Electromagnetic induction heating type powder vibrating vacuum thermoforming device and method

A technology of electromagnetic induction heating and vacuum hot pressing, applied in the field of powder metallurgy and ceramic product production, can solve the problems of complex hot pressing sintering equipment, increase production cost, low heating efficiency, etc., to improve manufacturing capacity and mold service life, reduce Static pressure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

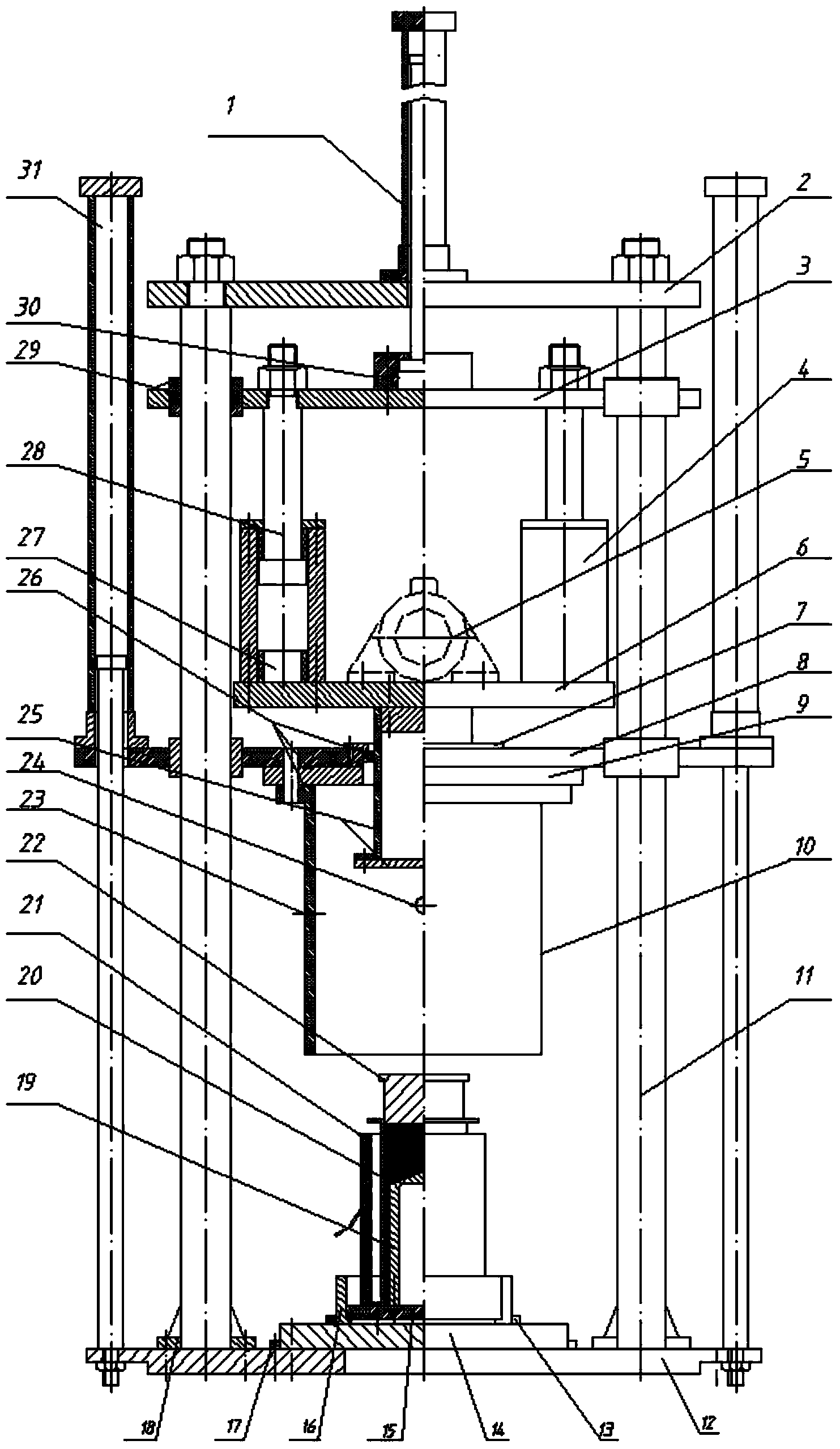

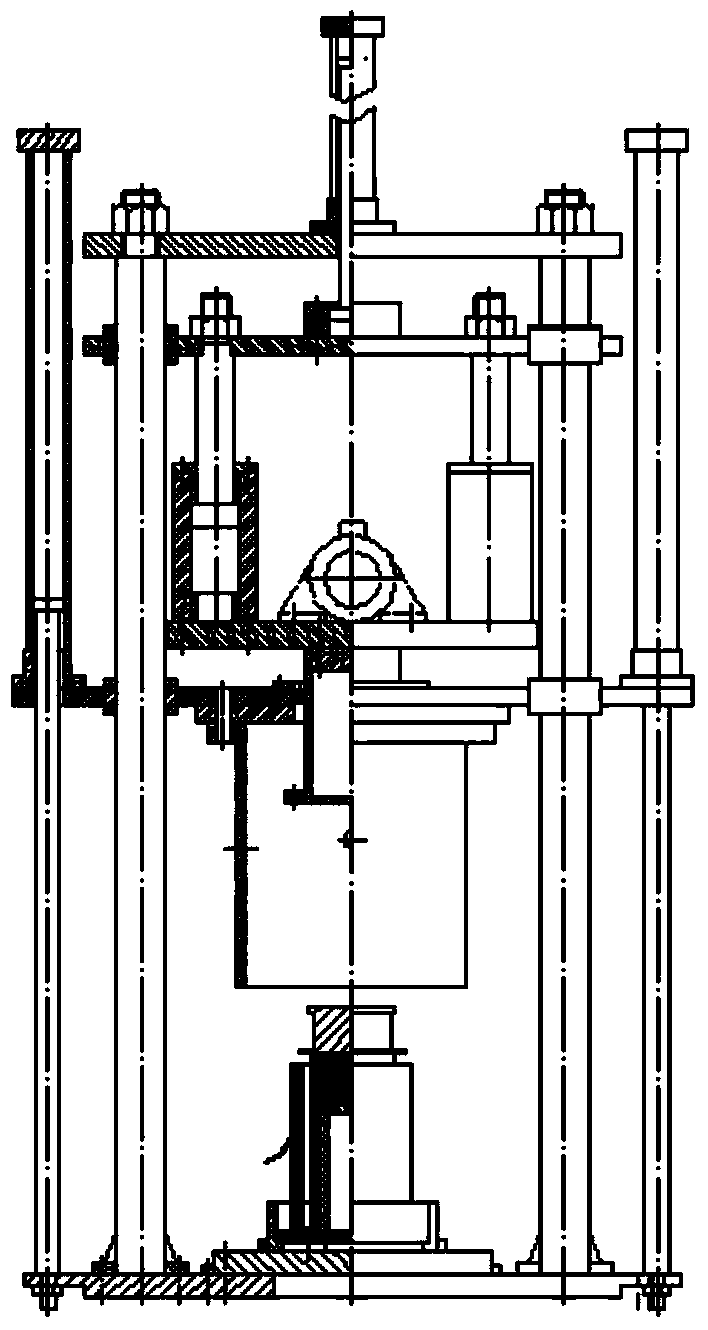

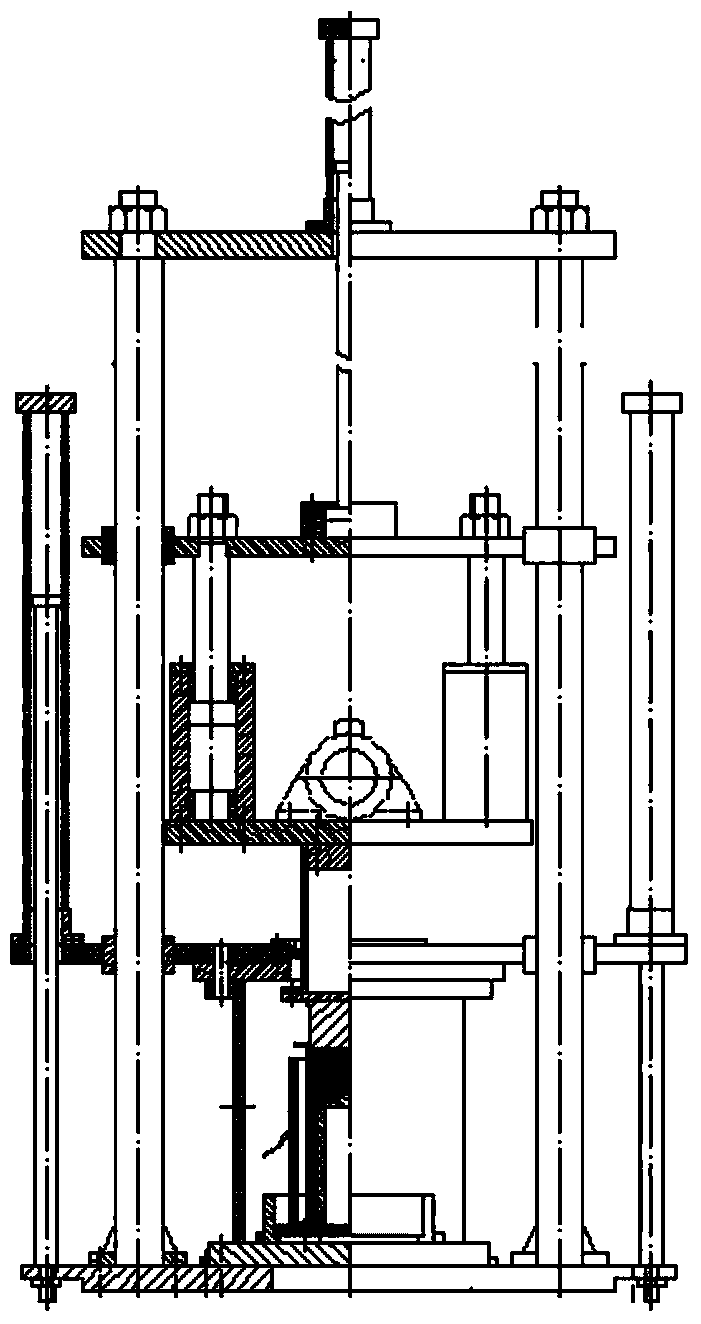

[0028] figure 1 As shown, this example is an electromagnetic induction heating type powder vibration vacuum hot pressing forming device to form an annular cylindrical compact.

[0029]An electromagnetic induction heating type powder vibration vacuum hot pressing forming device includes: a fuselage frame, an air pumping sealing mechanism, a vibration loading and buffering mechanism, a static load loading mechanism, an electromagnetic induction heating part, a mold assembly, a vibrating pressure head and a mechanism cooling part . During work, the vacuum pump passes through the vacuum pump connection block 24 on one side of the sealing frame 10, so that the mold assembly, electromagnetic induction heating coil 21, and vibrating pressure head 25 are placed in the vacuum environment in the sealing frame 10, and each component in the sealing fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com