Biomedical magnesium or magnesium alloy implantation material with multiple surface protection

A technology of magnesium alloys and polymer materials, applied in the field of biomedical materials and devices, can solve the problems of long research and development time, harm, and large research and development investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

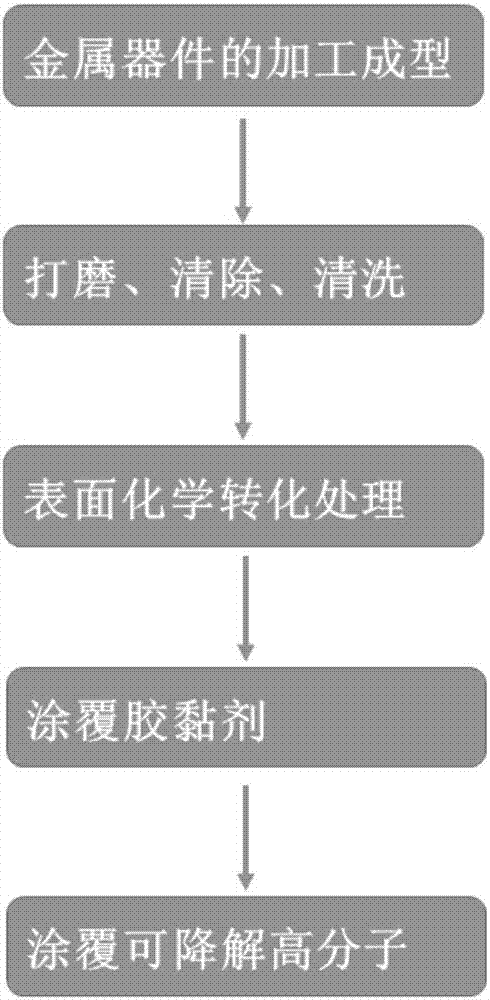

[0153] Embodiment 1, the preparation of the biomedical material or device of the magnesium alloy of tool composite protective coating or pure magnesium

[0154] (1) Processing magnesium / magnesium alloy materials into biomedical devices with specific shapes

[0155] The processing method adopted can be mechanical processing methods such as die-casting, extrusion and cutting commonly used for magnesium / magnesium alloys, and laser cutting or engraving can also be used.

[0156] (2) Surface cleaning

[0157] Surface cleaning includes mechanical cleaning and chemical cleaning. According to the surface oxidation degree of pure magnesium / magnesium alloy, common mechanical cleaning, chemical cleaning and ultrasonic cleaning methods can be used: the surface of pure magnesium / magnesium alloy is polished by abrasive belt, and mechanically removed Oxide on the surface, adjust the surface roughness; use a chromium trioxide aqueous solution with a concentration of 10-30wt.%, soak the magne...

Embodiment 2

[0176] Embodiment 2, the preparation of the pure magnesium needle of tool composite protective coating

[0177] (1) Processing and preparation of medical pure magnesium needles

[0178] Pure magnesium is made into needles with diameters of 0.6 mm and 1.2 mm and lengths of 30 mm and 50 mm respectively by die-casting. One end is sharpened with sandpaper and the surface is polished.

[0179] (2) Surface cleaning

[0180] 1) Cleaning with a chromium trioxide aqueous solution with a concentration of 10-30 wt.%.

[0181] 2) Ultrasonic cleaning with acetone.

[0182] 3) Ultrasonic cleaning with deionized water.

[0183] 4) Ultrasonic cleaning with absolute ethanol.

[0184] The ultrasonic frequency is 50kHz. The cleaning time of each step is 10 minutes, and the magnesium needles after cleaning are blown dry with nitrogen gas.

[0185] (3) Chemical conversion treatment

[0186] Soak the cleaned magnesium needle substrate in an aqueous solution containing 100g / L potassium perman...

Embodiment 3

[0192] Embodiment 3, the preparation of the magnesium alloy needle of tool composite protective coating

[0193] (1) Processing and preparation of magnesium alloy needles

[0194] The WE43 magnesium alloy was extruded to produce needles with diameters of 0.6mm and 1.2mm and lengths of 30mm and 50mm, one end was sharpened with sandpaper, and the surface was polished.

[0195] (2) Surface cleaning

[0196] 1) Use a chromium trioxide aqueous solution with a concentration of 15wt.% for cleaning.

[0197] 2) Ultrasonic cleaning with acetone.

[0198] 3) Ultrasonic cleaning with deionized water.

[0199] 4) Ultrasonic cleaning with absolute ethanol.

[0200] The ultrasonic frequency is 50kHz. The cleaning time of each step is 10 minutes, and the magnesium needles after cleaning are blown dry with nitrogen gas.

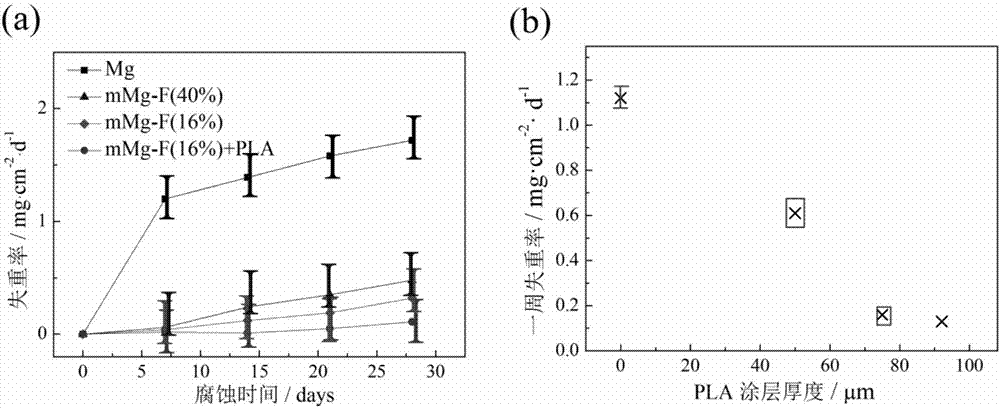

[0201] (3) Chemical conversion treatment

[0202] Soak the cleaned WE43 substrate in a hydrofluoric acid aqueous solution with a concentration of 16% (mass percentage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com