Section bar steel ring welding line sander

A technology of grinding machine and grinding mechanism, which is applied to machine tools suitable for grinding workpiece edges, grinding machines, and machine tools designed for grinding workpiece rotating surfaces, etc. problems, to achieve the effect of simple structure, convenient operation, improved production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

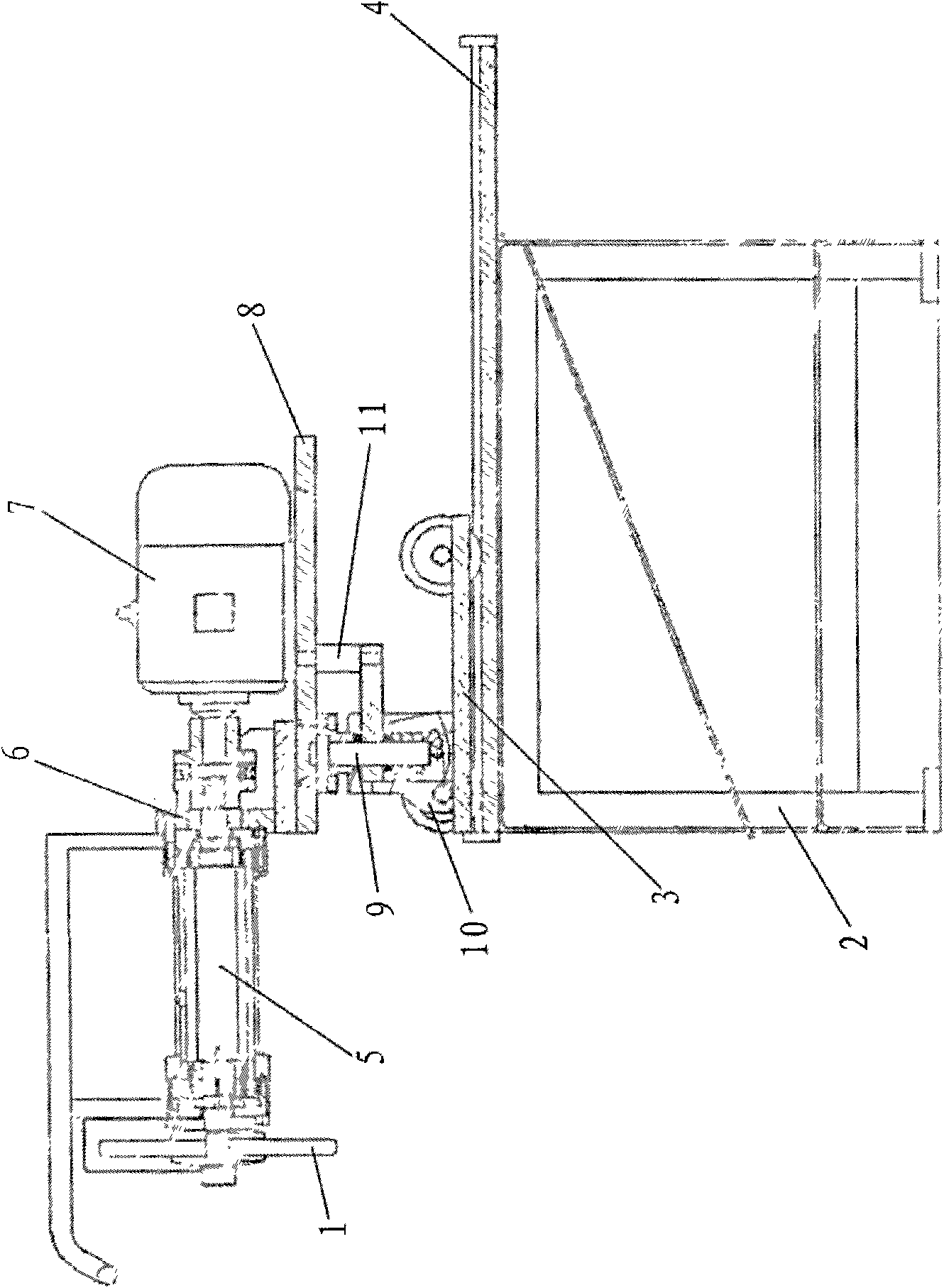

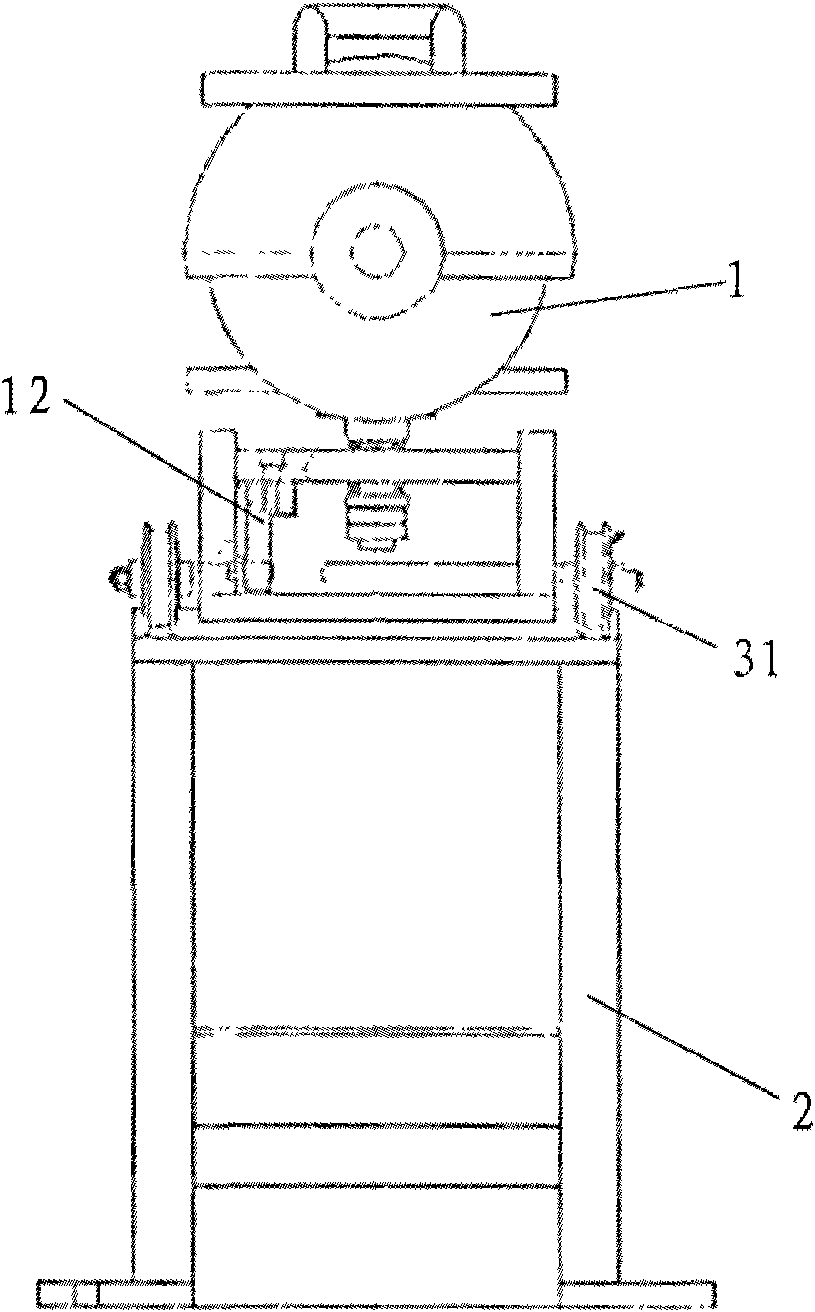

[0017] Embodiment: structure as shown in the figure, the present invention comprises frame, steel ring positioning mechanism and grinding mechanism, wherein grinding mechanism, comprises the connecting rod that is connected on the frame and the electric grinding wheel 1 that is installed on the connecting rod, this grinding machine The mechanism is arranged on the top of the base and can rotate around the connecting shaft; the positioning mechanism includes a longitudinal trolley 3 installed in the track on the base 2 and a chute frame 4 hinged with the frame, and the chute frame 4 has a positioning slider , place the steel ring to be processed between the longitudinal block and the chute frame, and make it move forward along the chute frame, said longitudinal block 3 is arranged in the chute on the chute frame, and the chute frame 4 is installed on base 2.

[0018] The connecting rod is the main shaft 5, the frame is the main shaft support 6, the main shaft 5 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com