Patents

Literature

196 results about "Production chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain of production. The chain of production consists of the various stages involved in the production of a particular product. The chain of production for furniture may include the following steps: The chain of production involves a series of stages, which add value to the end product.

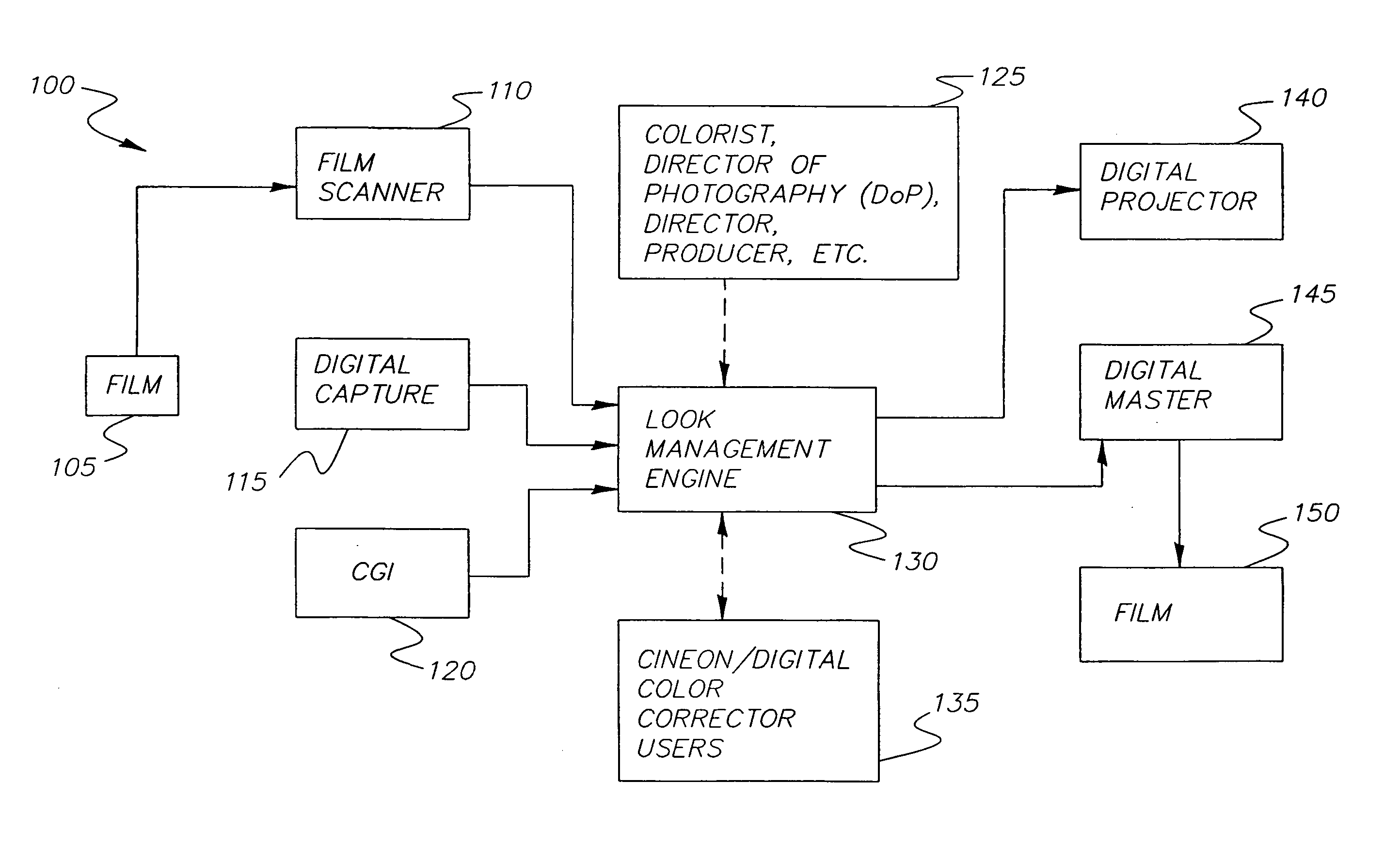

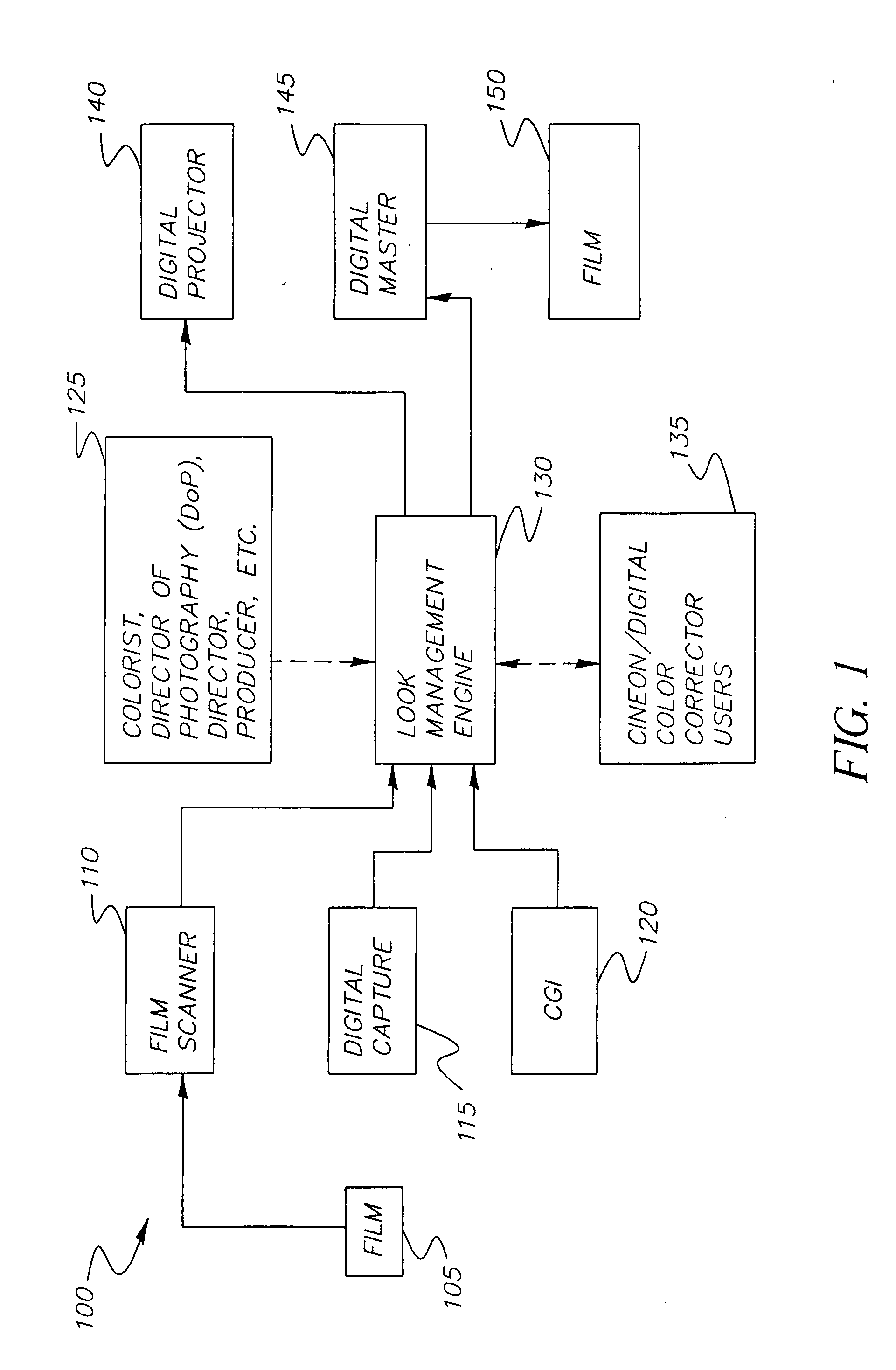

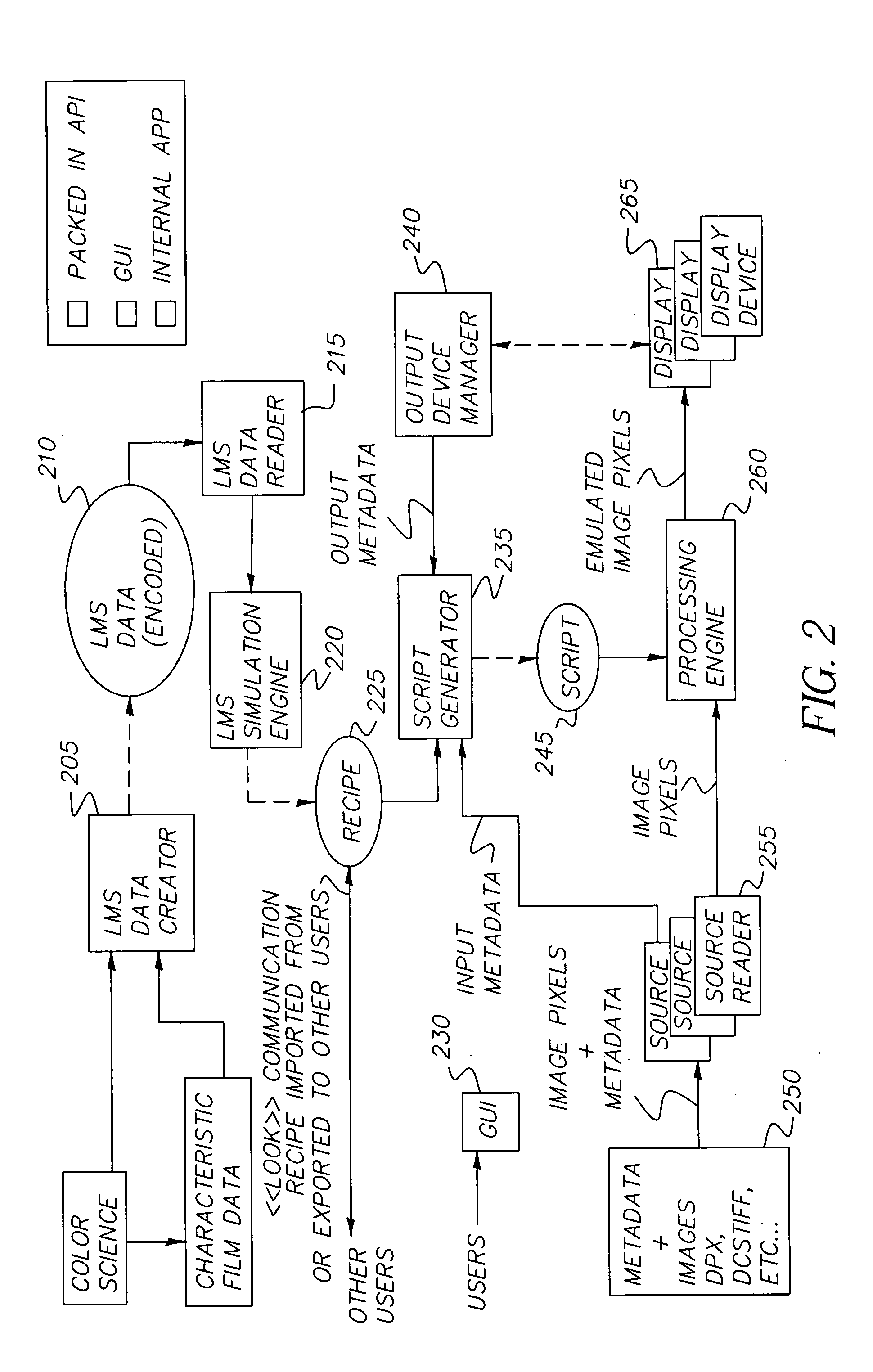

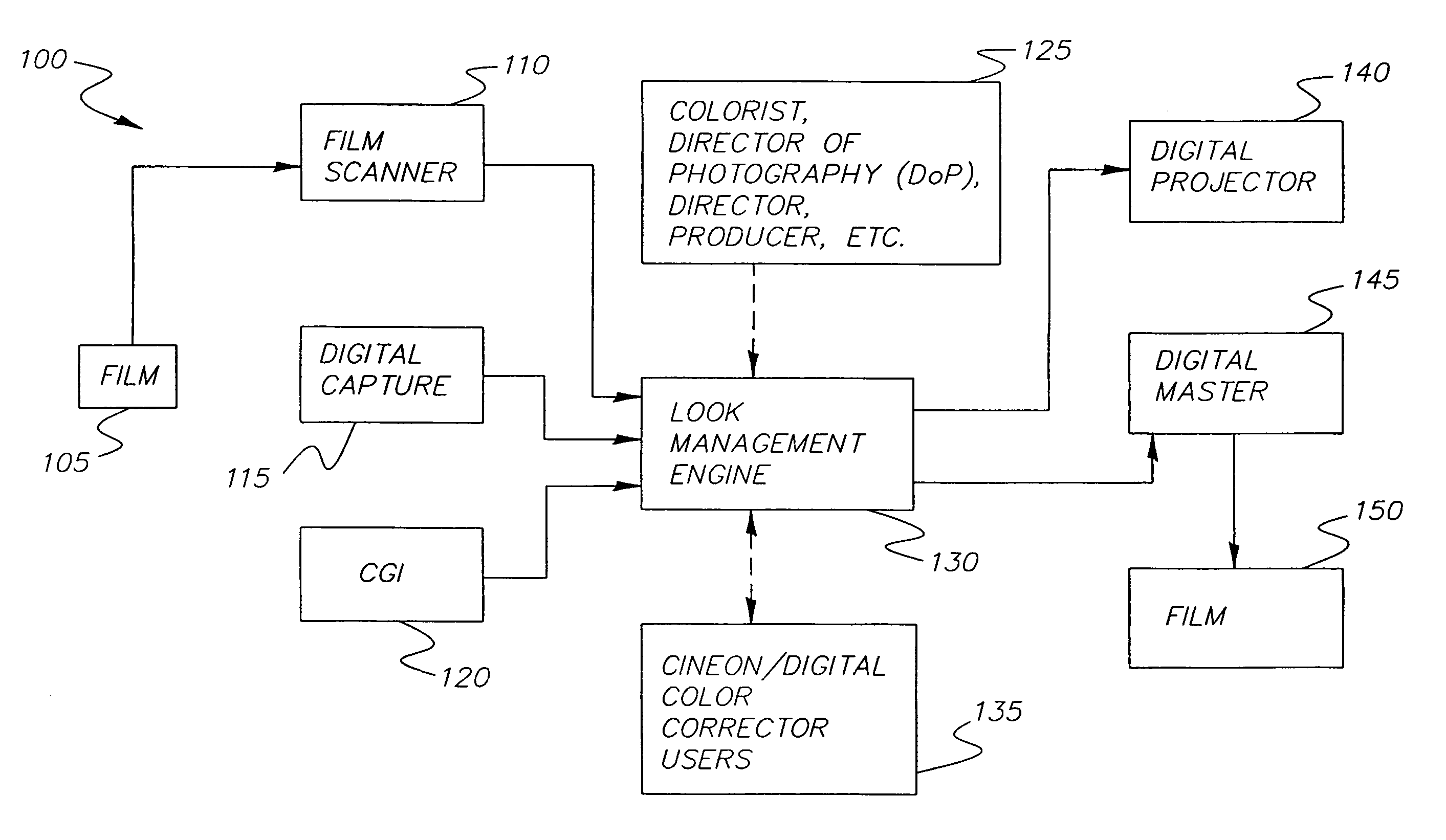

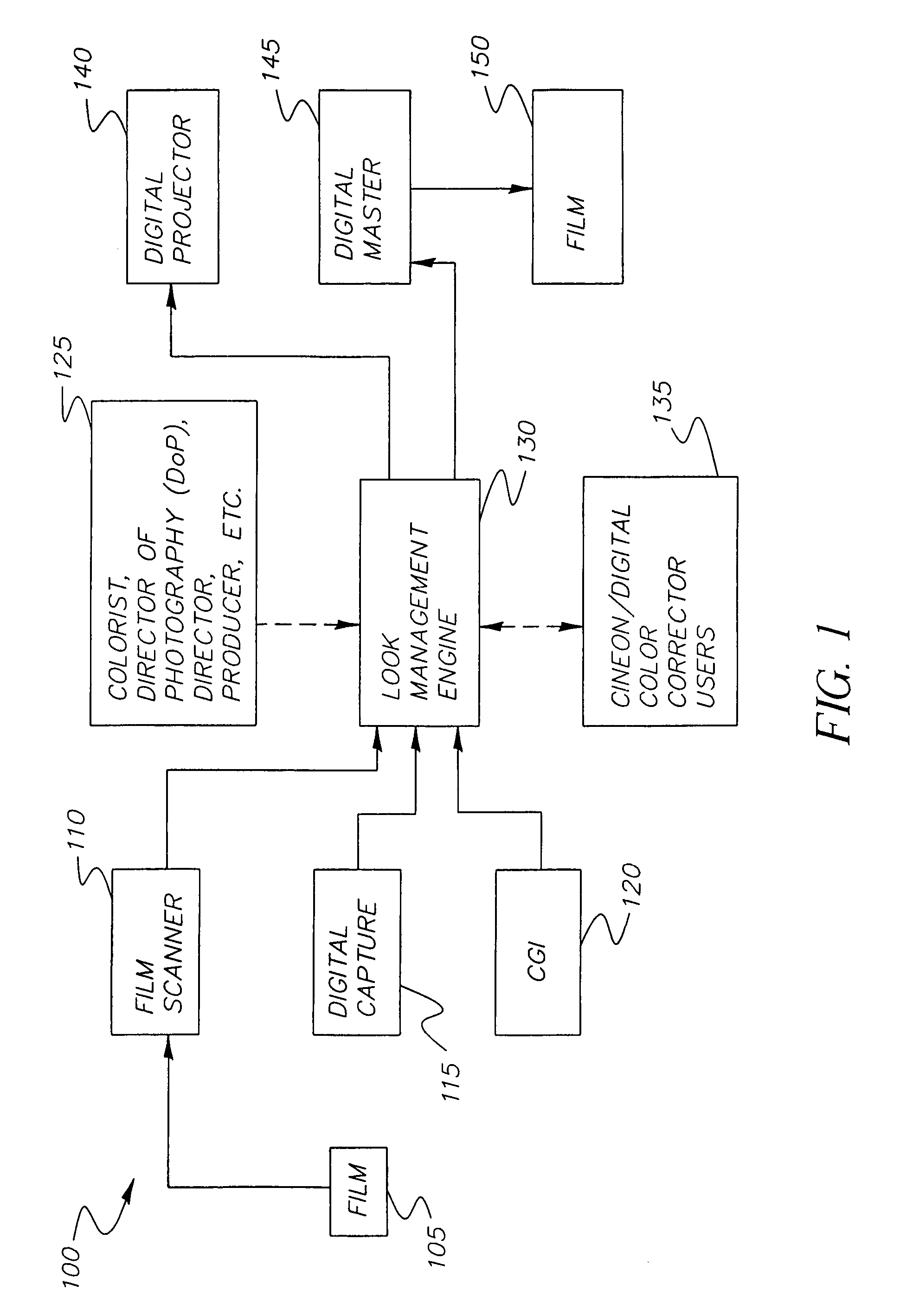

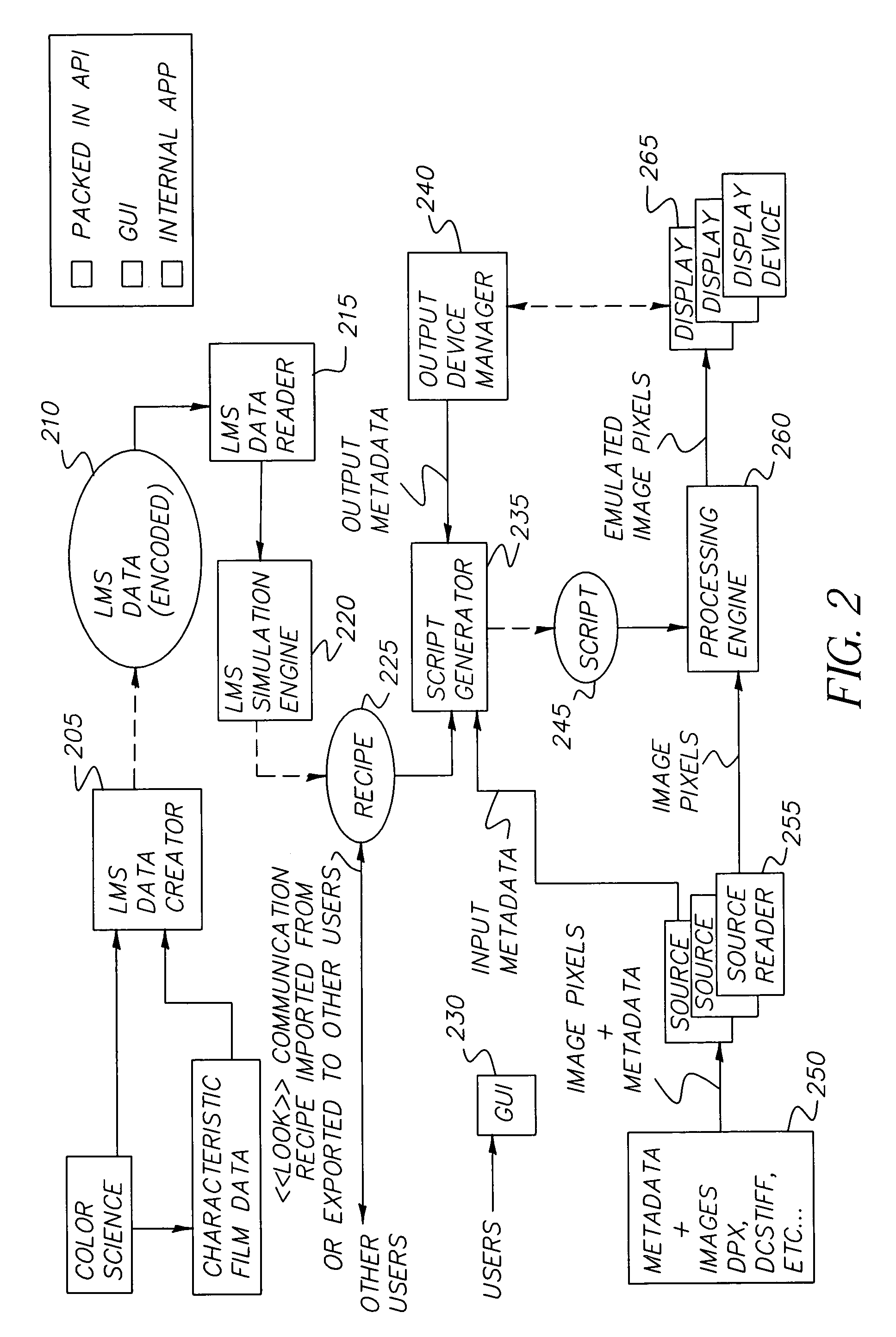

Method and system for preserving the creative intent within a motion picture production chain

A method for communicating and preserving creative intent within a motion picture production chain, including a production stage, and at least one of a subsequent laboratory or post production stage, including capturing an original image of a scene during the production stage; generating a look representative of a creative intent, wherein the look is a digital representation of a creative alteration of the captured original scene image; and applying the look to the captured original scene image and confirming approval of the look during the production stage. The digital representation of the look is stored as a recipe for generating the creative alteration, and communicated from the production stage to at least one of the subsequent laboratory and post-production stages for applying the look to the captured motion picture footage during subsequent laboratory and post-production stages.

Owner:EASTMAN KODAK CO

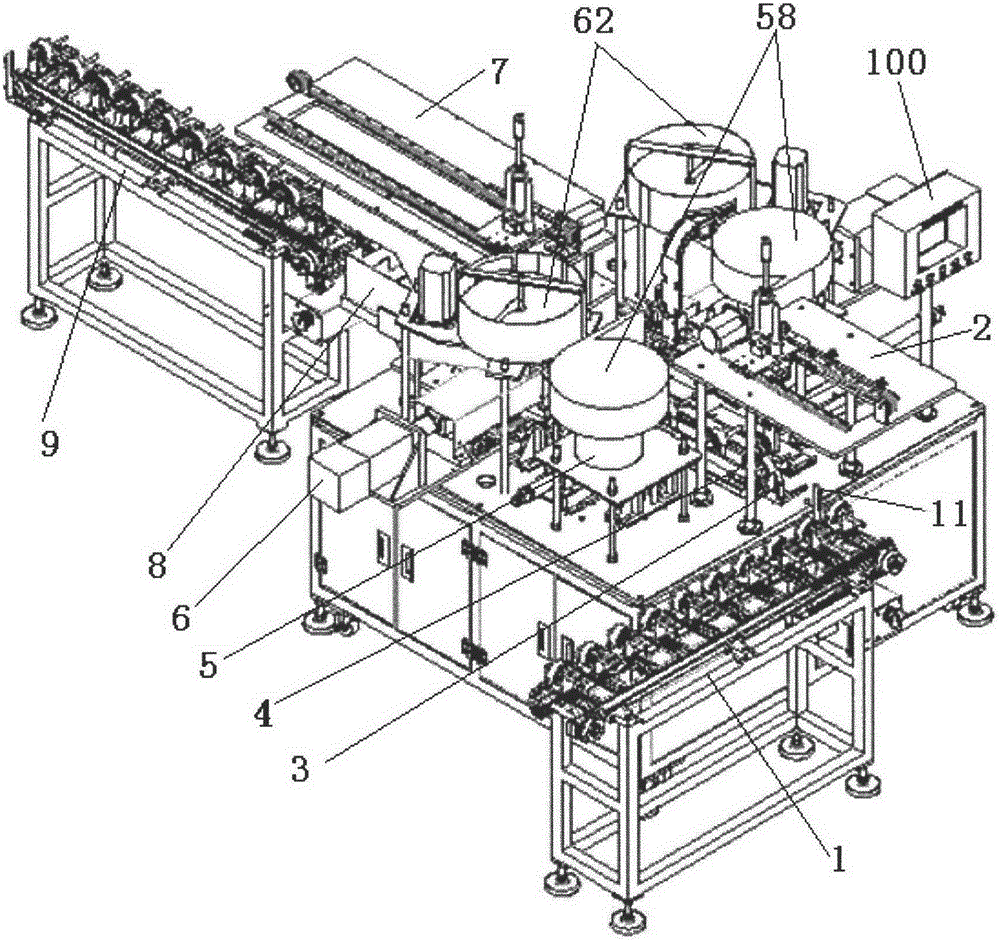

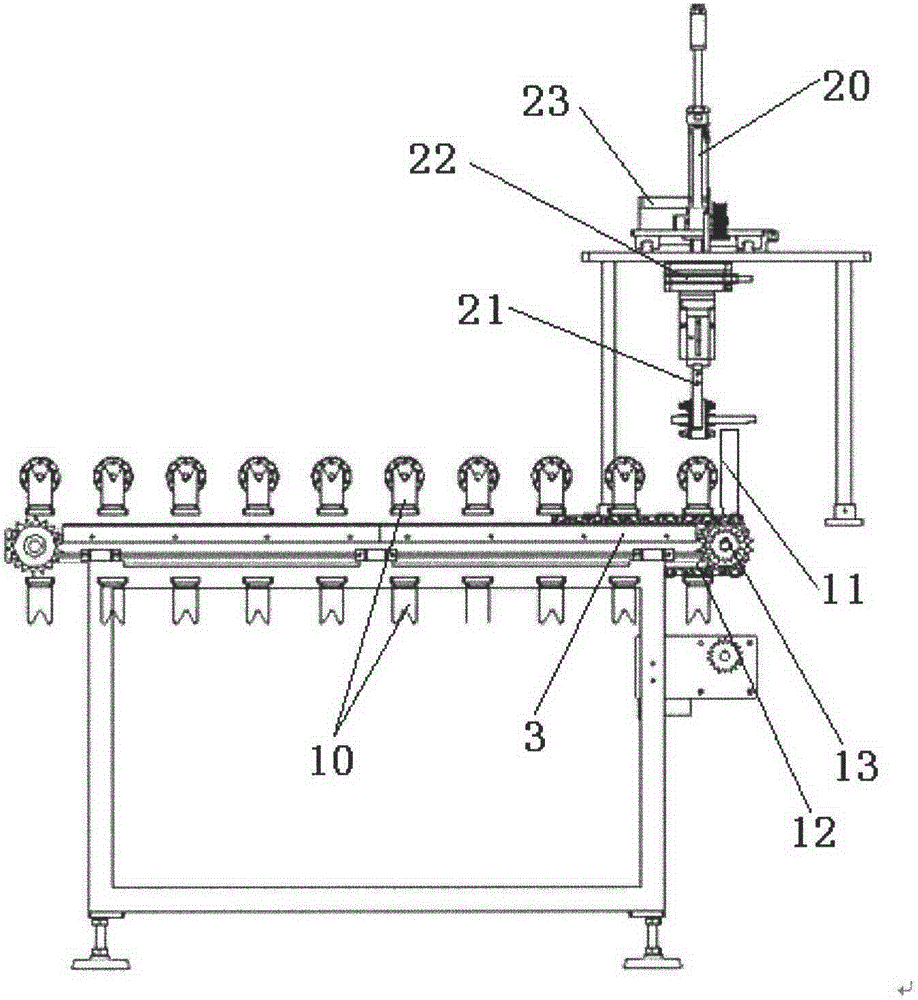

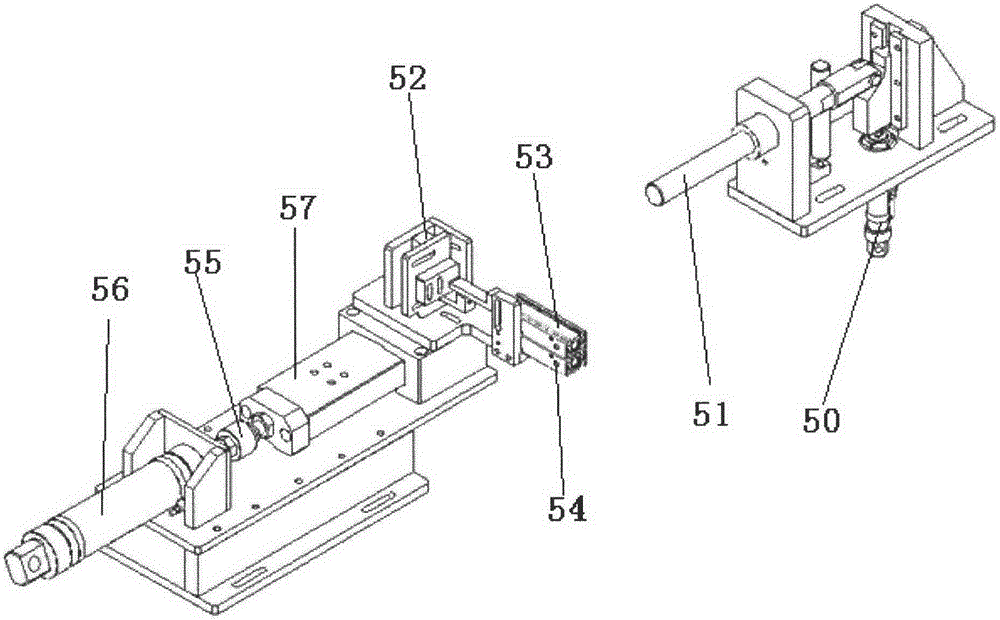

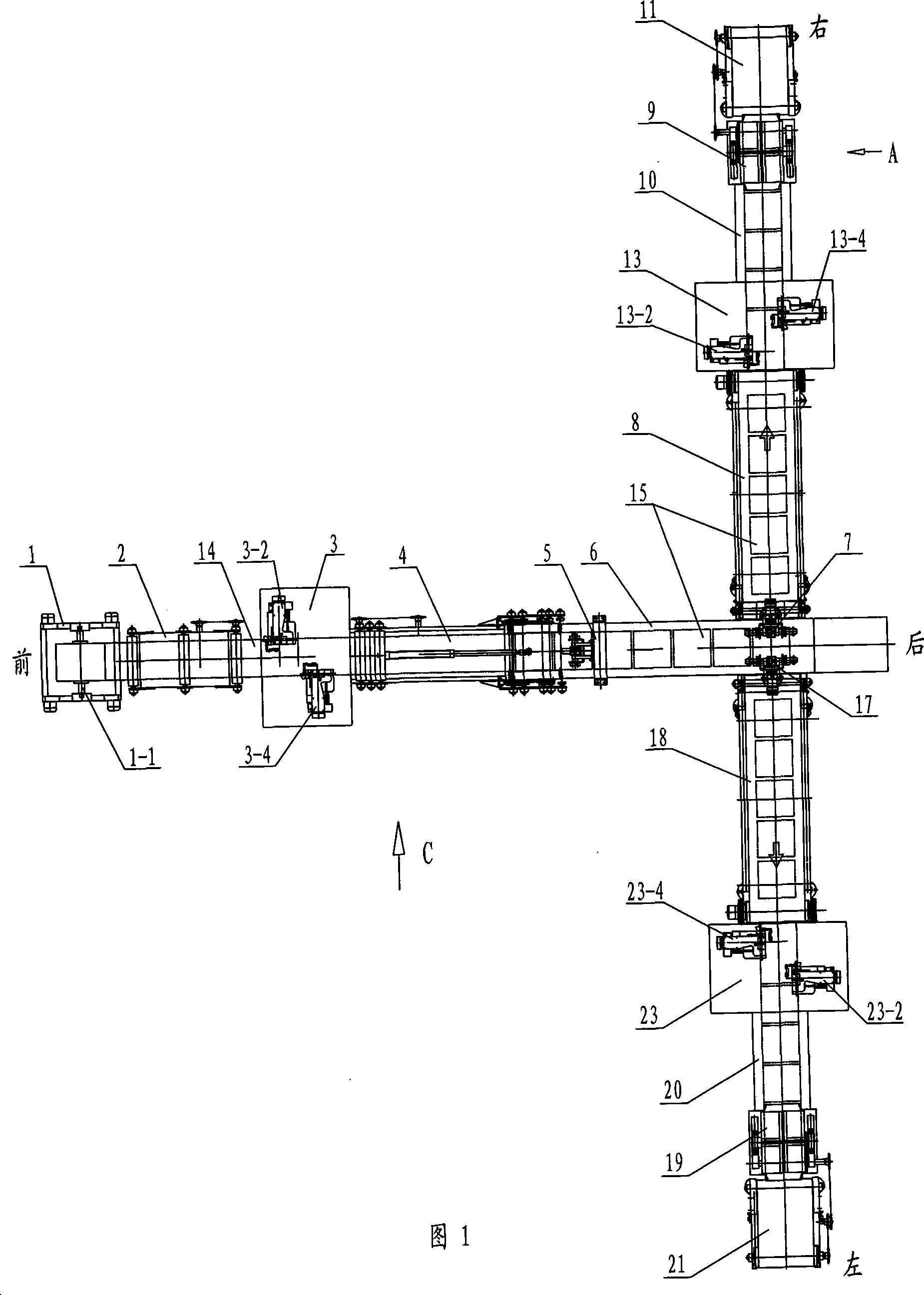

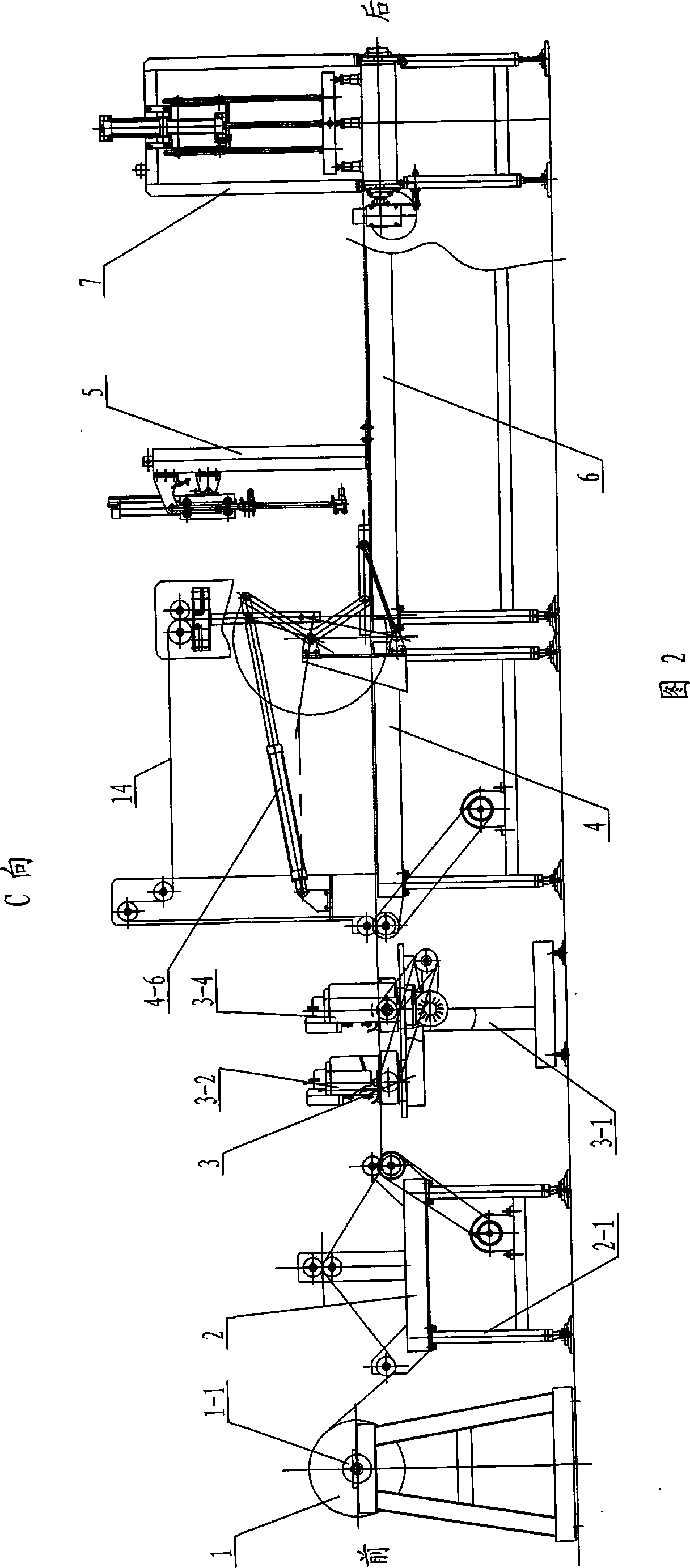

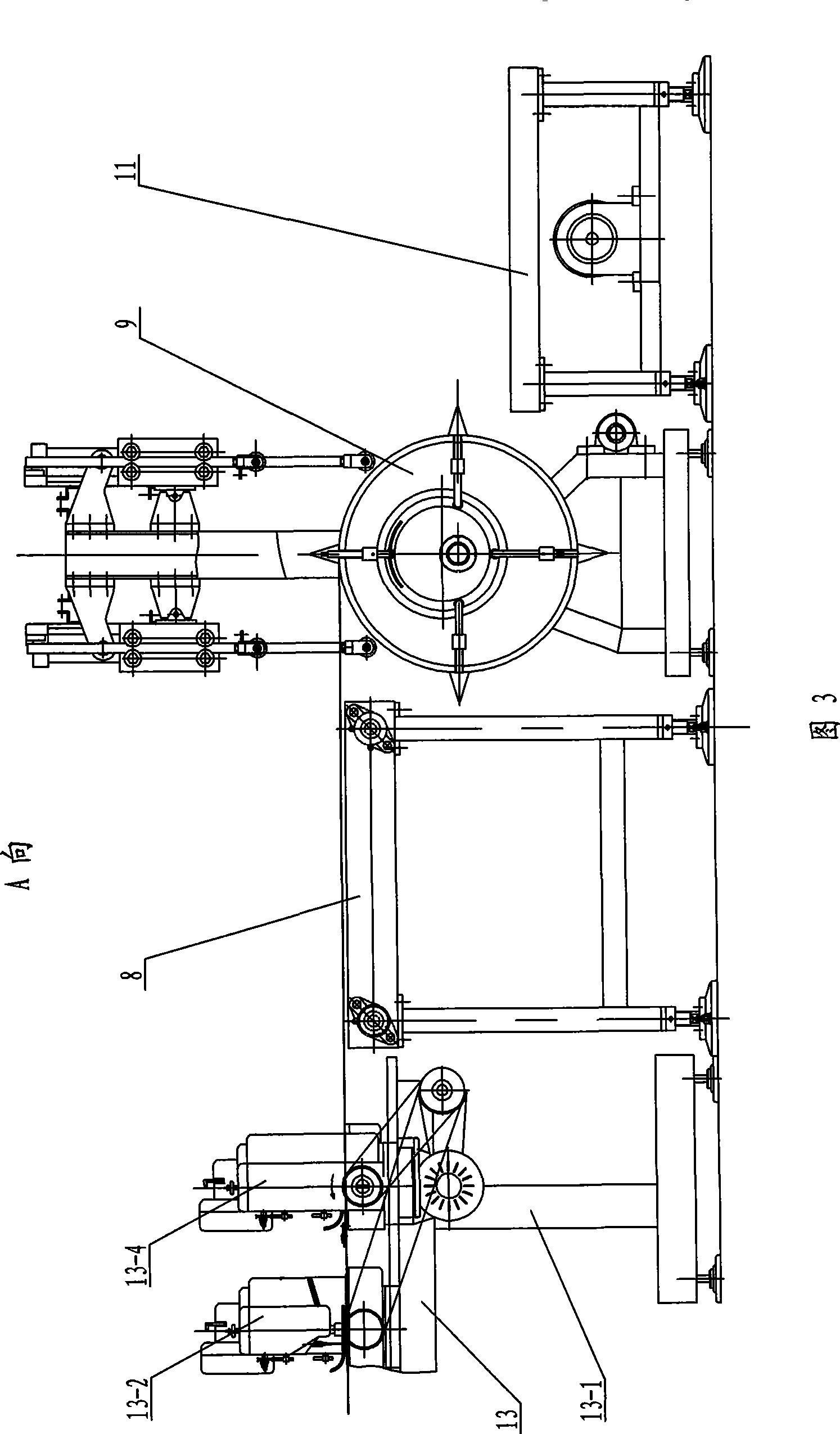

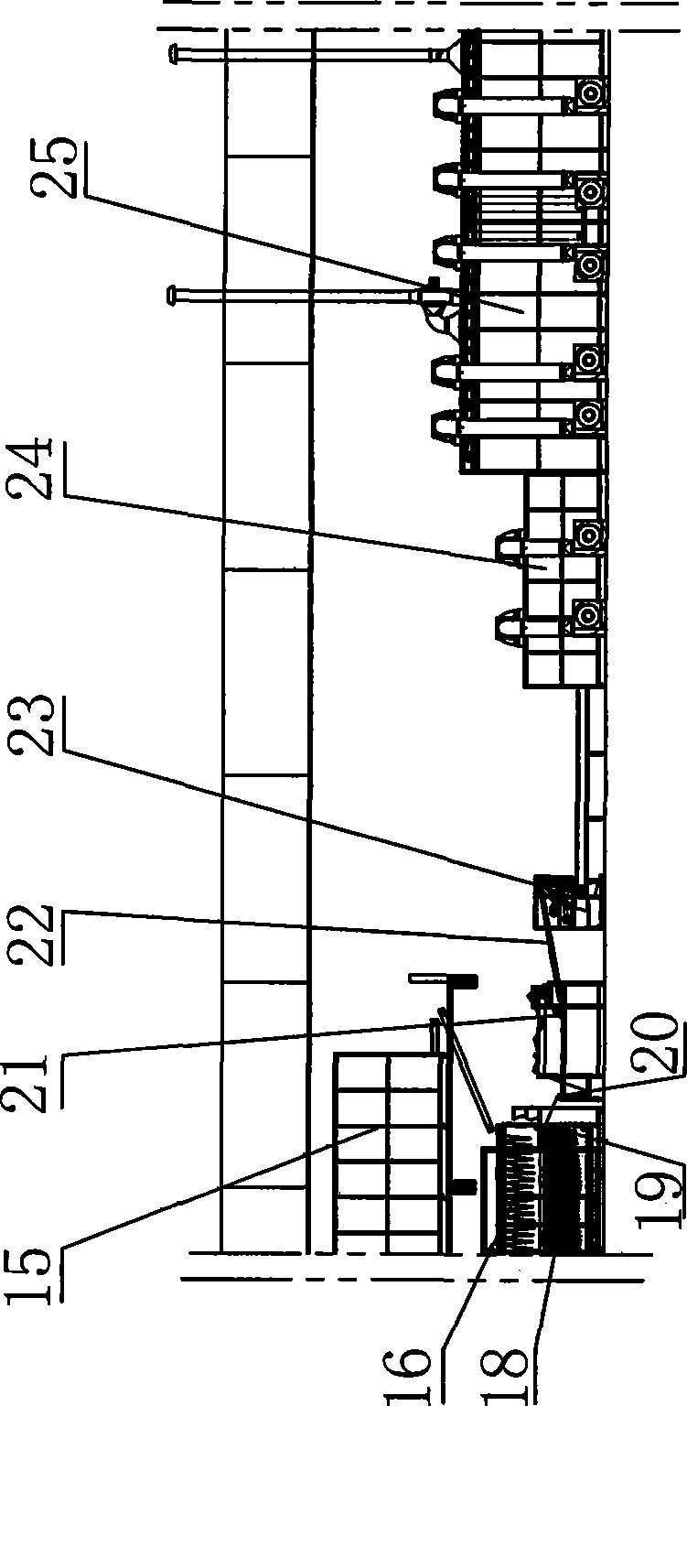

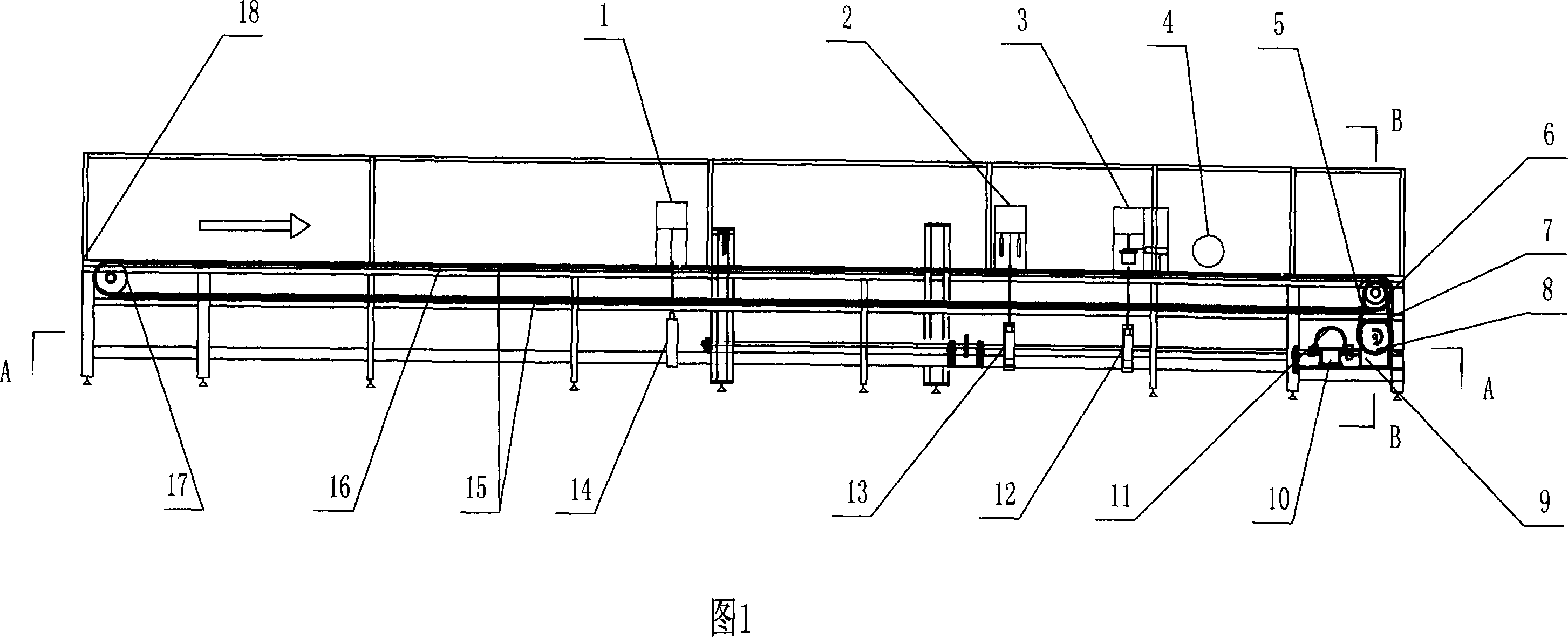

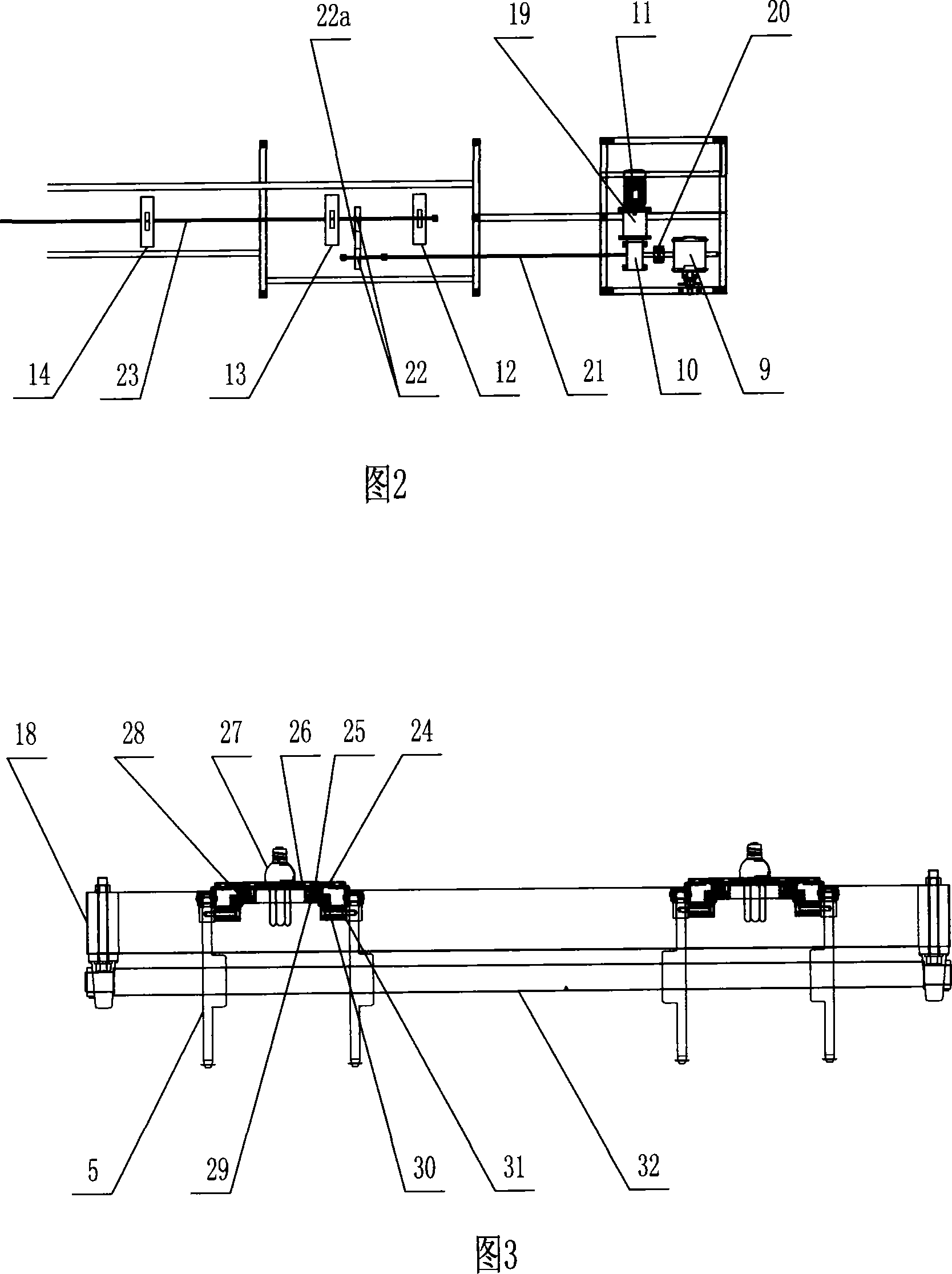

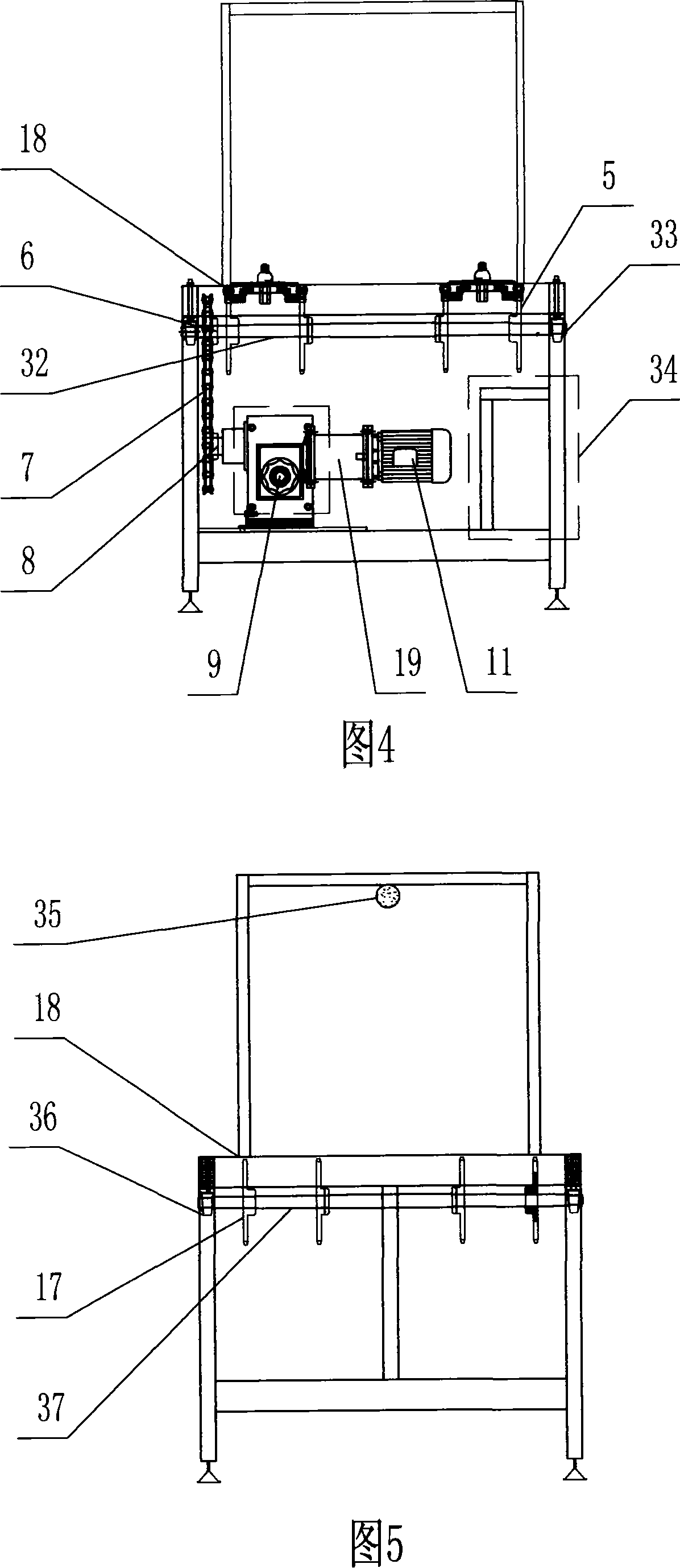

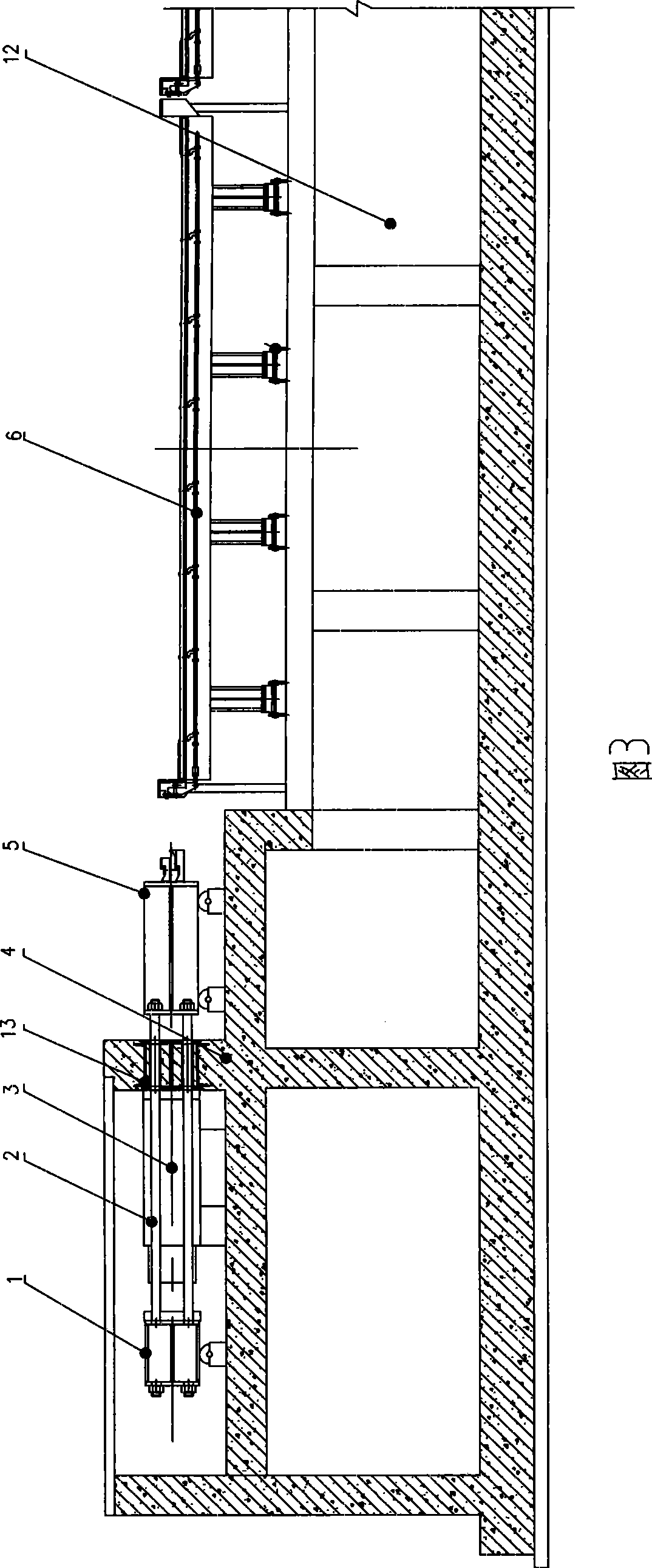

Full-automatic integrated device for bearing pressing and liner installation

InactiveCN102744601ARealize automatic assemblyImprove securityAssembly machinesProduction chainEngineering

The invention discloses a full-automatic integrated device for bearing pressing and liner installation, comprising an automatic feeding production chain for conveying products, a material takeout mechanism, a positioning mechanism, a lifting transportation mechanism, a liner installation mechanism, a bearing pressing mechanism, a discharging mechanism, an NG material platform, and a finished product production chain; the automatic feeding production chain is arranged below the material takeout mechanism; the positioning mechanism is used for positioning the products on the automatic feeding production chain; the lifting transportation mechanism conveys the products on the automatic feeding production chain to the liner installation mechanism and the bearing pressing mechanism; the discharging mechanism and the NG material platform are arranged at the back end of the bearing pressing mechanism; the finished product production chain is arranged at the back end of the discharging mechanism; the bearing pressing mechanism is provided with a bearing feeding tray; and the liner installation mechanism is provided with a liner vibrating tray. With the mode, the full-automatic integrated device for bearing pressing and liner installation saves manpower, is simple to operate, has high assembly accuracy and strong common property, and is safe and reliable.

Owner:吴江市昊睿精密机械设备有限公司

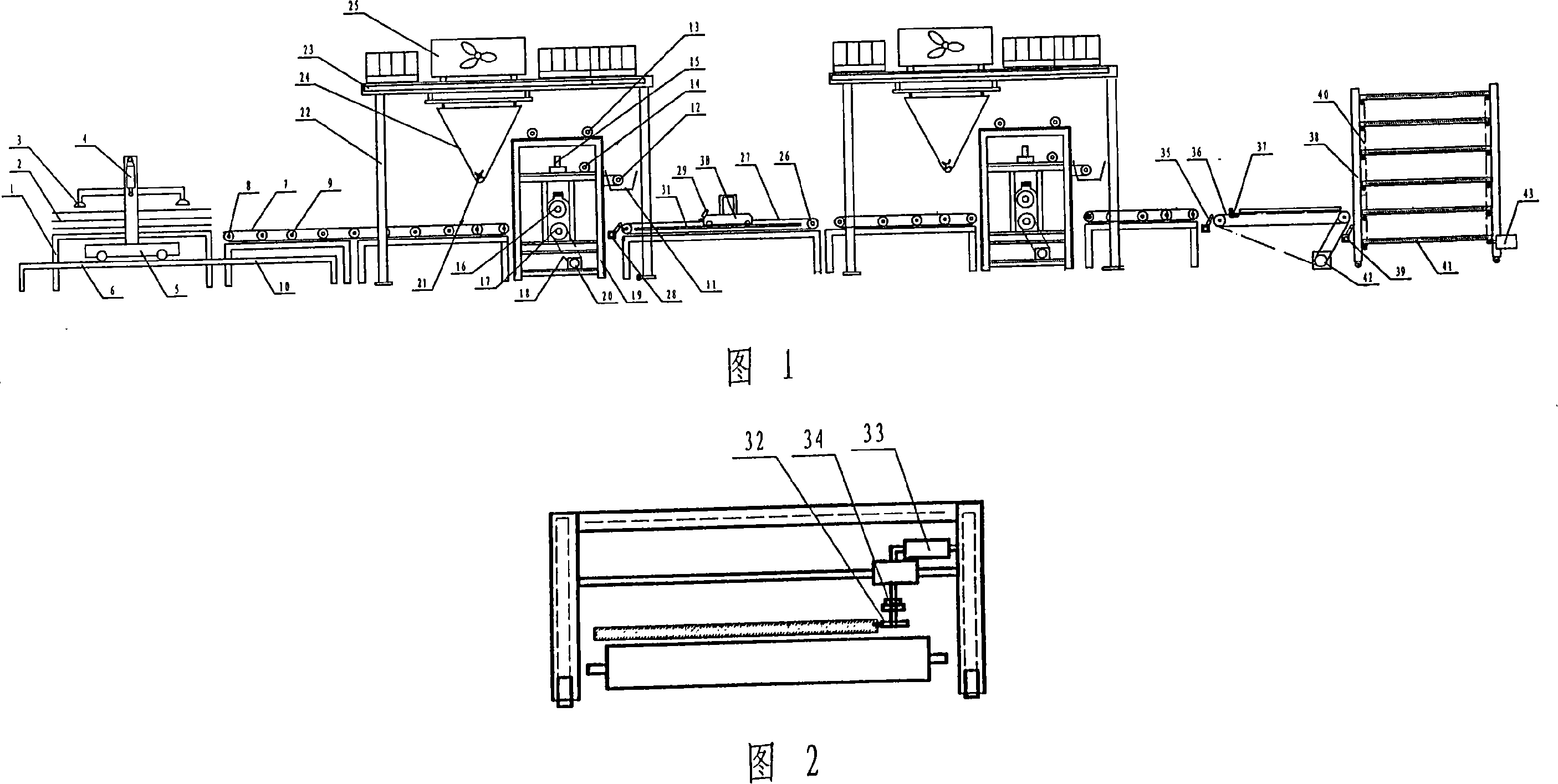

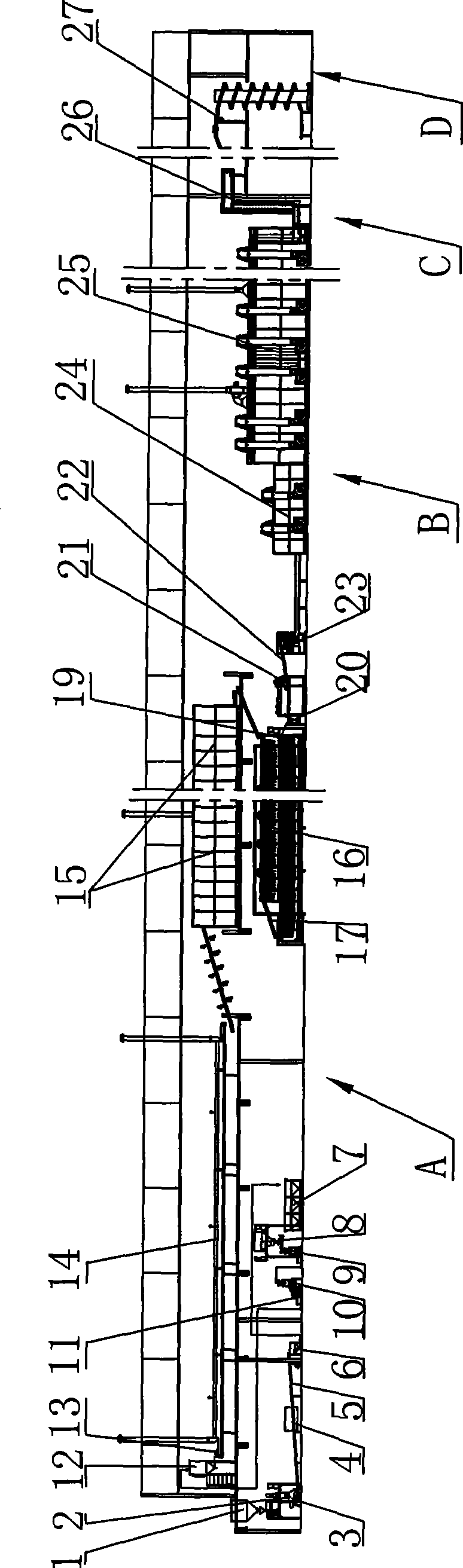

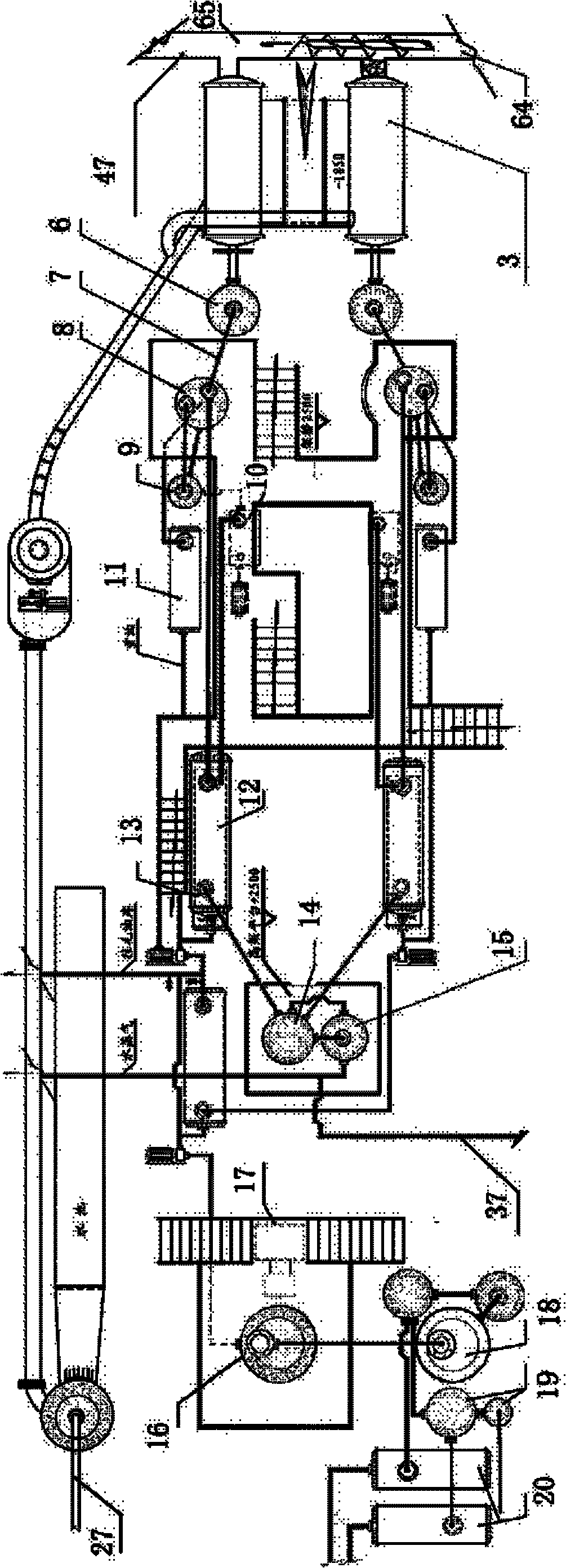

Compound thermal insulation wall plate and external wall heat-insulation board producing line

InactiveCN101138866AIncrease productivityEasy to operateDischarging arrangementCeramic shaping plantsProduction lineThermal insulation

The present invention discloses a production line of a composite heat proof wall plate and an external heat proof plate of an external wall. The production line includes an automatic mounting moulding board mechanism, cloth-net roll mechanisms, a reseau cloth automatic cutting mechanism and an automatic plate-sending, shelf-installing and shelf-sending mechanism which are orderly linked by a belt feeding production chain. Mixing and material-dropping mechanisms are arranged above a section of belt feeding production chain between the automatic mounting moulding board mechanism and a first group of cloth-net roll mechanism and between a forward group of cloth-net roll mechanism and a next group of cloth-net roll mechanism. At least two groups of matched mixing and material-dropping mechanisms and the cloth-net roll mechanisms are arranged. The production line can produce the composite heat proof wall plate and at the same time can also produce the external heat proof plate of an external wall and has the characteristics of high production efficiency, simple and convenient operation and high quality of processing.

Owner:泰安鲍文特科技有限公司

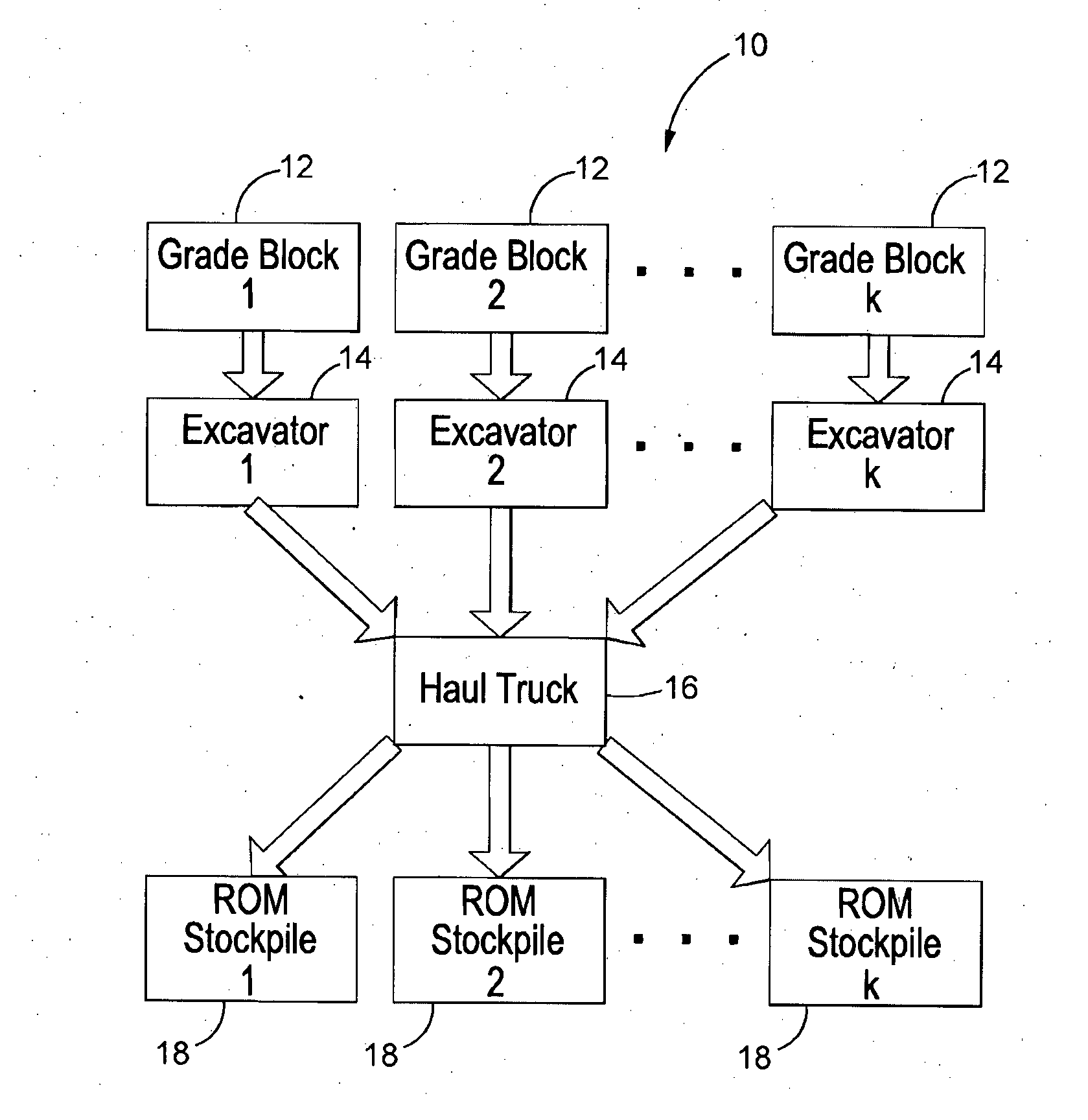

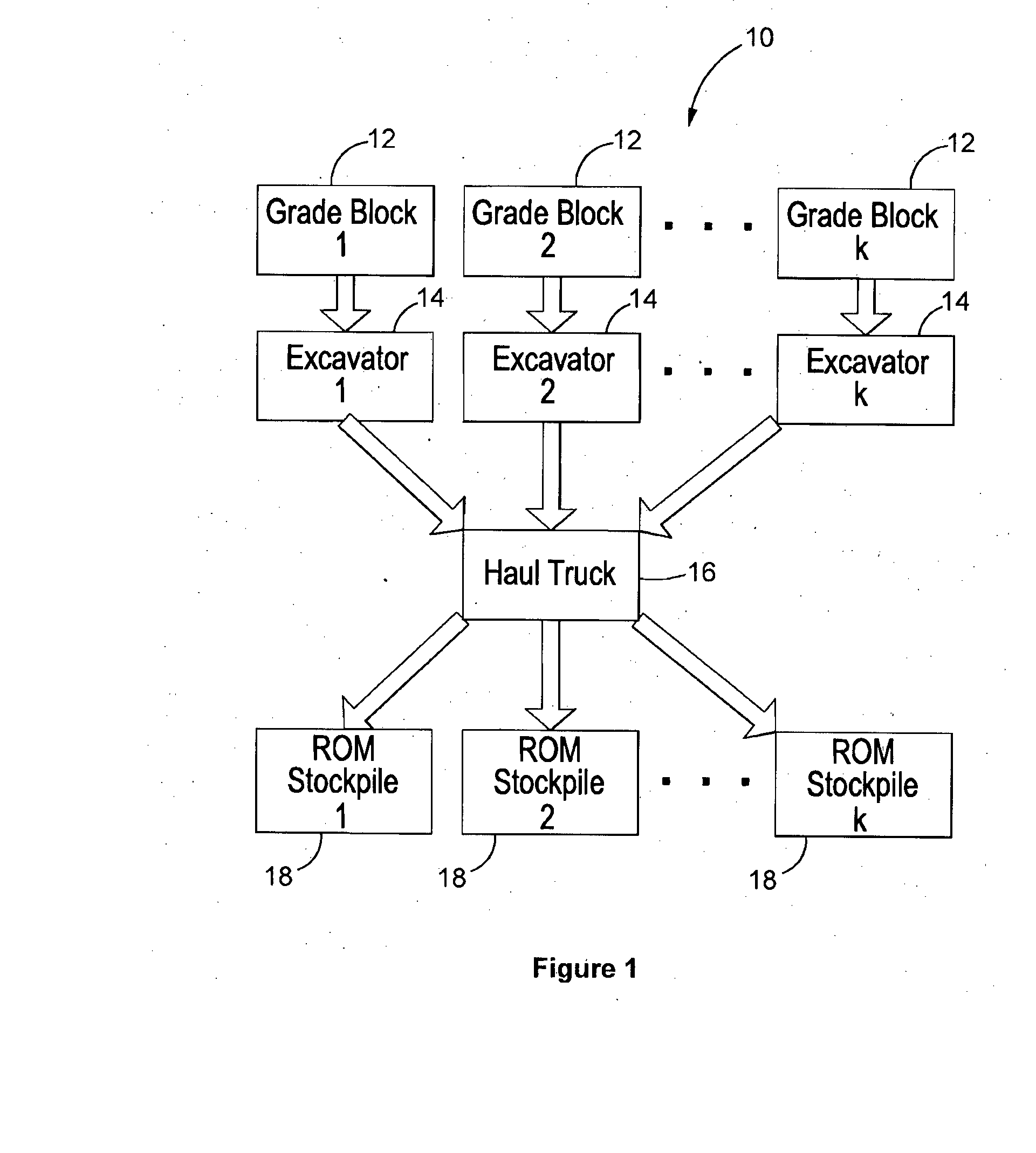

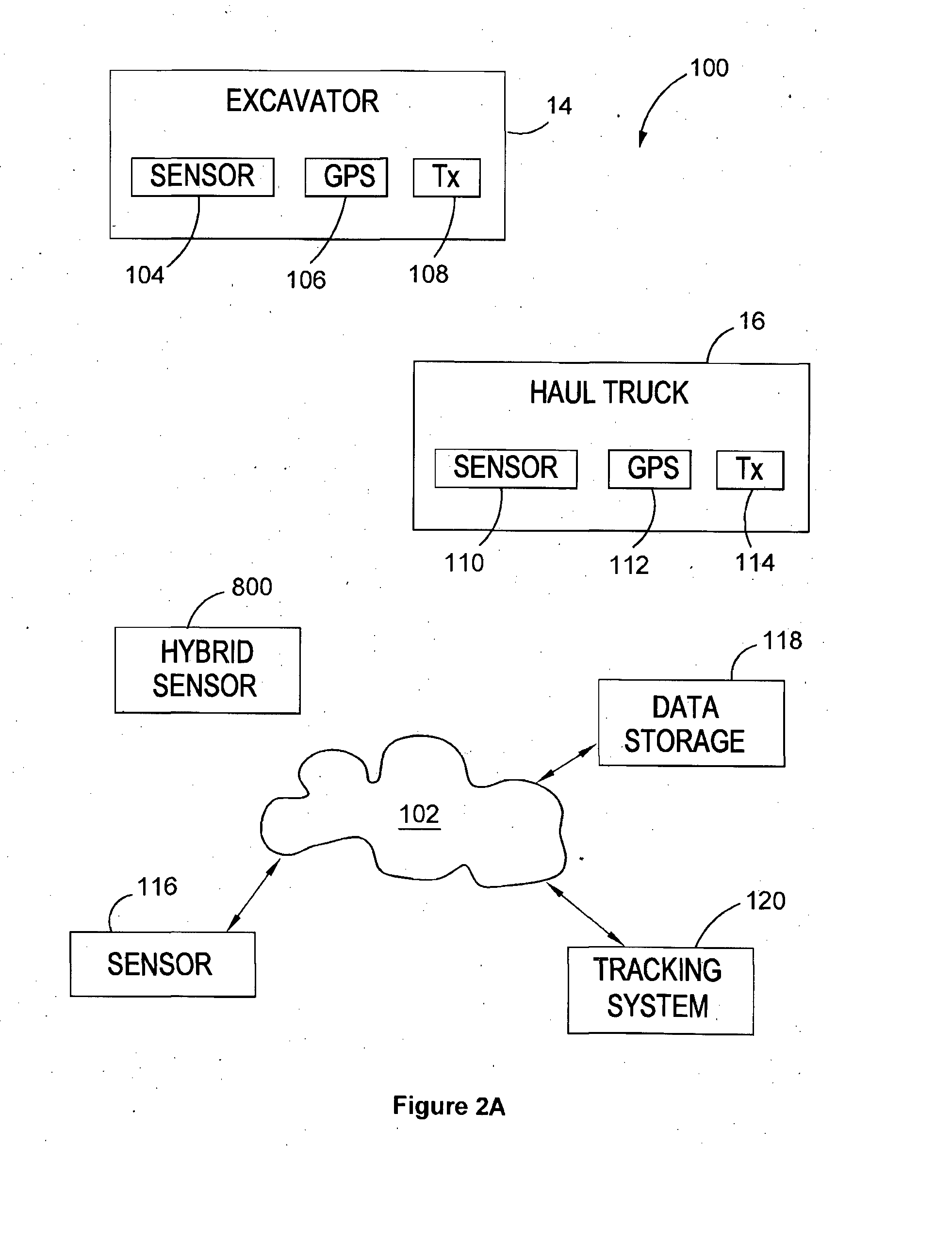

Method and system for tracking material

Methods and systems are described for tracking material through a production chain or operational process chain in which the material is transferred via a plurality of spatially distinct lumped masses of material (12, 14, 16, 18). A dynamic state space (430) is maintained descriptive of the plurality of spatially distinct lumped masses of material, wherein a quantity of entries in the dynamic state space is augmented or diminished dependent on a quantity of spatially distinct lumped masses being tracked. Measurements relating to an observed lumped mass of material are fused into the dynamic state space and a dynamic covariance matrix to provide an updated estimate of material in the plurality of spatially distinct lumped masses of material.

Owner:TECHNOLOGICAL RESOURCES

Method and system for preserving the creative intent within a motion picture production chain

Owner:EASTMAN KODAK CO

Shawl production chain

InactiveCN101387051AHigh degree of automationReduce Human Intervention FactorsSewing apparatusProduction rateProduction line

The invention provides a square towel production line, which relates to a sewing production line. The invention is to resolve the problems of manual production, low production rate and difficult quality guarantee existing in the prior production of square towel. A damp unreeling machine, a synchronous conveyor, a first double-head sewing device, a material taking conveyor and a conveyor are orderly arranged on the ground from the front to the rear along the longitudinal direction; a first transverse conveyor, a second double-head sewing device, a first middle conveyor, a first head cutting machine and a first material receiving machine are orderly arranged on the ground from the side end of the tail part of the conveyor along the transverse direction; a first sewing machine and a second sewing machine which are opposite to each other are fixedly arranged on a sewing machine rack platform; two beaders are fixedly arranged on the sewing machine rack platform respectively and on the front ends of the first sewing machine and the second sewing machine; a brander is fixed on the conveyor; and a first transverse material taking machine is arranged on a machine rack of the back end of the conveyor. The equipment of the invention has the advantages of harmonious operation and high automation, and improves the production rate by 5 to 6 times, simultaneously lowers labor intensity and ensures the quality.

Owner:张广生

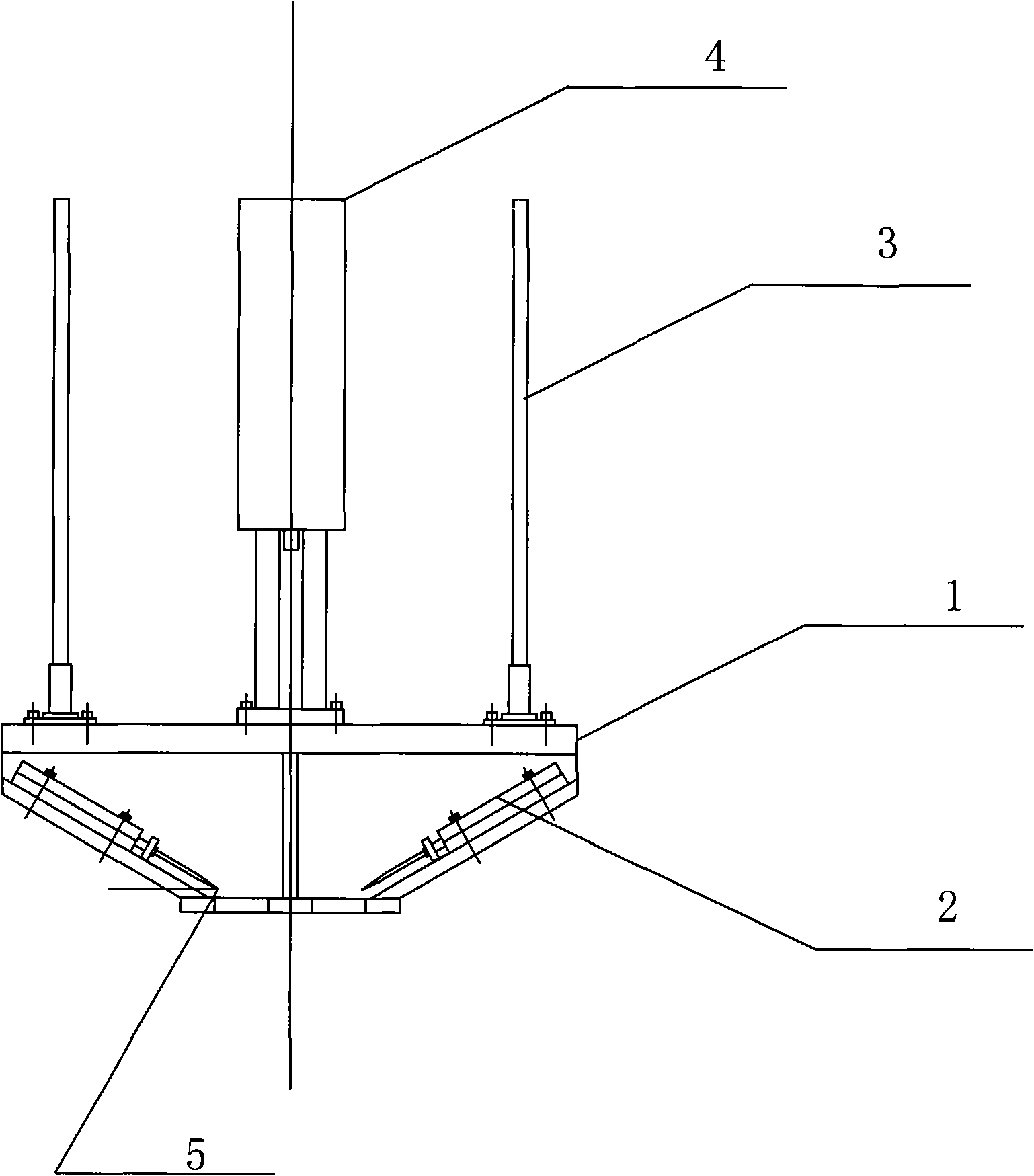

Automatic baiting needling device of vehicle roof board production chain

InactiveCN101332601ASmooth feedingReduce labor intensityGripping headsConveyor partsProduction lineNeedle penetration

The invention relates to an automatic feeding needling device for automobile roof production line, in particular to an automatic feeding mechanism for the automobile roof production line, which belongs to the technical field of mechanical structure. The device comprises a cylinder base fixing bracket, an oblique needling slide cylinder, a guide post, a lifting slide cylinder and a pricking needle, wherein, the lifting slide cylinder, the oblique needling slide cylinder and the guide post are respectively arranged on the cylinder base fixing bracket, and the pricking needle is arranged on the oblique needling slide cylinder. The automatic feeding needling device is characterized by simple, compact and reasonable structure, can realize automatic material taking action for various soft materials with different textures, thicknesses and specifications, has flexibility to adapt to different products and ensures automatic feeding stability; the automation degree is high and workpiece feeding is stable; and the device can improve production efficiency, reduce labor intensity of workers and improve product quality.

Owner:刘明春

Production chain of instant dry rice noodles and technique for producing the same

The invention discloses an instant dried rice noodle production line and production technology, The production line comprises: rich falling bucket, air-jetting rice polisher, specific gravity sand removing machine, rice color sorting machine, rice conveyor, rice pumping machine, jet rich washing machine, water riche separating tank, first stage pulp mill, second stage pulp mill, pulp screen, pulp storing machine, stirring type automatic pulp falling machine, noodle steaming machine, sheet jelly pre-drying machine, sheet jelly freezing machine, first sheet jelly recovering machine, second sheet jelly recovering machine, drum type transition conveyor, noodle cutting machine, rice noodle conveyor, quantitative cutting machine, automatic shaping machine, drying machine, air-cooling machine and packaging and conveyor disposed according to the material conveying flow. The production line and production technology of the present invention can realized the full-automatic production from raw material to finished product of instant dried rice noodle, achieve instant dried rice noodle with good quality, and high production efficiency.

Owner:BUHLER WUXI COMML

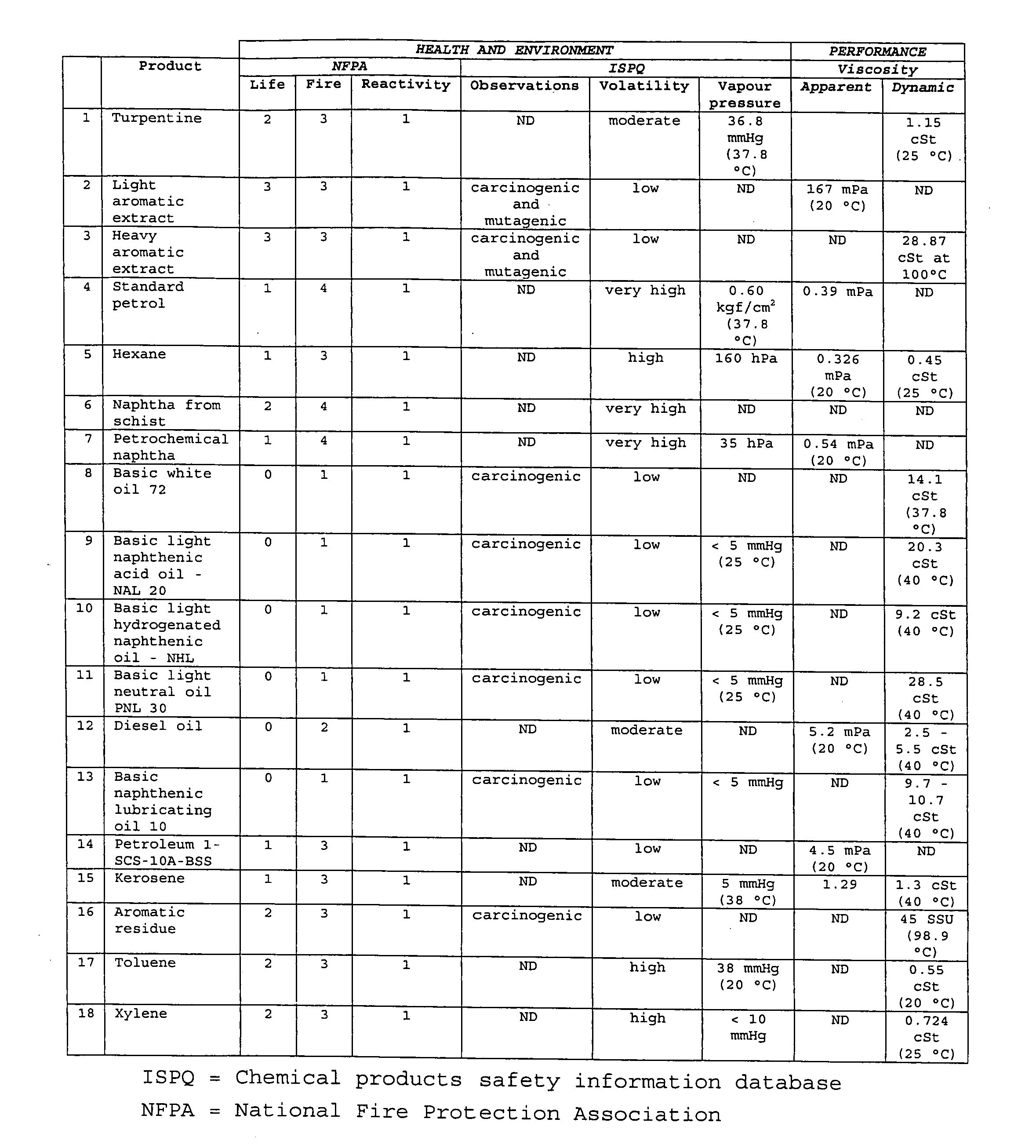

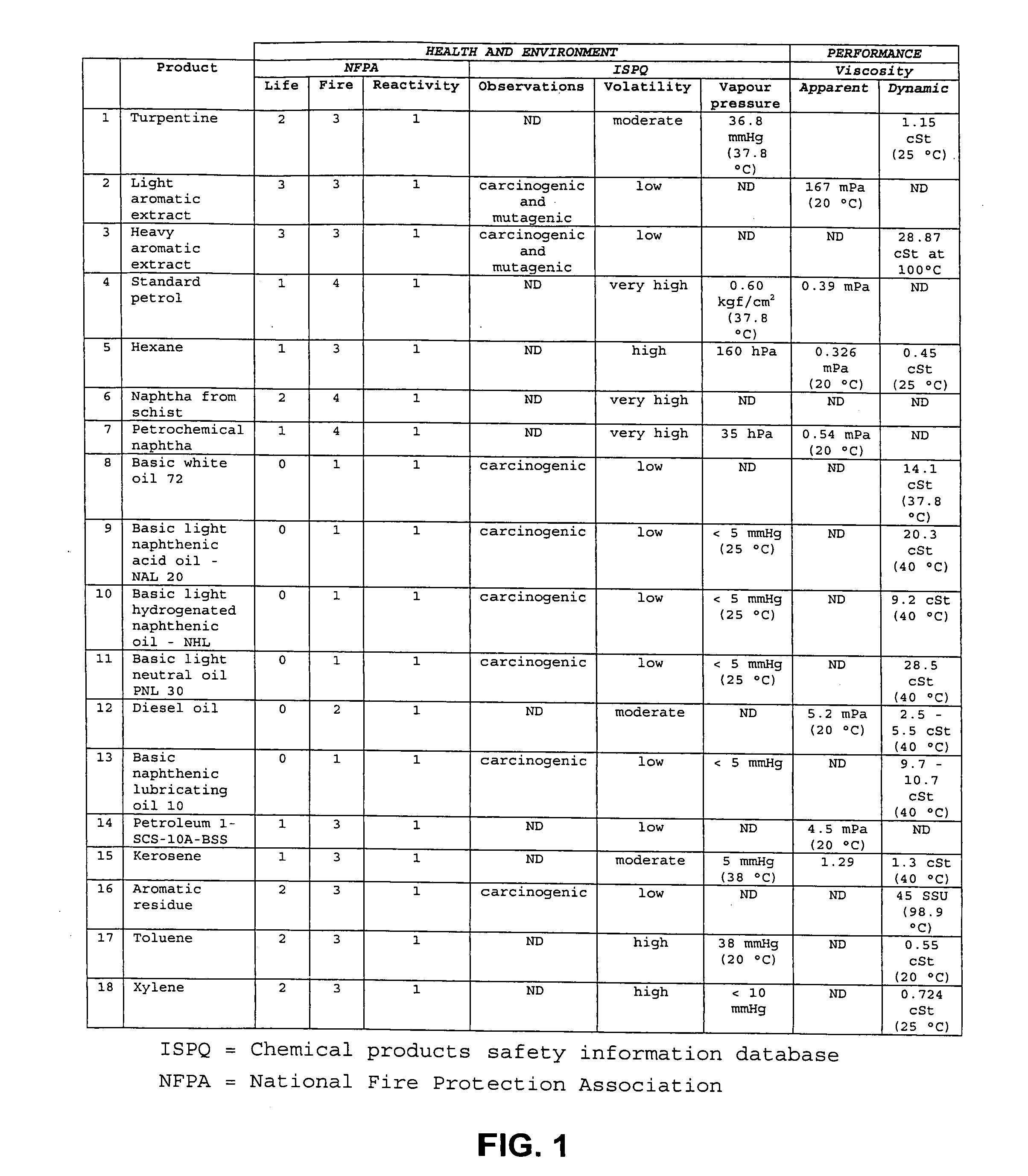

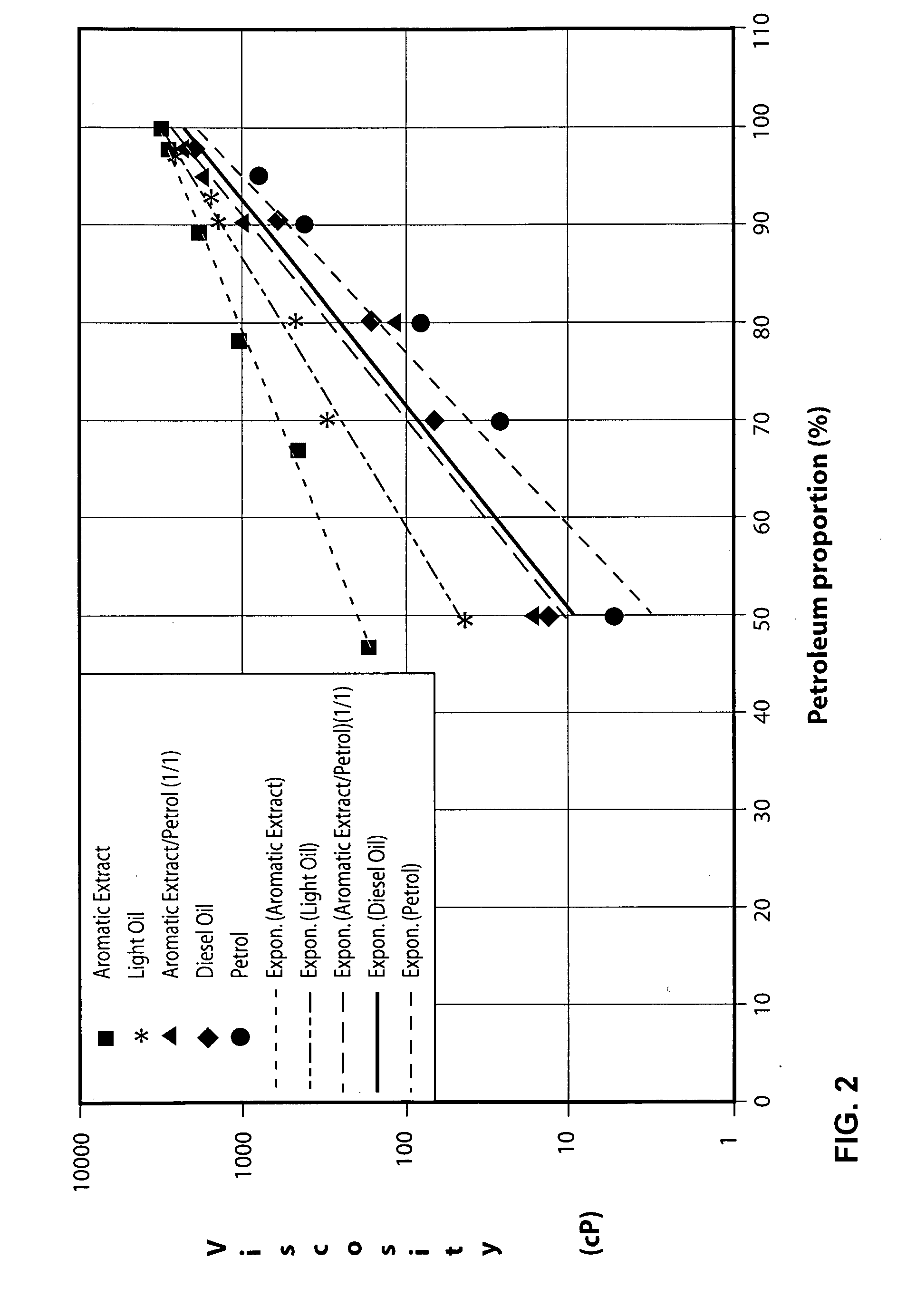

Sustainable method for recovery of petroleum

The present invention comprises a method of Enhanced Petroleum Recovery (EPR) combining technical, economic, environmental and social effectiveness to increase the recovery factor of onshore or offshore fields having a high degree of exploitation, more precisely through the use of a substance miscible with the diverse types of petroleum of low fluidity found in various regions. More specifically, the present invention refers to the use of solvents such as light liquid fractions of petroleum, for example diesel oil and gas oil, a light petroleum, and the essential oils derived from renewable sources such as for example biodiesel, used pure or mutually admixed in any proportion, for injection into a geological formation through an injection well, there resulting a final mixture (petroleum / injected solvent) presenting much lower viscosity and much greater fluidity than the original petroleum, having an impact throughout the petroleum production chain. The present patent presents real gains in all phases of the production chain.For the purposes of the present invention biodiesel is understood to be oil having characteristics similar to diesel produced from mineral sources, however having been produced from renewable sources, usually agricultural sources.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Sesame white spirit and preparation method thereof

InactiveCN105062748ALong aftertasteHas the effect of black hairOrganic active ingredientsAlcoholic beverage preparationSnow moldLactarius

The invention discloses sesame white spirit and a preparation method thereof. The sesame white spirit is prepared from the following raw materials in parts by weight: 400-450 parts of waste distiller's grains, 100-110 parts of rice, 100-110 parts of chaff, 10-11 parts of enteromorpha, 20-22 parts of sesame, 3-4 parts of the root of polygonum multiflorum, 2-3 parts of semen cuscutae, 4-5 parts of cornu cervi pantotrichum, 4-5 parts of the fruits of Chinese wolfberry, 25-30 parts of yeast for making hard liquor, 0.5-1 part of tea polyphenol, and 0.5-0.7 part of xylo-oligosaccharide. According to the sesame white spirit and the preparation method thereof, the waste distiller's grains are taken as the raw material for preparing the white spirit, so that the production chain of a yellow rice wine plant is extended, and the prepared white spirit is mellow and plump, and long in aftertaste; the chaff is subjected to puffing treatment, so that the raw material is loose; the tea polyphenol with selective bacteriostatic action is added, so that bacteria, such as lactic acid bacteria, capable of generating acid is inhabited, while bacterial colony balance of fungi, such as mould, is maintained, and therefore, the problem that the acid content of the fermented materials increases rapidly during stacking and fermenting is solved; the added xylo-oligosaccharide can protect the liver, and in addition, the sesame white spirit also can black hair.

Owner:ANHUI YUNJIU GRP

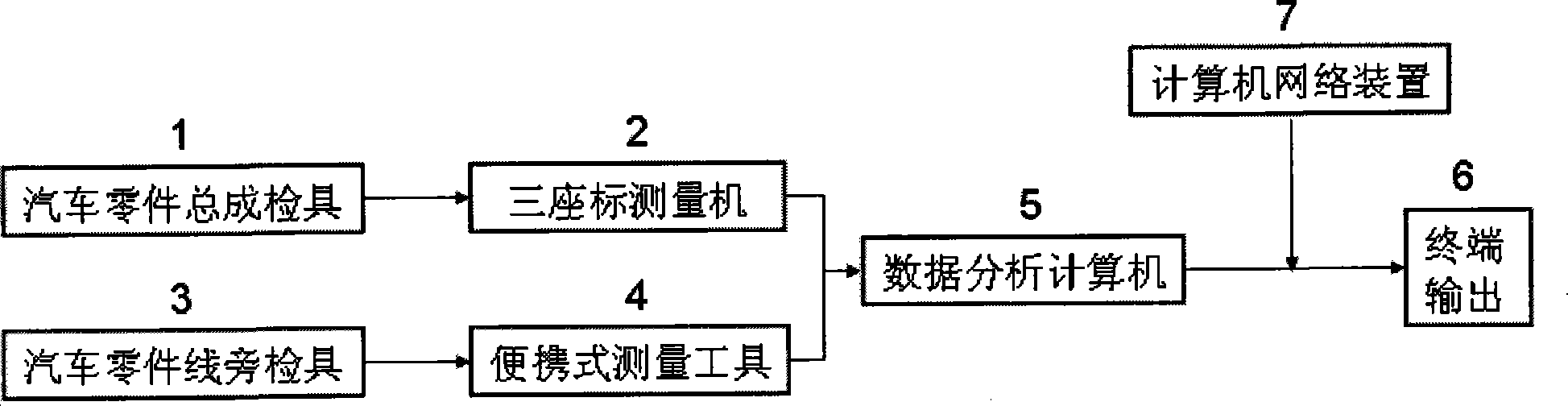

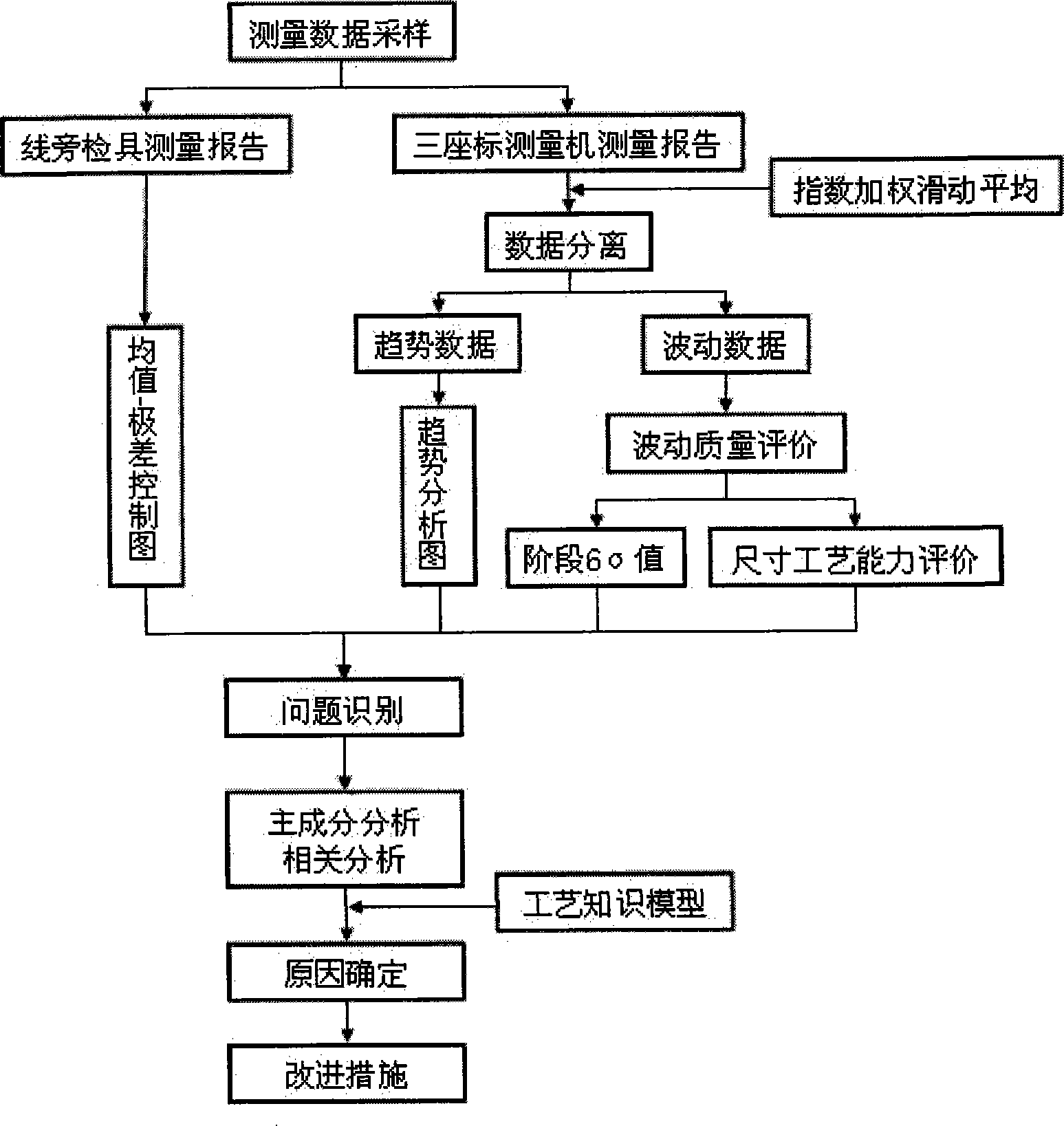

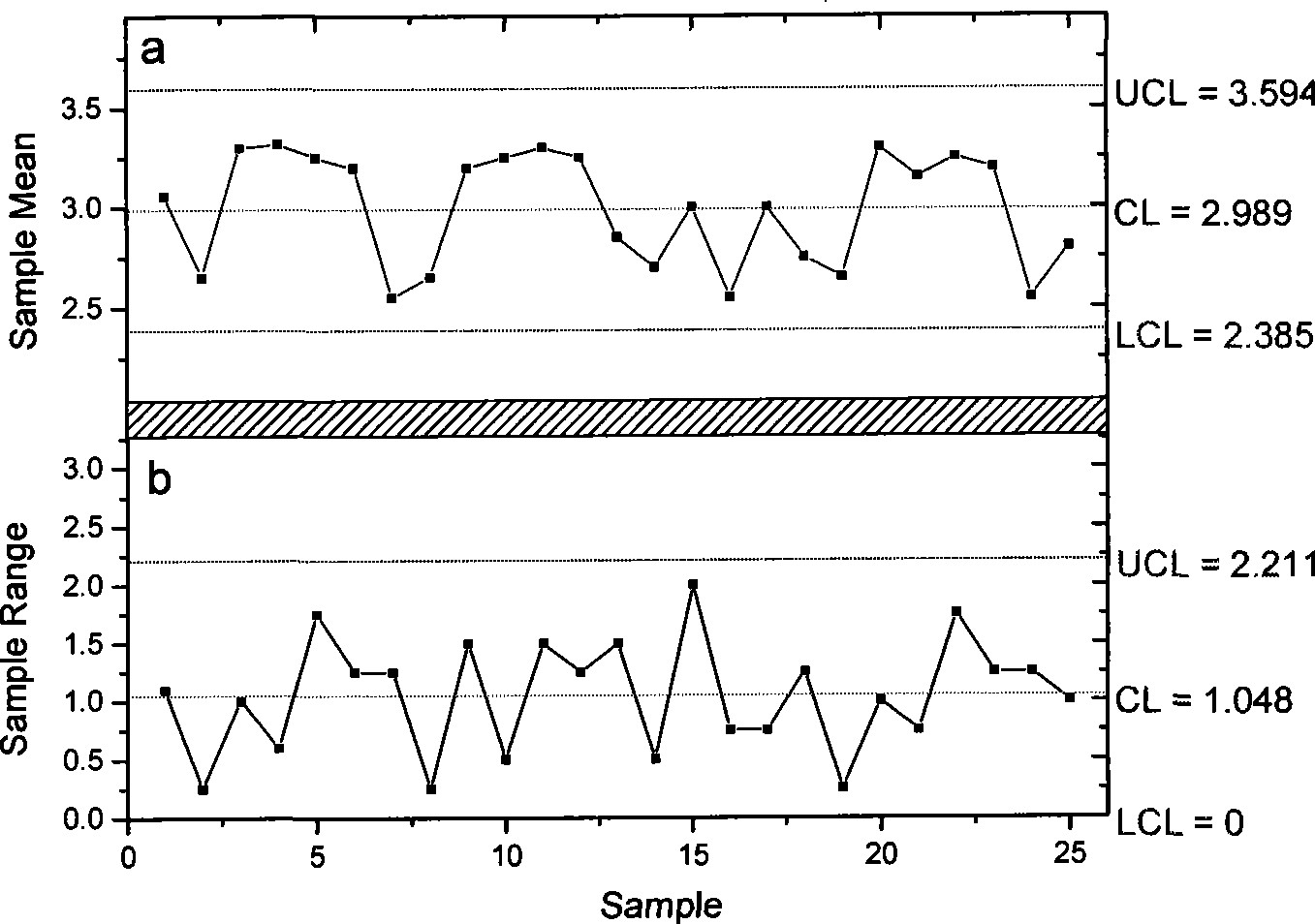

Vehicle element size quality control system and method

InactiveCN101246369AImprove efficiencyHigh precisionMeasurement devicesTotal factory controlControl systemQuality control system

The invention relates to a auto components dimension quality control system and method for method comprising dividing components dimension quality supervising into lines side checking apparatus measuring control and off-line three coordinate measuring machine supervising. According to quality and control claim of product, the line side checking apparatus and off-line three coordinate measuring machine sample the product in different time and turn, detects the sample on detection apparatus or three coordinates checker and gather measuring data, analysis the measuring results and alarm in case of defect. The computer net device manages the defect components information found in data-handling procedure and provides to relative duty terminal. A plurality of terminals can be arranged in each zone in factory. The invention provides criterion for controlling and improving auto components dimension quality, is better than traditional method in efficiency and accuracy, and can efficiently evaluate, monitor and analysis the production chain state.

Owner:DONGHUA UNIV

Method of producing whole extinction polyester fiber

InactiveCN101054741AAbsolute Addition ReductionIncrease drapeMelt spinning methodsMonocomponent polyesters artificial filamentProduction linePolyester

The present invention relates to a process for preparing full-dull polyester fibres related to the field of production of synthetic fiber. Common semi-dull or optical polyester chip is selected as main raw materials for production, a composite spinning module of core-skin type or island -type is adopted to perform a melt spinning, the raw material slicers are split into two or more components, full-dull master batches are added only to one of the components during feeding, then conventional manufacturing technique of POY and DTY is utilized to work out full-dull polyester fibres. Said process not only reduces greatly the fabricating cost of full-dull polyester fibres due to that the absolute adding amount of master batch is substantially reduced; but also can effectively overcome spinning technological difficult problems in traditional master batch method, prolong the service lifetime of the prefilter and the spinning module. Therefore, without great reconstruction, the existent composite spinning production chain can be used for exploitation and production of full-dull polyester fibres and satisfies the higher requests of top grade loomages for lustrous surface improvement.

Owner:中国石化仪征化纤股份有限公司

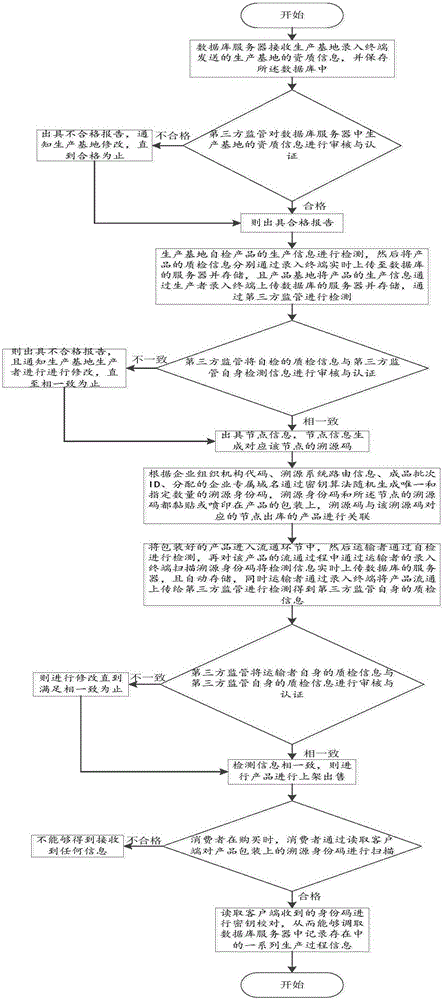

Product quality control traceability method

The invention provides a product quality control traceability method which is applied to a product traceability system. The product traceability system comprises input terminals and a server which is provided with a database which stores product information. The product information comprises the node information of a number of nodes in the whole product chain from raw materials to finished products. A number of input terminals are comprised. A number of steps are comprised, and audit and certification are carried out from production to circulation through third-party supervision. The data authenticity in product production and circulation is improved. The whole production process is effectively supervised. Unqualified agricultural products into the market are greatly reduced. The phenomenon of production chain reputation fall is avoided.

Owner:杭州维甄科技有限公司

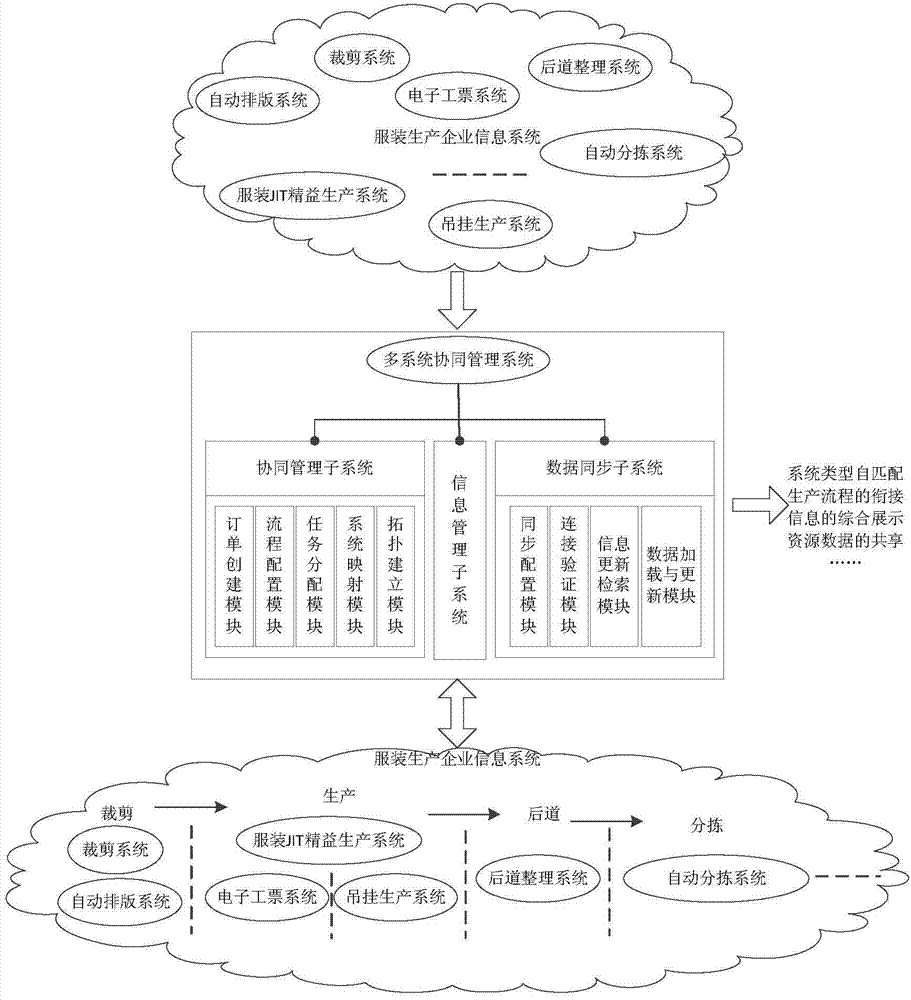

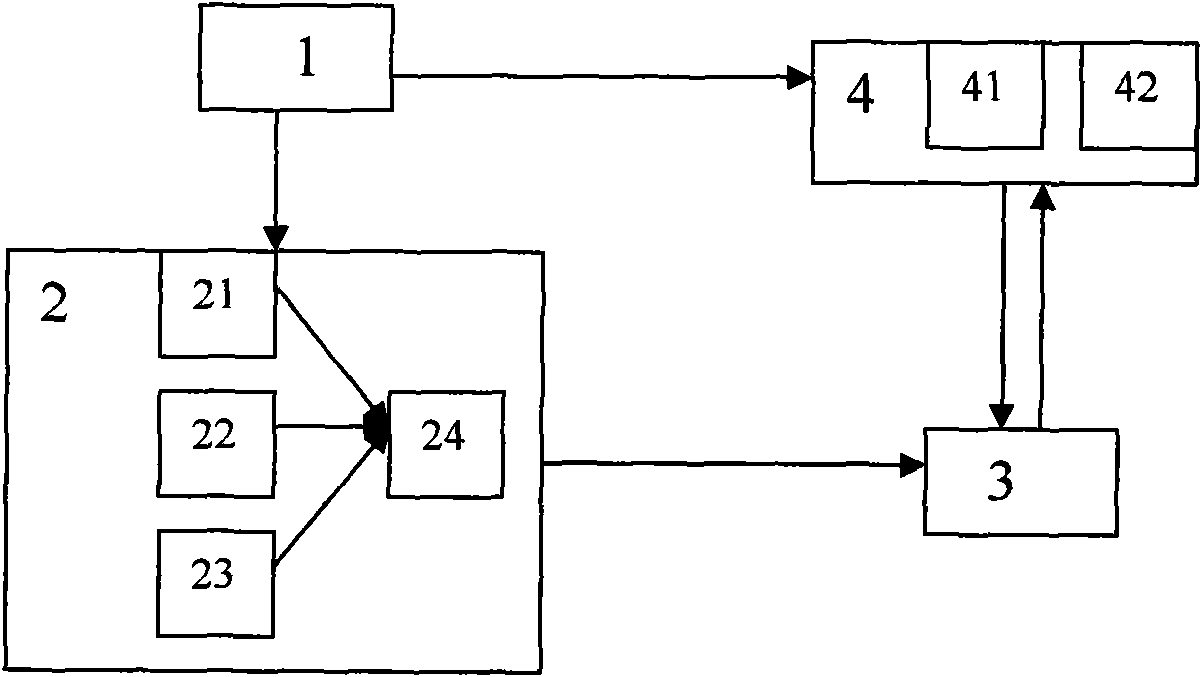

Multi-system cooperative system and method for production process control of discrete manufacturing enterprises

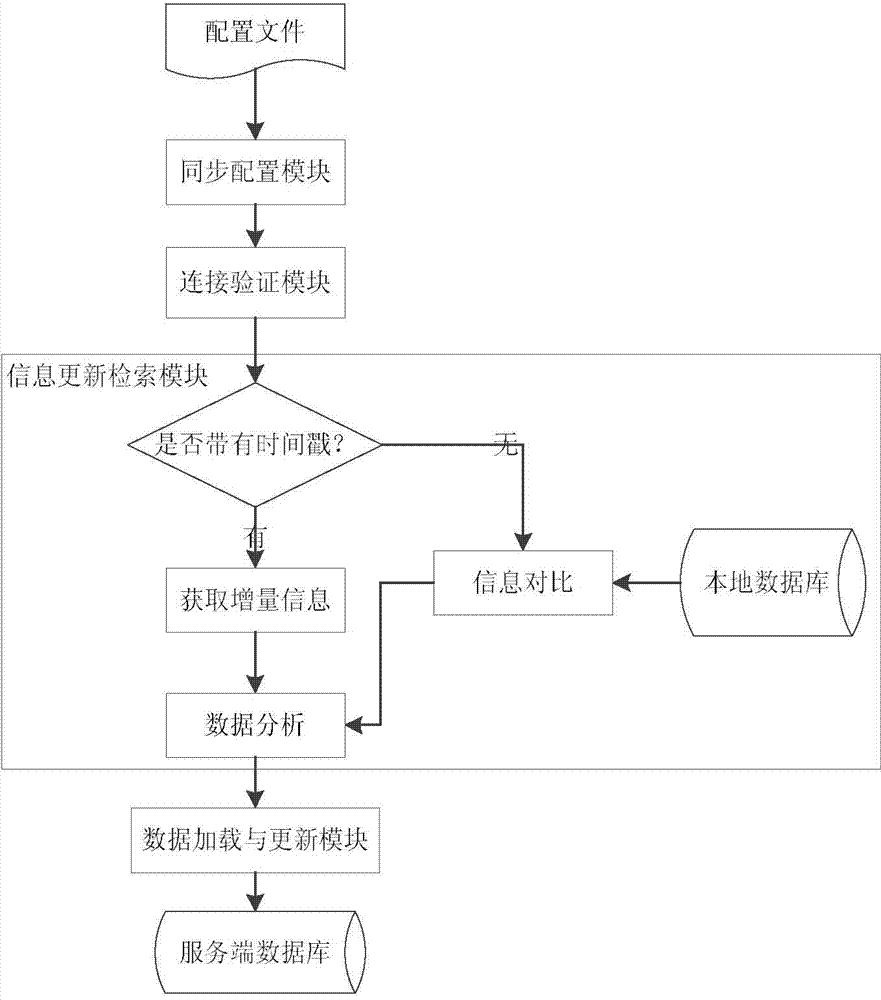

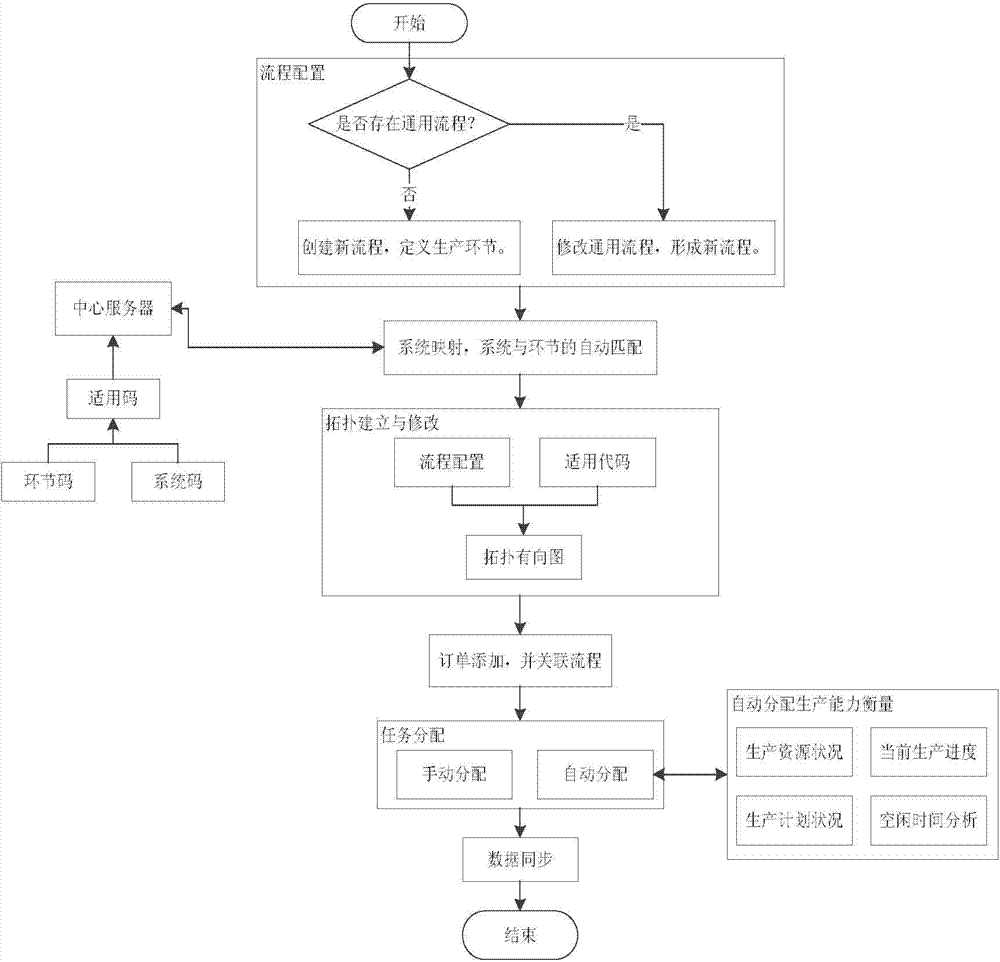

ActiveCN104331767AGet production dataImprove efficiencyResourcesManufacturing computing systemsData synchronizationProduction schedule

The invention discloses a multi-system cooperative system and method for production process control of discrete manufacturing enterprises. The multi-system cooperative system is used for cooperative work and data sharing of a production management system with multiple production chains during production, and comprises an information management subsystem, a cooperative management subsystem and a data synchronization subsystem. The multi-system cooperative method includes: configuring the process and defining the production chains; conducting system mapping to finish automatic correlation of the systems and the production chains; building topology, and displaying topology connection directed graphs of systems in real time according to the production process configuration and regular files; dynamically adjusting the topology relation and building a final connection directed graph of the production systems; adding orders and selecting corresponding production processes for the orders; distributing tasks; synchronizing and updating data and mastering the production schedule in real time. The multi-system cooperative system and method achieves organic interconnection and data sharing of independent systems through effective integration of the discrete systems, achieves smart production of the enterprises and improves the whole efficiency.

Owner:NANTONG MINGXING TECH DEV CO LTD +1

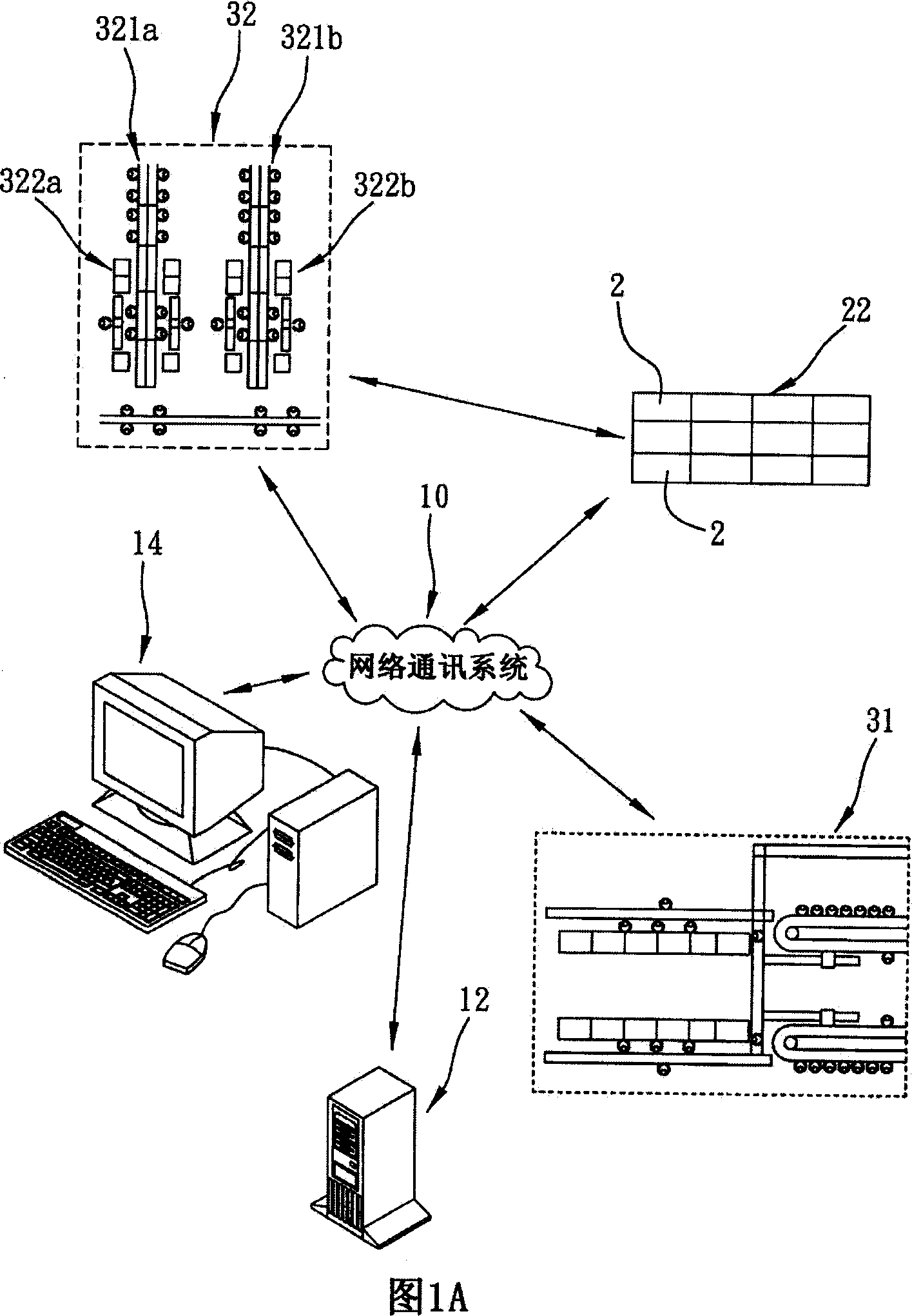

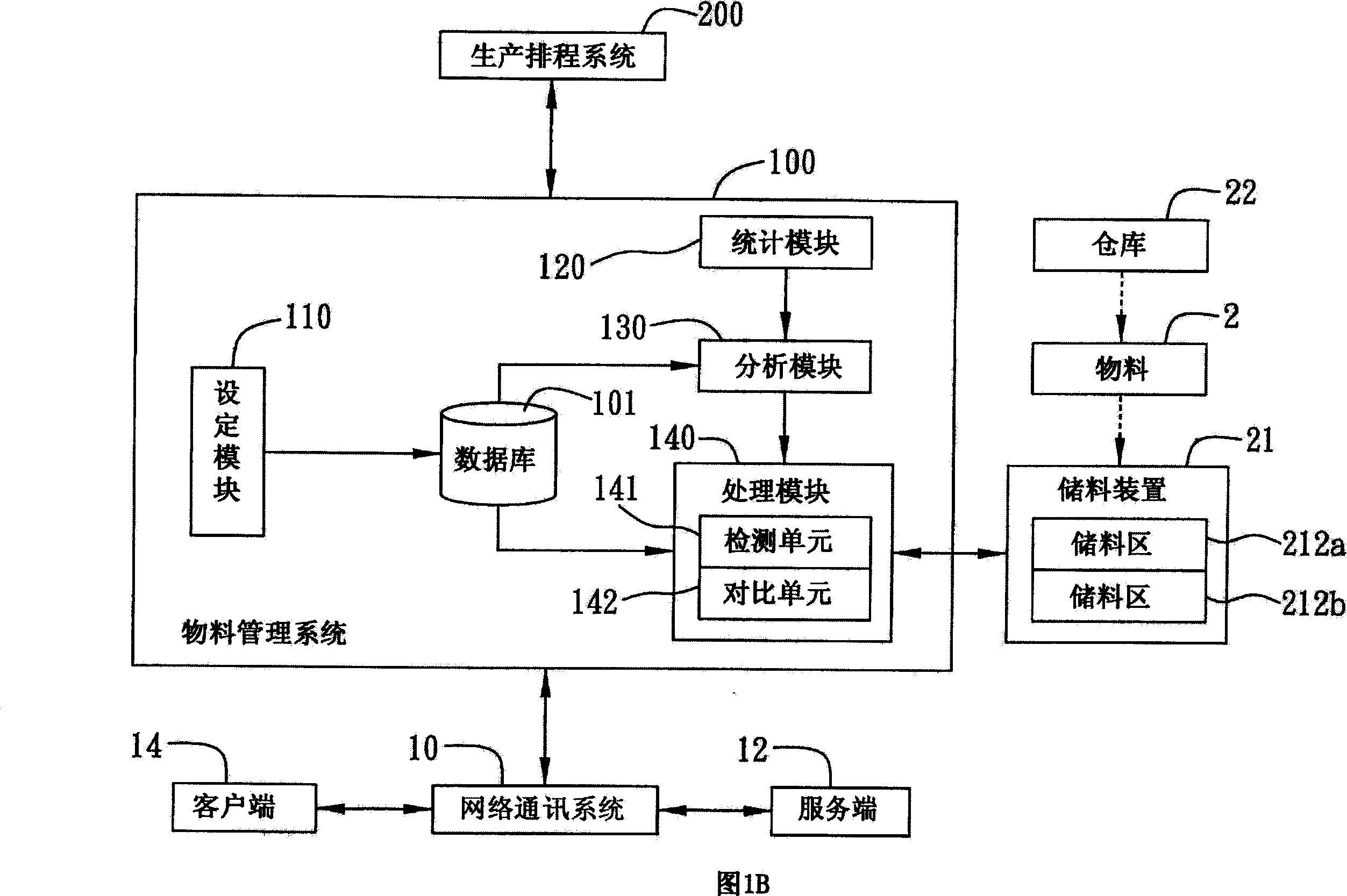

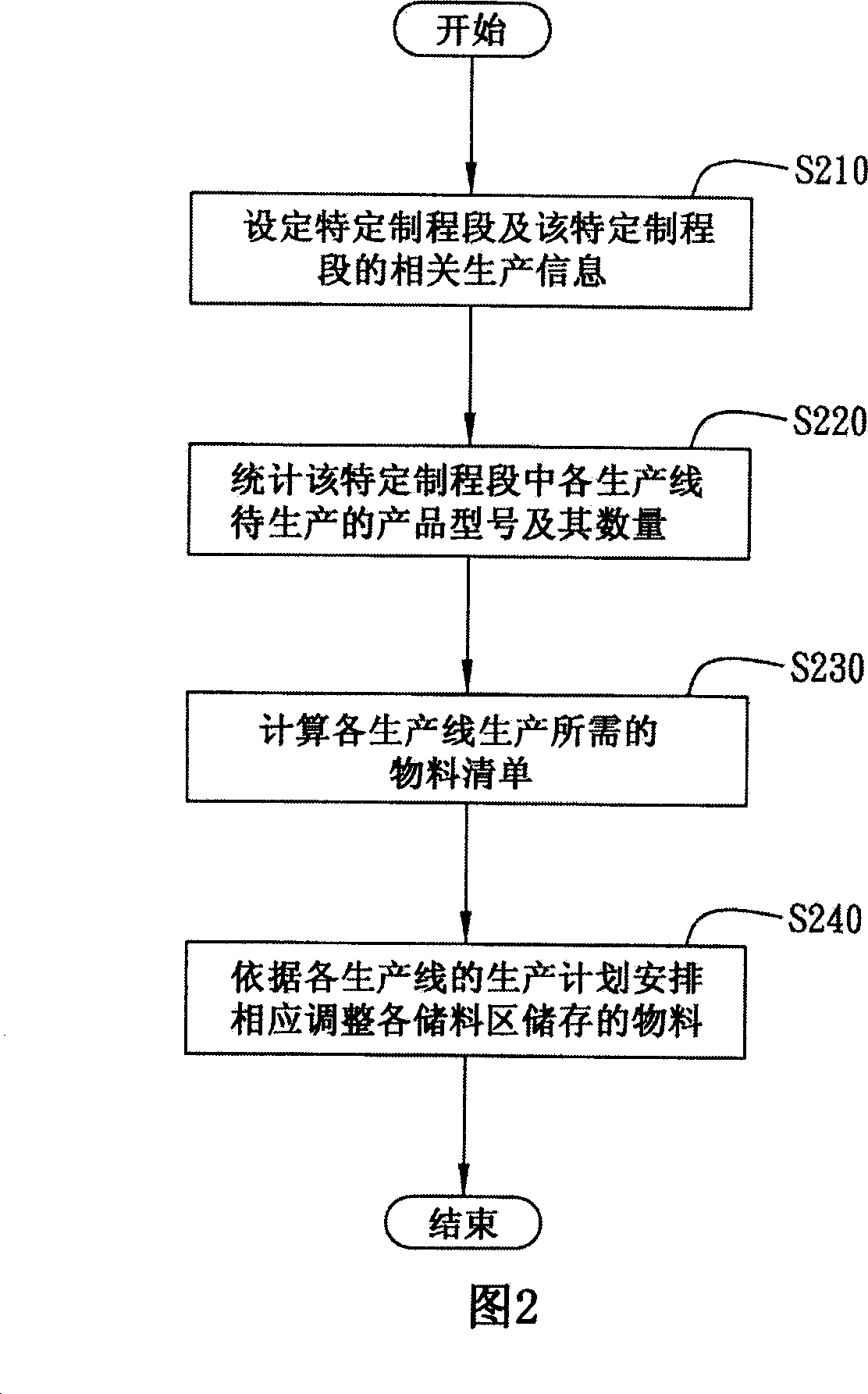

Material management method and system

InactiveCN1991876AImprove coherenceMeet a small amount of diverse production needsResourcesProduction scheduleProduction line

A material control method and system is applied in the production chain work management, the method includes steps as following: setting the process segment and material information needed in production cause; statistic the production schedule information material; generating the material demand information according to the set data of production schedule information material and material demand information; adjusting the stored material and executing the corresponding stock preparation. The material control system includes: setting module, statistic module, analysis module and processing module; the material control method and system is according to the production schedule of every production chain, managing the relative stock preparation dynamically, increasing the work consistency of adjacent process segment, increasing the real time and flexibility of stock preparation, improving efficiency of work.

Owner:INVENTEC CORP

Full-automatic assembly production chain of energy-saving lamp

InactiveCN101083190ANovel ideaReasonable process structure designSequential operation station machinesCold cathode manufactureProduction chainEngineering

The invention relates to the energy-saving lamp full automatic-assembly assembly line. It belongs to the energy-saving lamp manufacture equipment technology area. Its characteristic lies in that the rack intermediate deck coordinate installs the work piece conveying appliance by the transmission chain drive, the one output end of the decelerator which installs on the sublayer of the rack and connects the motor driver connects the dynamic major axis which coordinates the cam major axis driver, another output through the cam dismember coordinates to the work piece conveying appliance, above the work piece conveying appliance fit establishes automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment, compression moulding cam, soldering lamp base cam, dial nail cam which installs on the cam major axis separately connects the automatic compression moulding equipment, automatic soldering lamp base equipment, automatic dial nail equipment. The line flow has rational design, the automation pattern substitutes manual work, reduces the suggestion factor of the quality flaw, enormously raises the production efficiency and the product quality, creates the scale effect, take a foundation for promoting the enterprise brand image.

Owner:王佩诚

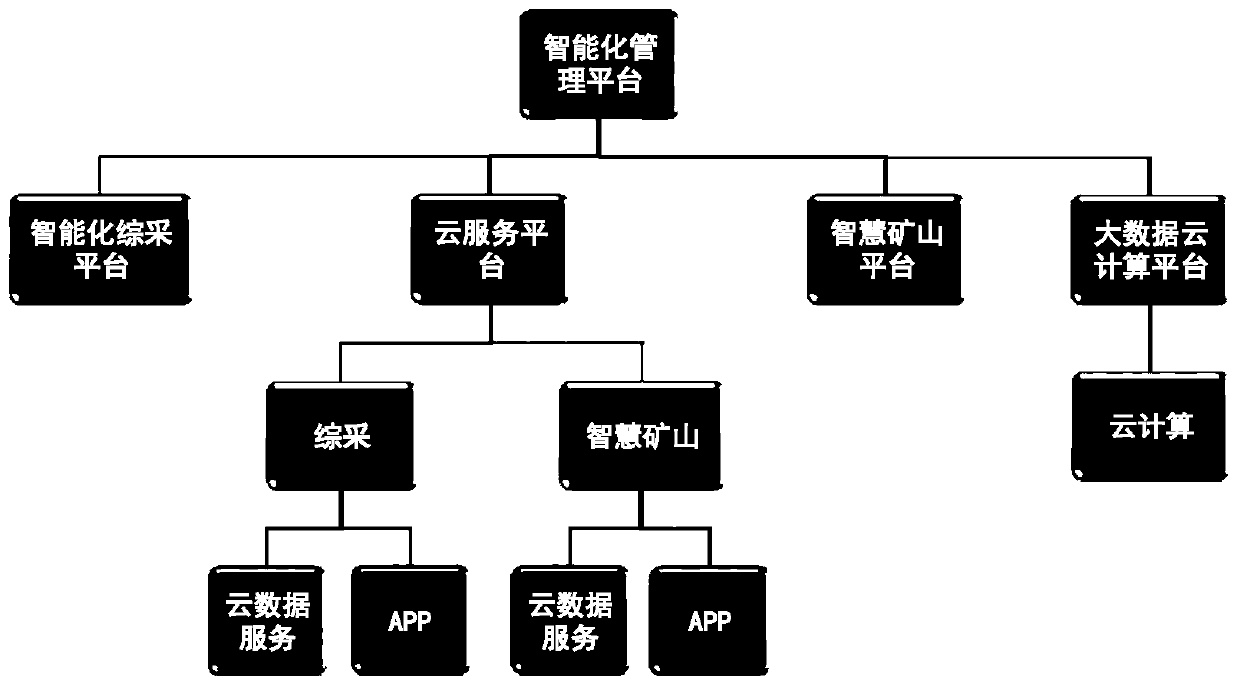

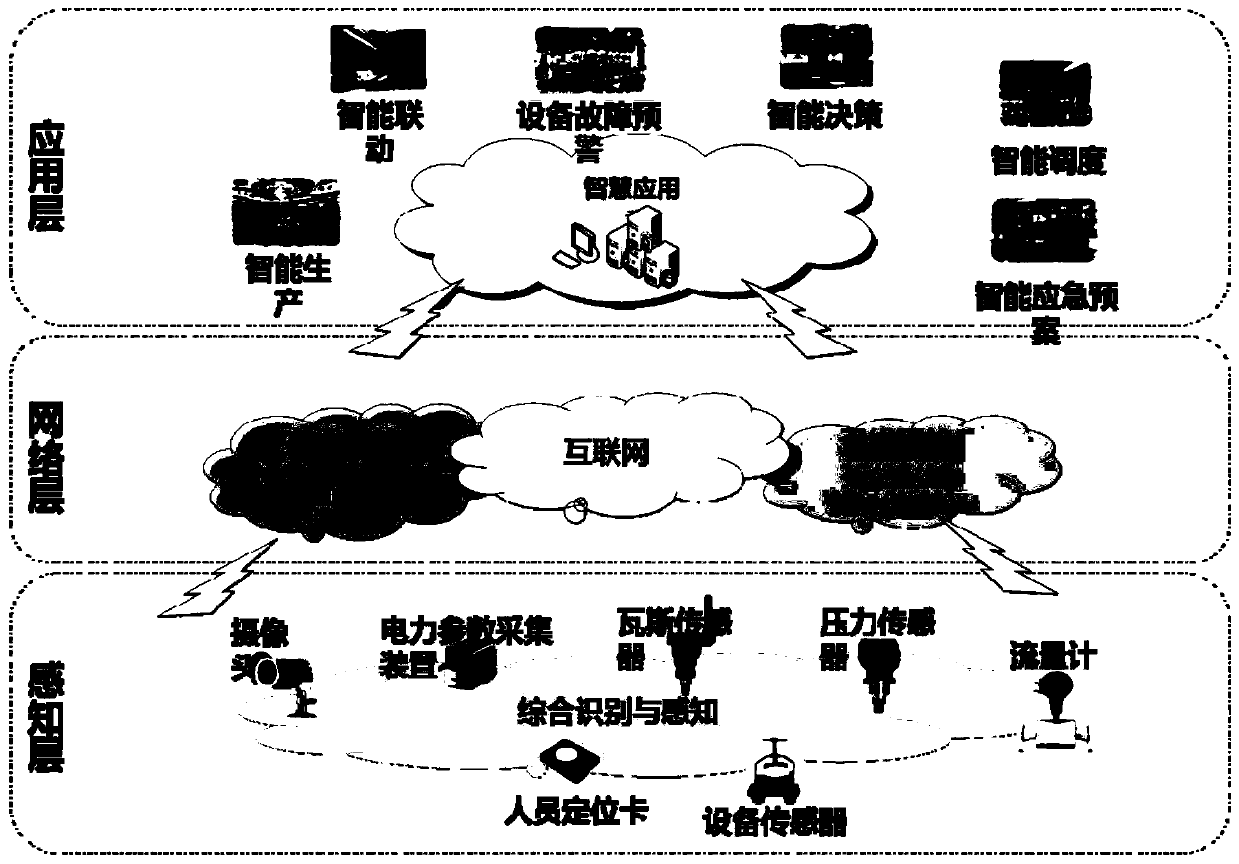

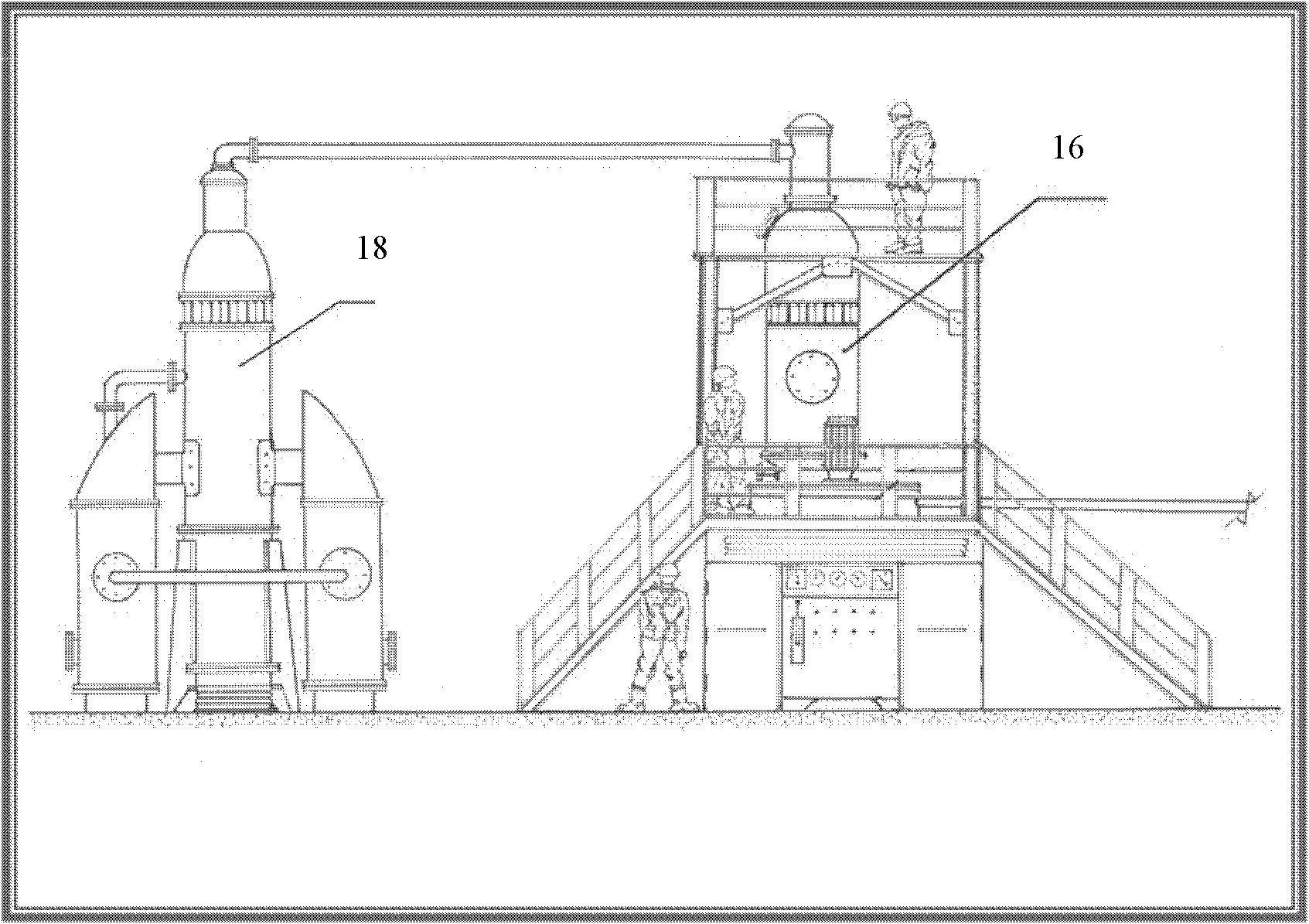

Intelligent control system for mine full-production chain

ActiveCN110568829AEnsure production safetyEnsure safetyResourcesTotal factory controlMobile endThe Internet

The invention an intelligent control system, particularly to an intelligent control system for a mine full-production chain, and belongs to the technical field of mine production. An intelligent management platform, an intelligent fully mechanized mining platform and an intelligent mine platform are combined; and based on centralized control, mobile application, the Internet of Things, cloud computing, big data and other technologies, the intelligent control system, in which real-time production monitoring, remote control, mobile command and intelligent decision management are integrated, forthe mine full-production chain is realized for the whole mine production and production auxiliary automatic system. The system can realize multi-level scheduling of managers and technical engineers, ensures the production safety, network safety and data safety of the whole production chain, working conditions of all system devices for coal mine production, auxiliary production and the like are monitored in real time at any time and any place via an under-well or ground PC terminal, a webpage or a mobile terminal, and scheduling management and decision command can be efficient.

Owner:西安合智宇信息科技有限公司

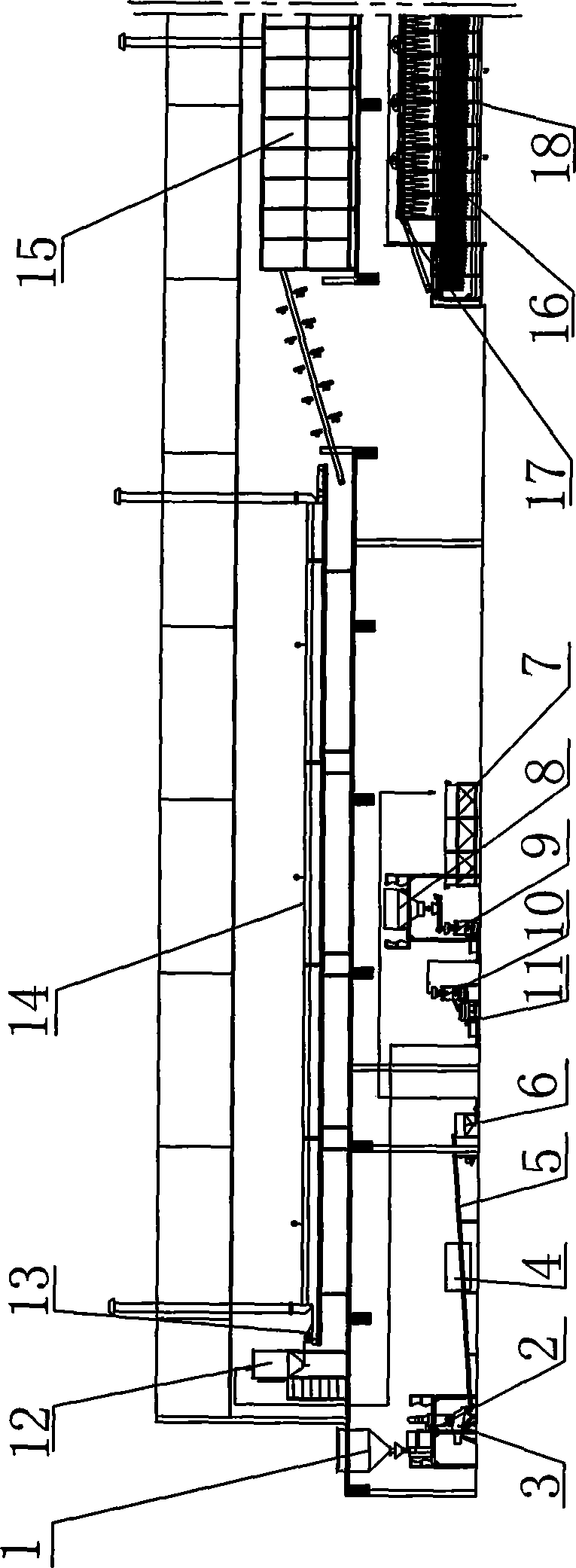

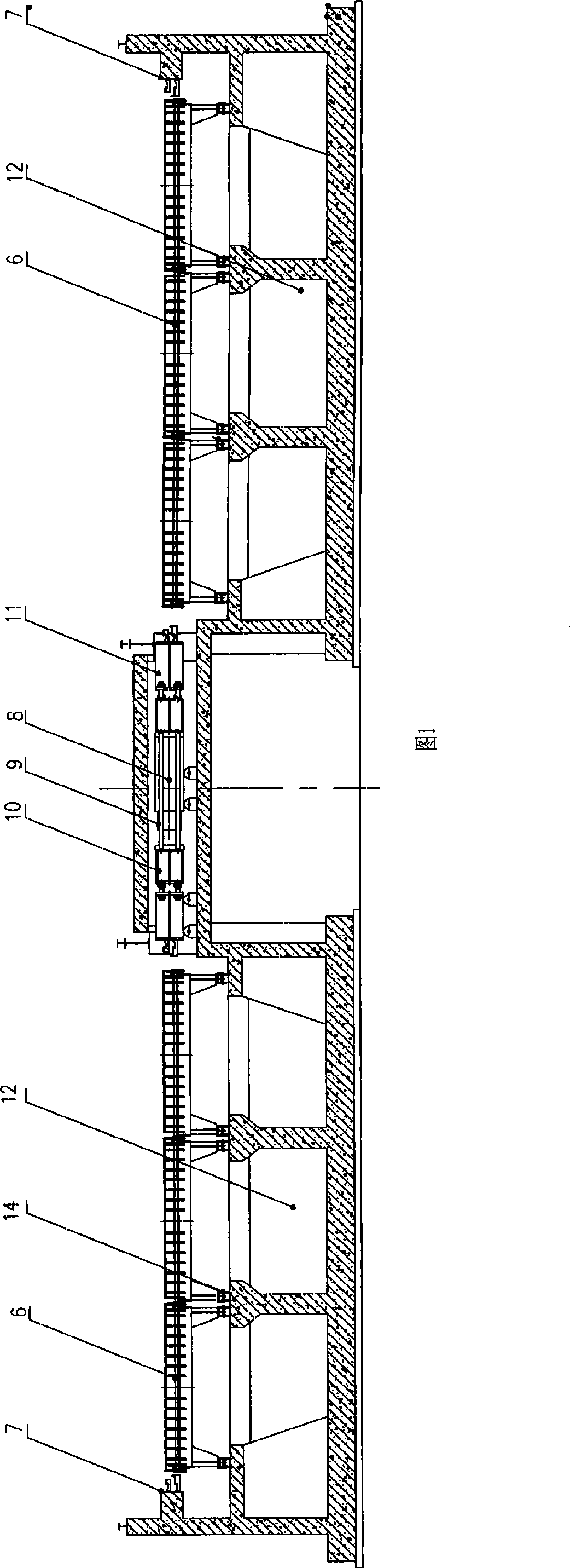

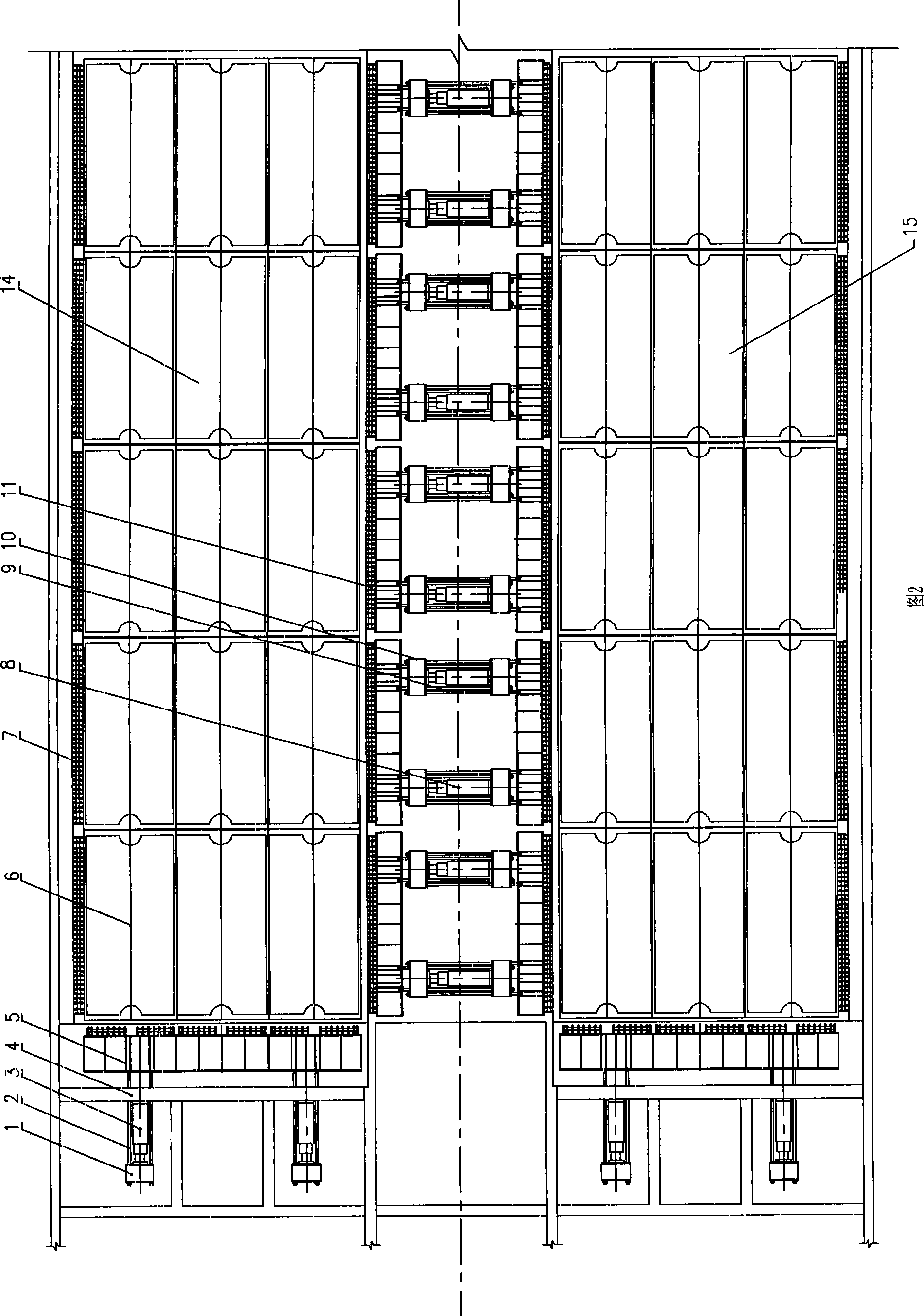

Bidirectional pre-tensioned rail plate long-surface pedestal production chain

InactiveCN101380777AReduce manufacturing costReduce displacementCeramic shaping plantsProduction lineProduction chain

A bidirectional pre-tensioned track board long surface pedestal production line comprises two symmetrically arranged production zones. Steel models are arranged in the production zones. Horizontal tensioning end beams and longitudinal tensioning end beams are respectively arranged on four edges of every production zone. A horizontal tensioning mechanism is arranged between the adjacent edges of the two production zones. Longitudinal tensioning mechanisms are respectively arranged on one lateral edge or two lateral edges of the two production zones. The horizontal tensioning mechanism comprises a horizontal tensioning jack. The two ends of the horizontal tensioning jack are respectively provided with horizontal tensioning small end beams. The horizontal tensioning small end beams on the two ends are respectively connected with the end beams on the adjacent edge of the other production zone in a transmitting way. The longitudinal tensioning mechanism comprises a longitudinal tensioning jack. A longitudinal tensioning small end beam is arranged on the external end of the longitudinal tensioning jack. The longitudinal tensioning small end beam is connected with the end beam on the adjacent edge of the production zone in transmitting way. The bidirectional pre-tensioned track board long surface pedestal production line greatly lowers the production cost and improves the production efficiency.

Owner:欧阳炎

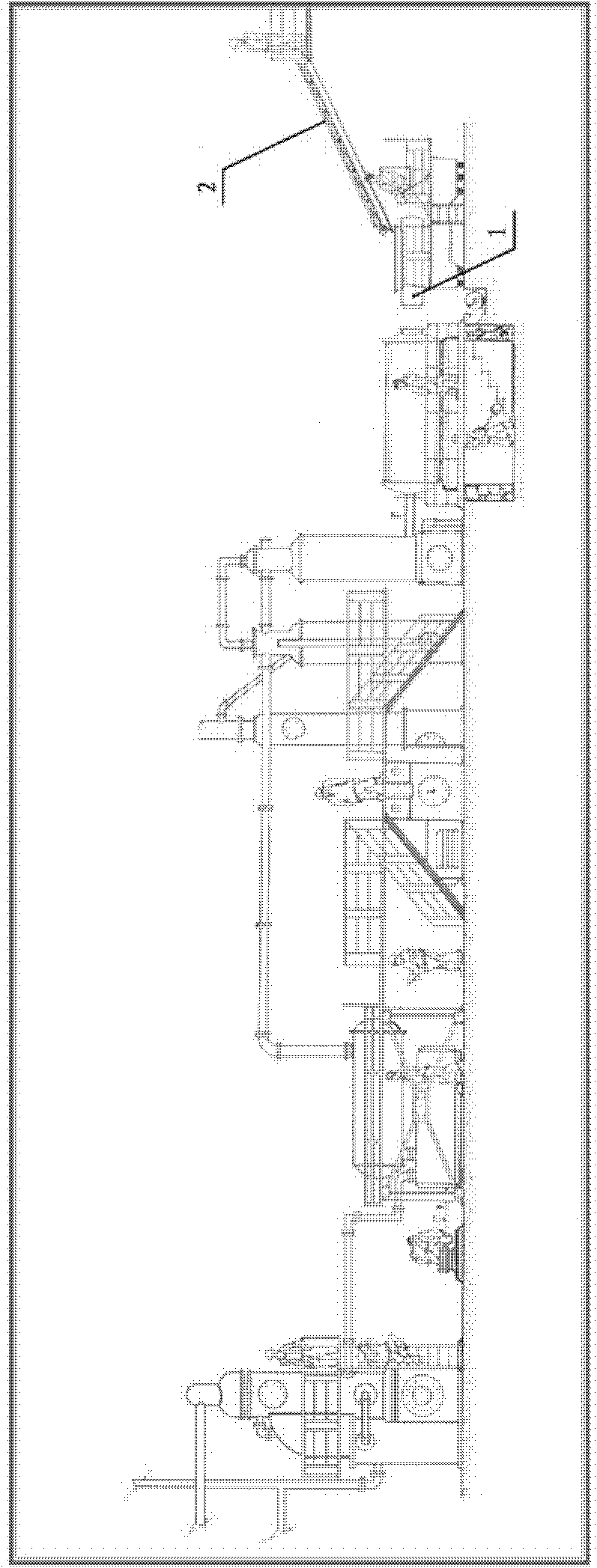

Production equipment for comprehensively utilizing renewable energy resources of waste and old plastics, tires and waste engine oil

InactiveCN101824332AAvoid secondary pollutionNo emissionsSolid waste disposalTreatment with plural serial stages onlyThermal energySlag

The invention discloses production equipment for comprehensively utilizing renewable energy resources of waste and old plastics, tires and waste engine oil, comprising main equipment, secondary equipment, tertiary equipment, a cracking furnace tail gas processing environment-friendly system, a reutilization system generating electric energy with combustible gases, a hot gas recovery system and an environmentally-friendly high-energy low-sulfur coal system which are matched mutually, thereby providing a complete set of the production equipment for comprehensively utilizing the renewable energy resources of the waste and old plastics, the tires and the waste engine oil. The equipment can relatively adequately utilize the renewable energy resources, circularly develops and utilizes slag and heat energy of water and gas, forms a circular environmentally-friendly production chain with considerable economical values and greatly changes the single function of the conventional equipment.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

Food security traceability visualized system

InactiveCN102737280ATo achieve the purpose of traceability managementGuaranteed visual controlData processing applicationsFood safetyCollection system

Disclosed in the invention is a food security traceability visualized system, comprising an RFID electronic tag, a product information collection system, a product information integrated management server and a visualized inquiring terminal. The RFID electronic tag is connected with the product information collection system through an electronicmagnetic wave; the output terminal of the product information collection system is connected with the product information integrated management server through a data bus or a network; and the visualized inquiring terminal is connected with the product information integrated management server through the network. According to the invention, a whole production chain, a whole supply chain and a storage environment of the food can be monitored, so that an objective of trace management on the food can be achieved; therefore, consumers and regulators can query on the security and the quality of the food everywhere at anytime.

Owner:HEFEI VRVIEW INFORMATION TECH

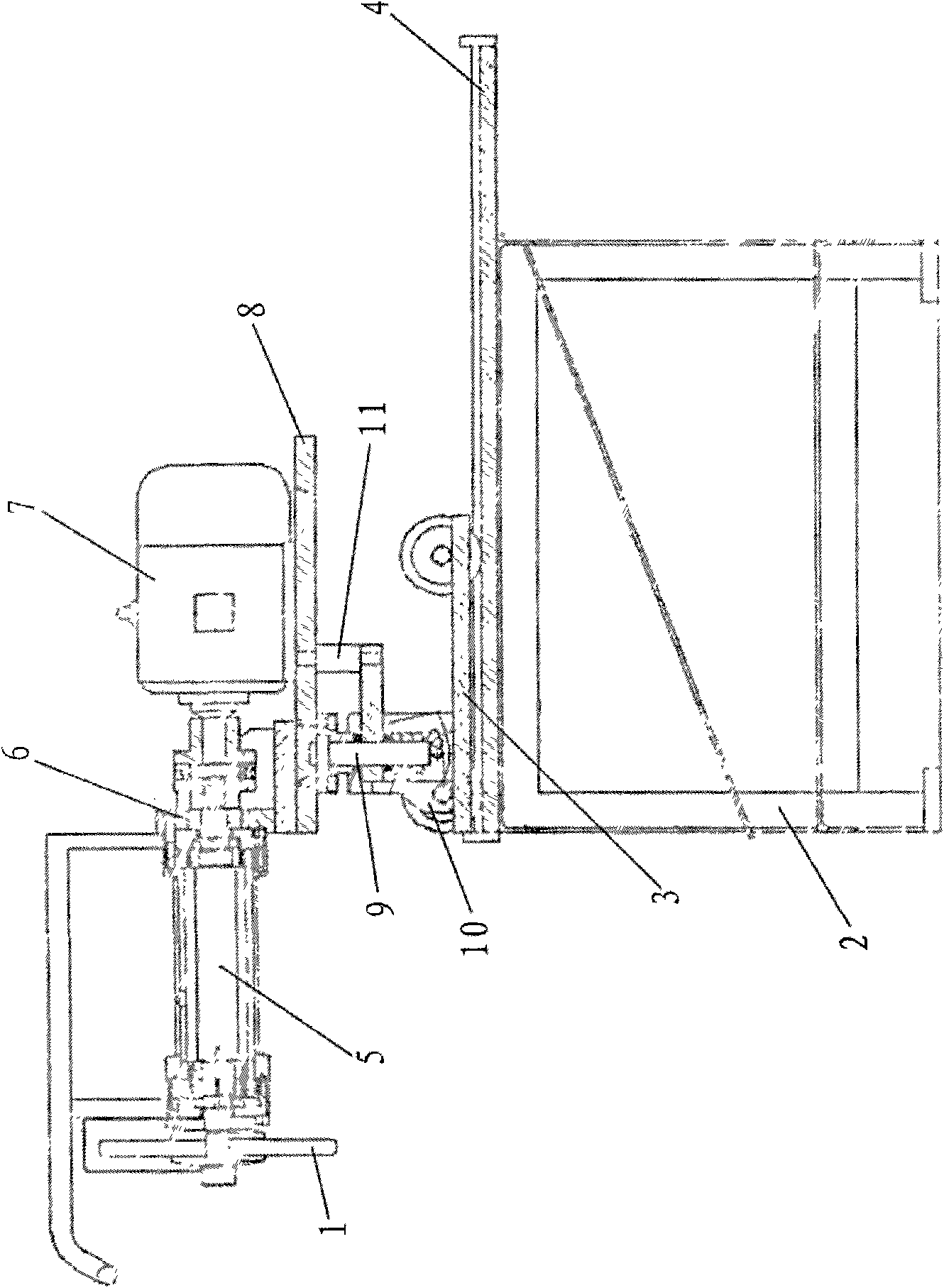

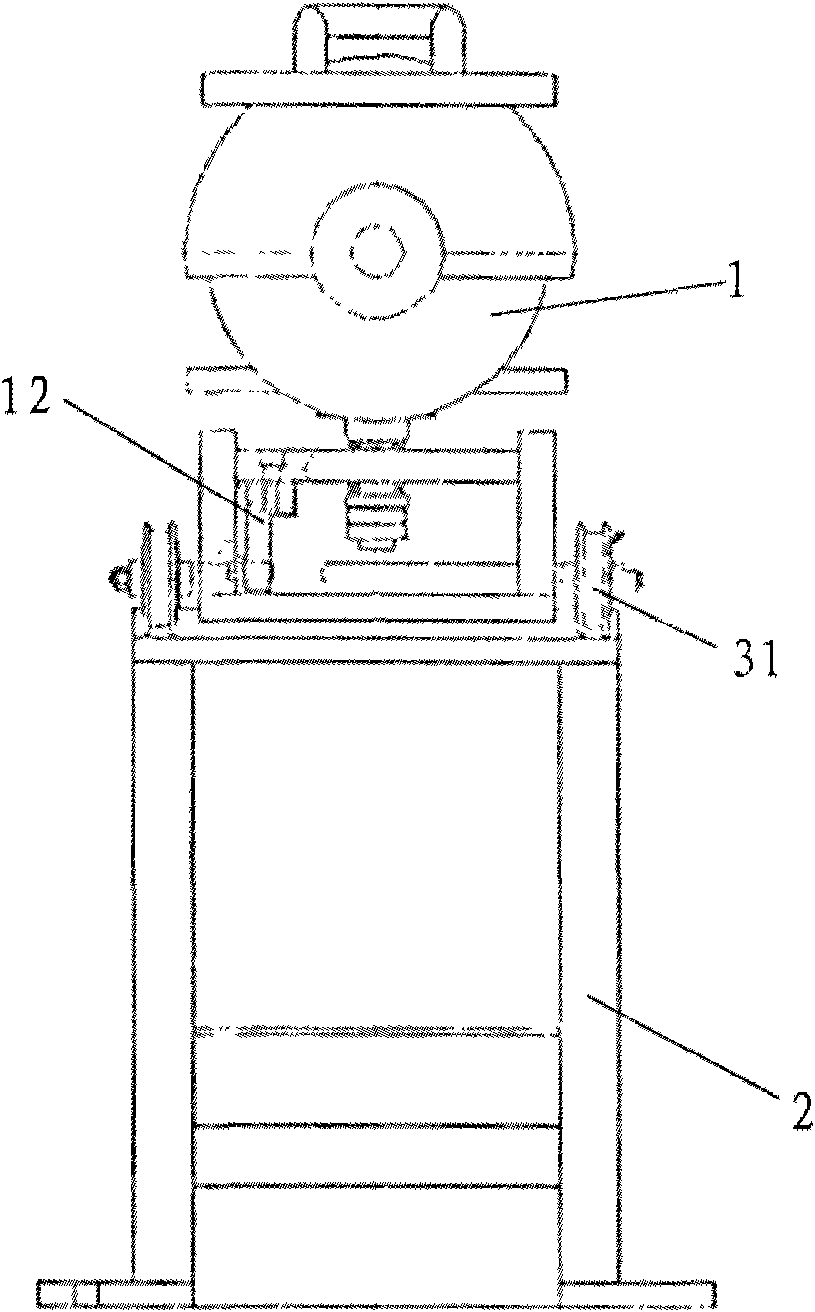

Section bar steel ring welding line sander

ActiveCN101564822AFully automatedGuaranteed appearanceEdge grinding machinesRevolution surface grinding machinesSanderProduction chain

The invention discloses a section bar steel ring welding line sander, which includes a frame, a steel ring positioning device and a sanding mechanism, wherein the sanding mechanism includes a linkage rod connected on the frame and an electric disc sander installed on the linkage rod, and the positioning device includes a longitudinal tackle installed in the track on the foundation and a chute rack hinged with the frame above the longitudinal tackle. The slide way rack is equipped with a positioning sliding block; the steel ring to be machined is placed between the longitudinal tackle and the chute rack, and moves forward along the chute rack; the longitudinal tackle is arranged in the chute, and can be used with steel ring production chain, thereby improving productivity effect and product quality, and is good for realizing automatic production of steel ring.

Owner:XIAMEN SUNRISE GRP

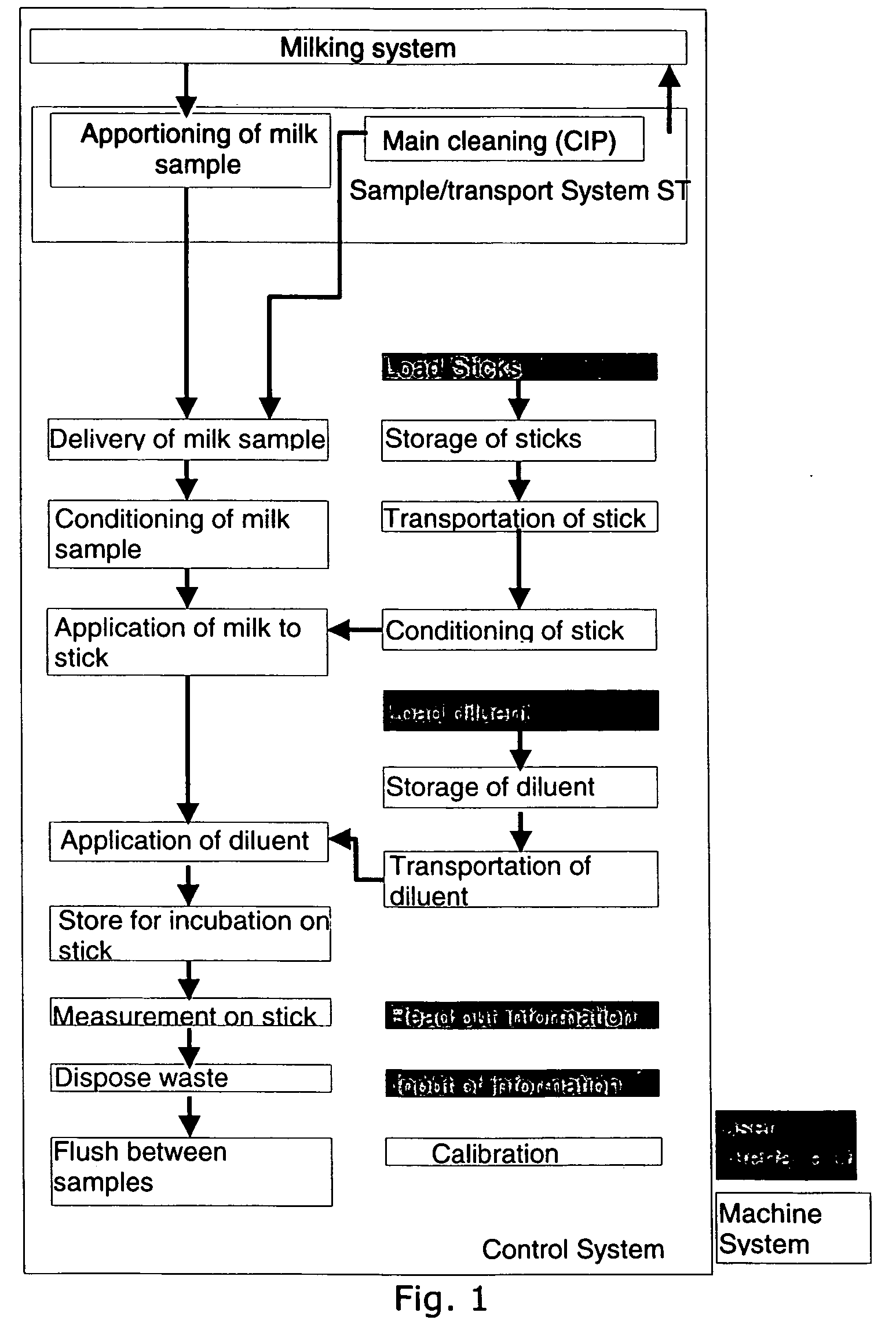

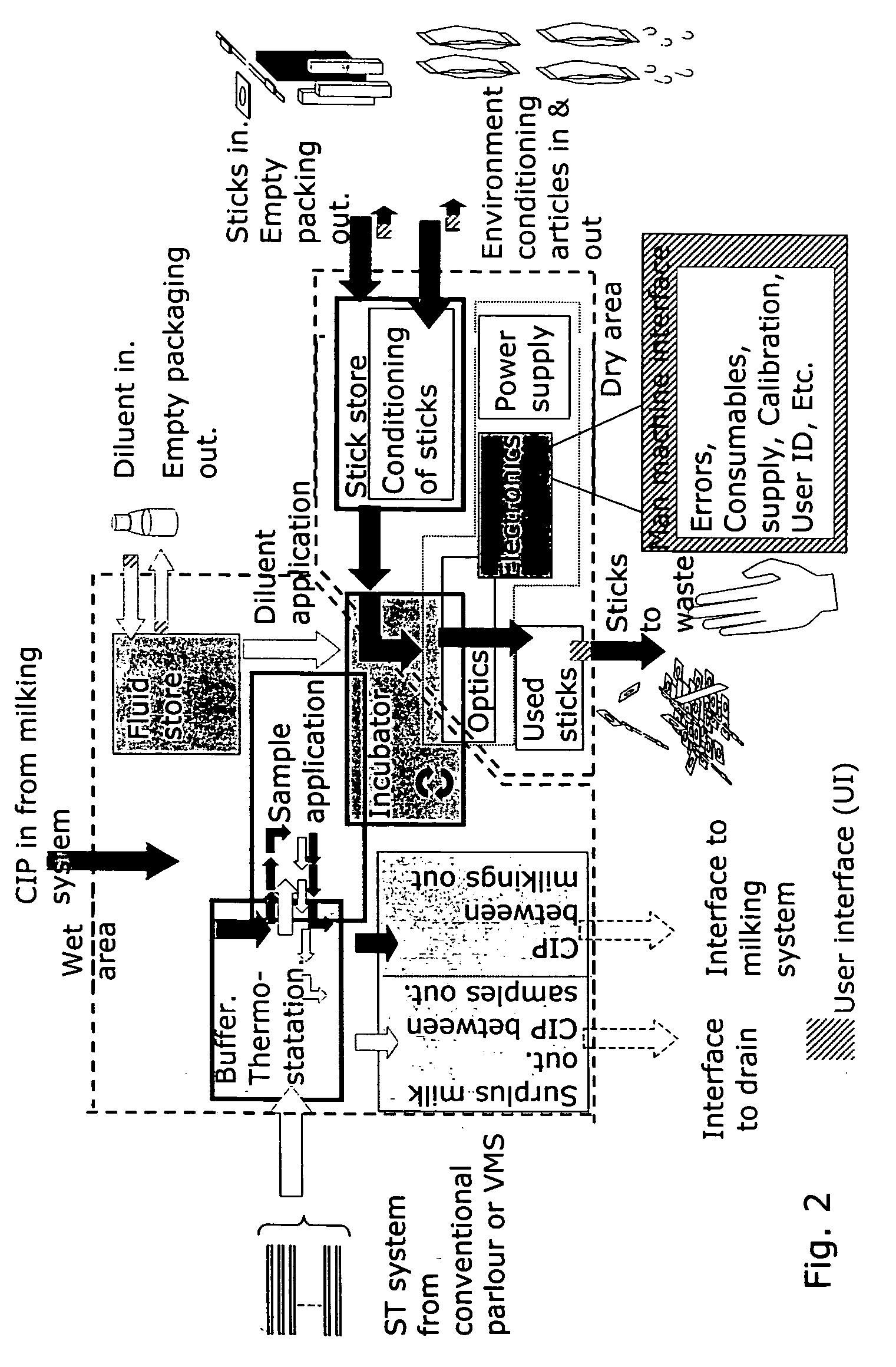

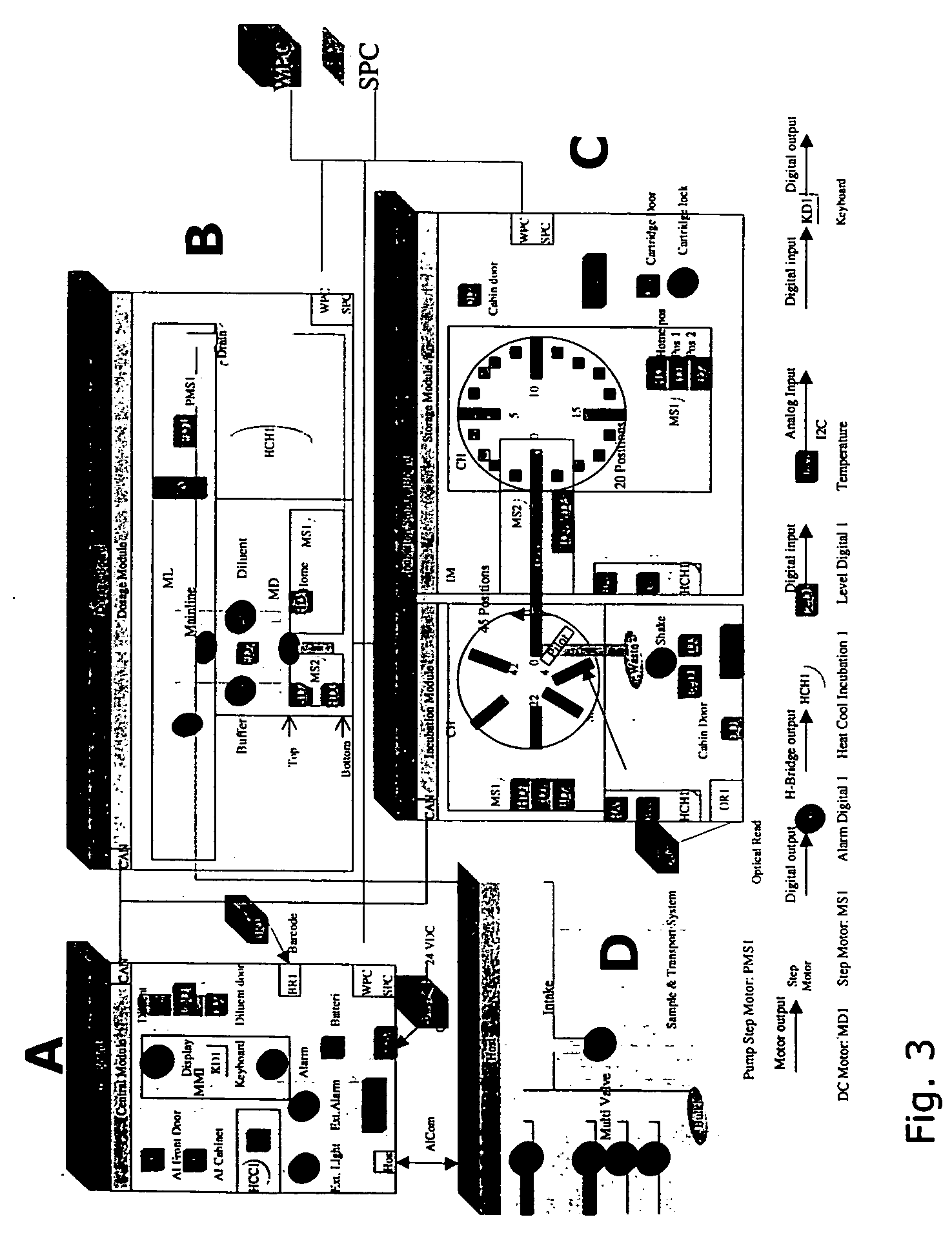

Apparatus for analysing fluid taken from a body

ActiveUS20050003522A1Minimize exchangeMinimize flow of heatBioreactor/fermenter combinationsBiological substance pretreatmentsMammalProduction chain

The present invention relates generally to an apparatus for analysing fluid taken from a body, and more in particularly for analysing body fluids from mammals. The analysis apparatus is coupled to a dairy system for milking of cows, wherein it may be useful to analyse the status of the milk. The apparatus is preferably located as early as possible in the production chain in order to obtain results as close as possible to the cows. Hence the environment in which the apparatus is to be used may be harsh towards internal apparatus modules or consumables, therefore the apparatus is isolated and the internal environment is conditioned regarding humidity, temperature as well as the amount of ammonium. Furthermore the steps for analysing milk is automated inside the apparatus in order to avoid influence from the external environment.

Owner:LATTEC

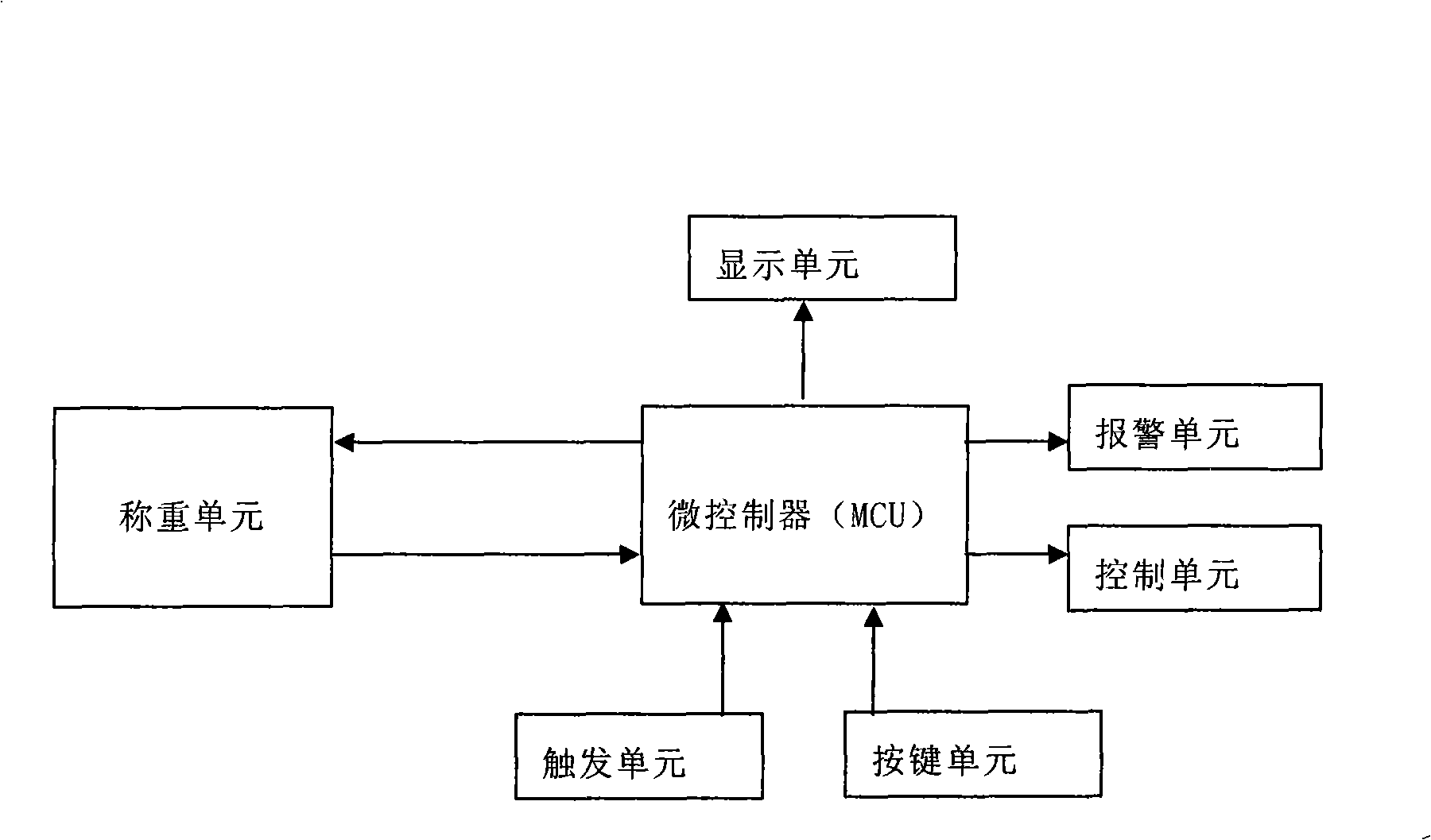

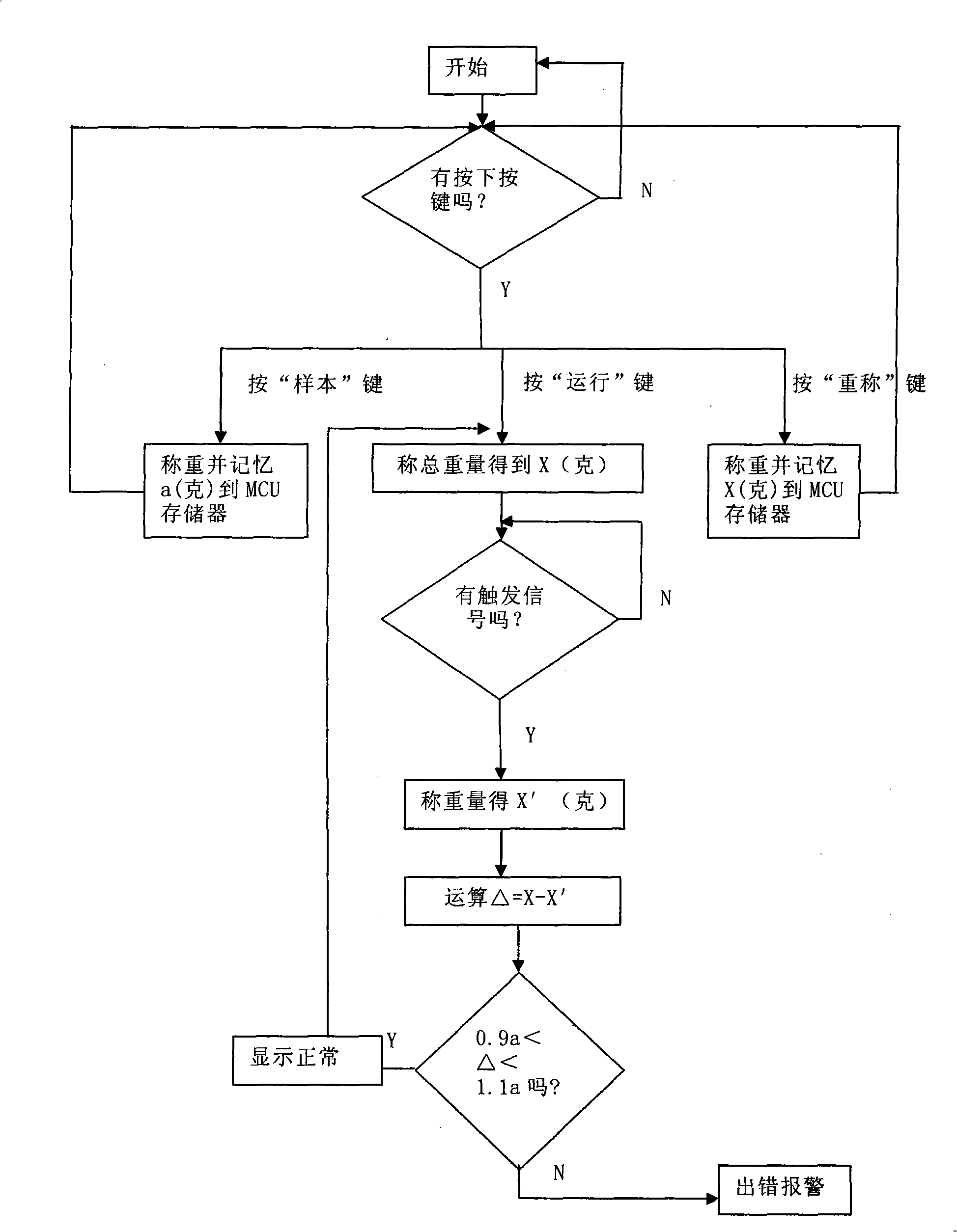

Method for detecting left parts and device thereof

The invention discloses an apparatus for testing accessories leakage, including a weighing unit, a microcontroller MCU connected to the weighing unit, a triggering unit connected to the microcontroller, a key-press unit for executing man-machine dialog, and a control unit controlled by the microcontroller MCU to control the production chain. The weighing unit is used to weigh and count the accessories, adding accessories to the production chain are strictly controlled, few or more accessories placing will alarm, pause the production chain operation until the manual handling falls to normal, then the production chain will operate again.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Symbiotic culture method of shrimp, soft-shelled turtle and rice

InactiveCN103749222AImprove the breeding effectImprove the level of farmingClimate change adaptationPisciculture and aquariaFecesPrawn

A symbiotic culture method of shrimps, soft-shelled turtles and rice comprises the following steps: (a) selecting five or more mu rice fields as a feeding pool of shrimps and soft-shelled turtles, ditching on the periphery of the feeding pool and arranging soft-shelled turtle escape-proof devices on the edges of the ditches at the depth ranging from 80 to 120 centimeters, wherein the percentage of the ditches in the feeding pool is ranging from 20% to 30% per mu; (b) sowing rice seeds in June with the density of rice transplanting ranging from 70% to 80% and managing the rice fields in a conventional way after rice transplanting until the rice is harvested in the first ten-day period of November; (c) breeding shrimp species in a free-range manner, particularly putting shrimps with shrimp eggs weighing 1 to 1.5 kilograms per mu in the rice fields in May and putting baby shrimps weighing 5 to 7.5 kilograms per mu in the rice fields in July; (d) breeding soft-shelled turtle species in a free-range manner, particularly putting in 15 to 25 baby soft-shelled turtles weighing 125 grams to 175 grams per mu in the rice fields in April, collecting and enabling the soft-shelled turtles to come into season at the Spring Festival. The symbiotic culture method of shrimps, soft-shelled turtles and rice is a kind of recycling economy and an environmental-friendly cultivation technique in a high-quality and efficient environment. Accordingly, freshwater shrimps are fed in the rice fields, soft-shelled turtles are put in a shrimp feeding pool, the shrimps eat injurious insects in the rice fields, the soft-shelled turtles eat baby shrimps bred by the shrimps and feces of the shrimps are absorbed by the rice. The symbiotic culture method is a high-quality, efficient and clean culture production chain.

Owner:浙江吴越农业股份有限公司

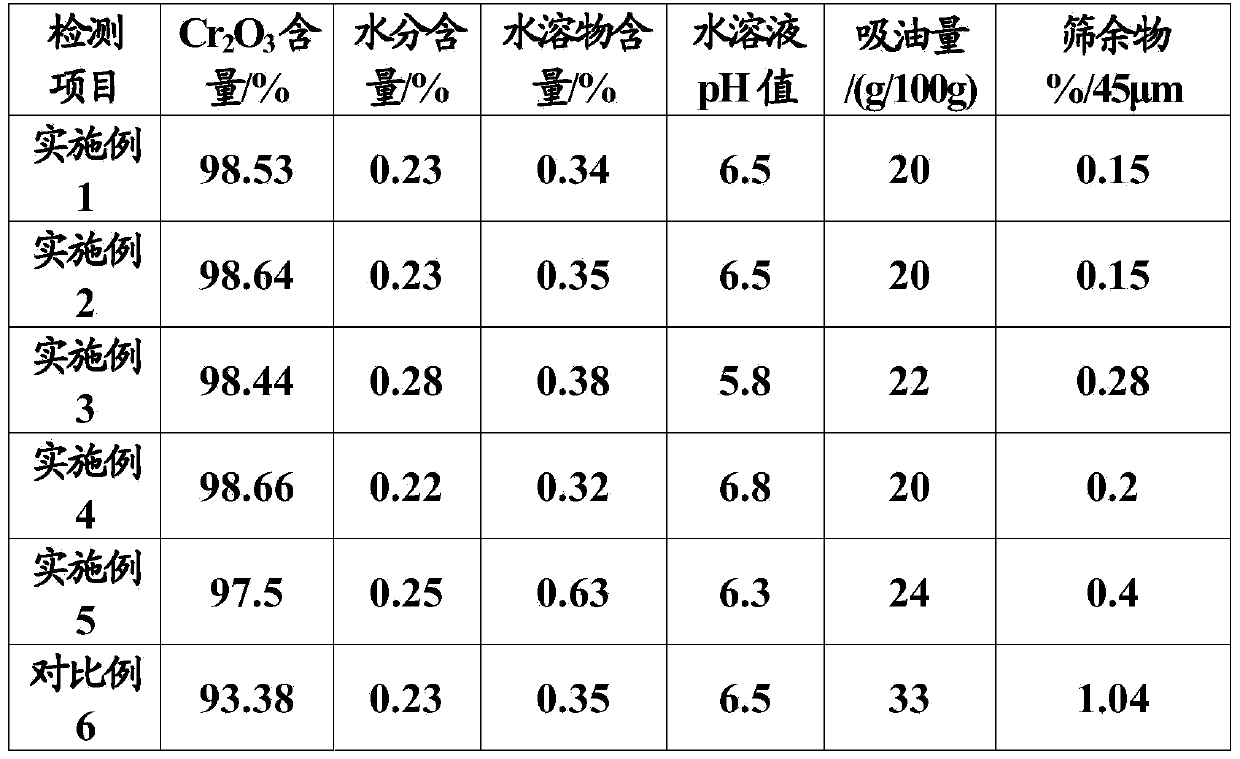

Method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green

ActiveCN103613133AReduce COD valueEfficient disposalMultistage water/sewage treatmentChromium oxides/hydratesLiquid wasteNaphthoquinone

The invention relates to a method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green. The method comprises the following steps: a) carrying out liquid phase reaction between the naphthoquinone production liquid waste and the vitamin K3 production wastewater at 80-260 DEG C, wherein the naphthoquinone production liquid waste is excessively used relative to a necessary dosage of complete reduction; b) adding a reducing agent into the obtained reaction mixture to reduce the residual hexavalent chromium; c) regulating the pH of the obtained reaction mixture to 5.5-8.5 to separate out chromium hydroxide, and separating to obtain the chromium hydroxide and filtrate; and d) transforming the chromium hydroxide obtained in the step c) into chromium oxide green. The method can be used for effectively treating the naphthoquinone production liquid waste and the vitamin K3 production wastewater generated in a vitamin K3 production chain and recycling effective components in the liquid waste to turn waste into wealth and improve the economic and environmental protection benefits at the same time.

Owner:绵阳市安剑皮革化工有限公司

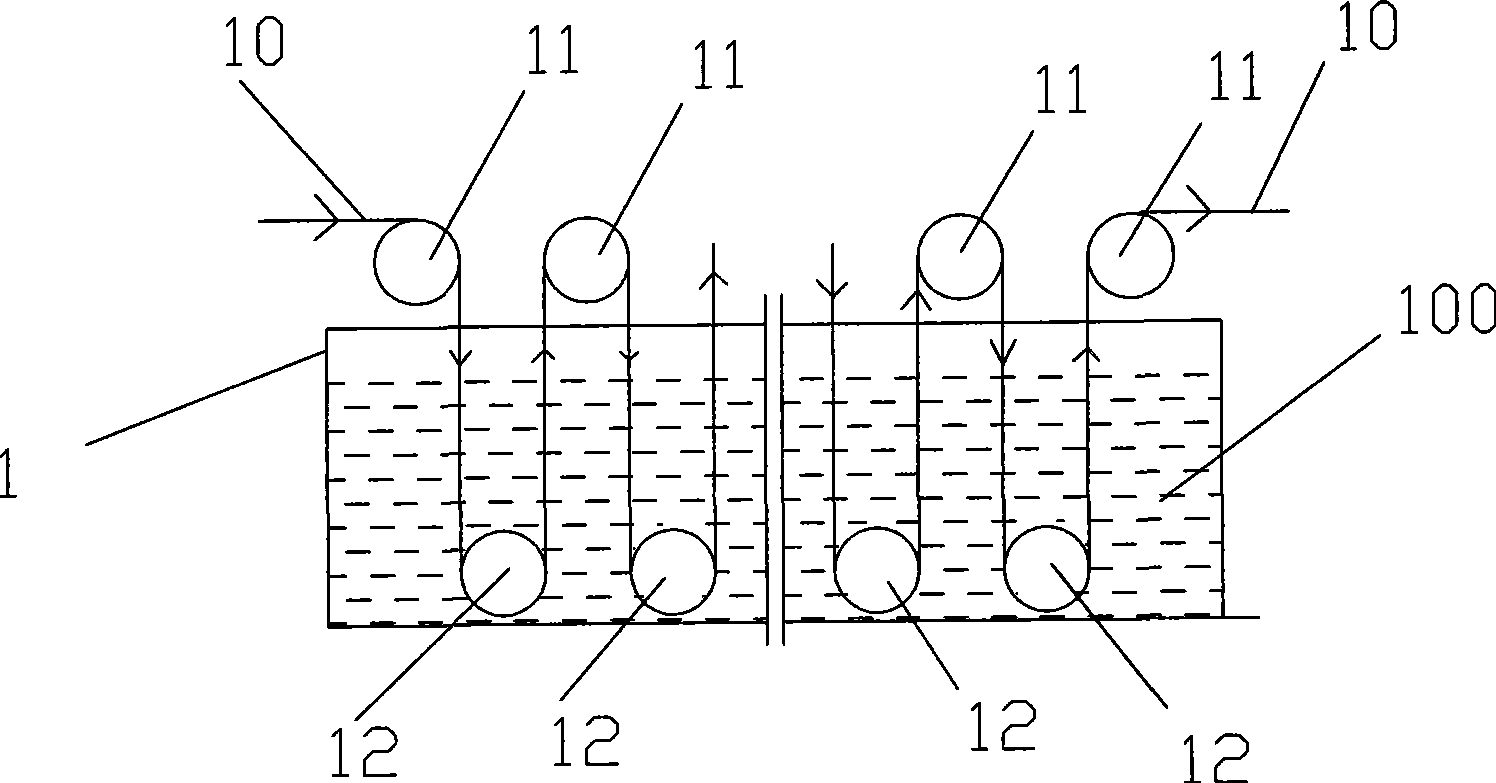

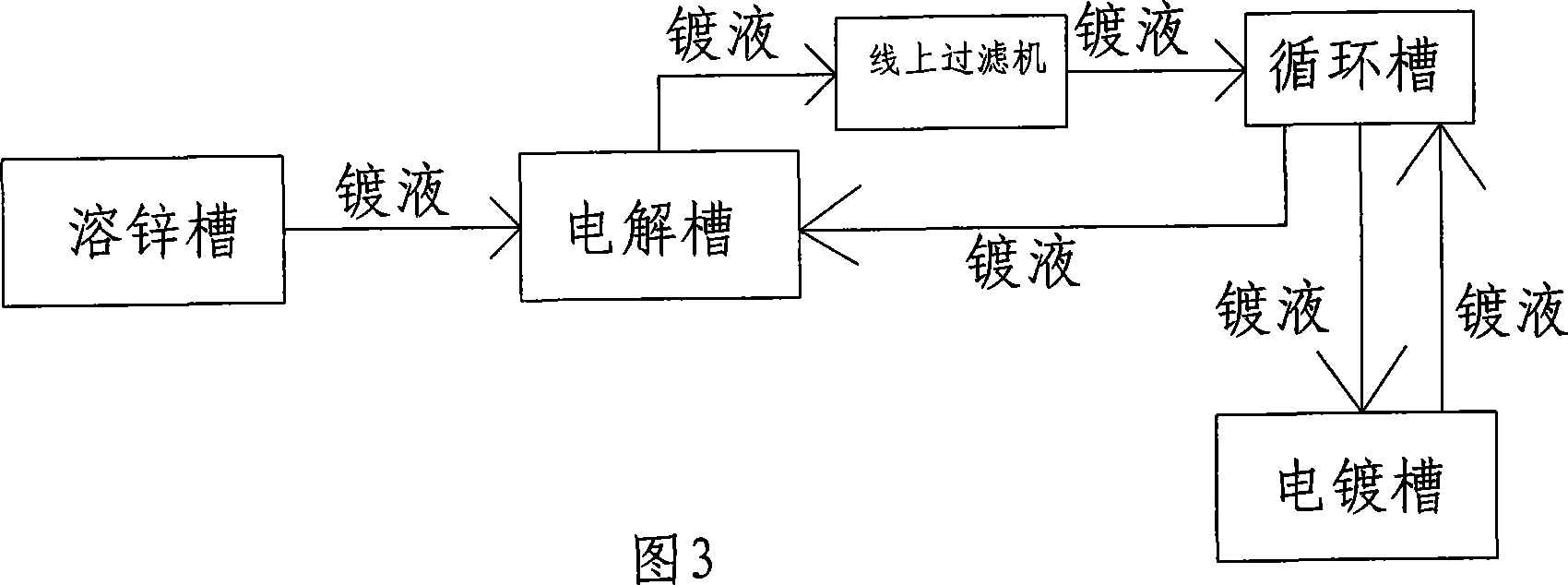

Apparatus and technology for controlling and improving plating solution PH value on fingerprint resistant production chain

The invention provides a technical method for controlling and raising the PH value of galvanizing solution on a fingerprint resistant continuous and automatic production line of the electro-galvanizing and roller coating of a rolled plate; the galvanizing solution rich in zinc ions enters a galvanizing bath from a dezincification bath; the technique is characterized in that: after entering the galvanizing bath from the dezincification bath, the galvanizing solution enters a circulating tank after going through an on-line filtering machine and then enters the galvanizing bath from the circulating tank; the galvanizing solution in the galvanizing bath returns to the galvanizing bath through the circulating tank; and the galvanizing solution is electrolyzed by the current density of 0.1A / dm<2> to 0.3A / dm<2> in an electrobath. The electrobath is internally provided with three anodes and two cathodes at intervals. The technical proposal has the advantages of not only removing hazardous metal impurities, but also increasing dezincification speed, particularly properly raising the PH value, increasing the overpotential of hydrogen, reducing hydrogen evolution, fining electro-galvanizing layers and reducing electric energy consumption, thereby greatly improving product quality.

Owner:长江润发(江苏)薄板镀层有限公司

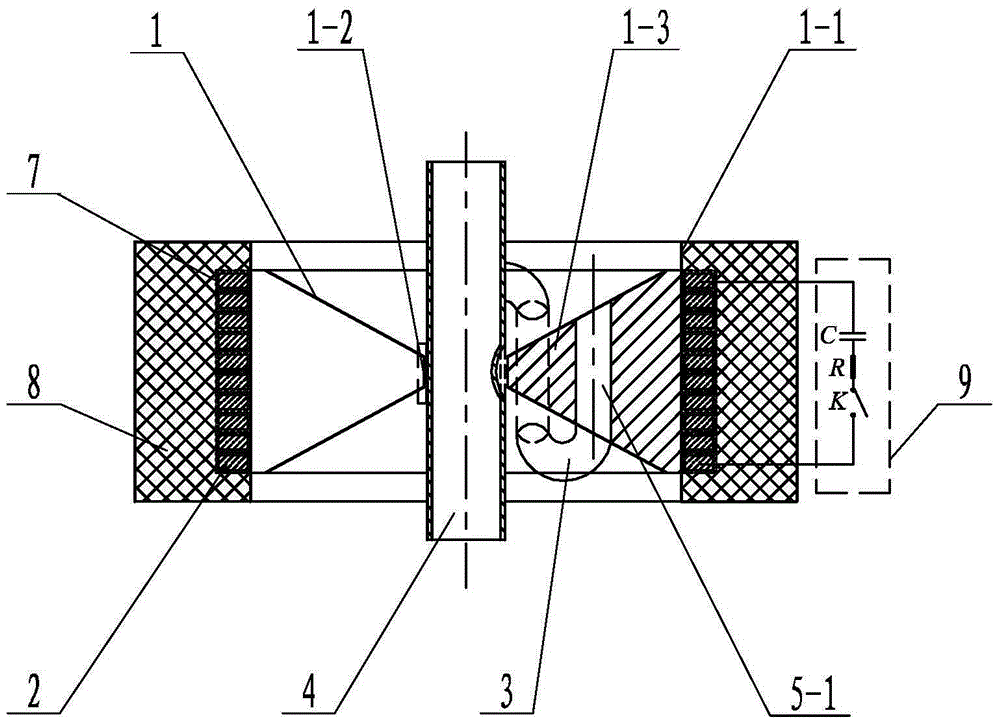

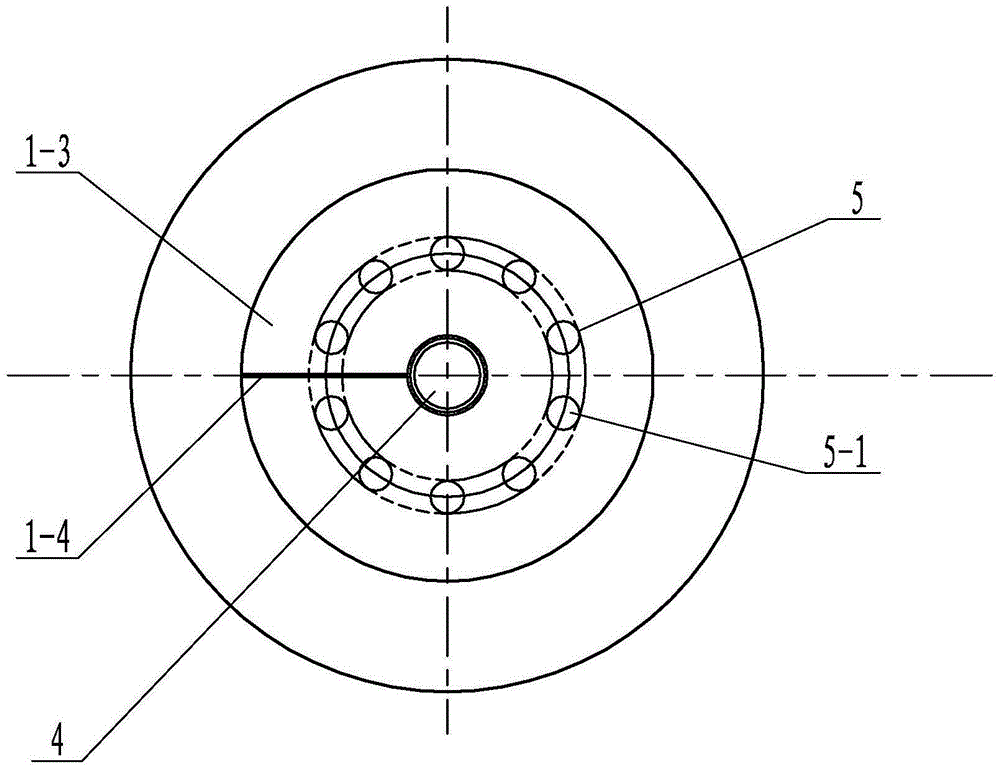

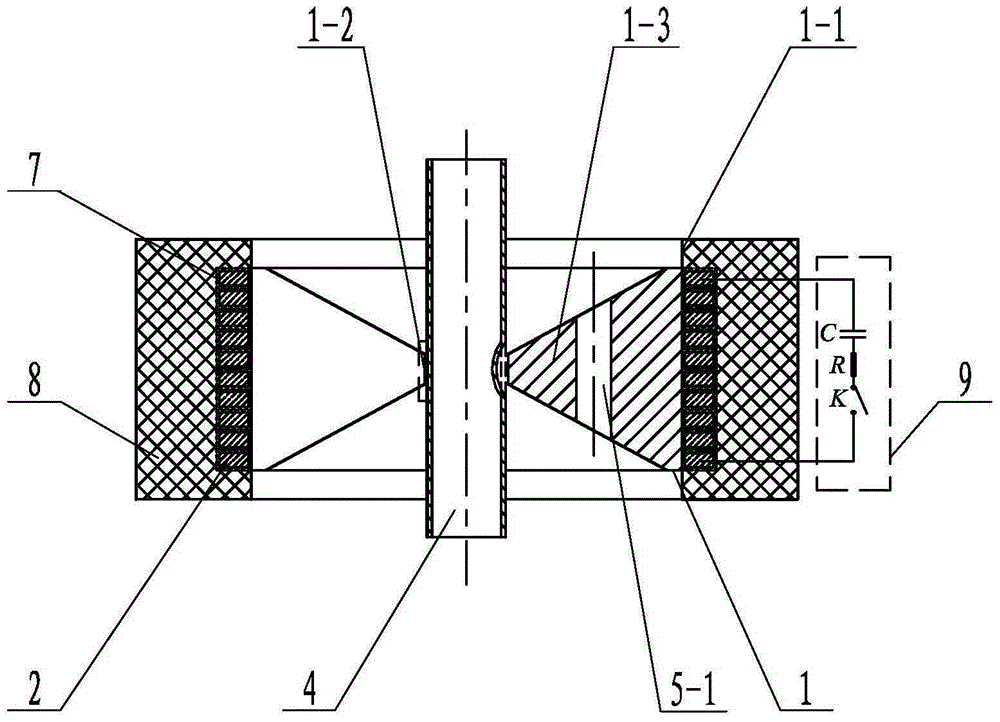

Magnetic collector for magnetic pulse forming

Owner:HARBIN INST OF TECH

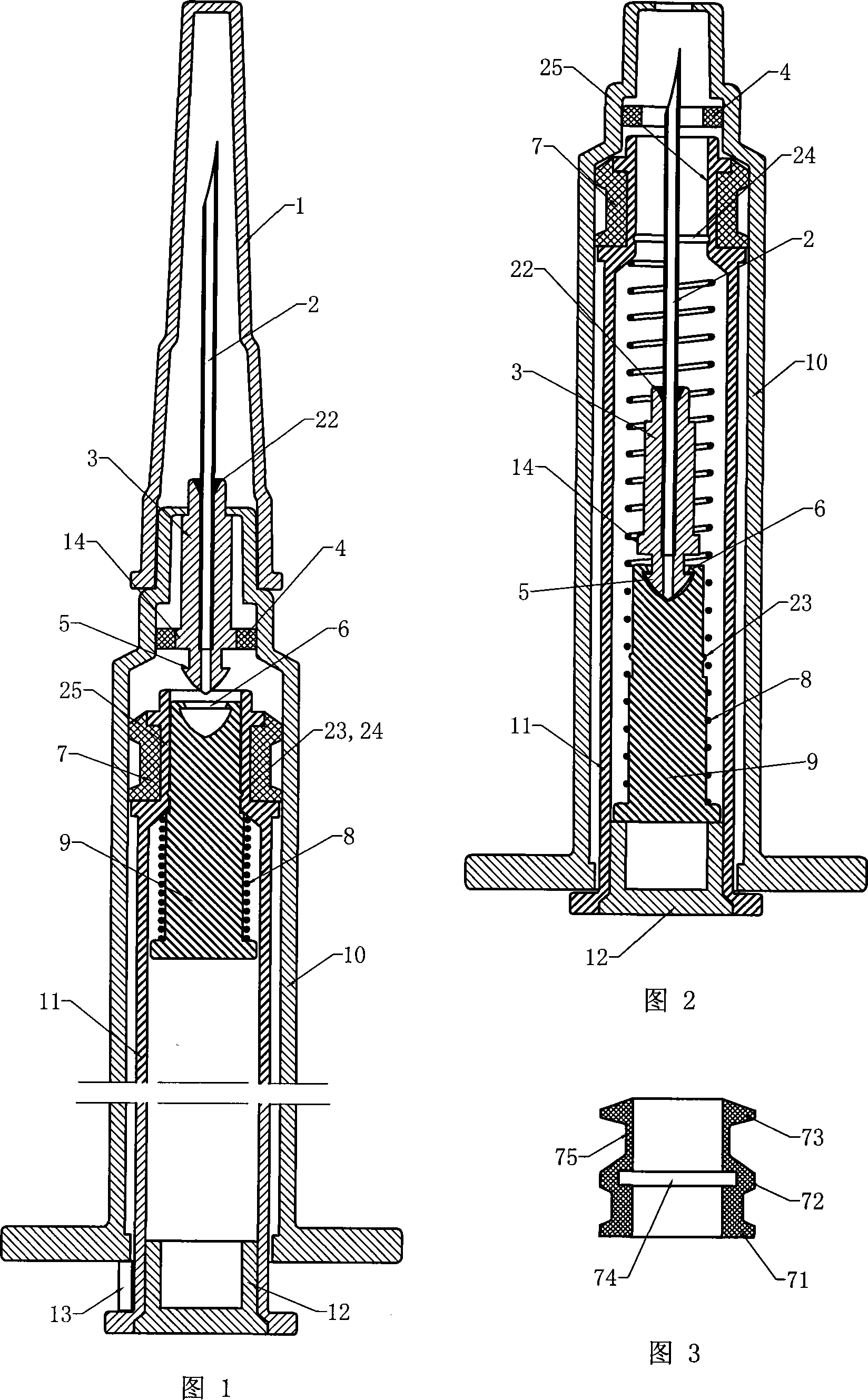

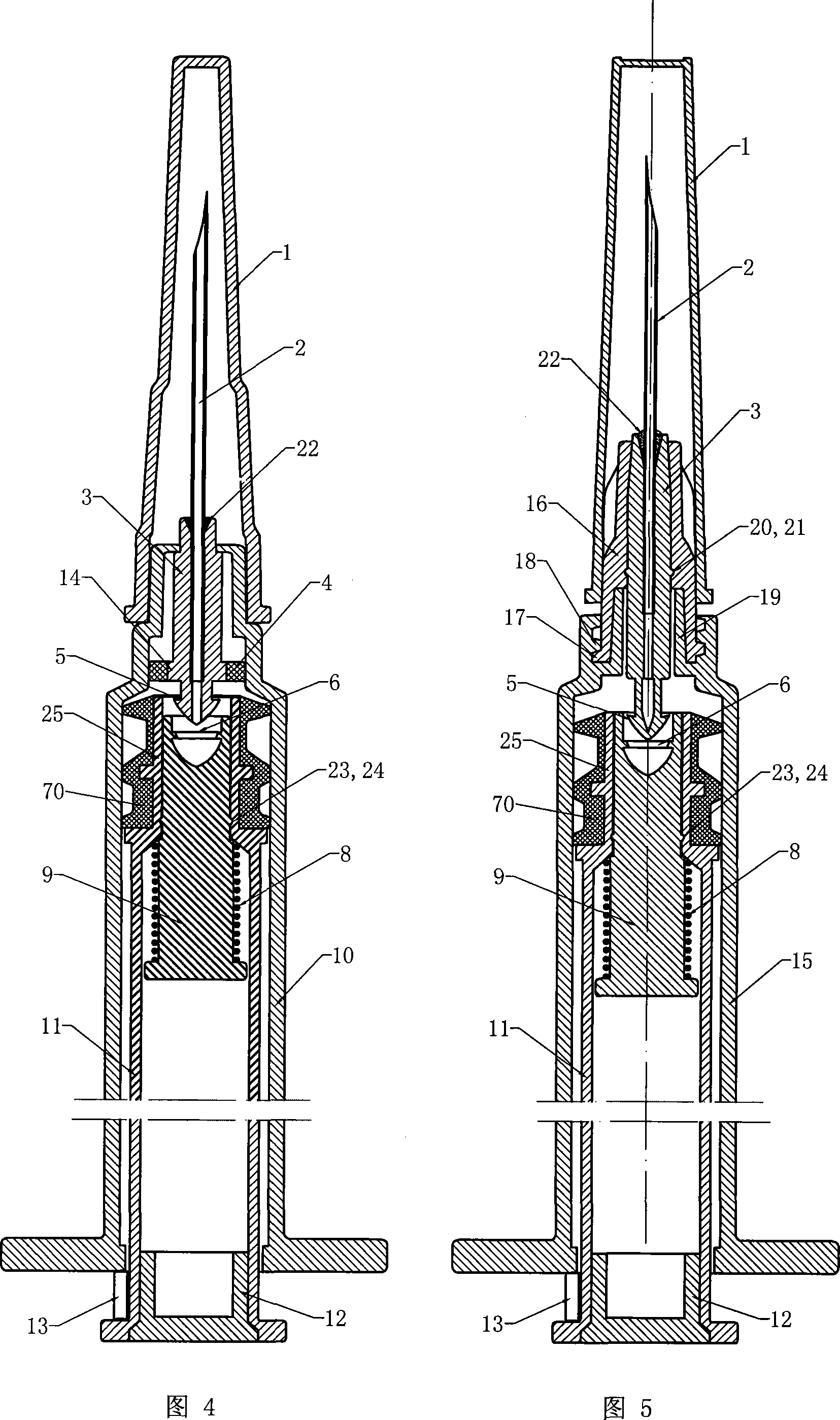

Spring type safety self-destruction syringe

InactiveCN101143238ANovel structureSimplify the assembly processInfusion syringesIntravenous devicesProduction chainStructural engineering

The present invention relates to a spring type safe self-destruction injector which consists of a steel needle, a nerlsbed, an injection tube and a core rod. The upper part of the nerlsbed is installed with the steel needle, and the lower end is provided with a convex ring. A gasket is arranged between the wall of the convex ring and the internal wall of the upper part the injection tube. The core rod is a hollow cylindrical structure, the top of which is arranged with a rubber plug and the lower end of which is arranged with a bottom plug. A diminishing pipe is arranged on the upper part of the core rod. The diminishing pipe is provided with an end plug. A snap groove is arranged on the internal wall of the diminishing pipe. The external wall of the end plug is provided with a snap convex ring. The snap convex ring and the snap groove are matched together by a snap buckle. A steel needle back-pull equipment is arranged between the end plug and the lower end of the nerlsbed. The steel needle back-pull equipment is composed by a snap hook which is arranged at the lower end of the nerlsbed, a snap ring which is arranged at the top end of the end plug and a spring which is arranged at the lower end of the end plug. The present invention has the features of novel structure, simple assembling technology and so on, and is suitable for production chain large-scale mechanization manufacturing.

Owner:罗松能

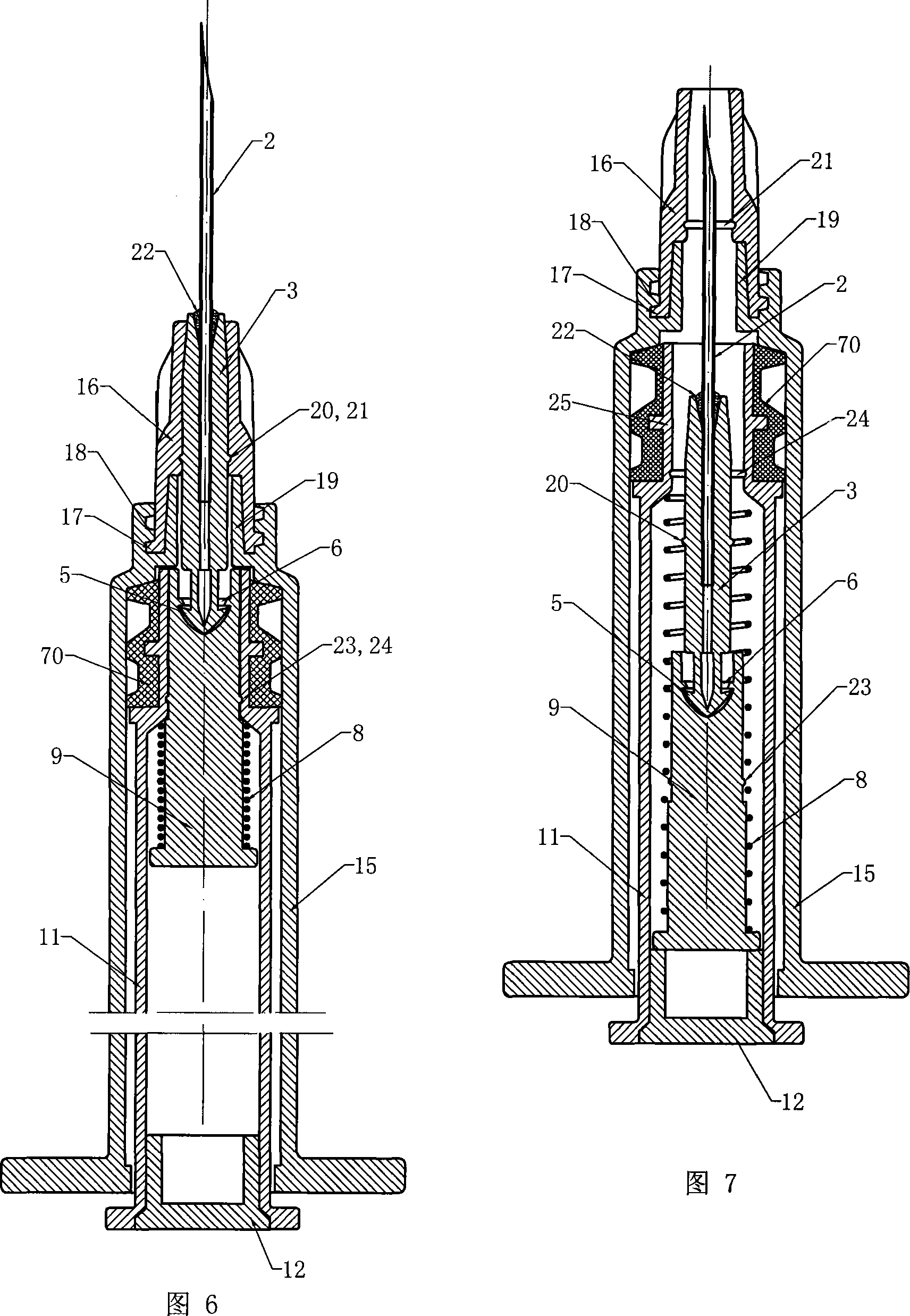

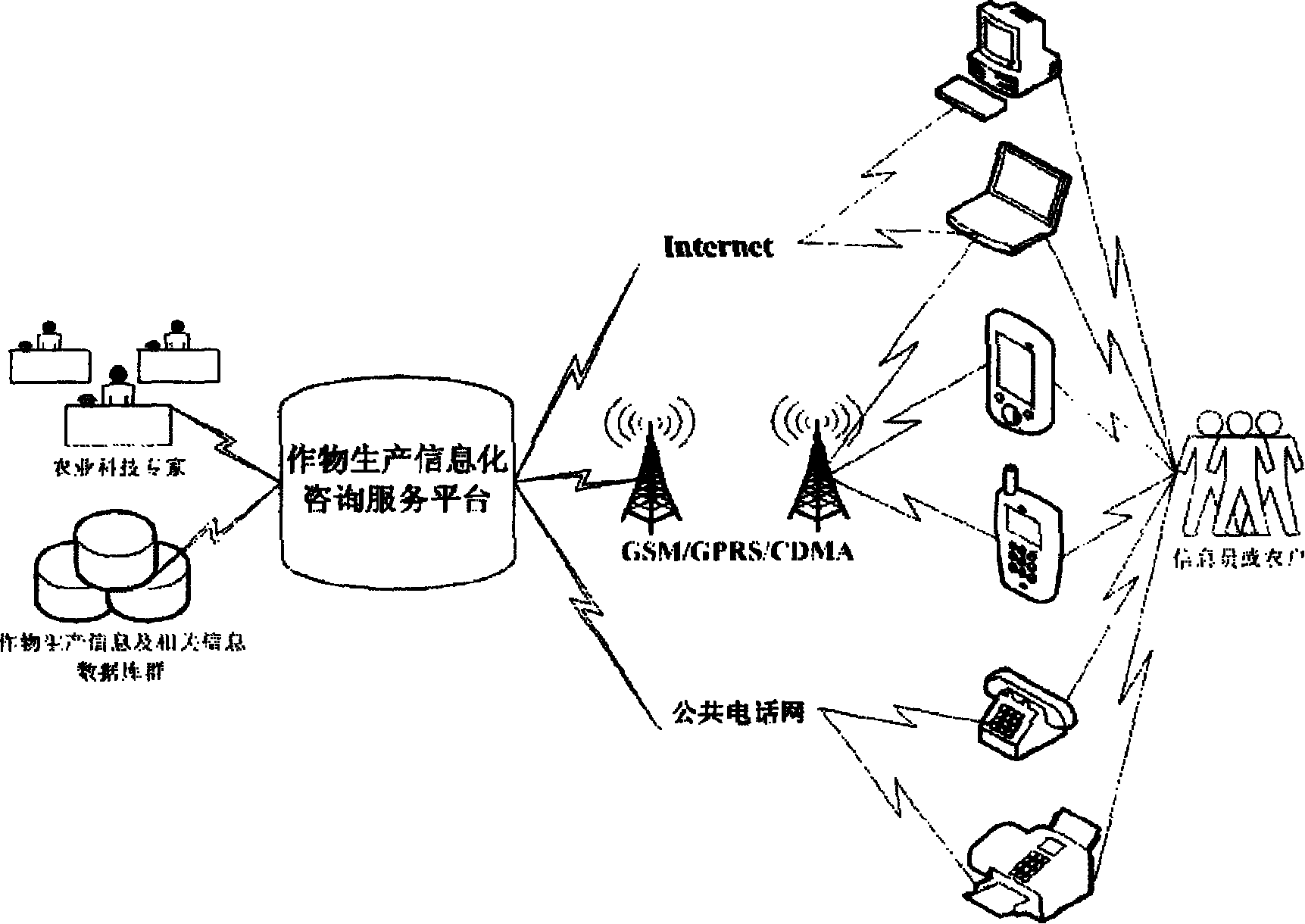

Construction method for crop production informationization service platform

InactiveCN101170607ASpecial service for subscribersSpecial data processing applicationsInformatizationSystems research

The invention provides a 'crops production informatization service platform construction method', belonging to the technical field of modern agriculture, and aims to solves the problems of the current agricultural informatization construction in our country, such as incomplete reflection of farmer's demand, disconnection of information dissemination chain, low popularization rate, poor information quality and data dispersion, poor real-time and compliant property of the existing expert system, and shortage of system service relative to the whole crops production process. In order to realize the crops production informatization, the invention depends on the newly achievement in scientific research on crops production and the intellectual resources of agricultural and scientific experts, integrates the modern information technique and network technique, systemically researches, attains and integrates various information, techniques and related data required by the crops production chain, develops systems and software of crops consulting service, constructs the crops production informatization platform and the service system thereof suitable for national conditions in our country, establishes the network-based crops information service center to provide the all-around information service before, during and after crops production, explores the new transformation model of agricultural scientific and technological achievements, and helps to broaden the application of agricultural science and technology and greatly improve the popularization, efficiency and level of agricultural science and technology.

Owner:王运圣 +1

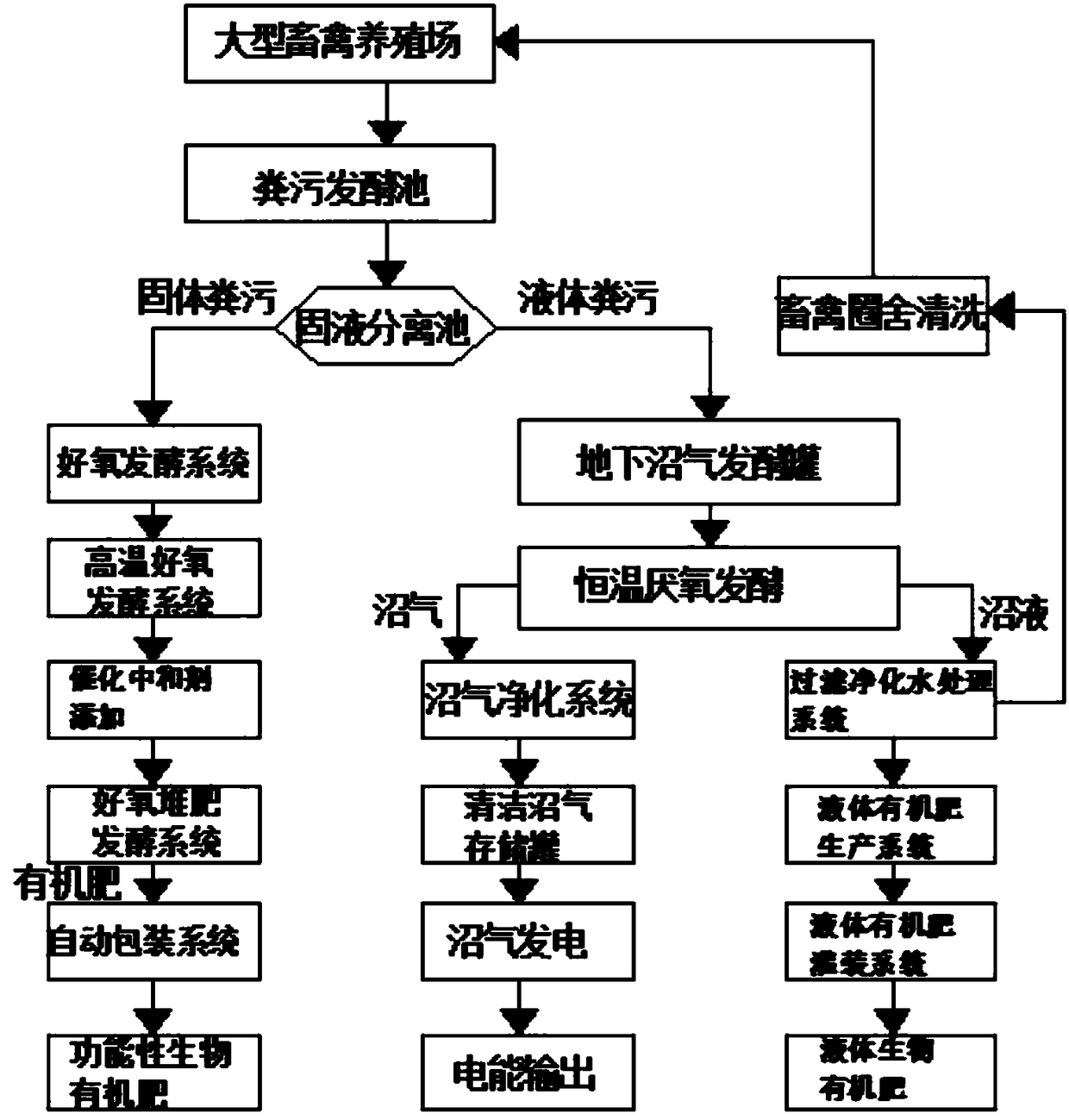

Method for harmless treatment and resource utilization of manure of large livestock and poultry

PendingCN108285363ACreate economic efficiencyProduction chain harmony and balanceCalcareous fertilisersBio-organic fraction processingElectricityLiquid manure

The invention discloses a method for harmless treatment and resource utilization of manure of large livestock and poultry. The method comprises the following whole technological process and method: separating solid manure and liquid manure of manure in a production field of a breeding farm of large livestock and poultry, then separately carrying out post-treatment to finally produce a functional biological organic fertilizer and a liquid biological organic fertilizer, and finishing energy source conversion by using biogas generated in the treatment process to generate electricity. According tothe method provided by the invention, separation and harmless treatment are carried out on the manure of the livestock and poultry, then the functional biological organic fertilizer and the liquid biological organic fertilizer are formed, and energy source conversion is finished by using biogas formed in the treatment process to generate electricity, so that harmless treatment and resource utilization of manure of large livestock and poultry are achieved, economic efficiency is created, the environment is protected, and the production chain of the nature is kept to be harmonious and balanced.

Owner:浙江泽华环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com