Vertical tube denitrification filler device

A technology of denitrification and standpipe, which is applied in the direction of granular microbial carrier treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc. It can solve the difficulties of installation and replacement, easy rupture of aeration pipe, oxygen utilization rate, The actual service area is small and other problems, so as to achieve the effect of easy maintenance and installation, stable and reliable performance, and reduced power consumption when starting up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

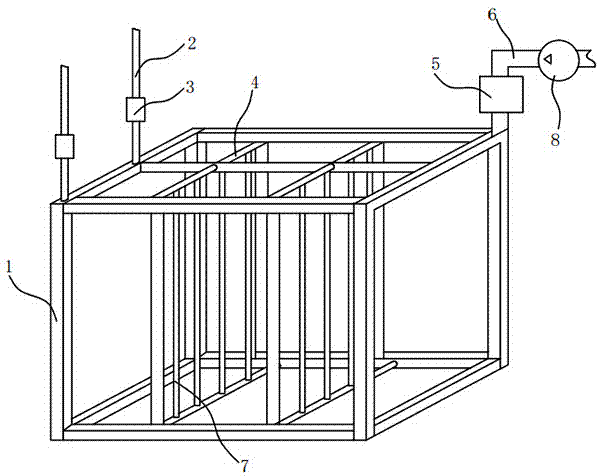

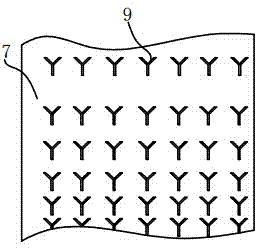

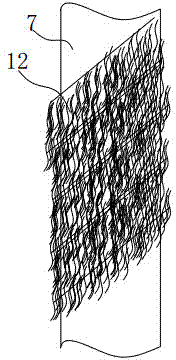

[0027] Embodiment 1: In the figure, said a kind of standpipe denitrification filling device includes a main pipe frame 1, a closed-circuit frame branch pipe 4 communicated with the main pipe frame 1, and a closed-circuit frame branch pipe 4 communicated with the closed-circuit frame branch pipe 4. The vertical aeration pipe 7, the air intake pipe 6 communicated with the main pipeline frame 1, the supply fan 8 communicated with the air intake pipe 6, the exhaust pipe 2 communicated with the main pipeline frame 1, are arranged on the The exhaust valve 3 on the exhaust pipe 2 and the air intake valve 5 arranged on the air intake pipe 6; the main pipeline frame 1 is formed by plugging PVC pipes or glass steel pipes, and the surface of the vertical aeration pipe 7 An aeration hole 9 is provided, and the vertical aeration pipe 7 is a pipe made of TPU or EMDP material; a denitrification filler 12 is woven around the periphery of the vertical aeration pipe 7, and the outer diameter of ...

Embodiment 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the denitrification filler 12 is composed of a nylon mesh 10 and a fiber 11 wound on the nylon mesh 10 at one end, and the denitrification filler 12 is stacked. Wrapped around the vertical aeration pipe 7, the service life is long and the installation is simple.

[0035] Preferably, the diameter of the nylon fibers 11 of the nylon mesh 10 is 0.1-3 mm.

[0036] Preferably, the mesh diameter of the nylon mesh 10 is larger than the length of the fibers 11, so as to form a good anoxic layer and anaerobic layer.

Embodiment 3

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the denitrification filler 12 is composed of a nylon intermediate rope 13 and a fiber 11 connected to the nylon intermediate rope 13 at one end, and the denitrification filler 12 is spirally wound on Around the vertical aeration tube 7, there is a gap 15 between two adjacent denitrification fillers 12, and the winding density of the denitrification filler 12 is positively related to the distance from the aeration tube, so that the aerobic layer, anoxic layer and anaerobic layer Smooth transition, better denitrification effect, low resistance loss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com