Permeable 3D printing cement-based material interface reinforcing agent and application thereof

A technology of cement-based materials and interface enhancers, applied in the direction of adhesives, inorganic adhesives, adhesive additives, etc., can solve the problems of interface strength improvement, complex process, high printing equipment requirements, etc. The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

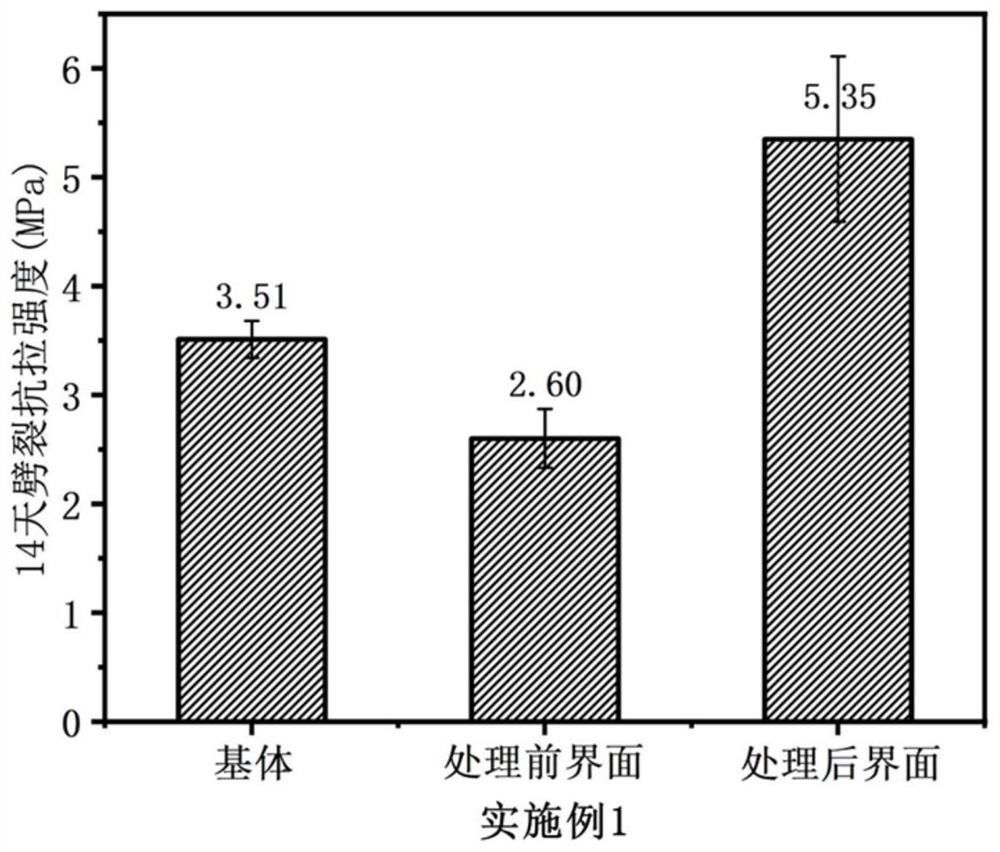

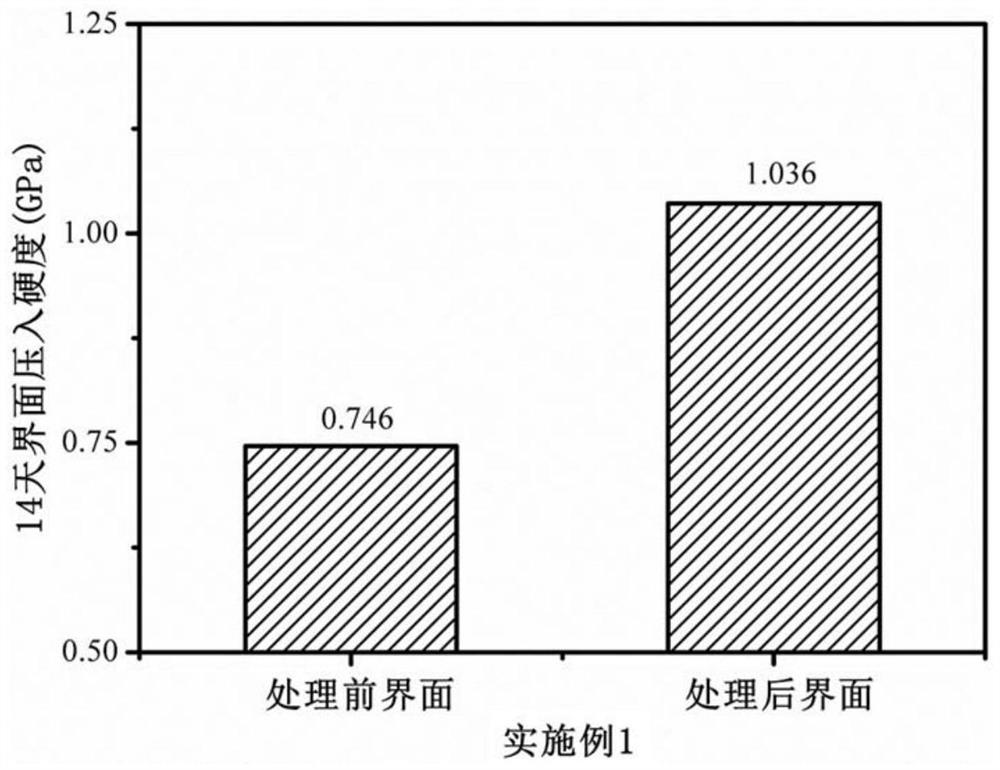

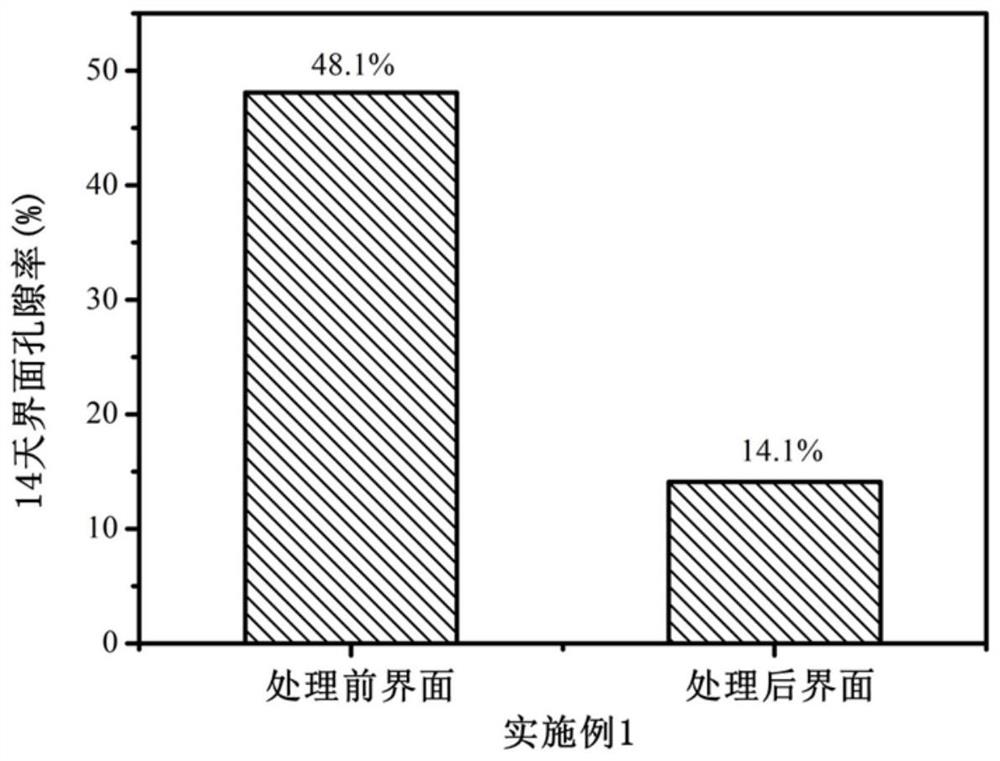

Embodiment 1

[0021] A permeable 3D printing cement-based material interface enhancer and application thereof, comprising the following steps:

[0022] Calcium formate: analytically pure;

[0023] Disodium edetate: analytically pure;

[0024] Sodium silicate solution: mass concentration 40%, modulus 3.3;

[0025] Lithium silicate solution: mass concentration 25%, modulus 4.8;

[0026] Nano-silica sol: Add sodium silicate solution dropwise to 1% acetic acid solution until pH=10.00±0.01.

[0027] 1) Dissolve calcium formate in a container with tap water at room temperature to prepare a calcium formate solution with a mass concentration of 10% as component A;

[0028] 2) At room temperature, mix 8.9 parts by mass of sodium silicate solution with 58 parts by mass of lithium silicate solution, and stir at 450 rpm for 1.5 h;

[0029] 3) Add 0.2 parts by mass of disodium edetate to the above solution, continue to stir at 450 rpm for 0.5 h; let stand for 12 h;

[0030] 4) Add 32.9 parts of nan...

Embodiment 2

[0035] A permeable 3D printing cement-based material interface enhancer and its application, its raw material formula and the preparation process of components A and B, that is, step 1)-step 4) are the same as in Example 1, and the subsequent steps are as follows:

[0036] 5) After the printing cement slurry to be processed has been formed for 24 hours, add component A twice at the gap of the vertical interface, each time at a dosage of 4 mL / m, with an interval of 6 hours, and then send it to the standard curing room for curing ;

[0037] 6) After the printing cement slurry to be processed is formed for 72 hours, add component B dropwise at the vertical interface gap twice, each time at a dosage of 4 mL / m, with an interval of 6 hours each time, and then maintain it in the standard curing room until 14 d age.

[0038] Example 2 provides enhanced effect on vertical printing interface at lower usage. Among them, the 14 d splitting tensile strength of the matrix material, the in...

Embodiment 3

[0040] A permeable 3D printing cement-based material interface enhancer and its application, its raw material formula and the preparation process of components A and B, that is, step 1)-step 4) are the same as in Example 1, and the subsequent steps are as follows:

[0041] 5) After the printing cement slurry to be processed is formed for 8 hours, add component A twice at the gap of the vertical interface, each time at a dosage of 4 mL / m, with an interval of 4 hours each time, and then send it to the standard curing room for curing ;

[0042] 6) After the printing cement slurry to be processed is formed for 24 hours, add component B dropwise at the gap of the vertical interface twice, each time at a dosage of 4 mL / m, with an interval of 4 hours each time, and then maintain it in the standard curing room until 14 d age.

[0043] Example 3 provides the enhanced effect of the earlier treatment on the vertical printing interface at lower usage. Among them, the 14 d splitting tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com