Patents

Literature

67 results about "Ejection time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Home > Terms > English (EN) > ejection time. ejection time. Ejection time is the moment when the mold opens to eject the part. For example, an ejection time of 42 seconds indicates that 42 seconds elapsed from the moment the mold closes for injection until the moment the mold opens for ejection.

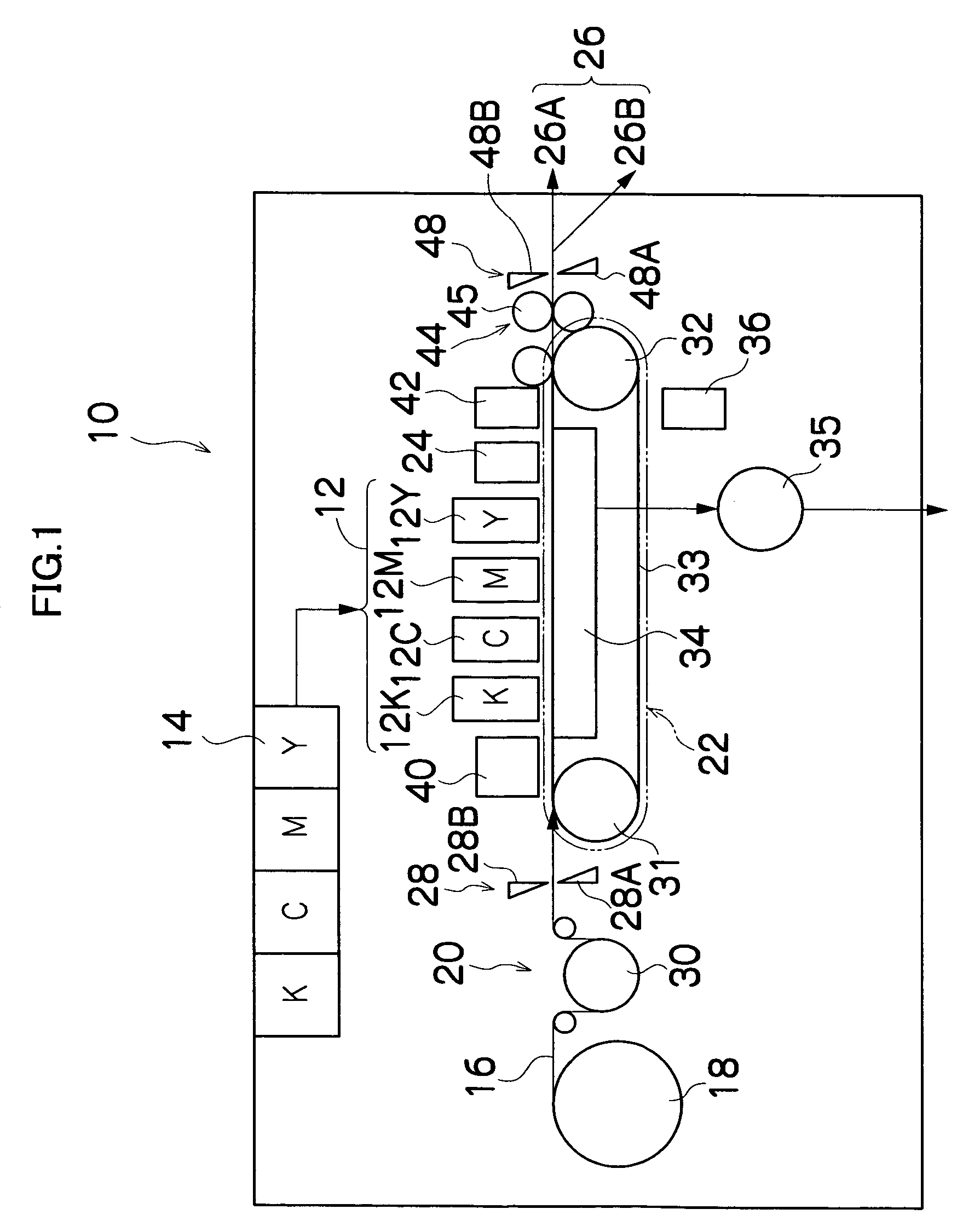

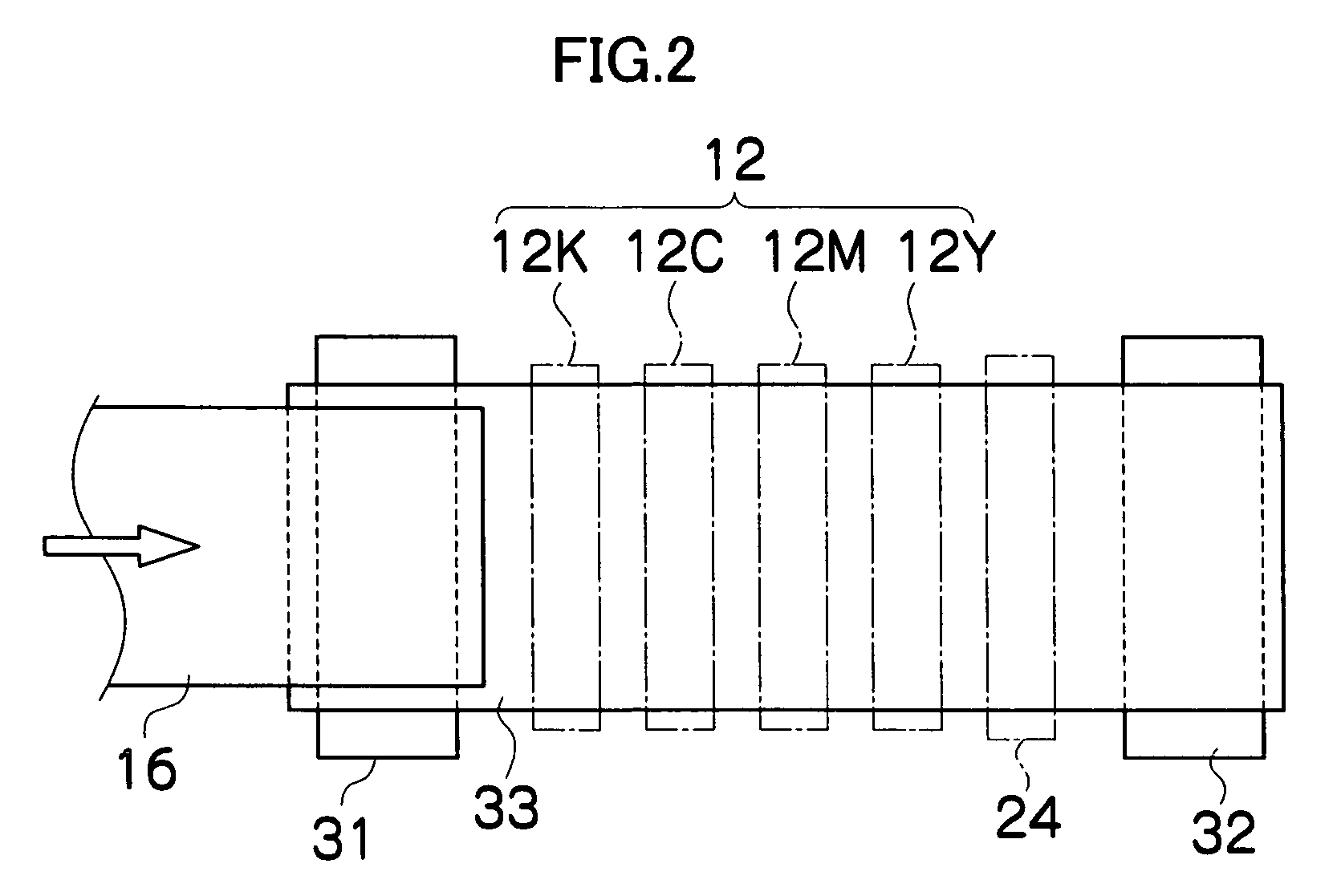

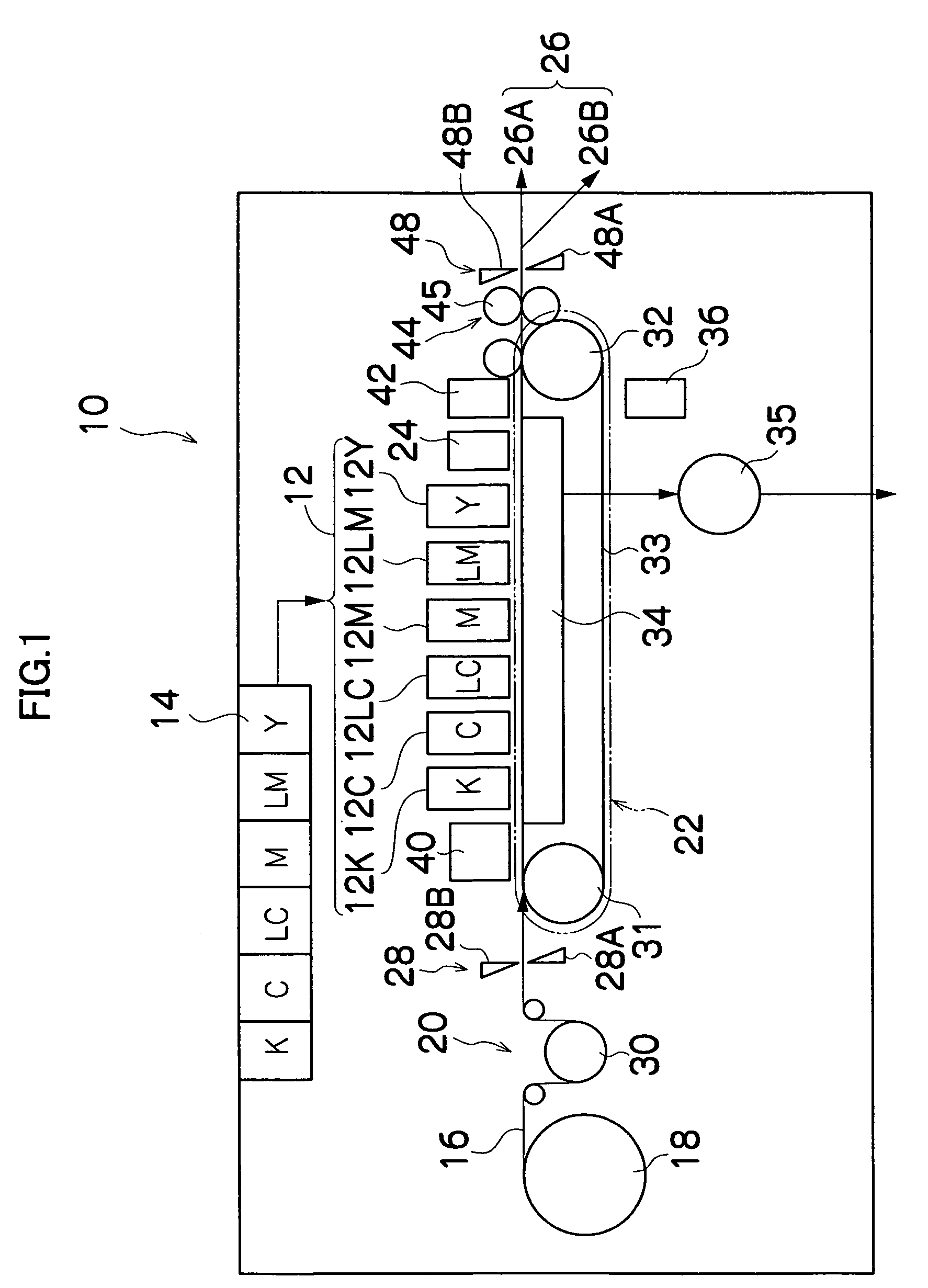

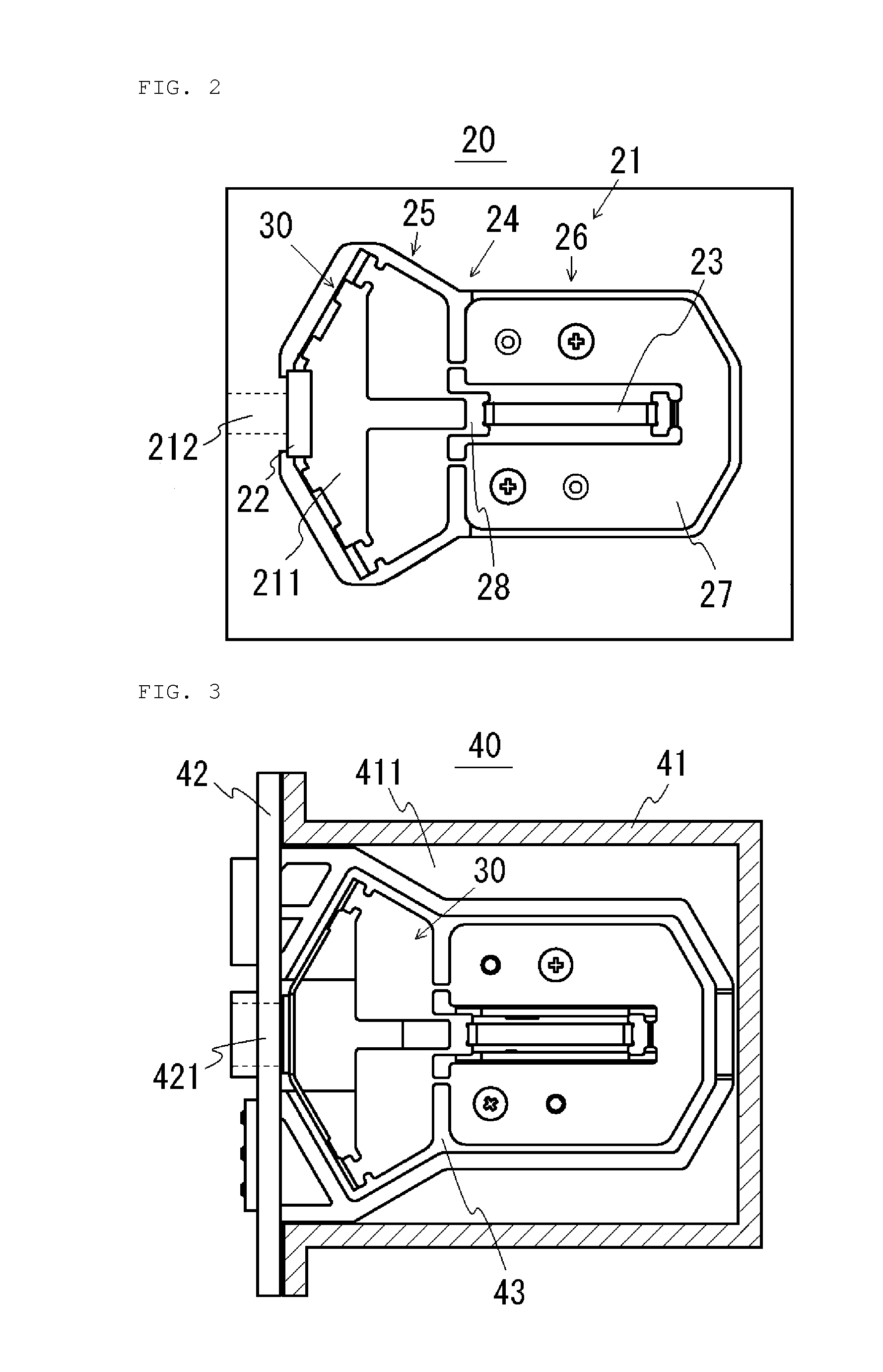

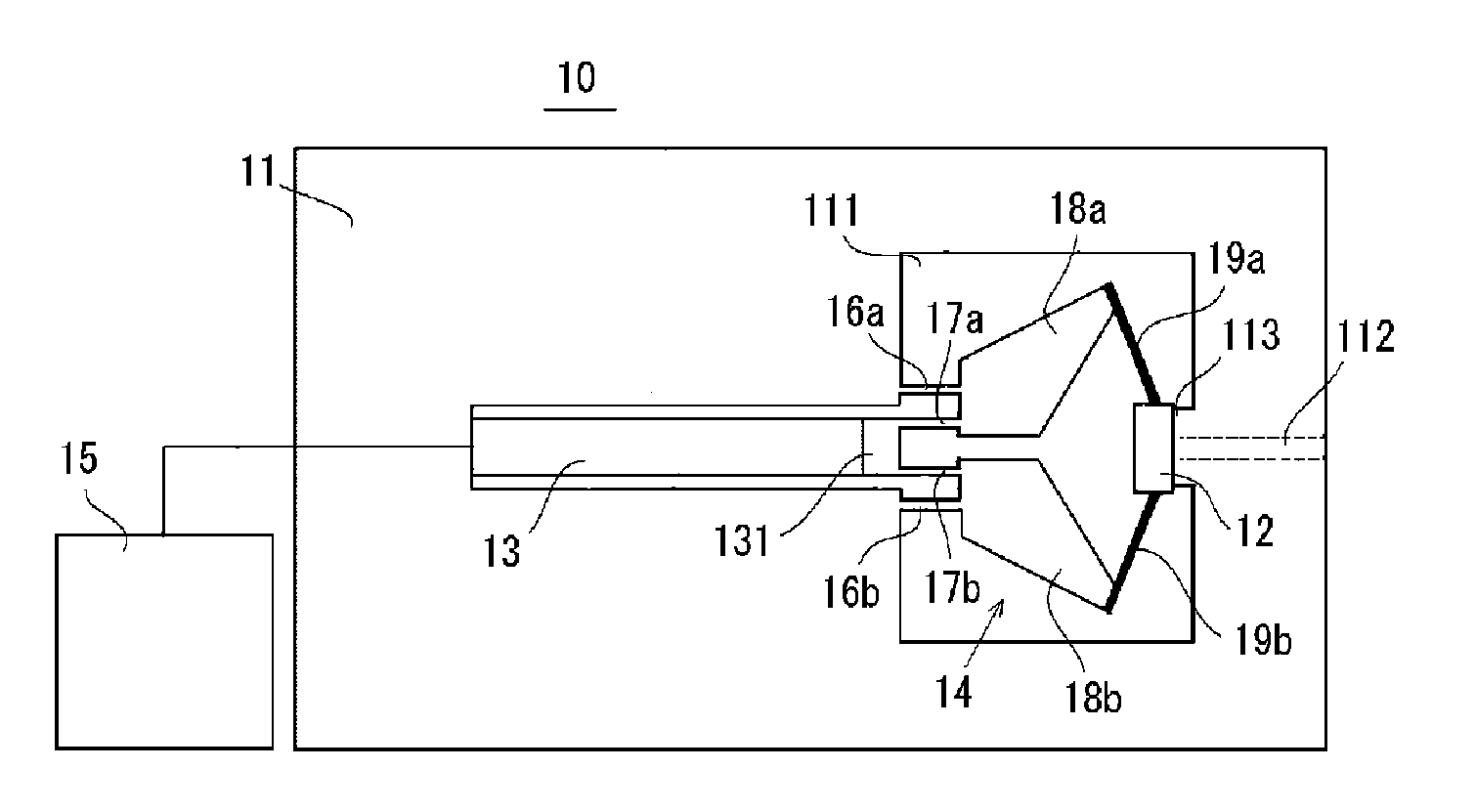

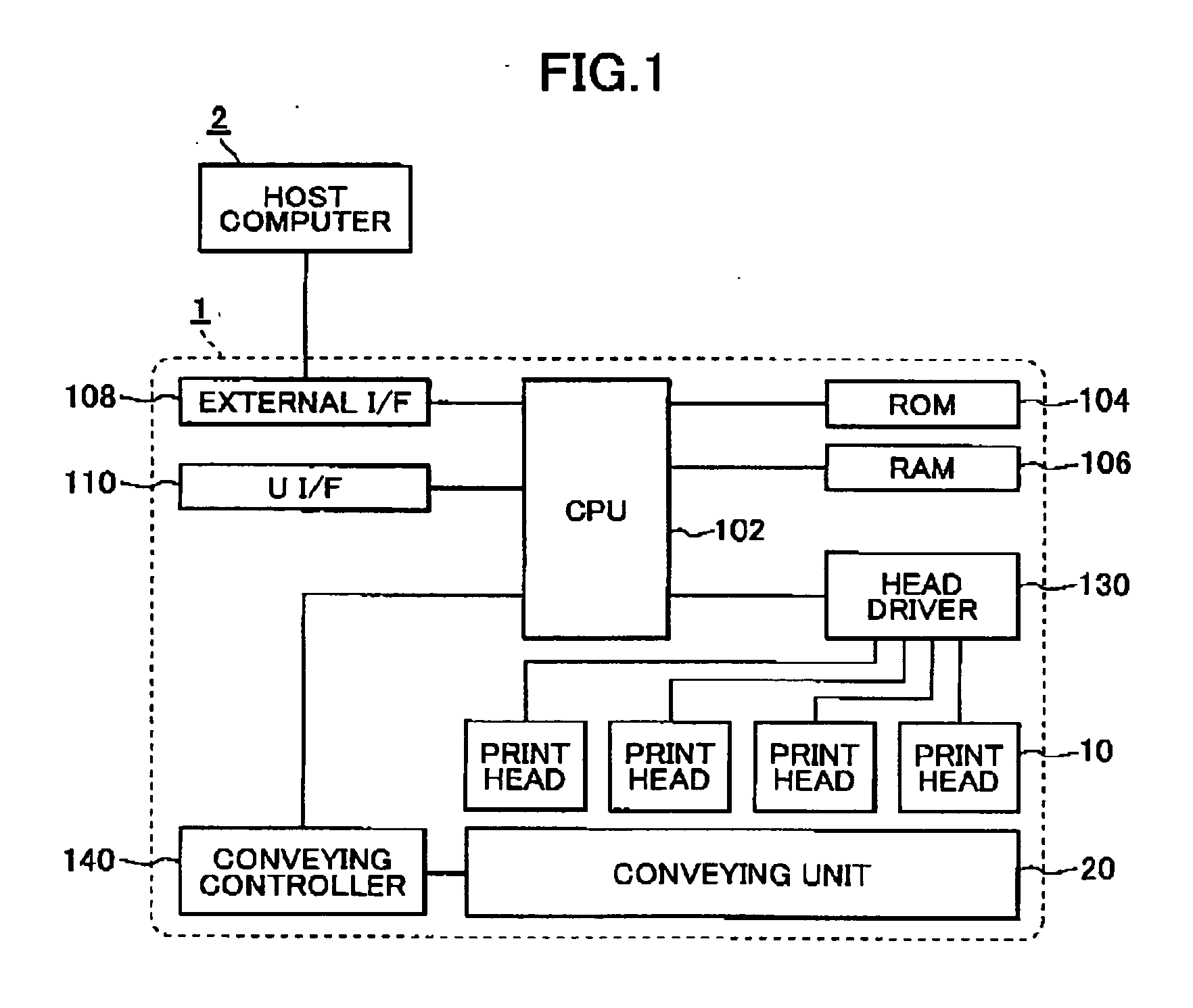

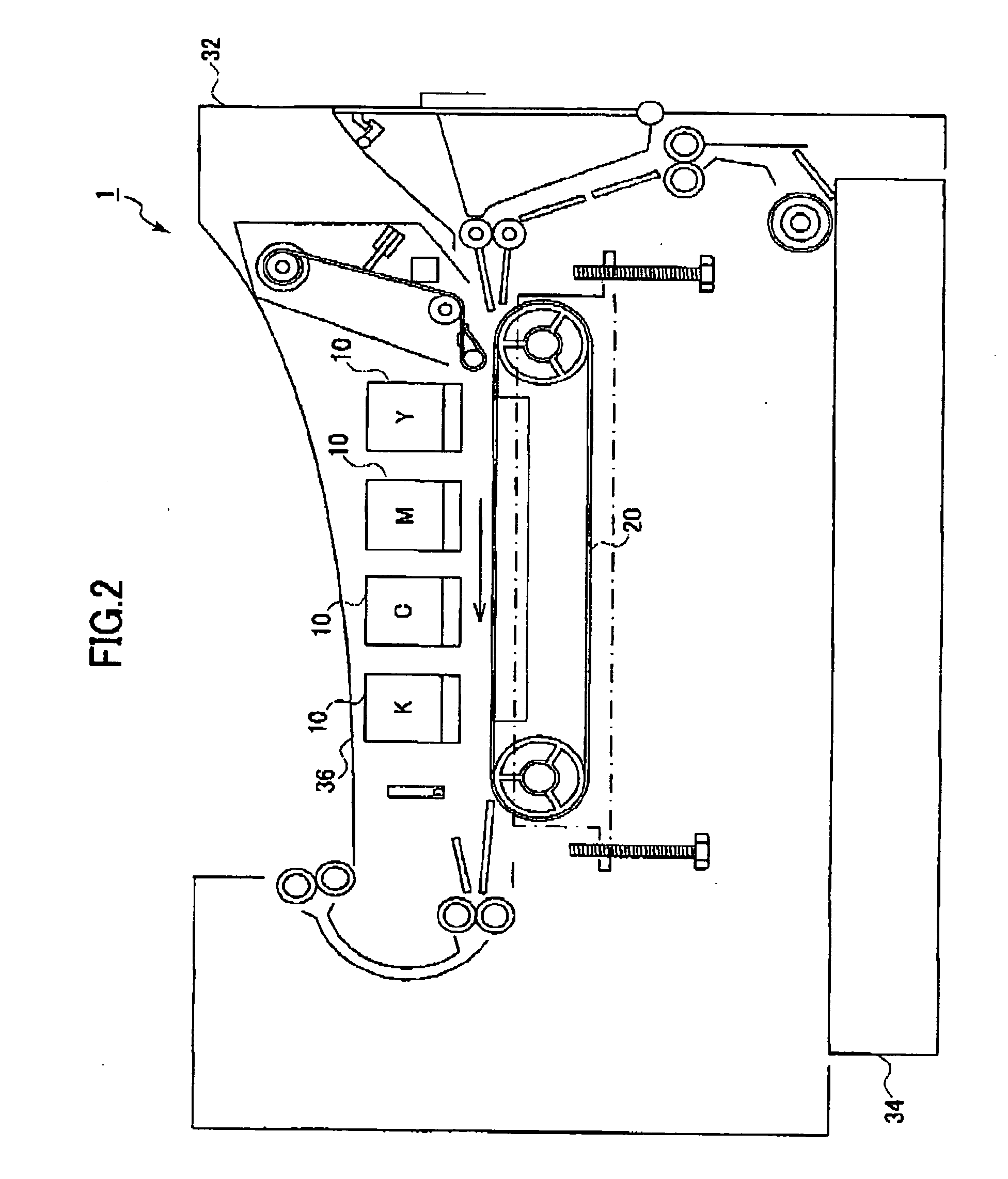

Image forming apparatus and method

InactiveUS7448706B2Deterioration can be suppressedOther printing apparatusImage formationRelative motion

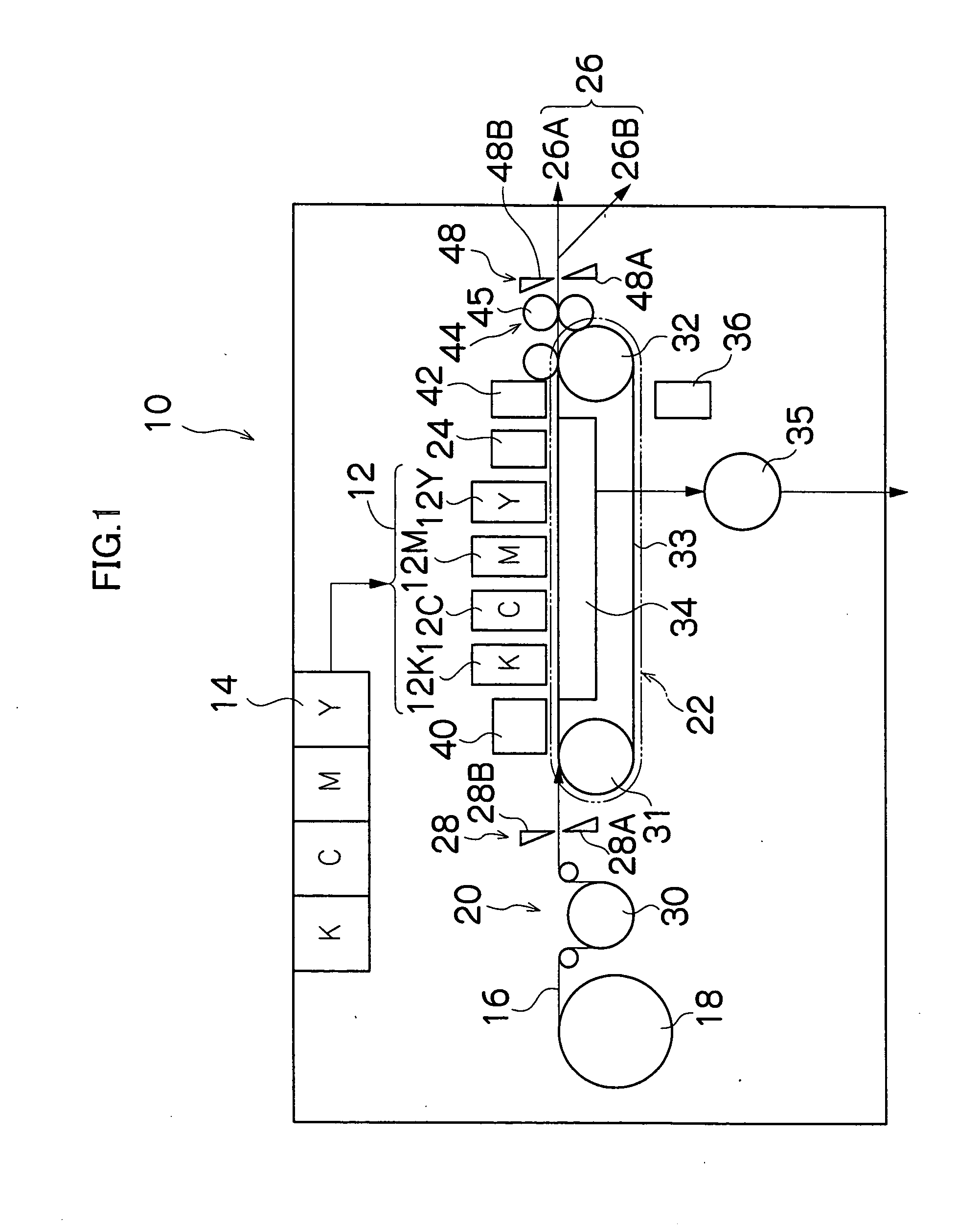

The image forming apparatus comprises: a recording head which includes a plurality of nozzles through which droplets of liquid are ejected to and deposited on a recording medium to form dots on the recording medium, the nozzles being arranged in a nozzle row; a conveyance device which causes the recording head and the recording medium to move relatively to each other by conveying at least one of the recording head and the recording medium in a relative movement direction; a storage device which, of information indicating an amount of deposition position displacement from an ideal deposition position of the dots formed by the droplets ejected from the nozzles, stores information about the amount of deposition position displacement in at least a direction perpendicular to the relative movement direction of the conveyance device; a line figure recognition processing device which carries out processing for recognizing line figures from image data for printing; an ideal line identification device which determines an ideal line obtained by linking centers of the respective dots formed when printing a line figure, assuming that there is absolutely no deposition position displacement produced by any of the nozzles, in respect of the line figure recognized by the line figure recognition processing device; and an ejection timing control device which, when printing a line figure, controls ejection timing of a defective nozzle which produces deposition position displacement in a direction perpendicular to the relative movement direction, according to the information about the amount of deposition position displacement stored in the storage device and the ideal line determined by the ideal line identification device, in such a manner that a deposition center position of a dot formed by a droplet ejected from the defective nozzle moves closer to the ideal line, along the relative movement direction.

Owner:FUJIFILM CORP

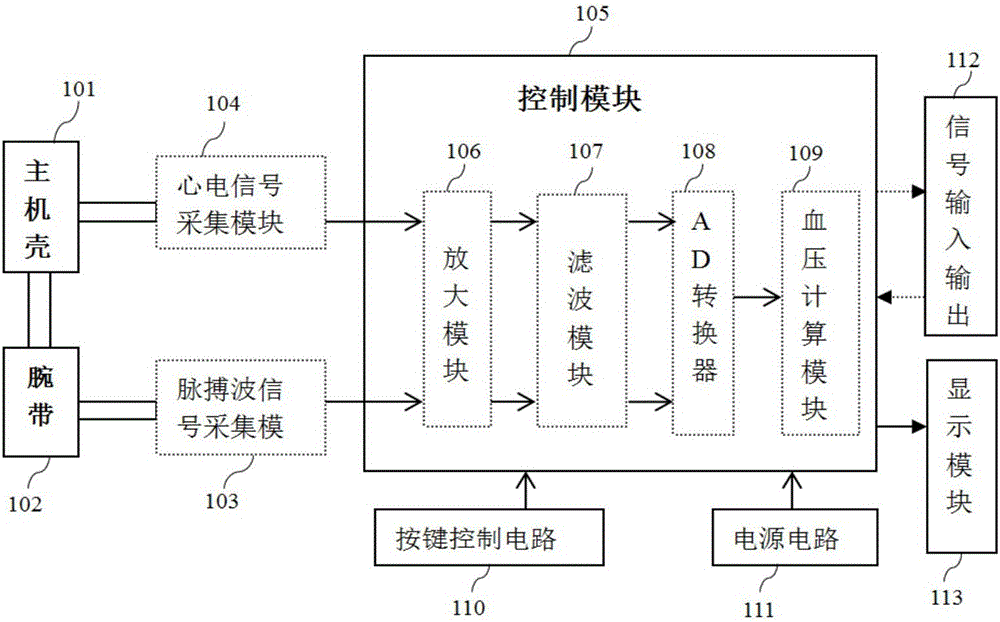

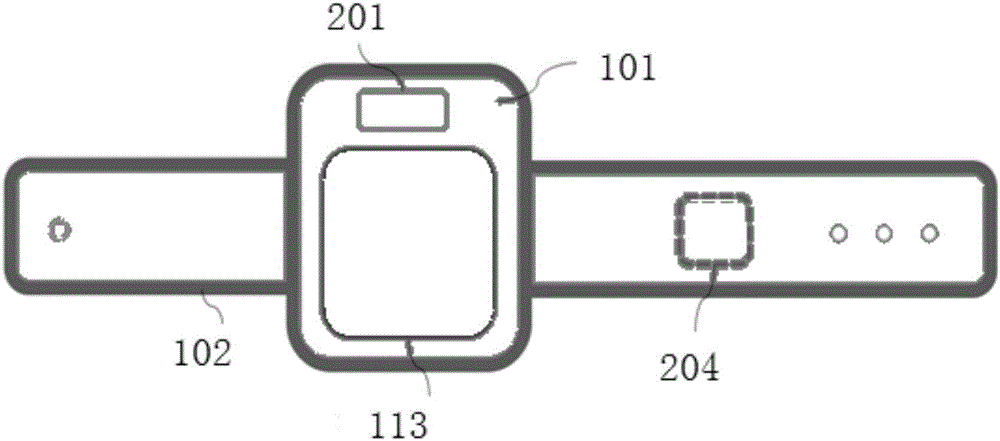

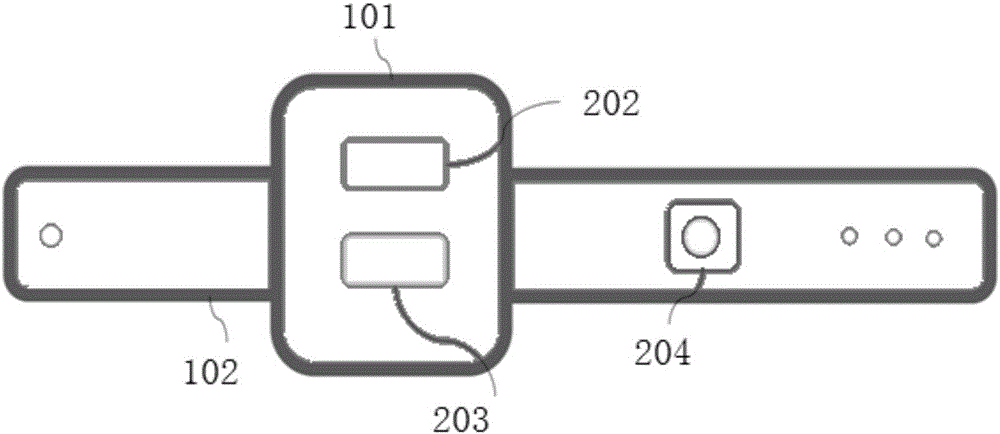

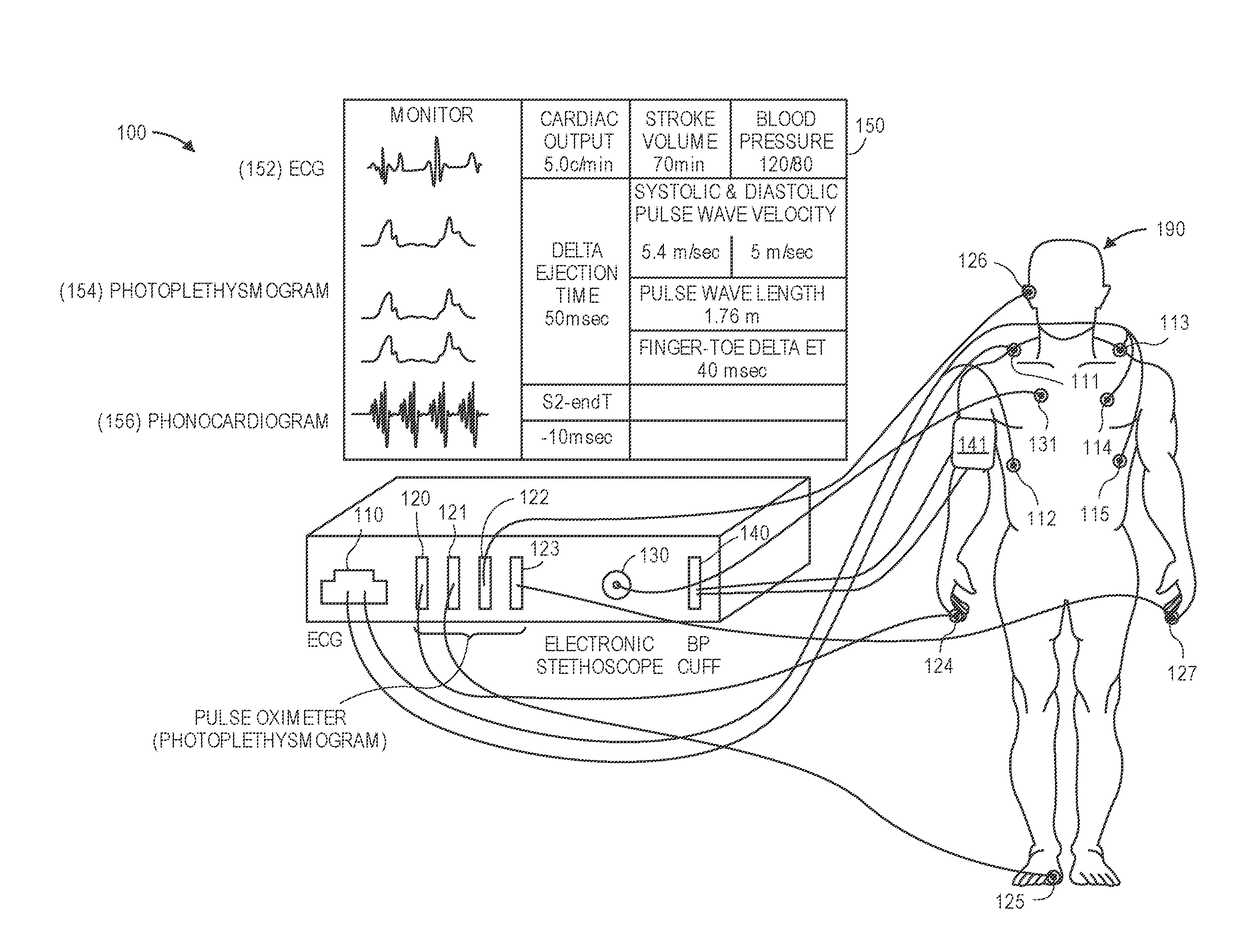

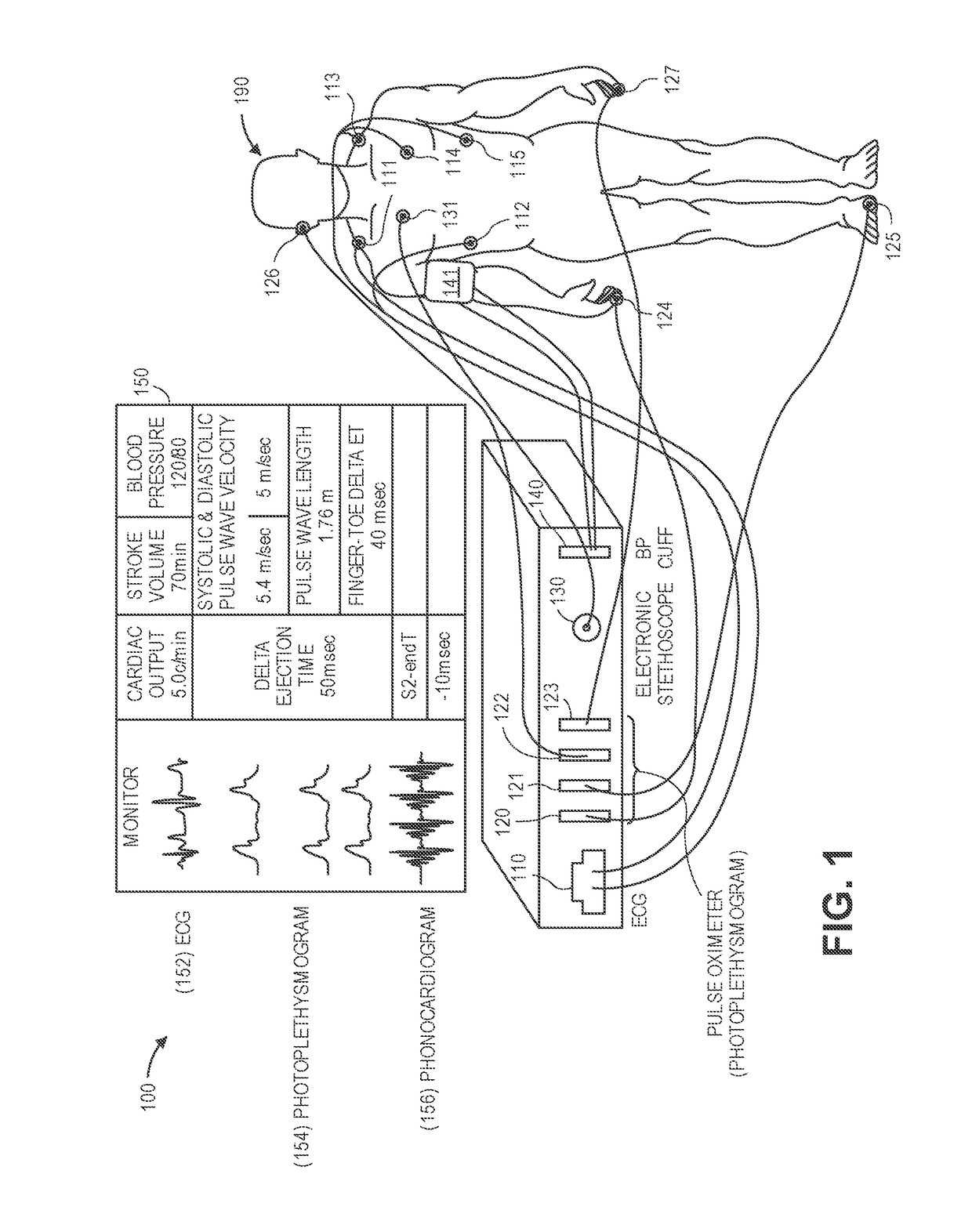

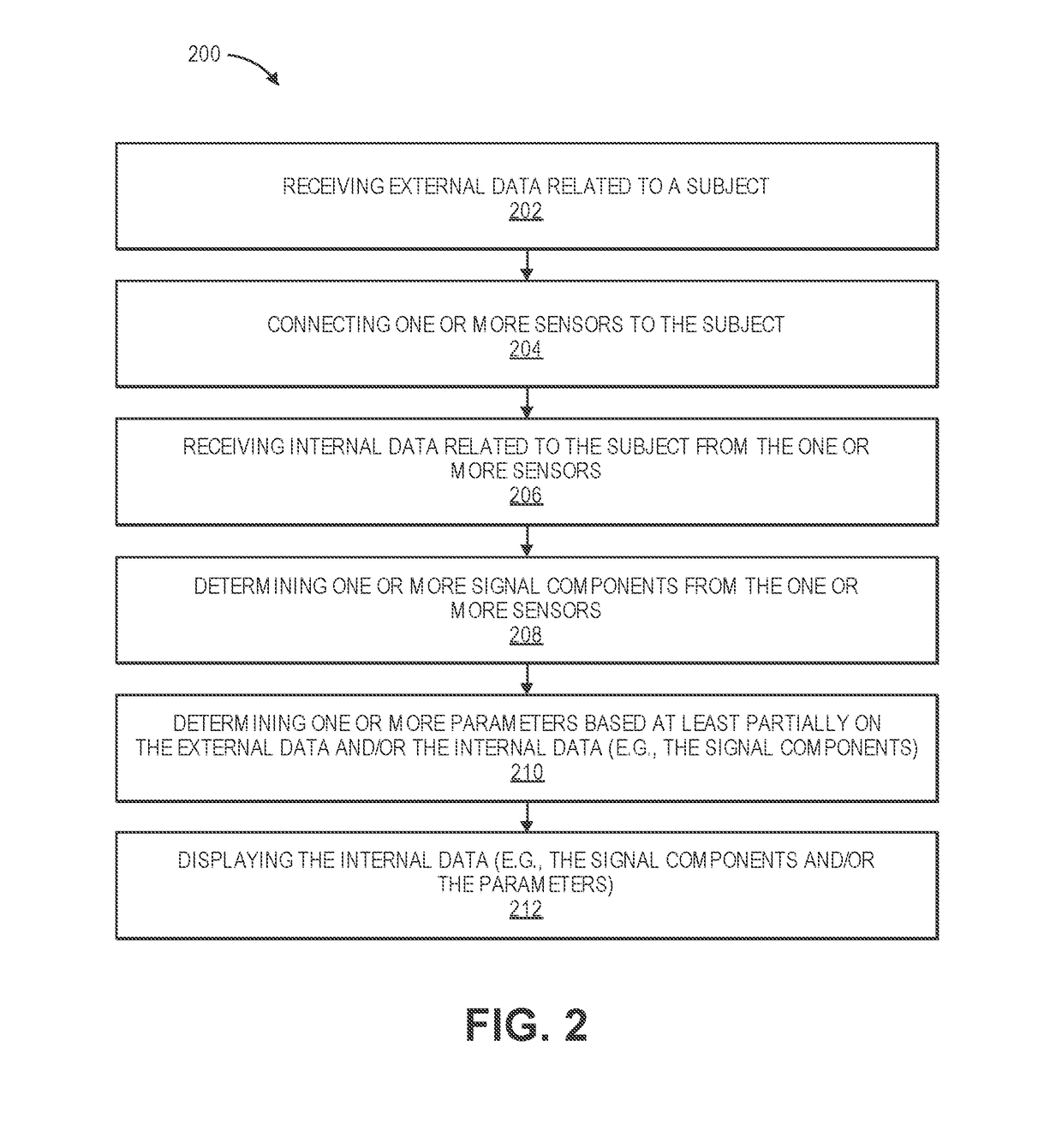

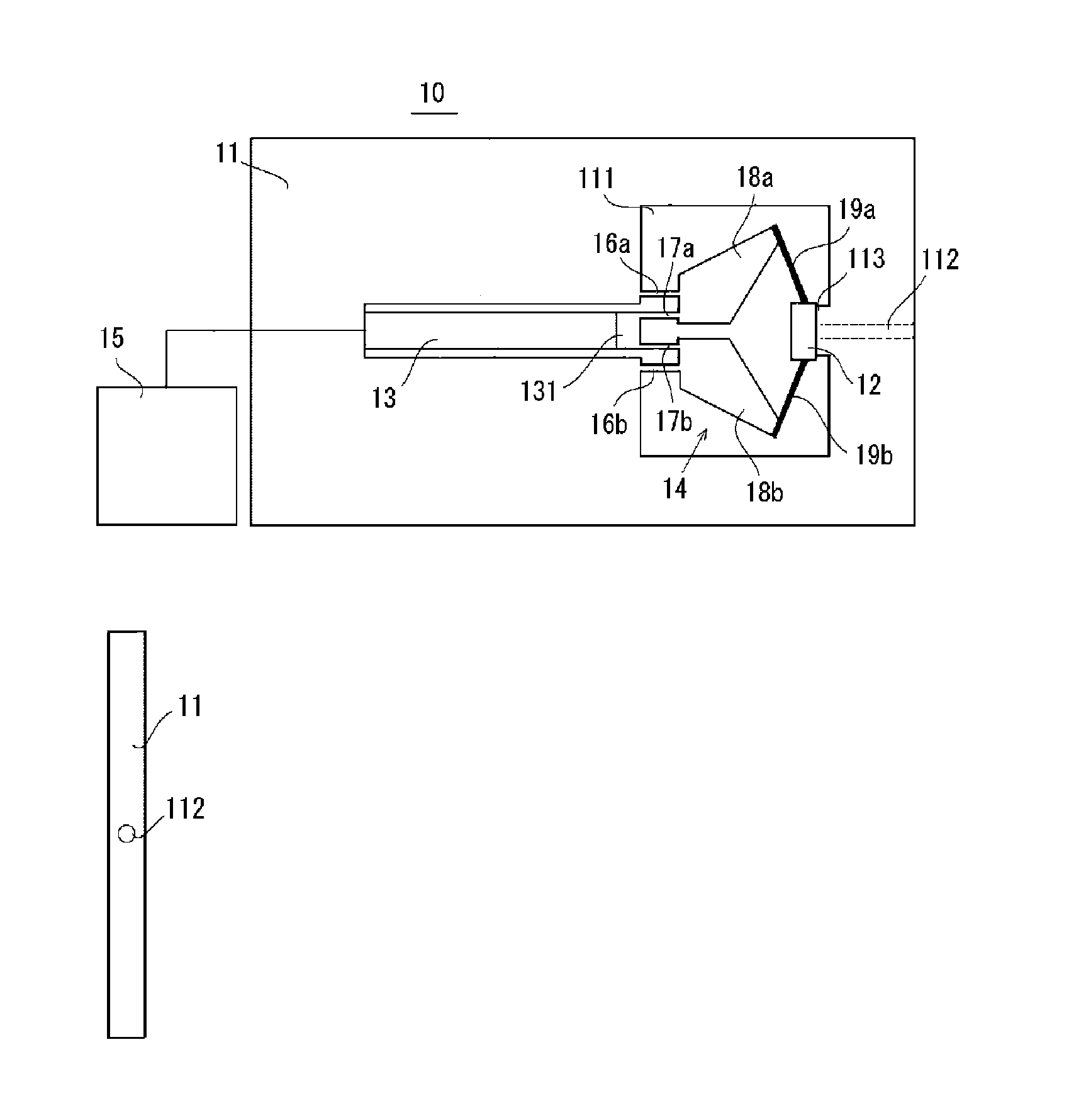

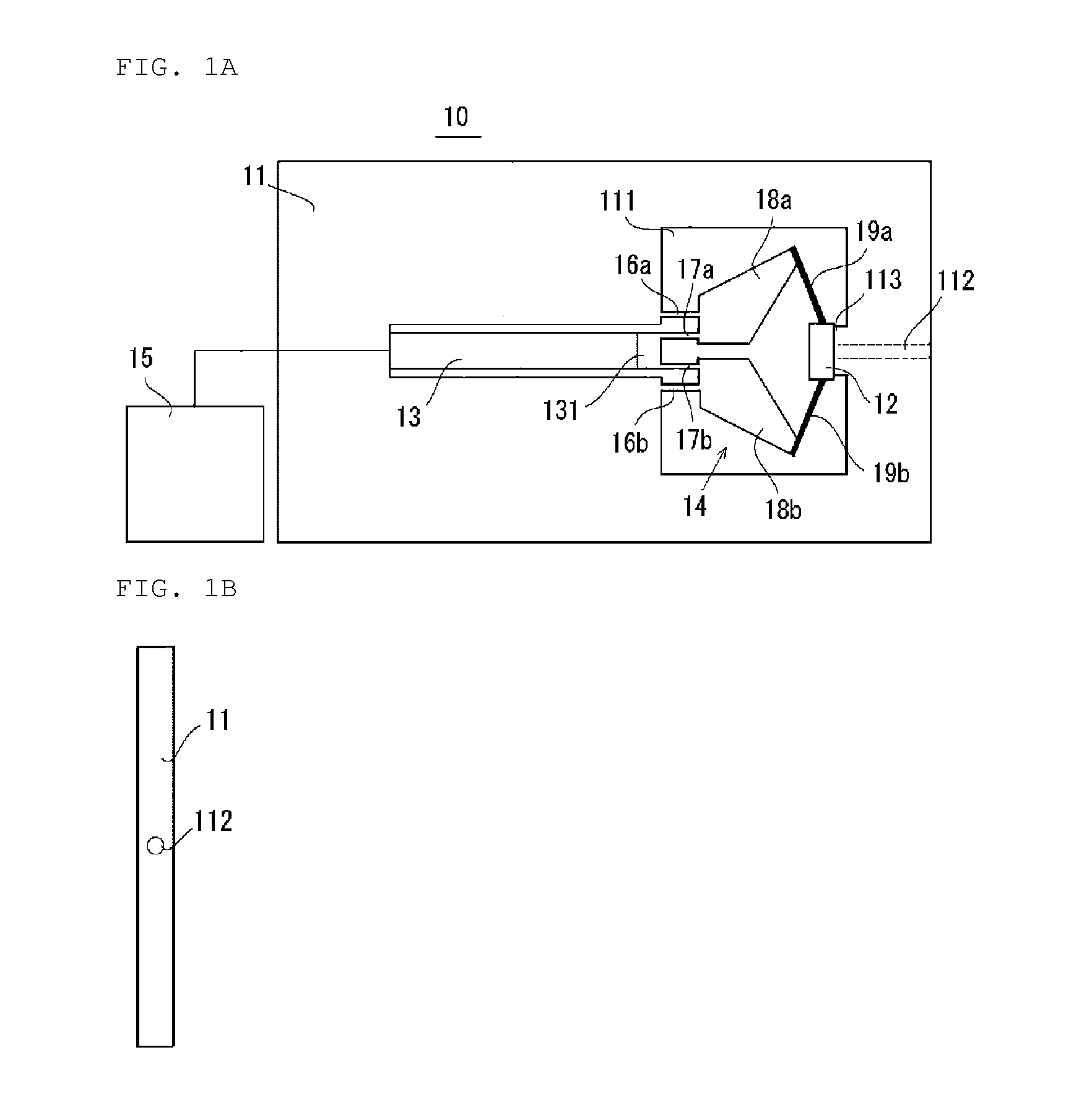

Continuous dynamic blood pressure monitoring device and method based on pulse wave transit

ActiveCN106618537ALong-term continuous monitoring of blood pressure changesEvaluation of blood vesselsSensorsEcg signalComputer module

The invention provides an independently researched and developed continuous dynamic blood pressure monitoring device and method based on pulse wave transit time (PWTT) and pulse wave transit velocity (PWV). According to the device, an electrocardiosignal collecting module (104) is arranged on a main case (101) in a wristwatch form, a pulse wave signal collecting module (103) is arranged at the position, corresponding to the wrist radial artery, of a wristband (102), and the electrocardiosignal collecting module (104) and the pulse wave signal collecting module (103) are in signal connection with a control module (105). The device and algorithm can obtain pulse waves in real time, the problem that in-vitro heart pulse waves are inconvenient to obtain is solved, the method for rapidly and accurately obtaining the cardiac ejection time point is provided, and the method is an important part of continuous dynamic blood pressure monitoring.

Owner:TIANJIN ONEHAL INFORMATION TECH

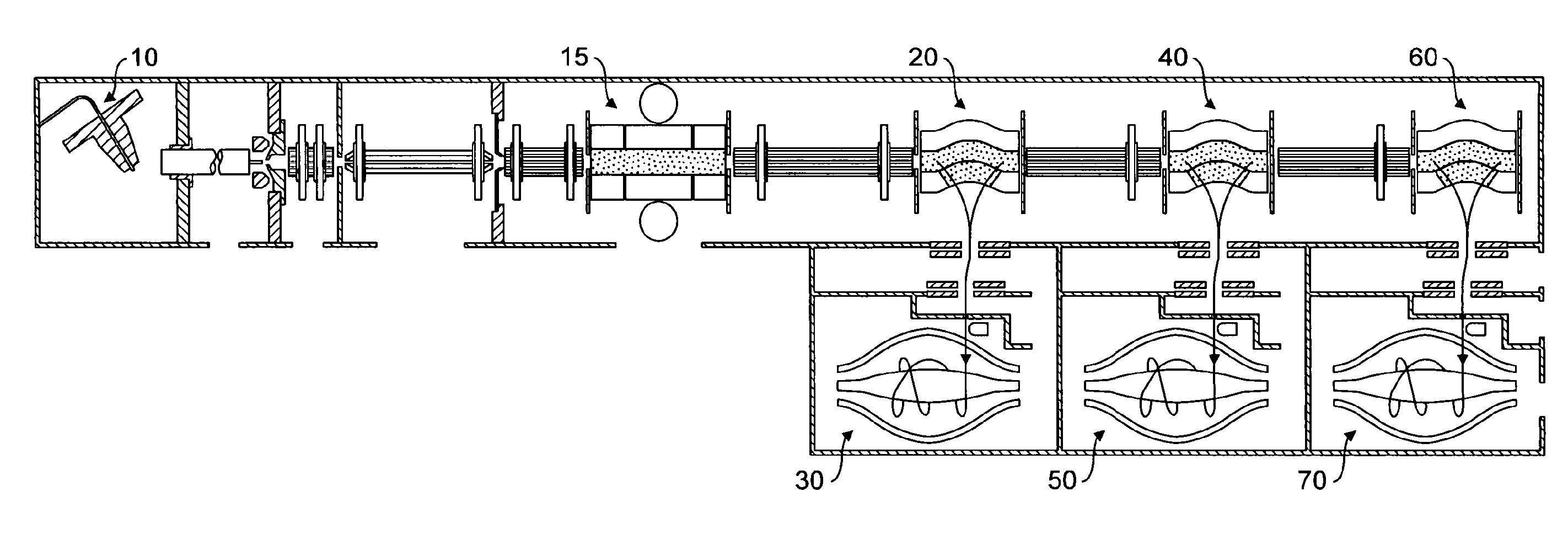

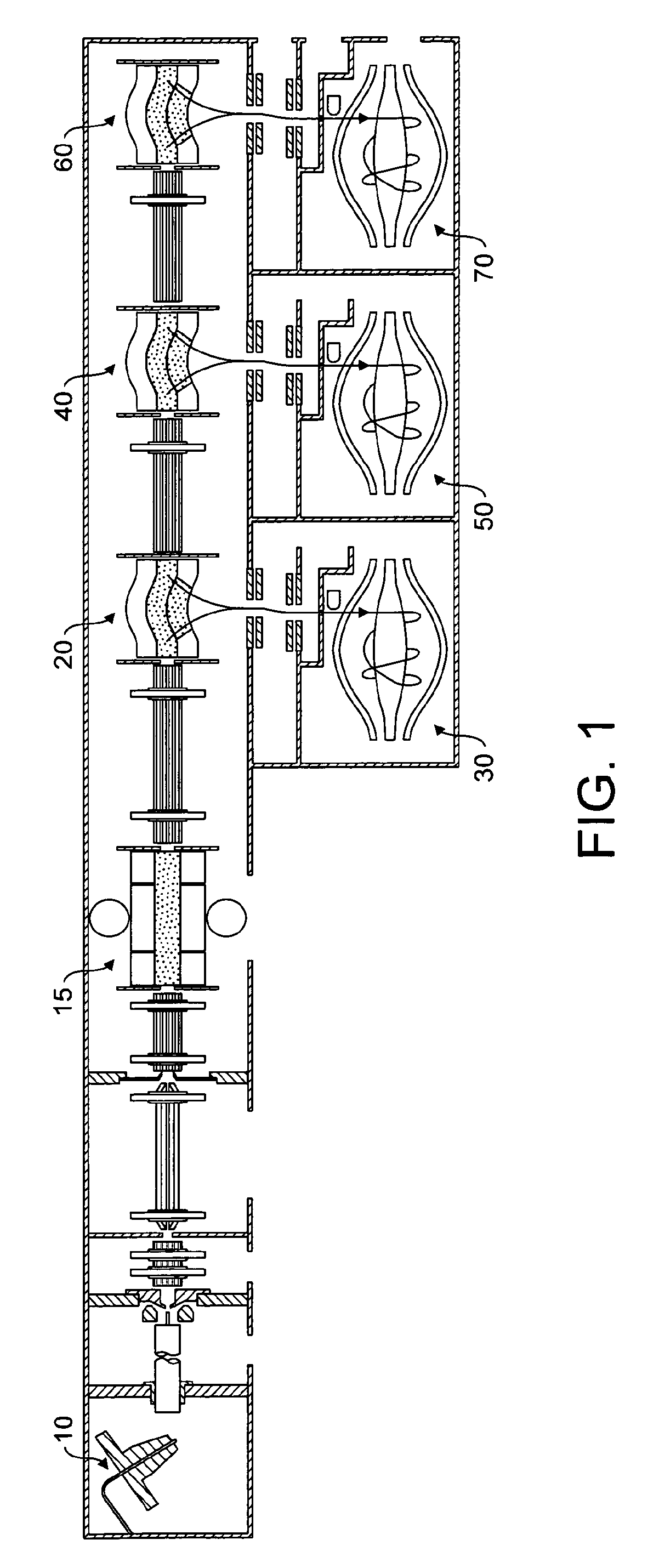

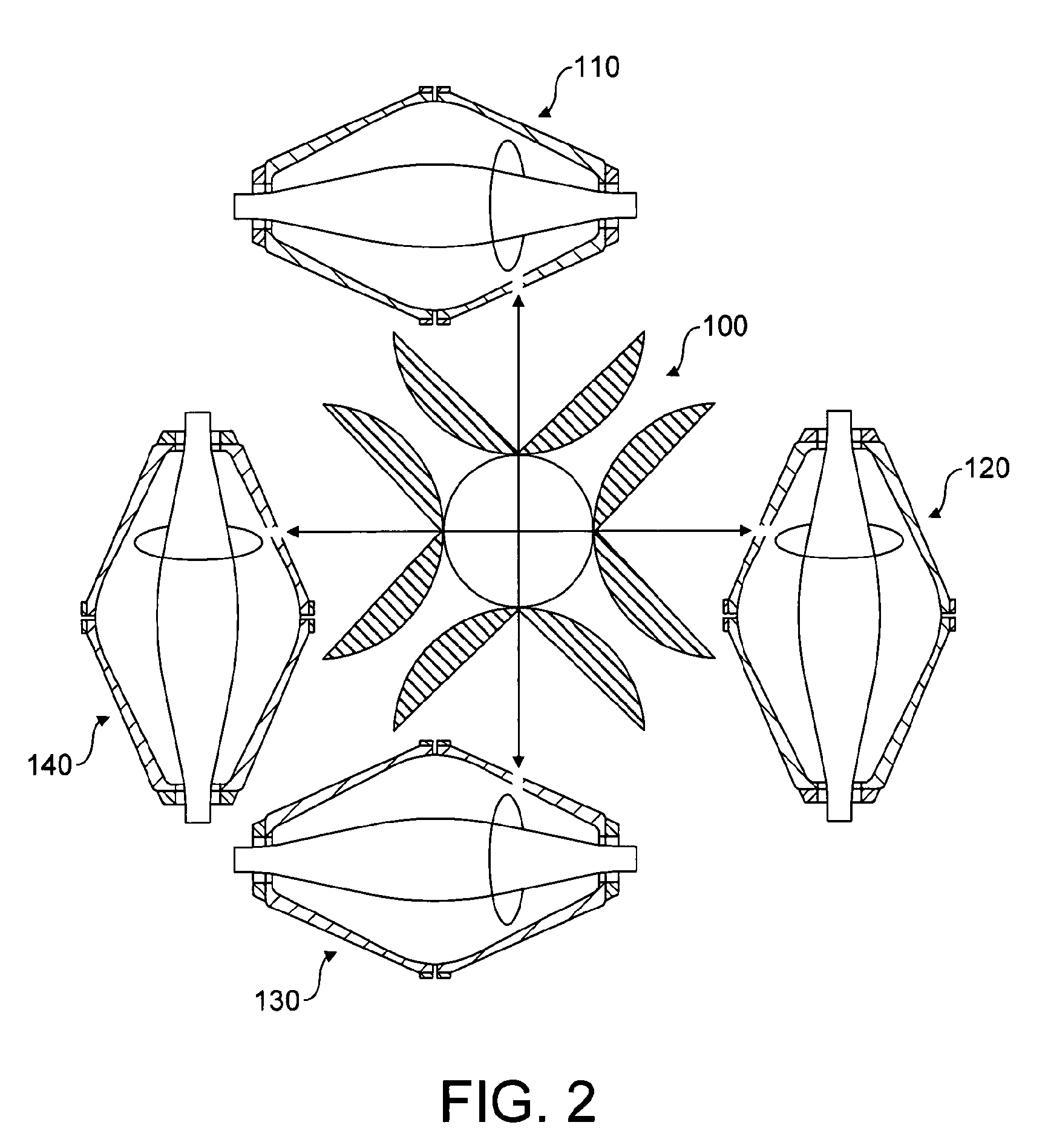

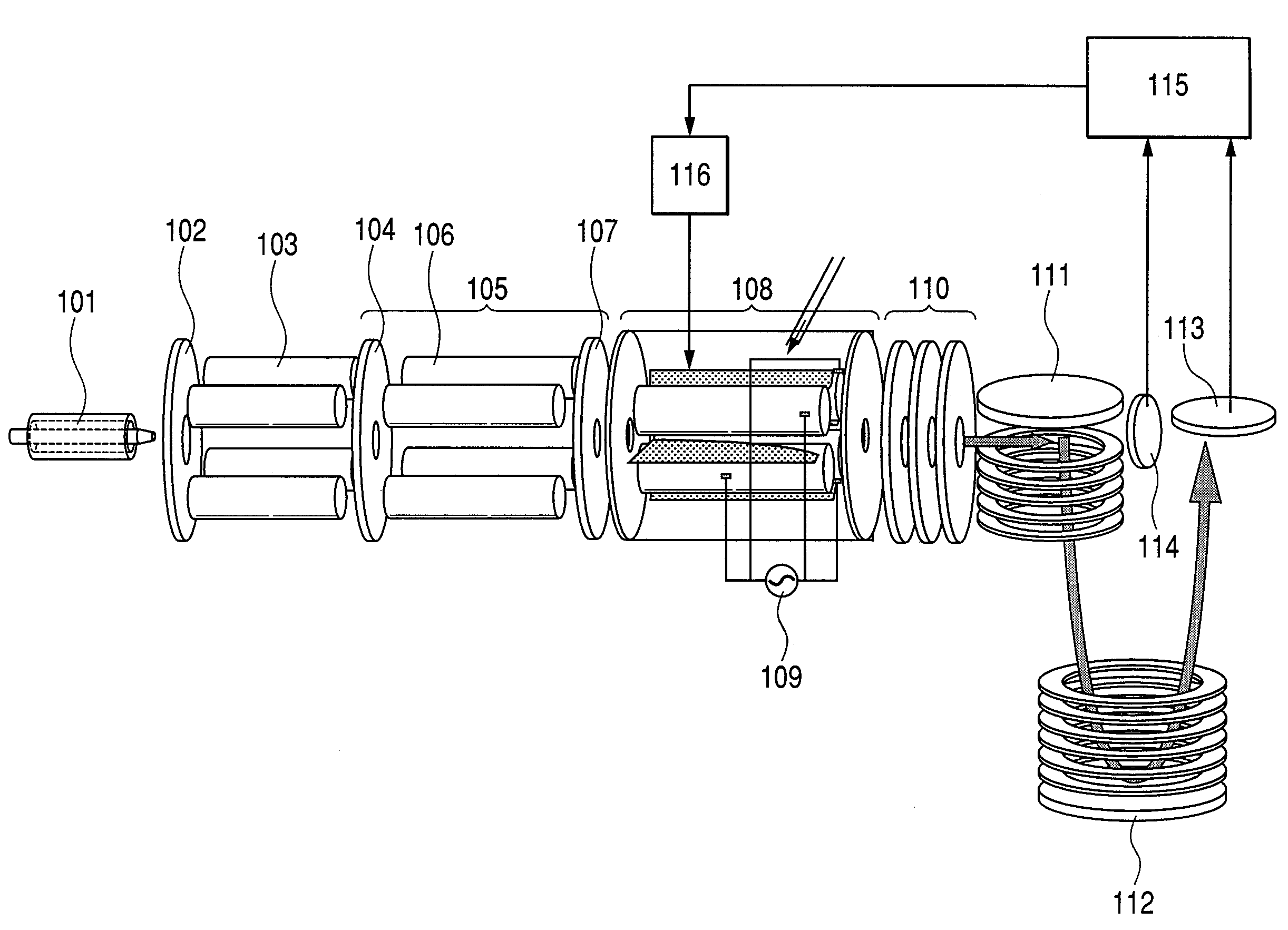

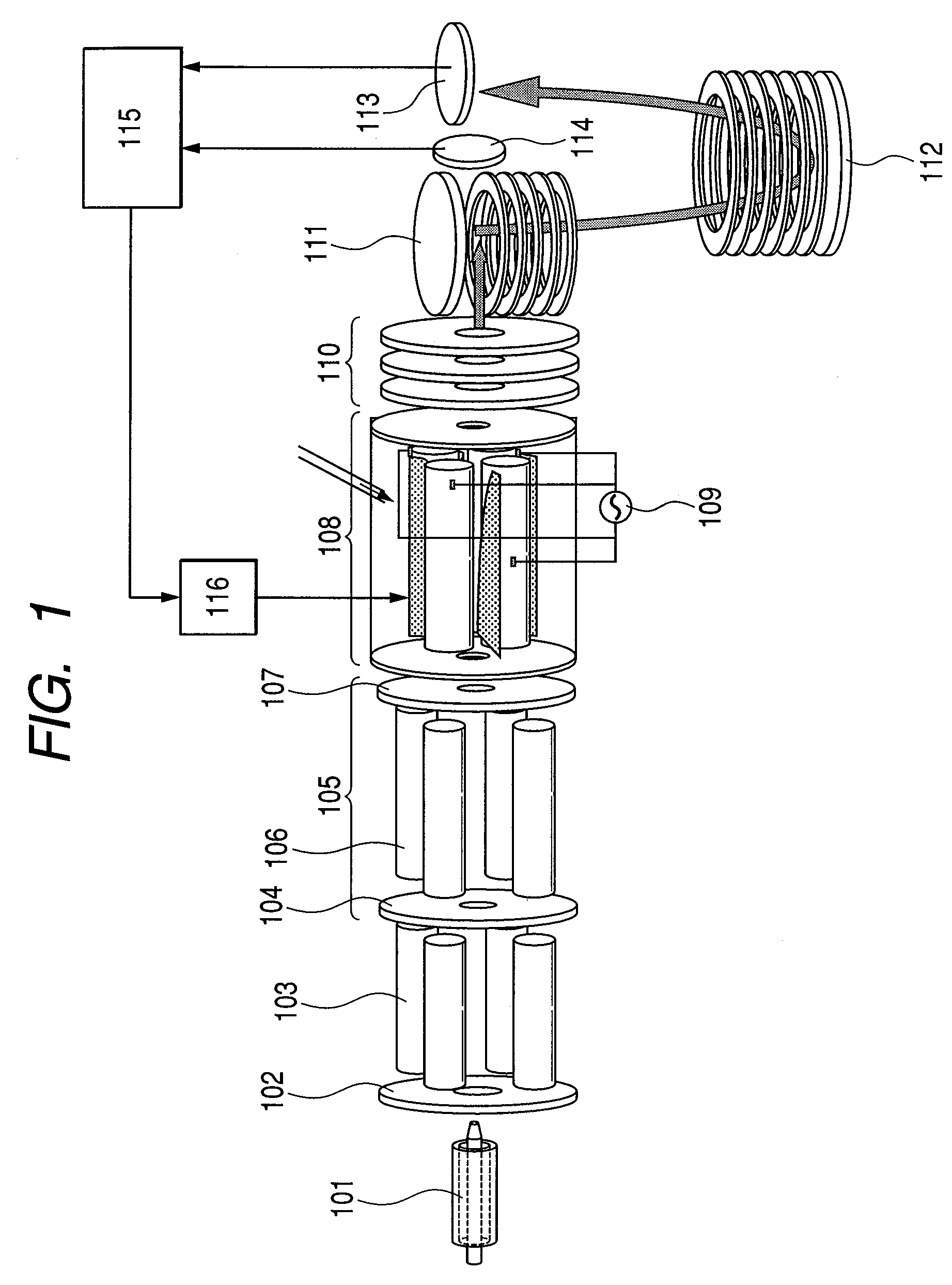

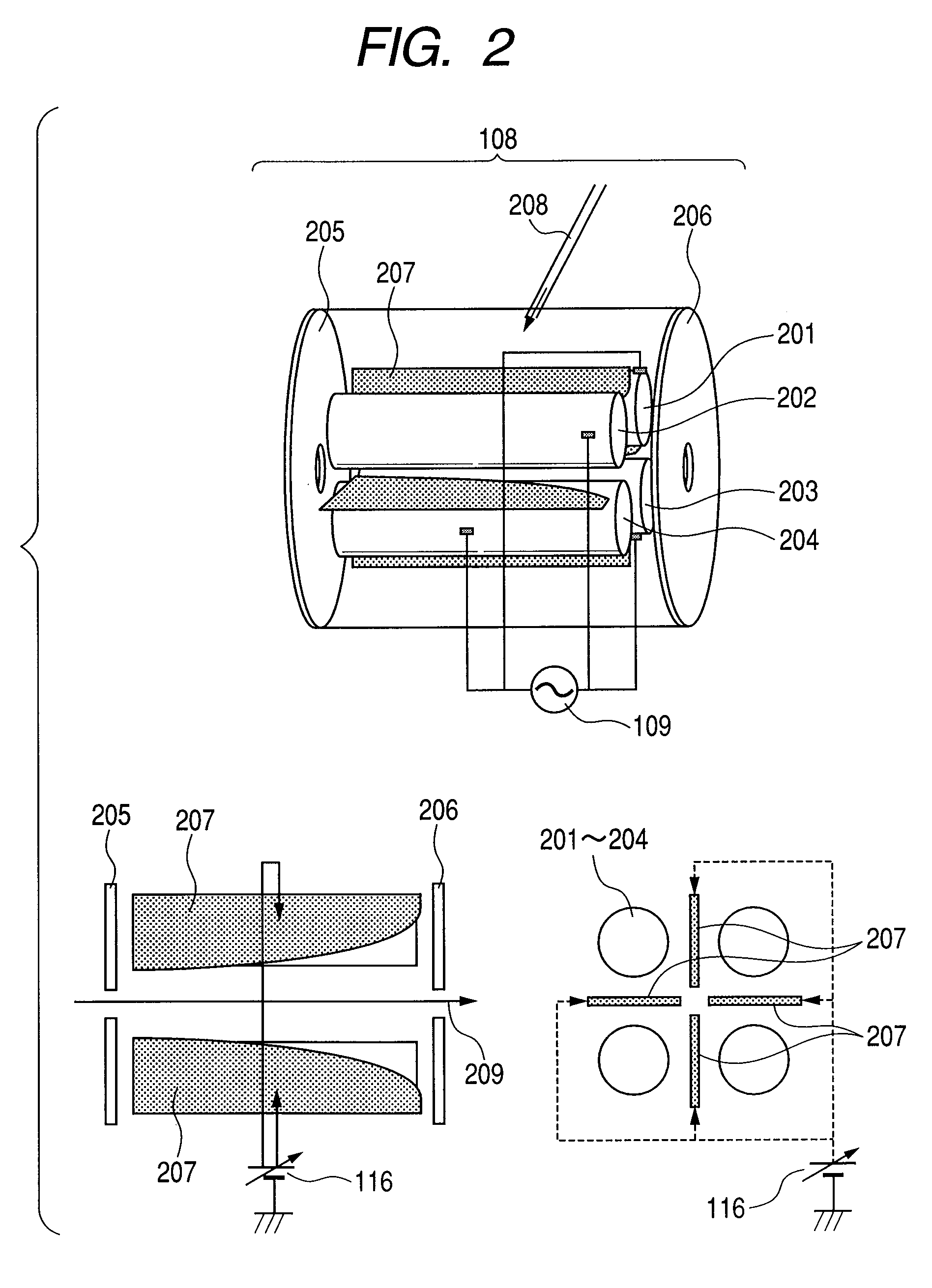

Parallel mass analysis

ActiveUS7985950B2Improve efficiencySamples introduction/extractionIsotope separationMass Spectrometry-Mass SpectrometryMass analysis

A system and method of mass spectrometry is provided. Ions from an ion source are stored in a first ion storage device and in a second ion storage device. Ions are ejected from the first ion storage device to a first mass analysis device during a first ejection time period, for analysis during a first analysis time period. Ions are ejected from the second ion storage device to a second mass analysis device during a second ejection time period. The ion storage devices are connected in series such that an ion transport aperture of the first ion storage device is in communication with an ion transport aperture of the second ion storage device. The first analysis time period and the second ejection time period at least partly overlap.

Owner:THERMO FISHER SCI BREMEN

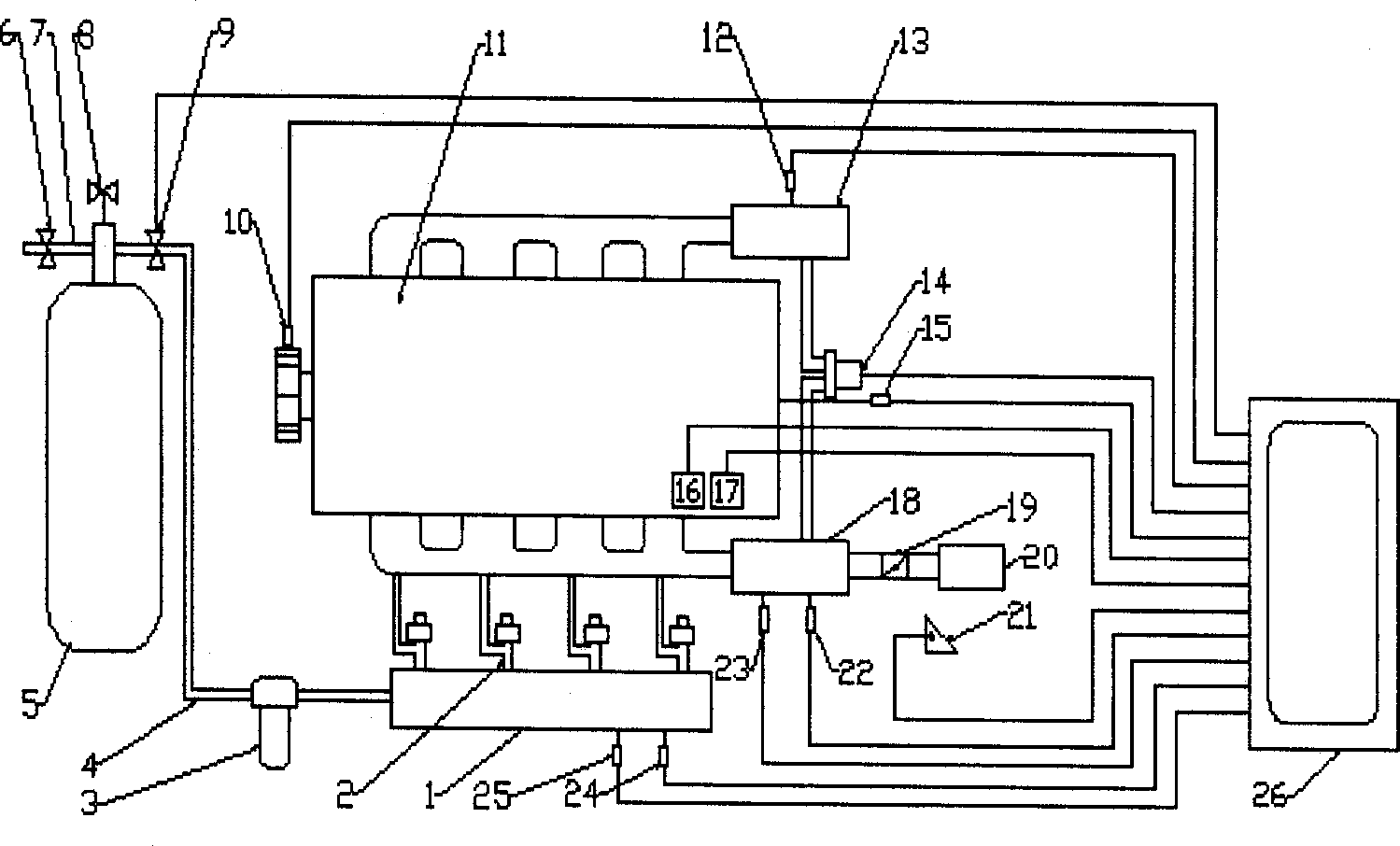

Apparatus and method for controlling internal combustion engine with hydrogen fuel

InactiveCN1800617AReduce residual hydrogenInhibit temperingElectrical controlInternal combustion piston enginesExternal combustion engineInlet valve

The invention relates to a method for controlling feeding fuel to the inlet pipe of hydrogen motor and relative device, which can apply variable combustion engine with hydrogen fuel and it can apply electric control on the hydrogen ejection time and ejection period. The invention comprises a group of sensors to supply the information of hydrogen feeding system and the motor; a group of valves and pipeline to supply hydrogen resource; a electric control unit as the control center of said device; a hydrogen ejection system formed by a hydrogen stable-pressure rail, a hydrogen ejection valve, and hydrogen guide nozzle for guiding the hydrogen ejected from hydrogen ejection valve to nearest inlet valve; a electric air-saving gate on the inlet pipe of motor, a waste gas recycle valve between the inlet pipe and outlet pipe; and a hydrogen safety release valve on the crank box of motor. The invention ejects the hydrogen at the position which is nearest to the motor inlet valve into burning room, to reduce the backfire possibility of inlet pipe, reduce the discharge of NOx and control early-burning.

Owner:镇江江奎科技有限公司 +1

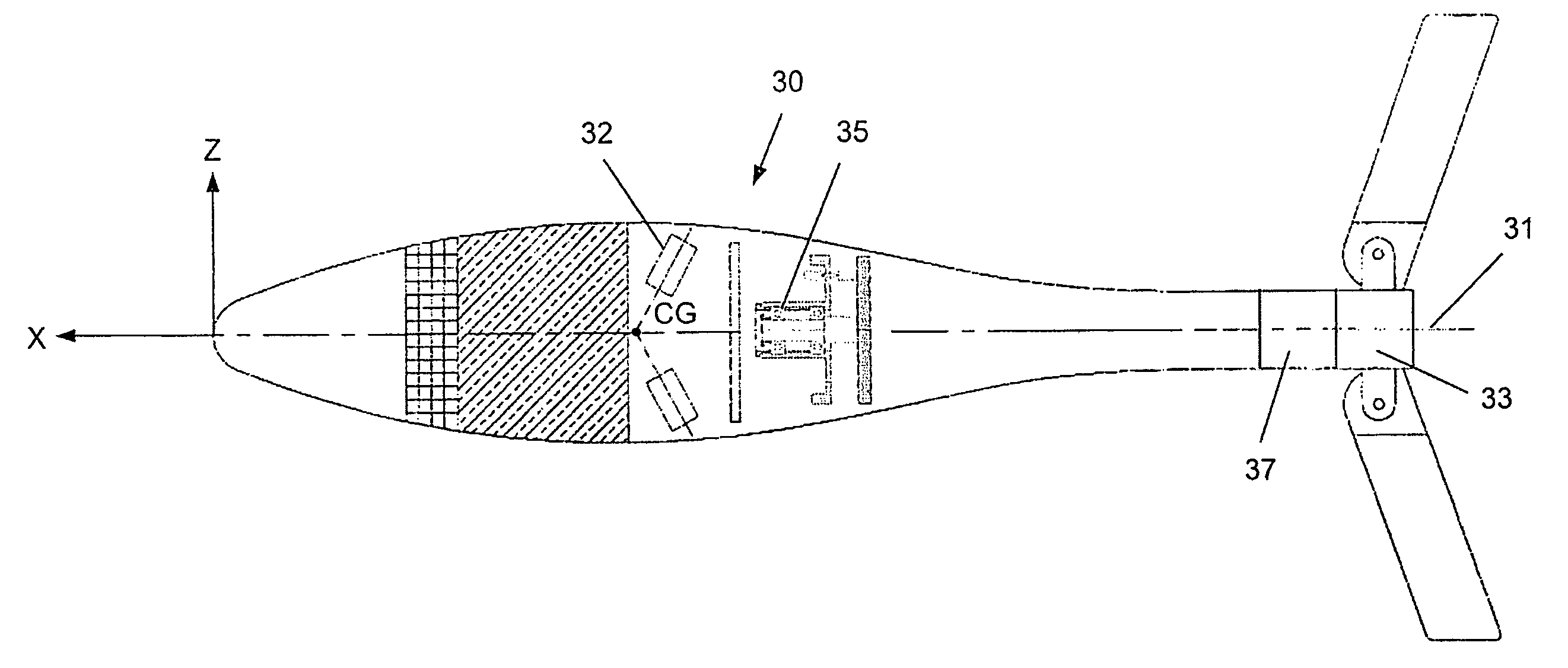

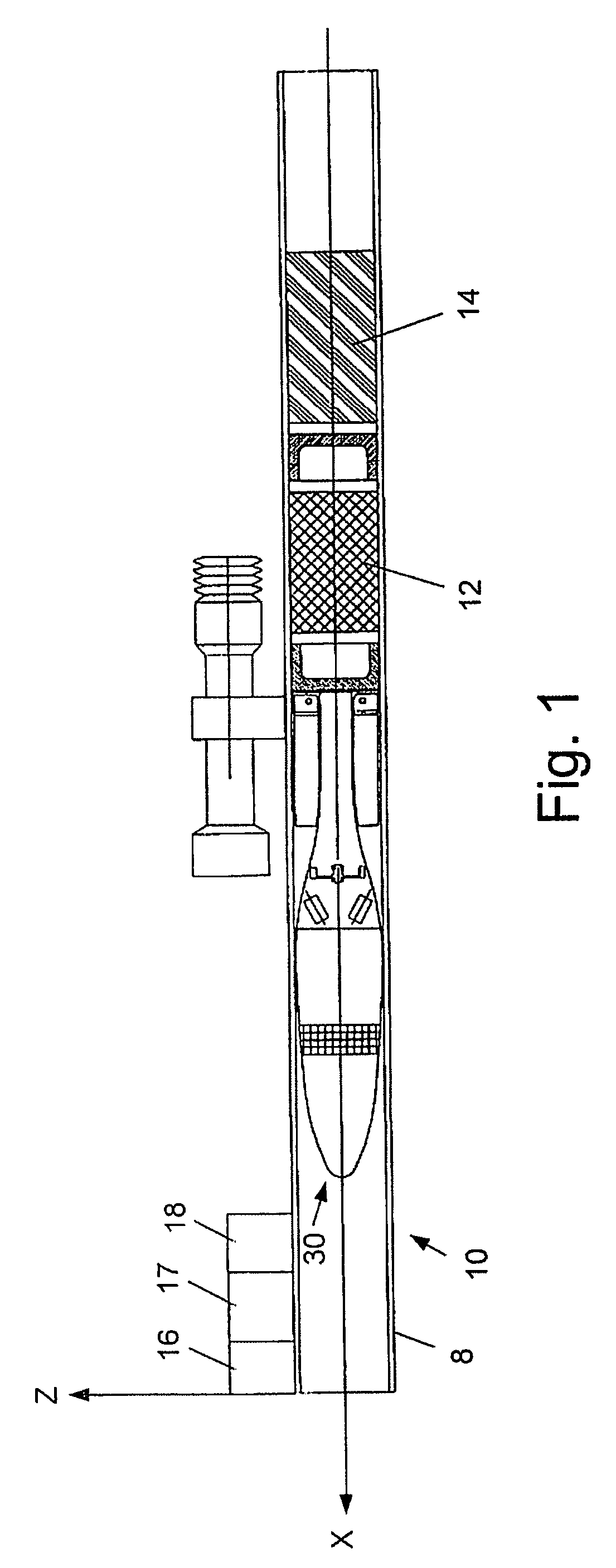

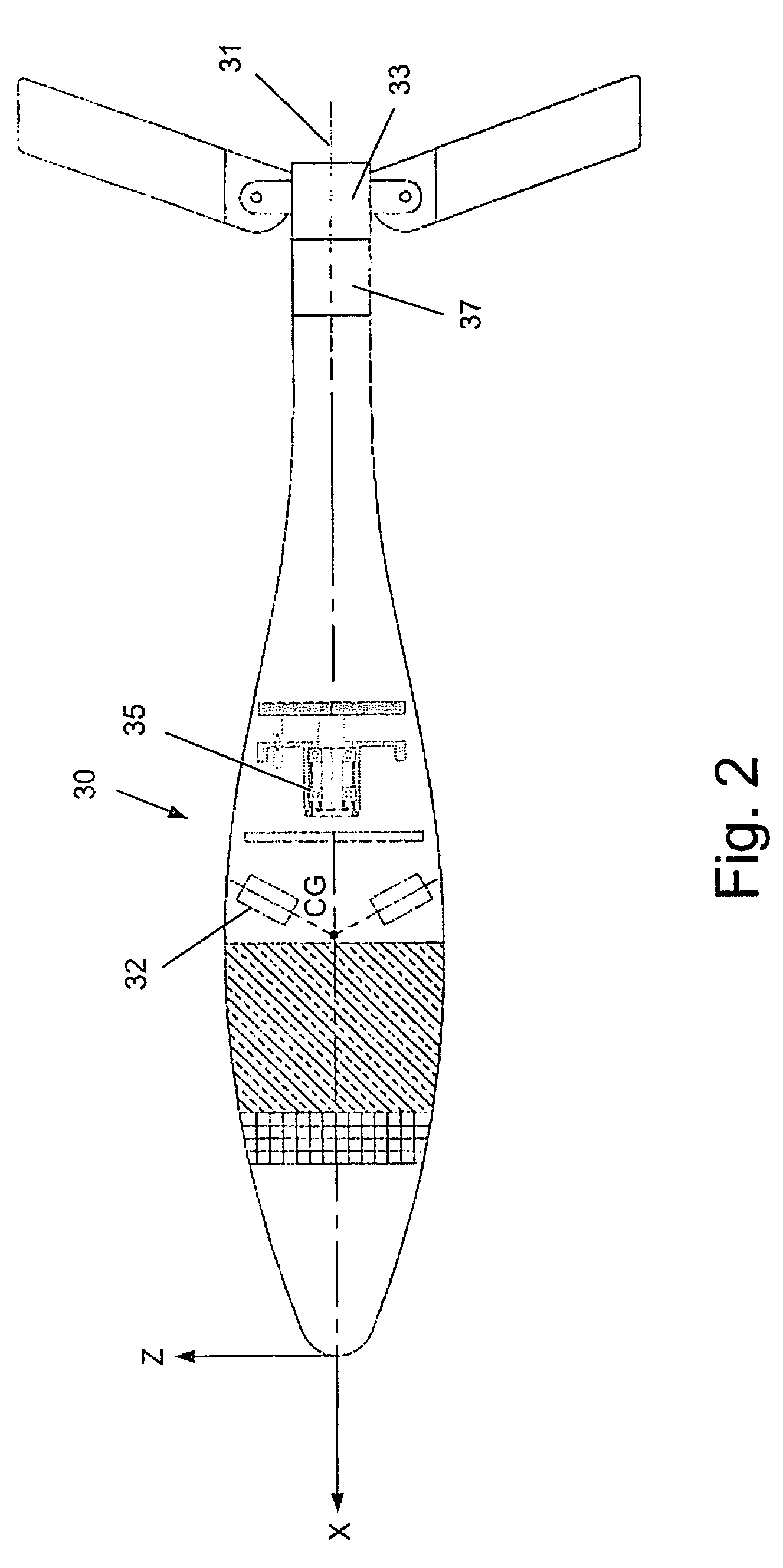

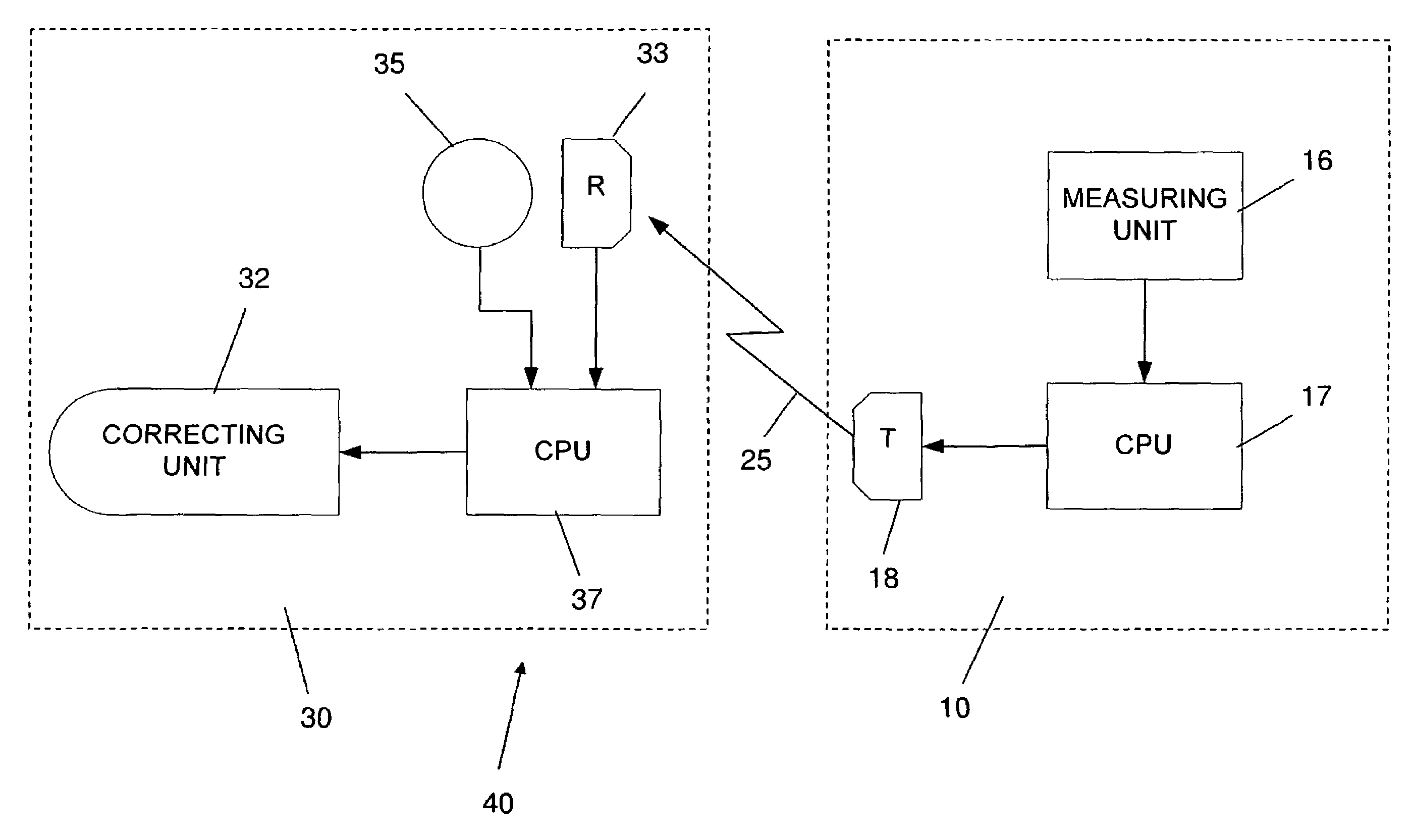

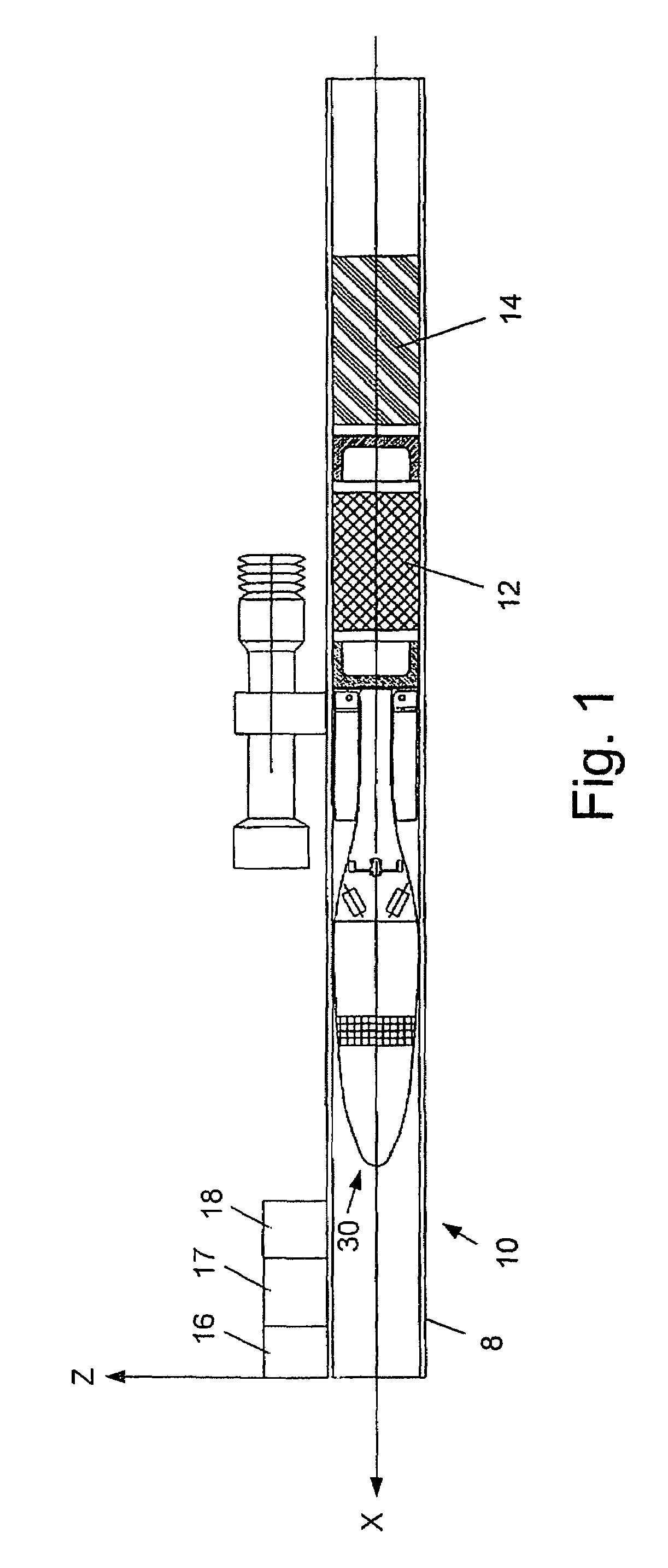

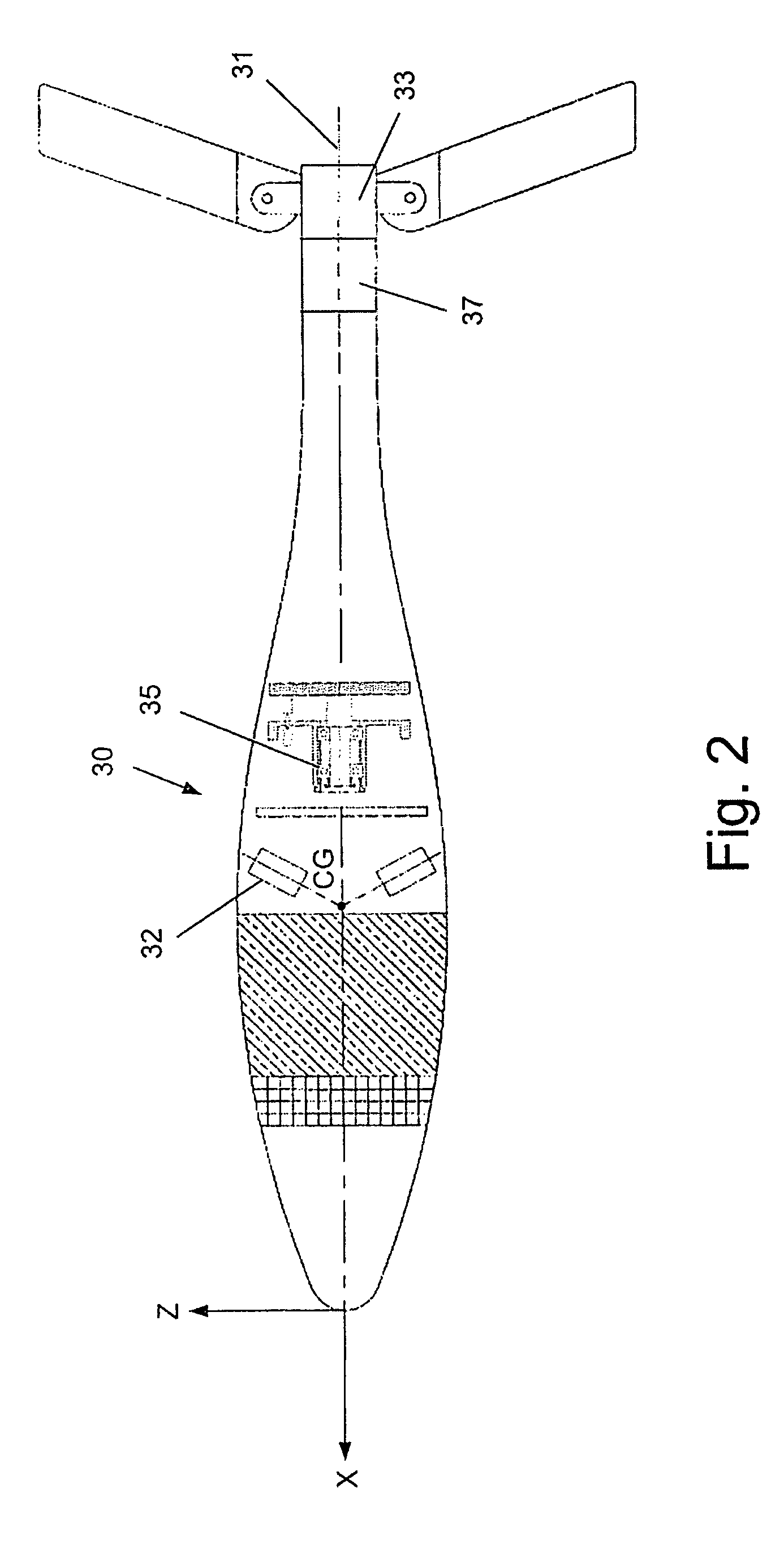

Method and system for adjusting the flight path of an unguided projectile, with compensation for jittering deviation

ActiveUS20060060692A1Prevent rotationAmmunition projectilesRocket launchersAngular deviationEngineering

A method for adjusting the flight path of an unguided projectile, which comprises the steps of: (a) Measuring the magnitude and direction of the jittering of a projectile launch tube, at an ejection time of a projectile from the launch tube; (b) Measuring a velocity deviation of the projectile from a nominal velocity; (c) Measuring an angular deviation of the sight of the launch tube, being equal to the angular deviation between a line coinciding with the direction of gravity and a line passing through the center of the launch tube and the center of the sight; (d) Determining a compensating impulse vector to be applied to the projectile during an initial flight path thereof based on the magnitude and direction of the jittering, velocity deviation and angular deviation; and (e) Applying the compensating impulse vector to the projectile by activating a flight correction unit, the thrust developed by the flight correction unit suitable for adjusting the flight path of the projectile by a magnitude and direction substantially equal to that of the compensating impulse vector.

Owner:THE STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG ARO VOLCANI CENT

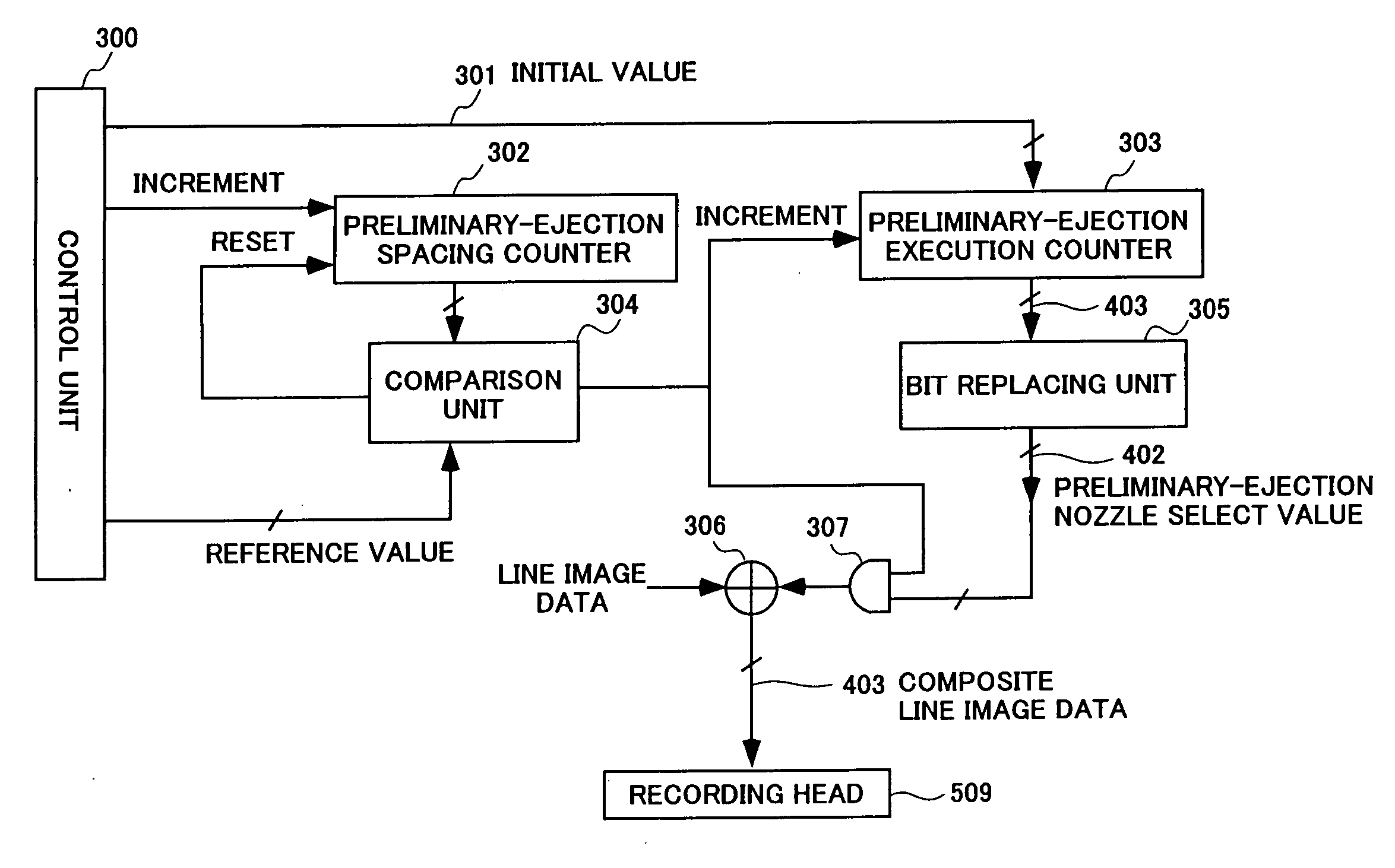

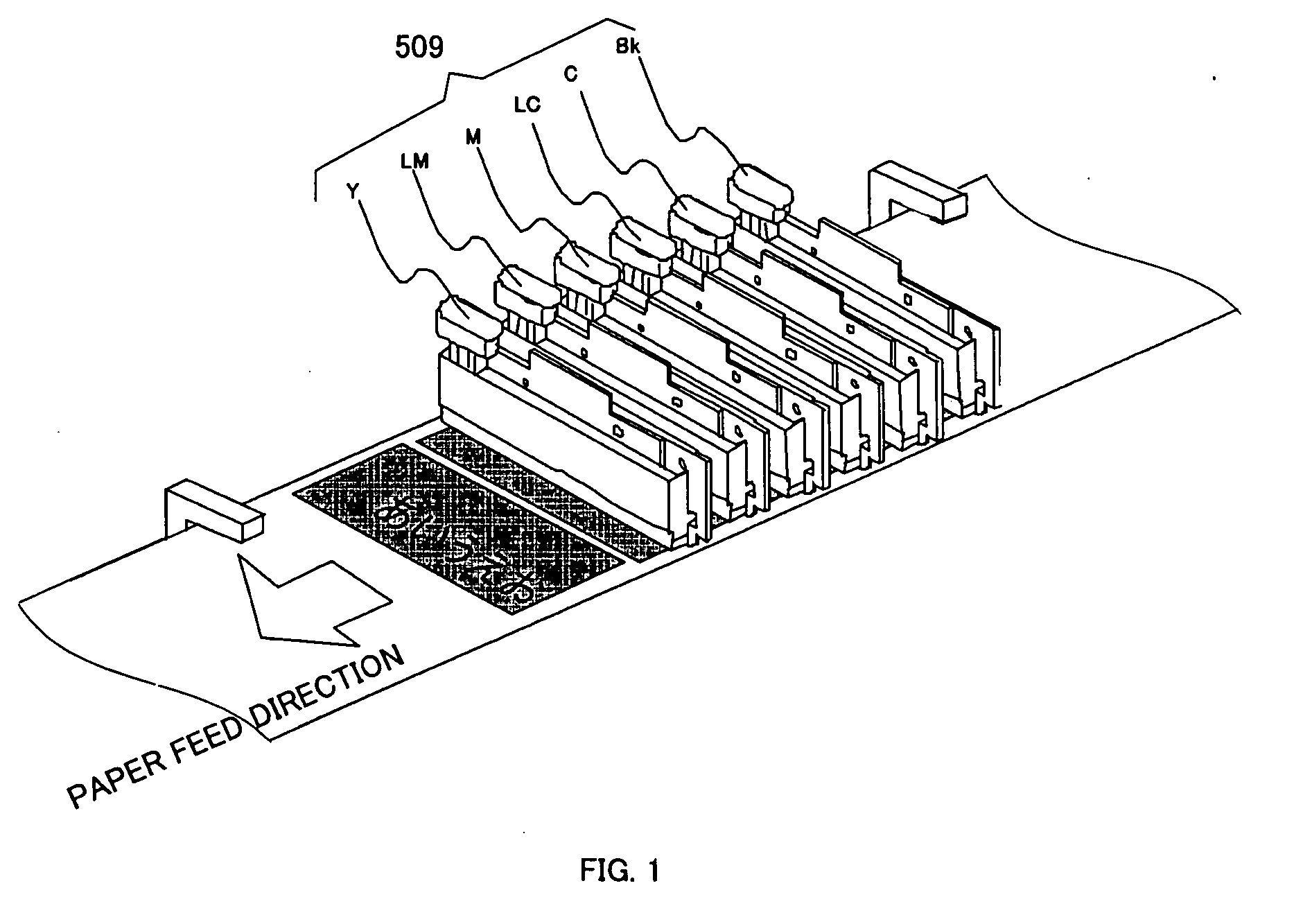

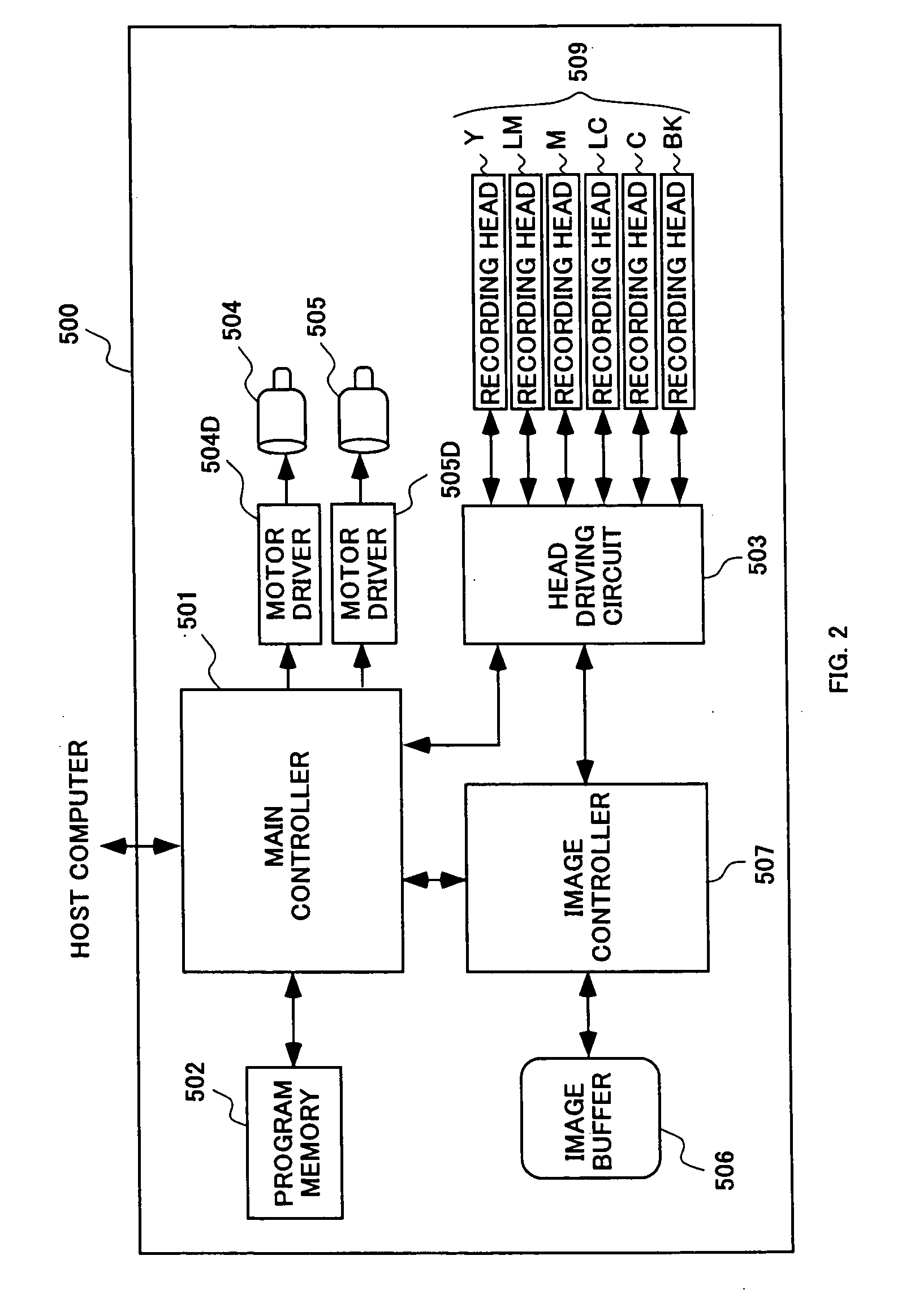

Ink jet printer and preliminary-ejection control method

The present invention makes it possible to continuously print for a long time with no print interruption and provides simple control for making a preliminary-ejected image pattern difficult to be visually recognized when paper preliminary-ejecting is performed on a printer that uses recording heads each having plural linearly-arranged ink-ejecting nozzles. To do so, a preliminary-ejection execution counter 303 is provided for counting the number of preliminary-ejection executions to determine nozzles, from which ink is ejected at each preliminary-ejection time, when ink is periodically ejected onto a recording medium from one or more nozzles at a time in a preliminary manner at a predetermined time during the image data recording operation through recording heads 509. The nozzles from which ink is ejected are determined based on a preliminary-ejection nozzle select value generated by exchanging the bit positions of the count value of the preliminary-ejection execution counter.

Owner:COPYER

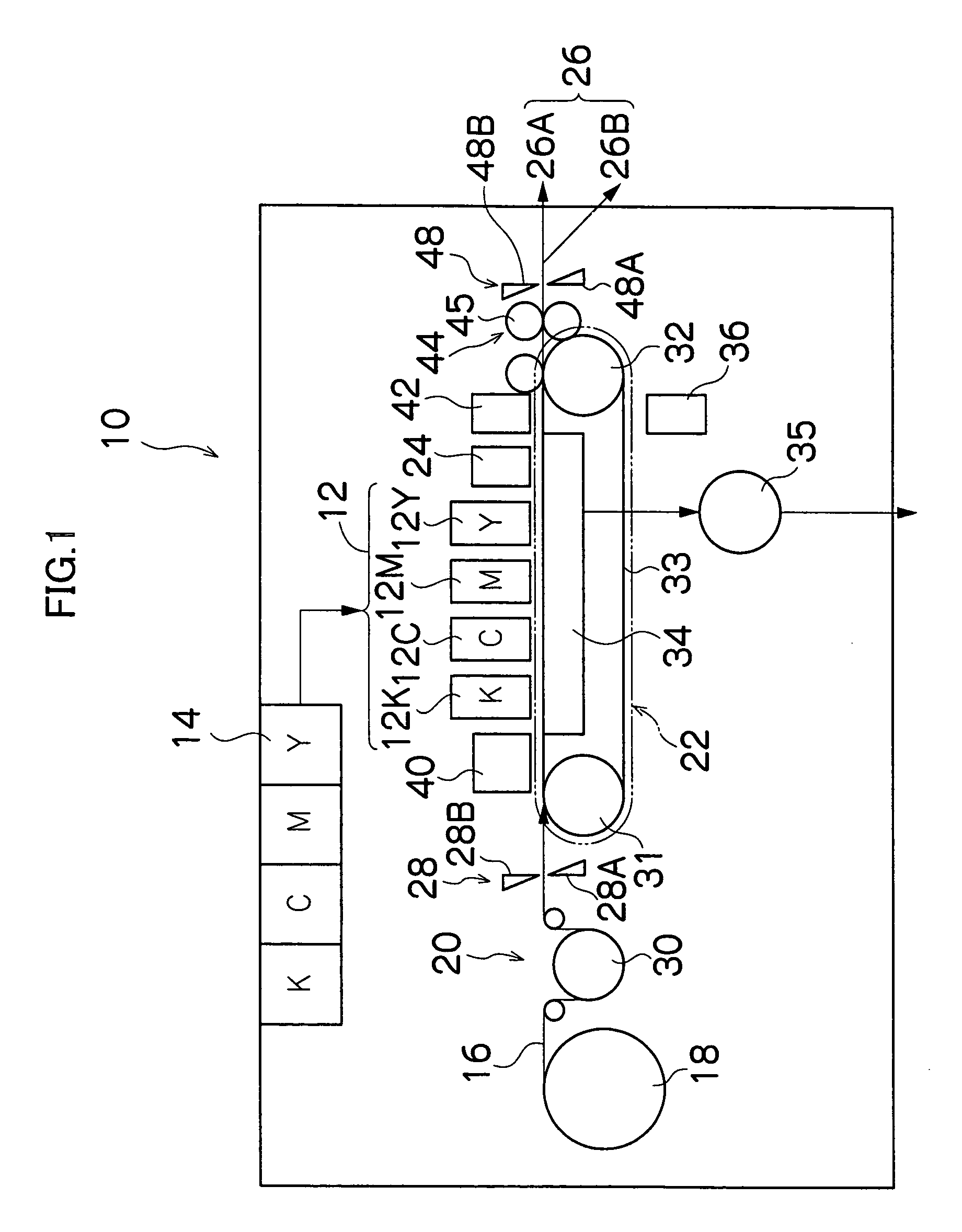

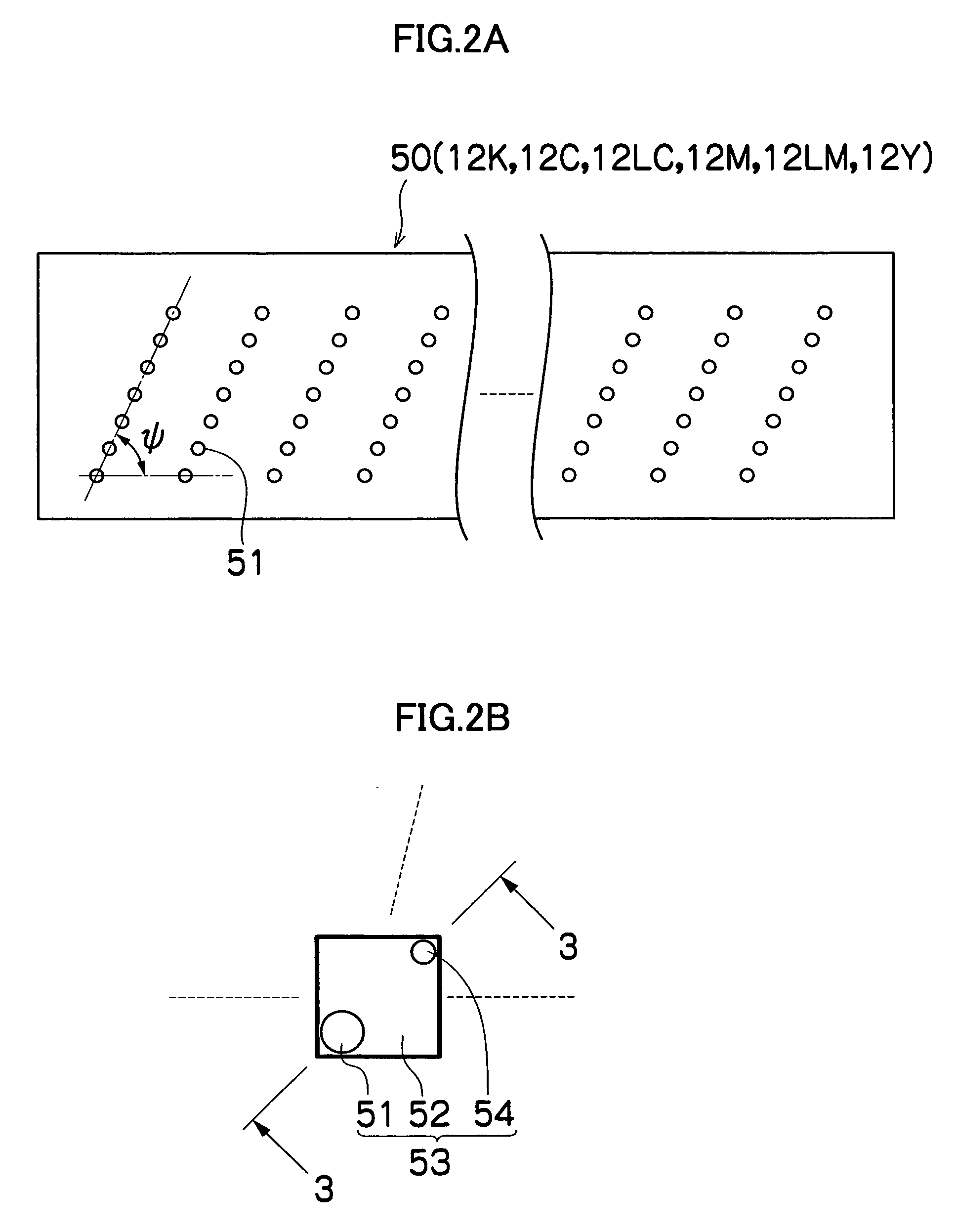

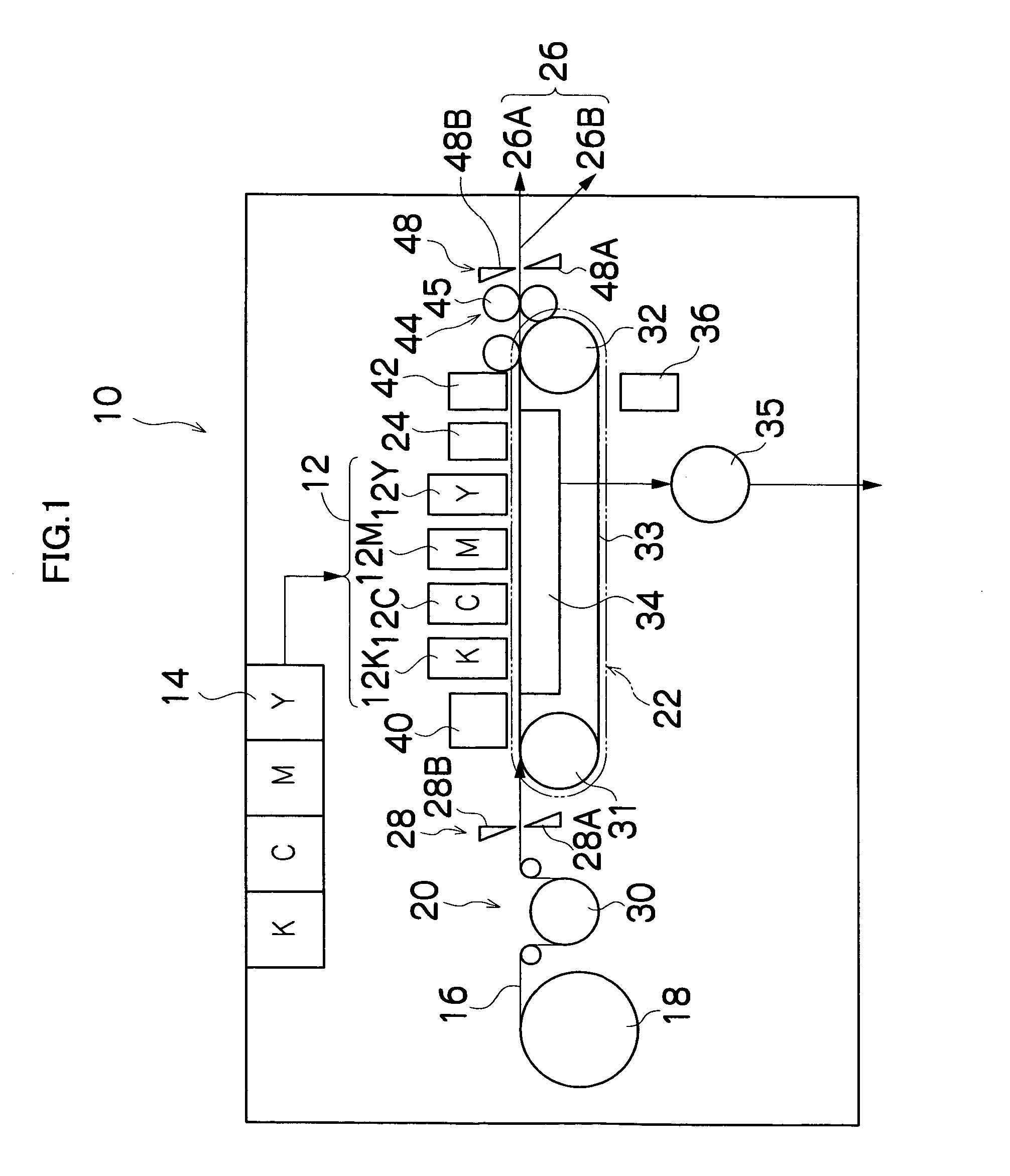

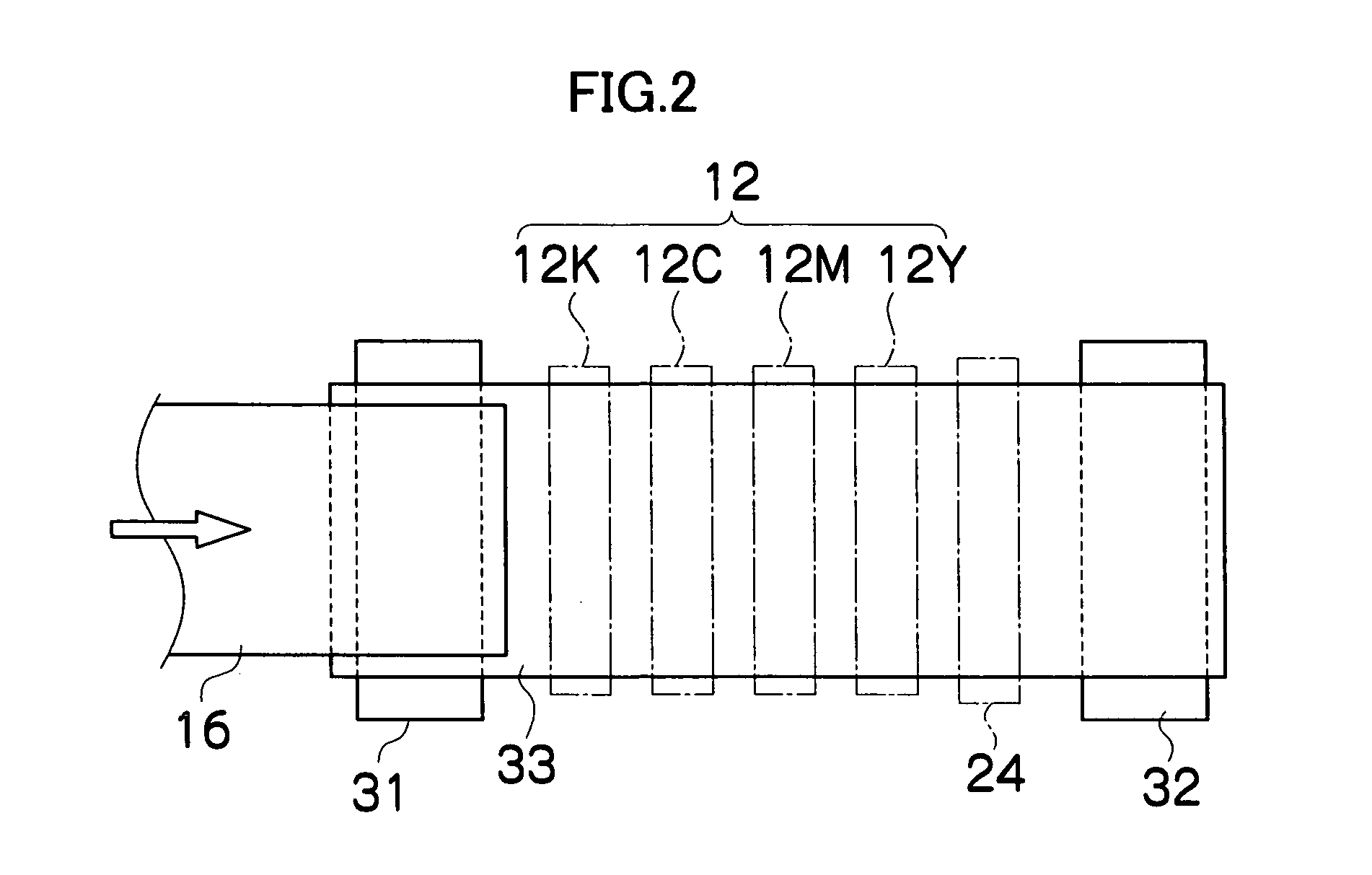

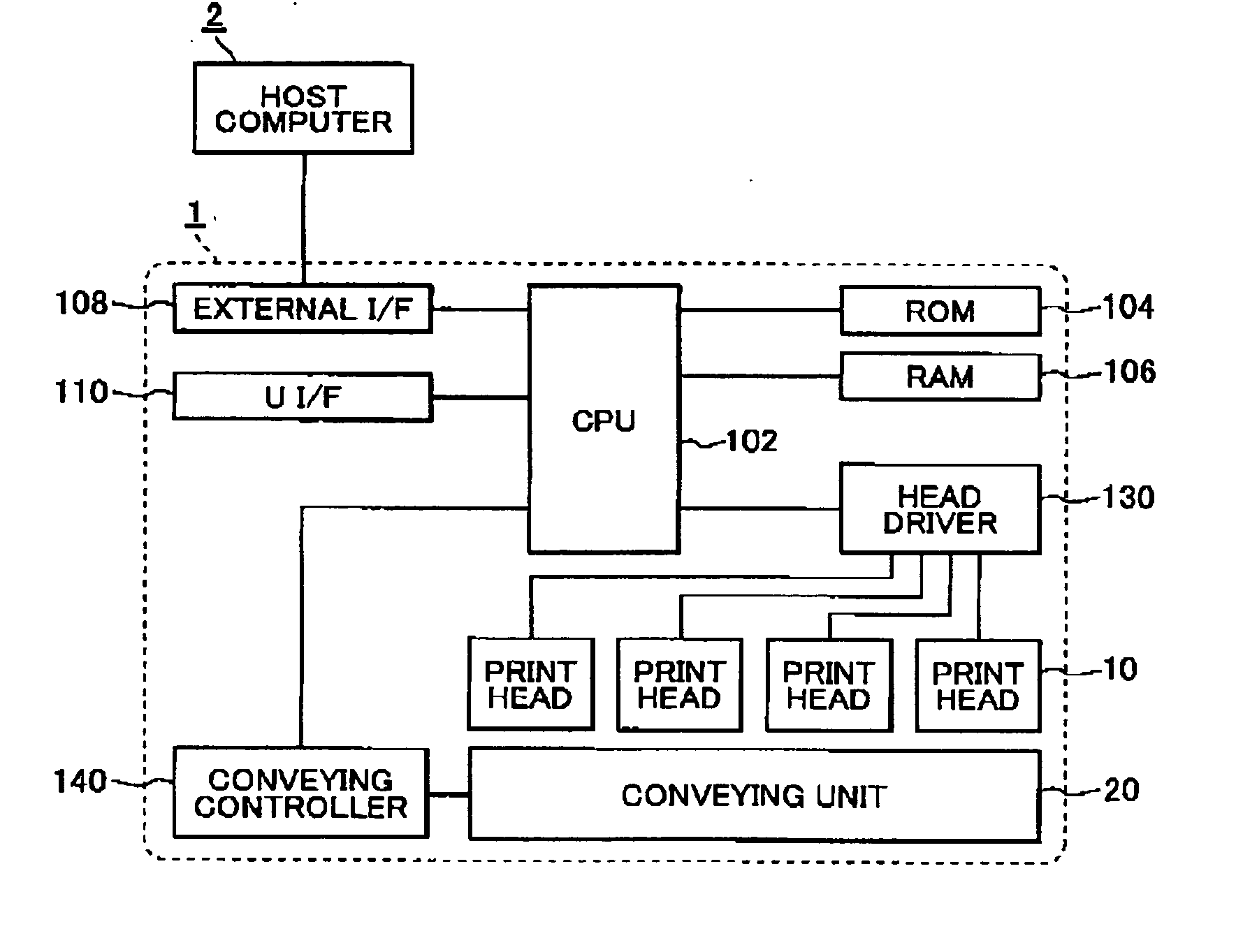

Image forming apparatus and droplet ejection control method

InactiveUS7216947B2Without increasing recording timeAvoid image distortionOther printing apparatusImage formationComputer science

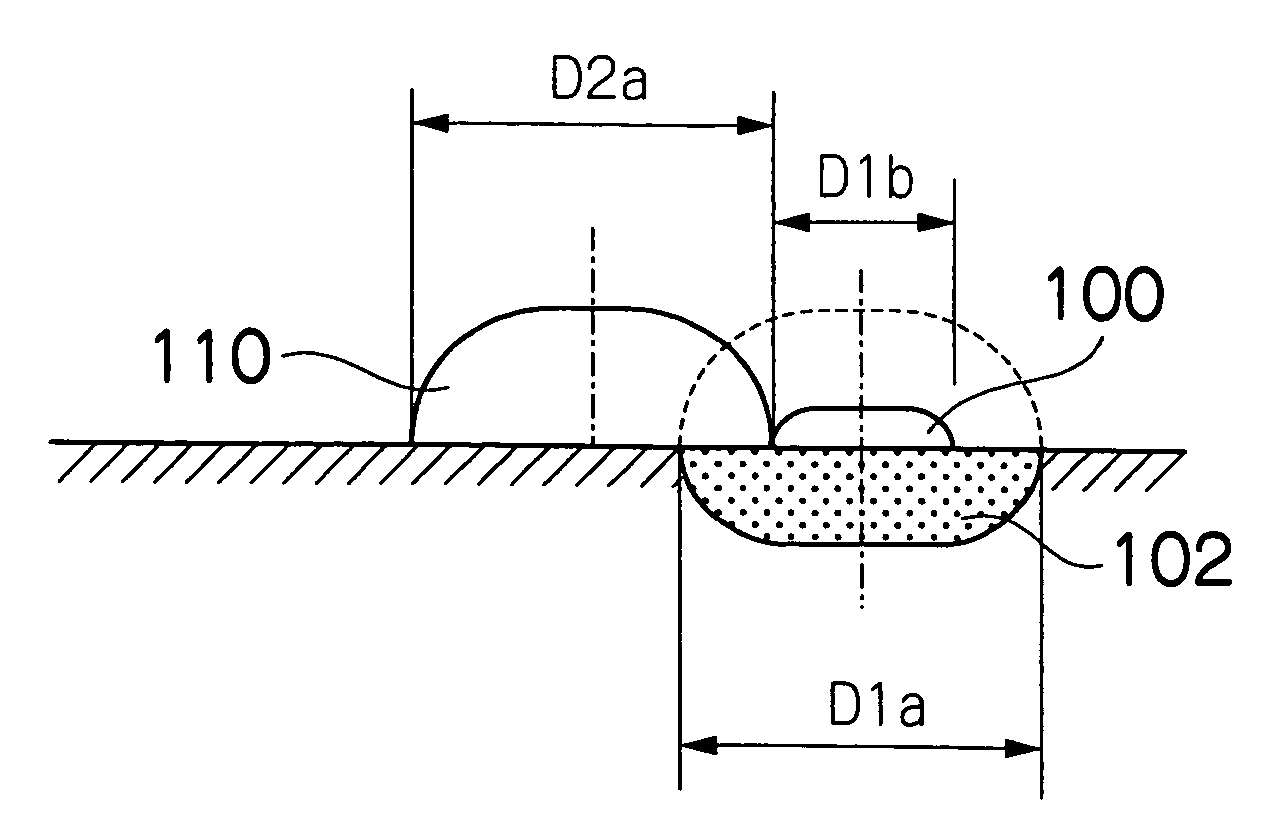

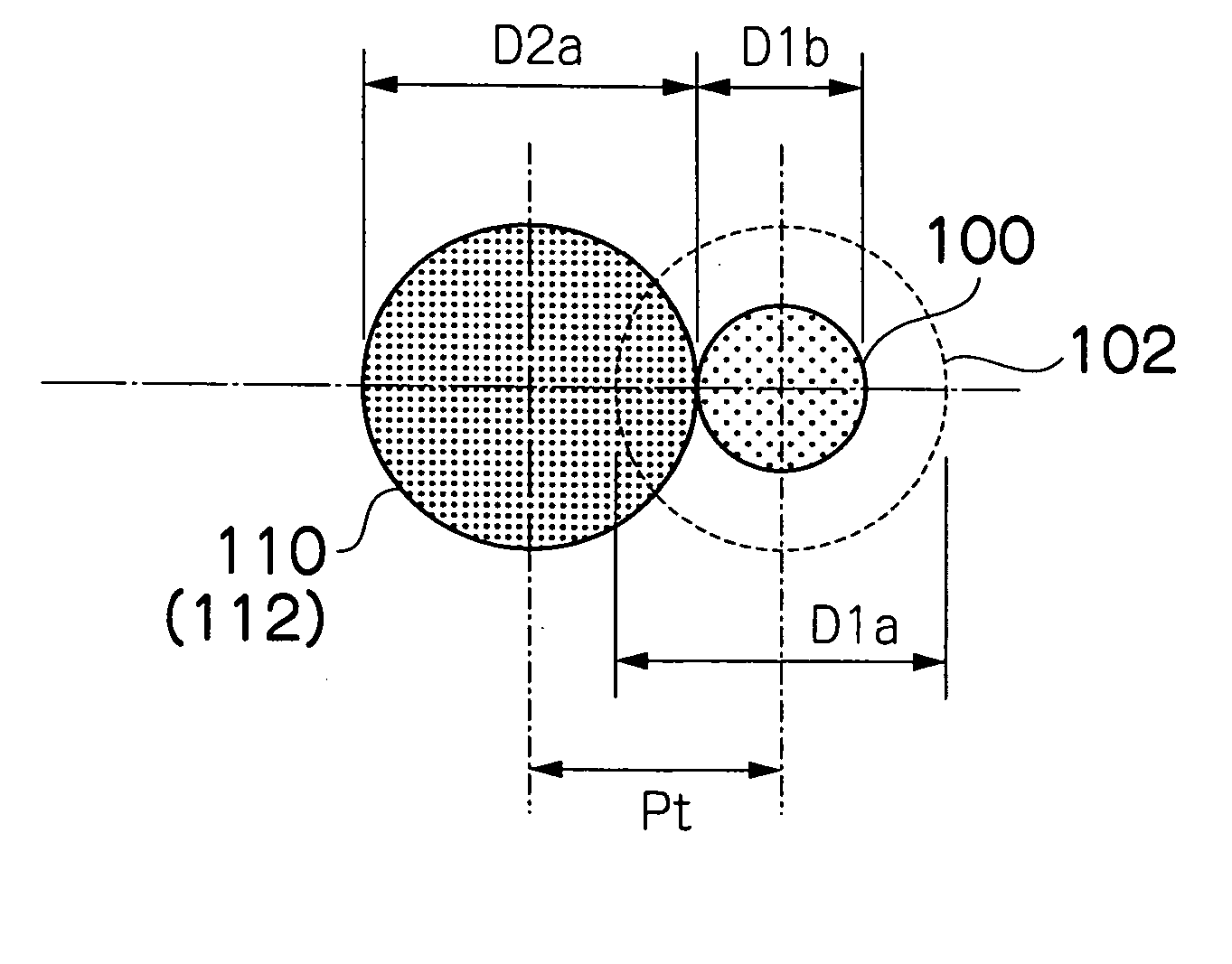

The image forming apparatus comprises: a recording head which ejects droplets of a liquid onto a recording medium; a droplet ejection control device which controls a droplet ejection timing of the recording head; and a conveyance device which relatively moves the recording medium and the recording head in a relative conveyance direction, wherein when the recording head performs ejection of a first droplet to form a first dot on the recording medium and then performs ejection of a second droplet to form a second dot overlapping with the first dot on the recording medium, the droplet ejection control device controls the droplet ejection timing of the recording head by taking a droplet diameter change time until a diameter of the first droplet deposited on a surface of the recording medium reaches D1b satisfying the following inequality as a droplet ejection time interval between the ejection of the first droplet and the ejection of the second droplet: D1b<2×Pt−D2a, where Pt is an interval between the first dot and the second dot on the surface of the recording medium, D2a is a diameter of the second droplet upon landing on the surface of the recording medium, and D1b is the diameter of the first droplet on the surface of the recording medium when the second droplet lands on the surface of the recording medium.

Owner:FUJIFILM CORP

Image forming apparatus and droplet ejection control method

InactiveUS20050062774A1Increase printing speedWithout increasing recording timeOther printing apparatusImage formationComputer science

The image forming apparatus comprises: a recording head which ejects droplets of a liquid onto a recording medium; a droplet ejection control device which controls a droplet ejection timing of the recording head; and a conveyance device which relatively moves the recording medium and the recording head in a relative conveyance direction, wherein when the recording head performs ejection of a first droplet to form a first dot on the recording medium and then performs ejection of a second droplet to form a second dot overlapping with the first dot on the recording medium, the droplet ejection control device controls the droplet ejection timing of the recording head by taking a droplet diameter change time until a diameter of the first droplet deposited on a surface of the recording medium reaches D1b satisfying the following inequality as a droplet ejection time interval between the ejection of the first droplet and the ejection of the second droplet: D1b<2×Pt−D2a, where Pt is an interval between the first dot and the second dot on the surface of the recording medium, D2a is a diameter of the second droplet upon landing on the surface of the recording medium, and D1b is the diameter of the first droplet on the surface of the recording medium when the second droplet lands on the surface of the recording medium.

Owner:FUJIFILM CORP

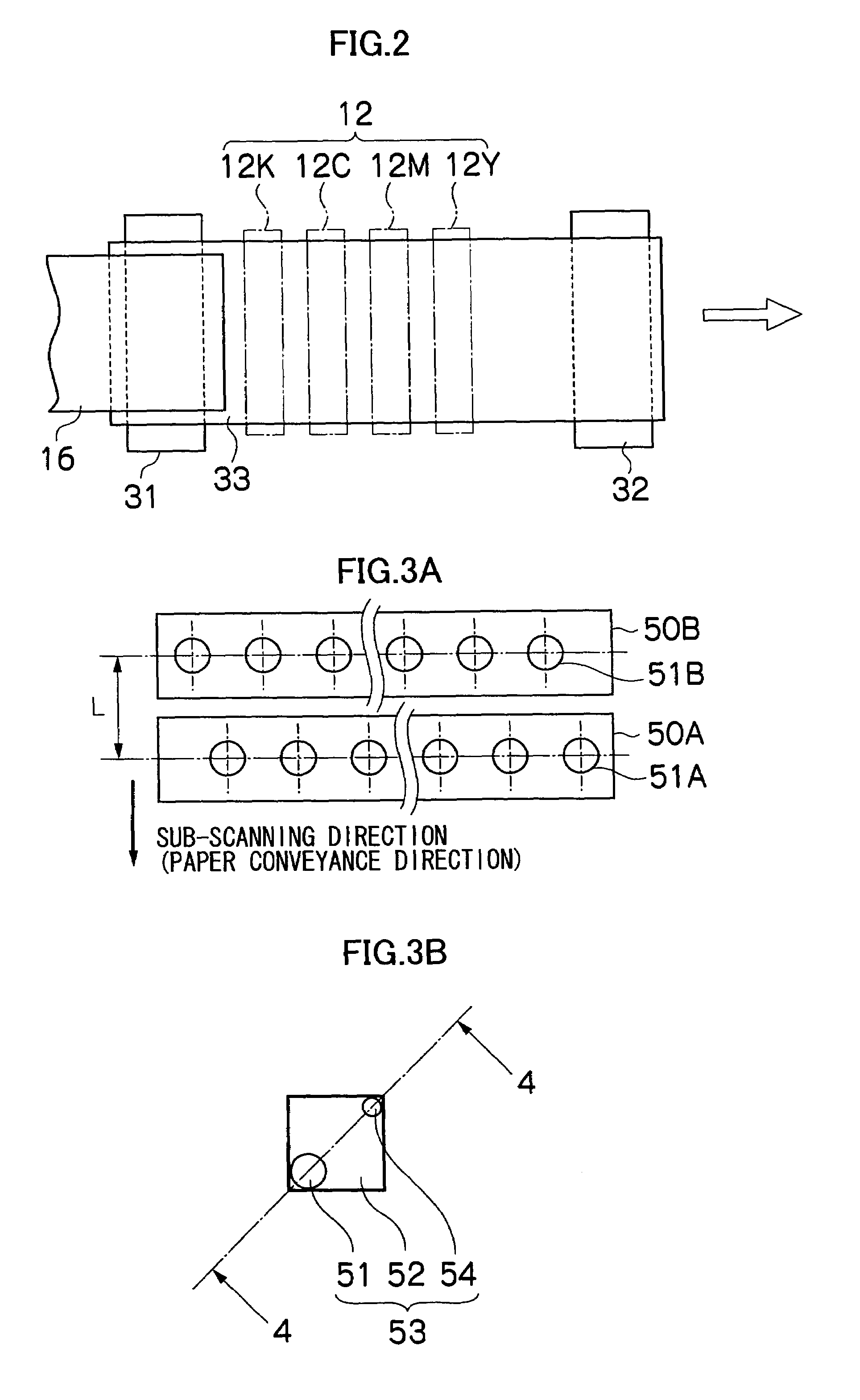

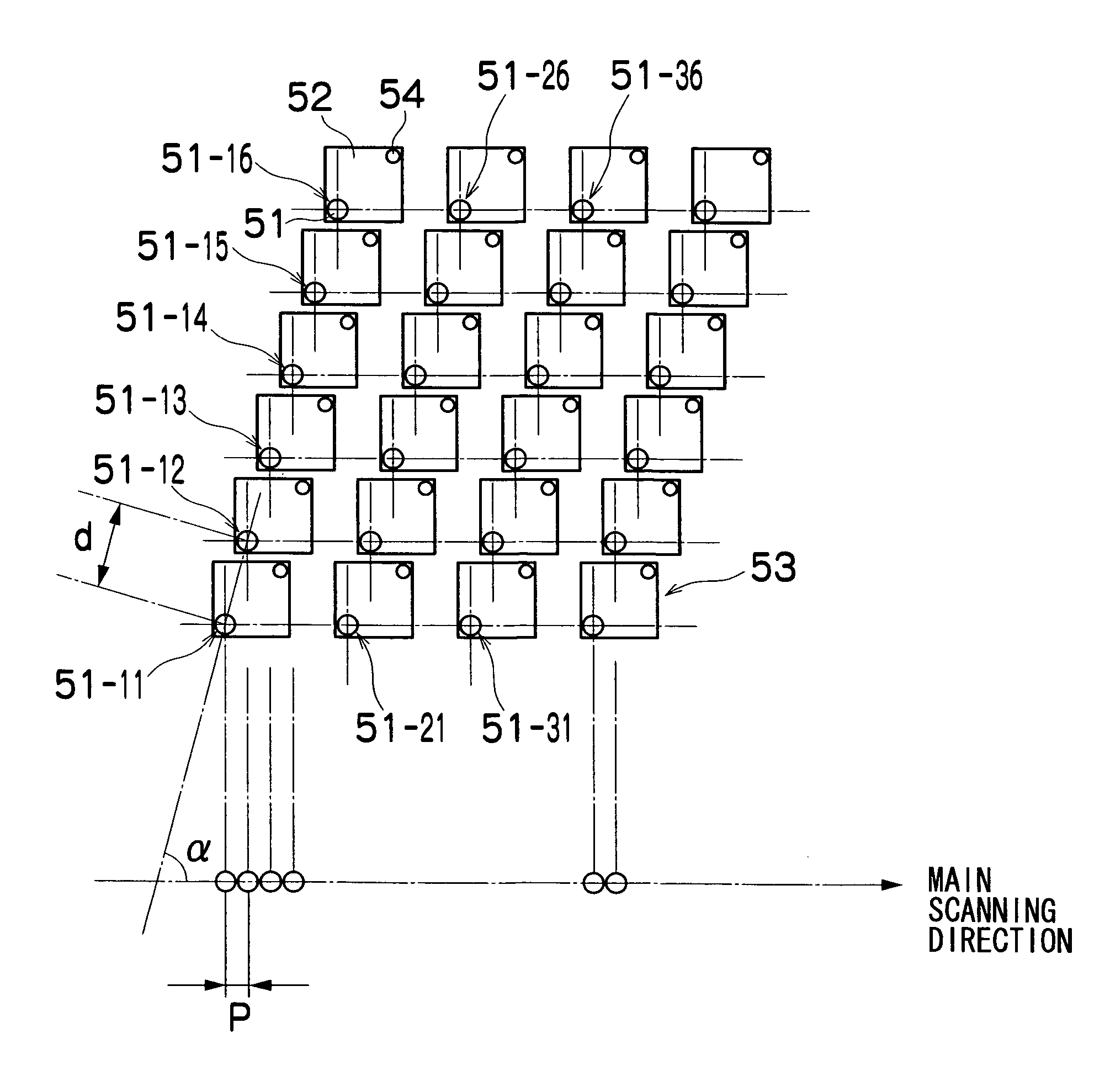

Liquid droplet ejection apparatus and image forming apparatus

InactiveUS20050219287A1Improve visibilityReduce the amplitudeOther printing apparatusEngineeringRelative motion

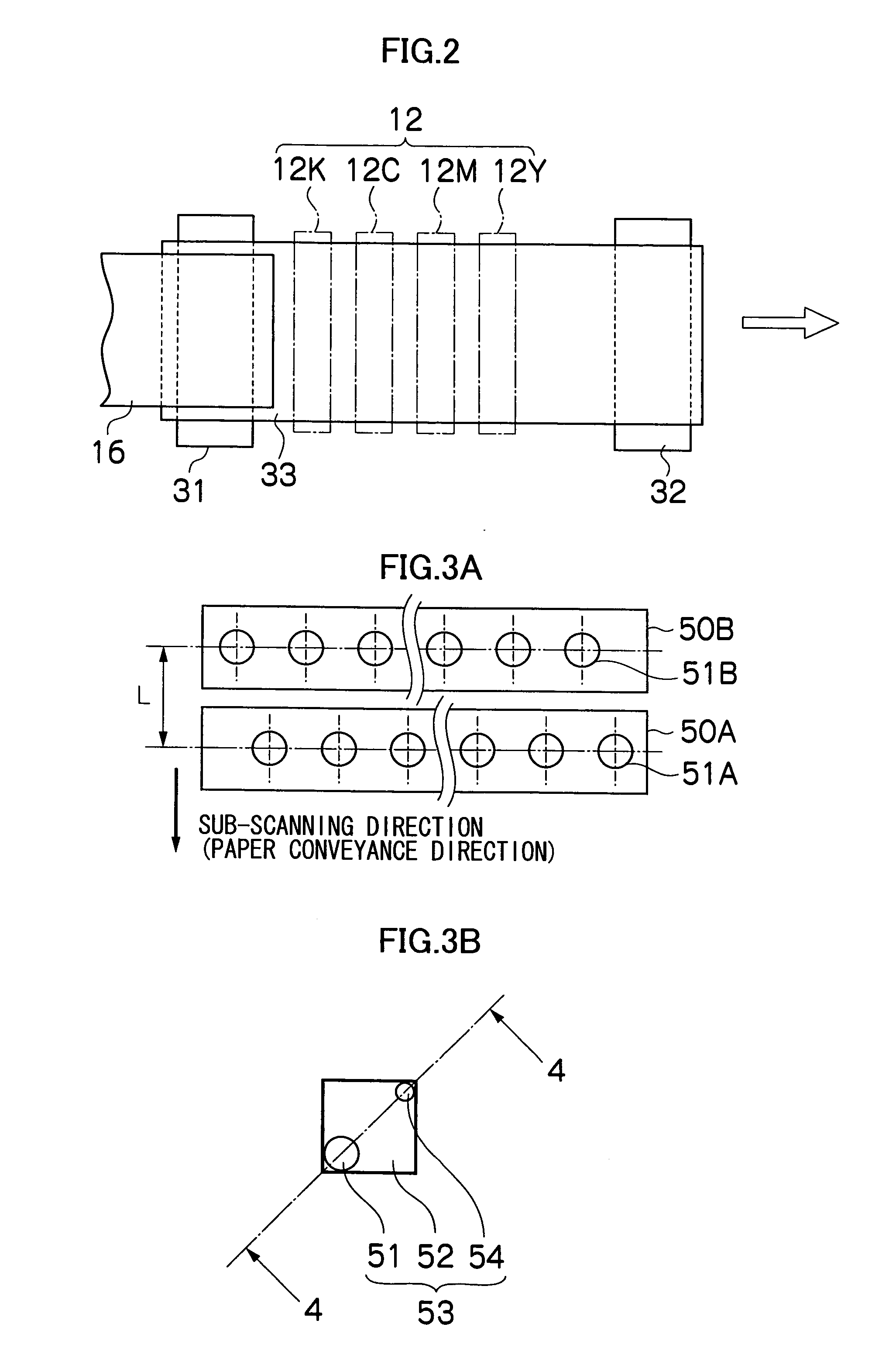

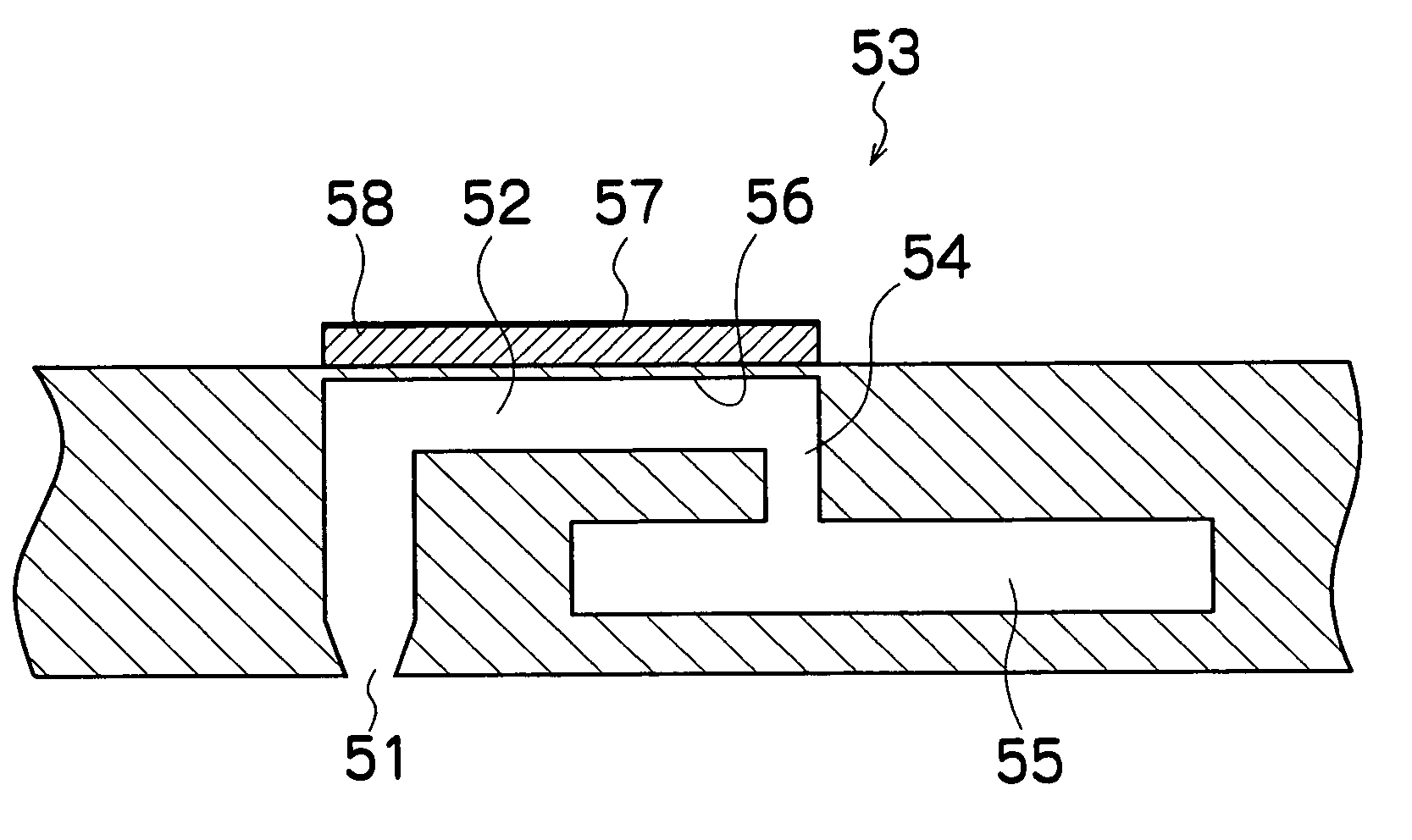

The liquid droplet ejection apparatus comprises: a plurality of ejection heads having an ejection surface in which nozzles for ejecting droplets of liquid towards an ejection receiving medium are arranged two-dimensionally; a conveying device which conveys at least one of the ejection heads and the ejection receiving medium in a fixed direction to cause relative movement of the ejection heads and the ejection receiving medium in a relative movement direction; and a droplet ejection control device which performs droplet ejection control whereby droplets of the liquid are ejected from the ejection heads towards the ejection receiving medium together with the relative movement caused by the conveying device, and a row of dots is formed by the droplets of the liquid landing on the ejection receiving medium in which at least some of the dots overlap in a main scanning direction substantially perpendicular to the relative movement direction, wherein when a position between nozzles at which a droplet ejection time difference between adjacent dots in the main scanning direction in one ejection head differs from a droplet ejection time difference between other adjacent dots is referred to as a specific time difference nozzle pair position in a corresponding ejection head, the ejection head is positioned so that the specific time difference nozzle pair position differs in the main scanning direction between at least two of the ejection heads.

Owner:FUJIFILM CORP

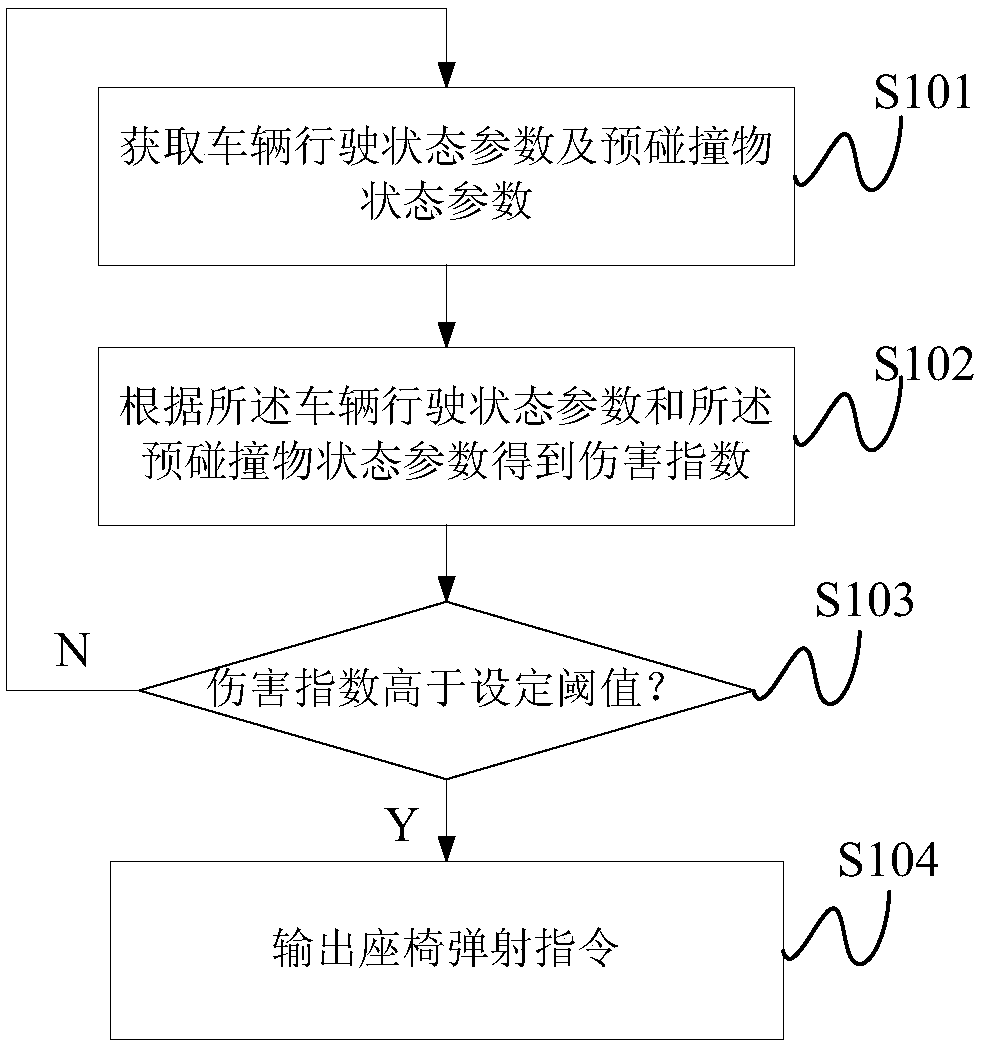

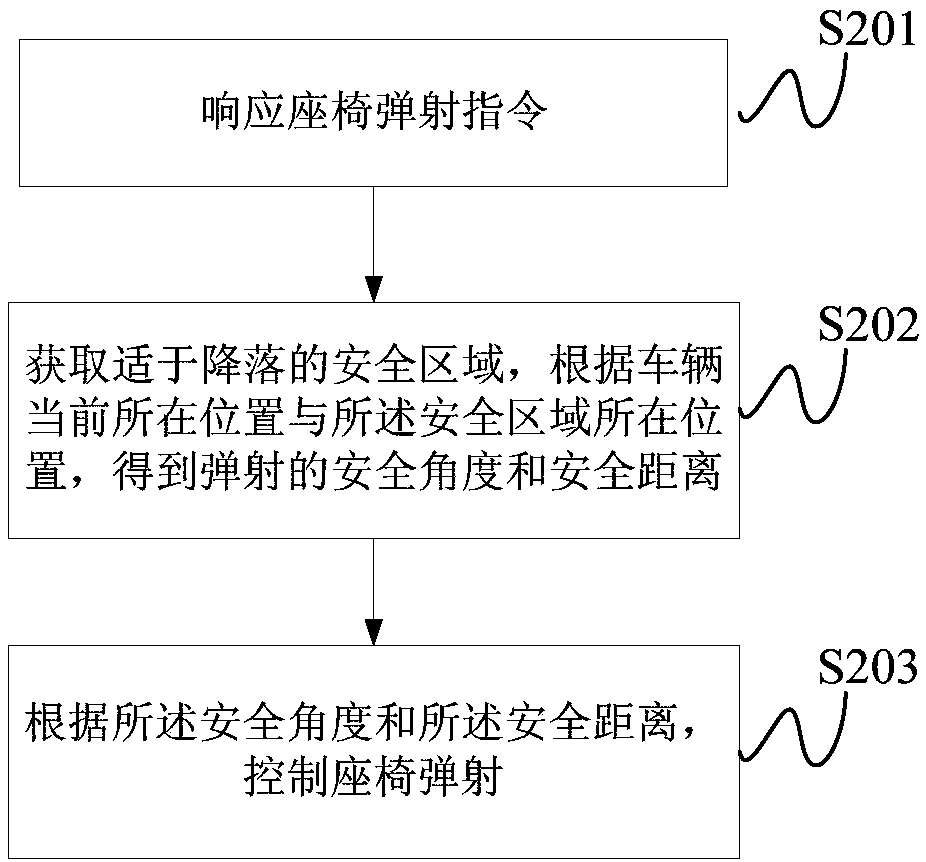

Method for determining seat ejection time and seat ejection control method and system

The invention provides a method for determining seat ejection time and a seat ejection control method and system. According to the method and device for determining the seat ejection time, a damage index can be obtained according to a running state parameter of a vehicle and a pre-collision object state parameter, and when the damage index is higher than a set threshold, a seat ejection instruction is output. In the running process of the vehicle, if the vehicle collides with the pre-collision object, whether it is necessary to execute the seat ejection instruction or not is judged according to the running state parameter of the vehicle and the pre-collision object state parameter, and the two parameters are used as pre-damage information for judgment so as to obtain the damage index, seatejection is started only when the damage index reaches a certain degree, and larger damage caused by ejection is avoided.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

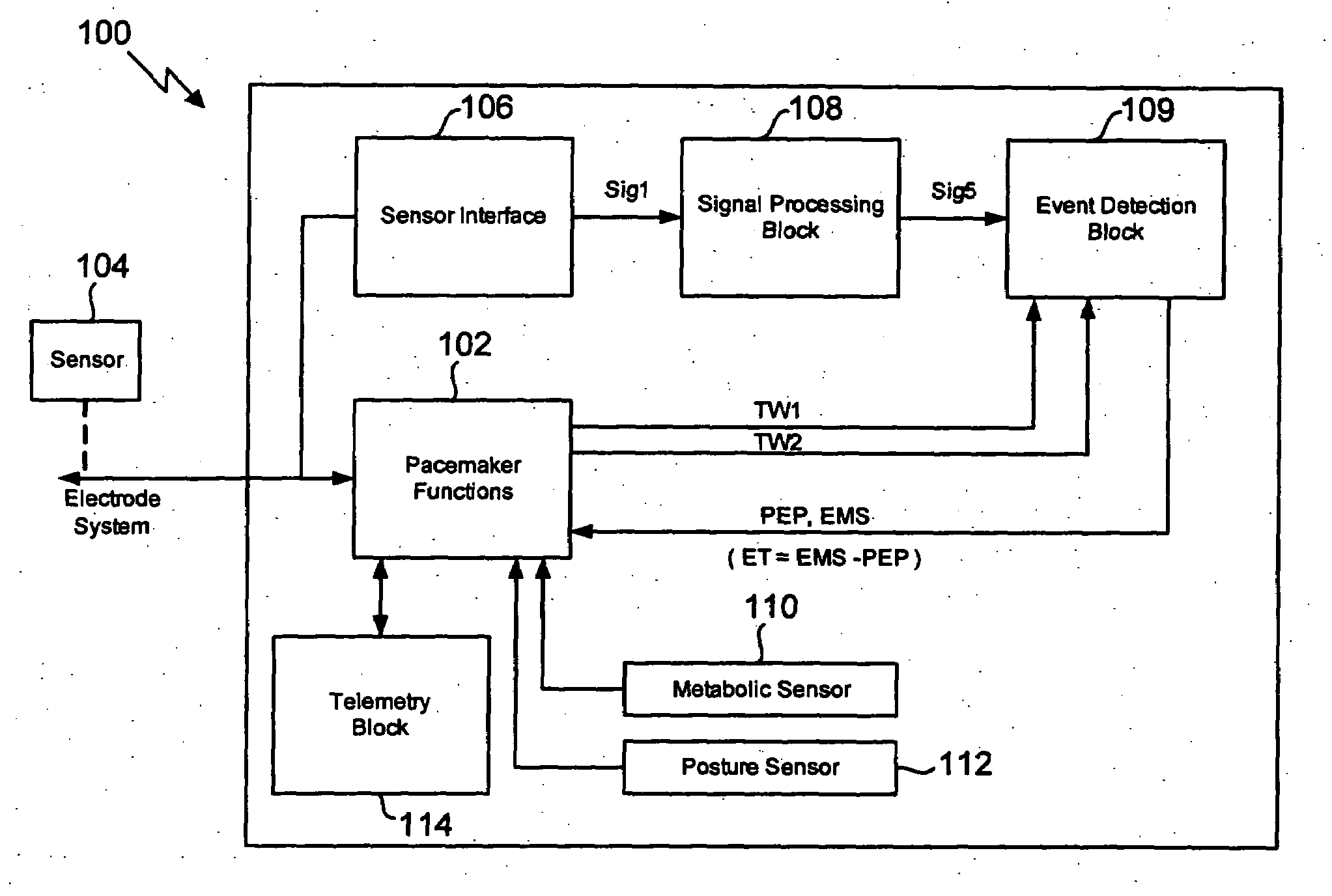

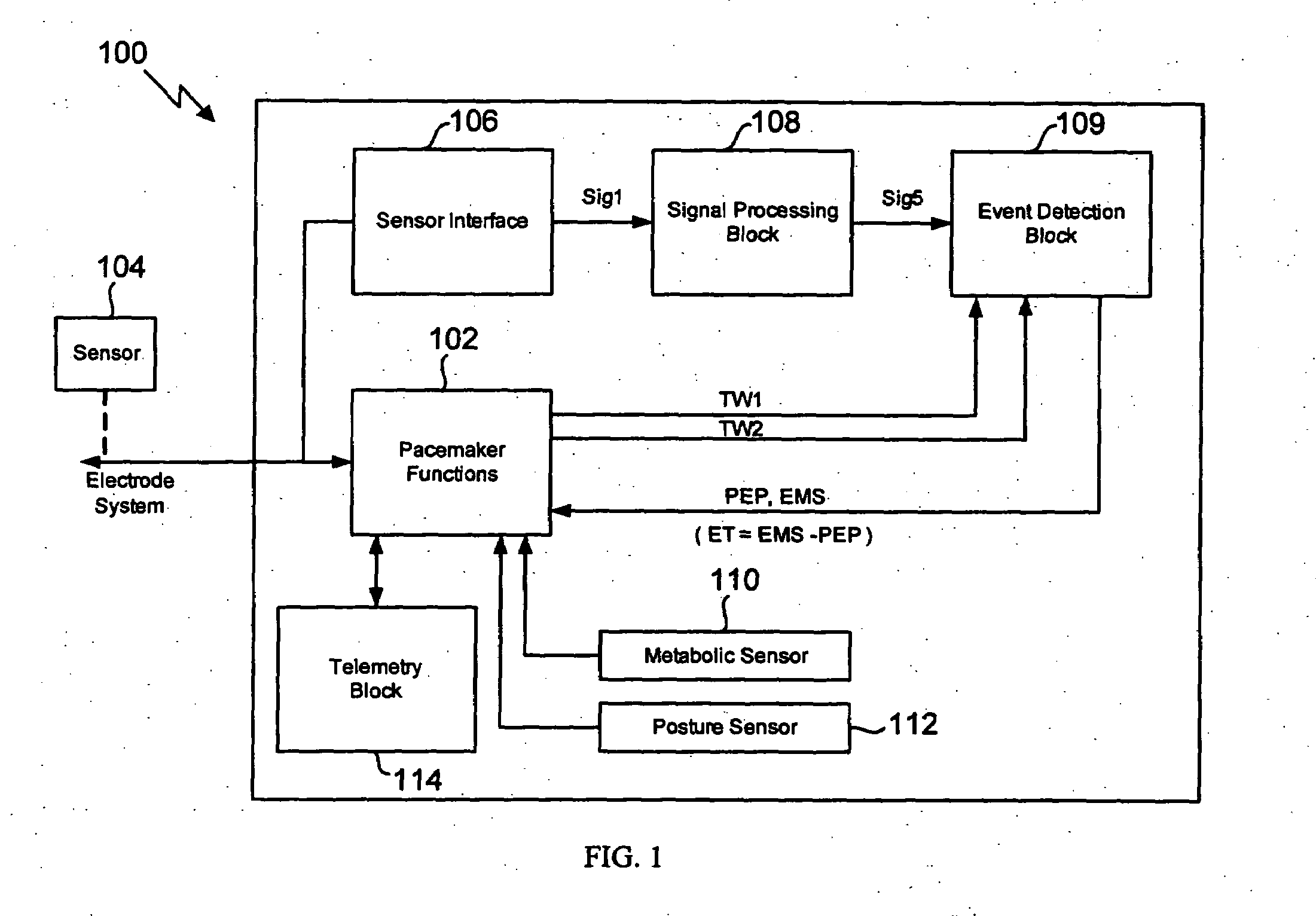

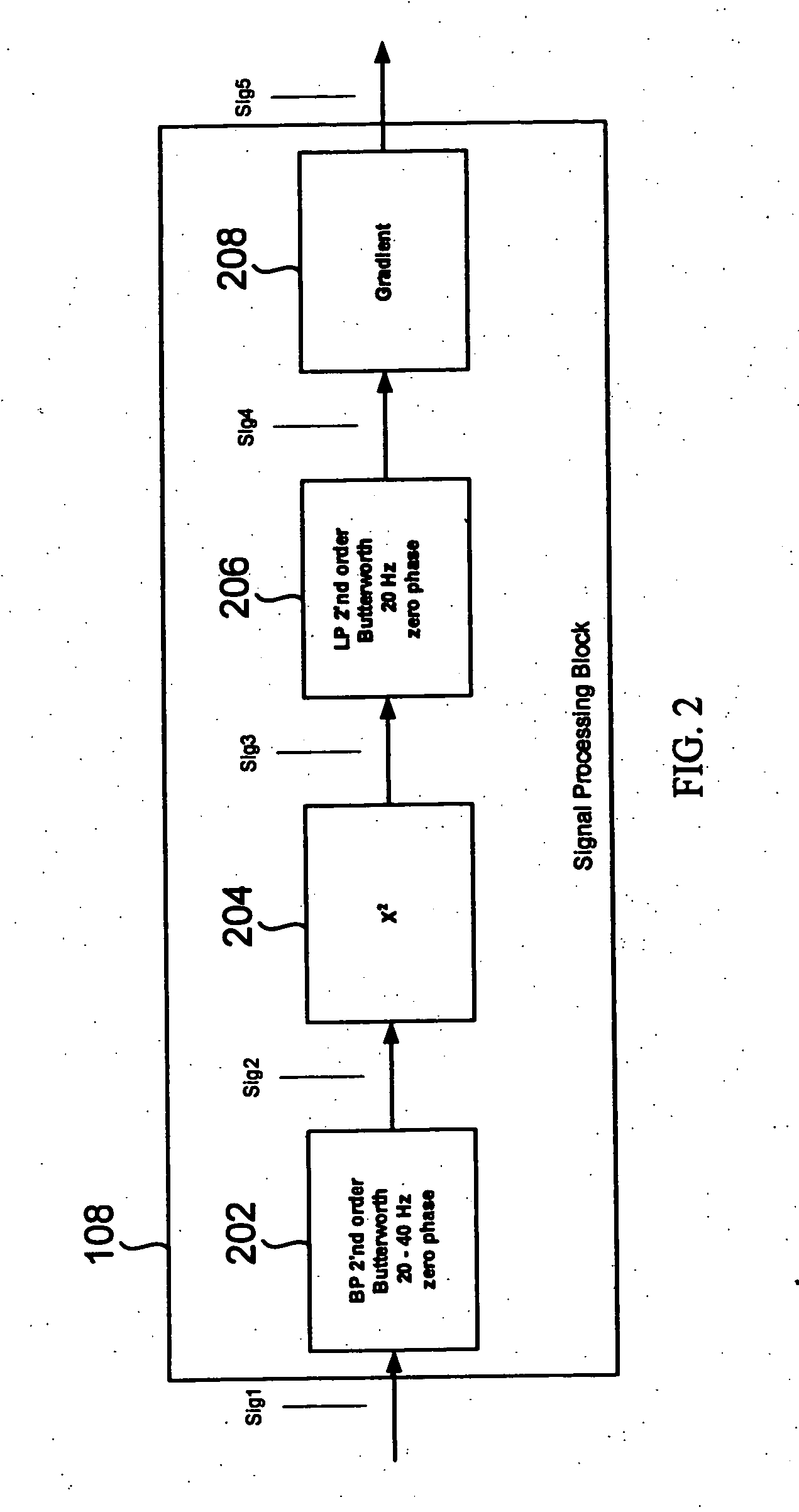

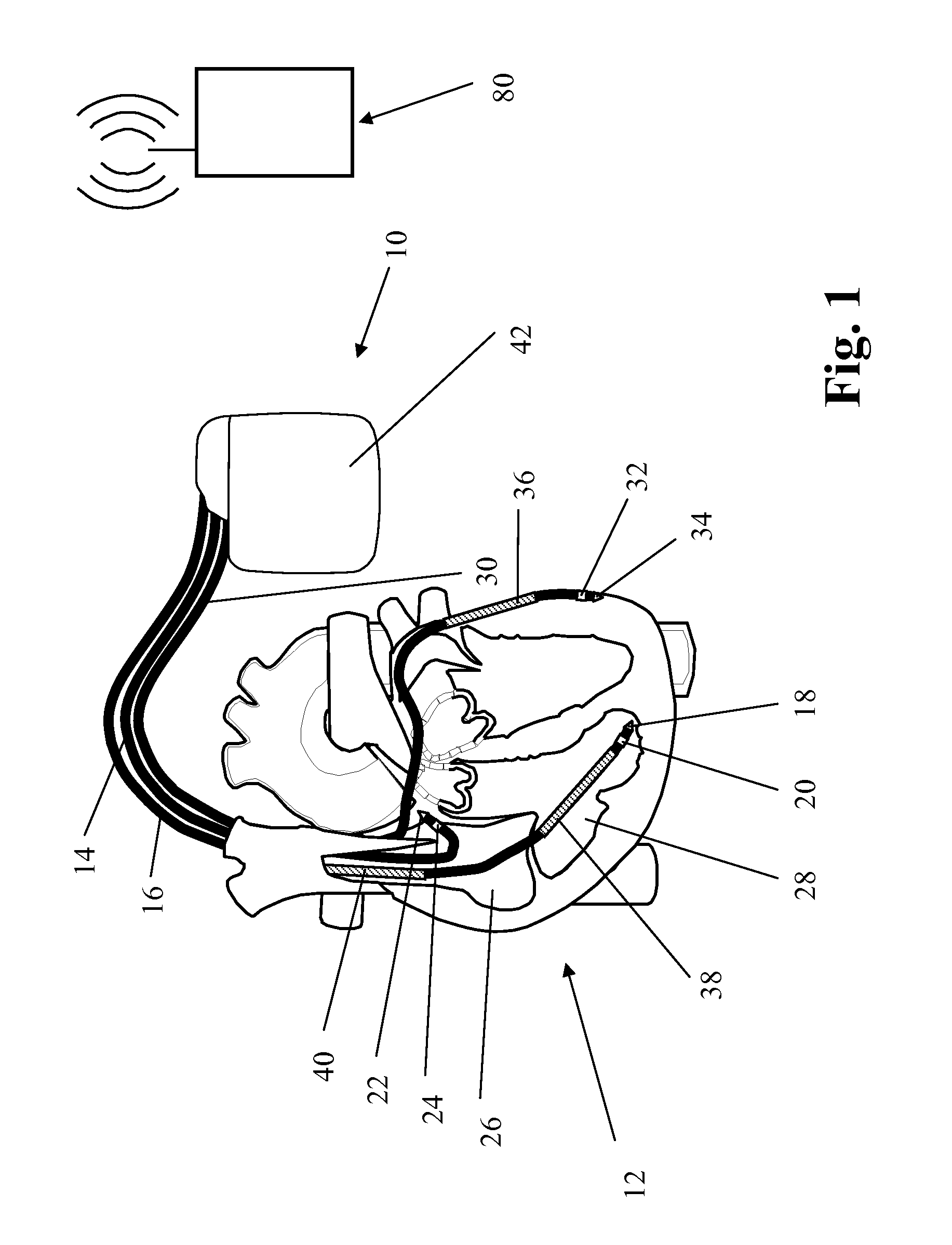

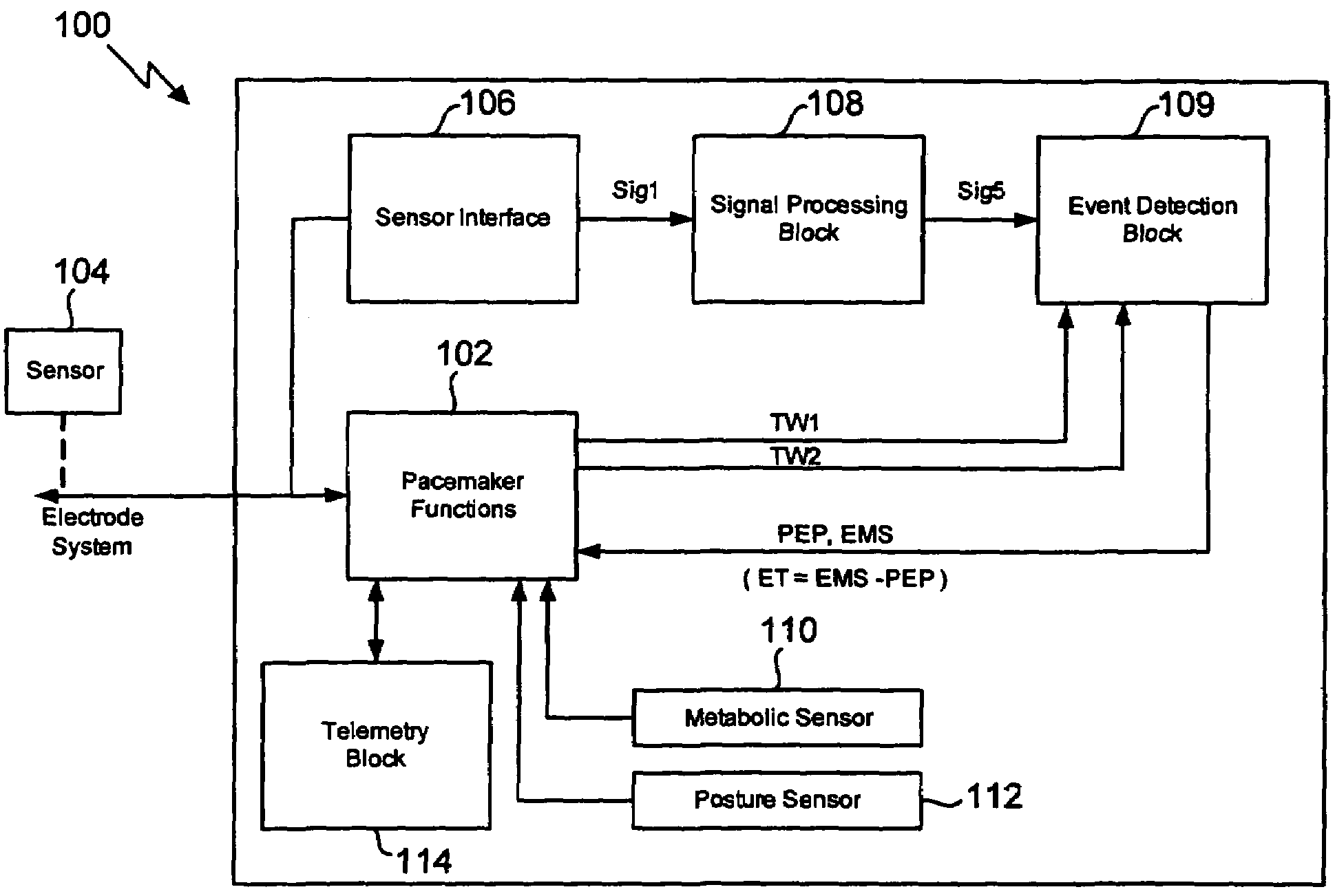

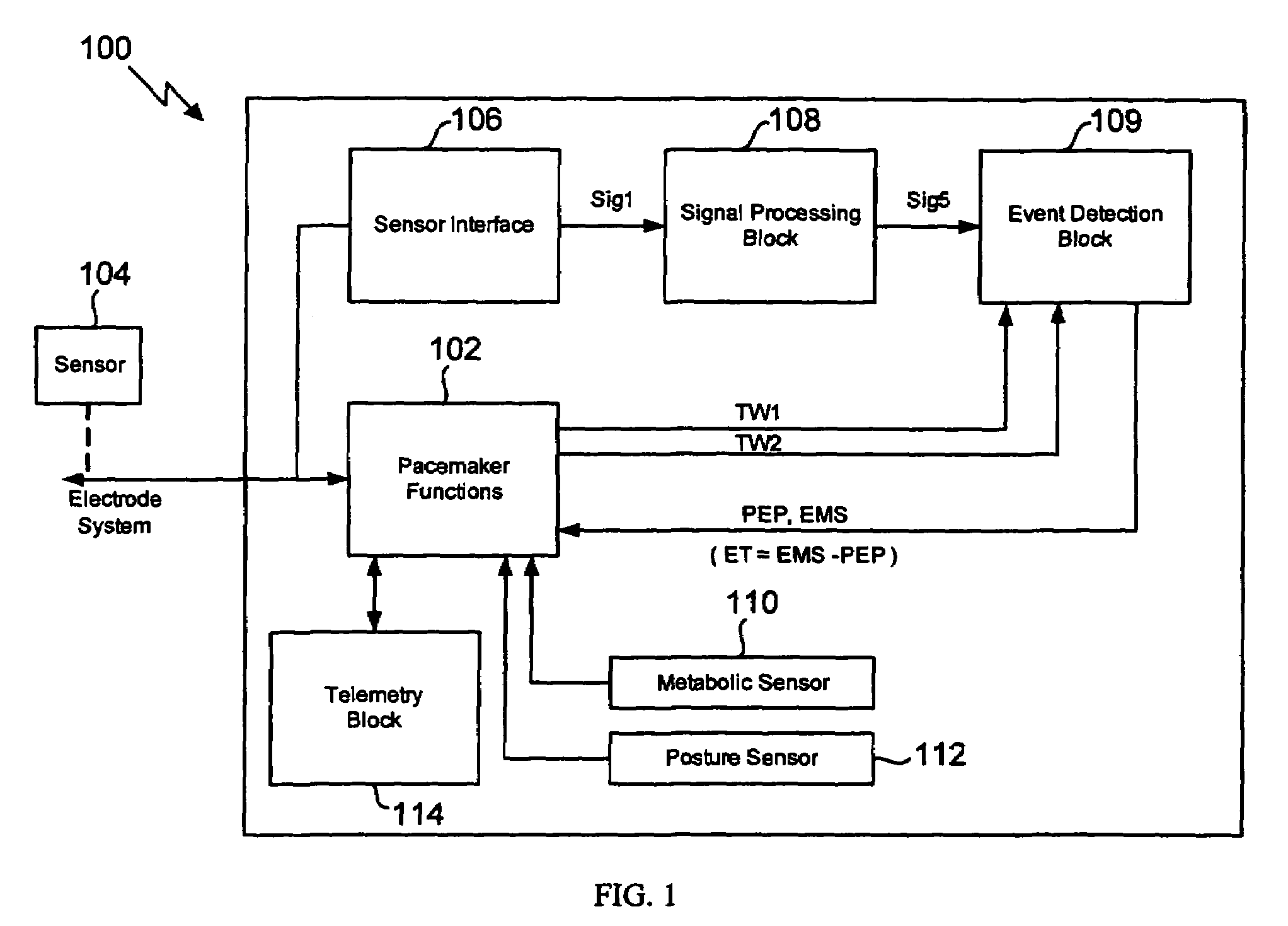

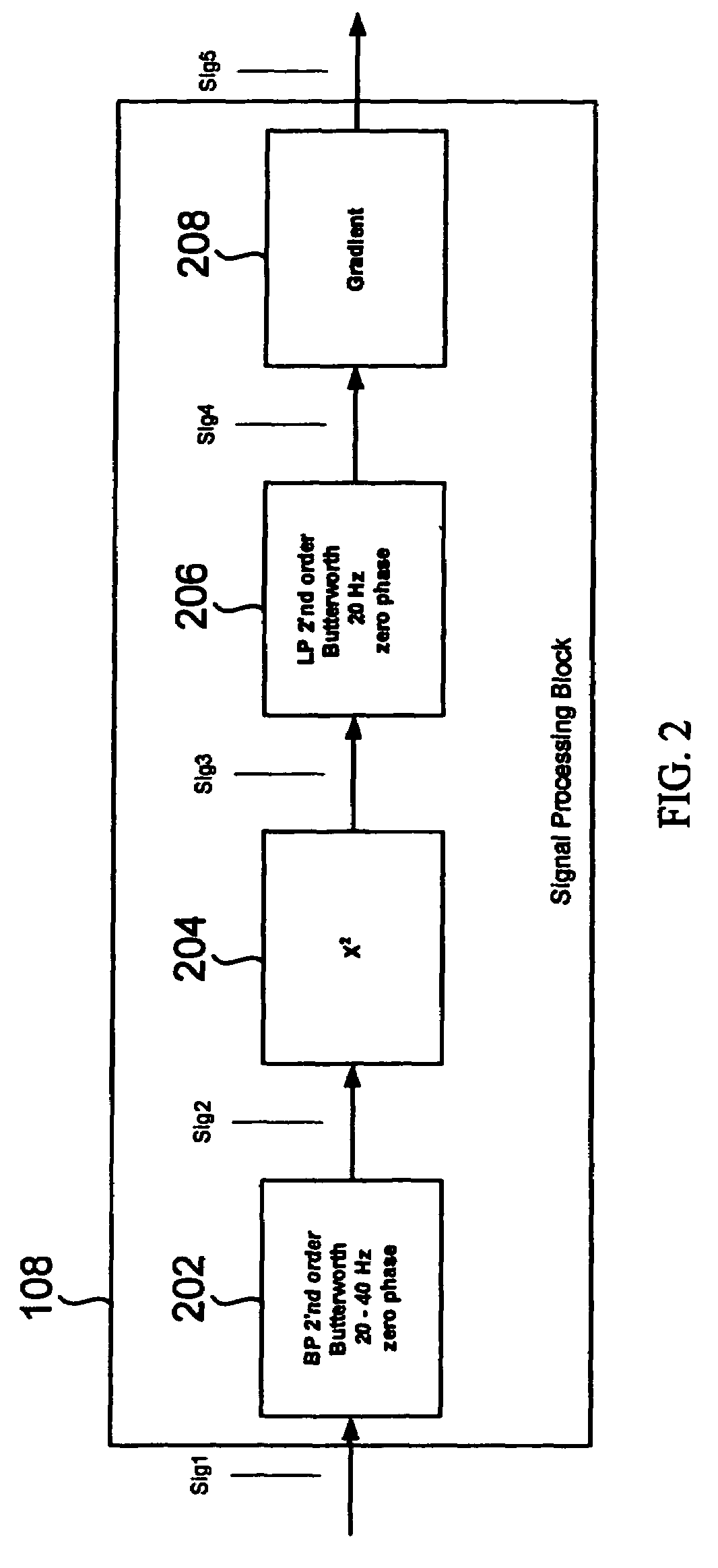

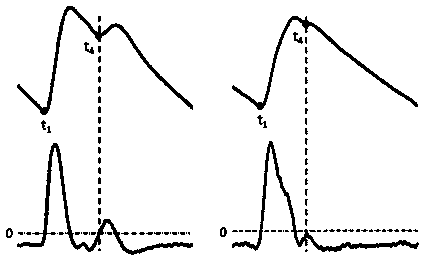

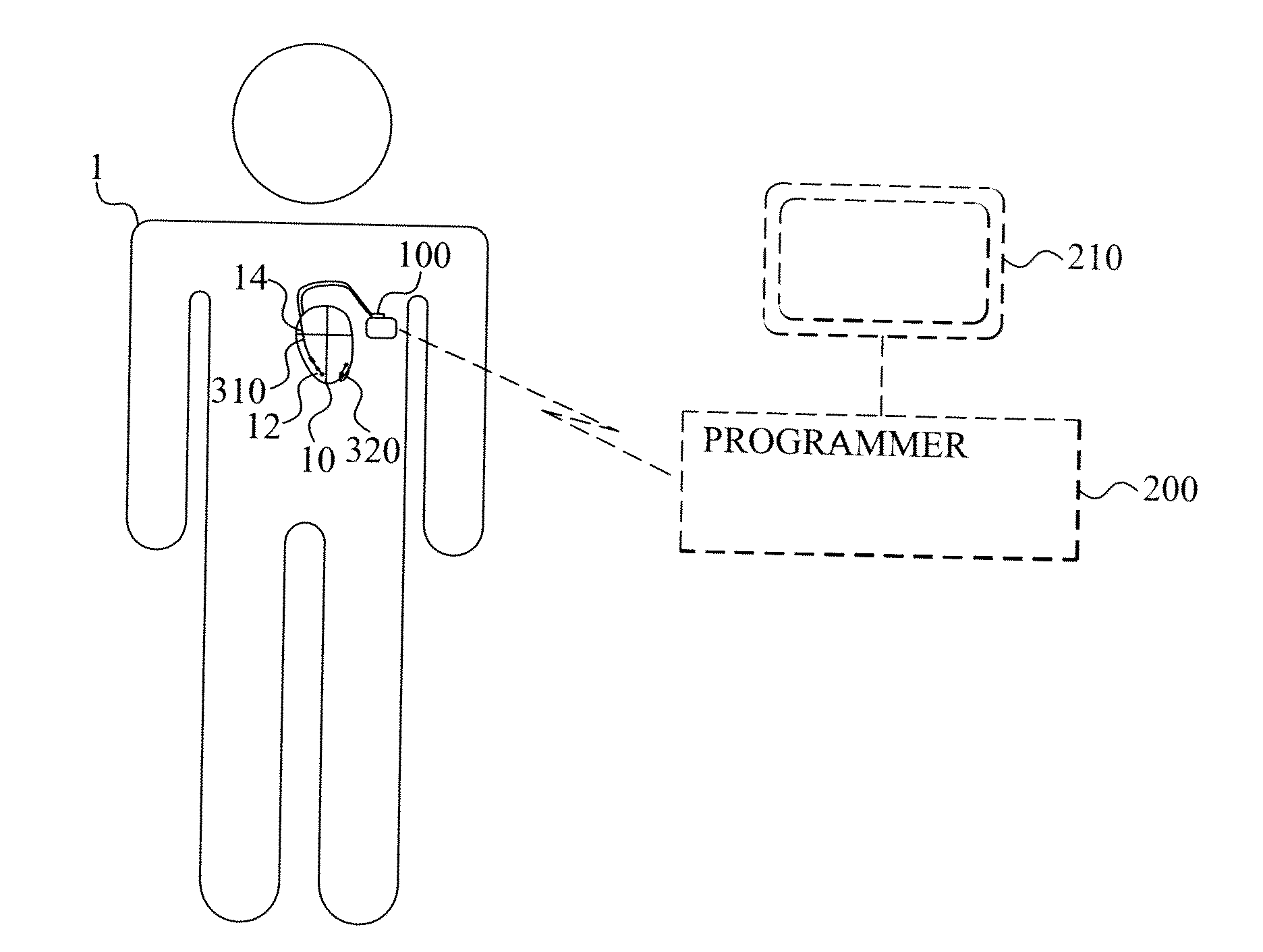

Method for extracting timing parameters using a cardio-mechanical sensor

In a method and apparatus for measuring the ejection fraction in a mammalian heart, the opening and closing of a heart valve is sensed with an implanted sensor, and a pre-ejection period is measured as a function of the sensed opening and closing of the heart valve. The ventricular ejection time also is measured, and the ejection fraction is determined as a function of the measured pre-ejection period and the ejection time.

Owner:ST JUDE MEDICAL

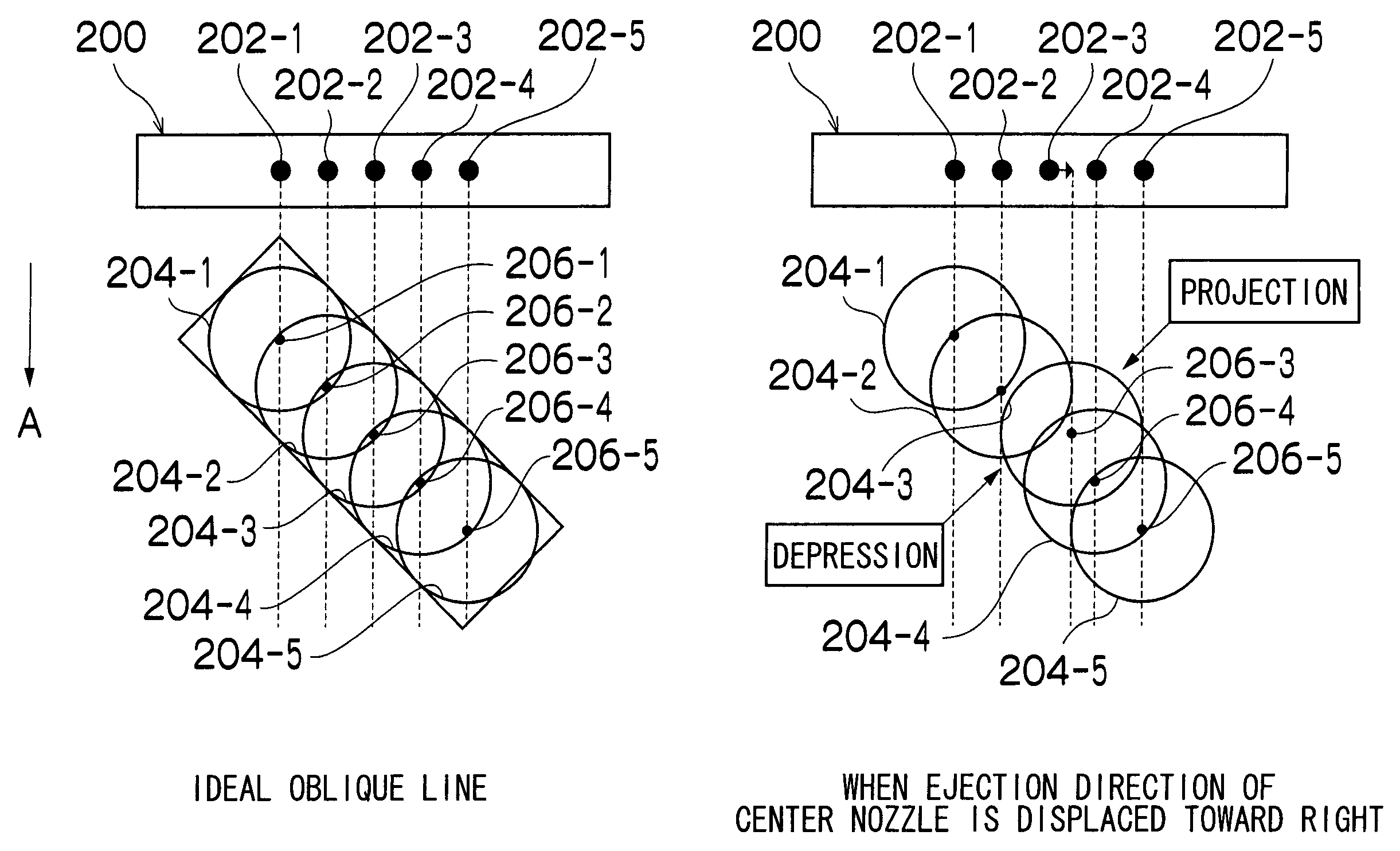

Image forming apparatus and method

InactiveUS20060066646A1Deterioration in line qualityPrecise positioningOther printing apparatusImage formationRelative motion

The image forming apparatus comprises: a recording head which includes a plurality of nozzles through which droplets of liquid are ejected to and deposited on a recording medium to form dots on the recording medium, the nozzles being arranged in a nozzle row; a conveyance device which causes the recording head and the recording medium to move relatively to each other by conveying at least one of the recording head and the recording medium in a relative movement direction; a storage device which, of information indicating an amount of deposition position displacement from an ideal deposition position of the dots formed by the droplets ejected from the nozzles, stores information about the amount of deposition position displacement in at least a direction perpendicular to the relative movement direction of the conveyance device; a line figure recognition processing device which carries out processing for recognizing line figures from image data for printing; an ideal line identification device which determines an ideal line obtained by linking centers of the respective dots formed when printing a line figure, assuming that there is absolutely no deposition position displacement produced by any of the nozzles, in respect of the line figure recognized by the line figure recognition processing device; and an ejection timing control device which, when printing a line figure, controls ejection timing of a defective nozzle which produces deposition position displacement in a direction perpendicular to the relative movement direction, according to the information about the amount of deposition position displacement stored in the storage device and the ideal line determined by the ideal line identification device, in such a manner that a deposition center position of a dot formed by a droplet ejected from the defective nozzle moves closer to the ideal line, along the relative movement direction.

Owner:FUJIFILM CORP

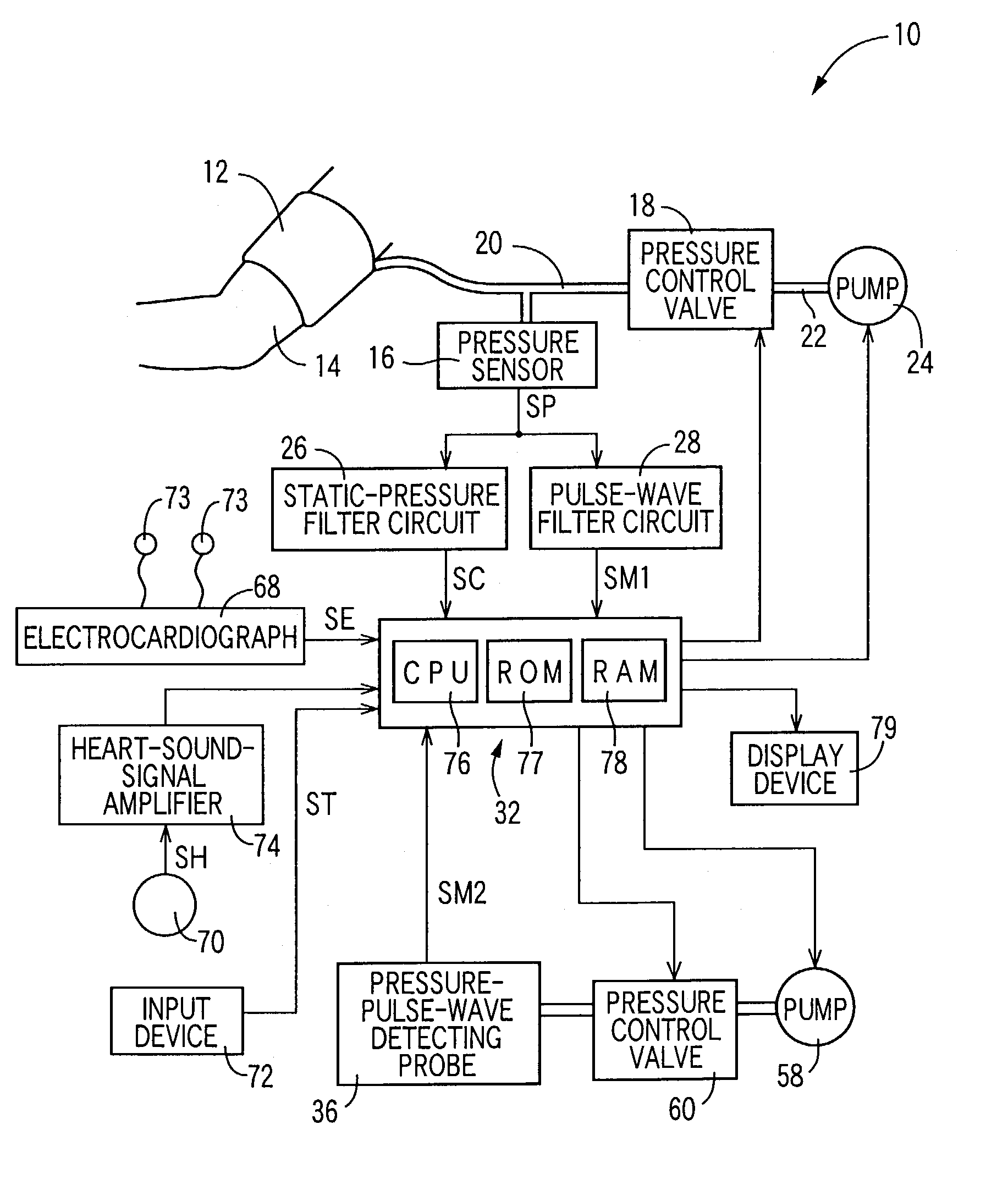

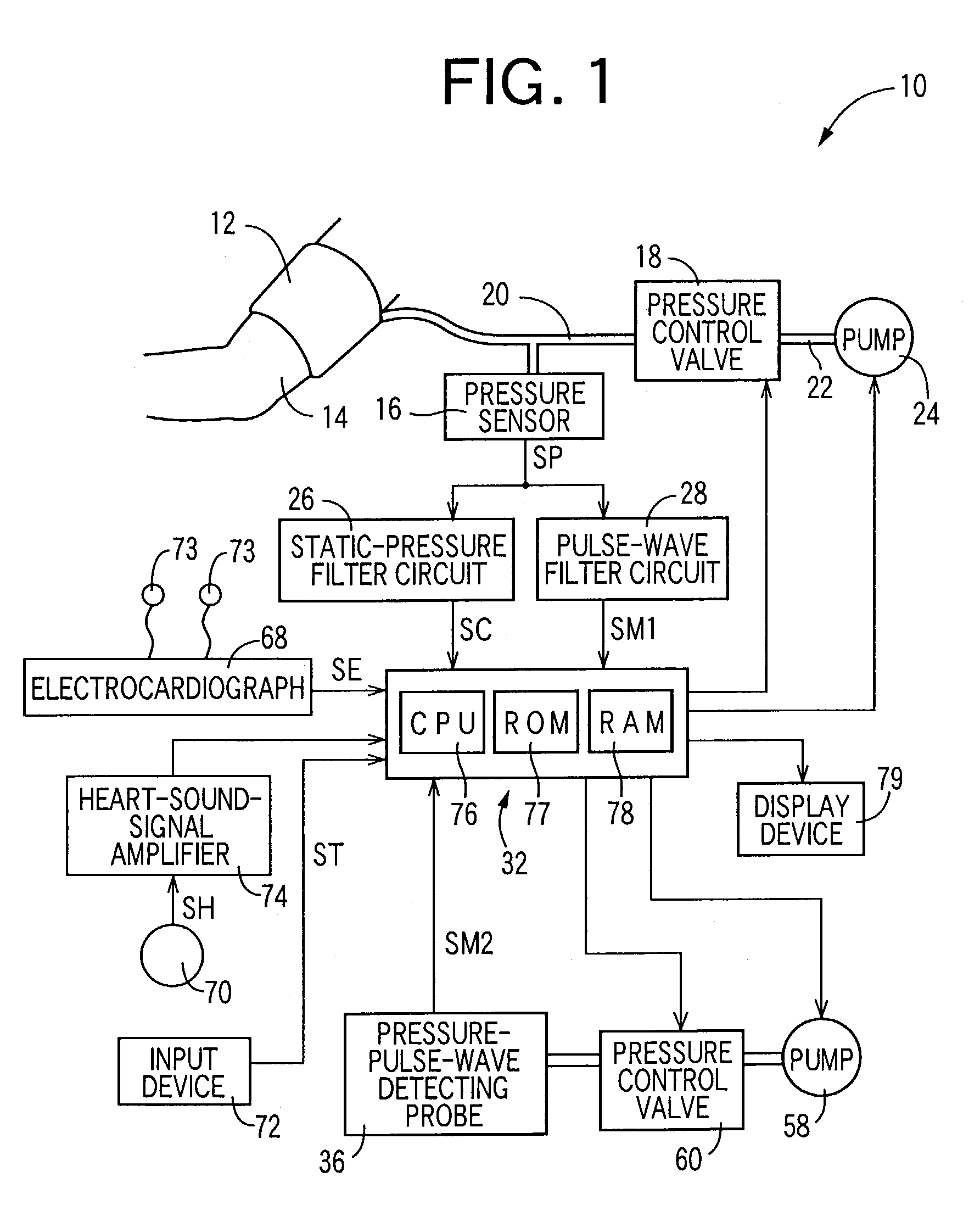

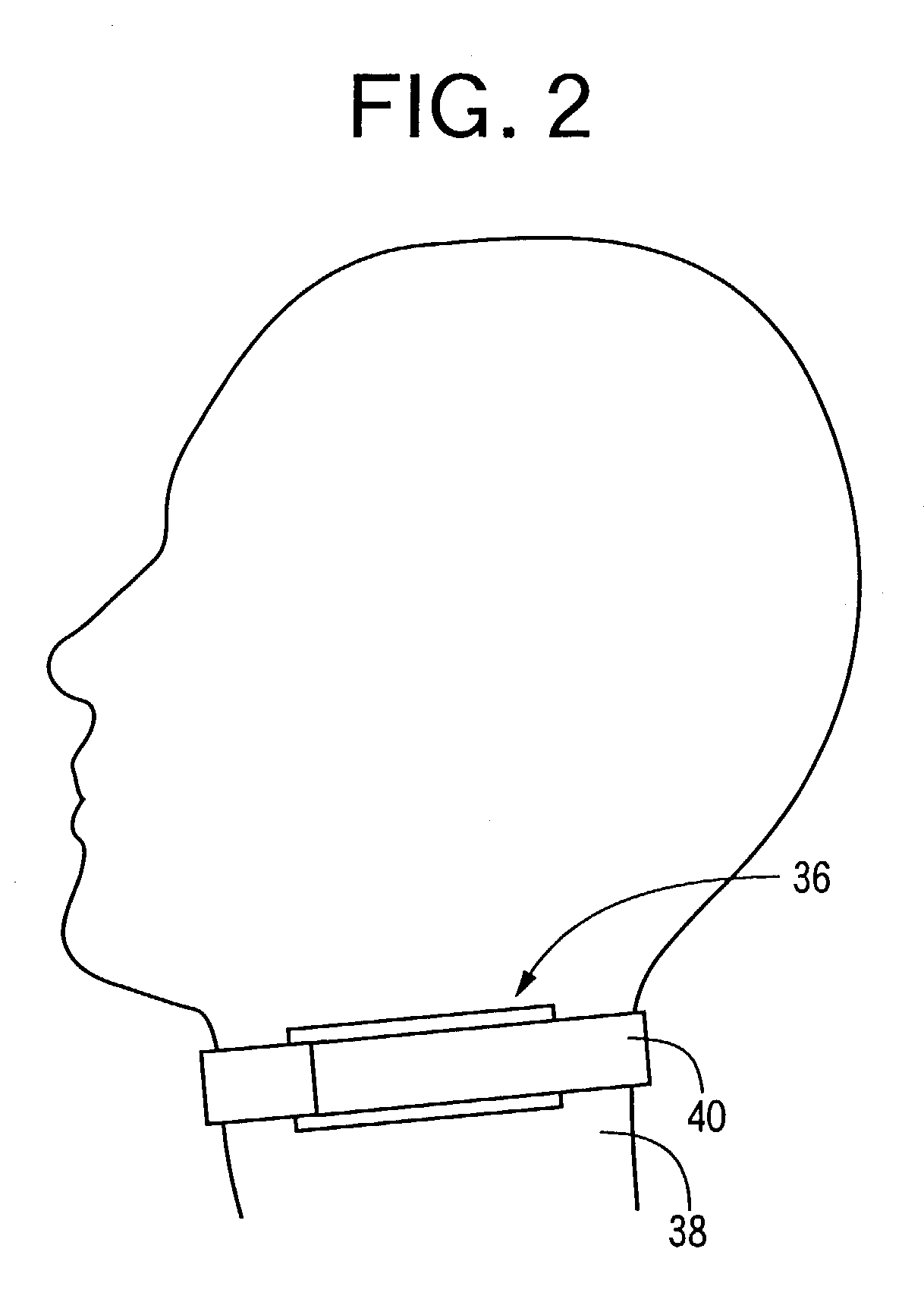

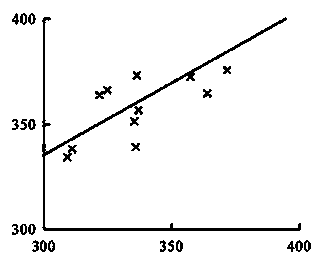

Arteriosclerosis inspecting apparatus

InactiveUS7029449B2Improve accuracyHigh precision diagnosisEvaluation of blood vesselsCatheterBiological bodyMeasurement device

An arteriosclerosis inspecting apparatus including an information obtaining device which obtains information that is related to a velocity at which a pulse wave propagates in a living subject, a blood-pressure measuring device which measures a blood pressure of the subject, a heart-rate measuring device which measures a heart rate of the subject, a pre-ejection-period measuring device which measures a pre-ejection period from a time of starting of contraction of the heart of the subject to a time of starting of ejection of blood from the heart, an ejection-time measuring device which measures an ejection time from the time of starting of ejection of blood from the heart to a time of ending of ejection of blood from the heart, and an arteriosclerosis-inspection-related-augmentation-index determining means for determining an arteriosclerosis-inspection-related augmentation index of the subject, based on the obtained pulse-wave-velocity-related information, the measured blood pressure, the measured heart rate, the measured pre-ejection period, and the measured ejection time, according to a predetermined relationship between (A) (a1) pulse-wave-velocity-related information, (a2) blood pressure, (a3) heart rate, (a4) pre-ejection period and (a5) ejection time, and (B) arteriosclerosis-inspection-related augmentation index.

Owner:COLIN MEDICAL TECH

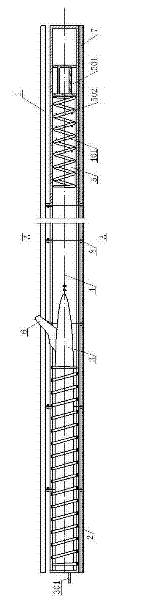

Steam catapult booster for aircraft takeoff

The invention provides an aircraft launching steam ejection boosting device which has a simple structure, a large ejection boosting force, sufficient continuous thrust, a short repeated ejection time interval, convenience for operation, a wide application range, convenience for transportation and installation and a high battle damage repairing speed. The aircraft launching steam ejection boostingdevice comprises a flight deck, a sliding pipeline, a steam ejection booster and an aircraft connector, wherein a deceleration resetting device is arranged at the front part of the sliding pipeline; and the back part of the sliding pipeline is provided with a heating device; the steam ejection booster comprises a bullet-shaped shell, a clapboard, overheating vaporizers, a water inlet pipe and a water spraying pipe, wherein the bullet-shaped shell is provided with an opening at the back part; the overheating vaporizers are distributed in a high-temperature steam generation room axially; the water inlet pipe arranged at the tail part of the shell passes through the high-temperature steam generation room to communicate with a high-temperature pressure-bearing water tank and has a check valve; the water spraying pipe is arranged on the high-temperature pressure-bearing water tank and is provided with an ejection control valve; the water spraying hole of the water spraying pipe is positioned at the front part of the high-temperature steam generation room; and a waste water recovery pipeline is arranged under the sliding pipeline.

Owner:刘忠德

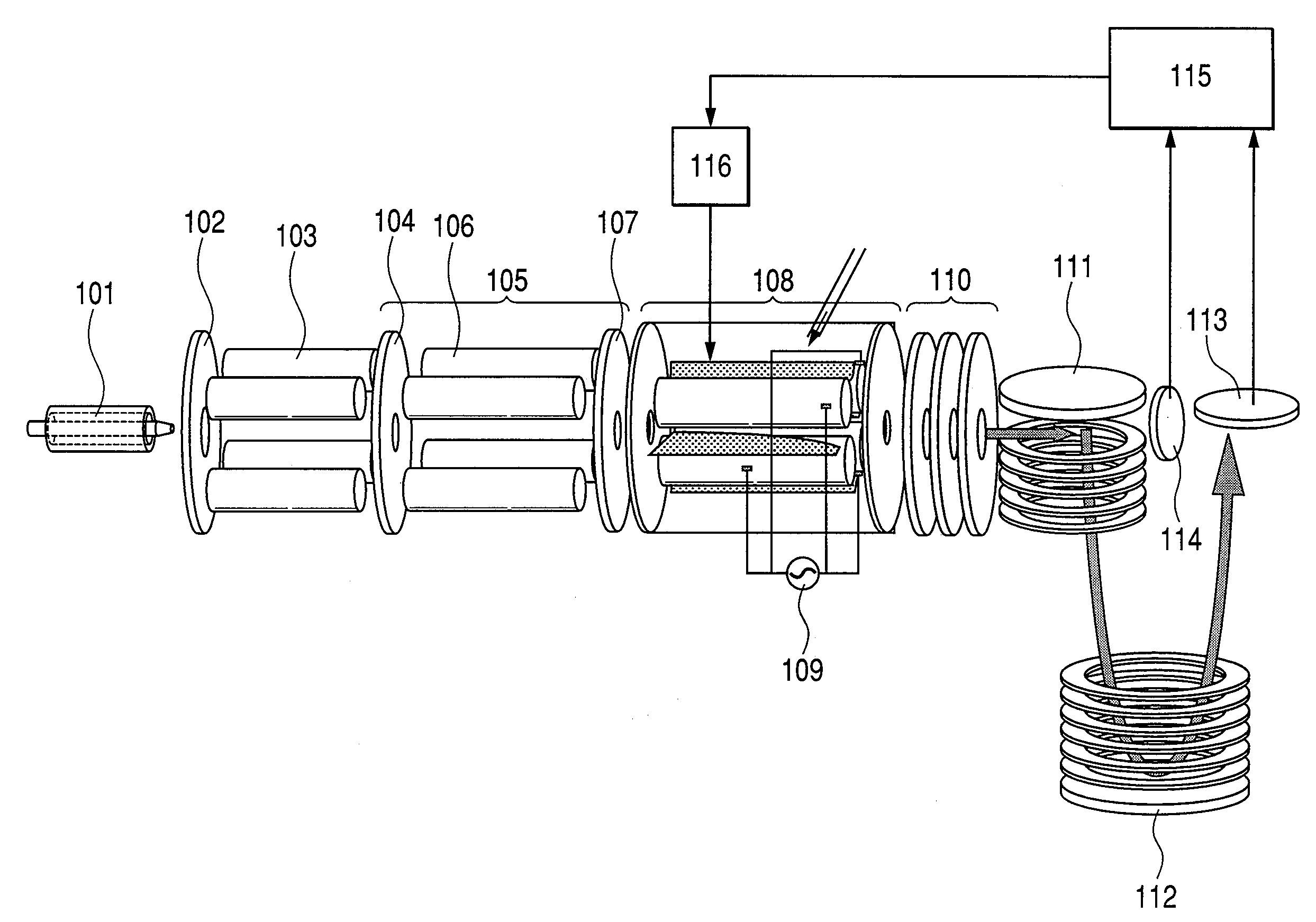

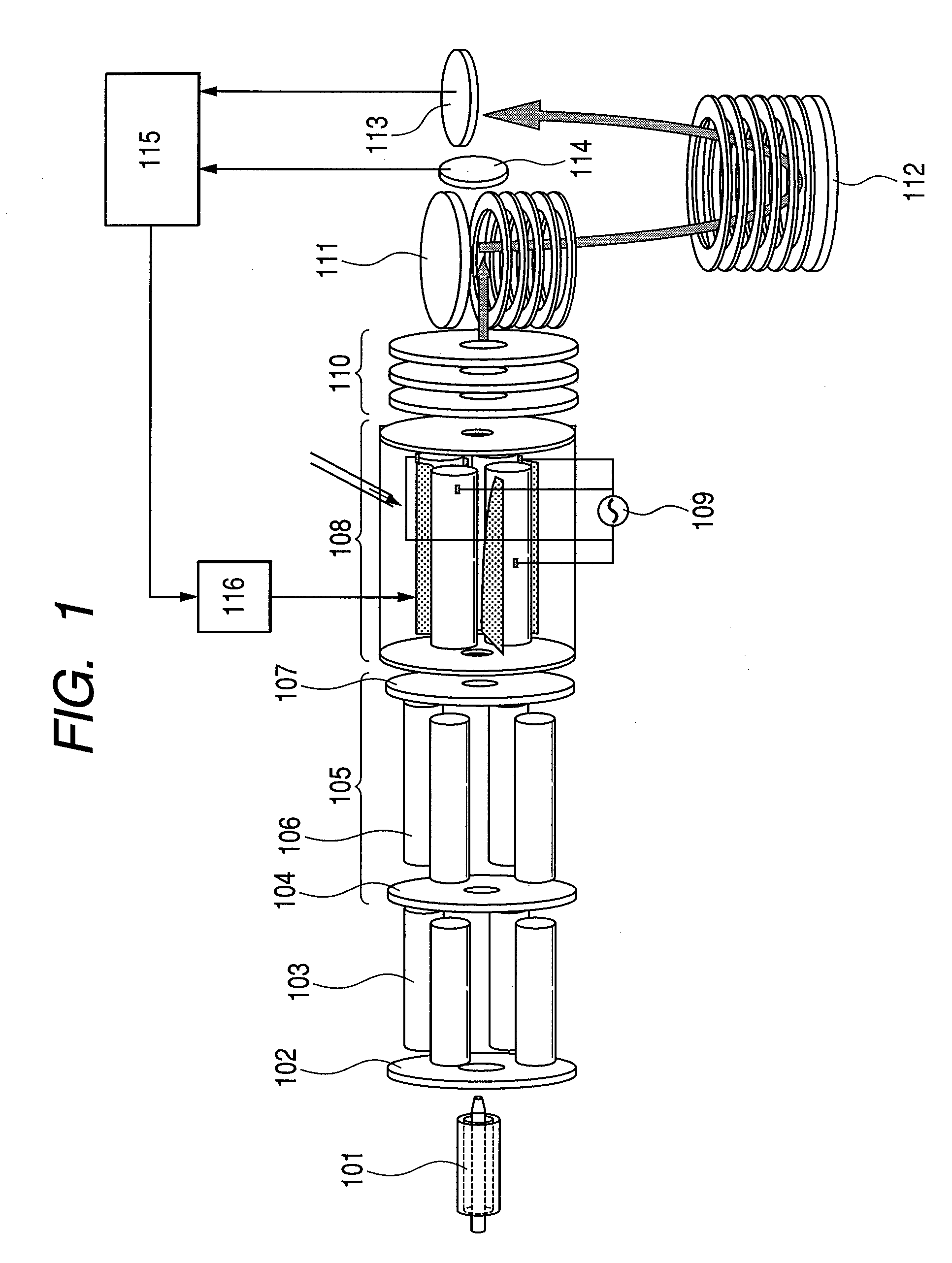

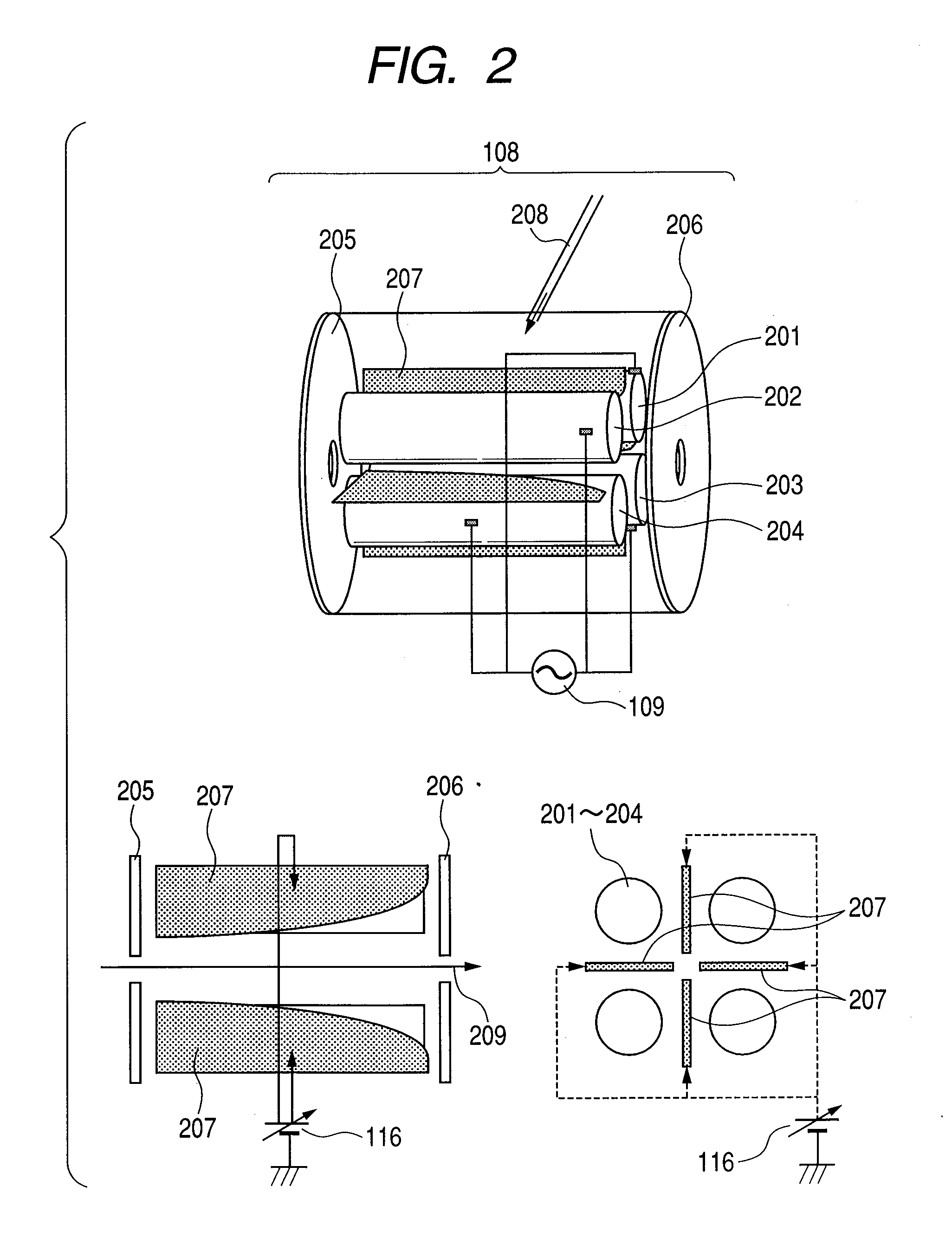

Mass spectrometer

ActiveUS20090020695A1Lengthen time distributionImprove utilization efficiencyIsotope separationSpectrometer combinationsAuxiliary electrodeConfusion

A mass spectrometer includes a linear multipole electrode, an auxiliary electrode that applies a DC potential on the center axis of the linear multipole electrode, and a DC power supply that supplies a DC power to the auxiliary electrode. The DC potential slope formed on the center axis of the multipole electrode is changed according to the measuring condition. The ejection time of ions can be adjusted optimally by adjusting the potential slope so as to satisfy the measuring condition. If the ejection time of ions is shortened, confusion of different ion information items that might otherwise occur on a spectrum can be avoided. If the ejection time of ions is lengthened, detection limit exceeding can be avoided and ions can be measured efficiently, thereby highly efficient ion measurements are always assured.

Owner:HITACHI HIGH-TECH CORP

Novel device and method to measure ventricular arterial coupling and vascular performance

A device and method for analyzing of a disturbed pattern of pulse wave front results in a non-invasive, real-time diagnostic tool of arterial vascular performance on both a global and regional scale. The device provides a single number quantifying how well the arterial tree as a whole is coupled to receive and distribute a stroke volume of a single heartbeat. Changing heart rate, contractility, volume status, and afterload will change stroke volume and ejection time. Different vasculatures with different properties (e.g., size and intrinsic stiffness) will be best matched for different stroke volumes and ejection times to provide optimal coupling. The device will allow finding the optimal set of parameters for individual patient.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Mass spectrometer

ActiveUS8044349B2Shorten injection timeShorten the timeIsotope separationSpectrometer combinationsMass analyzerAuxiliary electrode

A mass spectrometer includes a linear multipole electrode, an auxiliary electrode that applies a DC potential on the center axis of the linear multipole electrode, and a DC power supply that supplies a DC power to the auxiliary electrode. The DC potential slope formed on the center axis of the multipole electrode is changed according to the measuring condition. The ejection time of ions can be adjusted optimally by adjusting the potential slope so as to satisfy the measuring condition. If the ejection time of ions is shortened, confusion of different ion information items that might otherwise occur on a spectrum can be avoided. If the ejection time of ions is lengthened, detection limit exceeding can be avoided and ions can be measured efficiently, thereby highly efficient ion measurements are always assured.

Owner:HITACHI HIGH-TECH CORP

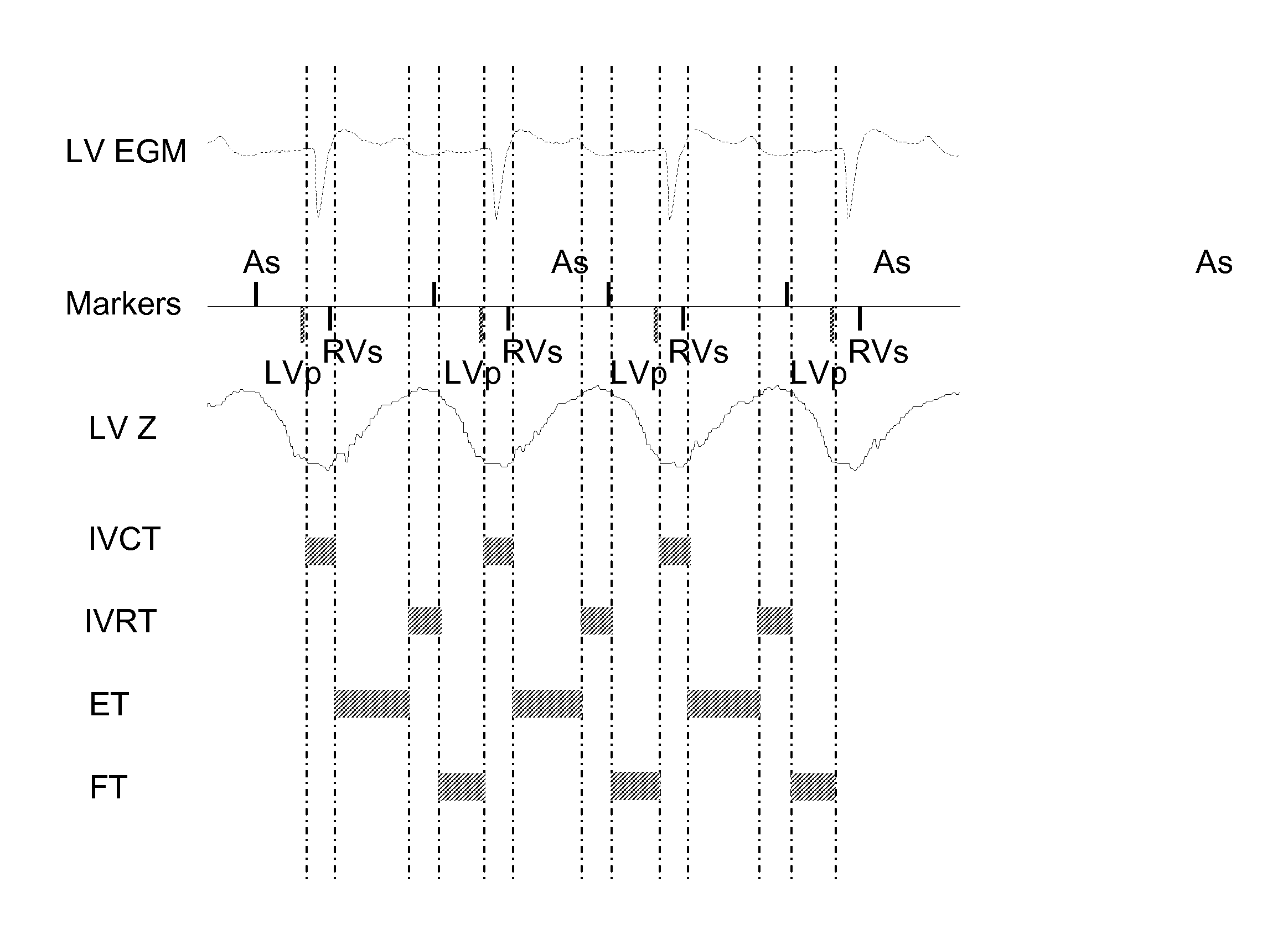

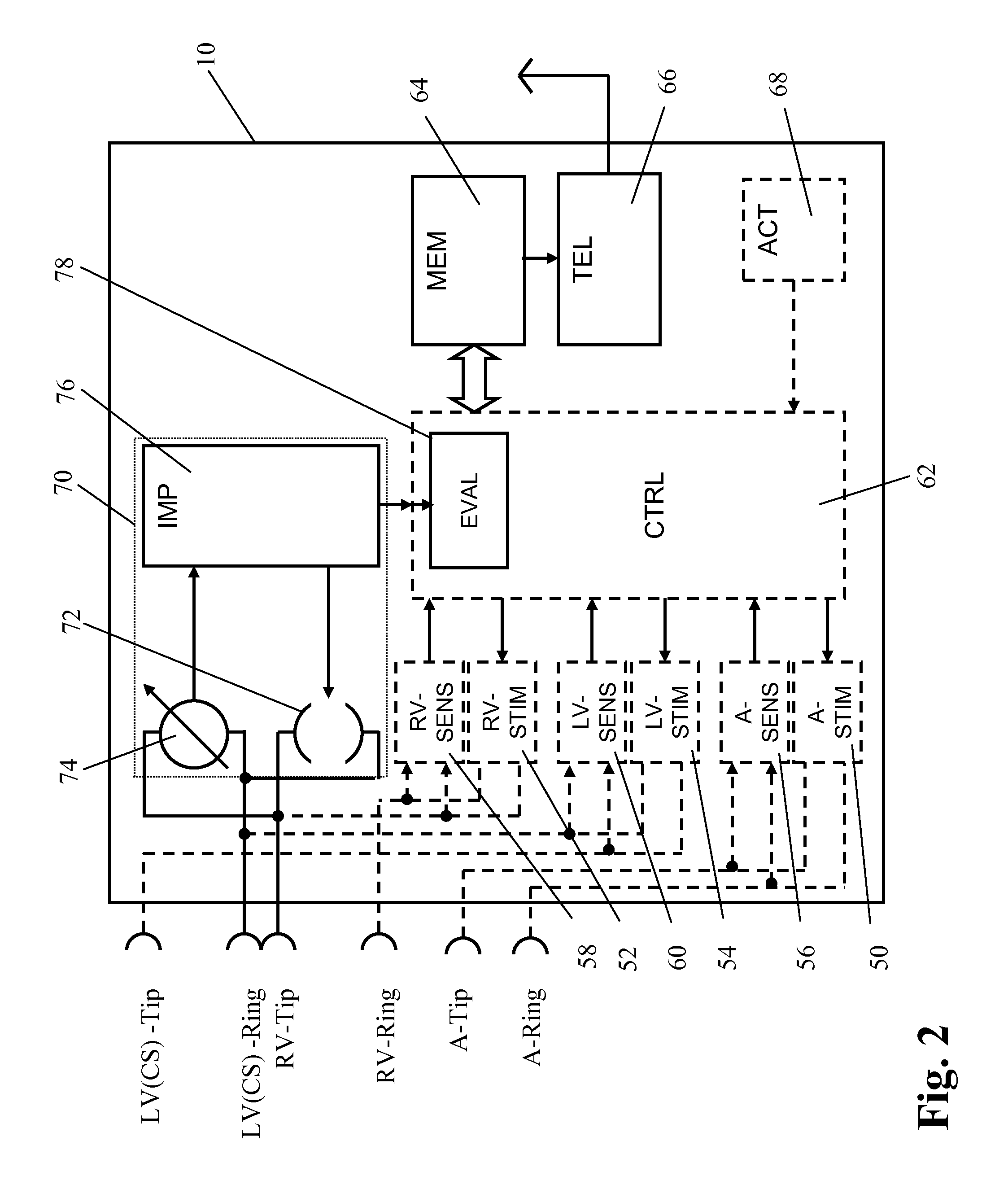

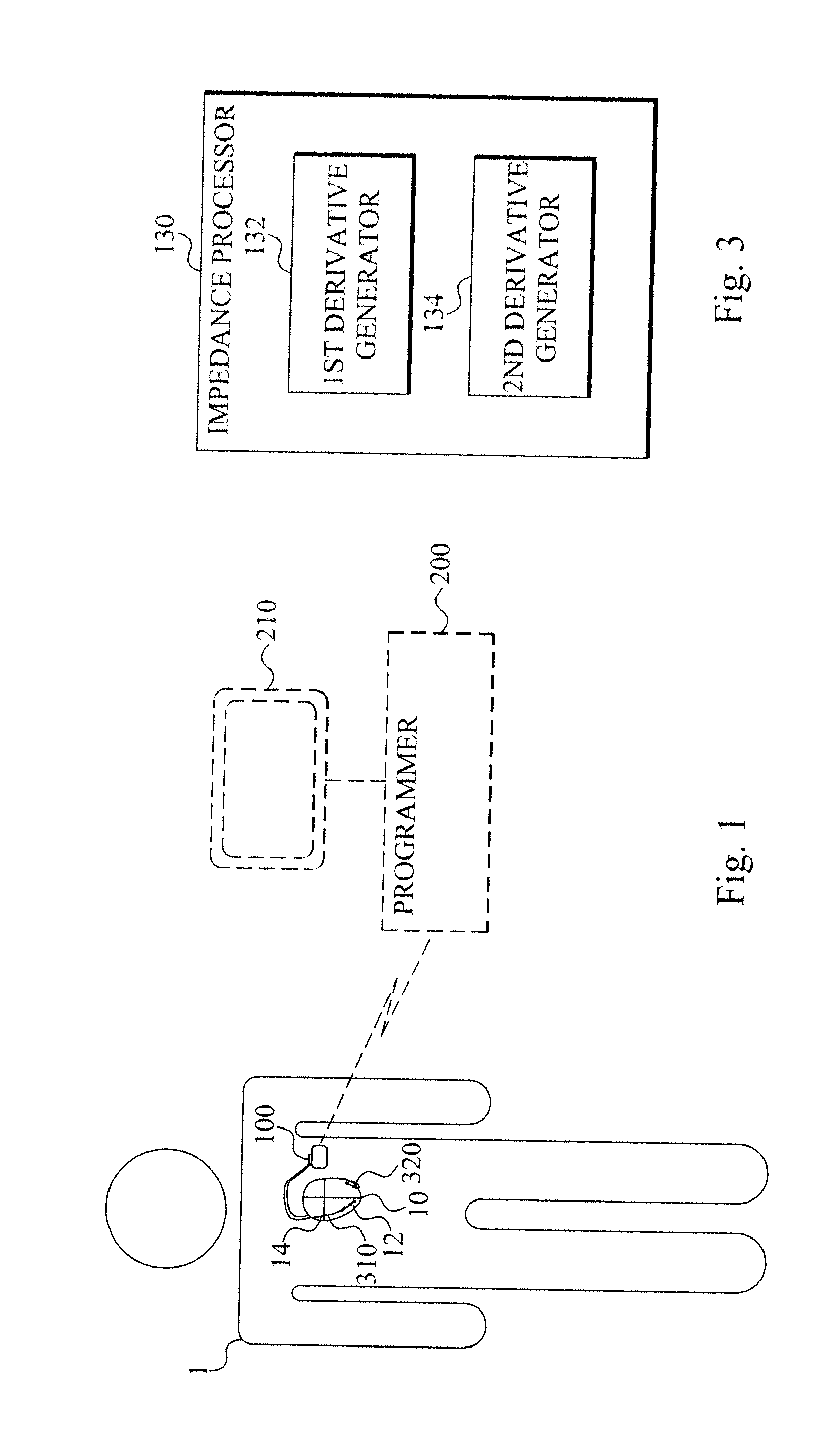

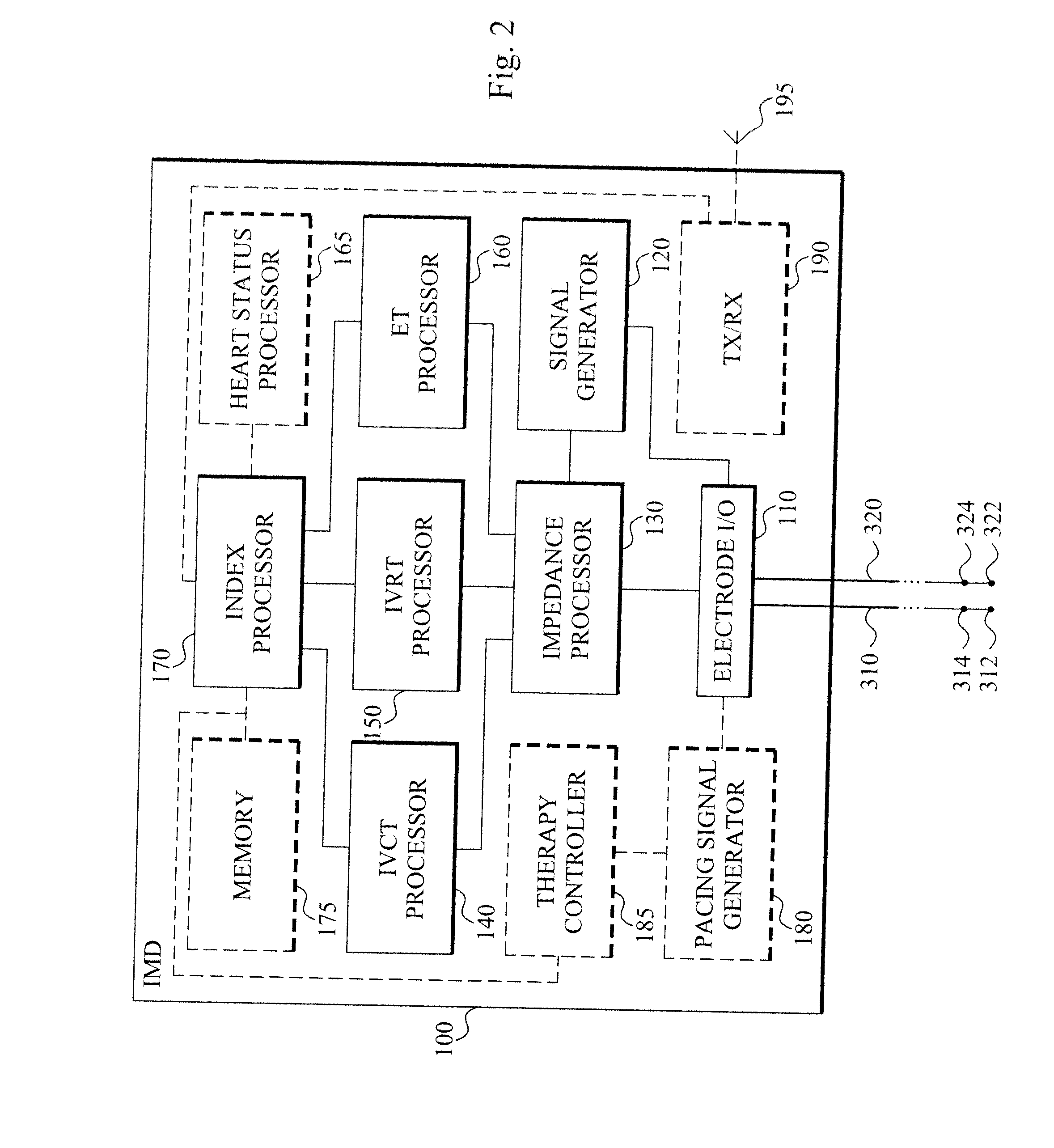

Apparatus and method to optimize pacing parameters

ActiveUS8843198B2Minimize indexOptimizationElectrocardiographyHeart stimulatorsIsovolumic relaxation timePerformance index

Owner:BIOTRONIK SE & CO KG

Method for extracting timing parameters using a cardio-mechanical sensor

In a method and apparatus for measuring the ejection fraction in a mammalian heart, the opening and closing of a heart valve is sensed with an implanted sensor, and a pre-ejection period is measured as a function of the sensed opening and closing of the heart valve. The ventricular ejection time also is measured, and the ejection fraction is determined as a function of the measured pre-ejection period and the ejection time.

Owner:ST JUDE MEDICAL

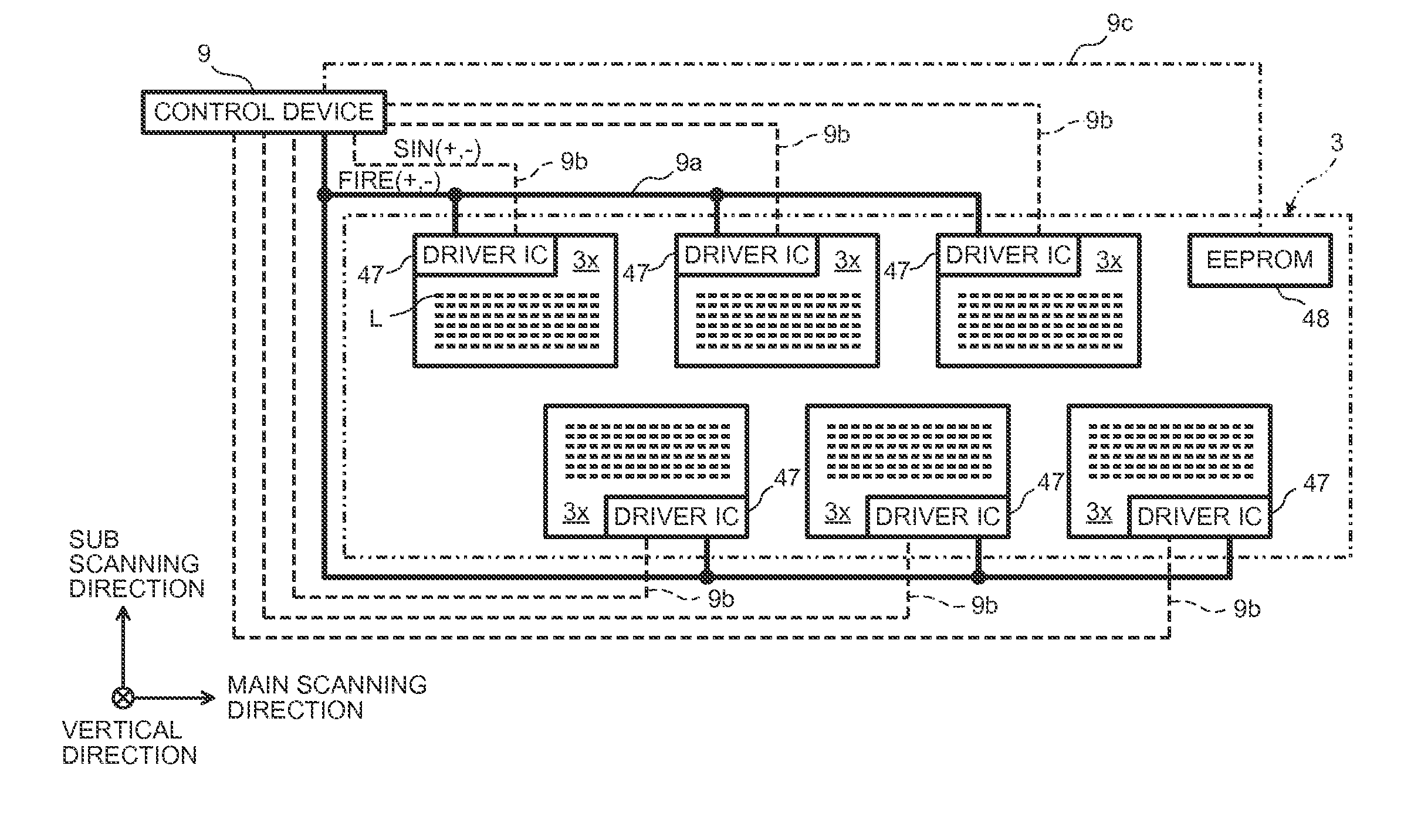

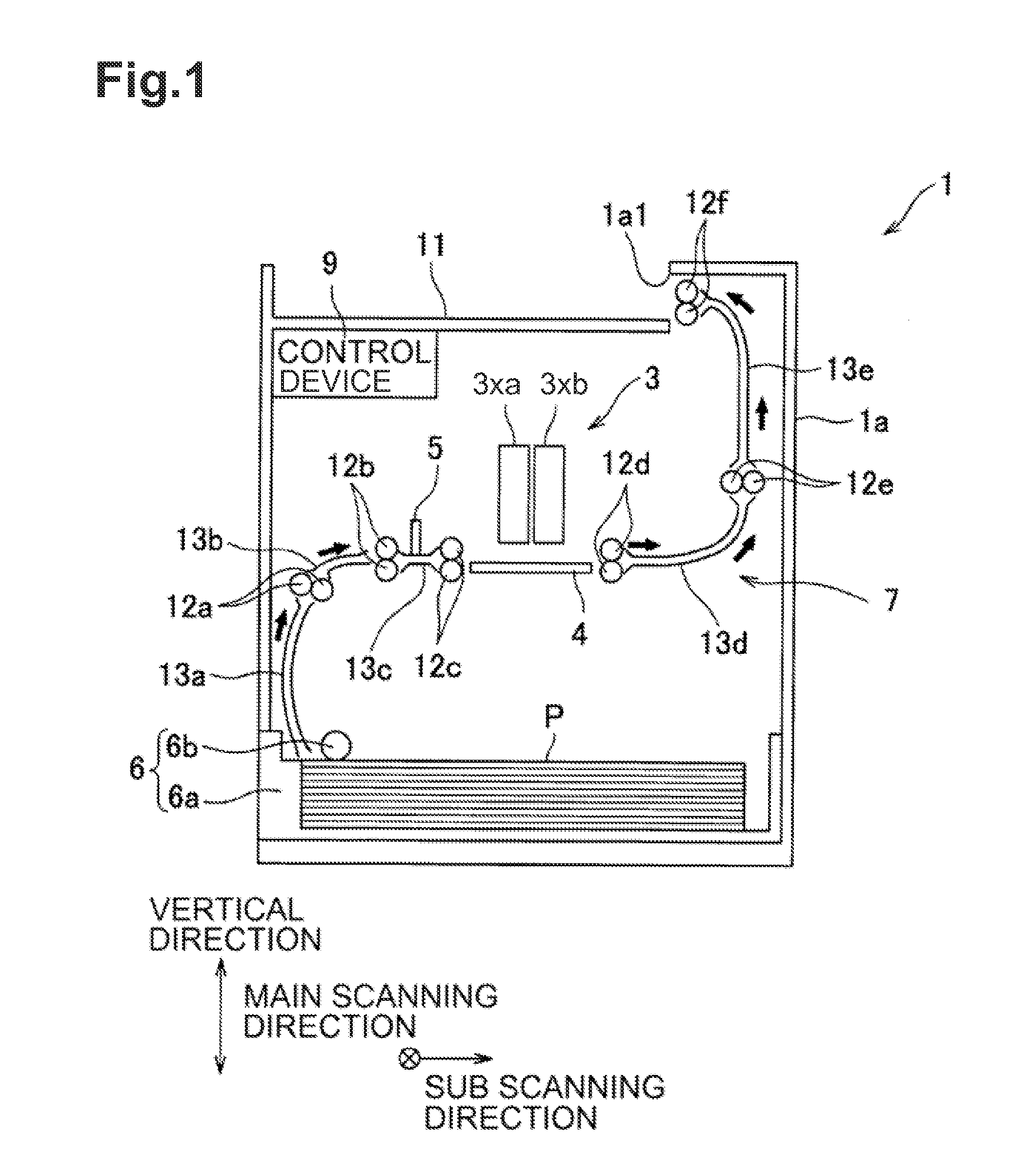

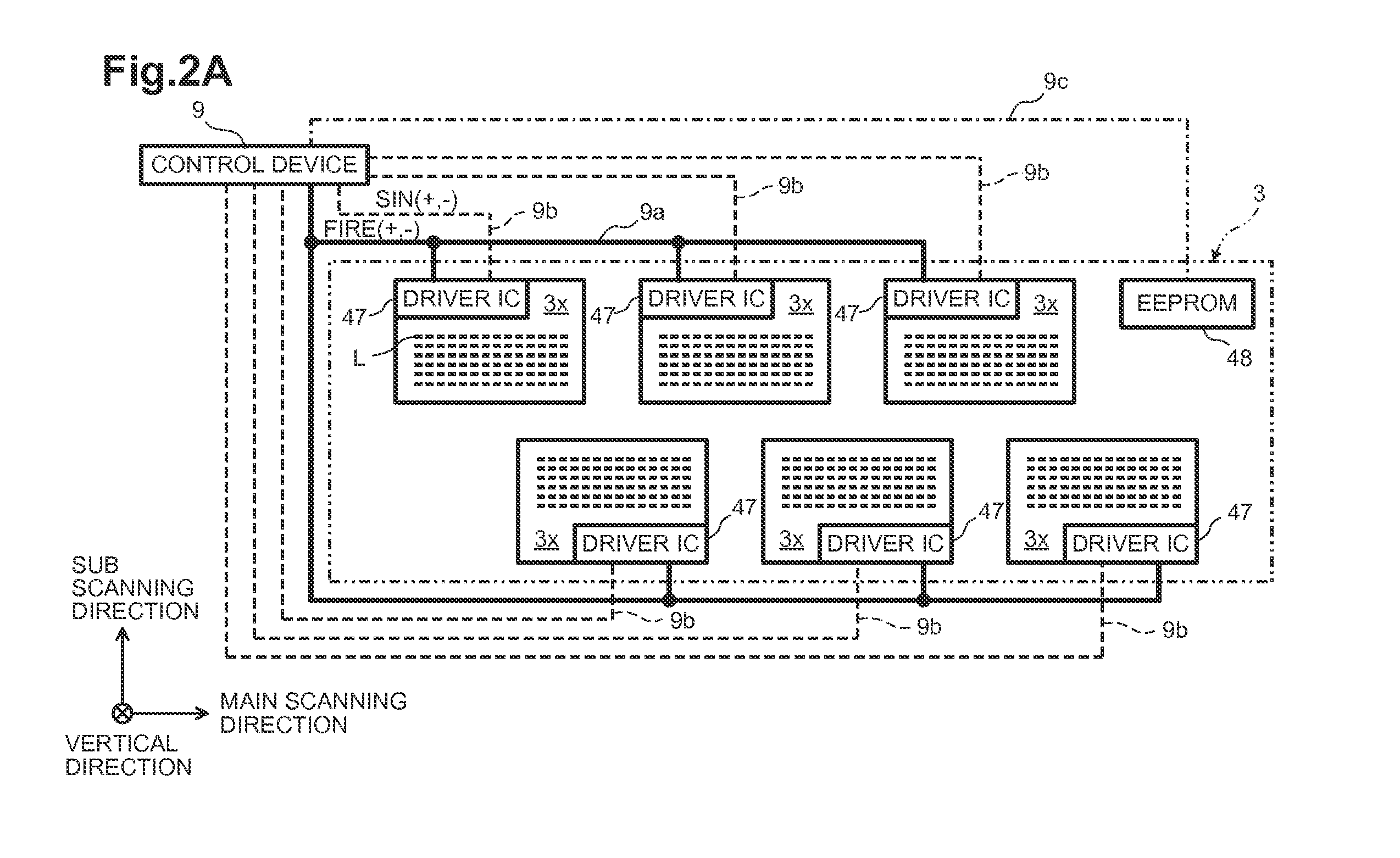

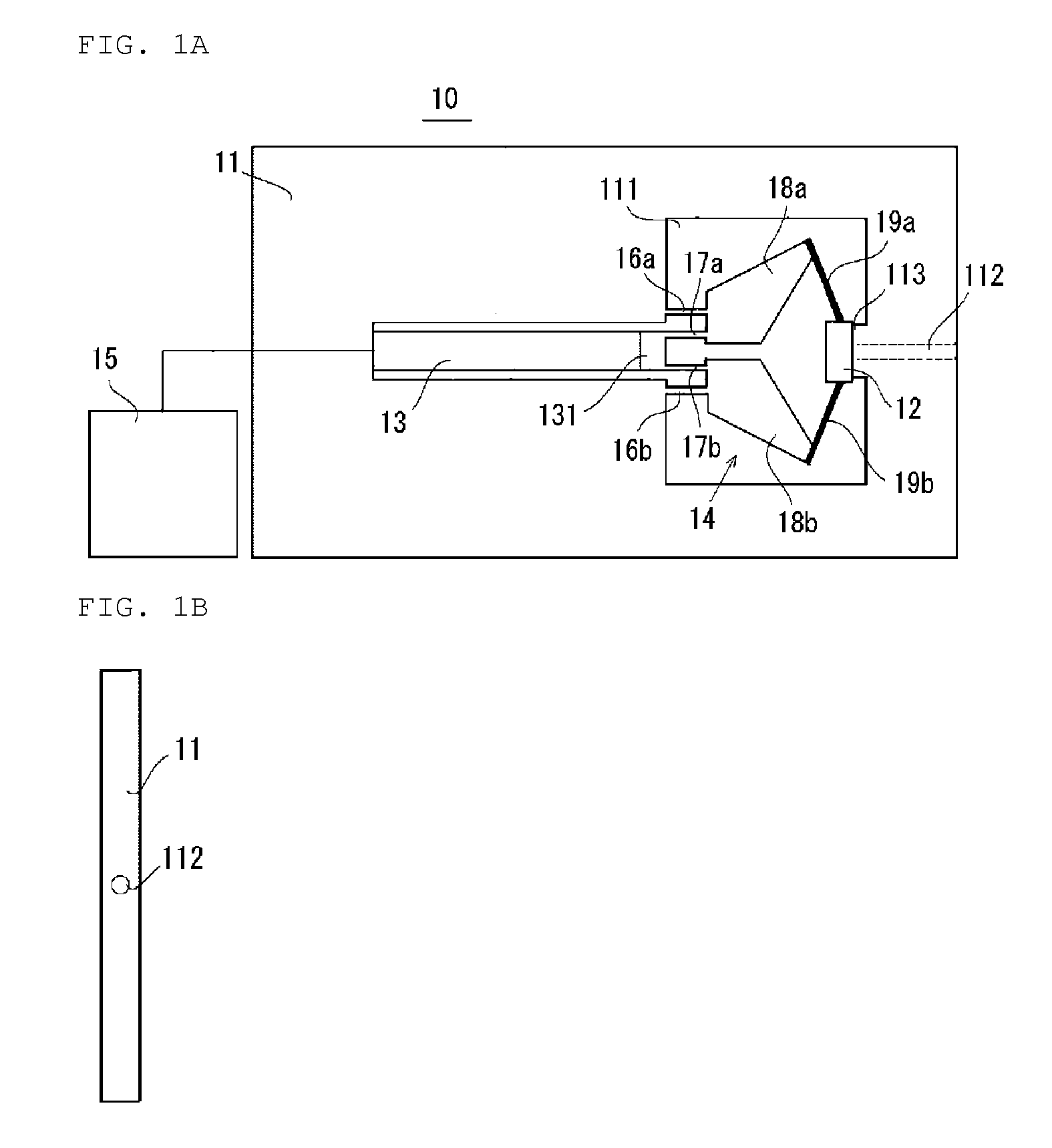

Liquid Ejecting Apparatus, and Non-Transitory, Computer-Readable Media Therefor

ActiveUS20140092155A1Reduce and prevent degradationReduce degradationOther printing apparatusControl signalPattern selection

A liquid ejecting apparatus may have a head with a plurality of head units. Each head unit may include a driver IC. An ejection timing signal (FIRE) may be transmitted from a control device to each of the driver ICs through an ejection timing signal line, which may be connected to the control device as a single line and split on its way to the driver ICs. The control device may further output delay information indicating a delay amount for the FIRE signal to the driver ICs through a control signal line through which a waveform pattern selection signal (SIN) is also transmitted. Each of the driver ICs may include a delay circuit that delays the FIRE signal by the delay amount indicated by the delay information.

Owner:BROTHER KOGYO KK

Measuring method and device for measuring systole time parameter

ActiveCN104068841AAccurate measurementLow costDiagnostic recording/measuringSensorsDisease monitoringPulse oximeters

The invention discloses a measuring method and device for measuring a systole time parameter. The measuring method comprises the steps of acquisition of a pulse oximeter signal, automatic extraction of a characteristic point and digital correction of a characteristic parameter. The device is taken as a hardware carrier of the method. More accurate LVET (Left Ventricular Ejection Time) and measuring results of relevant parameters are obtained on the basis of the pulse oximeter signal by means of a simple measure in order to rapidly obtain clinical diagnostic data related to initial screening of heart disease and cardiac function evaluation. Photoplethysmography equipment for realizing the functions comprises a pulse oximeter signal acquisition unit, a signal processing unit and a data output unit. The entire device is easy to wear, is low in manufacturing cost, and contributes to reduction of the cost on cardiovascular function evaluation and disease monitoring.

Owner:CHENGDU KANGTUOBANG TECH CO LTD

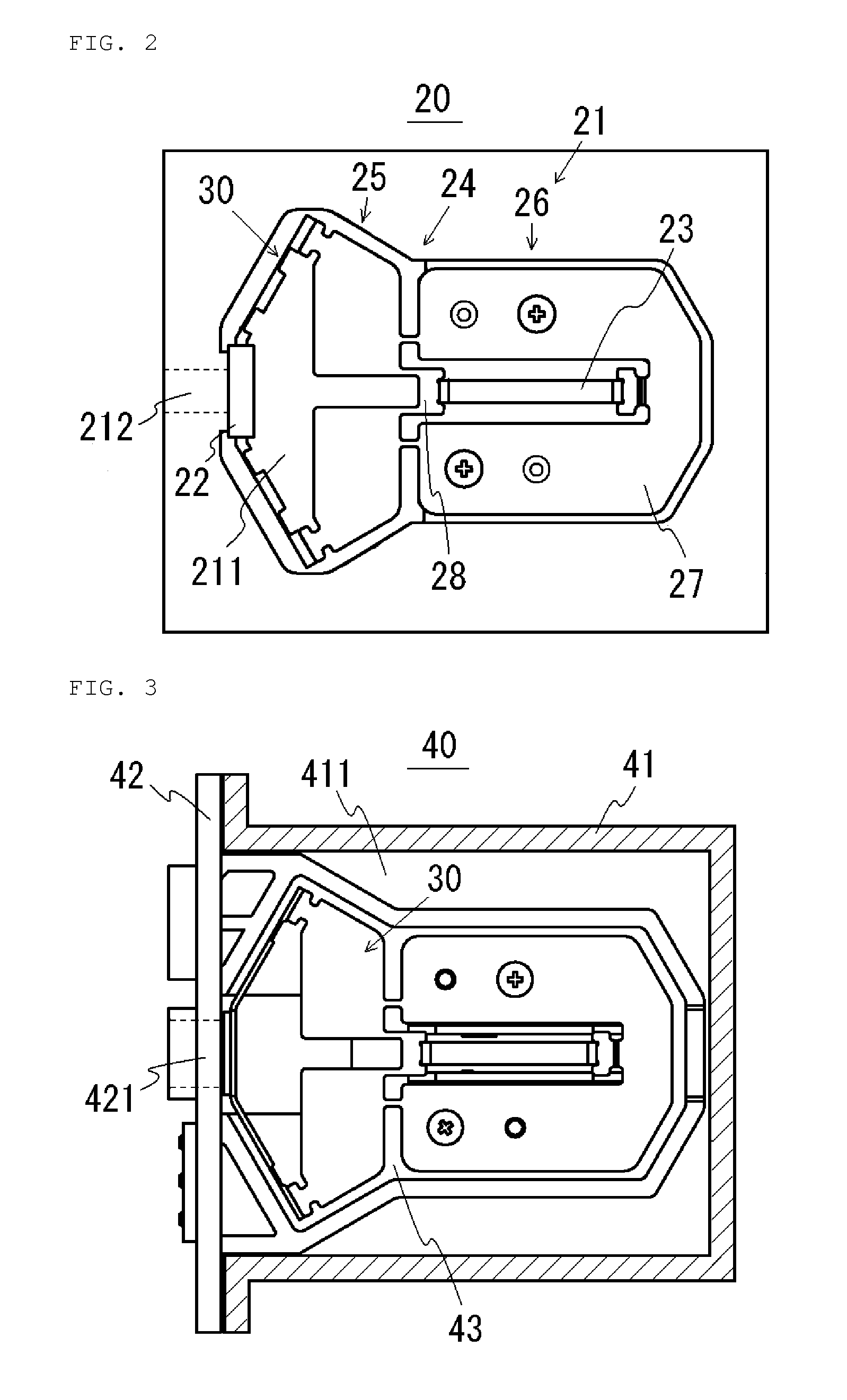

Piezoelectric valve, and optical particulate matter sorter provided with air-blowing means that uses piezoelectric valve

ActiveUS20150060337A1Stable supplyImprove responsivenessOperating means/releasing devices for valvesGas current separationParticulatesElectricity

A piezoelectric valve stably supplies gas even for a long gas ejection time, with a high responsivity to opening the valve, is provided. The piezoelectric valve, including a gas-pressure-chamber for receiving a compressed gas supplied from outside, a gas-discharge-channel through which the compressed gas is discharged from the gas-pressure-chamber, comprises: a valve body disposed in the gas-pressure-chamber and opens / closes the gas-discharge-channel; a piezoelectric element for producing a driving force to move the valve body as a displacement; a displacement-enlarging-mechanism for enlarging the displacement of the piezoelectric element to act on the valve body; and a driving unit having a signal-generating-unit for generating a signal comprising a pre-pulse and a main pulse and provides the signal generated by the signal-generating-unit to a driving circuit as an input signal to apply a driving voltage to the piezoelectric element to make the piezoelectric element expand and drive the valve body open.

Owner:SATAKE CORP +1

Method and system for adjusting the flight path of an unguided projectile, with compensation for jittering deviation

A method for adjusting the flight path of an unguided projectile, which comprises the steps of: (a) Measuring the magnitude and direction of the jittering of a projectile launch tube, at an ejection time of a projectile from the launch tube; (b) Measuring a velocity deviation of the projectile from a nominal velocity; (c) Measuring an angular deviation of the sight of the launch tube, being equal to the angular deviation between a line coinciding with the direction of gravity and a line passing through the center of the launch tube and the center of the sight; (d) Determining a compensating impulse vector to be applied to the projectile during an initial flight path thereof based on the magnitude and direction of the jittering, velocity deviation and angular deviation; and (e) Applying the compensating impulse vector to the projectile by activating a flight correction unit, the thrust developed by the flight correction unit suitable for adjusting the flight path of the projectile by a magnitude and direction substantially equal to that of the compensating impulse vector.

Owner:STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG (A R O) (VOLCANI CENT)

Piezoelectric valve, and optical particulate matter sorter provided with air-blowing means that uses piezoelectric valve

ActiveUS9114430B2Stable supplyImprove responsivenessOperating means/releasing devices for valvesGas current separationElectricityParticulates

A piezoelectric valve stably supplies gas even for a long gas ejection time, with a high responsivity to opening the valve, is provided. The piezoelectric valve, including a gas-pressure-chamber for receiving a compressed gas supplied from outside, a gas-discharge-channel through which the compressed gas is discharged from the gas-pressure-chamber, comprises: a valve body disposed in the gas-pressure-chamber and opens / closes the gas-discharge-channel; a piezoelectric element for producing a driving force to move the valve body as a displacement; a displacement-enlarging-mechanism for enlarging the displacement of the piezoelectric element to act on the valve body; and a driving unit having a signal-generating-unit for generating a signal comprising a pre-pulse and a main pulse and provides the signal generated by the signal-generating-unit to a driving circuit as an input signal to apply a driving voltage to the piezoelectric element to make the piezoelectric element expand and drive the valve body open.

Owner:SATAKE CORP +1

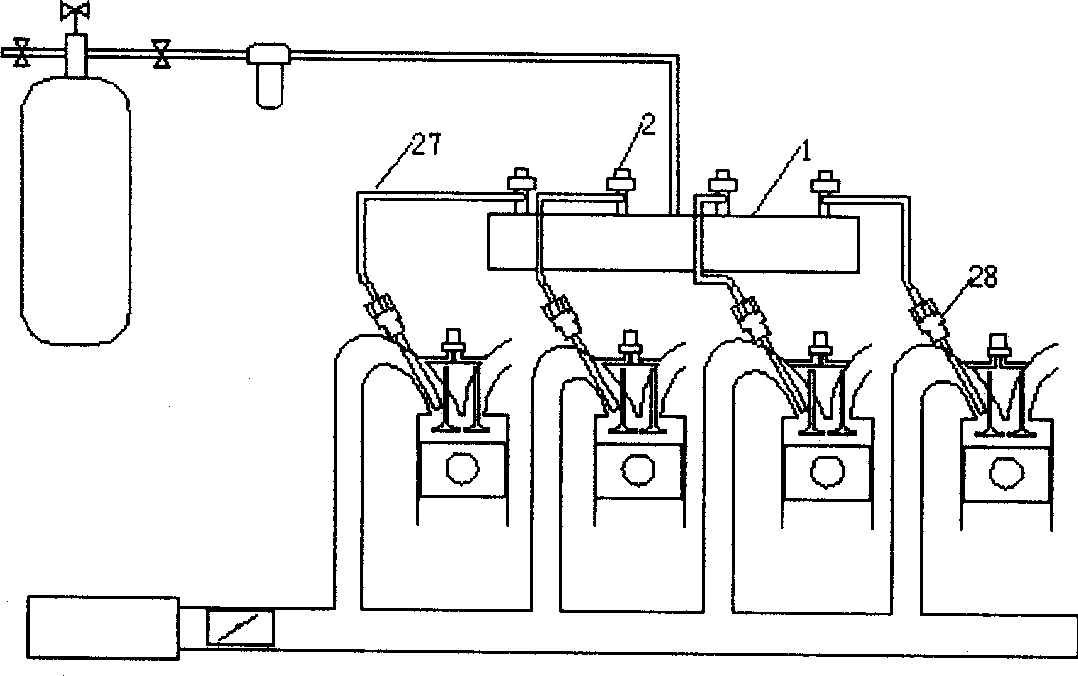

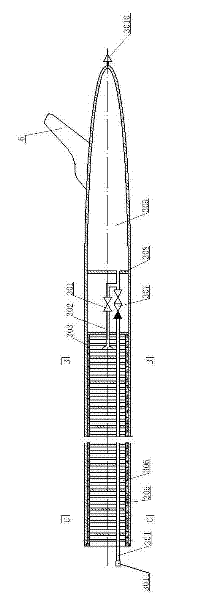

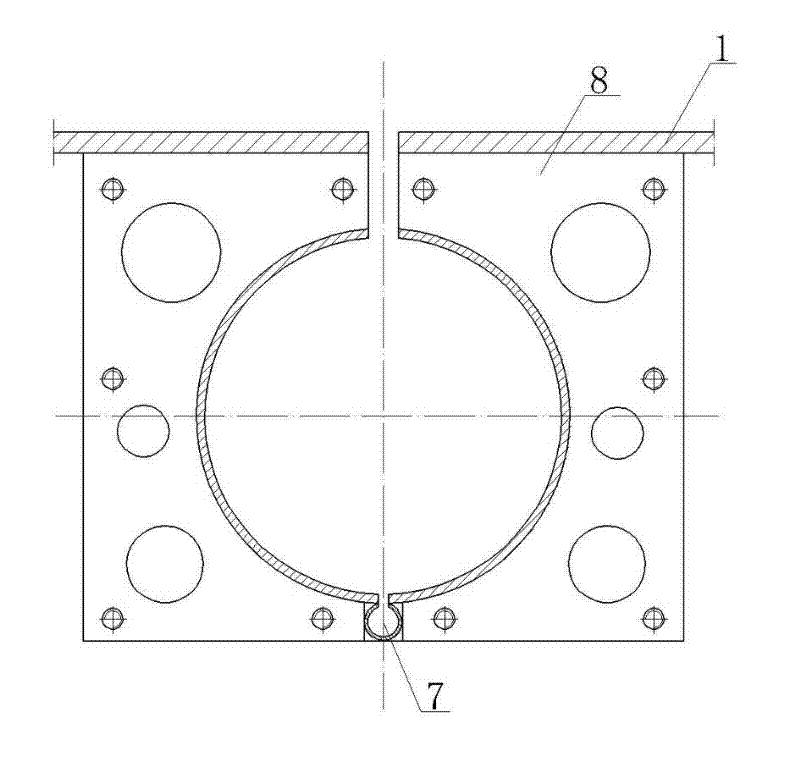

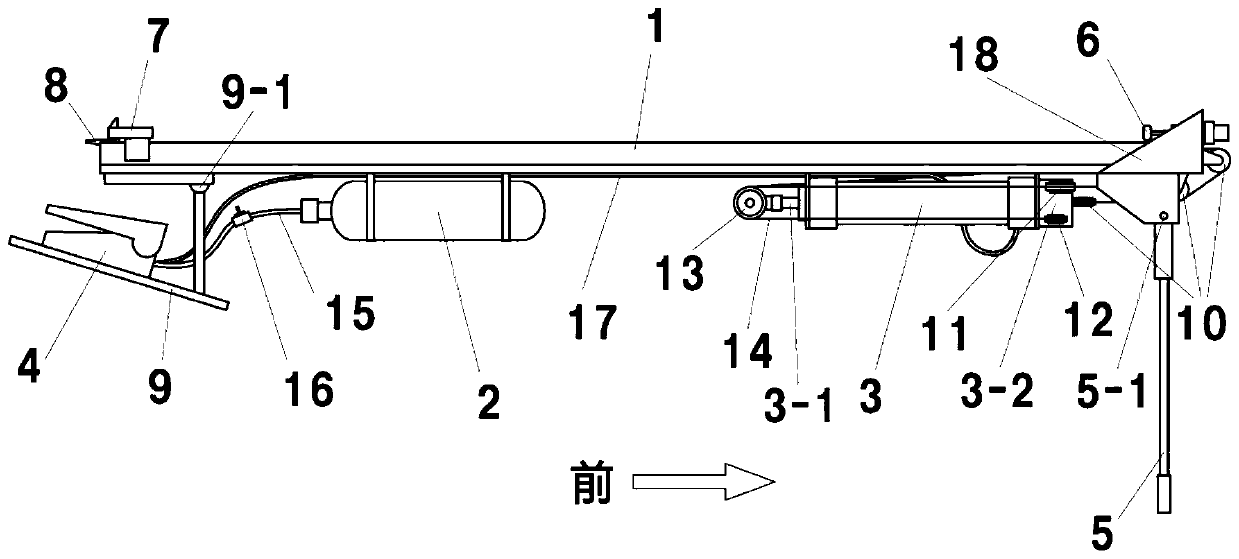

Portable ejection system of pneumatic fixed-wing unmanned aerial vehicle and working method of portable ejection system

The invention discloses aportable ejection system of a pneumatic fixed-wing unmanned aerial vehicle and a working method of the portable ejection system. The portable ejection system includes a guiding rail, a pulley, a pre-tension device, a pulley block, a buffer, a foot valve, a support, an air flask, an air cylinder, supporting legs and a steel rope. During ejection, power output and displacement of the air cylinder is conducted, the match of the pulley block and the steel rope makes output displacement and speed of the air cylinder magnified for eight times, so enough take-off speed is provided for an unmanned aerial vehicle, and at the same time, the requirement for the air cylinder is decreased. The match of contractible supporting legs and rotatable support makes that ejector have adaptability to rough terrain, meanwhile, size of the ejector is decreased and the ejector is convenient to carry. Powers of the ejection system come from a high-pressure tank, so the ejection times are ensured, dependence on external system is reduced, and physical exhaustion of operators is greatly decreased. The ejection system has the advantages of small size, light weight, simple structure, low cost, reusing for many times, carrying and operating by one person and superior performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

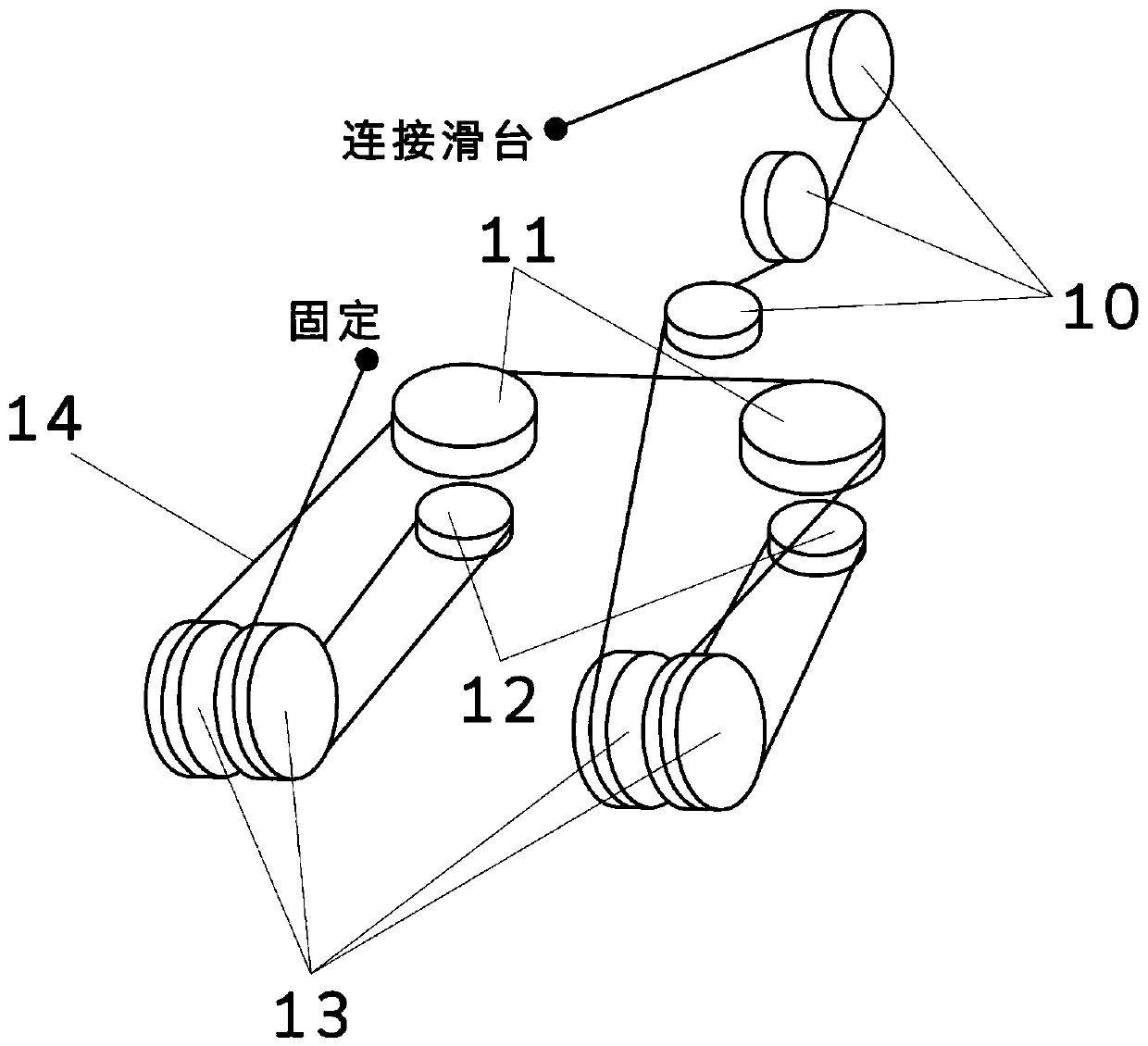

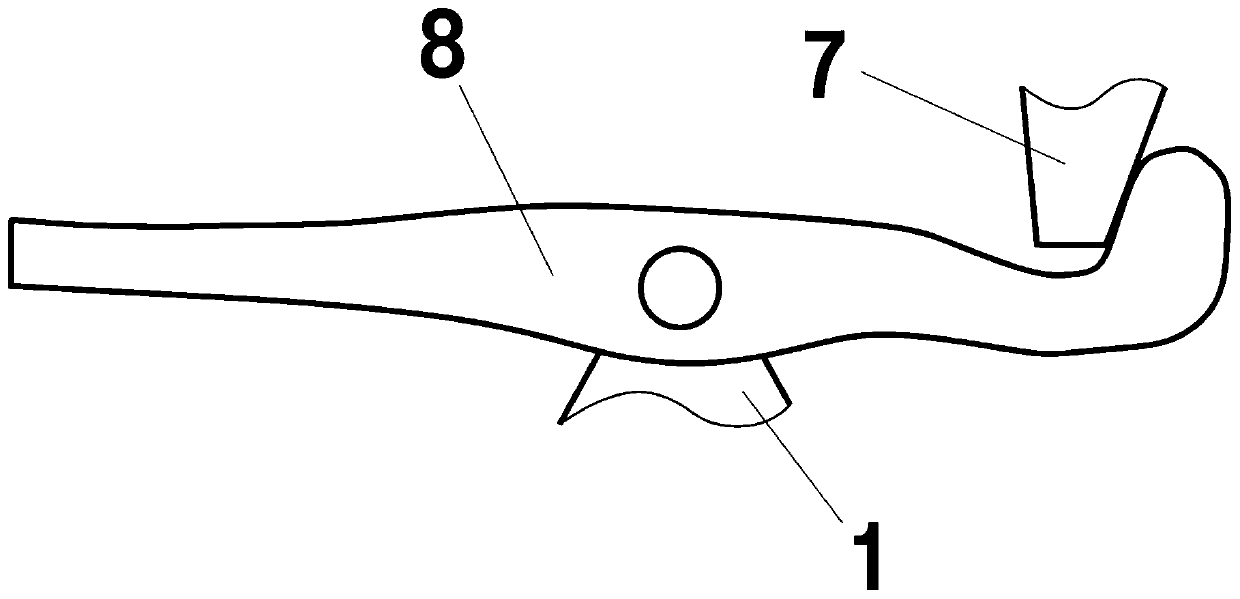

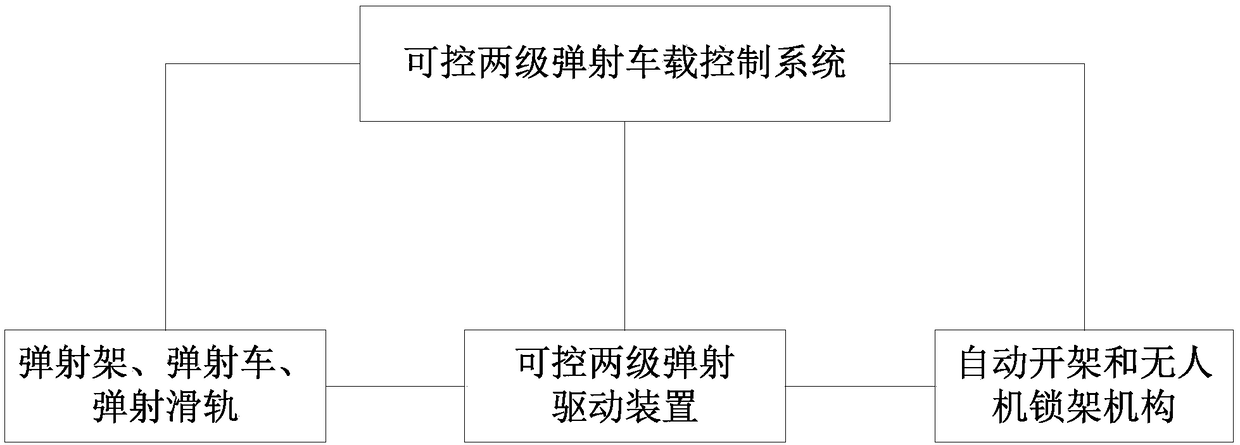

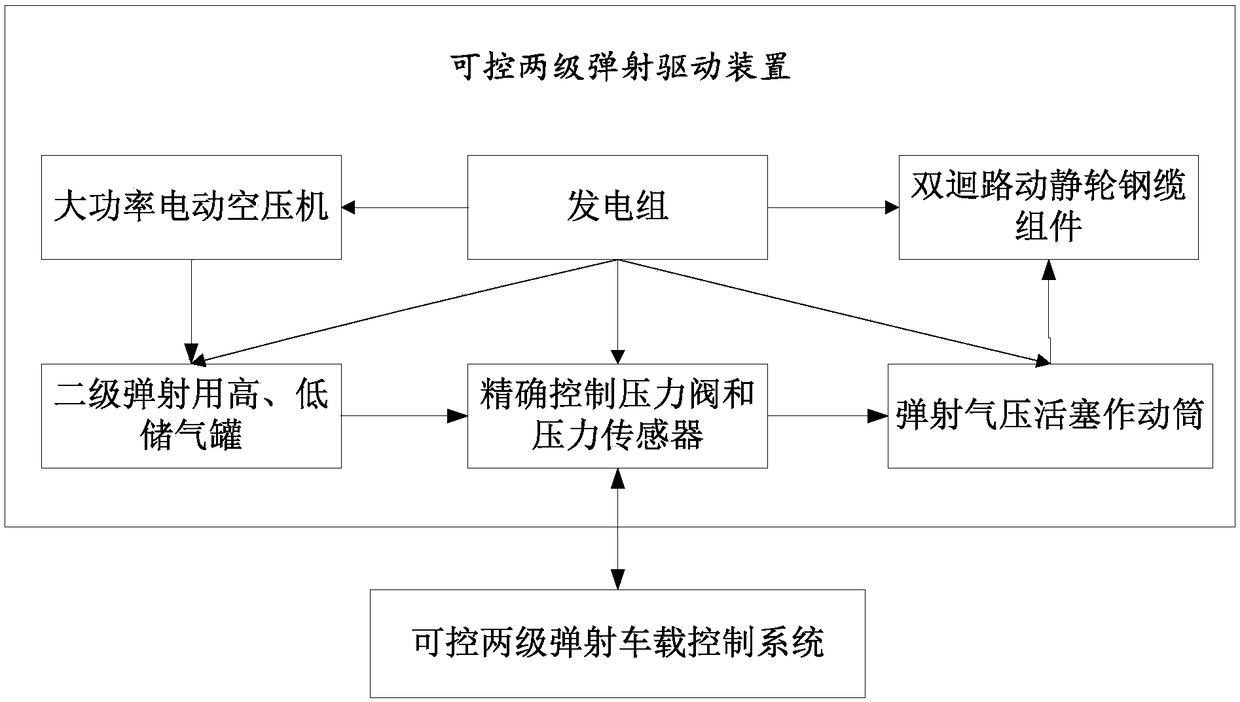

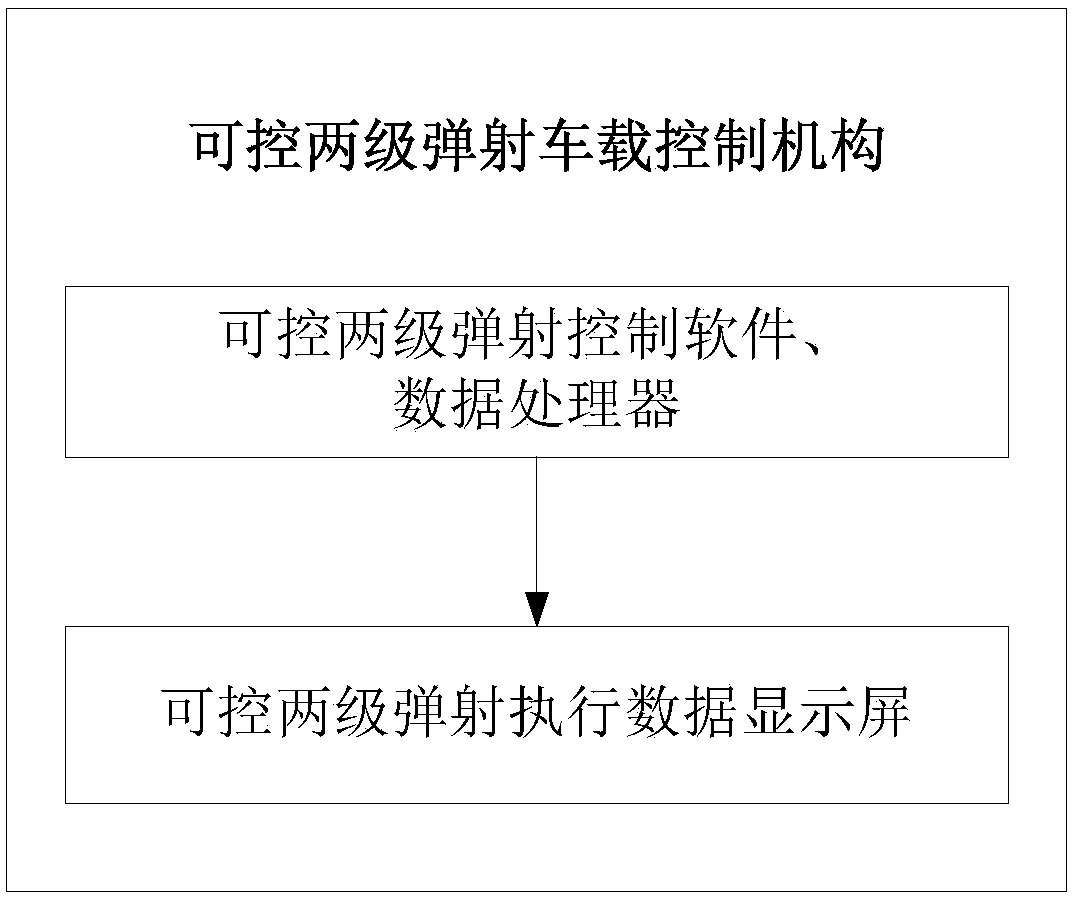

Controllable two-stage-ejection vehicle-mounted control system of unmanned aerial vehicle and ejection method

ActiveCN108082524ASufficient off-shelf speedReduced initial ejection accelerationLaunching/towing gearControl systemEngineering

The invention discloses a controllable two-stage-ejection vehicle-mounted control system of an unmanned aerial vehicle (UAV). The controllable two-stage-ejection vehicle-mounted control system comprises an ejection frame, an ejection vehicle, an ejection sliding rail, a controllable two-stage-ejection drive mechanism, a controllable two-stage-ejection vehicle-mounted control mechanism, an automatic opening frame and a UAV lock frame mechanism. The invention also discloses a control method of the controllable two-stage-ejection vehicle-mounted control system of the UAV. The control method comprises the steps of respectively generating high-pressure gas and low-pressure gas by an air compressor, sending the high-pressure gas and the low-pressure gas to a high-pressure gas container and a low-pressure gas container, activating first-stage movement of the ejection frame by the controllable two-stage-ejection vehicle-mounted control system while sending a time instruction for activating second-stage movement of the ejection frame to an ejection time relay and a time instruction for releasing an ejection lock fastener, and activating the second-stage movement of the ejection frame and releasing the ejection lock fastener by the ejection time relay. The controllable two-stage-ejection vehicle-mounted control system of the UAV realizes the reduction of initial ejection acceleration, soas to furthest avoid the problem of excessive initial overload during the ejection process and to meet the requirements of enough off-frame speed at the same time.

Owner:沈观清

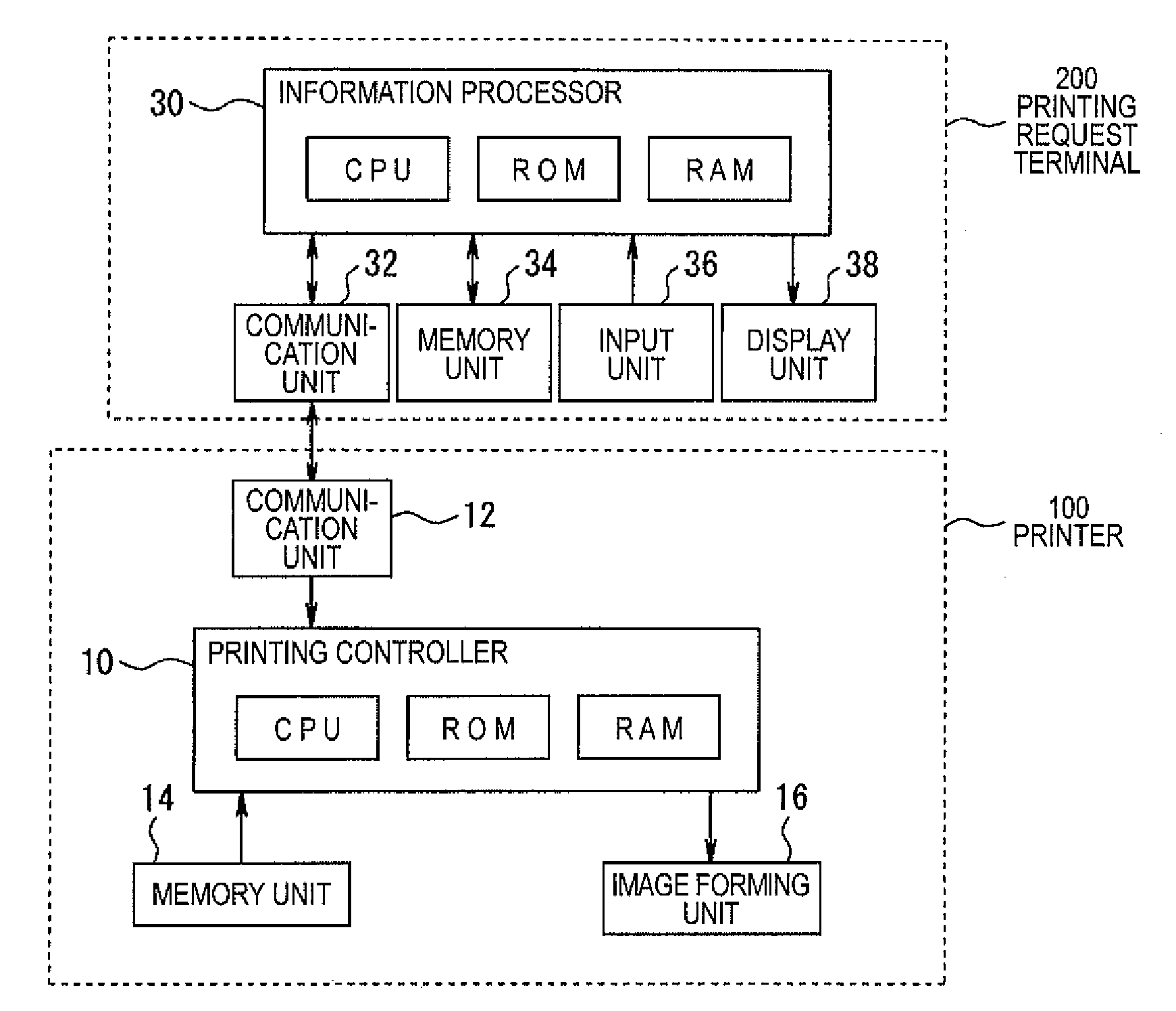

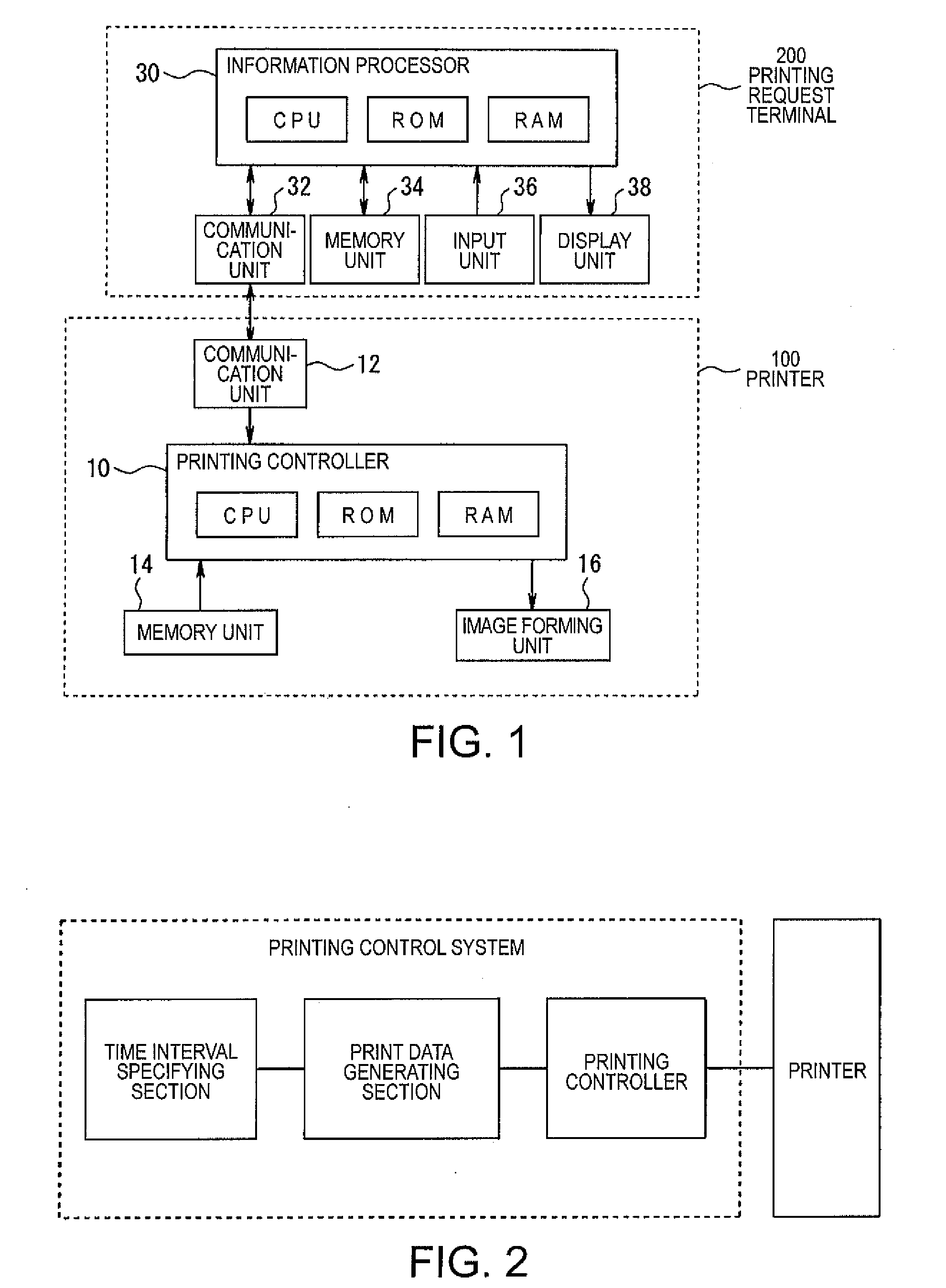

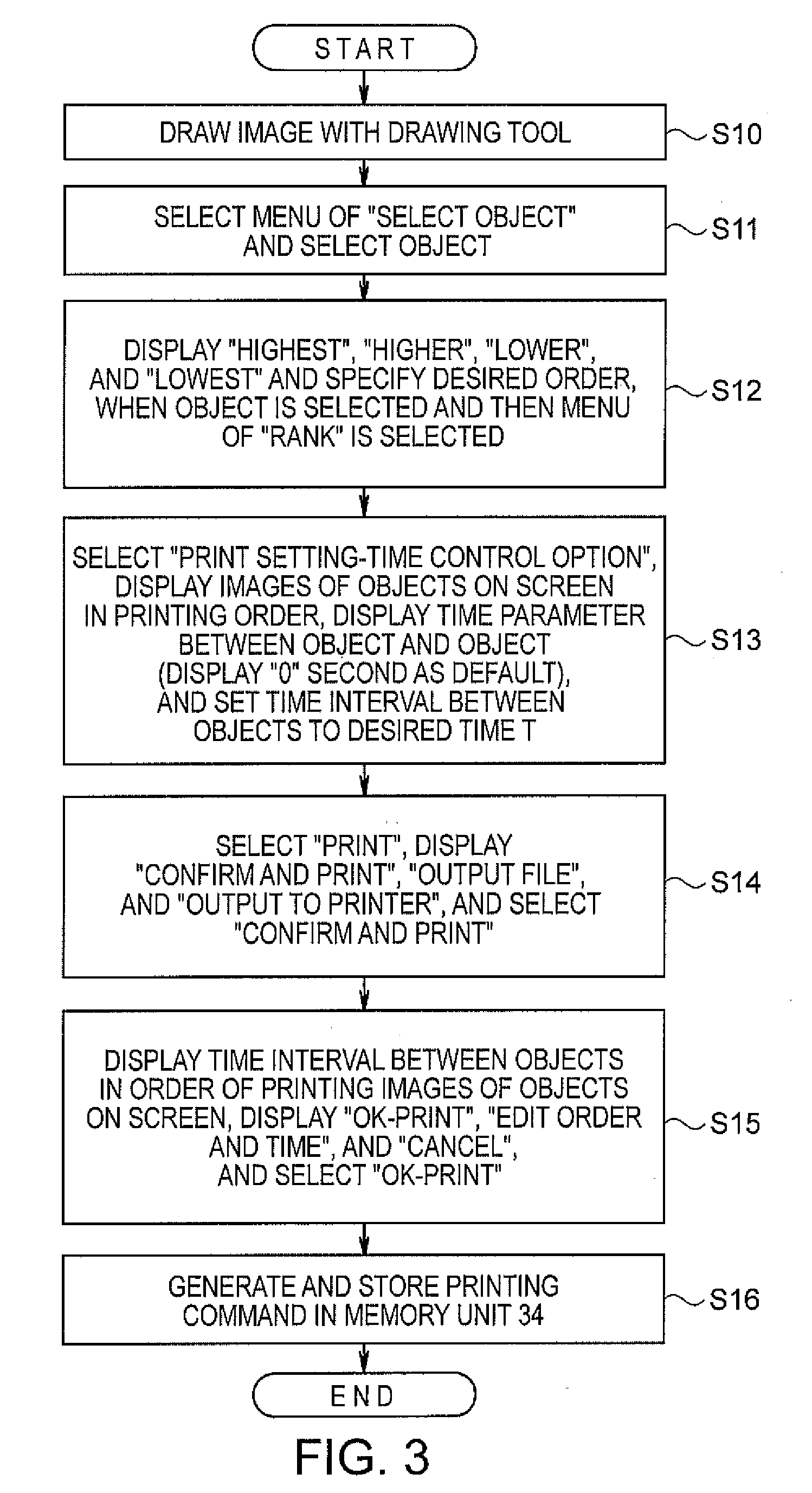

Printing Control System, Printing Request Terminal, Printer, and Printing Control Method

A printing control system controlling a printer performing a printing operation by ejecting a plurality of ink including specific color ink or special ink. A time interval specifying section specifies a time interval for ejecting the ink when the plurality of ink including the specific color ink or the special ink is ejected to perform the printing operation. A print data generating section generates print data for controlling the ejection of the ink every rank, which is determined as an ejection time of the ink as viewed in time series, on the basis of the time interval specified by the time interval specifying section. A printing control section allows the plurality of ink to be ejected in the time interval specified by the time interval specifying section by sequentially controlling the printer on the basis of the print data sequentially acquired from a first rank among the print data of all ranks generated by the print data generating section.

Owner:SEIKO EPSON CORP

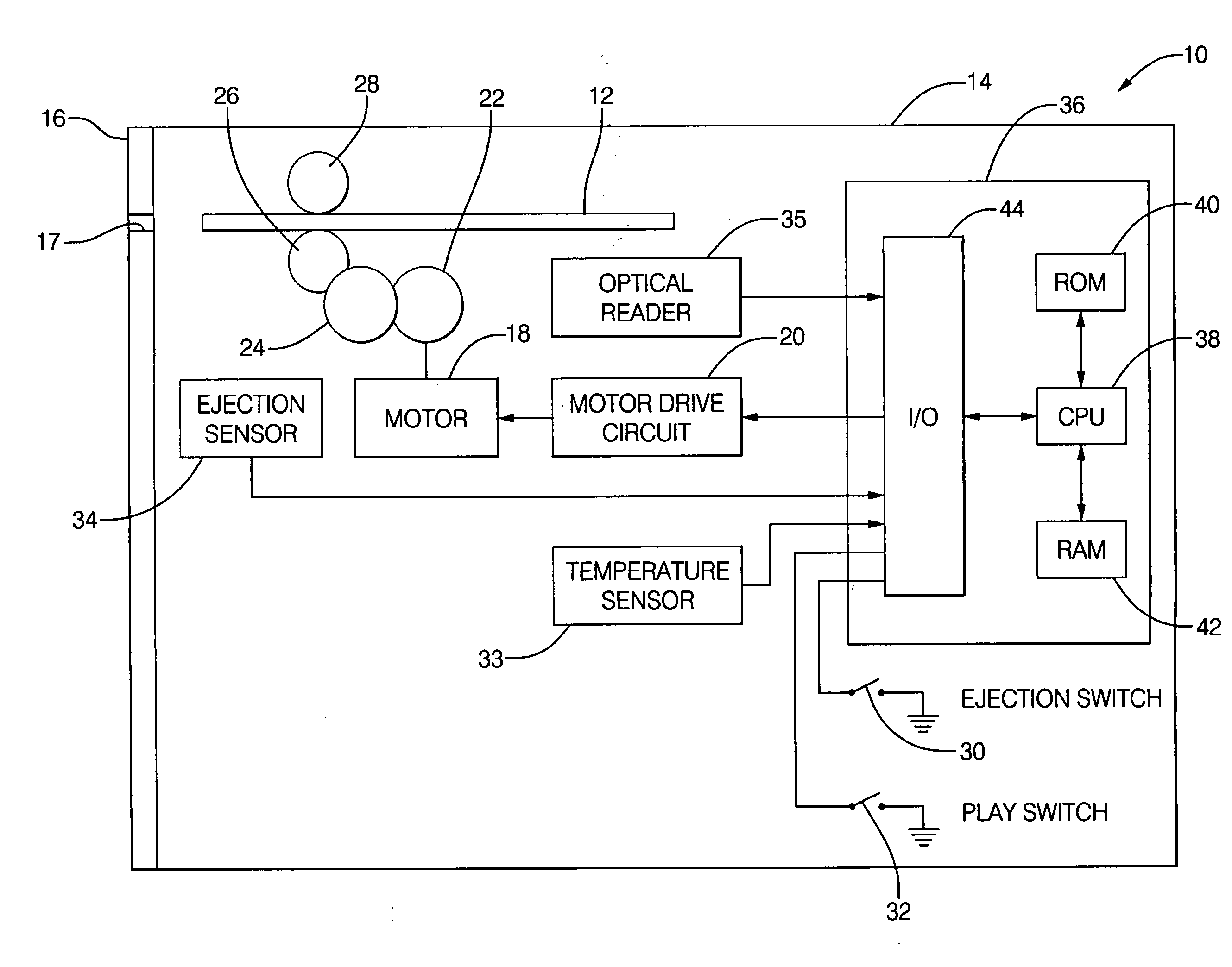

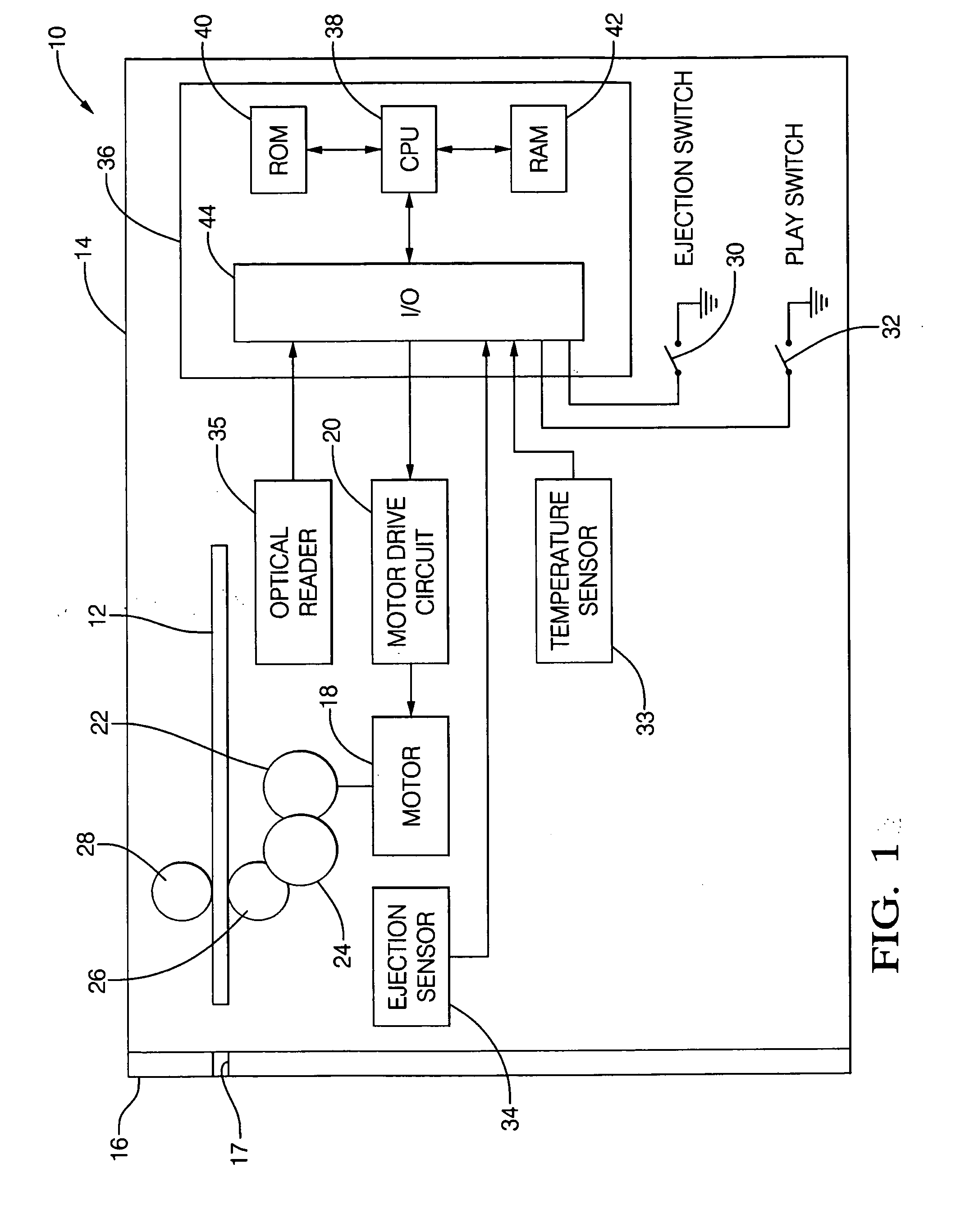

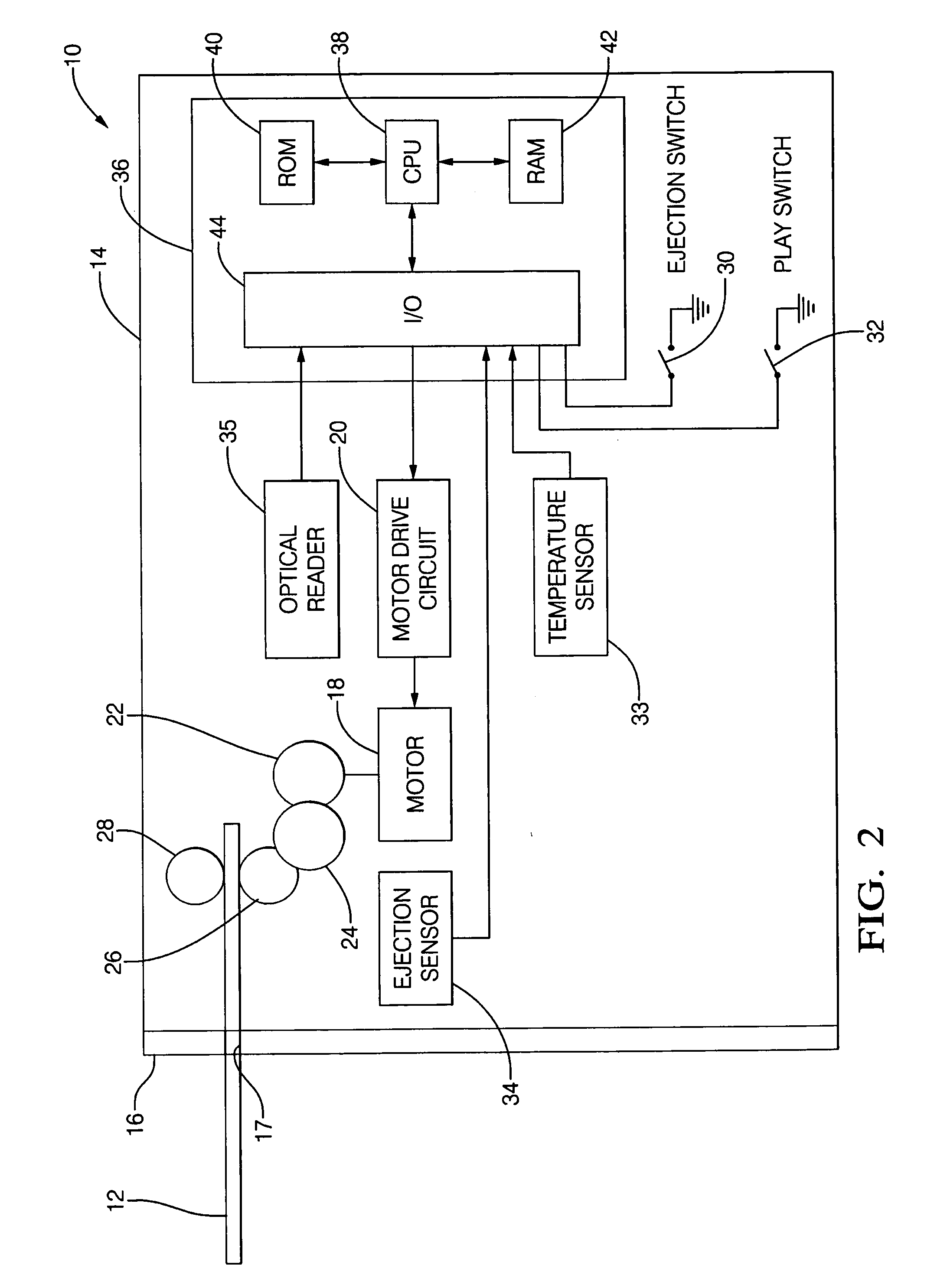

Compact disc player and method for controlling ejection of a compact disc from the compact disc player

A compact disc player and a method and an article of manufacture for controlling ejection of a compact disc are provided. The compact disc player includes a temperature sensor configured to generate a signal indicative of a temperature of the compact disc player utilizing a temperature sensor. The compact disc player further includes a controller operably communicating with the temperature sensor. The controller is configured to determine an ejection time interval value based on the signal. The controller is further configured to energize a motor coupled to a drive mechanism for a time internal corresponding to the ejection time interval value to induce the drive mechanism to move a compact disc to a predetermined position outwardly from a housing.

Owner:APTIV TECH LTD

Printing system and program therefor

InactiveUS20050231546A1Visual representation by matrix printersOther printing apparatusComputer printingComputer science

A printing system includes a host computer and a printer. The host computer generates pixel group data for a plurality of pixel groups as print data. The pixel group data is generated in a time series by processing pixel groups aligned in a paper conveying direction within an image foaming range. This data provides information for driving specific nozzles in each print head. The pixel group data also identifies non-ejection times indicating the number of times in the pixel group that ink droplets are not ejected from nozzles in succession. By considering the non-ejection times identified in this pixel group data to be “information for driving the nozzles,” the printer itself need not count nor identify the number of non-ejection times, but can drive the nozzles with drive waveforms corresponding to the number of non-ejection times.

Owner:BROTHER KOGYO KK

Method and device for estimating a myocardial performance parameter

InactiveUS20110106232A1ElectrotherapyDiagnostic recording/measuringIsovolumic relaxation timeCardiac muscle

An implantable medical device applies an electric signal to at least a portion of a heart in a subject. A resulting electric signal is collected from the heart and is used together with the applied signal for determining a cardiogenic impedance signal. The impedance signal is processed in order to estimate an isovolumetric contraction time, an isovolumetric relaxation time and an ejection time for a heart cycle. These three time parameters are employed for calculating a Tei-index of the heart. The Tei-index can be used as myocardial performance parameter in heart diagnosis and / or cardiac therapy adjustment.

Owner:ST JUDE MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com