Patents

Literature

120results about How to "Shorten the running distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-Reynolds-number airfoil profile with cooperative fluidic control, and control method thereof

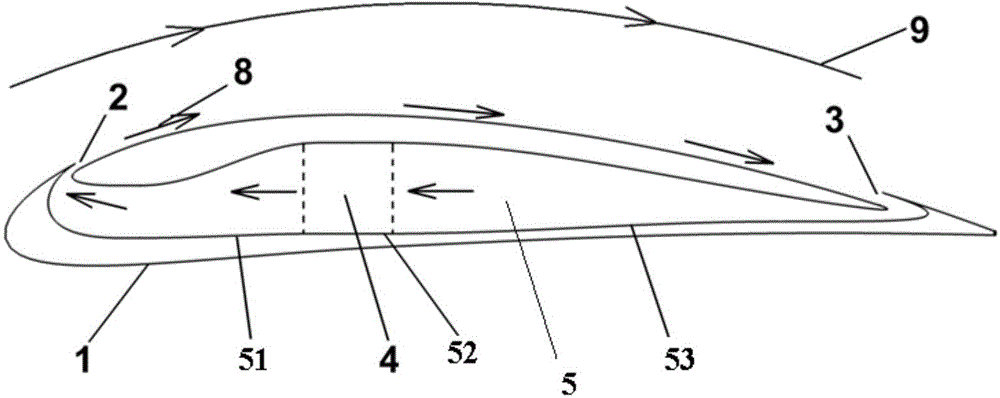

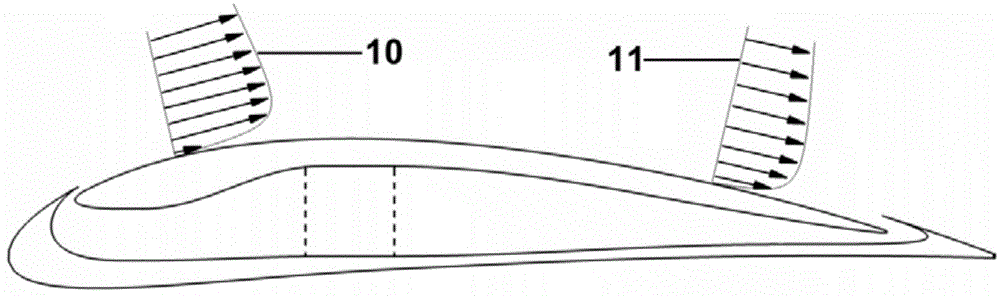

The invention provides a low-Reynolds-number airfoil profile with cooperative fluidic control, and a control method thereof. The low-Reynolds-number airfoil profile with cooperative fluidic control is characterized in that an air jet port (2) is formed in the front edge of the upper surface of an airfoil profile body (1); an air suction port (3) is formed in the rear edge of the upper surface of the airfoil profile body (1); the air jet port (2) is communicated with the air suction port (3) through an air flow pipeline (5) which is arranged inside the airfoil profile body (1); an air pump (4) which is used for driving air suction and air jet to be carried out simultaneously is mounted in the air flow pipeline (5); moreover, the air jet port (2) and the air suction port (3) are perpendicular to the upper surface of the airfoil profile body (1) respectively. The lift of the airfoil profile is greatly increased, the resistance is obviously reduced, and the stalling characteristic of the airfoil profile is improved, so that the aim of efficiently improving the aerodynamic performance of an aircraft is achieved; in addition, the low-Reynolds-number airfoil profile also has the characteristic of low energy consumption.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

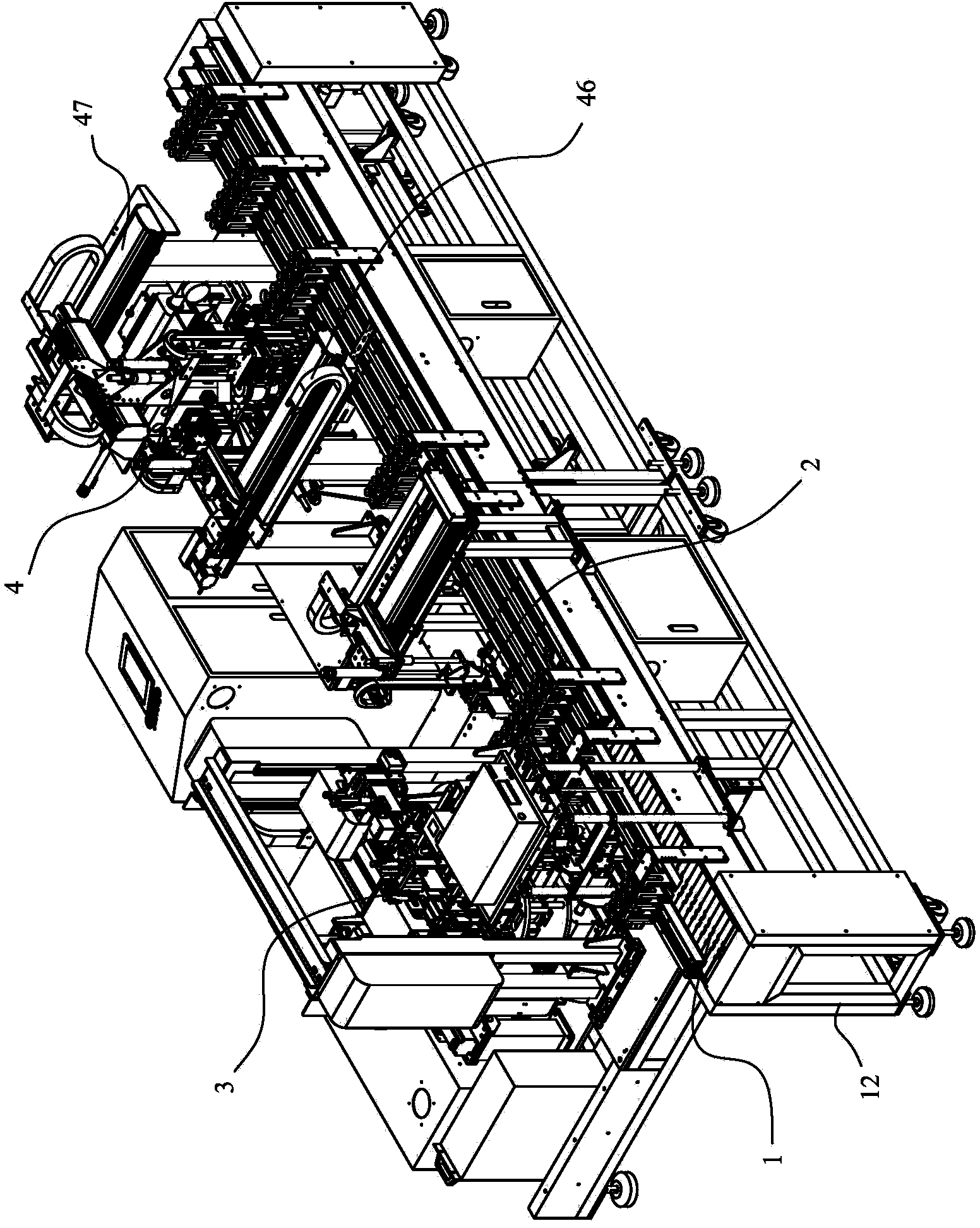

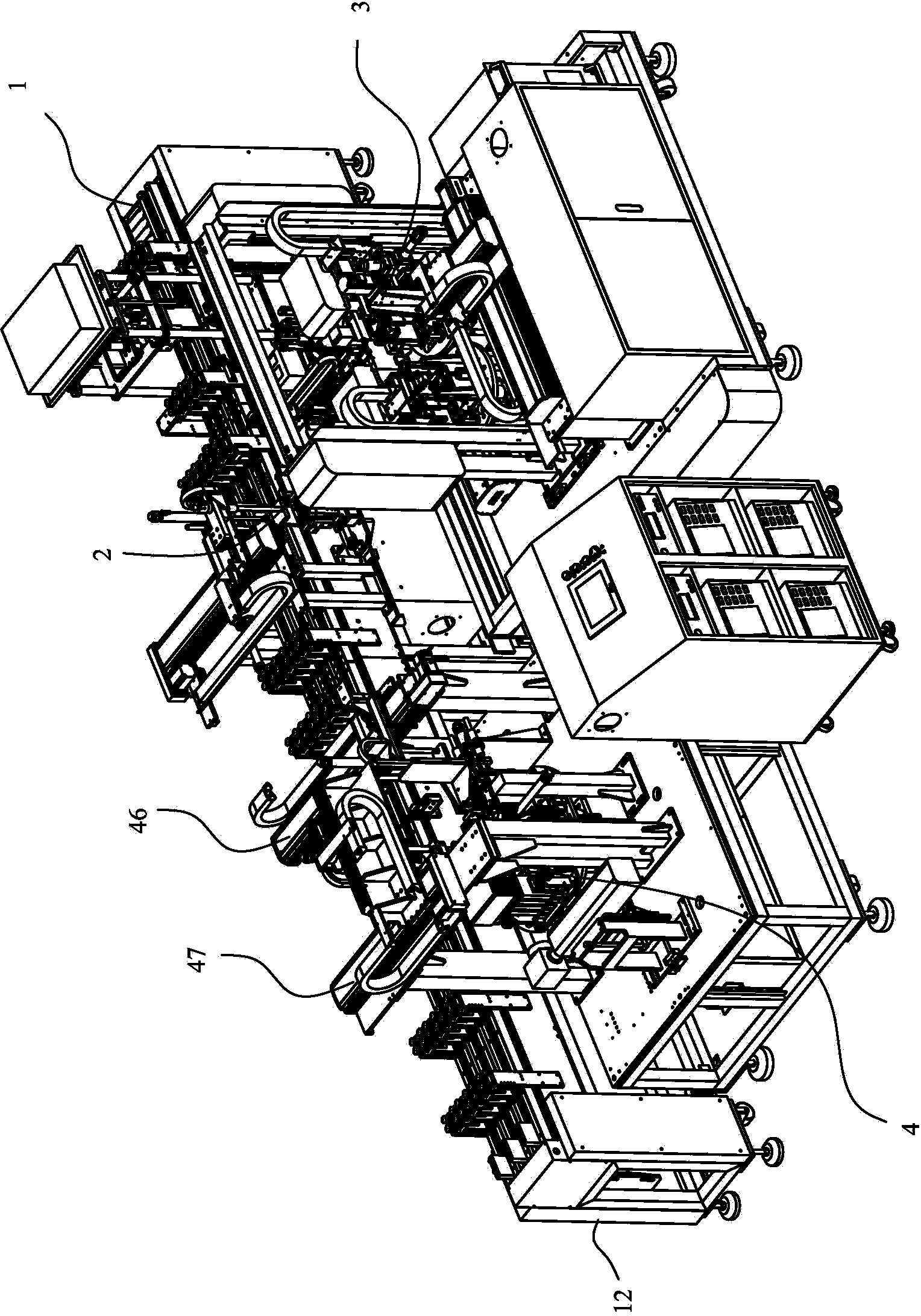

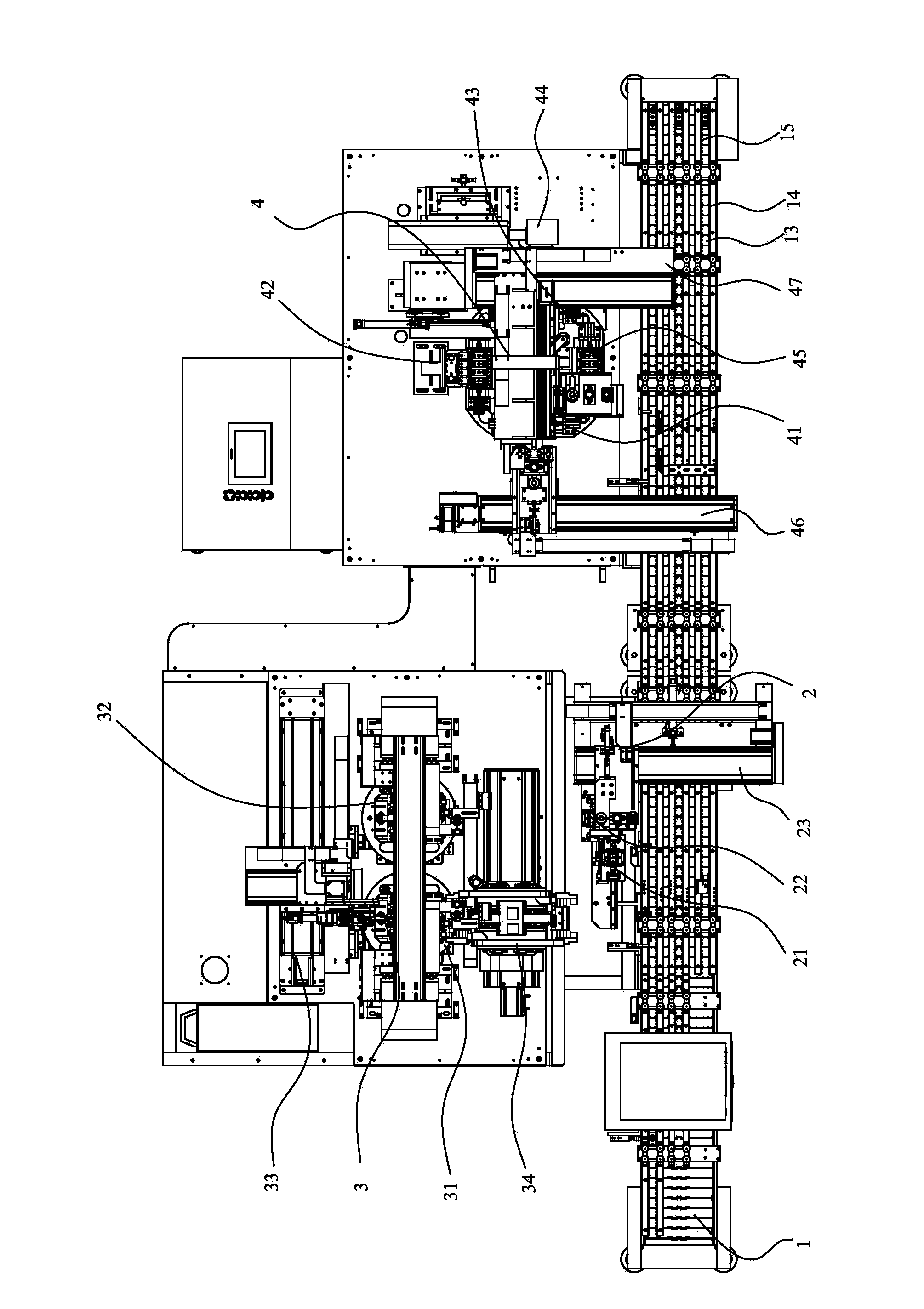

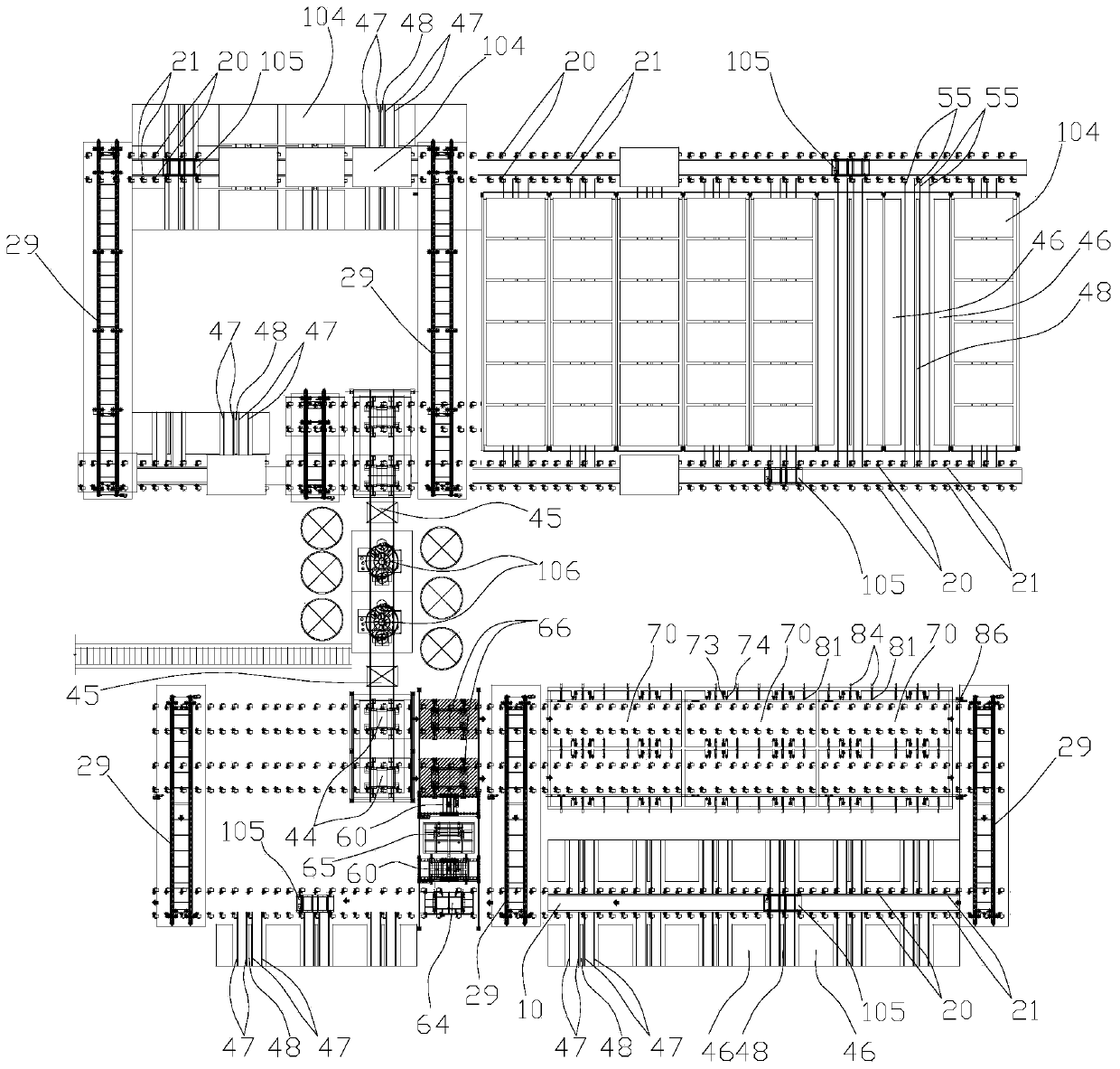

Automatic device for welding and detecting lithium battery

ActiveCN103904367AShorten the running distanceImprove work efficiencyAssembling battery machinesFinal product manufactureTransfer systemManipulator

The invention discloses an automatic device for welding and detecting a lithium battery. The automatic device comprises a transfer system, a temporary storage system, a welding system and a detecting system, wherein the transfer system comprises a transfer stander, a transfer belt and a transfer groove, the temporary storage system comprises a temporary loading-unloading station and a temporary storage loading-unloading mechanical hand, the welding system comprises a welding loading-unloading mechanical hand, a first welding rotating device, a second welding rotating device, a welding head mechanical hand and a welding control box, and the detecting system comprises a detection loading mechanical hand, a loading workstation, a leakage detector, a short-circuit detector, a laser labeling device, an unloading workstation and a detection unloading mechanical hand. The automatic device is compact in structure, reasonable in layout and low in space cost; a battery product is loaded onto the welding system to be welded from the transfer belt, labeled by the detecting system and unloaded through the transfer belt, full automation in control is realized, the labor intensity of workers can be alleviated, and the product quality and production efficiency can be improved.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

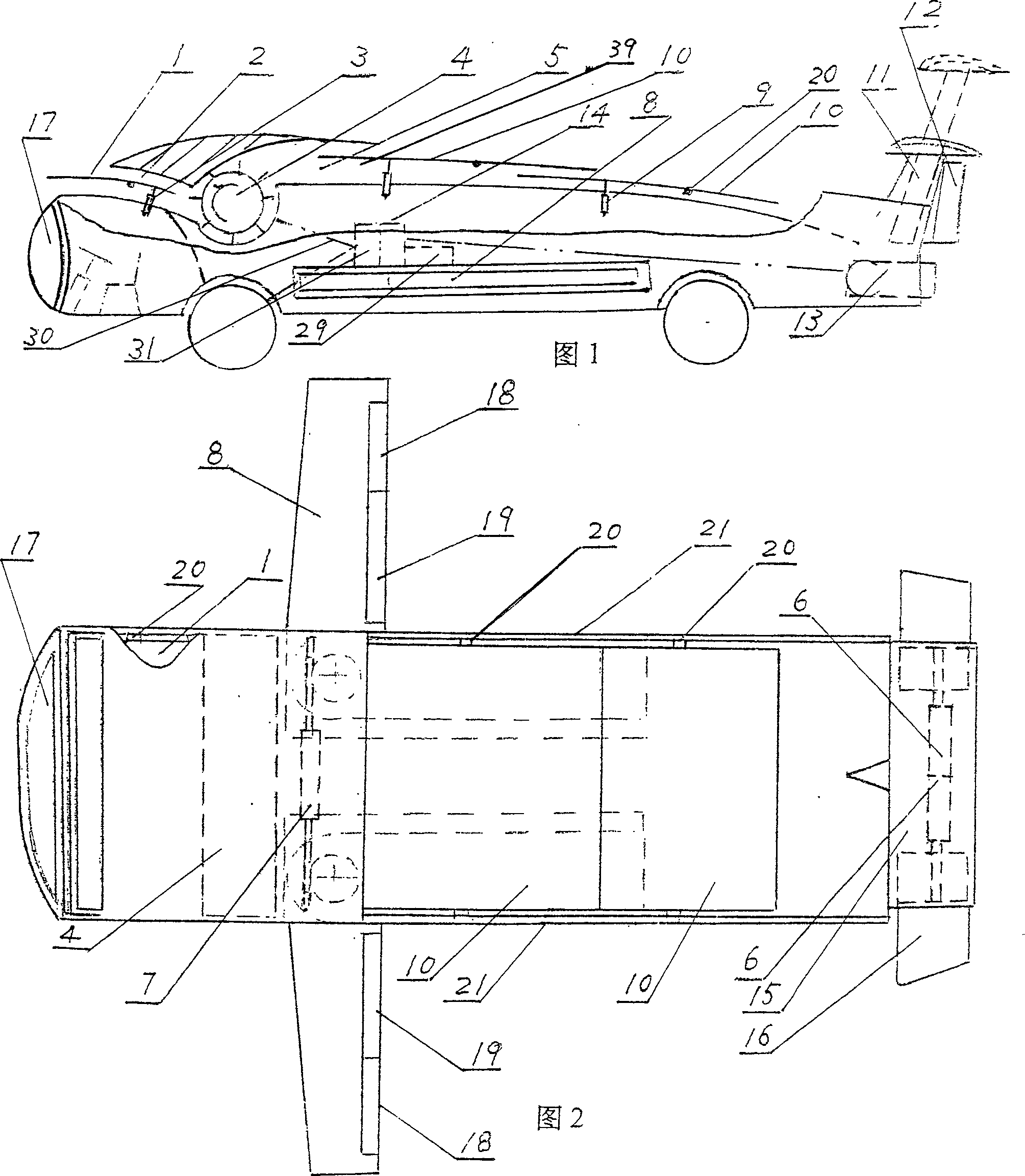

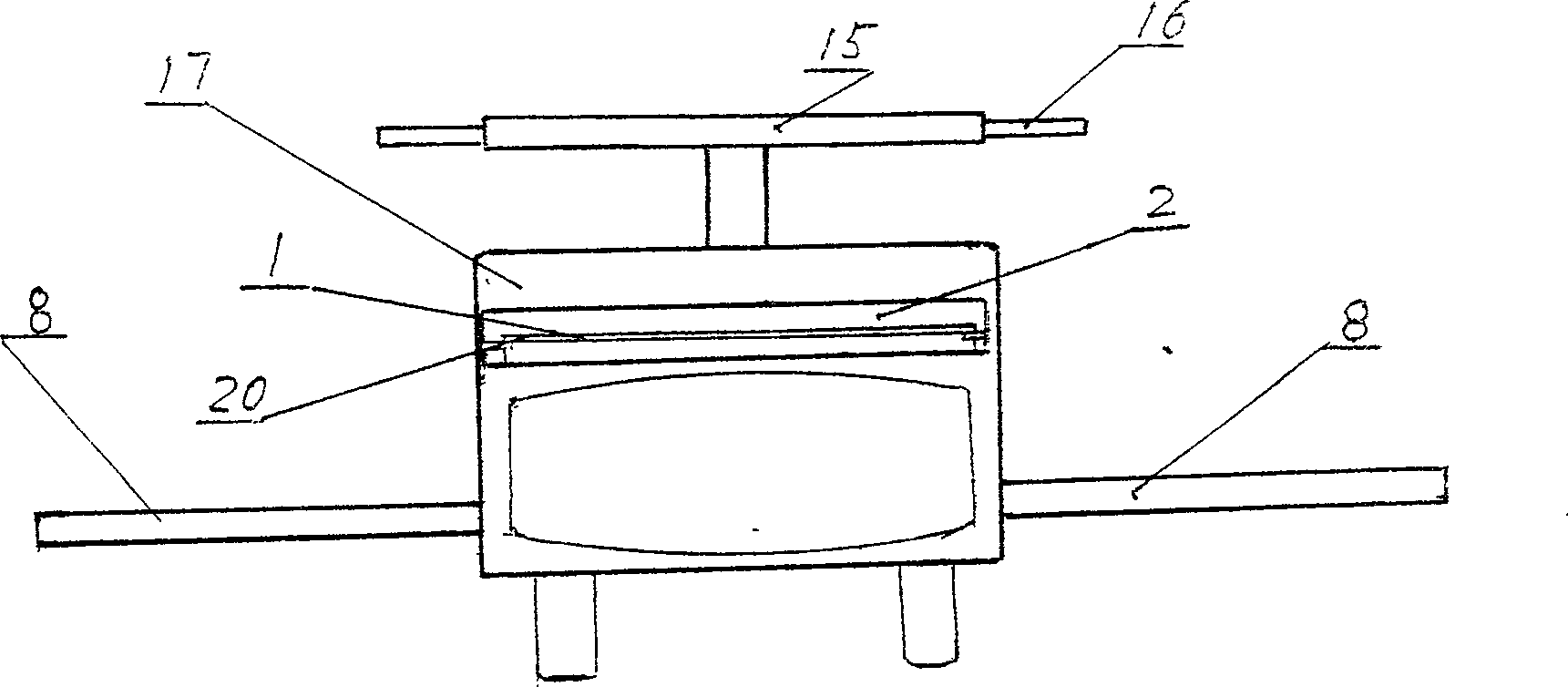

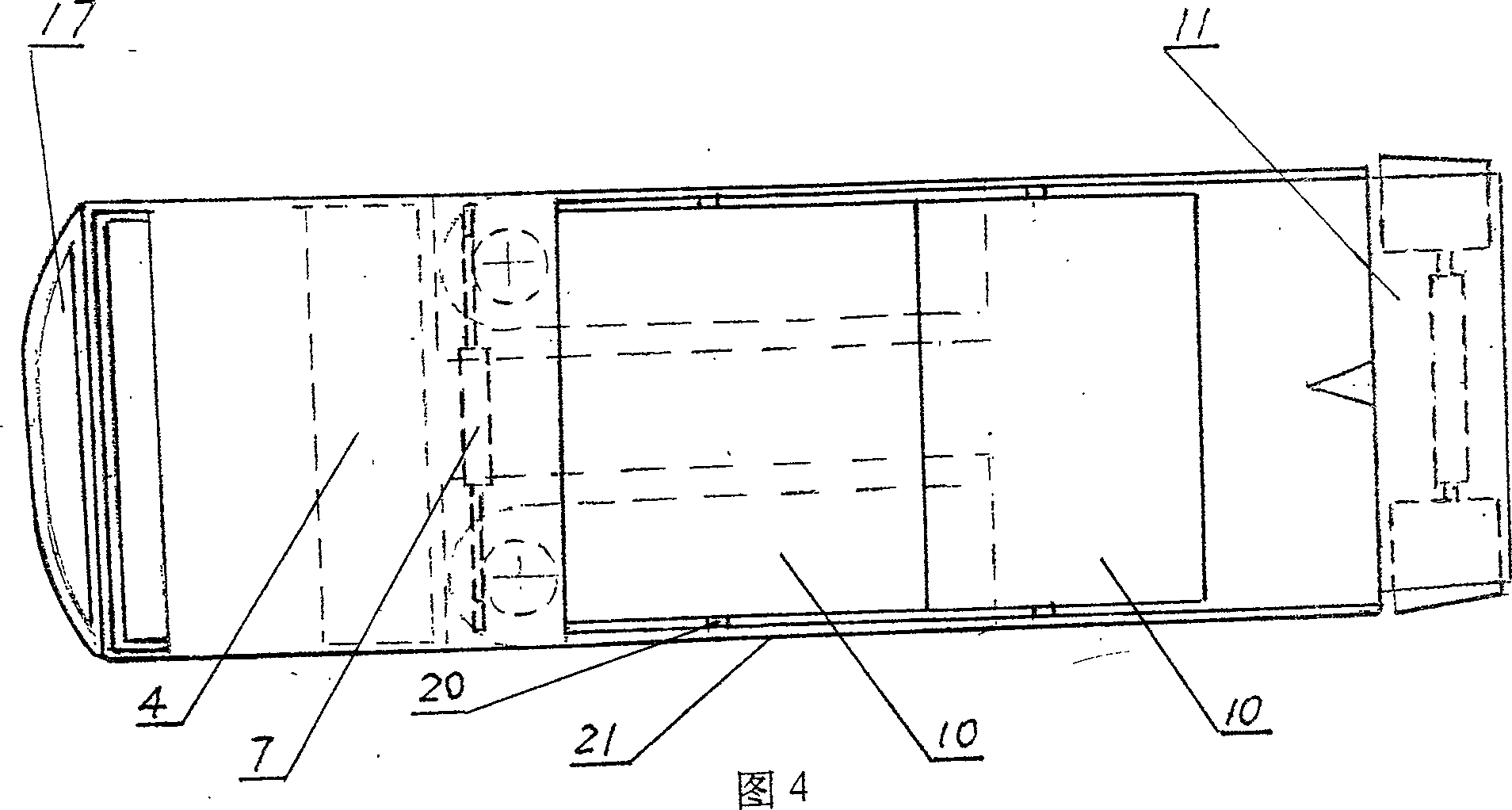

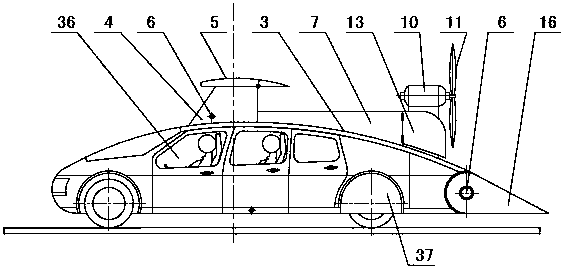

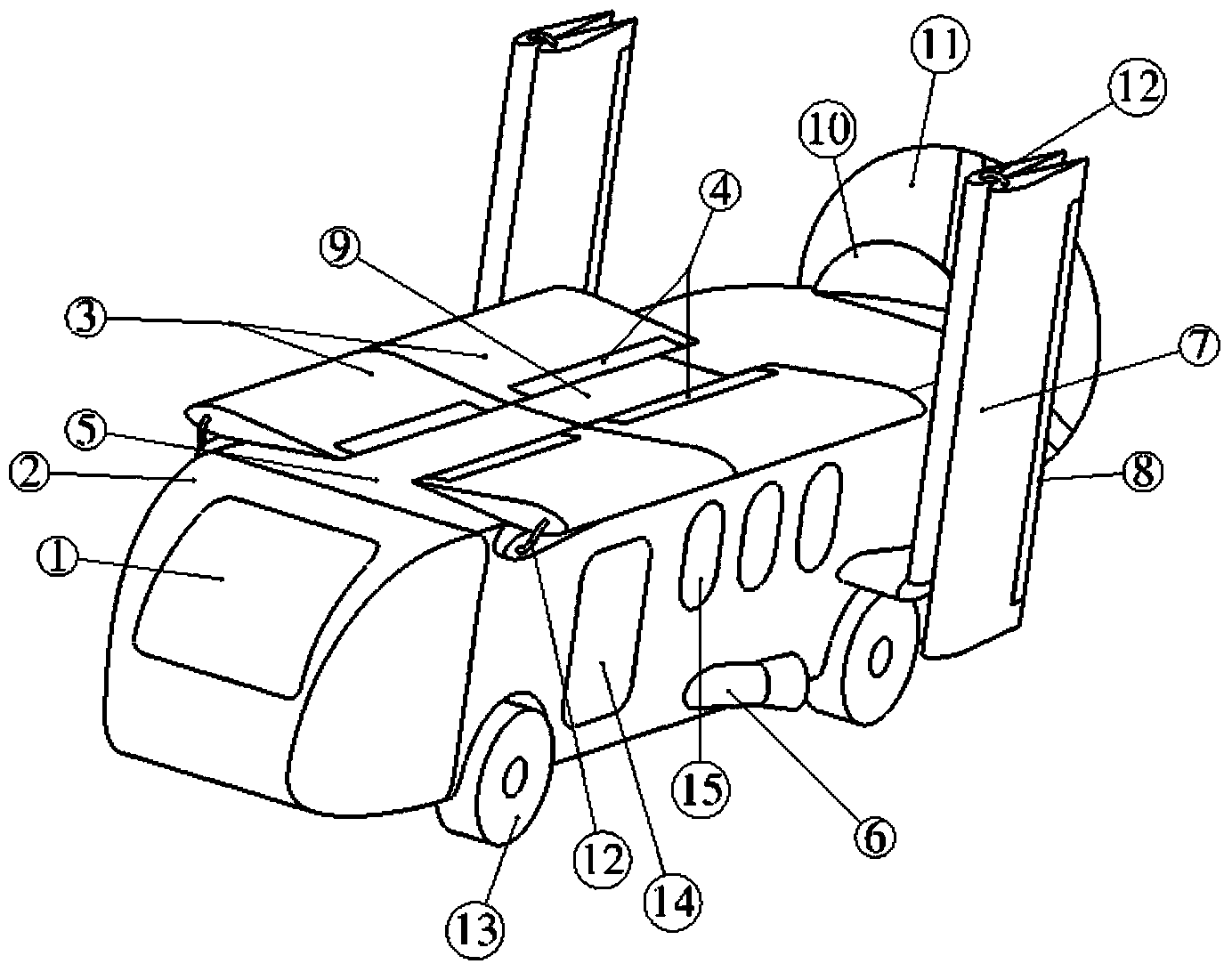

Hovercar

The invention relates to a hovercar which comprises a car, wherein, two symmetrical wings are installed on the car, and a horizontal tail is connected with a vertical tail at the tail part of a car body. The hovercar is characterized in that the end parts of the wings are movably connected with the car by a rotating mechanism; a wing 'blowing' and 'sucking' mechanism is installed at the upper part of the car body; and an auxiliary propeller which can provide forward and backward thrust is installed at the tail part of the car. As the hovercar is not different from a common car in performance on the ground, is equivalent to a mini-fixed wing aircraft in the flying state, and can ensure short takeoff and vertical landing, and can control the speed properly in the sky instead of in the airport, thus providing convenience in travel for people.

Owner:陈博

Cold sling method and device

ActiveCN101676174ALarge degree of freedom in energy collectionSimple structureLaunching/towing gearConstant powerGas cylinder

A aircraft carrier cold sling method and a device thereof are disclosed, which comply with the sling formula as accumulative energy swift release + high efficiency transmission = sling movement. The invention adopts gas-liquid fusion cylinder as the sling main body in cooperation with a gas cylinder and a control valve, under cold state and completely closed state of the sling machine, high energy gas collected in the gas cylinder in the sling machine enters into the gas-liquid fusion cylinder via the control valve to reach the gas reaching end to swift release energy, simultaneously pistons of all stages of the liquid reaching end of the gas-liquid fusion cylinder are pushed to carry out constant power high efficient cold sling loading. The cold sling energy recycling device adopts an energy recycling pump arranged on a reciprocate carriage, a zooming pump, and a spacing gear cylinder arranged on a guidance slide rail; or adopts a structure of hinging a movable slide rail at the front end of the guidance slide rail and arranging the energy recycling pump and the zooming pump on the movable slide rail. The aircraft carrier cold sling method and a device thereof in the invention breaks the bottleneck of passive energy storage, has strong freedom in energy accumulation and fast sling speed, can realize constant power super-high efficient transmission of enormous energy and sling in cold state won by stillness, and features simple structure, small volume, light weight, easy manufacture, small power consumption and extensive adaptability.

Owner:胡宣哲

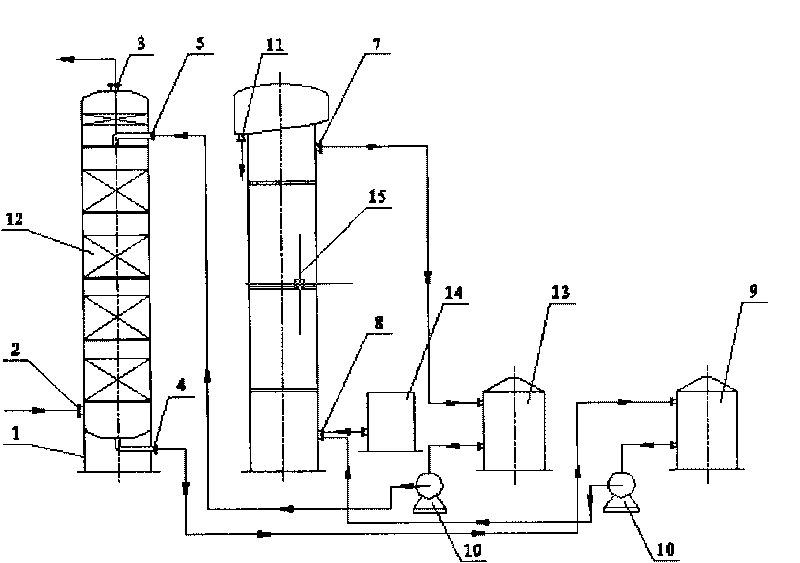

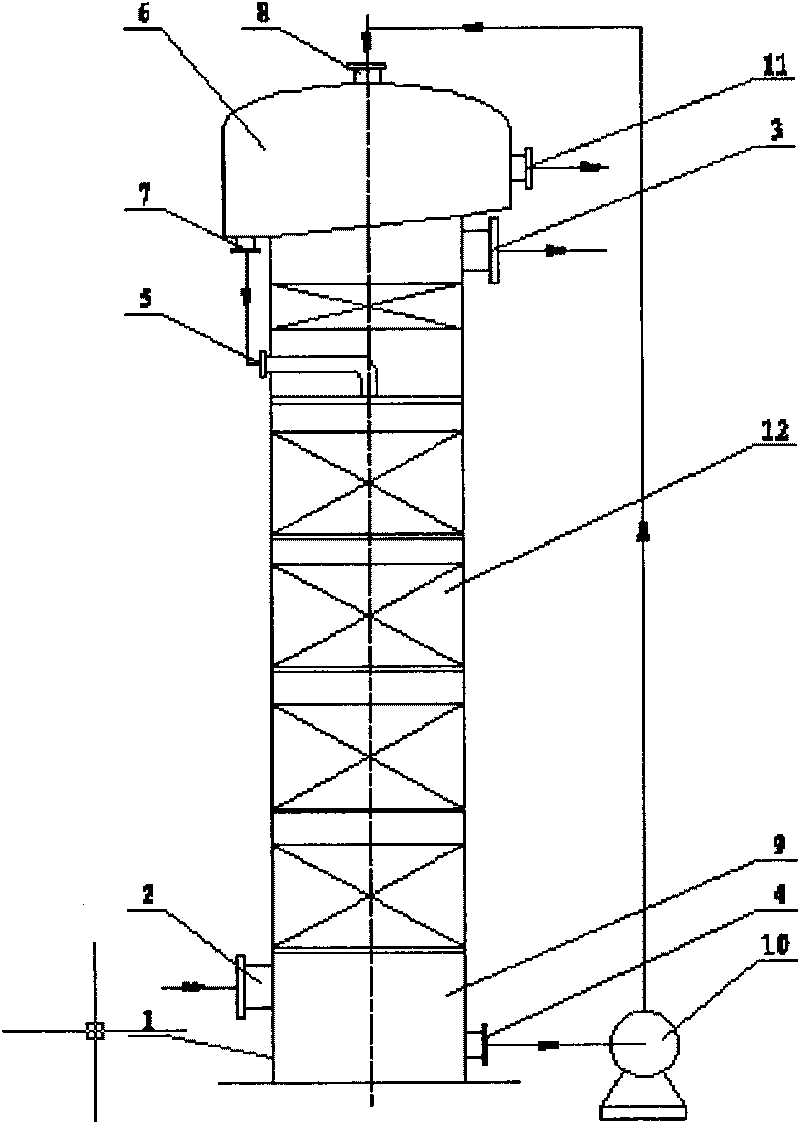

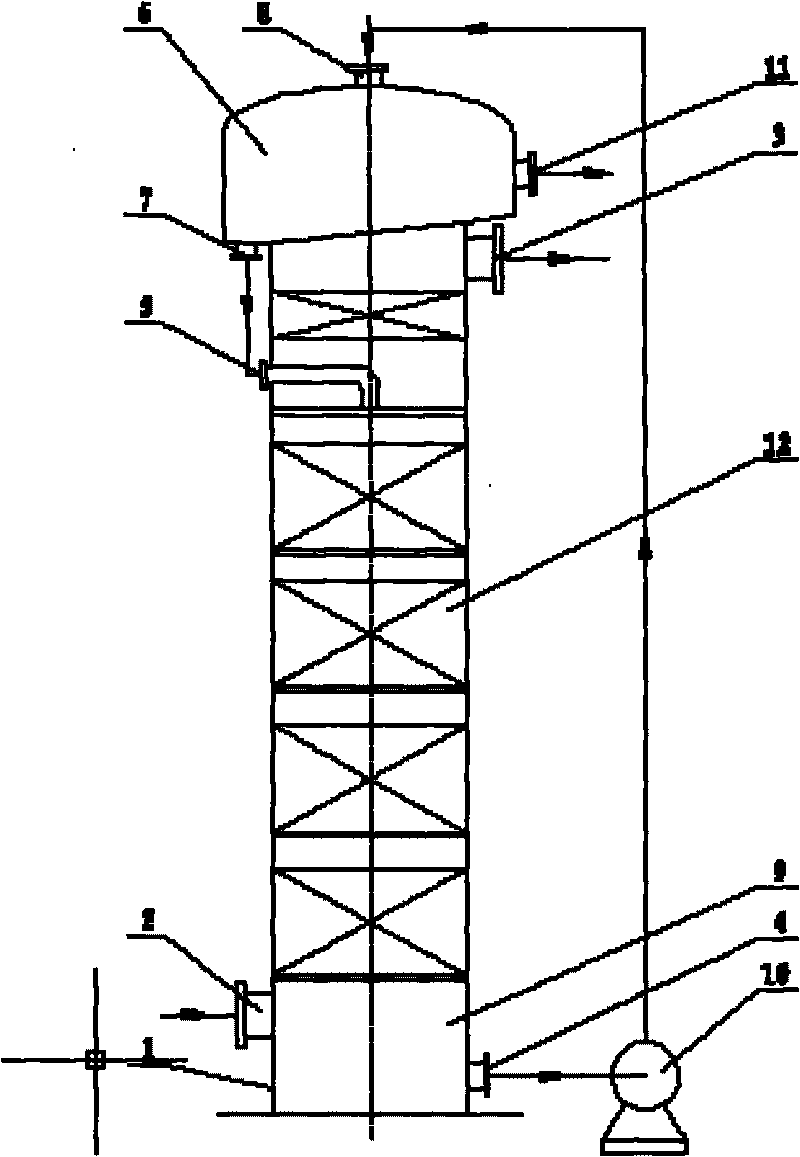

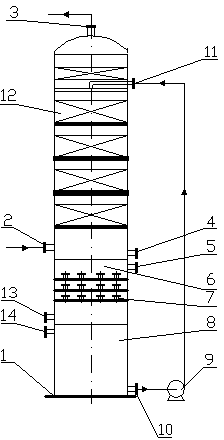

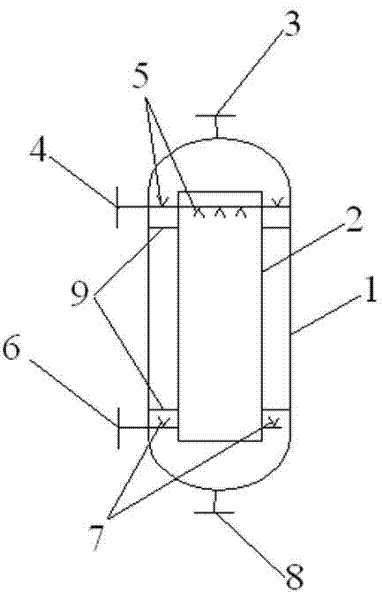

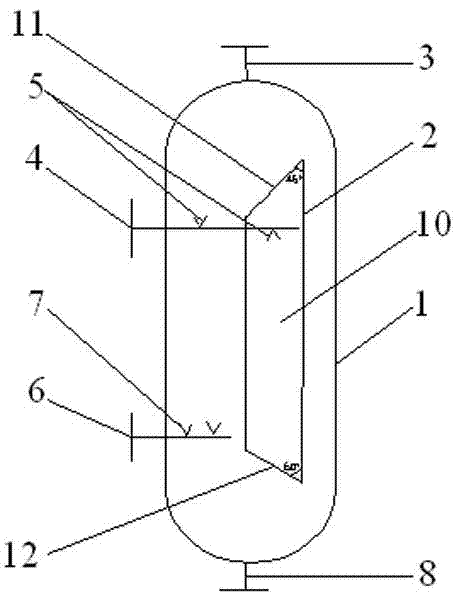

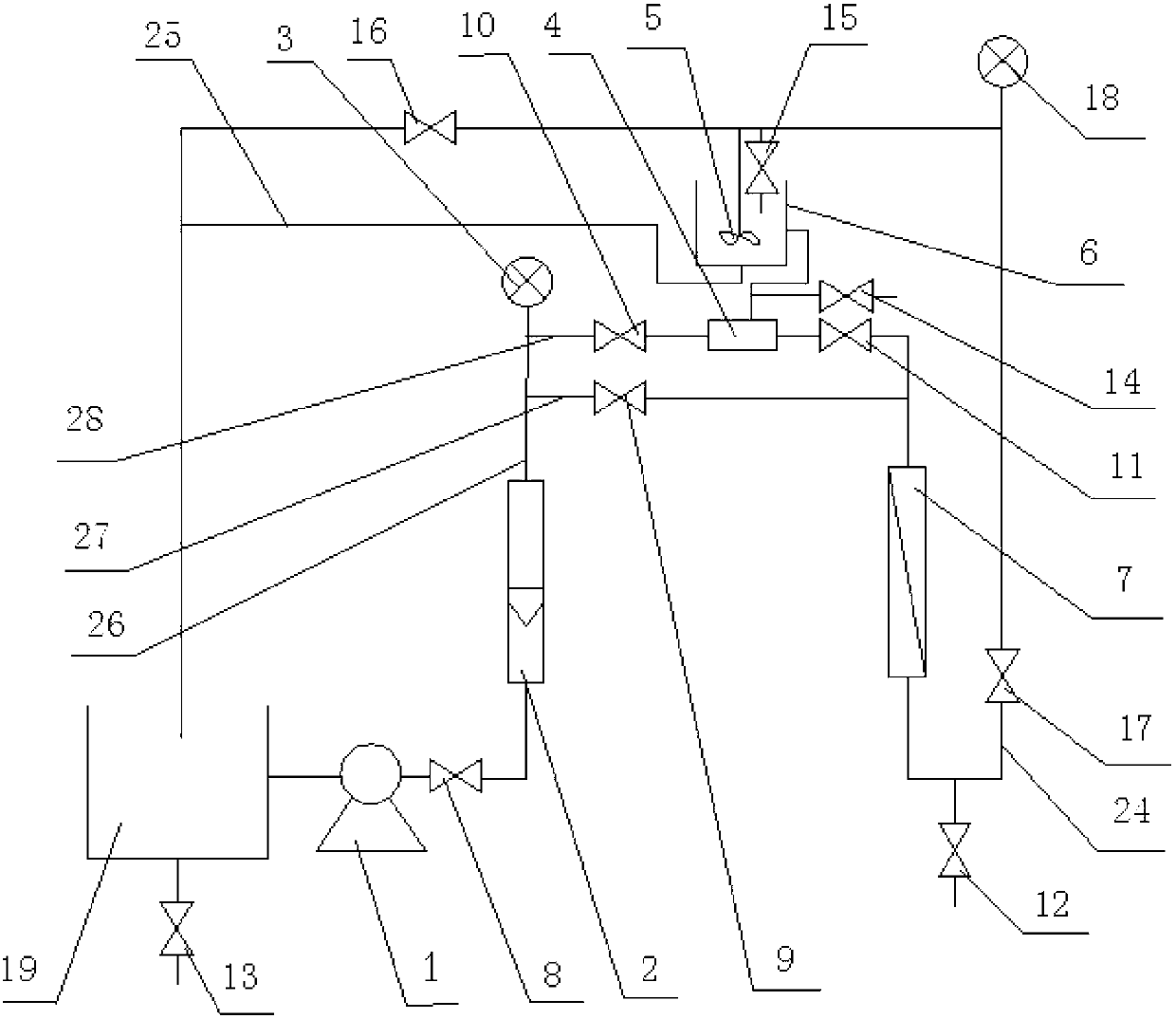

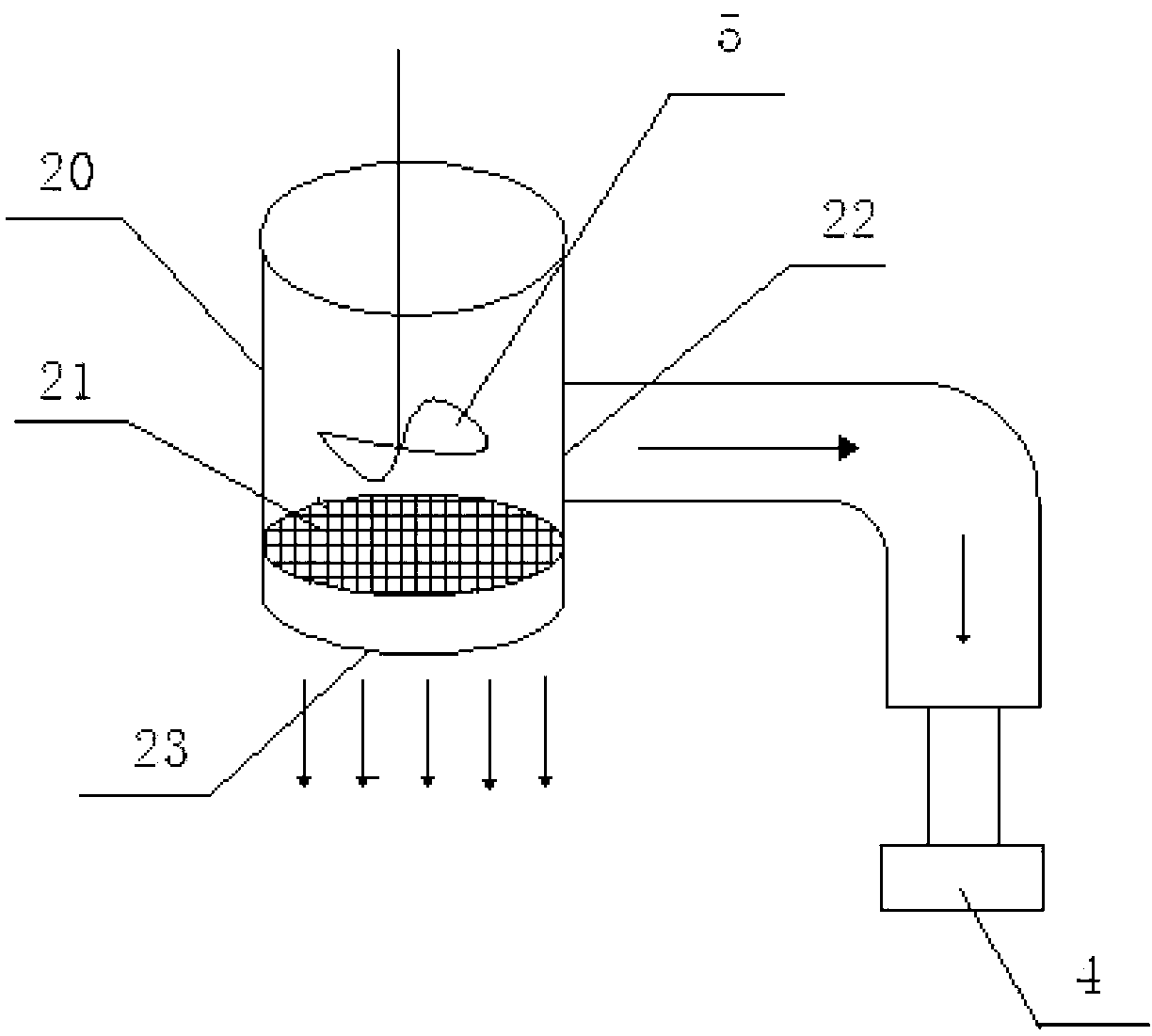

Self-adsorption ejector desulfurizing tower and manufacturing process thereof

InactiveCN101709231ASimple structureShorten the running distanceSulfur preparation/purificationGas purification by liquid washingHydrogenCoke oven

The invention discloses a self-adsorption ejector desulfurizing tower, which optimally designs and integrates four pieces of main equipment, namely a desulfurizing tower 1, a regenerating tower 15, a pregnant solution tank 9 and a barren solution tank 13, in a traditional coke oven gas desulfurizing system, into a whole, without increasing the diameter and the height of the tower, eliminates the regenerating tower, the barren solution tank and the barren solution pump, designs the skirt support part at the bottom part of the desulfurizing tower into the pregnant solution tank so as to store a desulfurizing circulation fluid, arranges a set of self-adsorption oxidizing and regenerating ejector 6 at the top of the desulfurizing tower 1, and uses the ejector 6 to suck air so as to oxidize and regenerate a desulfurized barren solution, wherein sulfur foams generated after regeneration automatically flow into a sulfur foam tank; the generated desulfurized barren solution is used for spraying a raw gas reversely flowing upwards from the lower part of the tower directly from the top of the tower through a liquid spreader so as to wash and absorb sulfureted hydrogen contained in a raw gas; the raw gas is changed into a pregnant solution which flows into the pregnant solution tank at the bottom of the desulfurizing tower; and a solution circulating pump pumps the pregnant solution into the ejector at the top of the tower to be oxidized and regenerated. The circulating operation realizes the function of using a piece of equipment to finish the work which is finished by four pieces of equipment. The self-adsorption ejector desulfurizing tower decreases the investment of the equipment, simplifies the production process, reduces the energy consumption and improves the desulfurizing efficiency.

Owner:林吉萍

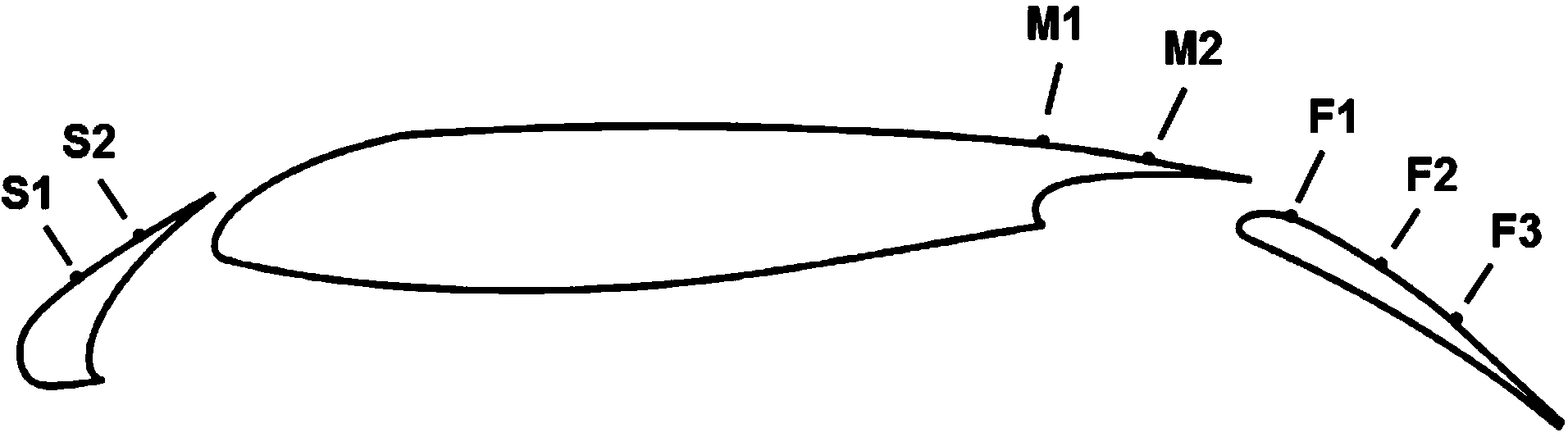

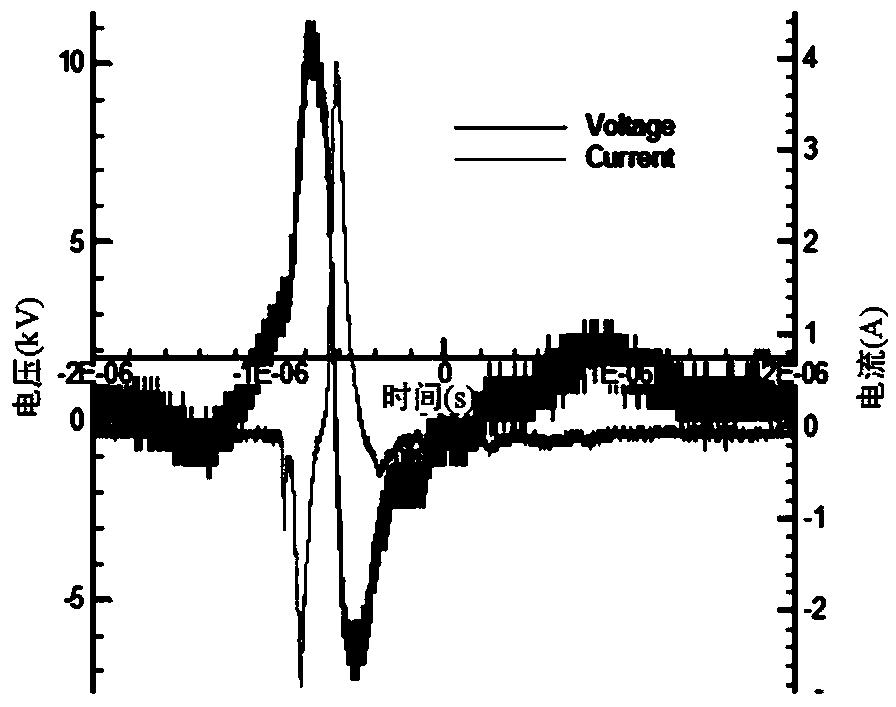

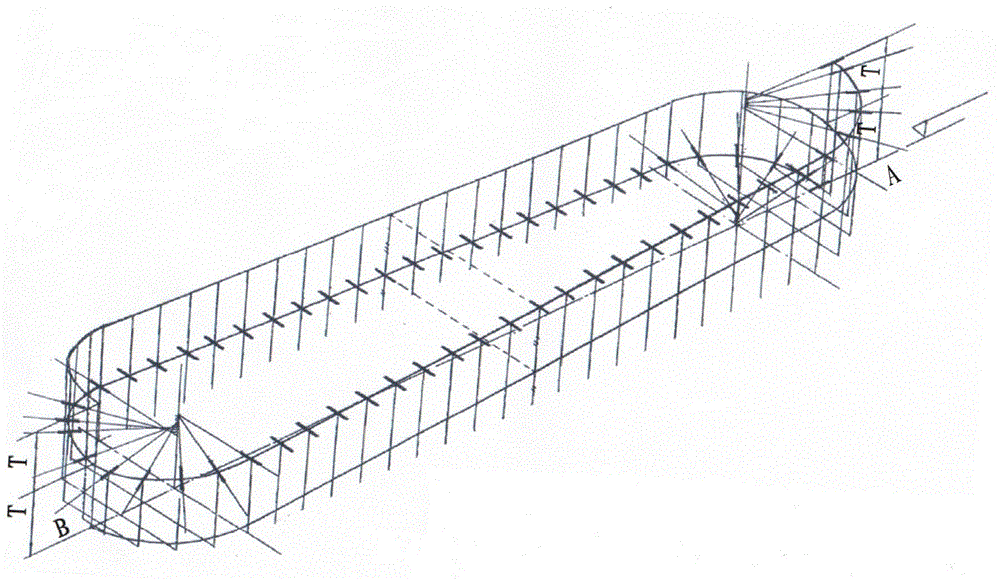

Method for controlling plasma flow of wing lift-rising apparatus

InactiveCN103523208AImprove the lift-to-drag ratioIncrease lift coefficientAir-flow influencersLeading edgeTrailing edge

The invention relates to a method for controlling plasma flow of wing lift-rising apparatus, and the technical scheme is characterized in that: plasma exciters are laid on the suction face of the leading edge slat, the suction face of the main wing trailing edge and the suction face of the trailing edge flap. The plasma exciter is composed of electrodes in asymmetric layout and separated by an insulating material, the electrode on the upper surface of the insulating material is connected with the high-voltage terminal of a pulse plasma power supply, and the electrode on lower surface is earthed. The laying positions of the plasma exciters are at the leading edge and the trailing edge of a separation point. When the leading edge slat and the trailing edge flat are deployed during the launching and the landing of an airplane, a signal of 'on' is emitted and the plasma exciters are turned on; and when the leading edge slat and the trailing edge flat are fold by the airplane, a signal of 'off' is emitted and the plasma exciters are turned off. The method helps to effectively control the flow separation of the suction faces of the leading edge slat, the main wing trailing edge and the trailing edge flap when the airplane is in a launching or landing state, substantially improving wing lift-drag ratio and maximum lift coefficient, and further improve the launching and landing weight of the airplane and shorten the running distance.

Owner:AIR FORCE UNIV PLA

Multi-spiral ramp type stereoscopic parking garage

InactiveCN102877673AImproved internal performanceGuaranteed uptimeParkingsParking spaceParking brake

The invention discloses a multi-spiral ramp type stereoscopic parking garage, and belongs to the technical fields of automotive parking garages. The multi-spiral ramp type stereoscopic parking garage is characterized in that the parking garage is designed by applying the basic features of a multiple thread, namely an equal pitch and the same lift. A double-spiral ramp type stereoscopic parking garbage is taken for example; phase positions at an interval of 180 degrees on an axial cross section are designed; starting points of two independent spiral surfaces A and B are subjected to an equal lead and an equal floor height and are subjected to equidirectional hovering rise along a ring form in a closed area; a reversing road is designed at a connecting line of one pair of equal-height points selected on each floor of the two spiral surfaces, namely, an up one-way road A can lead to a down one-way road B through the reversing road on each floor; and the purposes of searching a parking space for parking and coming in and out of the garage are completed. Ground and underground parts which are relatively independent exist. The multi-spiral ramp type stereoscopic parking garage has the beneficial effects that the internal operation capacity of the parking garage is improved manyfold in structure principle compared with those of the schemes of various self-propelled parking garages applying designs most approaching the prior art; automobiles run smoothly and sequentially; the economical efficiency is good; and the garage capacity rate is high.

Owner:杨金奎 +1

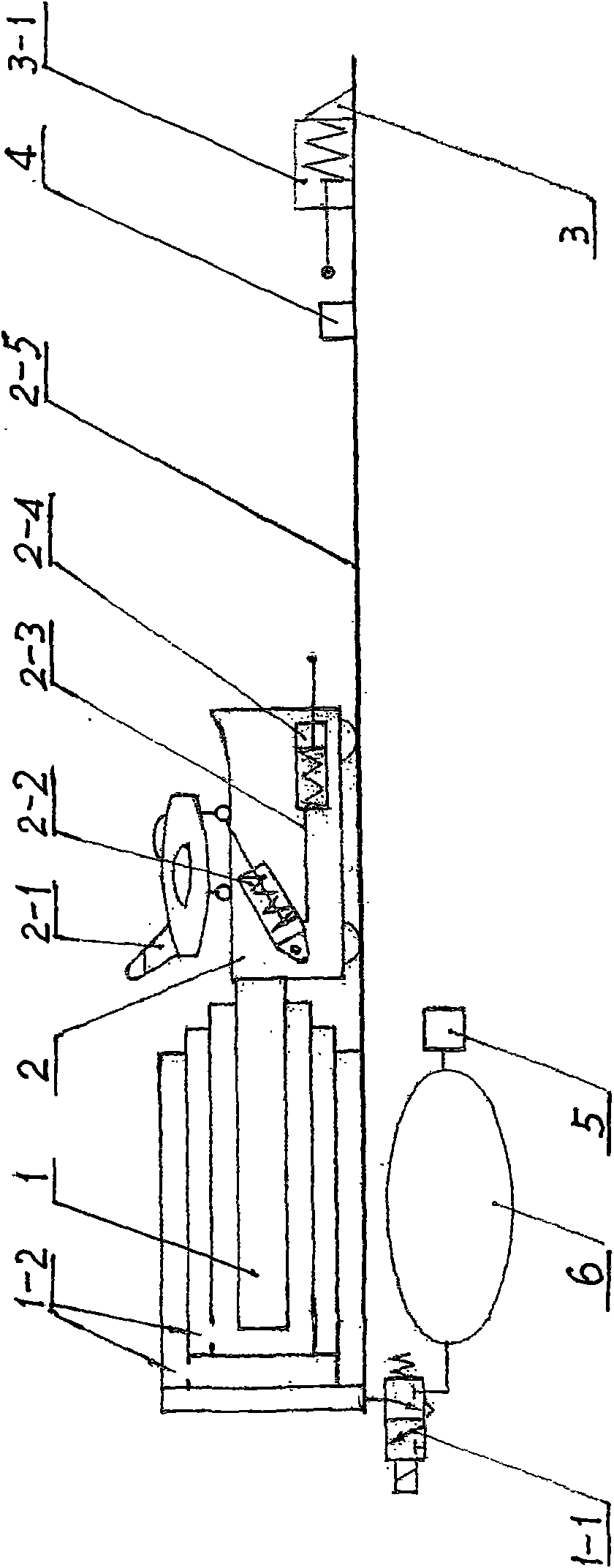

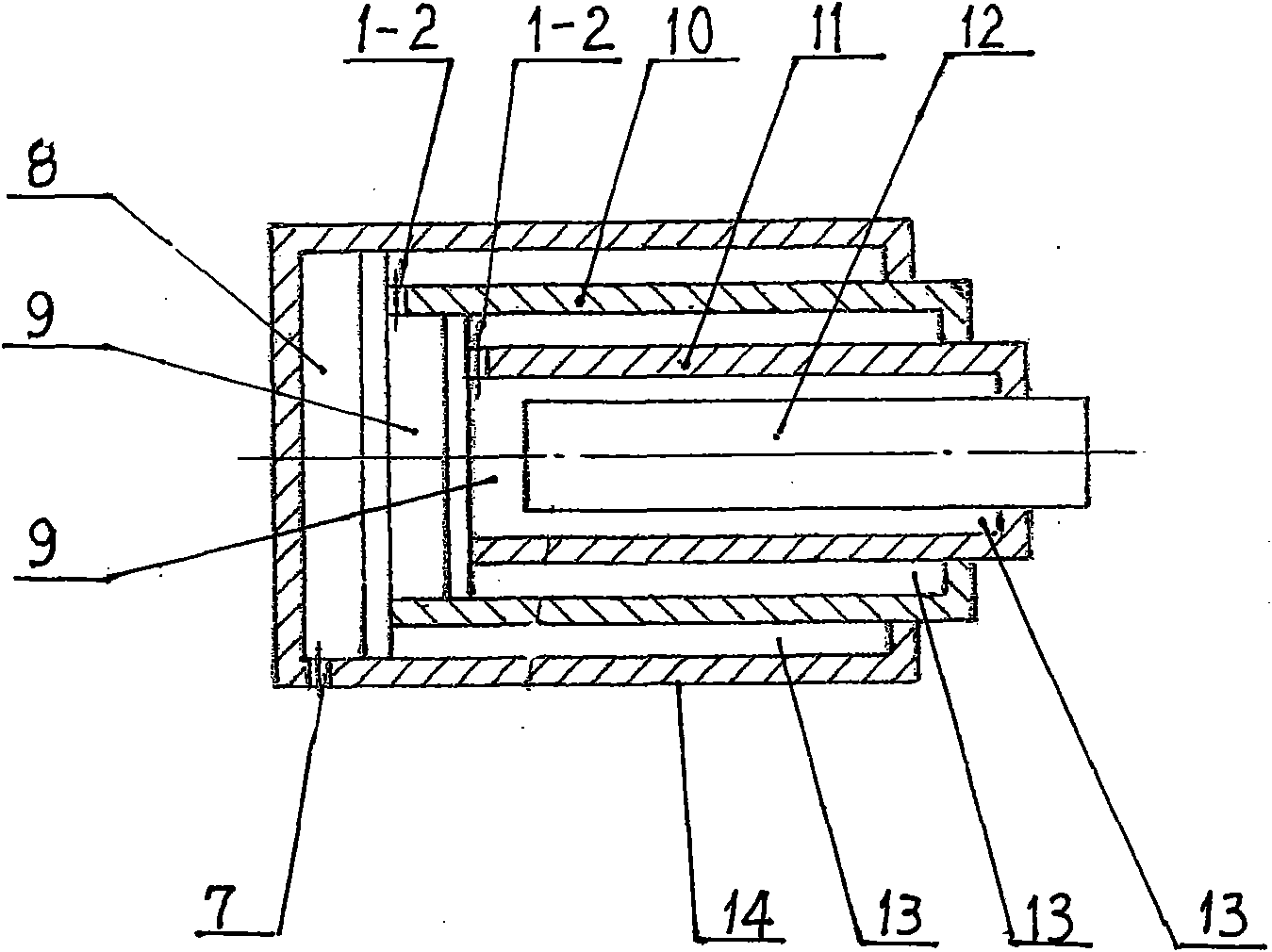

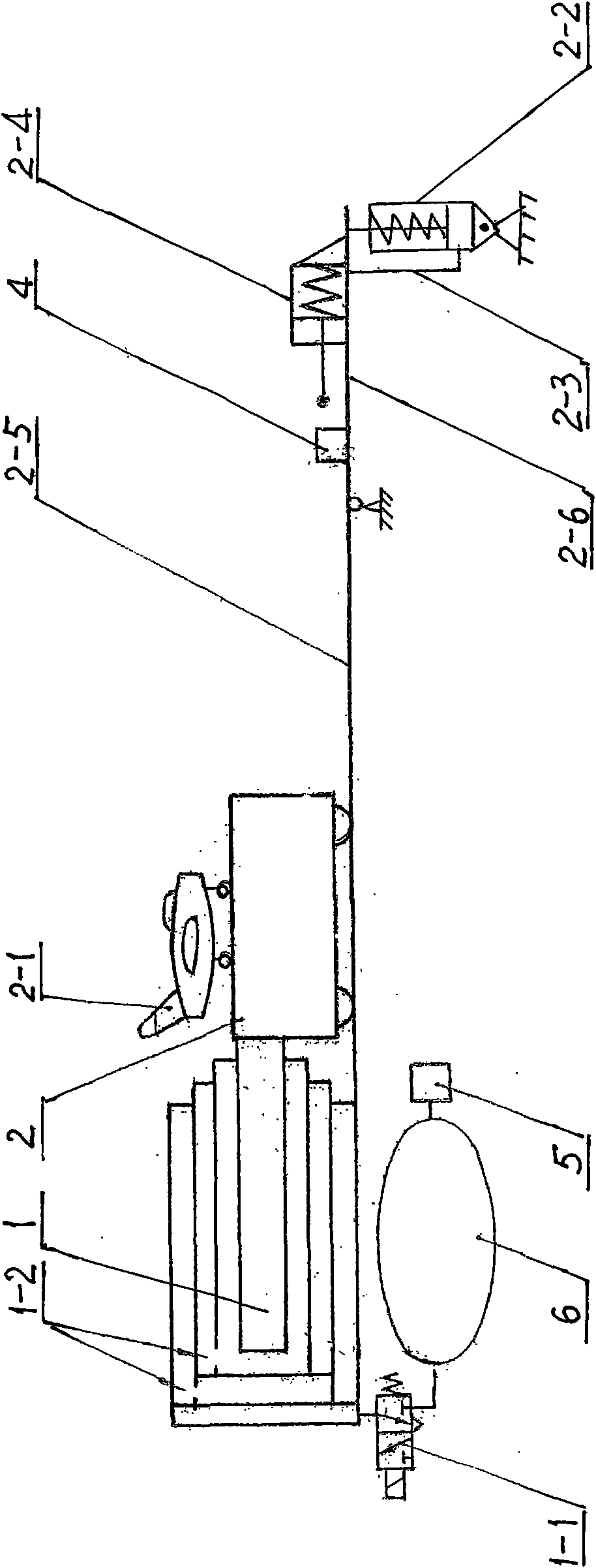

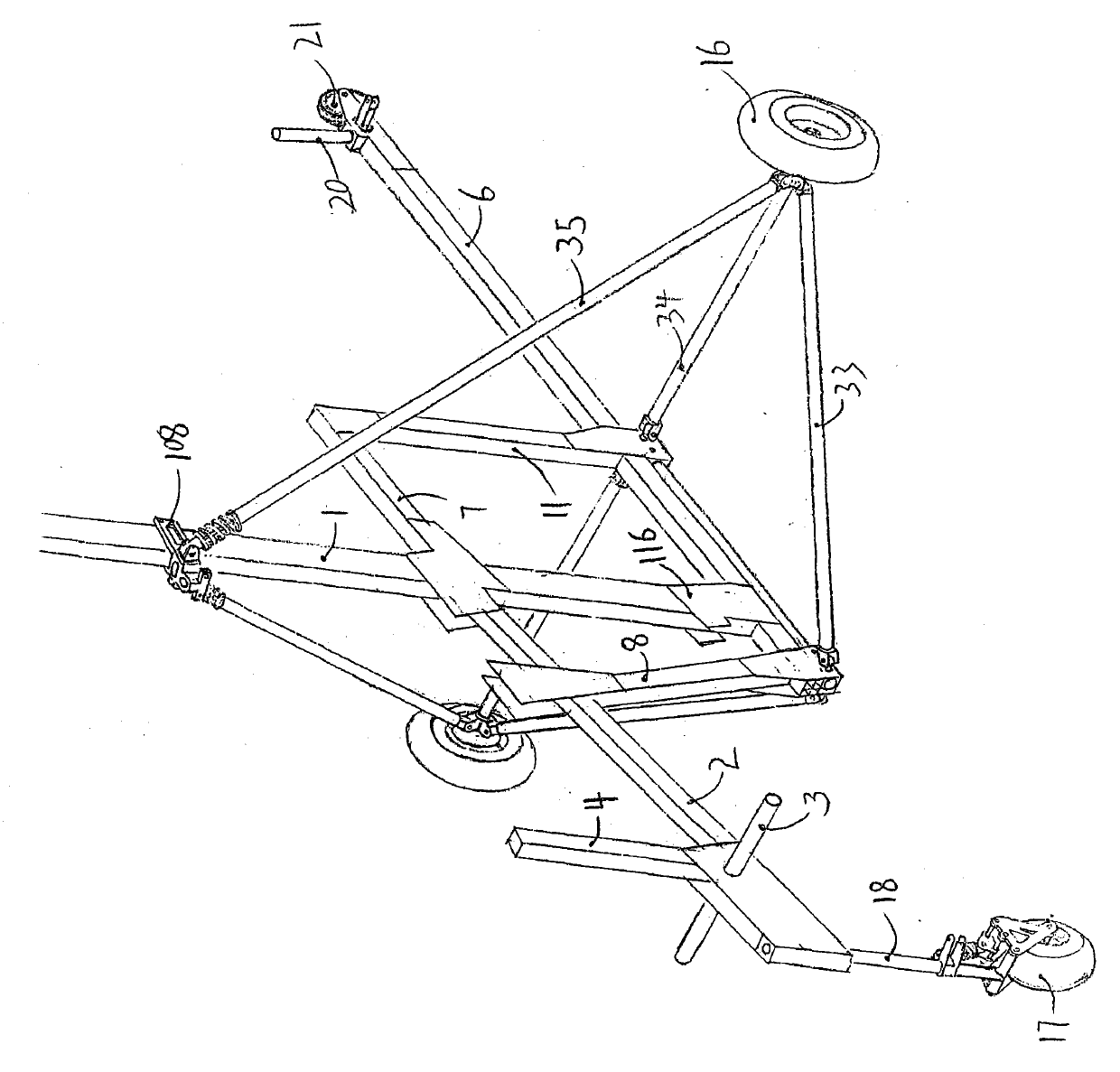

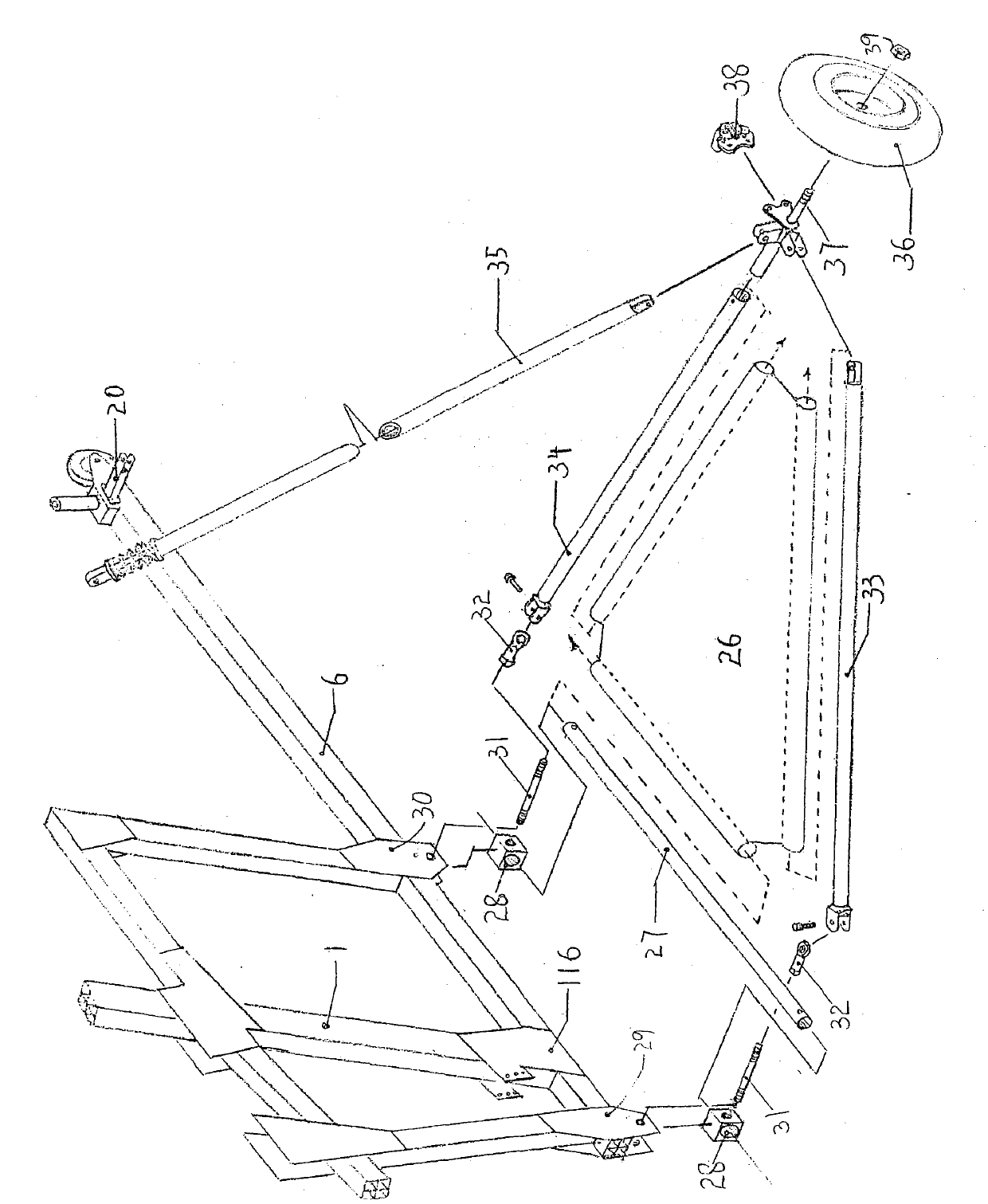

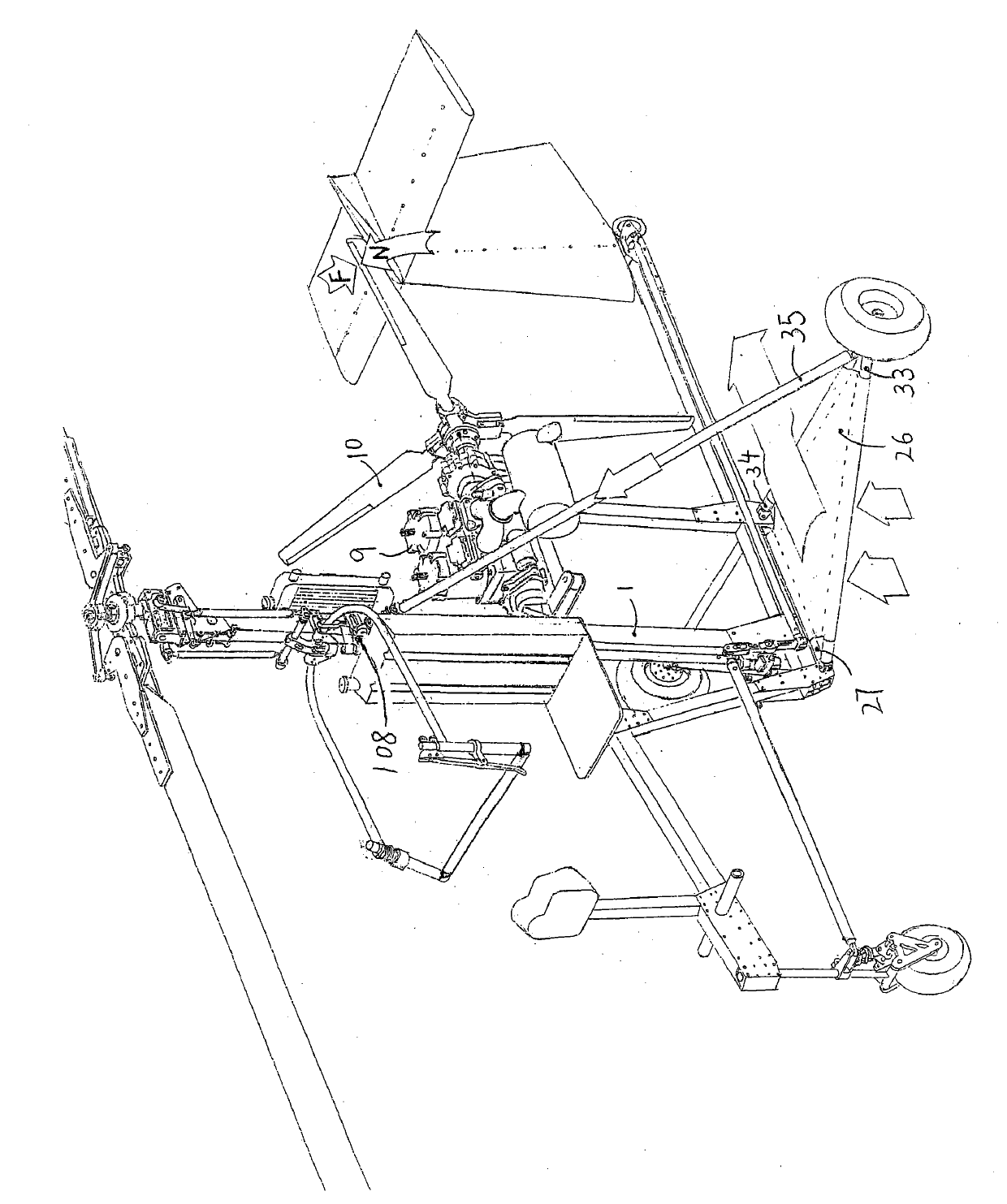

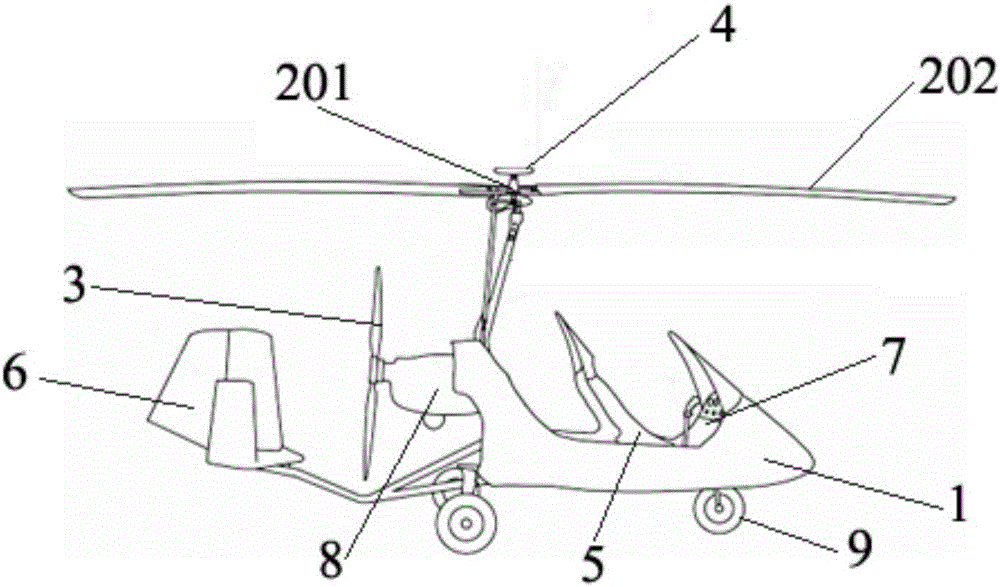

Single-man manual-control rotorcraft

The invention provides a single-man manual-control rotorcraft which is composed of a rotorcraft body, a rotor shaft cantilever tilt structure, a full-manual-control mechanism and a rotor head mechanism having an internal variable distance function. The rotorcraft body has a high-gravity center normal-three-point undercarriage structure, wherein the main rotorcraft body consists of a vertical column, a front beam, a back beam, an engine bracket and a front support beam. A steering wheel is arranged right ahead and empennages are arranged at the back. A driver seat and an engine are respectively at the front and the back of the vertical column. In the rotorcraft, a push-type propeller provides power and a three-point frame-type individual damping support mechanism having a rotor reactive force balancing device is used for balancing the reactive force generated to the rotorcraft body by air during operation of the rotor, so that the rotorcraft is improved in takeoff and landing stability. By means of the full-manual-control mechanism having a steering linking function, a driver can complete the operations comprising distance change of the rotor, rotor shaft tilt, flying direction turning and braking just like driving a motorbike.

Owner:王略

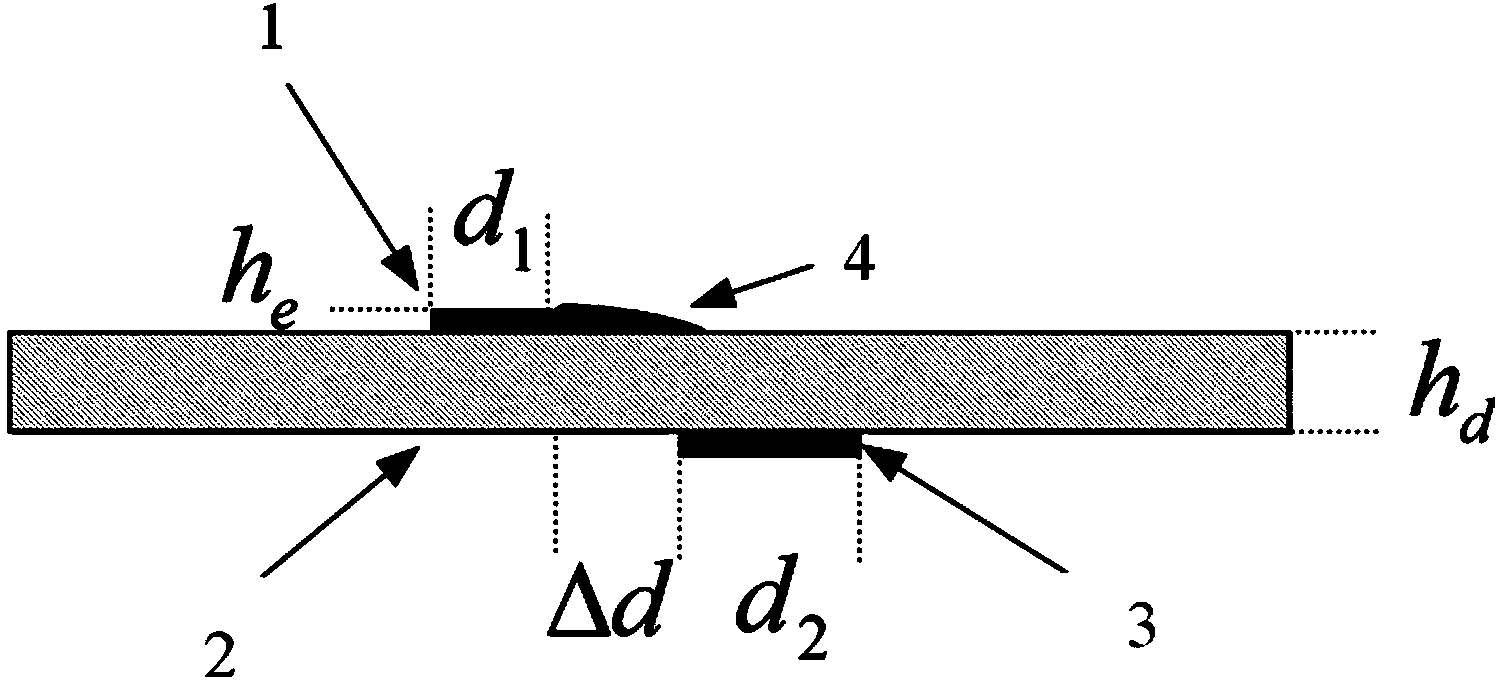

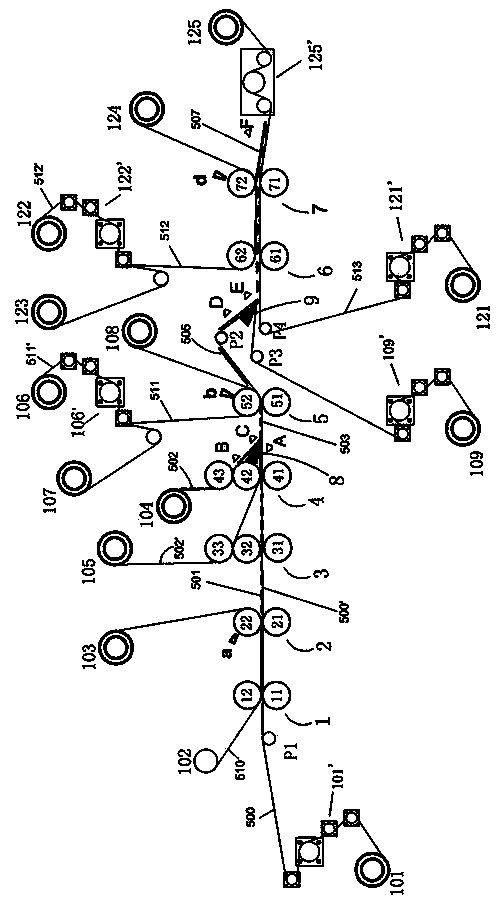

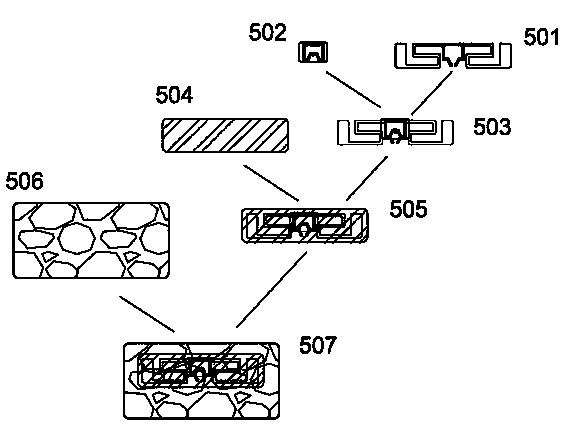

Method and equipment for manufacturing separated type RFID (radiofrequency identification) tags for antennas

InactiveCN103971151AShorten the running distanceIncrease productivityAntenna supports/mountingsAdhesivesPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a method and equipment for manufacturing separated type RFID (radiofrequency identification) tags for antennas. The method includes S1, enabling a drive shaft (21) and a drive shaft (51) of a first conveying mechanism to drive a carrier tape with an aluminum foil to convey the aluminum foil at the speed of V1; compositing an adhesive tape with the carrier tape with the aluminum foil, and performing die cutting on the adhesive tape and the carrier tape with the aluminum foil by the aid of an antenna circular cutting die (22) to obtain aluminum foil antennas; S2, conveying a base tape with RFID units at variable speeds in certain periods, separating the RFID units from the base tape when the base tape passes a flat scraper, and adhering the RFID units on the upper surfaces of the corresponding aluminum foil antennas on the carrier tape to form tag modules; S3, enabling the drive shaft (51) to drive a PET (polyethylene terephthalate) film with gum, performing die cutting on the PET film with the gum by the aid of a PET film circular cutting die (52) to form PET films, and enabling the PET films to cover the corresponding tag modules on the upper surface of the carrier tape to form semi-finished products. The antenna circular cutting die (22) is arranged at the edge of the drive shaft (21), and the PET film circular cutting die (52) is arranged at the edge of the drive shaft (51). The method and the equipment have the advantages that the equipment is provided with a plurality of conveying mechanisms, the conveying mechanisms are controlled by a master control unit, accordingly, repeated compositing, die cutting, waste discharging and secondary asynchronous aligning, transferring and labeling operation can be completed, and various separated type tag products can be automatically produced.

Owner:SHENZHEN HYAN MICROELECTRONICS

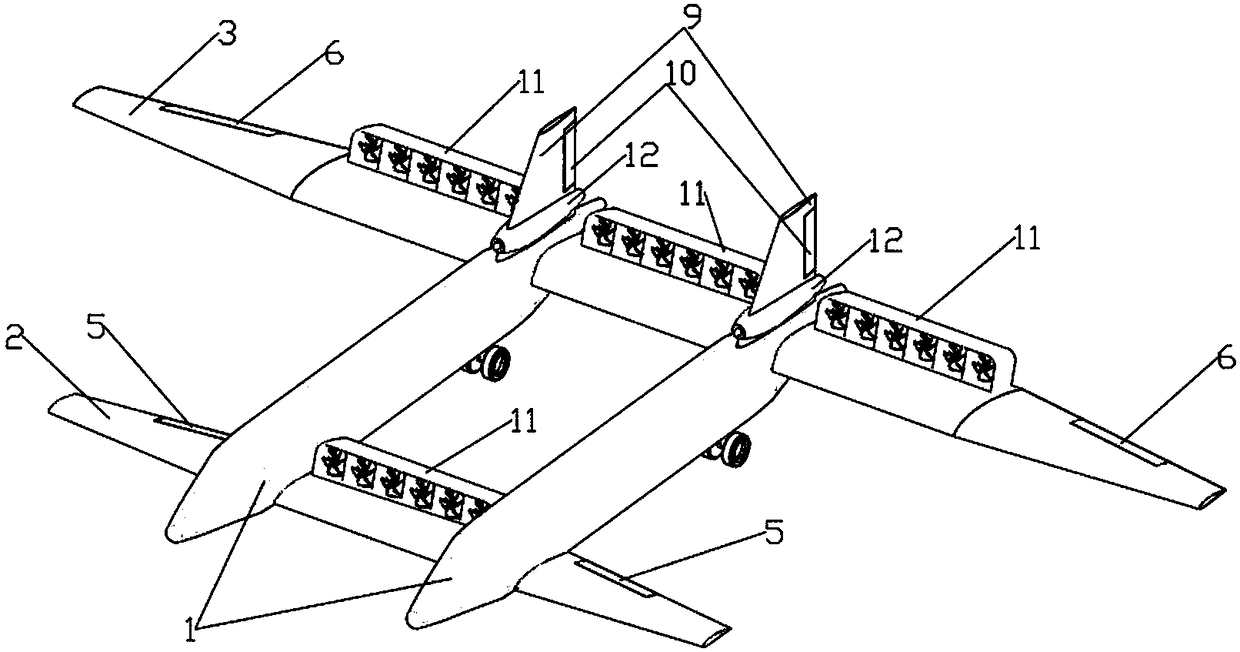

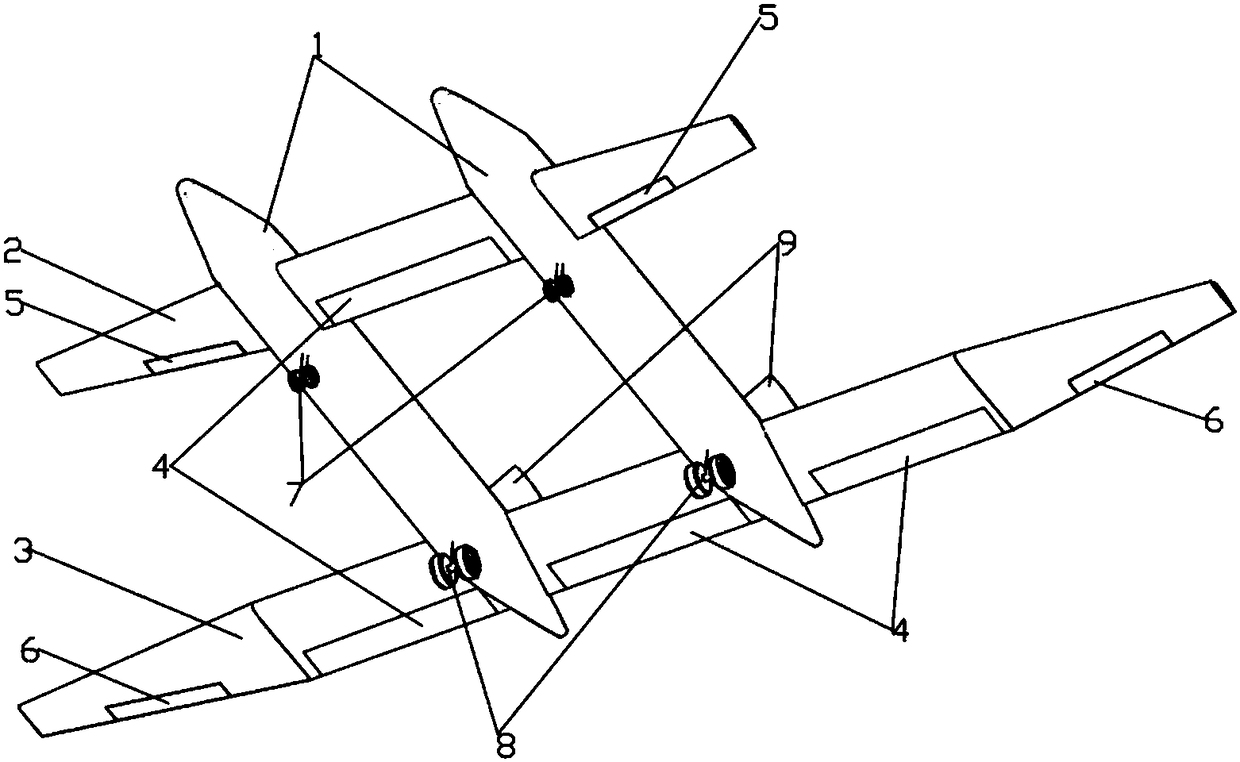

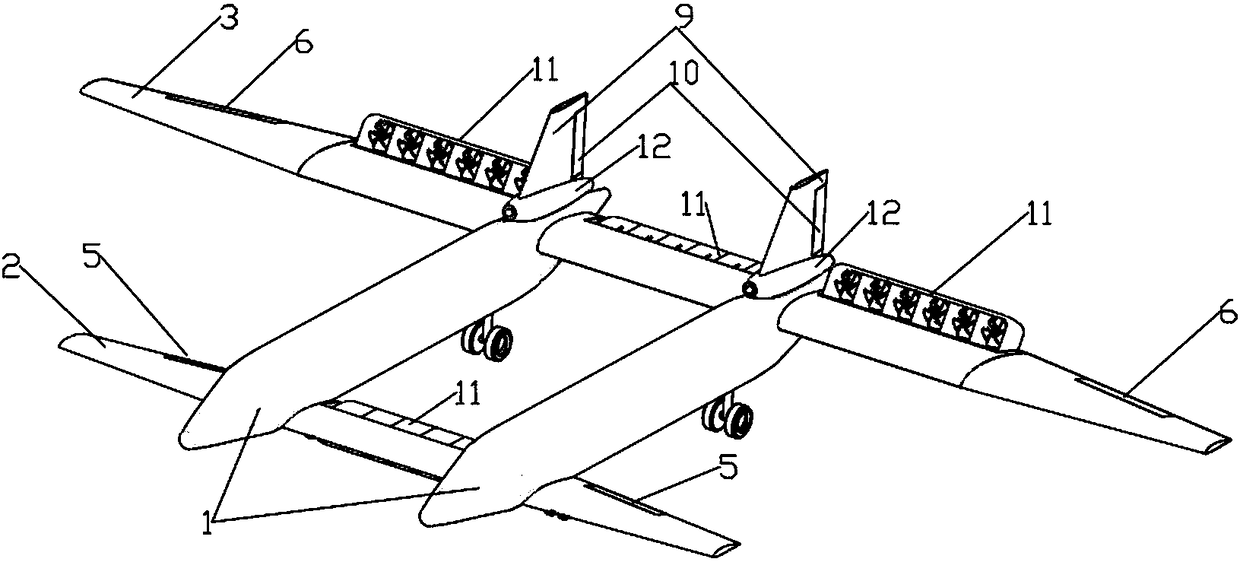

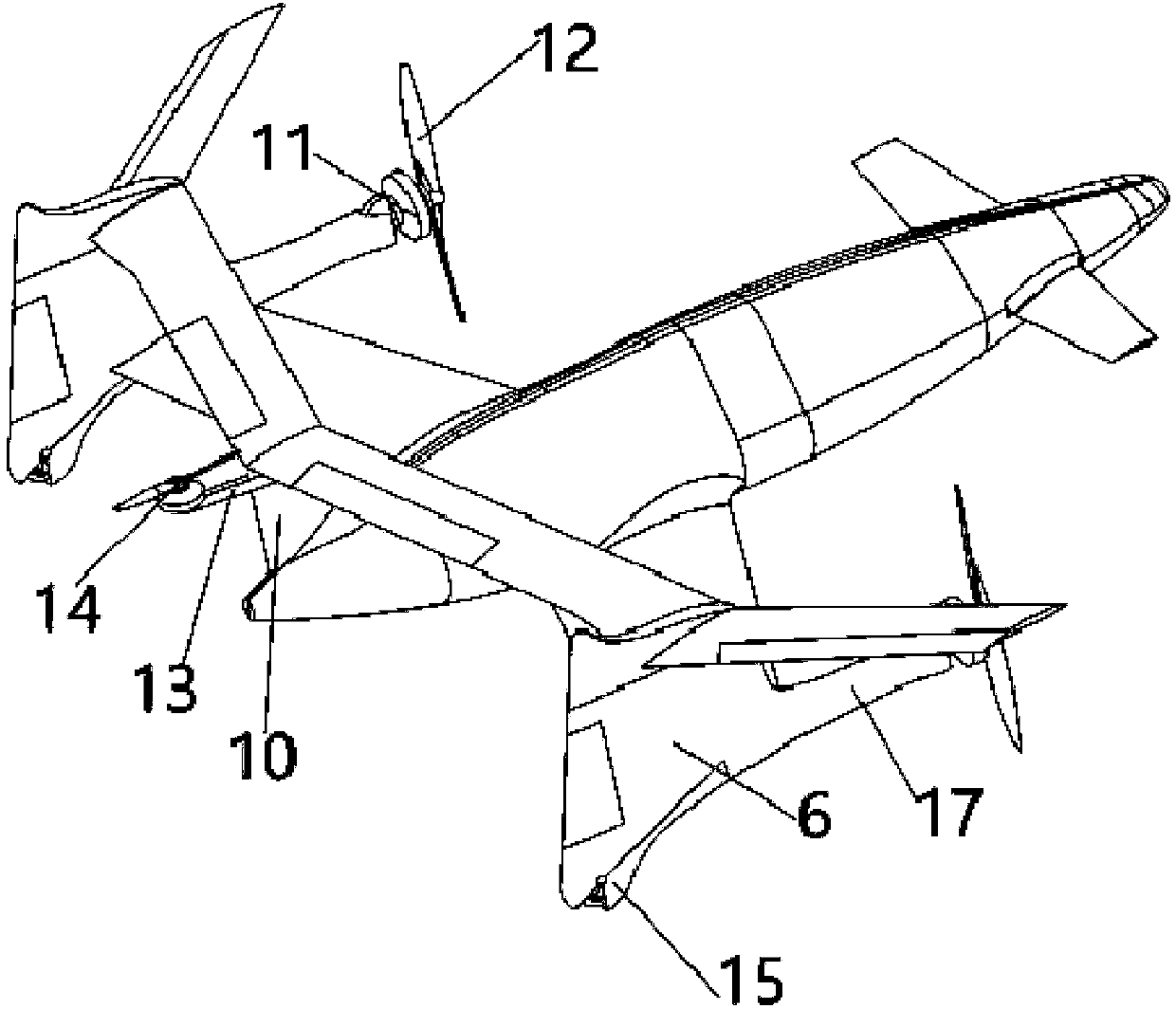

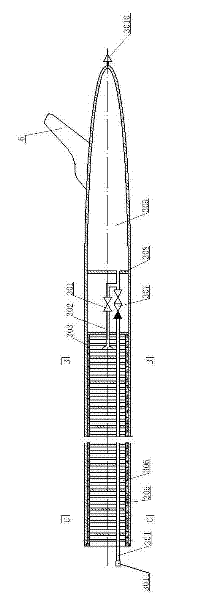

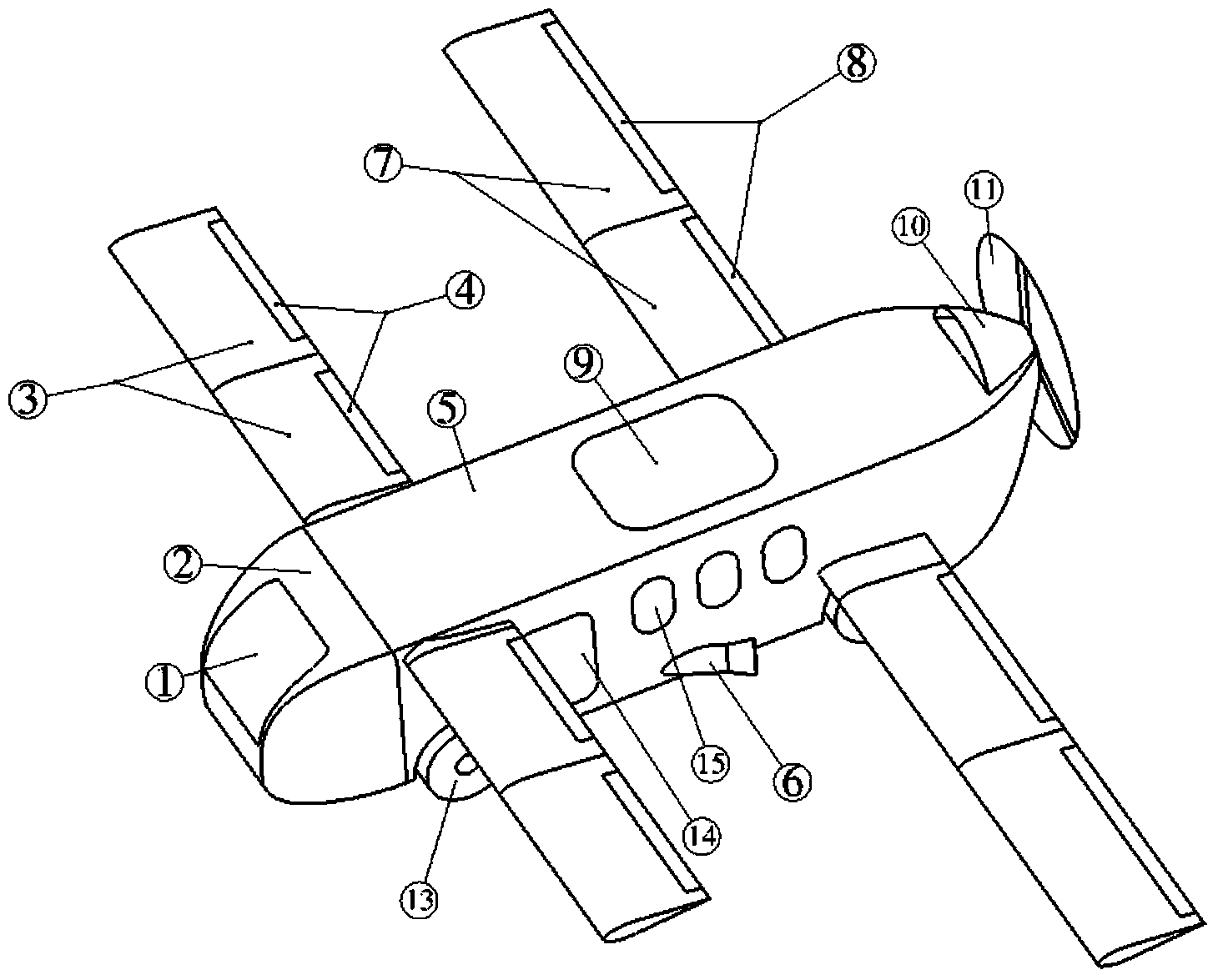

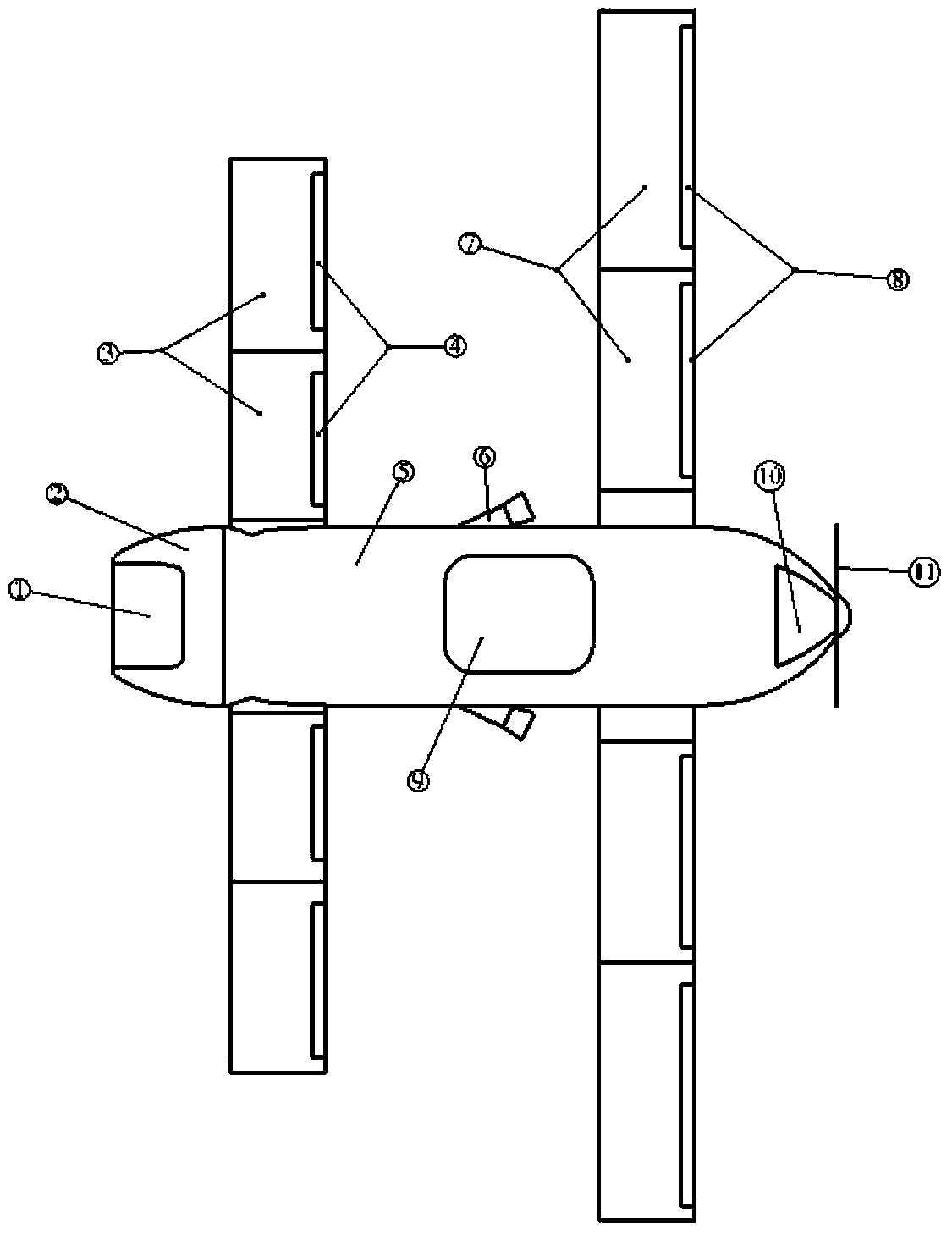

An unmanned aerial vehicle using distributed ducted power and capable of short-distance take-off and landing

ActiveCN108569399AExtend battery lifeImprove aerodynamic efficiencyAircraftsElectricityLanding performance

The invention provides an unmanned aerial vehicle using distributed ducted power and capable of short-distance take-off and landing and relates to the technical field of unmanned aerial vehicles. Theunmanned aerial vehicle has two fuselages. A front wing connects and traverses the fronts of the two fuselages, and a rear wing connects and traverses the tail portions of the two fuselages. Verticaltail wings are respectively installed directly above the tail portions of the two fuselages. An oil-electricity hybrid power scheme is adopted to prolong endurance of the unmanned aerial vehicle, andreduce weight, vibration and the oil consumption rate of a power system. Ducted power assemblies distributed on the upper surfaces of trailing edge flaps of the wings suction boundary layer airflow onthe upper surfaces of the wings so as to increase the aerodynamic efficiency of the wings. Distributed arrangement of the power system avoids a problem that malfunction of one engine causes a runawayunmanned aerial vehicle, thus improving safety of the unmanned aerial vehicle. The trailing edge flaps drive the ducted power assemblies to deflect so as to change a thrust direction, thus shorteningsliding distances in take-off and landing stages of the unmanned aerial vehicle, improving take-off and landing performance of the unmanned aerial vehicle, and expanding the application range of theunmanned aerial vehicle.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

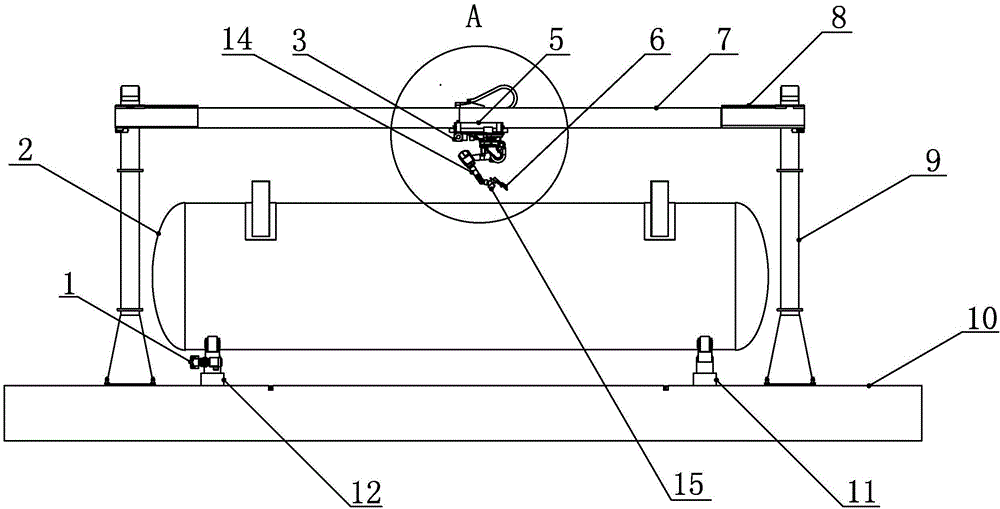

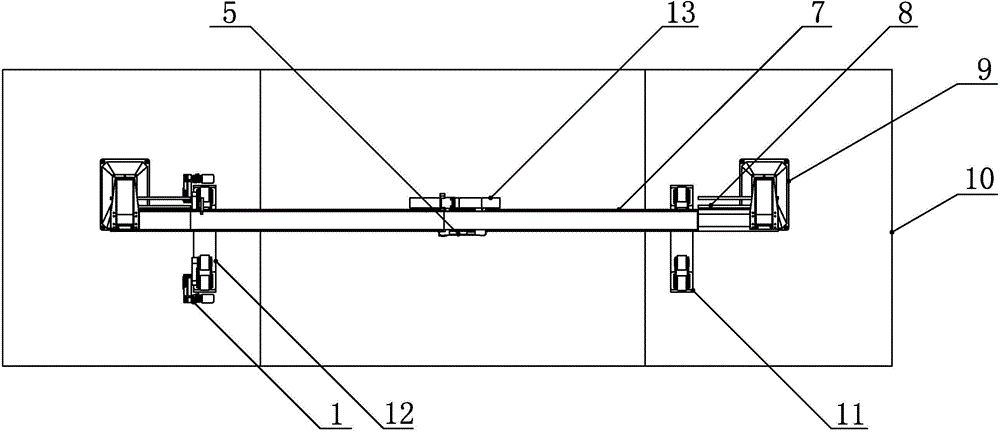

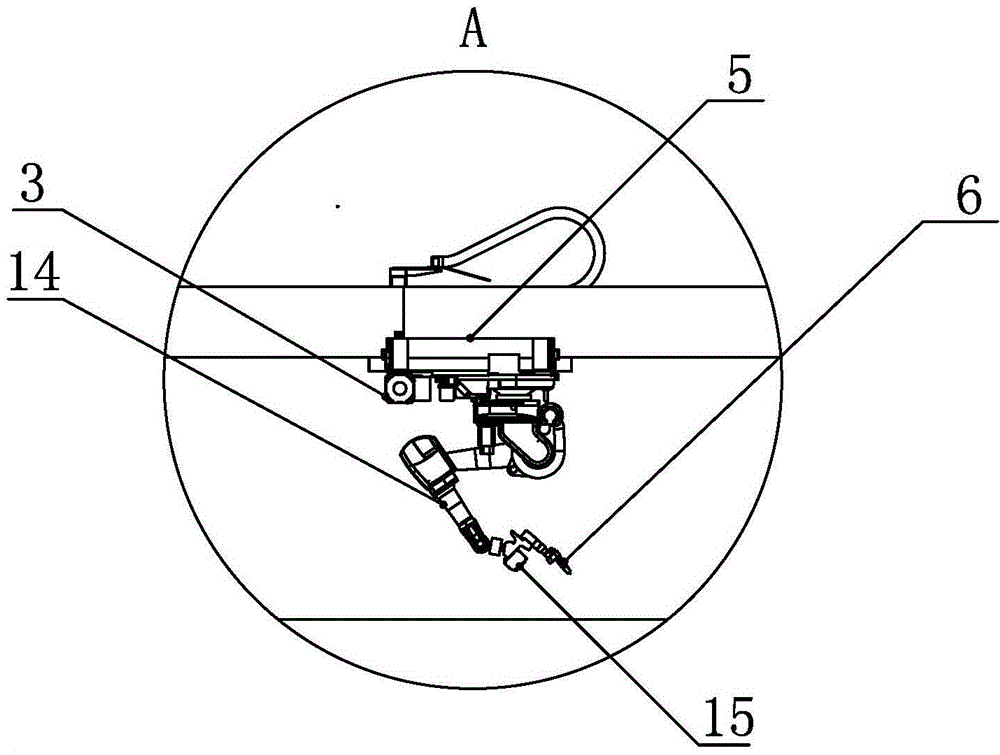

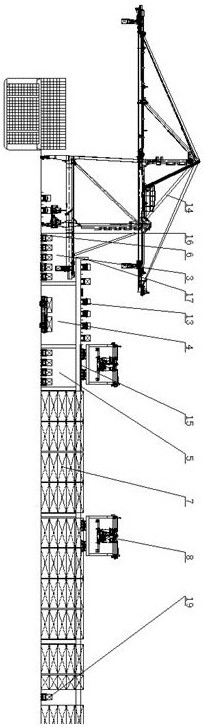

Robot welding workstation for low-temperature tank external components

ActiveCN104785958AAchieve rotationPrecise weld seamWelding/cutting auxillary devicesAuxillary welding devicesControl systemRobot control

The invention provides a robot welding workstation for low-temperature tank external components, and relates to a welding system for welding low-temperature tank external components. The robot welding workstation for low-temperature tank external components is high in automation degree, good in welding quality and high in welding efficiency. The robot welding workstation for low-temperature tank external components comprises a workbench, and a welding system and a control system are arranged on the workbench. The welding system comprises a portal frame, and a laterally-hung walking mechanism is mounted on a horizontal guide rail of the portal frame and comprises a robot mounting base, wherein a servo motor and a welding robot are mounted on the robot mounting base, and a welding gun and a three-dimensional laser scanner are mounted on a mechanical arm of the welding robot. Rolling wheel frames are arranged on the workbench, and each set of rolling wheel frame comprises a driven rolling wheel frame and a driving rolling wheel frame provided with a regulating motor. The control system comprises a robot control unit, a PLC control unit, a scanner control unit, a welding control unit and a communication bus.

Owner:徐州智畅机器人系统有限公司

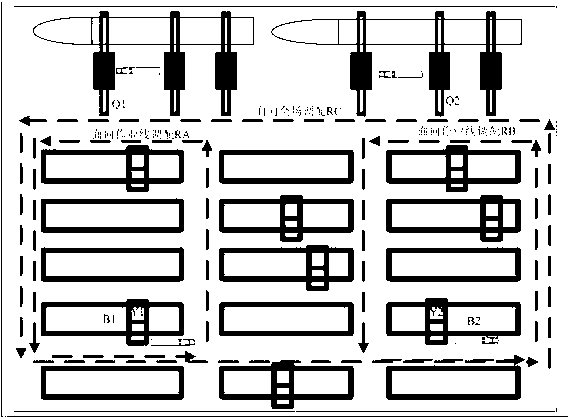

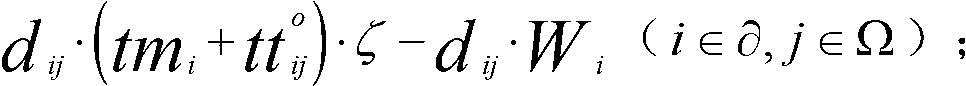

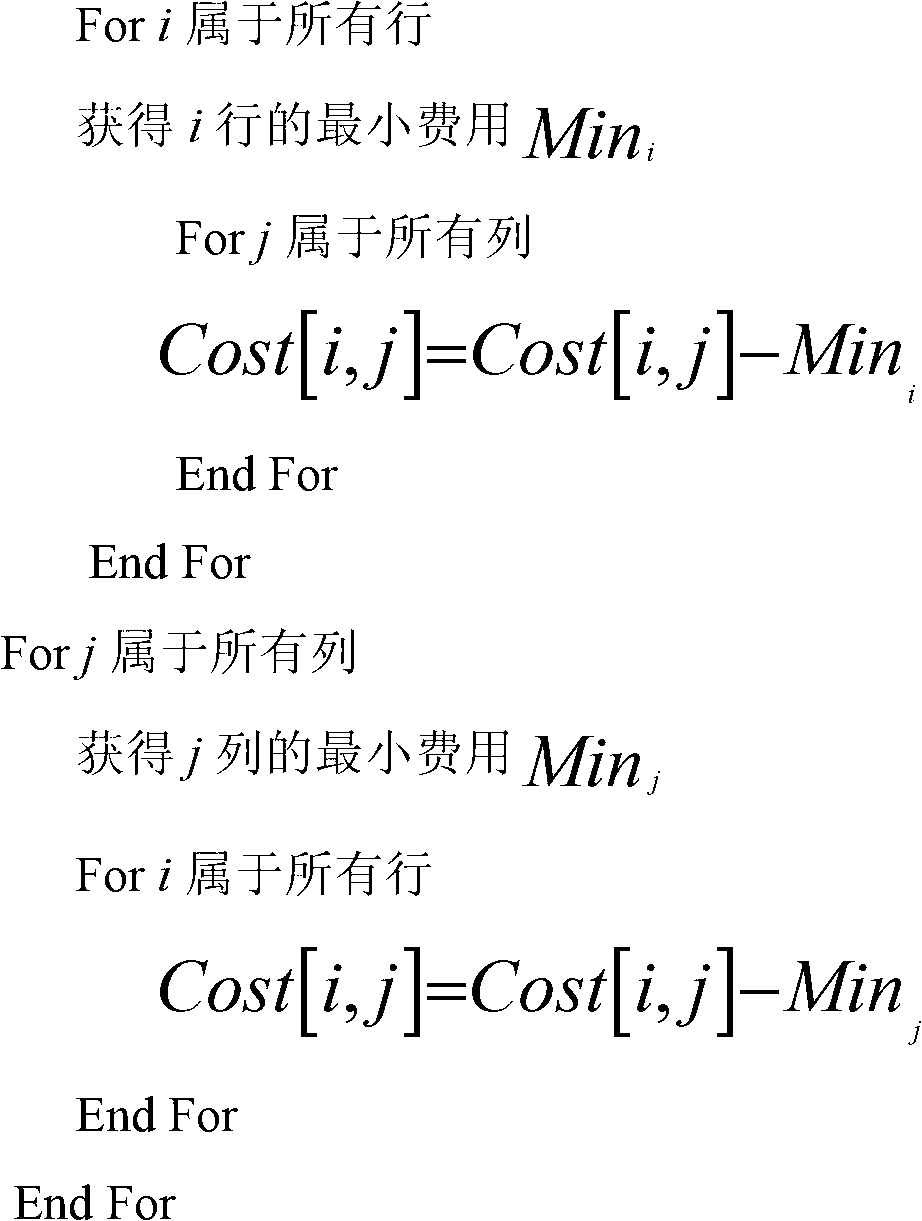

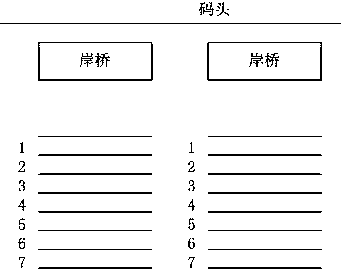

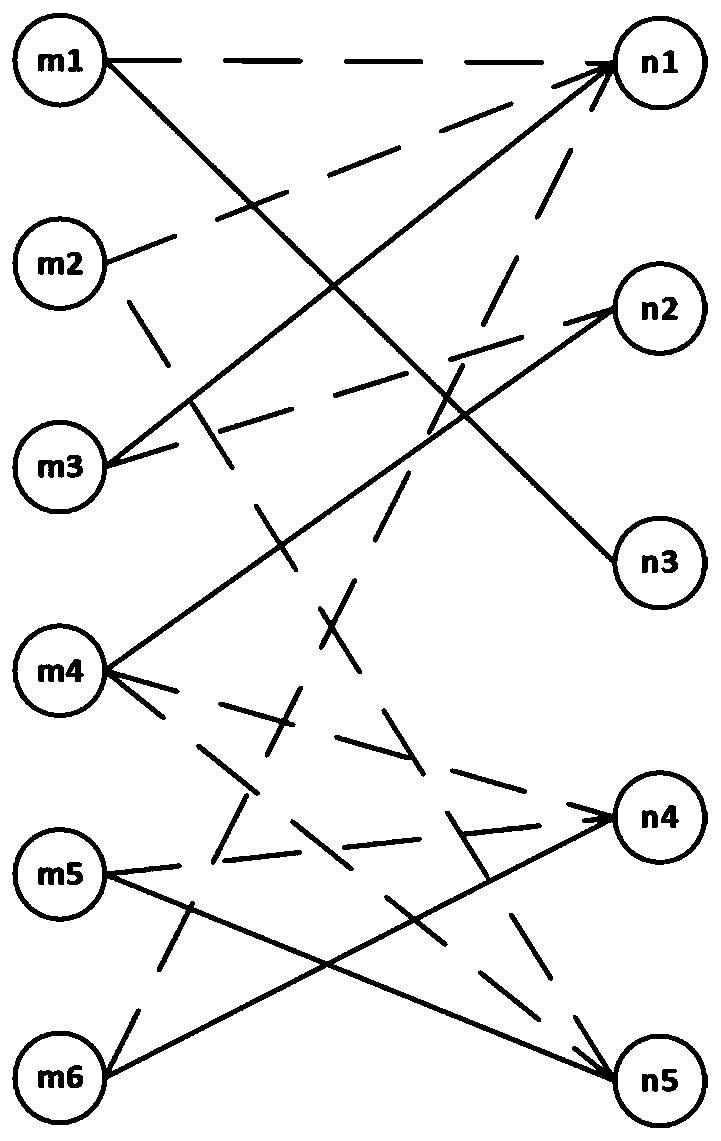

Control method for allocating yard trailers of container terminal

InactiveCN103020783AIncrease production capacityShorten the running distanceResourcesTask completionReduction rate

The invention provides a control method for allocating yard trailers of a container terminal. The control method is an allocation method conforming to the integral terminal instead of being only specific to a certain operational level of the terminal. The allocation method is implemented in an allocation decision making system for the yard trailers of the container terminal, and the allocation arrangement which is implemented by the control method for all the trailers dynamically serves all shore bridges. The control method has the advantages that as tests by the control method show, running distances of the yard trailers in non-working states are shortened, idle periods of shore cranes and yard bridges are shortened, the quantity of the trailers is reduced, the productivity of the container terminal can be effectively improved owing to the allocation arrangement for the yard trailers, and energy consumption is reduced. Besides, the average task completion time and the total transportation energy consumption of container trucks are smaller than actual values, and minimum decrement rates of the average task completion time and the total transportation energy consumption are 12.7% and 13.6% respectively.

Owner:TIANJIN PORT (GROUP) COMPANY

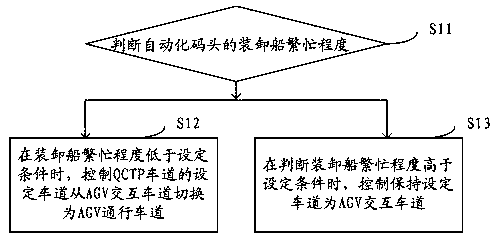

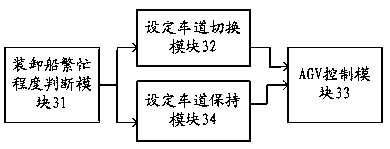

Automated guided vehicle AGV path optimization method and system in automated container terminal quay crane transpoint QCTP operation

InactiveCN109213163AShorten the running distanceImprove work efficiencyPosition/course control in two dimensionsAutomated guided vehicleDegrees of freedom

The invention discloses an automated guided vehicle AGV path optimization method and system in an automated container terminal quay crane transpoint QCTP operation. The busyness degree of loading andunloading a ship of the automated container terminal is judged; when the busyness degree of loading and unloading a ship is lower than a set condition, a set lane of the QCTP lane is controlled to beswitched from an AGV interaction lane to an AGV passing lane so that the AGV can pass on the set lane; when the busyness degree of loading and unloading a ship is higher than a set condition, the setlane is kept as the AGV interaction lane. According to the automated guided vehicle AGV path optimization method and system in an automated container terminal quay crane transpoint QCTP operation in the application, a set lane is set; when the ship loading and unloading operation is busy, the set lane is used as the AGV interaction lane; when the ship loading and unloading operation is not busy, the set lane is used as the AGV interaction lane; when the ship loading and unloading operation is not busy, the set lane is switched into the AGV passing lane for use, thereby reducing the AGV operation path, improving the AGV driving degree of freedom, thereby improving the AGV operation efficiency.

Owner:QINGDAO PORT INT +1

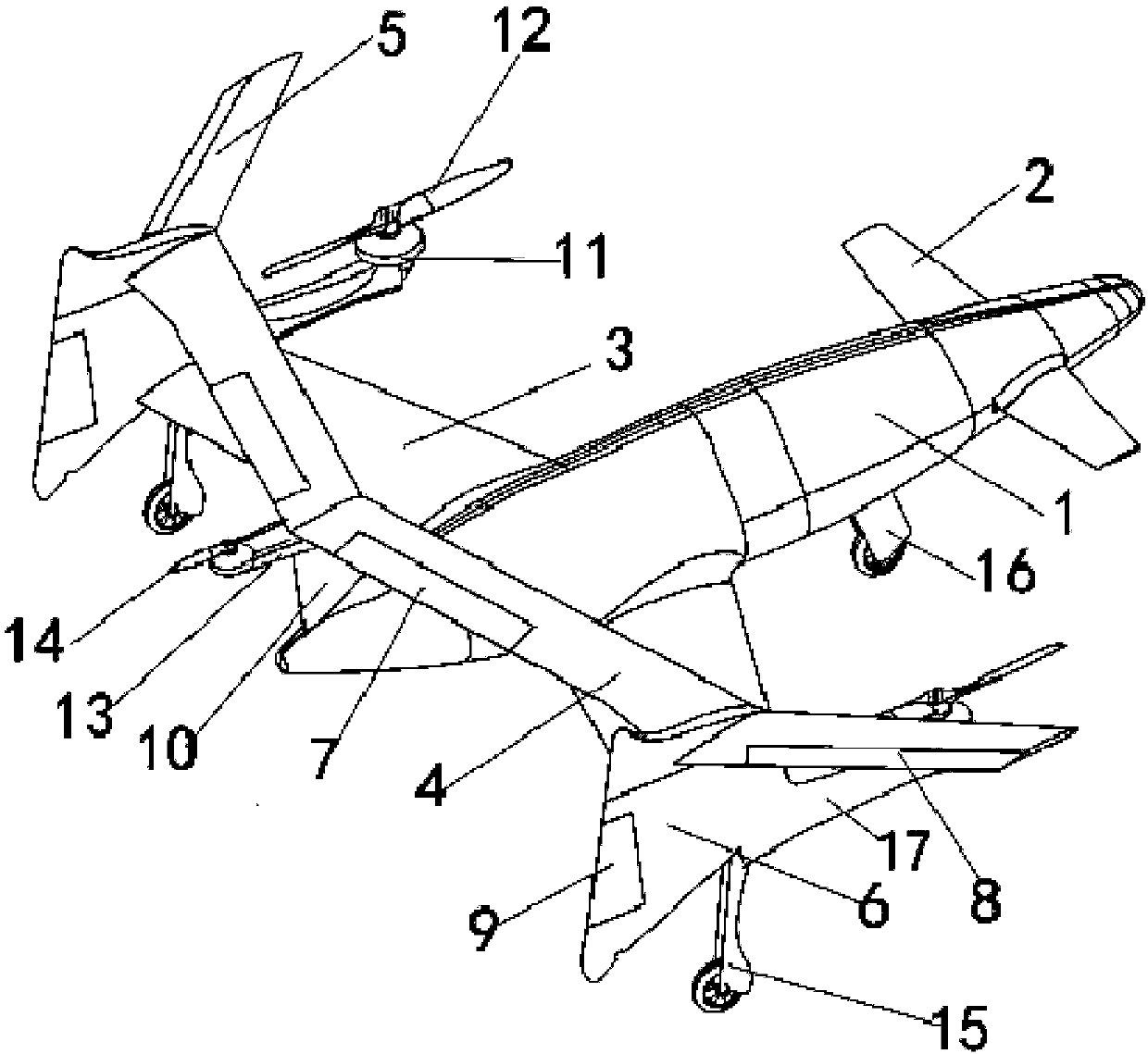

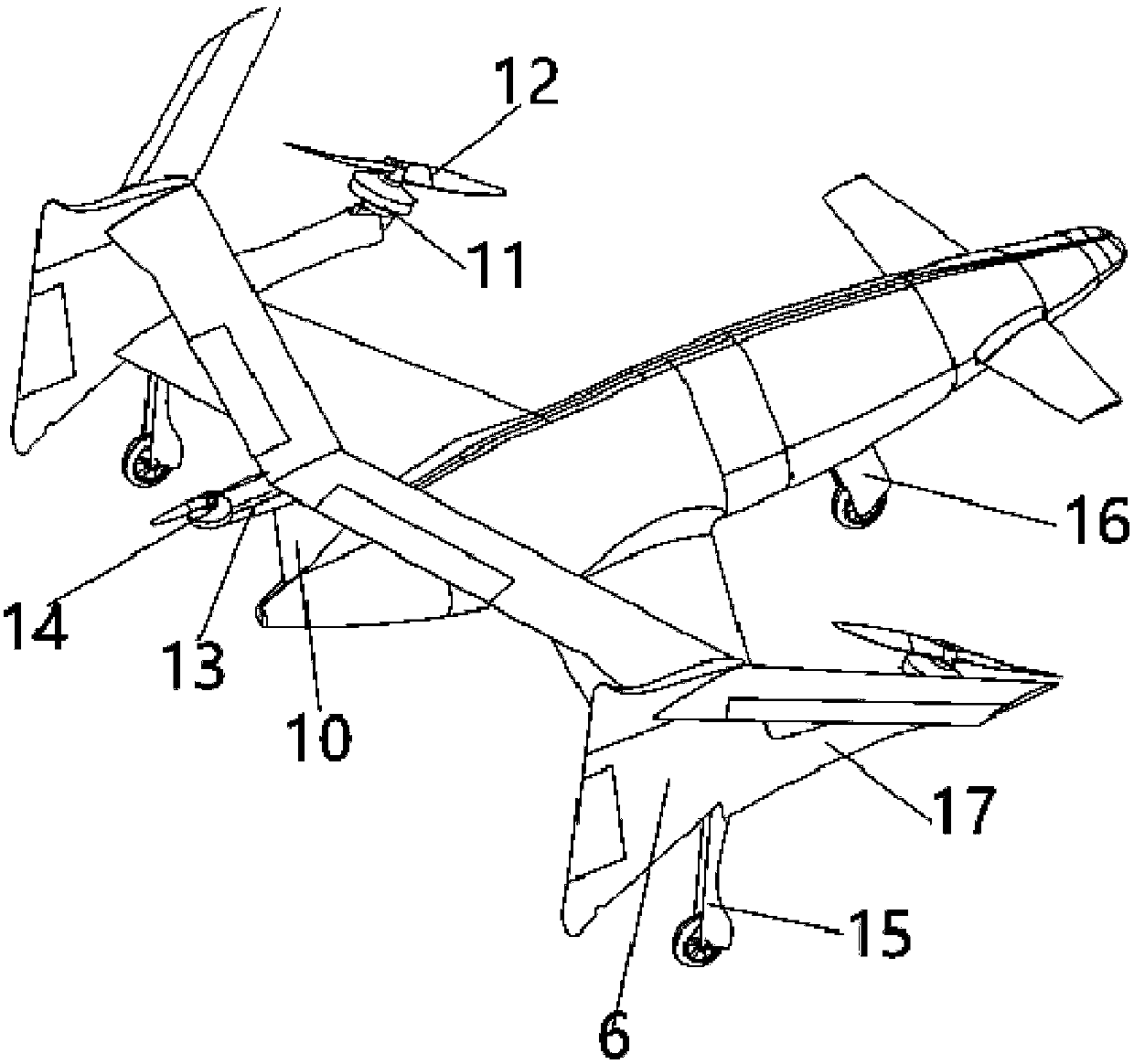

Short take-off vertical landing aircraft

PendingCN108045575AWith short takeoff/vertical landing performanceIncrease task loadAircraft stabilisationCanard-type aircraftLanding performanceFlight vehicle

Disclosed is a short take-off vertical landing aircraft comprising a fuselage, main engines, a vertical fin, and main wings, upper wings, end wings and canards which are arranged at both sides of thefuselage; the outer sides of the end wings are provided with extension wings; the two extension wings are provided with ailerons; the two upper wings are provided with elevators; the tail portions ofthe two end wings are provided with rudders; the lower parts of the two end wings are provided with forward direction stretching support structures, and each forward direction stretching support structure is provided with a main engine, a main engine propeller and a propeller dip angle driving device; the lower portion of each end wing is provided with a retractable main undercarriage; and the rear portion of the vertical fin is provided with a backward stretching support structure, and the backward stretching support structure is provided with an attitude-adjusting engine propeller. The shorttake-off vertical landing aircraft not only has short distance take-off and vertical landing performance, but also takes into account flight performance of high speed, long endurance and large voyage, and so on.

Owner:刘行伟

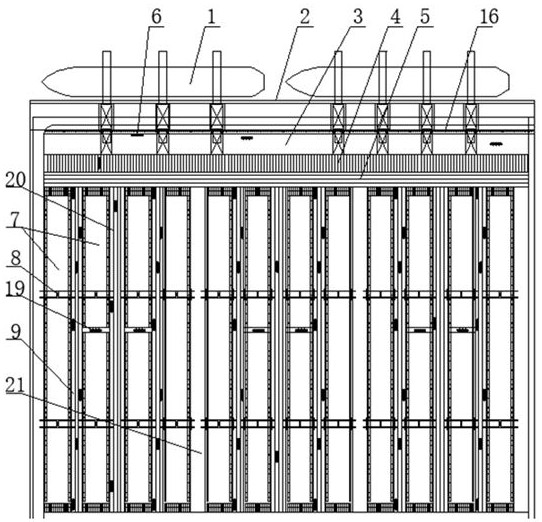

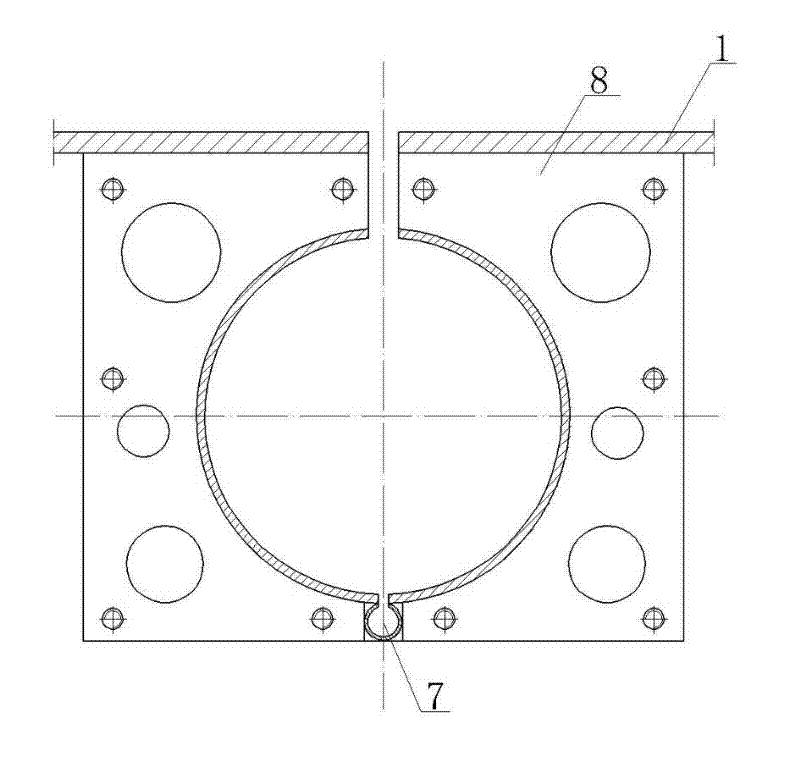

Efficient regeneration desulphurization tower

InactiveCN103409176AImprove the ability of oxidation regenerationFully contactedGas purification by liquid washingSulfurProcess engineering

An efficient regeneration desulphurization tower comprises a desulphurization tower 1, a coal gas inlet 2, a coal gas outlet 3, a pregnant solution outlet 4, a lean solution inlet, a regenerator 6, a lean solution outlet 7, a pregnant solution inlet 8, a solution recirculating pump 10, a sulfur foam outlet 11, a lean solution groove 13, a high-pressure air inlet 14 and a gas-liquid distributor 16, wherein the lean solution groove is formed in the tower bottom at the lower end of the desulphurization tower, and the lean solution outlet and the sulfur foam outlet are formed in the lower section; stuffing is mounted in the desulfuration section in the tower; the set of regenerator is mounted at the upper part of the lean solution groove; a solution circulating line is mounted outside the tower body; with the aid of one solution recirculating pump, the solution circulating inside and outside the tower body via the lean solution inlet, the pregnant solution outlet, the pregnant solution inlet and the lean solution outlet is realized. The desulphurization tower has an optimized structure, utilizes the large diameter of the desulphurization tower, shortens the move distance of the solution, and reduces the loss of system heat and various materials, also the resistance force to 0.02-0.03 MPa. Moreover, the energy consumption is reduced by 20-30 percent, and an efficient regenerator is adopted for oxidation regeneration of the pregnant solution and has the advantages of small size, strong regeneration capacity and stability in operation.

Owner:林吉萍

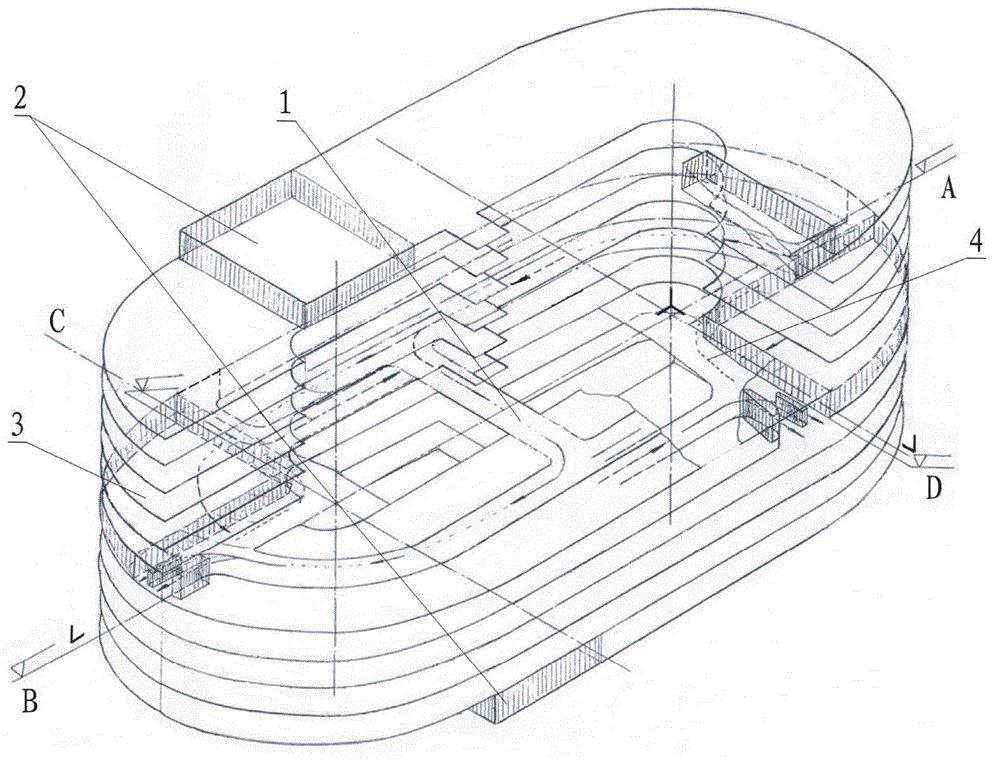

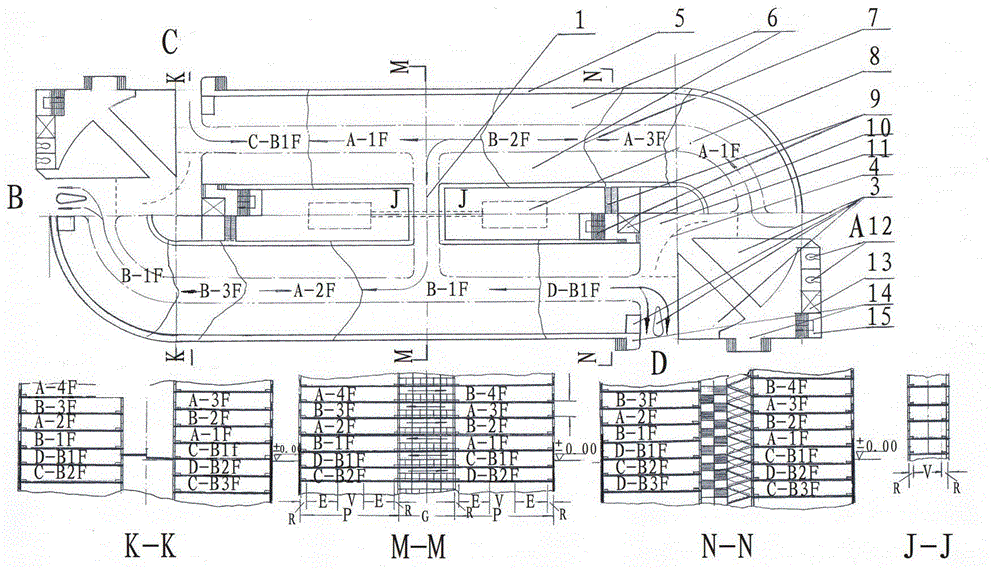

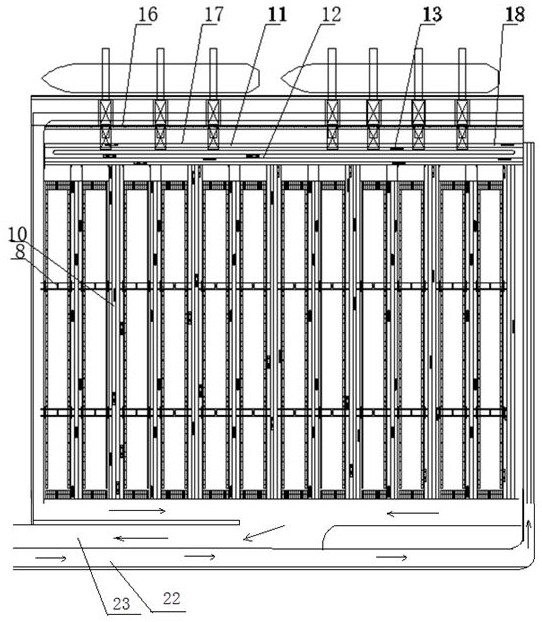

Three-dimensional automatic container wharf

The invention discloses a three-dimensional automatic container wharf. The container wharf comprises a container yard, a lower-layer horizontal transportation operation area and an upper-layer container truck transportation operation area which are located between the wharf and the container yard. The container yard is divided into an upper layer and a lower layer; the lower layer comprises an interaction area of an automatic double-cantilever portal crane and automatic horizontal transportation equipment and an automatic horizontal transportation equipment lane; and the upper layer comprisesan interaction area, parallel to a container area, of the automatic double-cantilever portal crane and a container truck. The lower-layer horizontal transportation operation area comprises an interaction area of a quay crane and the automatic horizontal transportation equipment, an automatic horizontal transportation equipment parking area, and an automatic horizontal transportation equipment high-speed operation area; and the upper-layer container truck transportation operation area comprises an interaction area of the quay crane and the container truck and a container truck high-speed lane.The occupied area of a wharf depth shoreline is reduced in a double-layer three-dimensional framework form, the space can be effectively utilized, the harbor gathering and harbor dredging time is shortened, the harbor gathering and harbor dredging traffic pressure is relieved, and the operation distance and time of a receiving and dispatching box are reduced, so that the wharf operation efficiencyis improved.

Owner:QINGDAO PORT INT +1

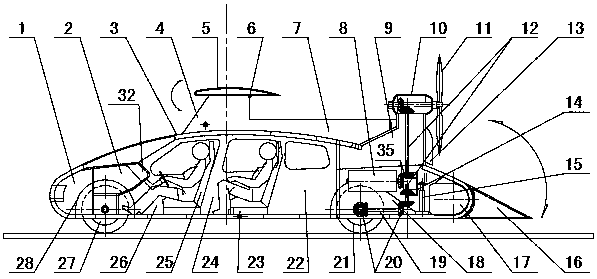

Flying car

ActiveCN103770589AEasy to liftReduce approach speedConvertible aircraftsAircraft convertible vehiclesPropellerEngineering

A flying car comprises a body, a cockpit, a passenger cabin, a baggage cabin, an equipment cabin, a body tail, wheels, airfoils and a propeller which are sequentially combined. As the combined longitudinal section of the body and the body tail is in the shape of an airfoil section, the body can generate lifting force when the flying car runs on a road surface and flies in air, the areas of the airfoils and spans can be relatively decreased under the same loading condition, the airfoils are mounted on hollow flat columns on two sides of the top face of the body, a distance is reserved among the airfoils and the arc top face of the body, and the length, the width and the height of the shape of the flying car are smaller than those of a bus when two ends of each airfoil are folded downwards, so that the flying car can safely and freely take off, land and run on an expressway. At present, cars are popular, urban streets and expressways are frequently jammed, and the flying car can relieve the contradiction and is conveniently, rapidly and safely used for private families and businesses, so that the flying car has wide domestic and foreign markets.

Owner:WUHAN LANTIANXIANG AVIATION TECH

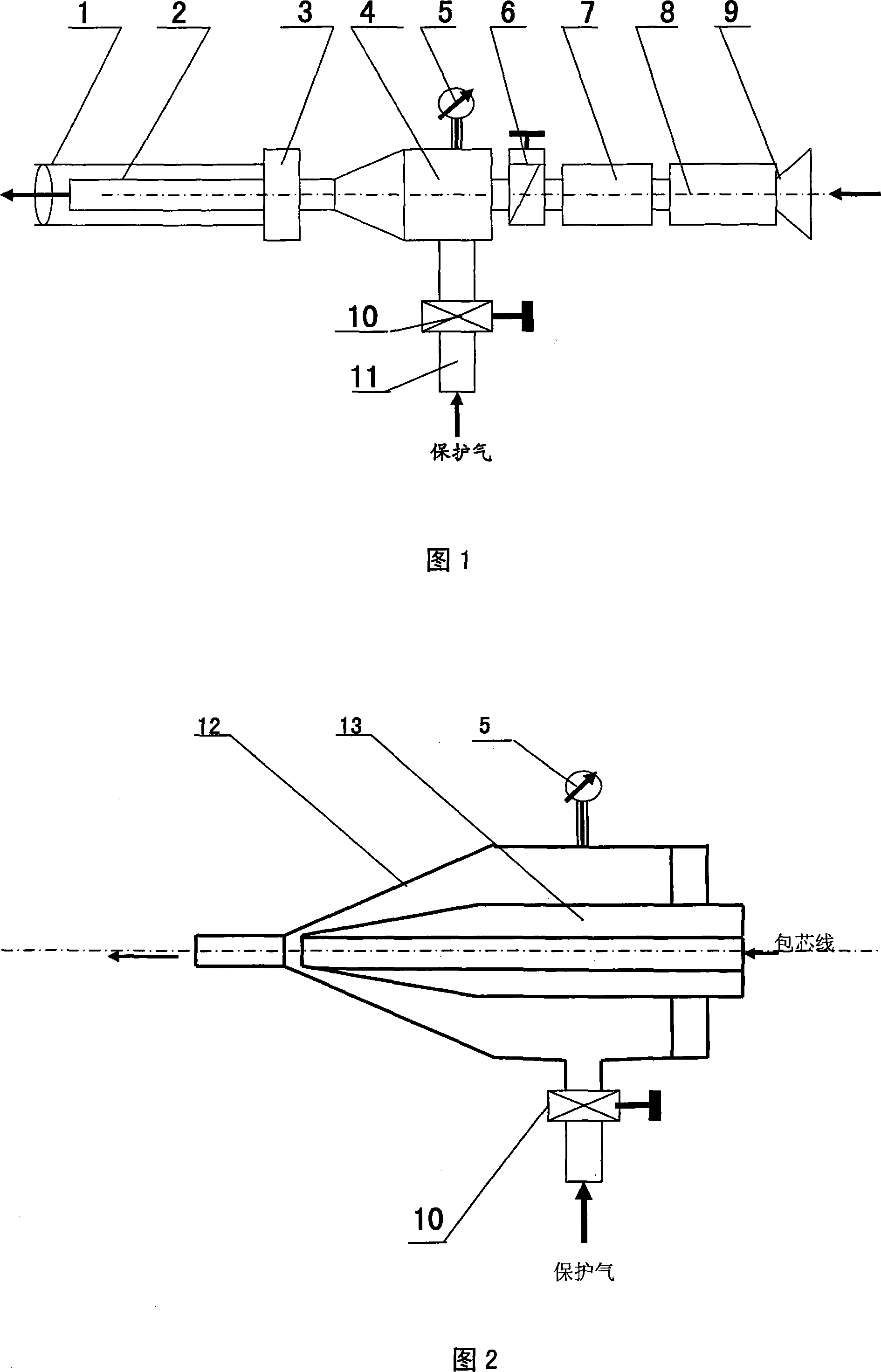

Method of on-line thread feeding and furnace protecting of ironmaking blast furnace and thread feeding device thereof

InactiveCN101109024AShorten the running distanceReduce wire feed resistanceBlast furnace componentsBlast furnace detailsSlagCoal

The invention provides a wire-feeding and furnace protection method of blast furnaces and the wire-feeding device. The purpose is to solve the following problems: conventionally, the Ti-containing furnace protection materials are added into the furnace together with the furnace materials through the top of the furnace. The application of Ti-containing powders will have significant impact on the production system of the furnace. At the same time, the Ti-containing materials will decrease the output of the furnace. In addition, the titanium oxide of the Ti-containing materials is uniformly mixed in the entire slag so that the titanium oxide density in the slag is lowered significantly. The key points of the invention are described in the followings: a wire-feeding device is connected with the coal-spraying mouth of the furnace blast blowpipe. The furnace protection material cored wires are sent to the furnace along the cored wire access of the wire-feeding device. The port through which the furnace protection material cored wires flow into the furnace is just the coal-spraying mouth of the furnace blast blowpipe.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

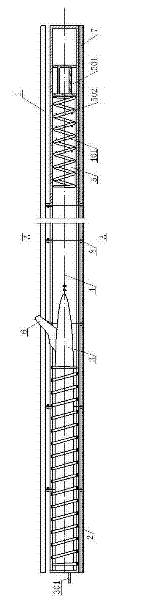

Steam catapult booster for aircraft takeoff

The invention provides an aircraft launching steam ejection boosting device which has a simple structure, a large ejection boosting force, sufficient continuous thrust, a short repeated ejection time interval, convenience for operation, a wide application range, convenience for transportation and installation and a high battle damage repairing speed. The aircraft launching steam ejection boostingdevice comprises a flight deck, a sliding pipeline, a steam ejection booster and an aircraft connector, wherein a deceleration resetting device is arranged at the front part of the sliding pipeline; and the back part of the sliding pipeline is provided with a heating device; the steam ejection booster comprises a bullet-shaped shell, a clapboard, overheating vaporizers, a water inlet pipe and a water spraying pipe, wherein the bullet-shaped shell is provided with an opening at the back part; the overheating vaporizers are distributed in a high-temperature steam generation room axially; the water inlet pipe arranged at the tail part of the shell passes through the high-temperature steam generation room to communicate with a high-temperature pressure-bearing water tank and has a check valve; the water spraying pipe is arranged on the high-temperature pressure-bearing water tank and is provided with an ejection control valve; the water spraying hole of the water spraying pipe is positioned at the front part of the high-temperature steam generation room; and a waste water recovery pipeline is arranged under the sliding pipeline.

Owner:刘忠德

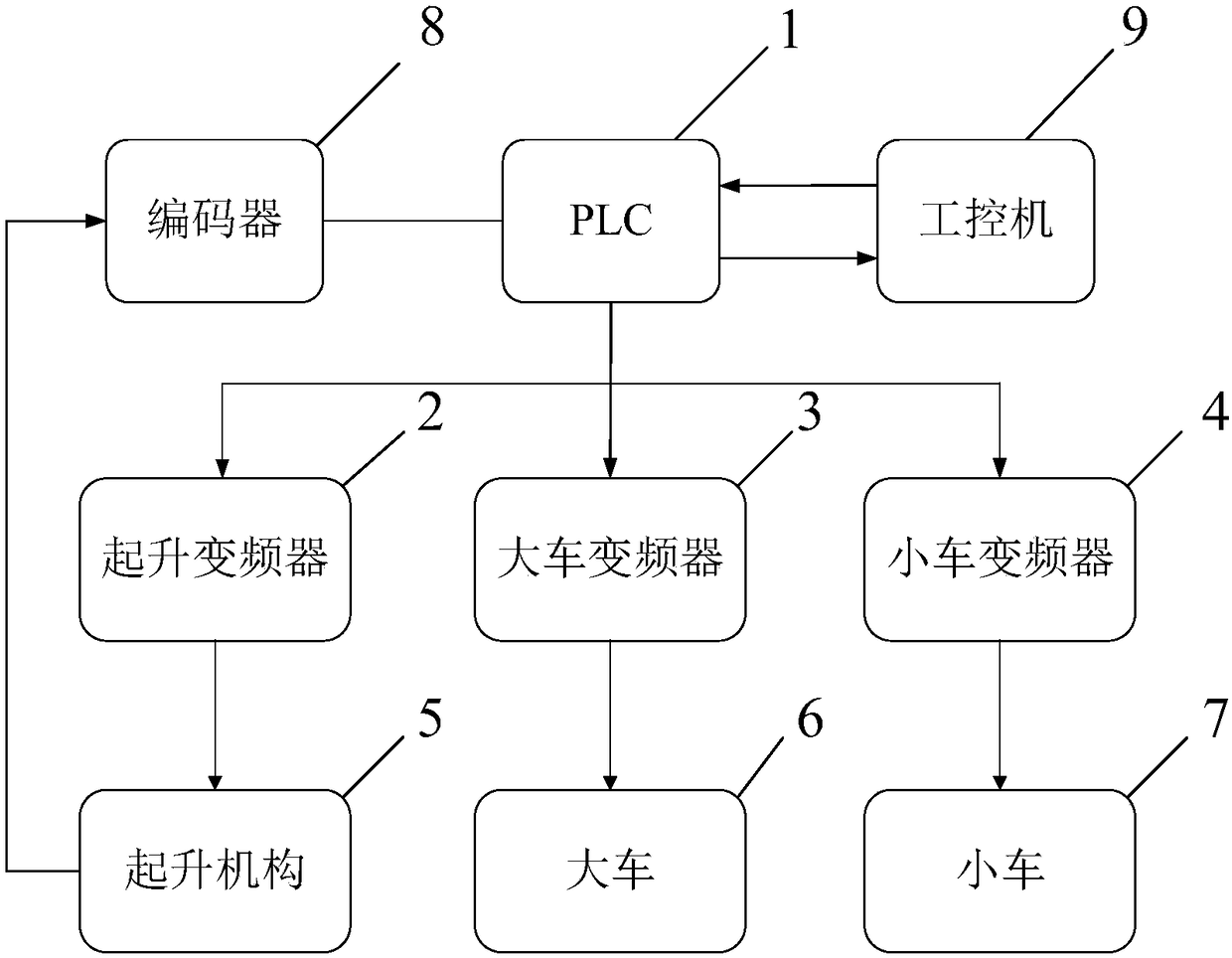

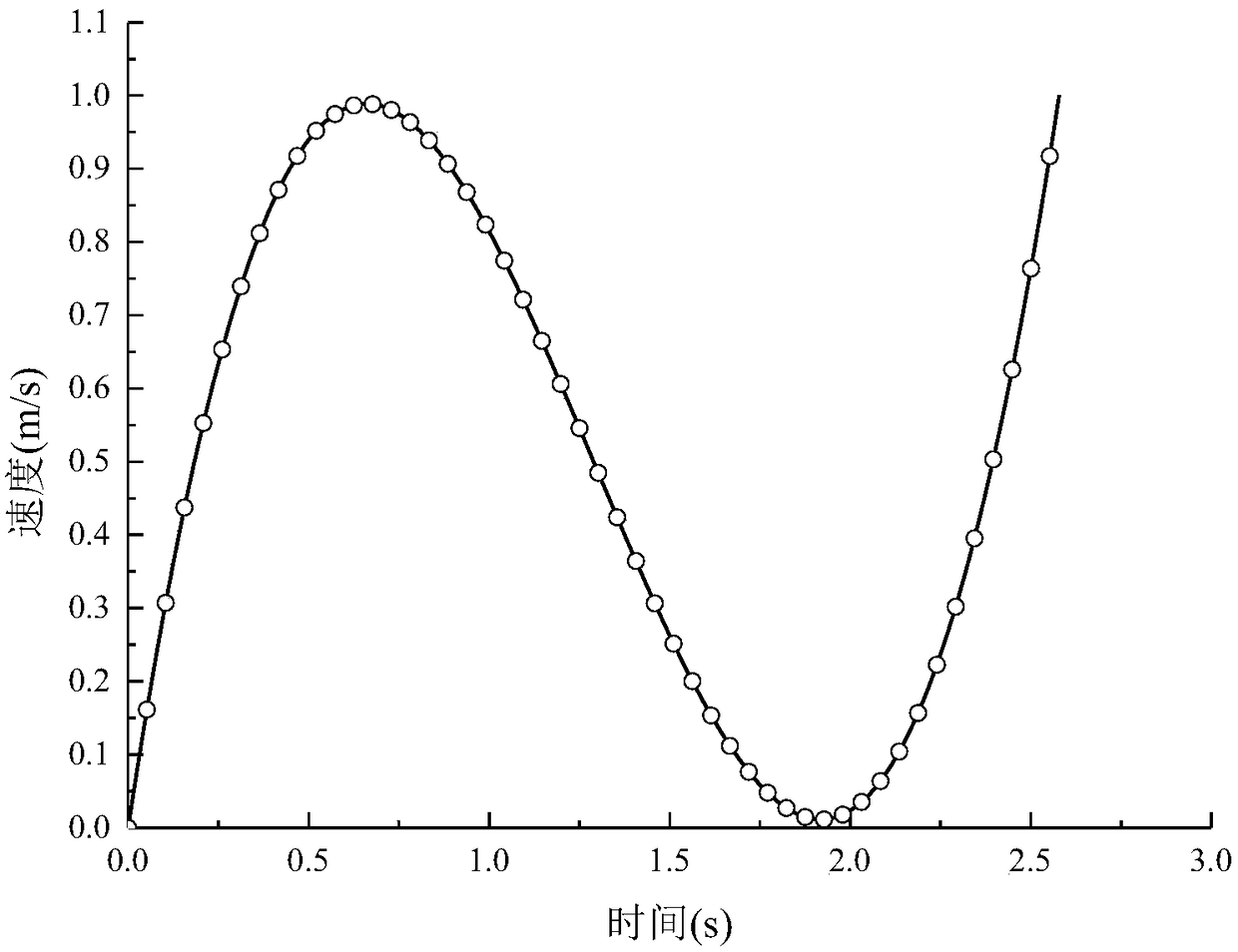

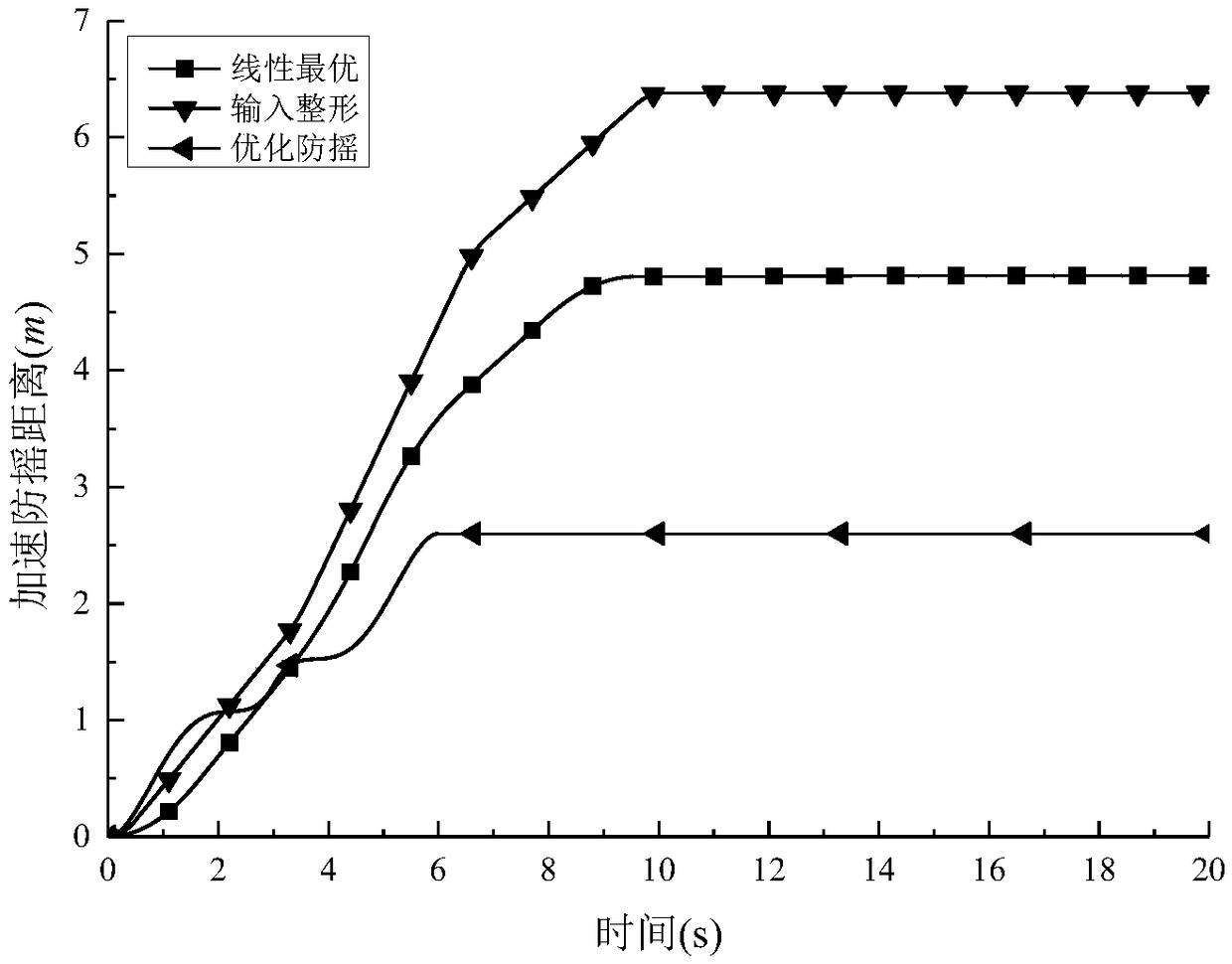

Crane open loop optimal anti-rocking control method

InactiveCN108584723ASuppresses and eliminates load swingImprove stabilityCranesKinetic analysisOperation safety

The invention discloses a crane open loop optimal anti-rocking control method. Based on the crane kinetic analysis, crane operation state parameters are used as boundary constraint conditions to realize anti-rocking control of shortest crane operation distance, shortest acceleration or deceleration operation time and optimal operation trajectory; and a mathematical model among the crane operationspeed, the operation time and the lifting rope length is built synchronously based on the numerical value analysis and the computer simulation technology. The open loop optimal control method is builtbased on optimal operation distance and acceleration or deceleration time; and the control method has the characteristics of short anti-rocking distance, high response speed and the like, can effectively inhibit the load deflection, improves the crane operation safety and operation stability, is simple in implementation, easy to realize engineering application and high in control precision, and facilitates the crane intelligent and automatic transportation.

Owner:WUHAN UNIV OF TECH

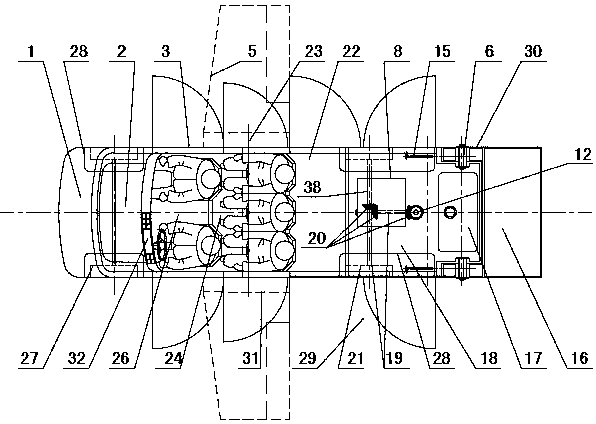

Flying passenger car

InactiveCN103522858AReduced takeoff and landing roll distancesShorten the running distanceAircraft convertible vehiclesShortest distanceEngineering

The invention discloses a novel-arrangement flying passenger car. Two serial type foldable wings are respectively arranged at the car roof of the front portion of a car body and the rear lower portion of the car body. The front wing can be folded through a folding mechanism arranged at the wing root position and can be collected at the top of the car body after being folded. The rear wing can be folded twice through two folding mechanisms to be attached to the rear portion of the car body, and the two folding mechanisms are arranged at the wing root and in the middle of the rear wing. The flying passenger car uses an engine arranged at the tail portion of the car body as a power device, and a small booster rocket is arranged in the middle of the car body and is used for assisting to achieve short-distance take-off of the flying passenger car in a poor take-off place environment. The flying passenger car is simple in flying principle, combines the functions of a general passenger car with the functions of a small transport plane, is strong in practicability and is a developable land-air vehicle.

Owner:BEIHANG UNIV

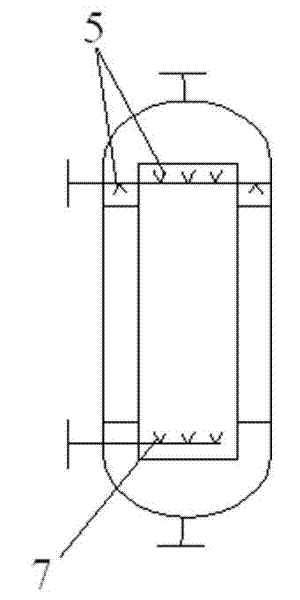

Carbonylation reacting kettle

ActiveCN102430381AShorten the running distanceIncrease heightChemical/physical/physico-chemical nozzle-type rreactorsCarboxylic preparation from carbon monoxide reactionEngineeringCarbonylation

The invention relates to a carbonylation reacting kettle, comprising a kettle body, and a separation plate which is arranged in the kettle body and used for separating the kettle body to form an upstream and a downstream area of which the two ends communicates with each other. A liquid outlet is arranged on the bottom part of the kettle body, and a gas outlet is arranged on the top part of the kettle body. A liquid inlet and a liquid distributor are arranged on the upper part of the kettle body. A liquid jetting opening of the liquid distributor of which at least one opening faces upwards is arranged in the upstream or located in the vertical extending area of the upstream which faces the top part, and a liquid jetting opening of the liquid distributor of which at least one opening faces downwards is arranged in the downstream area or located in the vertical extending area of the downstream area which faces the top part. A gas inlet and a gas distributor are arranged on the lower part of the kettle body. A gas jetting micro-pore of the gas distributor is located in the upstream or located in the vertical extending area of the upstream which faces the bottom part, and the opening faces upwards. The arrangement position of the liquid distributor is higher than that of the gas distributor.

Owner:陕西煤业化工技术开发中心有限责任公司

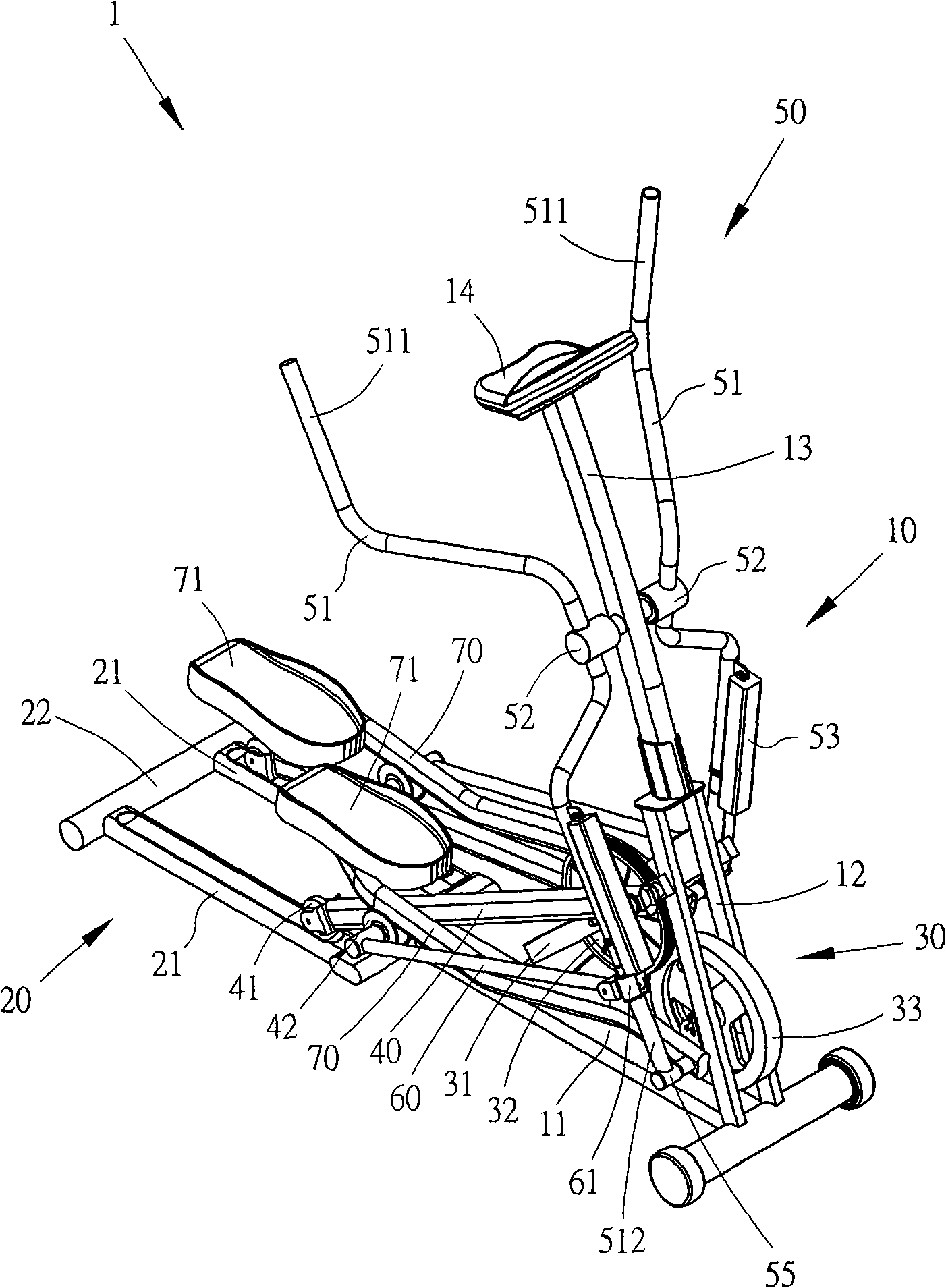

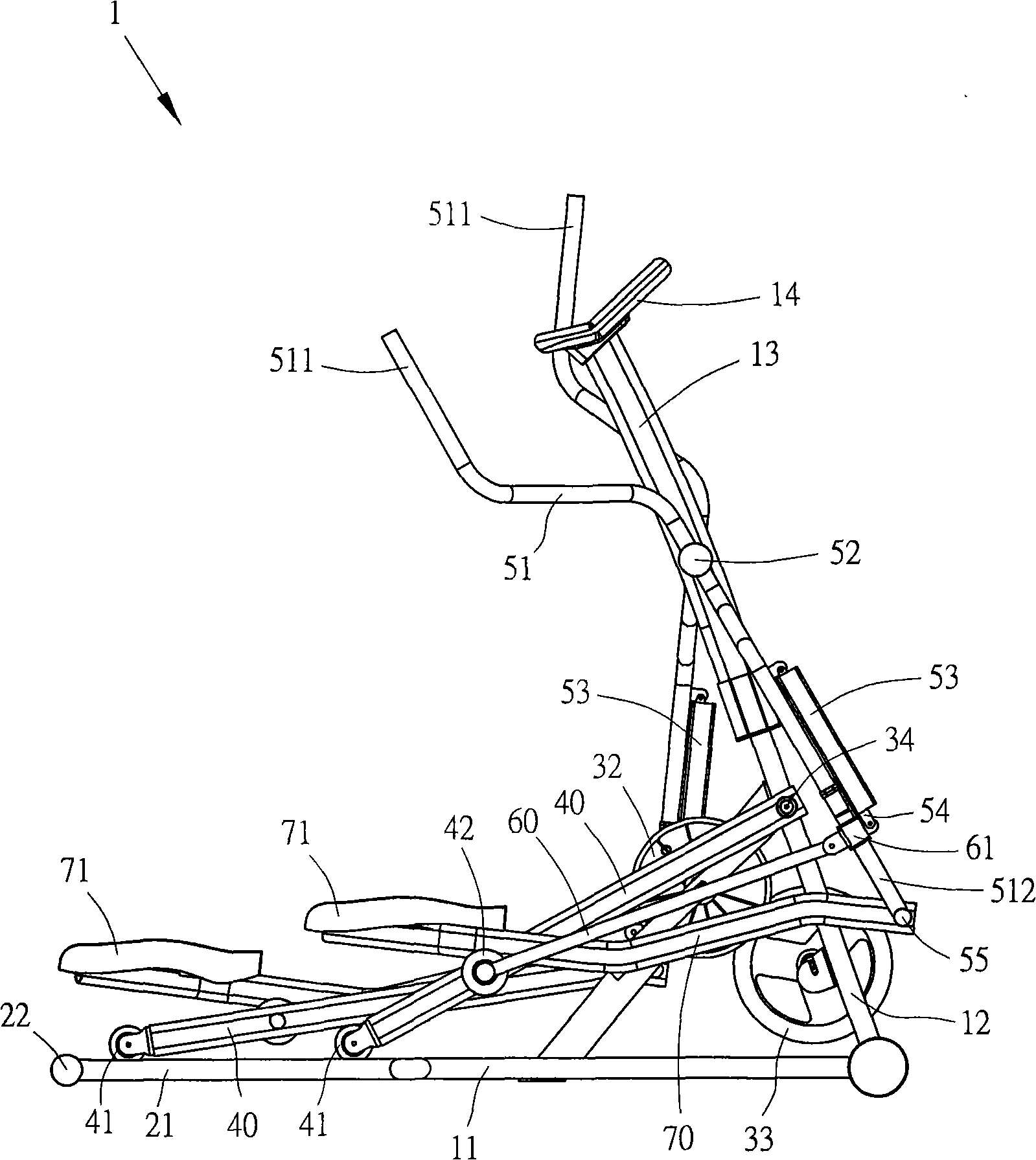

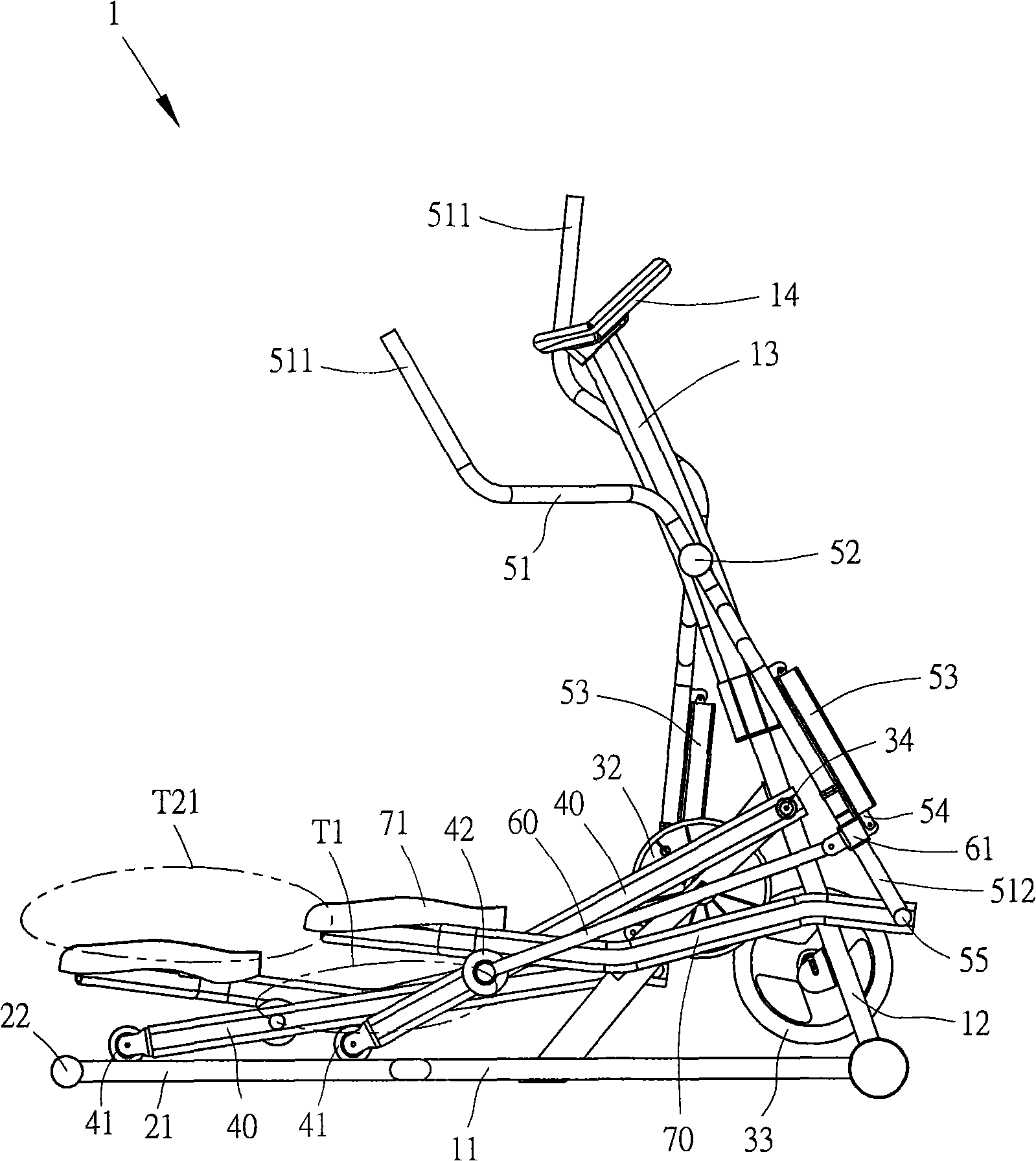

Elliptical exercise machine

InactiveCN101357258AThe swing amplitude is reducedShorten the running distanceMovement coordination devicesCardiovascular exercising devicesEllipseReciprocating motion

The invention relates to an elliptical trainer which comprises a frame, a first guiding mechanism arranged on the frame; a rewinding mechanism arranged on the frame and provided with two opposite rewinding contacts that can move on a closed track; two first connection rods which are respectively equipped with a first end, a second end and a support device, wherein, both first ends are pivoted with the two rewinding contacts respectively; both second ends perform reciprocating motion under the guidance of the first guiding mechanism; a second guiding mechanism which is pivoted on the frame and equipped with a lower end part; two second connection rods which are respectively equipped with a first end and a second end, wherein, both first ends are connected with the lower end part of the second guiding mechanism; both second ends are pivoted on the corresponding first connection rods; two support rods which are provided with a first end and a second end respectively, wherein, both first ends are pivoted on the lower end part of the second guiding mechanism; both support rods moves corresponding to the first connection rods with the support of the support device. The trainer can extend the travel of the motion track of the pedal and provide an adjustable feet exercise travel for a user.

Owner:JOHNSON HEALTH TECH

Airport gate position intelligent distribution method and system

InactiveCN110378537AImprove automated scheduling capabilitiesReduce walking distanceForecastingResourcesCivil aviationDistributed computing

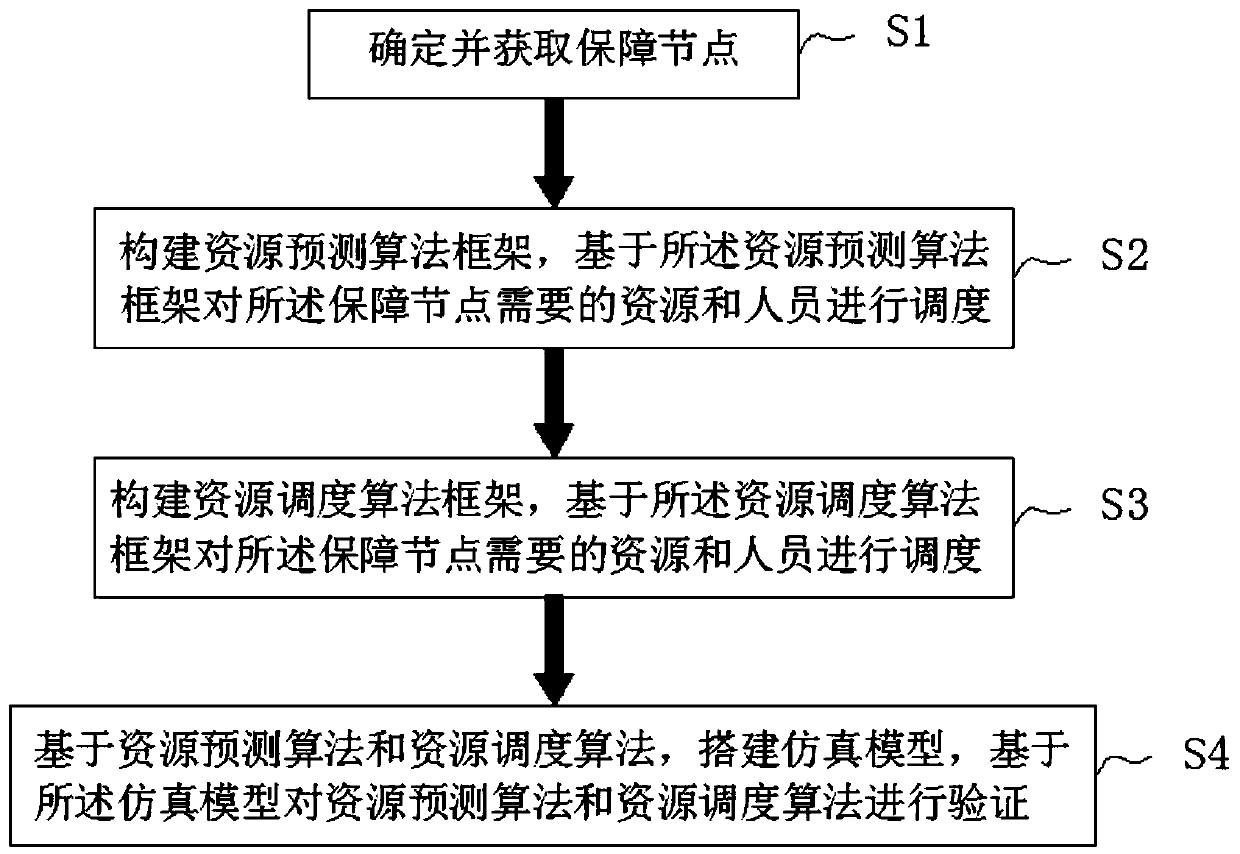

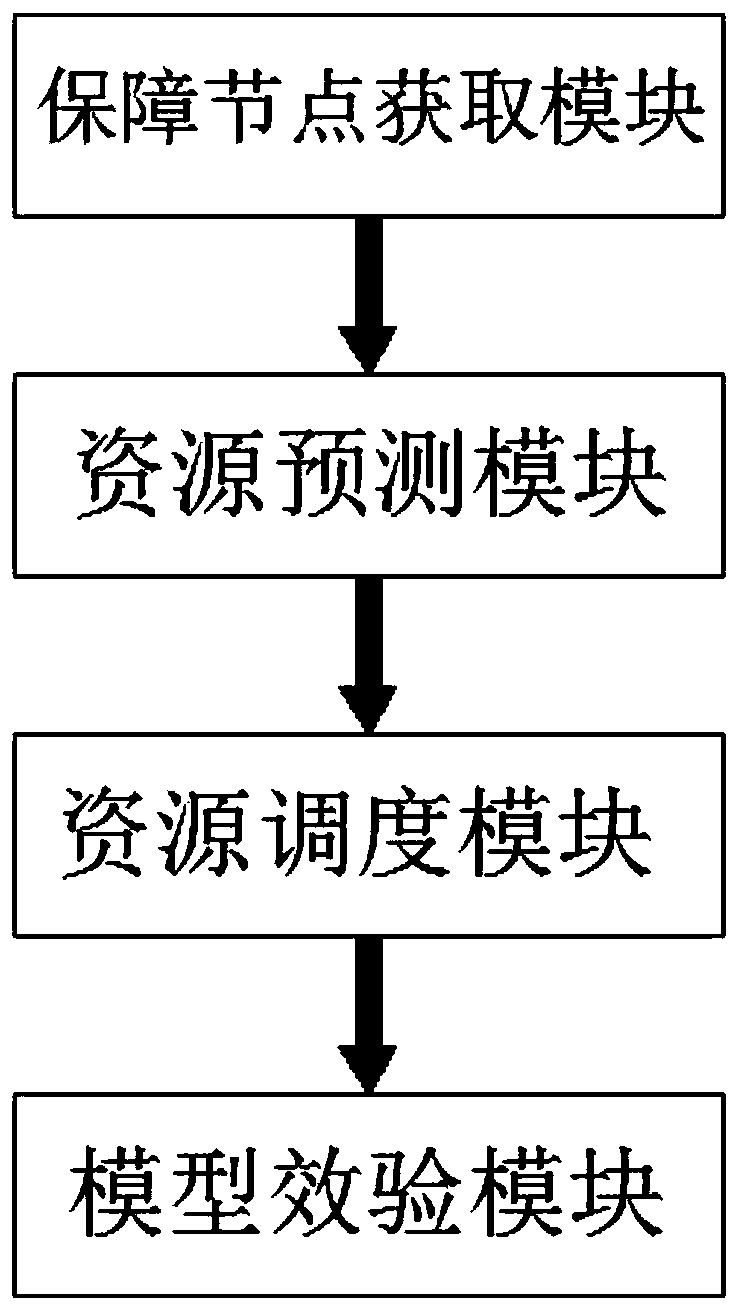

The invention discloses an airport gate position intelligent distribution method and an airport gate position intelligent distribution system, and relates to the field of civil aviation information. The method comprises the following steps: determining and obtaining a guarantee node; constructing a resource prediction algorithm framework, and scheduling resources and personnel required by the guarantee node based on the resource prediction algorithm framework; constructing a resource scheduling algorithm framework, and scheduling resources and personnel required by the guarantee node based onthe resource scheduling algorithm framework; the method is based on a resource prediction algorithm and a resource scheduling algorithm. According to the airport resource automatic scheduling method,the problem that only single resource allocation is considered traditionally is solved. The time-place-personnel-equipment linkage collaborative allocation algorithm is established, and the airport resource automatic scheduling capacity is comprehensively improved.

Owner:四川青霄信息科技有限公司

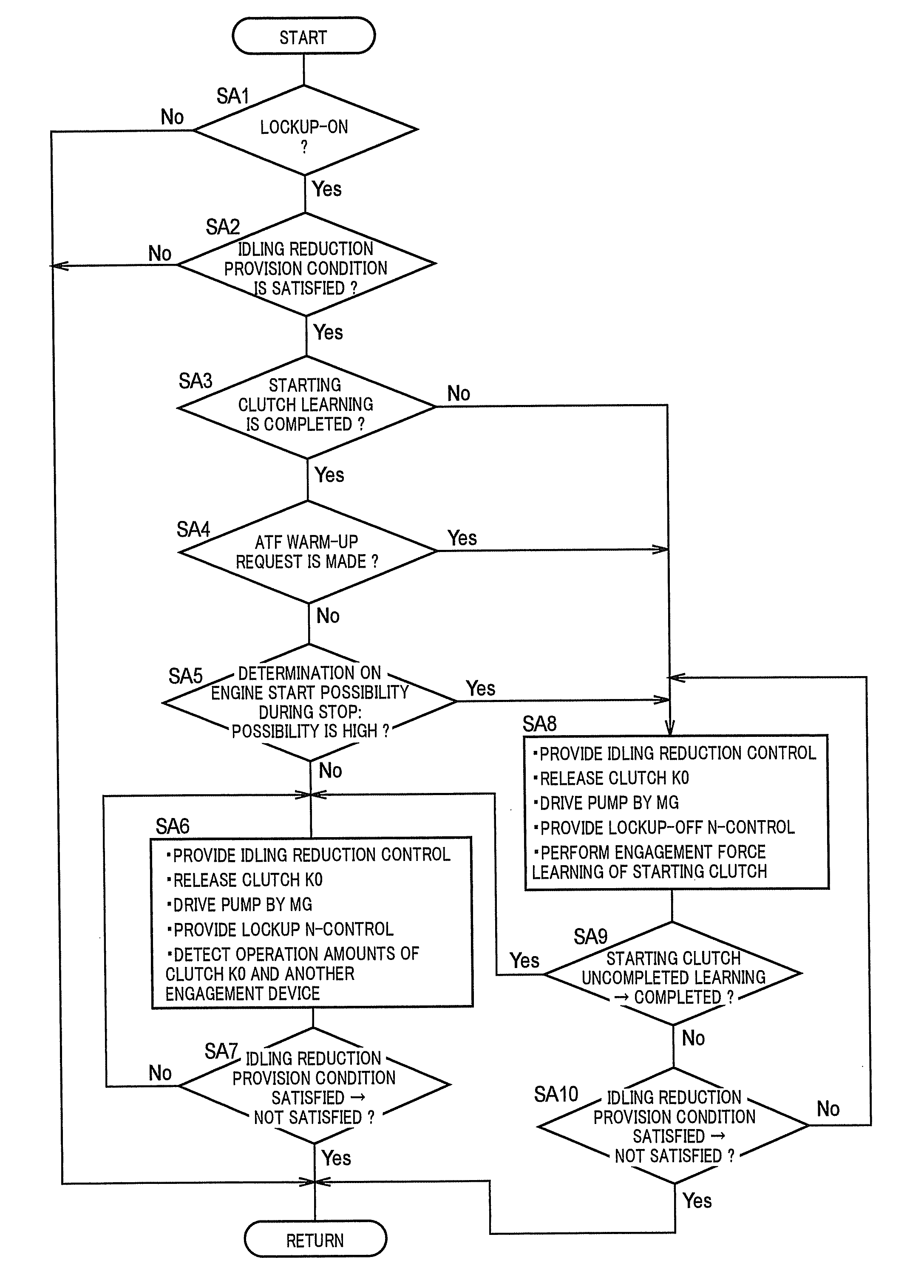

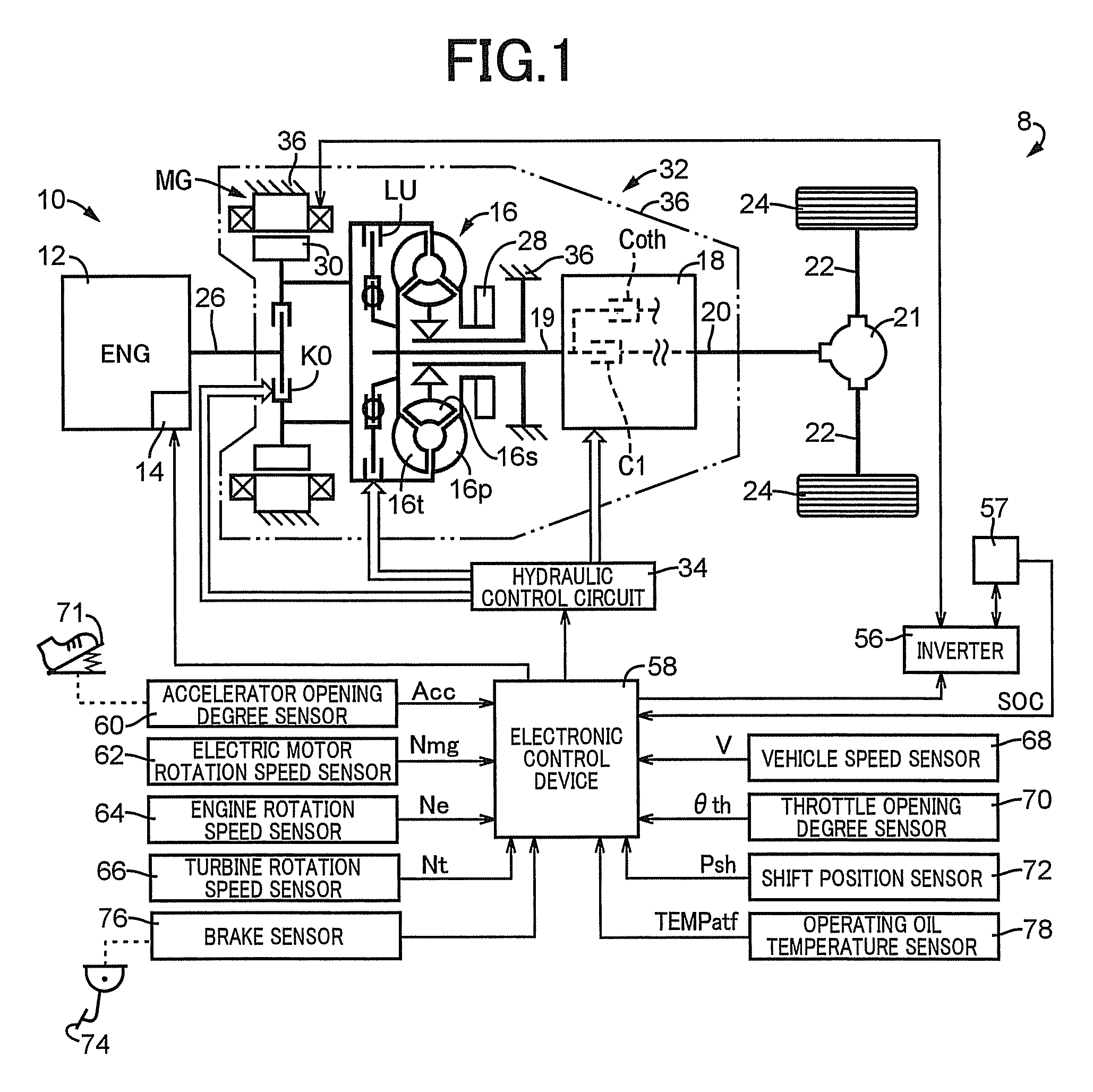

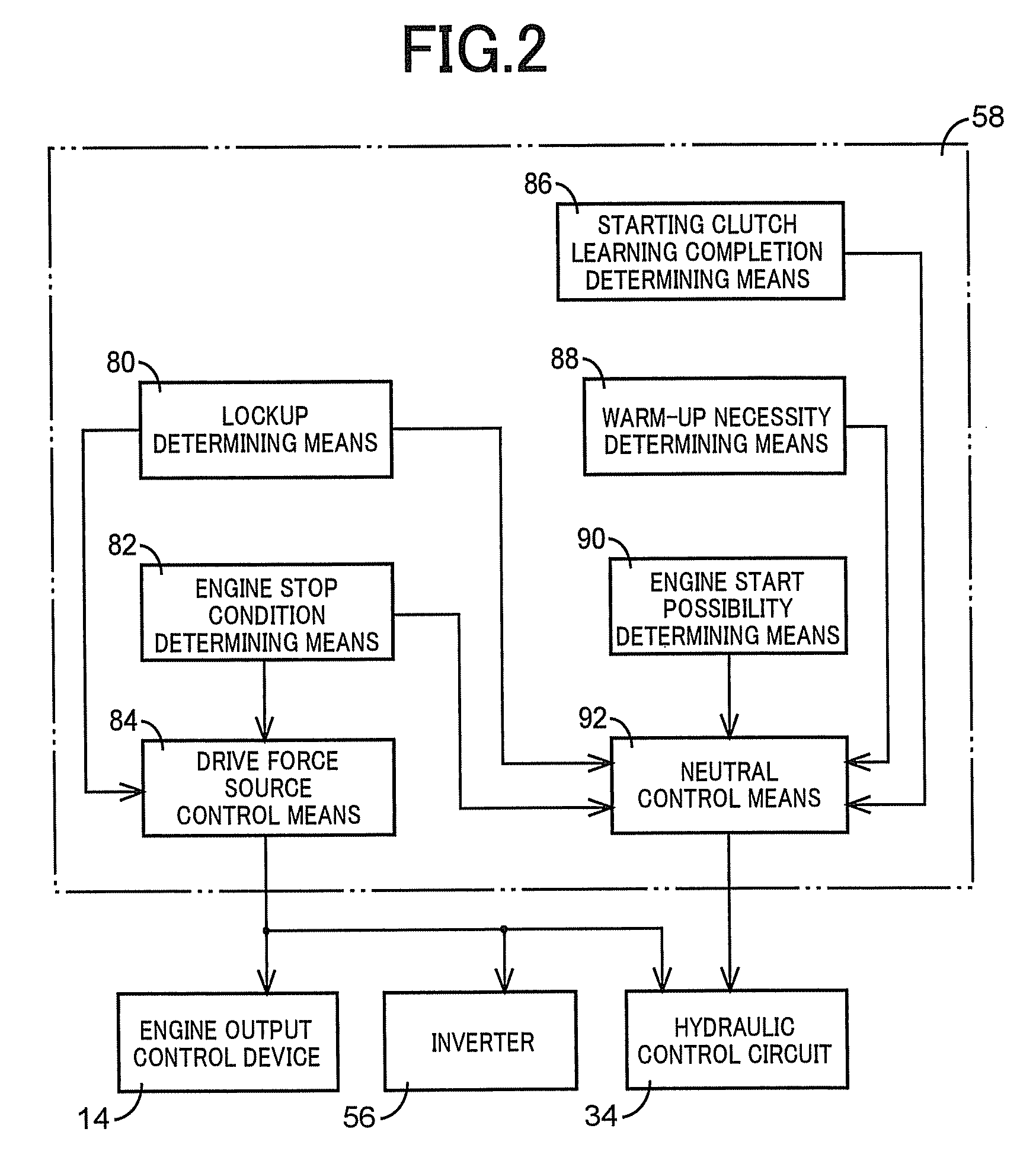

Vehicle drive apparatus control apparatus

ActiveUS9127765B2Reduce power lossSmall sizeClutchesGas pressure propulsion mountingDrive wheelTransmitted power

A control device of a vehicle drive device includes a mechanical oil pump, a hydraulic power transmission device transmitting power of the engine and the electric motor to drive wheels via an interposed engagement device when it is engaged. While the electric motor drives the mechanical oil pump while an operation of the engine is stopped, the control device executing neutral control of putting the engagement device into a slip state or released state to suppress power transmission between the hydraulic power transmission device and the drive wheels, the hydraulic power transmission device including a lockup clutch mechanically coupling input and output members of the hydraulic power transmission device when engaged, the lockup clutch being engaged during executing of the neutral control. Also, after it is determined that the engine is likely to be restarted after a stop of operation while the vehicle remains stopped, the lockup clutch being released.

Owner:TOYOTA JIDOSHA KK

Cleaning method and cleaning system of tubular membrane

InactiveCN103341324AHigh flux recovery rateStable fluxSemi-permeable membranesParticle flowEngineering

The invention discloses a cleaning method and a cleaning system of a tubular membrane, and provides a cleaning method and a cleaning system which can recover the membrane flux. The cleaning method comprises the following steps of: cleaning with clean water; cleaning through mixing particles, clean water and air: after mixing particles, clean water and air, and cleaning the mixture of particles, clean water and air in the tubular membrane, wherein air bubbles are broken caused by the collision of air bubbles and particles, energy is released extensively to cause partial vibration, and meanwhile, the particles and air bubbles are both rubbed with the membrane so as to lead to falling of pollutants on the surface of the membrane; and discharging the pollutants to complete the cleaning process. According to the cleaning method disclosed by the invention, the step of cleaning by mixing particles, clean water and gases is added; the air bubbles generated by the gases can be collided with the particles, and energy is released extensively so as to lead to partial vibration; turbulence is formed in a membrane component; particles flow rapidly in a system; and the air bubbles and particles are both rubbed with the surface of the membrane so as to remove surface pollutants. The cleaning effect and the cleaning efficiency can be improved greatly by combining with two aspects.

Owner:TIANJIN POLYTECHNIC UNIV

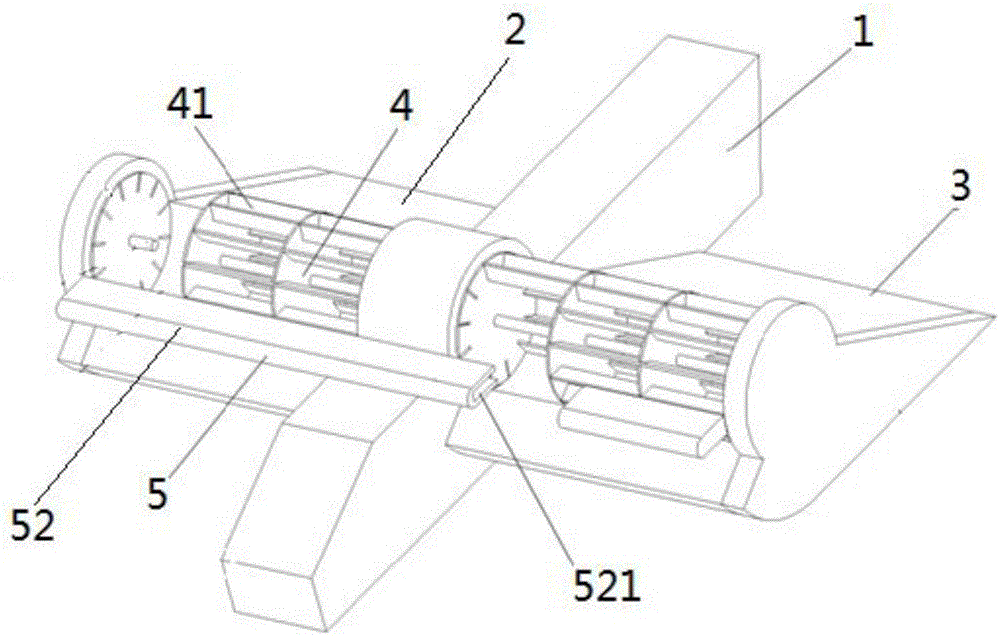

Glove vane aircraft

ActiveCN104986323AShorten the running distanceImprove the efficiency of converting liftWingsAircraftsFuselageHigh-lift device

The invention discloses a glove vane aircraft. The glove vane aircraft comprises a first glove vane (2) and a second glove vane (3) which are symmetrical to each other about an aircraft body (1). Glove vane rollers (4) are arranged on the first glove vane (2) and the second glove vane (3). In the aircraft running state, roller bodies (41) in the glove vane rollers (4) bear air flow opposite to the running direction of the aircraft. The glove vane aircraft is characterized in that the glove vane aircraft further comprises a high lift device (5) which is arranged on the air inlet sides of the glove vane rollers (4) and used for providing a power source for the glove vane rollers (4), and therefore the glove vane rollers (4) can obtain extra power. Due to the adoption of the structure, for the same glove vane aircraft, the running distance of the glove vane aircraft can be greatly reduced, and in other words, the glove vane roller lift force conversion efficiency of the glove vane aircraft is improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

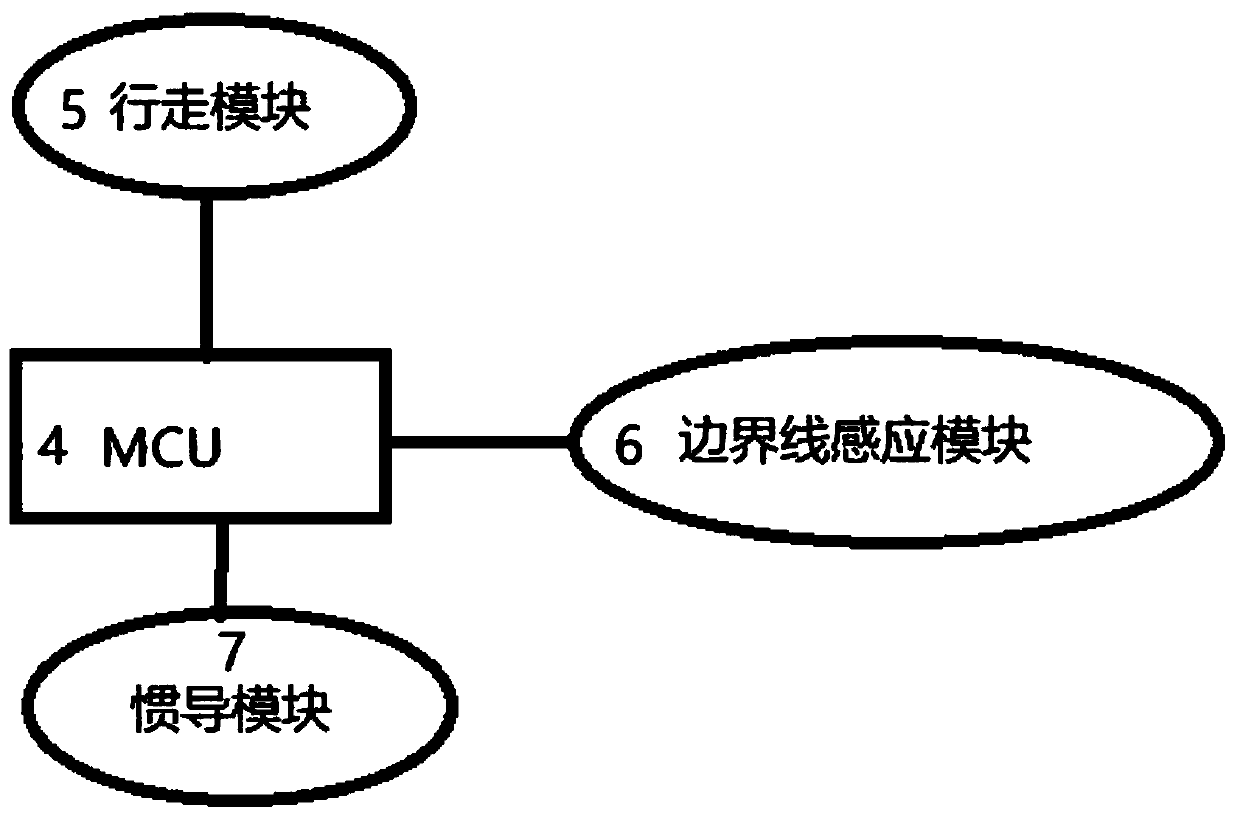

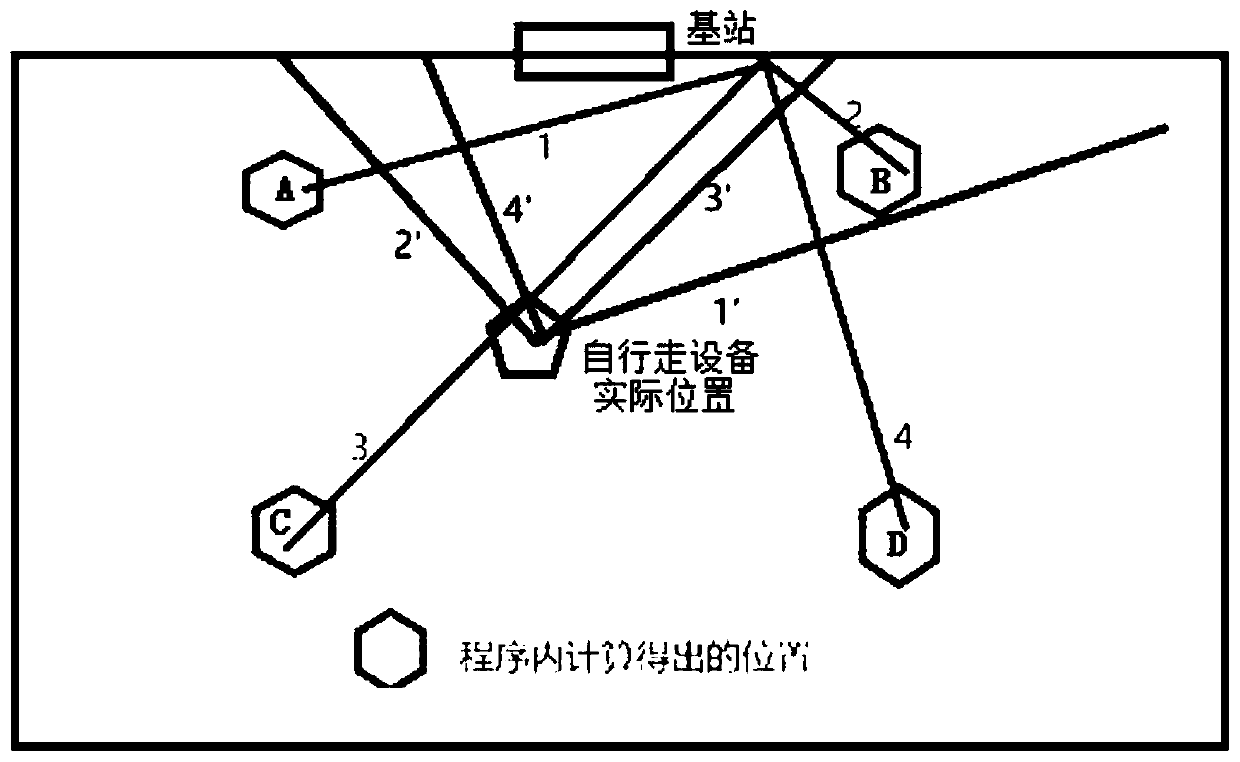

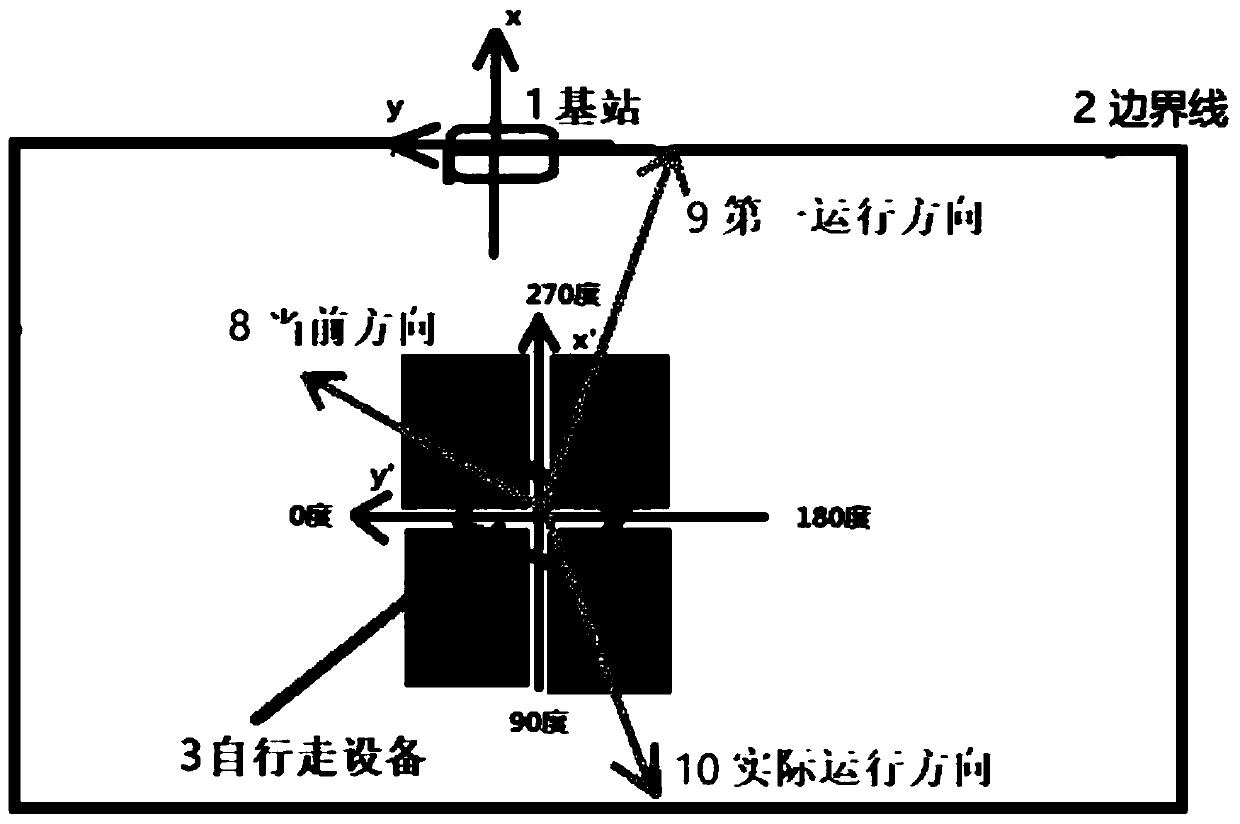

Method for returning self-walking device to base station and self-walking device

PendingCN111090284AShort return pathReduce complexityPosition/course control in two dimensionsSimulationReal-time computing

The invention discloses a method for returning a self-walking device to a base station and the self-walking device. The method comprises the following steps of recording reference position parametersof the self-walking equipment in advance; when the self-walking equipment needs to return to the base station, comparing the reference position parameters with the current position and / or current direction of the self-walking equipment, and calculating to obtain a first running direction; controlling the self-walking equipment to determine an actual running direction according to the first runningdirection; and after walking to a boundary line according to the actual running direction, returning to the base station along the boundary line in a shorter path. Through recording of the referenceposition parameters, the shorter return path can be calculated when the self-walking equipment needs to return to the base station, so that the problem that the self-walking equipment needs to wind the boundary line for a circle to reach the base station due to inappropriate route direction selection in the prior art is solved.

Owner:NANJING SUMEC INTELLIGENT TECH CO LTD

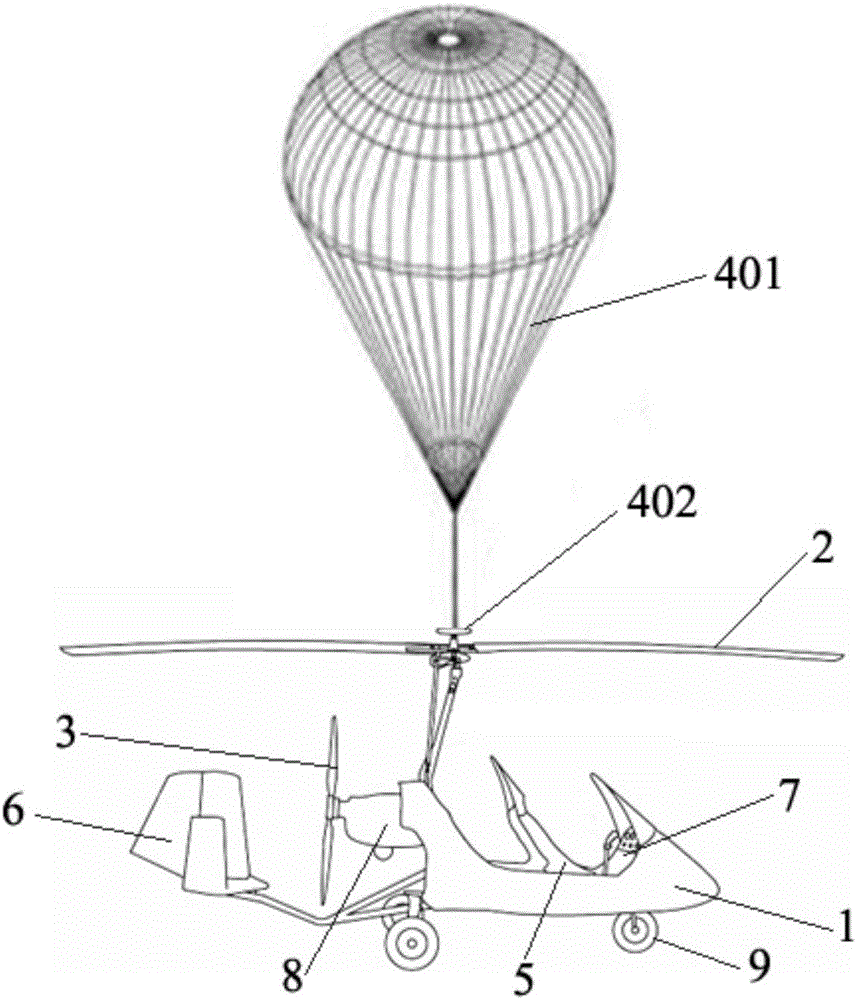

Parachuting autogyro and method thereof

The invention discloses a parachuting autogyro. The parachuting autogyro comprises a fuselage, a rotor wing device, a screw propeller device and a parachute device, wherein the fuselage comprises a cabin and a tail vane; a control system is arranged at the front end of the cabin; an engine is arranged at the rear end of the cabin; an undercarriage is further arranged under the fuselage; the rotor wing device is arranged at the top of the fuselage and comprises a rotor wing head and rotor wing sheets which are symmetrically arranged at the periphery of the rotor wing head; the rotor wing device is arranged at the tail part of the cabin and is connected with the engine through a gear box; and the parachute device is arranged above the rotor wing head and comprises a complete machine parachute, a storage cabin for storing the complete machine parachute and a catapult for opening the parachute. The parachuting autogyro has the following effects (1) the safety is high; (2) a taking-off and landing distance is short; (3) the stability is high and the wind resistance is strong; and (4) the cost performance is relatively high.

Owner:SUN HAWK HENAN AVIATION IND CO LTD

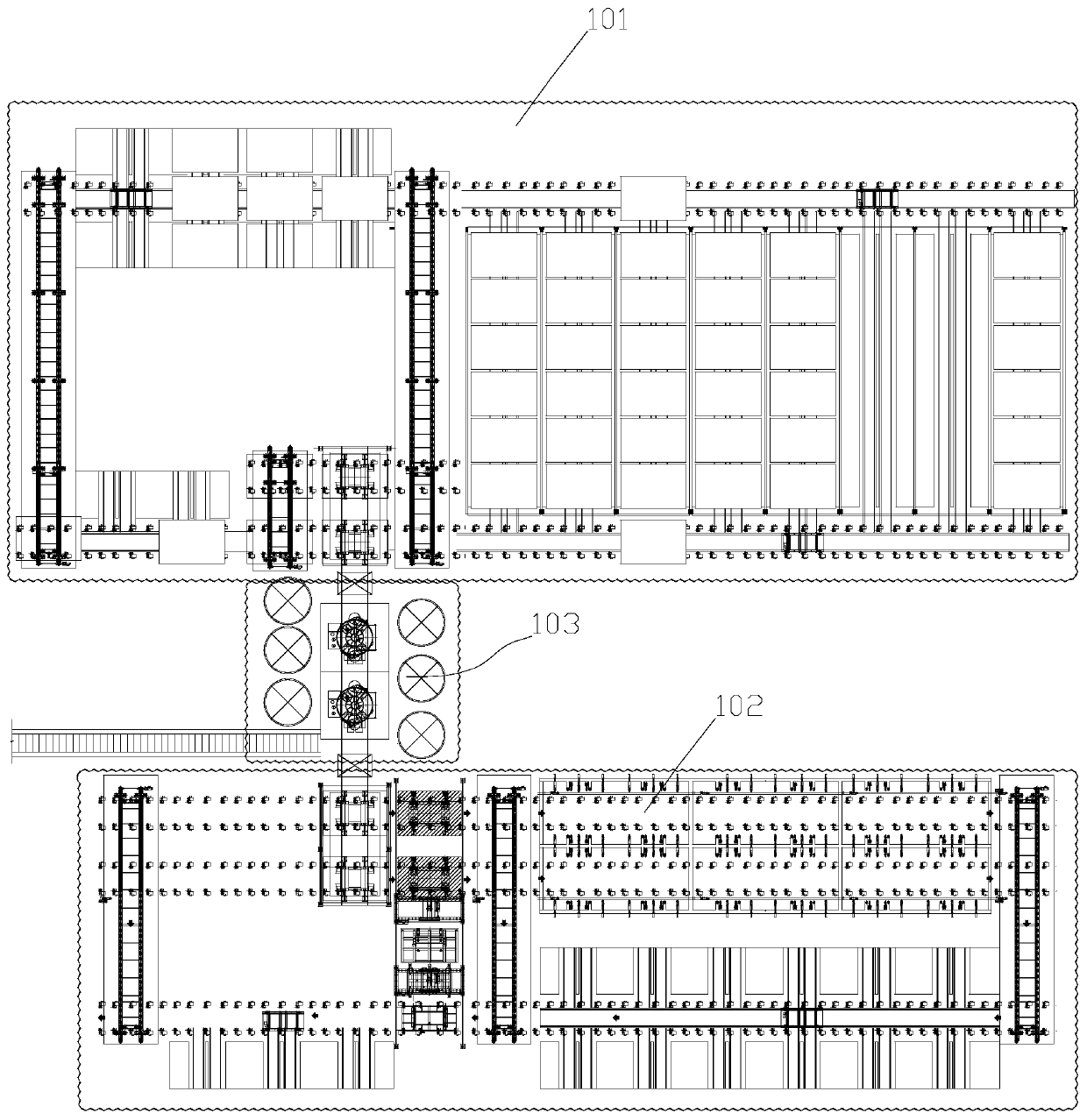

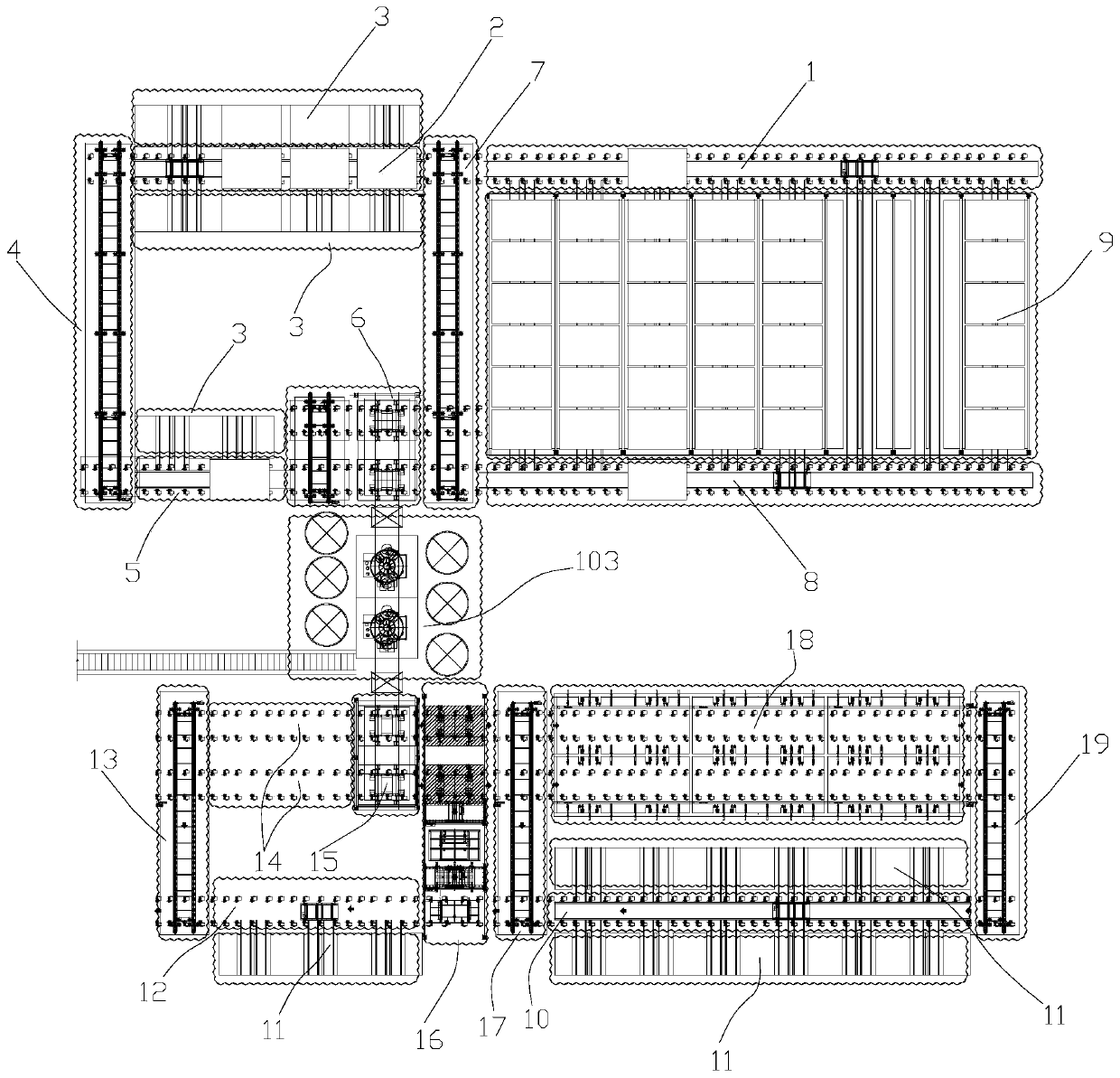

Multipurpose precast concrete component production line and application method thereof

ActiveCN110900815ALow maintenance energy consumptionLight weightCeramic shaping plantsArchitectural engineeringChain link

The invention discloses a multipurpose precast concrete component production line. The production line comprises a special-shaped component operation area, a plate component operation area and a concrete stirring operation area and further comprises a plurality of concrete mixing main machines, a plurality of online empty mold operation mold conveying channels, a plurality of off-line empty mold operation stations, a plurality of mold transverse moving devices using circulating chains, a plurality of combined primary and secondary mold carriers, a plurality of secondary overlapping devices, aplurality of pouring points, a concrete conveying elevated track arranged from a concrete stirring operation area to the pouring points, and a plurality of self-propelled concrete conveying elevated hoppers. The invention further discloses a using method of the multipurpose precast concrete component production line. The production line is advantaged in that the production line is reasonable and ingenious in structural design, suitable for simultaneous online production of precast concrete components needing different curing systems, and suitable for simultaneous online production of the precast concrete components needing different empty mold operation time.

Owner:东莞市中机建科实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com