Implants comprising biodegradable metals and method for manufacturing the same

A manufacturing method and implant technology, applied in the direction of bone implants, joint implants, spinal implants, etc., can solve problems such as the limitation of interface adhesion strength, achieve excellent interface strength, easy biodegradation rate, excellent The effect of interface adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] Implant material made from pure magnesium

[0053] Manufacturing costs also increase exponentially due to the higher purity when high purity materials with low dopant content are used. Therefore, its commercial value deteriorates. In each example, in order to determine the dopant concentration of magnesium that can be used as an implant material, different amounts of iron and nickel were added during the manufacture of magnesium, and its corrosion characteristics were evaluated (hereinafter, the dopant concentration is 0.01% or less Magnesium, known as pure magnesium or 100% magnesium). Firstly, each magnesium with different dopant concentrations is filled in a stainless steel (SUS 304) crucible with an inner diameter of 50 mm, in which ultra-pure reagent-grade magnesium (99.9999%) is mixed with the following different contents of iron and nickel : (1) 400ppm (0.04%) and 10ppm (0.001%); (2) 70ppm (0.007%) and 5ppm (0.0005%); (3) 10ppm (0.001%) and 35ppm (0.0035%). Ne...

example 2

[0055] Manufacture of magnesium calcium alloy

[0056] A magnesium alloy is made by mixing magnesium and calcium. Among them, pure magnesium (purity 99.995%) containing dopant 10ppm (0.001%) iron and 35ppm (0.0035%) nickel is mixed with 0.8%, 5%, 10.5%, 23%, and 33% calcium respectively, and The mixed materials were respectively charged into a stainless steel (SUS304) crucible with an inner diameter of 50 mm. Subsequently, in order to prevent the magnesium alloy in the crucible from coming into contact with the air, the temperature of the crucible was increased to a range of about 700°C to 1000°C with a resistance heater while flowing argon gas around the periphery of the crucible to melt the magnesium alloy. The completely molten magnesium alloy is quenched to produce a solid magnesium alloy. The crucible is stirred to mix the elements in the molten magnesium alloy with each other. In addition, during quenching, the crucible is immersed in water to rapidly cool and harden th...

example 3

[0059] Manufacturing of Mg-Ca Alloy by Rapid Quenching by Gas Blowing

[0060] First use a heater to melt the magnesium alloy, and then spray the molten magnesium alloy into a small hole with a diameter of about 3mm by using argon spraying method to solidify it to make a rapidly quenched magnesium alloy material . If this method is used, the rapid cooling and hardening rate of the magnesium alloy material is much higher than in Examples 1 and 2, thus exhibiting an extremely fine structure.

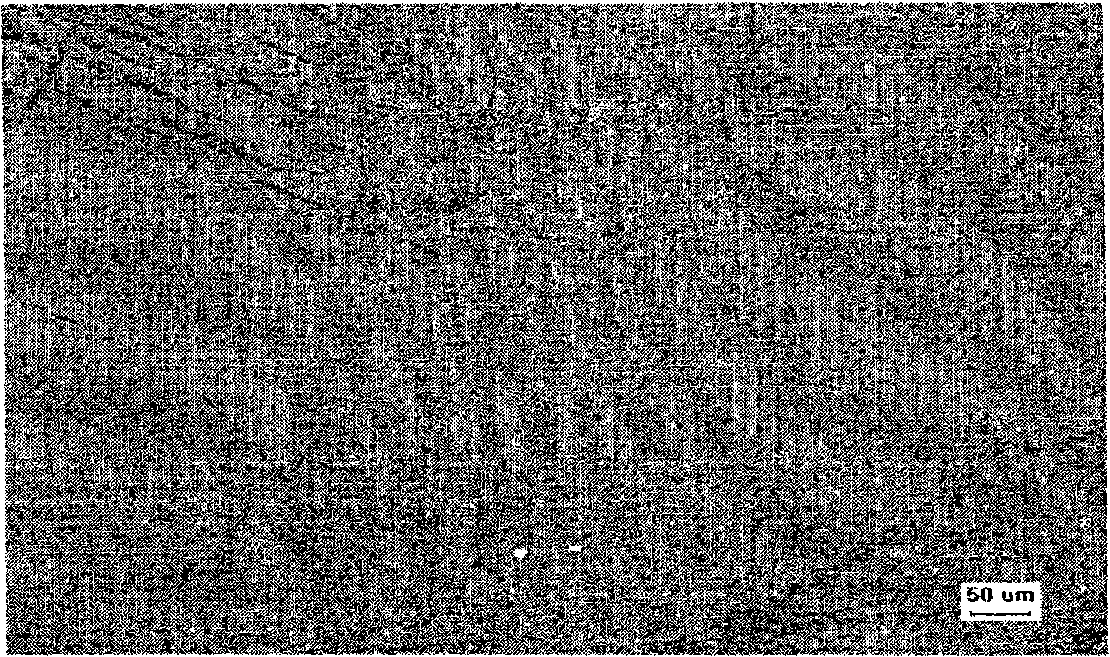

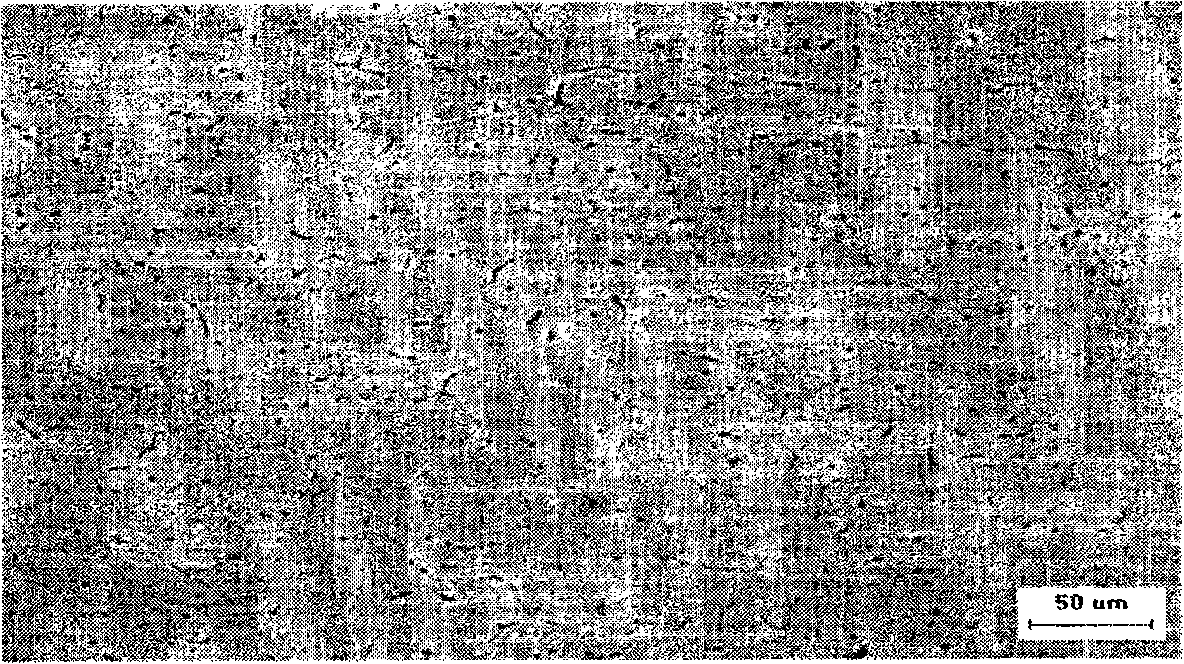

[0061] Figure 8 The photo shows Mg made by the above method 0.67 Ca 0.33 The cross-section of the alloy observed under an optical microscope, while Figure 7 It shows the cross-section of the magnesium alloy material made by immersing the crucible in water and quenching under an optical microscope. Compare Figure 8 and Figure 7 it can be discovered Figure 8 The size of the composite phase (composition phase) in is extremely fine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com