Patents

Literature

160results about How to "Reduce static pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

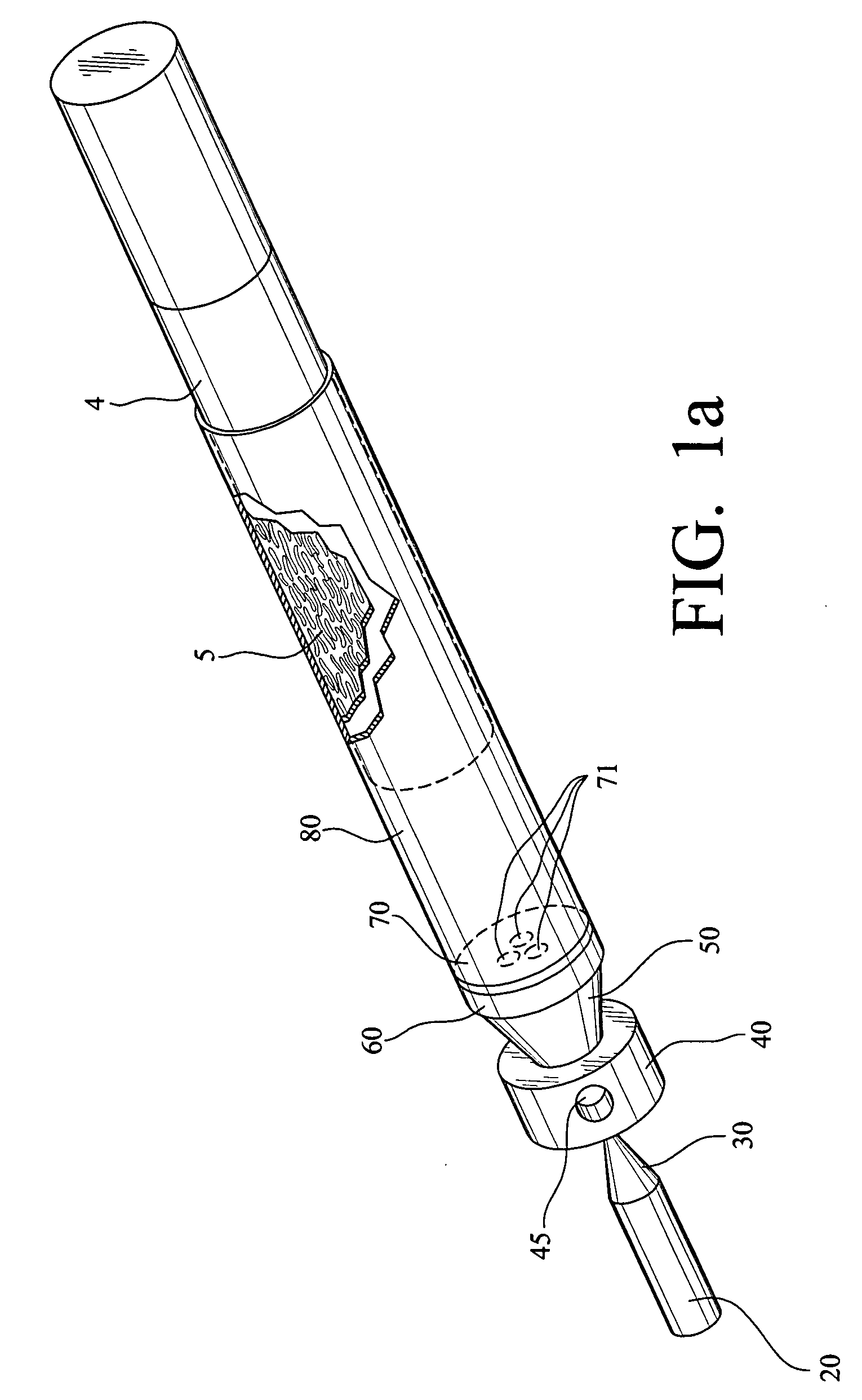

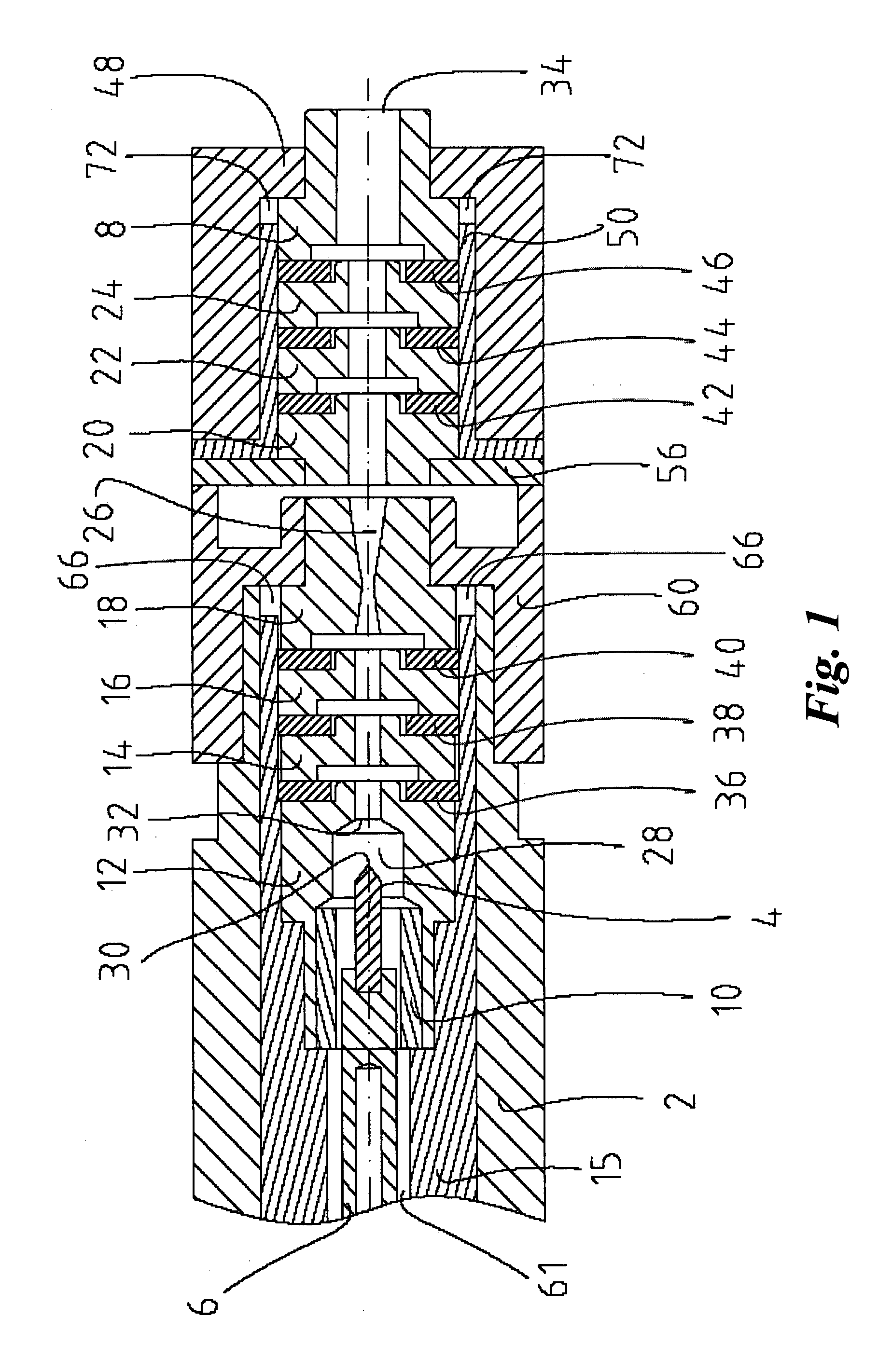

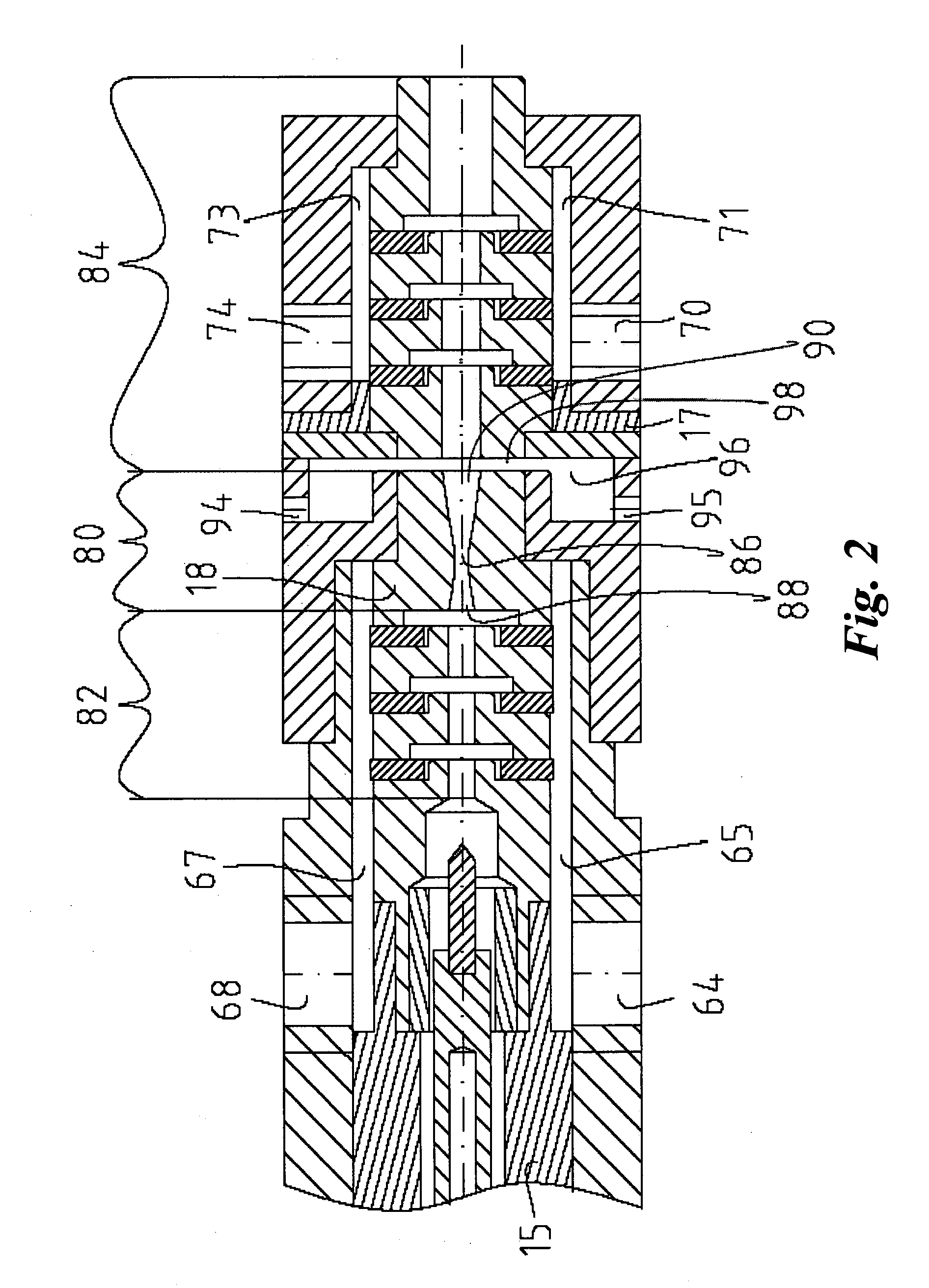

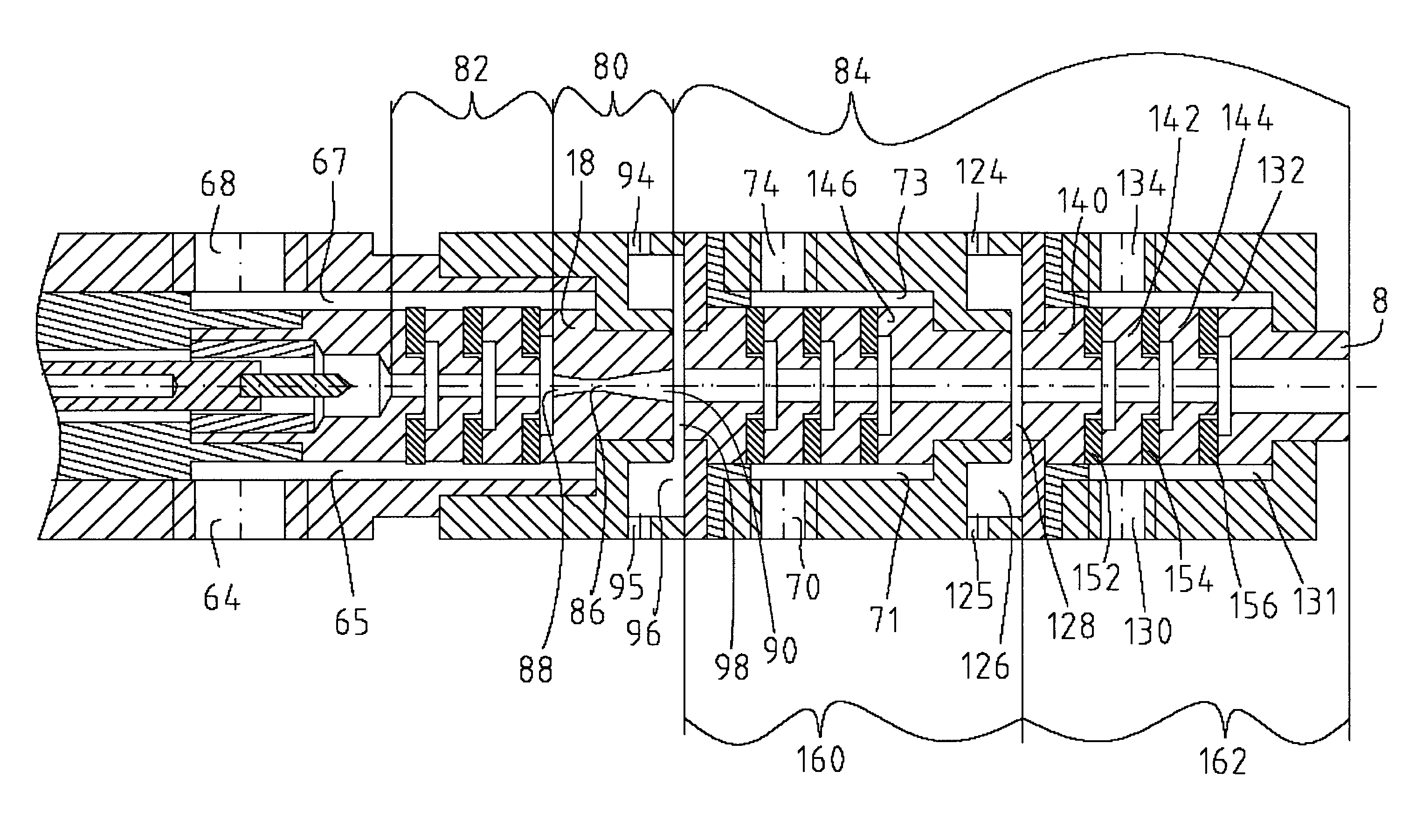

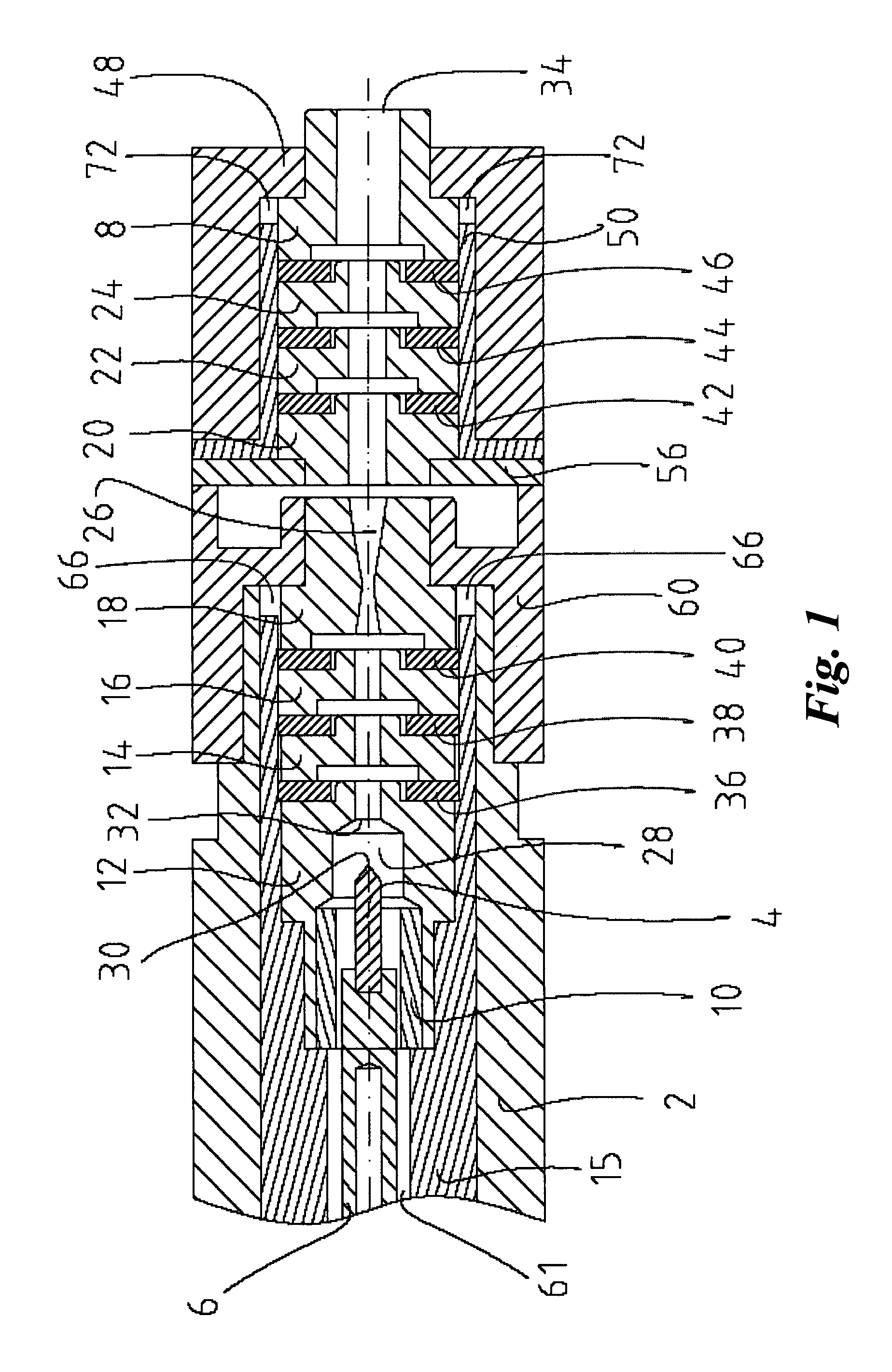

Gas micro burner

InactiveUS7488171B2Low mass flow rateSmall volumeFuel lightersBurner material specificationsProduct gasProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

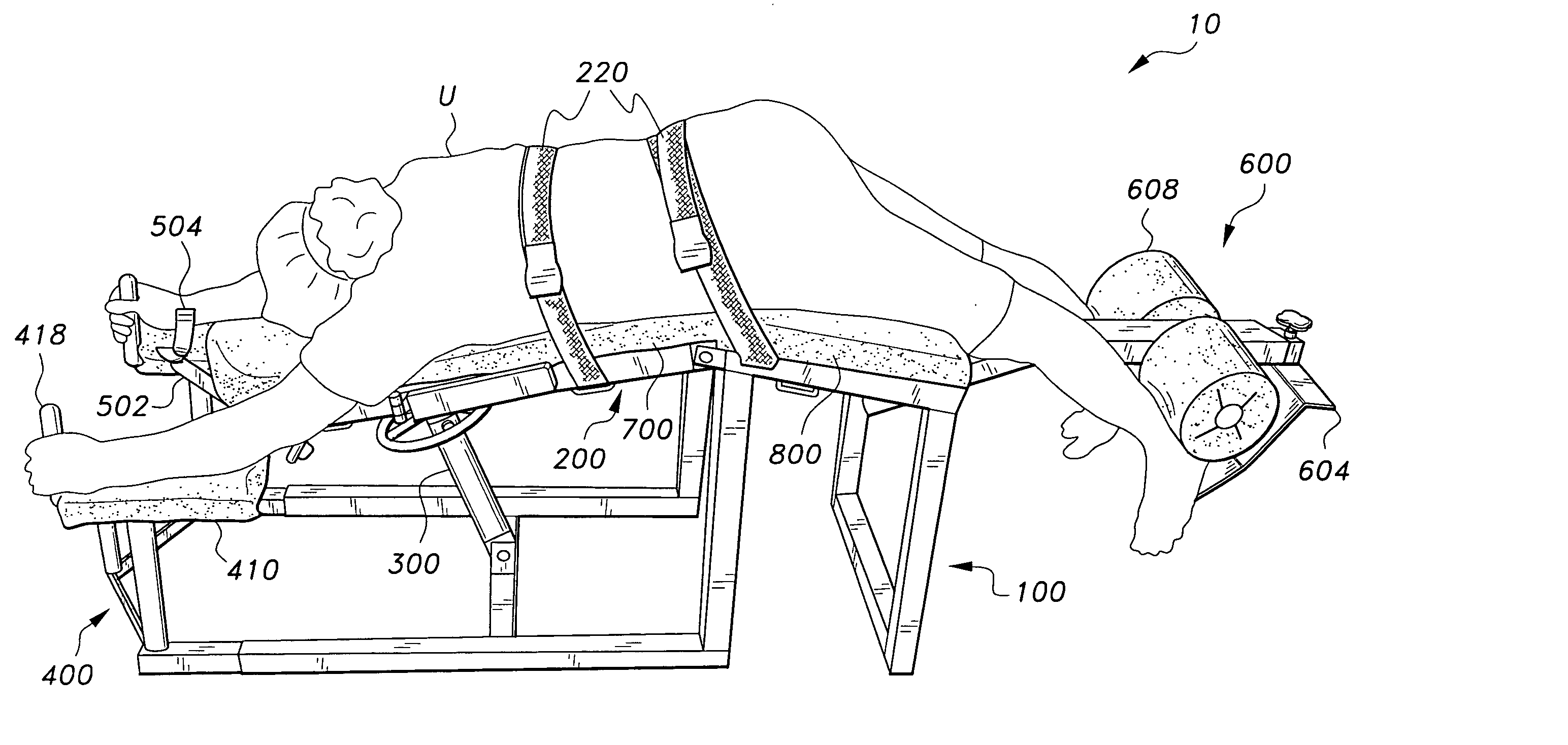

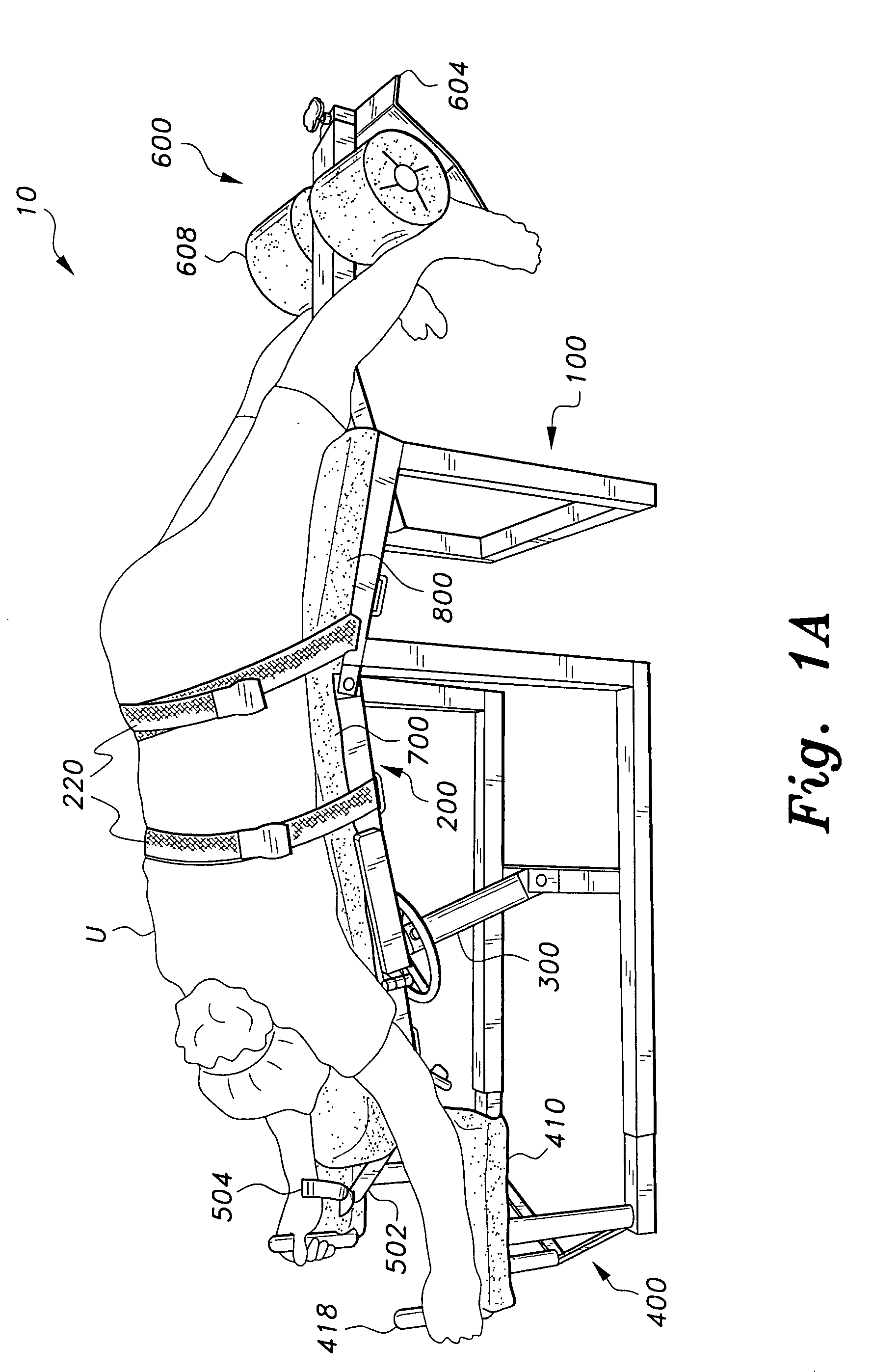

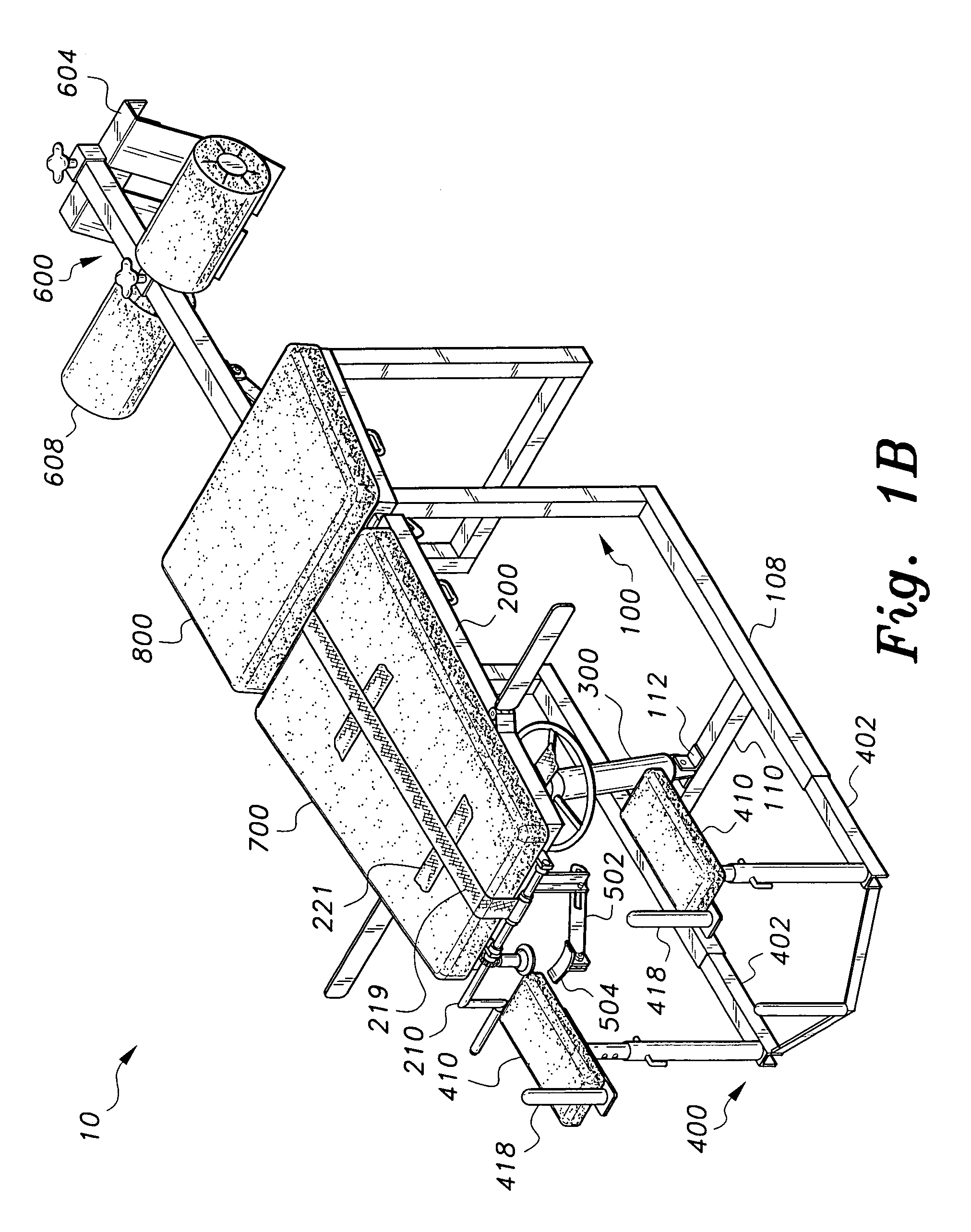

Back traction and muscle stretching bench

InactiveUS20050181917A1Decrease static pressureBeneficial in treatmentChiropractic devicesStiltsEngineeringThigh musculature

Owner:DAYAL SOORYA

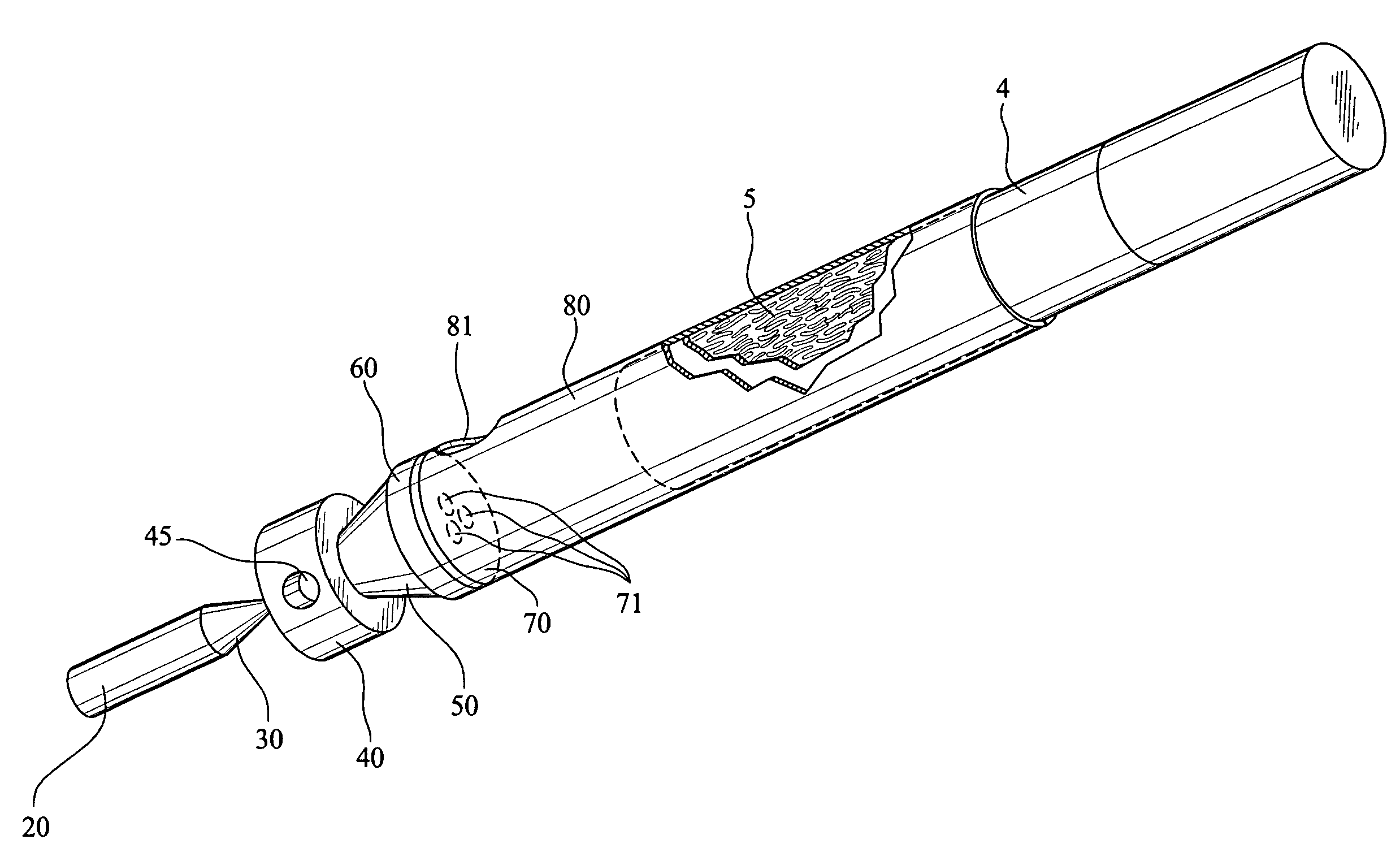

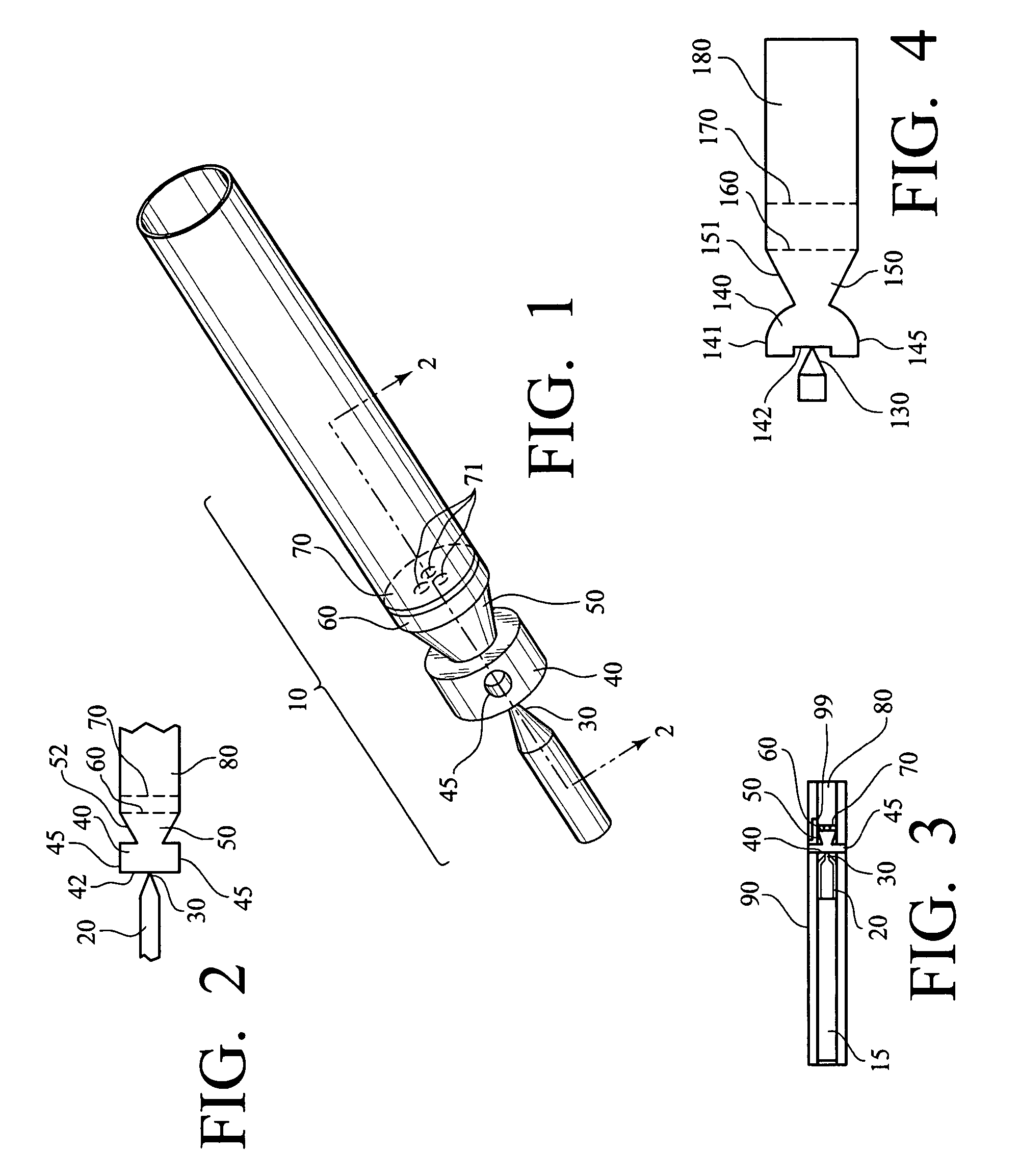

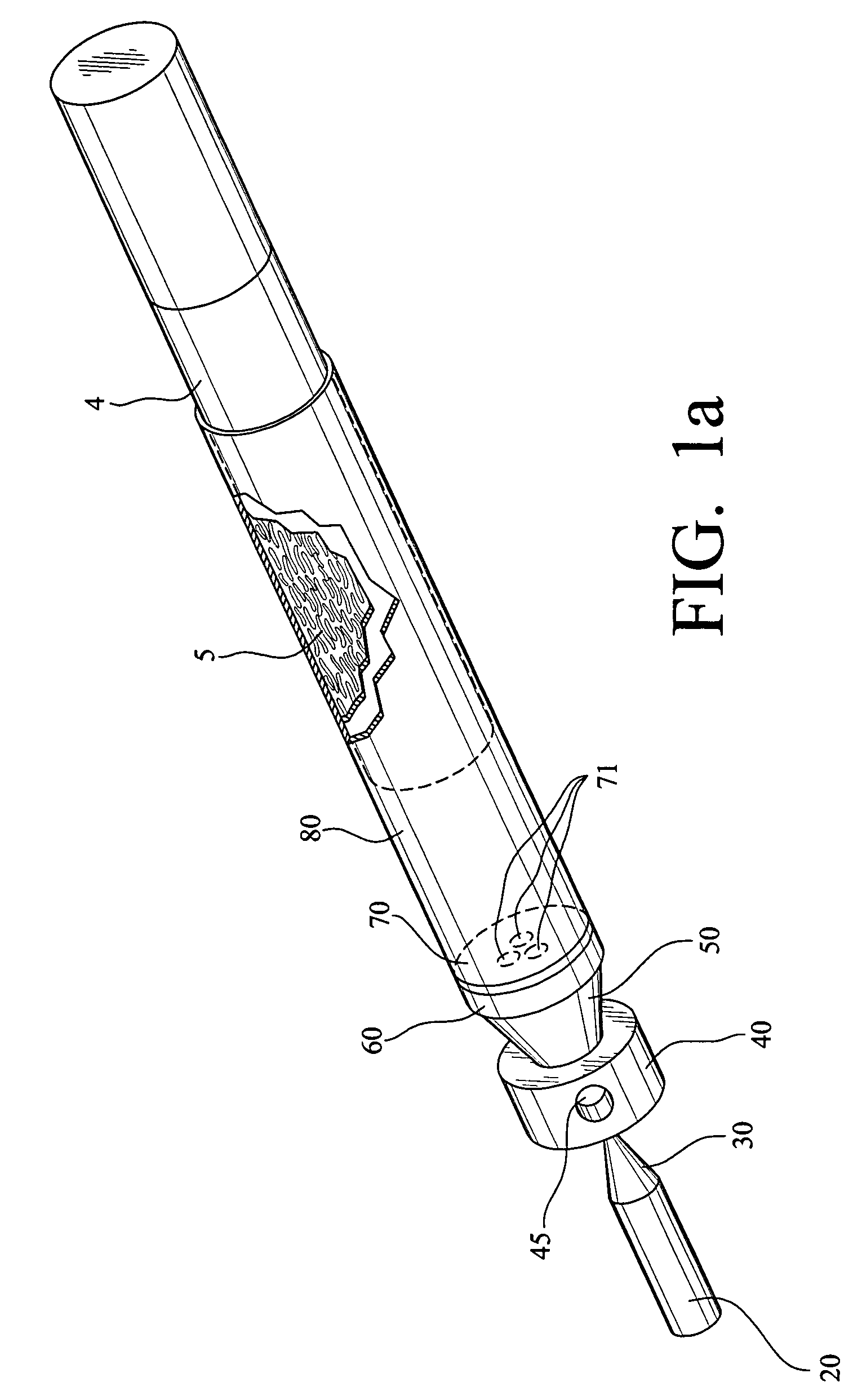

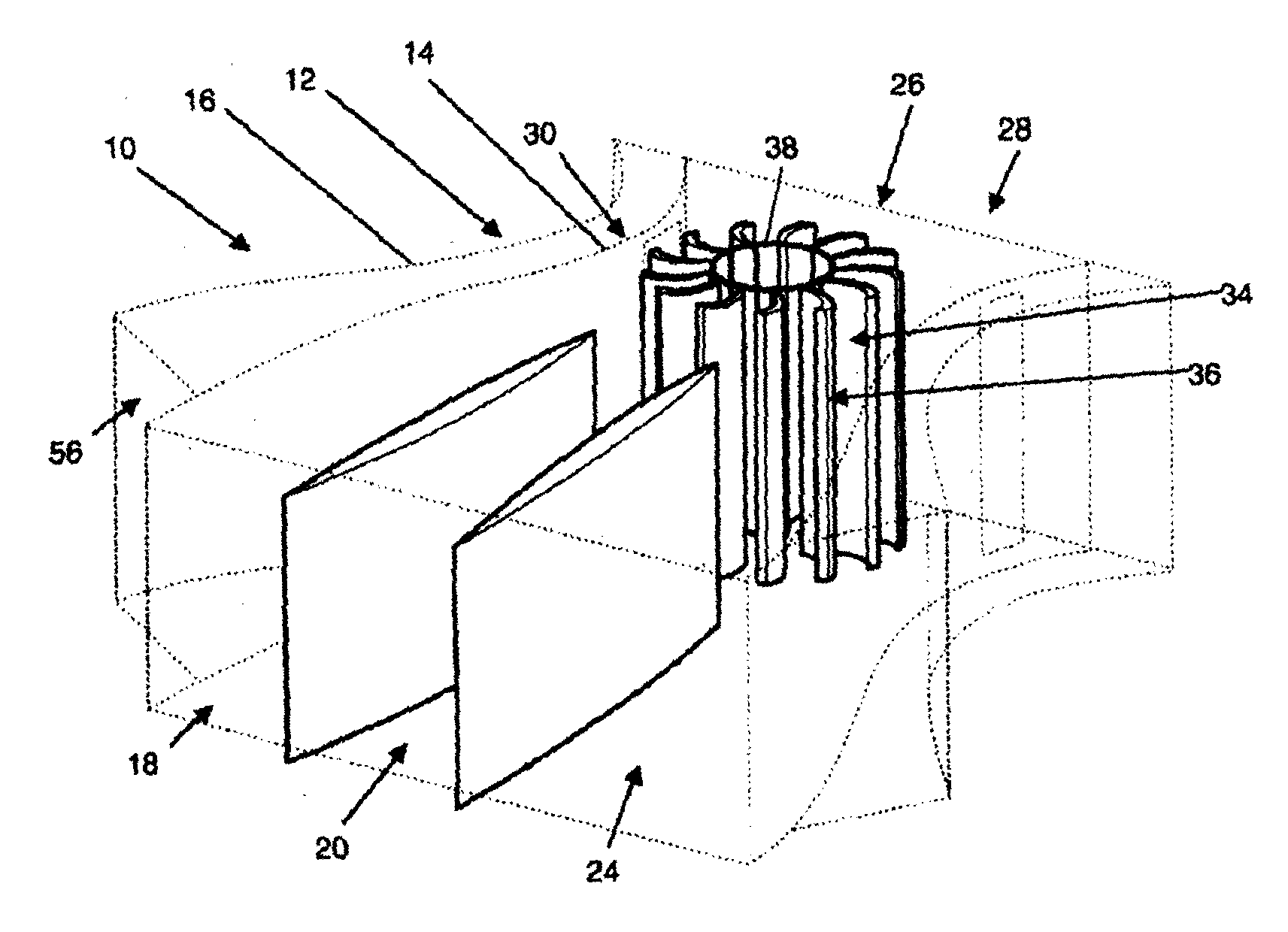

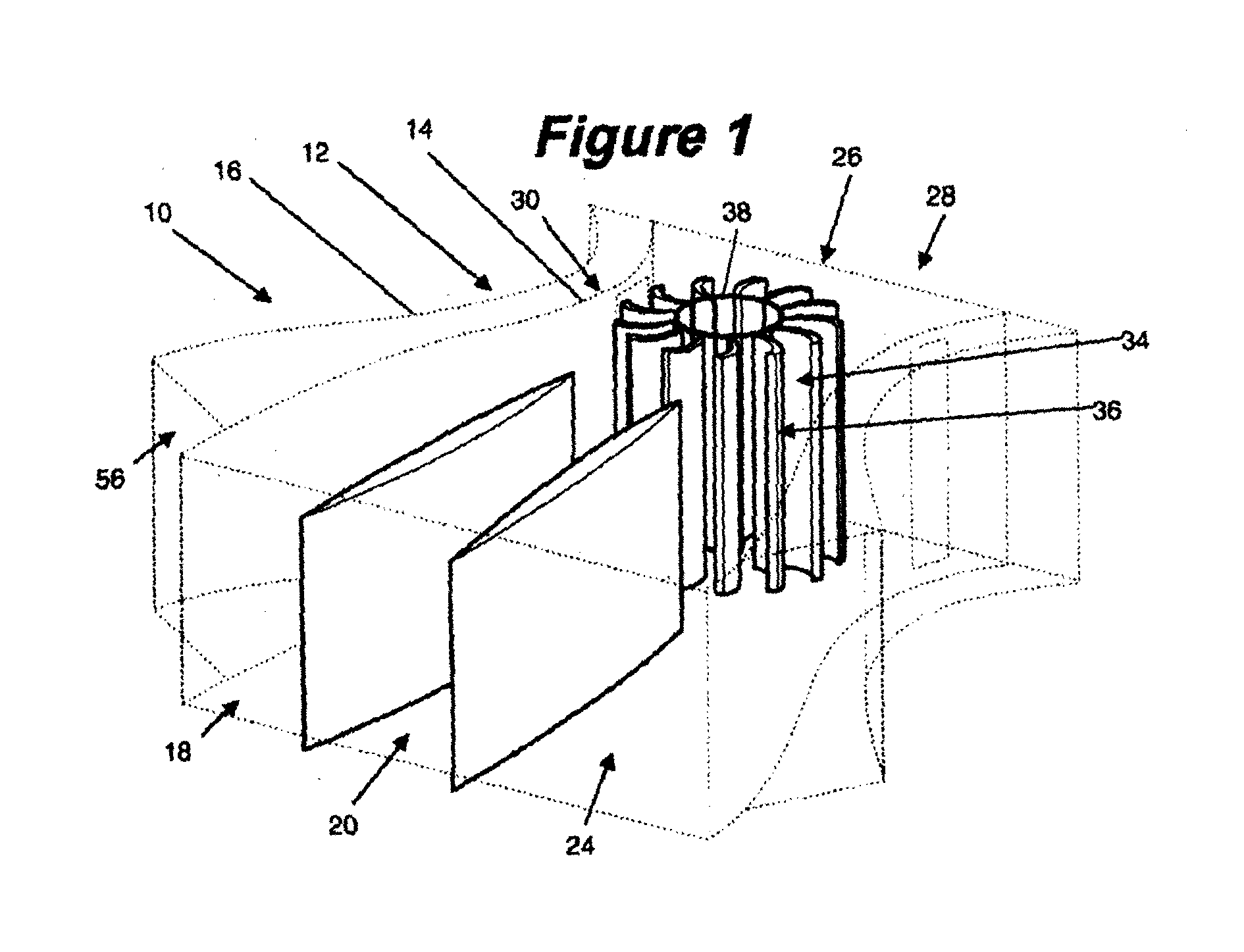

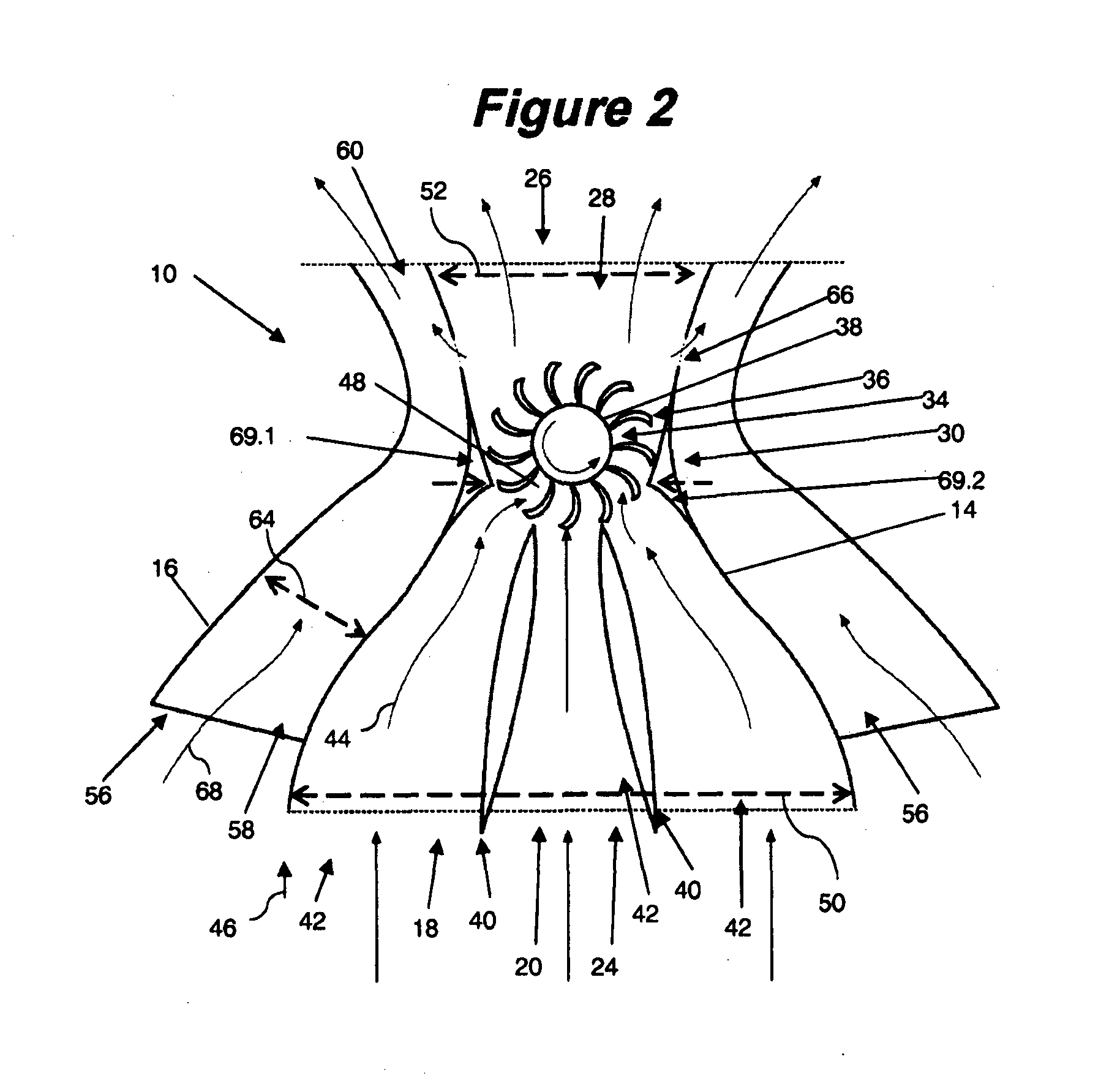

Gas micro burner

InactiveUS20050069831A1Low fuel mass flow rate requirementLow mass flow rateFuel lightersBurner material specificationsGas burnerProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

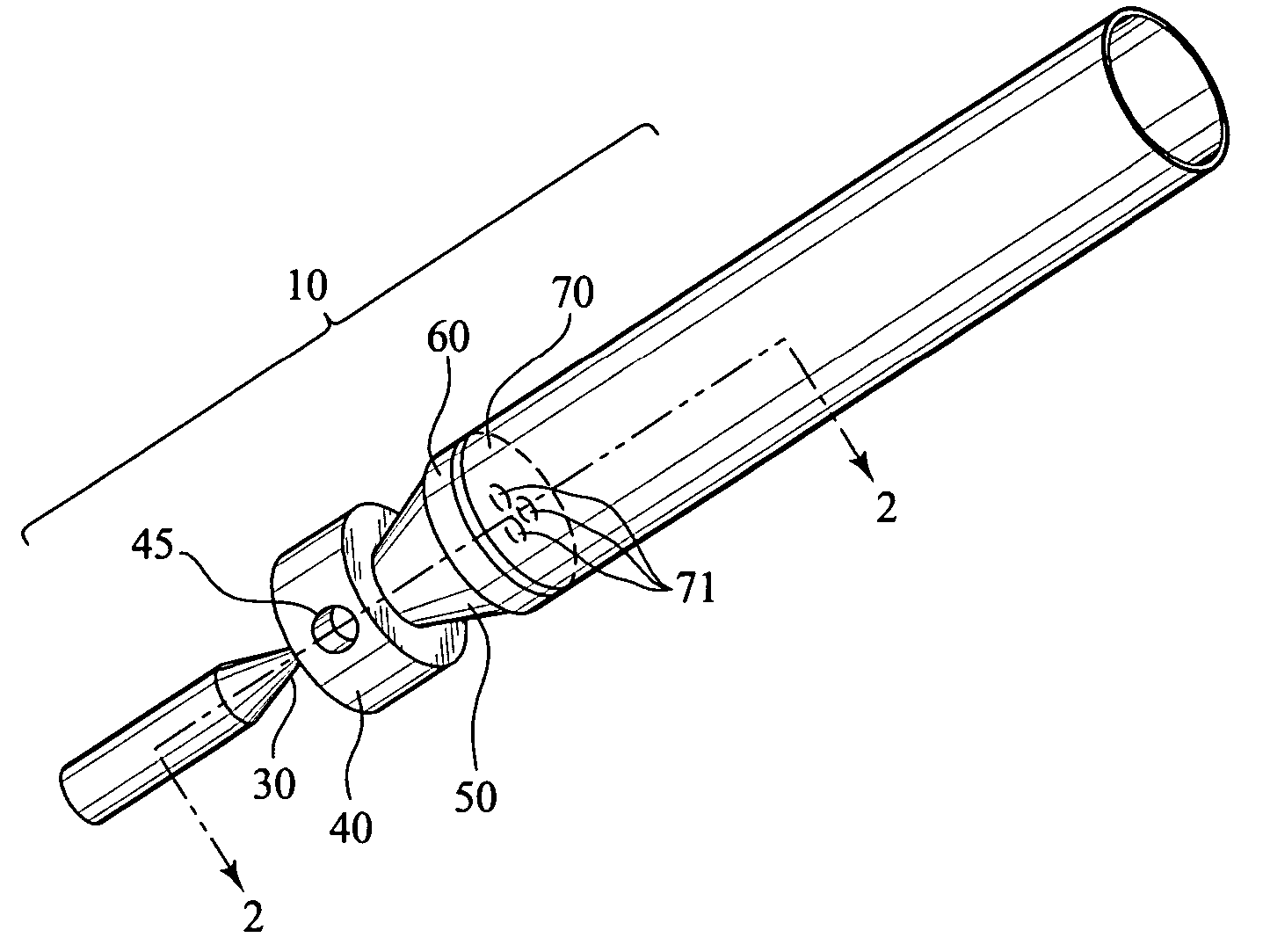

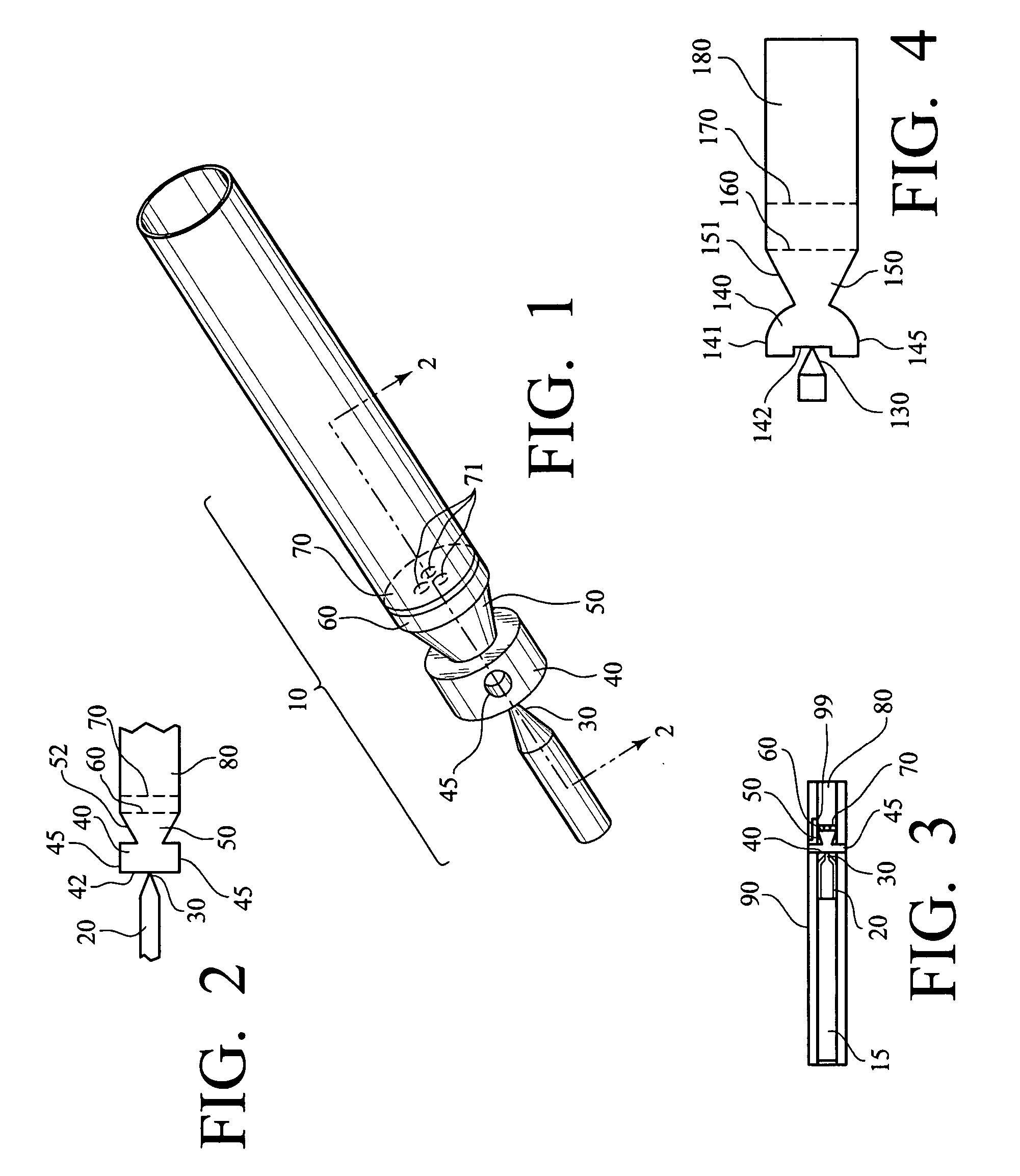

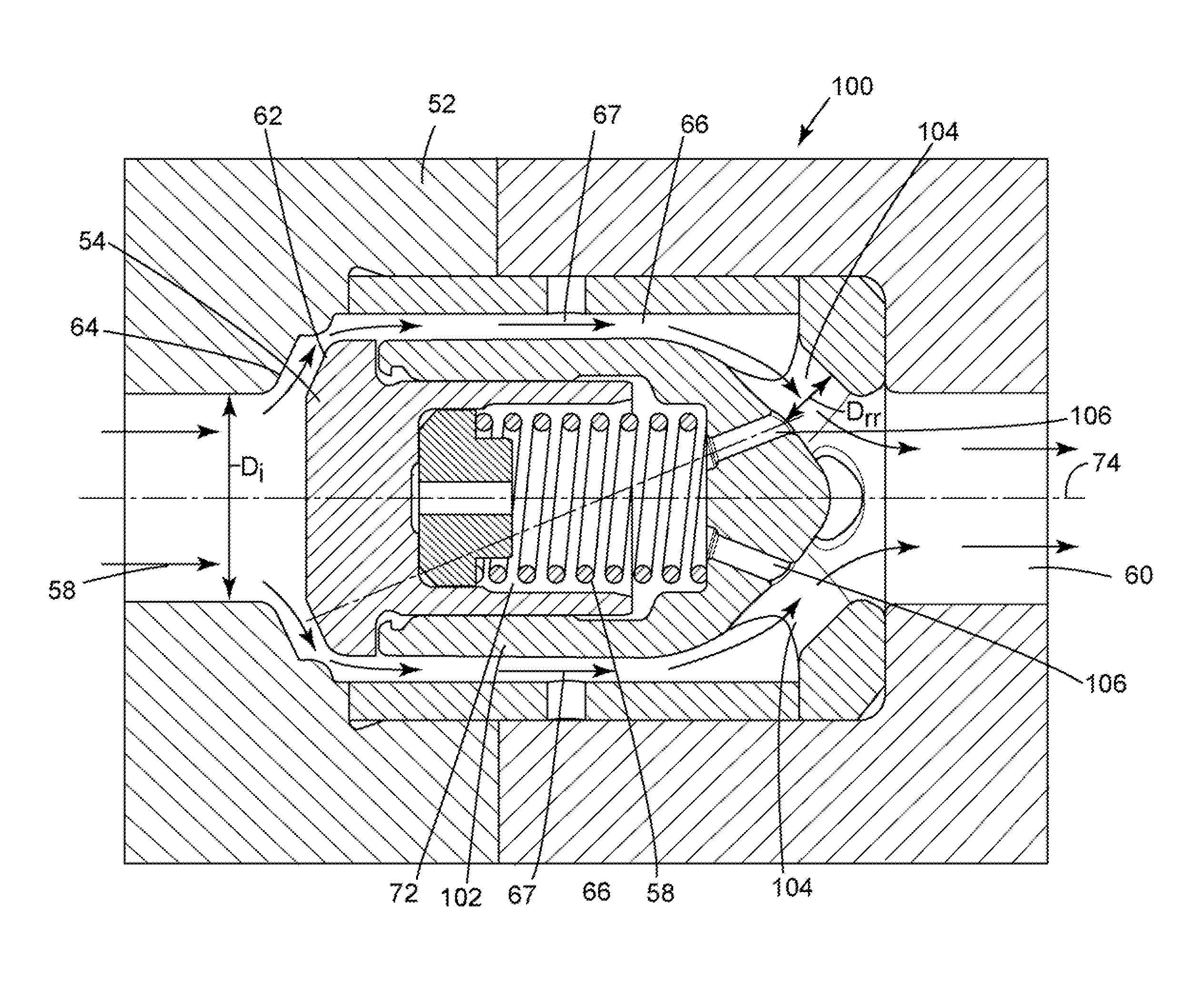

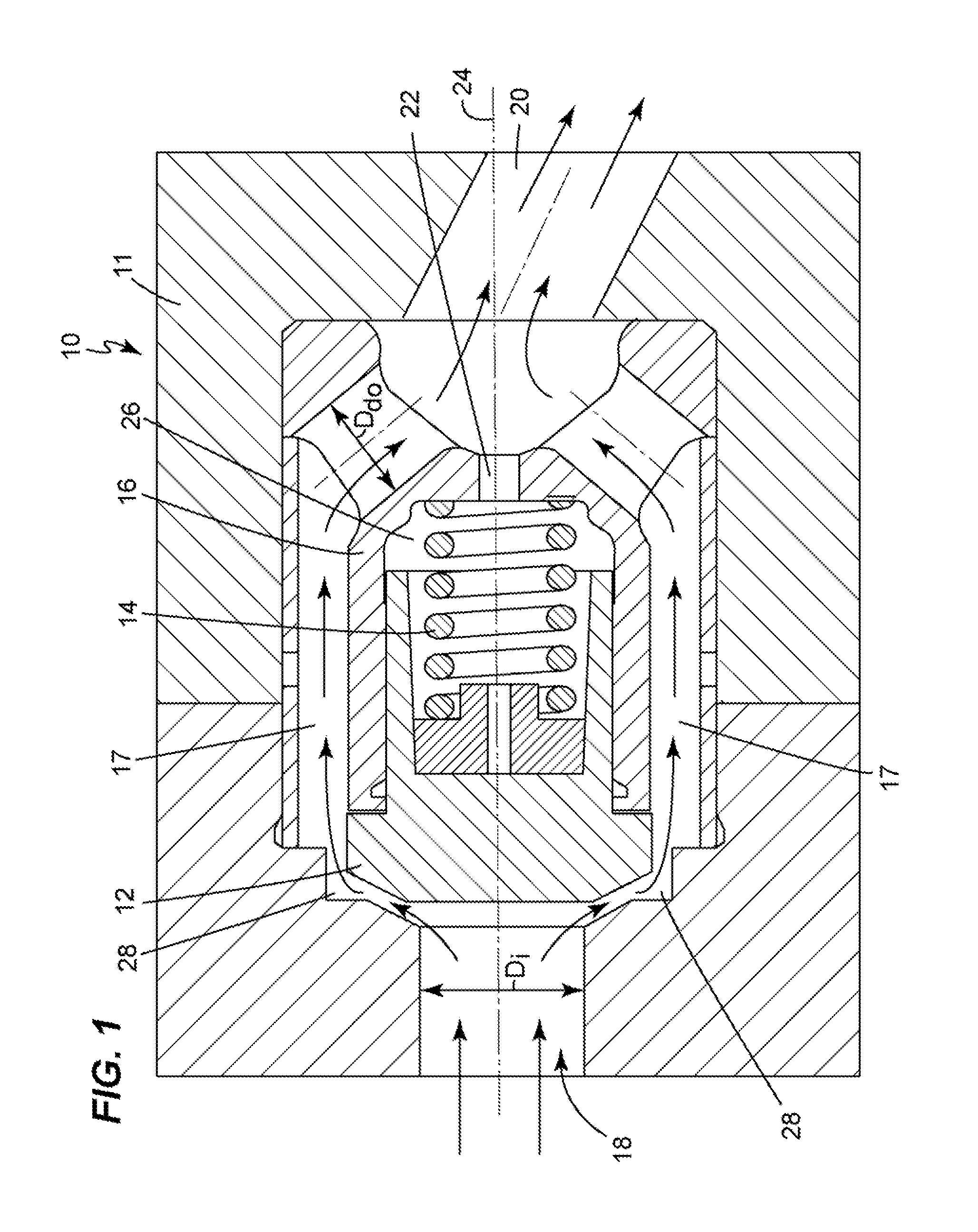

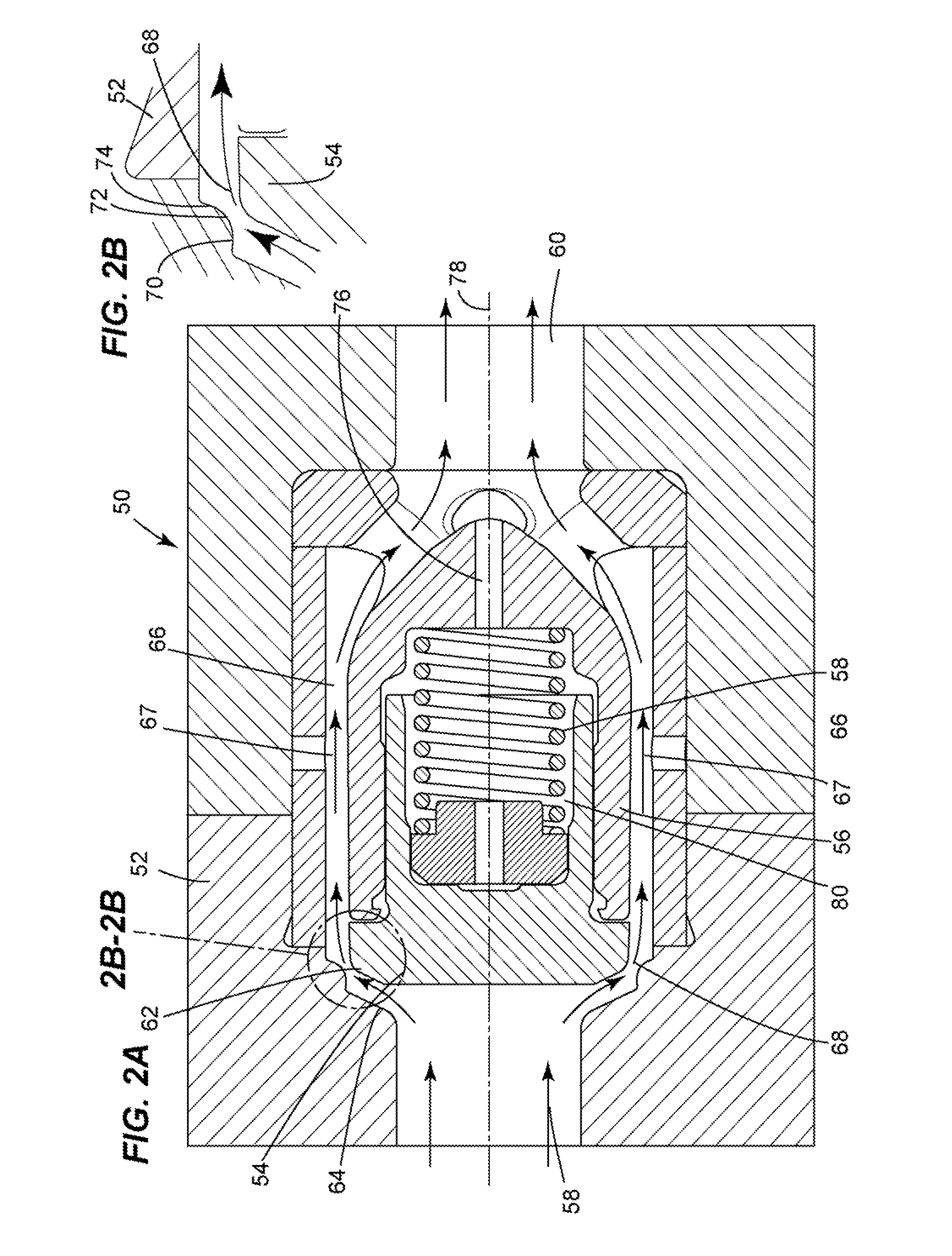

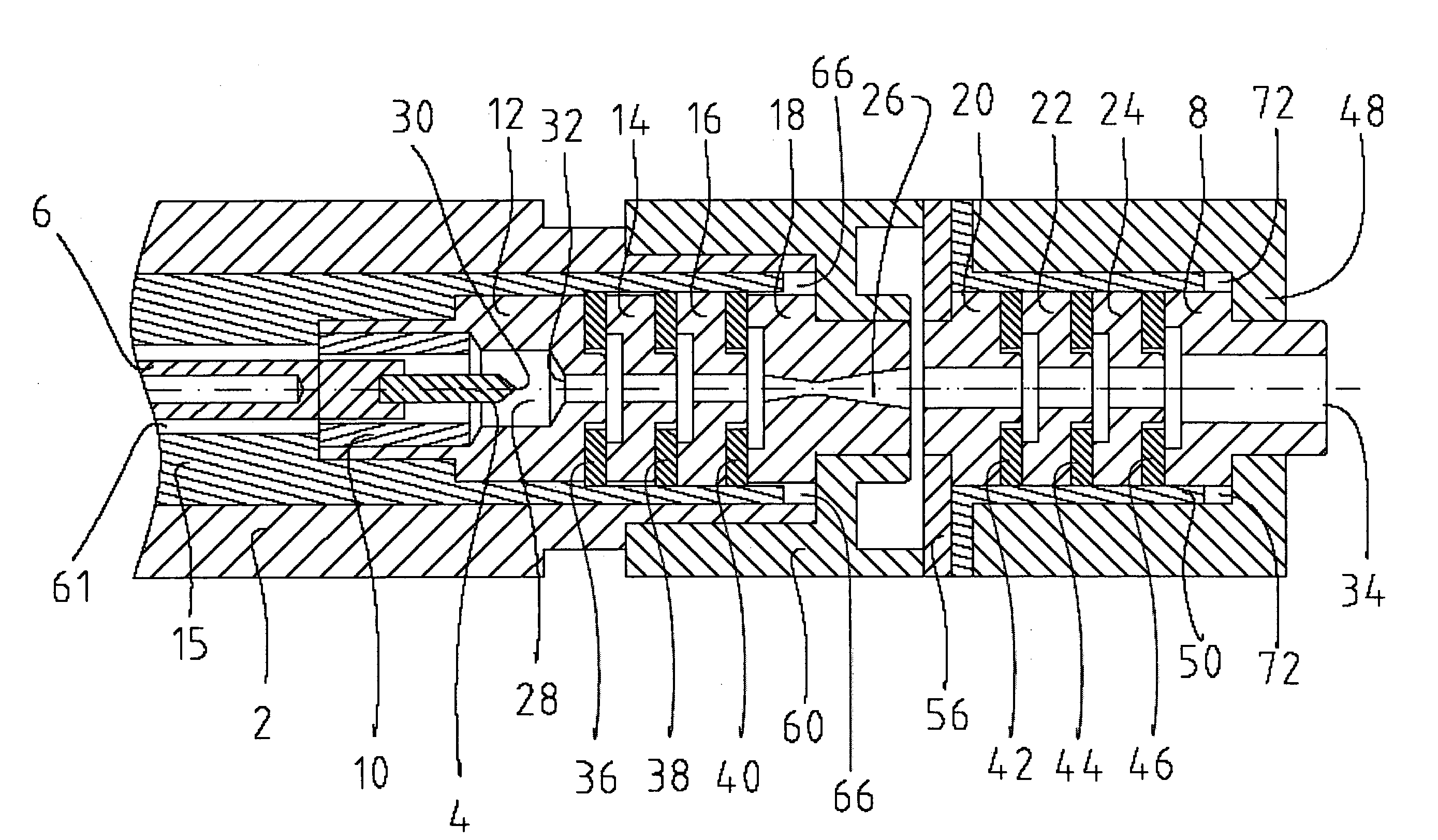

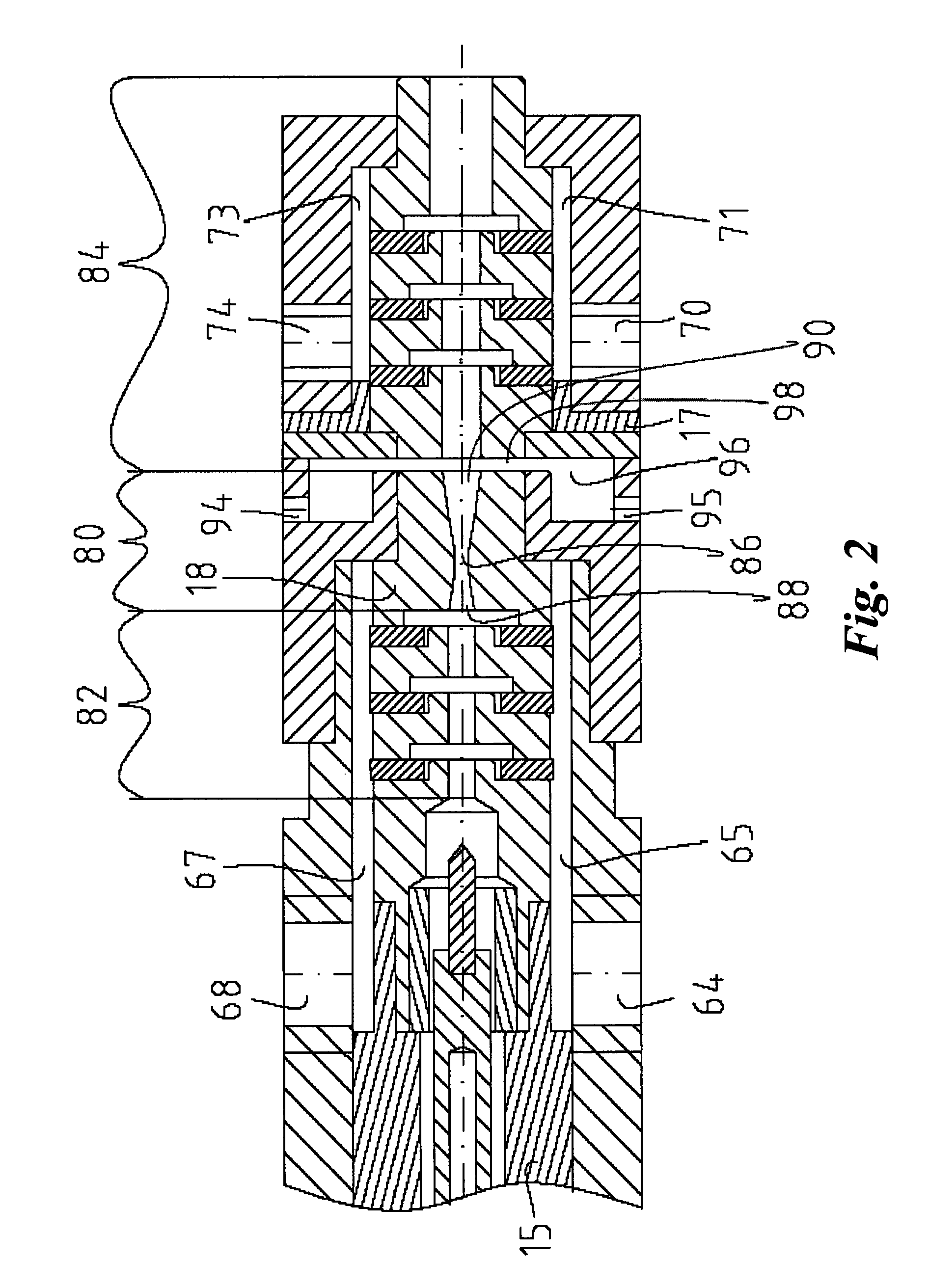

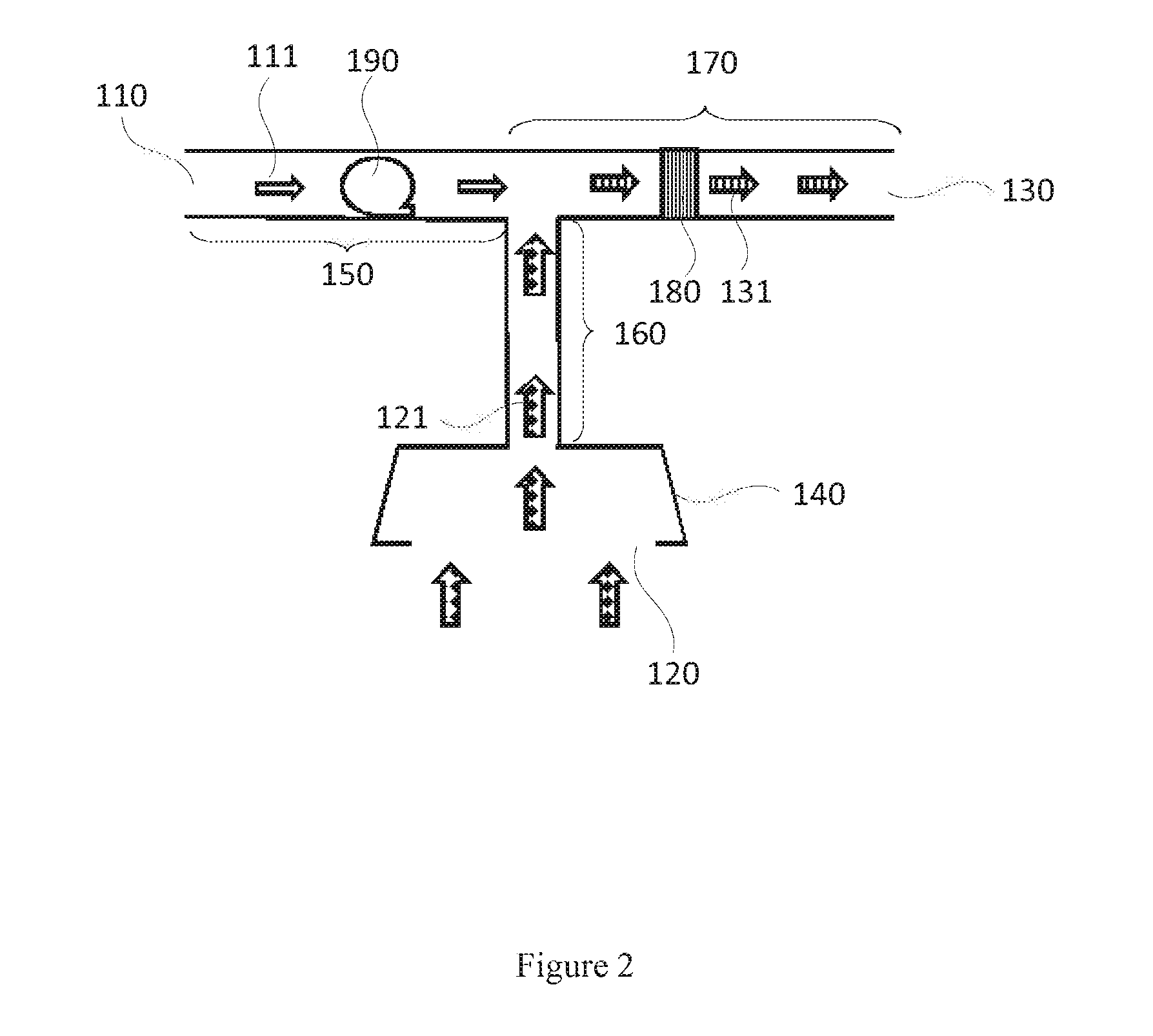

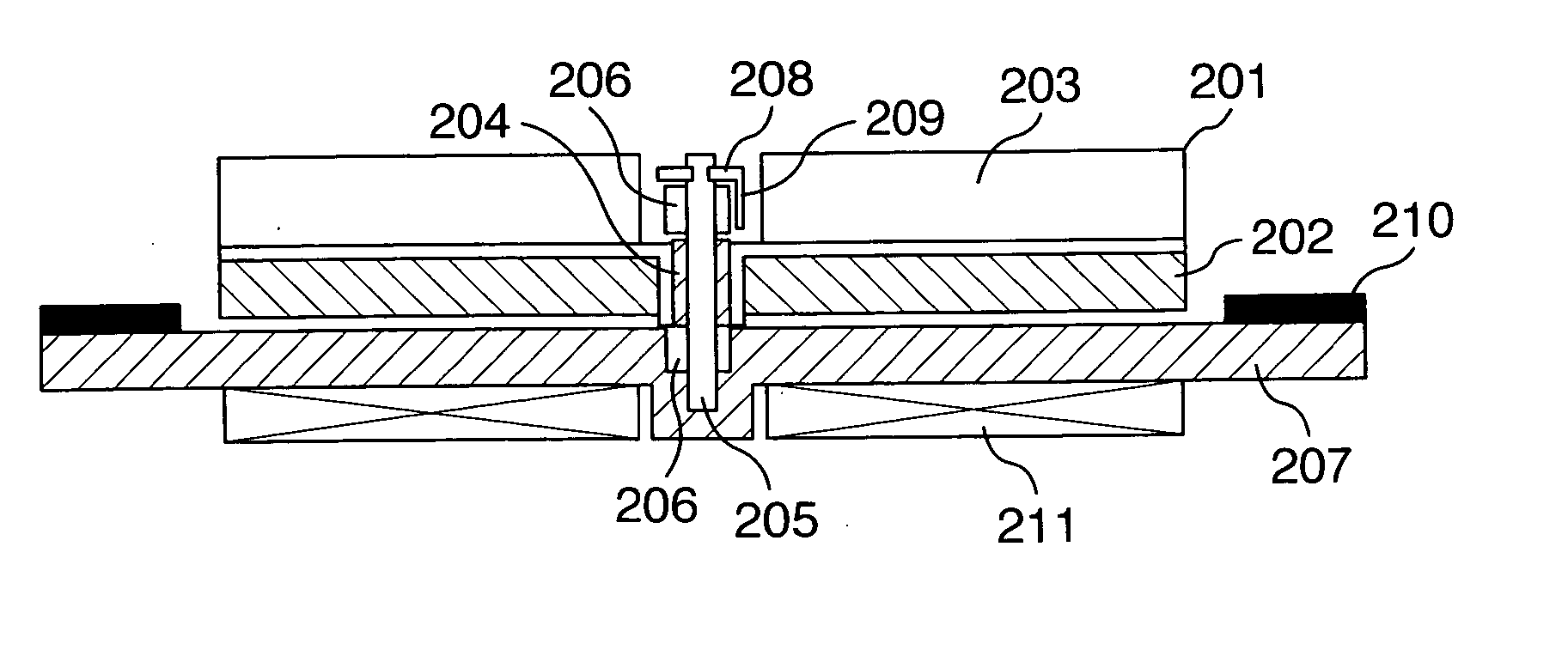

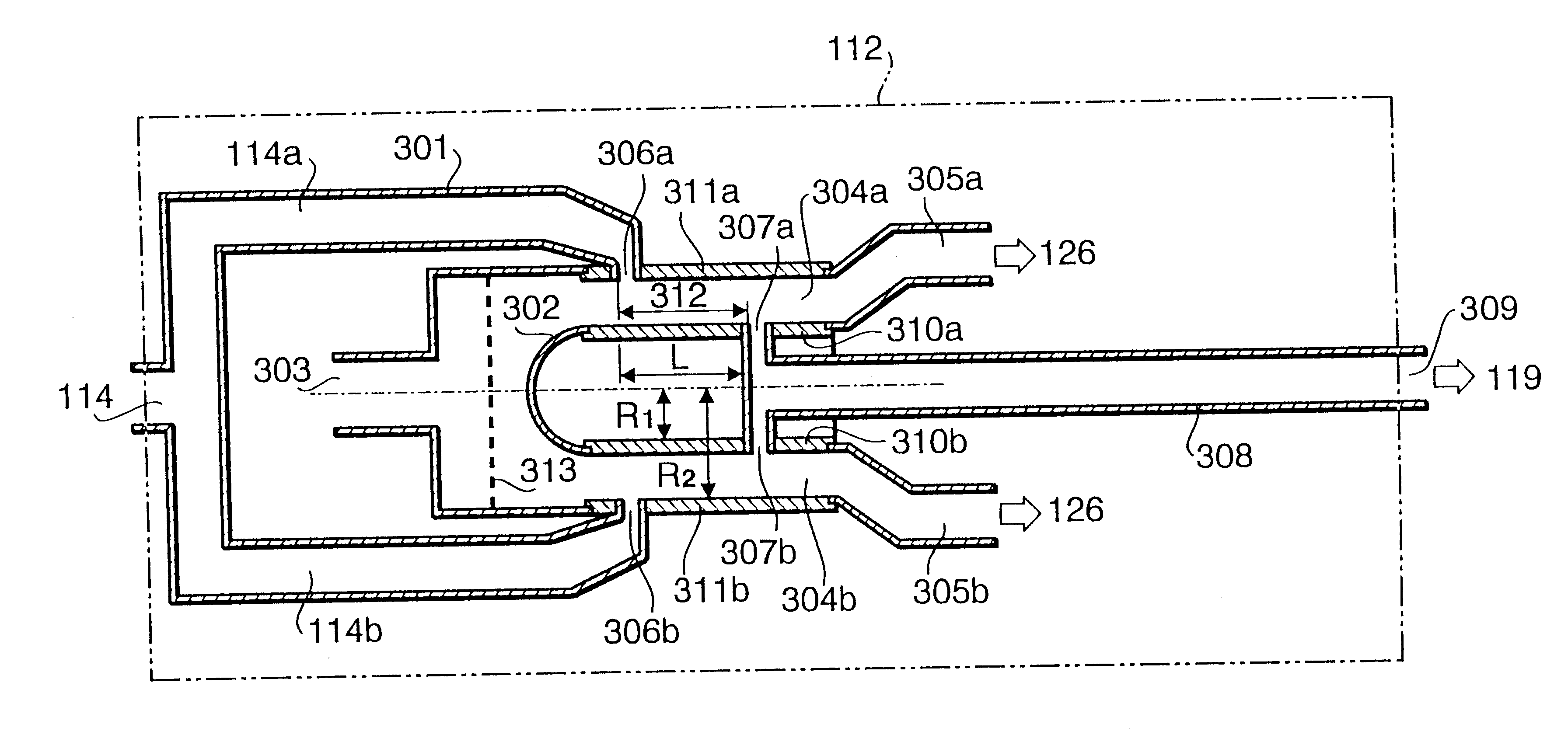

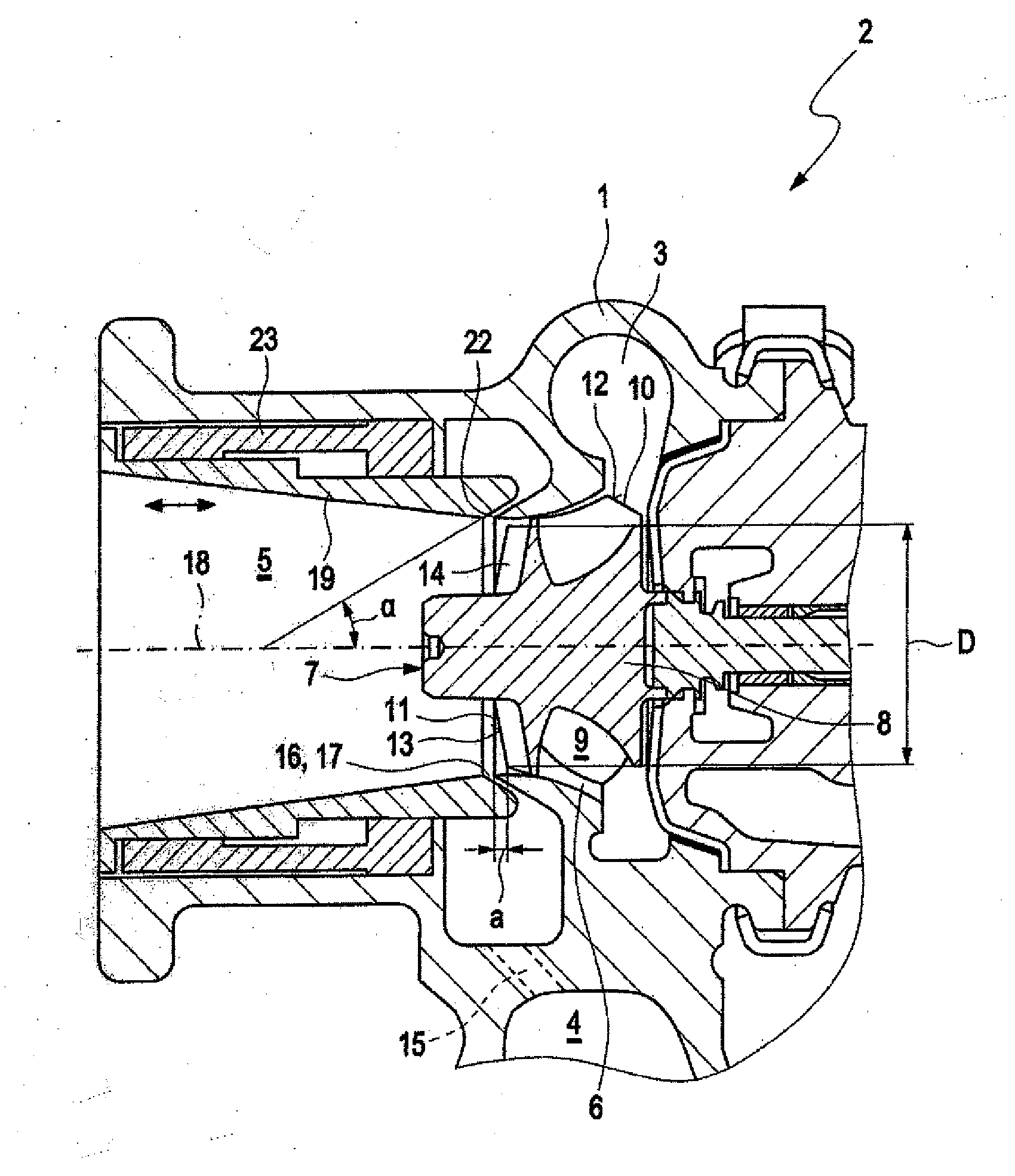

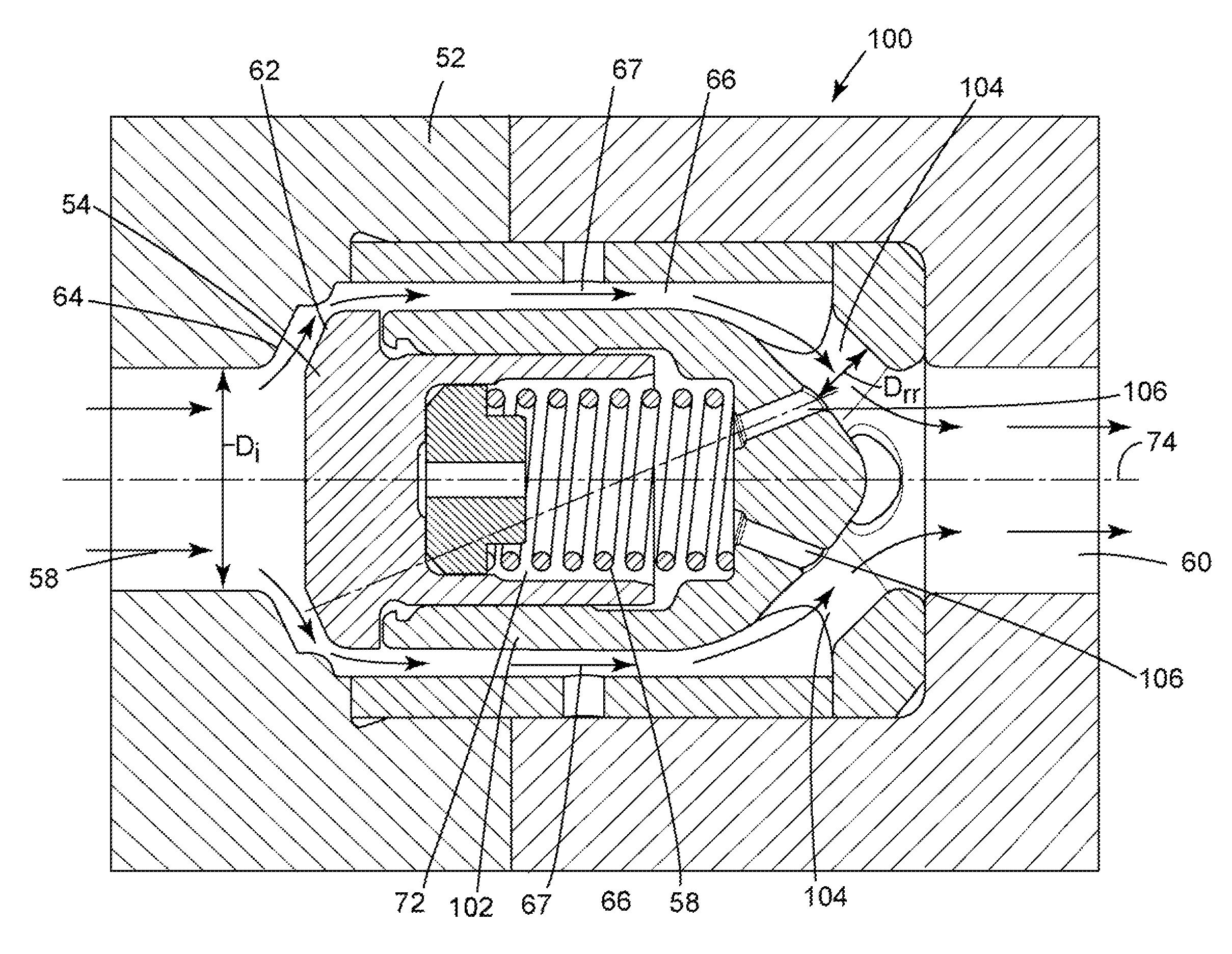

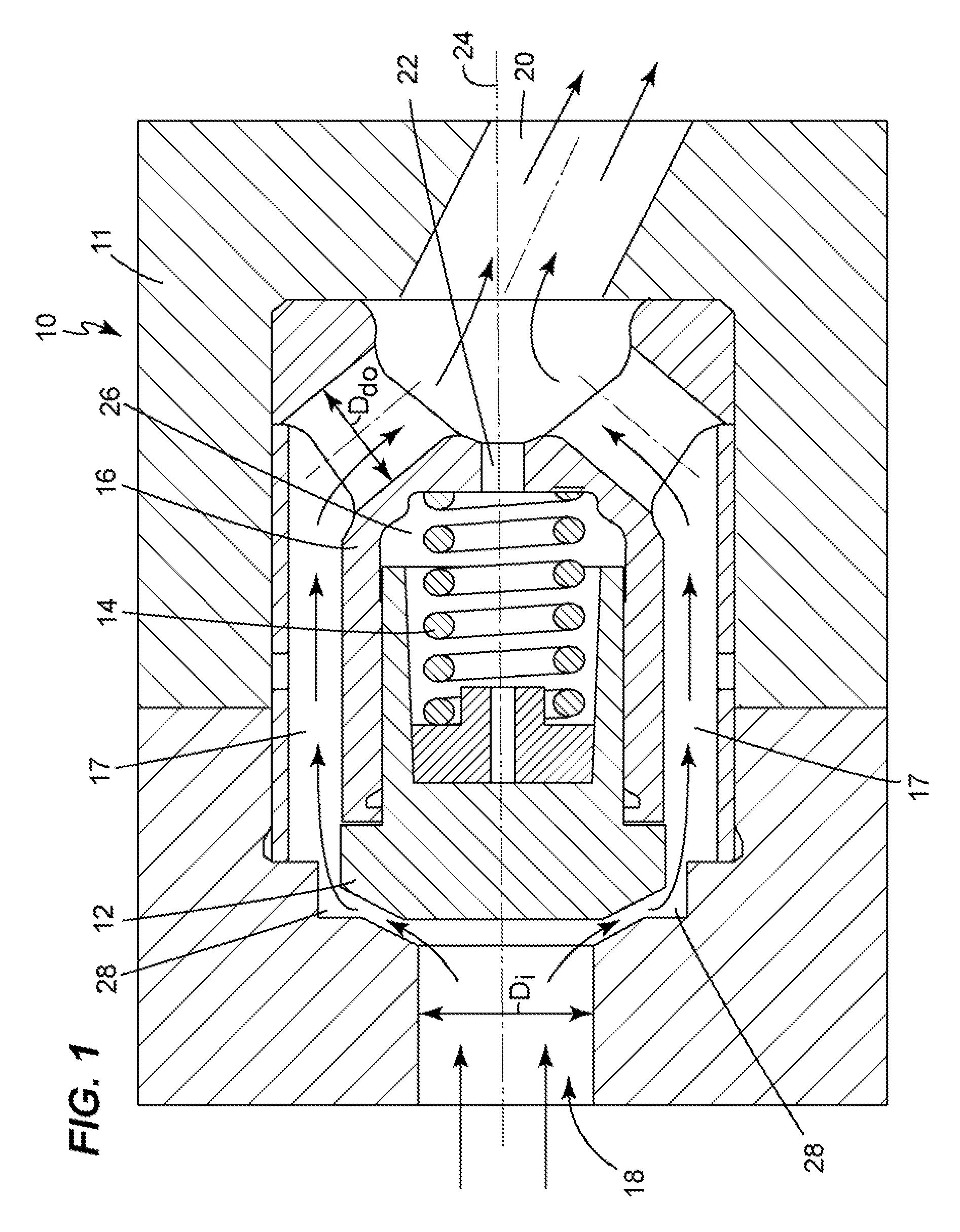

Poppet valve with diverging-converging flow passage and method to reduce total pressure loss

ActiveUS20100024891A1Stabilizing dynamic openingImprove performanceCheck valvesValve members for absorbing fluid energyEngineeringMechanical engineering

A poppet valve is disclosed that include a valve body, a poppet guide disposed inside the valve body so as to form a a flow passage from a flow inlet to a flow outlet of the valve, a poppet shutter disposed inside the poppet guide, and a converging-diverging flow passage formed by a portion of an outer surface of the poppet shutter and a corresponding portion of an inner surface of valve body. A method for reducing a closing pressure force acting on a poppet shutter of a poppet valve is also disclosed.

Owner:NUOVO PIGNONE TECH SRL

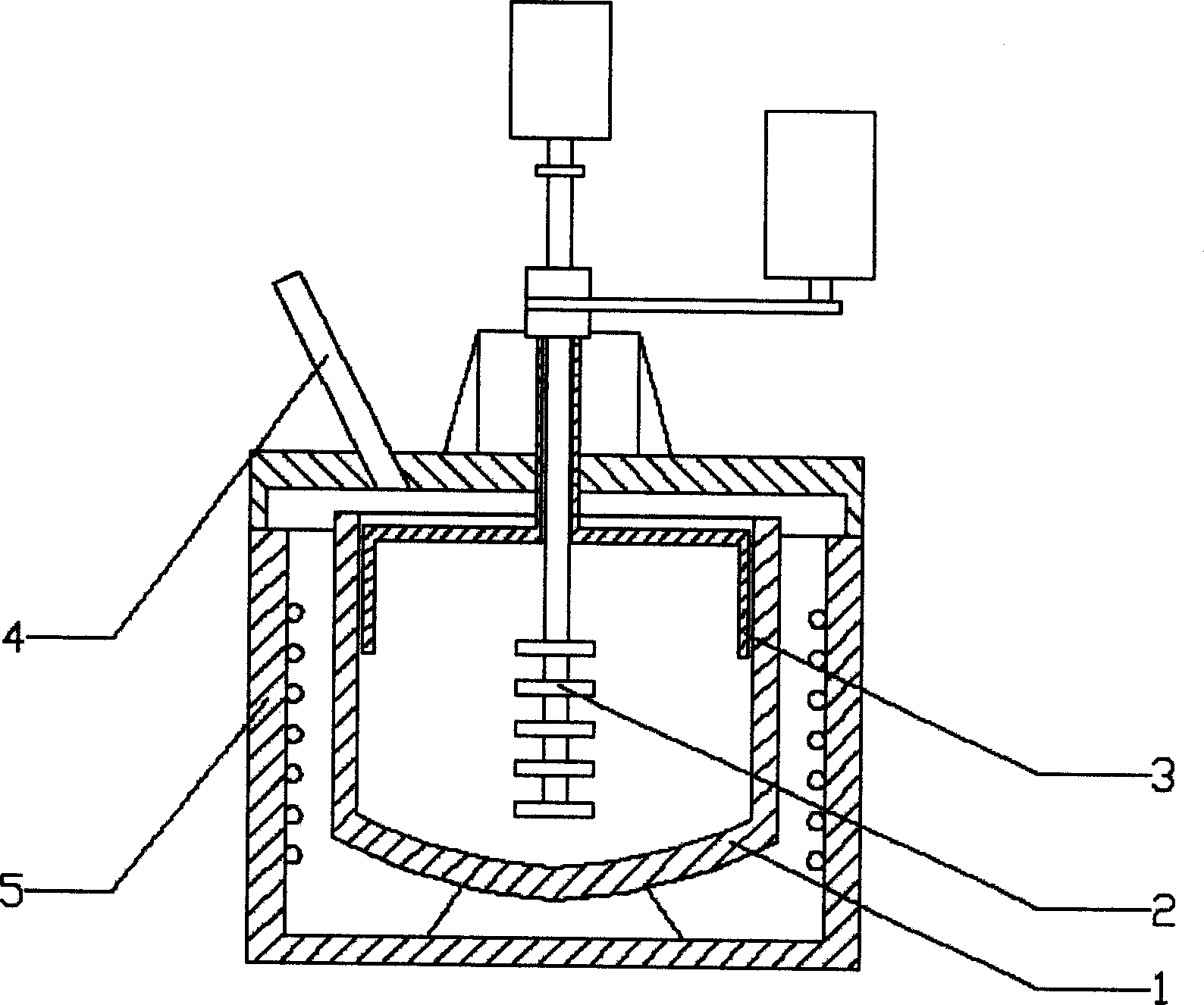

Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

The present invention relates to a vacuum mechanical double-stirring casting method for preparing granule reinforced aluminium base composite material. Said method includes the following steps: melting and purifying aluminium material, cooling and deslagging; under the condition of vacuum reverse slowly internal stirring to implement degassing process, adding the pretreated reinforcing granules onto the deslagged aluminium liquid surface, internal and external forward simultaneously stirring, mixing the reinforcing granules into the melt, stoping external stirring, under the condition of retaining stable liquid surface high-speed internal stirring so as to make the reinforcing granules be uniformly distributed in the liquid, heating, internal and external reverse double stirring and slowly rotating to implement degassing; adding alternant and fining agent, internal stirring slowly rotating so as to make them be mixed into melt and uniformly distributed, removing vacuum, tapping and casting to obtain ingot casting.

Owner:BEIJING JIAOTONG UNIV

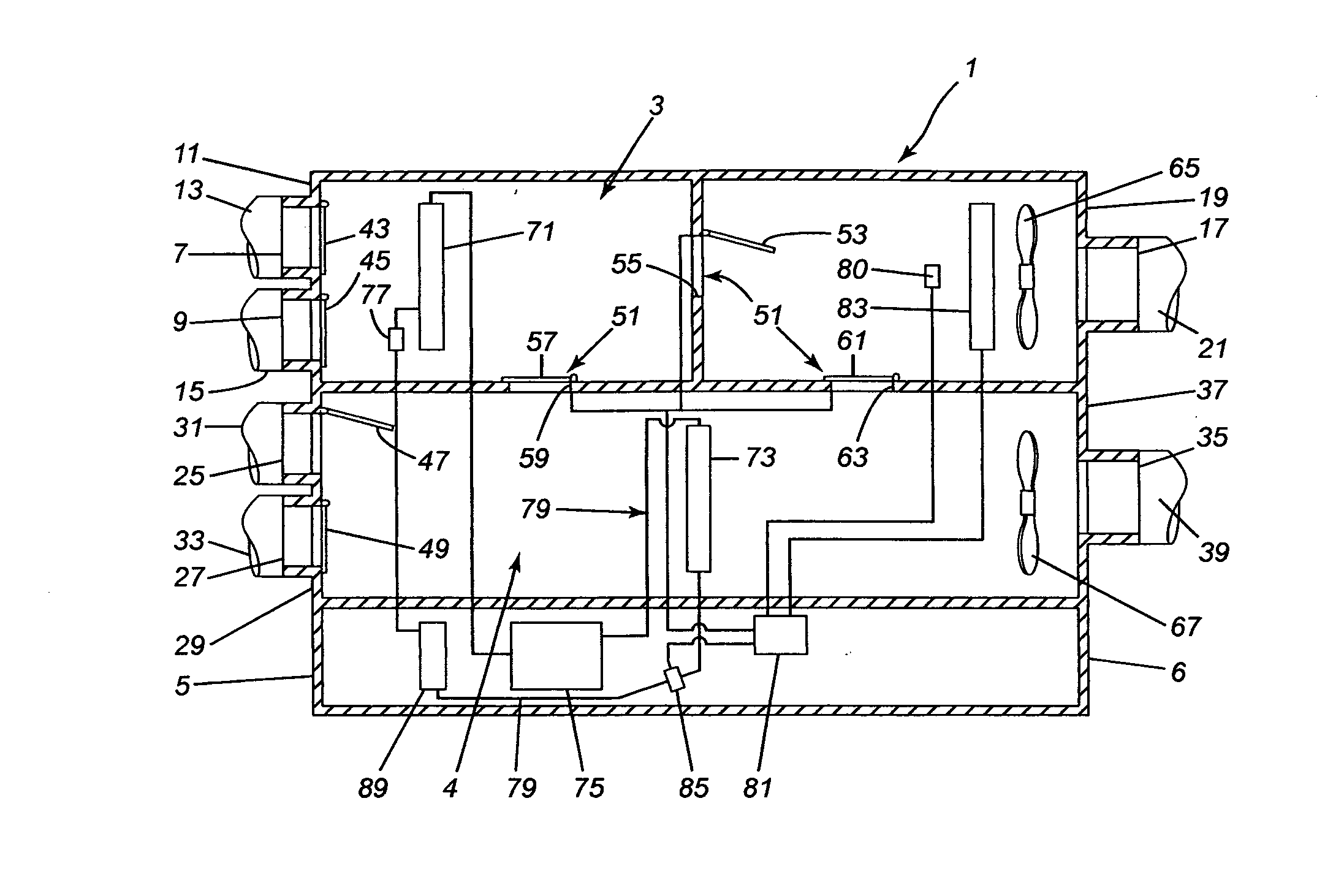

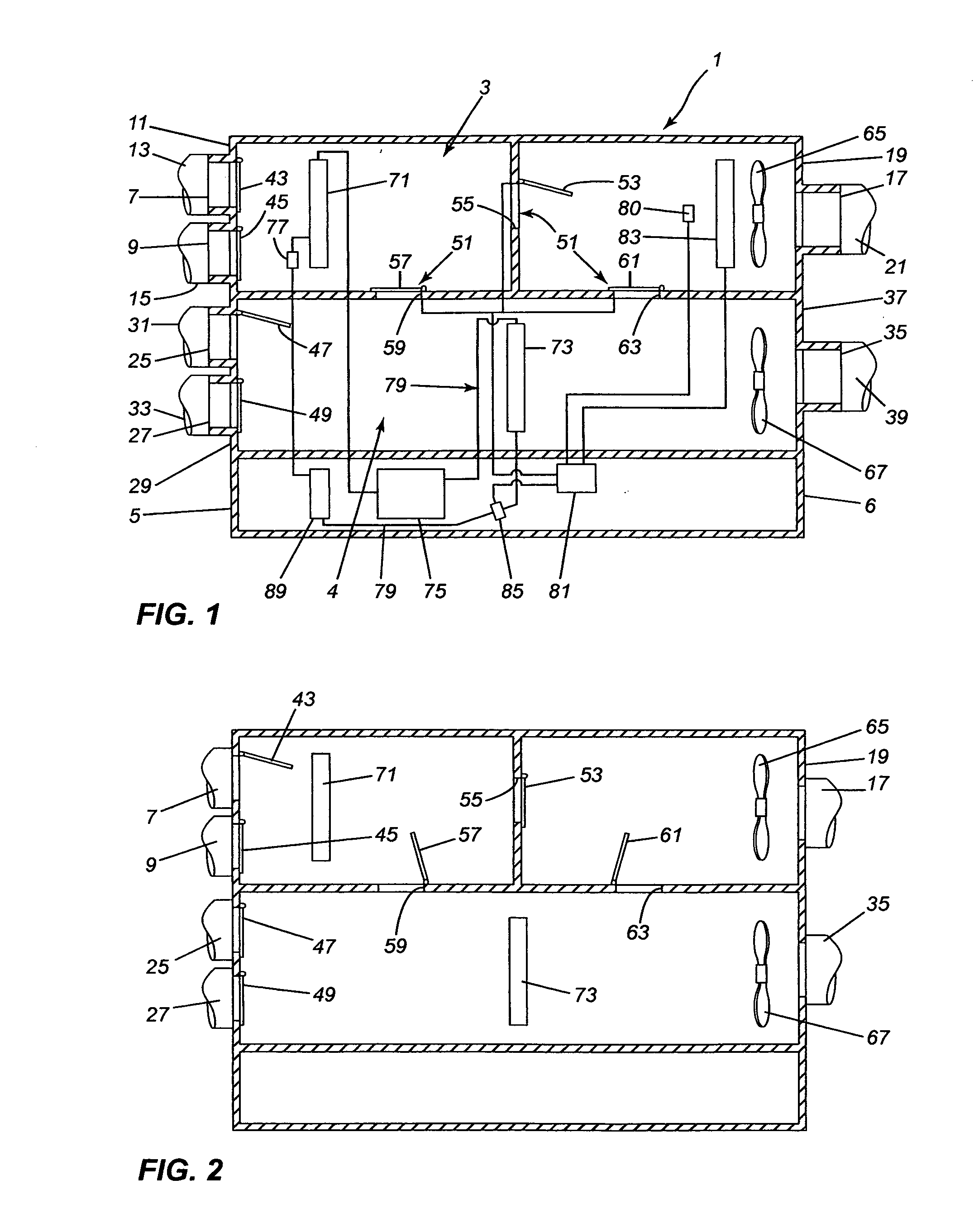

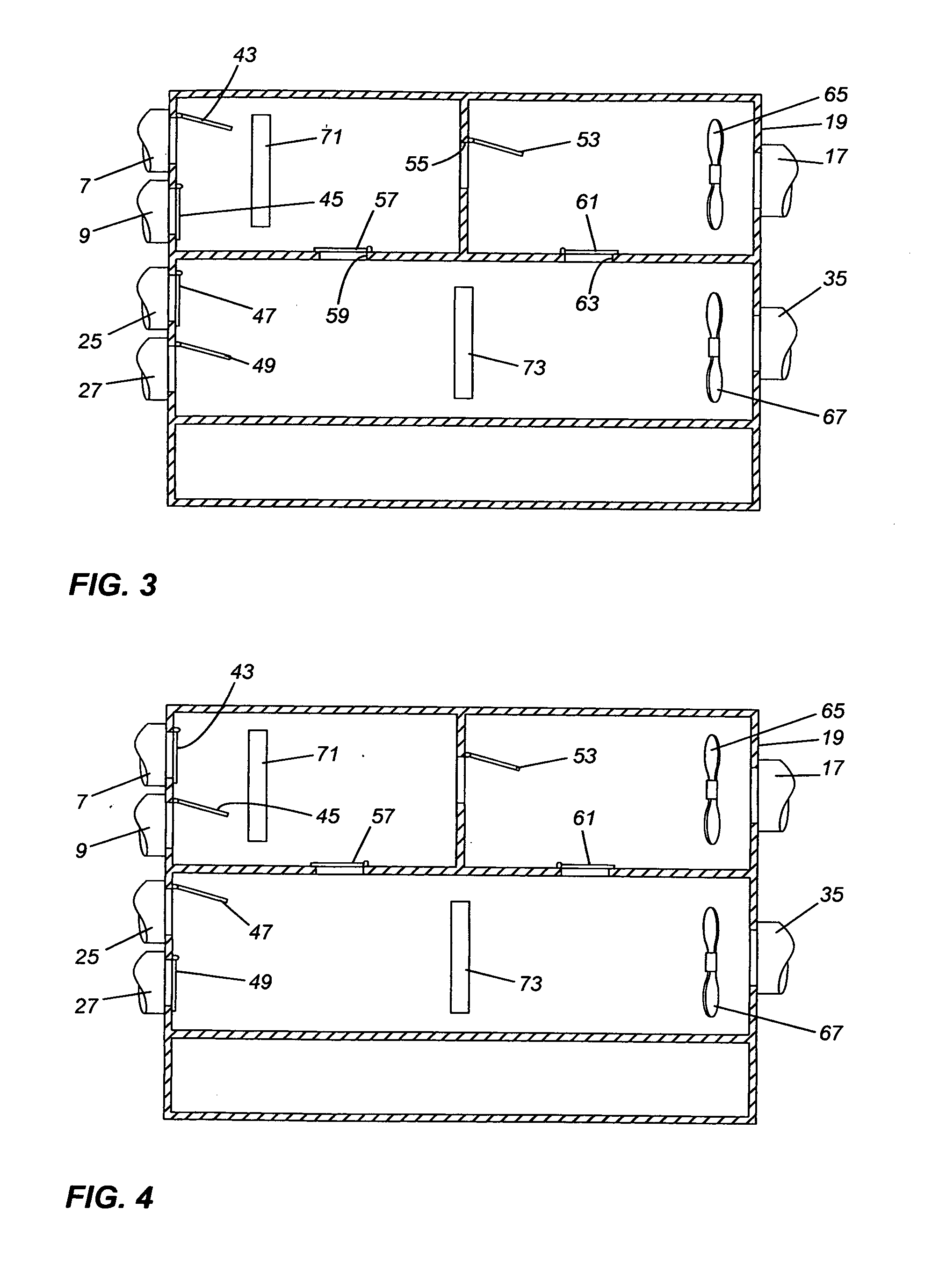

Air conditioning/dehumidifying unit

ActiveUS20120247132A1Easy and cheap to build , install , operate and serviceEfficient in operationEnergy recovery in ventilation and heatingHeat recovery systemsRefrigerantIndoor air

An air conditioning unit having: a first air passageway and a second air passageway adjacent to the first air passageway. Dampered air inlets are provided at one end of the first and second air passageways to selectively provide indoor air or outdoor air to each passageway. There is an indoor air outlet in the first air passageway and an outdoor air outlet in the second air passageway, both outlets at the other end of the passageways. There is a first blower in the first passageway and a second blower in the second passageway for moving air through each passageway. The unit has a refrigerant system with an evaporator in the first passageway, a compressor, a condenser in the second passageway, and a refrigerant line joining the evaporator, the compressor, and the condenser, in series, in a closed loop. The unit can be used in an air conditioning mode, a dehumidifying mode and a purge / ventilating mode. The unit is particularly suited for use in an indoor swimming pool.

Owner:DEHUMIDIFIED AIR SOLUTIONS INC

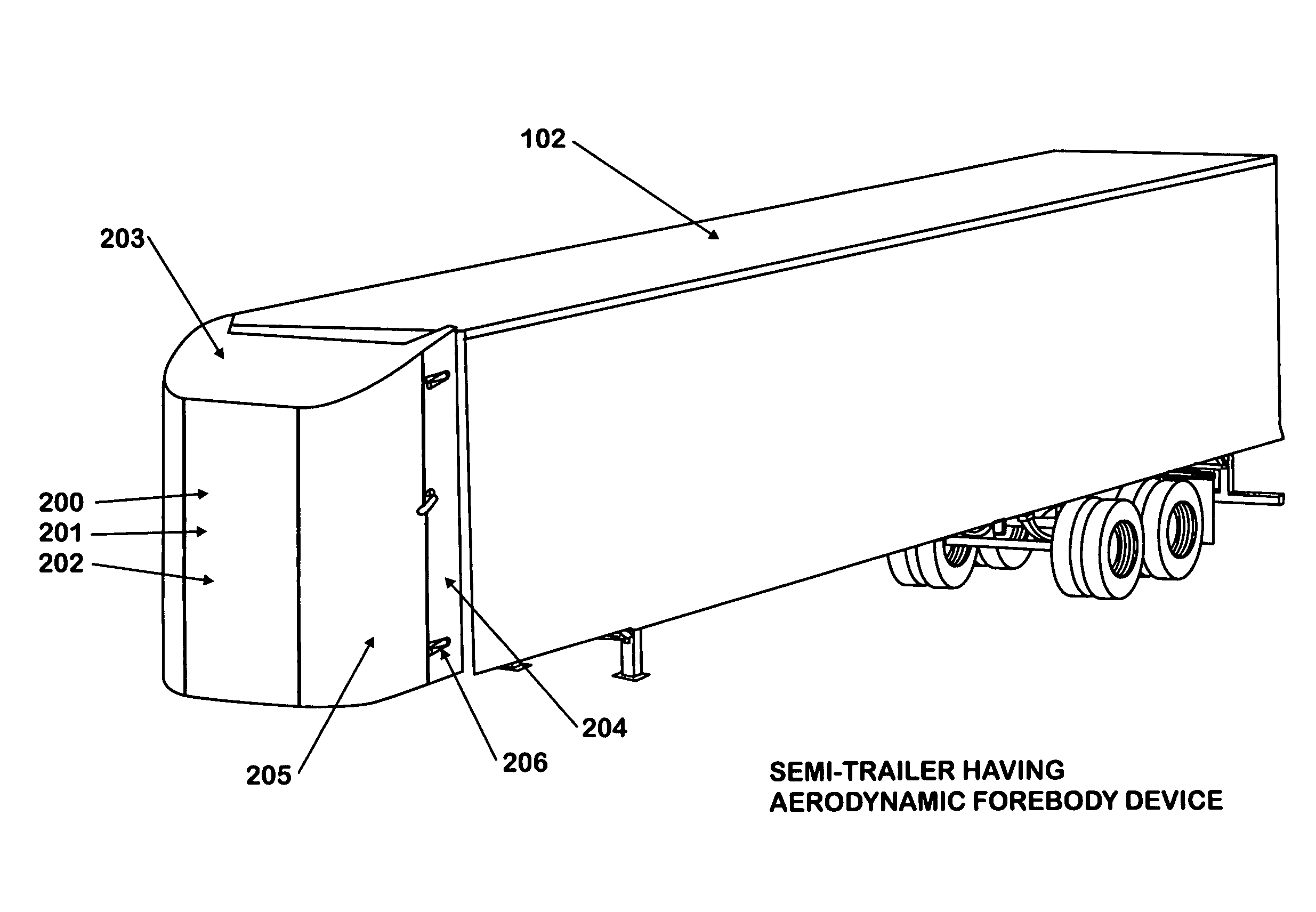

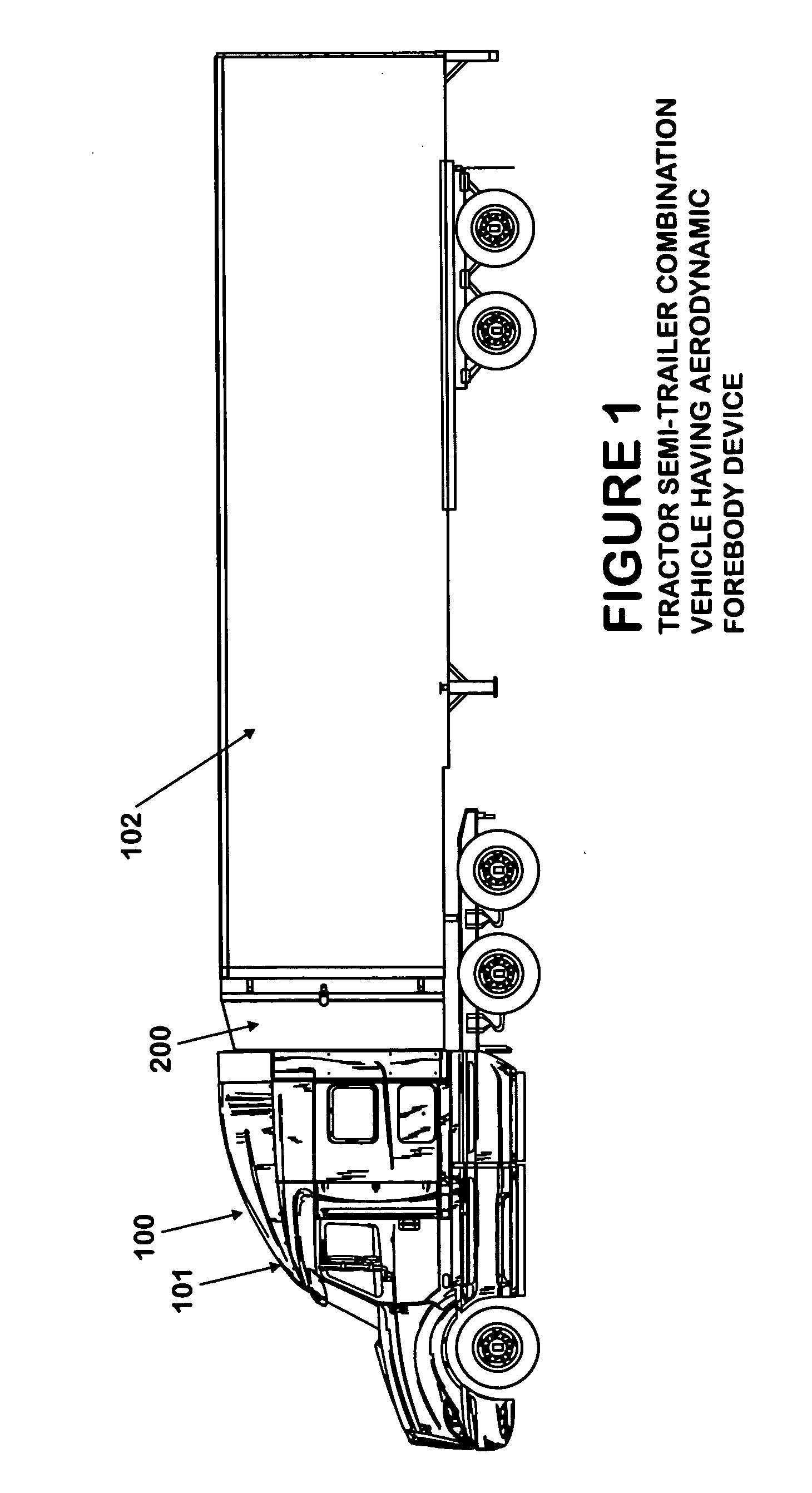

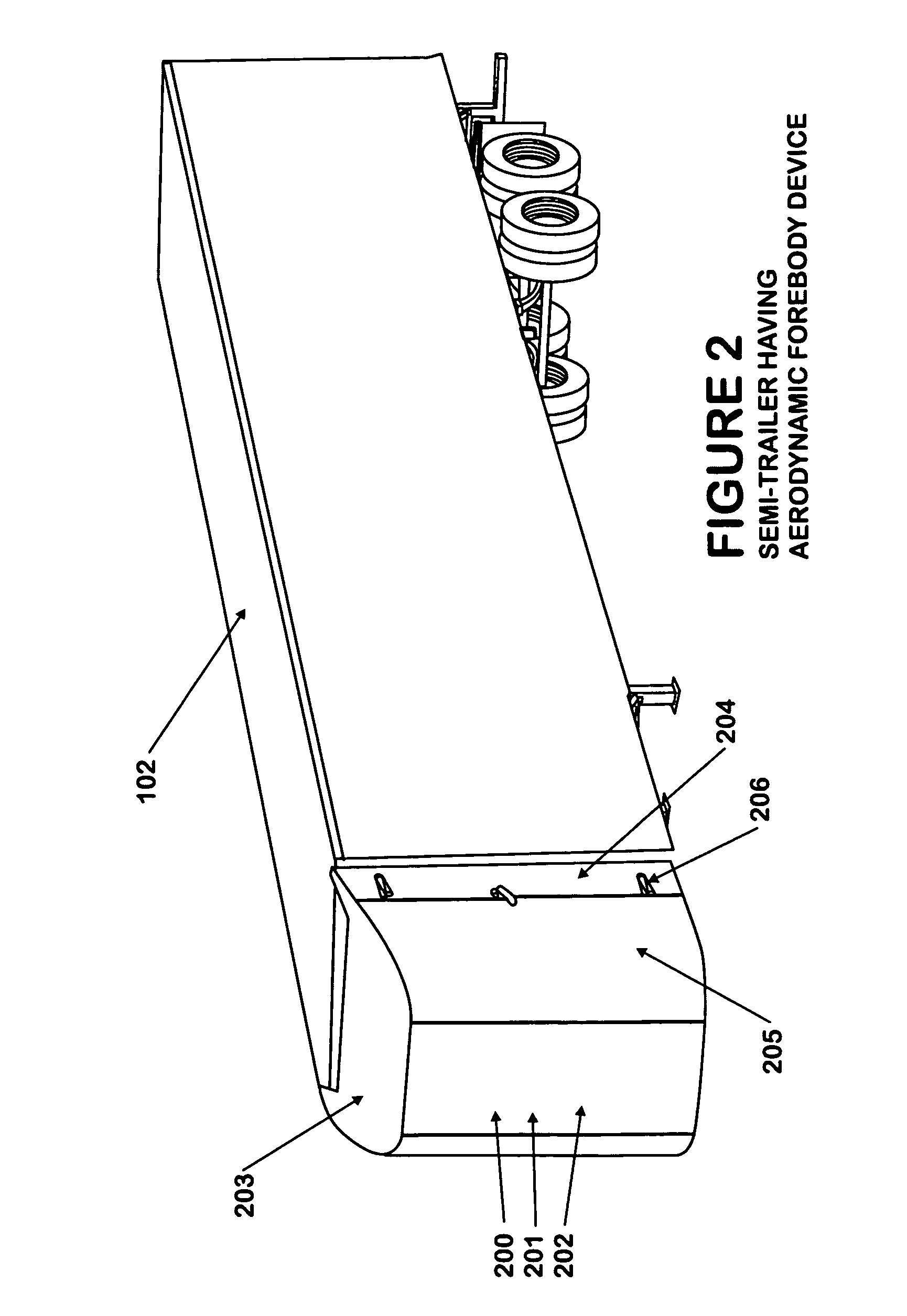

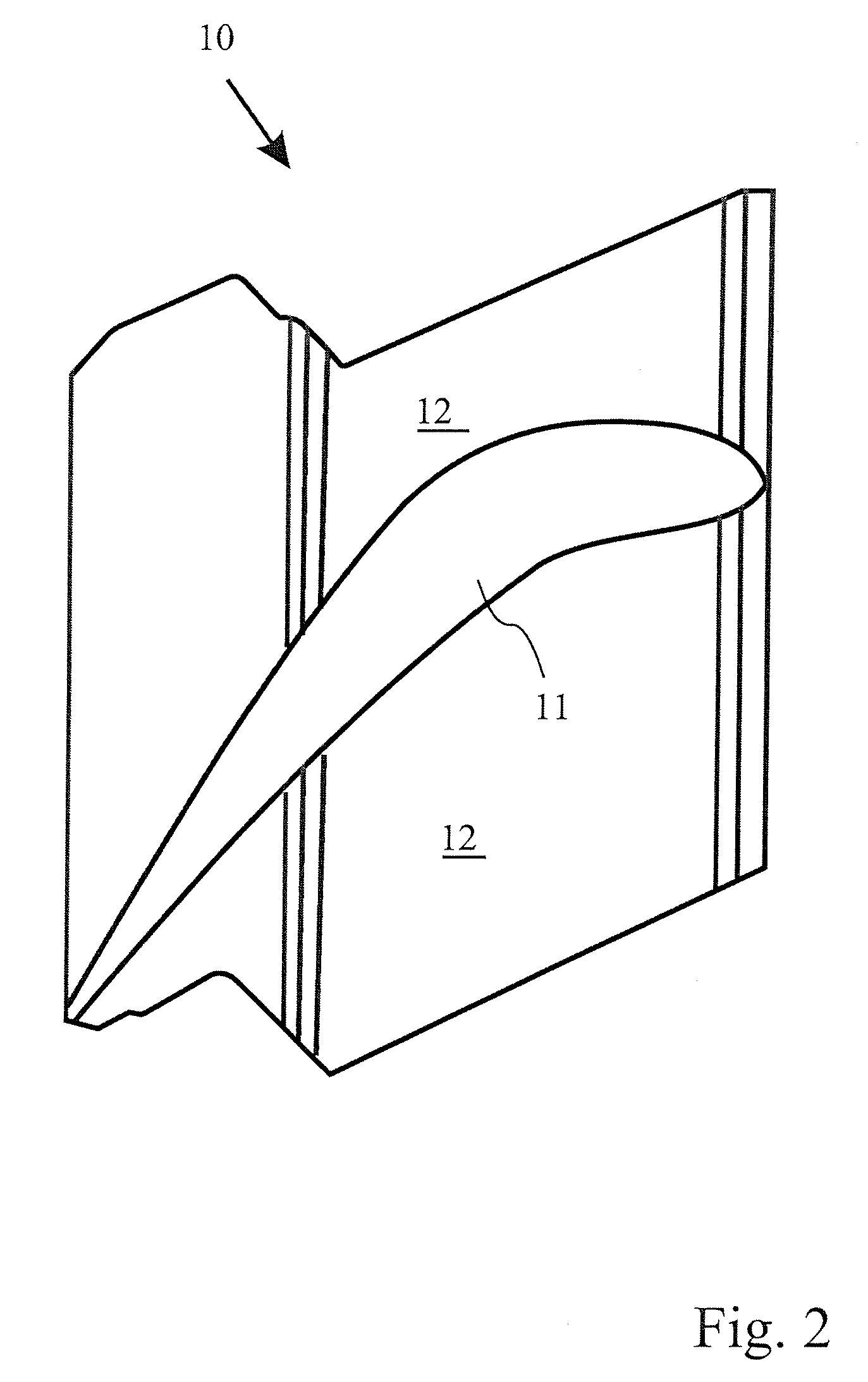

Aerodynamic forebody shape for van trailer

InactiveUS20080217957A1Reduce static pressureReduce air resistanceVehicle seatsWindowsAerodynamic dragSubject matter

An aerodynamic forebody device is provided for use with a tractor-trailer combination vehicle to be installed on the front of the semi-trailer. By optimizing the inclination angle of the top surface of the aerodynamic forebody device, aerodynamic drag is minimized. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:INT TRUCK INTPROP LLC

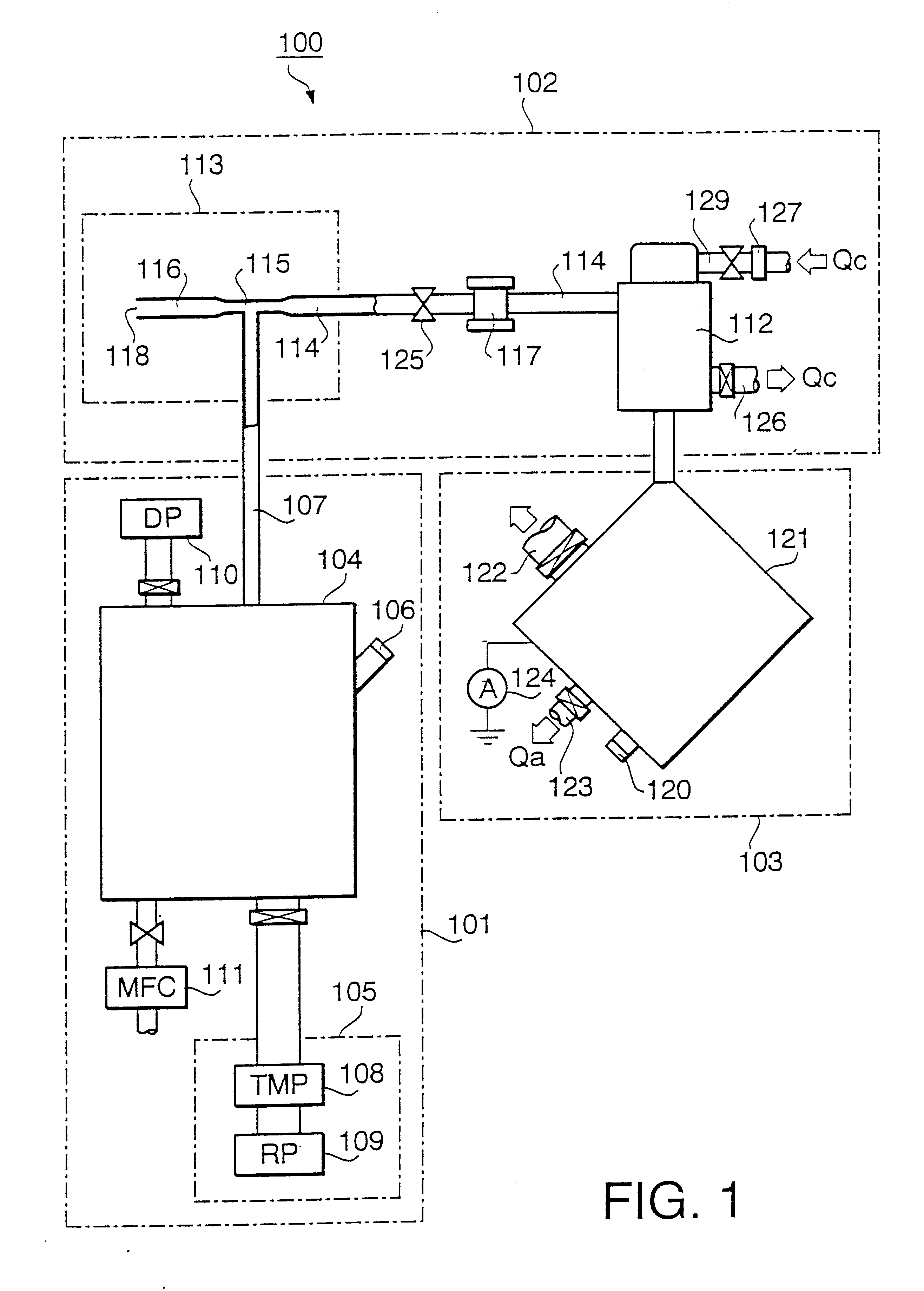

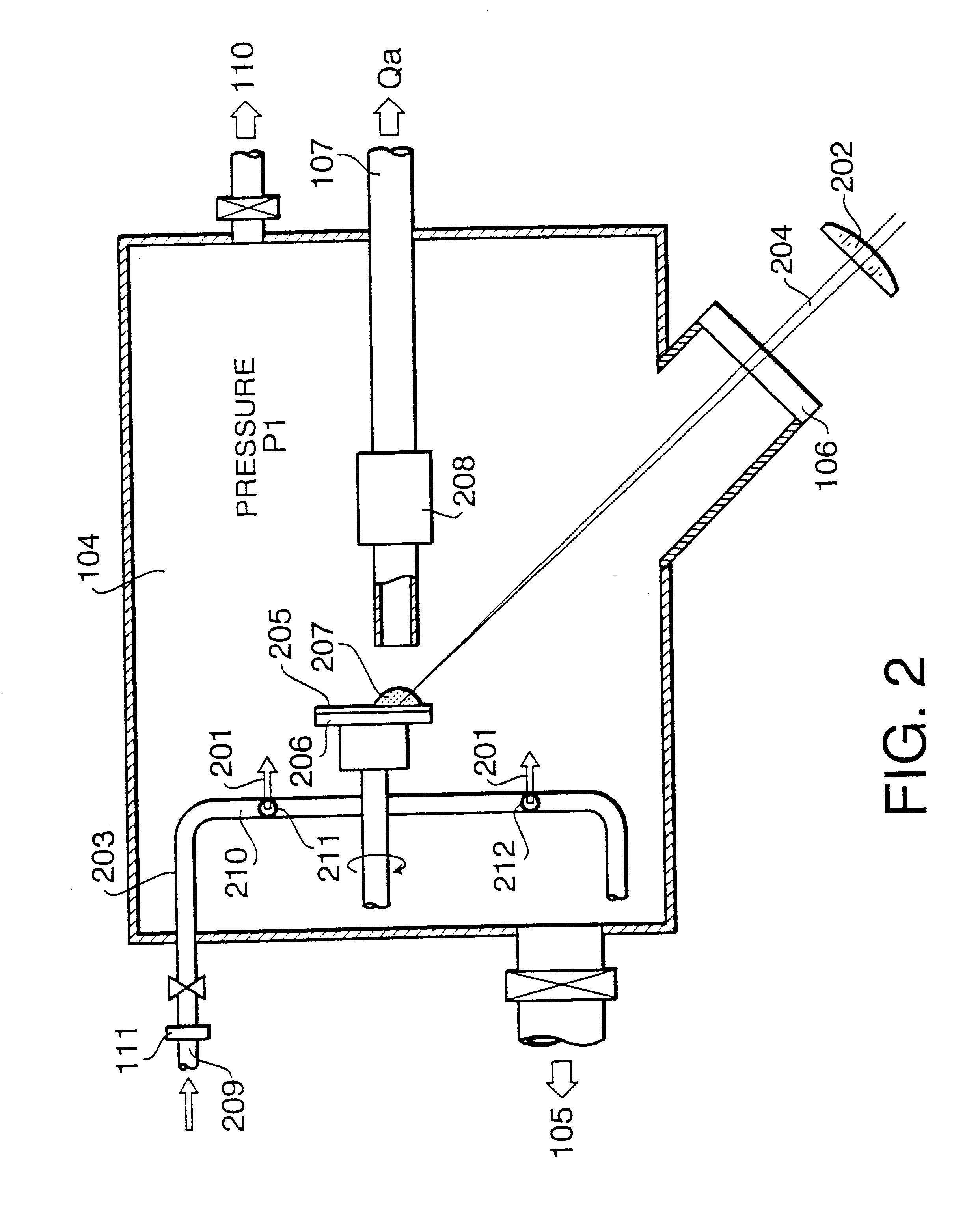

Plasma spraying device and method

ActiveUS20080185366A1High level of homogeneityAvoid insufficient heatingMolten spray coatingEfficient propulsion technologiesHigh pressurePlasma channel

A device and a method for plasma spraying are disclosed. The device comprises, a cathode, an anode, a plasma channel formed by the anode and intermediate electrodes, and one or more flowable material injectors. The plasma channel has a throttling portion that divides the plasma channel into a high pressure portion near the cathode formed by at least one intermediate electrode and a low pressure portion near the anode. During operation, a plasma generating gas is heated by the arc maintained between the cathode and the anode, forming plasma. When the plasma passes through the throttling portion, its speed increases to a supersonic speed, and at the same time its static pressure drops. Flowable materials are injected in the plasma flow in the low pressure portion. The particles in the flowable materials are heated by the plasma and the resultant heated particles and plasma are output from the outlet of the plasma channel.

Owner:PLASMA SURGICAL INVESTMENTS

Plasma spraying device and method

ActiveUS7928338B2High level of homogeneityAvoid insufficient heatingMolten spray coatingEfficient propulsion technologiesHigh pressurePlasma channel

A device and a method for plasma spraying are disclosed. The device comprises, a cathode, an anode, a plasma channel formed by the anode and intermediate electrodes, and one or more flowable material injectors. The plasma channel has a throttling portion that divides the plasma channel into a high pressure portion near the cathode formed by at least one intermediate electrode and a low pressure portion near the anode. During operation, a plasma generating gas is heated by the arc maintained between the cathode and the anode, forming plasma. When the plasma passes through the throttling portion, its speed increases to a supersonic speed, and at the same time its static pressure drops. Flowable materials are injected in the plasma flow in the low pressure portion. The particles in the flowable materials are heated by the plasma and the resultant heated particles and plasma are output from the outlet of the plasma channel.

Owner:PLASMA SURGICAL INC

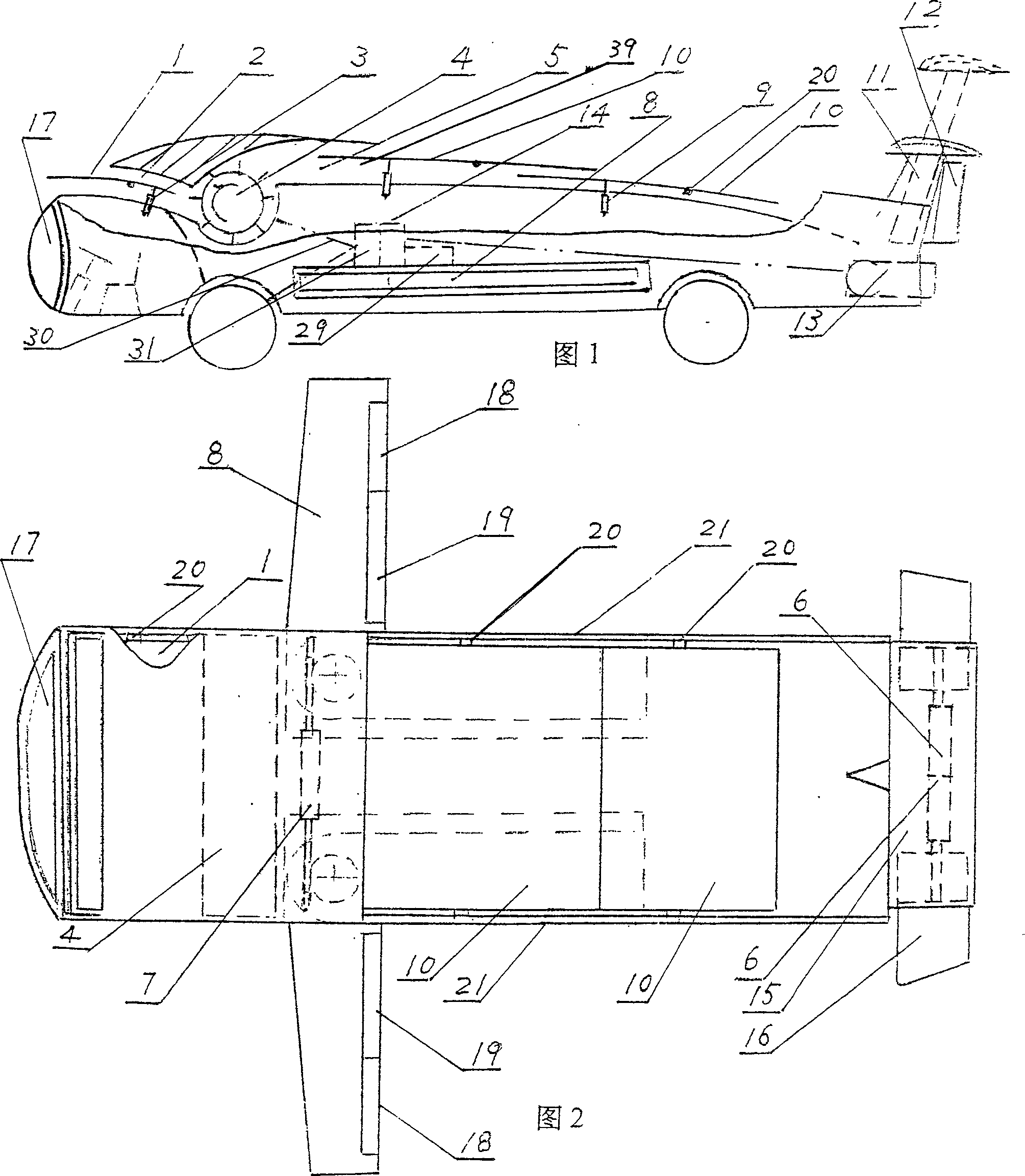

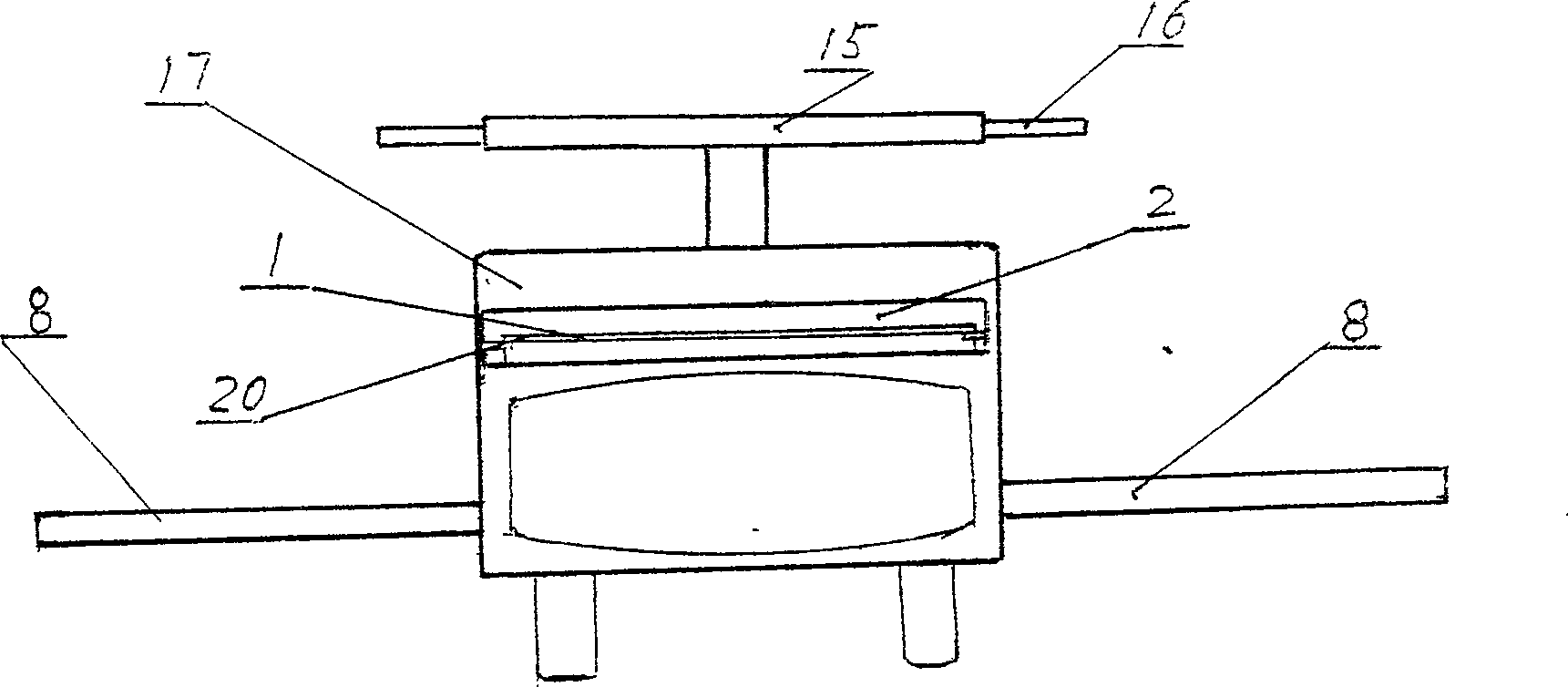

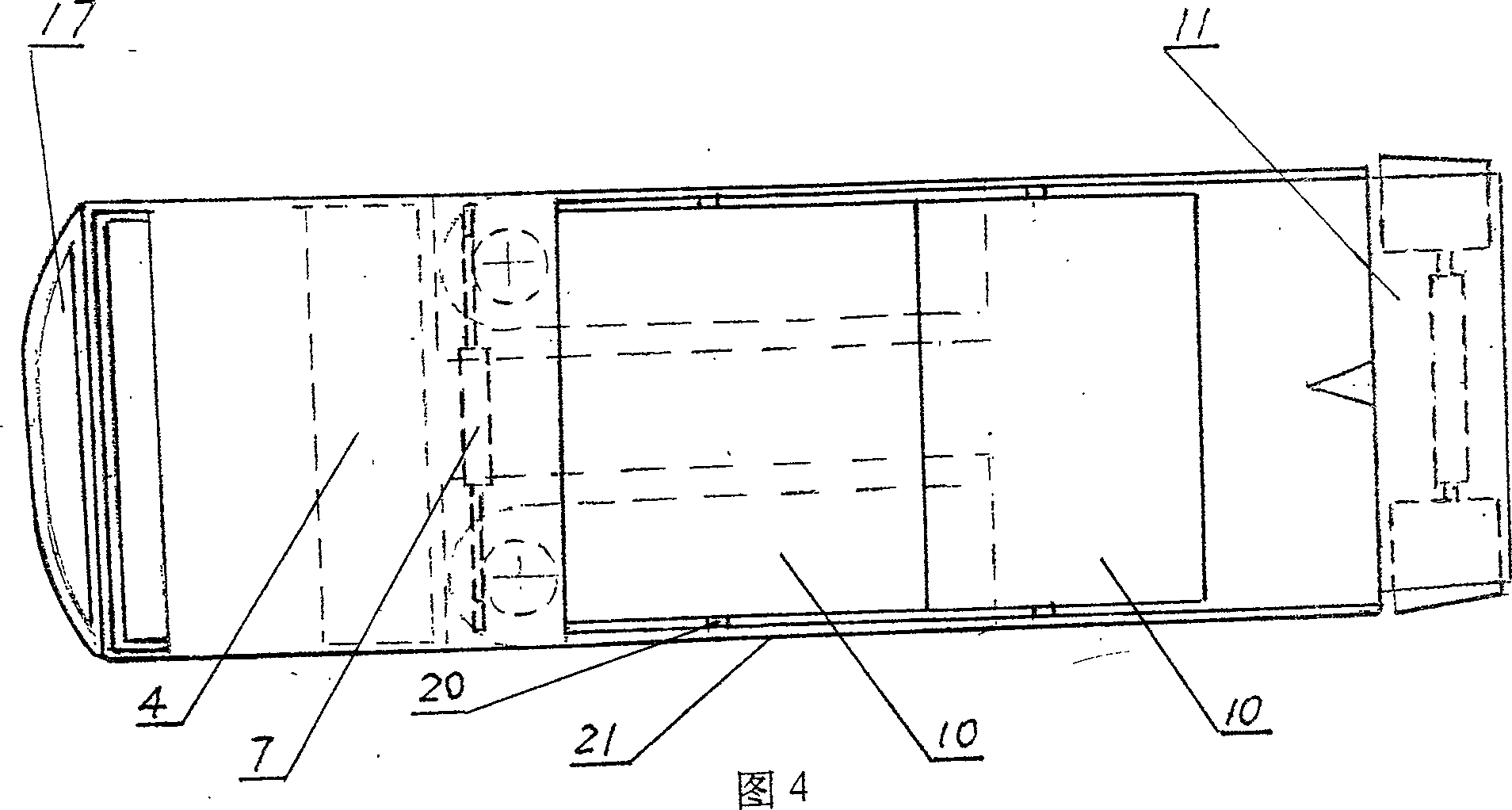

Hovercar

The invention relates to a hovercar which comprises a car, wherein, two symmetrical wings are installed on the car, and a horizontal tail is connected with a vertical tail at the tail part of a car body. The hovercar is characterized in that the end parts of the wings are movably connected with the car by a rotating mechanism; a wing 'blowing' and 'sucking' mechanism is installed at the upper part of the car body; and an auxiliary propeller which can provide forward and backward thrust is installed at the tail part of the car. As the hovercar is not different from a common car in performance on the ground, is equivalent to a mini-fixed wing aircraft in the flying state, and can ensure short takeoff and vertical landing, and can control the speed properly in the sky instead of in the airport, thus providing convenience in travel for people.

Owner:陈博

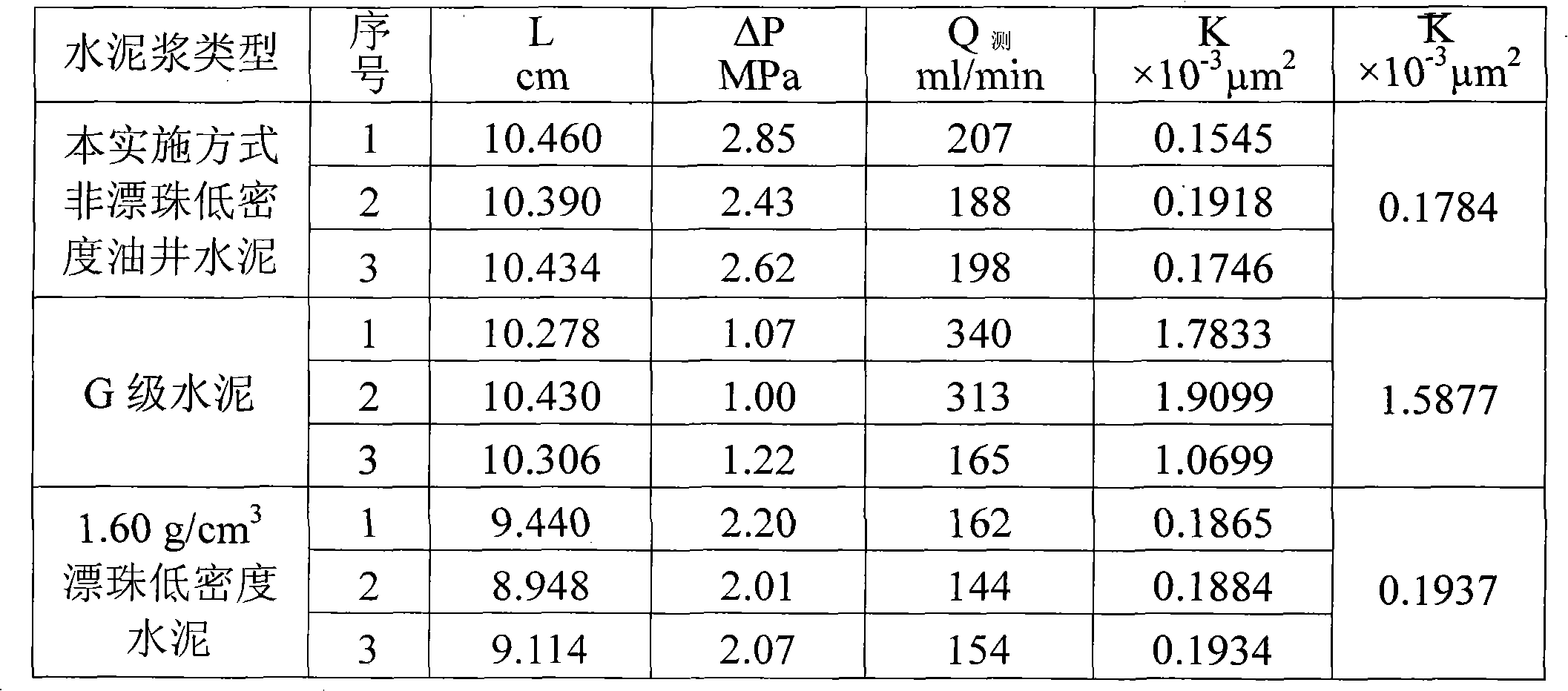

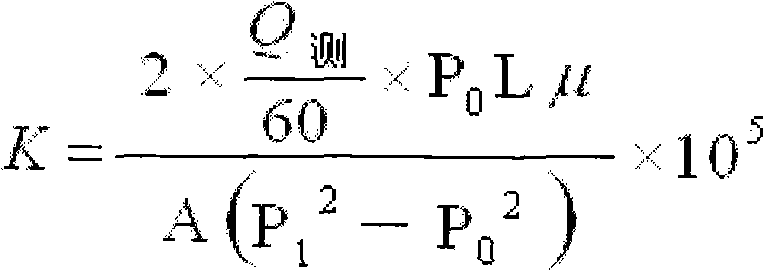

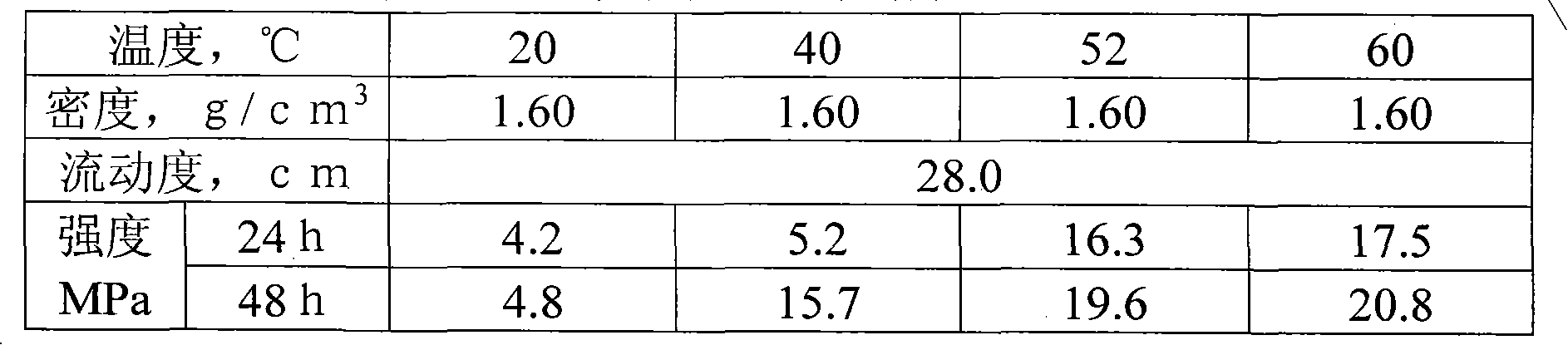

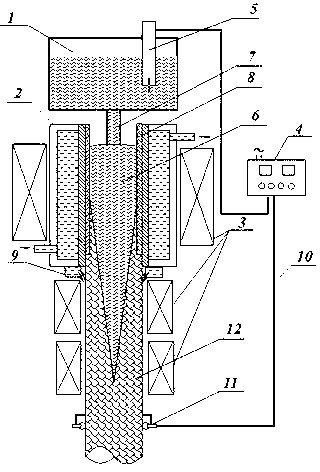

Non-floating bead low-density oil-well cement

The invention relates to low-density oil-well cement, in particular to non-floating bead low-density oil-well cement. The invention solves the problems of low early strength, poor slurry flowability and stability and short service life of the traditional non-floating bead pulverized fuel ash low-density cement. The non-floating bead low-density oil-well cement comprises oil-well cement, pulverized fuel ash, an aldosterone sulfonate condensate dispersing agent, nano silicon ash stone and an early strength agent, and the mass content of SiO2 in the nano silicon ash stone is larger than or equalto 96 percent. The cement has good stability, good compactness, high early strength, long service life, good rheological property and controllable densification time and meets the requirement of a low-pressure stratum oil field cementation well on the performance of the cement.

Owner:哈尔滨太行兴隆水泥有限公司

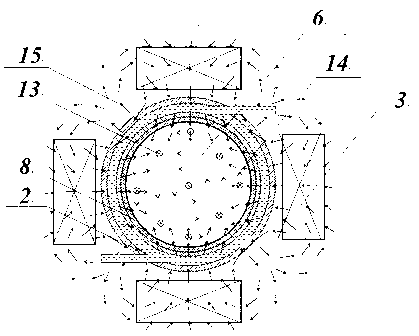

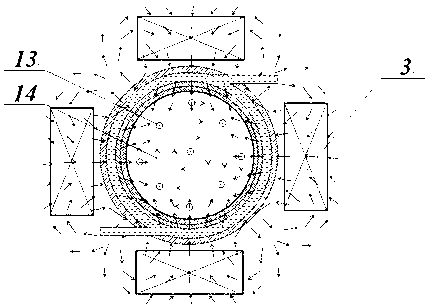

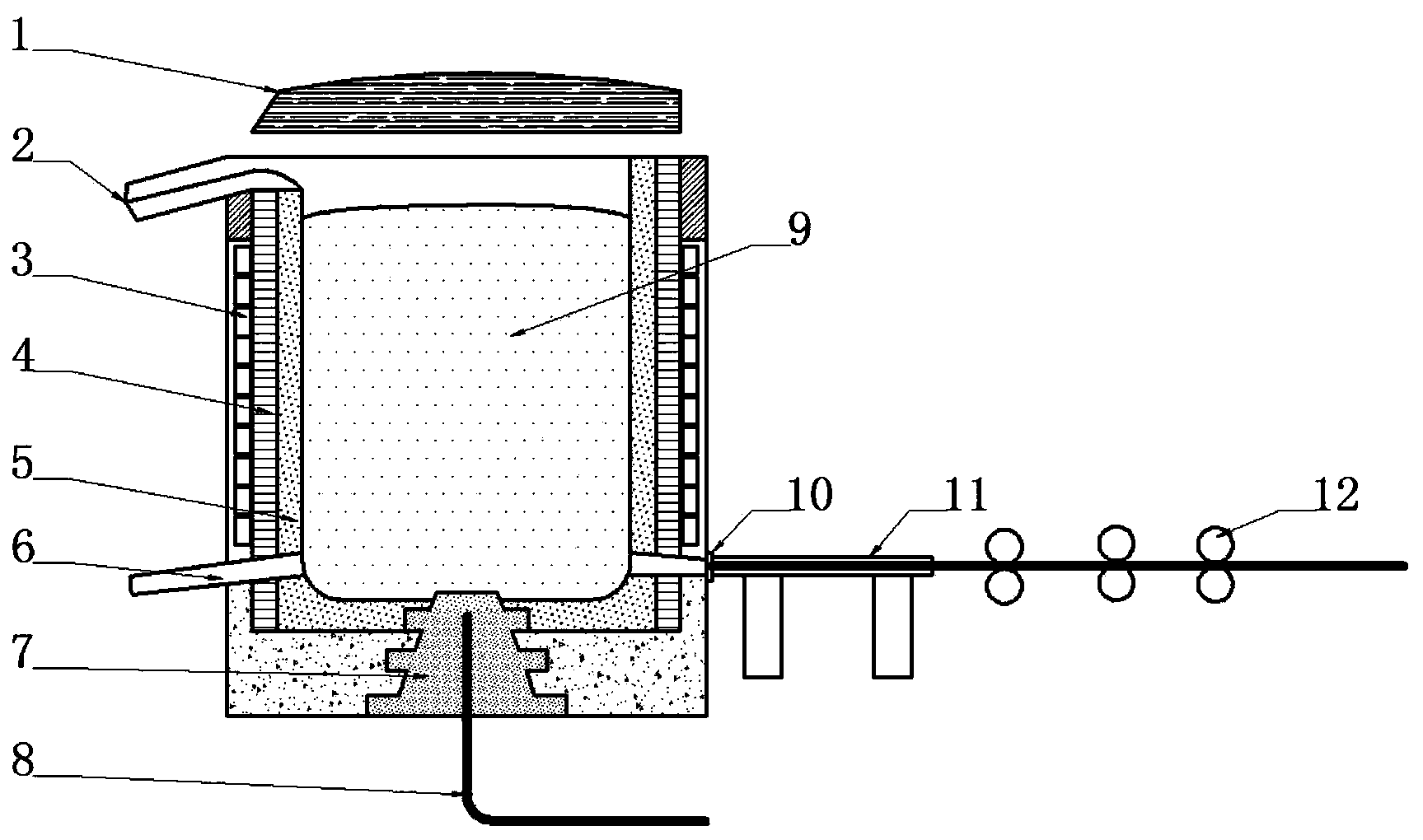

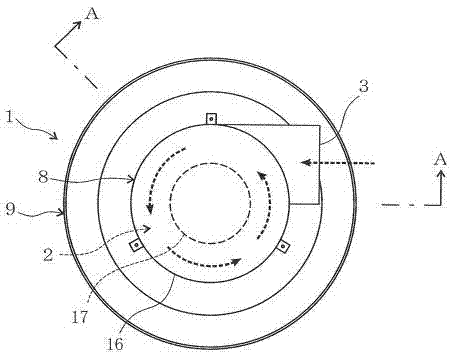

Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

The invention discloses a low-energy-consumption electromagnetic stirring method for continuous casting. The hot top composite novel low-energy-consumption electromagnetic stirring technique is used. A hot top is arranged in a crystallizer, a steady magnetic field with no energy consumption and low energy consumption is exerted on the periphery simultaneously, an electrode bar is inserted in a tundish, a roller electrode is arranged at the solidifying tail end of a continuous casting billet, and therefore alternating current can be exerted on all non-solidification metal melts between the crystallizer and the solidifying tail end. The alternating current and an additional steady magnetic field are acted with each other so as to enable all the non-solidification metal melts in the whole continuous casting billet in a continuous casting process to generate electromagnetic stirring force for driving the continuous casting melts to rotate clockwise and counterclockwise, thereby stirring non-solidification structures, smashing dendrites of solidification front edges of the melts, refining the solidification structures, reducing segregation and cracks. The invention further provides a metal continuous casting device which can be applied to a continuous casting process of various molten metals prone in segregation and draw an alloy continuous casting billet with refined solidification structure, small segregation and no crack.

Owner:SHANGHAI UNIV +1

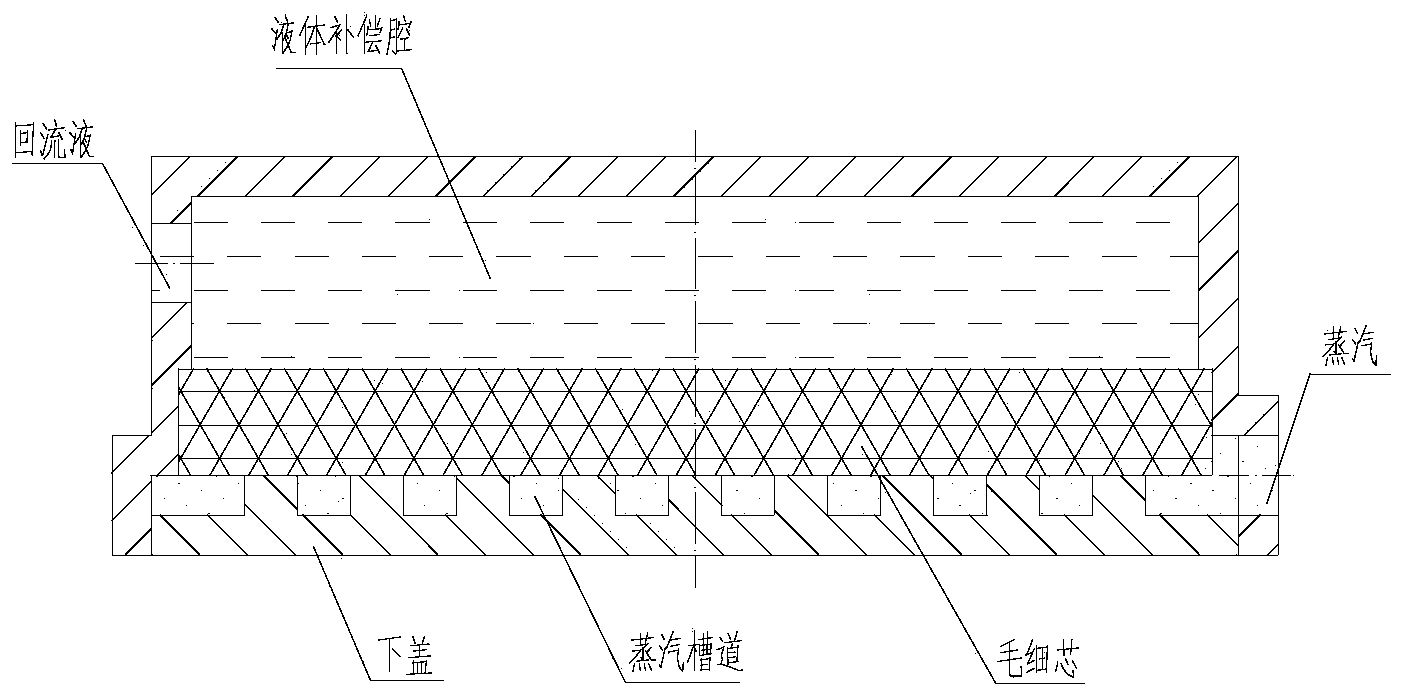

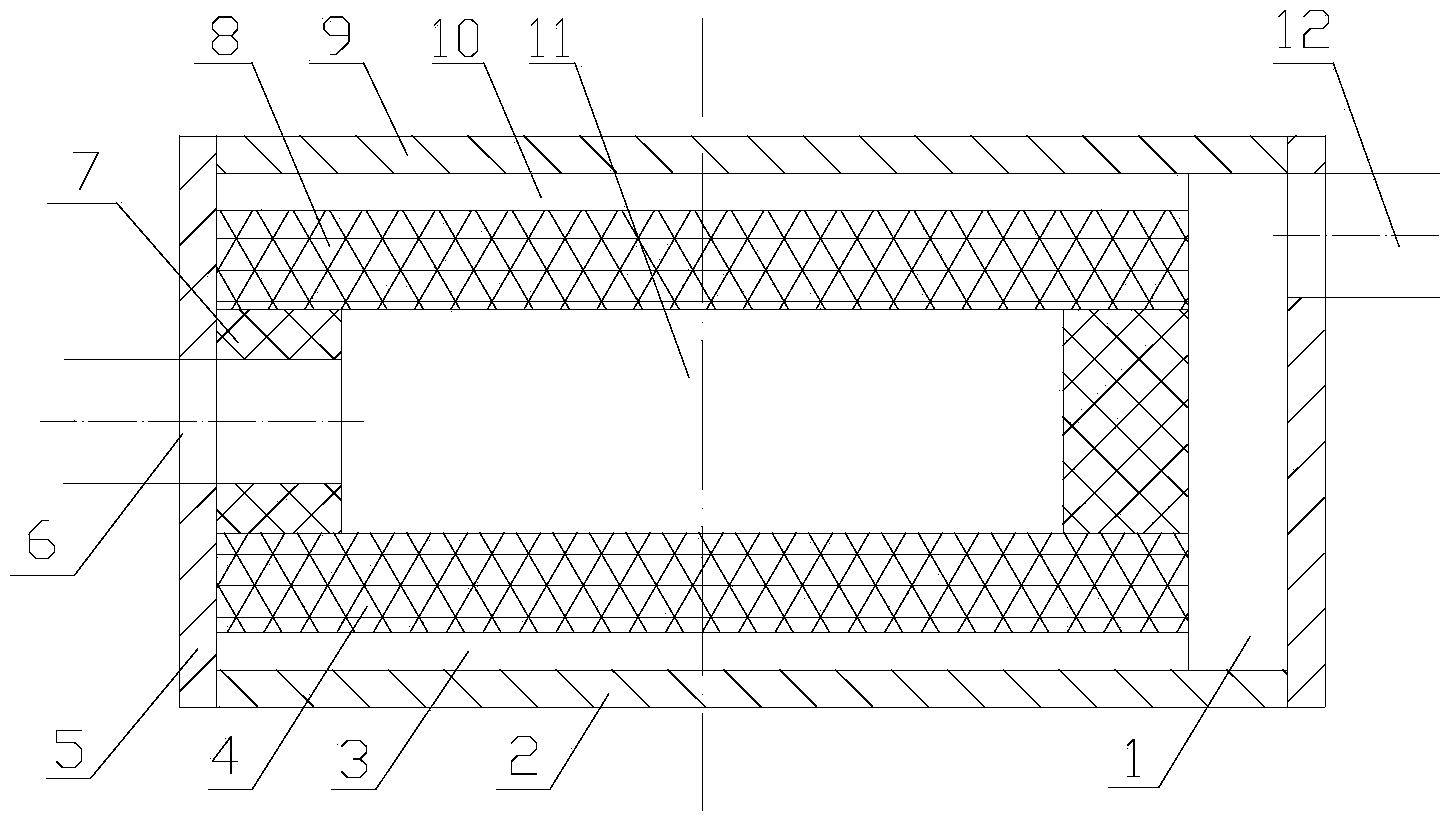

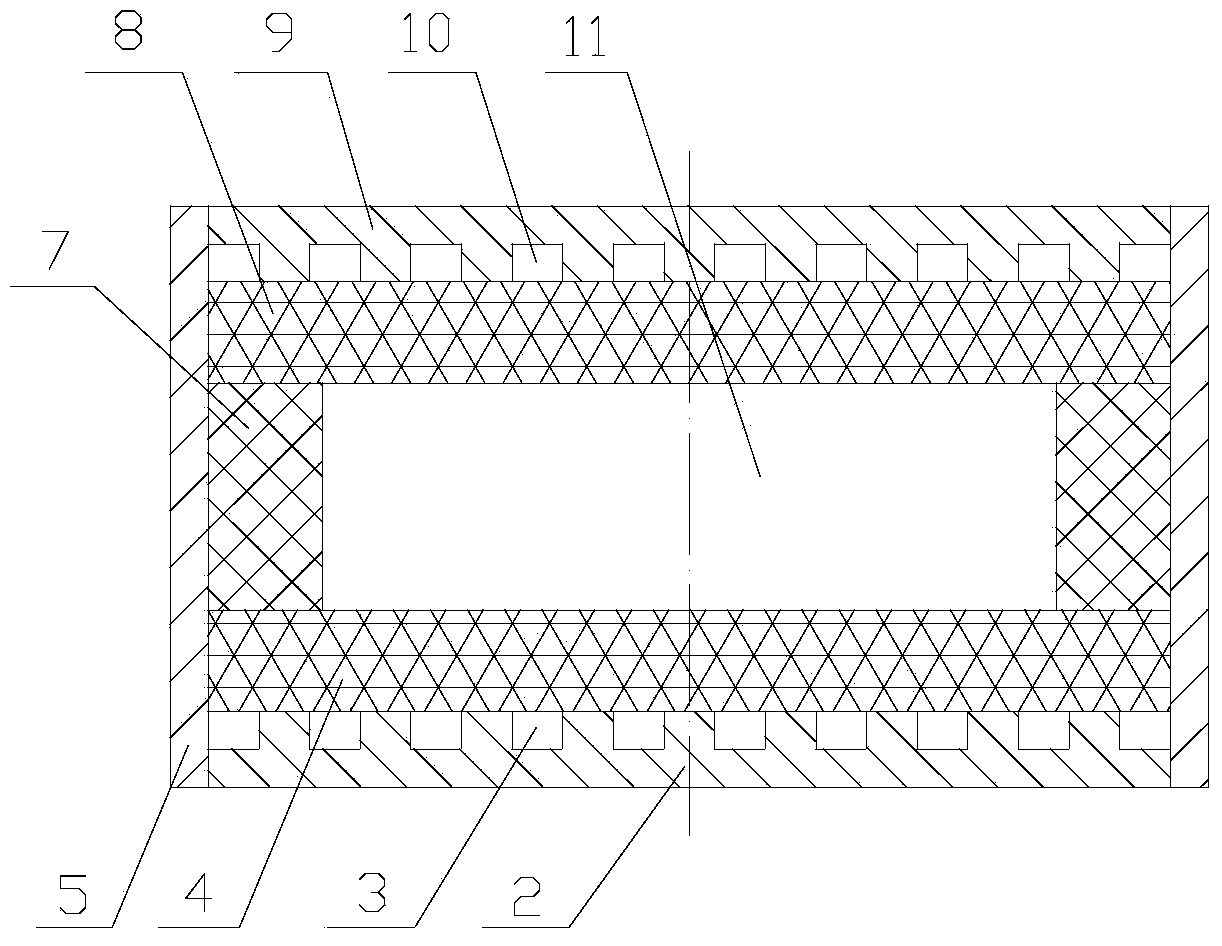

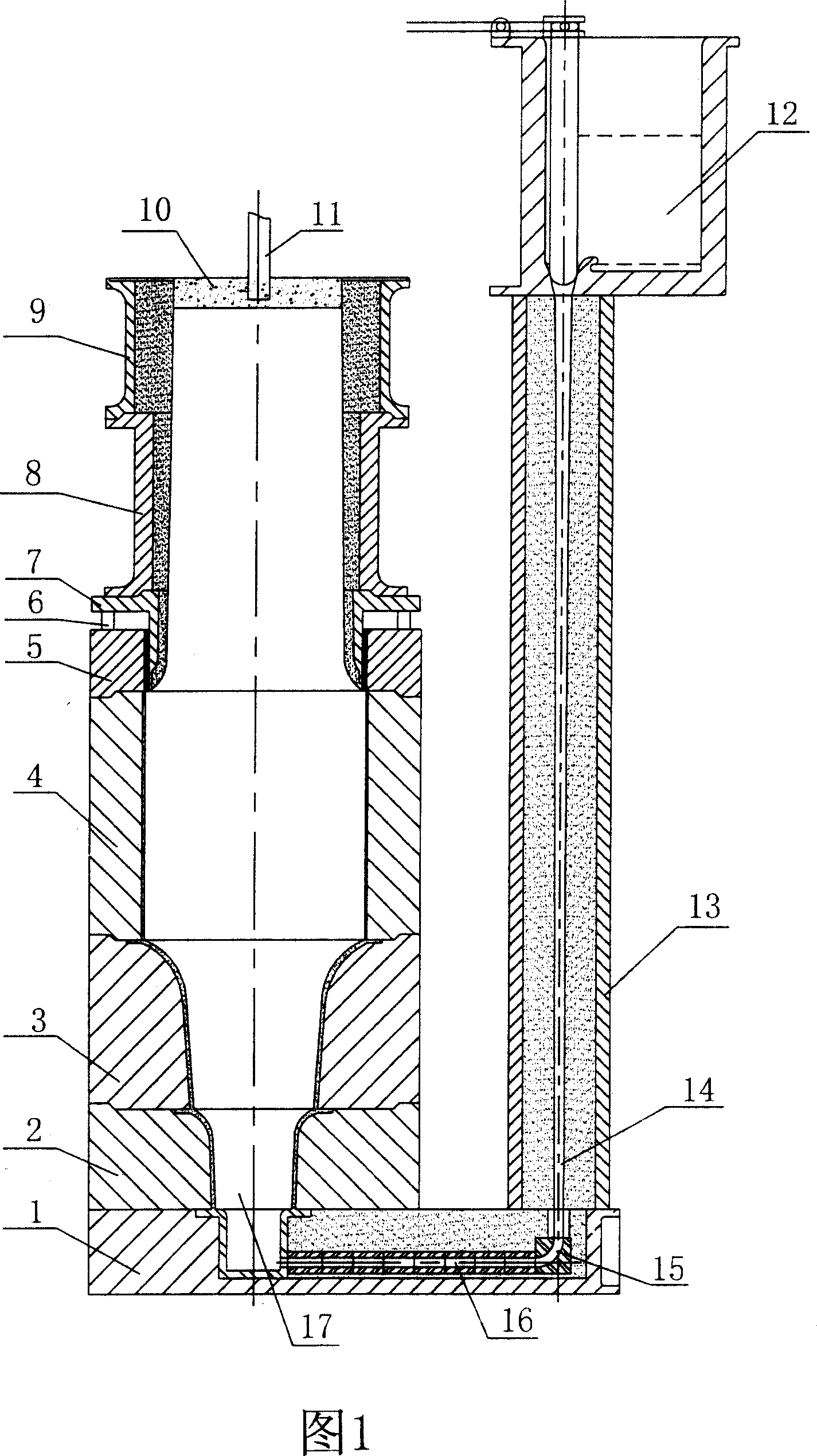

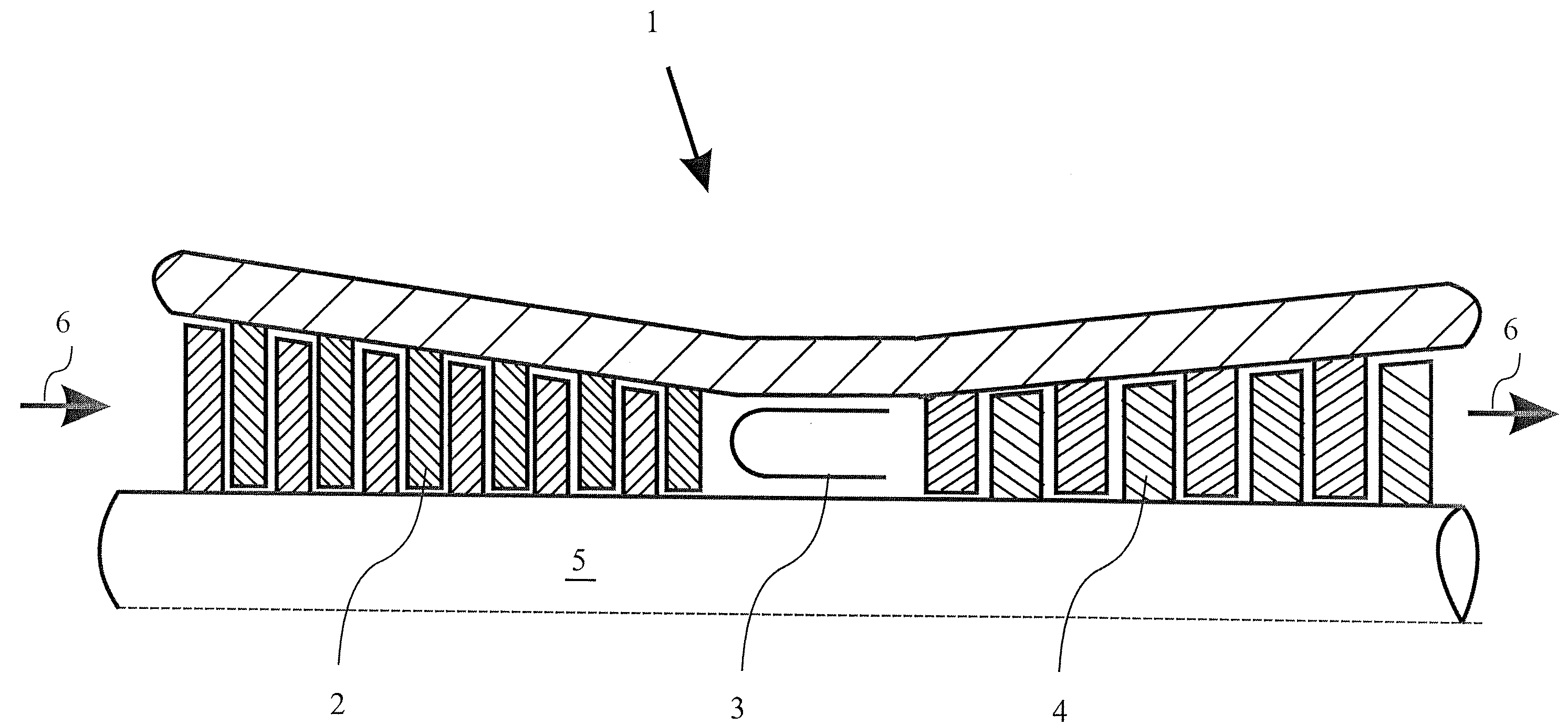

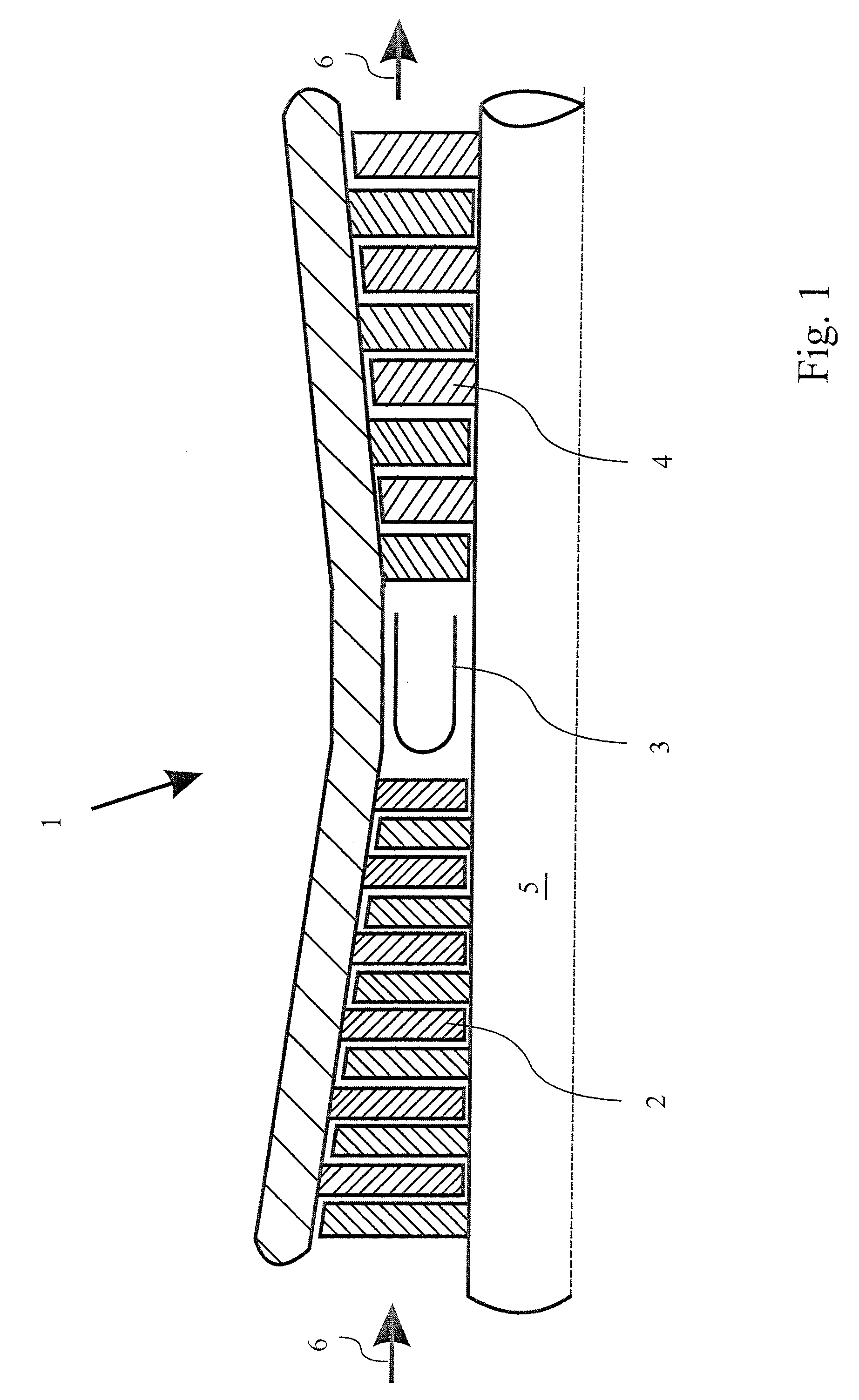

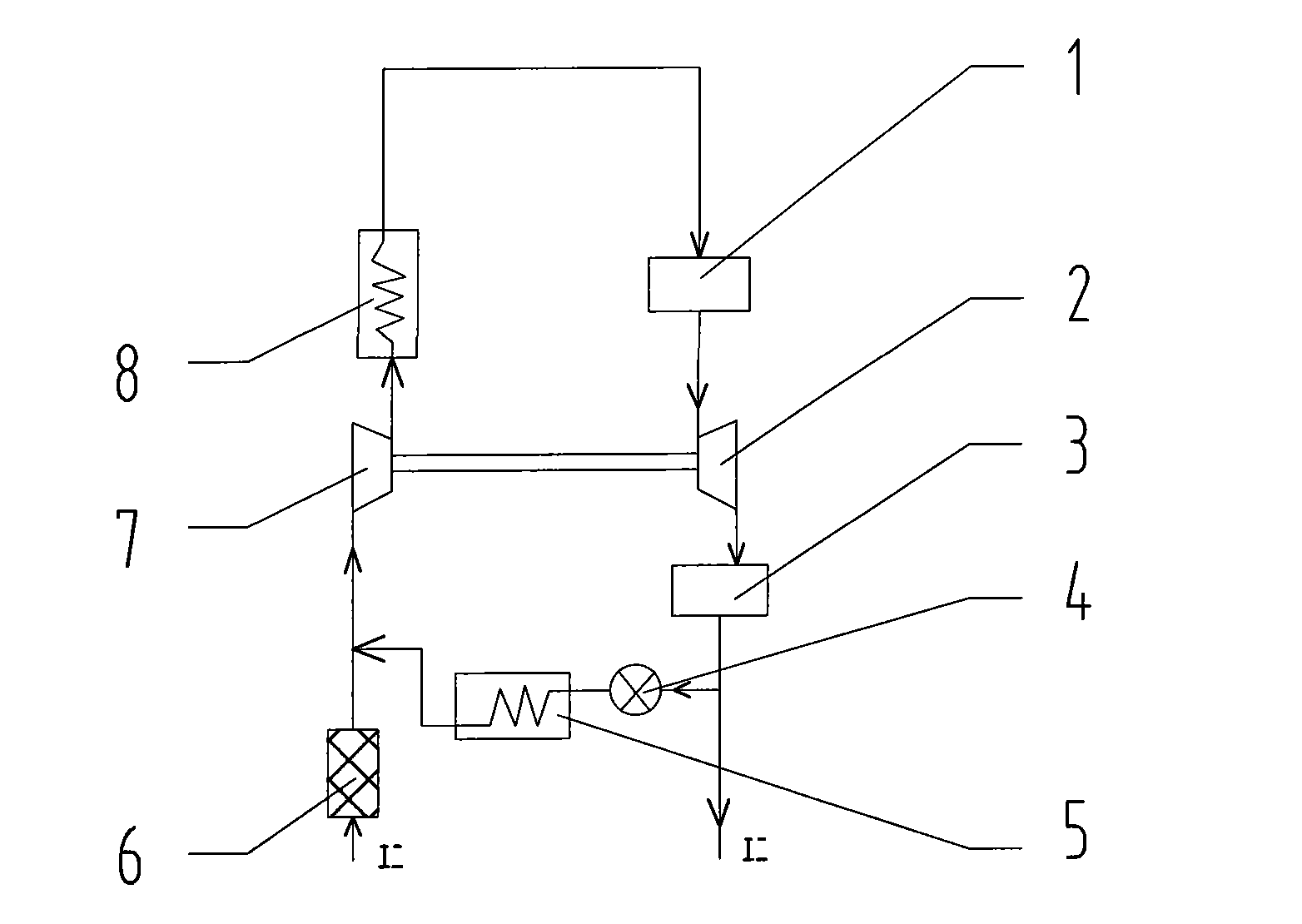

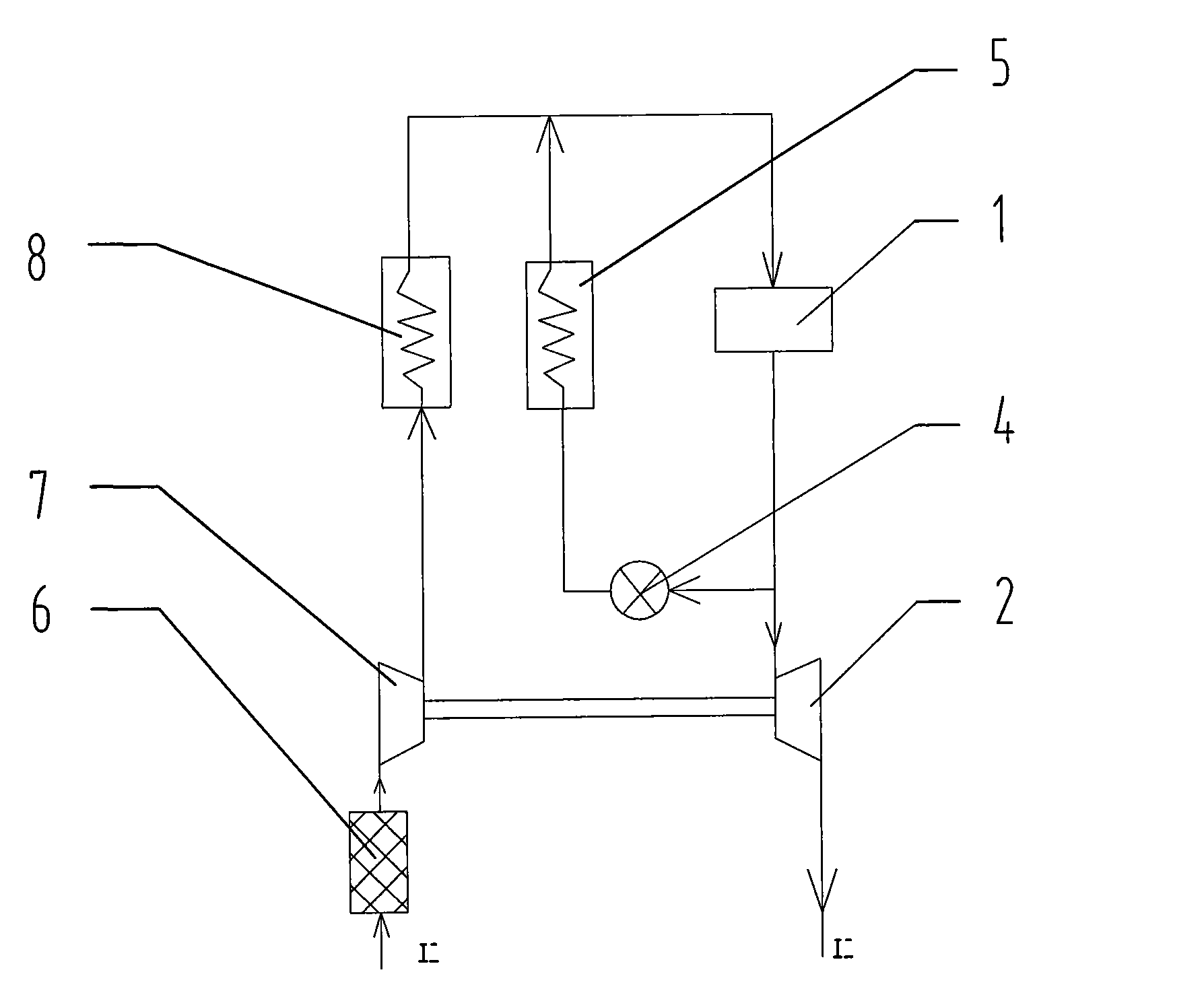

Double-capillary-core evaporator applied to flat-type LHP system

ActiveCN103712498ALower operating temperatureSmall fluctuations in operationIndirect heat exchangersEvaporatorEngineering

The invention discloses a double-capillary-core evaporator applied to a flat-type LHP system. The double-capillary-core evaporator comprises a main body, a lower end cover, an upper end cover, a lower capillary core, an upper capillary core and a wire mesh. The upper end cover and the lower end cover are fixedly arranged on the two end faces of the main body respectively, and a plurality of through grooves are respectively formed in the upper end cover and the lower end cover to form an upper steam channel and a lower steam channel. The upper capillary core and the lower capillary core are contained in closed space and are in close contact with the end covers respectively; the capillary cores are sealed through the wire mesh to define a compensation cavity, a steam cavity is formed by surplus space, located on one side of the compensation cavity, in the closed space, the steam cavity is communicated with a condensing device through a steam outlet, the compensation cavity is communicated with the outside through a backflow liquid pipe, and after steam flowing out from the steam channels is gathered to the steam cavity, the steam is condensed in the outside and flows into the compensation cavity from the backflow liquid pipe to compensate for working media in the upper capillary core and the lower capillary core. According to the double-capillary-core evaporator, the heat transmission capacity of the LHP system can be improved, influences of lateral wall heat conduction on the compensation cavity are reduced, the operation temperature of the LHP system is lowered, and the operation performance of the LHP system is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

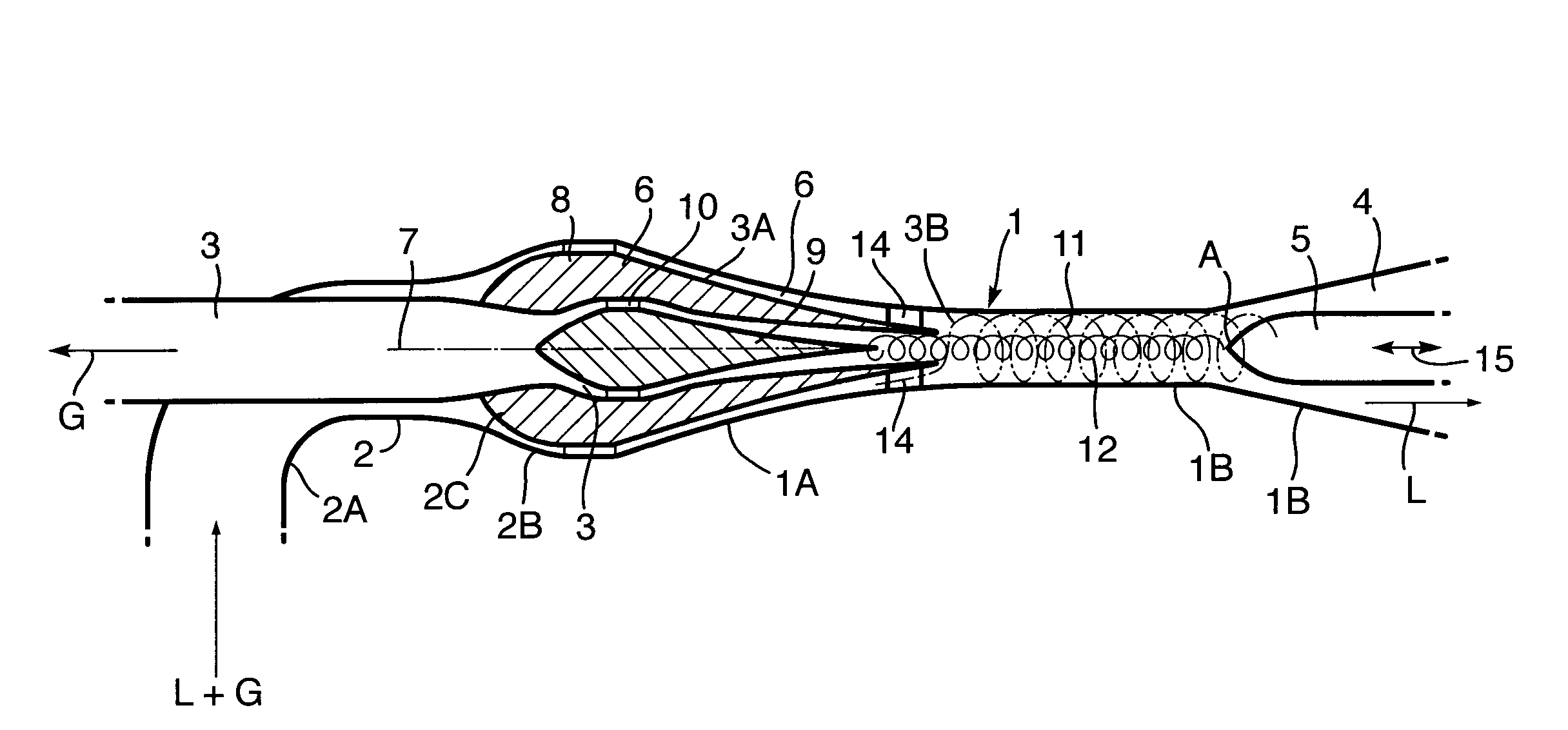

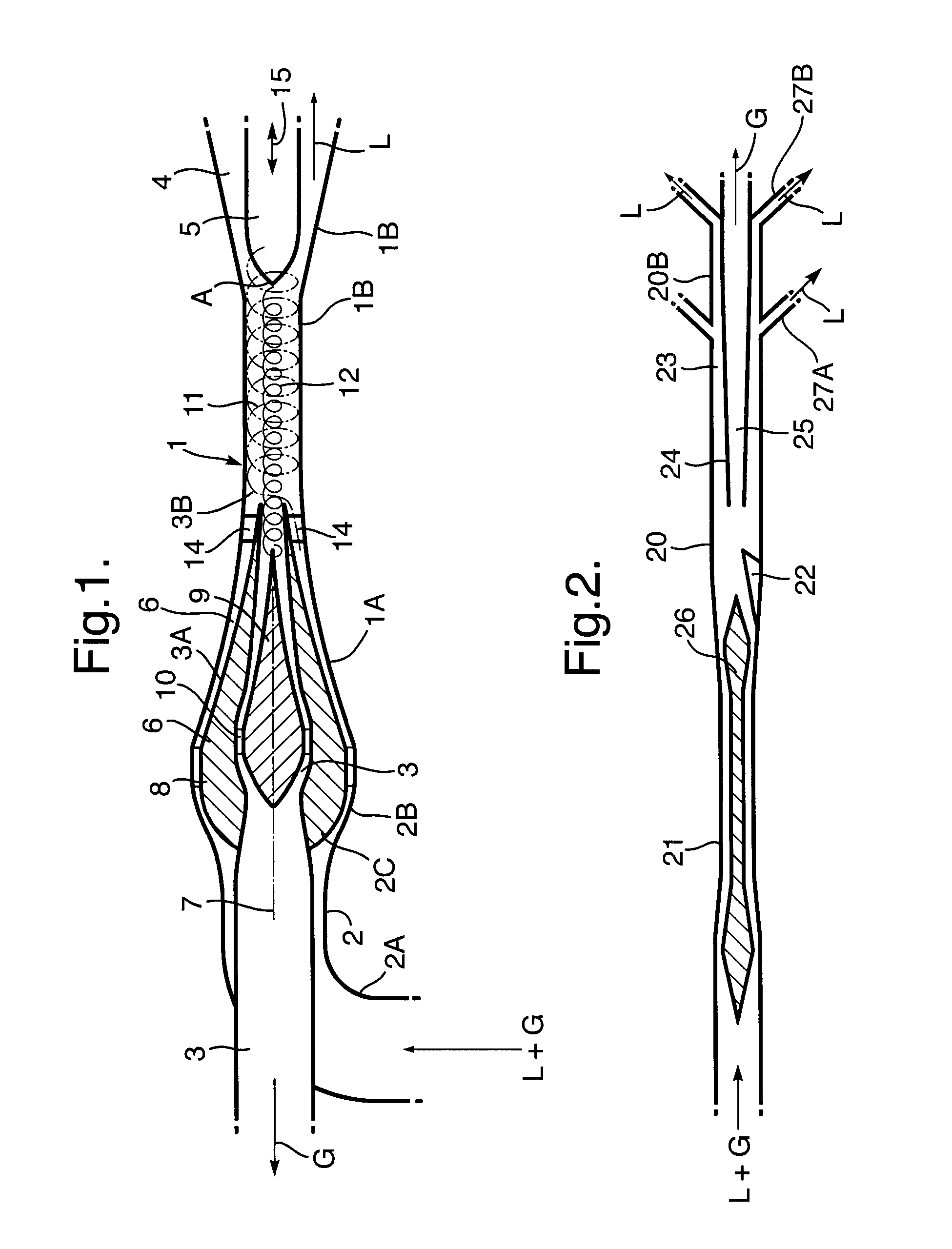

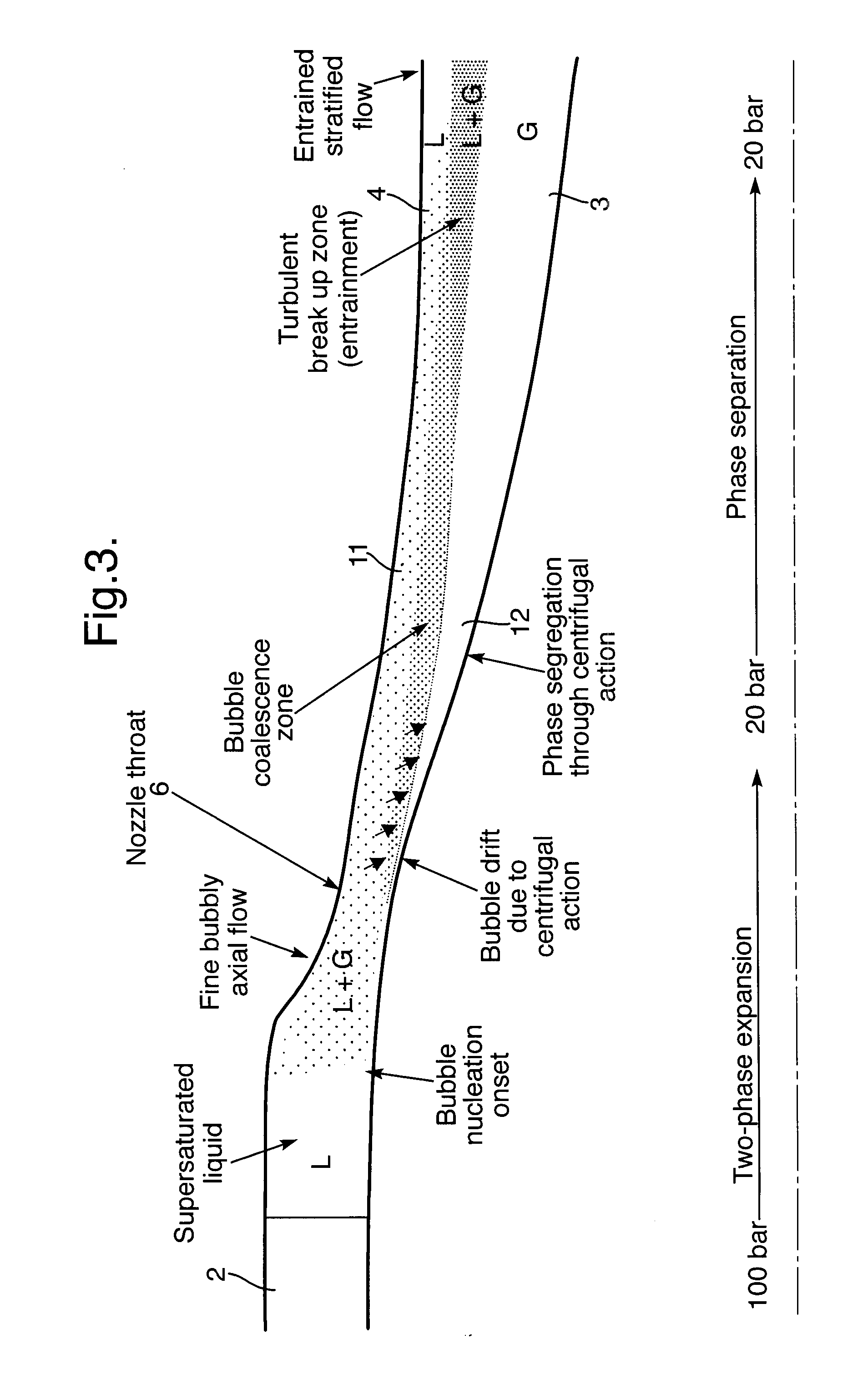

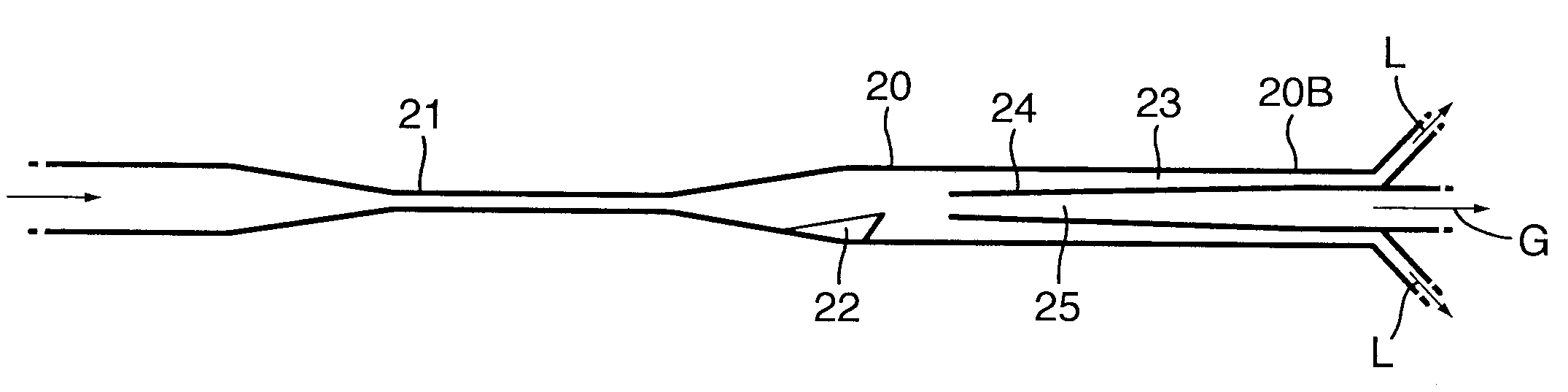

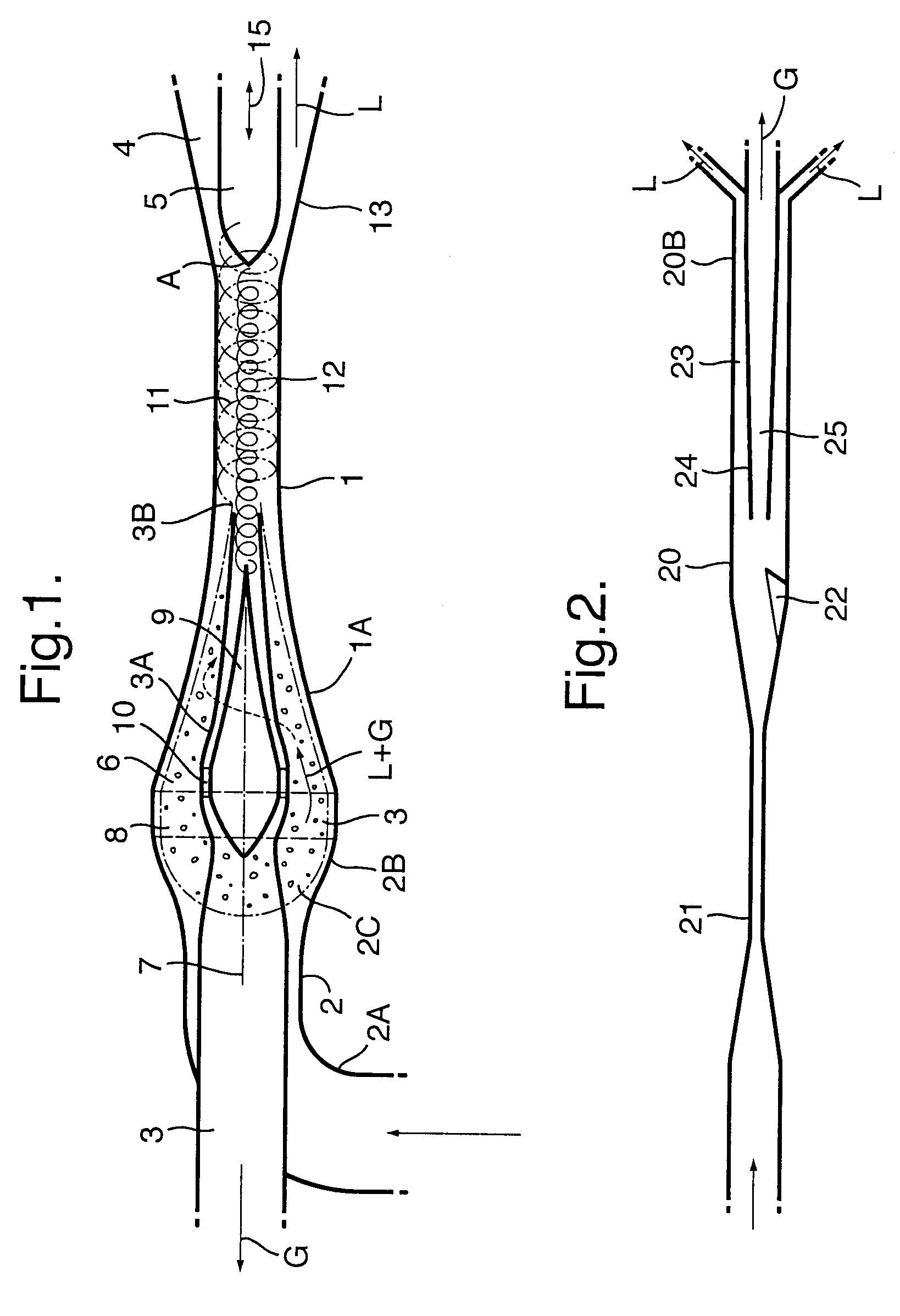

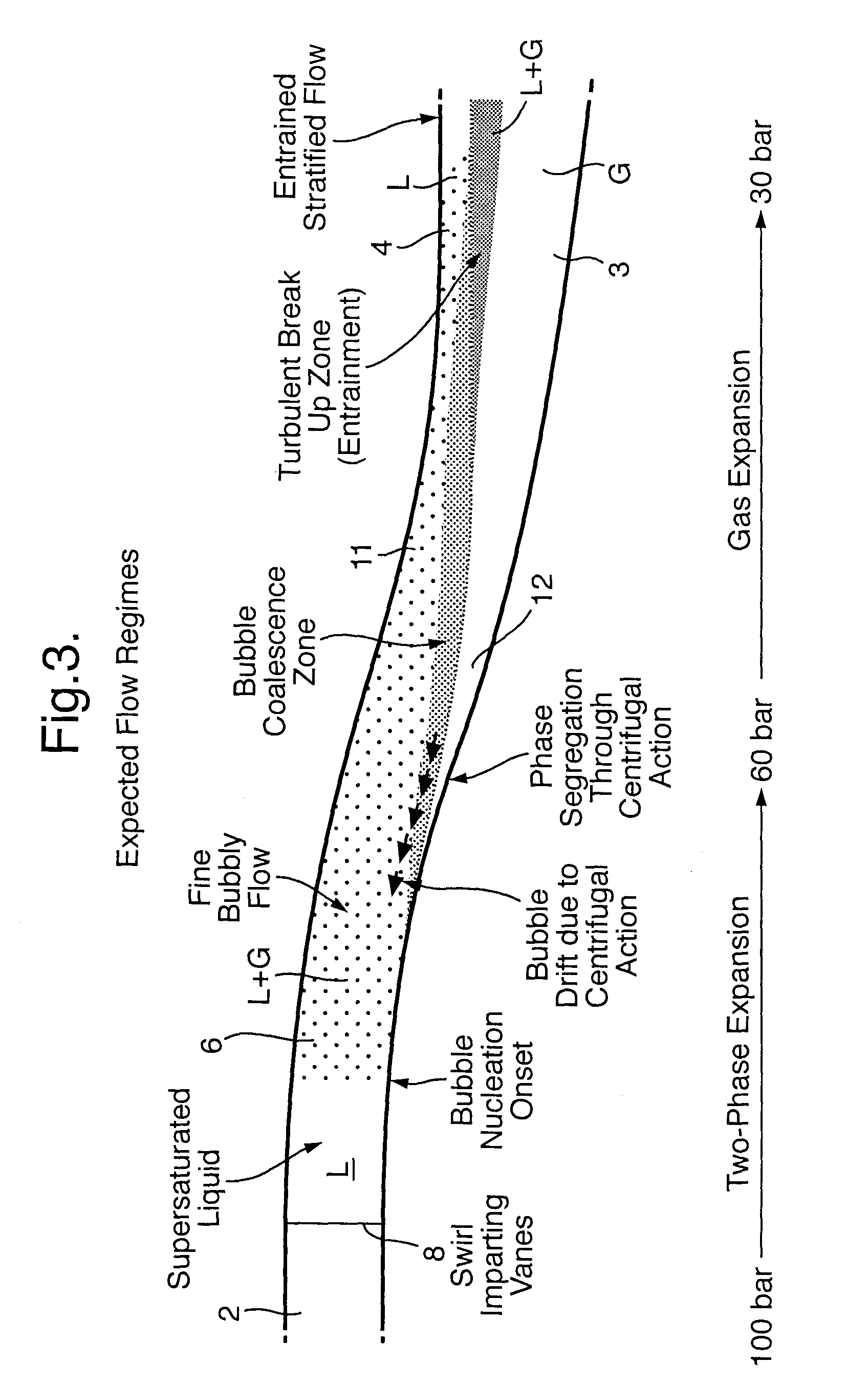

Cyclonic liquid degassing separator and method for degassing a fluid mixture

ActiveUS20090205488A1Reduce static pressureLow speed of soundLiquid degasificationReversed direction vortexEvaporationProduct gas

A method and cyclonic separator are disclosed for degassing a fluid mixture comprising a carrier liquid and gaseous and / or vaporizable components, wherein: the fluid mixture is accelerated in a throat section (6, 21) of a vortex tube (1, 20) such that the static pressure of the fluid mixture is decreased and vaporizable components evaporate into a gaseous phase and the fluid mixture flows as a substantially homogeneously dispersed gas-liquid mixture through the throat section; the accelerated fluid mixture is induced to swirl within a tubular mid section of the vortex tube such that the fluid mixture is separated by centrifugal forces into a degassed liquid fraction and a gas enriched fraction; the degassed liquid fraction is induced to flow into a annular liquid outlet conduit (4, 21); and the gas enriched fraction is induced to flow into a central gas outlet conduit (3, 24). An advantage of inducing the fluid mixture to flow as a substantially homogeneously dispersed gas-liquid mixture through the throat section is that the velocity of sound in such a mixture is low, thereby increasing the Mach number and the pressure reduction in the throat section and enhancing evaporation of gas bubbles in the mixture.

Owner:SHELL OIL CO

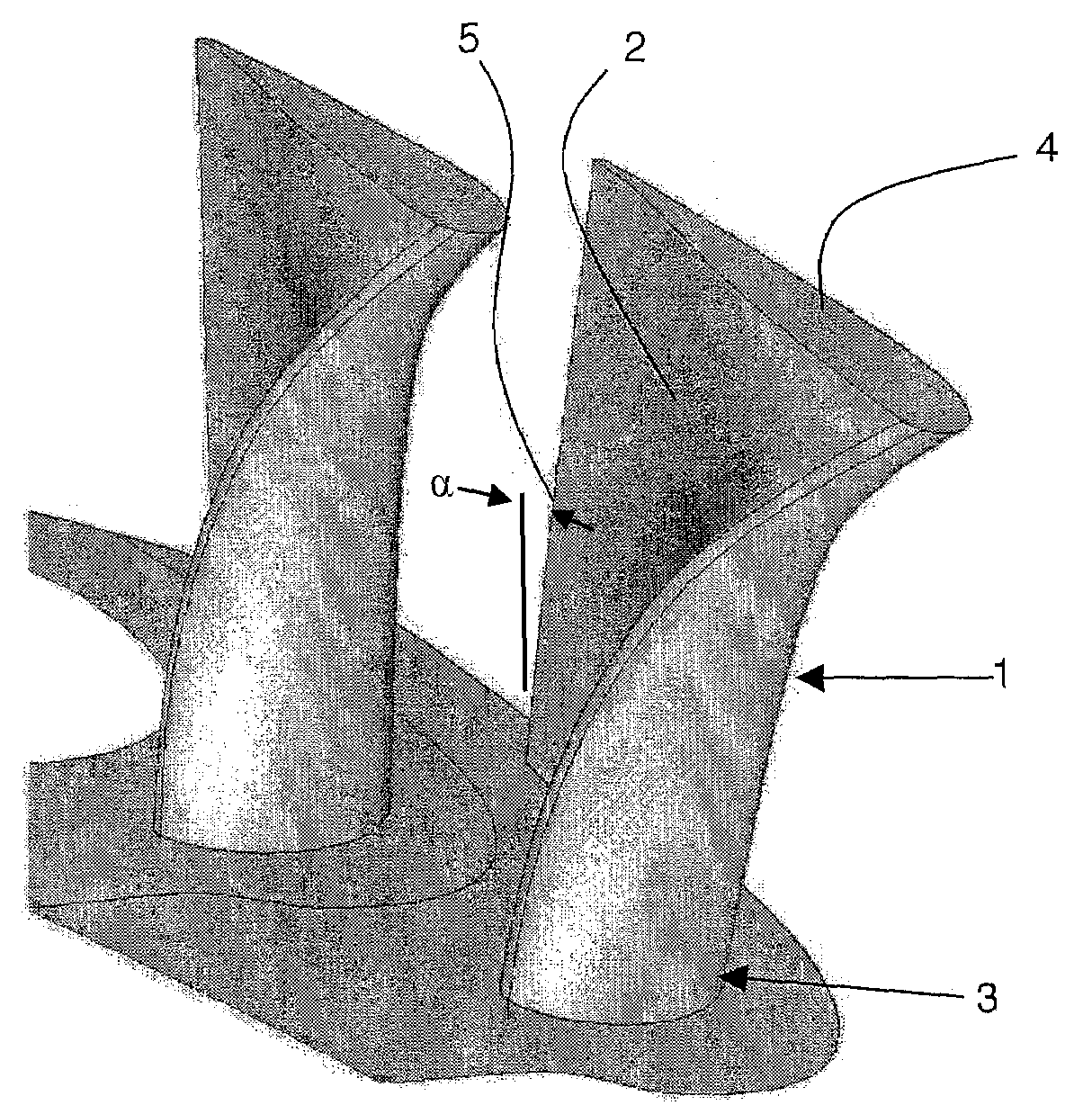

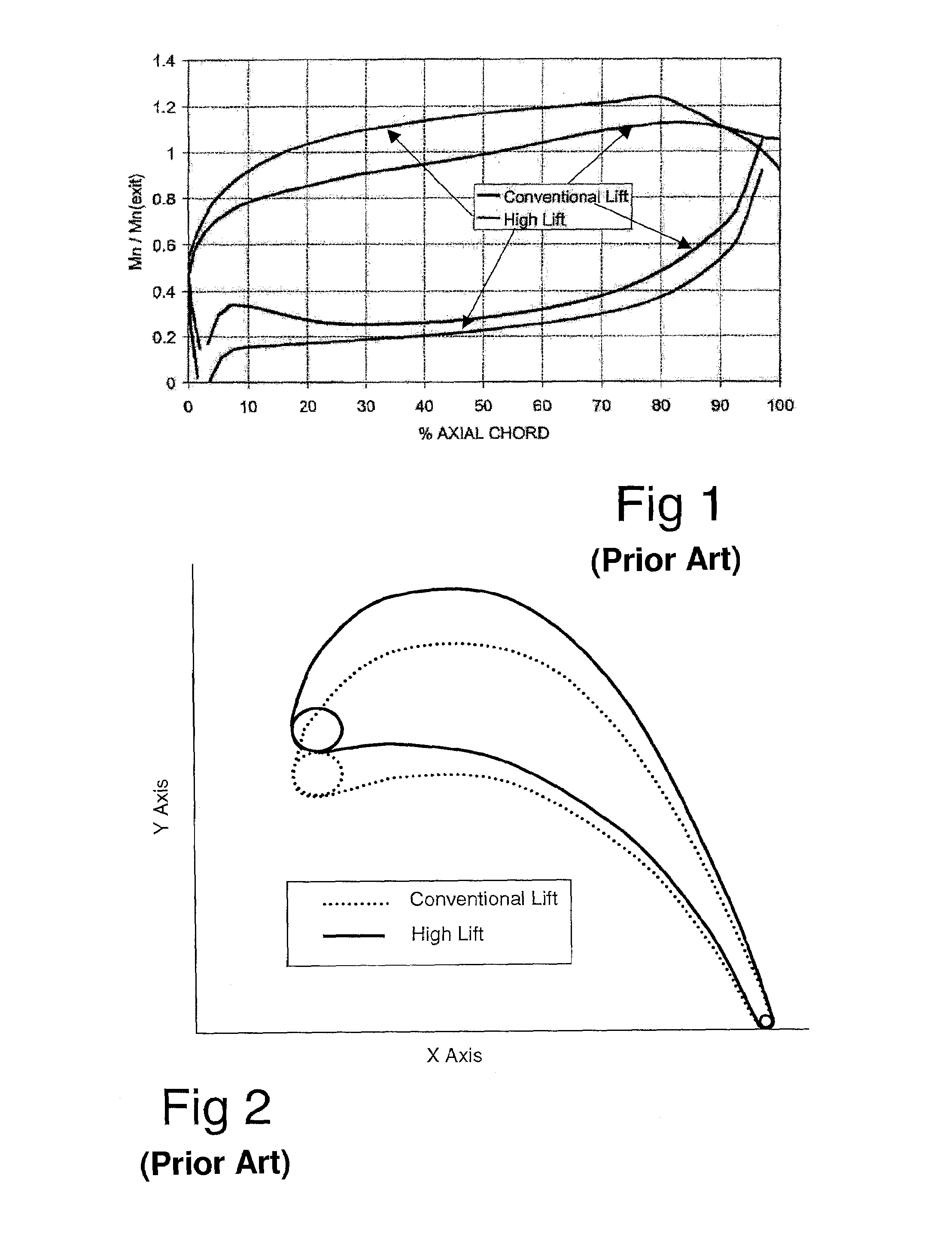

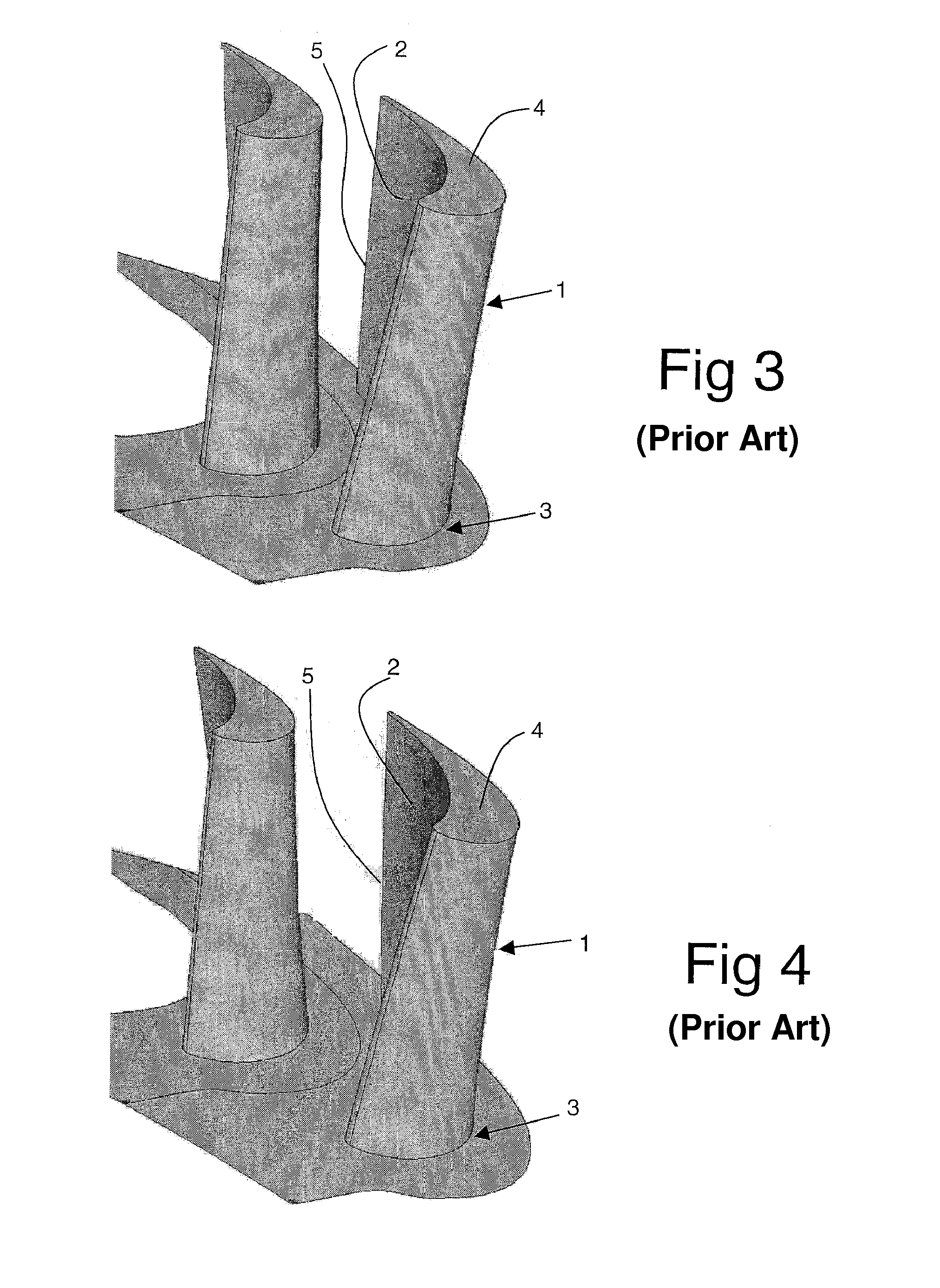

Turbine rotor blade for gas turbine engine

InactiveUS7217101B2Reduce leakage lossReduce manufacturing costPropellersEngine manufactureLeading edgeTurbine blade

A rotor blade for a gas turbine engine includes a blade root (3) and an aerofoil projecting therefrom, the aerofoil having a leading edge and a trailing edge (5), a generally concave pressure surface (2) and a generally convex suction surface (1). The aerofoil shape of the blade varies in section along the length thereof such that:the chord-wise convex curvature of the rear suction surface decreases towards the tip (4) of the blade;the convex curvature of the early to mid suction surface increases towards the tip;the stagger of the aerofoil section increases towards the tip; andthe trailing edge (5) is a straight line.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Process for preparing large cast steel support roller

The process of making cast steel supported roller is suitable for integral casting of cast steel supported roller of 5-100 ton weight. The present invention has adopts computer simulation, coating iron mold with sand, rotary cavity filling, heat insulating casting head technology, electrically casting head heating technology and sliding roller neck technology; and designs pouring system and casting mold design by means of new design principle and successive solidification principle. Adopting sliding roller neck technology and electrically casting head heating technology can avoid cracking in the cast steel supported roller.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

Air purification apparatus and method

InactiveUS20160279556A1Prolong lifeReduce noiseMechanical apparatusDomestic stoves or rangesEngineeringNoise reduction

An air purification apparatus and air purification method is disclosed. Air to be purified is drawn into an air purification unit for purification by a negative pressure, wherein the negative pressure region is created by a fan blower, and the air to be purified does not pass through the fan blower to prevent the fan blower being contaminated by the pollutants which presented in the air to be purified. With the present invention, the lifespan of the fan blower can be extended, and the fire alarm risk caused by accumulated pollutants can be decreased. The fan blowers with lower power consumption can be used to achieve the beneficial effects of energy saving and noise reduction.

Owner:LAW SUI CHUN

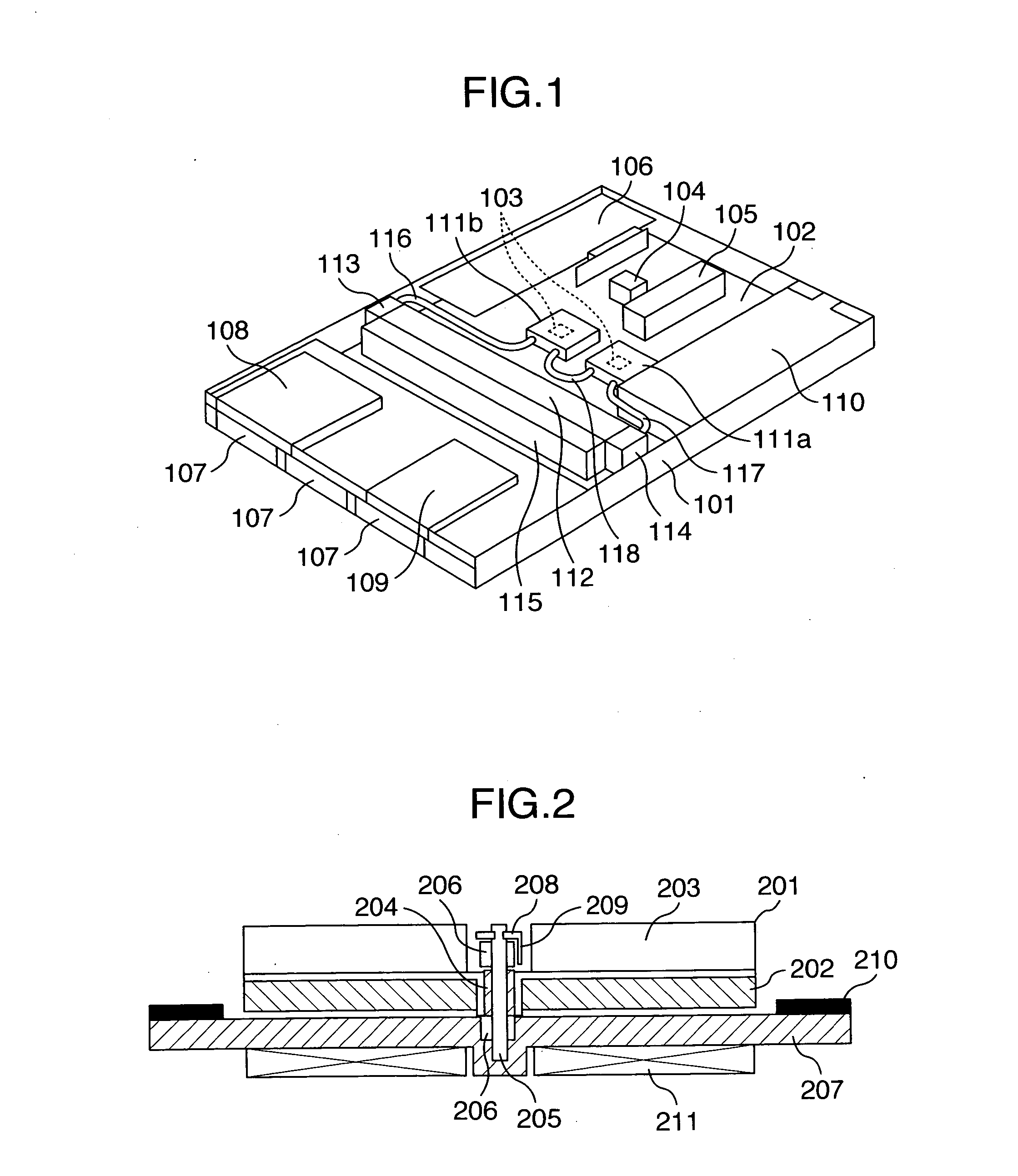

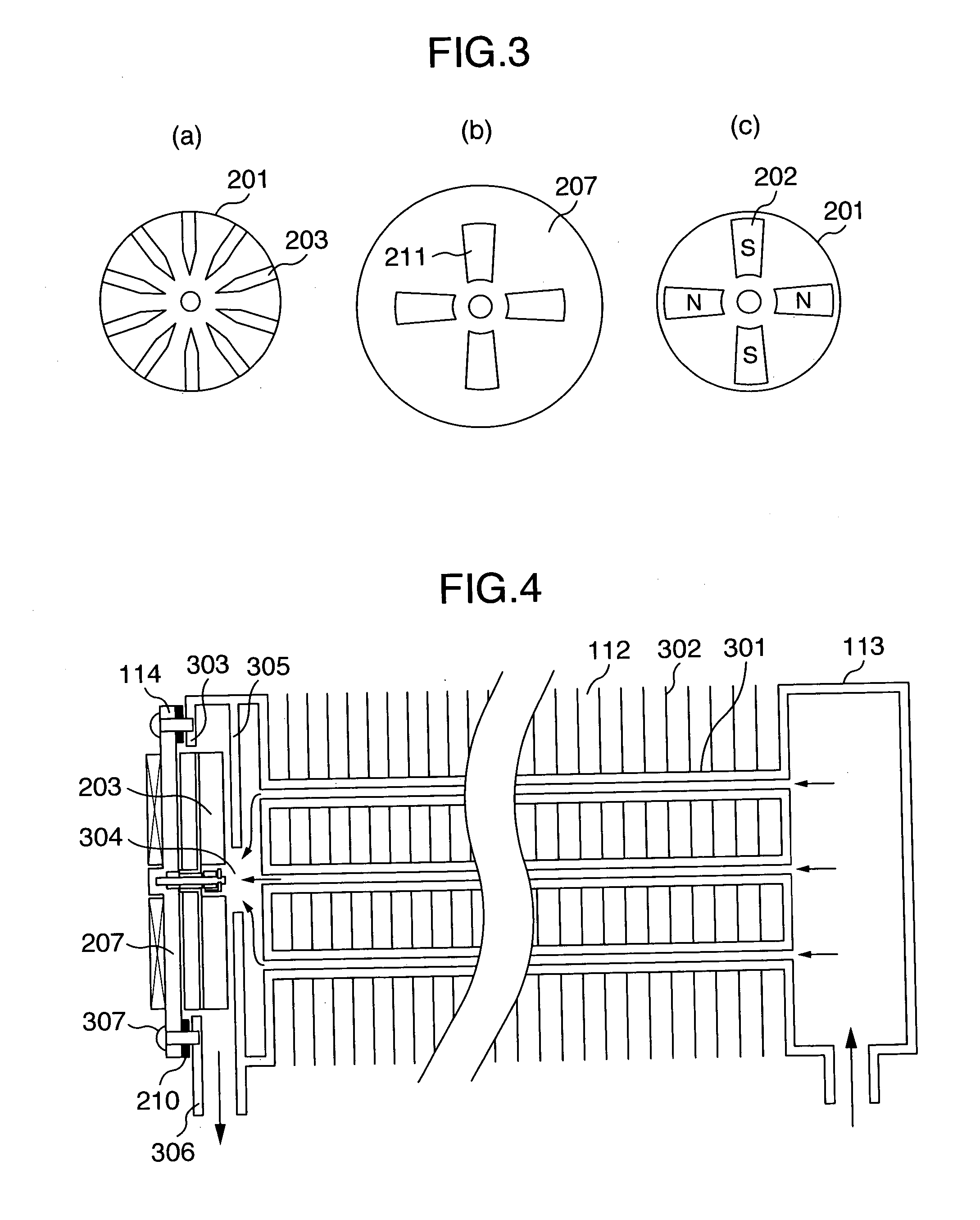

Liquid circulation system and liquid cooling system therewith

InactiveUS20060018775A1Minimize pressure drop lossLow efficiencyPositive displacement pump componentsSemiconductor/solid-state device detailsImpellerLiquid cooling system

A pump equipped with an impeller having a plurality of vanes is installed through a packing at an opening section formed on a wall surface of one of components in a liquid circulation passage, such as a radiator so that the impeller of the pump section may be disposed herein. Inside the component, there is provided a partition plate formed with a hole at such a position as to face the center of the impeller. A port is provided between a wall surface having the opening section and the partition plate. By the rotation of the impeller, a liquid flow is produced toward the port from the inside of the compartment through the hole.

Owner:HITACHI LTD

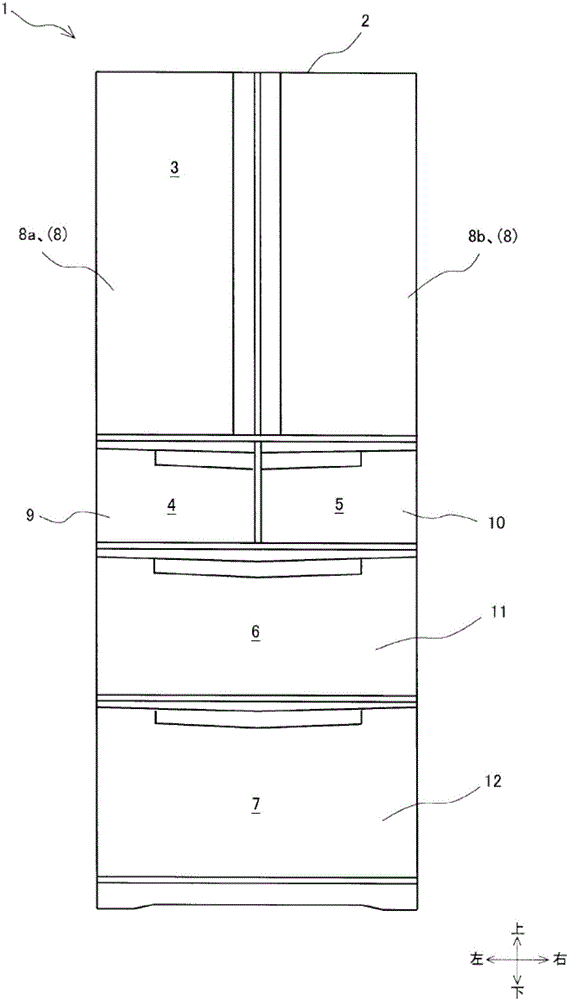

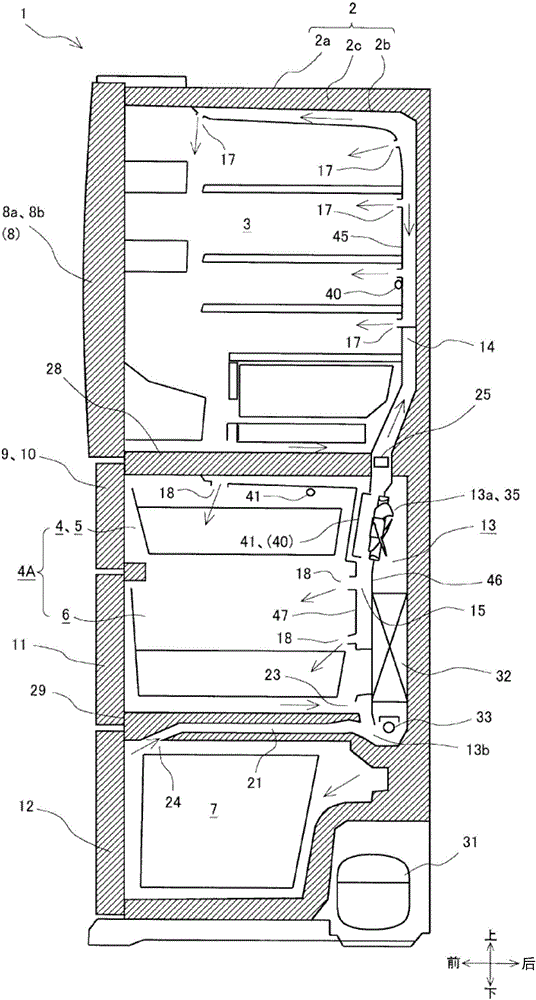

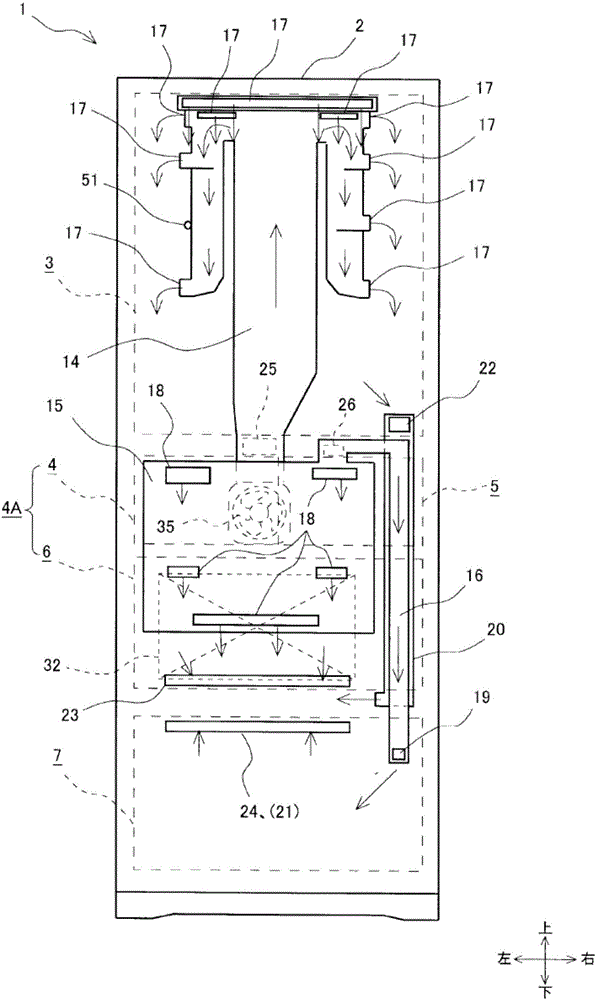

Refrigerator

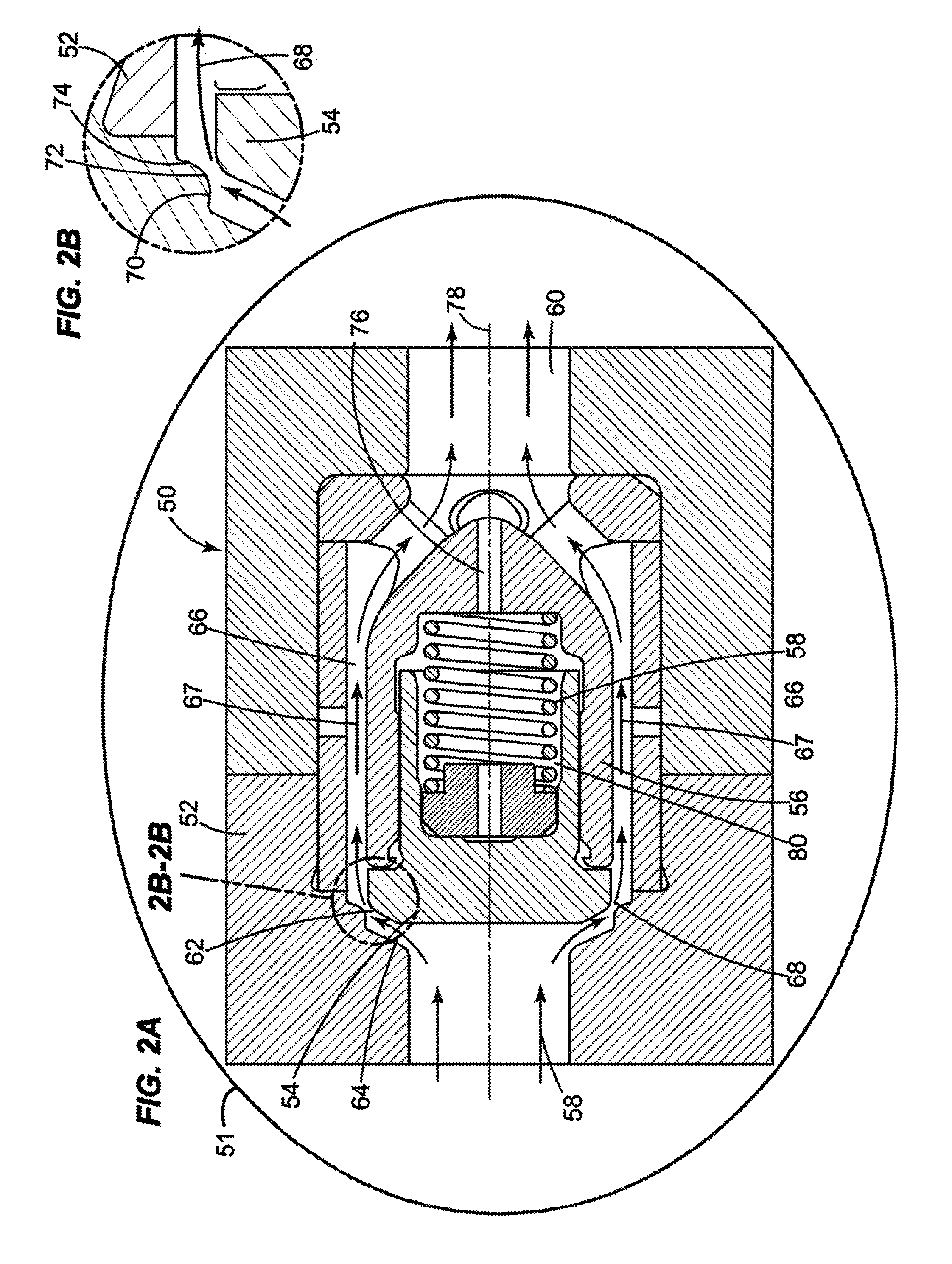

InactiveCN106247741AContainment leakImprove cooling efficiencyLighting and heating apparatusCooling fluid circulationCold airEngineering

The subject of the invention is to provide a refrigerator with reduced pressure loss when cold air is blew. The means for solving the problem is as follows, according to the refrigerator, a shielding device 50 blocking an air blower comprises a fan cover 51 blocking a fan 37 (not shown) and is provided with an opening part 64 at the upper end of the fan cover 51, a supporting base 53 supporting the fan cover 51, and a suction pipe 59 connected with the opening part 64 of the fan cover 51. When the fan cover 51 is in a close state, cold air blew from the fan (not shown) is provided to a store room 3 through the suction pipe 59 and air providing pipes.

Owner:HAIER SMART HOME CO LTD +1

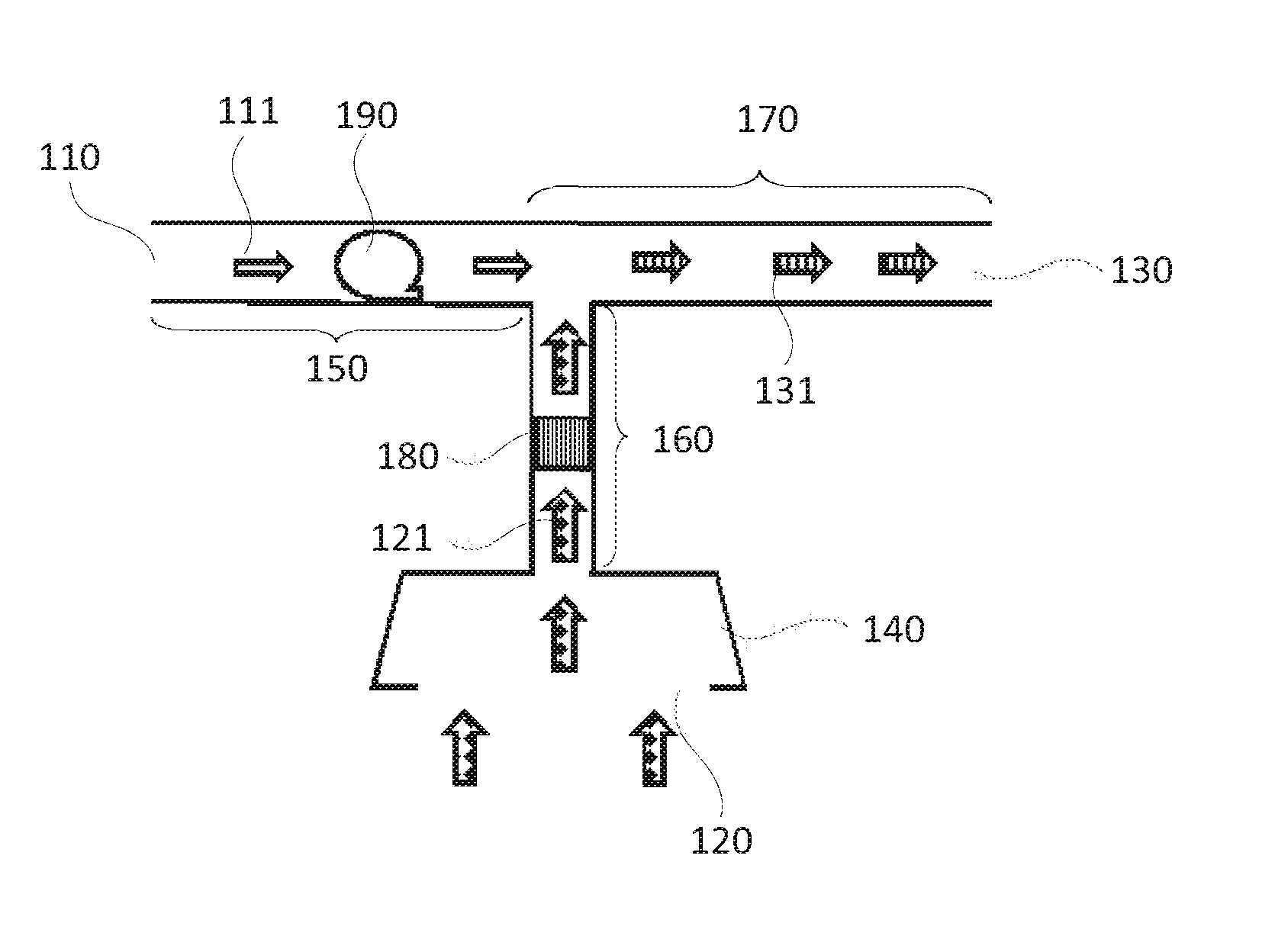

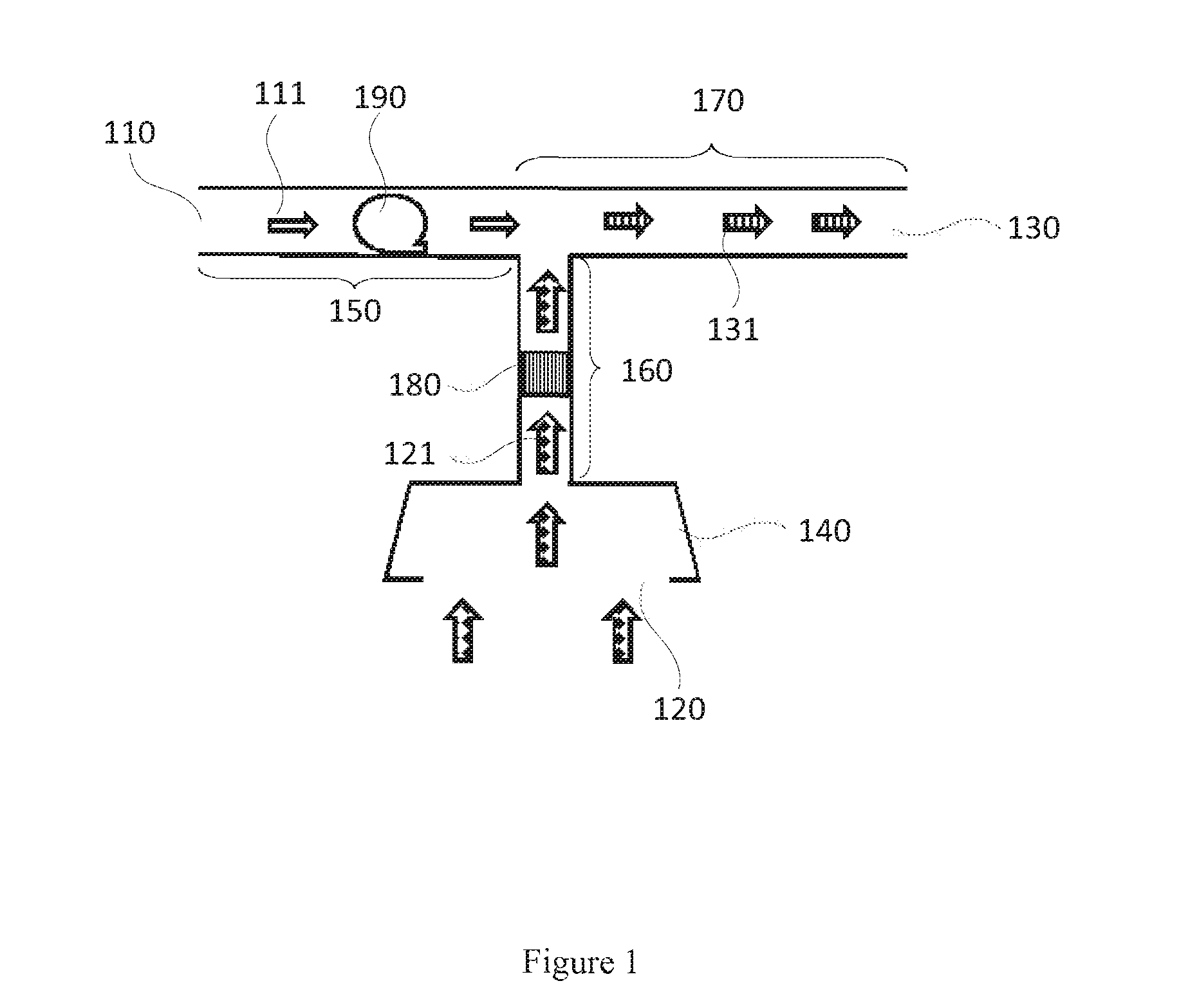

Wind turbine air flow guide device

InactiveUS20130136576A1Increase flow rateReducing static air pressurePump componentsReaction enginesEngineeringTurbine

The invention extends to an air flow device for wind turbines which includes a number of flow paths which assist in the movement of air through the air flow device which assists in increasing the efficiency and power output of the wind turbine. The air flow device includes flow passages alongside a central channel which houses the wind turbine.

Owner:WOJNAR SEBASTIAN

Cyclonic Separator and Method for Degassing a Fluid Mixture

ActiveUS20080289502A1Reduce static pressureLiquid degasificationReversed direction vortexGas phaseProduct gas

A method and cyclonic separator are disclosed for degassing a fluid mixture comprising a carrier liquid and one or more gaseous and / or vaporizable components, wherein: —the fluid mixture is accelerated in a throat section (6) of a vortex tube (1) such that the static pressure of the fluid mixture is decreased and vaporizable components evaporate into a gaseous phase; —the accelerated fluid mixture is induced to swirl within the vortex tube such that the fluid mixture is separated by centrifugal forces into a degassed liquid fraction and a gas enriched fraction; —the degassed liquid fraction is induced to flow into a liquid outlet conduit (4) which is located at or near the outer circumference of the vortex tube (1); and—the gas enriched fraction is induced to flow into a gas outlet conduit (3) which is located at or near a central axis of the vortex tube (1).

Owner:SHELL OIL CO

Fine particle classification apparatus and method for classifying aerosol particles in a sheath gas

InactiveUS6809314B2Reduce static pressureIncrease gas velocityGas current separationSamples introduction/extractionPhysicsProduct gas

A fine-particle classification apparatus includes an aerosol generation section which generates an aerosol containing fine particles in a medium background gas, a fine-particle classification section which classifies the fine particles contained in the aerosol in a sheath gas, and an introduction section, between the aerosol generation section and the fine-particle classification section, which introduces the aerosol generated in the aerosol generation section into the fine-particle classification section. The introduction section uses a carrier gas with an adequately high velocity to introduce the aerosol generated in the aerosol generation section to the classification section using a pressure difference.

Owner:PANASONIC CORP

Sealing element for use in a fluid-flow machine

ActiveUS20080213096A1Disadvantage is reduced and avoidedReduce gapPropellersPump componentsEngineeringCooling fluid

A sealing element for sealing a component gap with respect to a flow, in particular for use in a fluid-flow machine, specifically in a turbomachine is provided. In addition a fluid-flow machine is provided including such a sealing element for sealing a component gap. The sealing element includes a hollow profile enclosing a cavity. Arranged in the hollow profile are a first opening and a second opening, which are spaced apart from each other in the longitudinal direction of the hollow profile. The first opening is formed as an inlet opening for a cooling fluid into the cavity of the hollow profile, the second opening is formed as an outlet opening for the cooling fluid from the cavity of the hollow profile. With the sealing element arranged in a fluid-flow machine, the sealing element can consequently be internally cooled by means of the cooling fluid. Furthermore, the sealing element uses the pressure gradient occurring in the flow in the direction of flow to form a stable cooling fluid flow.

Owner:ANSALDO ENERGIA SWITZERLAND AG

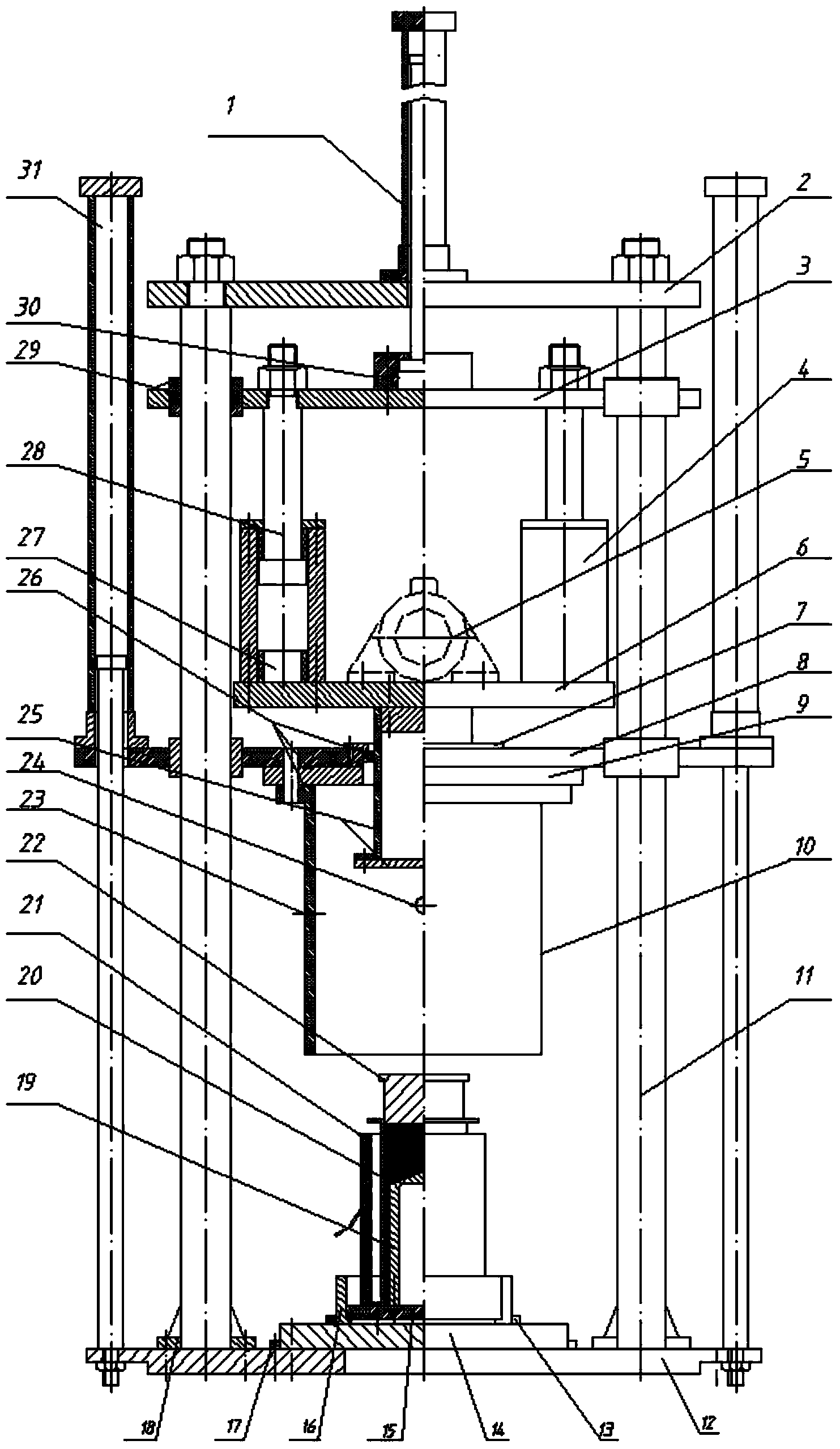

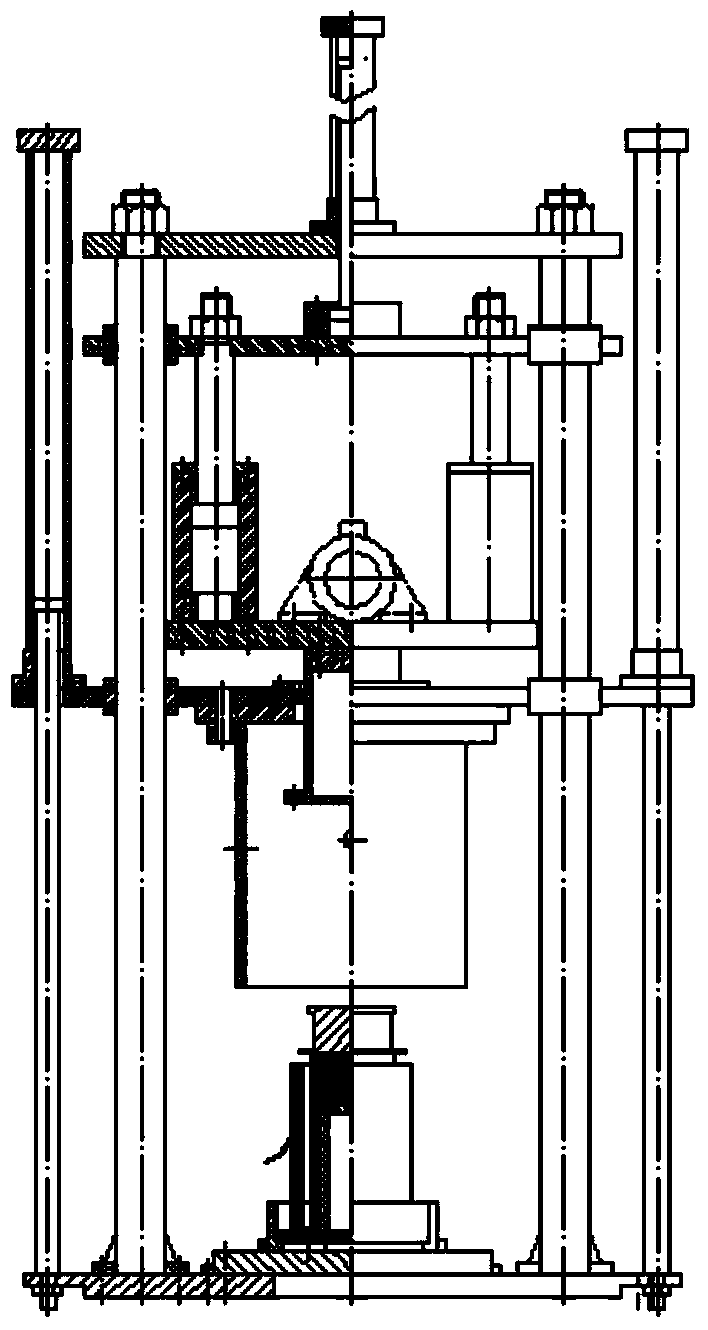

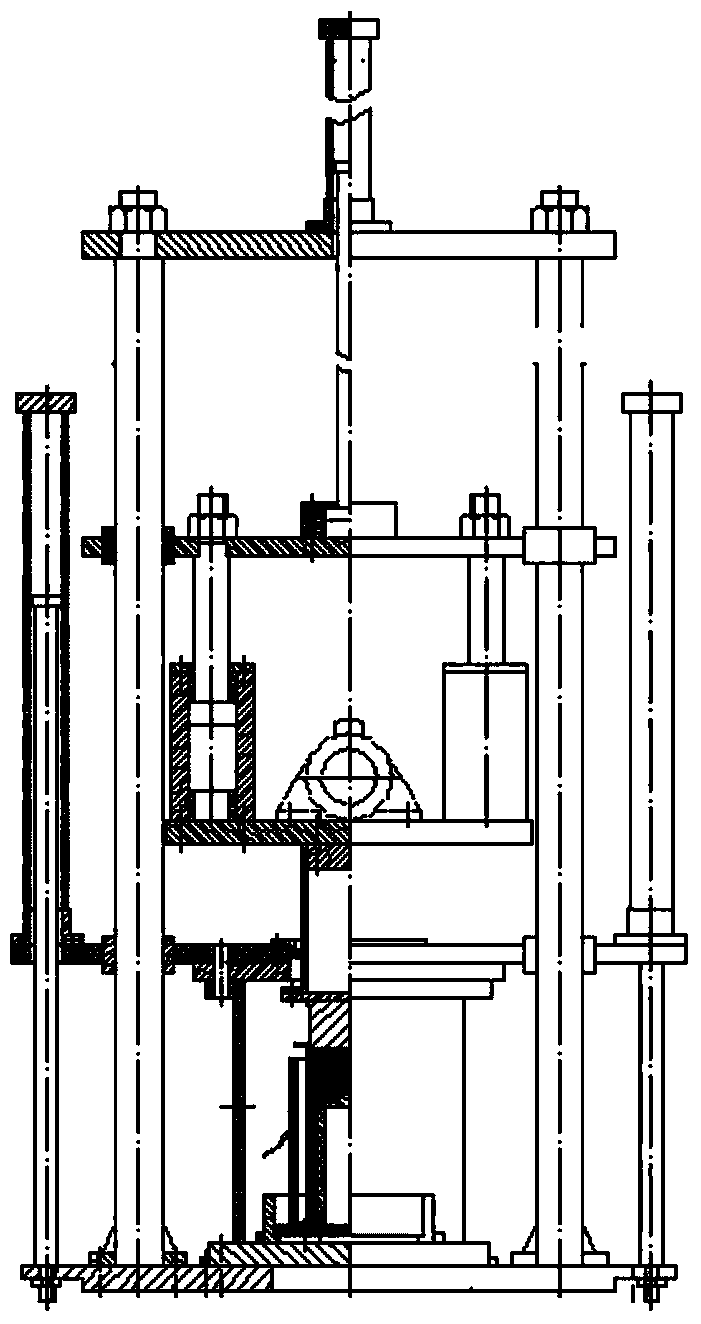

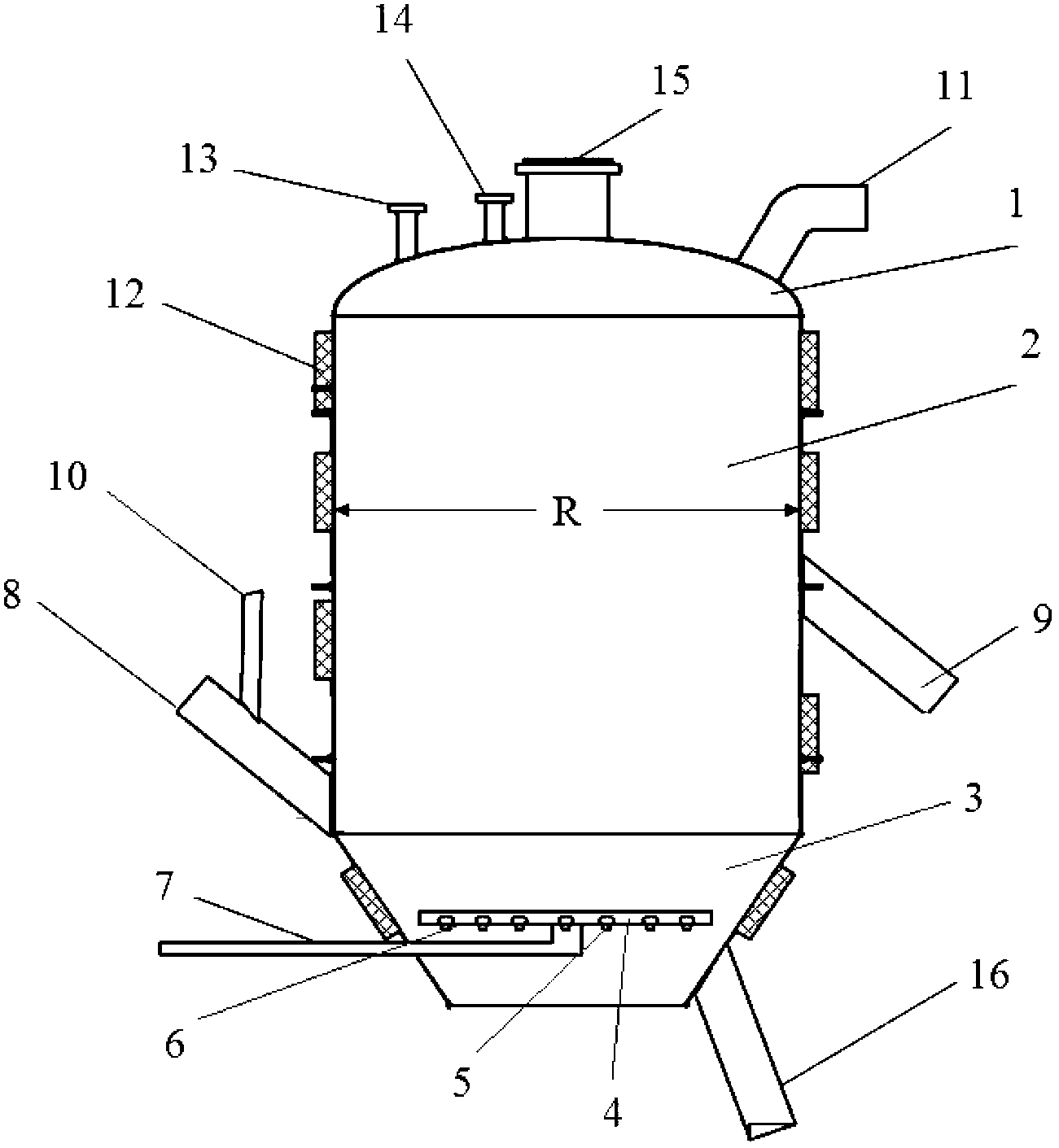

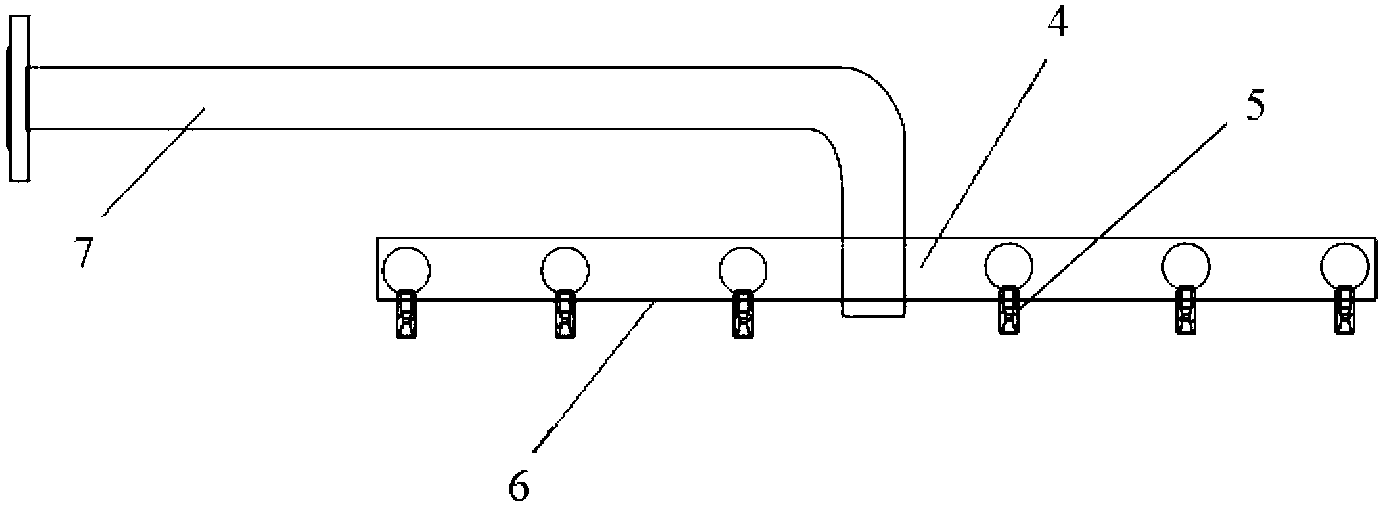

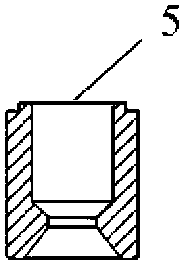

Electromagnetic induction heating type powder vibrating vacuum thermoforming device and method

The invention relates to an electromagnetic induction heating type powder vibrating vacuum thermoforming device and method and belongs to the technical field of powder metallurgy and ceramic production. The thermoforming device mainly comprises a machine body frame, an air extracting seal mechanism, a vibrating loading and buffering mechanism, a static load loading mechanism, an electromagnetic induction heating portion, a die assembly and a vibration pressing head. During formation, an electromagnetic induction heating coil is located on the periphery of a female die, the vibrating pressing head abuts against an upper punch from upside, and vibration is transmitted to powder through the upper punch; the female die, the upper punch, the electromagnetic induction heating coil, and the vibrating pressing head are located in a sealing frame for seal, and therefore integration of a vacuum or controlled atmosphere, induction heating and the characteristics of the vibrating hot pressing sintering production method is achieved. The electromagnetic induction heating type powder vibrating vacuum thermoforming device is simple in structure, low in cost, low in energy consumption, high in efficiency, and easy to popularize.

Owner:SOUTH CHINA UNIV OF TECH

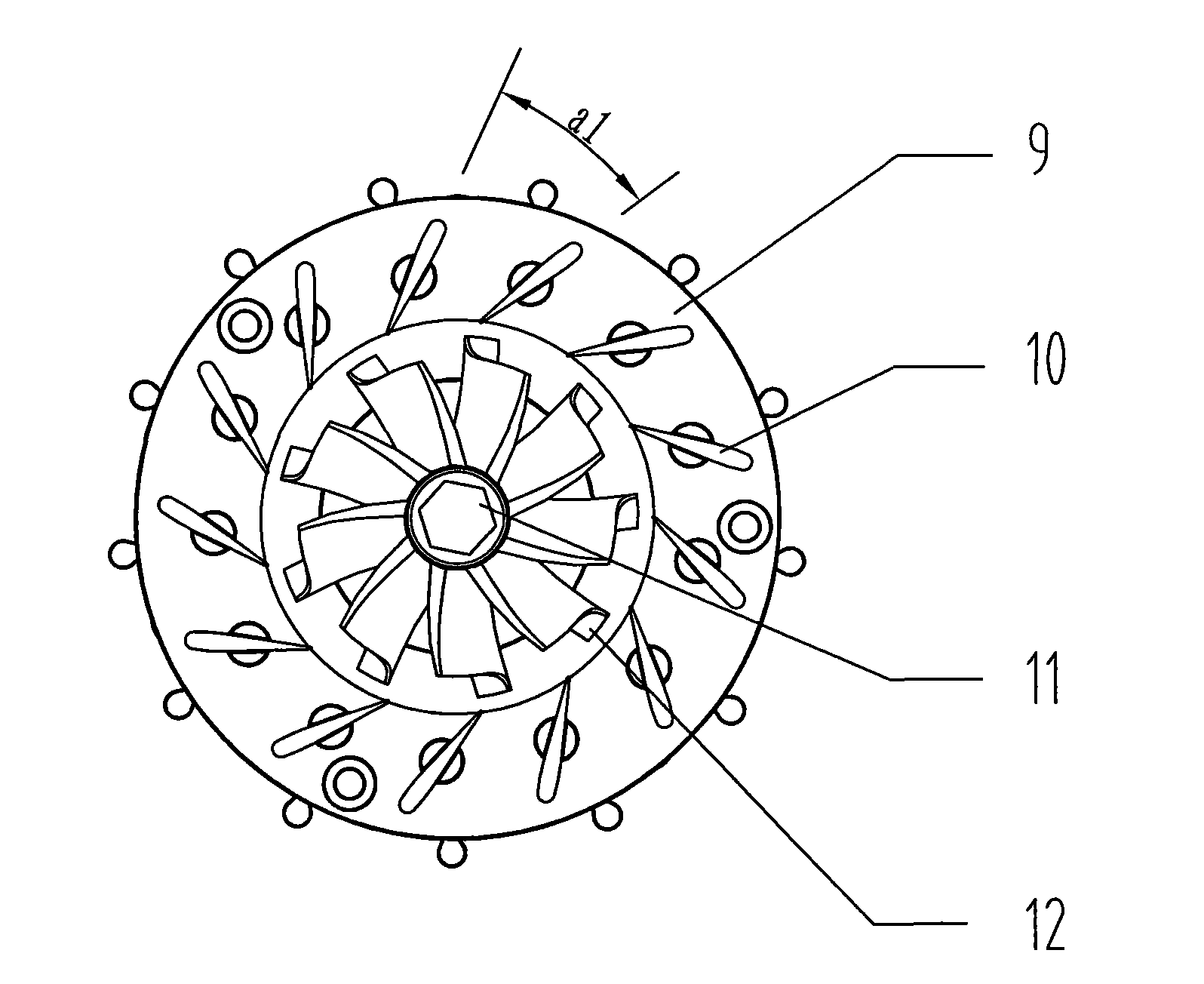

Device for producing coarse titanium tetrachloride by low-temperature fluidizing chlorination

ActiveCN102701274AReduce vibration intensityReduce static pressureTitanium halidesSlagDiffusion resistance

The invention discloses a device for producing coarse titanium tetrachloride by low-temperature fluidizing chlorination. The device comprises a furnace top, a furnace body and a furnace bottom, wherein the furnace bottom is provided with a gas distributor which is communicated with a gas inlet pipe and comprises a chassis and a plurality of gas nozzles uniformly distributed on the chassis; a gas outlet of each gas nozzle is upward; the furnace body is in a straight cylinder shape; the side wall of the furnace body is provided with a charging opening and a slag discharging opening; the charging opening is positioned at the bottom of the furnace body and is arranged opposite to the slag discharging opening; the arrangement position of the slag discharging opening is higher than that of the charging opening; and the vertical distance of the slag discharging opening to the charging opening is 1.2-2.2m. With the adoption of the device, production large scale is easily realized, static pressure and diffusion resistance in the furnace are reduced, the vibration strength of the furnace body is reduced; reverse backmixing of the gas is inhibited, the mass transfer and heat transfer rate are improved, the contact time and contact surface of carbide slag and chlorine are ensured, the transformation rate of TiC is improved; and the device is beneficial to continuous operation of a chlorination furnace and is convenient in manufacturing, transformation and maintenance compared with the traditional chlorination furnace.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

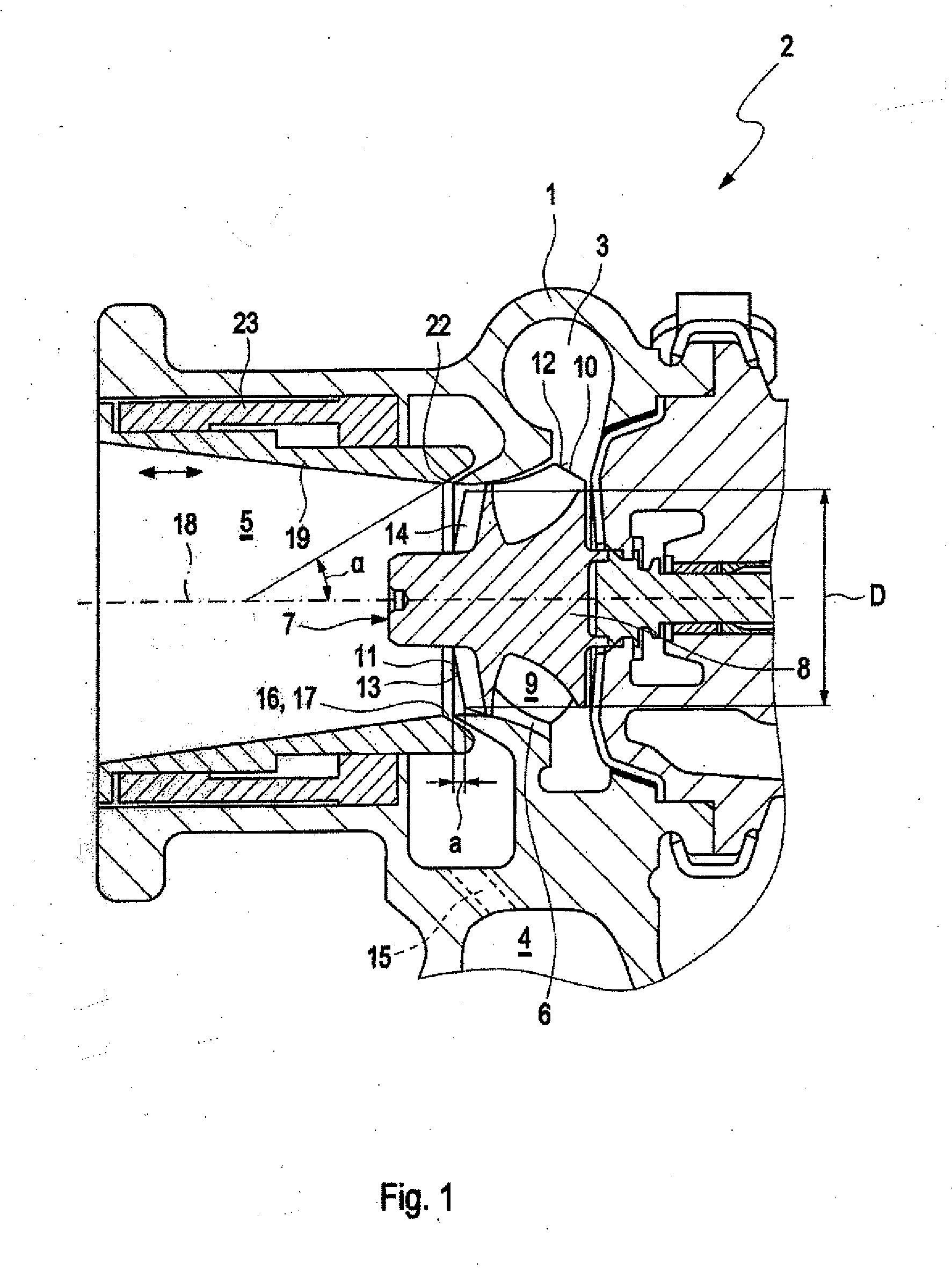

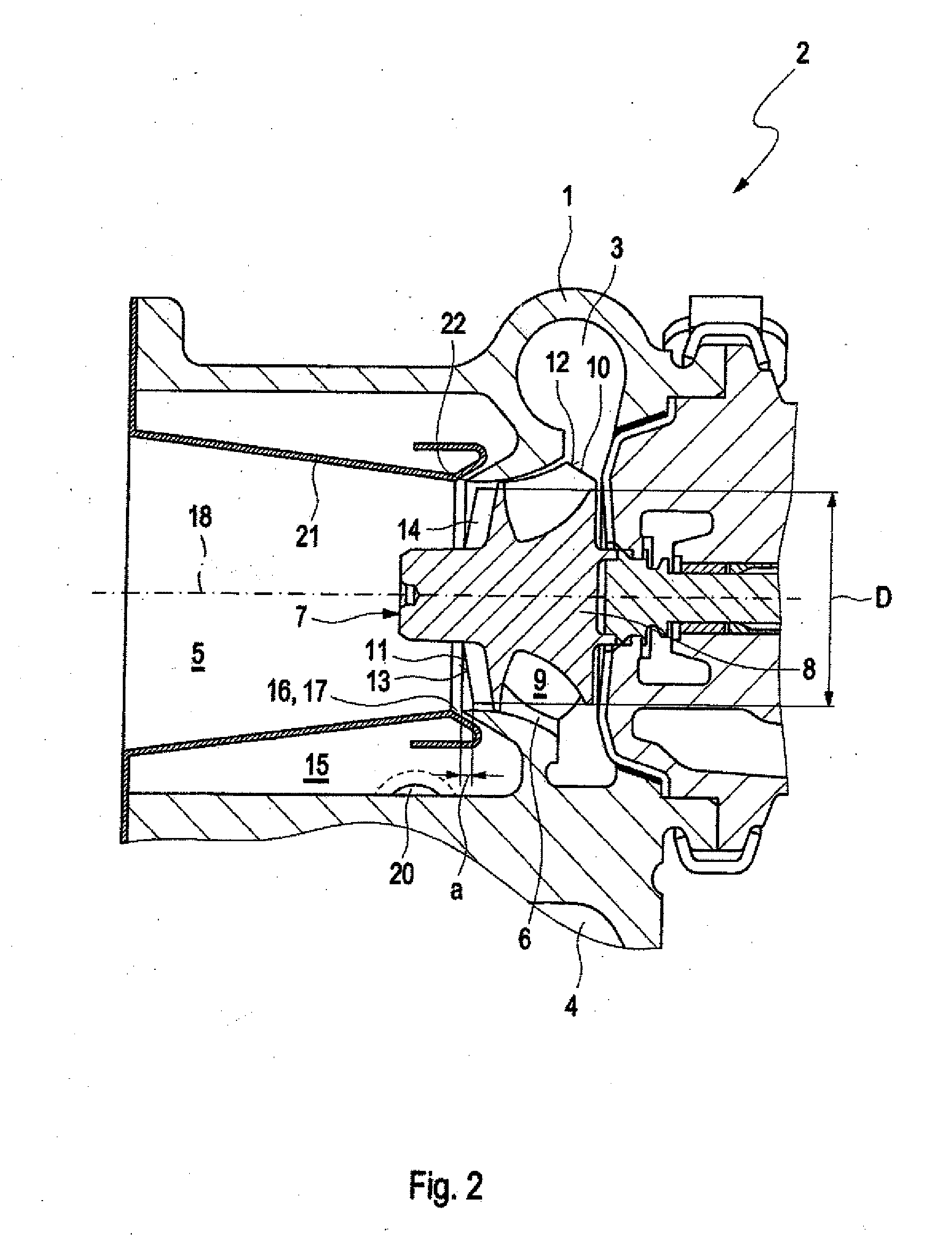

Exhaust gas turbine and method of controlling the turbine

InactiveUS20150240656A1Reduce static pressureReduce pollutant emissionsWind motor controlEngine fuctionsImpellerTurbine wheel

In an exhaust gas turbine with a guide section for the exhaust gas turbine comprising a flow-through duct for conducting exhaust gas through the exhaust gas guide section, wherein the flow-through duct includes a wheel chamber in which a turbine wheel is rotatably supported and wherein, downstream of the wheel chamber, the flow-through duct has an outlet portion and upstream of the wheel chamber, the flow-through duct has an inlet portion with a bypass duct being formed in the exhaust gas guide section for by-passing the wheel chamber, the by-pass duct forms an annular opening adjacent the turbine wheel for directing by-pass exhaust gas into the exhaust gas outlet portion in an annular flow pattern along the outlet portion duct wall.

Owner:IHI CHARGING SYST INT

Poppet valve with diverging-converging flow passage and method to reduce total pressure loss

ActiveUS8136547B2Stabilizing dynamic openingImprove performanceCheck valvesValve members for absorbing fluid energyEngineeringMechanical engineering

A poppet valve is disclosed that include a valve body, a poppet guide disposed inside the valve body so as to form a flow passage from a flow inlet to a flow outlet of the valve, a poppet shutter disposed inside the poppet guide, and a converging-diverging flow passage formed by a portion of an outer surface of the poppet shutter and a corresponding portion of an inner surface of valve body. A method for reducing a closing pressure force acting on a poppet shutter of a poppet valve is also disclosed.

Owner:NUOVO PIGNONE TECH SRL

Asymmetric split turbine of turbocharger

ActiveCN101634244AAddressing High Discharge Pressure RequirementsReduce control difficultyNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

The invention discloses an asymmetric split turbine of a turbocharger, comprising an engine. The engine is provided with an exhaust tube of the engine, a turbine casing and a turbine rotor, wherein, the turbine casing is provided with a casing high pressure flow channel and a casing low pressure flow channel, the exhaust tube of the engine is provided with a high pressure exhaust manifold and a low pressure exhaust manifold, the high pressure exhaust manifold is connected with the casing high pressure flow channel, the low pressure exhaust manifold is connected with the casing low pressure flow channel, and the A / R value of the casing high pressure flow channel is less than that of the casing low pressure flow channel. By adopting the asymmetric split structure, the two flow channels of the turbine casing have different A / R values and are respectively connected with different exhaust pipelines of the engine, thus effectively lowering the exhaust back pressure of part of engine cylinders and reducing the influence of EGR operation process on the pressurizing unit. The asymmetric split turbine has good succession, simple structure, easy upgrade and switch of products, low cost and easy and fast realization of engineering.

Owner:康跃科技(山东)有限公司

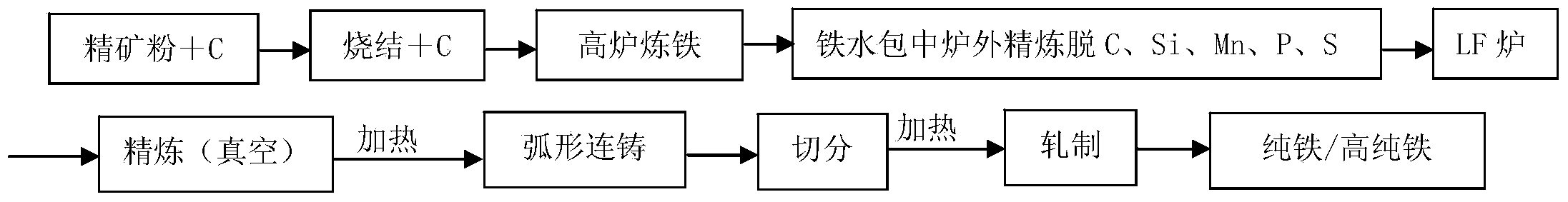

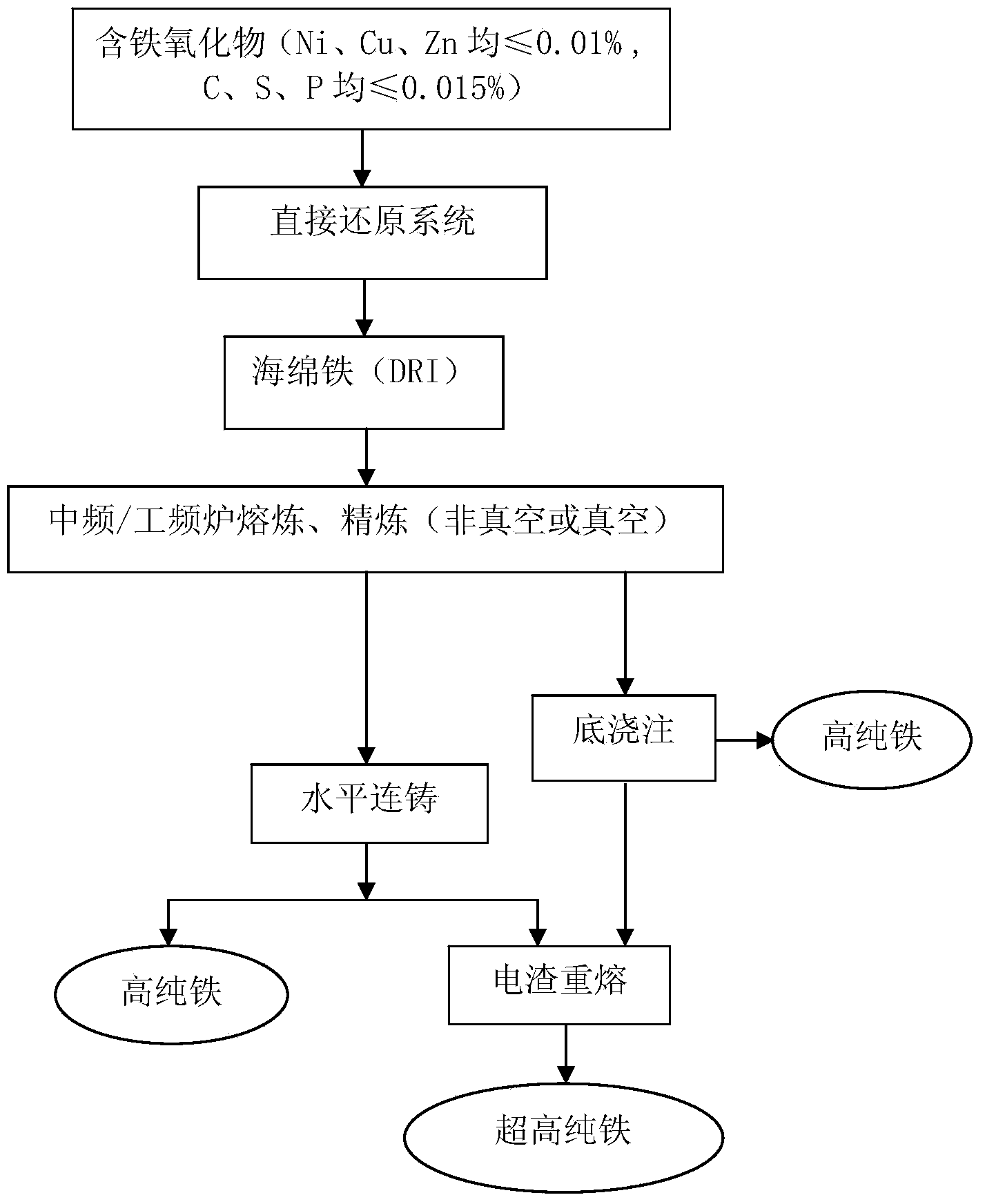

Method for producing high-purity pure iron

ActiveCN104141024AExtend your lifeUniform temperatureIncreasing energy efficiencyBrown iron oxideControl mode

The invention relates to a method for producing high-purity pure iron. The method includes the following steps: iron oxide is reduced in a layered-control mode through a direct-reduction system to manufacture sponge iron; the sponge iron is added into a medium-frequency or power-frequency induction furnace for smelting, and composite slag forming constituents are added in batches; after smelting and slagging-off are conducted, composite slag forming constituents are added, argon-oxygen mixed gas bottom blowing is carried out on the medium-frequency or power-frequency induction furnace through porous bricks at the bottom, blowing of the mixed gas is stopped when the temperature of molten steel reaches 1620 DEG C to 1650 DEG C, standing is carried out on the molten steel for 25 minutes to 35 minutes, then slagging-off is conducted, a proper amount of aluminum is added into the molten steel for 1 minute to 2 minutes, argon bottom blowing is carried out through the air bricks at the bottom of the induction furnace at the moment, and stopped when the temperature is continuously raised to range from 1640 DEG C to 1680 DEG C, horizontal continuous casting or bottom casting is conducted after standing is conducted on the molten steel for 15 minutes, and the low-impurity pure iron with the iron content larger than 99.9% is obtained, wherein the contents of more than twenty elements are all smaller than 0.01%. Meanwhile, the pure iron with the higher purity can be produced through vacuum refining or electroslag remelting. By means of the method, the flow path is short, devices are simple, and investment is saved.

Owner:武汉桂坤科技有限公司

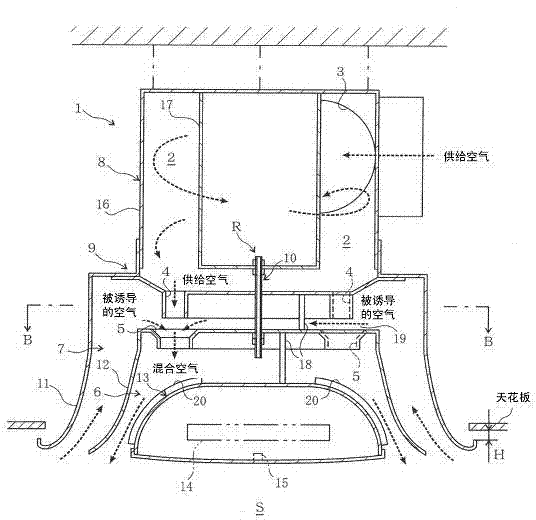

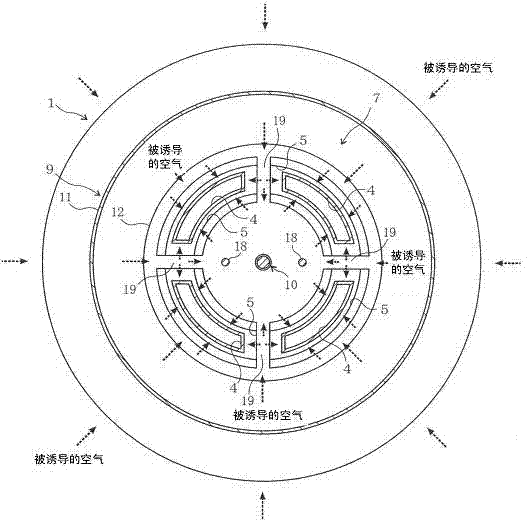

Induction blow-out vent

ActiveCN102374624AIncrease reachReduce static pressureDucting arrangementsCondensate preventionInjection airWaste management

Owner:KIMURA KOHKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com