Induction blow-out vent

A technology of air outlet and ejection outlet, which is applied in the field of inductive air outlet to achieve the effects of easy manufacture, low static pressure, and elimination of uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

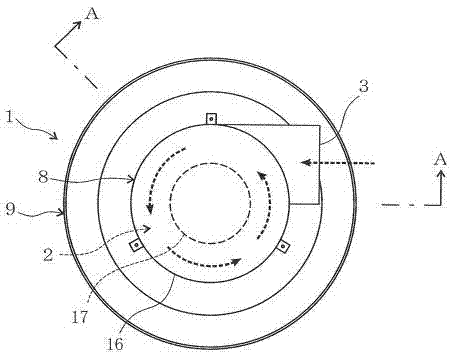

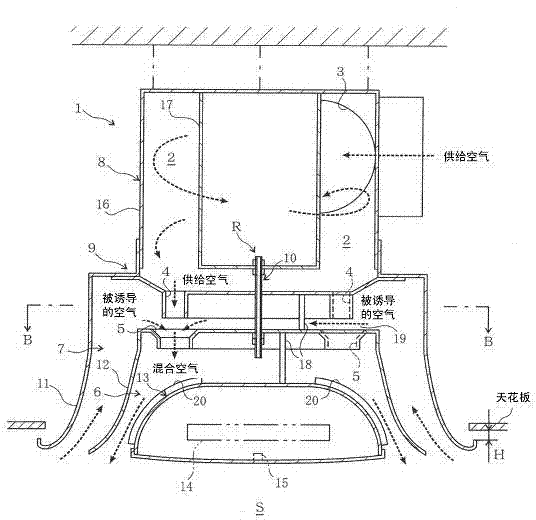

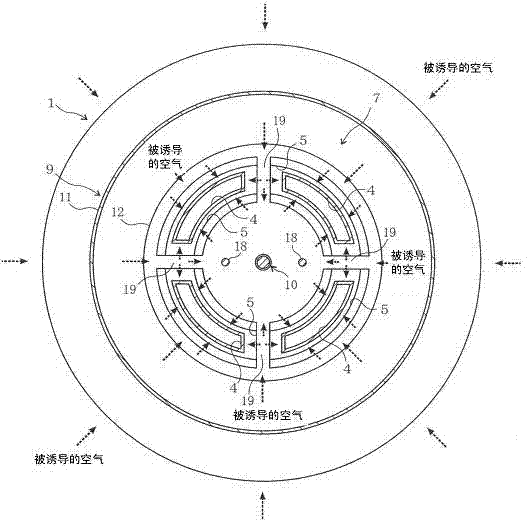

[0044] Figure 1 to Figure 5 An example of the induction air outlet of the present invention is shown. The induction air outlet is provided with a main body 1 that induces the air in the air-conditioned space S to be mixed with the supply air sent in from the outside, and blows the mixed air to the air-conditioned space S. . The main body 1 is composed of a supply air introduction part 8 having a partition part 2 , and an outlet part 9 having an air outlet 4 , an induction port 5 , a mixed air outlet duct 6 , and an induction duct 7 . The air-conditioned space S is a space such as a room or a hall of various buildings such as an office building, a hospital, and a restaurant. An induction air outlet is provided on the ceiling or the like of the air-conditioned space S. As shown in FIG. Air-conditioning air and the like are supplied to the induction outlet through ducts and the like from an air conditioner (not shown). In addition, the dashed-line thick arrows in each drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com