Controlled degradation differential arc oxidized metallic support and manufacture method thereof

A technology of micro-arc oxidation and metal support, applied in the direction of support, anodic oxidation, electrolytic coating, etc., can solve the problems of too fast, completely degraded within about 2 months, complex anodic oxidation process, and insufficient corrosion resistance , to achieve the effect of avoiding function reduction, degradation rate reduction and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

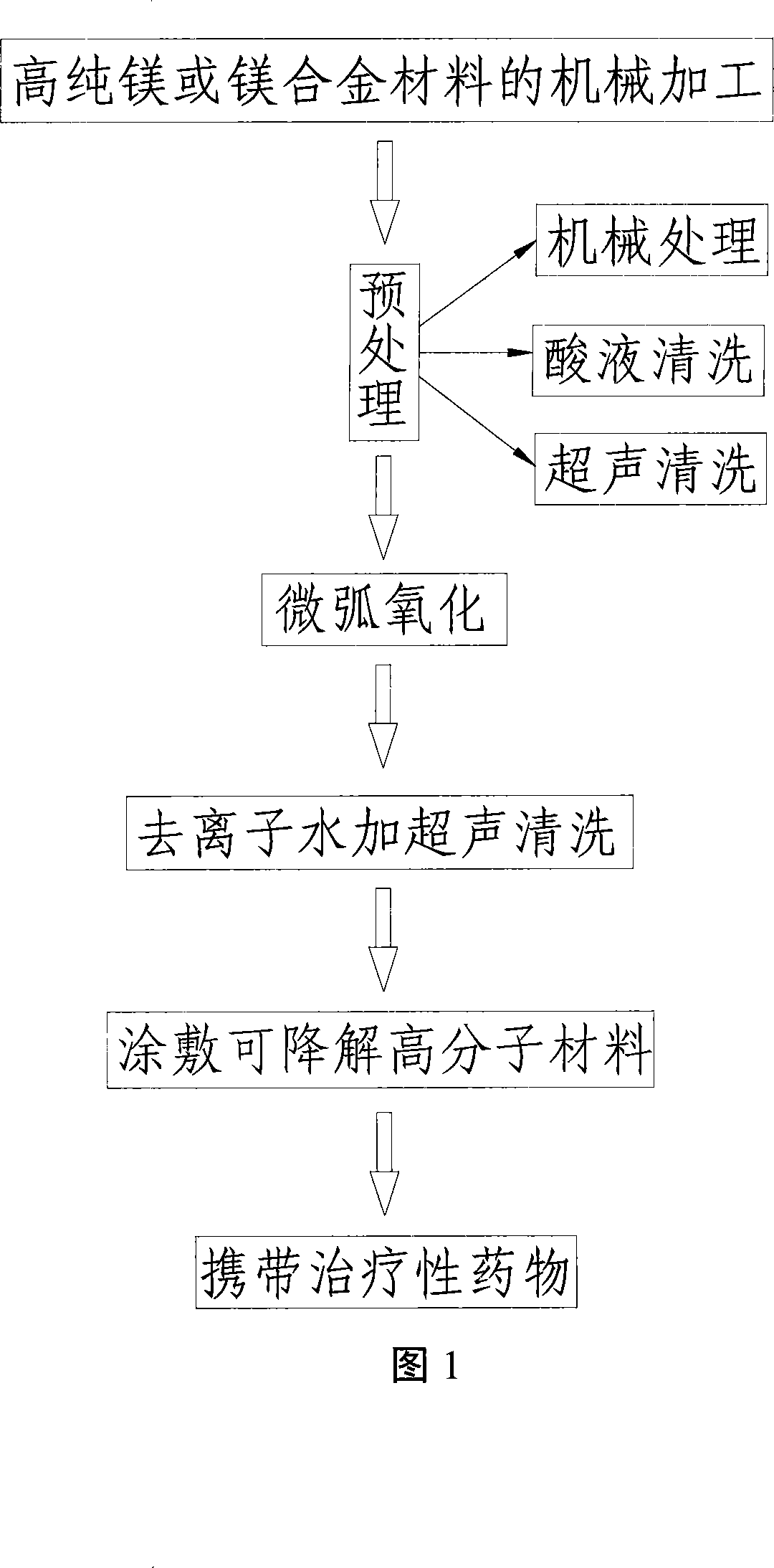

[0029] Figure 1 is a flow chart of the method for preparing a metal stent by micro-arc oxidation under controllable degradation of the present invention. The preparation method mainly includes the following steps:

[0030] (1) select degradable magnesium or magnesium alloy as the substrate of the bracket, and machine it into a bracket;

[0031] (2) Pretreating the stent to remove oxides on the surface of the stent;

[0032] (3) the support is put into the micro-arc oxidation electrolyte, the support is used as the anode of the electrolytic cell, and direct current or alternating current is passed through to carry out the micro-arc oxidation treatment, so that the surface of the support has a micro-arc oxidation film layer;

[0033] (4) cleaning the stent after the micro-arc oxidation treatment with deionized water and an ultrasonic cleaning machine in sequence;

[0034] (5) Spraying a degradable polymer material on the surface of the cleaned stent, the degradable polymer mate...

Embodiment 1

[0059] In this embodiment, the high-purity magnesium material is selected as the matrix. After the high-purity magnesium is polished, it is carved into a vascular stent with a laser; it is first polished with gradually finer sandpaper, and the oxide on the surface is mechanically removed; then it is immediately immersed in chromic acid with a mass concentration of 80g / L solution, pickling at 80°C for 10 minutes; then place the magnesium metal bracket in a KQ-700DA table-top numerical control ultrasonic cleaning machine, and clean it at a frequency of 60kHz for 15 minutes.

[0060] Utilizing ultrasonic waves to clean the surface of the stent should include steps: (1) using a concentration of 75% medical ethanol solvent to clean for 5 minutes; (2) using a concentration of 99.5% acetone analytically pure solution to clean for 5 minutes; (3) using deionized Wash with water for 5 minutes. Finally, place the cleaned magnesium alloy stent in a dryer to dry.

[0061] Then put the bra...

Embodiment 2

[0066] After the AZ91D magnesium alloy is polished, it is laser engraved into a vascular stent. First sand with progressively finer sandpaper to remove surface oxides. Immediately immerse in a chromic acid solution with a mass concentration of 100g / L, and pickle at 100°C for 10 minutes. Then place the magnesium metal bracket in the ultrasonic cleaning pool of KQ-700DA and clean it for 15 minutes at a frequency of 80 kHz. Cleaning the surface of the stent by ultrasonic waves should include (1) cleaning with a medical ethanol solvent with a concentration of 75% for 5 minutes; (2) cleaning with acetone analytically pure solution with a concentration of 99.5% for 5 minutes; (3) cleaning with deionized water 5 minutes. Finally, place the cleaned stents in a dryer to dry.

[0067] Then put the bracket in the electrolyte, take two identical magnesium alloy brackets as the cathode and anode of the electrolytic cell, and conduct micro-arc electrodeposition on the surface of the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com