Patents

Literature

743 results about "Metal working" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

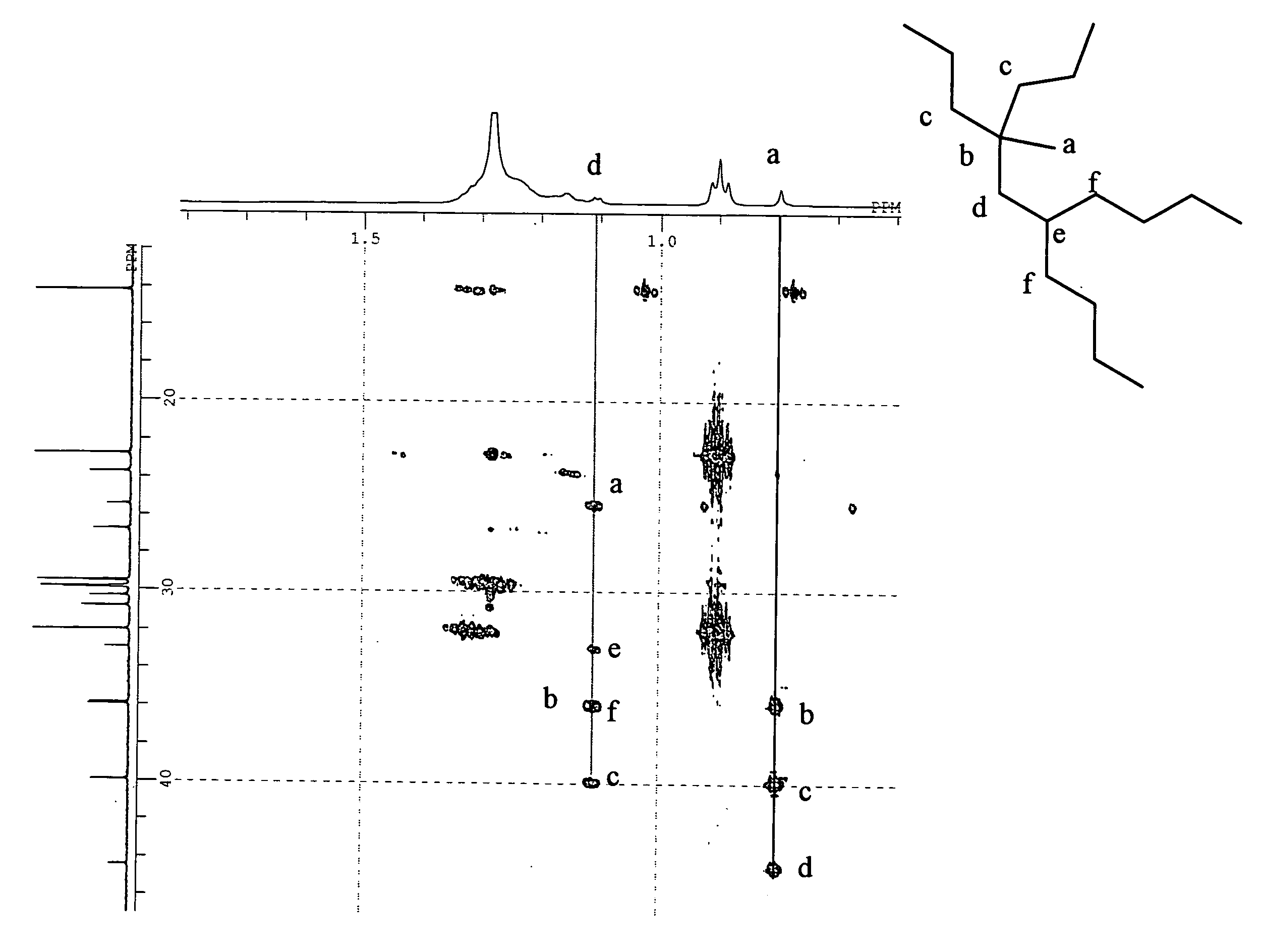

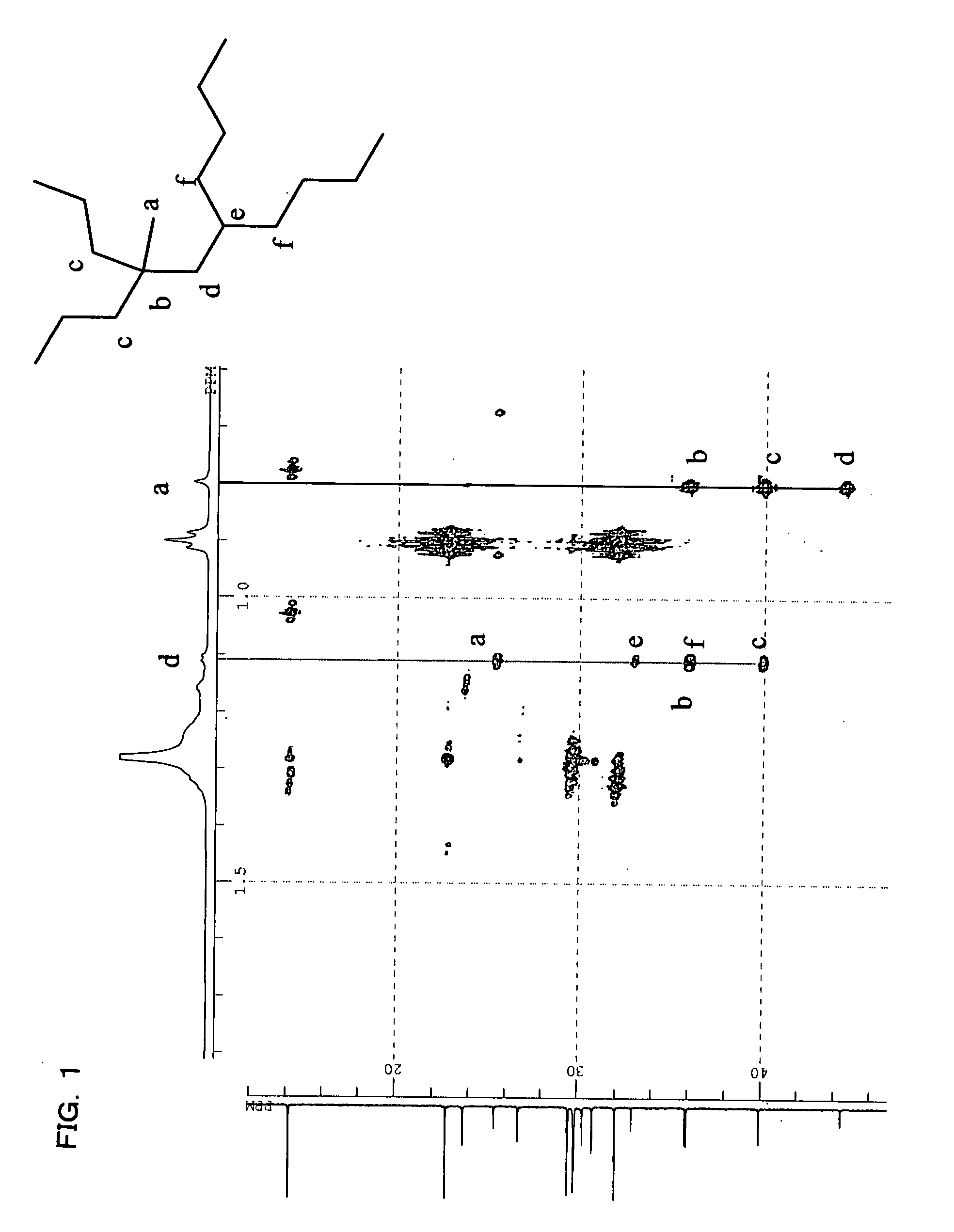

Process for producing saturated aliphatic hydrocarbon compound, and lubricant composition

InactiveUS20080146469A1Low-temperature fluidityImprove Oxidation StabilityHydrocarbon by hydrogenationCatalystsAlpha-olefinCoordination complex

The present invention provides a process for producing a saturated aliphatic hydrocarbon prepared using an α-olefin as a raw material and represented by the general formula (1), including the steps of: (I) producing a vinylidene olefin by dimerizing the α-olefin in the presence of a metallocene complex catalyst; (II) further dimerizing the vinylidene olefin in the presence of an acid catalyst; and (III) hydrogenating the obtained dimer. Further, there are provided a lubricant composition containing the saturated aliphatic hydrocarbon compound produced by the above process, a bearing oil consisting of the lubricant composition, and making use of the same, a bearing and gyral equipment. The saturated aliphatic hydrocarbon compounds produced by the process of the present invention have low-temperature fluidity, exhibiting low evaporativity, and excellent in thermal stability and oxidation stability. Thus, the saturated aliphatic hydrocarbon compounds are suitable for use as, for example, a base oil of lubricant composition for hydraulic pressure, turbine, working machine, bearing, gear, metal-working, etc.

Owner:IDEMITSU KOSAN CO LTD

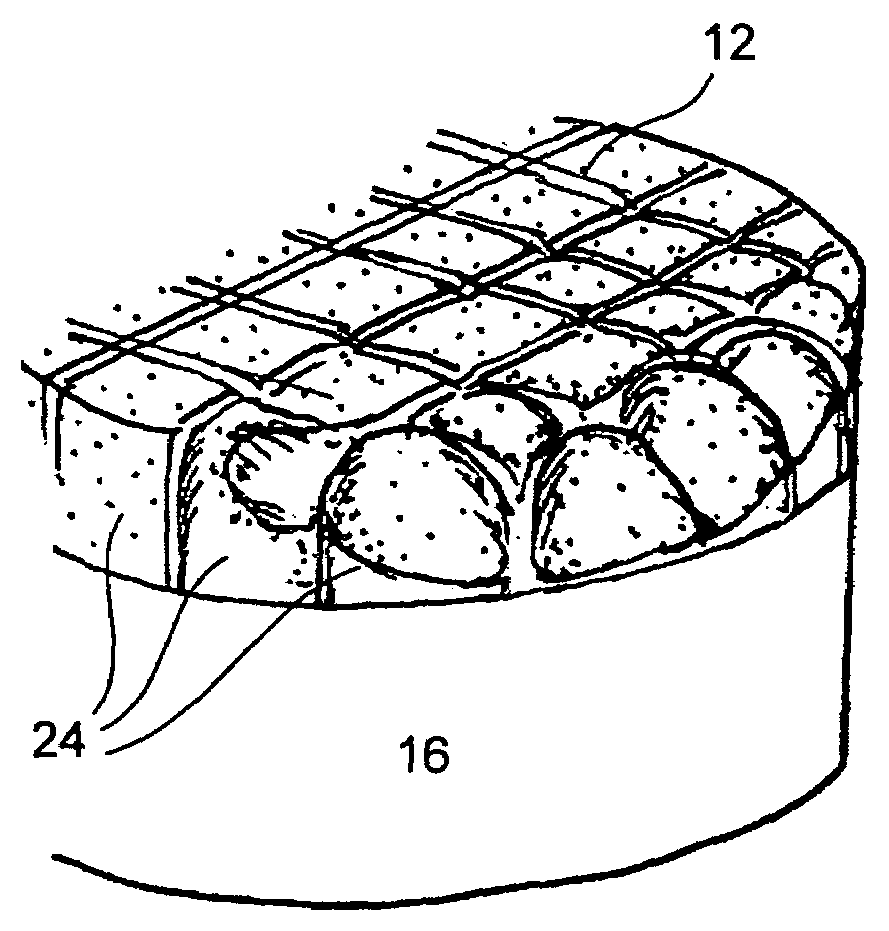

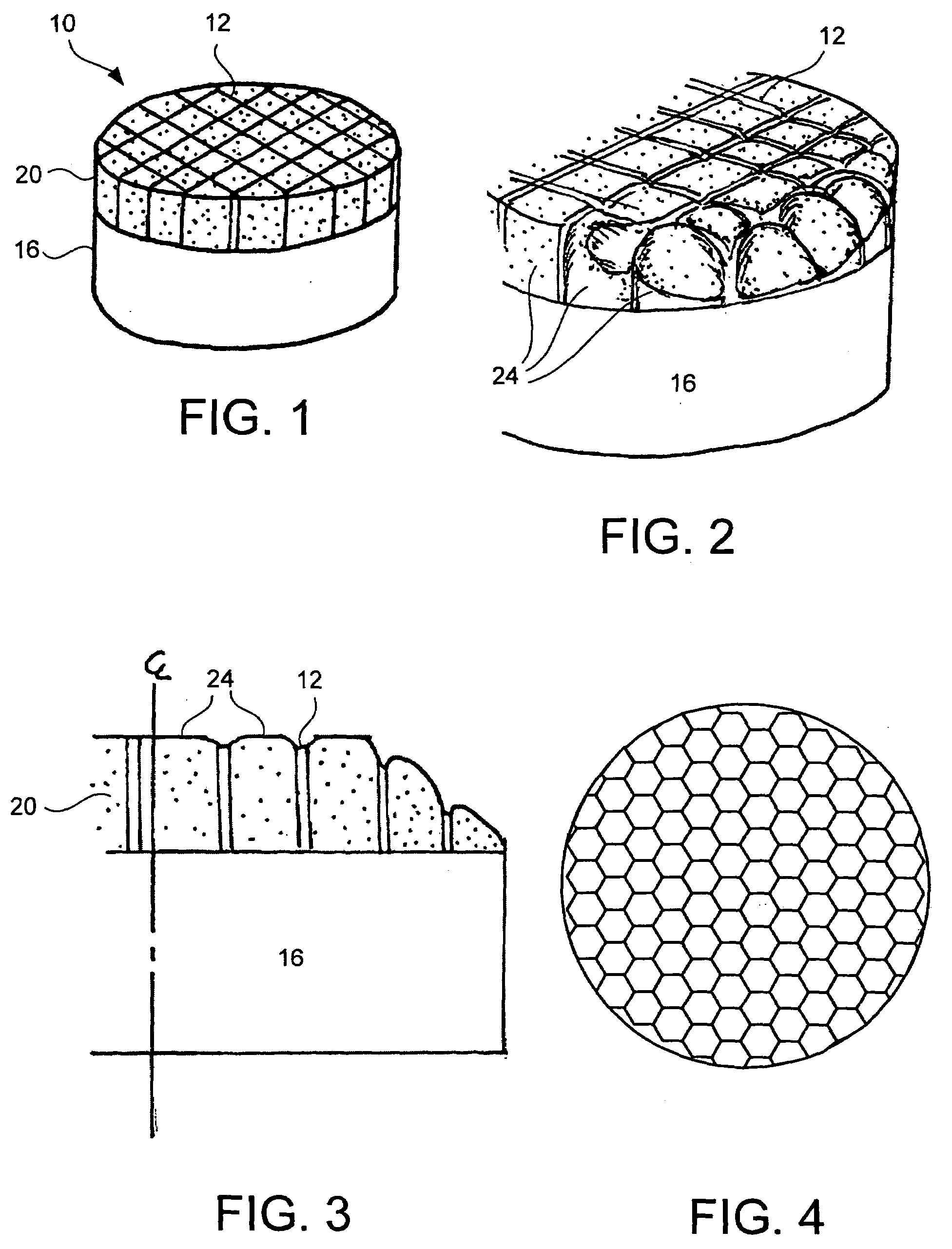

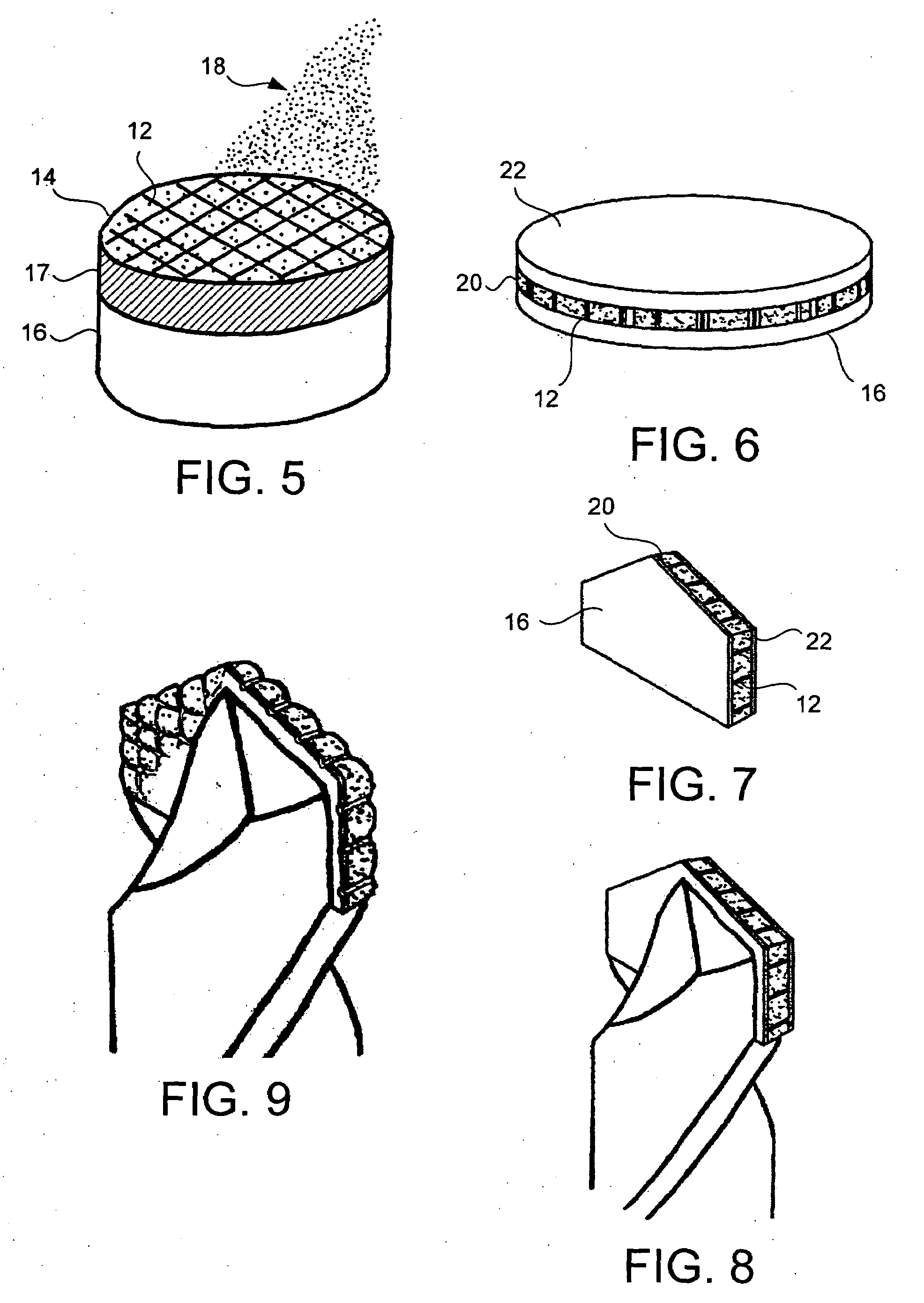

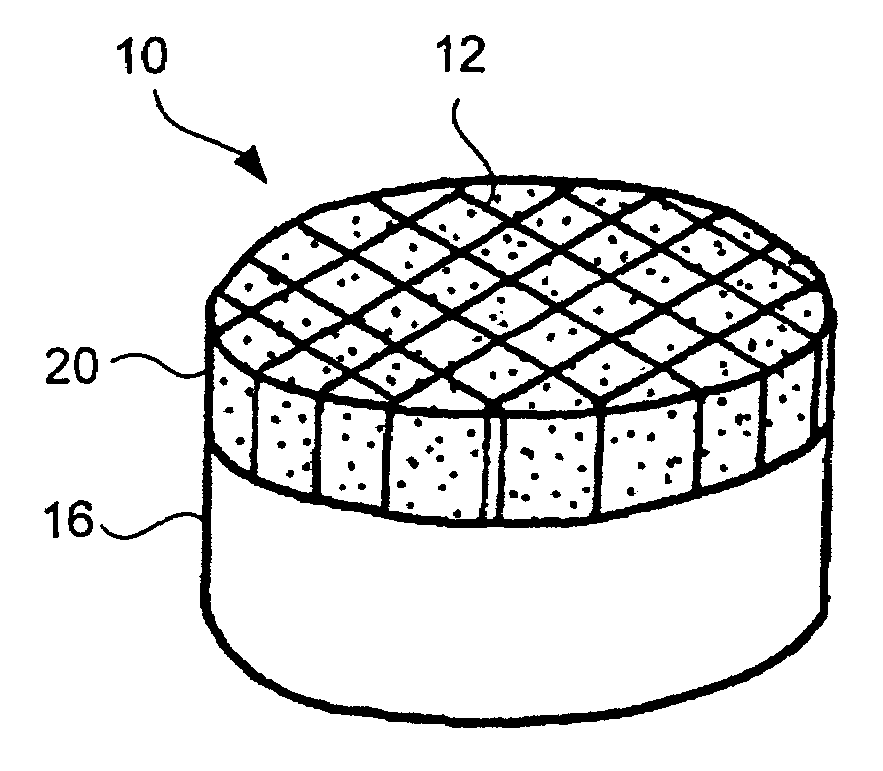

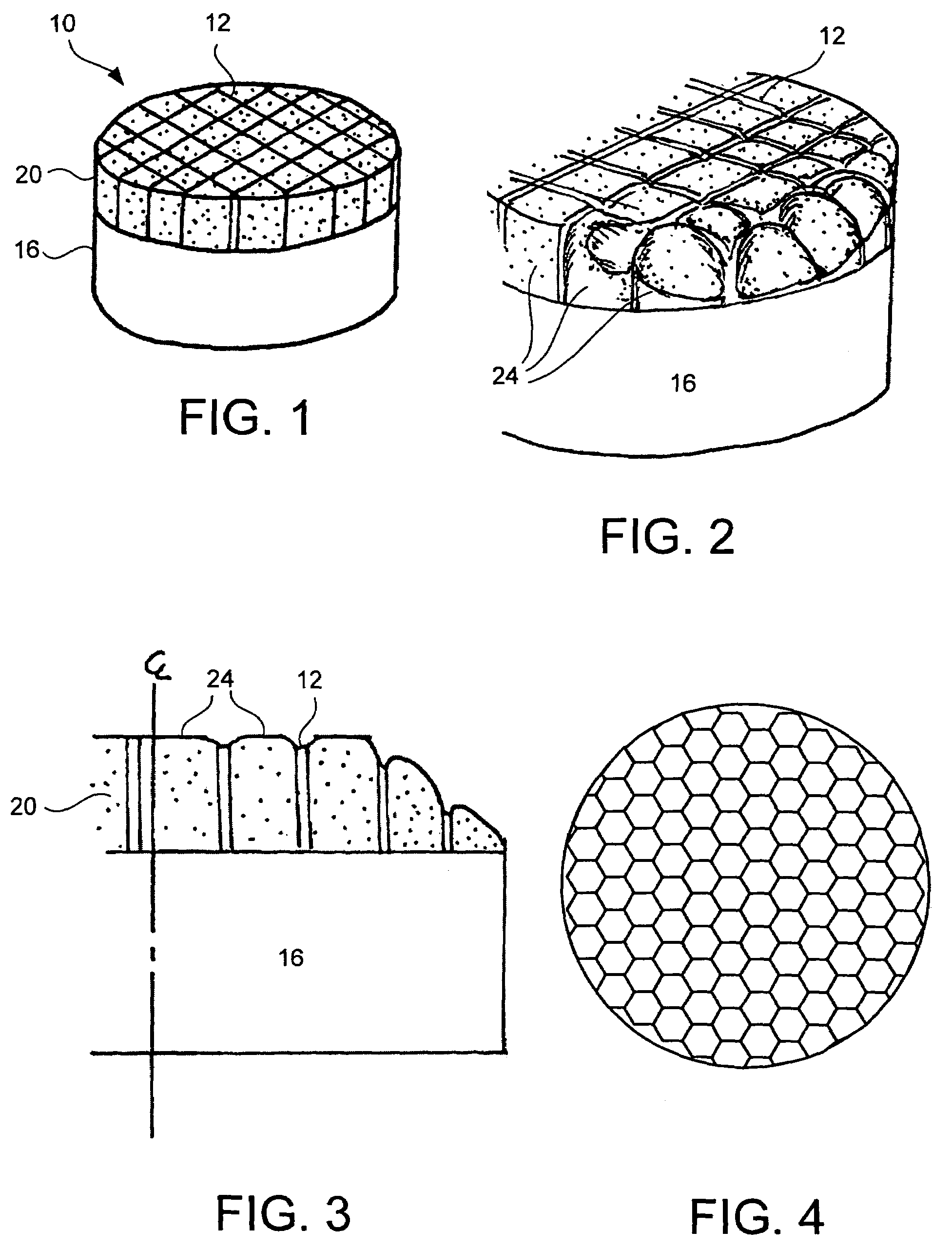

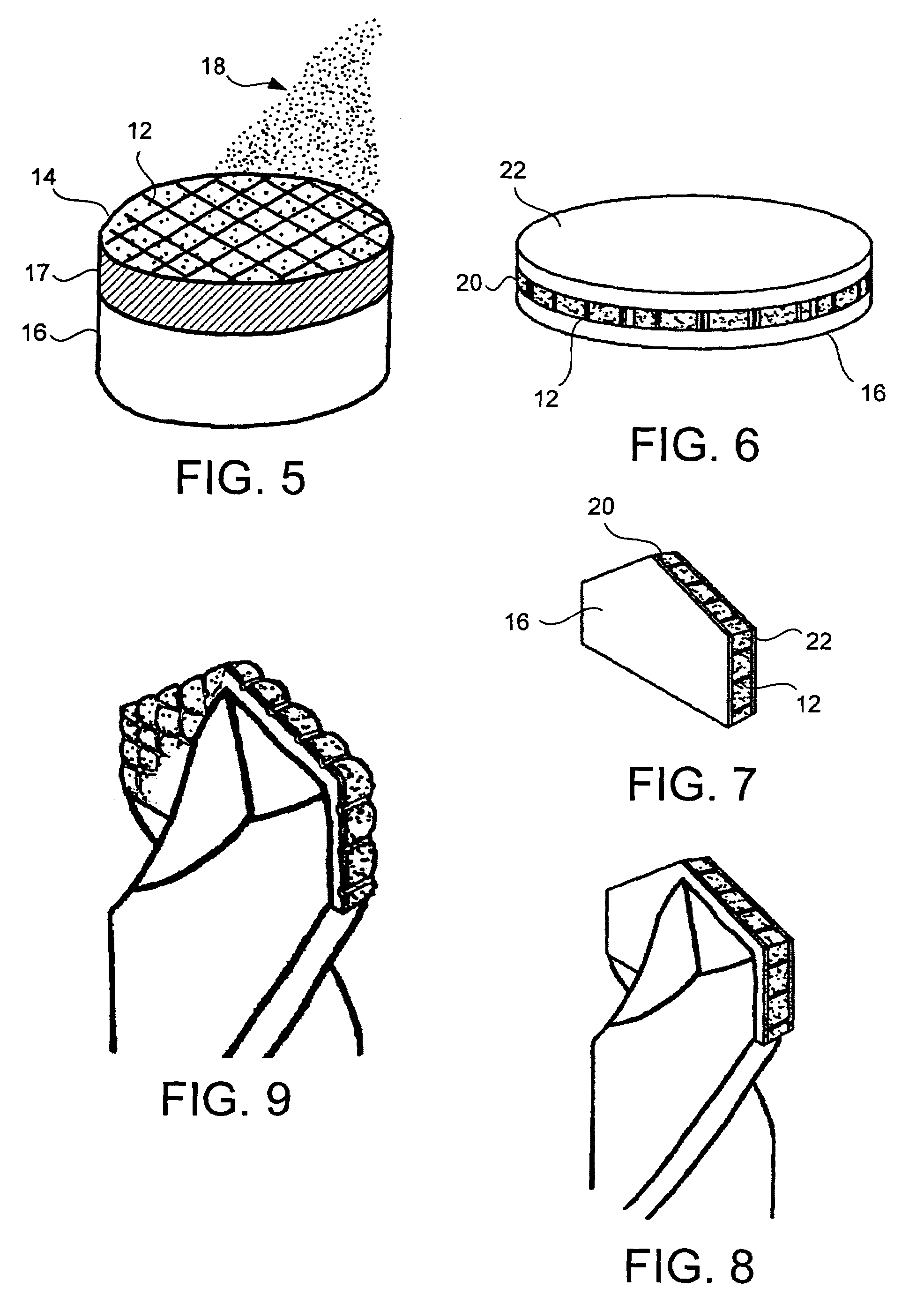

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS20080023230A1Wide applicationProperty is limitedPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

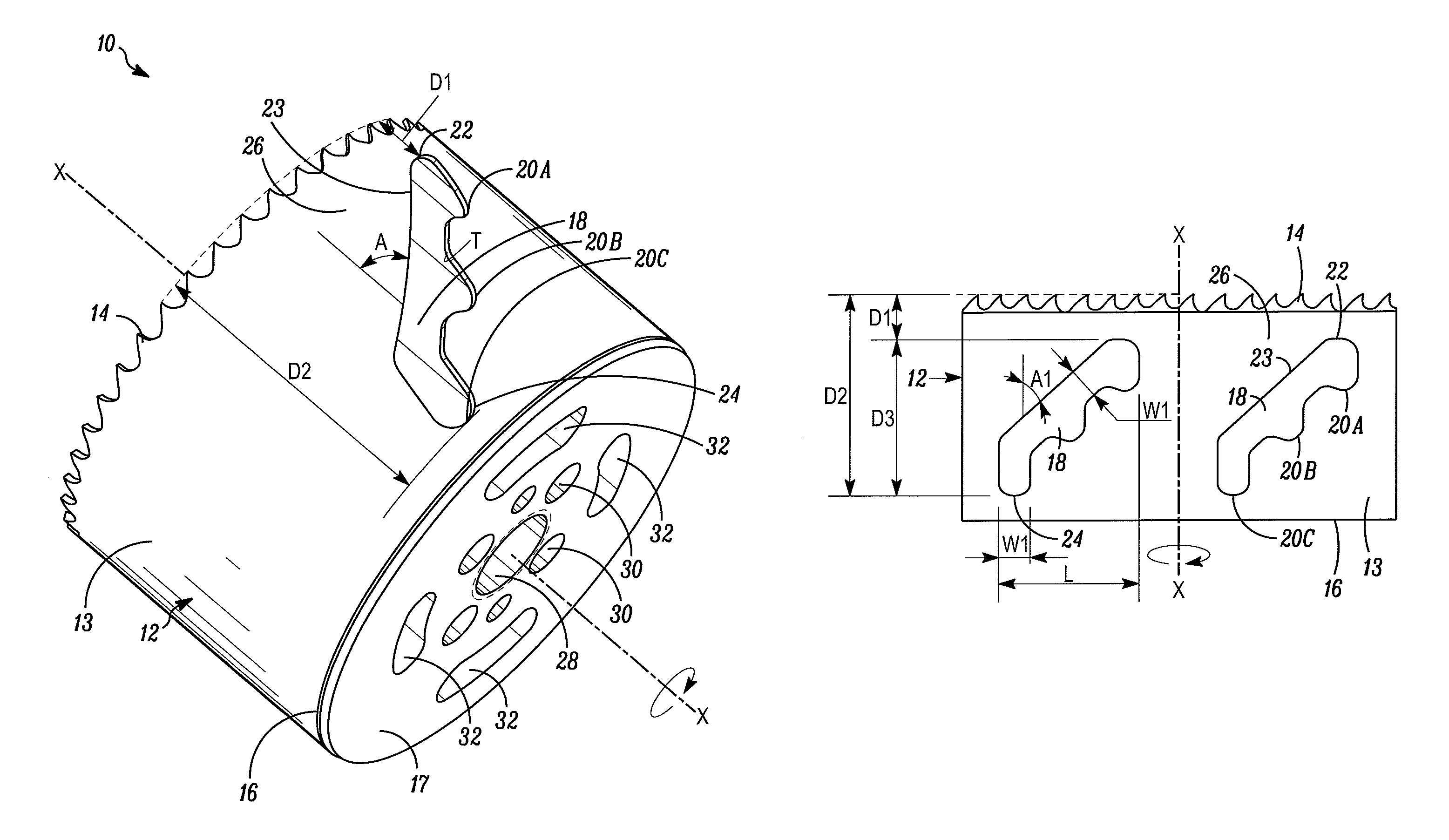

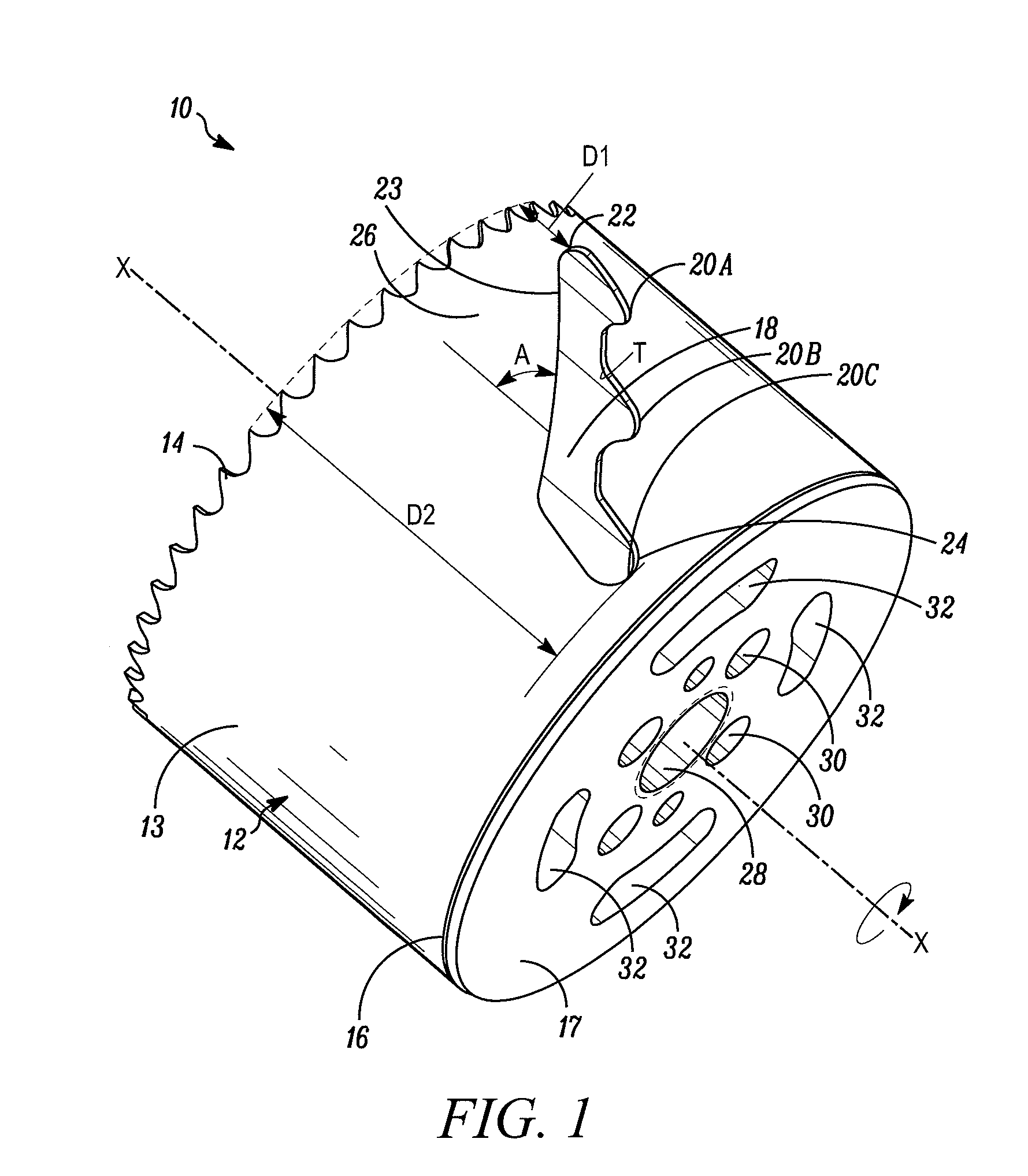

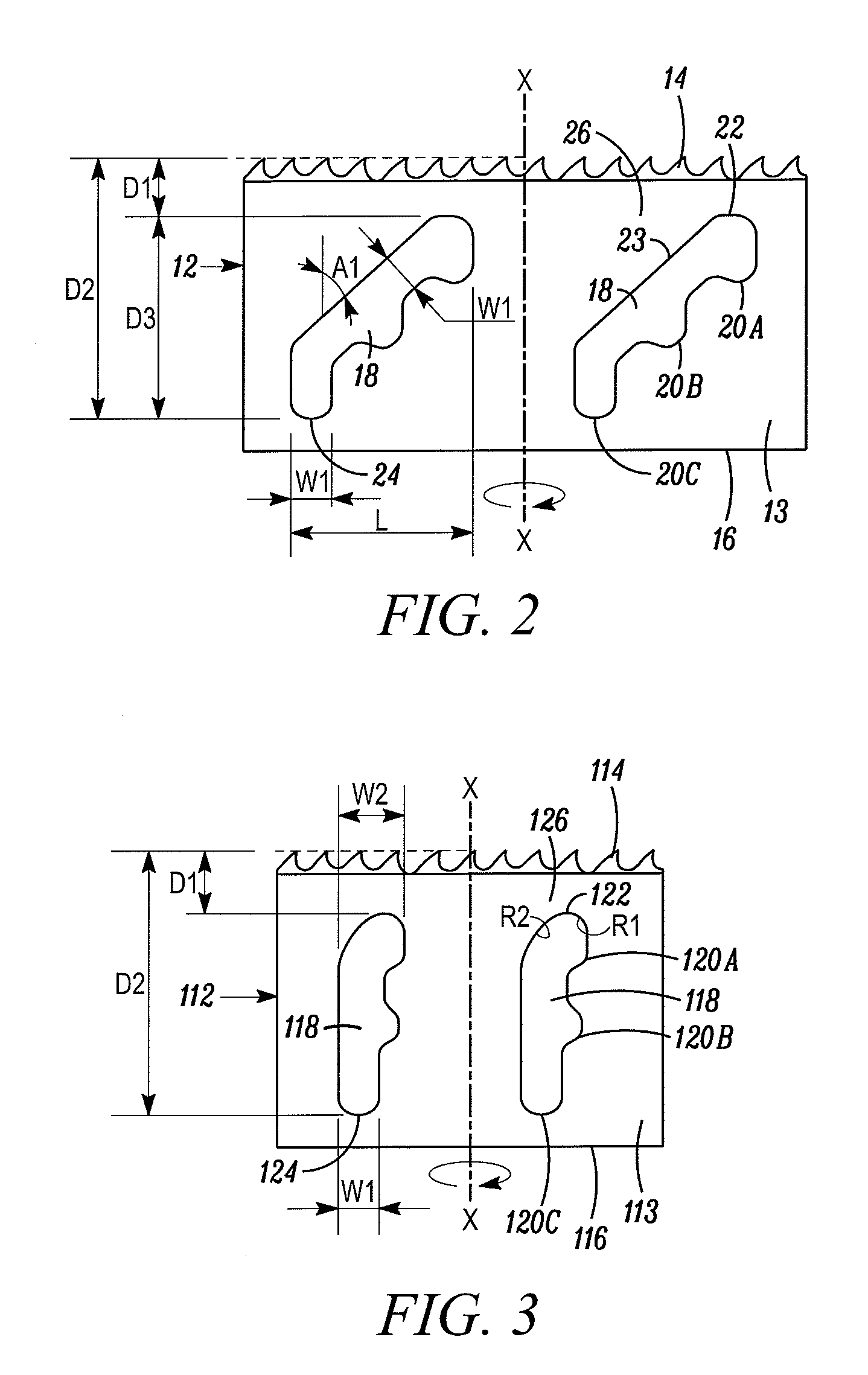

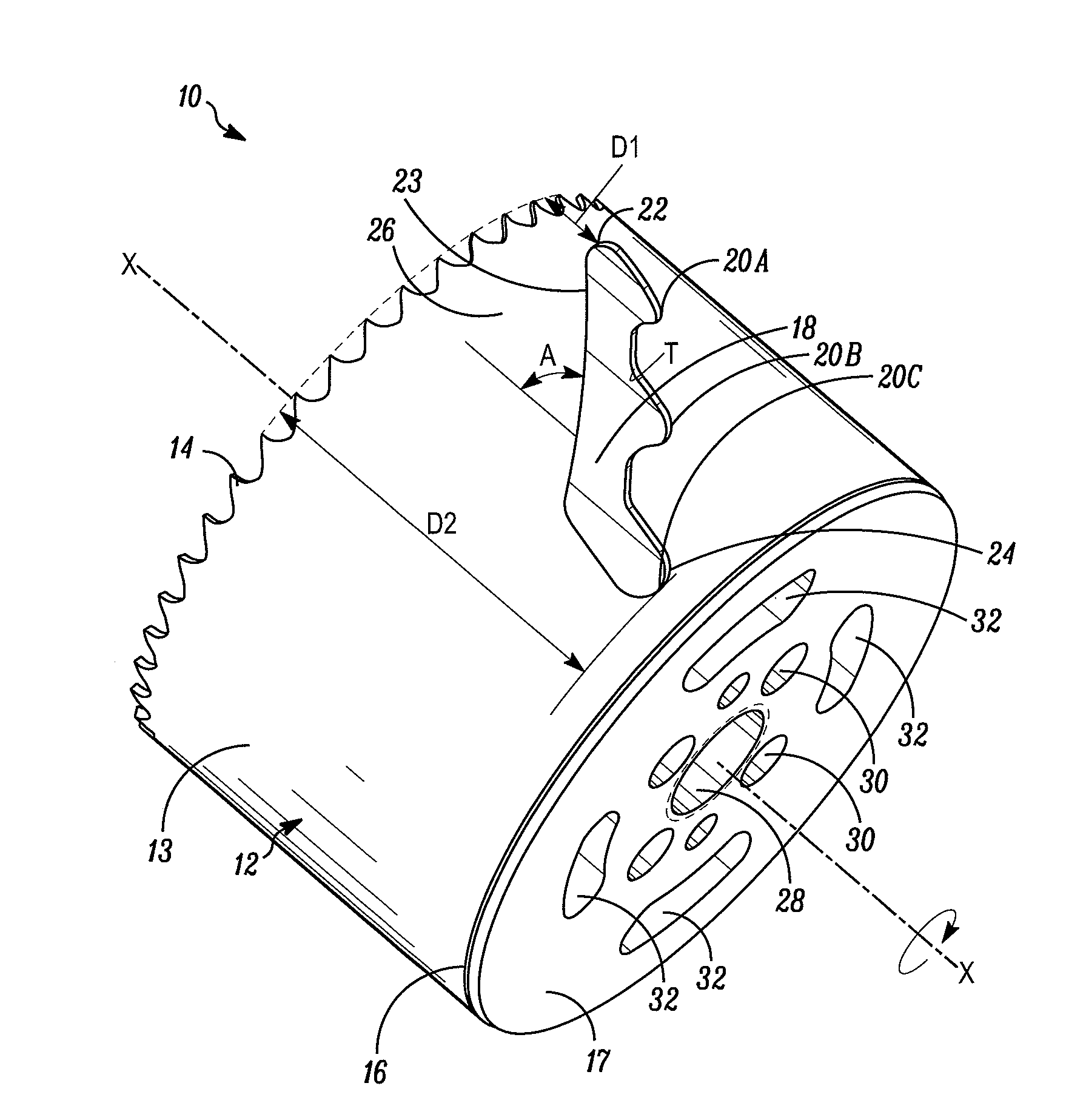

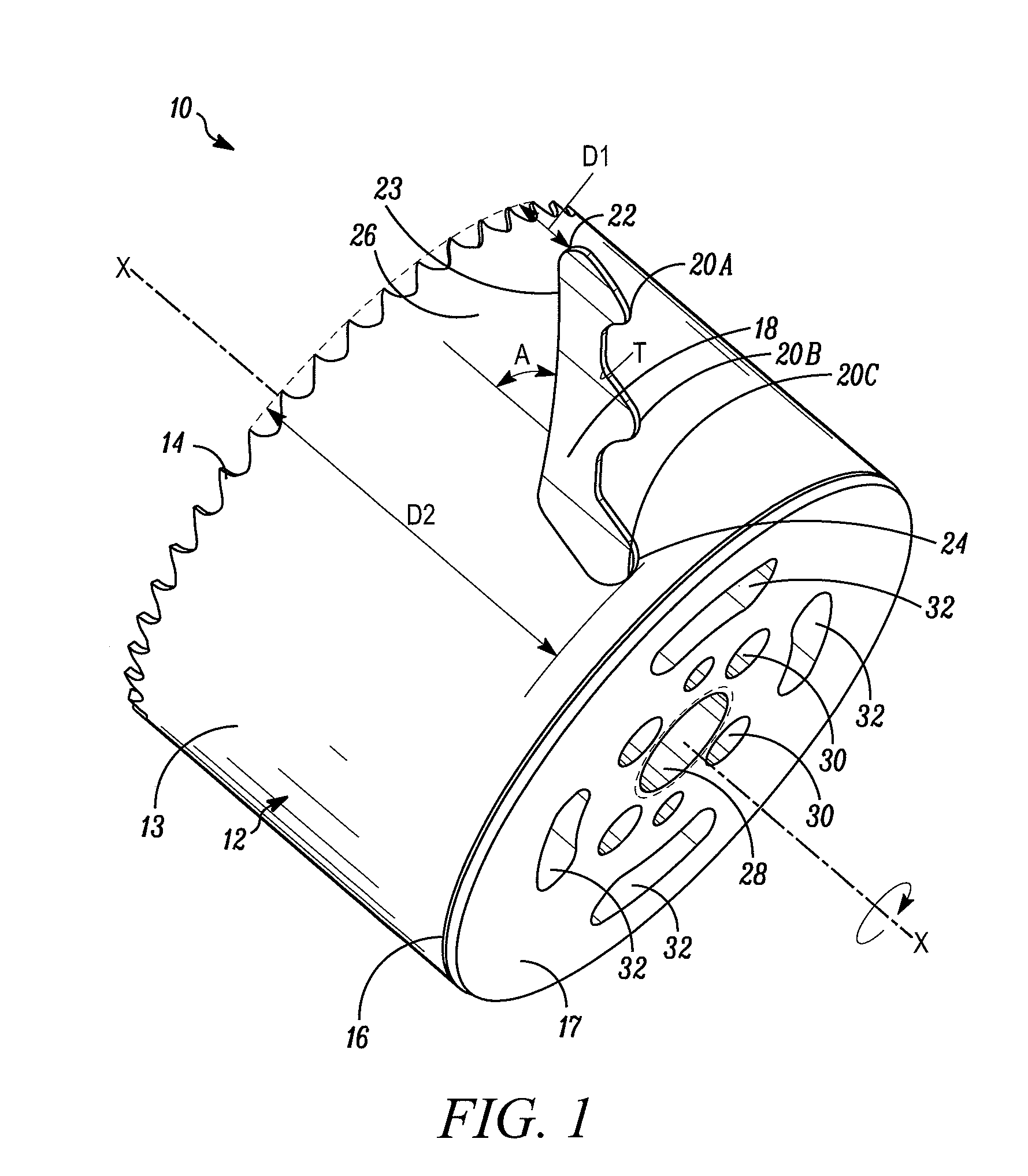

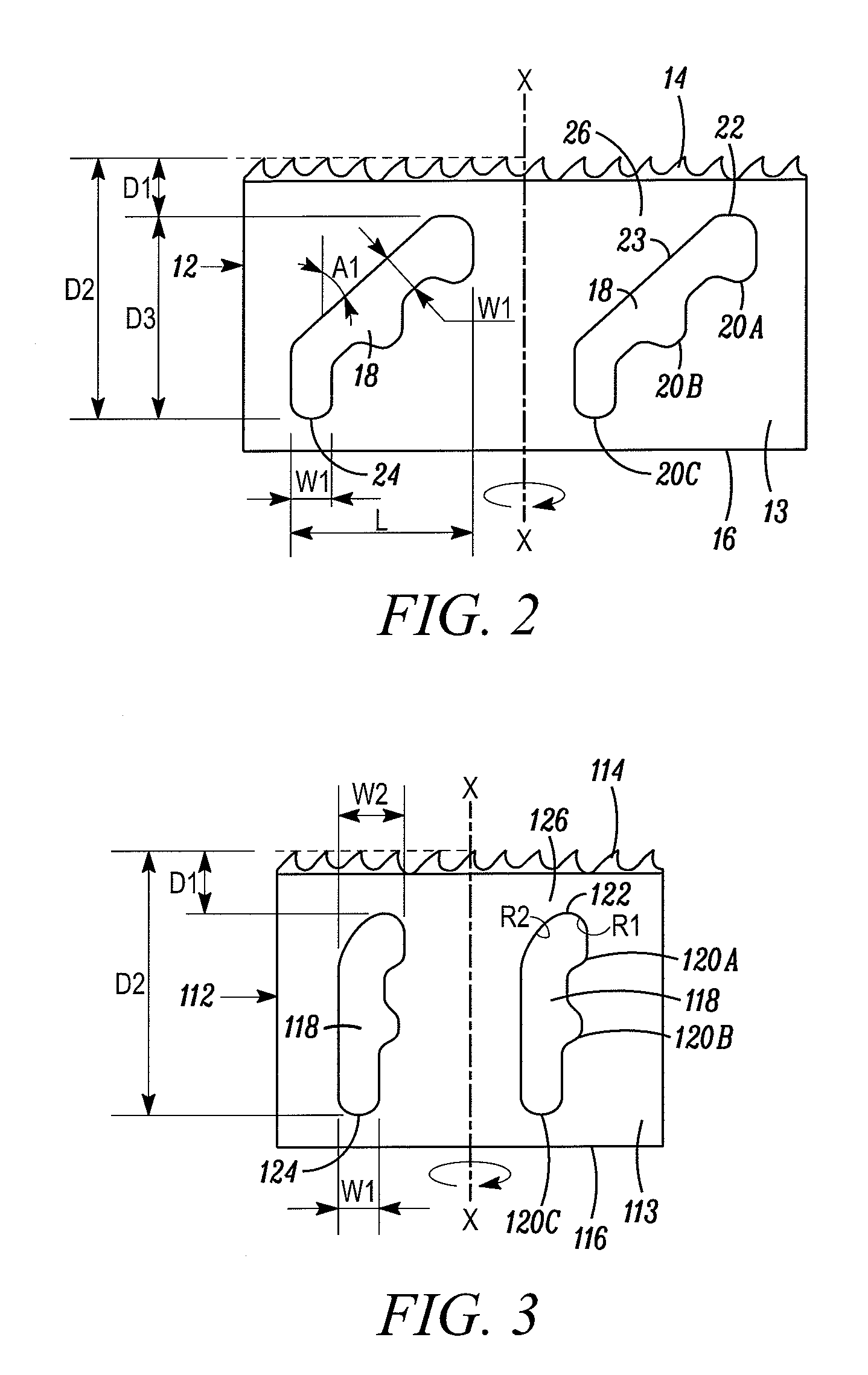

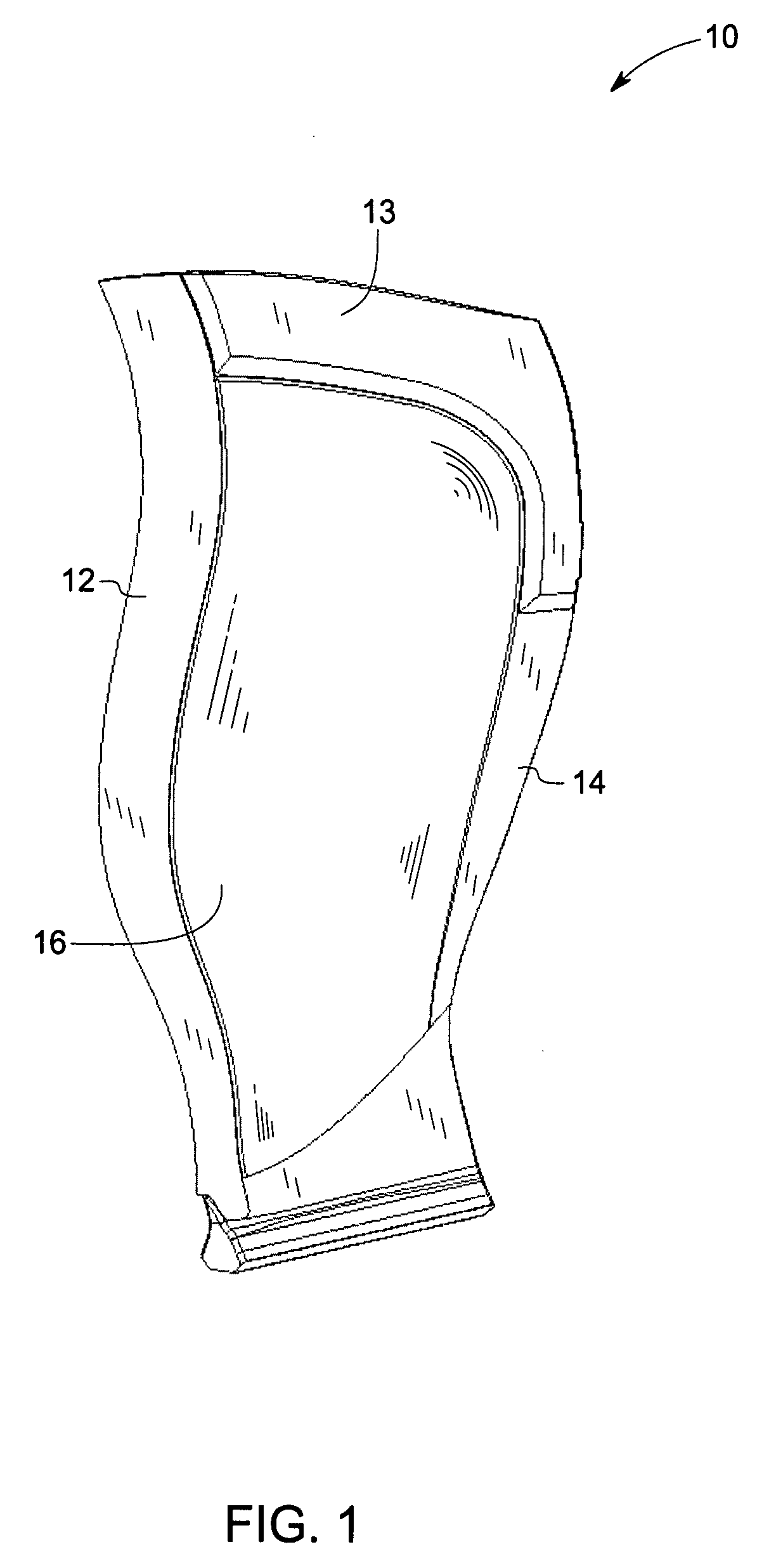

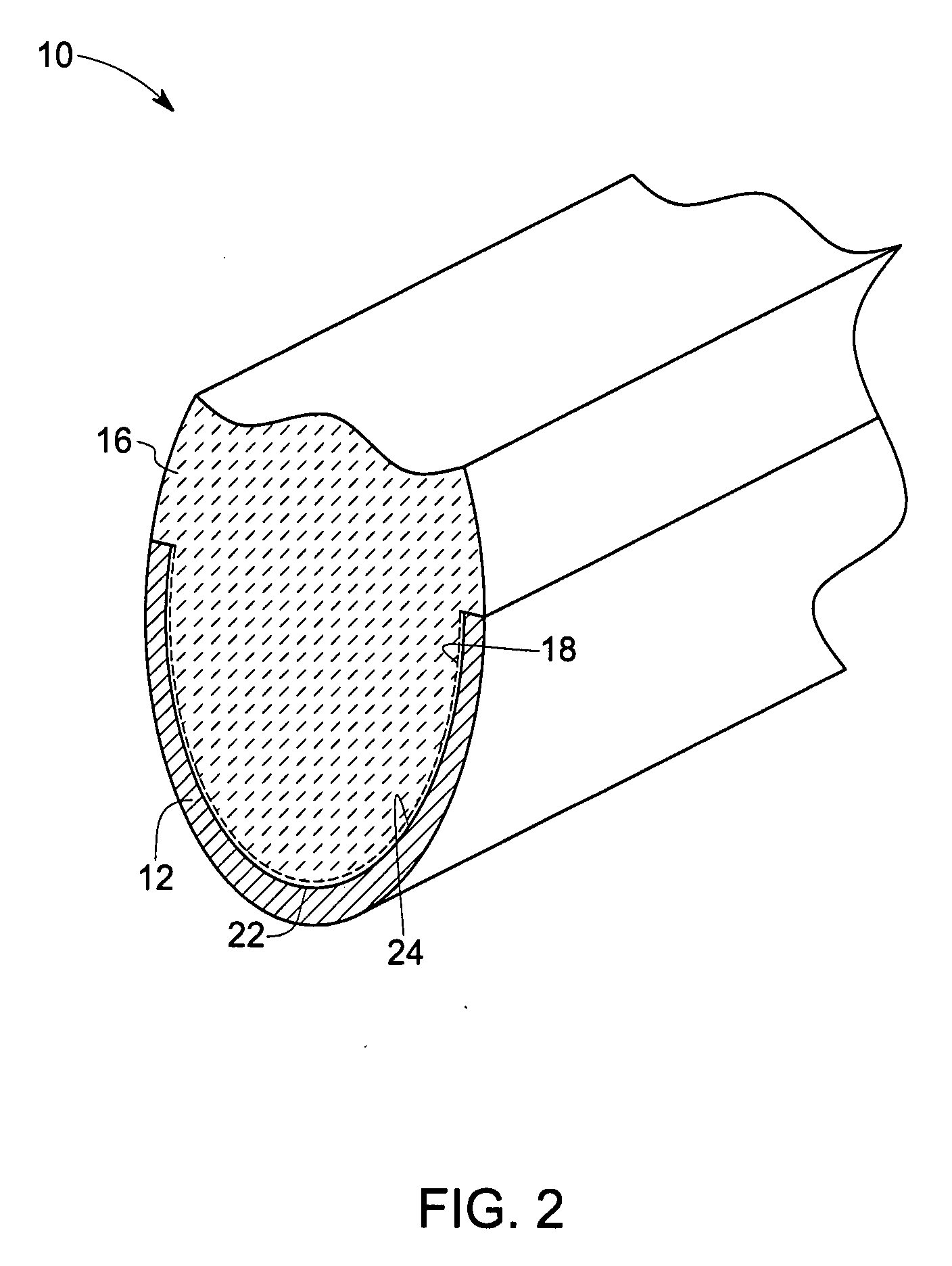

Hole cutter with minimum tooth pitch to blade body thickness ratio

ActiveUS8573907B2Avoid collectingSmall volumeTransportation and packagingCircular sawsEngineeringMetal working

A hole cutter for cutting a work piece, such as a wood and / or metal work piece, has a substantially cylindrical blade body defining a wall thickness within the range of about 0.032 inch to about 0.038 inch, and a cutting edge formed on one end of the blade body including a plurality of teeth defining an average tooth pitch within the range of about 3.5 TPI to about 5.5 TPI for cutting the work piece and forming chips therefrom. The substantially cylindrical blade body and cutting edge define an average tooth pitch to blade body thickness ratio of at least about 110.

Owner:BLACK & DECKER INC

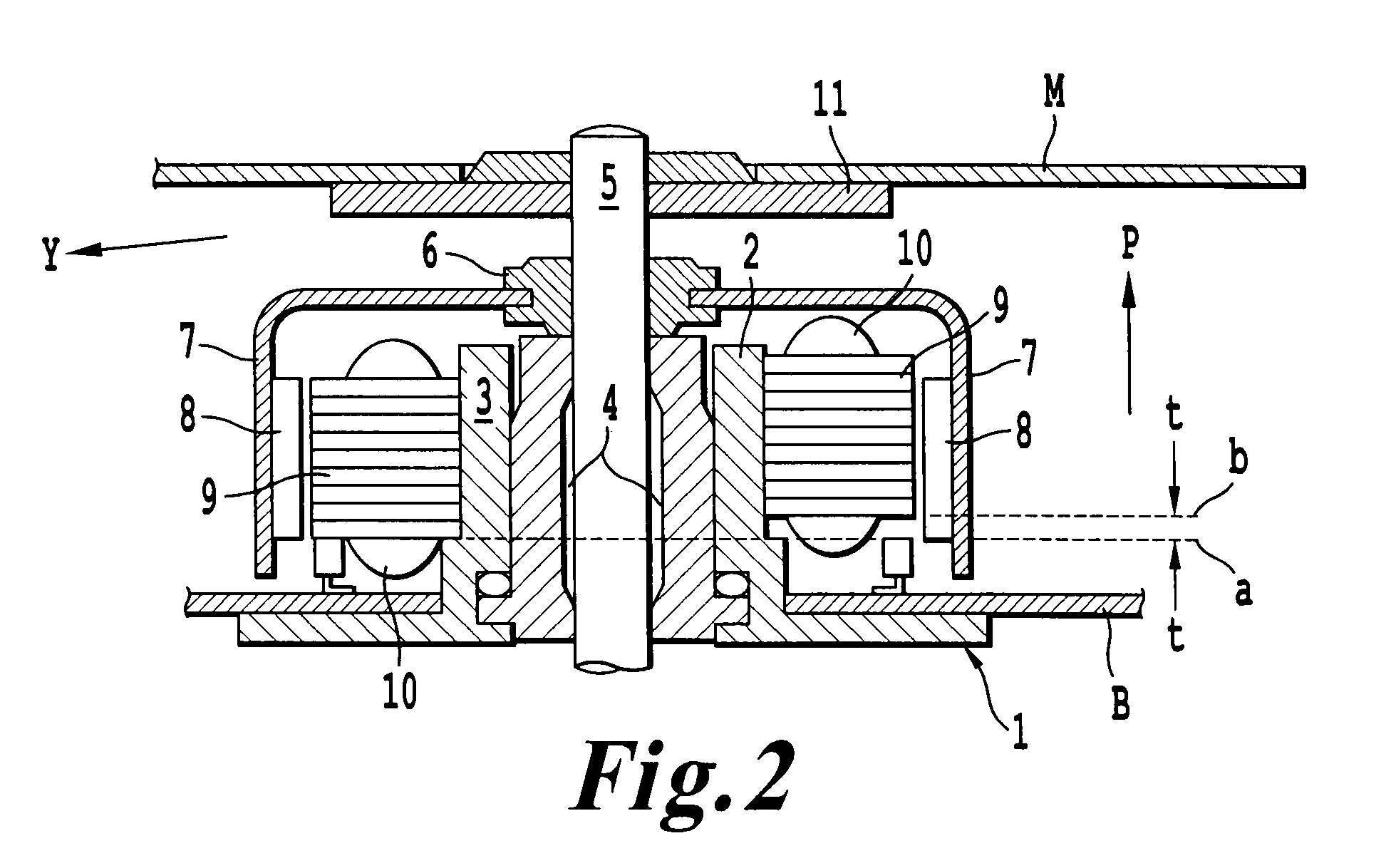

Air gap magnetic mobile robot

A mobile robot for cleaning, stripping, reconditioning or refurbishing a coating on a metal work piece has a remote controlled power module for locomotion and a working head for removing the coating. The robot is held on the metal work piece by magnets mounted on the robot but spaced from the work piece.

Owner:DCP WATERJET HLDG INC

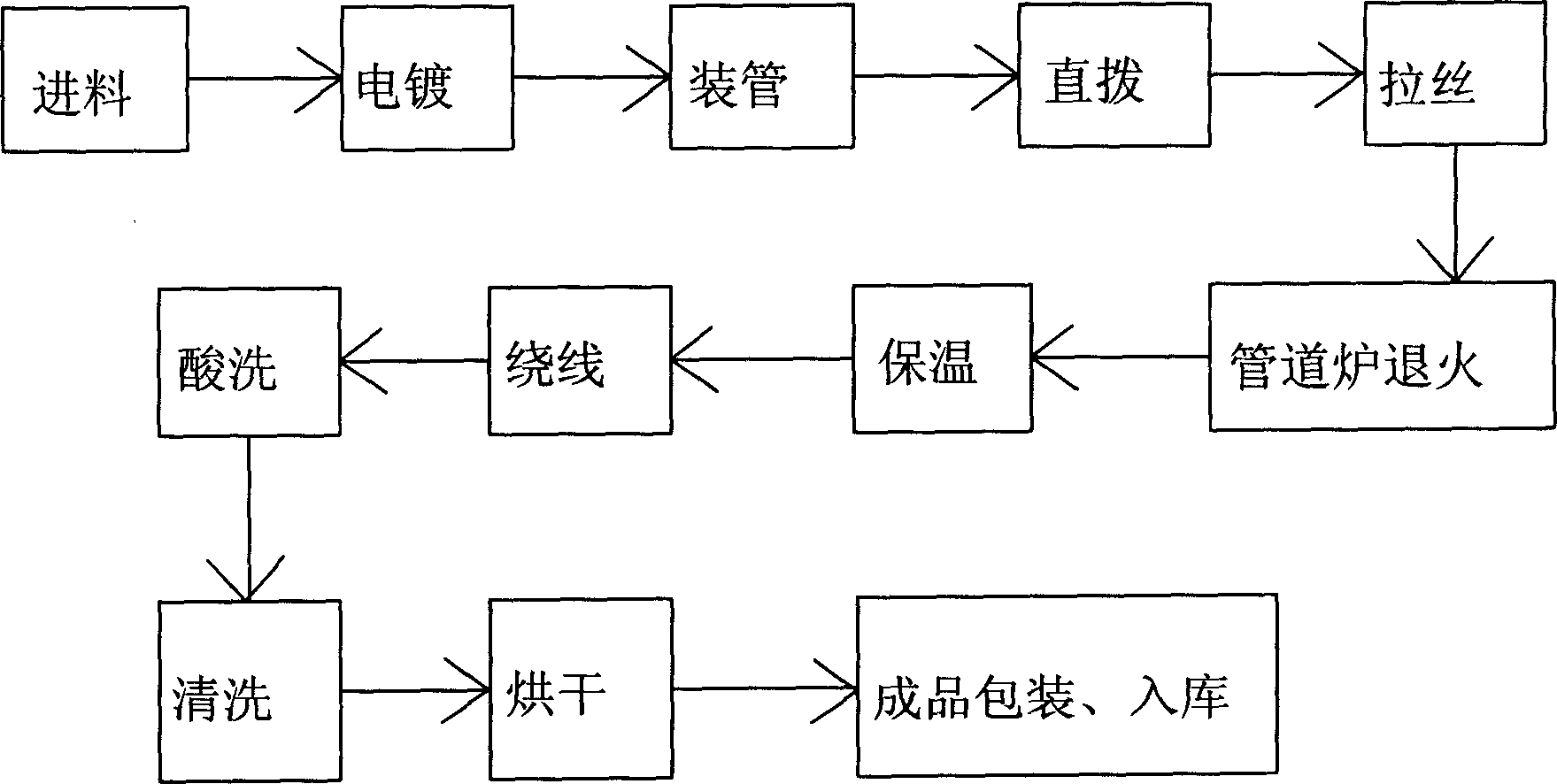

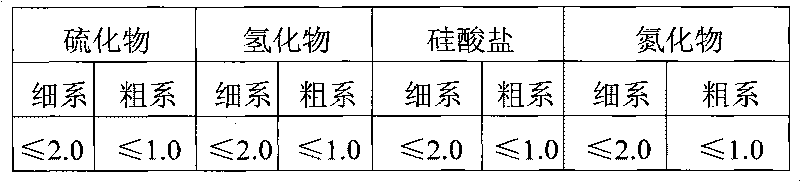

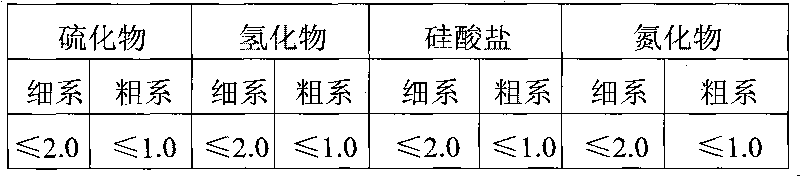

Metal fiber wire and its producing process

InactiveCN1900345AOvercome the pullOvercome the disadvantages of changing chemical elementsMetal fiberManganese

The present invention belongs to the field of metal processing technology, and is especially one kind of metal fiber wire and its production process. The metal fiber wire is made with the material comprising C 0.03-0.08 wt%, Mn 0.20-0.46 wt%, Si 0.40-0.63 wt%, Ce or La 0.02-0.10 wt%, Al 4.8-5.9 wt%, Cr 15-26 wt%, Cu 0.05-2 wt%, S 0.03-0.04 wt%, P 0.04-0.05 wt% and Fe 66-81 wt%. The making process includes the steps of: feeding material, electroplating, tubing, straightening, drawing, annealing, maintaining temperature, winding, acid pickling, washing, stoving, etc. The metal fiber wire has single fiber diameter up to 6 micron, strength higher than 16 N / sq cm, elongation of 1.40 %, and high comprehensive performance.

Owner:周建华

Hole Cutter With Minimum Tooth Pitch to Blade Body Thickness Ratio

ActiveUS20110170970A1Avoid collectingSmall volumeTransportation and packagingCircular sawsEngineeringMechanical engineering

A hole cutter for cutting a work piece, such as a wood and / or metal work piece, has a substantially cylindrical blade body defining a wall thickness within the range of about 0.032 inch to about 0.038 inch, and a cutting edge formed on one end of the blade body including a plurality of teeth defining an average tooth pitch within the range of about 3.5 TPI to about 5.5 TPI for cutting the work piece and forming chips therefrom. The substantially cylindrical blade body and cutting edge define an average tooth pitch to blade body thickness ratio of at least about 110.

Owner:BLACK & DECKER INC

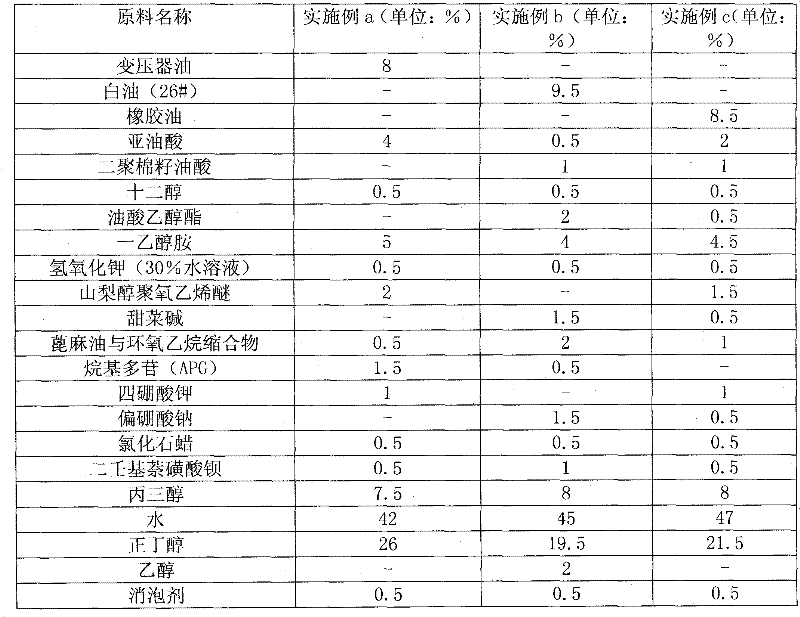

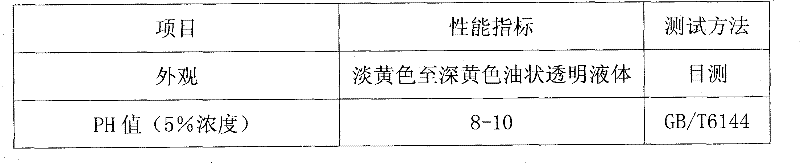

Heavy-duty metal processing cutting lubricant and preparation method thereof

The invention discloses a lubricant for heavy-load machining of metals and a preparation method thereof. The lubricant comprises mineral oil, component A, component B, component C, component D, component E and an antirust agent, and the sum weight percentage of the above-mentioned raw materials is 100%. The preparation method is as follows: adding mineral oil in a container capable of stirring and heating, allowing the temperature of the container to rise to 75 to 80 DEG C, adding component A and component B, allowing the temperature of the container to maintain 75 to 80 DEG C, allowing the mixture in the container to react for 30 min, adding component C and the antirust agent, carrying out insulation and an reaction for 30 min, adding component D, carrying out insulation and an reaction for 30 min, cooling the container to a temperature of 30 DEG C, adding component D, and carrying out filtering and packaging so as to obtain a finished product. The lubricant for heavy-load machining of metals provided in the invention costs little, is nonflammable and has excellent performance. The preparation method for the lubricant in the invention has the characteristics of low cost, simple operation and easiness in large scale popularization and application.

Owner:圣保路石油化工(天津)股份有限公司

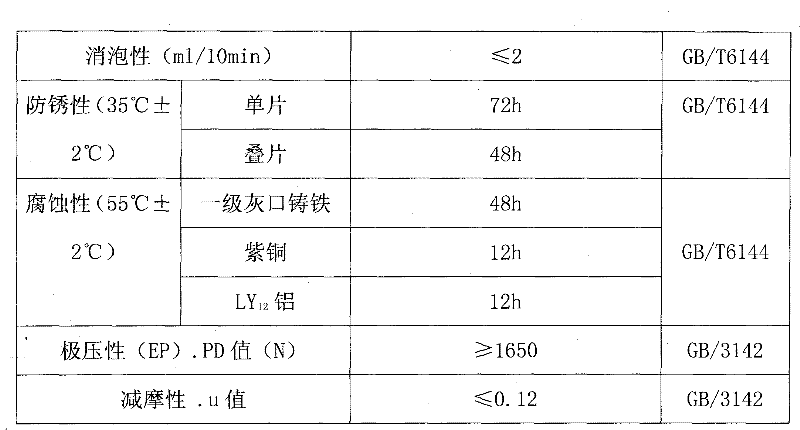

High precision high rigidity closed type fluid static pressure / dynamic-static pressure rotary table

ActiveCN101407024AImprove carrying capacityReduce volumeShaftsLarge fixed membersBall bearingKinematic pair

The invention provides a closed fluid static pressure / dynamic static pressure revolving worktable with high precision and rigidity, and relates to the field of automatic equipment of precision machinery. A plurality of axial bearings and radial bearings arranged along the axial direction are fixed by a plurality of slewing rings and bearing guide rails; the revolving worktable is provided with a balanced bearing to balance; kinematic pairs of a plurality of bearings rotate synchronously and are connected; fixed pairs of the bearings are connected through a base of the worktable; and sliding pairs of the radial bearings and bearing pairs of the axial bearings move rigidly, integrally and synchronously; and a relatively still sliding surface of the sliding pair of each bearing is provided with an oil chamber. Under the conditions that fluid pressure of the revolving worktable is same and the volume is equal, the axial rigidity, the radial rigidity and the bearing capacity are multiply improved, and the improved multiple is in direct proportion to the number of the bearings. The revolving worktable has the advantages of convenient design, simple manufacture, low cost, high precision and no abrasion. The revolving worktable is a key part of a high-precision metal working machinery, in particular to a functional part of large and oversize heavy equipment by using the key technology, and has more remarkable advantages in manufacturing equipment in the fields of navigation, astronavigation, large aircraft, and the like.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

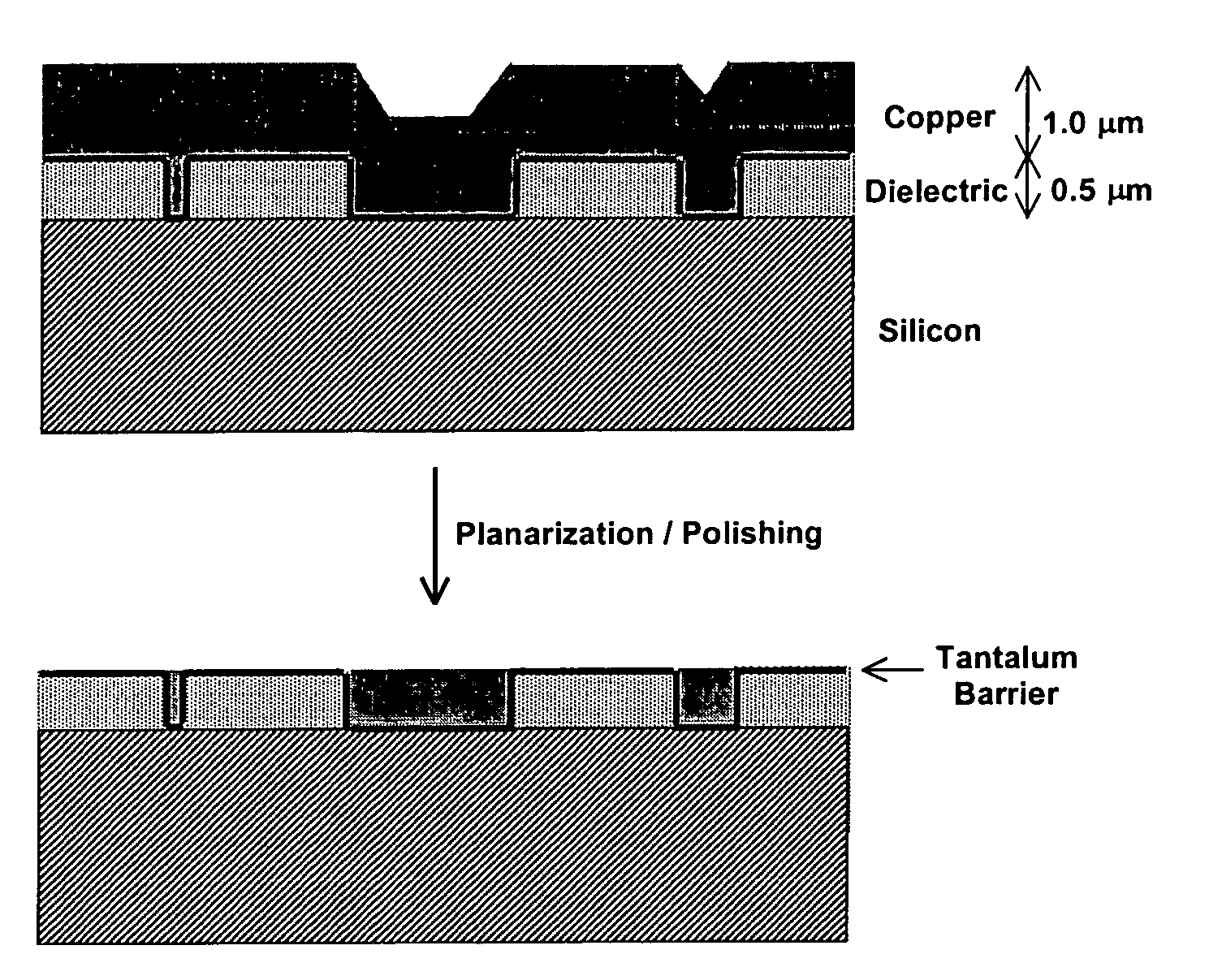

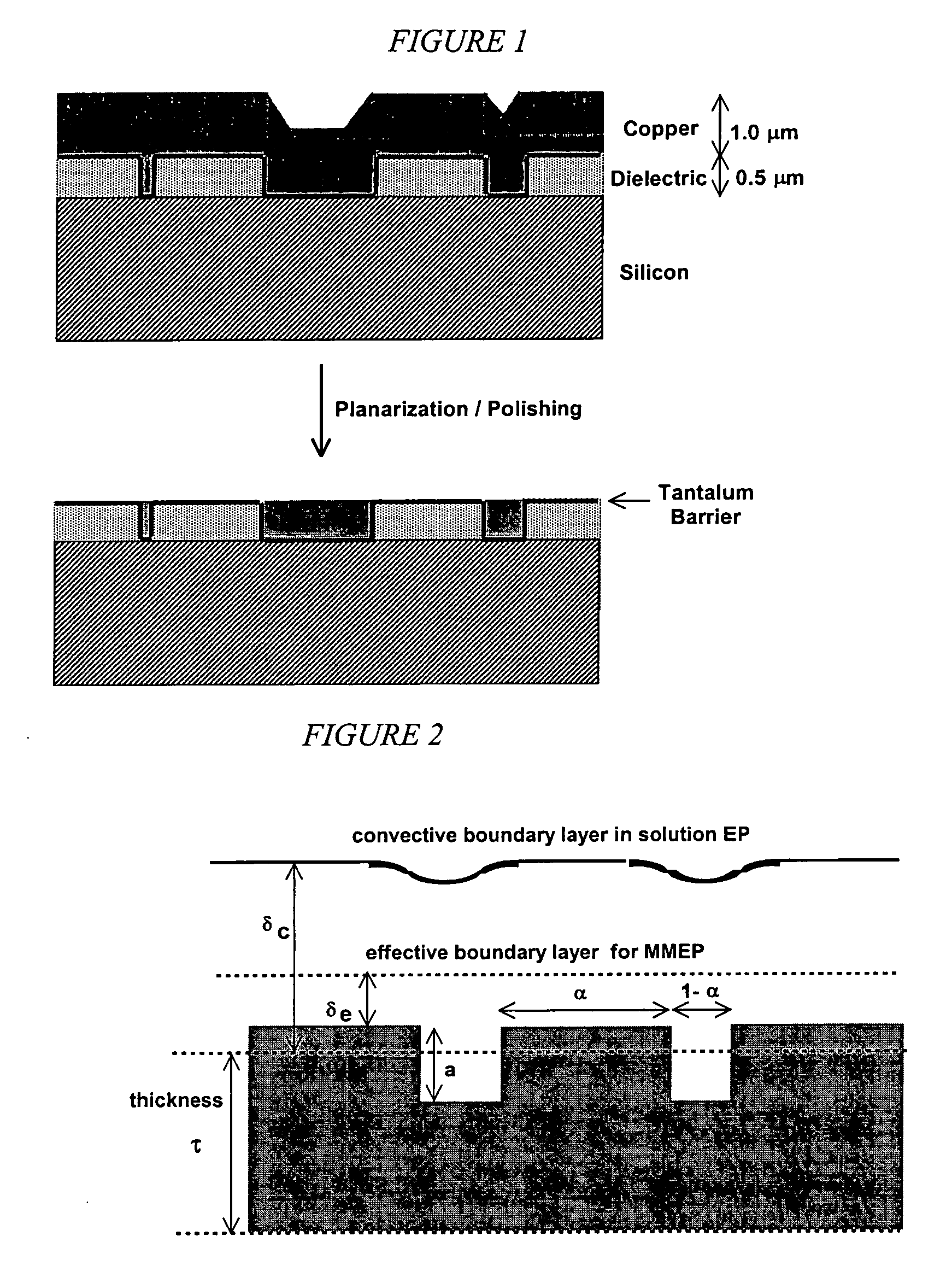

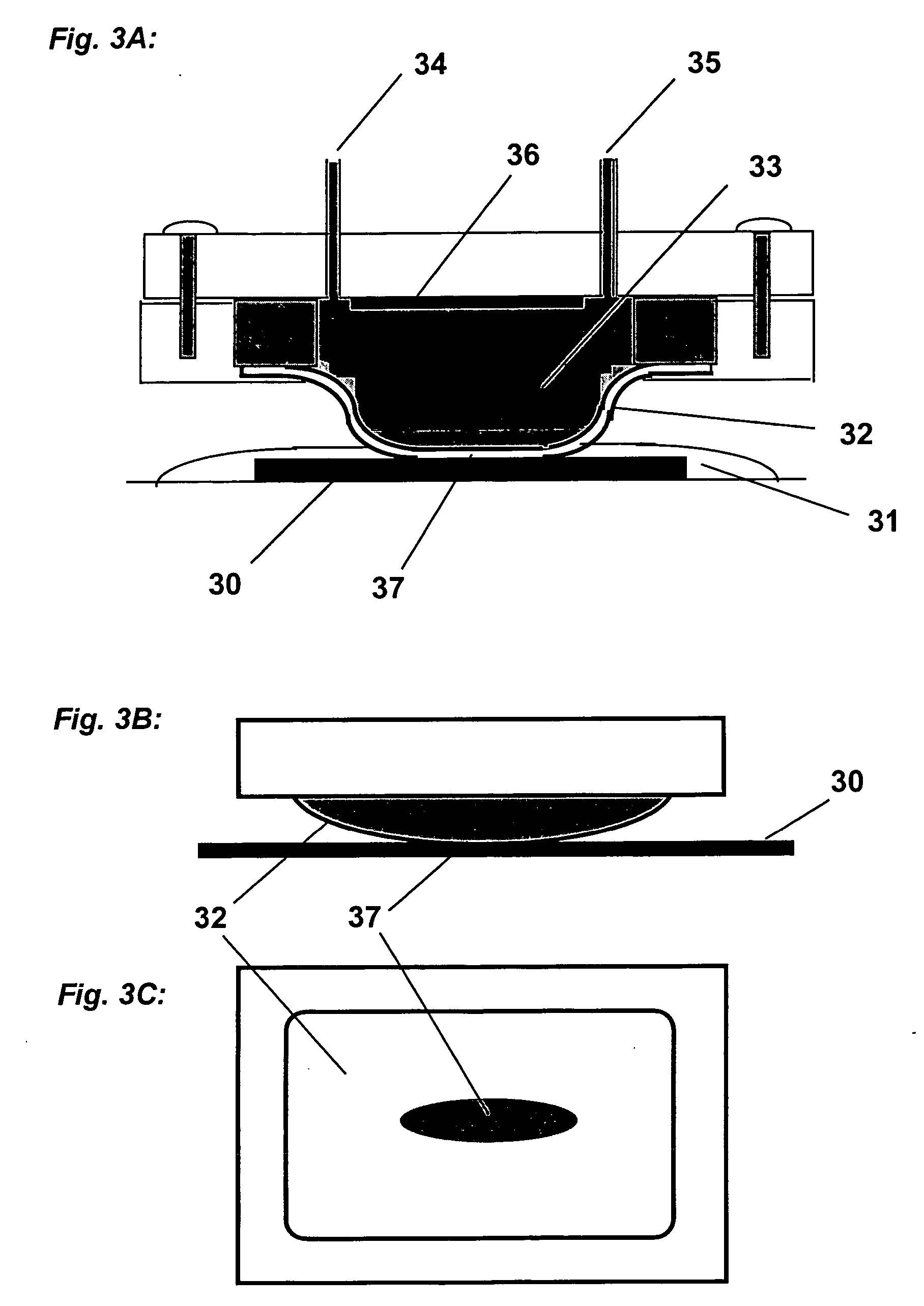

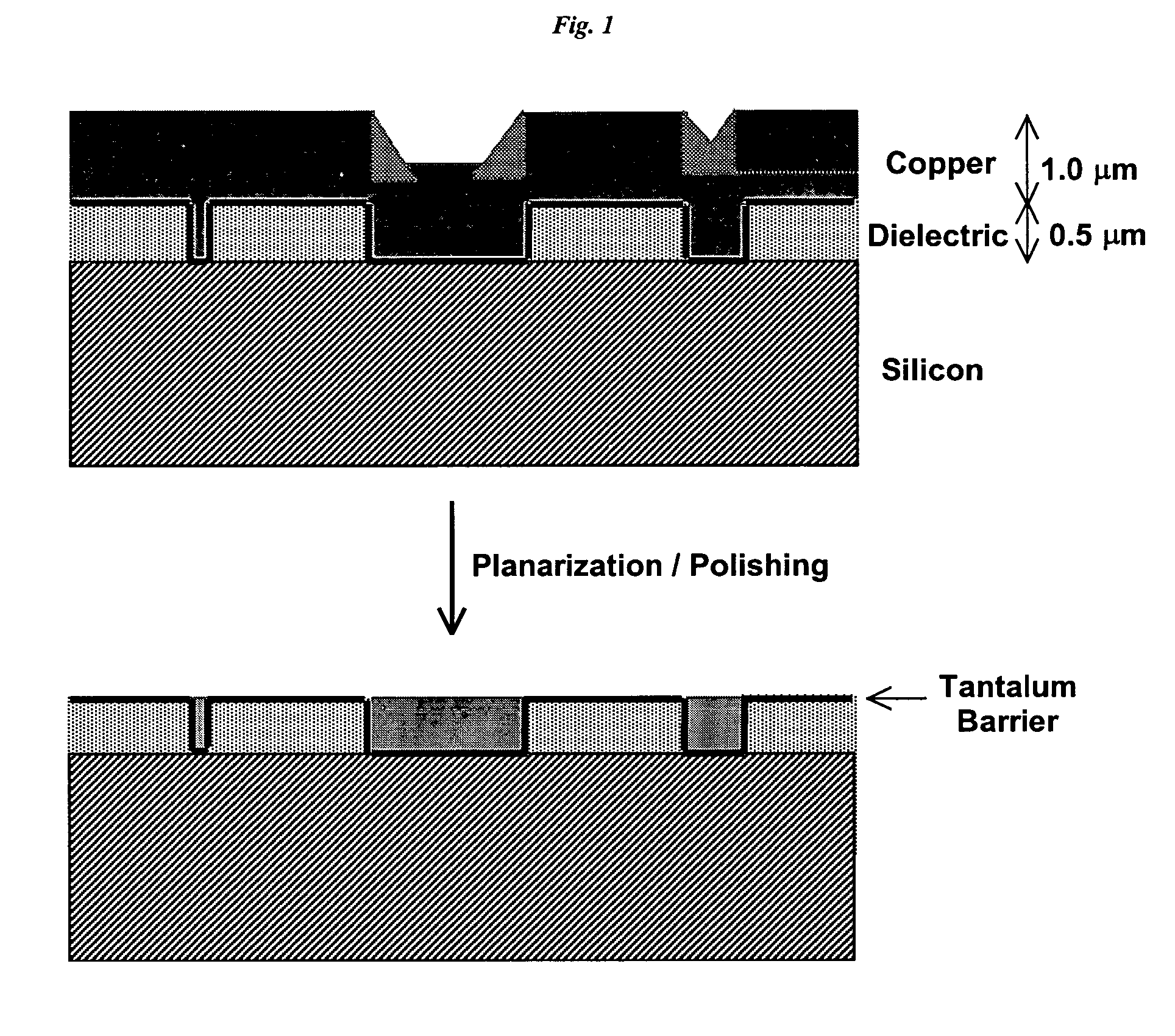

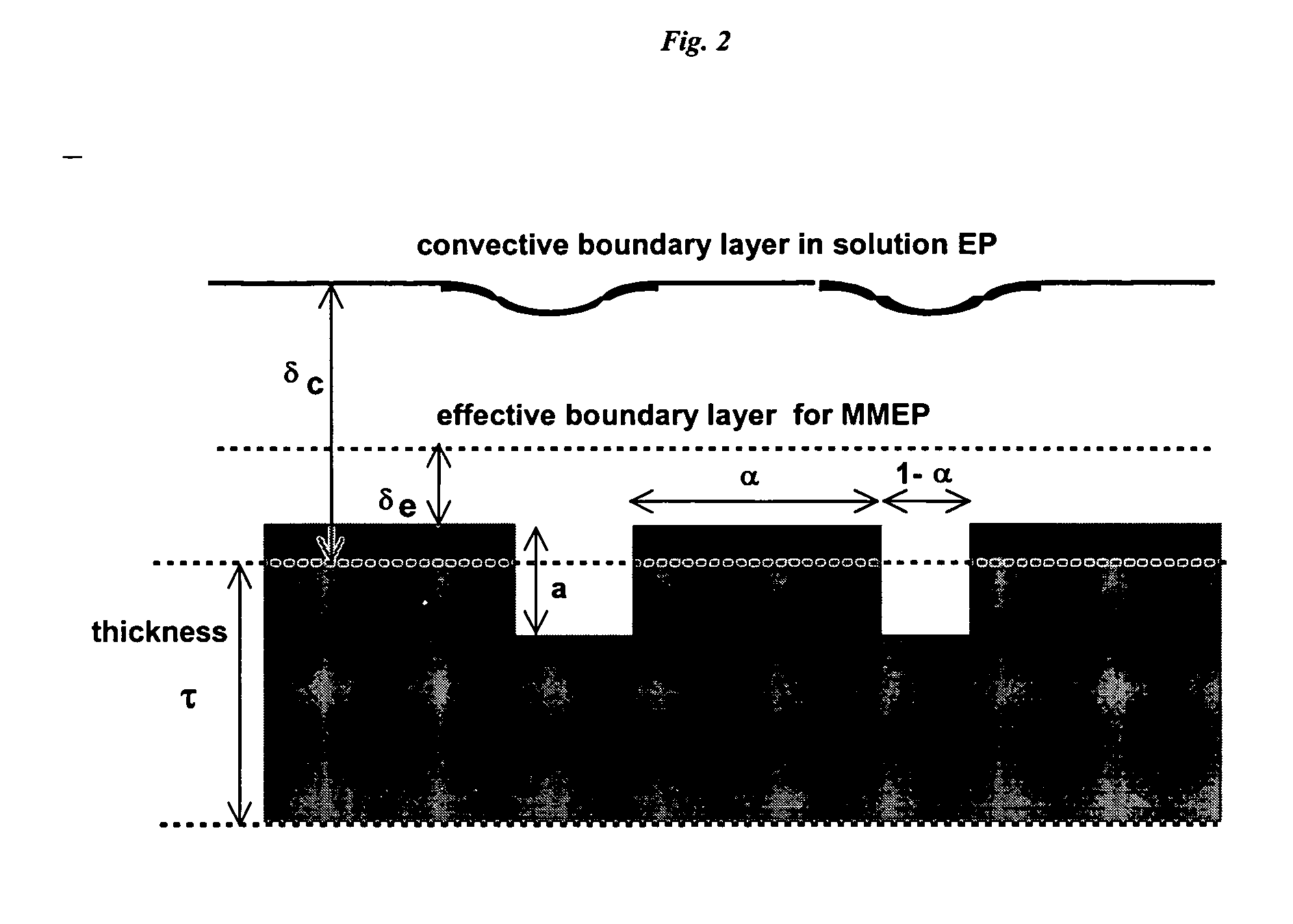

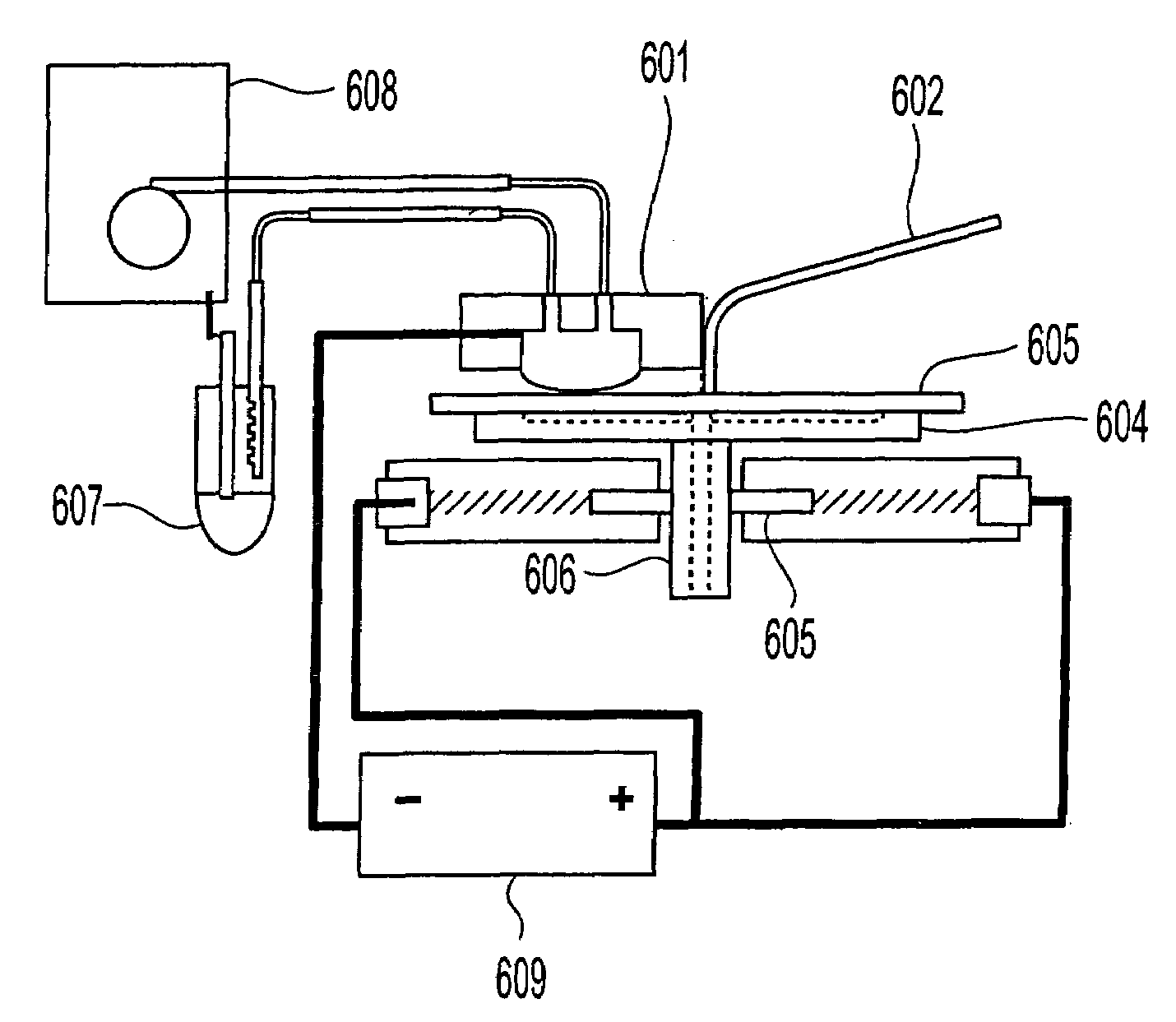

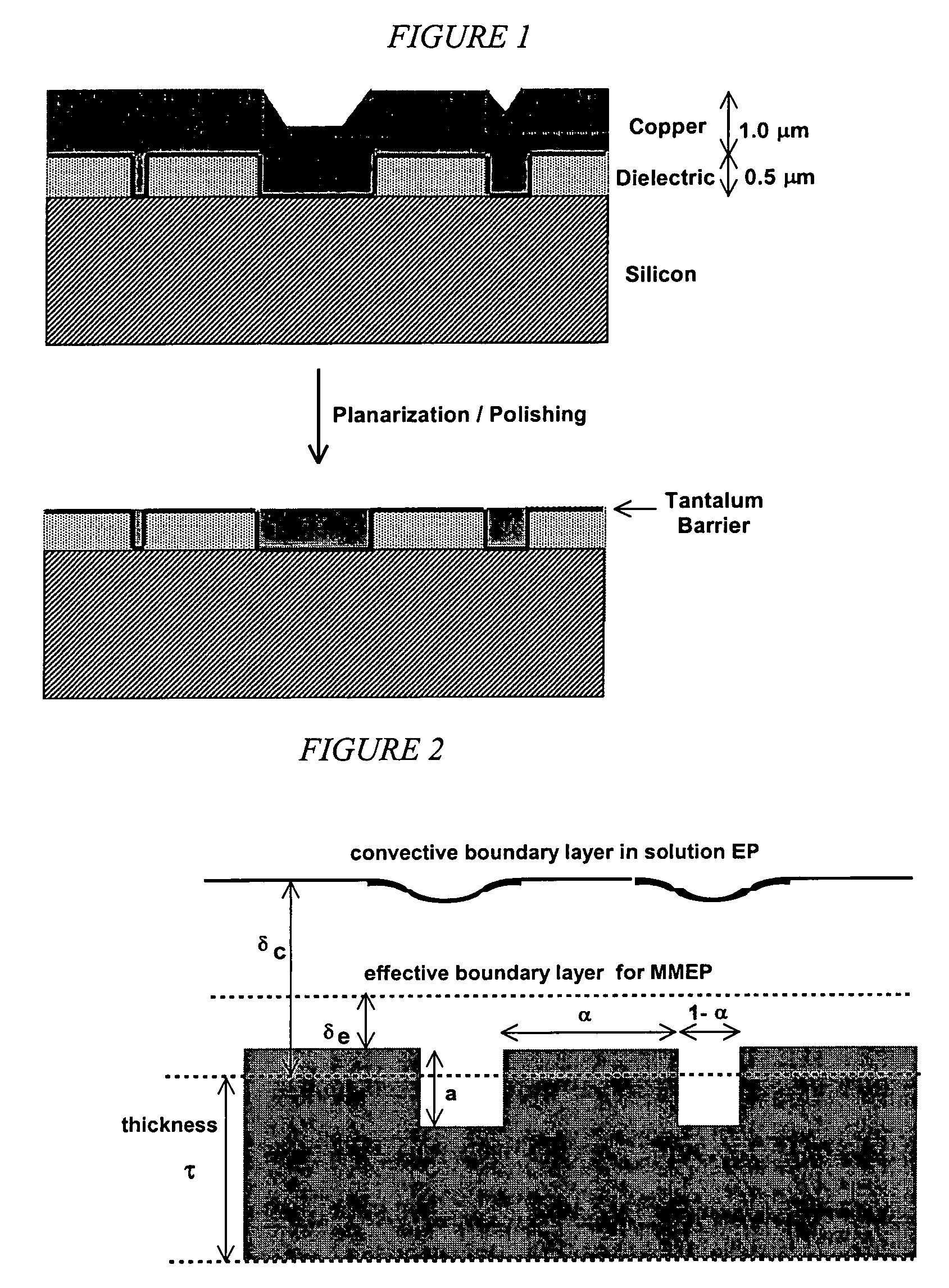

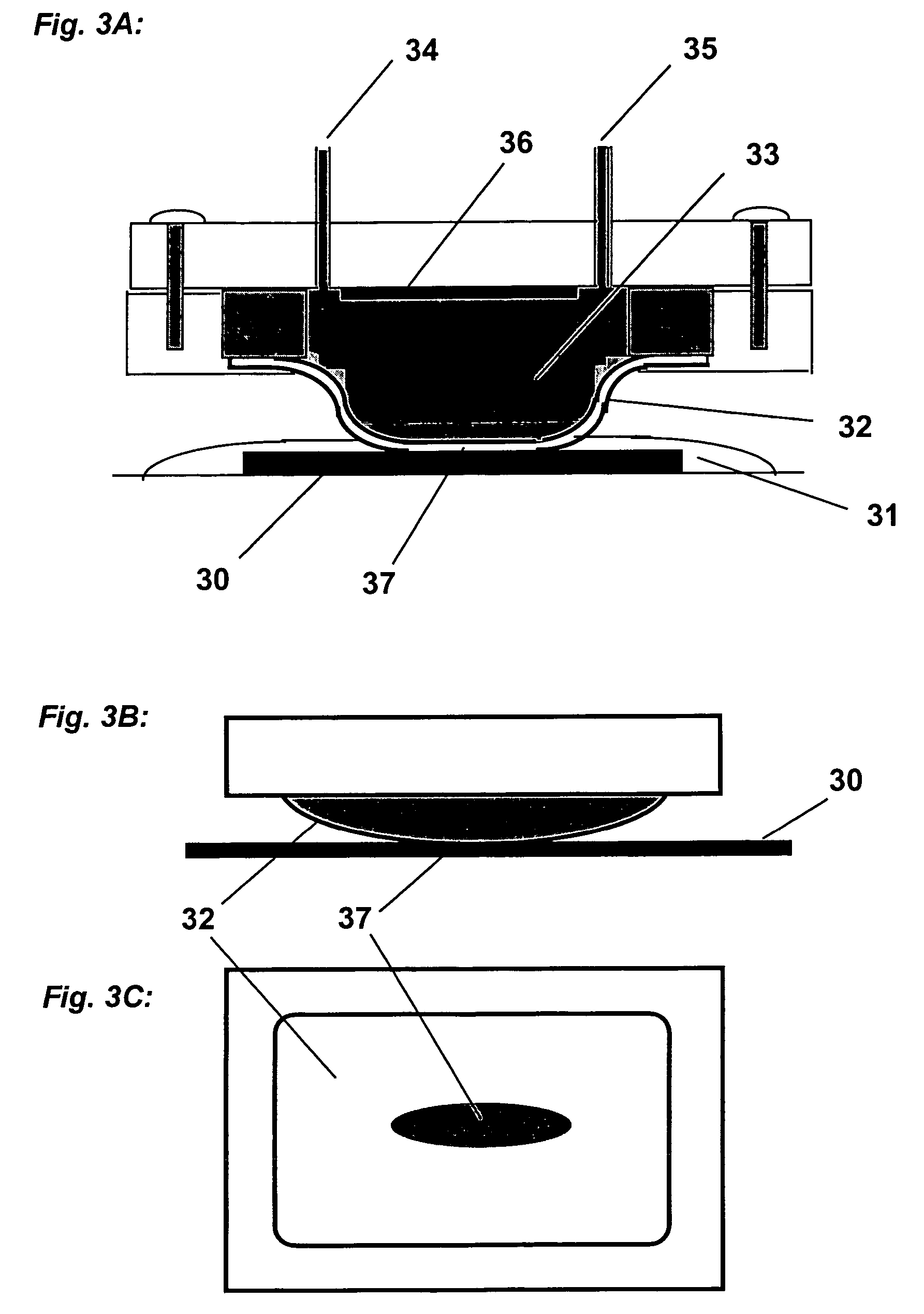

Apparatus adapted for membrane-mediated electropolishing

InactiveUS20070051619A1Reduce roughnessImprove abilitiesCellsSemiconductor/solid-state device manufacturingElectricityElectrolysis

This invention provides a membrane-mediated electropolishing apparatus for polishing and / or planarizing metal work-pieces. The work-piece is wetted with a low-conductivity fluid. The wetted work-piece is contacted with a first side of a charge-selective ion-conducting membrane, wherein the second side contacts a conductive electrolyte solution in electrical contact with a electrode. Current flow between the electrode and the work-piece electropolishes metal from the work-piece. This invention also provides a half-cell adapted for use in membrane-mediated electropolishing having a fully or partially enclosed volume, a conductive electrolyte which partially or essentially fills the enclosed volume, an electrode which is in contact with the electrolyte, and a charge-selective ion-conducting membrane which seals one surface of the enclosed volume, cavity or vessel in such a way that the internal surface of said membrane contacts the electrolyte solution or gel and the external surface is accessible to contact the work-piece.

Owner:EI DU PONT DE NEMOURS & CO

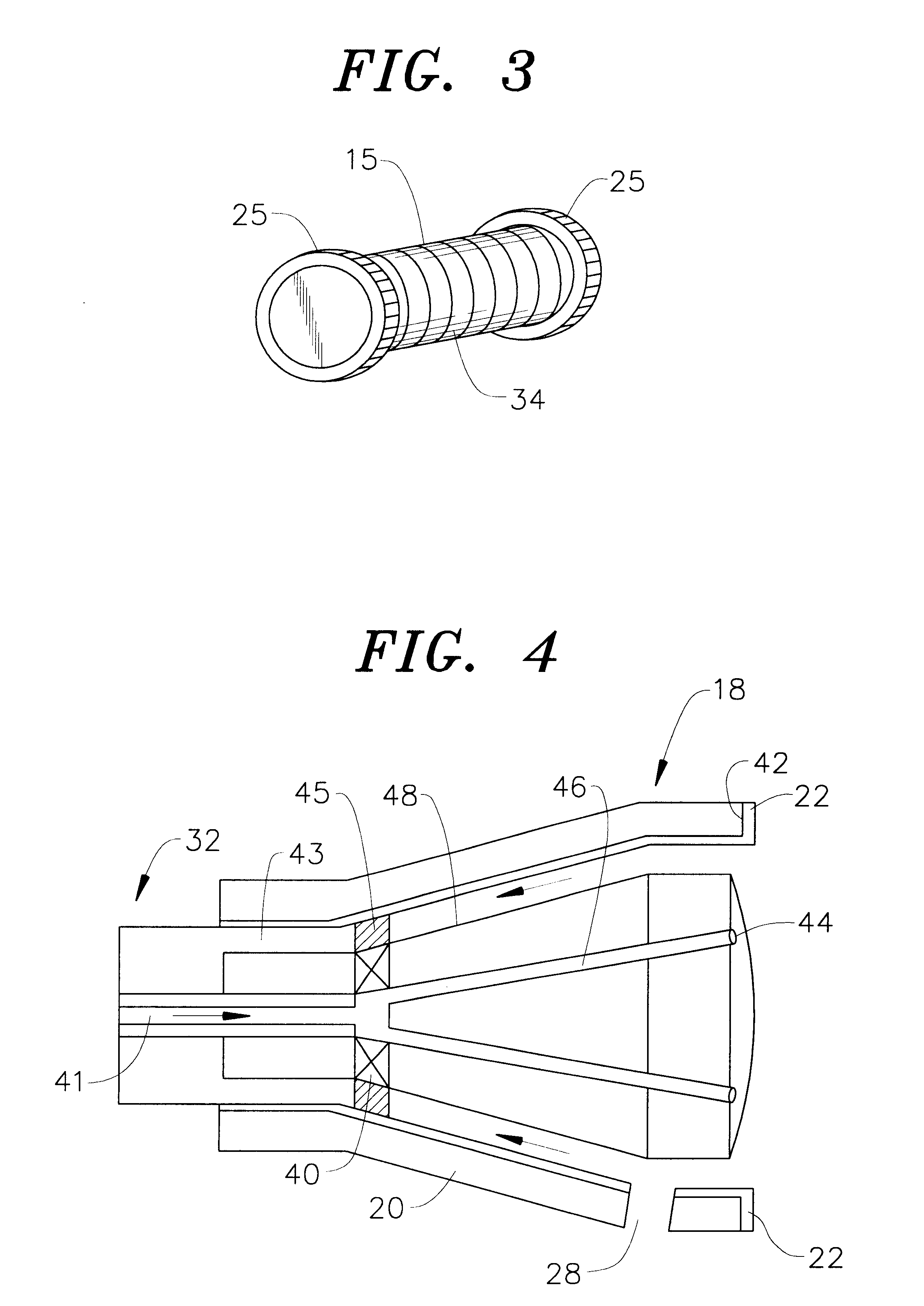

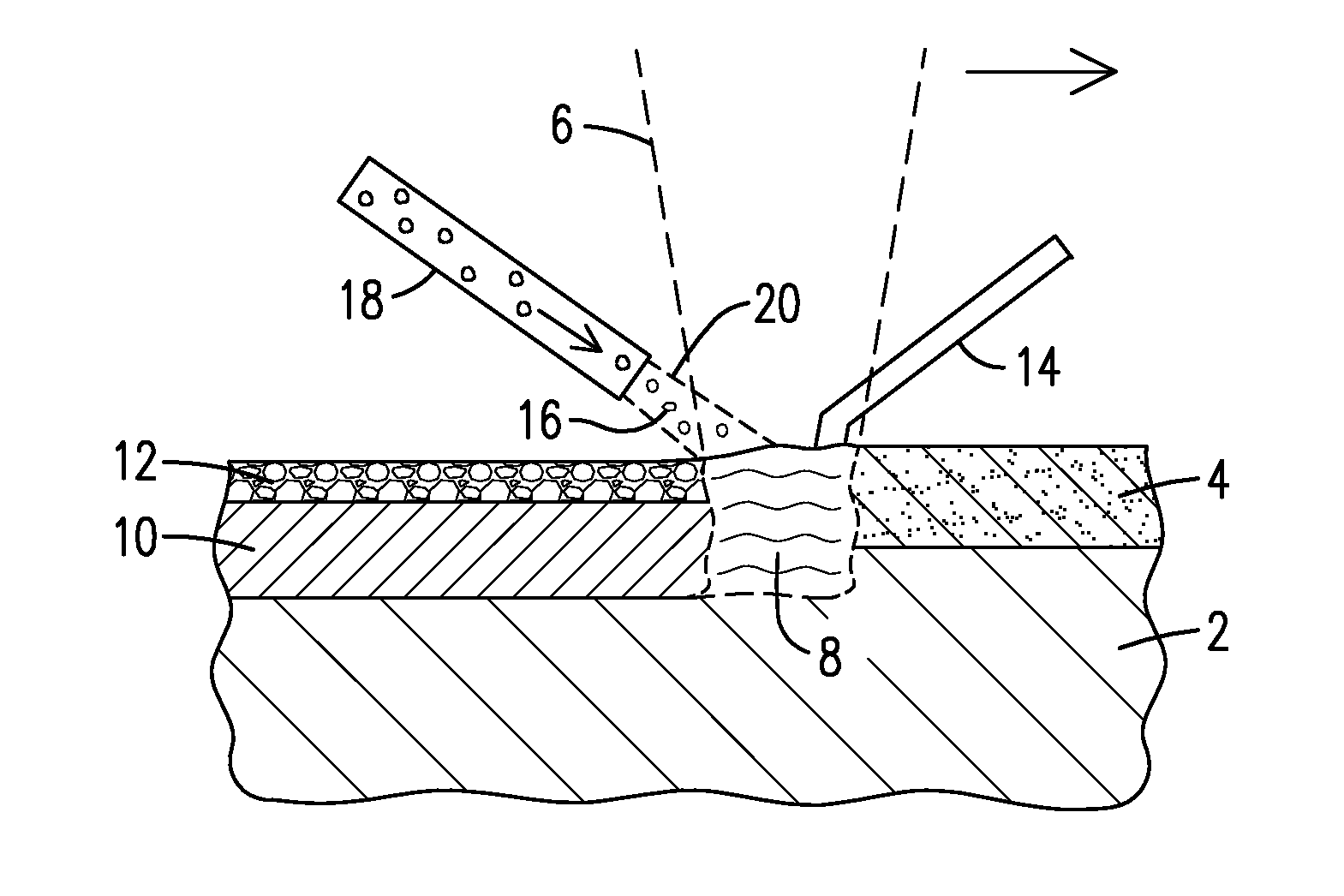

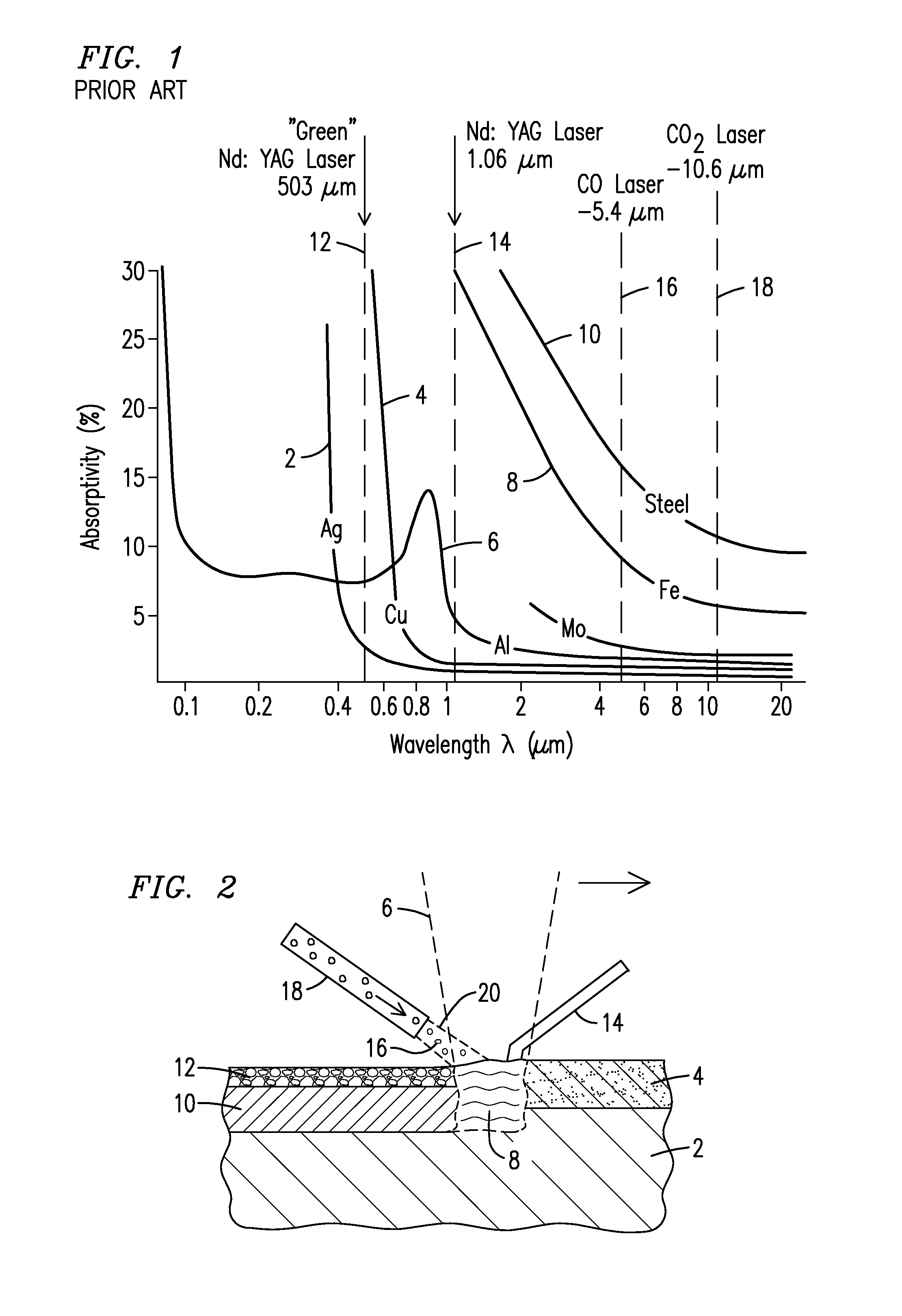

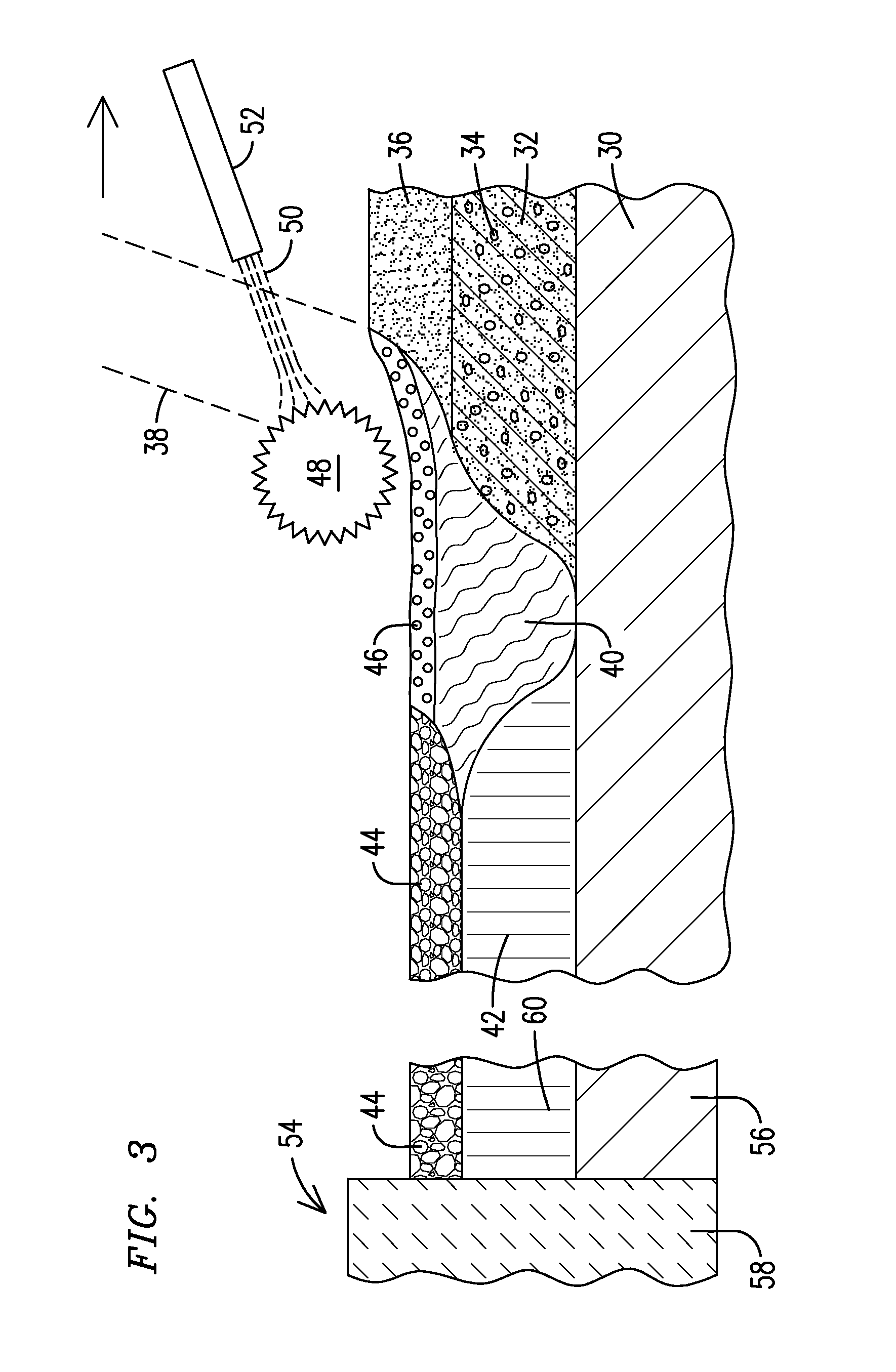

Laser metalworking of reflective metals using flux

Methods for laser processing of reflective metals. A reflective metal (2) is heated by applying a laser beam (6) to a layer of flux (4) in contact with the reflective metal, in which the flux is a powdered flux composition. The laser beam (38) may be applied to a powdered flux composition (36) such that thermal energy absorbed from the laser beam is transferred to a reflective-metal filler material (32) situated on a support material (30), and the powdered flux composition and the reflective-metal filler material melt to form a melt pool (40) which solidifies to form a metal layer (42) covered by a slag layer (44).

Owner:SIEMENS ENERGY INC

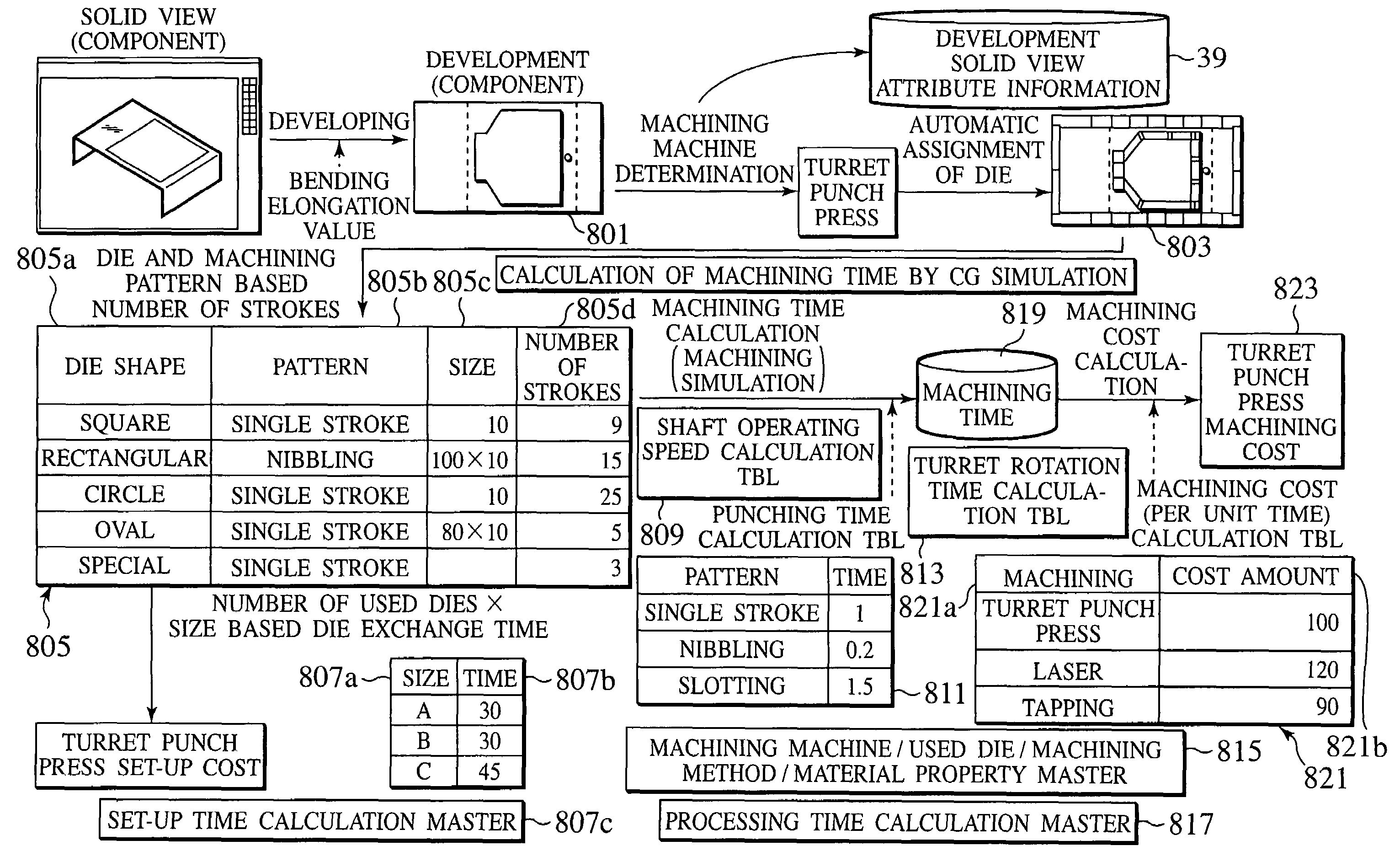

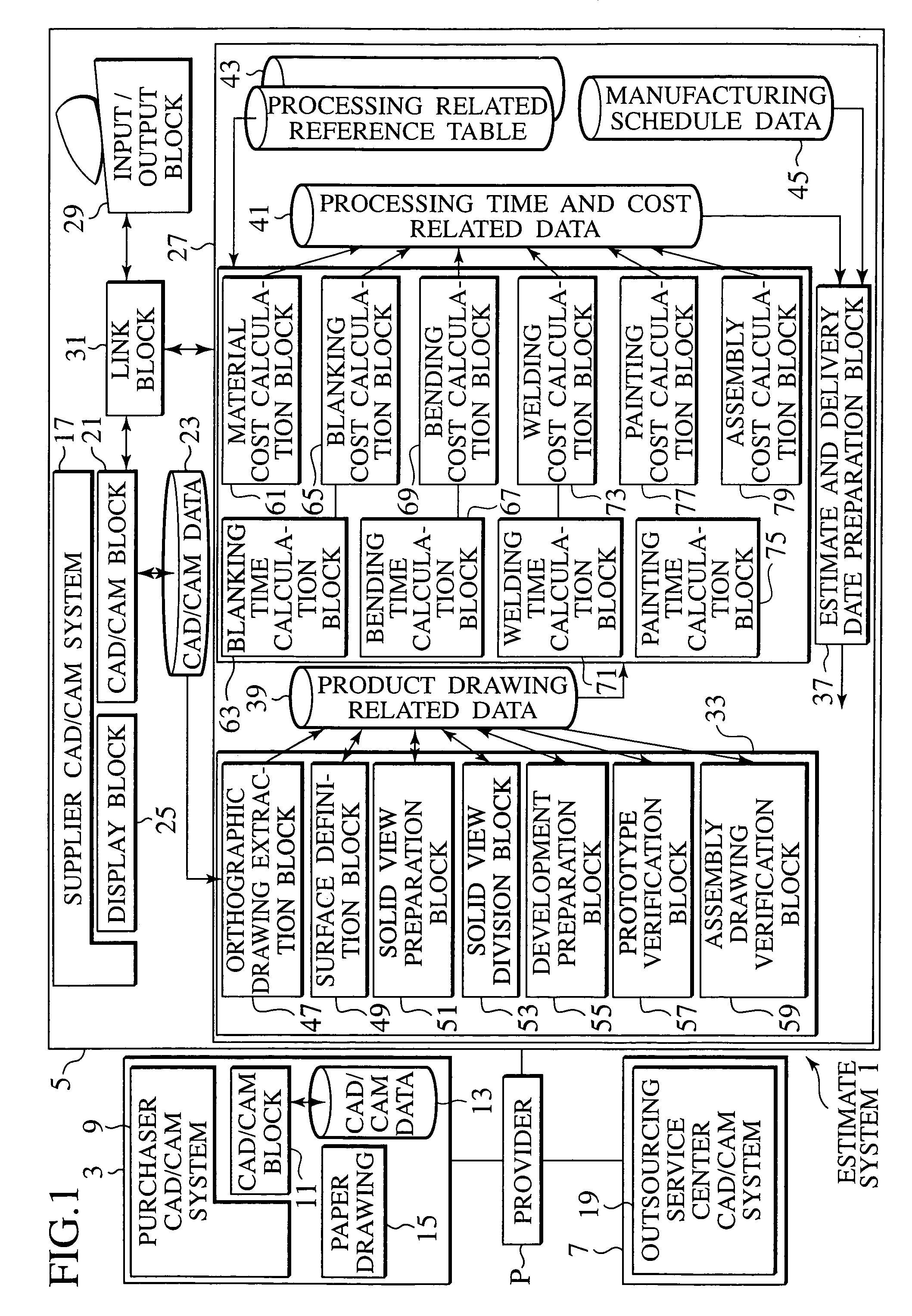

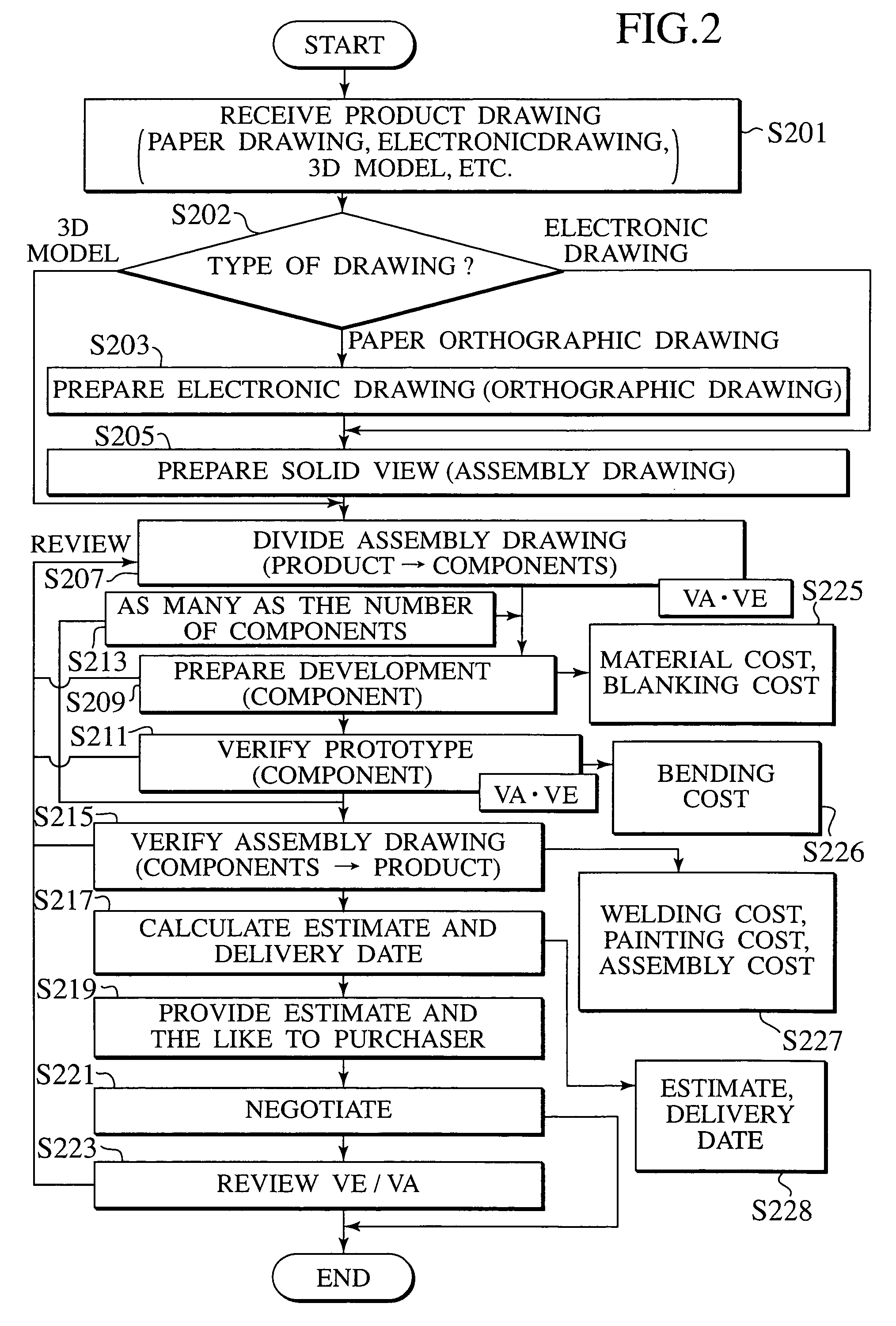

Method of preparing estimate for sheet metal working

A method is provided for preparing an estimate for sheet metal working. Data of bending lines and data of an associated processing time for the bending lines is stored. Data of holes and data of an associated processing time for the holes is stored. A three-dimensional view and a development drawing which realizes the three-dimensional view are prepared based on an orthographic drawing. A bending line and a hole on a product are detected based on at least one of data of the three-dimensional view and data of the development drawing. A processing time of the specified bending line is calculated based on the associated data of the bending lines. A processing time of the specified hole on the product is calculated based on the associated data of the holes. The processing time of the bending line and the processing time of the hole are stored in a processing time memory. A total processing time necessary to process the product is calculated by adding up the processing times stored in the processing time memory. The total processing time is converted to a cost of processing the product in consideration of a cost per processing time.

Owner:AMADA CO LTD

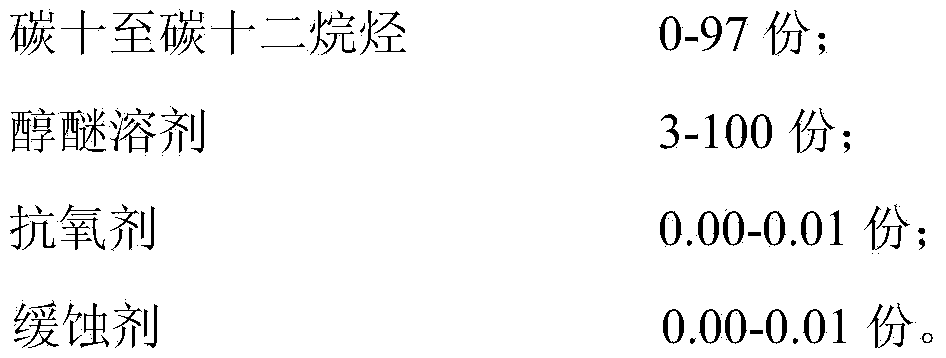

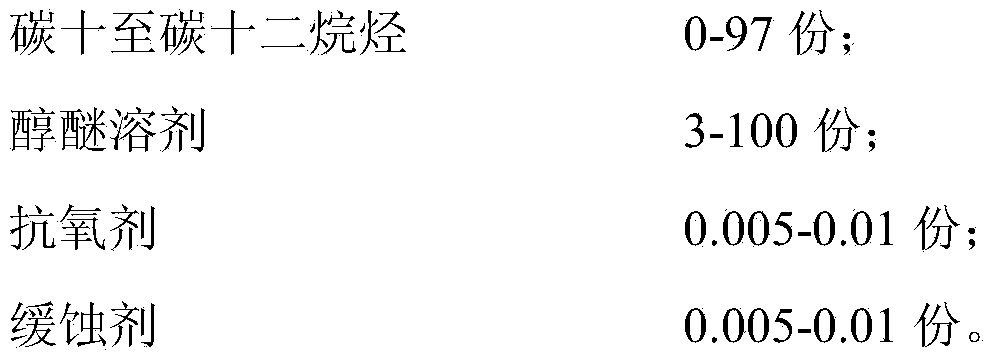

Environment-friendly safe solvent cleaning agent

InactiveCN103468434ANarrow distillation rangeHigh distillation recoveryNon-surface-active detergent solventsAlkaneWater based

The invention relates to an environment-friendly safe solvent cleaning agent which specifically comprises the following components in parts by weight: 0-97 parts of C10-C12 alkanes, 3-100 parts of alcohol ether solvent, 0.00-0.01 part of antioxidant and 0.00-0.01 part of corrosion inhibitor. The environment-friendly safe solvent cleaning agent provided by the invention is narrow in boiling range and the distillation recovery rate of the environment-friendly safe solvent cleaning agent can be above 95%; the environment-friendly safe solvent cleaning agent is also high in clearing ability, and has strong cleaning ability for polar dirt and nonpolar dirt; especially, the environment-friendly safe solvent cleaning agent can be used for thoroughly cleaning various metal working fluids, and oil-based and water-based cutting fluids without any residual and corrosion on metals; moreover, the shortcoming that the previous hydrocarbon type cleaning agents are wide in boiling range and only capable of dissolving and cleaning the nonpolar dirt are overcome. The cleaning agent is perfect in balance of cleaning ability, safety, dryness and reproducibility.

Owner:TIANJIN PRIMETECH CHEM

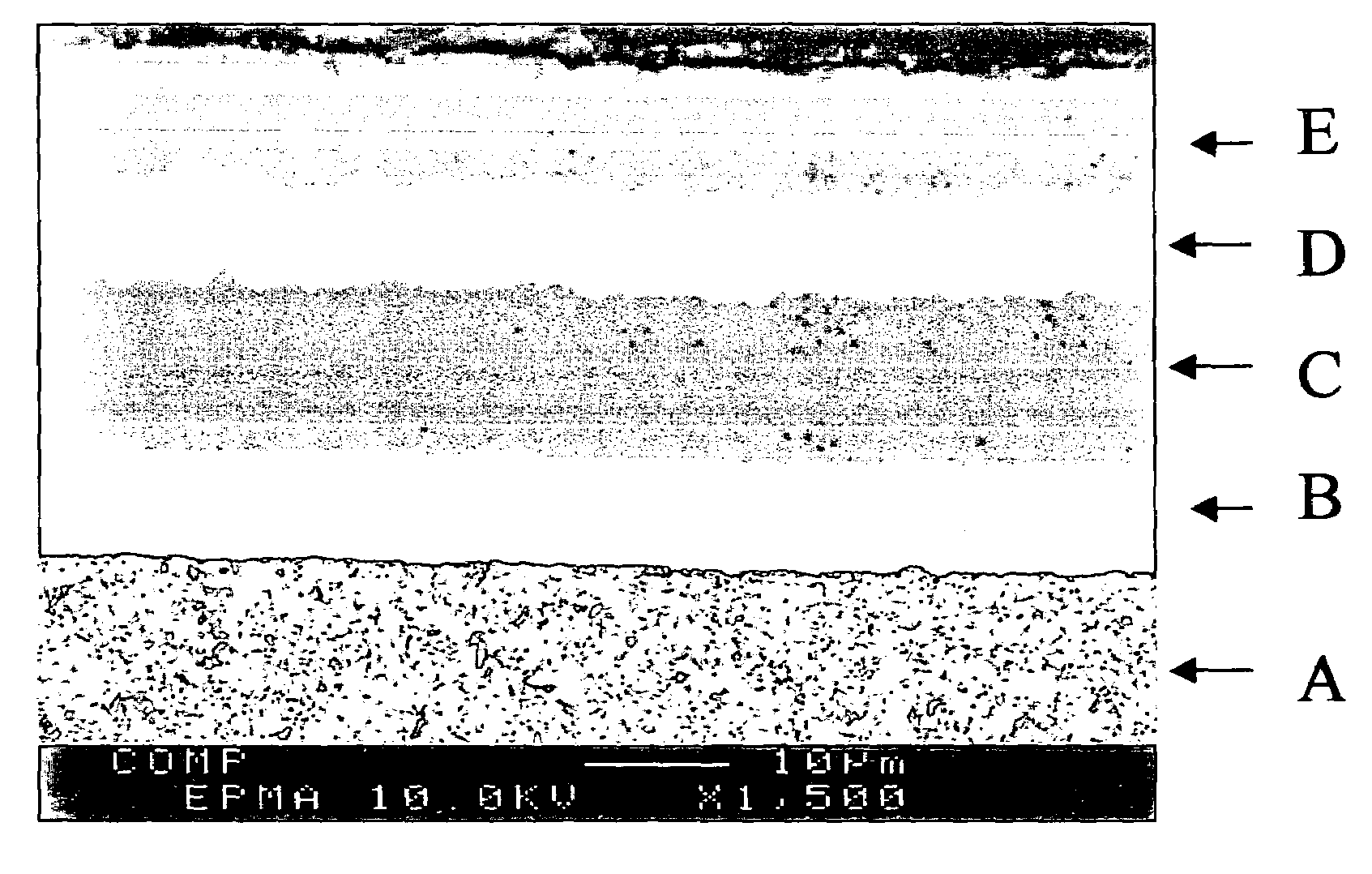

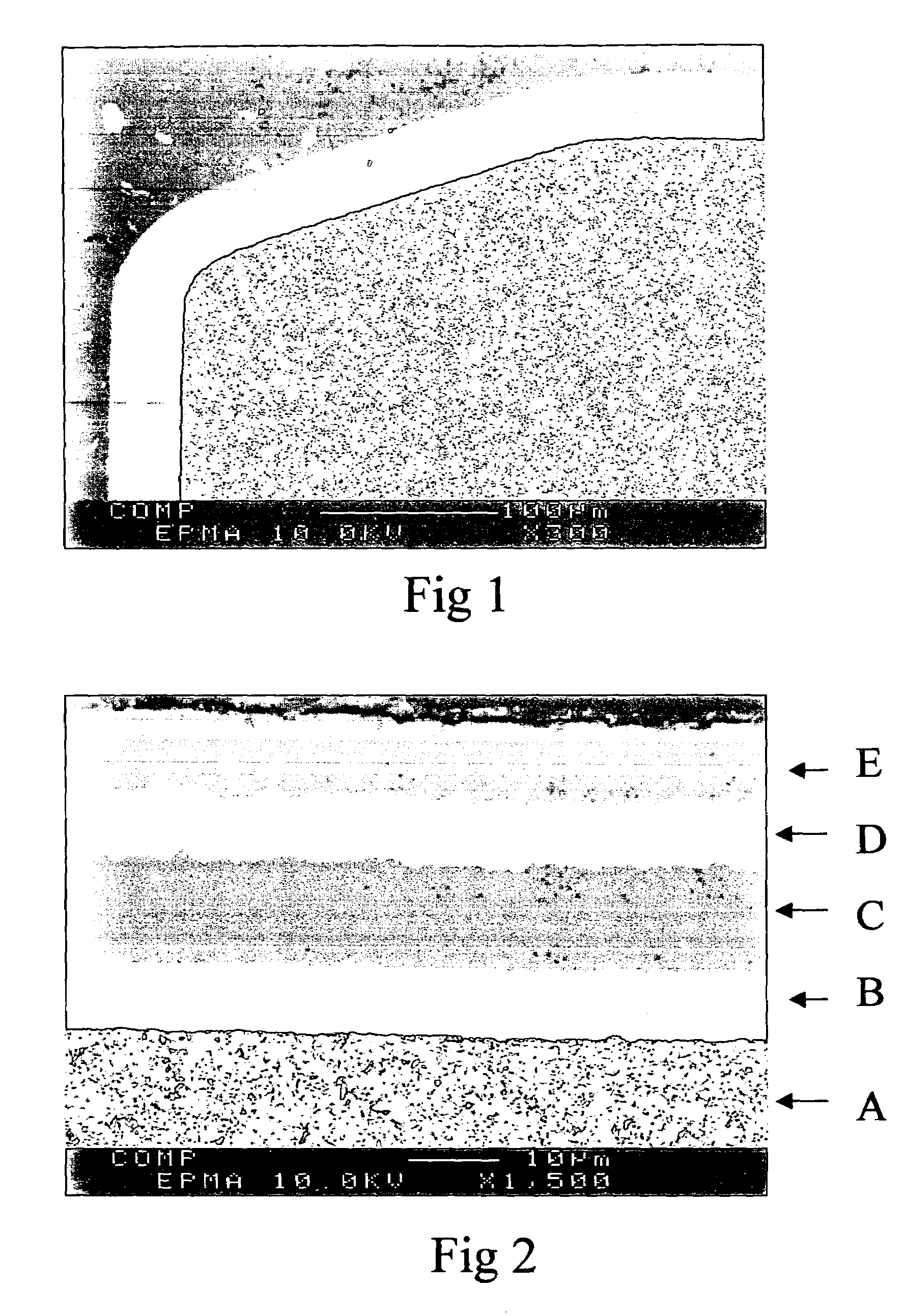

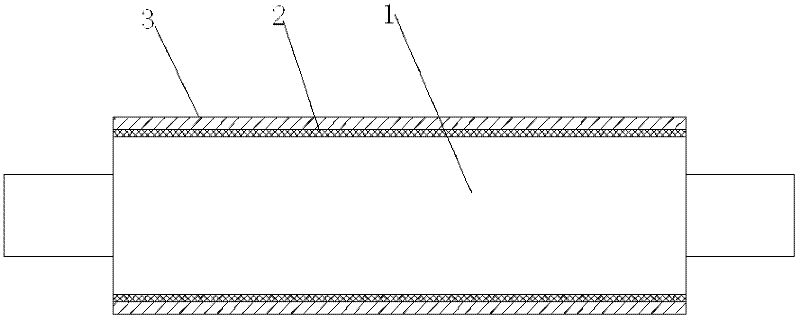

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS7585342B2Property is limitedWide applicationPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

Method for roughening metal surfaces and article manufactured thereby

InactiveUS20080253922A1Roughen the metal surfaceMachining electrodesElectrolysis componentsEngineeringMetal working

A method for surface roughening a metal work piece includes disposing the work piece proximate to a counter electrode. The work piece and the counter electrode are disposed in an electrolyte. An electric potential with current flow is applied between the work piece and the counter electrode to roughen the metal surface to a desired roughness.

Owner:GENERAL ELECTRIC CO

Membrane-mediated electropolishing

InactiveUS20070051639A1Efficiently planarizedElectrolysis componentsSemiconductor/solid-state device manufacturingElectrolysisAlloy

This invention provides a membrane-mediated electropolishing process for polishing and / or planarizing metal work pieces. The work piece is wetted with a low-conductivity fluid. The wetted work piece is contacted with a first side of a charge-selective ion-conducting membrane, wherein the second side contacts a conductive electrolyte solution in electrical contact with a cathode. Current flow between the cathode and the work piece electropolishes metal from the work piece. This process can be used for both pure metals and alloys, and provides several significant advantages over conventional electropolishing processes. This invention also provides an apparatus useful in the membrane-mediated electropolishing process.

Owner:EI DU PONT DE NEMOURS & CO

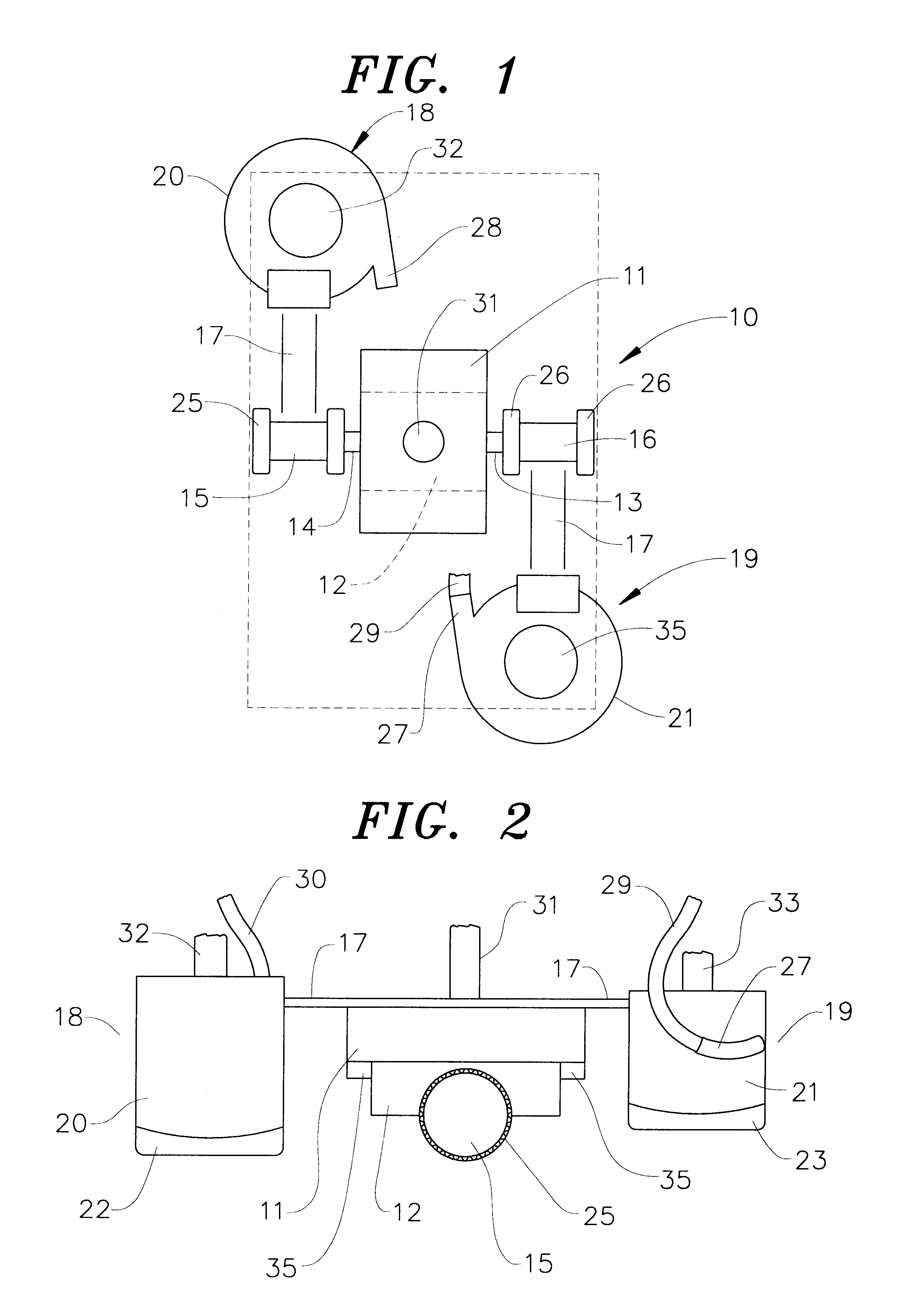

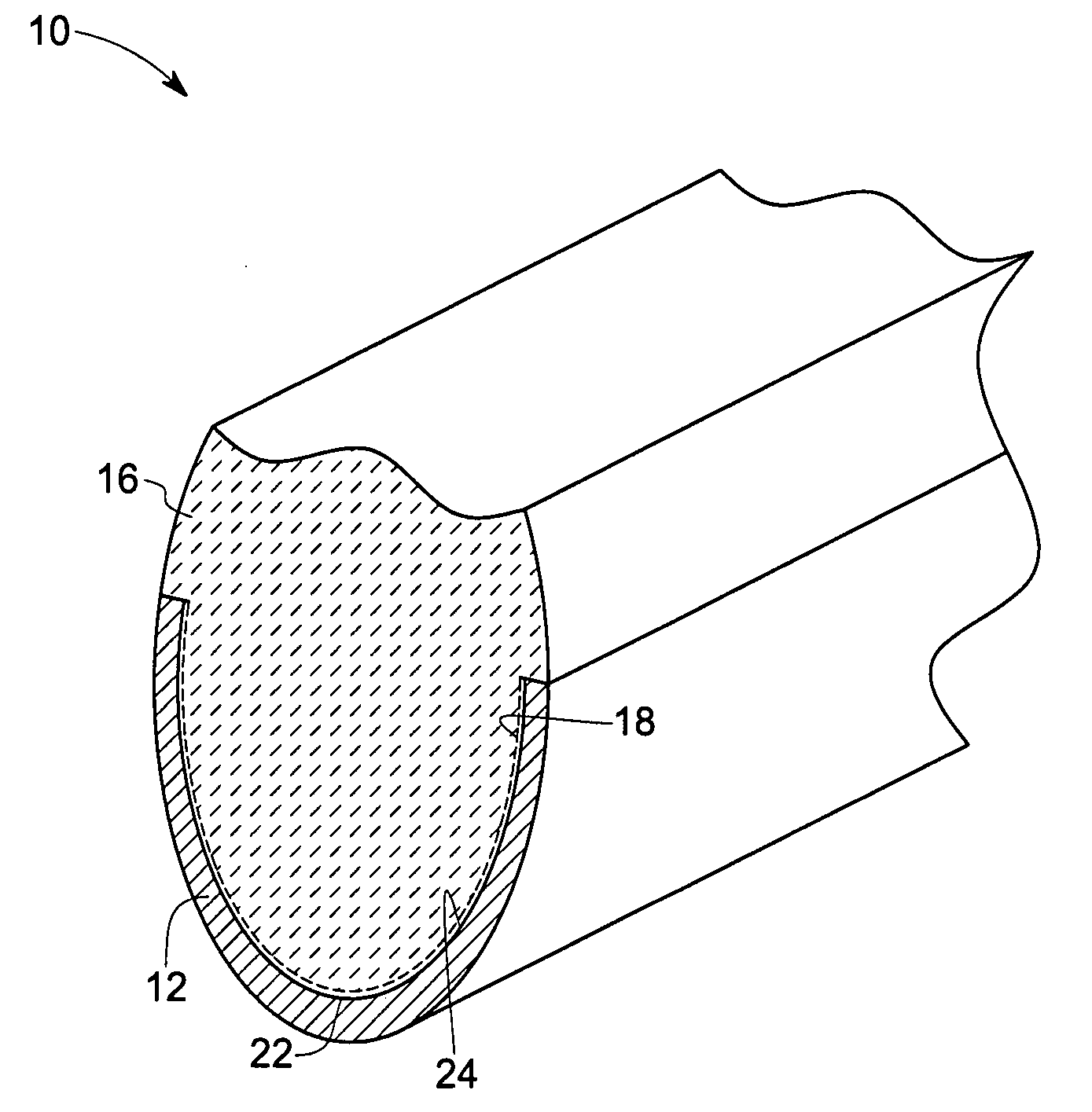

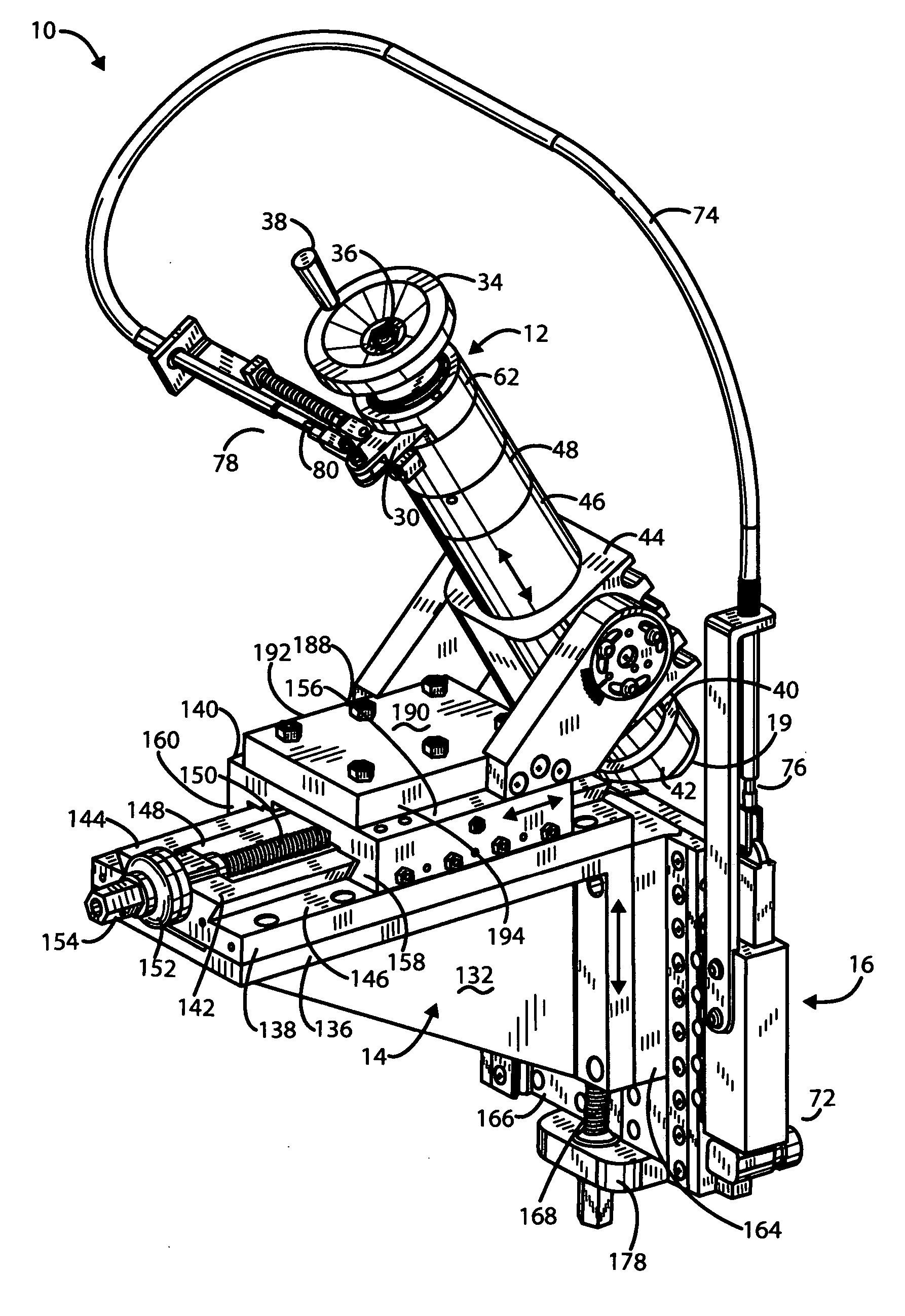

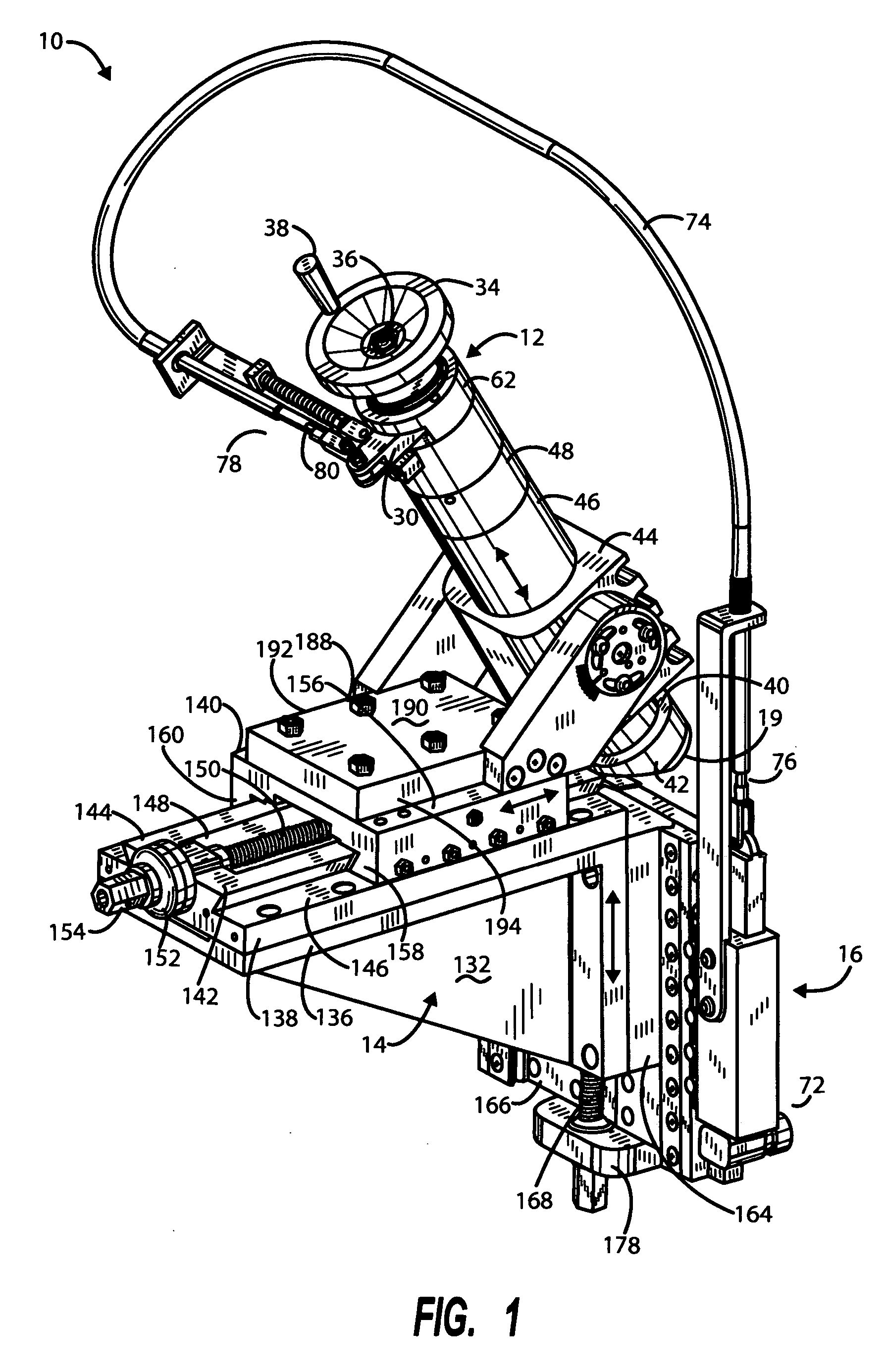

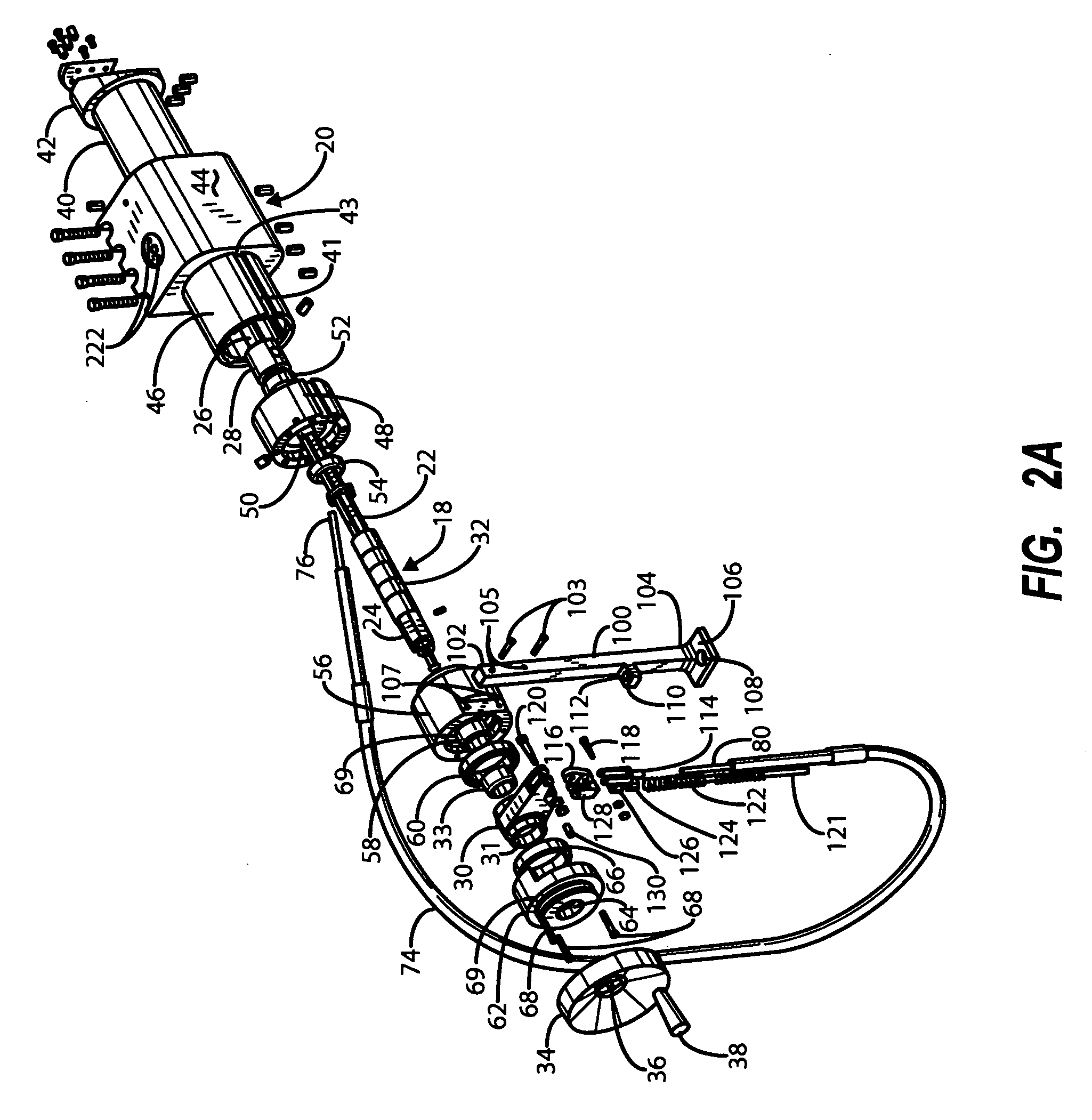

Swivel head module for a clamshell lathe

A swivel head assembly for a clamshell lathe is provided. The swivel head module includes an adjustable tool head assembly. The adjustable tool head assembly has a tool for machining a work piece, and is capable of being incrementally advanced in a radial direction against the work piece. The swivel head assembly further includes a means for positioning the metal working tool along an x-axis, y-axis, and z-axis. A tripper assembly is operatively coupled to the tool head assembly to incrementally urge the tool head against the work piece upon each revolution of the clamshell ring. The tripper assembly incorporates a solenoid for selectively incrementally advancing the tool against the work piece.

Owner:DONATO L RICCI +1

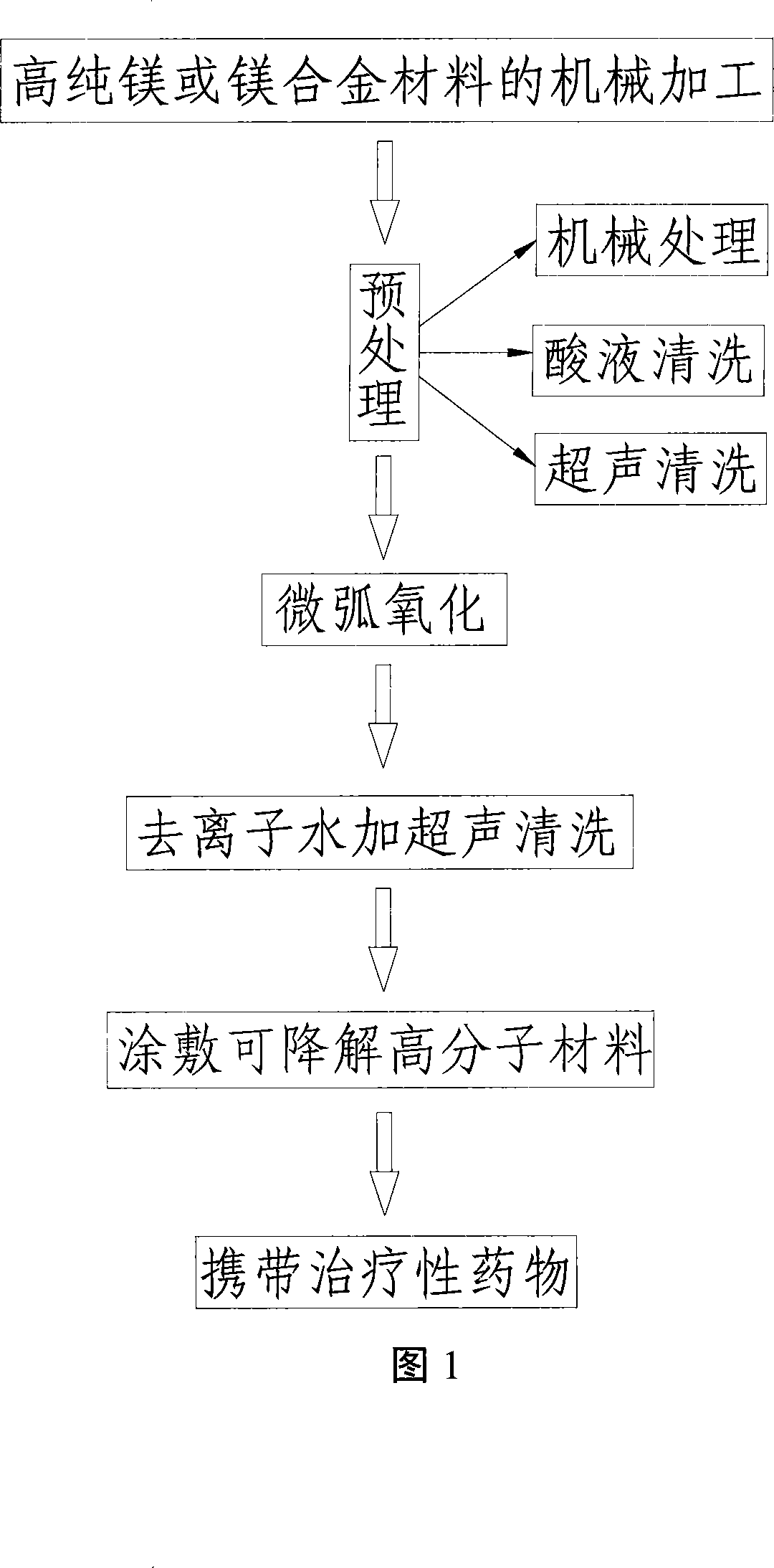

Controlled degradation differential arc oxidized metallic support and manufacture method thereof

ActiveCN101239009AImprove stabilityIncrease varietyStentsAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a micro arc oxidation metal bracket capable of controlling degradation and the preparing method. The bracket is provided with a micro arc oxidation film and a degradable polymer coating. The method comprises the steps showed as follows: processing a degradable metal into a bracket; pretreating the bracket to remove the oxide at the surface of the bracket; putting the bracket into the micro arc oxidation electrolyte, as the anode of an electrobath, the bracket is put in the direct current or alternating current to have micro arc oxidation treatment, ensuring the surface of the bracket have the micro arc oxidation film; cleaning the bracket after the micro arc oxidation treatment; spraying degradable polymer material at the bracket surface after being cleaned and the degradable polymer material carries therapeutic medicine. The micro arc oxidation film at the bracket can reduce the erosion speed of the bracket remarkably, can prolong the service life of the bracket and simultaneously guarantee the mechanical property of materials in the degradation process.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

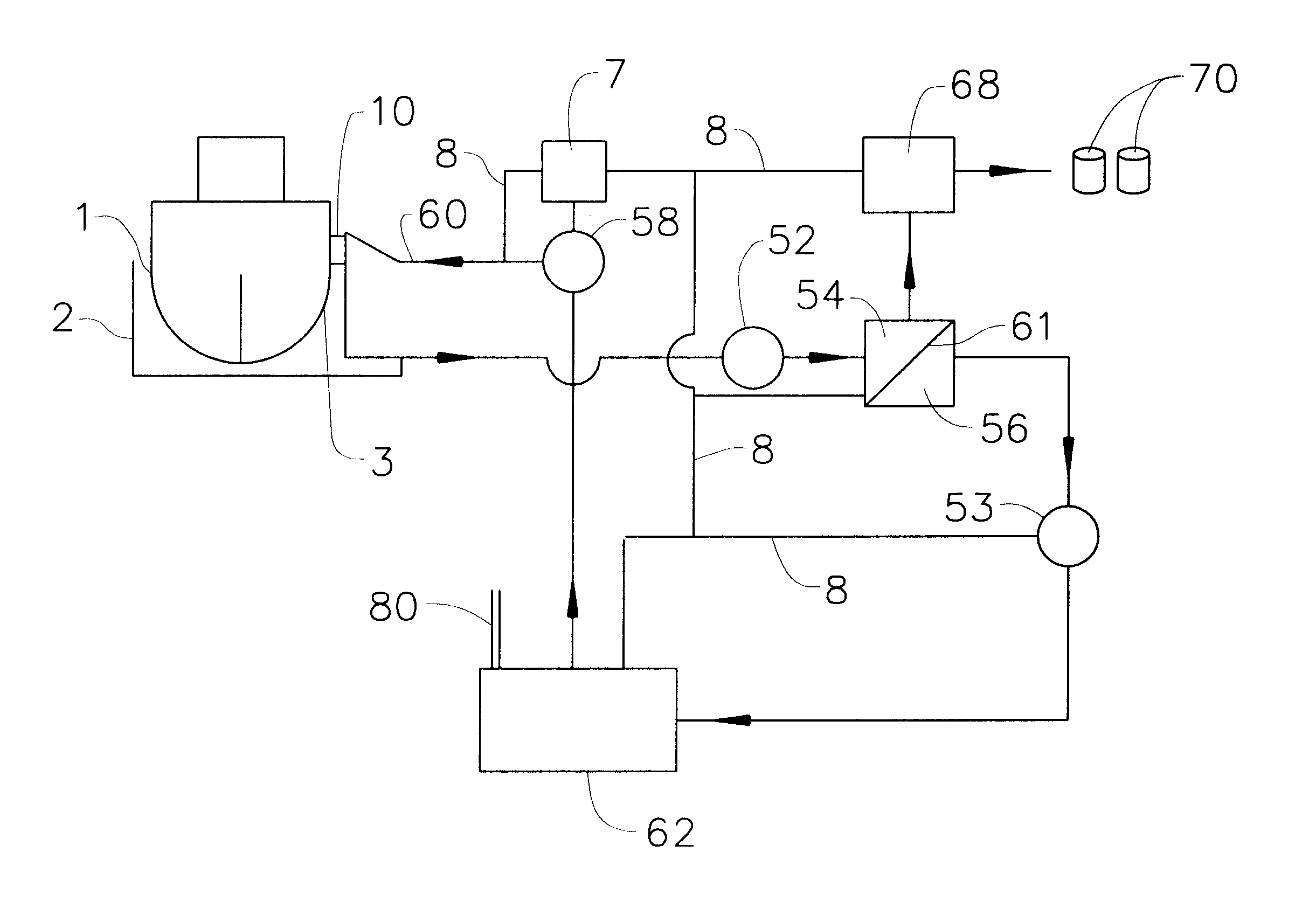

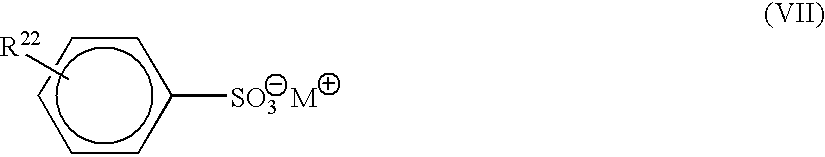

Water soluble metal working fluids

InactiveUS6706670B2Simple compositionReduce the temperatureOrganic chemistryWork treatment devicesMetal working fluidPhysical chemistry

This invention relates to novel water soluble metal working fluid compositions, their use to work metal, a process for working metal using such compositions and the metal worked article of manufacture. More particularly, this invention relates to fluid compositions useful in cutting, grinding, shaping and other metal working operations which require a lubricant. The terms "first Group A" and "second Group B" are used herein to denote different groups and not to indicate any sequence of use or selection as any possible combination or sequence of use of a component(s) is envisioned without limit of any kind. The disclosed fluid compositions are also anticorrosive and environmentally more acceptable than current oil based fluids. There has now been discovered an essentially odorless, substantially non-oil misting, water-soluble metal working fluid comprising at least one component selected from a first Group A herein and optionally one or more components selected from a second Group B herein preferably with the balance of the composition being water and other (optional) minor ingredients. When a component is employed from Group A and a component is employed from Group B the action of the combination generally enhances performance of the resulting combination with contain moieties from both Group A and Group B.

Owner:SOLUTIA INC

Lubricant compositions and methods

A process is disclosed for manufacturing a lubricant a composition comprising combining a superabsorbent polymer with a material for decreasing friction between moving surfaces. The superabsorbent polymer absorbs from about 25 to greater than 100 times its weight in water and may comprise a polymer of acrylic acid, an acrylic ester, acrylonitrile or acrylamide, including co-polymers thereof or starch graft co-polymers thereof or mixtures thereof. A product produced by the process includes the material for decreasing friction comprising a petroleum lubricant containing an additive, water containing an additive, synthetic lubricant, grease, solid lubricant or metal working lubricant, wherein the synthetic lubricant, grease, solid lubricant or metal working lubricant optionally contain an additive. A process comprising controlling the delivery of a lubricant to at least one of two moving surfaces in order to decrease friction between said moving surfaces, is also disclosed. This process includes applying the lubricant composition to at least one of the surfaces. The lubricant composition in this instance comprises a superabsorbent polymer combined with a material for decreasing friction between moving surfaces, wherein the material for decreasing friction comprises a petroleum lubricant, water, synthetic lubricant, grease, solid lubricant or metal working lubricant, and optionally an additive.

Owner:LEE COUNTY MOSQUITO CONTROL DISTRICT

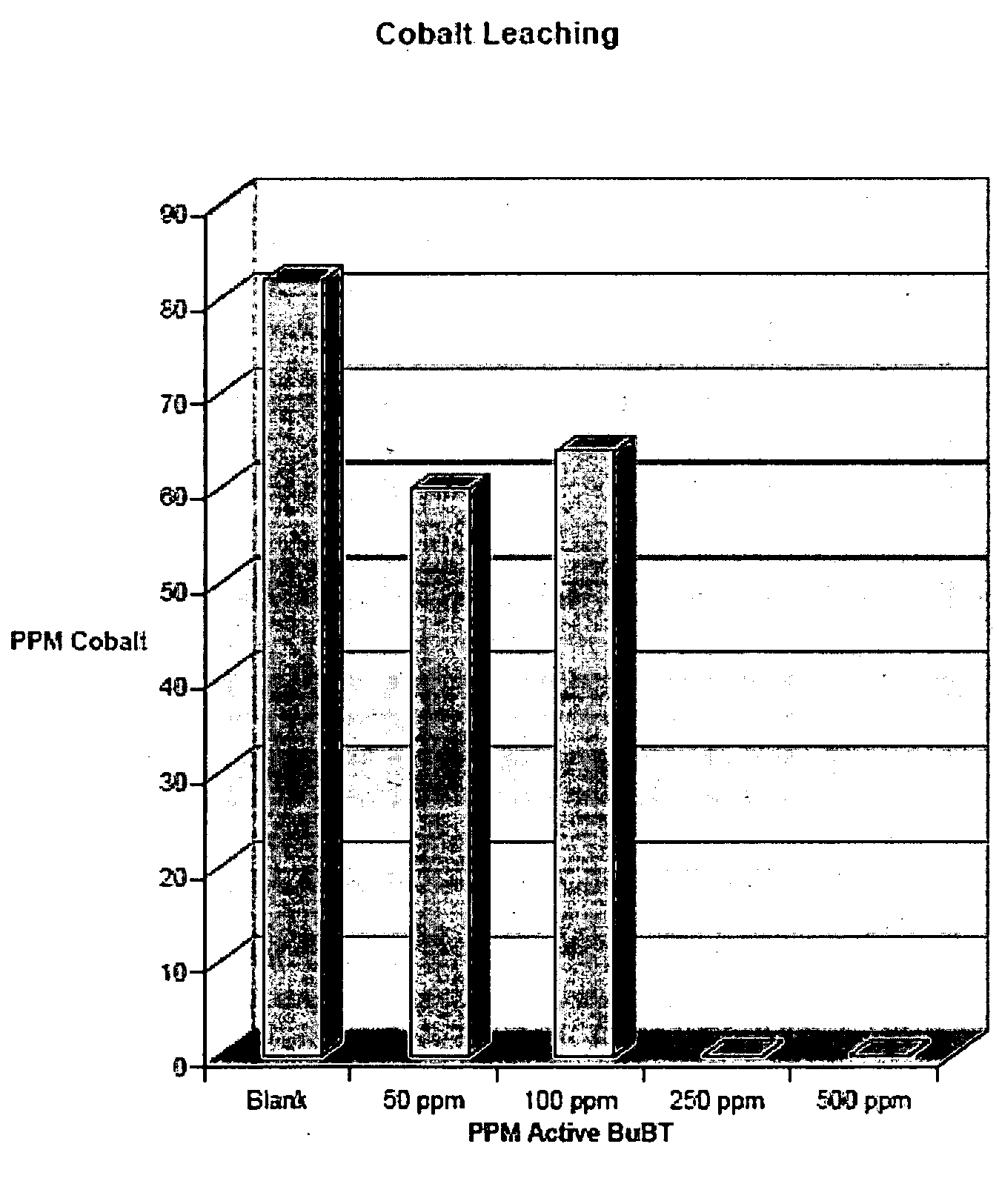

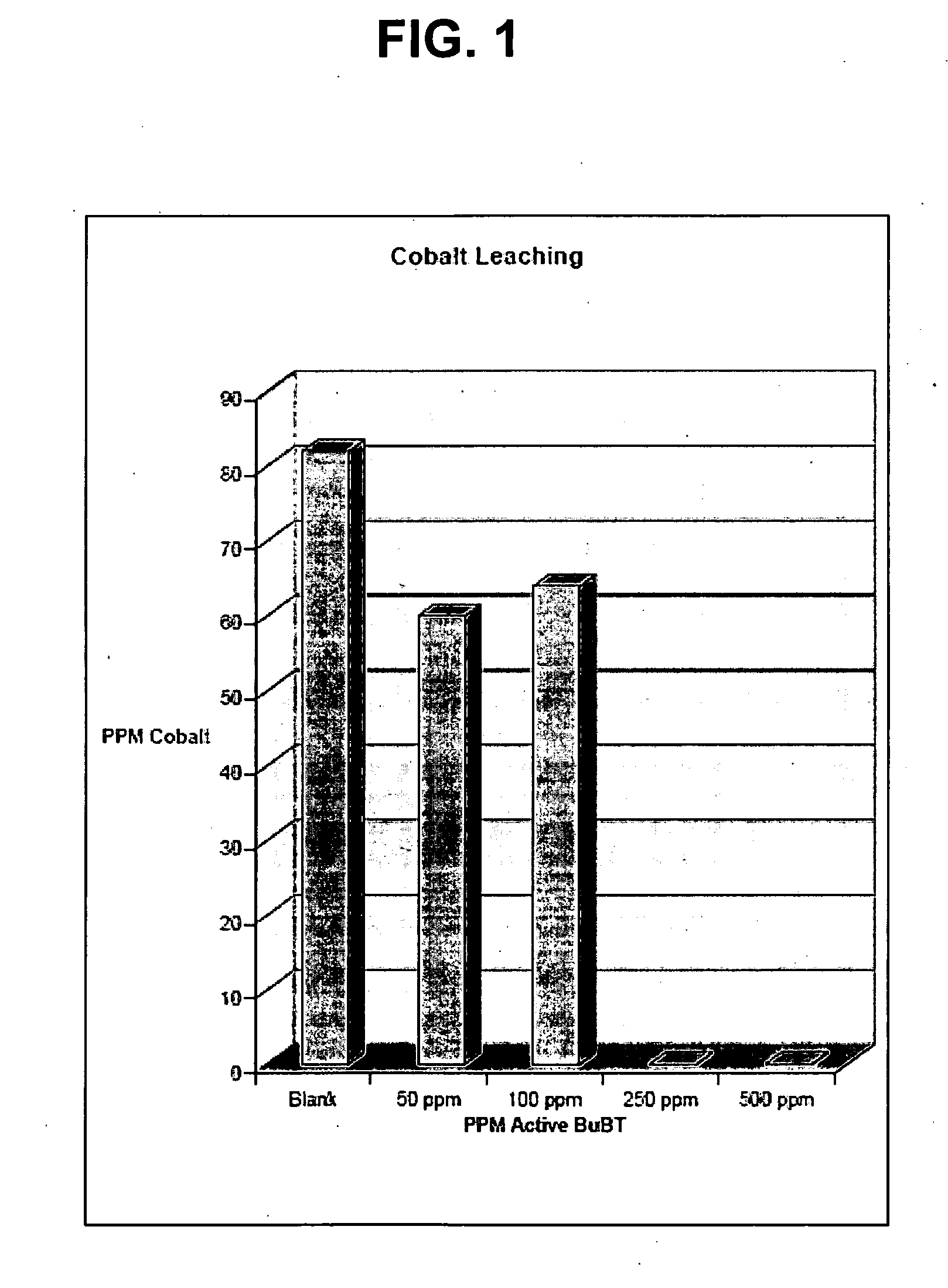

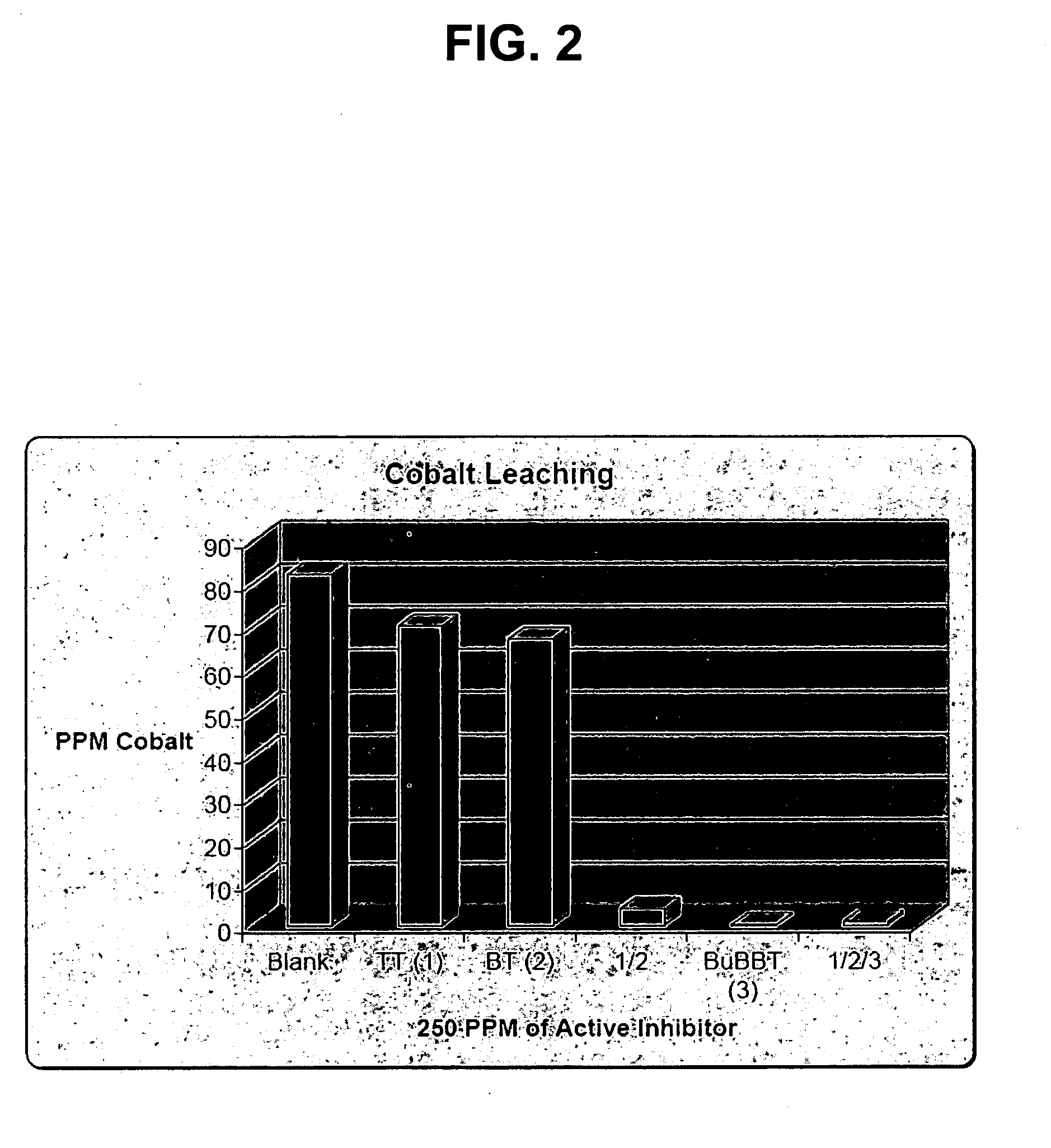

Use of triazoles in reducing cobalt leaching from cobalt-containing metal working tools

A method using one or more of certain triazoles in an amount effective to reduce cobalt leaching during a metal working process from a metal working tool comprising cobalt, such as tungsten carbide particles bonded by cobalt, wherein the one or more triazoles comprise at least butyl-benzotriazole, and optionally one or more other benzotriazoles. Also, a composition is provided which comprises a metal working fluid and one or more of these triazoles in an amount effective to reduce cobalt leaching from metal working tools comprising cobalt, such as tungsten carbide particles bonded by cobalt.

Owner:WINCOM

Method for high speed machining and coated cutting tool

InactiveUS7416778B2Guaranteed high speed operationLower performance requirementsPigmenting treatmentWorkpiecesCemented carbideTotal thickness

Owner:SANDVIK INTELLECTUAL PROPERTY AB

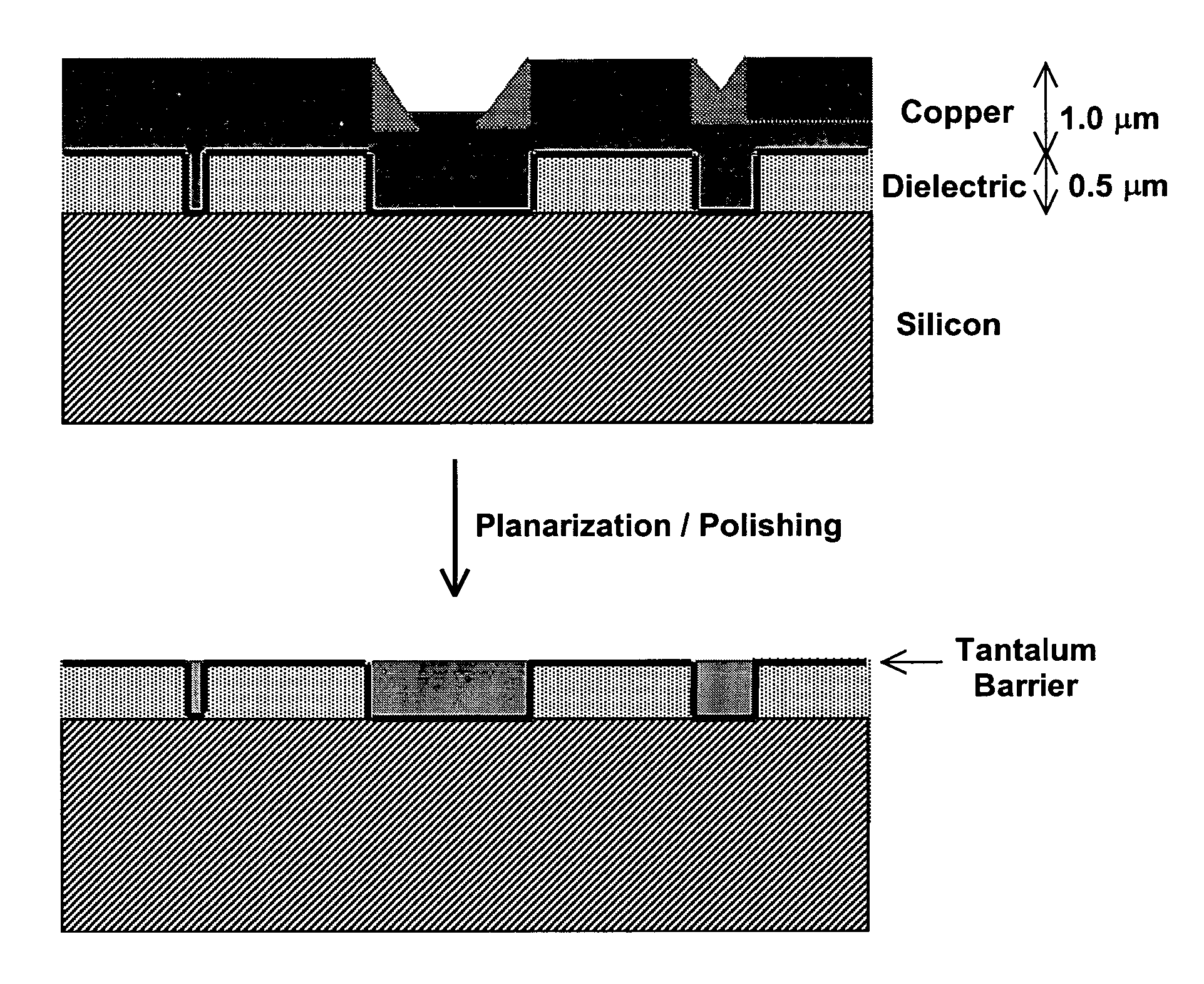

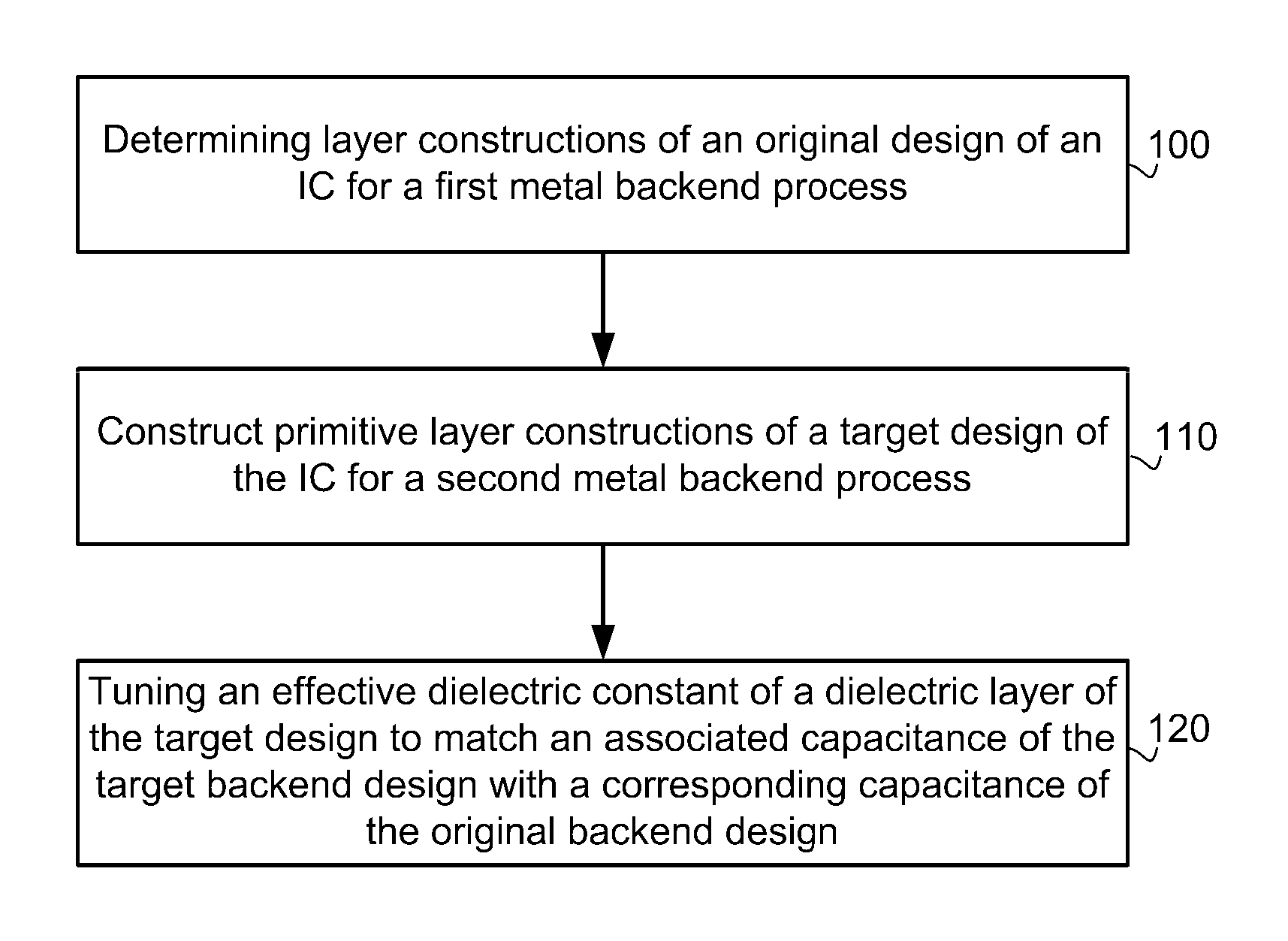

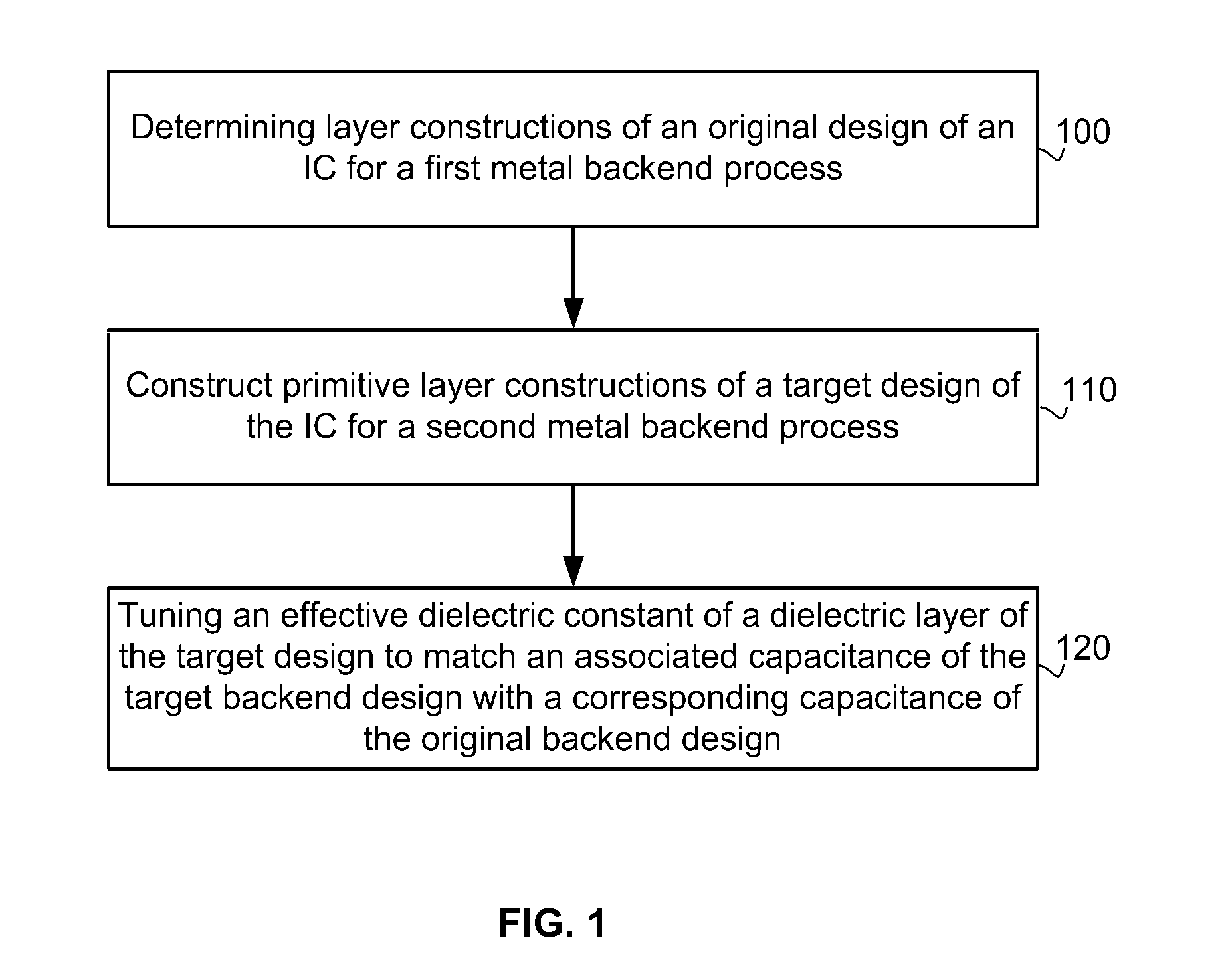

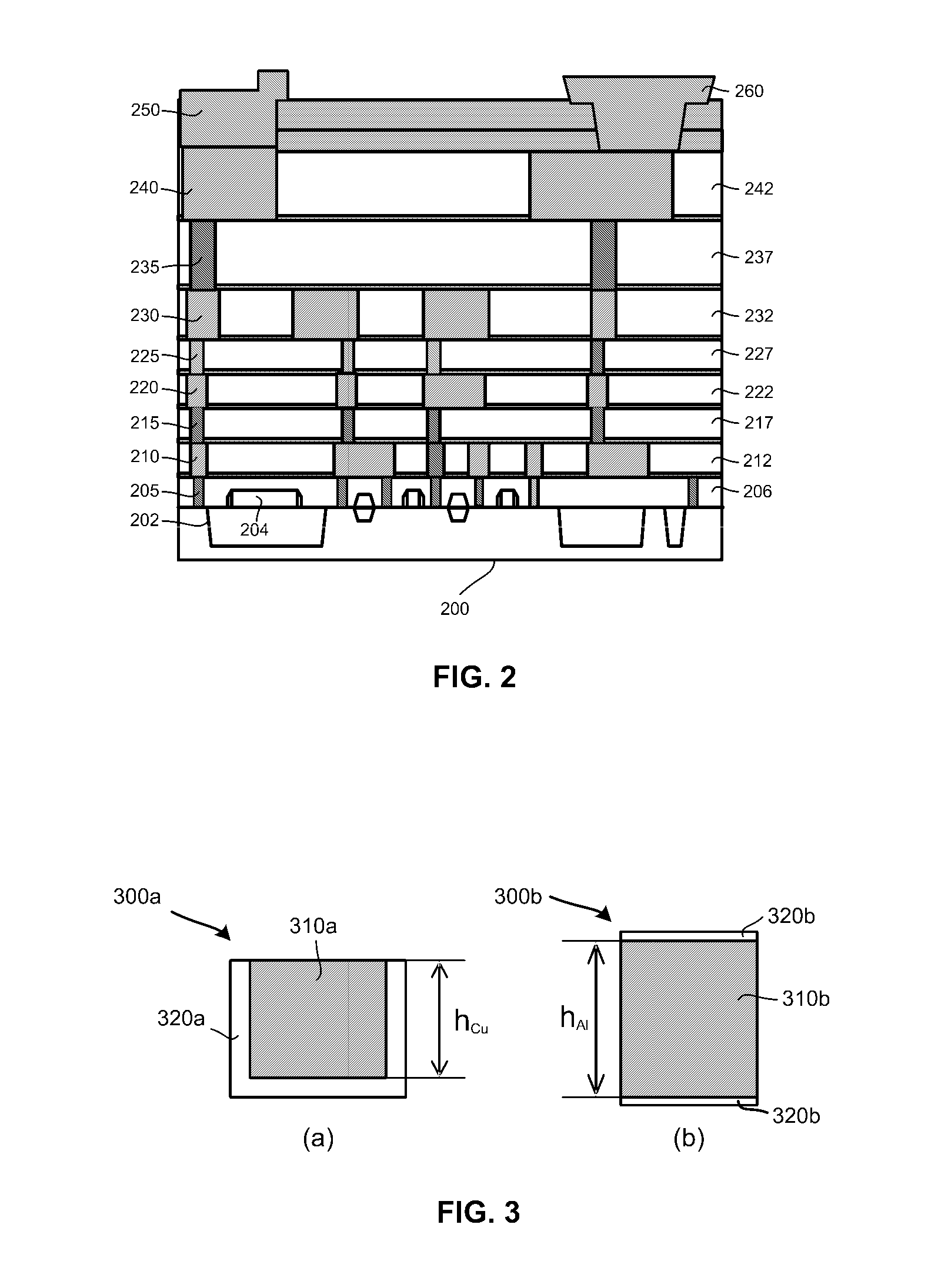

A method for processing IC designs for different metal beol processes

InactiveUS20070037384A1Easy to understandSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMetal fabrication

A method for processing IC designs for different metal BEOL processes is provided for enabling fabricating using a metal fabrication process an IC originally having a backend design for a different metal fabrication process. The method first determines layer constructions of an original design of an IC for a first metal backend process, and, based on the layer constructions of the original design of the IC, constructs primitive layer constructions of a target design of the IC for a second metal backend process. The method then tunes an effective dielectric constant of a dielectric layer of the target design to match an associated capacitance of the target backend design with a corresponding capacitance of the original backend design. The method can be used to convert a backend design of an IC from an old metal process (such as Al process) to a new metal process (such as Cu process), without redesigning the IC for the new metal BEOL fabrication process.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

Apparatus adapted for membrane-mediated electropolishing

InactiveUS7566385B2Generates virtually no waste productEfficient processingCellsSemiconductor/solid-state device manufacturingElectrolysisElectrical battery

This invention provides a membrane-mediated electropolishing apparatus for polishing and / or planarizing metal work-pieces. The work-piece is wetted with a low-conductivity fluid. The wetted work-piece is contacted with a first side of a charge-selective ion-conducting membrane, wherein the second side contacts a conductive electrolyte solution in electrical contact with a electrode. Current flow between the electrode and the work-piece electropolishes metal from the work-piece. This invention also provides a half-cell adapted for use in membrane-mediated electropolishing having a fully or partially enclosed volume, a conductive electrolyte which partially or essentially fills the enclosed volume, an electrode which is in contact with the electrolyte, and a charge-selective ion-conducting membrane which seals one surface of the enclosed volume, cavity or vessel in such a way that the internal surface of said membrane contacts the electrolyte solution or gel and the external surface is accessible to contact the work-piece.

Owner:EI DU PONT DE NEMOURS & CO

Wind tower flange ring forging part for wind power equipment and manufacture method thereof

The invention discloses a wind tower flange ring forging part for wind power equipment which has stable and reliable quality and can meet the use requirement under bad environments. The wind tower flange ring forging part comprises chemical elements with following weight: C is 0.14-0.17%, Si is 0.15-0.35%, Mn is 1.35-0.80%, P is less than and equal to 0.020%, S is less than and equal to 0.015%, Cr is less than and equal to 0.10%, Ti is less than and equal to 0.15%, Cu is less than and equal to 0.20%, V is 0.05-0.10%, (O) is less than and equal to 20ppm, (H) is less than and equal to 2.0ppm, and Fe in balance amount. A manufacture method of the wind tower flange ring forging part comprises the steps of: taking a billet steel which is made by the components as raw material; discharging; forging, sheet stamping and ring rolling; heat treating; and metal working to obtain the wind tower flange ring forging part. The method is characterized in that a work piece which is obtained by forging, sheet stamping and ring rolling is rough machined and is heat treated, wherein the step of heat treating comprises heat treating and normalizing. The product can meet the requirement of large-scale wind power equipment.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS

Pretreatment process for metal coating

InactiveCN102797002AImprove adhesionImprove corrosion resistanceMetallic material coating processesAdhesion forceMetal coating

The invention provides a pretreatment process for metal coating, comprising the following steps: pre-degreasing, degreasing, water washing one, water washing two, water washing three, and water washing four. The method replaces phosphatization by vitrification, and uses a phosphate-free environment-friendly vitrification agent for performing vitrification treatment to a workpiece, without waste residue or heavy metals, more environment-friendly and convenient to process. The vitrification film formed on the surfaces of the processed metal work pieces such as steels, zinc materials, galvanizing plates, electro-zinc plates and aluminium materials can improve the adhesion force and corrosion resistance, and is suitable for the coating by various types of paints. At the same time, the pretreatment process is simplified in technology, low in energy consumption and cost for all the steps processed at room temperature.

Owner:GUANGDONG LIANSU TECH INDAL

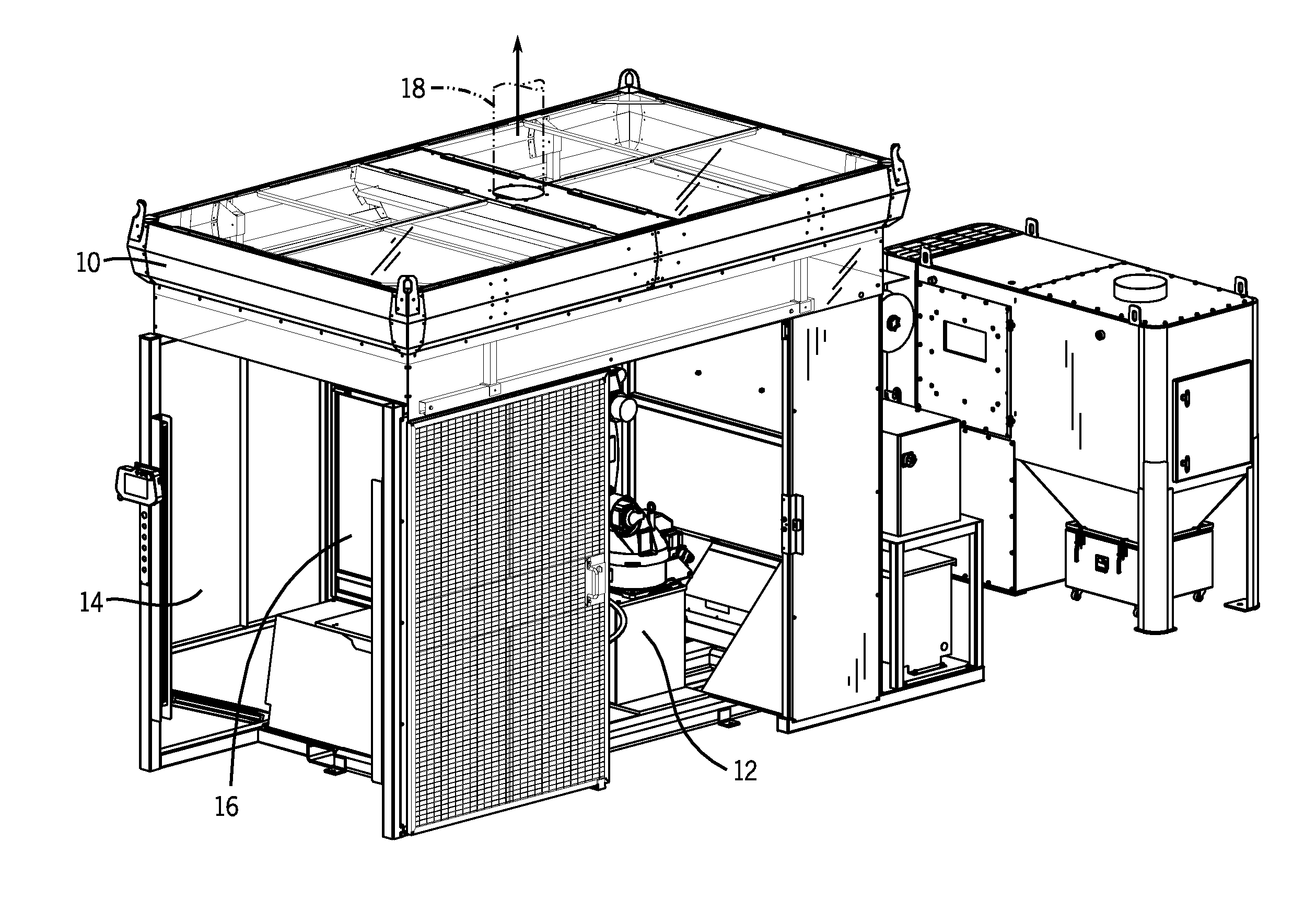

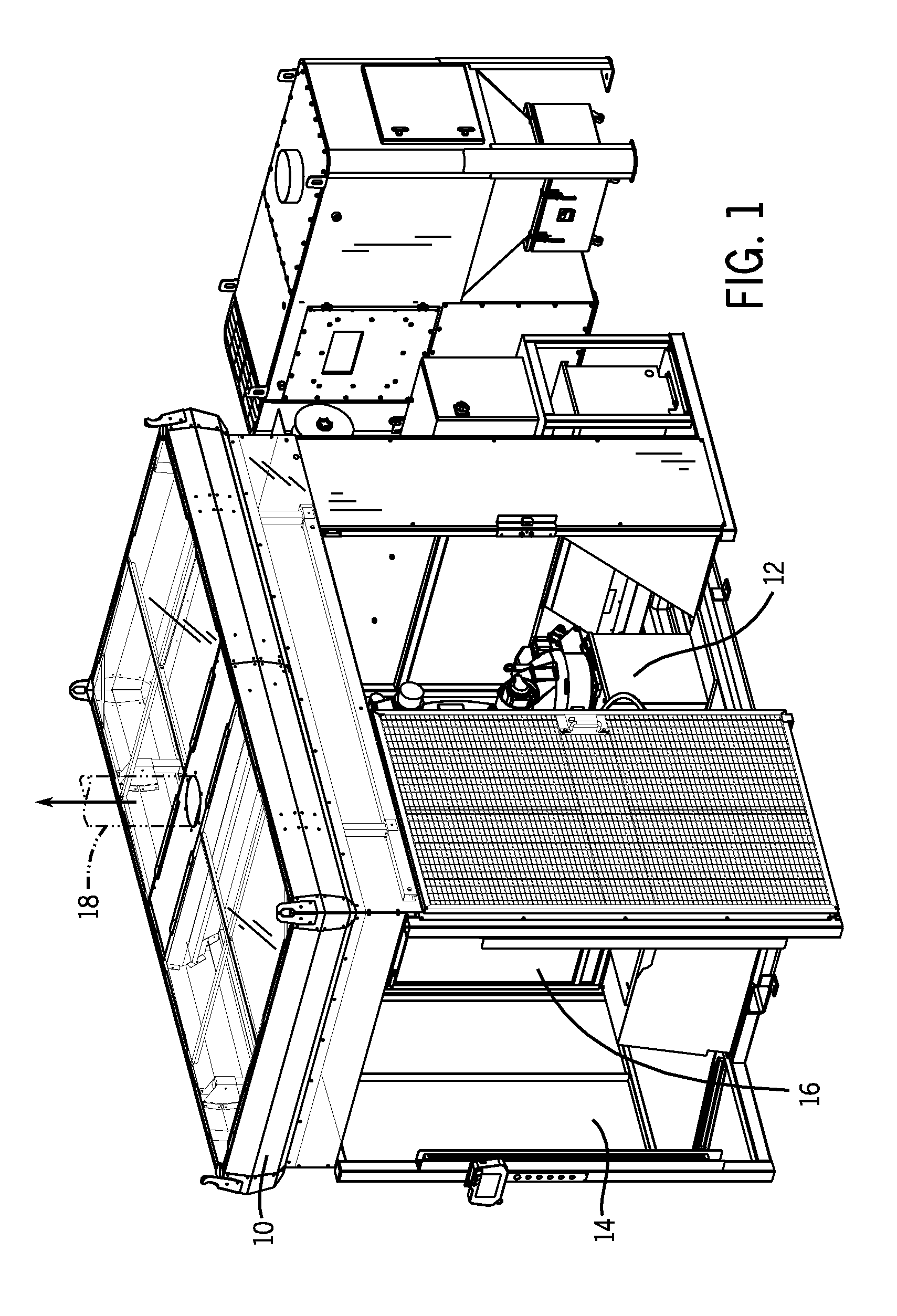

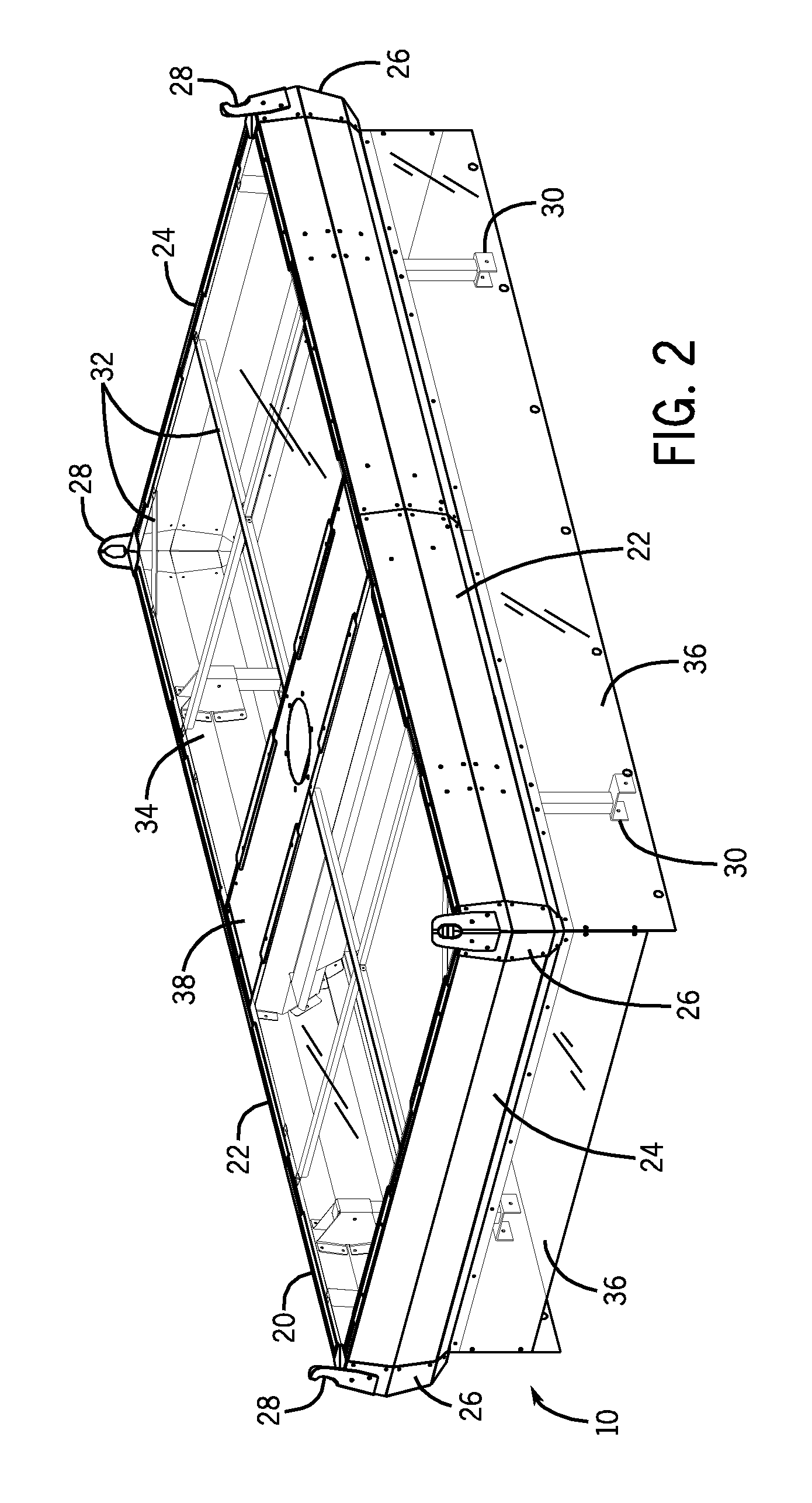

Welding fume extractor

ActiveUS20130122795A1Speed up the extraction processDomestic stoves or rangesGas current separationParticulatesEngineering

A fume extraction hood is designed to be positioned above a welding, cutting, or other metal-working location and to remove hot gases, smoke and fumes produced during these processes. The hood forms a box-like structure with an extractor rail structure disposed in an internal volume of the hood. The extractor rail structure comprises panels that force sharp turns in the gases, causing particulate matter to drop out of the gases both outside and inside the extractor rail. A primary path for gases accelerates and re-directs the gases entering into the extractor rail, and within the rail. The rail may form a dropout tray that can be removed for cleanout of collected particulate. The side and end rails of the hood may create a secondary path for gas not directly intaken into the extractor rail. This secondary path is re-directed towards the extractor rail, where gas is collected and particulate is forced to drop out as it joins the primary path.

Owner:ILLINOIS TOOL WORKS INC

Method for manufacturing composite straightening roll by overlaying

ActiveCN102430839ASurfacing less smoke and dustEasy to remove slagArc welding apparatusWelding/cutting media/materialsMetal workingMaterials science

The invention discloses a method for manufacturing a composite straightening roll by overlaying, comprising the steps of: at first, manufacturing a straightening roller body tempered by 42 CrMo; then overlaying a transitional layer which is 2-4mm thick on the straightening roller body; and then manufacturing a deposited metal working layer on the transitional layer through submerged arc overlaying. The roll surface of the straightening roll manufactured by the method for manufacturing the composite straightening roll by overlaying has the advantages of corrosion resistance, high temperature resistance, abrasion resistance and steel adhering resistance.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Wellbore servicing fluid comprising a cellulose ether

A cellulose ether having (i) one or more substituents selected from the group consisting of methyl, hydroxyethyl and hydroxypropyl, (ii) one or more hydrophobic substituents, and (iii) one or more cationic, tertiary amino, or anionic substituents, and having a retained dynamic viscosity, % η80 / 25, of at least 30 percent, wherein % η80 / 25=[dynamic solution viscosity at 80° C. / dynamic solution viscosity at 25° C.]×100, the dynamic solution viscosity at 25° C. and 80° being measured as 1% aqueous solution, is useful for modifying the viscosity of a composition selected from the group consisting of wellbore servicing fluids, cementitious formulations, ceramics, metal working fluids and cutting fluids.

Owner:UNION CARBIDE CORP

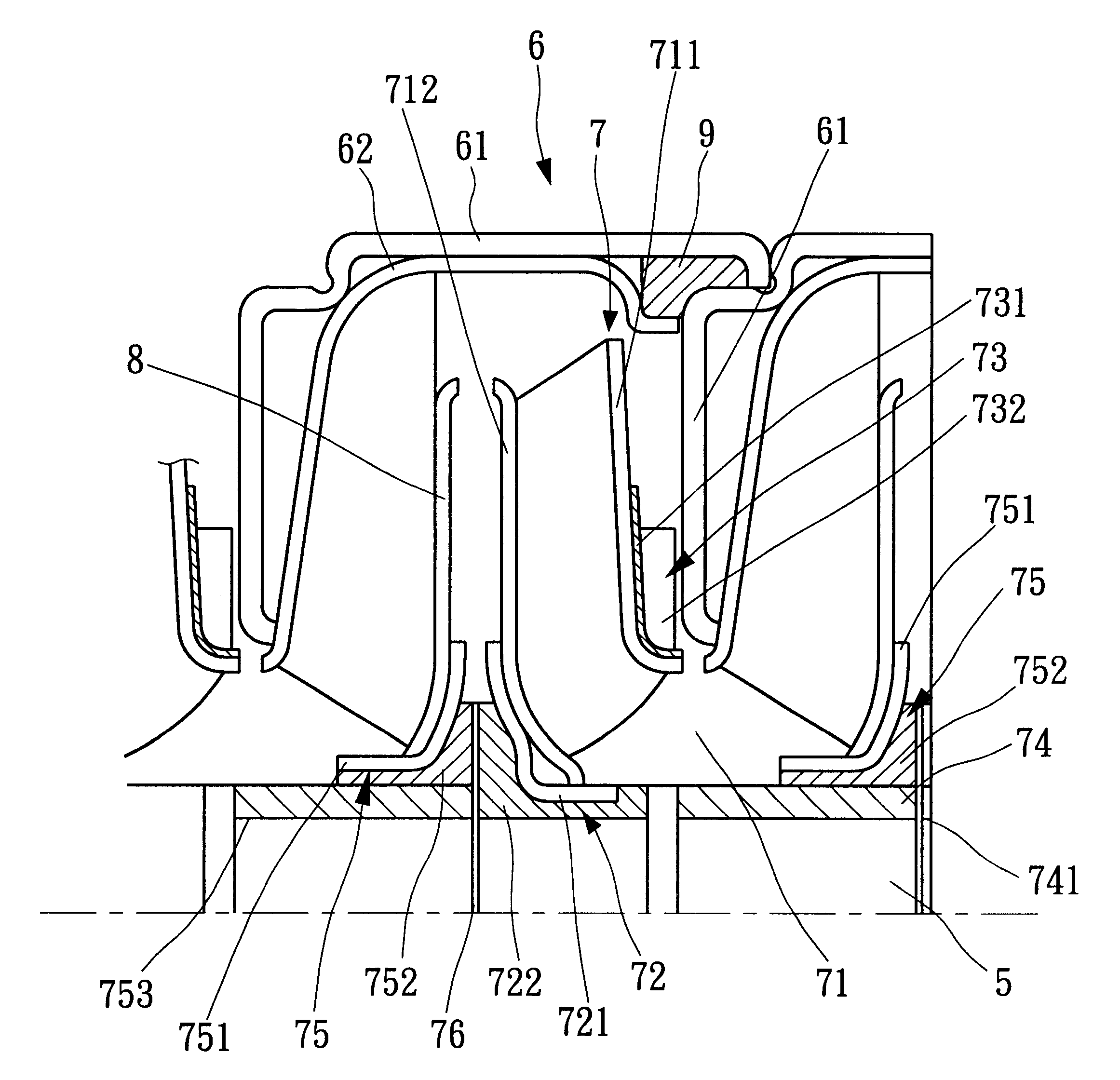

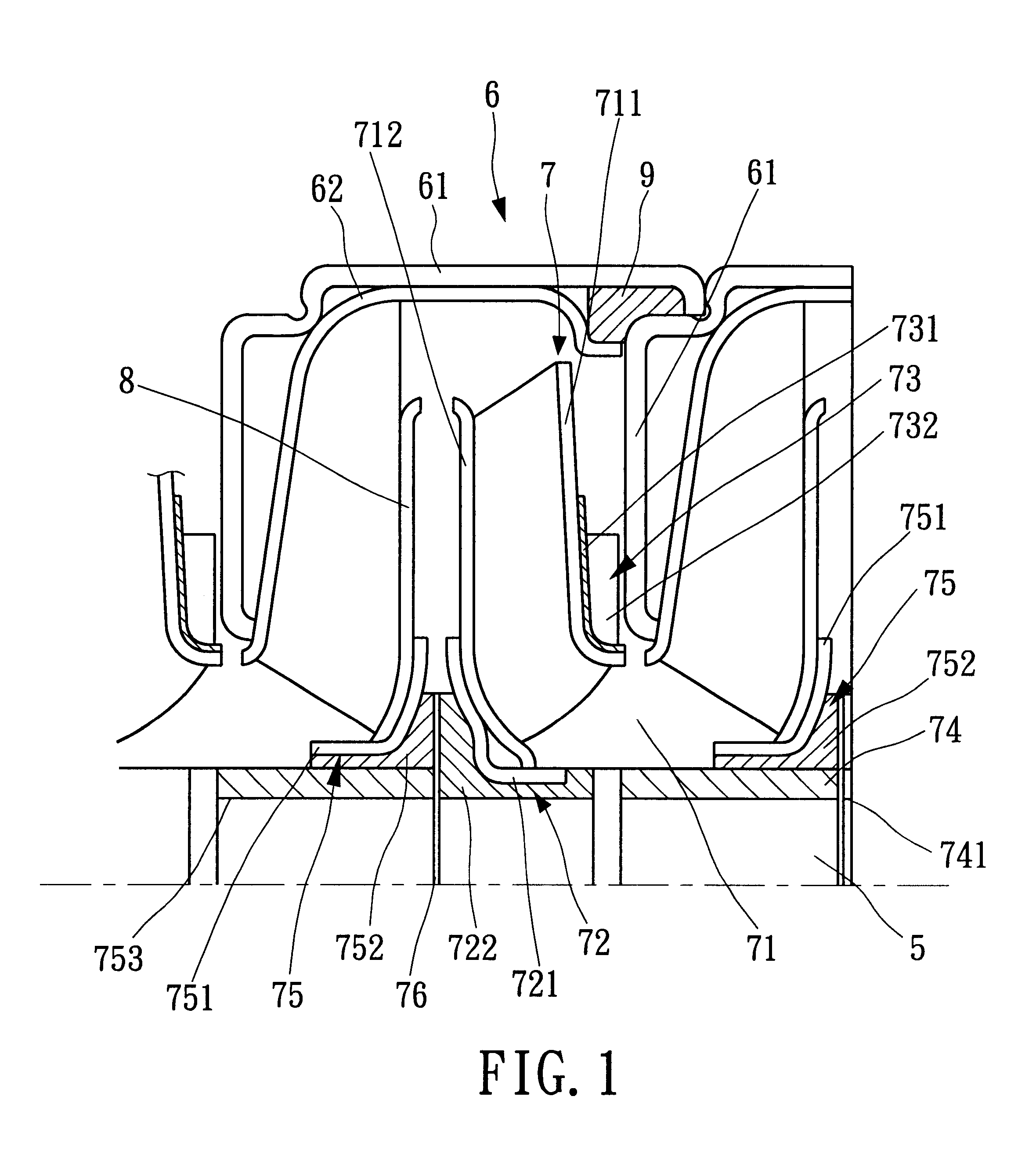

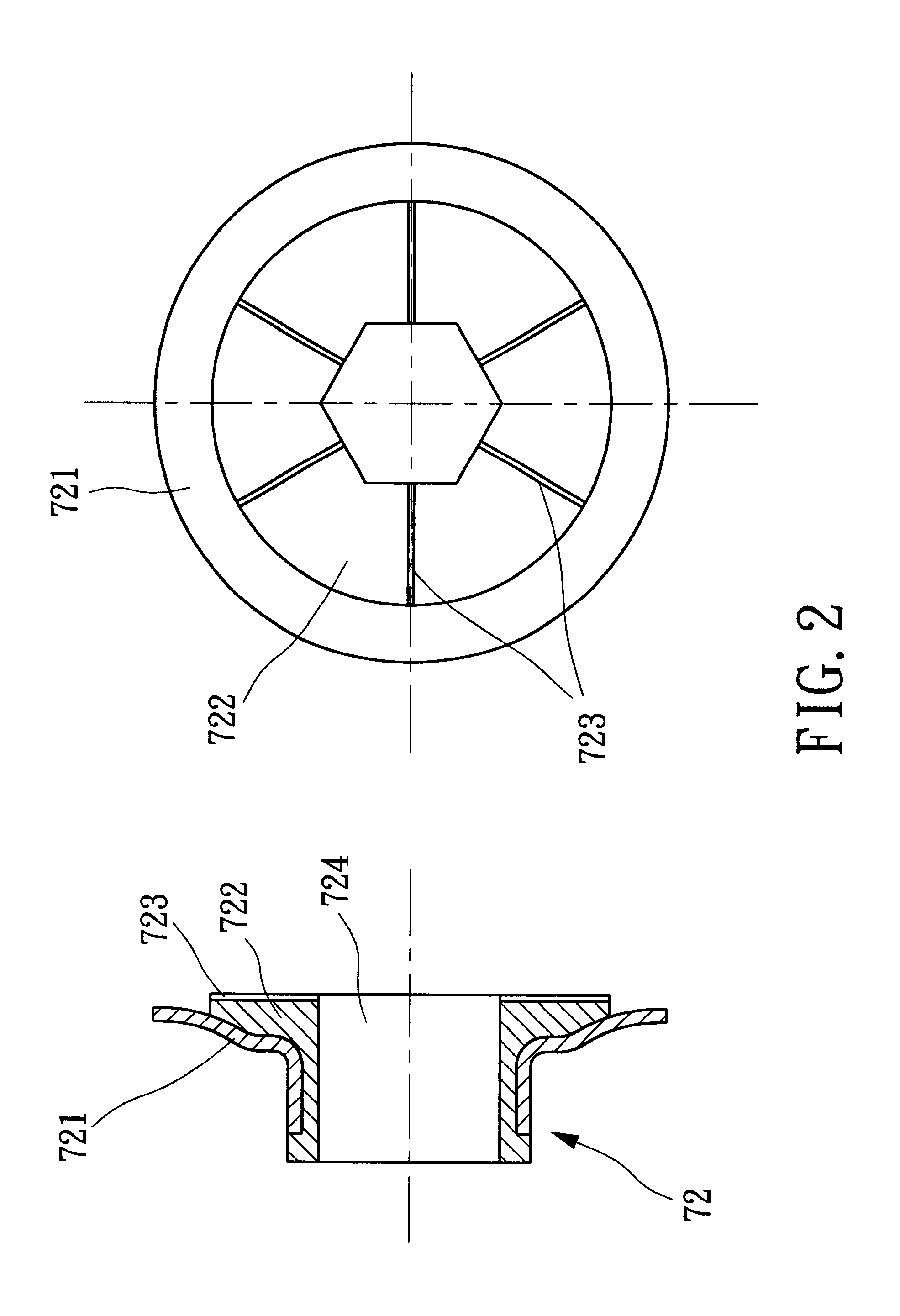

Floatable impeller for multistage metal working pump

InactiveUS6398493B1Reduce friction lossImprove pumping efficiencyPump componentsStatorsFriction reductionImpeller

A floatable impeller for multistage metal working pump includes an impeller hub which has an impeller metal working member supporting a rear wall of the impeller and an impeller plastic member integrally formed with the impeller working member. The impeller plastic member is engaged with and driven by the pump shaft. The impeller has a front wall attached with an impeller thrust ring which has a thrust metal working member integrally formed with a thrust plastic member located in front of the impeller front wall. The thrust plastic member serves as a bearing when rotating against a metallic pump shell of an adjacent pump unit for reducing friction loss. The impeller hub has axial grooves formed in the inside wall. The thrust plastic member has radial slots formed in the sidewall. The grooves and slots may collect and discharge grits and sands carried by fluid and generated by friction for reducing friction, improving pumping efficiency and enhancing pump durability.

Owner:IND TECH RES INST

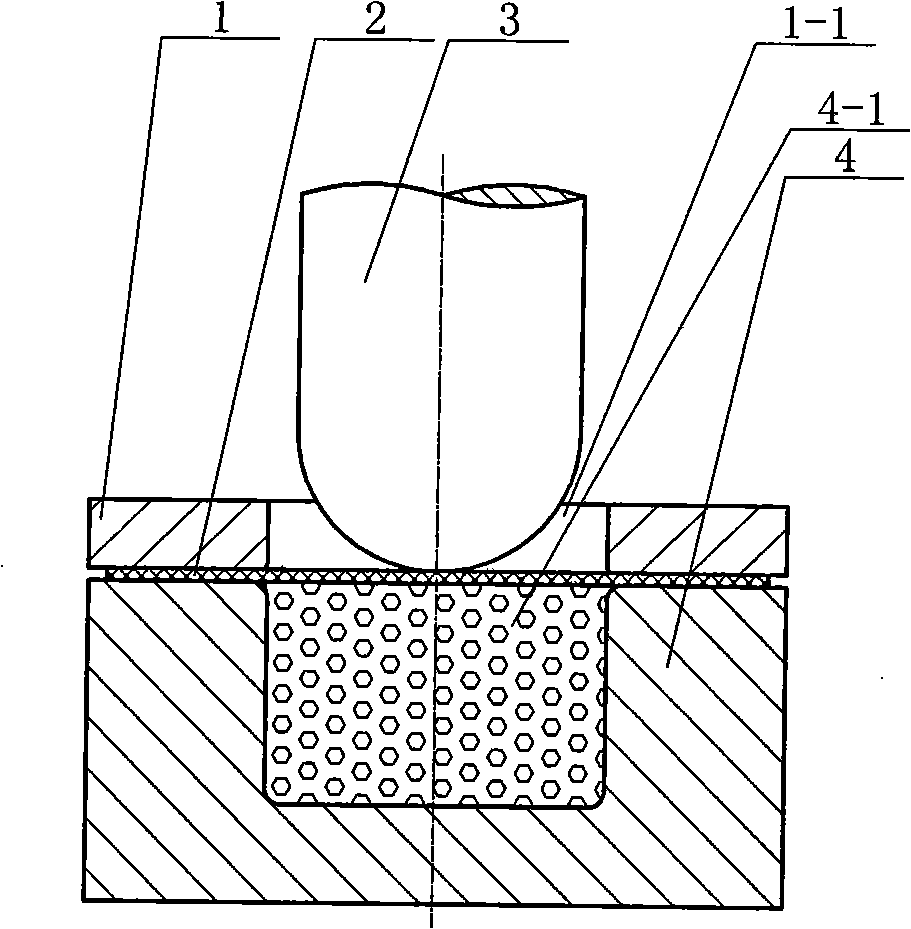

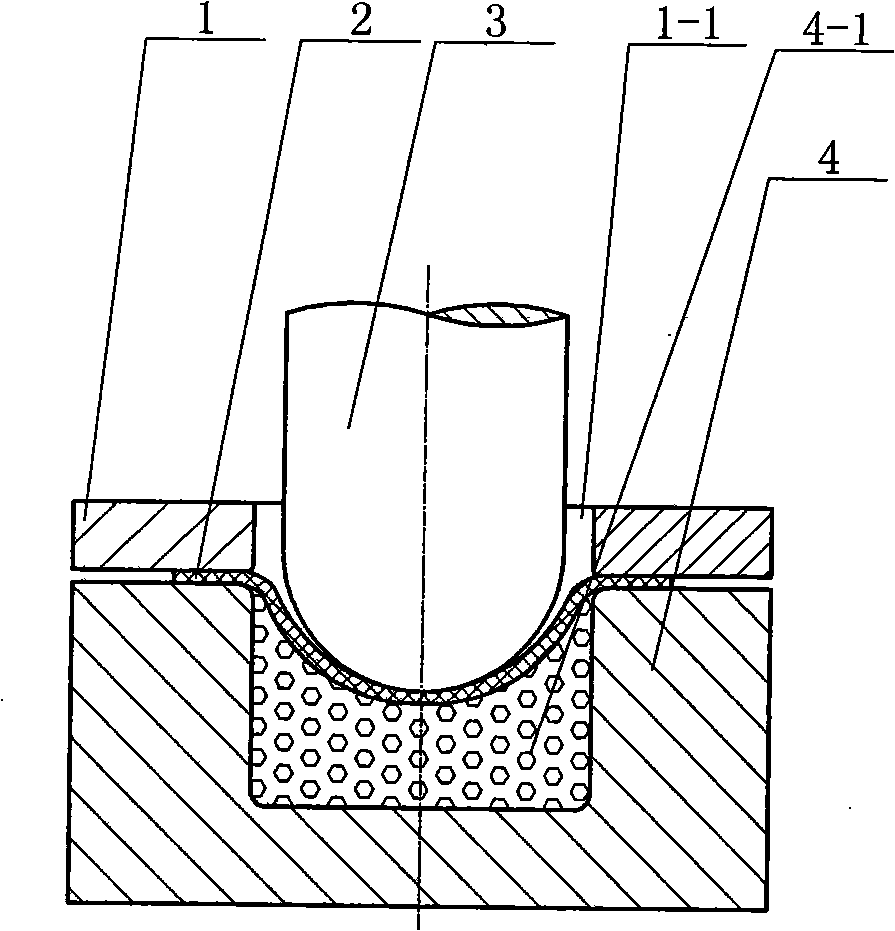

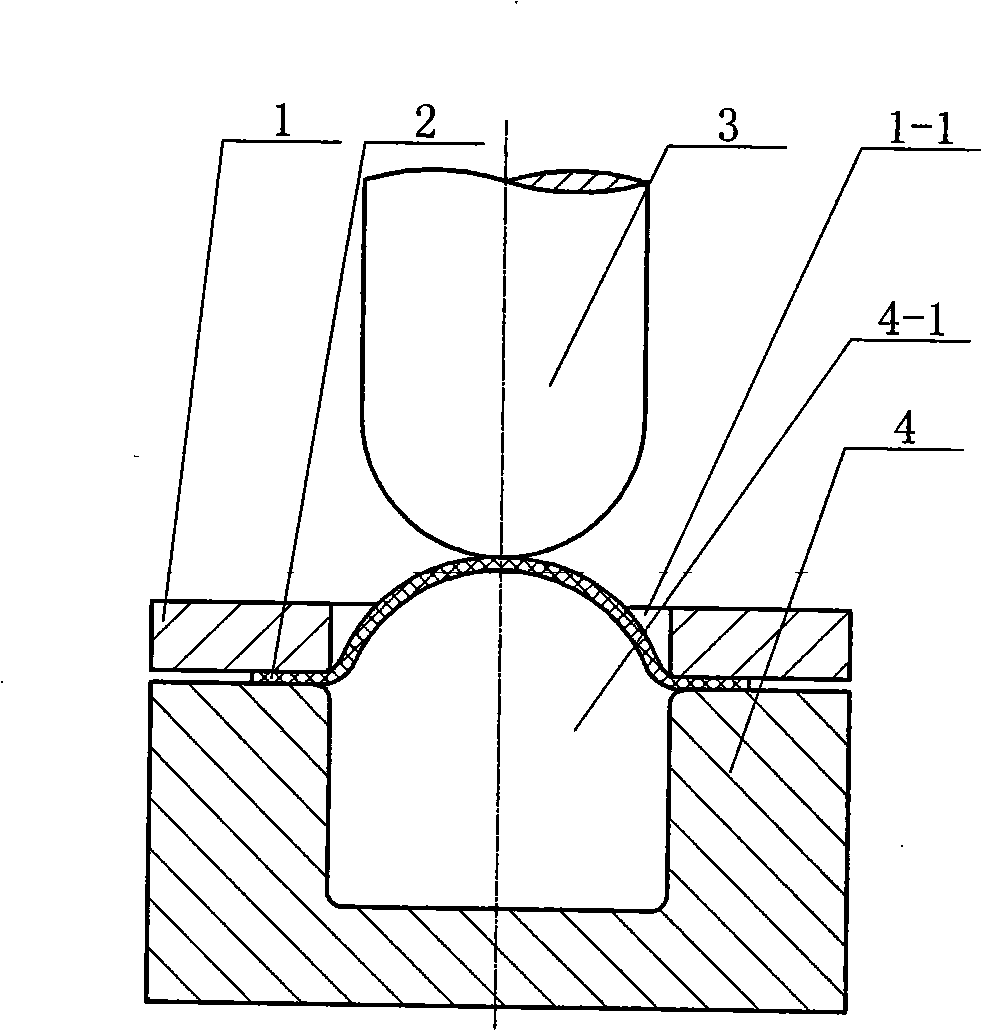

Metal processing and molding method for reducing plastic resilience

The invention discloses a metal processing and molding method that lowers plastic resilience and solves the problems that the stamping and molding process of high-intensity metal sheets is hard to satisfy molding requirements, needs large load and difficult processing due to the larger yield stress and resilience. A plate (2) is placed on a cavity die (4); a stamping ring (1) is placed on the plate (2) and stamping force is exerted; a punch (3) is moved downward to exert force, and the plate (2) is deformed and flows into a die space (4-1) of the cavity die; the punch (3) is removed; the stamping ring (1) is removed; the plate (2) is oppositely placed on the cavity die (4); the stamping ring (1) is placed on the plate (2) and the stamping force is exerted; the punch (3) is moved downward to exert force, and the plate (2) is deformed and flows into the die space (4-1) of the cavity die. The metal processing and molding method lowers the yield stress of the high-intensity metal sheets, and has the advantages of easy processing and molding, reasonable design, reliable working, remarkable effect, simple and convenient operation, easy implementation, high precision and stronger generalization value.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com