Method of preparing metal roller with surface relief microstructure

A technology of a metal roller and a manufacturing method, which is applied to the technology for producing decorative surface effects, microlithography exposure equipment, and photolithography exposure equipment, etc., which can solve the problems of low absorption rate, limited processing accuracy, and easy formation of crater effects and other issues to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

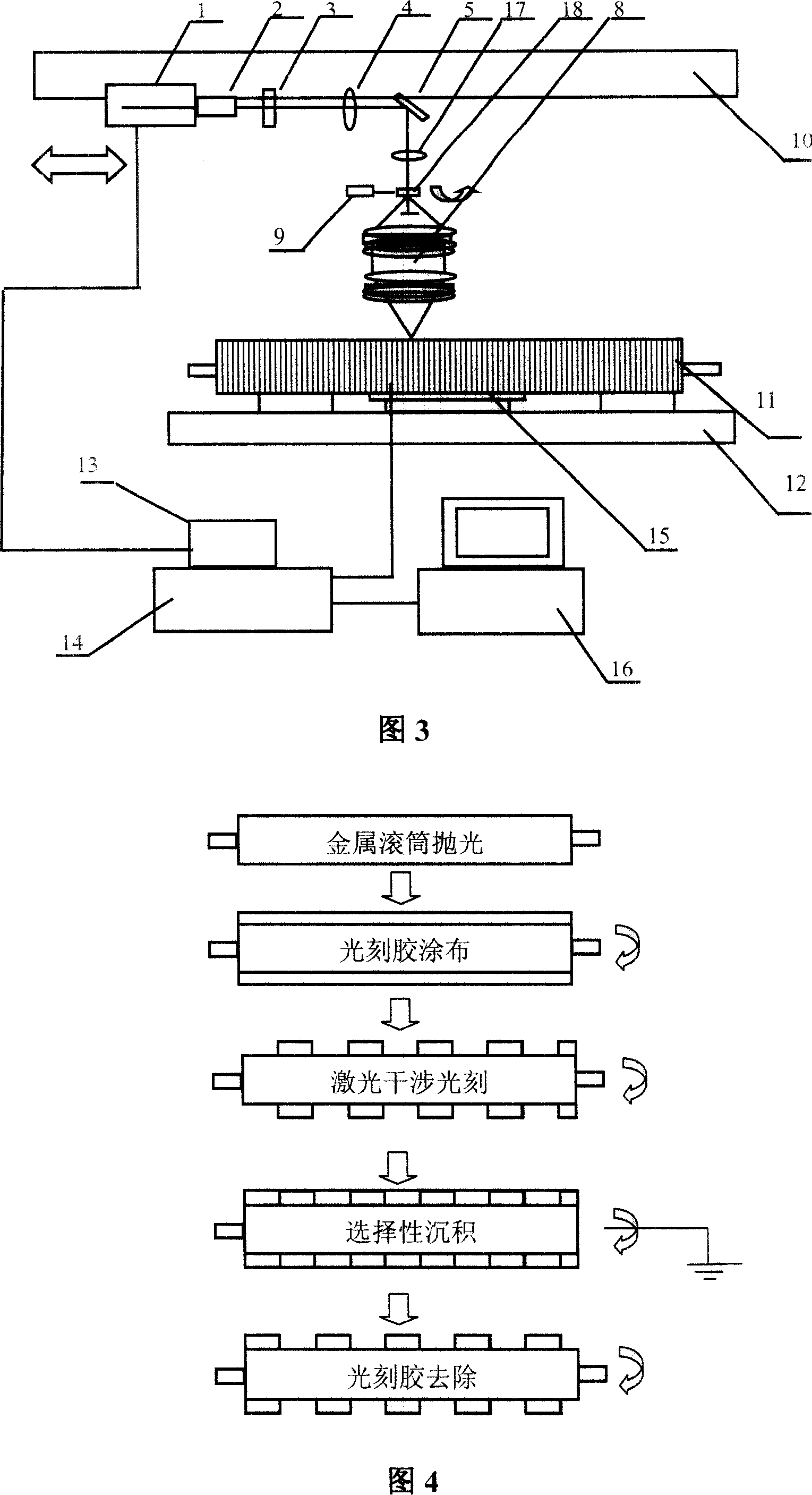

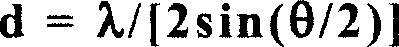

[0048] Embodiment 1: Referring to the accompanying drawing 4, a method for making a metal cylinder with a surface relief microstructure comprises the following steps:

[0049] [1] First make a polished metal roller;

[0050] [2] Coating photoresist;

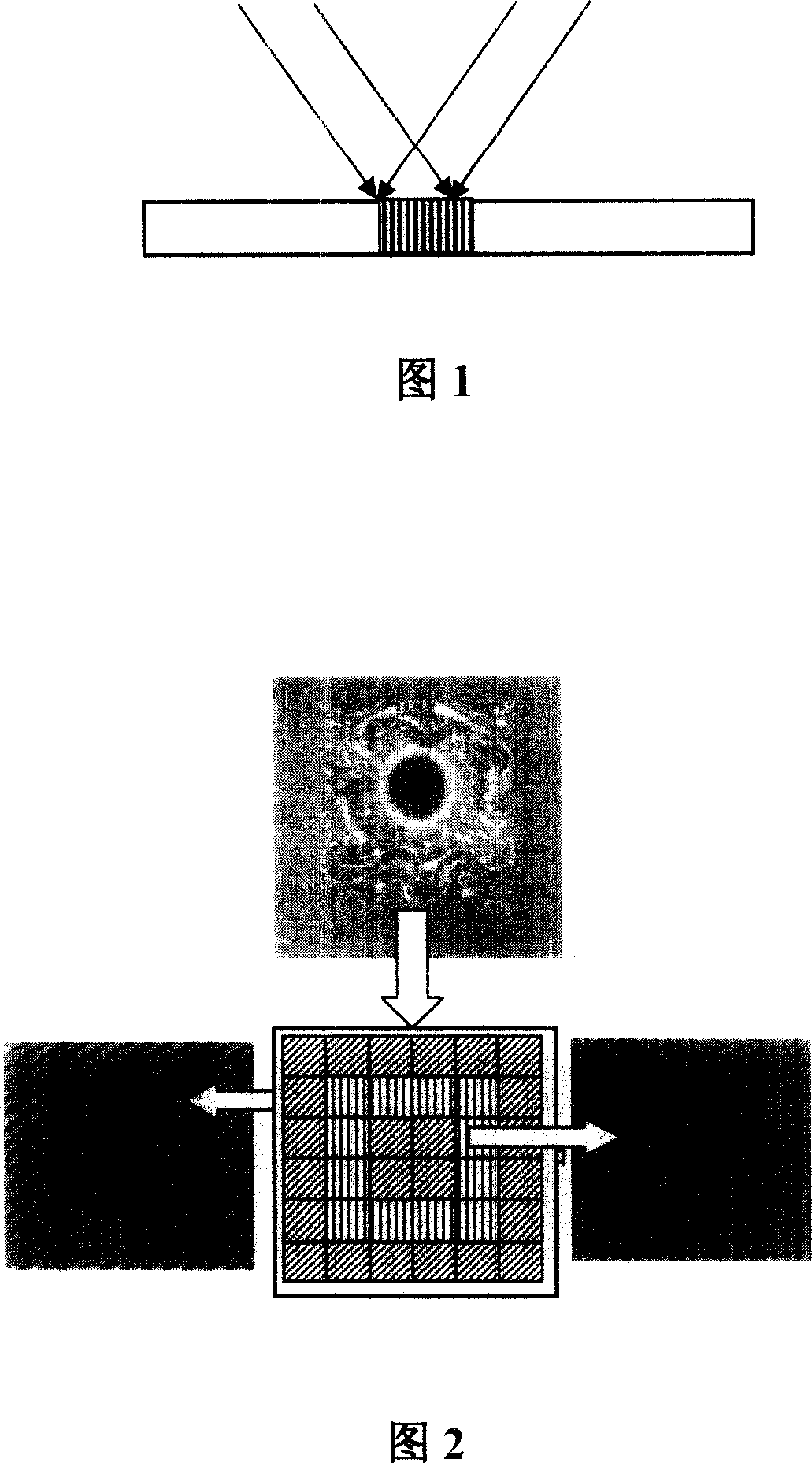

[0051] [3] Carry out interference lithography on the photoresist roller, adopt the interference lithography device shown in accompanying drawing 3,

[0052] Its lithography method is: convert the image distribution into a pulse control signal, according to the orientation and space frequency of the unit grating, simultaneously perform interference optical head, platform movement, high-speed rotation of the grating and light pulse input, line by line detour on the drum type photoresist On continuous exposure, the drum, optical head, and beam splitter do not need to pause during exposure until the entire image is produced.

[0053] The laser lithography direct writing system realizing the above method includes a DPSSL laser light...

Embodiment 2

[0059] Embodiment two: see accompanying drawing 4 shows,

[0060] [1] First make a polished metal roller;

[0061] [2] Coating photoresist;

[0062] [3] Perform interference lithography on a photoresist roller;

[0063] [4] Put the roller after photolithography into the developer to ensure that the bottom of the grating groove is exposed (up to the metal surface), and clean it;

[0064] [5] Activate the metal roller, place it in the electroforming solution, connect the metal roller to the cathode, and place the nickel metal material on the anode. After electrification, the anode nickel is ionized to form cations and deposit to the cathode. This forms a metal nickel-plated cylinder.

[0065] [6] After the deposition is completed, it is cleaned, and then the rotating drum is sprayed with an alkaline solution or a photoresist solvent to completely remove the photoresist.

[0066] [7] After cleaning, the microstructure processing of the metal drum is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com