A kind of nano-silver modified cnts composite material and its preparation method and application

A composite material and nano-silver technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of weak bonding strength and strong chemical connection, and achieve the improvement of interface wettability, excellent antibacterial and electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

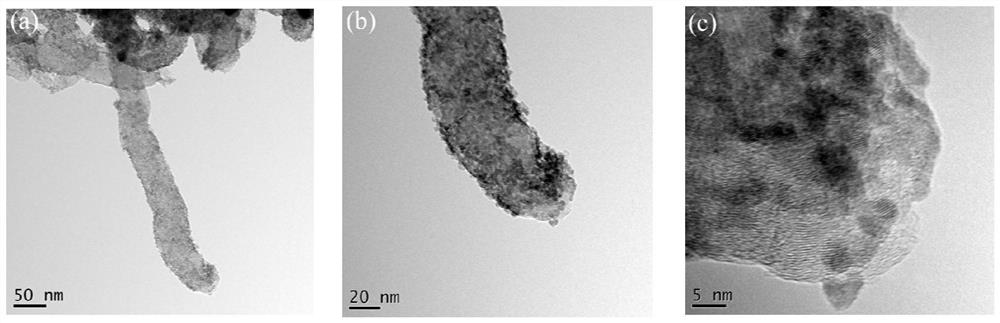

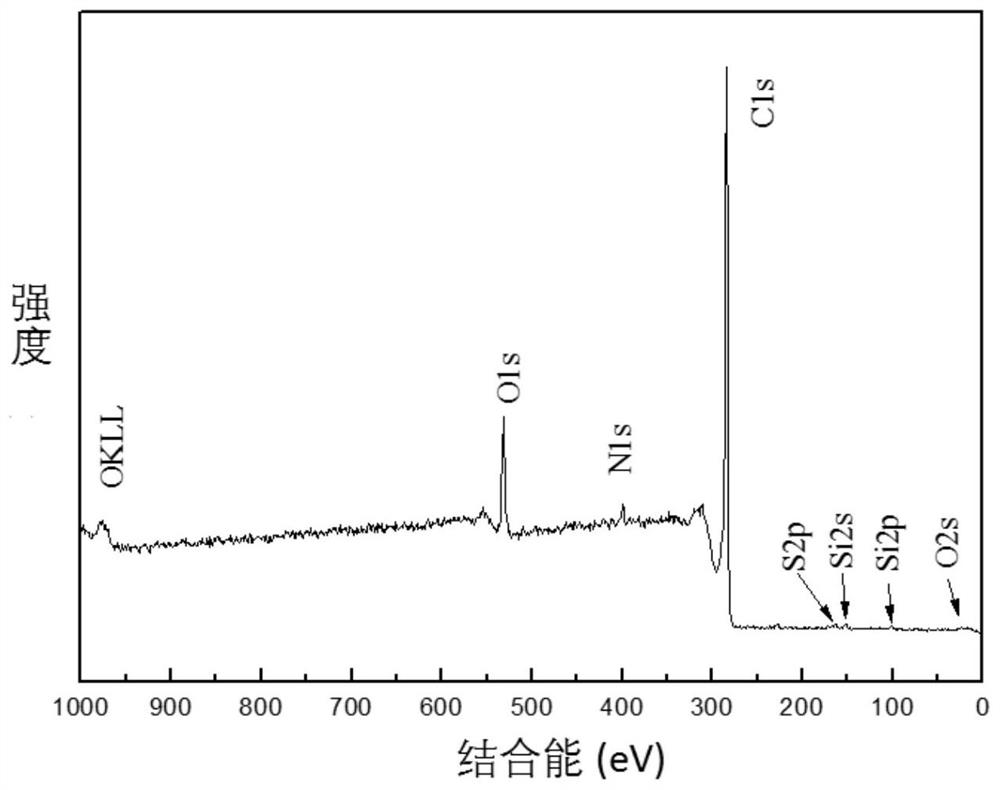

[0040] The preparation method of a nano-silver modified CNTs composite material (CNTs@AgNP) of the present embodiment, the specific steps are as follows:

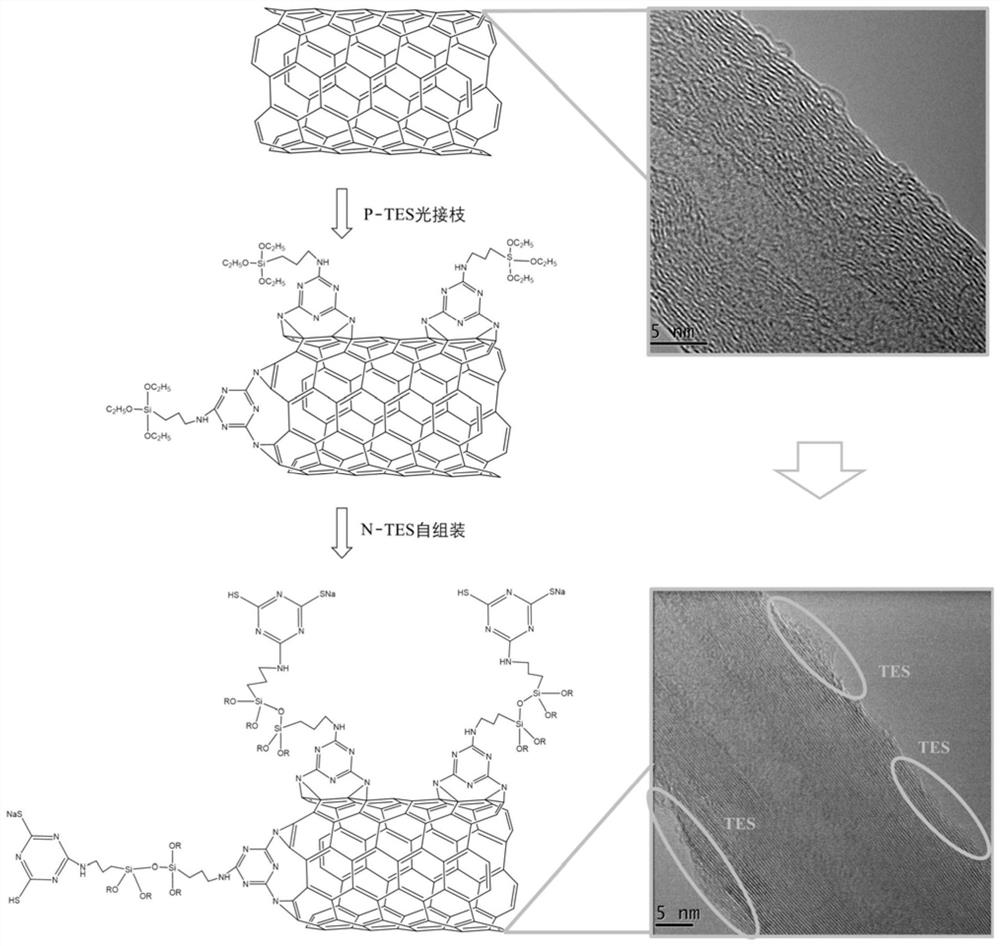

[0041] (1) P-TES photografting

[0042] Weigh 0.7g of CNTs into 100ml of P-TES alcohol solution (0.8g / L) and ultrasonically disperse for 10min. Then, the CNTs were extracted with a vacuum filtration device and placed in a vacuum drying oven at 100° C. for 4 h. Then put it into a mortar and grind it into powder, spread it evenly and place it at a wavelength of 365nm and a light intensity of 0.5J / cm 2 700s under UV light irradiation. Then, use alcohol to filter and wash 8 times on a vacuum filtration device to remove excess P-TES, and obtain P-TES photografted carbon nanotubes (CNTs-PTES).

[0043] (2) N-TES self-assembly

[0044] Put the CNTs-PTES prepared in step (1) into 100ml of N-TES aqueous solution (1g / L), and stir on a magnetic stirrer at room temperature for 60min, take the mixed solution to wash, and evaporate t...

Embodiment 2

[0051] The preparation method of a nano-silver modified CNTs composite material (CNTs@AgNP) of the present embodiment, the specific steps are as follows:

[0052] (1) P-TES photografting

[0053] Weigh 0.3g of CNTs into 100ml of P-TES alcohol solution (0.5g / L) and ultrasonically disperse for 10min. Then, the CNTs were extracted with a vacuum filtration device and placed in a vacuum drying oven at 100° C. for 4 h. Then put it into a mortar and grind it into powder, spread it evenly and place it at a wavelength of 256nm and a light intensity of 0.1J / cm 2 irradiated under UV light for 300 s. Then, use alcohol to filter and wash 8 times on a vacuum filtration device to remove excess P-TES, and obtain P-TES photografted carbon nanotubes (CNTs-PTES).

[0054] (2) N-TES self-assembly

[0055] Put the CNTs-PTES prepared in step (1) into 100ml of N-TES aqueous solution (0.5g / L), and stir on a magnetic stirrer at room temperature for 40min, take the mixed solution to wash, and evapo...

Embodiment 3

[0063] The preparation method of a nano-silver modified CNTs composite material (CNTs@AgNP) of the present embodiment, the specific steps are as follows:

[0064] (1) P-TES photografting

[0065] Weigh 1g of CNTs into 100ml of P-TES alcohol solution (1g / L) and ultrasonically disperse for 10min. Then, the CNTs were extracted with a vacuum filtration device and placed in a vacuum drying oven at 100° C. for 4 h. Then put it into a mortar and grind it into powder, spread it evenly and place it under a wavelength of 300nm and a light intensity of 1J / cm 2 500s under UV light irradiation. Then, use alcohol to filter and wash 8 times on a vacuum filtration device to remove excess P-TES, and obtain P-TES photografted carbon nanotubes (CNTs-PTES).

[0066] (2) N-TES self-assembly

[0067] Put the CNTs-PTES prepared in step (1) into 100ml of N-TES aqueous solution (2g / L), and stir on a magnetic stirrer at room temperature for 60min, take the mixed solution to wash, and evaporate to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com