Patents

Literature

140 results about "Order scheduling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A scheduling order is a pretrial order that governs the progress of a case as it proceeds toward a trial. A scheduling order provides deadlines for taking depositions, conducting written discovery, identifying and deposing expert witnesses, filing certain types of motions, and other deadlines appropriate to the case. It may also set a trial date.

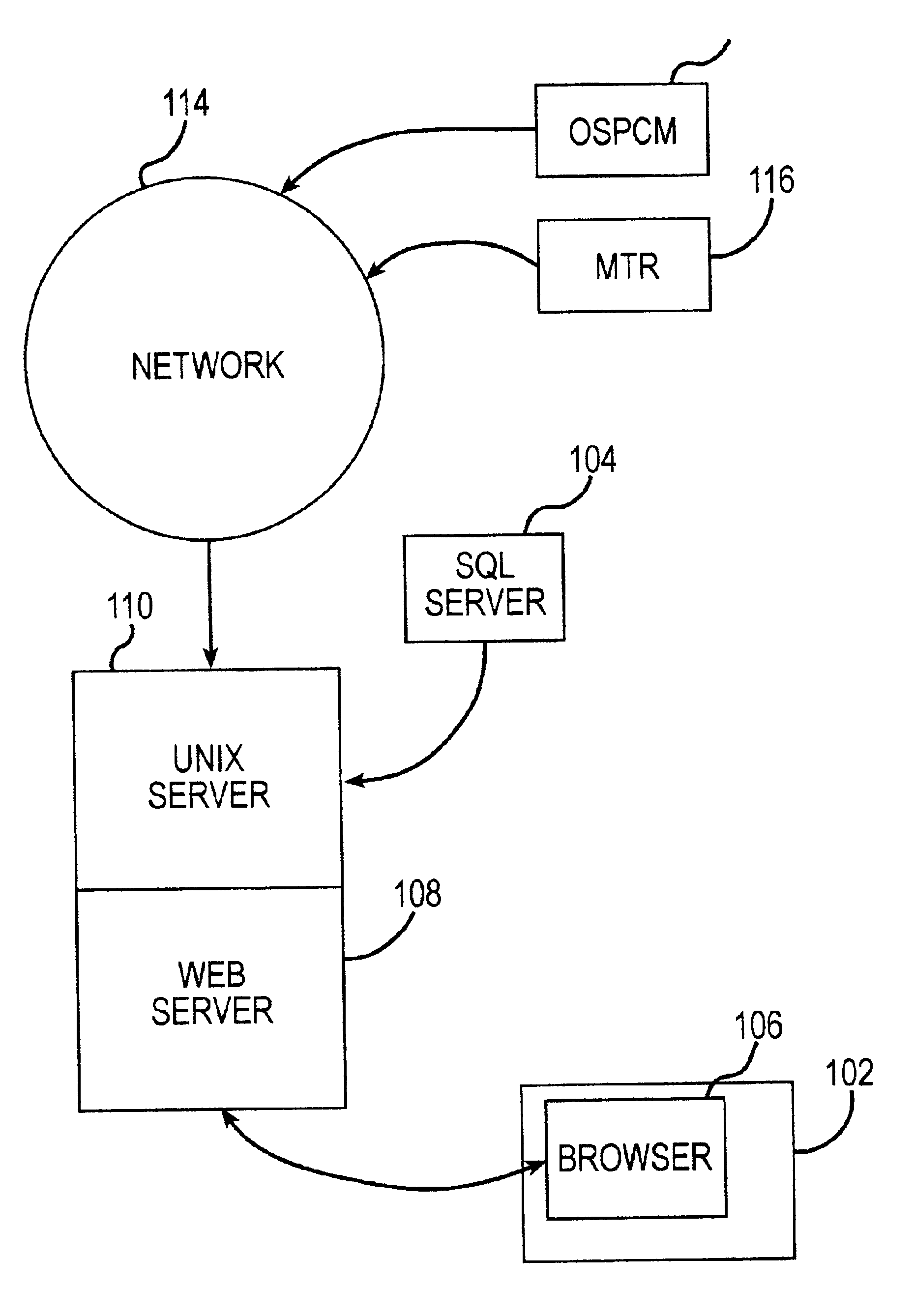

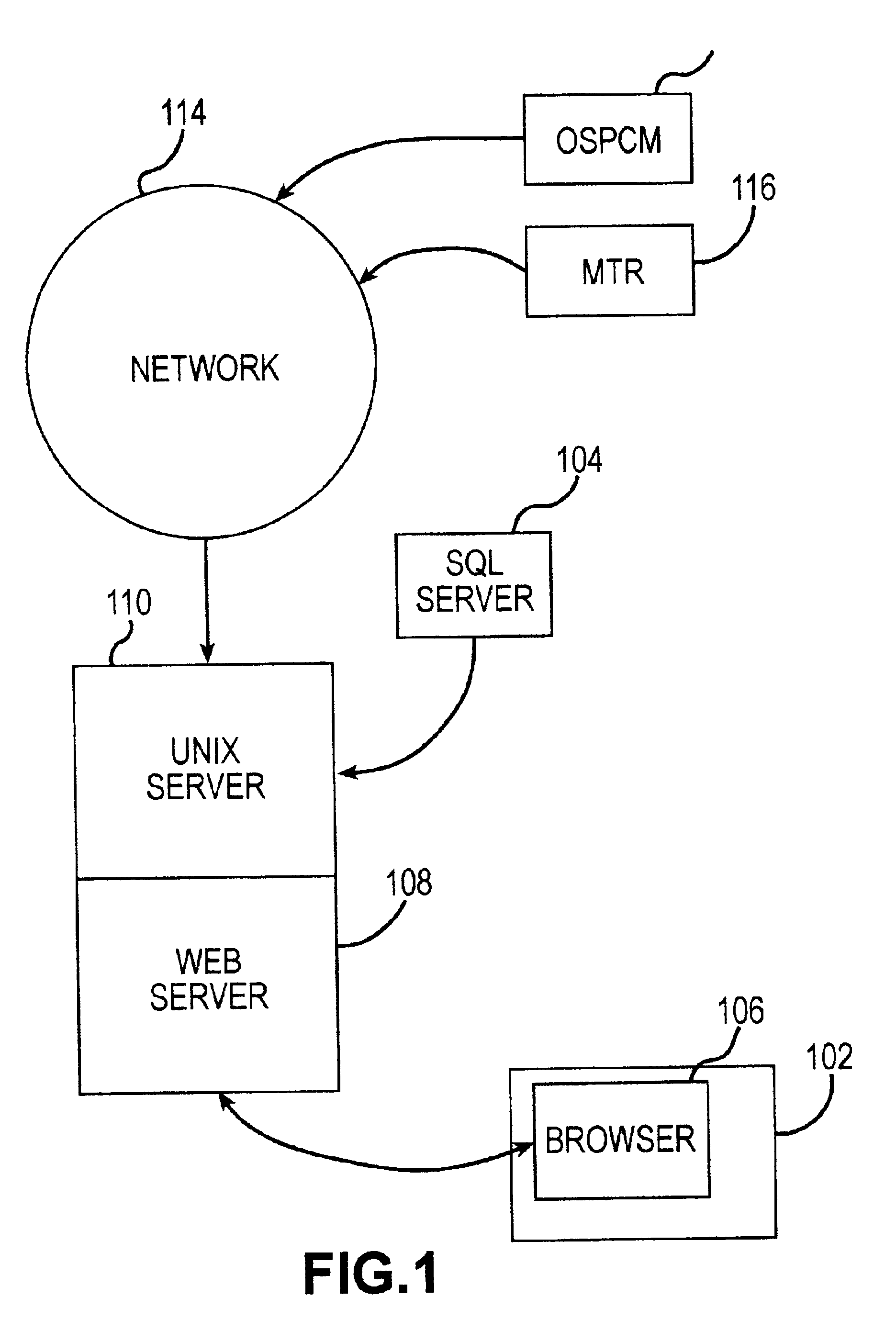

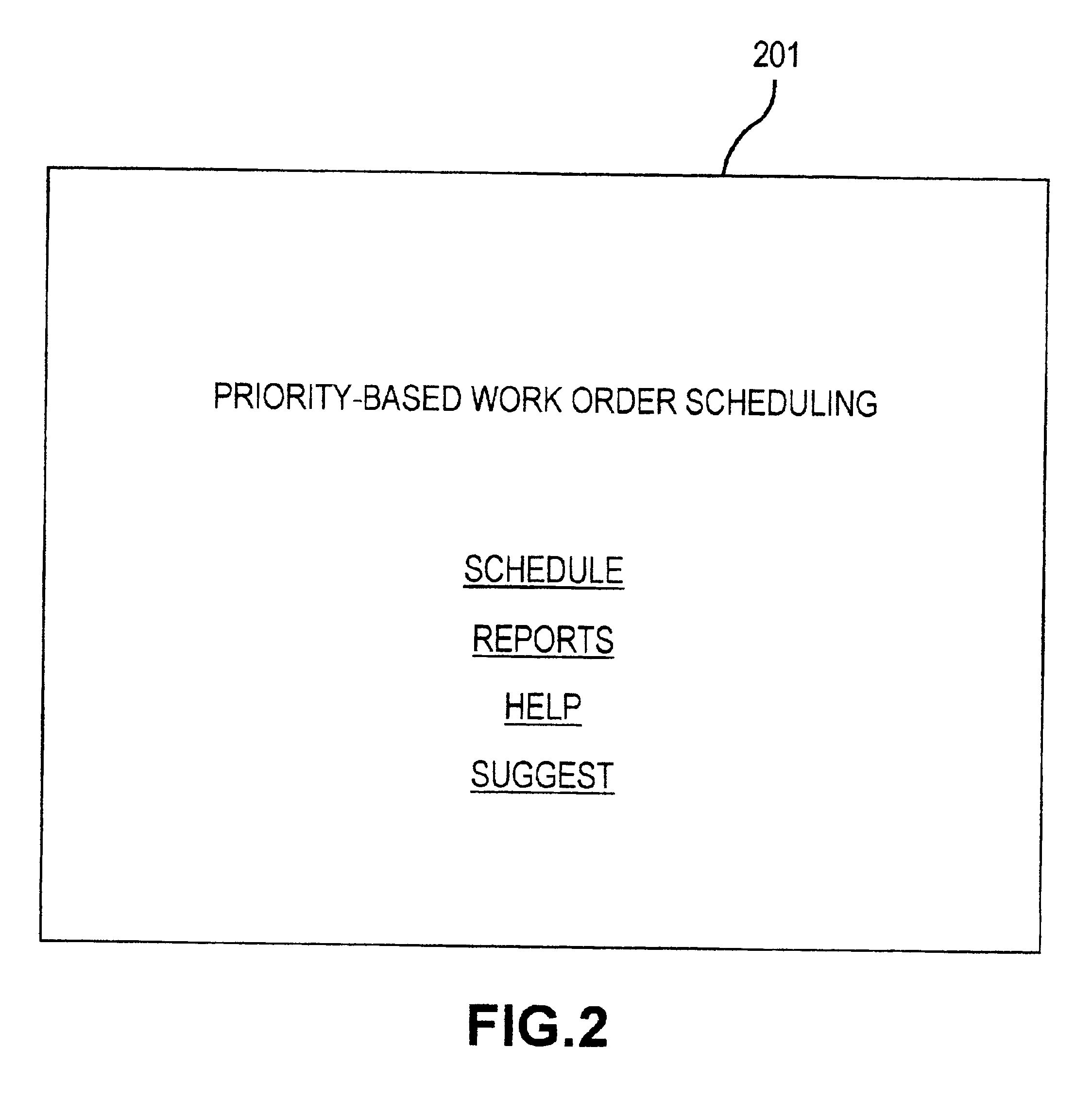

System and method for priority-based work order scheduling

InactiveUS6941514B2Convenient formatRegistering/indicating time of eventsDigital data processing detailsGraphicsGraphical user interface

A priority-based work order scheduling system includes a graphical user interface having displays for managing work orders stored in the system. Work orders are entered into the system via a work order entry computer. A time estimate for completing the work order is determined. Work order data associated with the work order is stored along with the time estimate to complete the work order in a database management system. A priority is assigned to the work order and stored in the database management system. Operationally, the scheduling system is used during scheduling meeting to assist in making scheduling determinations, and for updating work order data stored in the database management system. Work order data can be updated by engineers having authority to perform the updates outside of a scheduling meeting.

Owner:BELLSOUTH INTPROP COR

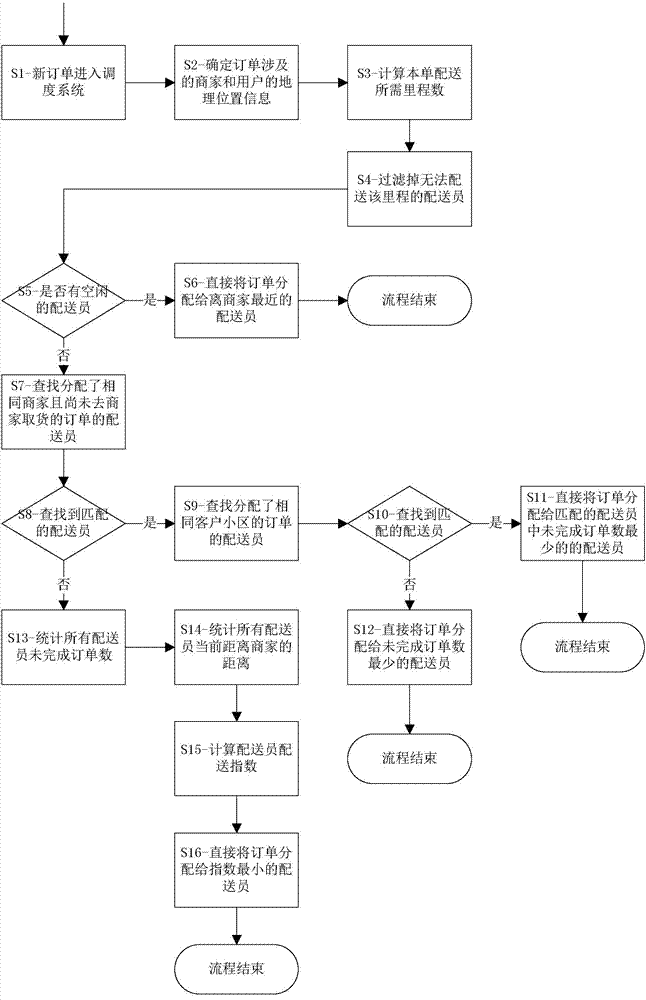

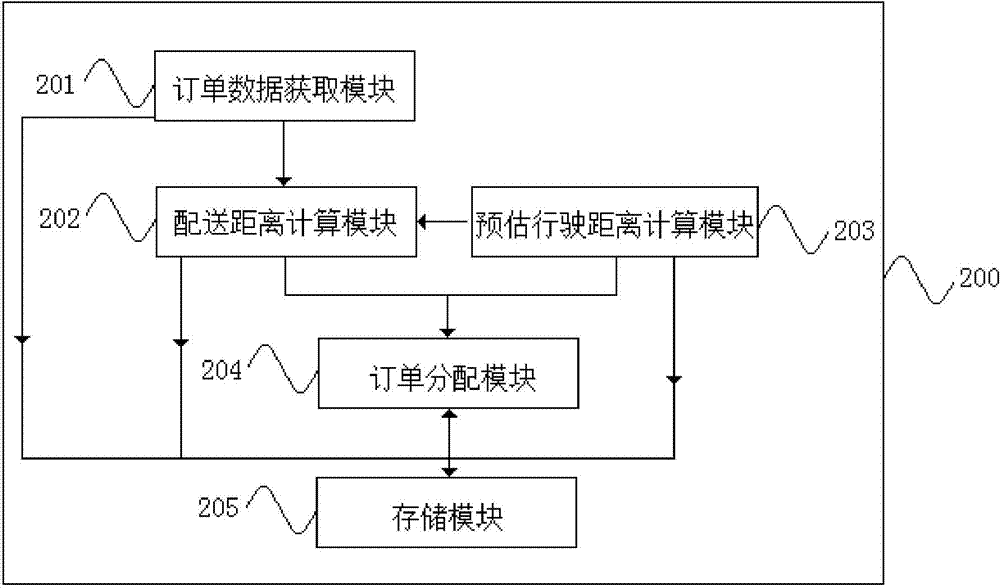

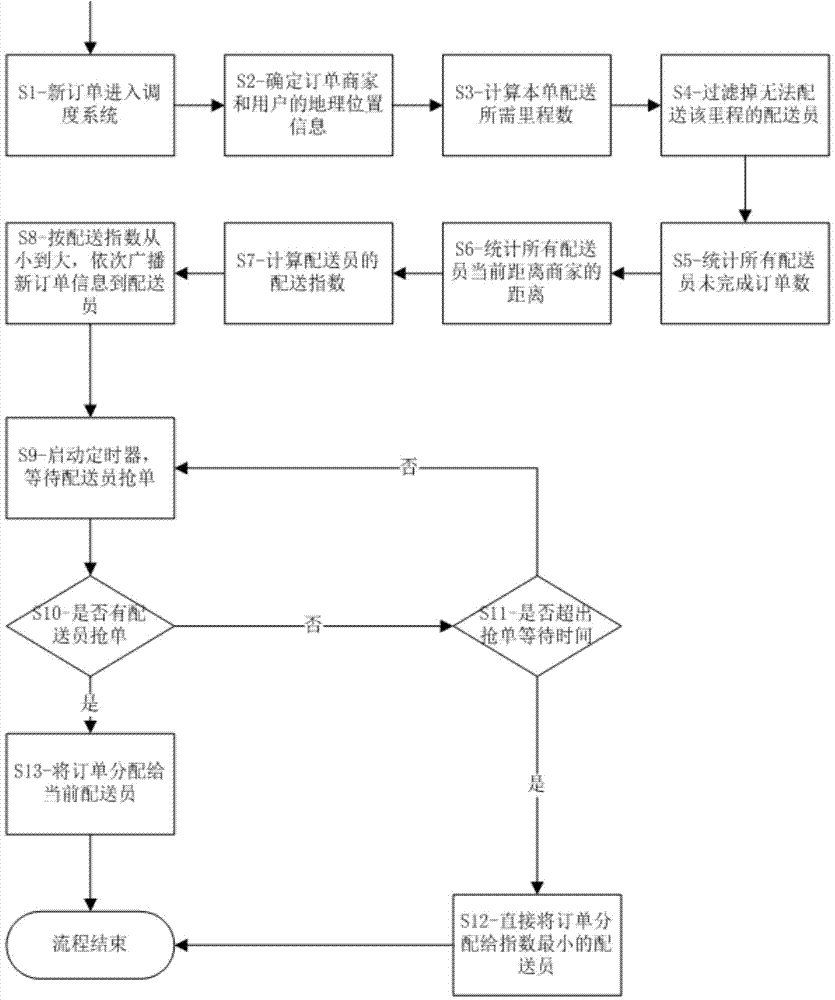

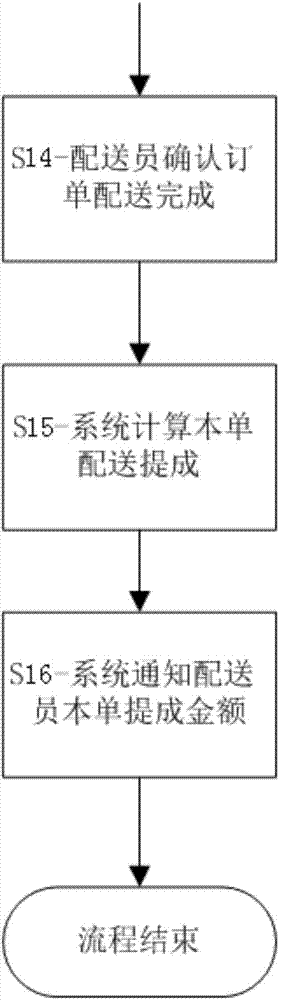

Intelligent order scheduling method and server, electric vehicle, mobile terminal and system

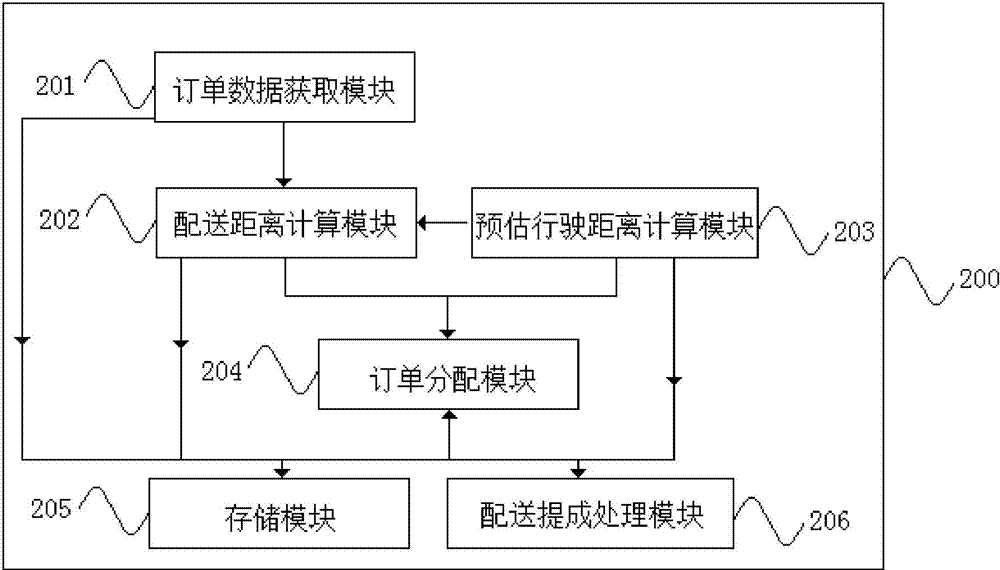

InactiveCN104751272AImplement schedulingReduce waiting timeResourcesLogisticsShortest distanceOrder scheduling

The invention discloses an intelligent order scheduling method. The intelligent order scheduling method comprises the following steps: obtaining a new order; obtaining geographic positions of a user and a merchant according to information in the new order; calculating a distribution distance between the geographic position of the user and the geographic position of the merchant according to the geographic position of the user and the geographic position of the merchant; monitoring electric vehicle data uploaded by a distribution worker electric vehicle monitoring system, and calculating a pre-estimated driving distance of an electric vehicle of each distribution worker; and carrying out intelligent distribution of the order according to the data. The invention further provides an intelligent order scheduling server, the electric vehicle applied to the intelligent order scheduling method, a mobile terminal applied to the intelligent order scheduling method, and a system applied to the intelligent order scheduling method. By the aid of the intelligent order scheduling method and server, the electric vehicle, the mobile terminal and the system, the short-distance and in-time distribution can be efficiently finished.

Owner:JINGYUAN SHANGHAI INFORMATION TECH CO LTD

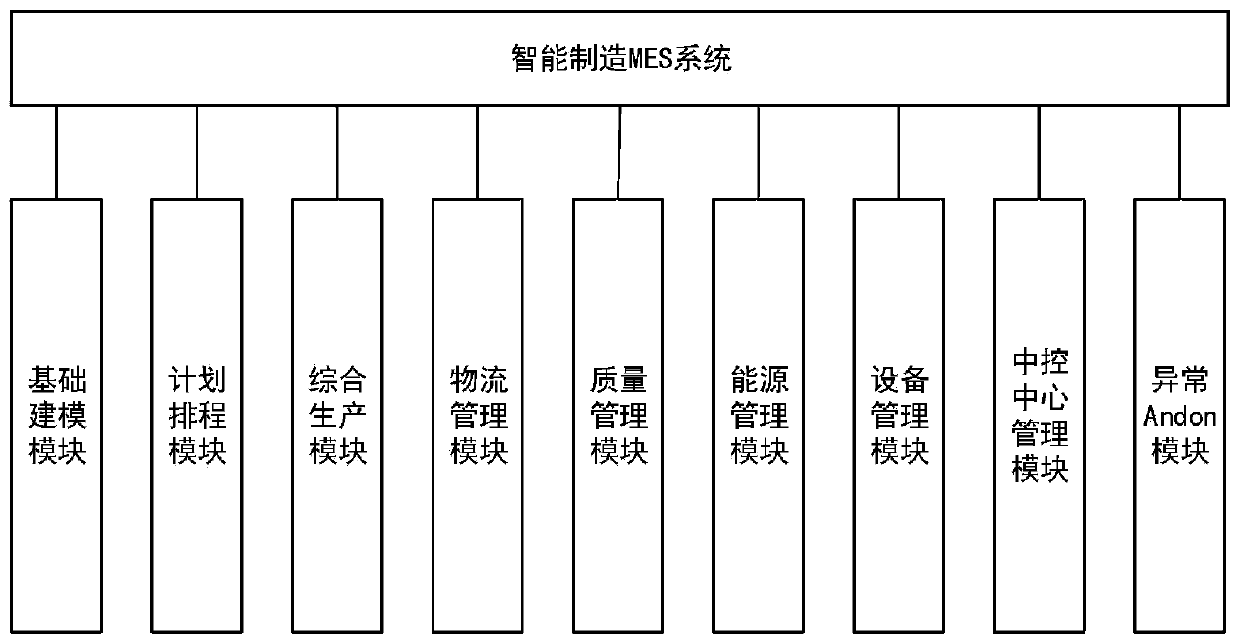

intelligent manufacturing MES system

InactiveCN110580026AIntelligent manufacturing whole process monitoringRealize the whole process monitoringEnergy industryTechnology managementMaterials preparationLogistics management

The invention discloses an intelligent manufacturing MES system which comprises a basic modeling module, a plan scheduling module, a comprehensive production module, a logistics management module, a quality management module, an energy management module, an equipment management module, a central control center management module and an abnormal Andon module. The basic modeling module is used for completing establishment of factory layout, establishment of product information and establishment of external resources. The plan scheduling module is used for establishing a production order, carryingout material preparation and distribution for a warehouse, work order scheduling, production execution, inspection, packaging and production warehousing. The comprehensive production module is used for managing a generated full-service process. The logistics management module is used for managing a production material taking management process and a production warehouse-in management process; andthe quality management module is used for carrying out inspection object maintenance on a purchasing department, a workshop department and a sales department. The invention provides a perfect intelligent manufacturing MES system, thereby realizing intelligent manufacturing full-process monitoring.

Owner:工业云制造(四川)创新中心有限公司

Intelligent order scheduling method and server, electric vehicle, mobile terminal and system

InactiveCN104751271AMaximize motivationReduce waiting timeResourcesLogisticsShortest distanceOrder scheduling

The invention discloses an intelligent order scheduling method. The intelligent order scheduling method comprises the following steps: obtaining a new order; obtaining geographic positions of a user and a merchant according to information in the new order; calculating a distribution distance between the geographic position of the user and the geographic position of the merchant according to the geographic position of the user and the geographic position of the merchant; monitoring electric vehicle data uploaded by a distribution worker electric vehicle monitoring system, and calculating a pre-estimated driving distance of an electric vehicle of each distribution worker; and carrying out intelligent distribution of the order according to the data. The invention further provides an intelligent order scheduling server, the electric vehicle applied to the intelligent order scheduling method, a mobile terminal applied to the intelligent order scheduling method, and a system applied to the intelligent order scheduling method. By the aid of the intelligent order scheduling method and server, the electric vehicle, the mobile terminal and the system, the short-distance and in-time distribution can be efficiently finished.

Owner:JINGYUAN SHANGHAI INFORMATION TECH CO LTD

Order scheduling method and system, computer device and storage medium

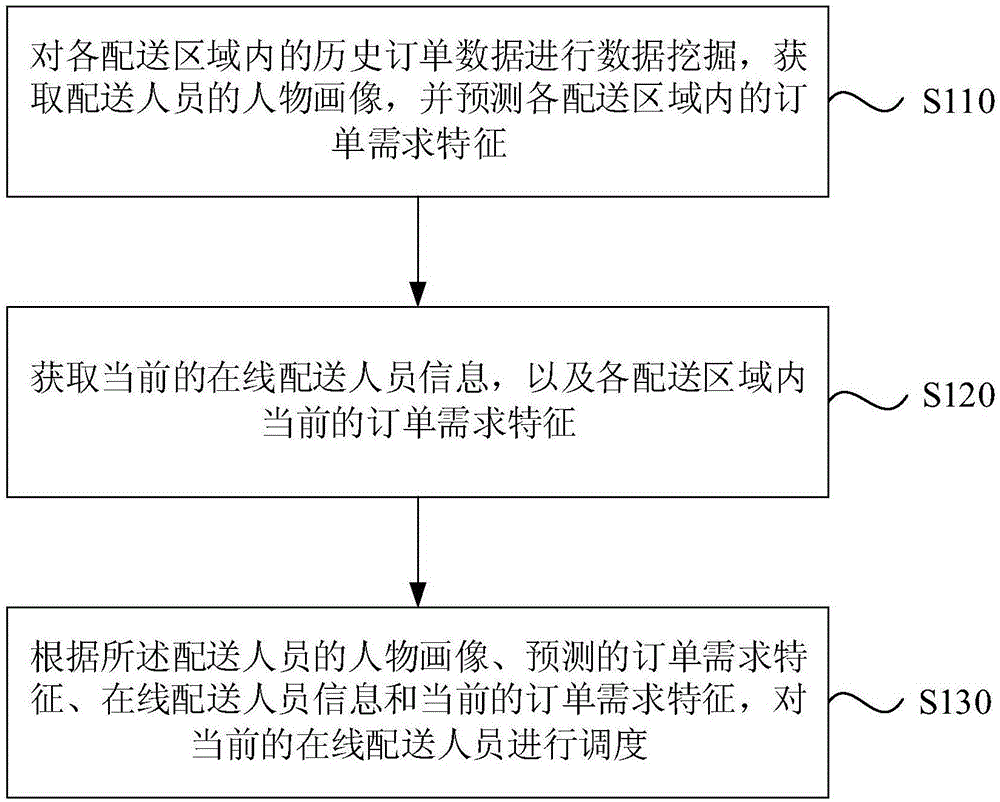

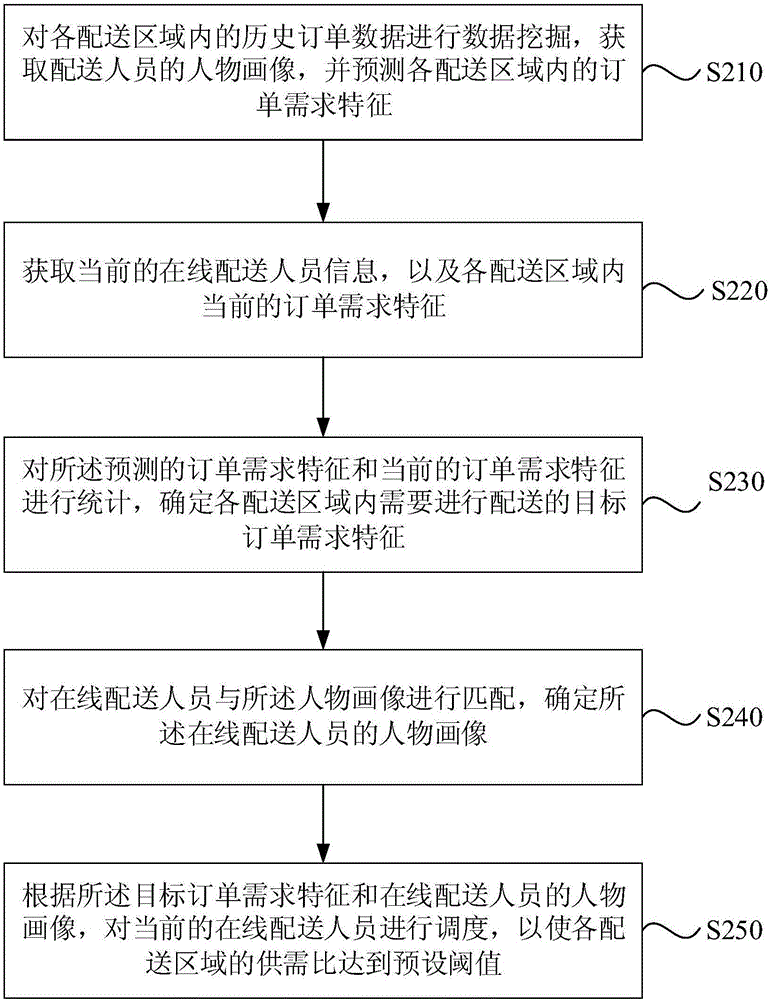

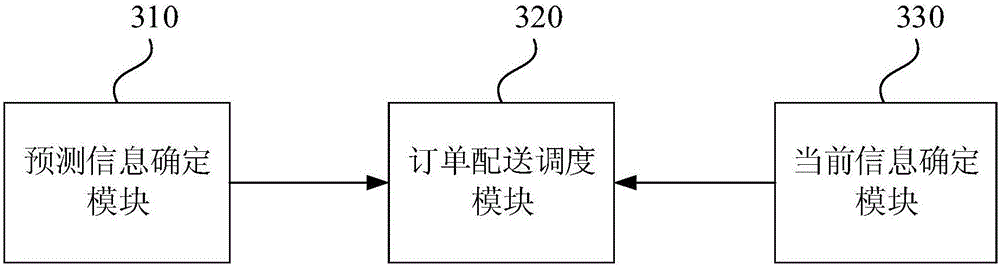

ActiveCN107437144ARealize reasonable deliveryReduce wasteResourcesLogisticsOrder schedulingComputer science

The embodiment of the invention discloses an order scheduling method and system, a computer device and a storage medium. The method includes the following steps: conducting data mining on historical order data within delivery regions, obtaining portraits of delivery workers, and predicating order demand features within the delivery regions; obtaining current online delivery worker information and current order demand features within the delivery regions; and scheduling the current online delivery workers on the basis of the portraits of the delivery workers, the predicated order demand features, the online delivery worker information and the current order demand features. The order scheduling method and system, the computer device and the storage medium solve the problem of the prior art that order supplying and demanding balance cannot be realized, achieve reasonable delivery of orders, reduce waste of order delivery resources, and guarantee order supplying and demanding balance in delivery regions to the maximum.

Owner:北京闪送科技有限公司

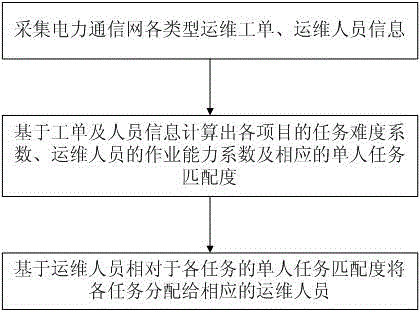

Operation and maintenance work order scheduling management method and system in electric power telecommunication field

InactiveCN106682743AImprove operation and maintenance efficiencyReduce operation and maintenance costsData processing applicationsApproaches of managementOrder scheduling

The invention discloses an operation and maintenance work order scheduling management method and system in an electric power telecommunication field. The method comprises steps of 1, work order and worker information acquisition: acquiring all types of operation and maintenance work orders and operation and maintenance worker information, wherein the operation and maintenance work orders comprise task identifiers, task categories, task work procedures, continuous time of accomplishing of each work procedure and task grade information, and the operation and maintenance worker information comprise operation and maintenance worker identifiers, operation and maintenance skills, skill coefficients of each operation and maintenance skill and worker available state information; 2, task and worker matching analysis: based on the work orders and worker information, calculating a task difficulty coefficient of each project, operation ability coefficient of each operation and maintenance worker and a corresponding single worker task matching degree; and 3, work order scheduling: based on the single worker task matching degree relative to each operation and maintenance worker, distributing each task to the corresponding operation and maintenance worker. According to the invention, based on the task matching degree, the operation and maintenance tasks are distributed to corresponding operation and maintenance workers, so the method is vivid and easy to use, operation and maintenance efficiency can be effectively improved and operation and maintenance cost can be reduced.

Owner:NARI INFORMATION & COMM TECH

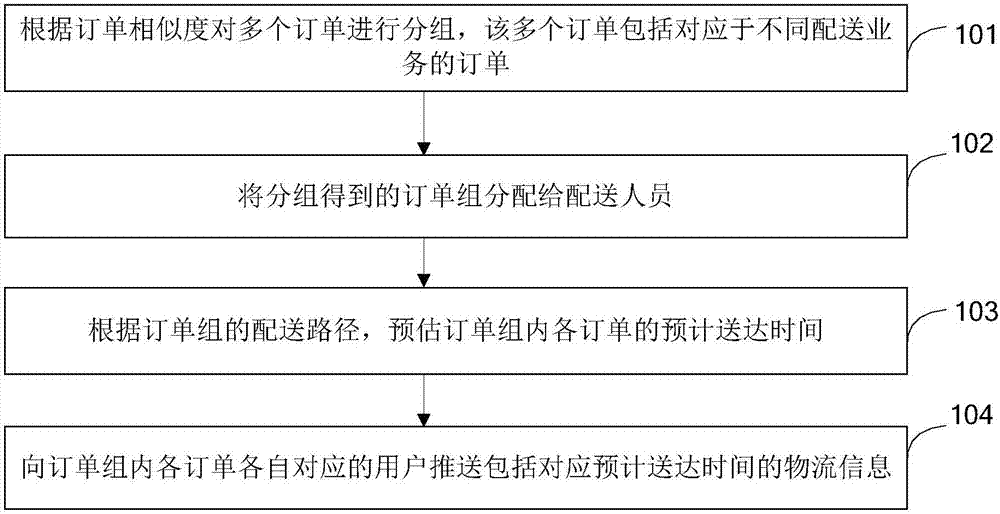

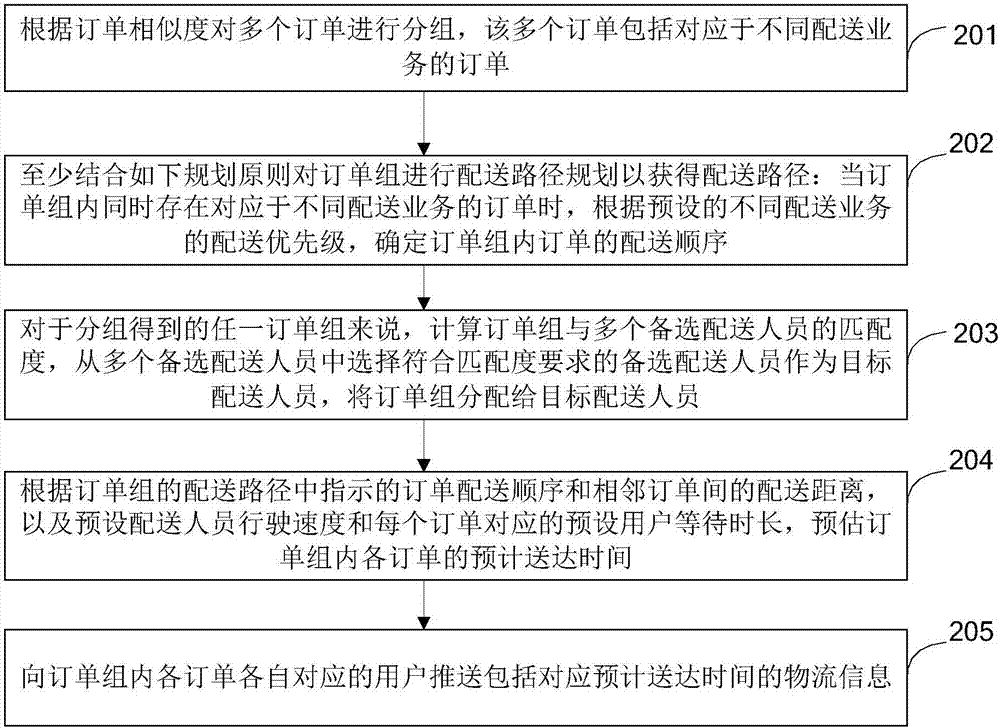

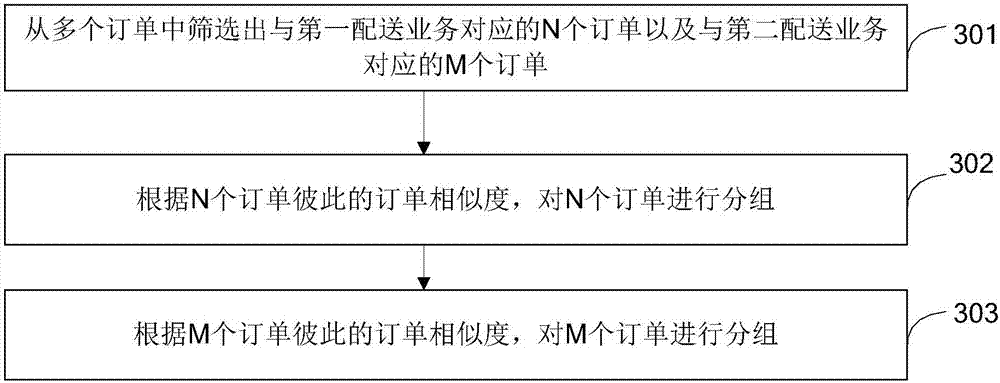

Order scheduling method and device

ActiveCN107392412AIncrease profitImprove experienceMessaging/mailboxes/announcementsResourcesLogistics managementOrder scheduling

The embodiment of the invention provides an order scheduling method and device. The method includes: grouping a plurality of orders according to order similarity; and distributing order groups, which are obtained by grouping, to delivery persons. The plurality of orders include orders corresponding to different delivery services, thus the different delivery services can be enabled to share the same batch of the delivery persons, and a utilization rate of the delivery persons is increased. In addition, for any one of the order groups obtained by grouping, an expected arrival time of each order in the order group is estimated according to a delivery route of the order group; and logistics information is pushed to a user respectively corresponding to each order in the order group, and the logistics information includes the corresponding expected arrival time. Therefore, each user can be enabled to know the fine-granularity logistics information such as the expected arrival time of the order, the user experience is improved, and the user viscosity is improved.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

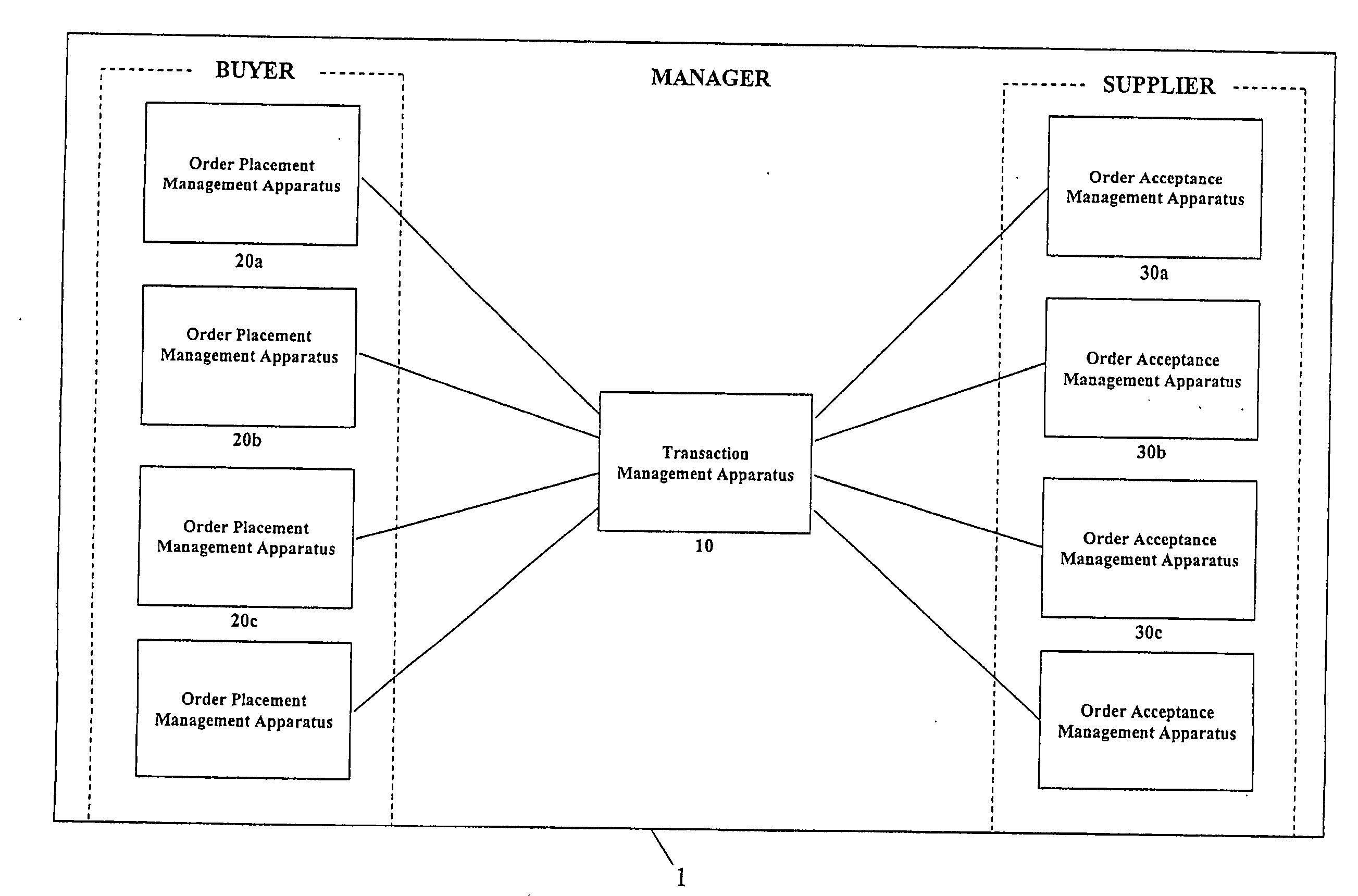

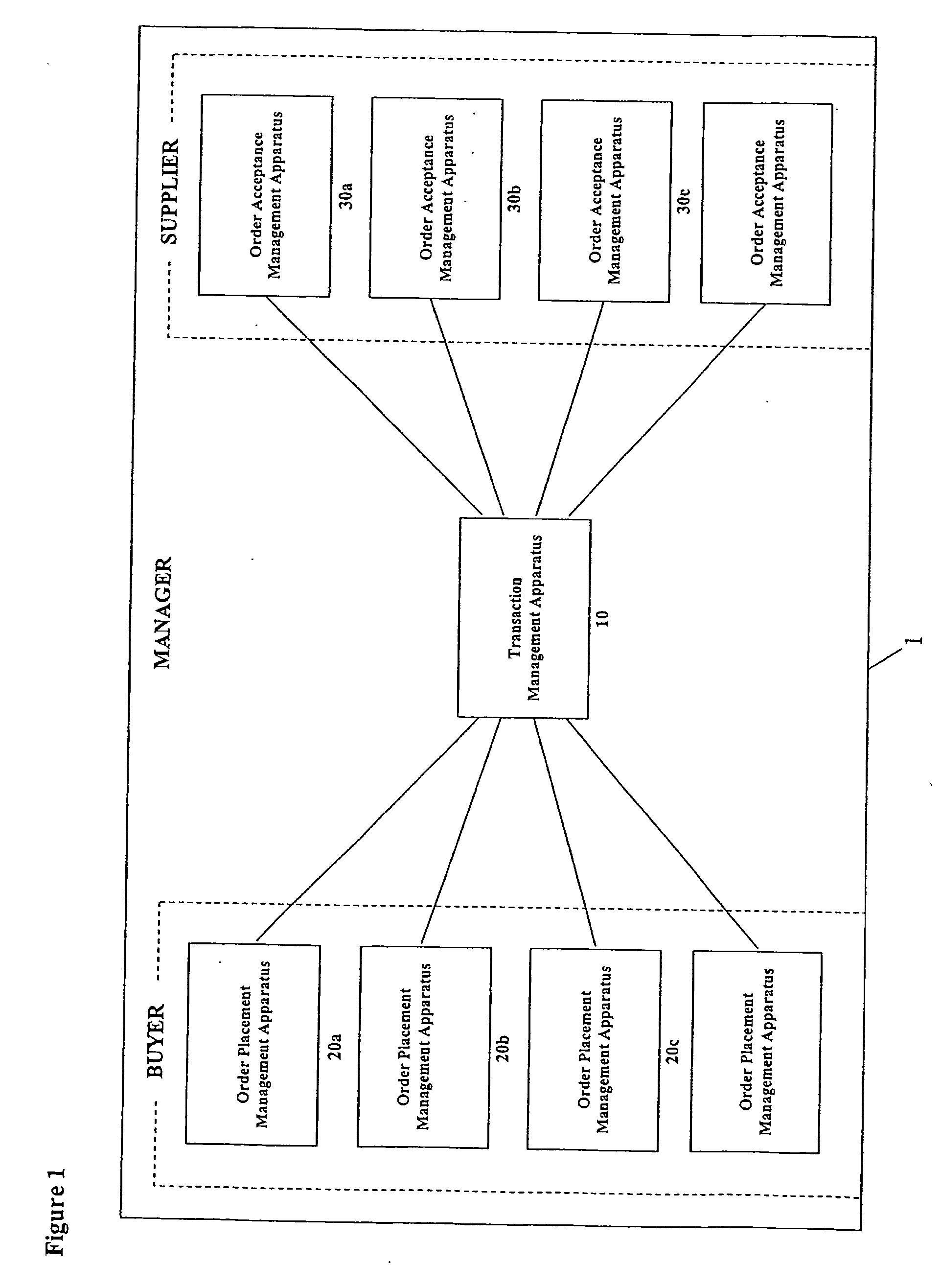

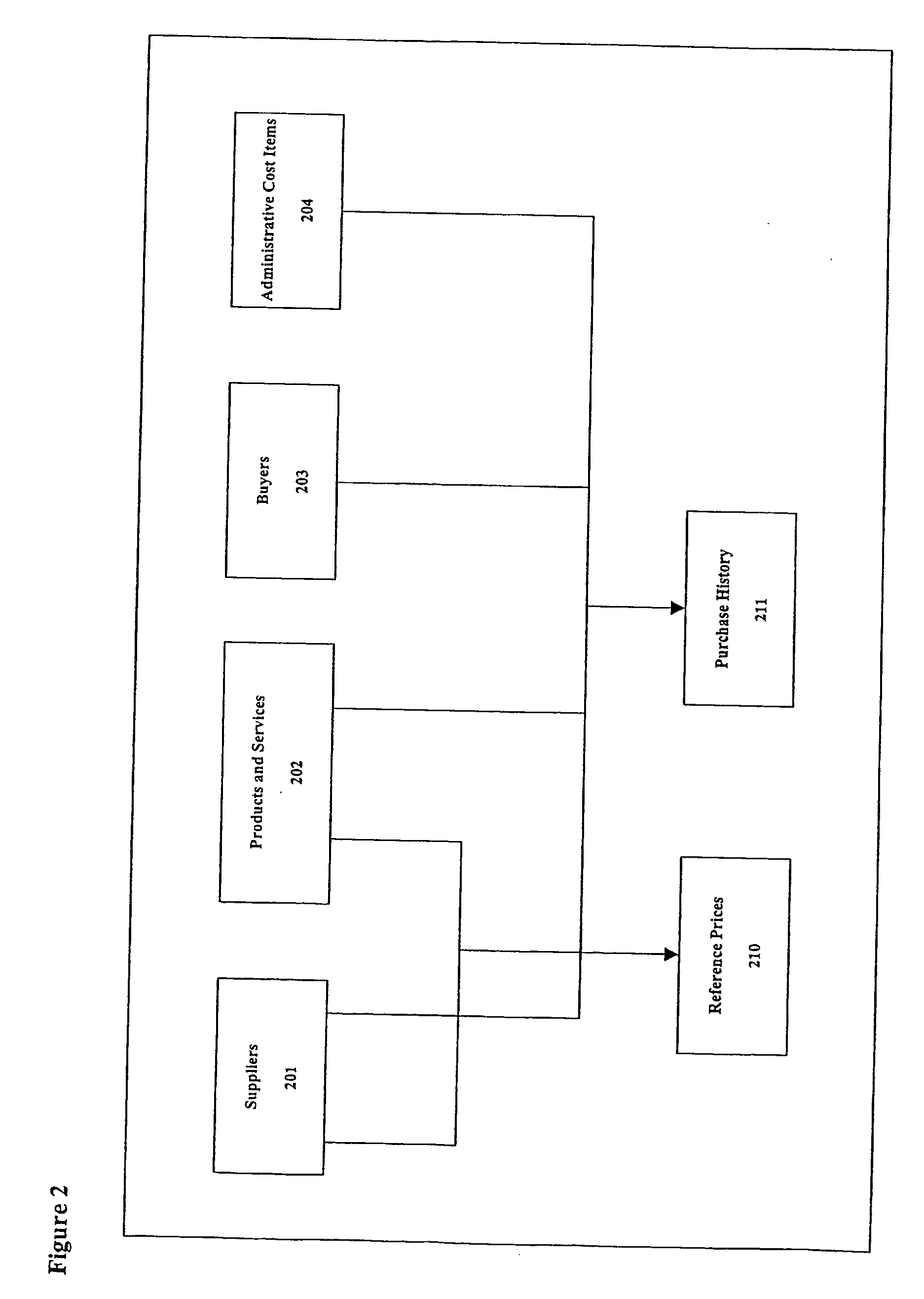

Order placement and acceptance management system

InactiveUS20060253334A1Precise and highly transparent quotationsImprove data securityBuying/selling/leasing transactionsTransaction managementOrder scheduling

An order placement and acceptance management system is presented. In an exemplary embodiment, an order acceptance management apparatus (“OAMA”) receives a predetermined quotation request transmitted by an order placement management apparatus. The OAMA generates a quotation result based on data on products and services which is segmented and stored in a database. The order placement management apparatus (“OPMA”) as well as a transaction management apparatus (“TMA”) store the quotation results transmitted by the OAMA in their own respective storage units, and the OPMA can choose amongst the received quotations to place an order. In an exemplary embodiment, other order placement management apparatuses can also use the quotation results and data on completed transactions which are stored in the transaction management apparatus as reference prices in order to estimate purchase prices for future transactions or evaluate quotations received from OAMAs.

Owner:A T KEARNEY

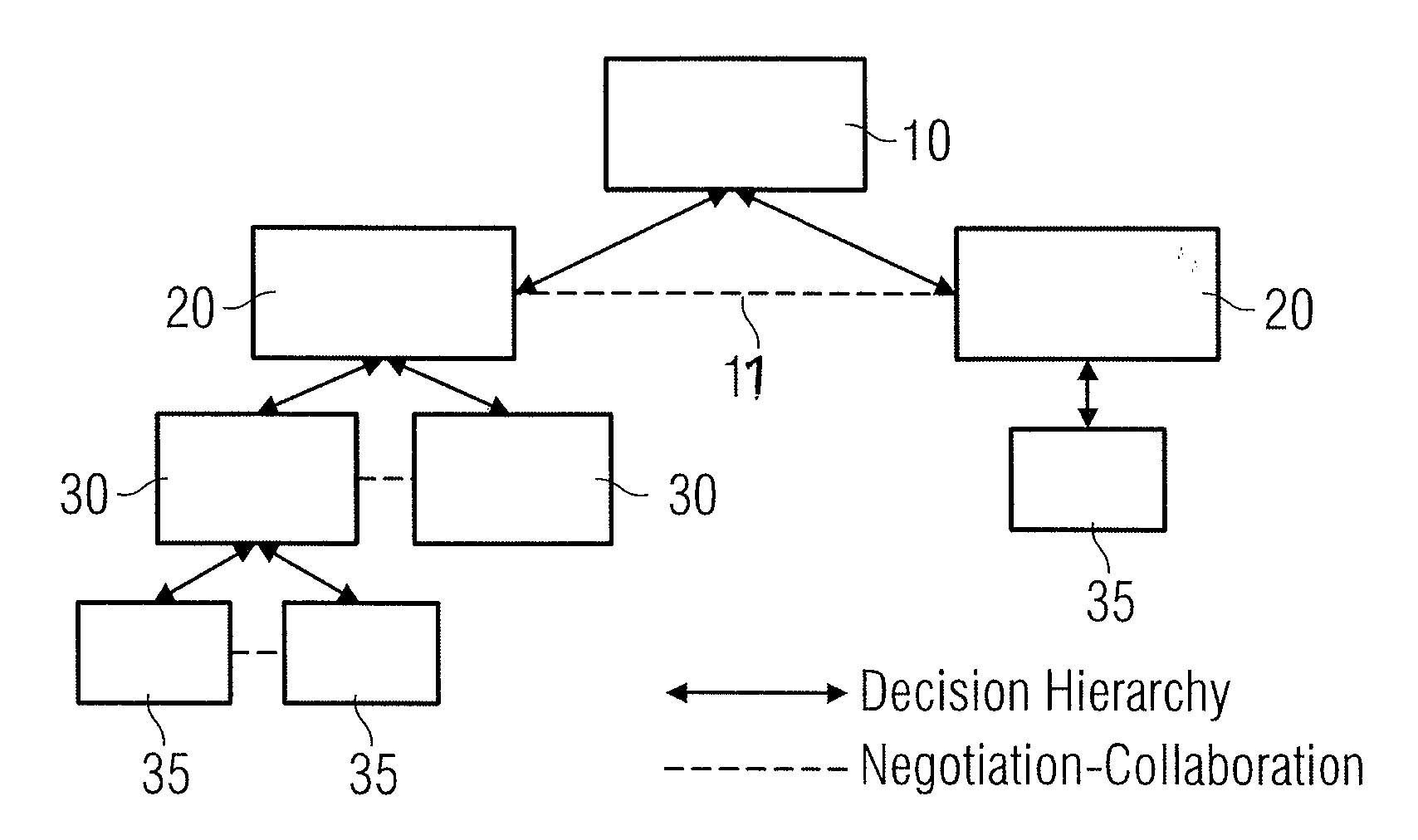

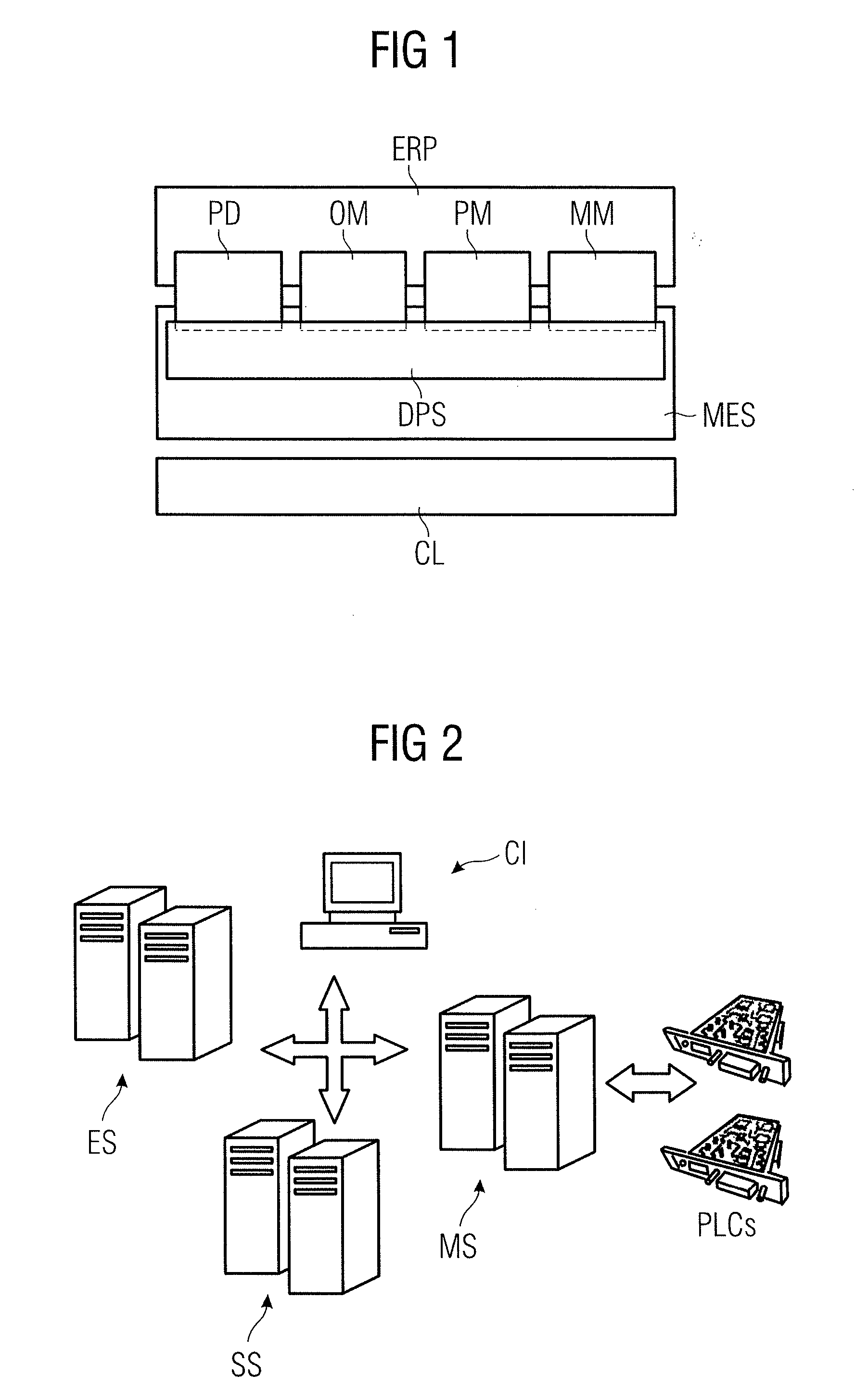

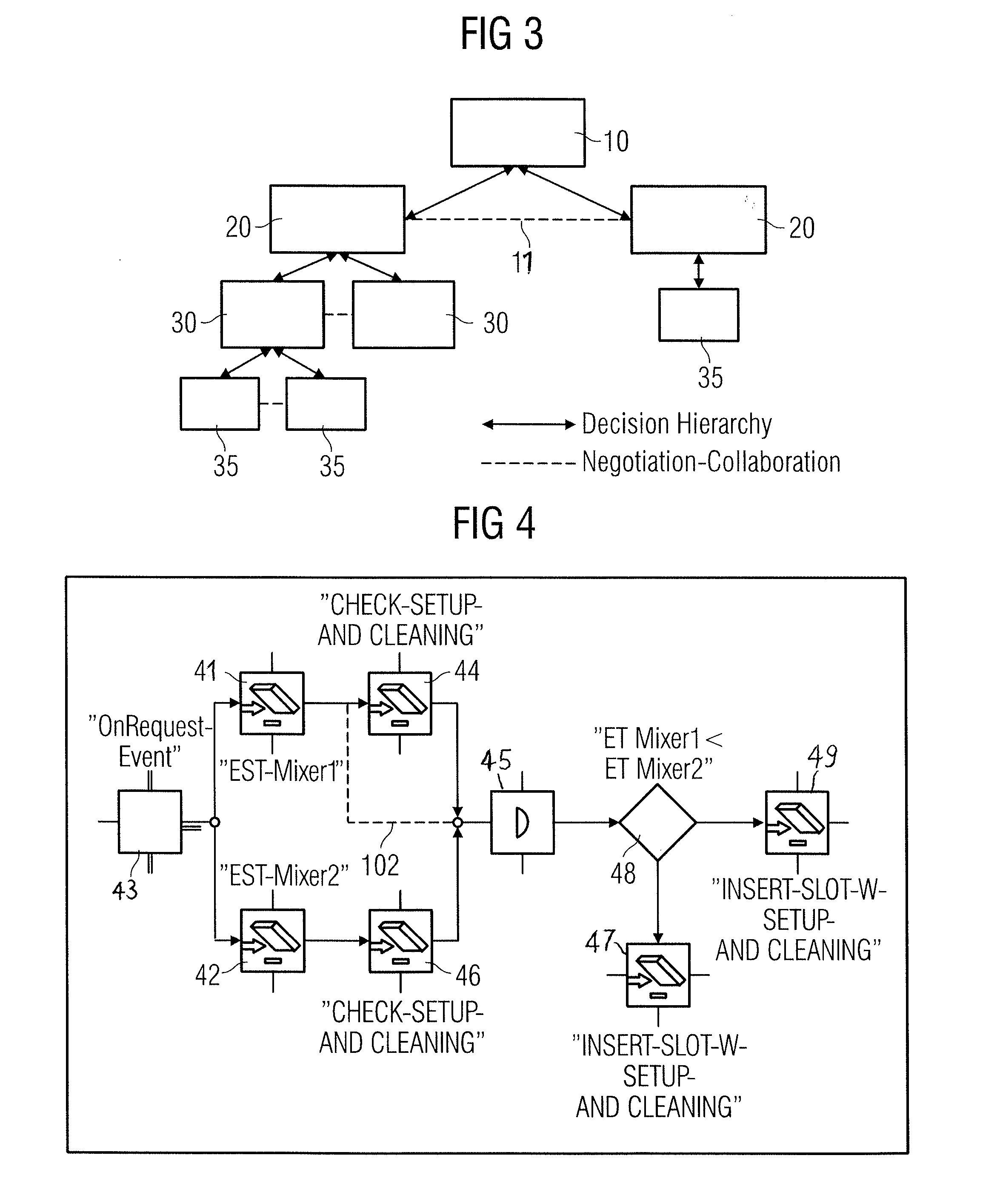

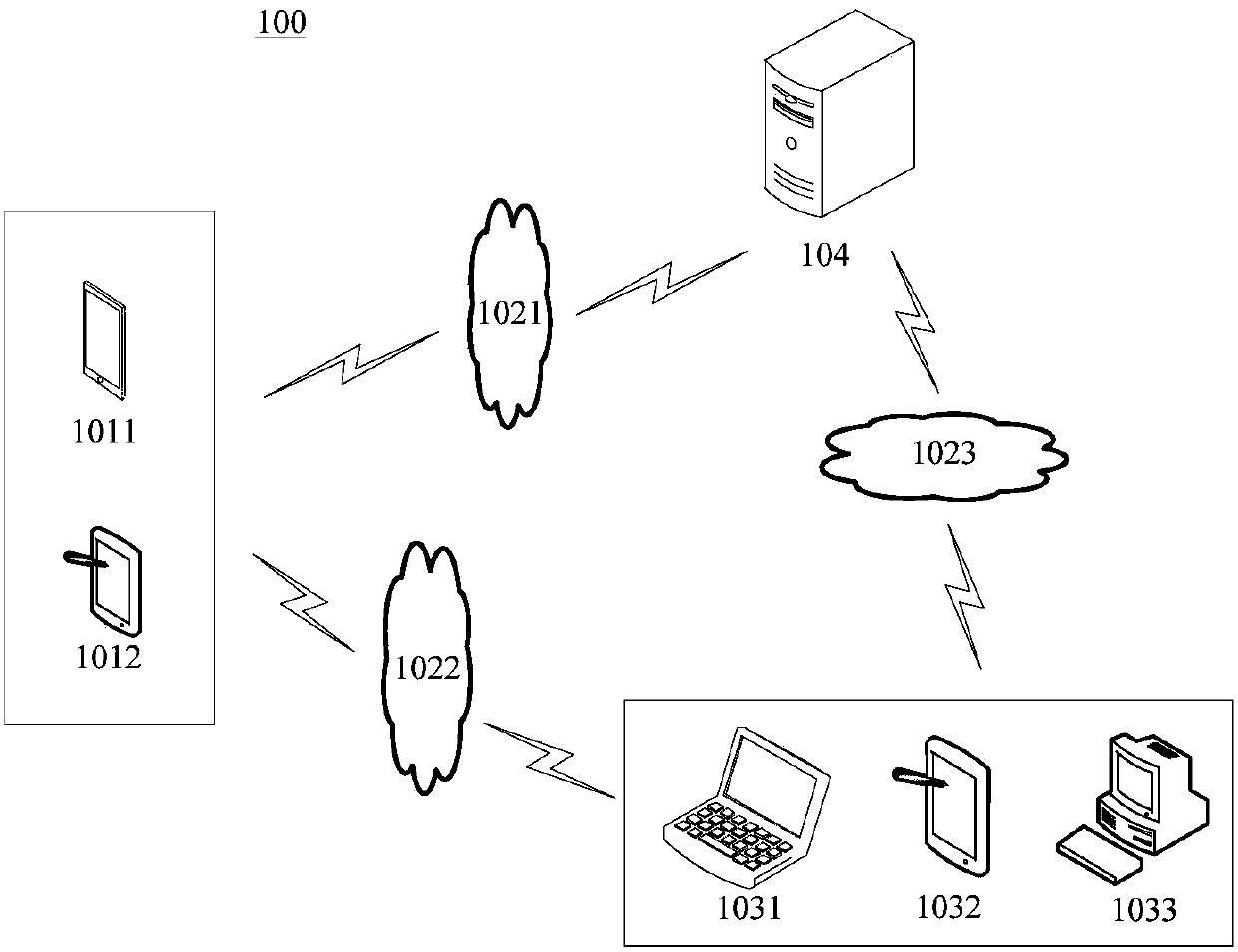

Scheduling System and Work Order Scheduling Protocol for Such a System

InactiveUS20080091289A1Available informationResourcesSpecial data processing applicationsManufacture execution systemOrder scheduling

A scheduling system (DPS) for planning and scheduling production in an industrial production system (CL), which scheduled production is to be executed by the production system (CL) under the control of a manufacturing execution system (MES), wherein: —said scheduling system is a multi-agent scheduling system (DPS); —at least a part of the behavior of the agents in said multi-agent system (DPS) is customizable by means of visually defined scheduling rules; —said scheduling system (DPS) and manufacturing execution system environment comprising: —editor means (CI) for visually defining both said manufacturing execution system (MES), and—an execution engine for executing said scheduling rules and control rules and making scheduling decisions on the basis of the execution of said scheduling rules and control rules.

Owner:SIEMENS AG

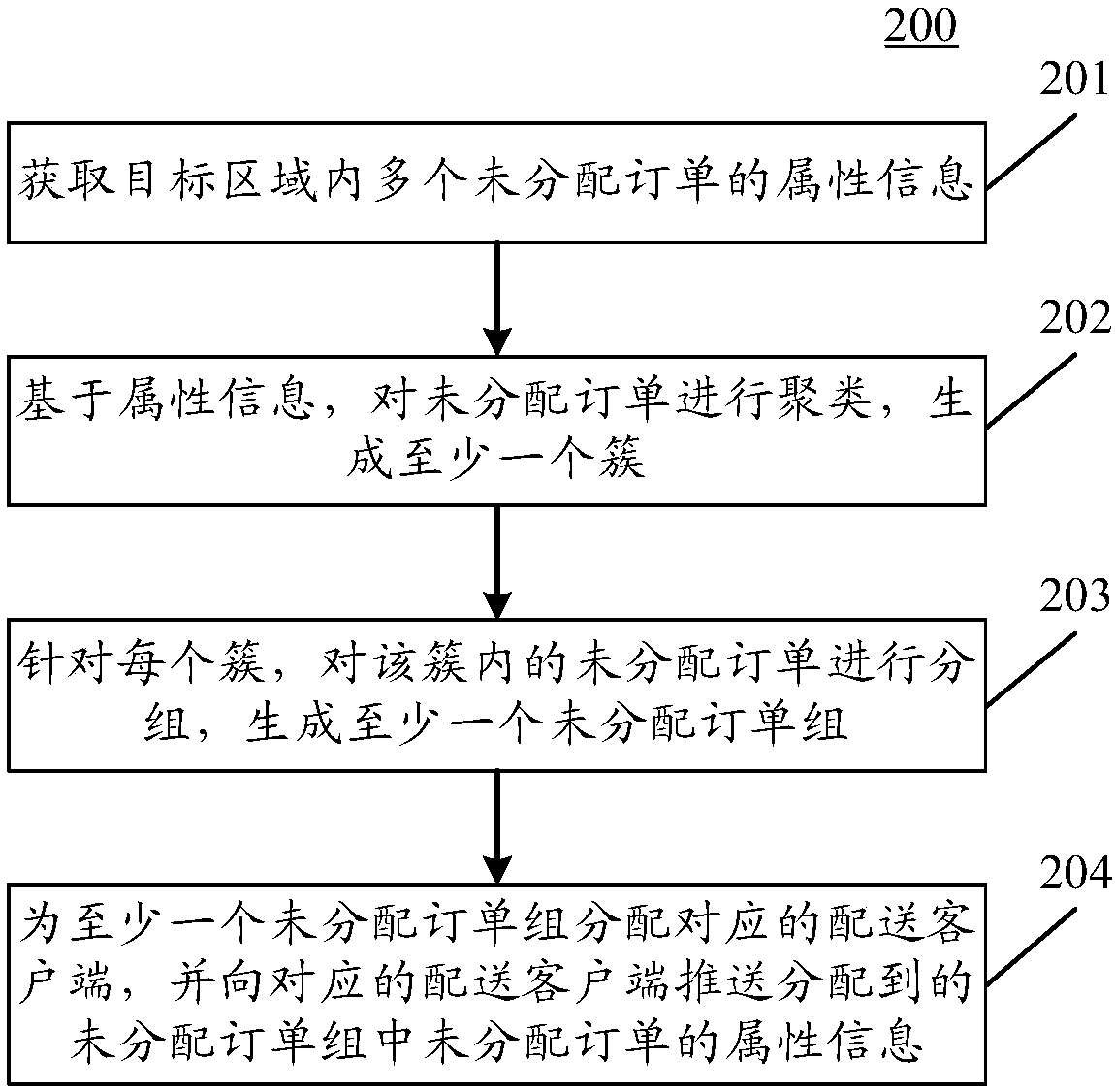

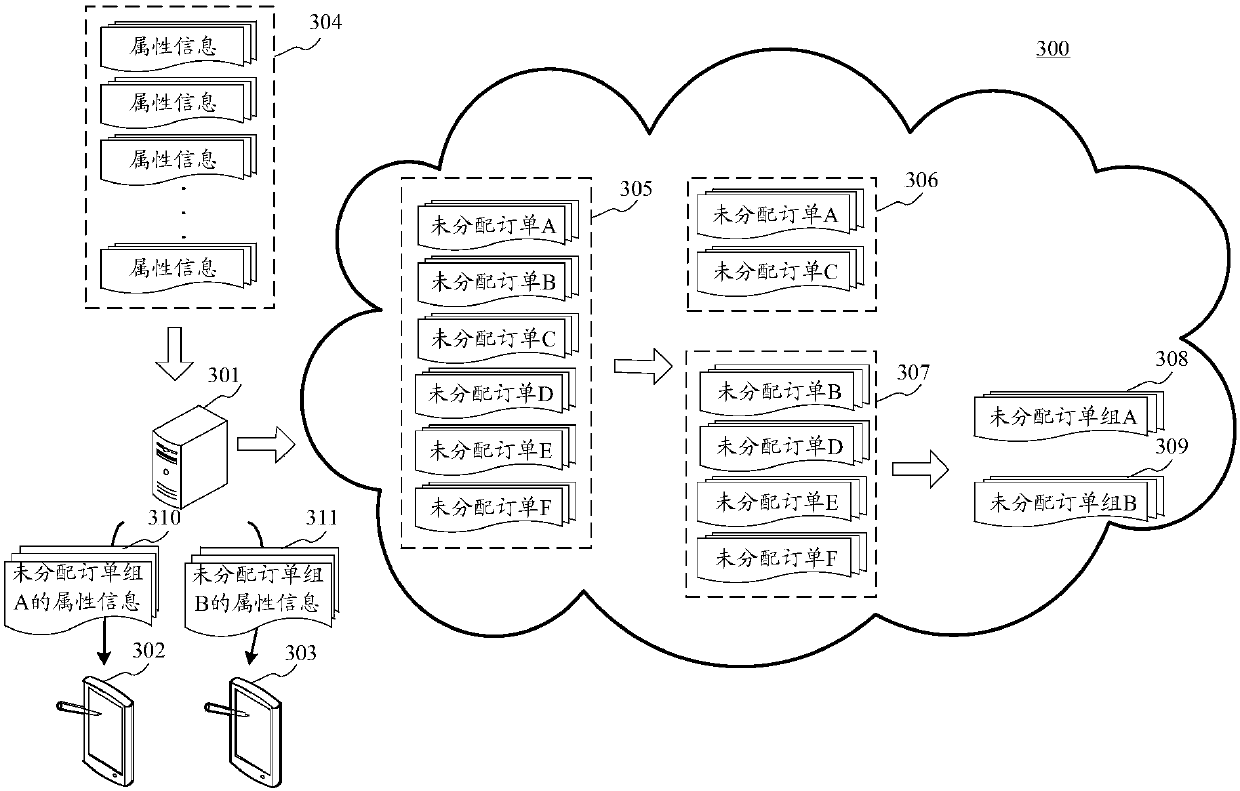

Information pushing method and apparatus

InactiveCN107844885APush implementationPush implements richBuying/selling/leasing transactionsResourcesOrder schedulingData mining

Embodiments of the invention disclose an information pushing method and apparatus. A specific embodiment of the method comprises the steps of obtaining attribute information of multiple unallocated orders in a target region; based on the attribute information, clustering the unallocated orders to generate at least one cluster; for each cluster, grouping the unallocated orders in the cluster to generate at least one unallocated order group; and allocating a corresponding distribution client to the at least one unallocated order group, and pushing the attribute information of the unallocated orders allocated to the unallocated order group to the corresponding distribution client. The embodiment provides another order scheduling mechanism. More targeted information pushing is realized.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

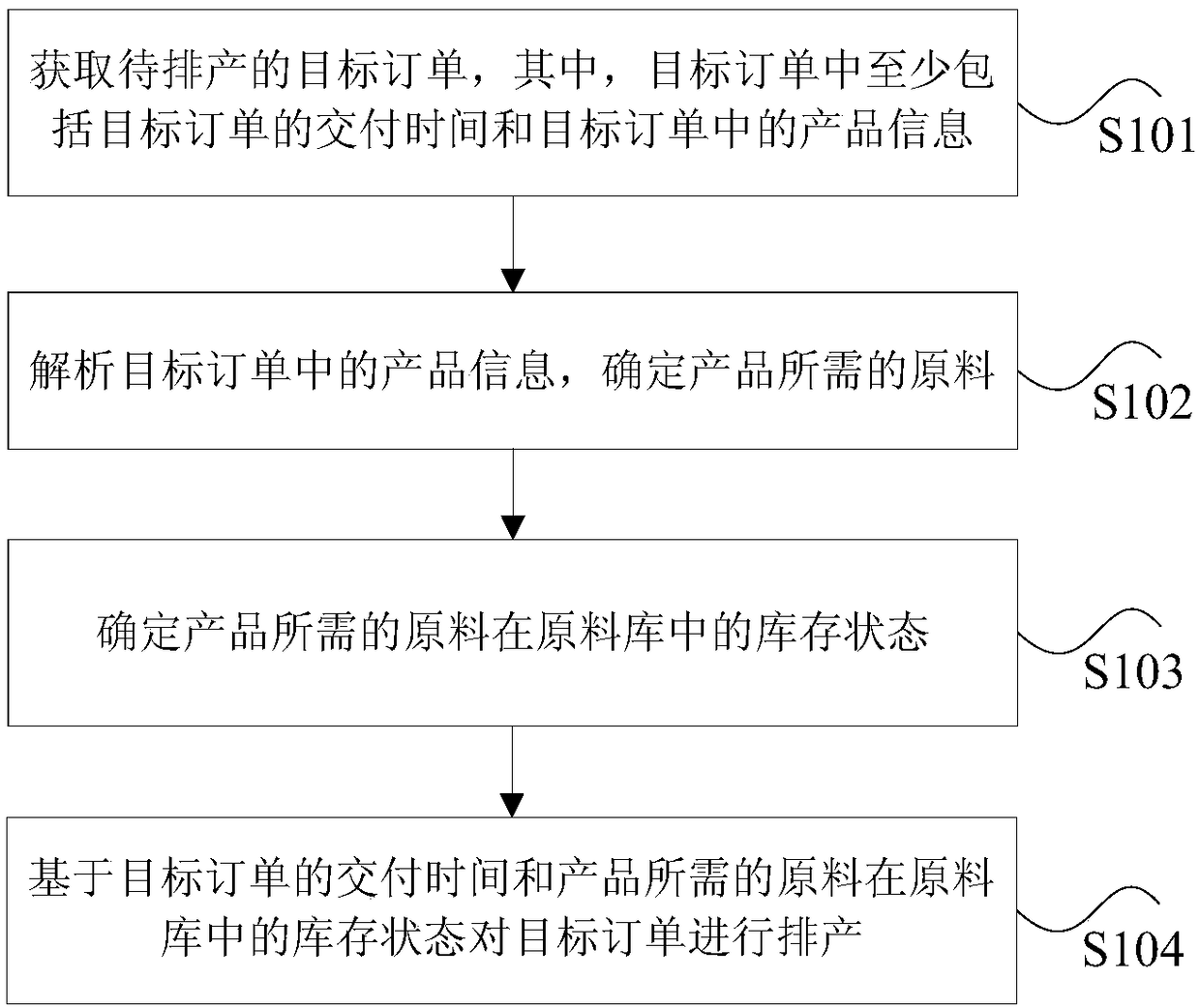

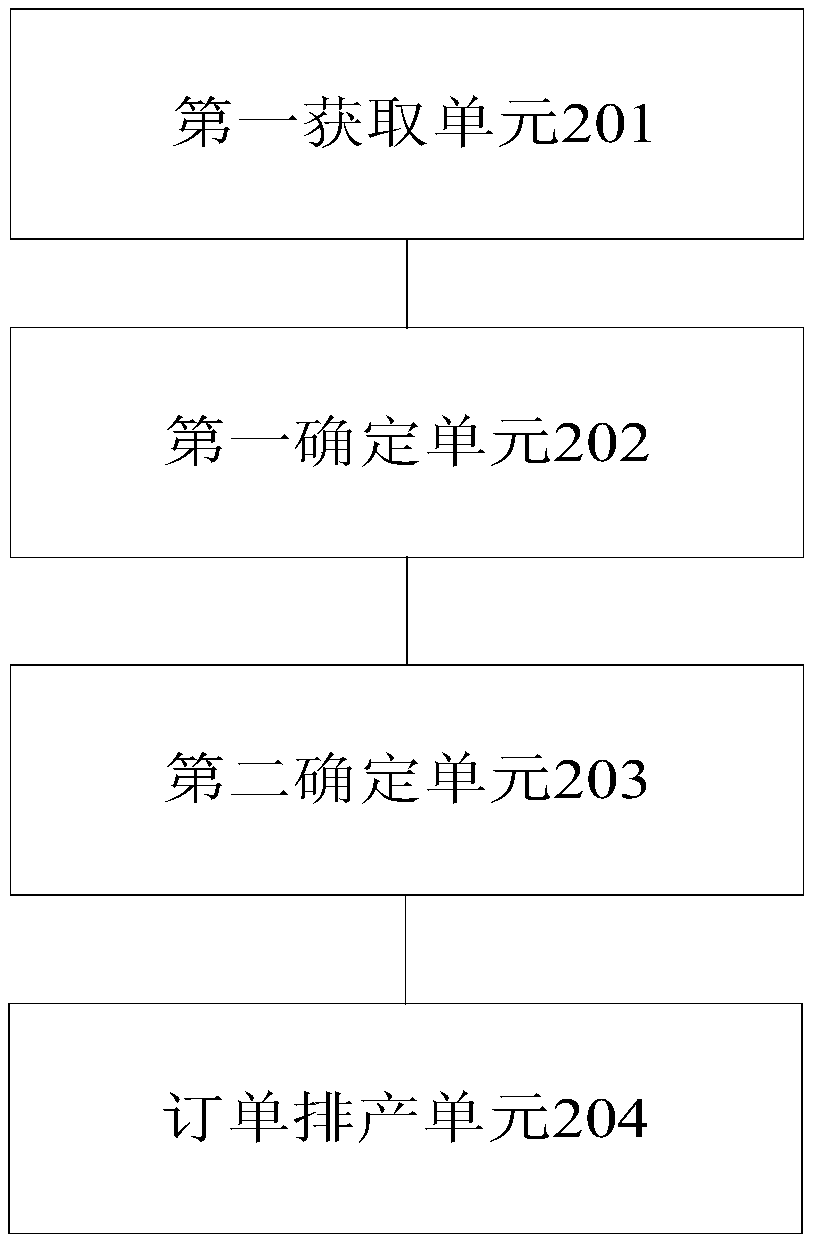

Order scheduling method and device, storage medium and processor

InactiveCN109472488ASolve unreasonable problemsIncrease productivityResourcesManufacturing computing systemsOrder schedulingOrder form

Disclosed are an order scheduling method and apparatus, a storage medium, and a processor. The method comprises the following steps of: acquiring a target order to be scheduled, wherein, the target order comprises at least a delivery time of the target order and product information in the target order; Analyzing product information in the target order to determine raw materials required by the product; Determine the stock status of raw materials in the raw material warehouse; Scheduling the target order based on the delivery time of the target order and the inventory status of the raw materials required by the product in the raw material warehouse, and solving the problem of unreasonable order scheduling planning in the related art through the present application.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

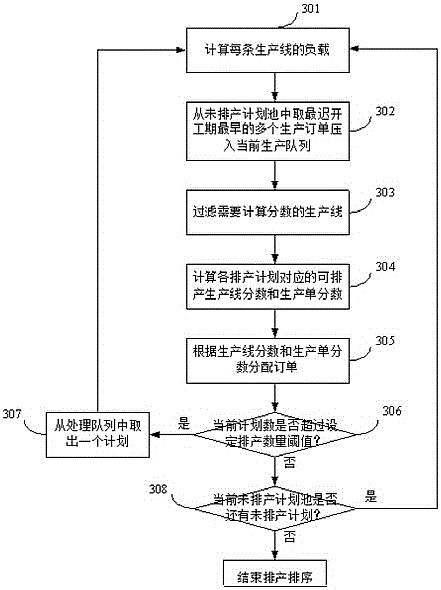

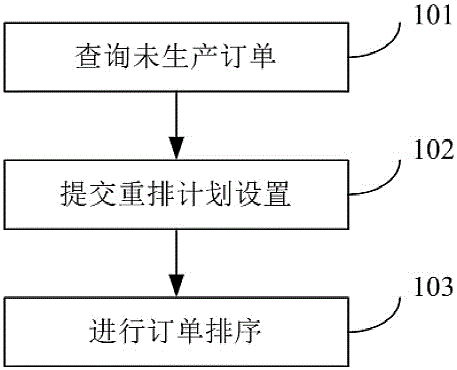

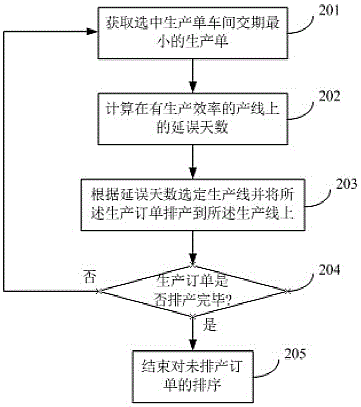

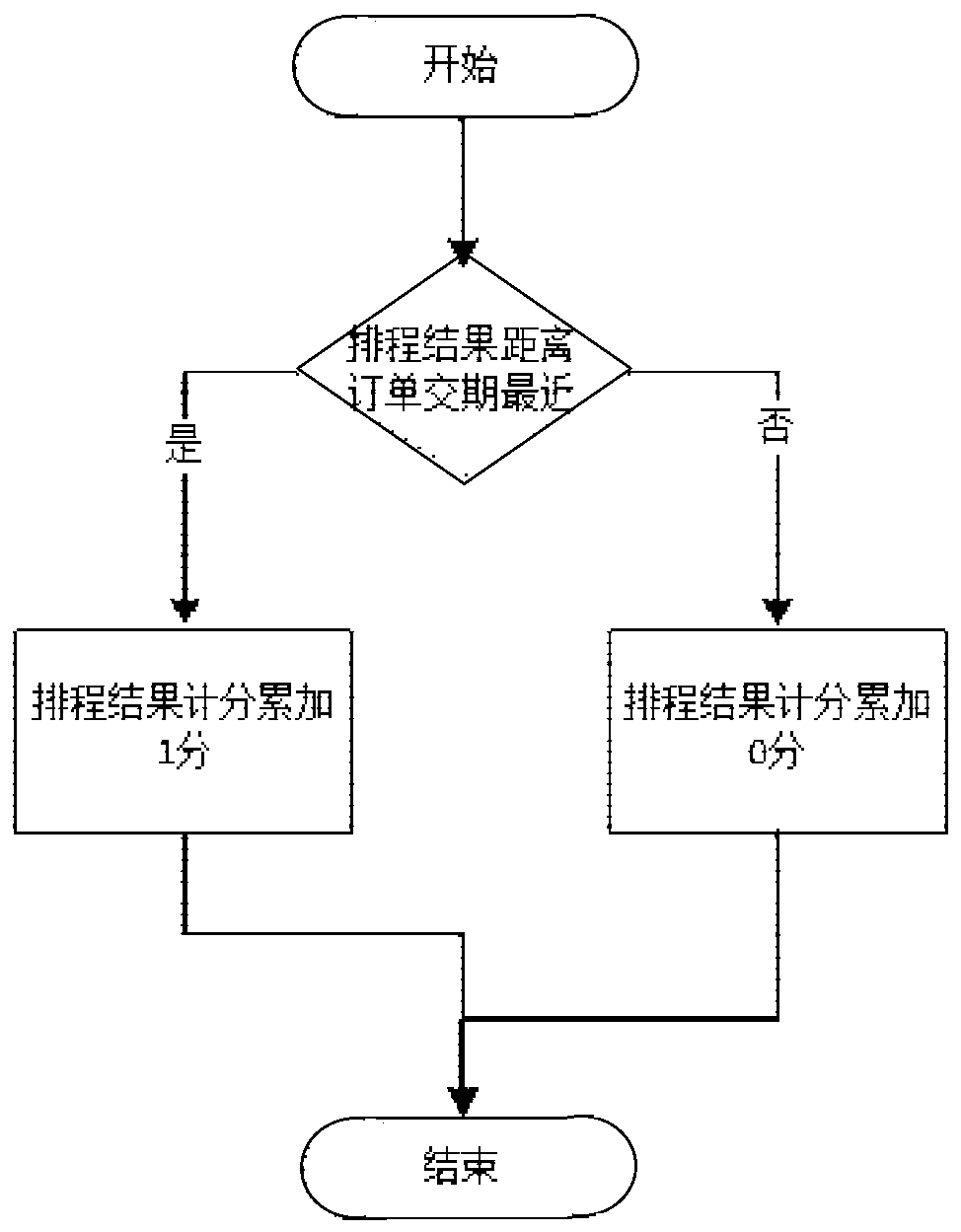

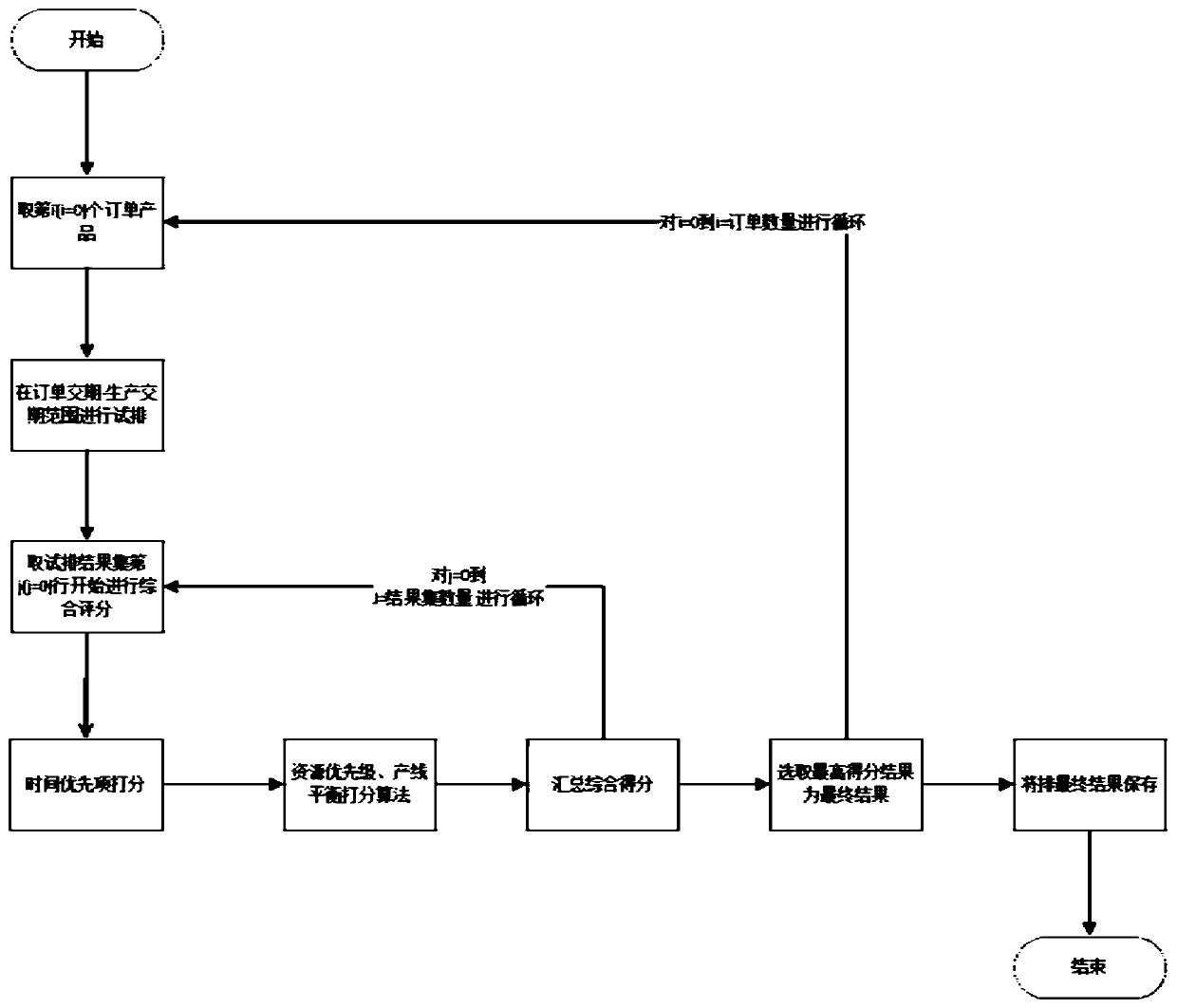

Production order production scheduling management method and production scheduling optimizer system

PendingCN106408112ARealize scientific managementImprove management efficiencyForecastingResourcesProduction lineOrder scheduling

Owner:广州亿澳斯软件股份有限公司

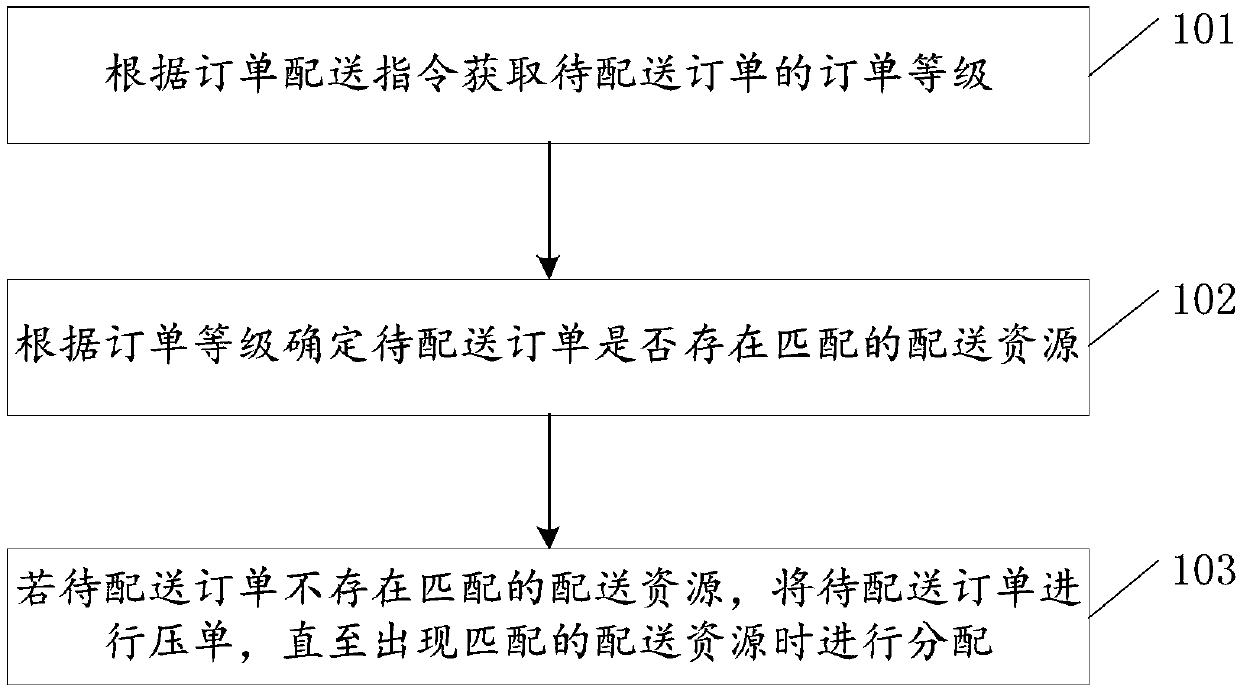

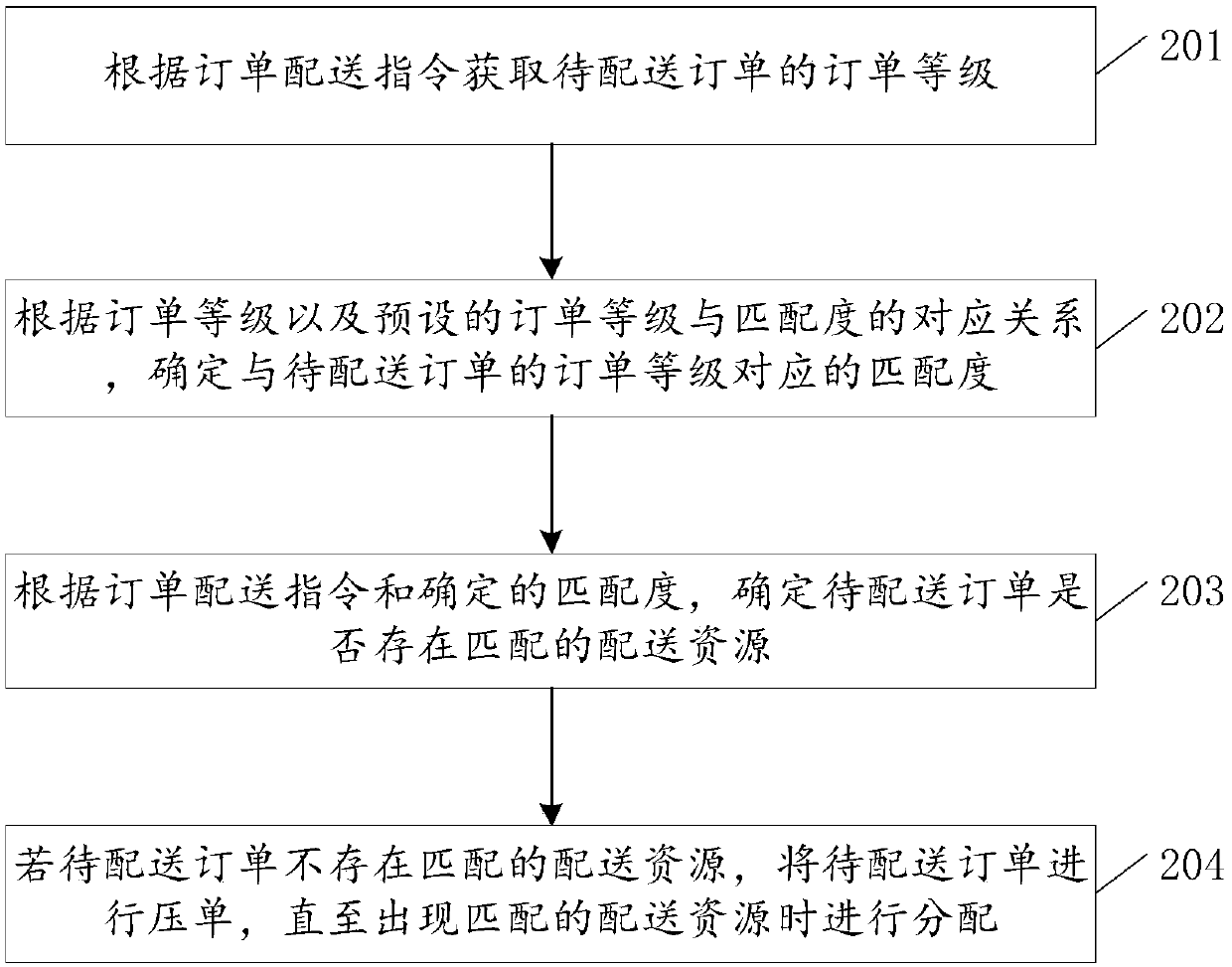

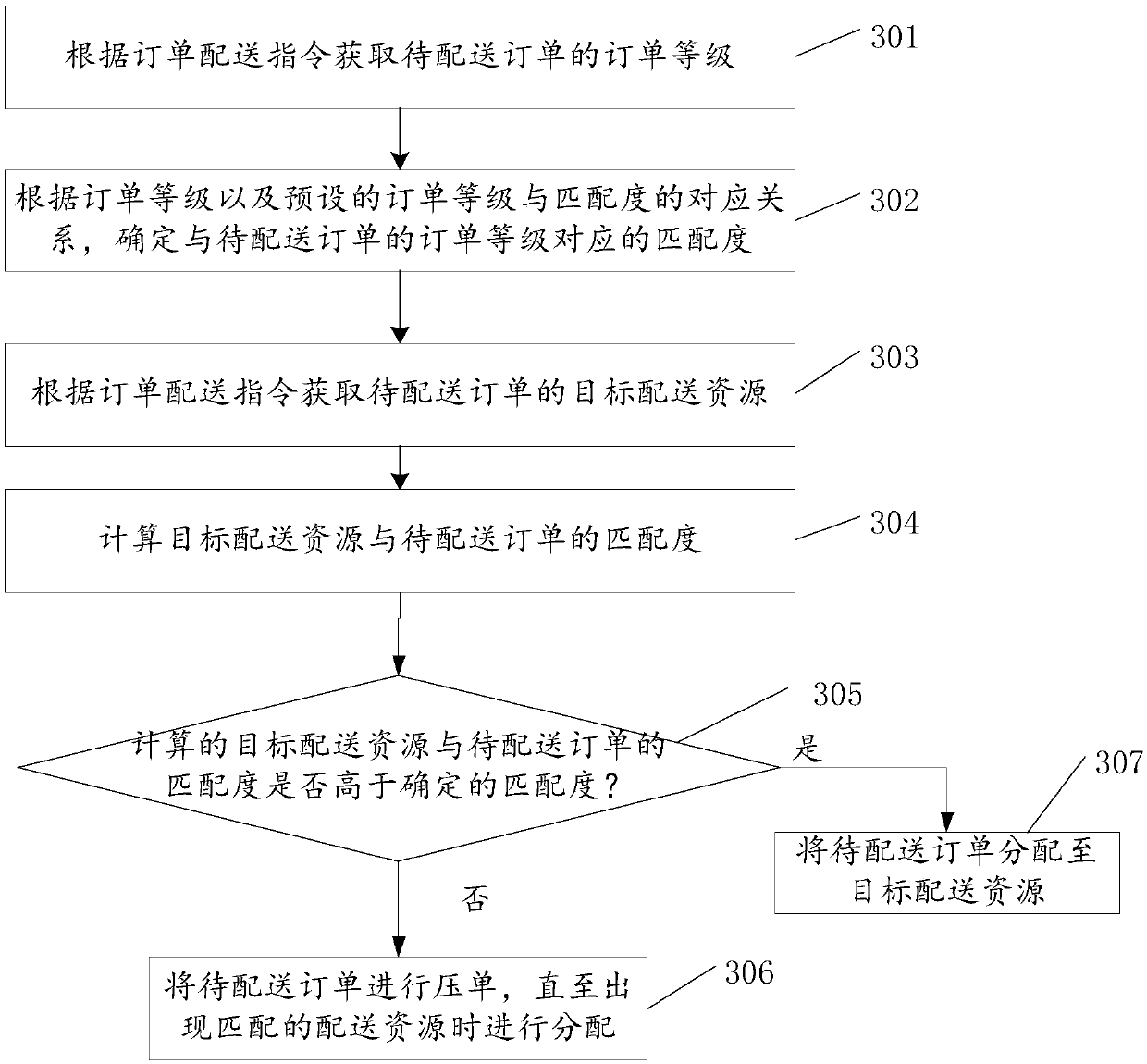

Order scheduling method and device, electronic equipment and storage medium

InactiveCN109636217AShorten the timeImprove distribution efficiencyResourcesLogisticsOrder schedulingOrder form

The embodiment of the invention relates to the technical field of communication, and discloses an order scheduling method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining the order level of a to-be-delivered order according to an order delivery instruction; Determining whether the to-be-delivered order has matched delivery resources or not according to the order level; And if the matched delivery resources do not exist in the to-be-delivered order, allowing the to-be-delivered order to be subjected to order pressing until the matched deliveryresources appear, so that the situation that a deliveryman needs to wait when arriving at a goods taking point is prevented, the delivery time is saved, and the delivery efficiency is improved.

Owner:RAJAX NETWORK &TECHNOLOGY (SHANGHAI) CO LTD

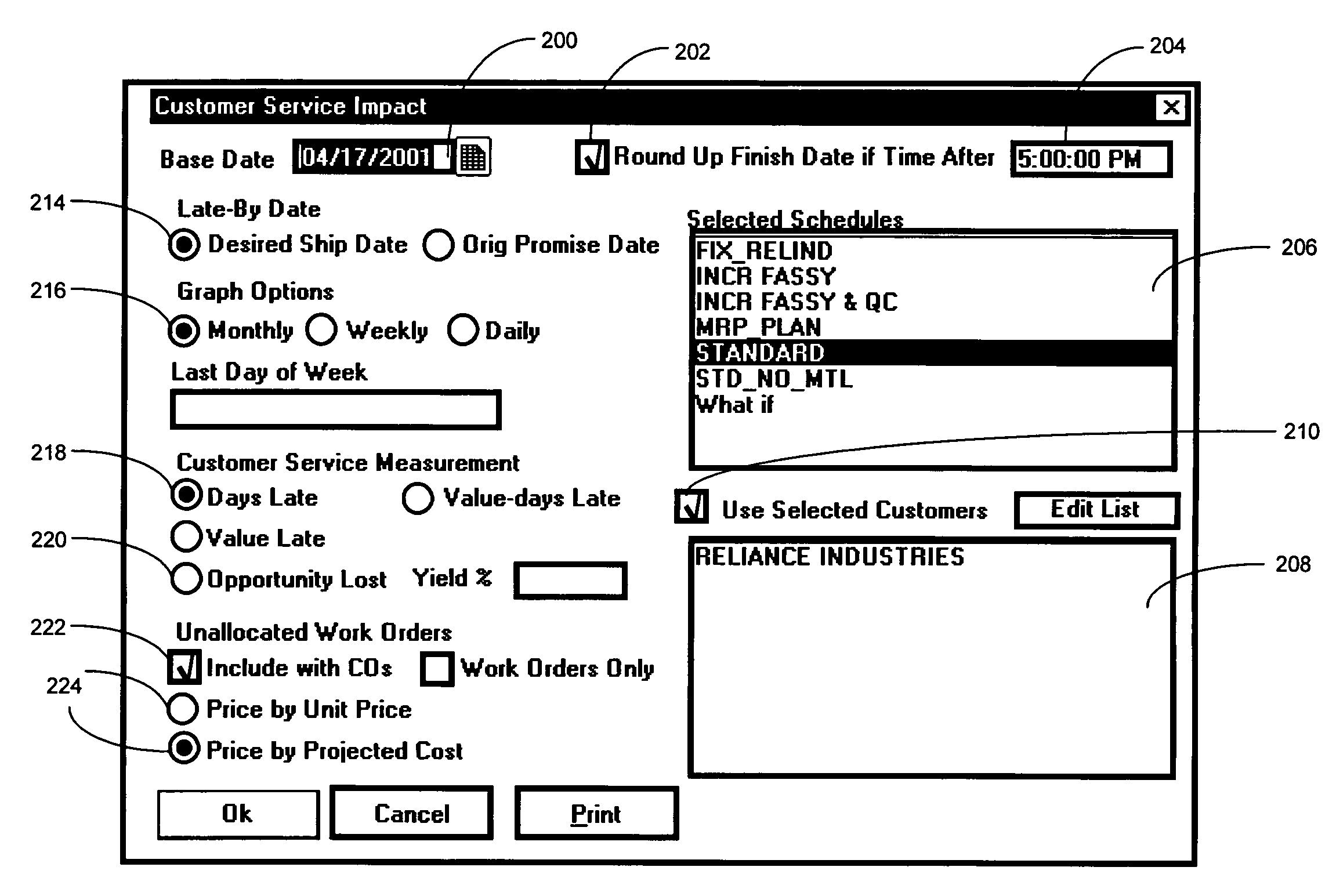

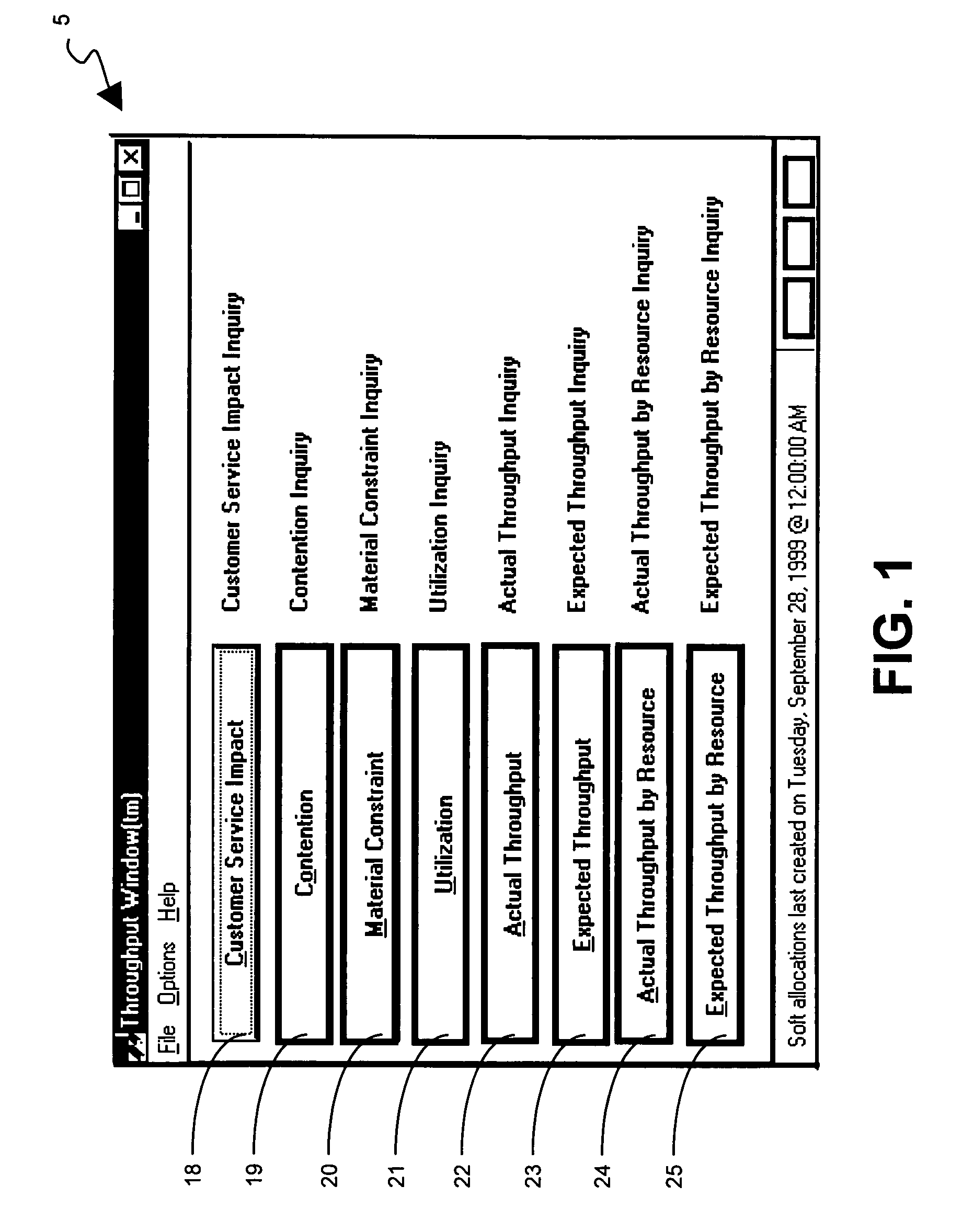

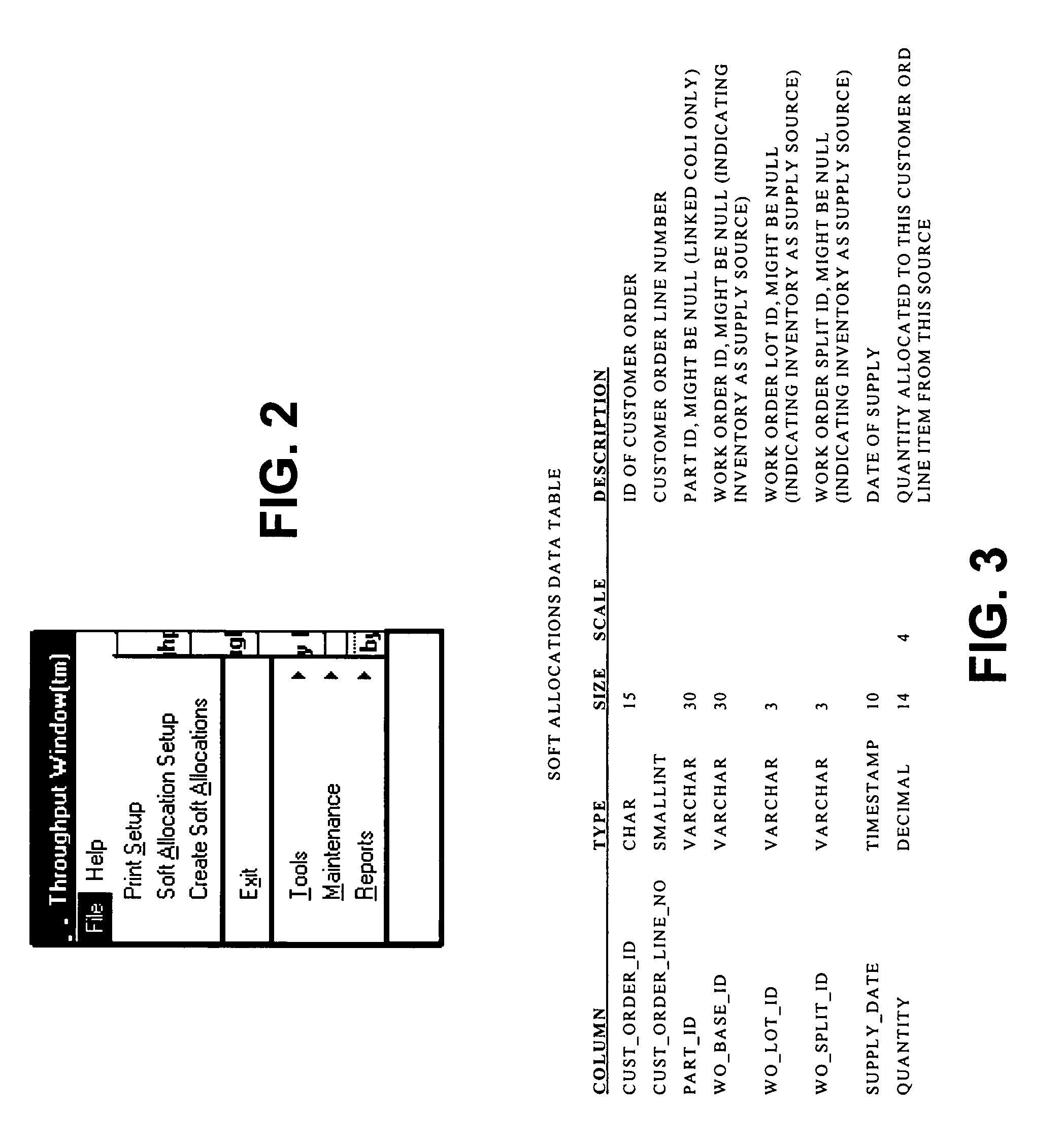

Computer program product for determining and reducing customer service impact

InactiveUS7647241B1Efficiently determinedGood serviceResourcesSpecial data processing applicationsOrder schedulingProgram planning

In general, in one aspect, the invention features a computerized method for determining customer service impact. The method includes receiving item orders having a requested completion date. The method also includes scheduling a scheduled completion date for each item order. The method also includes selecting at least one item order, each item order having a scheduled completion date. The method also includes comparing the scheduled completion date with the requested completion date for each selected item order. The method also includes deriving a customer service measurement for each selected item order based on the comparing step. The method can include the optional step of reporting and / or displaying customer service measurement data. In general, in another aspect, the invention relates to a system for determining customer service impact that performs the method steps just described.

Owner:PROFUSE GROUP

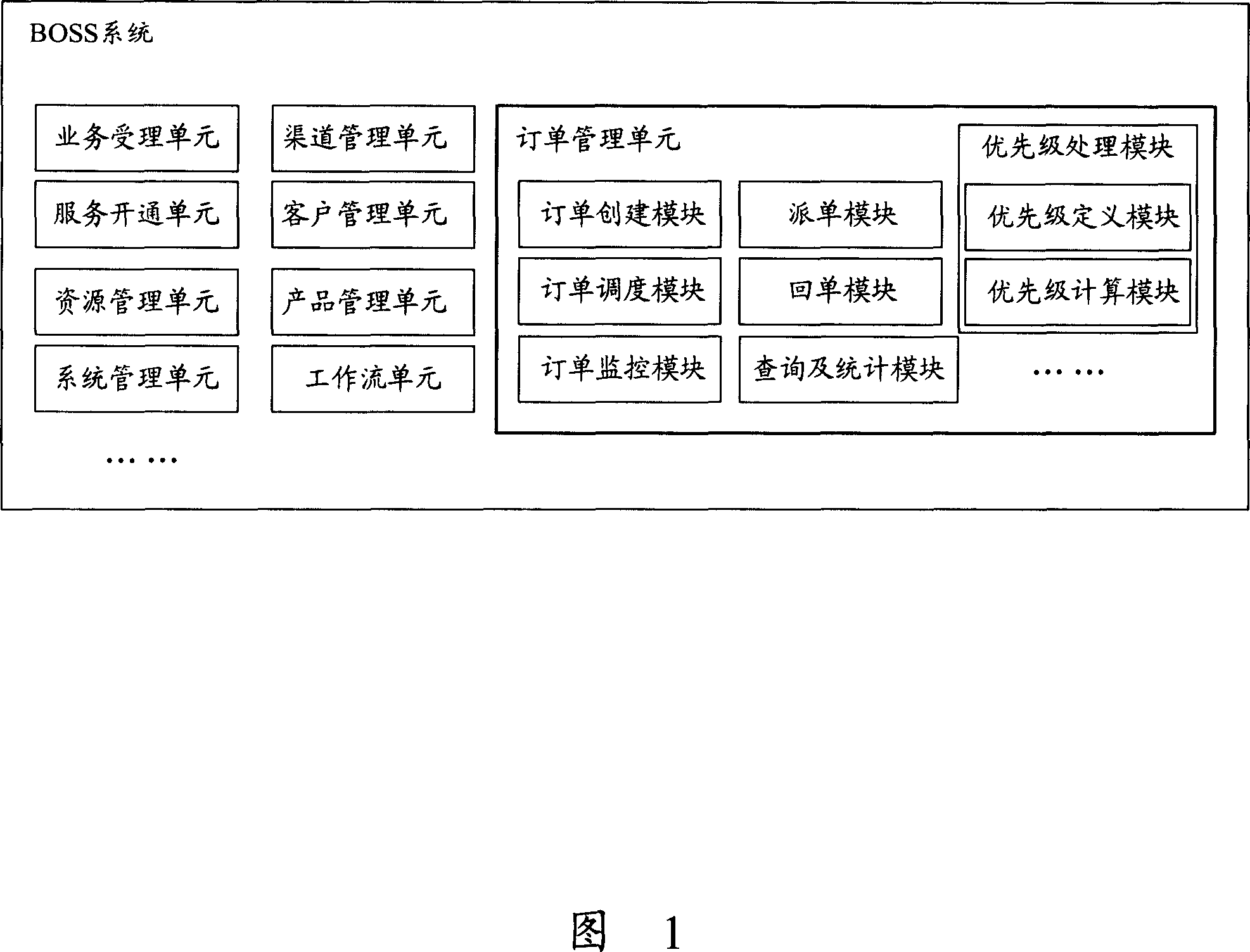

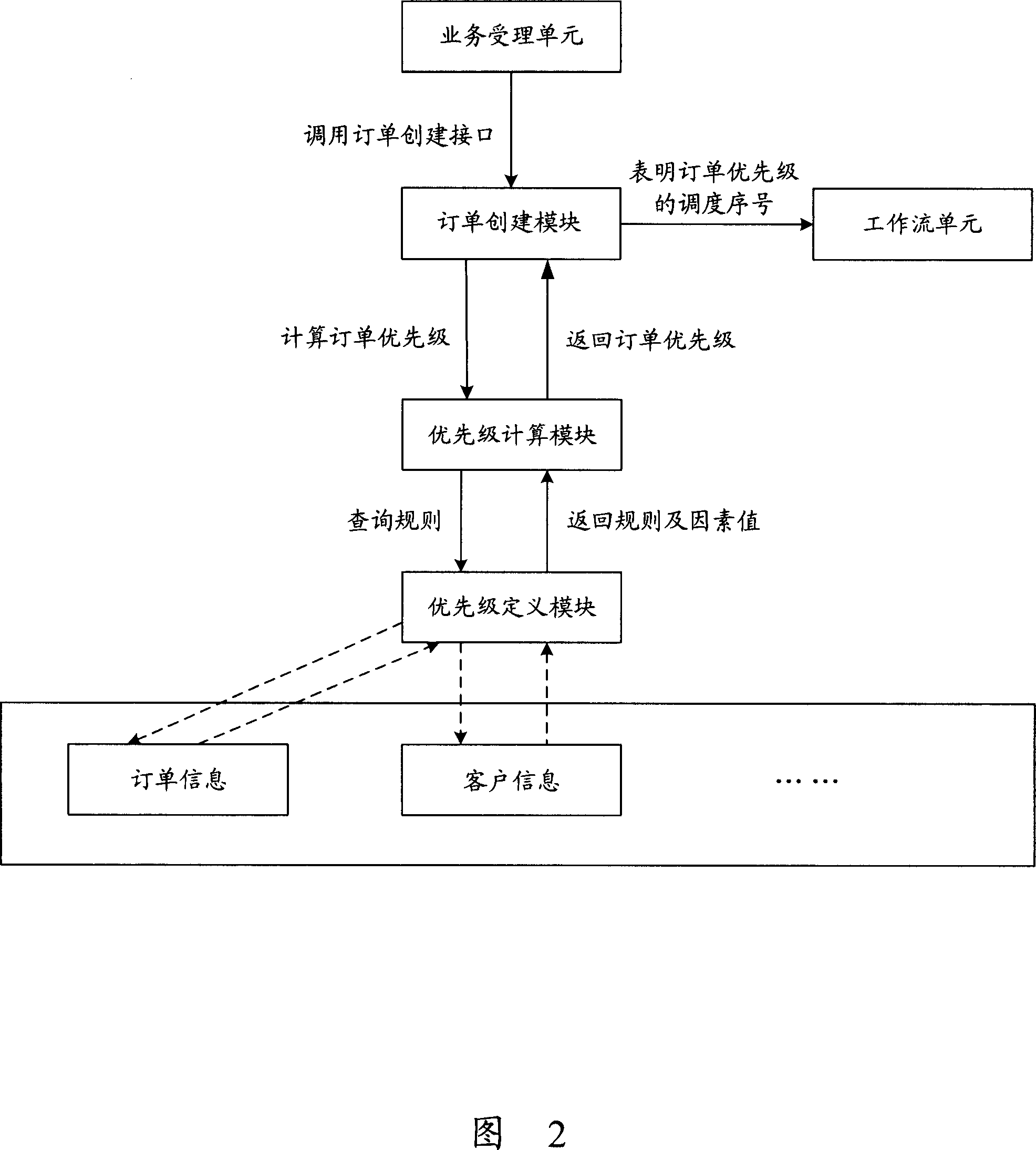

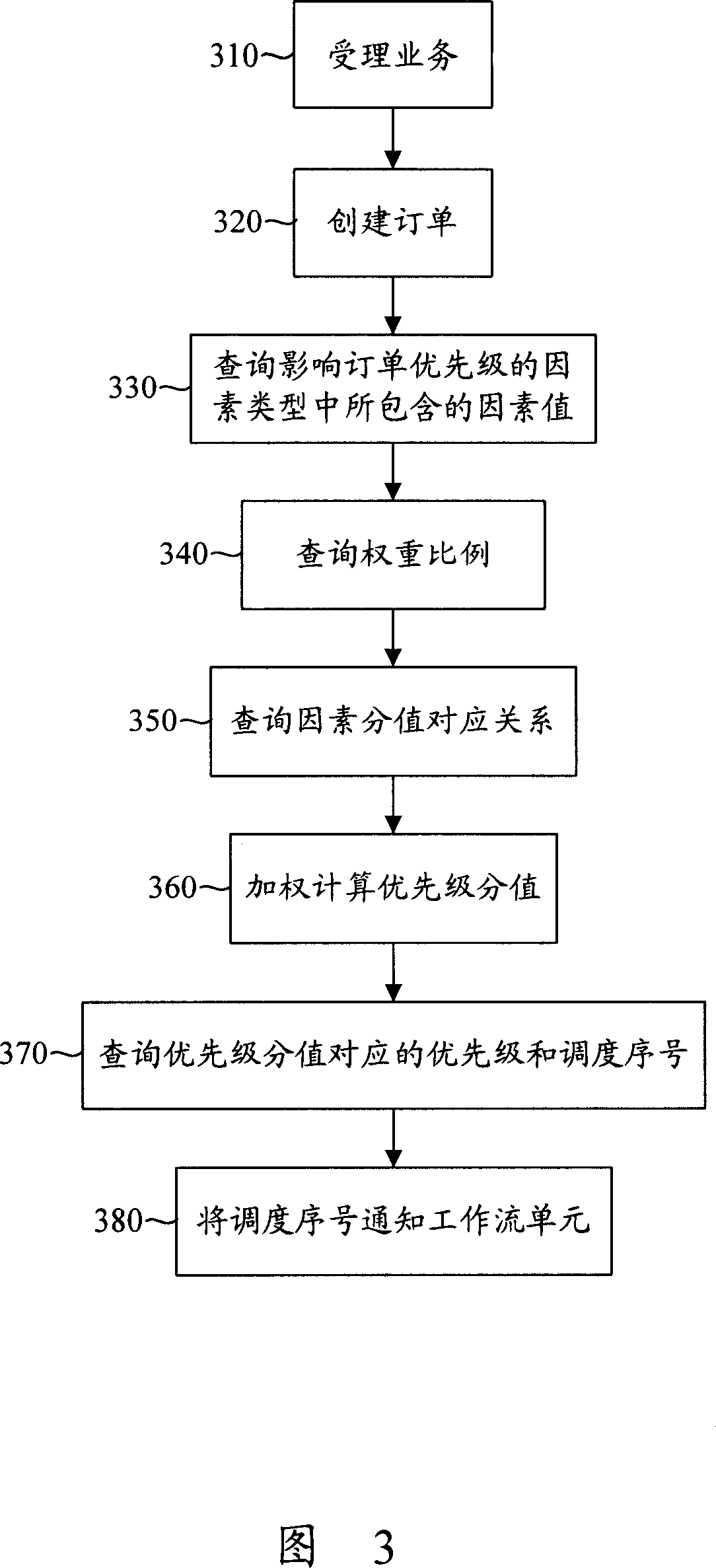

System and method for realizing order dispatch based on priority level

The invention discloses a priority based orders scheduling system, which includes order creation module and related priority processing module. The order creation module notifies priority processing module to determine the priority of an order, and receives the priority information form the priority processing module; the priority processing module performs weighted calculation on the factors that may impact the order priority, and send the result back to order creation module. The invention also discloses the method of priority based order scheduling, which includes: receive request of order scheduling; determine the factors that will impact order priority and perform the weighted calculation to get the priority information; schedule the order according to the obtained priority information.

Owner:HUAWEI TECH CO LTD

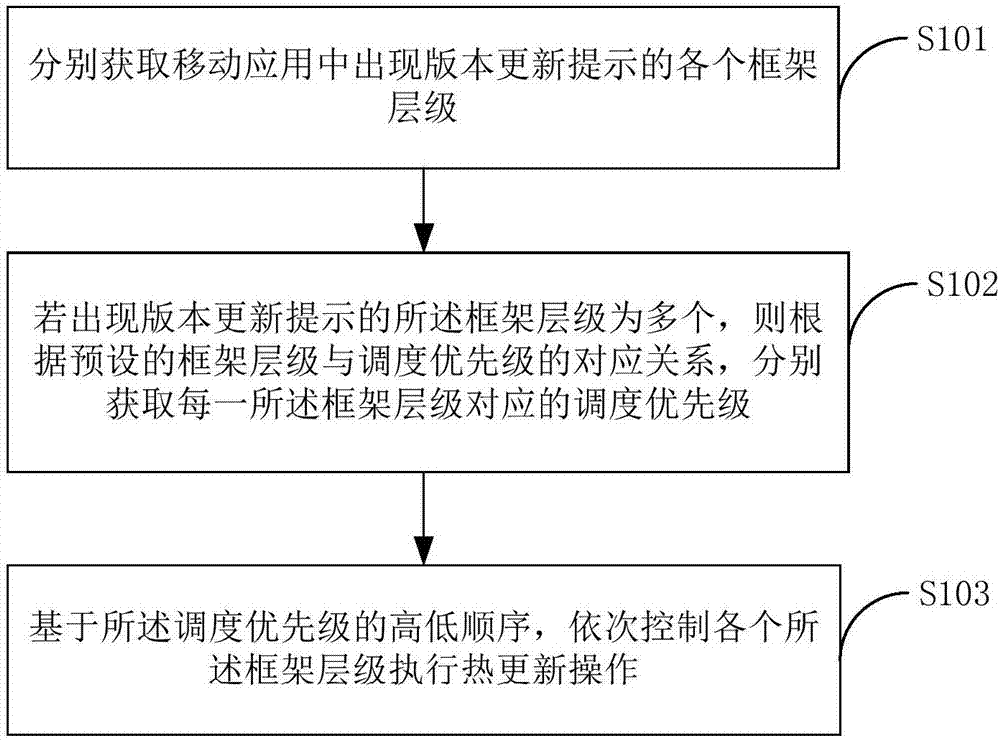

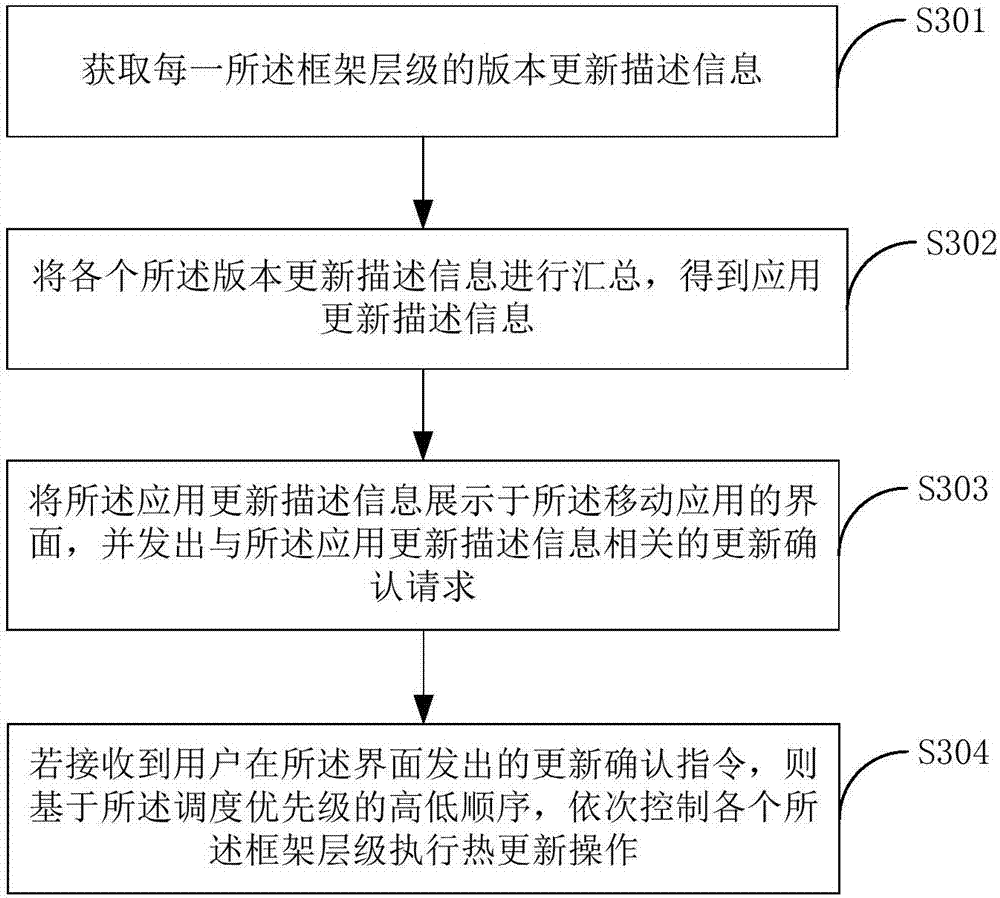

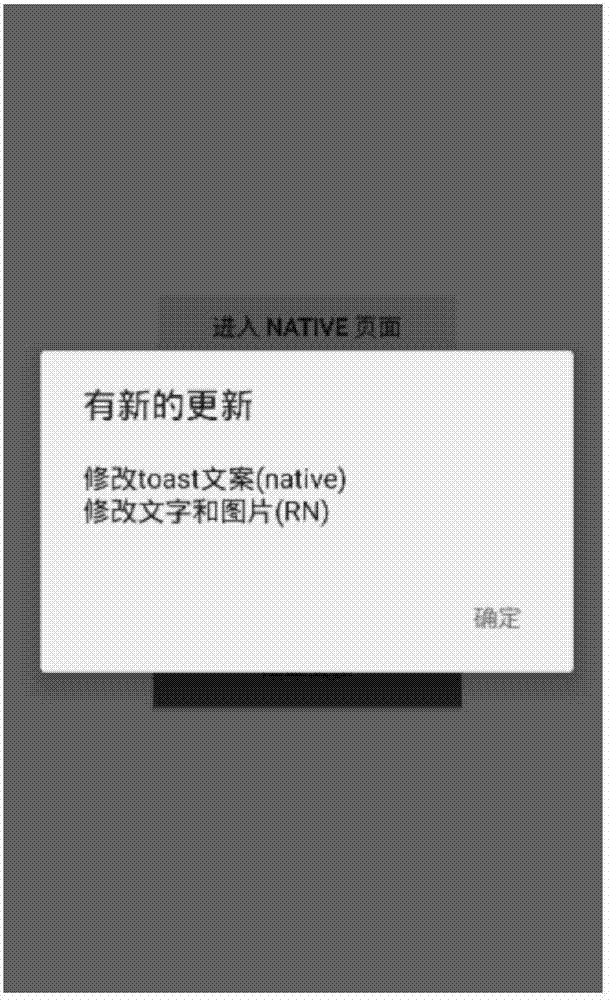

Hot-update method for mobile application and terminal equipment

ActiveCN107463400AAchieve orderly schedulingAvoid Hot Update PreemptionProgram loading/initiatingSoftware deploymentOrder schedulingTerminal equipment

The invention provides a hot-update method for a mobile application and terminal equipment and is applied to the technical field of the mobile application. The method comprises the steps of respectively acquiring each framework hierarchy having a version update prompt in the mobile application; if there are multiple framework hierarchies having the version update prompts, respectively acquiring a scheduling priority corresponding to each framework hierarchy according to a preset corresponding relation between the framework hierarchy and the scheduling priority; and sequentially controlling each framework hierarchy to execute a hot-update operation based on a descending order of the scheduling priorities. According to the hot-update method for the mobile application and the terminal equipment, each framework hierarchy is sequentially controlled to execute the hot-update operation based on the descending order of the scheduling priorities, ordered scheduling among the plurality of framework hierarchies is realized, the phenomenon of hot-update preemption or hot-update conflict occurring among the plurality of framework hierarchies is avoided, thus continuous normal running of the mobile application in a hot-update process can be guaranteed and the stability of the mobile application is improved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

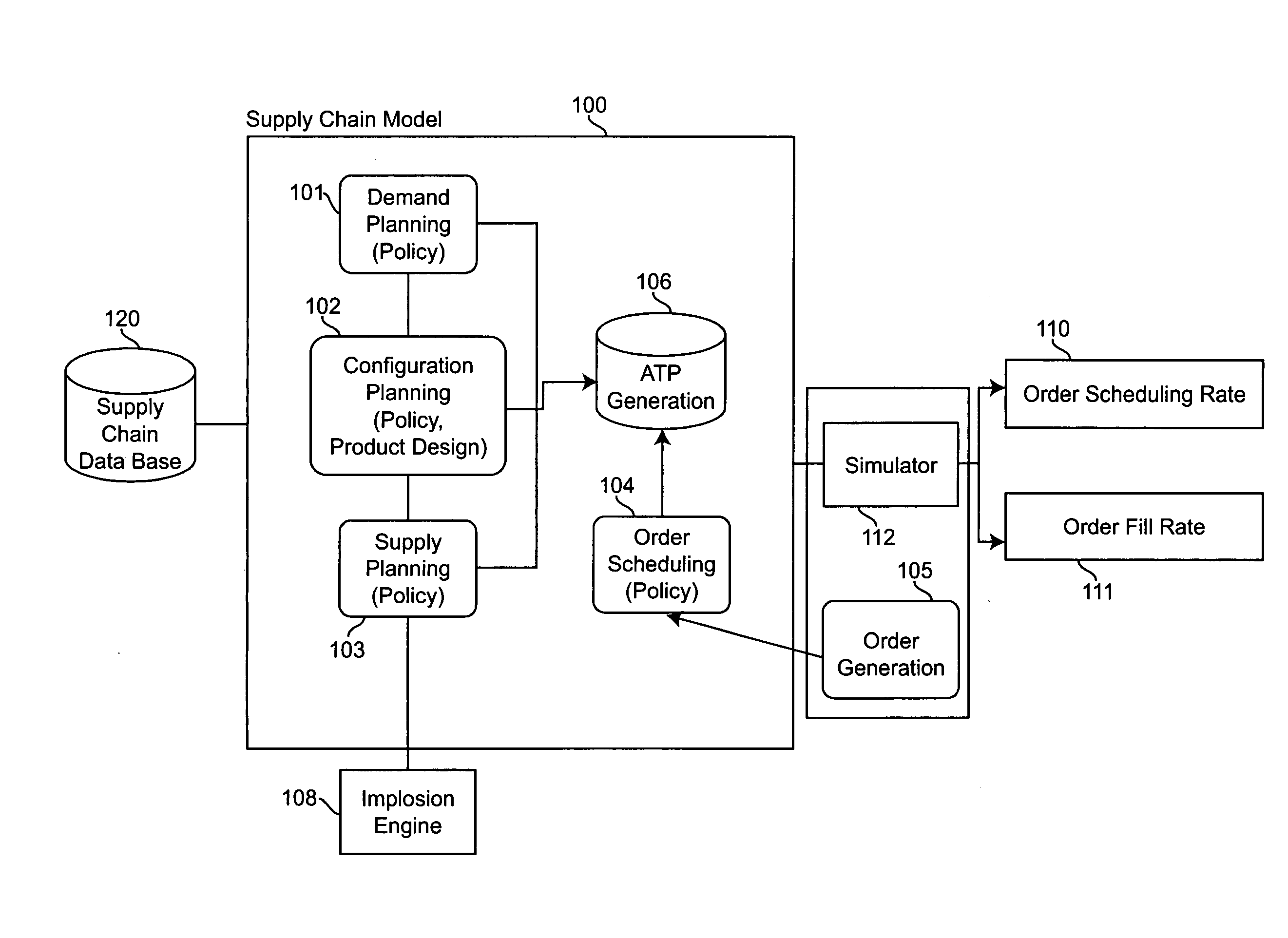

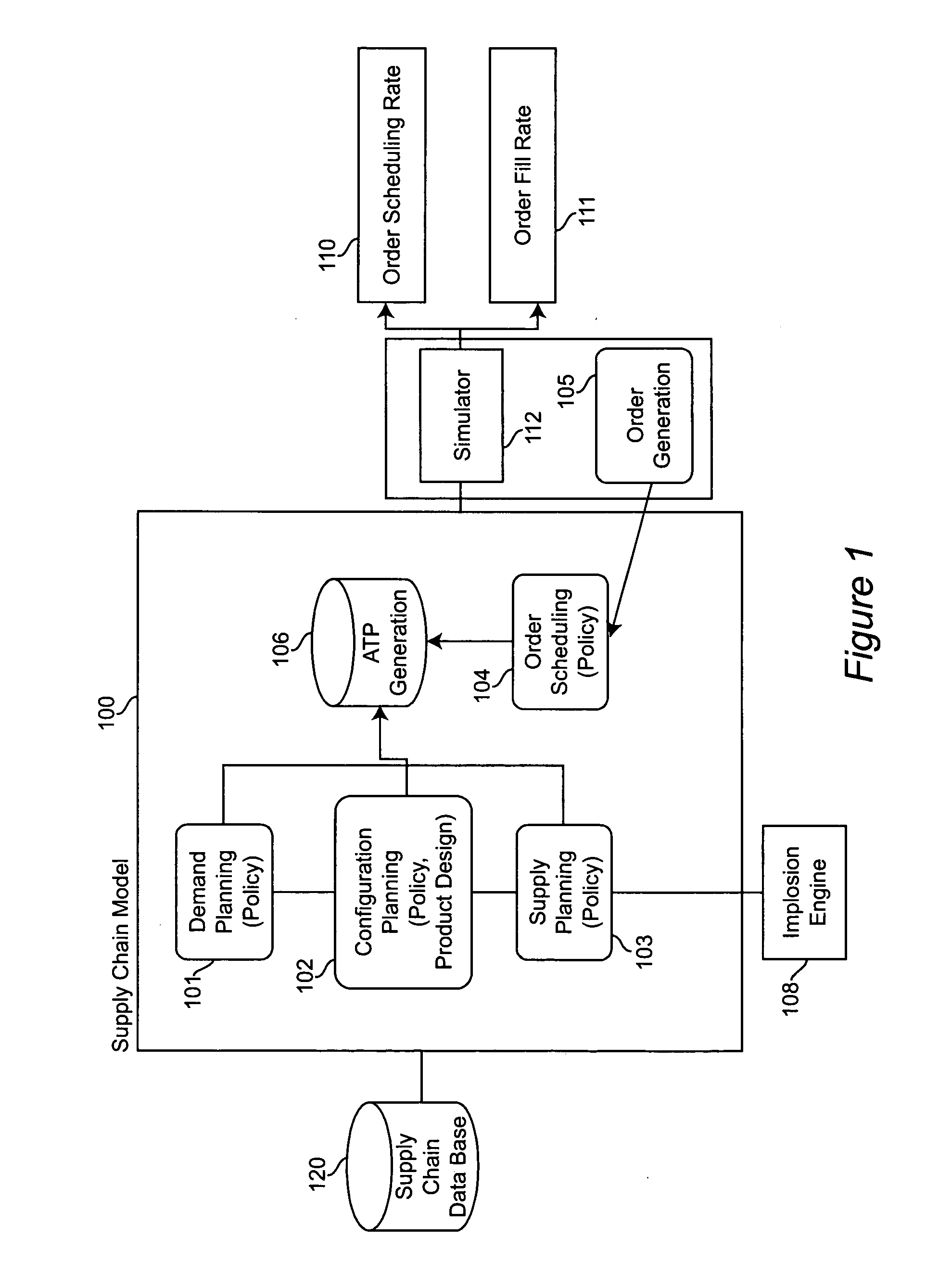

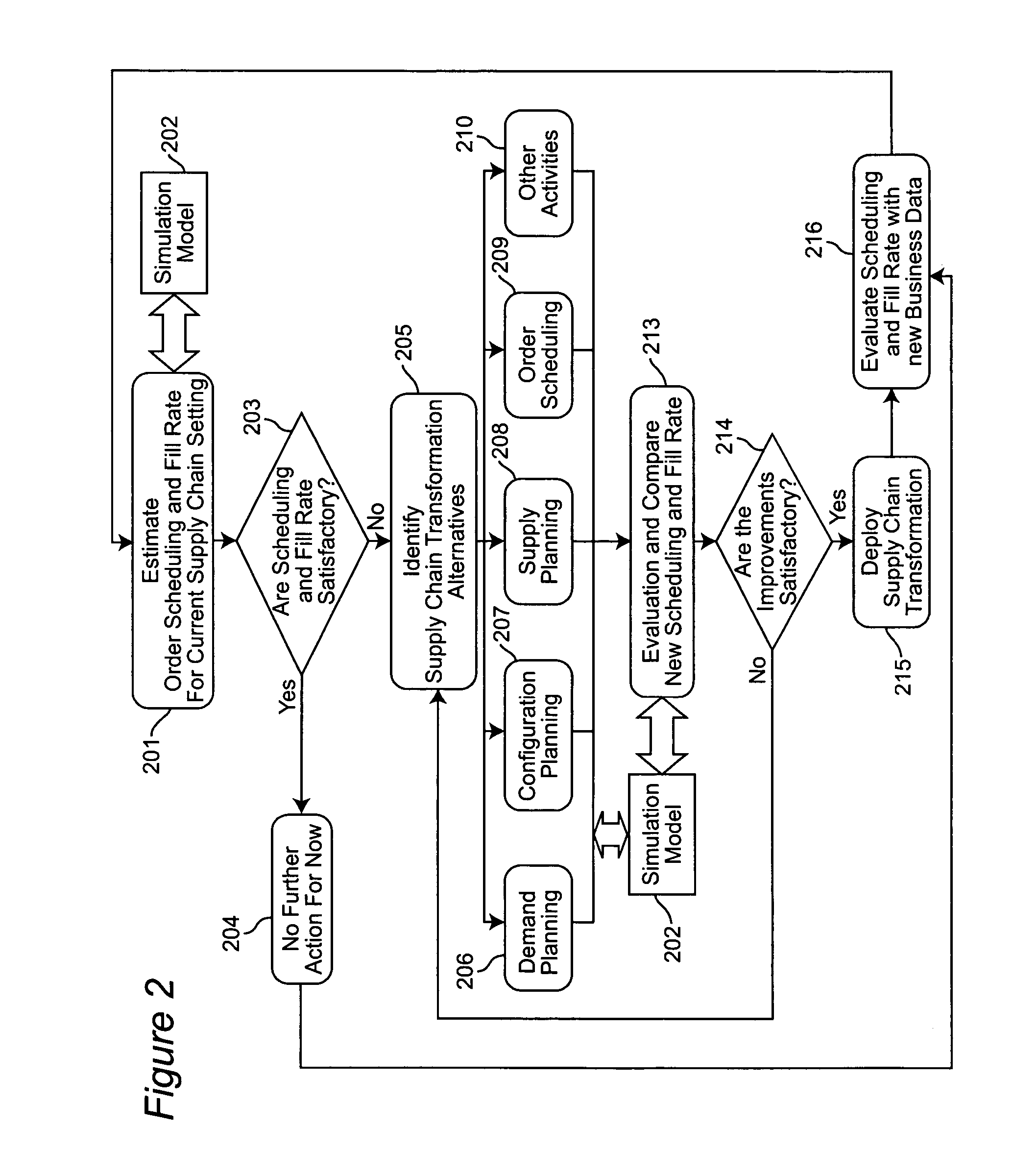

Method and system for estimating order scheduling rate and fill rate for configured-to-order business

InactiveUS20070010904A1Improve performanceTighter capacityResourcesSpecial data processing applicationsFill rateScheduling function

A system and method estimates performance of a supply chain's available-to-promise (ATP) and scheduling functions under various environmental and process assumptions. The supply chain's transformation alternatives are identified using a plurality of modules constituting a supply chain model and including a demand planning module, a configuration planning module, an order scheduling module and a supply planning module, each of said modules being reconfigurable using various policies, which policies, taken together, specify a particular supply chain design that is to be analyzed. A supply chain data base is accessed by the supply chain model to retrieve data elements that dictate appropriate policies within said plurality of modules. The supply chain performance is simulated based on settings of the modules and other environmental factors including demand uncertainty, order configuration uncertainty, supplier flexibility, supply capacity, and demand skew. Based on the simulation, scheduling and fill rate of new business settings are evaluated to determine if improvements to the supply chain are satisfactory.

Owner:IBM CORP

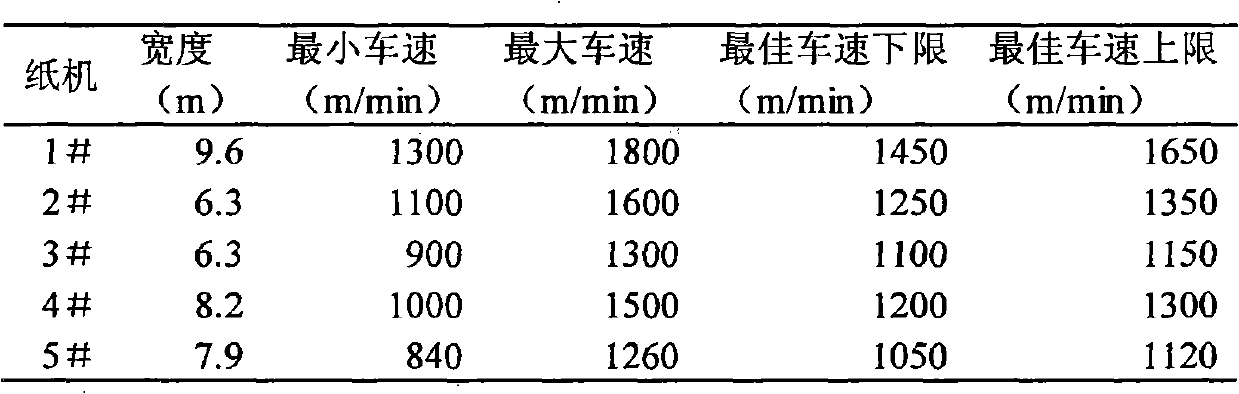

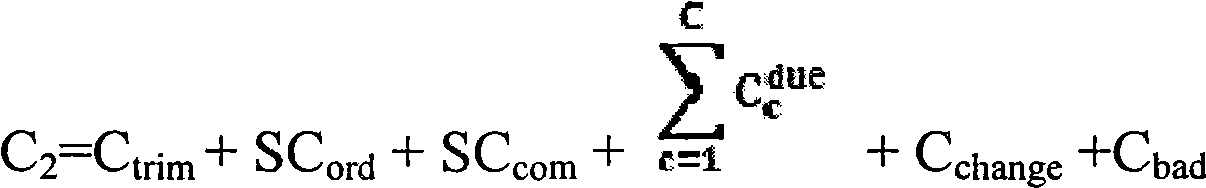

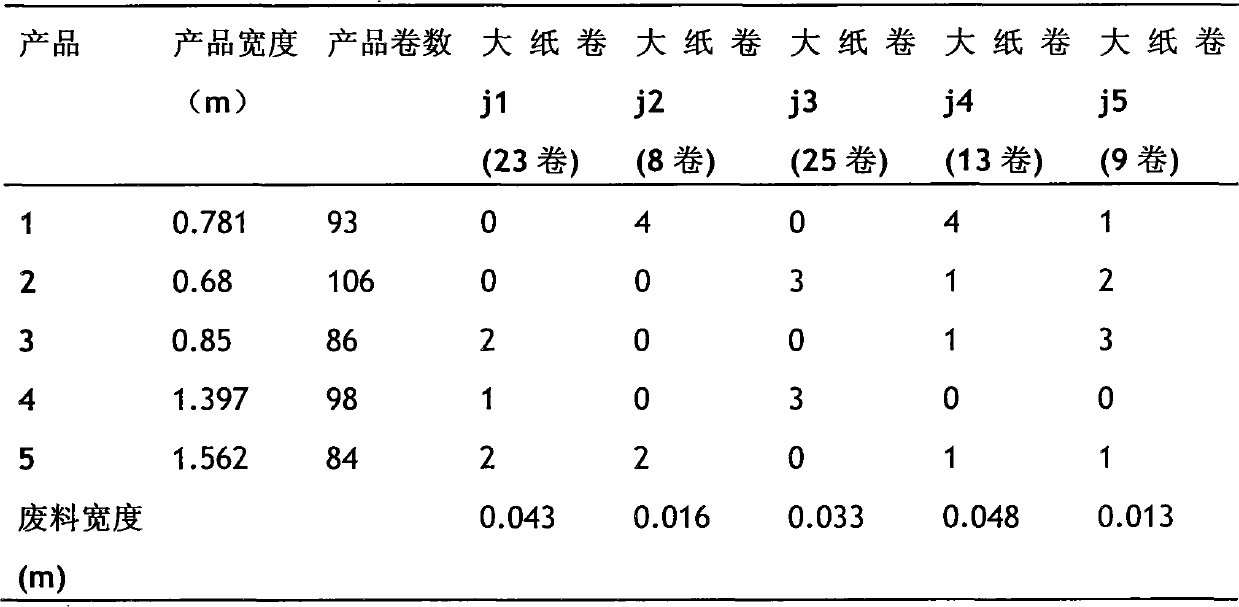

Comprehensive optimization method and system for order scheduling of pulping and paper making enterprises

InactiveCN101950388AAdjust model parameters on the flySolve the optimization problem of production scheduling and cutting toolsForecastingProduction lineOptimal scheduling

The invention discloses a comprehensive optimization method and a comprehensive optimization system for order scheduling of pulping and paper making enterprises. The method comprises the following steps of: 1, determining the number of products to be produced; 2, determining yield of various kinds of paper on different paper machines, sequence of producing the products by each paper machine and paper switching time during production of each paper machine in order to fulfill the aim of ensuring the minimum final cost; 3, determining a paper cutting plan of each kind of paper produced by each machine in order to fulfill the aim of ensuring the minimum production cost; and 4, arranging a corresponding paper machine for production according to the determined plan. The system comprises a real-time database, a papermaking production line model base, an optimal scheduling model base, an optimal cutter scheduling model base, a scheduling plan report base, a cutter scheduling plan report base and a man-machine interaction interface. The method and the system of the invention can completely solve the problem of optimization of scheduling and cutter scheduling of paper factories from order scheduling to paper cutter scheduling, has high feasibility and can solve the actual optimization problem well by adopting an advanced and precise model algorithm.

Owner:SOUTH CHINA UNIV OF TECH

Real-time and orderly scheduling method for electric vehicle aggregator with consideration of user participation

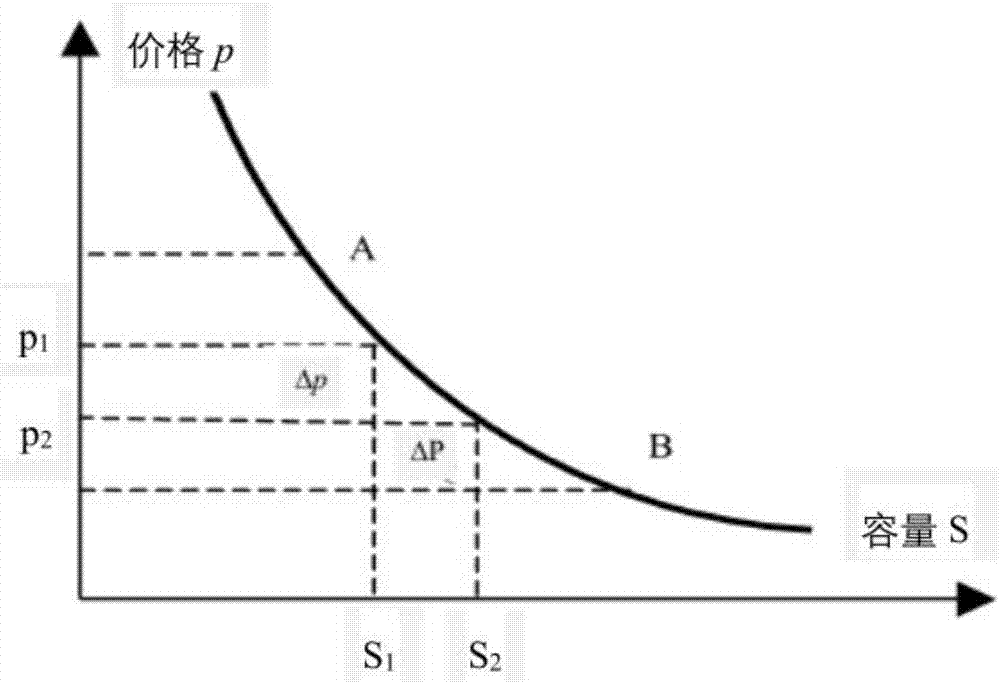

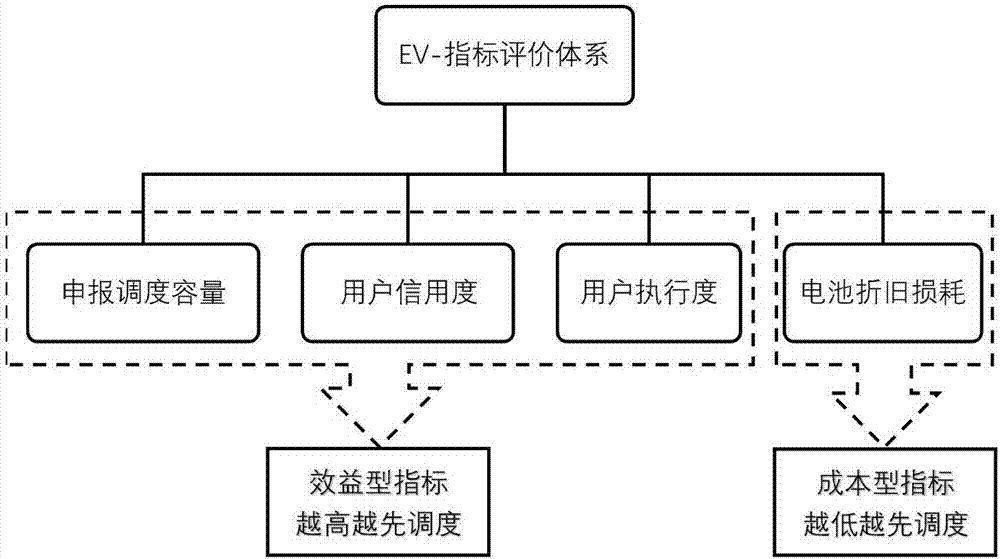

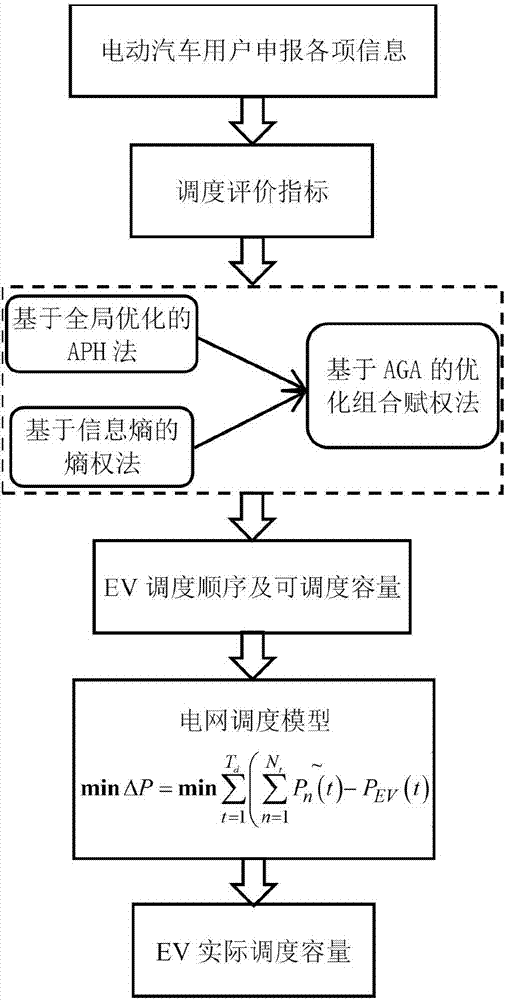

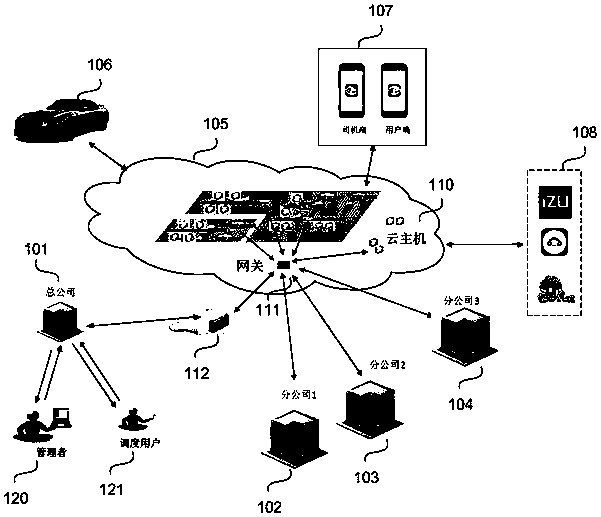

The present invention relates to a real-time and orderly scheduling method for an electric vehicle aggregator with the consideration of user participation, belonging to the field of smart grids. The method comprises the steps of (S1) analyzing an electric vehicle user to declare various information, (S2) using an optimized combination weighting method to establish an index evaluation system modelof the electric vehicle aggregator and solving the model, and obtaining index weights and a comprehensive evaluation value, and (S3) considering the management and adjustment of the scheduling capacities of the vehicles such that actual output / load is close to a given scheduling plan of a grid as possible. According to the method, the influences of multiple indicators of the electric vehicles on the scheduling plan can be comprehensively considered, and an ordered scheduling strategy in an electric vehicle aggregator of an agent side is proposed.

Owner:CHONGQING UNIV

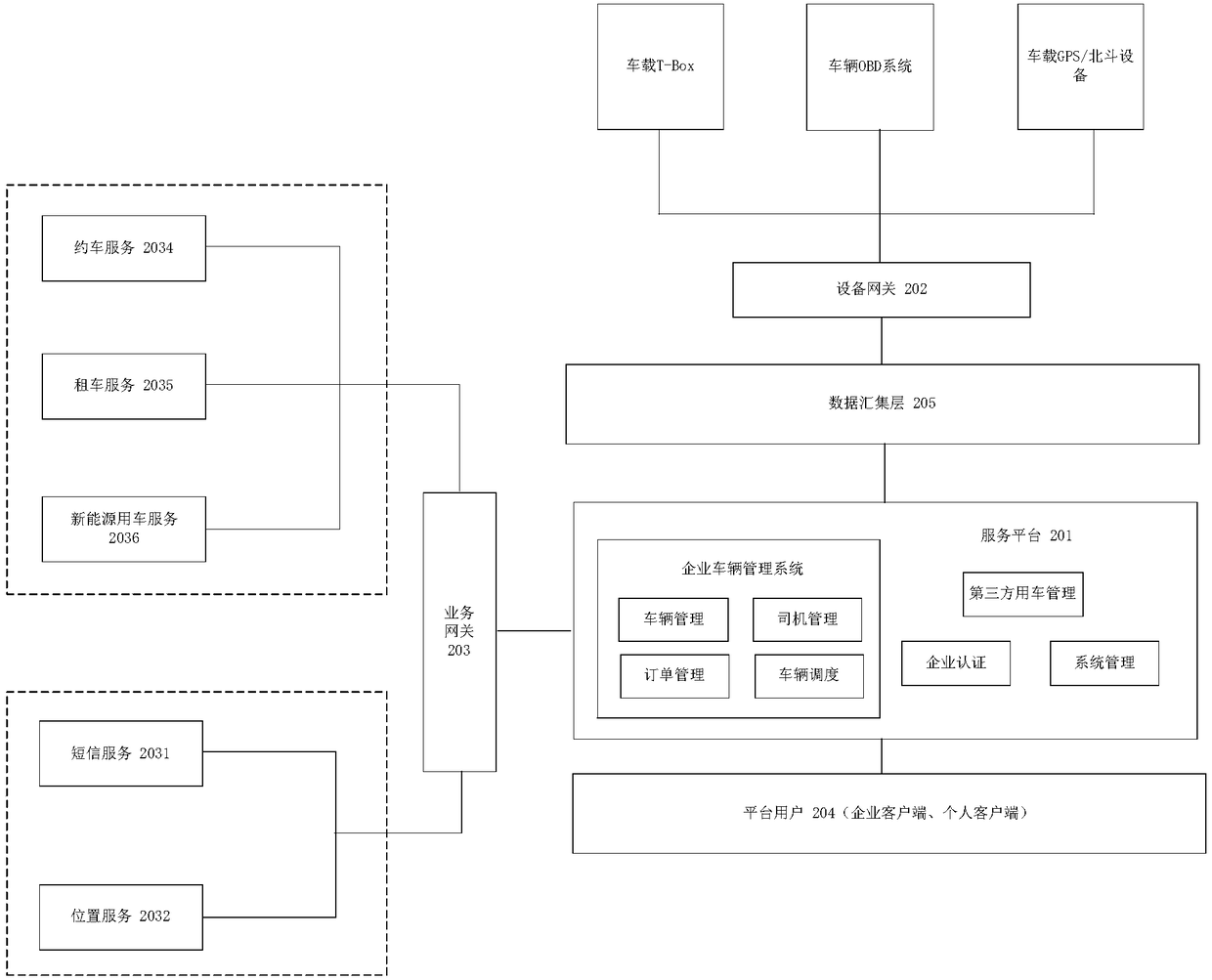

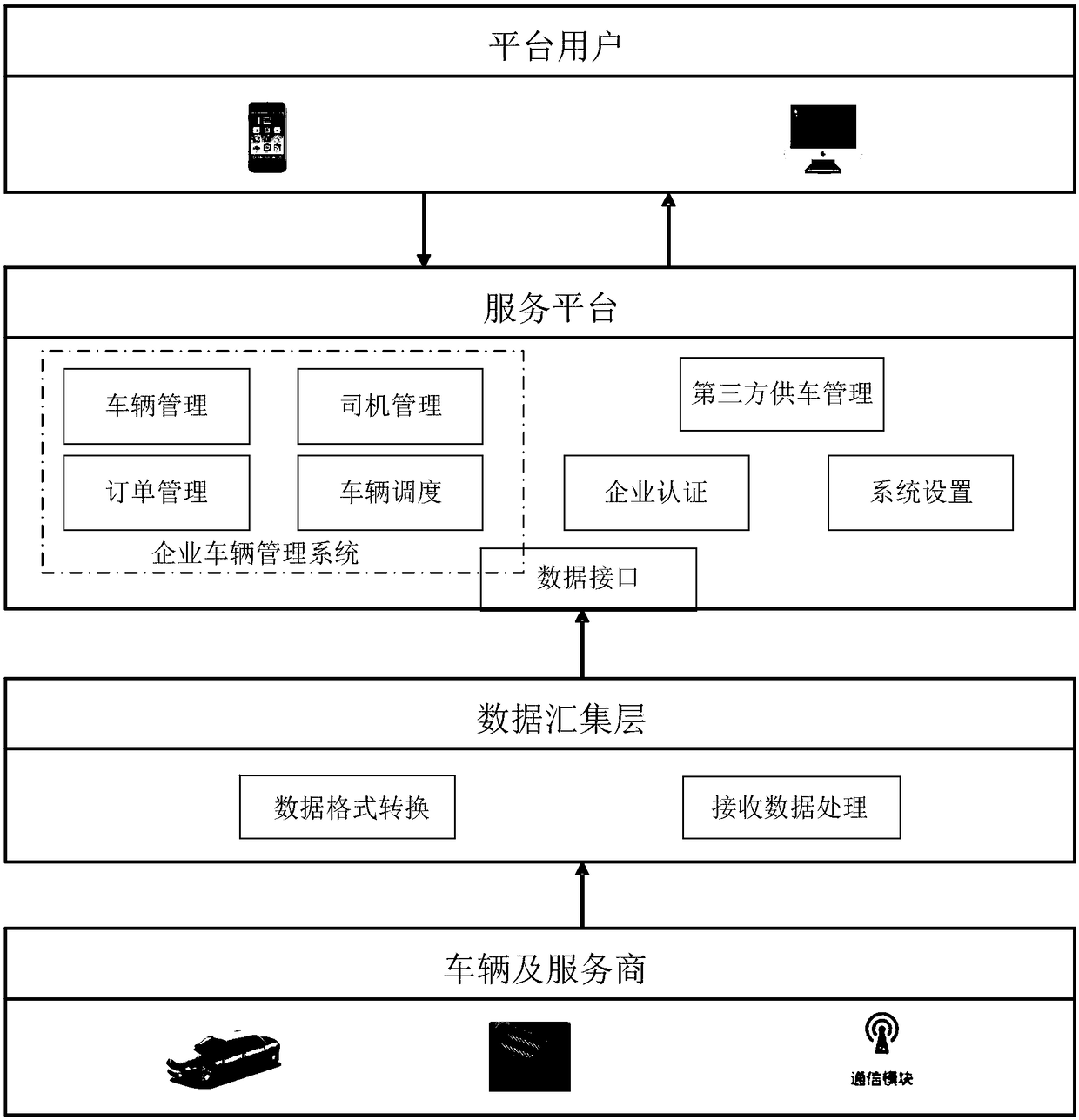

Enterprise vehicle management method

The invention relates to an enterprise vehicle management method. The enterprise vehicle management method comprises the steps that a login request from an employee application is received, and the login request is authenticated; responding to the result that the employee application passes authentication, a vehicle order from the employee application is received; the vehicle order is reviewed; and responding to the result that the vehicle order passes review, an enterprise self-purchased vehicle is arranged according to the vehicle order.

Owner:首汽租赁有限责任公司

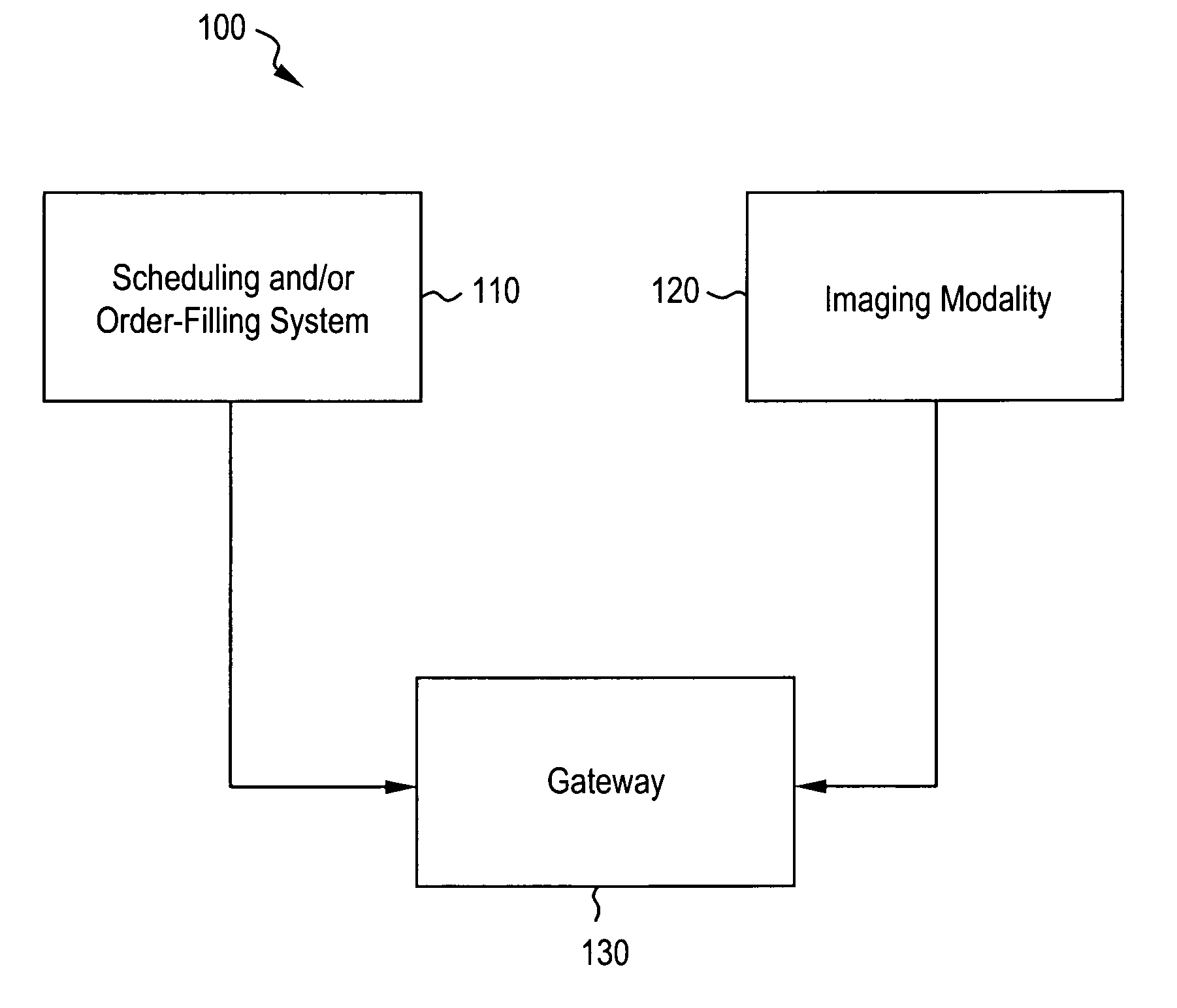

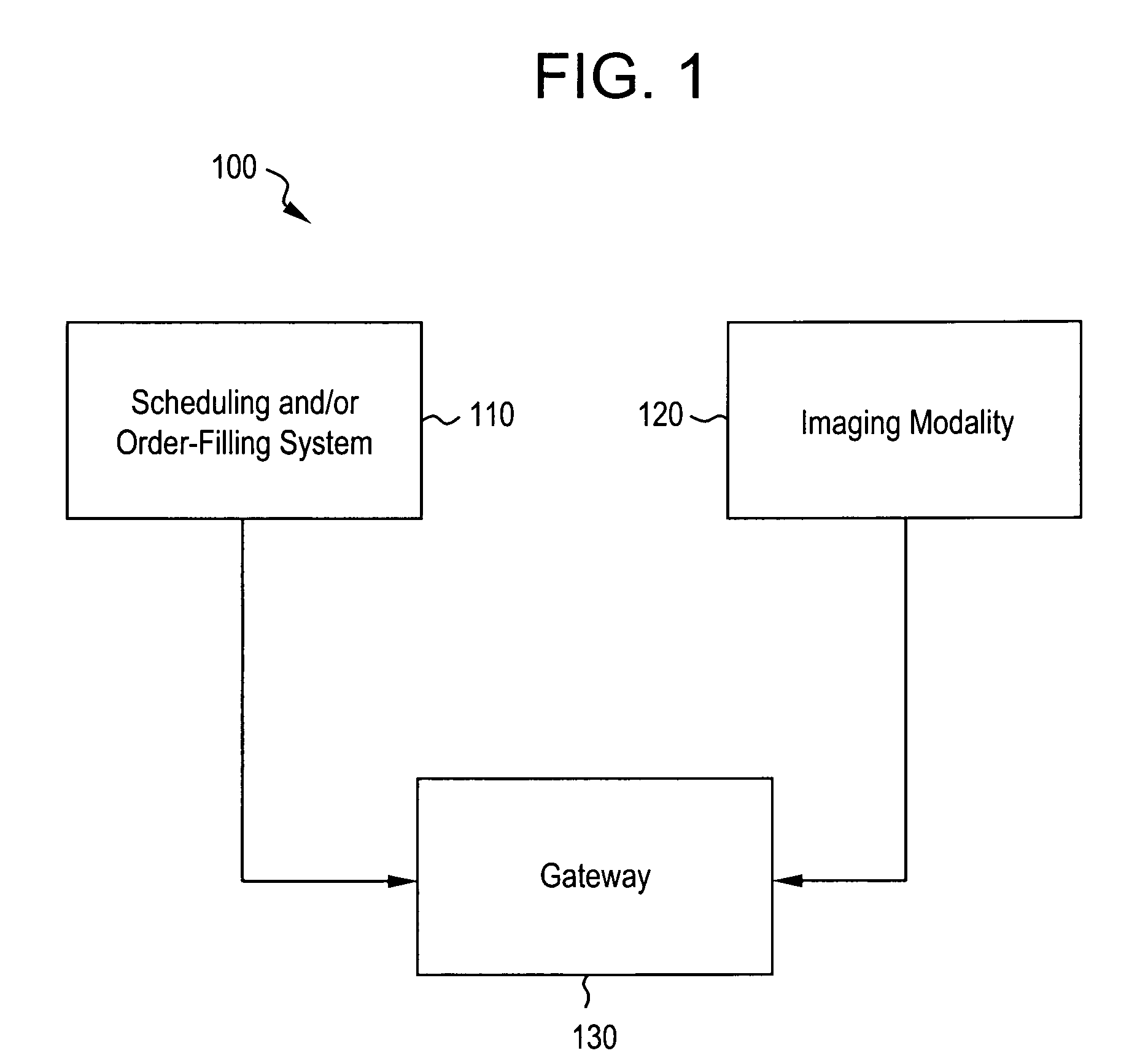

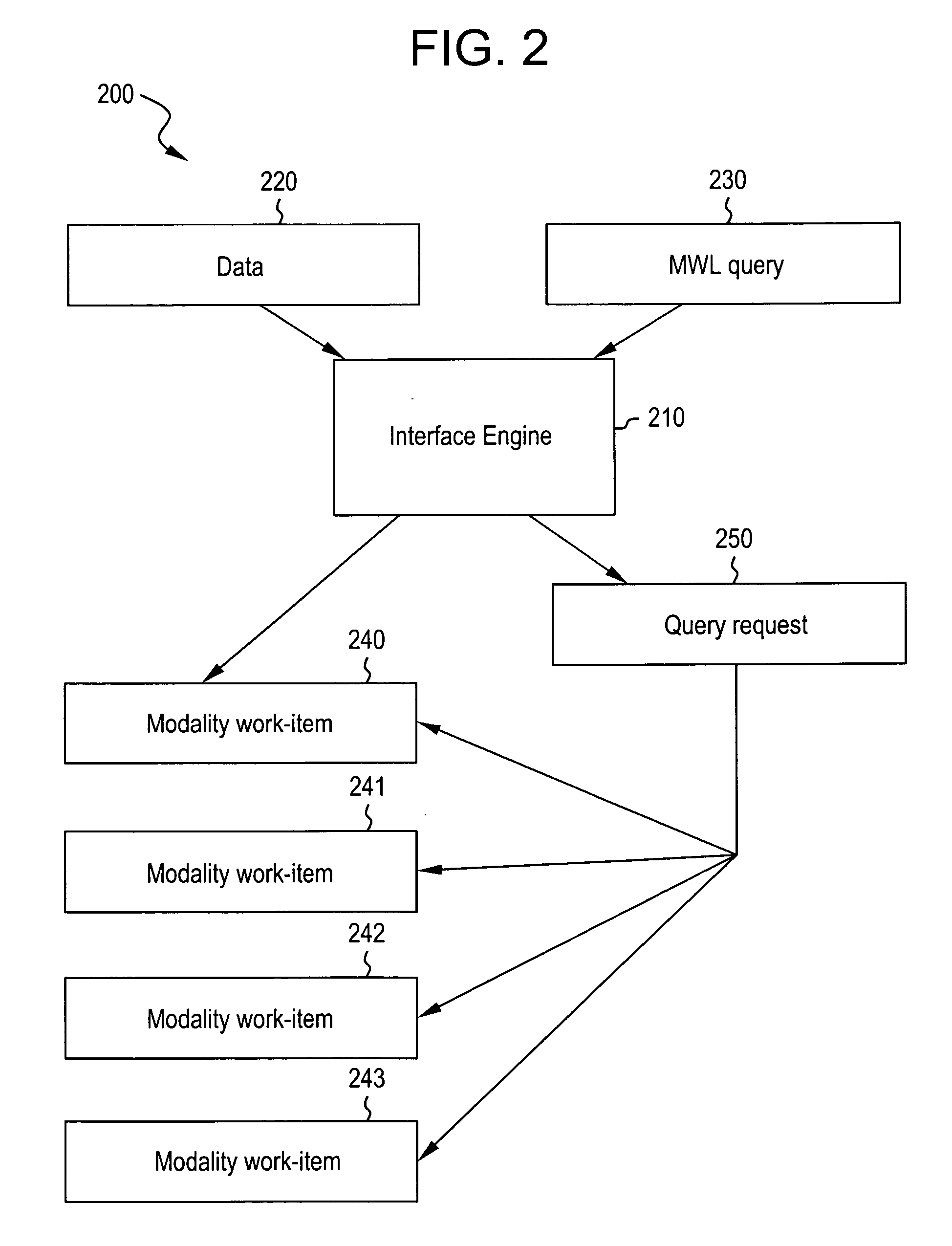

System and method for customizing workflow using standard formats for information transfer

ActiveUS20060111935A1Data processing applicationsMedical imagesOrder schedulingElectronic communication

Embodiments of the present system and method relate generally to standardized electronic communications in a healthcare setting. Certain embodiments of the system include a healthcare information acquisition and management system capable of using information that conforms to an industry standard format for information transfer, an order scheduling system capable of managing information flow within the healthcare setting, and a gateway system interconnecting the healthcare information acquisition and management system and the order scheduling system. In certain embodiments, the gateway system provides for a transfer of nonconforming information between the order scheduling system and the healthcare information acquisition and management system.

Owner:GENERAL ELECTRIC CO

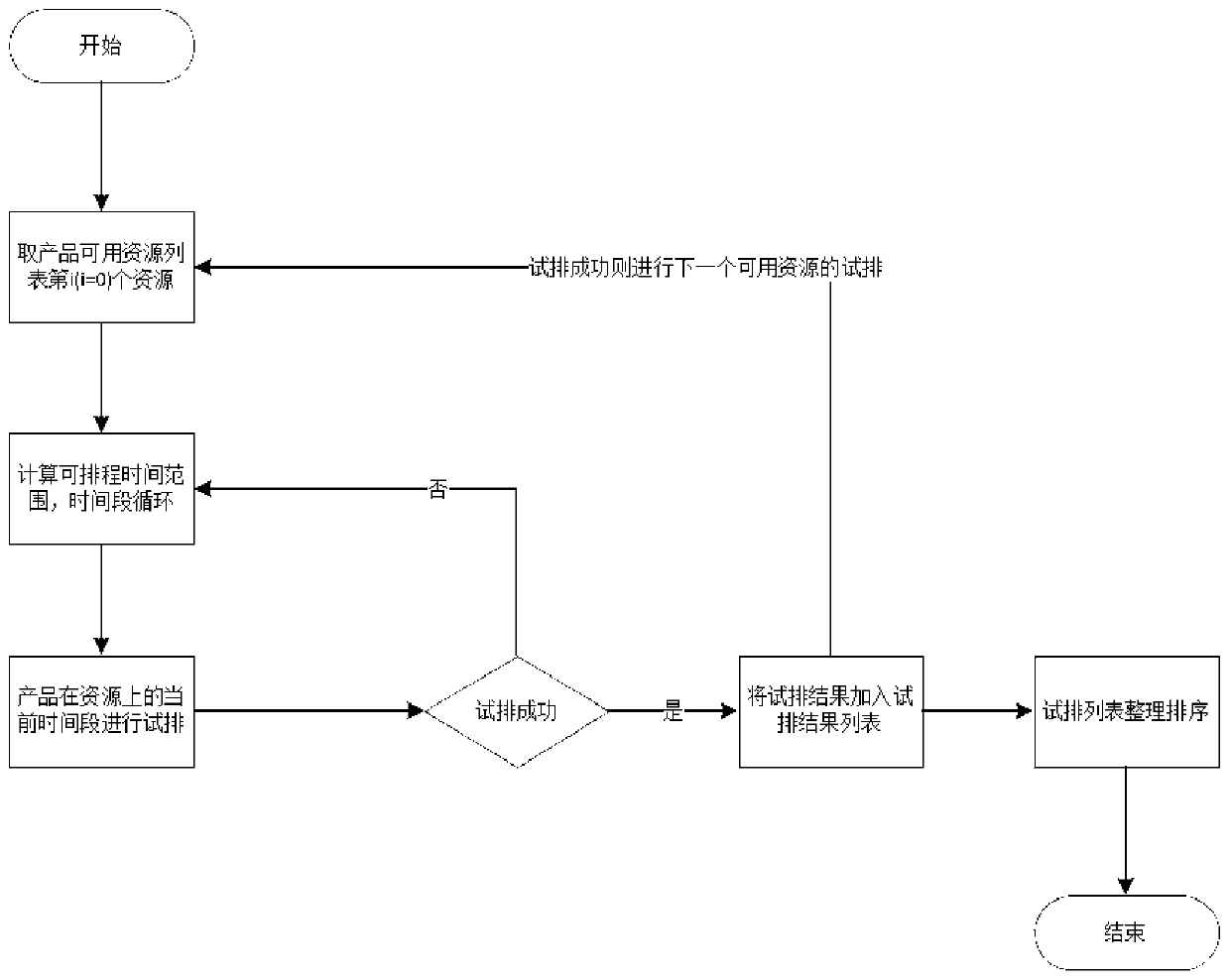

Order scheduling, allocating and dispatching method and system

ActiveCN110955206AMeet continuity requirementsEasy to operateTotal factory controlProgramme total factory controlProduction lineOrder scheduling

The invention discloses an order scheduling, allocating and dispatching method and system. The method comprises the steps of obtaining an order product and the delivery time, and storing the order product and the delivery time in an order list; obtaining the available resource storage, resource priority and production takt of the order product and storing the available resource storage, the resource priority and the production takt in an available resource list; calculating the production delivery time of the order product according to the delivery time of the order product, taking the i-th order product, and performing trial scheduling in a range from the order delivery time to the production delivery time to obtain a trial scheduling result set; taking the n-th resource in the availableresource list of the i-th order product, carrying out trial scheduling on the current order product on the resource, and adding the trial scheduling result into the trial scheduling result set; and taking the j-th trial scheduling result of the i-th order product for comprehensive scoring, and taking the result with the highest score as the final scheduling result of the current order product. According to the present invention, a production line equalization algorithm with the weight as the core is achieved, the basic requirement of the reverse production scheduling according to the deliveryperiod is kept, and the continuity requirement needed by production is met.

Owner:ZHONGTONG BUS HLDG

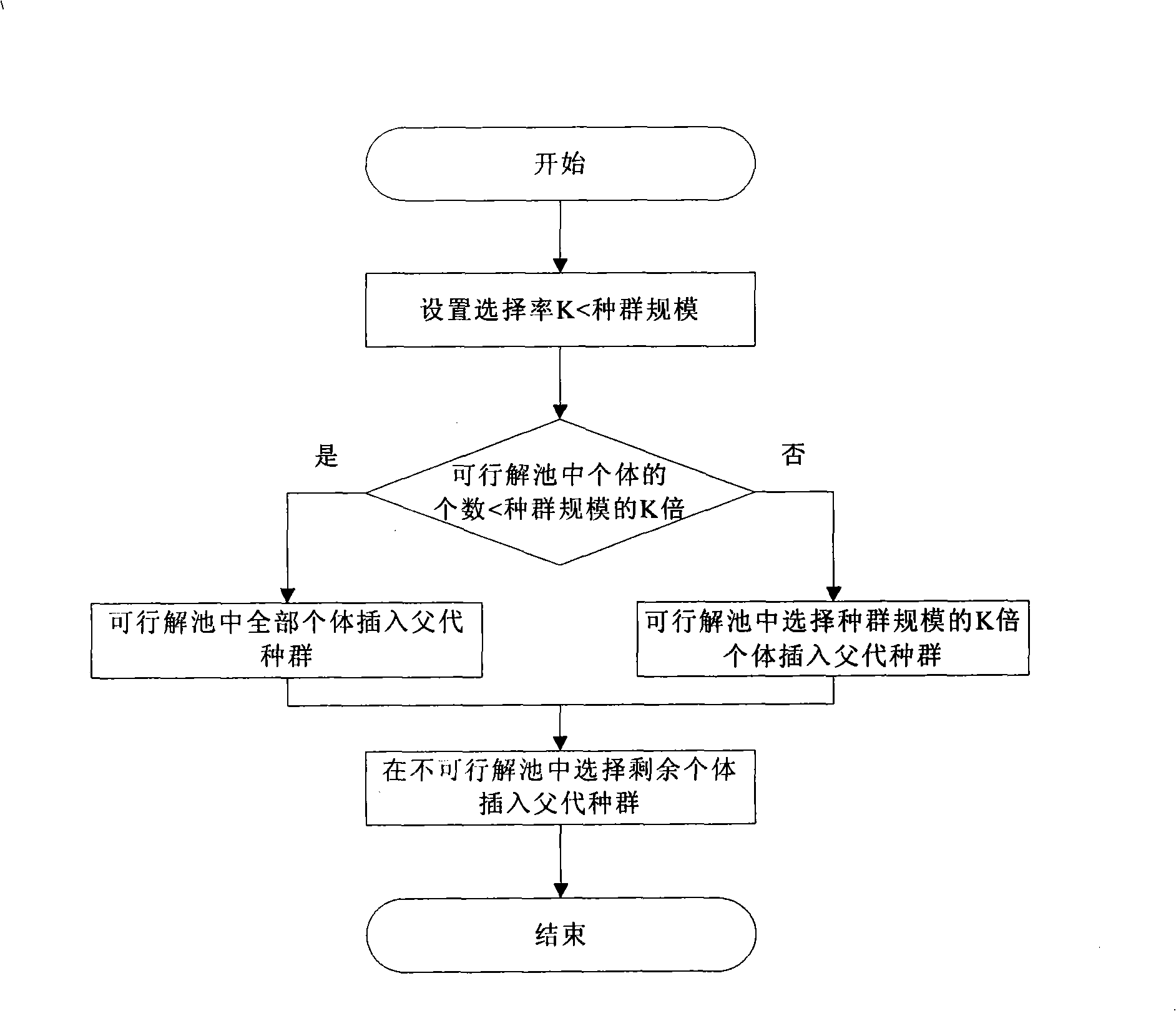

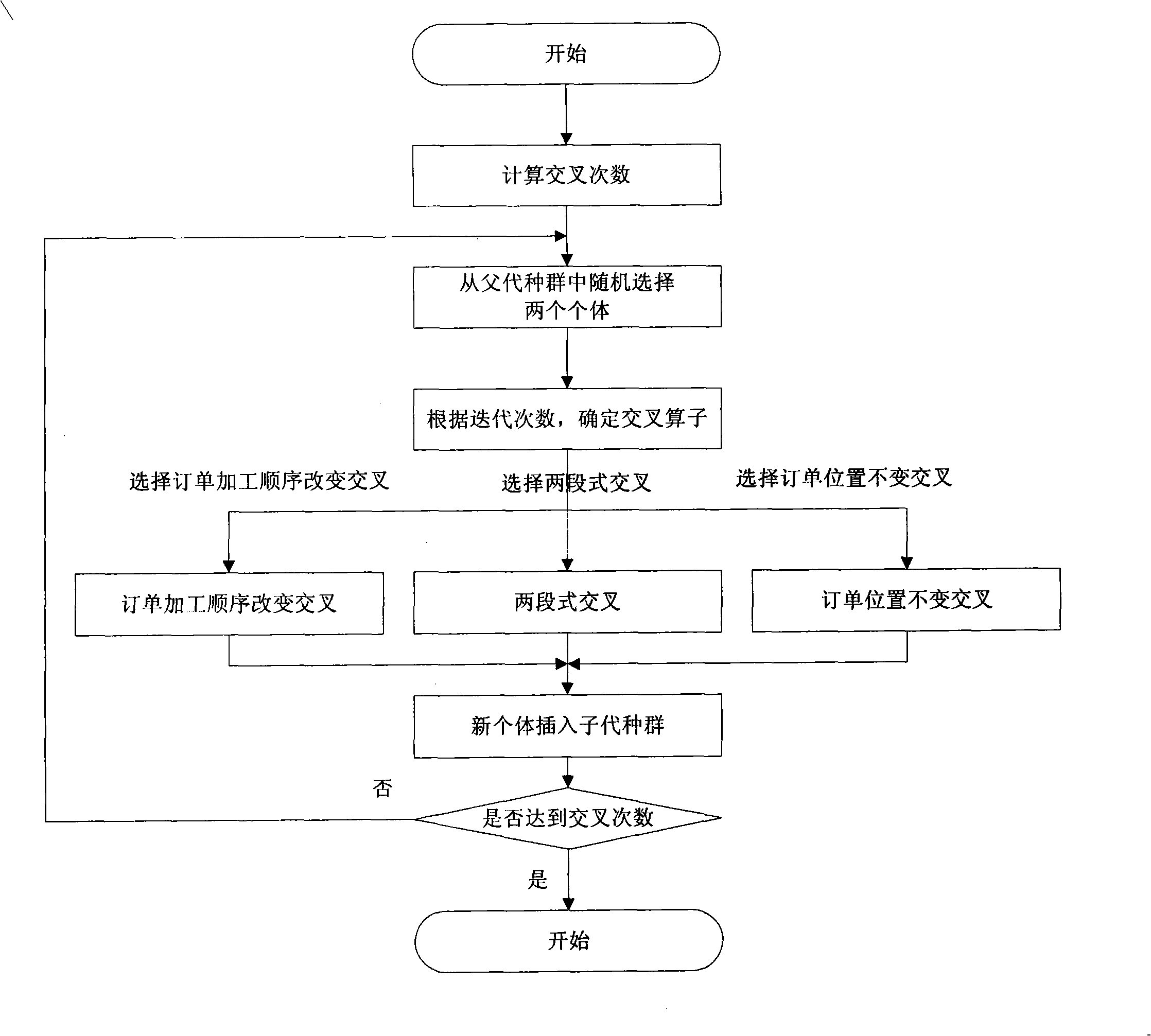

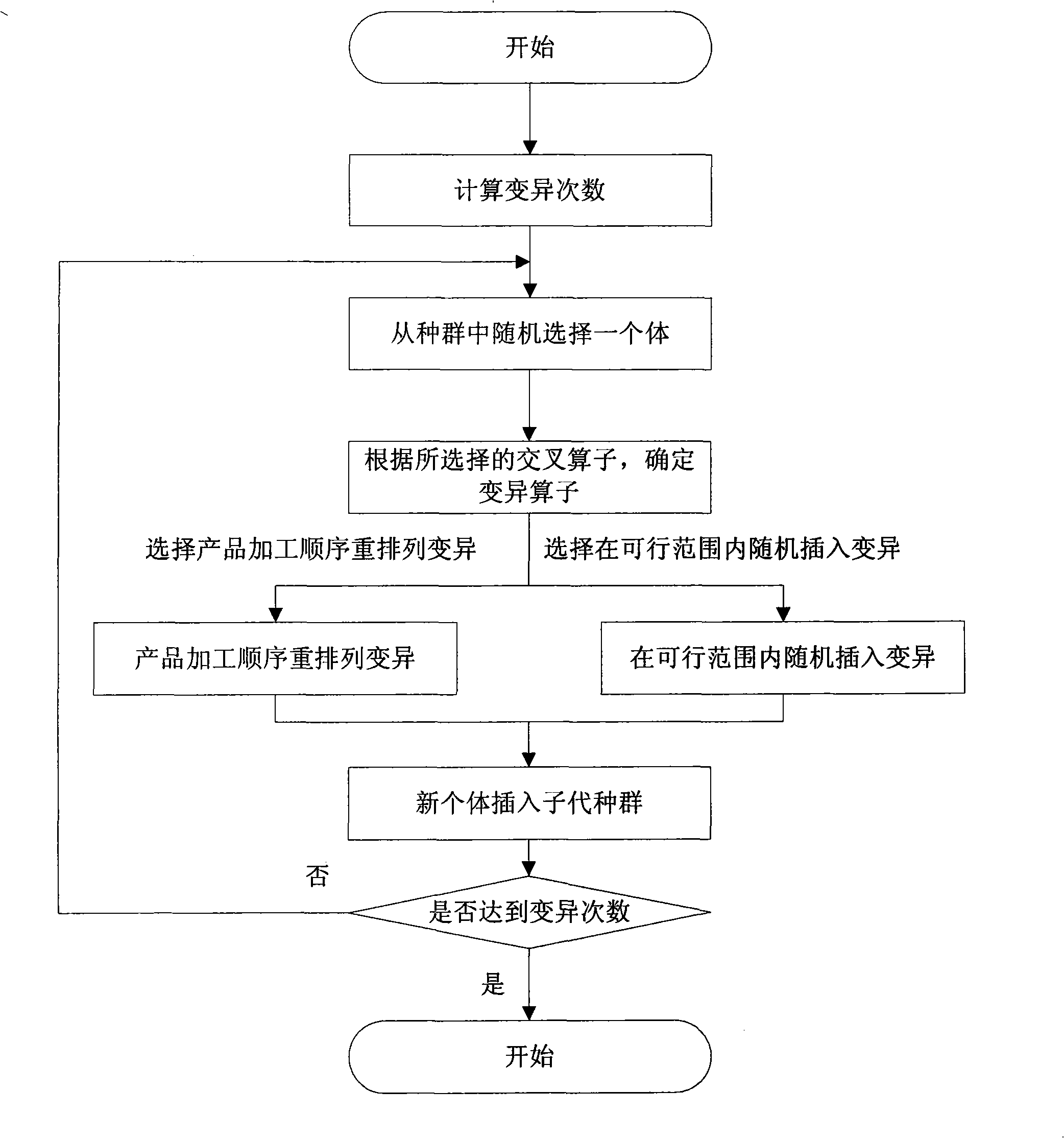

Genetic operation operator based on indent structure for producing quening system

The invention discloses a genetic operation arithmetic operator applied to a production scheduling system and based on order structure, which can select, cross and variate the solution selectivity in the feasible solution pool and the infeasible solution pool to obtain diverse genetic solution, thus providing a basis for the afterward scheduling optimization. Such genetic operation arithmetic operator processes in a crossed variation manner the order scheduling of complicated processes of multilayer BOM structure, and maintains the BOM structure of products in the process of genetic operations so as to simplify the design of genetic arithmetic, the optimization is not restrained by the limiting conditions. And the selective arithmetic operators lead the cluster to select the superior and eliminate the inferior for evolution, or the genetic arithmetic searches for guiding local extreme points, which promotes the effect and speed of astringency of the genetic arithmetic to a large extent.

Owner:永凯软件技术(上海)有限公司

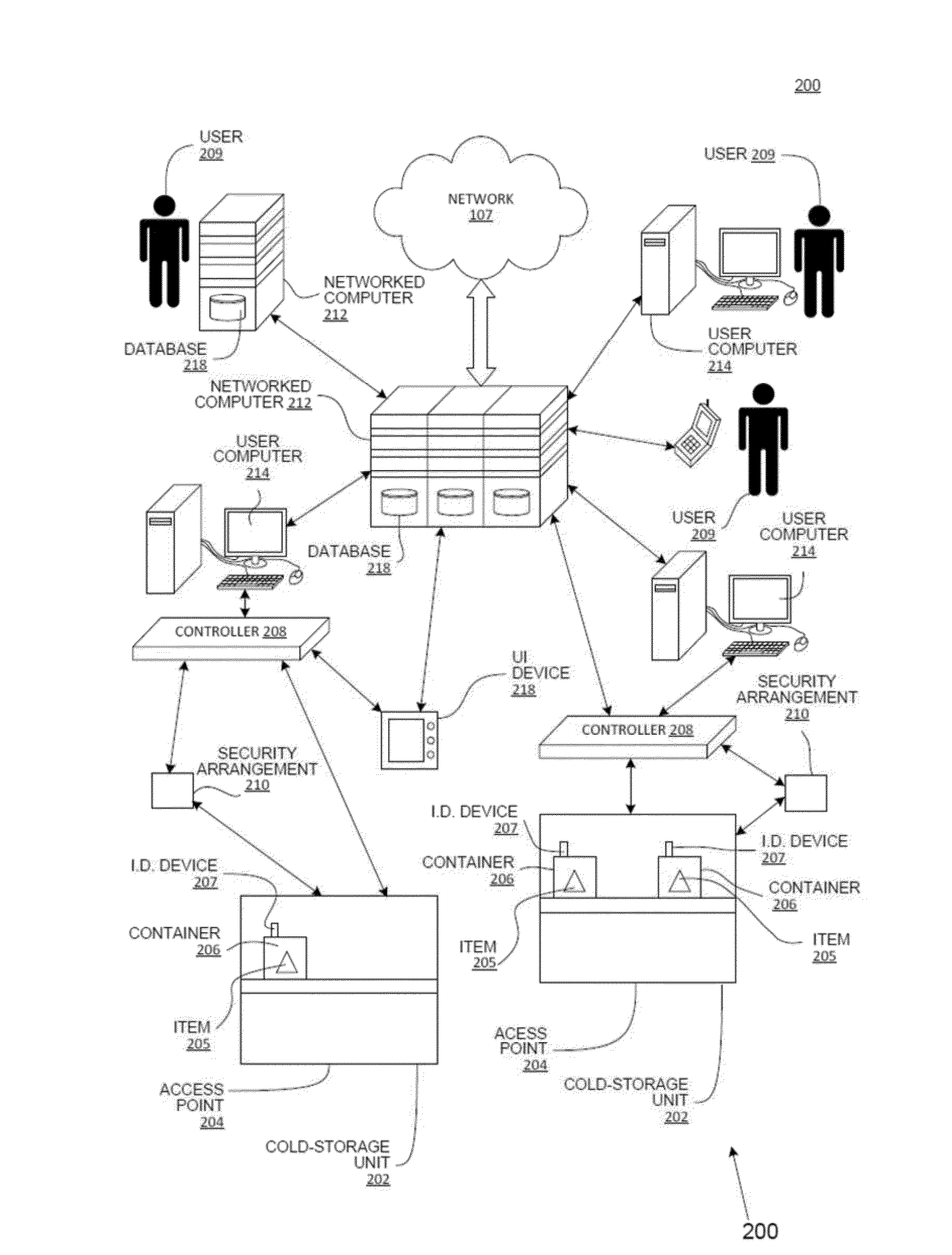

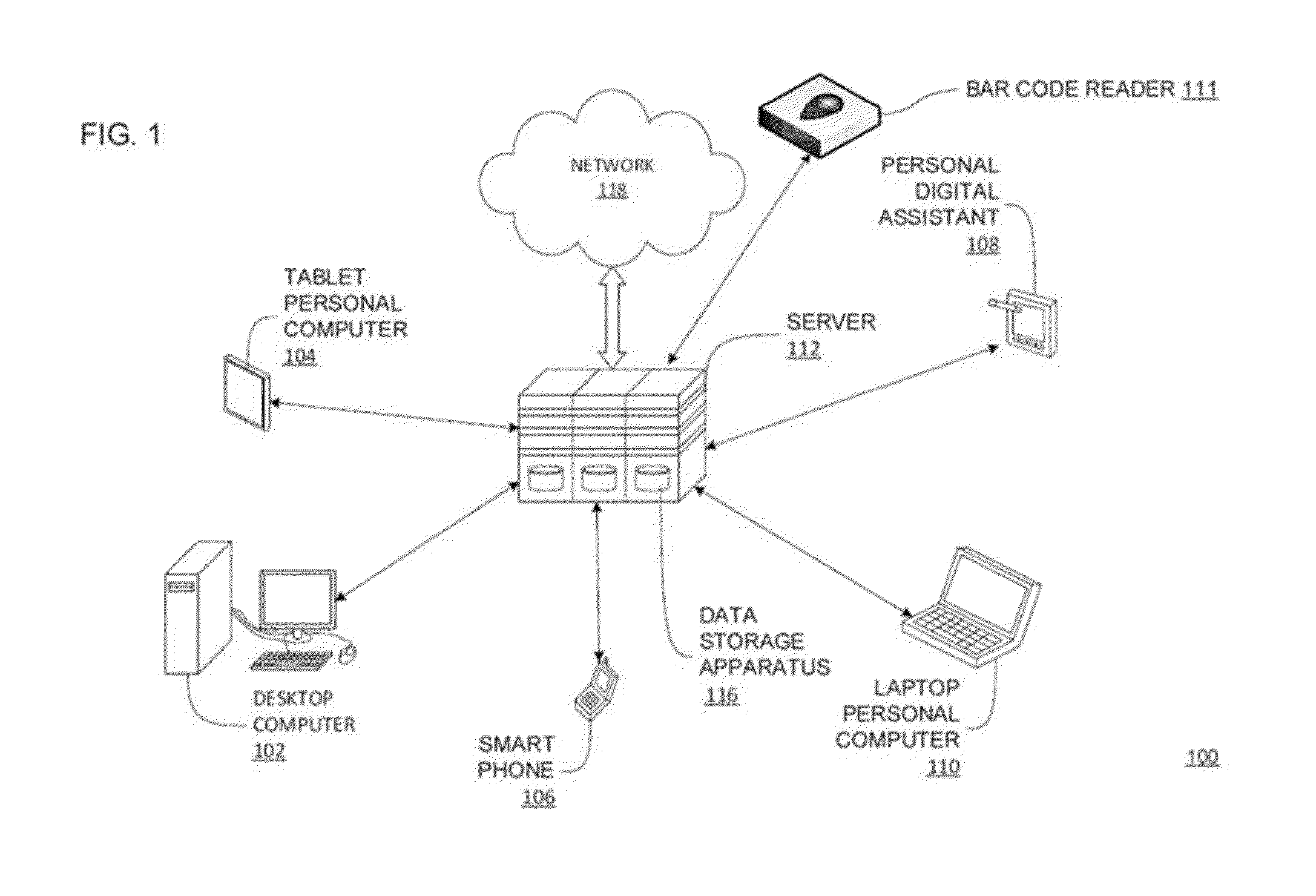

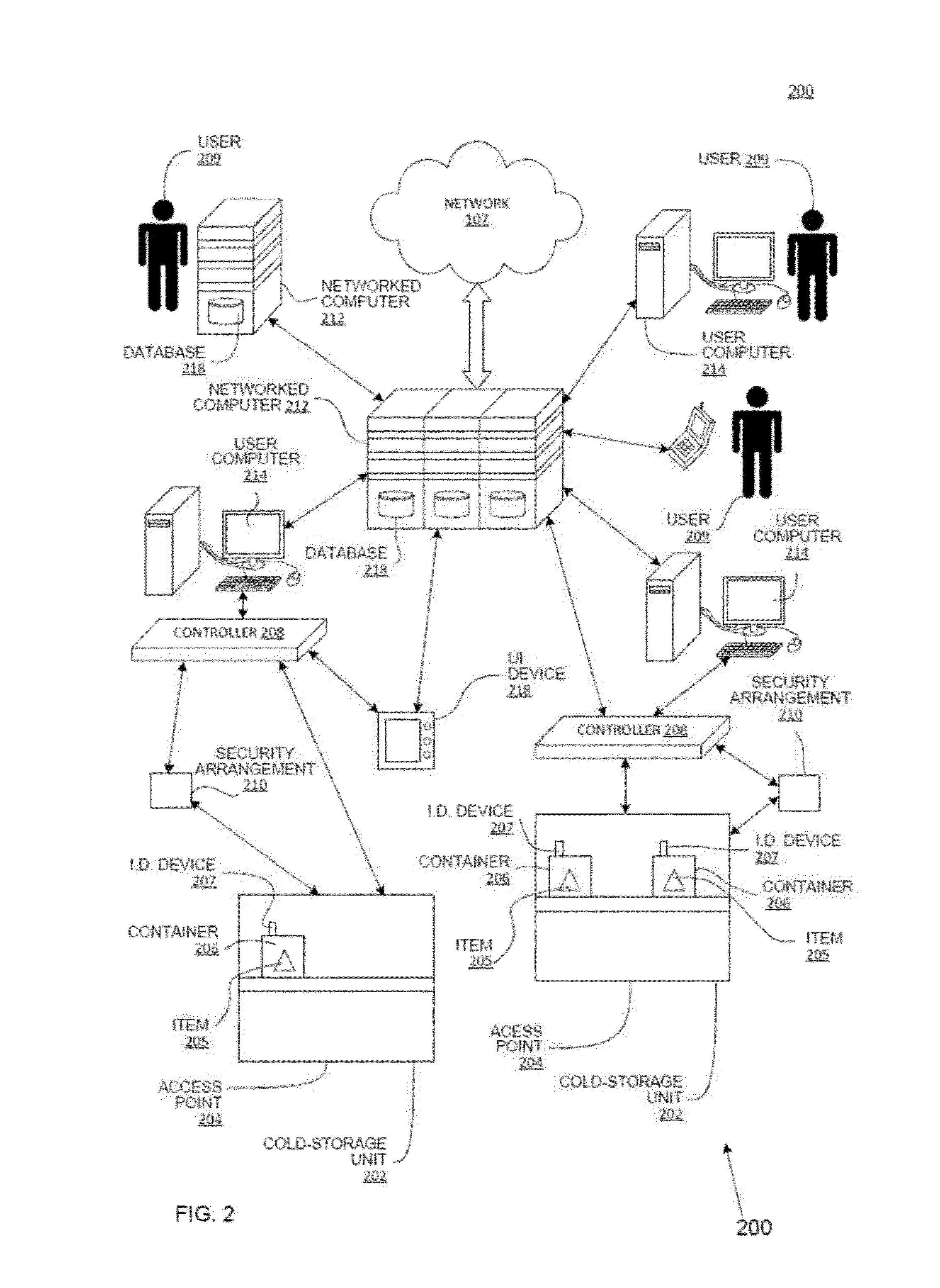

Actively controlled cold-storage system

A cold-storage management system includes a server that includes a network interface for communicating with at least one bar-code reader having an associated plurality of items that require cold-storage, and a data storage apparatus for storing beginning inventory for each item that requires cold-storage, shipment quantity information for each item that requires cold-storage, usage history for each item that requires cold-storage, usage on-board, low inventory alarm percentage, and order scheduling information for each item that requires cold-storage including date of next scheduled order for each item that requires cold-storage. The server also includes program instructions that, when executed by the processor, are configured to determine a current remaining quantity for at least one item that requires cold-storage by adding beginning inventory and shipment quantity information and subtracting usage history for each item that requires cold-storage currently being utilized and determine an expected remaining quantity for the item that requires cold-storage.

Owner:WILSON JEFF

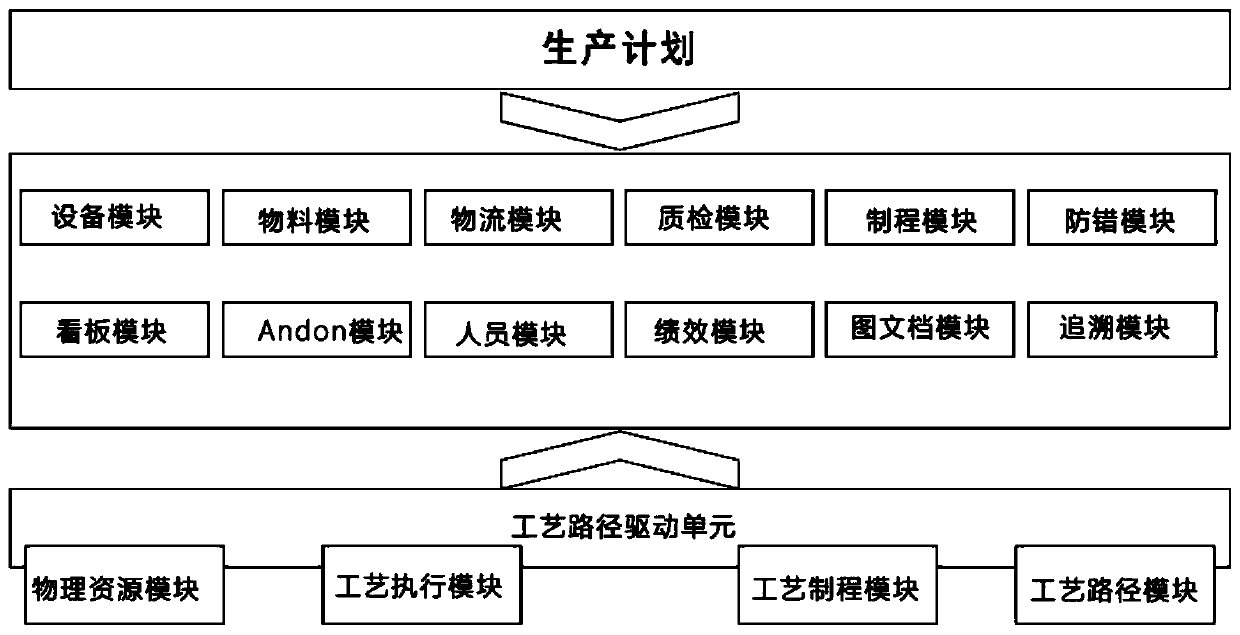

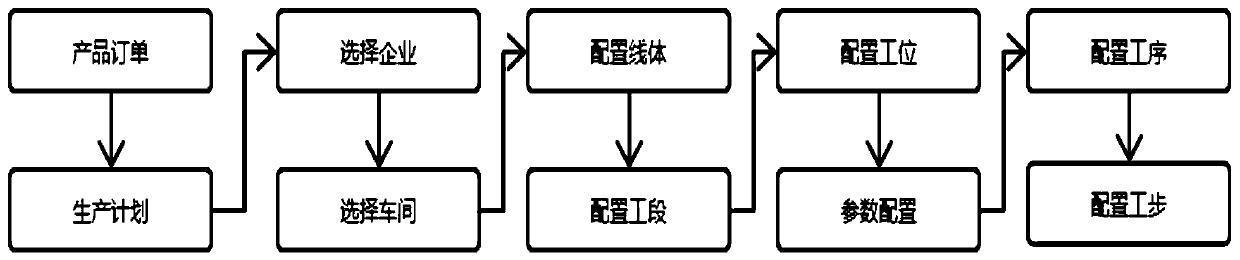

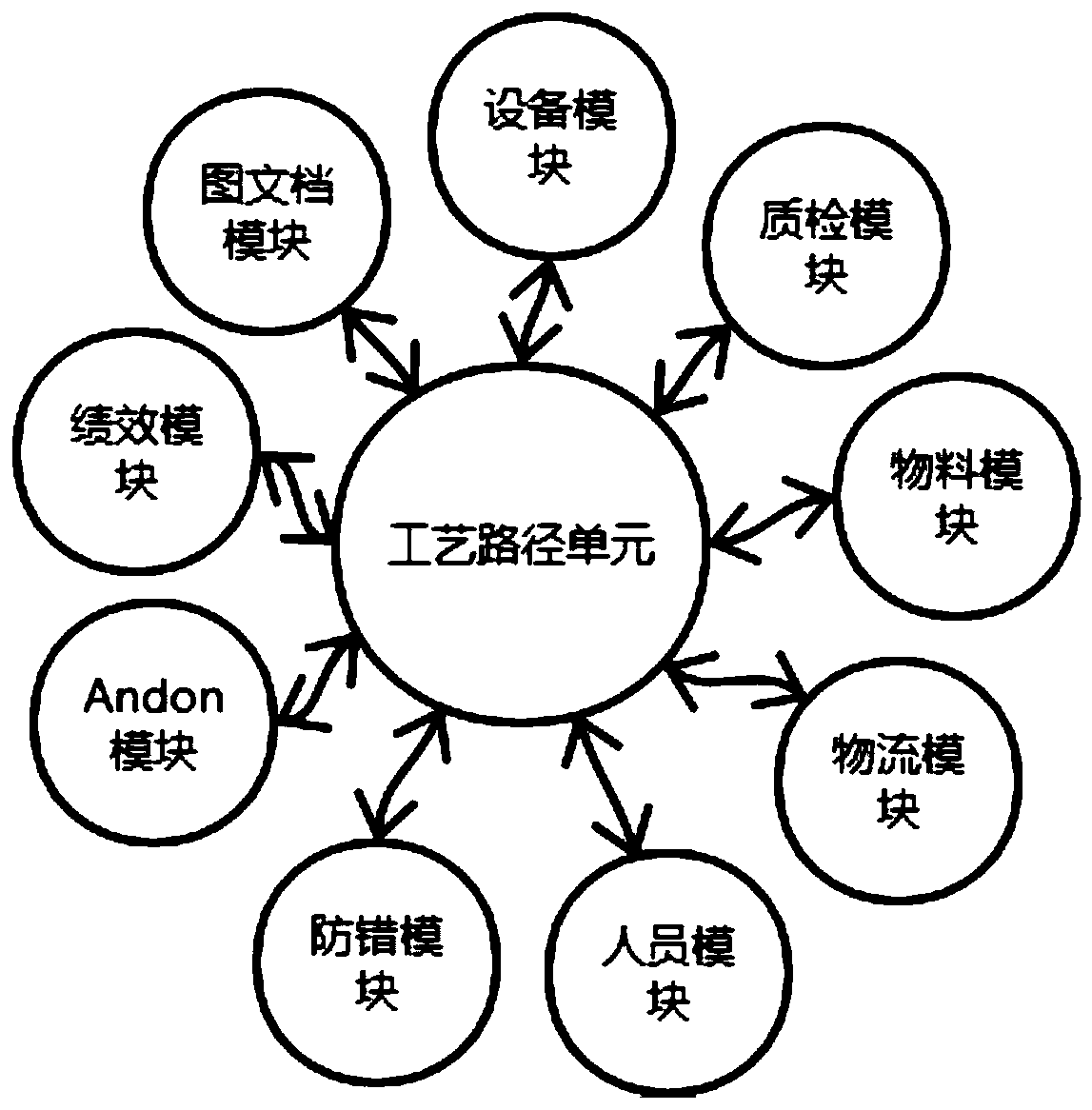

Order-oriented process route-driven general MES system

ActiveCN110109426AStable deliveryTotal factory controlProgramme total factory controlData connectionProduct order

The invention provides an order-oriented process route-driven general MES system, which comprises a production plan unit, a business unit and a process route driving unit, wherein the production planunit and the process route driving unit are in data connection with the business unit respectively; and the process route driving unit comprises a physical resource module, a process execution module,a process module and a process route module. With the production plan as a main line and the process route as the drive, the MES system is realized; a production order serves as the nerve center of execution of the MES system and goes through the process of product order acquisition, order scheduling and final product delivery, sub modules meeting the business units are formed after the plan is decomposed, each sub module is centered on the plan main line, own professional work is completed under guide of the center, and finally, smooth delivery of products is ensured.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV +1

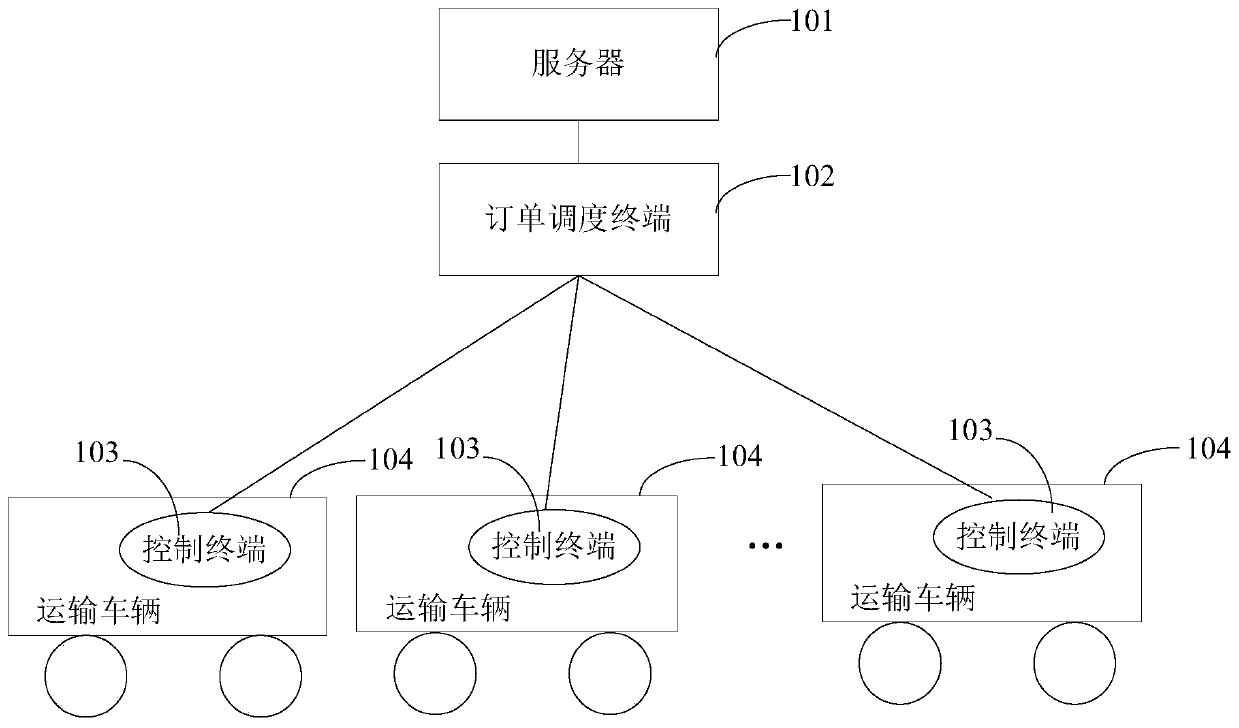

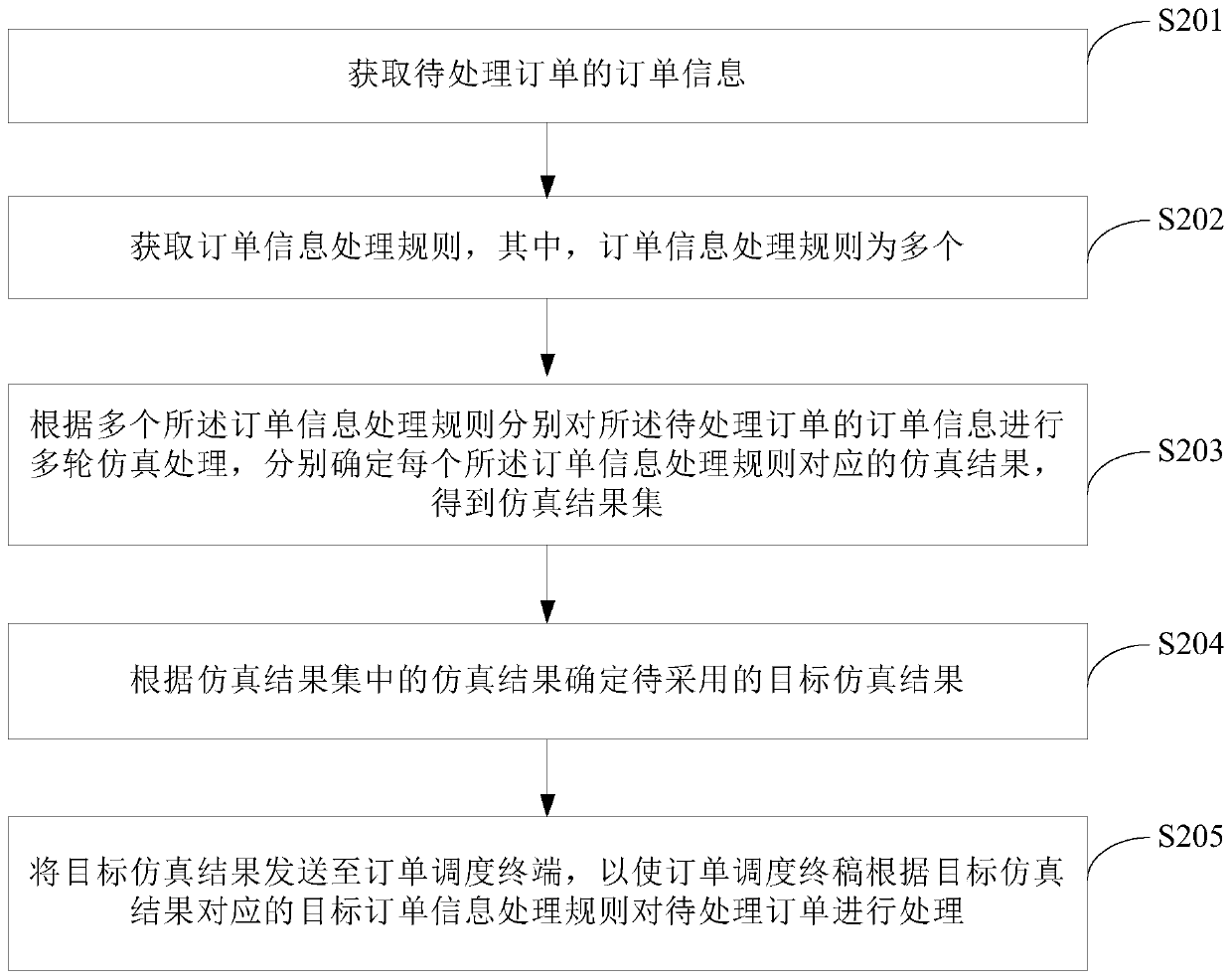

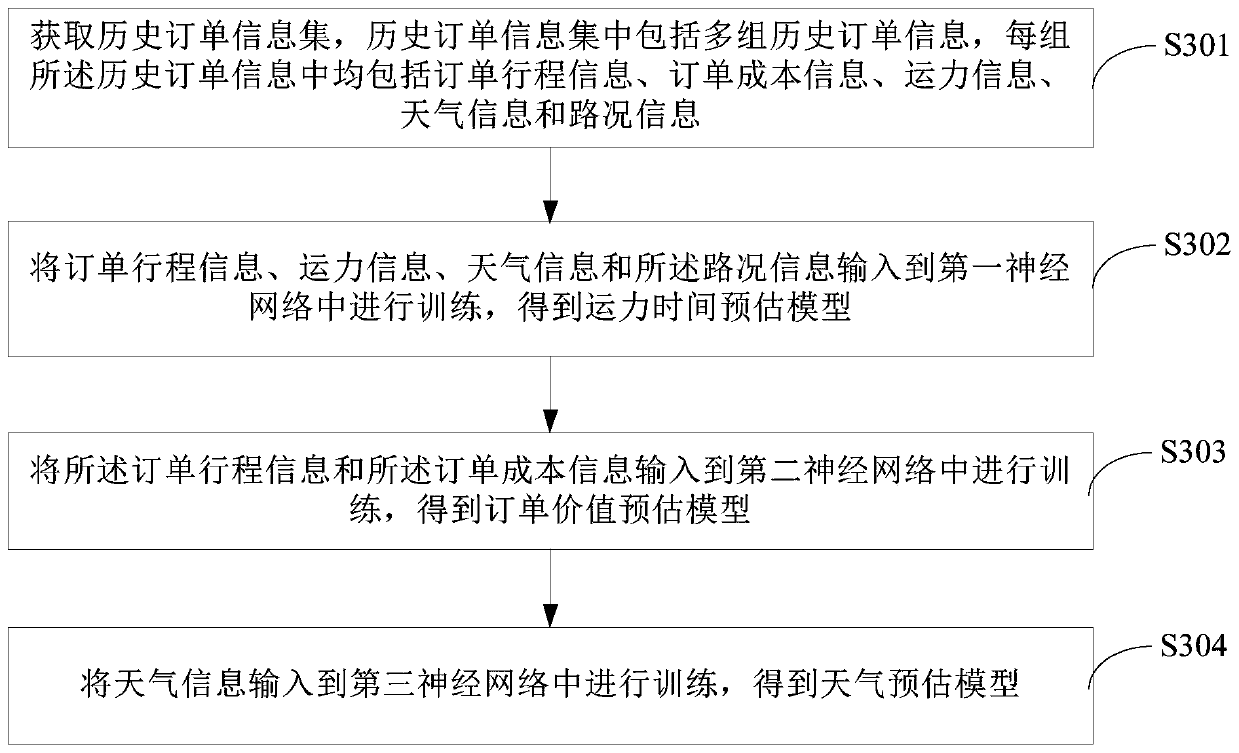

Logistics simulation method, device and equipment

ActiveCN110765615AReduce gapImprove accuracyDesign optimisation/simulationBuying/selling/leasing transactionsInformation processingLogistics management

The embodiment of the invention provides a logistics simulation method, device and equipment. The method comprises the steps of obtaining order information of a to-be-processed order, obtaining orderinformation processing rules, wherein a plurality of order information processing rules are provided; and performing multiple rounds of simulation processing on the order information of the to-be-processed order according to the multiple order information processing rules, determining a simulation result corresponding to each order information processing rule, and obtaining a simulation result set, determining a to-be-adopted target simulation result according to the simulation result in the simulation result set, and sending the target simulation result to the order scheduling terminal, so that the order scheduling final draft processes the to-be-processed order according to a target order information processing rule corresponding to the target simulation result. After the scheme is adopted, the difference between a simulation result and a real result is reduced, and the accuracy of a simulation test is improved.

Owner:HANGZHOU FABU TECH CO LTD

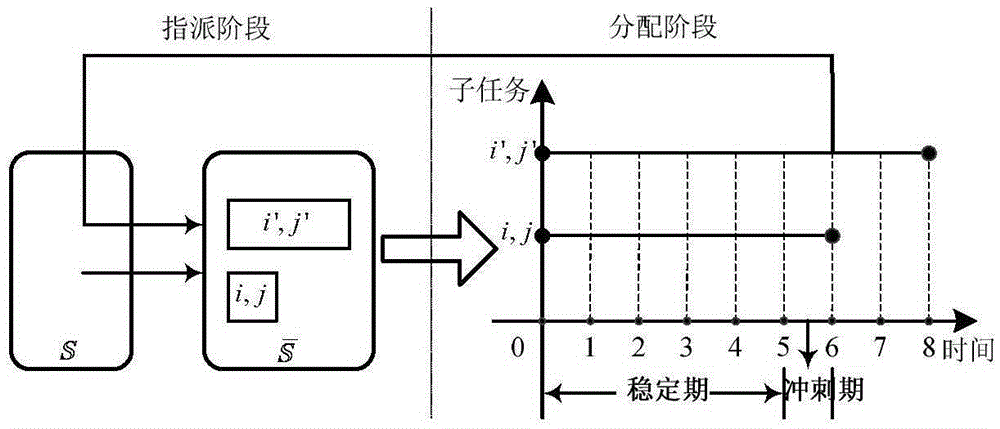

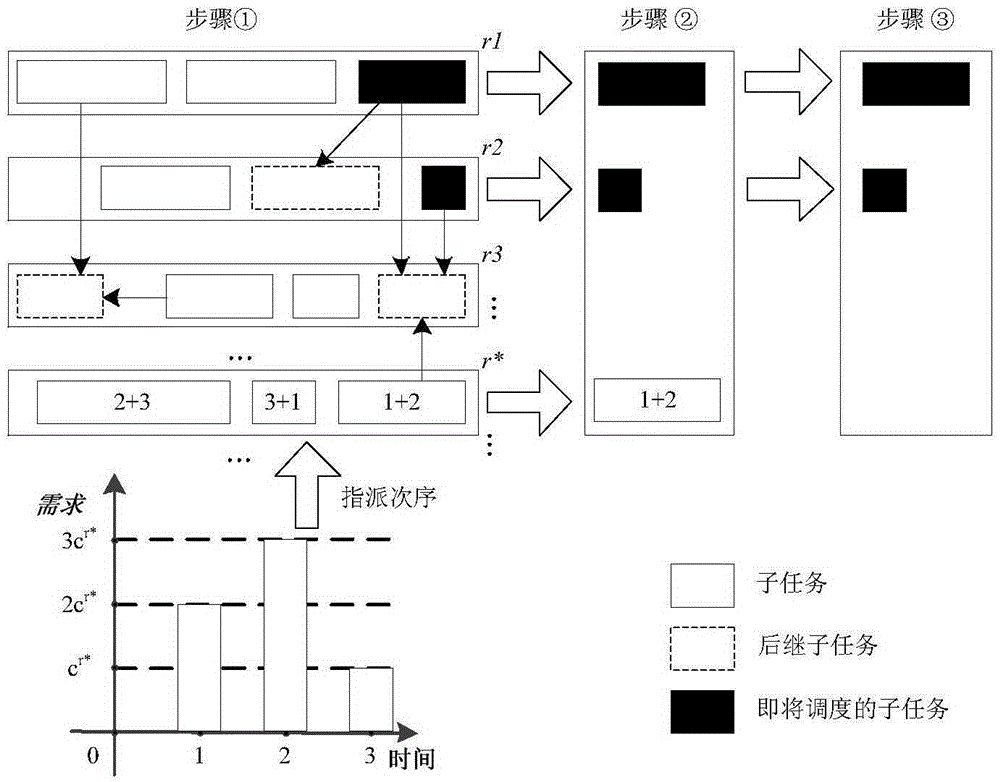

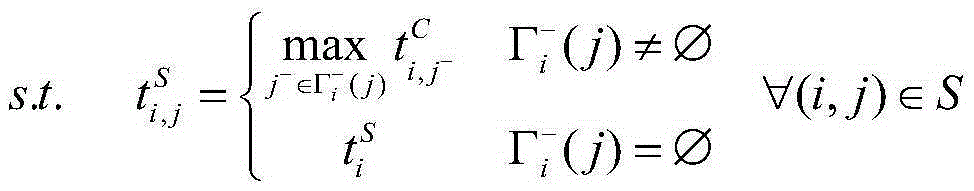

Multiple-resource partial order scheduling policy

ActiveCN105389204AExcellentTake advantage ofProgram initiation/switchingResource allocationCompletion timeResource utilization

The present invention provides a multi-resource partial order scheduling policy. A large number of tasks with a multi-resource demand and a complicated structure exist in NFV, and in actual task scheduling, task scheduling completion time affects user experience; traditional scheduling mostly focuses on stream scheduling study, and is incapable of considering a task structure, however, when a task has a partial order structure, the stream scheduling cannot ensure task scheduling time to be optimized; according to the multi-resource partial order scheduling policy provided by the present invention, in an NFV network architecture, a multi-resource task scheduling problem based on a partial order structure is formalized into a model of the multi-resource task scheduling problem based on the partial order structure; and a policy of simultaneously optimizing average and tail scheduling time is provided, and according to the policy, a task scheduling order is determined in a dominant resource priority (DRP) based mode, and resources are allocated with a maximum utilization allocation (MUA) method; and the DRP policy involved in the present invention has polynomial time complexity, a resource utilization rate close to 100%, and excellent fairness.

Owner:TSINGHUA UNIV

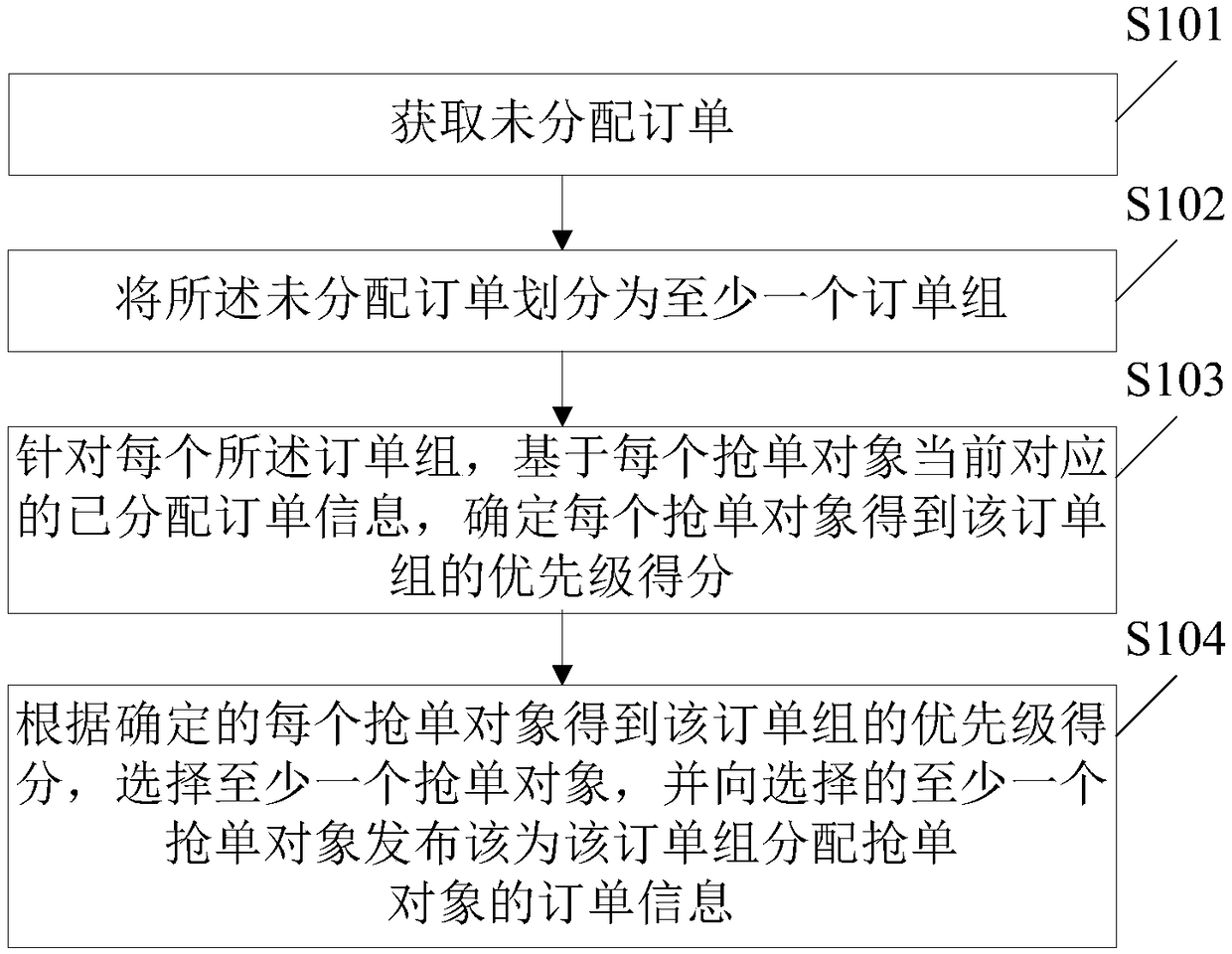

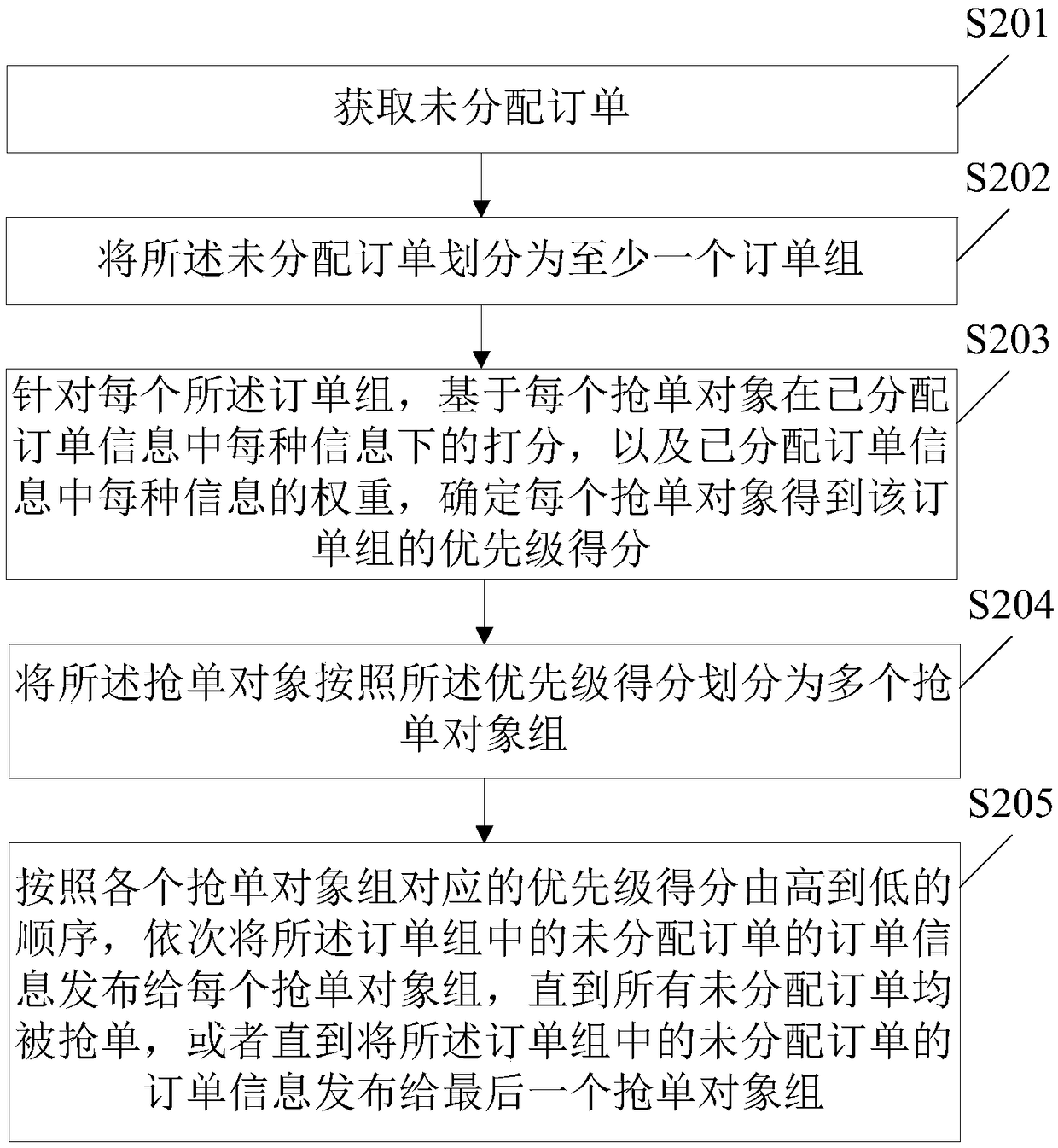

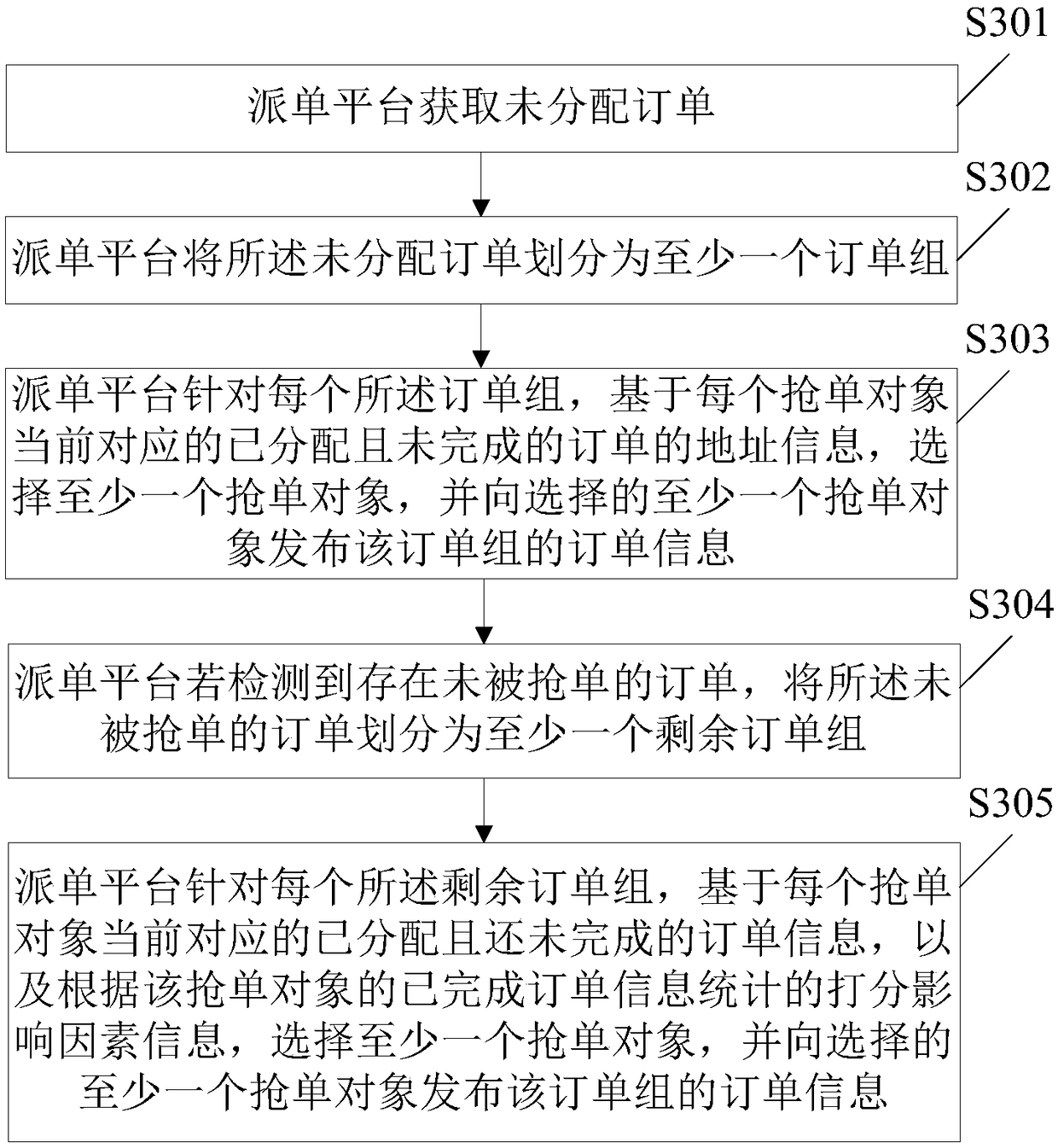

Order scheduling method and device and electronic equipment

InactiveCN108647892AGuaranteed autonomyImprove global dispatch efficiencyResourcesLogisticsOrder schedulingOrder form

The invention relates to the field of positioning technology, in particular to an order scheduling method. The method comprises the steps that unallocated orders are acquired; the unallocated orders are divided into at least one order group; for each order group, based on allocated order information currently corresponding to each order grabbing object, a priority score of each order grabbing object in obtaining the order group is determined; and according to the priority score of each order grabbing object in obtaining the order group, at least one order grabbing object is selected, and orderinformation of the order group is published to the selected order grabbing objects. Therefore, in the order allocation process, global order distribution efficiency can be improved while the autonomyof the order grabbing objects is ensured. The invention furthermore provides an order scheduling device and electronic equipment.

Owner:BEIJING SHUNFENG TONGCHENG TECH CO LTD

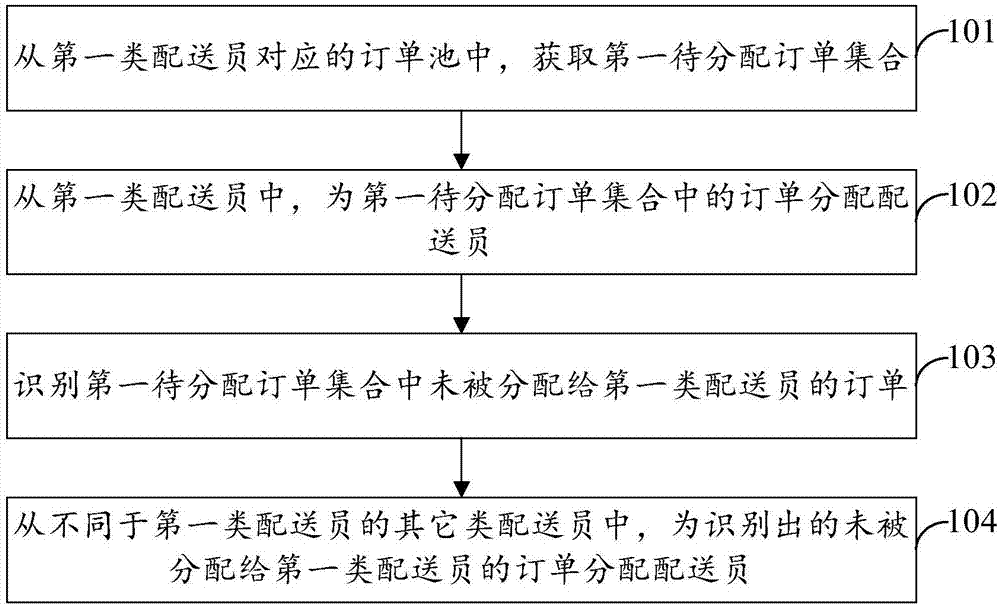

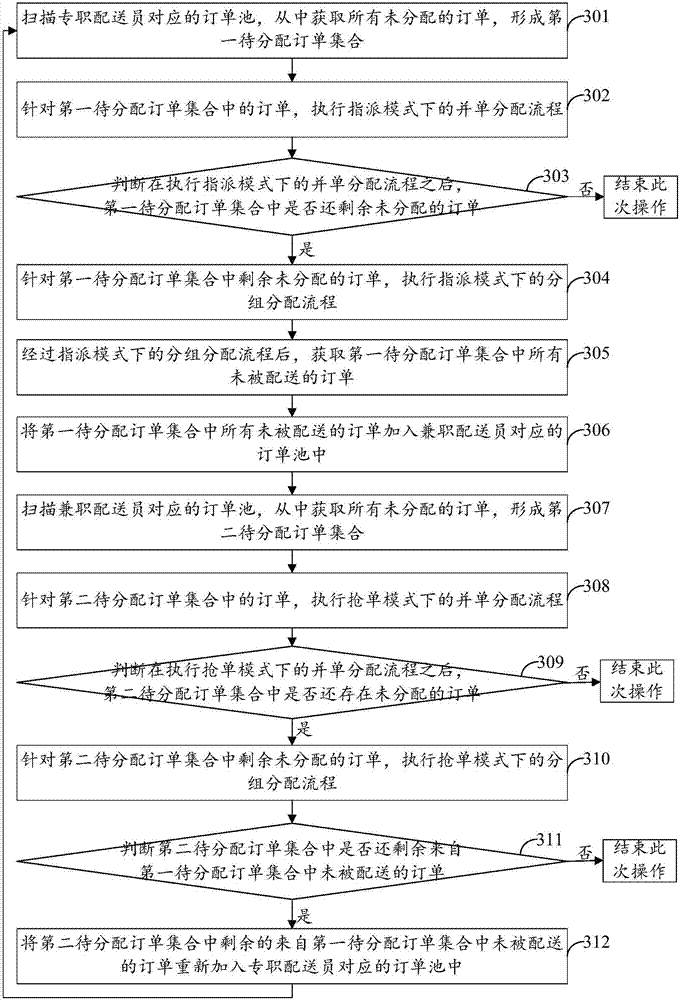

Order scheduling method and device

InactiveCN107480921AImprove distribution efficiencyReduce the probability of overtime deliveryBuying/selling/leasing transactionsLogisticsOrder schedulingOrder set

The embodiment of the invention provides an order scheduling method and device. The order scheduling method comprises a step of obtaining a first order set to be allocated from an order pool corresponding to a first type of deliverymen, a step of allocating deliverymen for orders in the first order set to be allocated from the first type of deliverymen, a step of identifying the orders which are not allocated to the first type of deliverymen in the first order set to be allocated, and a step of allocating deliverymen for orders which are not allocated to the first type of deliverymen from other types of deliverymen different from the first type of deliverymen. By using the technical scheme provided by the embodiment of the invention, the integrated scheduling of multiple types of deliverymen can be carried out, the complementation between multiple power capacities is realized, the further improvement of order delivery efficiency is facilitated, and the probability of order overtime distribution is reduced.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

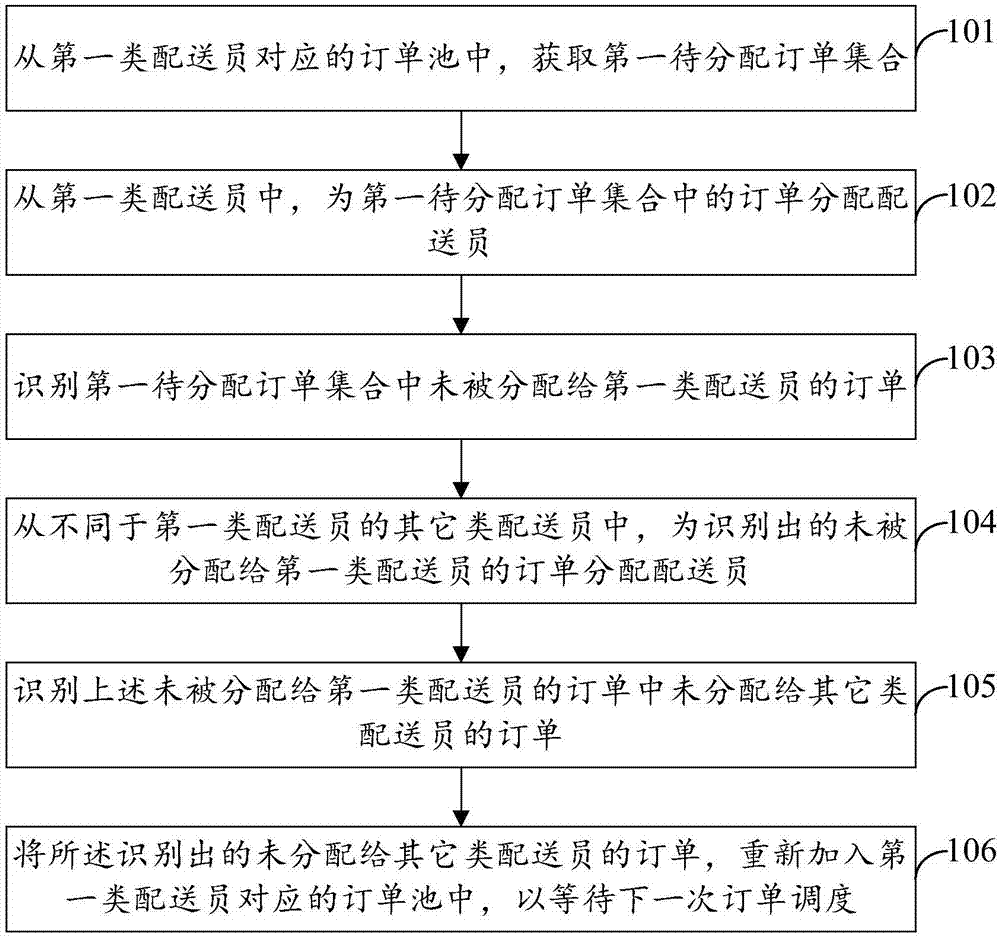

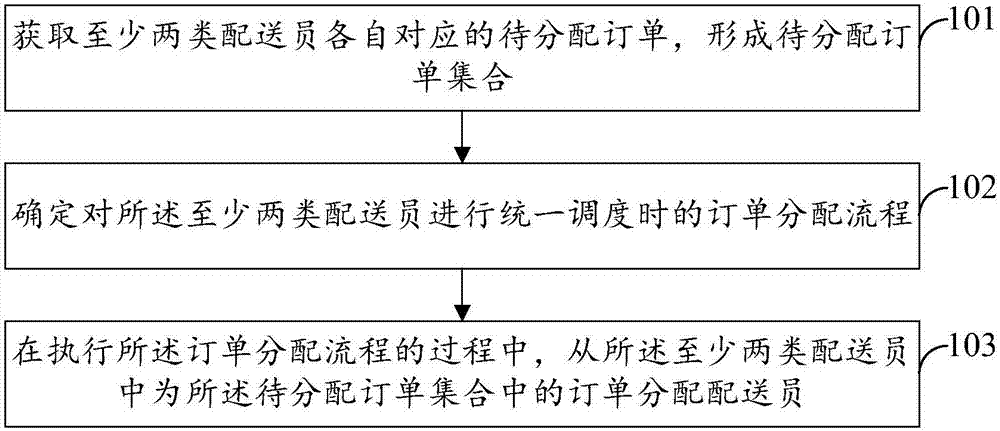

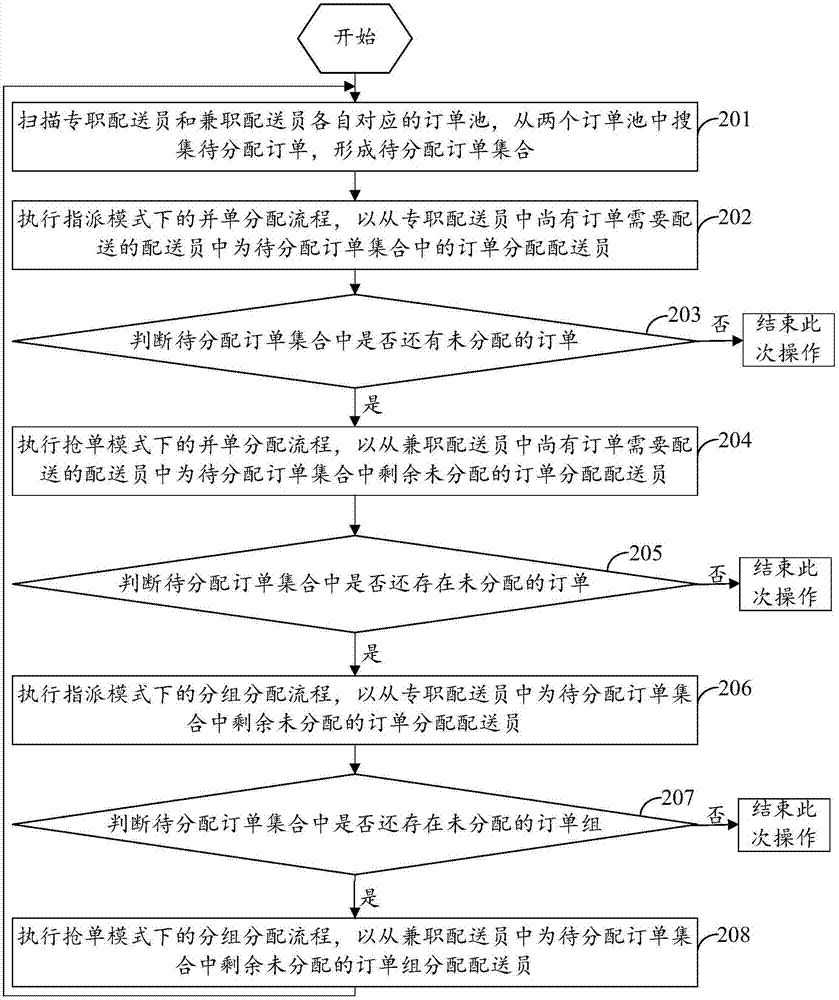

Order scheduling method and device

ActiveCN107403295AImprove distribution efficiencyReduce overtime deliveryResourcesLogisticsOrder schedulingOrder set

The embodiment of the invention provides an order scheduling method and device. The order scheduling method comprises the steps that to-be-allocated orders corresponding to at least two types of delivery staff are acquired to form a to-be-allocated order set; an order allocation process for uniform scheduling of all the delivery staff is determined; and in the process of executing the order allocation process, he orders in the to-be-allocated order set are allocated to delivery staff from at least two types of delivery staff. Through the embodiment, uniform scheduling can be performed on multiple types of delivery staff from the perspective of order fusion to realize complementation between multiple types of transport capacity, therefore, the delivery efficiency of the orders is further improved, and the probability of overtime delivery of the orders is lowered.

Owner:BEIJING XIAODU INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com