Pairing lengthening device for two-in-one pipeline

A pipeline group and group pair technology, which is applied in auxiliary devices, pipeline systems, welding equipment, etc., can solve the problems of reduced accuracy of medium and long pipe groups, time-consuming adjustment, slow productivity improvement, etc., and achieves high reliability and convenient operation. , the effect of low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

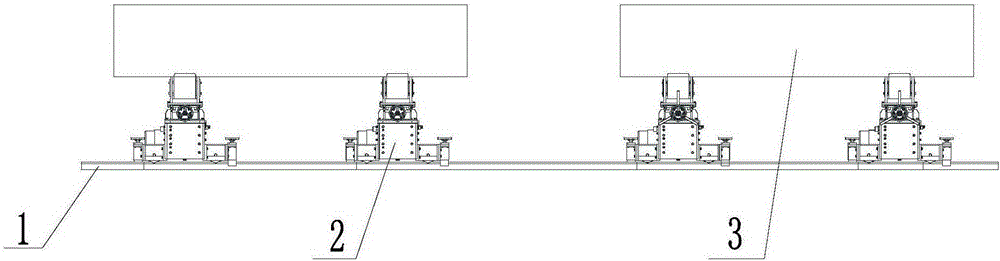

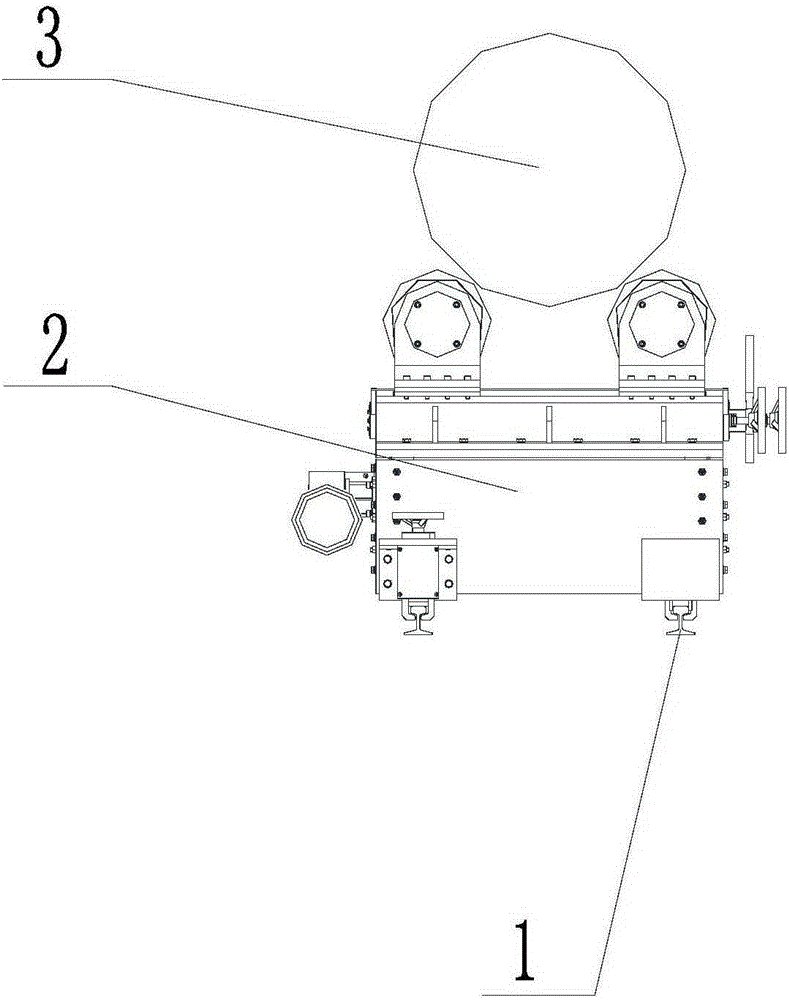

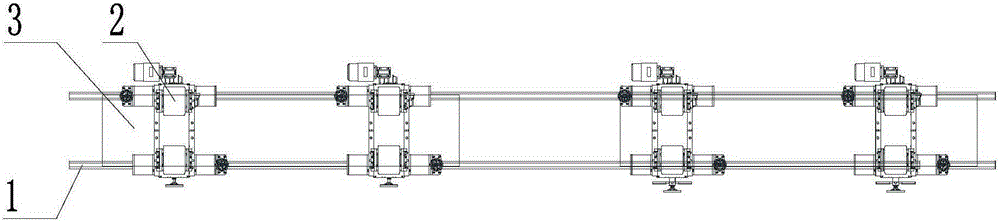

[0025] The two-to-one pipeline group butt joint length device of this embodiment includes a track 1, four paired roller frames 2 and two pipe fittings 3, and the paired roller frame 2 is arranged on the track 1 so that it can move along the track 1; the track 1 There are two, and the two tracks are arranged in parallel.

[0026] The paired roller frame 2 includes a radial adjustment roller device 4, a lifting device 5 and a running device 6. The running device 6 includes two pairs of wheels. The running device 6 is installed on the lower part of the paired roller frame 2 and can move along the track 1. 1, the radial adjustment roller device 4 can move up and down and is installed on the upper part of the pair of roller frames 2, the lifting device 5 is arranged between the traveling device 6 and the radial adjustment roller device 4 and is suitable for driving the radial adjustment roller device 4 up and down move.

[0027] The radial adjustment roller device 4 includes a rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com