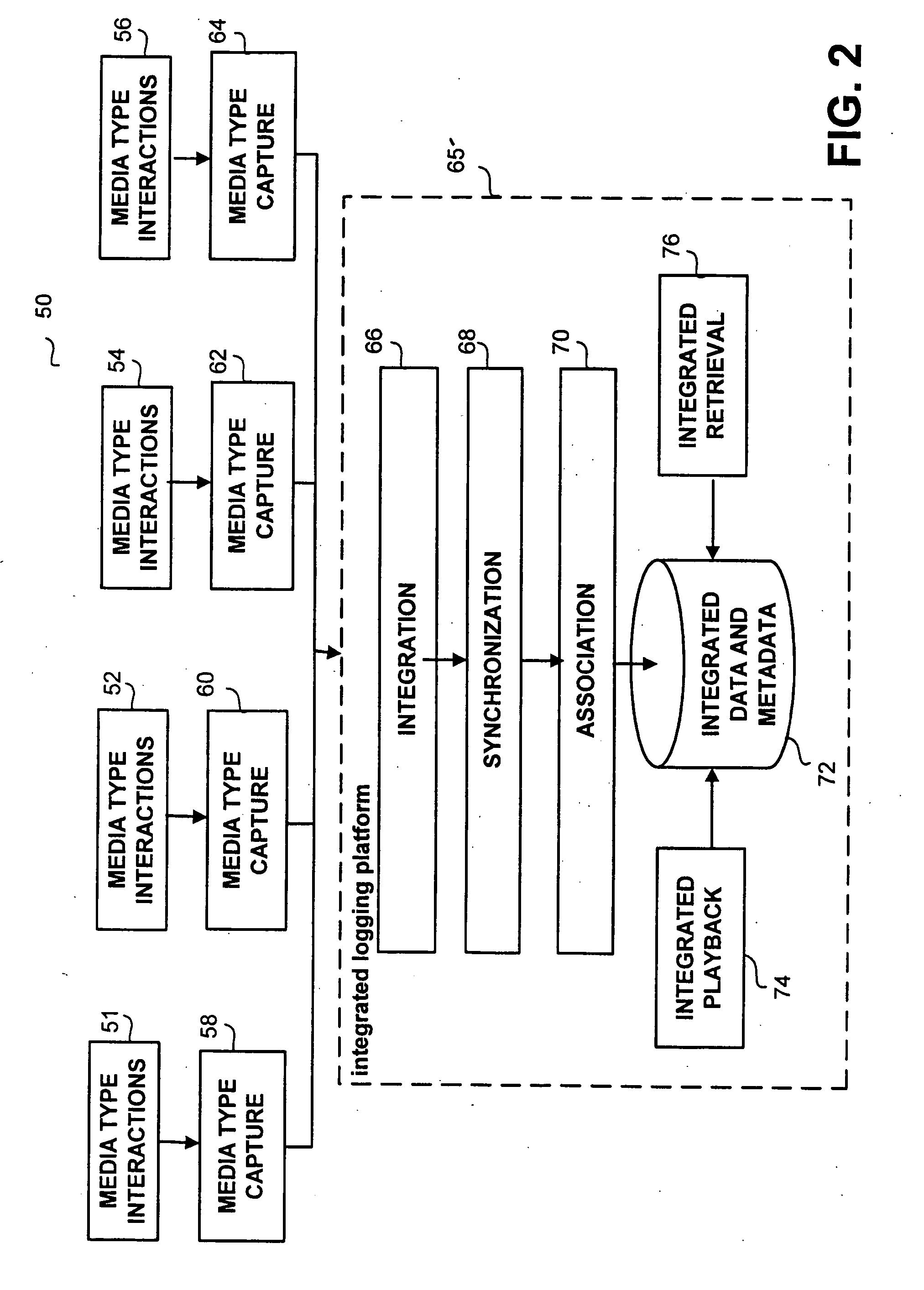

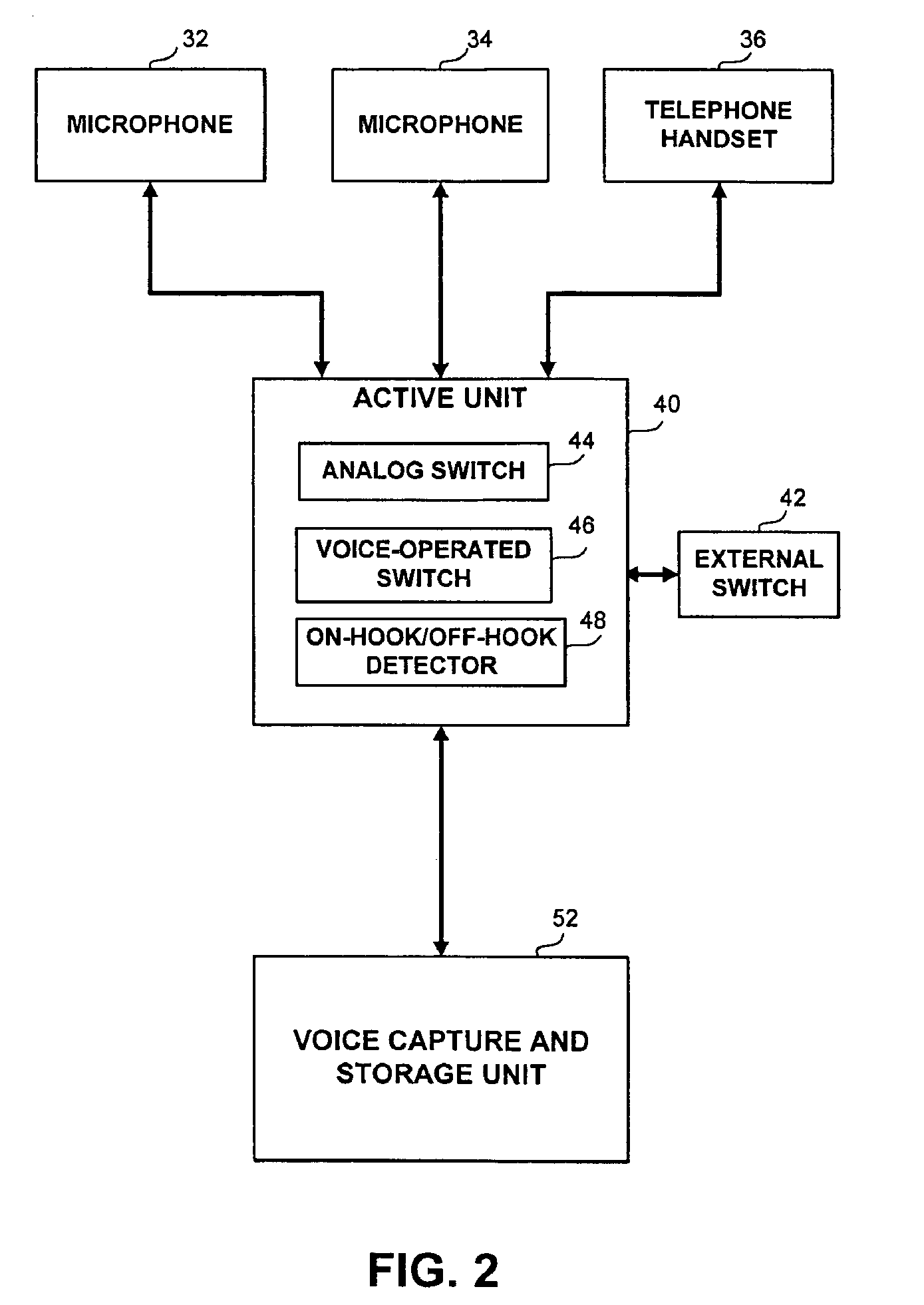

Apparatus, system and method for dispute resolution, regulation compliance and quality management in financial institutions

An apparatus, system and method for multimedia capturing, logging and retrieval are disclosed. The apparatus provides time synchronized voice and data interactions capturing and logging, secured playback and retrieval functionality for dispute resolution, for detecting negative and positive conduct, for business analysis and performance, and for quality management. The apparatus provides for synchronization and association of multi-media interactions for financial transactions in order to provide for the retrieval, playback, and review of the transaction-specific events in their temporally correct and integrated sequence.

Owner:NICE LTD

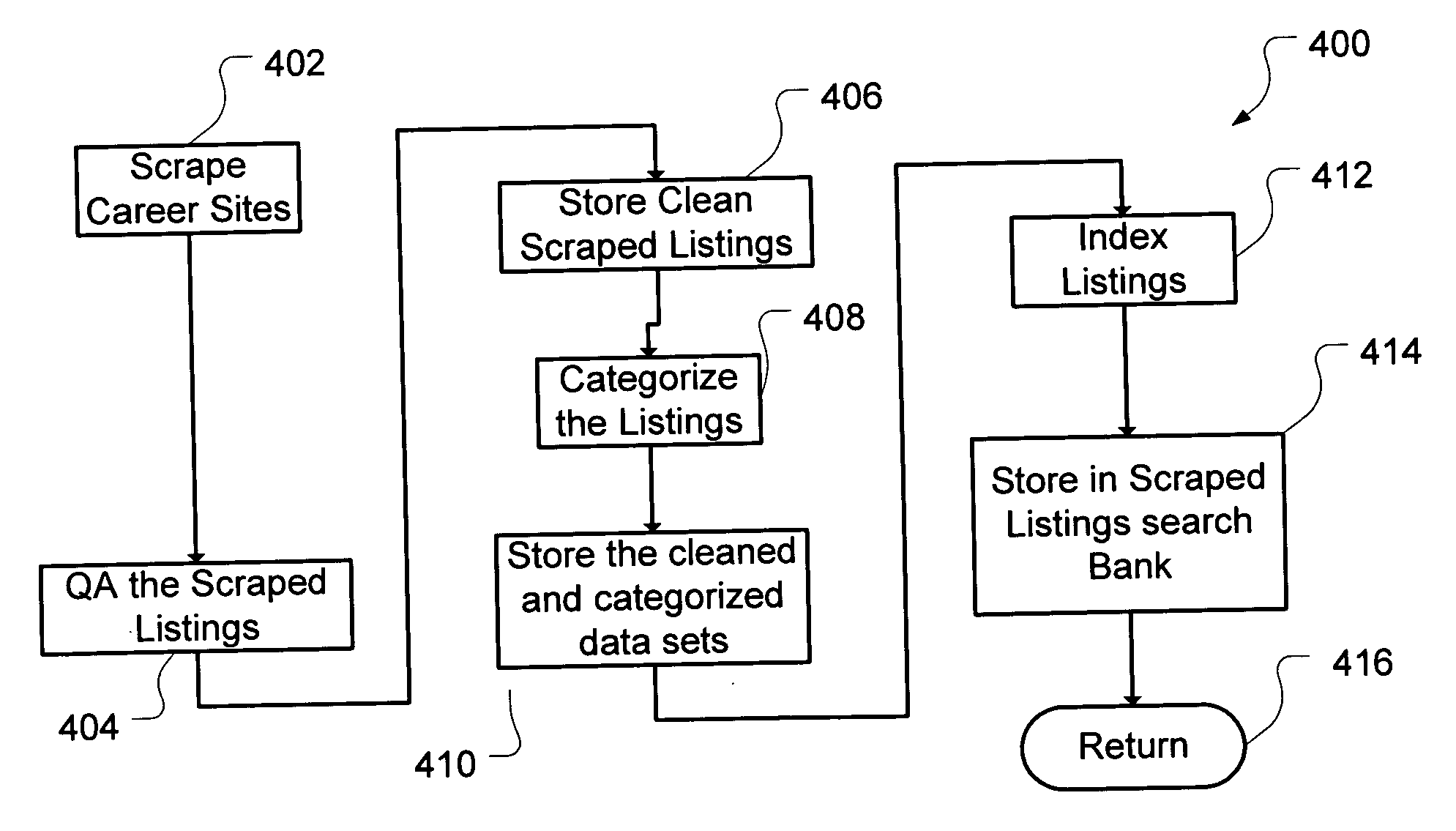

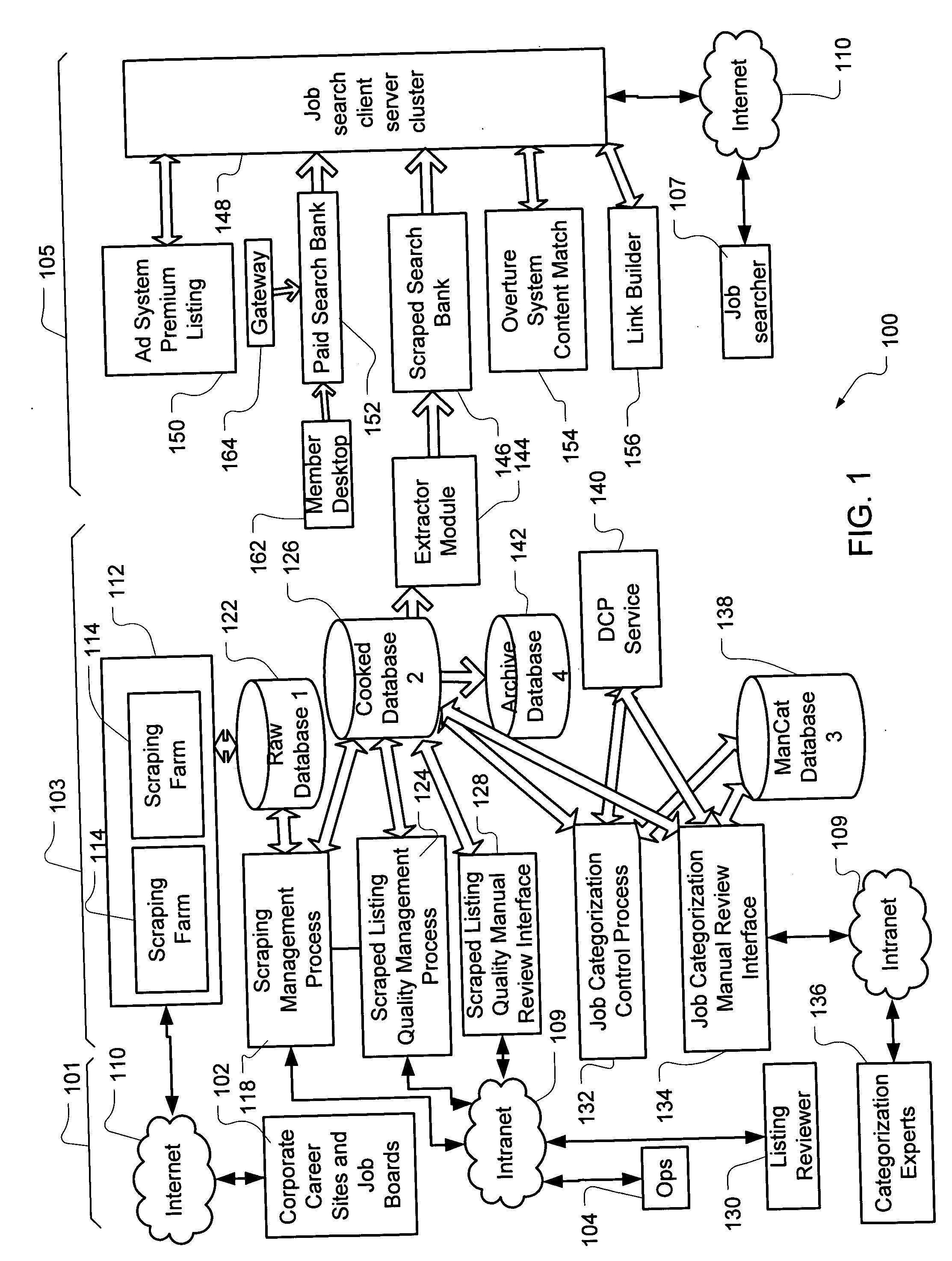

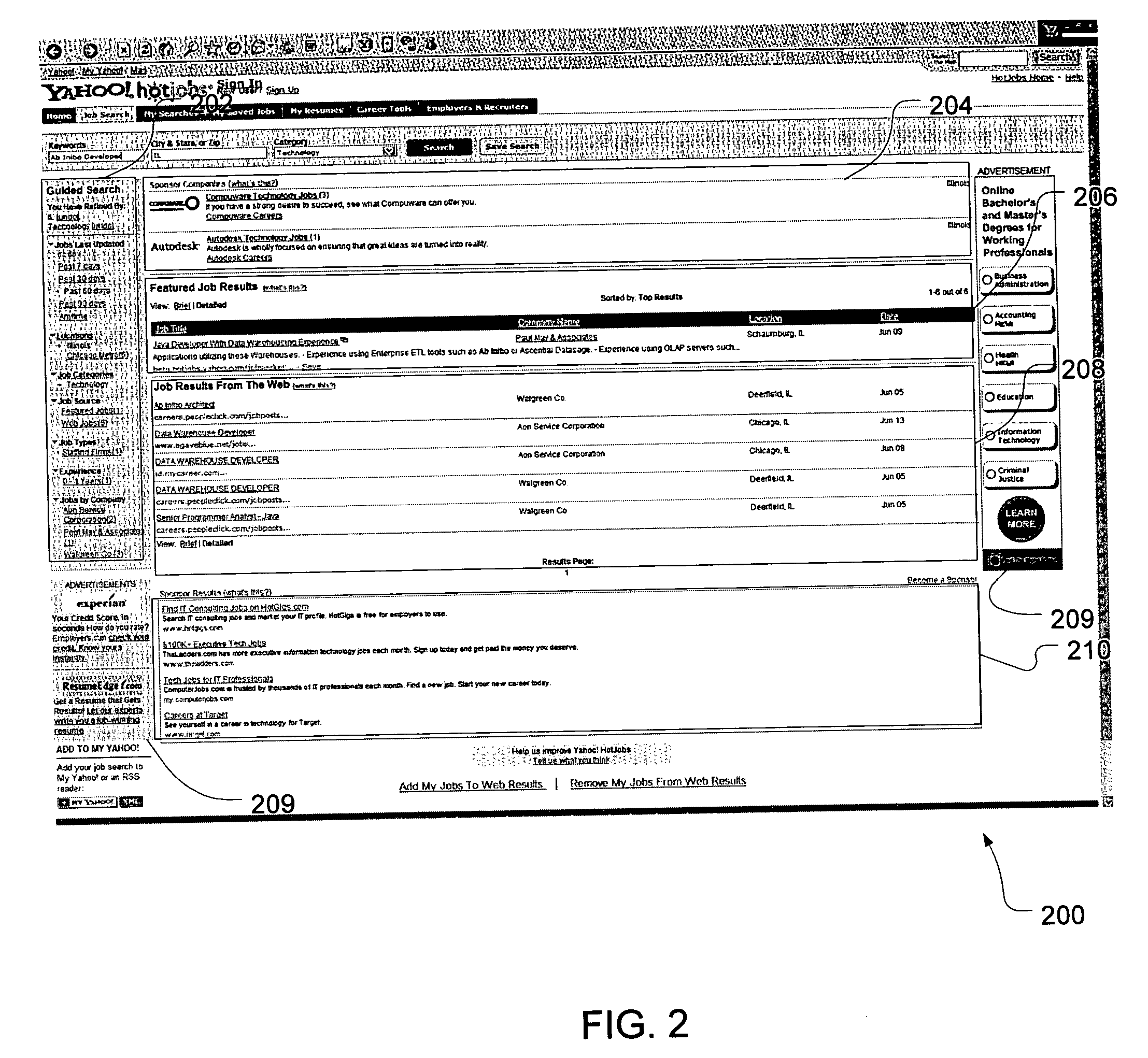

System and method for improved job seeking

ActiveUS20060206448A1Maximizes quality of informationMaximize its usefulnessDigital data processing detailsOffice automationWeb siteData set

A computer system and method for capture and handling job listings obtained from various often unrelated corporate and job board postings via the internet for examination by a job searcher. This system includes a scraping module having one or more scraping engines operable to scrape job information data set from job listings on the corporate career sites and job boards, wherein the scraping module receives and stores the scraped job information data set in a database. The system also has a scraping management interface module coordinating operation of and communication between the scraping engines and the career sites and job boards, a scraped listing quality management module coupled to the scraping management interface module analyzing selected scraped job information data stored in the database, and a job categorization module that examines and categorizes each job information stored in the database into one or more of a predetermined set of categories and returns categorized job information to the database, and an extractor module communicating with the database for compiling and transferring categorized job information data from the database to a search bank. The search bank is then accessible by a job searcher through a job search client server cluster connected to the Internet.

Owner:MICROSOFT TECH LICENSING LLC

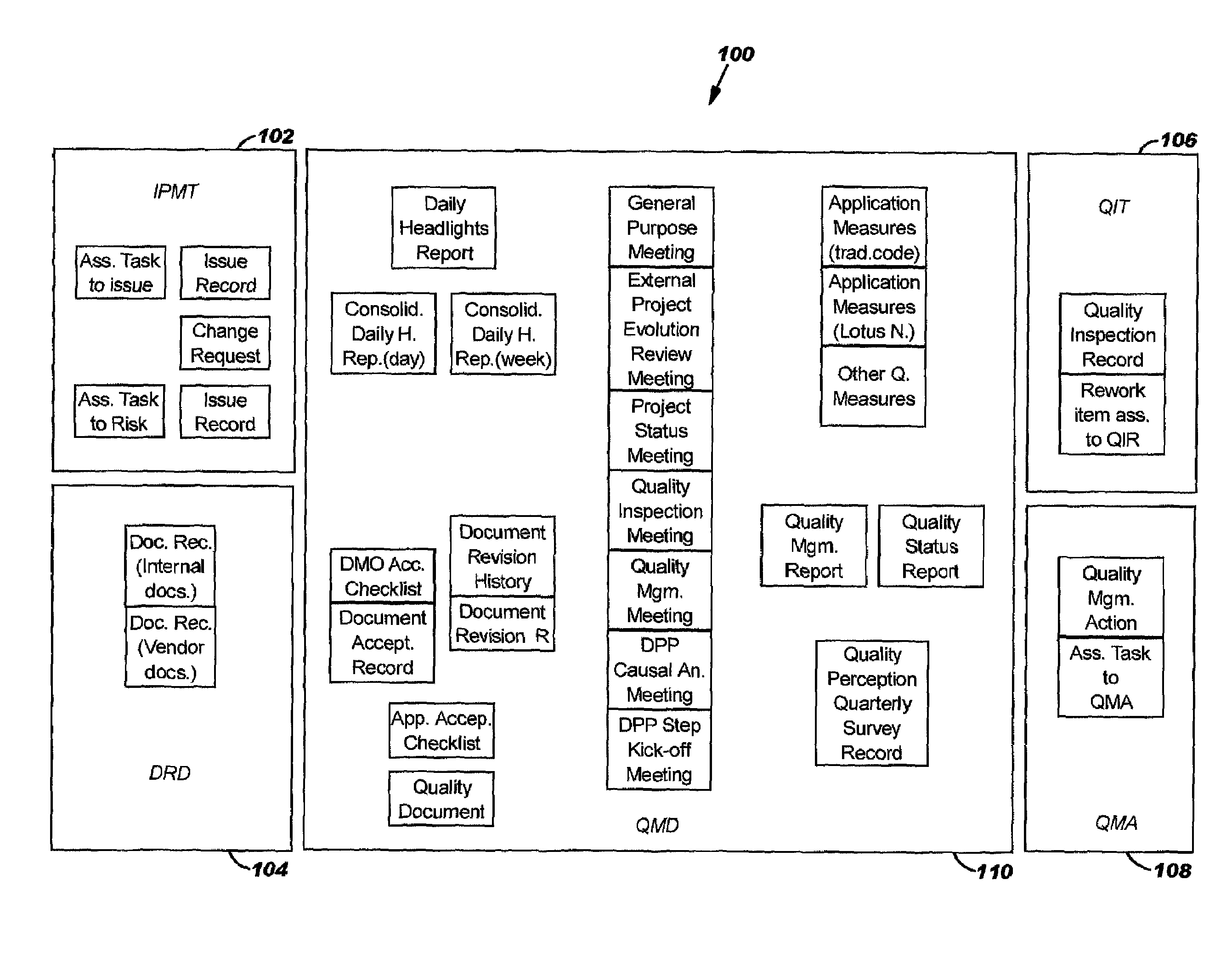

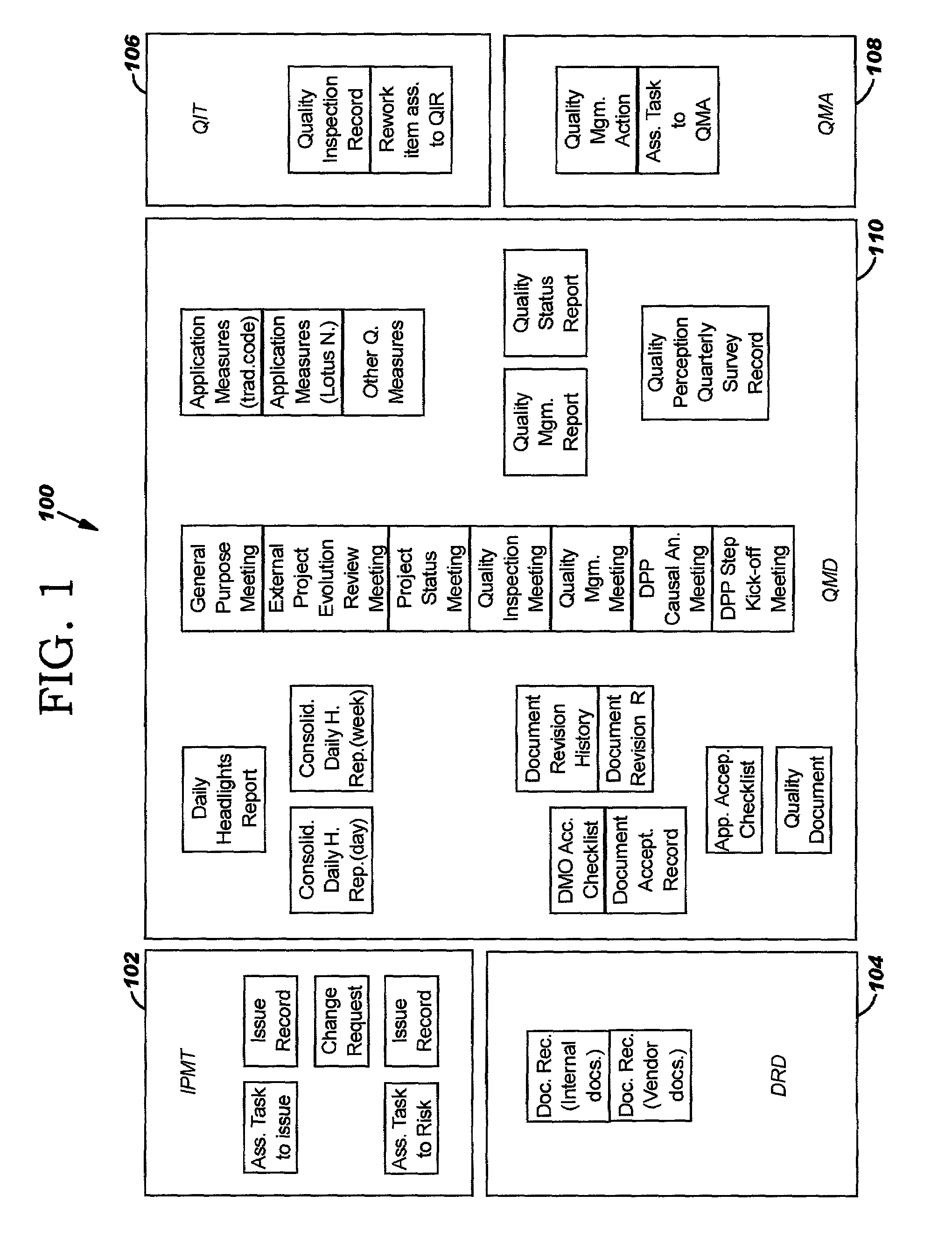

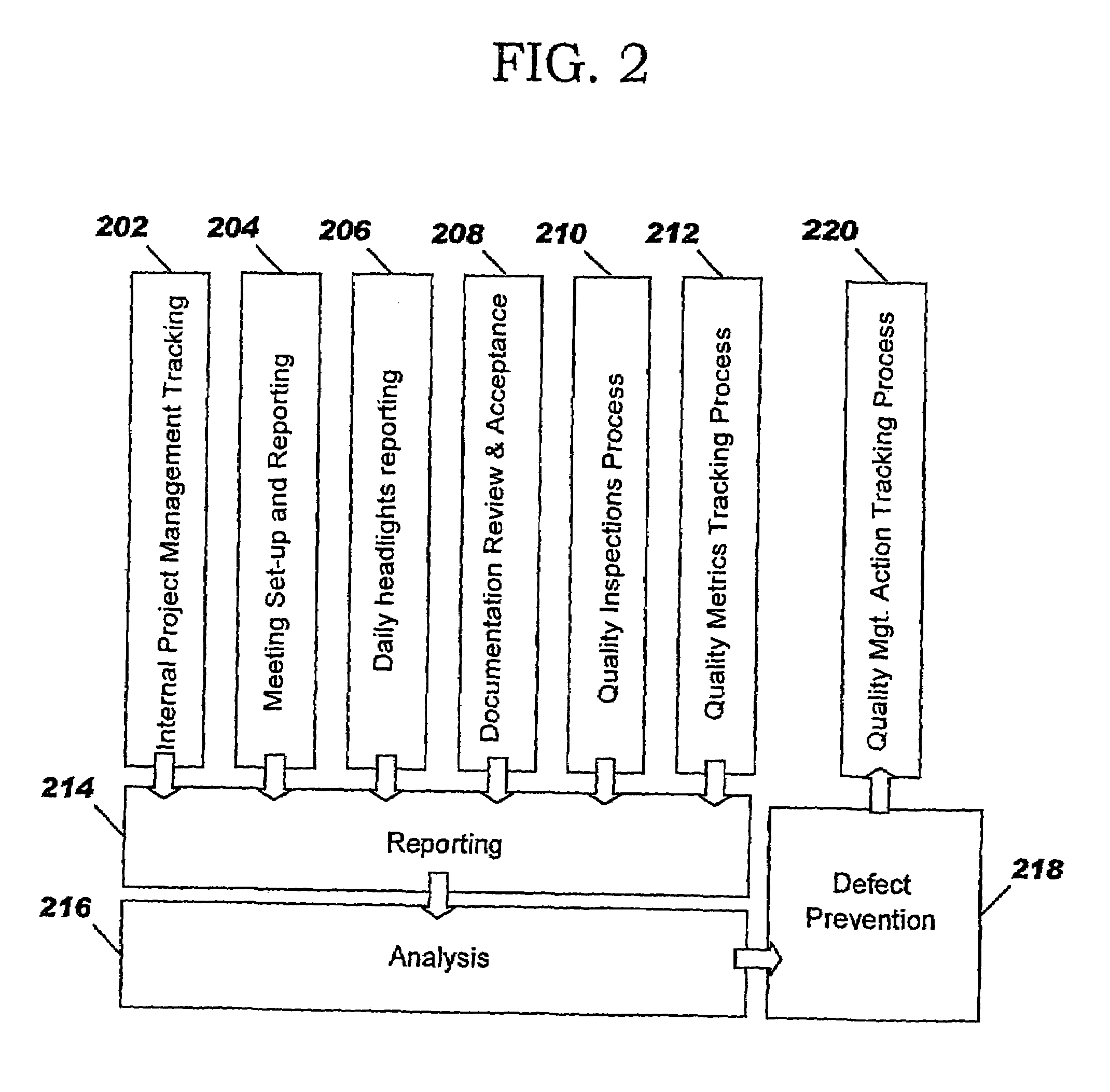

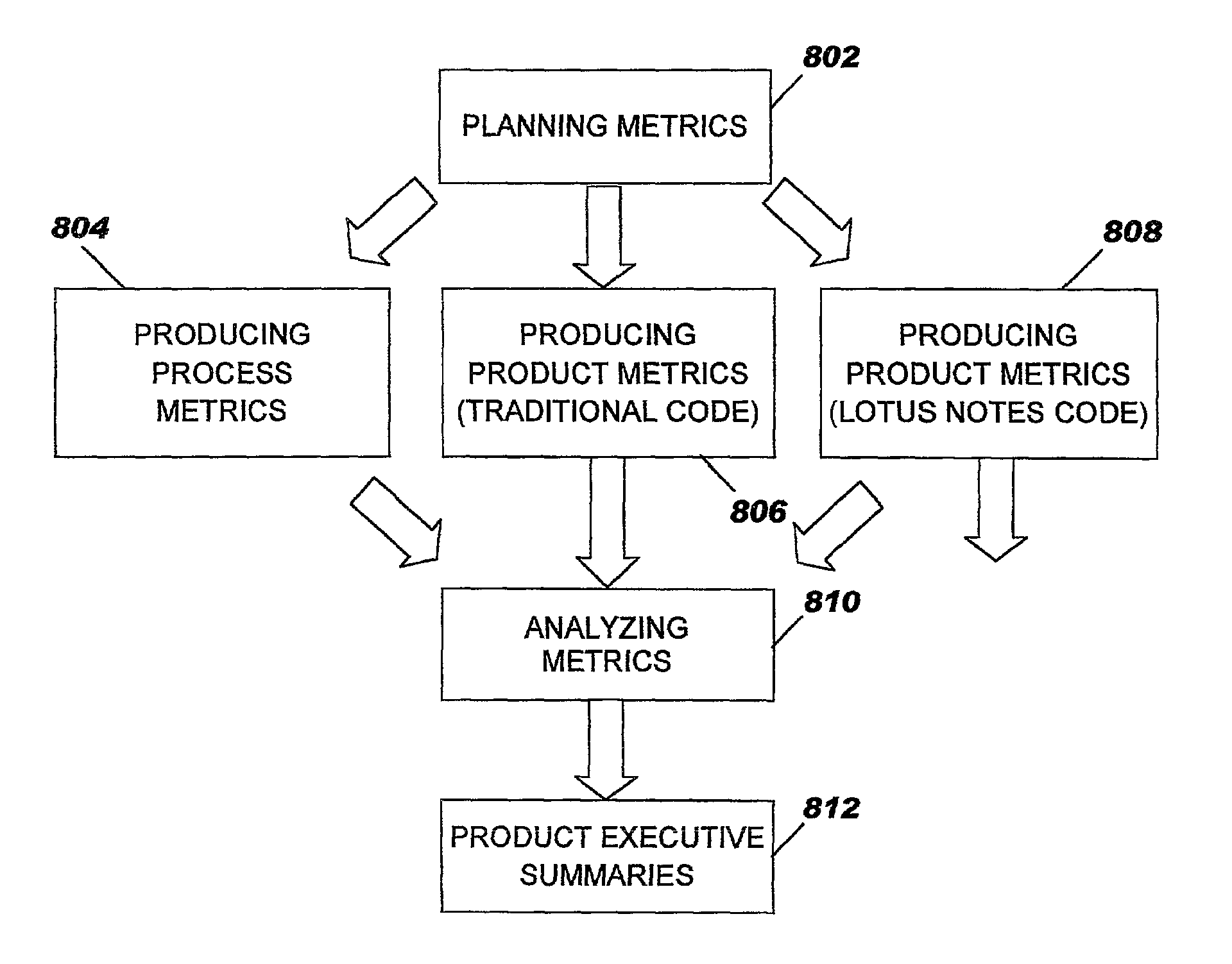

Method and system for a quality software management process

InactiveUS7337124B2Easy to deploySpeed up the processFinanceMultiprogramming arrangementsQuality processManagement process

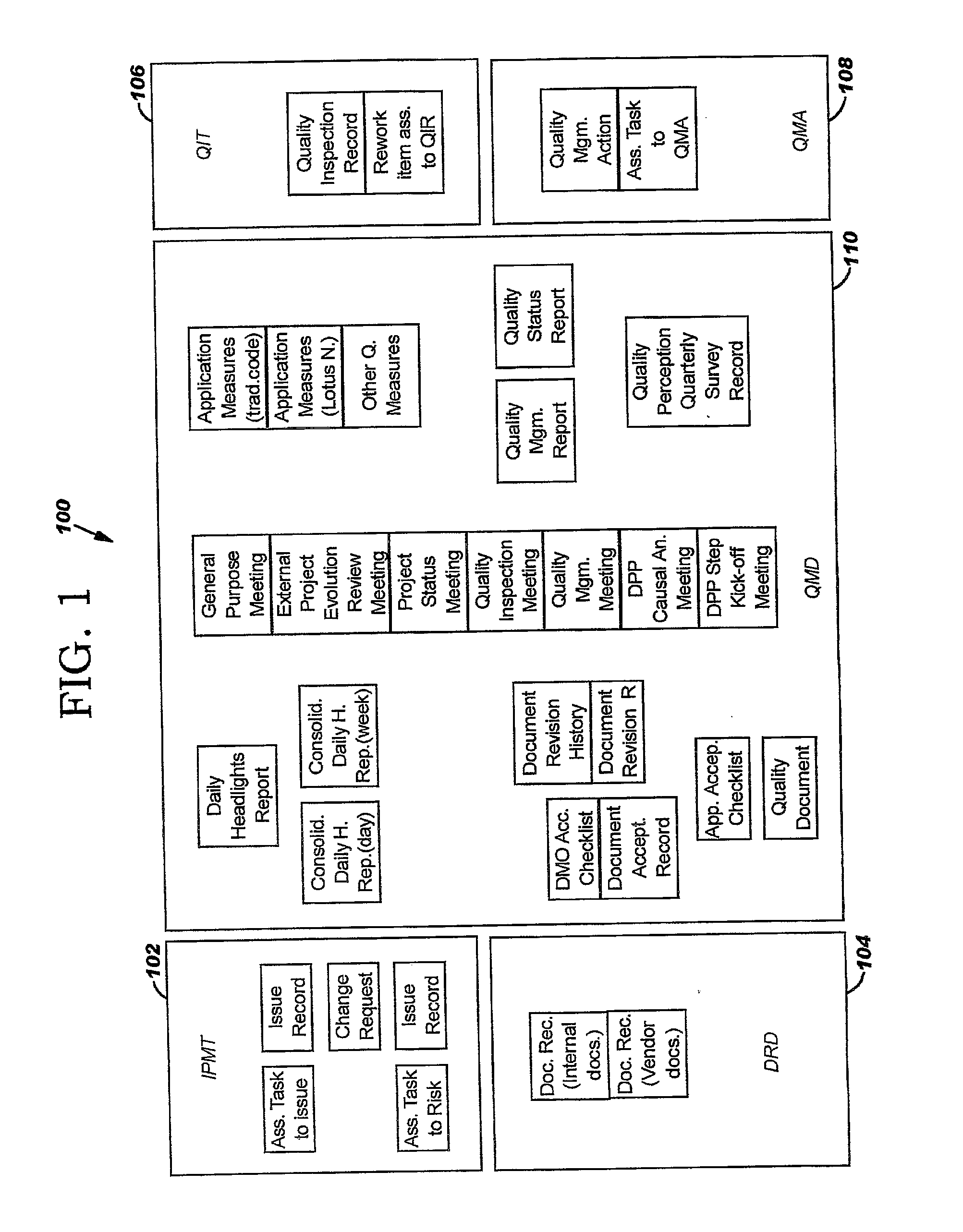

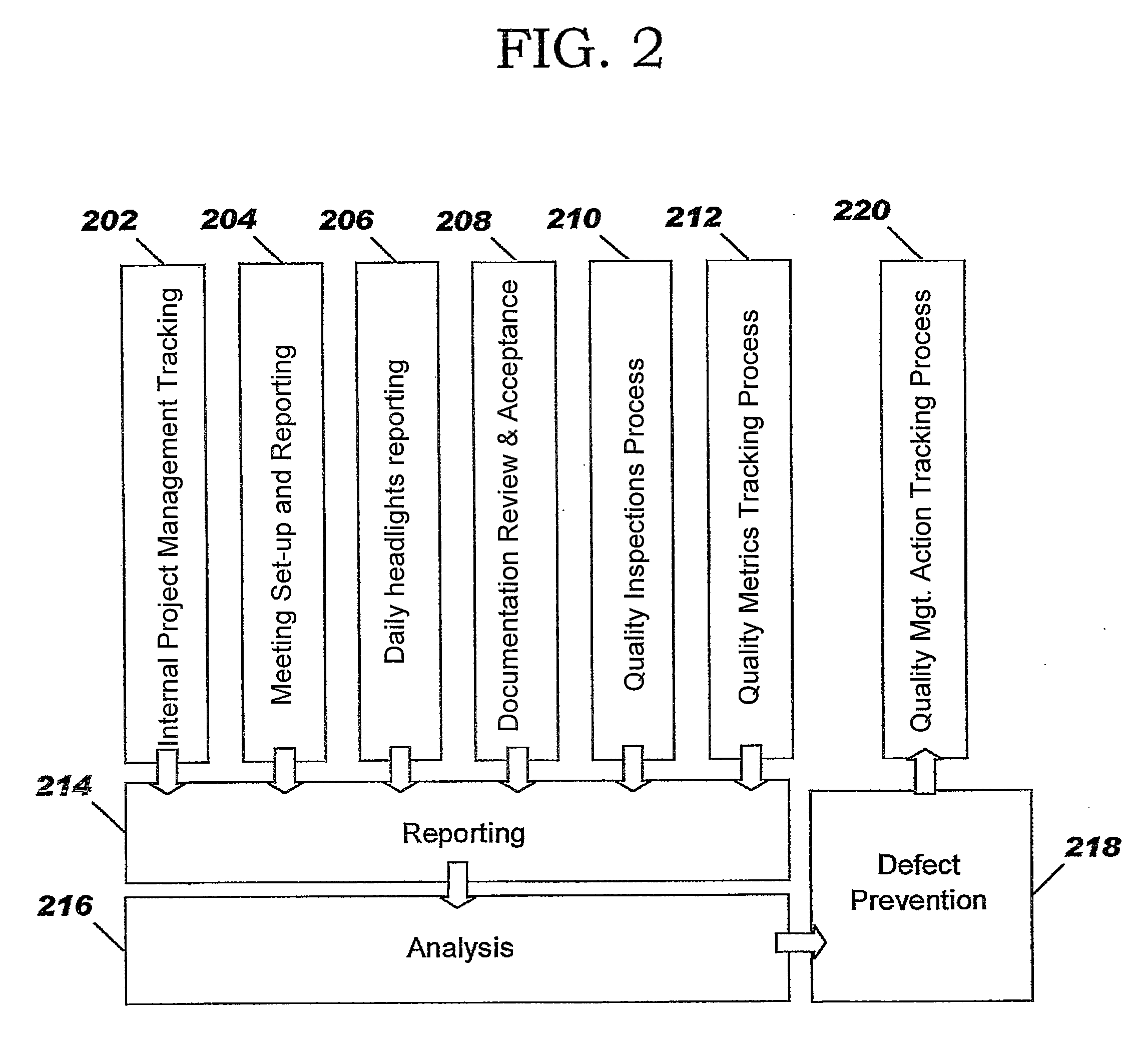

A quality management framework system and method for operating a quality plan in a product development organization having quality objectives. The system includes a plurality of computer implemented tools accessible by users for operating a plurality of quality processes. Data relative to the quality processes is collected and aggregated to generate quality reports. Reports are analyzed and problems are detected through a defect prevention process. Quality actions are initiated in a feedback quality management action tracking process.

Owner:IBM CORP

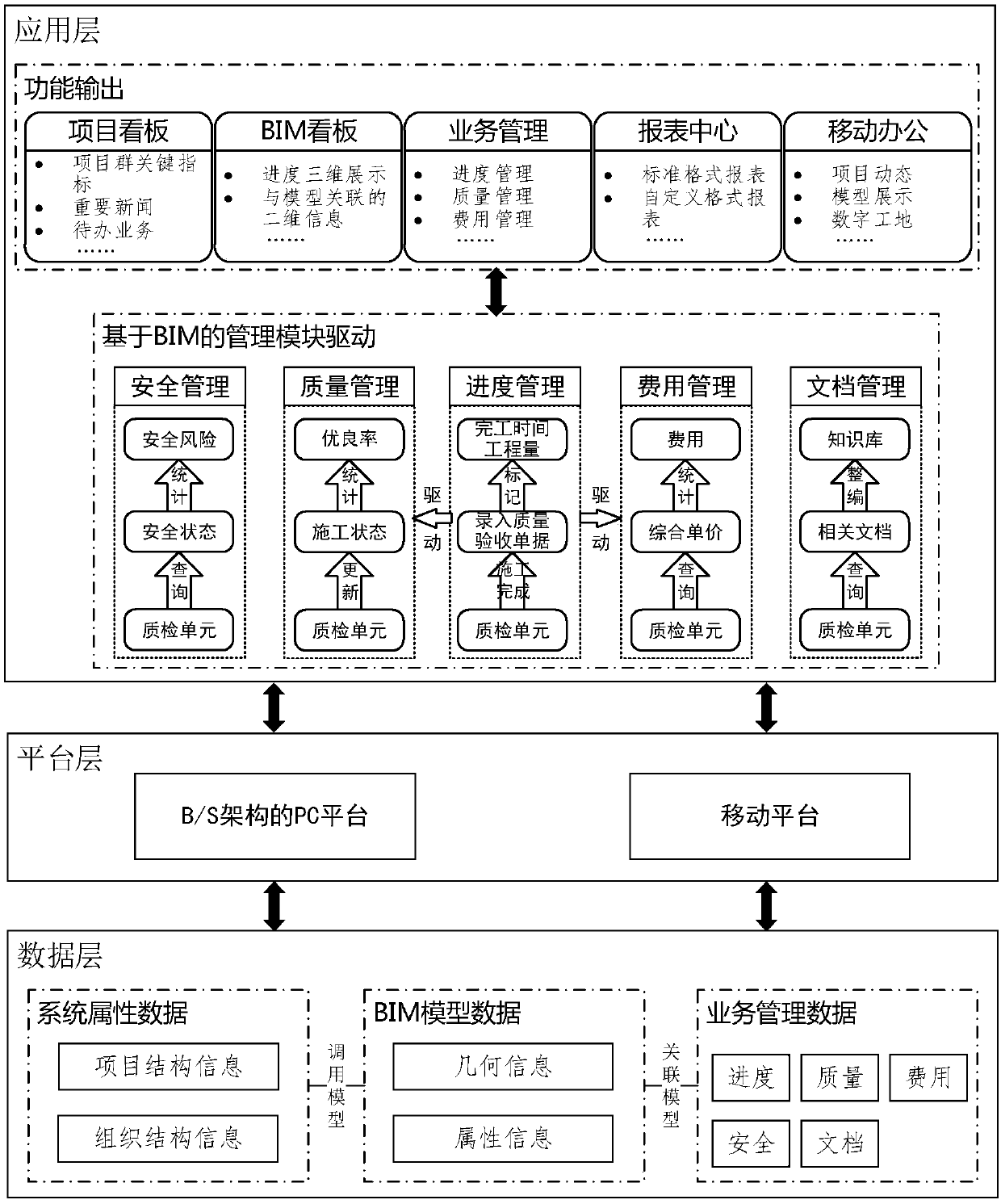

Digital management system and method for project construction processes

ActiveCN107622355AImprove acquisitionImprove circulation speedOffice automationResourcesBusiness managementProtocol Application

The invention discloses a digital management system for project construction processes. The system comprises a data layer, a platform layer and application layers, wherein the data layer comprises a BIM construction module which is created via a division principle of a construction quality management unit; the data layer comprises system attribute data, BIM model data and business management data;the platform layer consists of a B / S architecture-adopted PC platform and a mobile platform; the PC platform application layer consists of a project board module, a BIM board module, a business management module and a statement center module; a business management module comprises a progress management module, a quality management module, a safety management module, an expense management module and a document management module; and a mobile platform application layer is a mobile office layer which consists of a project dynamic module, a model display module and a digital construction site module. The system has the advantage of improving the management precision and efficiency of project construction processes.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Method and System for a Quality Software Management Process

InactiveUS20080092108A1Easy to deployOptimize workflowOffice automationResourcesQuality processManagement process

Owner:INT BUSINESS MASCH CORP

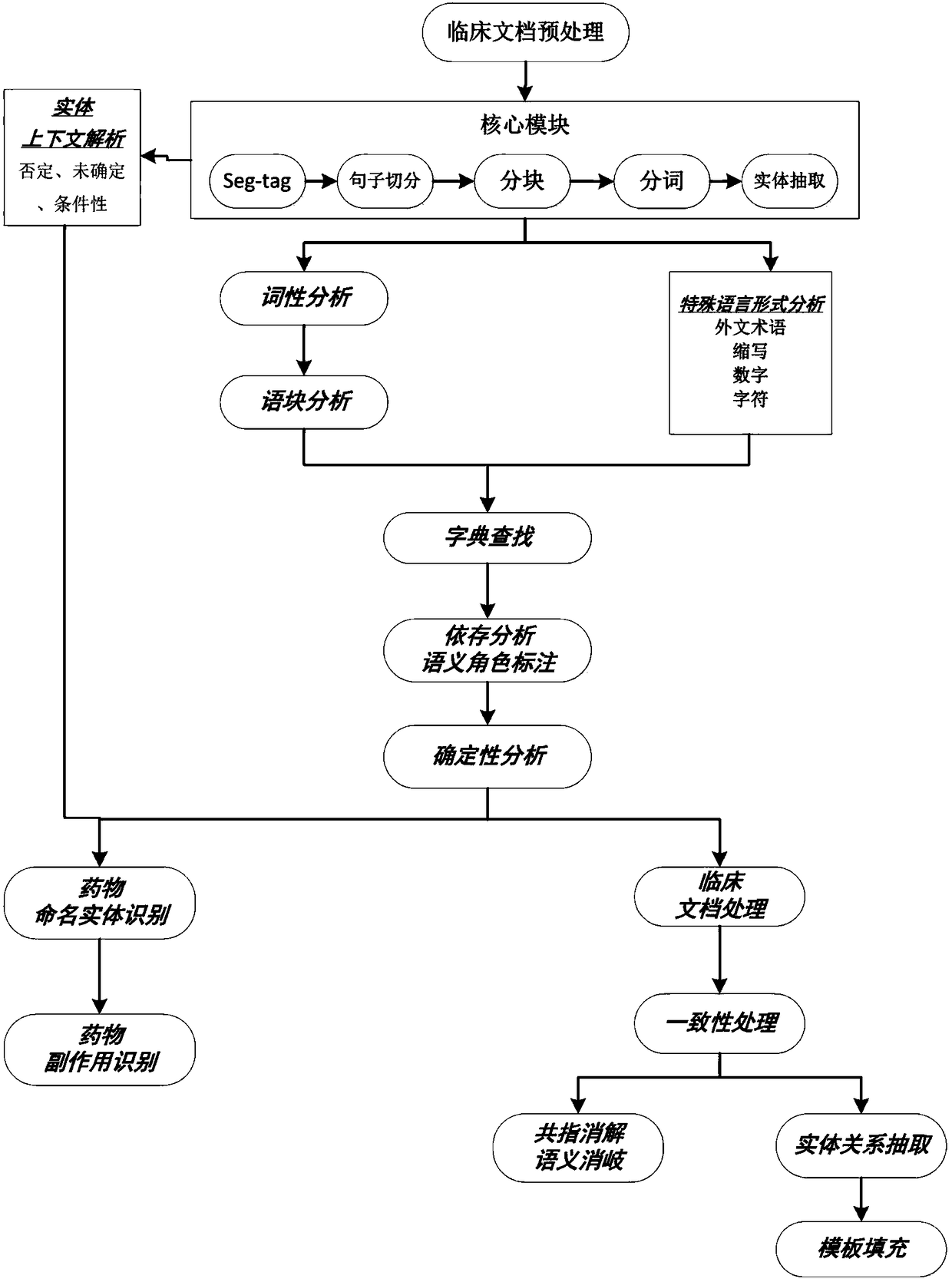

NLP-based electronic medical record data quality management method

PendingCN108447534AShorten cycle timeFast replySpecial data processing applicationsPatient-specific dataMedical recordQuality control

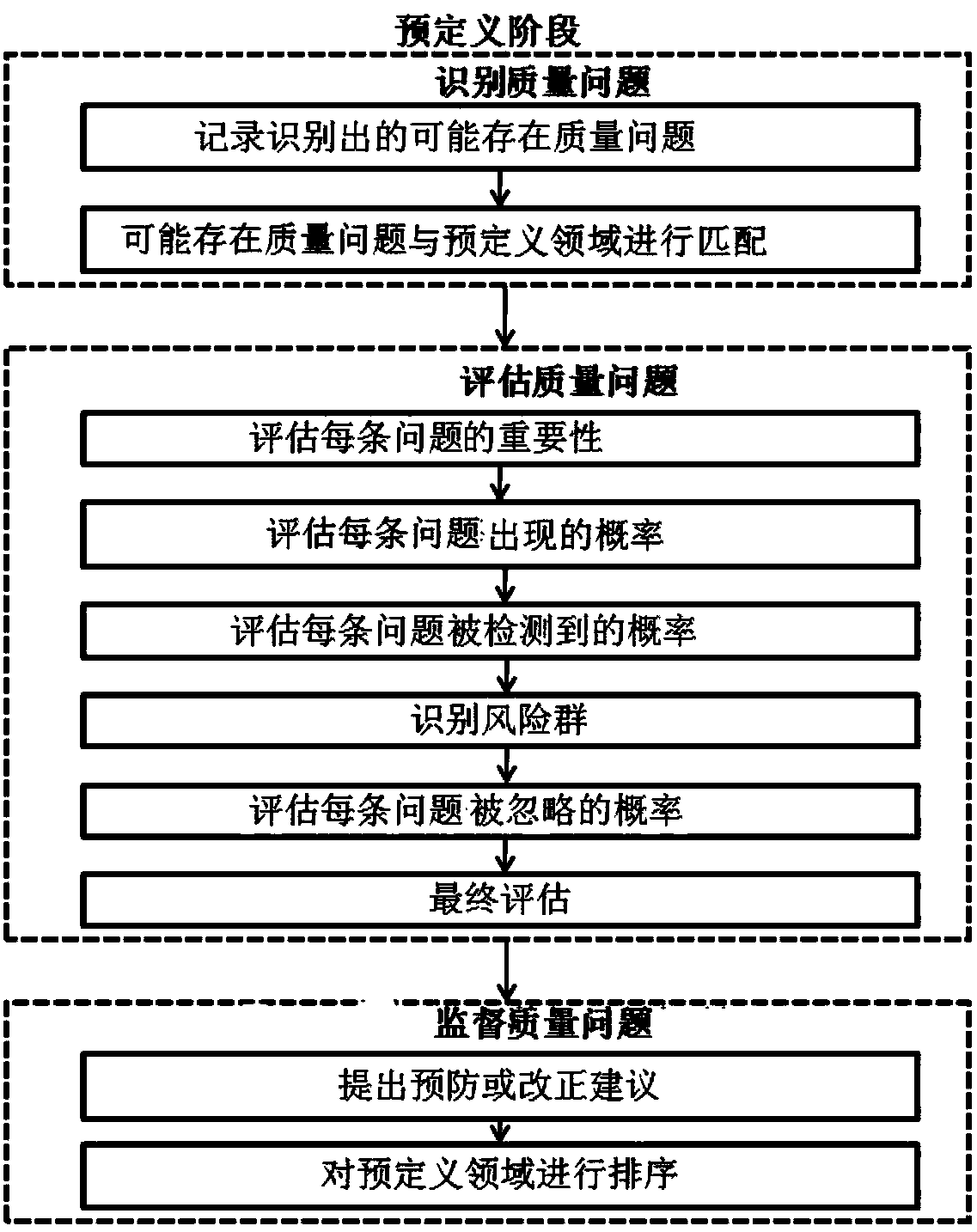

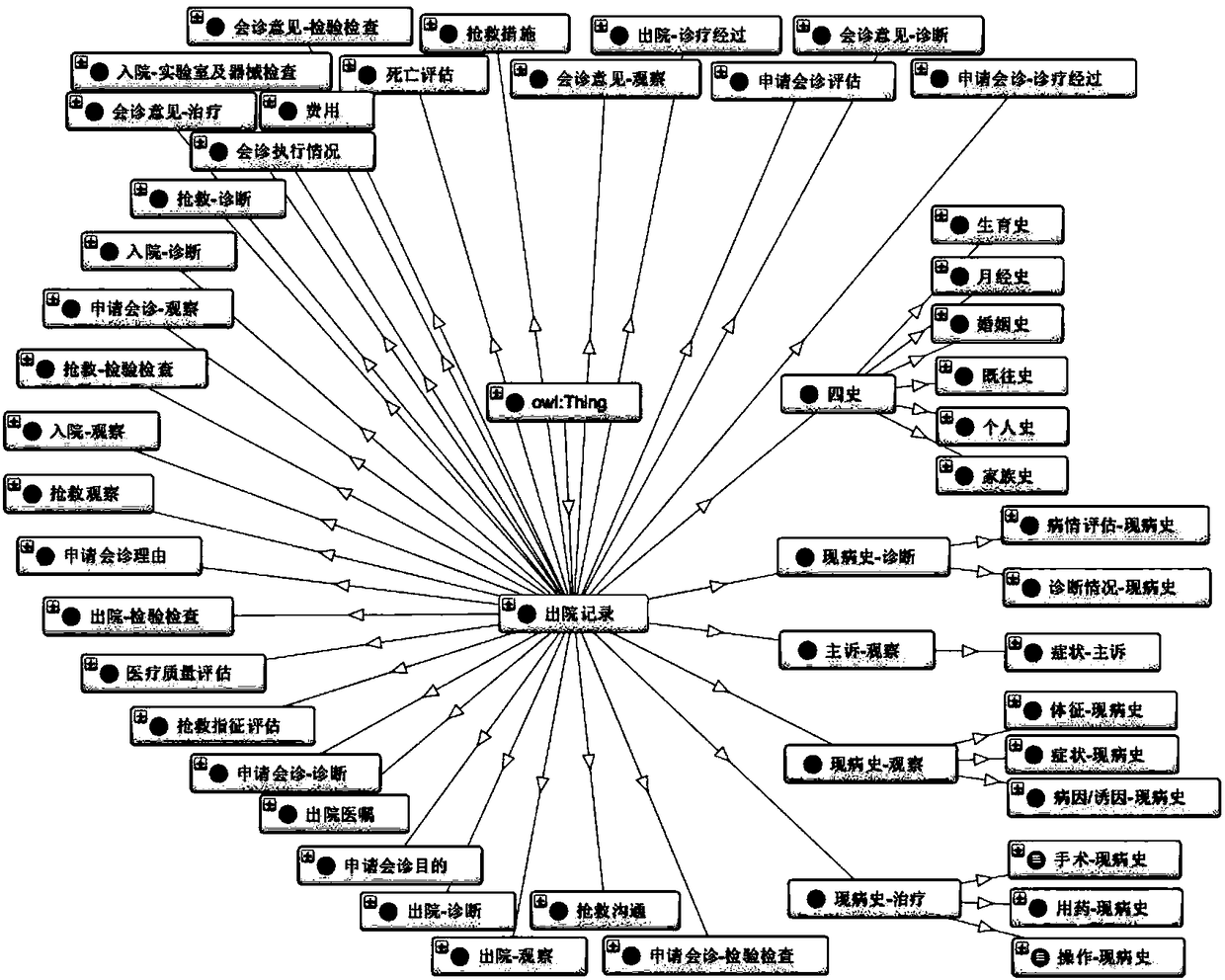

The invention discloses an NLP-based electronic medical record data quality management method. Electronic medical record operation and quality management operation are integrated in an intelligent mode, the quality requirements of the electronic medical record are converted to quality management knowledge, in match with electronic medical record ontology knowledge, a method of interaction operation of manual audit and intelligent audit is adopted, and quality check is carried out. The method particularly comprises the following steps of (1) preparation, (2) quality problem recognition, (3) quality problem evaluation, (4) quality problem monitoring and (5) quality report generation. Automatic and intelligent electronic medical record quality control is realized by introducing technologies such as an ontology and an NLP, the shortcomings of the existing manual quality audit are overcome, quality check is carried out on the electronic medical record in match with the ontology knowledge, the electronic medical record quality problem is thus found out, the efficiency is improved, and the generated result is more professional, accurate, objective, fair and just.

Owner:灵玖中科软件(北京)有限公司

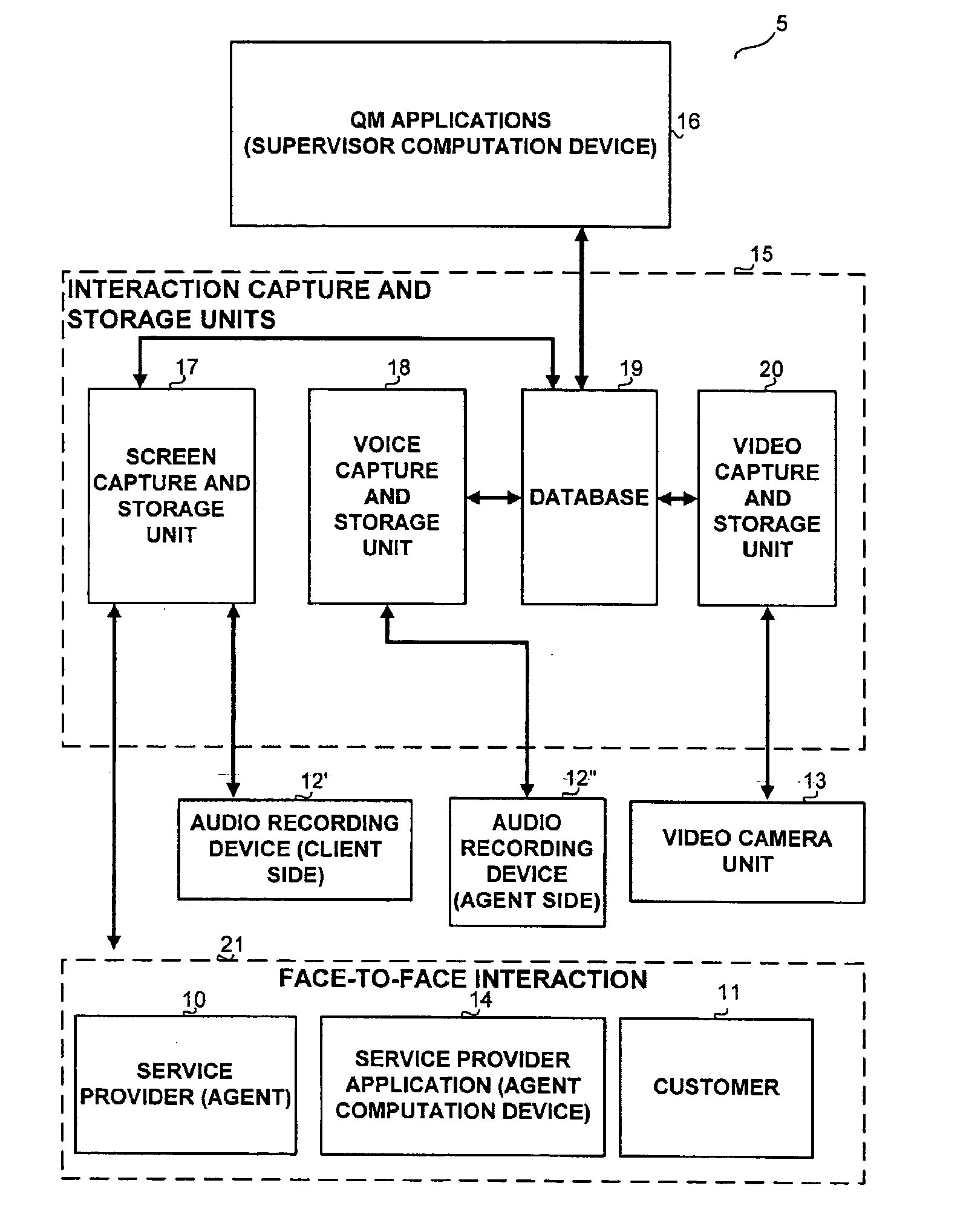

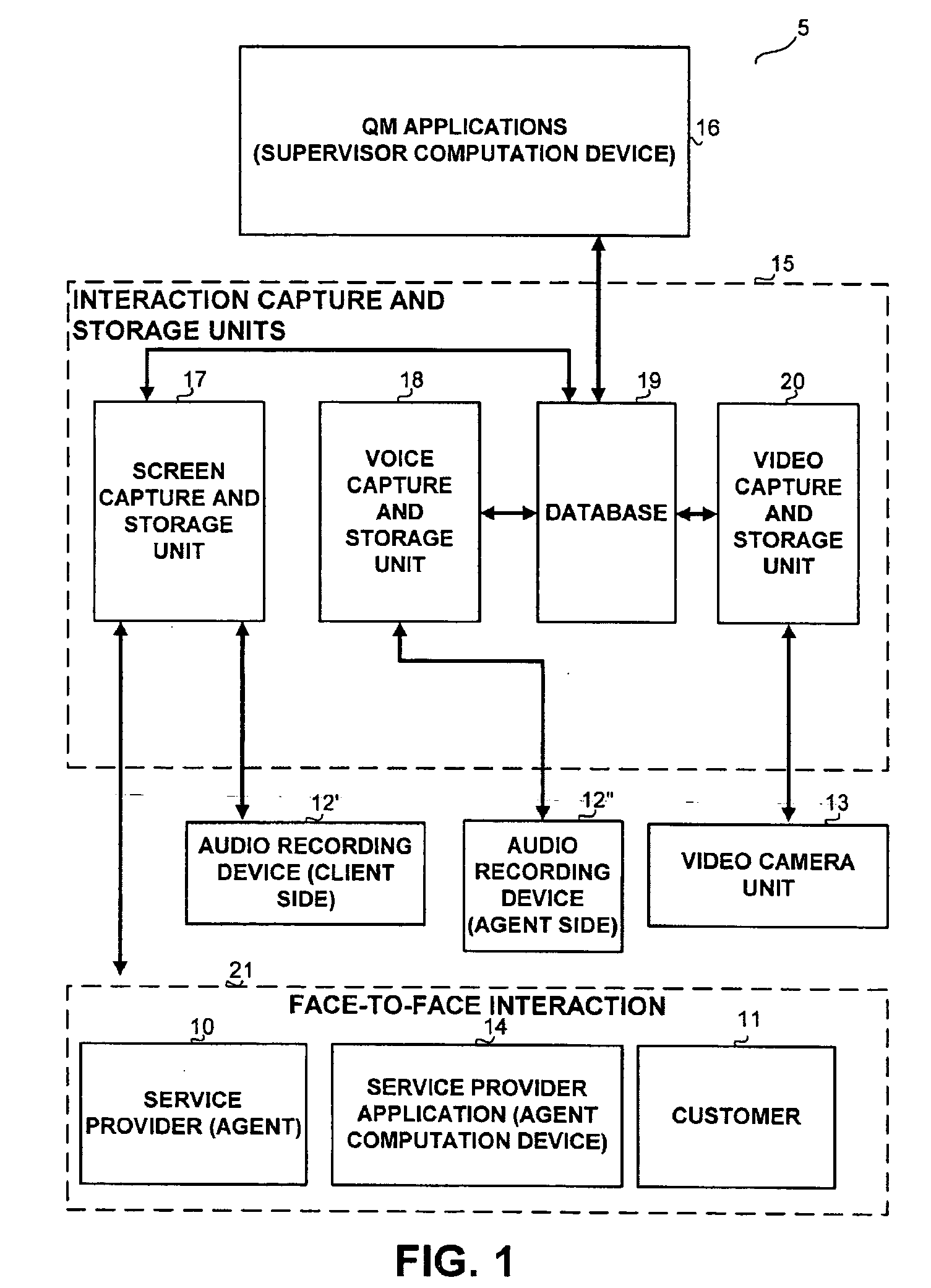

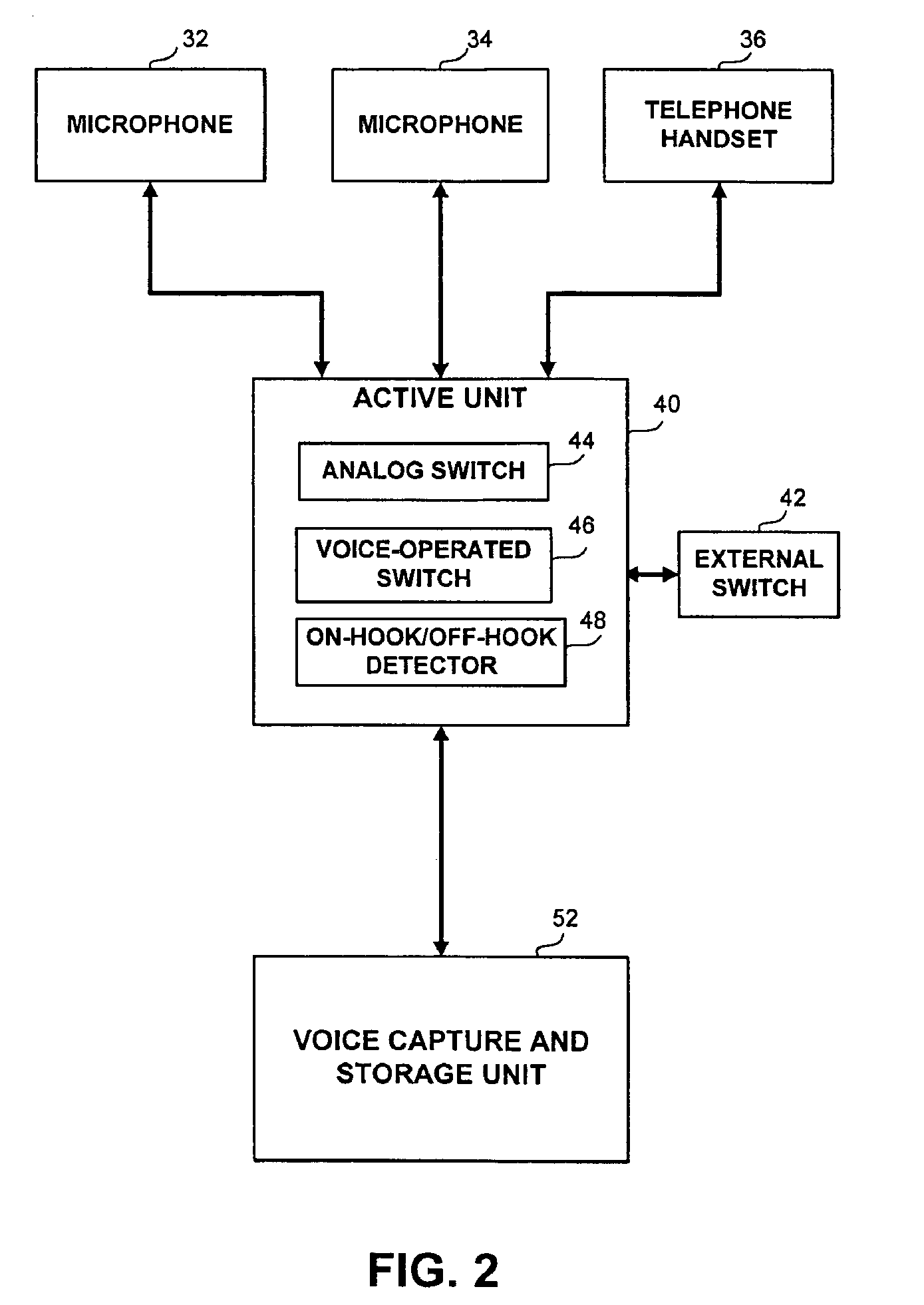

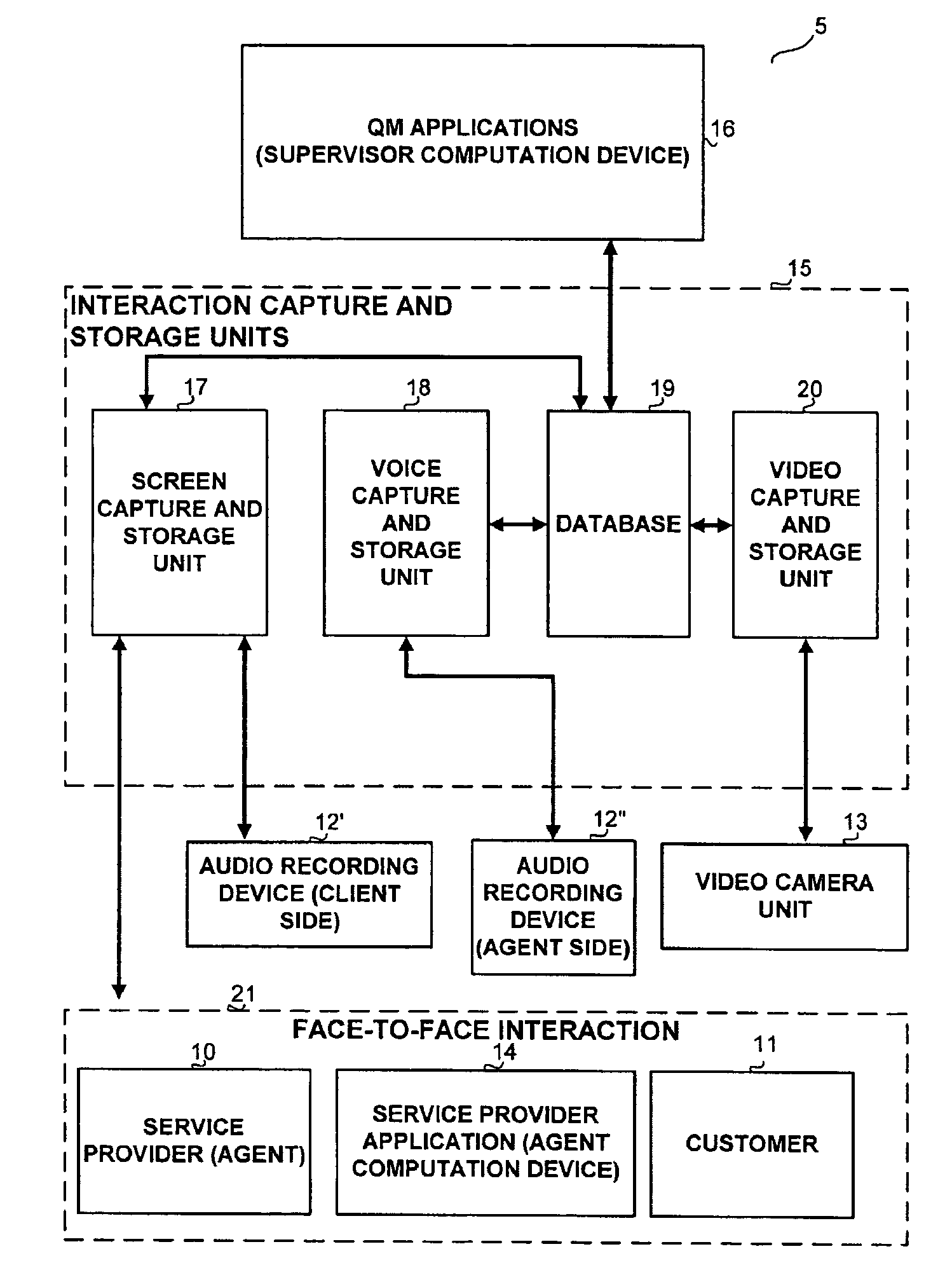

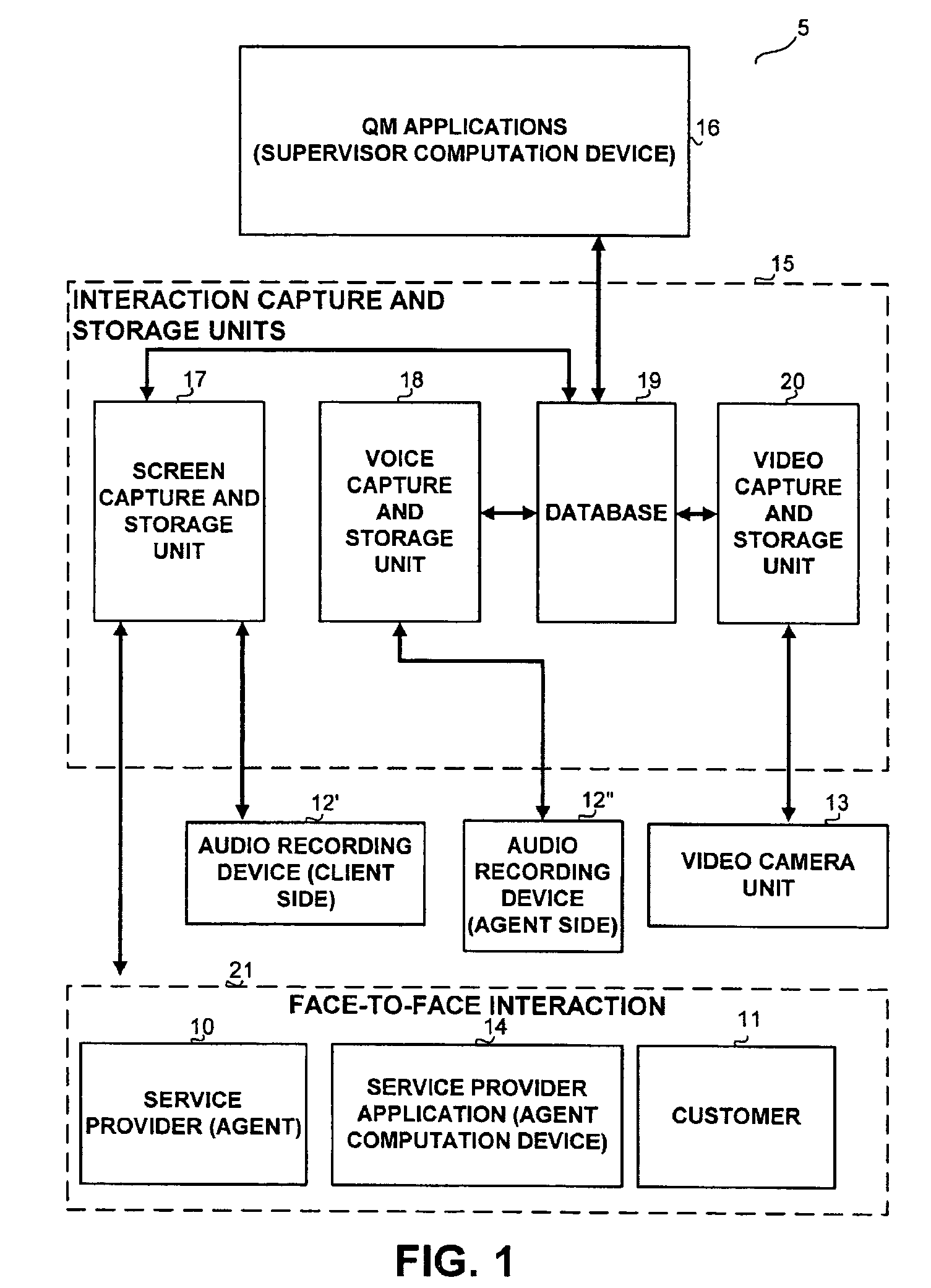

Advanced quality management and recording solutions for walk-in environments

ActiveUS20050015286A1Rapid positioningEliminate ambient noiseTelevision system detailsColor television detailsArtificial intelligenceQuality management

A system and method for capturing, logging and retrieval of face-to-face interactions characterizing walk-in environments. The system comprising a device for capturing and storing one or more face to face interactions captured in the presence of the parties to the interaction, and a database for storing data and metadata information associated with the face-to-face interactions captured.

Owner:NICE LTD

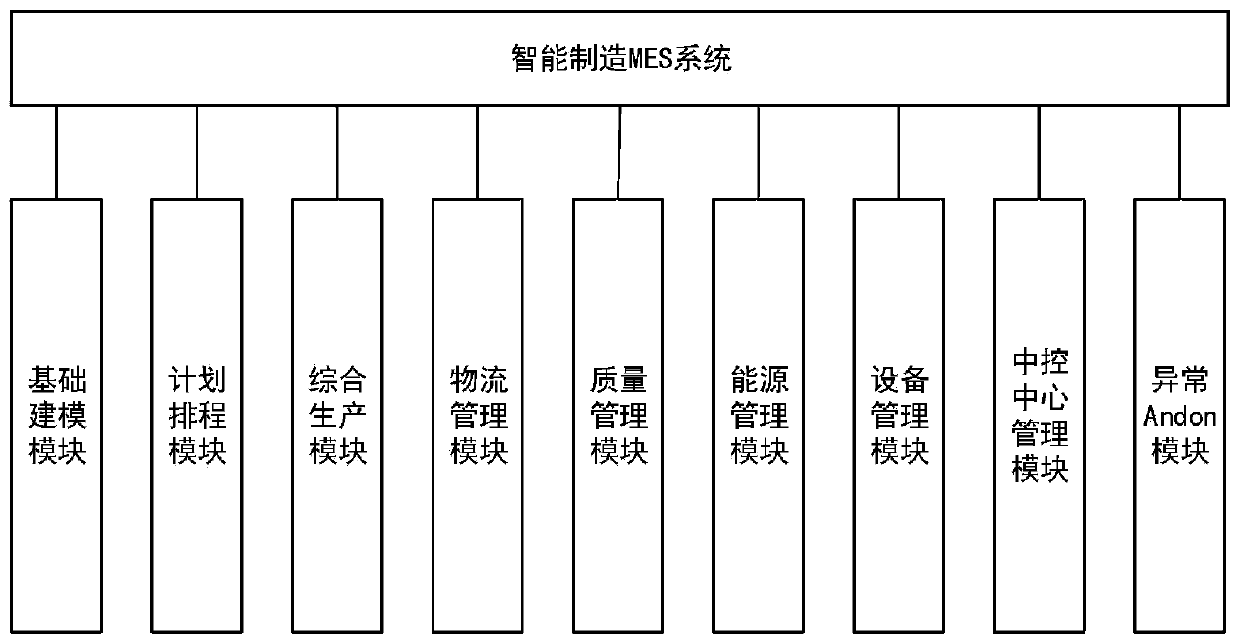

intelligent manufacturing MES system

InactiveCN110580026AIntelligent manufacturing whole process monitoringRealize the whole process monitoringEnergy industryTechnology managementMaterials preparationLogistics management

The invention discloses an intelligent manufacturing MES system which comprises a basic modeling module, a plan scheduling module, a comprehensive production module, a logistics management module, a quality management module, an energy management module, an equipment management module, a central control center management module and an abnormal Andon module. The basic modeling module is used for completing establishment of factory layout, establishment of product information and establishment of external resources. The plan scheduling module is used for establishing a production order, carryingout material preparation and distribution for a warehouse, work order scheduling, production execution, inspection, packaging and production warehousing. The comprehensive production module is used for managing a generated full-service process. The logistics management module is used for managing a production material taking management process and a production warehouse-in management process; andthe quality management module is used for carrying out inspection object maintenance on a purchasing department, a workshop department and a sales department. The invention provides a perfect intelligent manufacturing MES system, thereby realizing intelligent manufacturing full-process monitoring.

Owner:工业云制造(四川)创新中心有限公司

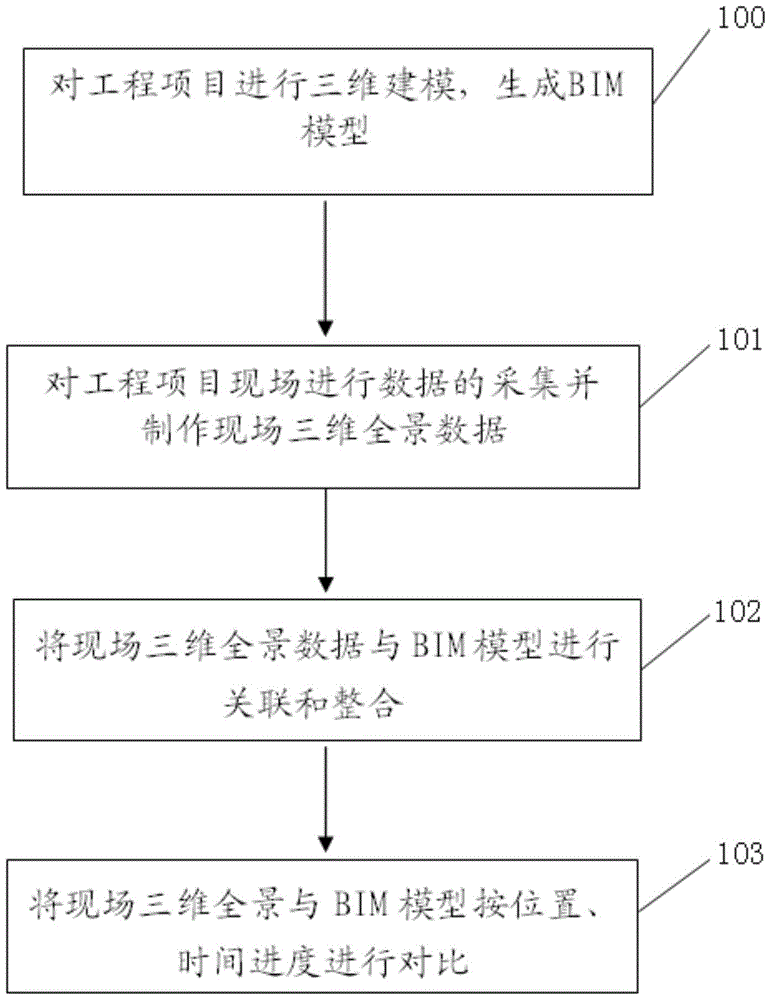

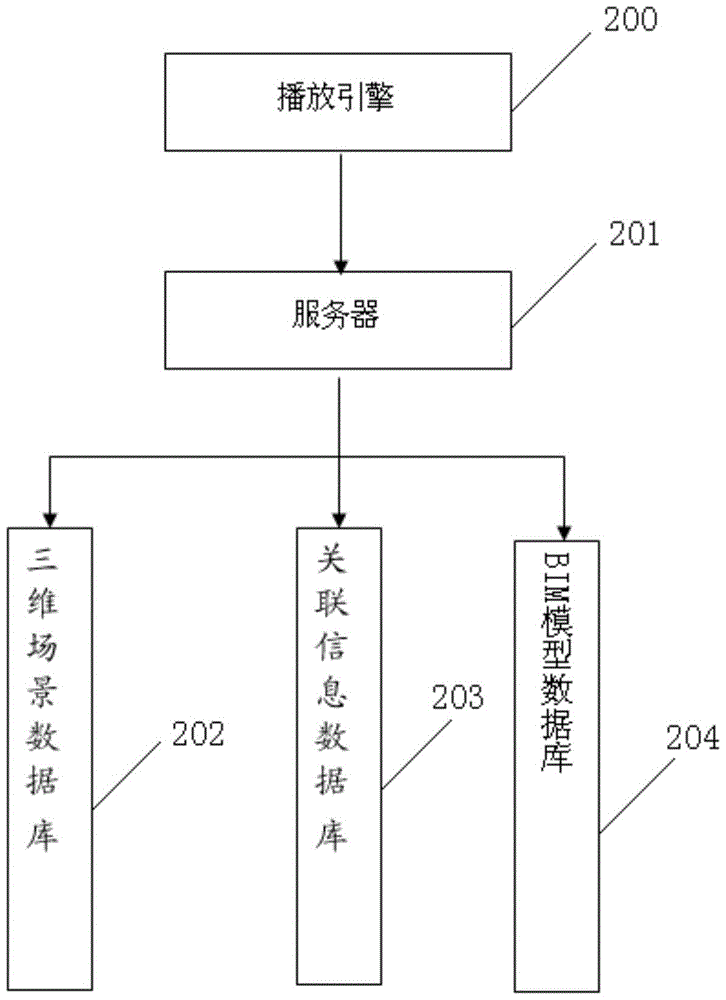

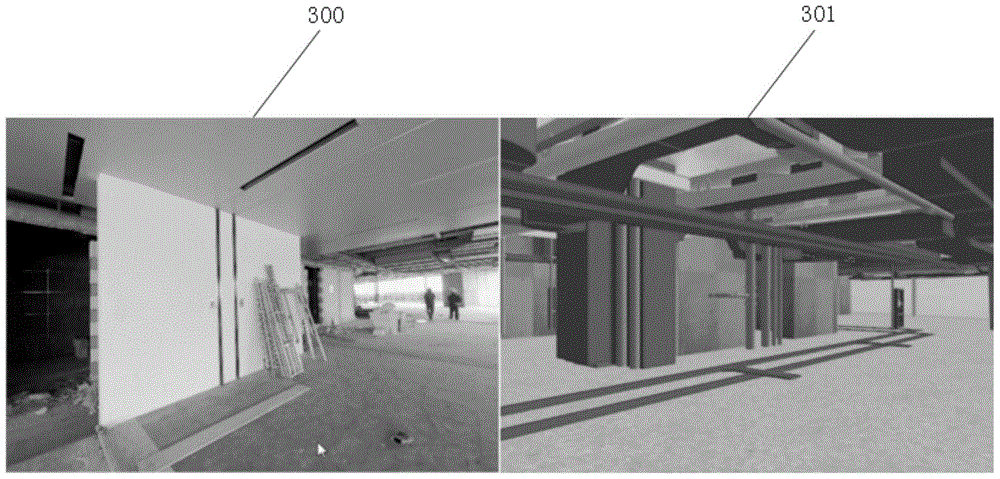

Method for carrying out engineering progress supervision by use of three-dimensional panoramic technology by combining BIM technology

InactiveCN105719200AImprove sensory perceptionImprove progressData processing applicationsDesign optimisation/simulationTime scheduleData acquisition

The invention discloses a method for carrying out engineering progress supervision by use of three-dimensional panoramic technology by combining BIM technology. The method comprise following steps of S1: constructing a BIM model for an engineering project; S2: carrying out three-dimensional data acquisition on a construction field of the engineering project and making a three-dimensional panoramic image of the engineering field; S3: associating and integrating the BIM model in the S1 and the three-dimensional panoramic image of the engineering field in the S2: and S4: carrying out synchronous comparison according to positions and carrying out switching comparison according to different time schedules on the associated and integrated data of the three-dimensional panoramic image and the BIM model. According to the invention, sense organ recognition between actual construction conditions and designing models is effectively improved; effective reference basis is provided for construction schedule conditions and onsite construction conditions; and schedule management and quality management of the whole designing and construction stage are effectively improved.

Owner:SHANGHAI JIETU TIANXIA NETWORK SCI & TECH

System and method for data quality management and control of heterogeneous data sources

InactiveUS7251693B2Simpler and efficient to useSave user time necessaryDigital data processing detailsDigital computer detailsData setData system

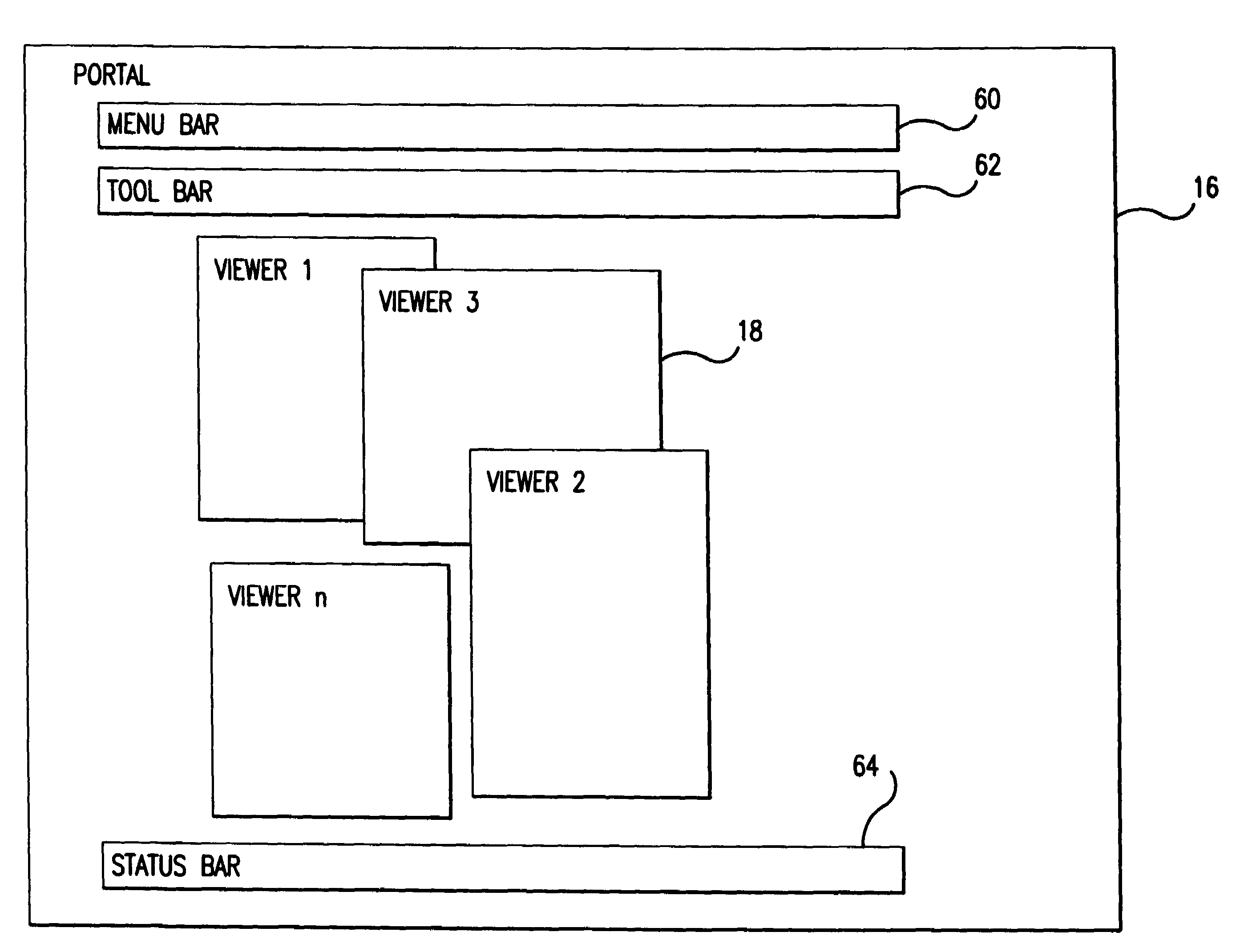

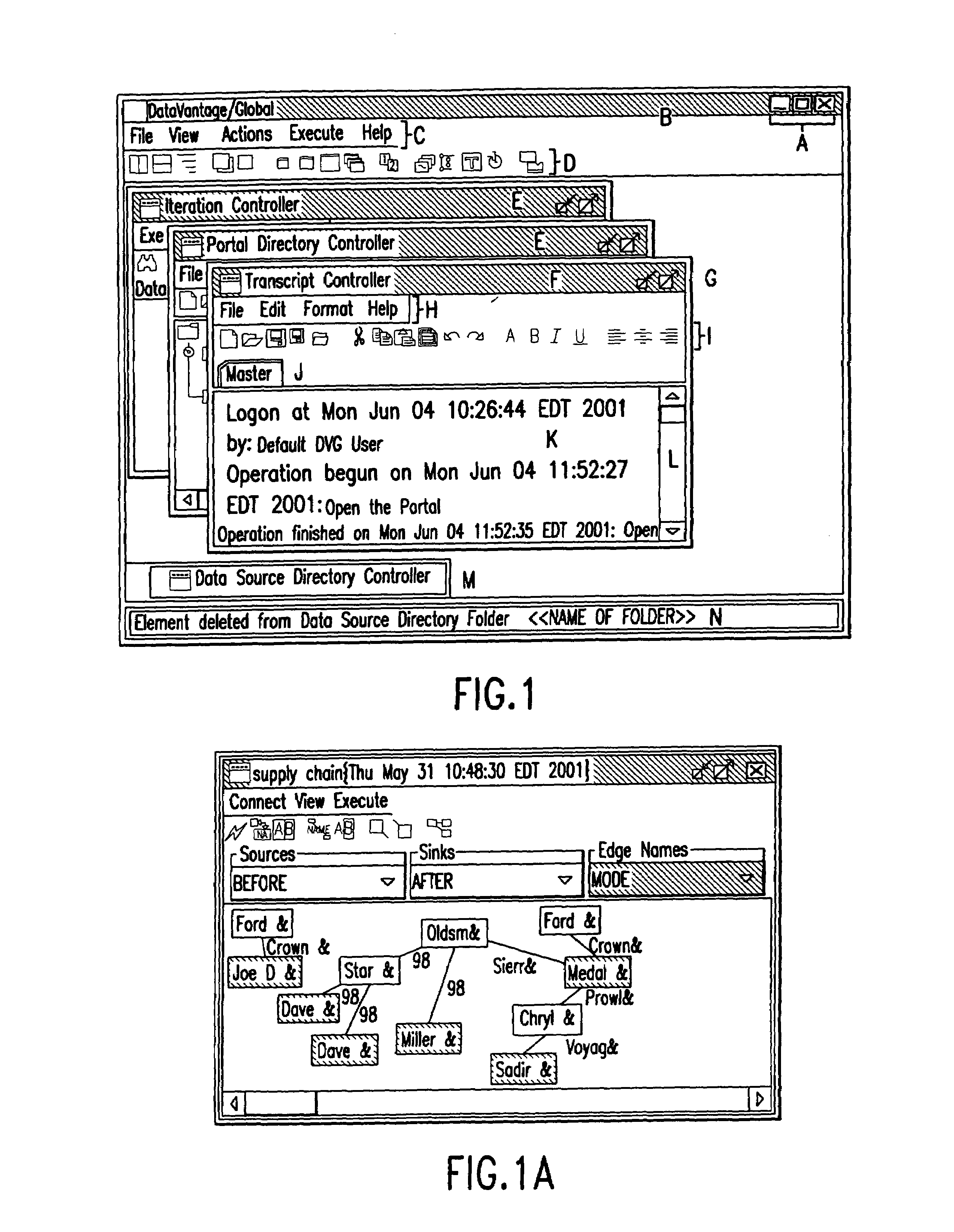

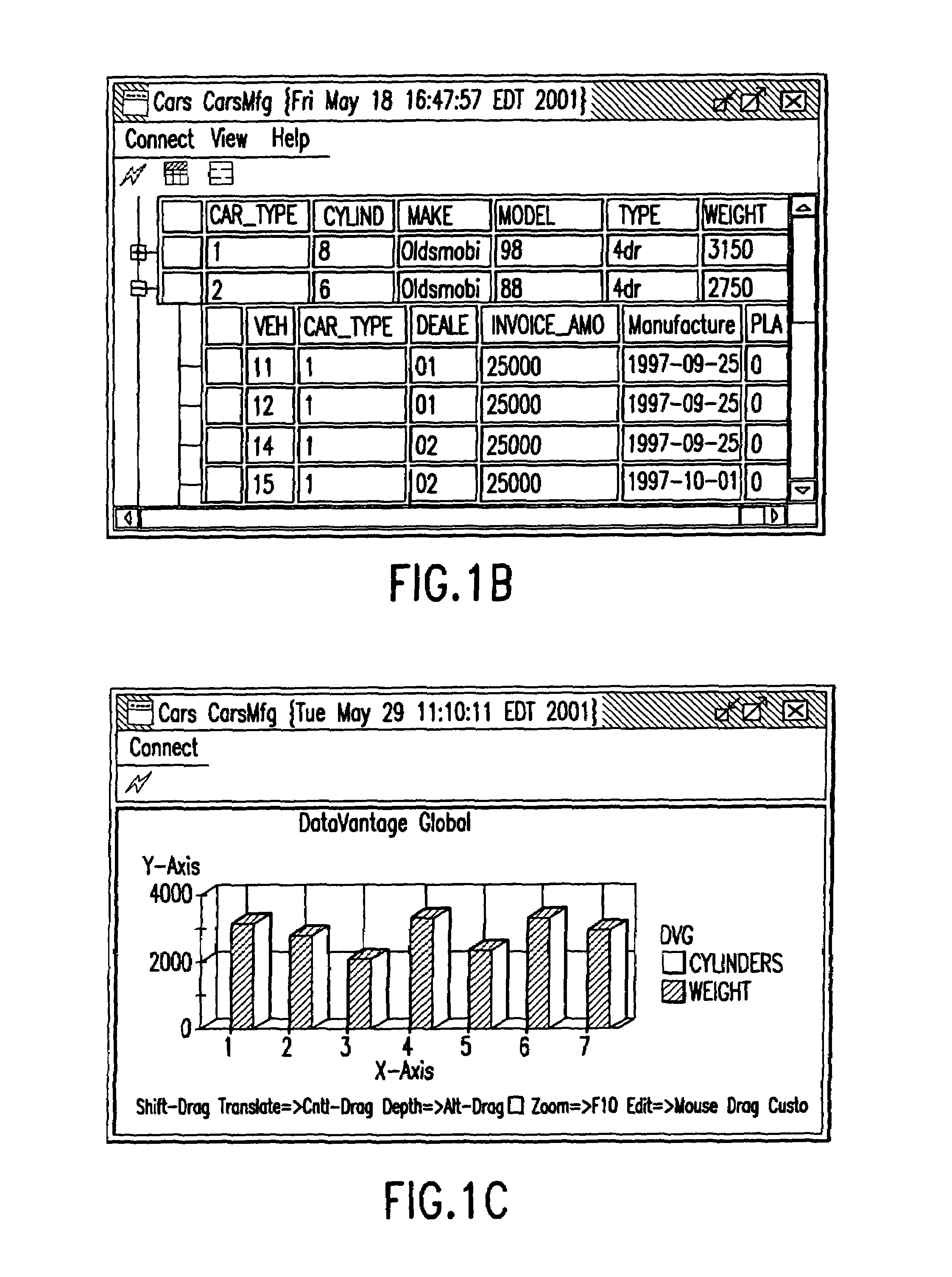

System and method for data quality management and control of heterogeneous data systems. In a preferred embodiment, the system functions as a resource management tool that simplifies the process of managing data systems. More specifically, the system provides connections to source data systems, allows users to view data structures and enables simple management and manipulation of data contained within possibly heterogeneous data systems. The system utilizes an advanced graphical user interface, which allows users to access and manage systems using a simple point and click methodology. The system uses portals, which are tools that collect, visualize, analyze and directly edit data sets associated with different data sources. In another aspect, the system keeps track of its operational status, allowing users to automatically reproduce in one logon session work done in the previous session, without the need to replicate previous data analysis. Various additional features of the system and methods are disclosed and illustrated.

Owner:DIRECT COMP RESOURCES

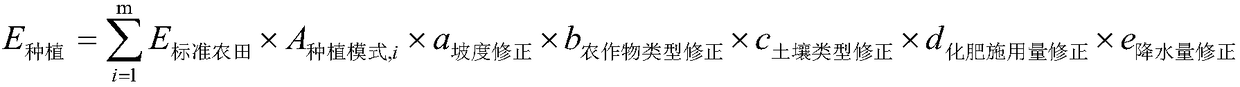

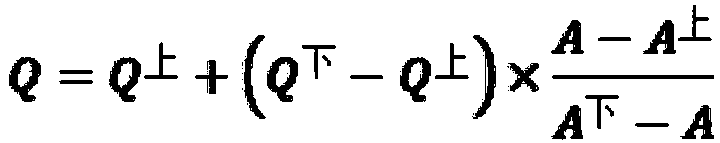

Water-quality simulation method based on control-unit water-environment-quality target management

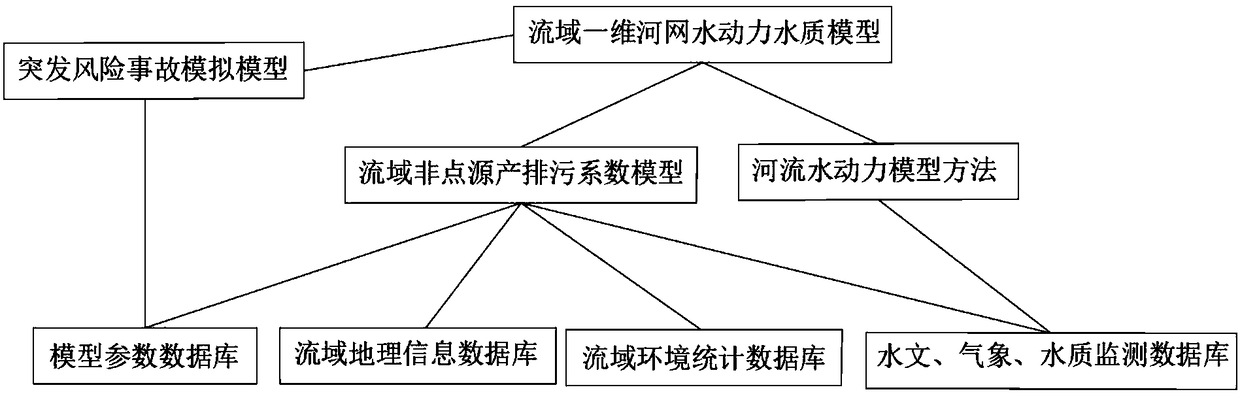

ActiveCN108287950ASolve the problem of land and water couplingData processing applicationsGeneral water supply conservationRiver networkStreamflow

The invention provides a water-quality simulation method based on control-unit water-environment-quality target management. The water-quality simulation method includes the steps that a database is built; a land-field control unit and a river-way subunit are divided; the flow, the area of the water surface and the volume of a water body of calculation unit grids are simulated through a hydraulicsmodel; the generation quantity of non-point-source pollutants in pollution sources is calculated through an output coefficient model, and the in-river sewage amount and the pollution load concentration of pollutants of a pollutant discharging opening are calculated; the water quality of the calculation unit grids is simulated through a one-dimensional water-quality model. In the water-quality simulation method, an emergent risk accident pollutant-discharging water-quality model is also used, and is used for simulating transmission of accident pollutants in a river network and the changing condition of the water quality of a downstream drainage basin after emergent-water-environment-risk-accident pollutant discharging.

Owner:CHINESE ACAD OF ENVIRONMENTAL PLANNING

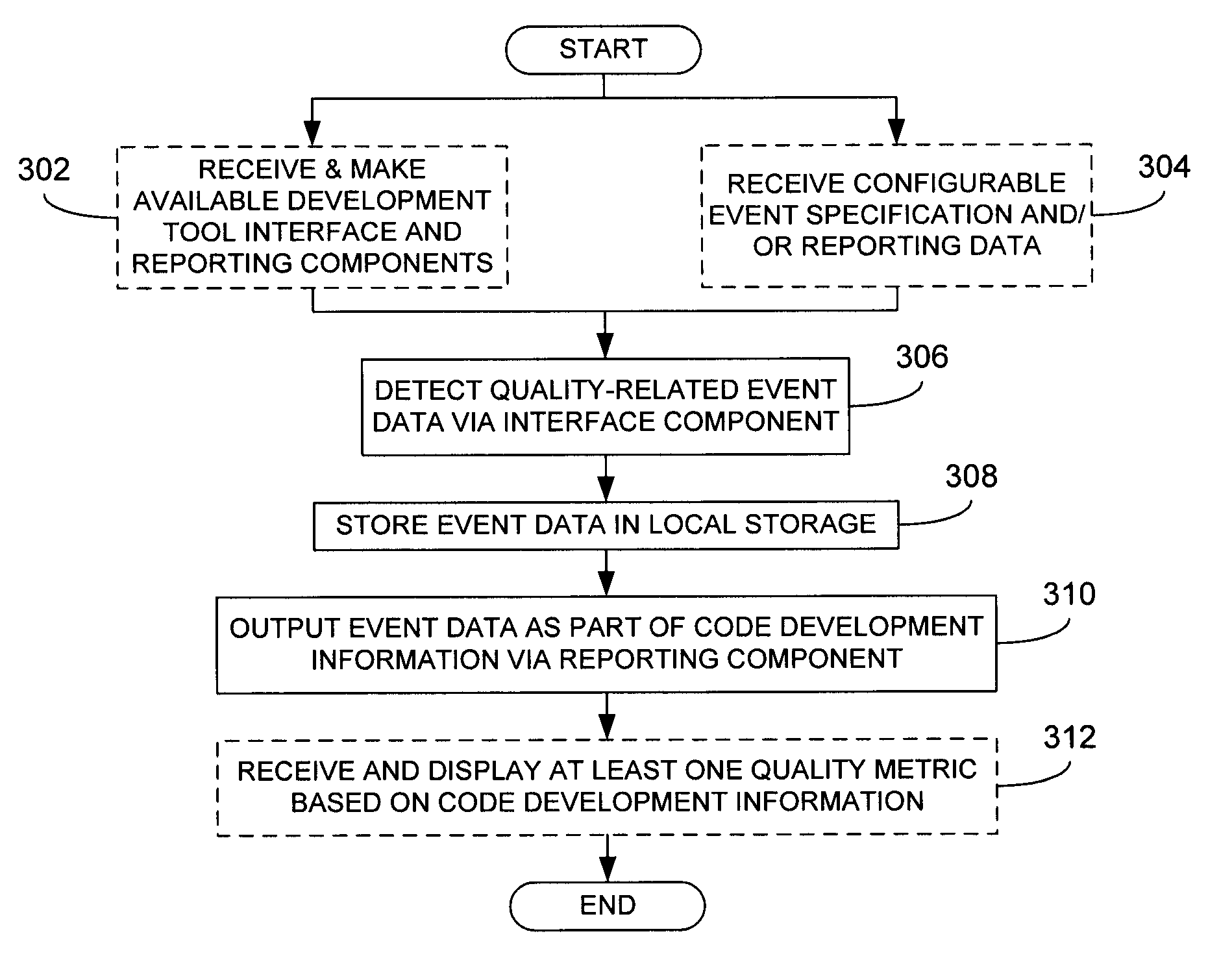

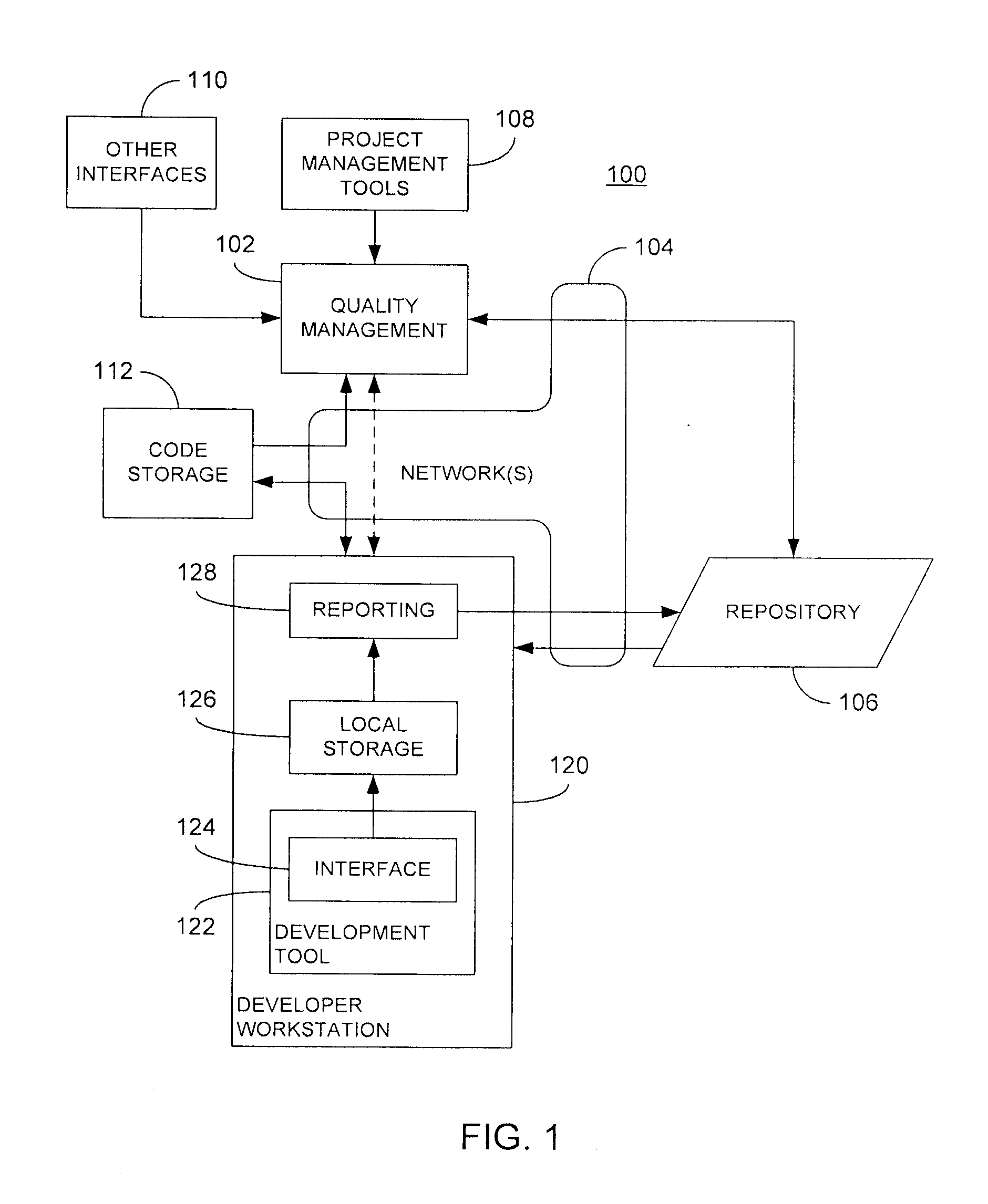

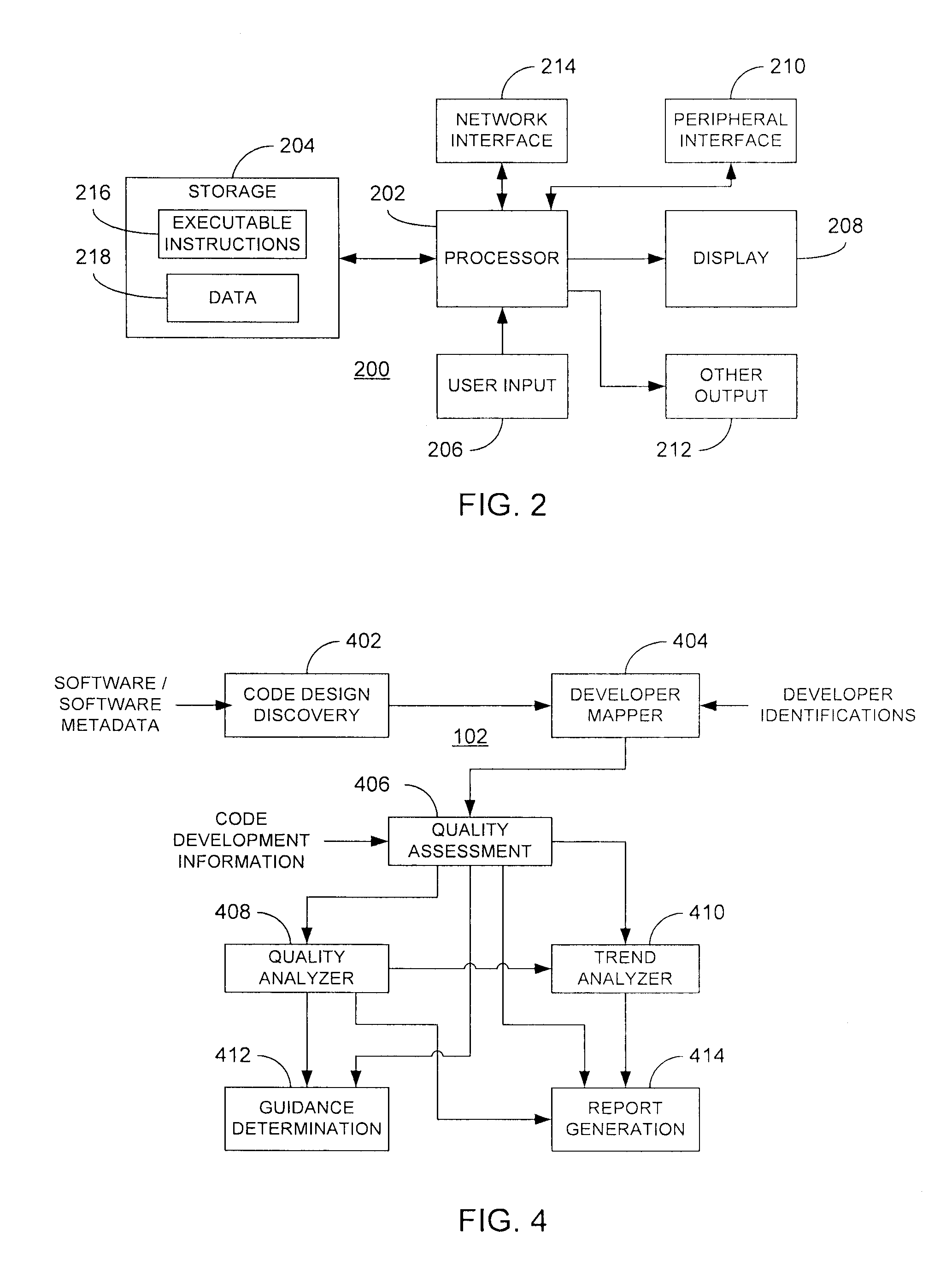

Collection and processing of code development information

ActiveUS20110055799A1Error detection/correctionSpecific program execution arrangementsHandling CodeDisplay device

Within each of a plurality of developer workstations contributing to a software development project, event data concerning at least one quality-related issue is collected via a development tool implemented by the developer workstation. The event data is stored locally and periodically output as at least part of code development information. The code development information is provided to a quality management component for subsequent processing, particularly the determination of one or more quality metrics. At least a portion of such quality metrics may be subsequently provided to the developer workstation for display on a suitable display device.

Owner:ACCENTURE GLOBAL SERVICES LTD

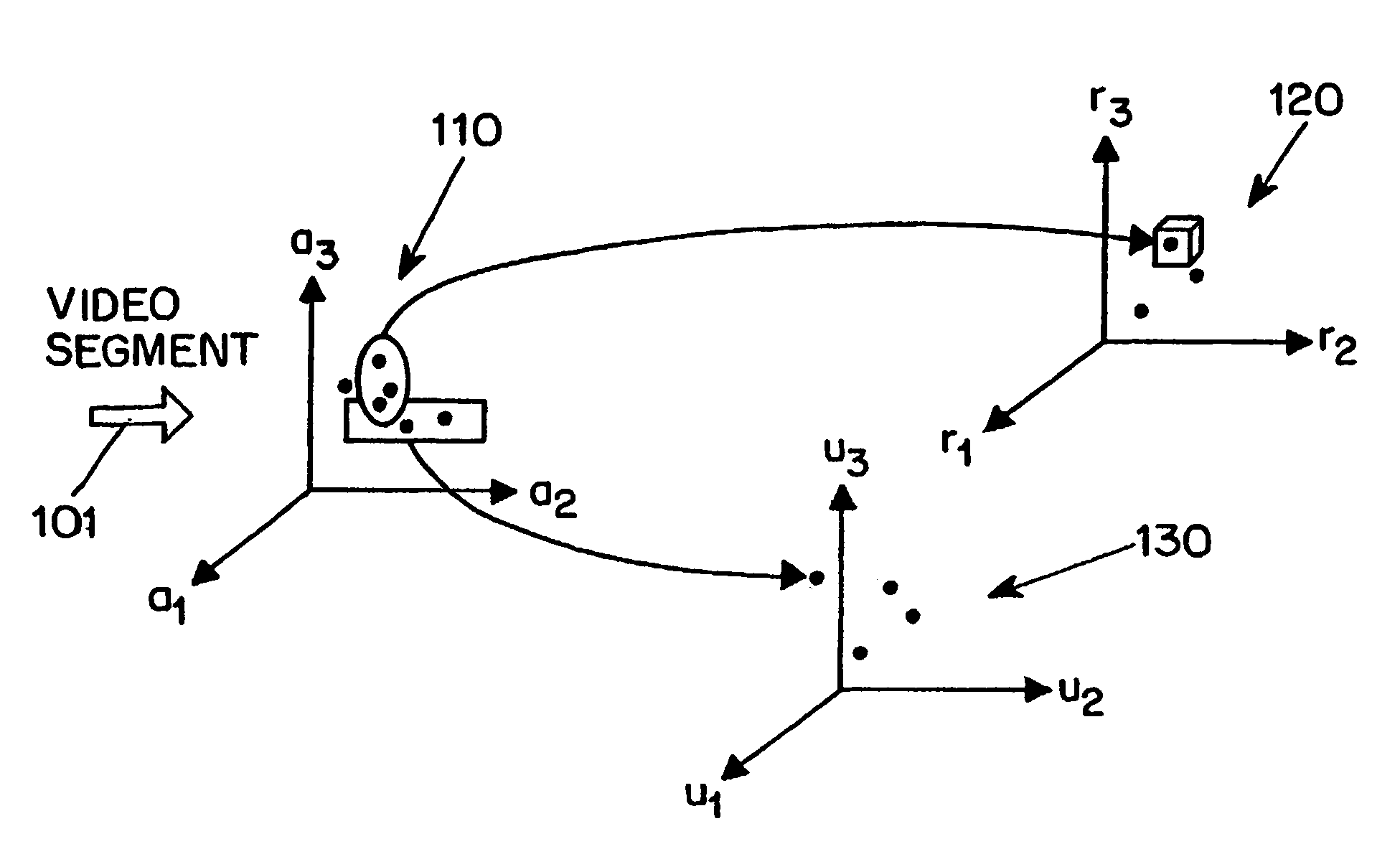

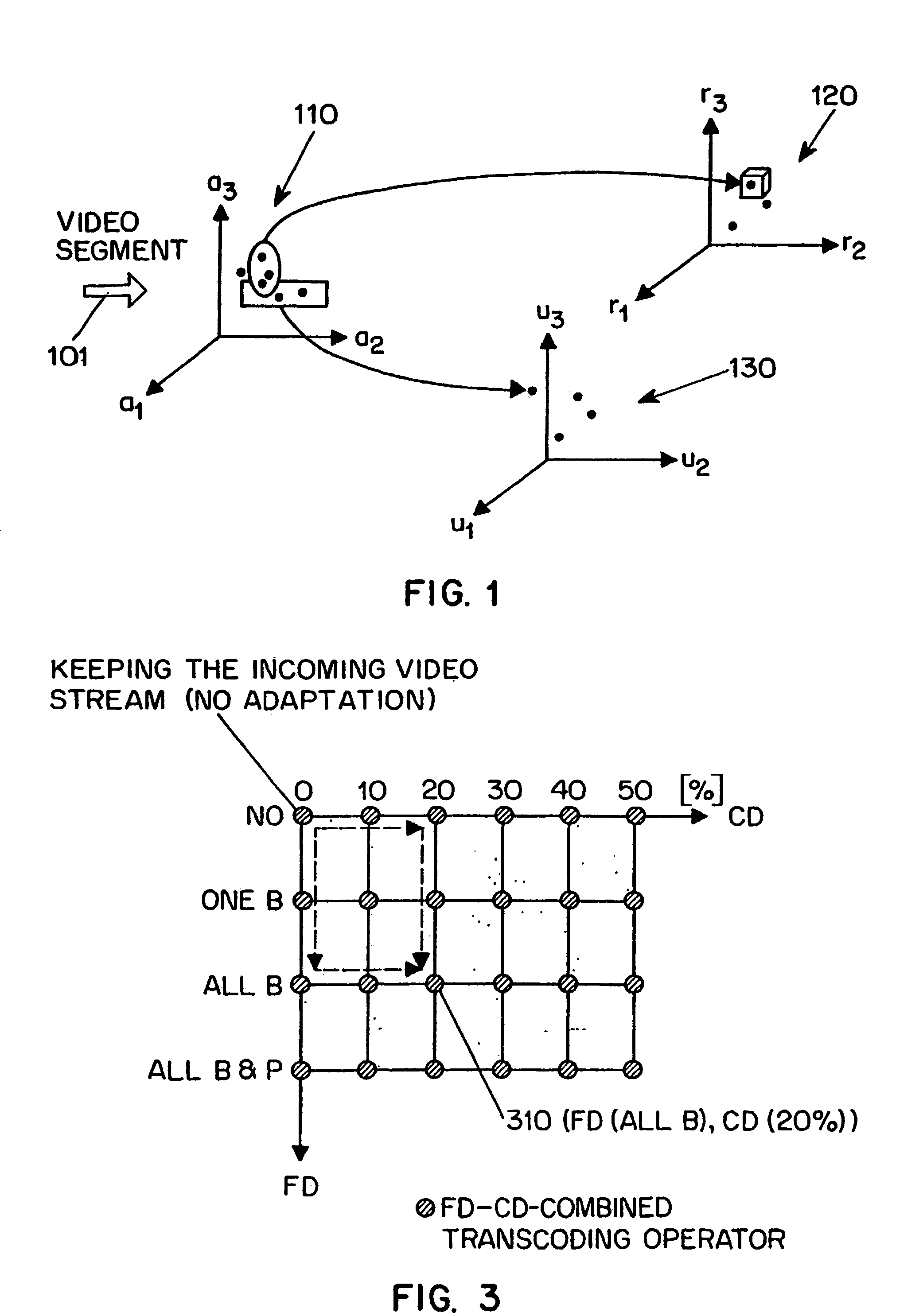

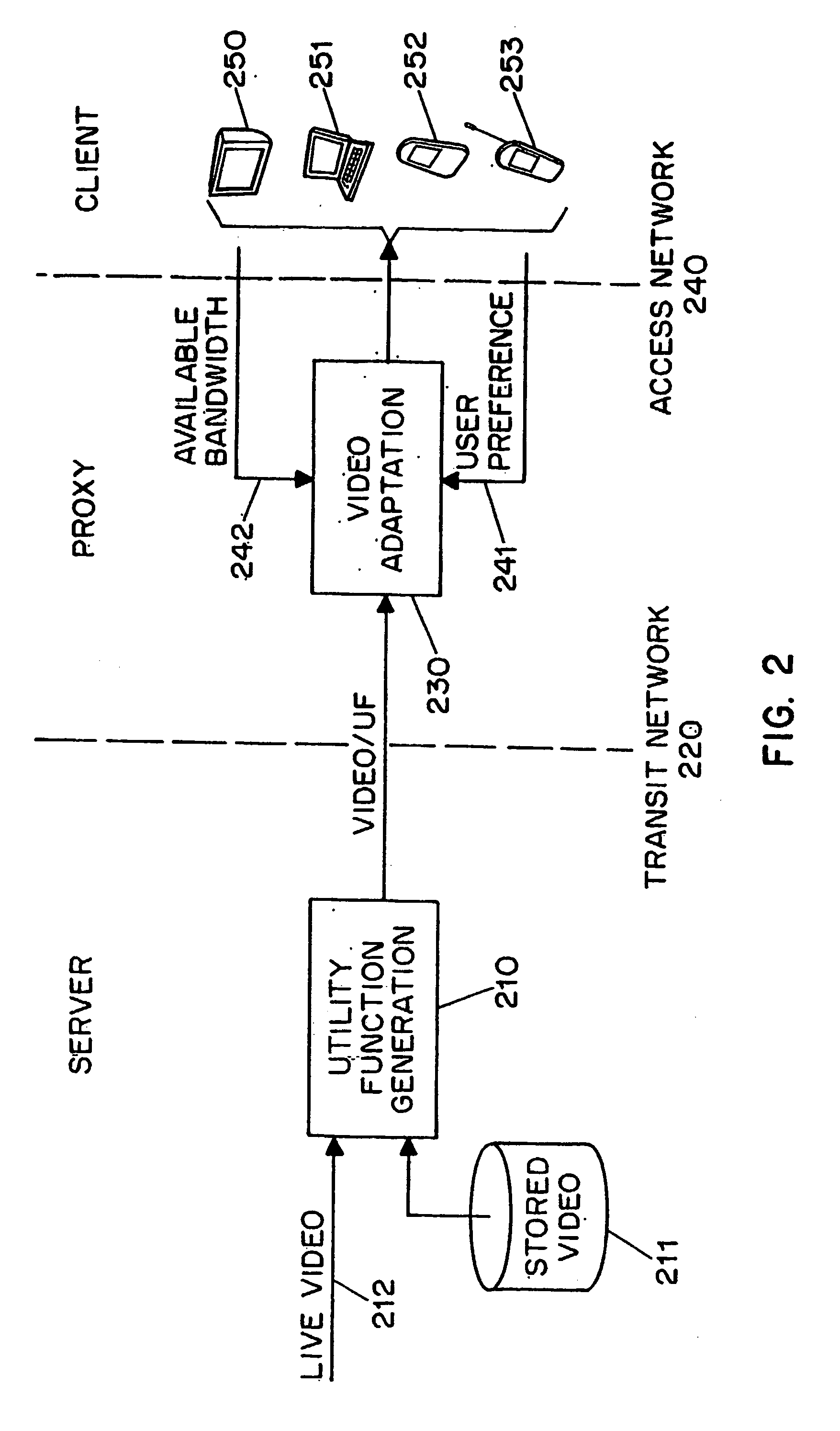

Method and system for optimal video transcoding based on utility function descriptors

InactiveUS20090290635A1Broad spectrumPicture reproducers using cathode ray tubesCode conversionData miningQuality management

Techniques for generating utility-based descriptors from compressed multimedia information are disclosed. A preferred method includes the steps of receiving least a segment of compressed multimedia information, determining two or more portions of utility based descriptor information based on one or more adaptation operations, each corresponding to a unique target rate, adapting the compressed multimedia segment by each the portions of utility based descriptor information to generate adapted multimedia segments, using a quality management method to generate measurement for each adapted multimedia segment, and generating a utility based descriptors based on the portions of utility based descriptor information and corresponding quality measurements.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

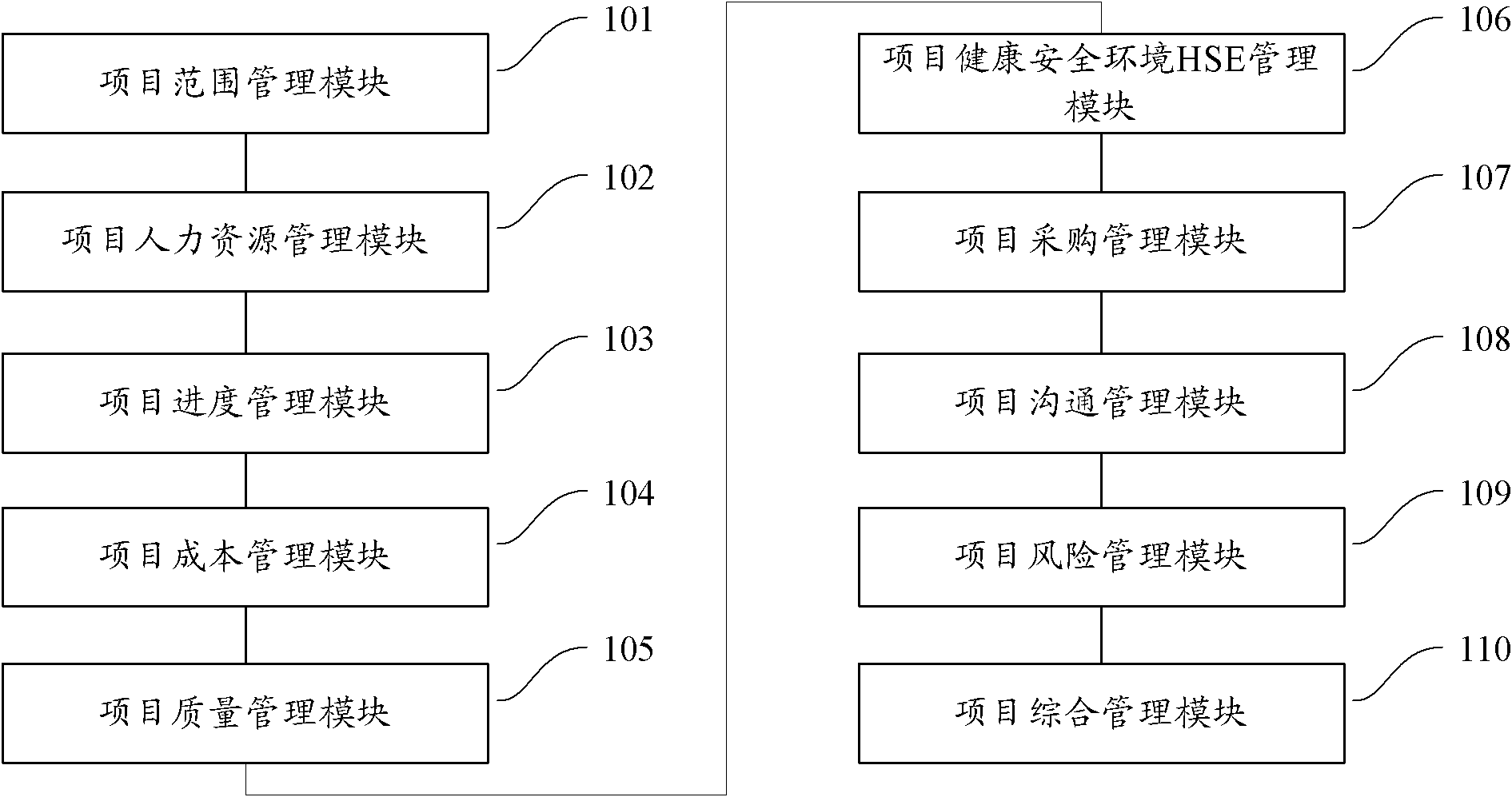

Workflow control system of project implementation

InactiveCN103177306AReduce riskEasy to controlResourcesCommunications managementProject risk management

The invention provides a workflow control system of project implementation. The workflow control system comprises a project range management module, a project human resource management module, a project progress management module, a project cost management module, a project quality management module, a project health safe environment HSE management module, a project procurement management module, a project communication management module, a project risk management module and a project comprehensive management module. By means of the workflow control system, workflow control efficiency can be improved, and requirements of all aspects on information sharing are met.

Owner:CHINA CAMC ENG

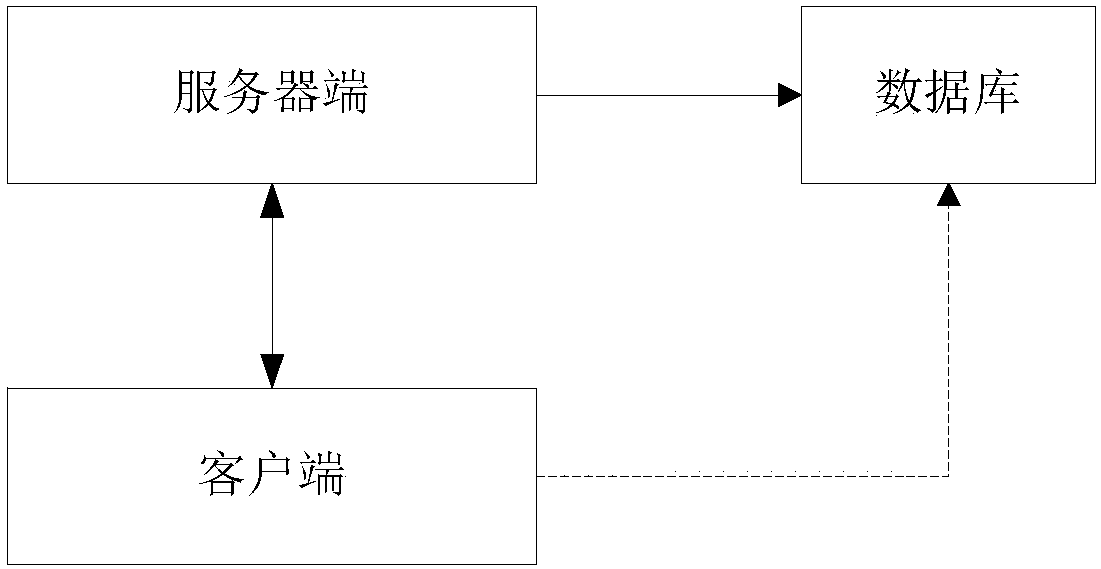

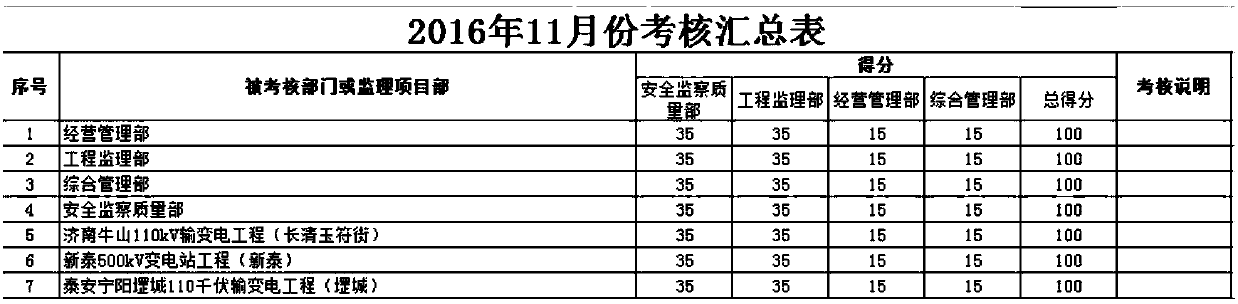

Overall process intelligent engineering supervision information management and control system

PendingCN107705020ARealize intelligent management and controlEasy to analyzeSustainable waste treatmentResourcesManagement unitSystems management

The invention relates to an overall process intelligent engineering supervision information management and control system. The overall process intelligent engineering supervision information management and control system includes a client, a server terminal and a database, wherein the client includes a personal office unit, an integrated management unit, an information center unit, an operation management unit, a safety quality management unit, a project management unit, a system management unit, a training management unit and an archives management unit; the server terminal is used for analyzing and controlling the data transmitted from the client, returning the result data of analysis and control to the client, and transmitting the original data and the result data of analysis and control to the database to save; and the database is used for saving the data transmitted from the server terminal. The overall process intelligent engineering supervision information management and controlsystem can provide quick, accurate and comprehensive engineering supervision information and complete and efficient analysis, and can manage and control the overall process of engineering supervision.

Owner:山东联诚工程建设监理有限公司 +2

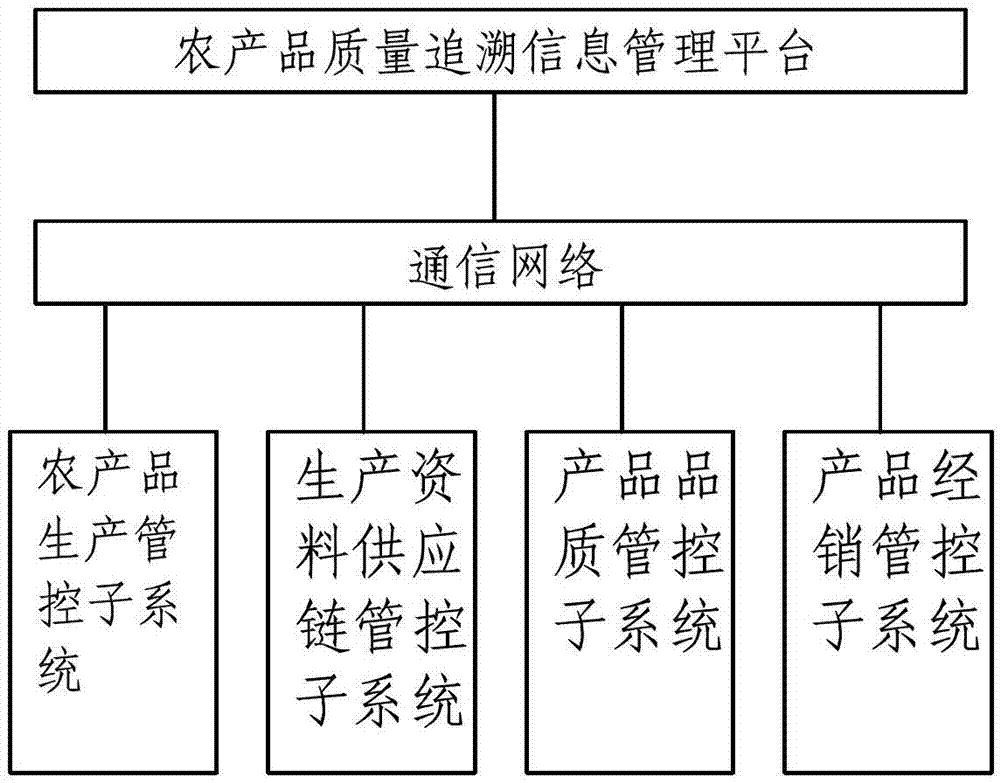

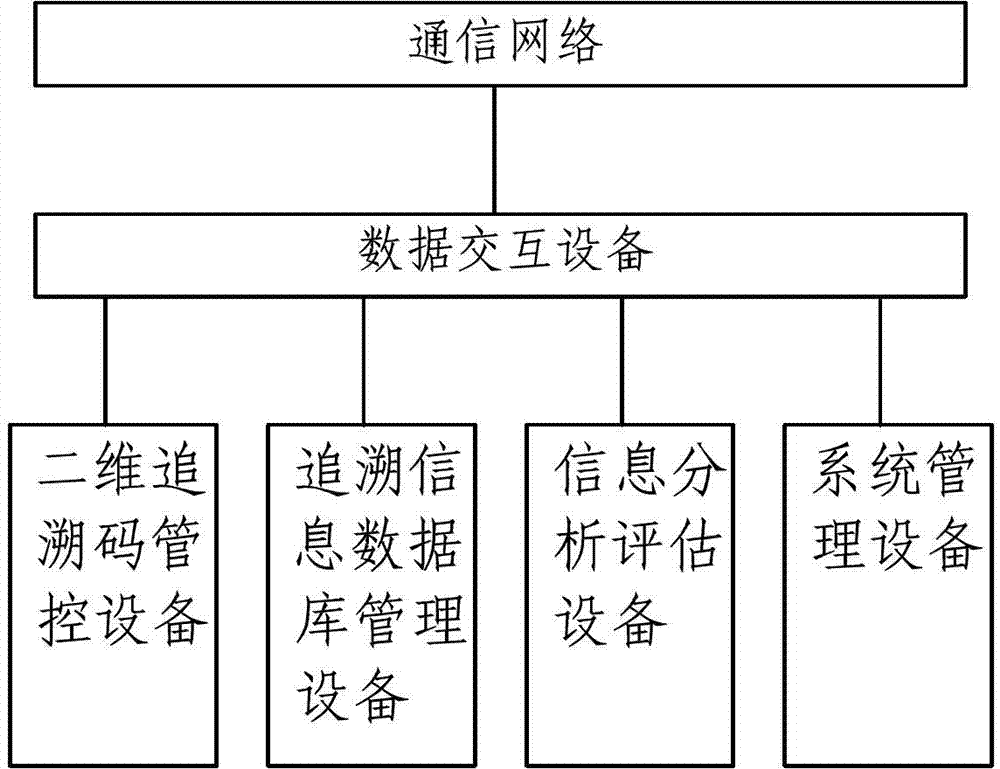

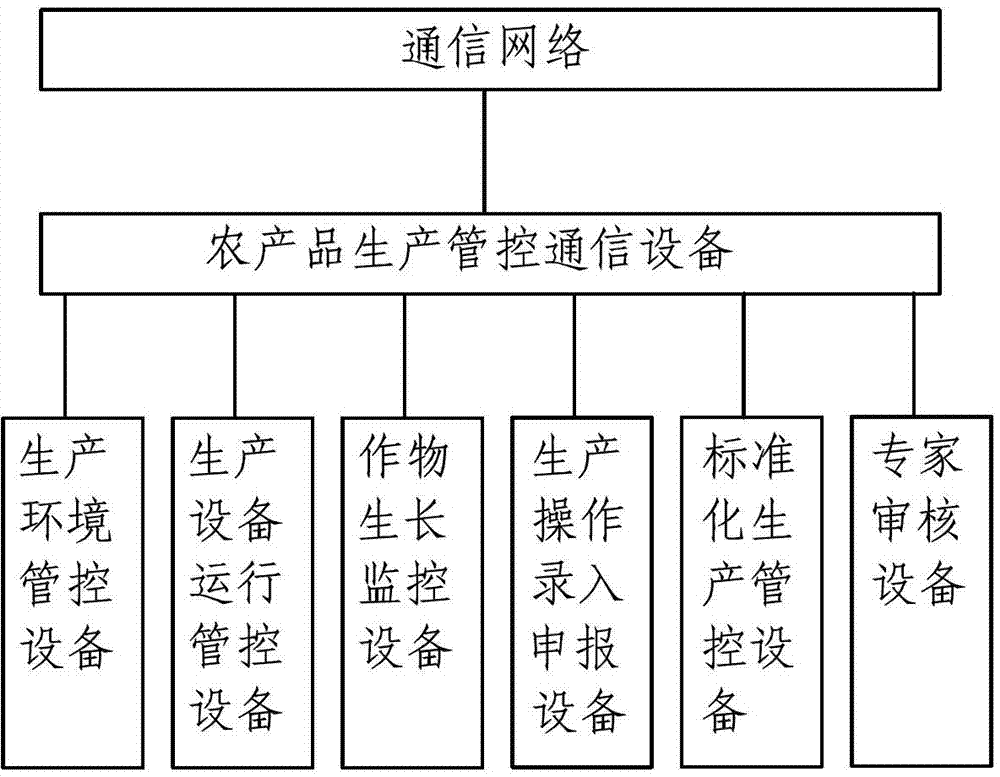

Agricultural product safe supply chain anti-fake management and control system

The invention provides an agricultural product safe supply chain anti-fake management and control system. The agricultural product safe supply chain anti-fake management and control system comprises an agricultural product quality tracing information management platform, an agricultural product production management and control system, a production material supply chain management and control subsystem, a product quality management and control subsystem, a product selling management and control subsystem and a communication network. The agricultural product quality tracing information management platform, the agricultural product production management and control system, the production material supply chain management and control subsystem, the product quality management and control subsystem and the product selling management and control subsystem are connected into the communication network. The agricultural product safe supply chain anti-fake management and control system takes the agricultural product quality tracing information management platform as the core, supports relevant equipment of other systems, receives, summarizes, analyzes and assesses information data of other subsystems, and build an agricultural product safe supply chain whole-process anti-fake management and control system. The agricultural product safe supply chain anti-fake management and control system forms effective supervision, control and supervision standardized production operation, and effectively ensures reality of information entry, thereby achieving safe supply of agricultural products.

Owner:QINGDAO ODO ENVIRONMENTAL TECH CO LTD

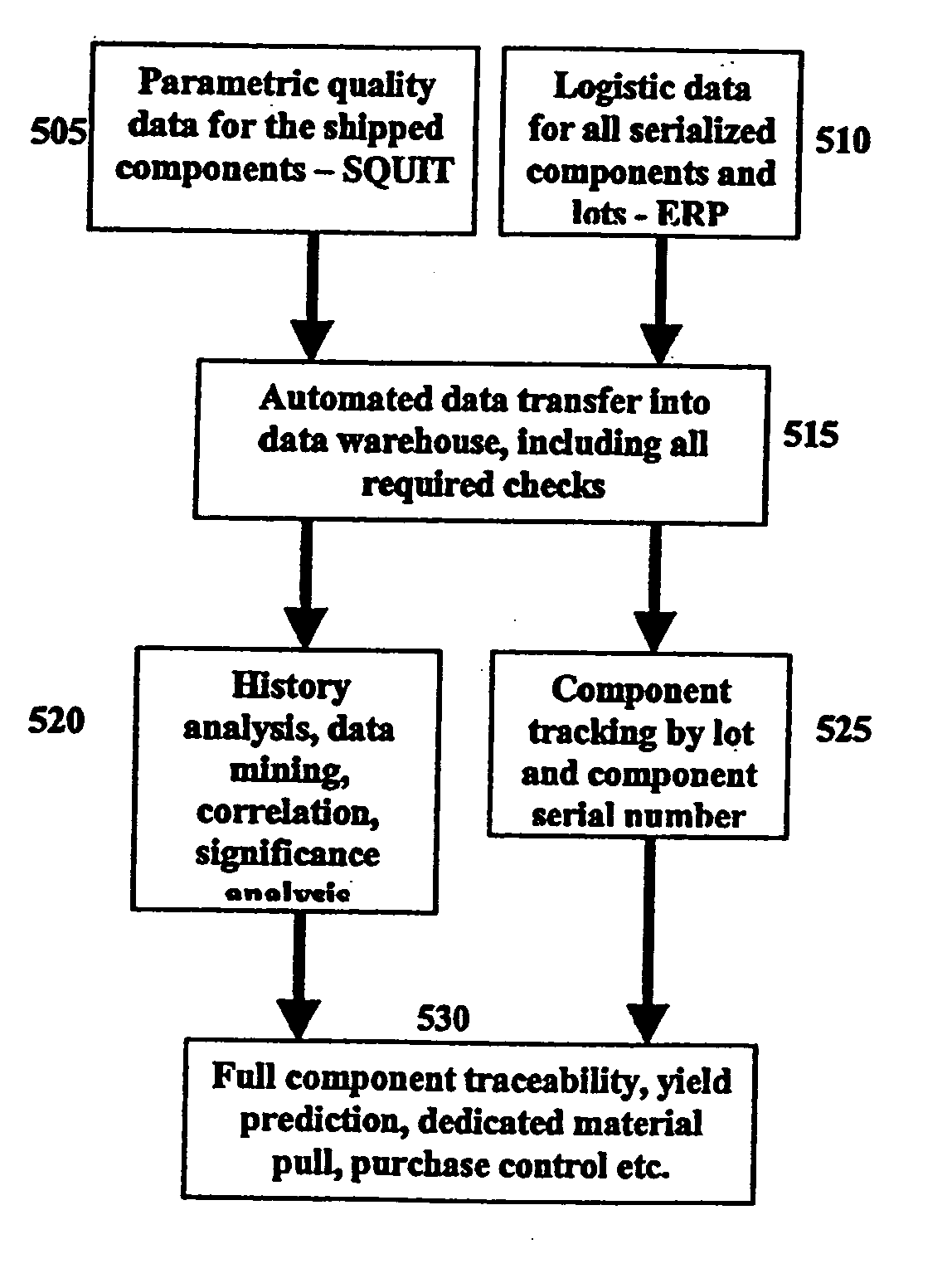

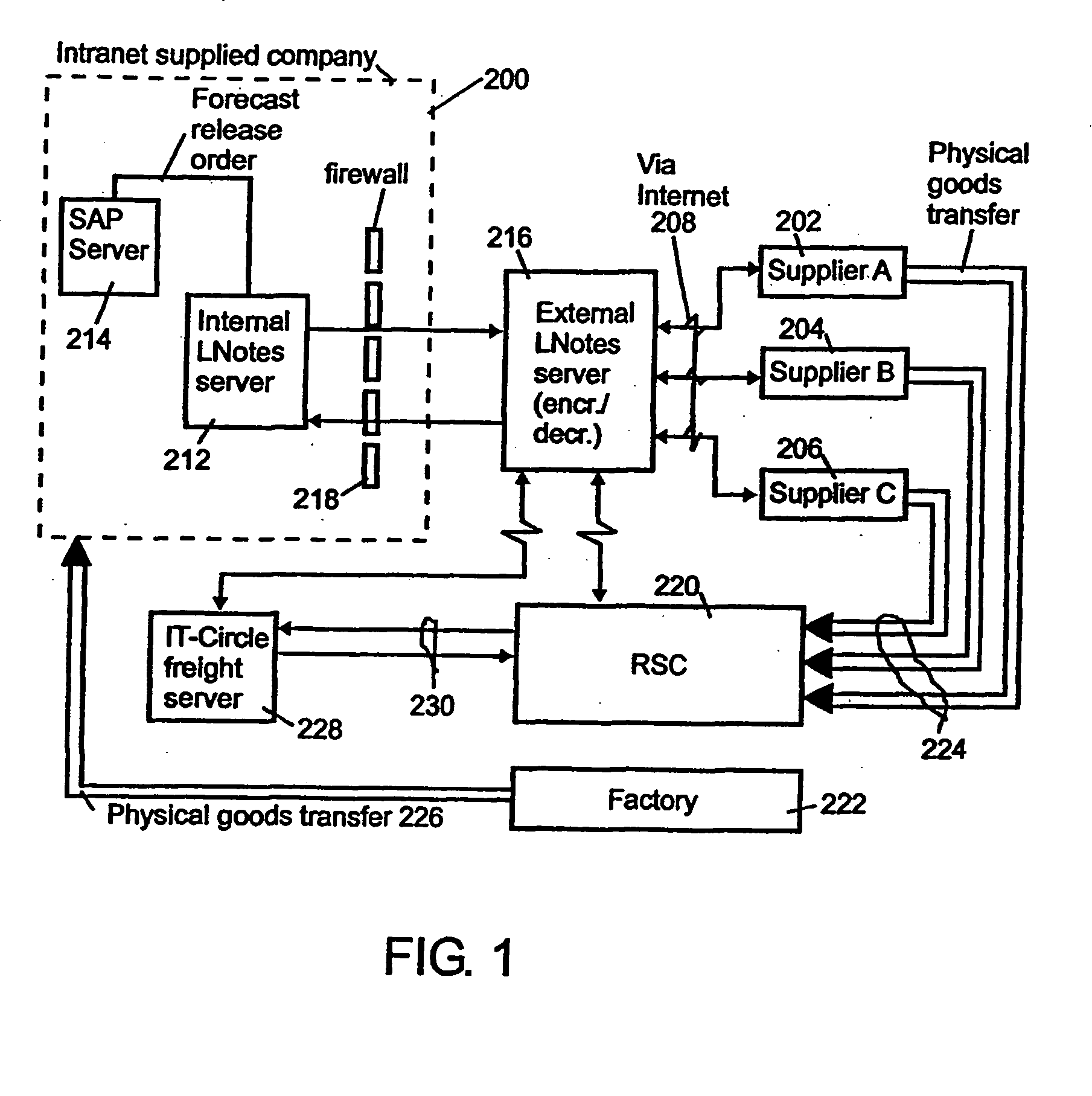

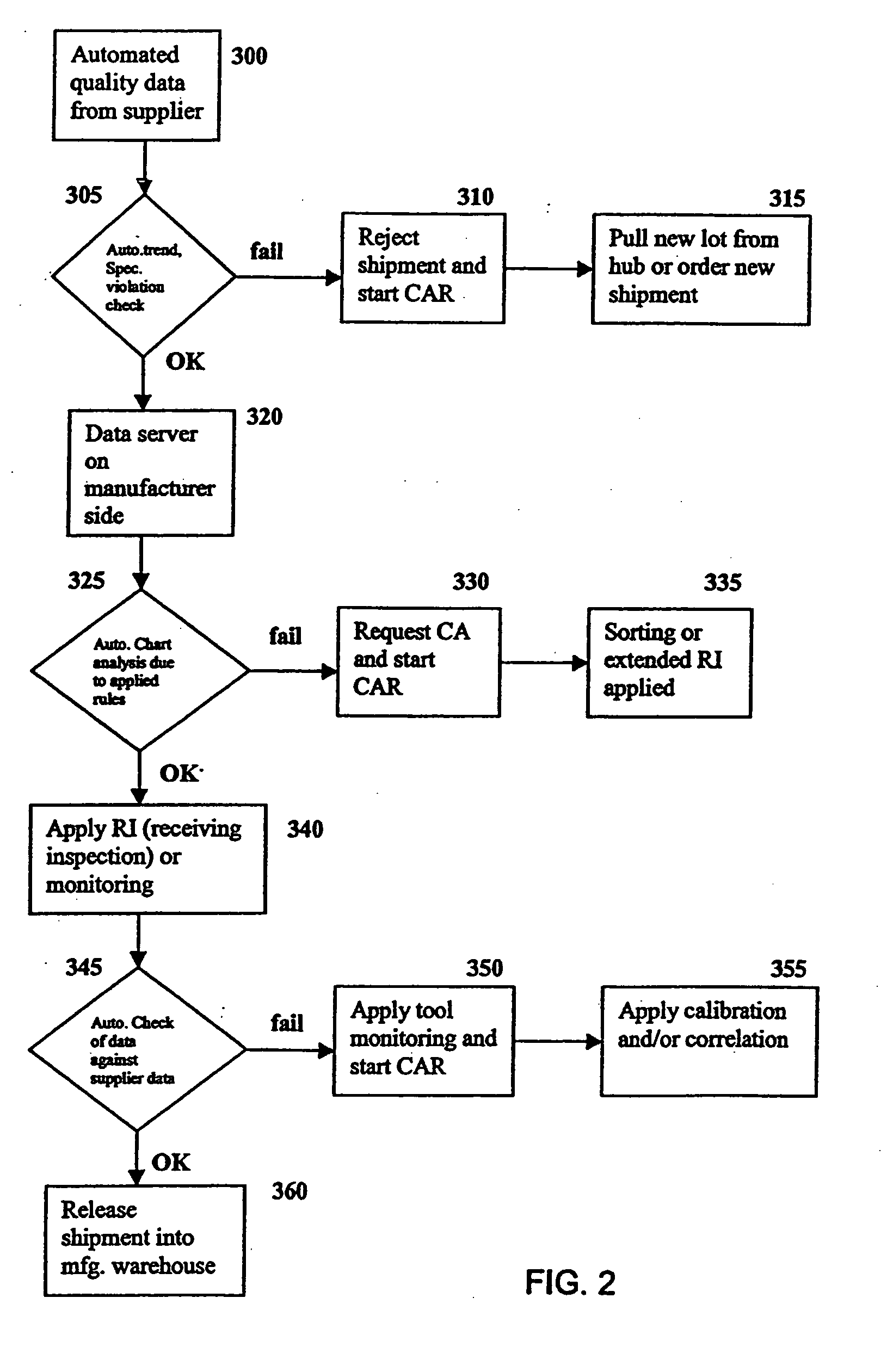

Method and system for computerizing quality management of a supply chain

InactiveUS20050159973A1Quality improvementYield predictionTechnology managementResourcesOriginal dataFeedback control

Owner:IBM CORP

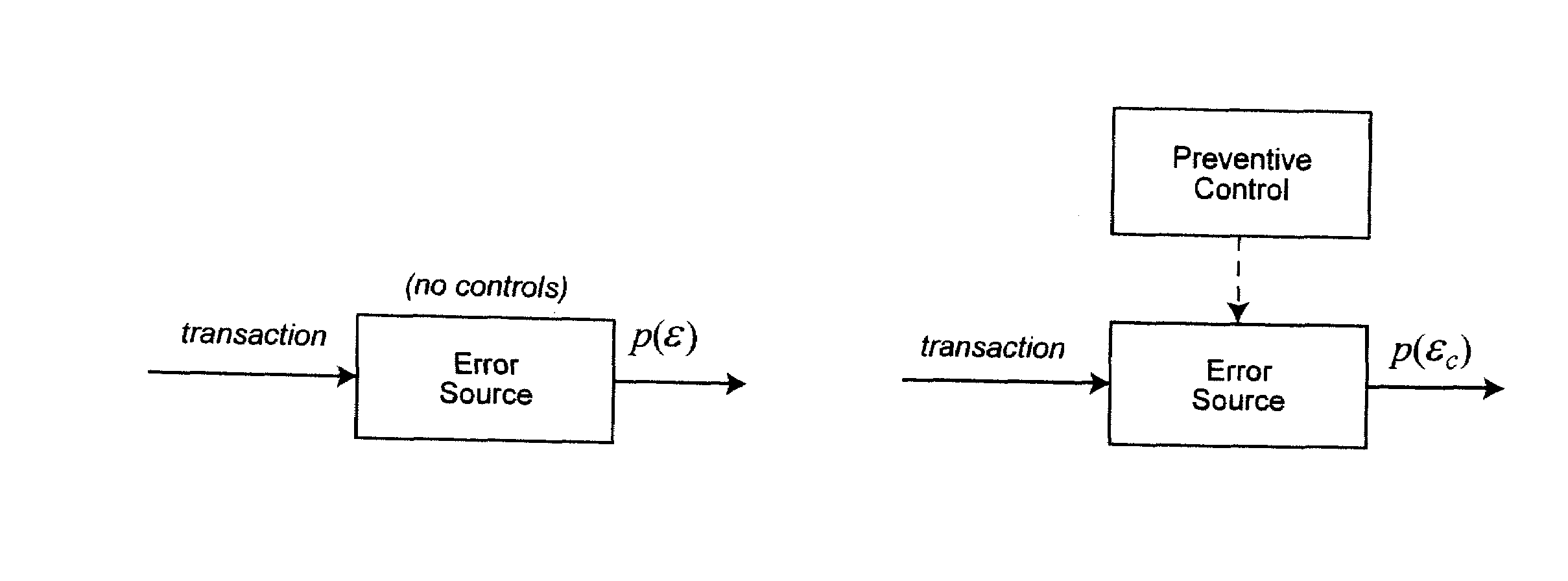

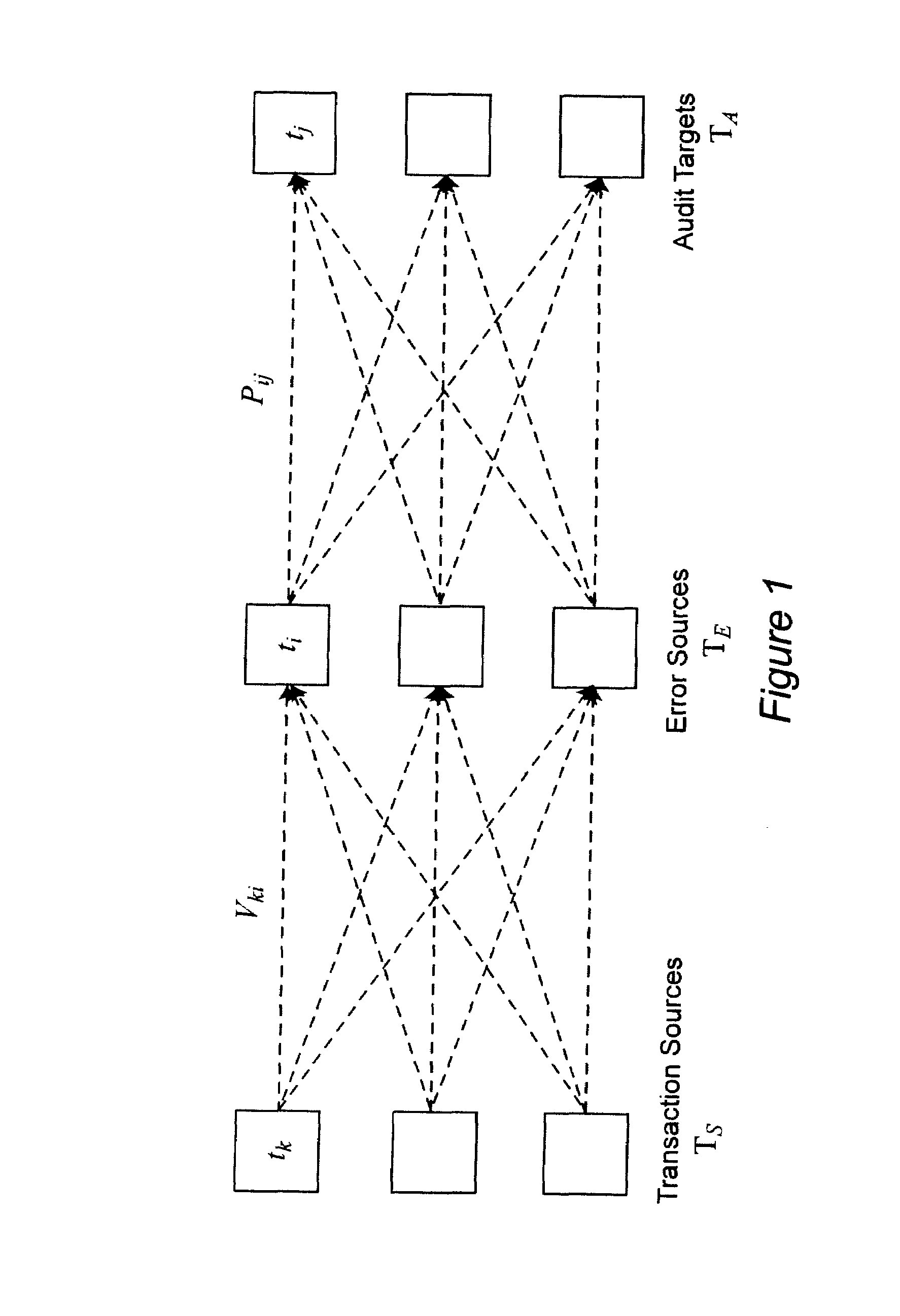

Data quality management using business process modeling

InactiveUS20080195440A1Impacts the overall quality of sales data.Low costResourcesComplex mathematical operationsDashboardInformation processing

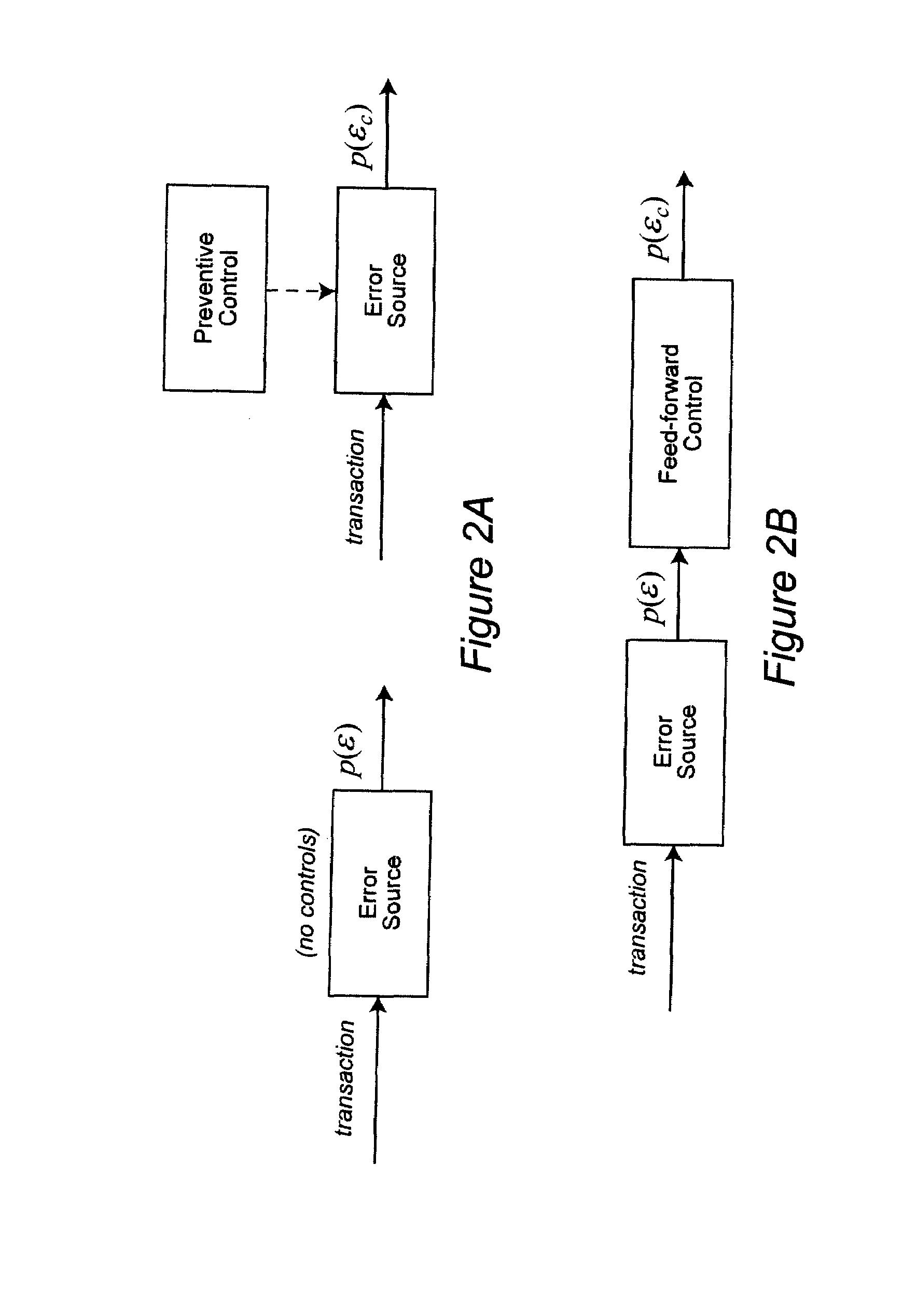

A business process modeling framework is used for data quality analysis. The modeling framework represents the sources of transactions entering the information processing system, the various tasks within the process that manipulate or transform these transactions, and the data repositories in which the transactions are stored or aggregated. A subset of these tasks is associated as the potential error introduction sources, and the rate and magnitude of various error classes at each such task are probabilistically modeled. This model can be used to predict how changes in transactions volumes and business processes impact data quality at the aggregate level in the data repositories. The model can also account for the presence of error correcting controls and assess how the placement and effectiveness of these controls alter the propagation and aggregation of errors. Optimization techniques are used for the placement of error correcting controls that meet target quality requirements while minimizing the cost of operating these controls. This analysis also contributes to the development of business “dashboards” that allow decision-makers to monitor and react to key performance indicators (KPIs) based on aggregation of the transactions being processed. Data quality estimation in real time provides the accuracy of these KPIs (in terms of the probability that a KPI is above or below a given value), which may condition the action undertaken by the decision-maker.

Owner:DOORDASH INC

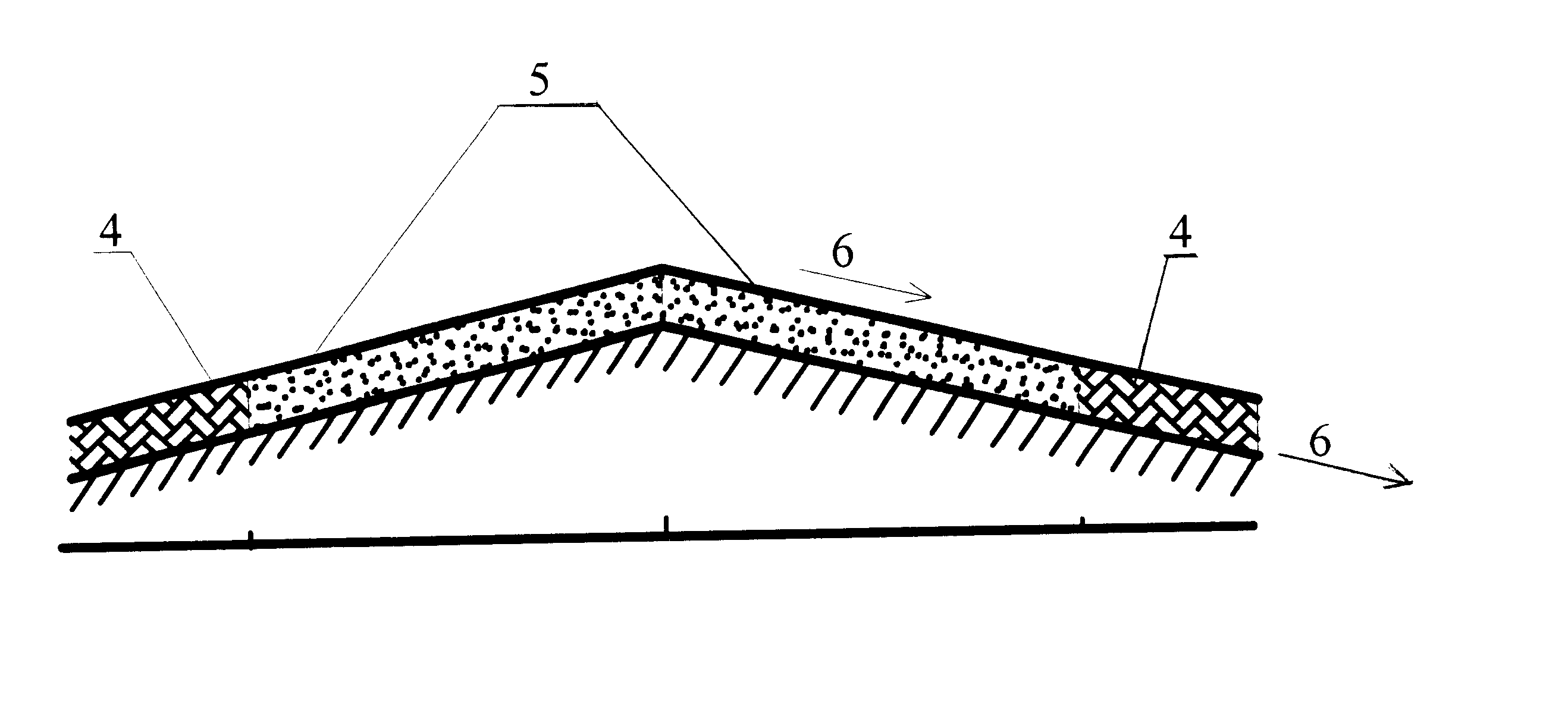

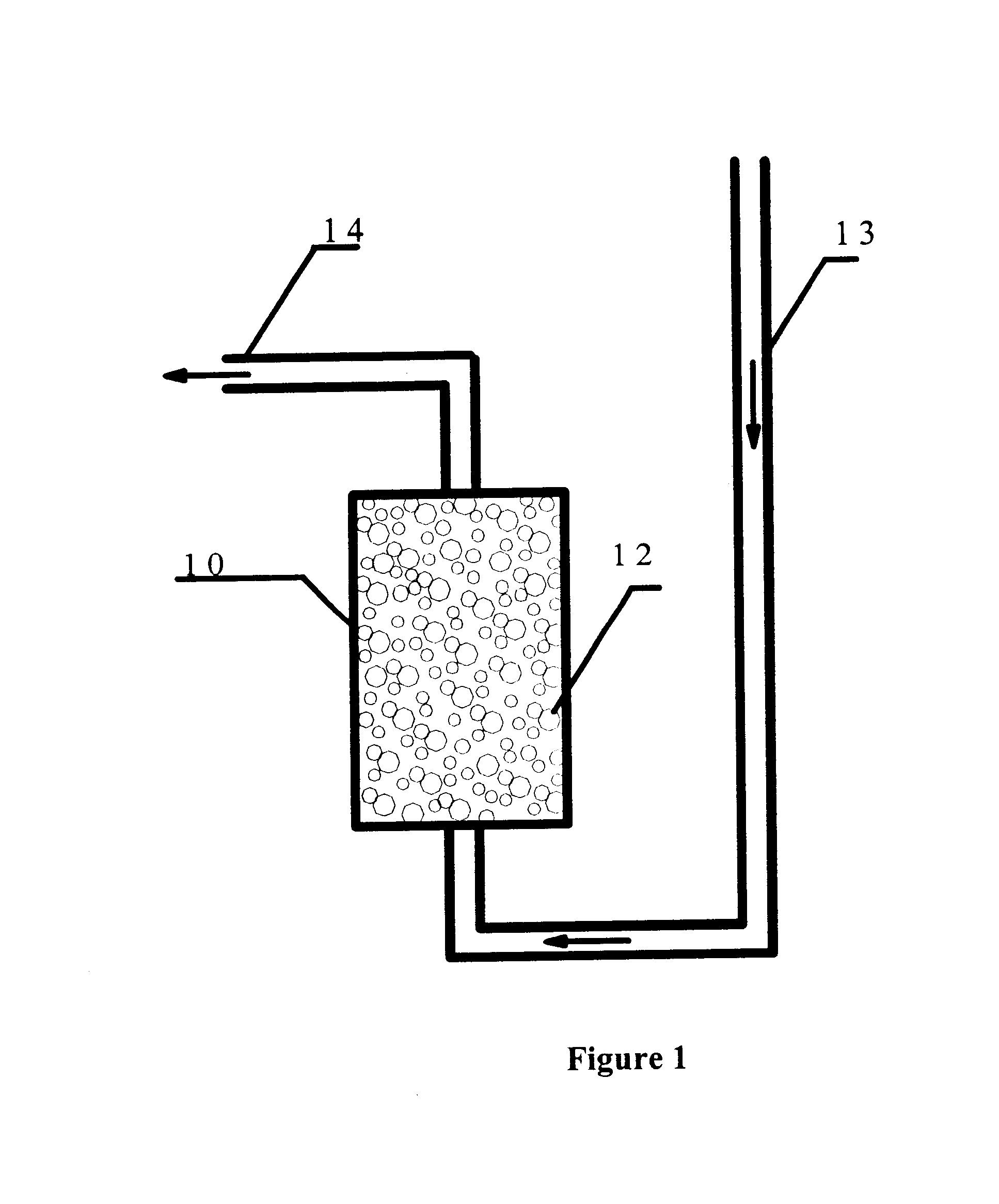

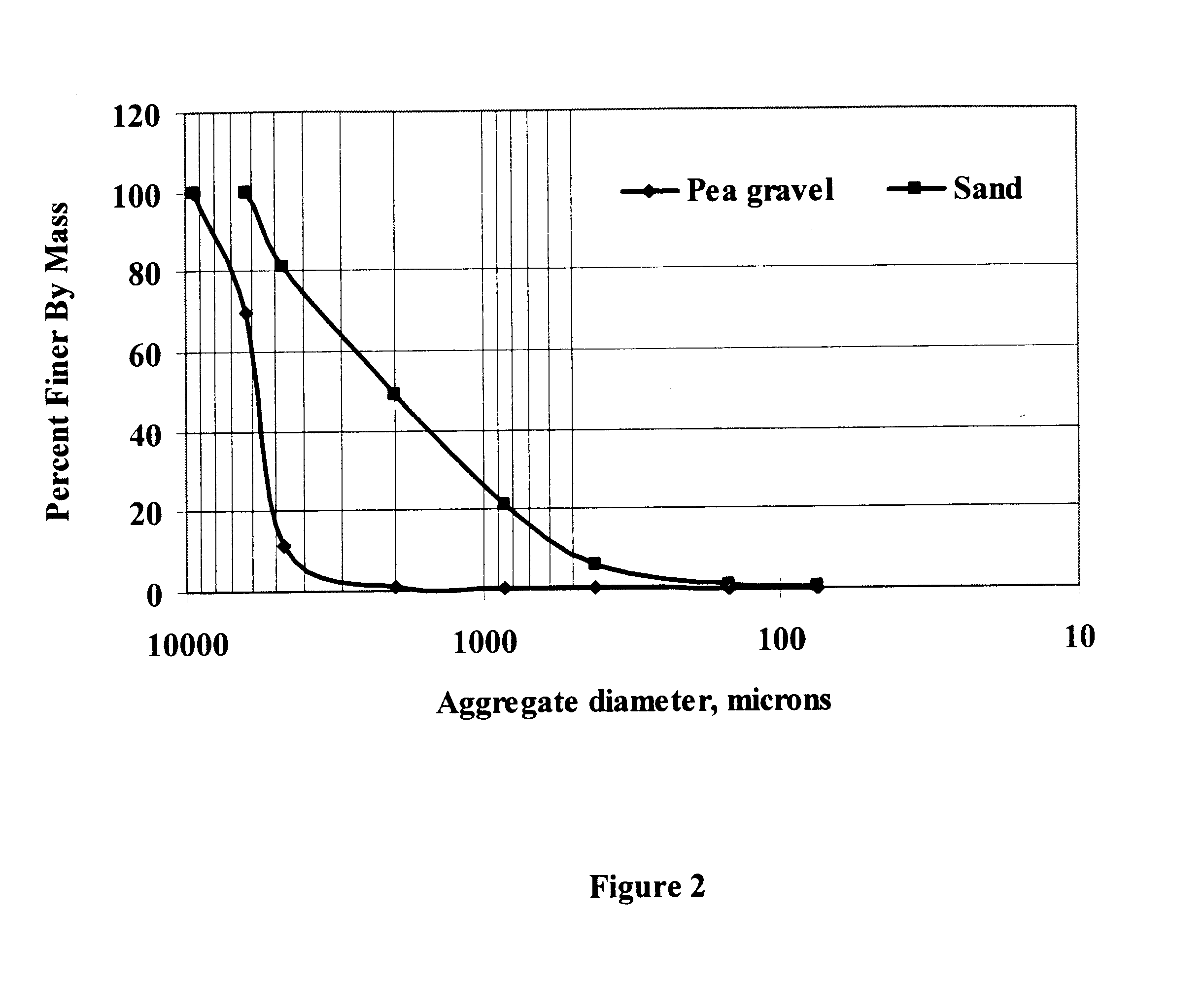

Porous pavement for water quantity and quality management

A pavement material for the capture of waterborne constituents. The pavement material comprises a porous pavement substrate and an amphoteric compound bonded to the substrate. The porous pavement material may have a hydraulic conductivity ranging from about 0.001 to about 1.0 cm / sec and may act as a storm water storage basin.

Owner:UNIT PROCESS TECH

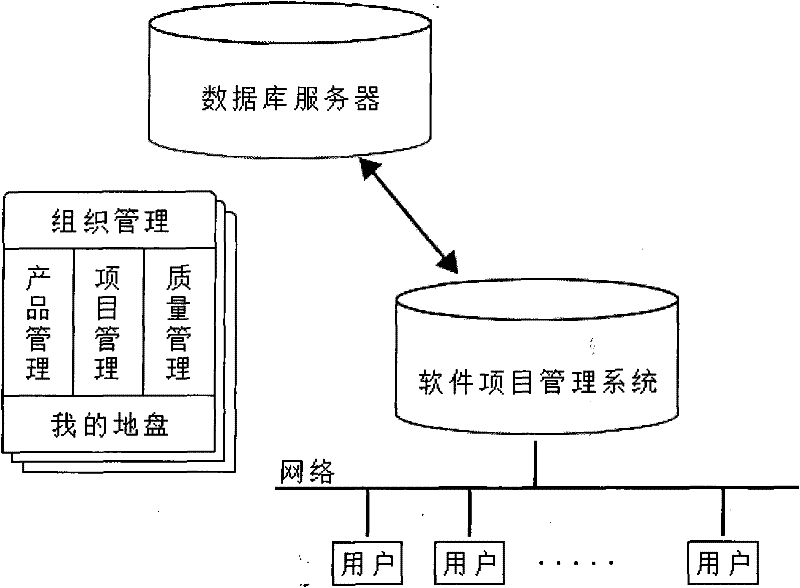

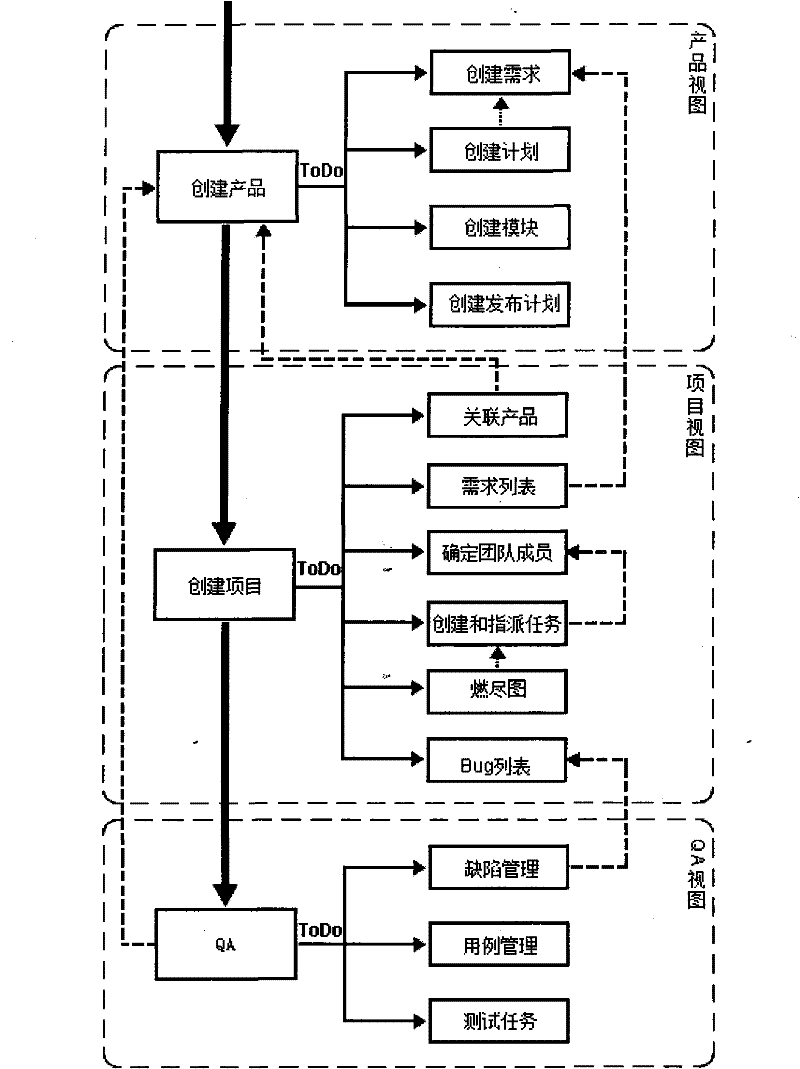

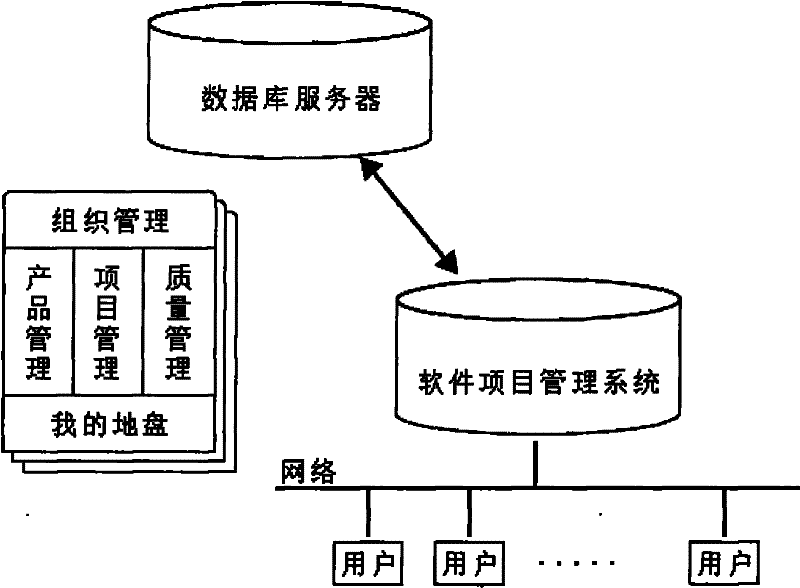

Software project management system

The invention relates to a software project management system used for the control management of the software product developing process. The software project management system comprises a database server, an organization and management module, a product management module, a project management module, a quality management module and a private zone module as well as a terminal equipment. Each module is connected with the database. The user terminal equipment is connected to the software project management system via network. The software project management system provided by the invention is integrated with product management, project management and testing management and also includes a plurality functions like event management, organization, management and the like; and the project developing speed is monitored in time to realize informatization and electronization of the software research and development process management and improve the efficiency and achievement of the project management so that the operation of the project is effectively managed.

Owner:ZHENJIANG HUAYANG INFORMATION TECH

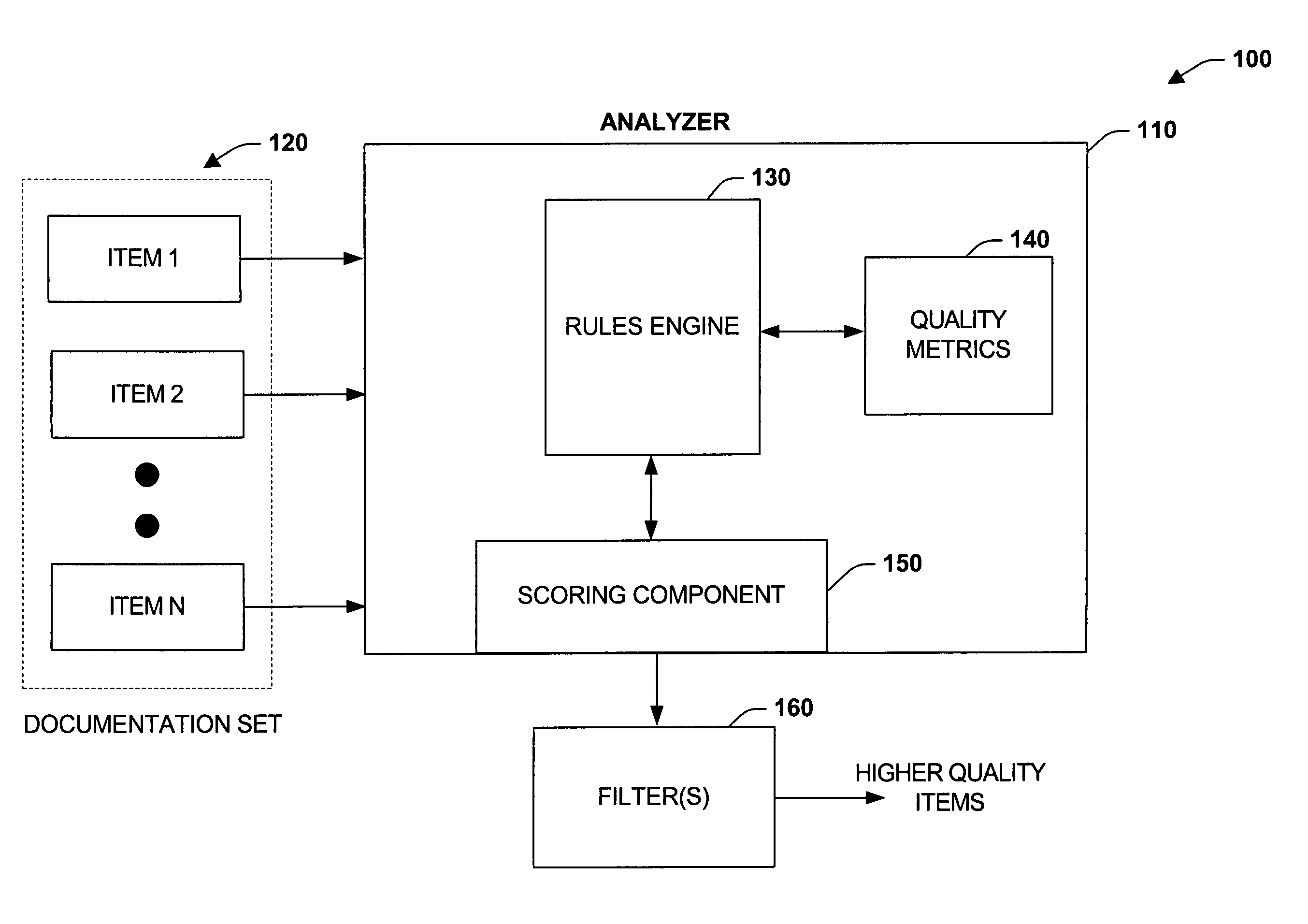

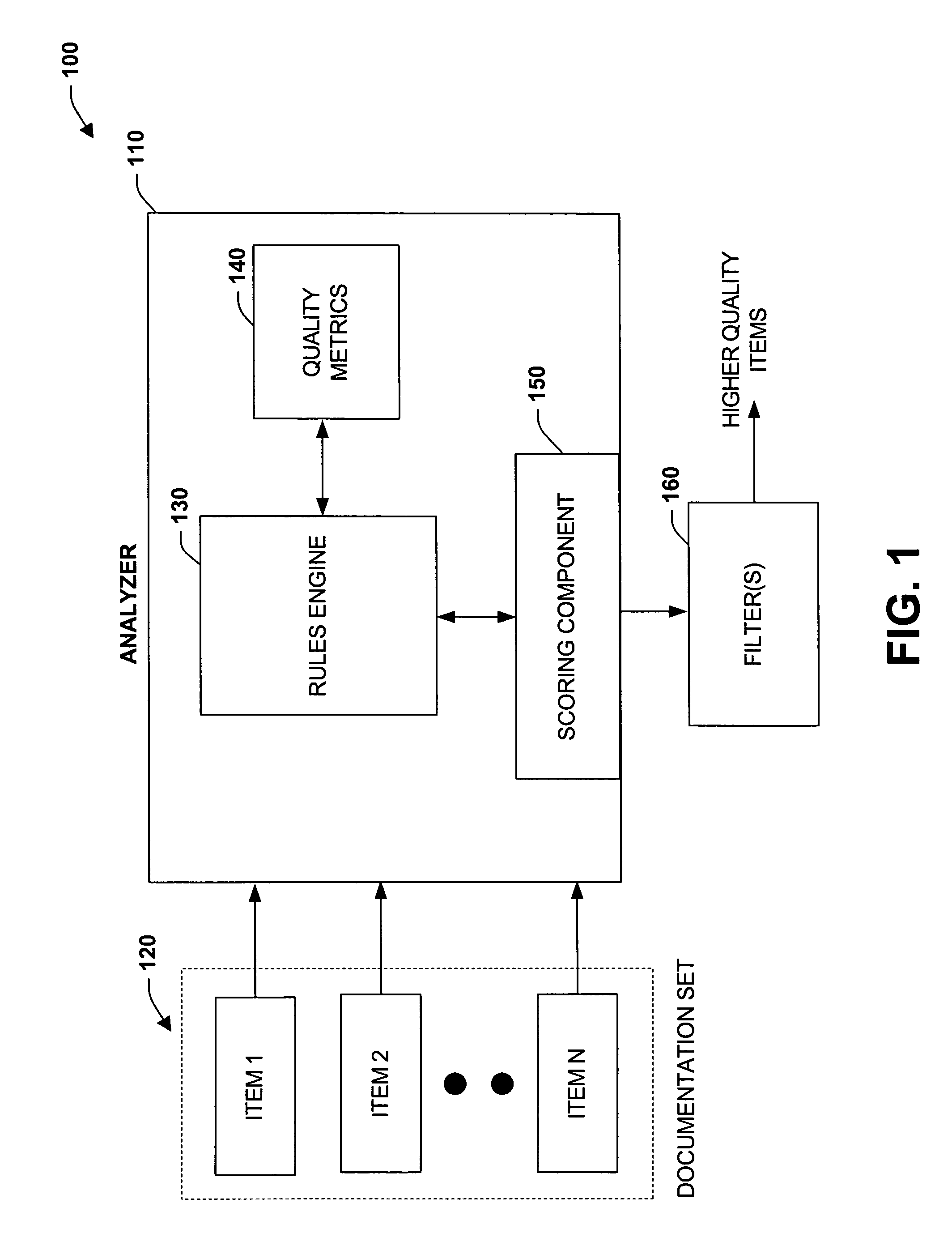

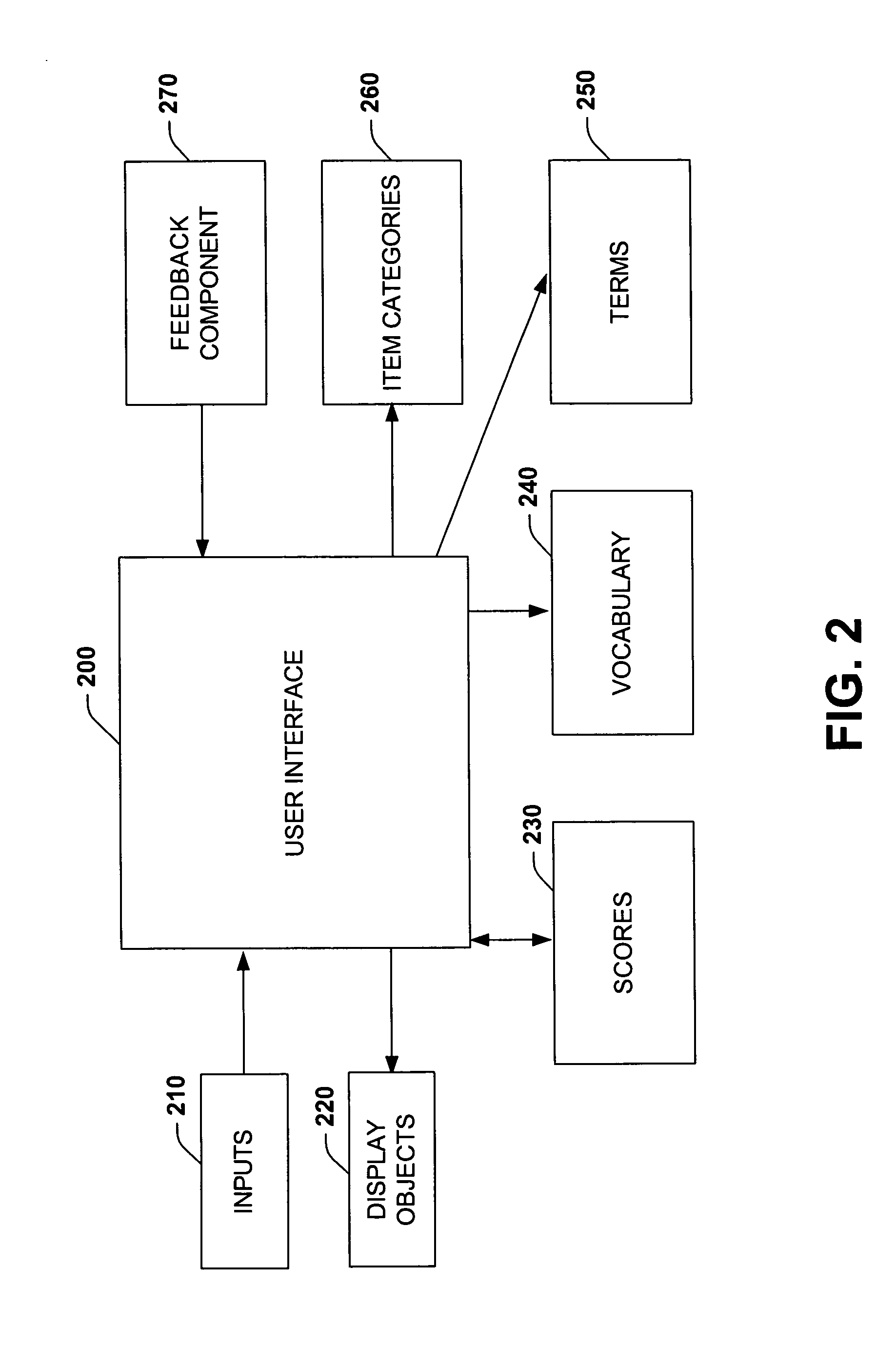

Quality enhancement systems and methods for technical documentation

InactiveUS20050125422A1Quality improvementFacilitate automated and interactive quality controlData processing applicationsNatural language data processingDocumentation procedureSubject matter

The present invention relates to a system and methodology to facilitate automated quality management and controls for one or more items appearing in a documentation set. Respective items are analyzed in accordance with a plurality of quality metrics that can be tracked according to an automated identification process. A system is provided that facilitates quality measurements of data and / or documents appearing in a documentation set, collection or database. A quality component tracks one or more quality metrics associated with the items, wherein the items can include topics, subtopics, or other categories. A rules engine automatically applies the quality metrics to the items to facilitate interactive quality assessments of the items, wherein a scoring component automatically ranks the items based at least in part on the interactive quality assessments of the items.

Owner:MICROSOFT TECH LICENSING LLC

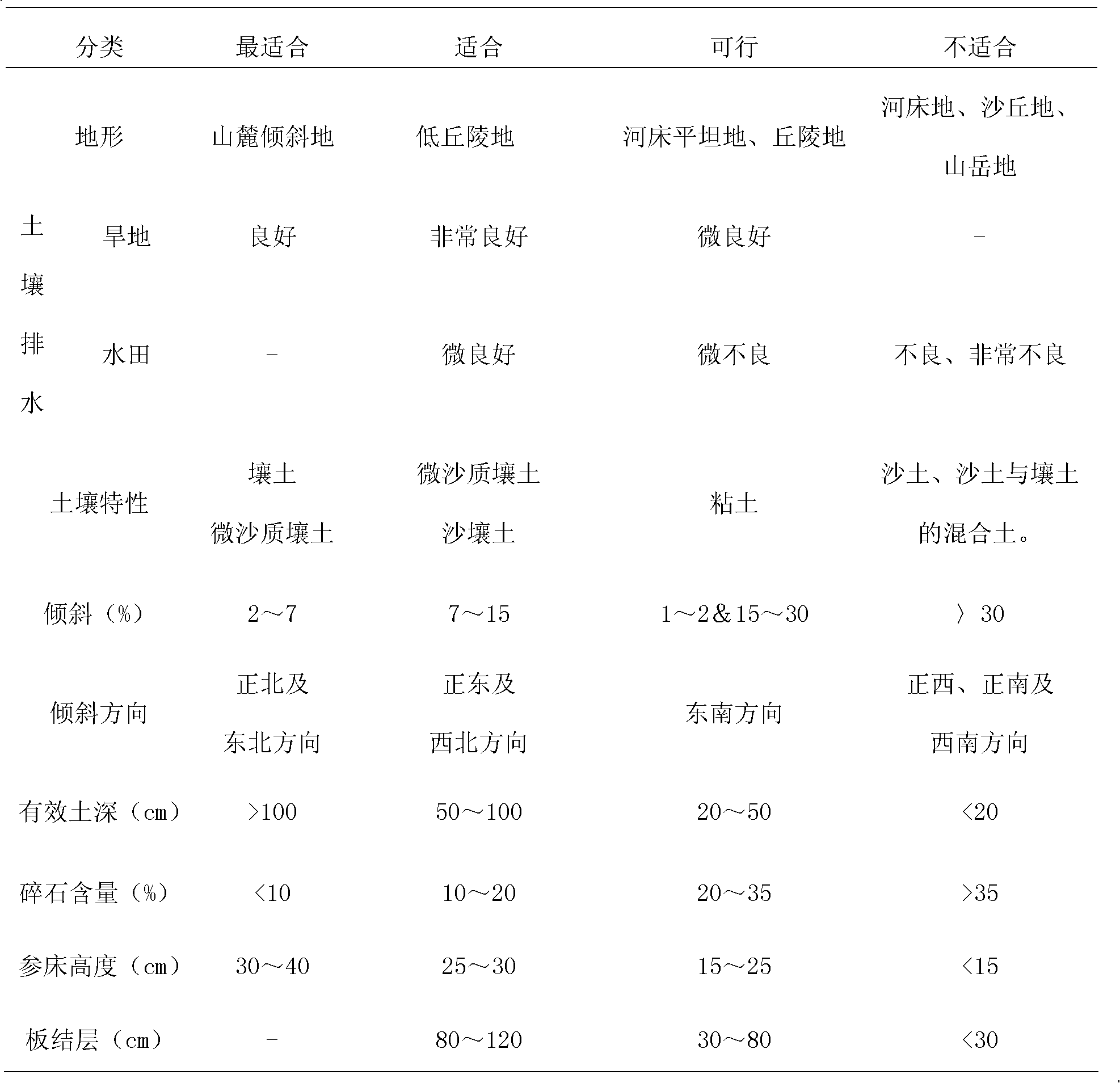

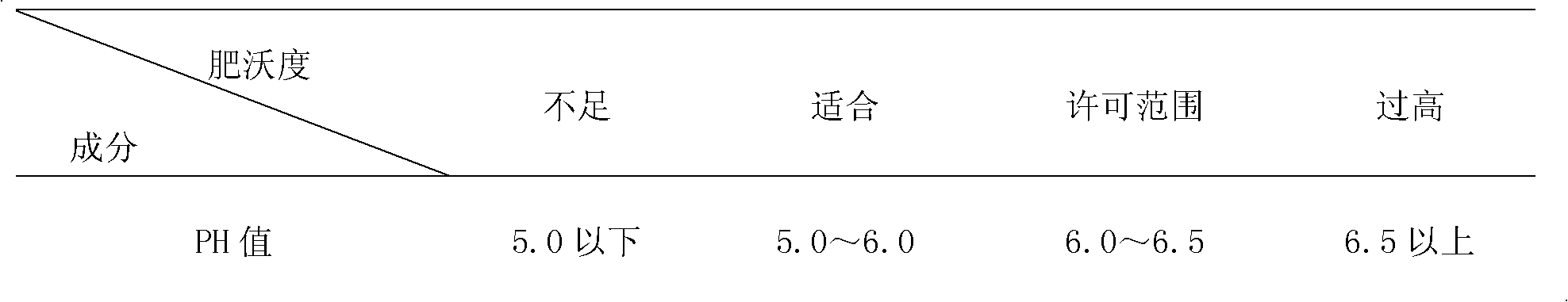

Standard planting method of non-forest ginseng

InactiveCN102138427ASolve pesticide residuesSolve the problem of excessive heavy metal contentHorticultureEcological environmentPesticide residue

The invention relates to a planting method of Chinese medicine, namely a standard planting method of non-forest ginseng. The method comprises the following steps: (1) land selection; (2) soil improvement; (3) selection of ginseng seeds and germination treatment; (4) making a soil bed; (5) seeding; (6) erecting a frame; (7) collecting seedlings; and (8) transplanting the seedlings and the like. The planted ginseng is transferred from a wild mountainous region to a non-forest flat land; and all links from land selection, soil detection and soil improvement to the selective application of a fertilizer of the improved soil, the application of the key technology of each production link, the ginseng preparation and the like comfort to the Chinese medicine GAP (good agricultural practice) production and quality management standard and standard production operation procedure, and the production and quality safety of the non-forest ginseng is guaranteed; and the technology not only can effectively protect the ecological environment and powerfully improve the land utilization rate, but also can solve the problems of pesticide residue and super-standard heavy metal content in the traditional ginseng planting process, thereby ensuring the quality of the ginseng raw medicine product.

Owner:吉林省集安益盛药业股份有限公司

Advanced quality management and recording solutions for walk-in environments

ActiveUS7728870B2Rapid positioningEliminate ambient noiseTelevision system detailsColor television detailsDatabaseQuality management

A system and method for capturing, logging and retrieval of face-to-face interactions characterizing walk-in environments. The system comprising a device for capturing and storing one or more face to face interactions captured in the presence of the parties to the interaction, and a database for storing data and metadata information associated with the face-to-face interactions captured.

Owner:NICE LTD

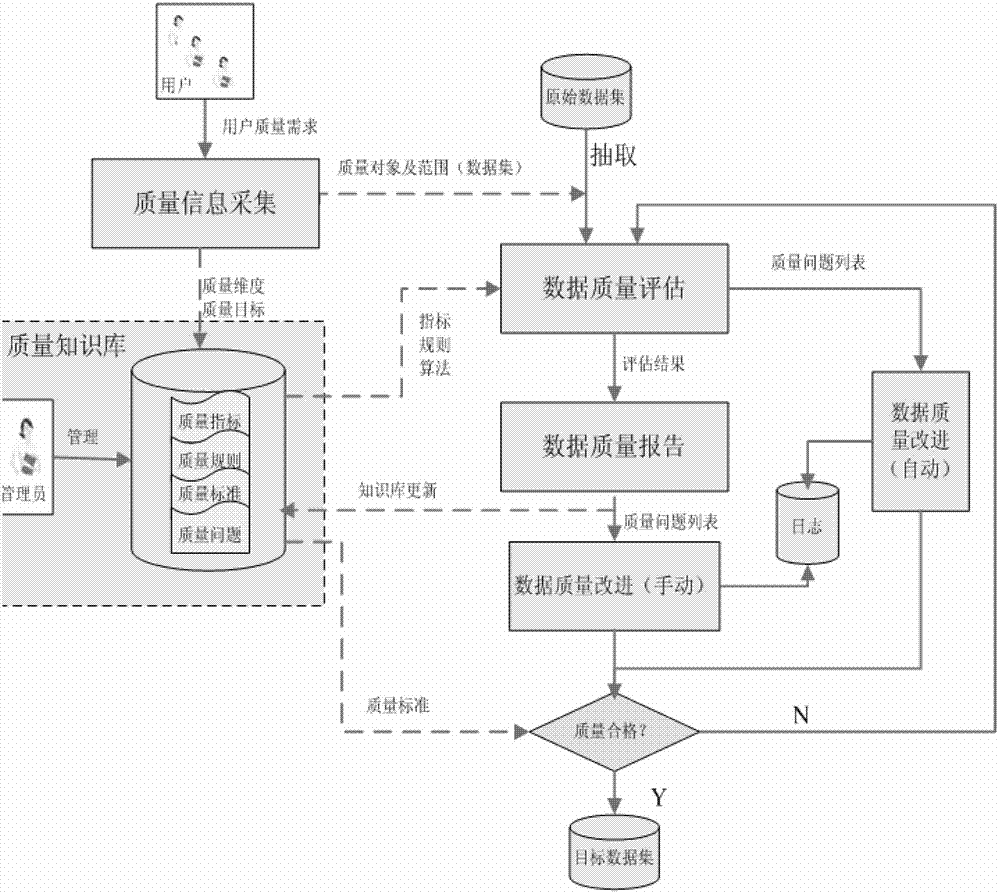

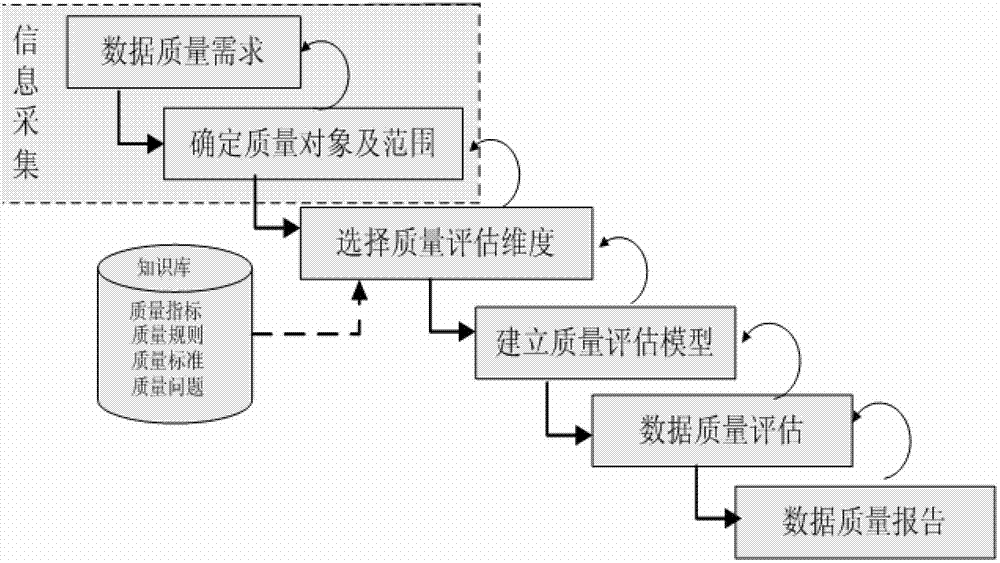

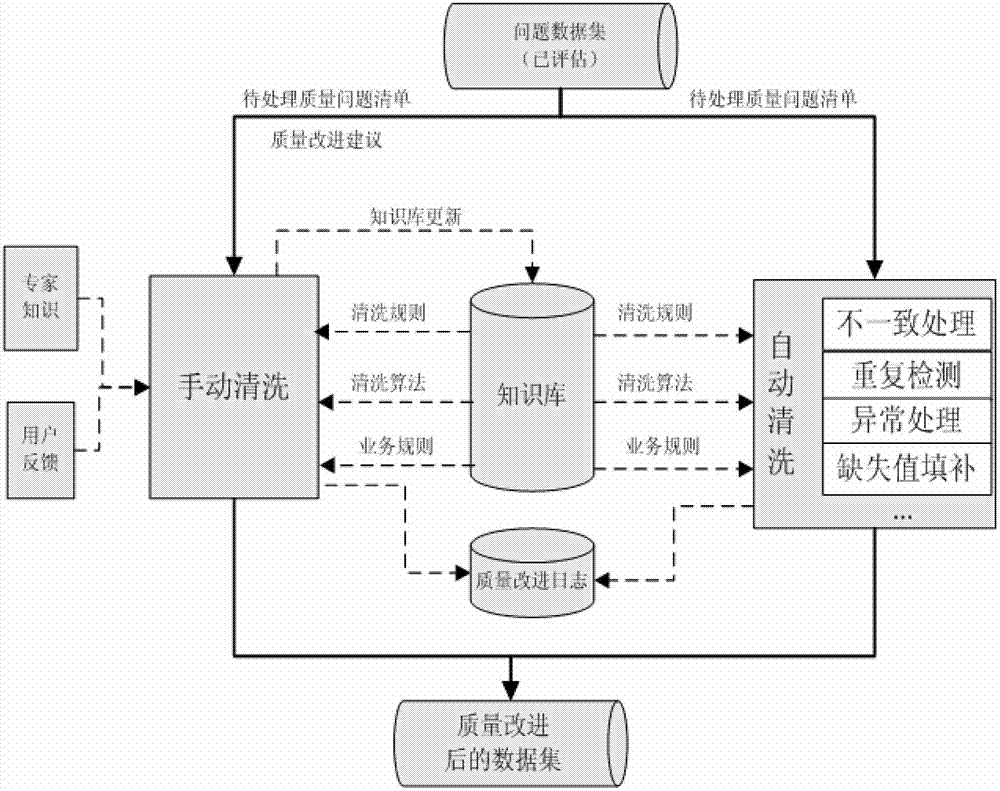

Data quality management method and system

The invention discloses a data quality management method and a data quality management system. The data quality management method comprises the following steps: managing a quality knowledge library; analyzing the data quality characteristics, and presetting a quality problem domain, a quality dimension domain, a quality rule domain and a quality standard domain; collecting quality information: selecting the quality dimension and the quality rules required by a user from the quality knowledge library, and extracting a data set meeting the user requirements from the original data sets; evaluating the data quality: evaluating the data quality according to the collected quality information, and generating and submitting a data quality report to the user or a quality manager according to the quality problem domain and the quality standard domain in the quality knowledge library; and improving the data quality: correcting the data quality problem detected in the evaluation of the data quality for improvement. The data quality management method and the data quality management system are applied to monitoring, evaluating and continuously improving the data quality in the whole hydrology industry based on the whole data processing procedure of the hydrology industry.

Owner:HOHAI UNIV

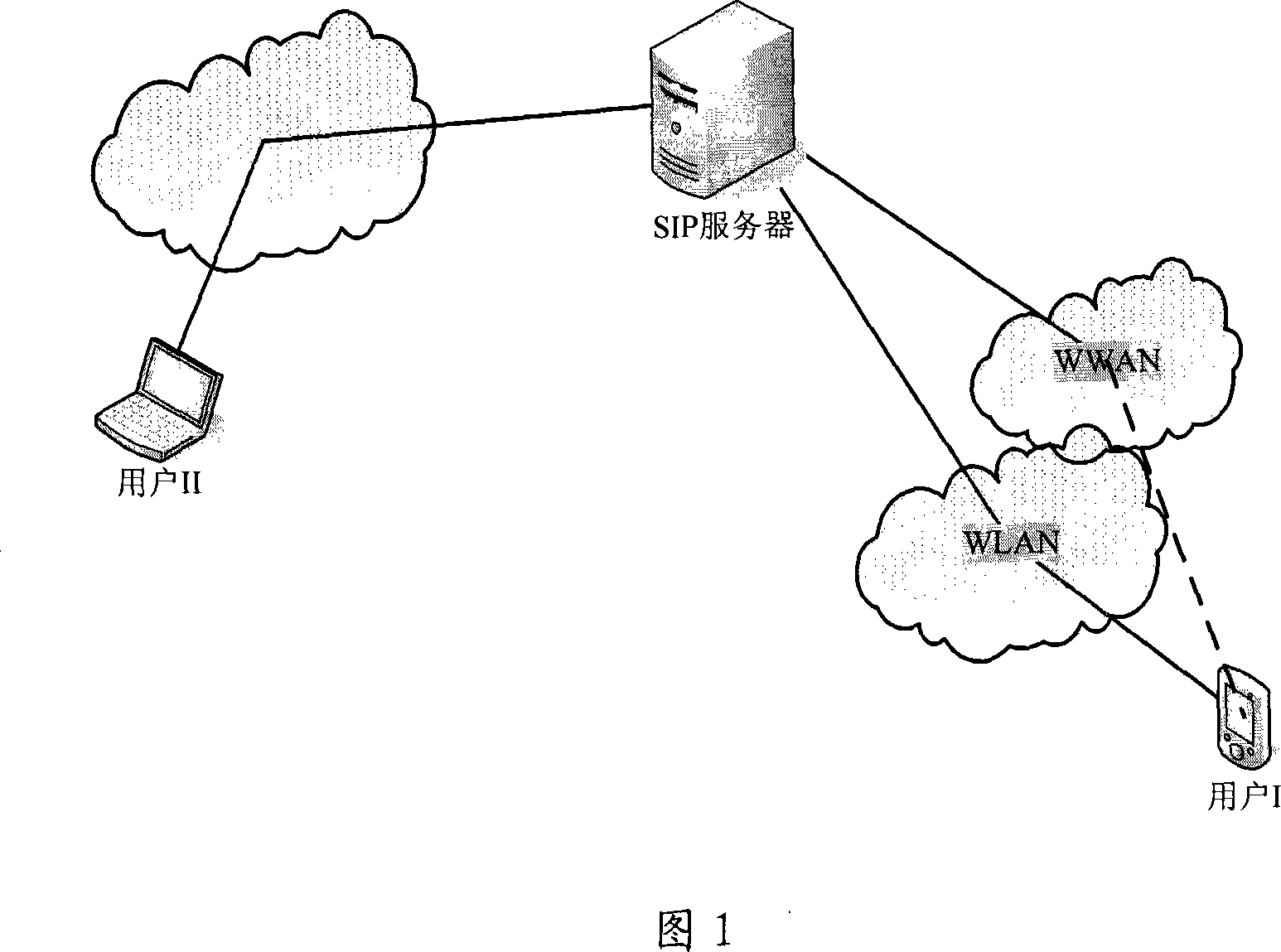

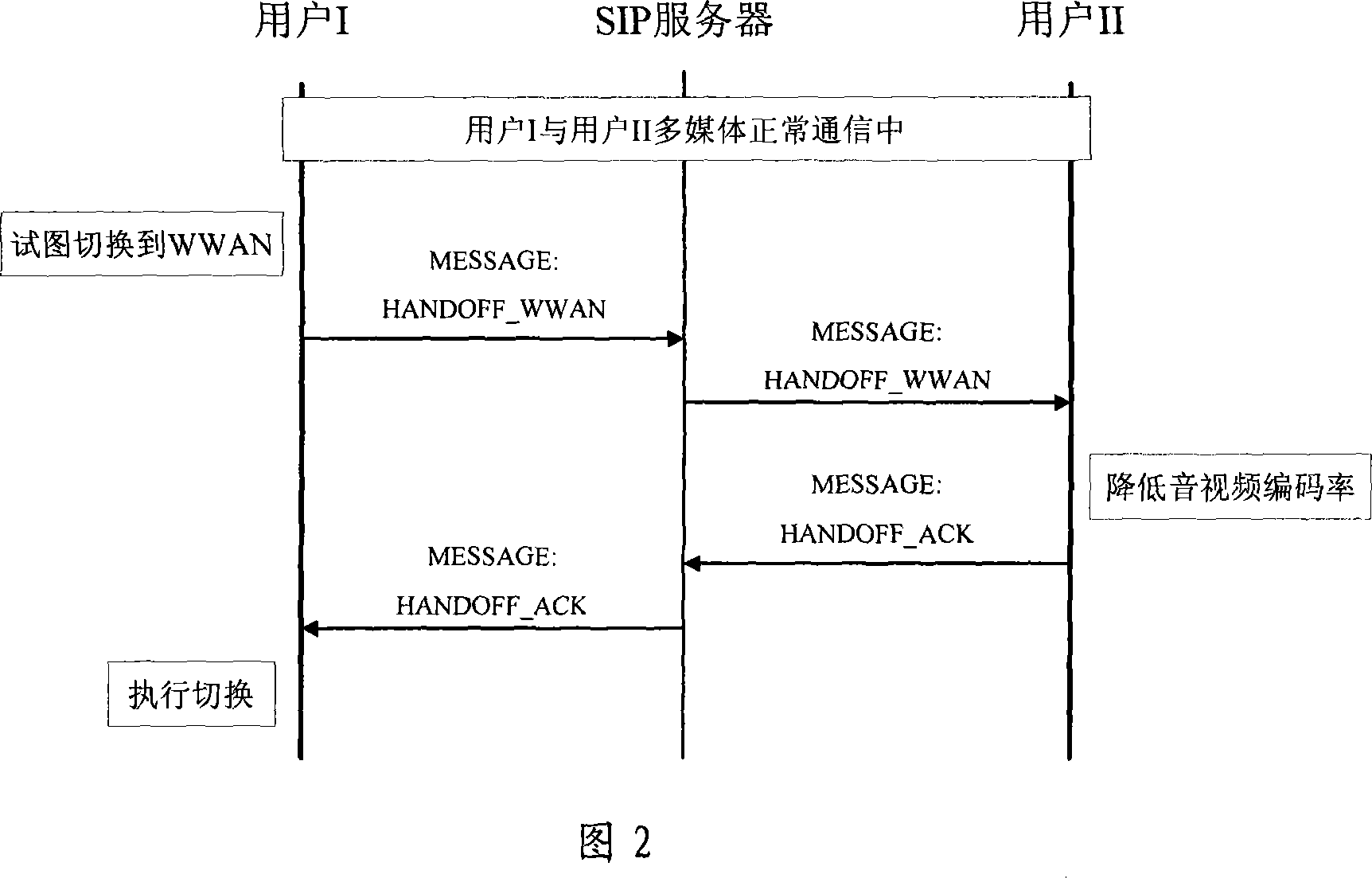

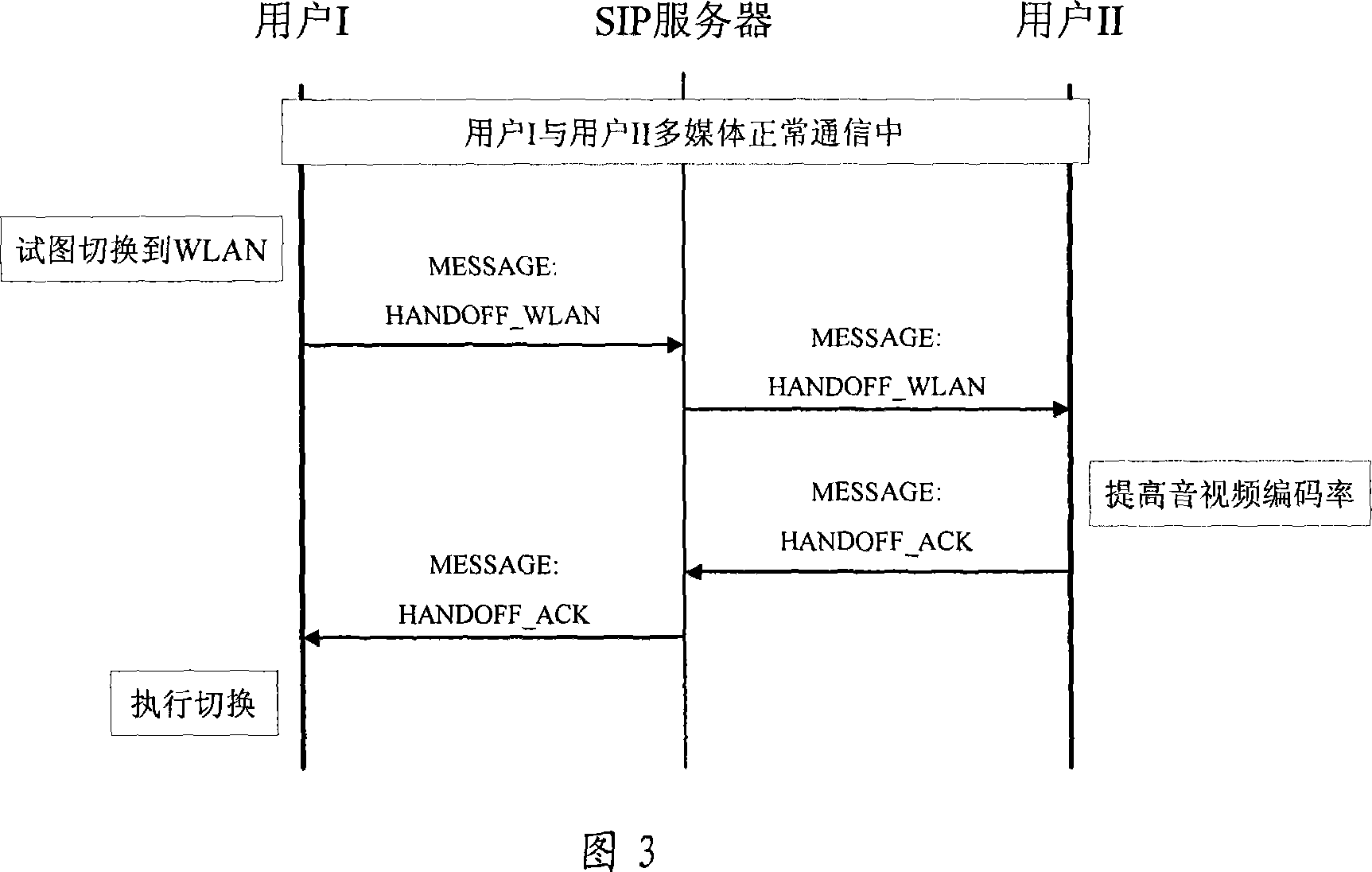

Multimedia session service quality management method under multiple radio network integrated environment

InactiveCN101035365ACommunication service quality impactJudgment method is accurateError preventionNetwork traffic/resource managementQuality of serviceNetwork Convergence

This invention relates to a variety of quality management methods of multimedia conversational service in wireless network convergence environment. It includes: user II sends a one-way multimedia sessions to user I, when user I decides to switch his terminal, he must do the following steps: A1) user I will judge the type of the target network when switching happens; A2) user I sent a switch signal to the user II, the switch signal records the type of the target network; A3) users II receives the switch signal which is sent in the steps A2) by users I, and then adjusts the local audio / video encoding rate according to the type of the target network in the switch signal; A4) after the step A3), user II sends a switch confirmed signal back to the user I; A5) user I waits for the switch confirmed signal of user II after the steps A2), when It receives the switch confirmed signal, implement of switching immediately. The invention can improve service quality of multimedia communication effectively.

Owner:SHANGHAI YINGLIAN SOMATOSENSORY INTELLIGENT TECH CO LTD

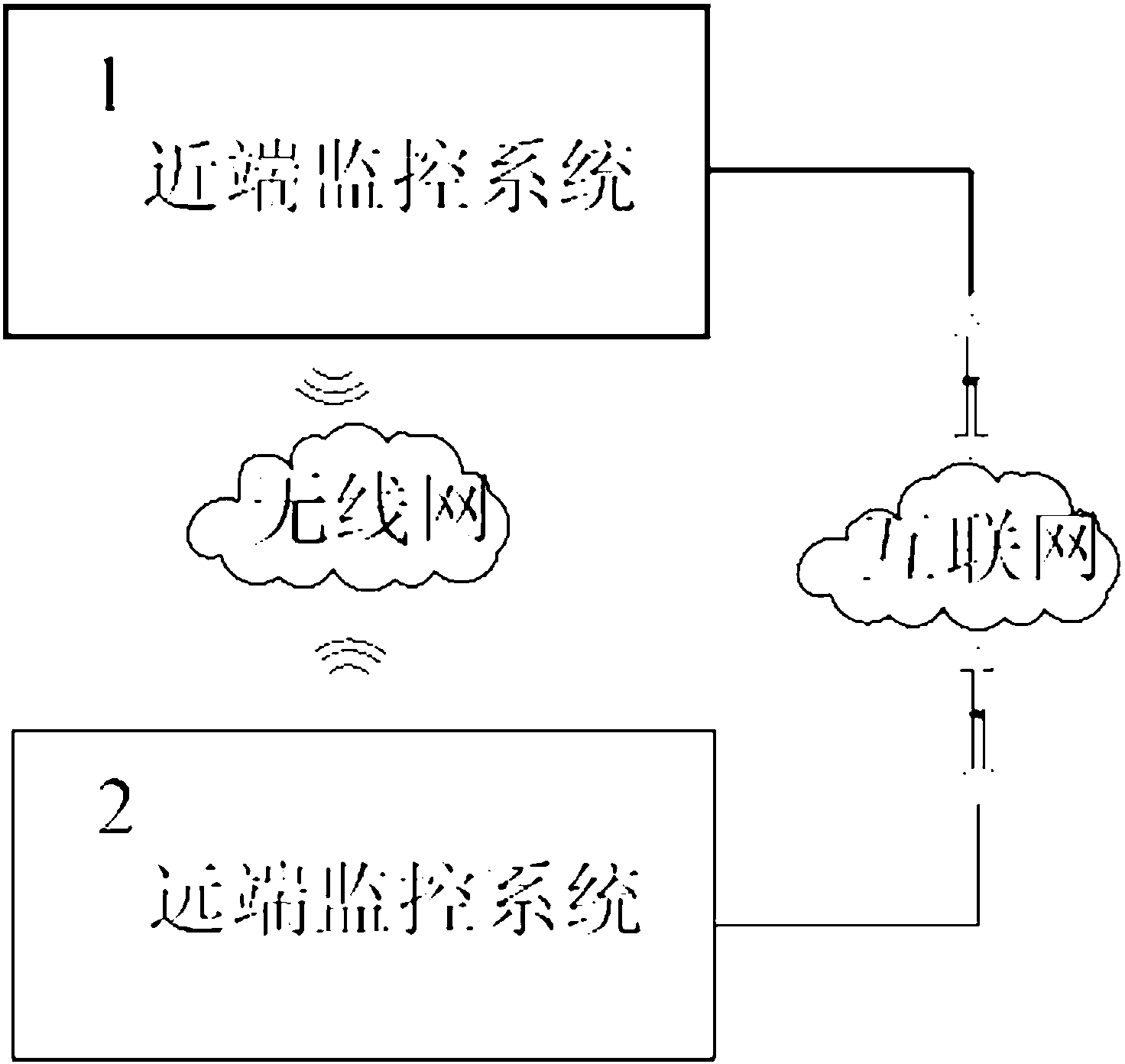

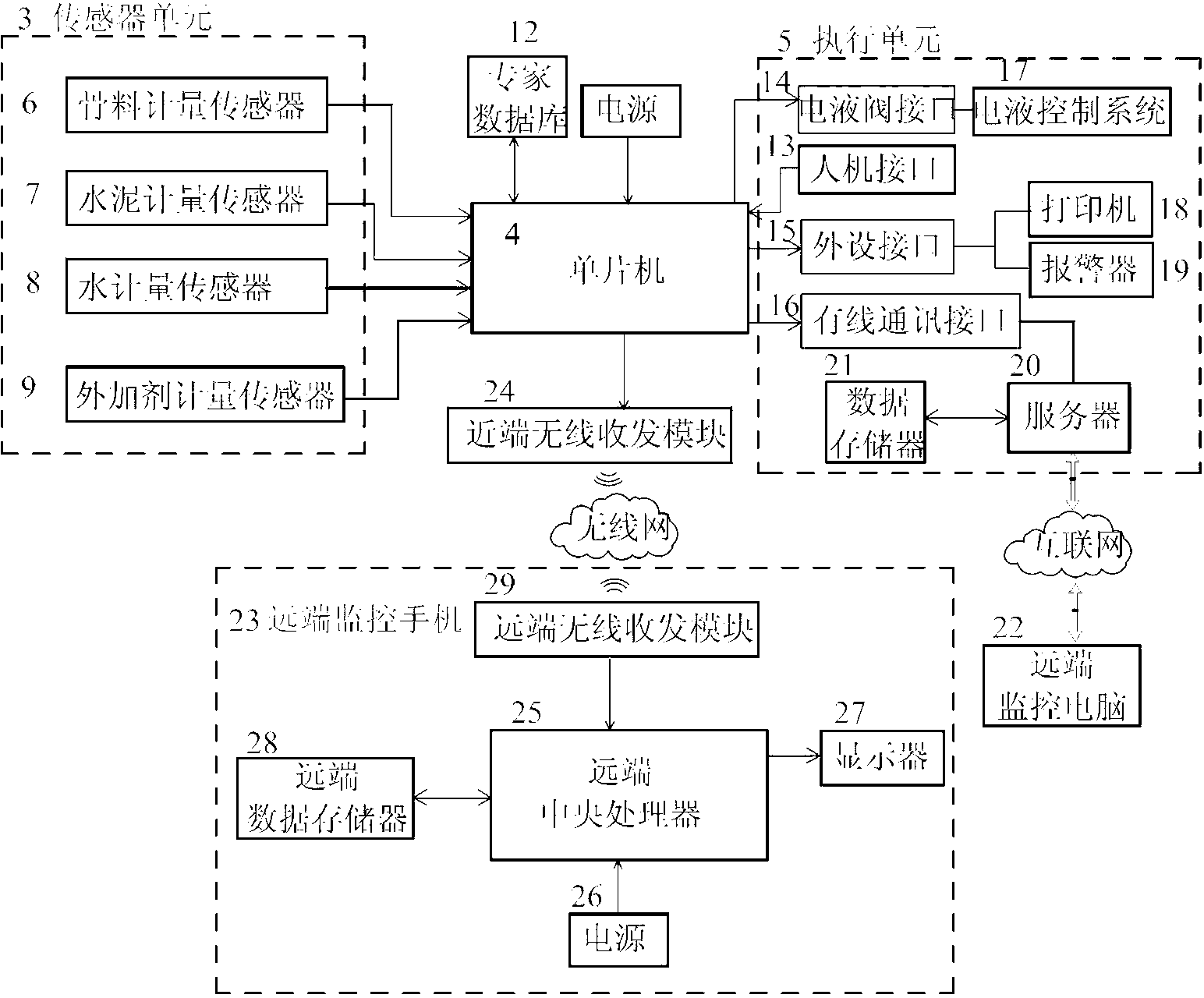

Dynamic quality remote monitoring system and method in production of cement concrete

ActiveCN103324177ARealize real-time detectionImprove product qualityTotal factory controlProgramme total factory controlElectronic documentWireless transmission

The invention discloses a dynamic quality remote monitoring system and method in the production of cement concrete. The remote monitoring system comprises a near-end monitoring system arranged at a cement concrete stirring station and a far-end monitoring system far away from the cement concrete stirring station, and the near-end monitoring system communicated with the far-end monitoring system through a wireless net and the internet. The dynamic quality remote monitoring system and method in the production of the cement concrete can realize real-time monitoring, on-site displaying, remote wireless transmission and remote monitoring of main parameters in the production of the cement concrete, and can transmit the parameters to a specified information platform to be stored as electronic documents, and any authorized department or person can know the data in real time through a remote monitoring mobile phone and a remote monitoring computer. Therefore, the production quality of the cement concrete is improved at the source, the unqualified cement concrete and the loss caused by the unqualified cement concrete are avoided, the detection efficiency can be improved, the work intensity of on-site management work is relieved for the quality management department, and real-time remote monitoring of engineering quality in the construction process is achieved.

Owner:湖州南浔双鑫建设发展有限公司

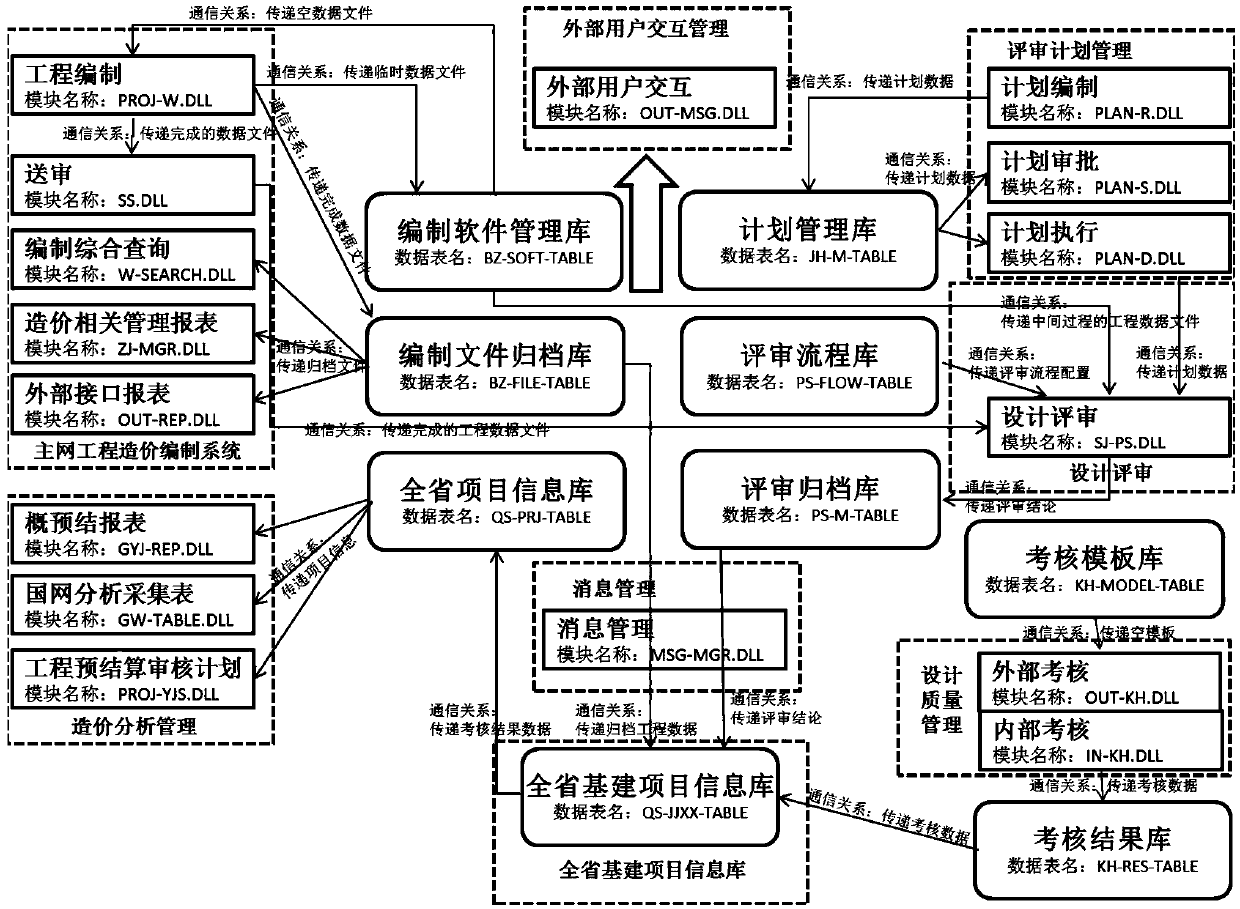

Electric power engineering design review and technical economic evaluation information system

InactiveCN105373885AImprove the level of intensive managementImprove Design ReviewsResourcesInformation repositoryEconomic management

The invention discloses an electric power engineering design review and technical economic evaluation information system. The electric power engineering design review and technical economic evaluation information system comprises a project review plan management module, a project review module, a province infrastructure project information database construction module, a design quality management module, an external user interaction management module, a main network engineering cost compilation system module, a cost analysis management module and a message management module. The system integrates demands of actual engineering project design review and technical economic management works, makes engineering project design review and technical economic management works have great improvement in standardization, unification, normalization and refinement, greatly improves an intensive management level, effectively and practically improves efficiency of engineering project design review and technical economic management works and brings about substantial economic and social benefits.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com