Patents

Literature

168results about How to "Improve interfacial wettability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

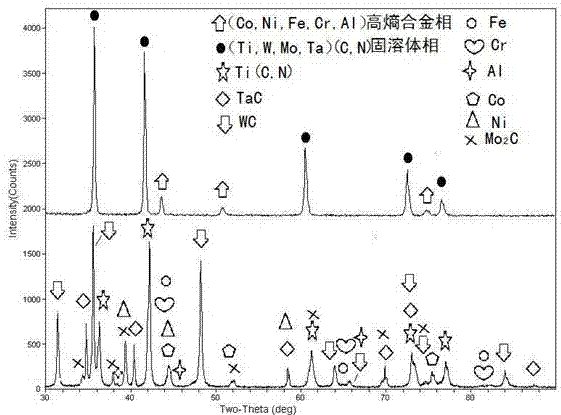

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

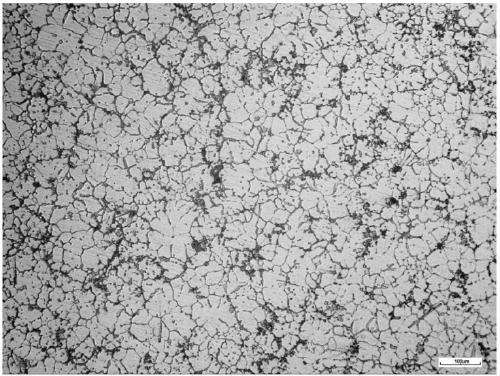

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

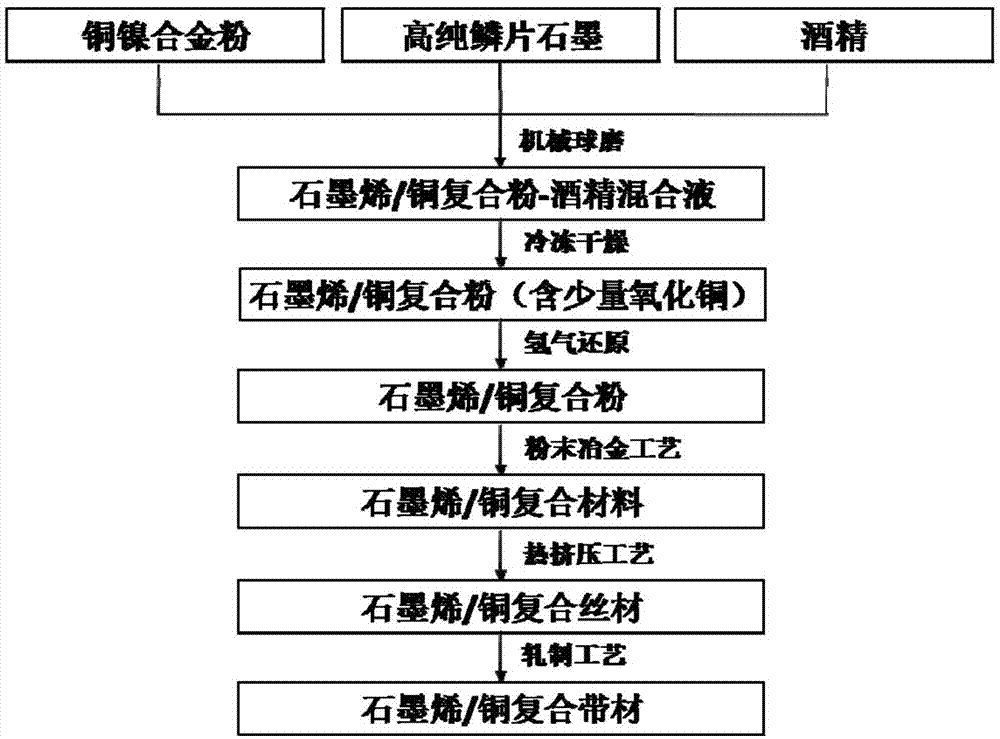

Graphene/copper composite and preparation method thereof

The invention provides a graphene / copper composite and a preparation method of the graphene / copper composite. Copper-nickel alloy powder and crystalline flake graphite are ball-milled mechanically jointly, alcohol is added as a wet milling medium during mechanical ball milling, and copper powder oxidation can be avoided. Graphene is stripped from the graphite by virtue of a mechanical force; at the same time, due to the presence of copper-nickel micro powder, a stripping process of the graphite is promoted; the spherical copper-nickel alloy powder is changed into sheeted powder by the action of the ball milling to obtain graphene / copper composite powder preliminarily; and a graphene / copper composite block, a composite wire and a composite tape are obtained by powder metallurgy, hot extrusion and rolling technologies. According to the composite, the graphene is dispersed uniformly; interface bonding between a matrix and a reinforcement; and the graphene / copper composite has excellent physical properties. According to the composite and the method, a technology is simple, a process is easy to control, and a scale production application is easy to achieve.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

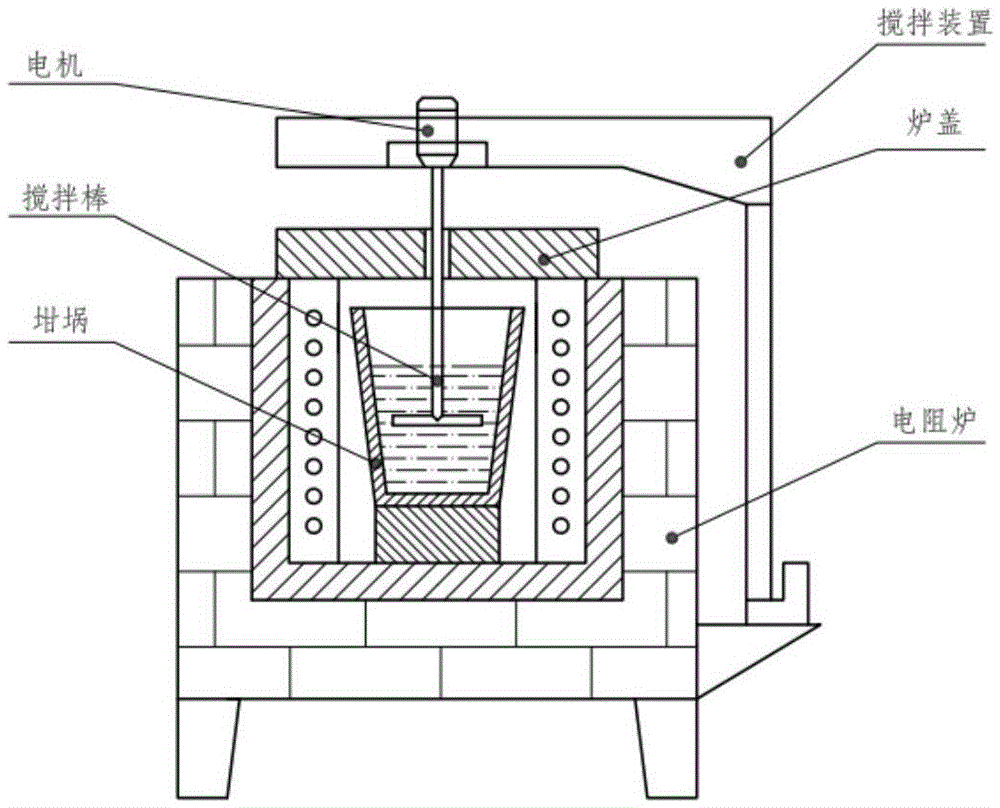

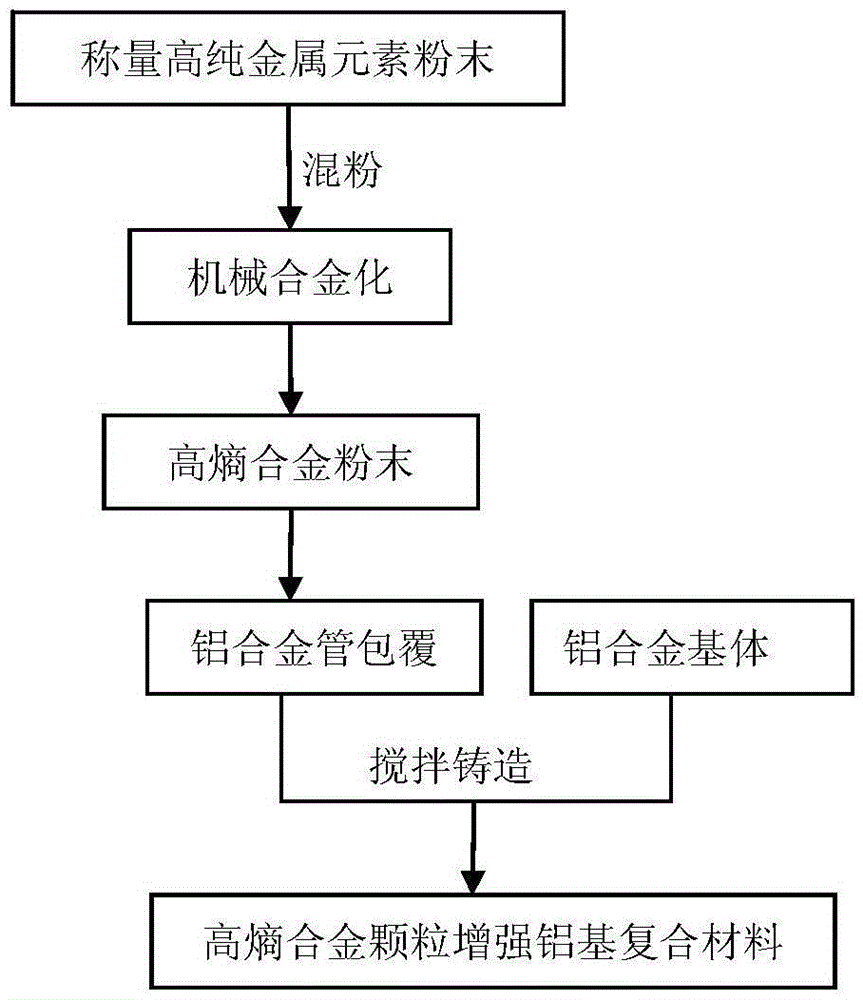

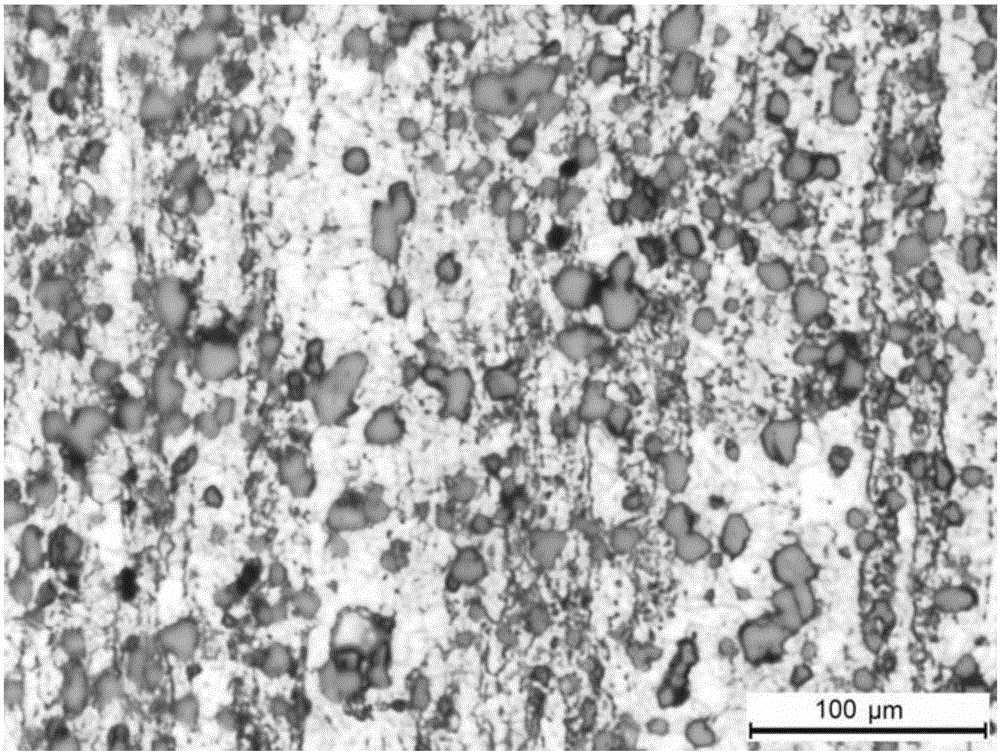

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

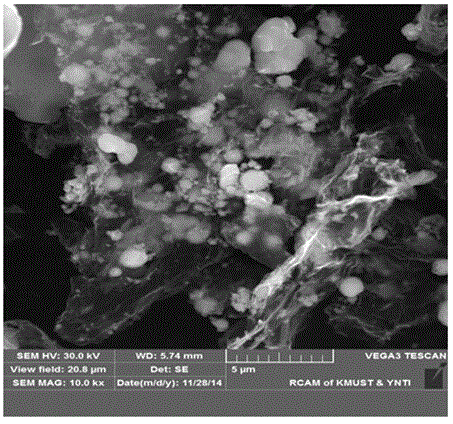

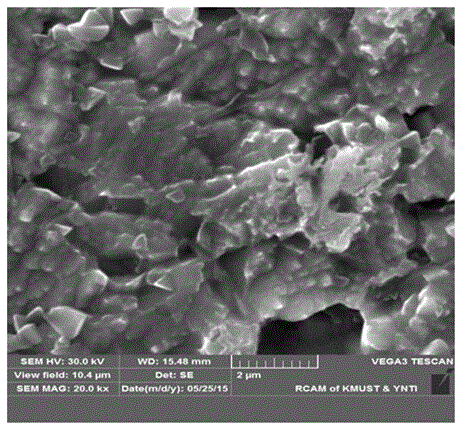

Preparation method of graphene-reinforced copper-based composite

ActiveCN105624445AImprove performanceEasy to organizeTransportation and packagingMetal-working apparatusSlurryCobalt

The invention discloses a preparation method of a graphene-reinforced copper-based composite and belongs to the field of preparation of high-strength and high-conductivity composites. The method comprises steps as follows: graphene, nano copper powder and cobalt powder in the required mass ratio are mixed in absolute ethyl alcohol, the mixture is physically dispersed under electromagnetic stirring, and then physically dispersed mixed slurry is added to a ball milling tank for mechanical ball milling; after evenly mixed slurry is centrifugally dried, obtained mixed powder is annealed and then subjected to hot-pressing SPS (spark plasma sintering) forming; an obtained block blank is annealed and then subjected to hot extrusion, and the graphene-reinforced copper-based composite is obtained. The graphene-reinforced copper-based composite prepared through the method has the good mechanical property, uniform structure and good heat and electricity conductivity.

Owner:KUNMING UNIV OF SCI & TECH

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

Additive for heat zinc coating auxiliary agent

InactiveCN101126142AHigh activityIncrease profitHot-dipping/immersion processesSlagSurface-active agents

The invention provides an additive used in hot-dip galvanizing assistant plating agent, belonging to the technical field of metal material plating. The invention is used for solving the problem of assistant plating efficiency. The technical proposal of the invention is that the additive is a de-ionized water solution; the water solution contains cation surface active agent and organic solvent of the long chain alkyl; the content of the long chain alkyl cation surface active agent is 100 to 800 gram per liter; the organic solvent can be ethanol, isopropyl alcohol, acetone or one of nickel and N-dimethyl formamide, with adding content of 30 to 160 gram per liter. The invention has the advantages that the assistant plating agent is made and the made element have a plating face with excellent wettability and compatibility, which can increase the activity and the utilization rate, improve the assistant plating efficiency, prevent plated element from escaping, prevent the plated element which is assistant plated from being secondarily oxidized in air, reduce zinc slag, prevent the zinc liquid from splashing and increase the surface quality of the made element. Furthermore, the invention can be directly added into the assistant agent, and then is evenly mixed, with the character of easy operation. The invention is not limited by the temperature of the assistant plating agent so that the invention can be used under room temperature.

Owner:陈冬

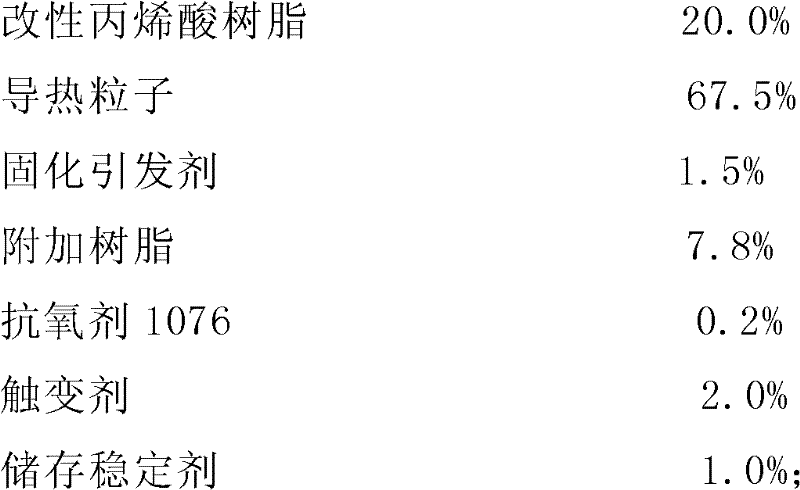

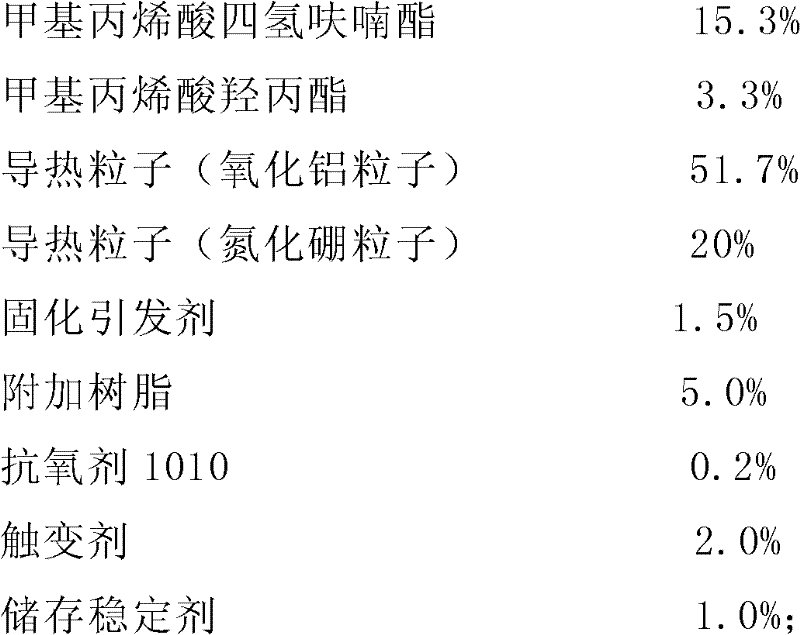

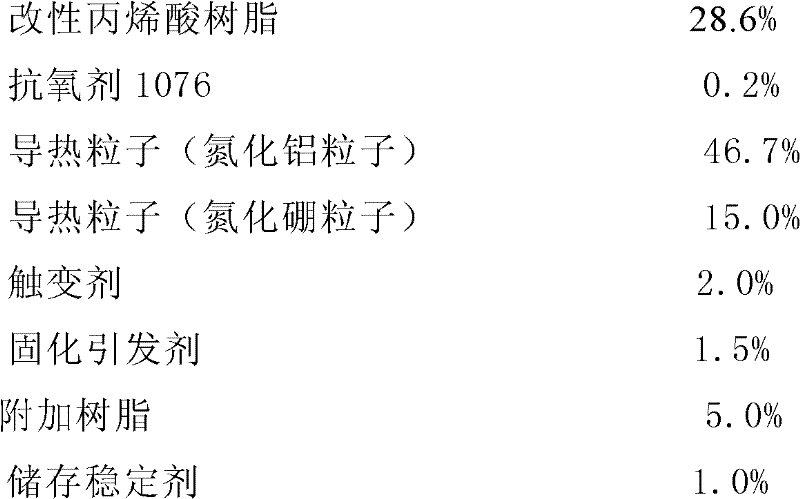

Fast cured thermal conductive adhesive and preparation method thereof

ActiveCN102504707AIncreased shear strengthFast curingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAcrylic resinAdhesive

The invention relates to a thermal conductive adhesive and a preparation method thereof. The thermal conductive adhesive comprises 10 to 45 weight percent of modified acrylic resin, 50 to 85 weight percent of thermal conductive particles and 1 to 5 weight percent of curing initiator. Compared with the existing single-component thermal conductive adhesive, the thermal conductive adhesive disclosed by the invention can be suitable for surfaces of polar substrates such as metal, ceramic and glass, has high cutting speed after being cured and has high curing speed. Compared with the existing two-component thermal conductive adhesive, the thermal conductive adhesive disclosed by the invention has high curing speed and high cutting strength after being cured on one hand, and has no risk of incomplete curing caused by improper proportioning or nonuniform stirring on the other hand. The thermal conductive adhesive can be used for thermal conductive connection between various heat source generators and a radiator.

Owner:TIF ADVANCED MATERIALS SHANGHAI

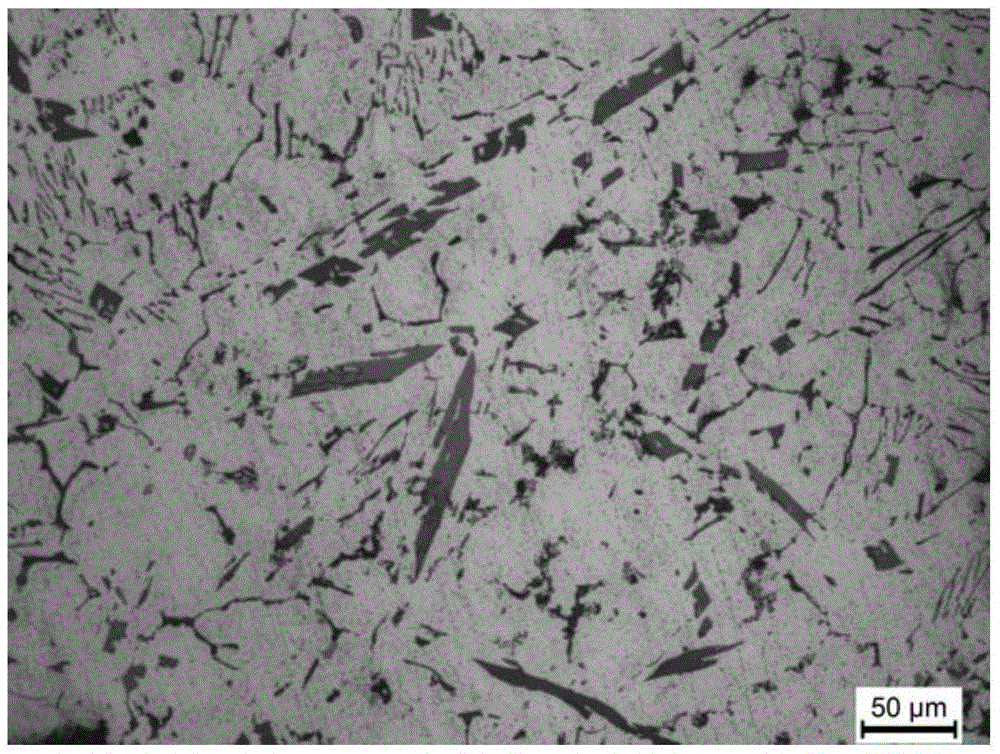

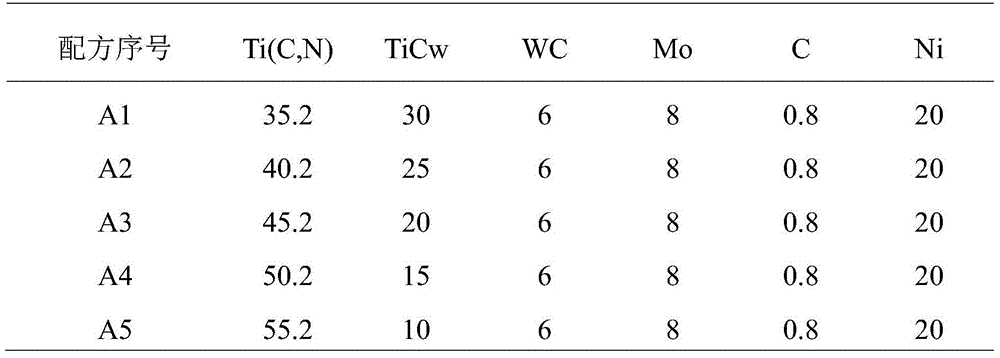

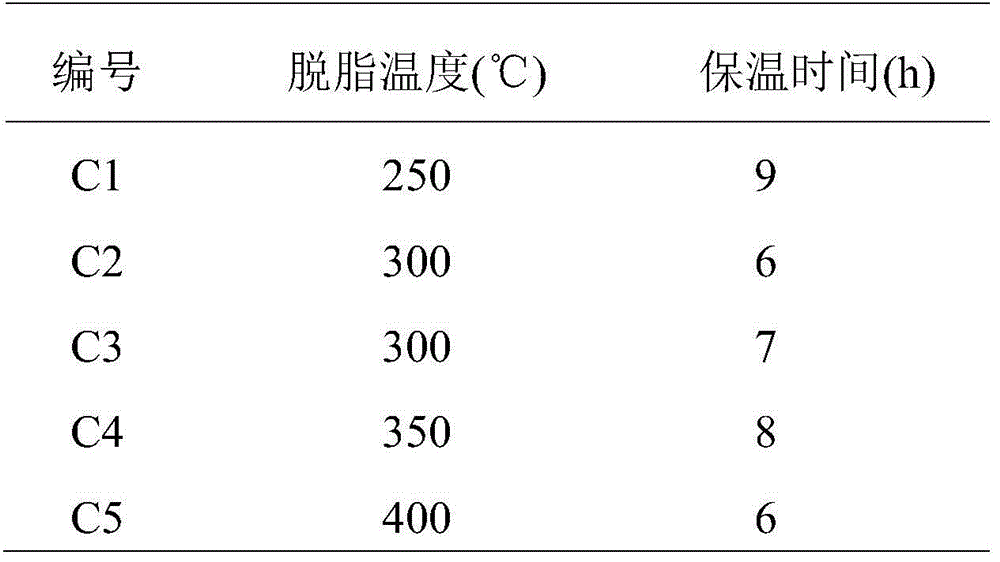

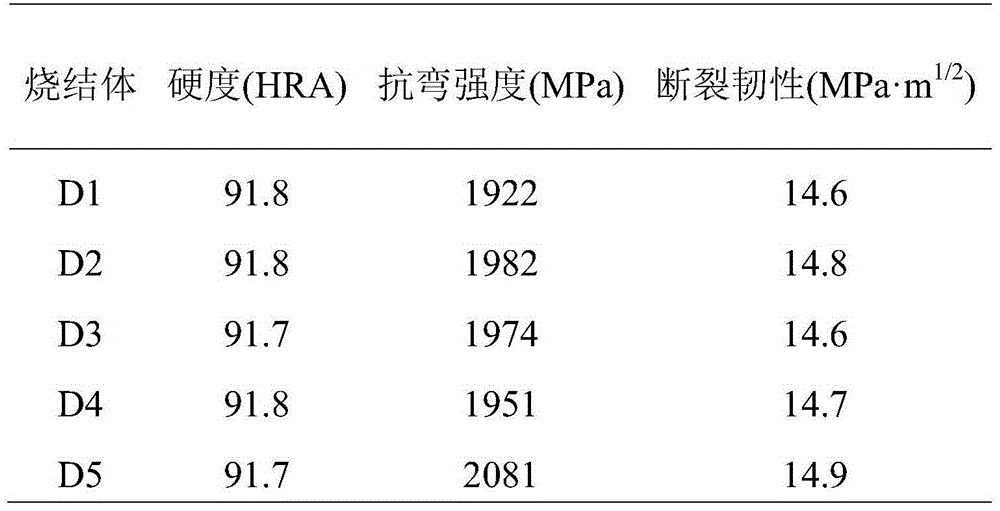

TiC crystal whisker-reinforced metal ceramic and preparation method thereof

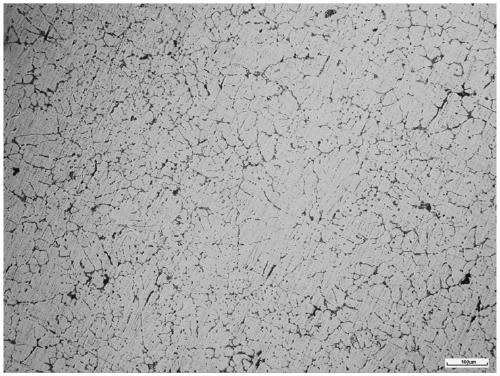

The invention discloses a TiC crystal whisker-reinforced metal ceramic and a preparation method thereof, belongs to metal ceramic and a preparation method thereof, and aims at improving bending strength and breaking tenacity of the existing Ti(C,N)-based metal ceramic. The TiC crystal whisker-reinforced metal ceramic disclosed by the invention is prepared from constituent material through ball-milling and mixing, TiC crystal whisker dispersing, drying and screening, die-forming, degreasing and vacuum-sintering, wherein a sintering tissue comprises a hard phase and a binding phase; the hard phase comprises two ceramic phases, and the binding phase is Ni-Mo-W sosoloid. The constituent materials comprise the following materials in percentage by weight: not less than 23% and not greater than 55.2% of Ti(C, N) powder, not less than 10% and not greater than 30% of TiC crystal whisker, not less than 6% and not greater than 10% of WC powder, not less than 8% and not greater than 15% of Mo powder, not less than 0.8% and not greater than 1.2% of C powder, not less than 20% and not greater than 32% of Ni powder. The TiC crystal whisker-reinforced metal ceramic prepared by the method disclosed by the invention has hardness capable of reaching 87.6 HRA-91.8 HRA, bending strength not less than 1920 MPa and breaking tenacity not less than 14.2MPa.m / 2, which are greatly improved, and has good popularization and application prospect in dry type cutting tools, hot-working dies, and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of copper-cladded silver-clad tungsten composite clad powder

ActiveCN103464742ASimple processHigh sintering activityLiquid/solution decomposition chemical coatingCopperPre treatment

The invention provides a preparation method of copper-clad silver-clad tungsten composite clad powder, which belongs to the technical field of powder processing and preparation in powder metallurgy. Tungsten powder is washed with alkali and acid and is sensitized and activated, so that preprocessed powder is produced, the surfaces of the preprocessed powder are cladded with silver, so that nano silver-cladded tungsten composite powder is produced, and finally, the silver-clad tungsten composite powder is cladded with copper, so that the copper-cladded silver-cladded tungsten composite clad powder, the copper content of which varies between 5 percent and 50 percent, is obtained. The cladding copper layer and the cladding silver layer in the composite clad powder prepared by the preparation method are uniform and intact, have high purity, and can be controlled in terms of quality. The introduction of the silver layer can remarkably improve the wettability of the tungsten-copper interface. The composite clad powder has good sintering property, the comprehensive properties of tungsten-copper composite material, such as thermal property and mechanical property, can be enhanced, and the composite clad powder can be used as material for the preparation of high-performance tungsten-copper composite material, and has a broad application prospect in the fields of electronic packaging, high-temperature materials, electric contact materials and the like.

Owner:WUHAN UNIV OF TECH

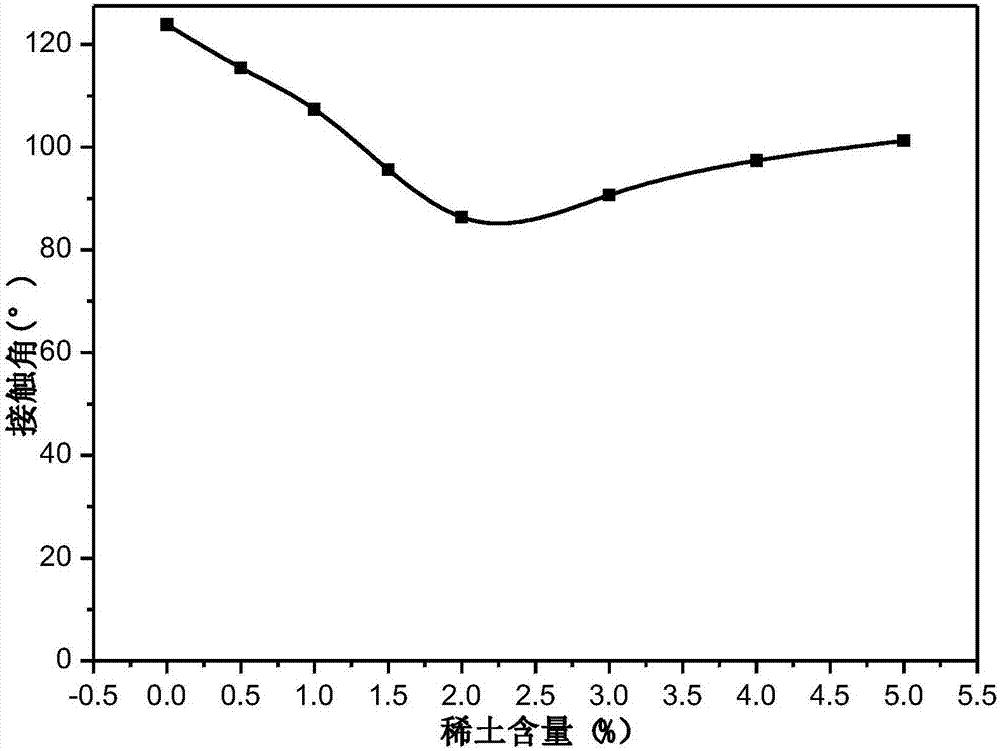

Preparation method for rare-earth-modified graphene reinforced metal matrix composite bar

The invention discloses a preparation method for a rare-earth-modified graphene reinforced metal matrix composite material. Oxidized graphene is subjected to modifying treatment through rare earth, and then high-dispersity rare earth modified graphene powder is obtained through reduction; the modified graphene powder and metal powder are subjected to ball-milling and powder mixing, and then ball-milled composite powder is packed into a bag; welding and sealing are conducted after vacuum pumping; and the rare-earth-modified graphene reinforced metal matrix composite material is prepared through processes of hot isostatic pressing and hot extrusion forming. By adding trace rare earth elements, oxidizing of the graphene and the metal powder in the preparation process can be reduced, dispersity and interfacial wettability of the praphene in a metal matrix are improved, and the mechanical and conductive properties of a graphene reinforced metal matrix composite material are improved. Meanwhile, the preparation method is simple and easy to carry out in process, low in production cost, suitable for scale production and has good market prospects.

Owner:JIANGXI UNIV OF SCI & TECH

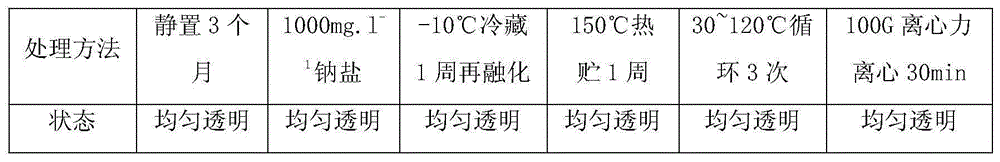

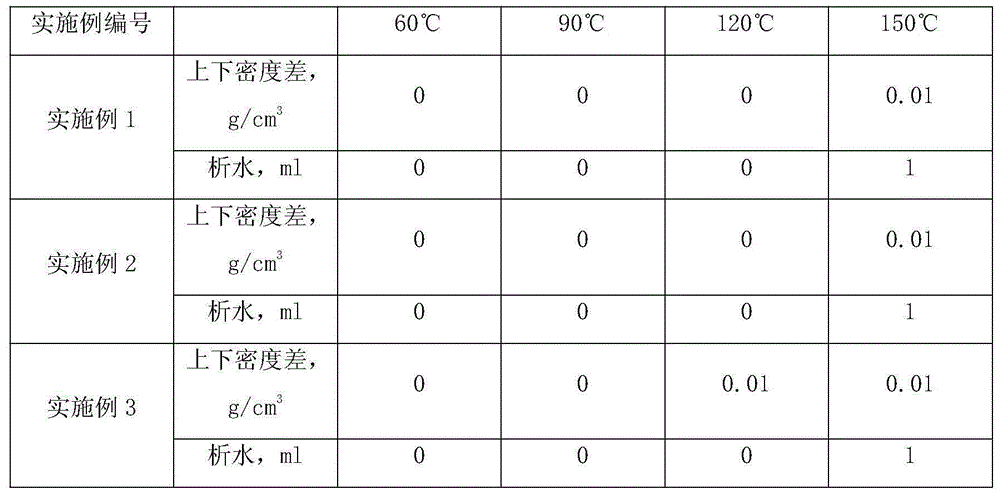

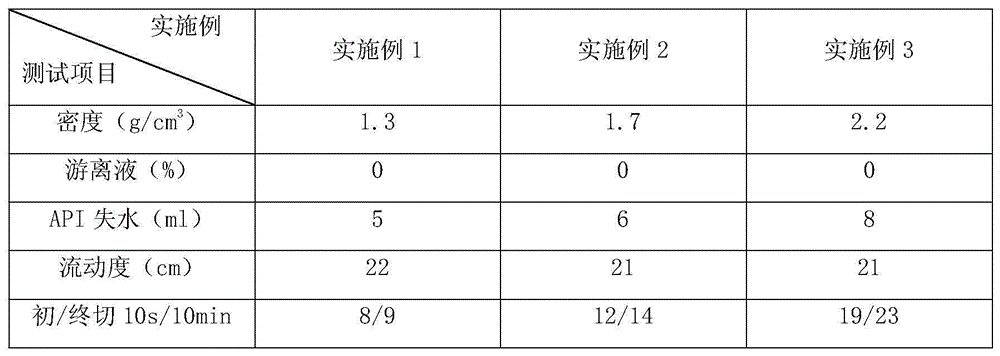

Emulsifying and flushing spacer fluid for improving cementing quality of oil-based drilling fluid and preparation method of emulsifying and flushing spacer fluid

ActiveCN105001841AImprove surface activityTemperature resistanceDrilling compositionGlycosideDiluent

The invention discloses an emulsifying and flushing spacer fluid for improving the cementing quality of an oil-based drilling fluid and a preparation method of the emulsifying and flushing spacer fluid. The spacer fluid is prepared from the following components in parts by weight: 200 parts of water, 5-10 parts of a surfactant, 70-75 parts of base oil, 4-15 parts of a suspension stabilizer, 0.2-3.0 parts of a fluid loss agent, 0.2-2.0 parts of a tackifier, 0.2-5.0 parts of a diluent, 80-400 parts of a weighting agent and 0.05 part of a defoamer, wherein the surfactant is prepared from cocoanut fatty acid diethanolamide CDEA and alkyl glycoside APG in a weight ratio of 1: 2. The emulsifying and flushing spacer fluid which has an emulsifying structure with permeating, dissolving, volume-increasing, carrying functions and the like has a preferable flushing capacity to the oil-based drilling fluid and mud cakes adhered to a casing wall. The surfacant molecules in the spacer fluid can be adsorbed on the surfaces of a casing and a well wall to improve the interfacial wettability, so that cement slurry and the casing and the well wall are better contacted and cemented, and therefore, the first and second interfacial cementation qualities for well cementation are improved.

Owner:SOUTHWEST PETROLEUM UNIV

Sulphydryl lignocellulose/montmorillonite composite heavy metal ion adsorbent and preparation and application thereof

ActiveCN105107471AImprove solubilityReduced levitation abilityOther chemical processesWater contaminantsCelluloseSorbent

The invention provides sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent and preparation and application thereof. The adsorbent is formed by sulphydryl lignocellulose and montmorillonite in a composite mode, wherein the mass ratio of sulphydryl lignocellulose to montmorillonite is 1:1-1.5:1, and insertion layers of sulphydryl lignocellulose enter between lamination layers of montomorillonite. The sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent is applied to removing heavy metal in waste water. The preparation method of the sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent has the advantages that preparation is easy, raw materials are easy to obtain, environmental friendliness is achieved, and no secondary pollution occurs; the obtained sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent is free of toxin, capable of being biologically degraded and low in cost and achieves simple and convenient adsorbing operation and a high adsorbing quantity when applied to removing heavy metal ions in waste water.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

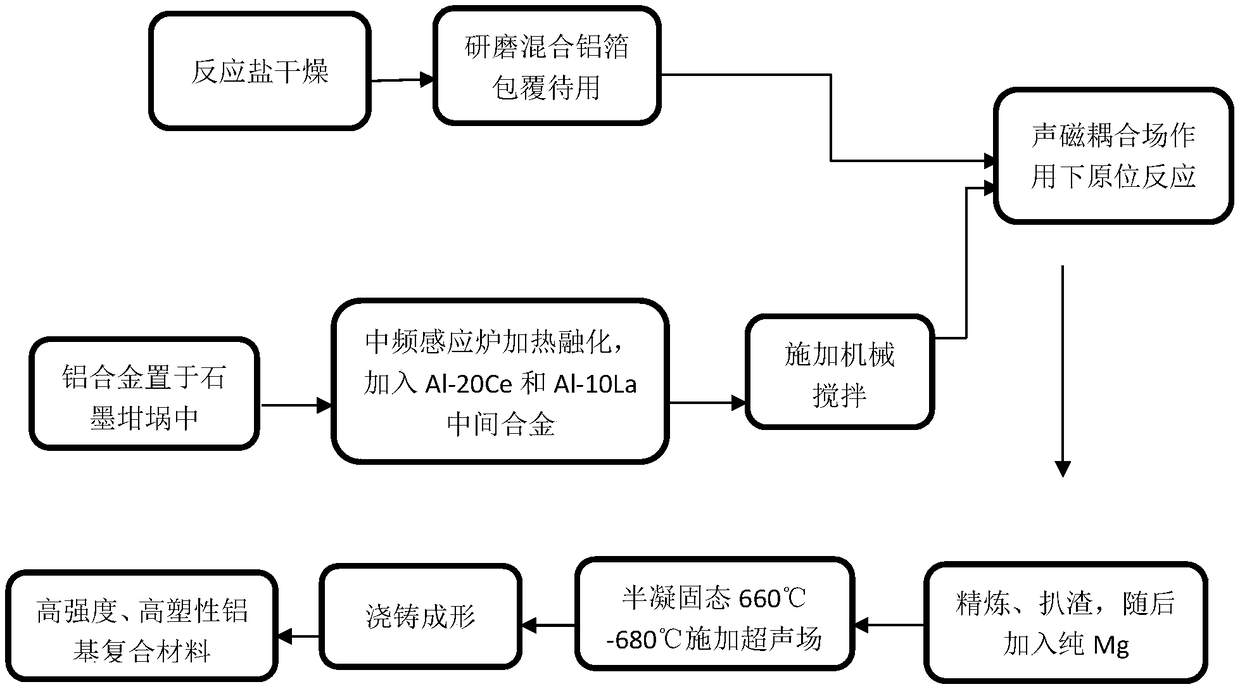

Method for regulating and controlling preparation of in situ binary nanoparticle enhanced aluminum based composite material

The invention relates to an in situ binary nanoparticle enhanced aluminum based composite material, in particular to a method for regulating and controlling the preparation of the in situ binary nanoparticle enhanced aluminum based composite material. A melt direct reaction method is used for preparing the binary nanoparticle enhanced aluminum based composite material; the aluminum alloy melting process uses mechanical stirring; rare earth middleintermediate alloy is added; through mechanical stirring, the melt generates vortex; the rare earth intermediatemiddle alloy is fast dispersed into the melt; in addition, the melt temperature can be more uniform. In the reaction process, an acoustic magnetic coupling field is exerted; through sound flow movement in two different directions, the uniform distribution of the enhanced particles in the metal melt in the whole melt is ensured; an ultrasonic field is exerted in the semi-solidified state; the continuous growth of the particles can be effectively inhibited, so that the distribution is more uniform; the prepared composite material is subjected to solid dissolution reinforcement through heat treatment, so that the grain particle dimension is smaller; the nanometer particles realize the scattered distribution in the crystals and on the crystal boundary; in addition, the particle and substrate interfaces are pure and achieves pollution-free effects; finally, the in-situ aluminum-based composite material is obtained.

Owner:JIANGSU UNIV

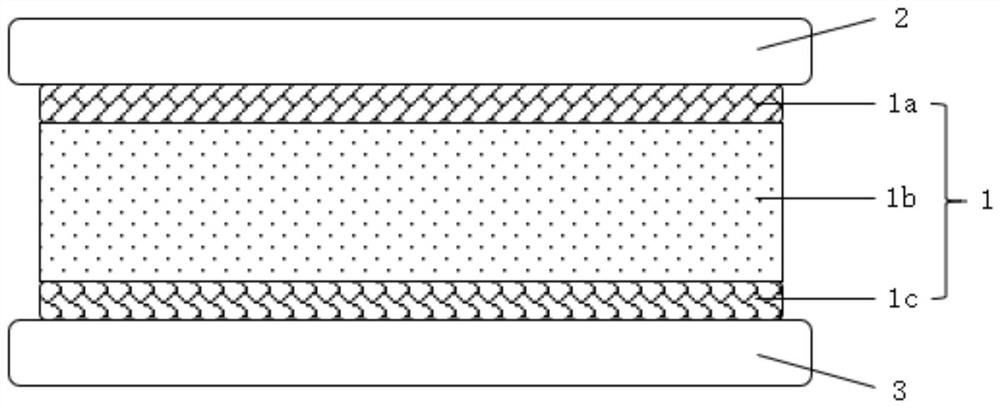

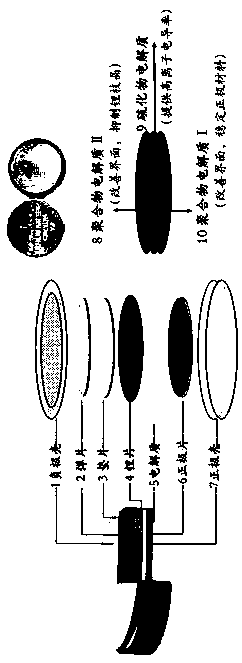

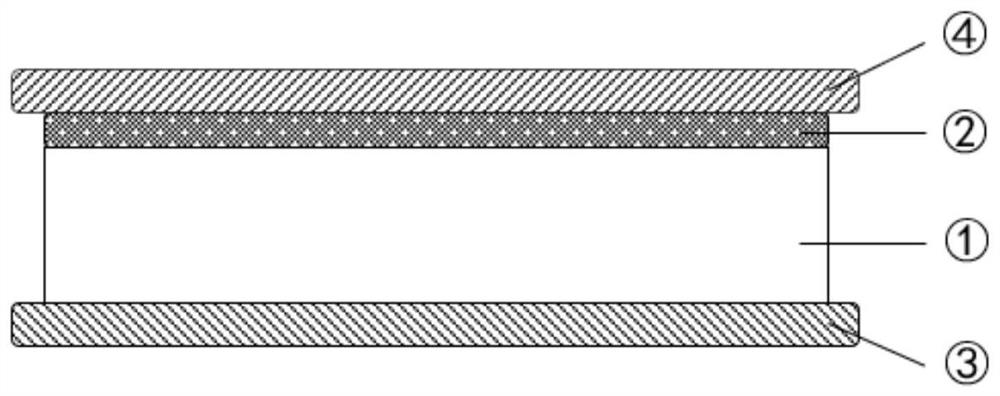

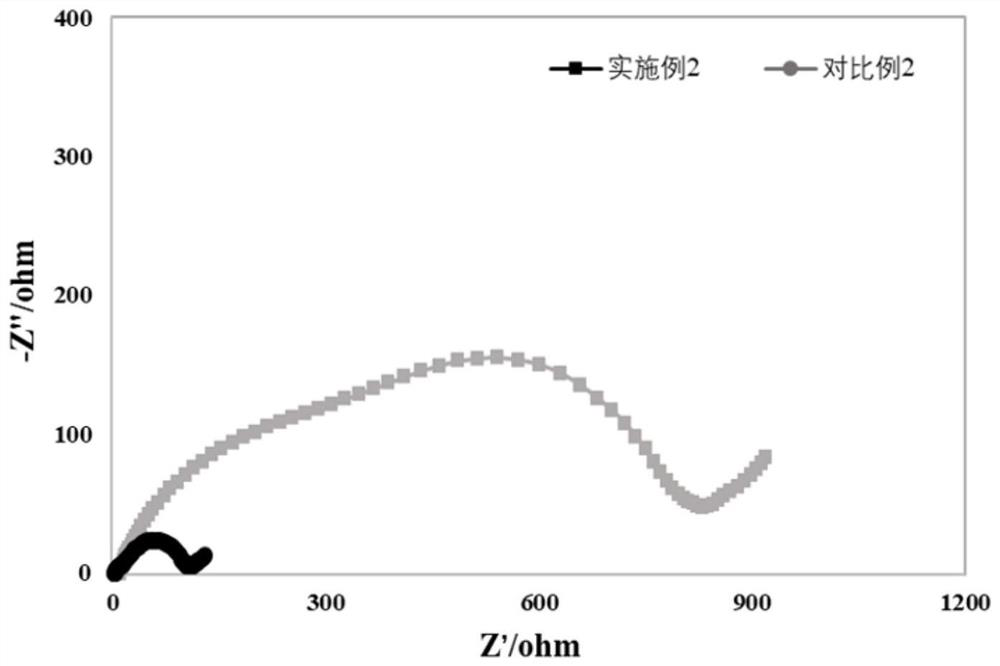

Solid electrolyte composite layer and lithium ion battery

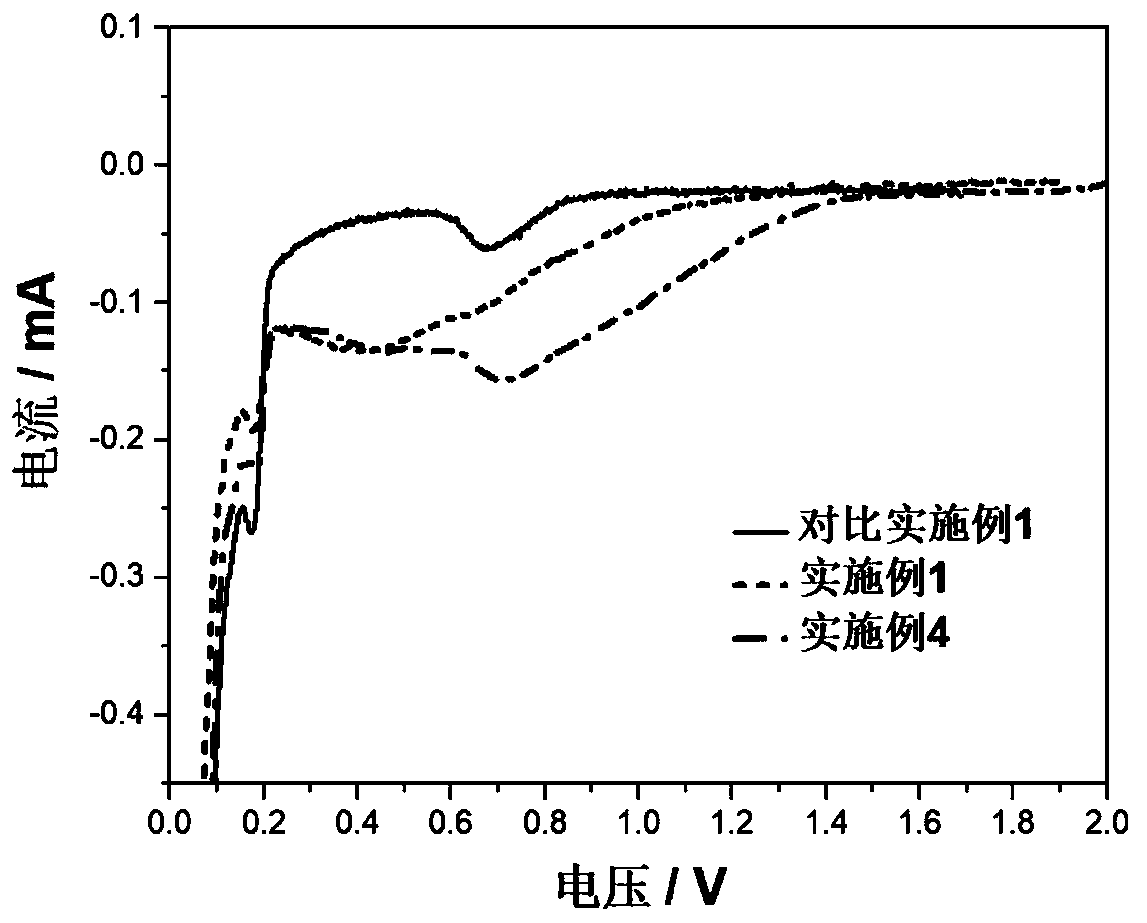

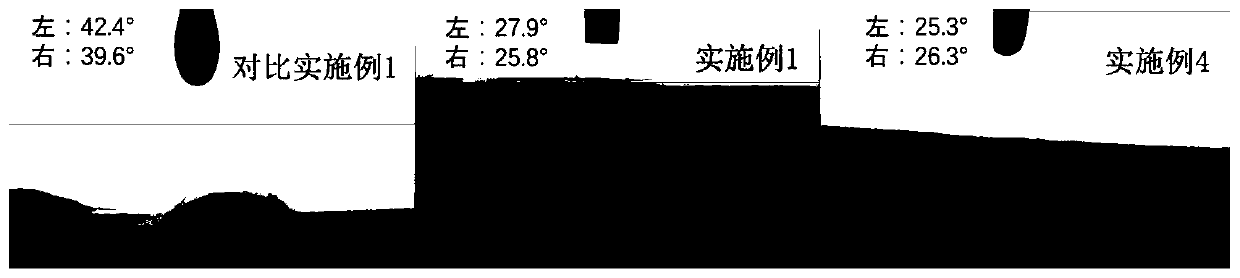

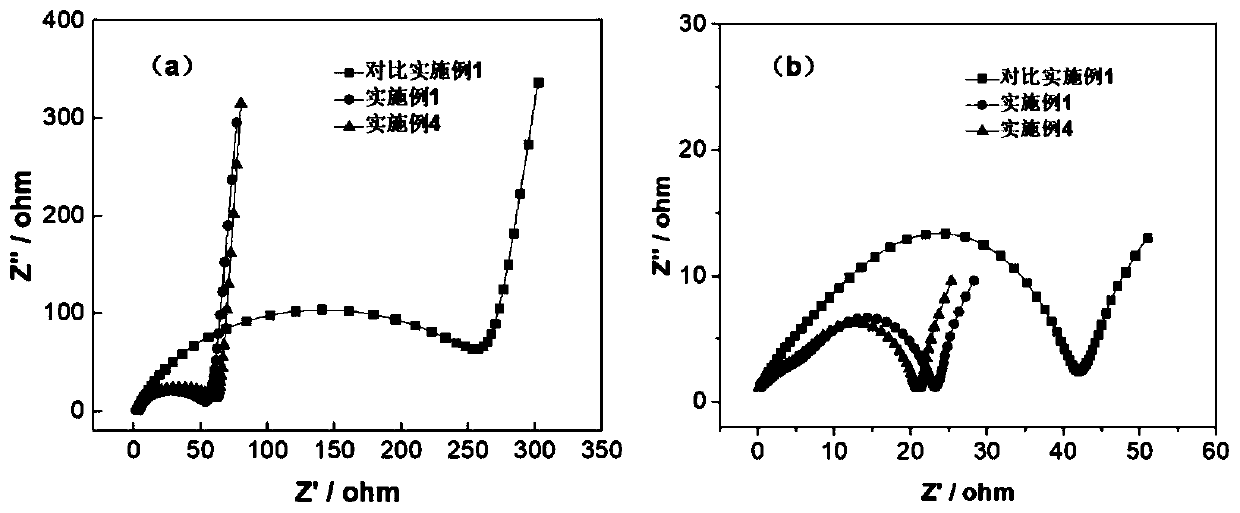

InactiveCN112599850AImprove interfacial wettabilityHigh mechanical strengthSecondary cells servicing/maintenanceElectrolyte immobilisation/gelificationSolid state electrolyteMetallic lithium

The invention provides a solid electrolyte composite layer and a lithium ion battery. The solid-state electrolyte composite layer comprises a near-positive-electrode-side solid-state electrolyte layer, a middle solid-state electrolyte layer and a near-negative-electrode-side solid-state electrolyte layer which are sequentially arranged in a stacked mode. The middle solid-state electrolyte layer comprises the inorganic ceramic electrolyte, the near-positive-electrode-side solid electrolyte layer comprises near-positive-electrode-side polymer with high oxidation resistance, and the near-negative-electrode-side solid electrolyte layer comprises a near-negative-electrode-side compound stable with metal lithium, so that the solid electrolyte composite layer is high in mechanical strength, and lithium dendrites are prevented from piercing the electrolyte; the requirements of high-voltage resistance of a positive electrode side and stability of a negative electrode side and metal lithium aremet, and meanwhile, the interface wettability of the solid electrolyte composite layer is good. The lithium ion battery comprises the solid electrolyte composite layer, and due to the fact that the solid electrolyte composite layer is high in mechanical strength, excellent in wettability and good in stability with positive and negative electrode interfaces, the lithium ion battery has the advantages of being small in battery internal resistance, good in cycle performance and high in safety.

Owner:ZHUHAI COSMX BATTERY CO LTD

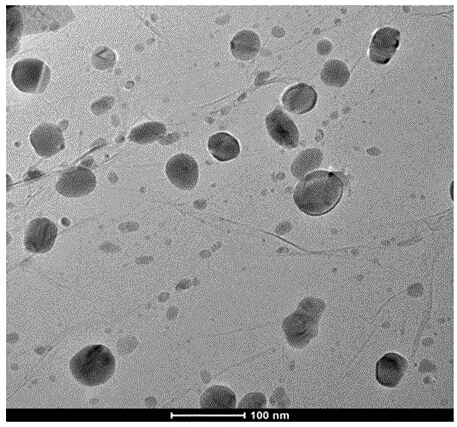

Preparation method of composite metal layer plated carbon nanotube/graphene composite material

ActiveCN109666915AImprove interfacial wettabilityImprove mechanical propertiesLiquid/solution decomposition chemical coatingChemical vapor deposition coatingCopper platingCarbon nanotube

The invention provides a preparation method of a composite metal layer plated carbon nanotube / graphene composite material. The preparation method comprises the following steps of uniformly mixing carbon nanotubes and graphene, adding a dispersant after pretreatment, and then forming a carbon nanotube / graphene film; under an inert atmosphere, using the film as a substrate, leading in reaction source gas of tungsten hexafluoride and molybdenum hexafluoride, leading in reducing gas, and making a reaction to obtain a carbon nanotube / graphite stratified material coated with tungsten and molybdenum;adding the stratified material into a copper plating solution, and then adding a reducing agent to make a reaction to obtain a composite metal layer plated carbon nanotube / graphene composite materialprecursor; and sintering the precursor to obtain a composite metal layer plated carbon nanotube / graphene composite material. According to the method, the surface of the carbon nanotube / graphene filmis coated with the tungsten and the molybdenum, the wettability of an interface between carbon and copper is greatly improved, the interface bonding strength is strengthened, and the mechanical properties, the electrical properties and the crocking resistance of the composite material are improved.

Owner:CENT SOUTH UNIV

Method for in situ preparing TiC granule reinforced magnesium base composite material

InactiveCN101214551AOvercome easily oxidative pollutionOvercoming pollutionAl powderMagnesium matrix composite

The invention discloses a method for preparing TiC particle reinforced magnesium base composite material in-situ in the technical field of compound material. The steps are as follows: preparing and mixing Al powder, Ti powder and C powder; the content of the Al powder is 0 wt to 50wt percent of the gross and the atom ratio of Ti atom to C atom is between 0.8 to 1.2; carrying through ball milling on the prepared and mixed powder and pressing the powder after ball milling into a precast block; arranging the pressed precast block and a Mg alloy pig into a vacuum heating device; pumping inert gases into a reaction chamber after vacuumized; heating, maintaining the temperature; mixing a fused mass after reaction, and then standing and casting to form after mixing. The technique of the invention is relatively simple and has a low cost. The TiC particle reinforced magnesium base composite material in-situ prepared has the advantages of petty particles of reinforced phase, uniform distribution, excellent combination with a basic body interface, light weight, high intensity and high mold quantity, etc.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of silver-based contact material containing graphene

InactiveCN105838914AEffective processing performanceImprove tissue uniformityElectric switchesInsulation layerHeat conducting

The invention discloses a preparation method of a silver-based contact material containing graphene. The silver-based contact material comprises silver oxide, tin oxide, nickel oxide, lanthanum oxide and silver-plated graphene, wherein the content of tin elements is 5-10 wt%, the content of nickel elements is 2-5 wt%, the content of lanthanum elements is 0.5-1 wt%, the content of the silver-plated graphene is 2.5-3.5 wt%, and the balance inevitable impurities, silver and oxygen. Through optimization selection of the ratios and process of the raw materials, the organization uniformity of the silver-based contact material prepared through the method is improved, and the electrical performance of the material is improved. SnO2 powder is prepared through a sol-gel process. Nano SnO2 is uniformly distributed and dispersed in silver base bodies. Contact resistance reduction caused by an insulation layer formed by enrichment of SnO2 can be avoided. The breaking effect of the oxide on the base bodies is reduced. The processing performance of the silver-based contact material can be effectively improved. The capability of welding resistance and electrical arc erosion resistance of the silver-based contact material are improved. The interface wettability between the graphene and metal is improved through the silver-plated grapheme, and the good interface bonding effect can be achieved, so that the electrical conductivity, the heat conducting property and electrical arc erosion resistance of the composite material are further improved, and the requirement for the performance of electrical contacts is met better.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

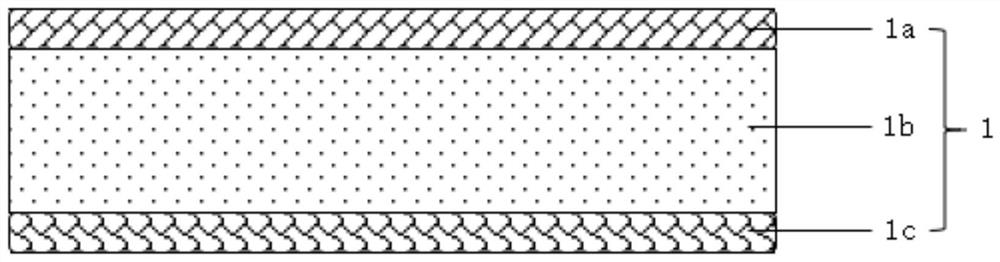

High-wettability sulfide-based composite electrolyte with 'sandwich' structure, and preparation method and application of high-wettability sulfide-based composite electrolyte

InactiveCN110247112AImprove wettabilityImprove compatibilitySolid electrolytesSecondary cellsSolid state electrolyteCompound a

The invention discloses a high-wettability sulfide-based composite electrolyte with a 'sandwich' structure, and a preparation method and application of the high-wettability sulfide-based composite electrolyte. The composite electrolyte is formed by compounding a polymer solid electrolyte, a sulfide solid electrolyte and a polymer solid electrolyte. The polymer solid electrolyte I is used for being in contact with a positive electrode material, so the interface wettability between sulfide and the positive electrode material caused by a space charge layer is improved, and the electrochemical stability of the positive electrode material in the charging and discharging process is improved. The polymer solid electrolyte is used for being in contact with a lithium metal negative electrode, so, on one hand, wettability between sulfide and the negative electrode material is improved, and on the other hand, growth of lithium dendrites on the surface of the metal negative electrode is inhibited. The sulfide-based composite electrolyte disclosed by the invention not only has relatively high ionic conductivity, but also has relatively good interface wettability and stability. According to the invention, a new idea is provided for the design and optimization of the solid electrolyte material, thereby facilitating further development and commercialization of an all-solid-state battery.

Owner:HARBIN INST OF TECH

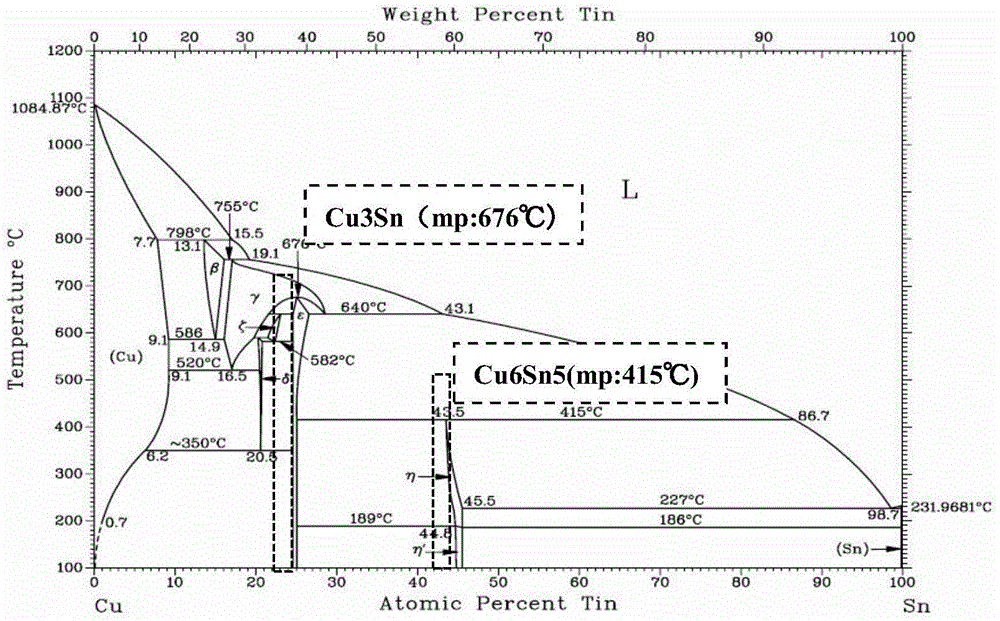

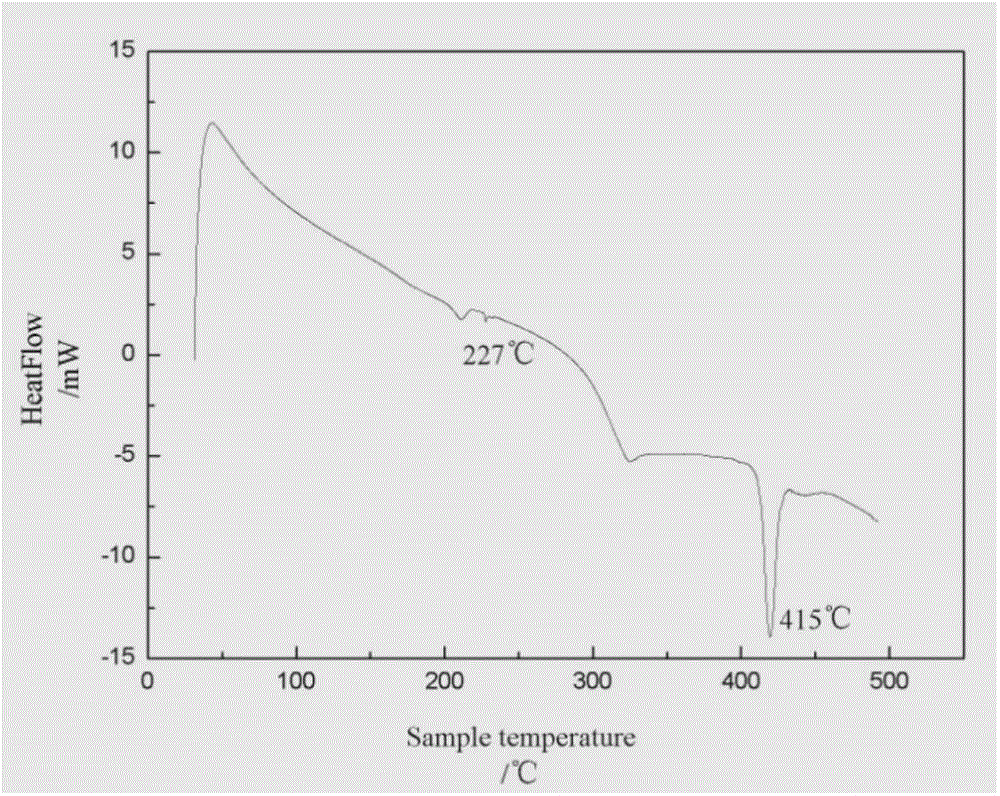

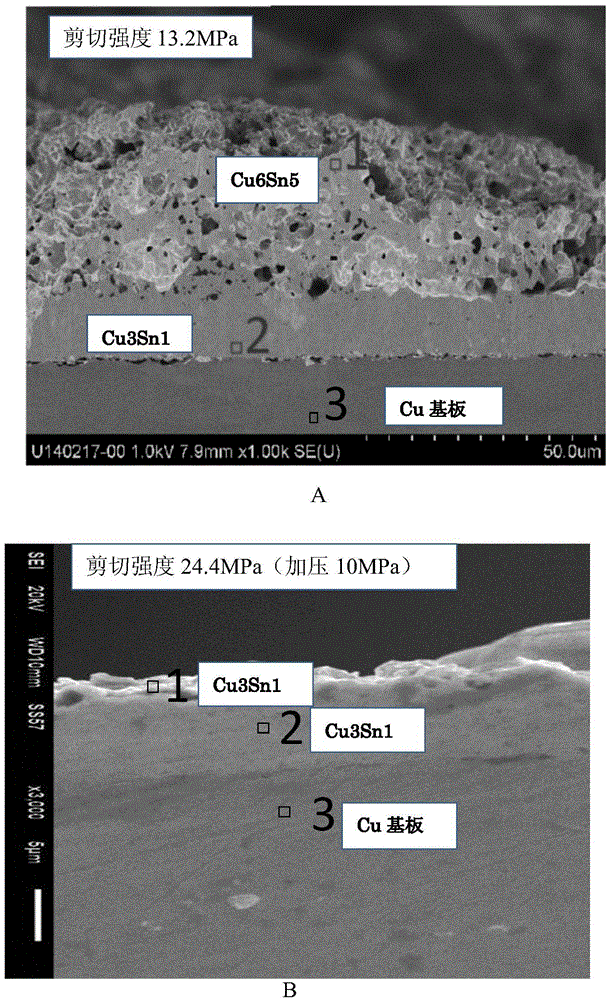

Sn-Cu high-temperature lead-free soldering paste, preparation method thereof and application method thereof

InactiveCN104588906AImprove mechanical propertiesWon't meltWelding/cutting media/materialsSoldering mediaEnvironmental resistanceWorking temperature

In order to solve the problems that soldering paste which is environmentally friendly, low in cost and reliable in welding joint under a high-temperature working environment does not exist at present, the invention provides a Sn-Cu lead-free soldering paste, a preparation method of the soldering paste and an application method of the soldering paste and belongs to the field of electronic packaging materials. The soldering paste is composed of tin powder, copper powder and rosin flux. The preparation method includes the steps that the rosin flux is added into the tin powder and the copper powder; next, the tin powder and the copper powder are mechanically mixed through a blender mixer for 10-15 min at the speed of 1,000-1,800 turns / min, and then the soldering paste is obtained. When the working temperature in the air is lower than 350 DEG C, the welding seam shear strength of the high-temperature lead-free soldering paste is greater than or equal to 10 MPa. If pressure of 5-10 MPa is exerted from the outside in the heat treatment process of a welding piece, the welding seam shear strength of the high-temperature lead-free soldering paste is greater than or equal to 20 MPa. The use temperature of samples welded through the soldering paste can reach as high as 400 DEG C, and the soldering paste is high in welding seam shear strength, simple in welding process, stable in performance and low in cost.

Owner:NORTHEASTERN UNIV +1

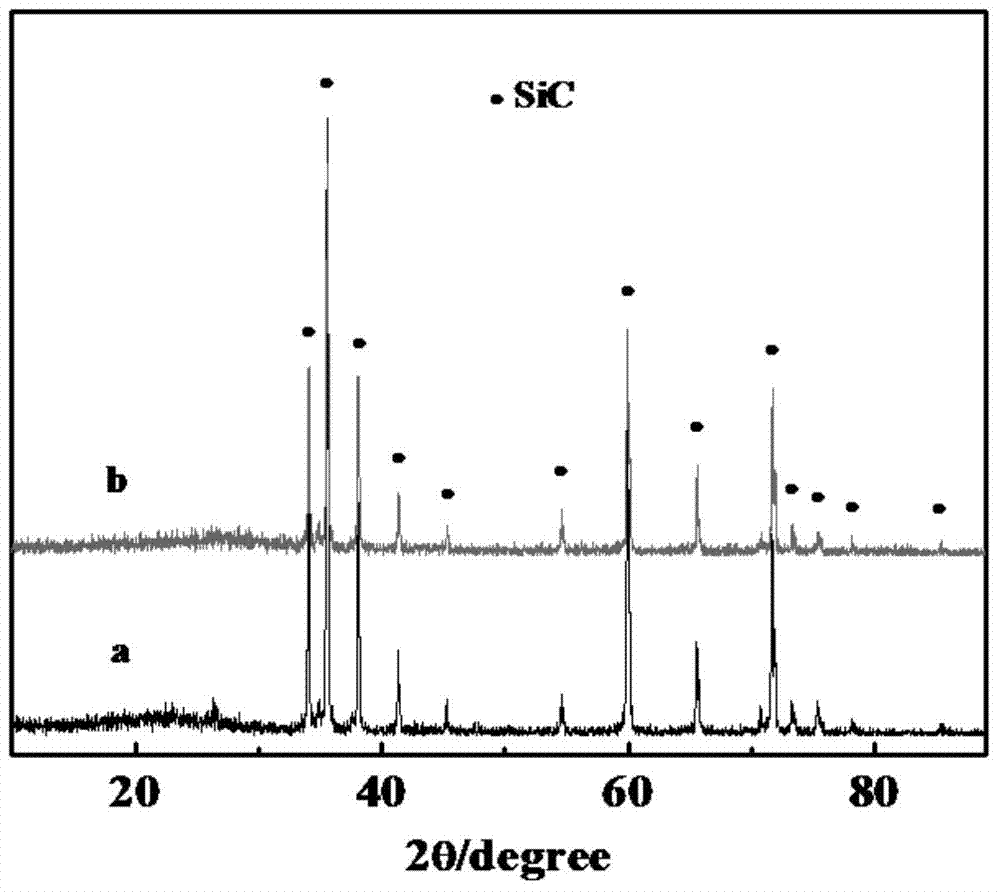

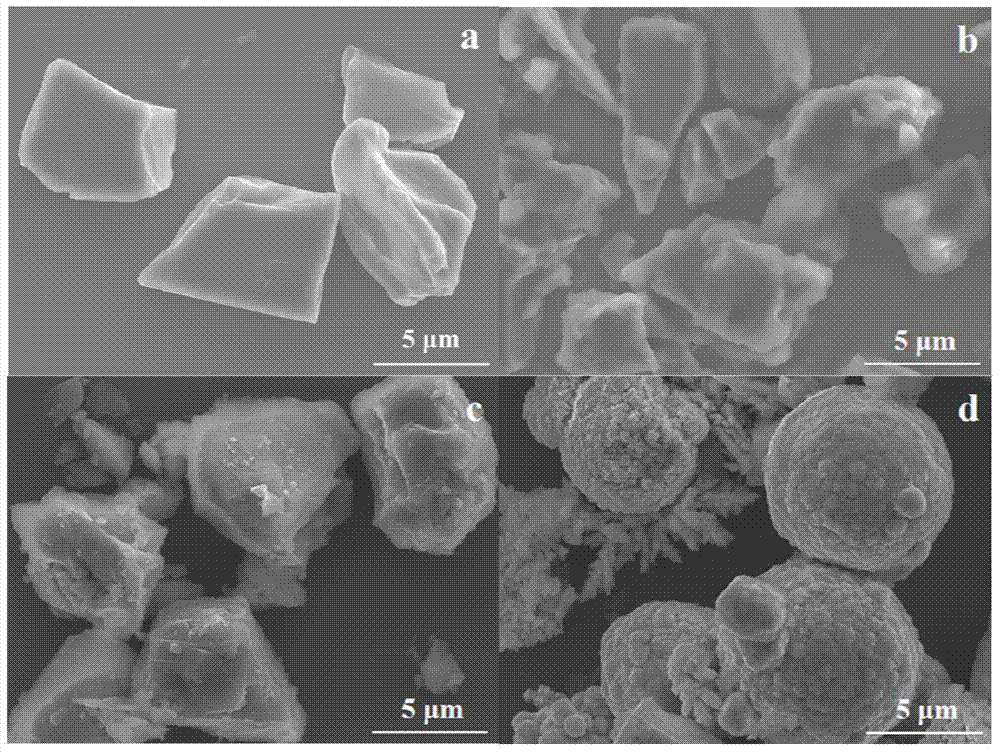

Low temperature glass phase enhanced SiCp/Cu composite material and preparation method thereof

ActiveCN104294071AImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

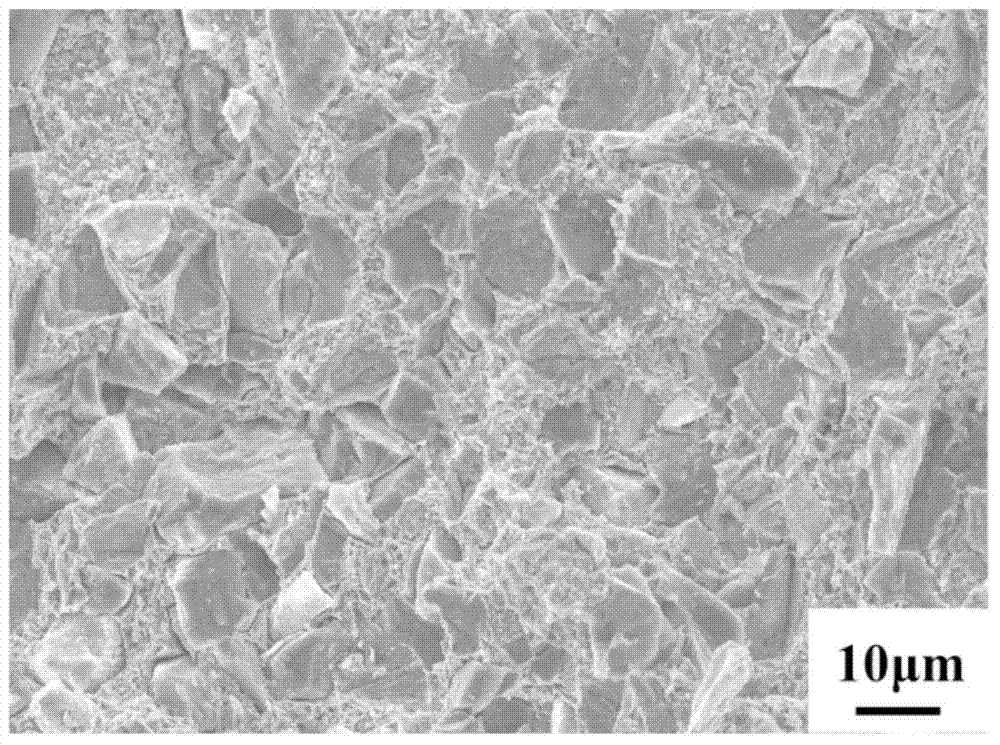

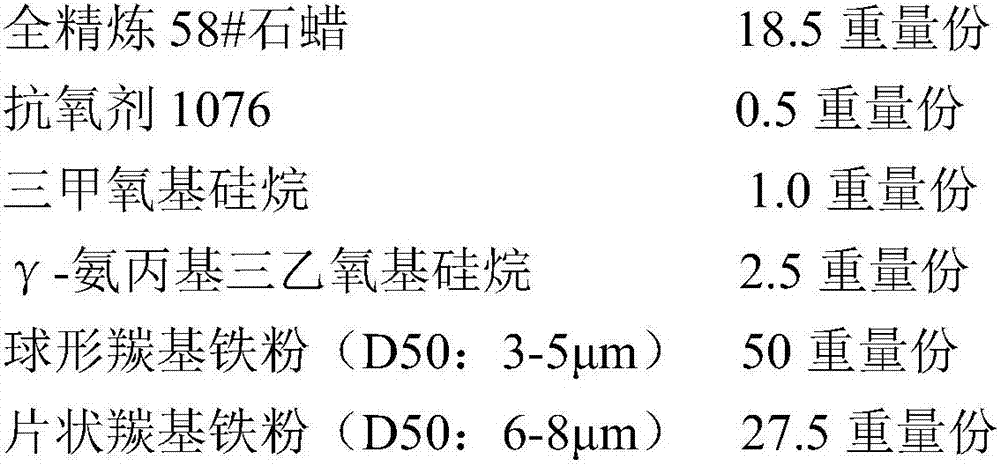

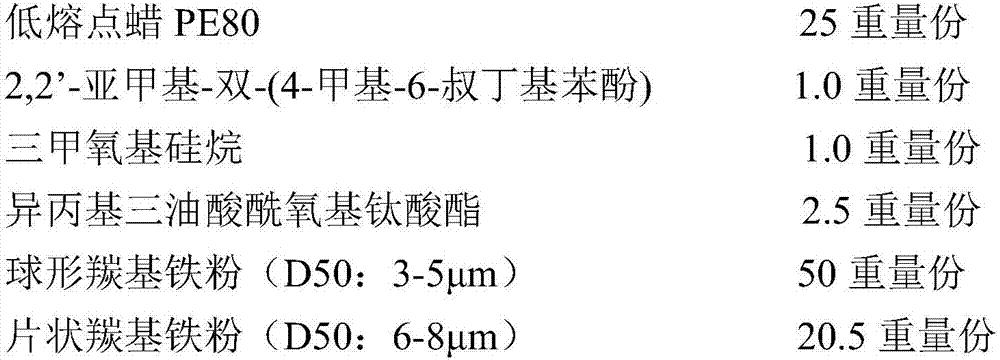

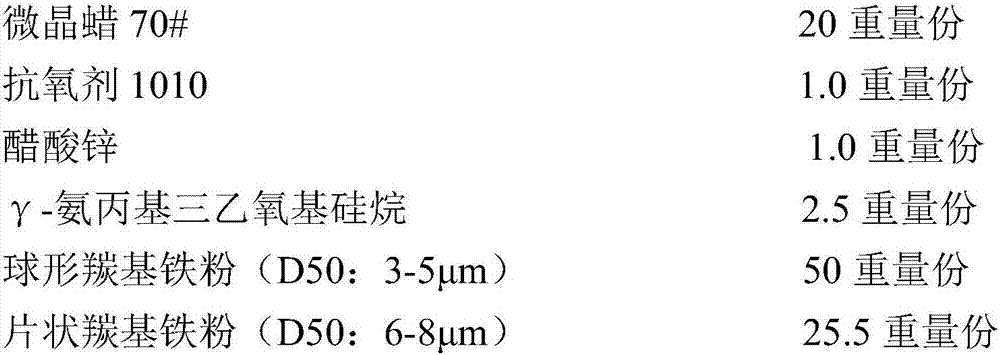

Phase change wave-absorption and heat-conducting material as well as preparation method and application thereof

InactiveCN108003841AExcellent interface wetting abilityGood interface wettabilityMagnetic/electric field screeningHeat-exchange elementsAntioxidantPhase-change material

The invention provides a phase change wave-absorption and heat-conducting material and a preparation method thereof. The phase change wave-absorption and heat-conducting material is prepared from thefollowing components in parts by weight: 15 to 25 parts of a basic phase change material, 0.1 to 5 parts of an antioxidant, 0.1 to 5 parts of a crosslinking agent, 0.1 to 5 parts of a coupling agent and 60 to 85 parts of wave-absorption and heat-conducting particles, wherein the solid-liquid phase transformation point of the basic phase change material is 40 to 80 DEG C. The phase change wave-absorption and heat-conducting material can be used for dissipating heat of electronic equipment.

Owner:HEFEI LCFC INFORMATION TECH

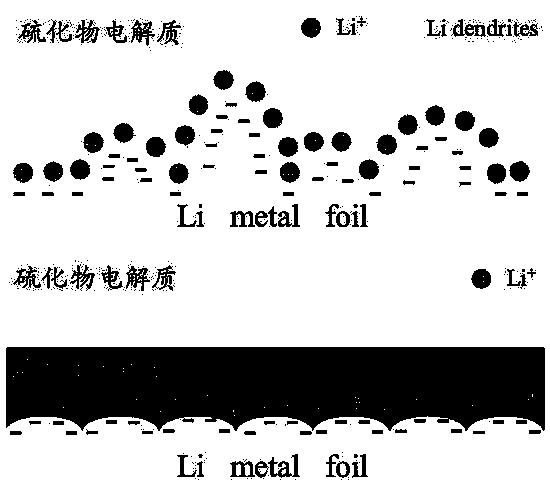

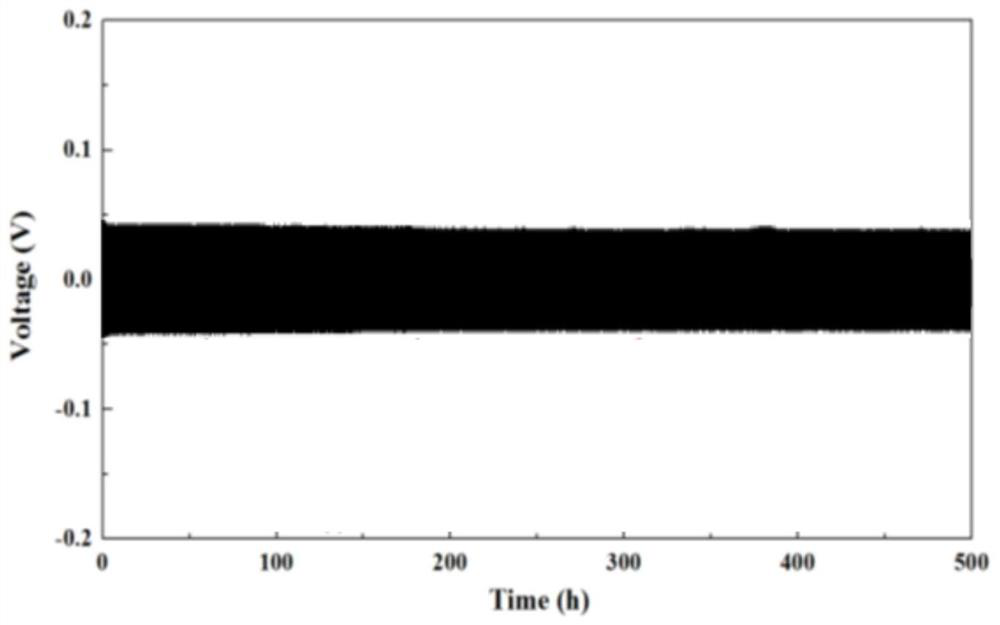

Interface layer and lithium ion battery comprising same

PendingCN113451580AImprove interface contact performanceImprove interfacial wettabilityCell electrodesSecondary cellsMetallic lithiumSolid state electrolyte

The invention relates to the technical field of lithium ion batteries, in particular to an interface layer and a lithium ion battery comprising the interface layer. Lithium halide generated by the in-situ reaction at the interface of a solid electrolyte and a metal lithium negative electrode can optimize the interface contact property and the interface wettability and provide a rapid ion diffusion path. The metal particles generated by the in-situ reaction at the interface of the solid electrolyte and the metal lithium negative electrode can guide the uniform distribution of an electric field, regulate and control the uniform deposition of the metal lithium in the circulation process, and inhibit the formation and growth of lithium dendrites. The lithium ion battery provided by the invention can effectively stabilize the interface between the electrode and the electrolyte, reduces the chemical reaction activity of the metal lithium negative electrode, avoids the side reaction at the interface, and shows higher cycling stability and coulombic efficiency in continuous charge-discharge cycles.

Owner:ZHUHAI COSMX BATTERY CO LTD

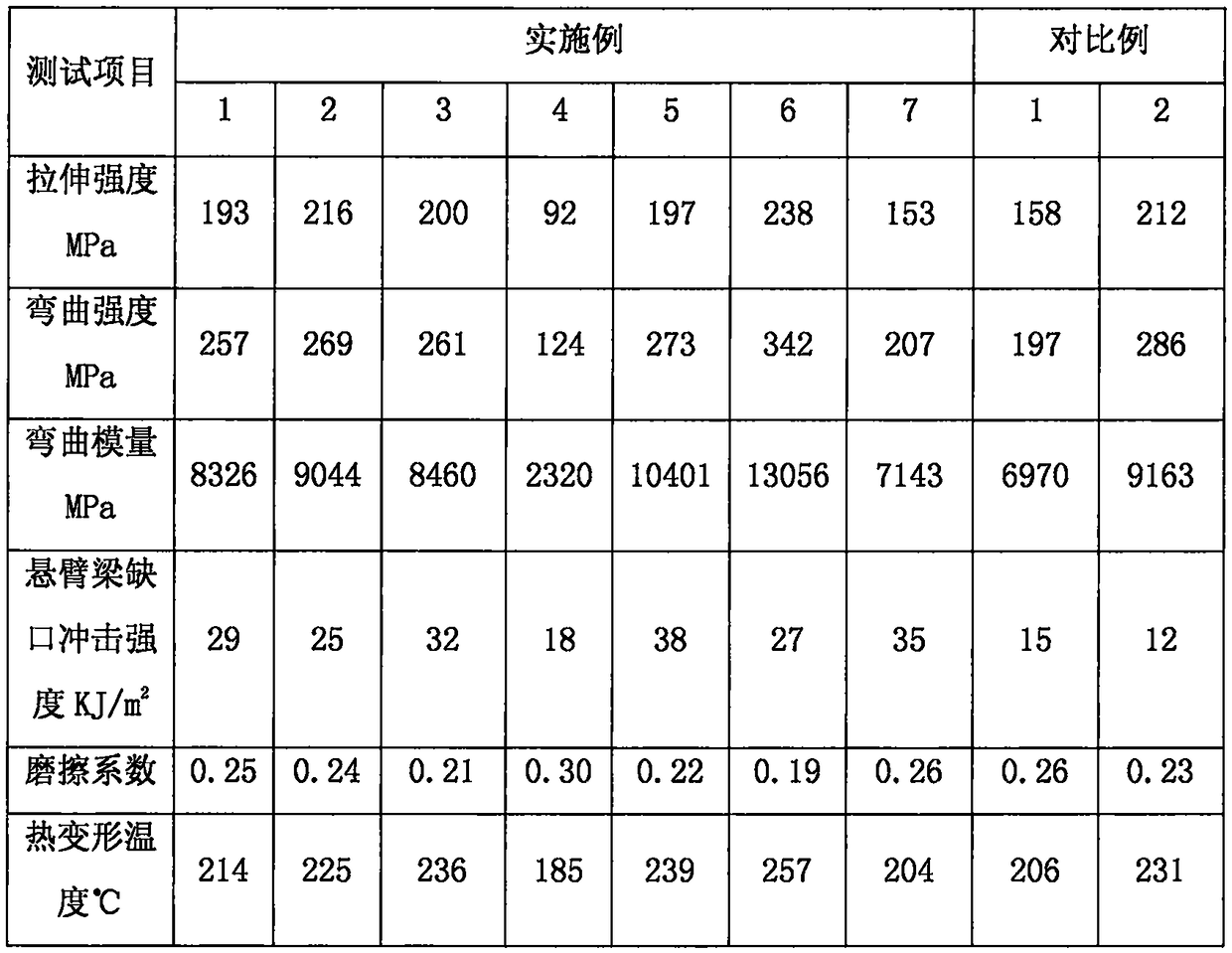

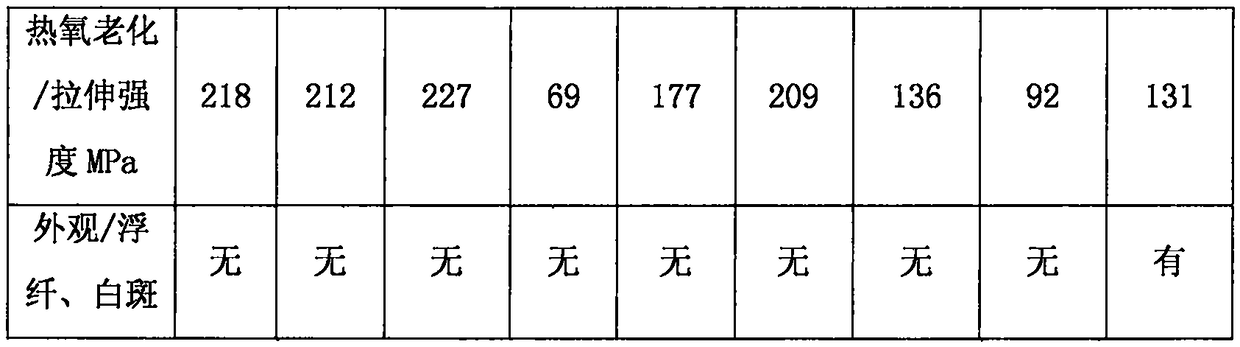

High-strength nylon composite and preparation method thereof

The invention discloses a high-strength nylon composite and a preparation method thereof. The composite is prepared from raw materials in percentage by mass as follows: 40wt%-99wt% of nylon, 0-40wt% of fiber, 0.05wt%-20wt% of a multifunctional material, 0.1wt%-2wt% of an oxidative aging resisting agent and 0.1wt%-2wt% of a lubricant. The preparation method of the composite comprises the steps as follows: nylon, the self-made multifunctional material, the oxidative aging resisting agent and the lubricant are uniformly mixed in a high-speed mixer in the mass ratio, a premix is obtained for lateruse, the premix is added from a main feeding port of a twin-screw extruder, short chopped fiber or continuous long fiber is added from a first side feeding port in proportion, for example, the self-made multifunctional material is added from a second side feeding port of the extruder in proportion in a filler form, the temperature of the extruder is controlled at 210-280 DEG C, the obtained material and drawn out, cooled and granulated, and the composite is obtained. Compared with the prior art, the composite has the advantages that the self-made multifunctional material has a synergistic effect with fiber after being added, the rigidity, toughness and thermal deformation of the prepared composite are substantially improved, meanwhile, the prepared composite material has no floating fiberand white spots in appearance, high wear resistance and lower strength reduction after thermo-oxidative aging.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

Preparation method for copper-based electric contact material with graphene

InactiveCN105719854AEffective processing performanceImprove tissue uniformityContactsCopper platingLanthanoid Series Elements

The invention discloses a preparation method for a copper-based electric contact material with graphene. The copper-based electric contact material comprises copper, tin oxides, dysprosium oxides, lanthanum oxides and copper-plated graphene, wherein the content of the tin element is 5-10 wt%, the content of the dysprosium element is 0.2-0.5 wt%, the content of the lanthanum element is 0.5-1wt%, the content of the copper-plated graphene is 1.5-2.5 wt% and the balance comprises unavoidable impurities, and the balance elements are copper and oxygen. According to the copper-based electric contact material prepared by the preparation method, by optimally selecting the proportion of raw materials and technology, the material is enhanced in texture uniformity and improved in electrical property, particularly the rigidity and wear-resisting property of the material are improved by doping rare earth elements, and the interface wettability between the graphene and the metal is improved by the copper-plated graphene, thus the acquisition of the good interface bonding is facilitated, the electrical conductivity, heat-conducting property and anti-arc erosion performance of the composite material are further improved, and the performance requirement of the electric contact can be better met.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Manufacturing method of composite lightweight flexible high thermal conduction carbon/metal connection member

ActiveCN105848450ALower interface thermal resistanceImprove composite effectModifications by conduction heat transferInterfacial thermal resistanceHeat sink

The invention relates to a manufacturing method of a composite lightweight flexible high thermal conduction carbon / metal connection member and belongs to the technical field of connection members. According to the method, firstly, surface treatment on brightness of a carbon material is carried out, one or more layers of metal is plated on the surface in a chemical or an electroplating mode, the treated carbon material and the metal are composited, the composition effect of the carbon / metal is greatly reinforced, and the interface thermal resistance between the two can be effectively reduced. According to the method, the manufactured composite lightweight flexible high thermal conduction carbon / metal connection member has higher thermal conduction coefficient than copper, and density is only one quarter of the copper. Through the method, requirements of weight reduction and efficient thermal conduction of the aerospace field and portable electronic devices can be satisfied; as the connection member is flexible, the distance and the position between the electronic device and a heat sink can be flexibly designed and adjusted, and strong designability is realized.

Owner:BEIJING UNIV OF CHEM TECH

A kind of nano tic0.5 particle in situ reinforced cu(al) composite material and preparation method thereof

The invention provides a nano TiC0.5 particle in situ reinforced Cu(Al) composite material and a preparation method thereof. The material comprises the following chemical components by weight percent: 0.37-25.22wt% of TiC0.5, 68.46-99.54 wt% of Cu and 0.09-6.32wt% of Al. The preparation method of the material comprises the following steps: proportionally burdening Ti2AlC powder and pure copper powder, wherein the proportion of Ti2AlC is 0.46-31.54wt%, and the proportion of Cu is 68.46-99.54wt%; carrying out ball milling and mixing materials, drying, and carrying out cold pressing and formation at the pressure of 140-180MPa; and carrying out constant pressure sintering at the temperature of 1100-1180 DEG C, protecting with argon, and insulating for 20-30 minutes so as to obtain the nano TiC0.5 particle in situ reinforced Cu(Al) composite material. With high compression strength, large deformation rate and high conductivity, the material can be widely used for preparing key devices of mechanical, electric, chemical and carrying tools.

Owner:BEIJING JIAOTONG UNIV

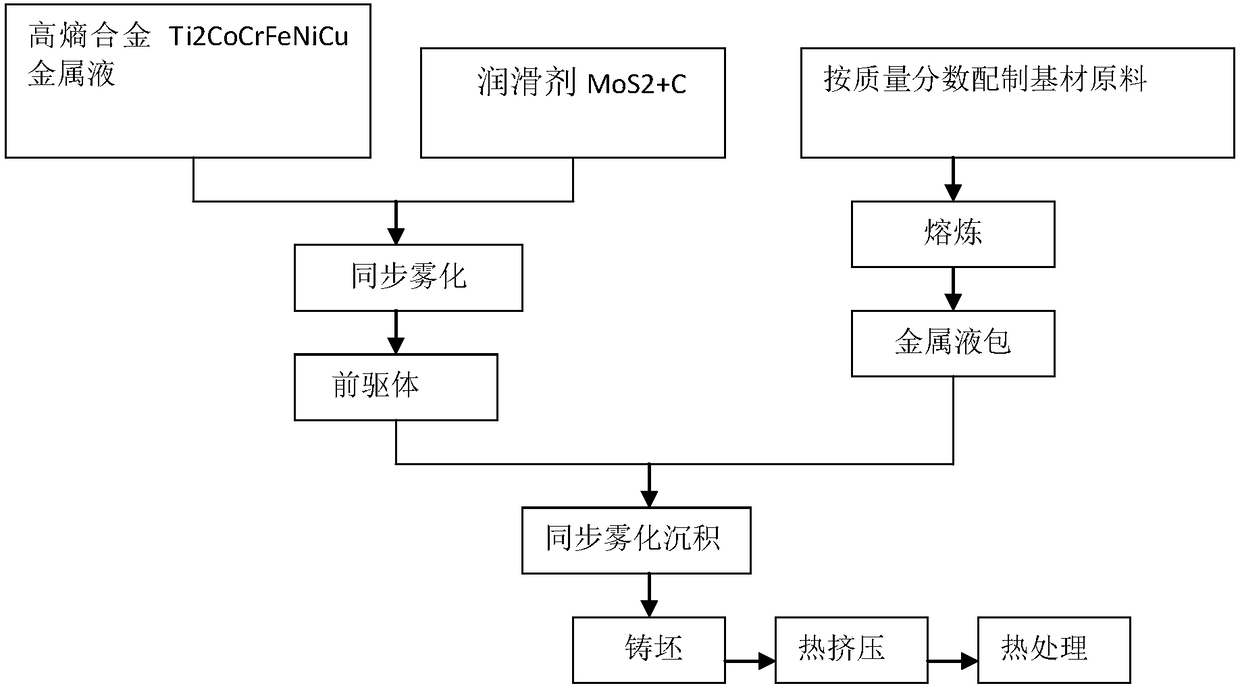

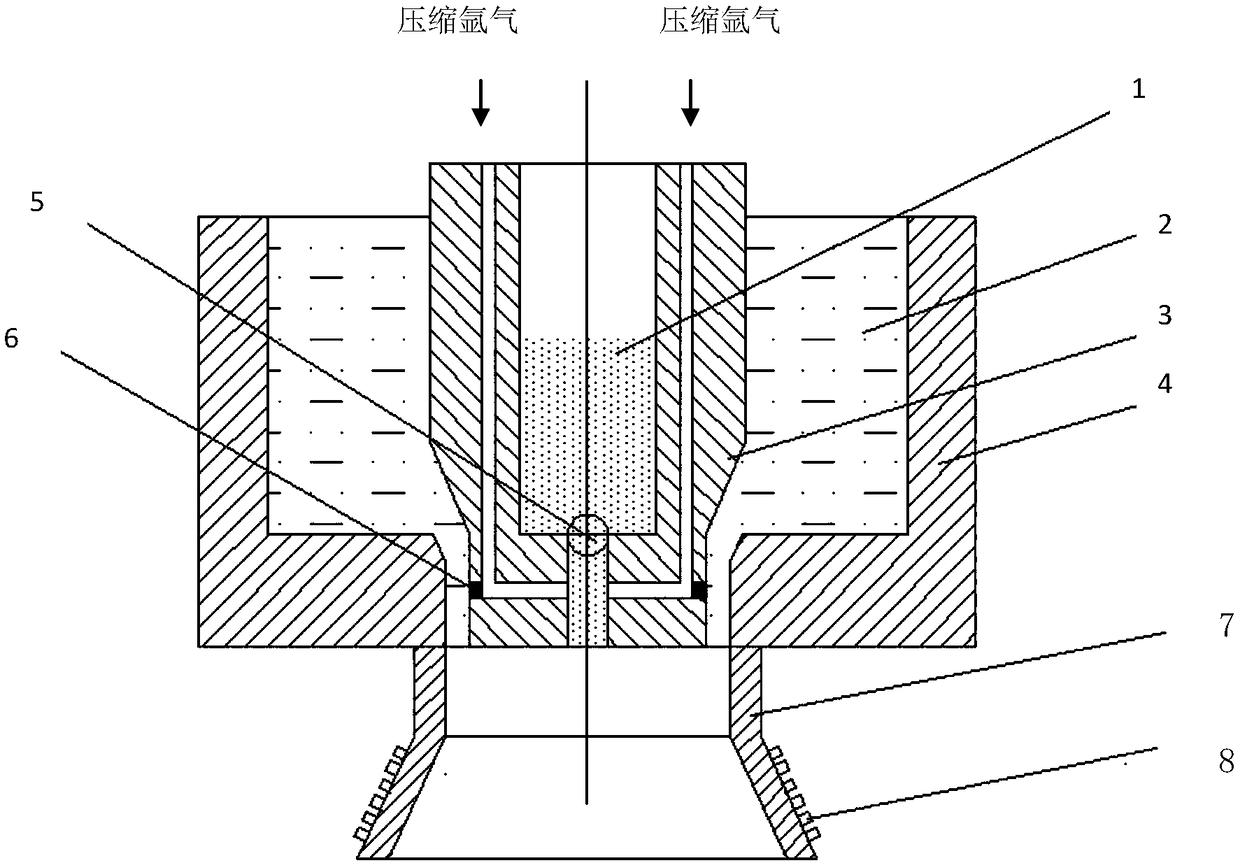

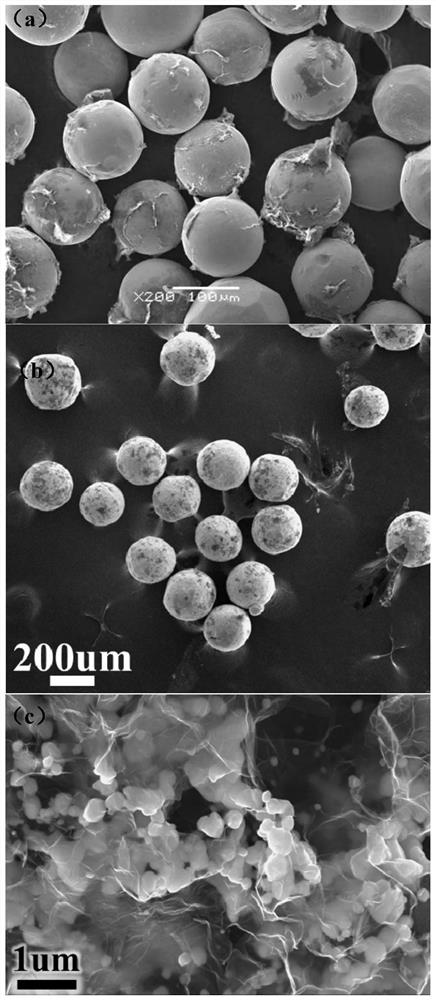

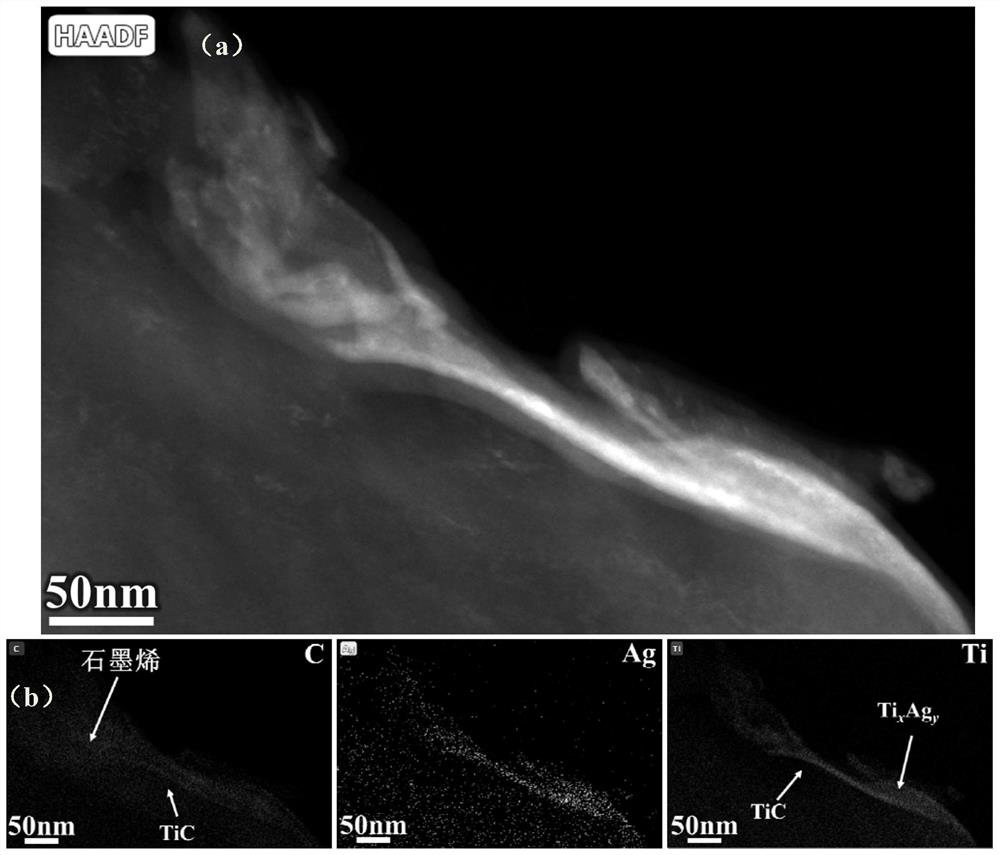

Aluminum alloy composite material with solid self-lubrication and preparation method thereof

ActiveCN108588501AImprove wear resistanceImprove the lubrication effectAdditive manufacturing apparatusDrilling rodsHigh entropy alloysAlloy composite

The invention discloses an aluminum alloy drill rod composite material with solid self-lubrication and a preparation method. The composite material consists of two parts: a substrate and a precursor,wherein the substrate comprises the following components in percentage by mass: 3.8-4.9% of Cu, 1.2-1.8% of Mg, 0.30-0.90% of Mn, and the balance of Al. The precursor is 20-30% of the substrate by mass; and the precursor is formed by a high-entropy alloy Ti2CoCrFeNiCu coating MoS2+C particles. The preparation method comprises the following steps: the precursor is prepared; the raw materials of thesubstrate are prepared; then, the precursor is injected in a solid particle fluidizing conveyor of spraying deposition equipment; finally, the raw materials of the substrate are molten by a cruciblesmelting furnace for flowing to a metal liquid pocket; and metal liquid and the precursor are synchronously atomized to form a solid-liquid atomization mixture for deposition to obtain a wear-resistance composite material casting blank with self-lubrication for extrusion molding.

Owner:JIANGSU UNIV OF TECH

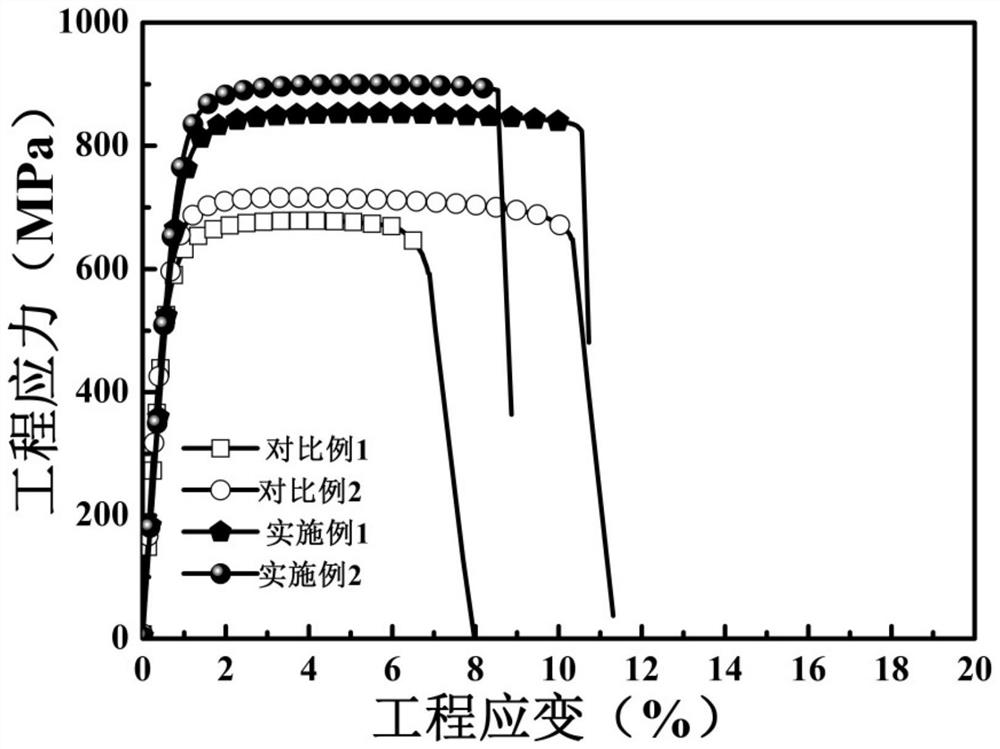

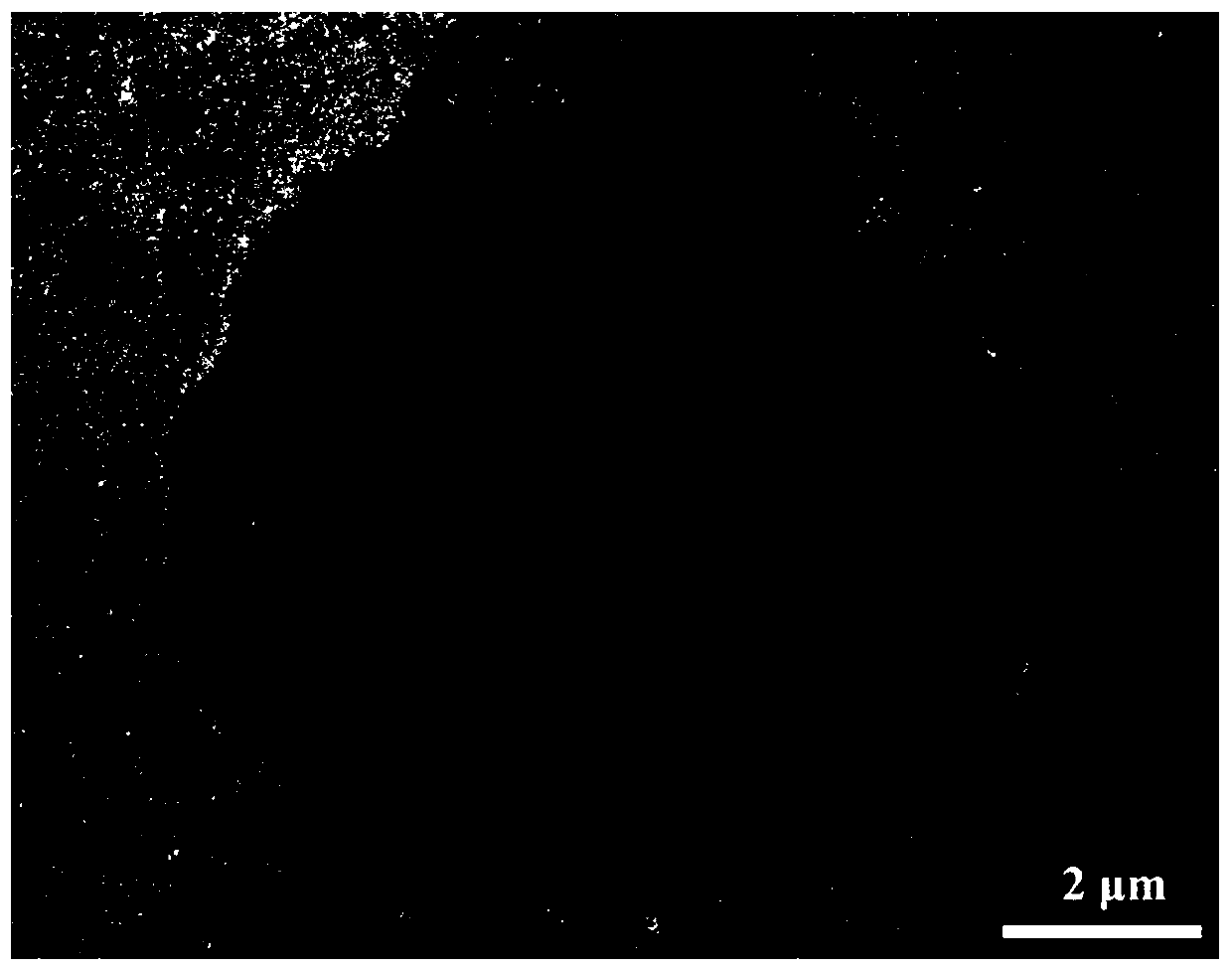

Preparation method of titanium-graphene composite material with matched reinforced-plasticity

InactiveCN113070471AEvenly dispersedAvoid serious structural damageCarbon compoundsTransportation and packagingTitanium matrix compositesTitanium

The invention belongs to the technical field of preparation of advanced metal-based composite materials, and particularly relates to a preparation method of a titanium-graphene composite material with matched reinforced-plasticity. The preparation method comprises the following steps that firstly, proper metal nanoparticles or nanolayers on the surface of graphene are selected for modification to prepare metal modified reduced graphene oxide nanopowder; the metal modified graphene is ultrasonically dispersed in a mixed solution of alcohol and deionized water, a proper amount of titanium alloy powder is slowly added into a dispersion solution, and uniformly stirring and dispersing are carried out in a water bath at 80 DEG C to obtain composite powder; and the composite powder is sintered and subjected to subsequent hot working deformation densification, and a titanium-graphene composite plate or bar with matched high reinforced-plasticity is obtained. According to the method, eutectoid elements in titanium alloy are adopted for modifying graphene, and metal nanolayer particles are formed. The load transfer strengthening effect of the graphene is enhanced, and the plasticity of the graphene strengthened titanium-based composite material is improved.

Owner:NORTHEASTERN UNIV

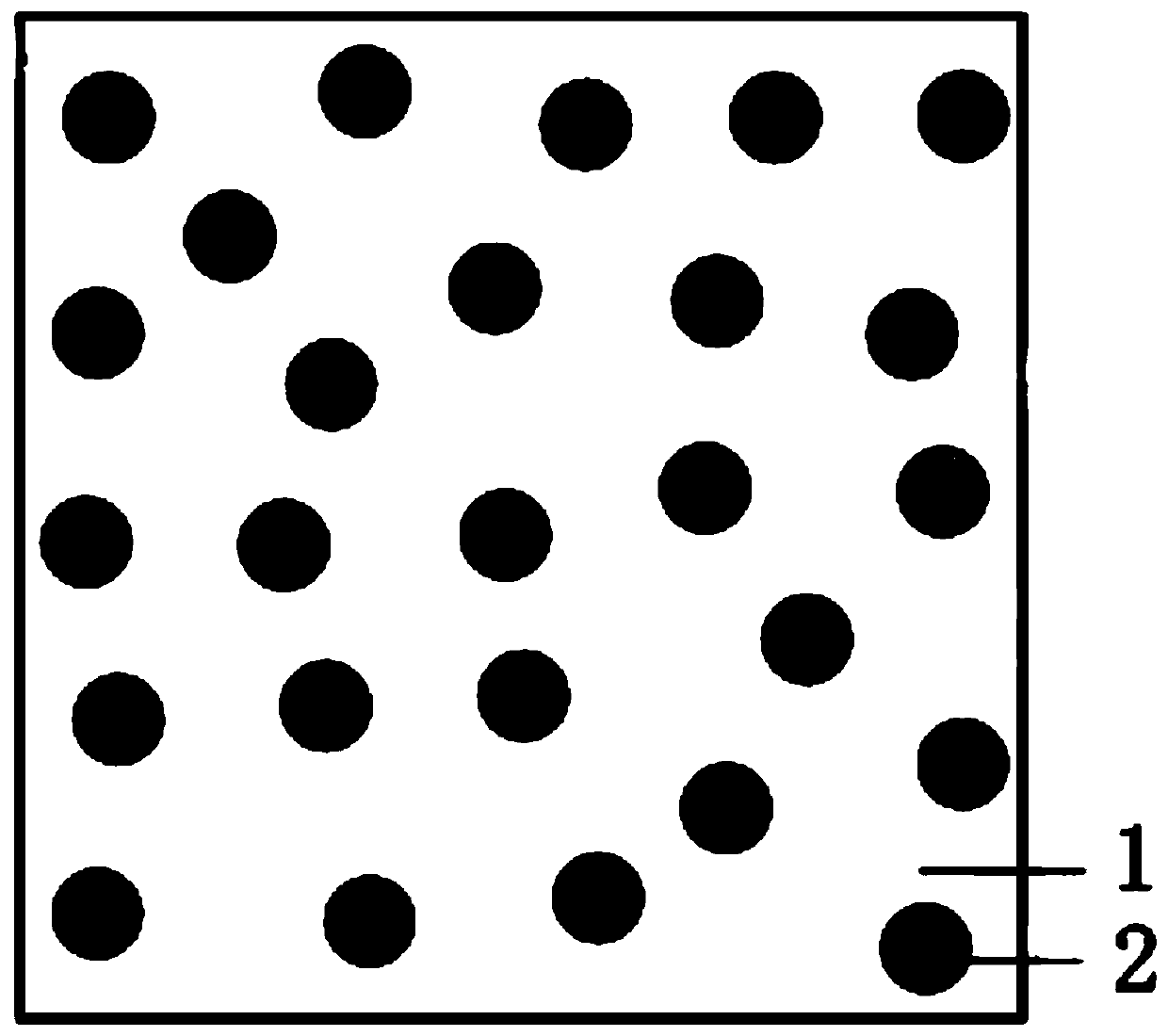

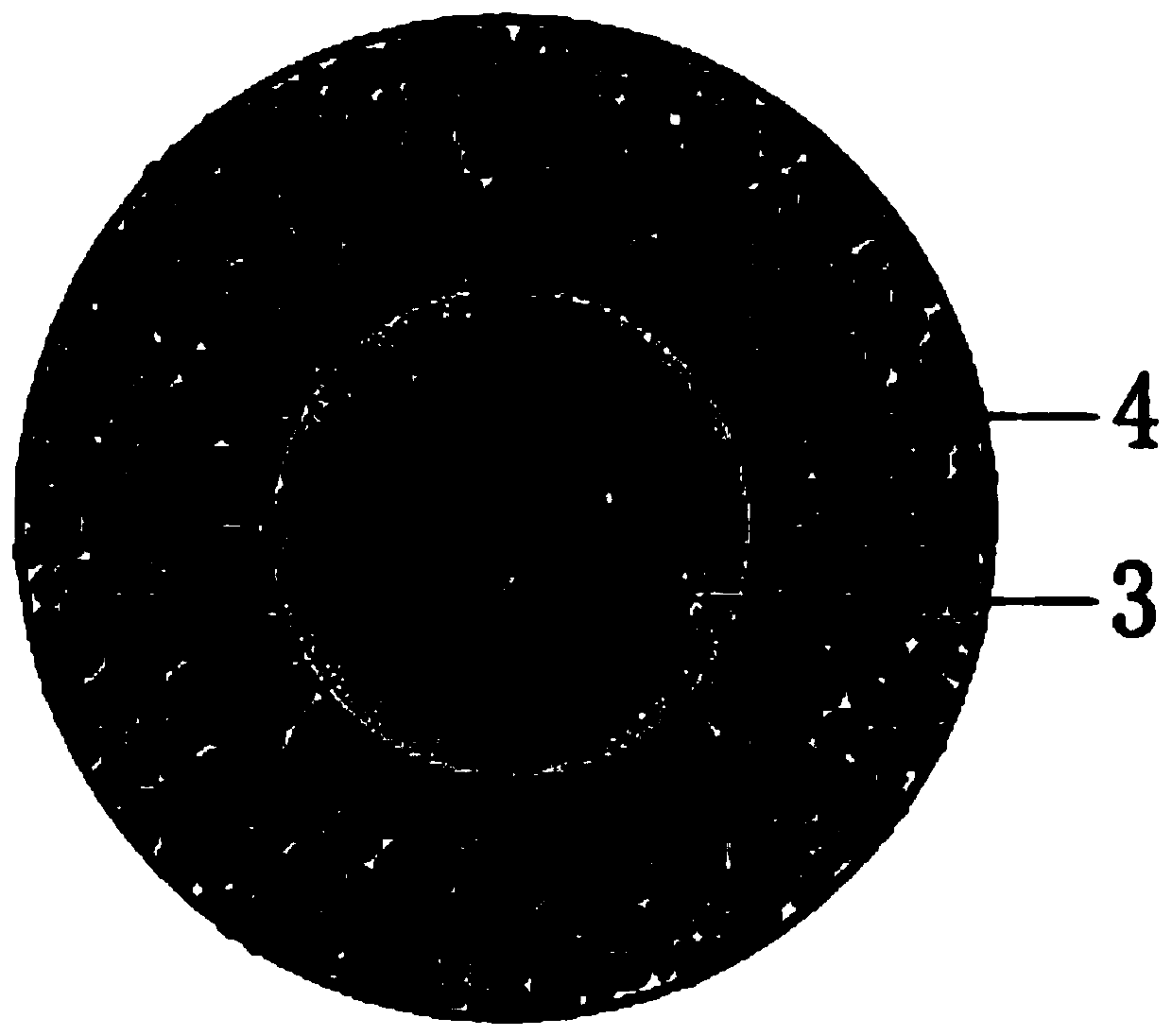

Titanium/titanium carbide core-shell structure reinforced aluminum matrix composite material and preparation method thereof

The invention discloses a titanium / titanium carbide core-shell structure reinforced aluminum matrix composite material. The material is composed of pure aluminum or aluminum alloy matrix and a titanium / titanium carbide core-shell particle reinforced phase. According to the reinforced phase, titanium serves as the core, a titanium carbide ceramic layer serves as a shell, and the dimensions of titanium carbide particles inside the shell change in a gradient manner. The invention further discloses a preparation method of the titanium / titanium carbide core-shell structure reinforced aluminum matrix composite material. According to the titanium / titanium carbide core-shell structure reinforced aluminum matrix composite material, the toughness of the composite material is improved because of thehigh-toughness titanium core, the strength of the composite material is improved because of the titanium carbide ceramic layer with the high volume fraction, and therefore, the aluminum matrix composite material has the high strength and the good toughness at the same time.

Owner:XIAN UNIV OF TECH

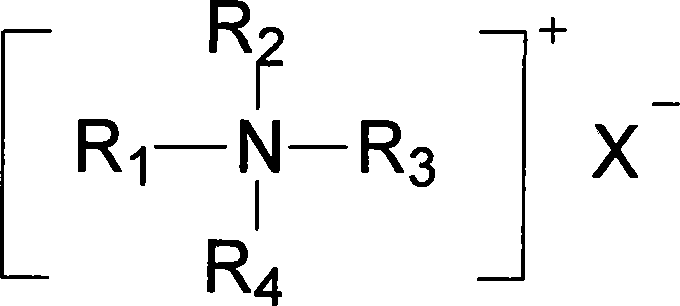

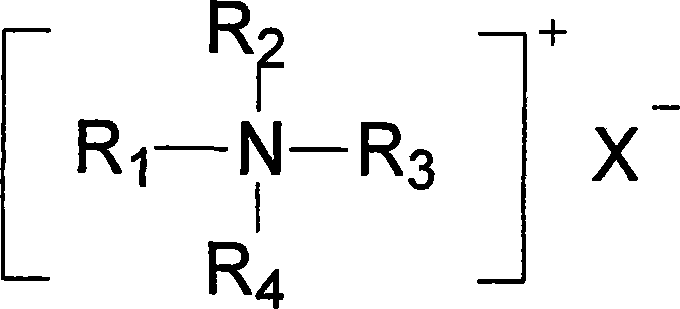

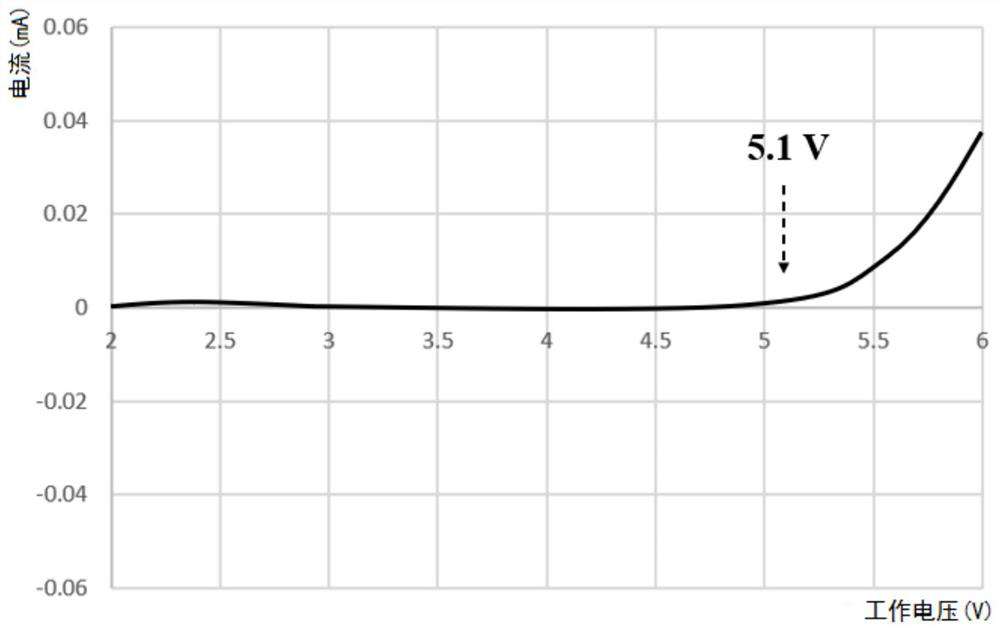

Battery electrolyte additive, and electrolyte and lithium ion battery using additive

PendingCN111384443AImprove interfacial wettabilityReduce interface contact resistanceSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentInterface impedance

The invention provides an additive applied to a battery electrolyte, which has a structure as shown in the following (I), and a substituent group is shown in the specification. The invention also provides an electrolyte and a battery using the additive. The additive provided by the invention can effectively reduce the interface impedance and charge transfer impedance between graphite, silicon carbon and other negative electrode materials and an electrolyte, thereby effectively improving the cycle stability and rate capability of the negative electrode materials.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com