Order scheduling, allocating and dispatching method and system

A scheduling method and order technology, applied in the field of CNC machine tools, can solve problems such as discontinuous work orders and unbalanced production lines, and achieve the effects of reducing model change losses, avoiding manpower waste, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

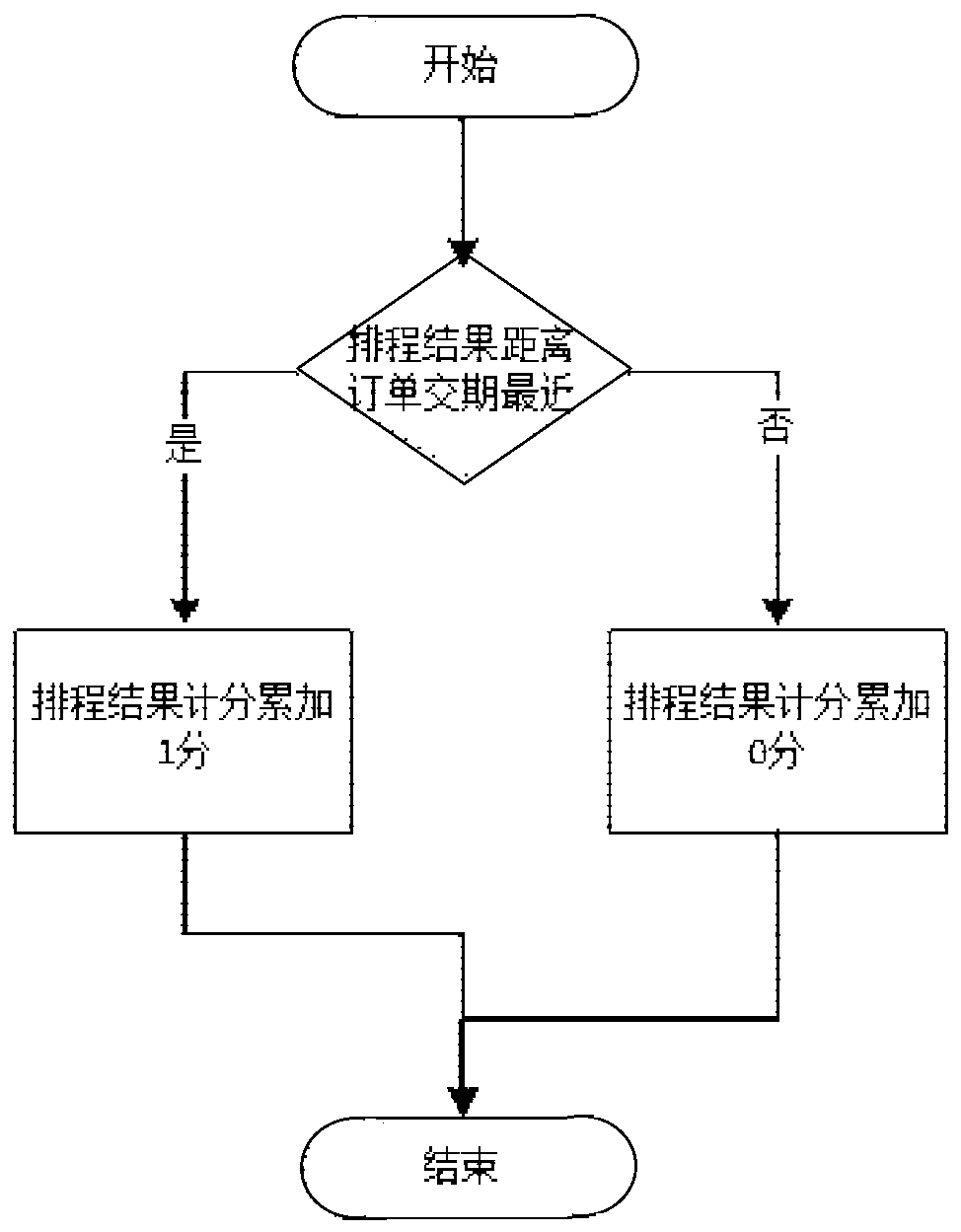

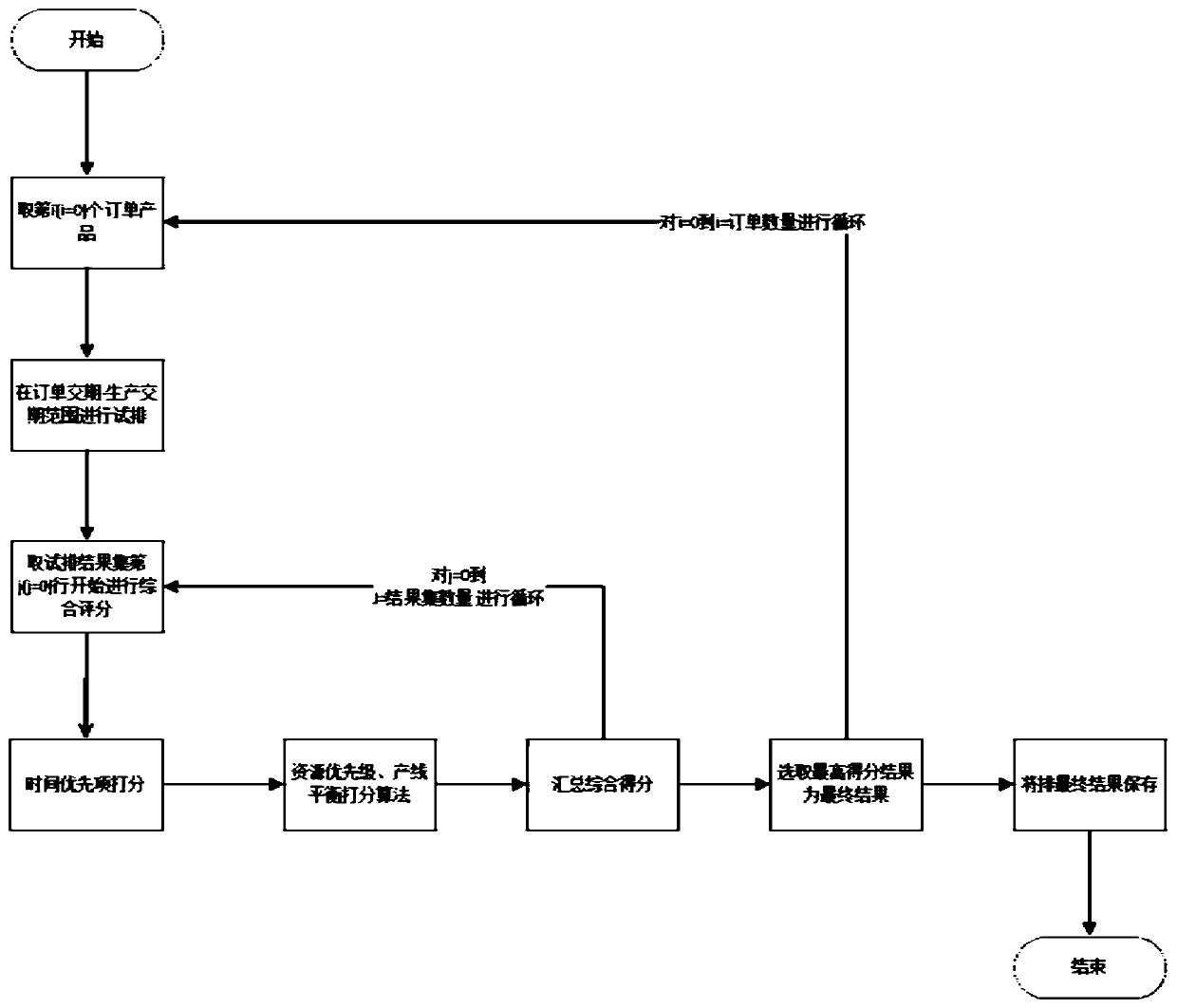

[0047] Such as figure 1 As shown, the present disclosure provides an order scheduling and allocation scheduling method, including:

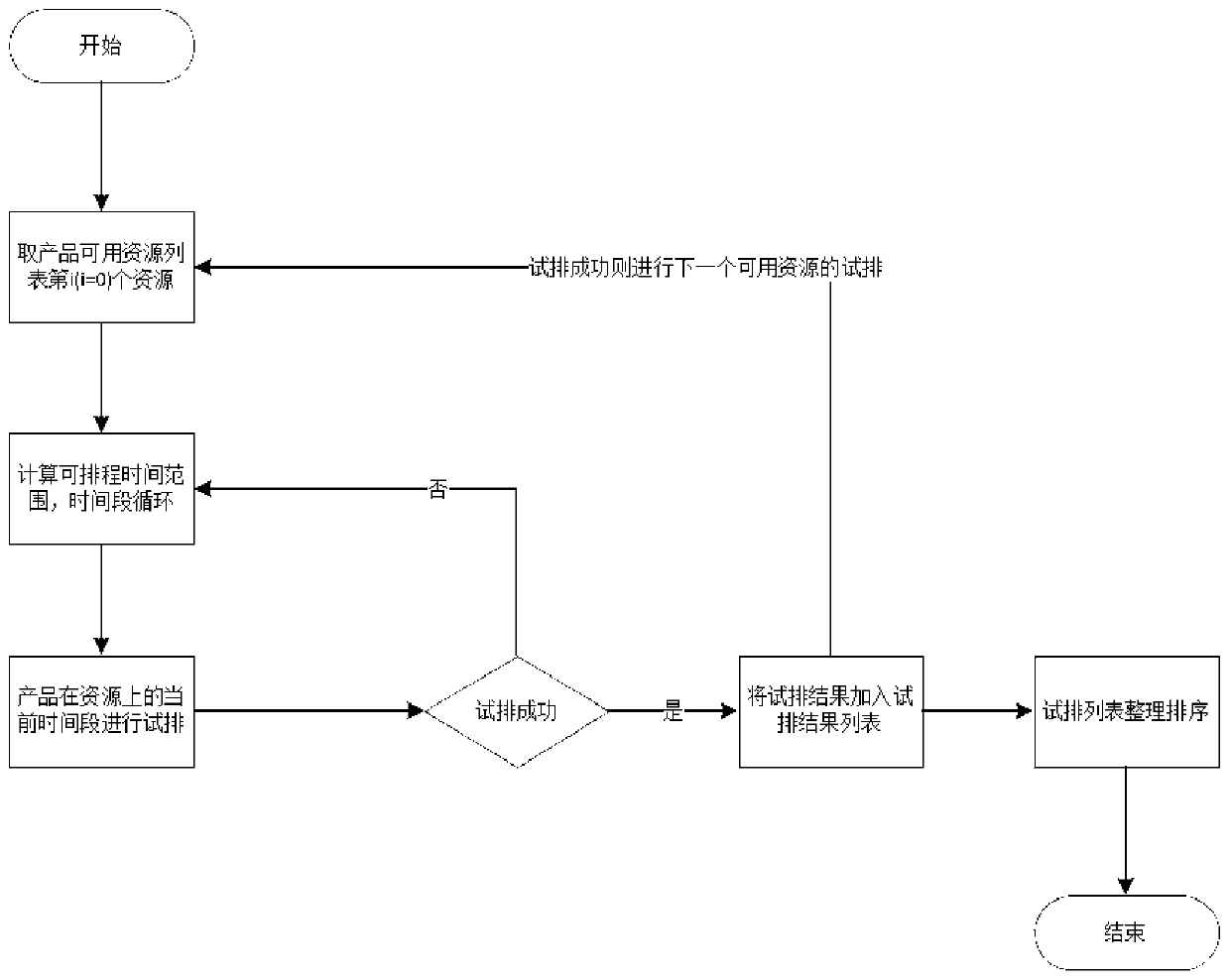

[0048] (1) Obtain the products to be scheduled in the planning cycle and the delivery time, and store them in the order list; obtain the available resources and resource priorities of the ordered products and store them in the available resource list; obtain the production status of the CNC machine tools on the production line, and store them in the CNC Machine status list;

[0049] (2) Carry out data modeling for the ordered products, and assign, sort and schedule the production plans of one or more production lines of the ordered products according to the delivery time of the ordered products, available resources and resource priorities, and the production status of the CNC machine tools ;

[0050] (3) Obtain the distribution, sorting and scheduling results of each production line of the ordered product, and use it for the processing process ...

Embodiment 2

[0084] The present disclosure provides an order scheduling and allocation scheduling system, including:

[0085] The data acquisition module is configured to obtain the products to be scheduled and the delivery time in the planning cycle, and store them in the order list; obtain the available resources and resource priorities of the ordered products and store them in the available resource list; obtain the production status of the CNC machine tools on the production line , stored in the state list of CNC machine tools;

[0086] The data processing module is configured to perform data modeling on the ordered products, and perform production planning on one or more production lines of the ordered products according to the delivery time of the ordered products, available resources and resource priorities, and the production status of the CNC machine tools Allocation sequencing and scheduling;

[0087] The data output module is configured to obtain the distribution, sorting and s...

Embodiment 3

[0098] The present disclosure provides a workshop, including several CNC machine tools and servers;

[0099] The server completes the steps described in the shop order scheduling and allocation scheduling method. And the distribution, sorting and scheduling results of each production line of the ordered product are transmitted to the data machine tool to complete the processing process of the ordered product.

[0100] The numerical control machine tool is used to collect production status information and transmit it to the server for storage; it is used to receive the distribution and scheduling results of each production line of the ordered product, and complete the processing process of the ordered product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com