Material management method and system

A management method and management system technology, applied in the field of material management, can solve problems such as lowering production efficiency, affecting normal packaging operations of products, backlogs, etc., and achieve the effects of improving work efficiency, improving continuity, and quickly replenishing and picking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

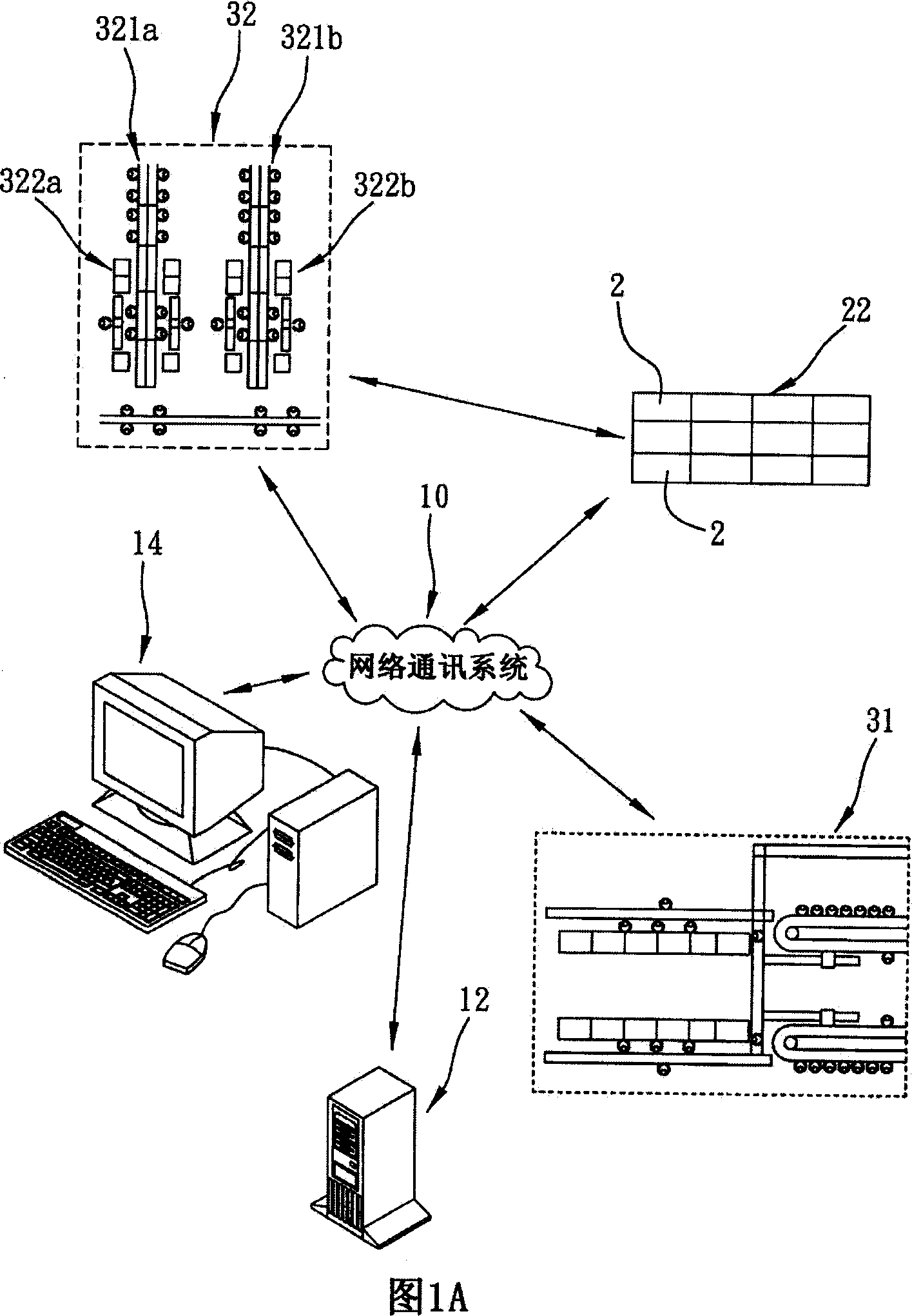

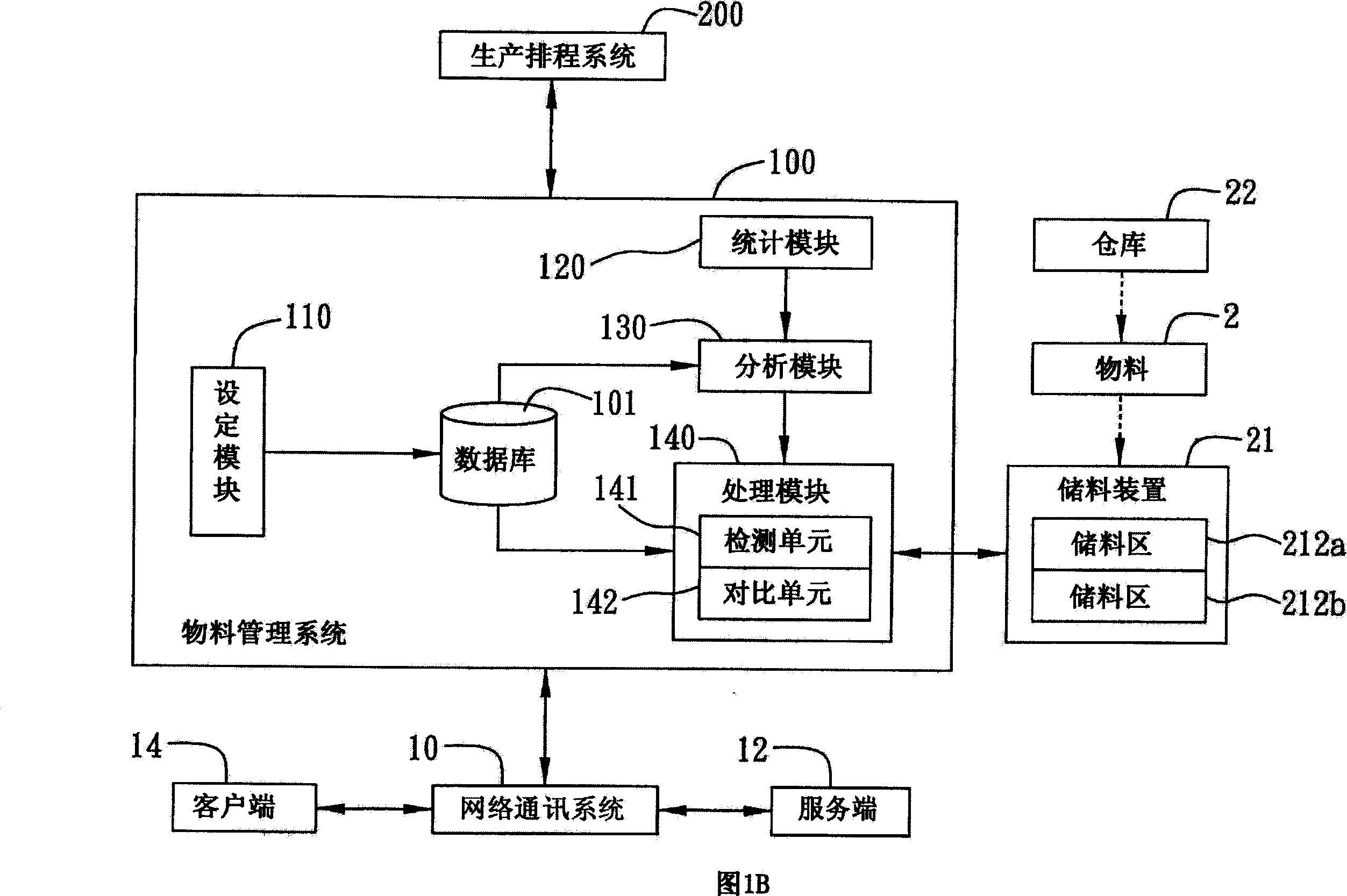

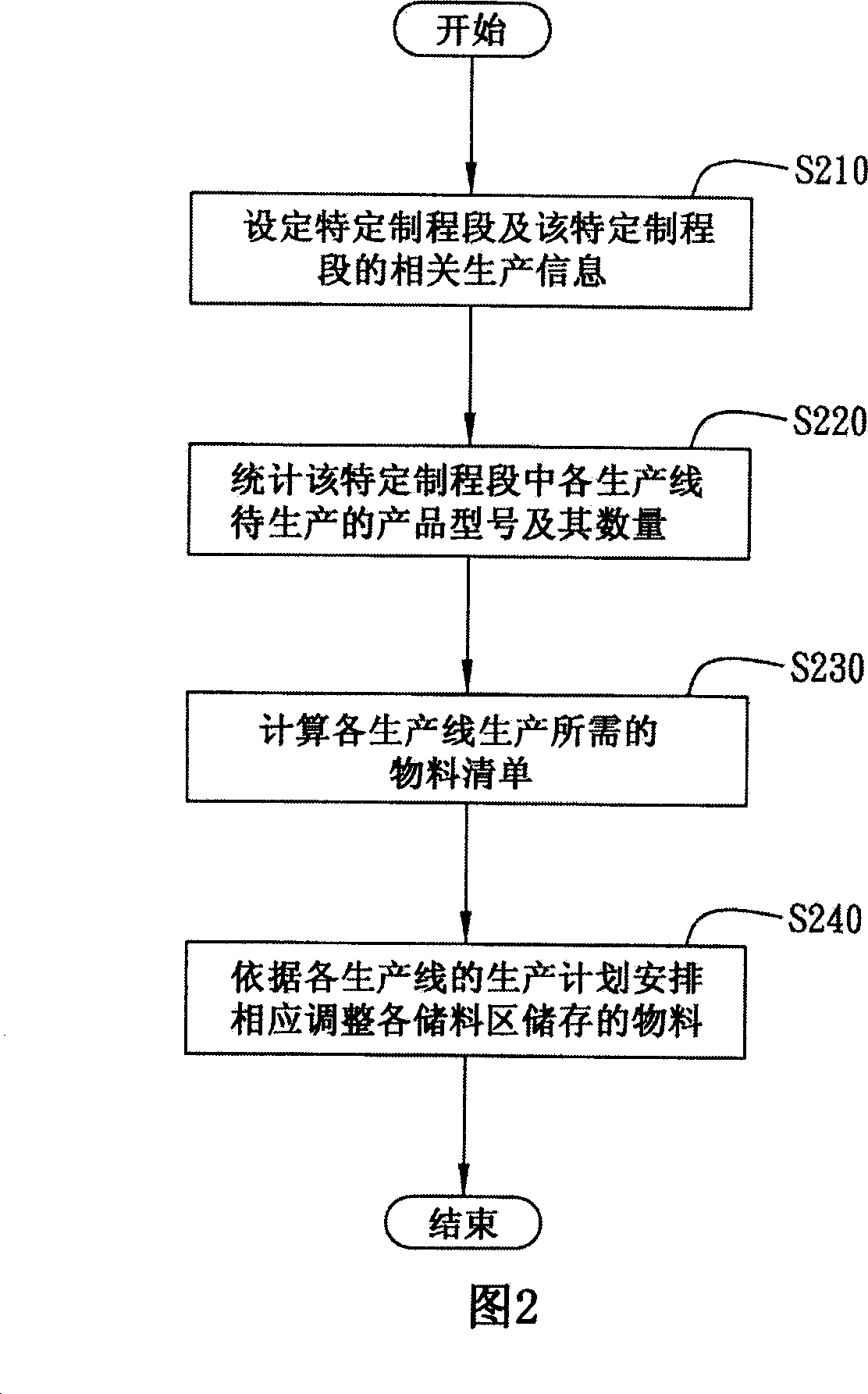

[0018] FIG. 1A is a schematic diagram of the overall architecture of the material management system of the present invention. The material management system of the present invention is applied in the replenishment operation of on-site production management. In this embodiment, the material management system is used to control the material preparation operation of the finished product packaging section 32, wherein the finished product packaging section 32 is adjacent to the finished product The manufacturing section 31 is responsible for packaging the finished products produced by the finished product manufacturing section 31 .

[0019] As shown in Figure 1A, the material management system of the present invention is set up in a network communication system 10 with a server 12 and a client 14, wherein the client 14 is respectively set in the finished product manufacturing section 31 and the finished product packaging section 32 , record the relevant production information of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com