Patents

Literature

667results about How to "Achieve growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-Walled Carbon Nanotube and Aligned Single-Walled Carbon Nanotube Bulk Structure, and Their Production Process, Production Apparatus and Application Use

ActiveUS20080318049A1Efficient productionIncrease freedomMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

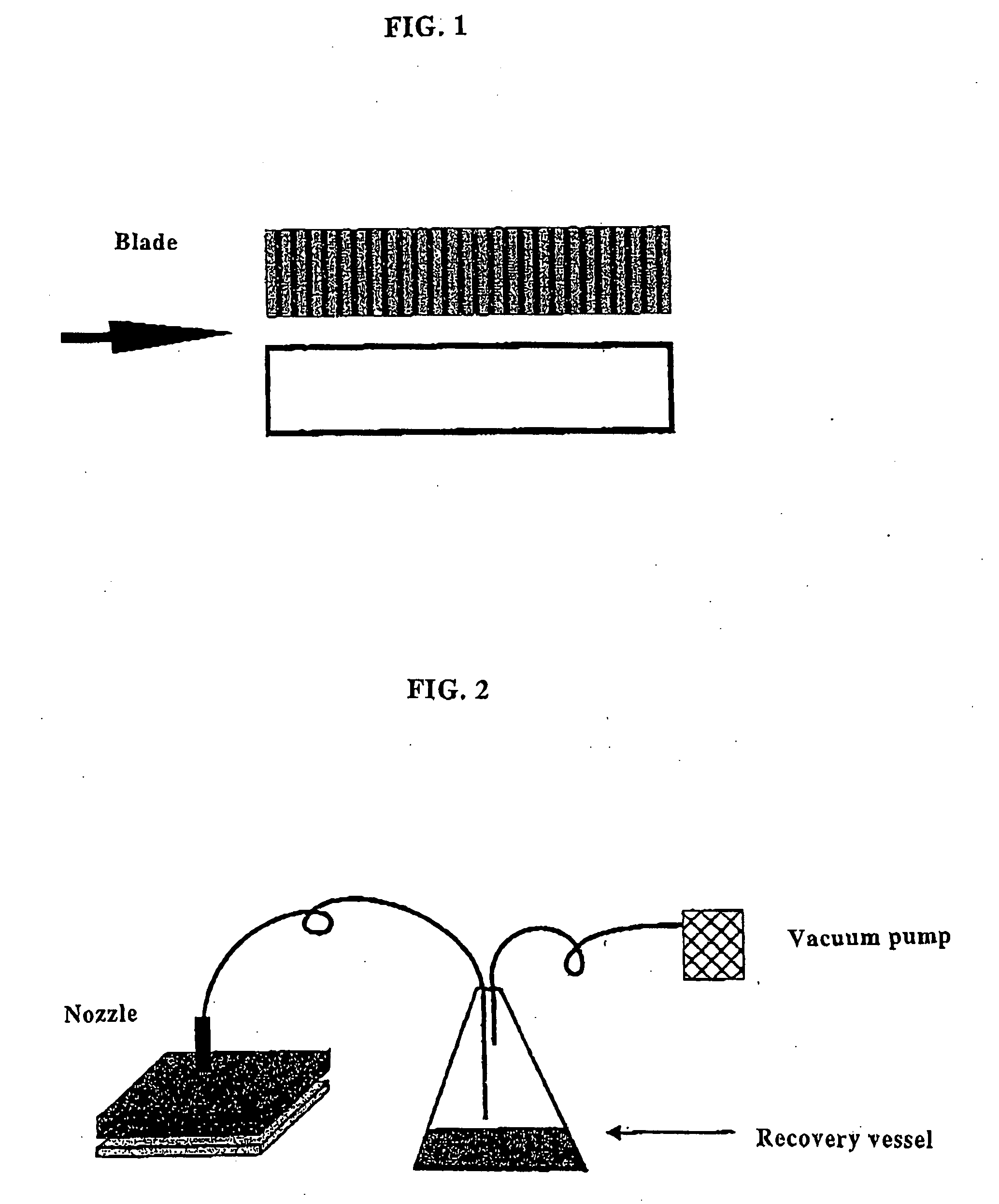

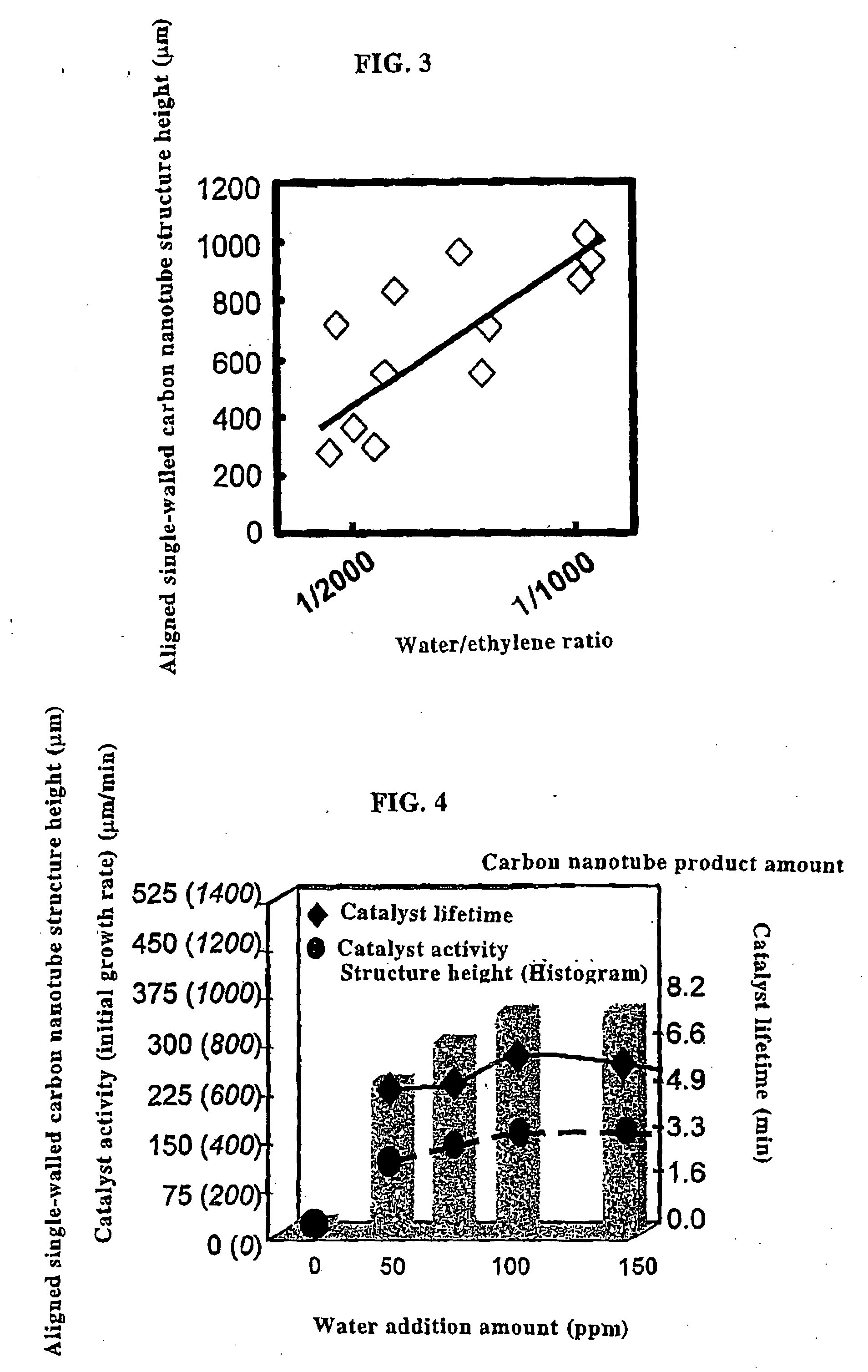

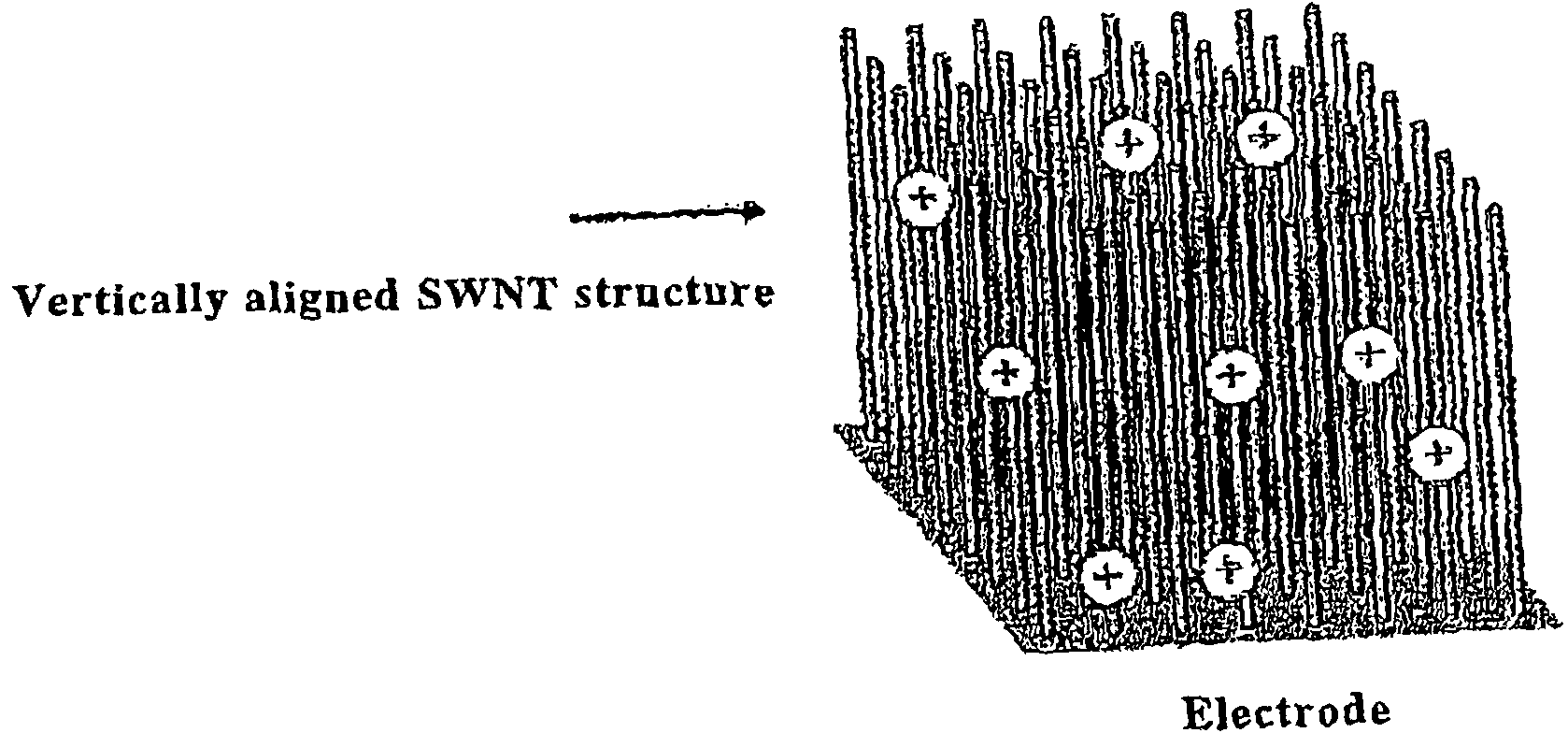

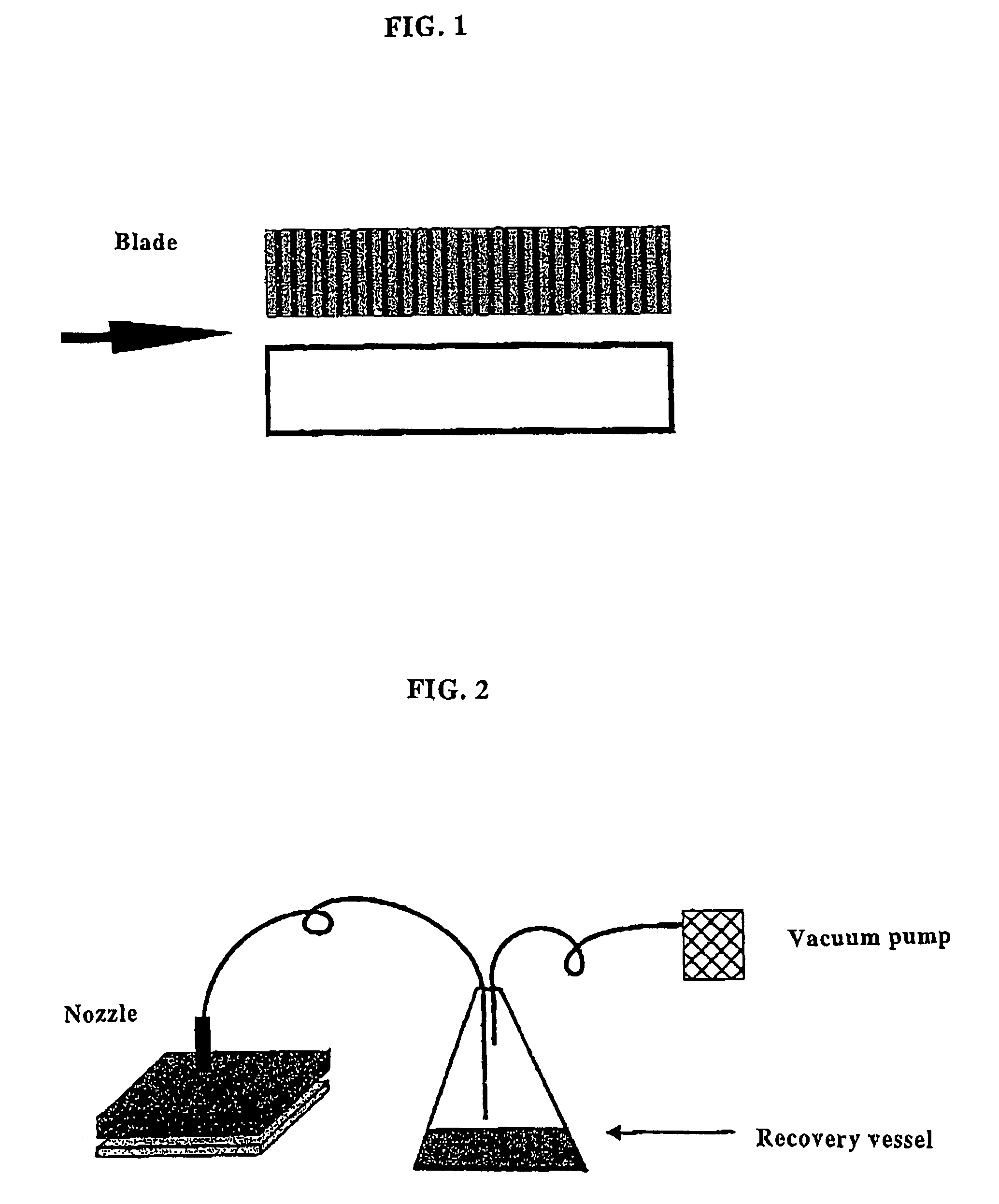

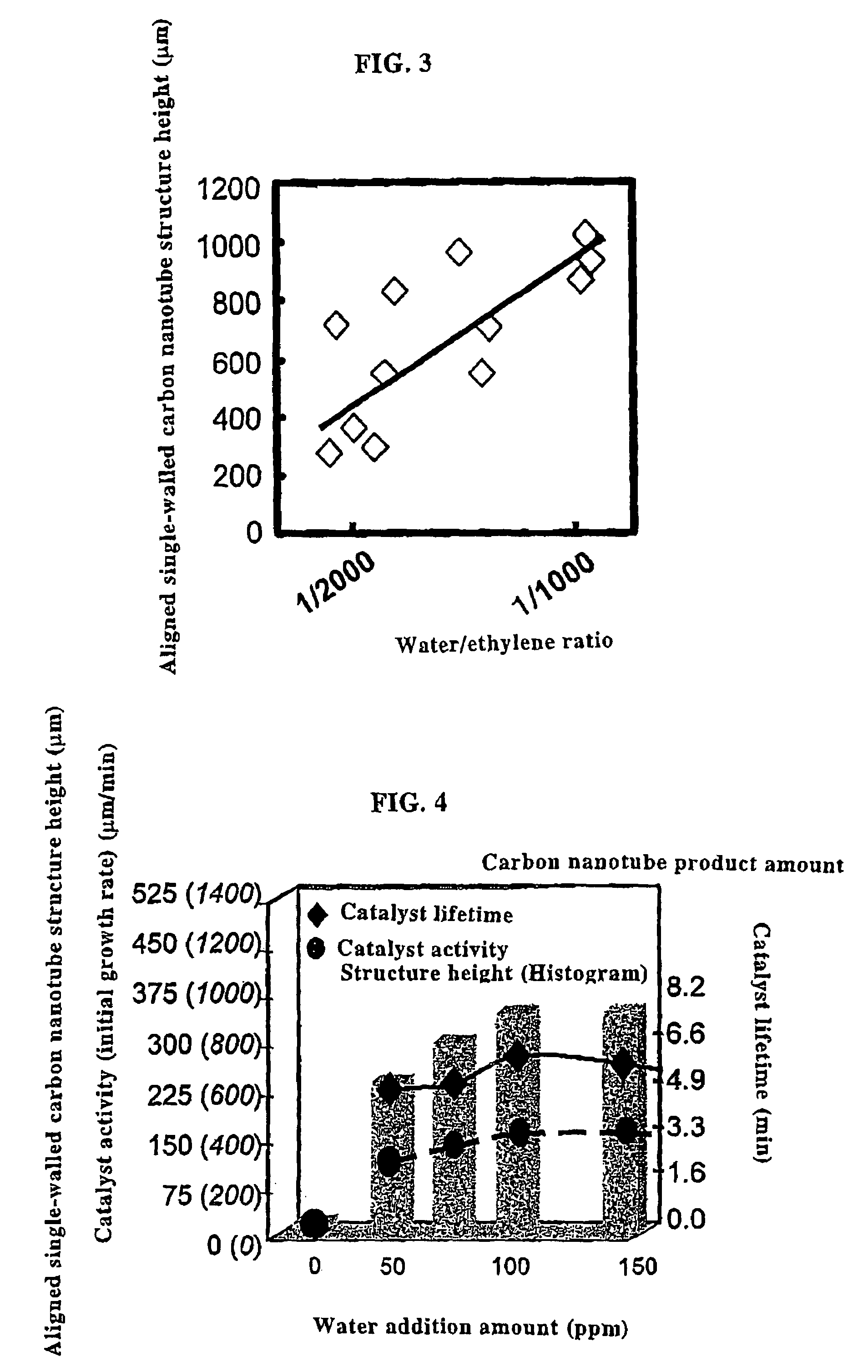

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Single-walled carbon nanotube and aligned single-walled carbon nanotube bulk structure, and their production process, production apparatus and application use

ActiveUS7854991B2Prolong lifeIncrease probabilityMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

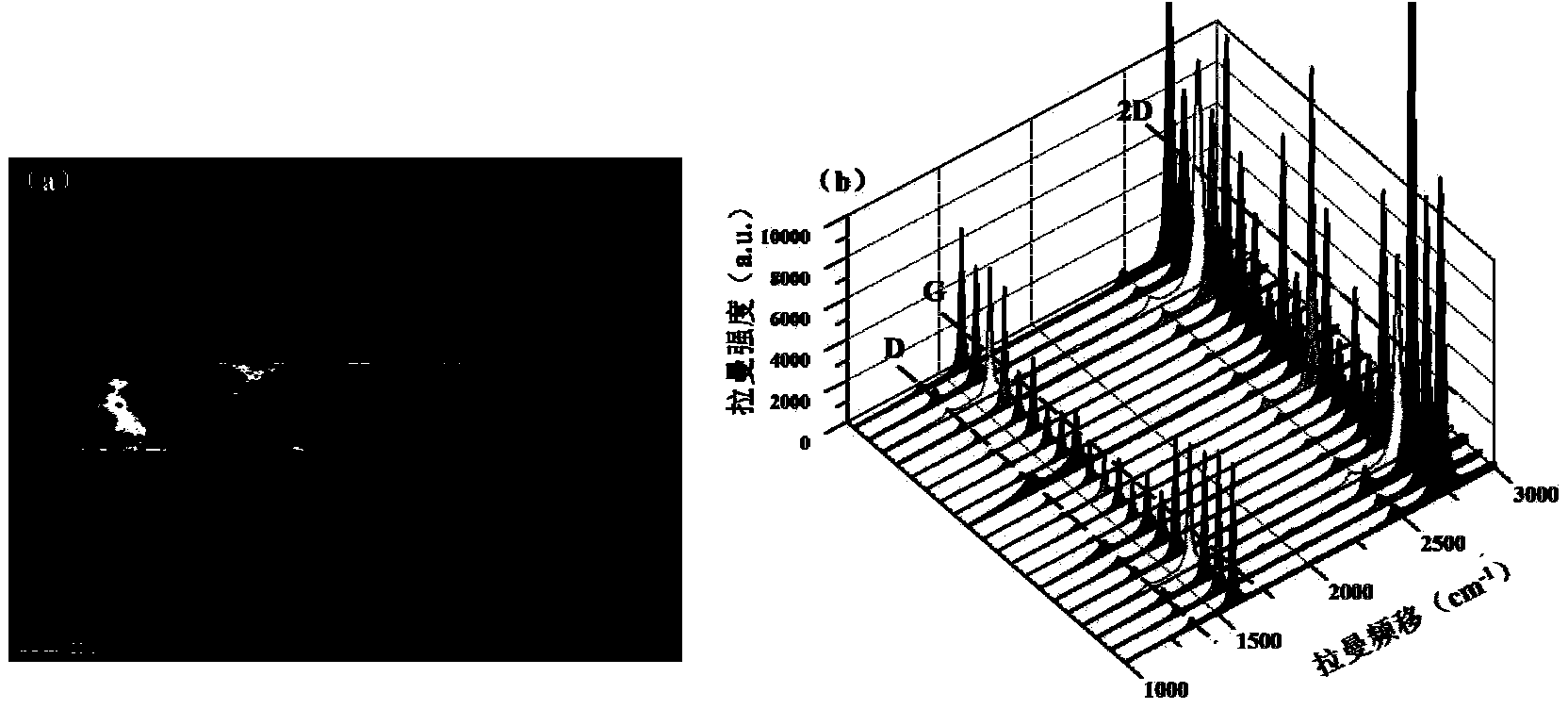

A method for direct growth of graphene on various substrates

ActiveCN102260858ASimple growth processAchieve growthChemical vapor deposition coatingNoble gasAtmospheric pressure

The invention discloses a method for directly growing graphine on various substrates. The method comprises the following steps: A) putting a substrate material in a plasma enhanced chemical vapor deposition (PECVD) cavity, vacuuming, heating the substrate to 400-600 DEG C, introducing hydrocarbon gases and other noble gases, and controlling the pressure of the gases to be at most 1Torr; and B) switching on a plasma power supply so that the hydrocarbon is ionized and cracked to active groups, and reacting on the substrate surface of 400-600 DEG C, thereby achieving the direct growth of the graphine. By the method in the invention, the problem that high-quality graphine is directly grown on the surface of a non-specific substrate is solved; and the method in the invention has an important sense at the aspects of exploring a large-area direct growth technology of graphine, understanding a growth mechanism of graphine, researching a fundamental physical problem of graphine, exploring practical applications of graphine films and broadening application ranges of graphine.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for preparing high-activity silicon collidal sol formed from superfine silicon dioxide particles

InactiveCN101070161AEvenly distributedOvercome the disadvantage of uneven sizeSilicaSilicic acidIon exchange

The invention discloses a kind of preparation method of silica sol of high activity. For this kind of silica sol, the particle is tiny and grain size of it is distributed narrowly. It is characterized in that it takes sodium silicate as raw material, natrium ion is took out using method of exchanging ion and then get active silicic acid solution, prepare silica sol of high activity whose grain size is 6-12 nm, content of silicon dioxide is accounting for 10-30%,content of sodium monoxide is accounting for 0.2-0.3%, and PH value is between 8.5 and 10.5,through controlling proportion, pH value of reaction and heating temperature of active silicic acid solution. Silica sol prepared using this method can satisfy needs of spinning sizing, organic polymerization catalysis and modifying technology. Compared to common ion-exchanging method, preparation method of the invention has advantages of tiny particle, equal granularity, synchronizing dehydration and purification and low energy wasting, and it can control size of particle according to needs of actual utilization.

Owner:LUDONG UNIVERSITY +1

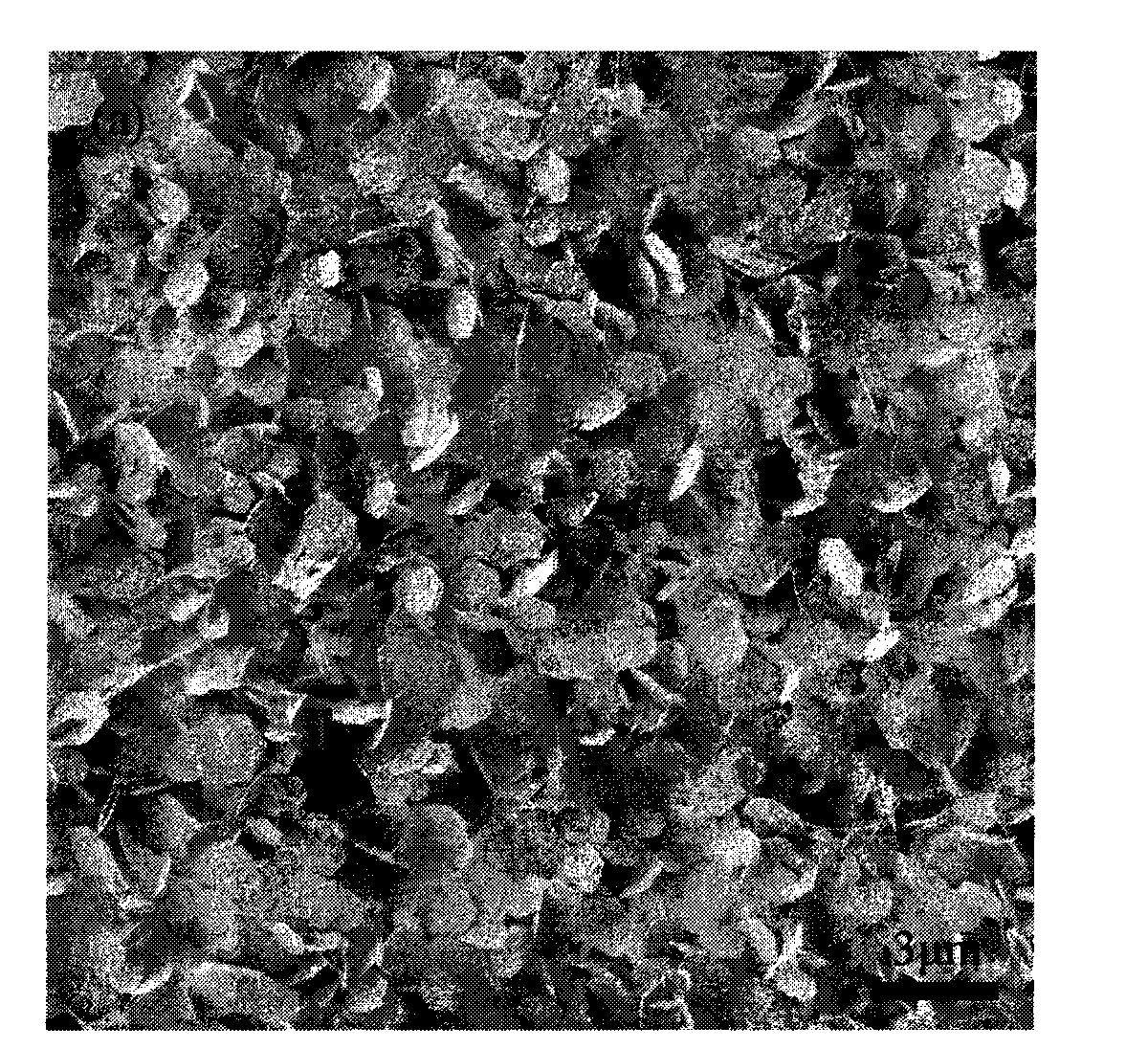

Two-dimensional transition metal disulfides monocrystalline, and preparation method and applications thereof

InactiveCN104846434AControl vulcanizationDegree of controlPolycrystalline material growthFrom chemically reactive gasesGas phaseSingle crystal

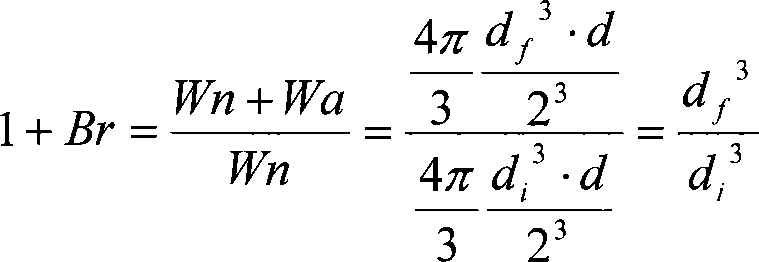

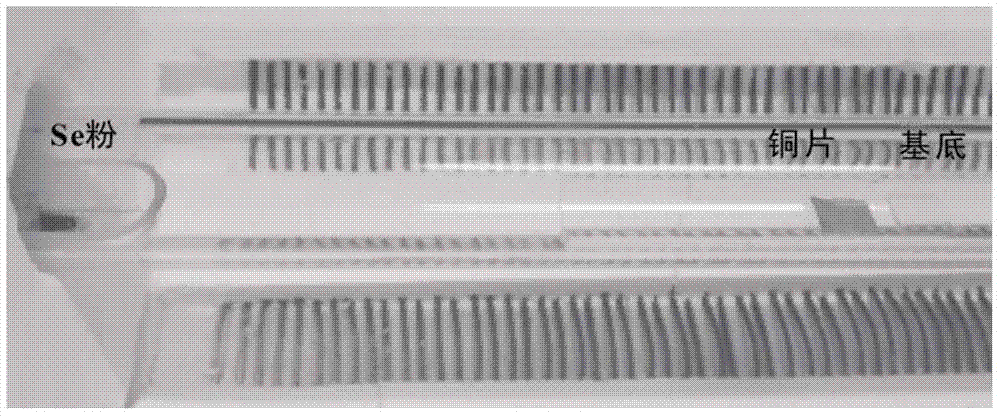

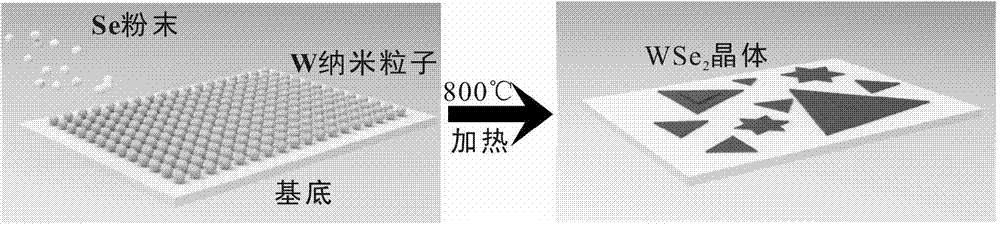

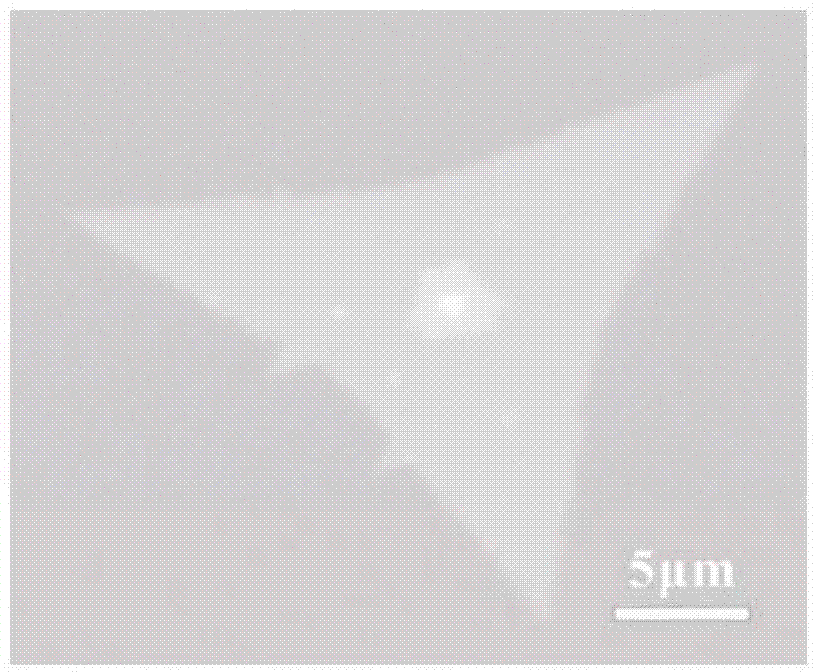

The invention discloses a two-dimensional transition metal disulfides (TMDs) monocrystalline, and a preparation method and applications thereof. According to the preparation method, in an inert atmosphere, assist control of the concentration of S or Se in a system is realized with common metal which is capable of reacting with sulfur family elementary substance (S, Se) and hydrogen so as to control sulfuration degree or selenylation degree of a transition metal layer, and controllable growth of TMDs monocrystalline is realized via chemical vapor deposition; deposition temperature is controlled to be 750 to 850 DEG C, and deposition time is controlled to be 5 to 15min so as to complete TMDs monocrystalline preparation; wherein, strict control on high-quality two-dimensional transition metal disulfides monocrystalline is realized via optimization of preparation parameters such as substrate sputtering treatment method, sulfur family elementary substance powder using amount, absorbed S / Se metal area and kinds, hydrogen concentration, growth temperature, and growth time.

Owner:WUHAN UNIV

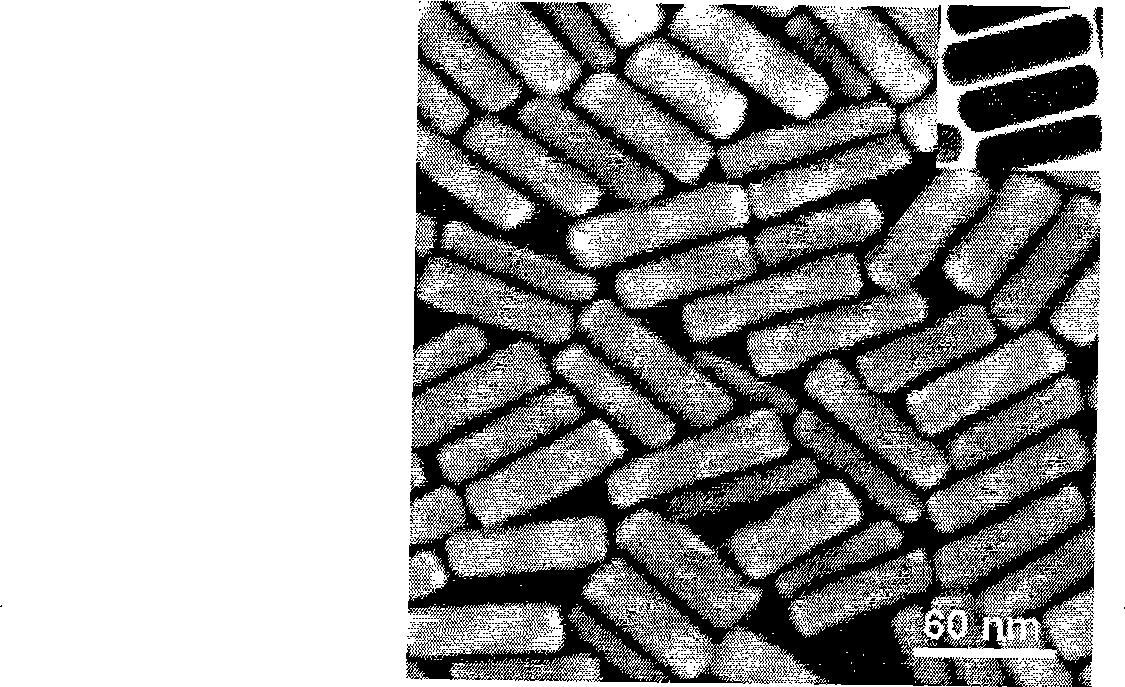

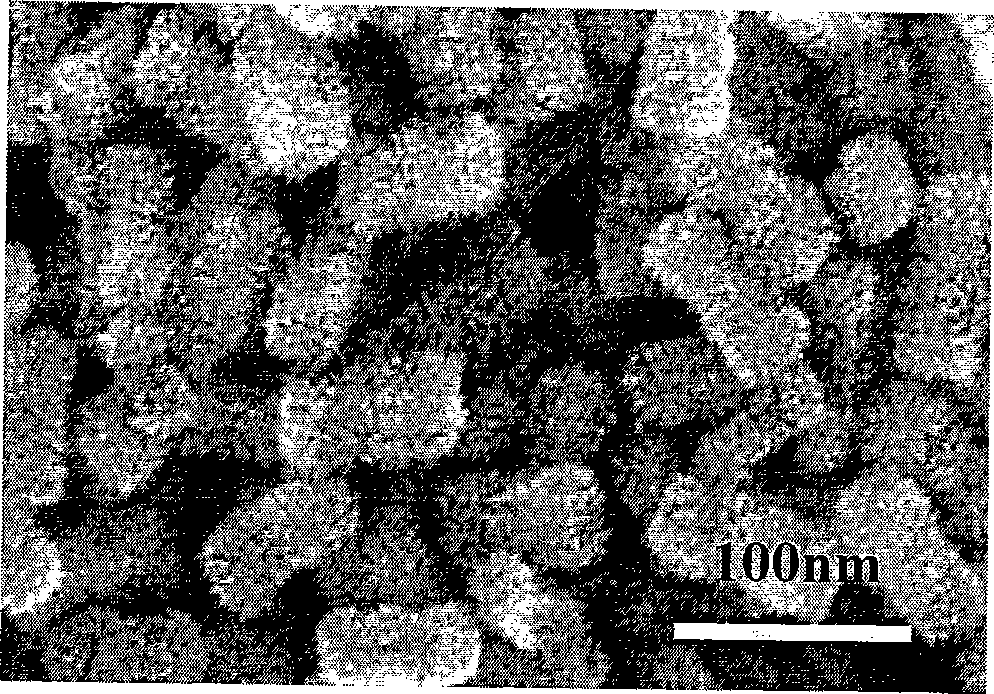

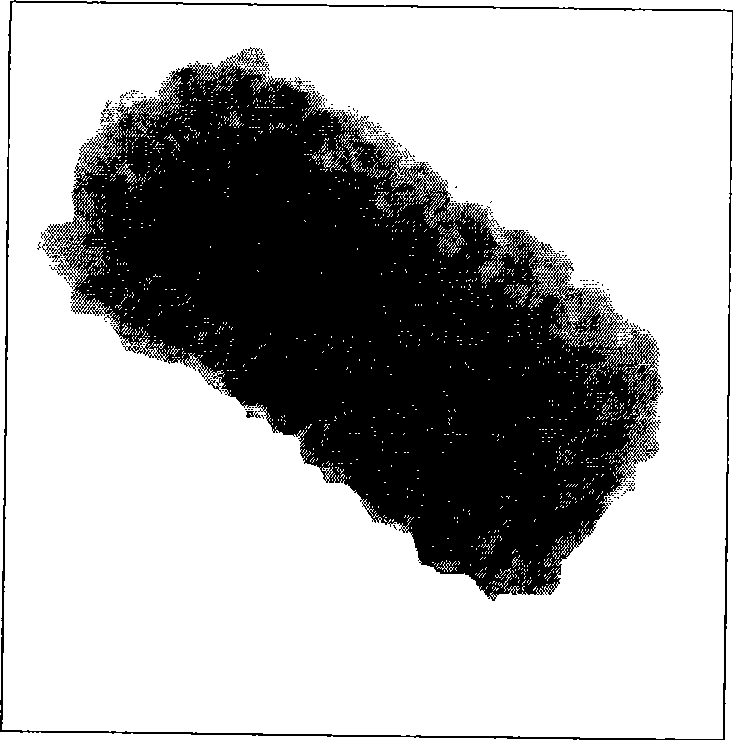

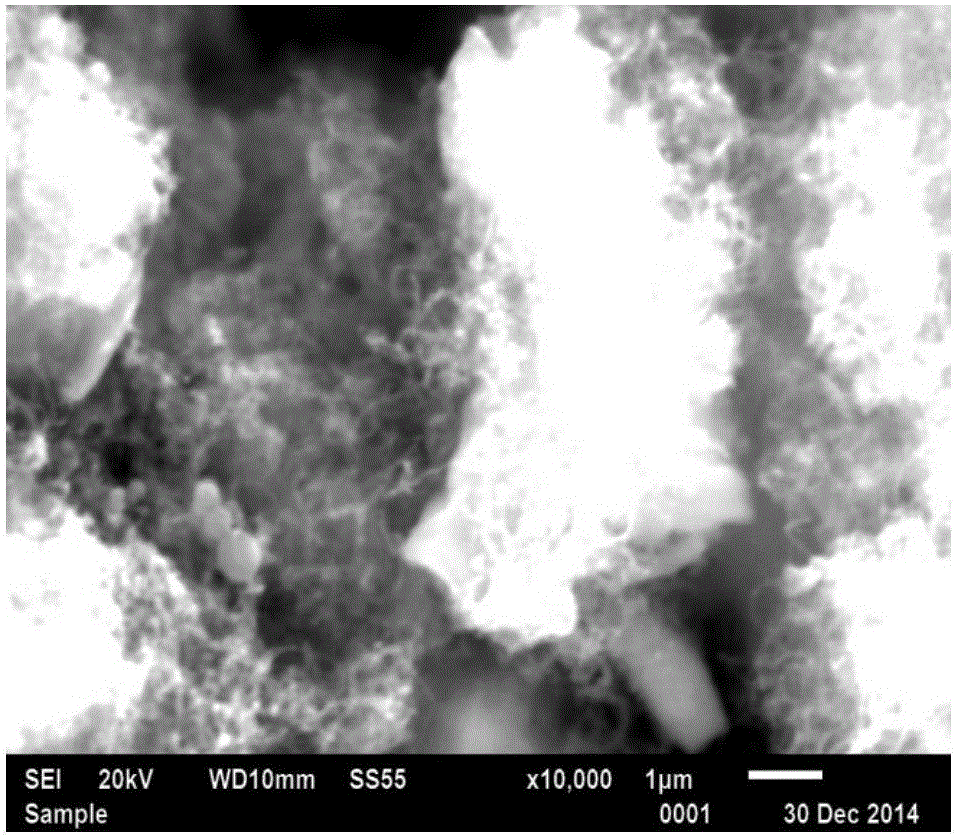

Bimetal nano rod of branched gold core/platinum shell structure and preparation method thereof

InactiveCN101450380AImprovement of poisoningLarge specific surface areaCoatingsPlatinumOptical property

The invention provides a dendritic gold-core / platinum-shell bimetal nanometer rod and a preparation method thereof. The dendritic gold-core / platinum-shell bimetal nanometer rod comprises a cylindrical gold nanometer-rod core and a porous platinum-shell layer covering the outer surface of the cylindrical gold nanometer-rod core; the diameter of the cylindrical gold nanometer-rod core is 10 to 15 nanometers; the length of the cylindrical gold nanometer-rod core is 55 to 60 nanometers; the thickness of the porous platinum-shell layer is 0.4 to 8 nanometers; and the length of platinum grains covering the outside of a nanometer rod is 2 to 4 nanometers. The preparation method provided by the invention has the advantages of simplicity, flexibility, environmental protection, green chemistry and low energy consumption. In addition, the obtained bimetal nanometer rod with a gold-core / platinum-shell structure has the characteristics of high yield, narrow size distribution, stable structure and adjustable optical properties.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

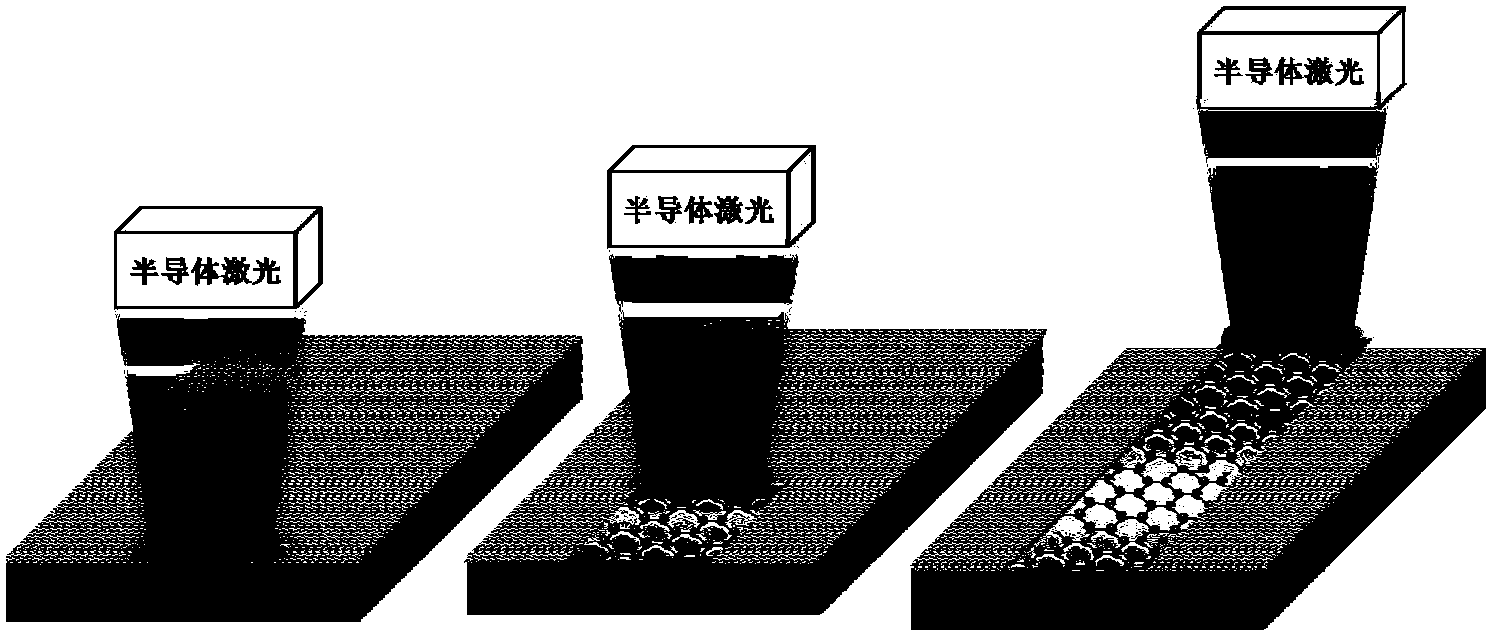

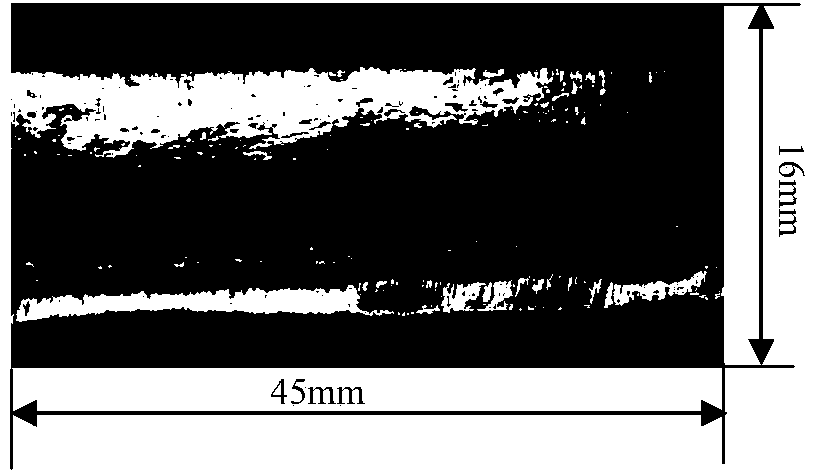

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

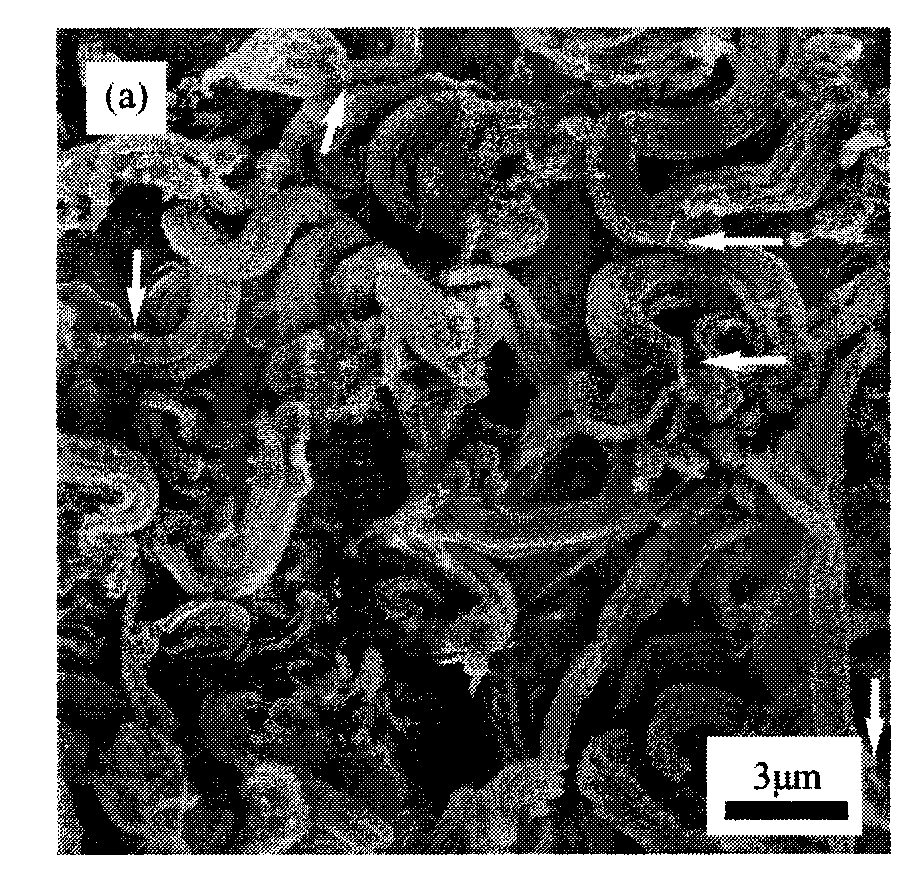

Method for preparing minor-diameter carbon nanotube array on surface of flaky material

The invention relates to a method for preparing a minor-diameter carbon nanotube array on the surface of a flaky material, which belongs to the technical fields of nanometer materials and the preparation process thereof. The method comprises the following steps: the nanoparticles including one or more of Fe, Co, Ni, Cu and Mo (active metals) are dispersed on various flaky materials such as a graphitic sheet, magnesia or layered double hydroxide according to the density (10<8>-10<12> grains / cm<2>), then the chemical vapor deposition is performed, and finally, the carbon nanotube array grows onthe flaky surface. The diameter of the nanotube is less than 20 nm in the array. The method is easy to operate, realizes the mass production of the carbon nanotube array and promotes the industrial application.

Owner:TSINGHUA UNIV

Protogenic alpine azalea introduction and acclimatization method

InactiveCN101095399ASeedling realizationAchieve growthCultivating equipmentsSoilless cultivationCuckooGreenhouse

The invention discloses a method for cultivating original alpine cuckoo, which comprises following steps: setting brandreth with its height being one meter in green house or booth, placing permeable and ventilating plastic crate on brandreth, feeding the plastic crate with 50-70% of humus soil or sward, 20-30% of perlite and 10-20% of decomposed wood dust, taking said mixing soil as culture medium, laying planus on said mixing soil, sowing original alpine cuckoo seed on planus, watering with normal procedure. The rate of emergence is 85%, and it is suitable to be used in south part of China.

Owner:戴悦

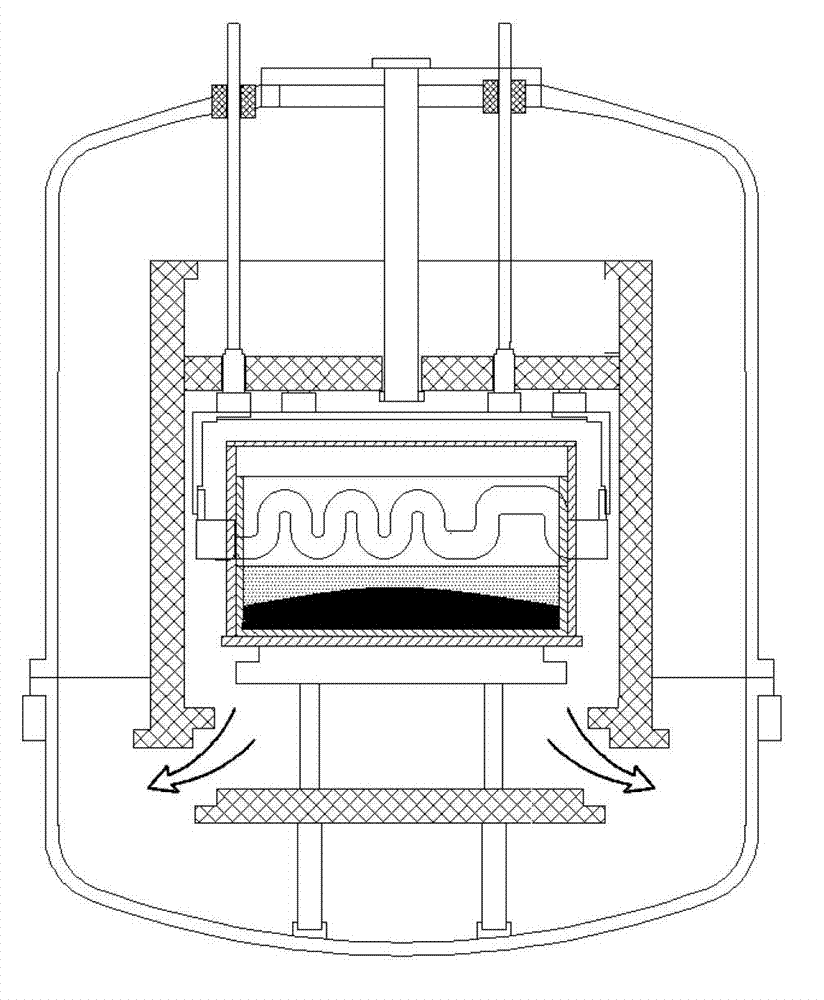

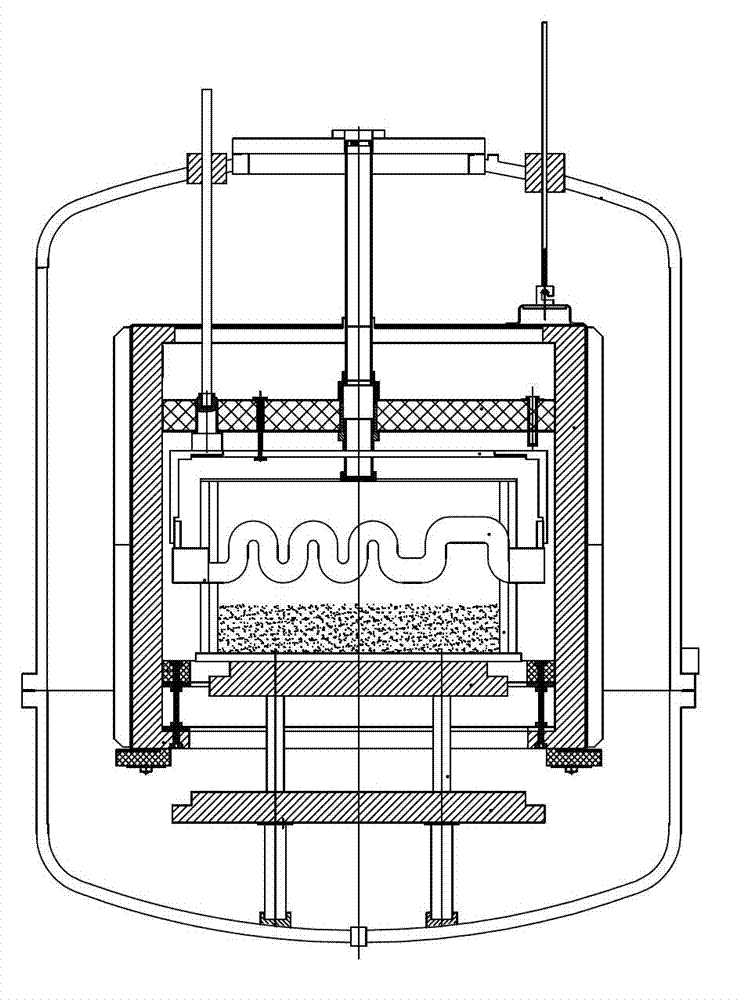

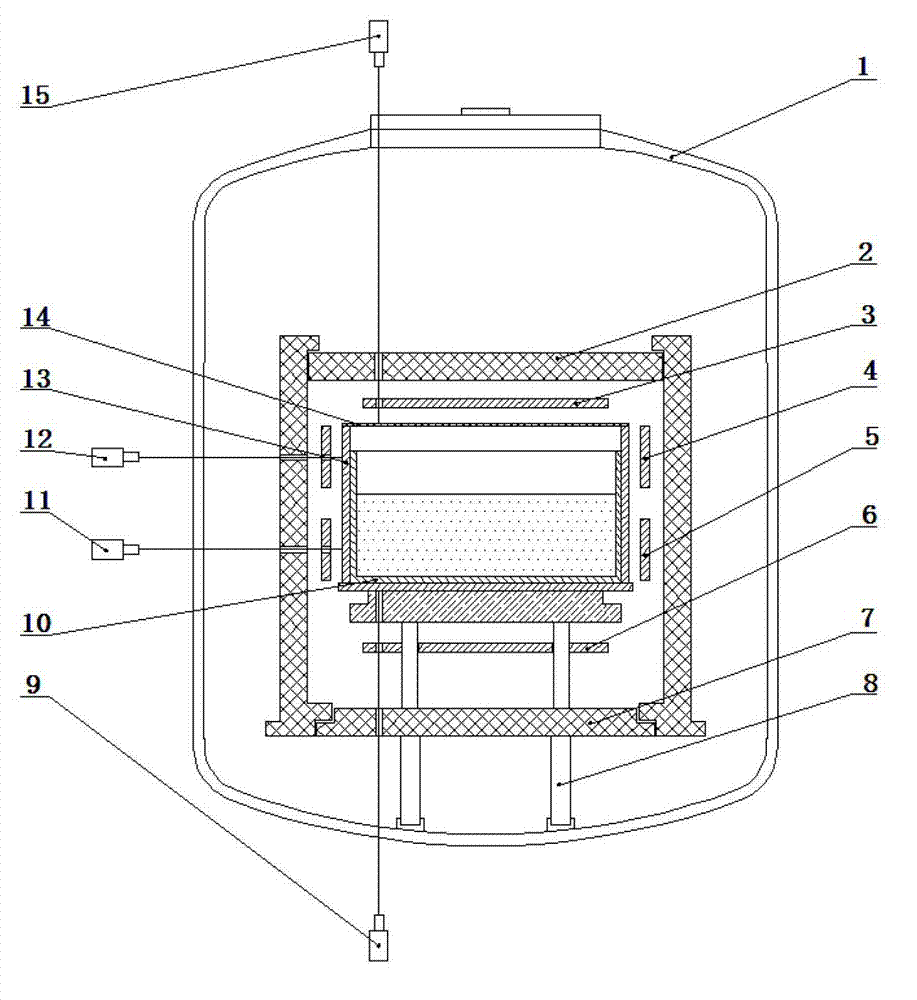

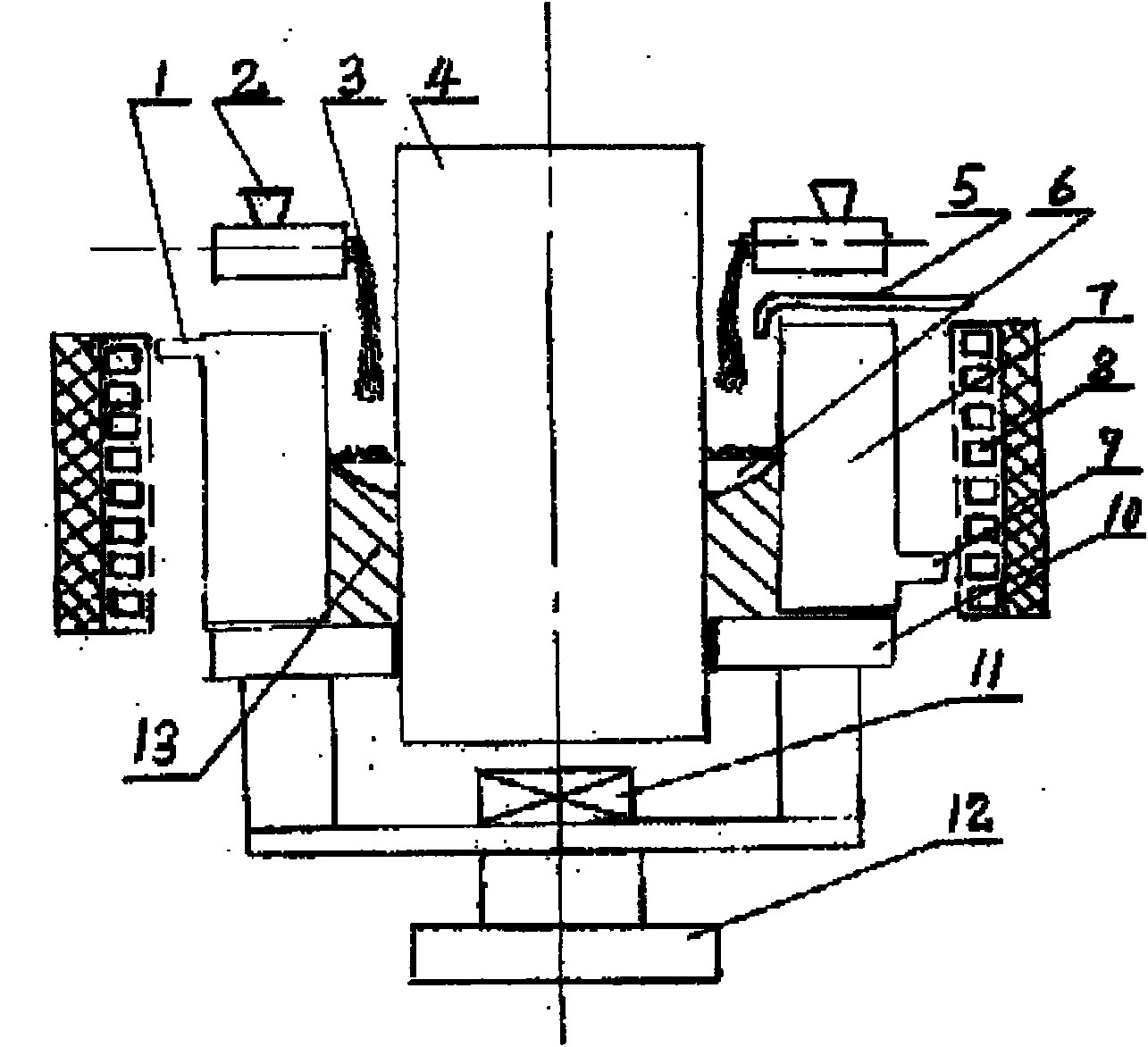

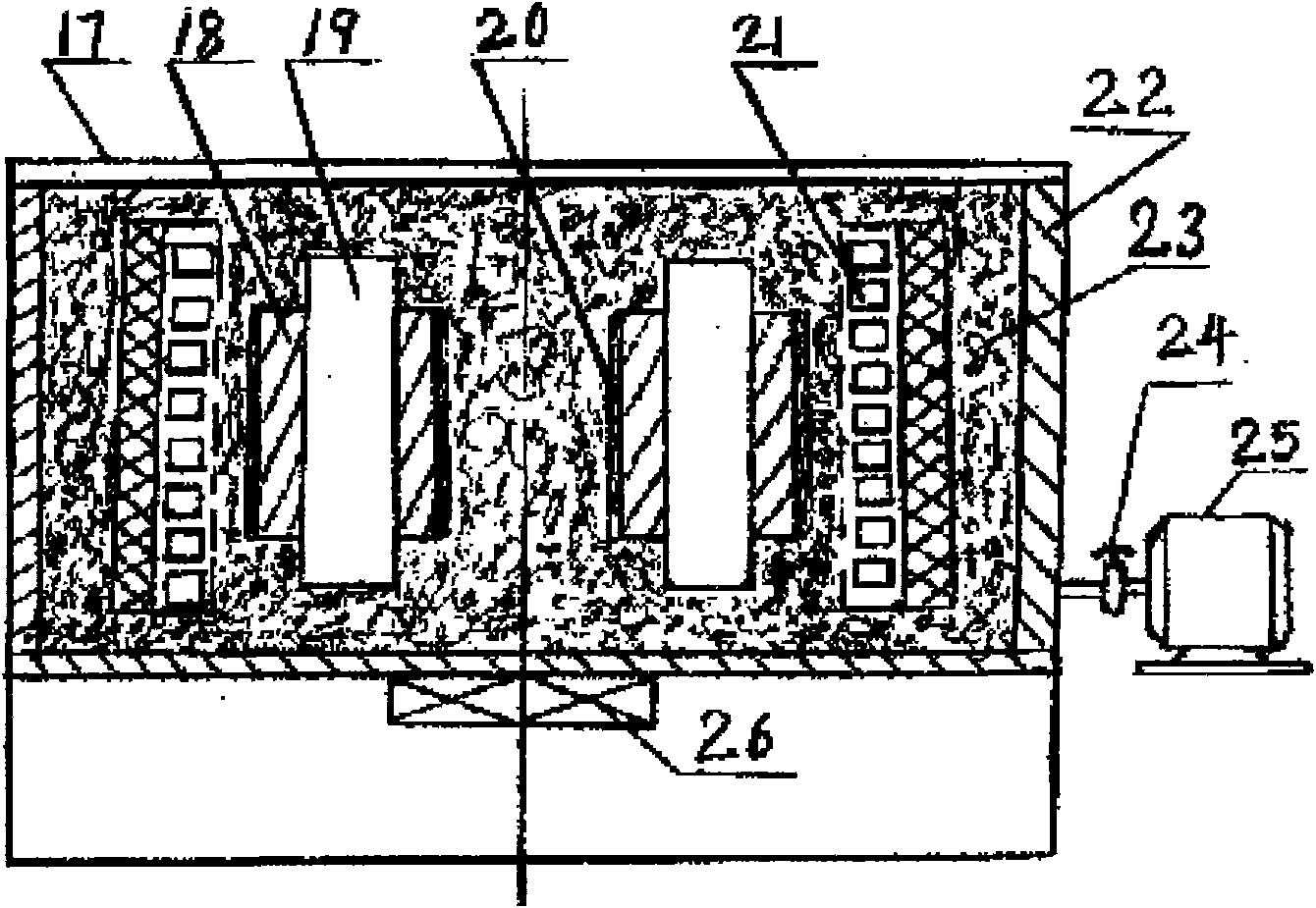

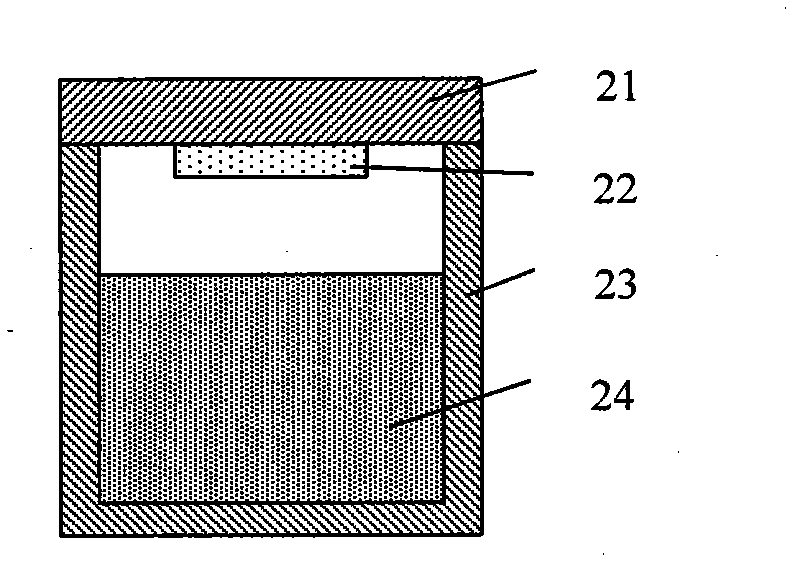

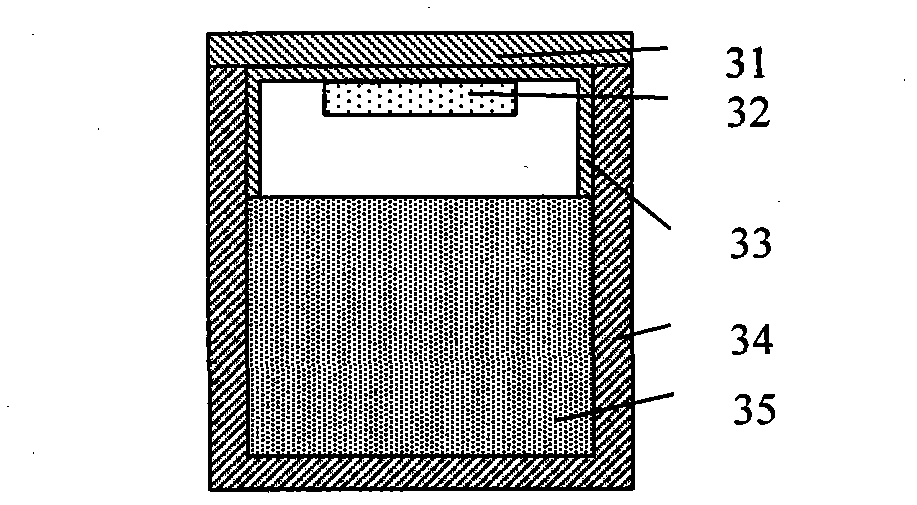

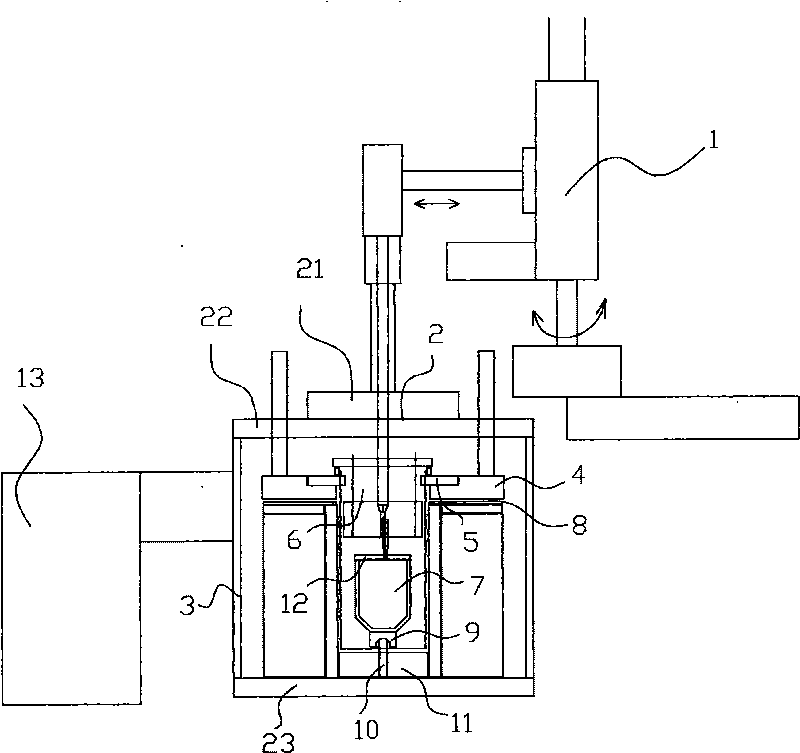

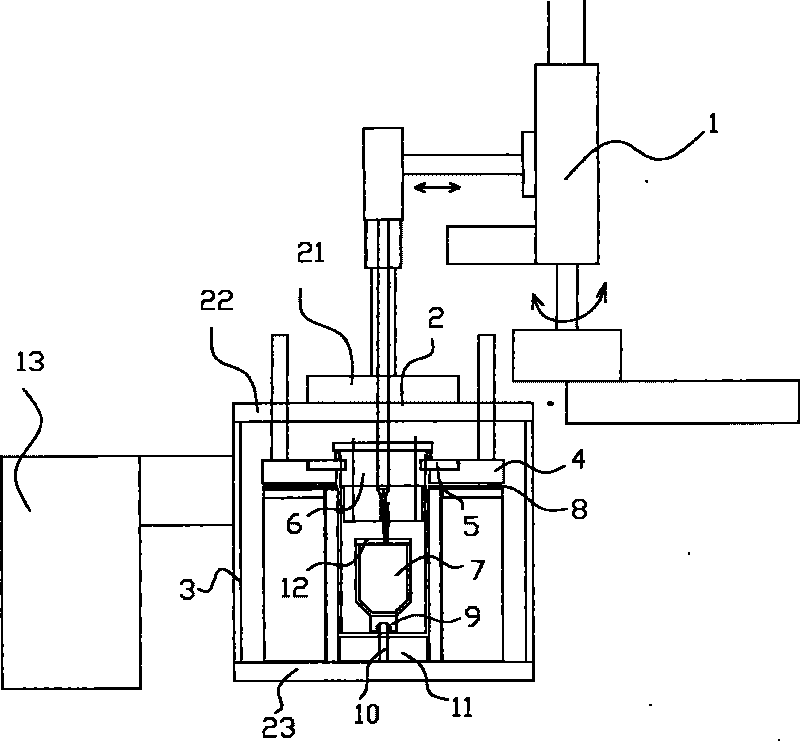

Ingot furnace thermal field structure based on multi-heater and operation method

ActiveCN102877117ASolve the problems of slow speed in the later stage and long crystal growth time at the cornersConvenient to achieve the purpose of not meltingPolycrystalline material growthFrom frozen solutionsManufacturing technologyMeasuring instrument

The invention relates to the field of manufacturing technology of polycrystalline silicon ingot furnaces, aiming to provide an ingot furnace thermal field structure based on multi-heater and an operation method. The ingot furnace thermal field structure comprises a crucible arranged in a furnace chamber; a thermal field of the crucible comprises a top heater, a side heater, a heat exchanger table located on the bottom of the crucible and a bottom heater located on the bottom of the heat exchange table; an infrared temperature measuring instrument coordinates with the top heater and the side heater; the infrared temperature measuring instrument or a thermoelectric couple coordinates with the bottom heater. An operation process of the operation method comprises a heating stage, a melting stage, a crystal growing stage, an annealing stage and a cooling stage. The ingot furnace thermal field structure and the operation method can effectively monitor the temperature of various portions of the thermal field, regulate power output of various heaters, establish more reasonable temperature gradient, adapt to high-feeding capacity and large-size ingot trend, enable crystal nucleus to form more uniformly during early time of crystal growth, enlarge crystals, reduce crystal boundary, improve crystal direction, reduce energy consumption and finally improve quality of crystal ingots.

Owner:杭州慧翔电液技术开发有限公司 +1

Mixed enzyme production process by solid fermentation of fruits and vegetables and microorganisms

InactiveCN104839638ARetain enzyme activityRetain non-enzyme active ingredientsFood preparationEnvironmental resistanceMicroorganism

The present invention discloses a mixed enzyme production process by solid fermentation of fruits and vegetables and microorganisms and the production process includes the following steps: step one, washing and cleaning fresh fruits and vegetables; step two, juicing the cleaned fruits and vegetables using a juice extractor and obtaining the fruit and vegetable juice and the fruit and vegetable residue; step three, adding water content adjusting raw materials according to different water content of the obtained fruit and vegetable residue to adjust the water content of the fruit and vegetable residue, and mixing the above materials evenly to obtain a base material; step four, putting the step three obtained base material into a fermentation bottle to conduct sterilization; step five, cooling the sterilized fruit and vegetable base material to room temperature, and inoculating microorganism liquid strains to conduct solid fermentation; and step six, after the end of solid fermentation, blending the obtained fruit and vegetable juice into the solid fermented materials, conducting low temperature drying, and thereby obtaining the fruit and vegetable and microorganism mixed enzymes containing both fruit and vegetable enzymes and microbial enzymes. The mixed enzymes can not only fully preserve the enzyme activity of fruits and vegetables, but also obtain the enzyme ingredients of microorganisms, and in addition, the production process can also achieve the full advantage of the entire fruits and vegetables, does not produce any waste, and is ecological and environmental protective.

Owner:杭州德润全健康产业发展有限公司

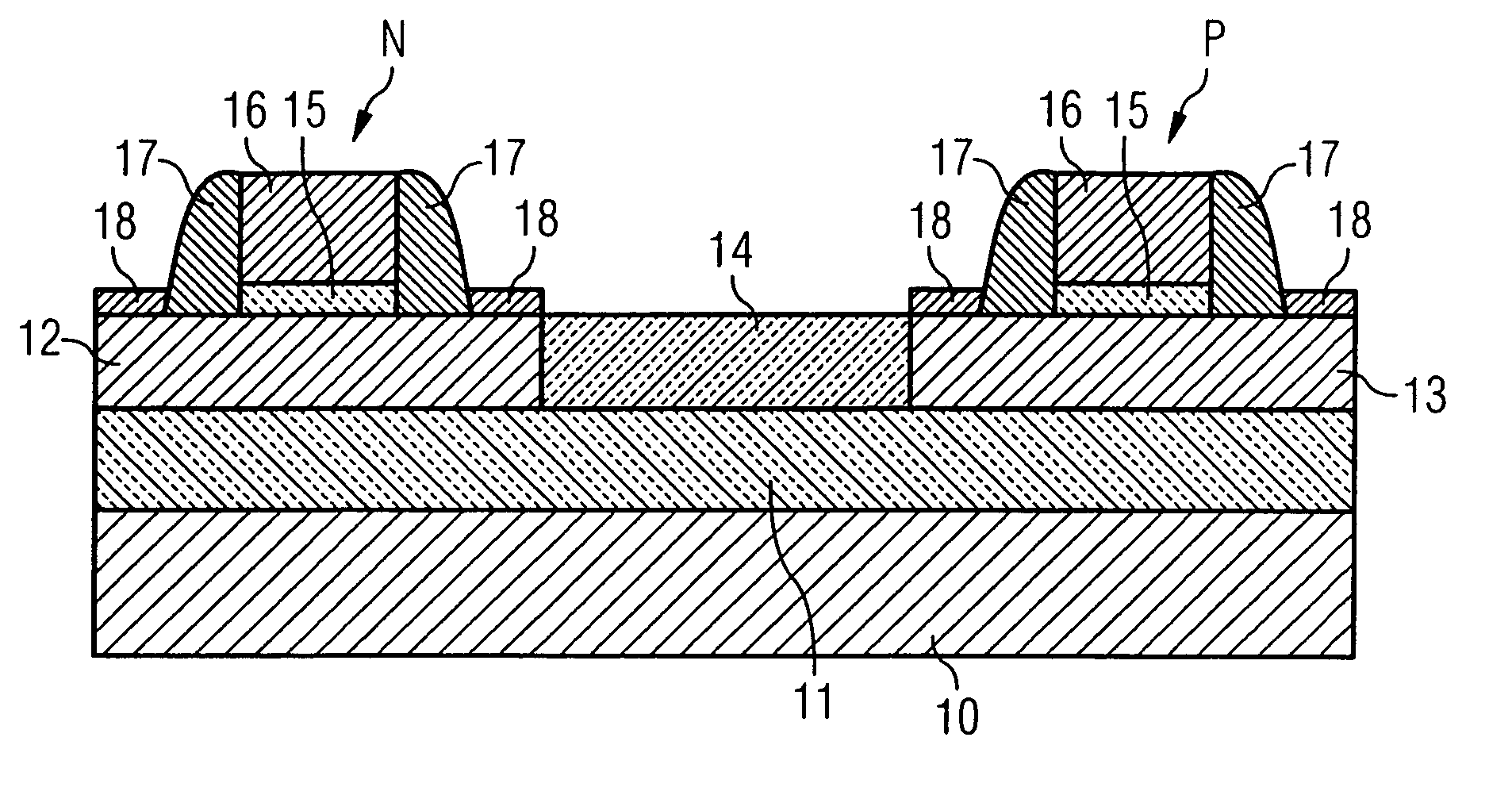

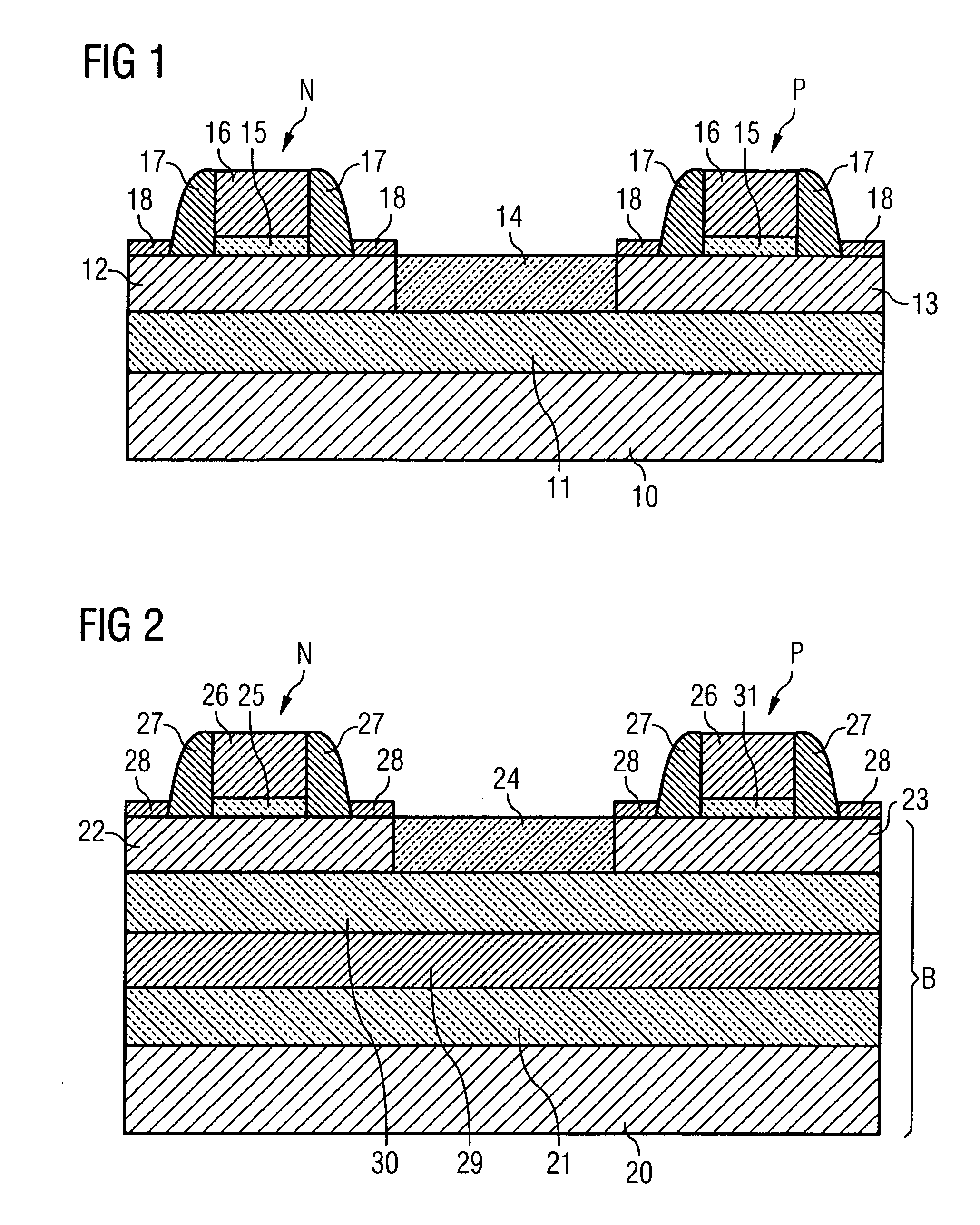

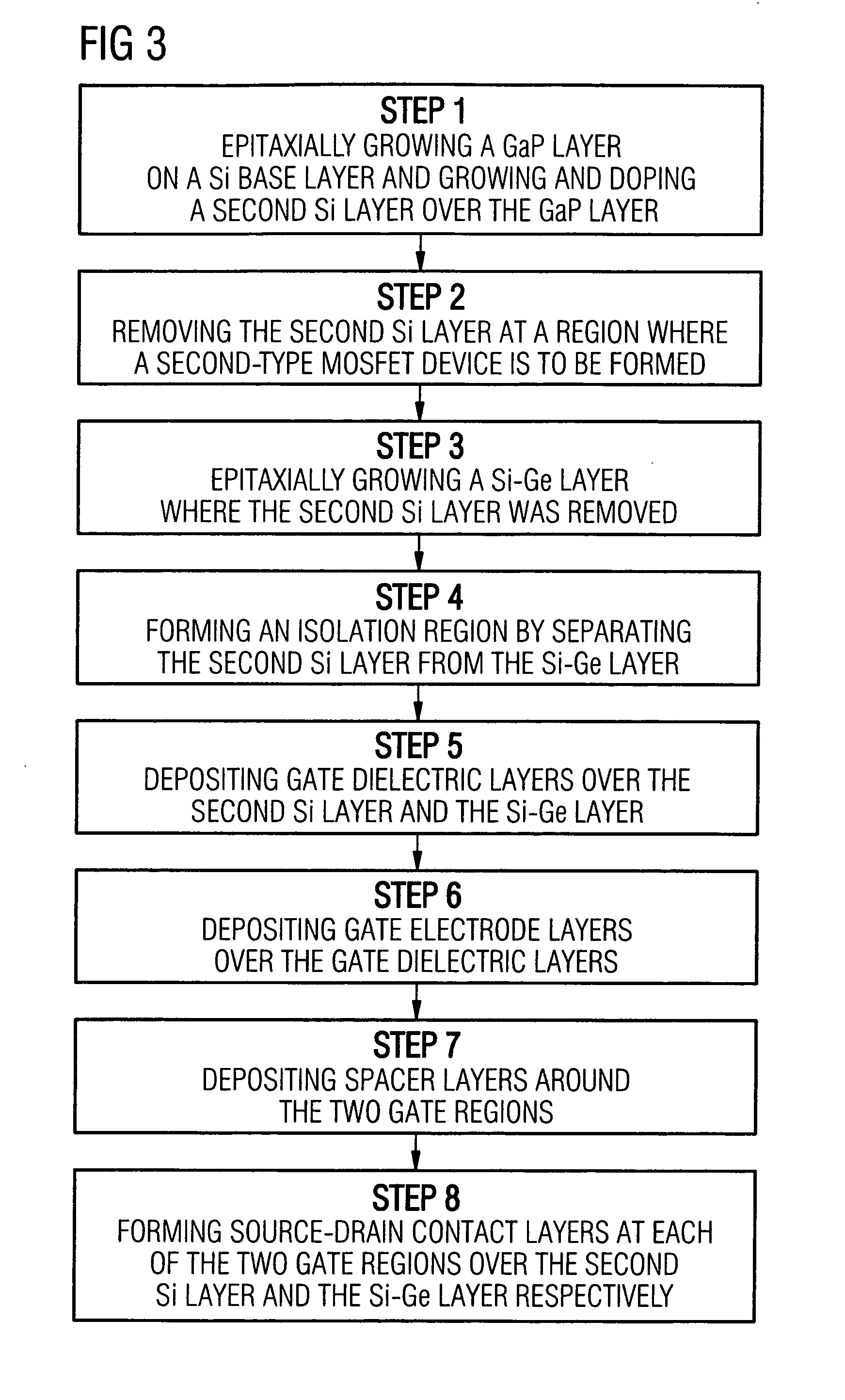

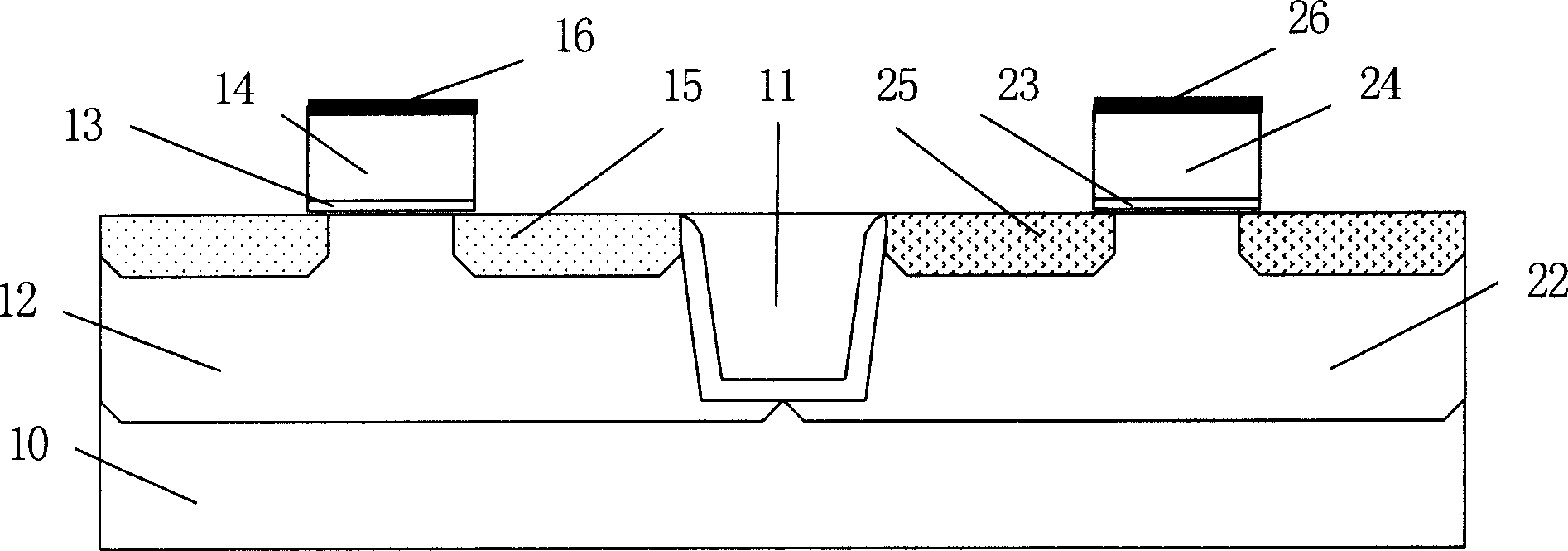

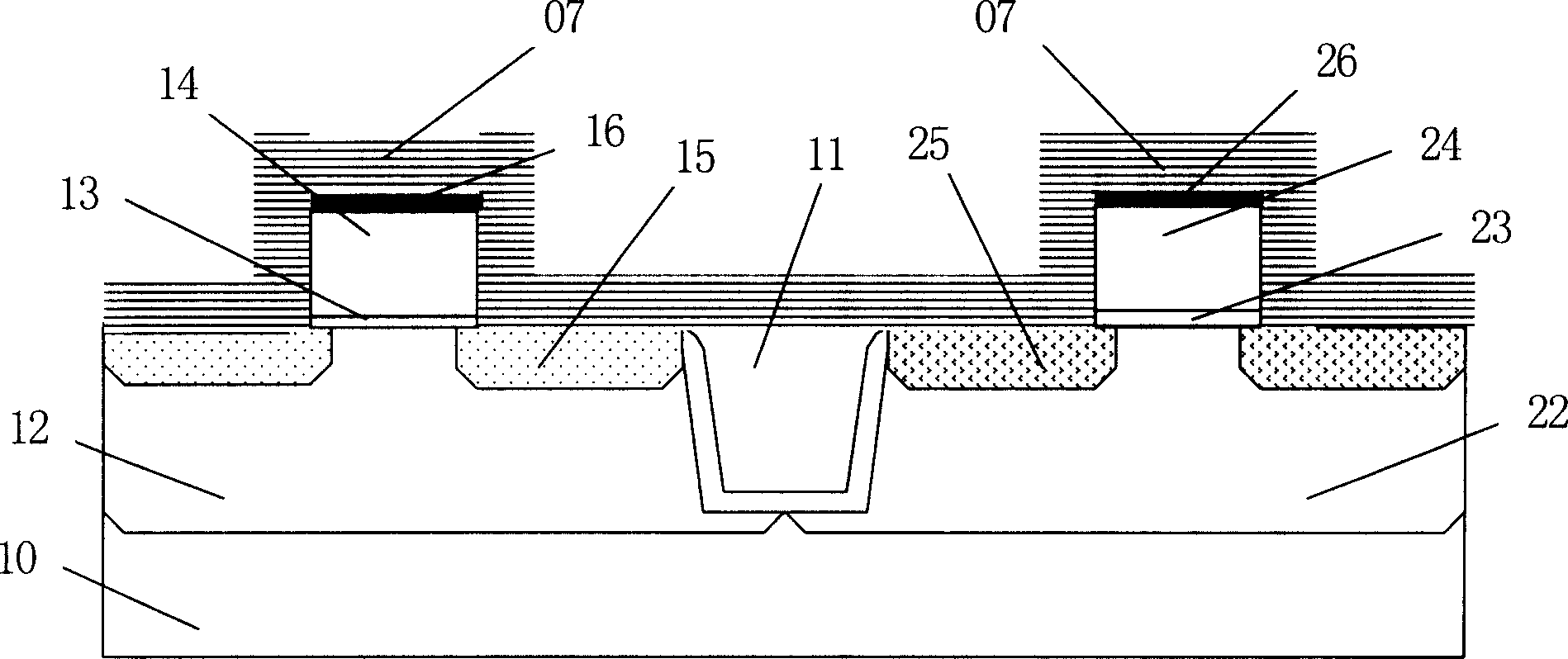

Semiconductor device and a method of manufacturing such a semiconductor device

InactiveUS20070252216A1Improve performanceImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesCMOSSemiconductor materials

A semiconductor device, specifically a Complementary Metal Oxide Semiconductor (CMOS) device, has a substrate on which are formed first and second field effect transistors. Each of the field effect transistors comprises a source-drain region, a channel of either an n-type or a p-type conductivity semiconductor material formed on the substrate, a first gate region, and a first dielectric region that separates the first channel from the first gate region. However, dissimilar semiconductor materials are used to form the channel regions of the first and second field effect transistors so that high electron and hole mobility can be achieved.

Owner:INFINEON TECH AG

Strain source-drain CMOS integrating method with oxide separation layer

ActiveCN1893028AAchieve growthNo erosionSemiconductor/solid-state device manufacturingCMOSSilicon-germanium

The integration methods include following integrated parts: method for manufacturing PMOS of epitaxial growth of source and drain poles on silicon germanium by using interval layer of oxide and hard mask of polysilicon as mask; method for manufacturing NMOS of epitaxial growth of source and drain poles on silicon carbon; and removing hard mask safely. The method produces strain source and drain CMOS with interval layer of oxide.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

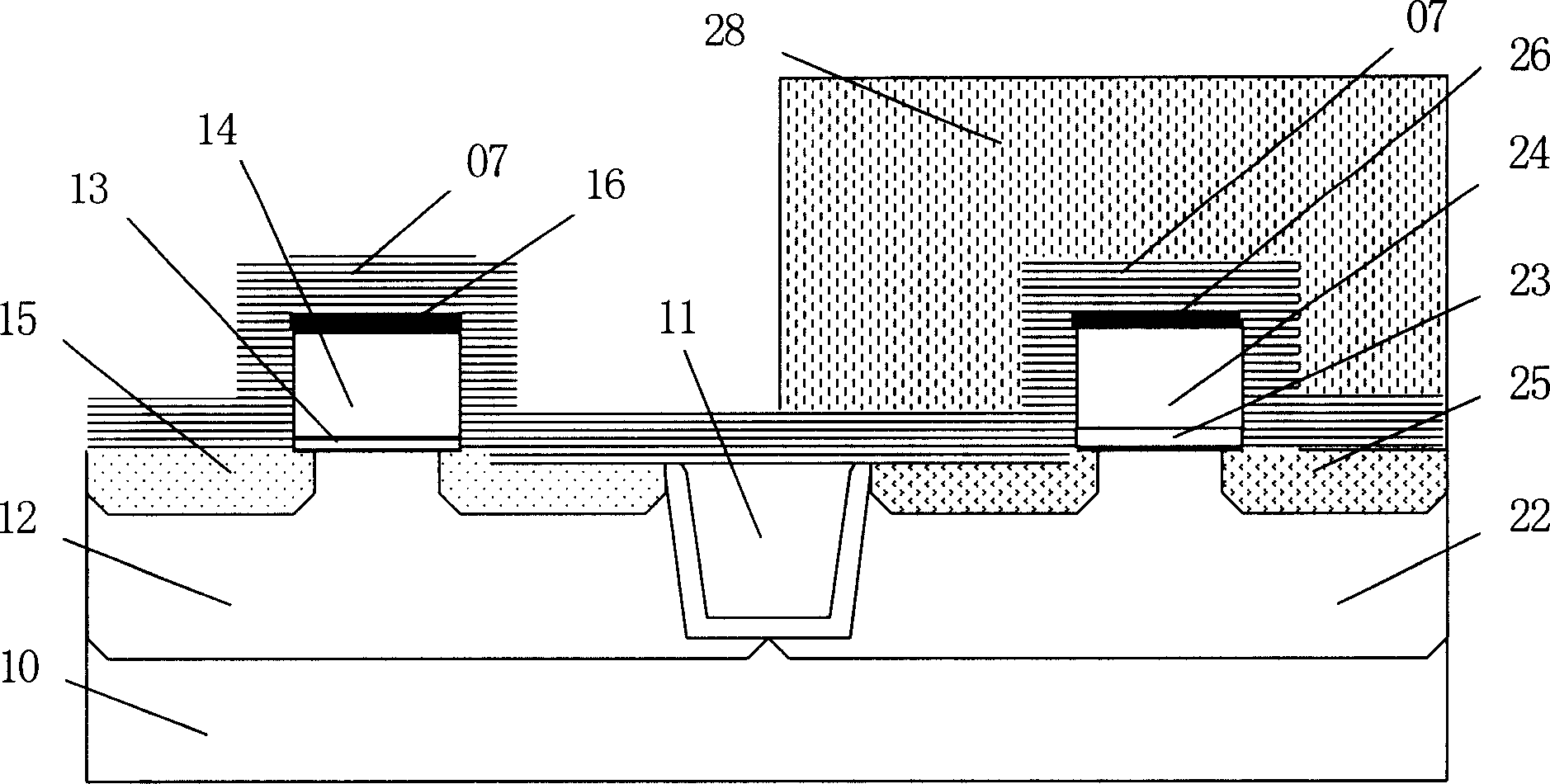

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

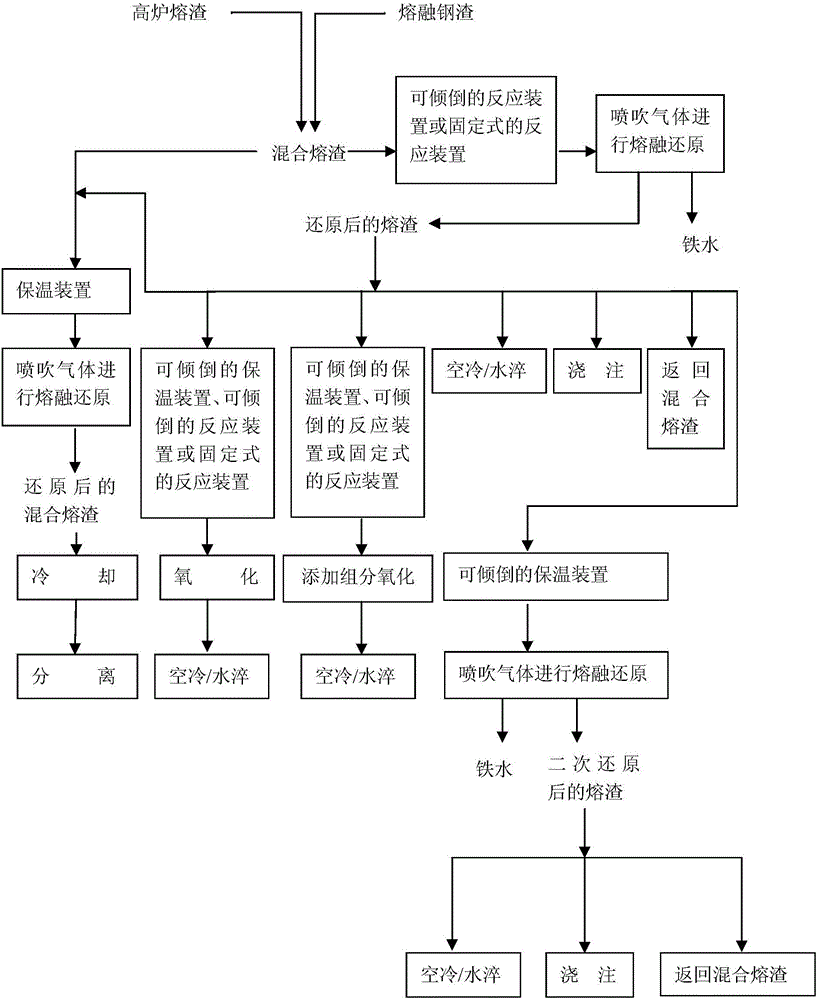

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

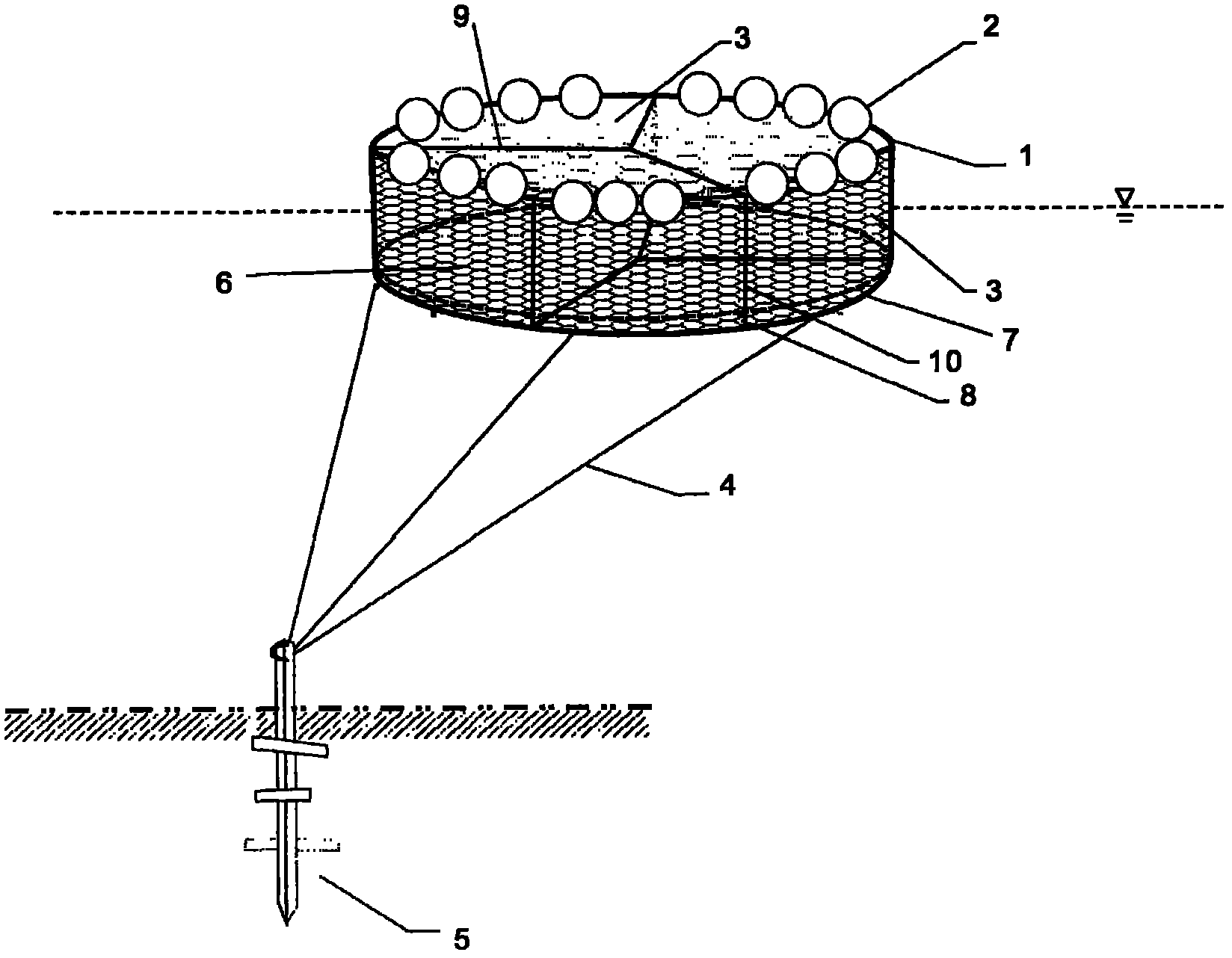

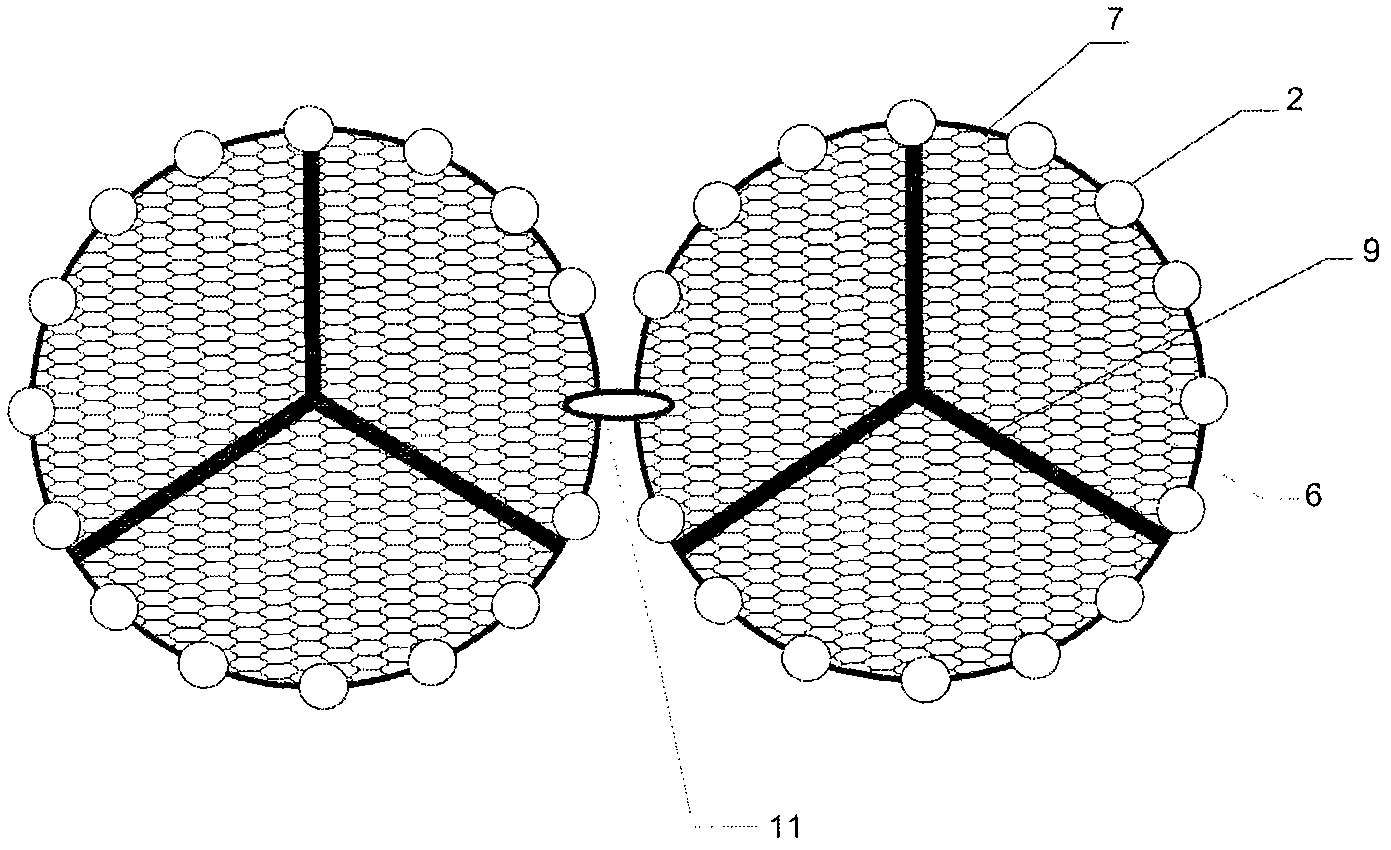

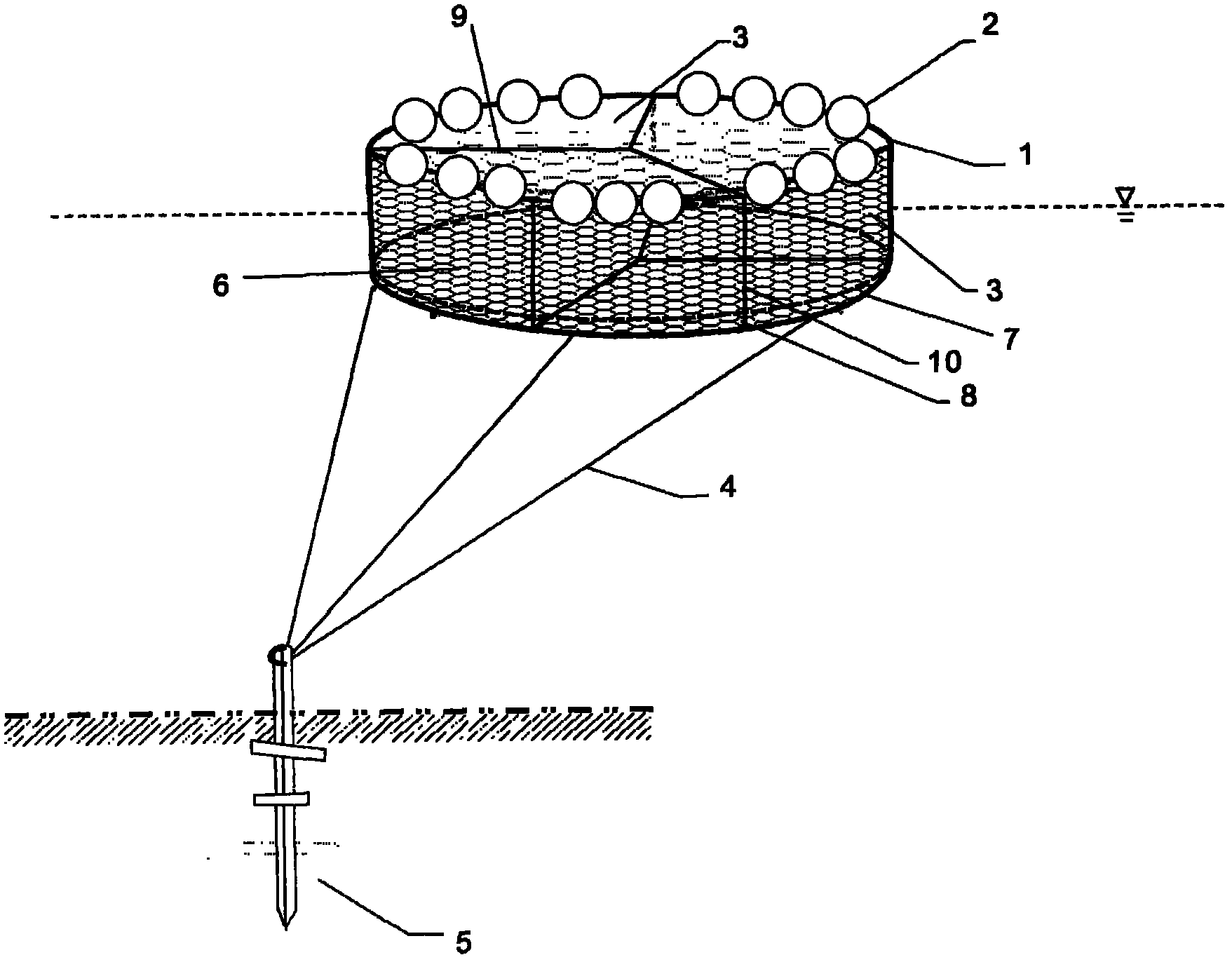

Method for constructing floating wetland

InactiveCN102060386AImprove purification effectStrong float resistanceSustainable biological treatmentBiological water/sewage treatmentEnvironmental engineeringAlternanthera

The invention relates to a method for constructing a floating wetland. A floating carrier and plants grown in the floating carrier form a floating wetland unit, and a plurality of floating wetland units are spliced on the water surface and fixed to the water bottom through ropes and foot piles, thereby forming a floating wetland; each floating carrier is a wire mesh barrel without a cover, and floating balls are threaded on the edge of the barrel top; a cattail bag is spread on the bottom surface of each barrel, the floating plants (alligator alternanthera) are grown on the cattail bag layer, and herbaceous plant seeds are sowed in the wire mesh barrel, so that the seeds are included and mixed in the alligator alternanthera, thereby forming one floating wetland unit; and the floating wetland units are cultured in a fertile still water body, and the cultured floating wetland units can be pulled to the target water area through a waterway and spliced to form the floating wetland of required area. The invention can treat the polluted water body, and beautify the landscape of the water area.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

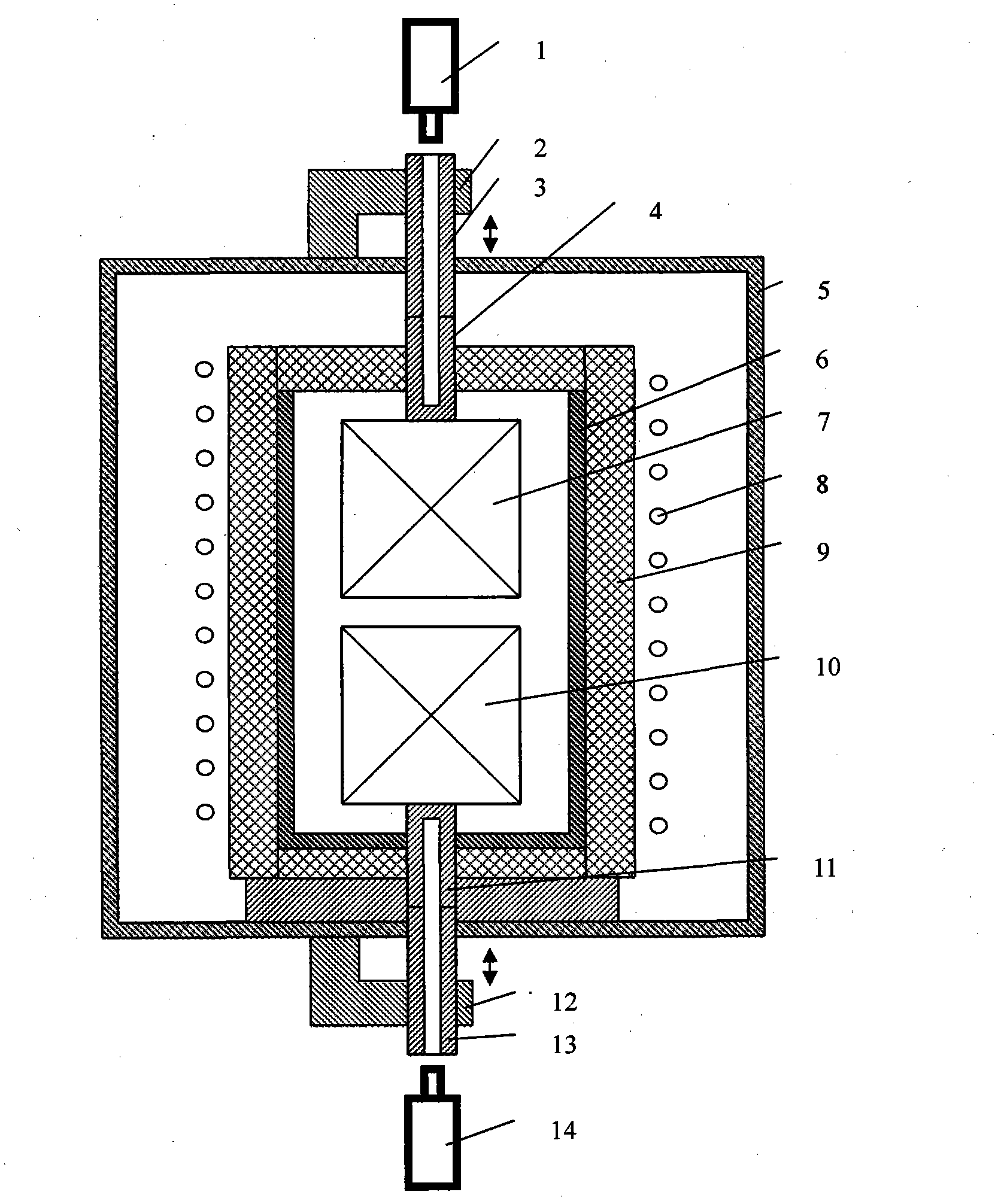

Method for growing silicon carbide mono-crystals through multi-crucible physical vapor transport technology, and device thereof

ActiveCN102925967ARealize separate temperature measurementAchieve growthPolycrystalline material growthFrom condensed vaporsGas phaseSeed crystal

The invention discloses a method for growing silicon carbide mono-crystals through a multi-crucible physical vapor transport technology, and a device thereof. The device is characterized in that the multi-crucible growth technology is adopted in the growth process of the silicon carbide mono-crystals, two graphite crucibles arrayed in a top-bottom manner are simultaneously placed in the graphite heating unit of a hearth, the upper crucible is suspended on a lifting rod, the lower crucible is inversely placed on a falling rod, two seed crystals are positioned at two ends of the graphite heating unit in a low temperature zone, a raw material is positioned in the middle of the graphite heating unit in a high temperature zone, and the temperatures of the upper crucible and the lower crucible are determined by a master temperature controller and a secondary temperature controller. The silicon carbide crystals growing though adopting the method have the advantages of high production efficiency and low production cost, so the method is suitable for the large-scale growth of the mono-crystals.

Owner:李汶军 +1

Selenium sustained-release edible fungus additive for selenium-rich culturing of edible fungus and preparation method thereof

InactiveCN102498950AAchieve growthTo achieve the effect of broad-spectrum nutritional fortificationHorticultureFertilizer mixturesBiotechnologyHydrogen

The invention discloses a selenium sustained-release edible fungus additive for selenium-rich culturing of edible fungus. The selenium sustained-release edible fungus additive is characterized by comprising the following components in parts by weight: 1-20 parts of selenium source, 950-1000 parts of attapulgite clay or modified attapulgite clay and 5-40 parts of beta-cyclodextrin, wherein the modified attapulgite clay is one-dimensional nano-state attapulgite clay which is modified by hydrogen type ion source (H<+>) irradiation. The composition achieves a stable release condition after 2-3 hours in a solution state, the selenium concentration in the solution state can achieve 40-60% of the original selenium concentration in the selenium sustained-release additive, and the stable release condition can be sustained for 90-120 days.

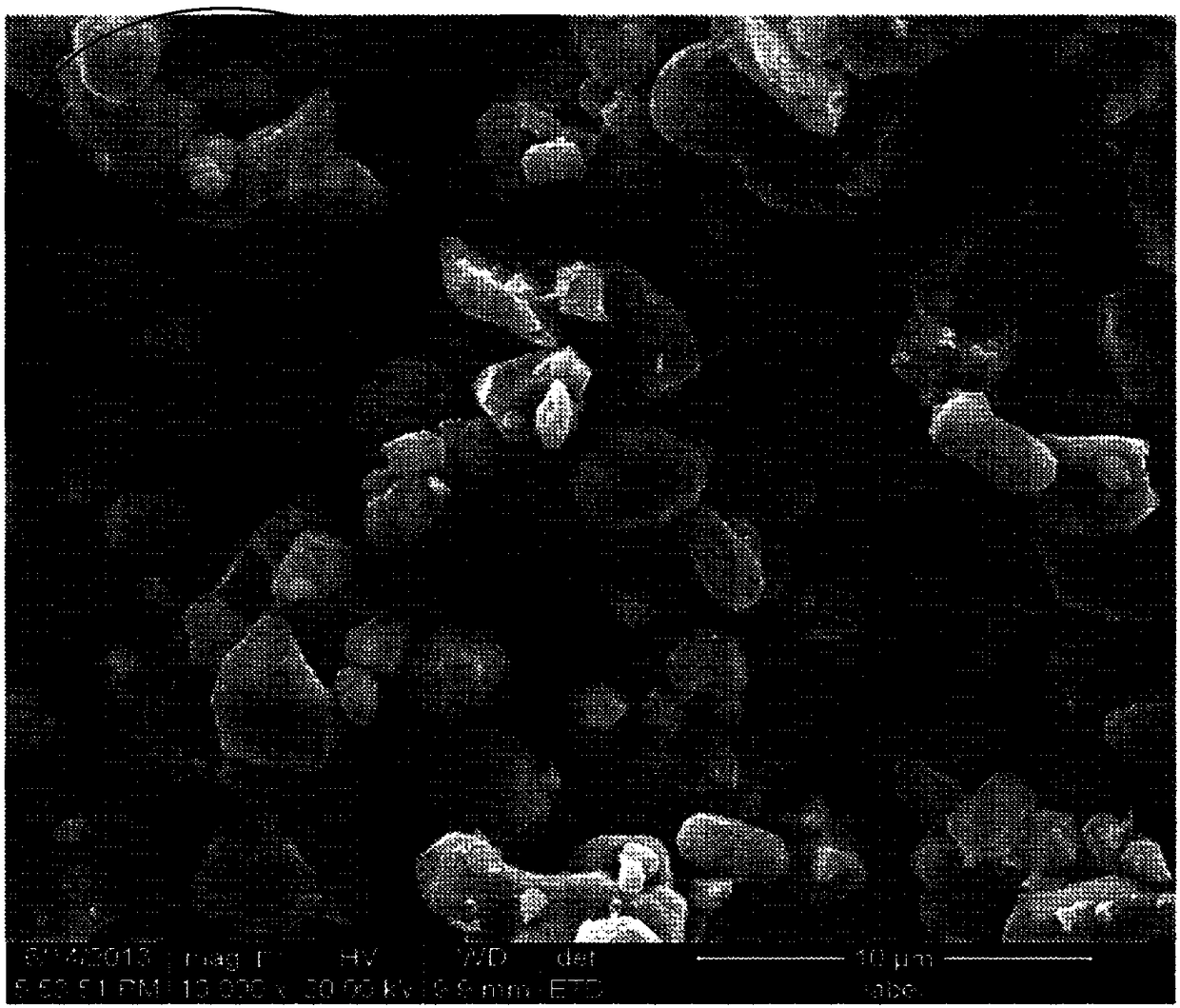

Single crystal lithium-rich manganese-based anode material, preparation method thereof, lithium ion battery

InactiveCN108598457ASmall particle sizeFacilitate functioningCell electrodesSecondary cellsManganeseSingle crystal

The invention relates to a preparation method of a single crystal lithium-rich manganese-based anode material. In the process of preparing a single crystal lithium-rich manganese-based anode materialby calcining a lithium-rich manganese-based material precursor, the method comprises the following steps: S1, firstly, pre-sintering the lithium-rich manganese-based material precursor, and carrying out crushing treatment to obtain scattered oxide of the lithium-rich manganese-based material precursor; S2, uniformly mixing the oxide of the lithium-rich manganese-based material precursor with a lithium source and then sintering to obtain the oxide of the lithium-rich manganese-based material precursor. More preferably, a small amount of additive is mixed while mixing lithium after pre-sinteringand crushing; and the mixed additive may induce crystal growth and grain boundary fusion, which is favorable for forming a single crystal and improving the structure of the crystal; pre-sintering andcrushing can reduce the particle diameter to a relatively desirable range, so that the sintered body has better kinetic performance and achieves better mixing uniformity when mixing lithium and mixing the additive, to promote the formation of the single crystal. By means of such a preparation method, a lithium-rich manganese-based anode material having a high degree of single crystallization anda uniform particle diameter can be obtained.

Owner:桑德新能源技术开发有限公司 +1

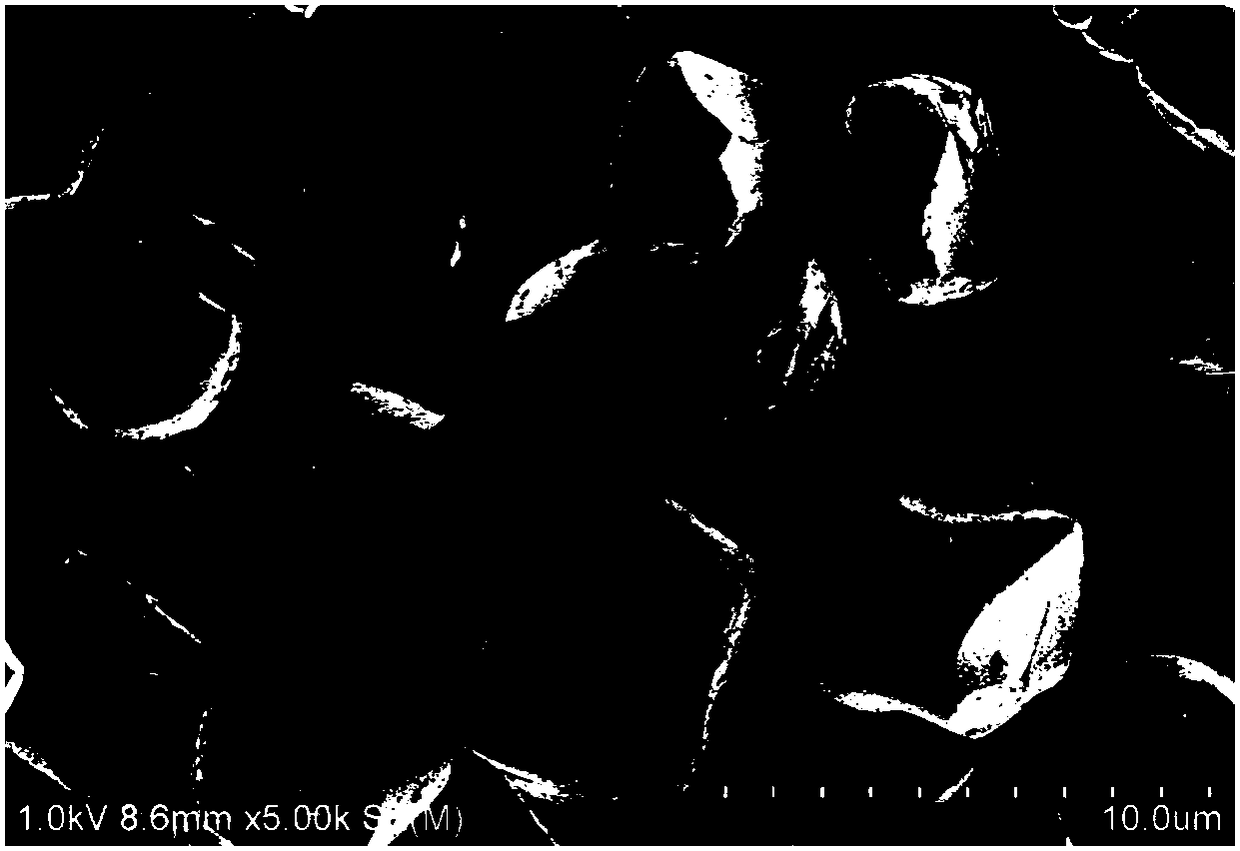

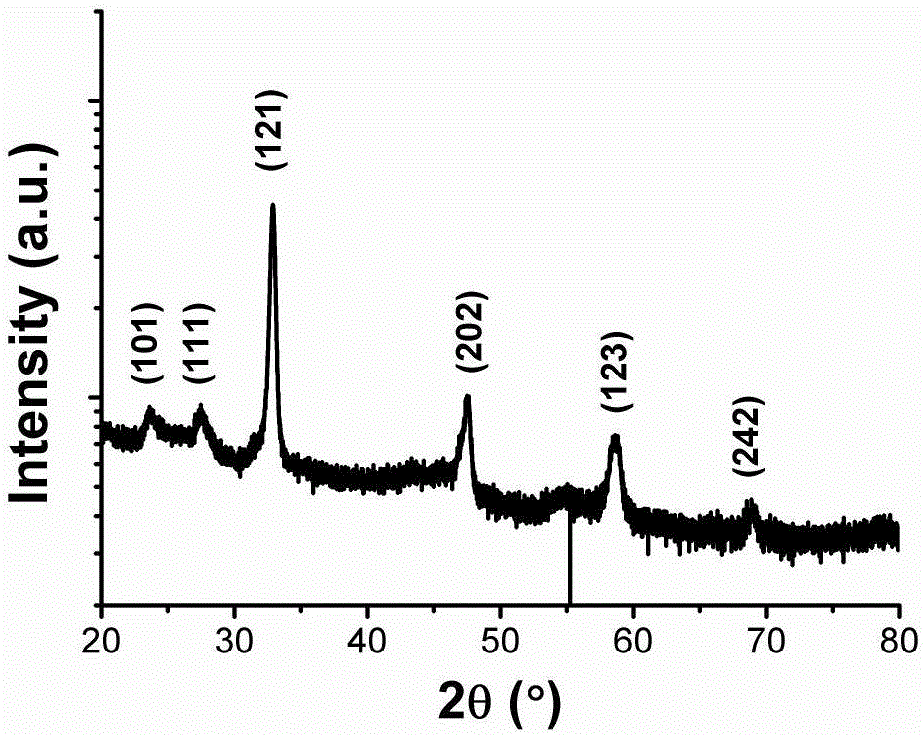

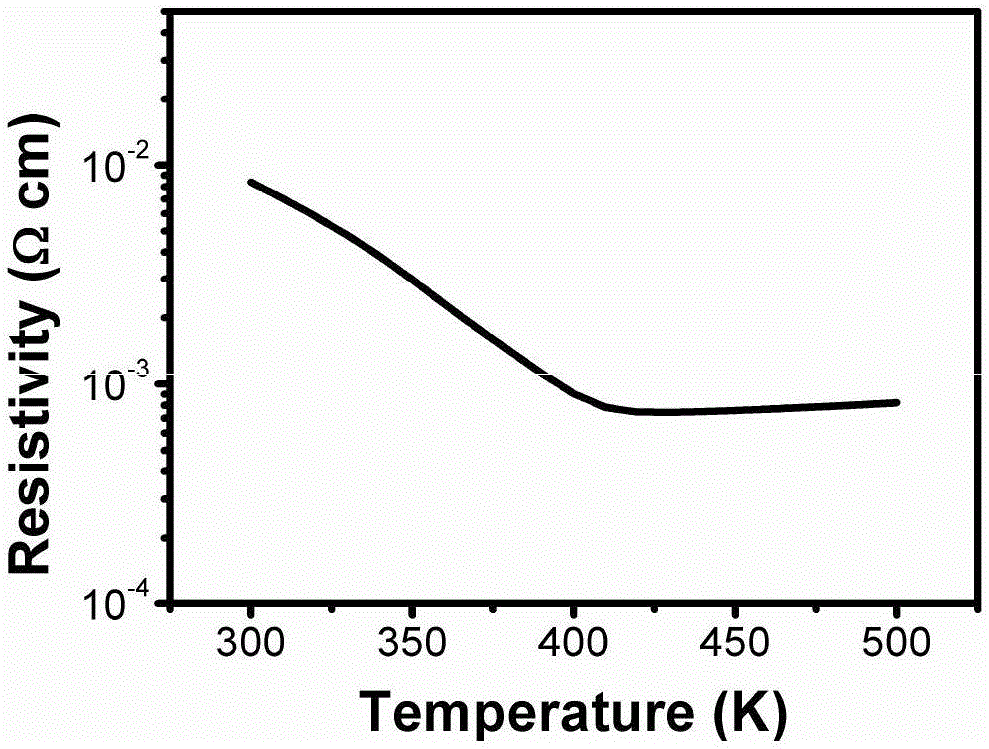

Preparation method of rare earth nickel-based oxide polycrystalline film material

InactiveCN106480413AAchieve non-epitaxial growthAchieve growthVacuum evaporation coatingSputtering coatingRare-earth elementStrontium titanate

The invention discloses a preparation method of a rare earth nickel-based oxide polycrystalline film material, and belongs to the field of inorganic nonmetal film materials. The preparation method comprises the steps that an oxide material buffer layer with lattice parameters similar with that of a rare earth nickel-based perovskite oxide material grows on the surface of a substrate material; and a rare earth nickel-based perovskite oxide film is further deposited on the surface of the buffer layer through a vacuum deposition method. The crystal structure of the rare earth nickel-based perovskite oxide material is the perovskite structure ReNiO3 of ABO3, and the Re position is one rare earth element or the combination of various rare earth elements. The materials of the buffer layer preferentially comprise strontium rubidium oxygen, strontium titanate, lanthanum doped strontium titanate, neodymium doped strontium titanate, barium titanate and calcium titanate. The preparation method of the rare earth nickel-based oxide polycrystalline film material is easy, convenient and efficient. The prepared film material has excellent temperature dependent and hydrogen-induced performance and can be further applied in the fields of functional electronic devices, fuel cells, infrared detectors and the like.

Owner:UNIV OF SCI & TECH BEIJING

Method for growing large-size high-temperature oxide crystals by using top-seeded temperature gradient method

InactiveCN101705516ARealize real-time controlSolve the problem of large thermal shockPolycrystalline material growthFrom frozen solutionsCzochralski methodCrucible

The invention relates to a method for growing large-size high-temperature oxide crystals by using a top-seeded temperature gradient method, which relates to a new process of crystal growth and comprises the following steps of: combining a Kyropoulos method, a Czochralski method (CZ), a heat exchange method (HEM), a temperature gradient technique (TGT) and a Bridgman-Stockbarge method together, creating a special high temperature vacuum crystal furnace with adjustable temperature gradient and temperature field center, and producing the large-size high temperature oxide crystals through charging, high vacuum pimping, material melting by temperature rise, crystal seed washing, real-time temperature field adjustment, seeding by CZ, multiple reducing processes, a shouldering process by CZ, an isodiametric process by the Kyropoulos method, heat exchange by HEM combined with isodiametric growth by a TGT technology (a diameter control technology is CZ weighting), ending and crucible separation by CZ and annealing. The method is also suitable for a high vacuum environment and an atmosphere protection environment. The method has the advantage that the lowest energy consumption and the lowest cost are utilized for producing multiple high-quality high-temperature oxide crystal material products.

Owner:UNIONLIGHT TECH

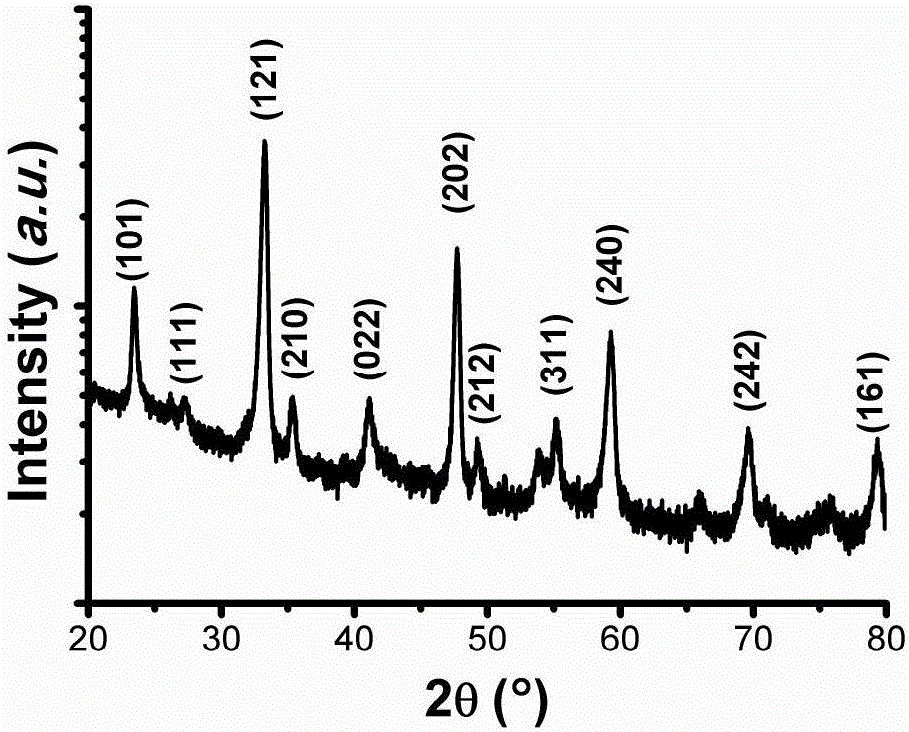

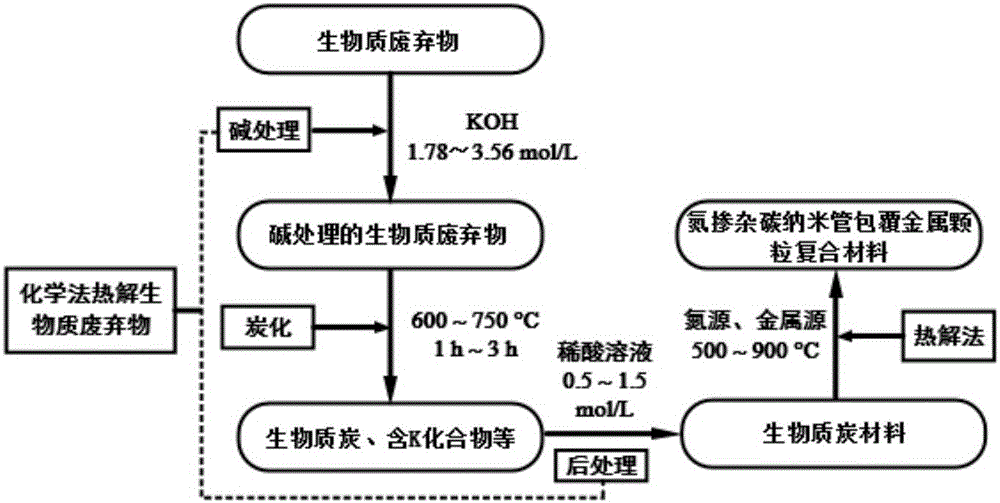

Method for using biomass waste for preparing nitrogen-doped carbon nanotube coated metal particle composite material

ActiveCN105772708AGood dispersionImprove stabilityTransportation and packagingMetal-working apparatusCarbon layerDispersity

The invention discloses a method for using biomass waste for preparing a nitrogen-doped carbon nanotube coated metal particle composite material. The method includes the following steps that firstly, the biomass waste and KOH are evenly mixed in deionized water, an obtained heterogeneous mixture is carbonized under the protection of inert gas, and biomass charcoal is obtained; and then, the biomass charcoal, a nitrogenous nonmetallic compound and water-soluble divalent metal salt are evenly mixed in methyl alcohol, the obtained heterogeneous mixture is subjected to pyrolysis under the protection of the inert gas, and therefore a target product is obtained. By the adoption of the method, a two-step pyrolysis technology is adopted for achieving growth of carbon nanotubes, and dispersion of metal nanoparticles and formation of a cooperative acting mechanism are promoted; the stability of the composite material is reinforced through the structure of carbon nanotube coated metal nanoparticles; the surface activity and dispersity of a carbon layer are improved through in-situ decoration of the nitrogen element; and the contact and active site point number is increased through the formation of a rich pore structure and the high specific surface area.

Owner:安徽皖瑞能源科技有限公司

Method for preparing porous silicon carbon nanotube composite negative electrode material of lithium ion battery by diatomite

InactiveCN105845911AUnique pore structurePore structure retentionCell electrodesSecondary cellsCarbon compositesPtru catalyst

The invention relates to a method for preparing a porous silicon carbon nanotube composite negative electrode material of a lithium ion battery by diatomite. The method is characterized in that the diatomite is a silicon source, comprises the steps of preparing porous silicon, preparing a porous silicon matrix surface supported catalyst precursor and preparing a porous silicon carbon nanotube composite material, has the advantages of availability in raw material, low cost, clearness in morphology of the prepared porous silicon, high capacity of the silicon carbon composite material, cycle stability, high production efficiency, low cost and the like, and is suitable for industrial production. Under the test in which current density is 100mA / g, the initial reversible specific capacity of a negative electrode, prepared from the material, of the lithium ion battery reaches 1,529.1mAh / g, the reversible specific capacity reaches 885.4mAh / g after circulation of 40 times, and the subsequent cycle capacity is almost unchanged; and through the rate performance test, the reversible specific capacity is restored to about 800mAh / g when the current density is restored to 100mA / g, and the test shows that the material is high in connection tightness performance.

Owner:NORTHEAST DIANLI UNIVERSITY

UiO-66-NH2 composite material as well as preparation method thereof and application of composite material in seawater desalination

ActiveCN108654402AImprove desalination performanceEasy to operateSemi-permeable membranesGeneral water supply conservationTriethoxysilaneSeawater desalination

The invention discloses a UiO-66-NH2 composite material as well as a preparation method thereof and an application of the composite material in seawater desalination. The UiO-66-NH2 composite materialcomprises a carrier modified by 3-aminopropyltriethoxysilane and a UiO-66-NH2 film layer, wherein the UiO-66-NH2 film layer is covalently attached to the carrier. According to the preparation methoddisclosed by the invention, the carrier modified by the 3-aminopropyltriethoxysilane is placed into a UiO-66-NH2 film reaction solution for a reaction to obtain the UiO-66-NH2 composite material; andthe UiO-66-NH2 composite material disclosed by the invention has the simple preparation method and excellent seawater desalination treatment performance, and is suitable for large-scale promotion.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

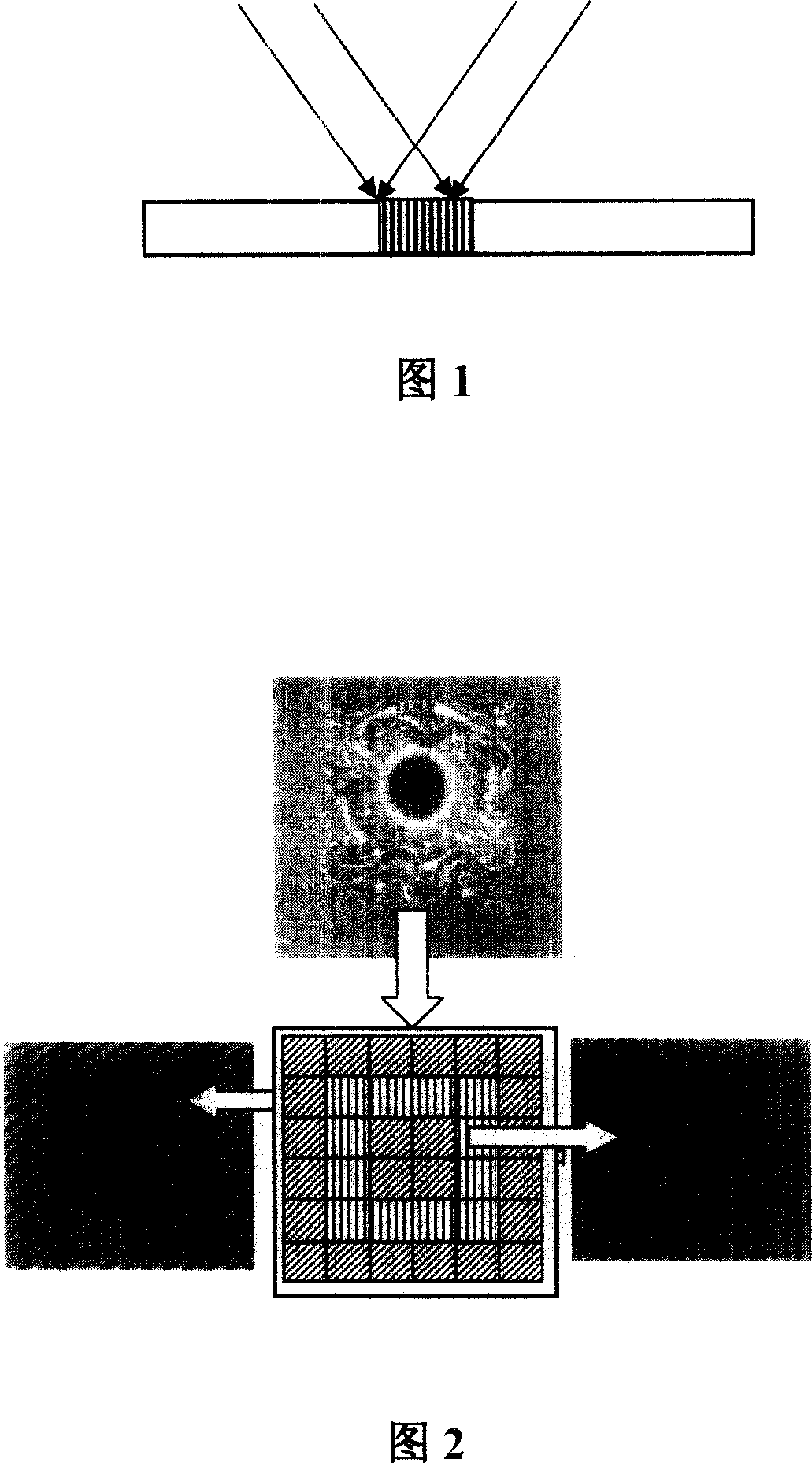

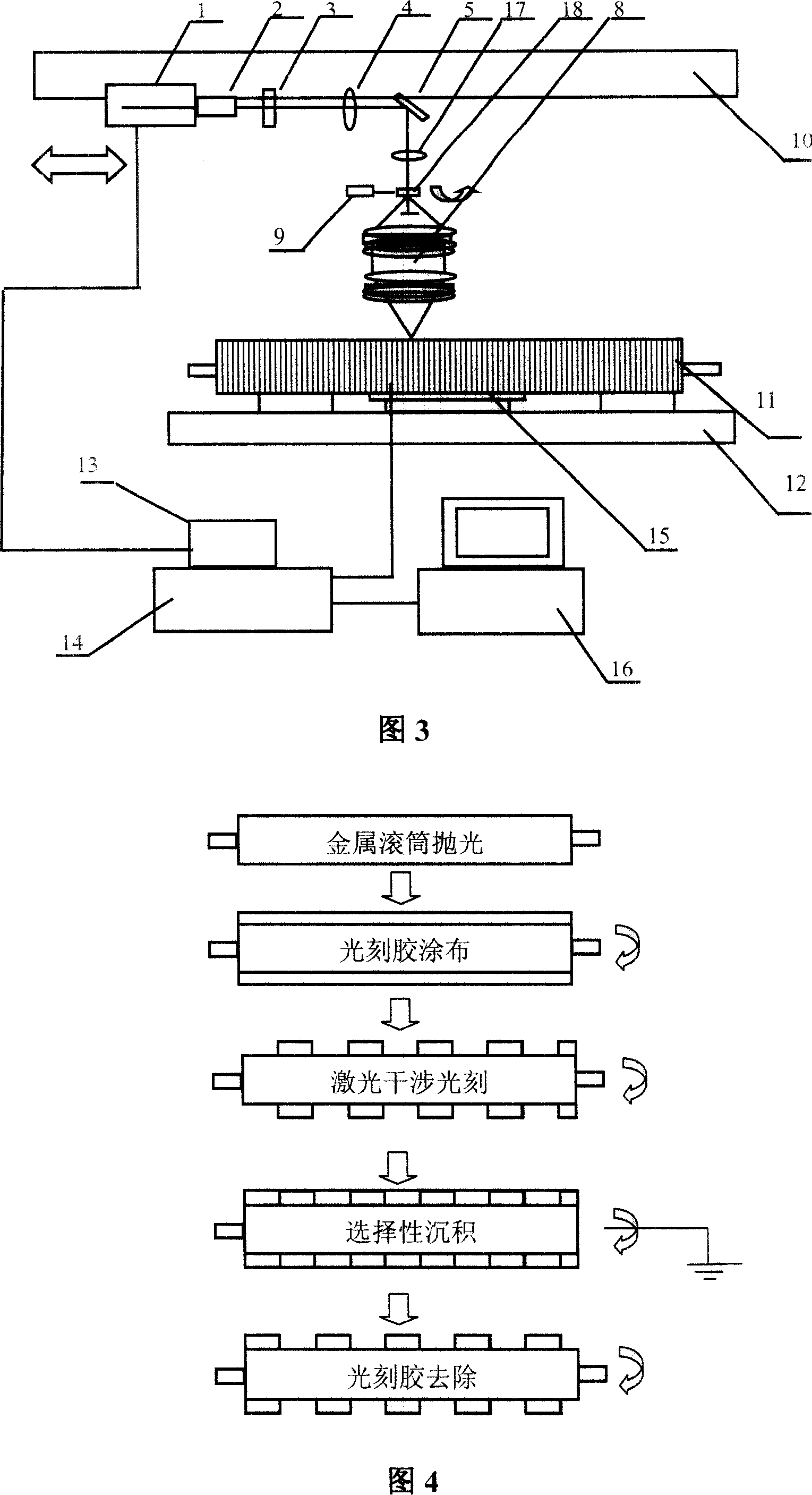

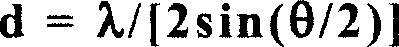

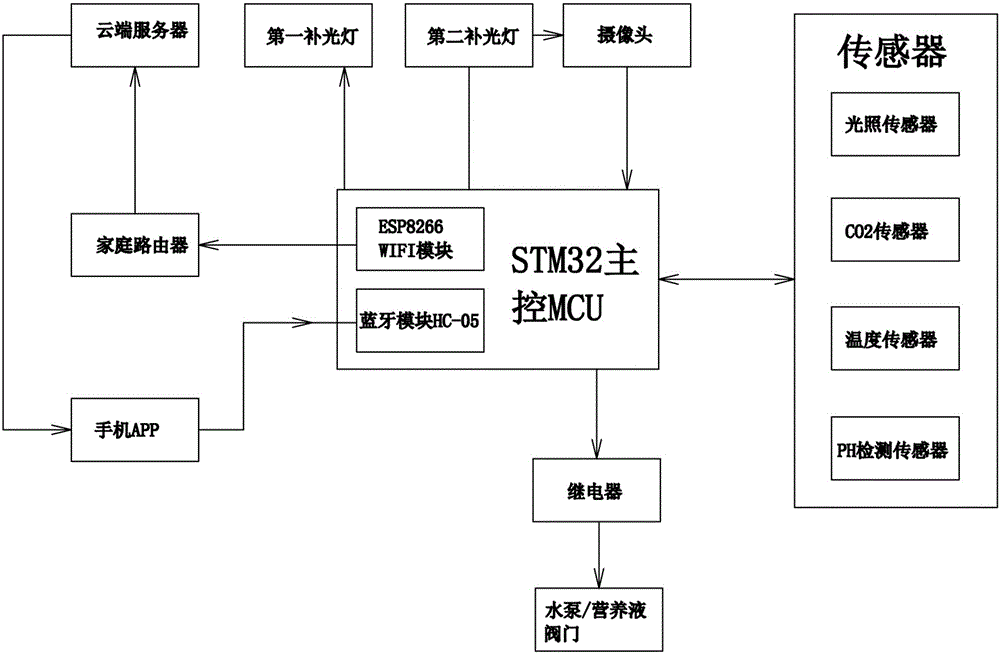

Method of preparing metal roller with surface relief microstructure

ActiveCN101016634ANo patchworkHigh hardnessDecorative surface effectsPhotomechanical exposure apparatusResistGrating

The invention discloses a preparing method of metallic roller with surface relief microstructure, which comprises the following steps: (1) applying photo resist on the metallic roller; producing microstructure mask on the photo resist; removing light part until metallic surface emergence through development; (2) placing the processing metallic roller in electromoulding solution; connecting to electrical source negative pole; proceeding metallic electrodeposition with the thickness of deposition at 150-500 nanometer; (3) getting out of metallic roller from electromoulding solution; removing surplus photo resist; getting the metallic roller. This invention combines the photolithographic process and electromoulding to realize the production of metallic roller.

Owner:苏州迈塔光电科技有限公司 +2

Intelligent WIFI household plantation automatic control system based on mobile phone APP

InactiveCN105159365AAchieve growthImprove growth efficiencySimultaneous control of multiple variablesAutomatic controlCrop

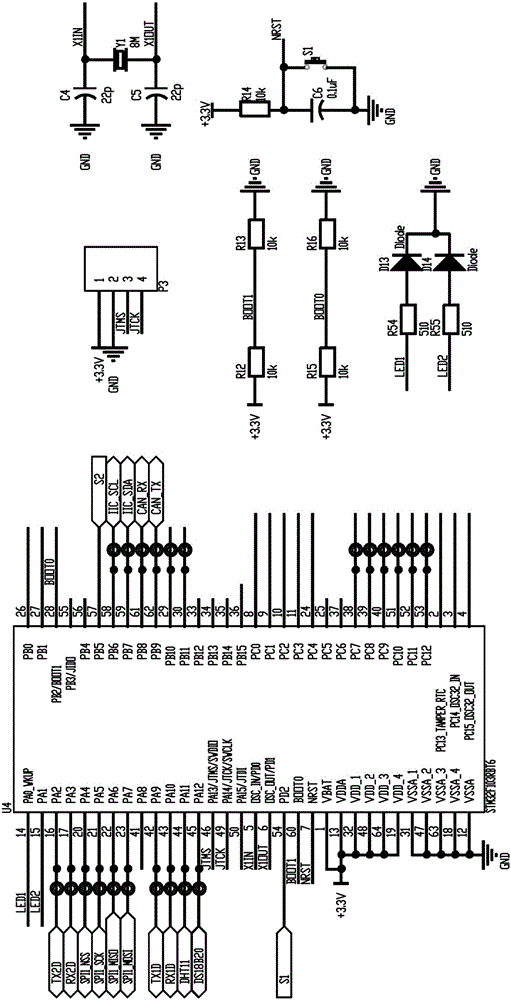

The invention discloses an intelligent WIFI household plantation automatic control system based on a mobile phone APP. The intelligent WIFI household plantation automatic control system includes a master control MCU, a sensor, a camera, a light supplement lamp, a relay, a household router, a cloud server, and the mobile phone APP, the sensor, the camera, and the light supplement lamp are arranged at the planted crops and are connected with the master control MCU, the master control MCU generates control orders based on the received environment variables and transmits the control orders to the light supplement lamp and the relay to respectively control illumination, water volume, and nutrient solution delivery, the household router is connected with the master control MCU, the cloud server is connected with the household router, the master control MCU uploads the received environment variables and the video data to the cloud server via the household router, and the mobile phone APP downloads the data via the cloud server. On the basis of the plantation requirement of different vegetables, the intelligent WIFI household plantation automatic control system inducts the current growth environment, controls the environment input, and realizes scientific plantation.

Owner:武汉市摩多创意科技有限公司

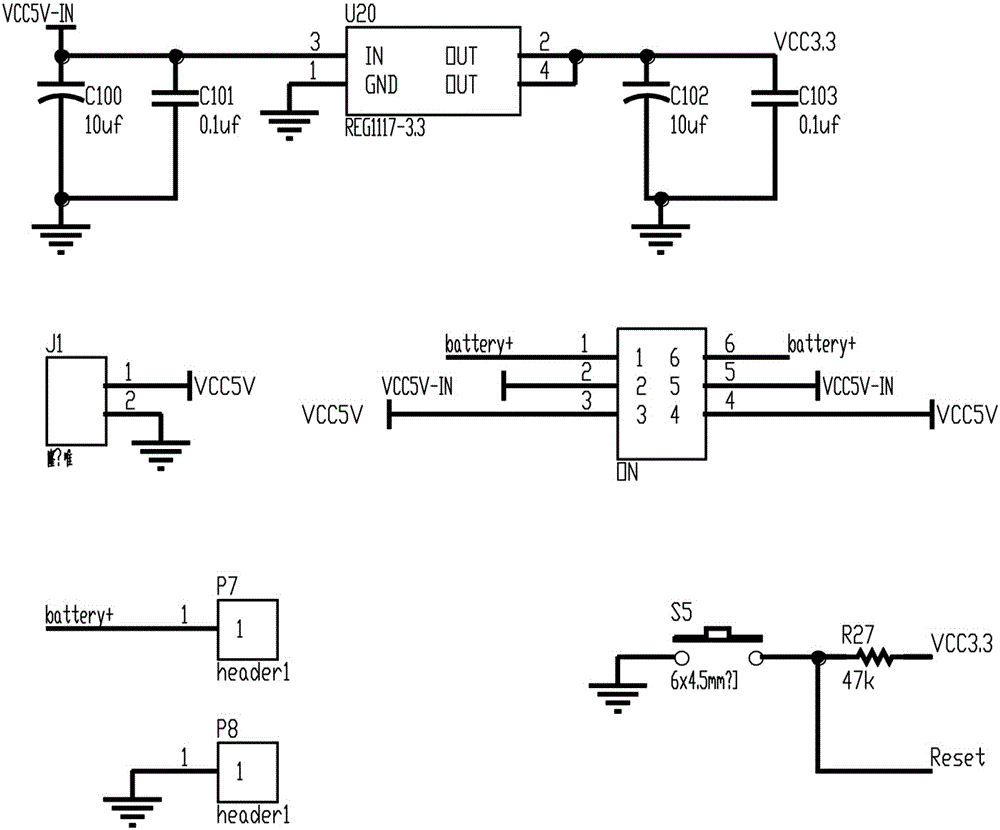

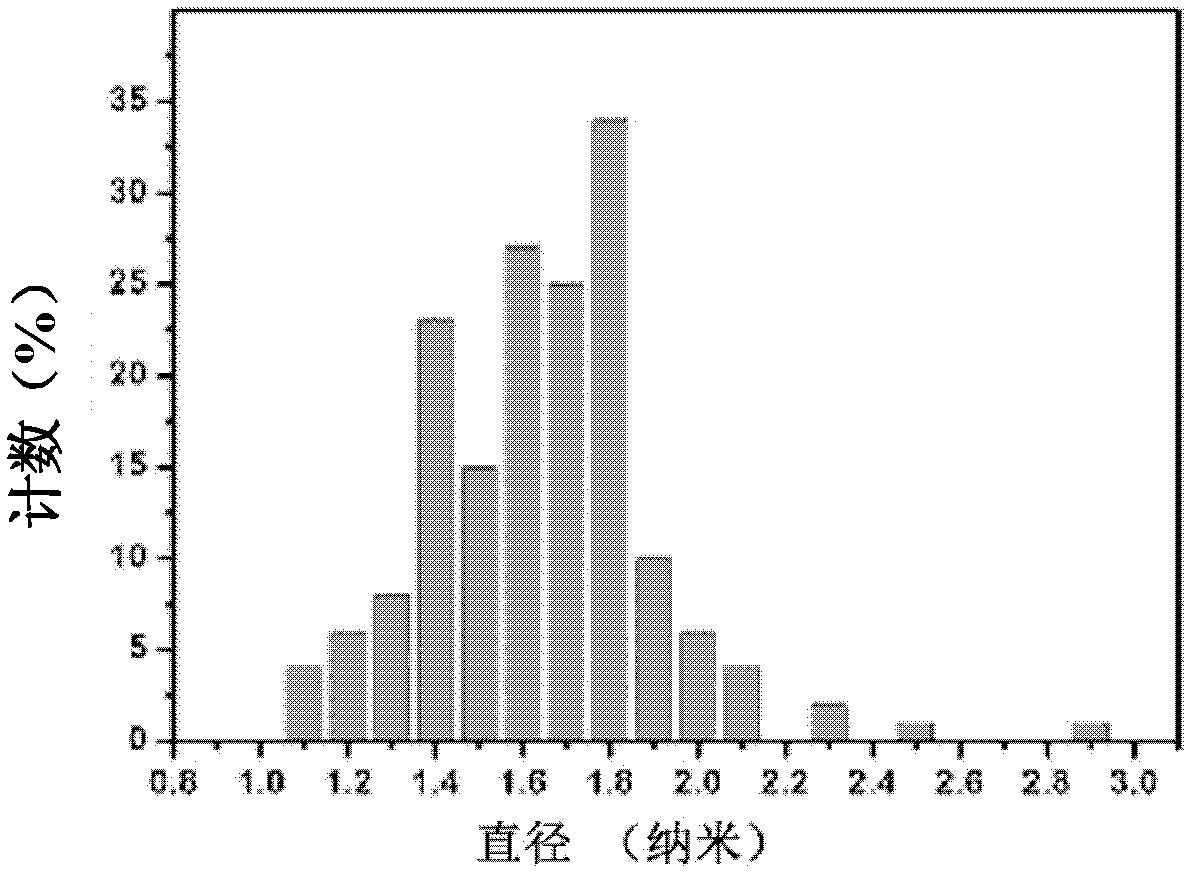

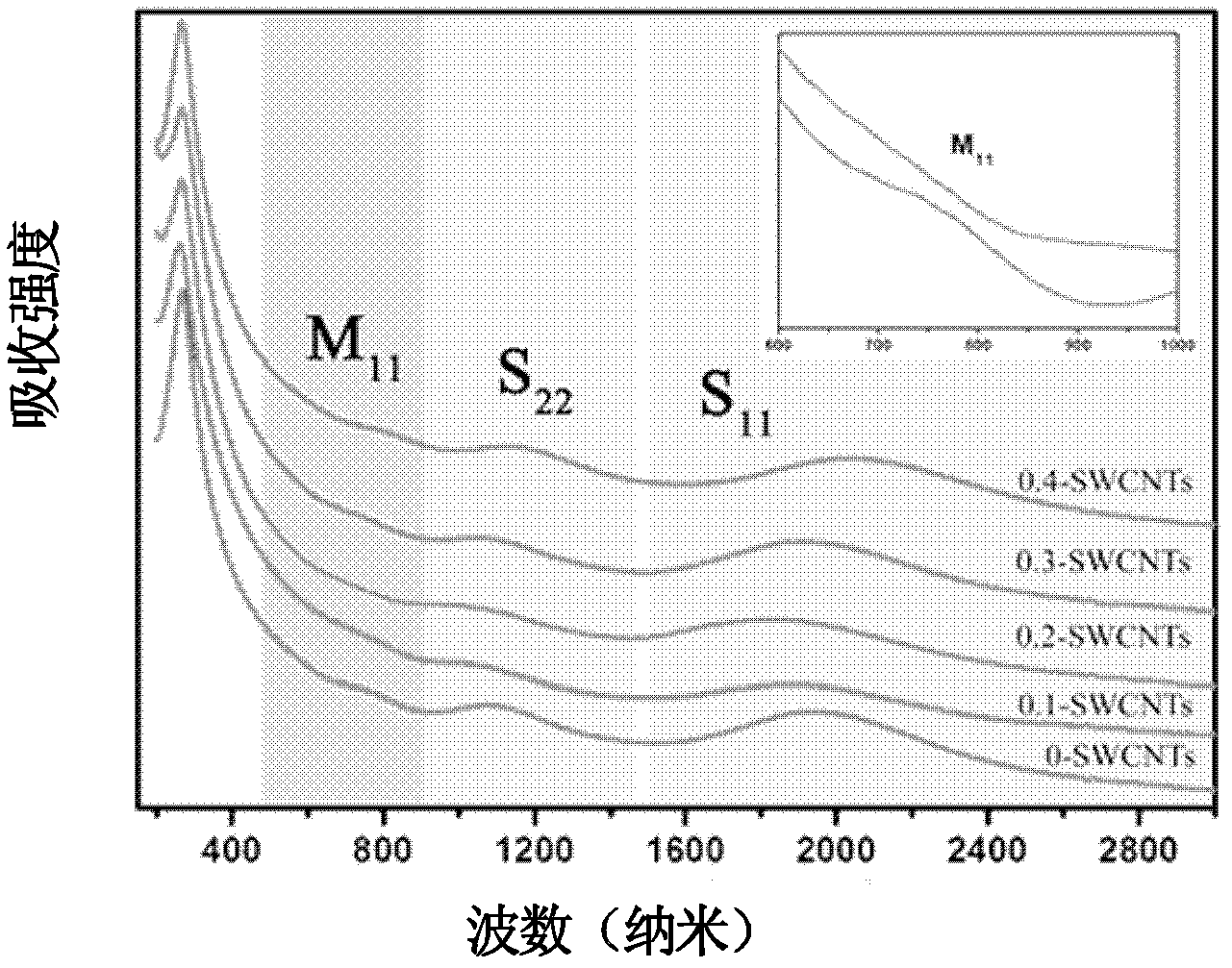

Method for directly growing semiconductor type single-walled carbon nanotube with floating catalyst and auxiliary oxygen

The invention relates to massive and controllable preparation field of semiconductor type single-walled carbon nanotubes, specifically to a method for directly growing the semiconductor type single-walled carbon nanotube with floating catalyst and auxiliary oxygen. The method comprises the following steps of: taking ferrocene as precursor of the catalyst, taking right amount of sulphur powder as growth promoter, and taking hydrogen as a carrier gas; simultaneously introducing a carbon source gas and small amount of oxygen to grow the single-walled carbon nanotube, and etching the small-diameter and metallic single-walled carbon nanotube in situ; and finally, obtaining a sample in which the semiconductor type single-walled carbon nanotube is dominant, wherein content of the semiconductor type single-walled carbon nanotube is 90 wt%, and diameter distribution of the semiconductor type single-walled carbon nanotube is 1.4-1.8 nm. With the method, massive and directly controlled growth ofthe semiconductor type single-walled carbon nanotube with narrower diameter distribution is realized; and the method solves the problems, such as that the separation process of the existing chemical and physical methods seriously damages the intrinsic structure of the single-walled carbon nanotube and the process is complex, and sample amount is less, diameter distribution is wider and the diameter is smaller in the direct preparation technology, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

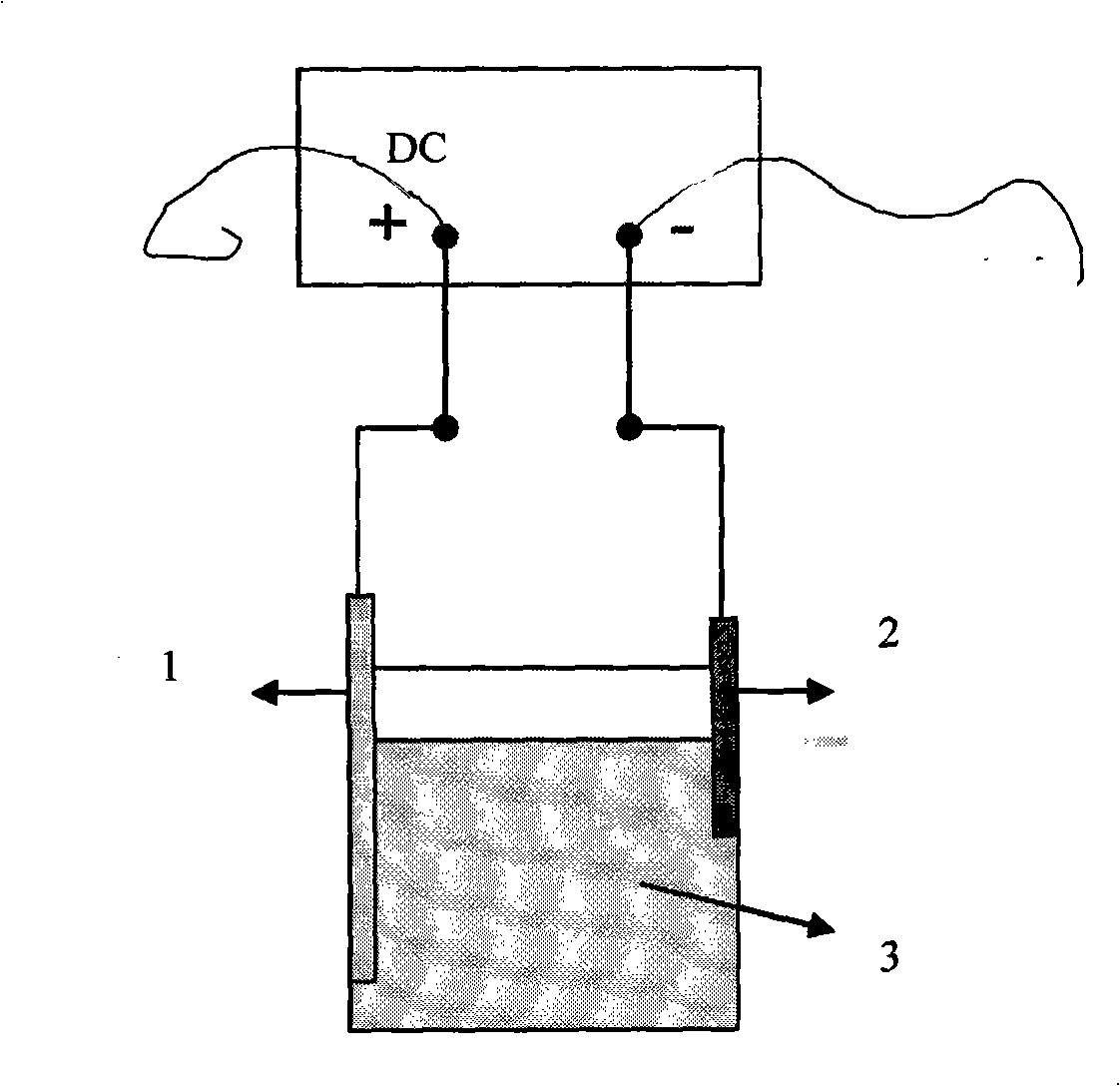

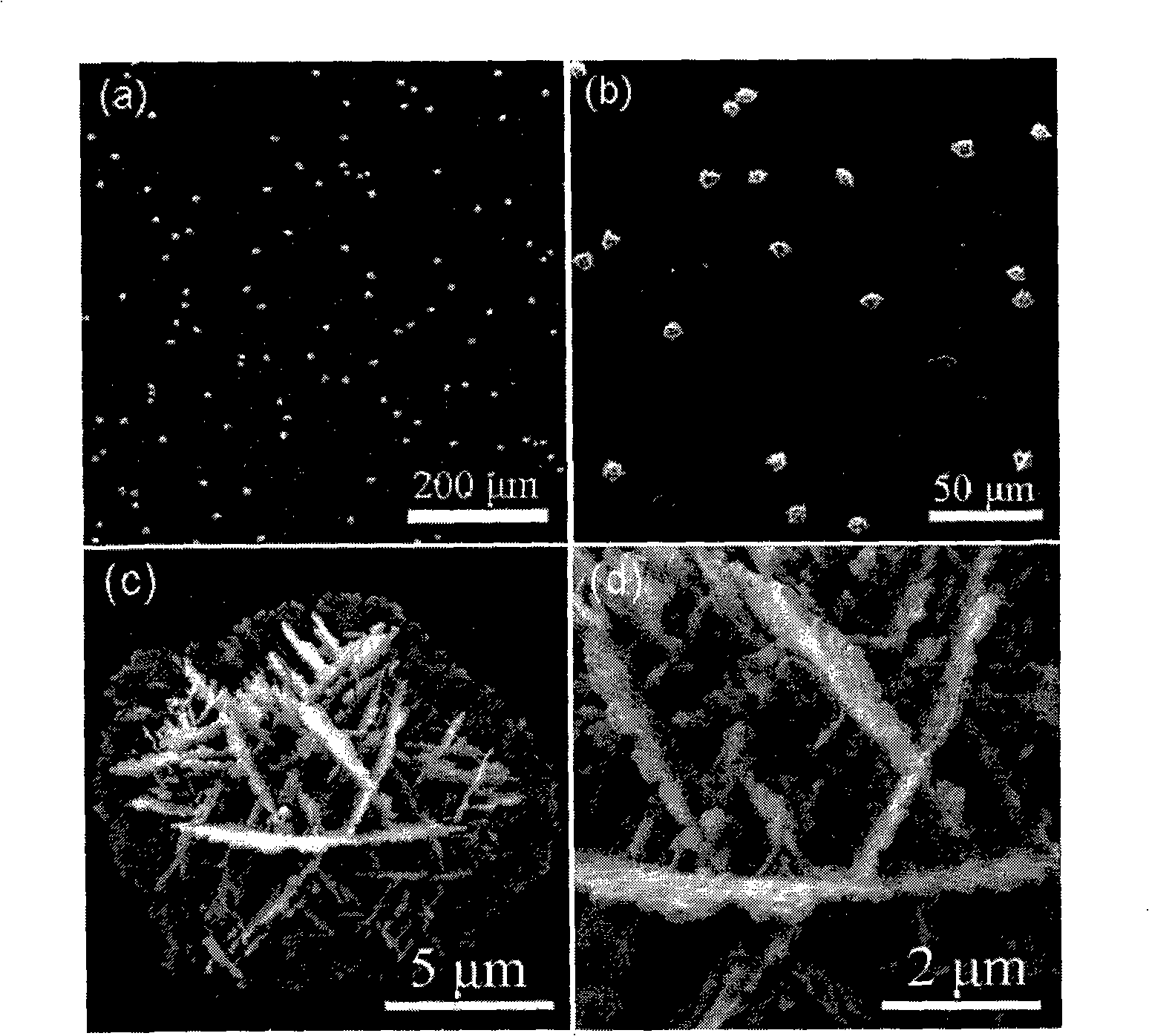

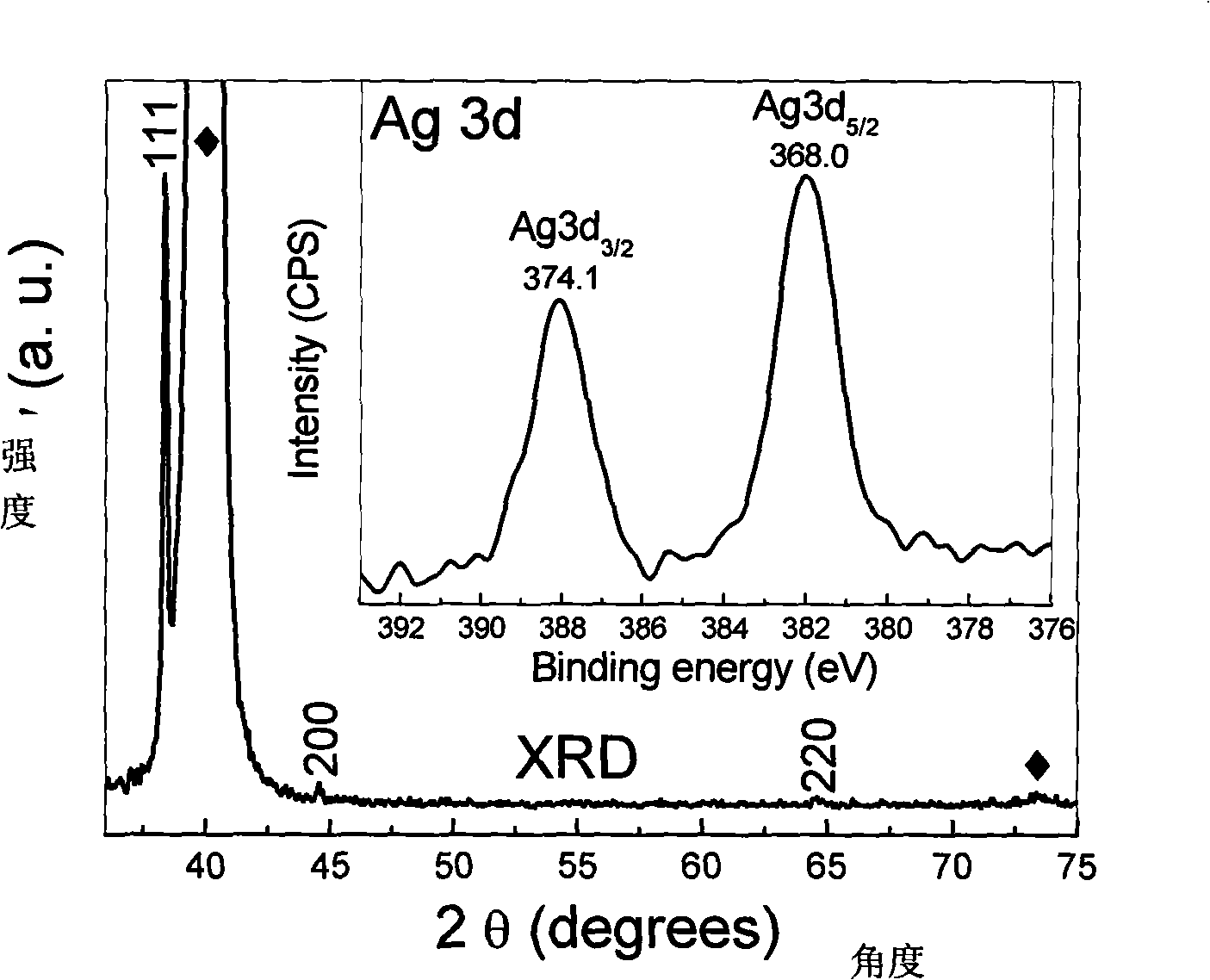

Synthetic method of load type floriform silver nanostructured material

The invention discloses a synthesizing method of a loading flower-shaped nano silver structural material, which is characterized in that a silver plate with high purity is taken as an anode, a platinum film electrode is taken as a cathode, a silver nitrate solution with the concentration of 0.003 to 0.01 mol / L is taken as an electrolytic solution, and the volume of the electrolytic solution is 20 to 100 mL; the range of constant voltage is adjusted to be 50 to 200 mV during electrolytic deposition, and the time of the electrolytic deposition lasts for 2 to 15 minutes; the cathode of the loading nano silver structural material is repeatedly rinsed by deionized water after the reaction, and then dried in nitrogen. The synthesizing method of the loading flower-shaped nano silver structural material realizes the growth anisotropy of crystal, leads the size and the microstructure of the nano metallic structure to be controllable, does not need any addition agent and electrode surface modification, and achieves simple control of appropriate voltage and concentration of the electrolytic solution; the synthesizing method is ultra-simple, and has convenient operation, easy-separated products and high purity and well industrial application prospect.

Owner:NANJING UNIV

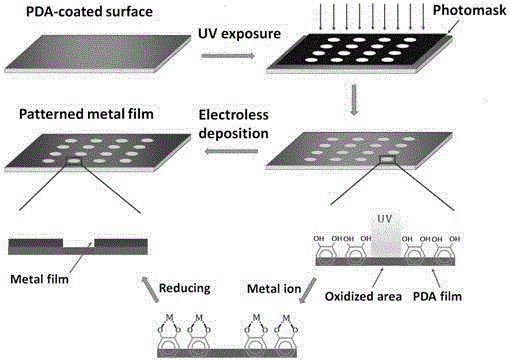

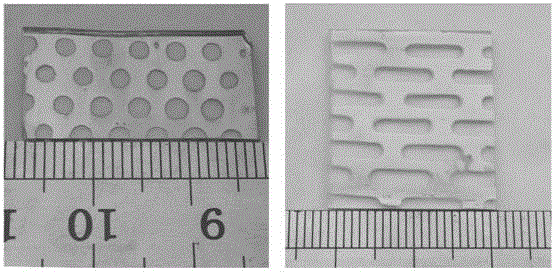

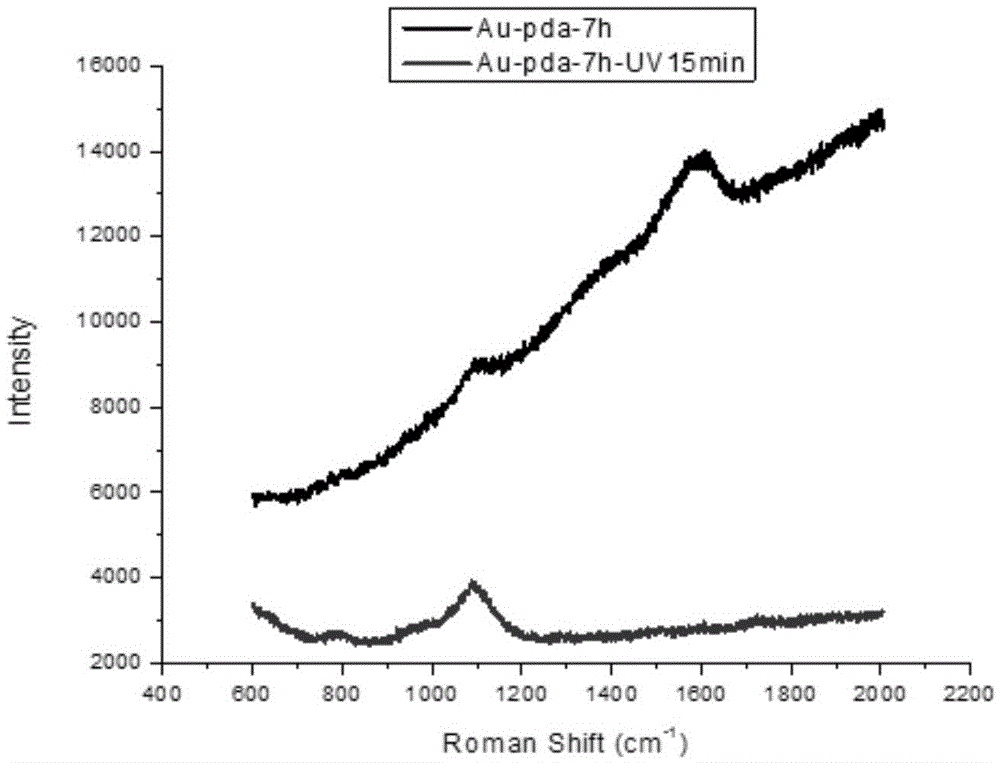

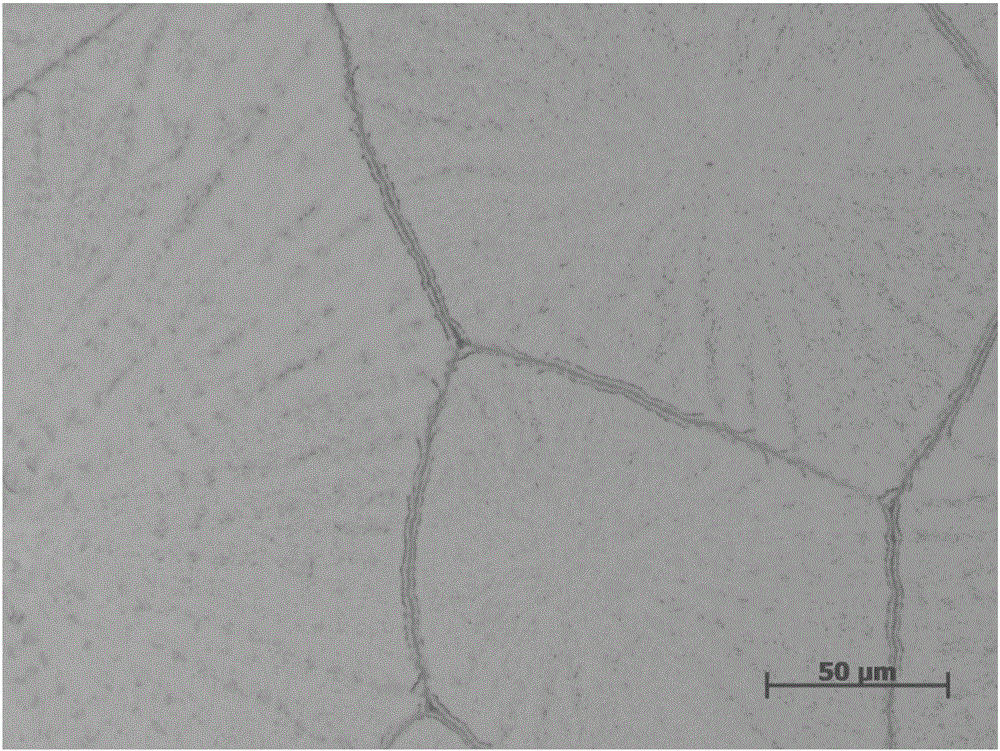

Method for manufacturing patterned metal film based on poly-dopamine and product thereof

InactiveCN105671525APatterned realizationImprove adsorption capacityLiquid/solution decomposition chemical coatingPlanar substrateUltraviolet lights

The invention discloses a method for manufacturing a patterned metal film based on poly-dopamine and a product thereof. The manufacture method comprises the steps that first, a clean substrate is dipped in a dopamine solution with the pH value of 6-9 and the concentration of 0.1-10 mg / ml till a poly-dopamine film is formed on the surface of the substrate; the substrate is taken out, is washed with water and then is blow-dried with nitrogen, so that the substrate adhered with the poly-dopamine film is obtained; then a photomask is placed on the substrate adhered with the poly-dopamine, and then the substrate is radiated for 3-15 minutes in the ultraviolet light with the intensity of 10-35 mw / cm<2>, is cleaned with double distilled water, and is blow-dried with nitrogen, so that a substrate with an ultraviolet oxidized poly-dopamine is obtained; and finally metal ions are deposited on the substrate with the ultraviolet oxidized poly-dopamine. The method disclosed by the invention is applicable to any solid materials which can be both planar substrates and curved or porous surface substrates, and different pattered metal films can be manufactured; and the manufactured patterned metal films can be applied to microcircuits, microarrays and bioinstrumentation.

Owner:SOUTHWEST UNIVERSITY

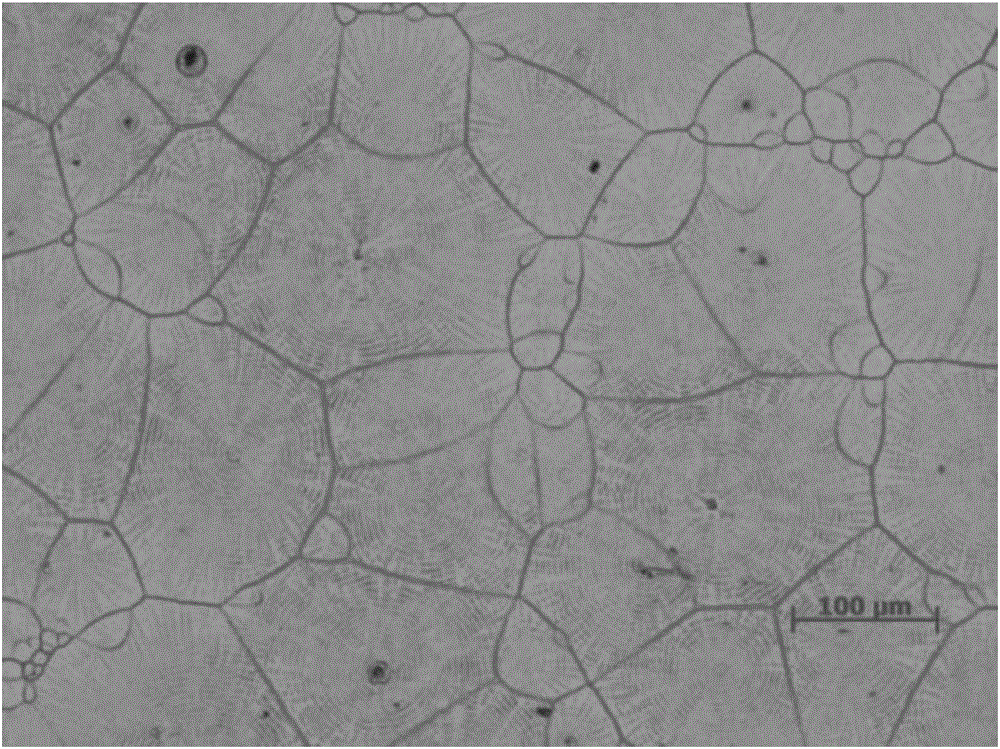

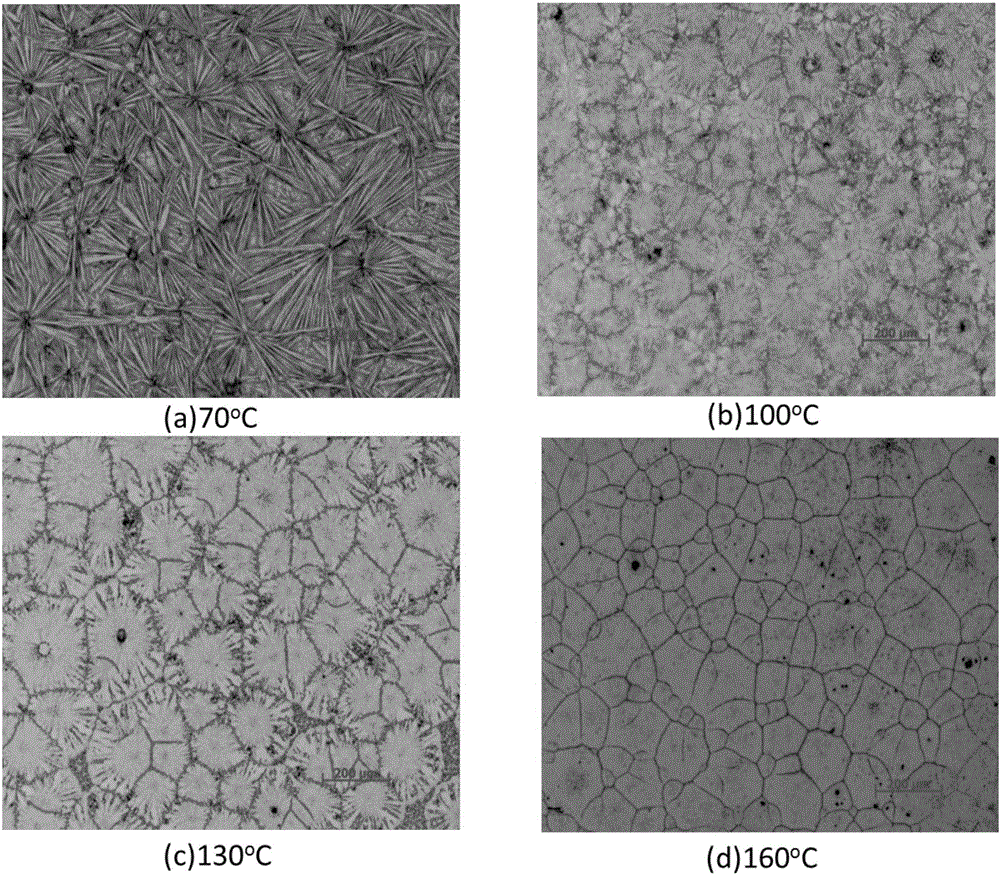

Large grain organic and inorganic hybrid perovskite film preparation method

ActiveCN106159088AEasy to controlEasy preparation of controlled substrate temperatureSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisSolar battery

The invention discloses a large grain organic and inorganic hybrid perovskite film preparation method, belonging to the perovskite type solar battery and correlated photoelectric semiconducting material field, and can prepare a uniform and compact large grain film through the steps of configuration of an organic and inorganic hybrid perovskite precursor solution, stirring and heating, spin coating, annealing, etc. The method requires no spin coating in a multistep approach, ca easily control the temperature of a room temperature substrate, has no strict requirements on an annealing and cooling rate, and can manufacture a film efficiently. The method realizes virtual grain film growth through adjusting the grain dimension of a perovskite light-absorption layer, thereby reducing grain inner defects, and increasing the carrier transport efficiency; in addition, the method controls grain boundary defects, greatly improves perovskite crystal film environment stability, and enhances perovskite thin-film device performances. A perovskite type virtual monocrystalline film prepared in the low temperature solution method can assemble hysteresis free, efficient and stable perovskite type solar batteries and correlated film transistor, electroluminescent and laser emission photoelectric semiconductor devices.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com