Patents

Literature

3696results about How to "Heating up fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

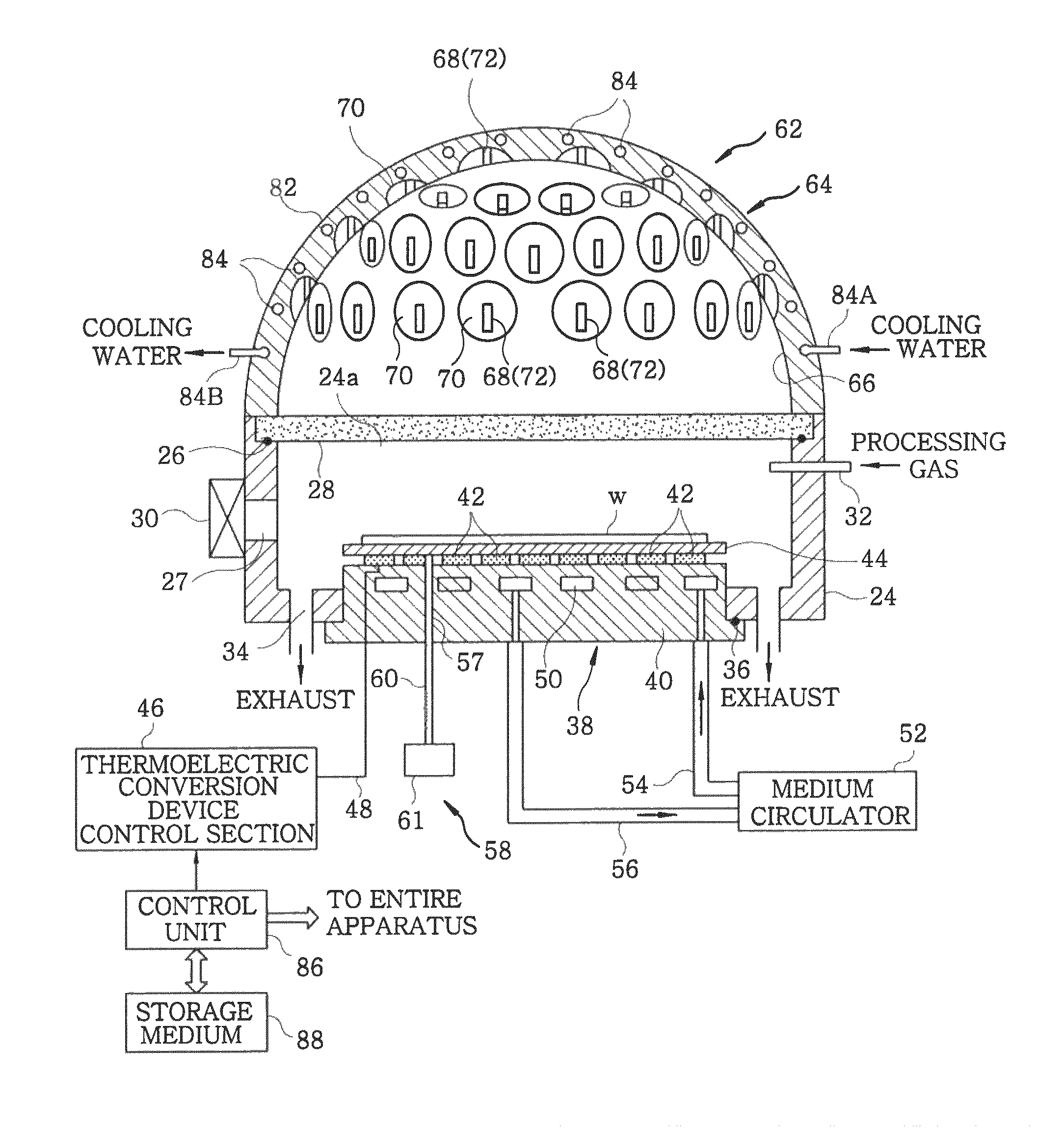

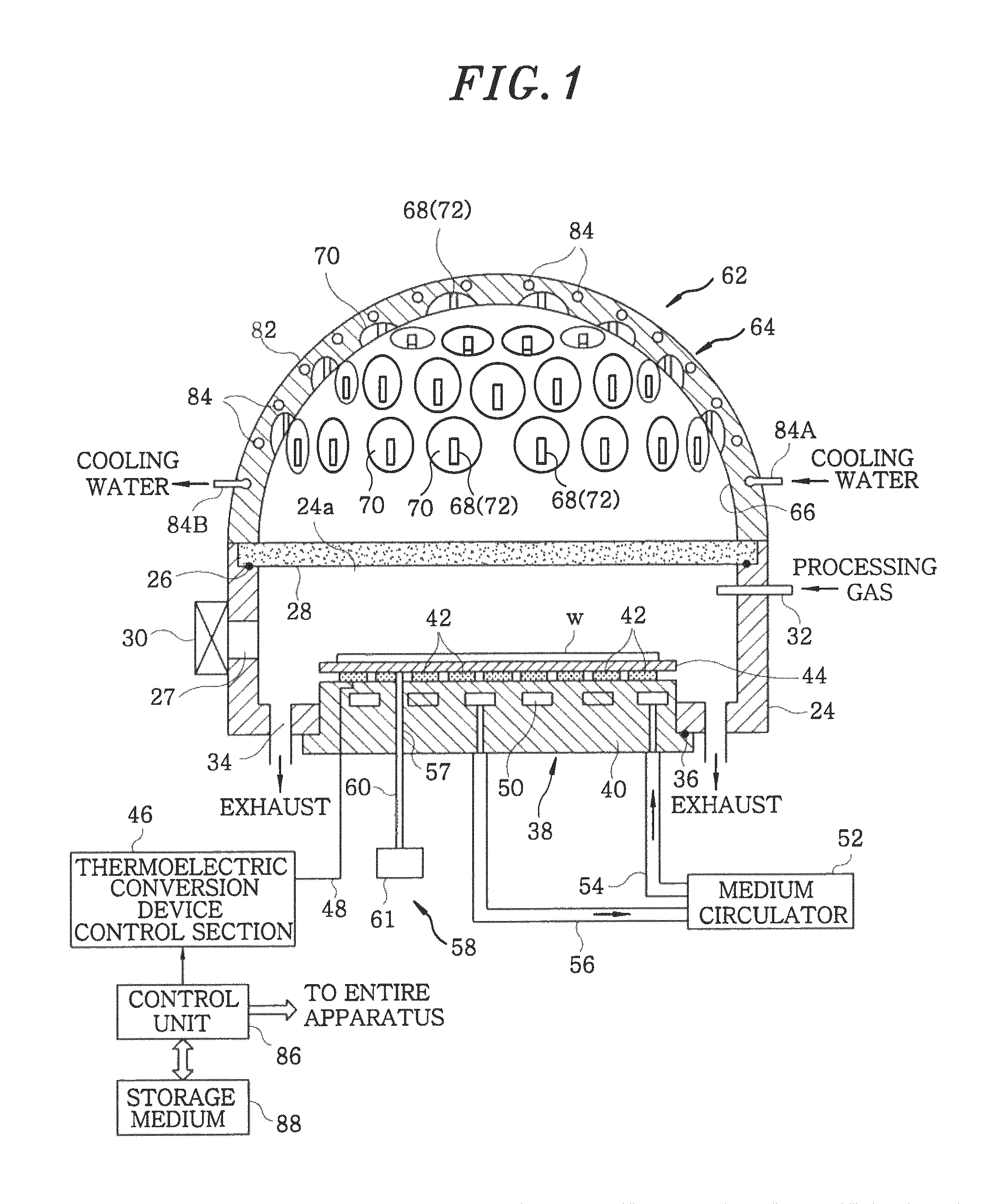

Heating apparatus, heat treatment apparatus, computer program and storage medium

ActiveUS8041197B2Efficient solutionRapidly heating up and coolingDomestic stoves or rangesDrying solid materials with heatLength waveSemiconductor

A heating apparatus for heating a target object W is provided with a plurality of heating light sources, including LED elements for applying heating light having a wavelength within a range from 360 to 520 nm to the object. Thus, a temperature of only the shallow surface of the object, such as a semiconductor wafer, is increased / reduced at a high speed in uniform temperature distribution, irrespective of the film type.

Owner:TOKYO ELECTRON LTD

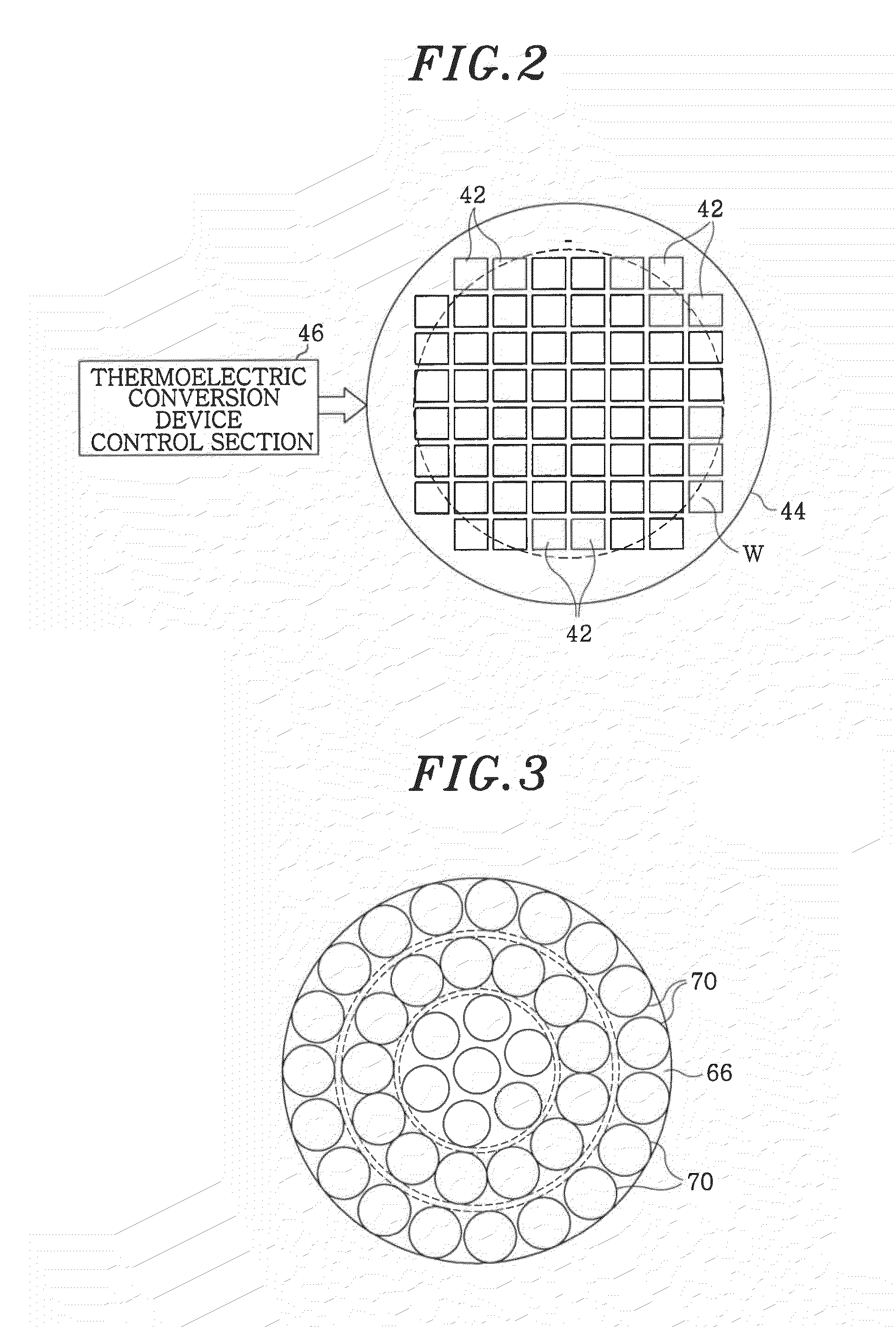

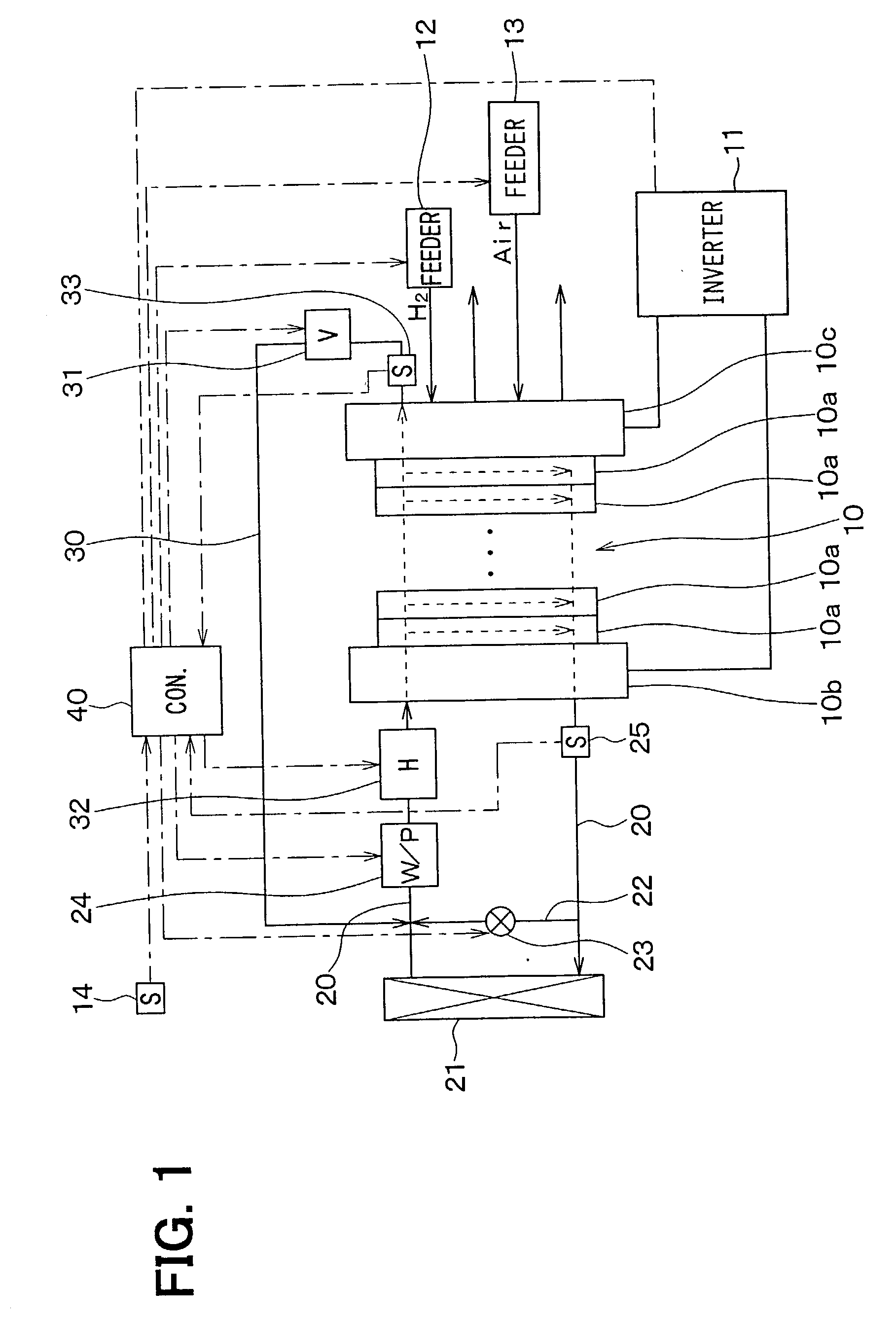

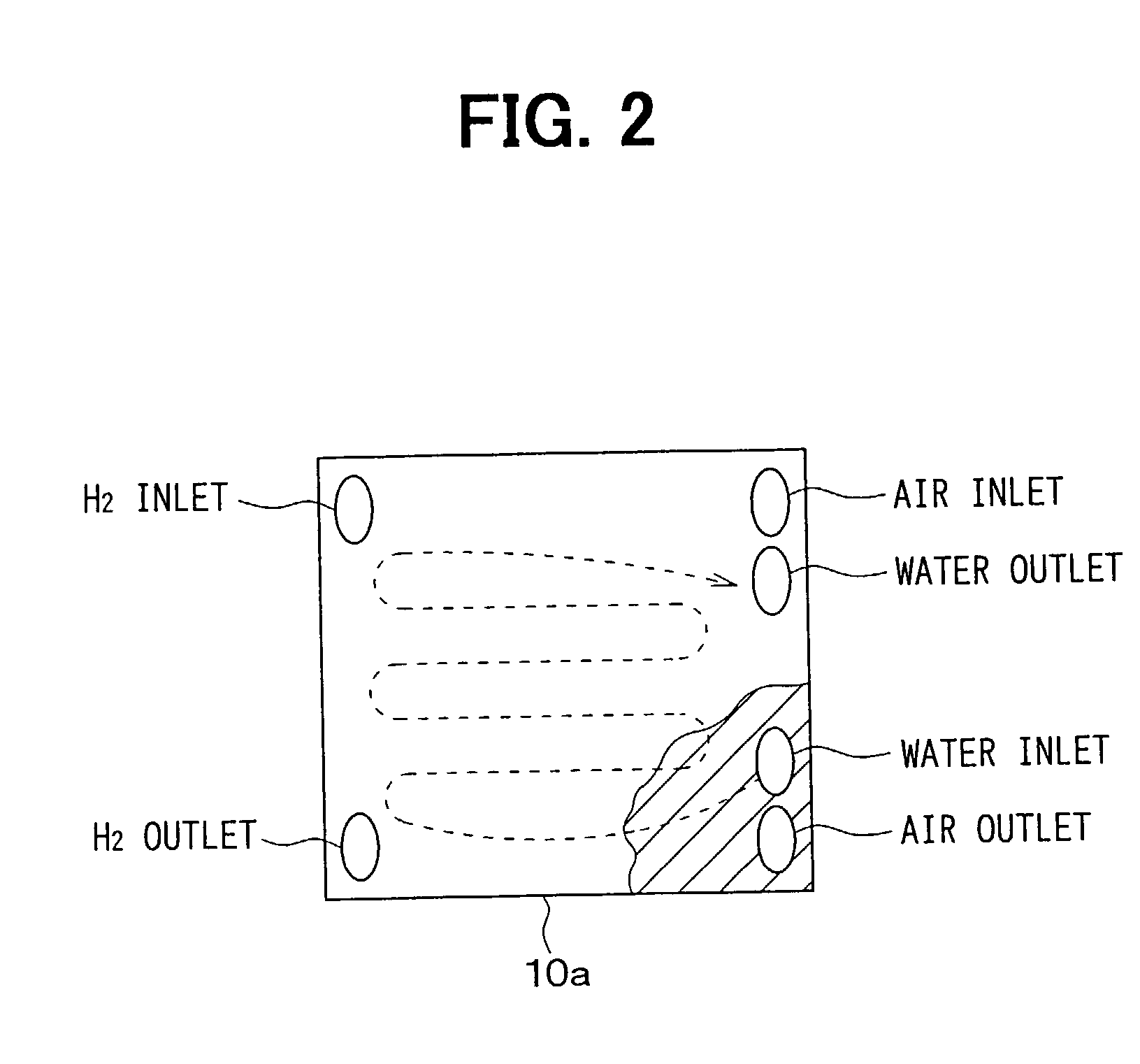

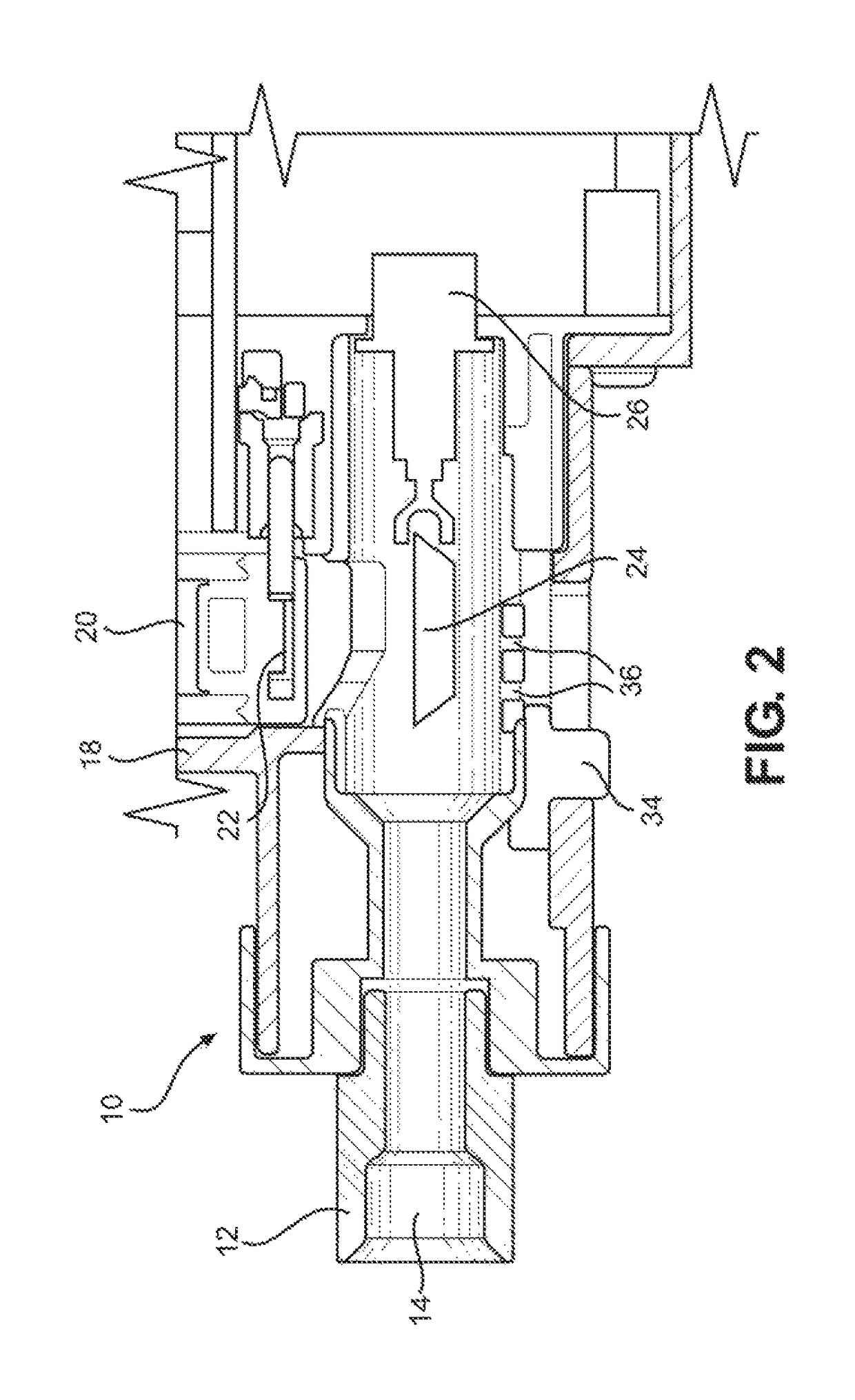

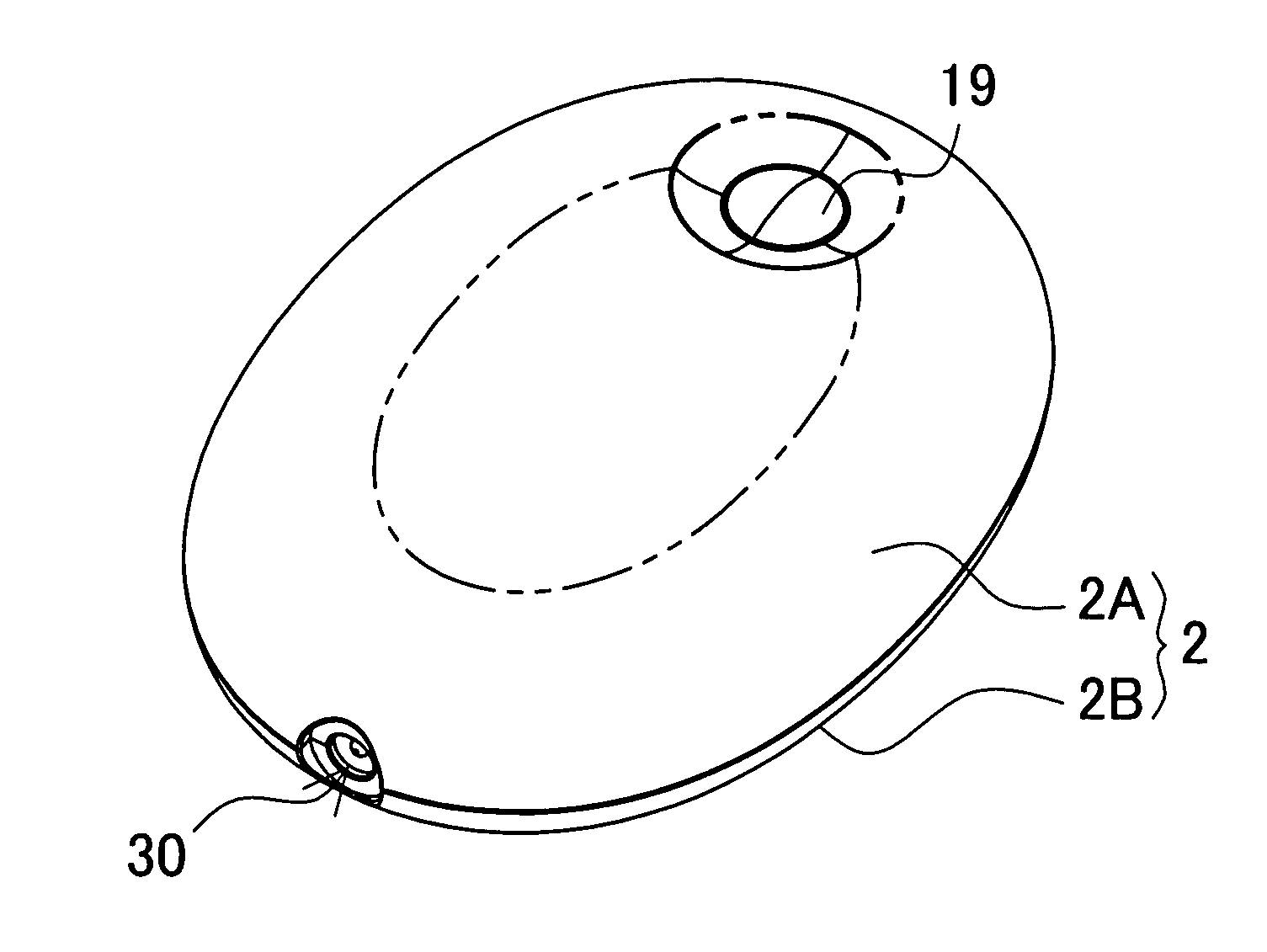

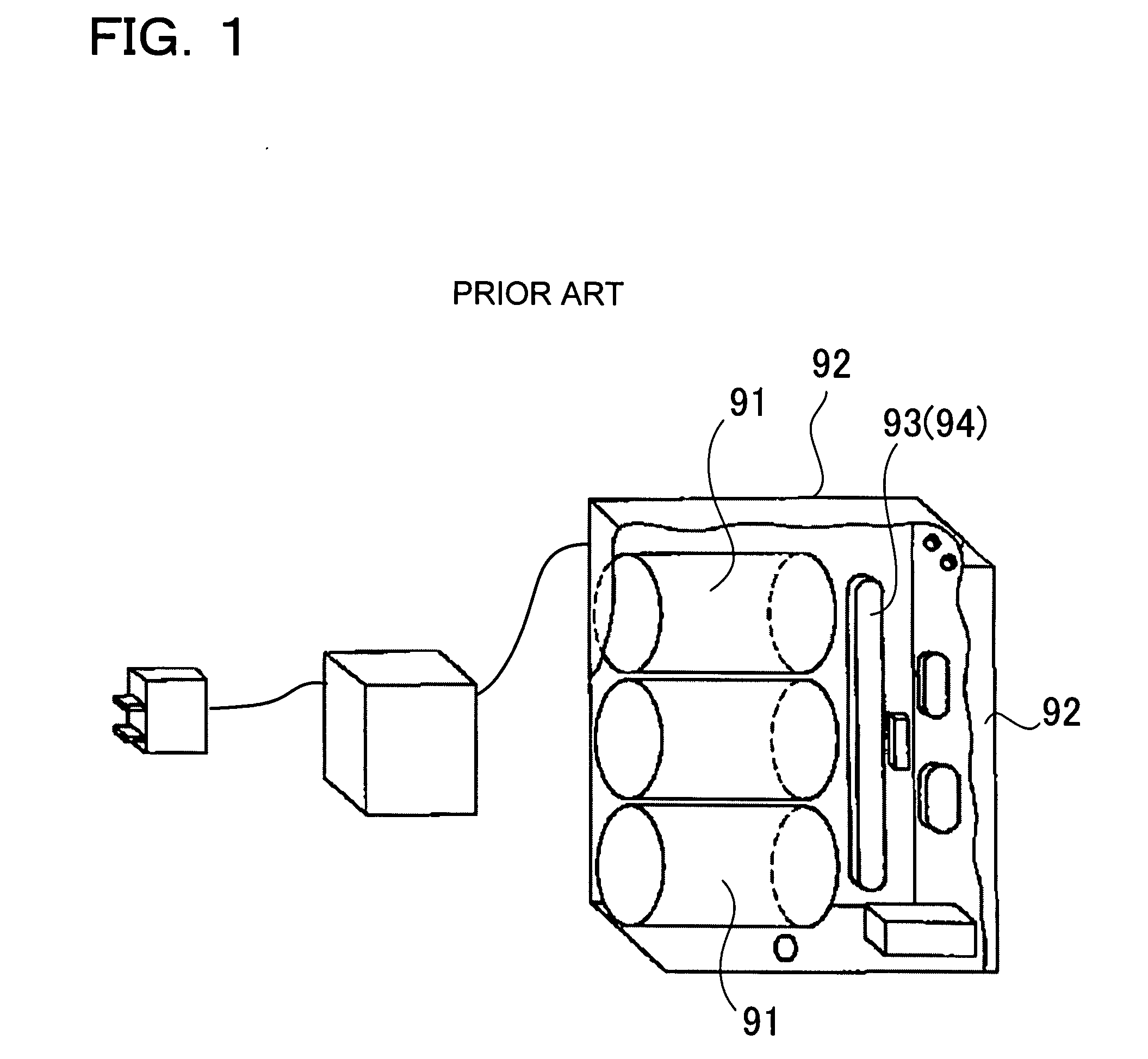

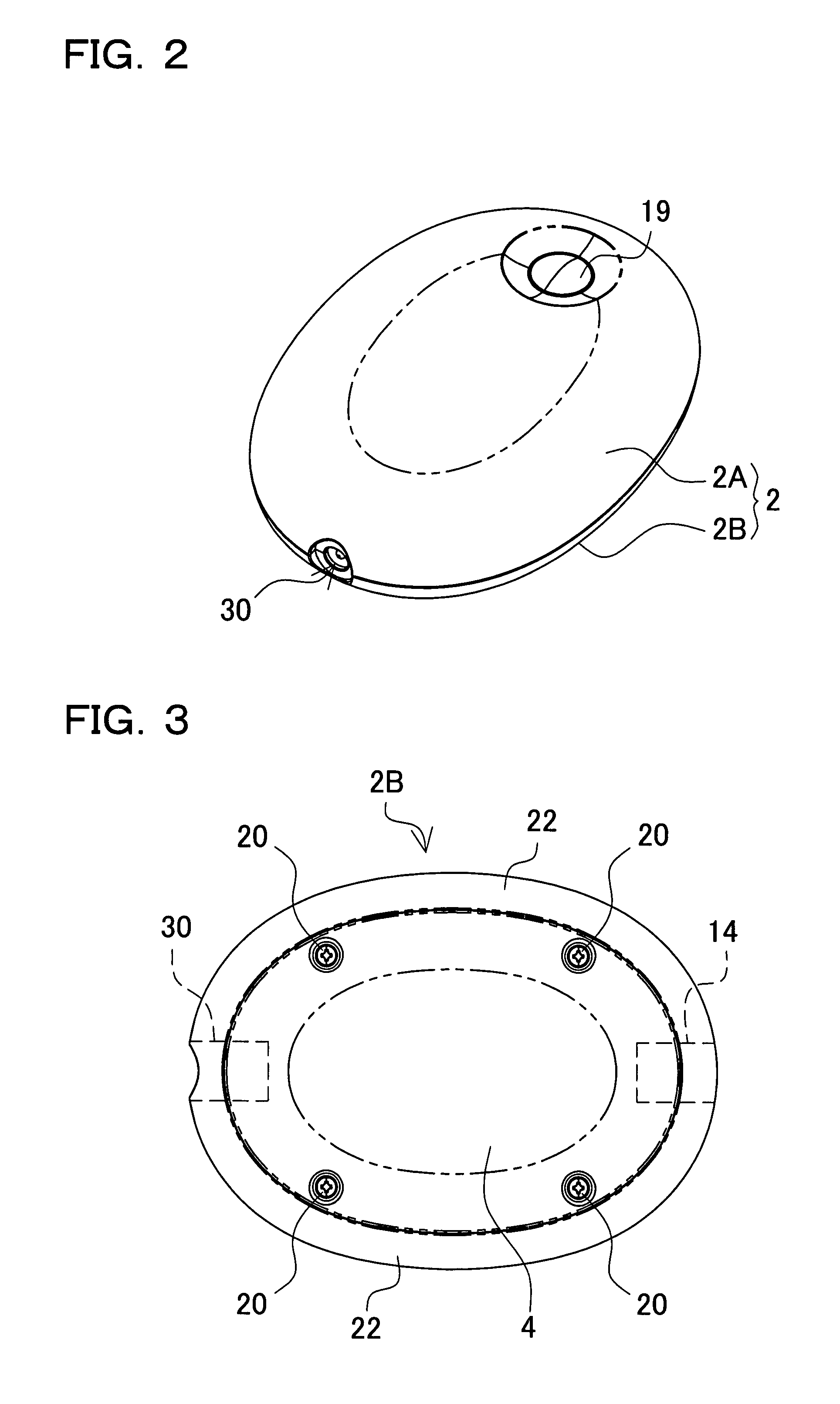

Fuel cell system

InactiveUS20030031905A1Small sizeHeating up fastFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell system includes a fuel cell constructed by plural stacked cells, a circulation path through which a thermal medium is circulated into each cell, a heater for heating the thermal medium, a bypass path through which the thermal medium is circulated into a part of each cell while bypassing the other part thereof, and a flow control valve for controlling a flow amount of the thermal medium circulated in the bypass path. The thermal medium can be circulated into only the part of each cell in a warm-up operation, so that the part of each cell is collectively heated. An amount of the thermal medium circulated into the other part of each cell is controlled, so that all of each cell is finally warmed up in the warm-up operation.

Owner:DENSO CORP

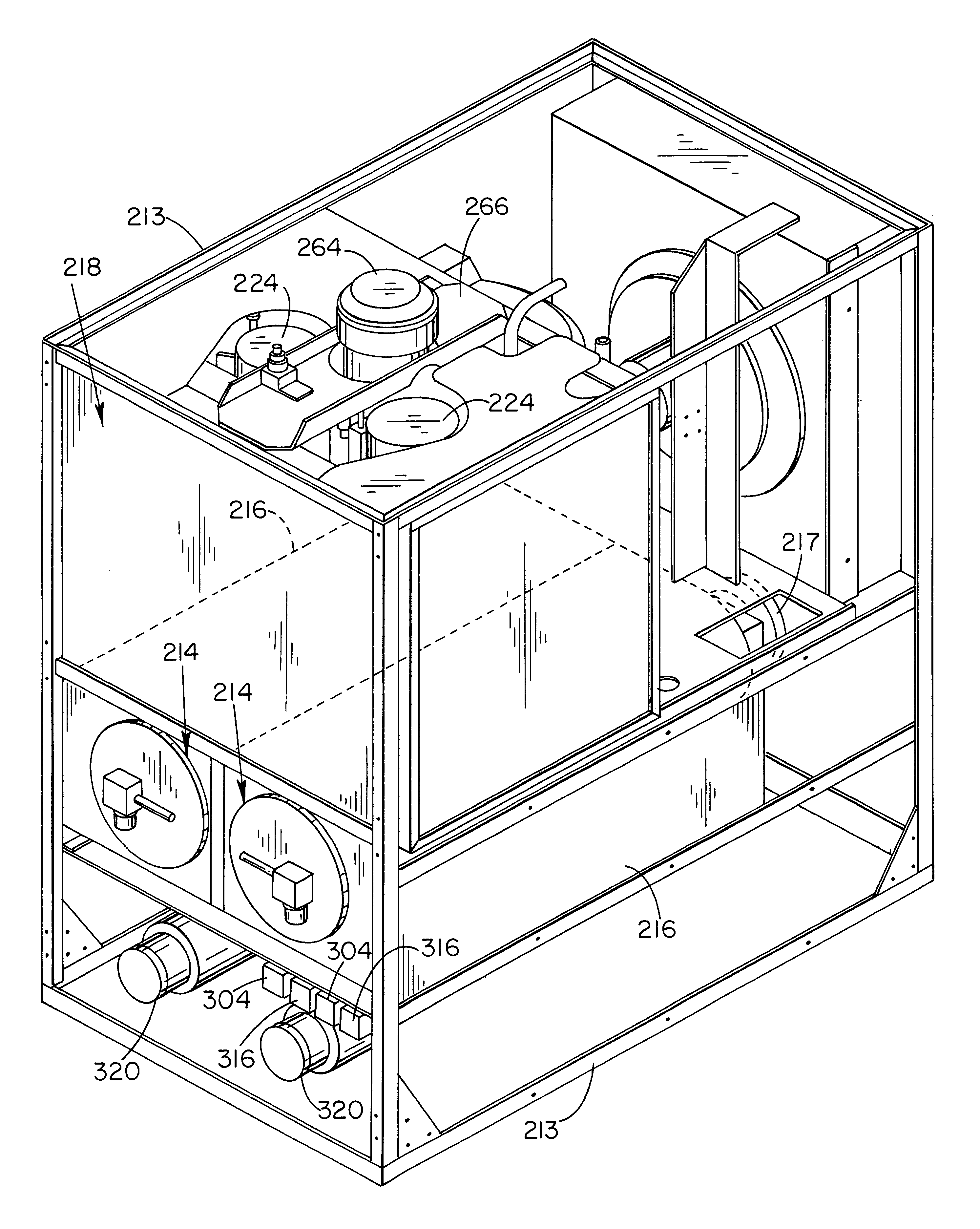

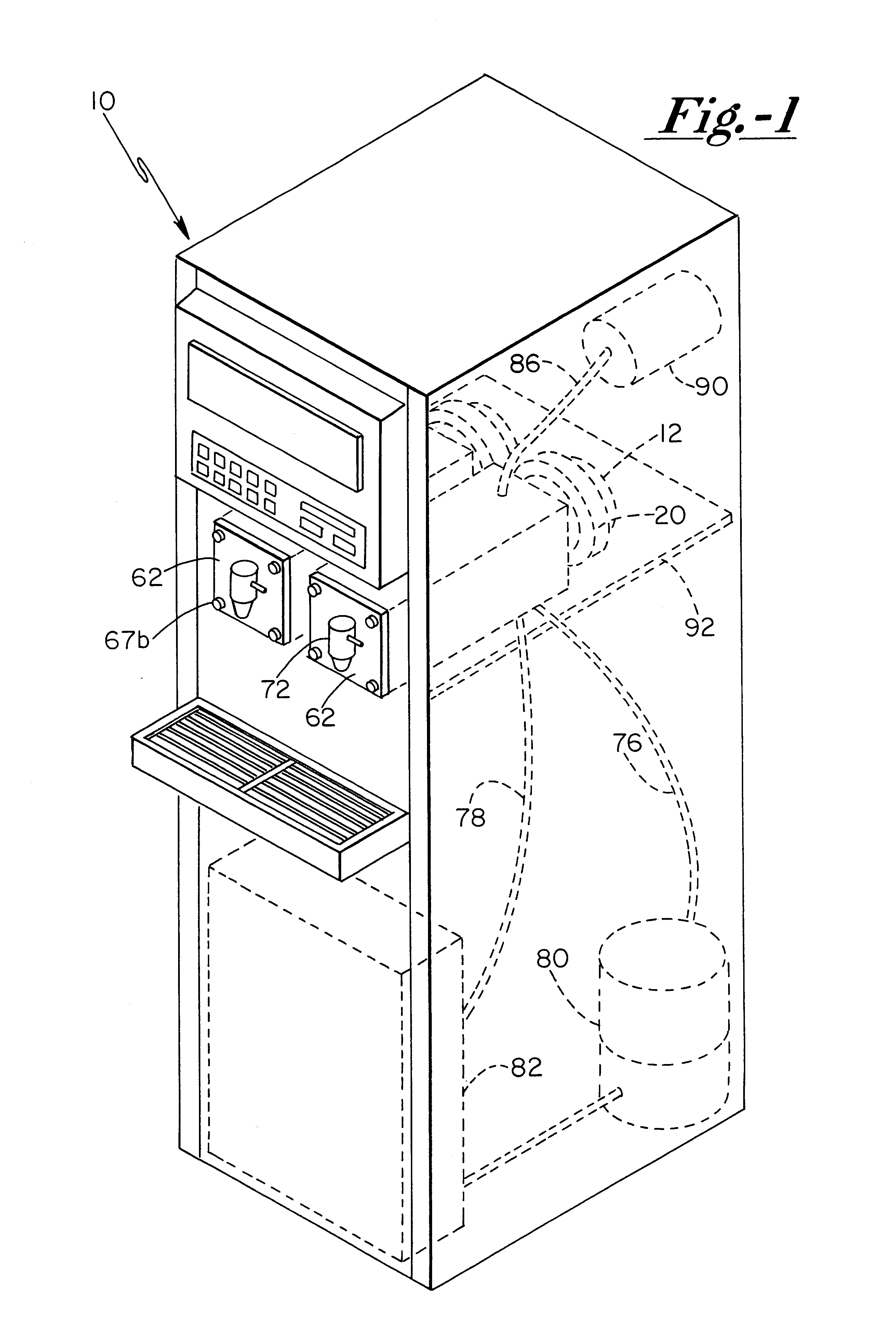

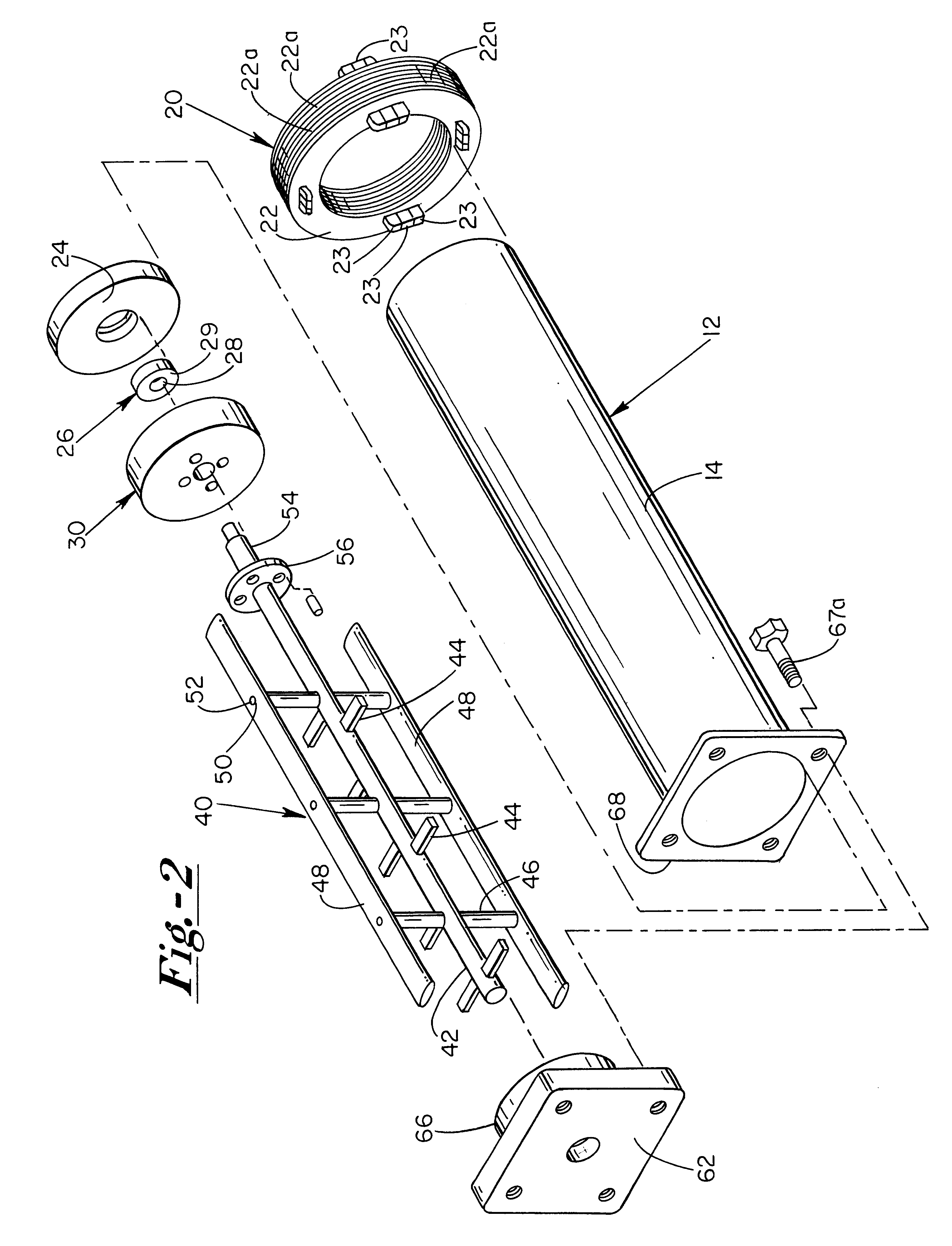

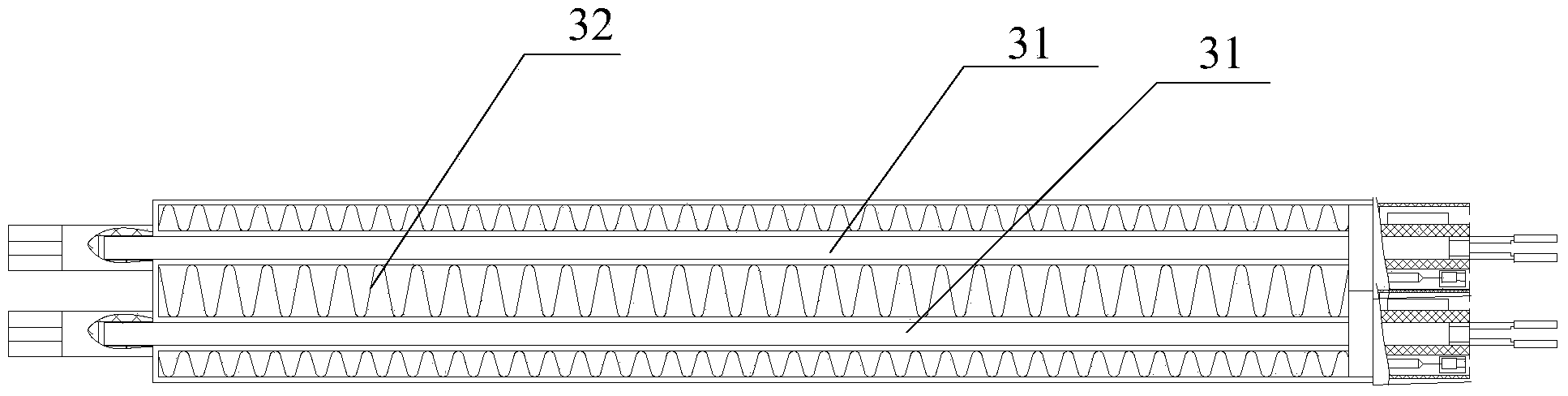

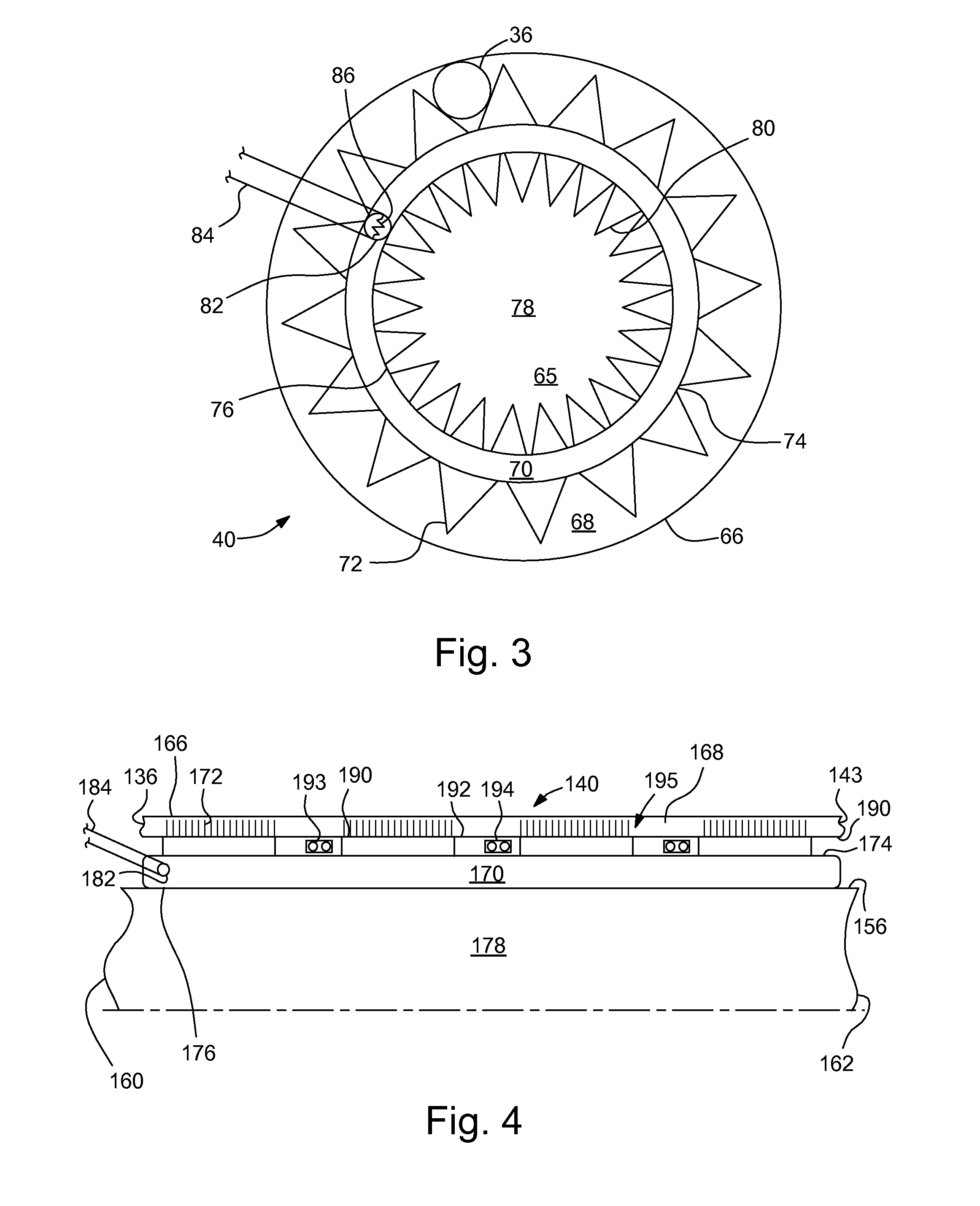

Semi-frozen food product producing machine

InactiveUS6220047B1Low viscosityShort cycleMagnetic circuit rotating partsDomestic cooling apparatusCarbon dioxideCooling power

The present invention includes a dual purpose carbonator / blending bottle connected to a source of beverage syrup, a source of potable water and to a source of pressurized carbon dioxide gas. The dual purpose bottle is retained within an ice bank water bath tank. A pair of ratio valves provide for metering the water and syrup at a desired ratio. The mixed beverage first flows through a serpentine coil, also located in water bath, and then flow into the dual purpose bottle. A refrigeration system provides for cooling an evaporator located in the water tank for forming the ice bank thereon. The carbonated beverage then flows from the bottle into a freeze cylinder. The freeze cylinder also includes a further evaporator coiled around an exterior perimeter thereof. The freeze cylinder evaporator is connected to and cooled by the same refrigeration system that cools the evaporator in the water bath tank. A scraping mechanism within the cylinder provides for scraping frozen beverage from the inner surface of the cylinder. A control mechanism provides for controlling the refrigeration system and the cooling of both evaporators. The beverage is therefore pre-cooled to a temperature just above its freezing point before delivery to the freeze cylinder. Thus, less cooling power is needed to reduce the beverage to a frozen state. The present invention utilizes a method of controlling the operation of the refrigeration system and the cooling of both evaporators thereof. The control system provides for directing refrigerant to one or the other of the evaporators as is most efficient so as to avoid short cycling or pressure build up. The present invention uses a control strategy that can more accurately maintain a pre-selected temperature differential between the inlet and outlet temperatures of the evaporators. The control algorithm utilizes a proportional integral differential control approach that safely permits a much narrower temperature difference so that a greater length of each freeze cylinder evaporator can be utilized for efficient heat transfer cooling.

Owner:CORNELIUS INC

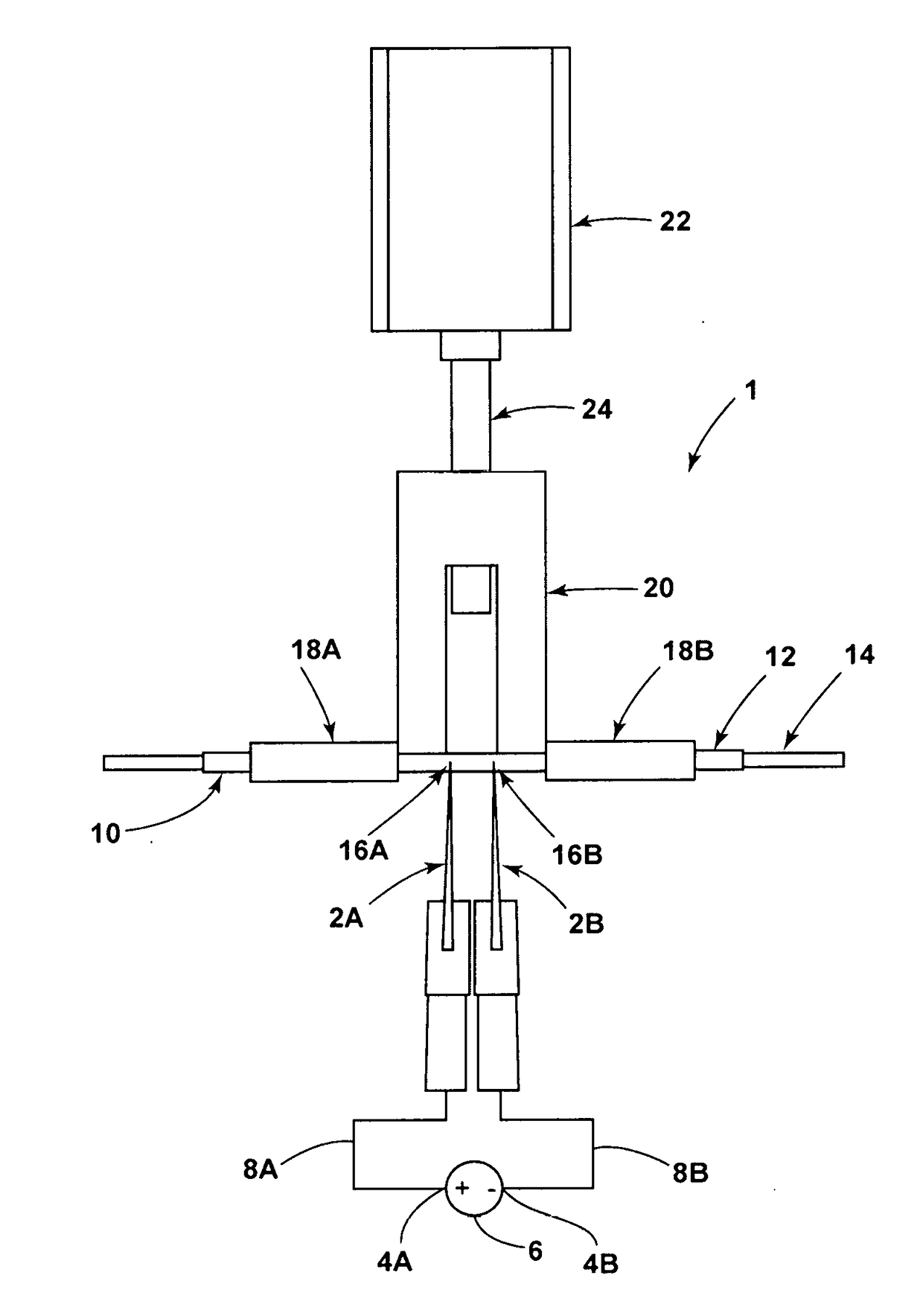

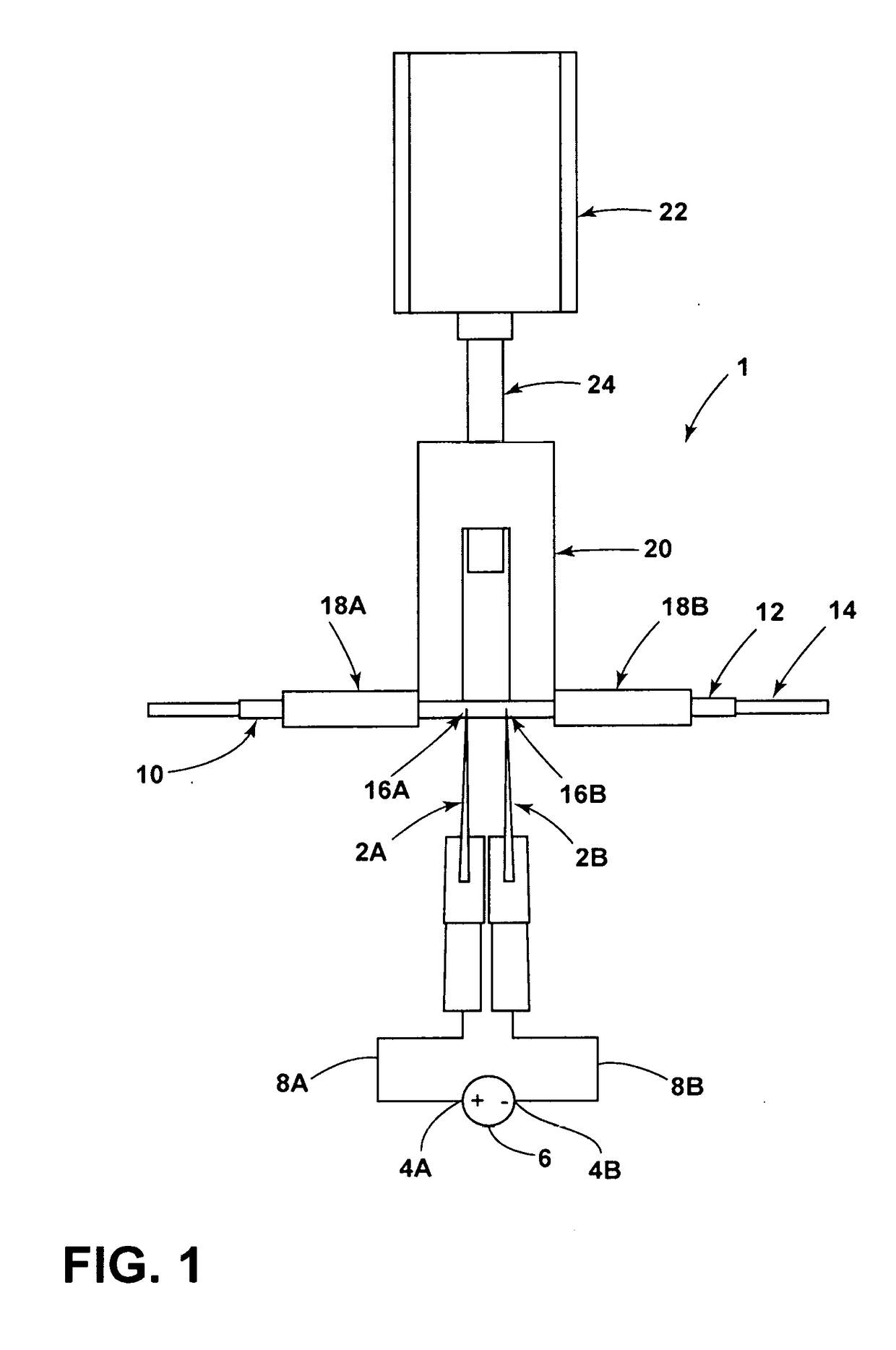

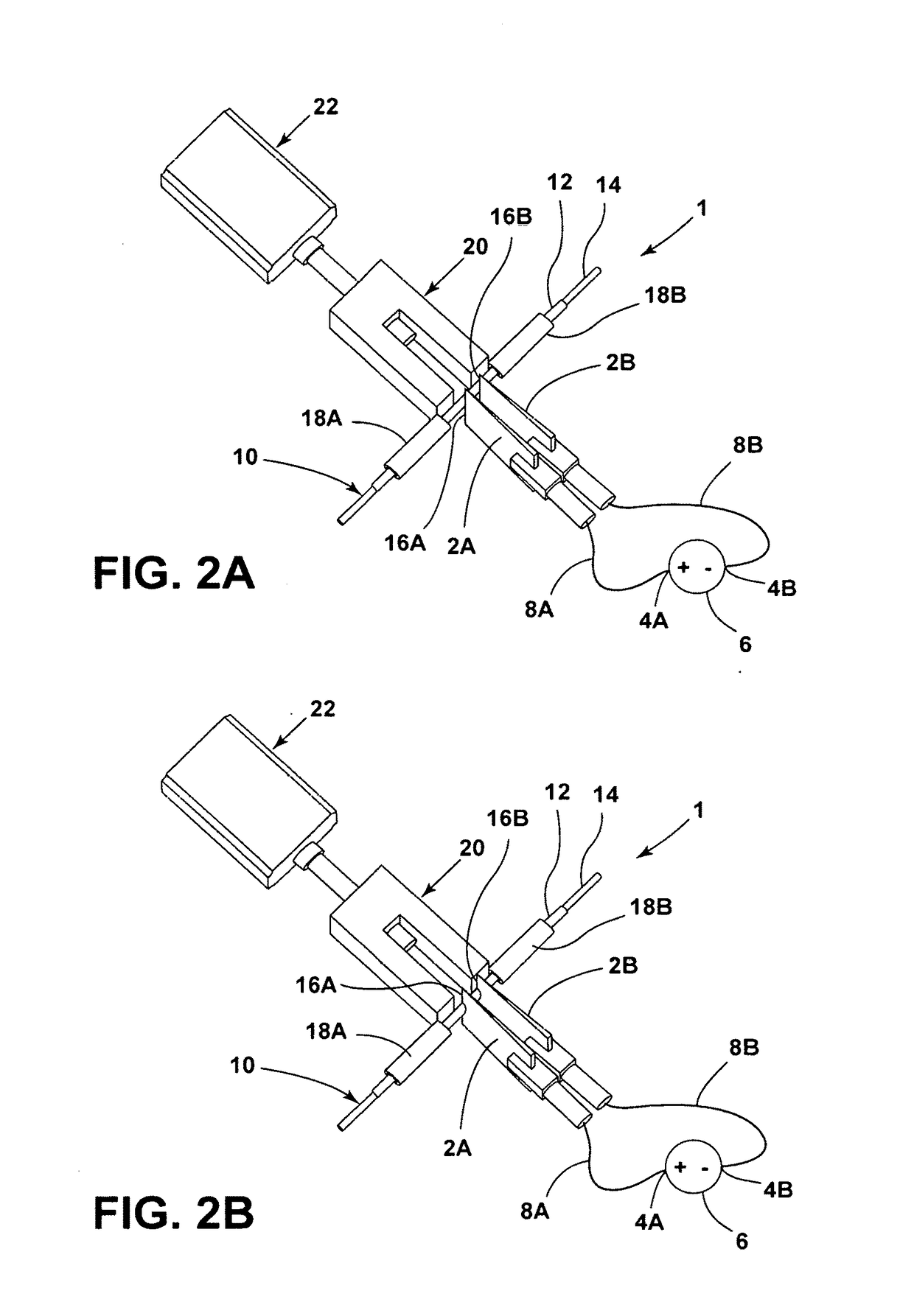

Cutting mechanism for carbon nanotube yarns, tapes, sheets and polymer composites thereof

ActiveUS20170129182A1Easy to cutRobust cutting method3D object support structuresManufacturing data aquisition/processingPower flowCarbon nanotube yarn

A cutting mechanism includes electrodes that are utilized to cut or score a non-conductive outer material of a filament or sheet. The electrodes contact a conductive reinforcing material of the filament or sheet to complete an electric circuit. Electric current flows through and heats the conductive material to oxidize or otherwise separate / cut the conductive material and any remaining non-conductive material.

Owner:NAT INST AEROSPACE ASSOC +1

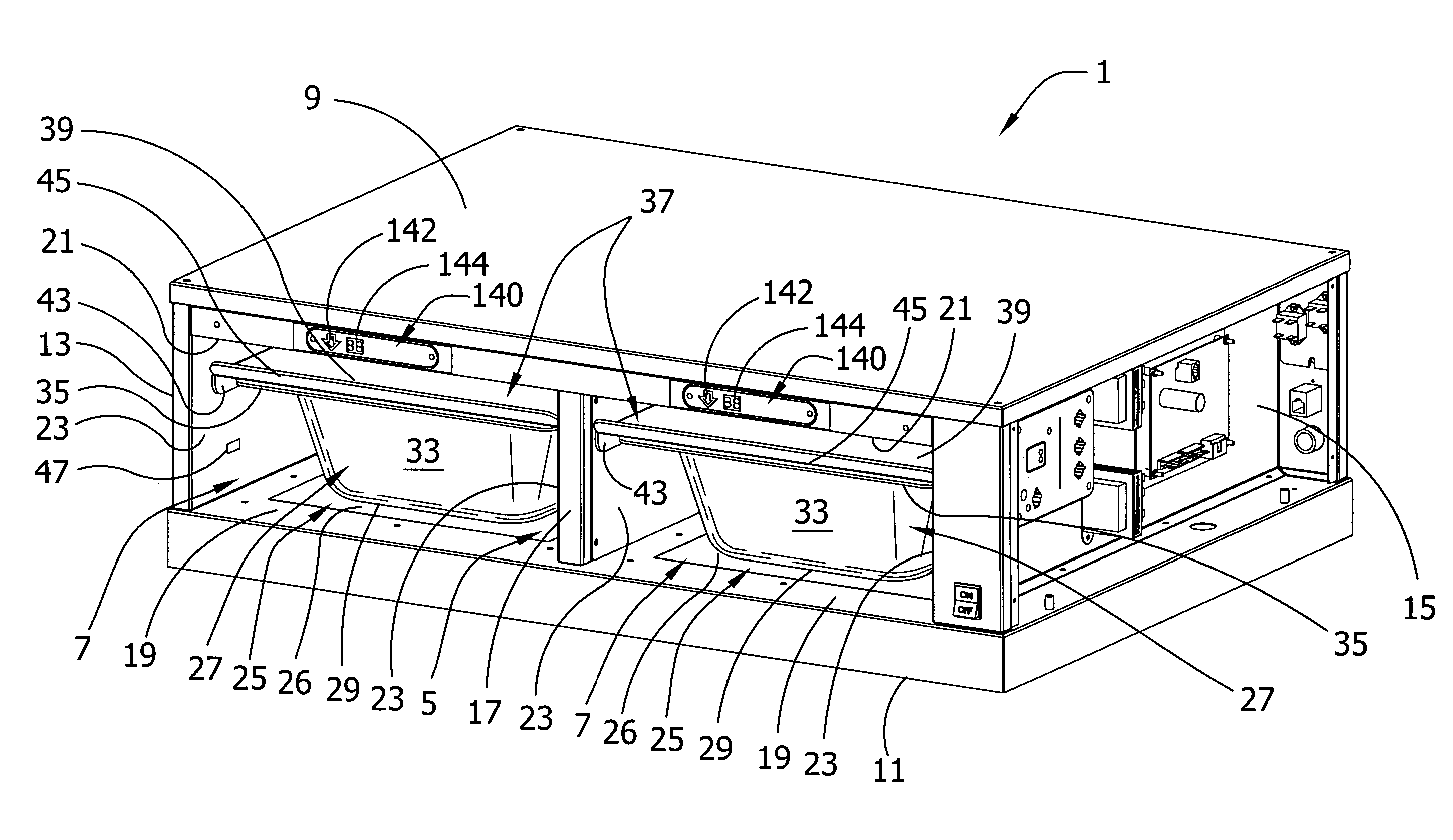

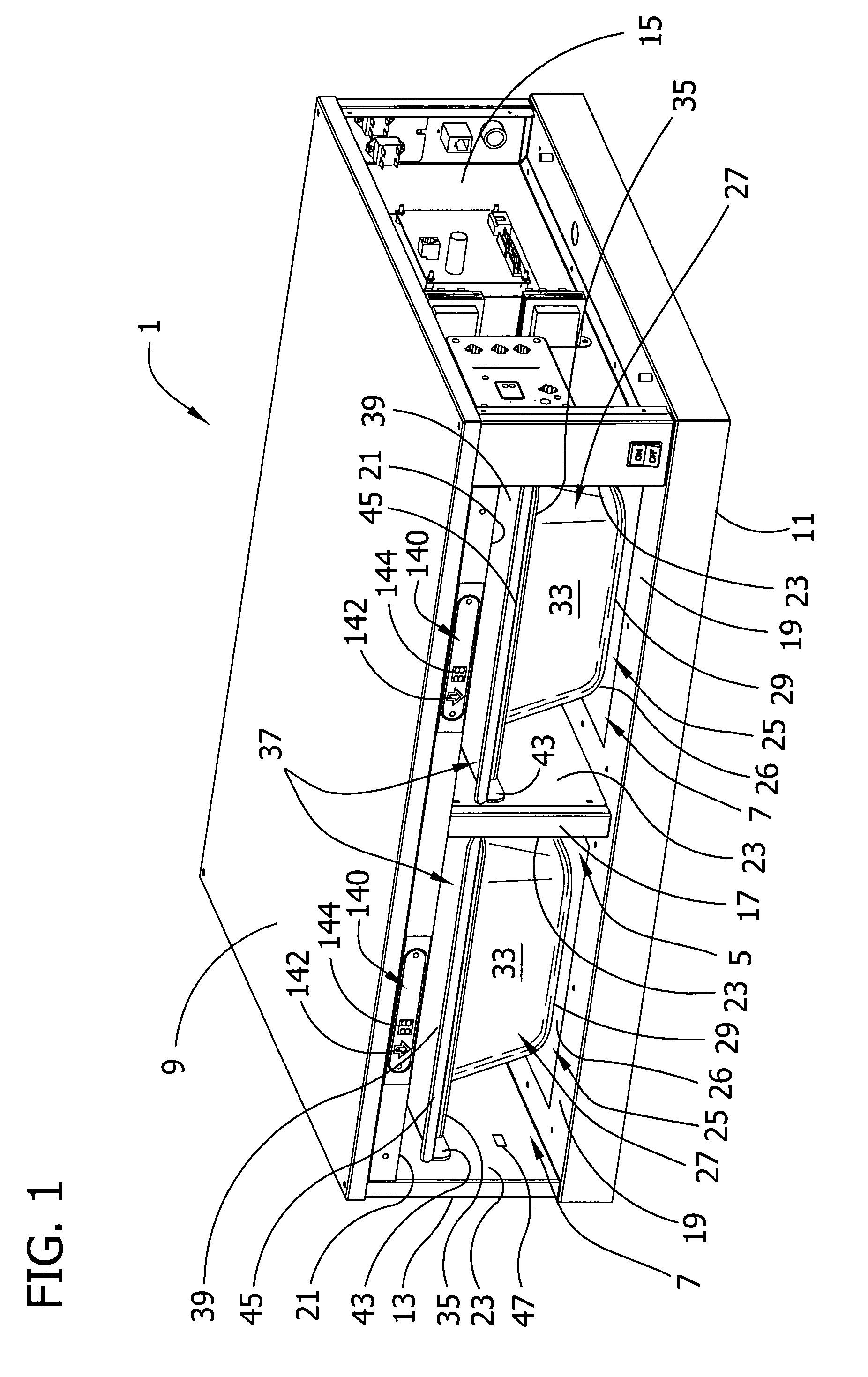

Food warming apparatus

InactiveUS7328654B2Improve product qualityHeating up fastDomestic stoves or rangesElectrical heating fuelEngineering

Owner:DUKE MANUFACTURING COMPANY

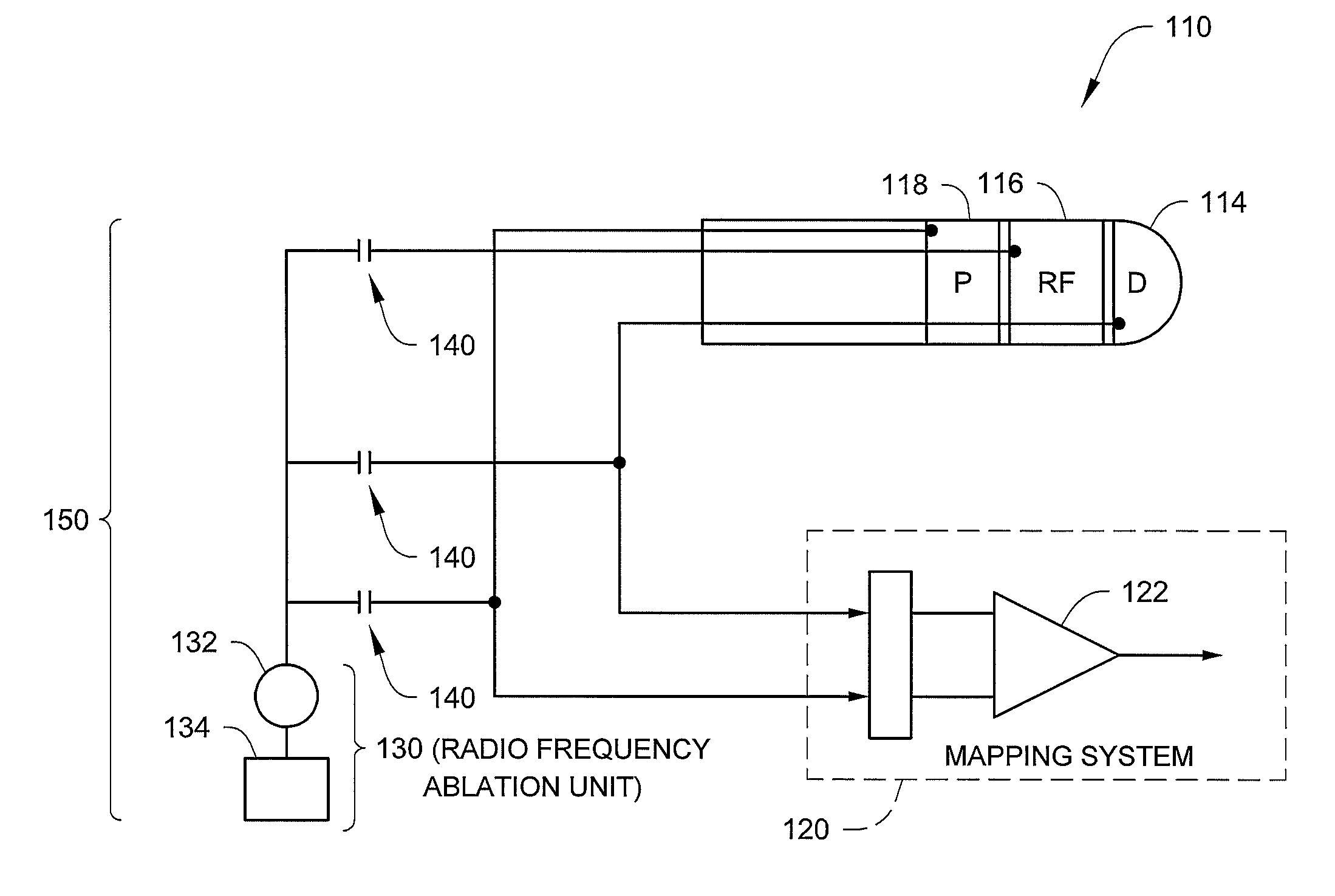

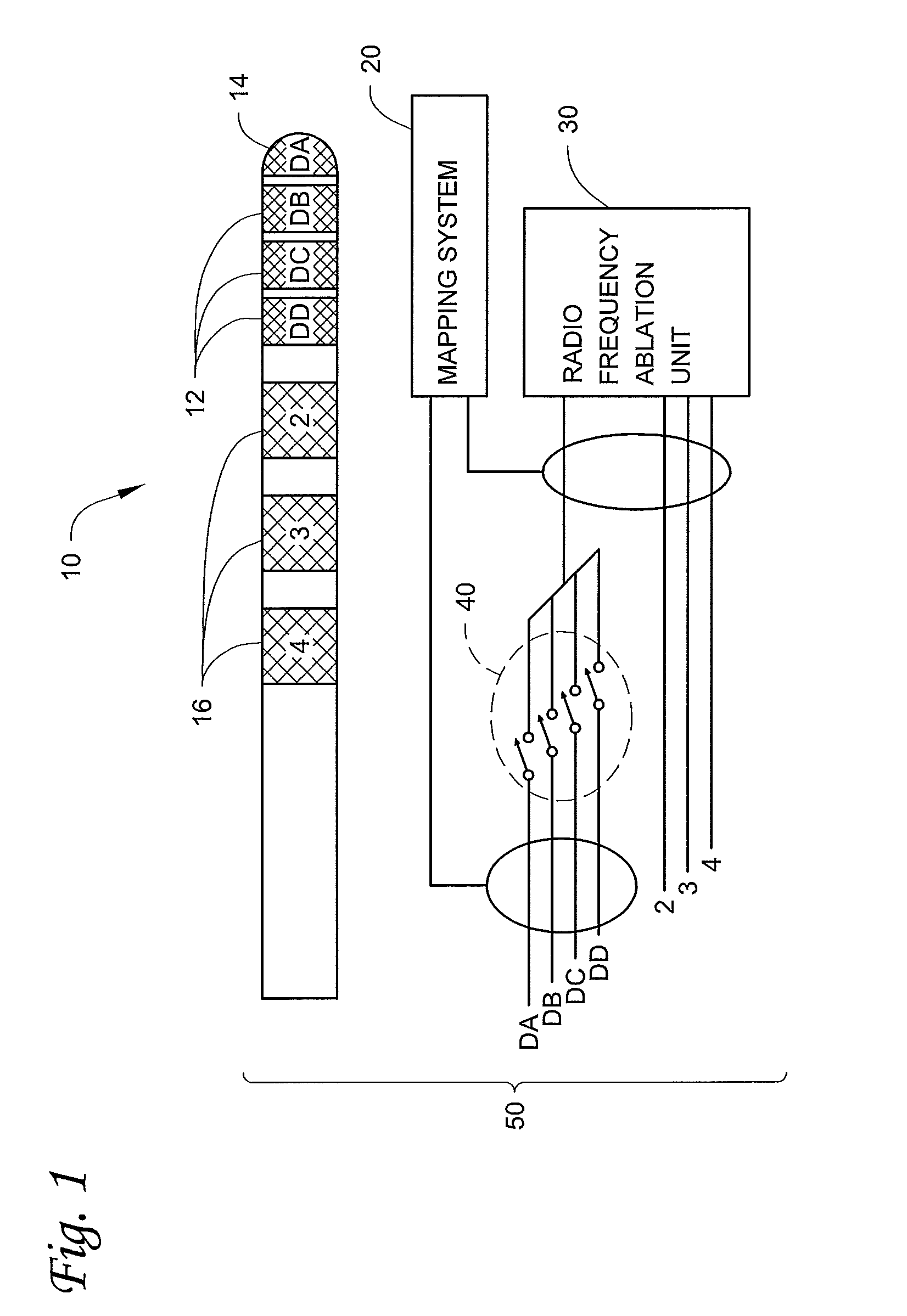

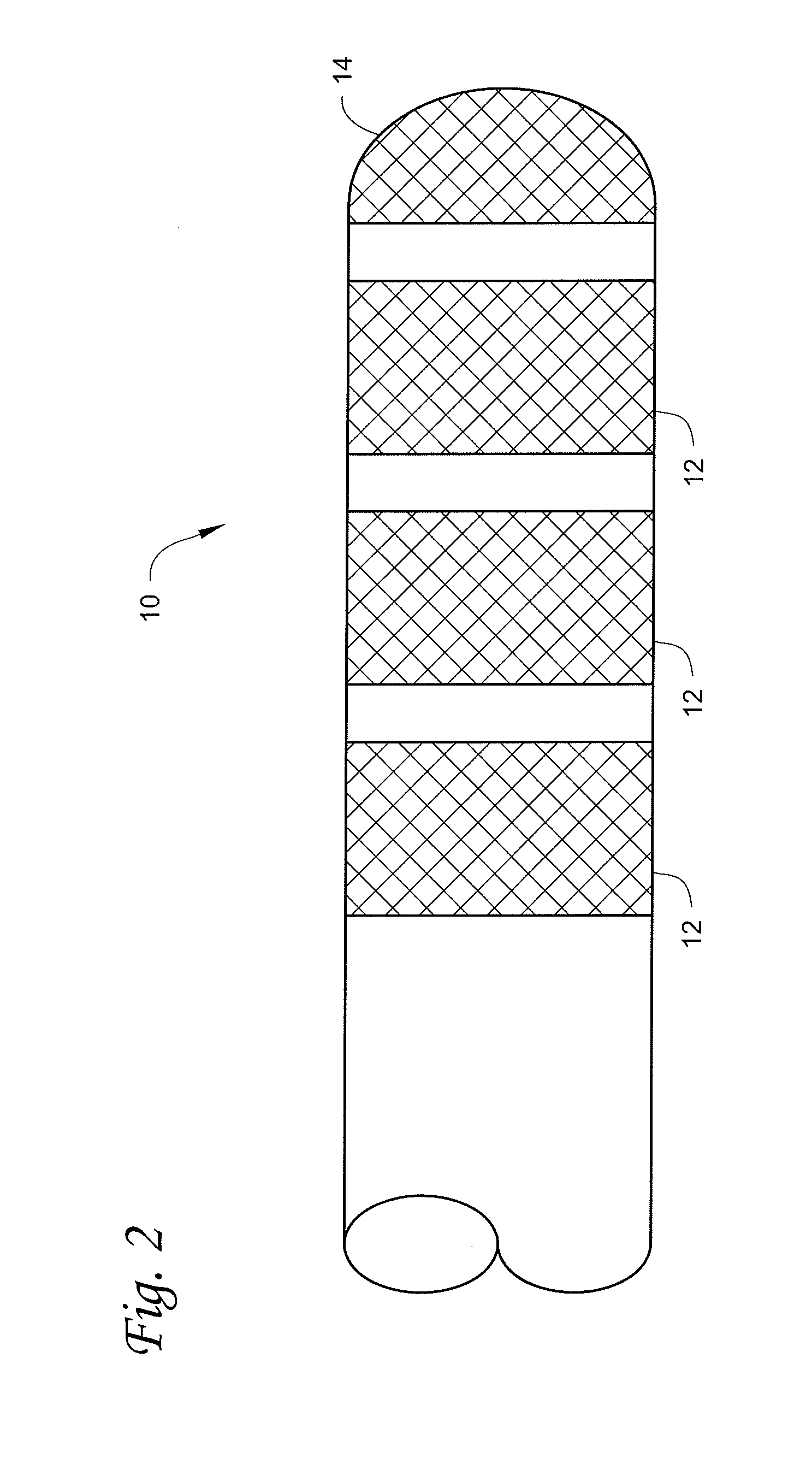

Mapping and ablation catheter system

ActiveUS8538501B2Sufficient energyReduce impactElectrocardiographyCatheterCapacitanceBiomedical engineering

A mapping and ablation catheter system including a radio frequency ablation source having an output, a mapping device, a catheter, and two or more capacitive components. The catheter may include two or more catheter electrodes, wherein two of the two or more catheter electrodes may be electrically coupled to the mapping device. Each of the two or more catheter electrodes may be electrically coupled to a capacitive component, wherein each capacitive component may be electrically coupled to the output of the radio frequency ablation source such that energy delivered to each catheter electrode of the two or more catheter electrodes passes through the capacitive component.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

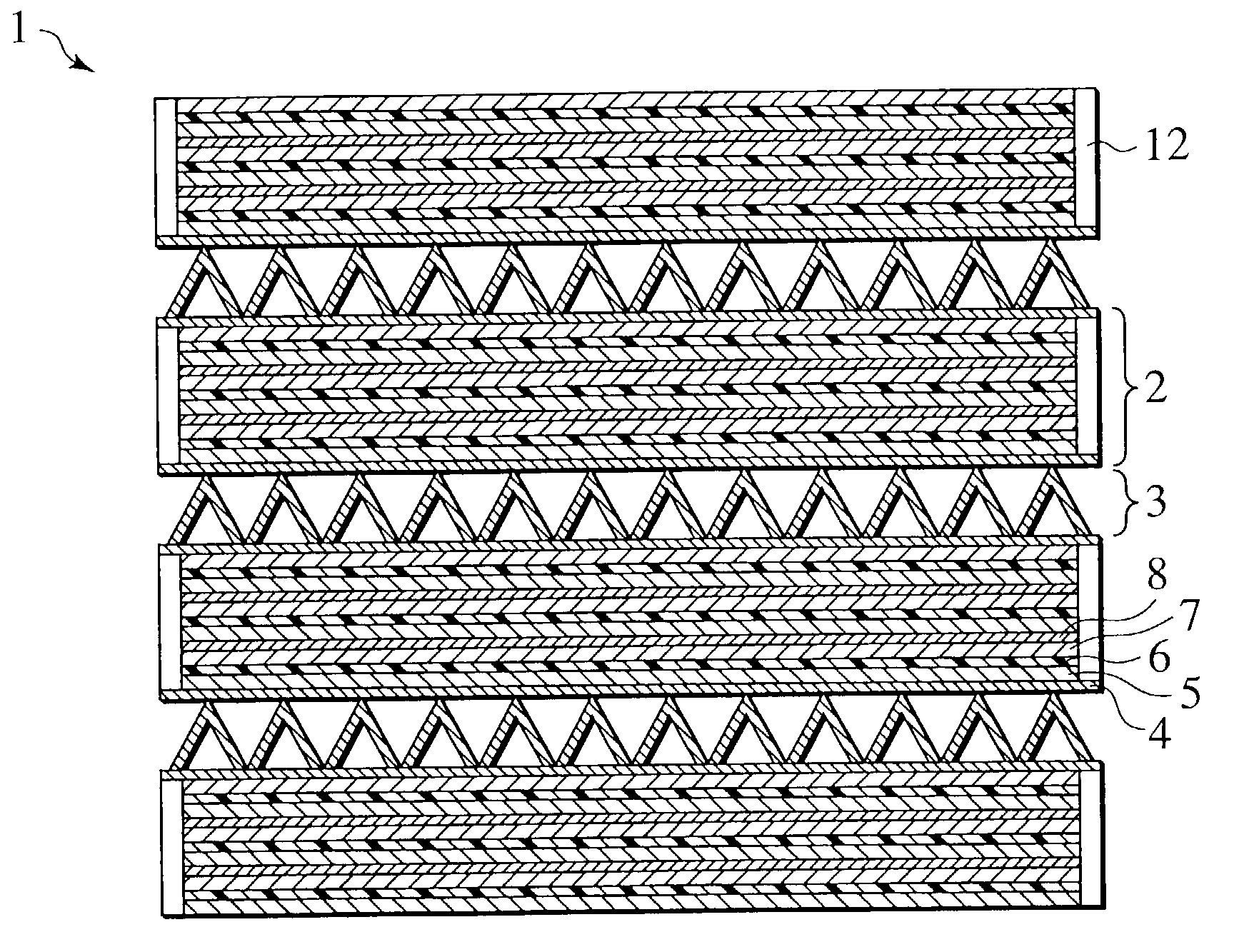

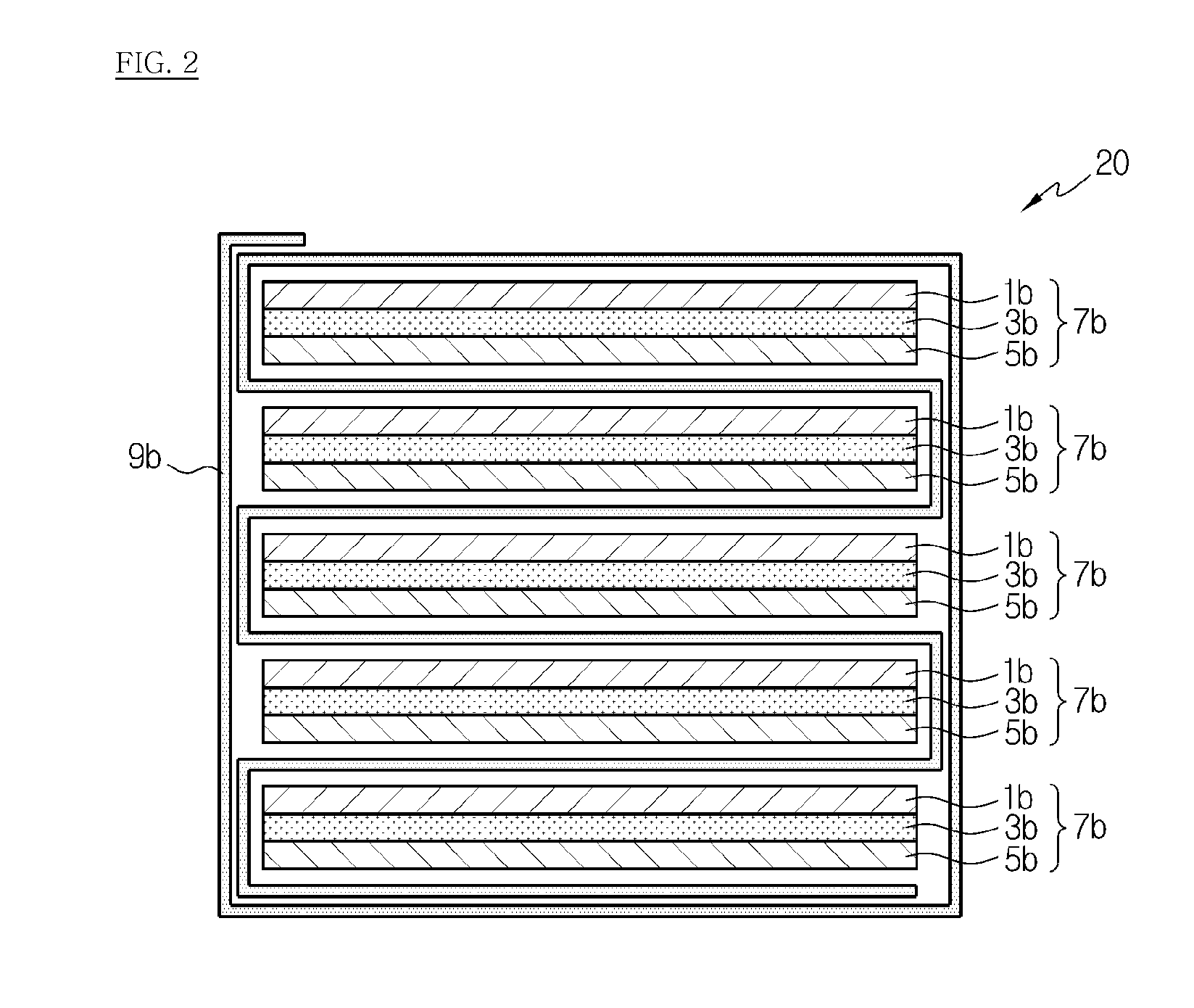

Battery system with excellent controllability for temperature

InactiveUS7264902B2Reduce heating capacityImprove thermal efficiencyPrimary cell to battery groupingFinal product manufactureEngineeringControllability

A battery system of the present invention includes one or more cell groups, each having a positive electrode, a negative electrode and a solid electrolyte layer, and one or more heat mediating structures adjacent to the cell groups. The cell groups and the heat mediating structures are alternately stacked. A solid electrolyte is applied to the electrolyte layer. The respective cell groups have a thin plate shape, and adjacent thereto, the heat mediating structures are provided.

Owner:NISSAN MOTOR CO LTD

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

Compound amino acid organic fertilizer and production method of compound amino acid organic fertilizer

The invention disclose a compound amino acid organic fertilizer, which is characterized in that the compound amino acid organic fertilizer consists of the following ingredients in parts by weight: 5 to 10 of compound amino acid, 0.3 to 0.5 of microbial yeasts, 16 to 29 of inorganic fertilizers, 5 to 10 of humic acid fertilizers and 0.2 to 1 of trace elements. A production method of the compound amino acid organic fertilizer comprises the following steps that: firstly, compound amino acid water solution, the microbial yeasts and the humic acid fertilizers are respectively prepared, then, inorganic compounds containing boron, copper, iron, manganese and zinc are added into the compound amino acid water solution, and the chelation is carried out at a temperature being 80 to 110 DEG C so that the mixture becomes free-state chelated amino acid salt; after the metering, 10 to 50kg of raw materials are added into each ton of farmyard manure to be mixed, then, the mixed materials are placed into a warehouse for natural stacking and curing for 3 to 5 days and can be pelletized and packed to leave factories. The compound amino acid organic fertilizer can be used as a base fertilizer and an additional fertilizer and belongs to a compound organic fertilizer capable of improving the amino acid content of high-quality fragrant rice and fruit and vegetables, improving the fruit and vegetable quality and improving the sugar content of sugarcanes.

Owner:GUANGXI YUXIN BIOLOGICAL TECH

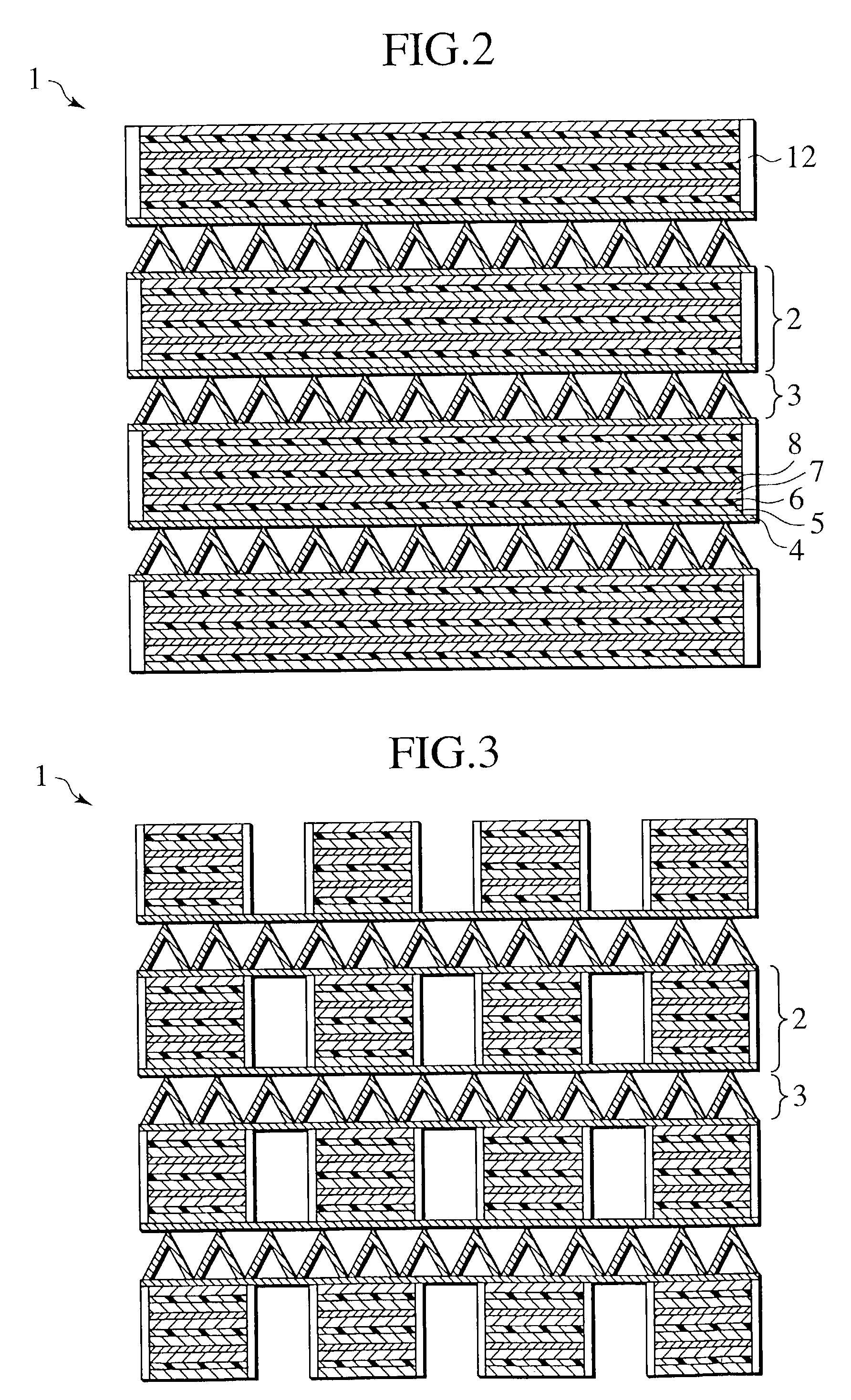

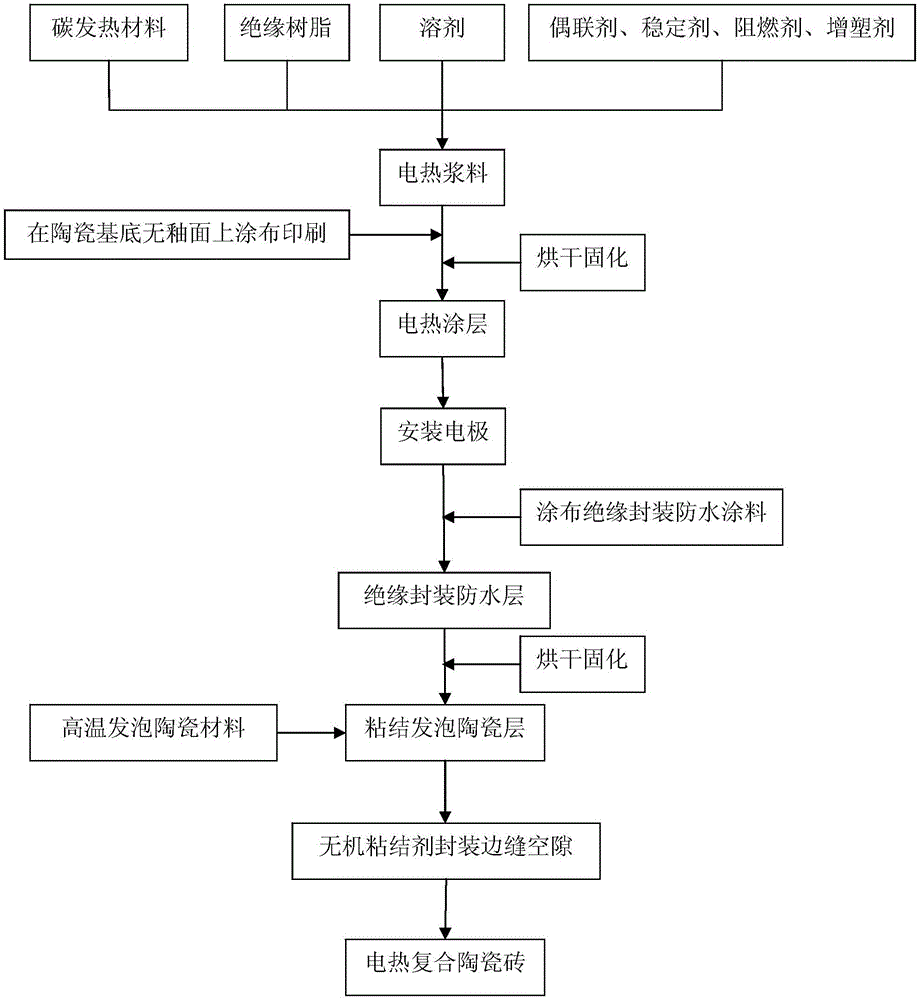

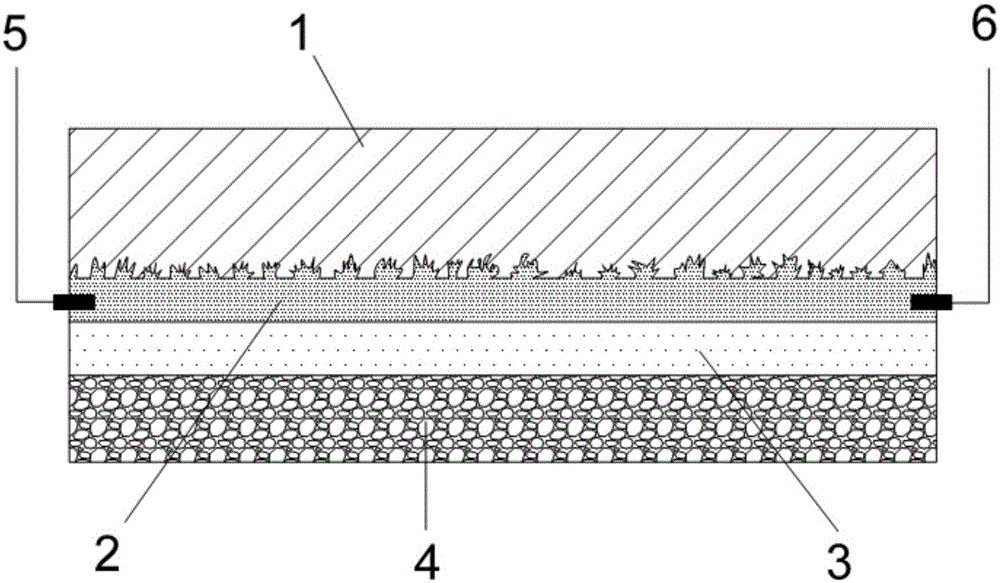

Electrothermal composite ceramic brick and preparation method thereof

The invention discloses an electrothermal composite ceramic brick and a preparation method thereof. An electrothermal coating layer, a guiding-out wiring electrode, a coating insulation packaging waterproof layer and an application foaming ceramic layer coat an unglazed surface of a ceramics substrate in order. The electrothermal coating layer coats the unglazed surface of the ceramics substrate in an electrothermal slurry form, the electrothermal slurry permeates the green body of the ceramics substrate, and the penetration depth is less than the thickness of the ceramics substrate and more than 0.5mm. Because of the penetration, the electrothermal coating layer of the electrothermal composite ceramic brick is combined with the ceramics substrate tightly, a surface heating mode is achieved, the thermal efficiency is high, normal and safe usage can be achieved under a voltage of 24-380V, the heating power is 90-120w / m<2>, and the temperature of the ceramics substrate can reach 18-50 DEG C through a temperature control device. The insulation packaging waterproof layer and the foaming ceramic layer outside the electrothermal coating layer can prevent heat from outward transmission effectively, heat loss is lowered, and the whole safety and reliability of the ceramic brick are raised.

Owner:GUANGDONG TIANBI CERAMICS

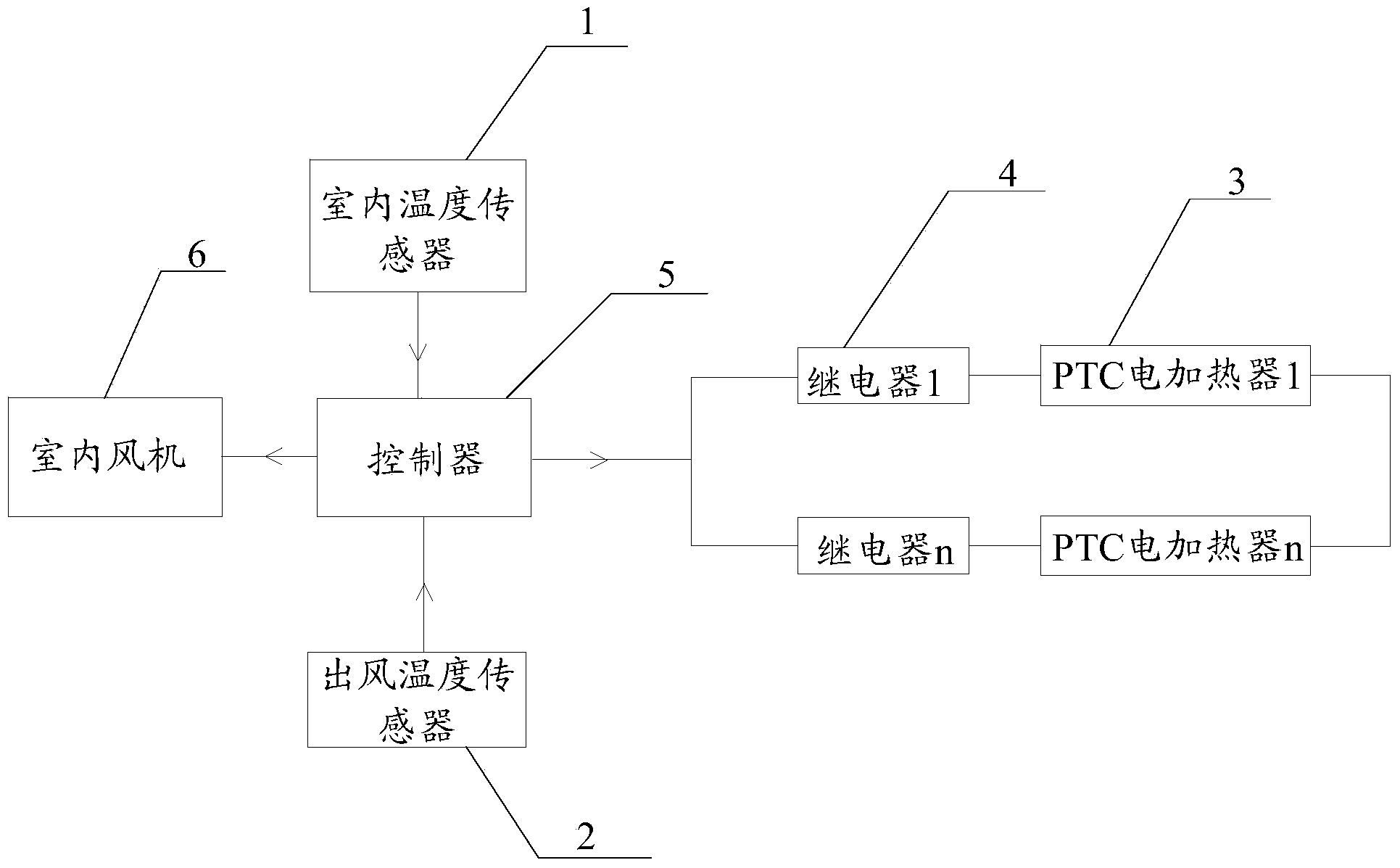

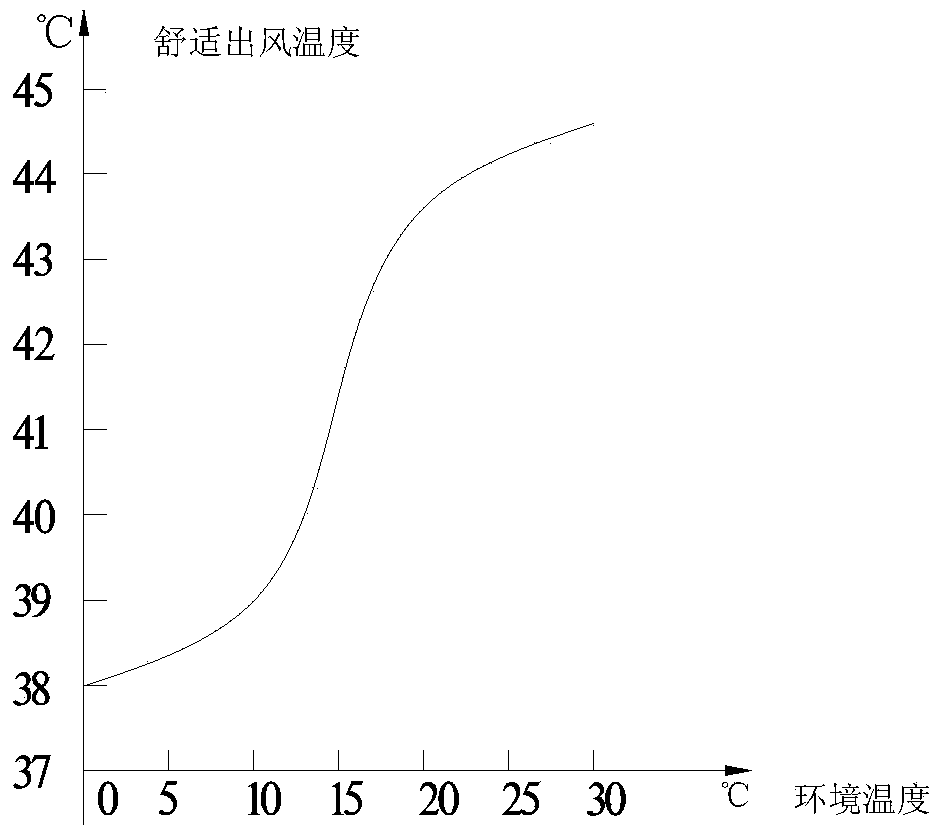

Air conditioner and heating control method thereof

ActiveCN103528134AComfortable air temperatureHeating up fastSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAir temperature

The invention discloses an air conditioner. The air conditioner comprises a compressor, an indoor draught fan, an indoor temperature sensor, an air outlet temperature sensor, a PTC electric heater and a controller, wherein the indoor temperature sensor is used for collecting and outputting indoor environment real-time temperature to the controller when an air conditioner heating mode is started; the air outlet temperature sensor is used for collecting and outputting actual air outlet temperature of the air conditioner to the controller when the air conditioner heating mode is started; the controller is used for working out the comfortable air outlet temperature according to the prestored comfortable outlet air temperature-environment temperature changing curve and the indoor environment real-time temperature and comparing the difference value delta T between the actual outlet air temperature and the comfortable air outlet temperature, and when the delta T exceeds the threshold, the controller controls the working state of the PTC electric heater to enable the delta T to be in the range of the threshold. The invention further discloses a heating control method of the air conditioner. According to the air conditioner and the heating control method of the air conditioner, fast temperature rise and air outlet comfort can be achieved, the structure is simple, and the reaction is sensitive.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

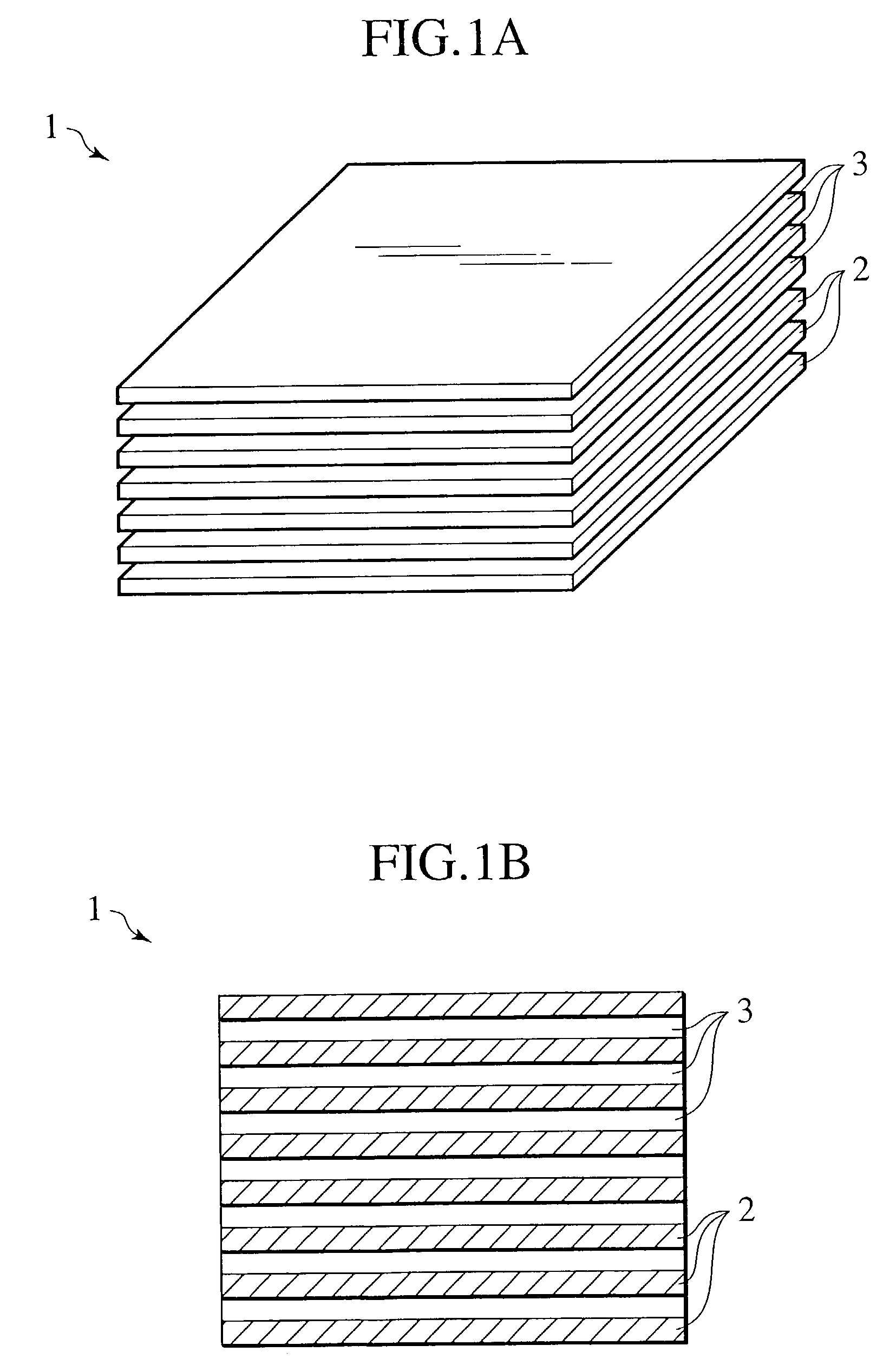

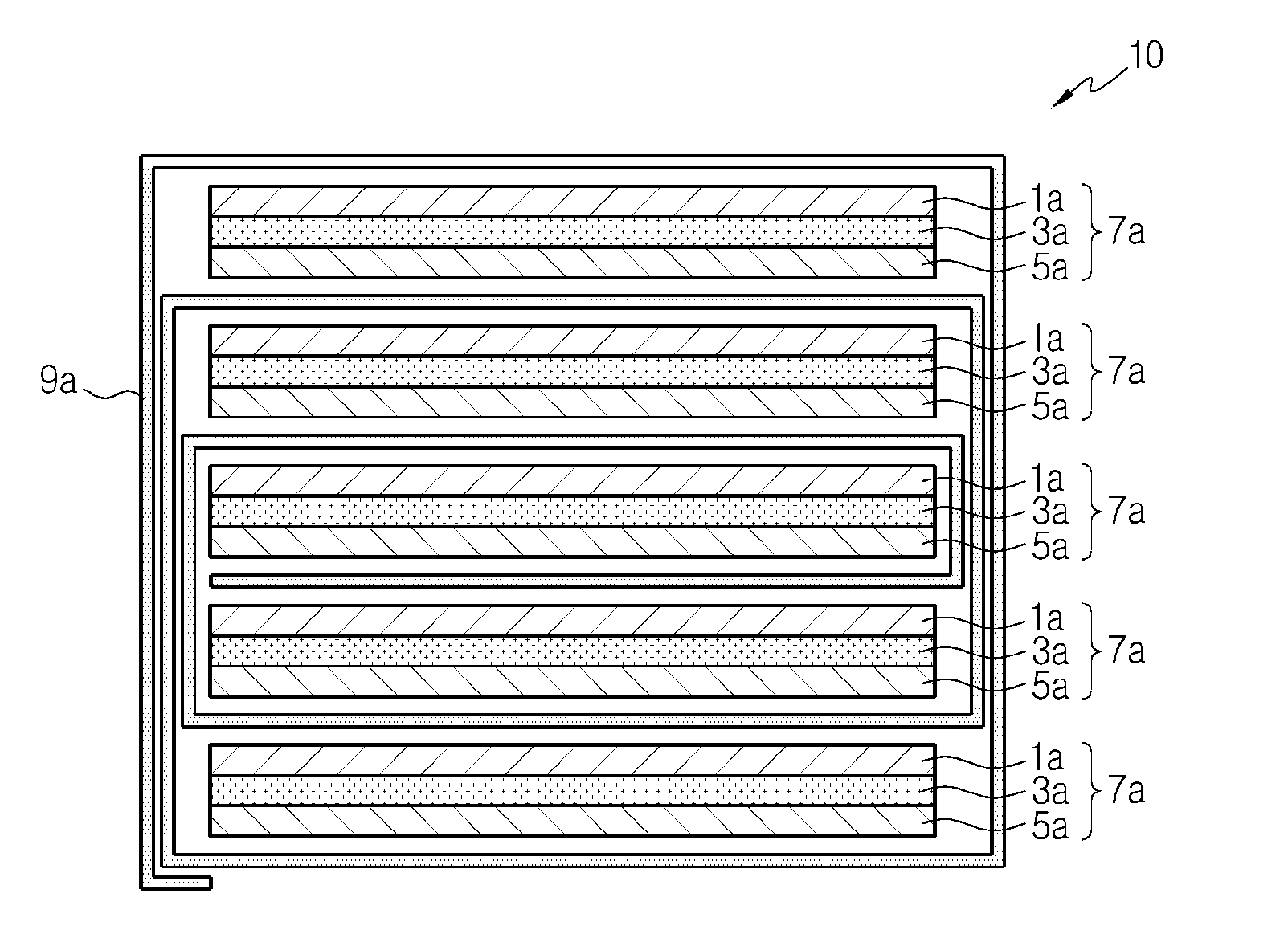

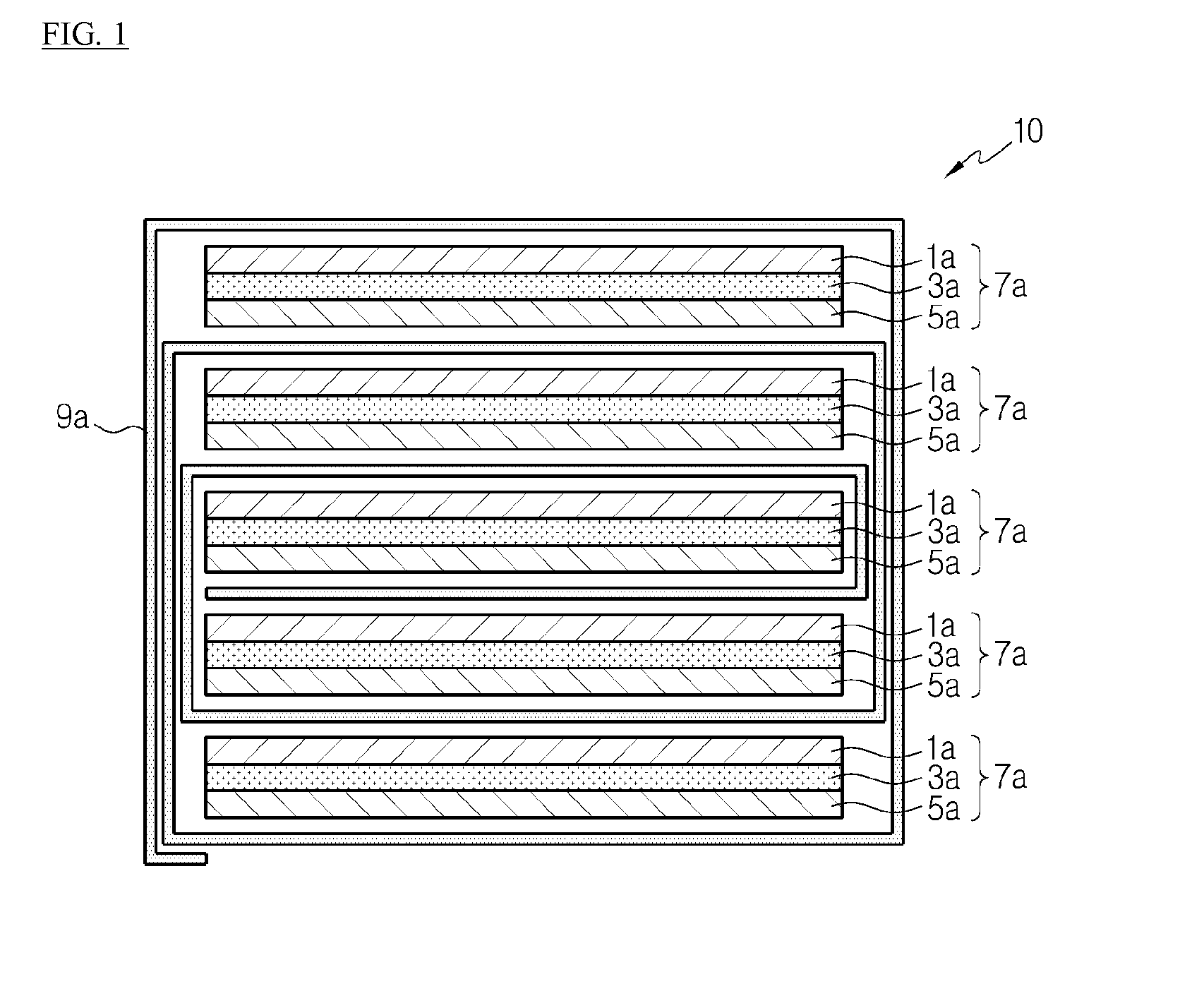

Electrochemical device having different kinds of separators

ActiveUS20100261047A1Prevent ignition and explosionReduce temperature increase rateFinal product manufactureJackets/cases materialsPolyolefinPorous coating

An electrochemical device includes a plurality of unit cells, each having a first separator and a cathode and an anode positioned at both sides of the first separator, and a continuous single second separator interposed between adjacent unit cells in correspondence with each other in a laminated pattern and arranged to surround each unit cell. The first separator includes a heat-resisting porous substrate having a melt point of 200° C. or above and a first porous coating layer formed on at least one surface of the heat-resisting porous substrate and made of a mixture of a plurality of inorganic particles and a binder polymer. The second separator includes a polyolefin porous substrate and a second porous coating layer formed on at least one surface of the polyolefin porous substrate and made of a mixture of a plurality of inorganic particles and a binder polymer.

Owner:LG ENERGY SOLUTION LTD

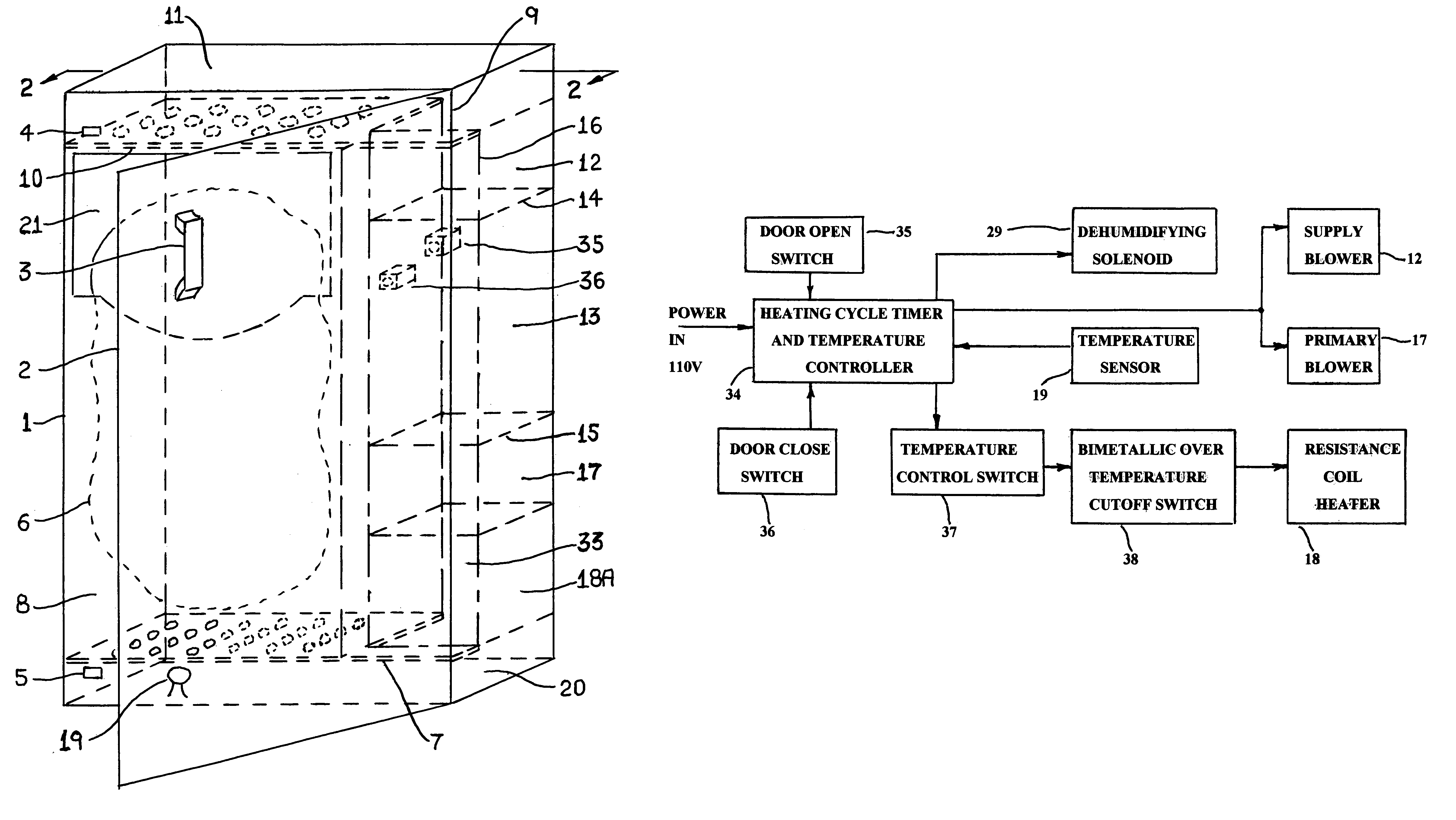

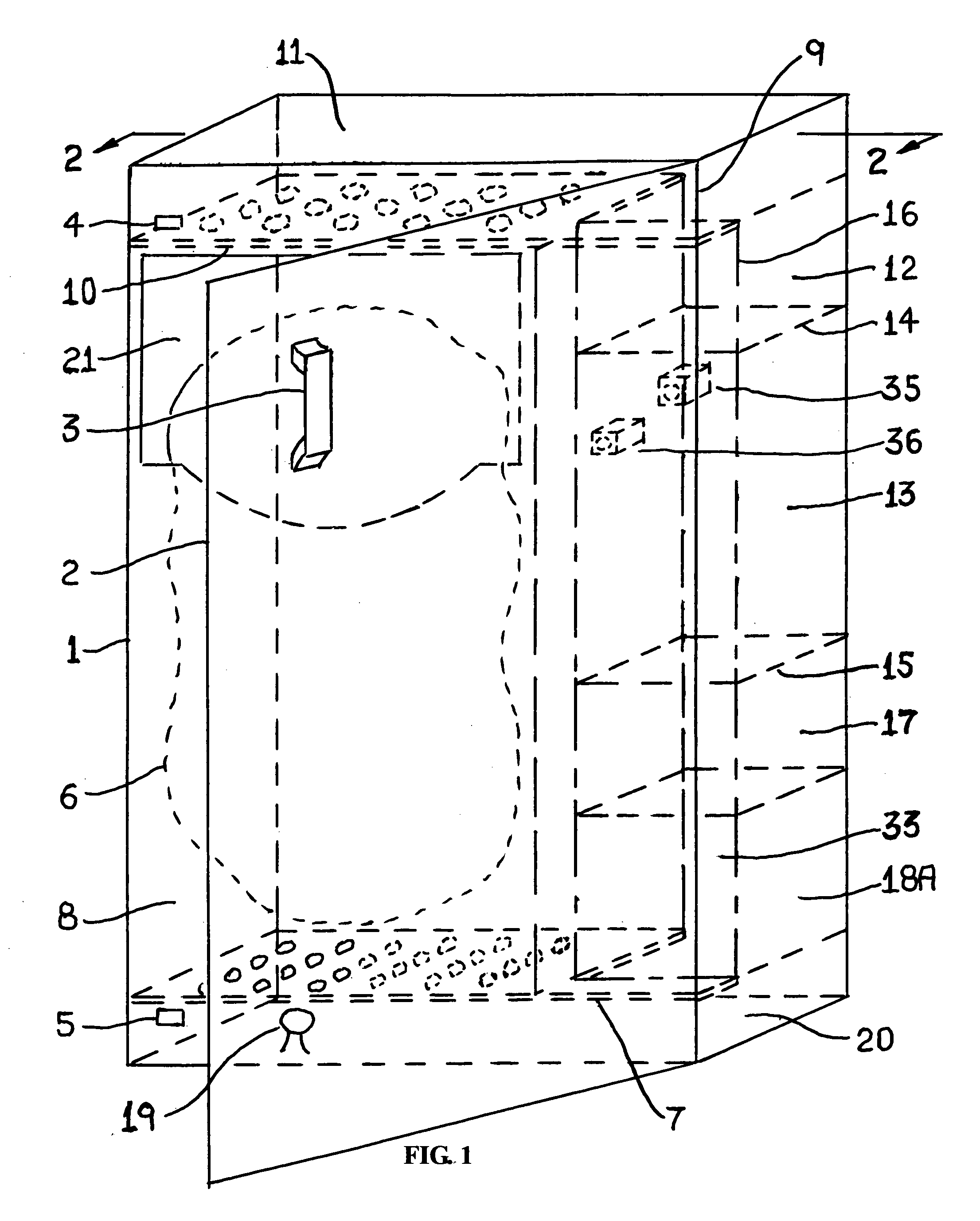

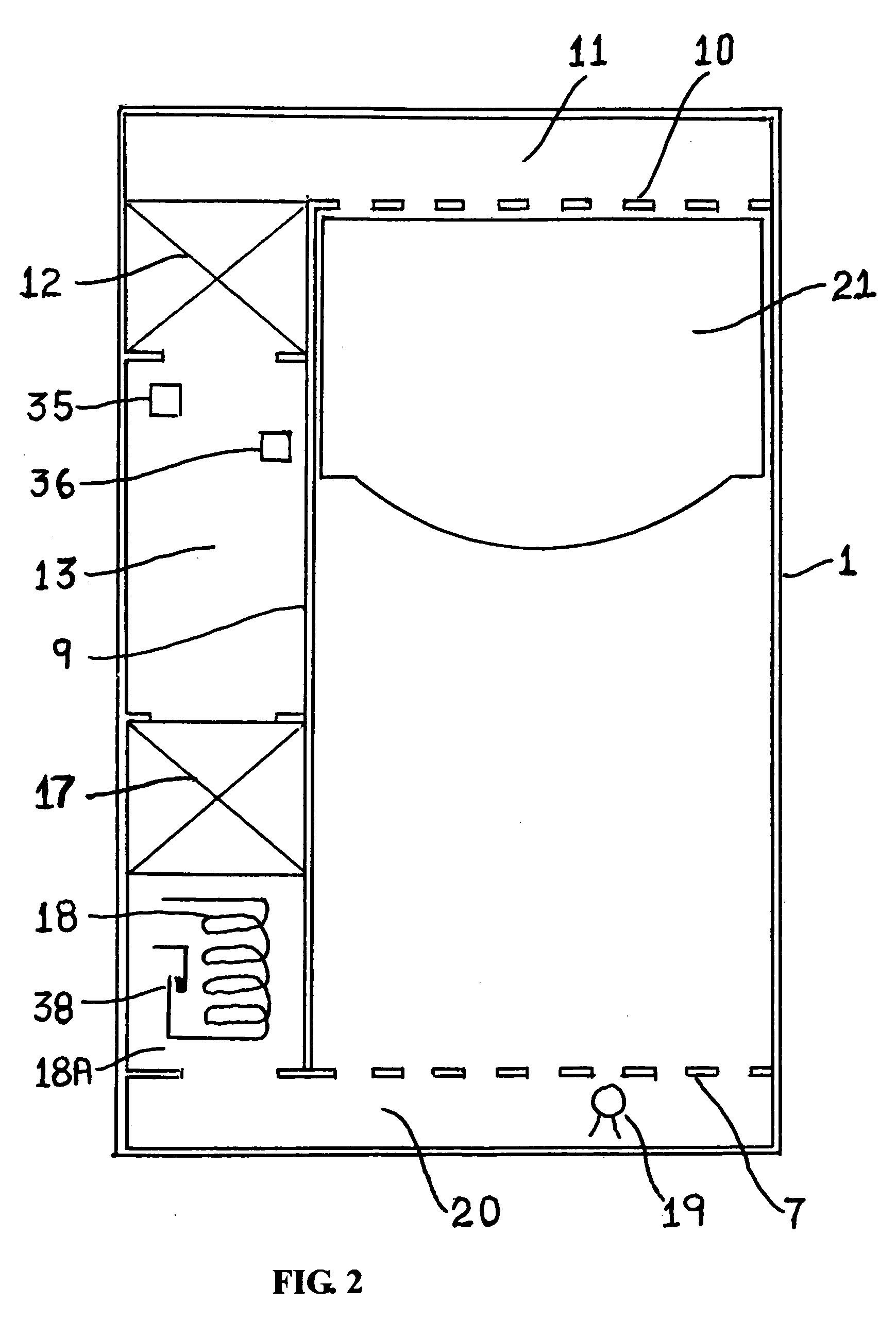

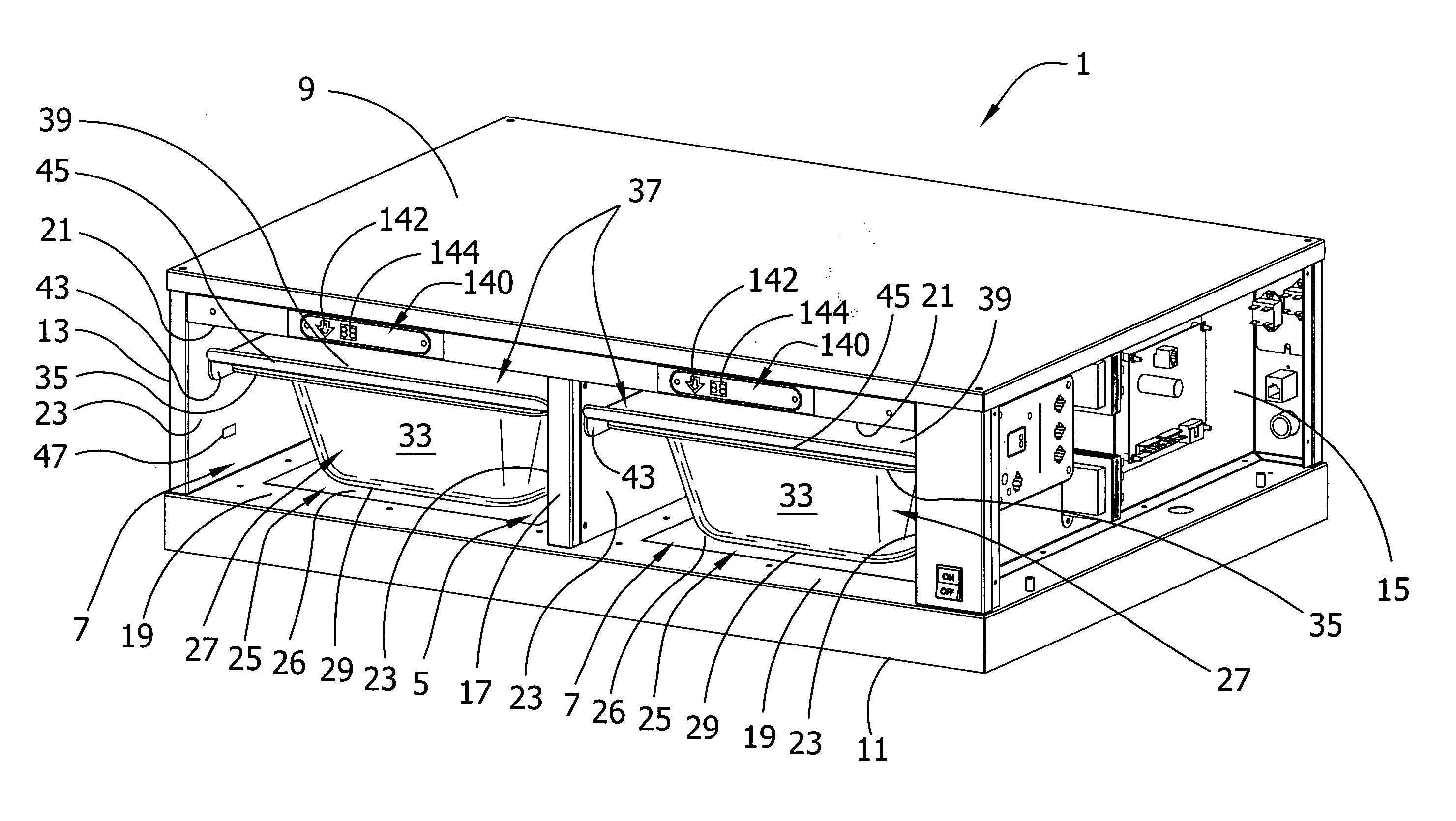

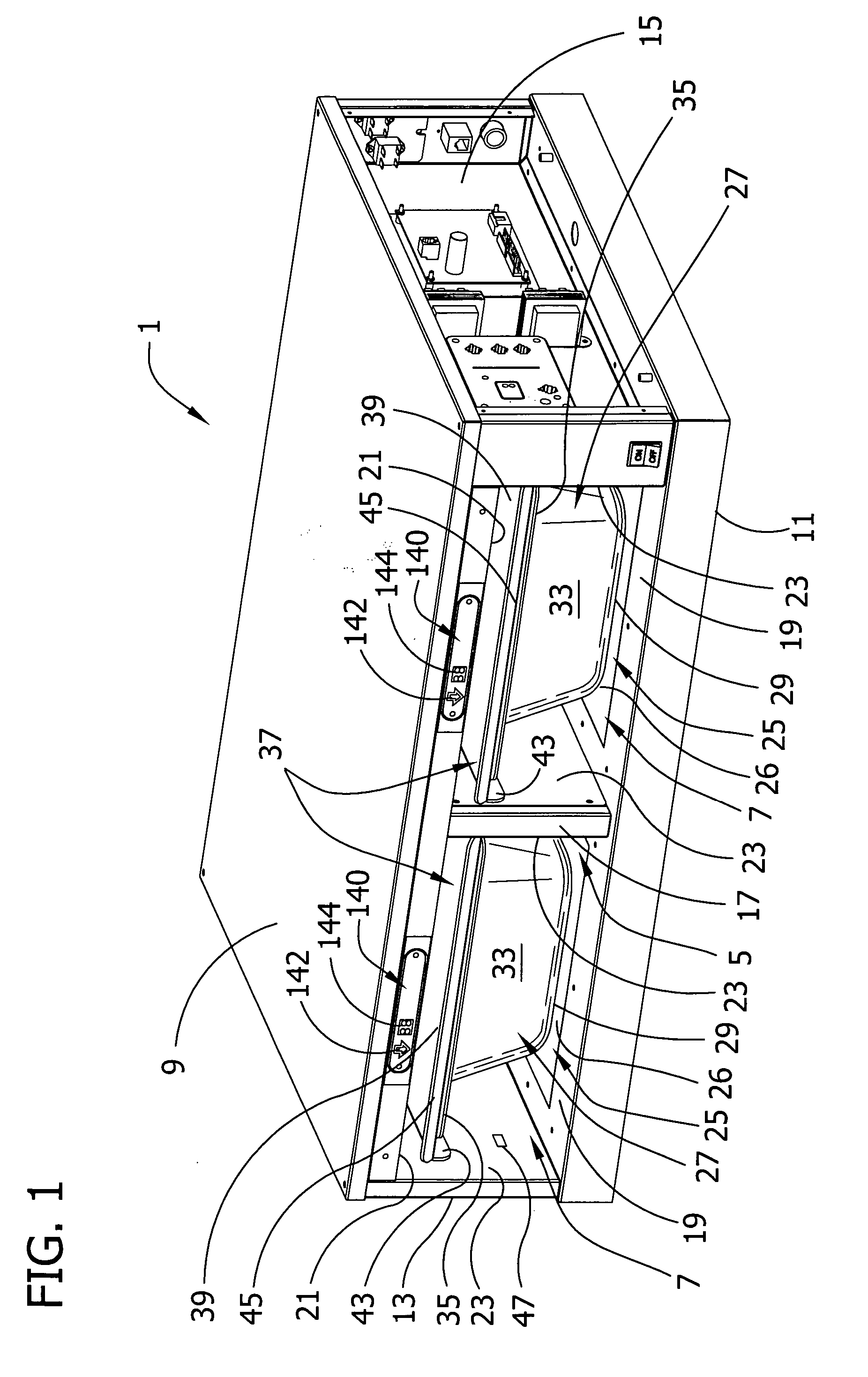

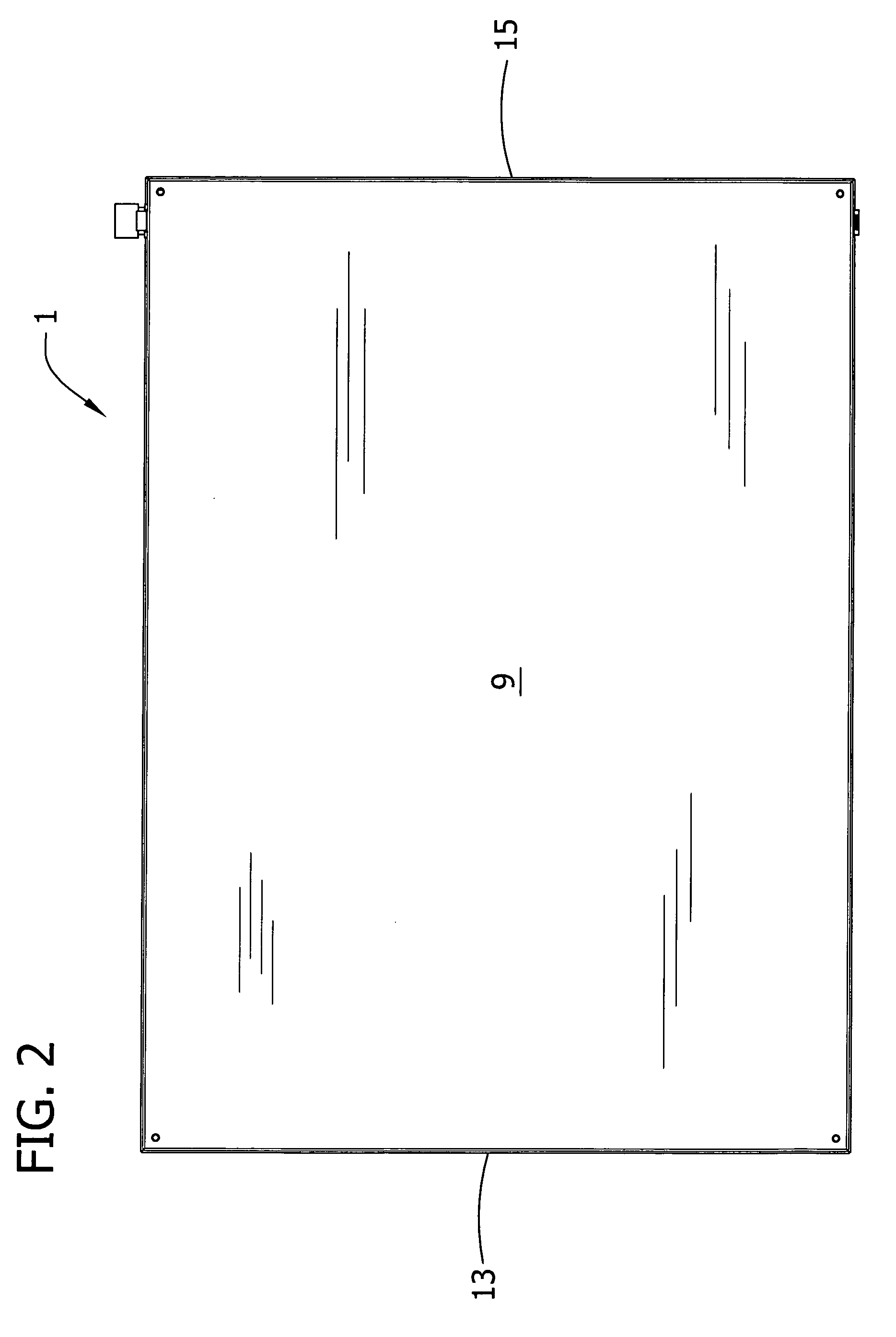

Large plush towel warmer and dehumidifier

InactiveUS7171761B1Rapid responseEffective timeAgriculture tools and machinesHeater elementsUser satisfactionBathtub

An increased air pressure forced hot air towel warmer comprising a substantially airtight enclosure configured to be more desirable and user friendly when placed in close proximity to a tub or shower whether mounted within cabinetry, on the wall or when permanently installed between existing standard 16 inch on center wall support studs while protruding as little as possible into the room. Intended for use with large area plush towels and bath sheets for which insertion in a limited width wall enclosure or shallow depth cabinetry leads to greater vertical depth of towel material to be penetrated and substantially increases the resistance to air flow, therefore back pressure, thereby necessitating increased supply pressure to maintain adequate hot air flow through the towel. Increased supply pressure is created without objectionable noise by use of low noise rotary blowers and associated pressure accumulator cavities arranged in tandem such that their respective pressure gradients are additive. Experience has also shown that all towels exhibit some degree of adsorbed moisture, the present invention includes an embodiment for increasing user satisfaction by removing excess adsorbed moisture during the warming cycle to achieve dehumidification by means of periodic short time interval ejection of the warmed moisture laden air within the enclosure with simultaneous replacement by room air to sequentially reduce the moisture content retained within the warmed towel.

Owner:HUNTS BARNEY DEAN

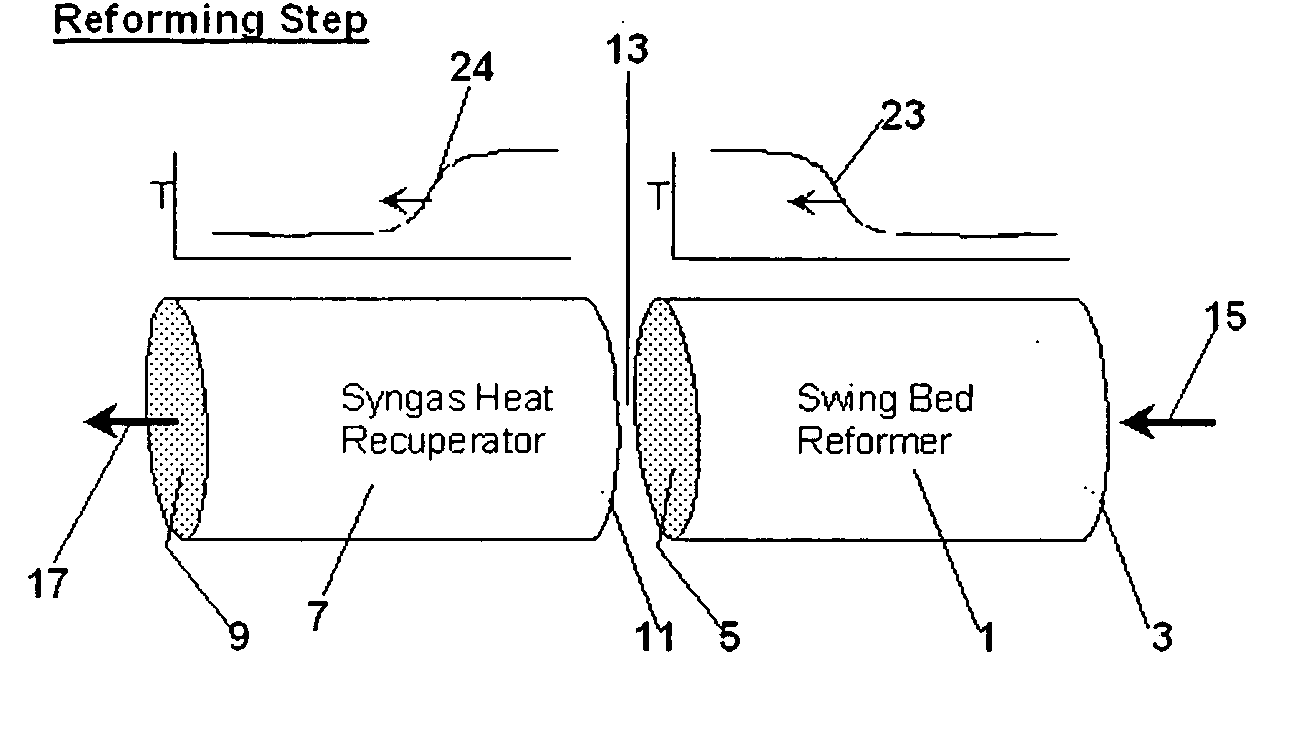

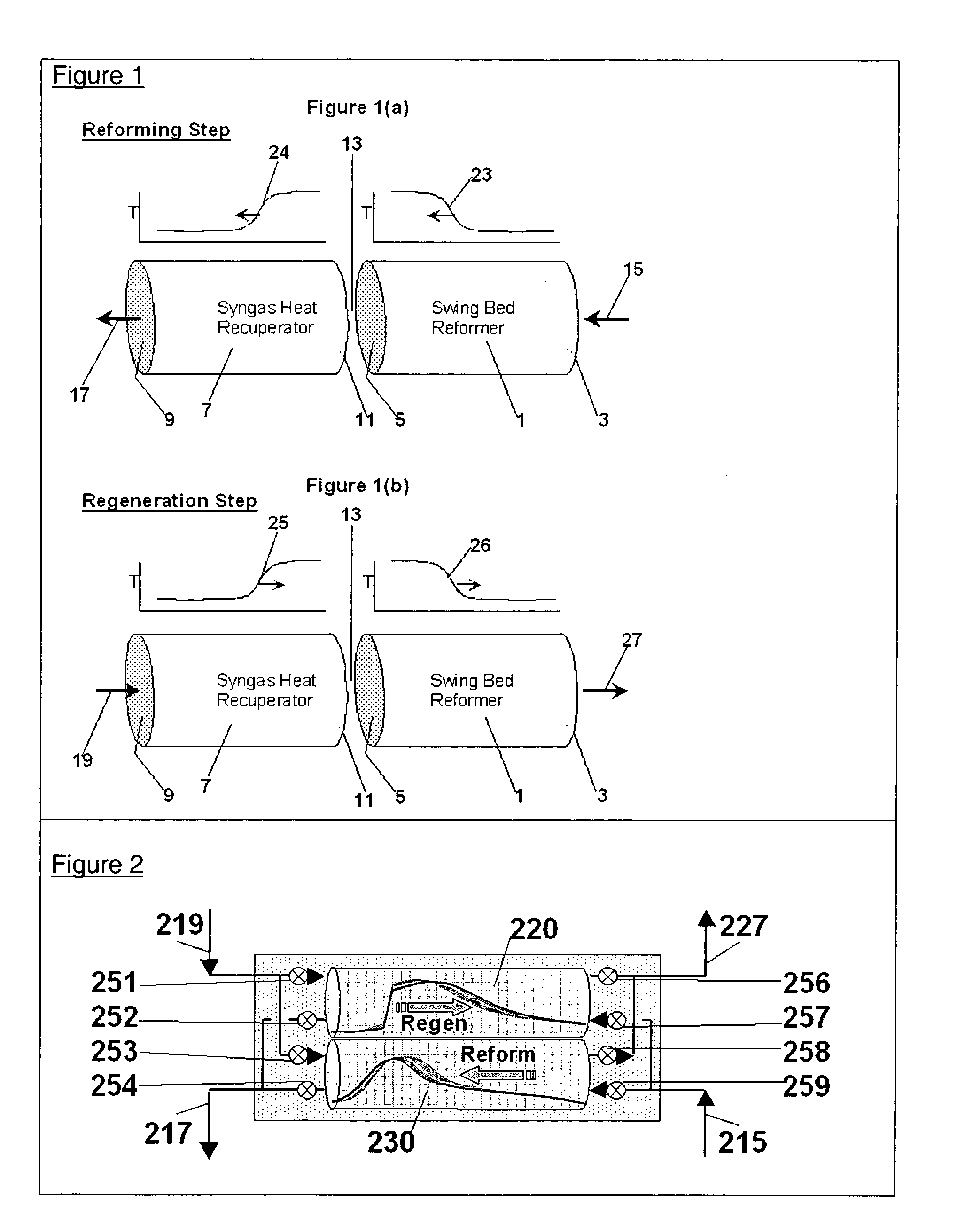

Solid oxide fuel cell systems having temperature swing reforming

InactiveUS20040241505A1Improved heat integrationReduce eliminateHydrogenChemical industrySyngasFuel cells

The present invention provides an improvement in the process of producing energy from fuel cells. A cyclic reforming process, referred to as temperature swing reforming, provides an efficient means for producing a hydrogen containing synthesis gas for use in solid oxide fuel cell applications. In one embodiment, at least some synthesis gas which is first produced in the temperature swing reforming process is combusted with air to provide the heat for the regeneration step of the temperature swing reforming process. The syngas produced in TSR is particularly well suited for use in solid oxide fuel cell applications.

Owner:EXXON RES & ENG CO

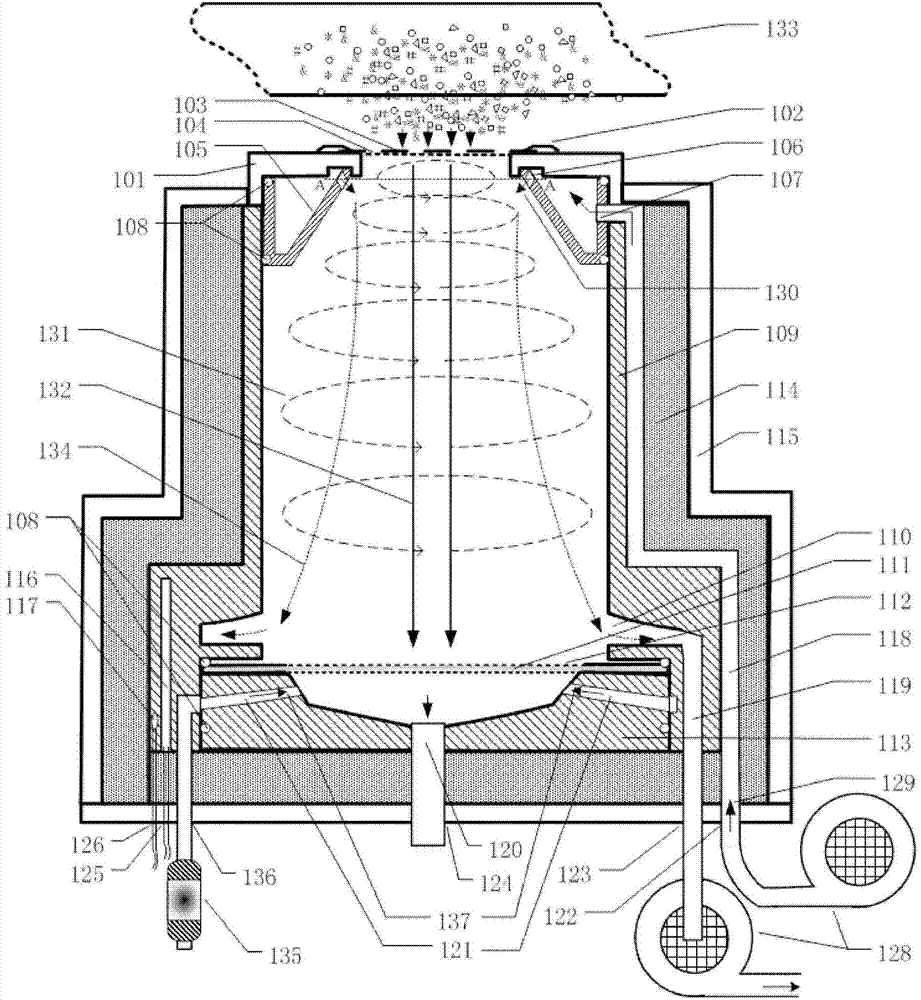

Detection equipment and detection method

ActiveCN104517799AAmplify the collectionRealization of generationComponent separationSamples introduction/extractionMetro stationGas phase

The invention discloses detection equipment and a detection method. The detection equipment comprises a sampling device used for collecting a sample to be detected, a preprocessing sample injection device used for preprocessing the sample from the sampling device, and a sample analysis device used for separating the preprocessed sample from the preprocessing sample injection device and analyzing the separated sample. The detection equipment is miniaturized, can quickly and accurately detect gas-phase matters or particulate matters without unpacking, and is high in accuracy and suitable for security check of airports, ports, metro stations and the like.

Owner:NUCTECH CO LTD

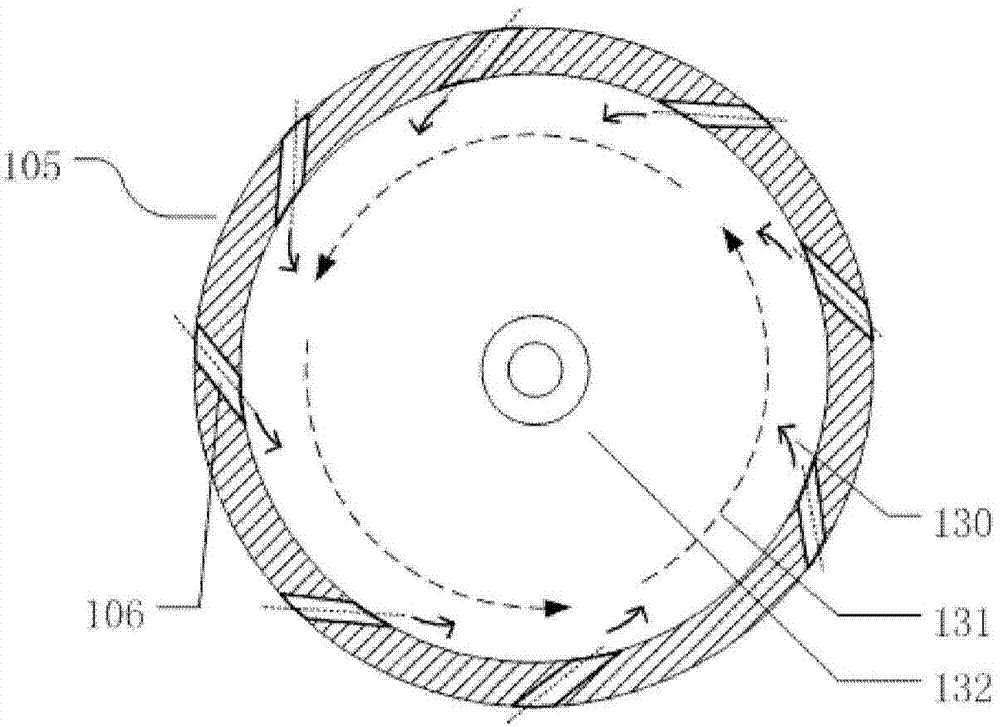

Heat pipe type spherical disc type solar energy light and heat collector

InactiveCN1908549ALow costPromote absorptionSolar heating energySolar heat devicesHeating effectEngineering

The present invention relates to a heat pipe type spherical disc type solar energy light and heat collector, belonging to the solar energy heat collection establishment technical field, which includesa spherical reflecting mirror disposed on the solar energy optical tracker system and a steam drum supported above the reflecting mirror. The steam drum is made up of an inlet and an outlet and stored up with working medium. A heat pipe type vacuum heat collecting pipe is arranged on the focusing part of the spherical reflecting mirror. The heating zone of the heat pipe type vacuum heat collecting pipe is positioned on the condensing wimble of the spherical reflecting mirror. The cooling zone of the heat pipe type vacuum heat collecting pipe is inserted into the working medium of the stream drug. The invention has simple technology, low cost, scientific design and easy to generalization and application. It has been found that the invention has fast tempera the rise, excellent heating effect, high efficiency, suitable for large scale industrialization production, secure and reliable performance.

Owner:HOHAI UNIV

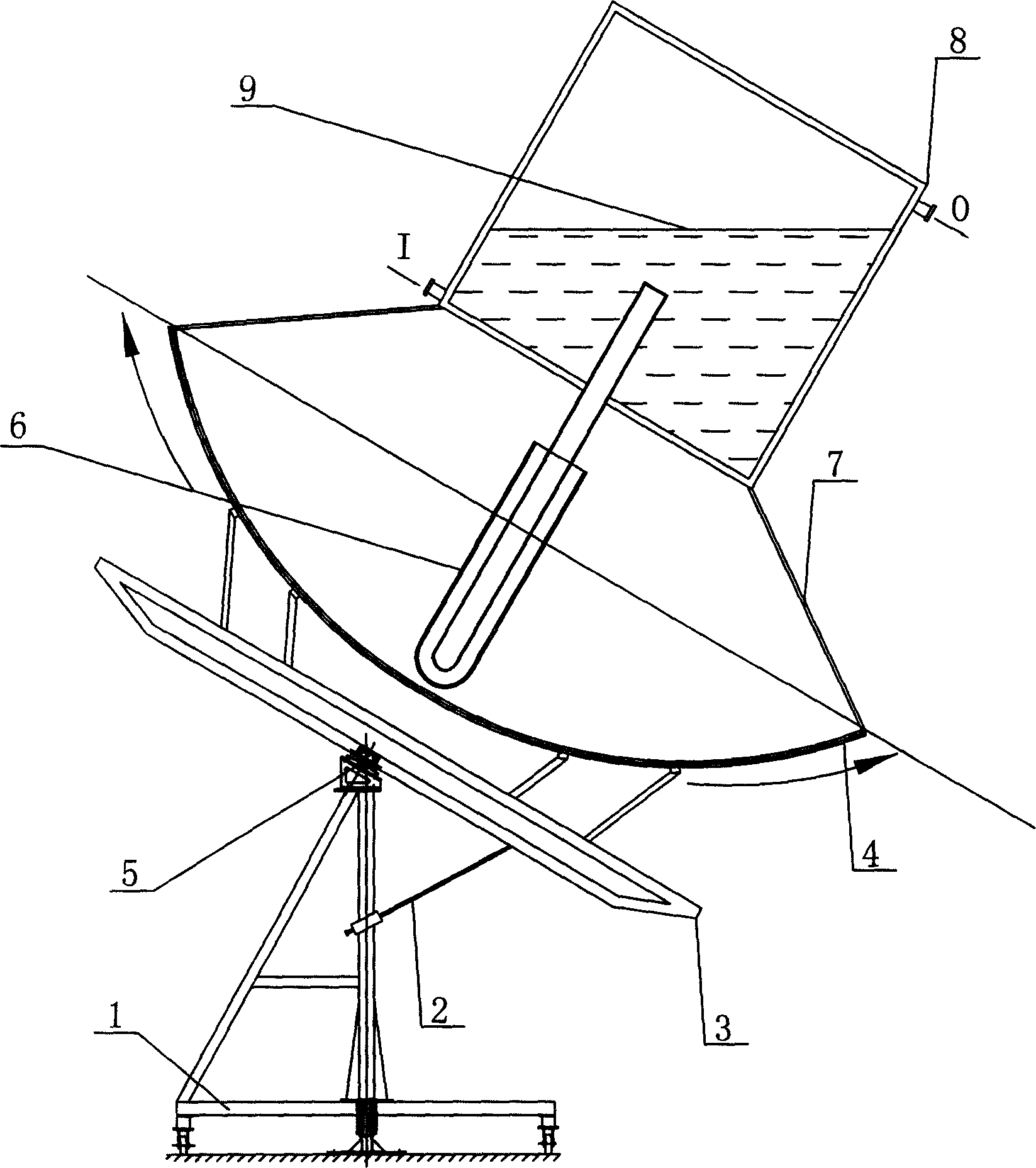

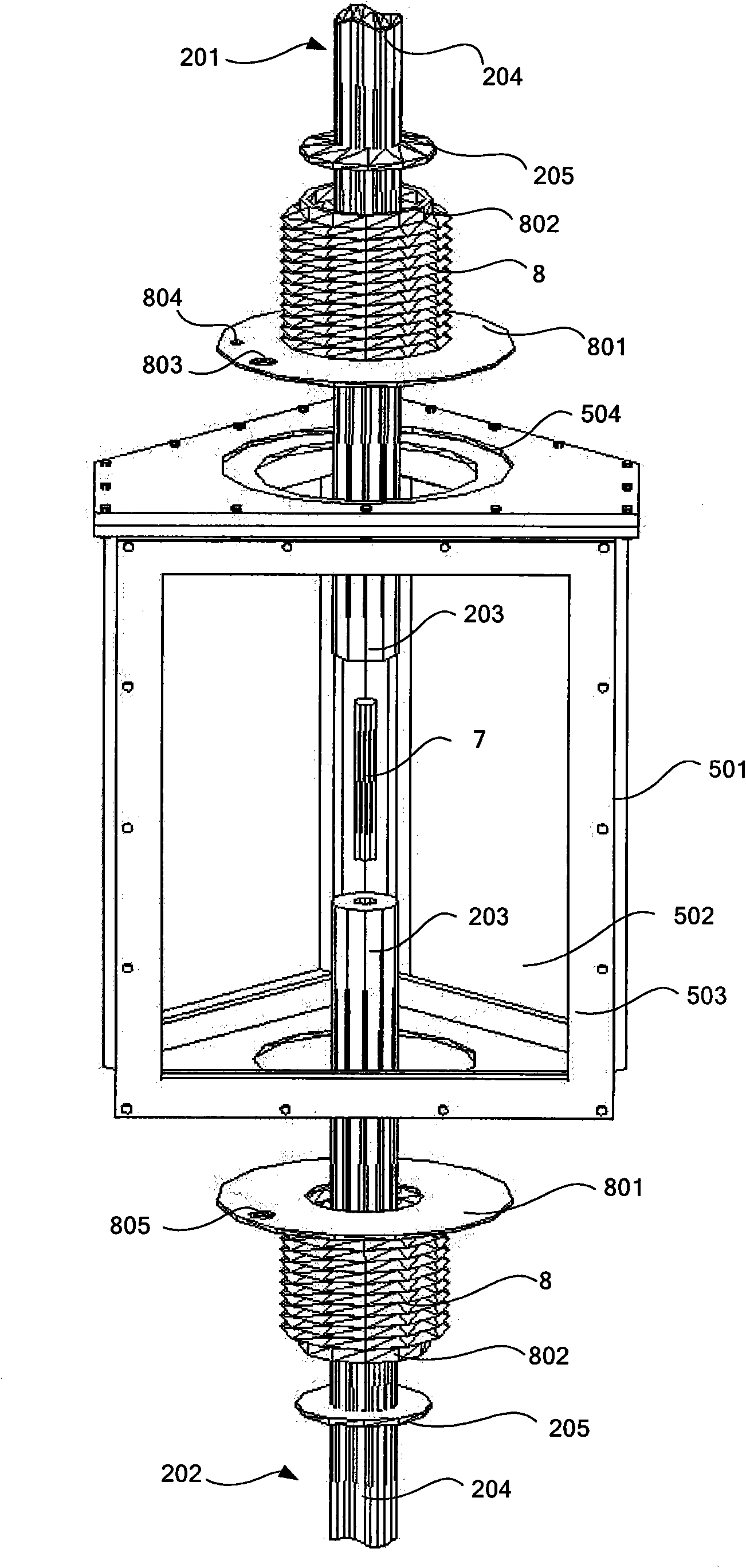

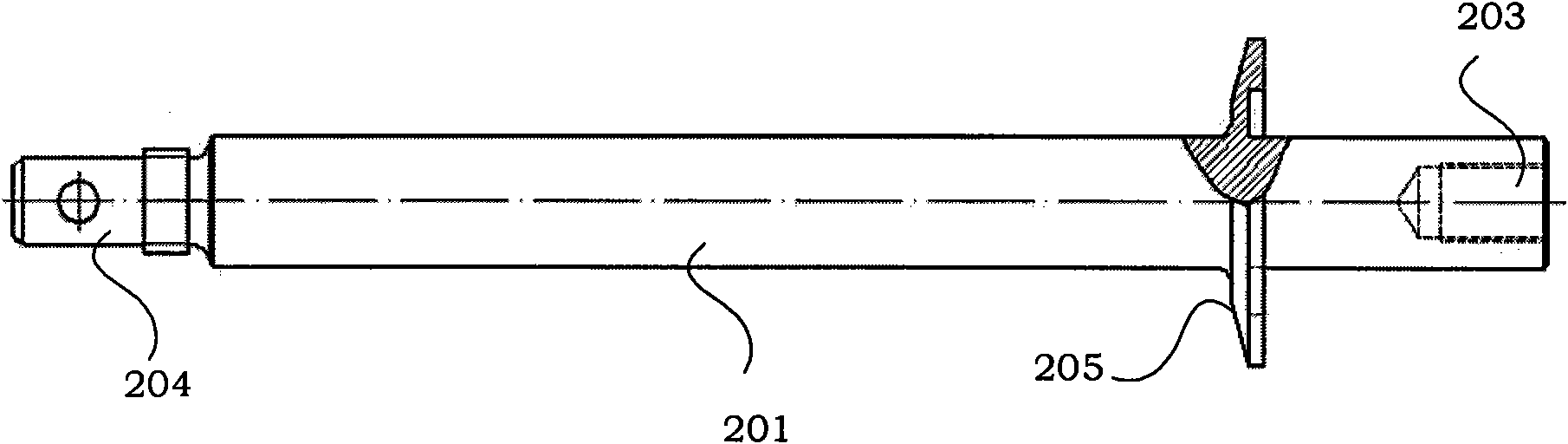

Test device for surface deformation and material and test method thereof

InactiveCN101672749AHeating up fastFast mechanical loadingMaterial strength using tensile/compressive forcesUsing optical meansOptical testStrength of materials

The invention discloses a test device for surface deformation of a material and a test method thereof, wherein the device comprises a material mechanical property test machine, an infrared fast heating device, a surface deformation optical test system, a temperature collecting device, a vacuum system and a clamp. The clamp fixes a sample in a vacuum chamber of the vacuum system and is connected with the material mechanical property test machine, the infrared fast heating device supplies thermal load for the sample, and the surface deformation optical test system measures the surface deformation of the sample. The device and the test method can simultaneously heat, apply stress and synchronously test deformation field in the surface. The coupling simulation of an aero-engine under service environment with high temperature and loading level, and the surface deformation condition of the structural material with high temperature under the environment are tested.

Owner:BEIHANG UNIV

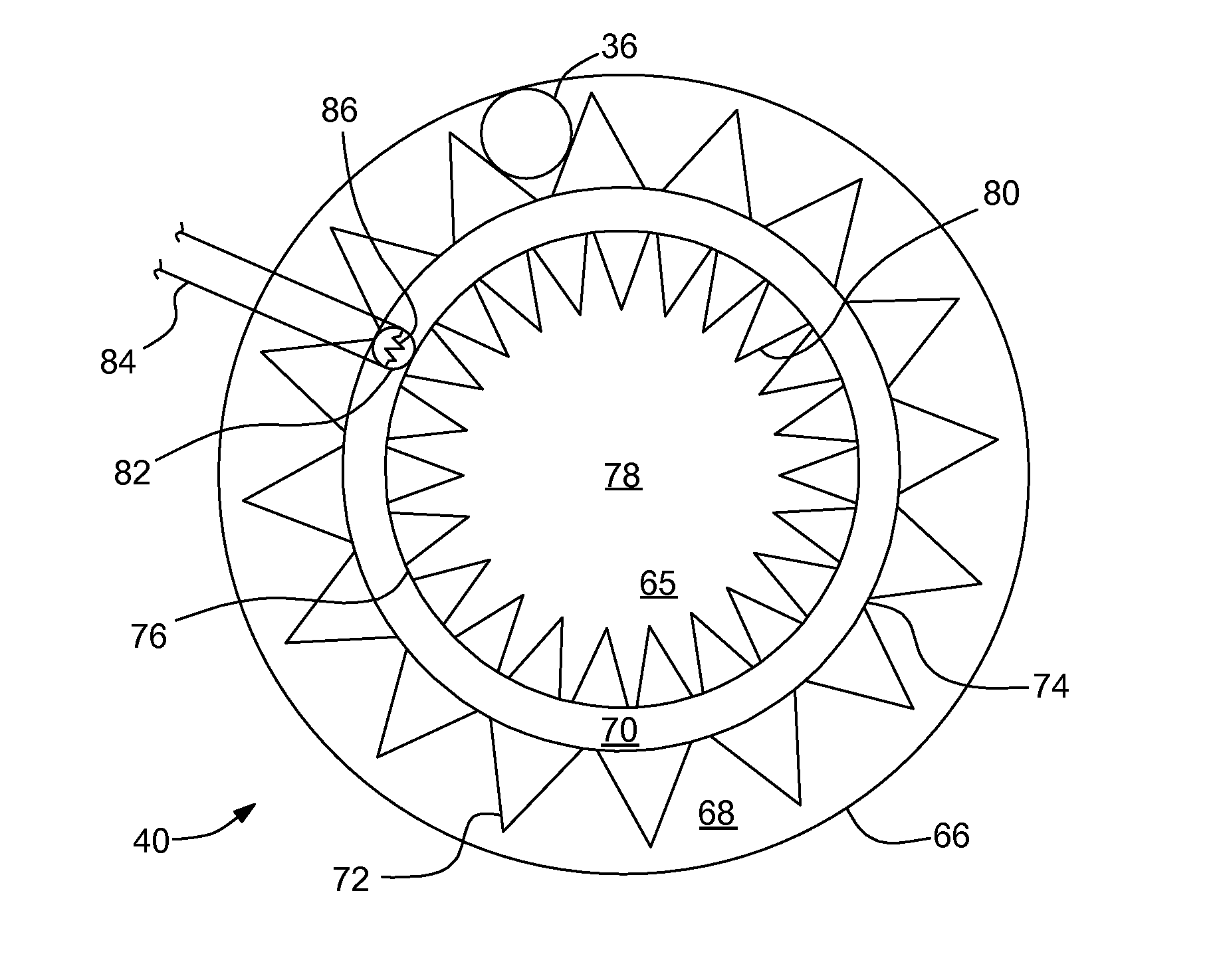

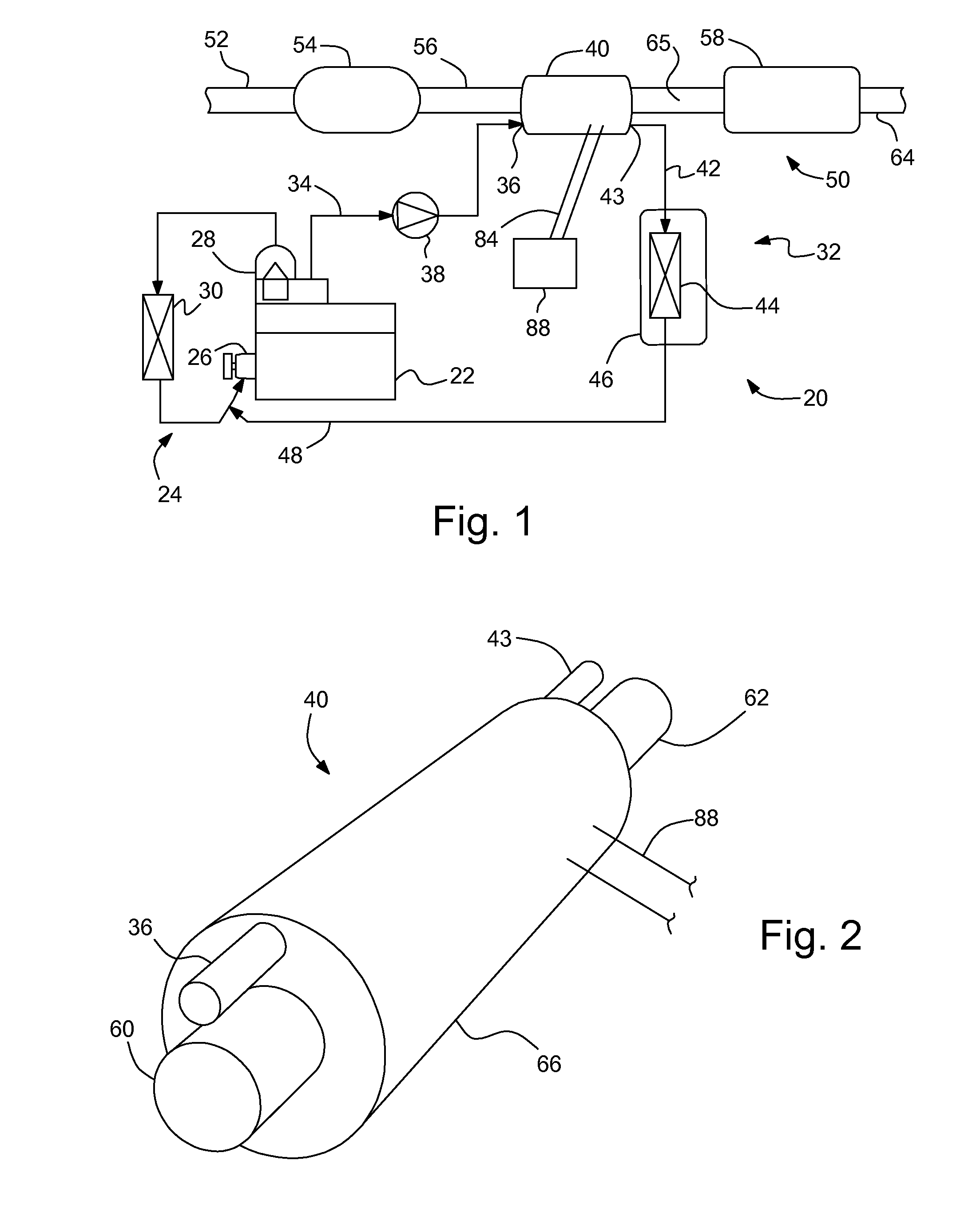

Exhaust gas waste heat recovery

InactiveUS7921640B2Faster engine warm upImprove economyInternal combustion piston enginesExhaust apparatusPower flowEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Food warming apparatus and method

InactiveUS20060185527A1Improve product qualityHeating up fastDomestic stoves or rangesElectrical heating fuelEngineeringIngested food

Owner:DUKE MANUFACTURING COMPANY

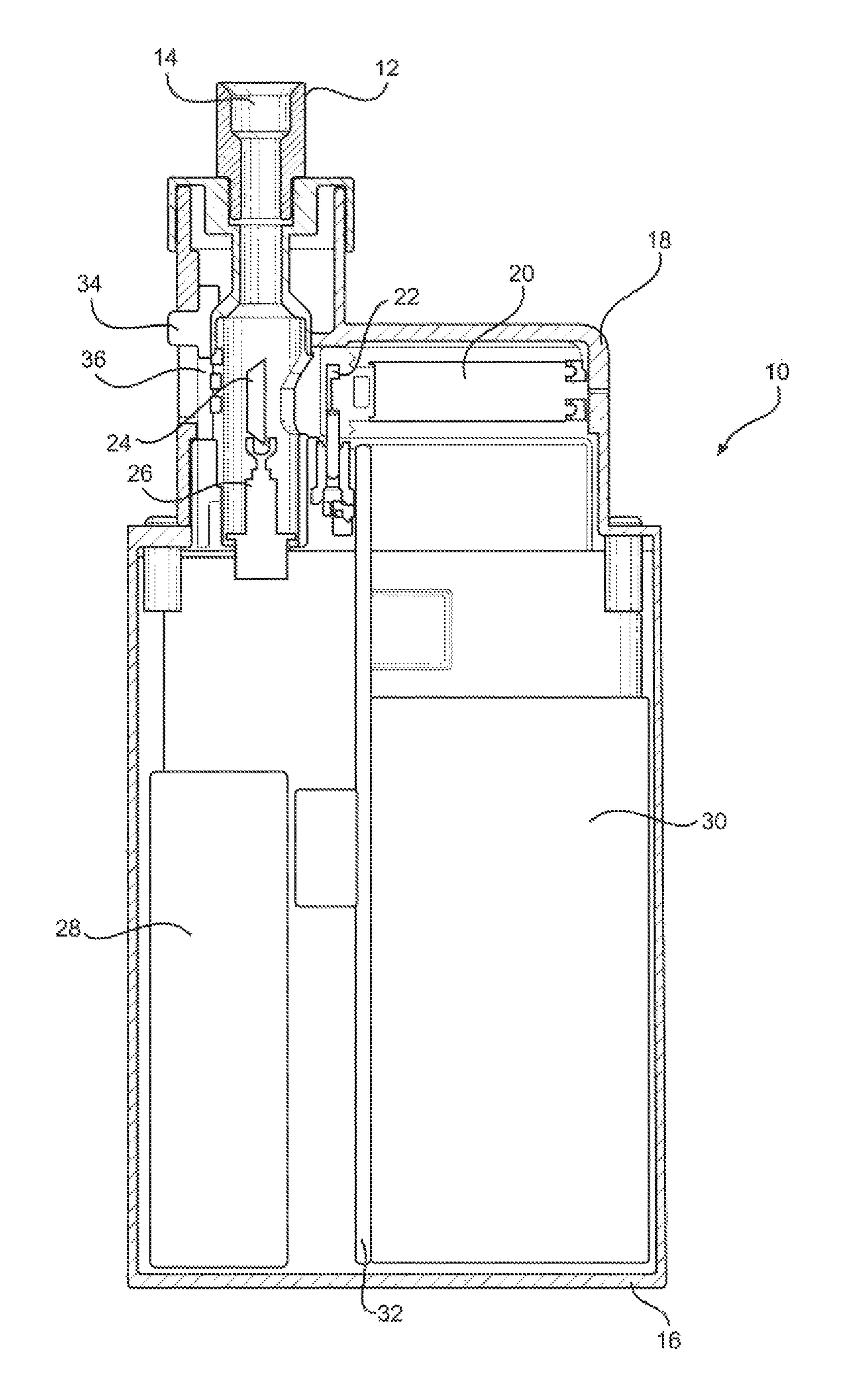

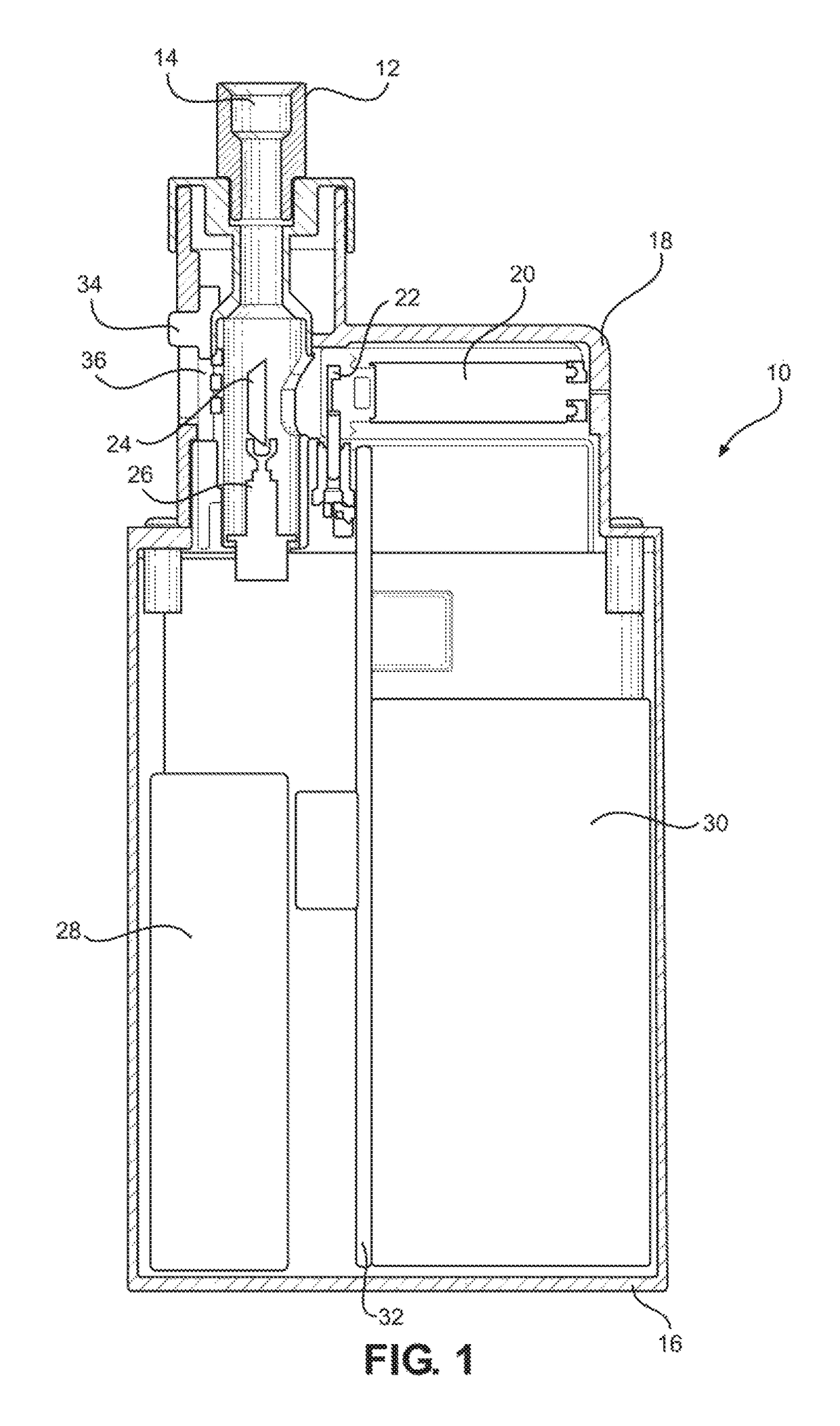

Heater element for a vaporization device

ActiveUS9968136B1Lose efficiencyQuickly heat upHeater elementsTobacco pipesBiomedical engineeringHeating element

A heater element for a vaporizing device, a vaporizing device containing the heater element, and a method for vaporizing fluid ejected by an ejection head. The heater element includes a conductive material having a concave area. The concave area of the heater element captures and vaporizes fluid ejected from an ejection head in the vaporization device. The concave area of the heating element has a cavity volume that is at least sufficient to retain an entire volume of liquid to be vaporized.

Owner:FUNAI ELECTRIC CO LTD

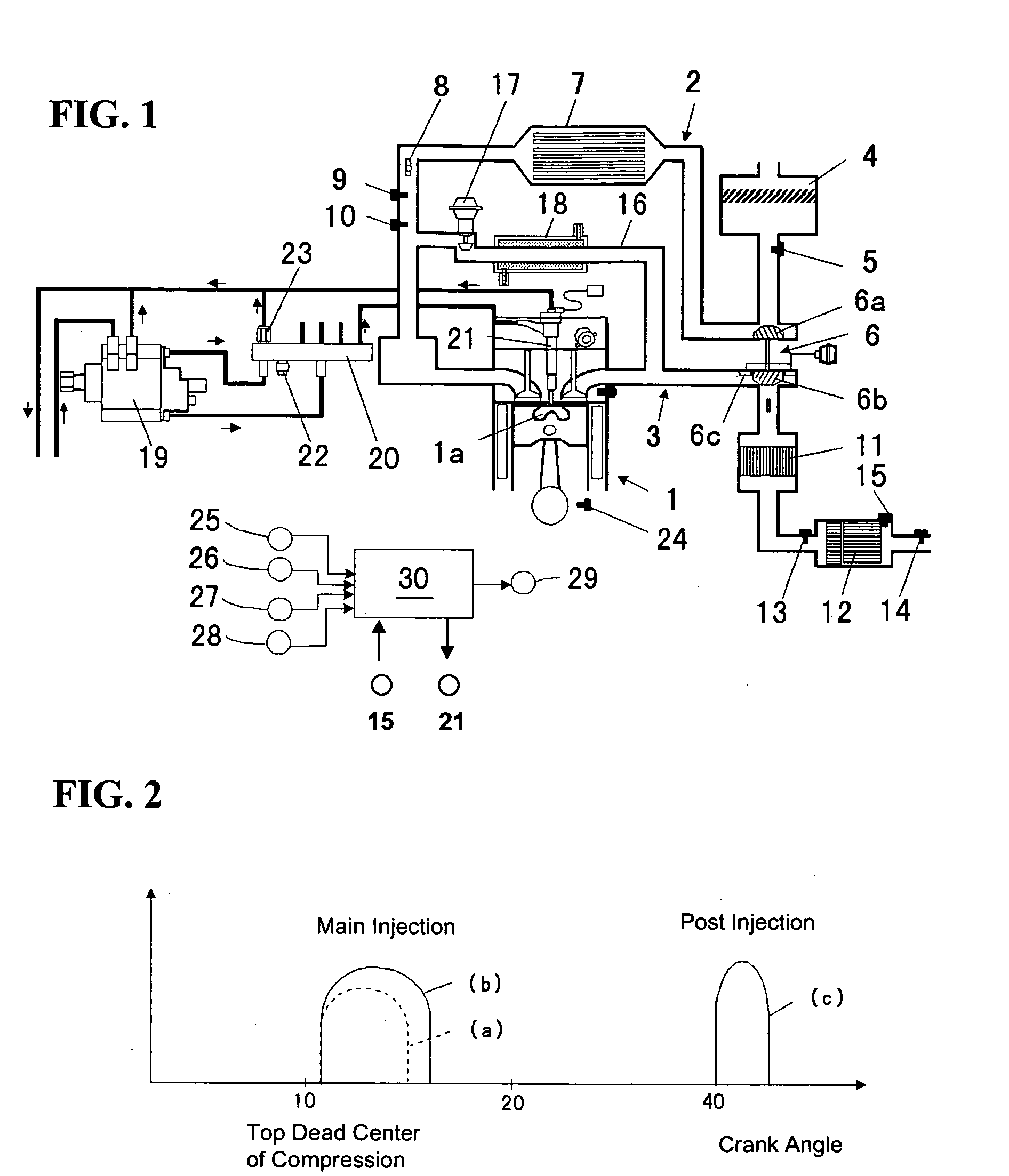

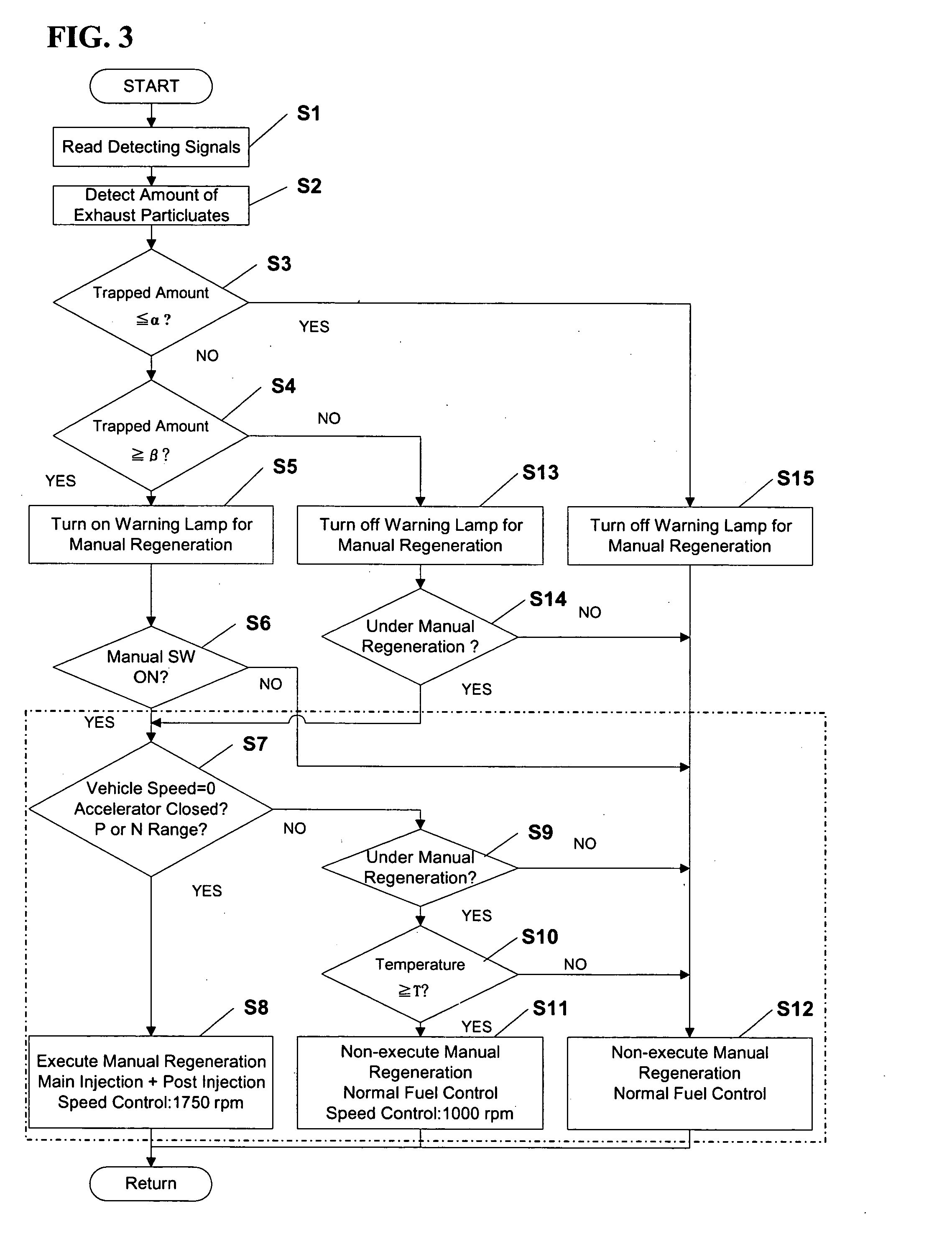

Exhaust gas purification device of engine for vehicle

InactiveUS20050050883A1Suppresses deterioration of durabilityHeating up fastElectrical controlInternal combustion piston enginesParticulatesFuel efficiency

There are provided a particulate filter and a manual regeneration switch. When the manual regeneration switch is operated and the vehicle is in a stop state, the engine speed is adjusted to a first target higher than a normal idle speed to regenerate the filter. Meanwhile, when the vehicle changes from its stop state to its driving state, the engine speed is adjusted to a second target higher than the normal idle speed but lower than the first target in the event that the temperature of the filter is high, while the engine speed is adjusted to the normal idle speed in the event that the temperature of the filter is low. Accordingly, deterioration of the durability of the filter due to its rapid temperature increasing can be suppressed, avoiding disadvantages of fuel efficiency and vehicle start feeling.

Owner:MAZDA MOTOR CORP

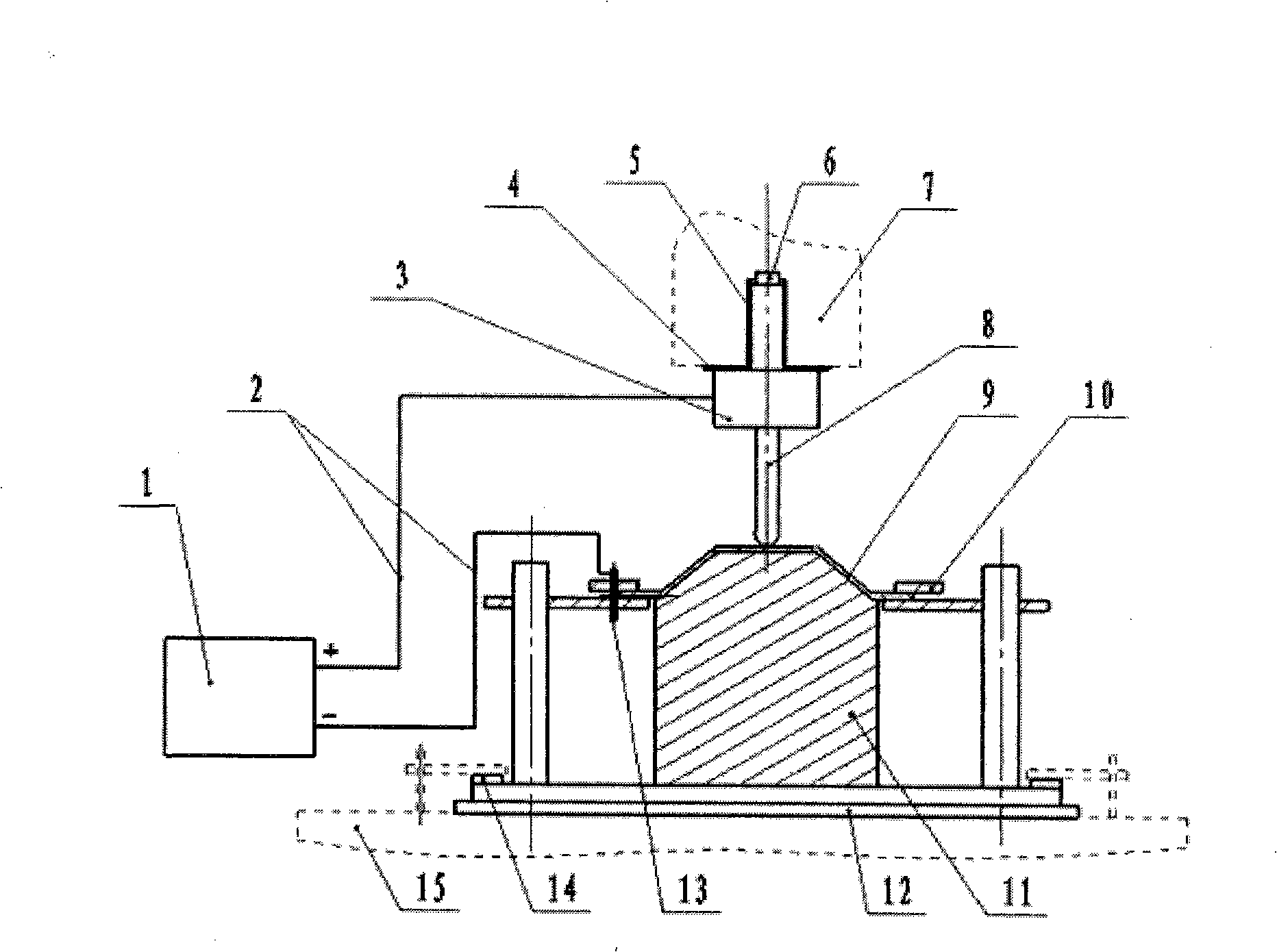

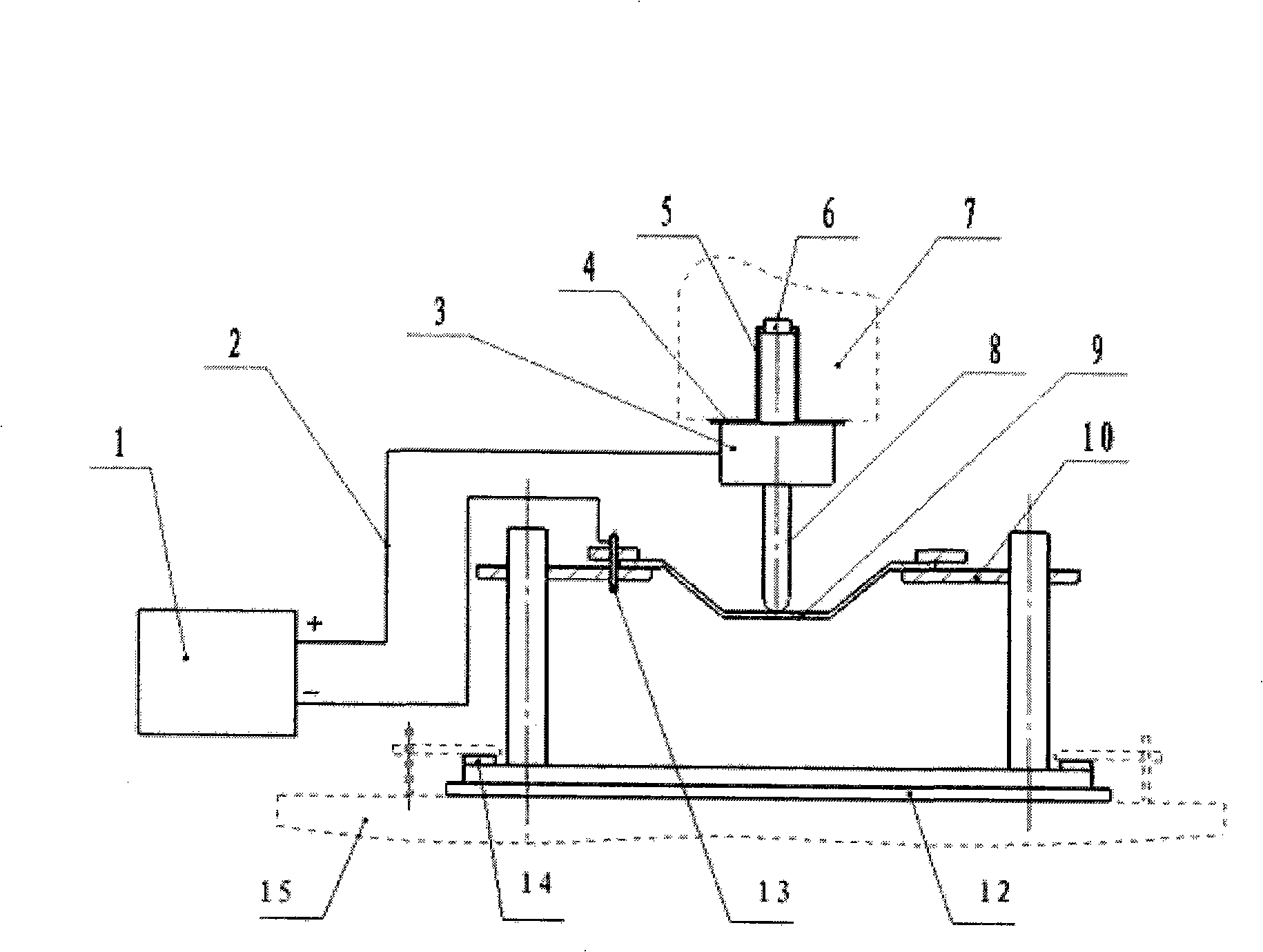

Electrical heating numerical control incremental forming processing method and device for plate

The invention relates to a device and a method of the electrical heating numerical control incremental forming processing of a sheet metal and belongs to the technical field of the sheet metal incremental forming processing. The key points of the device and the method lie in that a large current-carrying wire is used for forming an auxiliary power supply, a forming pressure head, a forming clamp and the sheet metal into a current loop; the power supply provides a low-voltage large current to cause the materials in a processing area to generate joule heat and to be softened in the sheet metal processing and forming so as to ensure the smooth implementation of the incremental forming processing. The heating method is fast in temperature rising, convenient in control and low in price, thus solving the problem that other heating methods are complex to control, improving the processing precision and being favorable for forming complex parts. At the same time, the method is suitable for the incremental processing of sheet metals such as the titanium magnesium sheet metal, and the like, which are hard to be plastically formed at normal temperature.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Hand warmer

InactiveUS20080053979A1Avoid failureImprove the temperature environmentMechanical apparatusSurgeryElectrical batteryRechargeable cell

In a hand warmer, a heat dissipating plate is thermally coupled to a heater that is supplied with current by a battery that is accommodated in a case. The battery is a box-shaped rechargeable battery of a box-shaped rechargeable lithium-ion battery or lithium-polymer battery that has flat surfaces opposed to each other. The heater is a heating element that is opposed to the flat surface of the battery. A shielding plate is arranged between the heating element and the flat surface of the battery. The heat dissipating plate that is thermally coupled to the heating element is secured to the case on the surface side of the case. In the hand warmer, the flat surface of the box-shaped rechargeable battery, the shielding plate and the heat dissipating plate are arranged in a stack structure. The heat dissipating plate is heated by the heating element.

Owner:SANYO ELECTRIC CO LTD

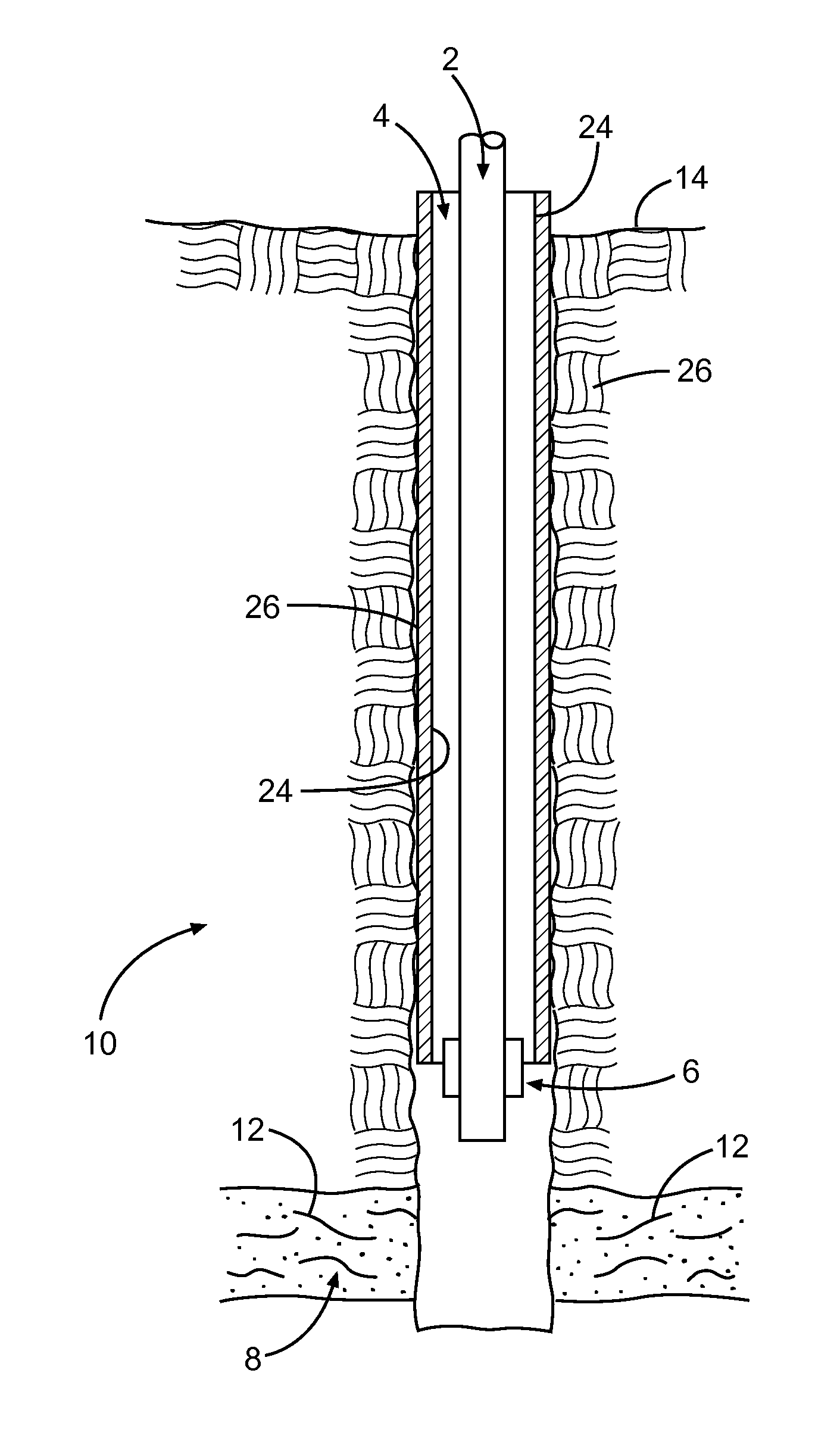

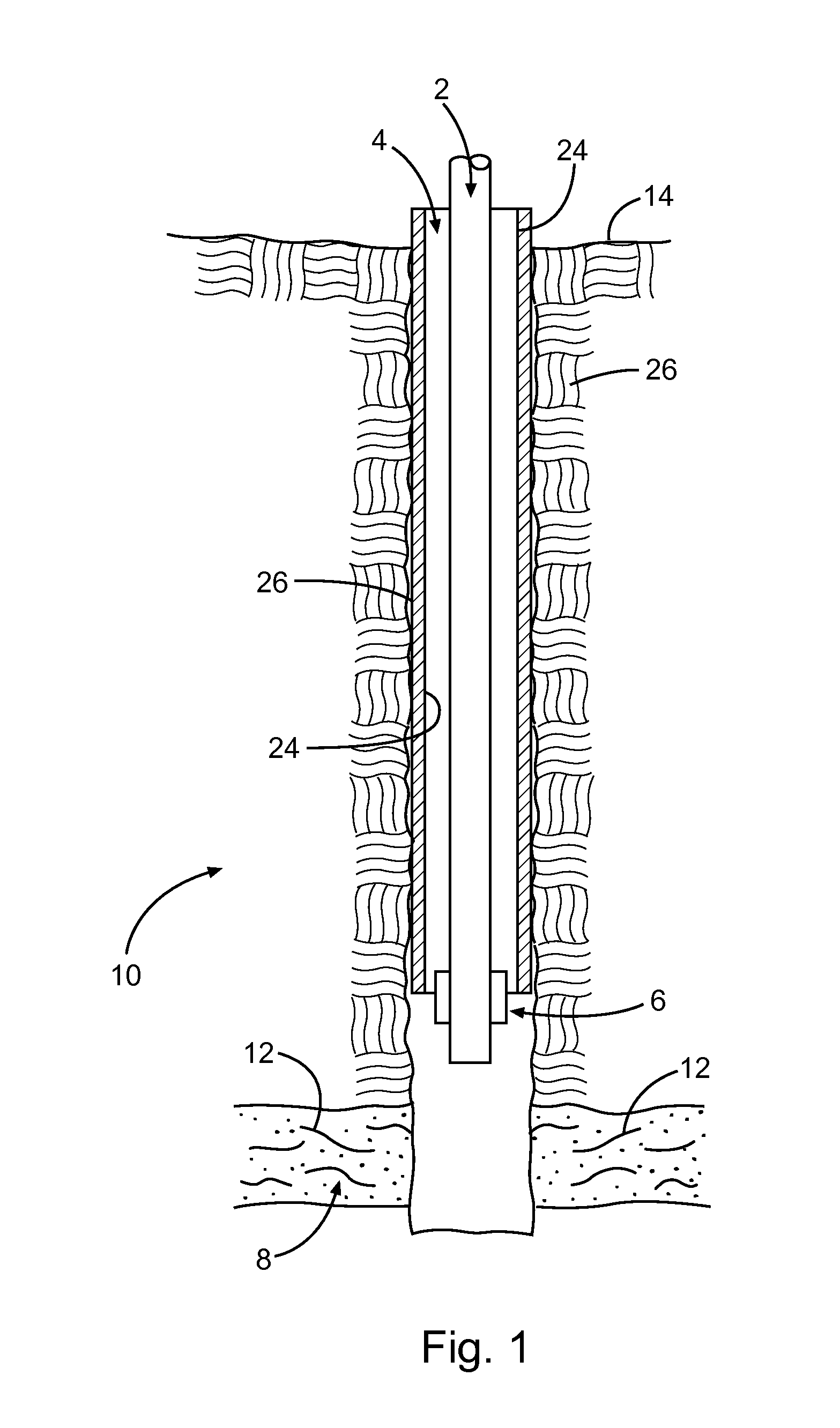

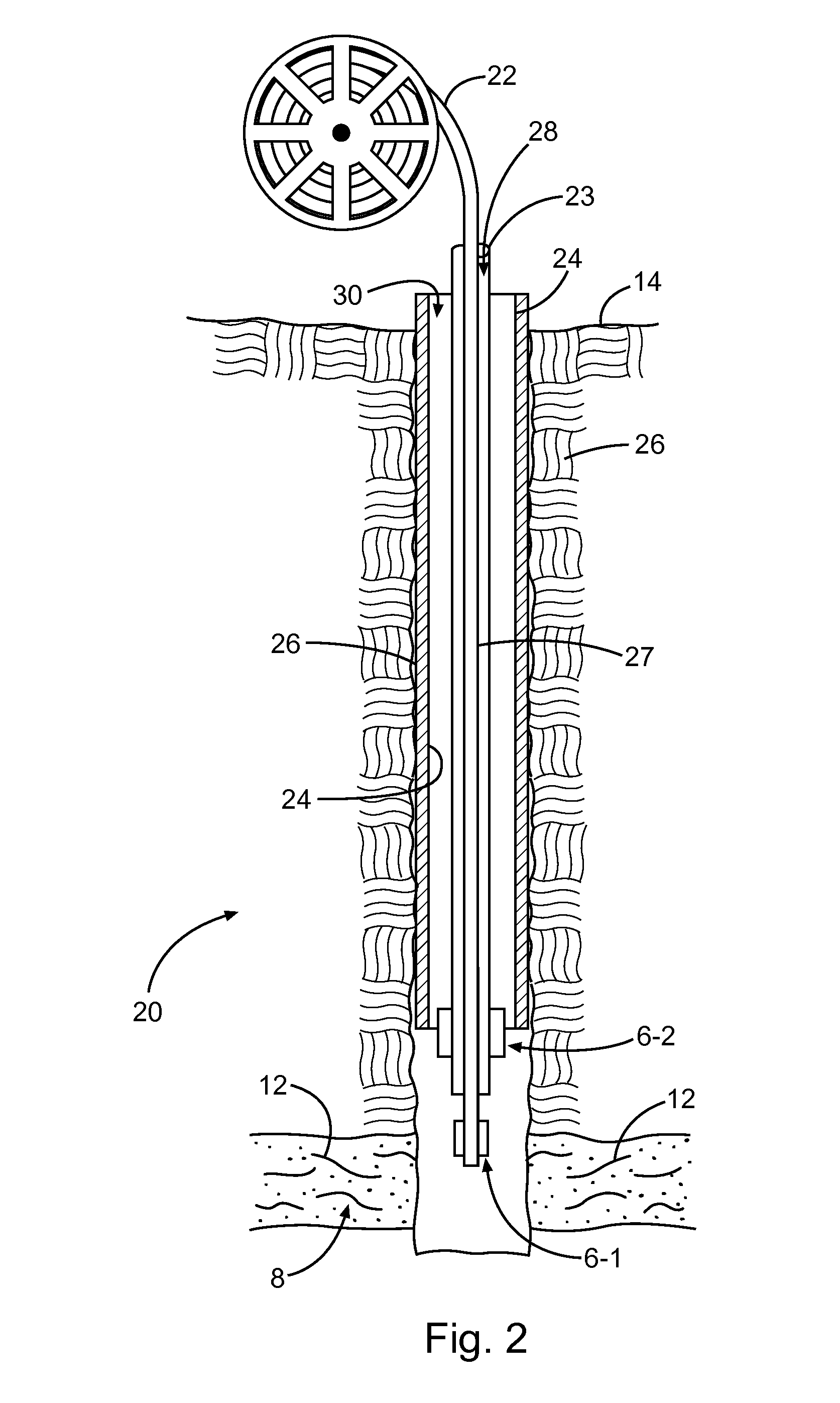

Methods for treatment of a subterranean formation

The present invention relates to methods of treating subterranean formations. In various embodiments, the present invention provides a method of treating a subterranean formation including placing a first aqueous composition and a second aqueous composition in a subterranean formation. The placing includes injecting the first aqueous composition through a tubular passage in a wellbore. The placing also includes injecting the second aqueous composition through an annular passage in the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

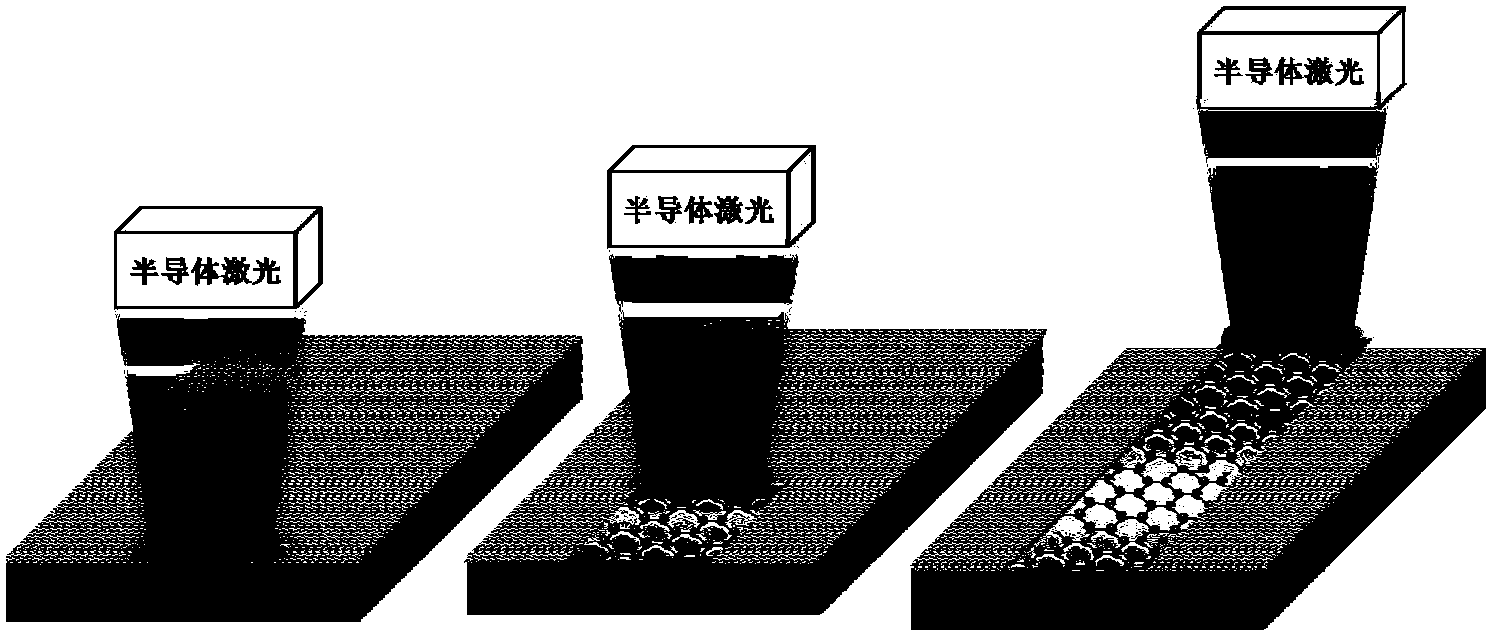

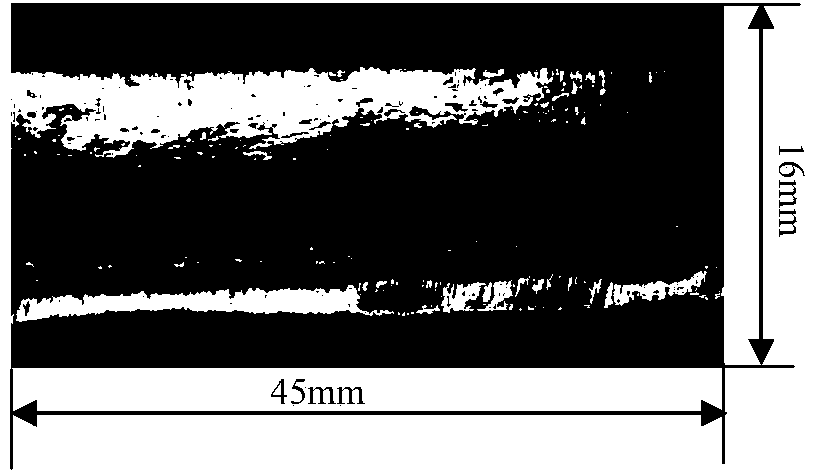

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

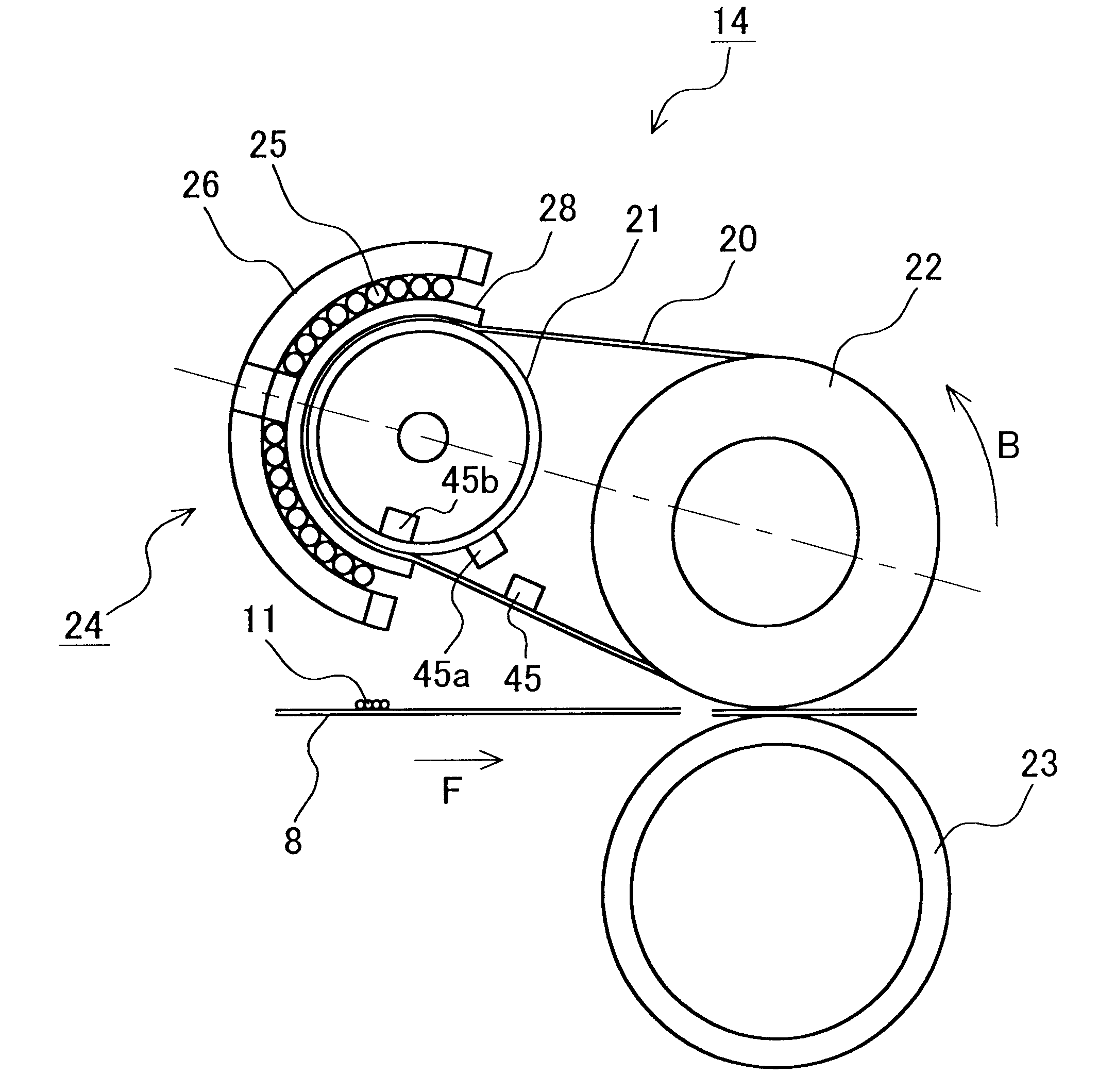

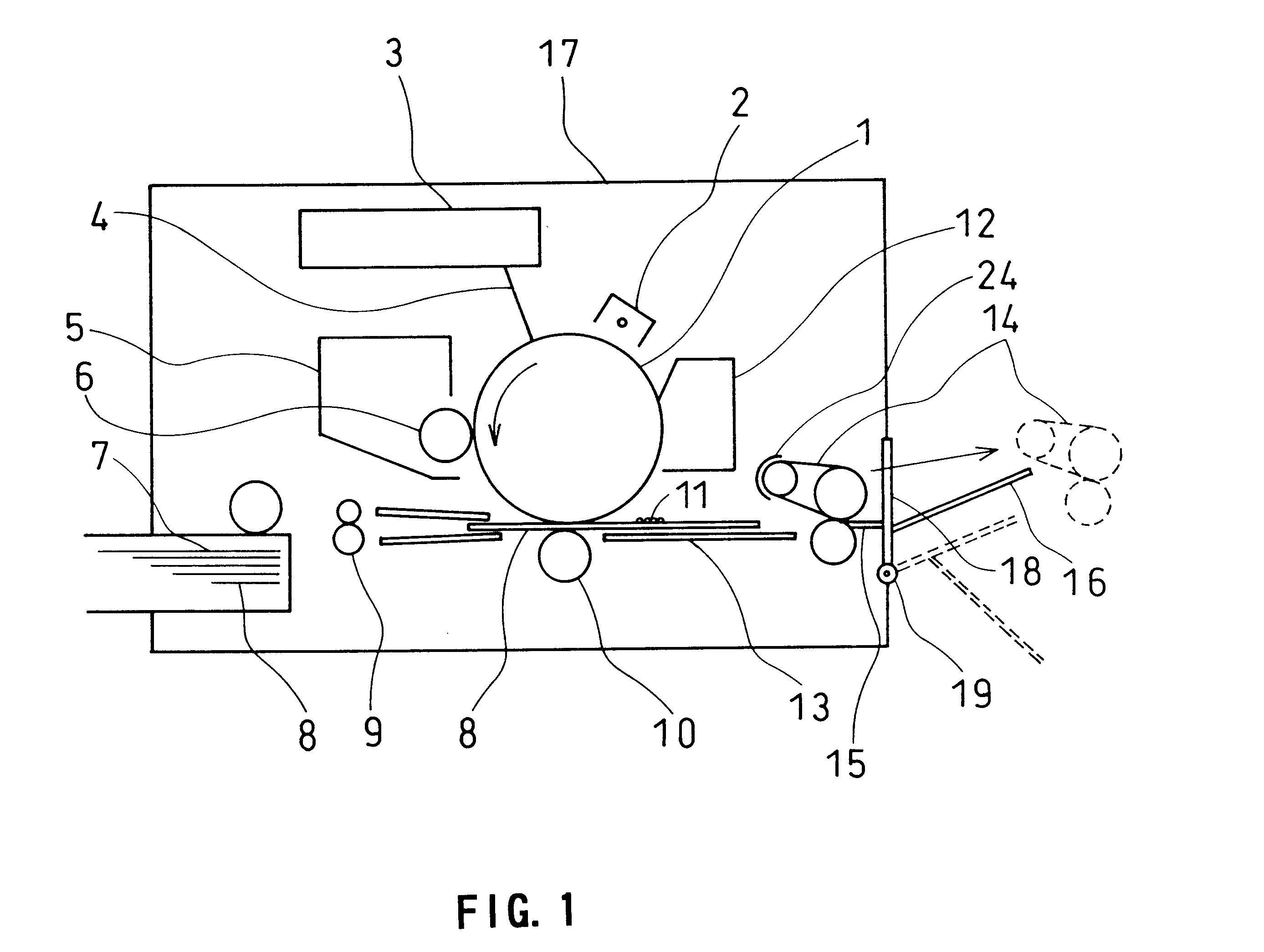

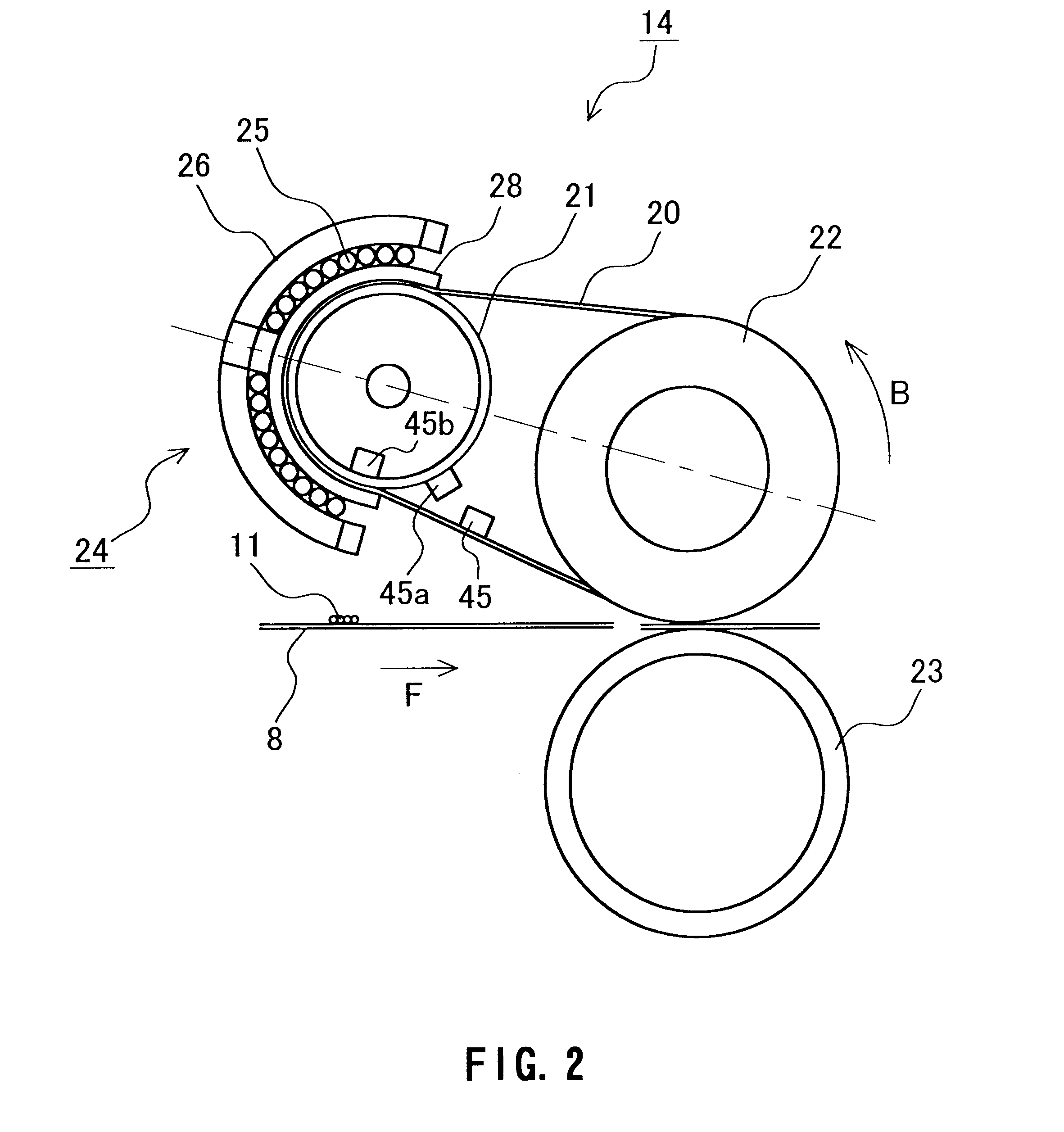

Image heating device and image forming apparatus using the same

InactiveUS6725009B1Solve large capacityShort warm-up timeOhmic-resistance heatingElectrographic process apparatusHeat resistanceMagnetization

An image heating device with a small thermal capacity that can be heated rapidly. The image heating device includes a fixing belt (20) having a heat resistance; a rotatable heat-generating roller (21), which is at least partially conductive and arranged in contact with an inner peripheral surface of the fixing belt (20); a fixing roller (22), the fixing roller and the heat-generating roller (21) movably suspending the fixing belt (20) therebetween; and a magnetization means (24) for heating the heat-generating roller (21) through magnetization, which is arranged outside the heat-generating roller (21). In this image heating device, the magnetization means (24) heats the heat-generating roller (21) through magnetization after a rotating operation of the heat-generating roller (21) is started.

Owner:PANASONIC CORP

Thallus for producing biological fertilizer by employing cane sugar filter mud fermentation

A cell for producing biological organic fertilizer fermented mainly by sucrose filtered mud is disclosed, which is characterized by weight percentage of components are: yeasts 30%-35%, streptomyces 30%-35%, bacillus 30%-40%. Using the inventive cell for producing biological organic fertilizer, temperature increases fast when fermenting, filtered mud in sugar factory decomposes rapidly, and produced biological organic fertilizer is stable in quality.

Owner:谭宏伟

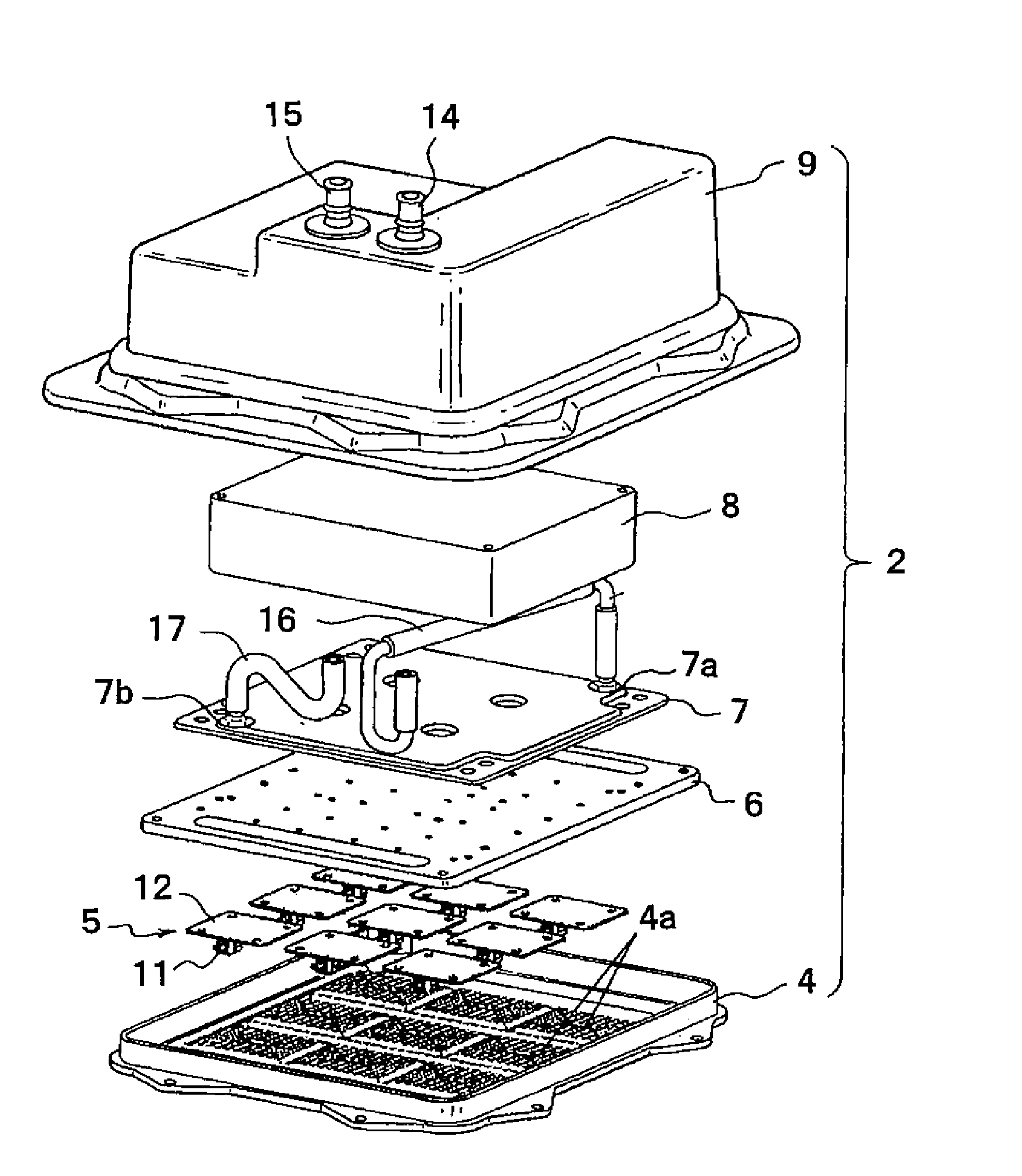

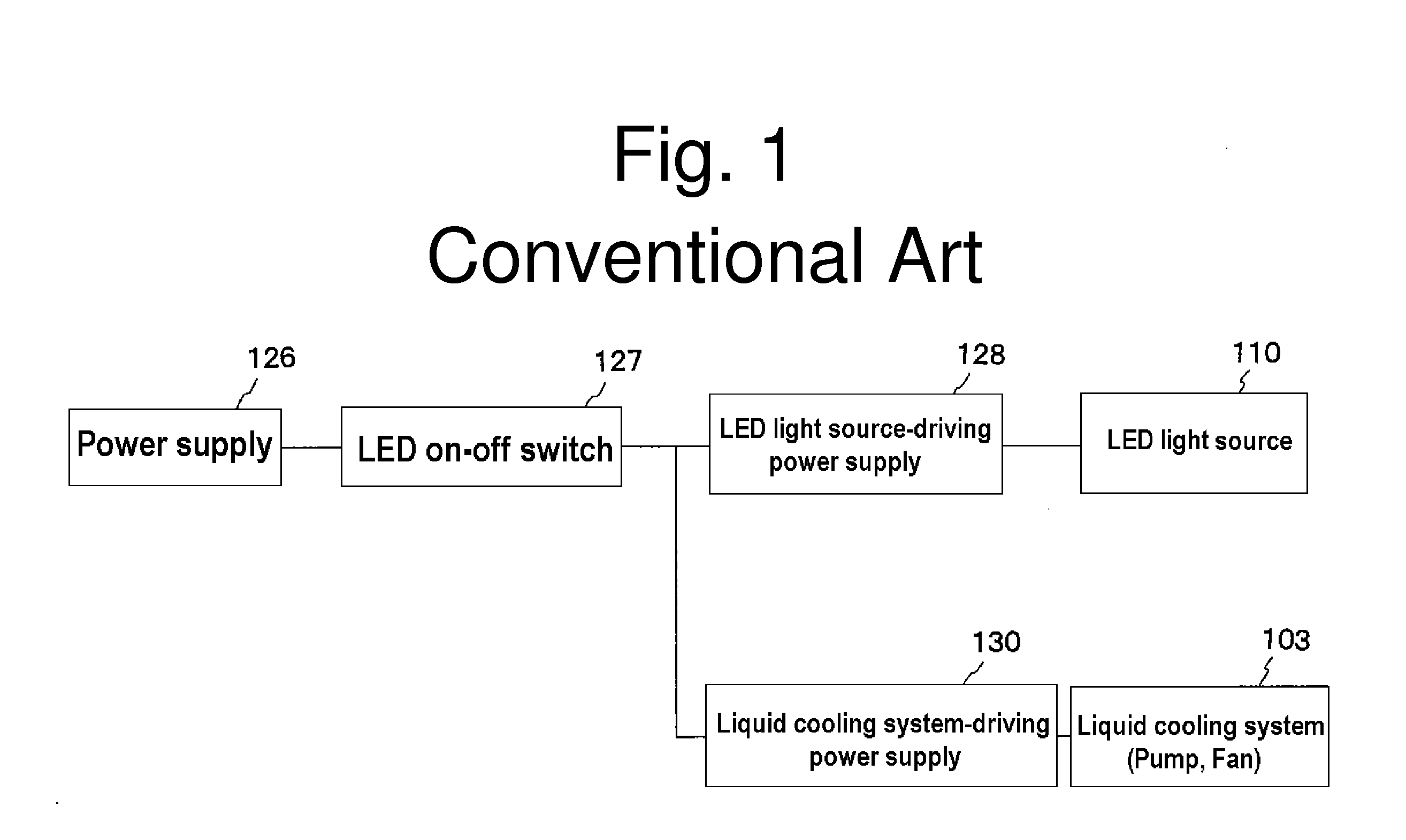

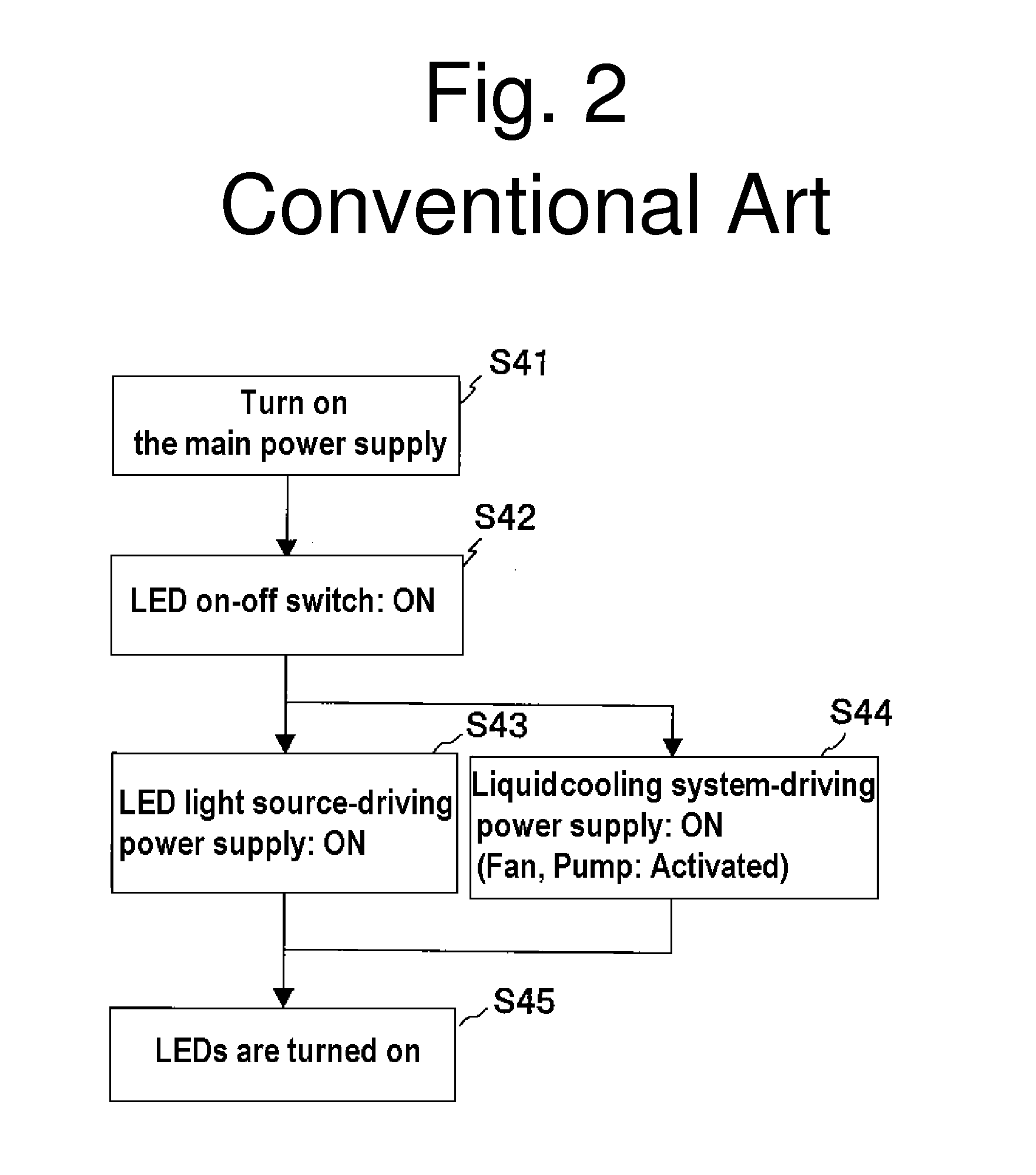

Liquid-cooled LED lighting device

InactiveUS20100134017A1Improve reliabilityIncrease temperaturePoint-like light sourceLighting heating/cooling arrangementsEffect lightLiquid cooling system

A liquid-cooled LED lighting device can be provided in which a temporal increase in the temperature of the tubing and the circulation pump when the LED light sources are turned off is prevented to ensure high reliability. The liquid-cooled LED lighting device can include an LED light source, a liquid cooling system including a heat receiving jacket and a radiator, an LED light source-driving power supply for supplying power to the LED light source, and a liquid cooling system-driving power supply for supplying power to the liquid cooling system. The LED lighting device can include a control unit, such as a timer circuit. The control unit can maintain supply of the power to the liquid cooling system for a predetermined period of time after supply of the power to the LED light source is stopped.

Owner:STANLEY ELECTRIC CO LTD

Composite bacterium agent for organic material fermentation

The invention relates to an organic materials zymolysis complex bacillus agent in the field of zymolysis bacillus agent technology. It comprises: low temperature bacteria, Bacillus cereus, gliotoxin, pseudomonas, slim streptomycete, high temperature bacteria and high temperature actinomyces with the weight ration 4:2:1:1:3:2:2. The low temperature bacterium is enzyme yeast with the heat resisting temperature below 20 deg. The high temperature bacterium is enzyme yeast with the heat resisting temperature below 70 deg. The heat resisting temperature below 70 deg of the high temperature actinomyces bellows 70 deg.

Owner:青岛地恩地生物科技有限公司

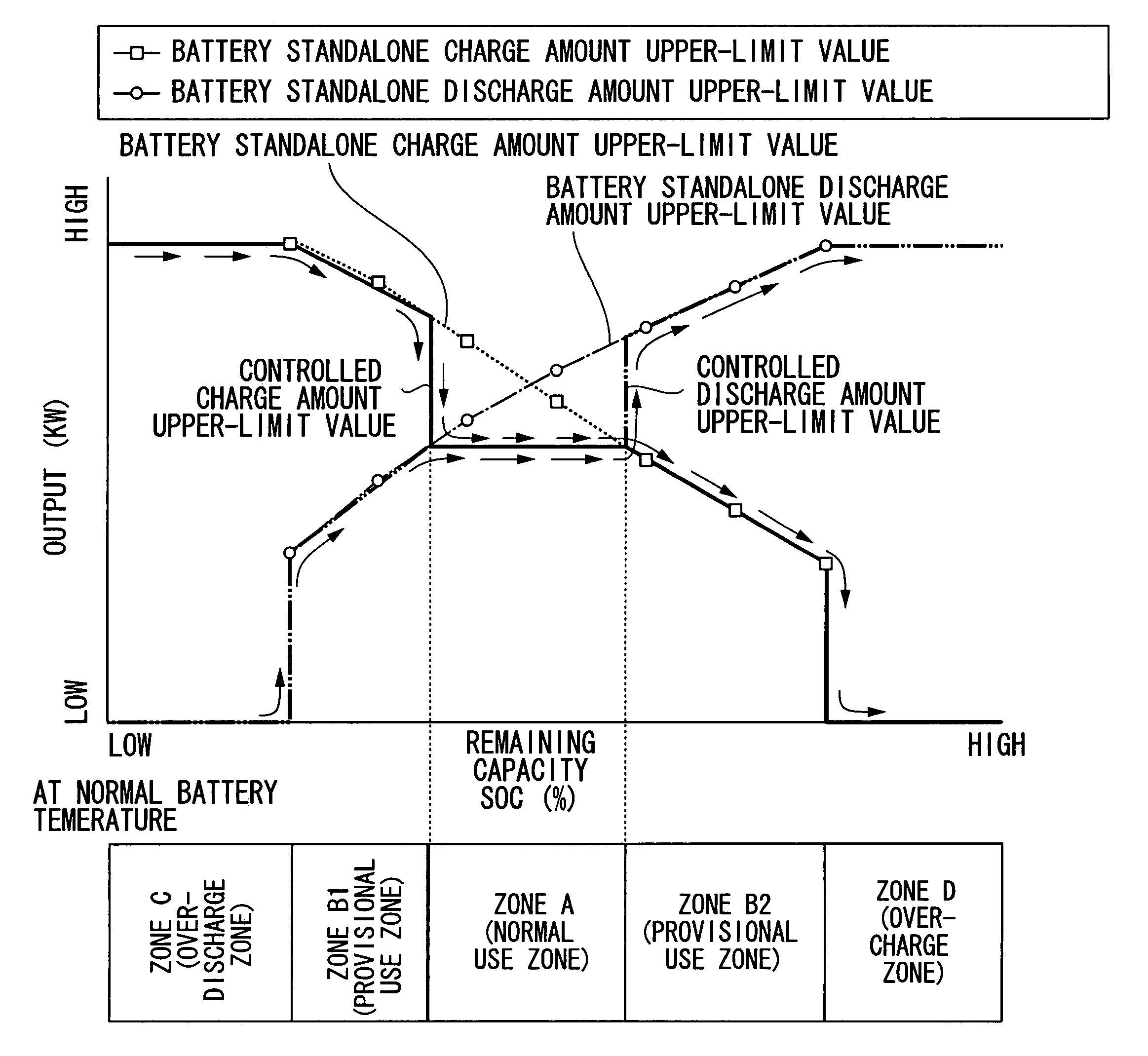

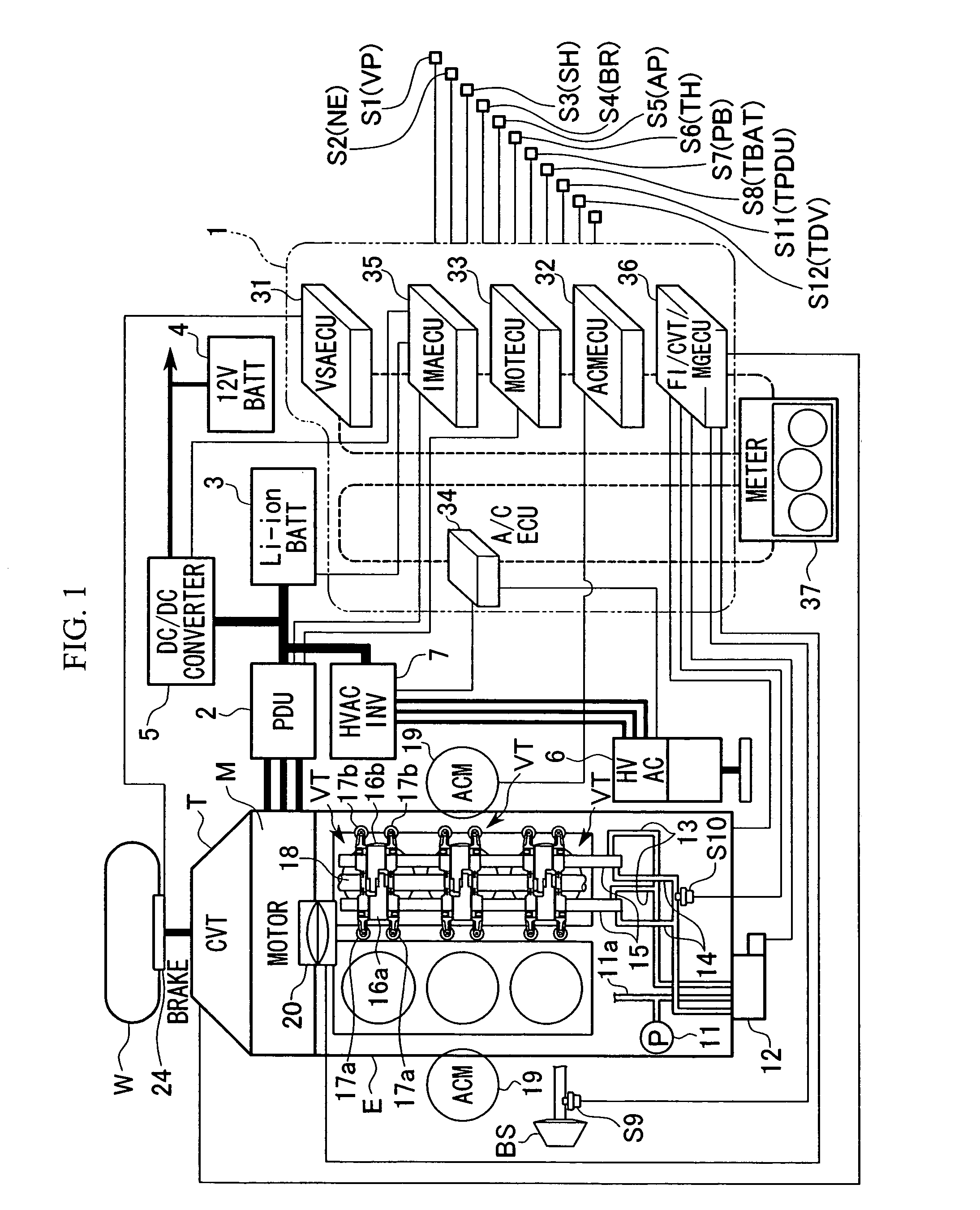

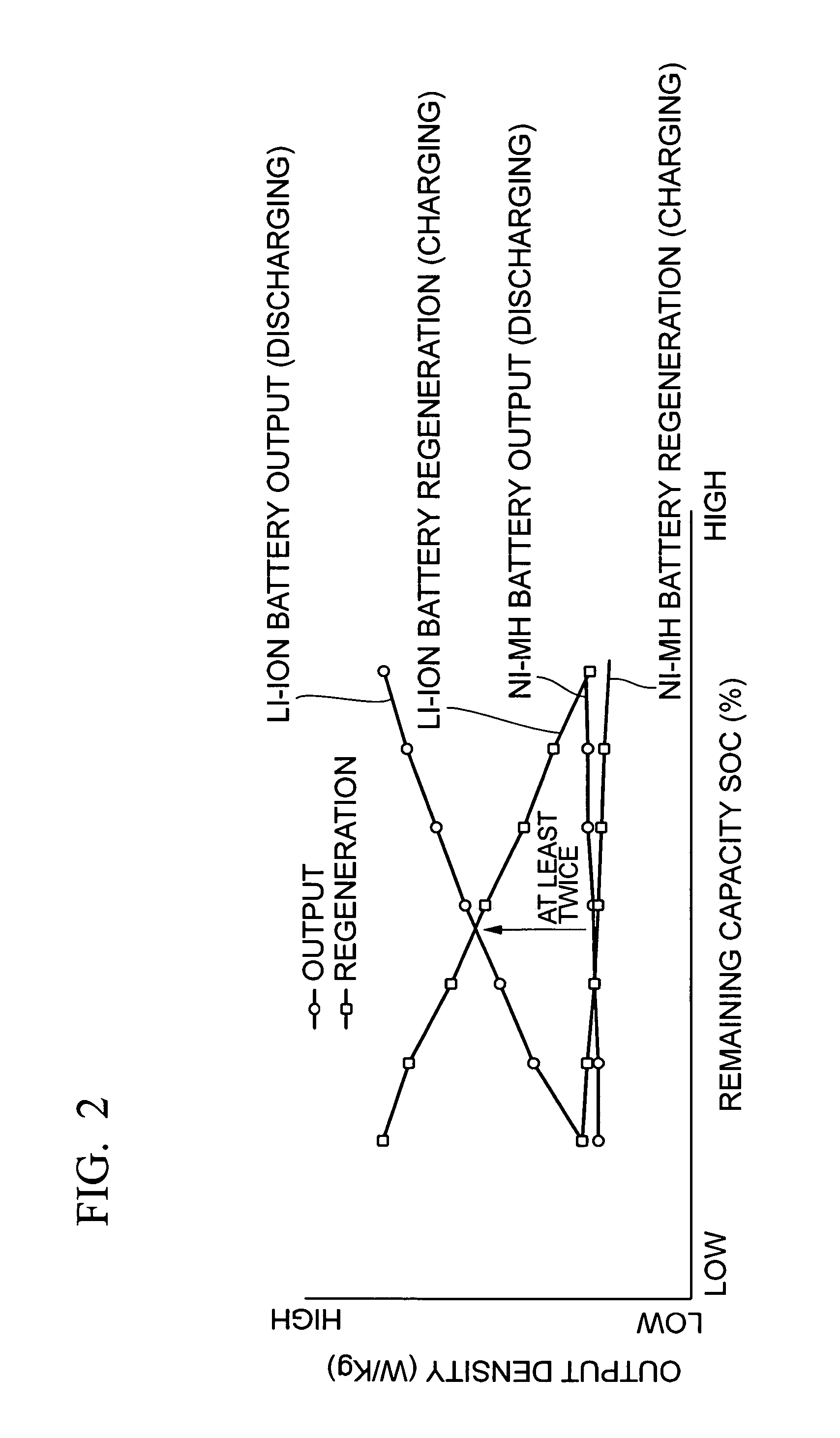

Control device for motor-driven vehicle

InactiveUS7610124B2Improve efficiencyHigh energyBatteries circuit arrangementsDigital data processing detailsMotor driveProcess engineering

A control device for a motor-driven vehicle, the control device includes: a zone determining unit that determines at least a normal use zone, a discharge zone, an over-discharge zone, a charge zone, and an over-charge zone; and a control unit controlling the motor by stipulating the charge and discharge power of the storage unit for each zone that is determined by the zone determining unit, setting the normal use zone to be in a predetermined range that includes a remaining capacity at which the discharge output according to the remaining capacity of the storage unit and the charge input according to the remaining capacity of the storage unit are equivalent, and making the discharge output and the charge input in the normal use zone to be a predetermined value regardless of the remaining capacity of the storage unit in the zone.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com