Patents

Literature

30results about How to "Easy maintenance and installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

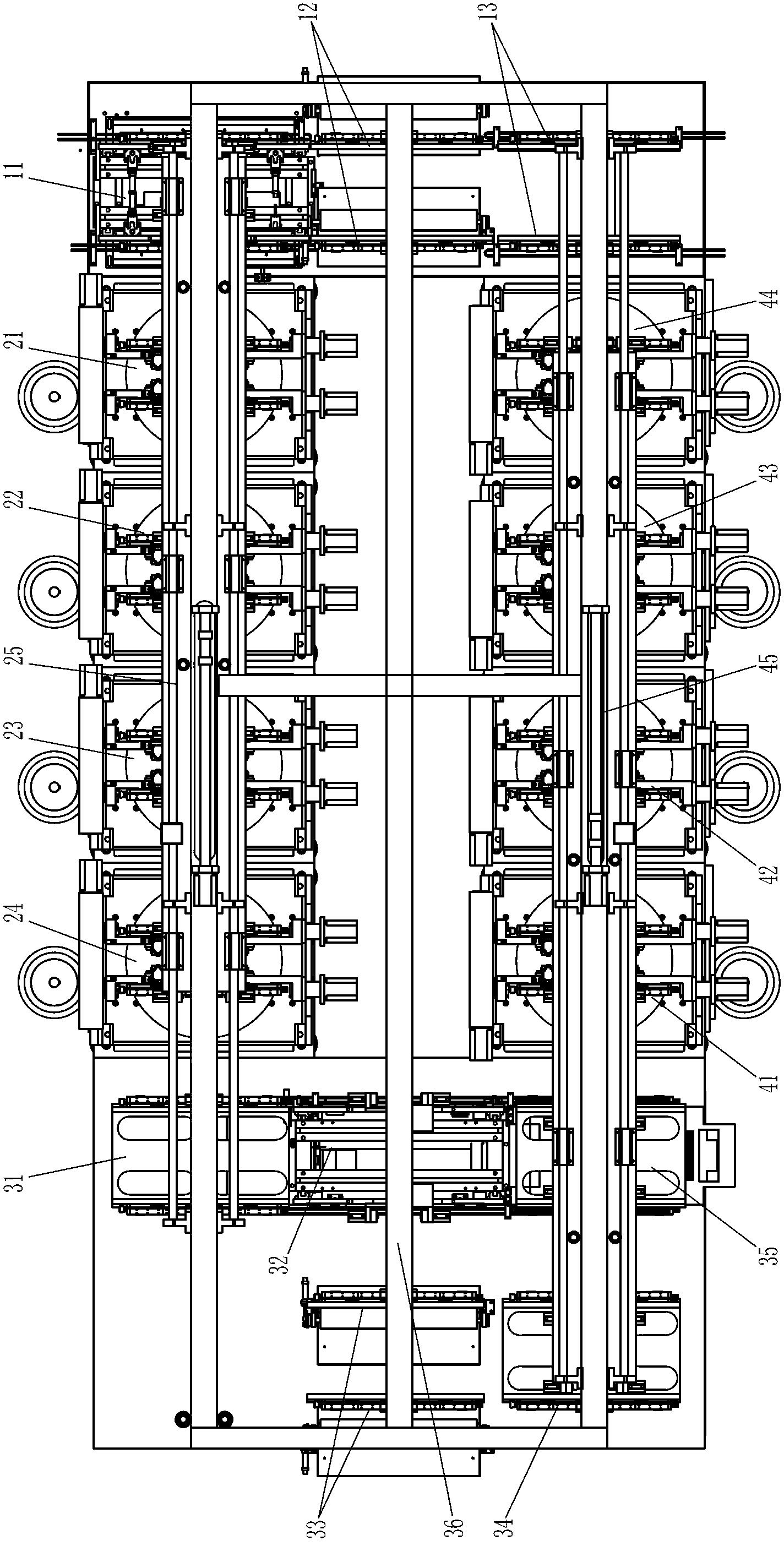

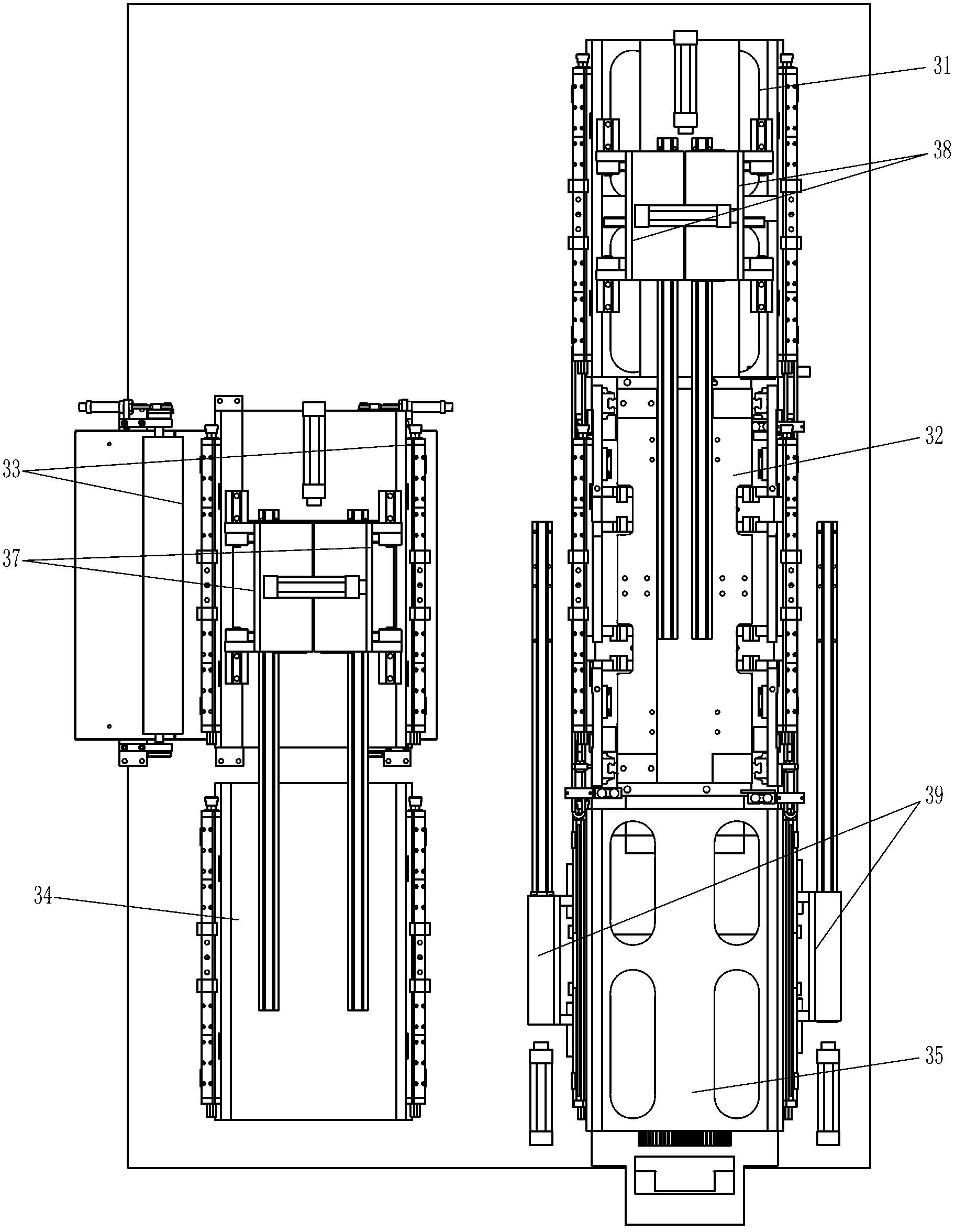

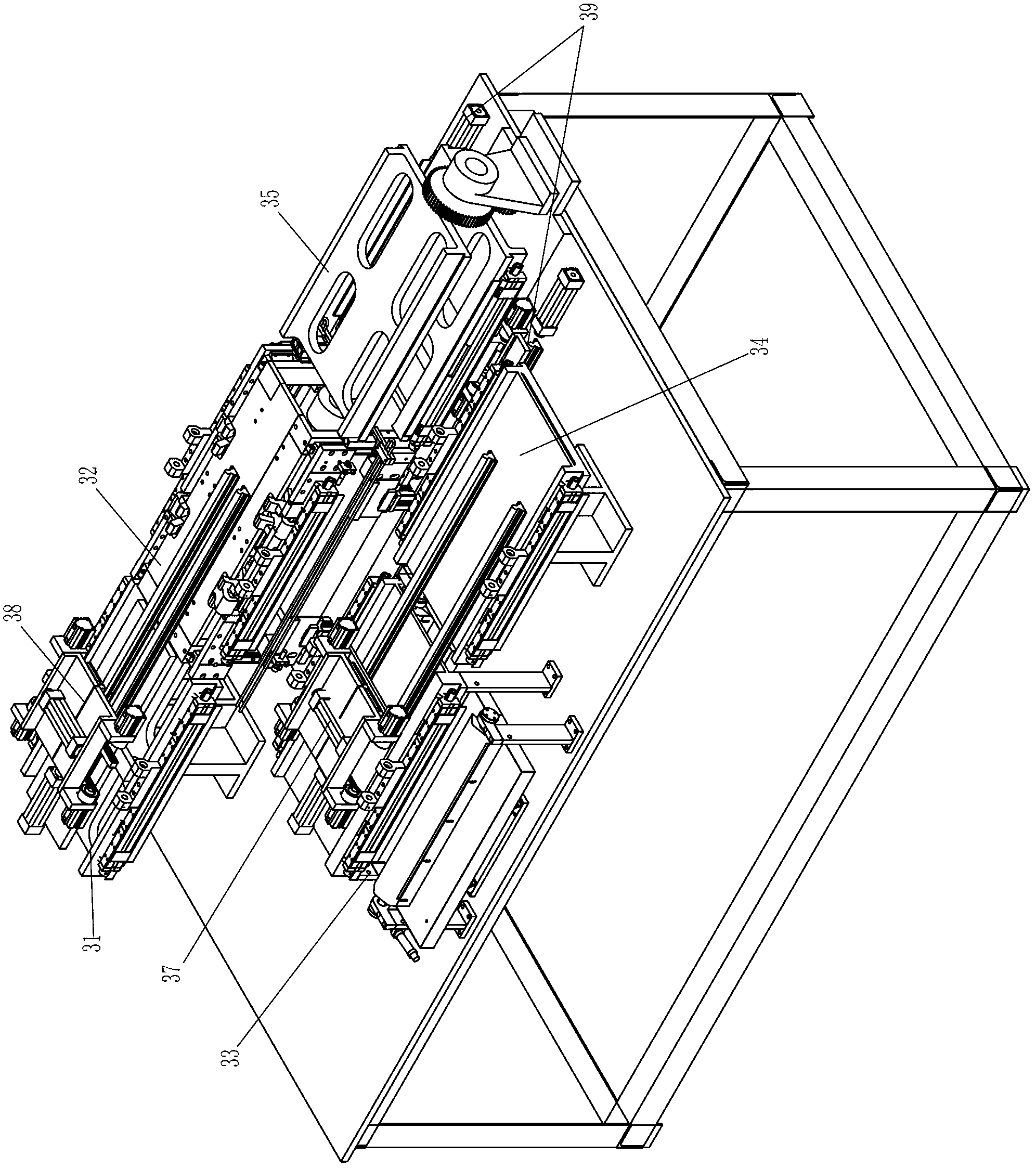

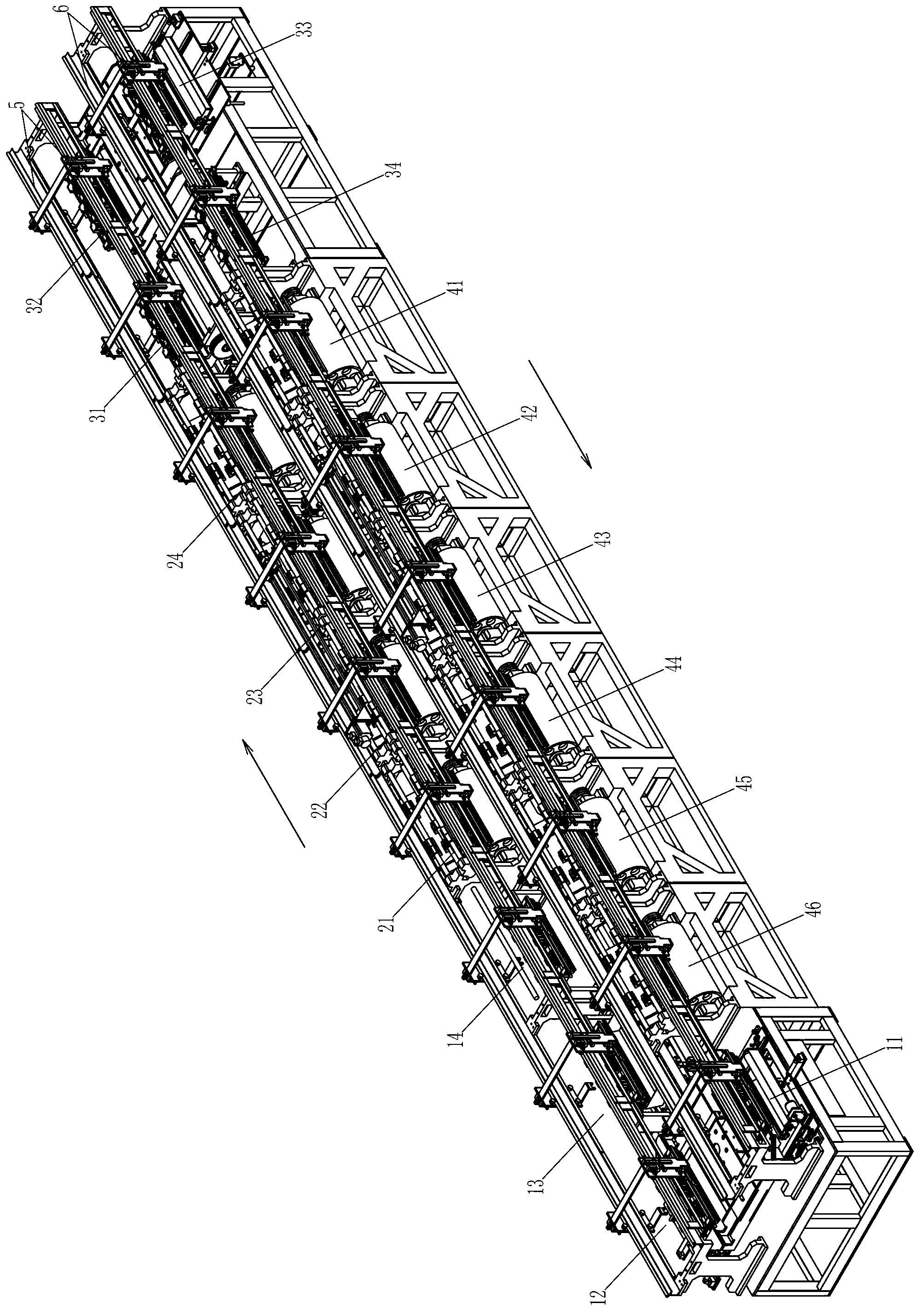

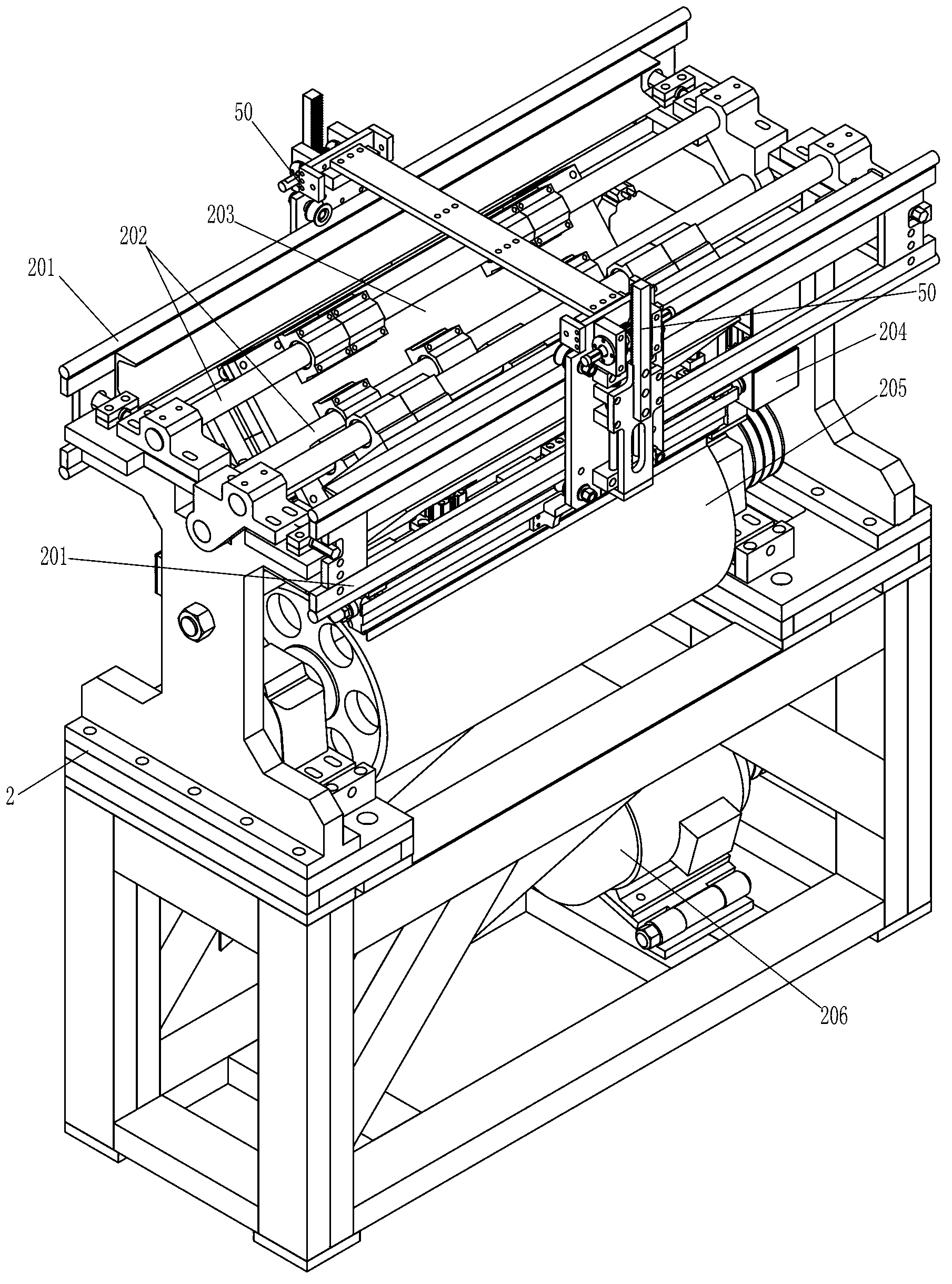

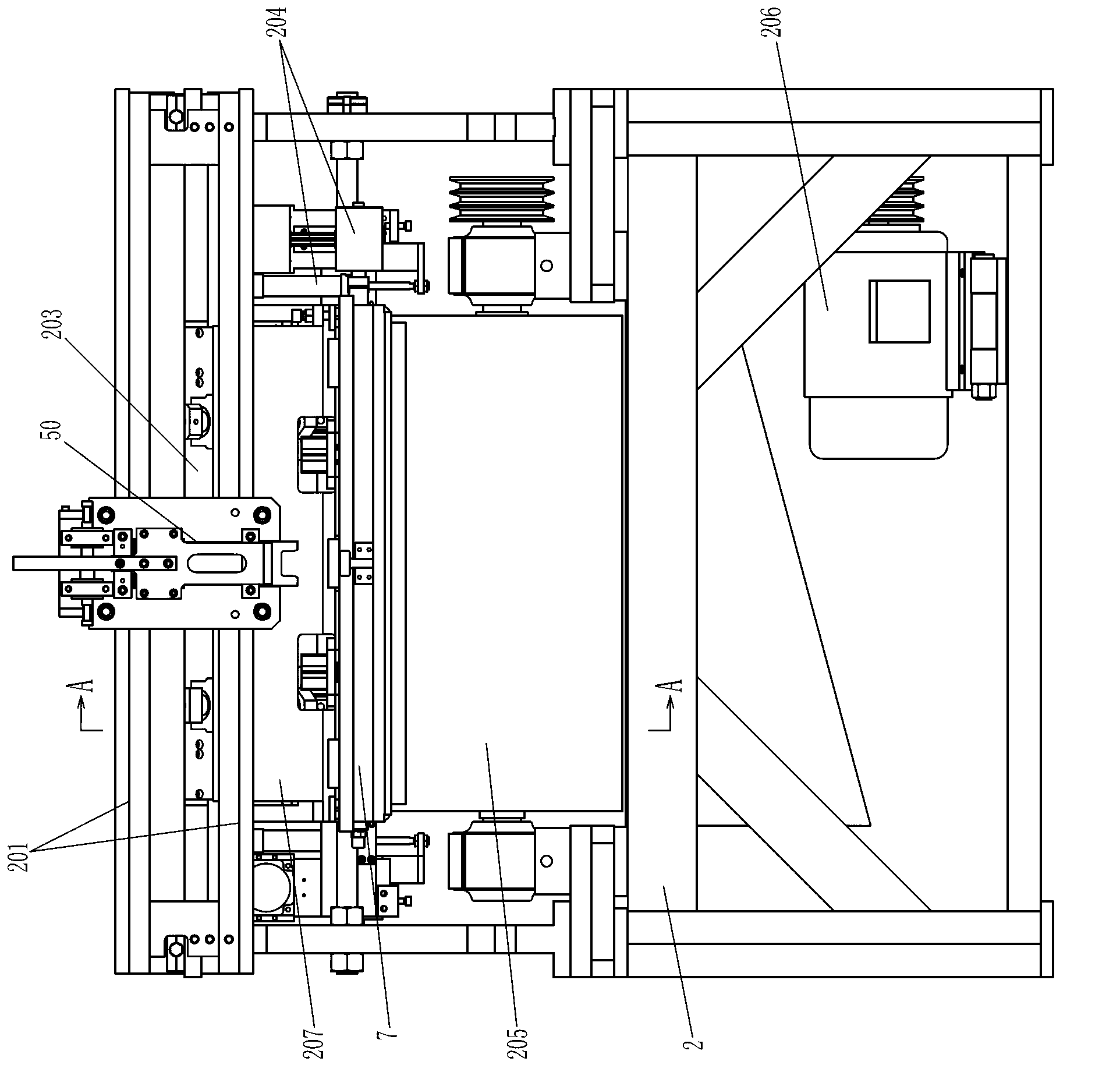

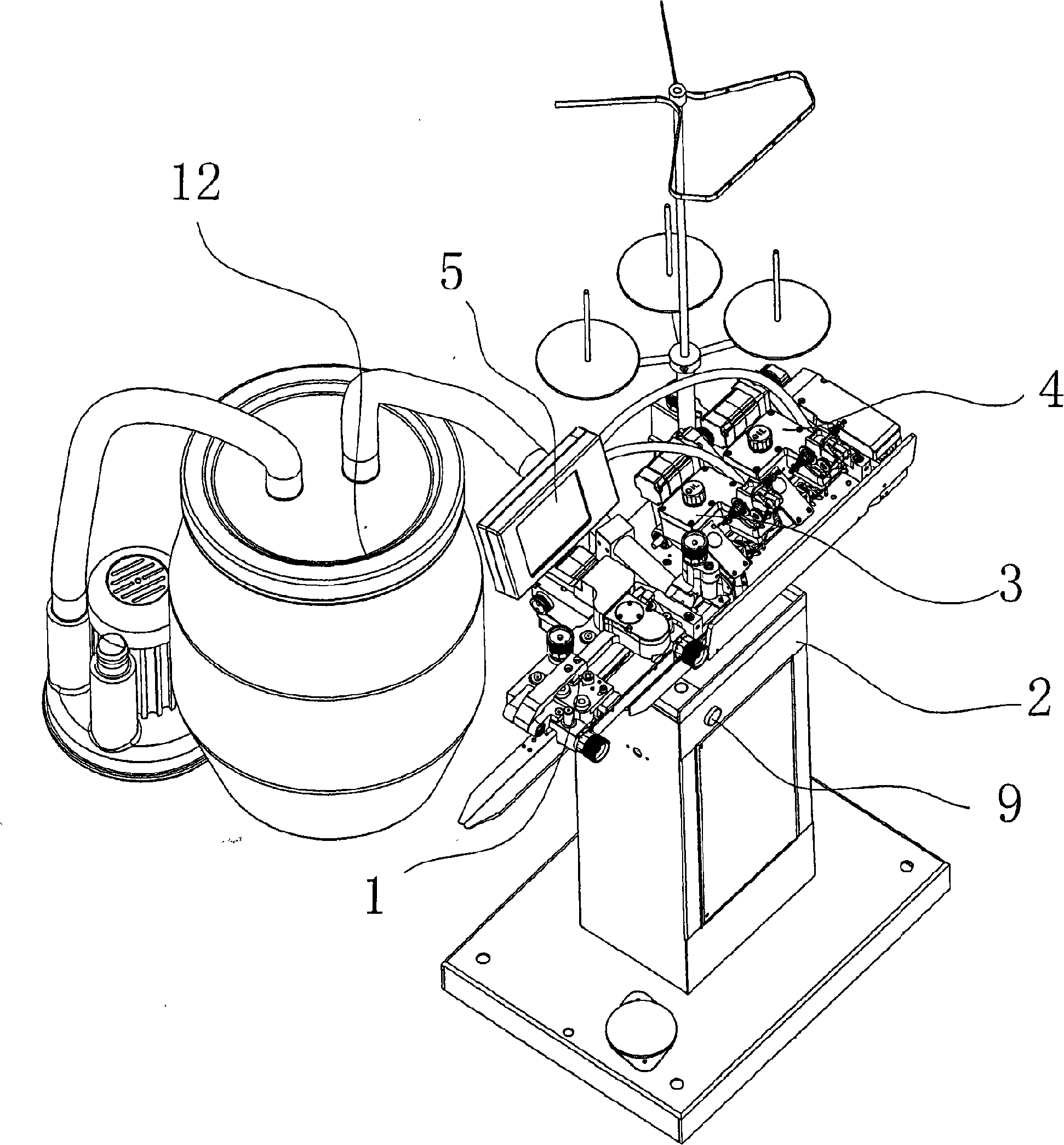

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

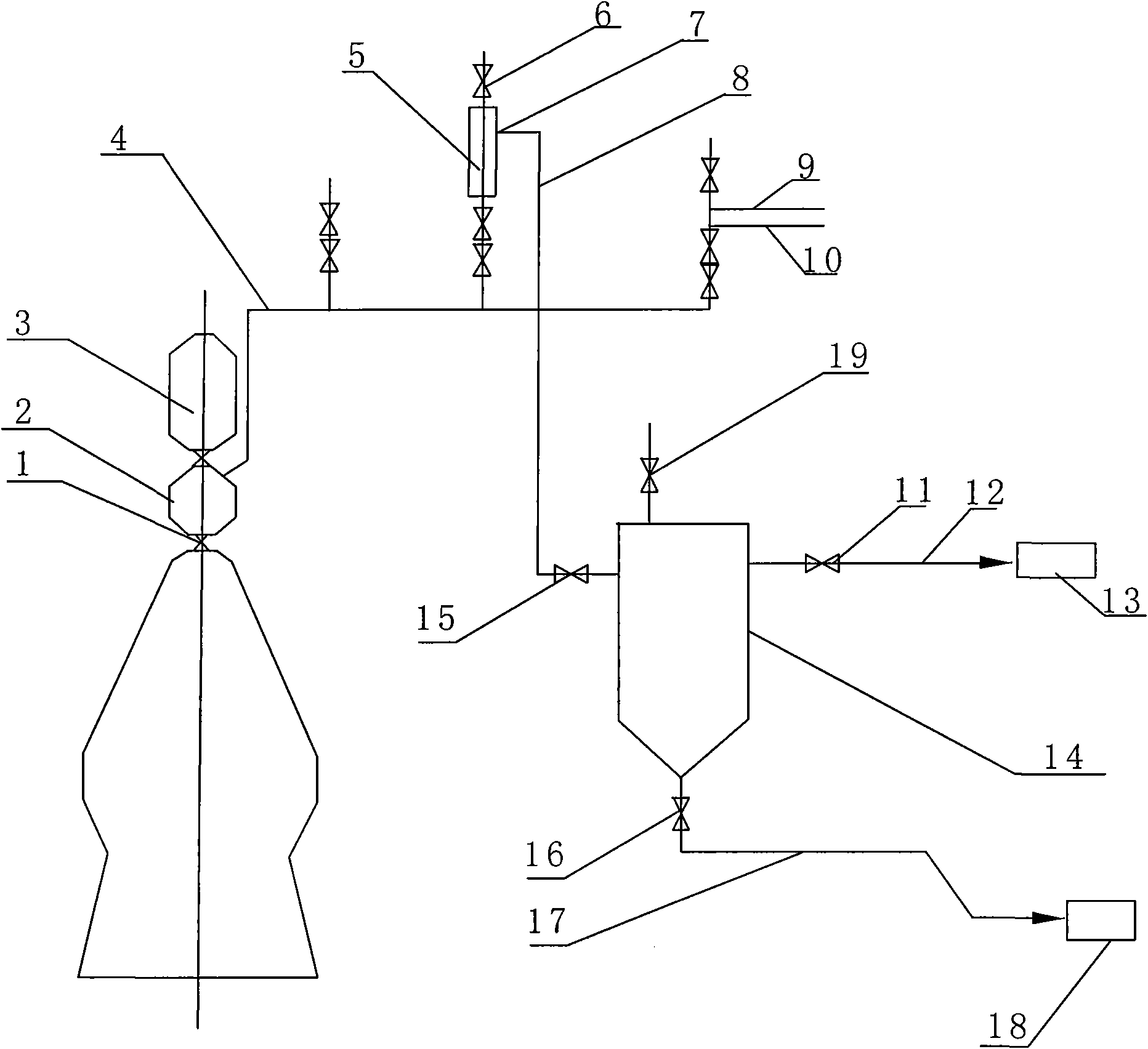

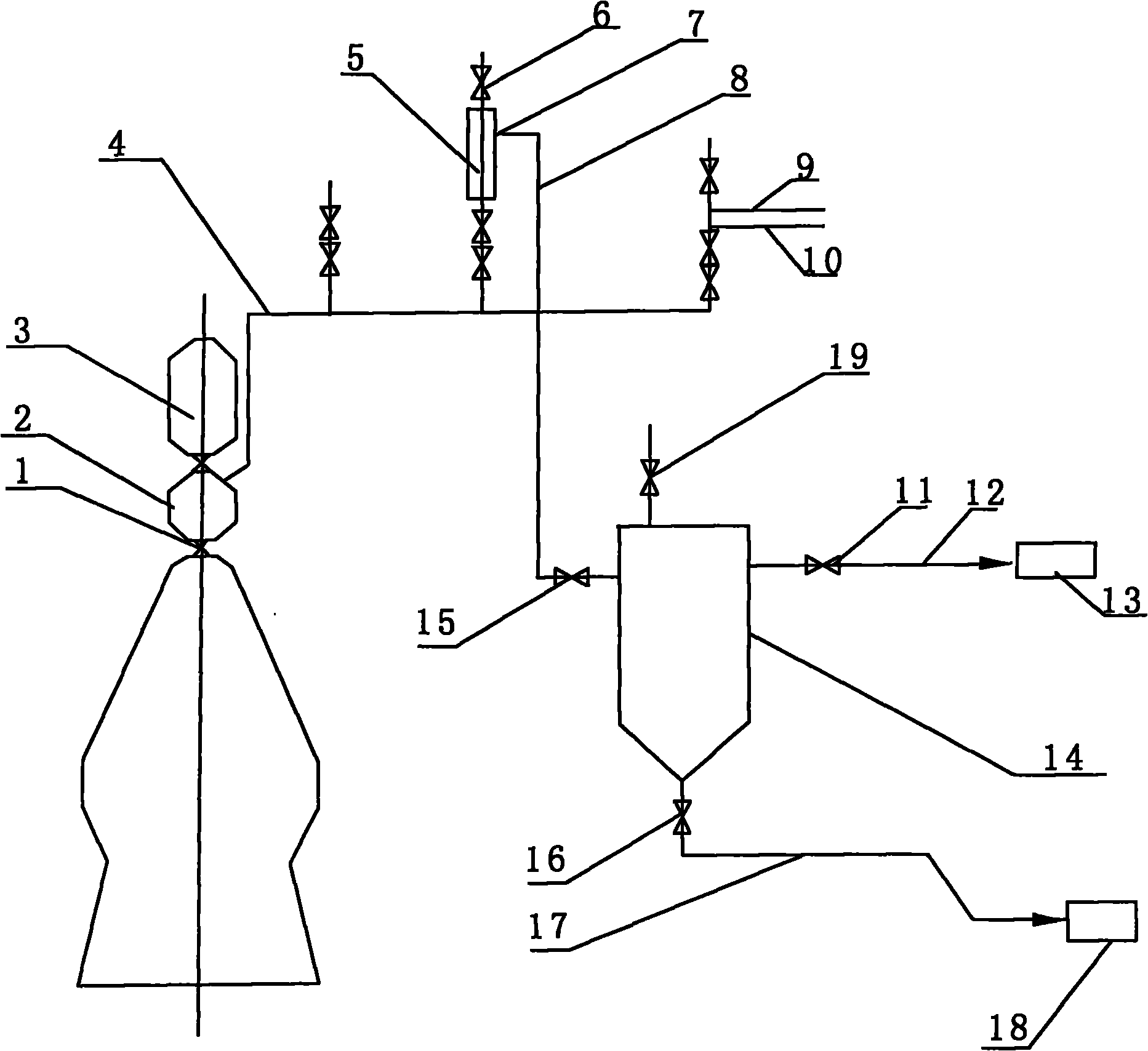

Coal-gas recovering process and device of charging, equalizing and bleeding of blast furnace

InactiveCN101892336AEfficient recyclingEmission reductionBlast furnace componentsBlast furnace detailsCycloneSocial benefits

The invention relates to coal-gas recovering process and device of charging, equalizing and bleeding of a blast furnace. The coal-gas recovering process comprises the following steps that: crude gas equalized and bled from a discharge tank of a blast furnace charging system enters into a furnace top coal gas noise reduction cyclone dust remover via a bleeding pipe; a cut off valve arranged at the furnace top coal noise reduction cyclone dust remover is closed, and a half-cleaned coal gas cut off valve is opened; half-cleaned coal gas formed by the primary dust removal of the crude coal gas via the furnace top coal gas noise reduction cyclone dust remover enters into a bag dust remover via a pipeline and the half-cleaned coal cut off valve; cleaned coal gas dedusted by the bag dust remover enters into a coal gas pipe network, and dust collected by the bag dust remover is conveyed to a dust recovering system for reutilization via a dust discharge outlet, a dust discharge valve and a dust delivery pipeline. The invention has the advantages of simple recovering process and device and easy operation; with the process, not only harmful gas during charging, equalizing and bleeding can be effectively recovered, but also emission of greenhouse gases is reduced; and the invention has significant economic benefits and social benefits.

Owner:ANSHAN HENGTONG BLAST FURNACE EQUIP ENG TECH CO LTD

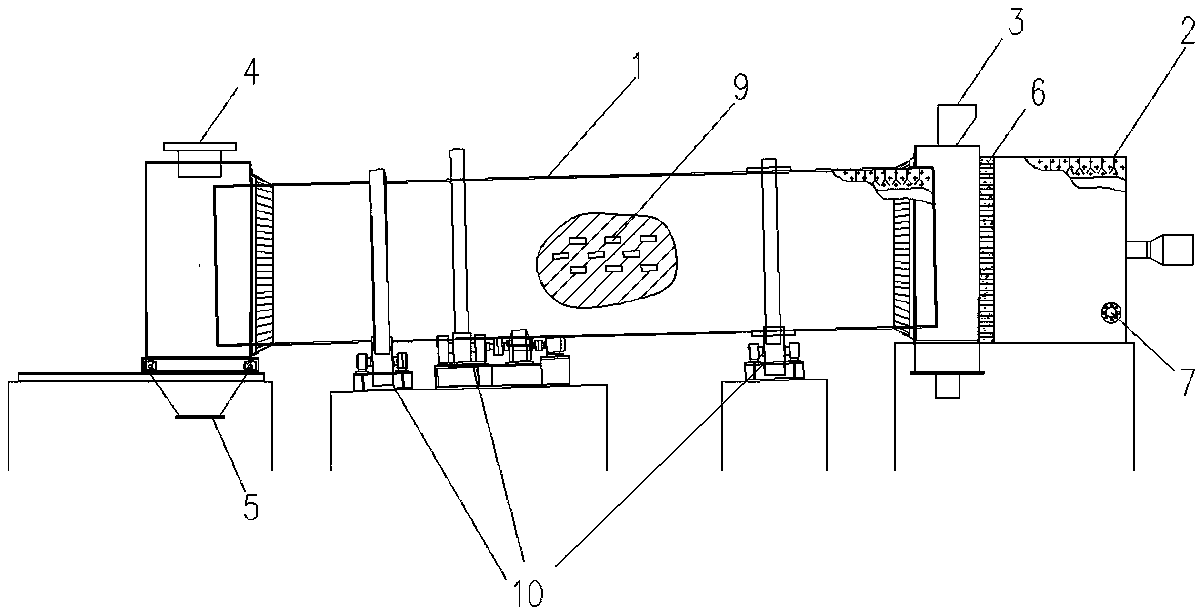

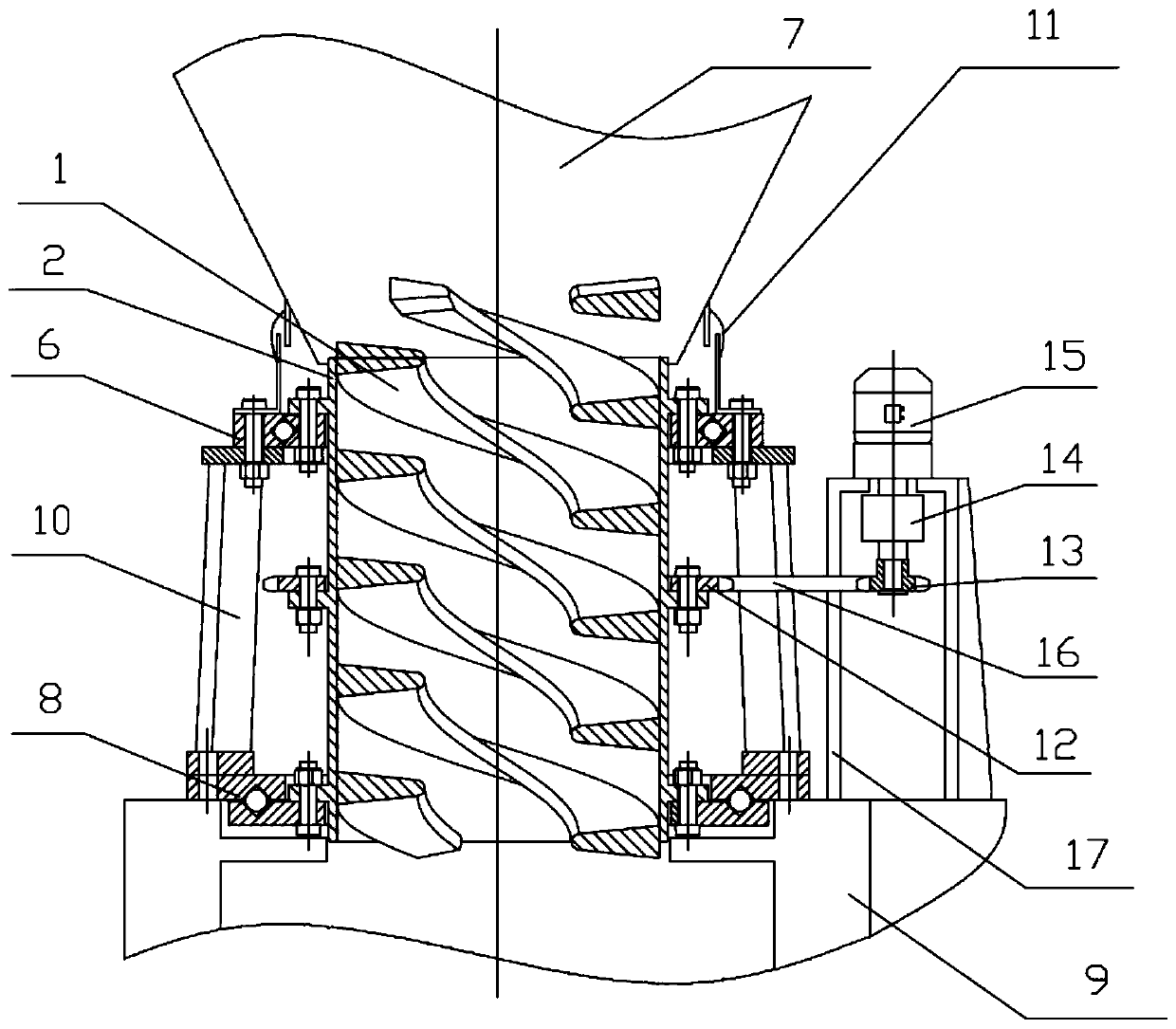

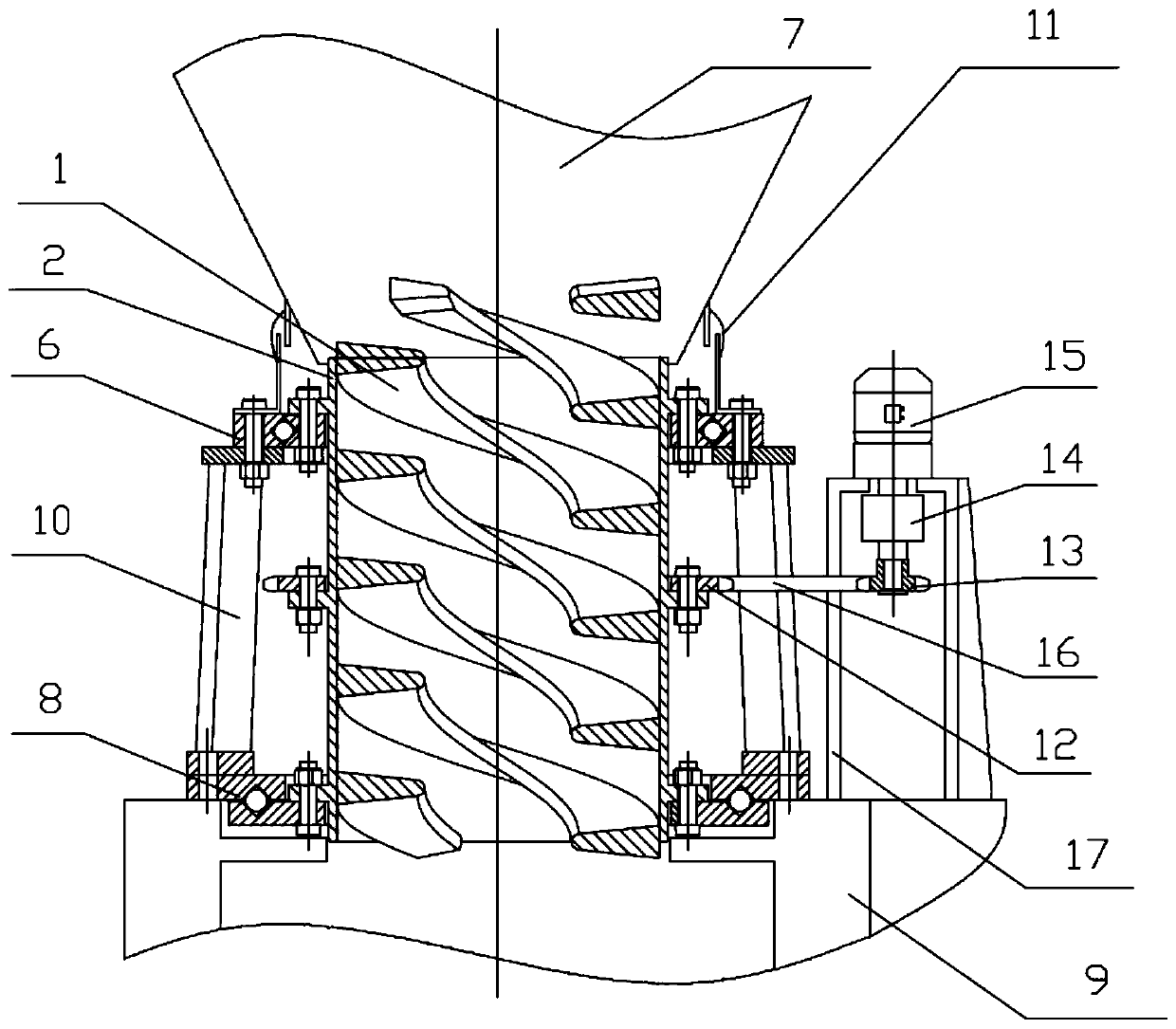

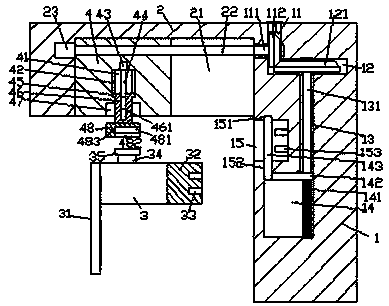

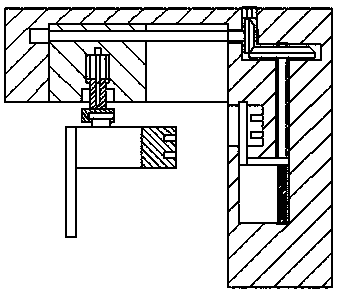

A dedicated rotary kiln for pyrolysis oxidation of solid waste salt

PendingCN109282641AExtended service lifeEasy maintenance and installationFurnace componentsRotary drum furnacesSlagTreatment field

A dedicated rotary kiln for pyrolysis oxidation of solid waste salt relates to the treatment field of industrial inorganic waste and includes a rotary barrel and a heating furnace. The front end of the rotary barrel communicates with the heating furnace. The top of the front end of the rotary barrel is provided with a feed hopper. The top and bottom of the rear end of the rotary barrel are provided with a fume outlet and a slag outlet, respectively. A heat accumulating type porous fire resisting wall is disposed in a combustion chamber of the heating furnace at the connection with the rotary barrel for separating the rotary barrel and the combustion chamber of the heating furnace. The heat accumulating type porous fire resisting wall can prevent open fire from emerging into the rotary kilnto directly contact the solid waste salt so as to lead melting of the organic dry salt. The rotary kiln guarantees that the solid waste salt will not be glued and pyrolysis oxidation reaction will beconducted completely, and has advantages of high heat exchange efficiency, high transportation efficiency and high pyrolysis efficiency.

Owner:JIANGSU JINNIU ENVIRONMENTAL ENG EQUIP

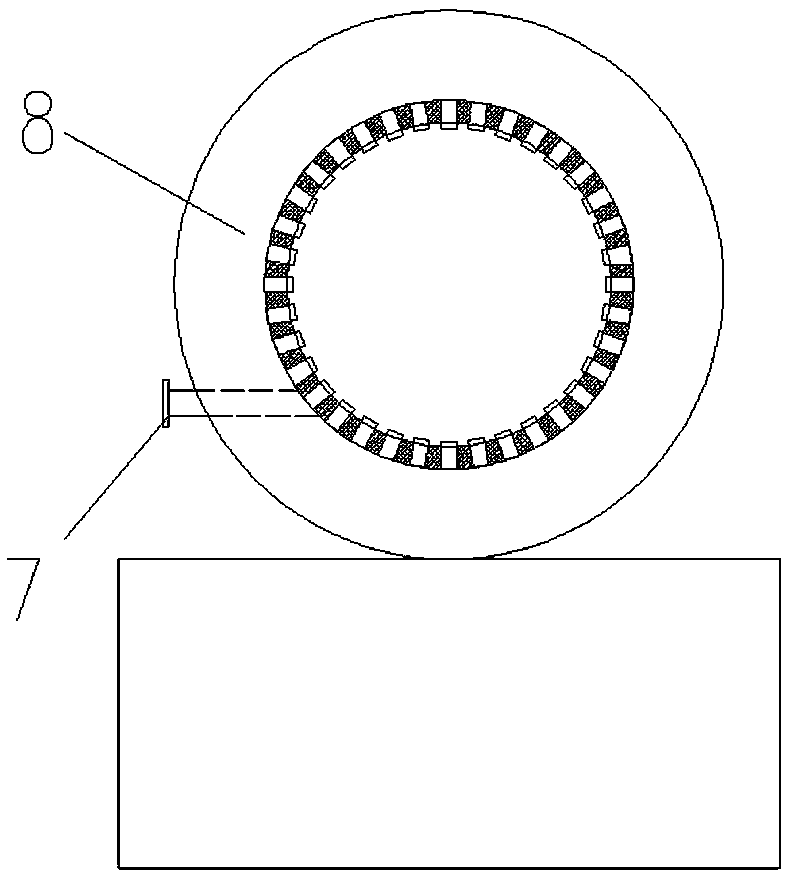

Large-capacity inverter module with high-current/high-voltage IGBT directly connected in parallel

PendingCN109510474AOptimization pathSmall sizeConversion constructional detailsCooling/ventilation/heating modificationsCapacitanceHigh voltage igbt

The invention discloses a large-capacity inverter module with high-current / high-voltage IGBTs directly connected in parallel. The large-capacity inverter module comprises a water-cooled plate, discrete IGBT devices, a laminated busbar, a first absorbing capacitor, a driving loop, an AC side convergence busbar, a current sensor, a DC side laminated busbar, a second absorbing capacitor, a DC side negative convergence busbar and a DC side positive convergence busbar, wherein the number of the discrete IGBT devices is six, and the six discrete IGBT devices are sequentially and evenly arranged on the water cooling plate from top to bottom. The large-capacity inverter module with the high-current / high-voltage IGBTs directly connected in parallel have the advantages that the calculation of current impedance of the branch circuits connected in parallel is precise, the consistency is guaranteed, a high current sharing coefficient is realized, the cable lengths of the devices of different phasesof the driving loop are identical, and the paths are separated and do not interfere with one another; and the large-capacity inverter module adopts a main loop layout design, makes full use of space,optimizes circuit paths, is high in power density, has small overall module size, is simple, is convenient to maintain and install, and has good electrical properties.

Owner:江苏同芯电气科技有限公司

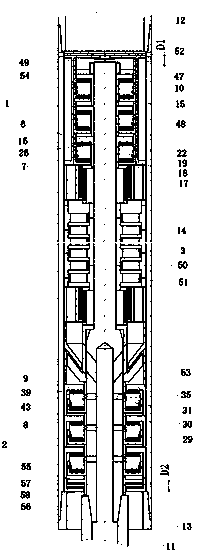

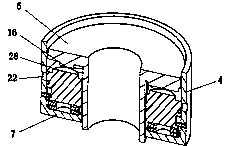

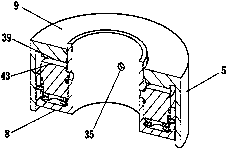

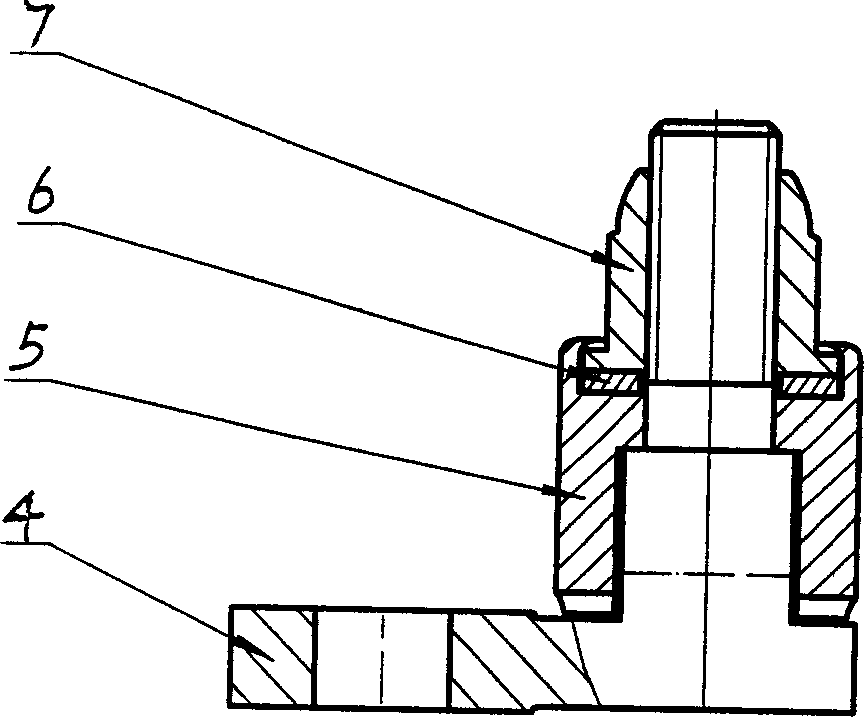

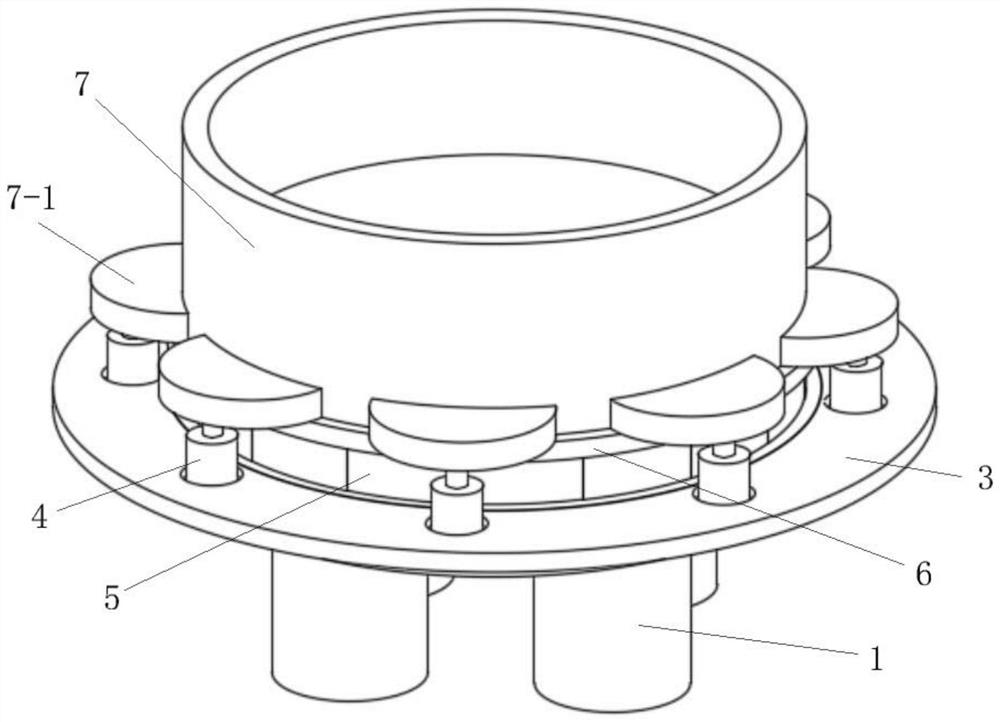

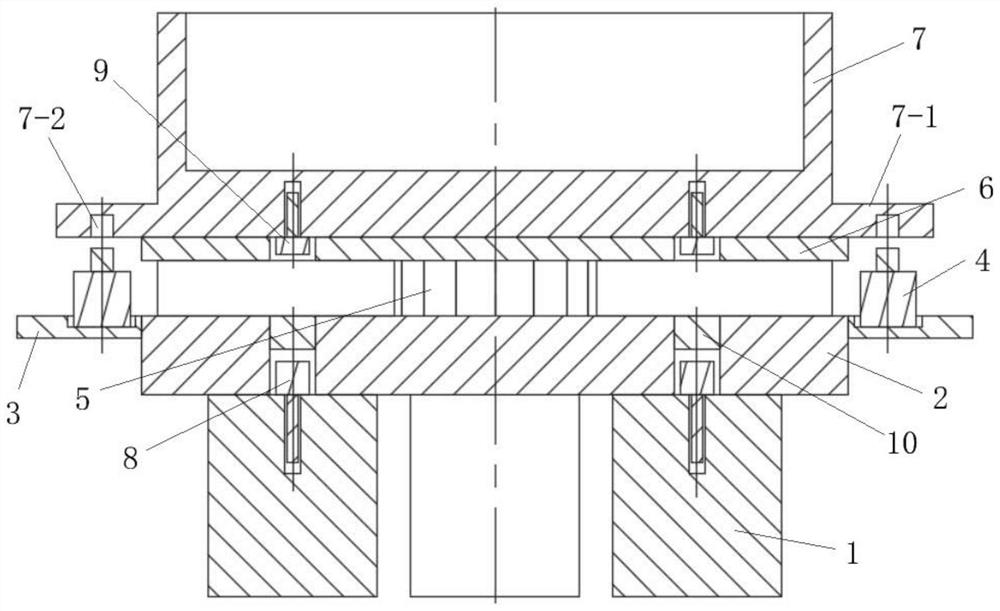

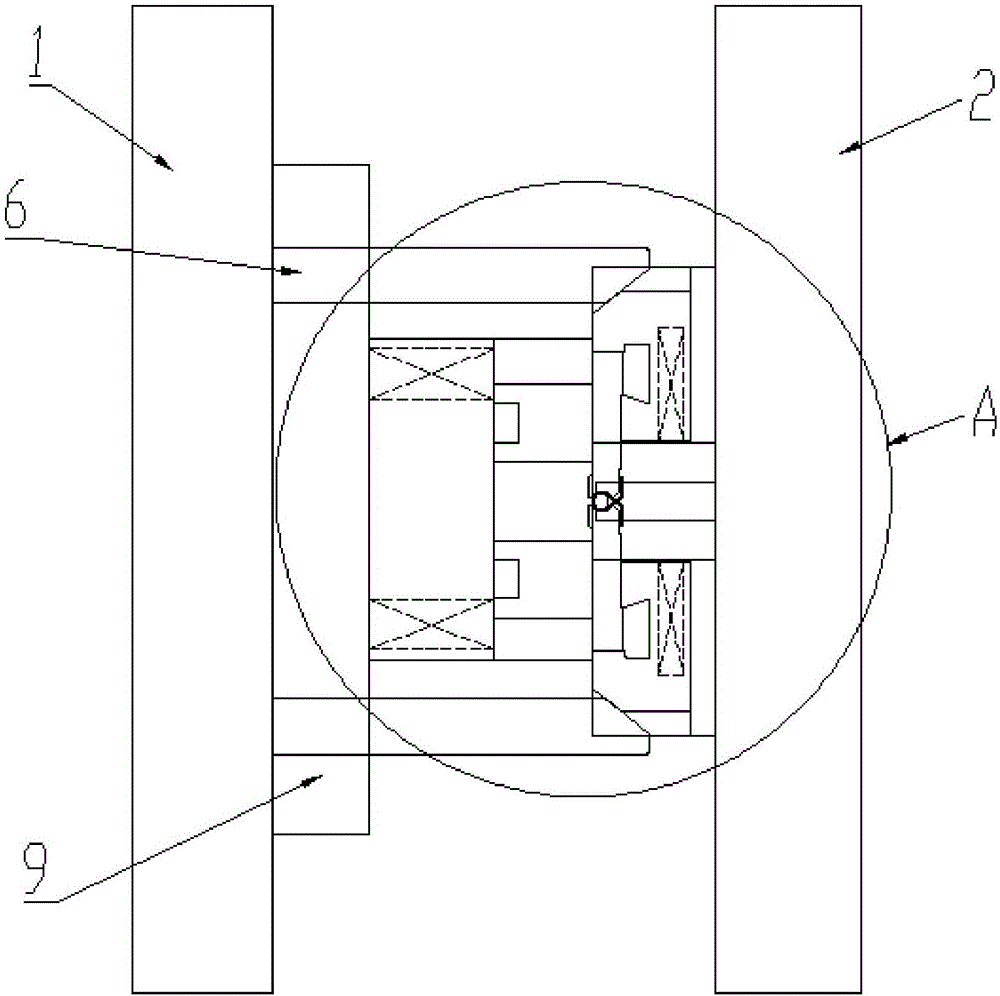

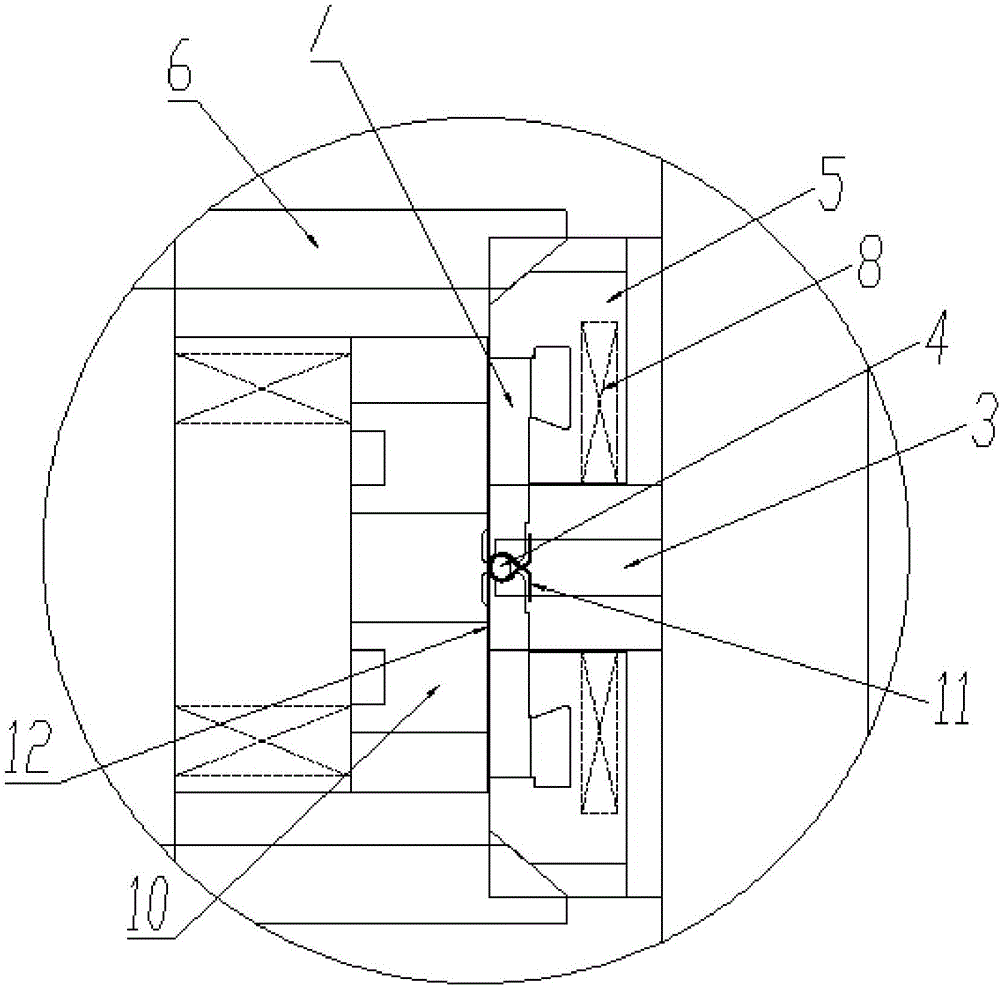

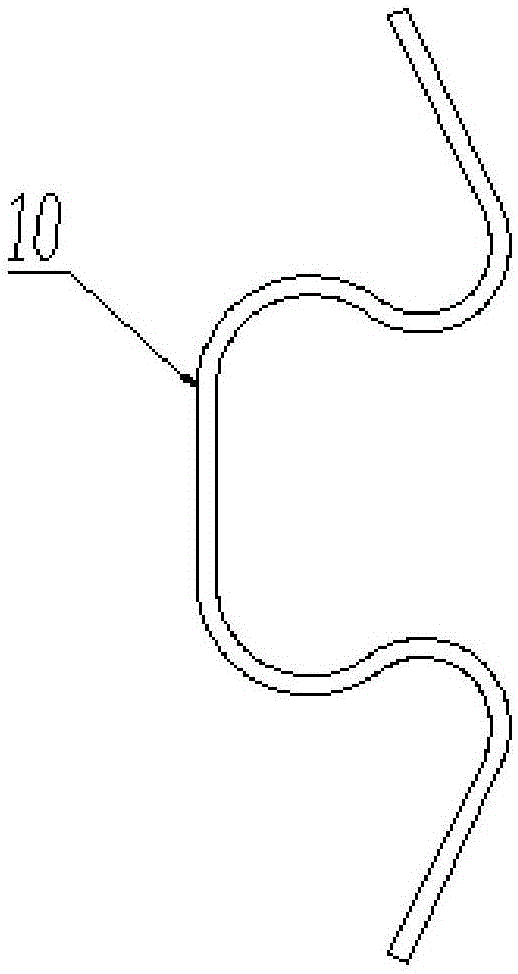

Thrust bearing pack for automatically regulating axial load of turbodrill

InactiveCN103821821AExtend your lifeEasy maintenance and installationBearing componentsBorehole drivesEngineeringDynamic balance

The invention relates to a thrust bearing pack for automatically regulating the axial load of a turbodrill. The thrust bearing pack is composed of an upper bearing pack and a lower bearing pack, wherein the upper bearing pack is mounted at the top end of a turboshaft; the lower bearing pack is mounted at the bottom end of the turboshaft. The upper bearing pack is composed of 3-5 pairs of upper bearings, and the upper bearings are composed of upper bearing movable rings and upper bearing static rings; the lower bearings are composed of 3-5 pairs of lower bearings, and the lower bearings are composed of lower bearing movable rings and lower bearing static rings; a bearing head fastening nut and an output connector are in threaded connection with the turboshaft, and the upper bearing movable rings and the lower bearing static rings are tightly pressed on the turboshaft; the upper bearing movable rings and the lower bearing movable rings synchronously rotate along with the turboshaft. According to the thrust bearing pack, the opening degree of a flow guide hole is automatically regulated according to the size and the direction of the axial load of the turboshaft, a hydraulic load generated by a turbine section is in dynamic balance, the bearings no longer bear an impact load, and the service life of the turbodrill is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

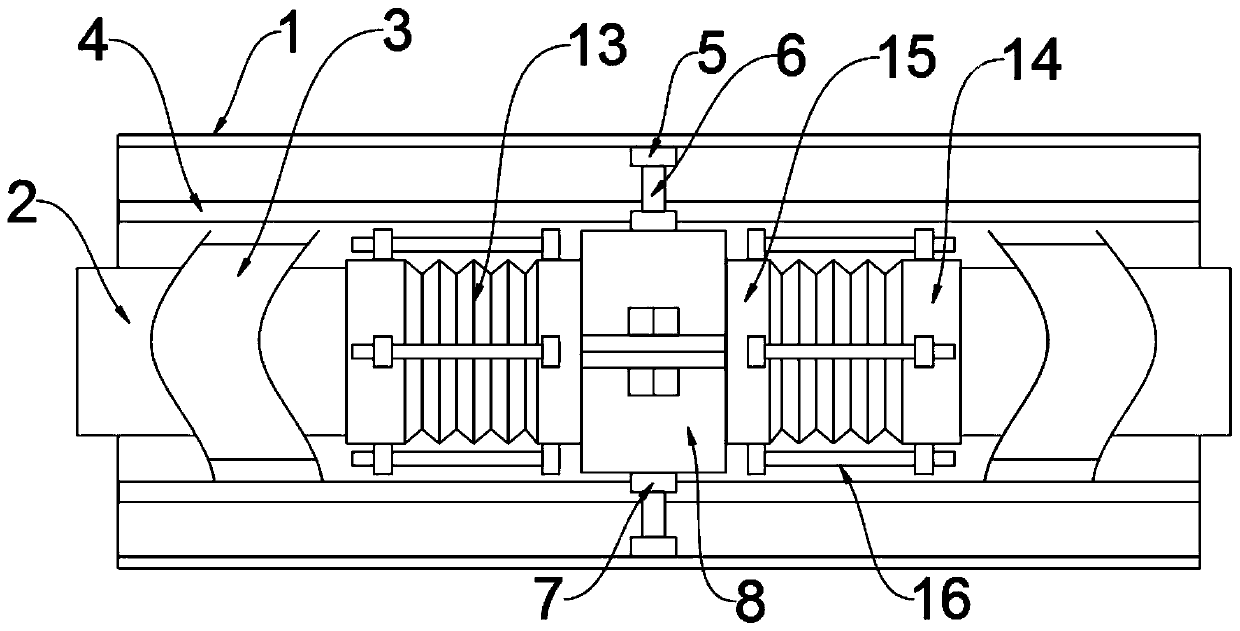

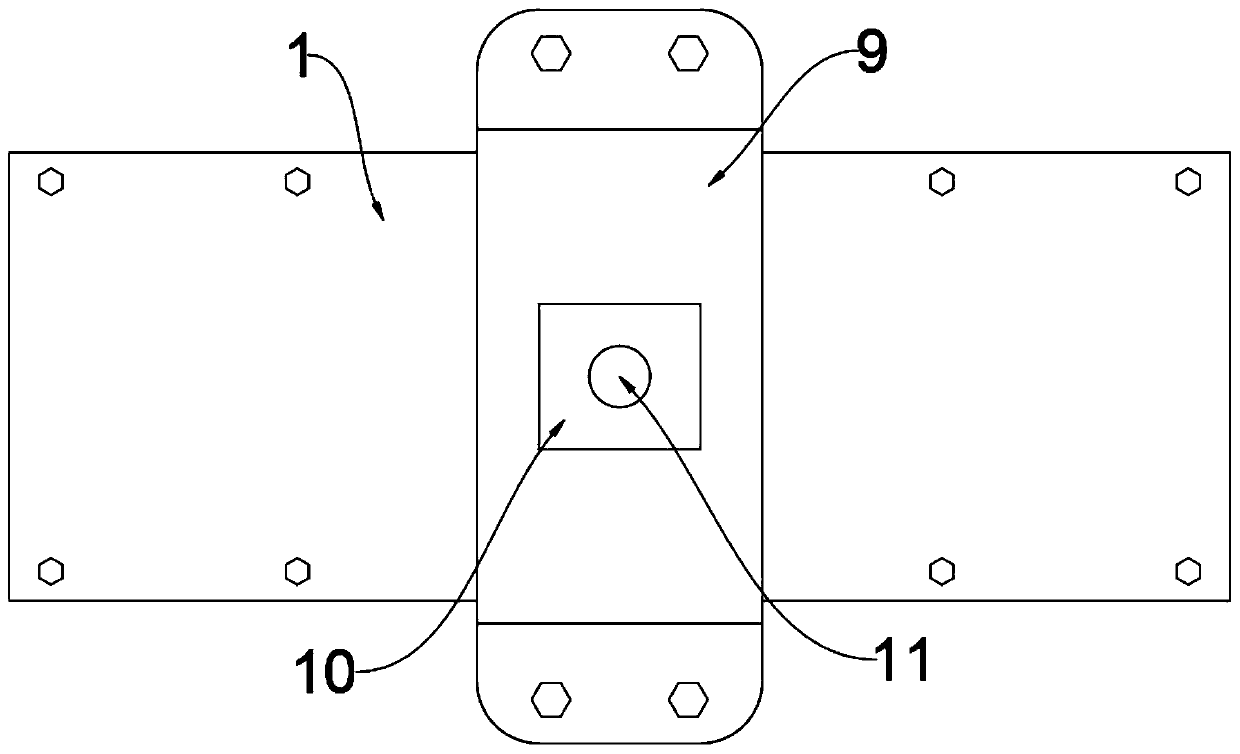

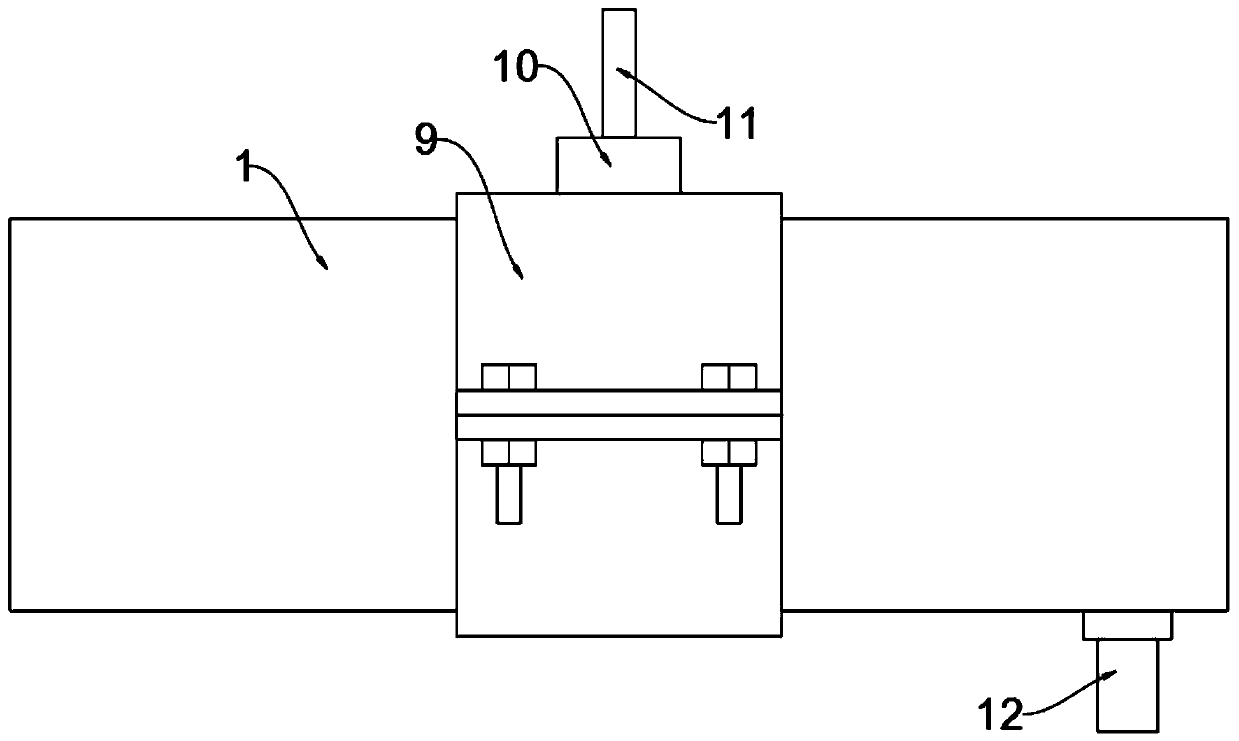

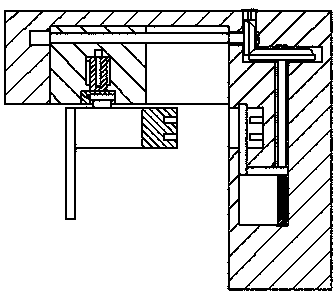

Plate grid ejection mechanism of lead-acid battery plate grid die casting machine

The invention discloses a plate grid ejection mechanism of a lead-acid battery plate grid die casting machine, and the mechanism comprises a fixed framework and a movable framework, wherein two working shafts which are parallel mutually and are arranged at an interval and a driving device for driving the working shafts to rotate are arranged on the fixed framework; and the movable framework is supported on an eccentric mechanism arranged on the two working shafts and can rotate in a reciprocating manner along with the two working shafts under the drive of the driving device, and the eccentricmechanism on the working shafts is used for pushing the movable framework to enable a thimble carried on the movable framework to move up and down. The plate grid ejection mechanism of the lead-acid battery plate grid die casting machine can regulate the ejection time, ejection speed and ejection distance of the thimble according to the requirements; furthermore, the smooth lifting and smooth falling of the thimble can be ensured on the structure, and the balanced and smooth ejection of a plate grid can be further ensured; and in addition, the plate grid ejection mechanism further has the advantages of simple structure, convenience in manufacturing, convenience in maintenance and mounting, smooth and reliable actions, high controllability and the like, thereby creating conditions for realizing automatic production of a whole plate grid production line.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

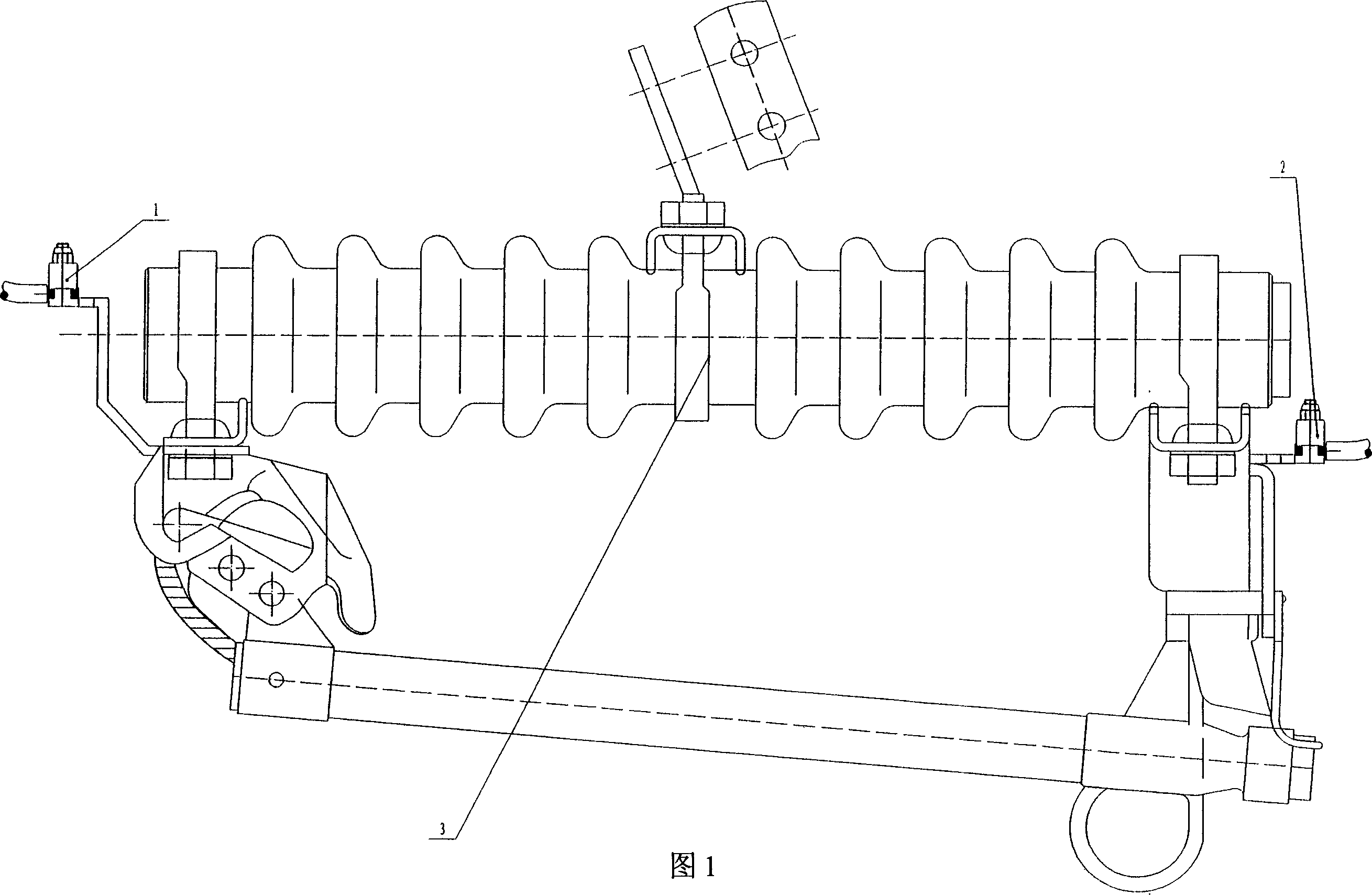

Rain cover for disconnector mechanism

InactiveCN106158488AImprove reliabilityEasy maintenance and installationElectrical apparatusEngineeringElectric power

The utility model relates to a rainproof cover for a knife gate mechanism, which relates to a rainproof cover for an outdoor isolating switch. The connection between the traditional isolation switch rotating link and the mechanism box is not tightly sealed, resulting in the infiltration of raindrops and the DC grounding of the system. The rain cover of the knife gate mechanism is in the shape of a trumpet with an upper opening and a lower opening, the upper opening is hooped on the cylindrical surface of the rotating link of the isolation switch and forms a seal at the connection, and the lower opening is located in the box body of the knife gate mechanism. superior. According to the invention, a rainproof cover with a downward trumpet-shaped opening is installed at the connection between the rotating connecting rod of the isolation switch and the box body of the knife gate mechanism, so as to avoid the DC grounding of the system. The invention is used for the rainproof protection of the outdoor isolation switch in the electric power industry.

Owner:国网黑龙江省电力有限公司齐齐哈尔供电公司 +1

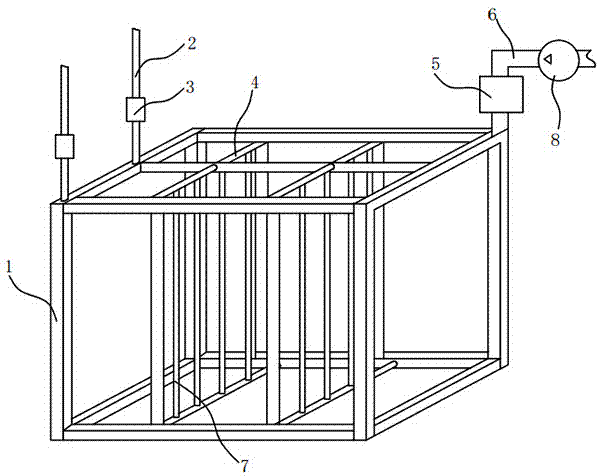

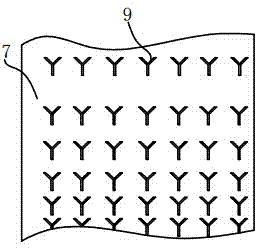

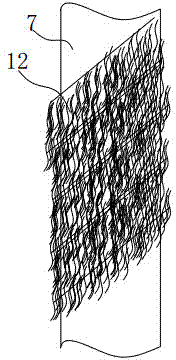

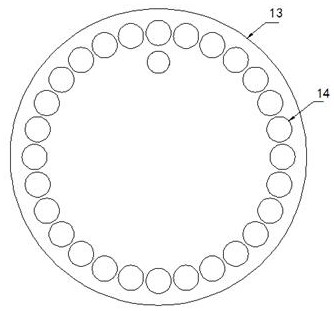

Vertical tube denitrification filler device

InactiveCN104743671AHigh strengthSolution to short lifeTreatment with aerobic and anaerobic processesTreatment with microorganism supports/carriersFiberVertical tube

The invention relates to a vertical tube denitrification filler device. The vertical tube denitrification filler device comprises a main pipeline frame, a closed circuit frame branch pipeline, a vertical aerator pipe, an air inlet pipe, an air supplier, an exhaust pipe, an air evacuation valve and an air inlet valve, wherein an aeration hole is formed in the surface of the vertical aerator pipe; denitrification filler is woven at the periphery of the vertical aerator pipe, outer diameter of the denitrification filler is 30-100mm, and the denitrification filler is made from fibers and completely covers the surface of the aerator pipe. The vertical tube denitrification filler device has the advantages that denitrification filler is directly arranged at the periphery of the vertical aerator pipe, the closed circuit frame branch pipeline is taken as an air circulating branch circuit, and oxygen utilization rate is high; the vertical tube denitrification filler device has a complete aeration functional module unit, maintenance and mounting are facilitated, performance is stable and reliable, and continuous or interrupted operation can be realized; the vertical aerator pipe is high in strength, resistant to corrosion and long in life, the aeration hole realizes self-closing function at water pressure, online cleaning can be carried out, blockage is prevented, and starting-up energy consumption is reduced; and denitrification filler can realize sludge reduction, and compared with the traditional activated sludge process, reduction amount of the residual activated sludge can be more than or equal to 50%.

Owner:JIANGSU BOKAI ENVIRONMENTAL SCI & TECH

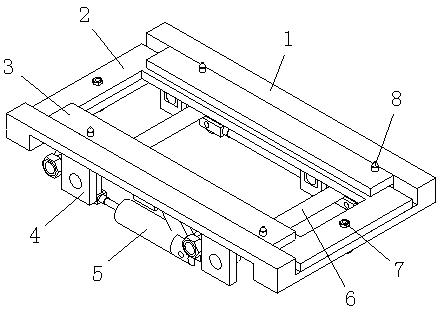

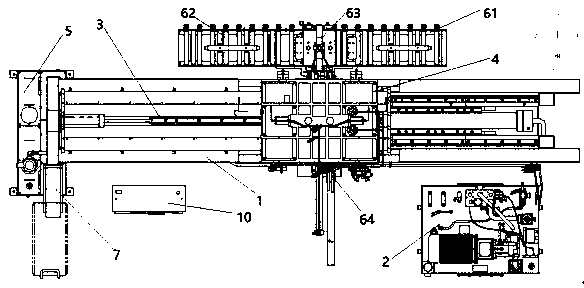

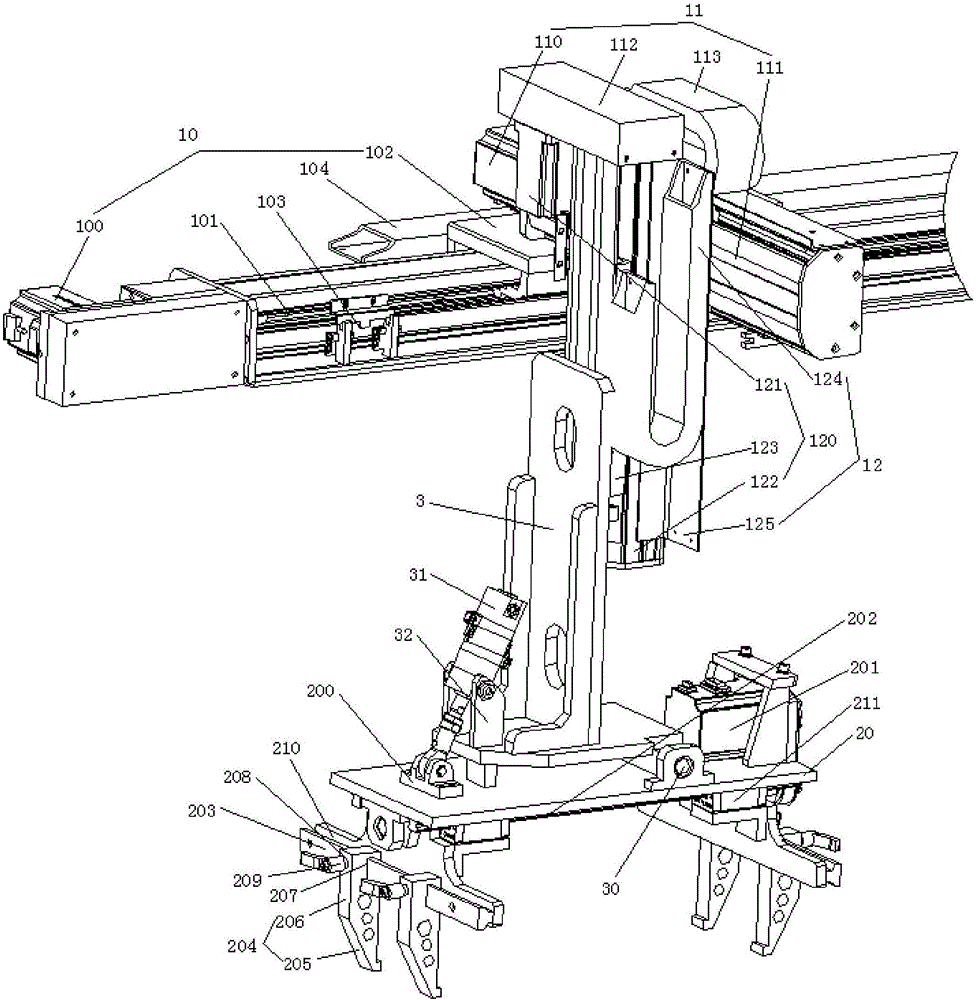

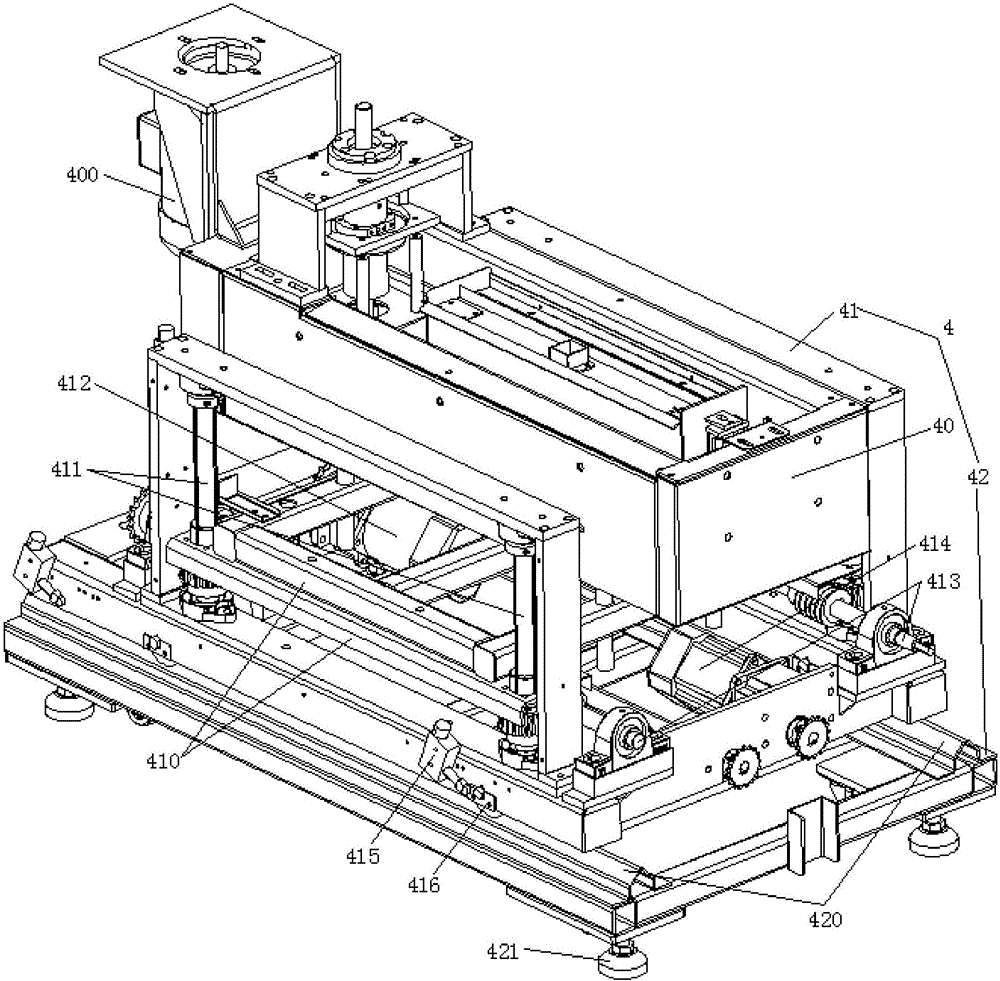

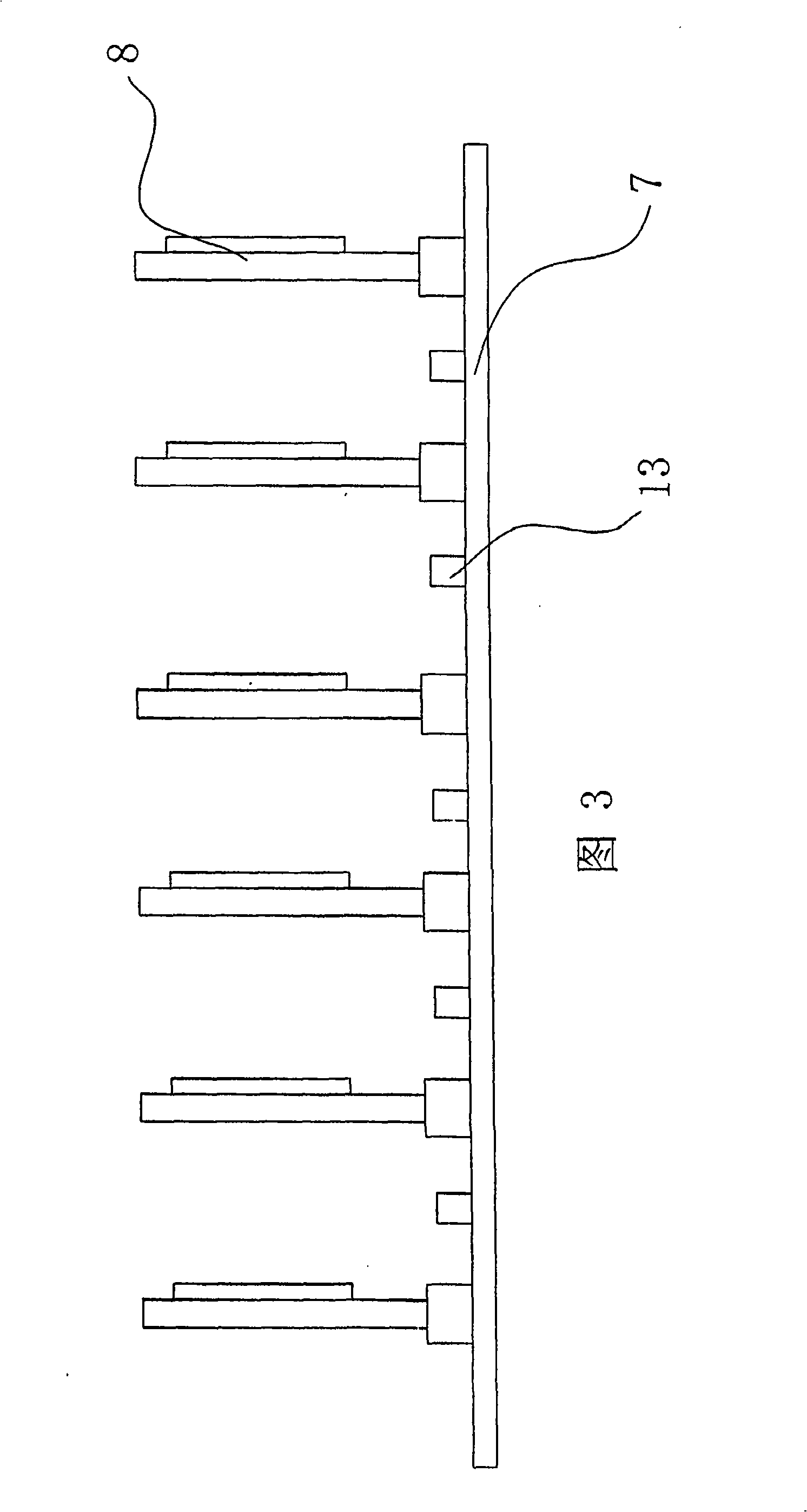

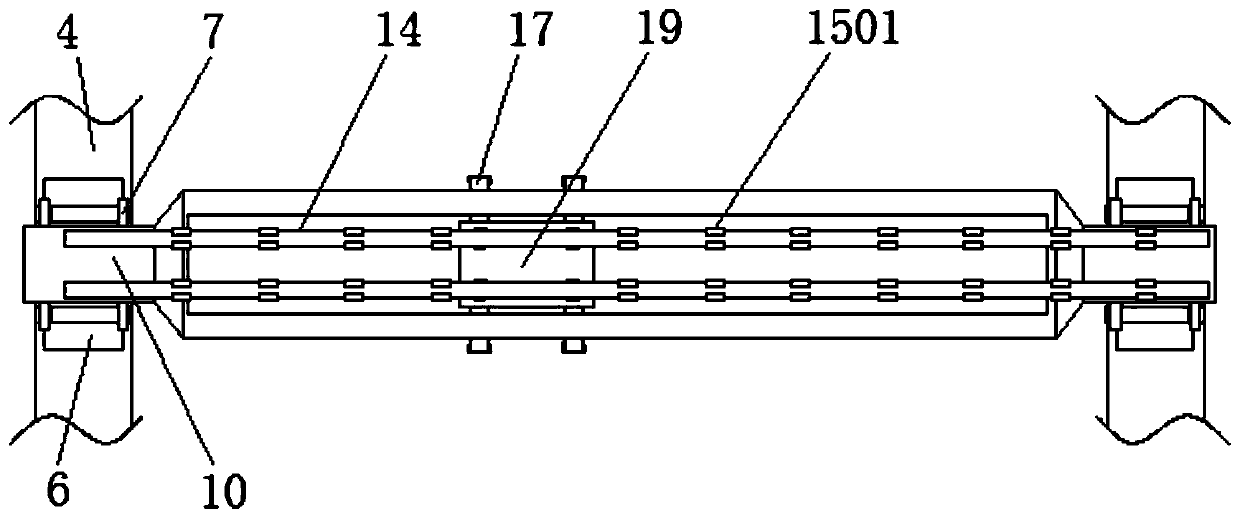

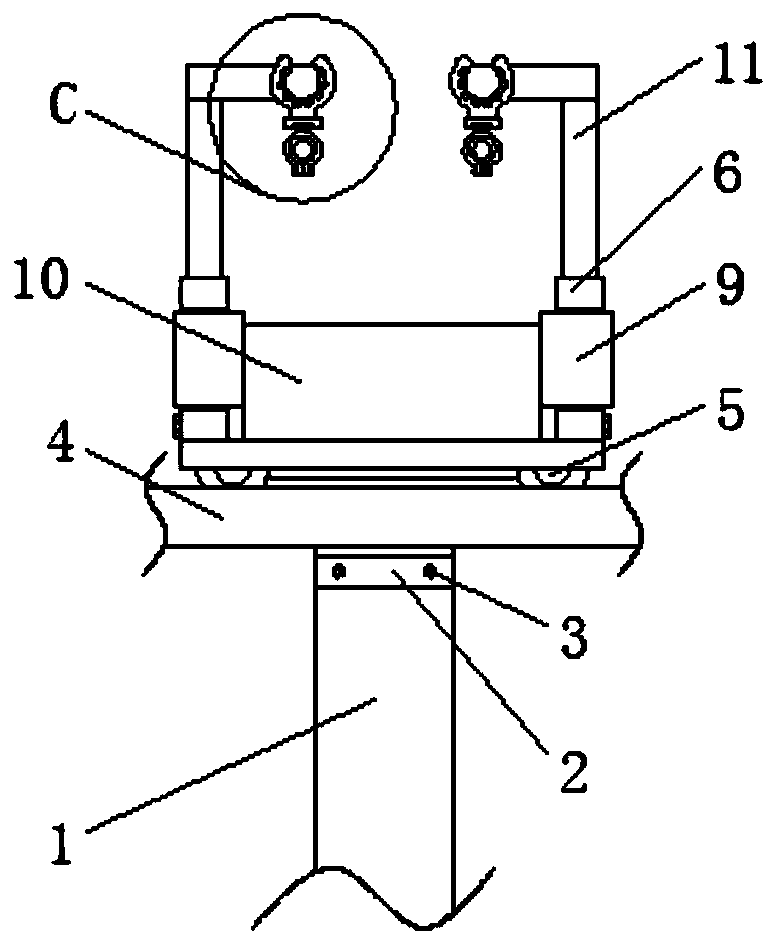

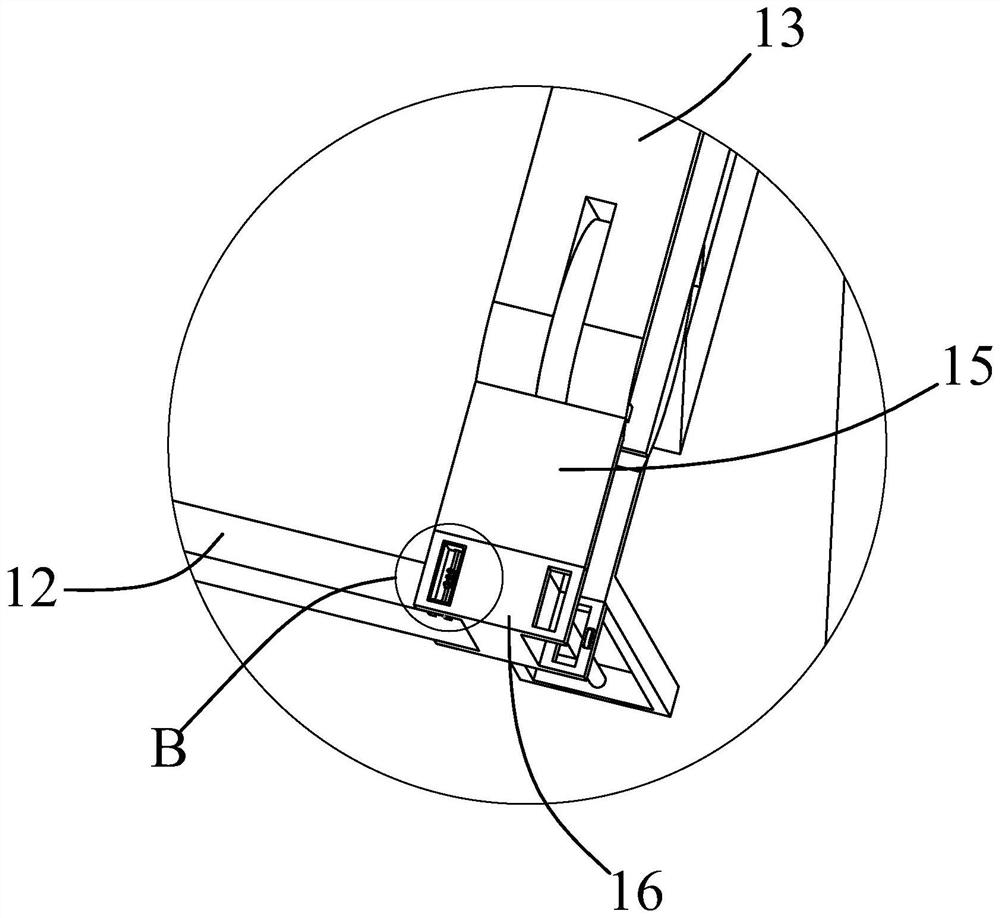

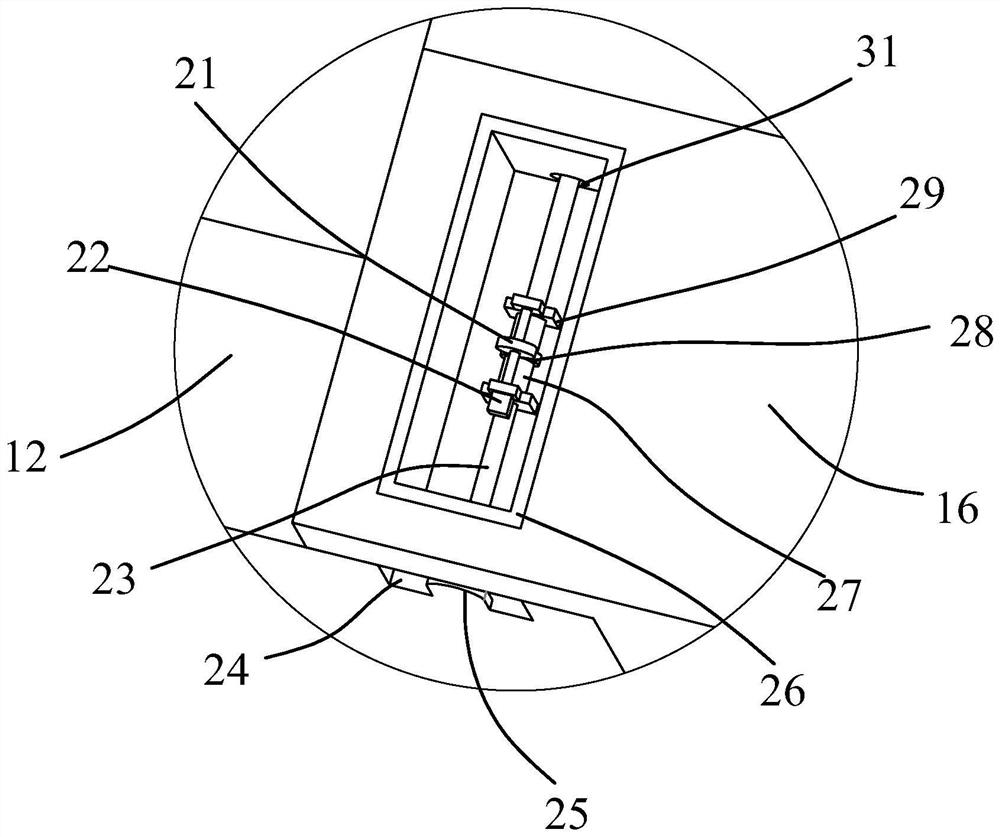

Automatic crystal blank grinding and polishing system and butt joint machine thereof

ActiveCN103273398AReduce time spentReduce waiting timeSpherical surface grinding machinesGrinding work supportsButt jointEngineering

The invention discloses a butt joint machine. A rotating arm which rotates vertically is installed between a butt joint position and a waiting position, a butt joint lower fixture seat is mounted on the rotating arm, a butt joint upper fixture seat is mounted at the butt joint position, and the waiting position is vacant; when the rotating ram rotates to the butt joint position, the butt joint lower fixture seat is positioned right below the butt joint upper fixture seat, and when the rotating arm rotates to the waiting position, a fixture needle of the butt joint lower fixture seat is downward; a rotating frame which rotates horizontally is installed between a cleaning position and a butt joint powder staining position, and front and back groups of fixture seats are mounted on the rotating frame; and the fixture seats at the butt joint position and the cleaning position are laterally arranged in rows along fixture length directions, and the fixture seats at the butt joint powder staining position and the waiting position are laterally arranged in rows along fixture length directions. The invention further discloses an automatic crystal blank grinding and polishing system using the butt joint machine. According to the automatic crystal blank grinding and polishing system and the butt joint machine thereof, the structure is reasonable, actions are simple, the cost is low, the operation is reliable, and the efficiency is high.

Owner:虞雅仙

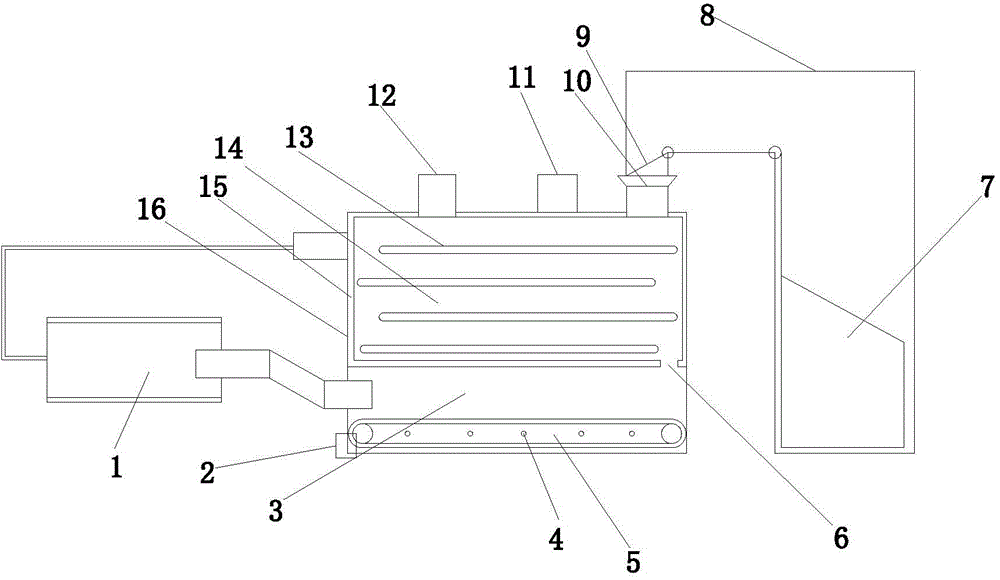

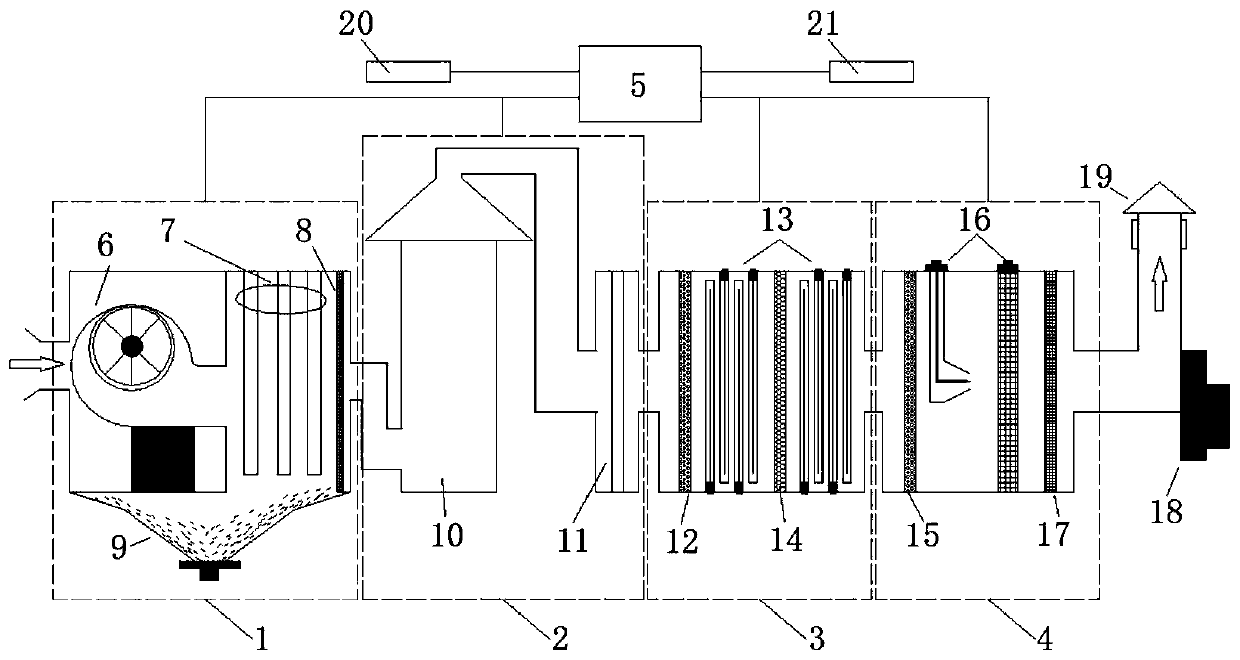

Clean and environment-friendly waste gasification heat storage method and device

ActiveCN104482540AHigh economic valueIncrease heat storageIncinerator apparatusCombustorCombustion chamber

The invention discloses a clean and environment-friendly waste gasification heat storage method and device. According to the method, the gas is dried in manifold cycles in a drying chamber and then goes into a combustion chamber; the high-temperature gas obtained after combustion goes into a combustor to store heat and perform secondary drying on the drying chamber; combustion residue is discharged by use of a chain tray; the waste heat gas used by the combustor goes into the jacket of the drying chamber to heat the jacket; the device comprises a stove and a gas-tight chamber arranged beside the stove; a lifting feeding device is arranged in the gas-tight chamber; the upper end of the gas-tight chamber is communicated with the feeding hole of the stove; the drying chamber is arranged in the stove; a layer of jacket is arranged outside the drying chamber; the combustion chamber is arranged under the drying chamber; the drying chamber is communicated with the combustion chamber by use of a feeding hole; the chain tray is arranged at the bottom of the combustion chamber; a slag outlet is formed in the outlet end of the chain tray; the combustion chamber is connected with the combustor by use of a fire outlet duct; the outlet of the combustion is communicated with the jacket; the smoke outlet is formed in the jacket; a moisture outlet is formed in the drying chamber.

Owner:湛江市粤绿环保科技有限公司

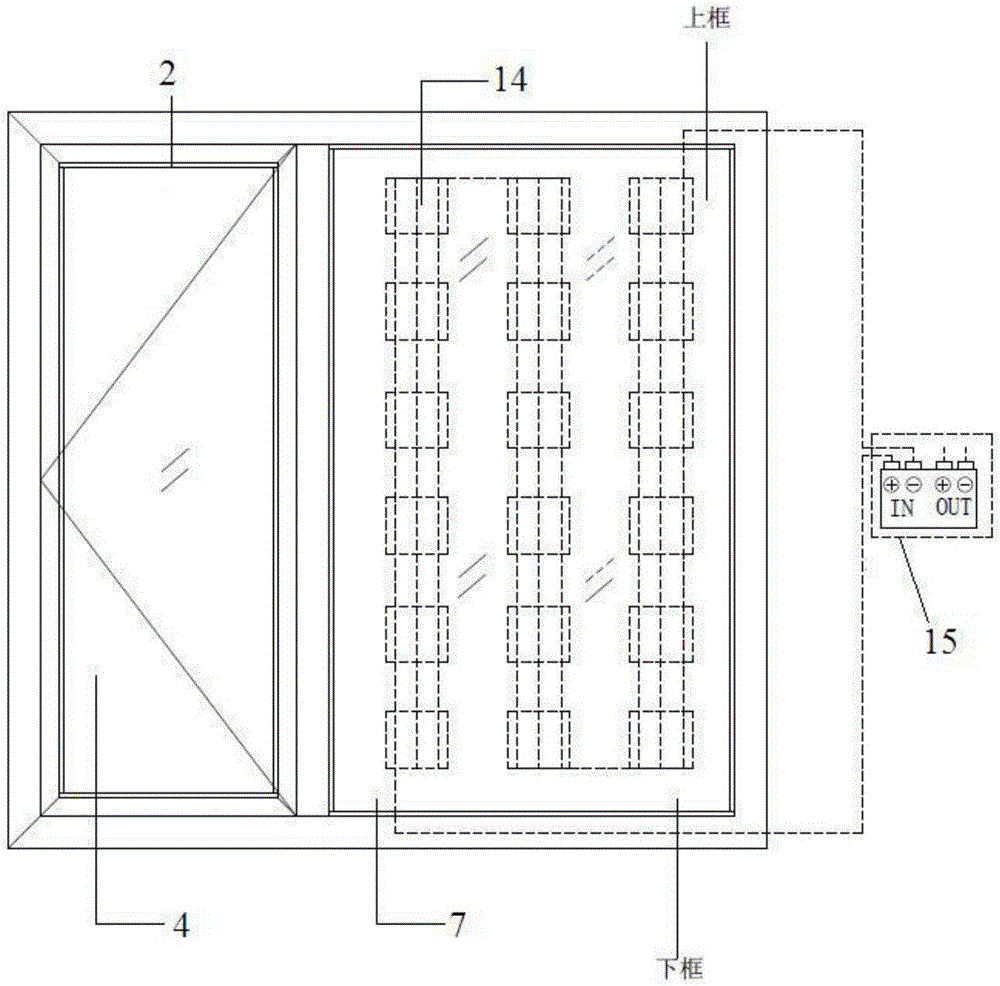

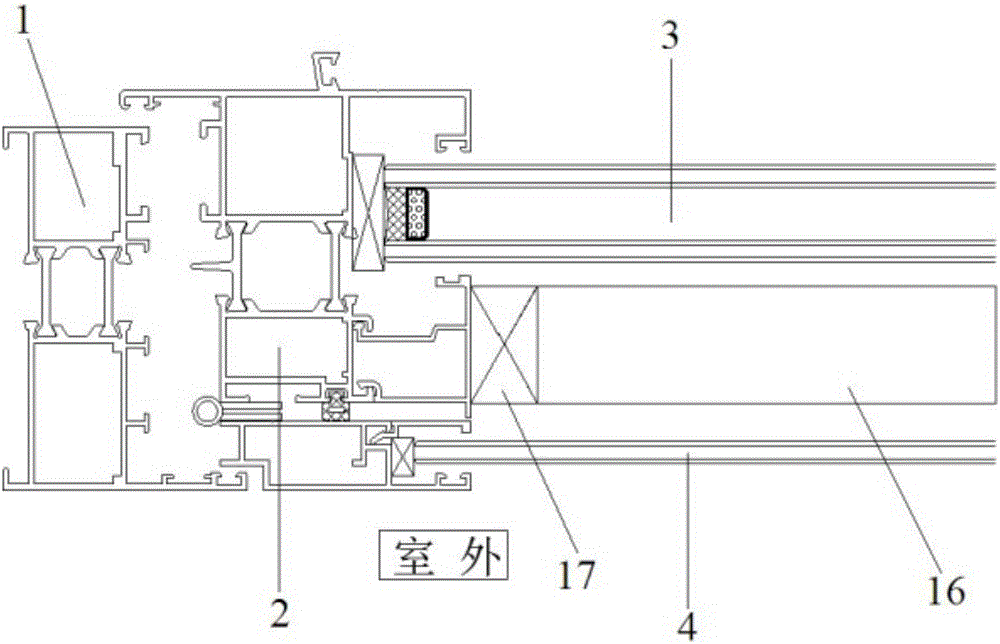

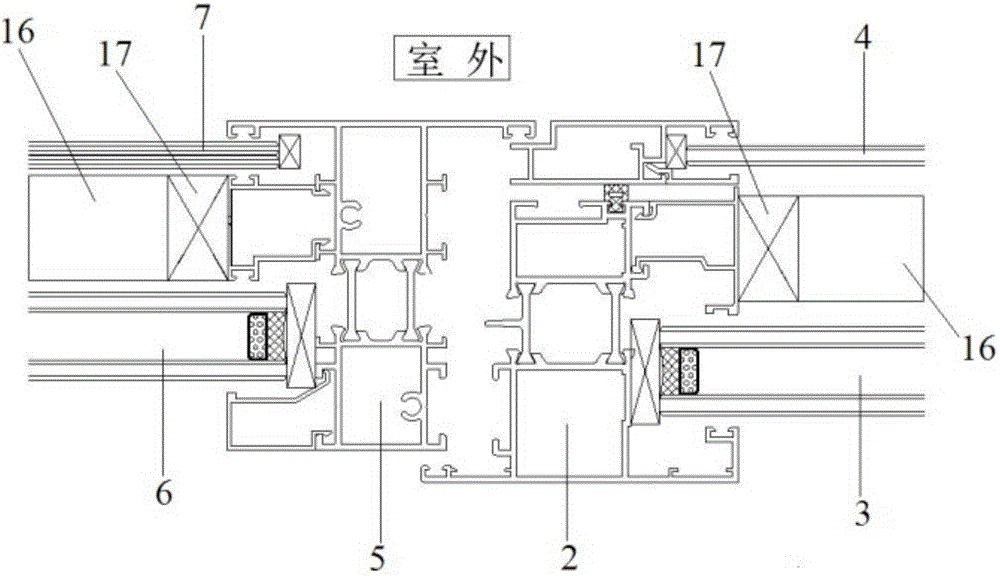

Detachable inwards opened hollow glass embedded photovoltaic window shade

InactiveCN106703605AAchieve multi-functional integrationDoes not damage the structurePhotovoltaic supportsDoor/window protective devicesEngineeringSilicon

The invention discloses a detachable inwards opened hollow glass embedded photovoltaic window shade. The detachable inwards opened hollow glass embedded photovoltaic window shade comprises a window frame, an openable sash unit and a fixed sash unit, wherein the openable sash unit and the fixed sash unit are arranged inside the window frame; the openable sash unit is composed of an opening sash, a first hollow double glass and a single glass, wherein the first hollow double glass and the single glass are arranged inside the opening sash, the first hollow double glass is arranged outside and the single glass is arranged inside; the fixed sash unit is composed of a fixed sash, a second hollow double glass and a photovoltaic glass, wherein the second hollow double glass and the photovoltaic glass are arranged inside the fixed sash, the inside the lower frame profile of the fixed sash is provided with a wire port, wires and fixing glue, the photovoltaic glass is arranged outside and composed of, from inside to outside, an ultra clear tempered glass layer, an EVA (ethylene-vinyl acetate copolymer) layer and an ultra clear tempered glass layer, and silicon photovoltaic battery panels are uniformly laid inside the EVA layer. The detachable inwards opened hollow glass embedded photovoltaic window shade achieves heat insulation performance, can adjust indoor light intensity and meanwhile is convenient to mount, dismount and maintain and capable of achieving a photovoltaic generation function.

Owner:江苏建科土木工程技术有限公司

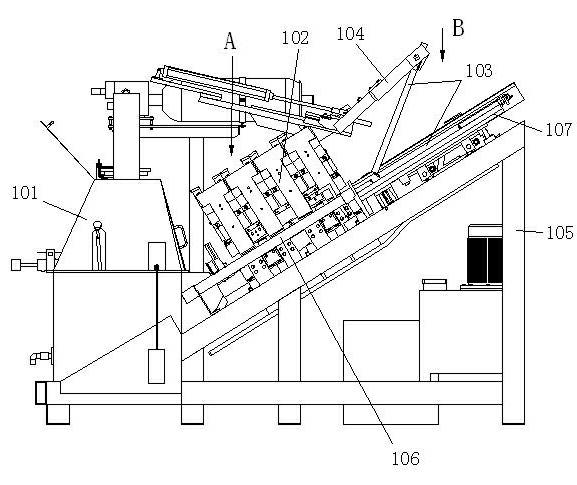

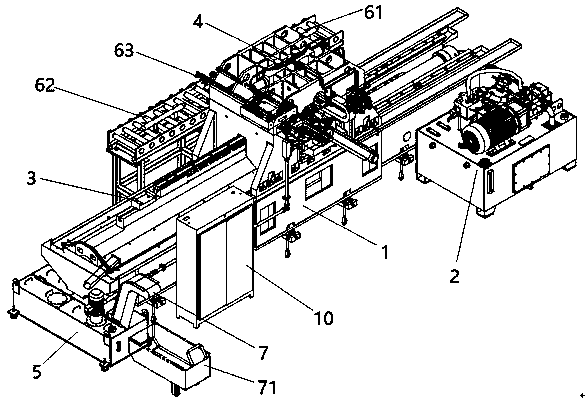

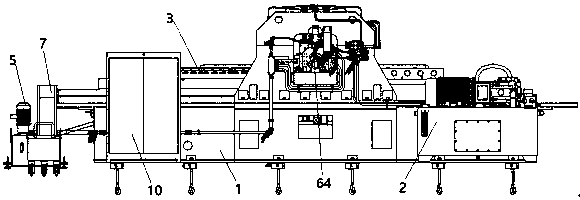

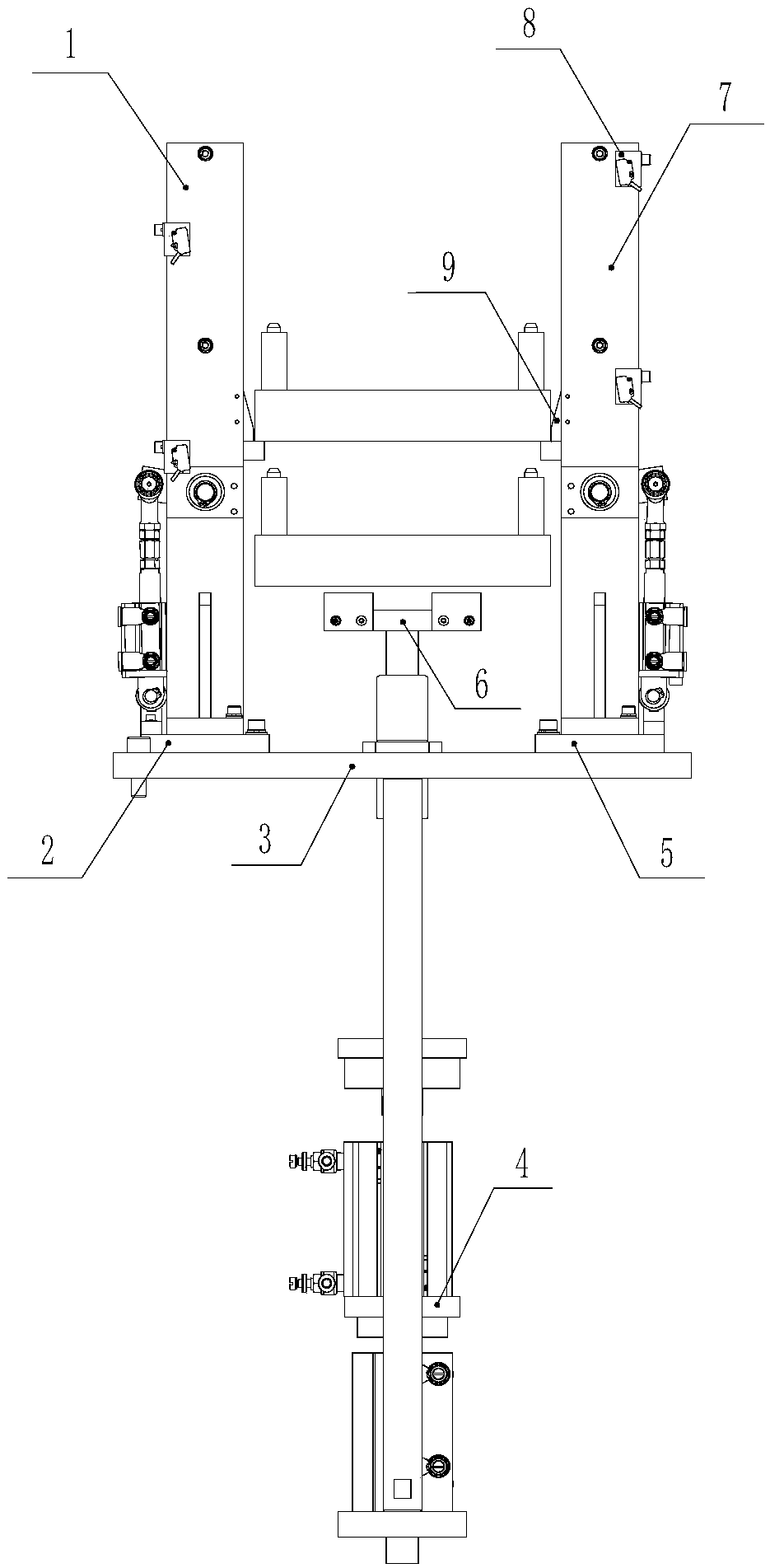

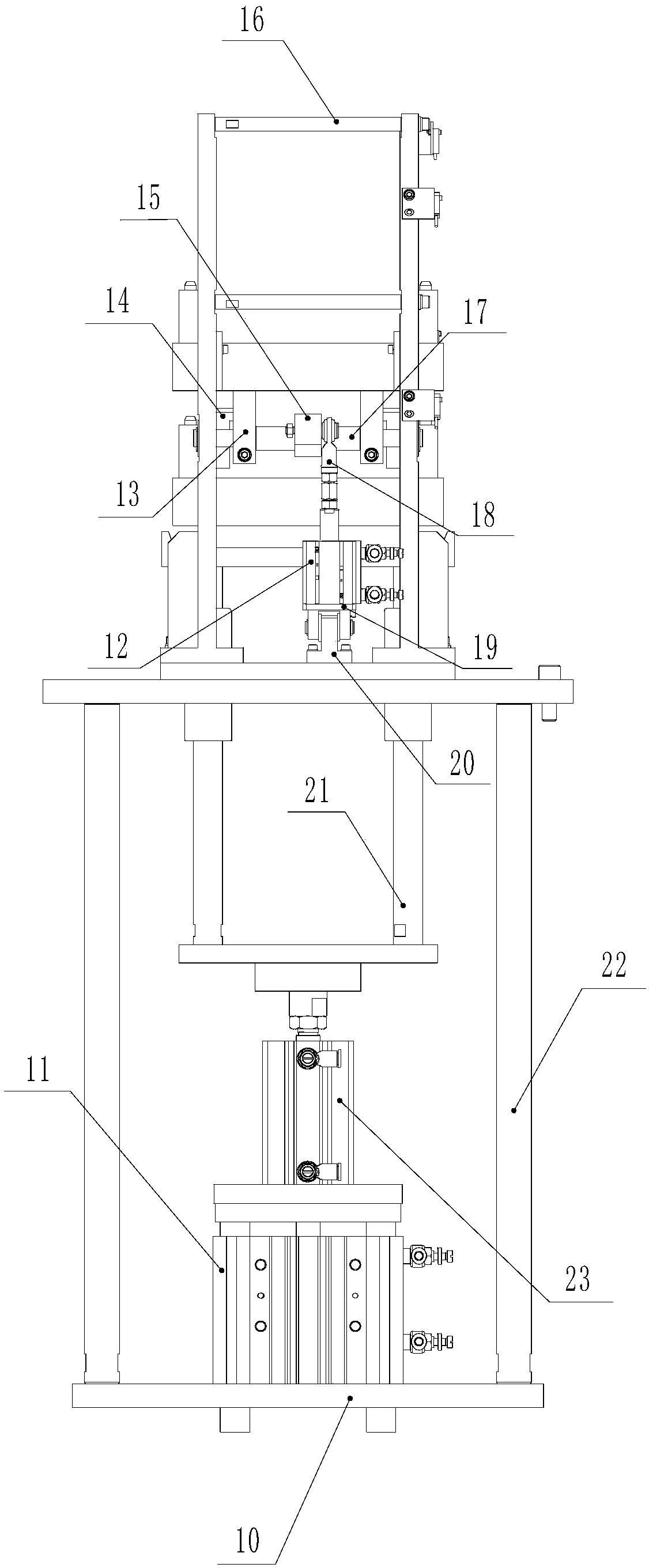

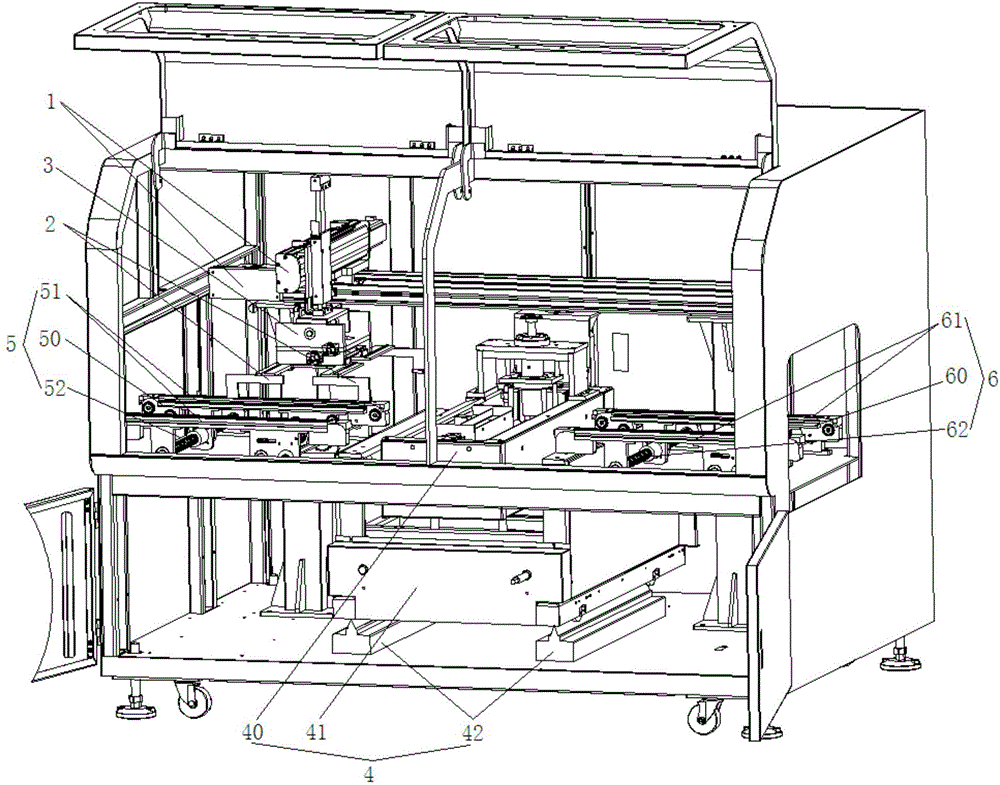

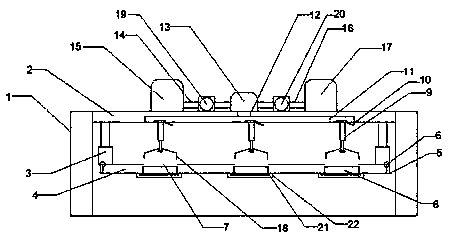

Broaching machine special for horizontal machining air cylinder

InactiveCN111014809AImprove efficiencyEasy maintenance and installationBroaching accessoriesBroaching machinesPhysicsElectrical control

The invention provides a broaching machine special for a horizontal machining air cylinder. The broaching machine includes a machine bed, a hydraulic system, a cutter system, a fixture system, a loading and unloading system, a cooling system, a chip removal system and an electrical control system, the machine bed is connected with the hydraulic system, the cutter system, the fixture system, the loading and unloading system, the cooling system, the chip removal system and the control system, the machine bed is horizontal and rectangular, and a main sliding plate is arranged on the machine bed,and driven by an oil cylinder to move horizontally in the long axis direction of the machine bed; the cutter system includes a broach and a knife holder, and the broach is fixed to the main sliding plate through the knife holder; the cooling system is connected with the chip removal system, and located at the same end of the machine bed; and the hydraulic system is located at the other end, away from the cooling system, of the machine bed, and the loading and unloading system includes a loading and unloading conveying mechanism and a feeding and discharging oil cylinder. According to the provided broaching machine special for the horizontal machining air cylinder, after loading, the position of a machine tool can be automatically aligned, the difficulty of loading is reduced, and the production efficiency of the air cylinder is improved.

Owner:CHANGSHA SISHENG INTELLIGENT EQUIP

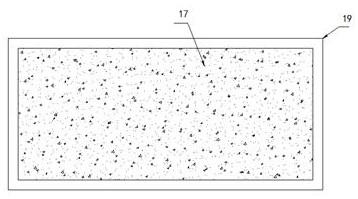

Heat treatment workshop waste gas plasma purification device and purification method

PendingCN111482064AThe structure of the device is reasonable and compactEasy maintenance and installationCombination devicesGas treatmentActivated carbonPollutant

The invention provides a heat treatment workshop waste gas plasma purification device and purification method, and belongs to the technical field of waste gas treatment. The problems that existing heat treatment workshop waste gas treatment is not high in effect and poor in waste gas selectivity, and technological conditions do not conform to industrial characteristics are solved. The device comprises a mechanical dust removal module, a waste gas washing module, a plasma primary purification module and a plasma secondary purification module which are transversely and sequentially arranged in series; the mechanical dust removal module is used for carrying out mechanical dust removal and separation on granular smoke dust and dust in the waste gas; the waste gas washing module is used for purifying and separating water-soluble pollutants in waste gas, the plasma primary purification module comprises a first gas distribution plate, a dielectric barrier discharge assembly and a photolysis catalytic plate, and the plasma secondary purification module comprises a second gas distribution plate, a needle net discharge assembly and an activated carbon fiber filter net. The device is mainly used for purifying waste gas in heat treatment workshops.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

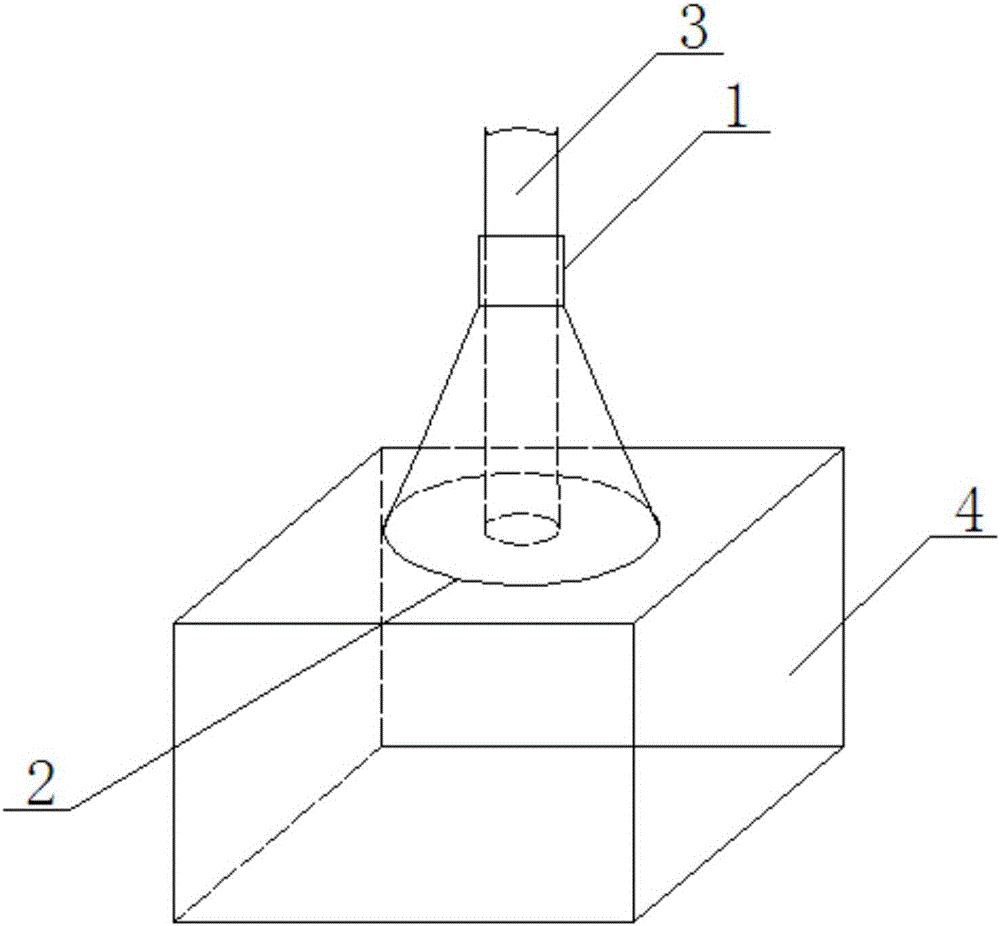

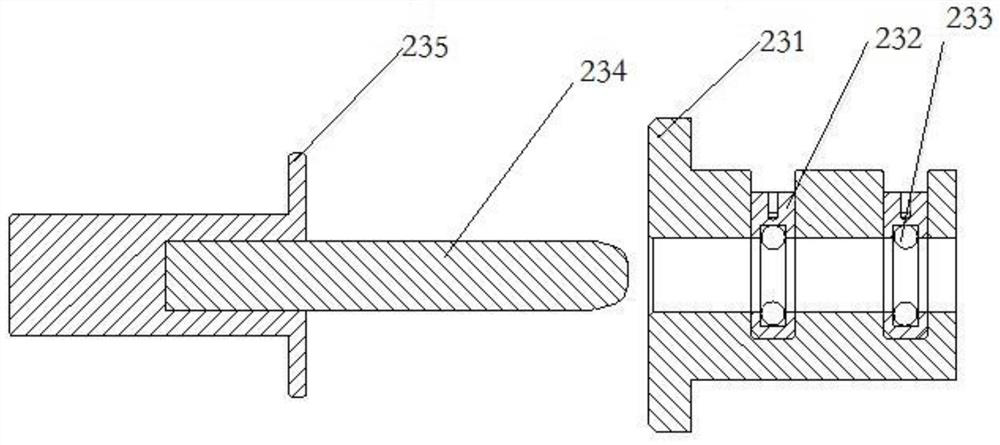

Material pressurizing device

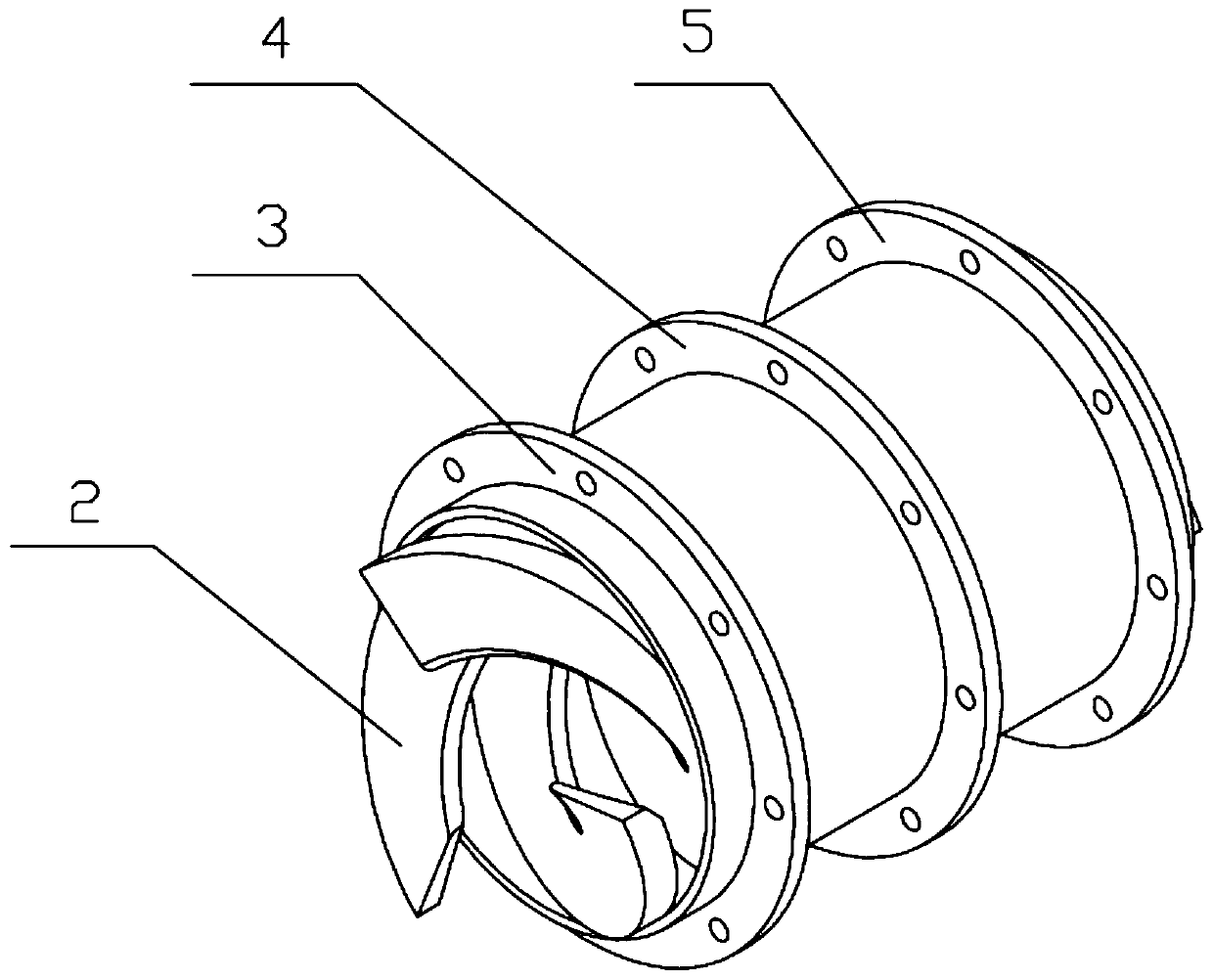

PendingCN109701692ASimple structure and manufactureEasy maintenance and installationGrain treatmentsEngineeringFlange

The invention provides a material pressurizing device, comprising a pipe body. The pipe body is hollow inside. The inner wall of the pipe body is provided with a downward spiral body. The outer wall of the pipe body is provided with an upper flange, a middle flange and a lower flange in sequence from top to bottom. A first rotation piece is fixed to the upper flange. An upper port of the pipe bodyis rotatably connected with a material bin through the first rotation piece. A driving device for driving the pipe body to rotate is fixed to the middle flange. A second rotation piece is fixed to the lower flange. A lower port of the pipe body is rotatably connected with a feeding inlet of a roller press through the second rotation piece. A first fixing support for fixing the first rotation piece and the second rotation piece is arranged between the first rotation piece and the second rotation piece. The first fixing support is fixed to a shell of the feeding inlet of the roller press. According to the material pressurizing device, the height between the material bin and the roller press can be greatly reduced so that the height of a workshop can be smaller, and cost in various aspects such as infrastructure, equipment height, equipment power and installation cost can be reduced.

Owner:NANJING XIPU CEMENT ENG GROUP

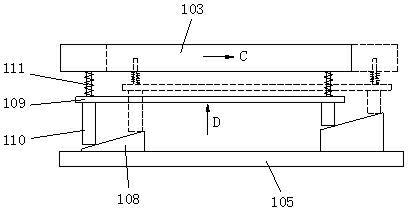

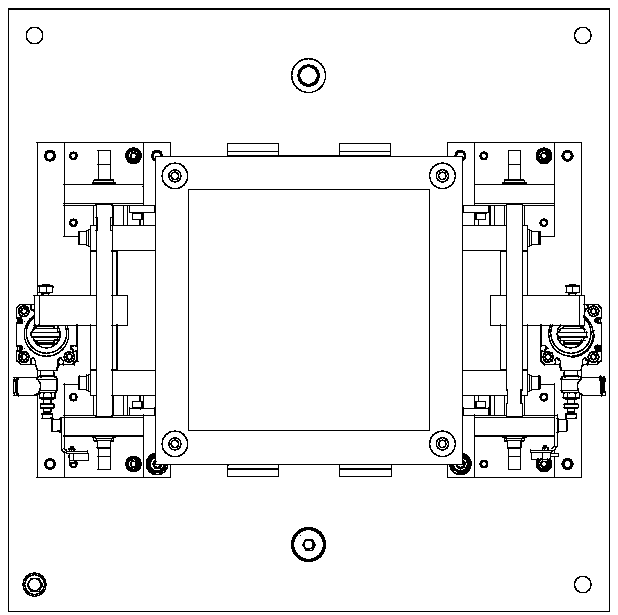

Pallet stacking device for palletizing conveying line

ActiveCN109205324ASimple structureEasy maintenance and installationStacking articlesHinge angleEngineering

The invention discloses a pallet stacking device for a palletizing conveying line. The pallet stacking device is mainly characterized in that a guiding shaft is mounted in a linear bearing, the bottomof the guiding shaft is mounted on a bracket, and a left supporting column is mounted on a left mounting plate; a left hinge seat is mounted on the top face of a base, the bottom of a left air cylinder is mounted on a left double-lug seat, and the left double-lug seat is mounted on the left hinge seat in a hinged mode; the top end of the left air cylinder is mounted on a left connecting block through a left joint bearing, a left jacking block is mounted on a left rotating shaft and clamped on a left limiting block, and a right supporting column is mounted on a right mounting plate; a right hinge seat is mounted on the top face of the base, the bottom of a right air cylinder is mounted on a right double-lug seat rod, and the right double-lug seat rod is mounted on a right hinge seat in a hinged mode; and the top end of the right air cylinder is mounted on a right connecting block through a right joint bearing, and a right jacking block is mounted on a right rotating shaft and clamped on a right limiting block. The pallet stacking device is simple in structure and quite convenient to maintain and mount, the automatic pallet stacking and collecting function is achieved, and the operation efficiency of the pallet stacking device is improved.

Owner:CHANGZHOU CHUANGSHENG INTELLIGENT EQUIP

Drop-off fusible cut-out without power-cut

InactiveCN1794398APrevent looseningAvoid missingSwitches with electrothermal releaseDistribution transformerMechanical engineering

This invention relates to an on-line drop-off fuse, in which, two wiring clips synchronous connectors are installed on both ends of the fuse composed of connectors, clip block bases, ring anti-loosing pads and collar nuts. This invention realizes the aim of non-power cut by contacting the connector with a lead directly and screwing the nut anticlockwise by an on-line quick tool to drive the clamp plate to move upward to install the lead or screwing the nut clockwise to drive the clamp plate to move downward to clamp the lead.

Owner:WUXI POWER SUPPLY JIANGSU PROVINCE ELECTRIC POWER

Cantilever welding module

InactiveCN106513914AEasy to controlHigh control precisionSoldering auxillary devicesMotor driveEngineering

The invention relates to a cantilever welding module which comprises an inlet and outlet connecting platform, a mobile platform, a grab claw, a tin furnace module, and further comprises a grab claw connecting plate as well as two grab claw fixing arms, wherein the grab claw comprises a grab claw mounting plate; one side at the lower end of the grab claw connecting plate is connected with the grab claw mounting plate through a grab claw rotary shaft; the other side at the lower end of the grab claw connecting plate is equipped with a regulating air cylinder; a supporting base which is rotatably connected with the outer surface of the regulating air cylinder is arranged on the grab claw connecting plate; an air cylinder connecting base which is rotatably connected with a movable end of the regulating air cylinder is arranged on the grab claw mounting plate; a grab claw servo control motor is arranged on the grab claw mounting plate, and a two-way lead screw is arranged on the lower surface of the grab claw mounting plate; and the two grab claw fixing arms are driven by the two-way screw, and hook claws are arranged on the grab claw fixing arms. The mobile platform drives the grab claw to operate, a grab claw servo control motor drives the two-way lead screw, and the two-way lead screw drives the grab claw fixing arms to gather together or stretch, so that the hook claws clamp or loosen workpieces, control is easy and precision is high; and the regulating air cylinder moves, so that a welding angle can be easily regulated.

Owner:深圳市浩宝技术有限公司

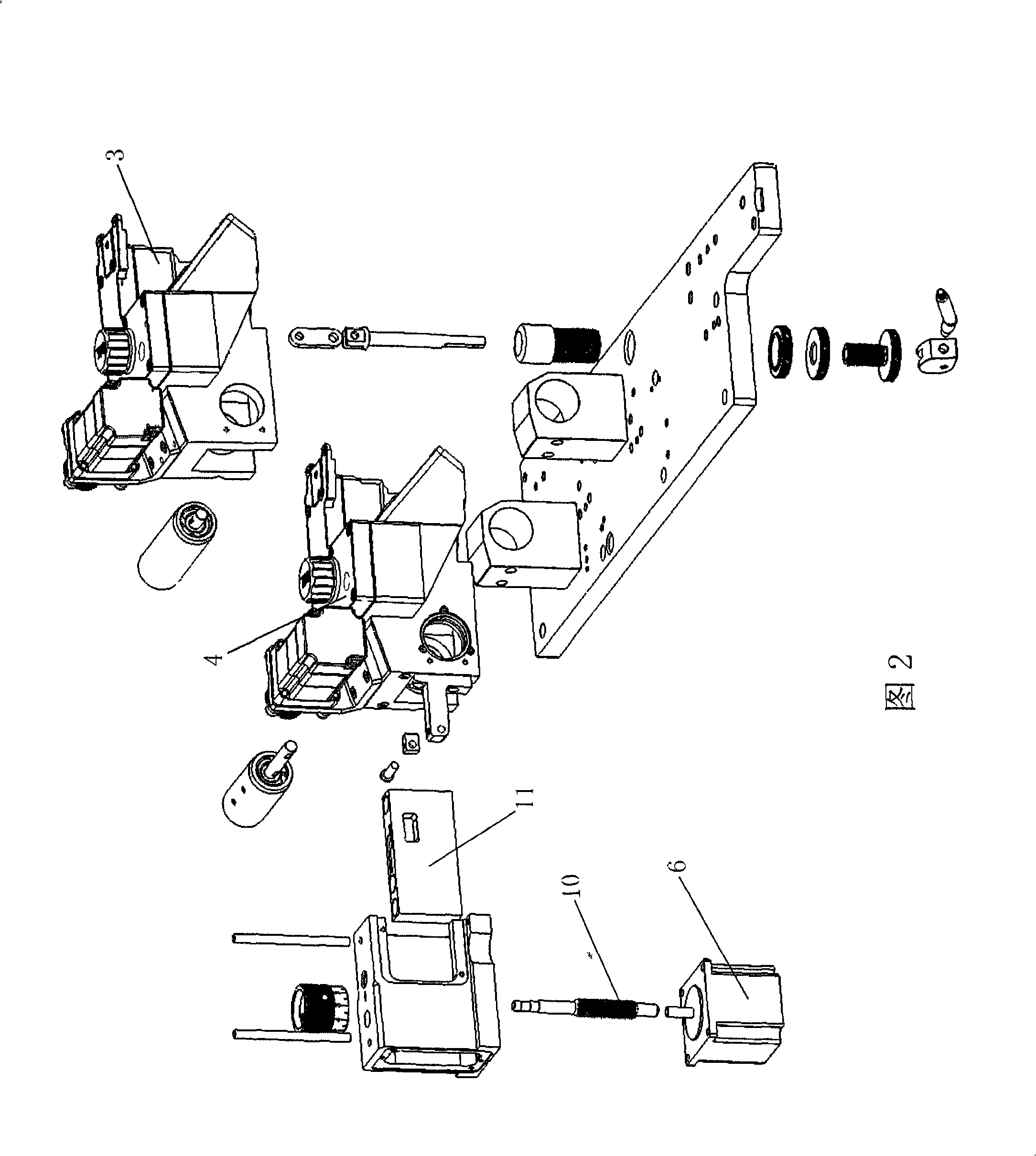

Toe seaming machine control system and toe seaming machine possessing same

InactiveCN101265645AUniform rotation angleConvenient rotation angleProgramme-controlled sewing machinesWorkpiece carriersMicrocomputerMotor drive

The invention discloses a control system for a toe linking machine, which includes a power supply part, a motor drive part, a microcomputer control part and a signal detection part. The invention is characterized in that the motor drive part is provided with a feeding device motor drive circuit, a first sewing device motor drive circuit, a second sewing device motor drive circuit, a conveying device motor drive circuit, and a sewing device lifting motor drive circuit; each motor drive circuit is correspondingly connected with the motor on each device; the microcomputer control part comprises a touch screen or a keyboard, an LCD and a microcomputer; each motor drive circuit, the touch screen or the keyboard, the LCD and the signal detection part are all connected with the microcomputer. The control system for the toe linking machine adopts the microcomputer control part to control each independent drive circuit, so as to drive the corresponding motors, and has the advantages of accurate control, even and beautiful toe suture lines, etc. The invention also discloses the toe linking machine with the control system.

Owner:何伟斌

Indoor vacuum circuit breaker convenient to maintain and install

InactiveCN112397340AEasy maintenance and installationPromote repairHigh-tension/heavy-dress switchesAir-break switchesRolling-element bearingStructural engineering

The invention relates to the technical field of vacuum circuit breakers, and discloses an indoor vacuum circuit breaker convenient to maintain and install. The indoor vacuum circuit breaker comprisesa base and a circuit breaker body, a placement groove is fixedly formed in the upper surface of the base, and the circuit breaker body is located in the placement groove; sleeves are fixedly arrangedat the left and right sides of the upper surface of the base, a first supporting rod and a second supporting rod are slidably arranged in the two sleeves correspondingly, and a first rotating shaft and a second rotating shaft are fixedly arranged at the left side and the right side of the circuit breaker body correspondingly. The ends, away from the circuit breaker body, of the first rotating shaft and the second rotating shaft are rotatably connected with the rod walls of the first supporting rod and the second supporting rod through first rolling bearings correspondingly, a limiting mechanism is arranged at the end of the first rotating shaft, and lead screws are arranged at the lower ends of the first supporting rod and the second supporting rod in a threaded mode. According to the circuit breaker, the circuit breaker body can be lifted upwards, the circuit breaker body can be rotated by an angle, and a worker can maintain the circuit breaker body conveniently.

Owner:西安鼎腾电子科技有限公司

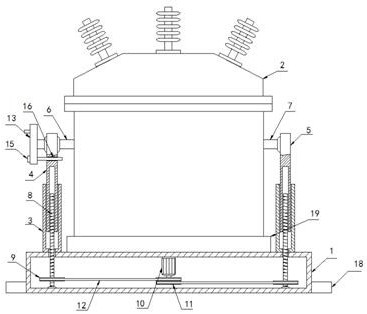

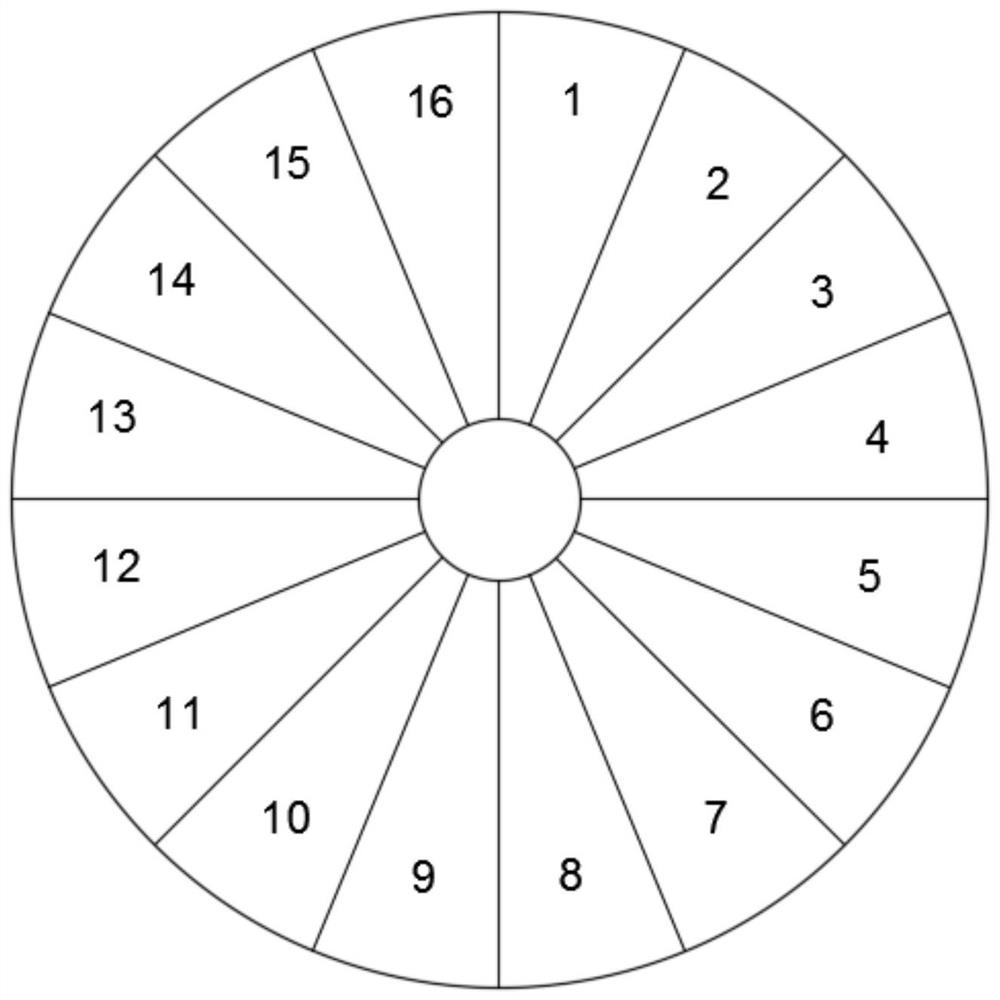

Rubber and plastic spring vibration reduction device for large coal mill base and foundation and using method of rubber and plastic spring vibration reduction device

PendingCN113007277ASimple structureReduce manufacturing costMachine framesNon-rotating vibration suppressionProcess engineeringCoal particle

The invention discloses a rubber and plastic spring vibration reduction device for a large coal mill base and a foundation and a using method of the rubber and plastic spring vibration reduction device. A rubber and plastic spring structure is mounted between the coal mill base and the foundation, and strong vibration brought by large particles and blocky coal gangue which randomly appear in input raw coal is absorbed. The device aims at strong vibration caused by large raw coal particles, blocky coal gangue, uneven raw coal feeding and the like, the sector rubber and plastic spring structure is adopted as a vibration reduction unit, a hydraulic jack set is matched to assist in mounting and maintenance of the rubber and plastic spring structure, vibration of the base is isolated from the foundation, wear of a transmission chain is relieved, and the interference on the connection state of the base and the transmission chain is reduced. Meanwhile, hydraulic jacks are matched to assist in vibration reduction, safety of a coal mill during working is ensured, and mounting and maintenance of a machine are also convenient. Compared with other vibration reduction devices, the rubber and plastic spring structure is lower in cost, mounting and maintenance are simpler, vibration can be effectively absorbed and reduced, the working efficiency of the coal mill can be improved, and noise pollution can be reduced.

Owner:NANJING INST OF TECH

Hanging planting production frame used for traditional Chinese medicine planting

InactiveCN108718815ABeautiful growthIncrease productionClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention discloses a hanging planting production frame used for traditional Chinese medicine planting. The production frame comprises a greenhouse body, a transverse rod bracket is arranged in the greenhouse body, and telescopic hanging frames are respectively arranged under the left and right sides of the transverse rod bracket; a plastic tube is arranged under the telescopic hanging frames,movable baffle plates are respectively arranged on the left and right sides of the plastic tube, and several openings are formed in the upper surface of the plastic tube; several nutrient substancesare arranged in the plastic tube and below the openings, and several spraying heads are arranged right above the openings; mist baffle plates are arranged on the spraying heads, the spraying heads arefixed to the portion under the transverse rod bracket, and on-off valves are arranged on the spraying heads; a delivery pipe is arranged on the tops of the spraying heads and connected with a mixingdevice through a connecting pipe, and a nutrient liquid delivery pipe is arranged on the left side of the mixing device; the other end of the nutrient liquid delivery pipe is connected with a nutrientliquid storage tank, a water supplying pipe is arranged on the right side of the mixing device, the frame can make the growth length of some vine-type traditional Chinese medicines reach maximum, yield and quality of the traditional Chinese medicines are improved, and irrigation is convenient.

Owner:湖北襄草源生态农业科技有限公司

Low-temperature pipeline mounting structure

PendingCN110966486AAvoid influenceEasy maintenance and installationSleeve/socket jointsThermal insulationAbsorbent cottonEnvironmental geology

The invention discloses a low-temperature pipeline mounting structure, relates to the field of low-temperature pipeline mounting, and aims to solve the problems that most existing low-temperature pipelines are directly fixed on external objects through hoops, and liquefied water on the outer surfaces of the pipelines is not collected and guided by a mechanism, so that the liquefied water easily affects other structures. A low-temperature pipeline is arranged in a protective outer housing; the outer surface of the low-temperature pipeline is wrapped with absorbent cotton; a drainage groove is formed in the bottom end of the interior of the protective outer housing; the absorbent cotton is located right above the drainage groove; a drainage pipe is fixedly connected to the outer surface of the bottom end of the protective outer housing; and the water inlet end of the drainage pipe is communicated with the interior of the drainage groove.

Owner:常州威华电子股份有限公司

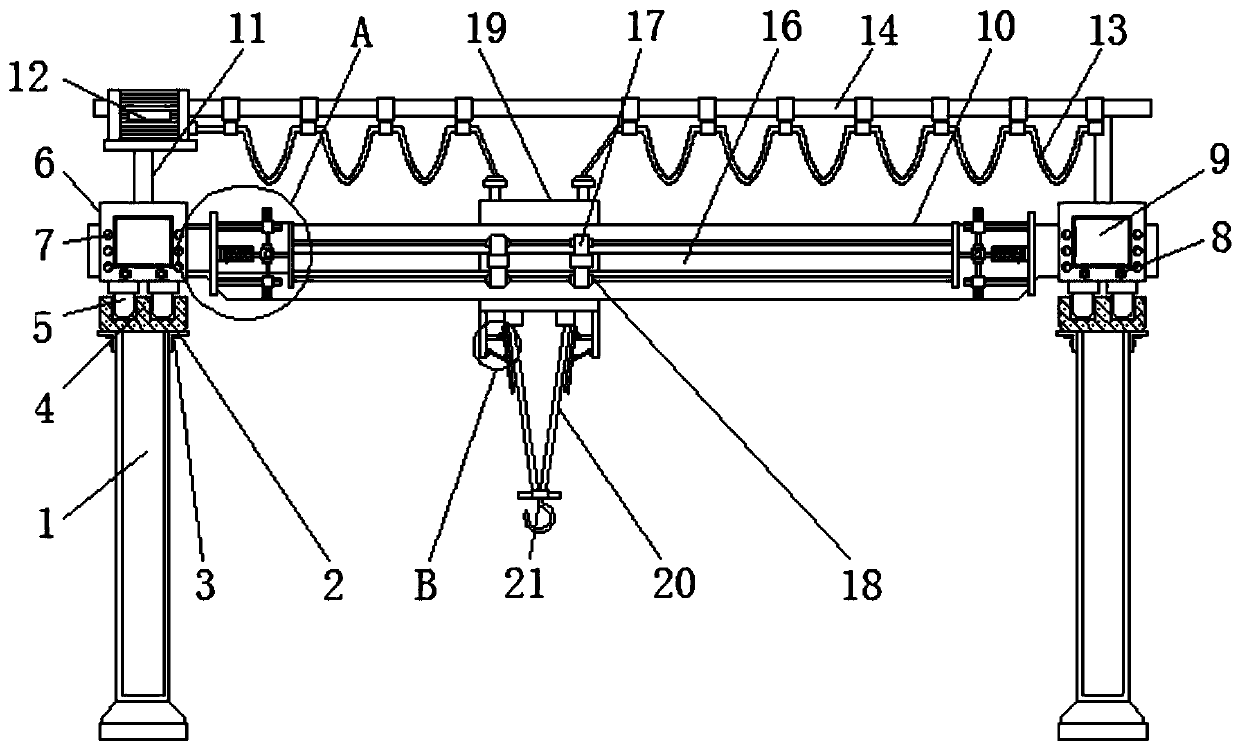

Metallurgical electric single-beam crane

PendingCN110356978AEffective and regularReduce impact forceTravelling cranesSafety gearArchitectural engineeringPulley

The invention discloses a metallurgical electric single-beam crane which comprises a support column. An installation steel plate is connected to the outer side of the top end of the support column, alongitudinal beam is fixed to the top end of the installation steel plate, an installation block is fixed to the top end of a first pulley, a single beam is welded and fixed to the rear side of the installation block, a control module is fixed to the front side of the top end of the support block, and a sliding rod is fixed to the top end of the support block, sliding grooves are formed in the front part and the rear part of the single beam, a second pulley is fixed on the inner side of the connecting piece, a winding steel wire is arranged in a winding box, an adjusting shaft is fixed on theouter side of the winding steel wire, and an anti-collision module is arranged on the inner side of the installation block. The metallurgical electric single-beam crane is convenient to maintain and install, can effectively regulate a line, can effectively reduce the impact force between the winding box and the support column, and can effectively ensure stable winding of a wound steel wire.

Owner:HENAN HENGYUAN HENGSHAN IND CO LTD

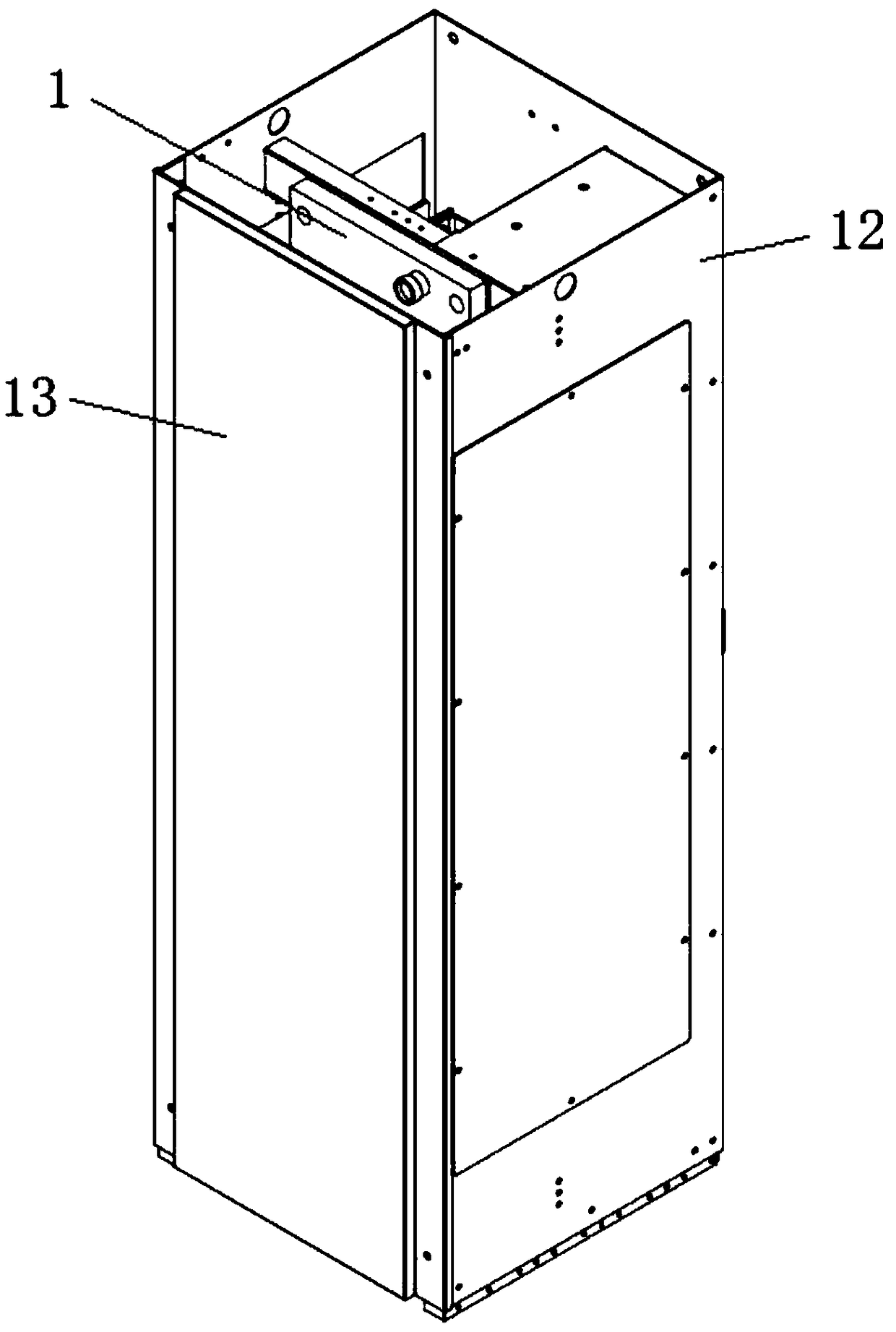

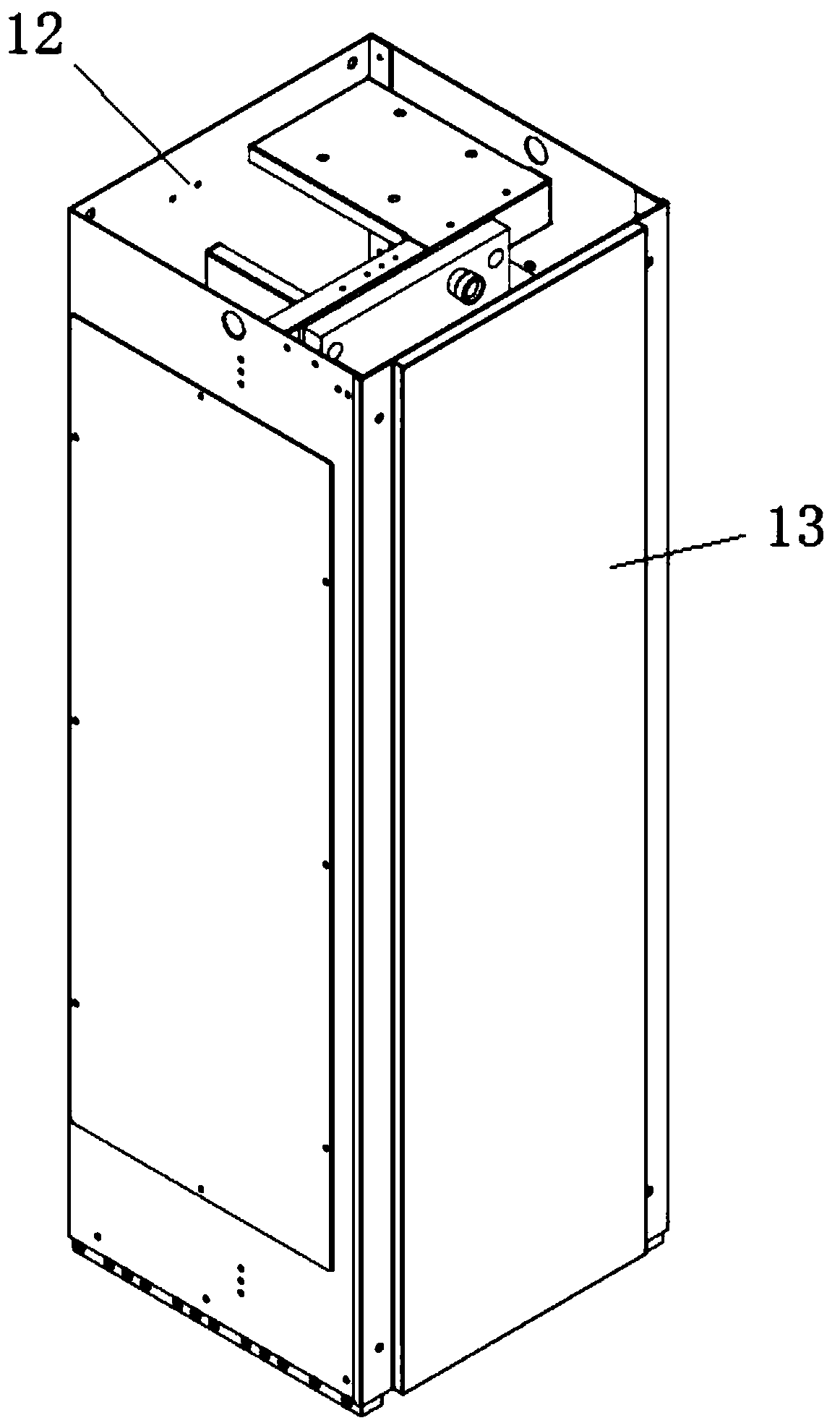

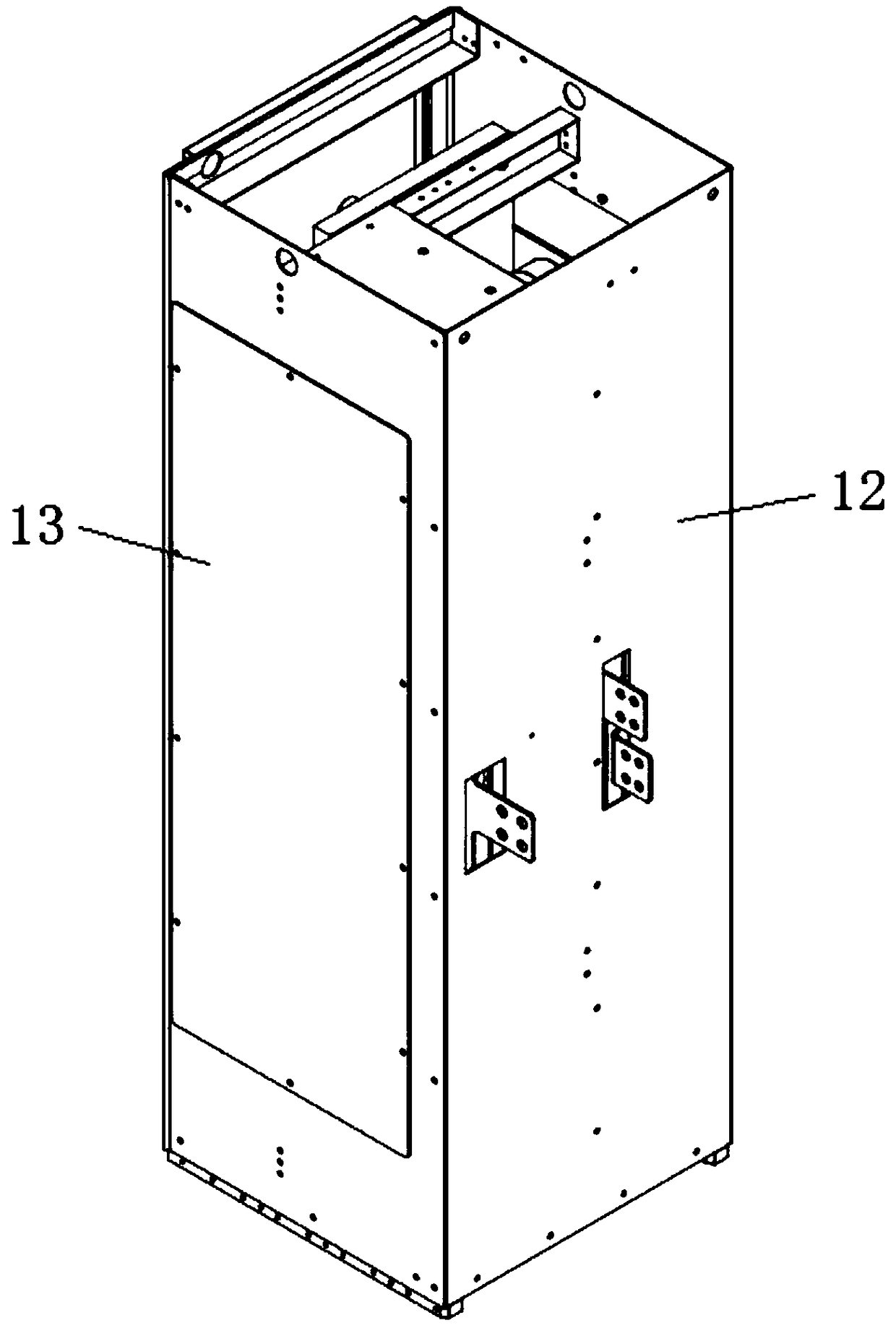

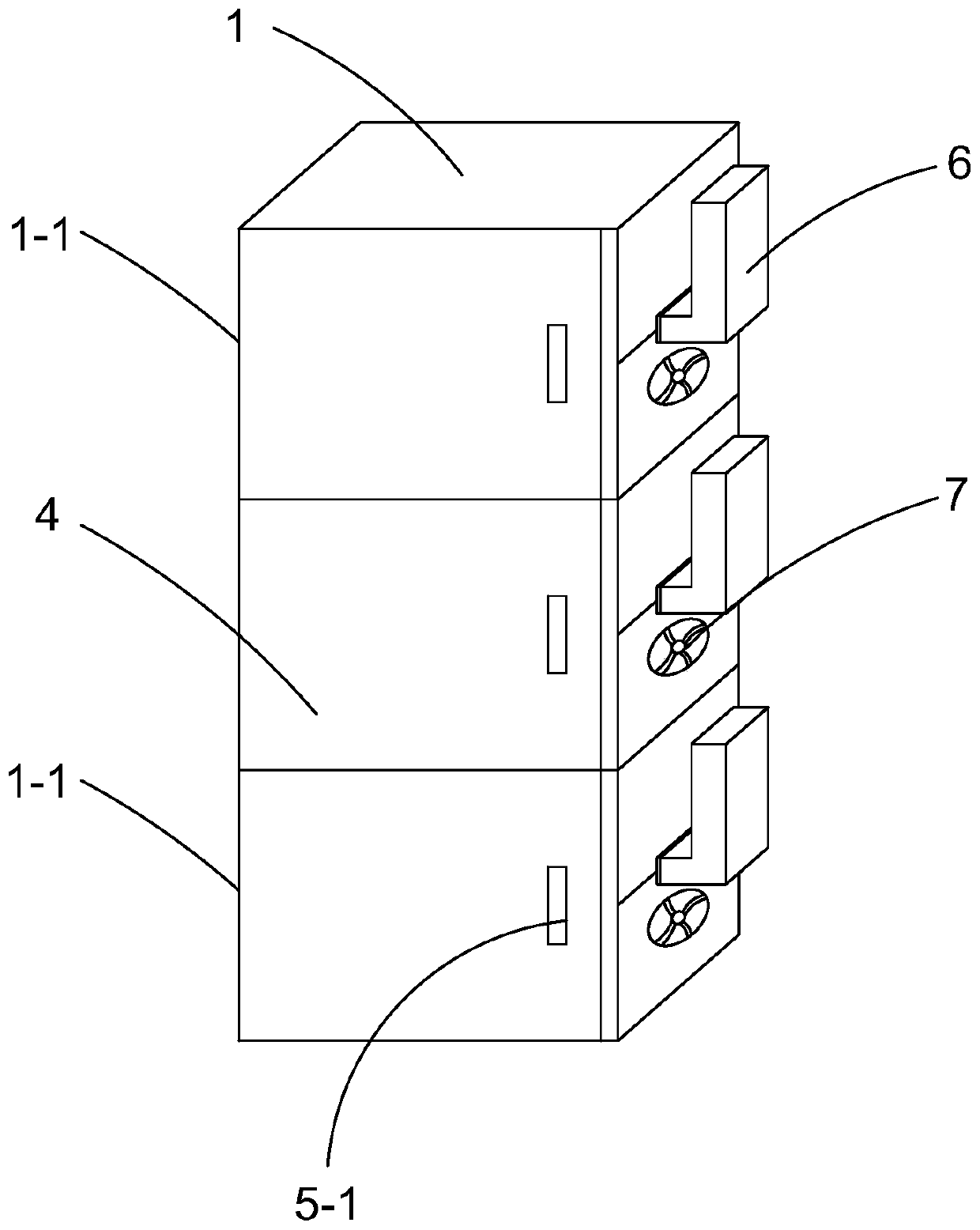

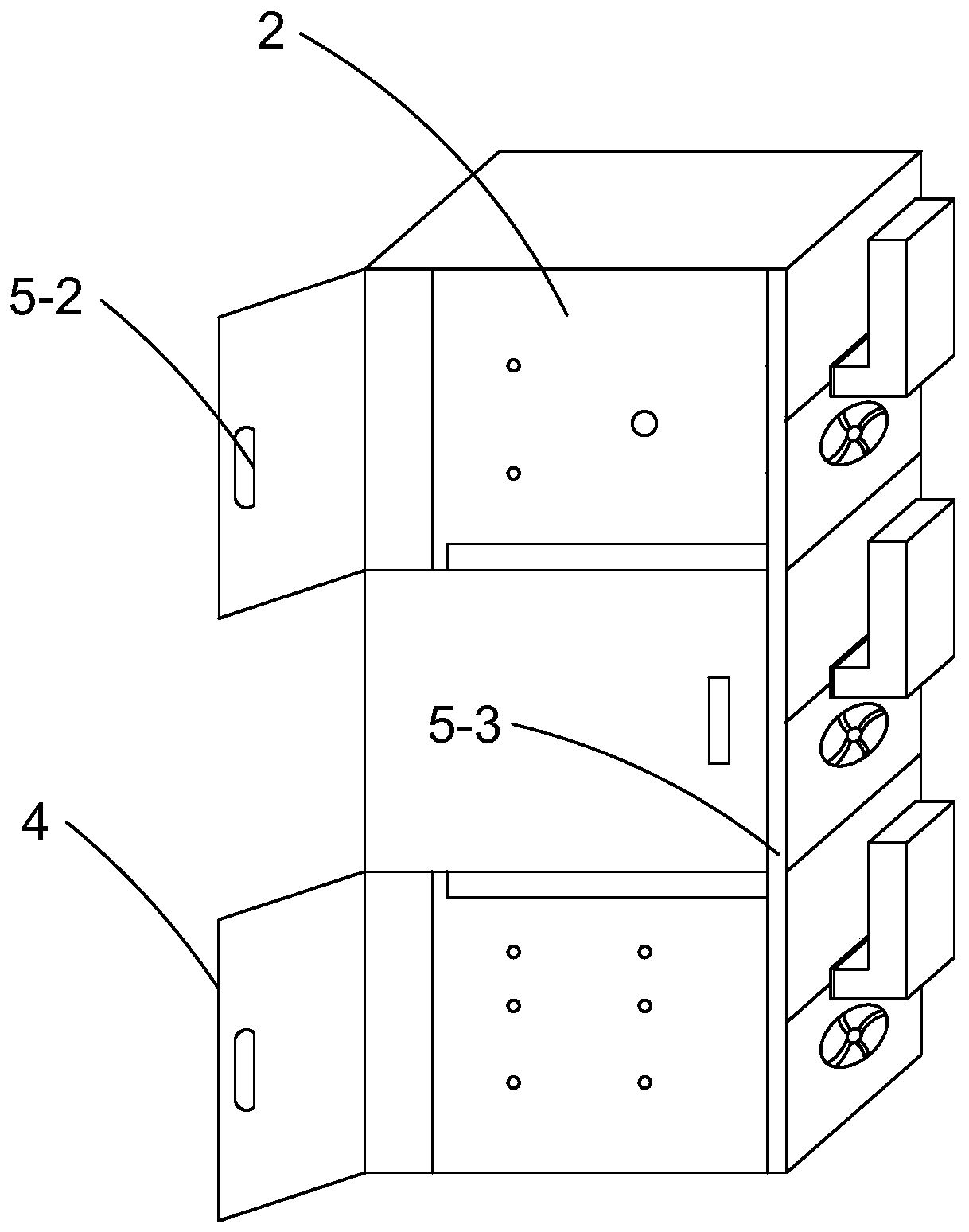

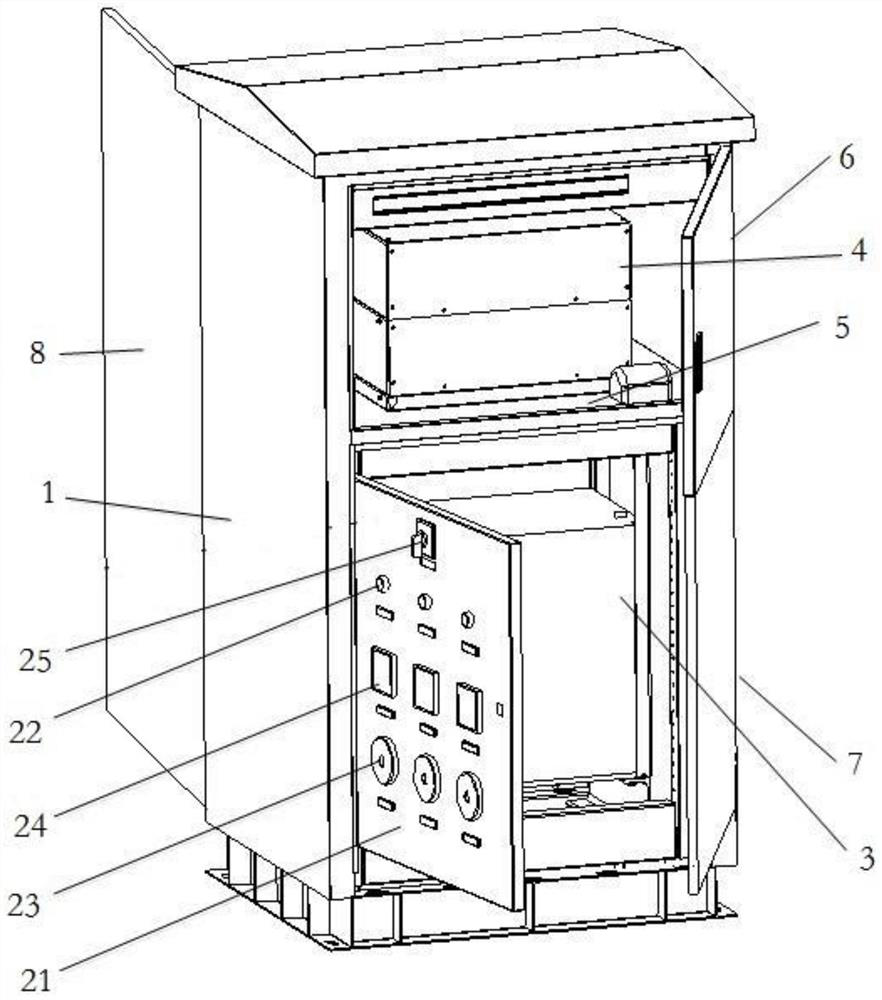

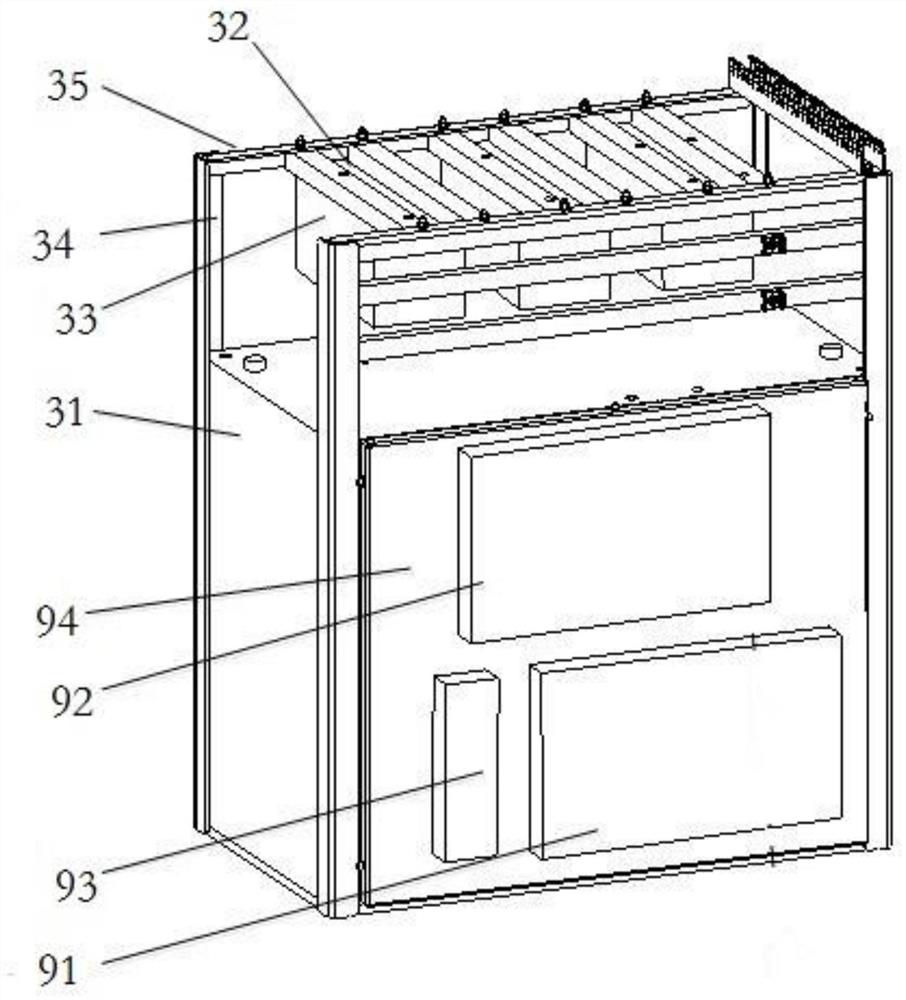

High-voltage switch complete equipment

InactiveCN111490469ALine layout is clearEasy maintenance and installationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringMechanical engineering

The invention provides novel high-voltage switch complete equipment which can be distributed and is good in heat dissipation. The equipment comprises a switch cabinet body and an electrical element mounting plate which is located in the switch cabinet body, fixedly connected with upper and lower end faces of the switch cabinet body and is used for mounting electrical elements. A plurality of slotsare formed in the electrical element mounting plate, partition plates for partitioning the interior of the switch cabinet body into sub-cabinets are inserted into the slots, cabinet doors and clamping mechanisms mounted on the cabinet doors are correspondingly arranged on the sub-cabinets, and heat dissipation mechanisms are further arranged at the two ends of each sub-cabinet.

Owner:QUANZHOU DAXIYANG ELECTRIC POWER TECH CO LTD

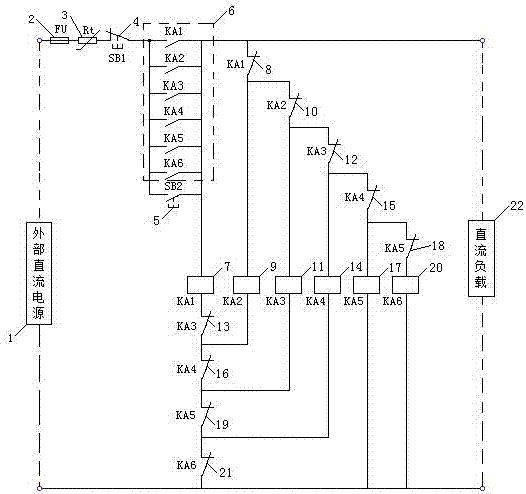

Adaptive wide-scope dc power source output short circuit protection device

ActiveCN106972458ATo achieve short circuit protectionImprove general performanceEmergency protective arrangements for automatic disconnectionShort circuit protectionEngineering

The invention discloses an adaptive wide-scope dc power source output short circuit protection device. The short circuit protection device comprises an external dc power source (1), a short circuit protection circuit, a start-protection-stop circuit, a middle relay coil, an interlocking circuit and a DC load (22). The short circuit protection device is advantaged in that not only can a problem of damage to a power source, electric components or equipment caused by easily-generated load short circuit in a wiring process of electrical equipment in the prior art be solved, but also a problem that a DC power source short circuit protection device can only protect power sources in a same commonly-used voltage grade but not power sources in non-commonly-used voltage grades is solved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

Iris recognizer

InactiveCN107563269AEasy maintenance and installationImprove mating stabilityCharacter and pattern recognitionAutomatic controlEngineering

The invention discloses an iris recognizer, which comprises a fixed seat, a moving device fixedly installed on the upper left side of the fixed seat, and an identification instrument. An empty groove is arranged in the bottom side of the right side of the moving device, and left and right extension devices are arranged in the empty groove. The first helical rod, the left side of the first helical rod is power-connected with the first power device, the helical thread on the first helical rod is connected with a fixed block for fixedly fitting connection with the identification instrument, and the fixed block is connected with the empty The front and rear inner surfaces of the groove are pressed against and moved in conjunction with each other. The first long chamber extending vertically is arranged in the fixed seat on the right side of the empty groove. A square cavity is provided inside the seat away from the side of the first long cavity, and an insertion groove is provided in the side of the fixed seat side above the left side of the square cavity; the present invention is simple in structure, easy to operate, and can automatically control the insertion work.

Owner:诸暨市柯晶机械技术开发有限公司

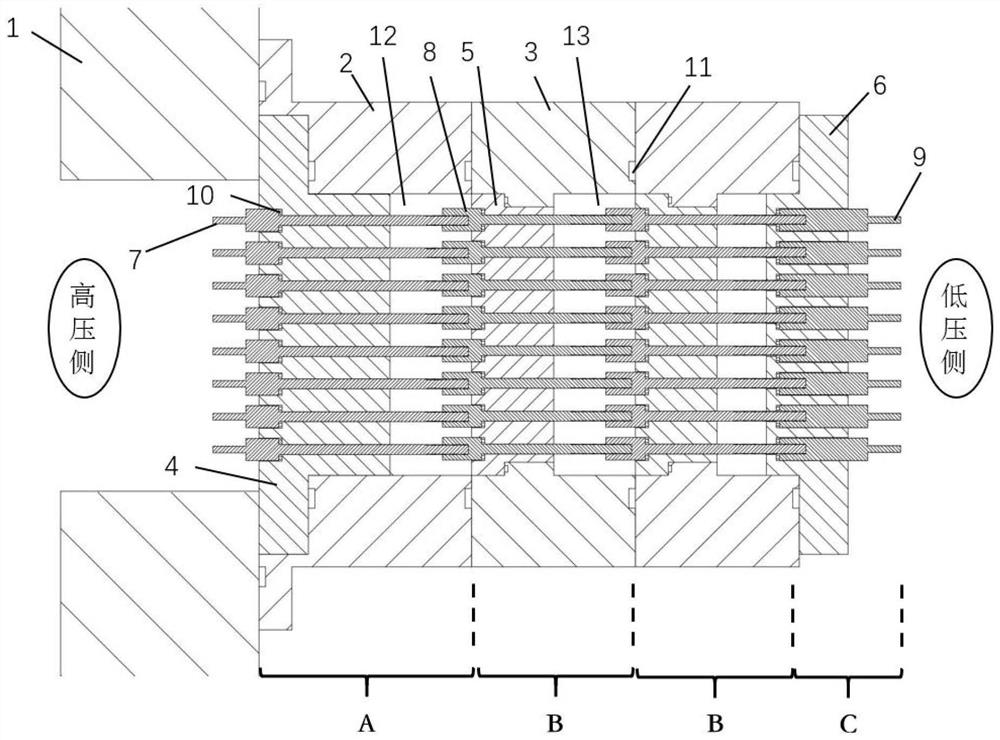

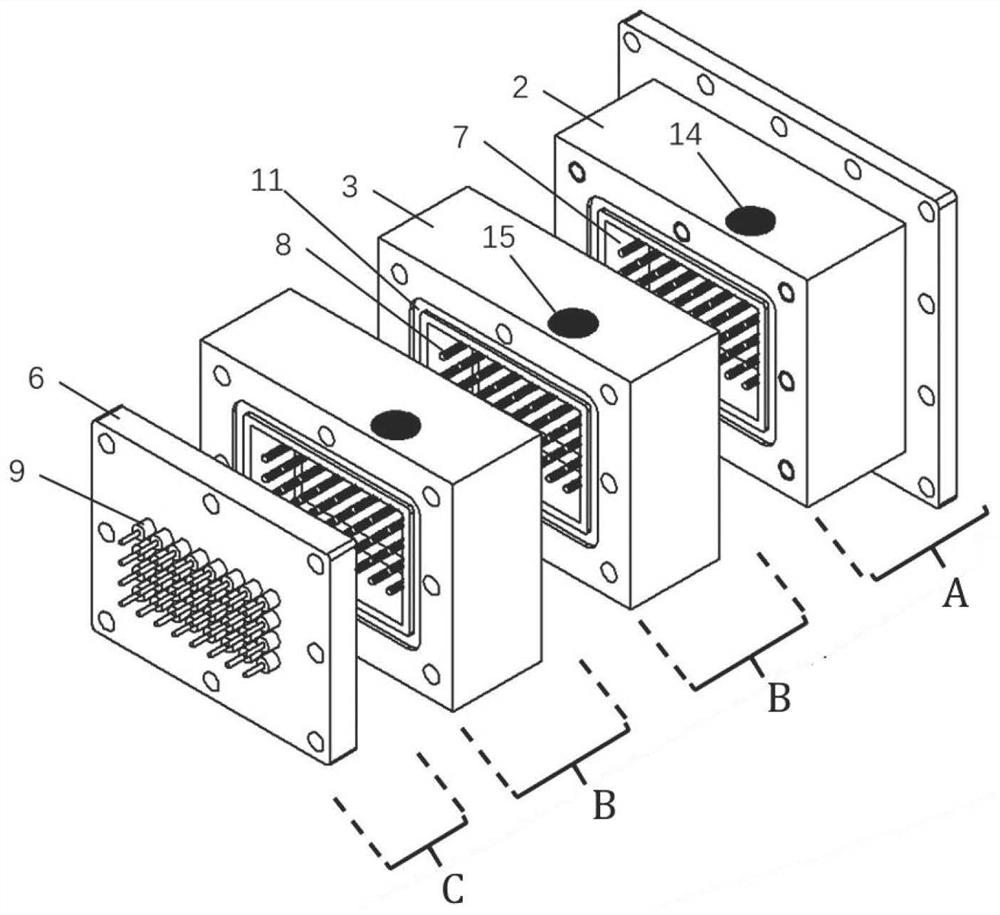

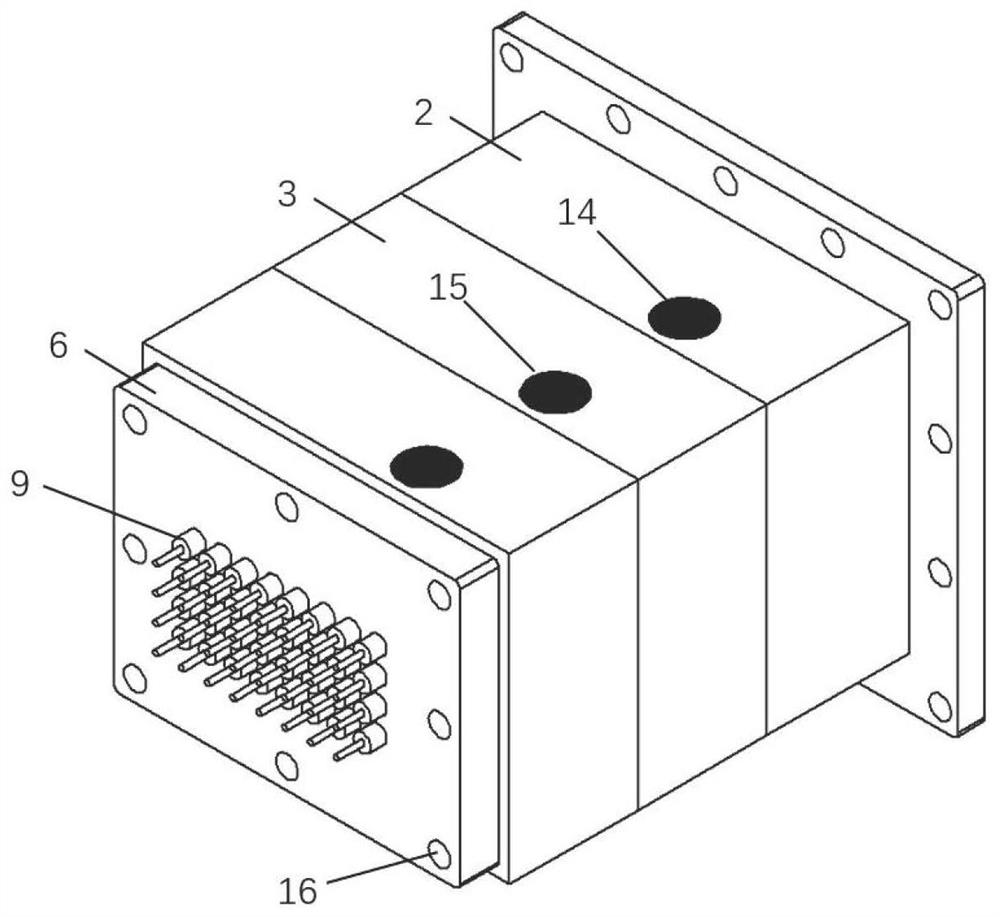

Modularized multi-cable via hole insulation sealing structure based on pressure compensation

ActiveCN113437712ASolve non-detachableSolution rangeElectrical apparatusPipesElectrical conductorEngineering

Owner:SHANGHAI JIAO TONG UNIV

Forming structure provided with lateral-pushing sliding blocks

InactiveCN106391787AReduce usageReduce maintenance costsMetal-working feeding devicesPositioning devicesBlock structureMaterials science

The invention discloses a forming structure provided with lateral-pushing sliding blocks. The forming structure provided with the lateral-pushing sliding blocks comprises an upper mold holder and a lower mold holder, wherein the upper mold holder and the lower mold holder are arranged in parallel. A lower mold insert core is fixed to the upper side face of the lower mold holder, and a mandrel is fixedly arranged on the lower mold insert core. The X-direction sliding blocks are symmetrically arranged on the front side and the rear side of the lower mold insert core. Slotting tools are arranged on the opposite outer side edges of the two X-direction sliding blocks correspondingly, and forming parts are fixedly arranged on the opposite inner side edges of the two X-direction sliding blocks correspondingly. A reset spring is arranged between each of the two sliding blocks and the lower mold insert core. Two demolding insert cores which are used for fixing edges of a product are arranged in the positions, corresponding to the front side and the rear side of the lower mold insert core, blow an upper pressing plate correspondingly. According to the forming structure provided with the lateral-pushing sliding blocks, in the forming process of the product, the product is preliminarily positioned through the mandrel and positioned for the second time through the two demolding insert cores, and the product is extruded for one-time formation through the pair of slotting tools and the forming parts driven by the sliding block structures; the forming quality is good, the product dimension is stable and reliable, and changing is unlikely to occur; and the whole forming structure is simple and convenient to maintain and mount.

Owner:BOXIANG ULTRA PRECISION TOOLING TECH KUNSHAN

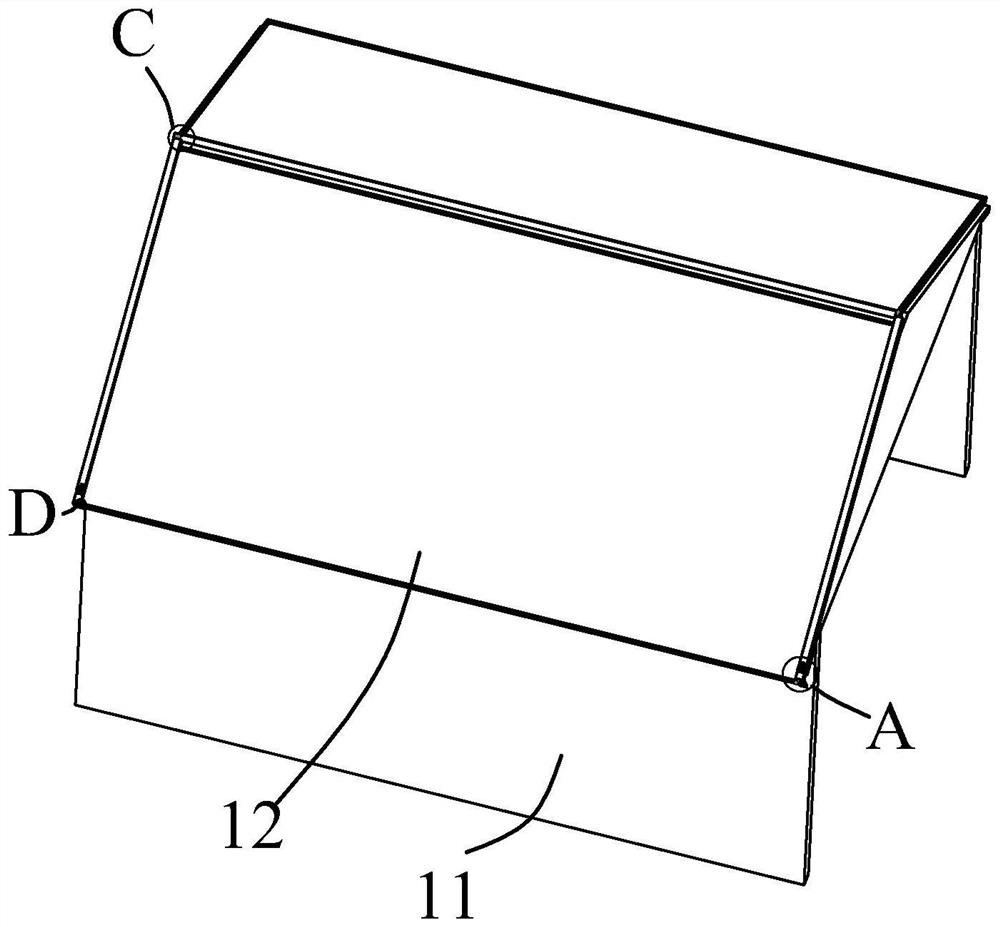

Building solar power generation equipment

PendingCN114567233AImprove protectionEasy maintenance and installationPhotovoltaic supportsPhotovoltaic energy generationDrive motorStructural engineering

The invention discloses building solar power generation equipment which comprises a house, a triangular face is arranged on the top of the house, symmetrical supports are arranged on the two sides of the triangular face on the top of the house, the support on one side face of the triangular face is fixedly connected with the house in a matched mode, and the support on the other side face of the triangular face abuts against the house. The lengths of the supports located on the fixed side are different, a side driving motor is fixedly arranged on one side of the support on the fixed side, one side of an output shaft of the side driving motor is fixedly connected with the support on the movable side in a matched mode, and symmetrical solar cell panels are arranged on the top of the house. The solar cell panels are clamped between the supports on the two sides of the house respectively. The solar cell panels can be moved and then telescopically moved to be placed on one side of an eave, and the solar cell panels are vertically placed, so that maintenance and installation by personnel are facilitated, and the solar cell panels are protected.

Owner:苏朵

Cabinet type trigger loop device

PendingCN113224661ANot affectedReduce difficultyBoards/switchyards circuit arrangementsSubstation/switching arrangement casingsEngineeringMechanical engineering

The invention discloses a cabinet type trigger loop device which comprises a cabinet body, a control panel, an energy storage trigger device, a board card control loop and a charging and discharging loop; the interior of the cabinet body is divided into an upper cavity and a lower cavity which are parallel up and down by a metal baffle; the board card control loop is mounted in the upper cavity; the control panel is hinged in the lower cavity, and the energy storage trigger device and the charging and discharging loop are respectively installed in the lower cavity. The cabinet type trigger loop device is assembled independently from a high-speed electromagnetic mechanical switch, the space in the cabinet body is separated by adopting the metal baffle, the metal baffle forms a shielding layer, the board card control loop is protected from being influenced by high-voltage current generated by the energy storage trigger device and the charging and discharging loop, and the reliability is high.

Owner:CHANGZHOU BORI ELECTRIC POWER AUTOMATION EQUIP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com