Patents

Literature

490 results about "Production schedule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The production schedule is a project plan of how the production budget will be spent over a given timescale, for every phase of a business project. The scheduling process starts with the script, which is analysed and broken down, scene by scene, onto a sequence of breakdown sheets, each of which records the resources required to execute the scene.

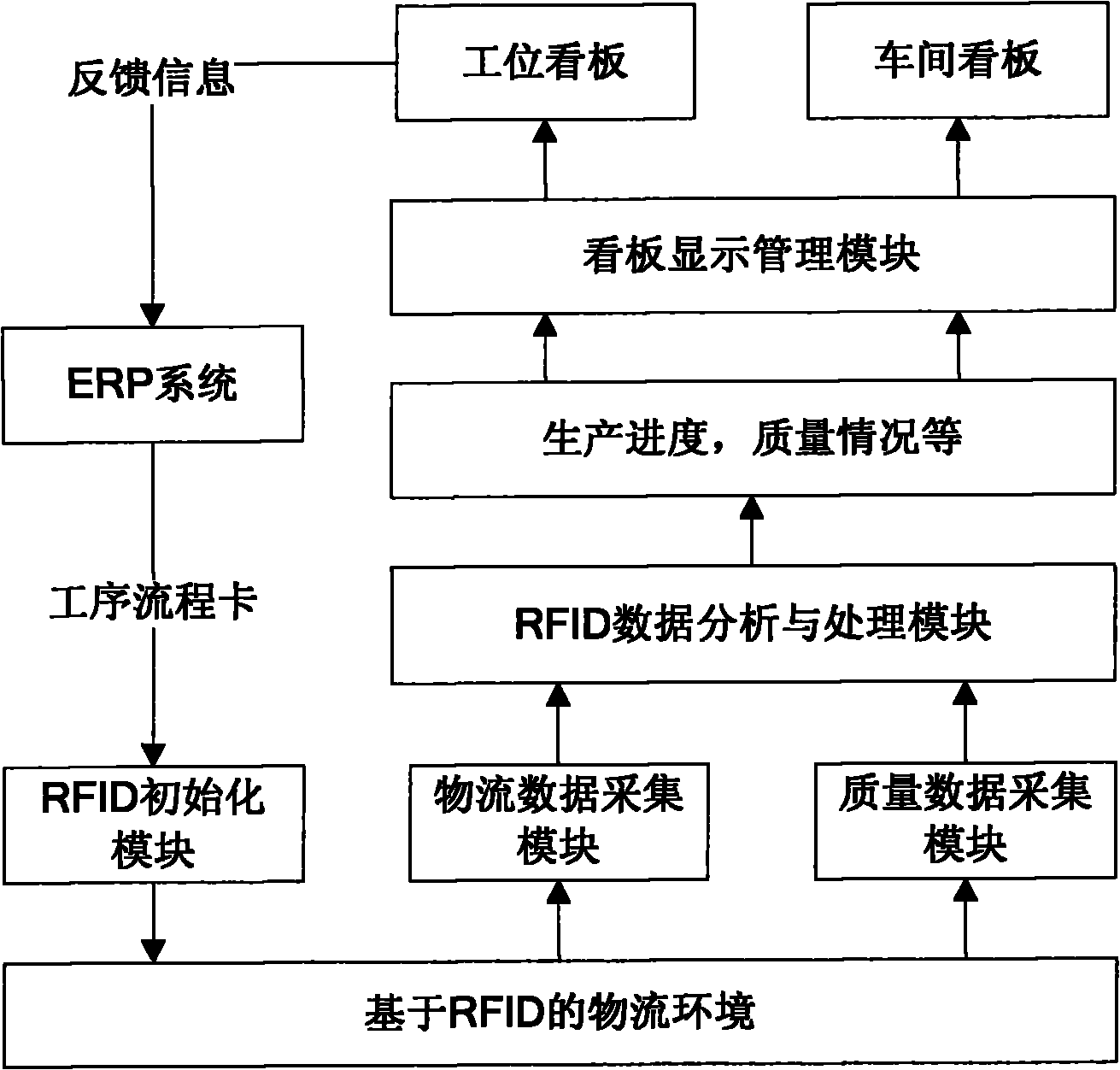

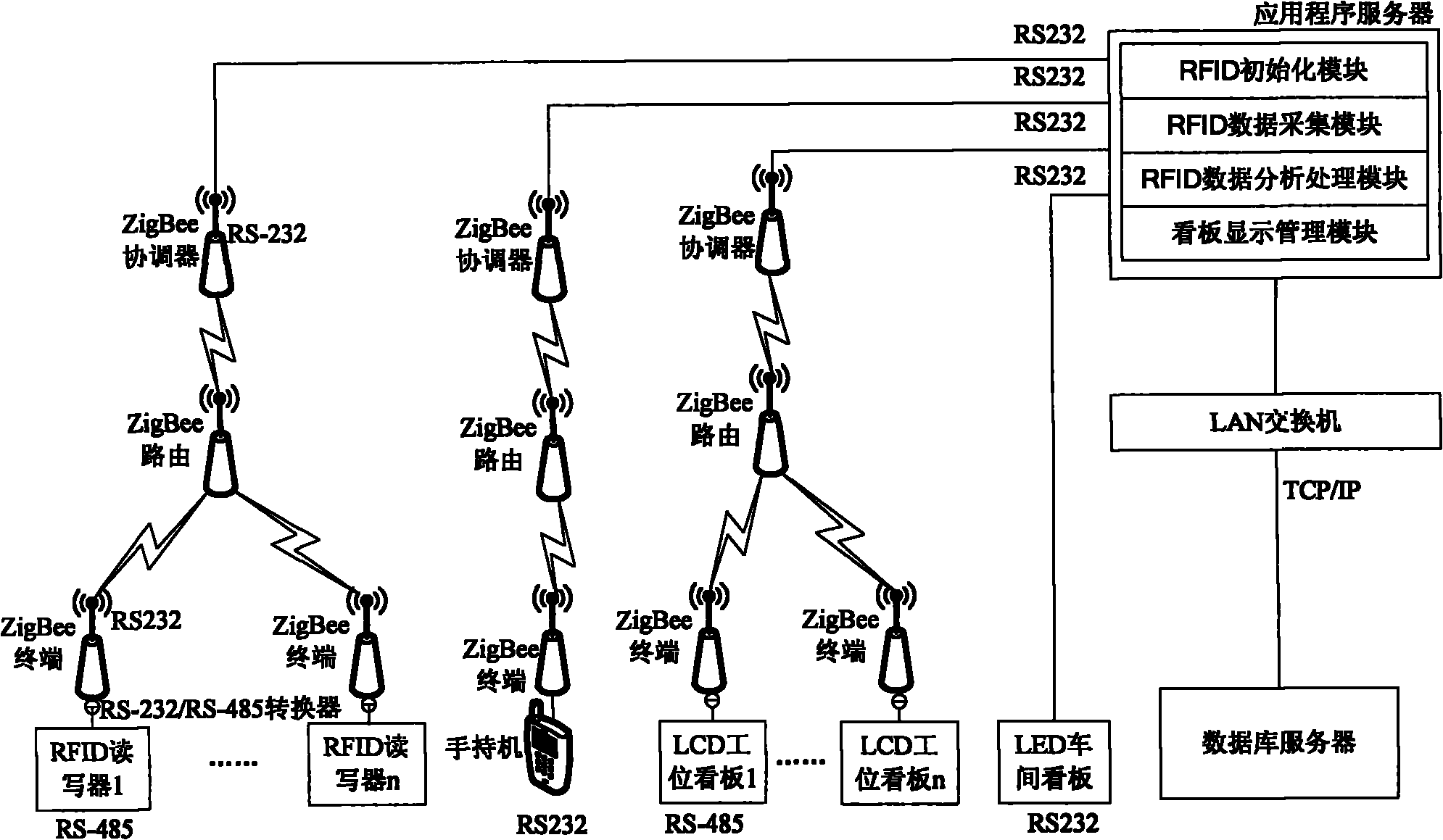

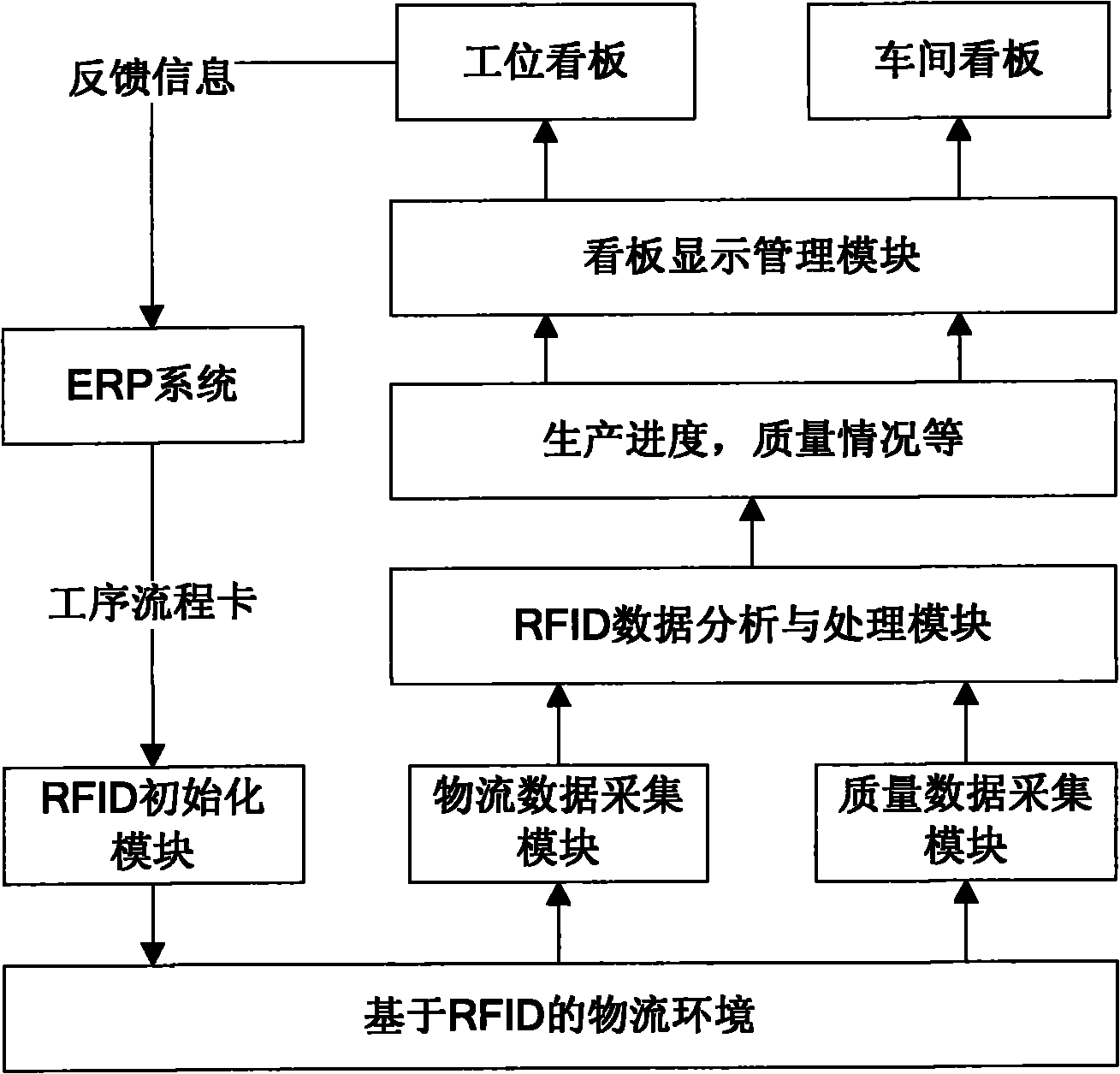

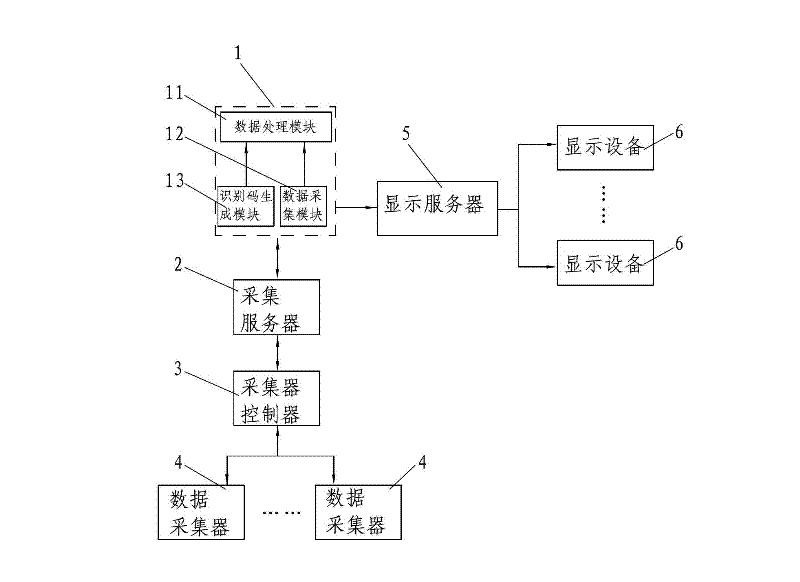

Visual production management and control method for discrete workshop

InactiveCN101819658AEffective Quality MonitoringQuality data to realize effective monitoring of production management in discrete manufacturing workshopsCo-operative working arrangementsProduction scheduleProcess module

The invention discloses a visual production management and control method for a discrete workshop. The method comprises the following steps of: establishing an association relationship between an RFID tag which is taken as a carrier for data acquisition of a workshop and a process flow card; acquiring information of the tag when the RFID tag passes through a working position; displaying the information of the process flow card associated to the tag on an electronic billboard; reading the RFID tag and filling quality information by using a handset at a quality testing working position; processing acquired information to form production schedule information and the quality information of the workshop; and displaying the production schedule information and the quality information on a working position billboard and a workshop billboard by using a billboard display management system. The method adopts a device which comprises an RFID initializing module, an RFID-based data acquisition module, an RFID data analyzing and processing module and a billboard display management module. By using the method, logistics and quality data in a production process can be acquired and transmitted in real time, paperless and visual production management of a discrete manufacturing workshop is realized, the information of logistics, quality and the like is effectively monitored, and the workshop management level of an enterprise is improved.

Owner:ZHEJIANG UNIV

Resistance welding superposition technology for PCB thick copper lines

ActiveCN101534612AIncreasing the thicknessInhibit sheddingNon-metallic protective coating applicationProduction scheduleCooking & baking

The invention discloses a resistance welding superposition technology for PCB thick copper lines, comprising the steps of: at first, printing resistance welding ink on the surface of a PCB and forming a first resistance welding layer via screen printing resistance welding; and pre-drying while remaining 75 DEG C and semi-hardening the first resistance welding layer after cooling; then printing the resistance welding on the first resistance welding layer once again in order to form a second resistance welding layer; pre-drying once again while remaining 75 DEG C and semi-hardening the first resistance welding layer and the second resistance welding layer after cooling; eventually, hardening the resistance welding layer and the second resistance welding layer completely subsequent to the segmented baking of the semi-hardened PCB. The invention requires only one-time resistance welding pattern transfer and high-temperature baking by the superposition printing on the thickness of the resistance welding, which increases the thickness of the resistance welding layer, thickens, in particular, the thickness of the resistance welding layer at corners of the lines, and avoids the problems of resistance welding blistering and falling in thermal impact procedures of post-processing procedure, and meanwhile, using the inventive technology shortens production procedure dramatically, speeds up production schedule and lowers production cost.

Owner:SHENZHEN BOMIN ELECTRONICS

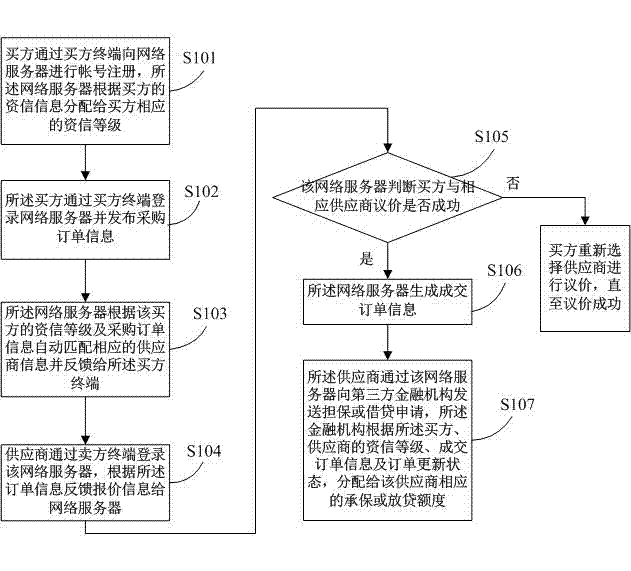

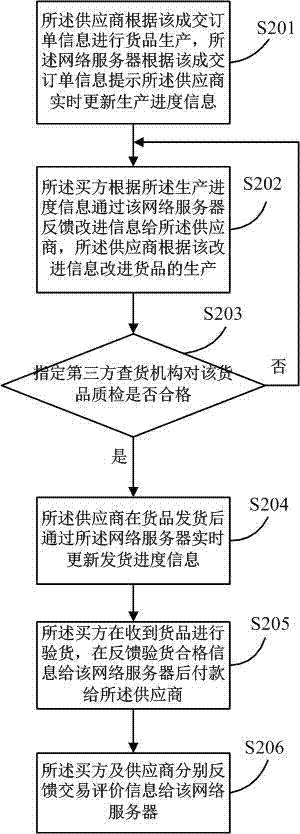

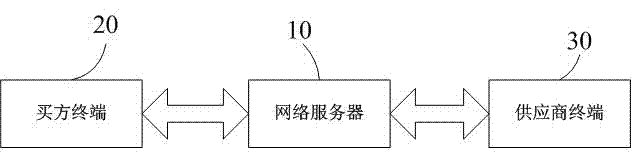

Method and system for e-commerce transactions

InactiveCN103971280AReal-time updateImplement queryBuying/selling/leasing transactionsProduction scheduleLogistics management

The invention discloses a method and a system for e-commerce transactions. The method comprises the following steps that a buyer releases purchase order information through a buyer terminal, a network server automatically matches corresponding supplier information, a matched supplier feeds back quotation information to the network server according to the order information, and the buyer bargains with the corresponding supplier according to the quotation information to generate transaction order information; the network server prompts the supplier to update production schedule information in real time; the supplier updates the production schedule information and delivery schedule information in real time through the network server, the delivery schedule information comprises commodity inspection schedule, customs clearance schedule and logistics customs clearance and dispatch schedule, and the buyer and the supplier respectively feed back transaction evaluation information to the network server. The method and the system disclosed by the invention can carry out automatic identification, matching and schedule tracking and prompting on two parties of transactions, realize real-time updating, query and feedback of the transaction status, reduce the transaction risk and cost, and improve the working efficiency and success rate of transactions.

Owner:SHENZHEN HONGHAI IMPORTS & EXPORTS

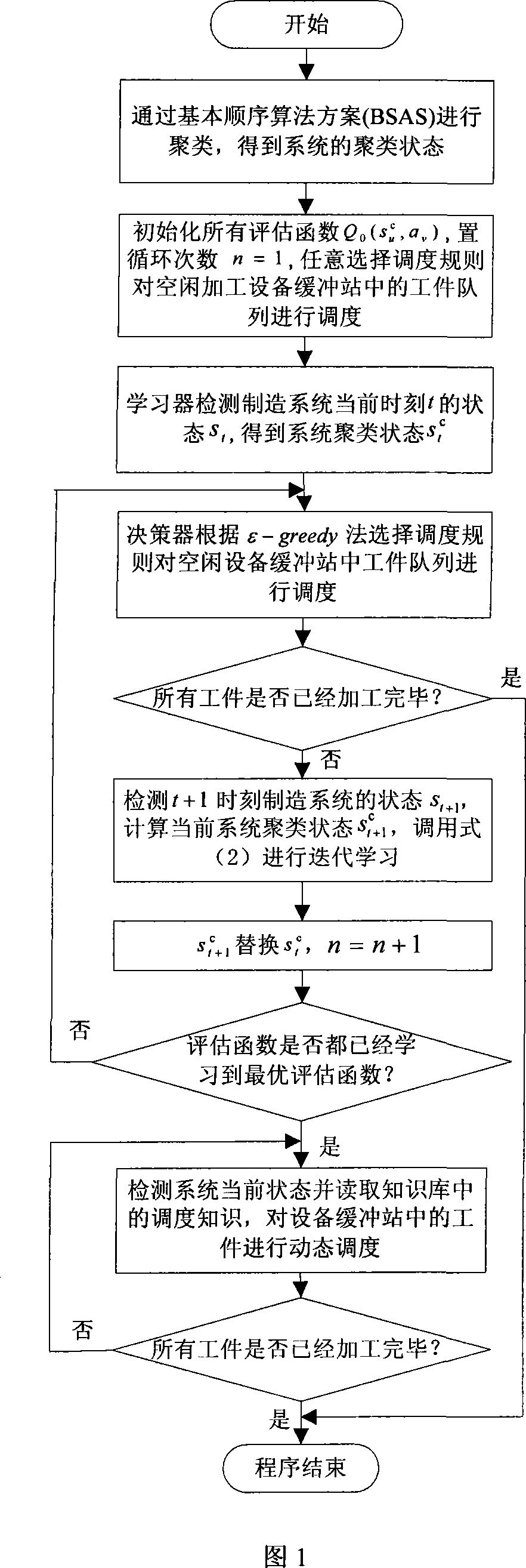

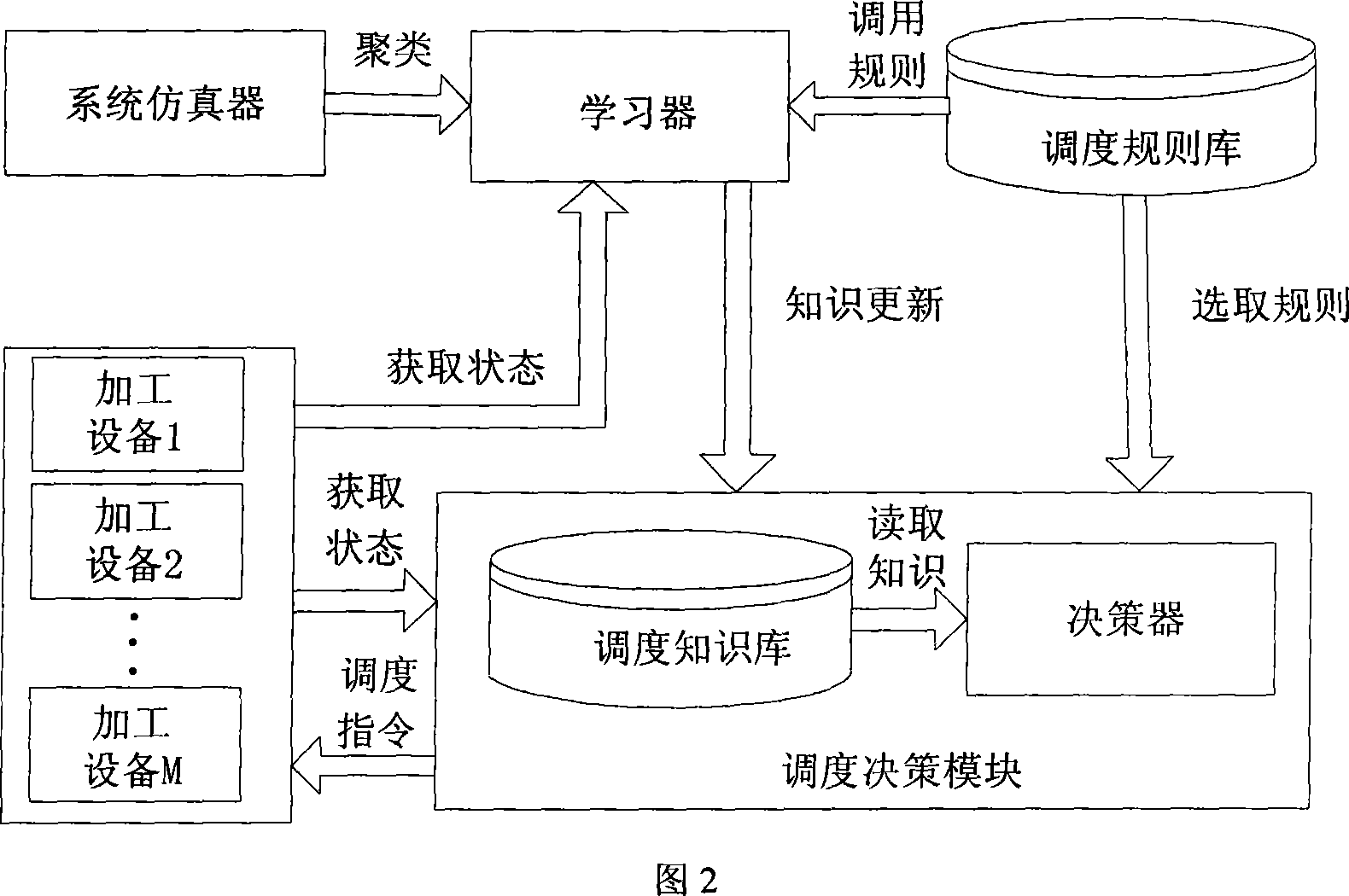

Self-adapting selection dynamic production scheduling control system accomplished through computer

InactiveCN101216710AReduce delaysReduce average time overdueTotal factory controlProgramme total factory controlLearning machineProduction schedule

A self-adaptive selection dynamic production scheduling control system, which is realized via a computer, is characterized in that: the system comprises a system emulator, a learning machine, a decision-making machine, a scheduling rules base, a scheduling knowledge base, a carrier, processing equipments and a buffer station thereof; the buffer station is provided with an optical grating, a sensor and a detection equipment; when a working piece reaches the buffer station and is processed, the learning machine detects the current system status for learning, so as to acquire dynamic scheduling knowledge about the system and update the knowledge in the scheduling knowledge base; when one processing equipment needs to be scheduled, the decision-making machine reads corresponding scheduling knowledge in the scheduling knowledge base according to the detected system status, acquires new scheduling knowledge through continuous interactive learning with the processing system, dynamically selects the scheduling rules based on the status of the processing equipments and the working piece in the system, and chooses the optimized scheduling rules to schedule the processing equipments. The invention can adapt to instable time-varying workshop dynamic production environments, obtain a better working-piece arrangement than prior rule-based scheduling technology, effectively reduce the process waiting time, and improve the fill rate of product delivery time.

Owner:SOUTHEAST UNIV

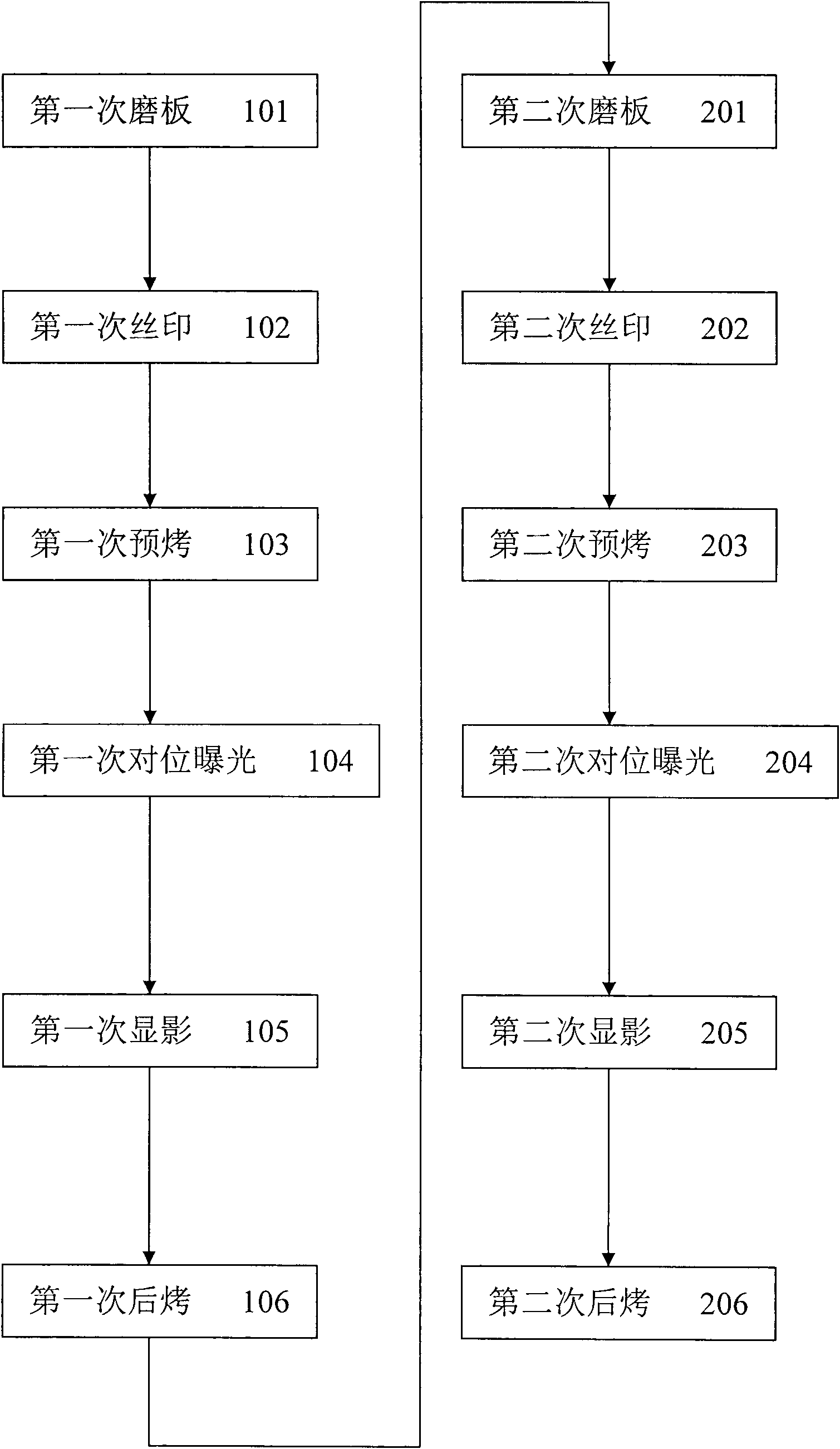

Production technology of PCB (Printed Circuit Board) solder mask

ActiveCN101668390AIncrease productivityImprove product qualityNon-metallic protective coating applicationCooking & bakingProduction schedule

The invention relates to a production technology of a PCB (Printed Circuit Board) solder mask, which comprises the following steps of: a first board grinding, a first silk screen, a first pre-braking,a first contraposition exposure, a first development, a first post-baking, a second board grinding, a second silk screen, a second pre-braking, a second contraposition exposure, a second developmentand a second post-baking, wherein the mesh number of the first silk screen is larger than that of the second silk screen, and the windowing size of the first contraposition exposure is larger than that of the second contraposition exposure. The production technology of the PCB solder mask better eliminates the harmful defects in the solder mask production process that green oil and the like easilysolders an oil plughole, the developing is dirty, the circuit becomes red, and the lateral erosion of a film printing and development is large and the like, thereby improving the production efficiency and the production quality, speeding up the production schedule and reducing the production cost.

Owner:大连崇达电子有限公司

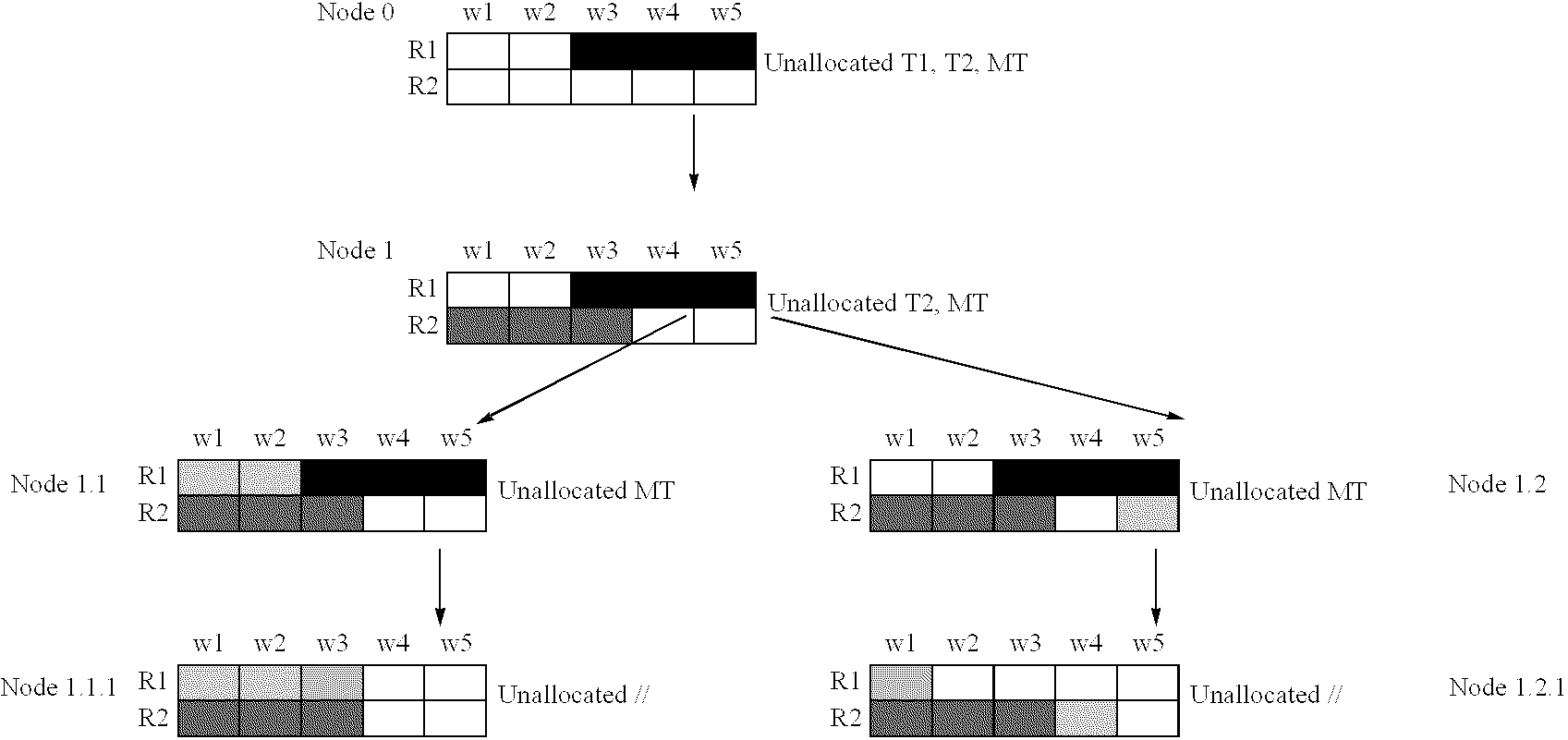

Real time asset optimization

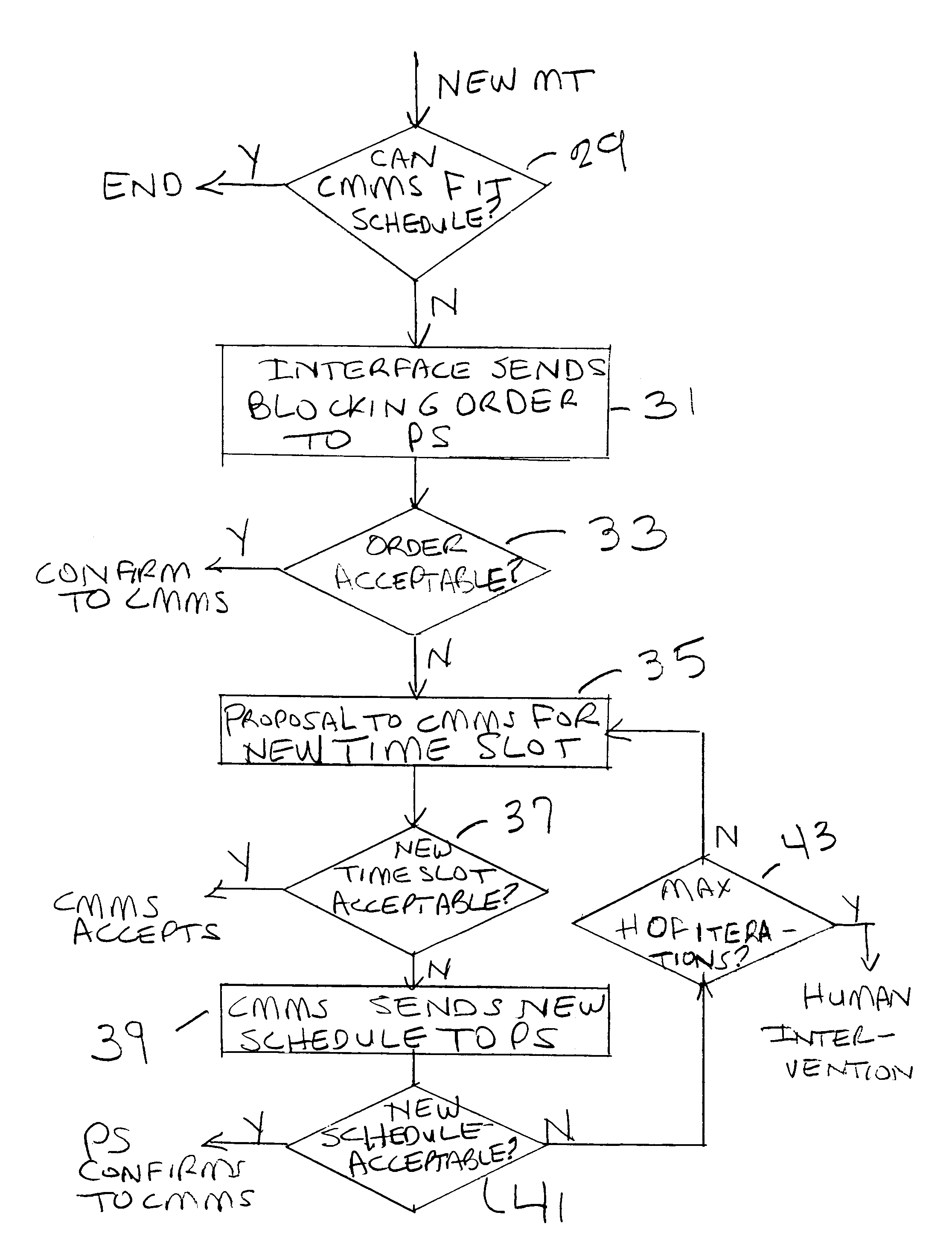

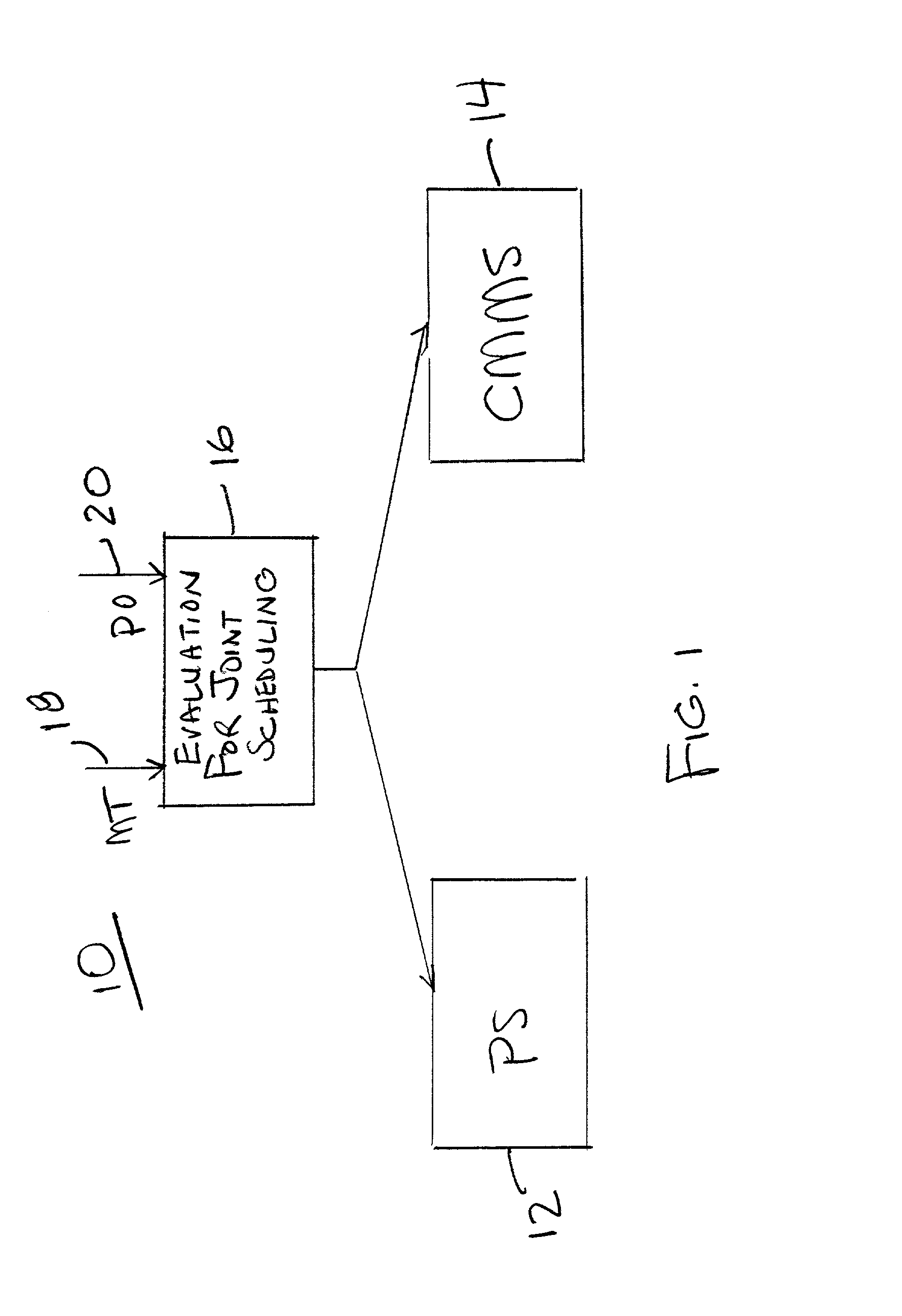

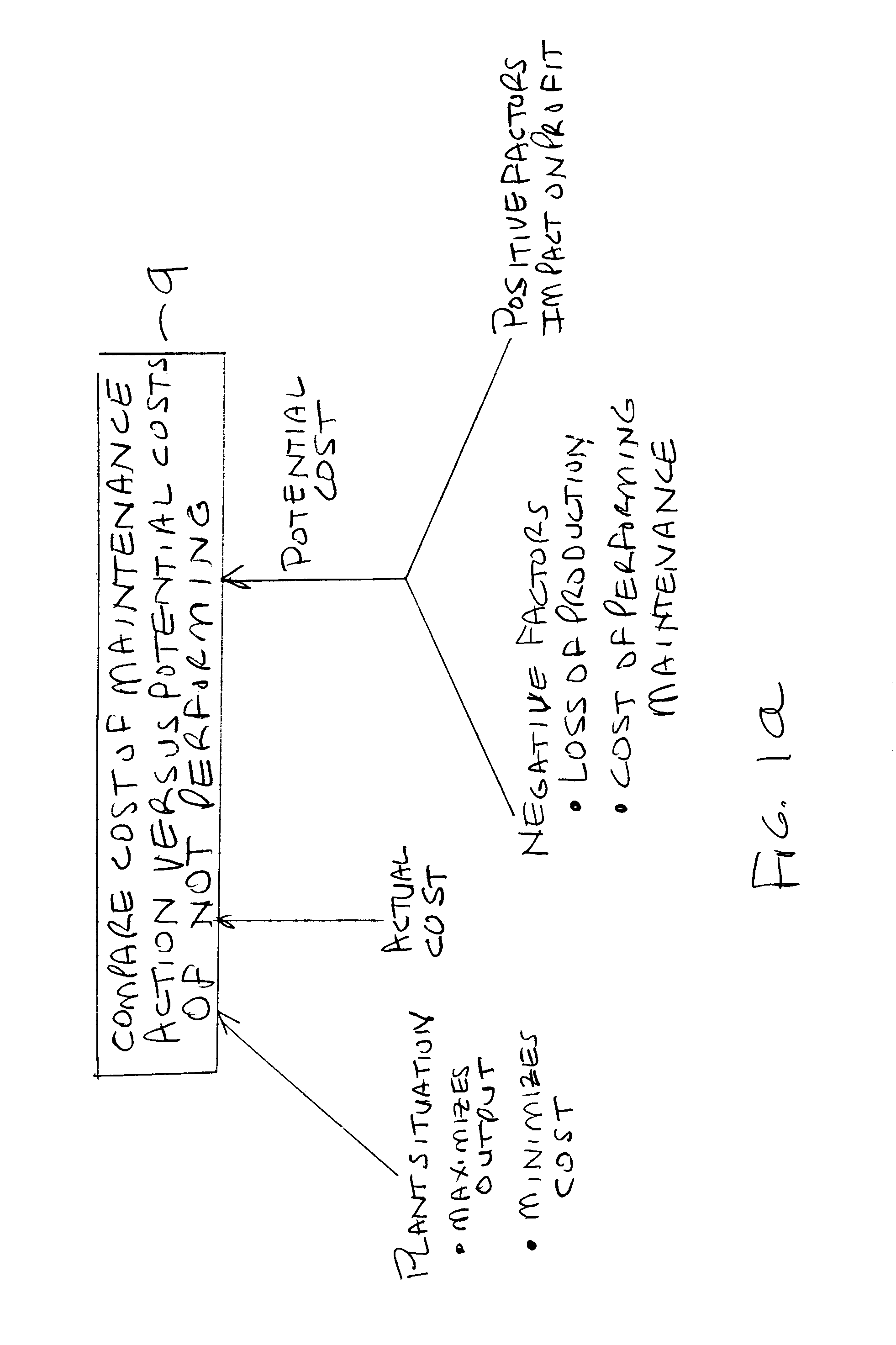

InactiveUS20030130755A1Technology managementResourcesComputerized maintenance management systemEngineering

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

Real time asset optimization

InactiveUS6999829B2Technology managementResourcesComputerized maintenance management systemTechnology assessment

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

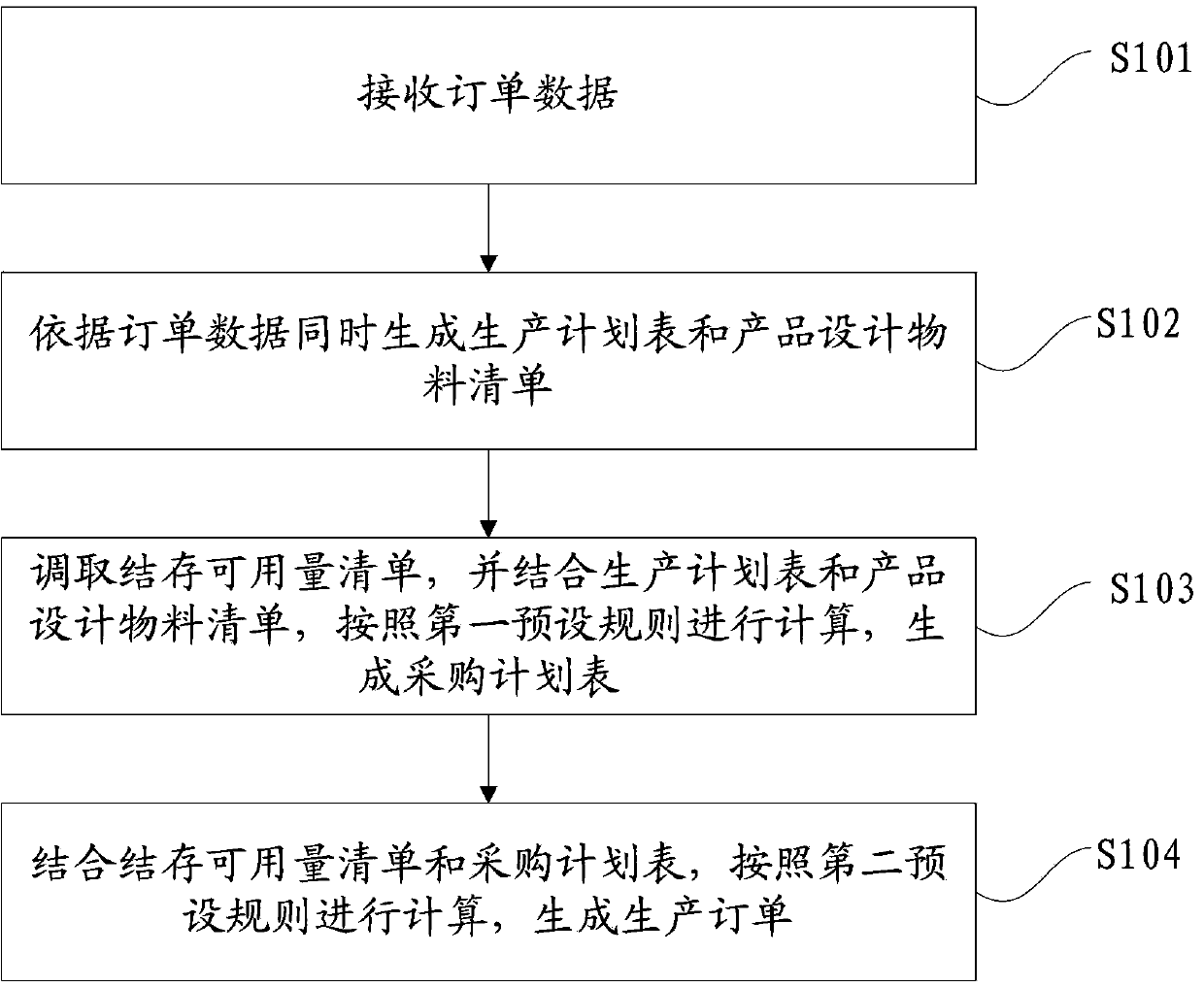

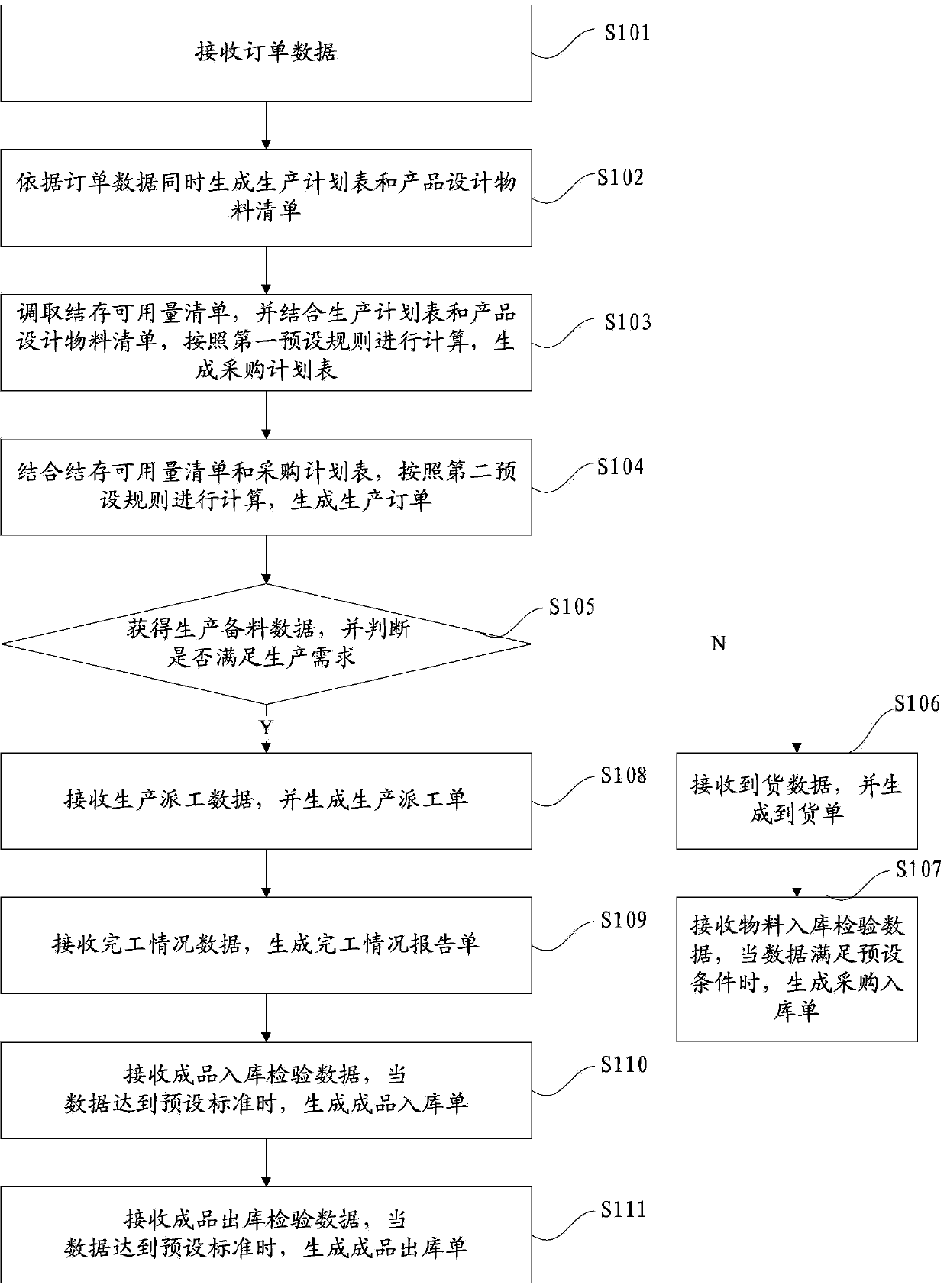

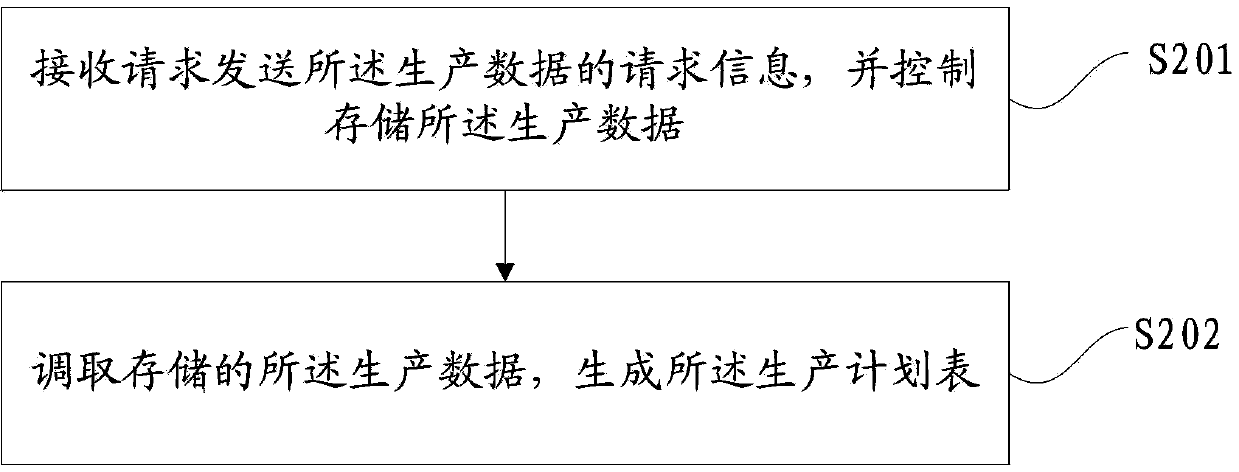

Production data processing method, device thereof, and system thereof

The invention discloses a production data processing method, a device thereof and a system thereof. The method comprises a step of receiving order data comprising production data and material data, a step of generating a production schedule according to the obtained production data and generating a product design material list according to the obtained material data at the same time, a step of calling a pre-stored balance amount, carrying out calculation according to a first preset rule with the combination of the production schedule and the product design material list, obtaining purchase material data and generating a purchase schedule corresponding to the purchase material data, a step of carrying out calculation with the combination of balance amount and the purchase schedule and according to a second preset rule, obtaining product order data, and generating a product order corresponding to the product order data. According to the above production data processing method, the product design material list and the production schedule are determined at the same time according to the concretely received order data, the flexibility is high, and the method, the device and the system are suitable for most small and medium enterprises.

Owner:HANGZHOU FUTURE POWER TECH +1

Manufacturing process for step circuit of PCB (Printed Circuit Board)

InactiveCN102651946AReduce copper thickness dropEliminate poor quality defectsConductive material chemical/electrolytical removalProduction scheduleEngineering

The invention discloses a manufacturing process for a step circuit of a PCB (Printed Circuit Board). According to the manufacturing process, different film patterns are adopted twice for manufacturing the circuit, during the primary film pattern circuit manufacture, a positive film circuit pattern is adopted, compensation is carried out a film substrate circuit at different positions according to copper thickness so as to manufacture a special circuit, and sunk copper plate electrification is carried out on the special circuit, so that the copper thickness meets the requirement; then board grinding is carried out by a twice board grinding mode so as to reduce the copper thickness difference of step positions; a dry film is enabled to be fully combined with the step positions by virtue of a film attaching and air compressing mode; and finally, normal circuit pattern manufacturing is carried out by utilizing a high-precision LDI (Laser Direct Imaging) exposure machine. Compared with the prior art, the manufacturing process for the step circuit can be used for eliminating the defects of open circuit at the position of the step circuit, notches, large deckle edges, serious lateral erosion, halfway etching and poor quality of thin lines and the like existing in the step circuit manufacturing process, improving the production efficiency and the production quality, quickening the production schedule and lowering the production cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

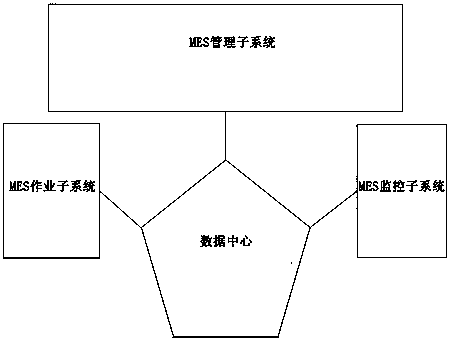

MES-based production system

InactiveCN107767015AGo digitalRealize process standardizationResourcesManufacturing computing systemsProcessing InstructionProduction schedule

The invention relates to an MES-based production system. A service order of an ERP system is pushed down to an MES system and a main production plan is issued automatically. The MES-based production system is composed of a data center, an MES management subsystem, an MES operation subsystem, and an MES monitoring subsystem. The MES management subsystem is used for invoking an execution process ofa CAPP / PDM system according to the main production plan, evaluating the capacity by combining data of a PM system, and forming a node plan and an operation plan of a production schedule. The MES operation subsystem is used for receiving the node plan and the operation plan that are formed by the MES management subsystem by a station integrated machine to invoke a process work sheet with an NC processing code, and sending an NC processing instruction to processing equipment of all workshops. And the MES monitoring subsystem is used for monitoring plan progress information, equipment state information, quality analysis information and dynamic capacity information of all workshops and feeding back the information to the data center in real time. With the system provided by the invention, dispersed production data information can be combined effectively to realize production coordination and collaboration.

Owner:NANJING INT MARINE EQUIP & SPARES

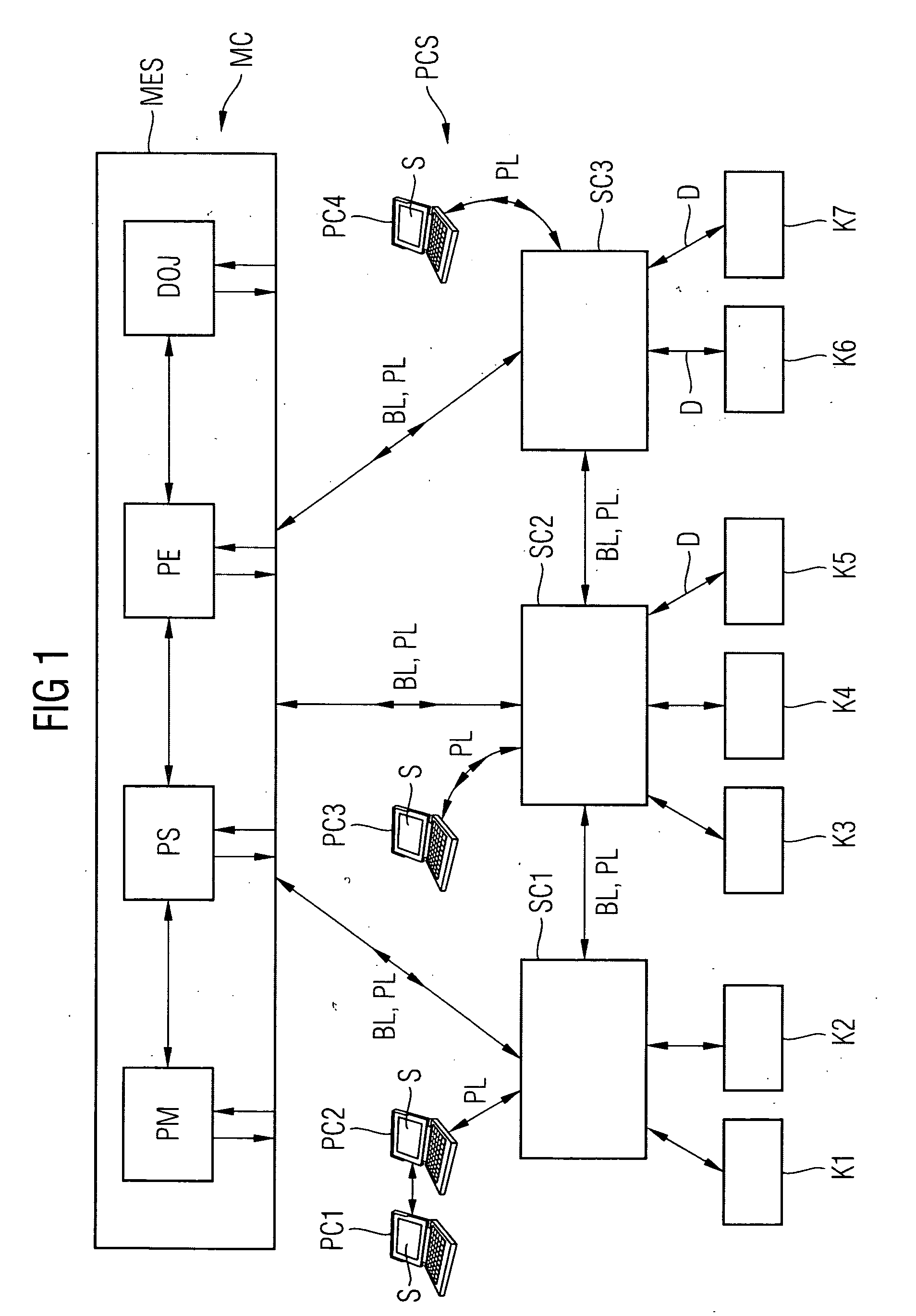

System and method for handling a production disturbance/opportunity event in a production execution system

InactiveUS20080294279A1Quickly reconfiguredMinimize impactProgramme controlResourcesProduction scheduleActuator

A system for handling a production disturbance / opportunity event includes a network having data processing units running a MES software for controlling / monitoring a production process operating production components. A production modeler defines a plant model of the production process, and a production scheduler generates an executable production schedule for the execution of operating procedures for the production components. A production executor executes the production process following the generated executable production schedule, and a production disturbance / opportunity event identifier detects a production disturbance event and identifies a production opportunity event which allows to maintain an efficiency of the production process at least as close as possible to an efficiency given by the executable production schedule as originally generated by the production scheduler. The production scheduler re-calculates an amended executable production schedule incorporating the identified production opportunity event, and the production executor executes the production process now following the re-calculated executable production schedule.

Owner:SIEMENS AG

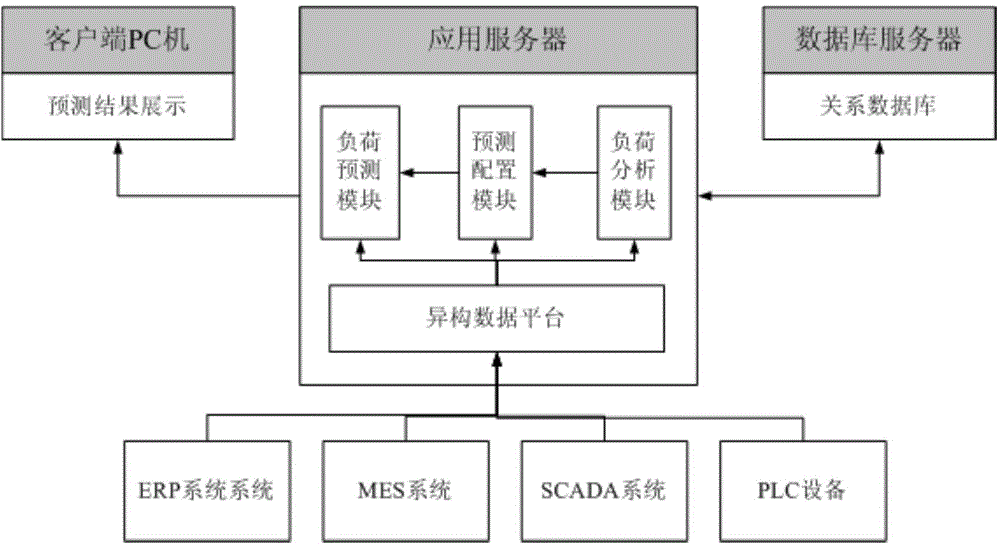

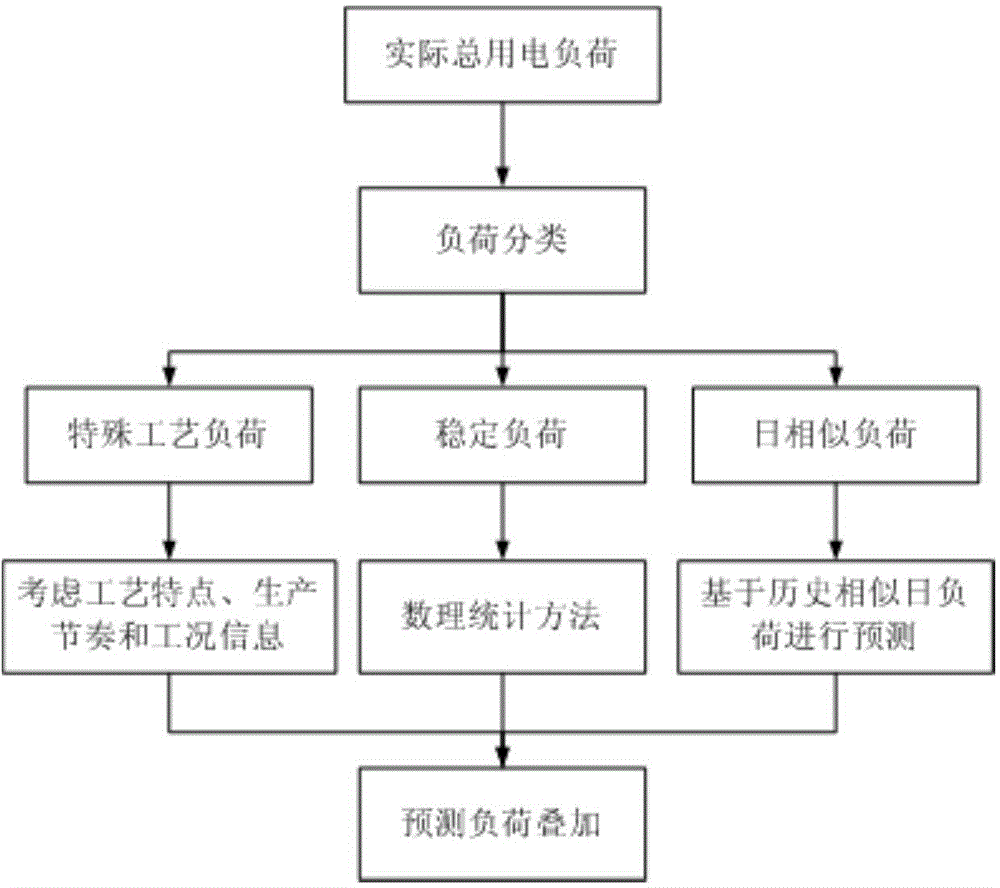

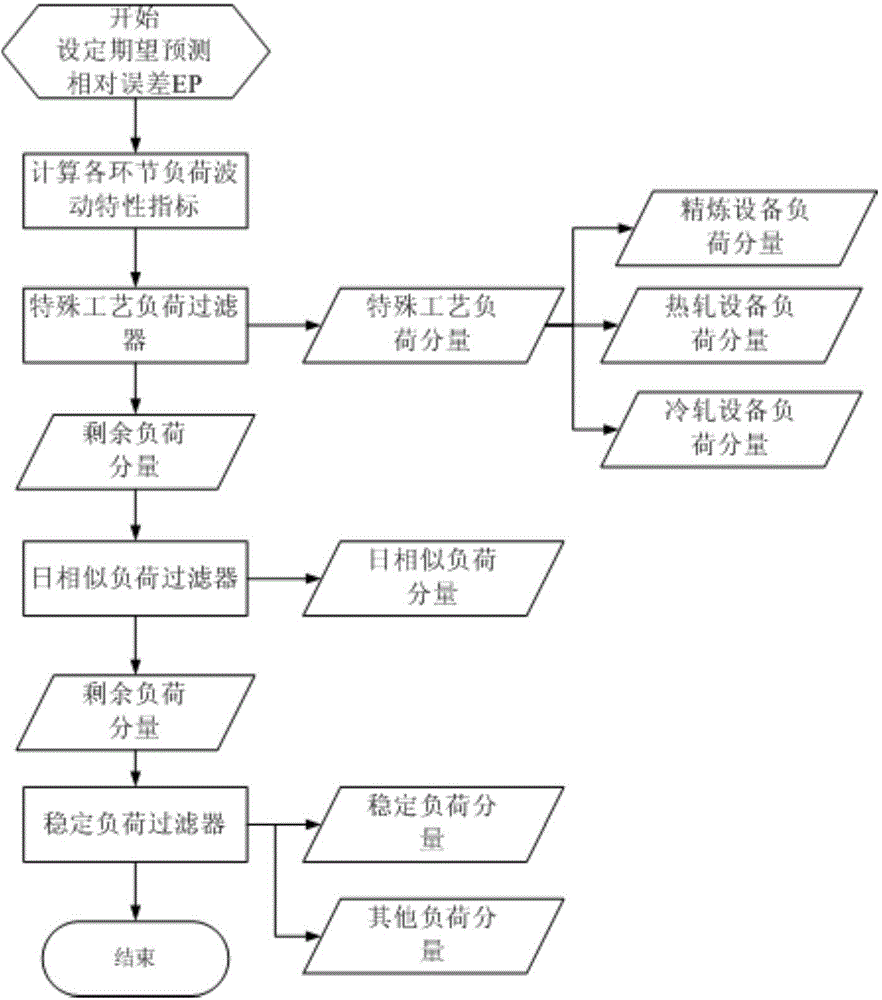

System for dynamically predicating power load of iron and steel enterprise in short period

The invention provides a system for dynamically predicating the power load of an iron and steel enterprise in a short period and belongs to the technical field of energy predication of iron and steel enterprises. According to hardware, the system comprises an application server, a relational data base server, a client side PC and a network device connecting all computers. The network device comprises a switch, network cables, a firewall and a router device. The application server and the relational data base server are connected to the switch through the network cables. The external client side PC is connected to a router. The router is connected with the switch through the firewall, so that communication between a client side and a server side is achieved. A software system comprises a heterogeneous data platform and a load predicating system. The load predicating system is composed of a load analyzing module, a predication configuration module and a load predicating module. The system for dynamically predicating the power load of the iron and steel enterprise in the short period has the advantages that the power utilization characteristics of each power utilization link, the technological feature, a production plan, a repair schedule and production working condition information are comprehensively considered, classified modeling is conducted, a predication value of the total load is obtained according to superposition of predication results, the predication value is in line with the reality of the iron and steel enterprise, information, technological rhythms and dynamic working condition information are fully considered in the process of dynamic predication, and models are better in adaptability.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

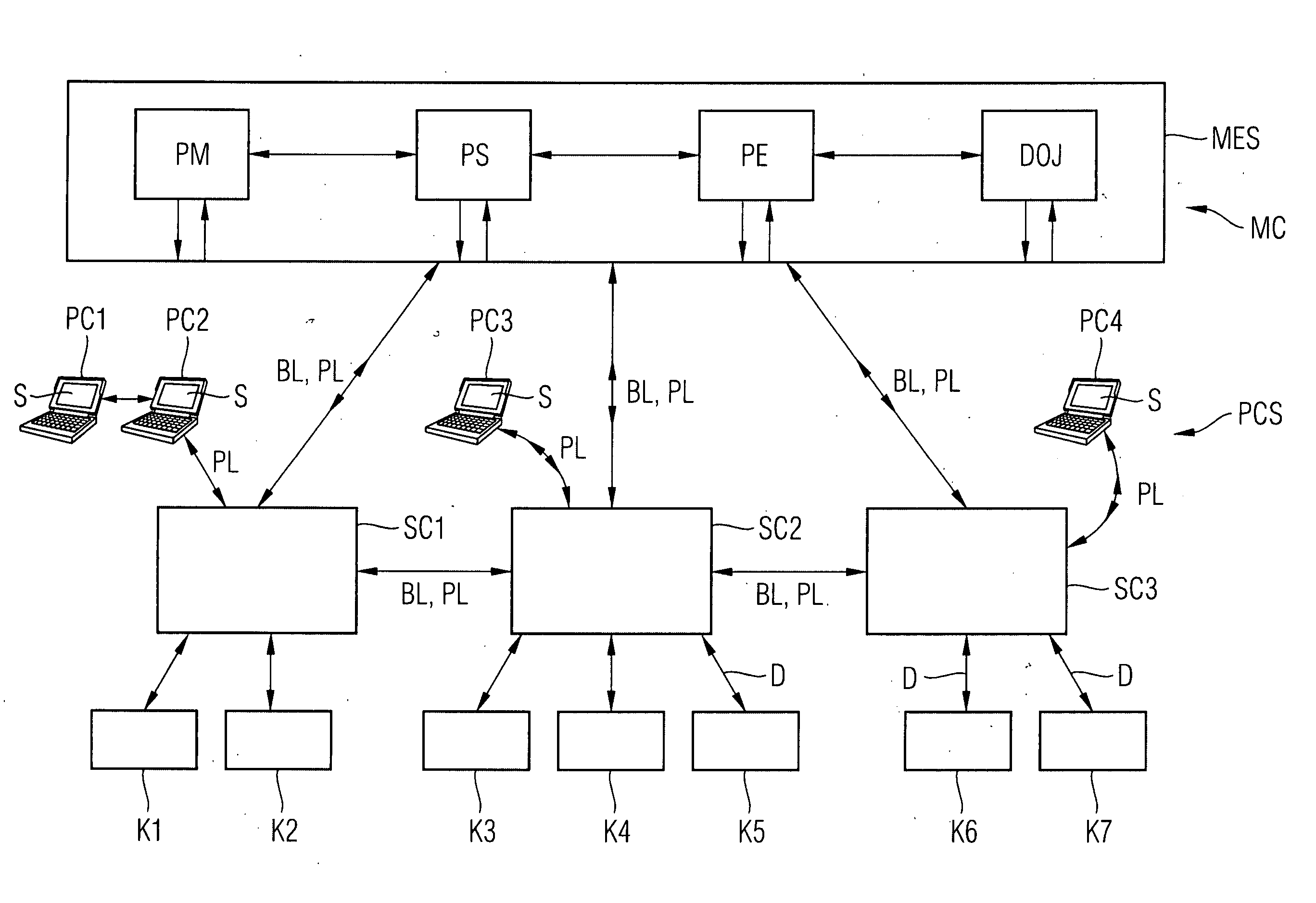

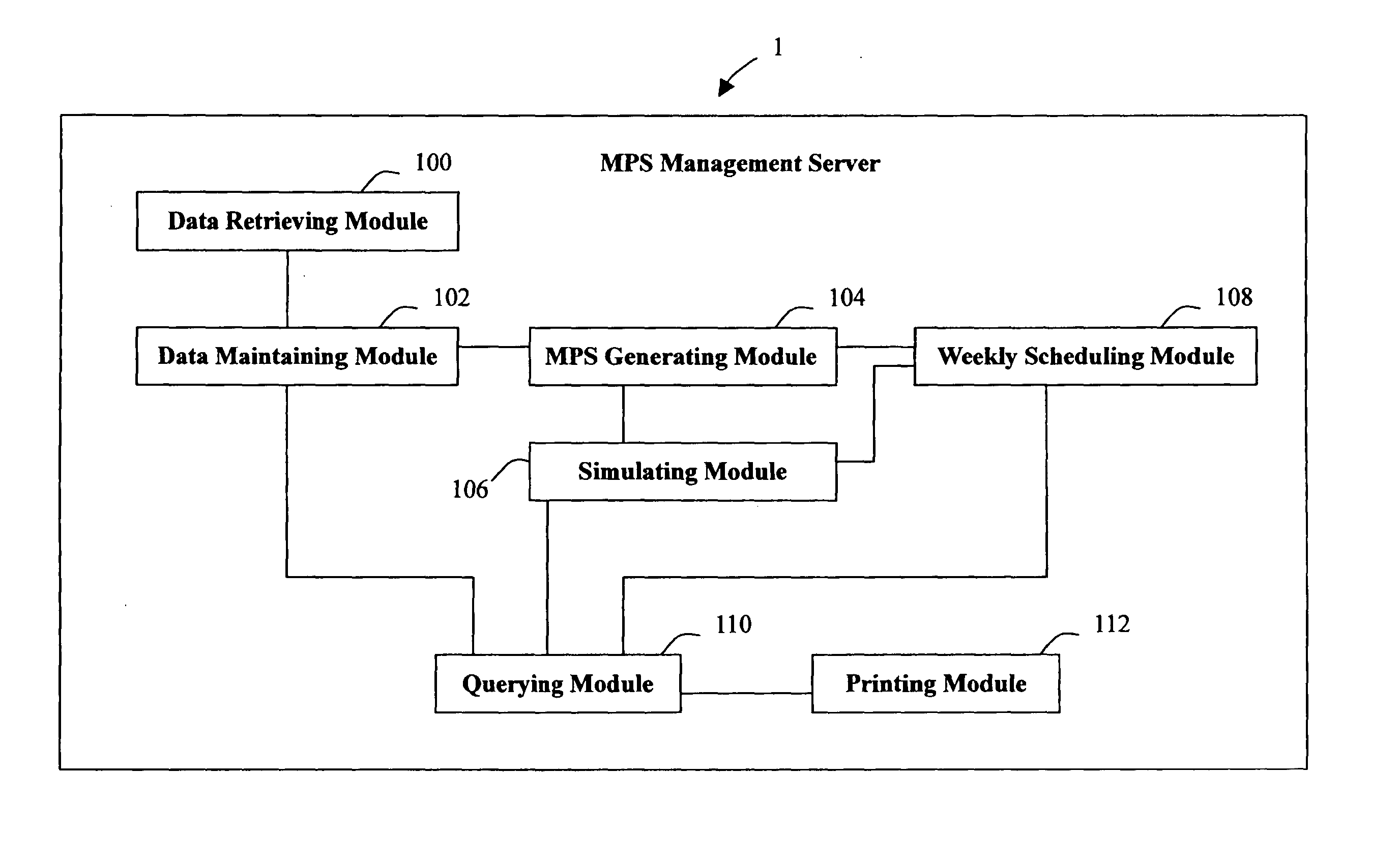

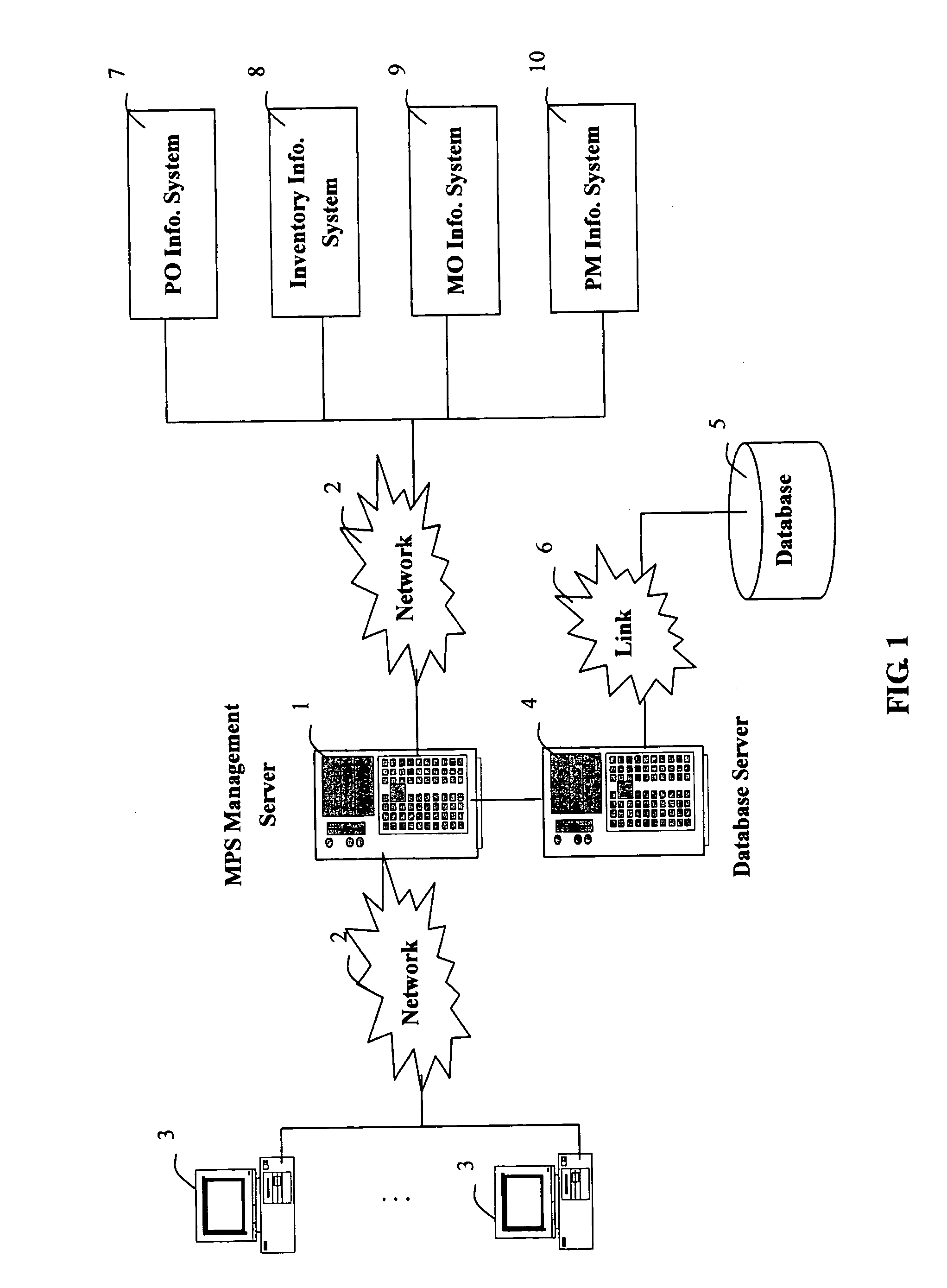

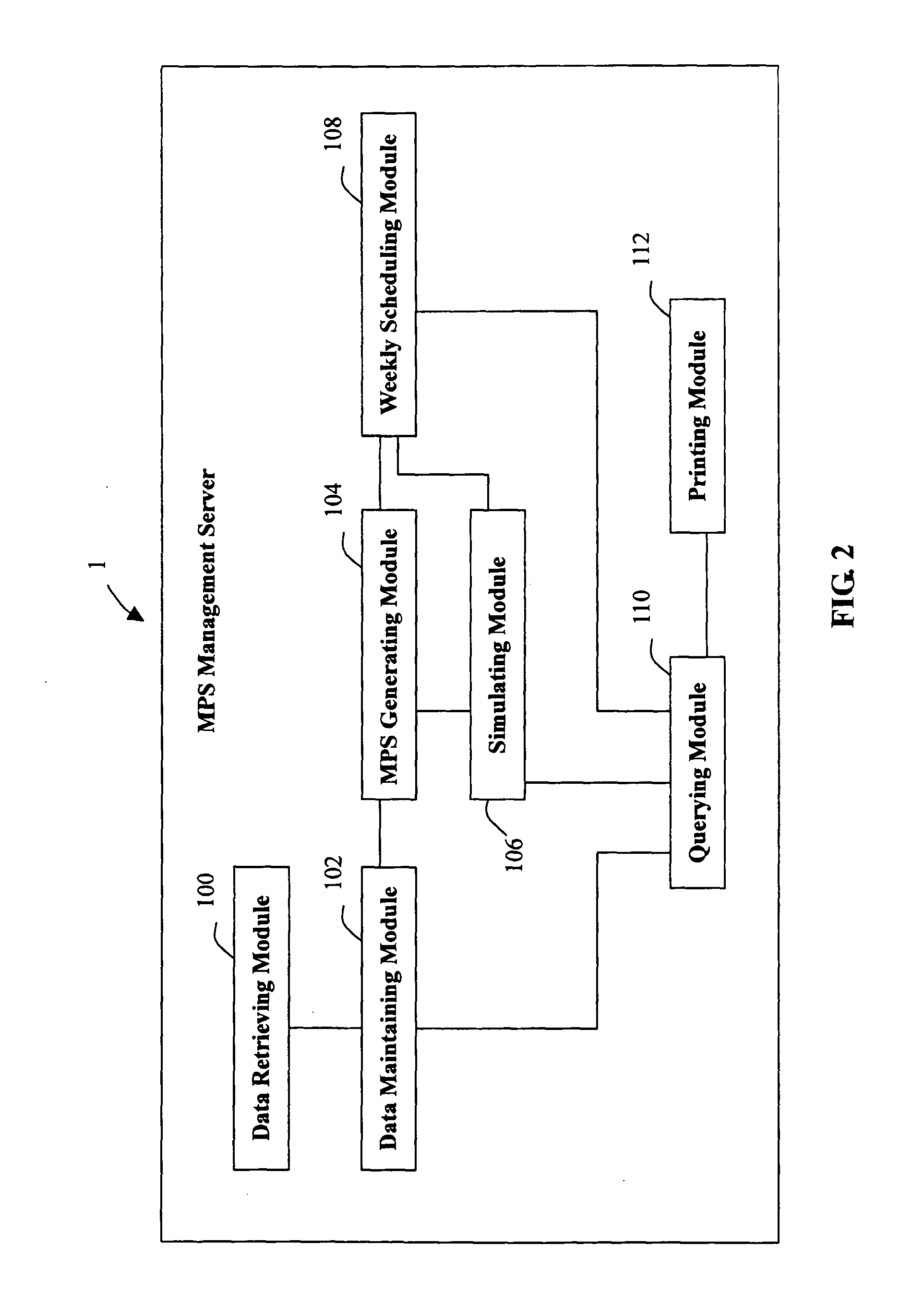

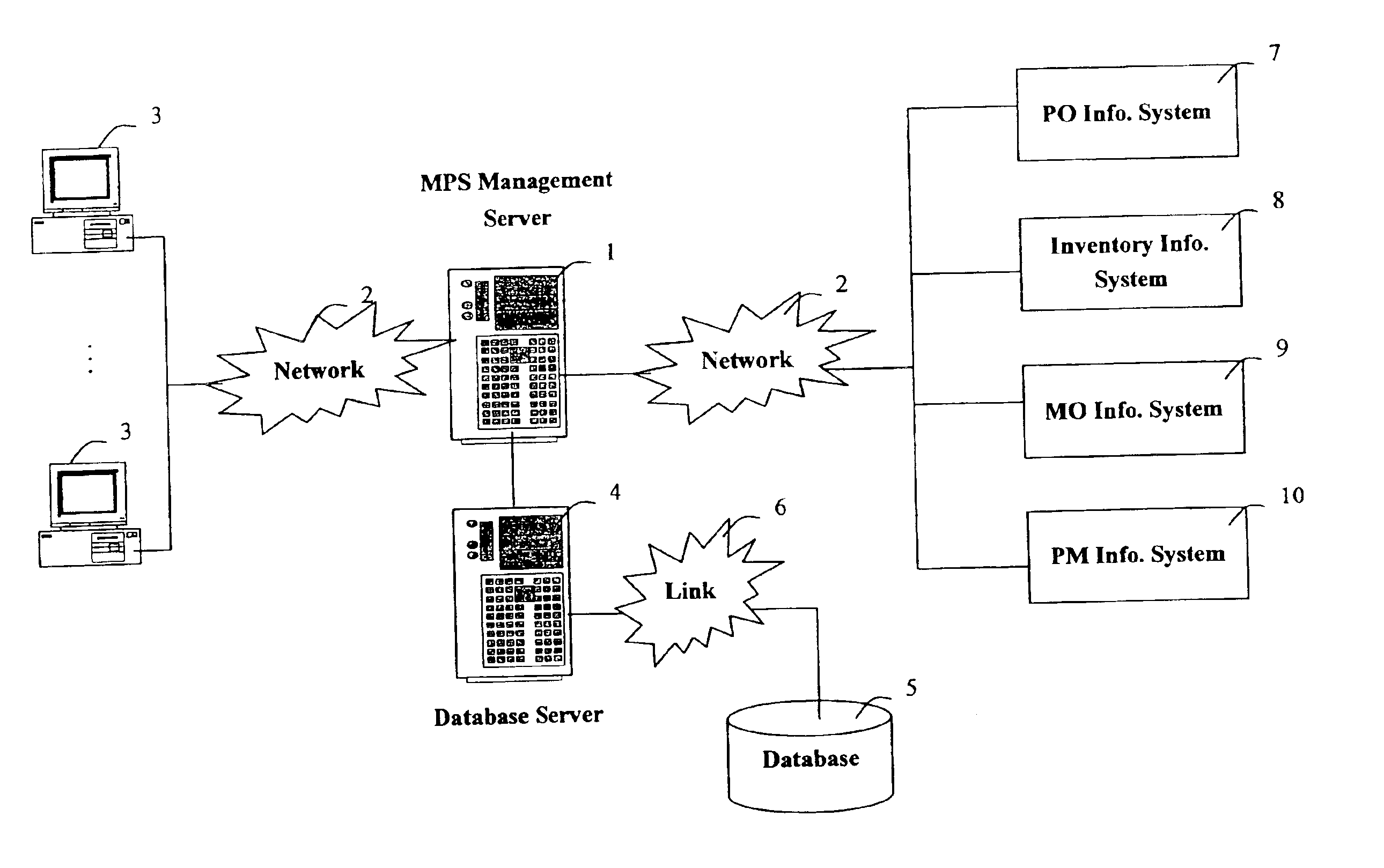

Master production scheduling management system and method

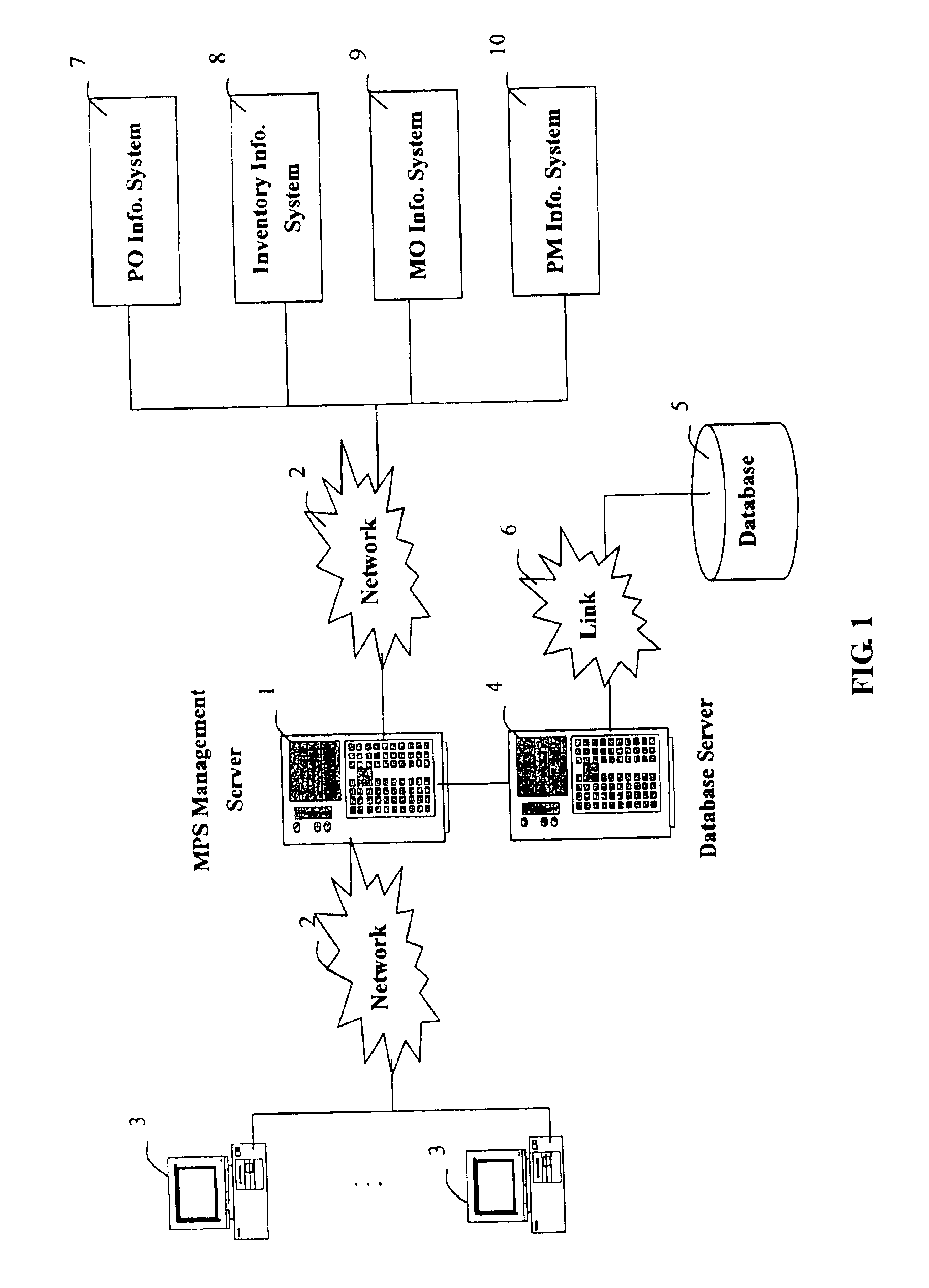

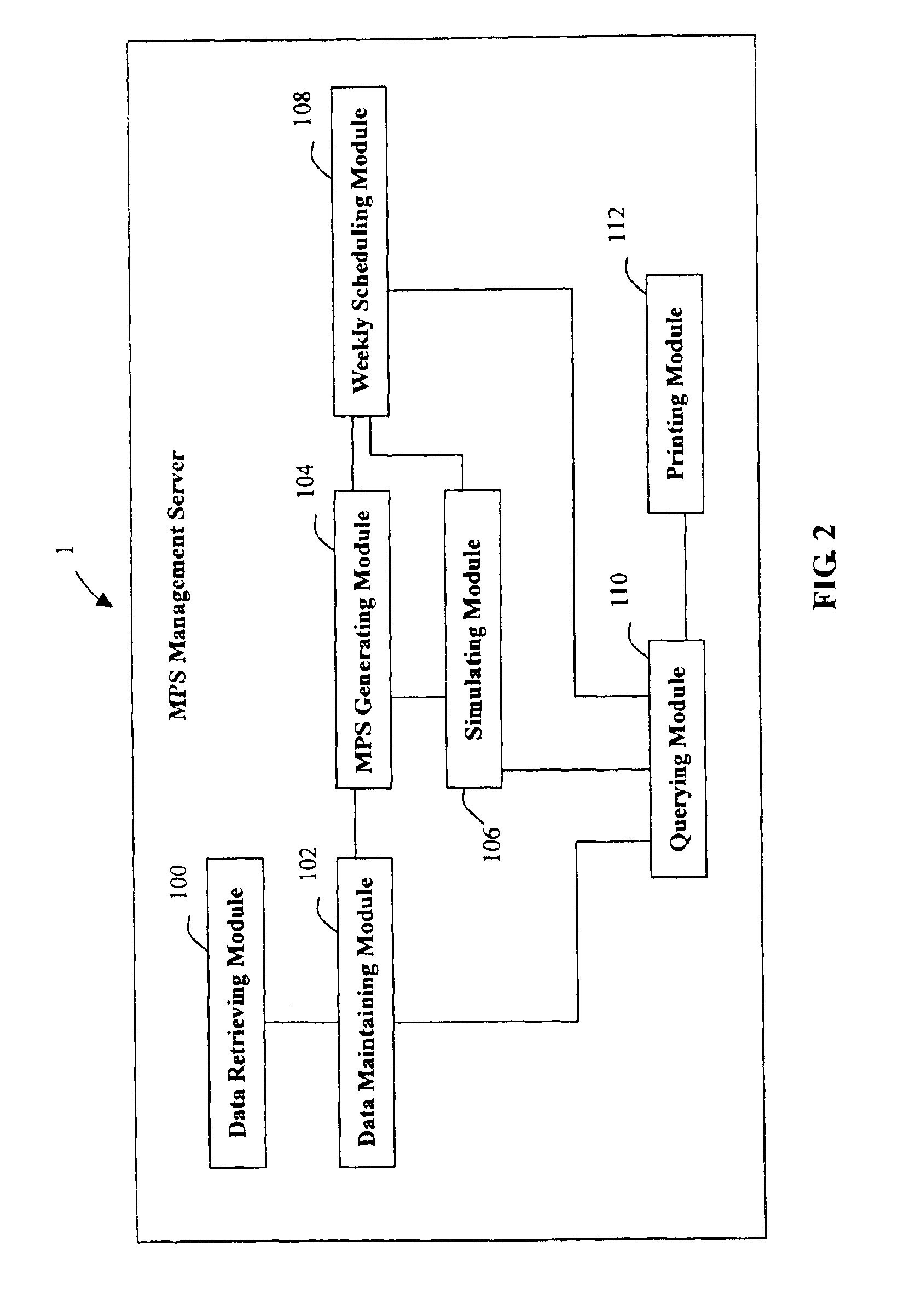

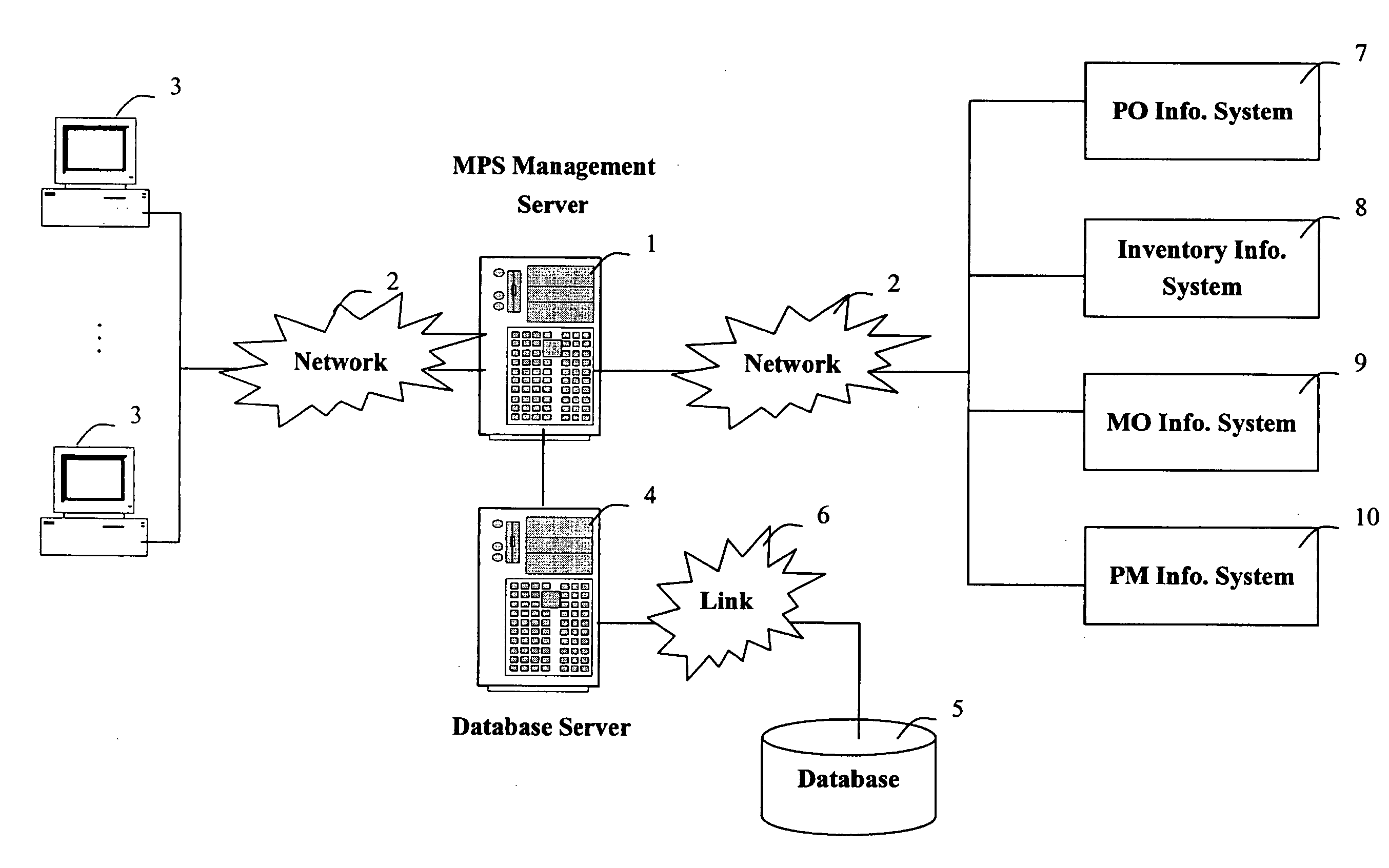

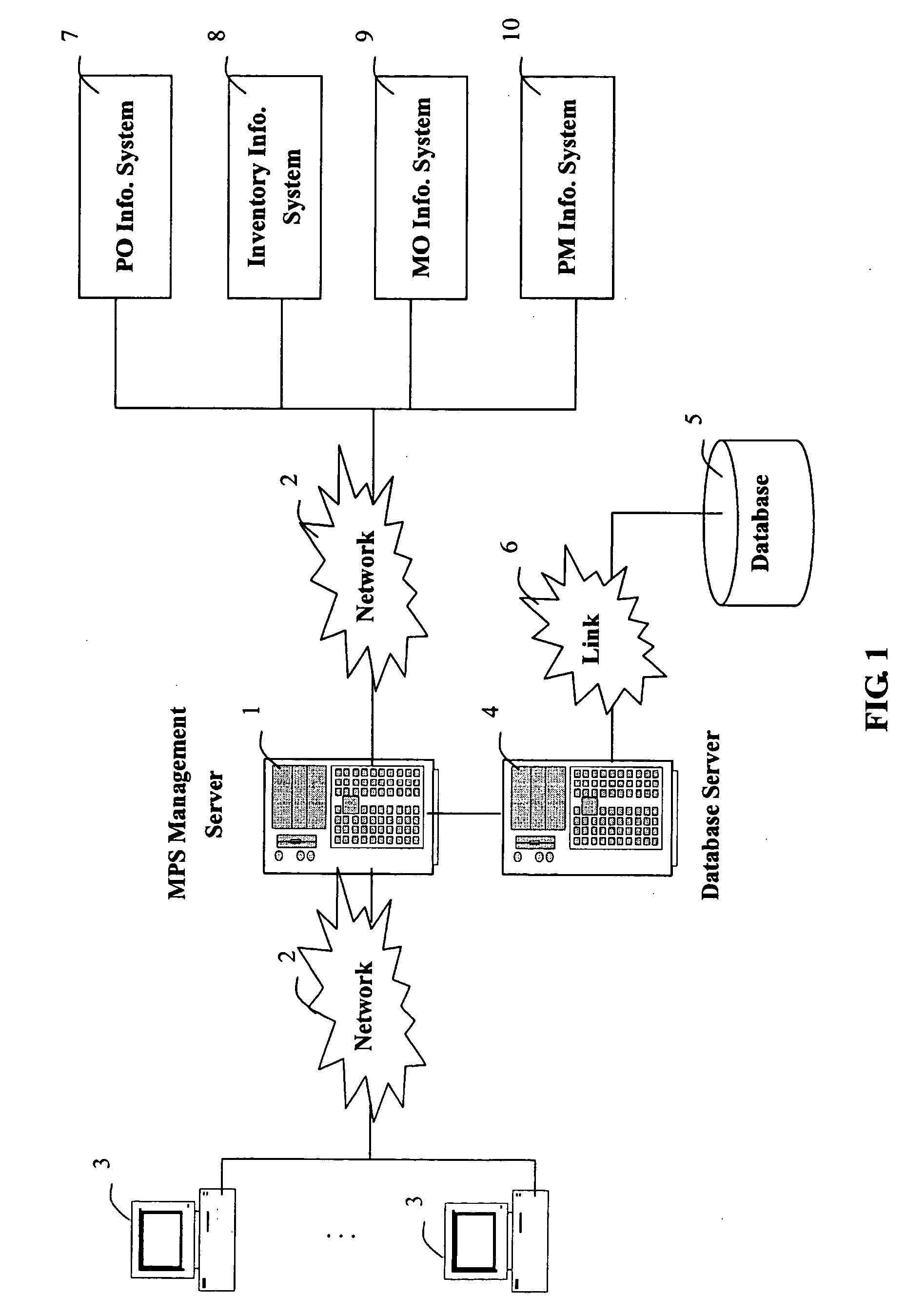

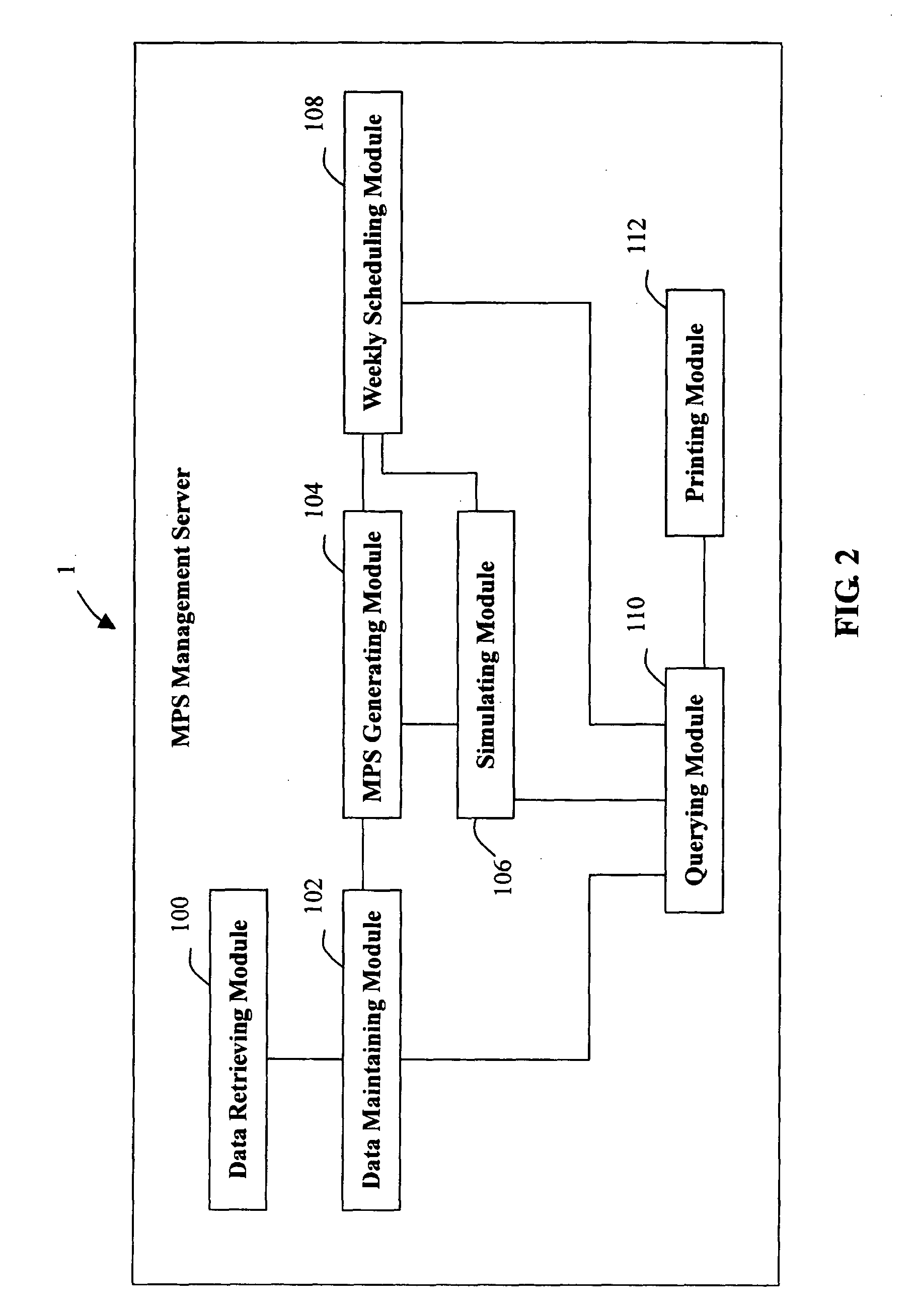

InactiveUS20040117048A1ResourcesSpecial data processing applicationsProduction scheduleNetwork management

A master production scheduling management system and method for efficiently generating master production schedules (MPSs) is provided. The system includes a plurality of client computers (3), an MPS management server (1), a database server (4) and a communication network (2) interconnecting the client computers, the database server, and the MPS management server. The MPS management server obtains data from external information systems by use of a data retrieving module (100), generates an original MPS based on the obtained data, and amends the original MPS to be an optimized MPS by simulating rough-cut capacity planning (RCCP) and material requirements planning (MRP). Employing the present invention, users can amend MPSs in time by simulating RCCPs and MRPs and arrange production schedules efficiently.

Owner:HON HAI PRECISION IND CO LTD

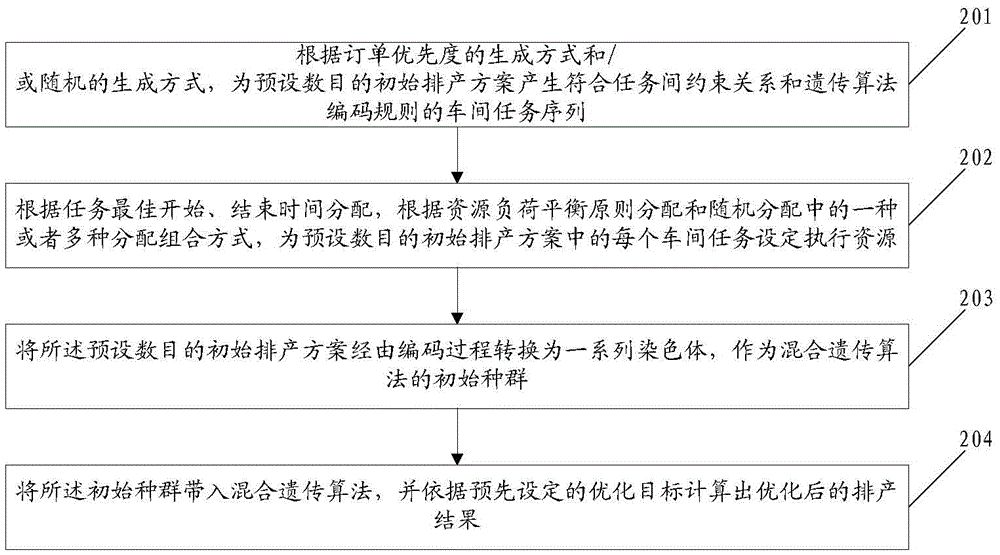

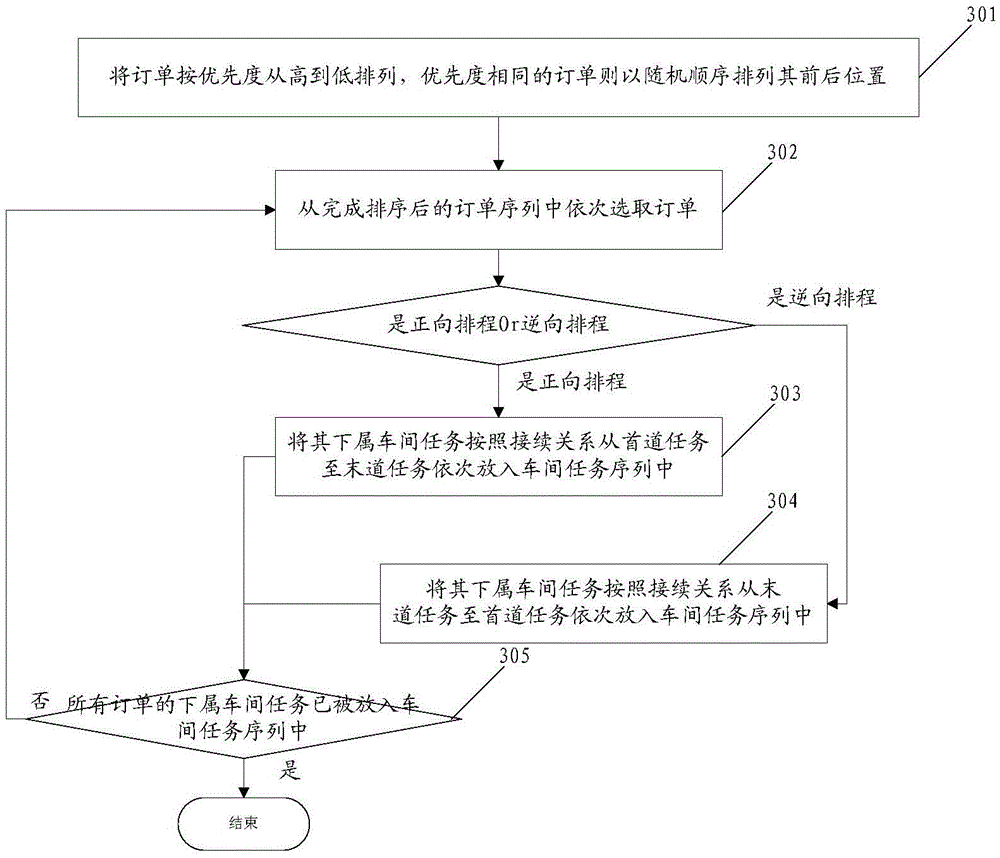

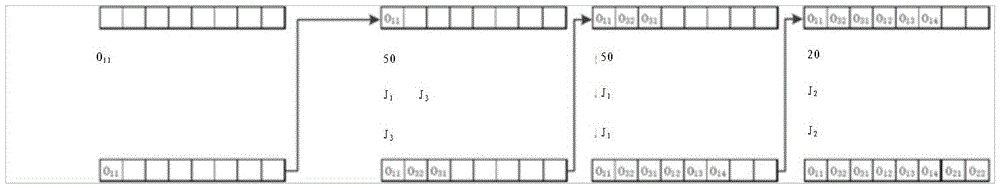

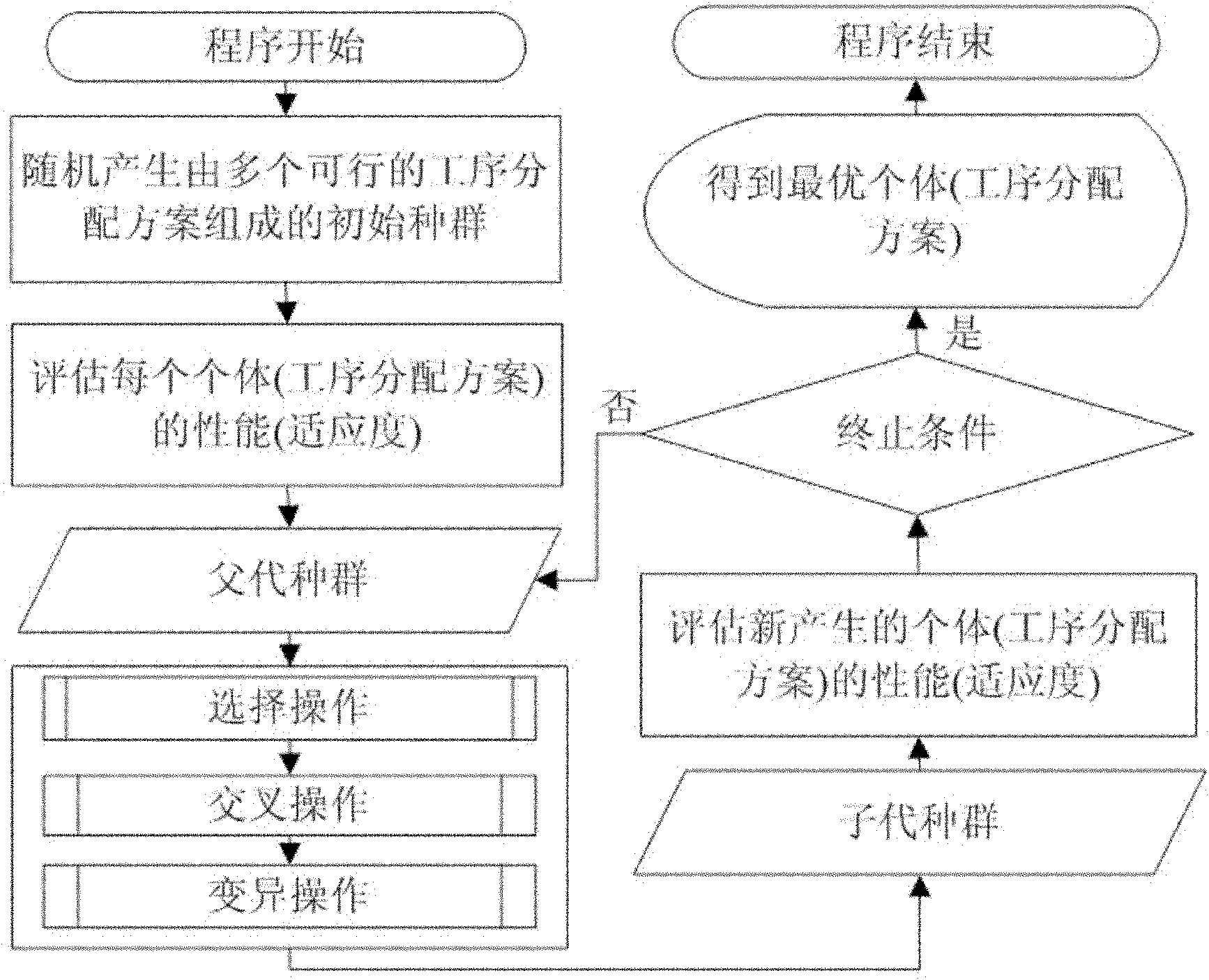

Hybrid genetic algorithm-based MES (Manufacturing Execution System) production planning and scheduling method

InactiveCN105629927AMaintain population diversityAvoid premature convergenceTotal factory controlProgramme total factory controlRandom assignmentPopulation

The invention is applicable to the technical field of workshop production planning management, and provides a hybrid genetic algorithm-based MES (Manufacturing Execution System) production planning and scheduling method. According to an order priority generation mode and / or random generation mode, a workshop task sequence which meets constraint relations between tasks and a genetic algorithm coding rule is generated for a preset number of initial scheduling schemes; according to the best task starting and ending time and according to one or more distribution combination modes in resource load balancing principle distribution and random distribution, execution resources are set for each workshop task in the preset number of initial scheduling schemes; the preset number of initial scheduling schemes are converted into a series of chromosomes through a coding process to serve as an initial population for the hybrid genetic algorithm; and the initial population is introduced to the hybrid genetic algorithm, and a scheduling result after optimization is calculated according to a preset optimization target. High efficiency of the MES production planning and scheduling results in the prior art is improved.

Owner:WUHAN KAIMU INFORMATION TECH

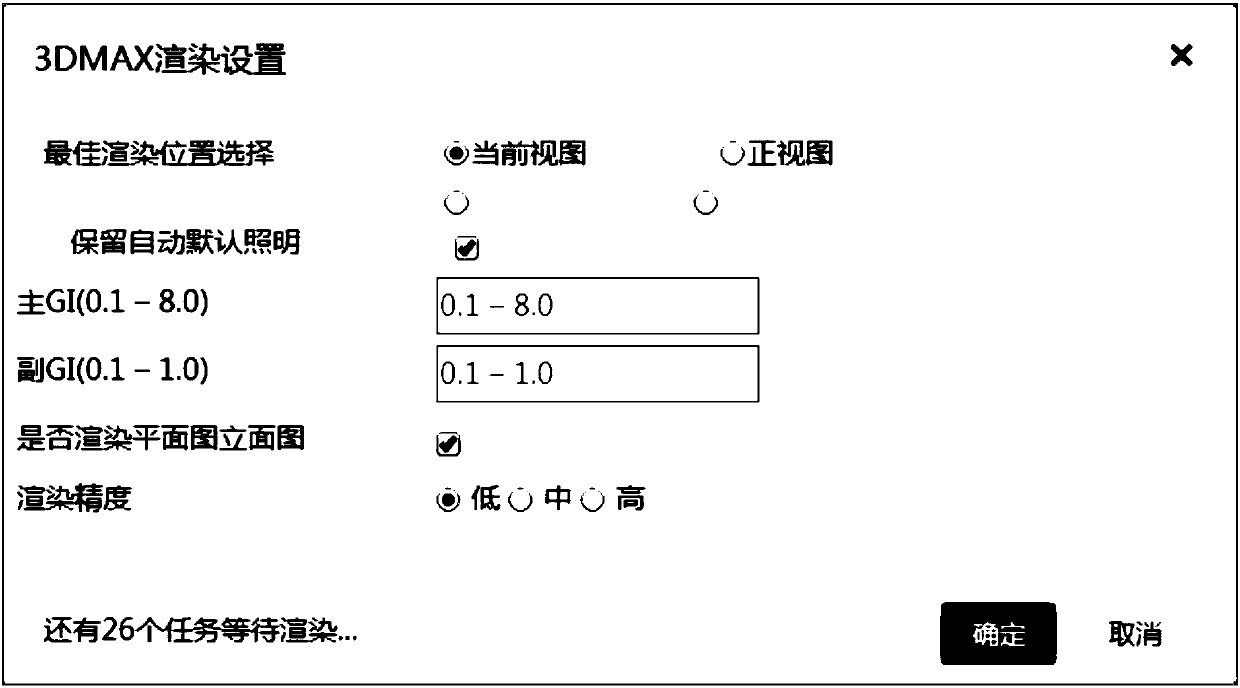

Bathroom product customizing and processing method and system

InactiveCN107563838AValid choiceMeet individual needsBuying/selling/leasing transactionsSpecial data processing applicationsProduction scheduleBarcode

A bathroom product customizing and processing method and system are provided. The method includes the following steps: (1) a product customizing step: (1.1) acquiring a scene, and arranging products in the scene, and (2) customizing the components of each product, and sending customization data to an SAP system to generate a customization order; (2) an order separating step: separating the customization order according to the model number, and generating production data and related drawings based on a BOM file; and (3) a product processing step: carrying out cutting according to cutting data and a BOM table, printing a barcode label, and pasting the barcode label on a cutting plate; scanning the barcode label to get the drawings, feeding back the production schedule, and processing the plate; and after processing, binding the finished product label. According to the invention, customization is carried out based on a scene, a customization order is generated, the order is separated according to the model number, and the parameters of components and the parameters of machining in the factory are generated. Product processing can penetrate all links of production. The efficiency and productivity are improved. The dependence on human labor is reduced. Scientific management is achieved, and the cost of production is reduced.

Owner:厦门乐石科技有限公司

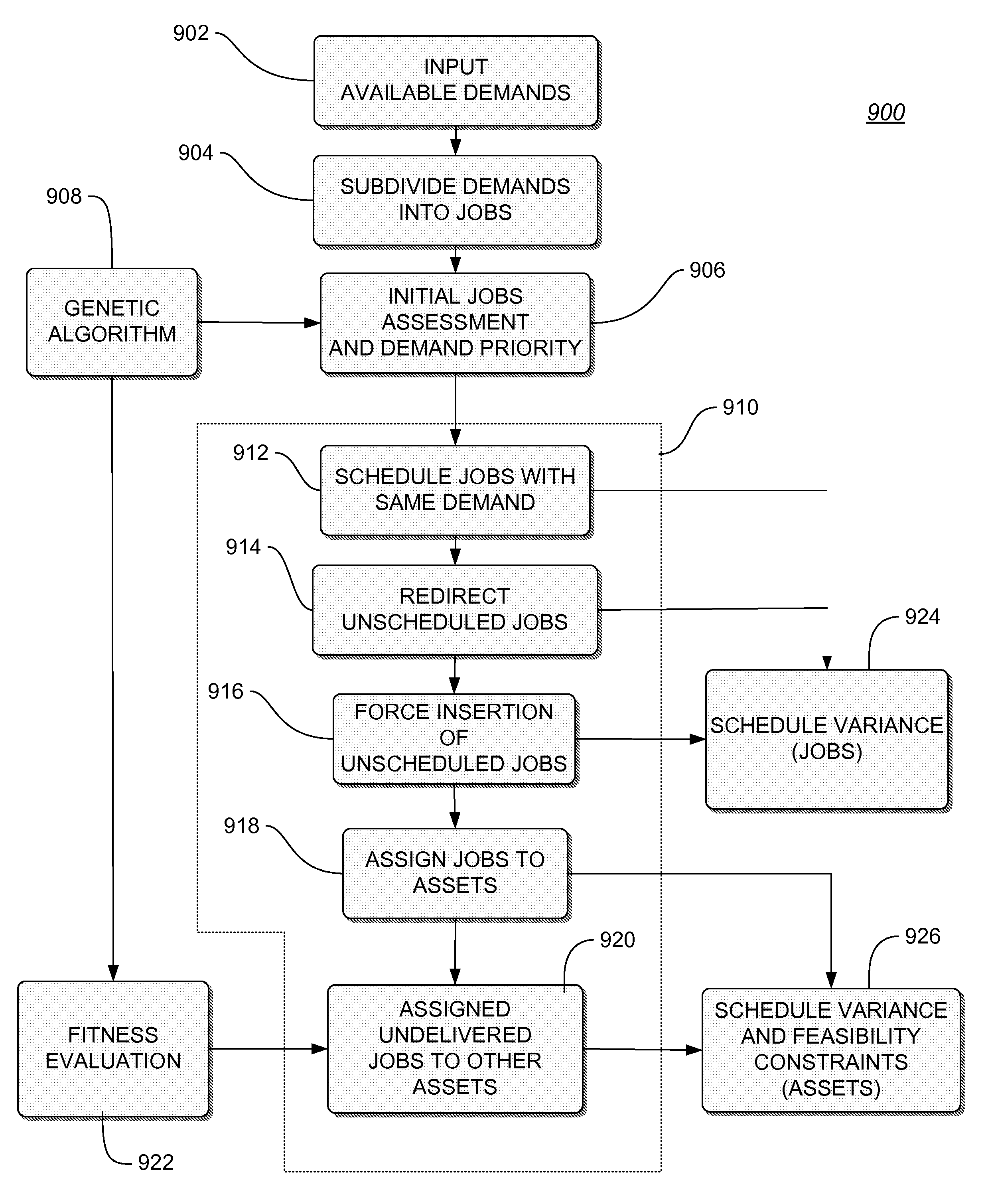

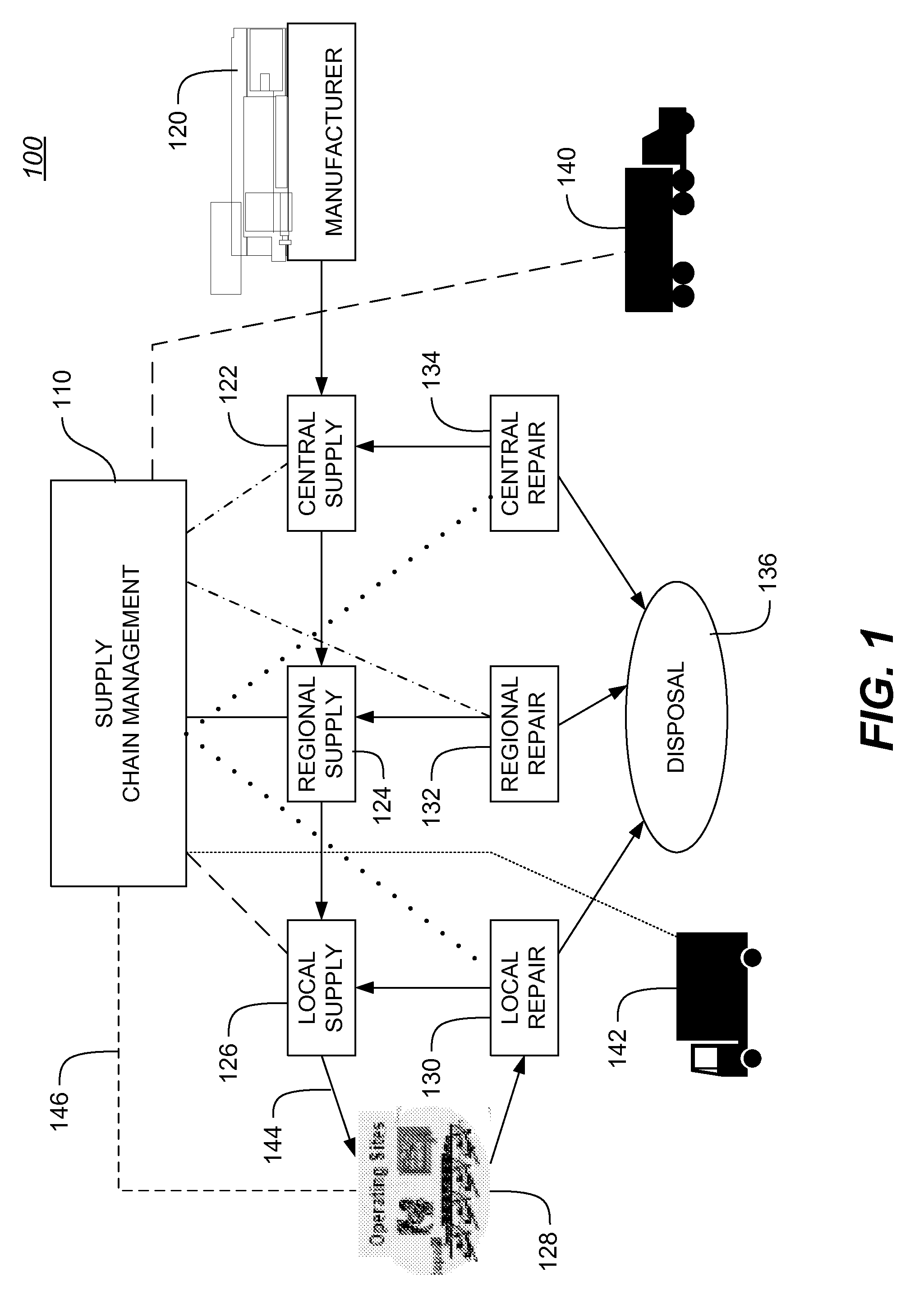

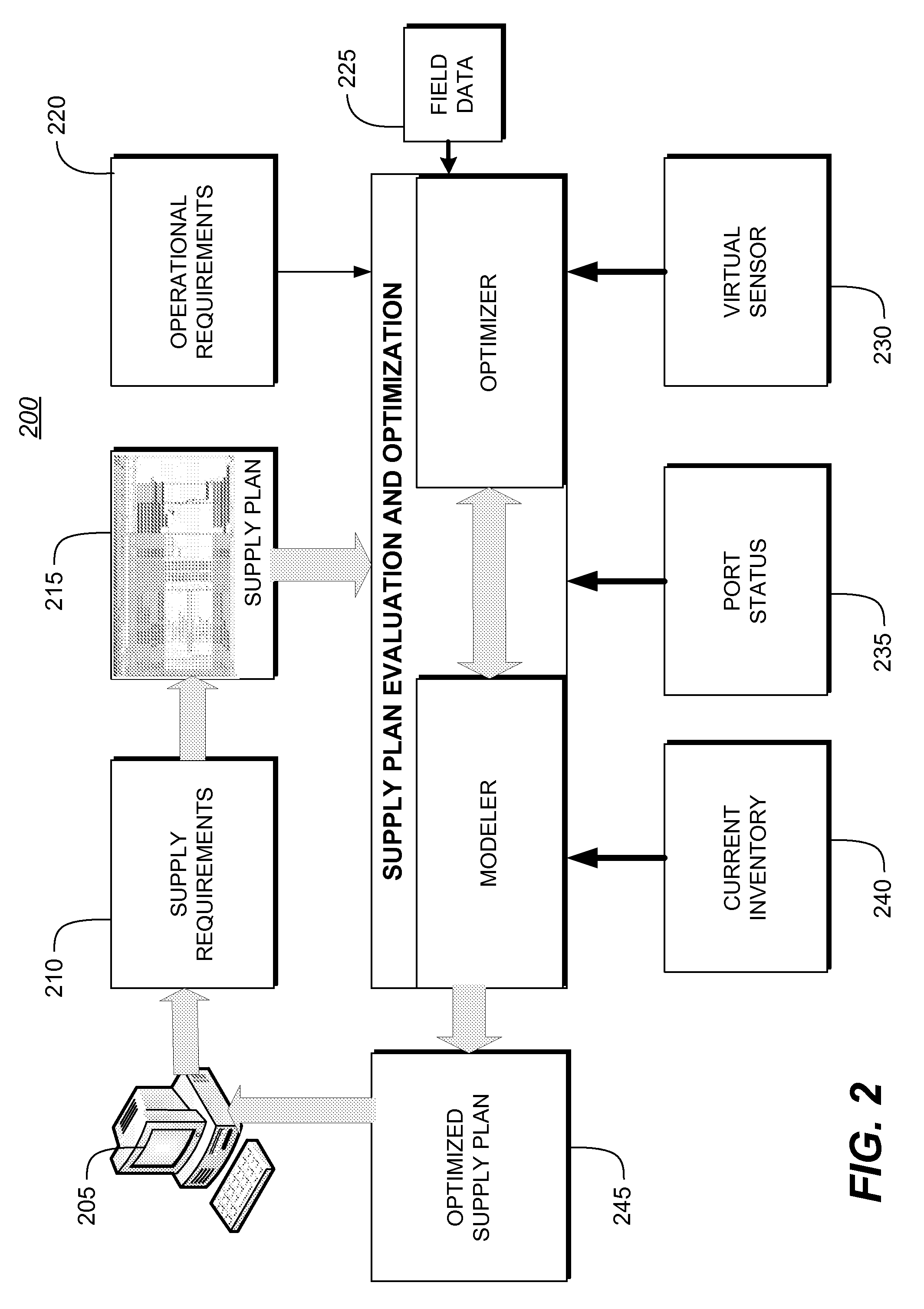

Systems, methods and apparatus for implementing hybrid meta-heuristic inventory optimization based on production schedule and asset routing

ActiveUS8655705B2Optimizes supply planMaximize availabilityInstrumentsProduction scheduleSupply planning

The disclosure relates generally to methods and apparatus to optimize a supply plan through a hybrid meta-heuristic approach based on genetic algorithms to optimize inventory and generate a supply plan. The apparatuses include a supply chain planner that interacts with the processes of a supply chain network. To provide a complete optimization for the type of platform being deployed in theater a heuristic algorithm is devised to decompose the supply plan problem into a production center schedule and an asset routing problem, which will be tackled one after the other. The decomposed supply plan problem is solved with different heuristic algorithms. Namely, genetic algorithms are used to optimize the supply plans based on ever changing set of operational demands from in theater and the priority of those demands to the assigned depots, while efficient constructive heuristics are used to deal with footprint and timing constraints.

Owner:LOCKHEED MARTIN CORP

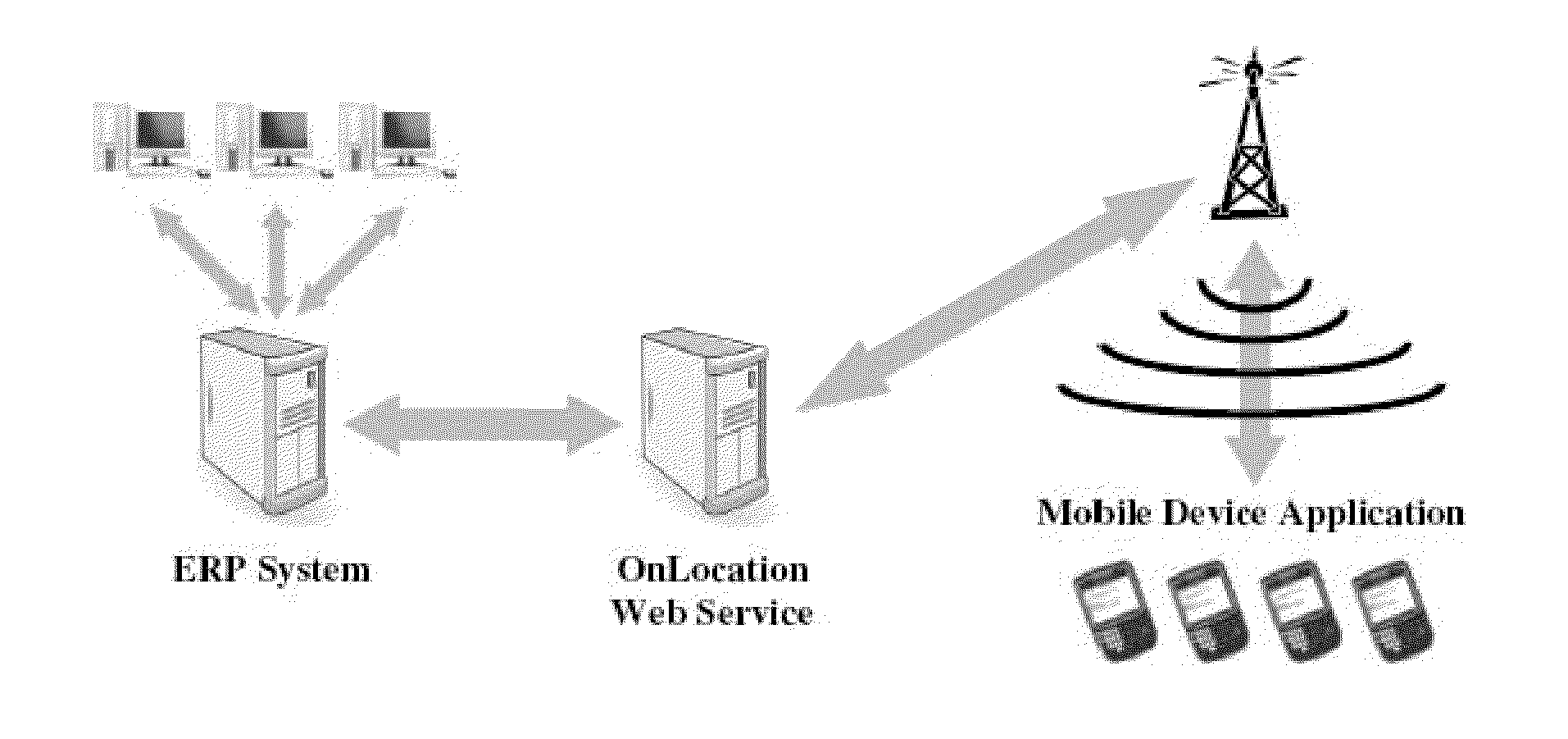

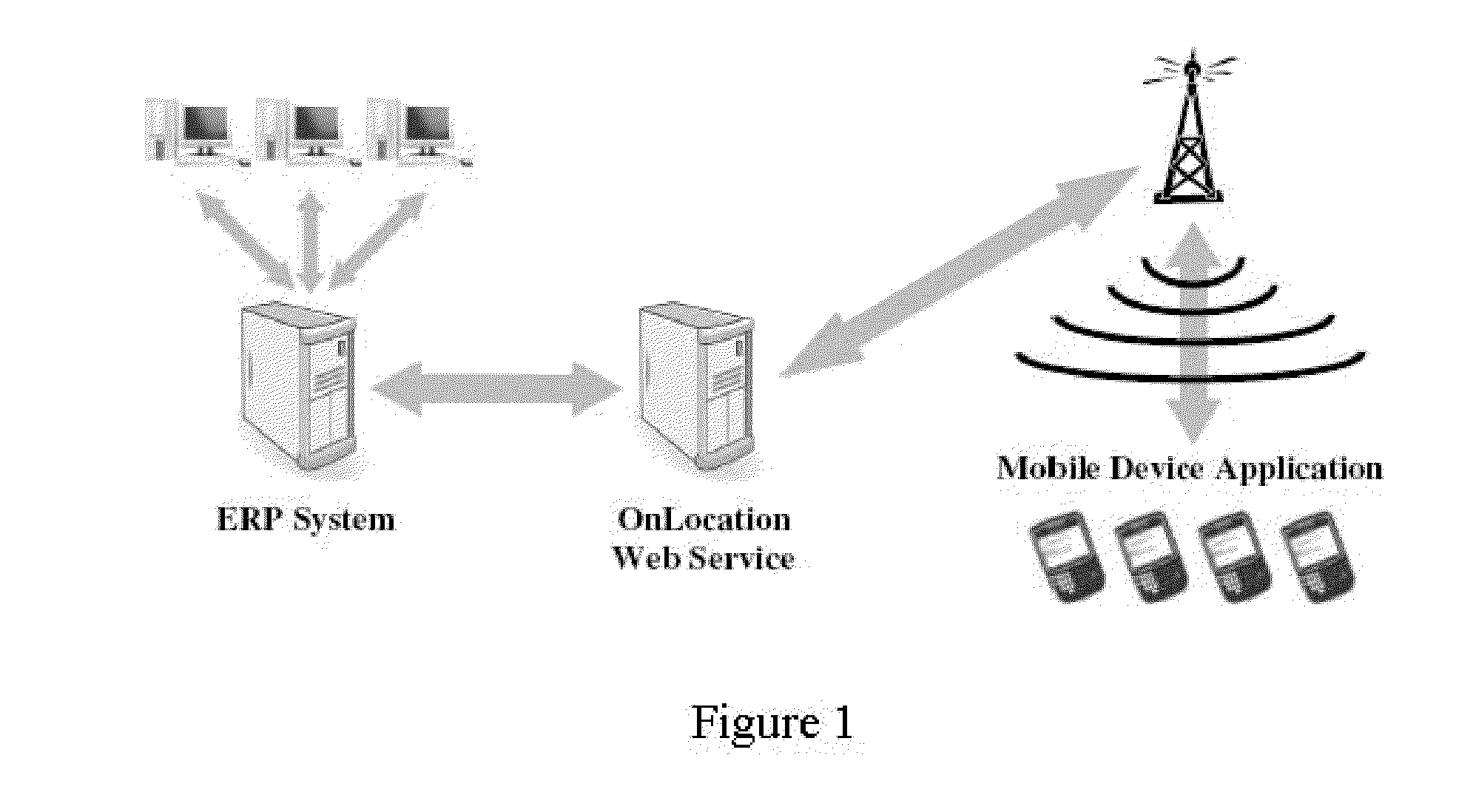

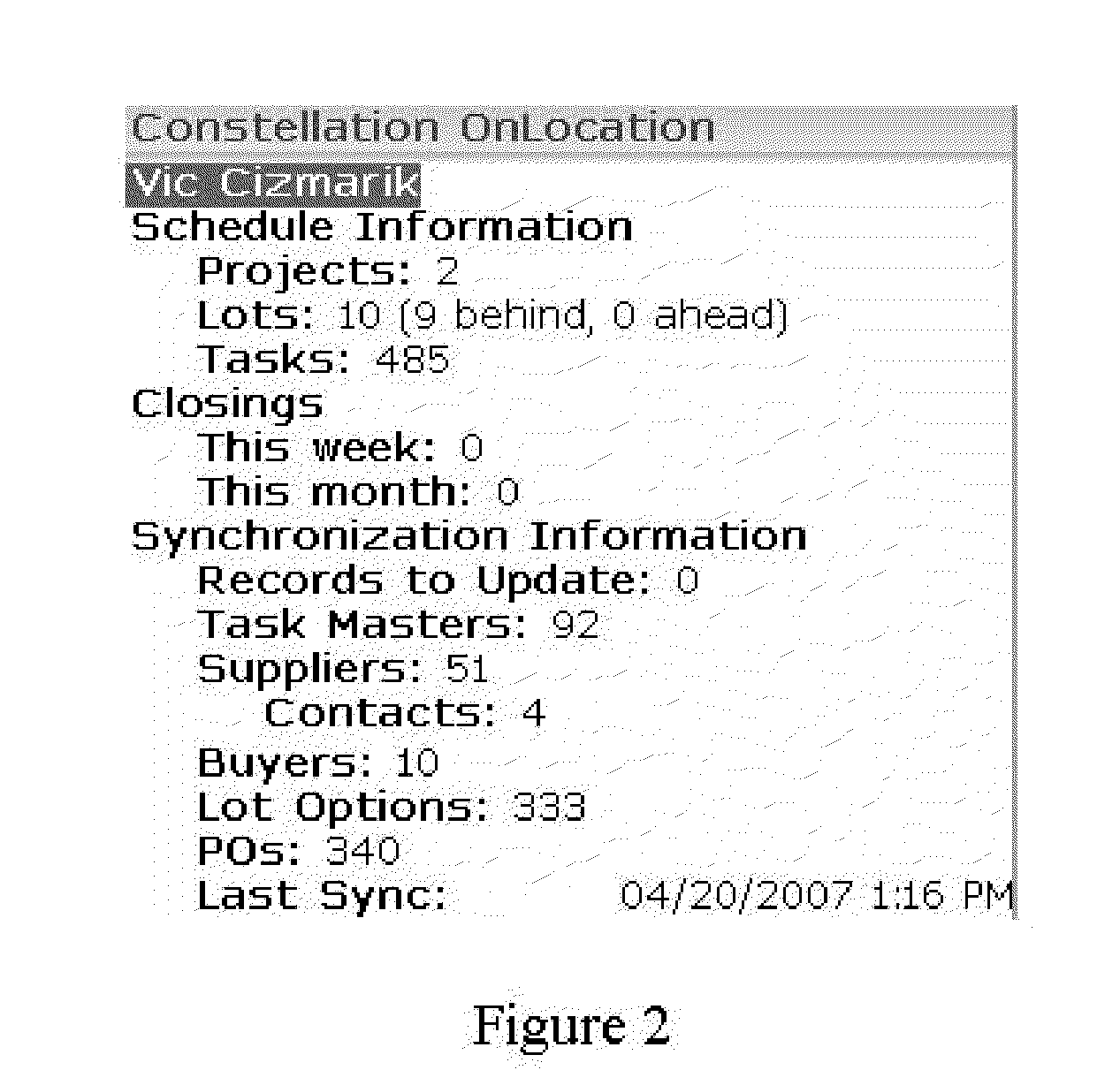

System and Method of Real-Time Homebuilding Scheduling

The invention consists of a method of real-time tracking of production schedules and timetables for one or more homebuilding developments, comprising: a) assigning one or more mobile devices to one or more users associated with projects and lots, the mobile devices providing access to project and lot information, including: lots for completion for each project, tasks for completion for each lot, assignment of suppliers and material to specific tasks, projected and actual times for completion of tasks, contact information for suppliers and invoicing information for payment of purchase orders upon task completion; and each mobile device capable of operating independently without a continuous connection to a central system; b) tracking performance of production tasks for each project via real-time monitoring by the users; c) reporting task performance data to a central ERP system and comparing real-time performance of the production tasks to scheduled timetables for the production tasks; d) enabling modification and updating of scheduled timetables for production tasks based on performance data for the production tasks and additional real-time input from the individuals; e) coordinating compensation for production activities with the performance data, including enabling payment for completed tasks from the mobile devices via purchase orders; f) synchronizing, on a sequential basis, updates to scheduled timetables and other information between the mobile devices and the ERP system.

Owner:CONSTELLATION HOMEBUILDER SYST

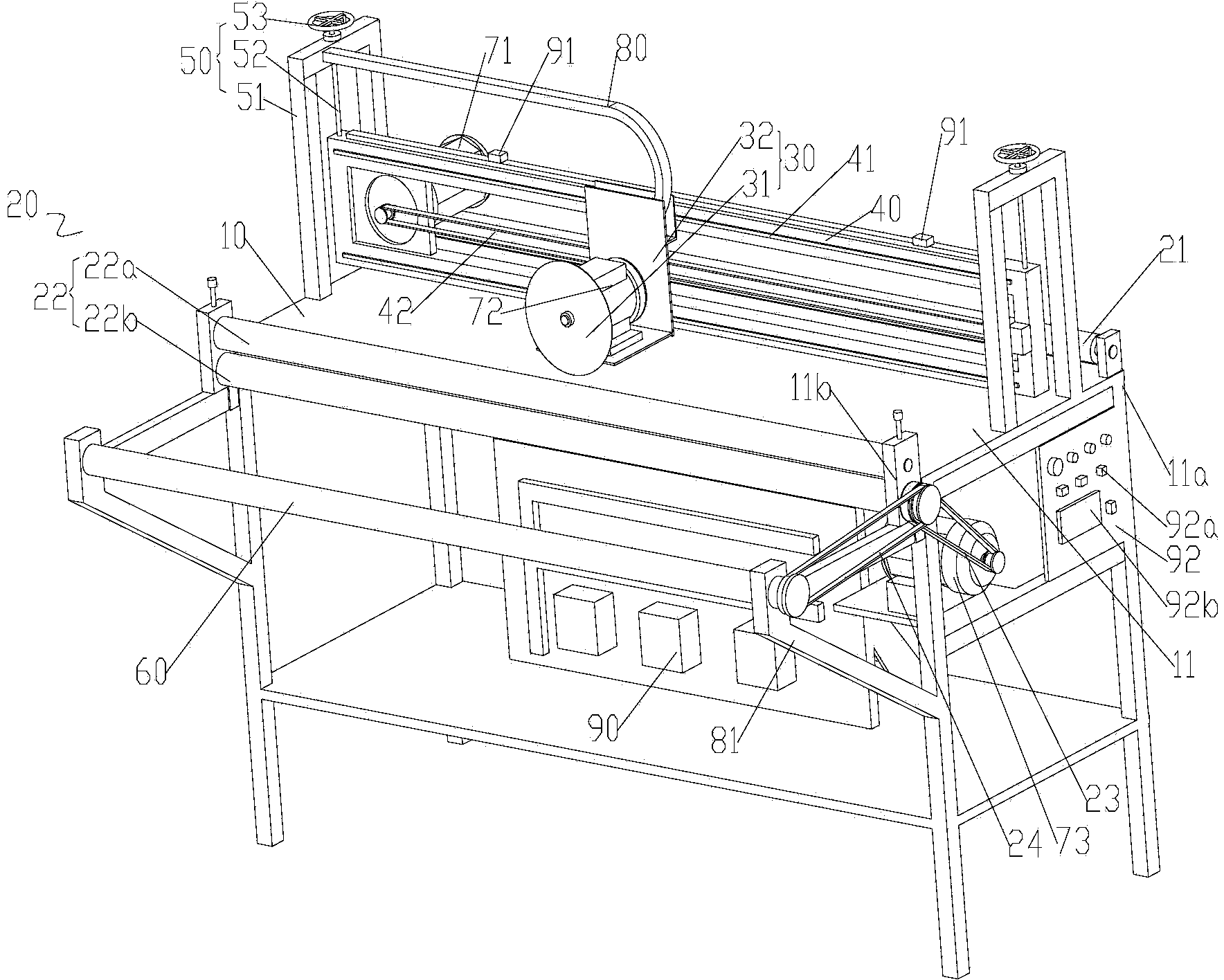

Cutting tool used for cutting sponge

InactiveCN104339399AAchieve pre-cutImprove consistencyMetal working apparatusProduction scheduleEngineering

The invention provides a cutting tool used for cutting a sponge, which comprises a stander, a material conveying part and a cutting part, wherein a cutting platform is arranged on the upper surface of the stander, the material conveying part is arranged on the cutting platform, the cutting part is movably arranged on the stander, the cutting part comprises a cutter, and a cutting space is formed between a cutting blade of the cutter and the cutting platform. Because the material conveying part is arranged, when the sponge is arranged on the cutting platform, the sponge moves on the cutting platform under the action of the material conveying part; and when the to-be-cut sponge moves into the cutting space, the cutting blade cuts the sponge along with the motion of the cutting part, so that precutting of the sponge is realized. Because the cutting tool is adopted for cutting the sponge, the automatic degree of sponge cutting is improved, the labor intensity of a worker is lowered, the working efficiency is improved, the characteristic of good consistency of the cut sponge is ensured, and a problem about production schedule delay is solved.

Owner:GREE ELECTRICAL APPLIANCE SHIJIAZHUANG +1

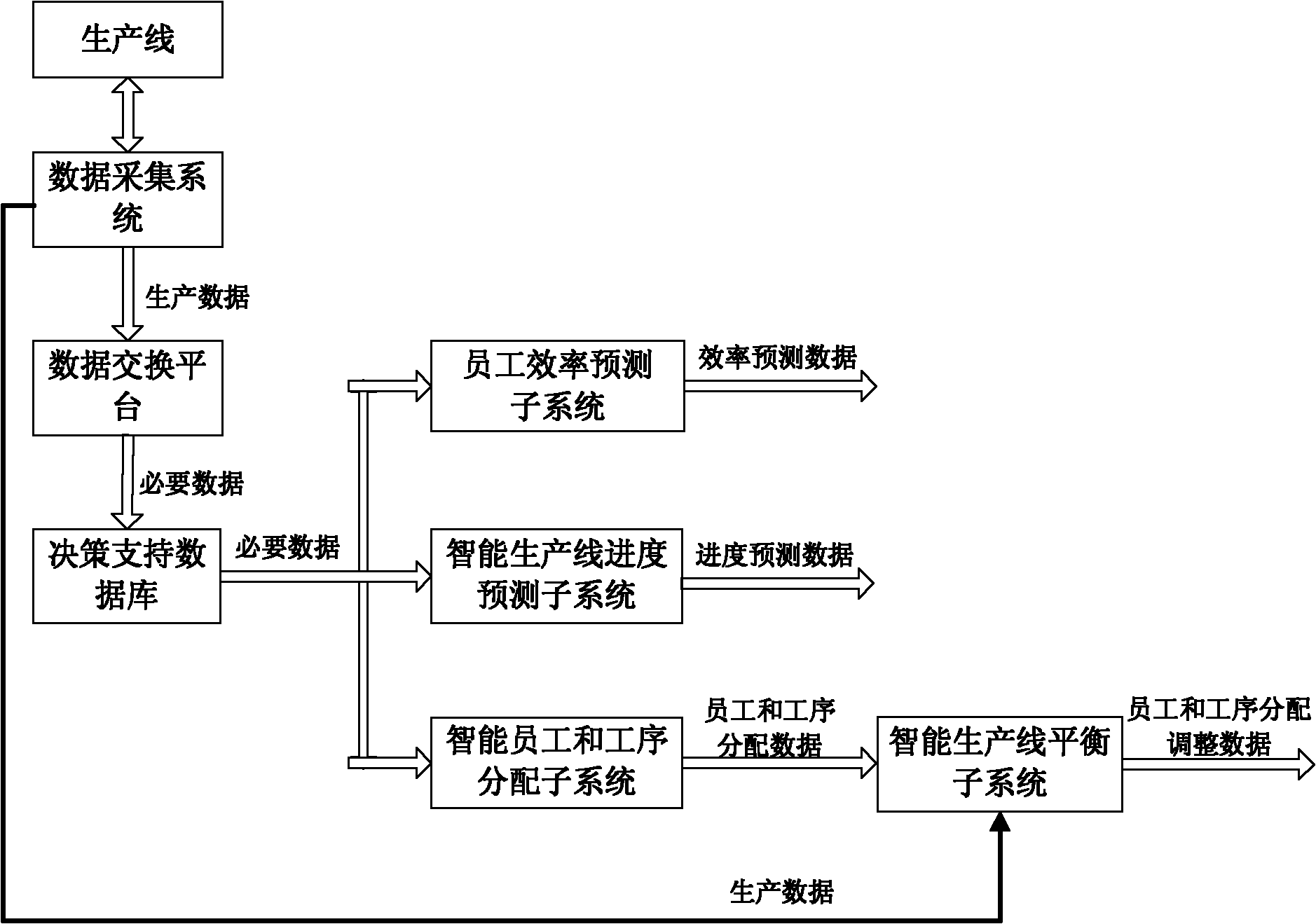

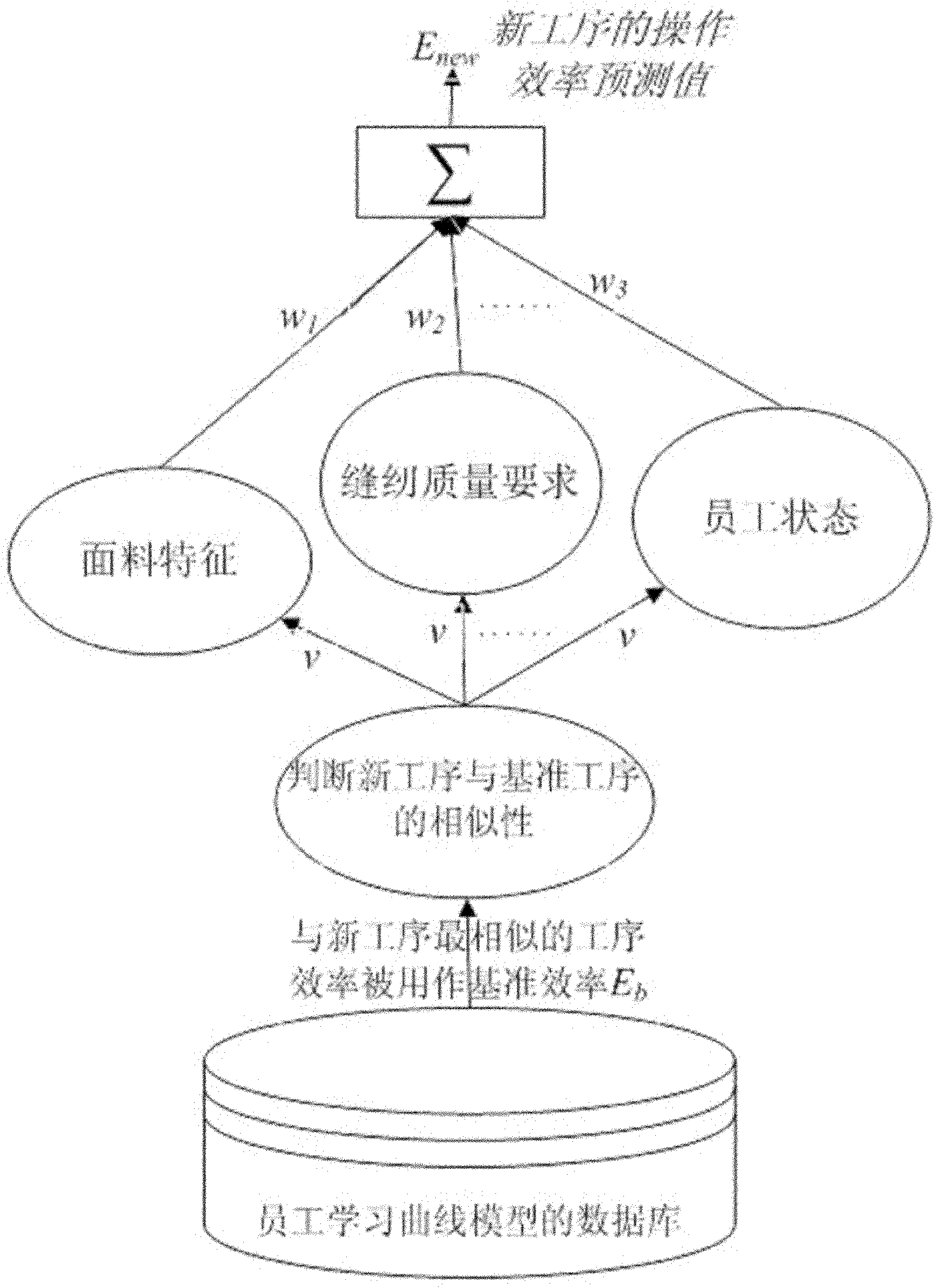

Intelligent production decision support system

InactiveCN102402716AForecasting Operational EfficiencyEfficient use ofData processing applicationsManufacturing computing systemsProduction scheduleData acquisition

The invention relates to an intelligent production decision support system, which is used for making production decision according to real-time production data acquired by a data acquisition system. The intelligent production decision support system comprises a data exchange platform, a decision support database and a staff efficiency forecasting subsystem, wherein the data exchange platform is used for receiving real-time production data from the data acquisition system, separating necessary data needed by the production decision and storing the necessary data to the decision support database, and the staff efficiency forecasting subsystem is used for reading the necessary data in the decision support database and outputting staff efficiency forecasting data according to internal factors and external factors affecting staff efficiency. The intelligent production decision support system further comprises a staff efficiency forecasting subsystem, an intelligent production line balancing subsystem and a schedule forecasting subsystem, wherein the staff efficiency forecasting subsystem is used for generating an optimal production procedure distribution scheme, the intelligent production line balancing subsystem is used for adjusting procedure distribution according to real-time production conditions and then ensuring balance of a production line, and the schedule forecasting subsystem is used for accurately forecasting the production schedule and the completion time of each production order.

Owner:THE HONG KONG POLYTECHNIC UNIV

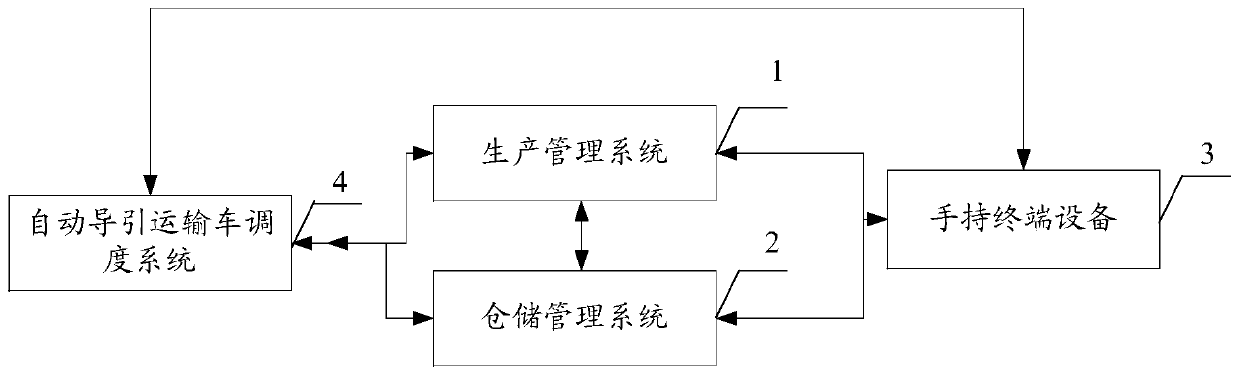

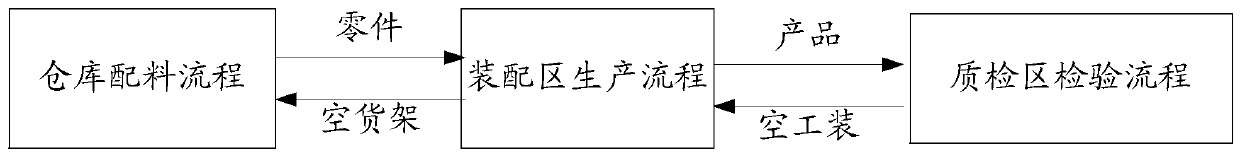

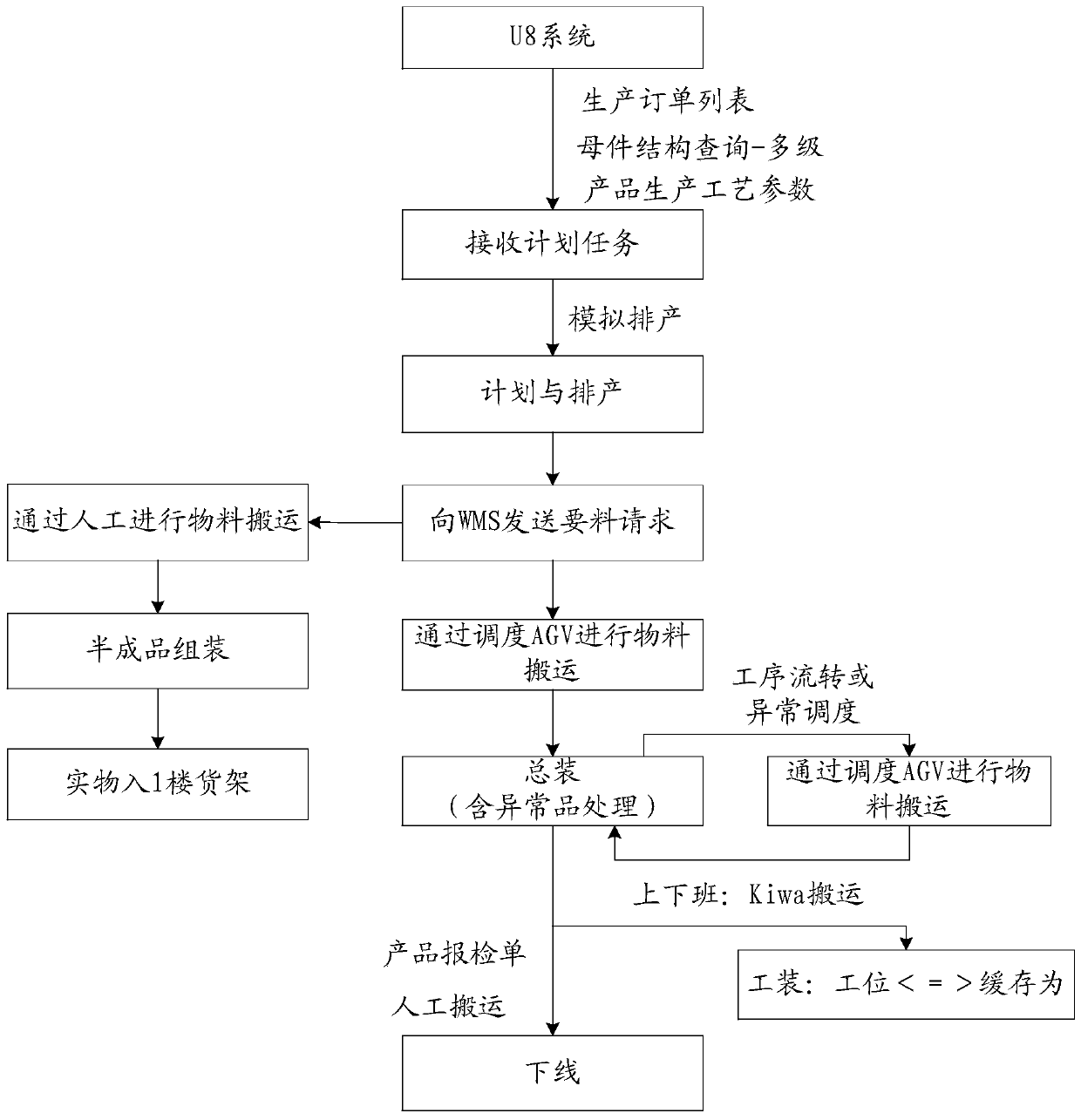

Pulsing production system based on automated guided vehicle (AGV)

ActiveCN109878964AIncrease production capacityGuarantee product qualityStorage devicesProduction scheduleHand held

The embodiment of the invention discloses a pulsing production system based on an automated guided vehicle (AGV). The pulsing production system comprises a production managing system used for generating a stores requisition according to the production schedule and the feeding schedule, and a storehouse managing system used for sending an allocation instruction based on inventory positions of all production materials on the stores requisition, and sending a cargo carrying instruction including information of the cargo type and the carrying starting point and / or end point position to an AGV dispatching system when receiving a cargo allocation completion instruction fed back by a hand-held terminal; the hand-held terminal generates a cargo carrying instruction according to assembly process information input by a user; and the AGV dispatching system comprises a plurality of AGVs of multiple types and a control processor, and the control processor generates a dispatching instruction according to the cargo carrying instruction, the cargo allocation instruction and the current positions and vehicle types of all the AGVs so as to control all the AGVs to execute the carrying task. The pulsing production system is suitable for production and manufacturing of small-batch and multi-variety products, the productivity can be effectively improved, and the product quality is ensured.

Owner:浙江国自智能装备有限公司

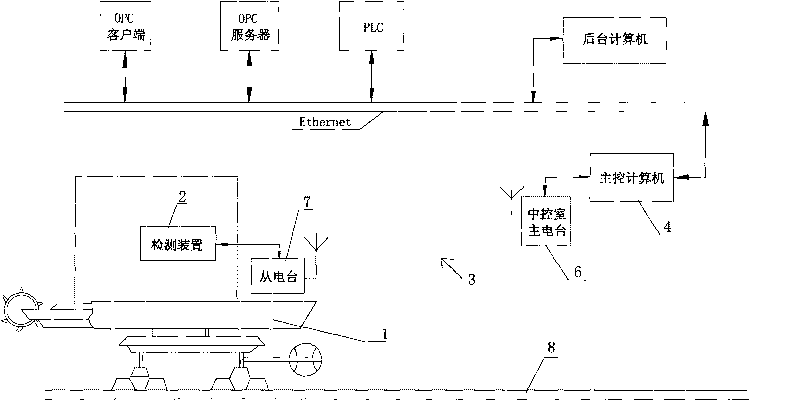

Stockyard operation dynamic display and real-time management system and management method thereof

InactiveCN101694576AFacilitate production schedulingEasy to controlComputer controlSimulator controlProduction scheduleApproaches of management

The invention discloses a stockyard operation dynamic display and real-time management system which comprises a detecting device used for detecting the operating state of a stacker-reclaimer; the detecting device is installed on the stacker-reclaimer respectively, and is communicated with a main control computer by a wireless communication device. The invention also discloses a management method of the stockyard operation dynamic display and real-time management system. Compared with the prior art, the main control computer can display the on-hand inventory of varieties in the stockyard, and the position and the operating state of the stacker and the reclaimer in real time, the control on the production situation of the stockyard and the production schedule on the stacker-reclaimer are convenient for middle control operators, the pragmaticality is high, the high-efficiency guiding action on the production is increased obviously, and the work efficiency is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

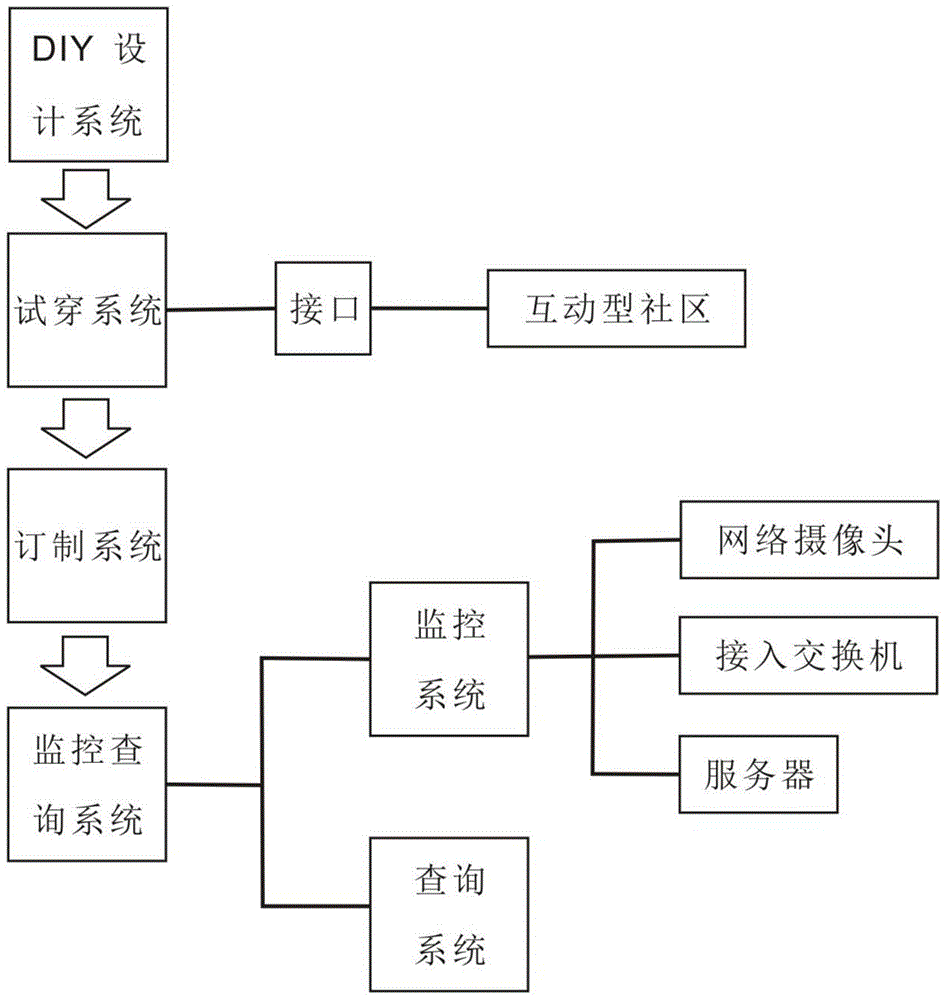

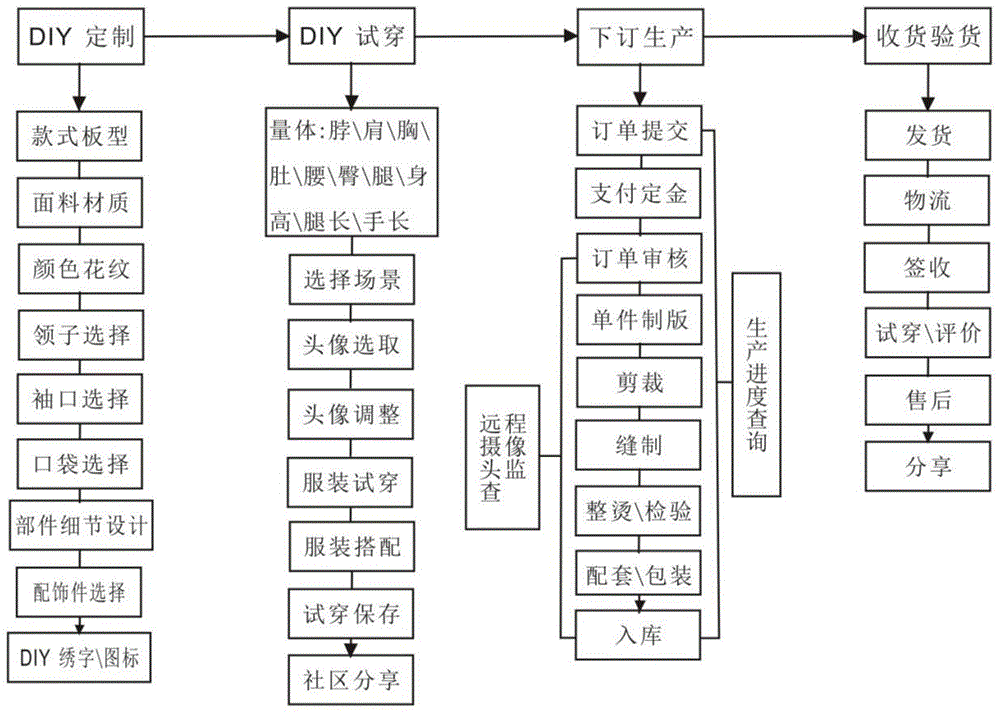

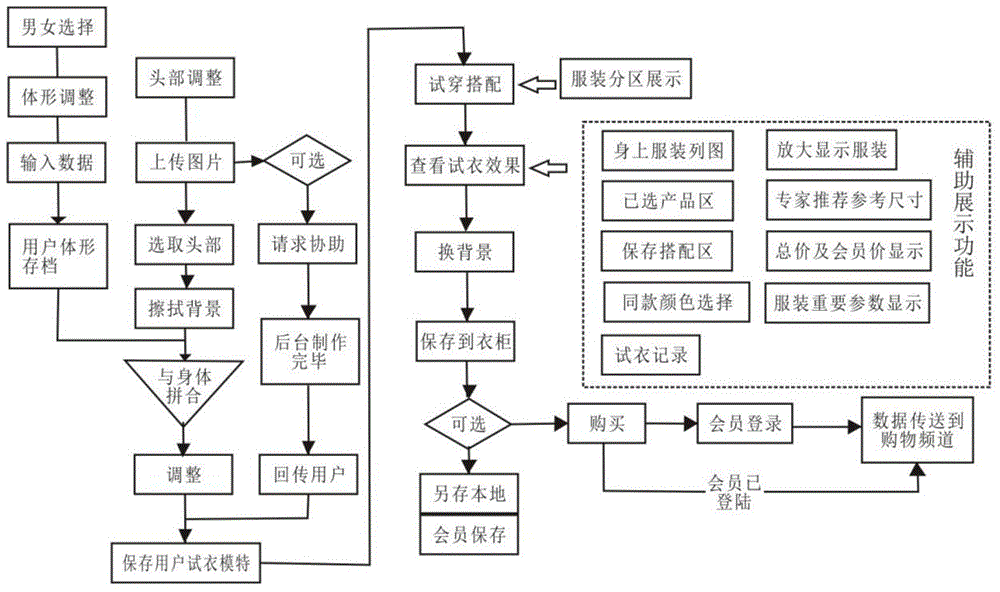

Garment on-line DIY customization system and garment on-line DIY customization method

The invention relates to a garment on-line DIY (Do It Yourself) customization system and a garment on-line DIY customization method. The garment on-line DIY customization system is characterized by mainly comprising a DIY design system, a try-on system, a customization system and a monitoring query system. During the on-line DIY customization by users, the garment on-line DIY customization method mainly comprises the following steps that: firstly, the garment DIY design is carried out; secondly, garments subjected to the DIY design are tried on; thirdly, on-line customization is carried out; and fourthly, monitoring and query are carried out. The garment on-line DIY customization system and the garment on-line customization method have the advantages that customers can design and try on the garments according to self body conditions and preference, the on-line customization on the try-on satisfaction garments can be carried out, and the production schedule query and the manufacturing flow process monitoring can also be carried out on the order placing garments. After the garments are tried on by the users, the sharing can be realized on interactive communities such as microblog through the connection with interfaces of the interactive communities.

Owner:GUANGZHOU UDL GARMENT

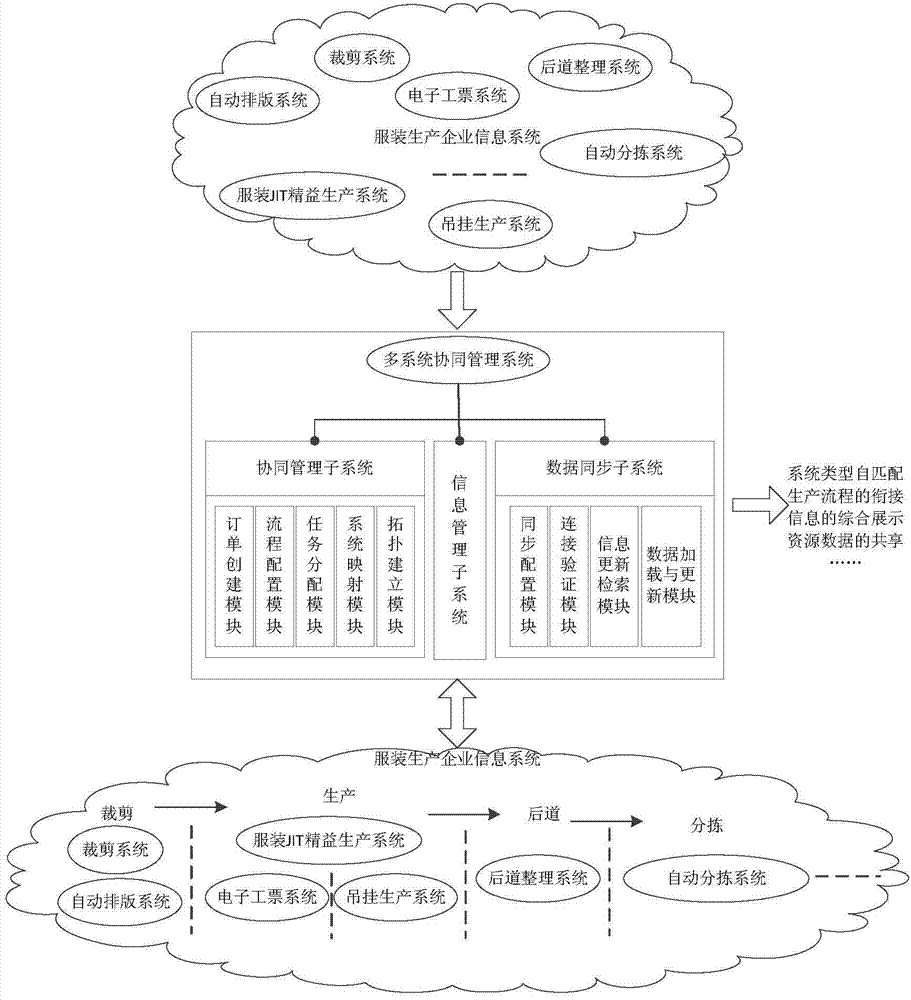

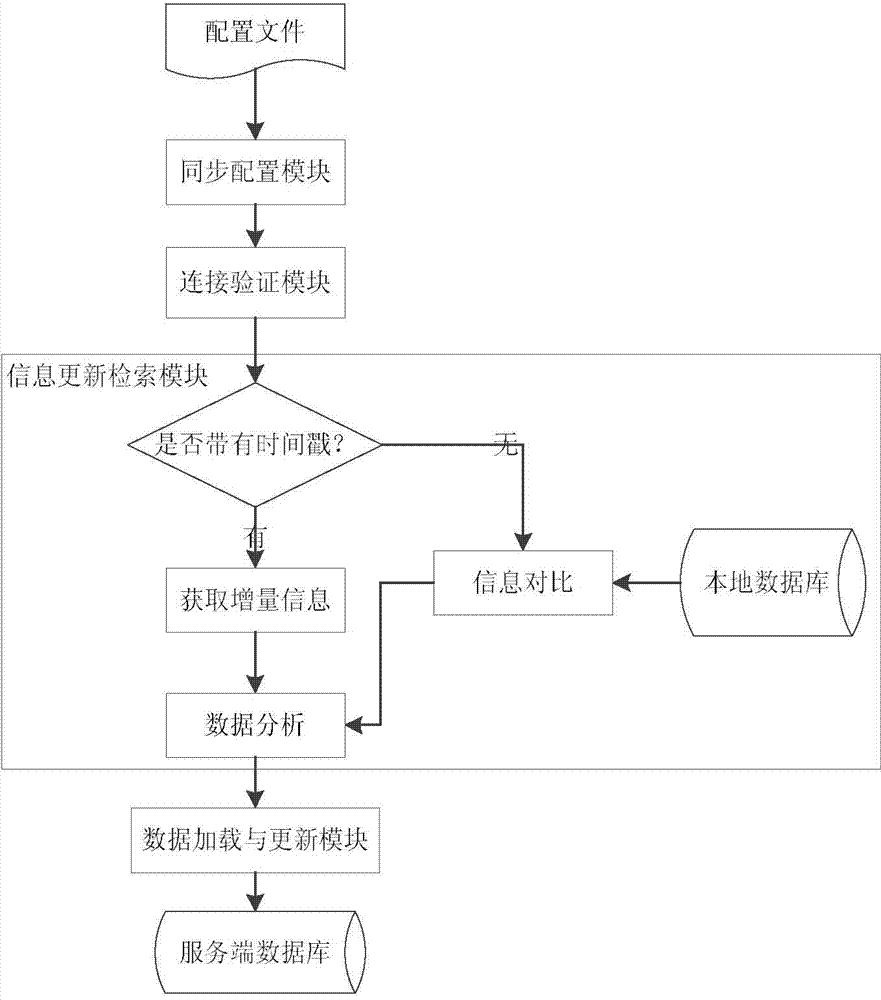

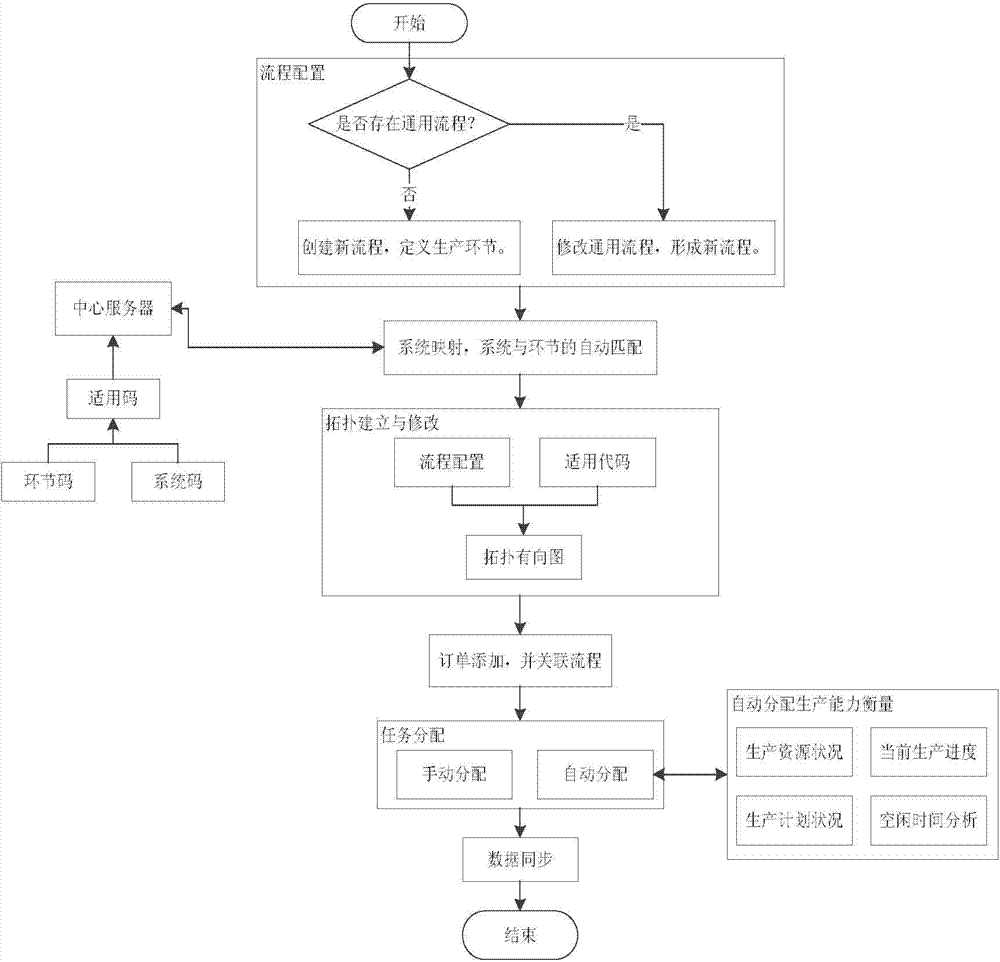

Multi-system cooperative system and method for production process control of discrete manufacturing enterprises

ActiveCN104331767AGet production dataImprove efficiencyResourcesManufacturing computing systemsData synchronizationProduction schedule

The invention discloses a multi-system cooperative system and method for production process control of discrete manufacturing enterprises. The multi-system cooperative system is used for cooperative work and data sharing of a production management system with multiple production chains during production, and comprises an information management subsystem, a cooperative management subsystem and a data synchronization subsystem. The multi-system cooperative method includes: configuring the process and defining the production chains; conducting system mapping to finish automatic correlation of the systems and the production chains; building topology, and displaying topology connection directed graphs of systems in real time according to the production process configuration and regular files; dynamically adjusting the topology relation and building a final connection directed graph of the production systems; adding orders and selecting corresponding production processes for the orders; distributing tasks; synchronizing and updating data and mastering the production schedule in real time. The multi-system cooperative system and method achieves organic interconnection and data sharing of independent systems through effective integration of the discrete systems, achieves smart production of the enterprises and improves the whole efficiency.

Owner:NANTONG MINGXING TECH DEV CO LTD +1

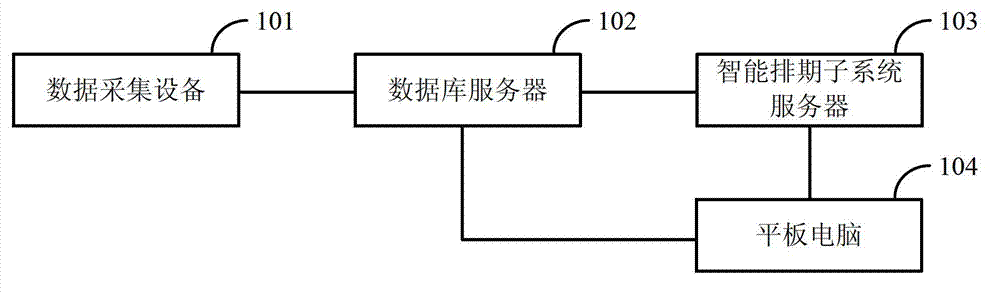

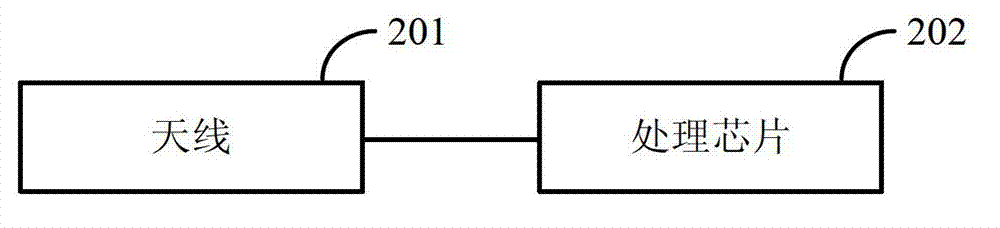

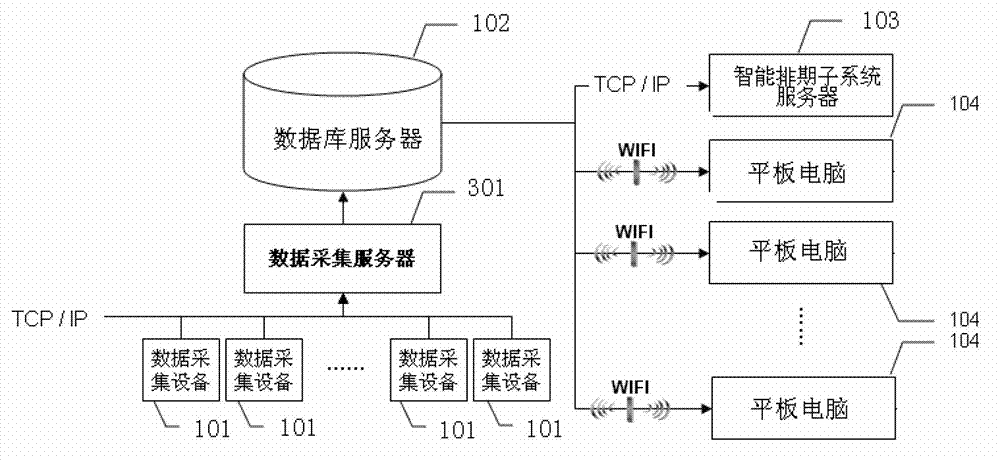

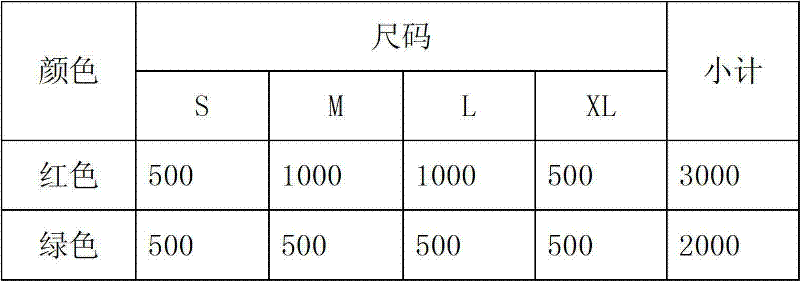

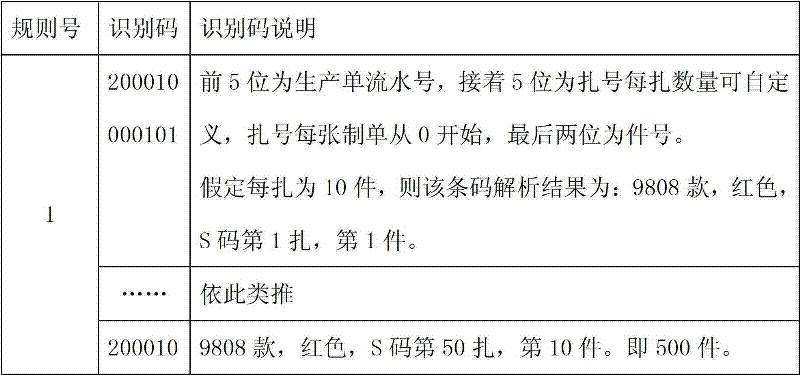

System and method for processing production data of garment pattern workshop

ActiveCN103116828AReasonable useReduce configurationResourcesManufacturing computing systemsTablet computerData processing system

The invention discloses a system and a method for processing production data of a garment pattern workshop. The system comprises data acquisition equipment, a database server, an intelligent schedule subsystem server and a tablet personal computer; the data acquisition equipment is arranged in a garment pattern production field of the garment pattern workshop and is used for acquiring the production field data in real time and synchronizing the production field data to the database server in real time; the database server is connected with the data acquisition equipment and is used for receiving and storing the production field data and synchronizing the production field data to the intelligent schedule subsystem server in real time; the intelligent schedule subsystem server is connected with the database server and is used for receiving the production field data and generating production schedule data according to the production field data; and the tablet personal computer is arranged in the garment pattern production field of the garment pattern workshop, is respectively connected with the database server and the intelligent schedule subsystem server and is used for acquiring the production field data from the database server and acquiring the production schedule data from the intelligent schedule subsystem server. The system and the method have the advantages that the latest production data can be quickly acquired in the production field at any time and in any place, and the system and the method are favorable for controlling a production status and optimizing and organizing production.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

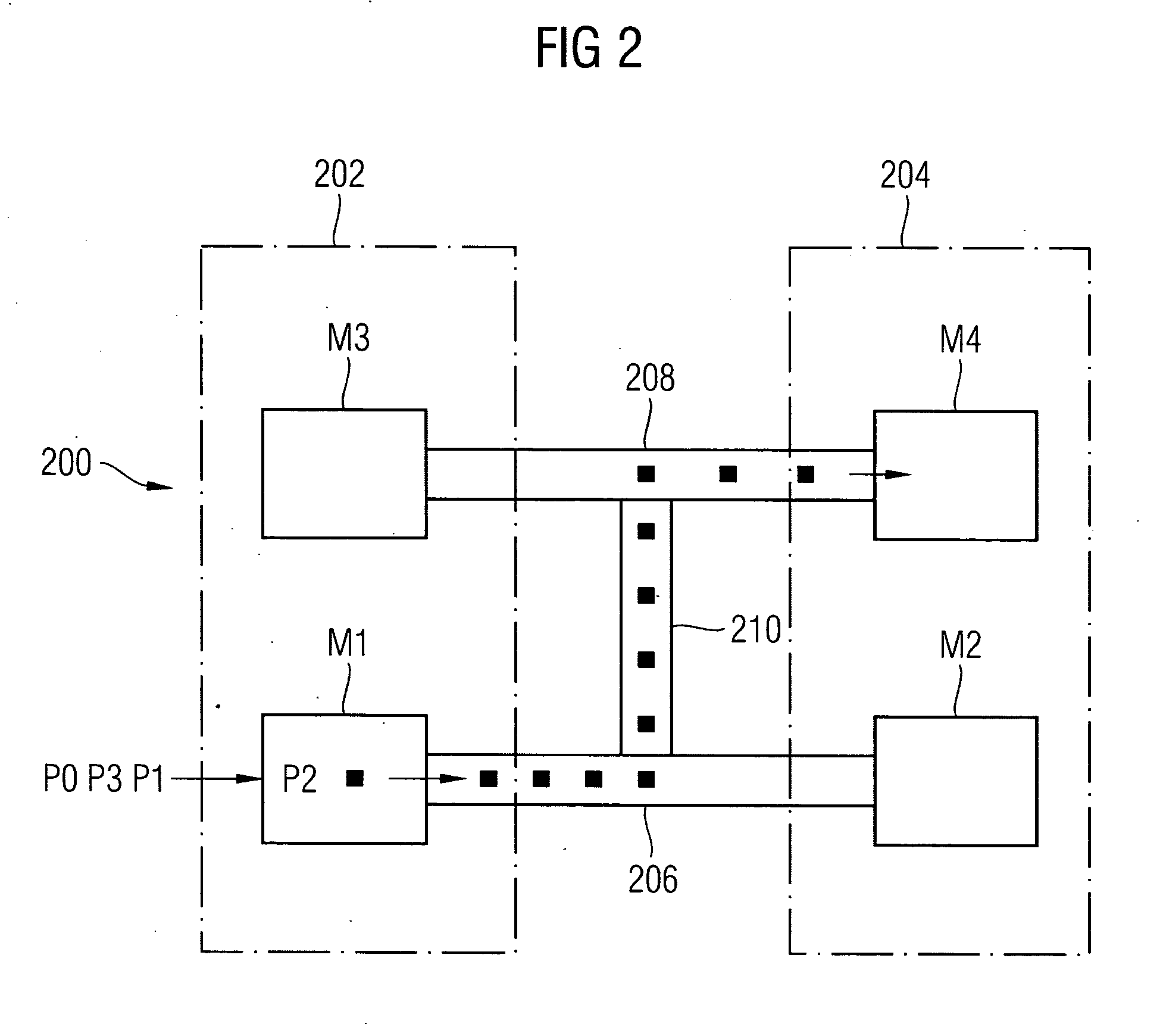

Master production scheduling management system and method

A master production scheduling management system and method for efficiently generating master production schedules (MPSs) is provided. The system includes a plurality of client computers (3), an MPS management server (1), a database server (4) and a communication network (2) interconnecting the client computers, the database server, and the MPS management server. The MPS management server obtains data from external information systems by use of a data retrieving module (100), generates an original MPS based on the obtained data, and amends the original MPS to be an optimized MPS by simulating rough-cut capacity planning (RCCP) and material requirements planning (MRP). Employing the present invention, users can amend MPSs in time by simulating RCCPs and MRPs and arrange production schedules efficiently.

Owner:HON HAI PRECISION IND CO LTD

Production capability simulating system and method

InactiveUS20040117227A1ResourcesSpecial data processing applicationsProduction scheduleData retrieval

A system and method for simulating production capability is provided. The production capability simulating system can simulate rough-cut capacity planning (RCCP) and material requirements planning (MRP) of a manufacturing enterprise, and make main production schedule (MPS) accordingly. The system includes a plurality of client computers (3), an MPS management server (1), a database server (4) and a communication network (2) interconnecting the plurality of client computers, the database server, and the MPS management server. The MPS management server obtains data from external information systems by use of a data retrieving module (100), and generates an original MPS based on the obtained data for simulating the RCCP and the MRP. The original MPS is amended to be an optimized MPS according to the simulating results. Employing the present production capability simulating system, users can amend MPS in time by simulating RCCP and MRP and arrange production schedules efficiently.

Owner:HON HAI PRECISION IND CO LTD

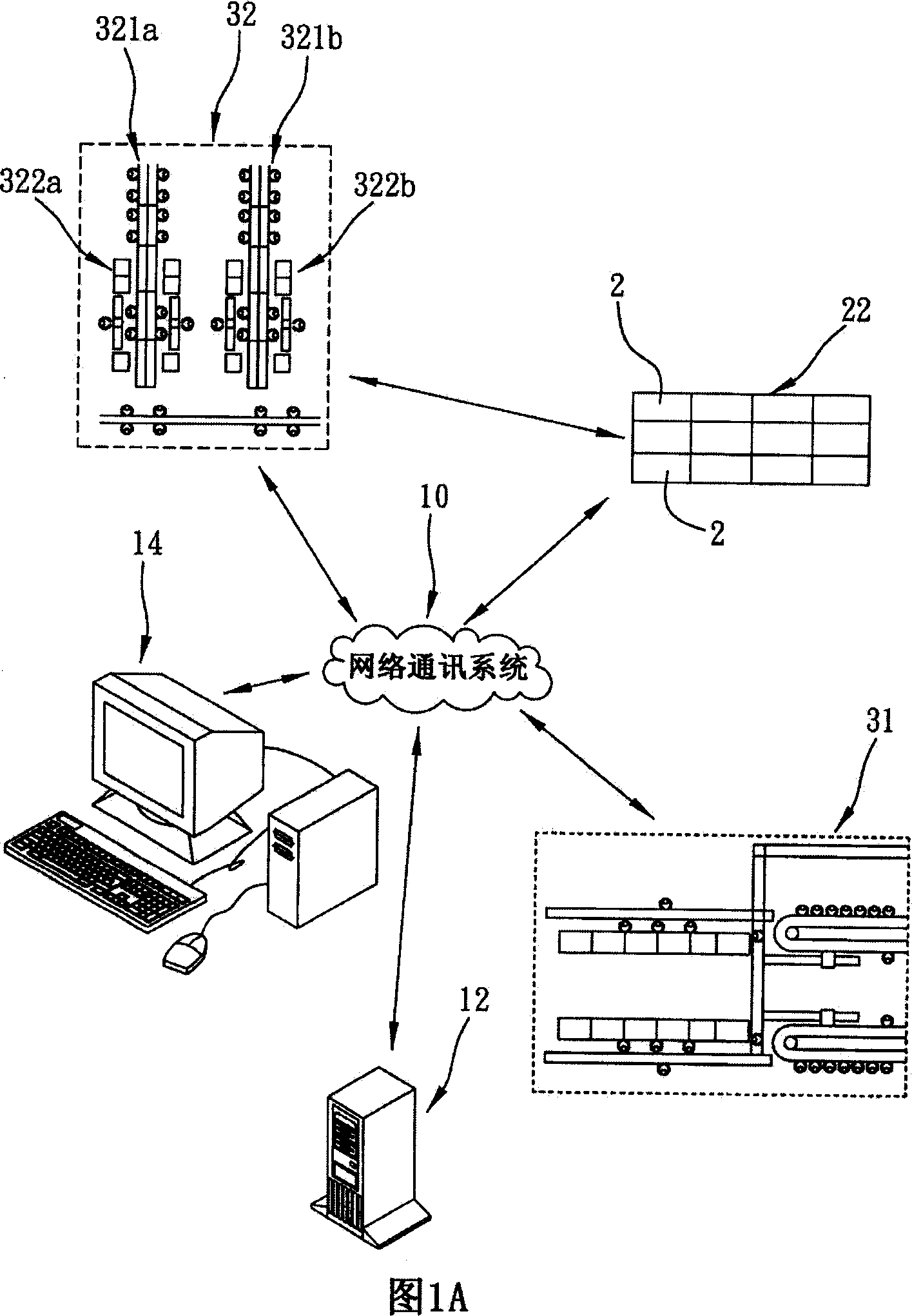

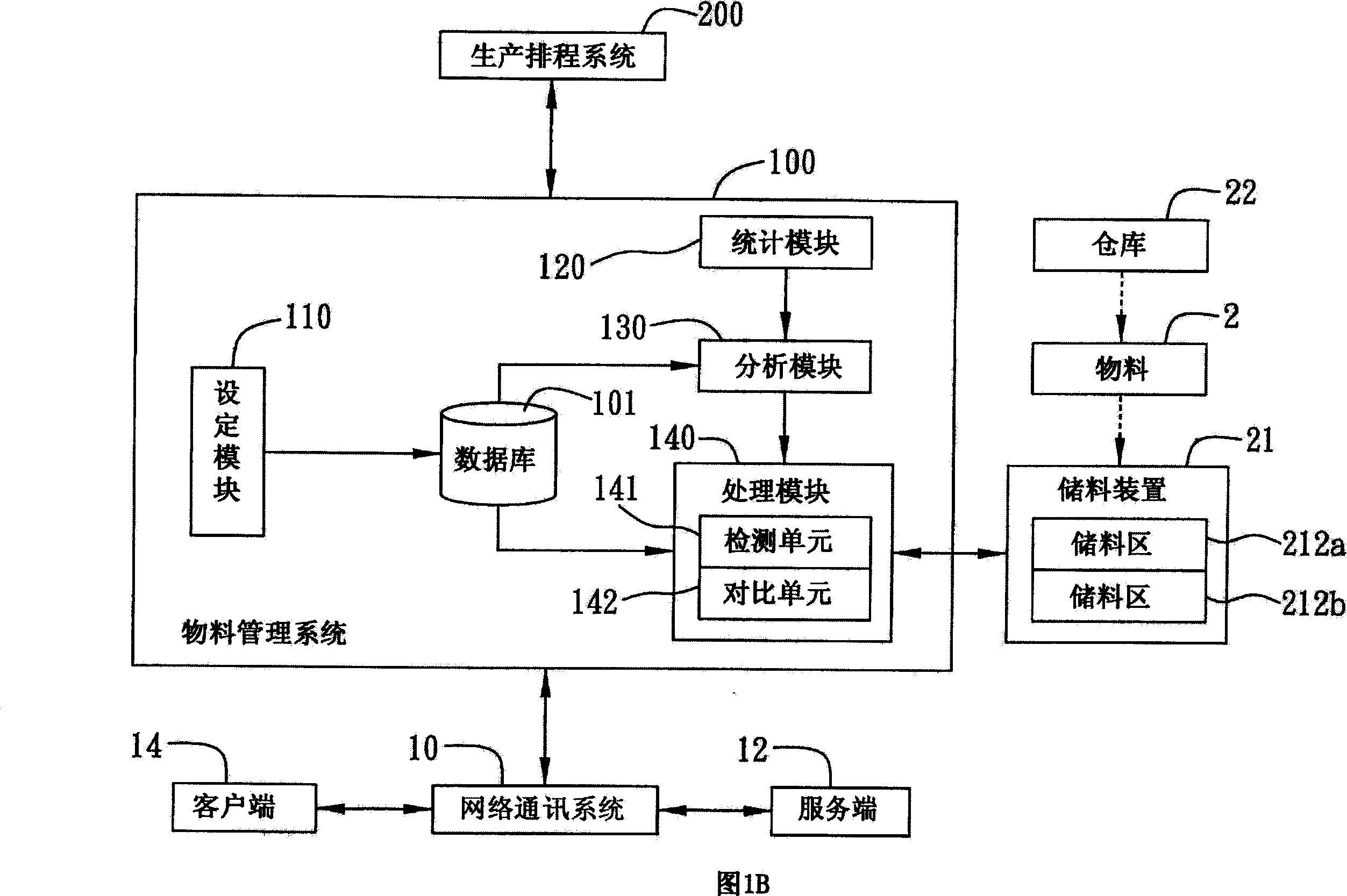

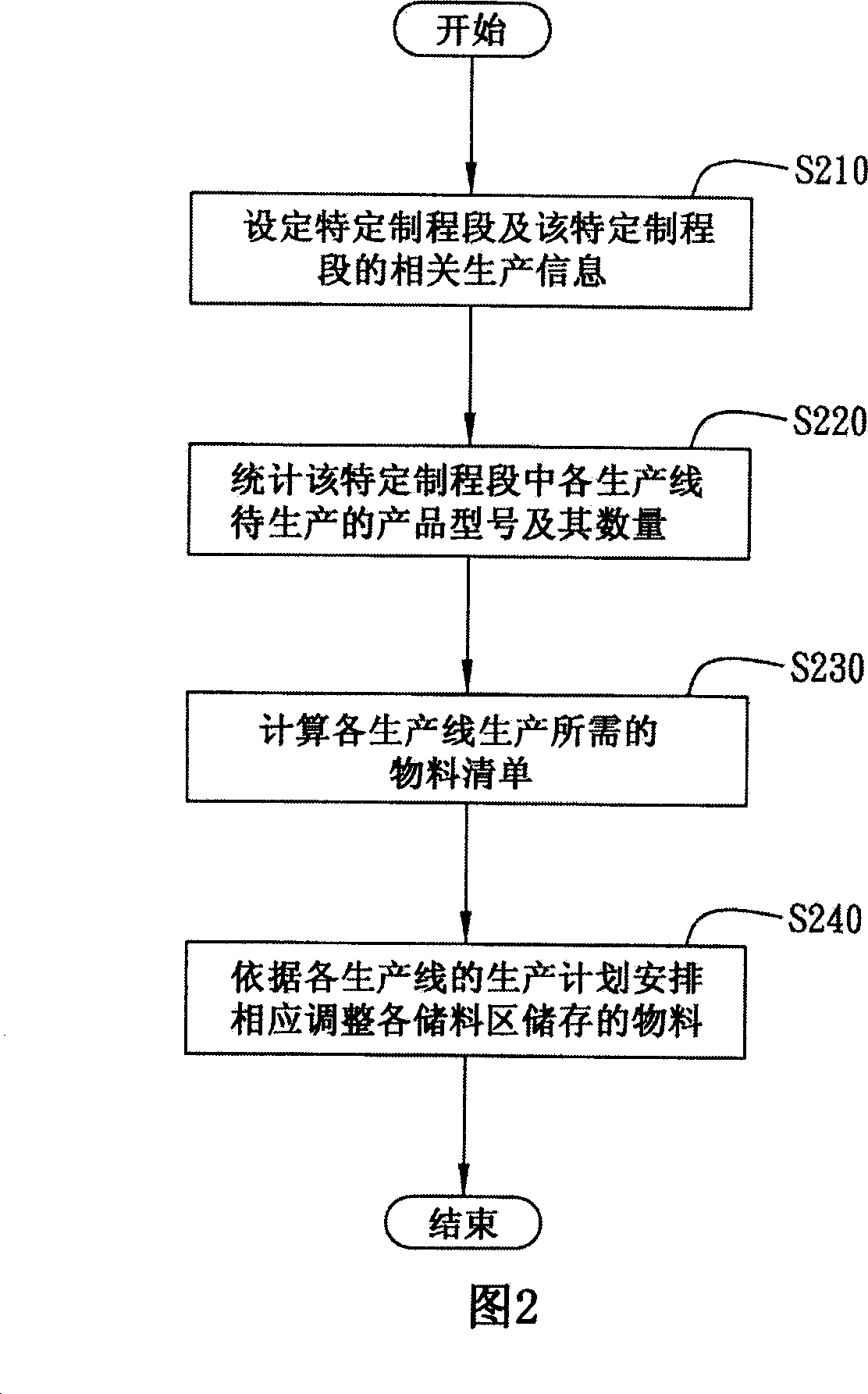

Material management method and system

InactiveCN1991876AImprove coherenceMeet a small amount of diverse production needsResourcesProduction scheduleProduction line

A material control method and system is applied in the production chain work management, the method includes steps as following: setting the process segment and material information needed in production cause; statistic the production schedule information material; generating the material demand information according to the set data of production schedule information material and material demand information; adjusting the stored material and executing the corresponding stock preparation. The material control system includes: setting module, statistic module, analysis module and processing module; the material control method and system is according to the production schedule of every production chain, managing the relative stock preparation dynamically, increasing the work consistency of adjacent process segment, increasing the real time and flexibility of stock preparation, improving efficiency of work.

Owner:INVENTEC CORP

Real-time control system in production field

InactiveCN102692900ACoordinating the number of workersIncrease productivitySensing record carriersTotal factory controlData displayReal-time Control System

The invention relates to a production management system, in particular to a real-time control system in a production field. A data collector, a collection server, a server and a display device are connected together through a network; staff information and production information of a product are collected through the data collector; the real-time production schedule is subjected to statistics through the server and compared with planned quantity, and the data is finally displayed on an LED (light-emitting diode) screen of a workshop through the display device. Simultaneously, the server also records delivery data of personnel in the production process and can find out corresponding person liable through the delivery data recorded by the personnel when a quality problem appears in a procedure of the product, so that a manager can know the production condition of the field in real time through the system, accurately and effectively coordinate the quantity of the operating personnel of each procedure so as to improve the production efficiency, simultaneously the quality of the product can be tracked and corresponding person liable can be found if the quality problem appears in the procedure of the product.

Owner:DONGGUAN TIANHUI SOFTWARE

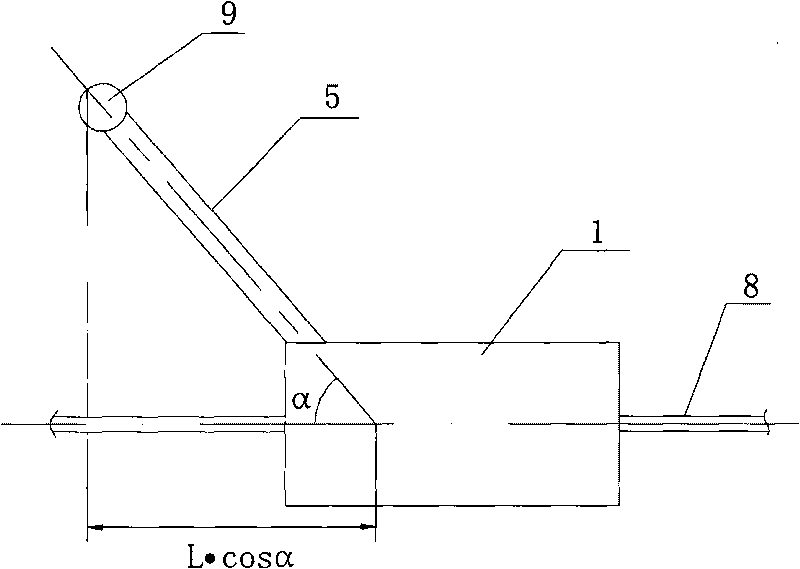

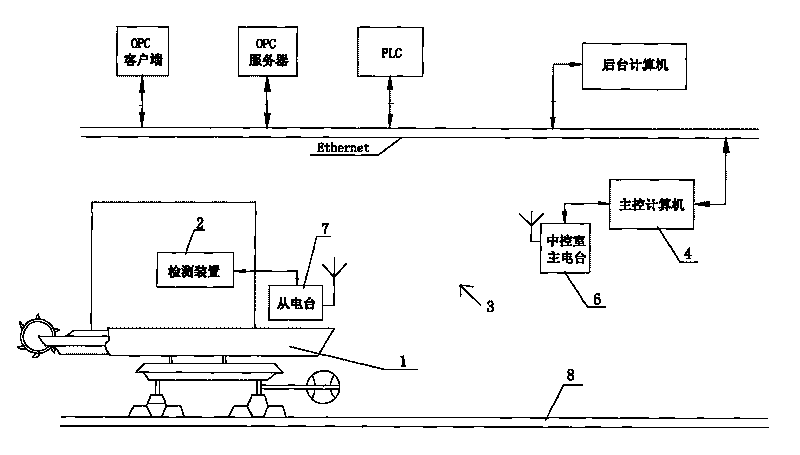

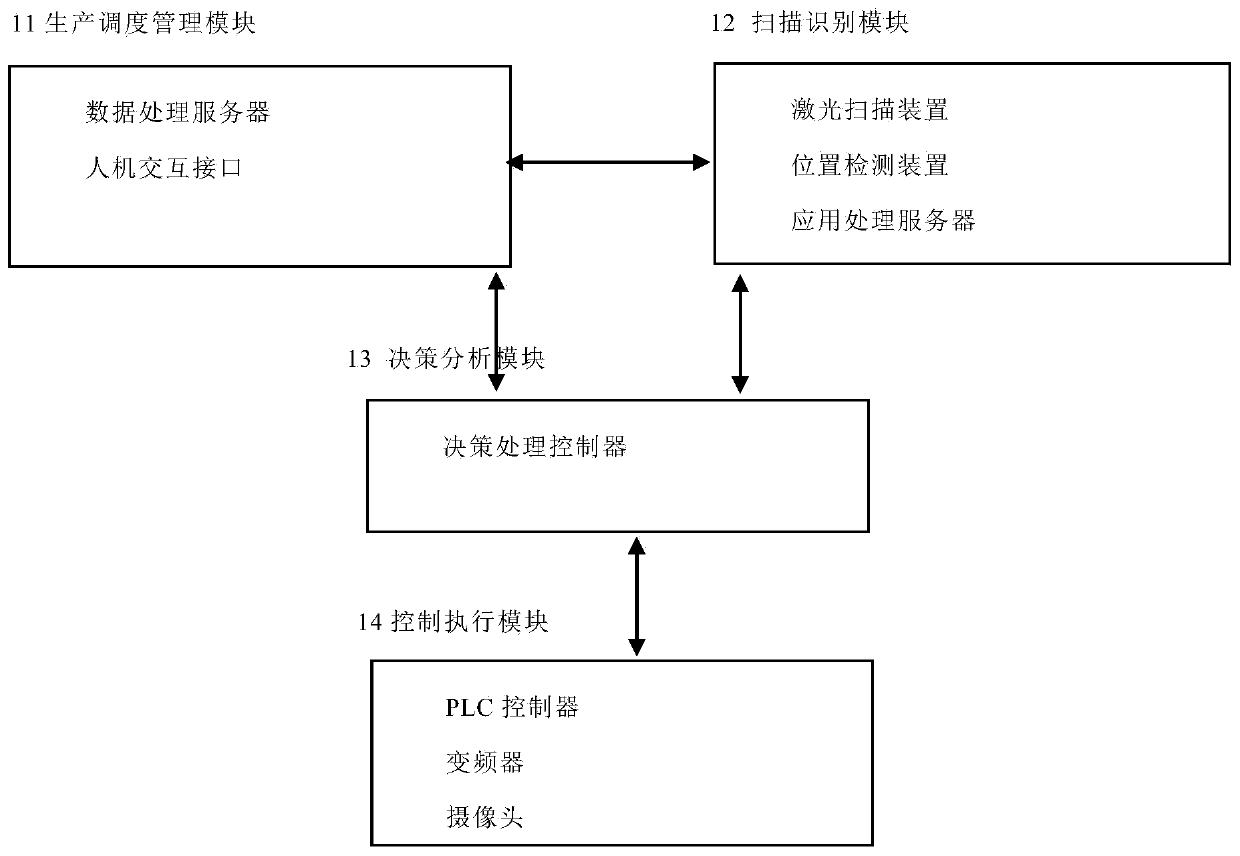

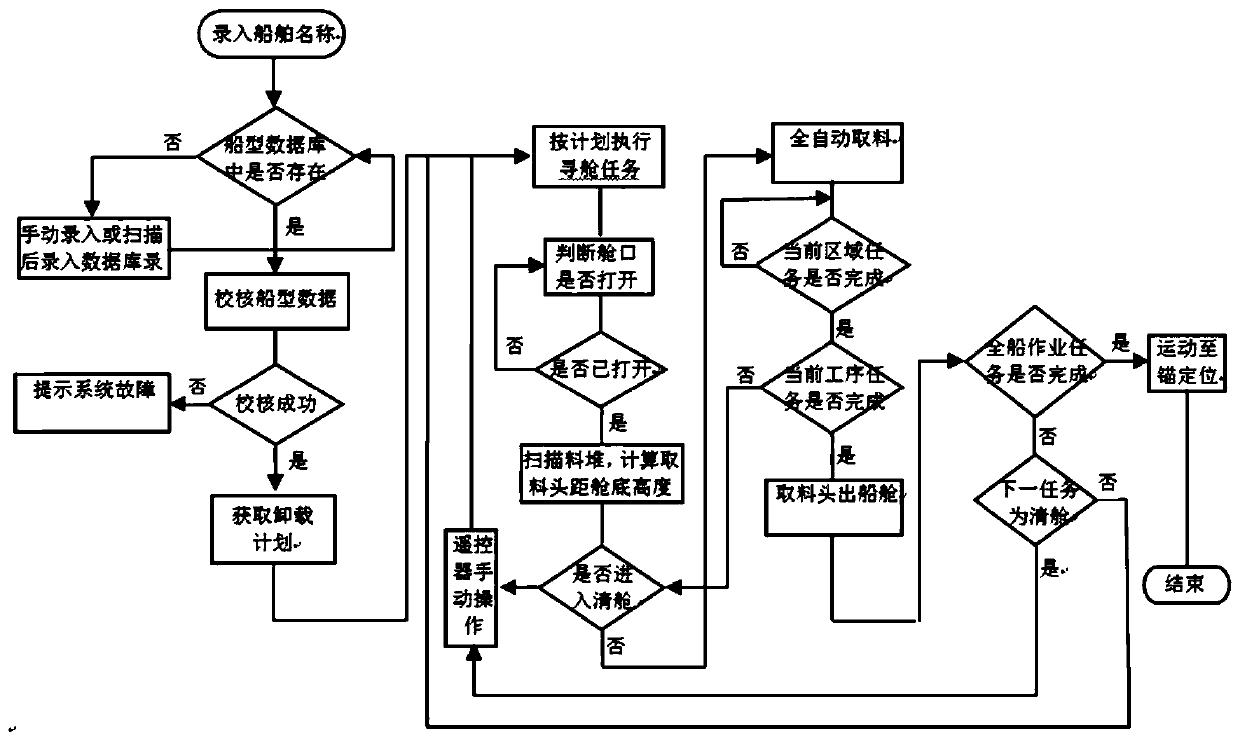

Digital system and control method for unmanned chain bucket type continuous ship unloader

PendingCN110182621ARealize dynamic trackingEnsure safetyLoading/unloadingProduction scheduleBulk cargo

The invention provides a digital system for an unmanned chain bucket type continuous ship unloader. The digital system comprises a production scheduling management module, a scanning recognition module, a decision analysis module and a control execution module. The production scheduling management module is arranged on a wharf control room or the continuous ship unloader, and comprises a data processing server and a human-machine interactive interface; the scanning recognition module is arranged on the continuous ship unloader, and comprises a laser scanning device, a position detection deviceand an application processing server; the decision analysis module is arranged on the continuous ship unloader, and comprises a decision processing controller; and the control execution module is arranged on the continuous ship unloader, and comprises a PLC, a frequency converter and a camera. According to the digital system, the unmanned operation of the bulk cargo wharf chain bucket type continuous ship unloader can be achieved, and the real-time performance of data processing of the continuous ship unloader is ensured, so that the safety of a material fetching head to enter and exit from acabin is ensured. The number of operators is reduced, and the labor cost is decreased.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

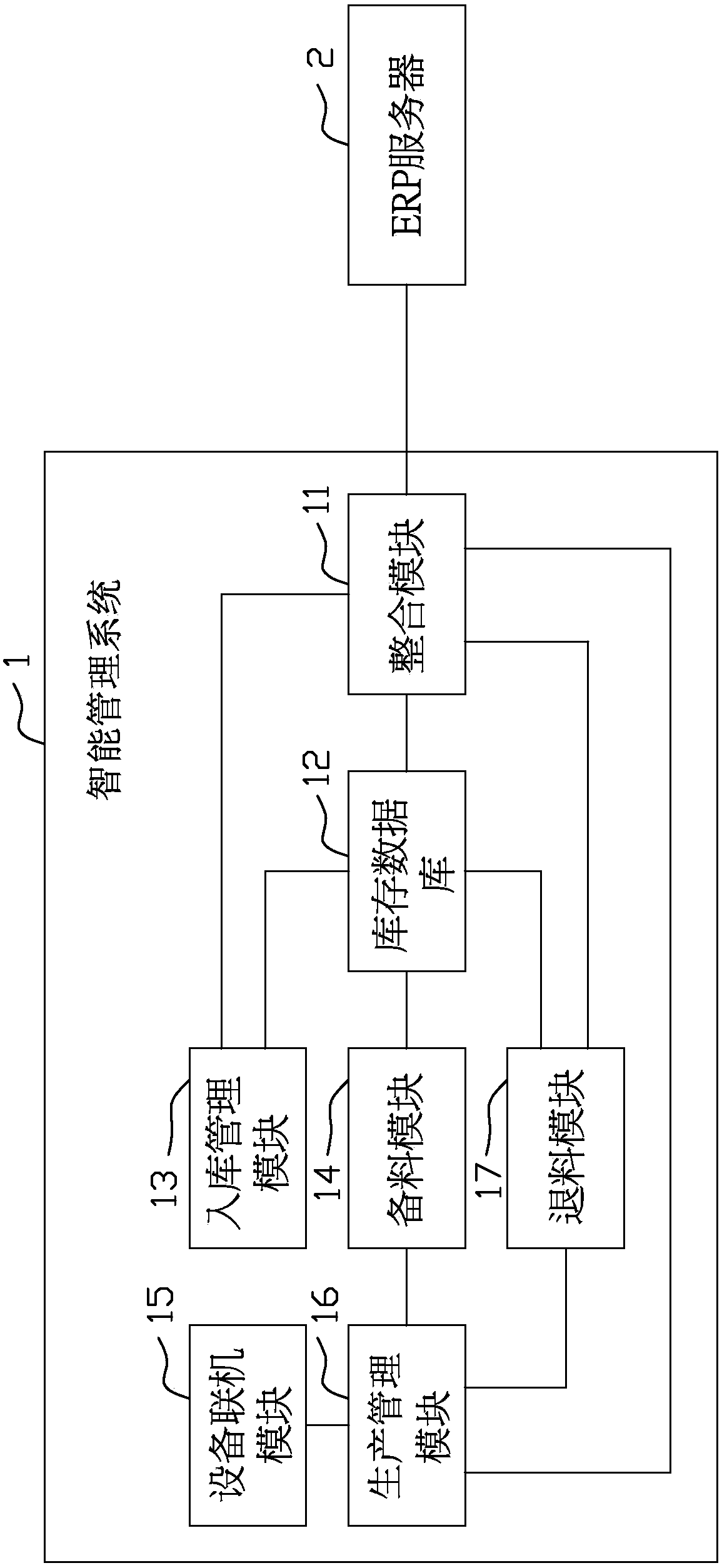

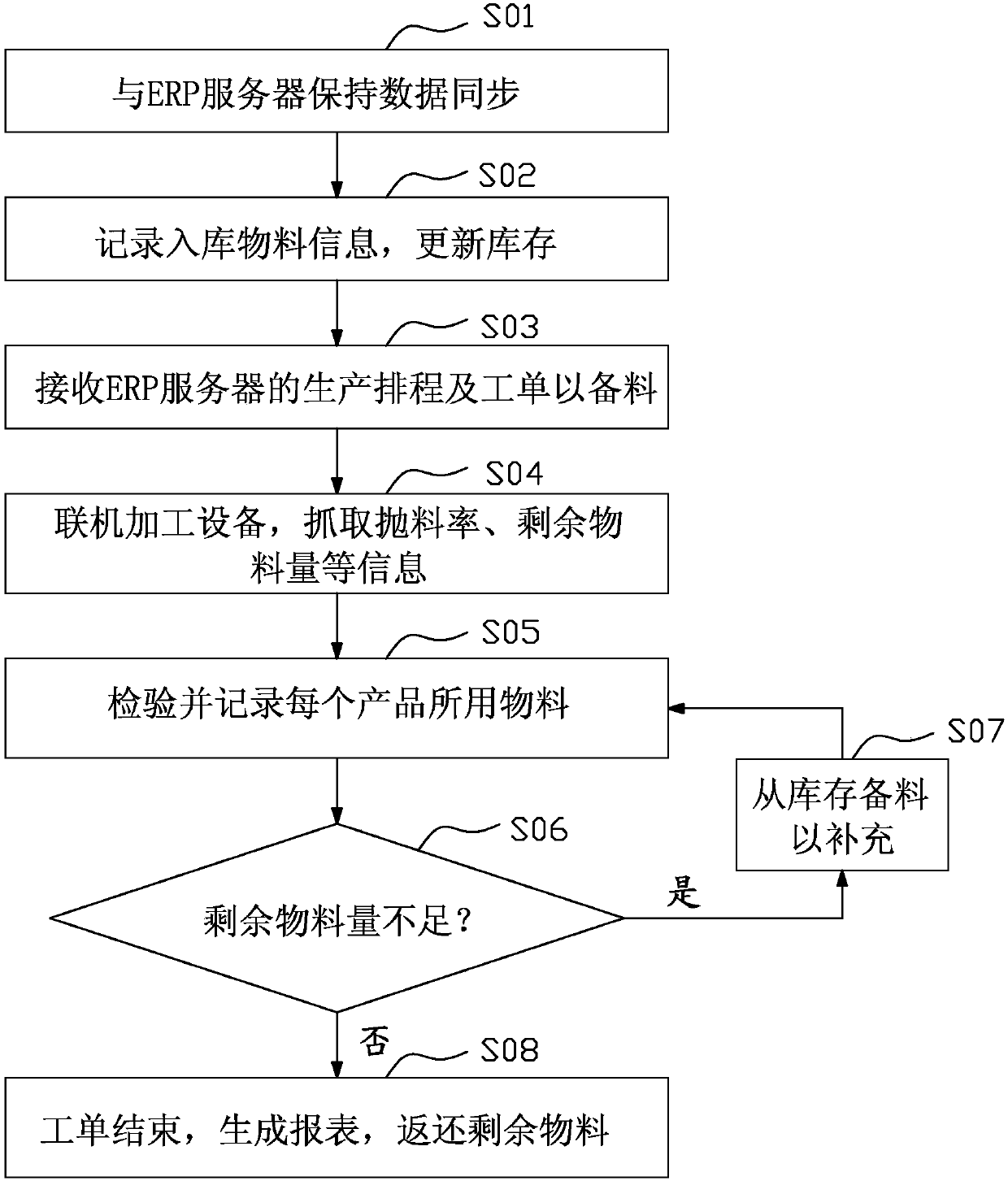

Intelligent management system and intelligent management method

InactiveCN107590625AEfficient managementSave human effortLogisticsManufacturing computing systemsData synchronizationProduction schedule

The invention provides an intelligent management system and an intelligent management method. The intelligent management system is connected with an ERP server, and comprises an integration module, aninventory database, a warehouse-in management module, a material preparation module, an equipment connection module, a production management module and a material returning module, wherein the integration module and the ERP server perform data synchronization; the inventory database stores and updates the inventory; the warehouse-in management module recognizes and records warehouse-in material information, a receipt is generated, and the inventory is updated; the material preparation module checks materials in the inventory for taking according to a received material preparation command; theequipment connection module is connected with processing equipment for grasping a throwing rate, a material surplus and the like; the production management module receives the production schedule andthe work order in the ERP server and receives the information such as the throwing rate and the material surplus, and a material preparation command is sent to the material preparation module according to materials on the work order; and the material returning module receives the information such as the throwing rate and the material surplus of the equipment, a work order report is generated after the work order is completed, and the remaining materials are counted and returned to the inventory. Due to the intelligent management system and the intelligent management method provided by the invention, material receiving, material issuing and material returning are integrated, and the inventory is effectively managed.

Owner:MITAC COMP (SHUN DE) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com