Patents

Literature

255results about How to "Reduce the degradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled degradation magnesium alloy coating bracket and preparation thereof

InactiveCN101214396AImprove mechanical propertiesExcellent pharmacological propertiesAnodisationStentsSurface cleaningPolymer chemistry

The invention relates to a controlled degradation magnesium alloy coating stent and a preparation method. The stent body is made of medical high purity magnesium or magnesium alloy by mechanical processing or laser carving; the stent body is provided with a drug-loading coating which bears curative drug; the surface of the stent body is provided with an anti-corrosive coating; the surface of the anti-corrosive coating is provided with a degradable polymer film drug-loading coating; the preparation method includes surface cleaning, preparation of the degradable polymer film drug-loading coating, and application of curative drug; through (1)surface cleaning, (2)preparation of the degradable polymer film drug-loading coating, and (3)application of curative drug, an oxide film is formed on the surface; different drugs and dosage can be fixed by regulating the molecular weight and the thickness of the polymer layer, the drug-loading quantity is more than 30 percent, which improves the fixed stability of the drug, greatly reduces the degradation speed of the magnesium alloy and controls release of the drug, delays corrosion of the magnesium alloy, extends the service life of the stent, is safe in use, and meets the clinical requirement.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

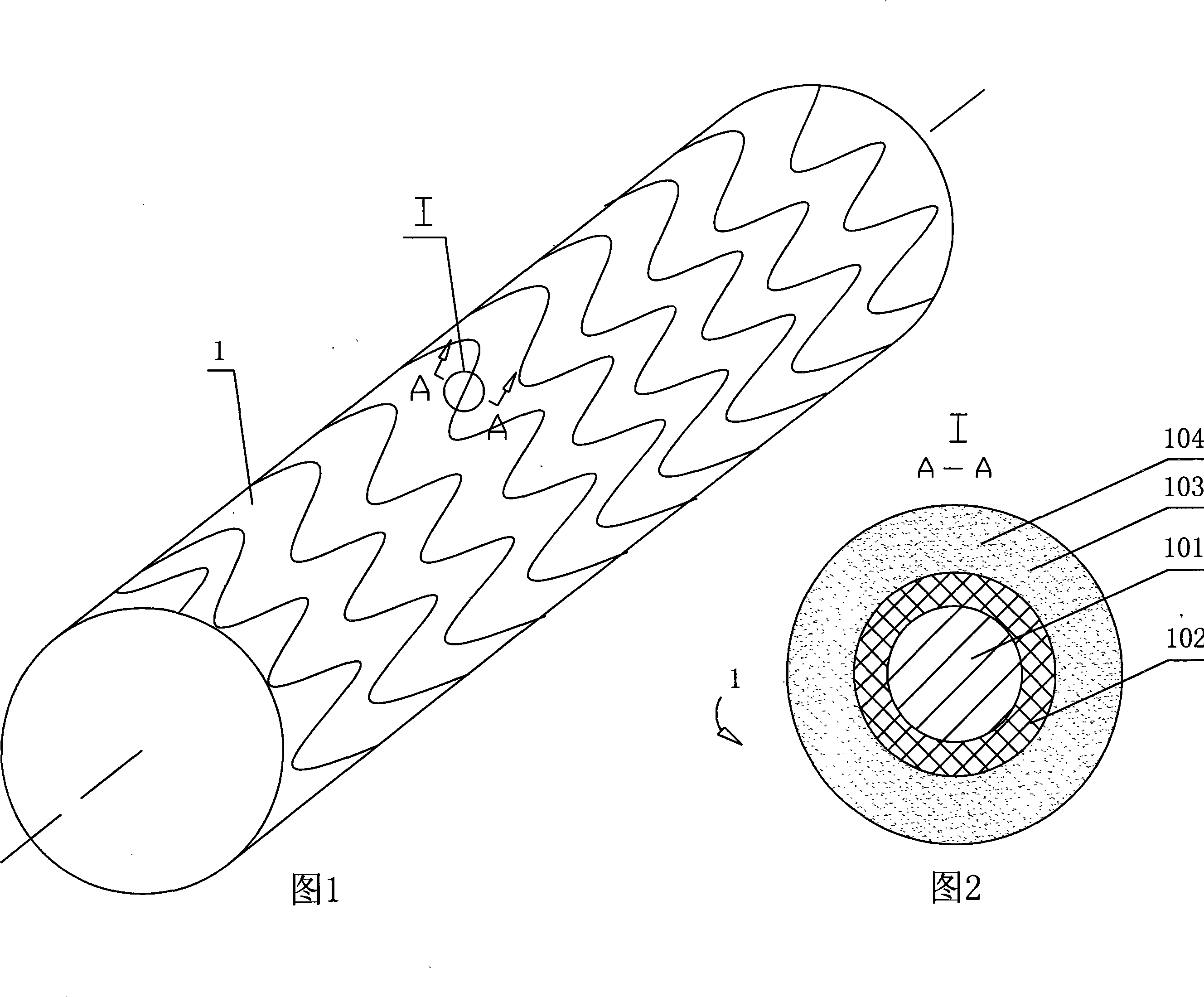

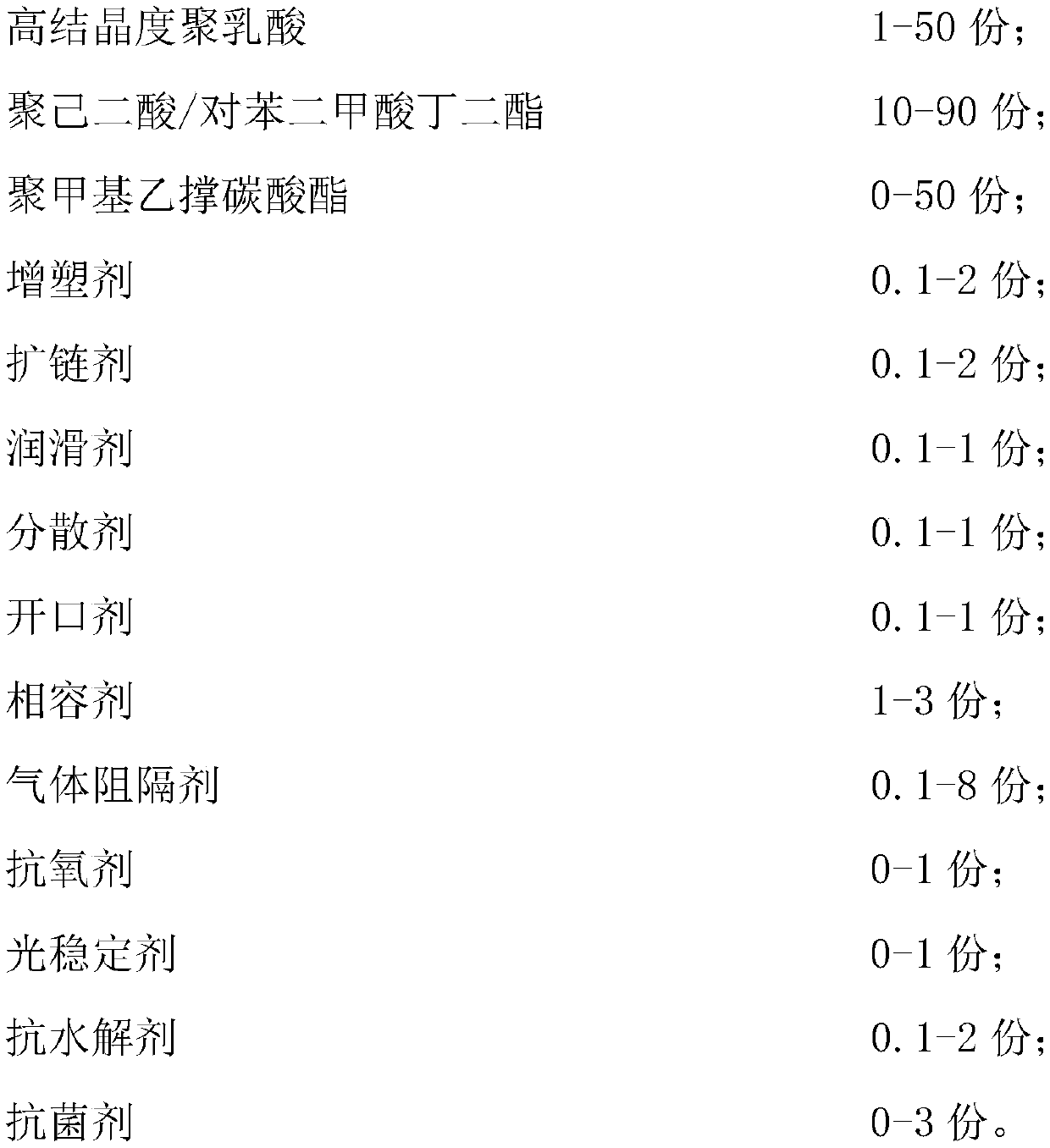

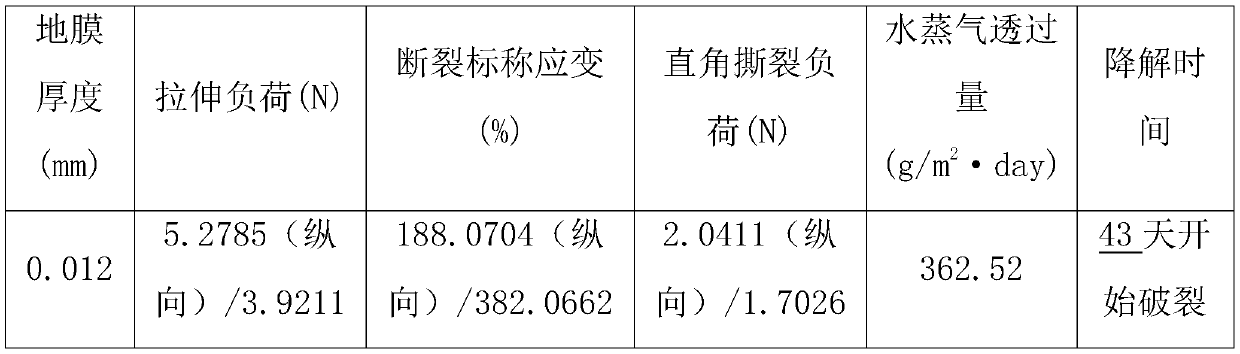

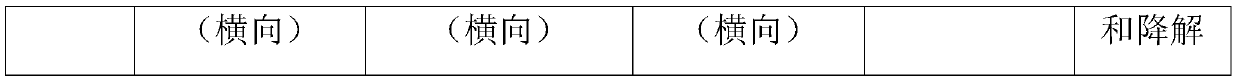

Controllable fully biodegradable mulching film and preparation method thereof

InactiveCN110330773AHigh water vapor barrierHigh tensile strengthClimate change adaptationPlant protective coveringsPolymer sciencePolybutylene

The invention belongs to the technical fields of biodegradable material modification and application, and relates to a controllable fully biodegradable mulching film and a preparation method thereof.The controllable fully biodegradable mulching film comprises the following raw materials in parts by weight: 1-50 parts of high-crystallinity polylactic acid, 10-90 parts of polybutylene adipate / butylene terephthalate, 0-50 parts of poly propylene carbonate, 0.1-2 parts of a plasticizer, 0.1-2 parts of a chain extender, 0.1-1 part of a lubricant, 0.1-1 part of a dispersant, 0.1-1 part of an opening agent, 1-3 parts of a compatibilizer, 0.1-8 parts of a gas barrier, 0-1 part of an antioxidant, 0-1 part of a light stabilizer, 0.1-2 parts of an anti-hydrolysis agent and 0-3 parts of an antibacterial agent. The raw materials are pretreated and uniformly mixed, the controllable fully biodegradable mulching film is obtained by extrusion and blow molding, and the thickness of the mulching film is0.005 to 0.020 mm. The fully biodegradable mulching film provided by the invention has good mechanical properties, excellent heat preservation and moisture retention performance, and can be completely degraded by itself; the mulching film degradation rate can be regulated according to the 'mulching film function period' of different crop mulching films in different regions to meet the needs of different crops in different regions.

Owner:深圳利峰达科技发展有限公司

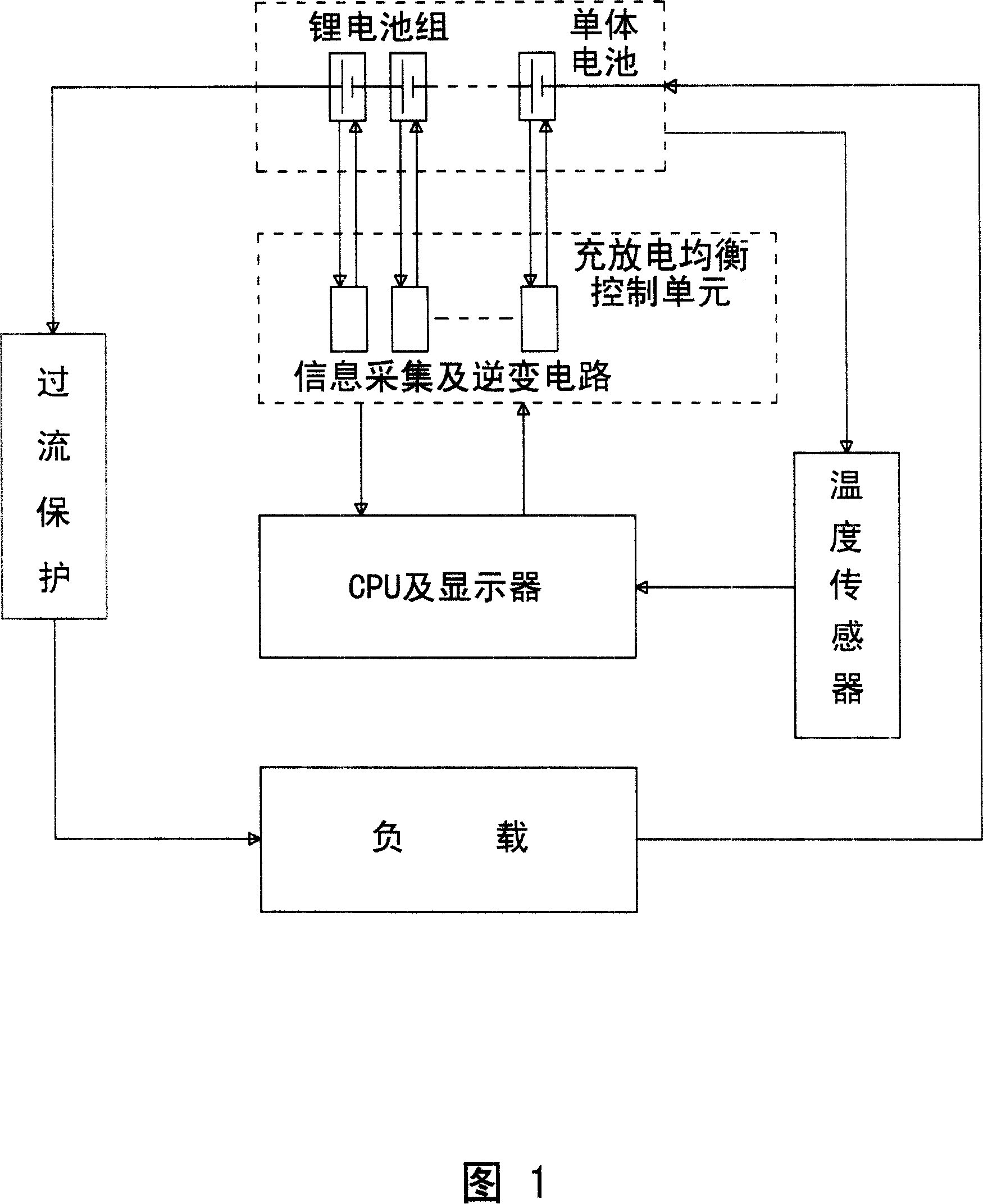

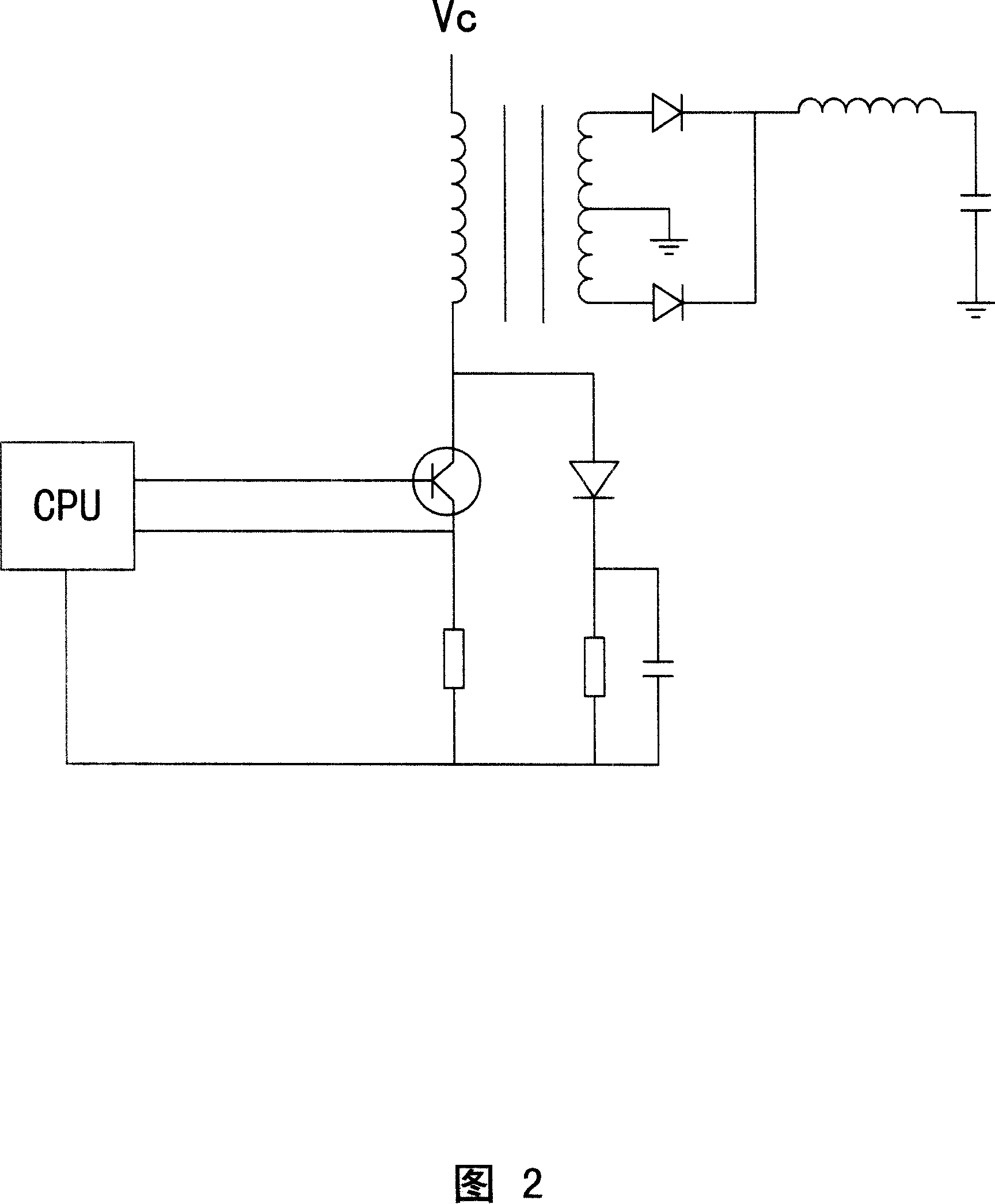

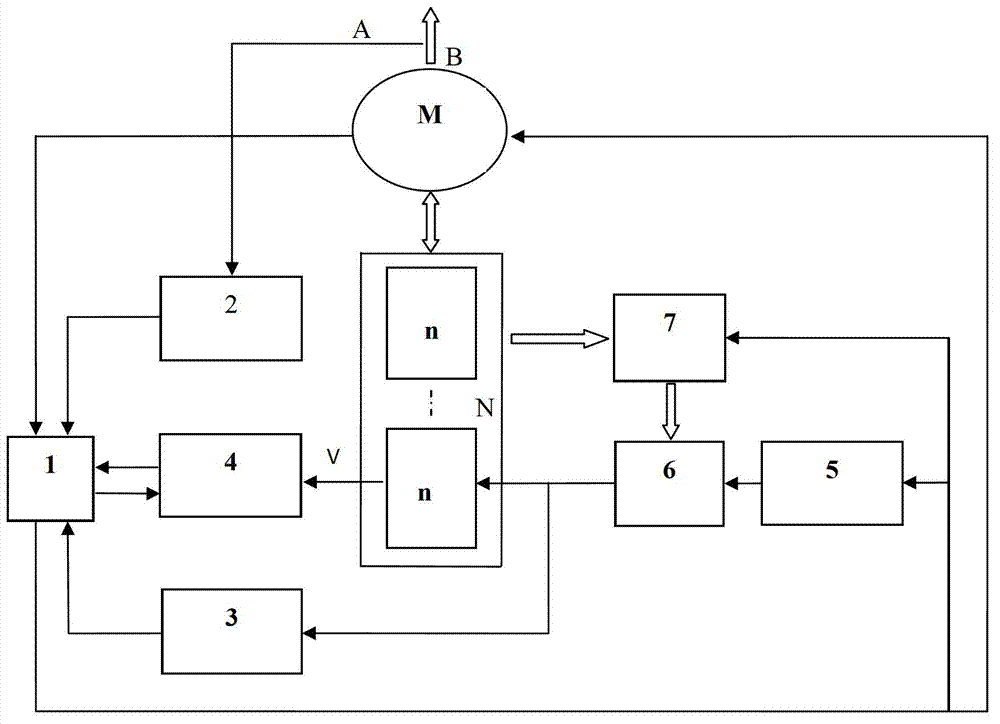

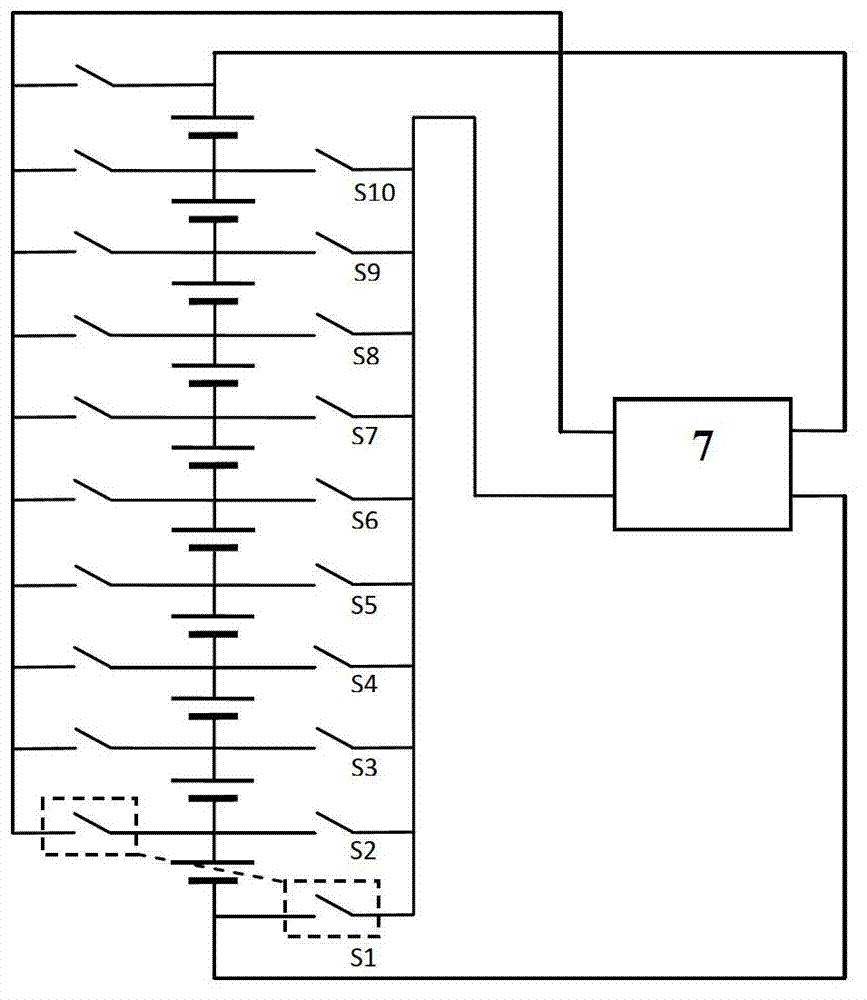

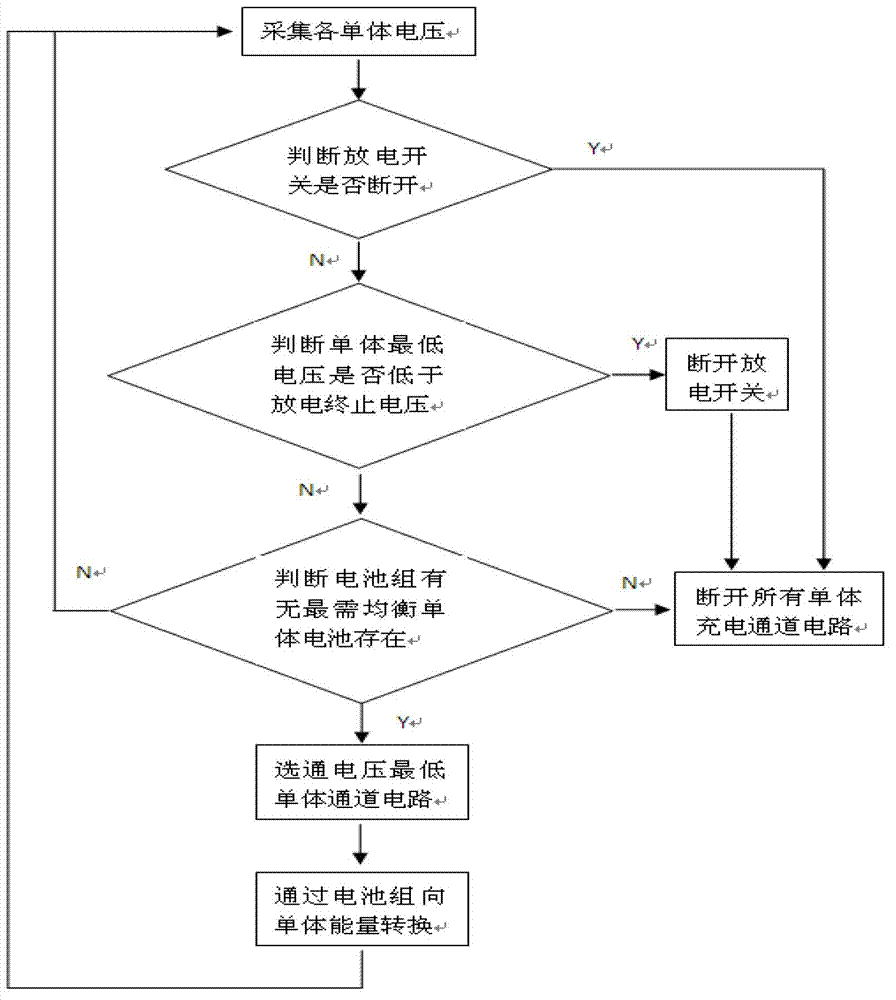

Charging-discharging automatic balancing method for serial power lithium battery

InactiveCN101026307ASlow down the rate of degradationNo overchargingBatteries circuit arrangementsSecondary cells charging/dischargingSystem safetyCharge and discharge

The invention regards each single battery in cascaded battery set (CBS) as a small heart. Only when each small heart is normal, integral heart combination can work effectively. Based on the comprehension, the invention sets up a control unit for balanced charging and discharging (CUBCD) for each single battery in CBS so as to form one to one mode to control each single battery in CBS. In parallel charging mode, being controlled by CUBCD, the invention charges each single battery. In discharging operation, being monitored by CUBCD, the invention activates inverter circuit to complement charging operation according to magnitude of energy needed by using energy of battery set self if over discharging occurs on a single battery. Harmonizing charging and discharging operations, the invention keeps synchronous charging and discharging operation among batteries so as to guarantee safe operation of system, prolong service life of battery set.

Owner:苏州市三环技贸有限公司

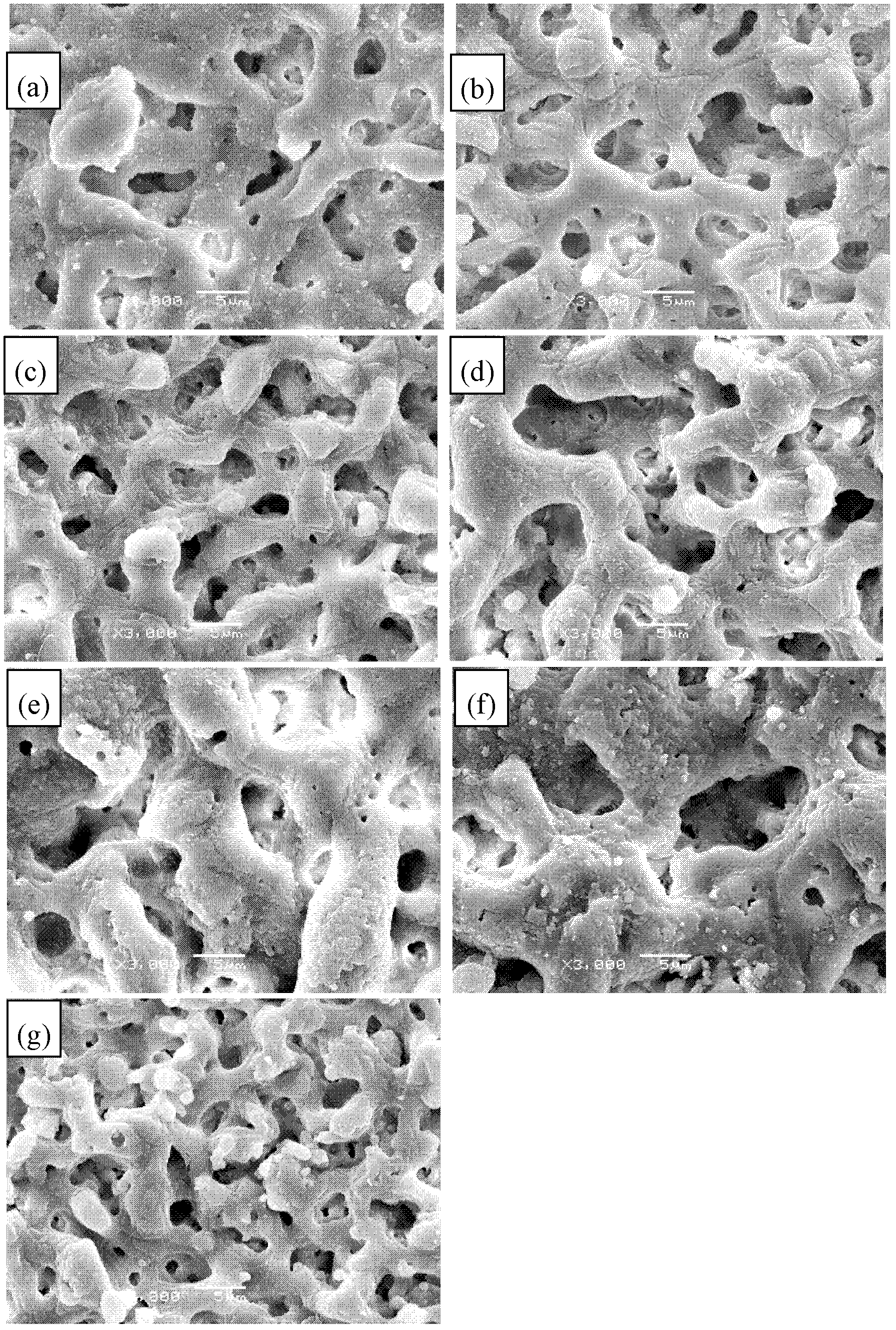

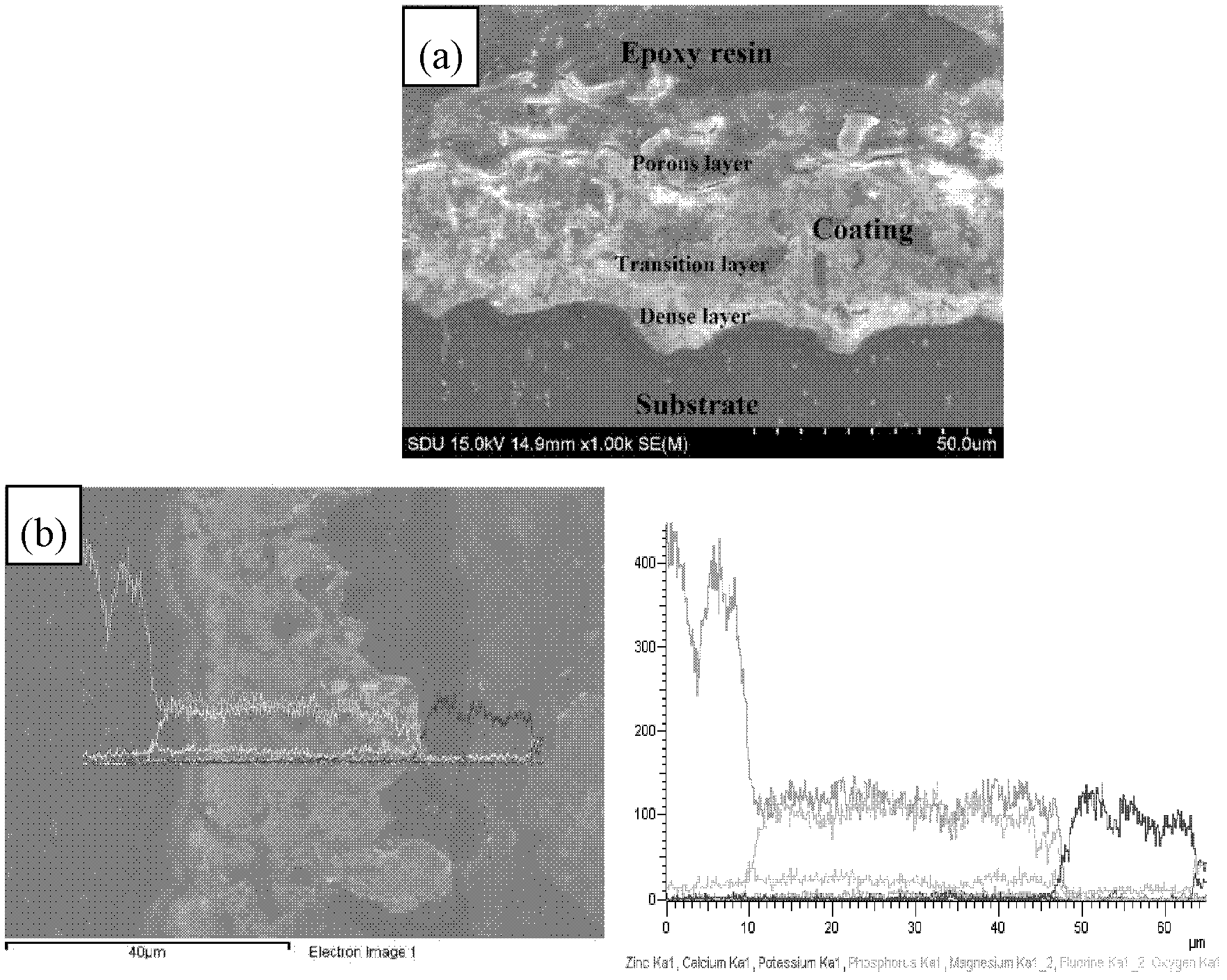

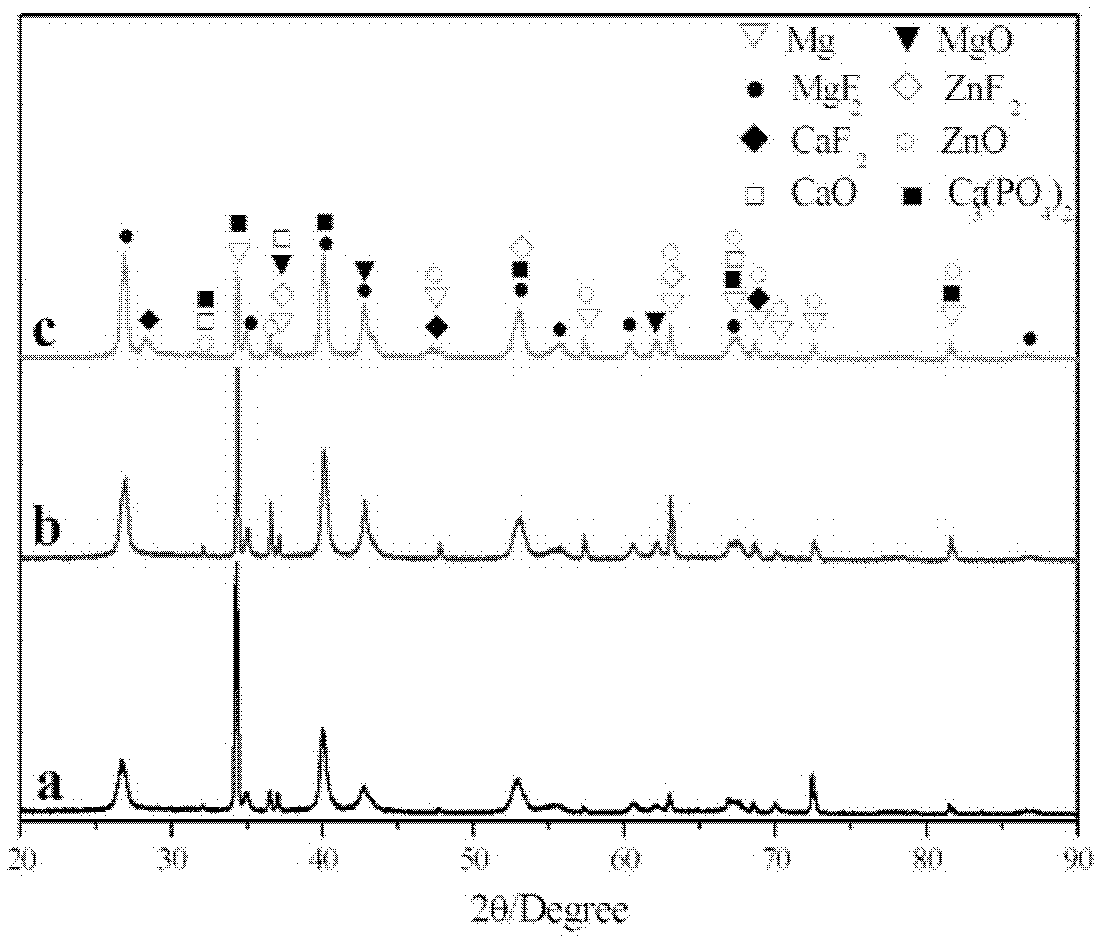

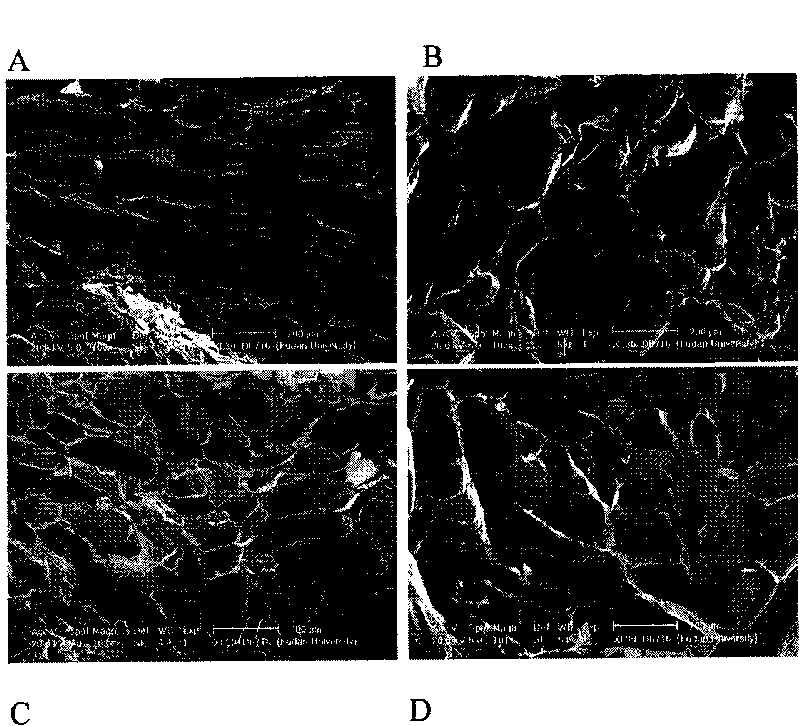

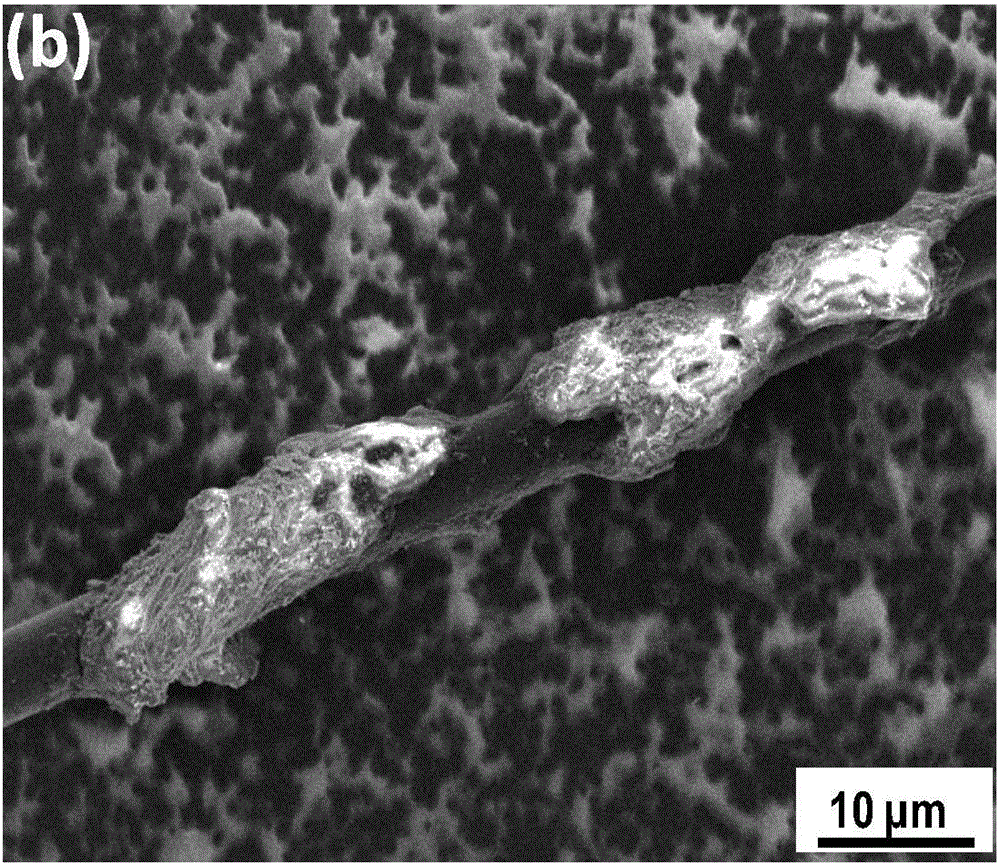

Preparation method of biological ceramic coating rich in calcium and phosphate phases on surface of magnesium alloy

ActiveCN102220620AHigh hardnessHigh densityAnodisationPhosphatisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a preparation method of a biological ceramic coating rich in calcium and phosphate phases on the surface of magnesium alloy, comprising the following steps of: adding (C6H5O7)2Ca3.4H2O and Na3PO4 to deionized water, and simultaneously adding KOH, NH4HF2, N(CH2CH2OH)3, C3H8O3 and H2O2 to prepare an electrolyte with a certain concentration ratio of calcium and phosphate; disposing the magnesium alloy in the electrolyte as an anode which is prepared through micro arc oxidation energization reaction. The calcium-phosphate ceramic coating obtained by the preparation methodconsists of three layers of a loose layer, a transition layer and a compact layer, wherein the surface of the loose layer consists of a plurality of uniformly distributed micropores, the transition layer is between the loose layer and the compact layer, and the compact layer and a substrate body form good metallurgical bonding; therefore, the coating has high rigidity, high density, high bonding force and good corrosion resistance and abrasion resistance; simultaneously, the mouse acute systemic toxicity test indicates that the coating has good biocompatibility, and the simulated body fluid soaking test indicates that the coating has good biological activity.

Owner:SHANDONG UNIV

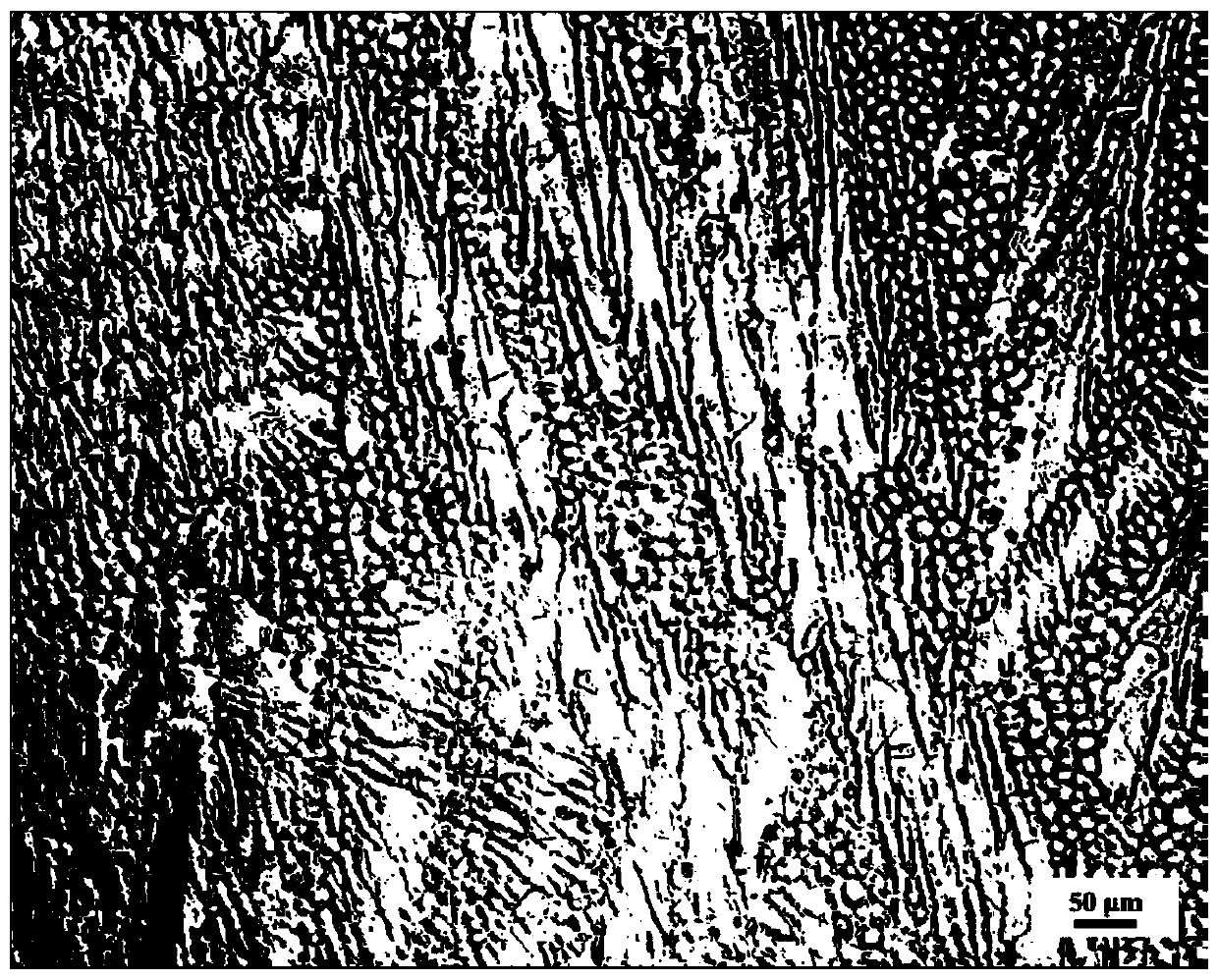

Magnesium Alloy With Adjustable Degradation Rate

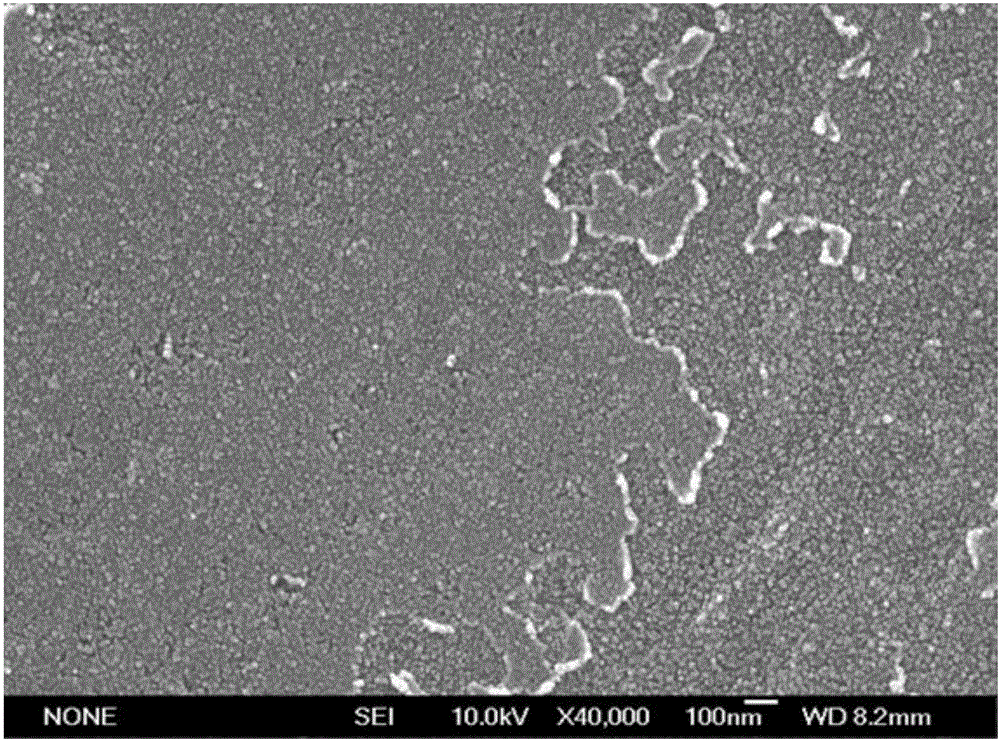

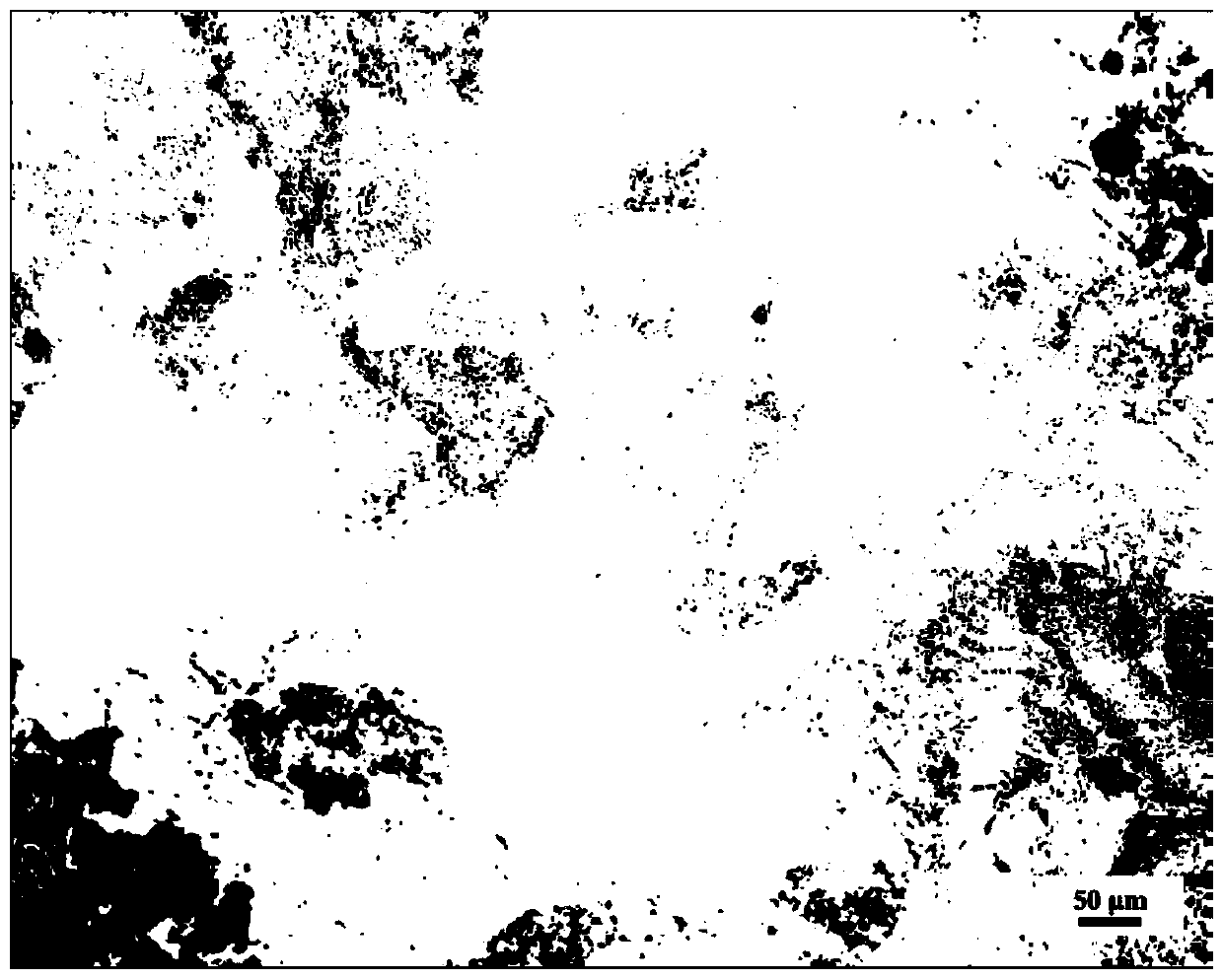

ActiveUS20140261911A1Reduce the degradation rateSurgeryPharmaceutical delivery mechanismMg alloysGrain structure

An alloy and an implant having a three-dimensional structure based on such alloy. The alloy comprises a MgZnCa alloy containing nanosized precipitates being less noble than the Mg matrix alloy and having a Zn content ranging 0.1 wt. % Zn to 2 wt. % Zn and a calcium content ranging from 0.2 wt. % to 0.5 wt. %, and having less than 0.04 wt. % of one or more other elements with the remainder being Mg. For these micro-alloys, any second phase generated during the solidification process can be completely dissolved by a solution heat treatment. Finely dispersed nanosized precipitates can then be generated by a subsequent aging heat treatment step. These precipitates are used to “pin” the grain boundaries and to prevent the coarsening of the grain structure during further processing to achieve grain sizes below 5 μm.

Owner:DEPUY SYNTHES PROD INC

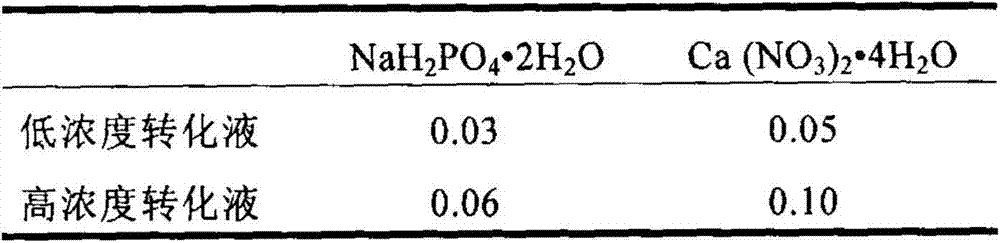

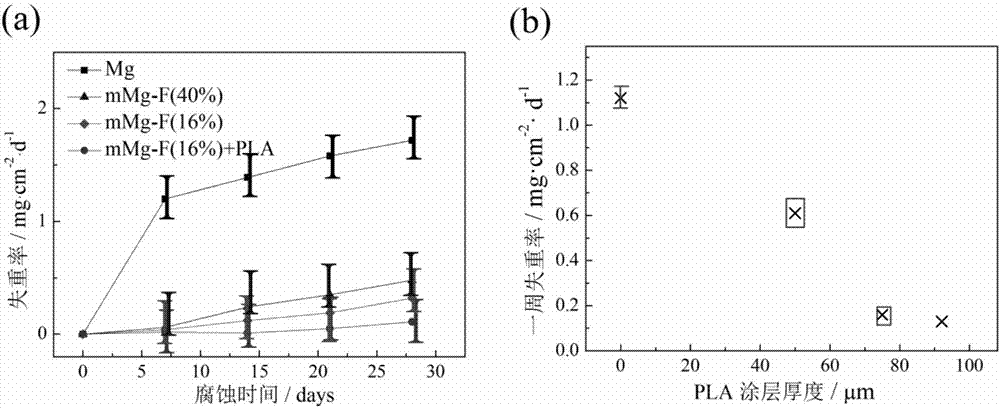

Preparation method of hydroxyapatite/polylactic acid composite coating on surface of medical magnesium alloy

InactiveCN103933611AHigh strengthReduce corrosion ratePretreated surfacesMetallic material coating processesAcid etchingCalcium nitrate tetrahydrate

The invention relates to a preparation method of a hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy, which comprises the following steps of polishing a magnesium alloy basal body to remove an oxidation layer on the surface; carrying out acid etching pretreatment and neutralizing treatment on the magnesium alloy basal body; preparing transfer solution from sodium dihydrogen phosphate dihydrate and calcium nitrate terahydrate; preparing a biomimetic calcium-phosphate coating; dissolving polylactic acid in a chloroform solvent to prepare polylactic acid solution; immersing the prepared magnesium alloy / hydroxyapatite composite material in the polylactic acid solution, and coating the polylactic acid coating on the surface of the magnesium alloy / hydroxyapatite composite material by adopting the solution dip-coating method; and putting the magnesium alloy material for 2-3 days till chloroform in the polylactic acid solution is completely volatilized, thereby obtaining the composite material of which the surface of magnesium alloy is wrapped with the hydroxyapatite / polylactic acid composite coating. Compared with the prior art, the preparation method of the hydroxyapatite / polylactic acid composite coating on the surface of medical magnesium alloy overcomes the disadvantages of the single coating, and therefore, the corrosion resistance and the biocompatibility of magnesium alloy are obviously increased.

Owner:TONGJI UNIV

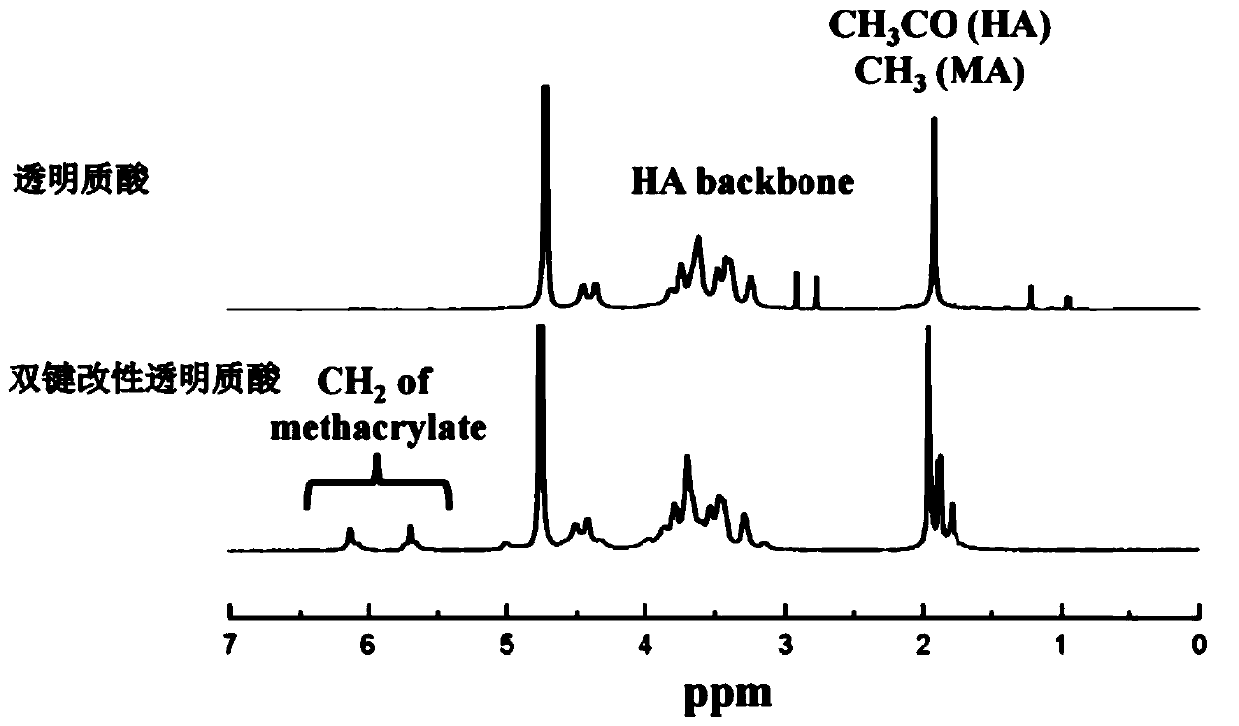

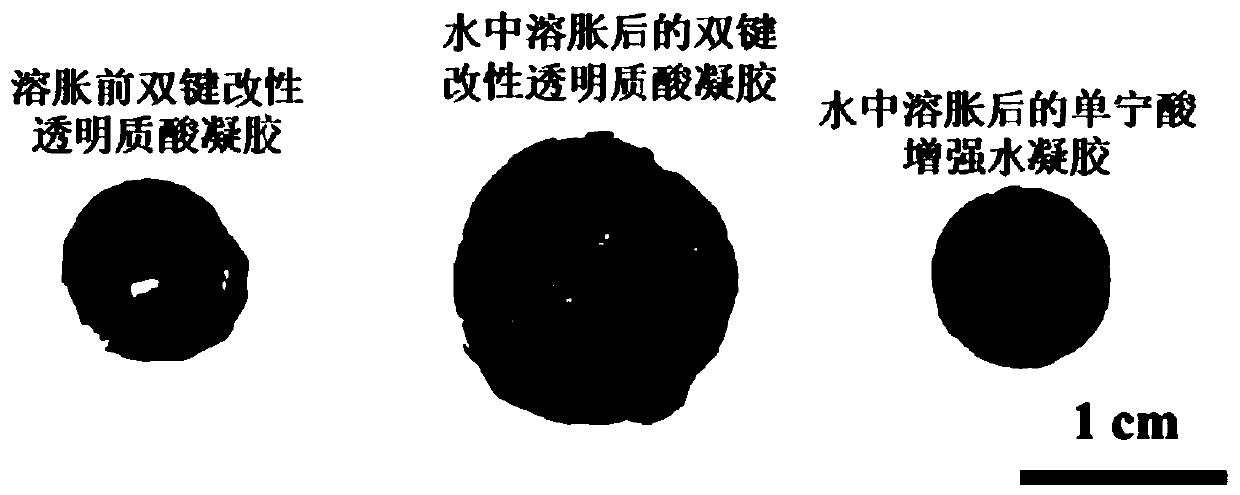

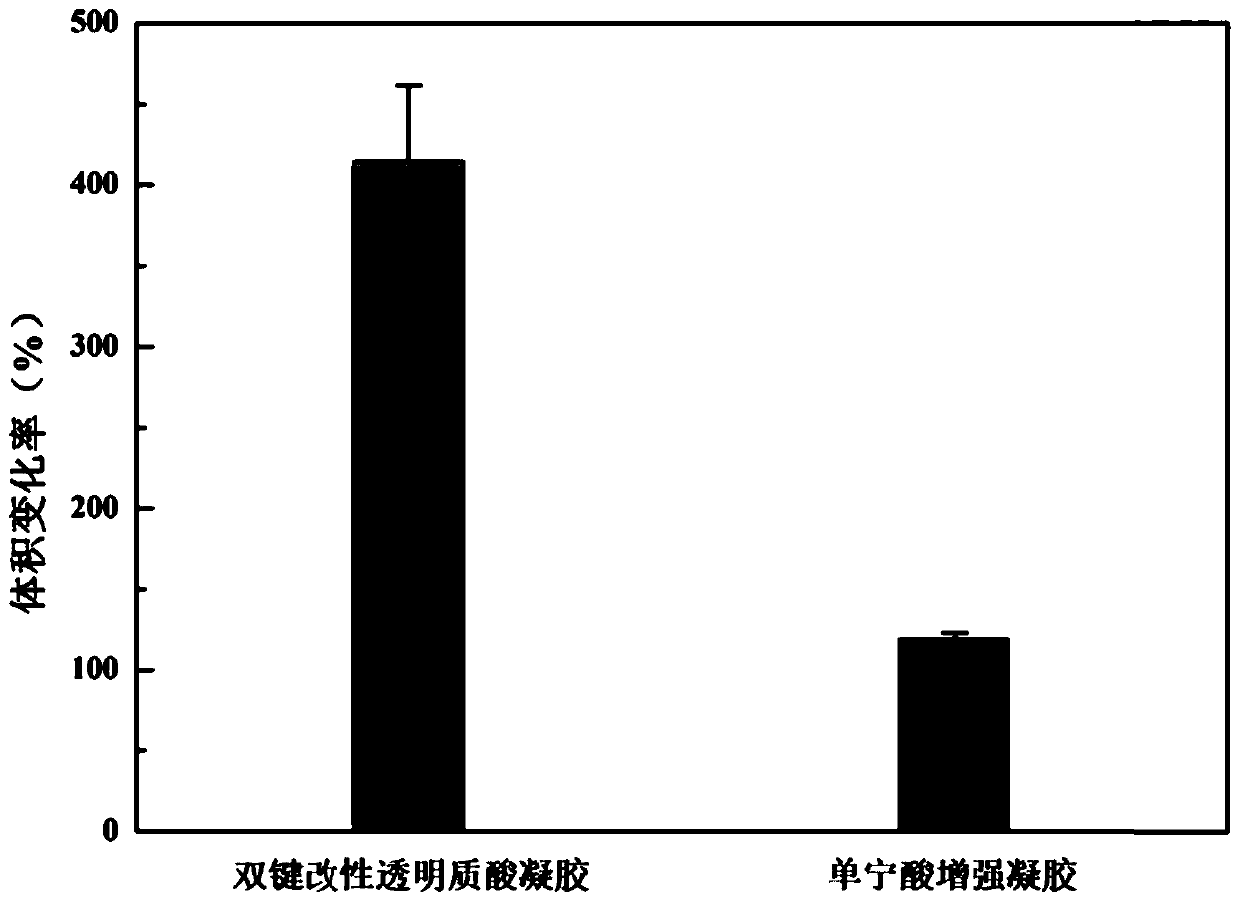

Polyphenol substance hydrogen bond enhanced hydrogel

PendingCN111286045AHigh mechanical strengthReduce the degradation rateAerosol deliveryOintment deliveryTissue repairPharmaceutical drug

The invention discloses polyphenol substance hydrogen bond enhanced hydrogel. The polyphenol substance hydrogen bond enhanced hydrogel is formed by hydrogen bond crosslinking of polyphenol substancesand hydroxyl-rich hydrogel. A preparation method of the polyphenol substance hydrogen bond enhanced hydrogel comprises the following steps: 1) crosslinking a hydroxyl-rich hydrogel matrix to obtain gel; and 2) soaking the gel in an alkaline solution of polyphenol substances, and carrying out a cross-linking reaction. The polyphenol substance hydrogen bond enhanced hydrogel can be used as a drug carrier or a tissue repair medical material. The mechanical strength of the polyphenol substance hydrogen bond enhanced hydrogel is remarkably improved, the degradation rate is greatly reduced, the comprehensive performance is remarkably improved, and the application prospect is wide.

Owner:GUANGDONG PROV MEDICAL INSTR INST

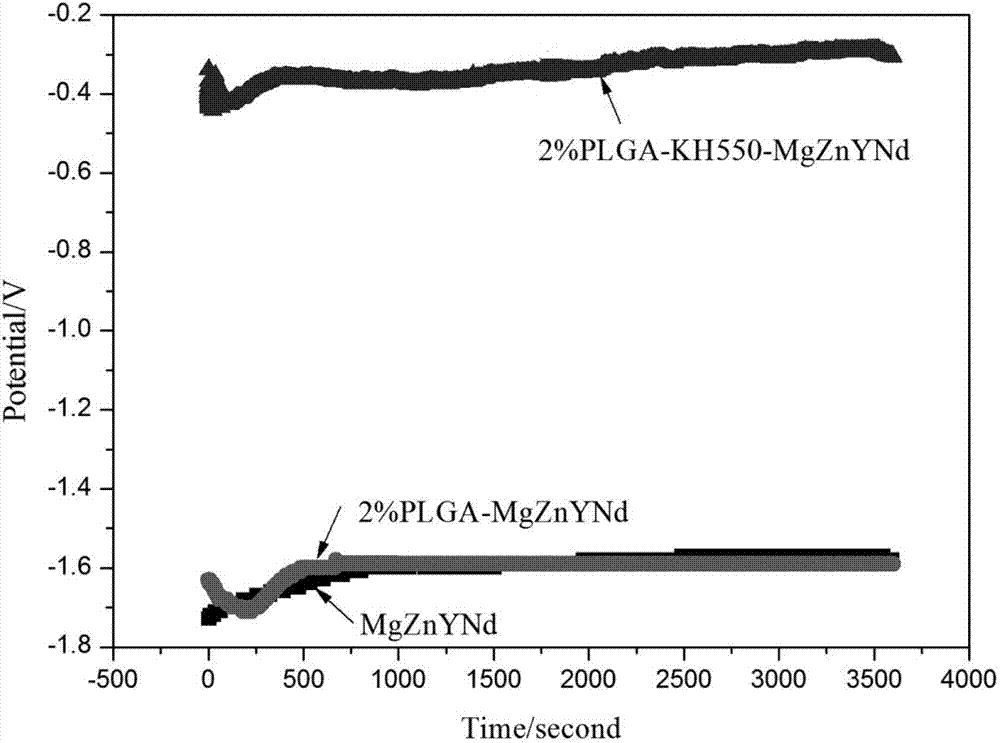

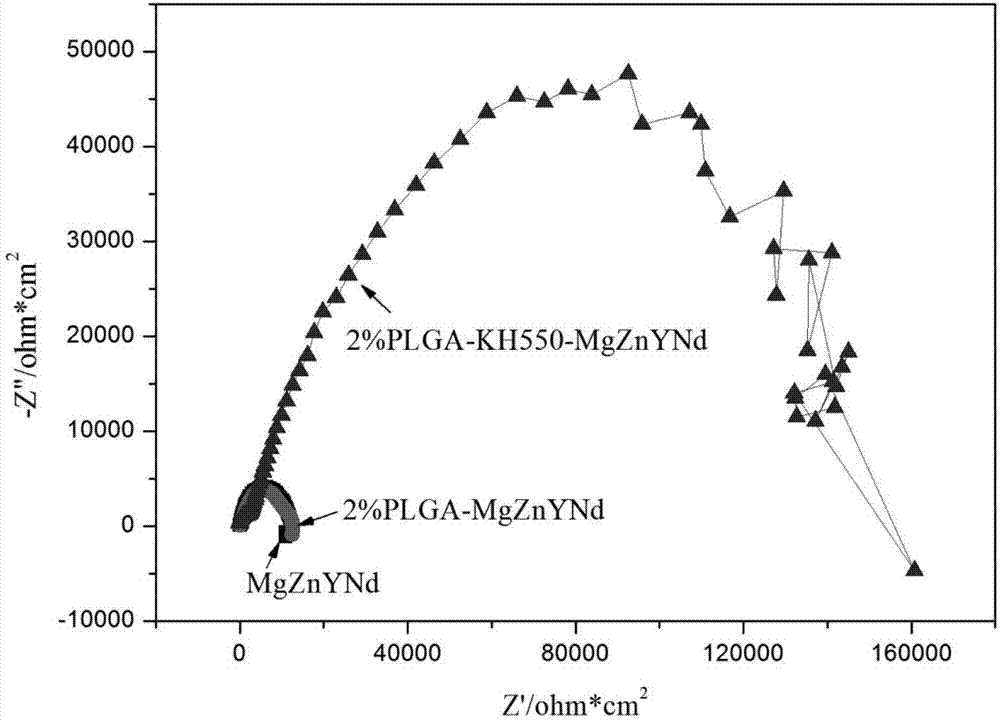

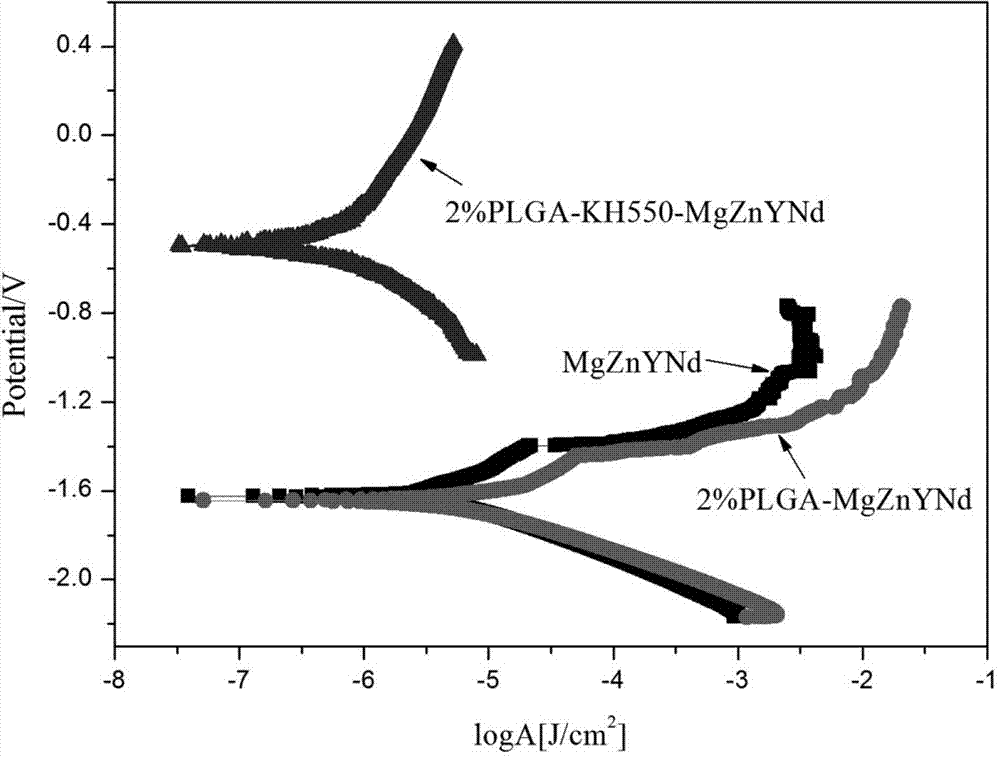

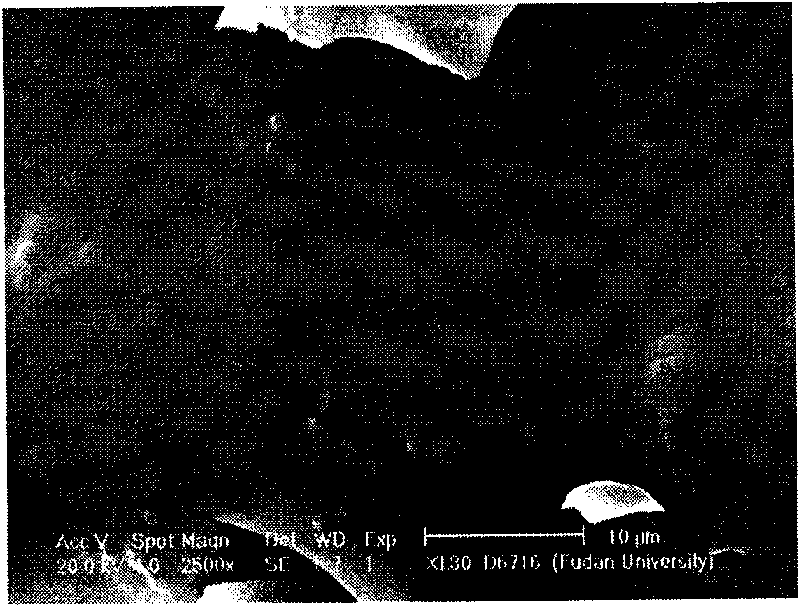

Preparation method of surface coating capable of lowering degradation rate of fully-degradable magnesium alloy vascular stent

ActiveCN104189963AReduce the degradation rateReduce sheddingSurgeryCoatingsMg alloysBiocompatibility

The invention relates to a preparation method of a surface coating capable of lowering the degradation rate of a fully-degradable magnesium alloy vascular stent. The method comprises the following steps: preparing a silane coupling agent on a magnesium alloy surface in a way that a silane coupling agent and an organic solvent are mixed, the silane coupling agent is grafted to the magnesium alloy surface of a biodegradable vascular stent by adopting a dip coating method and heating and curing are performed to form a coating; and preparing a polymer coating on the surface pre-treated by the silane coupling agent in a way that a spin-coating method is adopted to coat a polymer on a sample surface treated by the silane coupling agent, vacuum drying is realized and the polymer coating is formed after solvent volatilization. Through the technical scheme, a strong binding force exists between the polymer coating on the magnesium alloy surface pre-treated by the silane coupling agent and the surface of the fully-degradable magnesium alloy vascular stent, so that the magnesium alloy base body is prevented from excessively quick degradation, and the biocompatibility is improved; and as the coating is completely degraded with the base body at last, no toxic or side effects are brought to a human body.

Owner:JIANGSU FENGYUAN MEDICAL DEVICES CO LTD

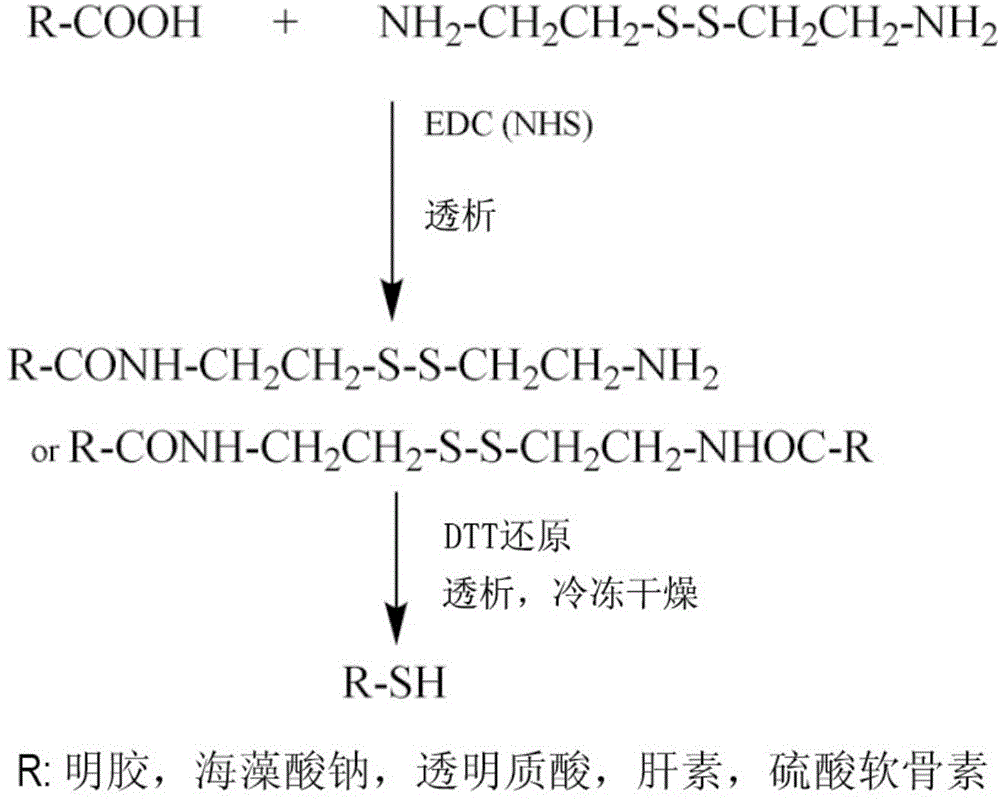

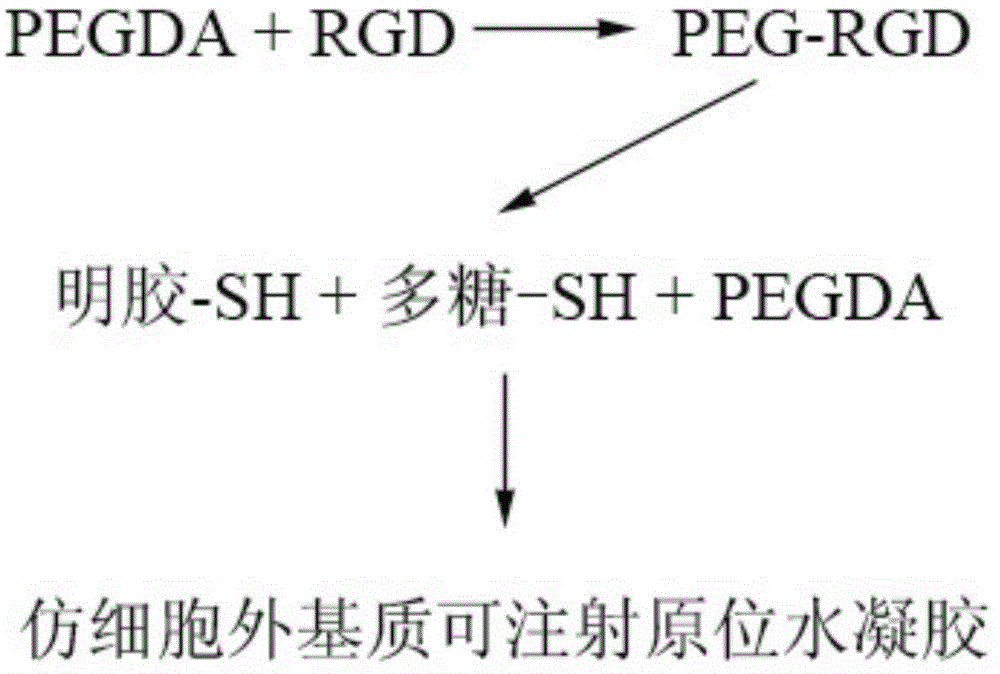

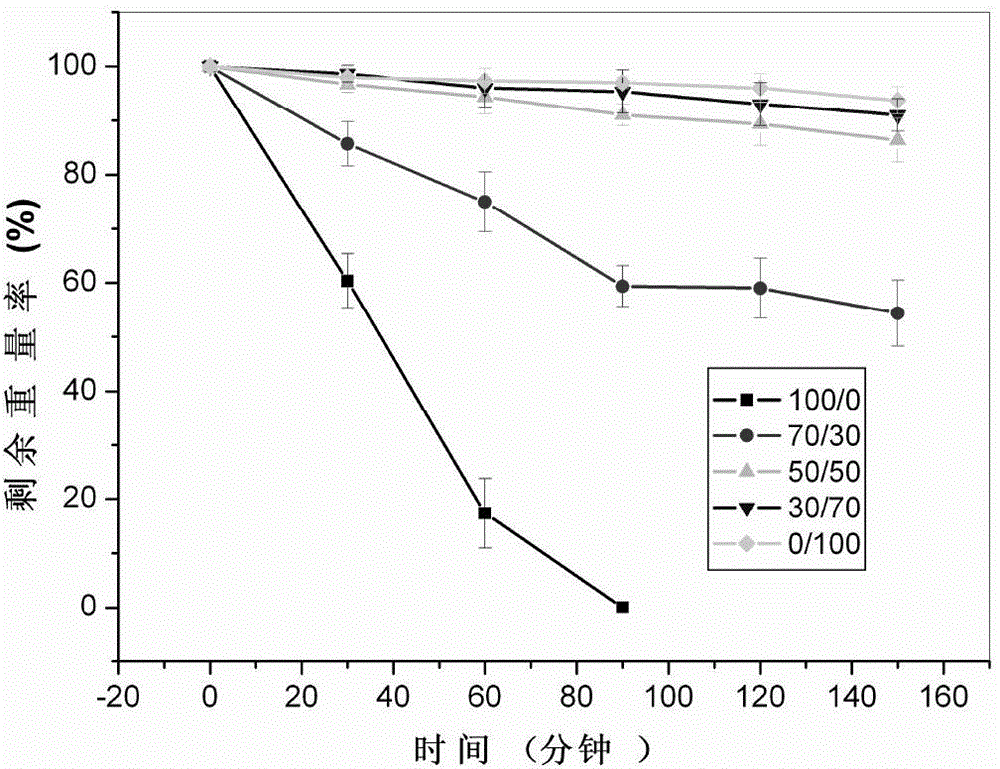

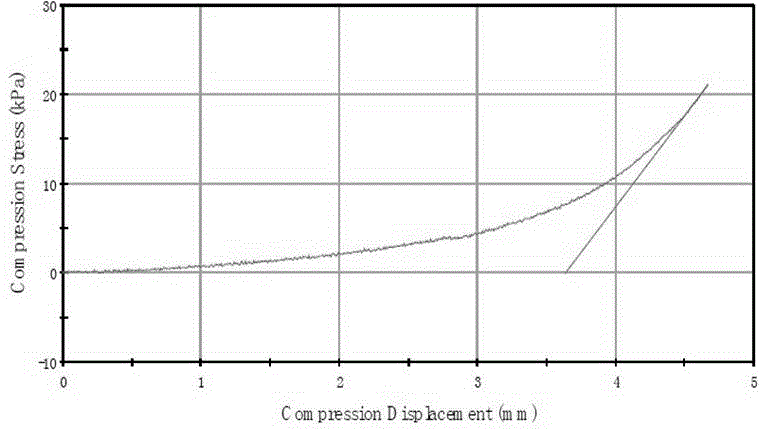

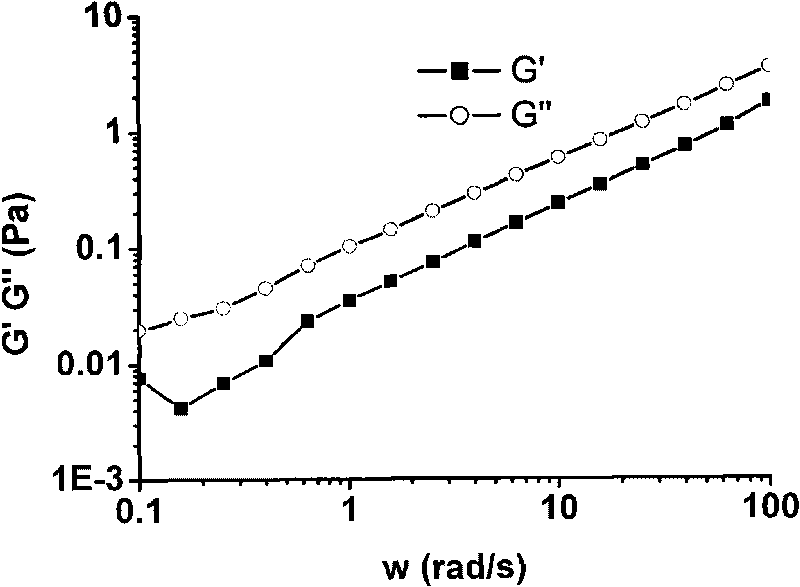

Imitated extracellular matrix injectable in-situ hydrogel and preparation method and application thereof

ActiveCN104307049ADegradation controllableControl releaseAnimal cellsPeptide/protein ingredientsCross-linkCell adhesion

The invention discloses imitated extracellular matrix injectable in-situ hydrogel and a preparation method and application thereof. The hydrogel is prepared by carrying out a cross-linking reaction between sulfhydrylation gelatin, sulfhydrylation polysaccharides or RGD-containing cell adhesion peptides and polyethylene glycol diacrylate. The composition of the hydrogel is similar to that of the extracellular matrix, so that the hydrogel has high biocompatibility, has the effects of controlled degradation, controlled release and / or cell behavior regulation in performance and can conveniently meet the requirements on different release rates of growth factors or medicines. Meanwhile, the clinical injectable and in-situ forming operation requirements can be met, and the hydrogel has good application prospects in tissue repair and regeneration.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

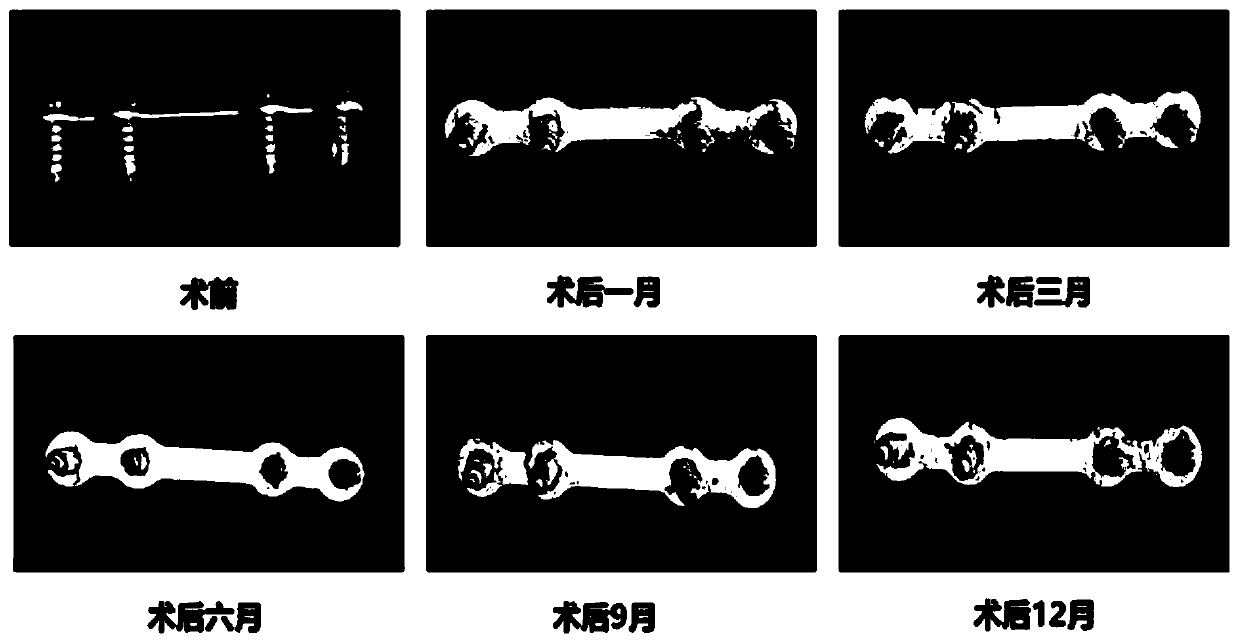

Degradable magnesium alloy implanting material for bone fixation and preparing method of degradable magnesium alloy implanting material

ActiveCN105349858AImprove and enhance mechanical propertiesImproved and enhanced biocompatibilityMg alloysBiomechanics

The invention relates to a degradable magnesium alloy implanting material for bone fixation and a preparing method of the degradable magnesium alloy implanting material. The implanting material is prepared from, by mass percent, 0.5-4% of Mg, 0.5-4% of Ag and the balance Y. The preparing method of the implanting material comprises the steps of ingot casting metallurgy, extruding, rolling and heat treatment. The prepared implanting material meets the requirement of plates, rods and profiles, wherein the plates, the rods and the profiles serve in biological fluid environments. By means of alloy materials, the good comprehensive mechanical performance needed by bone fixing materials is ensured, the beneficial effects of being capable of inhibiting bacteria, resistant to corrosion, free of cytotoxicity, good in biological mechanical property and the like are achieved, and the alloy materials can be degraded under the biological fluid environments. The implanting material can serve as bone nails or marrow nails or bone fraction plates or other various devices to be used under the medical conditions, and the comprehensive performance is good; and especially, the implanting material has both the biomechanical property and the biodegradable performance at the same time, and the typical defect of existing metal materials of a titanium alloy or stainless steel or high polymer materials in application of the department of orthopaedics is overcome.

Owner:CENT SOUTH UNIV

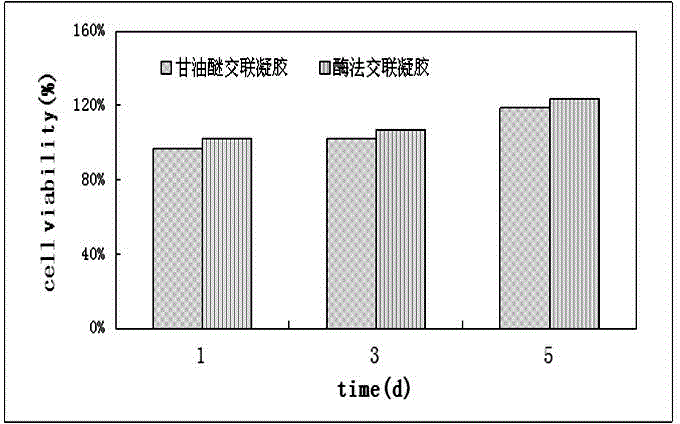

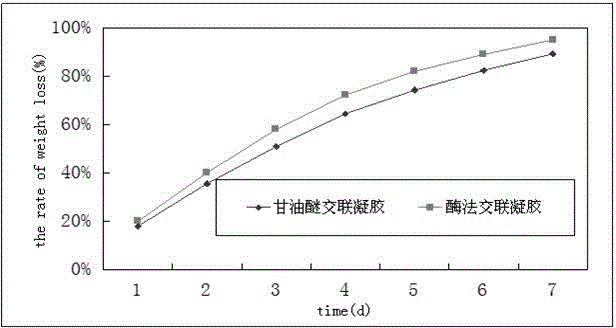

Collagen hydrogel for injection and preparation method thereof

InactiveCN103333508AReduce the degradation rateExtended retention timeProsthesisEnzymeChemical compound

The invention relates to collagen hydrogel for injection and a preparation method thereof. Organic solvents, organic sterilizing agents and the like are frequently introduced or remained in the existing collagen cross-linking technology; the product safety and the biocompatibility are poor. According to the invention, collagen is used as the raw material; hydrogel is formed by carrying out intramolecular or intermolecular cross-linking reaction of the raw material by using a cross-linking agent; enzyme or an epoxy compound is selected as the cross-linking agent; influence of the cross-linking agent remained in a product on performances of the product is lightened or eliminated in a cleaning or inactivating manner. The product disclosed by the invention is free from biological toxicity; damage of the product on human body is reduced; simultaneously, because of intramolecular or intermolecular cross-linking, the degradation rate of collagen is reduced; the in-vivo retention time of collagen is increased; furthermore, good performances for promoting new cells to form and grow in collagen in hydrogel are not influenced.

Owner:SHAANXI GIANT BIOTECHNOLOGY CO LTD

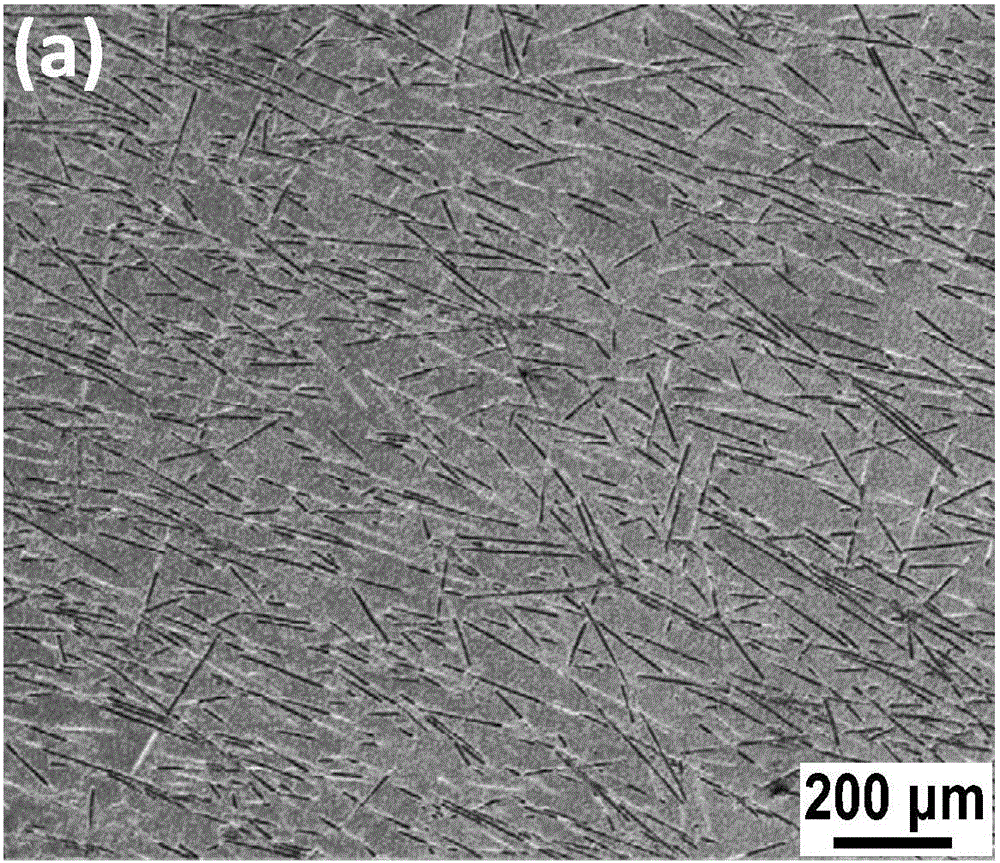

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a method for preparing a biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating. The method comprises the following steps of: pretreating a magnesium alloy substrate, wherein the adopted transfer solution is prepared from sodium dihydrogen phosphate dehydrate and calcium nitrate tetrahydrate; soaking a substrate sample obtained by pretreatment in the transfer solution for 5-100 hours, thus obtaining a calcium-phosphorus coating; soaking a calcium-phosphorus coating sample in an alkali fluoridated transfer solution for 10-48 hours, so as to obtain a fluoridated calcium-phosphorus coating, wherein the alkali fluoridated transfer solution is prepared from sodium hydroxide and sodium fluoride, the concentration of the sodium hydroxide is 3-4g / L, the concentration of the sodium fluoride is 4-5g / L, and heat treatment is not performed; performing heat treatment on the fluoridated calcium-phosphorus coating at the temperature of 300-350 DEG C for 2-5 hours, thus obtaining the fluoridated hydroxyapatite. According to performance detection, the fluoridated hydroxyapatite (FHA) coating prepared by combining a heat treatment process is shaped like a slender sheet and is divergently arranged from the center to the periphery; the electrochemical test proves that the self-corrosion potential of the substrate is improved through the FHA coating; the immersed corrosion experiment proves that an actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of a fluoridated apatite (FA) coating.

Owner:TONGJI UNIV

Preparation for treating and restoring infective wound surface and preparation method thereof

ActiveCN101721691ABactericidal Activity RetentionReduce the degradation rateOrganic active ingredientsPeptide/protein ingredientsWound surfaceProtein C

The invention belongs to the technical field of medication, in particular to a biological preparation for treating and restoring an infective wound surface and a preparation method thereof. The preparation disclosed by the invention comprises the following components in percentage by weight: 0.1 to 30 percent of staphylococcus lysozyme, 3 to 50 percent of chitosan or chitosan derivative and 30 to95 percent of collagen. The preparation method comprises the following steps: crosslinking the natural biodegradable chitosan derivative and the collagen serving as dressings to form hydrogel used asa carrier; and loading the staphylococcus lysozyme into the hydrogel to prepare a novel preparation with a function of promoting the healing of the wound surface and a bactericidal effect.

Owner:SHANGHAI HI TECH BIOENG +1

Method for preparing porous bone scaffold by laser and increasing performance by adding zinc oxide

InactiveCN103845762AGood biological propertiesHigh densityProsthesisSelective laser sinteringPhosphate

The invention relates to a method for preparing a porous bone scaffold by laser and increasing mechanical and biological performances of the porous bone scaffold by adding zinc oxide with little amount, which belongs to the bone tissue engineering field. Aiming at uncontrollable performances of aperture distribution, shape, space direction and connectivity in the preparation method of a traditional bone scaffold, and aiming at the disadvantages of poor mechanical property and fast resolving rate existed in tricalcium phosphate (beta-TCP), the invention provides the method for preparing the porous bone scaffold by using a selective laser sintering (SLS) technology, and provides the method for increasing performance by adding zinc oxide (ZnO). The method for preparing the porous bone scaffold has the advantages that the porous scaffold which enables three-dimensional interconnection is prepared by SLS, zinc oxide with little amount is added for introducing into a liquid phase, the particles densification can be promoted, crystal grain is refined, and the mechanical performance is improved, simultaneously, cell compatibility is increased, the degradation rate is reduced, and the biological performance is increased, so that the interconnected porous beta-TCP bone scaffold with enhanced mechanical performance and good biological performance can be finally prepared. The method has the advantages of simple preparation technology, convenient operation, low cost, easy control of technical parameter and the like.

Owner:CENT SOUTH UNIV

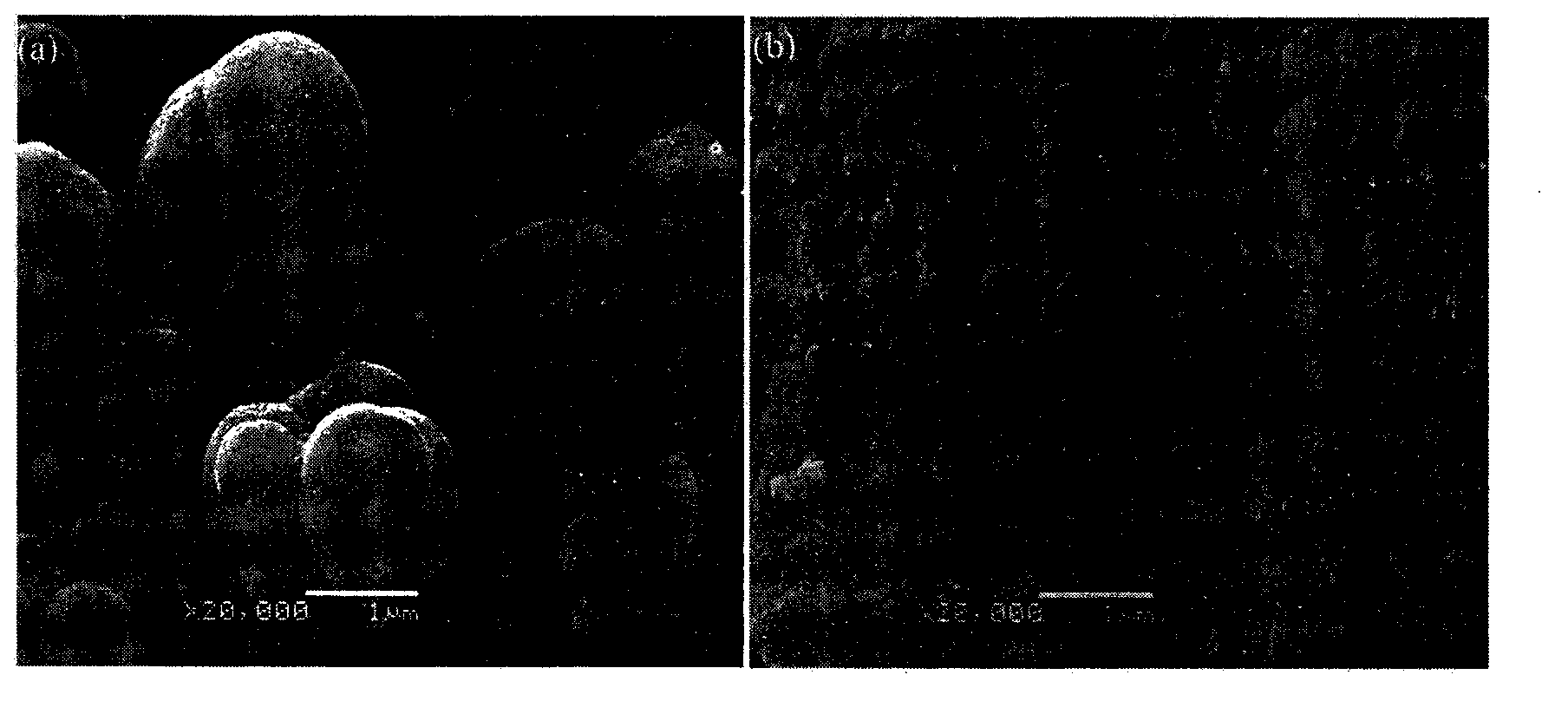

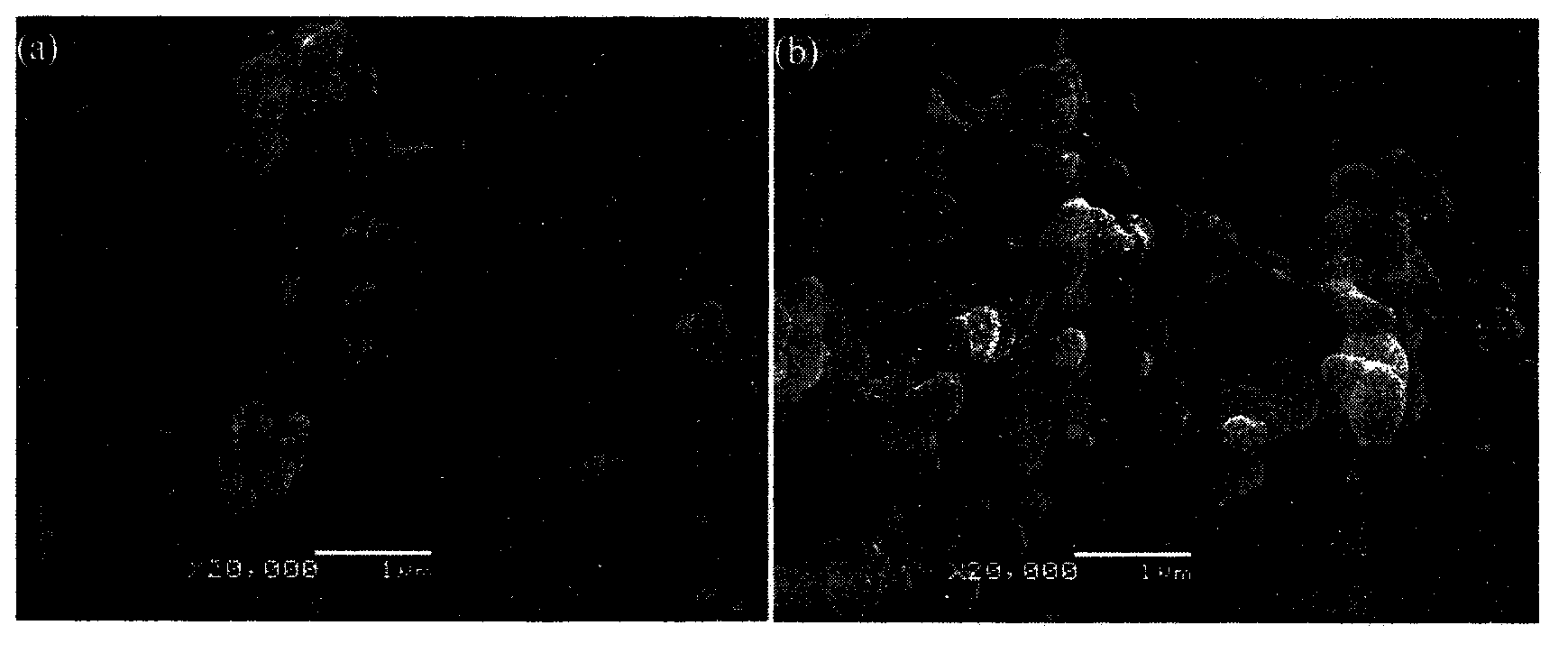

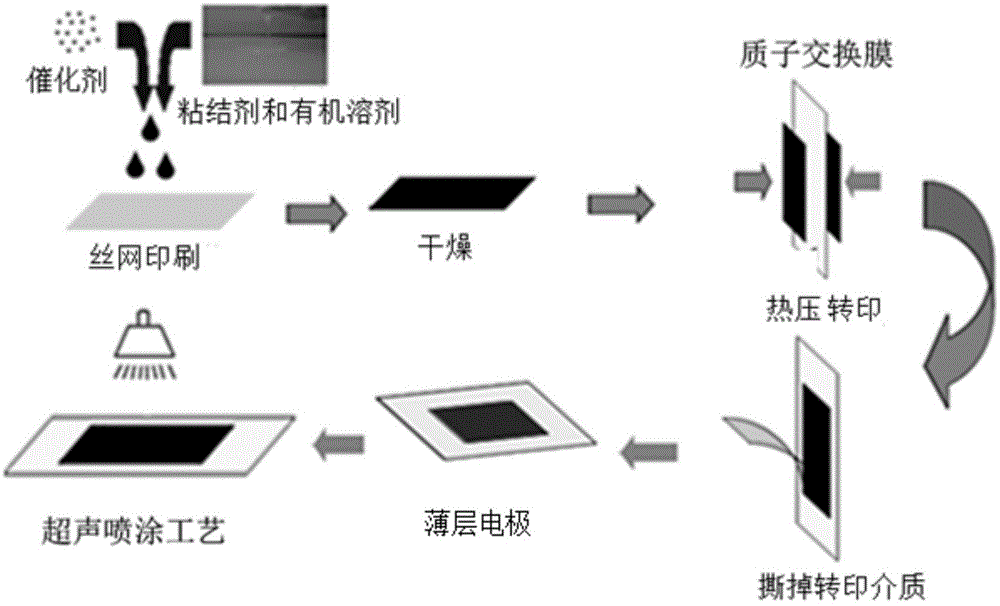

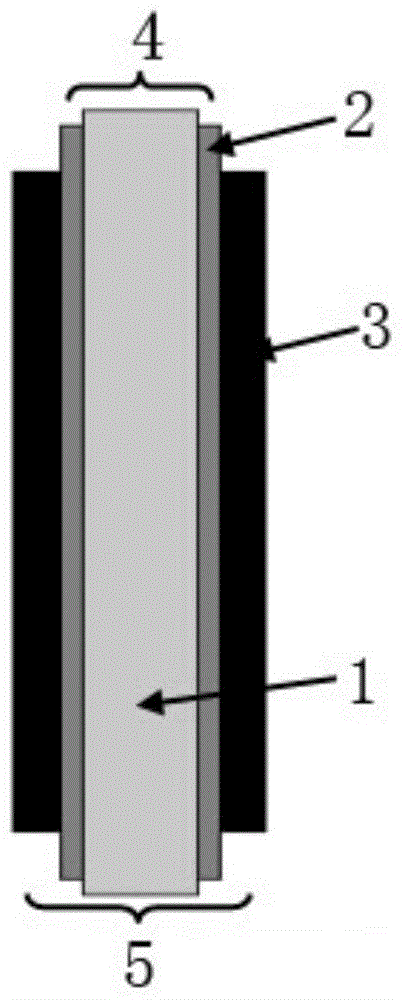

Production method of proton exchange membrane fuel cell membrane electrode

The invention discloses a production method of a proton exchange membrane fuel cell membrane electrode. A screen printing technology and an ultrasonic spraying technology which are two production technologies of membrane electrodes are adopted, an electrocatalyst slurry I undergoes the screen printing technology, an electrocatalyst slurry II undergoes the ultrasonic spraying technology and then is directly or indirectly supported on a proton exchange membrane, and the produced membrane electrode has a catalyst layer with a gradient network structure. The membrane electrode with high performance, long life, multiple layers and gradient network structure is produced by using different contents of an adhesive in different electrocatalyst slurries; and the compact structure of the catalyst layer in a thin layer electrode and an ultrasonic sprayed loose three-dimensional network structure make the interface resistivity of the catalyst layer lower than the that of the three-dimensional network structure, and the area of the introduced thin layer electrode is greater than the spray area when the effective area of the catalyst layer is ensured, so the contact part of a bipolar plate and the thin layer electrode can well facilitate electron conduction in the cell assembling process.

Owner:KUSN INNOVATION INST OF NANJING UNIV +1

Therapeutic methods and uses of sapogenins and their derivatives

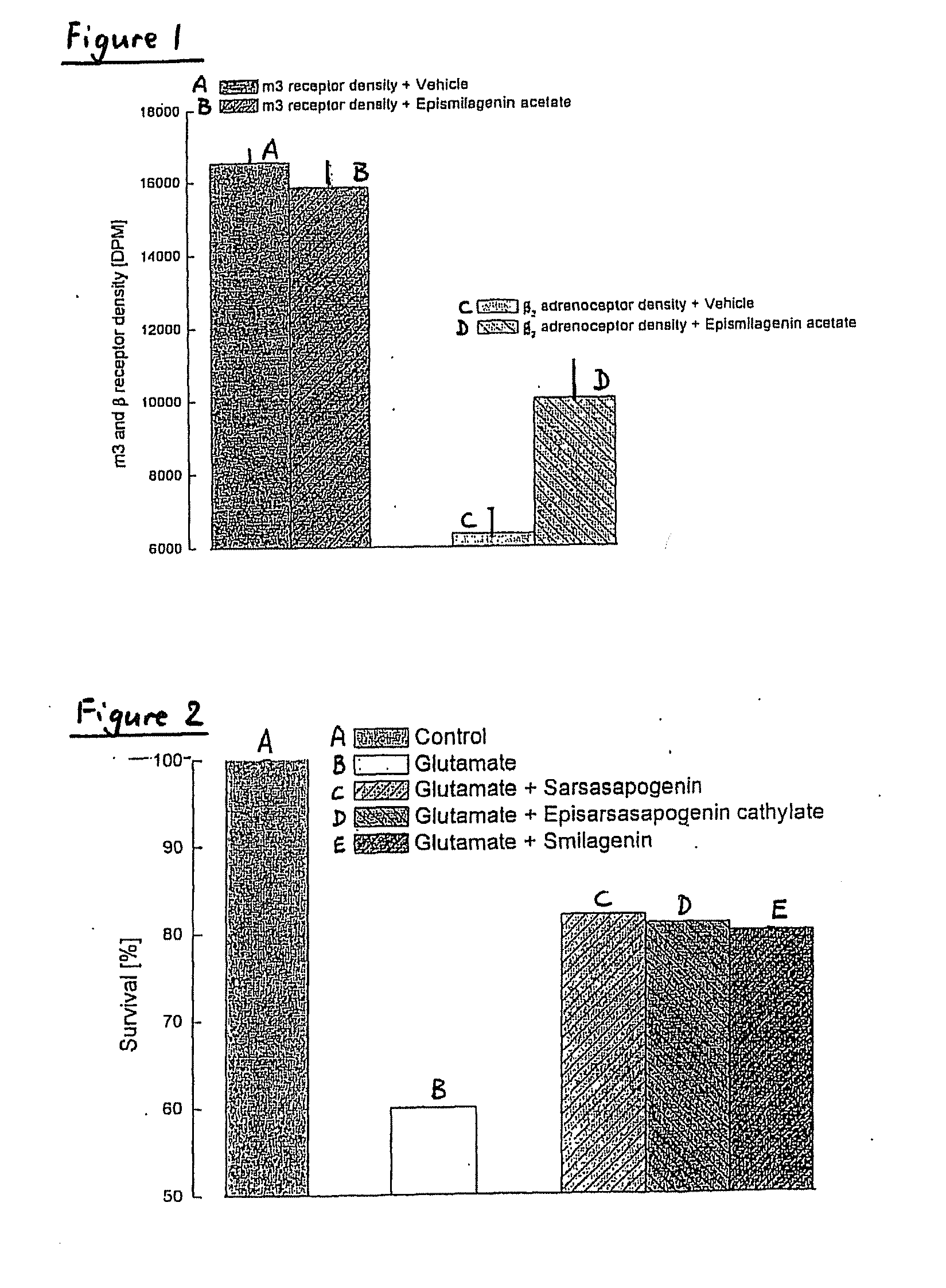

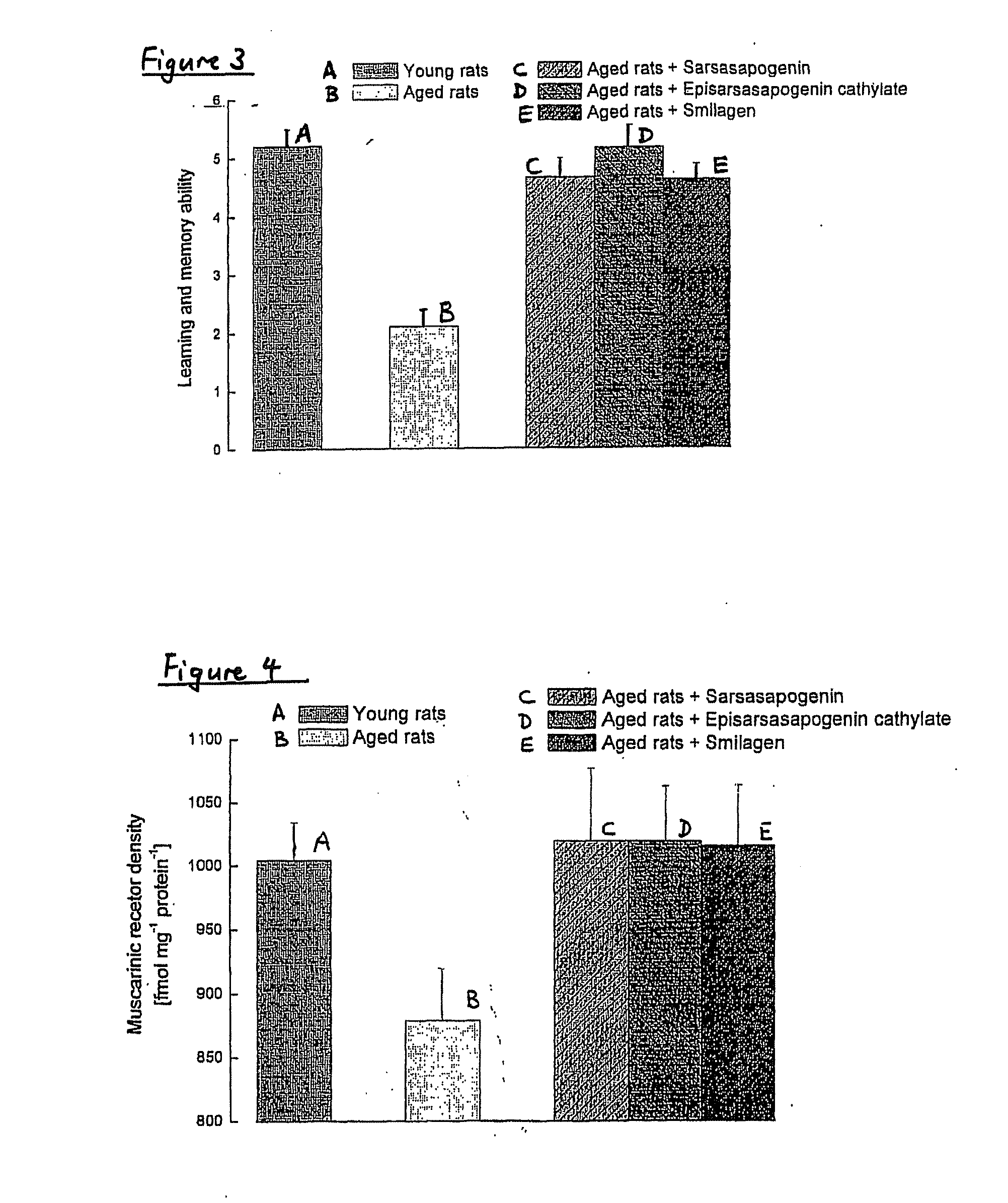

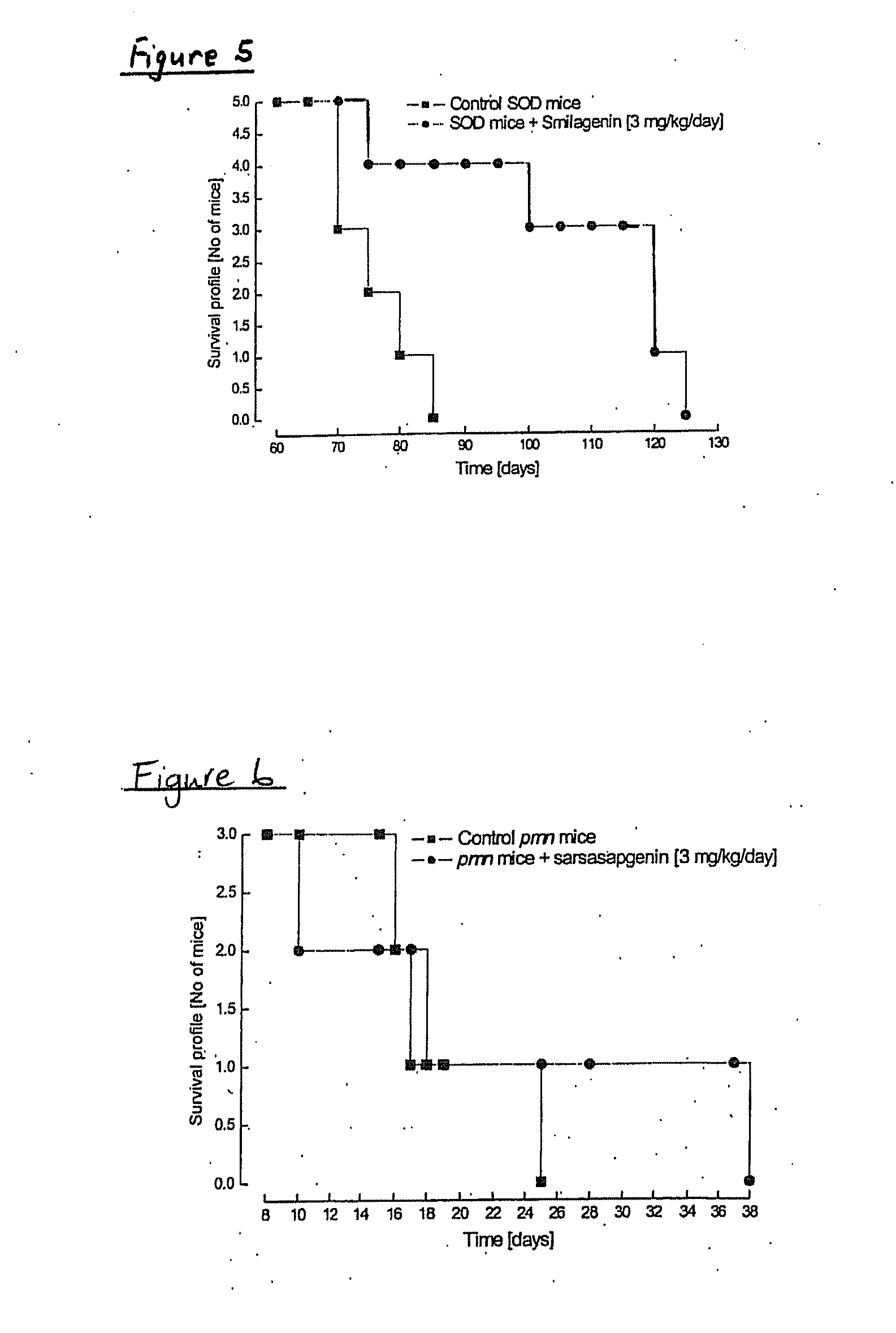

InactiveUS20110190249A1Increase synthesisFacilitated releaseOrganic active ingredientsSenses disorderMedicineSapogenin

The invention discloses therapeutic methods and uses of certain steroidal sapogenins, related compounds and derivatives thereof, in the treatment of non-cognitive neurodegeneration, non-cognitive neuromuscular degeneration, motor-sensory neurodegeneration or receptor dysfunction or loss in the absence of cognitive, neural and neuromuscular impairment.

Owner:PHYTOPHARM LTD

Absorbable medical chitin suture lines and their production

InactiveCN1552466AGood effectReduce the degradation rateSuture equipmentsHigh concentrationVegetable oil

An absorbable medical chitosan suture is prepared from chitosan and glycerine or vegetable oil through preparing coarse chitosan suture, preparing saturated high-concentration chitosan solution, twisting and coating film. Its advantage is high tension strength.

Owner:TIANJIN JIUKANG BIOLOGICAL ENG DEV

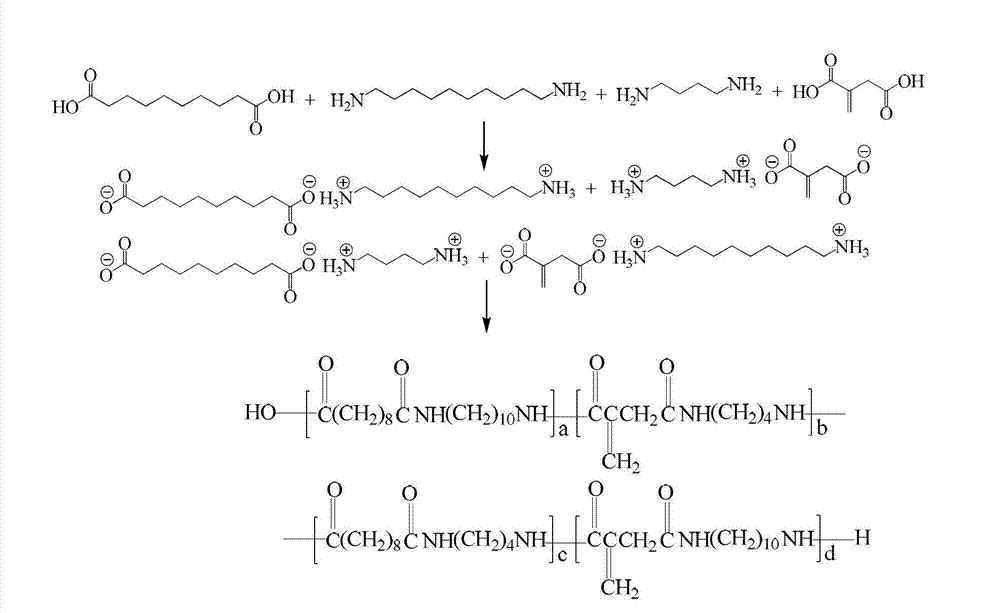

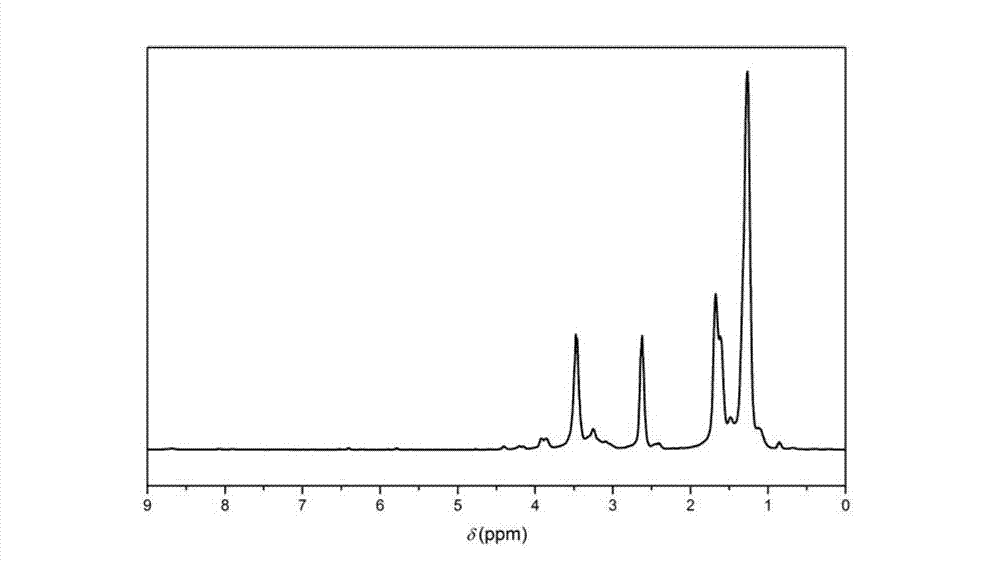

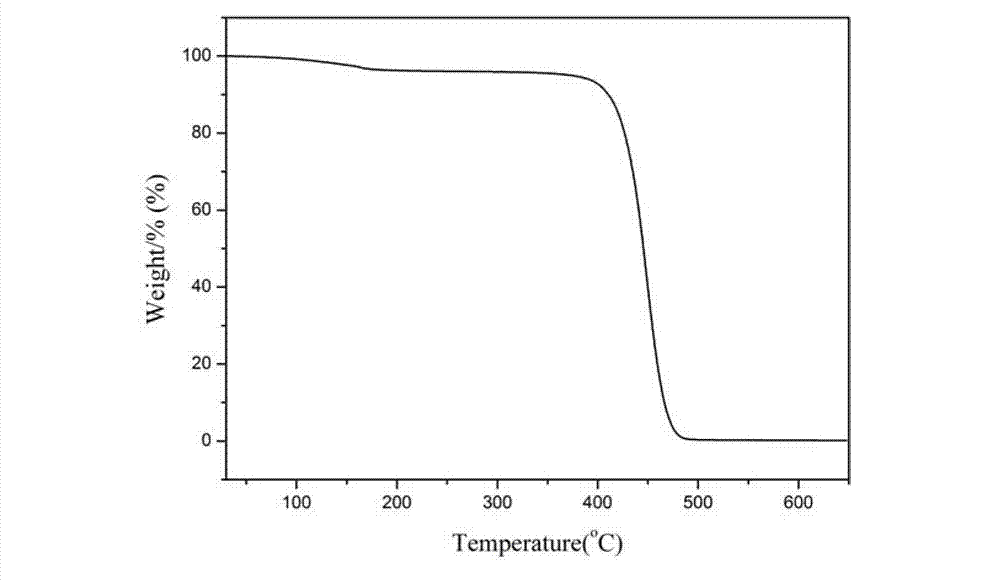

Biologic polyamide quadripolymer and synthesis method thereof

ActiveCN103030803AGood environmental stabilityReduce the degradation ratePolymer scienceSynthesis methods

The invention relates to a biologic polyamide quadripolymer and a synthesis method thereof, and belongs to the field of high molecular materials. The biologic polyamide quadripolymer is characterized in that the structural formula is shown as the specifications, wherein the four chain segments or chain links are arranged randomly. The invention also provides the synthesis method. The biologic polyamide quadripolymer has excellent environmental stability, a thermal crosslinking property, an irradiation crosslinking property and solvent corrosion resistance, and has physical and mechanical properties and a processing property which are equal to those of conventional polyamide.

Owner:BEIJING UNIV OF CHEM TECH

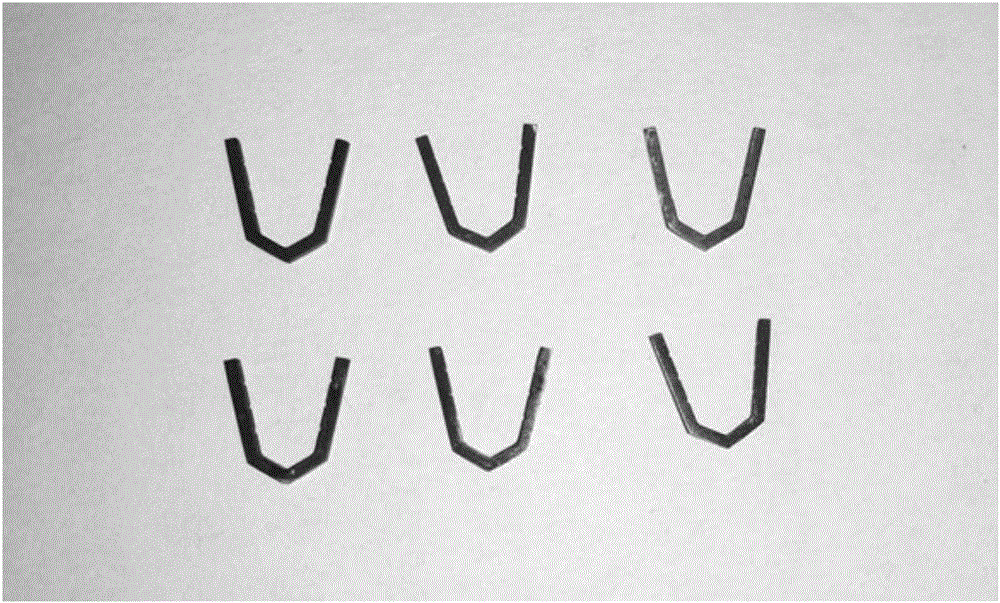

Method for preparing hemostatic clips through surface-passivated degradable magnesium alloy

InactiveCN105087980AImprove blood biocompatibilityReduce the degradation rateMetallic material coating processesWound clampsAlloy elementMagnesium alloy

Disclosed is a method for preparing hemostatic clips through surface-passivated degradable magnesium alloy. The magnesium alloy is composed of alloy elements including, by mass, 3% of Zn, 0.5-1.0% of Zr, 0.0-1.0% of Sr, 0.0-1.0% of Ca, 0.0-1.0% of Ag and the balance Mg. The preparation method includes the steps that ingots obtained through casting are squeezed into profile materials at the temperature of 250-400 DEG C, machined into the hemostatic clips, then subjected to aging treatment and finally subjected to surface passivating treatment. The method for preparing the hemostatic clips through the surface-passivated degradable magnesium alloy has the advantages that the hemostatic clips prepared through the method have proper obdurability and can meet the requirements for mechanical properties of materials by a broken end of a closed vessel; the degrading speed of the hemostatic clips made of the surface-passivated magnesium alloy is controllable, it is guaranteed that the hemostatic clips keep effective within two weeks in clinical use and can be completely corroded and degraded 1-2 months later after performing function.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

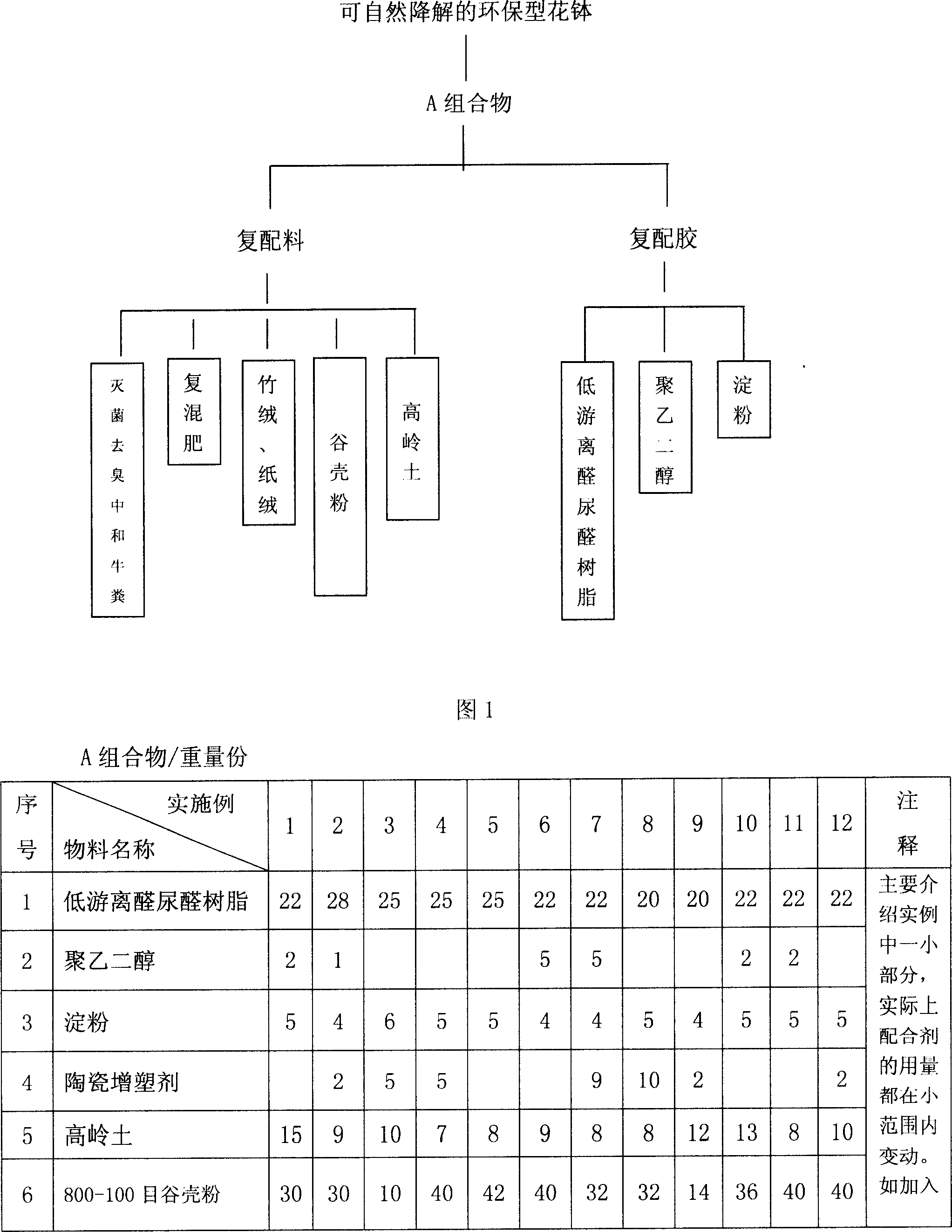

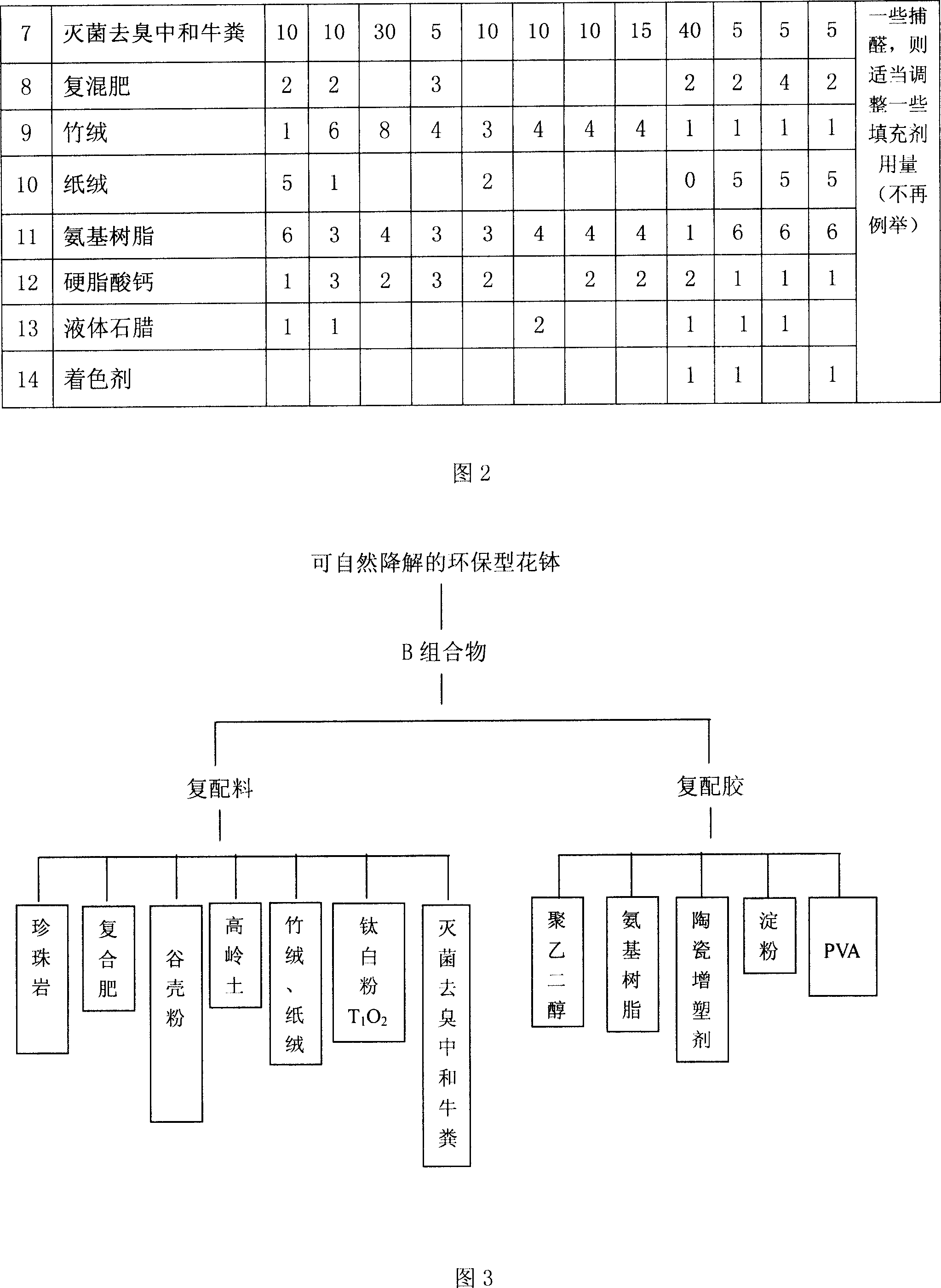

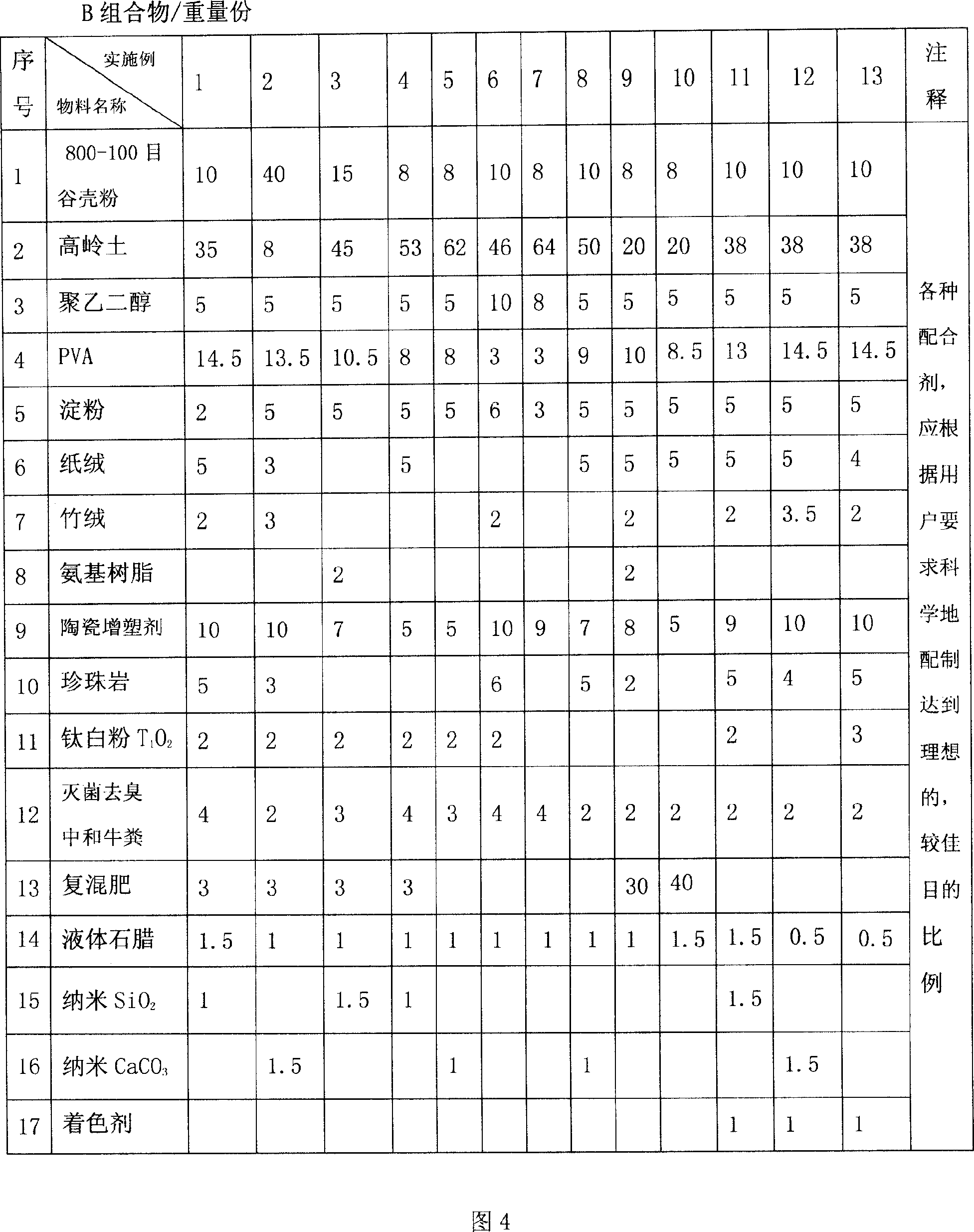

Naturally-degradable environmental-protection flowerpot and its manufacturing method

InactiveCN1935728AOvercome the limitations of single useSolve the problem of serious pollutionSolid waste managementCeramic shaping apparatusUreaWool

The invention discloses a naturally degradableenvironmental-protection flowerpot, comprising compound A, compound B or compound C, where the filler utilization of the compound A is 40-70%, and they are treated cow dung, compound fertilizer, bamboo wool, paper wool, chaff powder and kaoline; the structural material and adhesive utilization of the compound A is 20-50%, and they are lowly dissociative urea aldehyde resin, polyglycol and starch; the supporting assistant utilization of the compound A is 10-40%, and they are liquid paraffin, amino resin, ceramic plasticizer, calcium stearate and toughness reinforcing agent, such as nano SiO2 or nano CaCO3. And its basic manufacturing method comprises a flow of: raw materials-mixing- stirring or kneading-moulding- product. And the invention is suitable to make various environmental- protection plant ornamental and cultivating flowpots.

Owner:钱铁清 +1

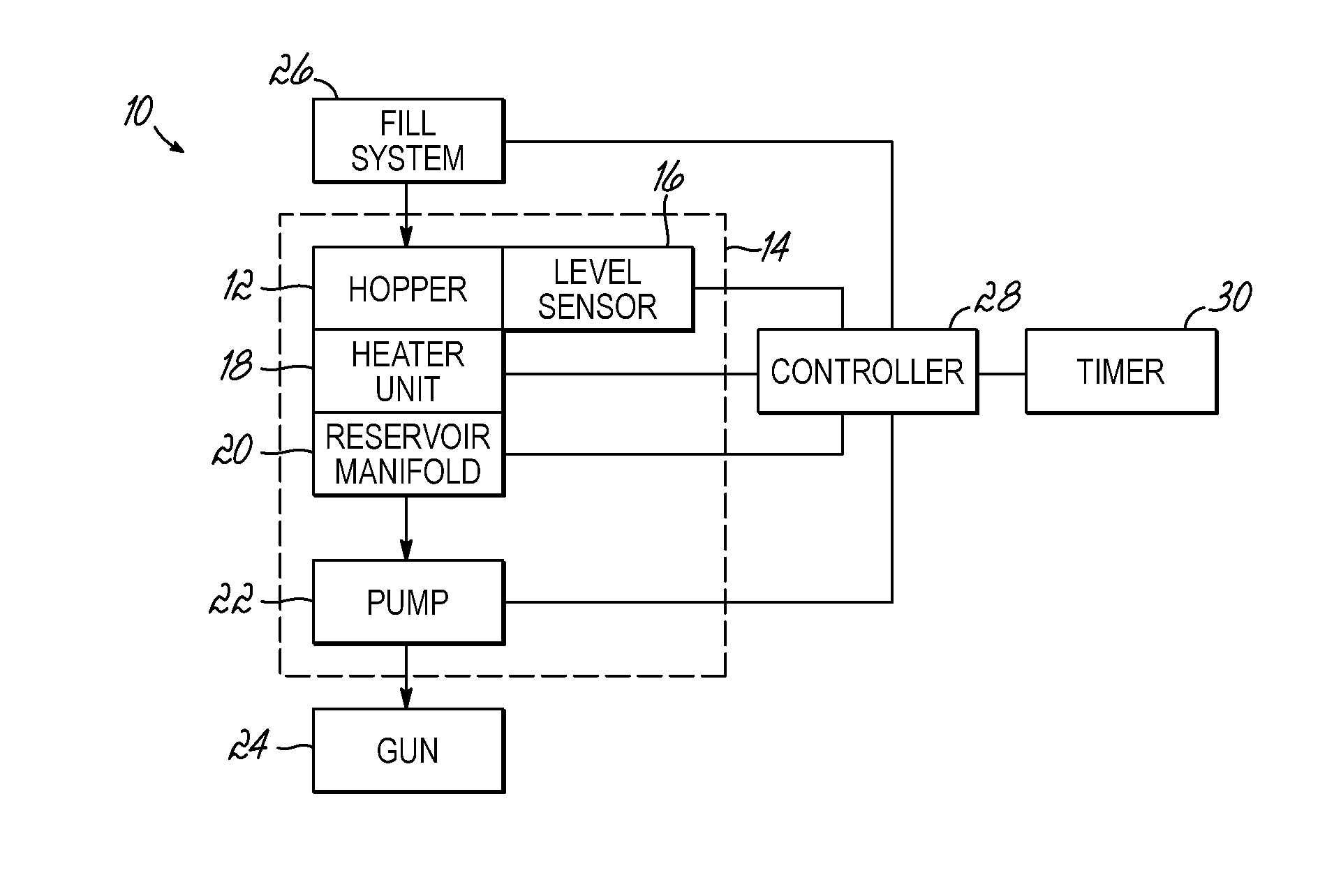

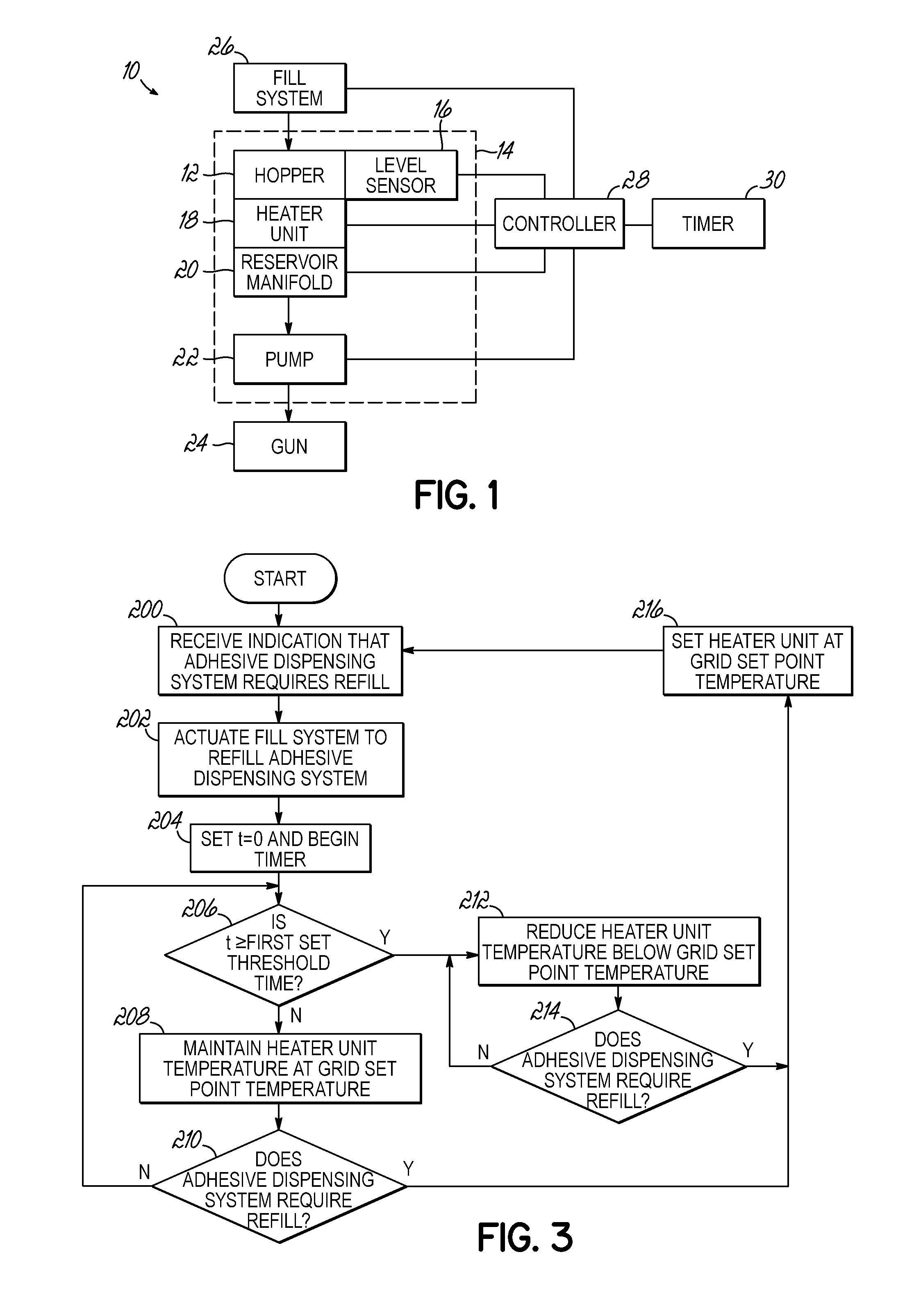

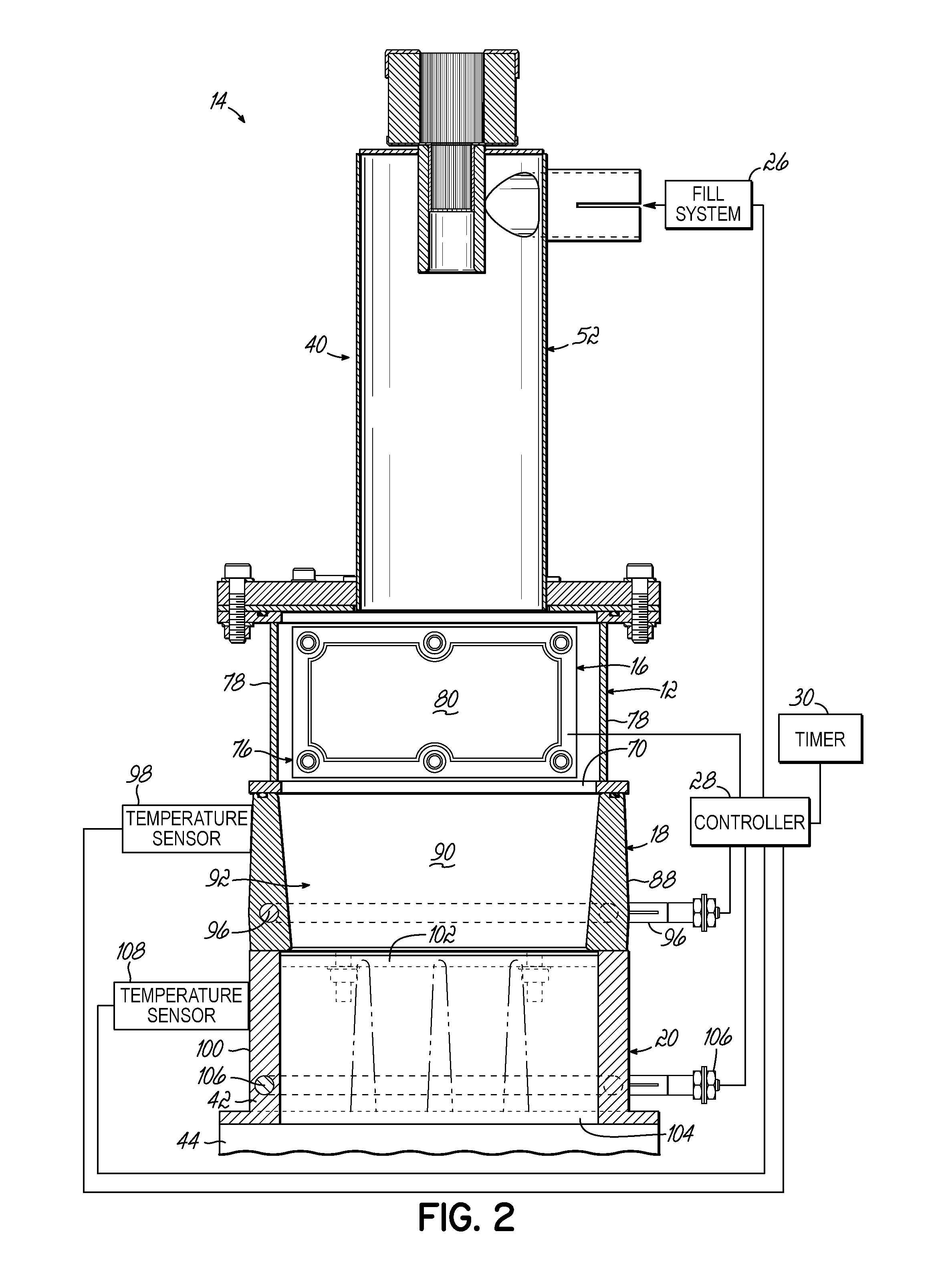

Adhesive dispensing system and method using smart melt heater control

ActiveUS20140116525A1Reduce the degradation rateMinimizing outgassingLiquid surface applicatorsValve members for heating/coolingOutgassingEngineering

An adhesive dispensing system is configured to automatically reduce the temperature of adhesive material to reduce degradation of the adhesive caused by holding the adhesive at an application temperature during periods of low throughput. To this end, a controller of the system operates a heater unit to maintain a unit set point temperature to heat and melt adhesive until a set threshold time has elapsed since the most recent supply of adhesive to the system by a fill system. Once the time elapsed since the most recent supply of adhesive exceeds the set threshold time, the heater unit is reduced in temperature to reduce the temperature of adhesive. This reduction is temperature is large enough to minimize degradation and outgassing but small enough to enable rapid warm-up times after a new supply of adhesive occurs.

Owner:NORDSON CORP

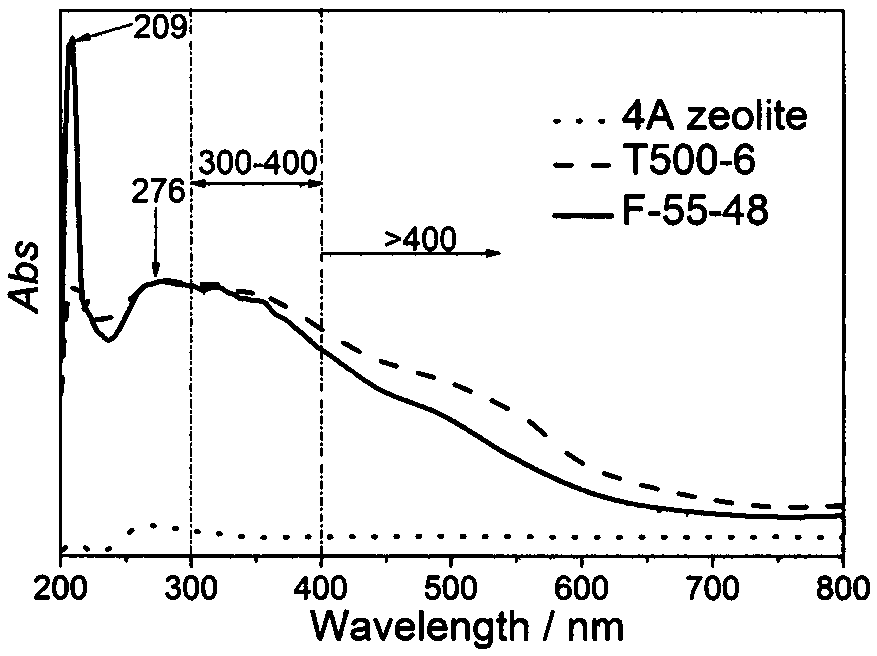

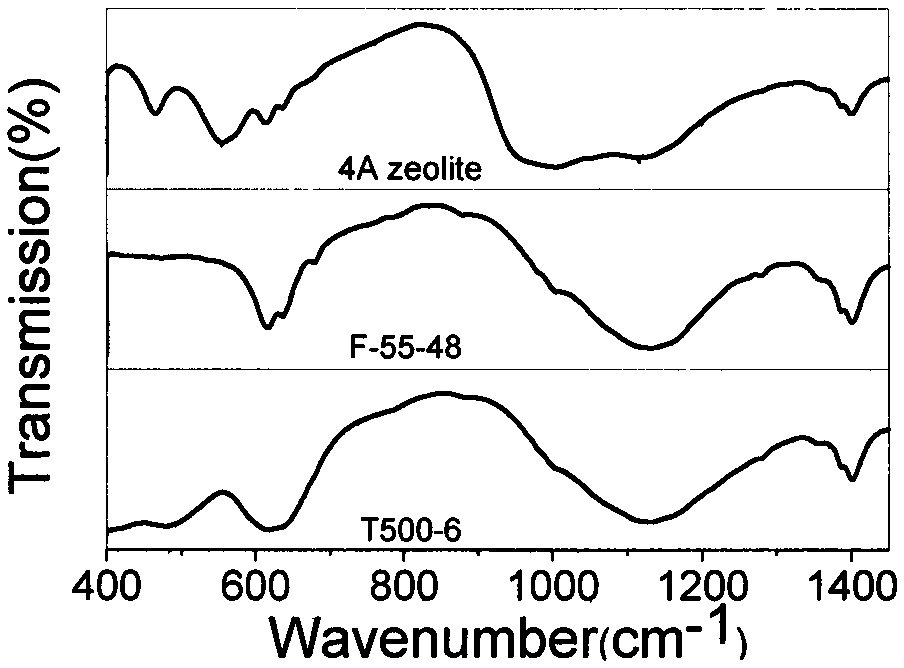

Zeolite Fenton catalyst containing isolated metal species as well as preparation method and application thereof

InactiveCN105618129AImprove catalytic performanceSimple preparation processMolecular sieve catalystsWater/sewage treatment by oxidationMetal chlorideFreeze-drying

The invention belongs to the technical field of wastewater treatment catalyst preparation and particularly relates to a zeolite Fenton catalyst containing an isolated metal species as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing zeolite with a metal chloride precursor solution to prepare a catalyst precursor; and then preparing the Fenton catalyst containing the isolated metal species with a freeze-drying method. According to the zeolite Fenton catalyst containing the isolated metal species prepared with the method, the tetra-coordinated isolated metal species content reaches up to 8.90%; in a process of degrading phenolic waste water, the catalyst has high phenol degradation catalysis efficiency and hydrogen peroxide utilization efficiency as well as low active species leakage amount; and the catalyst is simple in preparation process, low in device requirement and low in cost, can be produced on a large scale and is applied to an actual wastewater treatment process.

Owner:TIANJIN POLYTECHNIC UNIV

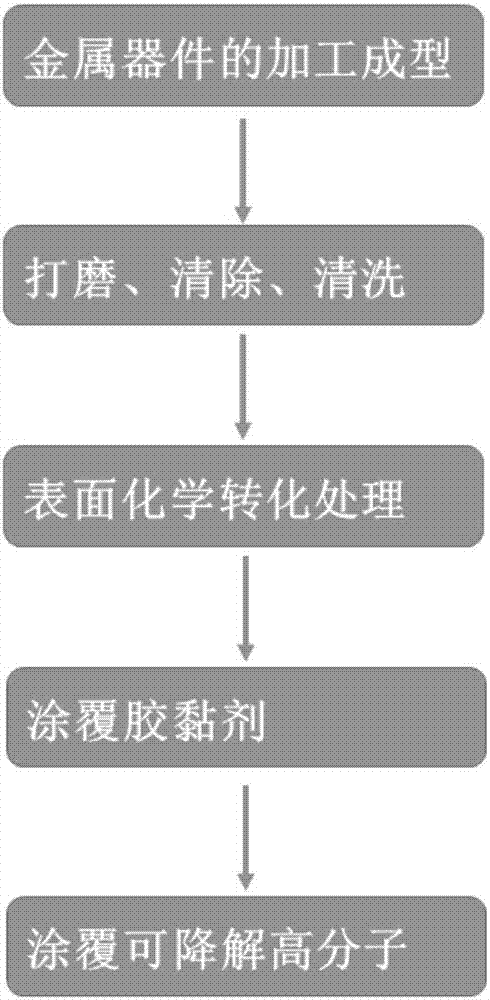

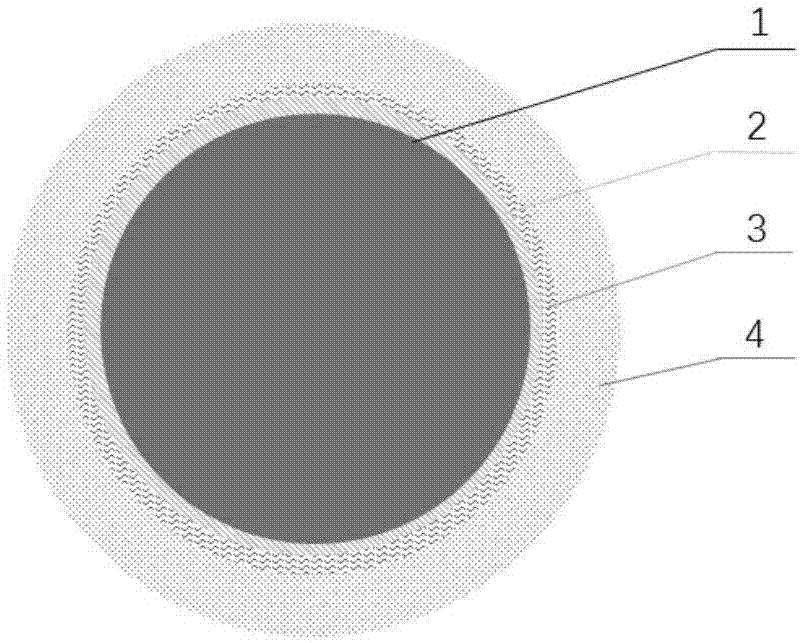

Biomedical magnesium or magnesium alloy implantation material with multiple surface protection

PendingCN107281543AImprove mechanical propertiesGood mechanical functionSurgeryMetallic material coating processesUltrasound attenuationInterventions therapy

The invention discloses a magnesium or magnesium alloy material or device with multiple surface protection layers and a production method. The magnesium or magnesium alloy material or device with multiple surface protection treatment has the aims that the initial mechanical attenuation of magnesium / magnesium alloy in a physiological environment is decelerated, the corrosion resisting property of the magnesium / magnesium alloy is improved, and the time of service is effectively prolonged. The protection treatment comprises the steps: 1) manufacturing a magnesium / magnesium alloy substrate, and cleaning the surface of the substrate; 2) carrying out chemical conversion treatment on the surface of the magnesium / magnesium alloy substrate, so as to grow a chemical conversion film, of which the thickness is several nanometers, on the surface of the substrate; 3) coating the chemical conversion film with an adhesive layer; 4) coating the outside surface of the adhesive layer with a degradable polymer film. The magnesium or magnesium alloy material or device with multiple surface protection treatment, provided by the invention, can be applied to biomedical implantation or intervention therapy and has the advantages of being good in initial corrosion resisting property in a human physiological environment, meeting clinical requirements of medical treatment and being finally in-vivo degradable.

Owner:NANJING NORMAL UNIVERSITY

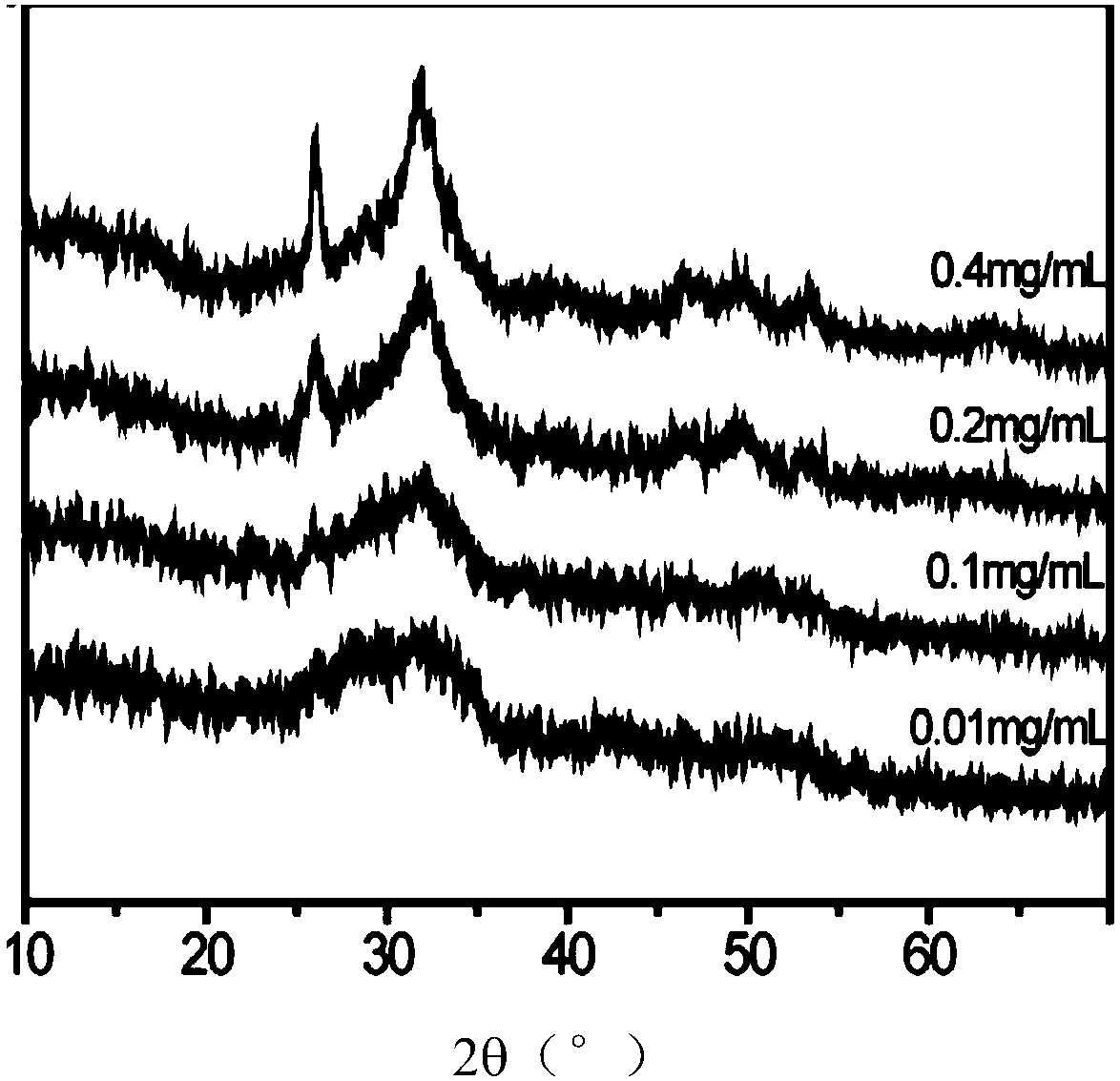

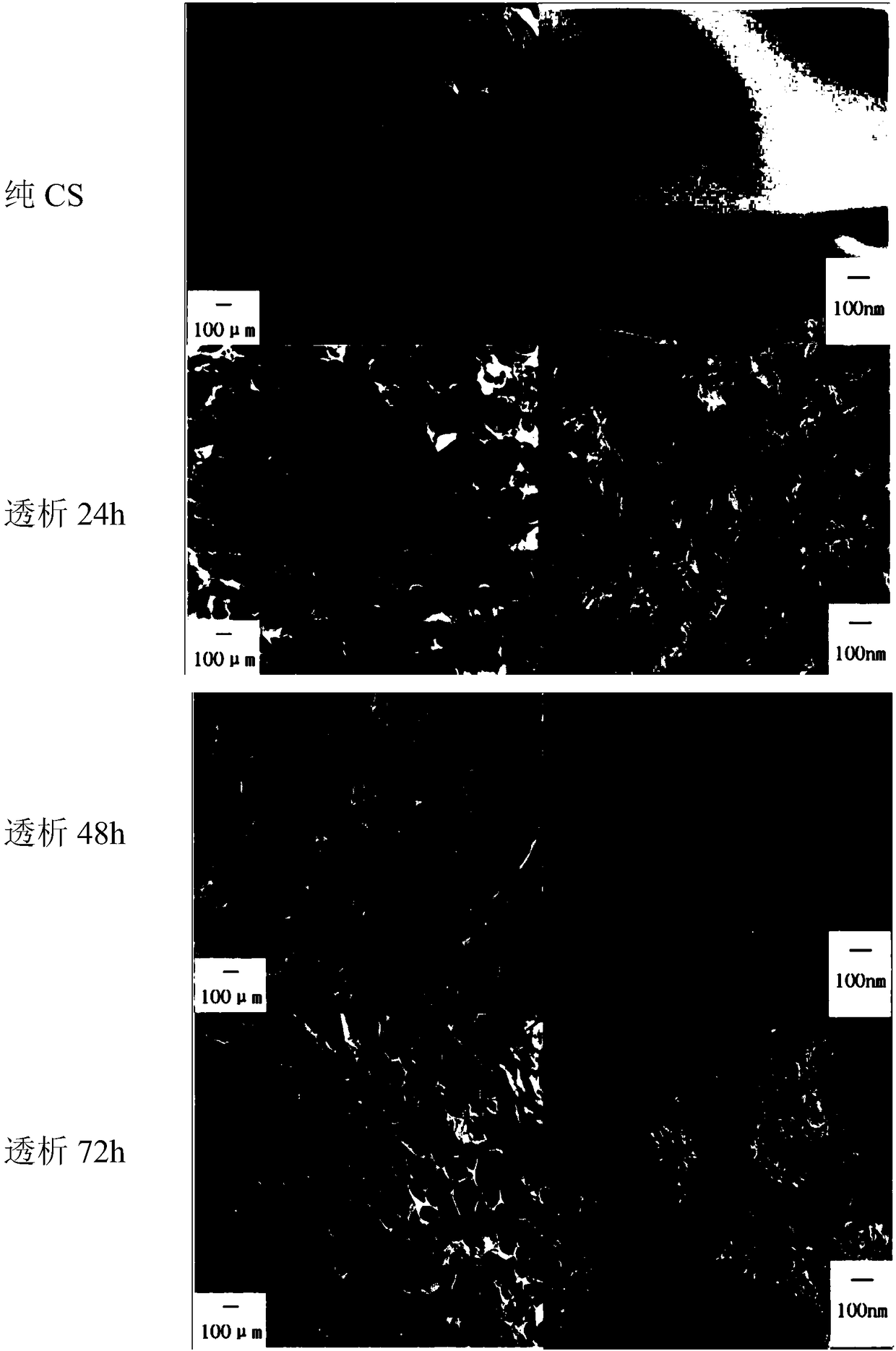

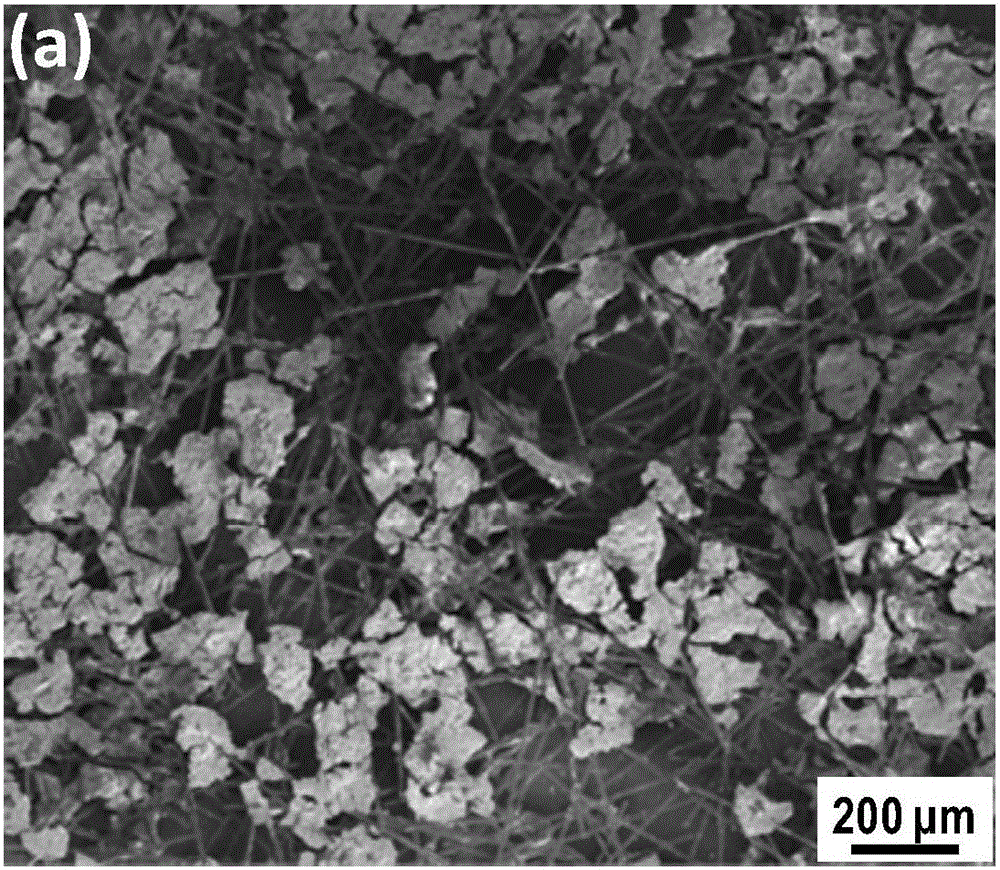

Nanometer hydroxyapatite/chitosan porous composite scaffold material as well as bionic dialysis mineralization preparation method and application thereof

InactiveCN108478880AGood biocompatibilityHigh biosecurityTissue regenerationProsthesisFreeze-dryingPorous composite

The invention belongs to the technical field of bone tissue engineering, and discloses a nanometer hydroxyapatite / chitosan porous composite scaffold material as well as a bionic dialysis mineralization preparation method and application thereof. The method comprises the following steps that (1) chitosan is dissolved in an acetic acid solution to obtain a chitosan solution; the chitosan solution isput into a container for freezing; freeze drying is performed to obtain an early-period chitosan porous scaffold; (2) the early-period chitosan porous scaffold is soaked in alkali liquid; water washing is performed until the pH is 7 to 8; freeze drying is performed to obtain a chitosan porous scaffold; (3) the chitosan porous scaffold is soaked in an alkaline phosphatase solution; then, the chitosan porous scaffold and the alkaline phosphatase solution are charged into a dialysis bag; the dialysis bag is put into a mixed solution of calcium glycerophosphate and CaCl2; constant-temperature constant-speed stirring is performed for mineralization; taking out, washing and freeze drying are performed to obtain the nanometer hydroxyapatite / chitosan porous composite scaffold material. The nanometer hydroxyapatite / chitosan porous composite scaffold material can be applied to the field of bone tissue engineering, particularly the bone defect repair.

Owner:JINAN UNIVERSITY

Method for improving sulforaphene stability

The invention relates to a method for improving sulforaphene stability. The sulforaphene is called SFE for short. The method comprises the following steps: dissolving the SFE into polyethylene glycol PEG, mixing uniformly, encapsulating in a closed container or dissolving the SFE in plant oil, fully mixing and encapsulating in the closed container. The added plant oil is one or more mixtures of soybean oil, corn oil, peanut oil, sesame oil, cottonseed oil, linseed oil, castor oil, rapeseed oil, sunflower seed oil, camellia oleosa seed oil and olive oil. By adopting the method, relative to the SFE, the water activity in the SFE is reduced, the stability of the SFE is improved, the stability of the SFE in the storage and transportation process is additionally achieved and the large-scale industrial application of the SFE for storage and transportation can be realized.

Owner:BEIJING UNIV OF CHEM TECH

Zirconium diboride-based composite material toughened by colloid-dispersed chopped carbon fibers and preparation method thereof

ActiveCN105906360AReduce the degradation rateReduce chemical reactionsPhenol formaldehyde resinAnhydrous ethanol

The invention discloses a zirconium diboride-based composite material toughened by colloid-dispersed chopped carbon fibers and a preparation method thereof and belongs to the technical field of ultrahigh-temperature ceramic-based composite materials. The zirconium diboride-based composite material is prepared from the raw materials including, by mass, 1-3 parts of the chopped carbon fibers, 15-25 parts of nano zirconium diboride powder, 1-3 parts of nano silicon carbide powder, 1-5 parts of phenolic resin, 0.1-0.5 parts of polyethyleneimine, and 60-100 parts of anhydrous ethanol. In the invention, the phenolic resin and the polyethyleneimine are subjected to a crosslinking reaction, wherein the short carbon fibers are uniformly dispersed in the colloid, thereby overcoming a problem of abrasion of the fibers during conventional ball-milling material blending. Through the colloid dispersion method, a high-temperature protective layer is formed on the surface of the carbon fibers, and further degradation rate during high-temperature sintering of the carbon fibers is reduced, interface bonding among fiber substrates is weakened, and debonding, bridge connection and pulling-out of the fibers are promoted. The zirconium diboride-based composite material has high compactness, high strength and high toughness.

Owner:DALIAN UNIV OF TECH

Degradable Zn-Ag series zinc alloy and preparing method and application thereof

InactiveCN110241330AReduce corrosion potentialImprove corrosion resistanceSurgeryTrace element compositionZinc alloys

The invention provides a degradable Zn-Ag series zinc alloy and a preparing method and application thereof. The zinc alloy is composed of Zn, Ag and a microelement. The mass percent of the Zn ranges from 89.85 to 99.4%, the mass percent of the Ag ranges from 0.01 to 10%, and microelement comprises one or multiple of Fe, Mg, Ca, Sr and Li. The mass percent of the microelement ranges from 0.01 to 0.55%. The method comprises the steps of heating metal zinc to be molten after burdening, adding metal silver, performing stirring until the metal silver is molten, adding the microelement, performing stirring, standing and pouring, and obtaining a zinc alloy cast ingot; and performing heat treatment and heat preservation on the zinc alloy cast ingot, and finally performing extrusion forming. The made zinc alloy has the higher strength and ultra-high plasticity, good anti-bacterium effect is achieved, and the alloy can serve as a degradable medical device implant to be applied into the human body to be subjected to non-toxic degradation.

Owner:湖南华耀百奥医疗科技有限公司

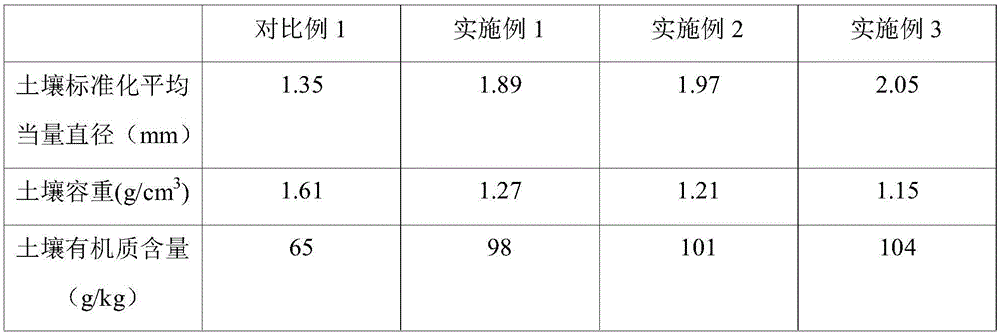

Soil conditioner for preventing soil hardening and preparation method of soil conditioner

InactiveCN106699355AReduce the degradation ratePrevent compactionCalcareous fertilisersBio-organic fraction processingMicrobial agentMonopotassium phosphate

The invention discloses a soil conditioner for preventing soil hardening. The soil conditioner is prepared from the following raw materials: rice husks, wheat hulls, banana fiber, cocoanut fiber, barks, turf, leguminous plant straws, bean cakes, vinasse, coffee residues, rape seed cakes, cottonseed cakes, fish meal, bone meal, medical stone powder, zeolite powder, bentonite, urea, ammonium sulfate, monopotassium phosphate, ferrous sulfate, magnesium sulfate, zinc sulfate, potassium chloride, calcium superphosphate, calcium peroxide, magnesium peroxide, borax, an agricultural water-retaining agent and a microbial agent. The invention further provides a preparation method of the soil conditioner for preventing soil hardening. The soil conditioner disclosed by the invention is low in raw material cost and scientific in component, and can well adjust the soil structure and prevent the soil hardening.

Owner:广西科茂信息咨询有限公司

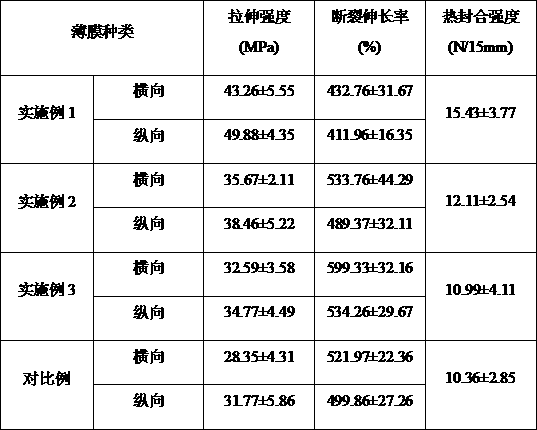

Low-cost high-biology-base full-biodegradable multi-layer coextrusion film for waistcoat pocket and preparation method of coextrusion film

InactiveCN109367173ALow costSolve the problem of "white pollution"Synthetic resin layered productsLaminationBlow moldingThermoplastic

A polylactic acid / polyadipate-butylene terephthalate (PLA / PBAT) modified material and a polyadipate-butylene terephthalate / thermoplastic starch (PBAT / TPS) modified material which can meet the blow molding requirement are prepared through melting reaction in a blending manner based on a multi-element blending modification technique of fully biodegradable materials; and a full-biodegrade three-layercoextrusion film is prepared by virtue of a multilayer coextrusion technique, the upper and lower layers are PLA / PBAT modified films, and the middle layer is a PBAT / TPS modifying film. The biology base content of the film can reach up to over 50%, the tensile strength is higher than that of a traditional PE film, the cost is relatively low, and the film has very important significances to the solving of ''white pollution'' problem and the promotion of the application of a full-biodegrade material in the field of waistcoat pockets.

Owner:束建军

Voltage dynamic balance management system of power lithium battery pack

InactiveCN102761165APrevent overchargingPrevent overcurrentBatteries circuit arrangementsElectric powerElectrical batteryMicroprocessor

The invention provides a voltage dynamic balance management system of a power lithium battery pack, which relates to a charging and discharging balancing circuit of a series power battery pack. The voltage dynamic balance management system comprises a microprocessor, Hall sensor modules, channel selecting modules, a switch driving circuit module and a DC / DC (Direct Current / Direct Current) transformer, wherein the microprocessor is used for gating a single battery in the battery pack by a first channel selecting module; an input end of the DC / DC transformer is connected with two ends of the battery pack; an output end of the DC / DC transformer is connected with two ends of the single battery by the switch driving circuit module and the switch driving circuit module; an input end of a first Hall sensor module is connected with a charging current input end and a discharging current output end of a charging and discharging switch; an output end of the first Hall sensor module is connected with the microprocessor; an input end of a second Hall sensor module is connected with a balancing charging current output end of the switch driving circuit module; an output end of the second Hall sensor module is connected with an input port of the microprocessor; an input end of the switch driving circuit module is connected with an output end of a second channel selecting module; and an output end of the circuit driving circuit module is connected with two ends of the single battery of the battery pack.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com