Patents

Literature

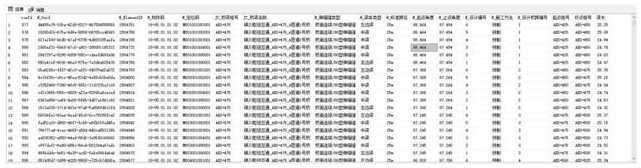

447results about How to "Improve docking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

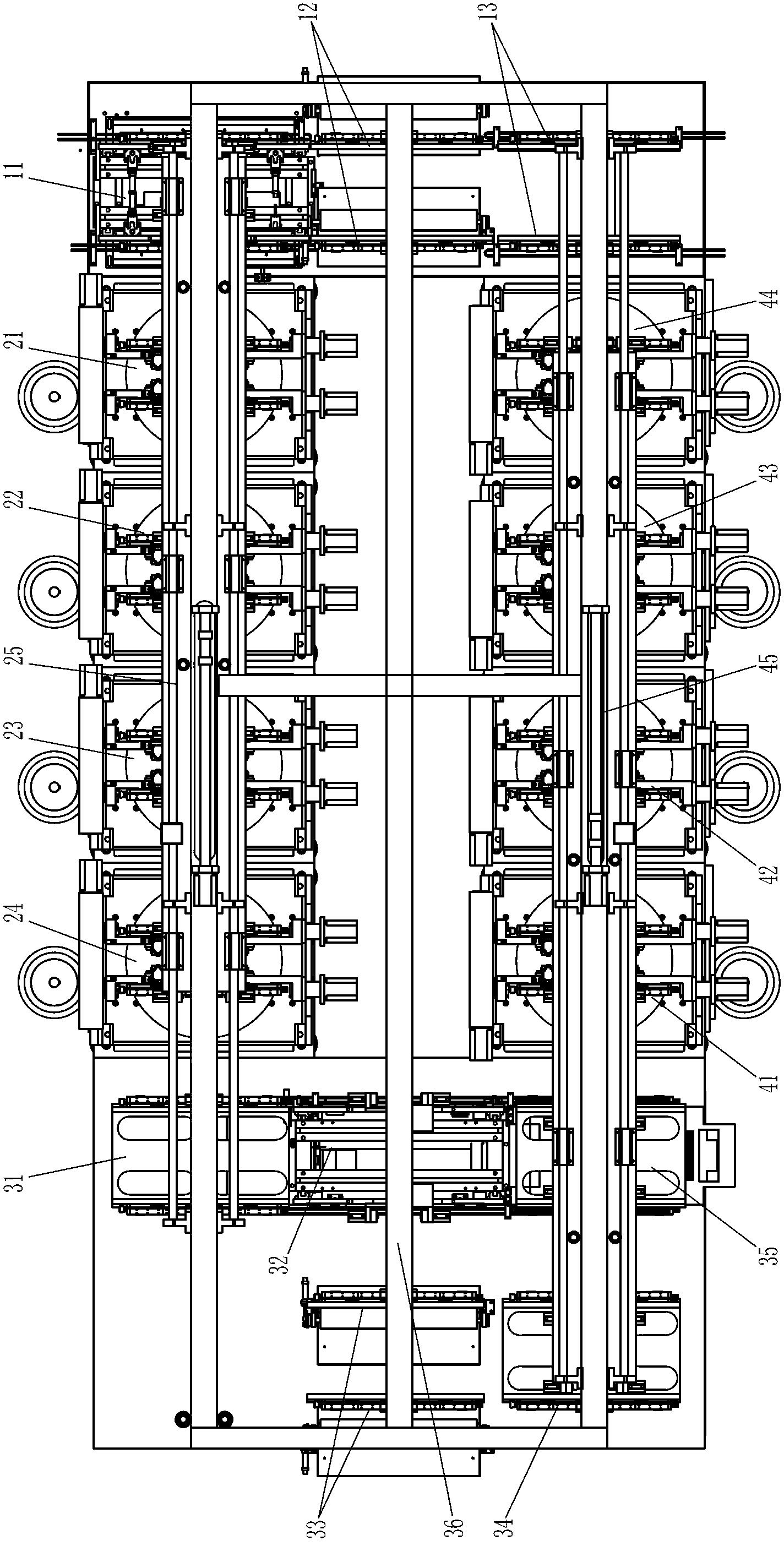

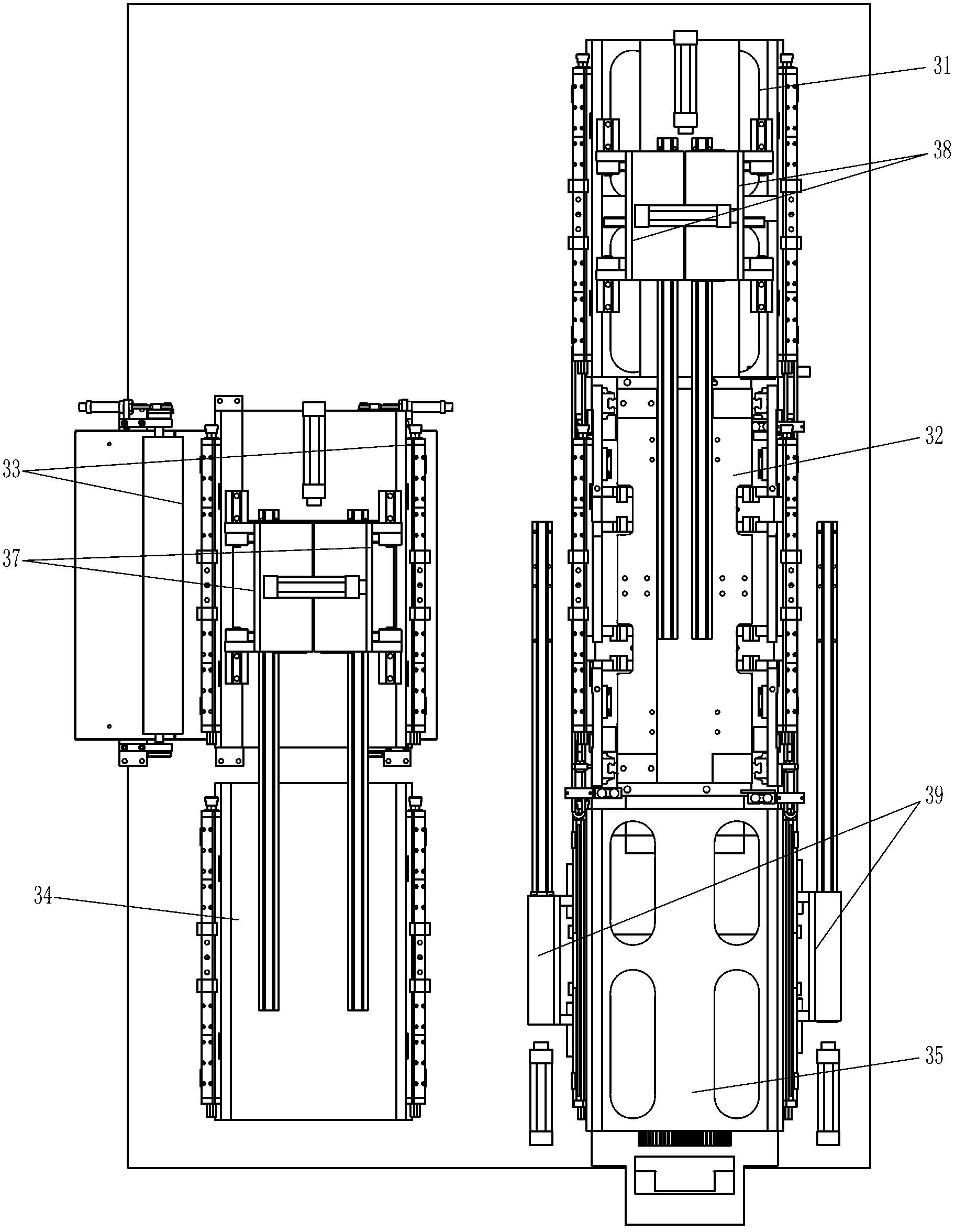

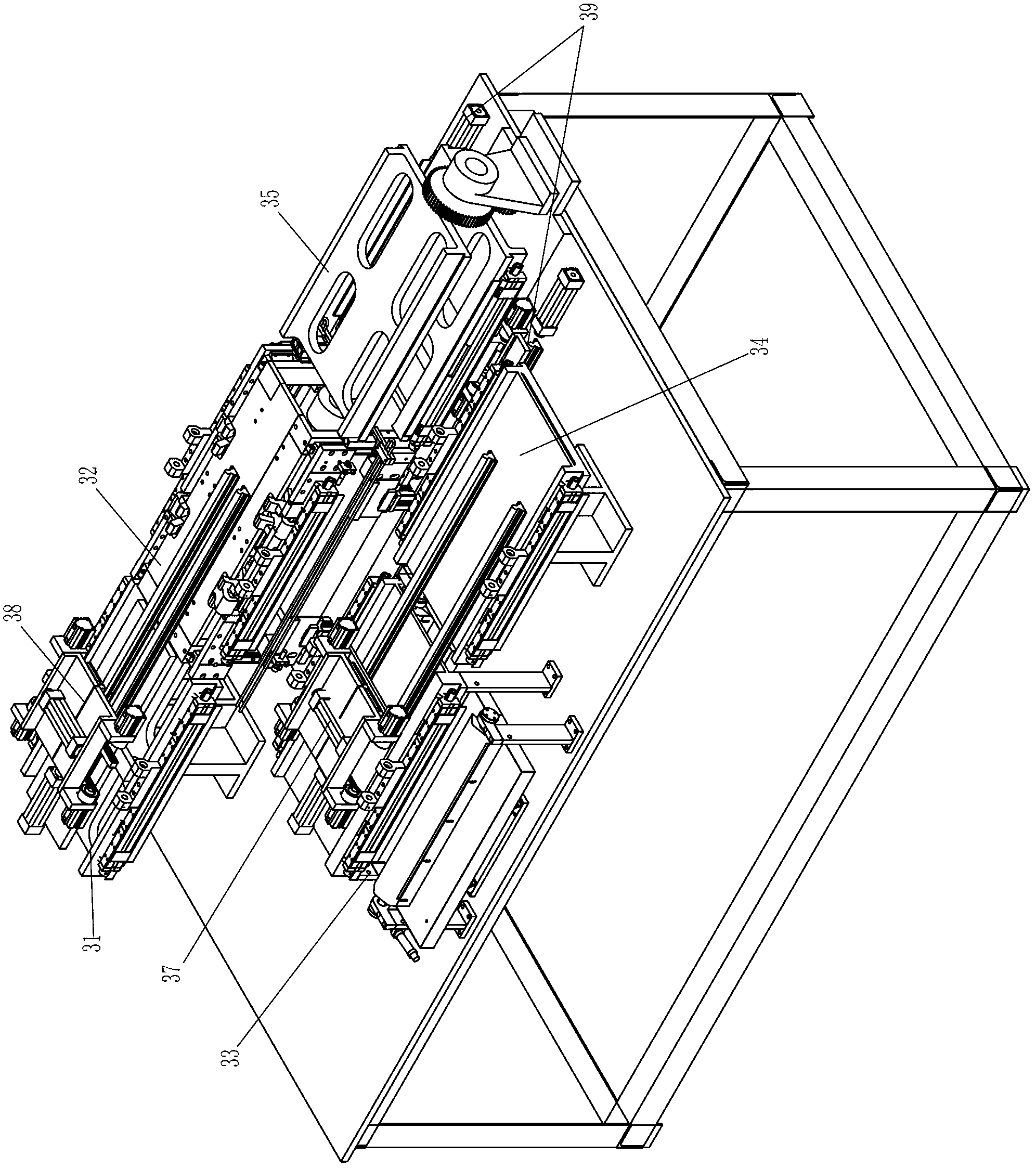

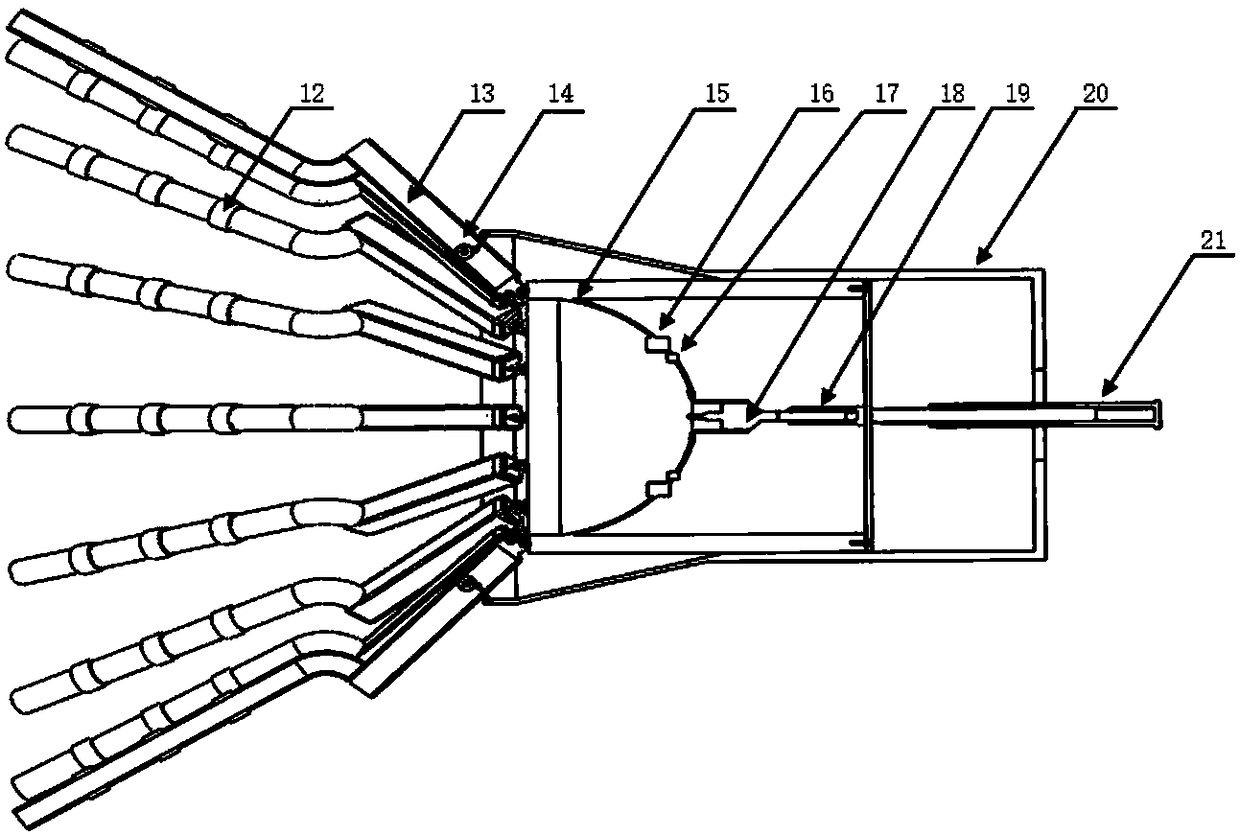

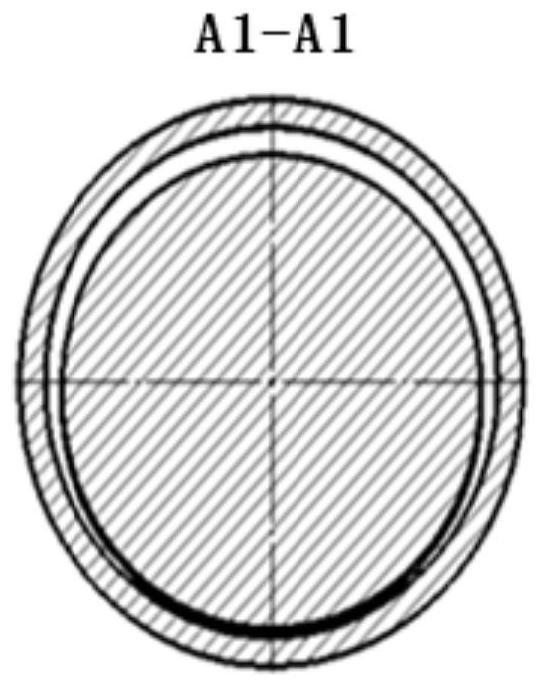

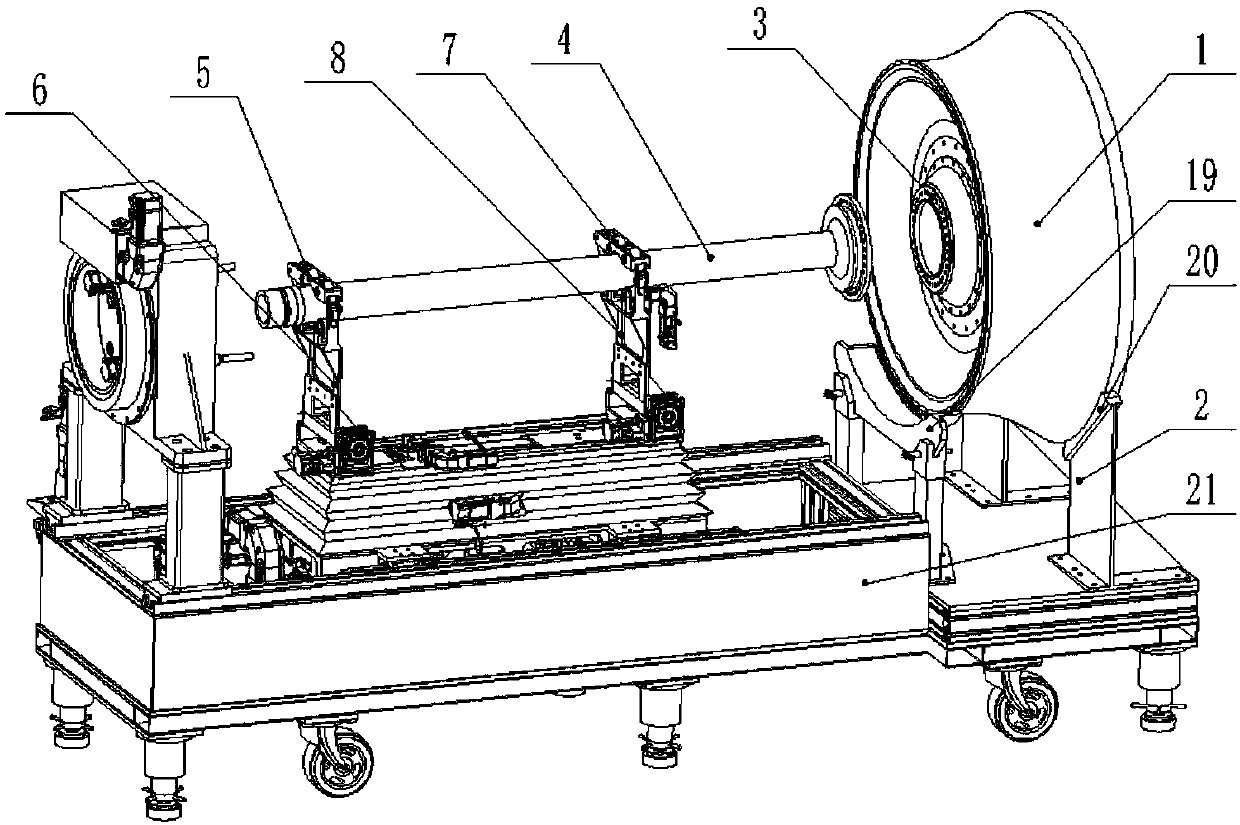

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

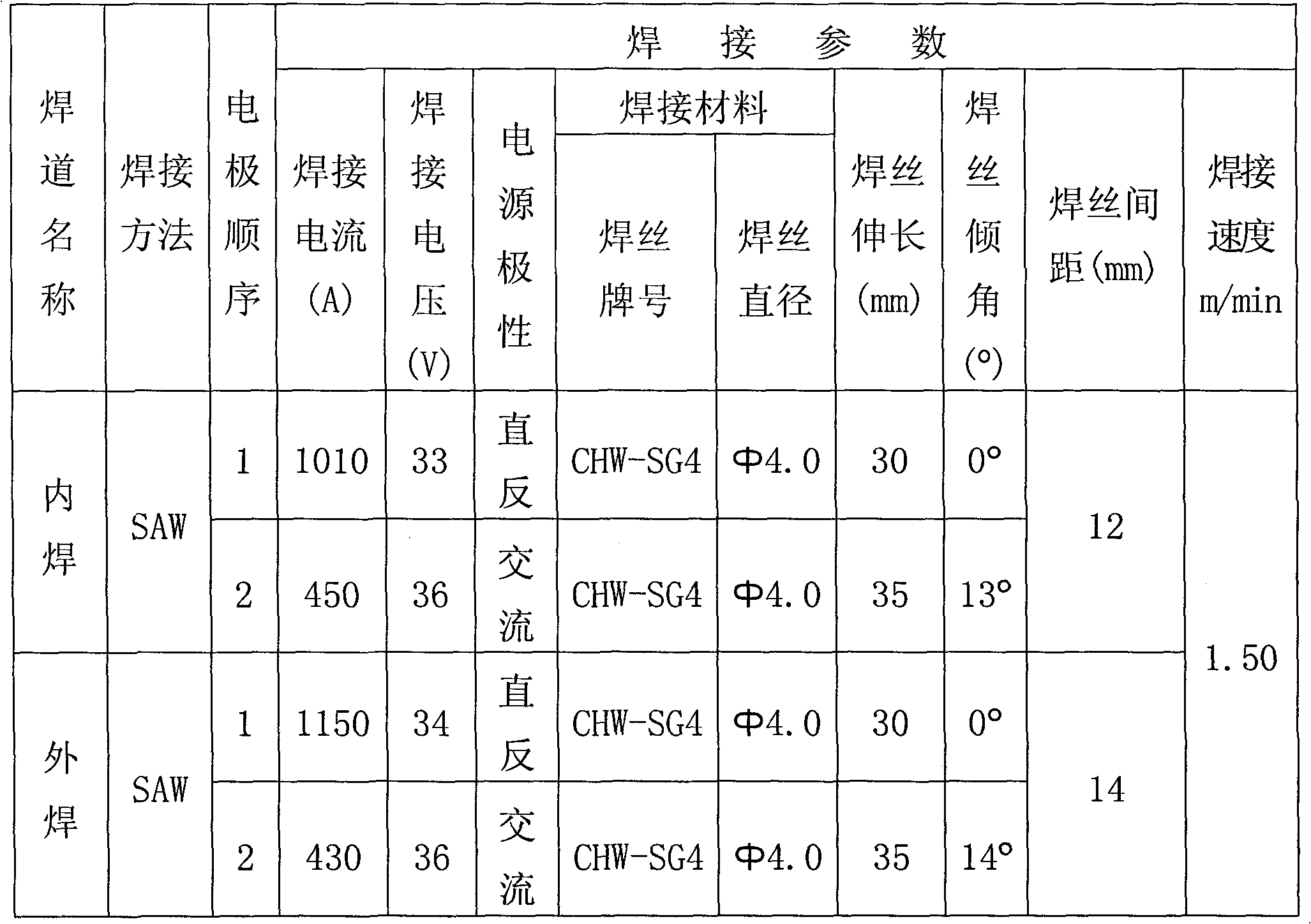

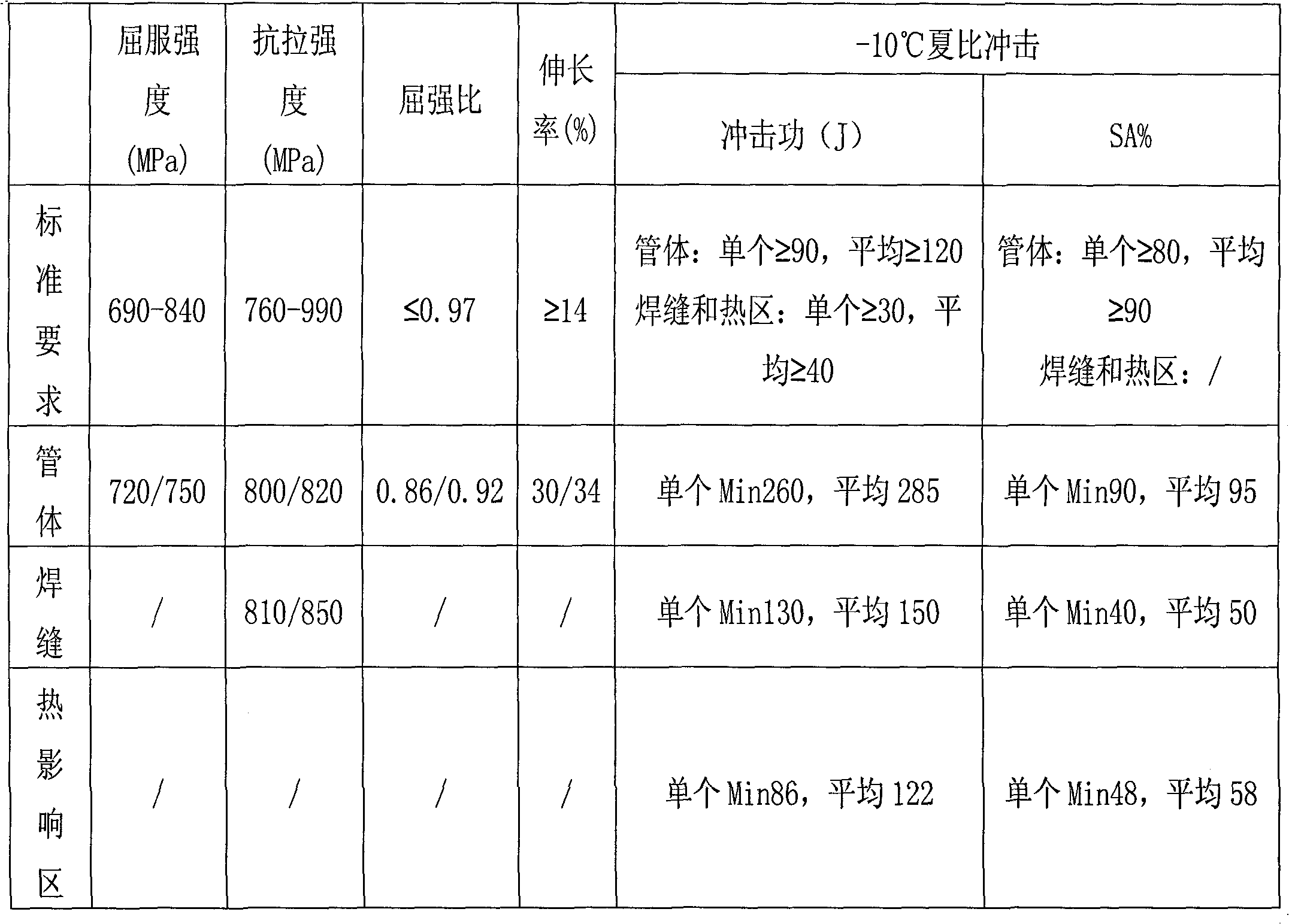

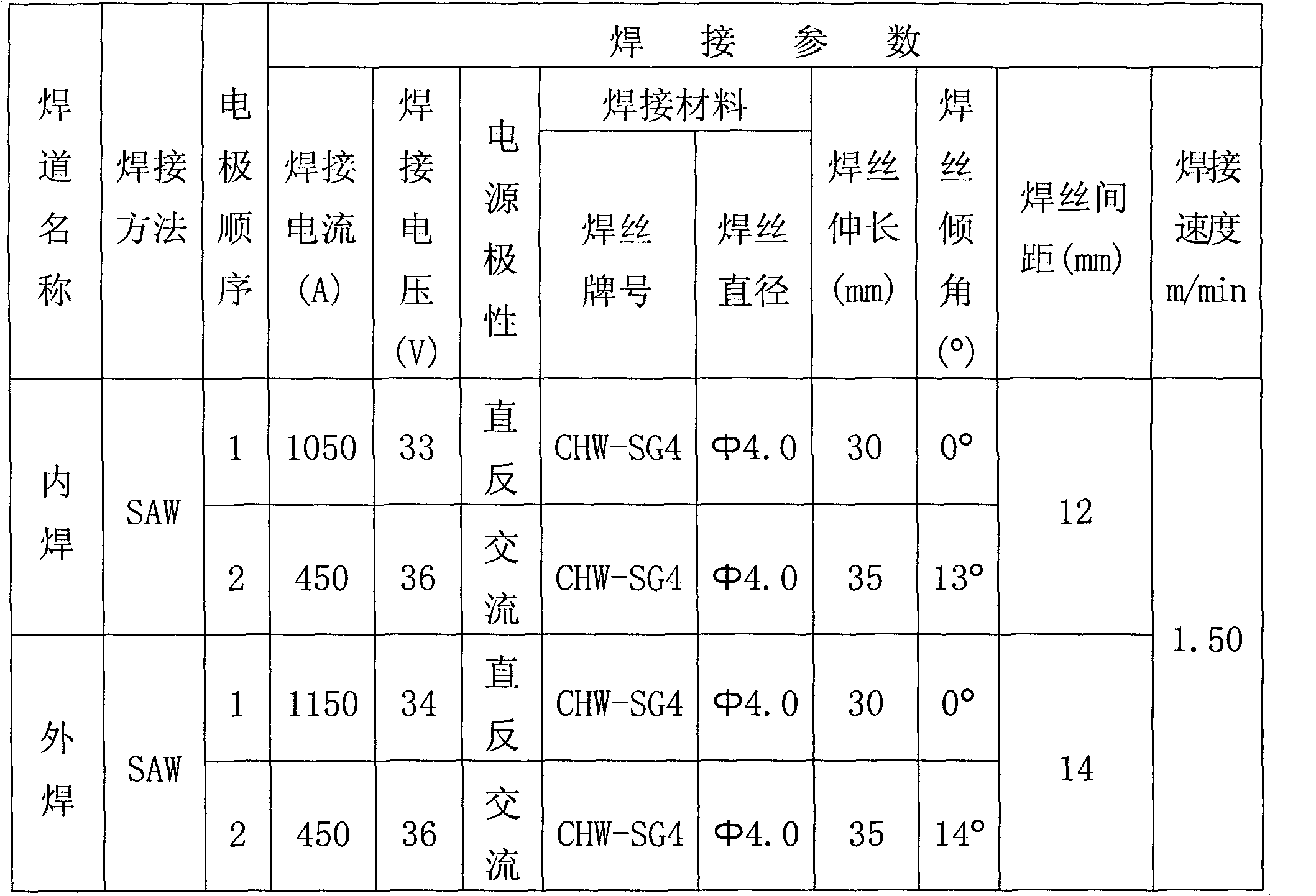

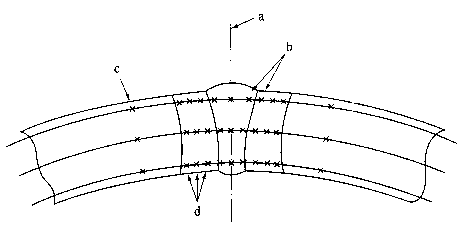

Method for manufacturing high-strength X80 steel spiral welded pipe

InactiveCN101205587AReduced dimensional accuracyImprove docking efficiencyArc welding apparatusWelding/cutting media/materialsUltrasound testSteel plates

The invention discloses a method for manufacturing a high-strength (X 80) steel spiral weld pipe. The weld pipe adopts a parent metal of X 80 rolled steel plate, and the chemical compositions of weld pipe are: 0.02 to 0.09 percent of C, 0.10 to 0.42 percent of Si, 1.50 to 1.85 percent of Mn, less than or equal to 0.022 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.45 percent of Cr, less than or equal to 0.50 percent of Ni, less than or equal to 0.30 percent of Cu, less than or equal to 0.35 percent of Mo, less than or equal to 0.025 percent of Ti, less than or equal to 0.11 percent of Nb, less than or equal to 0.06 percent of V, less than or equal to 0.06 percent of Al, less than or equal to 0.008 percent of N, less than or equal to 0.0005 percent of B, and less than or equal to 0.23 percent of Pcm. The manufacturing procedures includes: decoiling, leveling, edge milling, prebending, molding, internal welding, external welding, pipe end expending, hierarchical ultrasonic examination of parent metal, X-ray examination of welded seam, hydraulic pressure test, ultrasonic examination of welded seam, pipe end chamfering, finished product examination, etc. The (X 80) steel spiral weld pipe( ID: 1219mm, thickness:18.4mm) manufactured by the invention successfully solves the problem of poor stability and unsatisfactory welded seam performance, etc. in the manufacturing process of the high-strength (X 80) steel spiral weld pipe, thereby greatly improving the pass-rate and working efficiency.

Owner:CNPC BOHAI EQUIP MFG +1

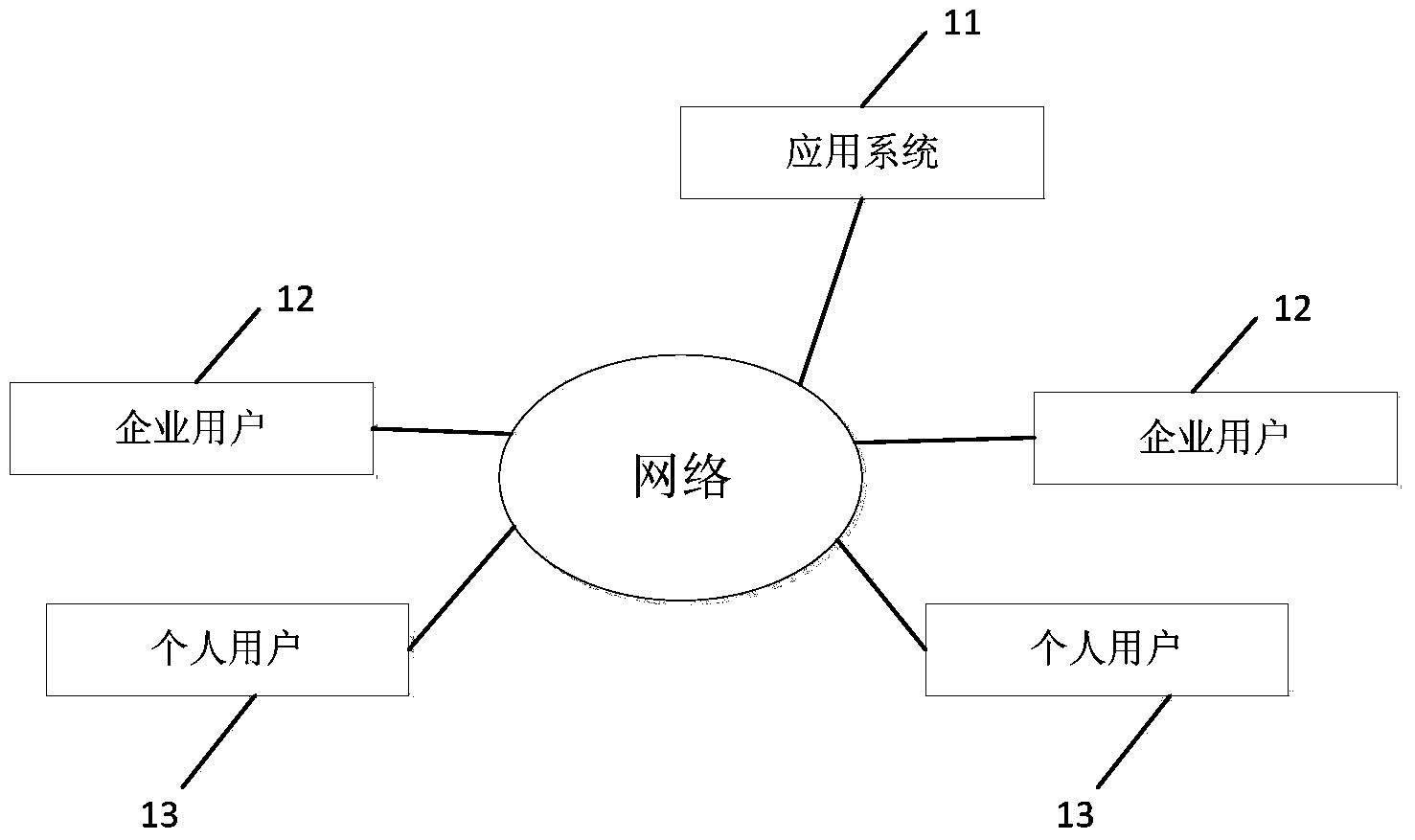

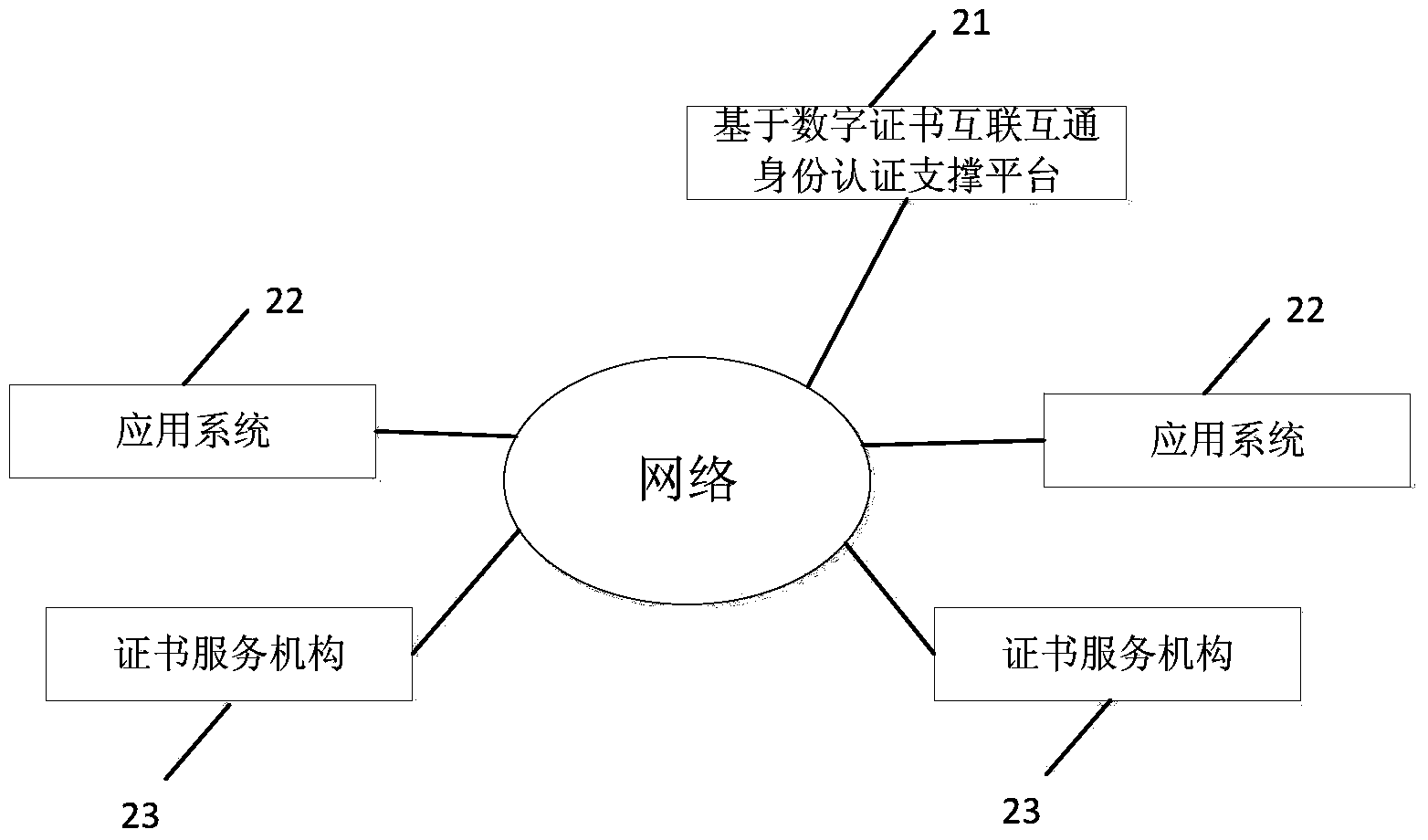

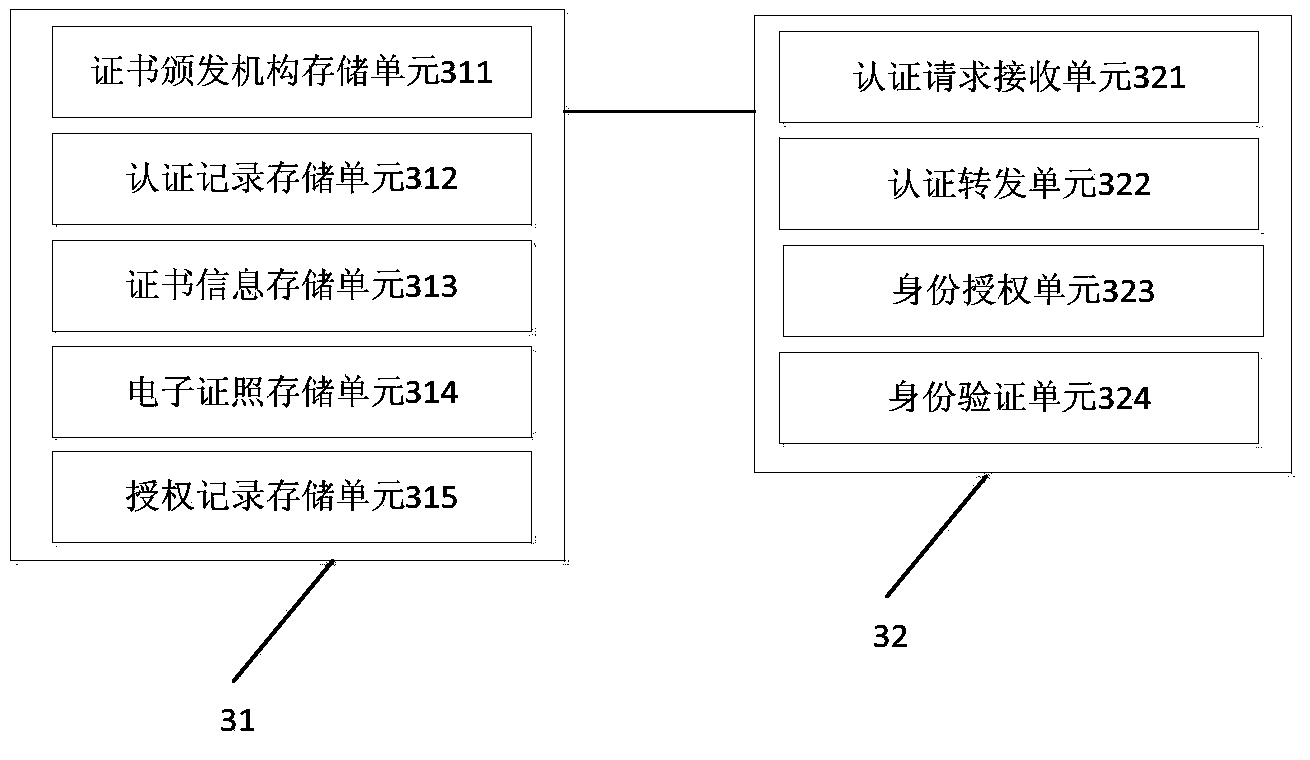

Identity authentication supporting platform and authentication method based on digital certificate interconnection and interworking

ActiveCN103475485AImprove docking efficiencySimplify the identity verification processUser identity/authority verificationDigital data authenticationInternet privacyEngineering

The invention discloses an identity authentication supporting platform and an authentication method based on digital certificate interconnection and interworking to solve the problems that an existing digital certificate is repeatedly issued and approved, and the using cost of a user is high and the using process is complex and to enable the identity of the virtual network to be relevant to the identity of the real world. The requests that digital certificate authentication needs to be carried out on application systems are centralized to the identity authentication supporting platform based on the digital certificate interconnection and interworking to be processed in a unified mode, the application systems are high in communicating efficiency, and the identity authentication procedures are simple and reliable. The identity authentication information based on the digital certificate interconnection and interworking can be shared, the digital certificate authentication does not need to be carried out on all application systems, and the identity authentication efficiency is improved.

Owner:ZHEJIANG ICINFO TECH

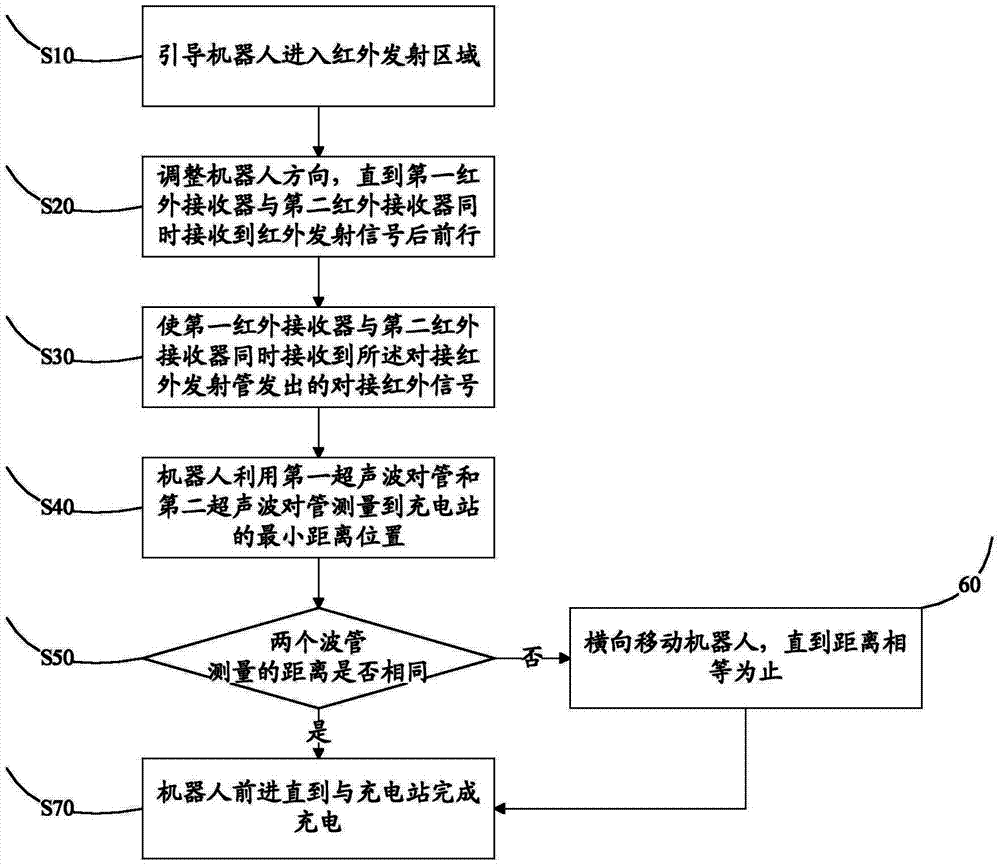

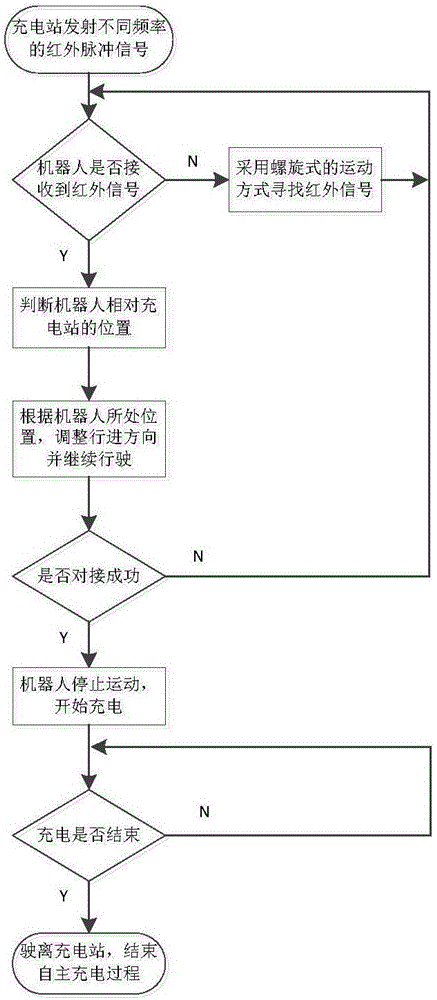

Dual-booting robot self-charging method

ActiveCN104298234AShorten the timeImprove docking efficiencyPosition/course control in two dimensionsButt jointCharging station

A dual-booting robot self-charging method comprises the following steps: a robot is guided to enter an infrared emission region; the direction of the robot is adjusted until a first infrared receiver and a second infrared receiver receive an infrared emission signal simultaneously, and then the robot moves forward; the direction of the robot continues to be adjusted to enable the first infrared receiver and the second infrared receiver to simultaneously receive a butt-joint infrared signal emitted by a butt-joint infrared emission tube; the robot uses a first ultrasonic geminate transistor and a second ultrasonic geminate transistor to measure the position at the minimum distance from a charging station so as to complete longitudinal location; whether the distances measured by the first ultrasonic geminate transistor and the second ultrasonic geminate transistor are the same is judged; if the distances measured by the first ultrasonic geminate transistor and the second ultrasonic geminate transistor are not the same, the current heading direction of the robot is taken as the longitudinal reference, the minimum sonar distance is kept unchanged, and the robot is transversely moved until the distances are the same; and if the distances are the same, the robot moves forward until the charging station completes charging. By adopting the dual-booting robot self-charging method of the invention, the time and algorithm for butt joint when the charging station is positioned on electrodes is reduced, and the efficiency of butt joint is improved.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

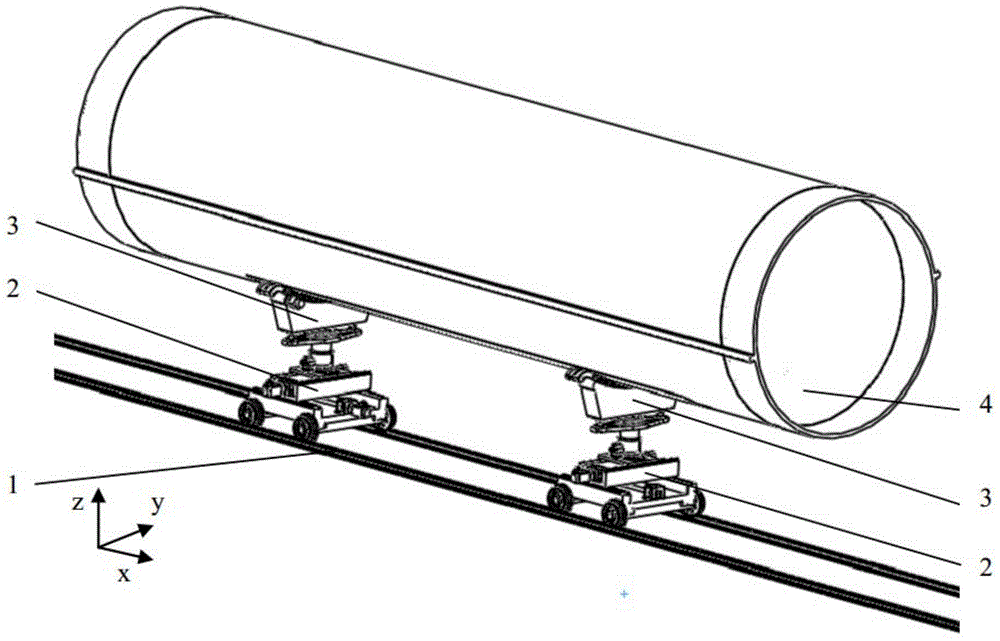

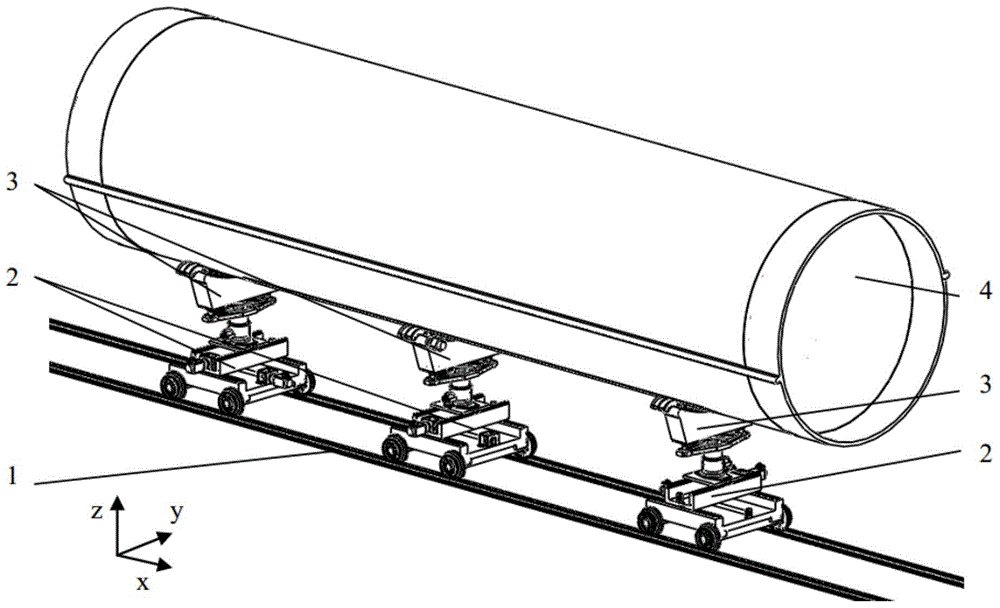

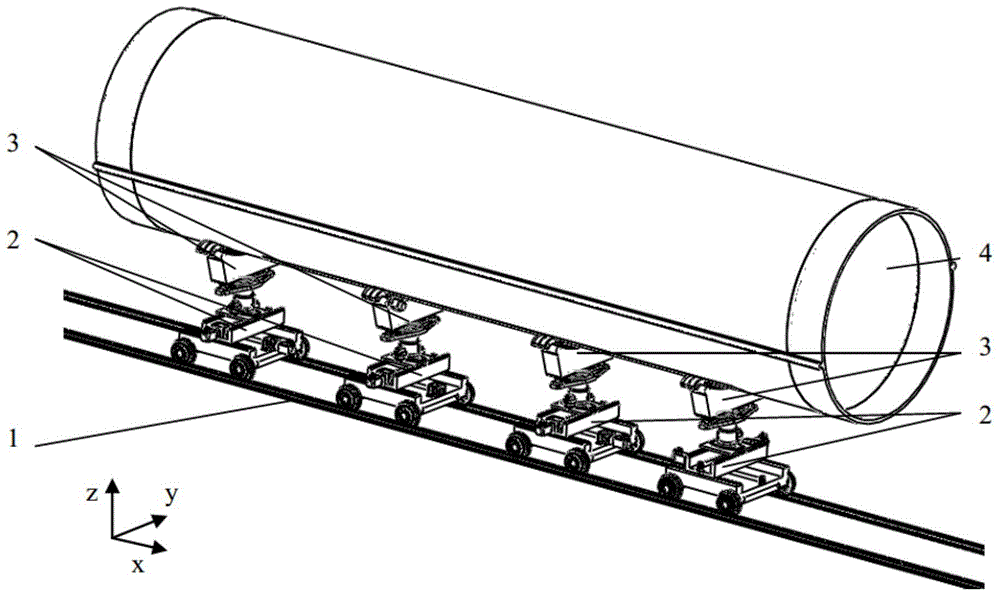

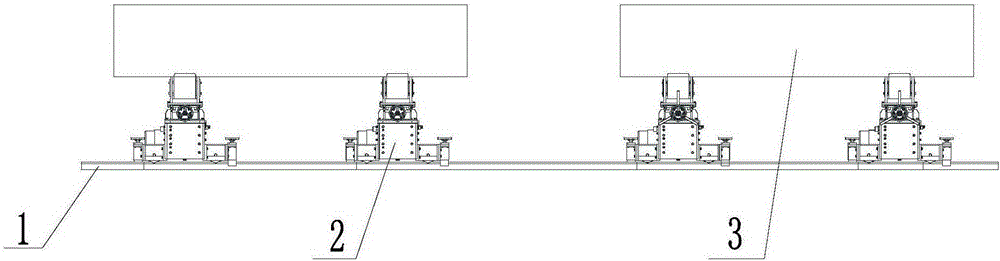

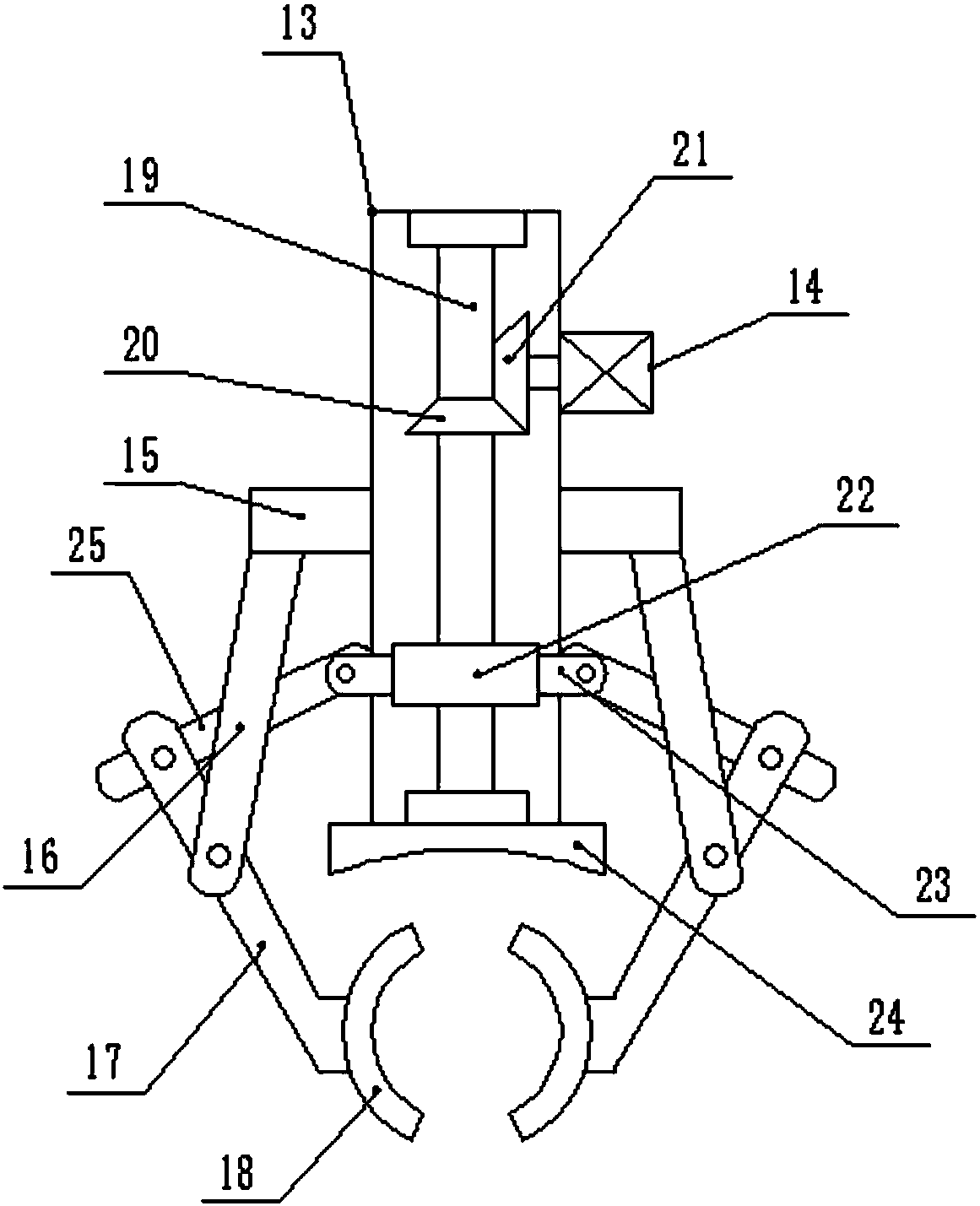

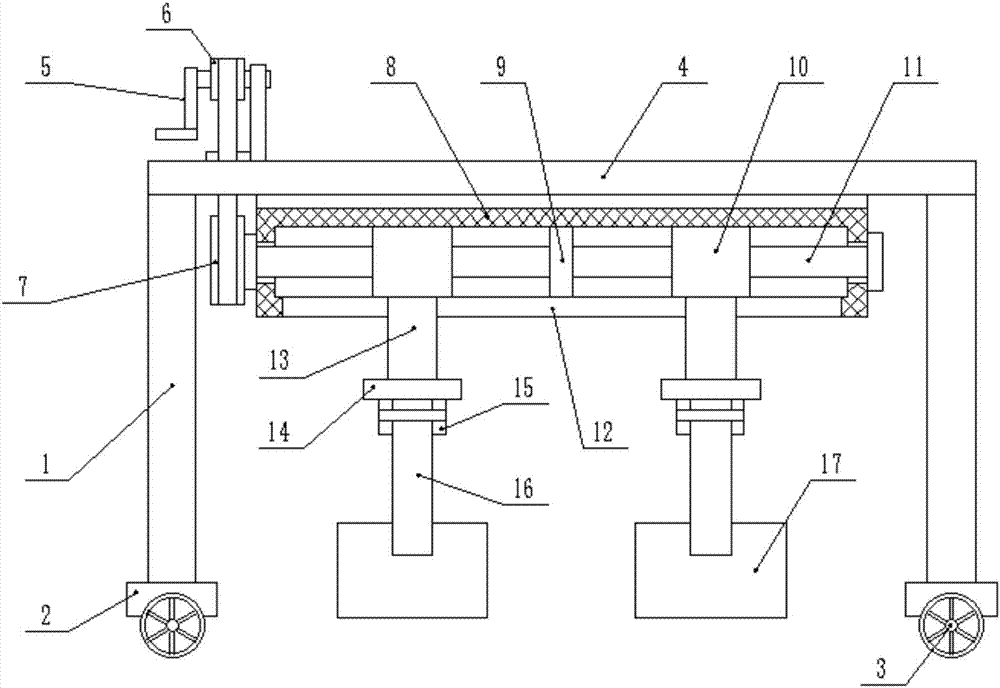

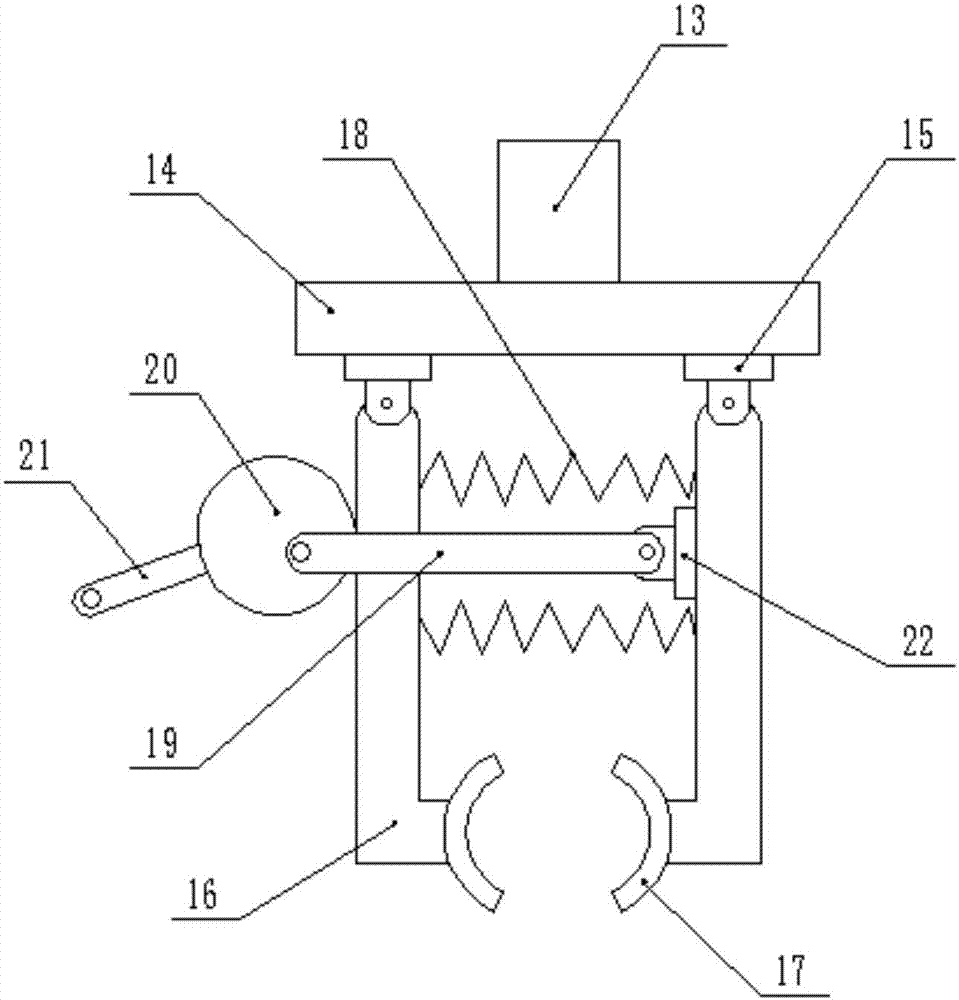

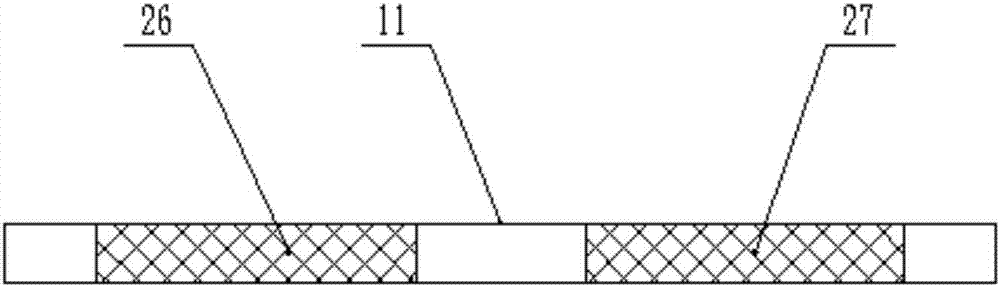

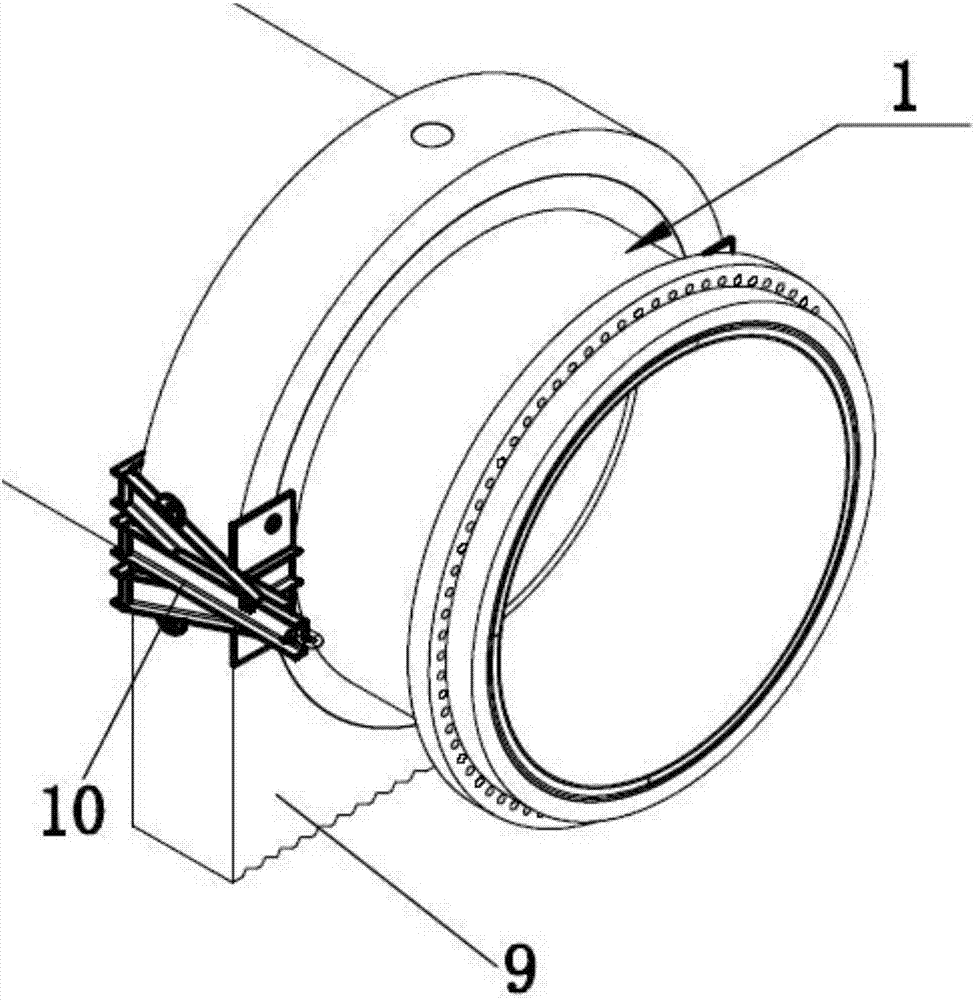

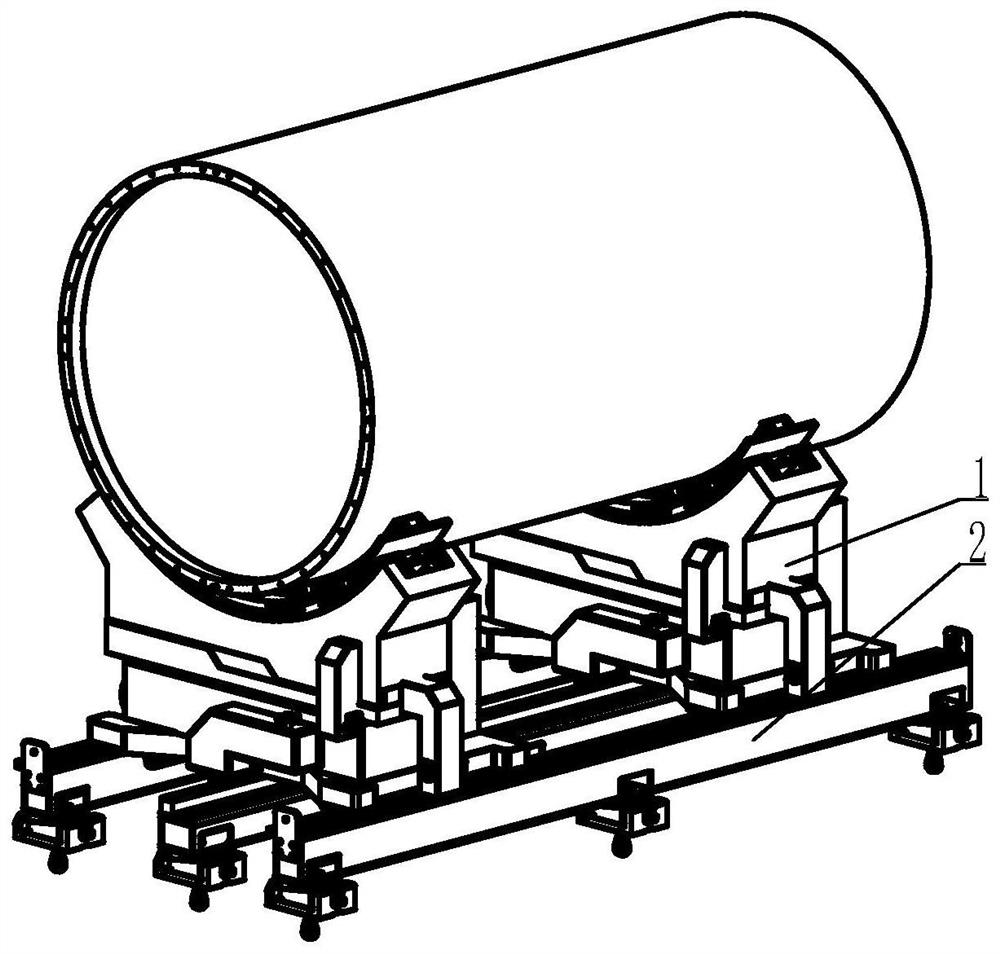

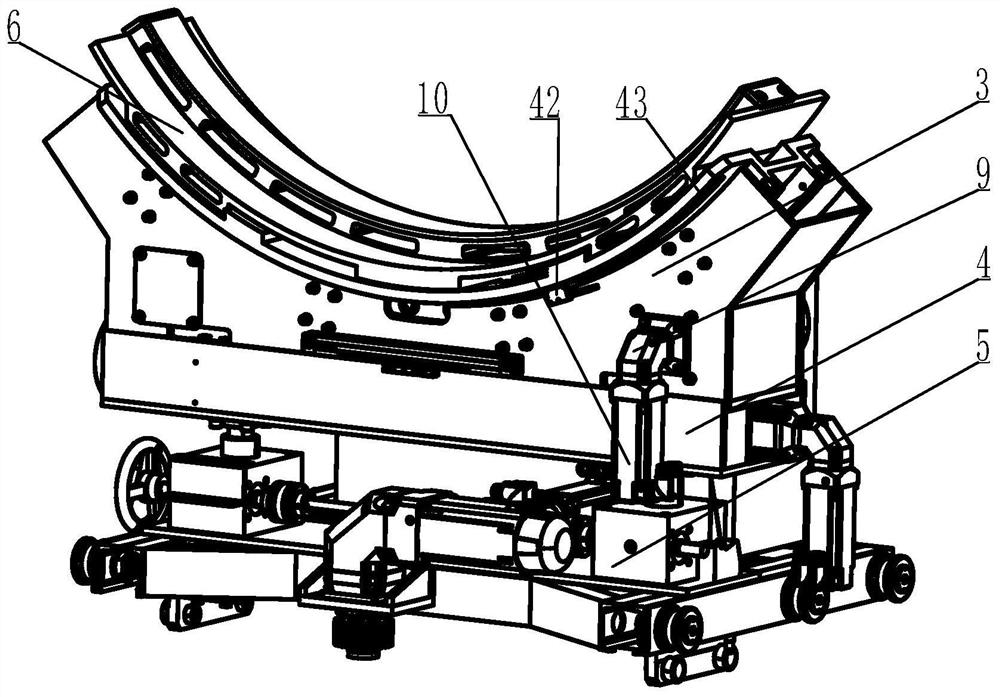

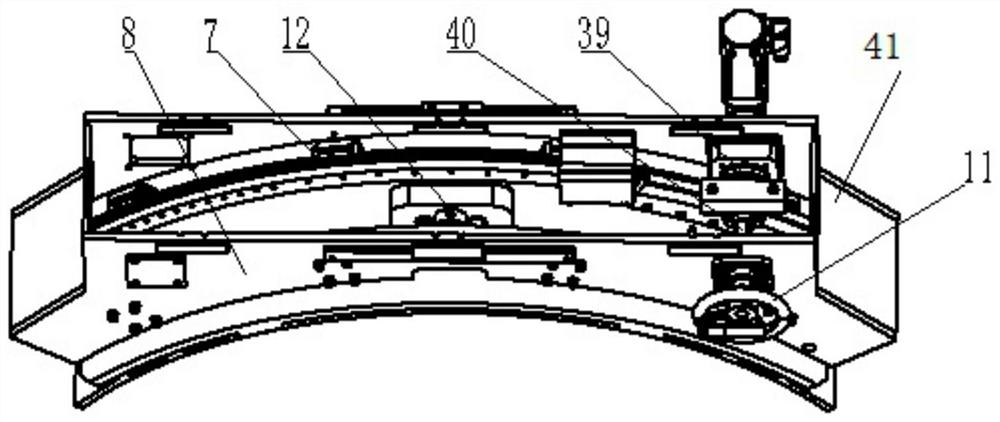

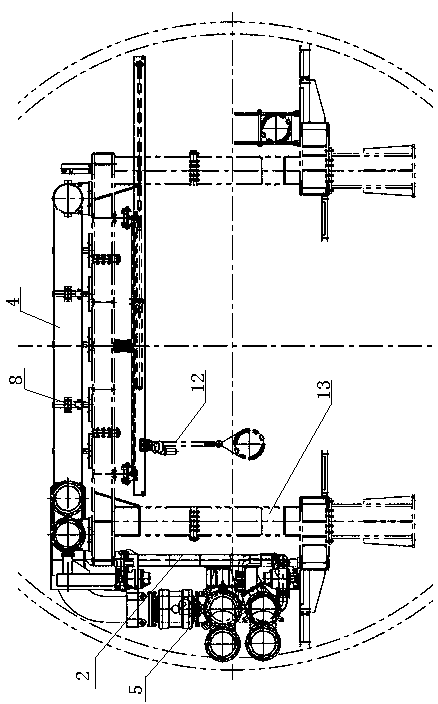

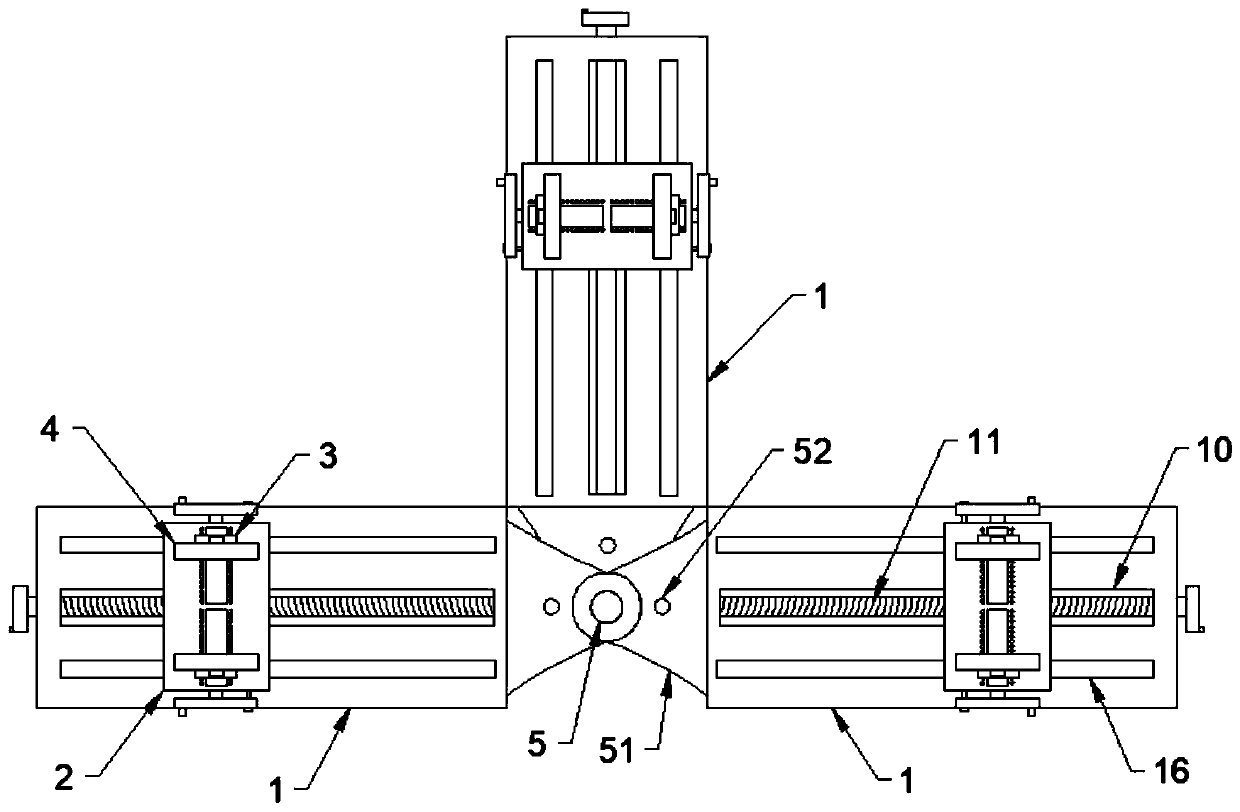

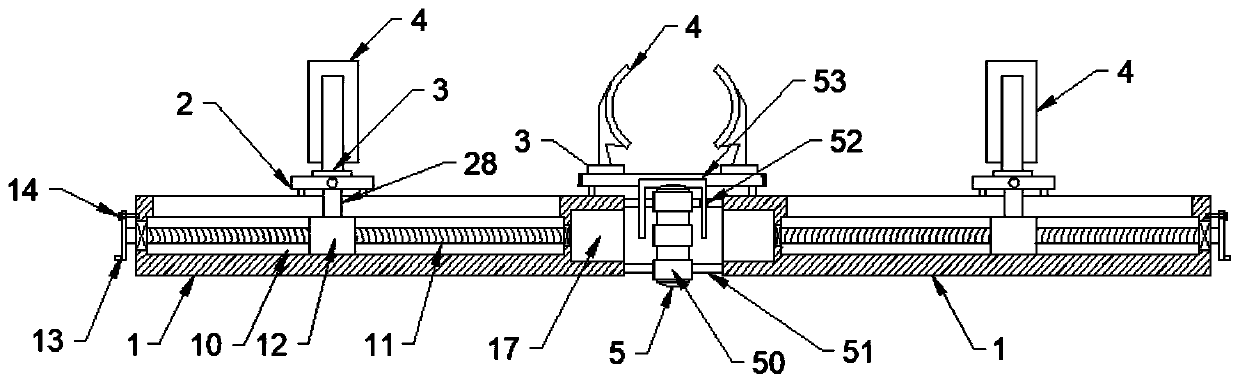

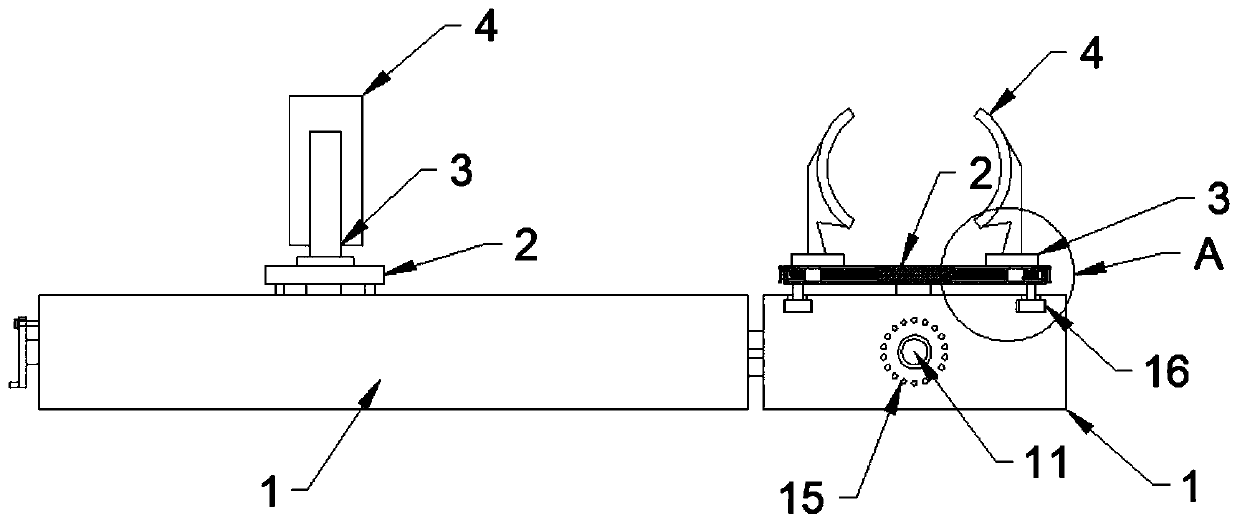

Co-location device for automatically butting and assembling large-sized thin-wall barrel-shaped members

InactiveCN104308767ALarge range of motionImprove operating precisionWork holdersMetal working apparatusRange of motionBarrel Shaped

The invention discloses a co-location device for automatically butting and assembling large-sized thin-wall barrel-shaped members and belongs to the field of assembling butting technologies. The co-location device comprises at least two sets of location mechanisms fixedly connected with the large-sized thin-wall barrel-shaped members to be assembled respectively, wherein each location mechanism comprises a slide chassis, a transverse posture adjustment platform, a vertical posture adjustment platform and a rotary posture adjustment platform. The device has the advantages of high operation precision, high automation level, large bearing capacity, high response speed and wide motion range, and can be used for accurately butting and assembling the large-sized thin-wall barrel-shaped members.

Owner:SHANGHAI JIAO TONG UNIV

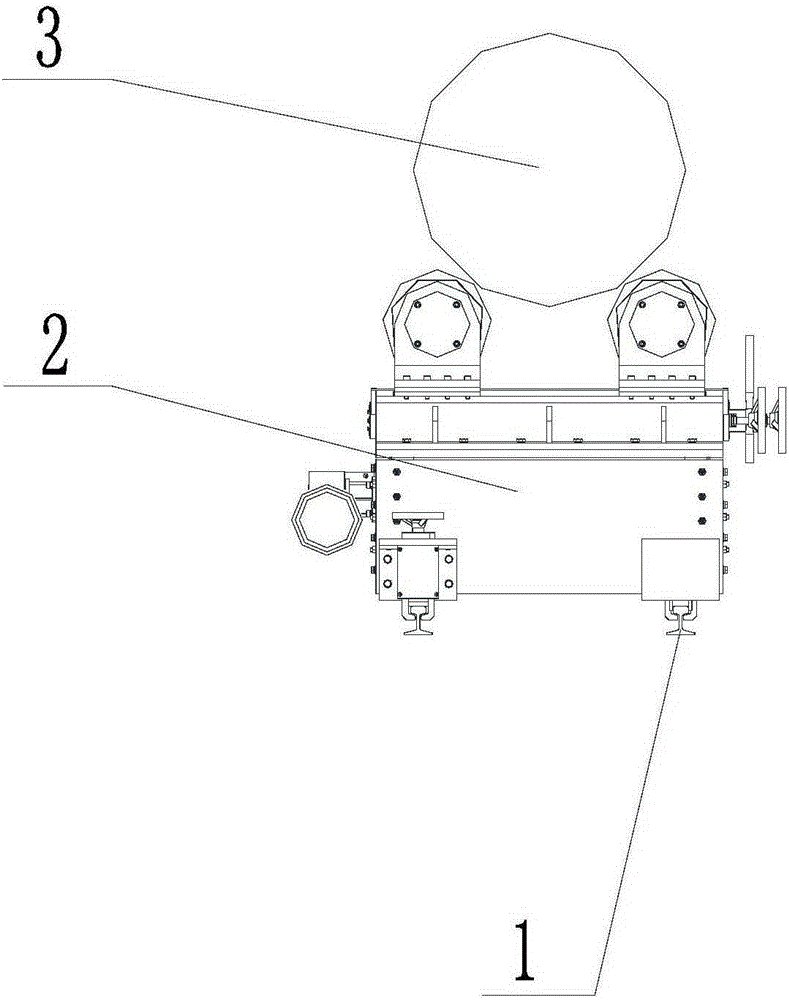

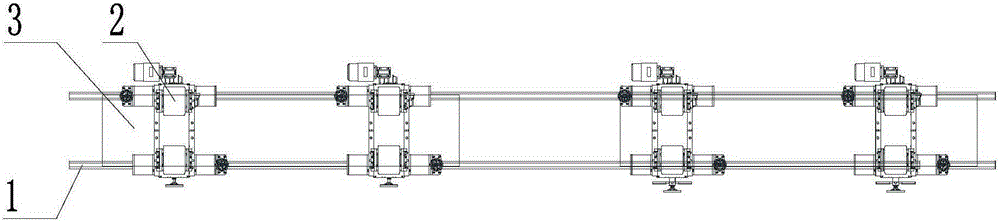

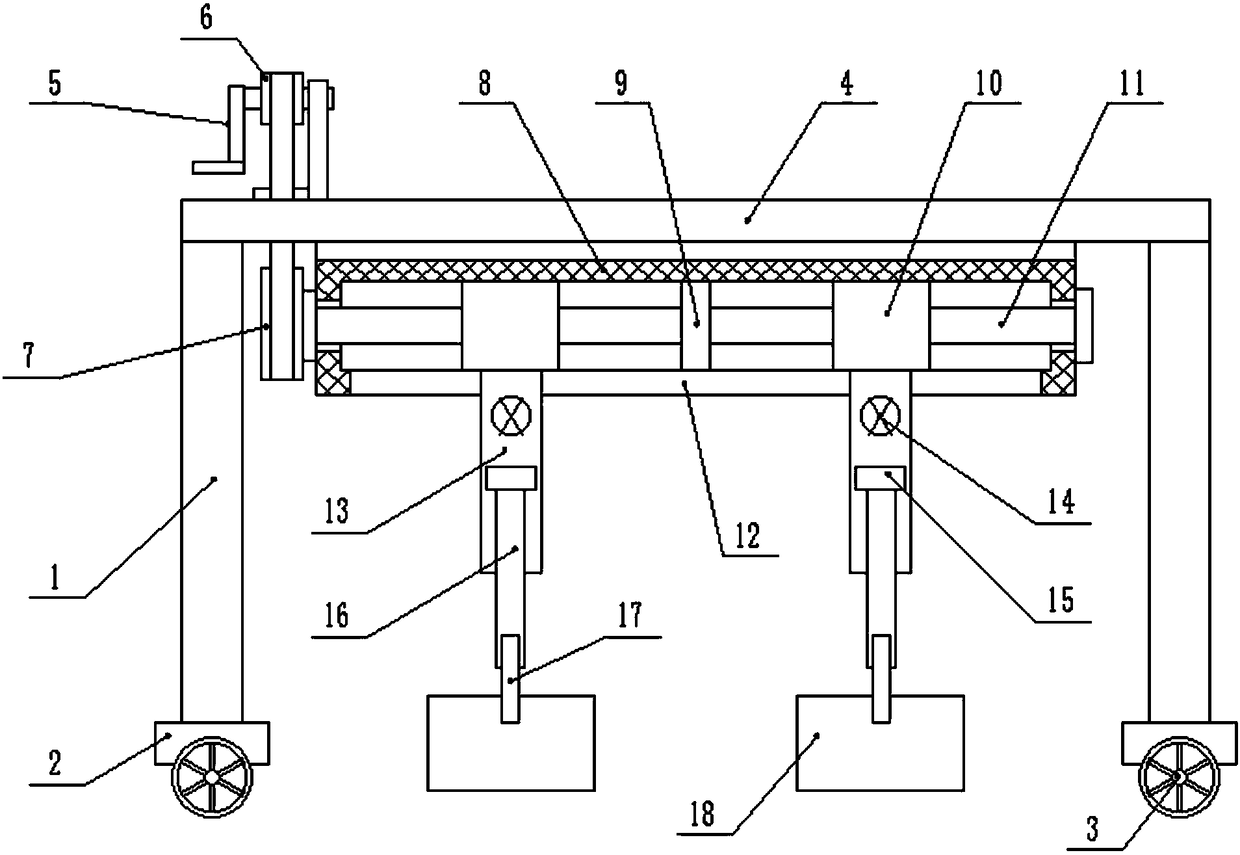

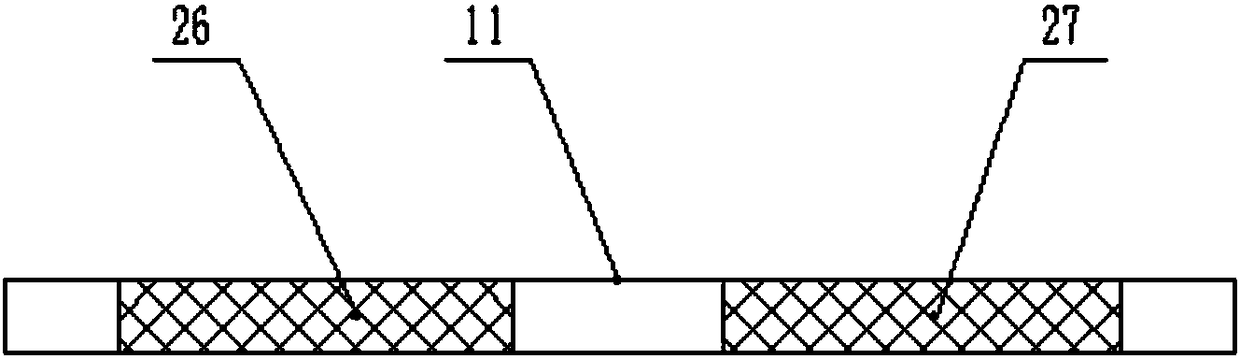

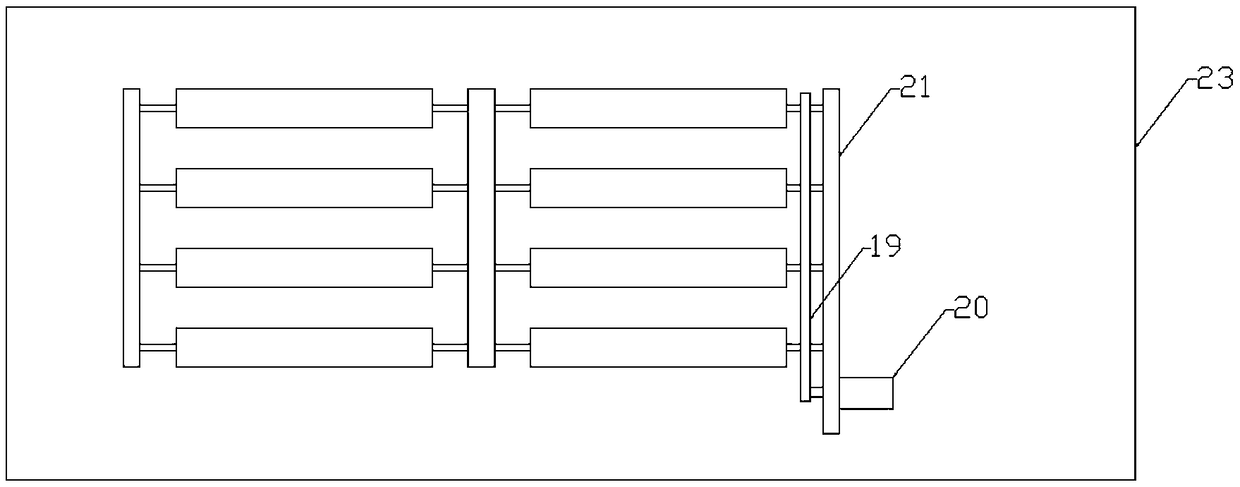

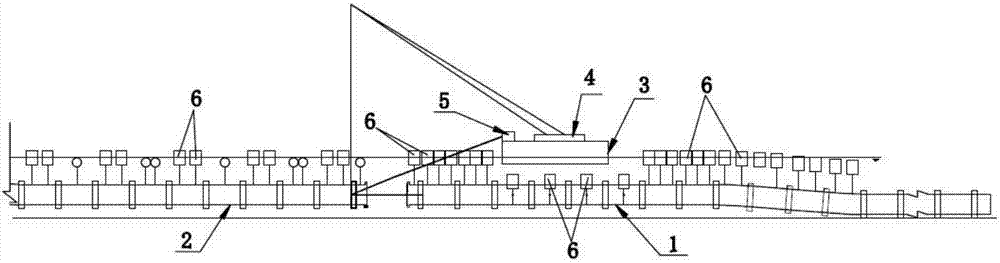

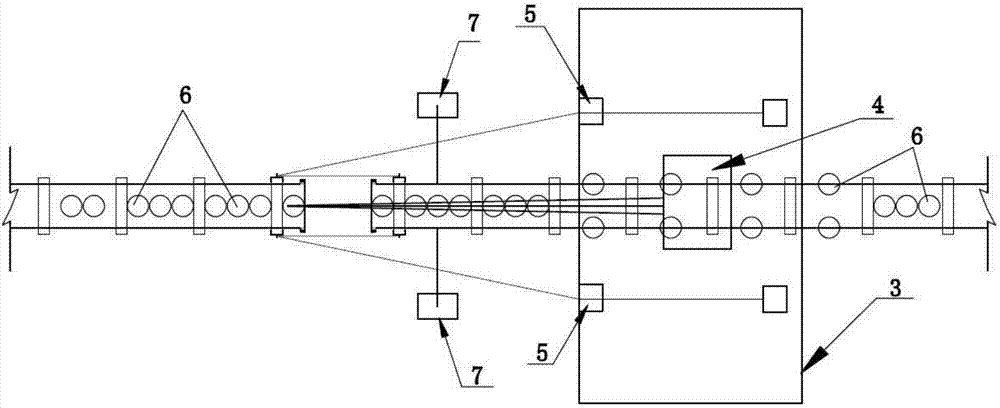

Pairing lengthening device for two-in-one pipeline

InactiveCN105195961AWon't accidentally moveRealize horizontal adjustment and alignment functionWelding/cutting auxillary devicesPipeline systemsManufacturing technologyModular design

The invention relates to a pairing lengthening device for a two-in-one pipeline and belongs to the technical field of equipment manufacture. The pairing lengthening device comprises a track and four pairing lengthening roller carriers, wherein the pairing lengthening roller carriers can be arranged on the track in the manner that the roller carriers can move along the track; each pairing lengthening roller carrier comprises radial roller adjusting devices, lifting devices and traveling devices; the traveling devices are mounted at the lower parts of the pairing lengthening roller carriers and arranged on the track in the manner that the traveling devices can move along the track; the radial roller adjusting devices can be mounted at the upper parts of the roller carriers in a vertically moving manner; the lifting devices are arranged between the traveling devices and the radial roller adjusting devices and are suitable for driving the radial roller adjusting devices to move vertically. According to the invention, since the pairing lengthening roller carriers adopt modular design, the design efficiency is improved and the production cycle is shortened.

Owner:NANJING AUTO ELECTRIC

Quotation system and quotation method

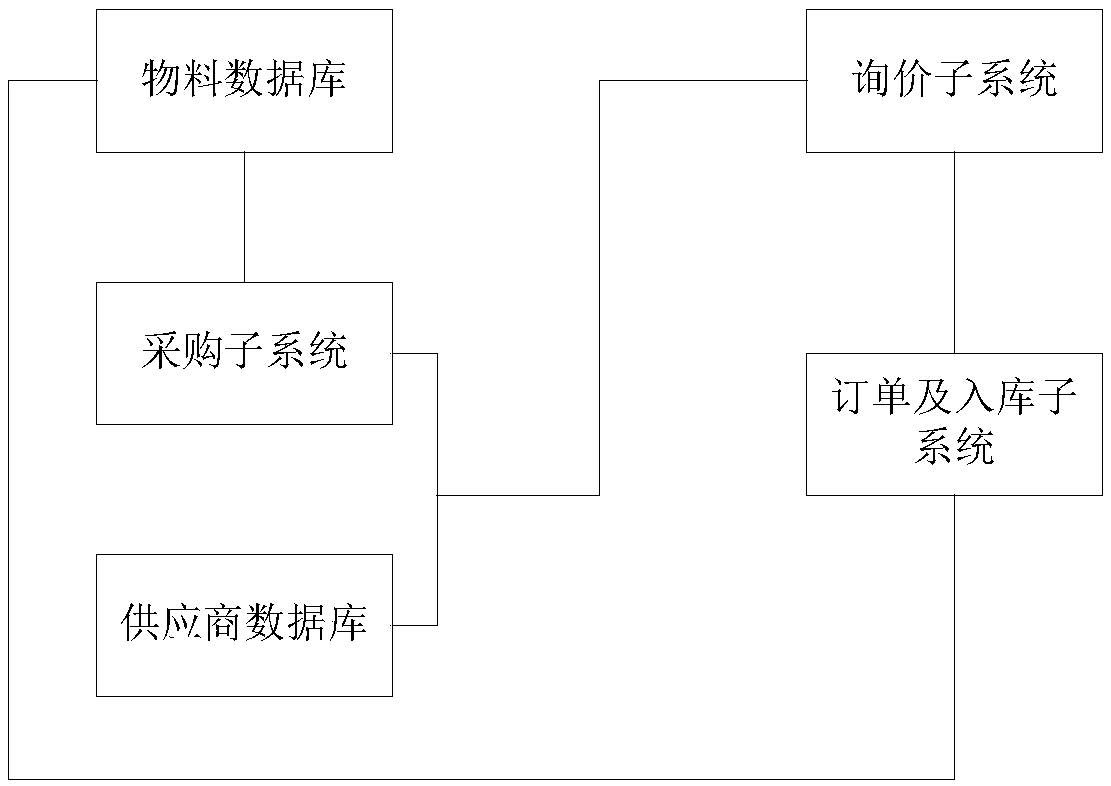

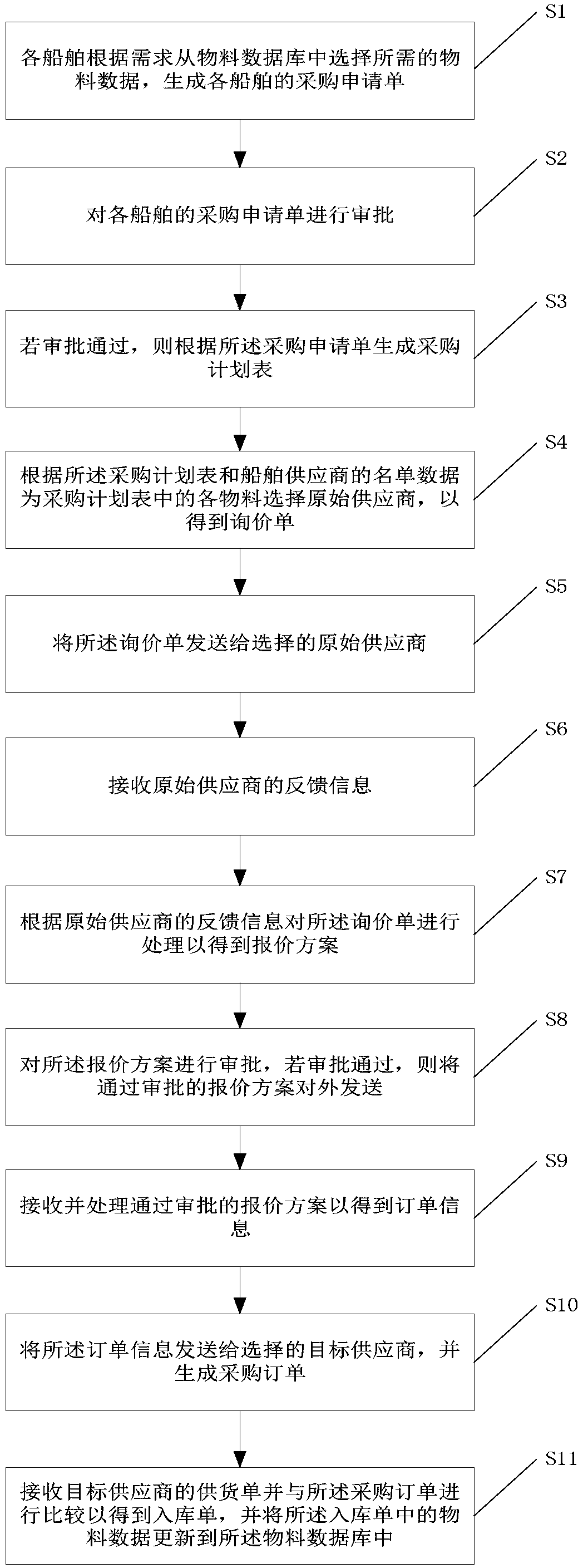

ActiveCN109034979AEasy to manageReduce the process of re-orderingOffice automationBuying/selling/leasing transactionsPurchase requisitionComputer science

The invention discloses a quotation system and a quotation method. The system comprises: a material database storing and updating the data of spare parts and materials required by a ship; after the purchase requisition is generated and approved by the purchase subsystem according to the material database, generating a purchase plan table, sending the purchase plan table and the list data of the ship supplier to the inquiry subsystem for processing to obtain an inquiry sheet, sending the inquiry sheet to the supplier, processing the inquiry sheet according to the feedback information of the supplier to obtain a quotation scheme, approving the quotation scheme, and sending the quotation scheme to the public after the approval; the order and warehousing subsystem receiving and processing thequotation scheme to obtain the order information, sending the order information to the selected target supplier, generating the purchase order, receiving the supply document of the target supplier andcomparing with the purchase document to obtain the warehousing document, and updating the material data in the warehousing document to the material database. The effect is that: correlation of data is strong, operation of each link is flexible, the work efficiency is improved.

Owner:上海互海信息科技有限公司

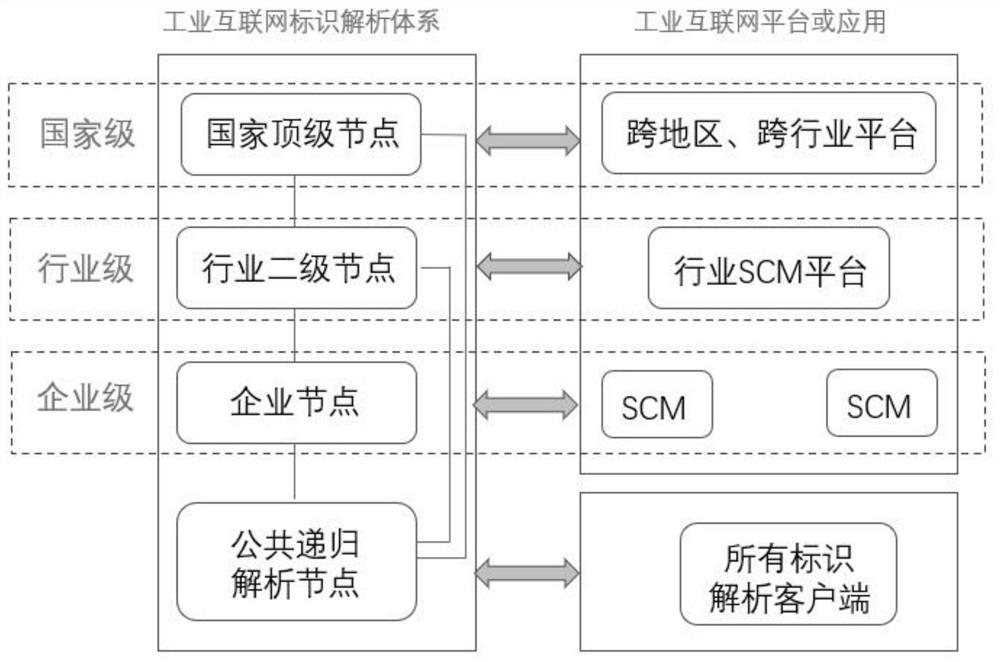

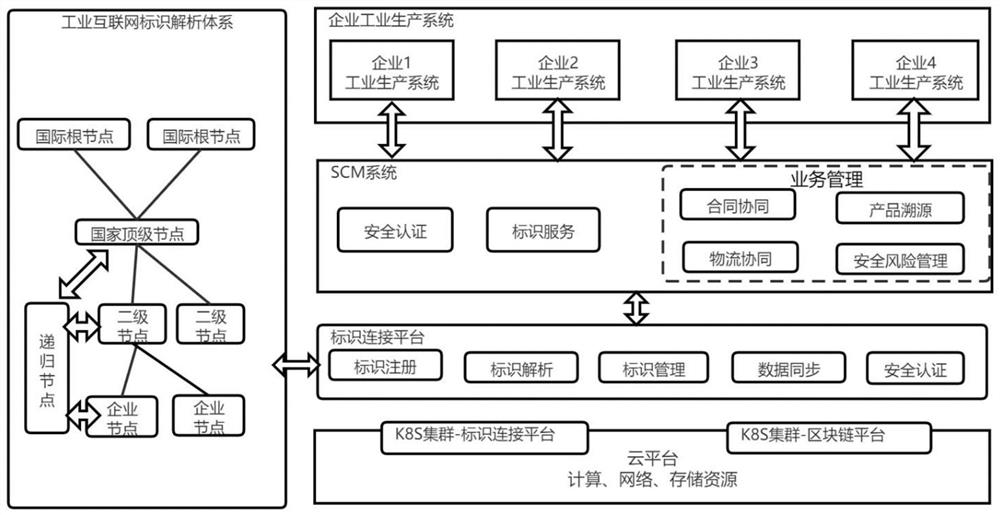

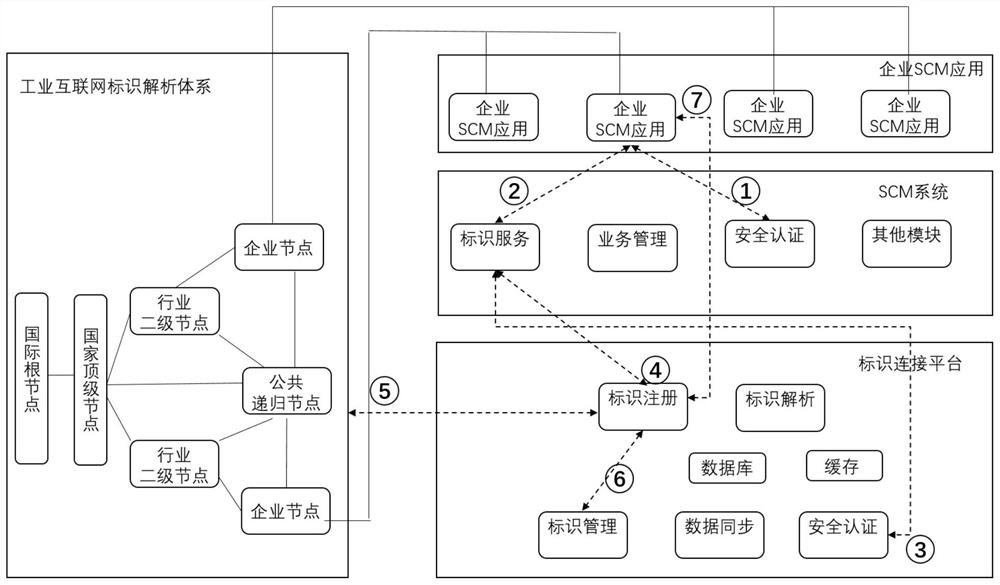

SCM-oriented industrial Internet identifier registration and analysis method and identifier connection platform and system

ActiveCN112491960ABreak the status quo of strong association constructionSimple dockingTransmissionManufacturing computing systemsThe InternetEngineering

The invention discloses an SCM-oriented industrial Internet identifier registration and analysis method and an identifier connection platform and system, and the method comprises the steps: calling aninterface of an industrial Internet identifier analysis system for identifier registration according to a client identifier registration request; storing the identifier mapping relationship of the identifier registration information into an identifier connection platform database, and returning the identifier registration information to the client; according to the client identifier analysis request, performing identifier analysis query in an identifier connection platform cache, an identifier connection platform database or an industrial Internet identifier analysis system, and returning theobtained corresponding identifier mapping relationship to the client. According to the invention, the SCM system is associated with the industrial Internet identifier analysis system through the identifier connection platform, so that the docking mode of the enterprise SCM application and a plurality of secondary nodes is simplified, the current situation that most of SCM applications are strongly associated and constructed with the industrial secondary nodes at present is broken through, and the identifier service docking efficiency is improved.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

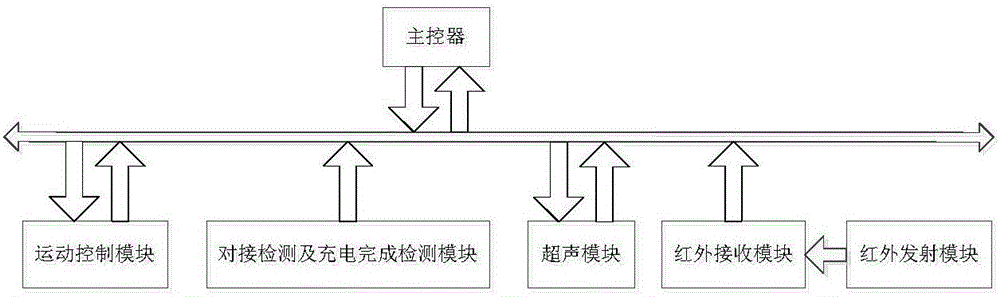

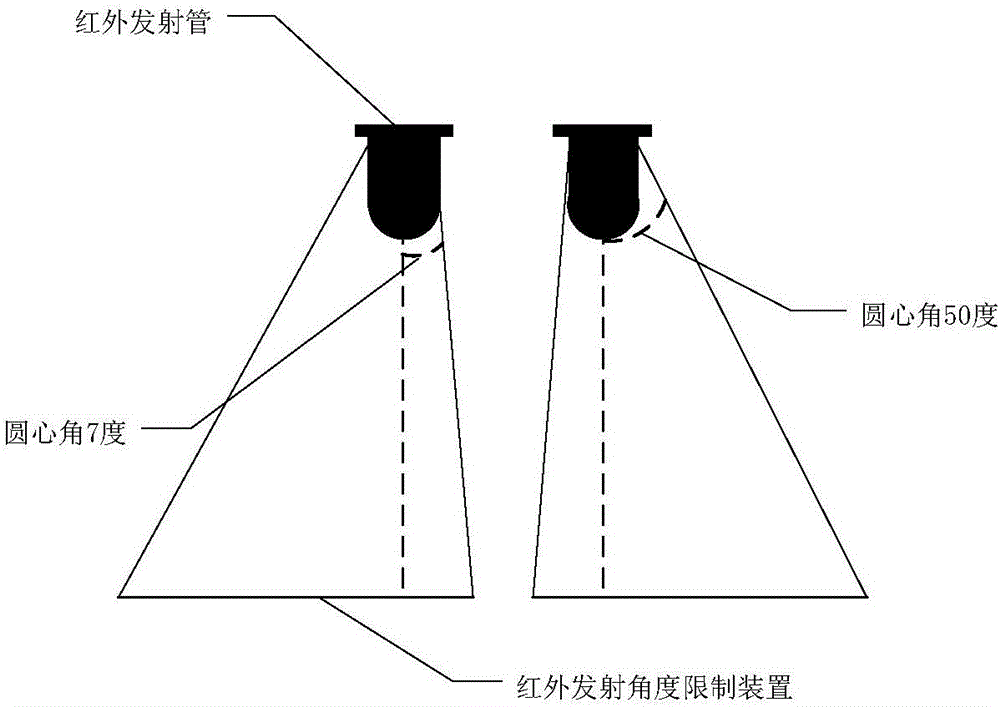

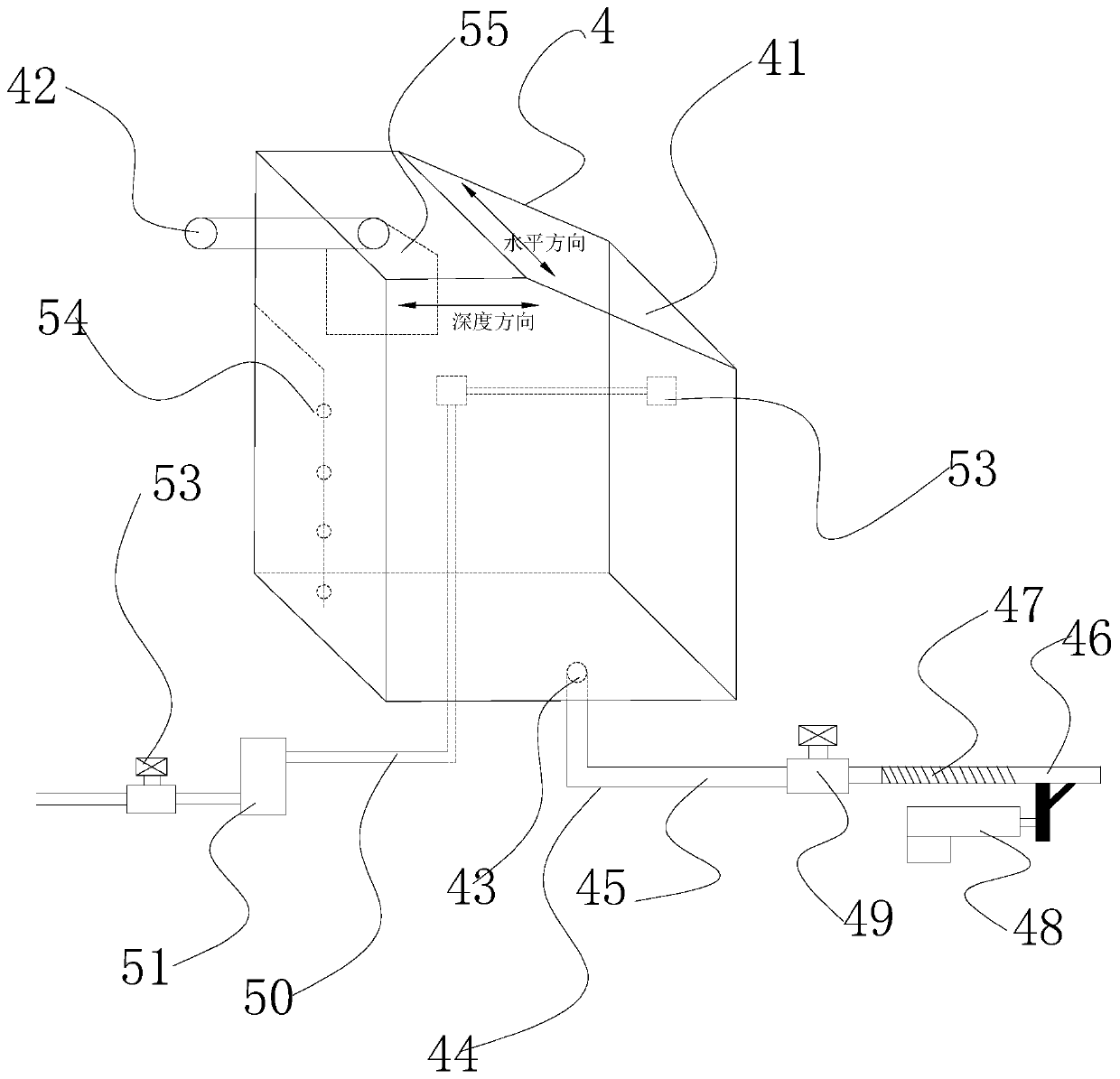

Autonomous charging system and charging method thereof for intelligent home accompanying robot

ActiveCN106406316AImprove docking success rateImprove docking efficiencyVehicular energy storagePosition/course control in two dimensionsUltrasonic sensorComputer module

The invention discloses an autonomous charging system and a charging method thereof for an intelligent home accompanying robot. An infrared emission module emits infrared pulse signals of different frequencies and the signals are transmitted to an infrared receiving module; a robot main controller controls movement of the robot, and charging butt joint between a charging station and the robot is realized during the moving process of the robot; a butt joint detection module is used for detecting whether the charging butt joint between the charging station and the robot is completed and transmitting the corresponding signals to the robot main controller after the butt joint is completed, and the main controller controls the robot to move and charging begins; and a charging completion detection module is used for transmitting the corresponding signals to the main controller after charging of the robot is completed, and the main controller controls the robot to automatically drive away from the charging station. The butt joint success rate and the efficiency are high, and 100% butt joint in limited space can be achieved; and as infrared and ultrasonic sensors are used, the use is simple, and the device cost is low.

Owner:SHANDONG UNIV

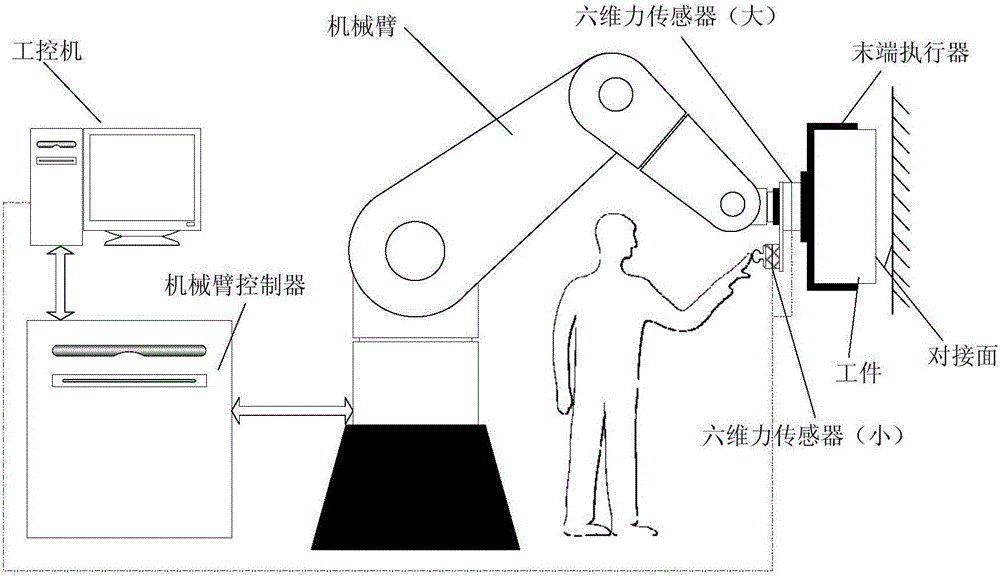

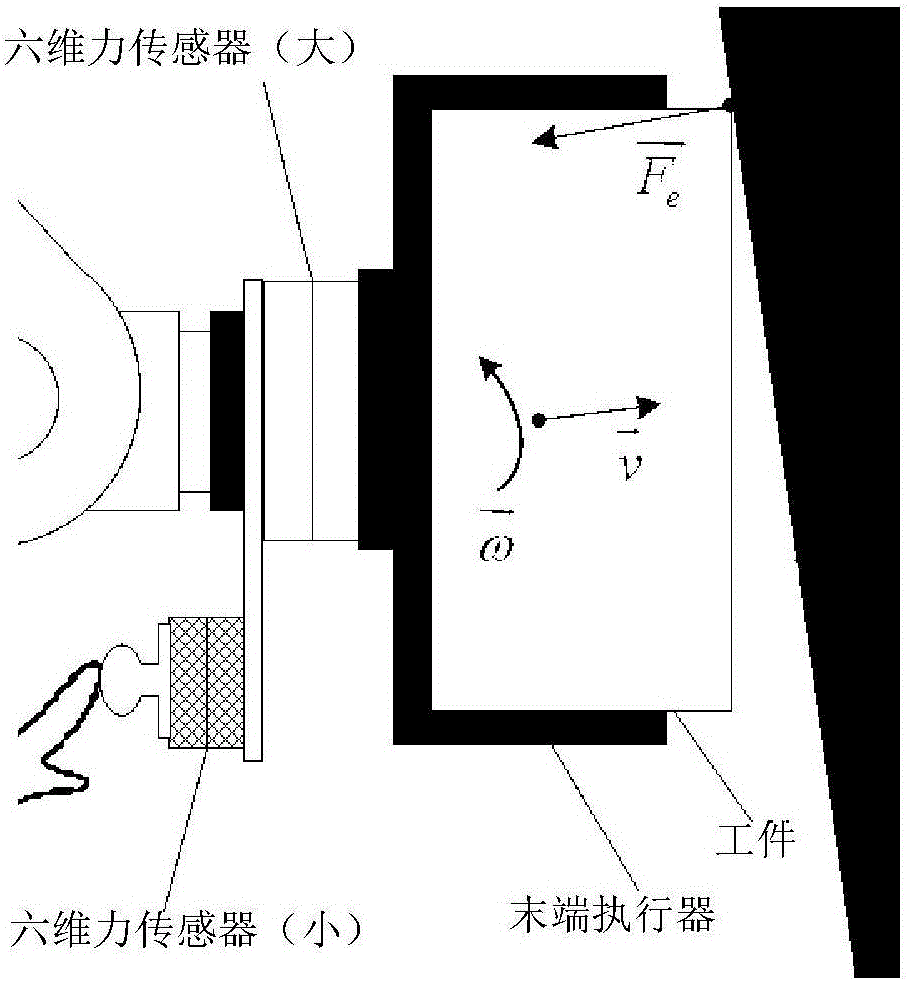

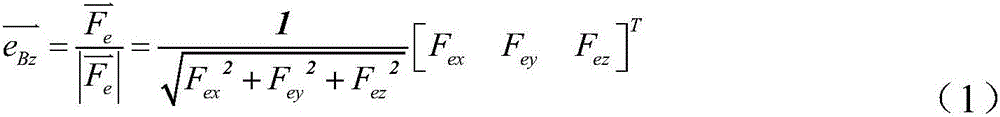

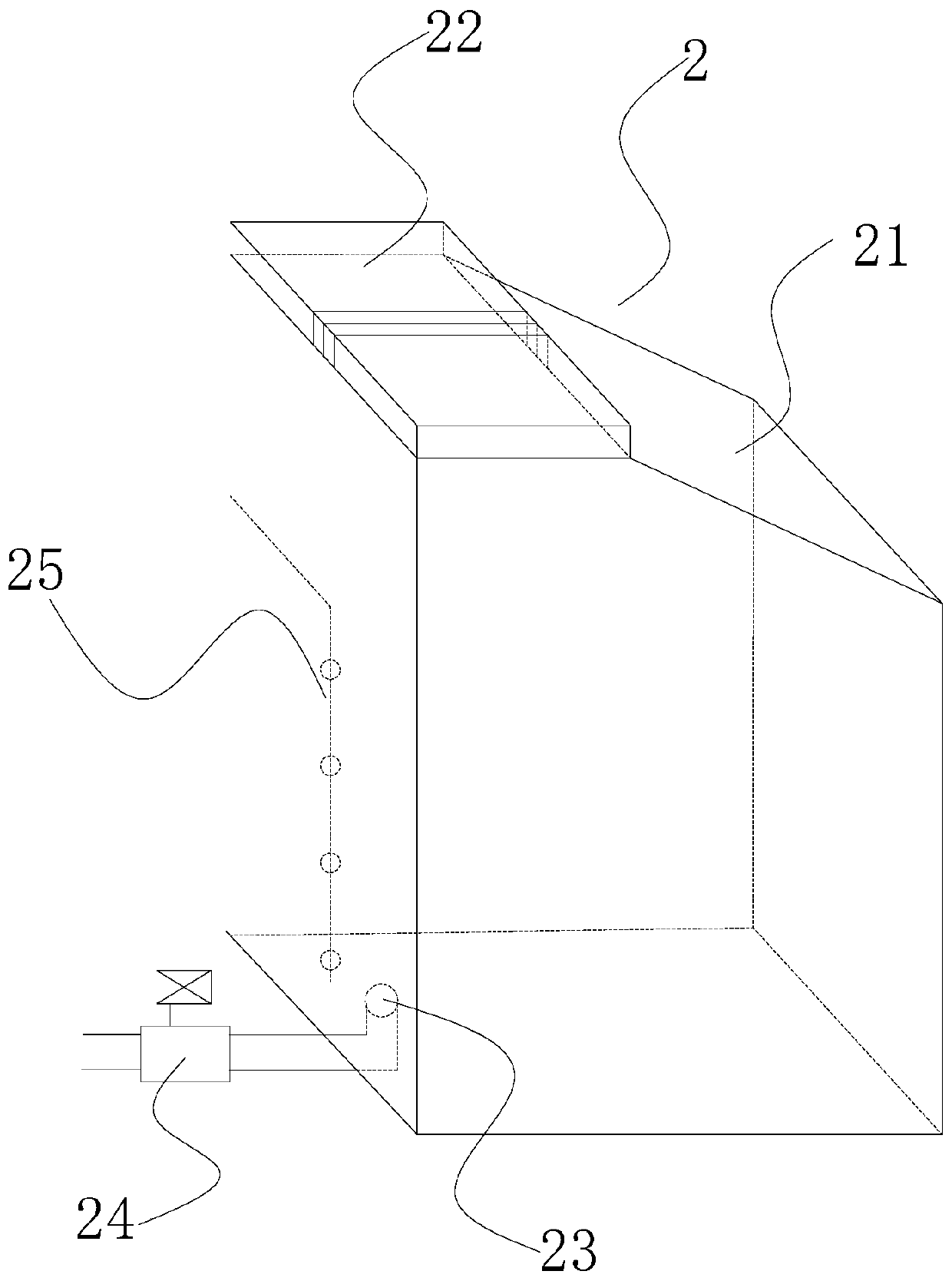

Force feedback-based industrial robot auxiliary assembling and flexible docking method

ActiveCN106625653AImprove docking efficiencyImprove fitting accuracyProgramme-controlled manipulatorVisual observationResultant force

The invention discloses a force feedback-based industrial robot auxiliary assembling and flexible docking method which is characterized in that a low-six-dimensional-force sensor is manually pushed or twisted to enable a workpiece at the tail end of an industrial robot to do corresponding instant motion; the workpiece docking posture is subjected to fine adjustment to realize posture adjustment for mounting the workpiece; and meanwhile, the moving track of the industrial robot is corrected in real time through a force / posture mixing control method according to feedback information of a high-six-dimensional-force sensor and an error between actual acting force and ideal acting force, so that contact force can be retained in a desired range, and flexible docking is realized. According to the force feedback-based industrial robot auxiliary assembling and flexible docking method, by means of force feedback and algorithm control, mounting equipment can be completely fitted with the mounting surface, and the fitting precision is much higher than that obtained by visual observation and manual following adjustment fitting; and repeated visual observation of the docking condition and repeated adjustment of the equipment posture are not needed, so that the docking efficiency is greatly improved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Intelligent water supply and discharging floor cleaning robot system and water supply and discharging control method thereof

InactiveCN110584550AFree laborImprove work efficiencyCarpet cleanersFloor cleanersRobotic systemsWater discharge

The invention provides an intelligent water supply and discharging floor cleaning robot system and a water supply and discharging control method thereof. The intelligent water supply and discharging floor cleaning robot system comprises a robot, a water supply and discharging device, a butt joint module and a water pumping and discharging module, wherein the butt joint module comprises a positionreturn system; the robot comprises a clear water structure and a sewage structure; the clear water structure comprises a clear water box and a clear water inlet opening; the sewage structure comprisesa sewage box and a sewage outlet opening; and the water supply and discharging device comprises a water supply pipe and a water discharging pipe. Particularly, the butt joint module also comprises afine adjustment system used for performing position fine adjustment on the robot after the robot enters a preset position; the water pumping and discharging module is connected with the butt joint module, and comprises a sewage liquid level sensor positioned in the sewage box and a clear water liquid level sensor positioned in the clear water box; the sewage liquid level sensor is coupled with a sewage outlet electromagnetic valve positioned in the position of the sewage outlet opening; and the clear water liquid level sensor is coupled with a clear water inlet electromagnetic valve positionedin the position of the water supply pipe. The intelligent water supply and discharging floor cleaning robot system and the water supply and discharging control method have the advantages that the work efficiency is high; and the butt joint effect is good, and the like.

Owner:江苏天策机器人科技有限公司

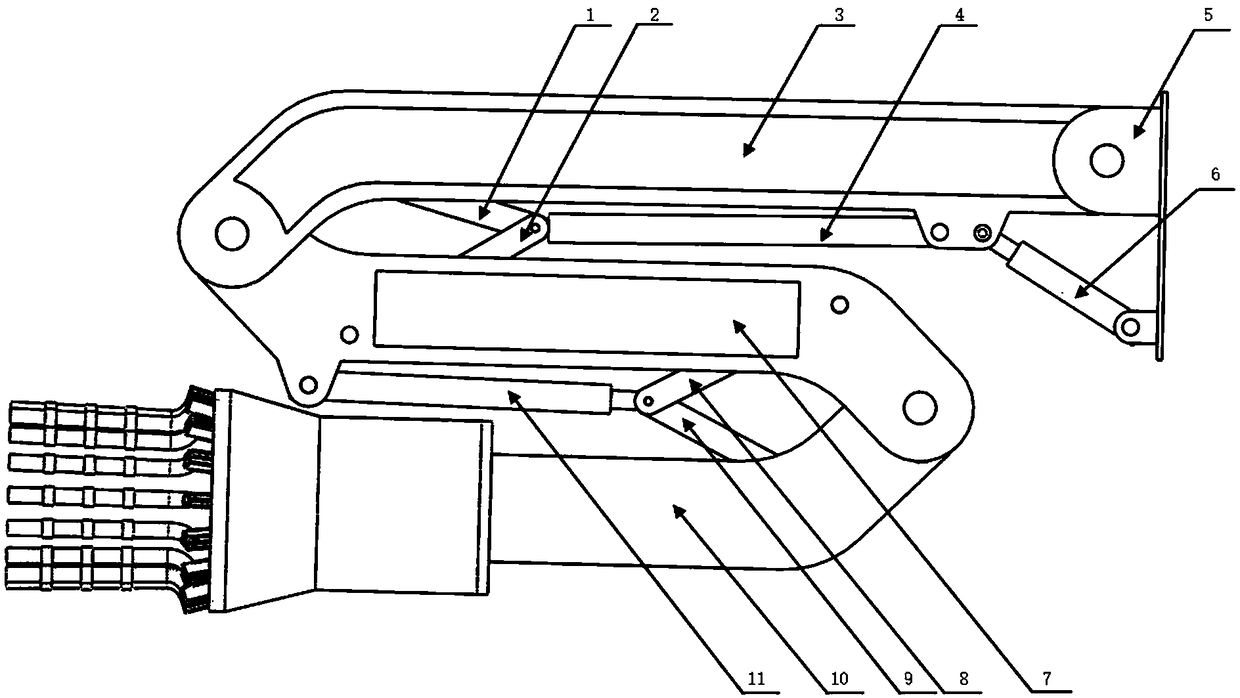

Transportable type device applicable to capturing and butt joint of underwater moving target

ActiveCN108502129AImprove power efficiencyImprove capture efficiencyUnderwater equipmentUnderwater manipulatorMarine engineering

The invention belongs to the field of related equipment of deep sea rendezvous and docking and discloses a transportable type device applicable to capturing and butt joint of an underwater moving target. The transportable type device comprises a mechanical arm, a guide cover capturing unit, a light source guide unit and a butt joint unit, wherein the mechanical arm is designed into a multi-joint type underwater mechanical arm and can be folded and stored after operation is finished; the guide cover capturing unit is mounted at the tail end of the mechanical arm and has opening and closing functions, so that the capturing of the underwater moving target is finished; the light source guide unit is used for sensing a position and a posture of the underwater moving target; the butt joint unitis used for carrying out mutual and accurate butt joint on a butt joint socket for the underwater moving target through a plug manner. With the adoption of the transportable type device disclosed by the invention, capturing and butt joint operation of the underwater moving target can be finished under a moving state in a higher-precision manner; meanwhile, influences caused by seawater interference are effectively overcome, the capturing success rate and the capturing efficiency are remarkably improved, and the accuracy and applicability of the butt joint operation are ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

Hoop type power cable wiring butt joint device

InactiveCN108183432AReasonable structureInnovative designApparatus for joining/termination cablesPower cableButt joint

The invention discloses a hoop type power cable wiring butt joint device. The device comprises a bracing frame, wherein an upper end of the bracing frame is equipped with a cross board, a middle portion of a lower end of the cross board is equipped with a guide sleeve, the guide sleeve is internally equipped with a screw, a left end of the screw is connected with a driven sprocket, an upper end ofthe driven sprocket is connected with an active sprocket through a chain, middle portions of two ends of the screw are connected with sliding blocks, lower ends of the sliding blocks are equipped with fixing sleeves, the fixing sleeves are internally equipped with screw rods, middle portions of upper ends of the screw rods are equipped with driven gears, right ends of the driven gears are connected with active gears, middle portions of lower ends of the screw rods are equipped with lifting blocks, two ends of the lifting blocks are fixed with lifting rods, the other ends of the lifting rods are hinged with first connection rods, and lower ends of the first connection rods are hinged with second connection rods. The device is advantaged in that clamping and fixing of power cables at two ends are realized, butt joint of the power cables after clamping is realized, not only can butt joint efficiency of the power cables be enhanced, but also labor intensity of workers can be further reduced, and butt joint demands of the multi-core power cables are satisfied.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

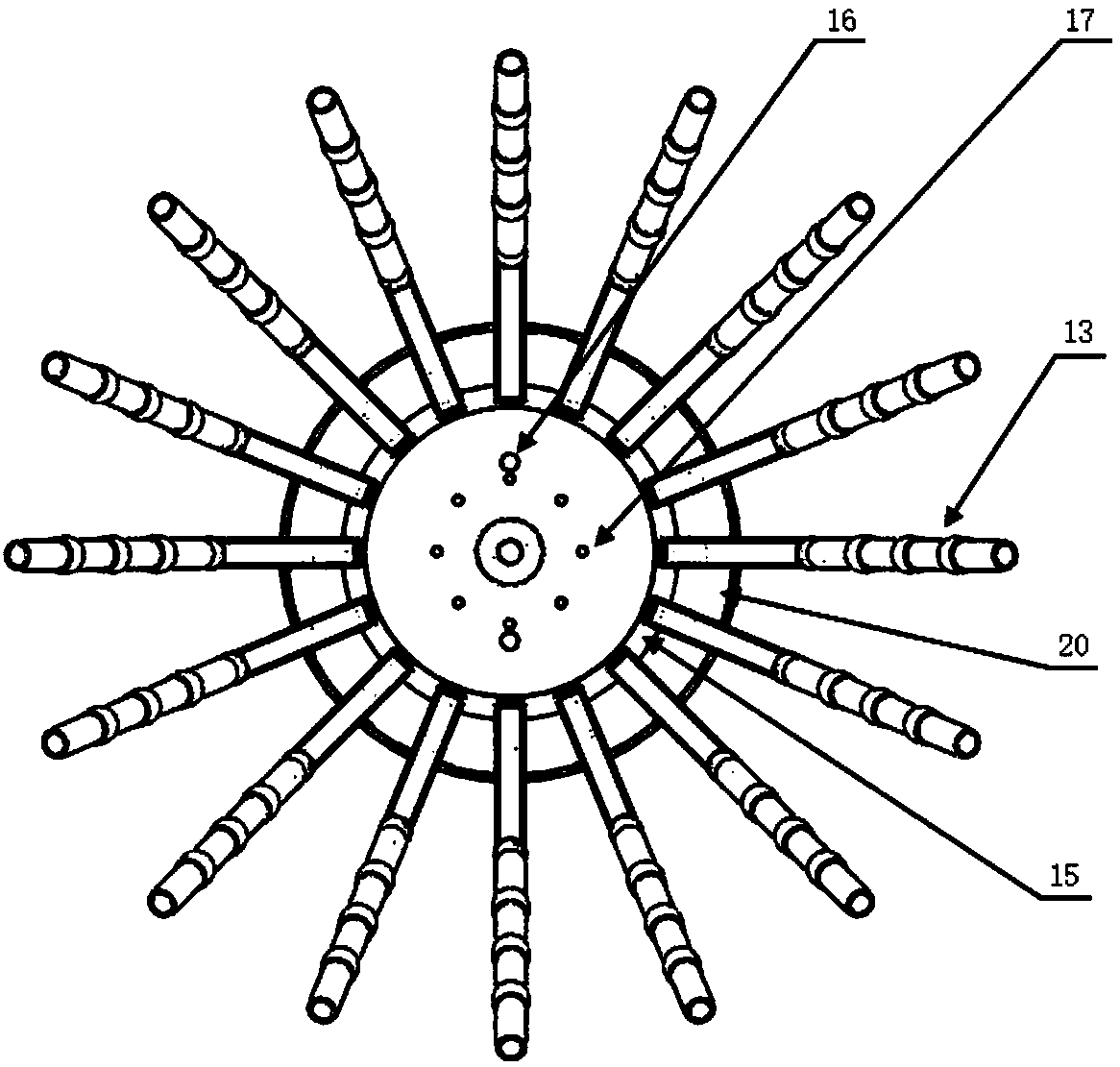

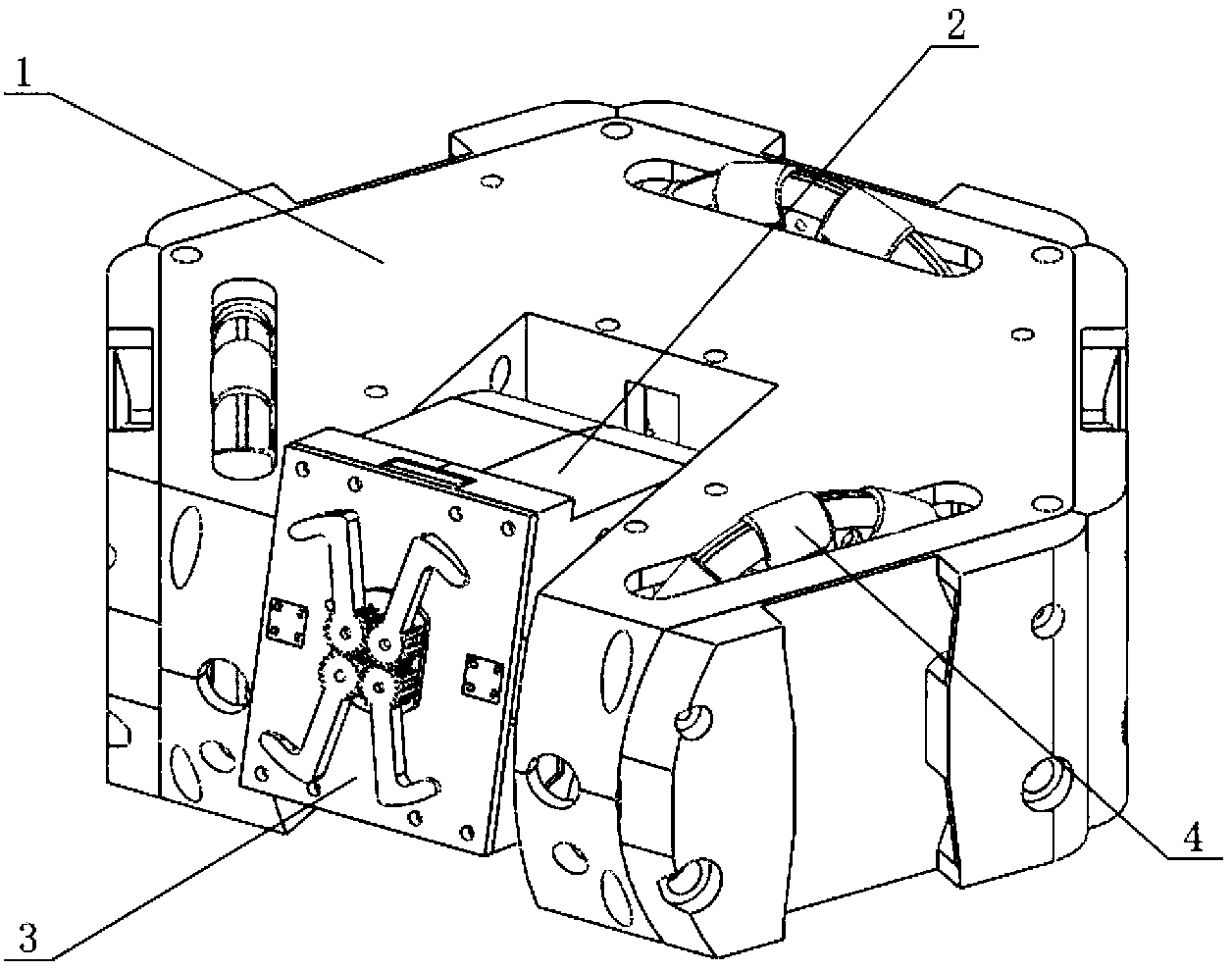

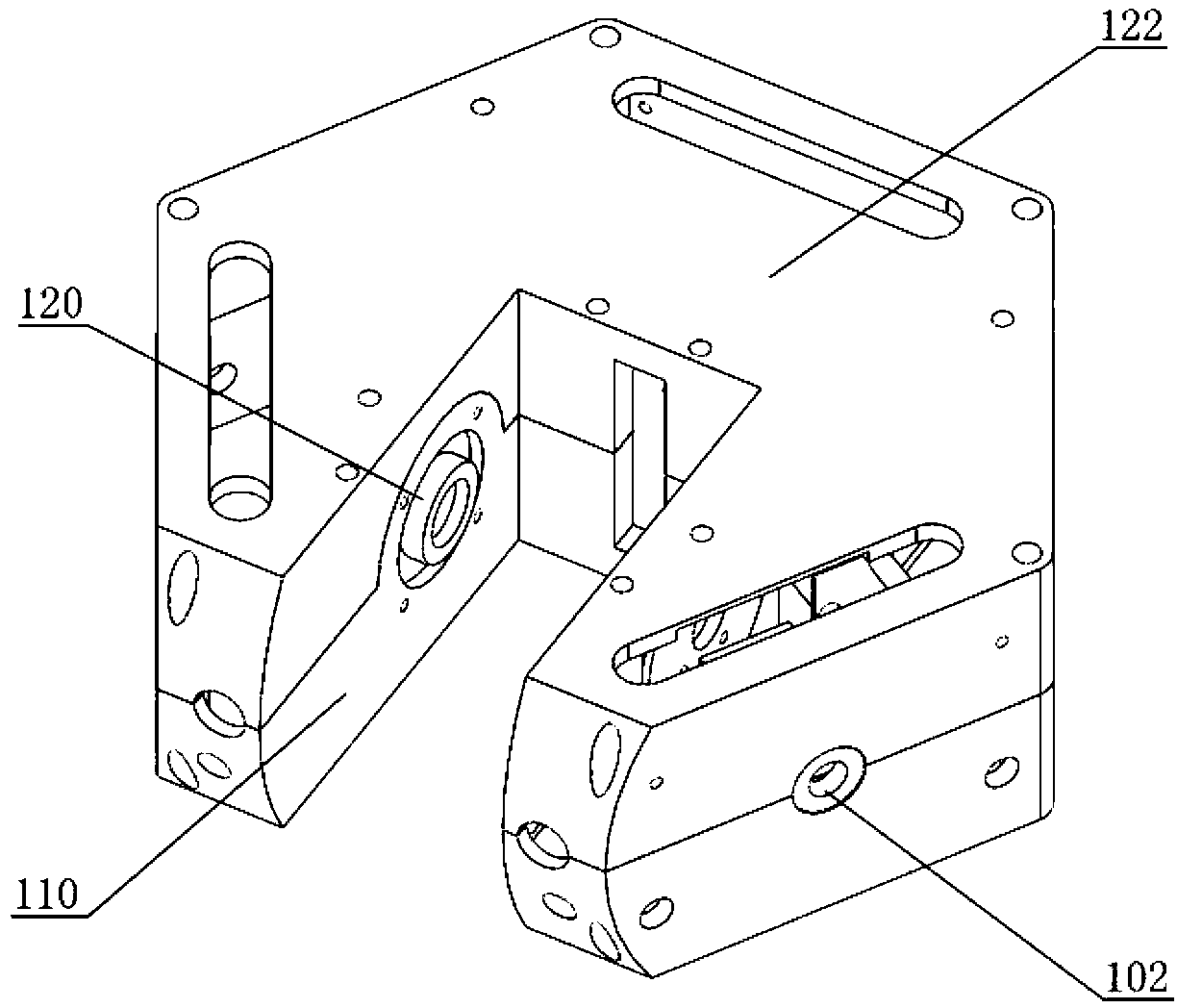

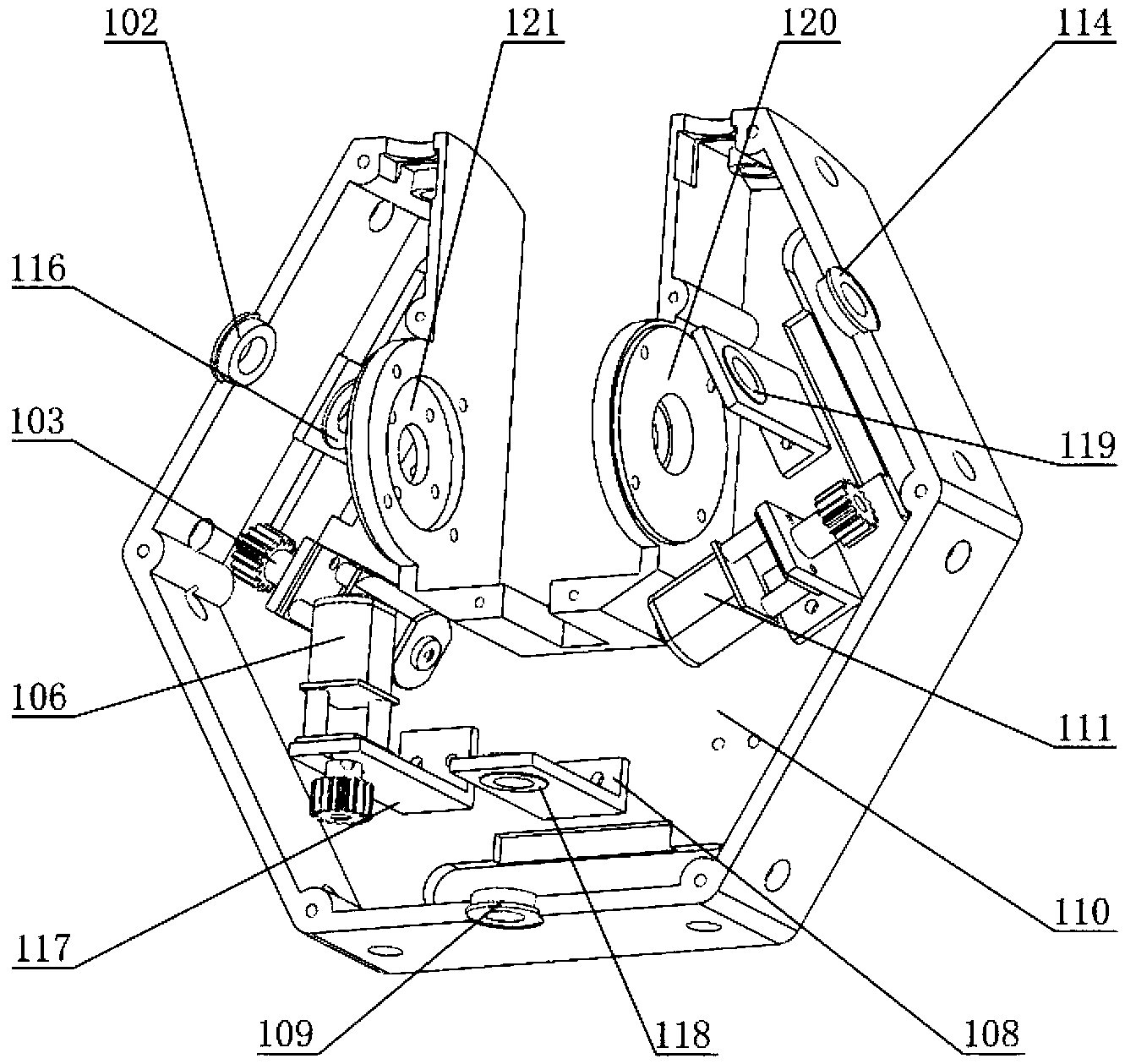

Omni-directional moving unit module structure of modularized self-reconfiguration robot

A unit module used for constructing a modularized self-reconfiguration robot comprises a machine body, a pitching joint, a docking device and a coupled wheel device. The machine body is of a hexahedron structure overall and comprises an upper casing part and a lower casing part, and a main circuit board and three driving motors are arranged on the inner wall of the machine body casings. The pitching joint is characterized in that a steering engine is fixed on a left steering engine fixing frame and a right steering engine fixing frame to form a U-shaped steering engine joint, and the pitching joint is connected with the machine body through a steering plate and a bearing. The docking device comprises a driving docking mechanism and a driven docking mechanism, wherein the driving docking mechanism drives gear rotating hooks to rotate through a stepping motor, and the driven docking mechanism which is a slotted plate and a driven docking surface of the machine body are in fixed installation. The coupled wheel device comprises three independent iso-structural omni-directional wheel movement mechanisms which are fixed with the machine body, are in regular triangle distribution and are driven by a direct current motor. The unit module has strong movement capability, can achieve omni-directional movement of single part, and docking between the modules is facilitated due to the fact that each unit module is provided with many docking surfaces.

Owner:NANJING PANDA ELECTRONICS +1

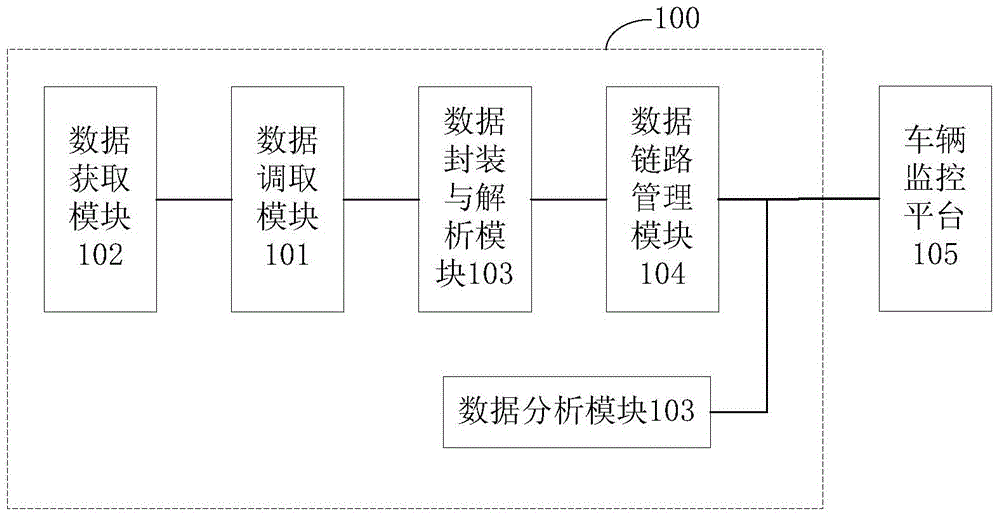

Vehicle-borne GPS terminal

ActiveCN104155667AAvoid damageThe docking process is simpleSatellite radio beaconingTransmissionEncapsulated dataComputer terminal

The invention discloses a vehicle-borne GPS terminal which comprises a data calling module which is used for calling relevant data from stored vehicle traveling data and the terminal data of a vehicle-borne GPS terminal, a data packaging and parsing module which is used for packaging the called data according to a preset protocol to obtain packaged data, and a data link management module which is used for sending the packaged data to a vehicle monitoring platform and sending response data which is returned by the vehicle monitoring platform and is packaged according to the preset protocol to the data packaging and parsing module so as to carry out parsing through the data packaging and parsing module to obtain the response data. According to the vehicle-borne GPS terminal, different vehicle-borne GPS terminals can be imitated according to actual needs, in this way when the vehicle monitoring platform is tested, the installation of different vehicle-borne GPS terminals on different vehicles is not needed any more, and the actual driving is not needed either.

Owner:GUOXINJUNCHUANG YUEYANG 6906 TECH CO LTD

Abutting device for wiring of tensioning power cable

InactiveCN107979035AReasonable structureInnovative designElectrical testingApparatus for joining/termination cablesPower cableEngineering

The invention discloses an abutting device for wiring of a tensioning power cable. The abutting device comprises a support rack, wherein a horizontal plate is arranged at an upper end of the support rack, a guide sleeve is arranged at a middle part of a lower end of the horizontal plate, a screw rod is arranged in the guide sleeve, a left end of the screw rod is connected with a driven chain wheel, an upper end of the driven chain wheel is connected with a driving chain wheel via a chain, sliding blocks are connected with middle parts of two ends of the screw rod, fixed posts are arranged at lower ends of the sliding blocks, support plates are arranged at lower ends of the fixed posts, first limitation blocks are arranged at two sides of a lower end of each support plate, a clamping rod ishinged with lower ends of the first limitation blocks, a clamping ring is arranged at an inner side of the clamping rod, a second limitation block is arranged at a middle part of the clamping rod andis hinged with a pull rod, and a rotation wheel is hinged with the other end of the pull rod. By the abutting device, power cables at two ends are clamped and fixed, abutting of the power cables after being clamped is further achieved, the abutting device is simple to operate, the abutting efficiency of the power cable is achieved, meanwhile, the labor intensity of a worker is also reduced, and the abutting demand of a multi-core power cable is satisfied.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

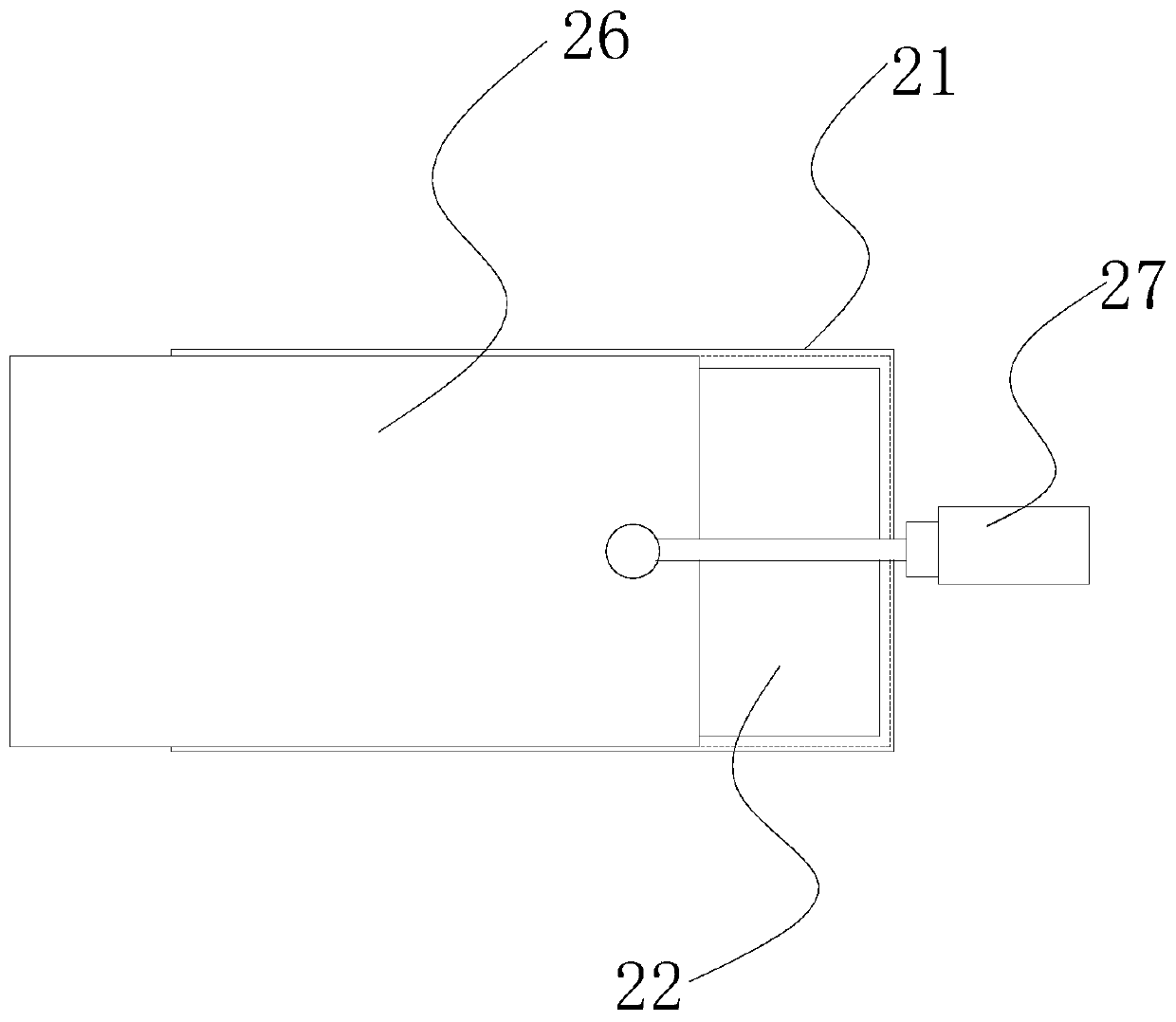

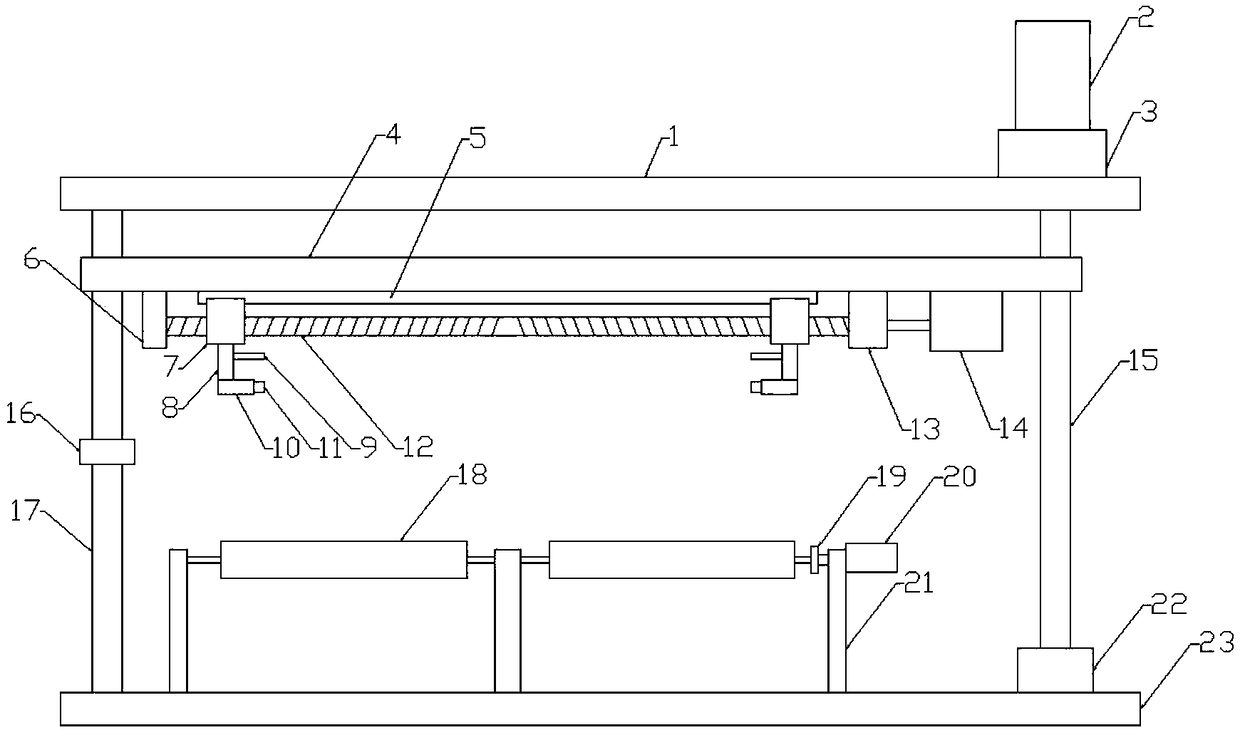

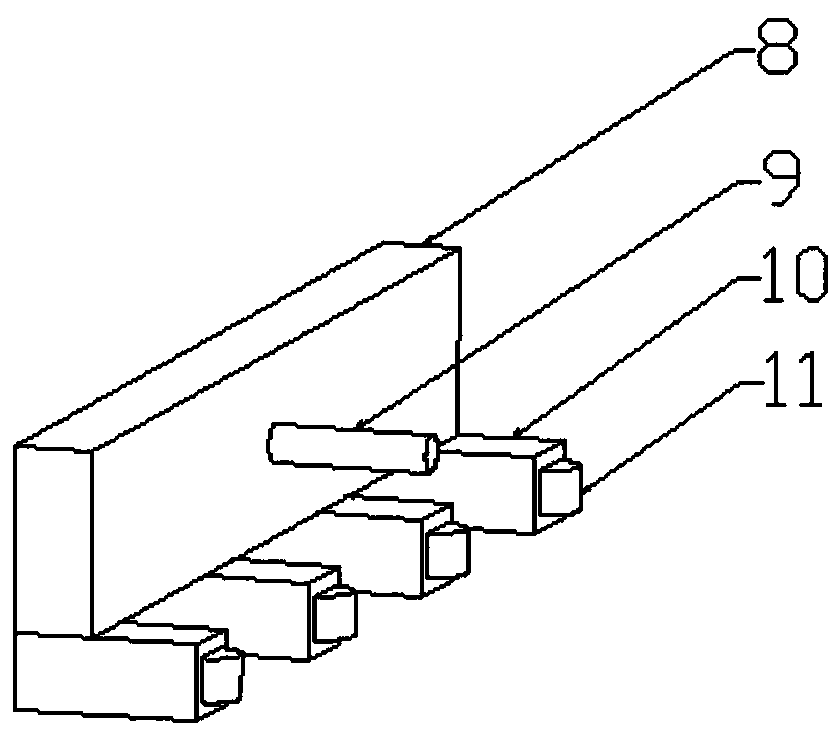

Correcting device for rectangular plate splicing

InactiveCN108637558ALabor savingImprove docking efficiencyWelding/cutting auxillary devicesAuxillary welding devicesButt jointSlide plate

The invention discloses a correcting device for rectangular plate splicing. The correcting device comprises a top plate and a bottom plate. A support is arranged at the middle portion of the bottom plate and provided with a plurality of rollers. A transmission motor is fixed to the side face of the support. A sliding rod is fixed to one end of the bottom plate, and a first lead screw supporting base is fixed to the other end of the bottom plate. A first motor transmission base is arranged at the upper end of the top plate. A lead screw is arranged in the first motor transmission base and the first lead screw supporting base. A stepping motor is fixed to the upper end of the first motor transmission base. The lead screw is provided with a sliding plate. A sliding rail is arranged at the lower end of the sliding plate. A second lead screw supporting base and a second motor transmission base are arranged at the two ends of the sliding rail. A both-way lead screw is arranged between the second lead screw supporting base and the second motor transmission base. The lower end of the sliding plate is further provided with a servo motor. The both-way lead screw is provided with symmetric sliding bases. The lower ends of the sliding bases are provided with connecting plates. A plurality of connecting rods are evenly distributed at the lower ends of the connecting plates. Wheels are arranged at the front ends of the connecting rods. According to the correcting device, the trouble of manual plate adjustment is saved, the operation process is simple and fast, plate position adjustment is accurate, and the plate butt joint efficiency is improved.

Owner:WUHU JUNRU THERMAL INSULATION MATERIAL CO LTD

Underwater butt-joint method for pipelines

ActiveCN107166092AEasy and fast dockingImprove docking efficiencyPipe laying and repairUnderwaterButt joint

The invention provides an underwater butt-joint method for pipelines. The underwater butt-joint method for the pipelines includes the following steps that S1, an air bag is used for lifting up the butt-joint end of the pipeline which has been installed, and a pulling closing device and a limiting device are installed; S2, a blind plate and a sand blocking plate of the butt-joint end of the pipeline which has been installed are disassembled, and the pipeline which has been installed is subjected to watering sedimentation; S3, a to-be-installed pipeline is subjected to watering sedimentation; S4, the butt-joint end of the to-be-installed pipeline is provided with a fixture which is provided with rolling wheels; S5, a steel wire rope of a winch penetrates the fixture of the butt-joint end of the to-be-installed pipeline, and is connected with the pulling closing device of the butt-joint end of the pipeline which has been installed; S6, the steel wire rope of the winch is tightened to make the to-be-installed pipeline attached to the pipeline which has been installed; S7, flange plates at the two ends are subjected to coarse positioning through a steel screw rod; S8, fixing bolts matched with the flange plates are installed and are tightened; and S9, the air bag is sequentially released in the direction of the pipeline which has been installed, the pipelines sink and are placed, and butt joint of the pipelines is completed.

Owner:CCCC FOURTH HARBOR ENG CO LTD

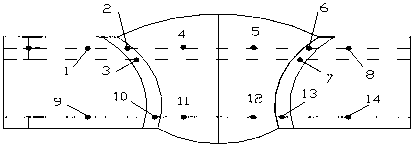

Spiral seam submerged-arc welded pipe butt joint process

ActiveCN103008999ASimple designIncrease automatic submerged arc weldingArc welding apparatusSlag (welding)Butt joint

The invention discloses a spiral seam submerged-arc welded pipe butt joint process and relates to the technical field of a spiral seam submerged-arc welded pipe. The process comprises the processing procedures of pipe end rounding, pipe end chamfering, steel pipe butt joint, prewelding, inner welding, outer welding, repair welding and circular seam nondestructive inspection. Compared with the traditional manual welding single-side welding double-sided forming process, the spiral seam submerged-arc welded pipe butt joint process has the advantages that the problems of welding quality stability influence and the like caused by great probability generation of defects such as air holes, slag clamping and cracks in the welding seam of the manual welding are solved, the butt joint quality and the efficiency of a steel pipe are greatly improved, the material consumption and the production cost can be greatly reduced, the field construction operation is convenient, and the batch production capability for producing butt joint pipes meeting API5L and relevant standard requirements is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

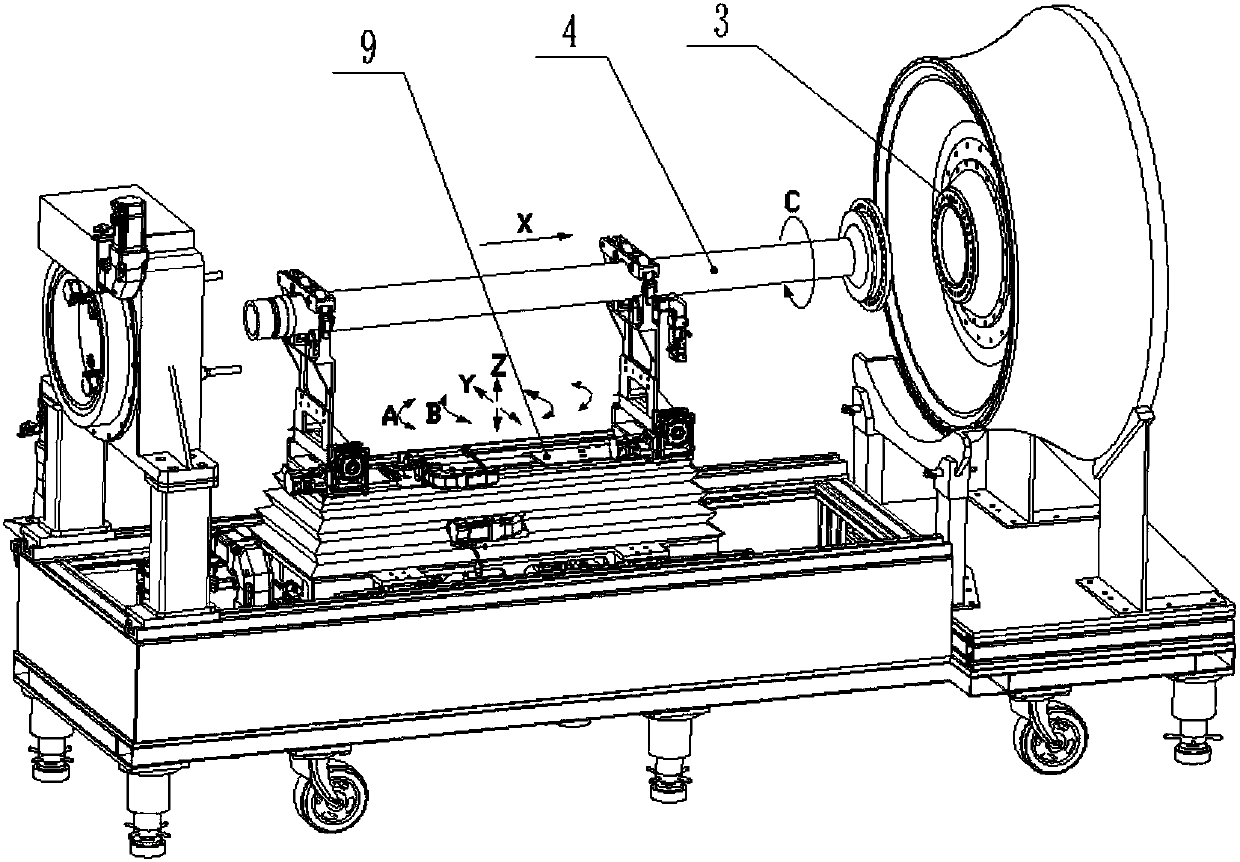

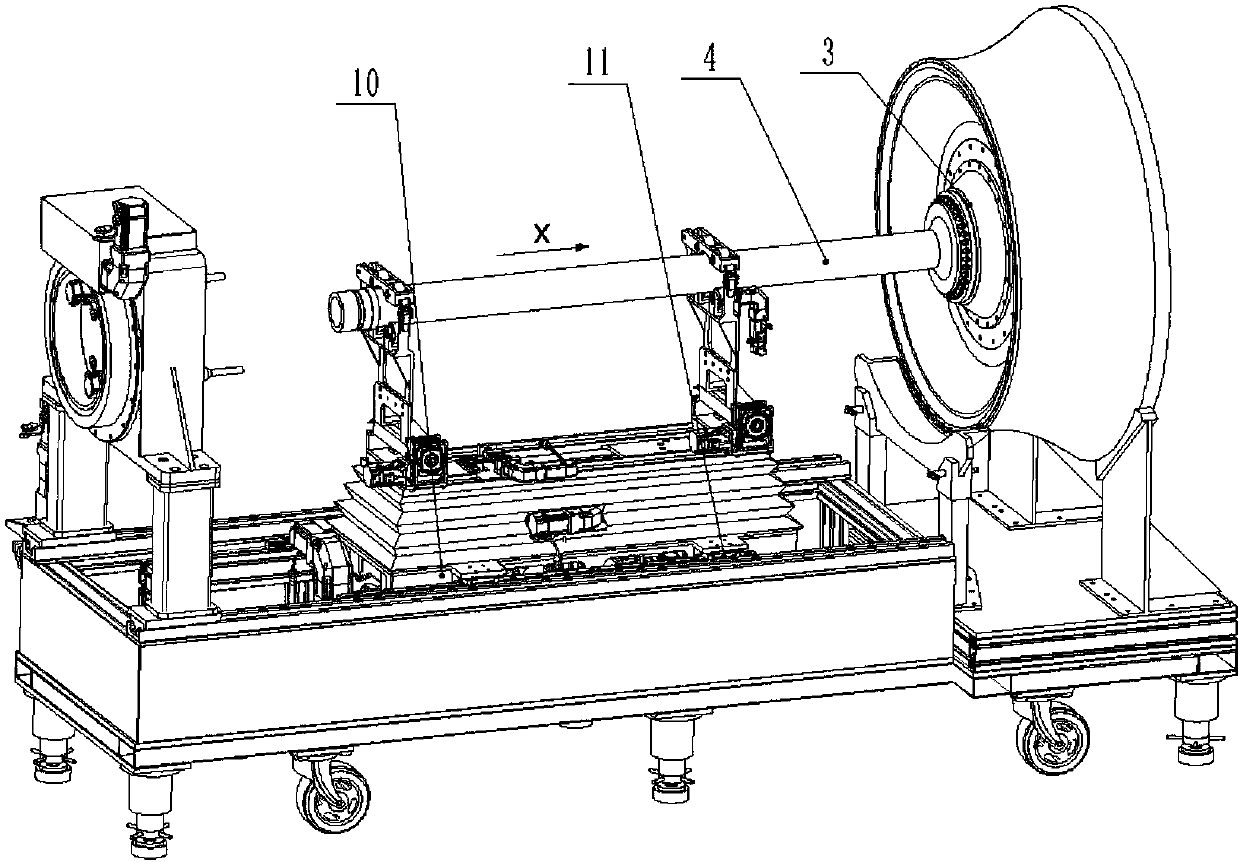

Flexible multi-degree-of-freedom butt joint posture adjusting mechanism

The invention discloses a flexible multi-degree-of-freedom butt joint posture adjusting mechanism which comprises a linear guide mechanism and two posture adjusting mechanisms, and the posture adjusting mechanisms are installed on the linear guide mechanism. Each posture adjusting mechanism comprises a rolling bracket for rolling adjustment, a guide groove for Y-direction translation adjustment and a lifting base for Z-direction lifting adjustment, wherein the rolling bracket is installed in the guide groove, the guide groove is installed in the lifting base, the lifting base is connected with the linear guide mechanism and translates on the linear guide mechanism in the X direction. The flexible multi-degree-of-freedom butt joint posture adjusting mechanism can realize automatic adjustment of postures of cabin section products, has the advantages of high automation degree, high butt joint precision and high assembly efficiency, can reduce the manual operation intensity of butt joint, and reduces manpower resources.

Owner:NANJING CHENGUANG GRP

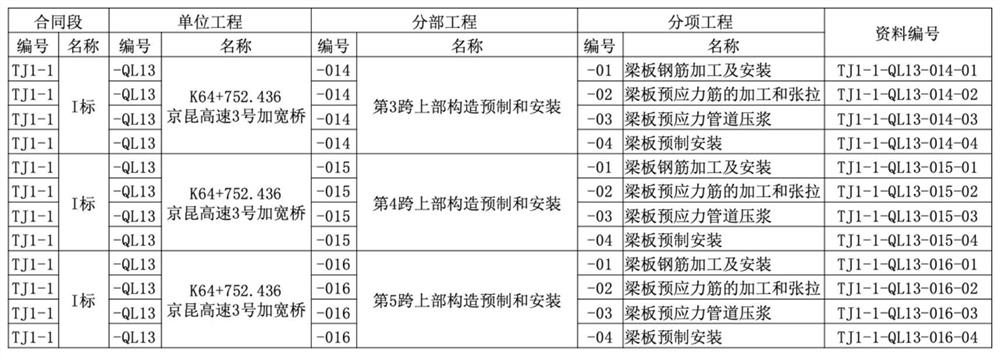

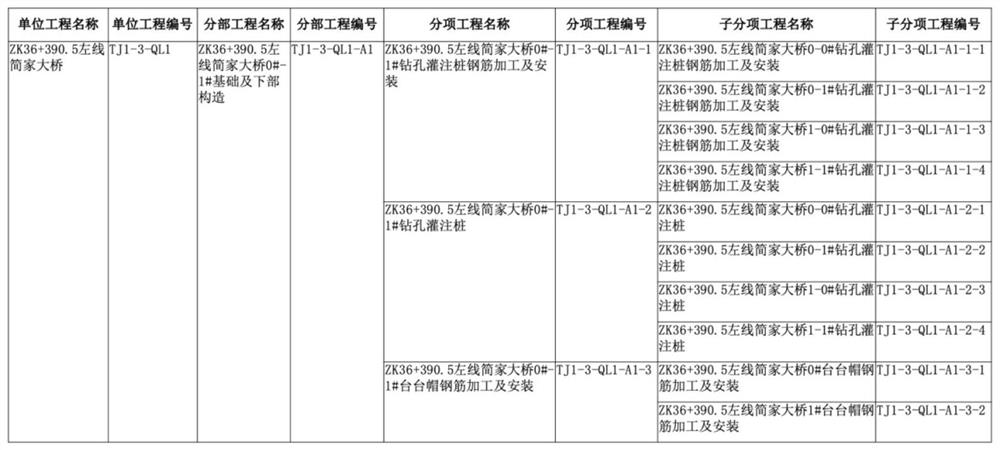

WBS automatic construction method and system based on highway engineering design information

The invention relates to the technical field of computers, in particular to a WBS automatic construction method and system based on highway engineering design information. The method comprises the following steps: S1, acquiring highway engineering design information data; s2, building a WBS template; s3, extracting corresponding data from the highway engineering design information data according to the WBS element meta-information of each level in the WBS template, and generating WBS elements, wherein the WBS elements and the WBS template jointly form WBS data of the highway engineering design information. According to the method, the WBS division efficiency is improved, the engineering design information is included, the association between the WBS hierarchy and the engineering design information and the BIM model is established, the data format is unified, butt joint with an informatization application system is facilitated, and the butt joint efficiency is high.

Owner:四川省交通勘察设计研究院有限公司 +1

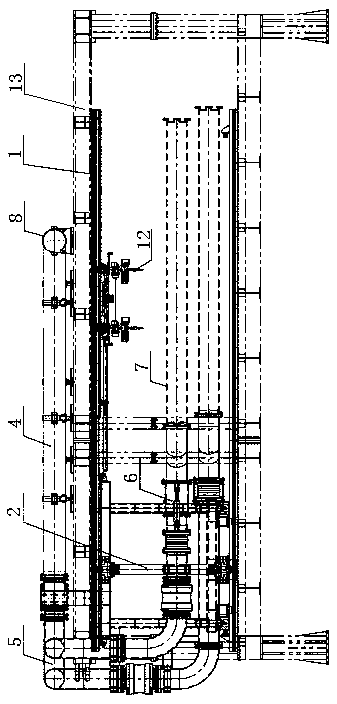

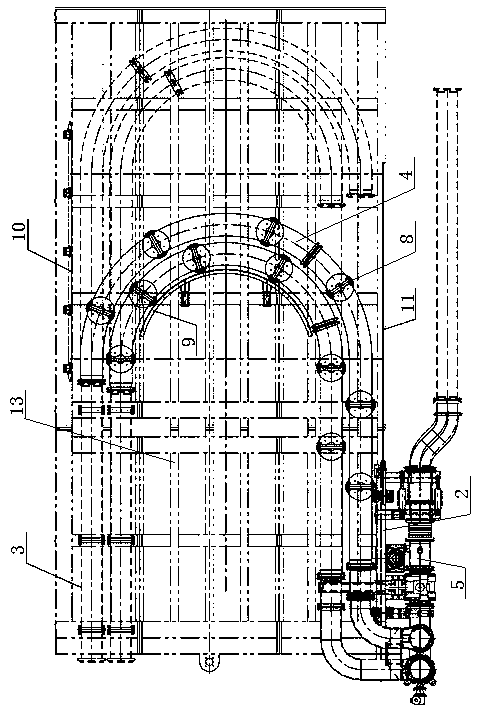

Mud-water shield mud pipeline extension device and extension method

ActiveCN110985036ASecurity extensionImprove docking efficiencyTunnelsGeotechnical engineeringMechanical engineering

The invention discloses a mud-water shield mud pipeline extension device and an extension method. The mud-water shield mud pipeline extension device and the extension method solve the problems of inflexible use and short service life of a mud pipeline extension device in the prior art. The mud-water shield mud pipeline extension device comprises a shield machine mud hard pipe, a mud hose, a walking frame mud hard pipe and a tunnel mud hard pipe which are sequentially connected. The walking frame mud hard pipe is movably arranged on a trailer through a walking mechanism. The mud hose is movablyarranged on the trailer through a sliding part. A mud pipe crane for hoisting the mud hard pipe is arranged on the trailer. According to the mud-water shield mud pipeline extension device and the extension method, a walking frame of a simple structure is adopted and moves along the track arranged on the side face of the trailer, and the occupation of the space of the trailer is reduced; the mud hose is not in direct contact with the trailer, the outer layer of the hose does not wear, and the service life of the mud hose is prolonged. In addition, the mud-water shield mud pipeline extension device is not limited by the tunnel turning radius and is suitable for mud-water shields with the large or small diameters, the structure is simple, the operation is flexible, the application range is wide, and the maintenance is convenient.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

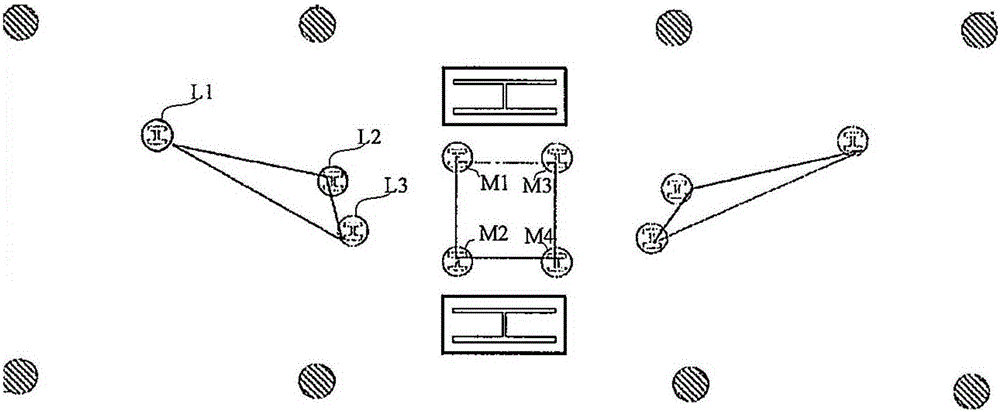

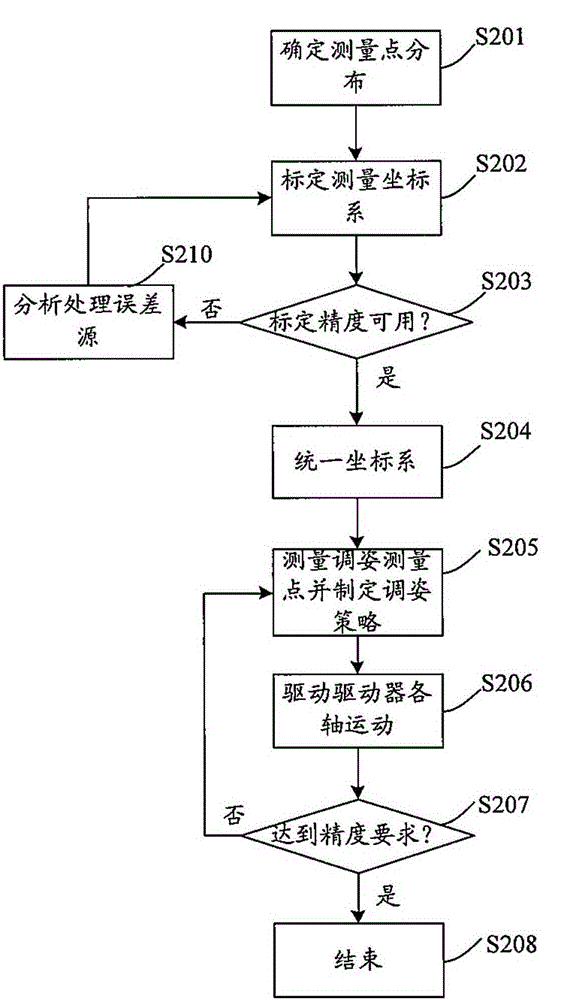

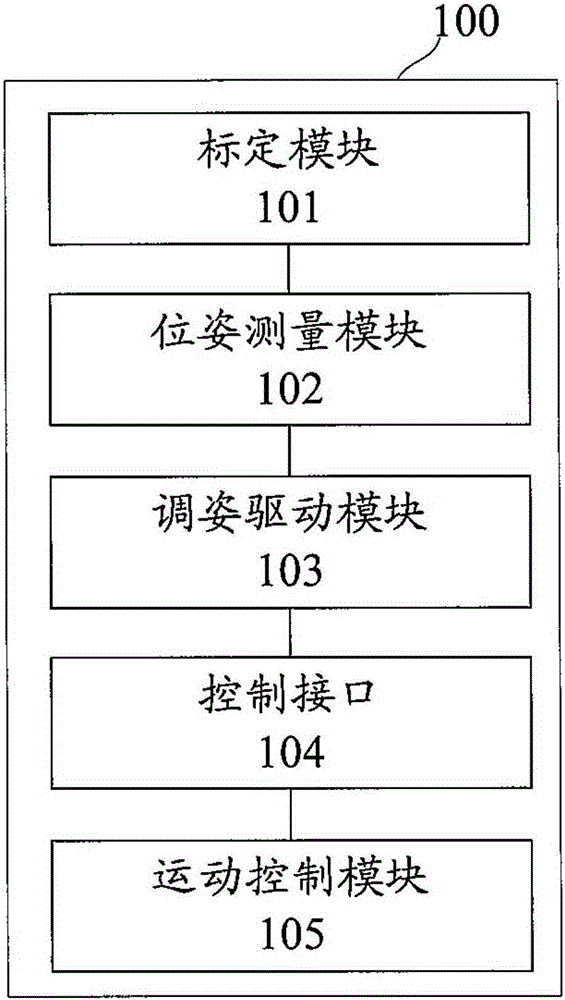

Docking measurement pose-adjusting method based on indoor GPS (iGPS)

InactiveCN105215669AImprove digitizationImprove flexibilityAircraft componentsMetal working apparatusMeasurement pointActuator

The invention provides a method for docking an object to be measured. The method comprises the steps that i, distribution of measurement points on the object to be measured is determined, and a measuring coordinate system related to a measuring spot is constructed based on the actual measurement positional values and the theoretical positional values of the measurement points; ii, the transformational relation between the measuring coordinate system and the design coordinate system of the object to be measured is constructed; iii, the position information of a pose measuring point and the position information of a drive measurement point are acquired, and the target coordinates to which an actuator corresponding to the drive measurement point is to move is determined based on the transformational relation; and iv, the actuator is driven based on the target coordinates. According to the method, measurement data and the theoretical data of a design model are comprehensively processed, and the digitization, flexibility and automation level of plane docking is improved. According to the technical scheme, the automation level of plane docking can be improved.

Owner:COMAC +1

Multidirectional pipeline butt joint device

InactiveCN111271511AMeet the docking requirements of different anglesQuick dockingPipe laying and repairButt jointPipe fitting

The invention discloses a multidirectional pipeline butt joint device. The multidirectional pipeline butt joint device comprises a sliding base, wherein pipeline clamping plates for clamping pipelinesare arranged on the front side and the back side of the top of the sliding base and are mounted on the top surfaces of butt joint sliding bases through fixture sliding bases, a butt joint adjusting device for driving the butt joint sliding bases to move transversely is arranged on the top surface of the sliding base, pipe diameter adjusting devices for adjusting diameters of pipes clamped by thepipeline clamping plates are arranged on top surfaces of the fixture sliding bases, one end of the sliding base is rotationally fixed on a rotating column through rotating connection rods, multiple sliding bases are rotationally fixed on the rotating column, and an angle limiting mechanism for limiting angle positions is arranged between the adjacent sliding bases. The sliding base can be fixed with the adjacent sliding base at various angles, butt joint requirements of pipe fittings at different angles can be met, meanwhile, rapid butt joint of multiple pipe fittings can be realized, so thatthe use range and use practicability of the butt joint device are greatly increased, and the butt joint efficiency of the multiple pipe fittings is improved.

Owner:彭茶妹

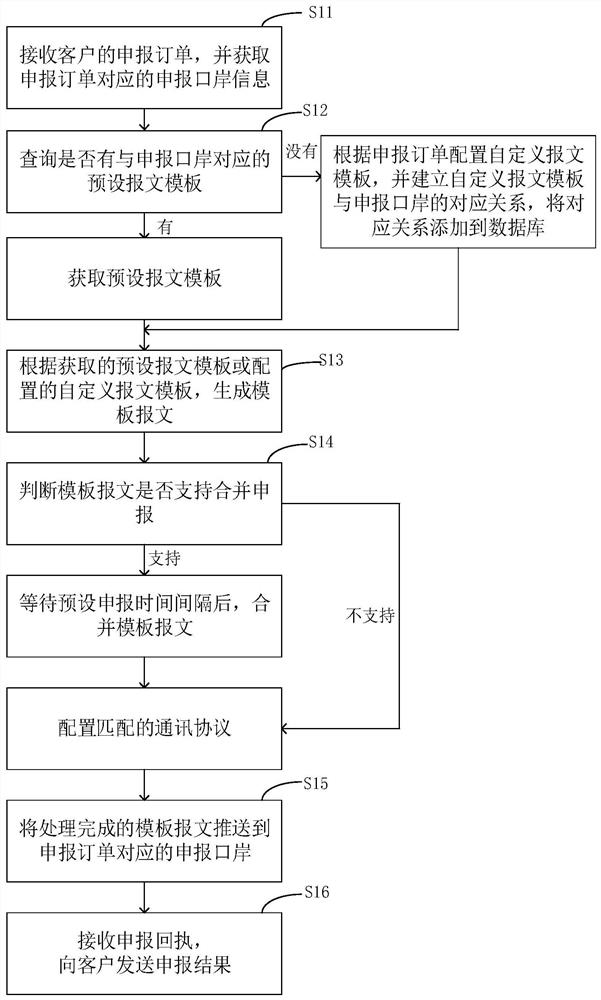

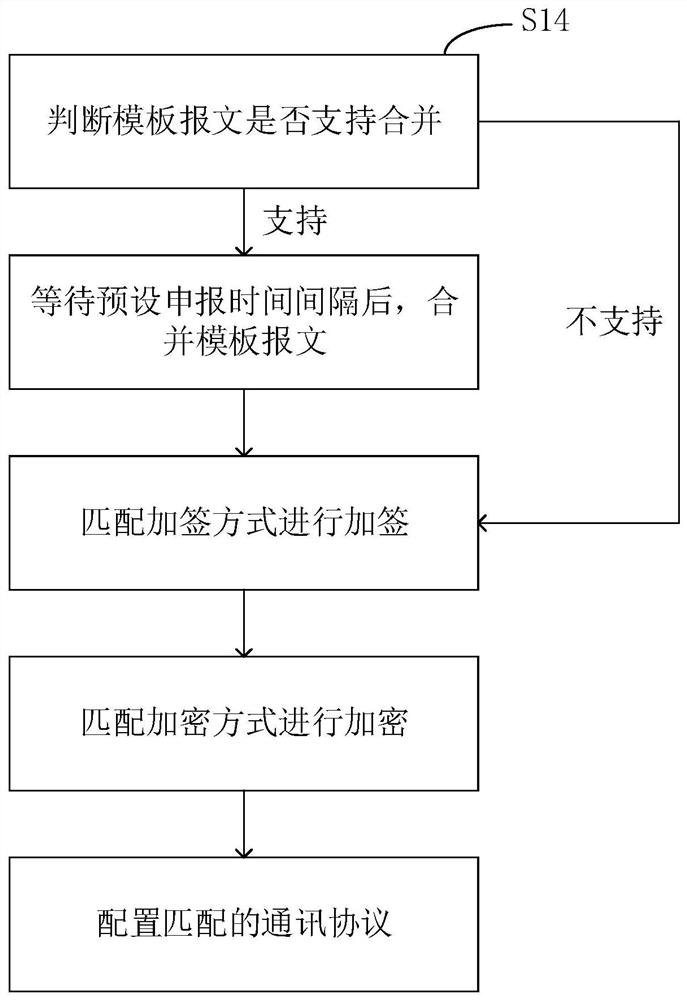

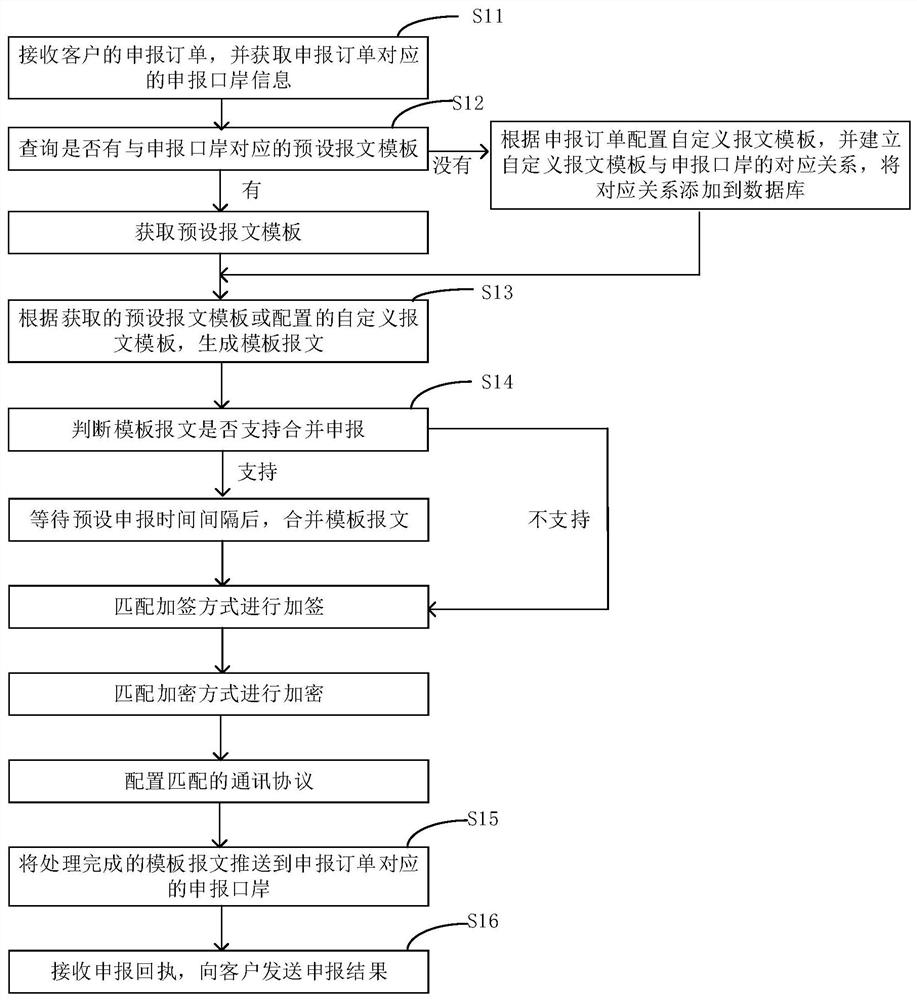

Cross-border trade e-commerce logistics information customs clearance declaration method and equipment

PendingCN111815400AEasy dockingImprove docking efficiencyDigital data protectionNatural language data processingLogistics managementEngineering

The invention relates to a cross-border trade e-commerce logistics information customs clearance declaration method, and the method comprises the steps of enabling the butt joint of a newly added portto be very convenient, and directly obtaining a preset message template corresponding to a declaration port for a non-special declaration port. For a special message port, only the corresponding self-defined message template needs to be configured according to the declaration order, so that the docking efficiency is greatly improved; the method further includes generating a template message according to the acquired preset message template or the configured custom message template; judging whether the template message supports combined declaration or not; if the combined declaration is supported, waiting for a preset declaration time interval, combining the template messages, and configuring a matched communication protocol; and if the combination is not supported, directly configuring amatched communication protocol. In the application, waiting for the preset declaration time is considered while the combination is performed. And the processed template message is pushed to a declaration port corresponding to the declaration order, a declaration receipt is received, and a declaration result is sent to the client in time.

Owner:SHANGHAI ZHONGTONGJI NETWORK TECH CO LTD

High-precision digital twinning butt joint assembling method for high-complexity and easy-to-deform aerospace cabin

PendingCN112380616AImprove docking efficiencyImprove docking accuracyGeometric CADForecastingPhysical spaceButt joint

The invention relates to a high-precision digital twinning butt joint assembly method for a high-complexity and easy-to-deform aerospace cabin, and the method comprises the following steps: constructing a digital twinning model based on actual measurement data, and providing a model for butt joint of a multistage shaft hole and the aerospace cabin; realizing optimal assembly path planning in a digital space by utilizing a path optimization algorithm and simulation software simulation verification interaction; and according to the optimal assembly path, achieving virtual-real interaction control execution of the multi-stage shaft hole matching butt joint process by virtual-real real real-time interaction of the digital space and the physical space,so that butt joint assembly of the aerospace cabin is completed. The phenomena such as dislocation and jamming in the butt joint process of the multistage shaft hole matched easily-deformed cabin can be avoided, the one-time butt joint successrate is guaranteed, and the butt joint efficiency and precision are improved; and meanwhile, achieving assemblability prediction and optimal matching of batch multi-stage shaft hole matching easily-deformed aerospace cabin, the traditional trial assembly process is avoided so that overall assemblability and assembly performance of the aerospace cabin are improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

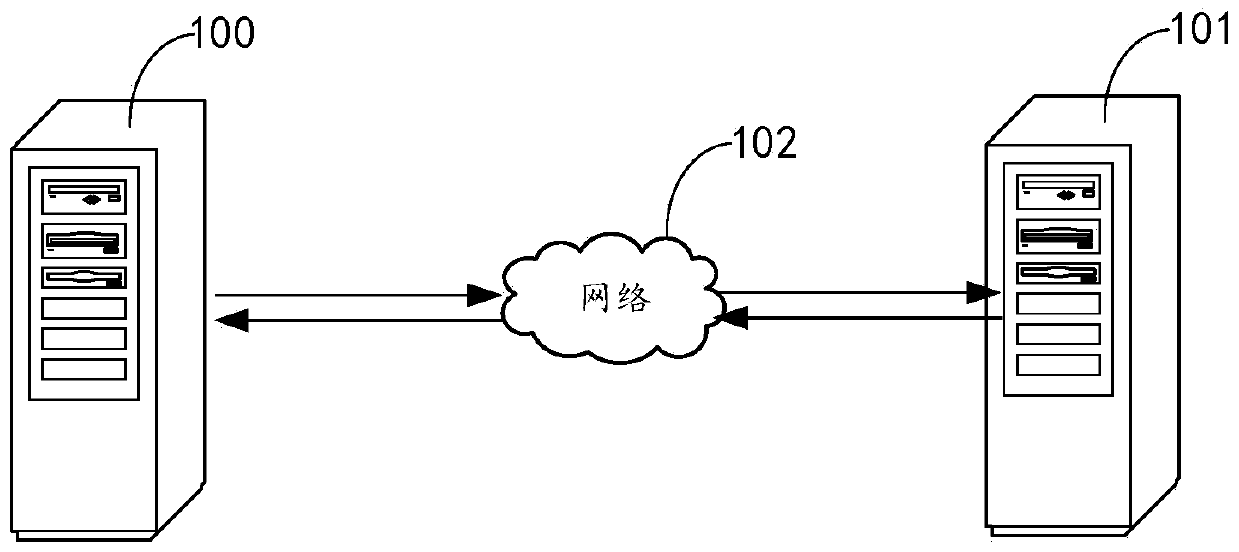

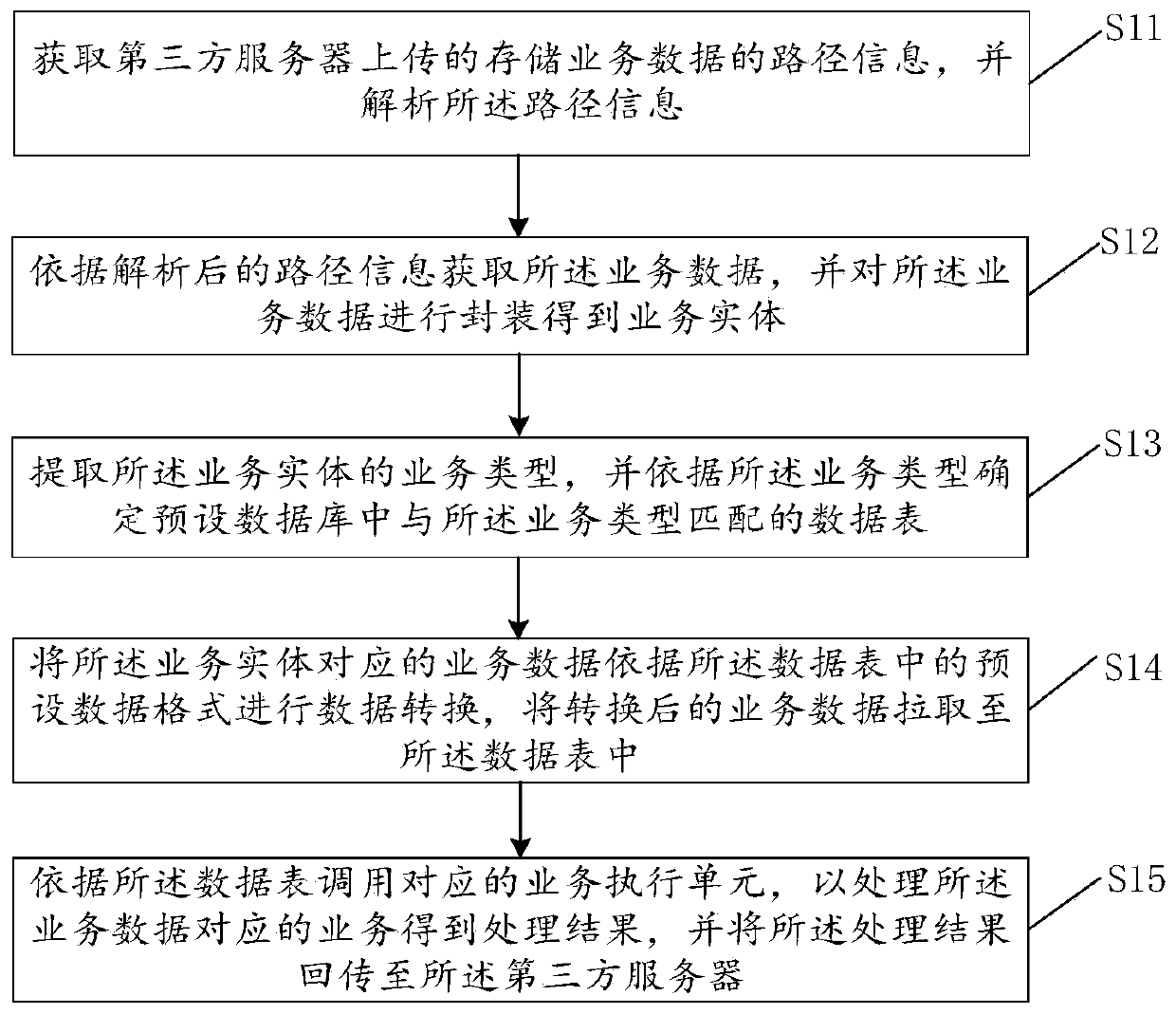

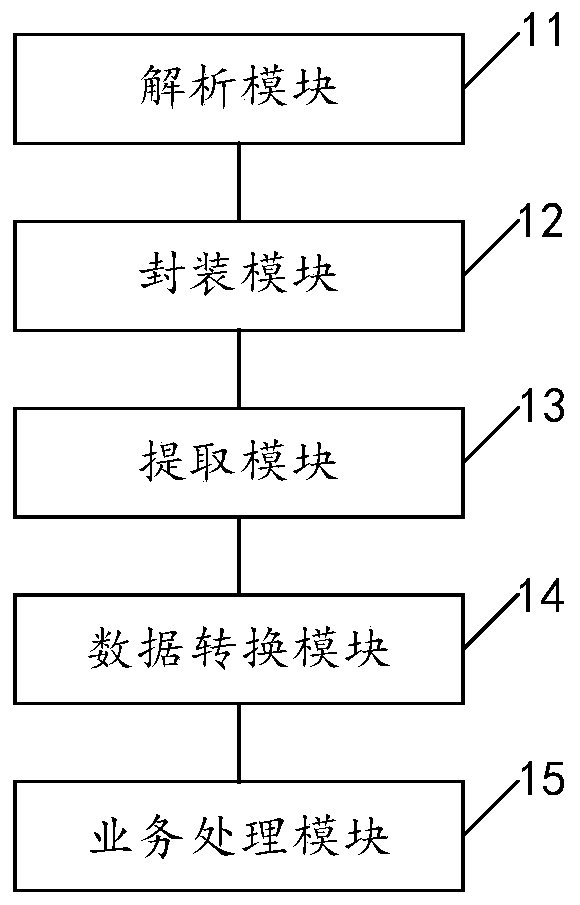

Business data processing method and device, computer equipment and storage medium

ActiveCN110765102ASimple planImprove docking efficiencyRelational databasesSpecial data processing applicationsDatasheetPathPing

The invention relates to a business data processing method, a system, computer equipment and a storage medium. The method comprises the following steps: acquiring the service data uploaded by a third-party server, and packaging the service data to obtain a service entity; extracting a service type of the service entity, and determining a data table matched with the service type in a preset database according to the service type; performing data conversion on the service data corresponding to the service entity according to a preset data format in the data table, and then pulling the business data into the data table; and processing the business corresponding to the service data according to the data table to obtain a processing result, and returning the processing result to the third-partyserver. According to the method, the service data uploaded by the third-party server are converted into the unified data model through path analysis and data format conversion, different service docking schemes do not need to be set for different third-party partners, and the docking efficiency with the partners is improved.

Owner:SUNING CLOUD COMPUTING CO LTD

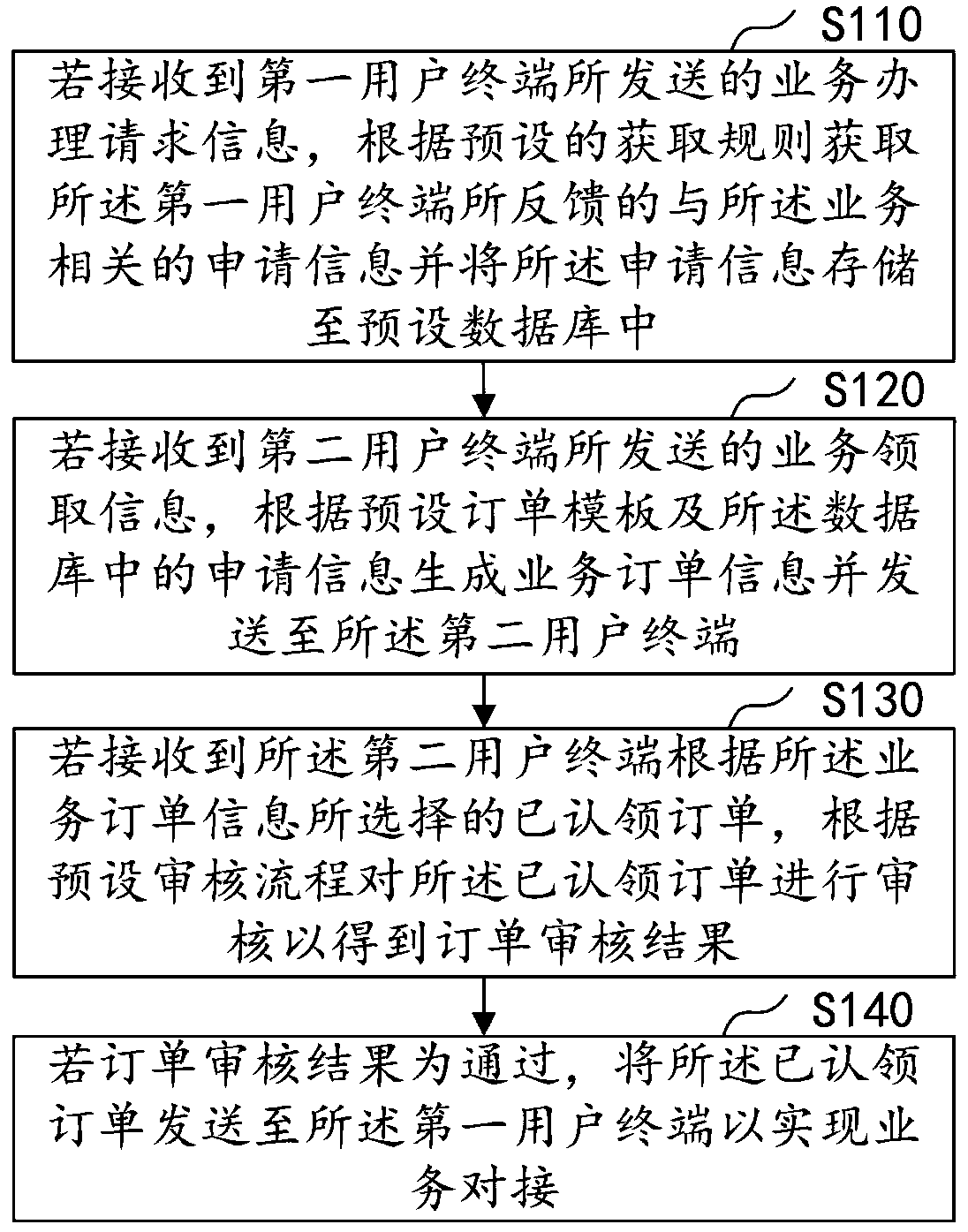

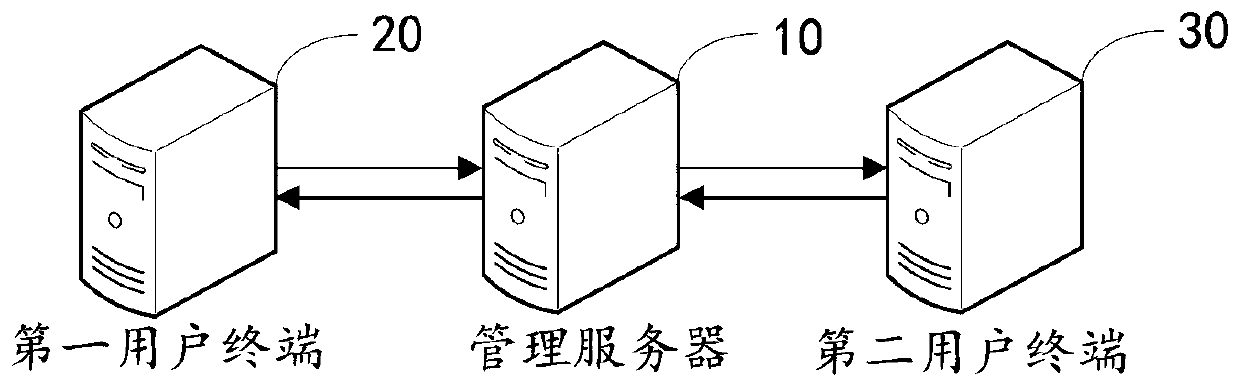

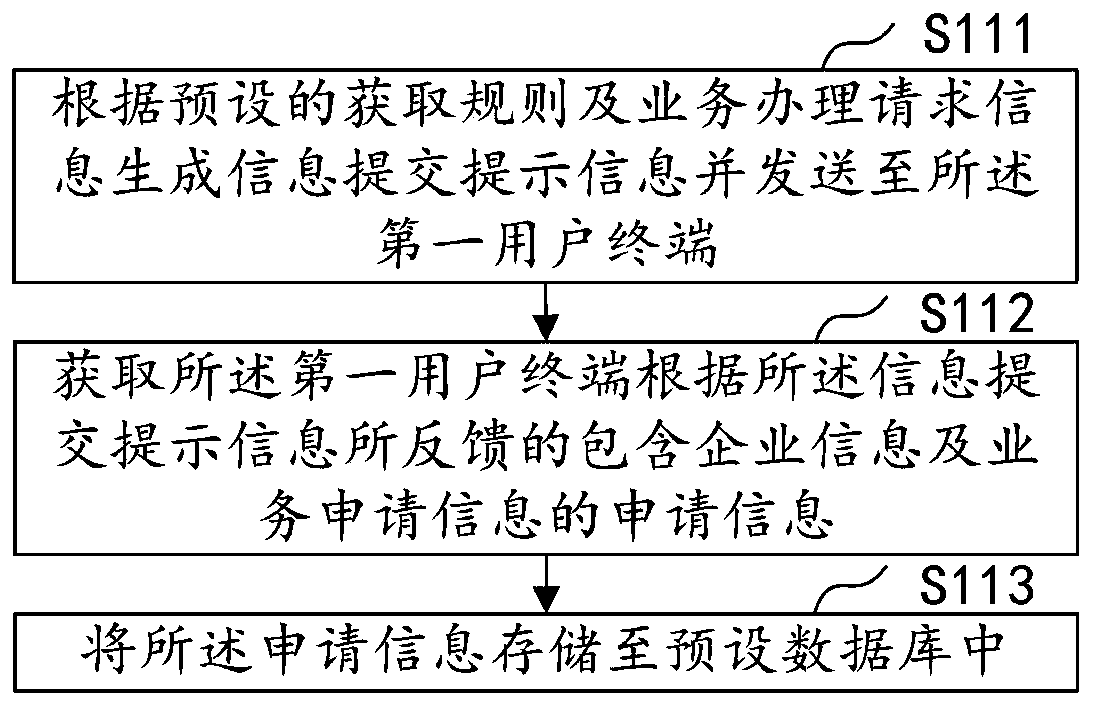

Service docking method and device, computer equipment and storage medium

PendingCN110060143AImprove docking efficiencyDatabase management systemsFinanceOperating systemInformation storage

The invention discloses a service docking method and device, computer equipment and a storage medium. The method comprises the steps that if service handling request information sent by a first user terminal is received, service -related application information fed back by the first user terminal is acquired according to an acquisition rule, and the application information is stored in a preset database; if the service receiving information sent by the second user terminal is received, service order information is generated according to a preset order template and application information in adatabase, and the service order information is sent to the second user terminal; if a claimed order selected by the second user terminal according to the service order information is received, the claimed order is audited according to a preset auditing process to obtain an order auditing result; and if the order audit result is passed, the claimed order is sent to the first user terminal to realize business connection. Based on the service data distribution technology, the docking efficiency of an enterprise during service docking is greatly improved through information interaction.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

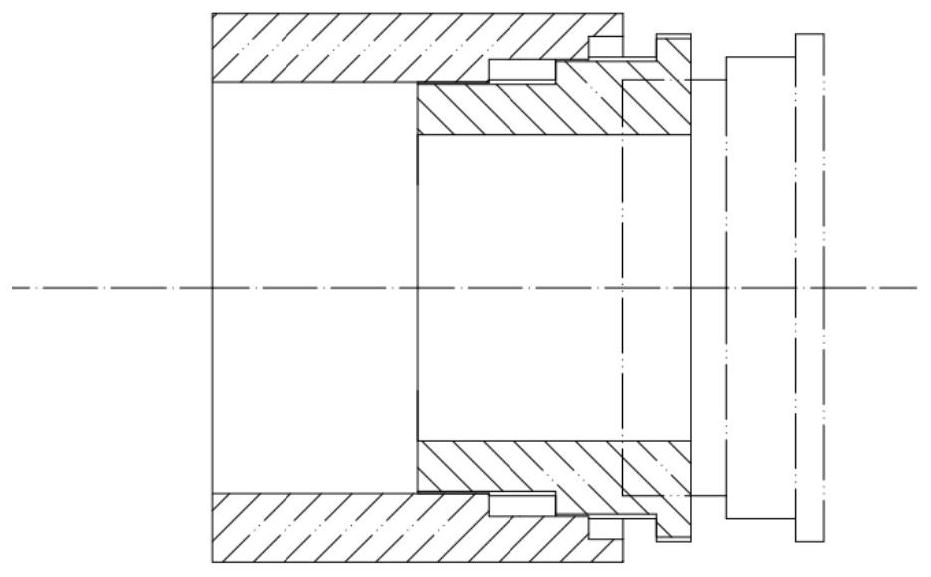

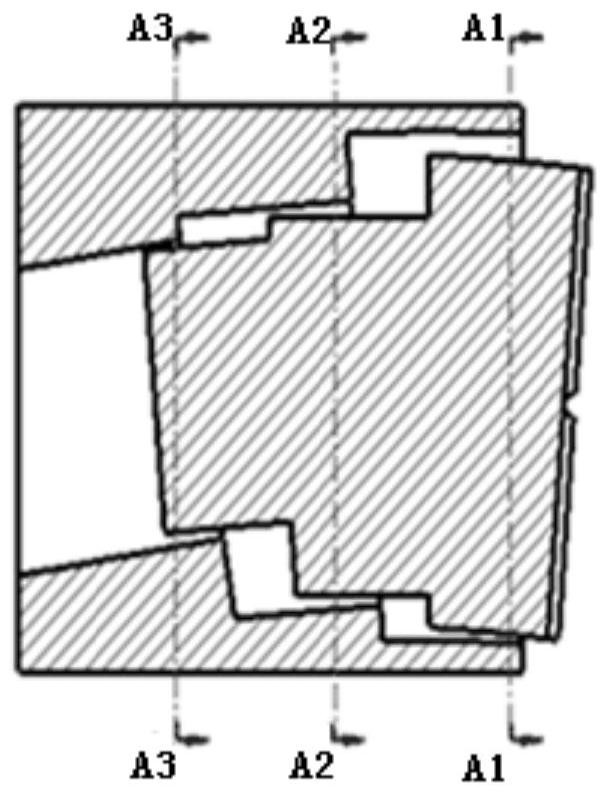

Assembling method for low-pressure turbine shaft-disc assembly of aero-engine

The invention discloses an assembling method for a low-pressure turbine shaft-disc assembly of an aero-engine. The assembling method comprises the following steps that workpieces are installed, the position and the posture of a turbine shaft are adjusted; the turbine shaft butts joint and is pre-installed; an indexable tightening system is fed to a front end operation area; a tightening shaft is tightened; and the indexable tightening system returns back. According to the assembling method for the low-pressure turbine shaft-disc assembly of the aero-engine, an assembly mode that an axis of a low-pressure turbine shaft-disc is horizontal is adopted, the position and the posture of the low-pressure turbine shaft with the large length are adjusted precisely and advantageously in the butt-joint process, centering positioning alignment and end face correct close fitting of the turbine shaft relative to a connecting disc are achieved, and the butt-joint and assembling precision is improved;a turbine shaft position and posture adjusting table is applied, quantitative position and posture adjusting is conducted on the low-pressure turbine shaft through a mechanical way, experiential methods such as traditional manual hanger operating are replaced, manual repeated trial assembly and correction are avoided, the butt-joint efficiency is improved, and assembly consistency requirements ofassemblies are met; and the indexable tightening system is adopted, worker skill requirements and the labor intensity are reduced, and the tightening efficiency is improved.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com