Phase change wave-absorption and heat-conducting material as well as preparation method and application thereof

A technology of heat-conducting materials and phase-change materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, and modification using liquid cooling, etc. It can solve the problem that heat-conducting sheets or wave-absorbing sheets cannot be used, and cannot achieve good heat dissipation effects. Problems such as poor heat conduction and wave absorption performance, to achieve the effects of good lateral thermal diffusion performance, excellent interface wetting ability, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

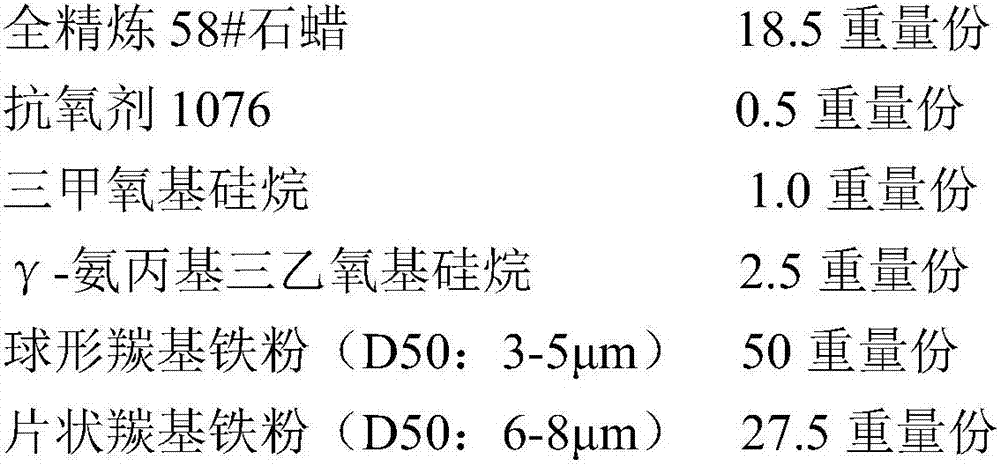

[0050] The mass formula ratio of each component of the phase-change wave-absorbing heat-conducting material is as follows:

[0051]

[0052] Add fully refined No. 58 paraffin wax, antioxidant 1076, and coupling agent γ-methacryloxypropyltrimethoxysilane to the planetary dynamic mixer according to the stated formula ratio, raise the temperature to 70°C, and stir for 45 Then add the cross-linking agent trimethoxysilane and stir for 10 minutes until the cross-linking agent is completely dissolved; add wave-absorbing and heat-conducting particles (spherical carbonyl iron powder and flake carbonyl iron powder) in batches, and stir for 75 Minutes, after observing that the mixture is uniform, vacuum defoaming was carried out for 45 minutes to obtain the phase-change wave-absorbing heat-conducting material sample 1.

Embodiment 2

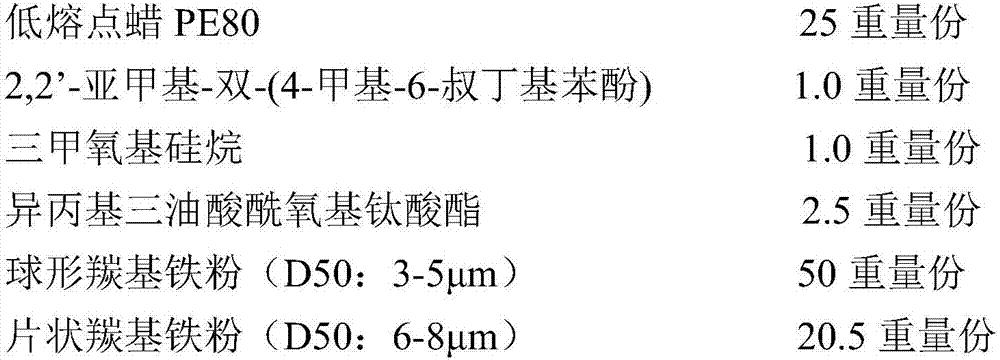

[0054] The mass formula ratio of each component of the phase-change wave-absorbing heat-conducting material is as follows:

[0055]

[0056] Add low melting point wax PE80, 2,2'-methylene-bis-(4-methyl-6-tert-butylphenol), coupling agent isopropyl trioil to the planetary power mixer according to the formula ratio Acid acyloxy titanate, raise the temperature to 70°C, stir for 45 minutes to form a uniform paste; then add the cross-linking agent trimethoxysilane, stir for 10 minutes until the cross-linking agent is completely dissolved; add wave-absorbing heat conduction in batches Heat conduction particles (spherical carbonyl iron powder and flaky carbonyl iron powder) were stirred for 75 minutes. After observing that the mixture was uniform, vacuum defoaming was performed for 45 minutes to obtain phase change wave-absorbing heat conduction material sample 2.

Embodiment 3

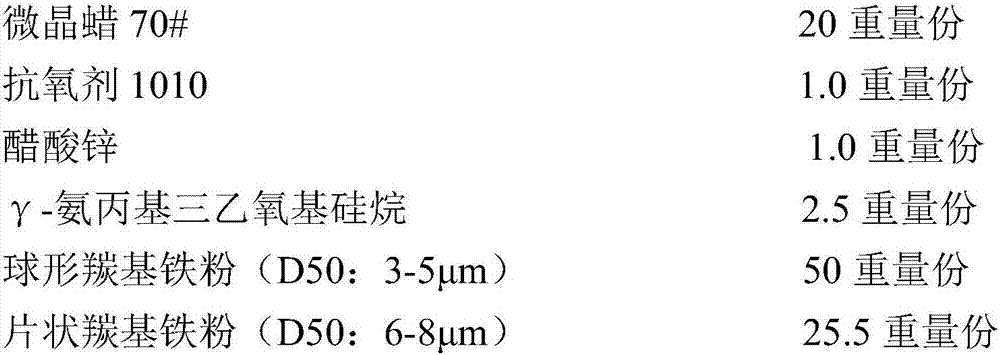

[0058] The mass formula ratio of each component of the phase-change wave-absorbing heat-conducting material is as follows:

[0059]

[0060] Add microcrystalline wax 70#, antioxidant 1010, and coupling agent γ-aminopropyltriethoxysilane to the planetary dynamic mixer according to the formula ratio, raise the temperature to 70°C, and stir for 45 minutes to form a uniform Paste; then add the cross-linking agent zinc acetate and stir for 10 minutes until the cross-linking agent is completely dissolved; add wave-absorbing and heat-conducting heat-conducting particles (spherical carbonyl iron powder and flake carbonyl iron powder) in batches, stir for 75 minutes, and observe that the mixture is uniform , vacuum defoaming was carried out for 45 minutes to obtain phase-change wave-absorbing heat-conducting material sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com