Patents

Literature

110 results about "Biodegradable magnesium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

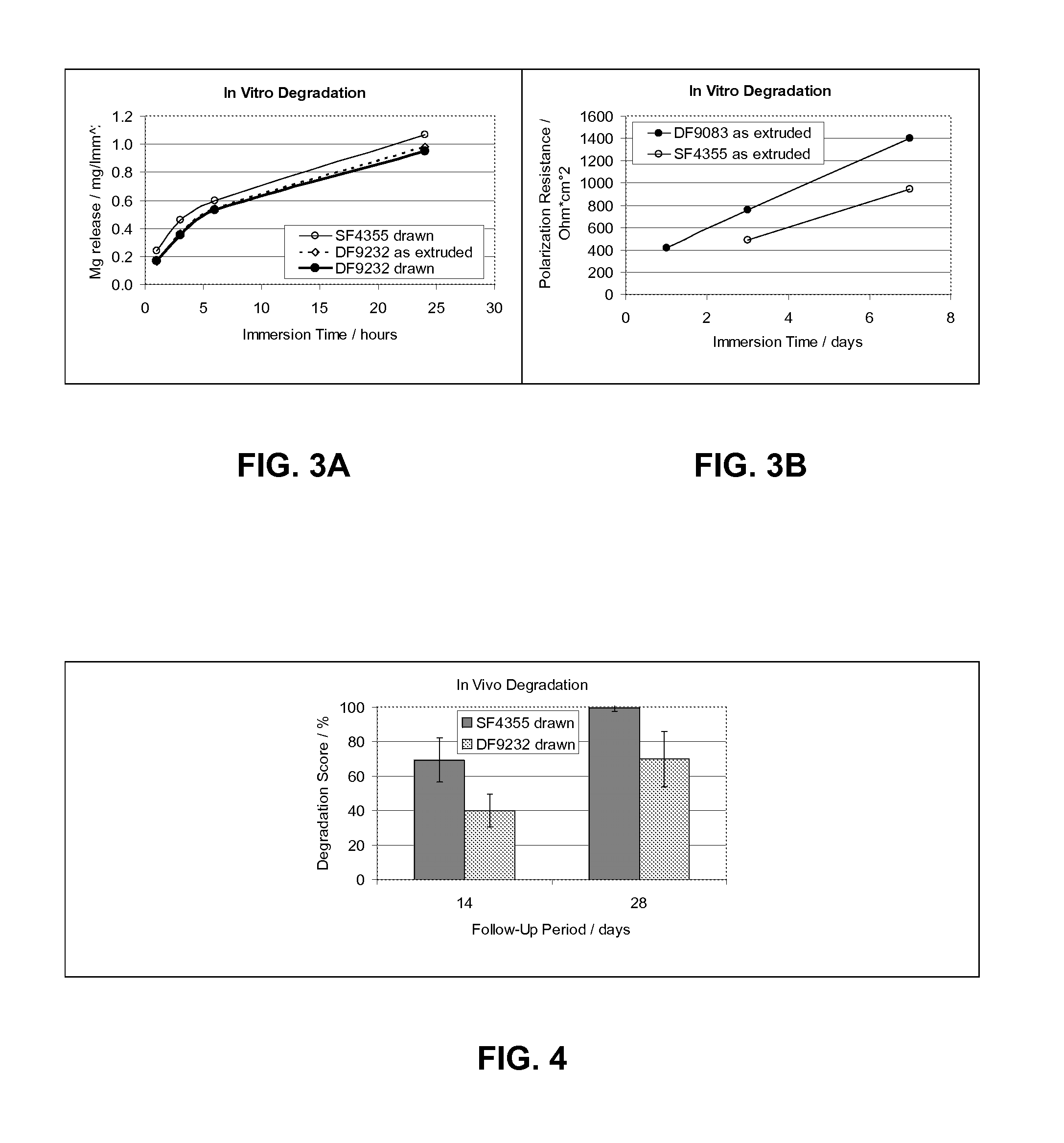

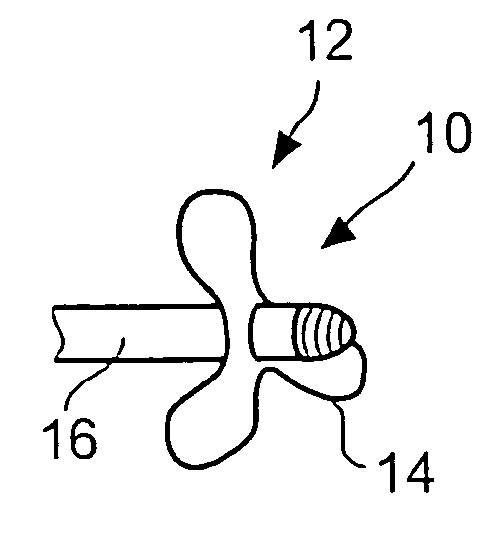

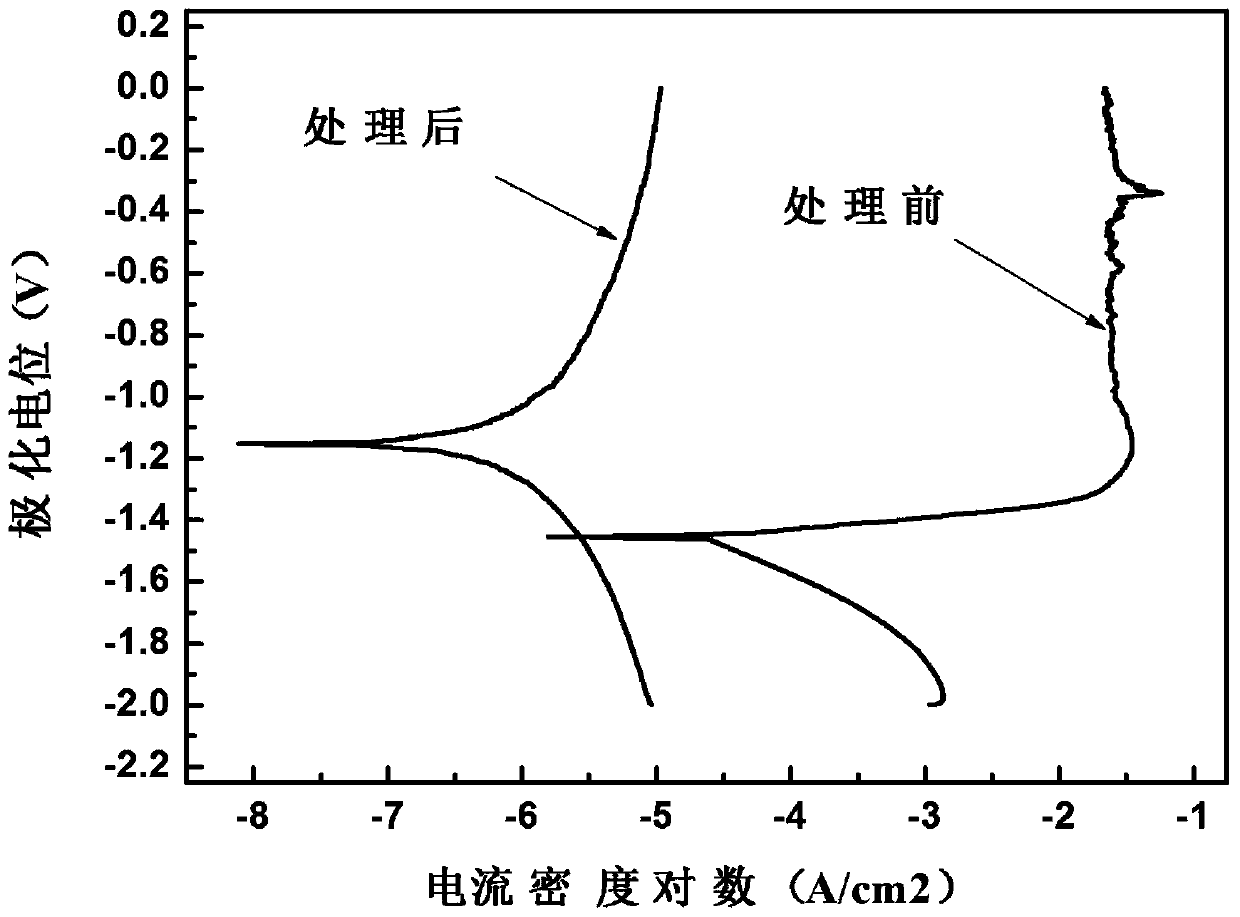

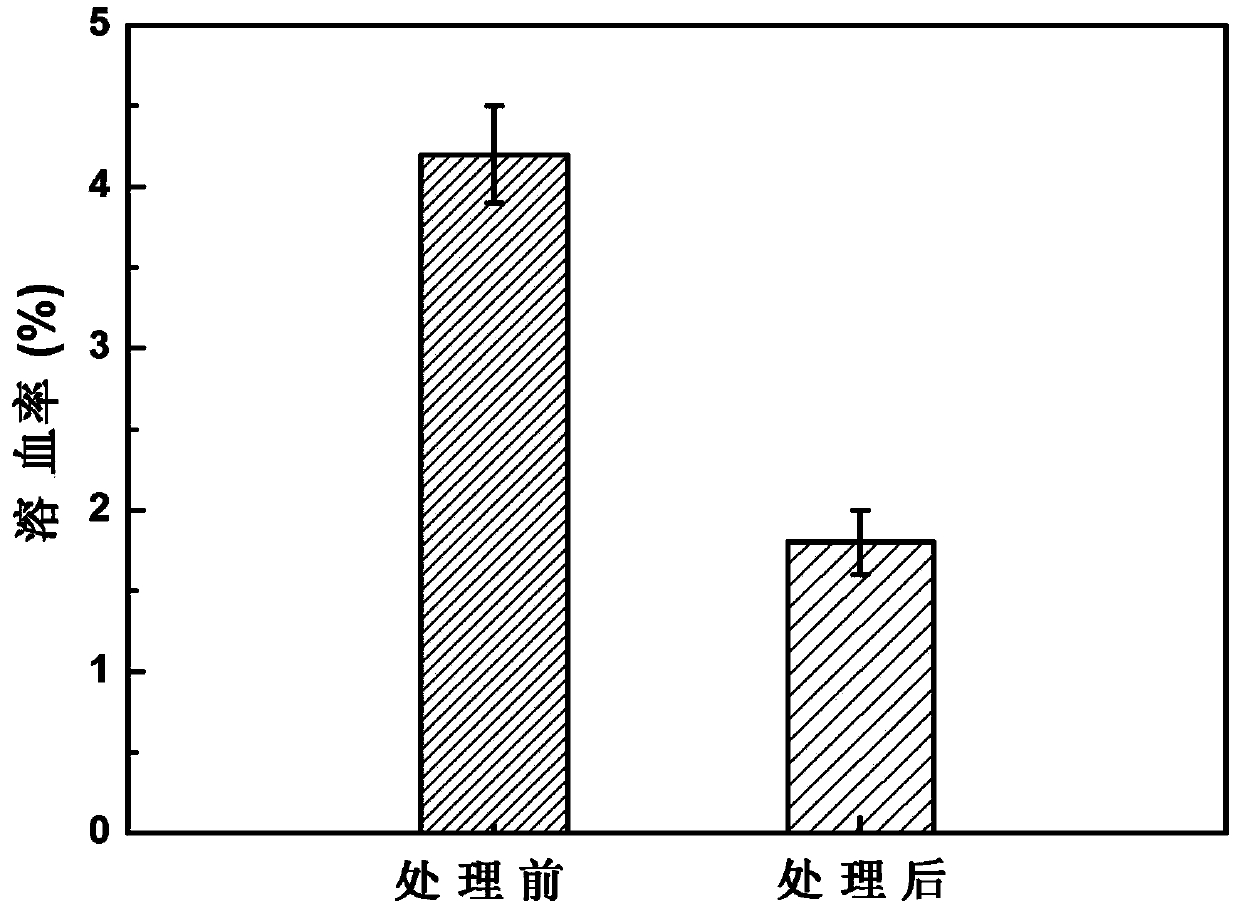

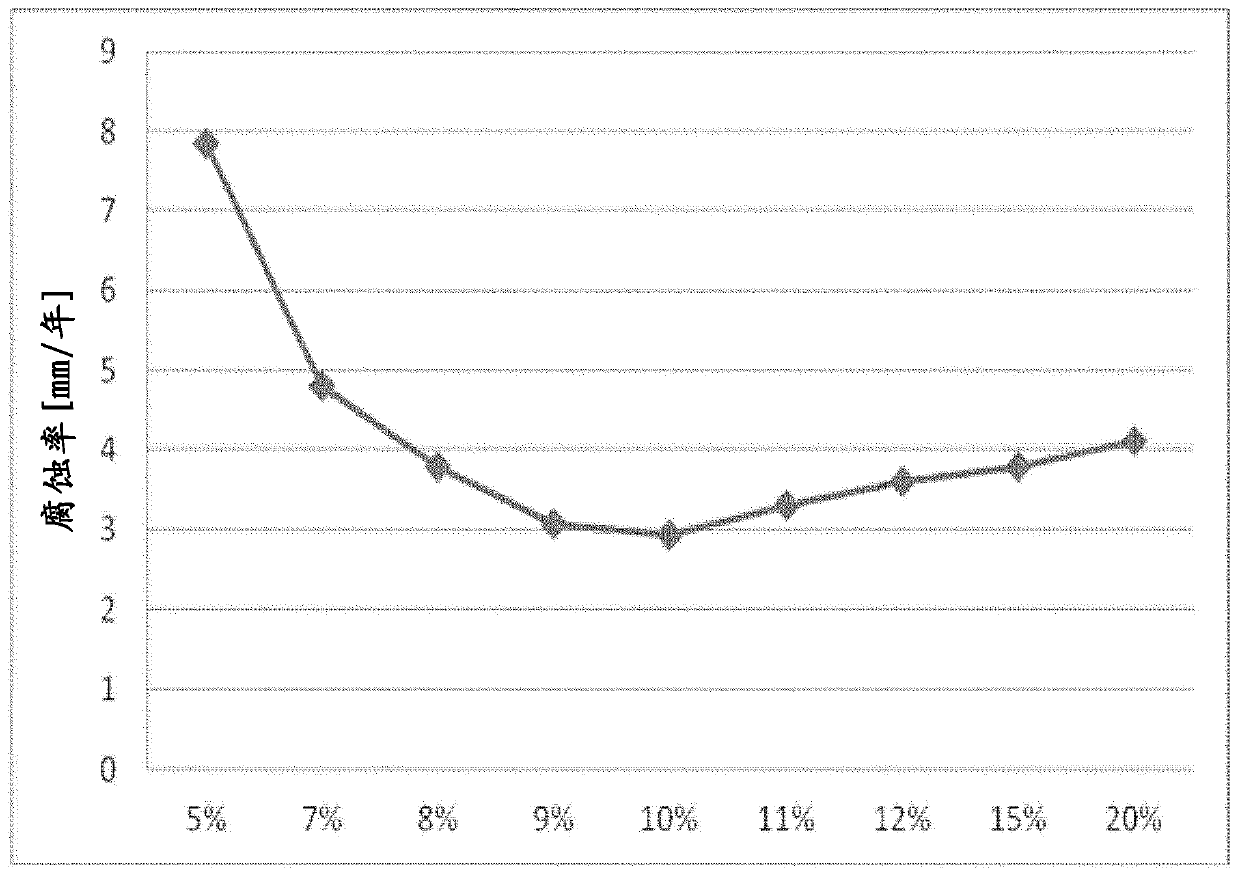

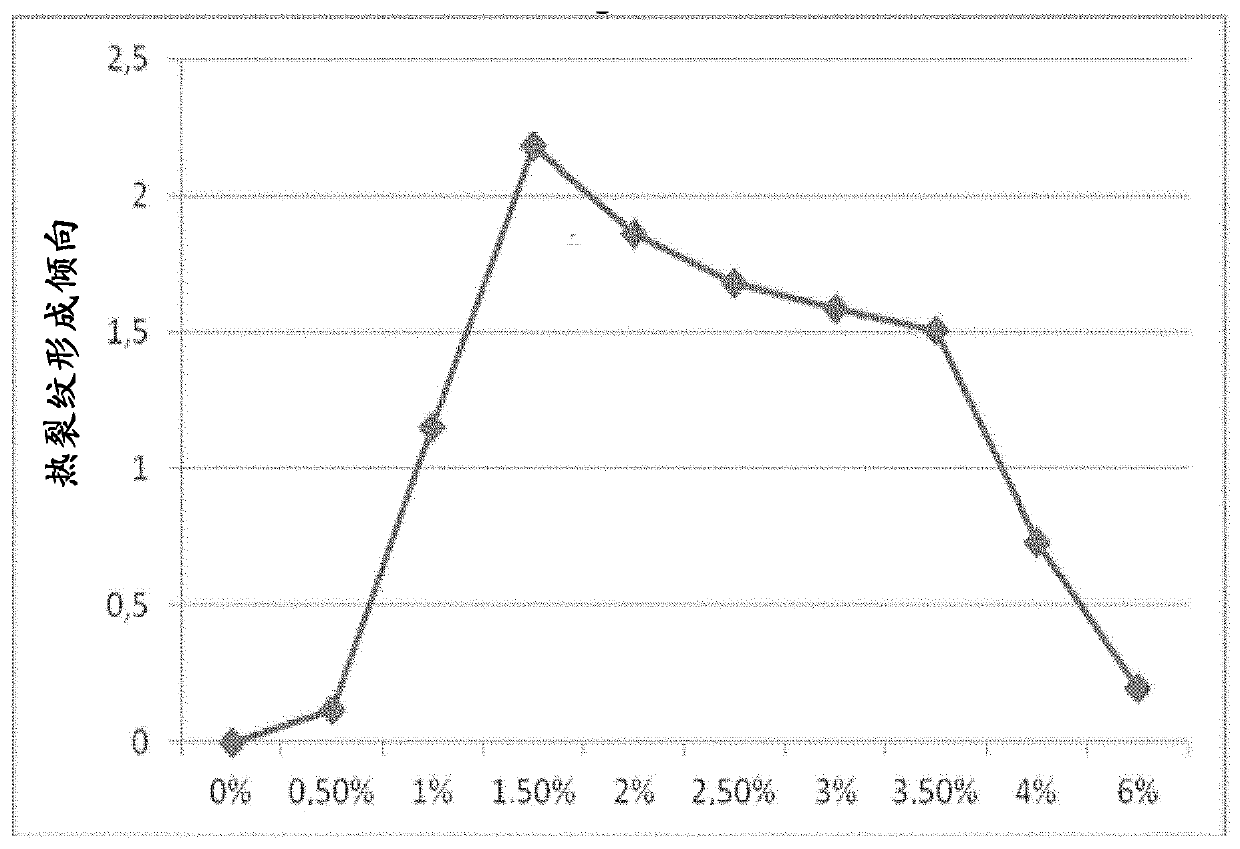

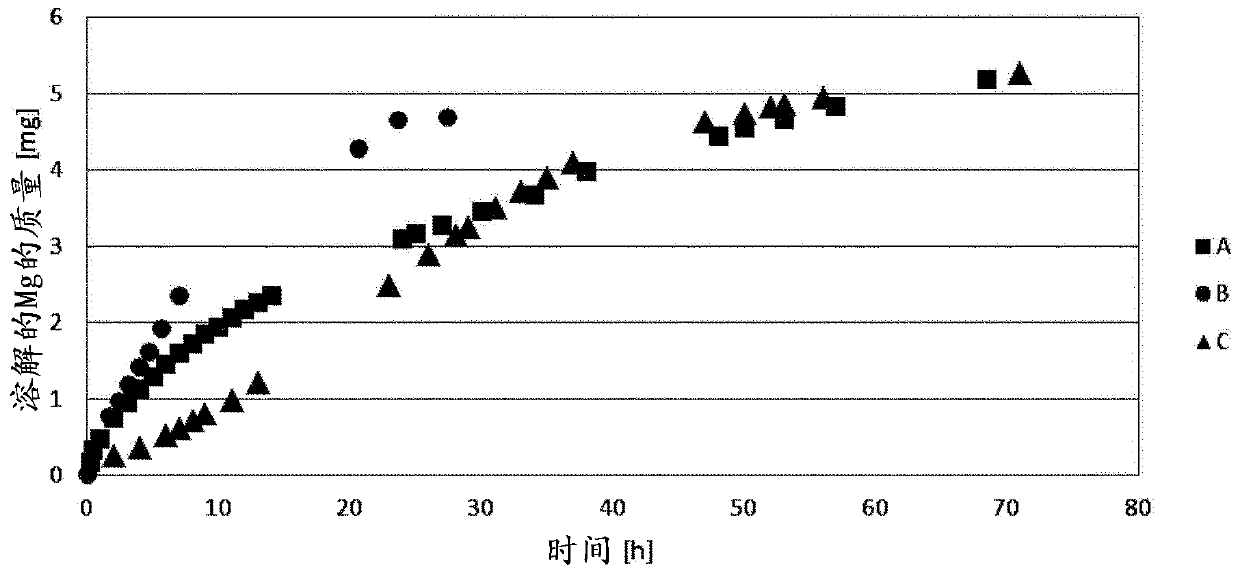

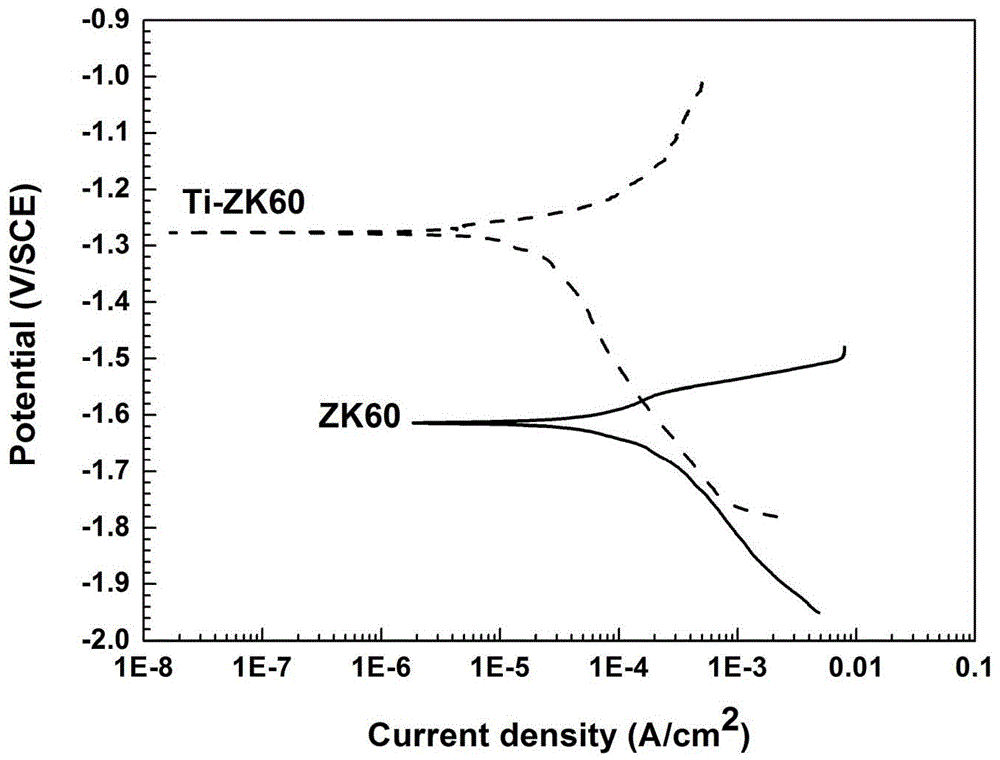

Magnesium has been suggested as a revolutionary biodegradable metal for biomedical applications. The corrosion of magnesium, however, is too rapid to match the rates of tissue healing and, additionally, exhibits the localized corrosion mechanism.

Implants and methods for treating bone

ActiveUS20060089715A1Eliminate needInternal osteosythesisSpinal implantsVertebra compression fractureBiodegradable magnesium

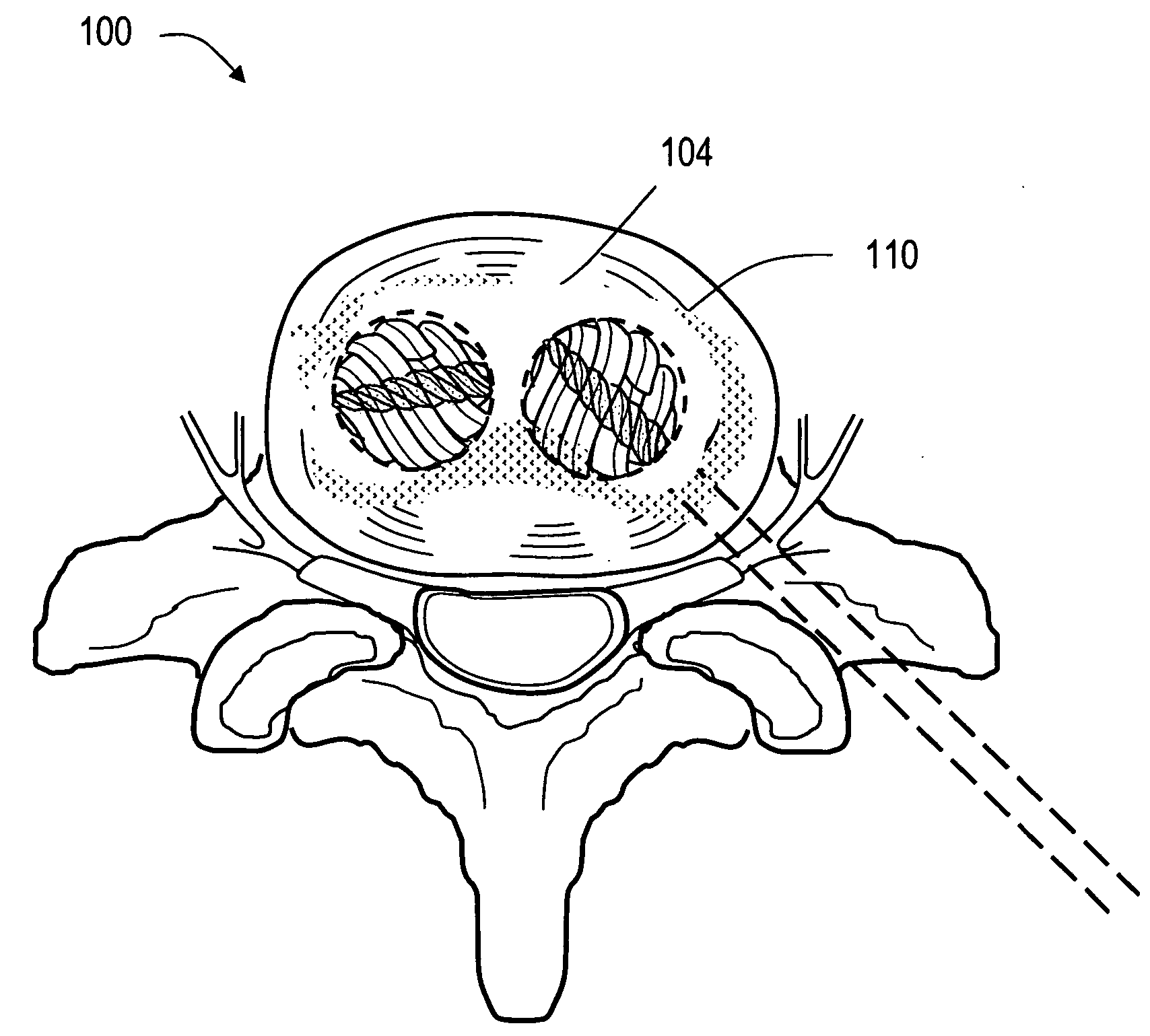

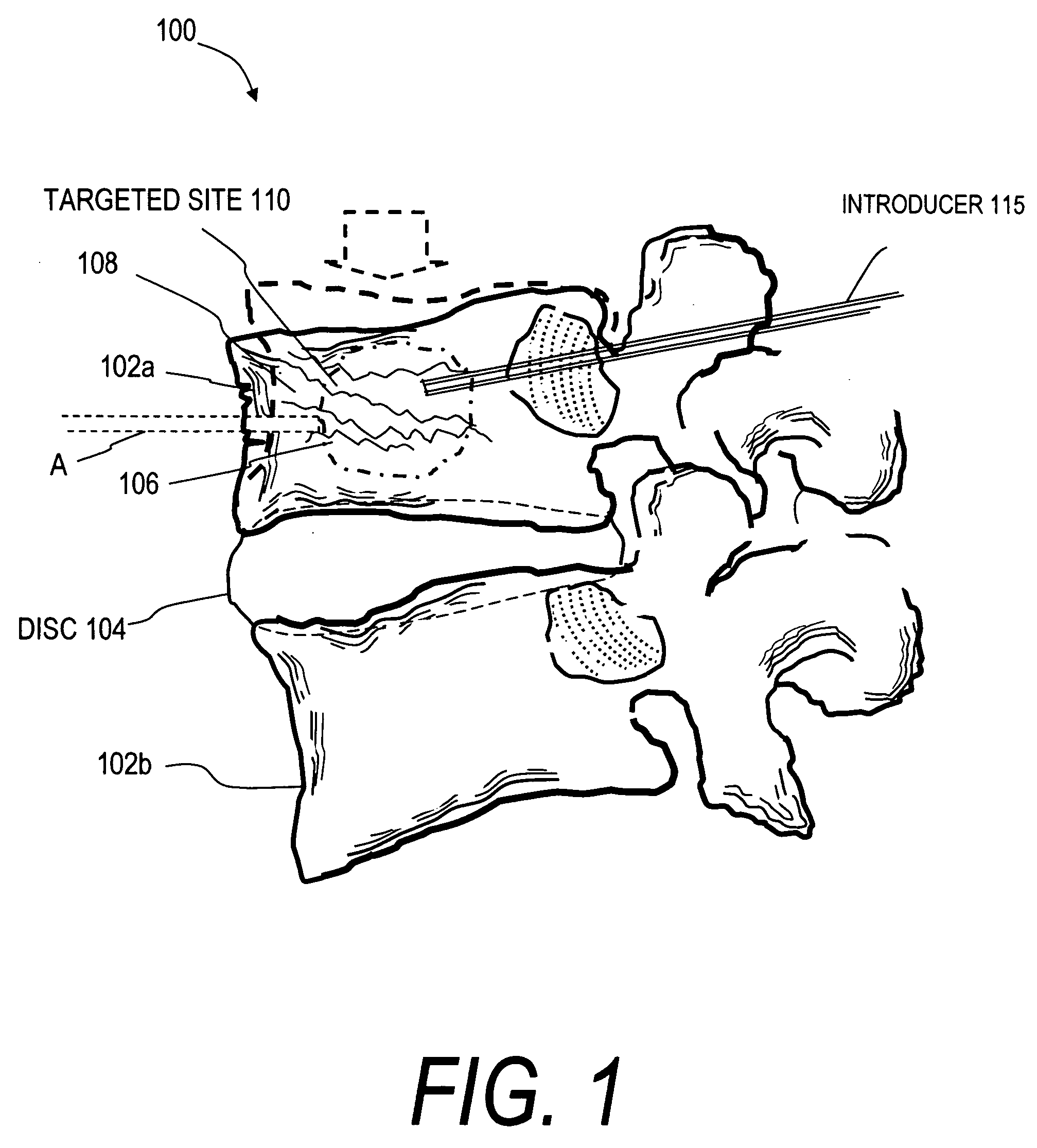

An orthopedic implant comprising a deformable, expandable implant body configured for treating abnormalities in bones, such as compression fractures of vertebra, necrosis of femurs and the like. An exemplary implant body comprises a small cross-section threaded element that is introduced into a bone region and thereafter is expanded into a larger cross-section, monolithic assembly to provide a bone support. In one embodiment, the implant body is at least partly fabricated of a magnesium alloy that is biodegradable to allow for later tissue ingrowth.

Owner:DFINE INC

Biodegradable Magnesium Based Metallic Material for Medical Use

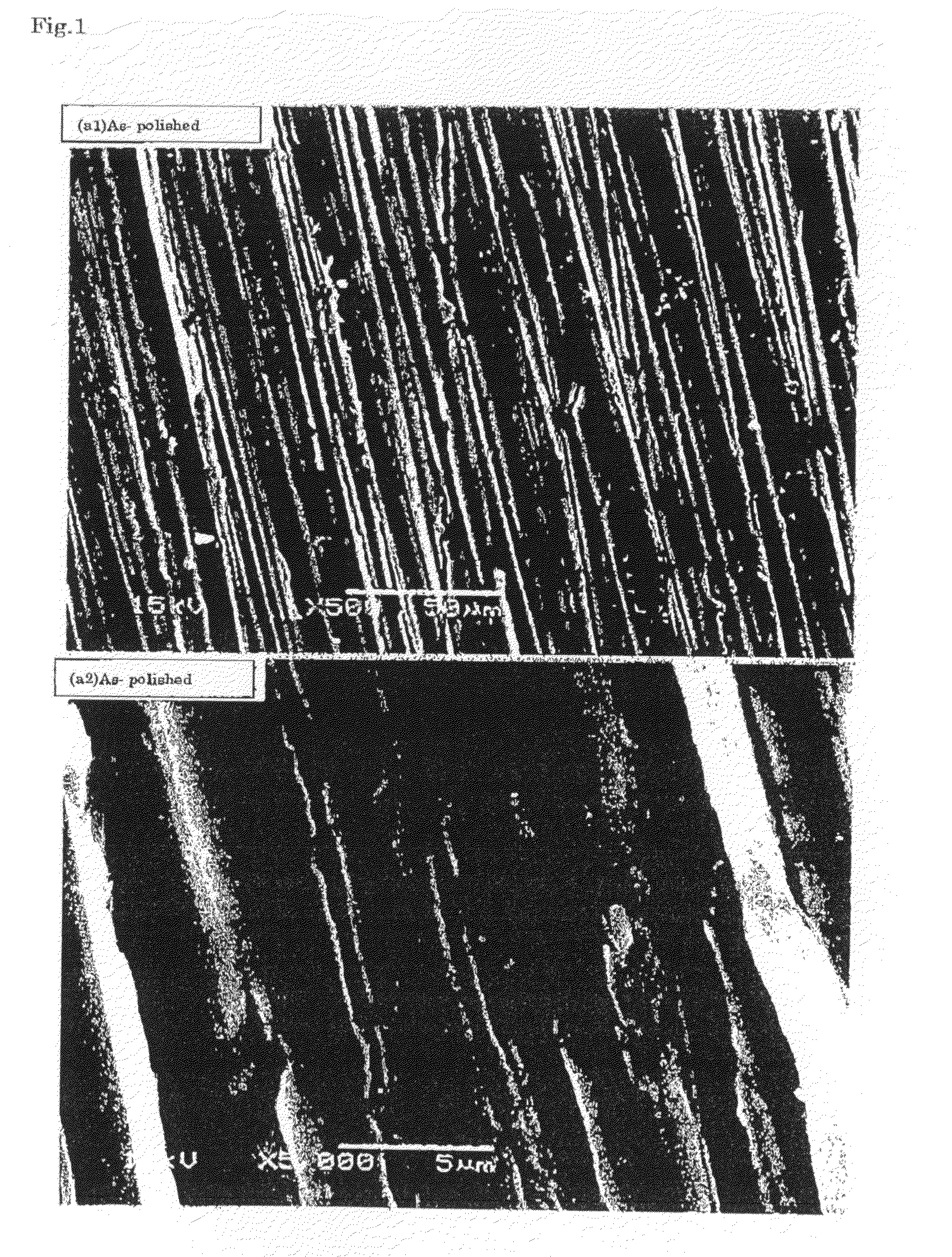

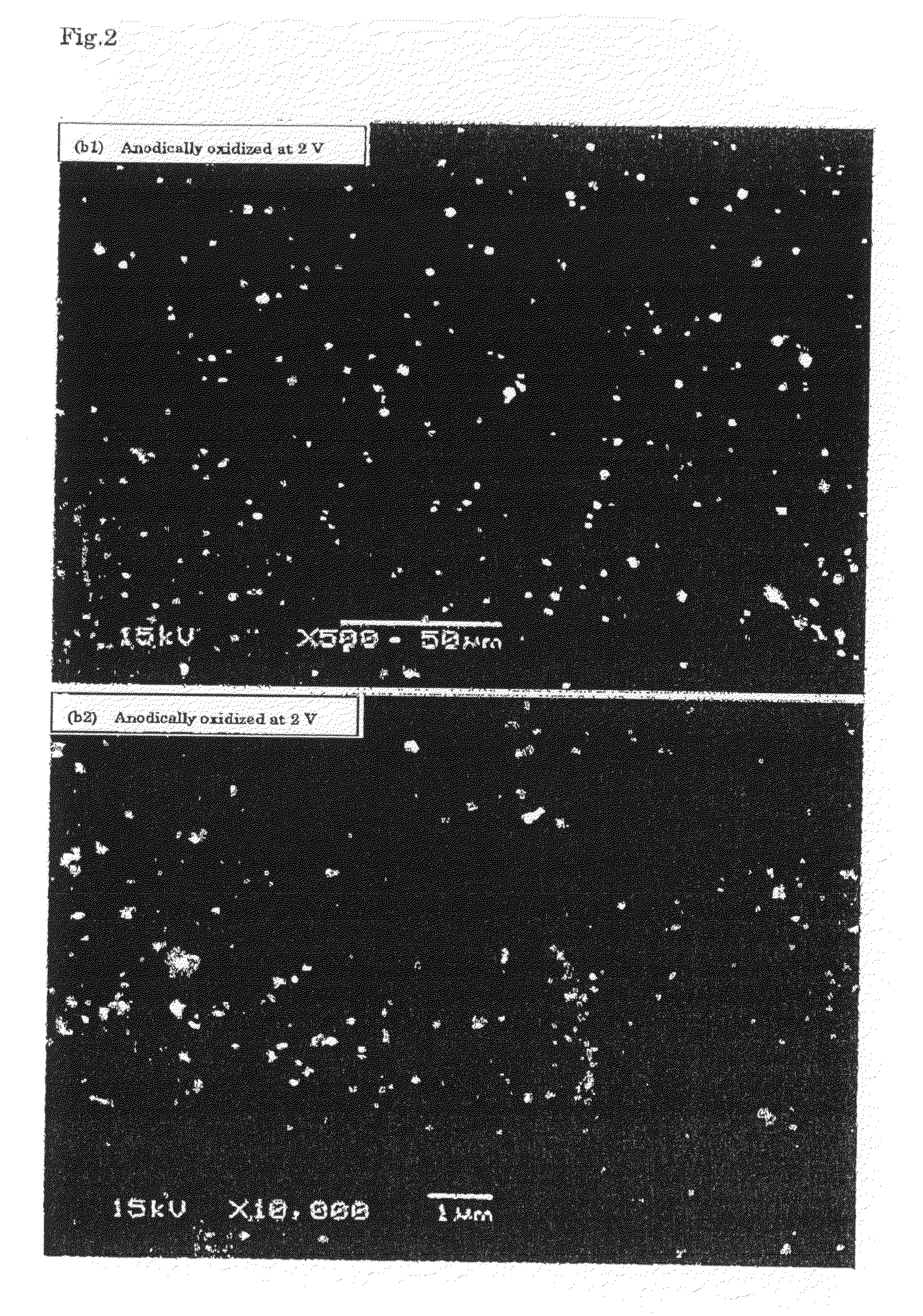

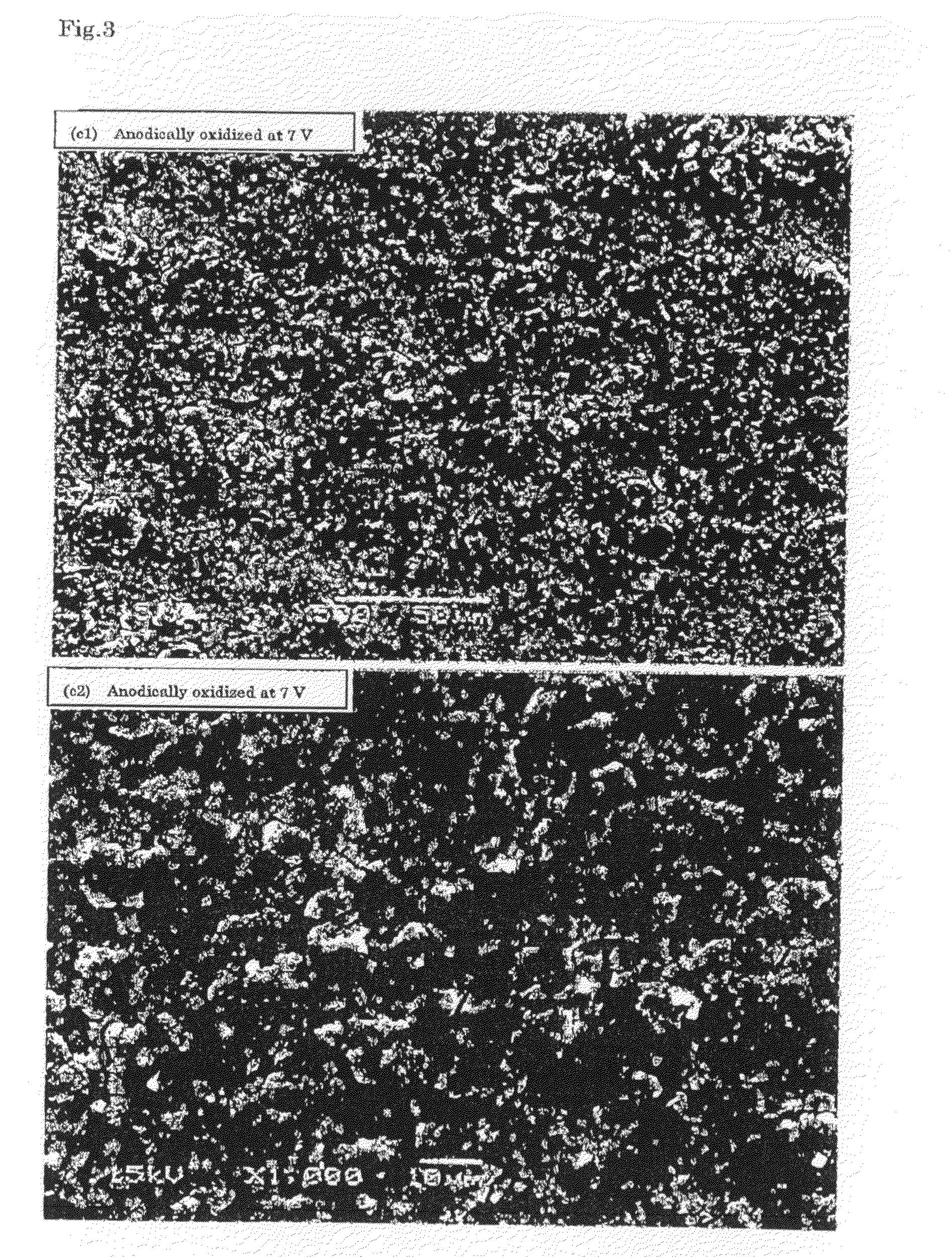

InactiveUS20090131540A1Suppressing deterioration of mechanical strengthImprove compatibilityBiocideInorganic non-active ingredientsRetention timeMetallic materials

A biodegradable magnesium based metallic material for medical use which is degraded and absorbed in vivo, characterized by comprising a film, which contains magnesium oxide and magnesium hydroxide and is formed on the surface of crystallized magnesium or a magnesium alloy by anodic oxidation. This magnesium based metallic material is capable of exhibiting desired mechanical properties such as strength and ductility at an early stage of implantation without changing the mechanical properties inherent to magnesium or its alloy and also controlling the retention time of the mechanical properties to be short or long in a desired manner.

Owner:NAT INST FOR MATERIALS SCI

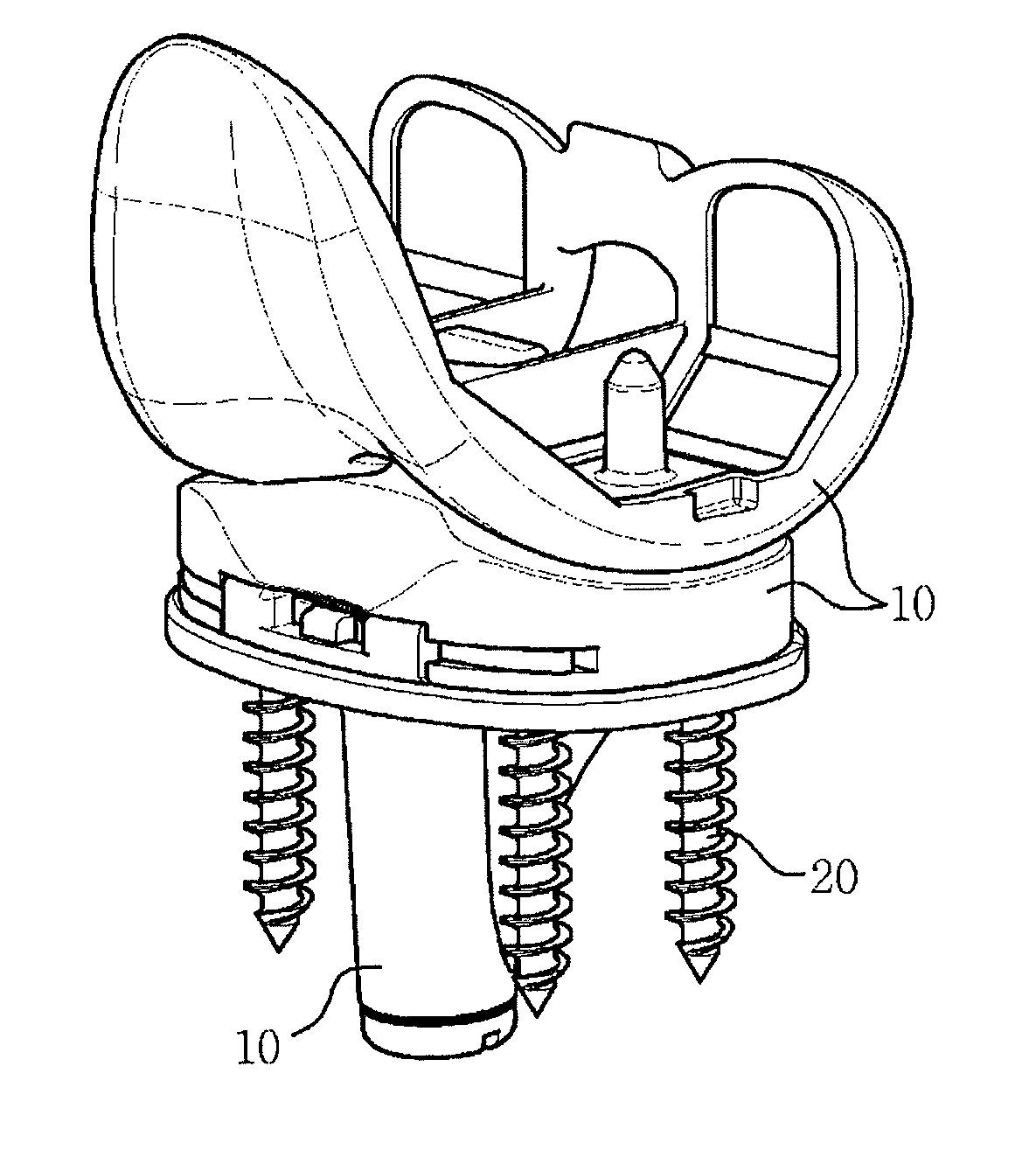

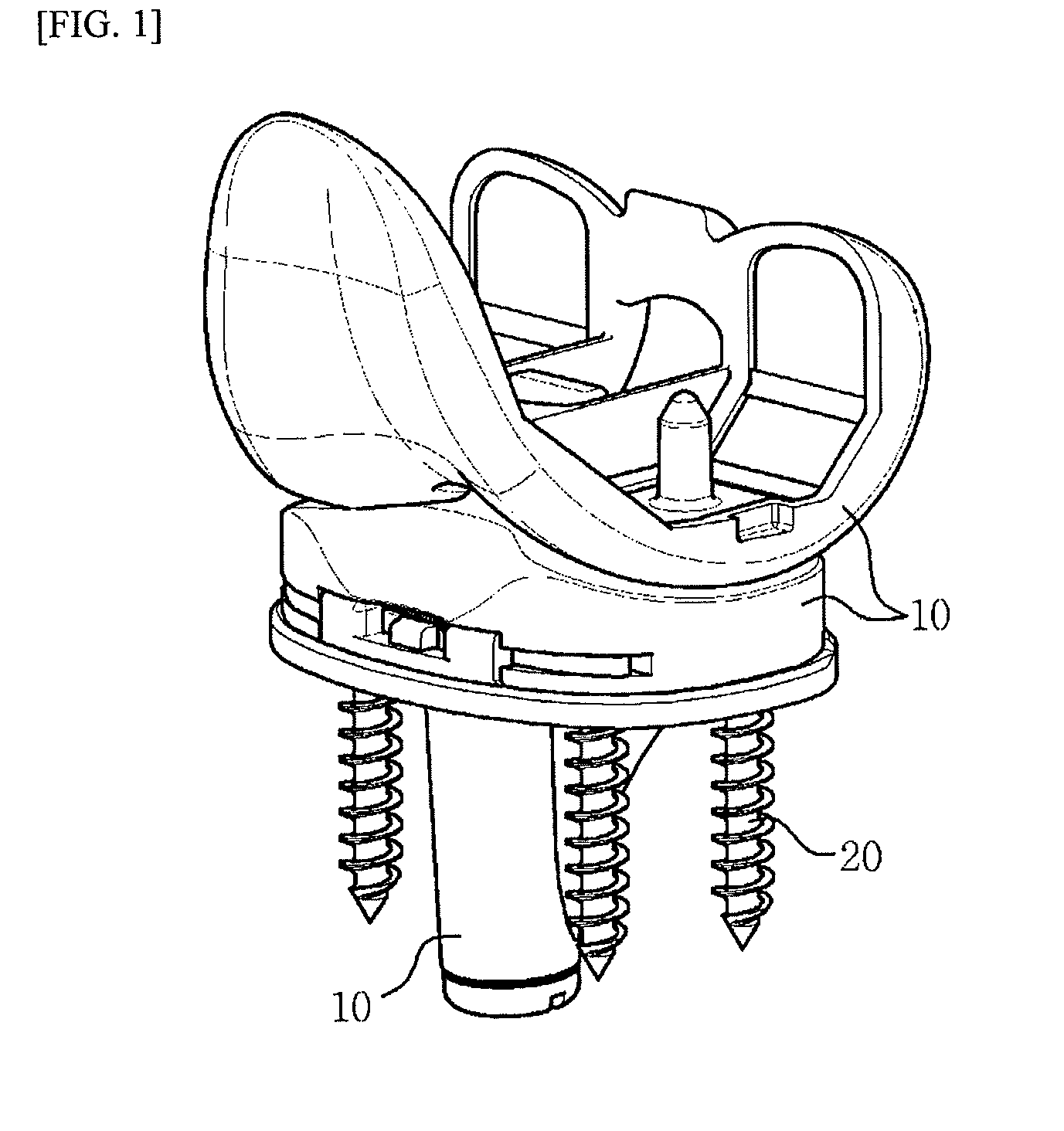

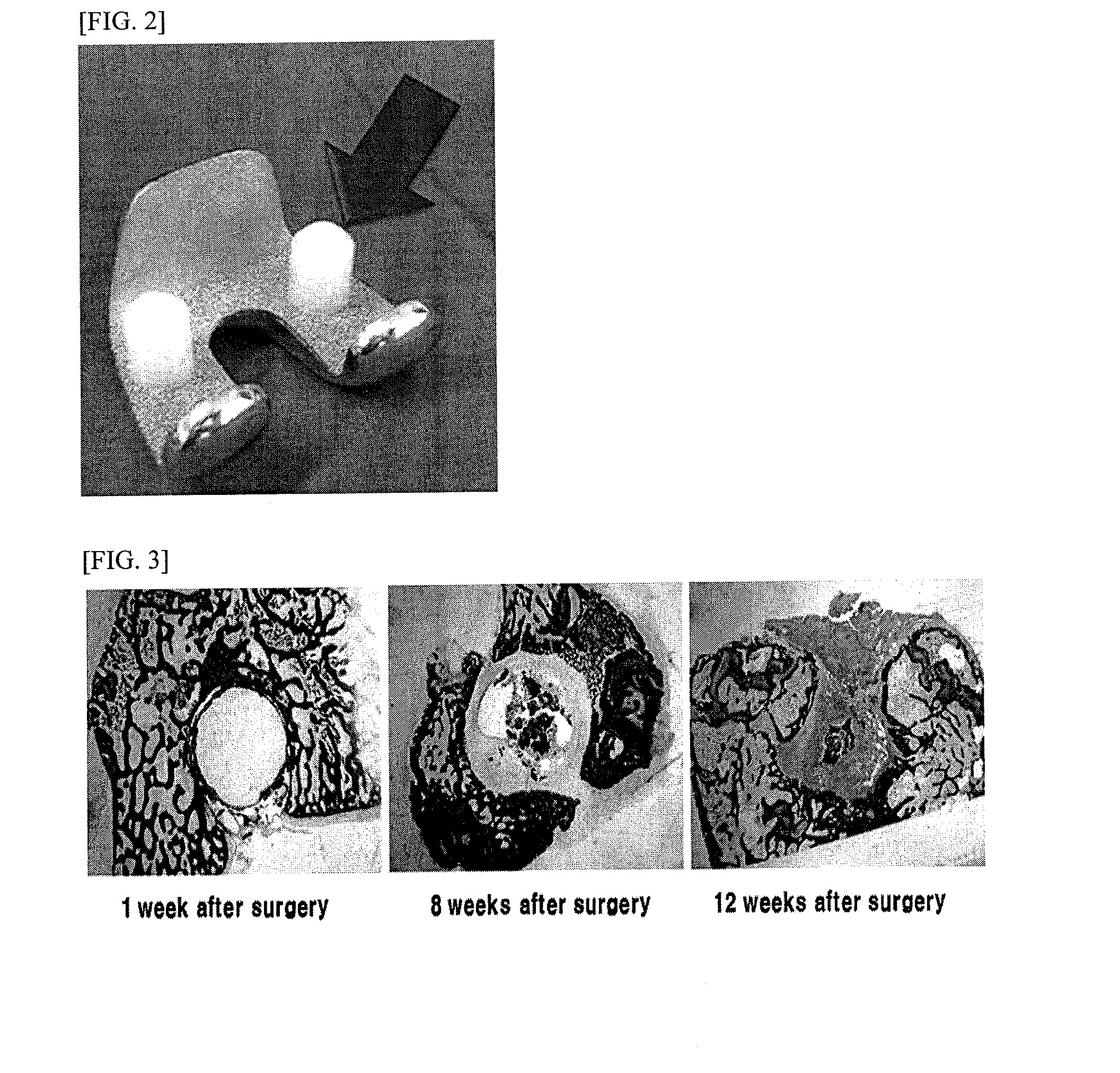

Implants comprising biodegradable metals and method for manufacturing the same

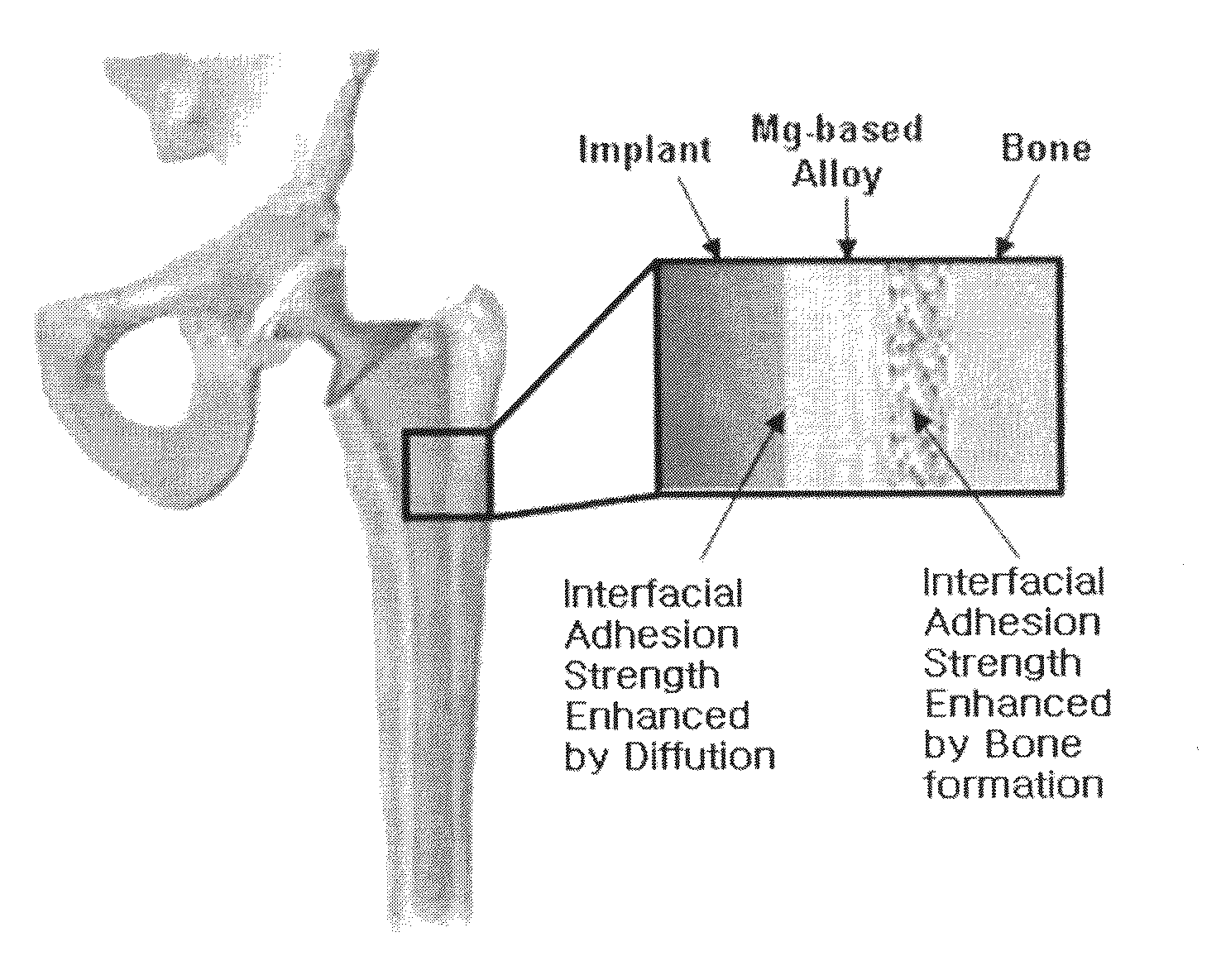

InactiveUS20100075162A1High strengthImprove interface strengthDental implantsInternal osteosythesisUltimate tensile strengthBiodegradable magnesium

The present invention provides an implant consisting of a biodegradable magnesium-based alloy or partially applied with the magnesium-based alloy, and a method for manufacturing the same. The implant according to the present invention is biodegradable, in which its biodegradation rate can be easily controlled, and the implant has excellent strength and interfacial strength to an osseous tissue.

Owner:U & I INC

Method for preparing biodegradable magnesium alloy intravascular stent

The invention discloses a method for preparing a biodegradable magnesium alloy intravascular stent in the technical field of biological materials. The method comprises the following steps of: performing stress relief annealing treatment on a magnesium alloy extrusion bar of phi20mm; processing the annealed bar into a tube blank, and extruding the tube blank; performing stress relief annealing treatment on the extruded capillary tube; cutting the annealed capillary tube to form a stent blank by laser; acid-washing and ultrasonically cleaning the cut stent in an ultrasonic cleaner to remove thecut residues; and performing electrochemical polish, ultrasonic cleaning and passivation on the stent. The extruded magnesium alloy capillary tube has uniform tube wall thickness and smooth surface, the tensile strength of the capillary tube can reach 320 to 370MPa, the yield strength can reach 260 to 300MPa, the elongation can reach 24 to 30 percent, and the corrosion rate of the capillary tube in simulated body fluid is 0.14 to 0.24mm / year. The polished intravascular stent has flat, smooth and bright internal and external surfaces. The preparation method provided by the invention can prepare the biodegradable intravascular stent meeting the clinical requirement.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

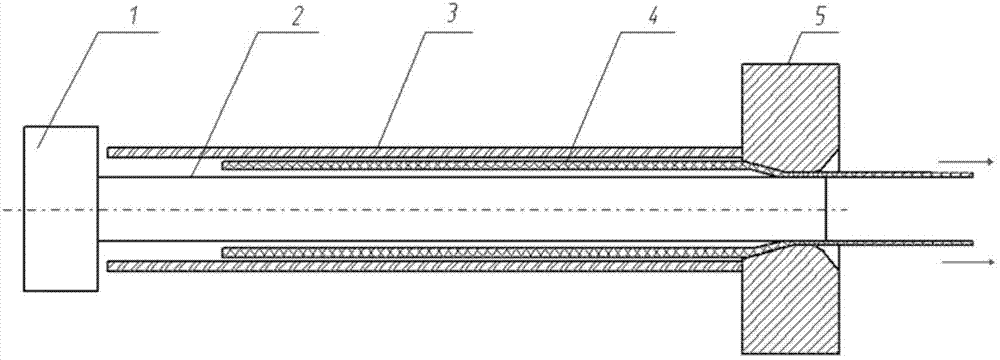

Precise machining method for capillary tube for biodegradable magnesium alloy intravascular stent

ActiveCN103394545ASmall sizeImprove surface qualityRoll mill control devicesMetal rolling arrangementsStress reliefIntravascular stent

The invention discloses a precise machining method for a capillary tube for a biodegradable magnesium alloy intravascular stent. The method comprises the following steps of: step 1, performing stress relief annealing and machining on a magnesium alloy extrusion bar to obtain a tube blank; step 2, extruding the tube blank to obtain a seamless extrusion tube blank, and performing stress relief annealing; step 3, performing multi-pass rolling and annealing on the annealed seamless extrusion tube blank to obtain a thin tube blank; and step 4, performing multi-pass drawing and annealing on the thin tube blank to obtain the capillary tube for the biodegradable magnesium alloy intravascular stent. The capillary tube produced by the method disclosed by the invention is accurate in dimension (a wall thickness error is not greater than 5%), can be more than 1 metre long, is high in surface quality, uniform in matrix structure, excellent in mechanical property, low in machining cost and high in machining efficiency, and can be subjected to industrialized batch production.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

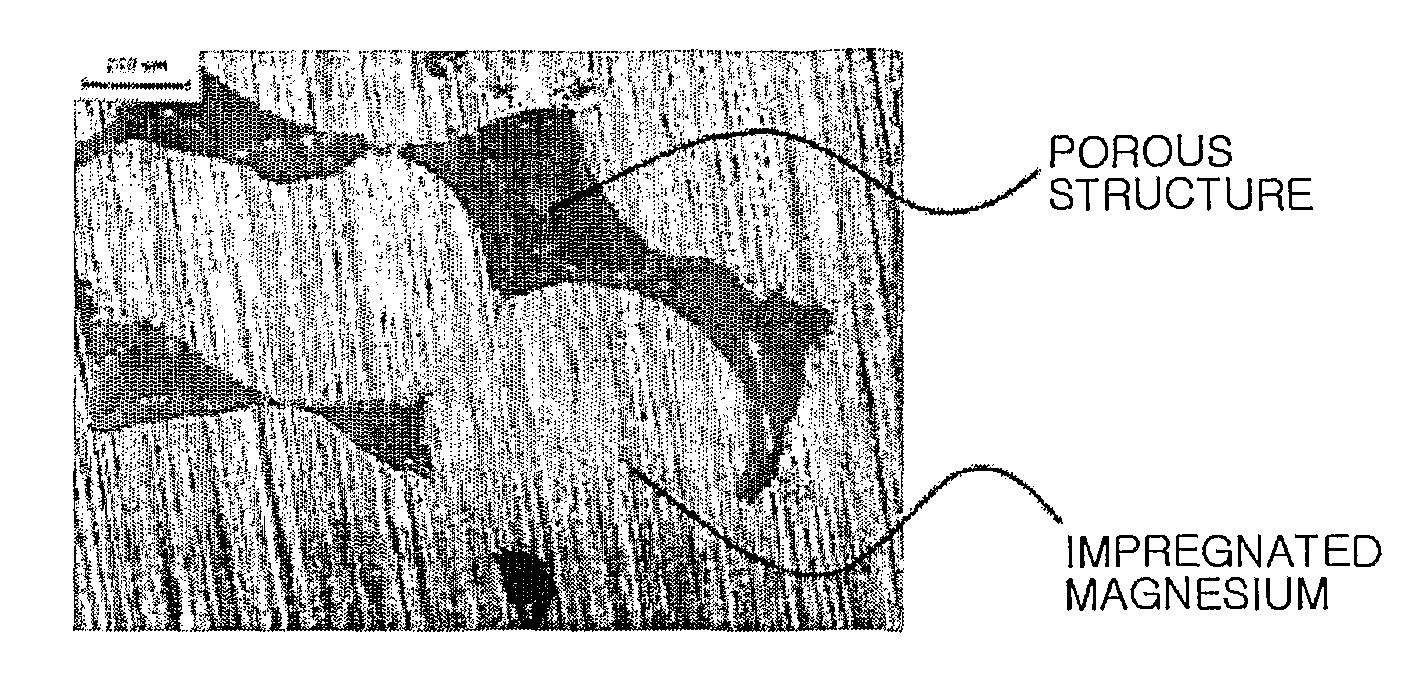

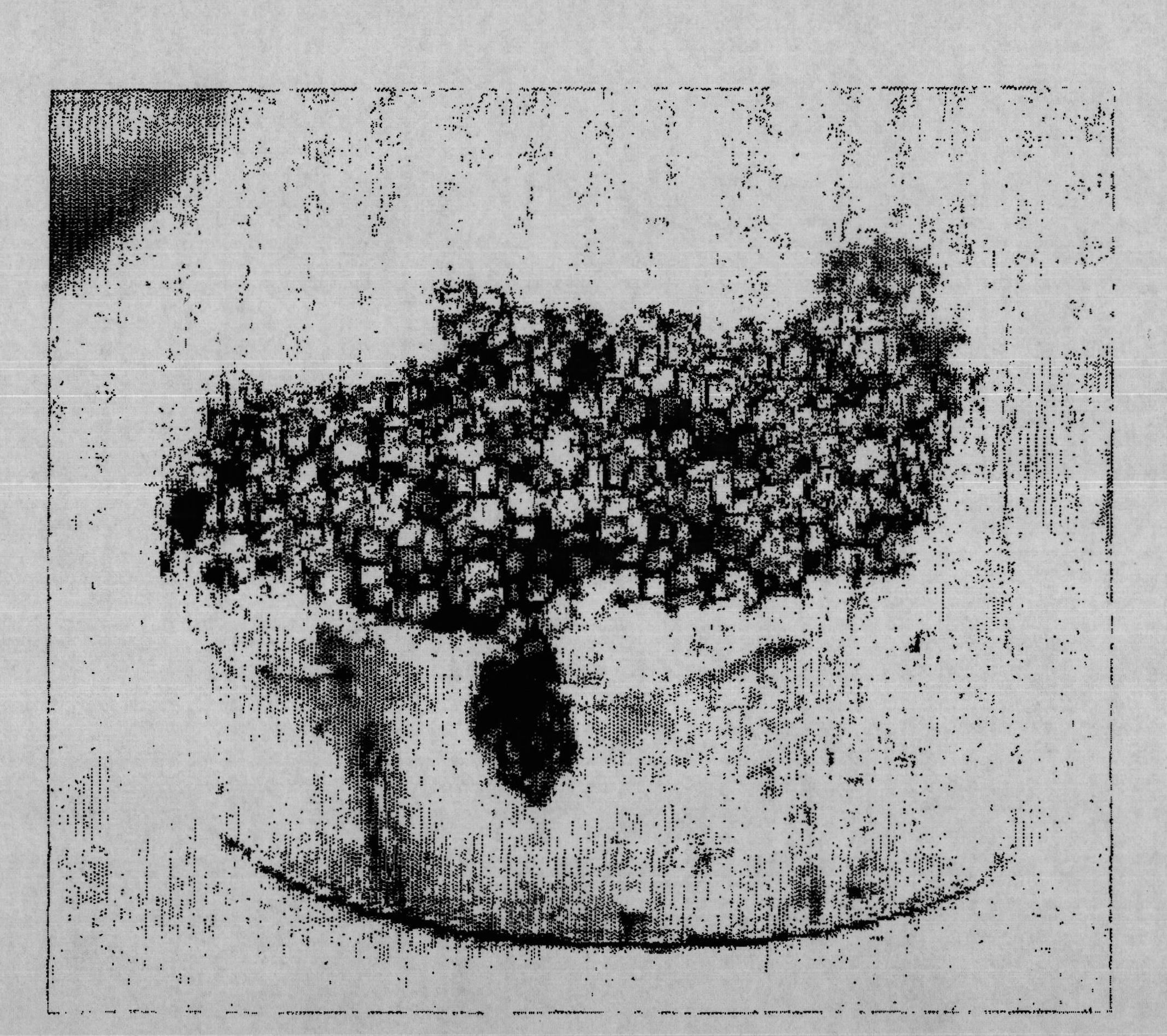

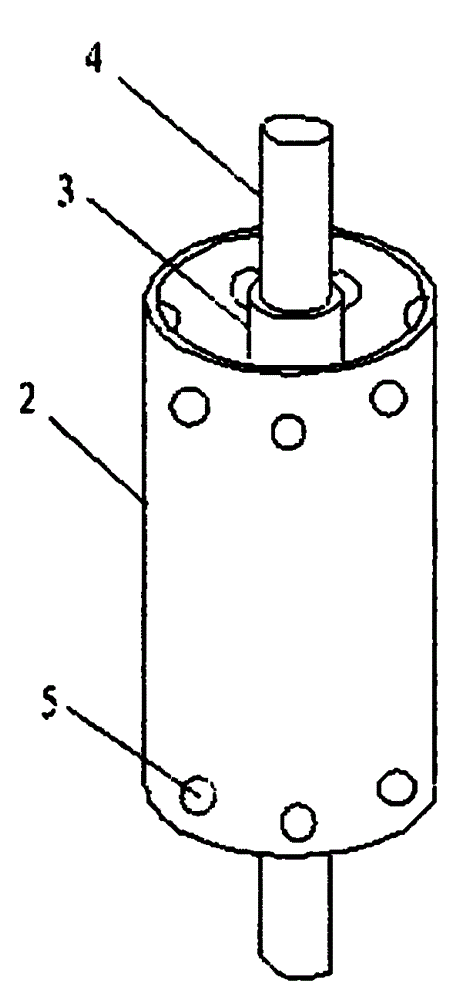

Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

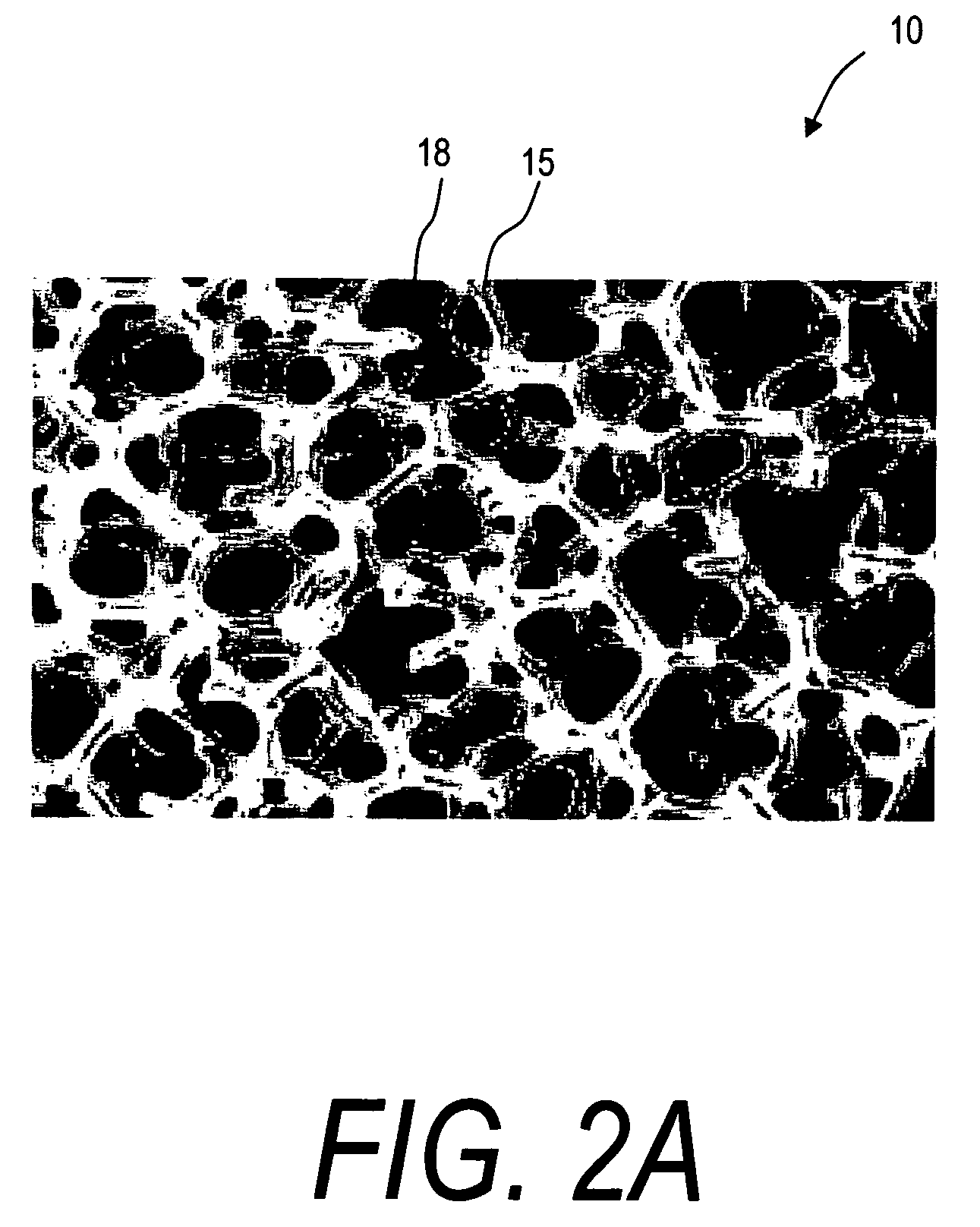

InactiveUS20110054629A1Improve bone formationImproved rate of bone formationDental implantsImpression capsAlloyMechanical property

The present invention provides a composite implant comprising pores of a porous structure filled with a biodegradable magnesium-based alloy. Further, the present invention provides a composite implant which filles pores of the porous structure prepared by a metal, a ceramic or a polymer with a biodegradable magnesium-based alloy. Mechanical properties of the composite implant of the present invention are improved because a magnesium-based alloy filled in its pores increases the strength of a porous structure comprised of a metal, a ceramic or a polymer. Further, it can be expected that the magnesium-based alloy filled in the porous structure is decomposed in a living body, thus increasing bone formation rate. Accordingly bone tissue can be rapidly formed because the composite implant of the present invention has high strength and excellent interfacial force between the composite implant and bone tissue, compared to conventional porous materials.

Owner:U & I INC

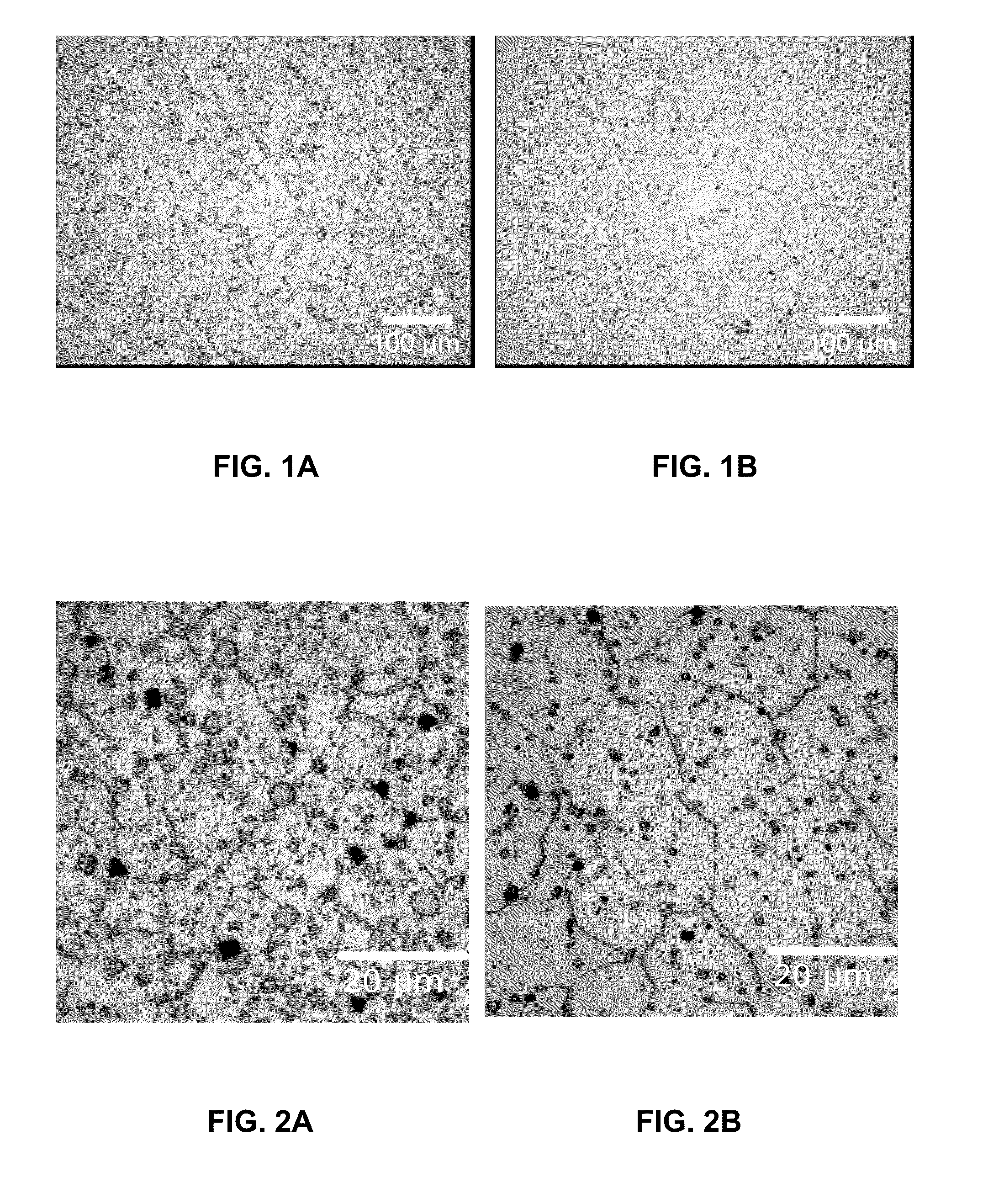

Implant Made of a Biodegradable Magnesium Alloy

ActiveUS20100082092A1Easy to processImprove material performanceStentsSurgeryBiodegradable magnesium

An implant made in total or in parts of a biodegradable magnesium alloy consisting of Y: 2.0-6.0% by weight, Nd: 1.5-4.5% by weight, Gd: 0-4.0% by weight, Dy: 0-4.0% by weight. Er: 0-4.0% by weight, Zr: 0.1-1.0% by weight, Li:0-0.2% by weight, Al: 0-0.3% by weight, under the condition that a) a total content of Er, Gd and Dy is in the range of 0.5-4.0% by weight and b) a total content of Nd, Er, Gd and Dy is in the range of 2.0-5.5% by weight, the balance being magnesium and incidental impurities up to a total of 0.3% by weight.

Owner:BIOTRONIK AG

Biocompatible and bioabsorbable suture and clip material for surgical purposes

The present invention concerns a suture and clip material for surgical purposes which at least in parts comprises a biodegradable magnesium alloy with the following proportions by weight of the alloy components: rare earth metals between 2.0 and 4.0% by weight, yttrium between 3.5 and 4.5% by weight, zirconium between 0.3 and 1.0% by weight, no aluminum or at most aluminum <0.01% by weight, and balance <0.5% by weight, in particular <0.3% by weight, wherein magnesium occupies the proportion by weight that remains to 100% by weight in the alloy.

Owner:BIOTRONIK VI PATENT

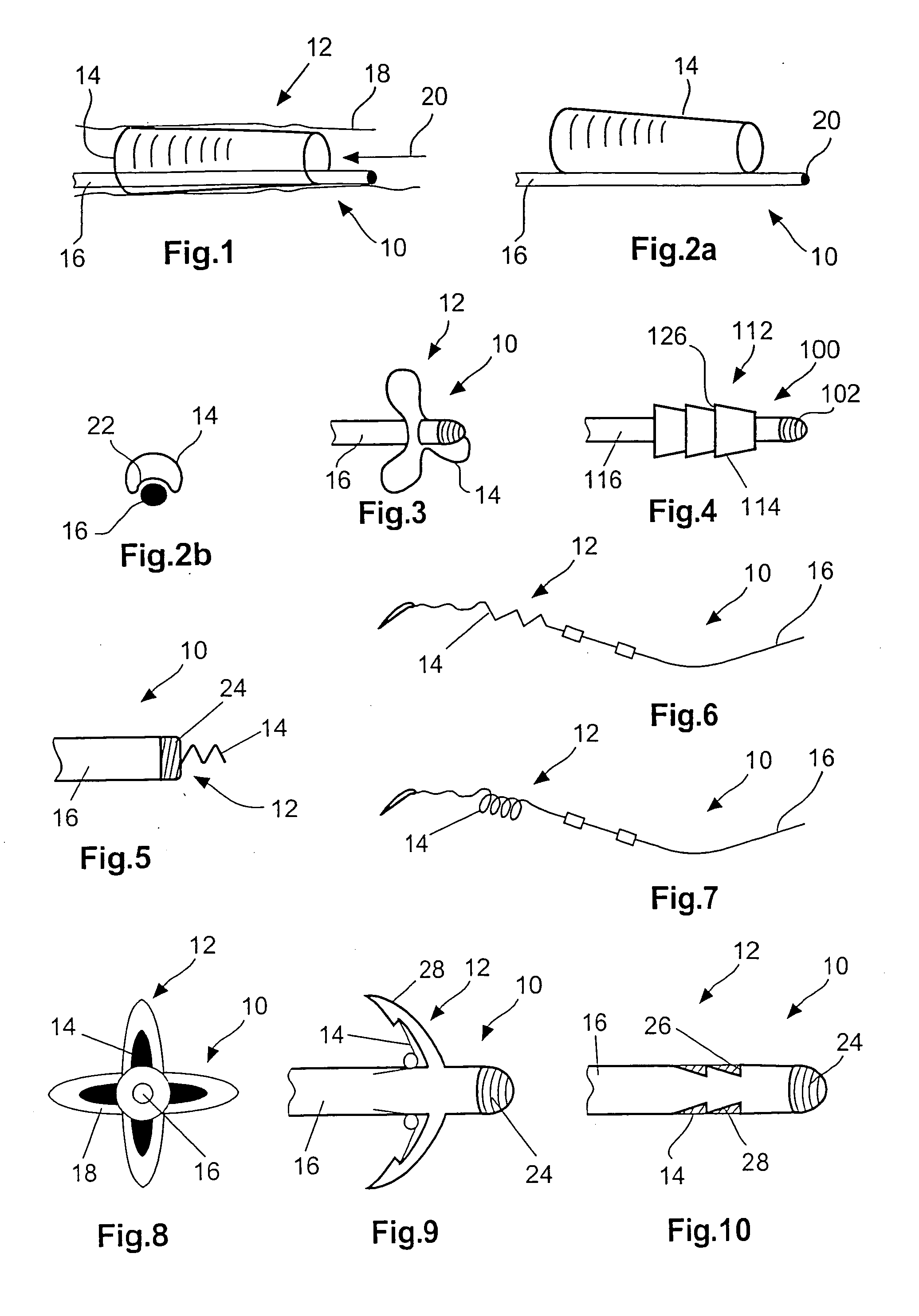

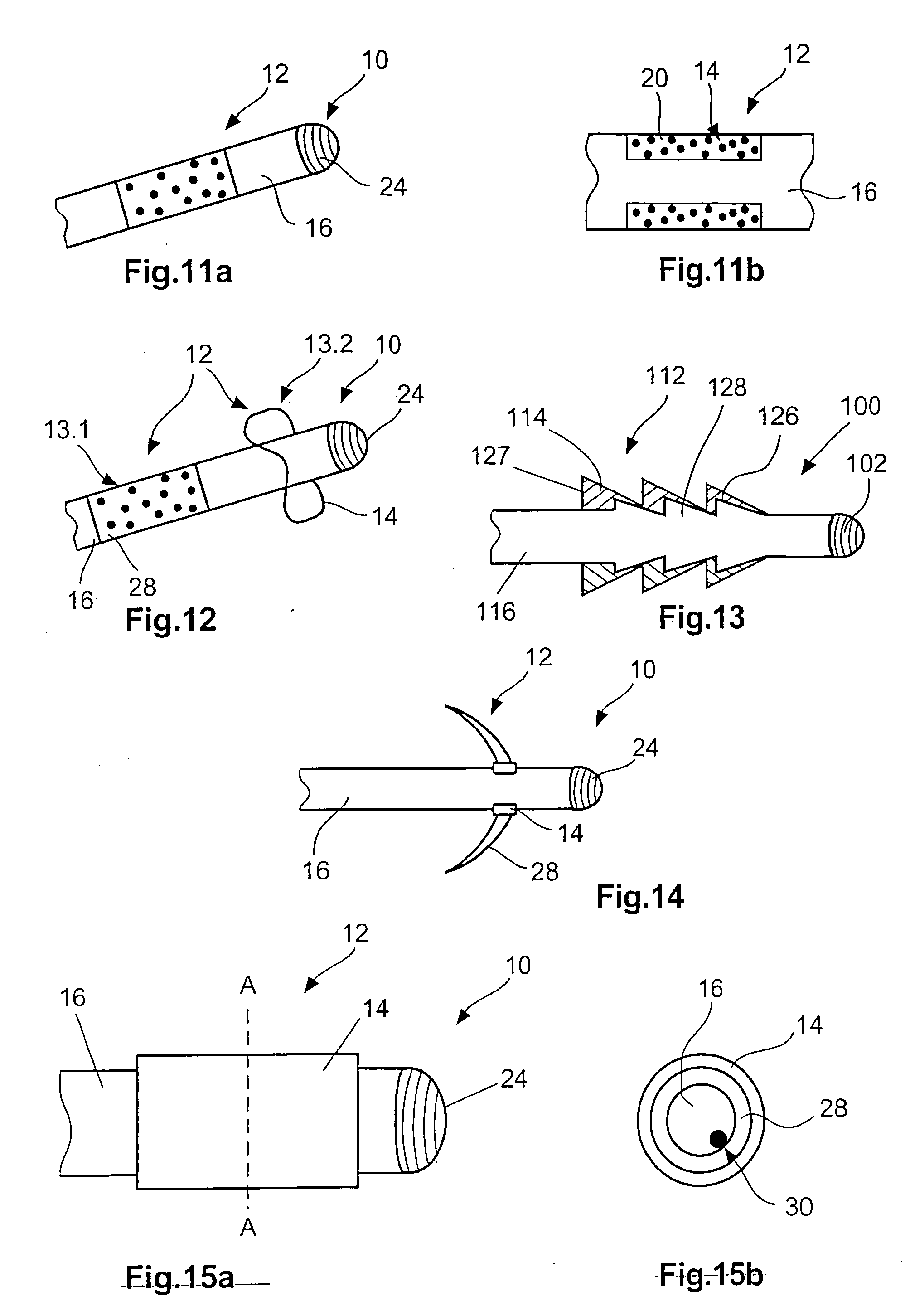

Fixing for implantable electrodes and catheters

InactiveUS20060020317A1Internal electrodesExternal electrodesImplantable ElectrodesBiomedical engineering

The invention concerns a fixing for implantable electrodes and catheters. The object of the present invention is inter alia to provide a fixing which takes better account of the different demands in the course of time of ordinary use of the implantable electrodes or catheters. For that purpose the fixing is distinguished in that it includes at least one first structural element comprising a biodegradable material, namely a biodegradable magnesium alloy.

Owner:BIOTRONIK SE & CO KG

Implants comprising biodegradable metals and method for manufacturing the same

ActiveCN101516292AExcellent interface strengthSuitable for maintaining initial stabilityDental implantsInternal osteosythesisUltimate tensile strengthBiodegradable polymer

The present invention provides an implant consisting of a biodegradable magnesium-based alloy or partially applied with the magnesium-based alloy, and a method for manufacturing the same. The implant according to the present invention is biodegradable, in which its biodegradation rate can be easily controlled, and the implant has excellent strength and interfacial strength to an osseous tissue.

Owner:U & I INC

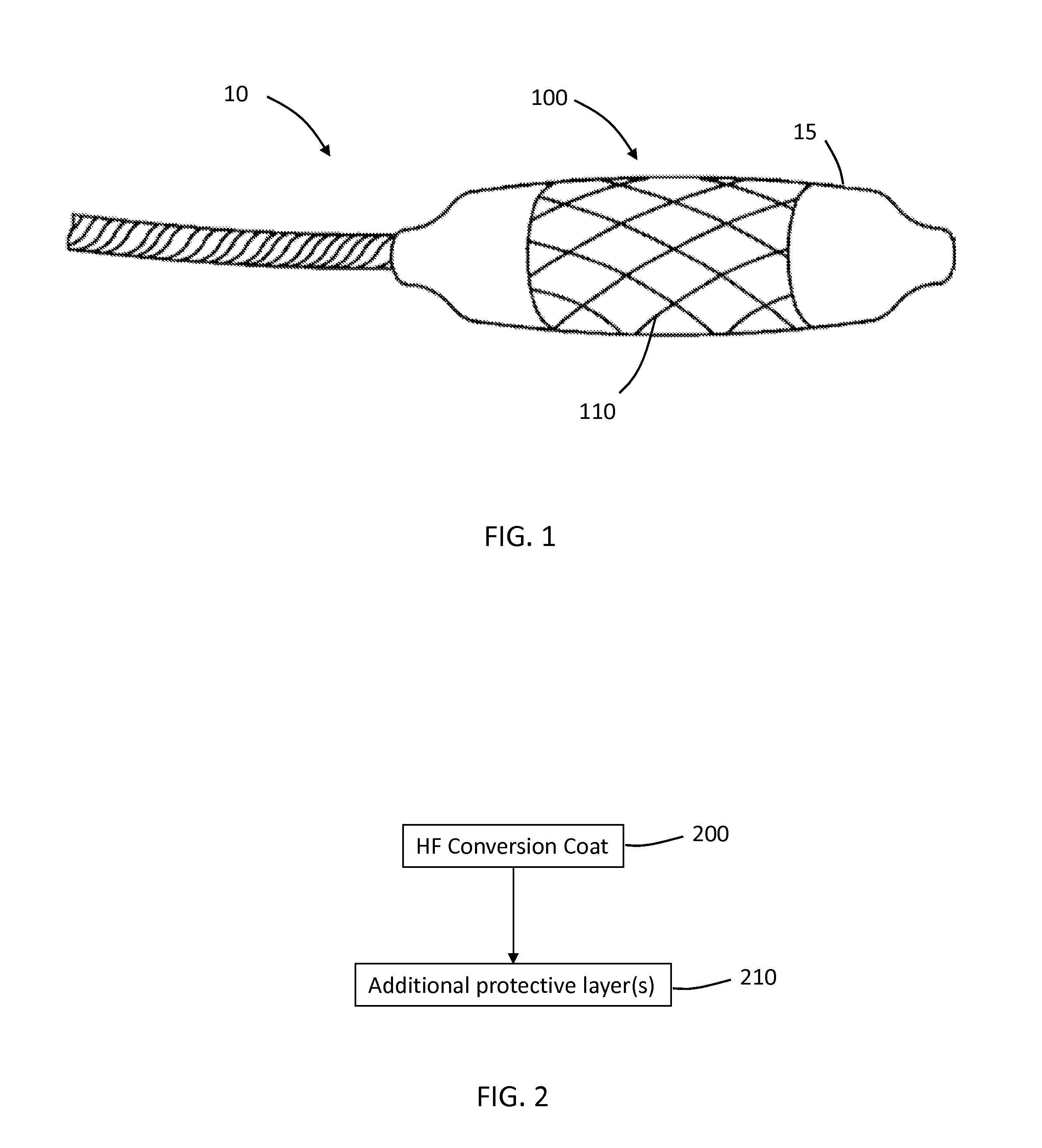

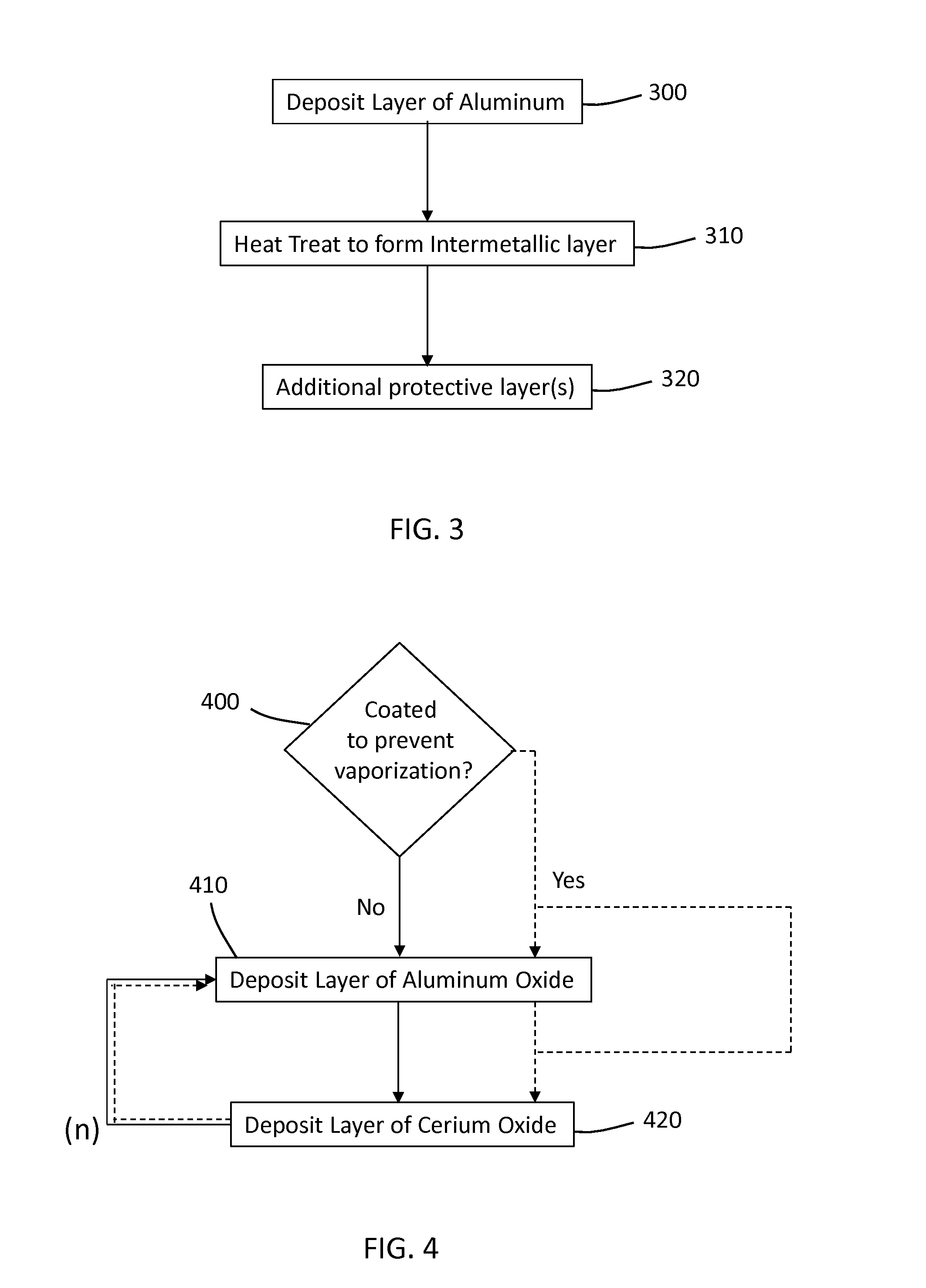

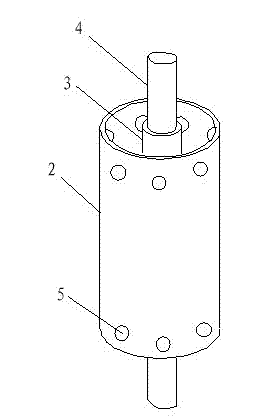

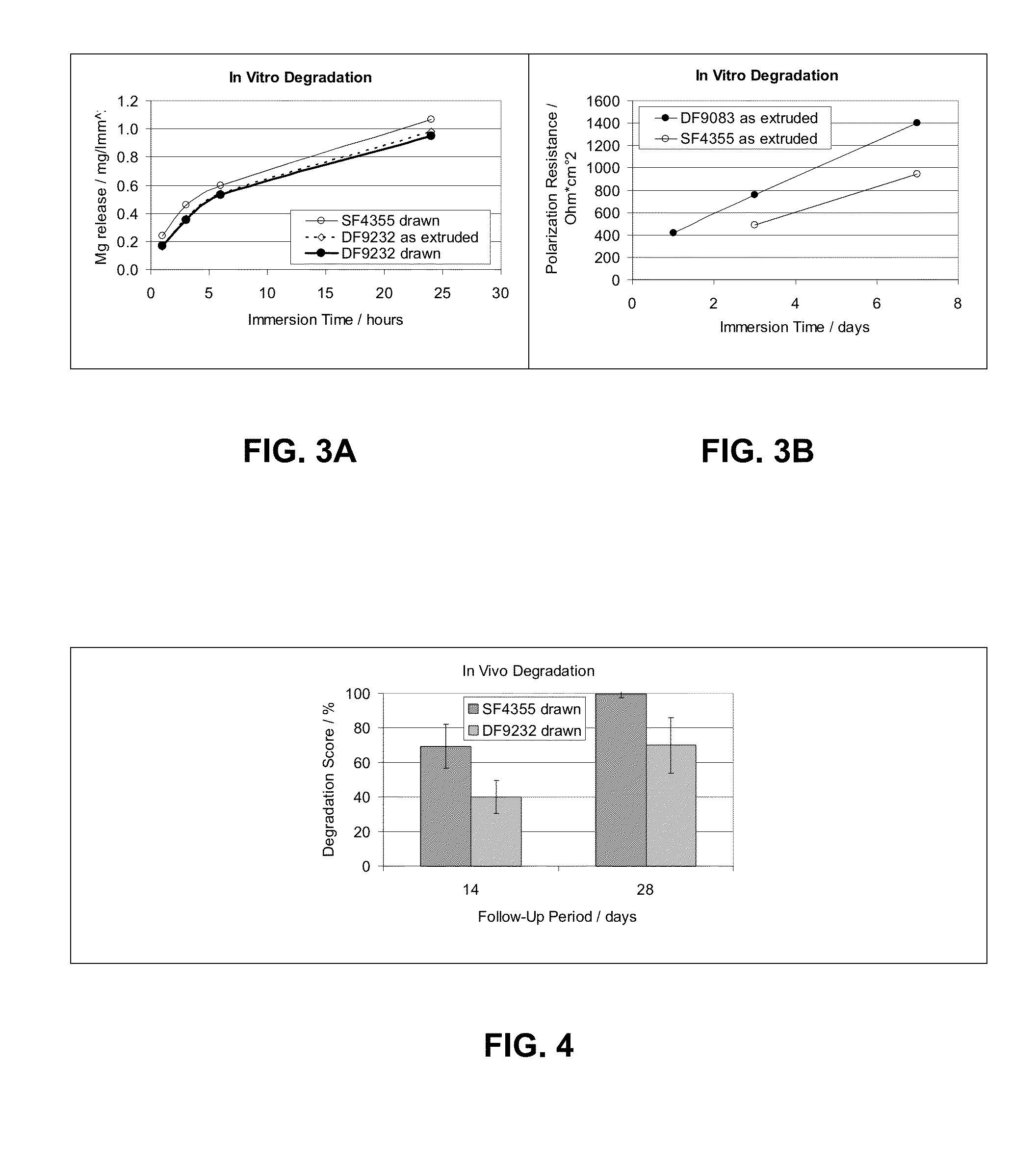

Protected Magnesium Alloys for Bioresorbable Stents

ActiveUS20160129162A1Uniform corrosionAvoid corrosionStentsSurgeryChromate conversion coatingInsertion stent

Biodegradable magnesium alloy implantable medical devices are protected to delay onset of corrosion, and thus biodegradability, or to corrode more uniformly. The protection allows for extended effective use of the devices while maintaining biodegradability. Examples of protective coatings include conversion coatings that at least partially remove exposed second phases from a surface of the magnesium alloy and coatings that provide a barrier between water and the surface of the magnesium alloy.

Owner:MEDTRONIC VASCULAR INC

Method for preparing strontium-containing hydroxyapatite coating on surface of biodegradable magnesium alloy

InactiveCN104888271AGood biocompatibilitySimple processMetallic material coating processesProsthesisCalcium nitrate tetrahydrateCalcium phosphate coating

The invention relates to a method for preparing a strontium-containing hydroxyapatite coating on the surface of a biodegradable magnesium alloy. The method comprises the following steps: polishing a magnesium alloy matrix to remove a surface oxidation layer, and cleaning; preparing a hydrothermal solution from calcium nitrate tetrahydrate, EDTA-2 Na, sodium dihydrogen phosphate dihydrate and strontium nitrate; and placing the well treated magnesium alloy matrix into the hydrothermal solution for hydrothermal reaction to obtain the strontium-containing hydroxyapatite coating, a biomimetic calcium phosphate coating, wrapping the magnesium alloy matrix. Compared with the prior art, as the hydrothermal method is adopted to prepare hydroxyapatite, not only is the degradation rate of the magnesium alloy in a human body effectively slowed down, but also the biocompatibility of the magnesium alloy is further improved. As strontium element is added into the hydroxyapatite coating, and as one of trace elements of the human body, strontium has the functions of promoting bone formation and inhibiting bone breakage, both the biological activity and the biocompatibility are improved.

Owner:TONGJI UNIV

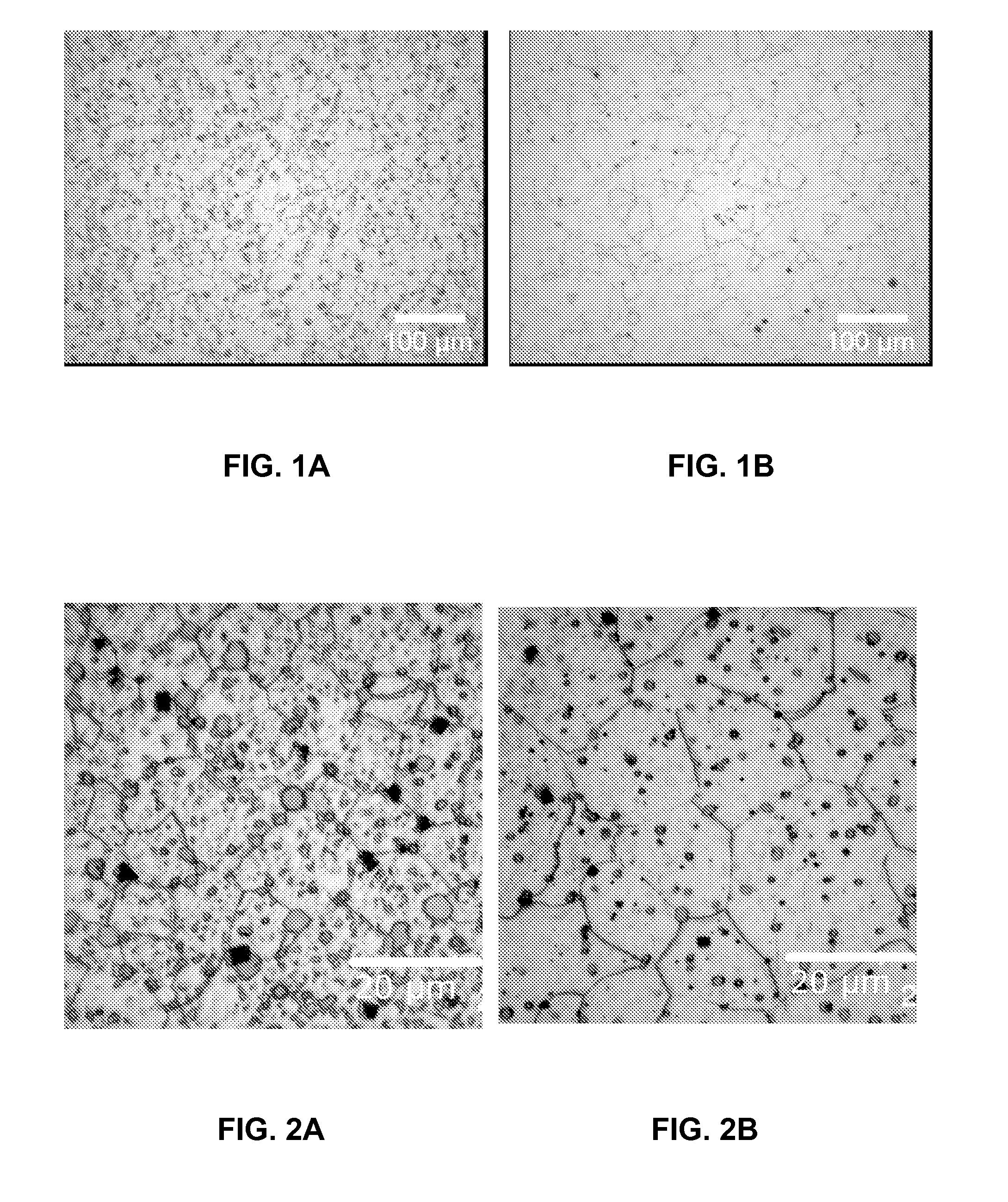

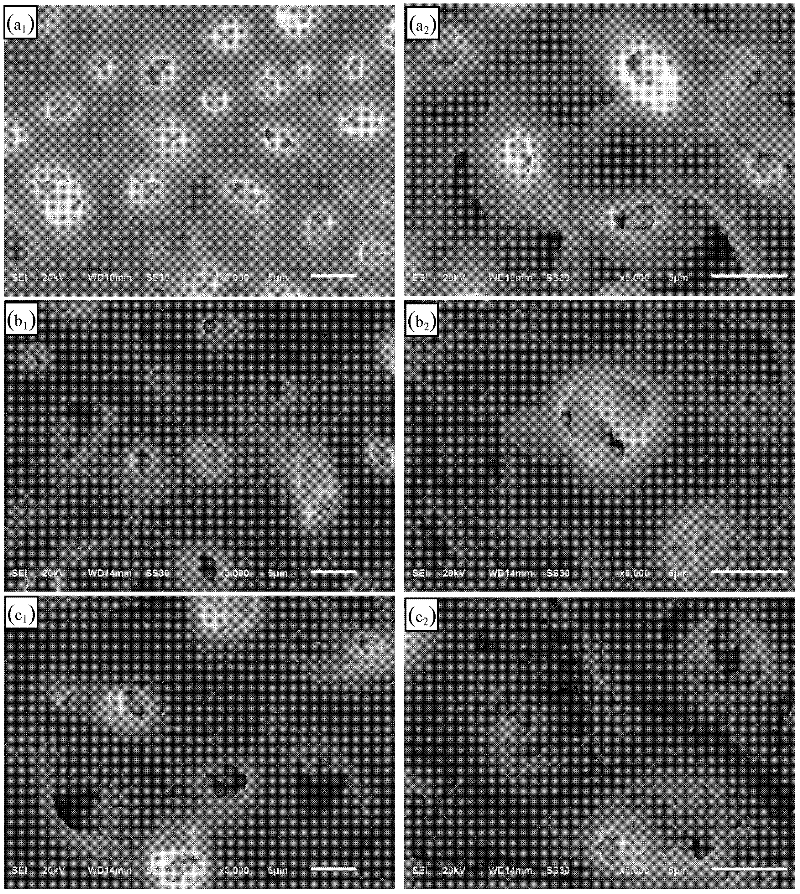

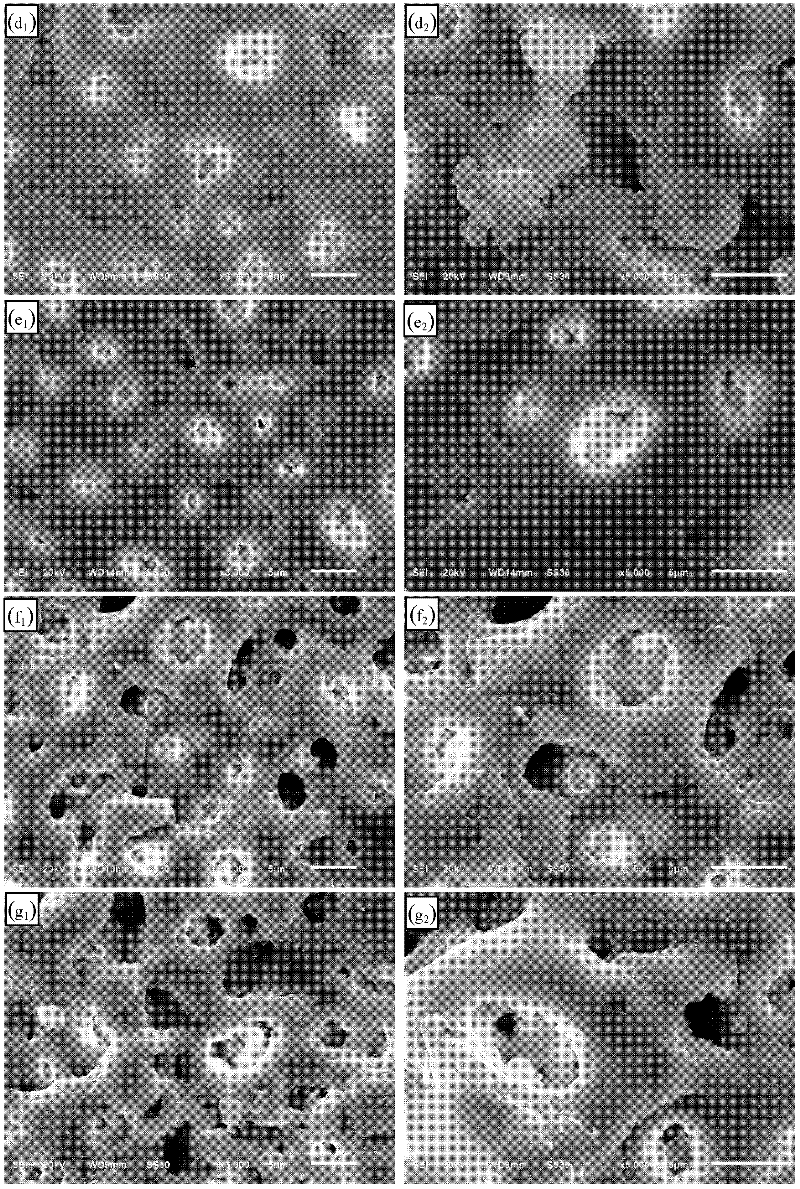

Biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material as well as production method and application thereof

ActiveCN103103427AHigh biosecurityImprove performanceProsthesisBiocompatibility TestingInterventional therapy

The invention relates to a biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material as well as a production method and application thereof. The biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material is suitable for being used as an implant material used in a human body environment. The biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material comprises the following components in percentage by weight: 0.1%-20.0% of Si, 0.1%-8.0% of Sr, 0.1%-10.0% of Ca and the balance of Mg. The biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material is a multi-element magnesium alloy system consisting of total nutrient elements of Mg, Si, Sr and Ca; the form, quantity and distribution of a plurality of second phases such as Mg2Si, Mg2Sr, Mg17Sr2, Mg2Ca, CaMgSi and the like in the magnesium alloy are controlled, so that the multi-element magnesium alloy with the optical comprehensive performances is obtained. The biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material disclosed by the invention has good biocompatibility and mechanical properties, and is a biodegradable magnesium alloy material with excellent comprehensive performances. Besides, the biomedical absorbable Mg-Si-Sr-Ca multi-element magnesium alloy material has a high application value in the fields such as interventional therapy for cardiovascular diseases, intraosseous implant and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

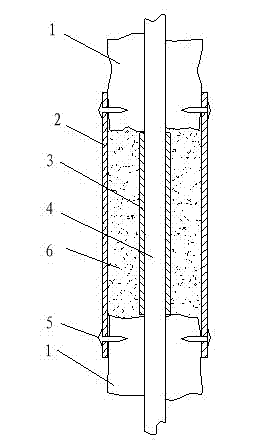

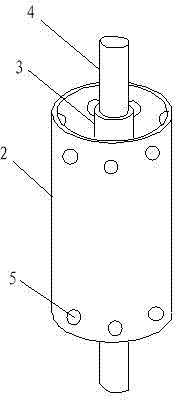

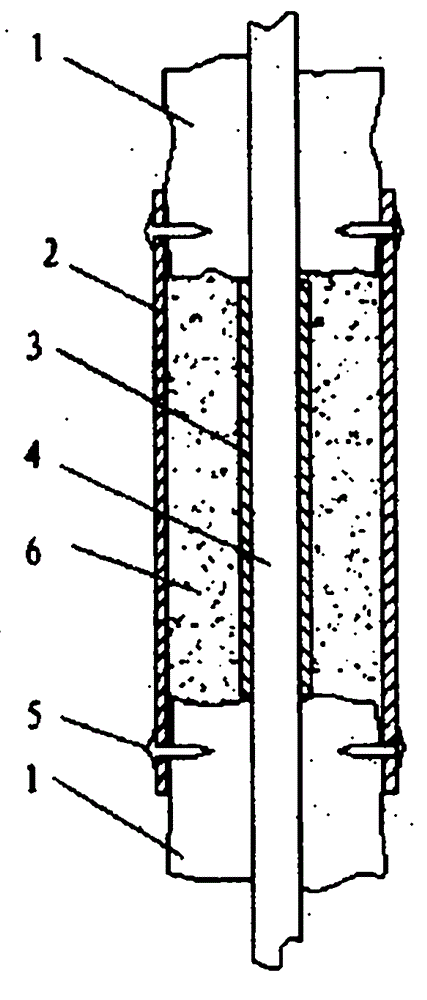

Bone grafting device for tubular bone defect healing

The invention relates to a bone grafting device for tubular bone defect healing, and belongs to the technical field of orthopedic medical devices. The bone grafting device is used for grafting tubular bones to promote the healing of the tubular bones, and comprises an outer sleeve, an inner sleeve and a connecting rod, wherein the inner diameter of the outer sleeve is matched with the outer diameter of the two ends of a tubular bone defect part required for bone grafting, and the inner sleeve is positioned in the outer sleeve; the connecting rod is inserted in the inner sleeve, and the diameter of the connecting rod is matched with the inner diameter of the inner sleeve; and the length of the connecting rod is greater than that of the inner sleeve, and the inner sleeve and the outer sleeve are made of biodegradable magnesium alloy. In the bone grafting device, the connecting rod in the inner sleeve can firmly connect the two ends of a defective tubular bone, a high-quality autologous cancellous bone is filled between the inner sleeve and the outer sleeve to simultaneously play roles of bone grafting and reinforced fixing, and the biodegradable magnesium alloy has a function of inducing bone formation, thereby the fracture healing is promoted. The bone grafting device has the advantages of firm bone grafting, high intensity, early ambulation for patients, and good clinical effect.

Owner:张英泽

Composite implant having porous structure filled with biodegradable alloy and method of magnesium-based manufacturing the same

InactiveCN102014798AIncrease spawn ratePromote generationDental implantsBone implantAlloyMechanical property

The present invention provides a composite implant comprising pores of a porous structure filled with a biodegradable magnesium-based alloy. Further, the present invention provides a composite implant which filles pores of the porous structure prepared by a metal, a ceramic or a polymer with a biodegradable magnesium-based alloy. Mechanical properties of the composite implant of the present invention are improved because a magnesium-based alloy filled in its pores increases the strength of a porous structure comprised of a metal, a ceramic or a polymer. Futher, it can be expected that the magnesium-based alloy filled in the porous structure is decomposed in a living body, thus increasing bone formation rate. Accordingly bone tissue can be rapidly formed because the composite implant of the present invention has high strength and excellent interfacial force between the composite implant and bone tissue, compared to conventional porous materials.

Owner:U & I INC

Biodegradable magnesium-lithium alloy material and preparation method thereof

The invention discloses a biodegradable magnesium-lithium alloy material and a preparation method of the biodegradable magnesium-lithium alloy material, wherein the biodegradable magnesium-lithium alloy material is composed of 7-14% of lithium, 0.5-5.0% of aluminum, 0.6-3.8% of zinc, 0.01-0.5% of zirconium, 0.1-0.5% of calcium, 0.3-0.7% of strontium and magnesium for the rest; the sum of the weight percentages of the components is 100%. The tensile strength of the material is 170-275 MPa; the yield strength is 125-255 MPa; the elongation rate is 15-65%; and the density is 1.31-1.60. The material can be used for processing blood vessel stents and joint prosthesis replacement parts.

Owner:BEIHANG UNIV

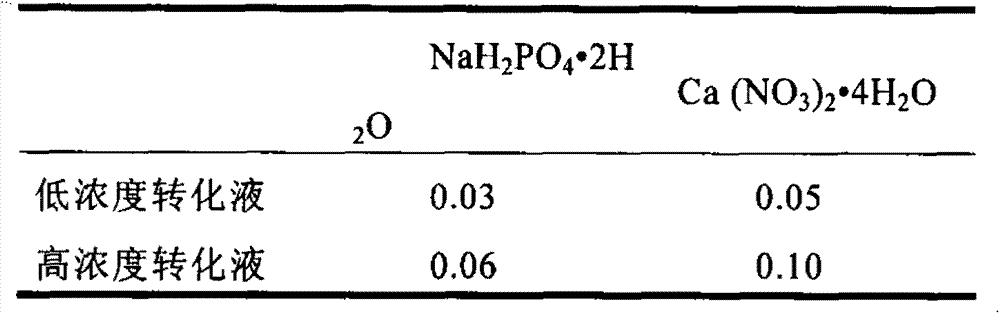

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a method for preparing a biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating. The method comprises the following steps of: pretreating a magnesium alloy substrate, wherein the adopted transfer solution is prepared from sodium dihydrogen phosphate dehydrate and calcium nitrate tetrahydrate; soaking a substrate sample obtained by pretreatment in the transfer solution for 5-100 hours, thus obtaining a calcium-phosphorus coating; soaking a calcium-phosphorus coating sample in an alkali fluoridated transfer solution for 10-48 hours, so as to obtain a fluoridated calcium-phosphorus coating, wherein the alkali fluoridated transfer solution is prepared from sodium hydroxide and sodium fluoride, the concentration of the sodium hydroxide is 3-4g / L, the concentration of the sodium fluoride is 4-5g / L, and heat treatment is not performed; performing heat treatment on the fluoridated calcium-phosphorus coating at the temperature of 300-350 DEG C for 2-5 hours, thus obtaining the fluoridated hydroxyapatite. According to performance detection, the fluoridated hydroxyapatite (FHA) coating prepared by combining a heat treatment process is shaped like a slender sheet and is divergently arranged from the center to the periphery; the electrochemical test proves that the self-corrosion potential of the substrate is improved through the FHA coating; the immersed corrosion experiment proves that an actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of a fluoridated apatite (FA) coating.

Owner:TONGJI UNIV

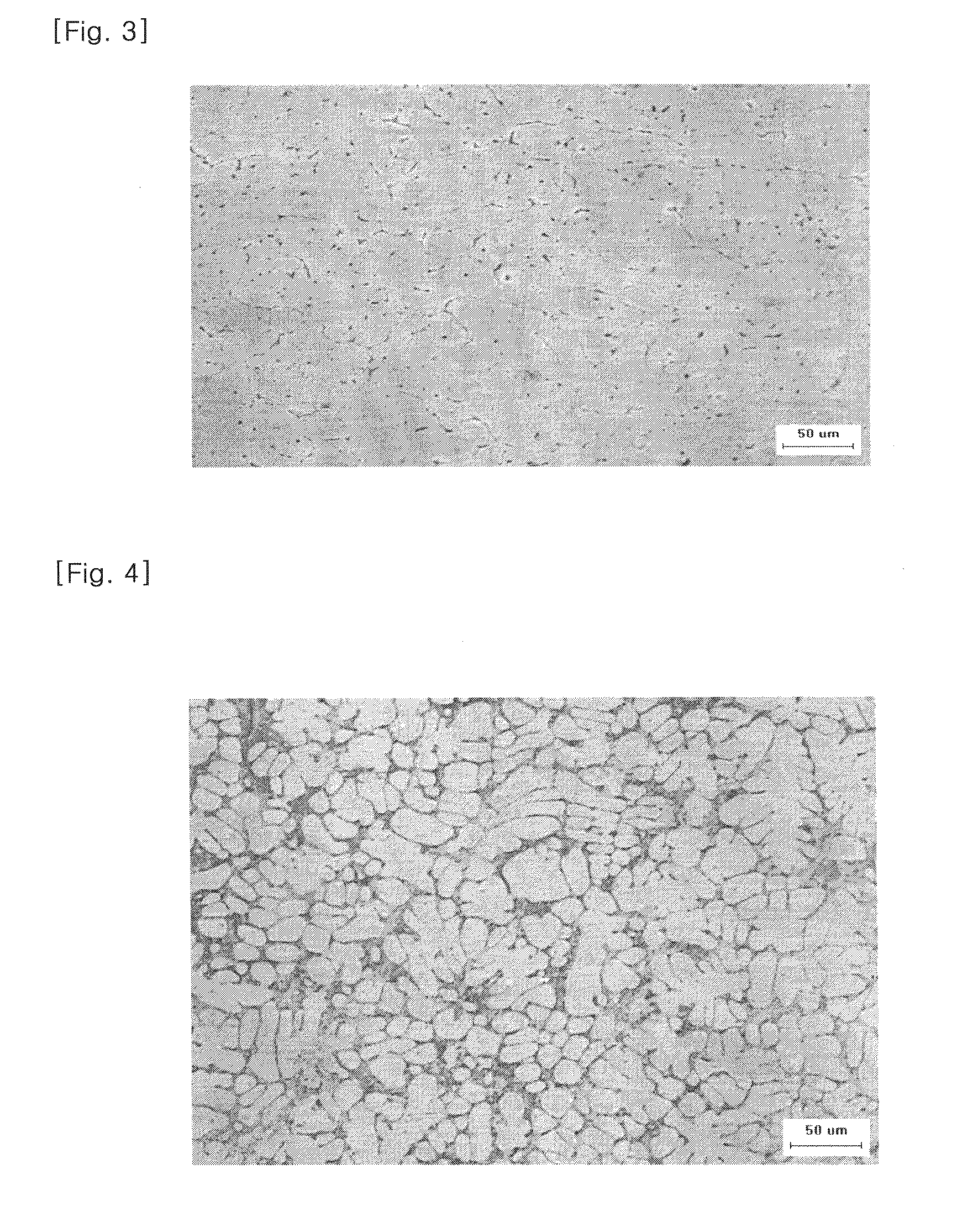

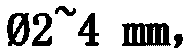

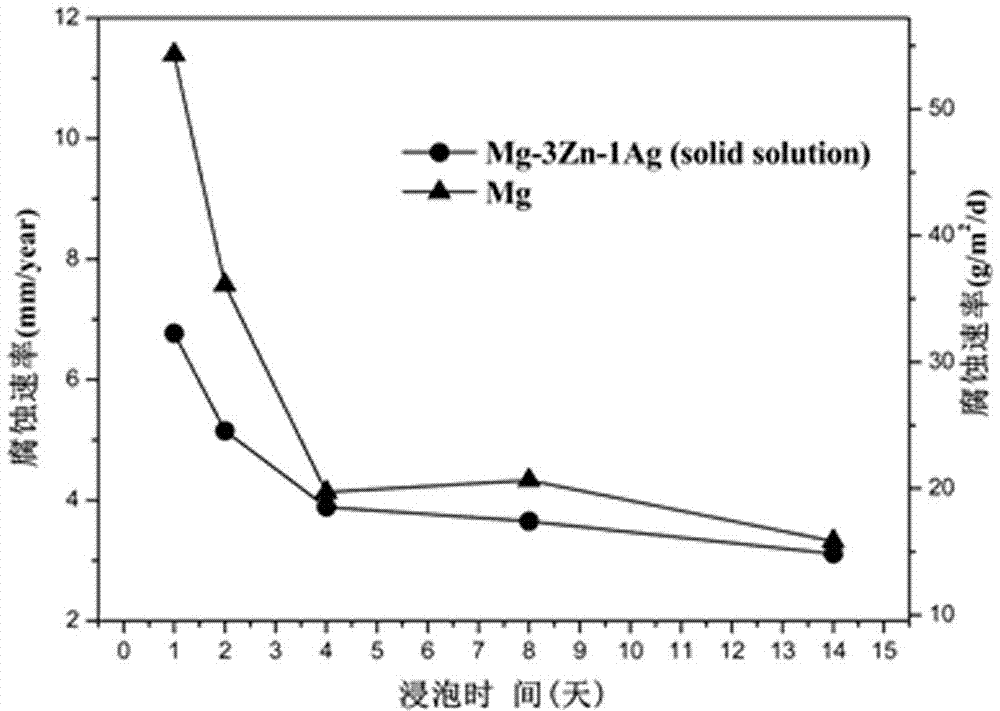

Preparation method of high-corrosion-resistance biodegradable magnesium alloy

The invention discloses a preparation method of a high-corrosion-resistance biodegradable magnesium alloy and belongs to the technical field of materials. The preparation method comprises the following steps: (1) preparing metallic magnesium, metallic zinc, metallic silver and metallic calcium as raw materials; (2) heating metallic magnesium to 760+ / -5 DEG C under the protection of N2 and SF6 mixed gas, melting, then sequentially adding metallic silver, metallic calcium and metallic zinc, stirring and uniformly mixing; (3) cooling to 740+ / -5 DEG C, introducing argon, and preserving heat and standing at 740+ / -5 DEG C for 10-20 minutes; (4) cooling to 720+ / -5 DEG C and casting; (5) heating to 300-320 DEG C and preserving the heat for 2-4 hours under the coverage of graphite powder, increasing the temperature to 350-450 DEG C, preserving heat for 8-12 hours, and cooling by water; (6) preserving the heat at 250-350 DEG C for 25-35 minutes, and then carrying out high-temperature plastic deformation; and (7) deforming at normal temperature and intermediately annealing for a plurality of times, and finally cooling by air to normal temperature. According to the method, by virtue of the single-phase fine-grain treatment, the magnesium alloy has high corrosion resistance and good mechanical property; the magnesium alloy can be used for manufacturing different implantable devices.

Owner:NORTHEASTERN UNIV +1

Preparation method of biodegradable magnesium alloy surface-modified hydroxyapatite coating

InactiveCN103446627AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a preparation method of a biodegradable magnesium alloy surface-modified hydroxyapatite coating. The method specifically comprises the following steps: cutting the magnesium alloy into samples; polishing the samples by aluminum oxide water-resistant abrasive paper to remove surface oxide layers of the magnesium alloy; sequentially ultrasonic-cleaning with deionized water and absolute ethyl alcohol for 5-30 minutes, and drying at room temperature; preparing a conversion liquid by adopting sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate; controlling the molar ratio of calcium and phosphorus at (1:1)-(2:1), the concentration of Ca<2+> at 0.01-0.2M and the P<5+> concentration at 0.01-0.2M; placing pre-treated matrix sample in the conversion liquid to be soaked for 5-100 hours to obtain a calcium and phosphorus coating; preparing the hydroxyapatite coating through the calcium and phosphorus coating by adopting a thermal treatment process: soaking the samples in calcium and phosphorus liquor for 24-72 hours; taking out and directly placing in a Muffle furnace; carrying out thermal treatment at 250-350 DEG C for 2-5 hours; detecting performance. According to the method provided by the invention, the samples taken out from the calcium and phosphorus liquor are placed in the Muffle furnace for direct thermal treatment, so that the method is simpler and easier to operate and control, and the samples can be converted into the hydroxyapatite coating to achieve a considerable corrosion resistant effect.

Owner:TONGJI UNIV

Implants comprising biodegradable metals and method for manufacturing the same

InactiveCN102512711AExcellent interface strengthSuitable for maintaining initial stabilityDental implantsImpression capsUltimate tensile strengthBiodegradable polymer

The present invention provides an implant consisting of a biodegradable magnesium-based alloy or partially applied with the magnesium-based alloy, and a method for manufacturing the same. The implant according to the present invention is biodegradable, in which its biodegradation rate can be easily controlled, and the implant has excellent strength and interfacial strength to an osseous tissue.

Owner:U & I INC

Method for carrying out surface modification upon biodegradable magnesium and magnesium alloy through iron ion implantation deposition

ActiveCN103498129AHigh bonding strengthImprove corrosion resistanceVacuum evaporation coatingSputtering coatingBiocompatibility TestingIon beam

The invention discloses a method for carrying our surface modification upon biodegradable magnesium and magnesium alloy through iron ion implantation deposition. The method belongs to the technical field of surface treatment. According to the invention, through ion implantation, a composite transition layer doped with iron ions is formed on the surface of magnesium and magnesium alloy. The transition layer is composed of Fe2O3 and MgO, and has a thickness of 20-50nm. An iron film with a thickness of 100-500nm is prepared on the transition layer with an ion-beam-assisted enhanced deposition technology. The transition layer preparation method provided by the invention assists in ensuring good bonding strength between the deposited iron film and the substrate. With the method provided by the invention, corrosion resistance, biocompatibility, and mechanical properties of magnesium and magnesium alloy are improved.

Owner:DONGGUAN MEIANMEIYE TECH CO LTD

A kind of preparation method of degradable magnesium alloy implant material

ActiveCN102268712AImprove biological activityHigh affinityAnodisationElectrolytic inorganic material coatingConstant powerPlasma electrolytic oxidation

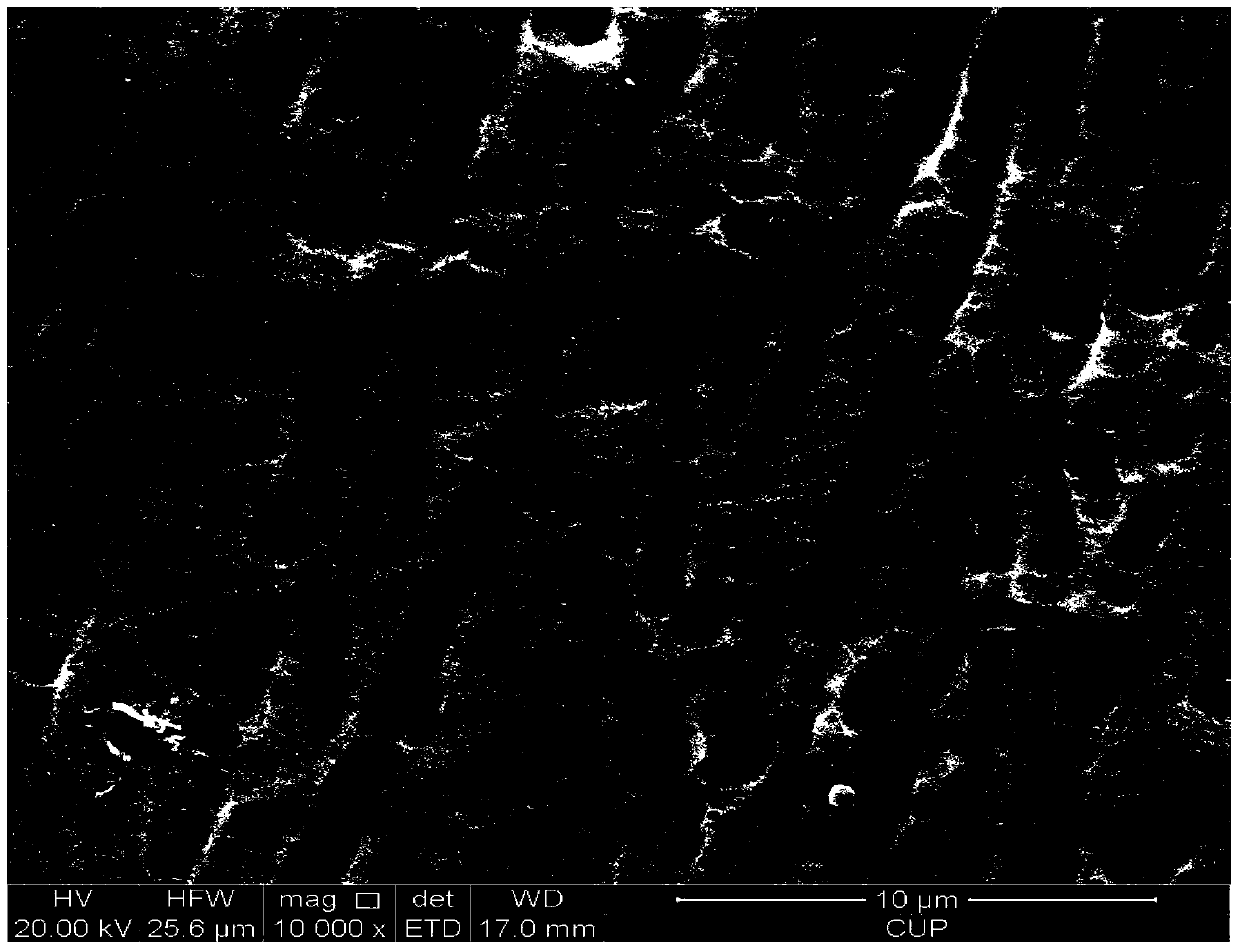

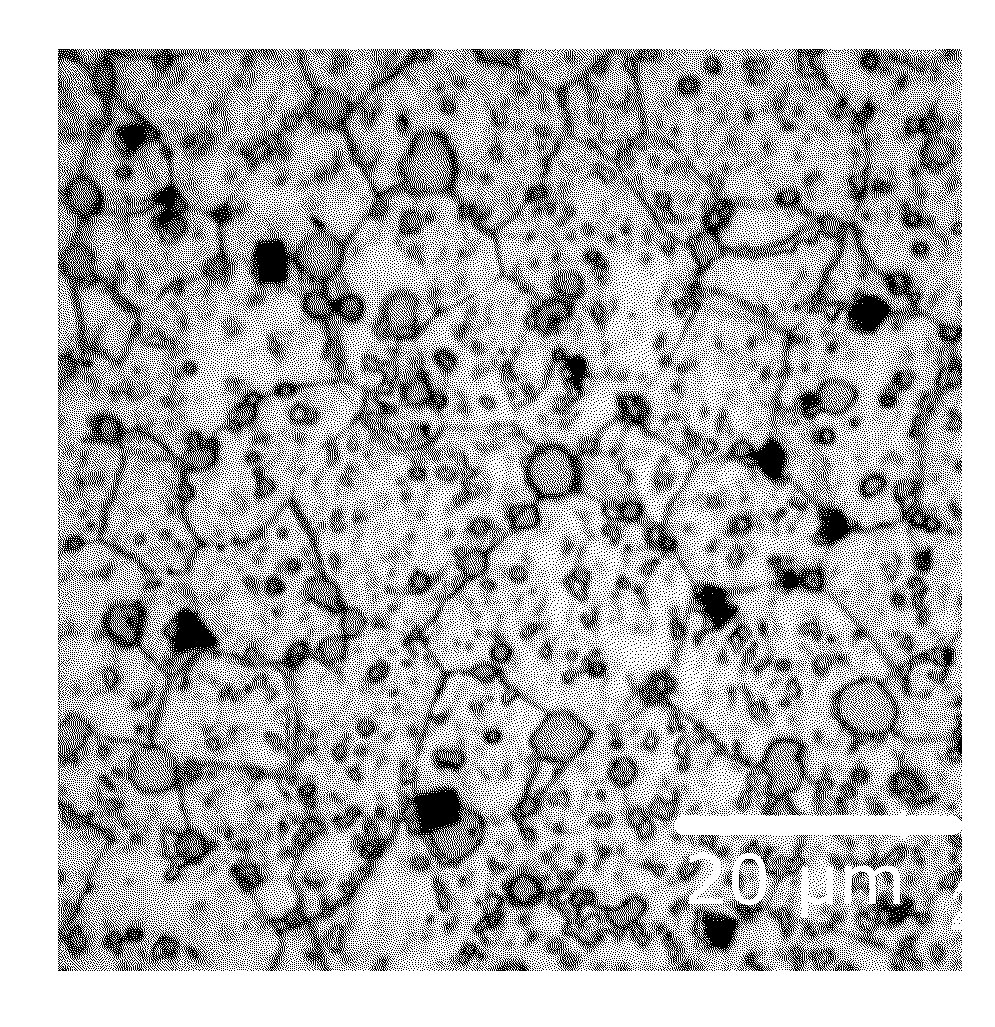

The invention relates to a method for preparing a degradable magnesium alloy implant material. In the method, (CH3COO)2Ca is added into a base electrolyte to serve as a calcium source, and a phosphate is also added in the base electrolyte to serve as a phosphorus additive to prepare an electrolyte; a magnesium alloy is placed in the electrolyte to serve as an anode; a microarc oxidation power supply is used for supplying electricity, wherein the power supply frequency range is 400-600Hz, the positive duty ratio is 30-50%, the negative duty ratio is 10-30%, and the ratio of the number of the positive pulses to the number of the negative pulses is 1:1; and the degradable magnesium alloy implant material is obtained through electrified reaction under a constant pressure or constant power mode. The implant prepared by the method in the invention has a surface composed of a loose layer and a compact layer, the loose layer surface is distributed with multiple micropores, and the compact layer is in good metallurgic bonding with a basal body so as to ensure a coating to have high hardness, compactness and cohesion as well as good resistance to wear and corrosion; and at the same time, mice acute toxicity tests prove that the coating has good biocompatibility, and simulated body fluid (SBF) soaking tests prove that the coating has good bioactivity, thus the degradable implant materialhas a wide prospect.

Owner:SHANDONG UNIV

Stent made of bio-degradable magnesium alloy with magnesium fluoride coating and organic coating

The present invention relates to stents which are produced from a magnesium alloy, which is degradable under physiological conditions, having an inorganic coating comprising magnesium fluoride and anorganic coating. The stents according to the invention can additionally be coated with at least one anti-inflammatory, anti-proliferative, anti-angiogenic, anti-restenotic and / or anti-thrombogenic active substance.

Owner:MEKO LASERSTRAHL MATERIALBEARBEITUNGEN EK

Implant made of a biodegradable magnesium alloy

ActiveUS20130060326A1Easy to processImprove material performanceStentsSurgeryMaterials scienceBiodegradable magnesium

An implant made in total or in parts of a biodegradable magnesium alloy consisting of Y: 2.0-6.0% by weight, Nd: 1.5-4.5% by weight, Gd: 0-4.0% by weight, Dy: 0-4.0% by weight, Er: 0-4.0% by weight, Zr: 0.1-1.0% by weight, Li:0-0.2% by weight, Al: 0-0.3% by weight, under the condition that a) a total content of Er, Gd and Dy is in the range of 0.5-4.0% by weight and b) a total content of Nd, Er, Gd and Dy is in the range of 2.0-5.5% by weight, the balance being magnesium and incidental impurities up to a total of 0.3% by weight.

Owner:BIOTRONIK AG

Preparation method of biodegradable magnesium alloy/calcium phosphate coating composite material

InactiveCN103484845AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium biphosphateCalcium phosphate coating

The invention relates to a preparation method of a biodegradable magnesium alloy / calcium phosphate coating composite material. The preparation method comprises the steps of pre-treating a matrix, preparing a conversion liquid, and preparing a bionic calcium phosphate coating to obtain the biodegradable magnesium alloy / calcium phosphate coating composite material. Compared with the prior art, the preparation method has the advantages that the prepared ZK60 magnesium alloy / calcium phosphate coating composite material can be used for remarkably improving the corrosion resistance of a ZK60 magnesium alloy, greatly reducing the degradation rate of the ZK60 magnesium alloy in a bionic body liquid and promoting the research and application of the ZK60 magnesium alloy in the medical field.

Owner:TONGJI UNIV

Implant

InactiveUS20130131814A1Improve initial strengthInitial bending strengthSurgeryJoint implantsArtificial jointsMedicine

The present invention provides an implant, which is used to fix an artificial joint in bone, including a biodegradable magnesium alloy.

Owner:U & I INC

Device for repairing fractured bones and method for manufacturing device

The invention discloses a device for repairing fractured bones and a method for manufacturing the device. The device comprises an outer sleeve, an inner sleeve and a connecting rod. The inner diameter of the outer sleeve is matched with the outer diameters of two ends of a tubular bone defect position with bone grafting requirements, the inner sleeve is positioned in the outer sleeve, the outer sleeve is longer than the inner sleeve, the connecting rod is inserted in the inner sleeve, the diameter of the connecting rod is basically identical to the inner diameter of the inner sleeve so that the inner sleeve can be clamped by the connecting rod, and the connecting rod is longer than the inner sleeve by 0.5-2cm. The inner sleeve and the outer sleeve are made of biodegradable magnesium alloy, and degradable high-polymer films with biocompatibility when in human bodies cover the surfaces of the inner sleeve and the outer sleeve. The device and the method have the advantage that the device is excellent in strength and biocompatibility.

Owner:HARBIN THE FIRST HOSPITAL

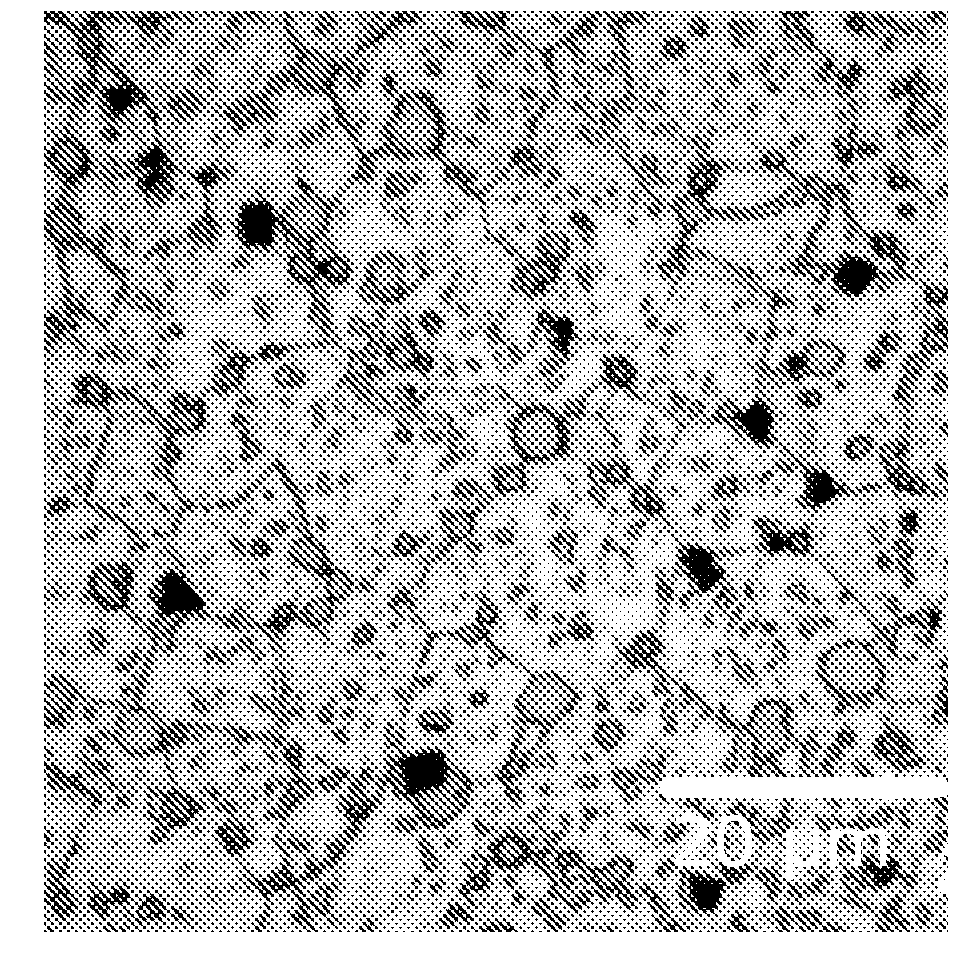

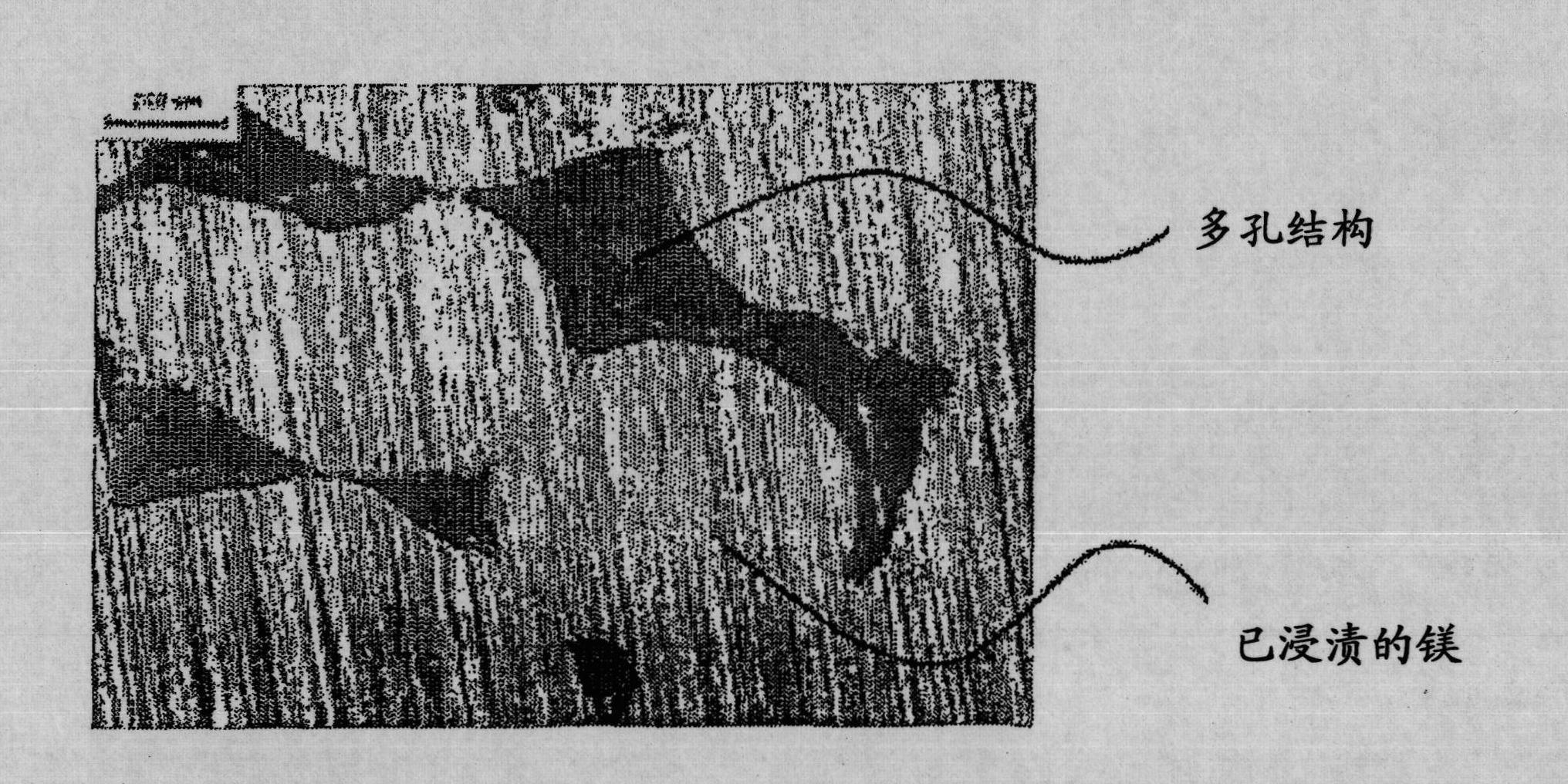

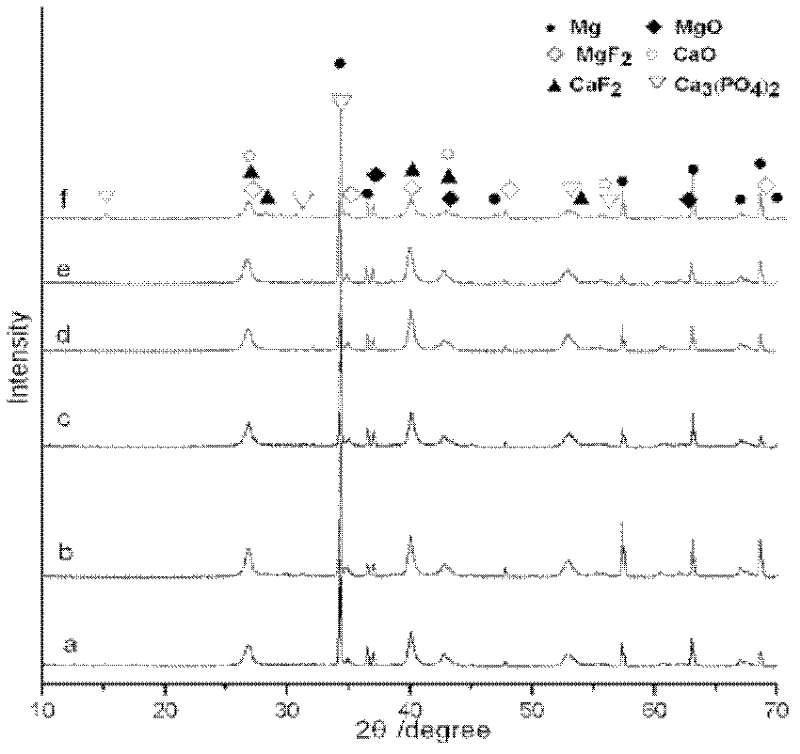

Method for preparing biodegradable magnesium or magnesium alloy and tricalcium phosphate composite material

InactiveCN101698116AControl degradation rateEasy to replaceProsthesisTri calcium phosphateBiodegradable composites

The invention discloses a method for preparing a biodegradable magnesium or magnesium alloy and tricalcium phosphate composite material, which comprises the following steps: (1) preparing a porous tricalcium phosphate blank, which is to prepare a porous tricalcium phosphate blank by using an organic foam impregnation method; and (2) permeating magnesium or a magnesium alloy, which is to permeate magnesium or a magnesium alloy into the porous tricalcium phosphate blank by using a fusant permeation method to preparing the magnesium or magnesium alloy and tricalcium phosphate composite material.The method has the advantages that: the prepared composite material has high degree of communication as well as well-guaranteed osteoinductive performance and biodegradability and can be used as material for hard tissue replacement and bone repair, completely degrade after being transplanted into a body for a certain time period and induce the formation of new bones; the production process is simple and does not need special equipment and production cost is low; and the method is suitable to prepare biodegradable composite materials with different properties.

Owner:CHONGQING UNIV

Implant made of a biodegradable magnesium alloy

InactiveUS20130041455A1Easy to processImprove material performanceStentsSurgeryBiodegradable magnesium

The present invention relates to implants made of a biodegradable magnesium alloy. The inventive implant is made in total or in parts of a biodegradable magnesium alloy comprising:Y: 0-10.0% by weightNd: 0-4.5% by weightGd: 0-9.0% by weightDy: 0-8.0% by weightHo: 0-19.0% by weightEr: 0-23.0% by weightLu: 0-25.0% by weightTm: 0-21.0% by weightTb: 0-21.0% by weightZr: 0.1-1.5% by weightCa: 0-2.0% by weightZn: 0-1.5% by weightIn: 0-12.0% by weightSc: 0-15.0% by weightincidental impurities up to a total of 0.3% by weightthe balance being magnesium and under the condition thata) a total content of Ho, Er, Lu, Tb and Tm is more than 5.5% by weight;b) a total content of Y, Nd and Gd is more than 2% by weight; andc) a total content of all alloy compounds except magnesium is more than 8.5% by weight.

Owner:BIOTRONIK AG

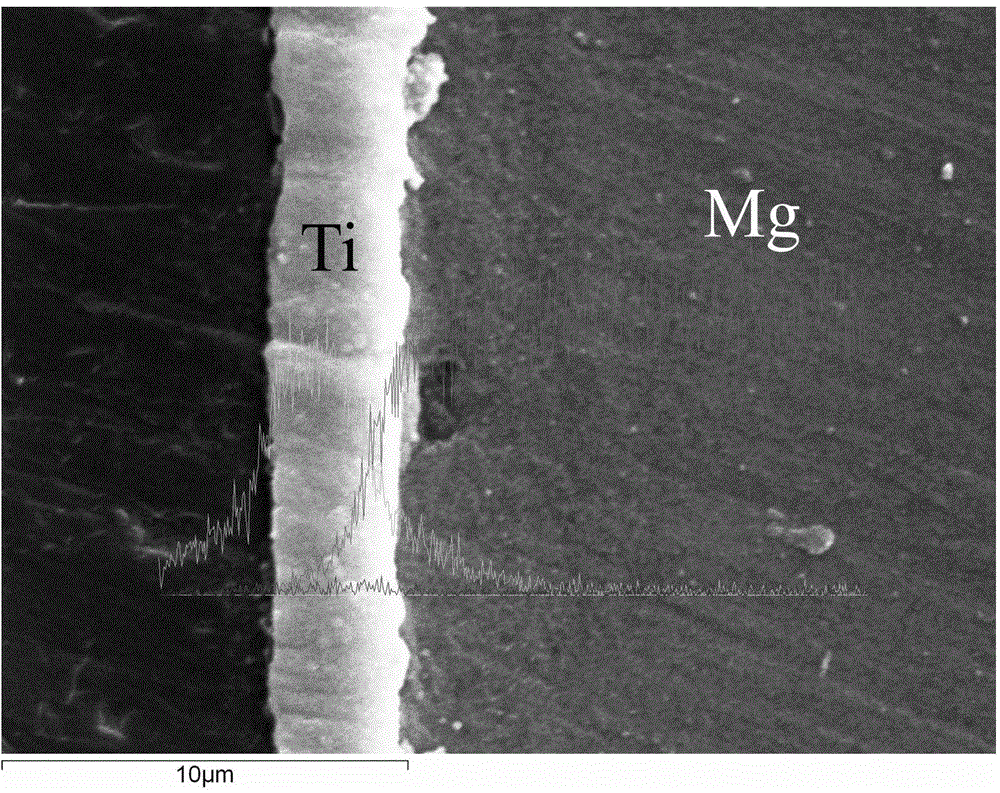

Method for modifying surfaces of biodegradable magnesium and magnesium alloy through titanium ion implantation and deposition

InactiveCN104878362AHigh bonding strengthReduce corrosion rateVacuum evaporation coatingSputtering coatingMixed oxideIon beam

The invention discloses a method for modifying surfaces of biodegradable magnesium and magnesium alloy through titanium ion implantation and deposition, and belongs to the technical field of surface treatment. The method is that mixed oxide transition layers are formed on the magnesium and magnesium alloy surfaces by the ion implantation method, wherein the transition layer is composed of titanium oxide and magnesium oxide and is 3 to 6 microns in thickness; then 2-4 microns titanium films are prepared on the transition layers by the ion beam reinforcing depositing technology. According to the method, the transition layers are prepared to ensure the high combination strength of the titanium depositing film layer and a matrix; the titanium deposition film and the transition layers can improve the corrosion resistance of the magnesium and the magnesium alloy.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com