Patents

Literature

440results about How to "Lower interface thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-thermal conductivity lubricating oil and preparation method thereof

ActiveCN102911762AImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

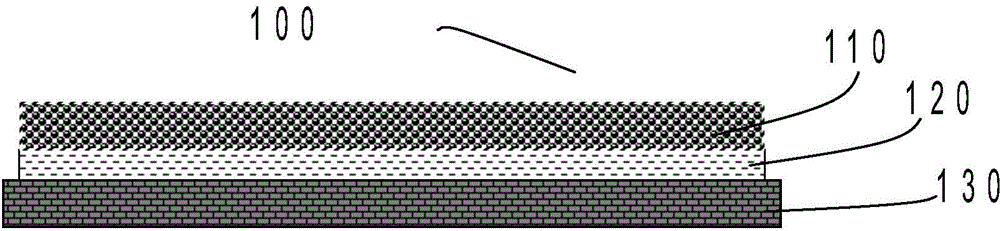

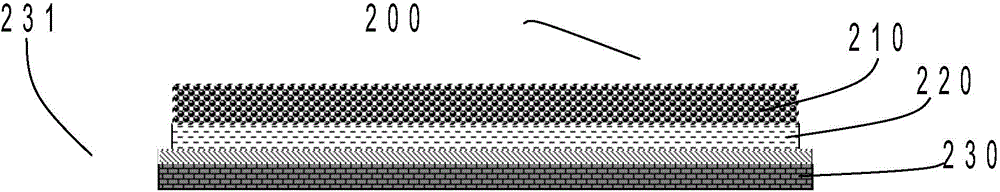

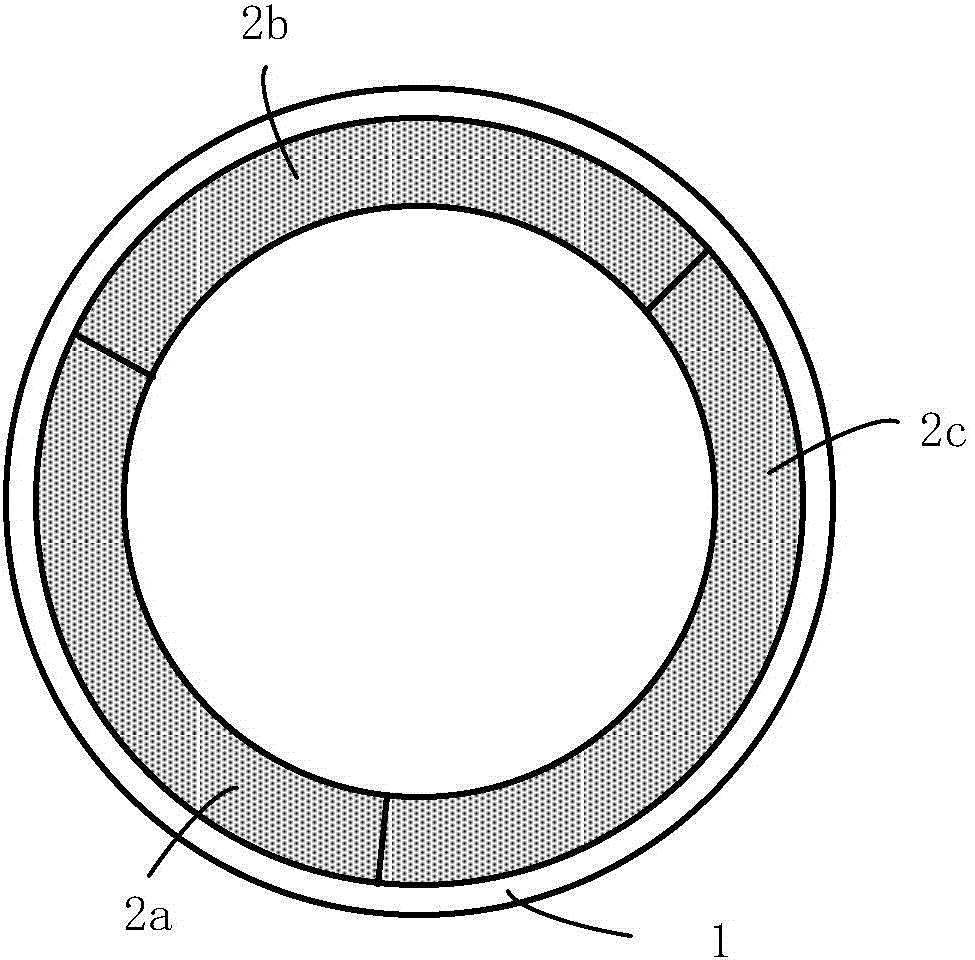

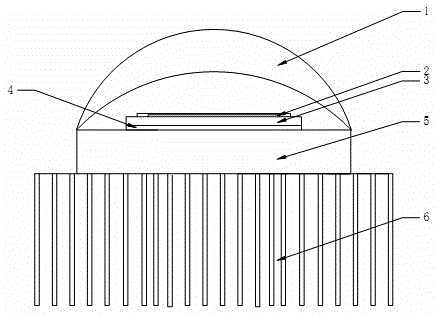

Wavelength conversion device, manufacture method thereof, correlative light-emitting device, and projection system

ActiveCN105278225AImprove luminous efficiencyImprove reflectivityDiffusing elementsProjectorsDiffuse reflectionProjection system

The invention discloses a wavelength conversion device, a manufacture method thereof, a correlative light-emitting device, and a projection system. The wavelength conversion device comprises a light-emitting layer, a diffuse reflection layer, and a ceramic substrate which are successively stacked. The light-emitting layer comprises fluorescent powder and first glass powder. The volume fraction of the fluorescent powder to the light-emitting layer is from 14.1 to 38.7 percent. The diffuse reflection layer comprises white scattering particles and the first glass powder. The volume fraction of the white scattering particles to the diffuse reflection layer is from 22.0 to 62.9 percent. The coefficient of linear expansion of the ceramic substrate is greater than that of the first glass powder but less than those of the ceramic substrate and the white scattering particles. By adjustment of the volume fraction of the fluorescent powder in the light-emitting layer and the volume fraction of the white scattering particles in the diffuse reflection layer, the light-emitting layer and the diffuse reflection layer have high enough light-emitting efficiency and reflectivity and low internal thermal resistance and interface thermal resistance so as to achieve a beneficial effect of obtaining emergent light with high light-emitting efficiency.

Owner:APPOTRONICS CORP LTD

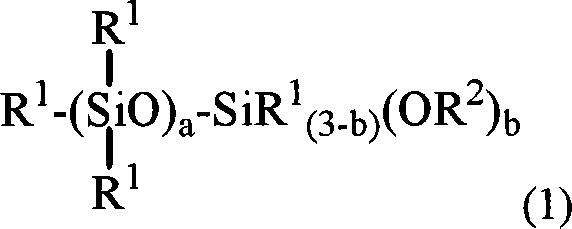

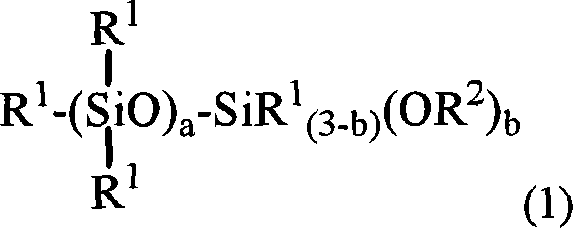

Heat conductive silicone grease composition and cured product thereof

InactiveCN101104738AImprove thermal conductivityImprove liquidityMaterial nanotechnologySemiconductor/solid-state device detailsConductive materialsContact resistance

Owner:SHIN ETSU CHEM IND CO LTD

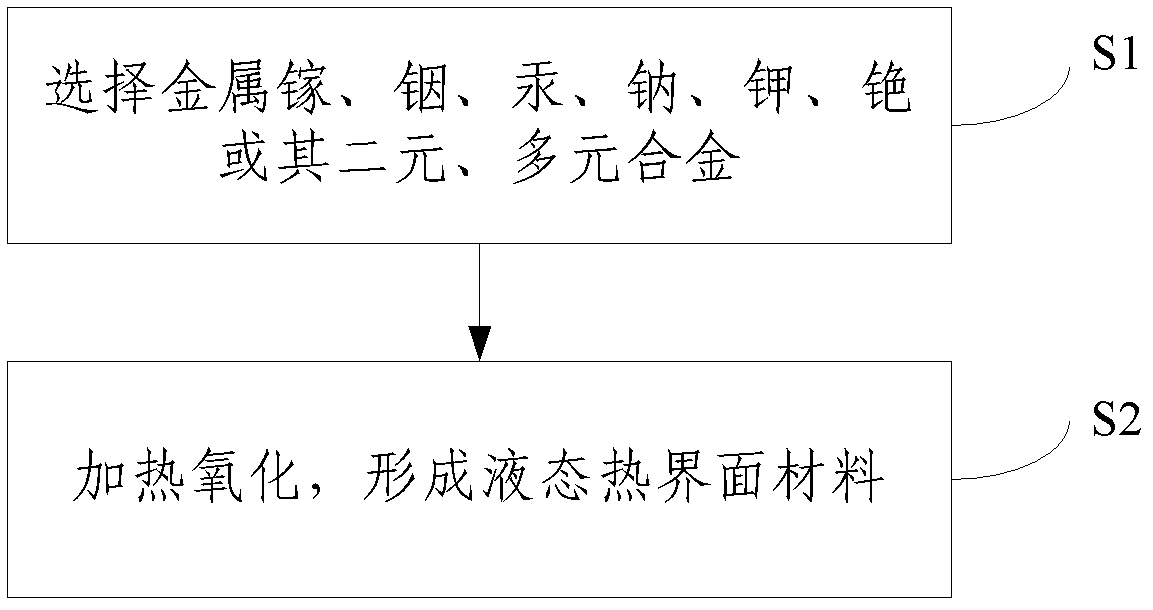

Thermal interface materials and manufacturing method thereof

The invention discloses thermal interface materials and a manufacturing method of the thermal interface materials. The interface materials are formed by means of heating and oxidization of metals such as gallium, indium, mercury, sodium, potassium, cesium or binary alloy and multicomponent alloy of the cesium. The manufacturing method comprises the following steps: selecting metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium, and enabling the metals or the alloy to become liquid and enabling the liquid metals or the alloy to be placed in air or oxygen through heating. By means of placing the metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium in the air and the oxygen to be oxidized to form the thermal interface materials, wettability between metal-based fluid and each interface can be greatly enhanced, thereby requirements of the thermal interface materials can be met. Due to the good thermal and wetting properties, the thermal interface materials can play significant roles in an aspect of electric chip thermal conductivity of the fields such as cryogenic engineering, boosters of computers, satellites and rockets and laser device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

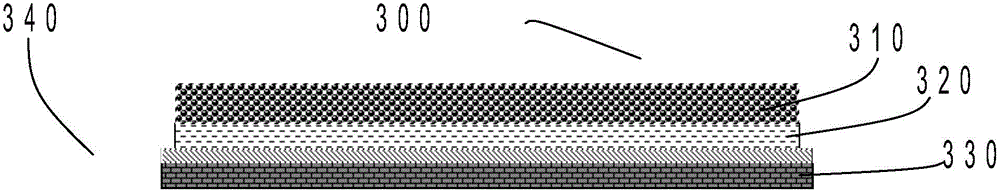

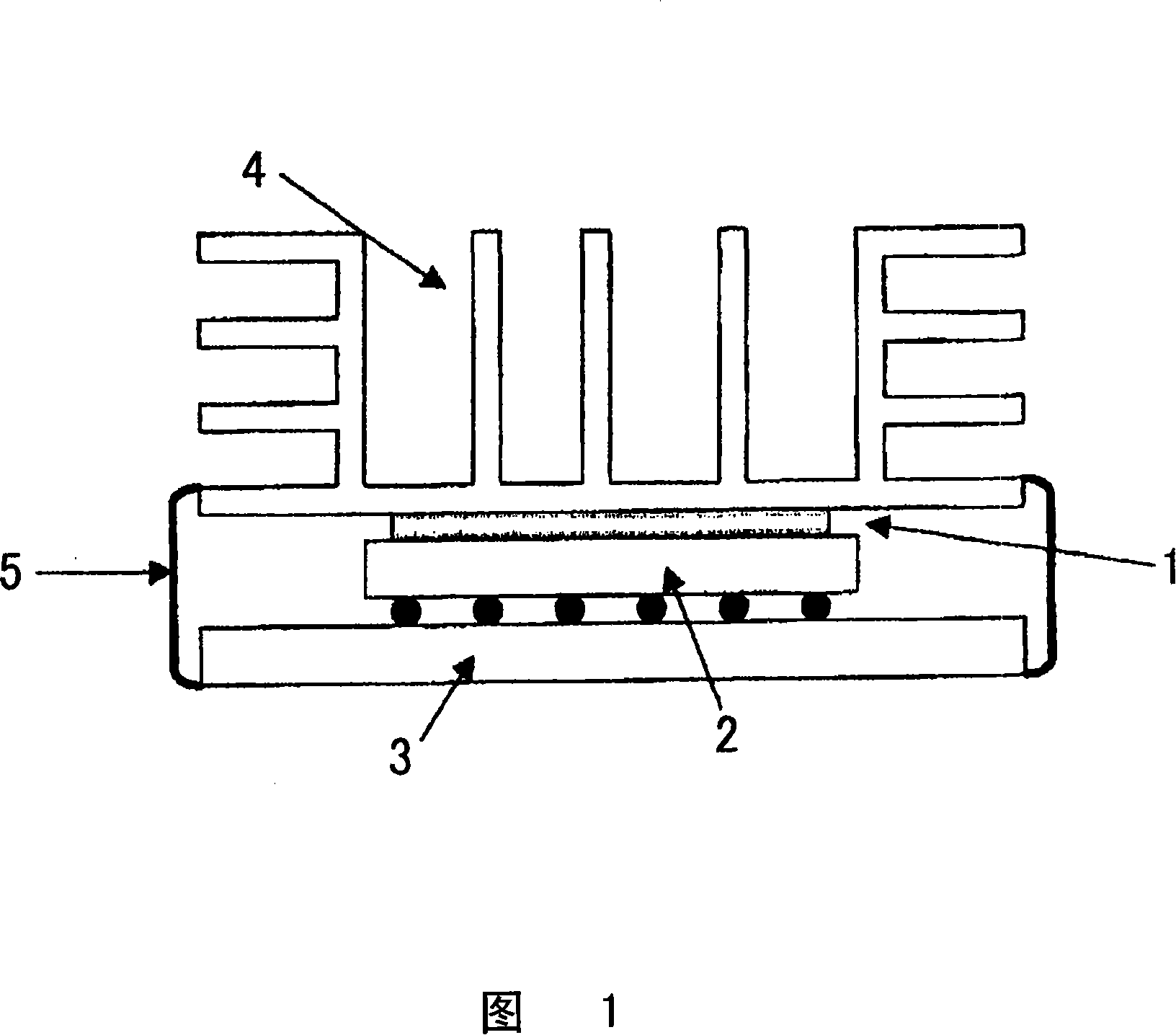

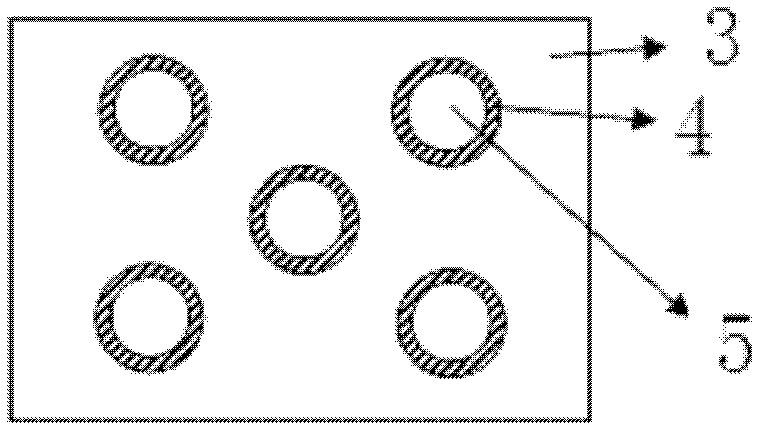

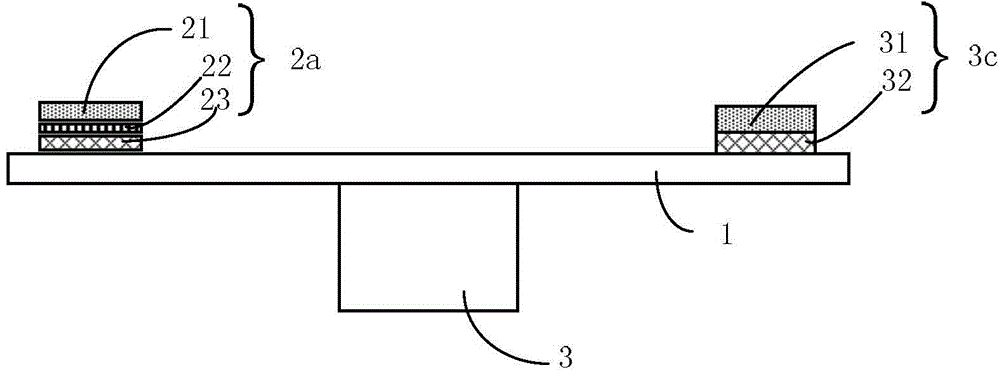

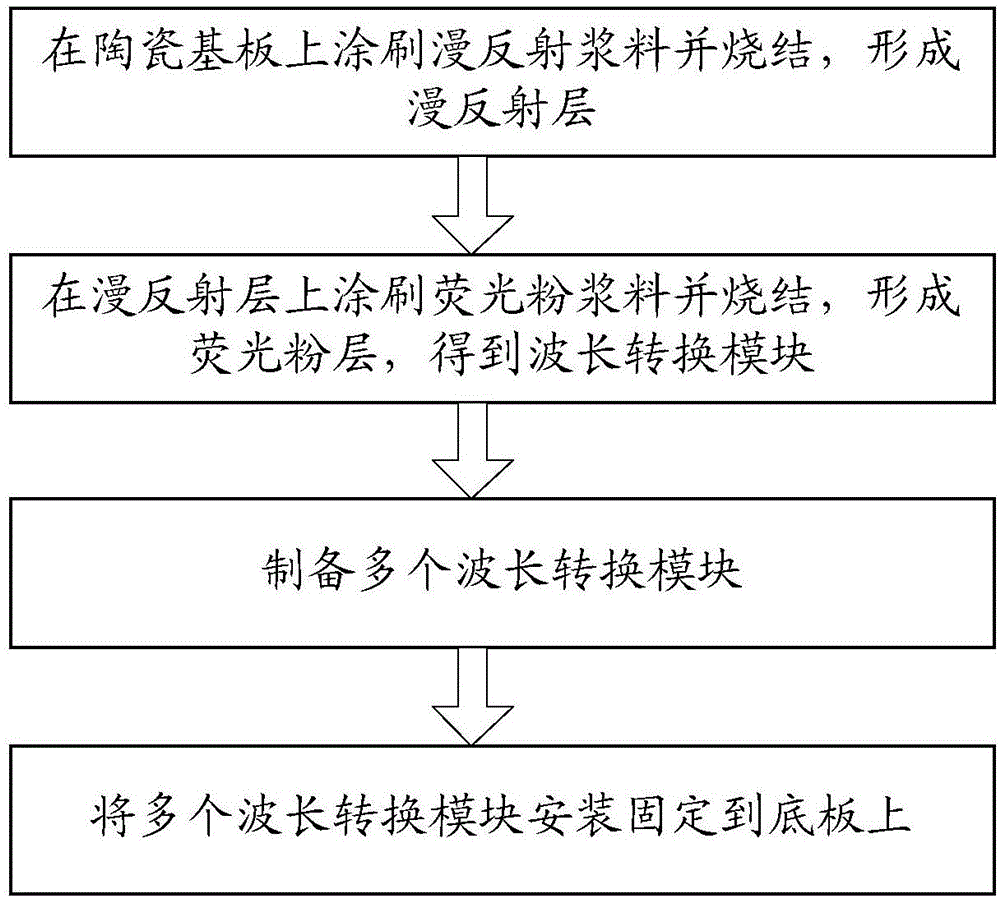

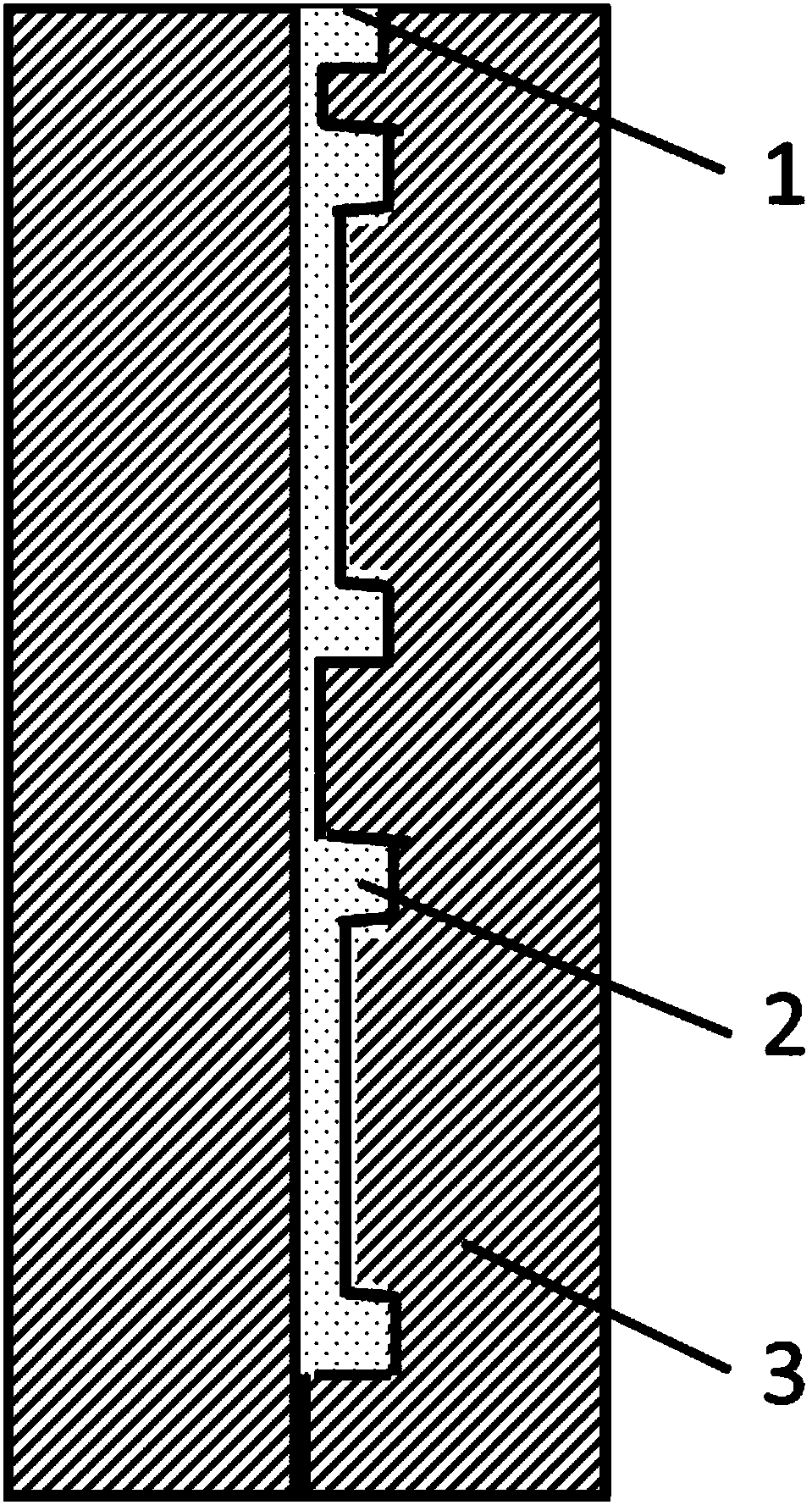

Manufacturing method of wavelength conversion device

ActiveCN104566229ALower interface thermal resistanceNot difficult to attachElectrical apparatusElectroluminescent light sourcesWavelength conversionCeramic substrate

Disclosed is a manufacturing method for a wavelength conversion device, comprising: preparing a plurality of wavelength conversion modules (2a, 2b, 2c), each wavelength conversion module (2a, 2b, 2c) comprising a ceramic substrate (23), a reflecting layer (22) and a fluorescent powder layer (21), said layers being stacked sequentially and formed into one piece; installing and fixing the plurality of wavelength conversion modules (2a, 2b, 2c) on one surface of a base substrate. By arranging different fluorescent powders respectively on the different wavelength conversion modules (2a, 2b, 2c), a plurality of wavelength conversion modules (2a, 2b, 2c) can be produced separately at the same time, thereby significantly shortening the production cycle. Each such module is produced independently and is thus not subject to the restrictions of the characteristics of other fluorescent powders. This is beneficial for the optimization of the various processes, and a wavelength conversion device having optimal performance is thereby obtained.

Owner:APPOTRONICS CORP LTD

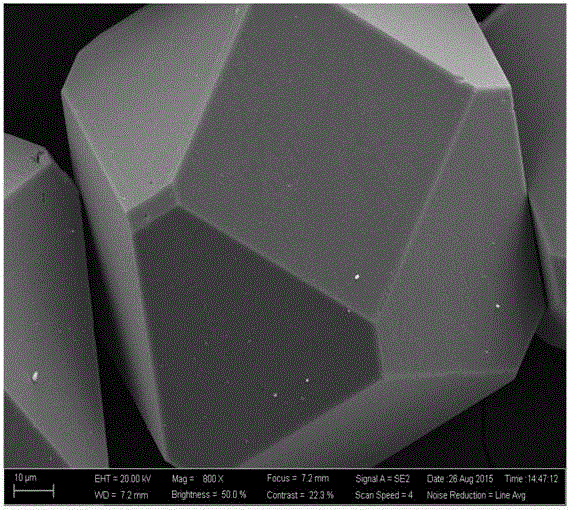

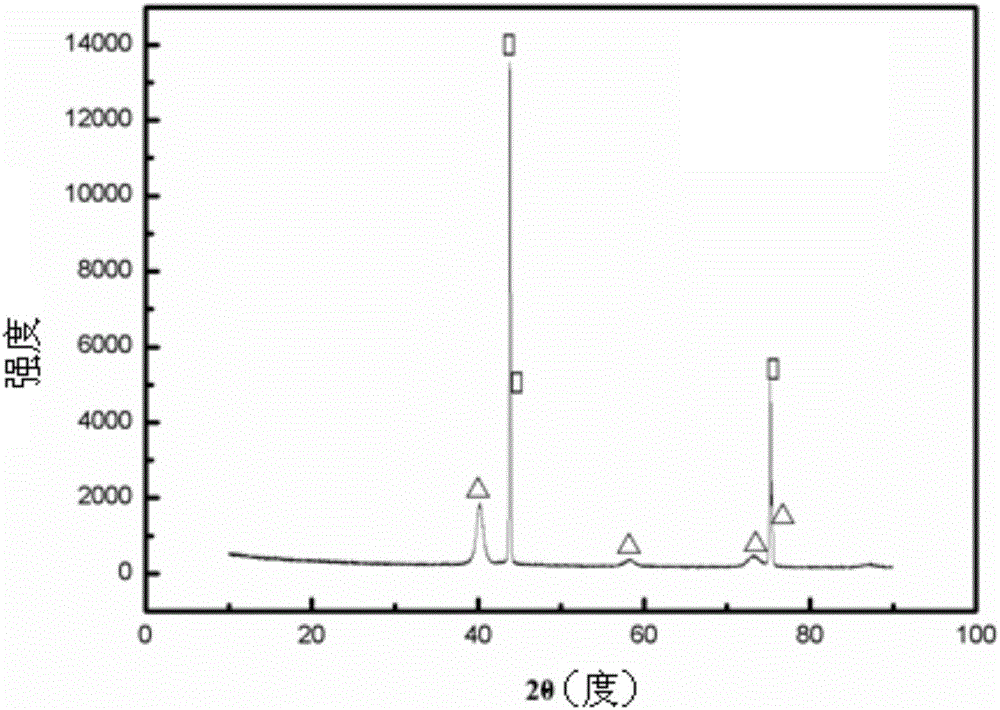

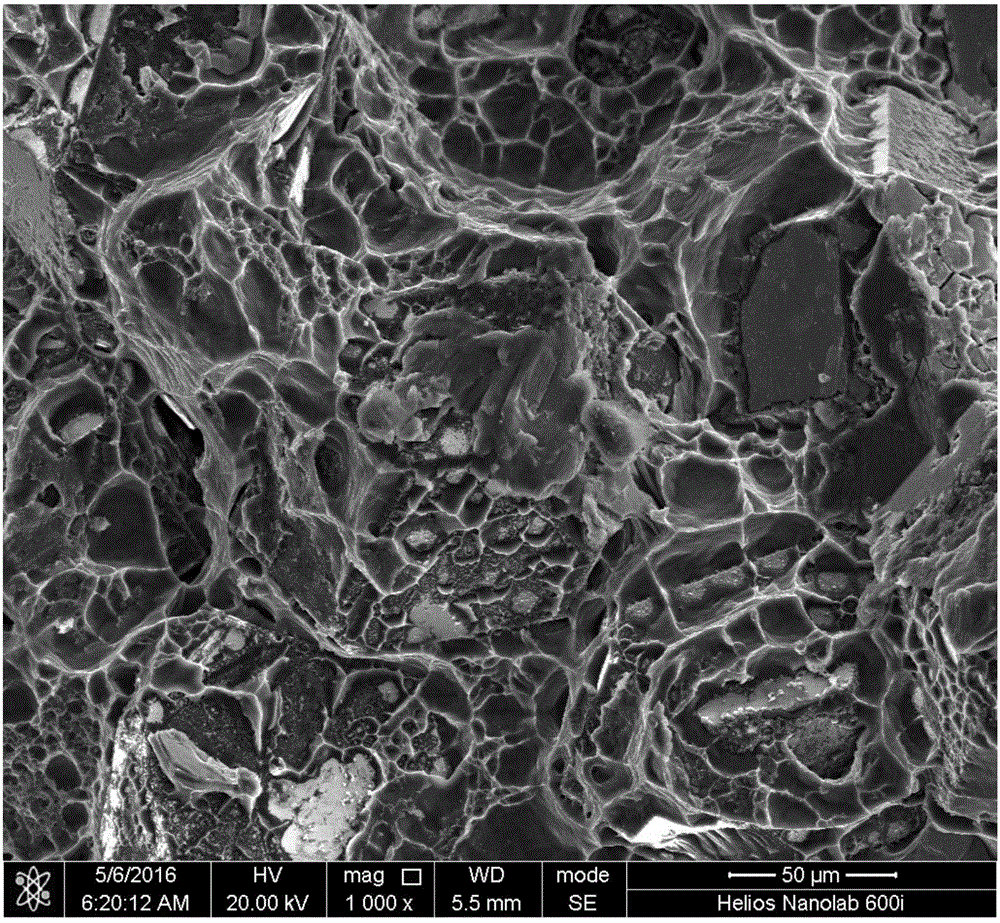

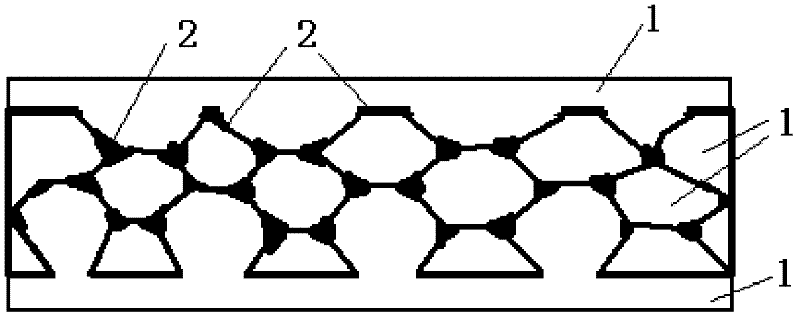

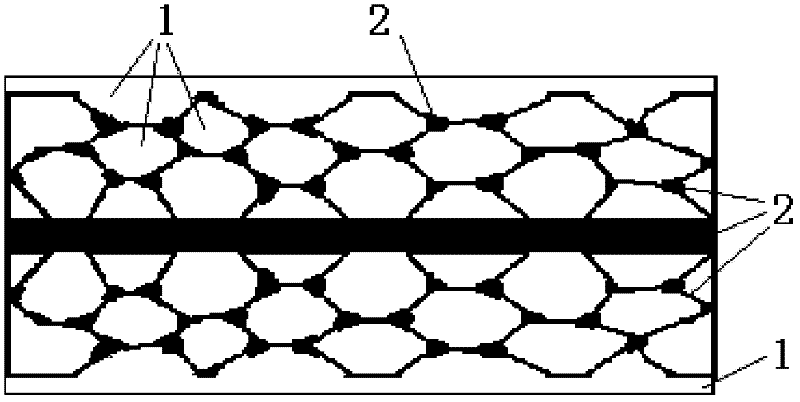

Method for preparing metal reinforced uranium dioxide nuclear fuel pellet

ActiveCN107256726ALow densityHigh strengthNuclear energy generationReactor fuel susbtancesMicro cellTwo step

The invention discloses a method for preparing metal reinforced uranium dioxide nuclear fuel pellets. The method mainly comprises two steps: firstly, preparing core-shell structure granules, namely performing low-temperature rapid pre-sintering on UO2 powder by using a Spark Plasma Sintering SPS technique, pelletizing, balling to obtain UO2 pellets, performing physical mixing on the UO2 pellets with metal (one of Mo, Cr, W and the like) micro powder to coat surfaces of the UO2 pellets by the metal micro powder, thereby obtaining metal coated uranium dioxide core-shell structure granules; secondly, preparing a nuclear fuel pellets, namely performing high-temperature liquidation on the metal powder on the surfaces of the UO2 pellets, thereby forming a micro cell structure continuous phase similar to a cytomembrane structure around the UO2 pellets, and obtaining the special metal reinforced UO2 nuclear fuel pellets with a UO2 substrate.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS +1

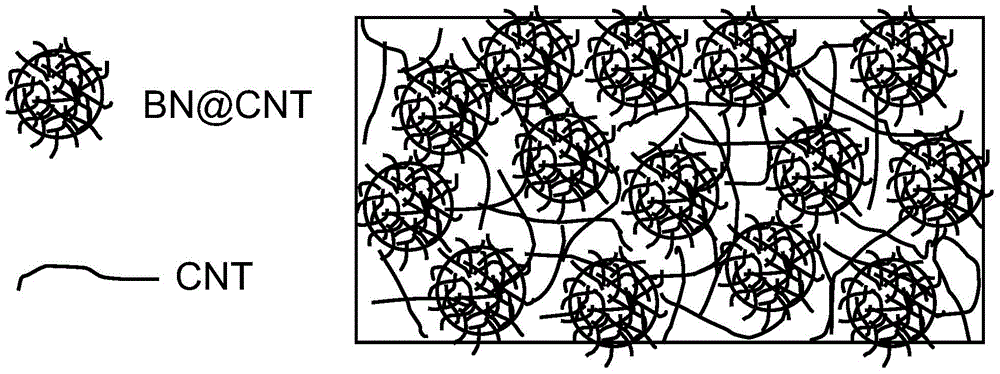

Aqueous heat dissipation coating and preparation method thereof

ActiveCN104804618AImprove cooling effectHigh thermal conductivityEpoxy resin coatingsBoron nitrideSlurry

The invention discloses an aqueous heat dissipation coating and a preparation method thereof. The aqueous heat dissipation coating comprises an aqueous dispersoid containing a base resin, nanometer carbon material-coated boron nitride composite powder and optional auxiliary materials. The composite powder comprises boron nitride and a boron nitride-coating nanometer carbon material. The preparation method comprises carrying out grinding dispersion on the aqueous dispersoid containing a base resin and the optional auxiliary materials to obtain dispersive slurry, at least adding slowly the composite powder into the dispersive slurry, carrying out high speed stirring and carrying out standing defoaming. The nanometer carbon material-coated boron nitride composite powder is used as a coating filler so that excellent thermal conductivity of the nanometer carbon material and boron nitride and conductive infrared radiation characteristics of the nanometer carbon material are fully utilized, interface thermal resistance of the nanometer carbon material and boron nitride is reduced, and the coating has the advantages of high thermal conductivity, high infrared radiation rate, construction convenience, safety, environmental friendliness and wide application prospect.

Owner:芜湖海泰科新材料有限公司

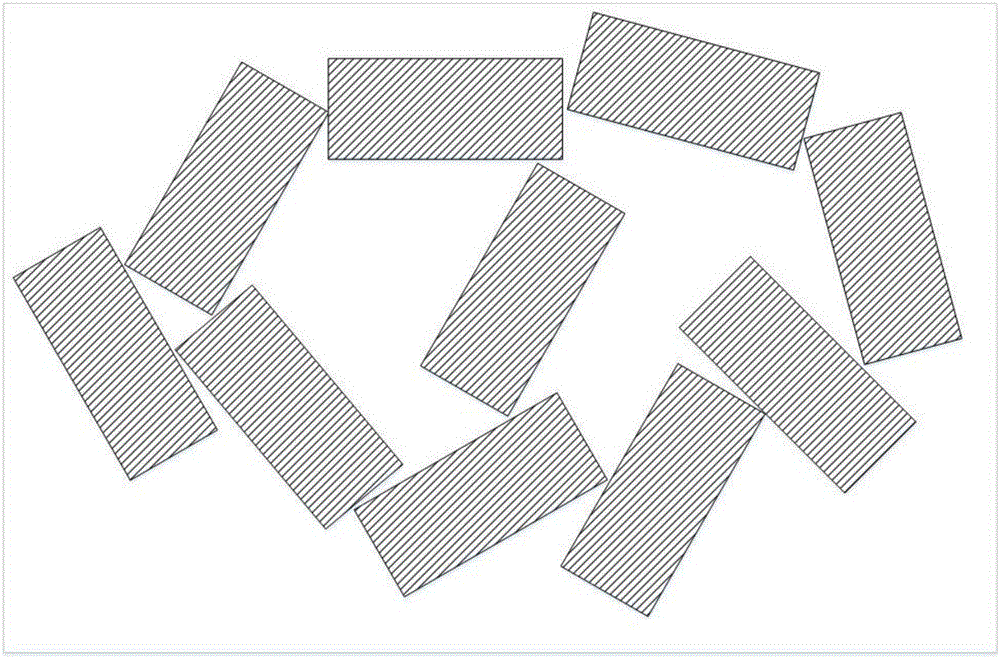

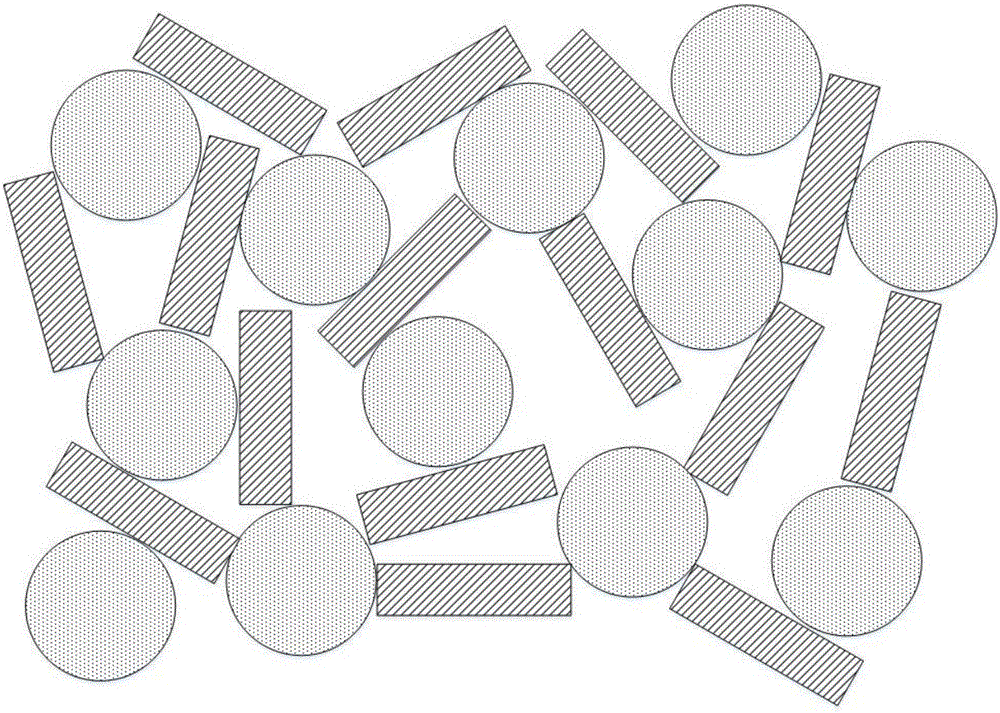

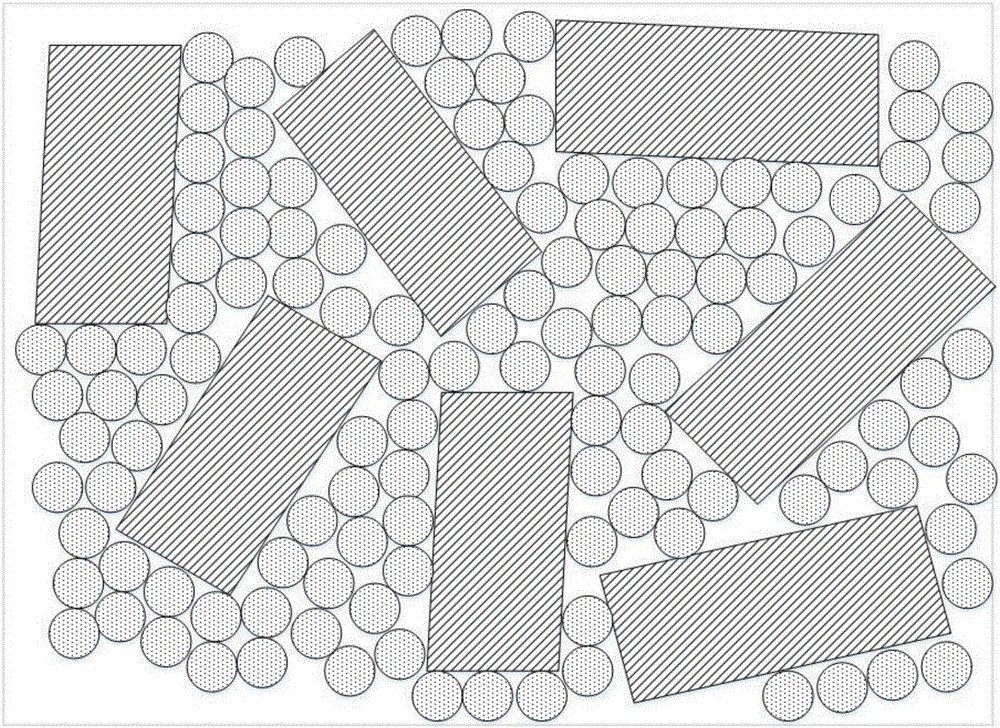

Low-filling high-heat-conductivity organic-inorganic compound

The invention discloses a low-filling high-heat-conductivity organic-inorganic compound which comprises, by weight, 50-1000 parts of organic component serving as a heat-radiating matrix, 100-400 parts of flaky inorganic matter serving as a first heat-conducting filler and 10-800 parts of non-flaky inorganic matter serving as a second heat-conducting filler.A heat-conducting network of two dimension / three dimension and two dimension / one dimension is formed in the organic heat-radiating matrix by compounding the inorganic heat-conducting fillers various in shape, so that the low-filling high-heat-conductivity organic-inorganic compound has high heat conductivity and good storage stability.

Owner:ANHUI UNIVERSITY

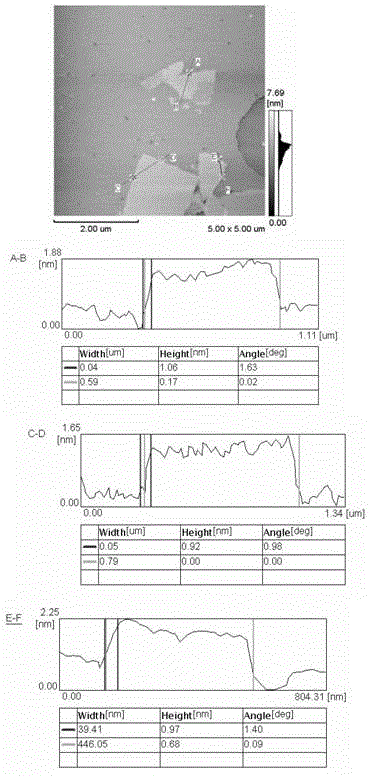

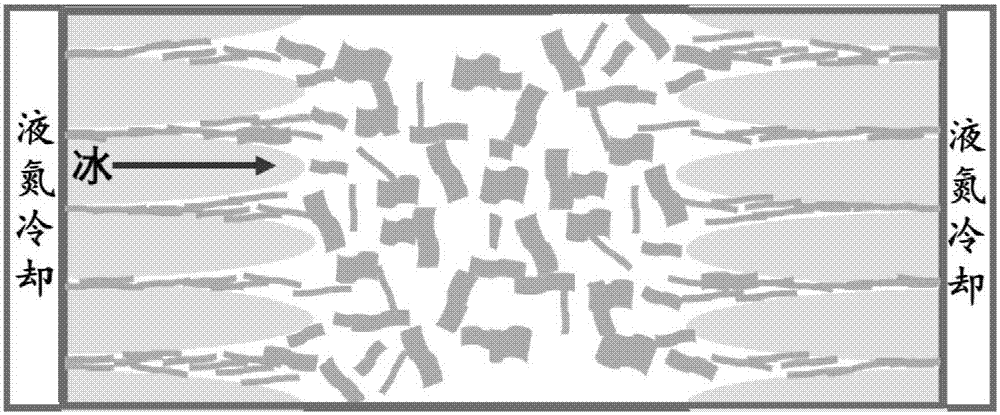

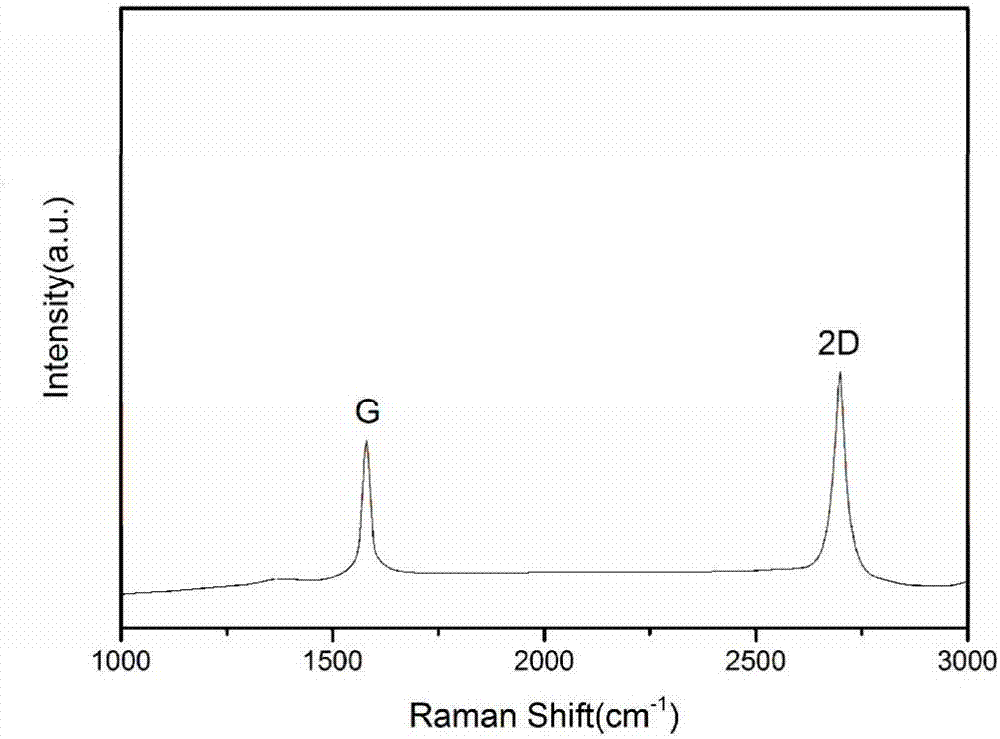

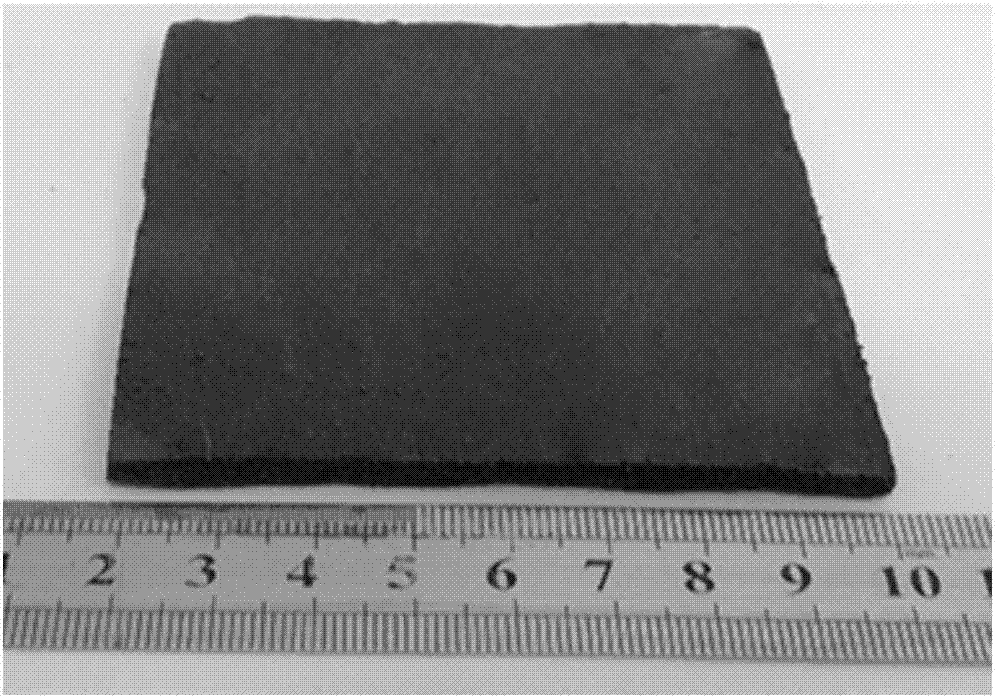

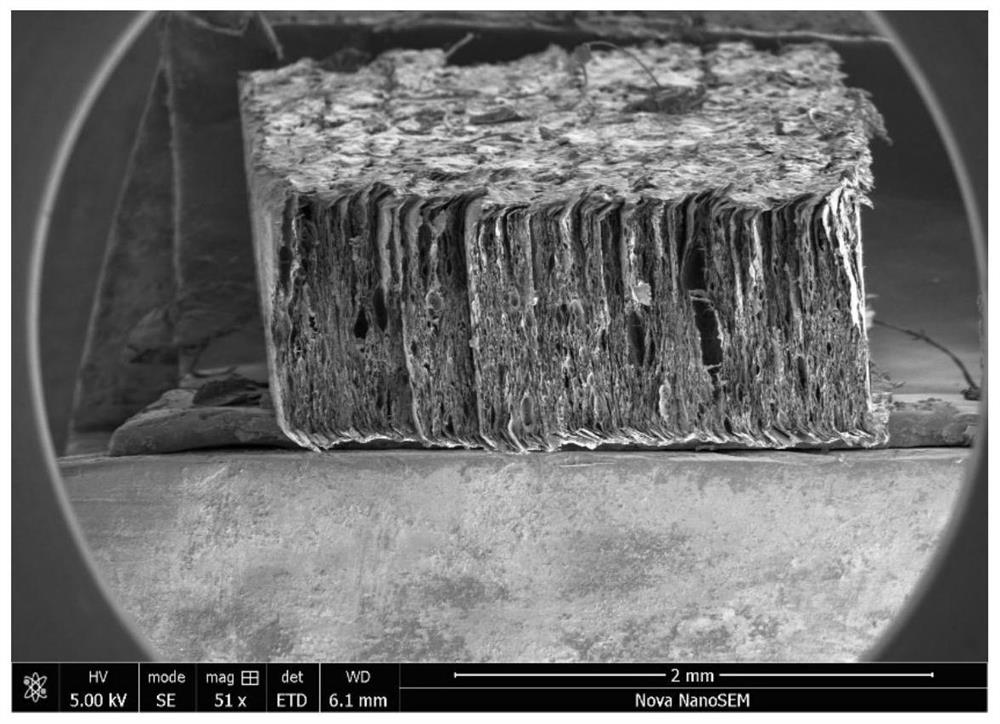

High-oriented graphene radiating film and preparation method thereof

ActiveCN107010618AHigh thermal conductivityLower interface thermal resistanceGrapheneCvd grapheneHeat treated

The invention provides a high-oriented graphene radiating film and a preparation method thereof, solving the problem of high oriented distribution of graphene and realizing the internal ultra-high heat conductivity. The preparation method includes the steps of preparing oxidized graphene dispersion liquid; performing high orientation treatment of graphene; freezing and drying to obtain the oxidized graphene foam; performing hydrazine hydrate reduction and acquiring graphene foam; pressurizing the graphene foam to obtain a graphene film; performing a post thermal treatment. The sample with controllable thickness and highly orienting distributed graphene can be prepared. The internal heat conductivity of the radiating film can reach 2400 W / (m.K), and the radiating filmcan be widely applied to the field of radiation.

Owner:HARBIN INST OF TECH

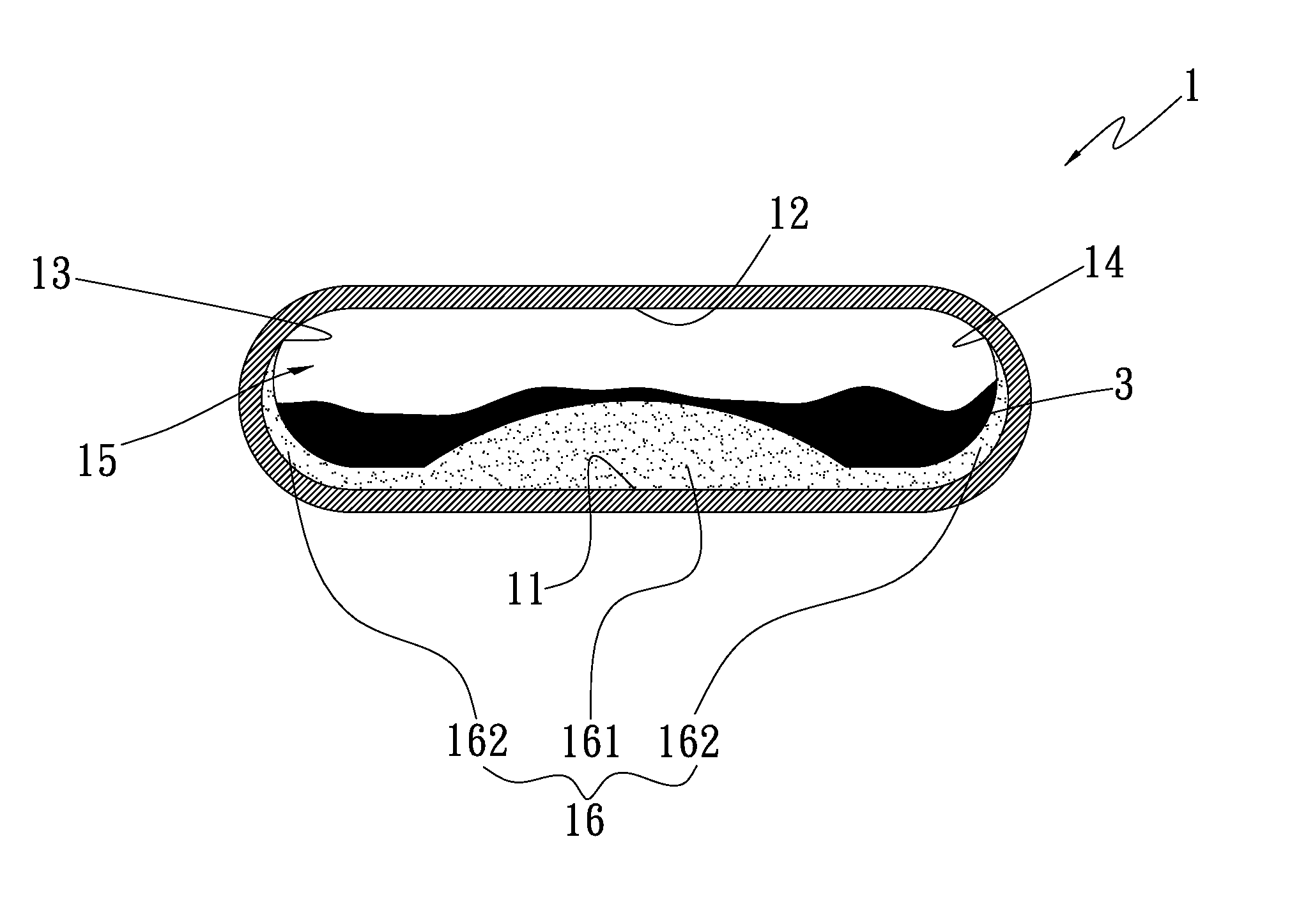

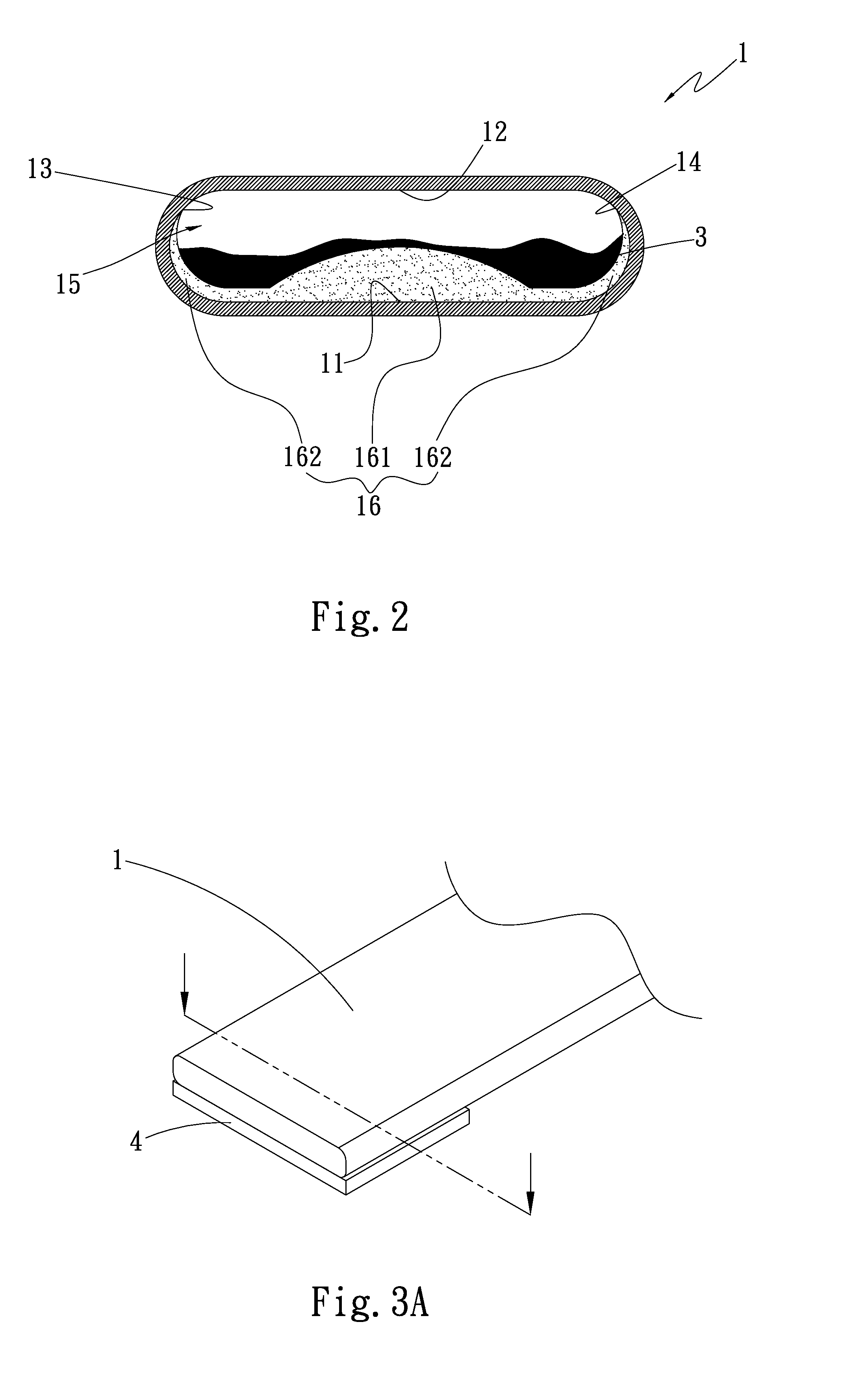

Heat pipe heat dissipation structure

InactiveUS20130213612A1Improve heat transfer efficiencyImprove abilitiesIndirect heat exchangersWorking fluidEngineering

A heat pipe heat dissipation structure includes a main body and at least one first capillary structure. The main body has a first inner side, a second inner side, a third inner side, a fourth inner side and at least one chamber filled with a working fluid. The first capillary structure is disposed in the chamber. The first capillary structure includes a first section disposed on the first inner side and a second section extending from two sides of the first section along the adjacent third and fourth inner sides. The first section has a thickness larger than that of the second section. The heat pipe heat dissipation structure has better heat transfer efficiency.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Preparation method of W-plated diamond/aluminum composite

ActiveCN105886849AAvoid introducingLong melting timeVacuum evaporation coatingSputtering coatingInterfacial adhesionFlexural strength

A preparation method of W-plated diamond / aluminum composite relates to a preparation method of a metal-based composite. In order to solve the technical problem that since diamond and aluminum react to produce Al4C3, the obtained composite has poor interfacial adhesion and low heat conductivity. The method includes: first, coating the surface of diamond particles with W; second, preheating; third, infiltrating under pressure: applying a pressure of 10-15 Mpa with an intra-furnace press so that molten aluminum infiltrates the W-coated diamond particles, cooling at a speed of 100 DEG C / h to below 300 DEG C, relieving pressure, turning off a vacuum furnace, and demolding to obtain the W-plated diamond / aluminum composite; diamond is 55-65% in volume fraction, > / =98% in compactness, up to 622 W / (m.K) in heat conductivity, down to 7.08*10-6 / K in thermal expansion coefficient and up to 304 Mpa in flexural strength. The invention belongs to the field of preparation of composites.

Owner:HARBIN INST OF TECH

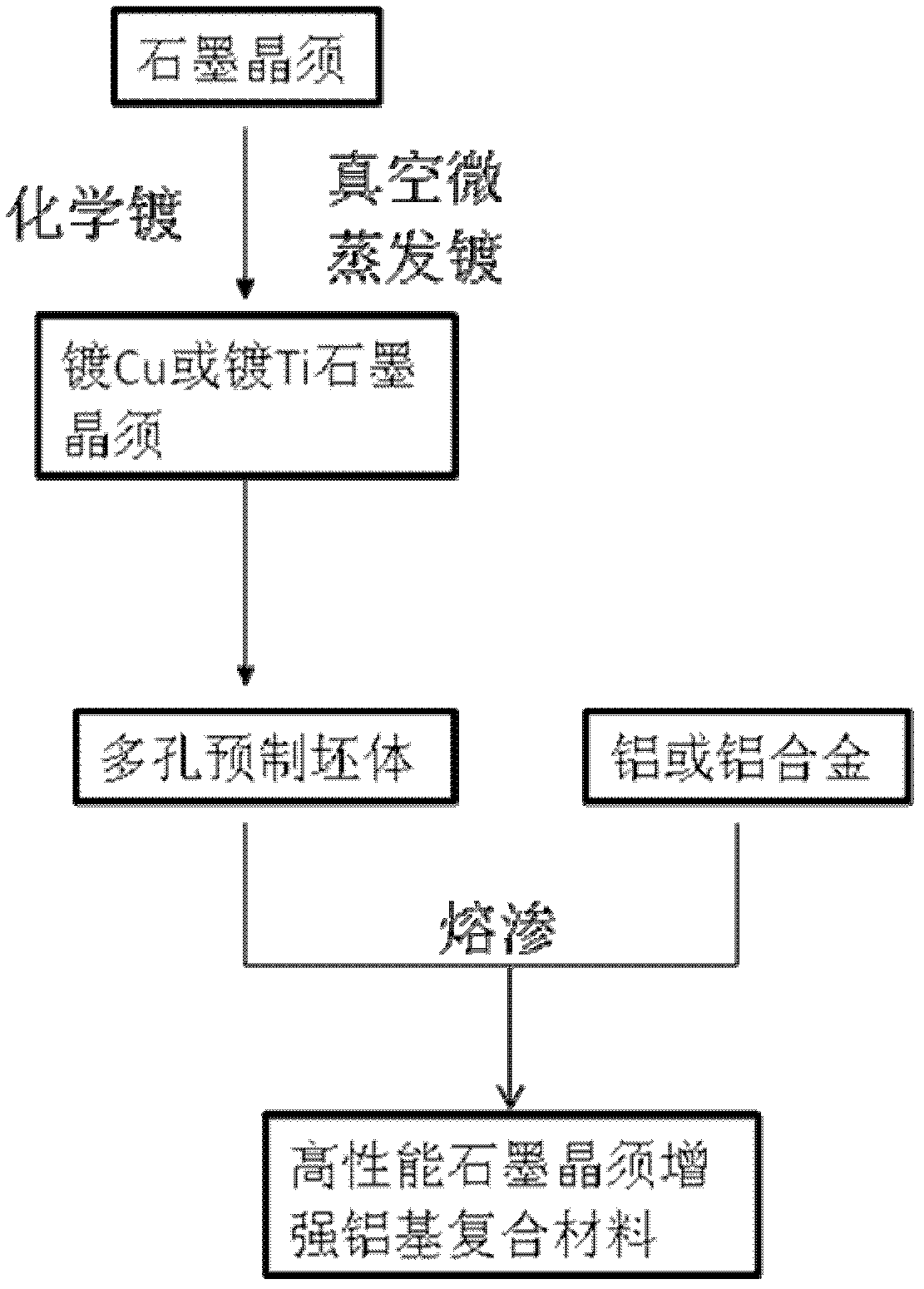

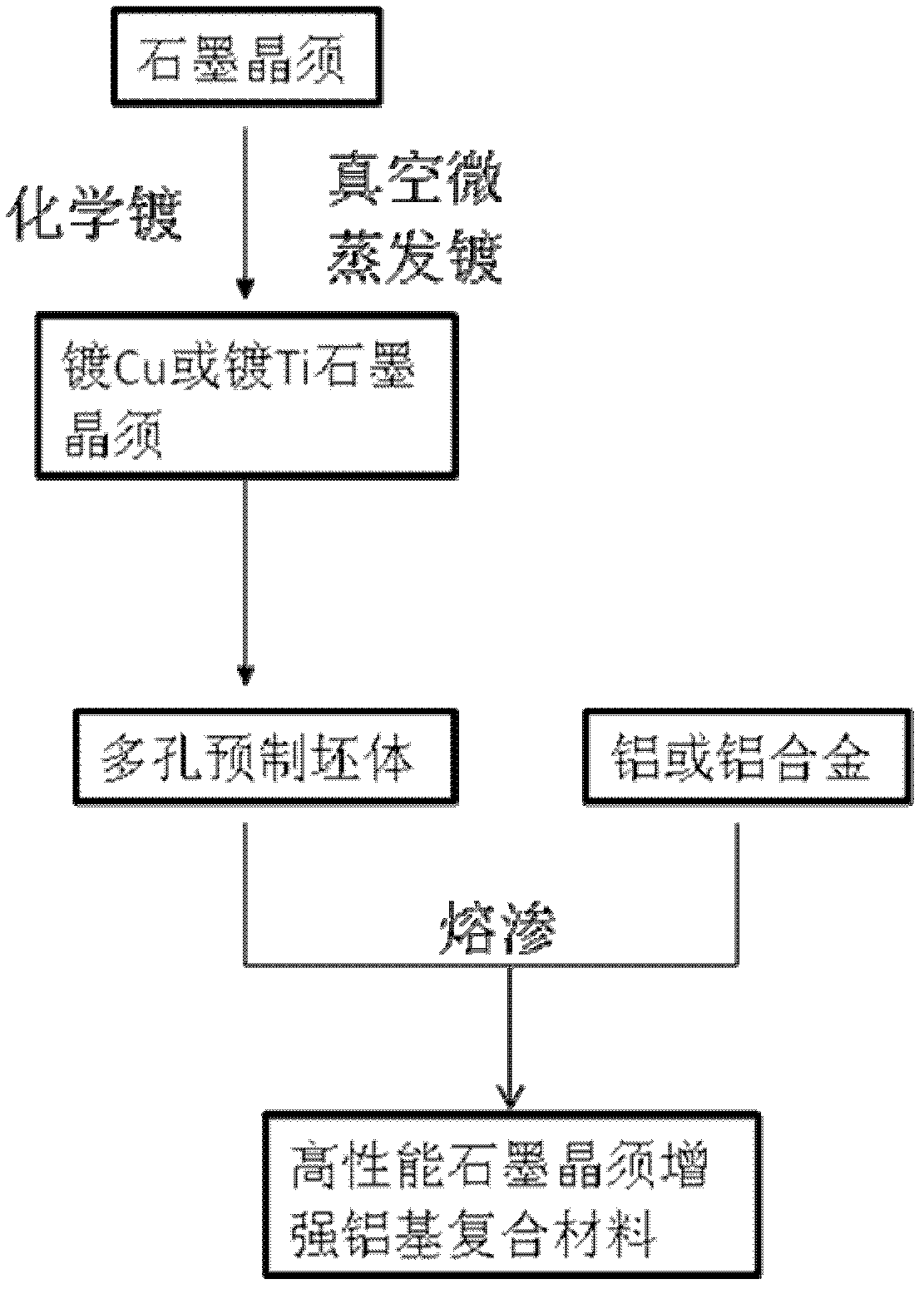

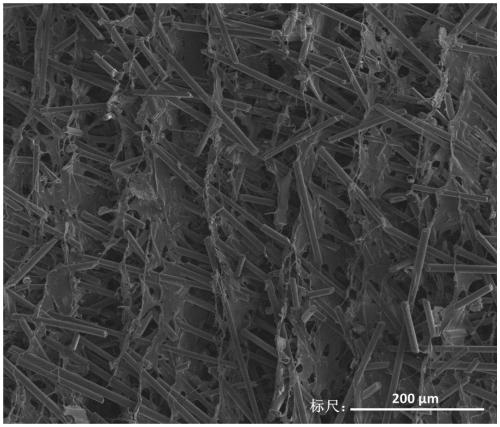

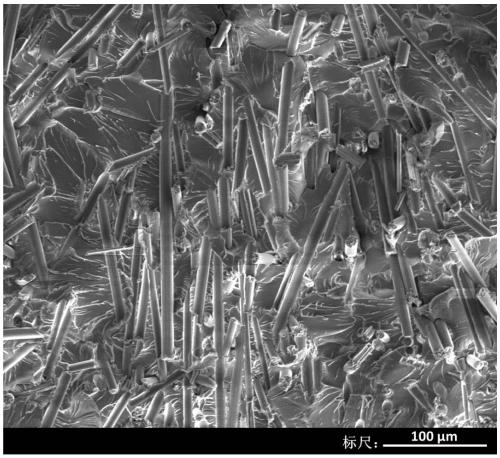

Method for preparing graphite whisker reinforced aluminum matrix composite material

InactiveCN102586703AHigh thermal conductivitySmall coefficient of thermal expansionThermal dilatationChemical plating

The invention discloses a method for preparing a graphite whisker reinforced aluminum matrix composite material. The composite material consists of plated high-reinforced-phase heat conducting graphite whiskers and matrix aluminum or aluminum alloy, wherein the volume fraction of the matrix aluminum or the aluminum alloy is 40%-65%, and the volume fraction of the plated graphite whiskers is 35%-60%. The production process comprises the steps of 1 adopting a chemical plating or vacuum salt bath plating method to plate copper or titanium on the surfaces of the graphite whiskers so as to form a plating layer with thickness of 0.1-1.5mum; 2 adding an appropriate amount of binder on the graphite whiskers with modified surfaces to perform die forming, and then adopting thermal degreasing to remove the binder and manufacture a porous prefabricated blank; and 3 stacking up the prefabricated blank and the aluminum or the aluminum alloy to perform vacuum pressure infiltration processing so as to finally obtain a graphite whisker-aluminum composite material part. The composite material prepared by means of the method has the advantages of being high in heat conductivity, low in thermal expansion coefficient, light in weight, high in densification, easy to process and the like.

Owner:UNIV OF SCI & TECH BEIJING

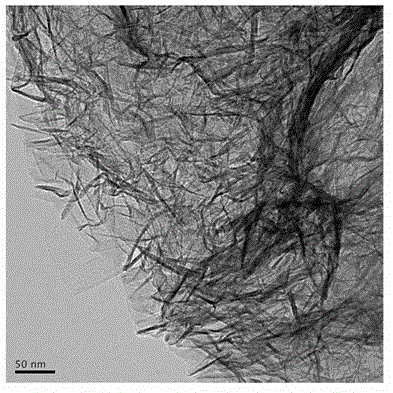

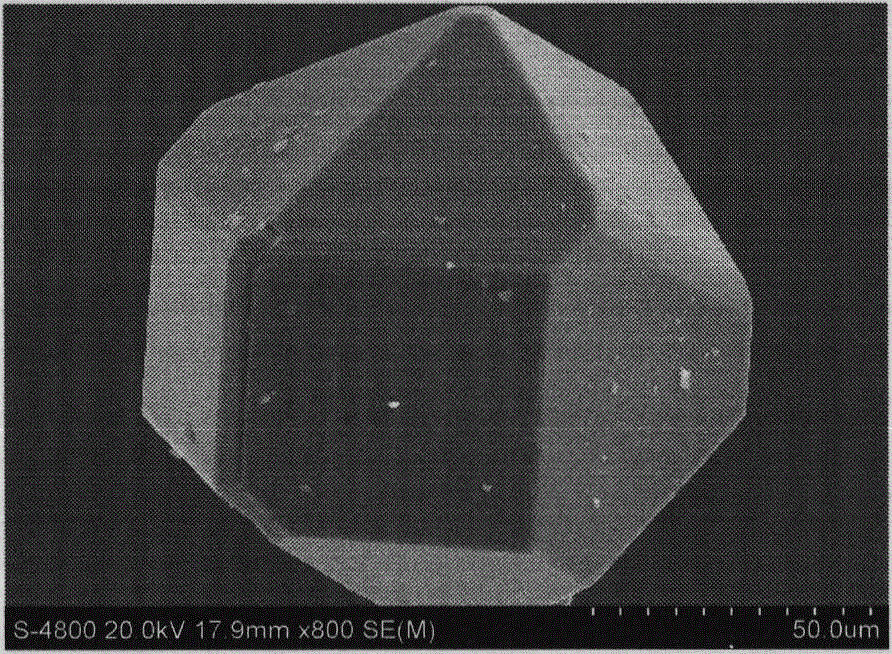

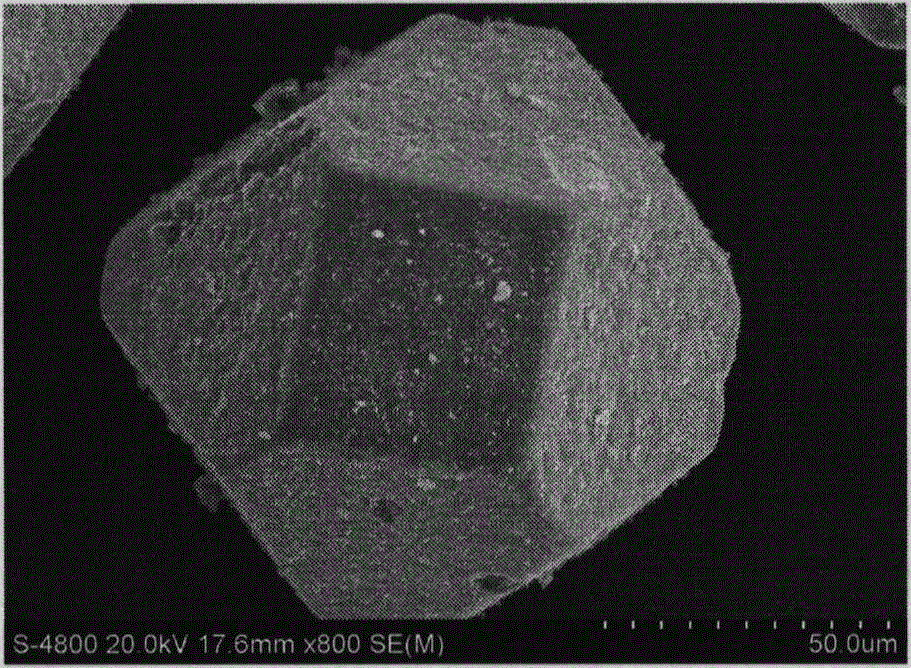

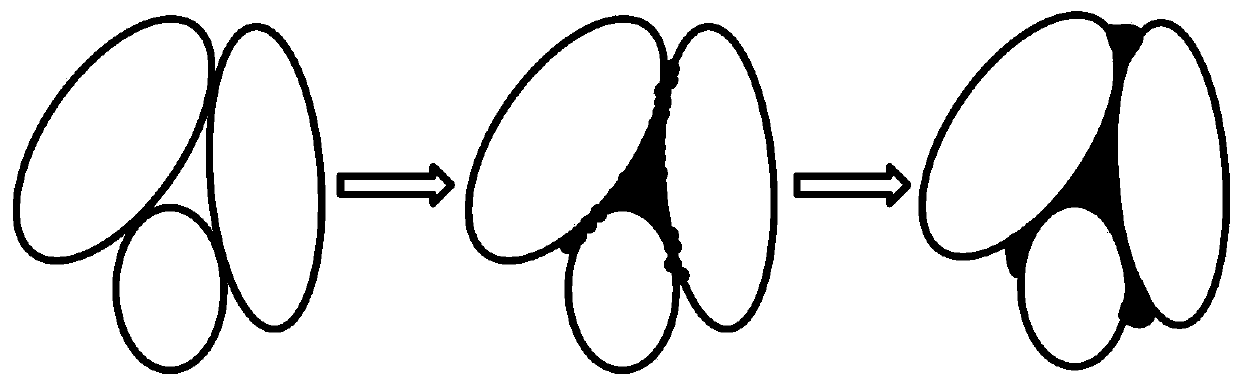

Superhigh-thermal-conductivity continuous diamond skeleton reinforced composite material and preparation method

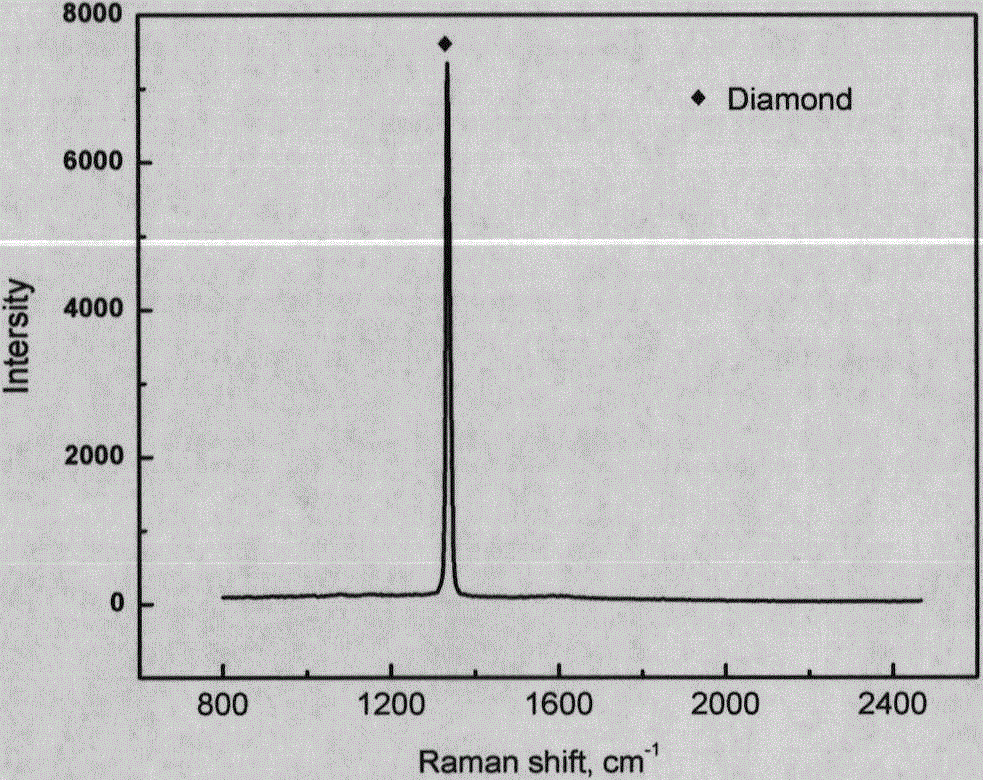

ActiveCN105695831AHigh thermal conductivityImprove mechanical propertiesChemical vapor deposition coatingHeat conductingGas phase

The invention provides a superhigh-thermal-conductivity continuous diamond skeleton reinforced composite material and a preparation method. The composite material is composed of a continuous diamond reinforced body and a base material. The continuous diamond reinforced body is prepared by depositing diamond films or diamond compound films on diamond particle preforms through a CVD method. The diamond compound films are graphene-wrapped diamond films or carbon-nanotube-wrapped diamond films. The base material is made of metal or polymer. Diamond powder is prepared into the performs, then the diamond films deposit on the surfaces of the performs through the CVD method, the diamond films are formed at the contact positions of adjacent diamond particles, and accordingly continuous heat conducting channels are formed between the isolated diamond particles. The deposited diamond films can serve as heat conducting bridges between the diamond particles, so that the dispersed diamond particles form a connection structure, accordingly high heat conductivity of diamond is fully used by the composite material, and the heat conductivity of the composite material is greatly improved.

Owner:CENT SOUTH UNIV

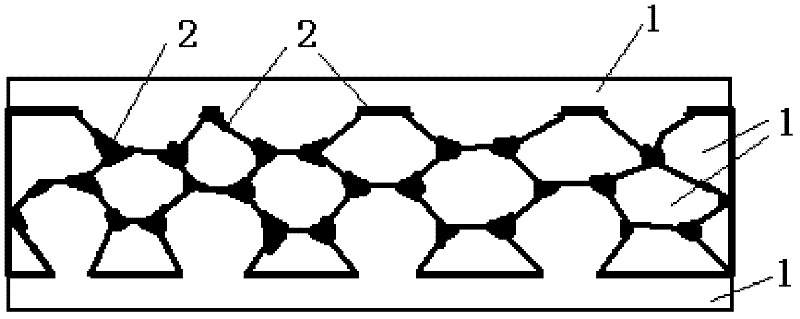

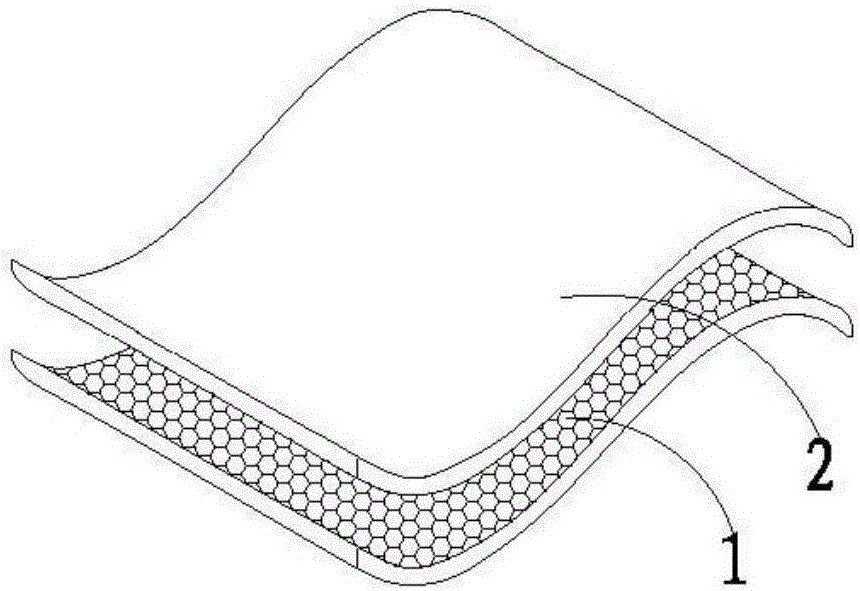

Elastic compound metal heat interface material and preparation method thereof

The invention belongs to the technical field of a heat interface material and discloses an elastic compound metal heat interface material. The elastic compound metal heat interface material is formed by compounding indium and a through-hole porous metal sheet, wherein the indium is filled in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet. The invention also discloses a preparation method of the elastic compound metal heat interface material. The method comprises the following steps: preparing the through-hole porous metal sheet at first; adding a proper amount of indium; heating for smelting indium so that smelted indium fills in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet; and finally cooling, thereby obtaining the elastic compound metal heat interface material. The two surfaces of the through-hole porous metal sheet are both through-hole porous metal and the middle core of the through-hole porous metal sheet is a metal solid. The compound material of the through-hole porous metal sheet and indium has higher elasticity and flexibility in the direction vertical to a mounting surface, so that the compound material can be quickly filled in bigger gaps caused by heat sink and an uneven silicon surface, the interface can be completely filled and the heat resistance of the interface can be kept.

Owner:SOUTHEAST UNIV

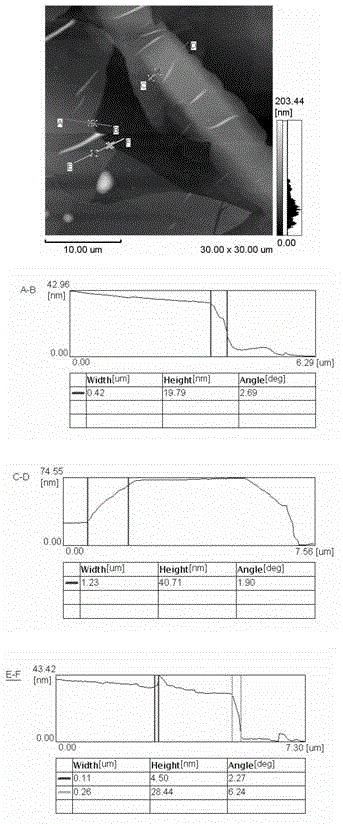

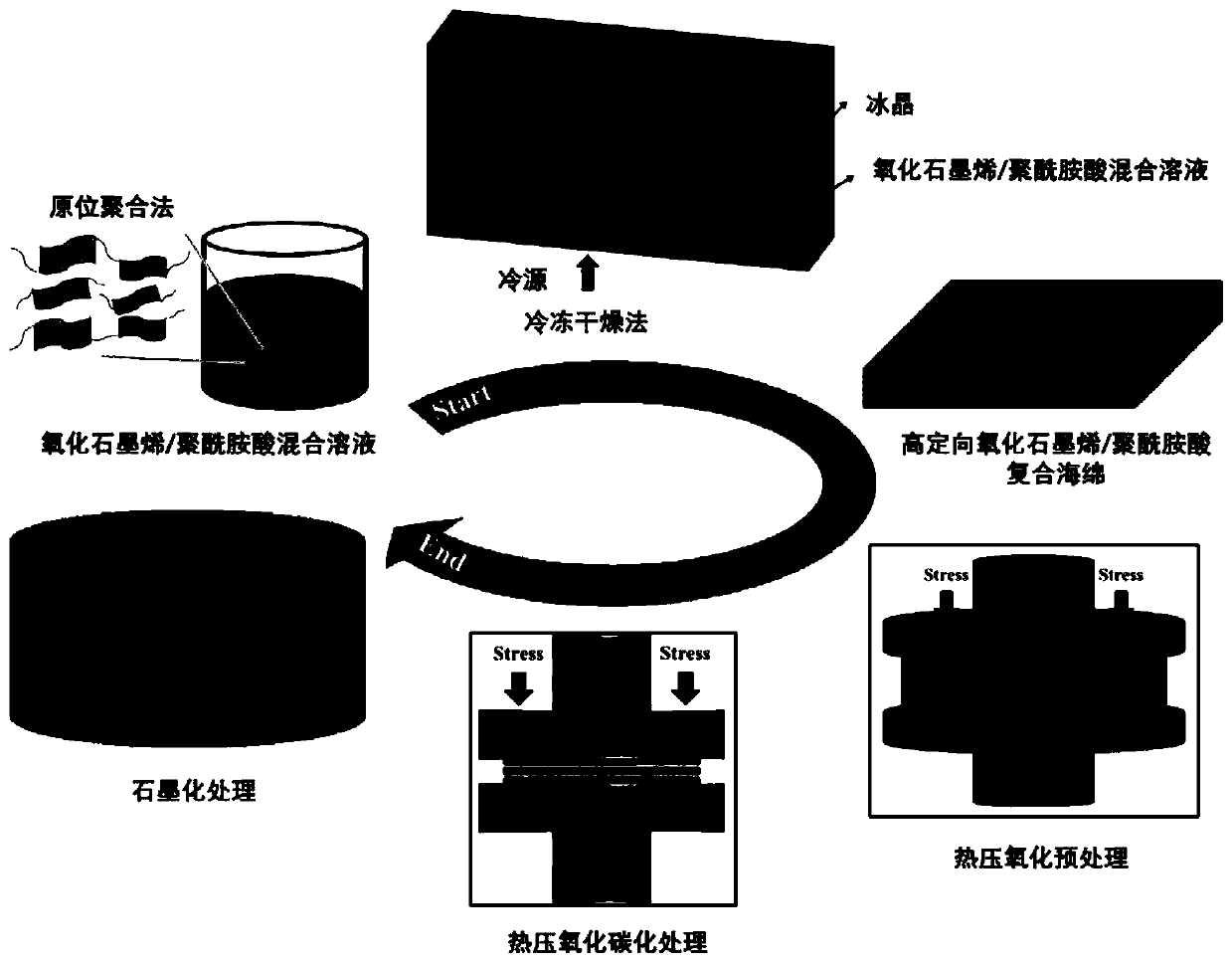

Preparation method of thermal conductive film based on graphene polyimide composite sponge precursor

The invention provides a preparation method of a thermal conductive film based on a graphene polyimide composite sponge precursor. The preparation method comprises the following steps that a grapheneoxide water solution is mixed with a polyimide precursor solution to obtain a graphene oxide / polyamide acid mixed solution, then the graphene oxide / polyamide acid mixed solution is frozen to obtain agraphene oxide / polyamide acid frozen sponge, a frozen drying method is adopted for drying to obtain a graphene oxide / polyamide acid composite sponge, the graphene oxide / polyamide acid composite spongeis placed in a hot pressing reactor, hot pressing oxidizing pre-processing is adopted and machinery pressuring is conducted to obtain a reduced graphene oxide / polyamide acid composite film, then vacuum hot processing and machinery pressuring are adopted to obtain a graphene / polyimide carbon film, then the graphene / polyimide carbon film is placed in a high-temperature graphitization furnace, and agradient temperature rising method is adopted to achieve graphitization of the carbon film. According to the technical scheme of the preparation method, the problem of dispersion of graphene is improved, the obtained film has a certain flexibility and high mechanical strength, and has better electrical and thermal conductivity, and the preparation technology is simple.

Owner:SHENZHEN STRONG ADVANCED MATERIALS RES INST CO LTD

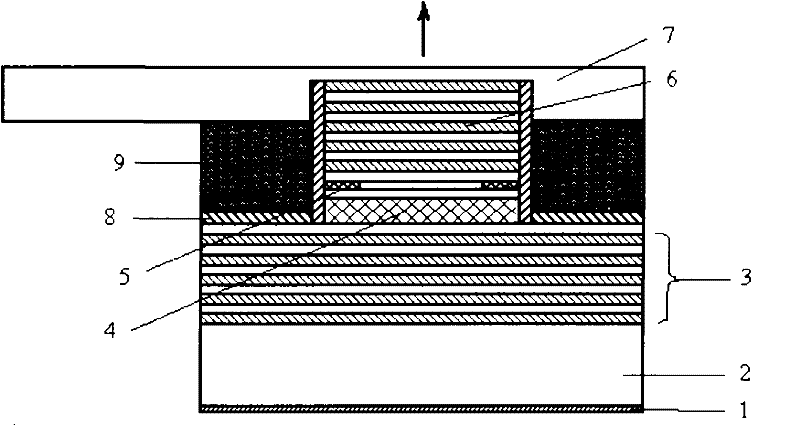

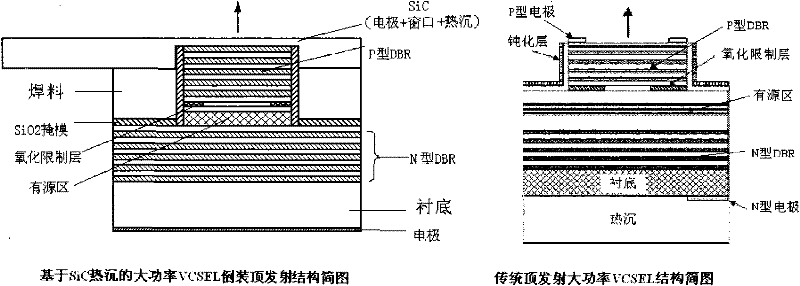

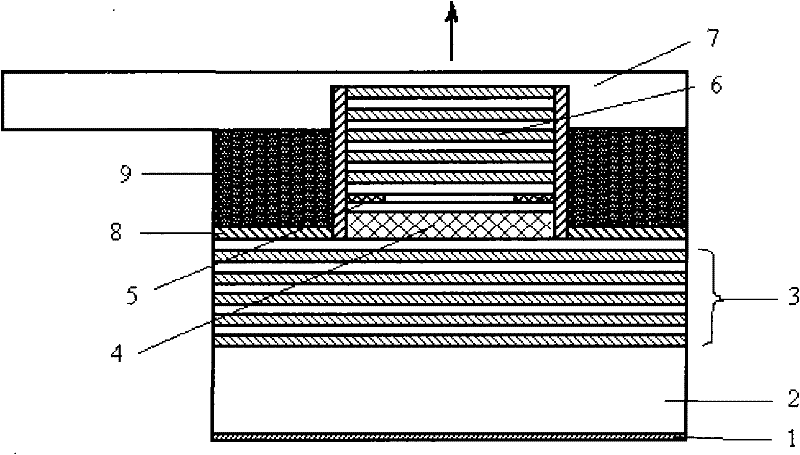

Single-mode high-power vertical-cavity surface-emitting laser based on sic heat sink

InactiveCN102263371AHigh thermal conductivityGuaranteed normal injectionLaser detailsSemiconductor lasersSic substrateHeat sink

The invention relates to a single-mode high-power vertical cavity surface-emitting laser based on a SiC heat sink. Including N electrode, SiC substrate, N-type DBR, active region, oxidation limiting layer, P-type DBR, SiC (electrode + window + heat sink), SiO2 mask, solder. The present invention is characterized by adopting a flip-chip top-emitting structure. The light output window is made on the P-type DBR, and the top light output method is adopted, and the heat sink is also placed at the end of the P surface. SiC wafers have high thermal conductivity, high electrical conductivity and high transmittance of near-infrared light after being modified by special technology. The P electrode, light window and heat sink in the traditional structure are replaced by SiC wafers, and the functions of the three are combined into one. The SiC wafer is used as an electrode, and the circular P electrode of the traditional VCSEL is replaced by a planar electrode or a non-uniform grid electrode; the SiC wafer is used as a heat sink material, and the thermal expansion coefficient is similar to that of GaAs materials, and it is directly flip-chip connected to the P surface in the epitaxial wafer; The SiC wafer simultaneously becomes the light exit window.

Owner:徐靖中

Heat-conducting composite material and preparation method thereof

ActiveCN109181316AFast heat conductionLower interface thermal resistanceHeat-exchange elementsFiberEmulsion

The invention provides a method for preparing a heat-conducting composite material. The method comprises the following steps: modifying spherical packing and flake or fiber packing; (2) fully dispersing the modified spherical packing and the modified flake or fiber packing in a mixed solution of water and ethanol, adding an adhesive, and uniformly stirring and mixing to obtain emulsion, wherein avolume ratio of the modified flake or fiber packing to the modified spherical packing is 10:1 to 1:1, and a volume ratio of the adhesive to the modified spherical packing is 1:5 to 1:2; (3) granulating the emulsion by a spray drying tester so as to obtain heat-conducting packing by virtue of continuous stirring; (4) stirring and mixing the heat-conducting packing, vinyl silicone oil, a curing agent, a catalyst and an inhibitor so as to obtain slurry, wherein the mass fraction of the curing agent is 2-5%, and the mass fraction of the catalyst is 0.02-0.05%; and (5) adding the slurry into a moldfor performing high-temperature curing, thereby obtaining the composite material. The invention further provides a heat-conducting composite material prepared by the preparation method.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Heat dissipation interface material used for packaging of high-power LED (light emitting diode) lamp and preparation method thereof

ActiveCN102746670AAvoid contact gapEasy to passPoint-like light sourceLighting heating/cooling arrangementsResin matrixThermal contact

The invention discloses heat dissipation interface material used for packaging of a high-power LED (light emitting diode) lamp and a preparation method thereof. The heat dissipation interface material is obtained by fully mixing flexible AB double-component condensed type room temperature curable silicone resin as matrix and dimethyl silicone oil and functionalized graphene microchip as thermally conductive filler. The unctionalized graphene microchip and silicone resin are mixed thoroughly on a two-roll mill to enable the functionalized graphene microchip to be dispersed in the silicon resin matrix uniformly so as to prepare the heat dissipation interface material with excellent performance. According to the heat dissipation interface material, the contact gap betweena LED chip module metal heat radiating base and a heat dissipation structure of a lamp shell is avoided and the interfacial thermal contact resistance is reduced, thereby forming highly efficient heat dissipation channel and accelerating heat transfer. The material provided by the invention has great benefit for the power, miniaturization, improvement of the reliability of product and increase of the life expectancy of the LED lamp.

Owner:GUANGDONG UNIV OF TECH

Graphite copper foil composite heat radiating plate

PendingCN106847767AAvoid debonding between layersImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesAdhesiveCopper foil

The invention belongs to the technical field of a heat radiating plate, and particularly to a graphite copper foil composite heat radiating plate. The graphite copper foil composite heat radiating plate comprises a net-shaped copper foil, and a graphite film which is formed on at least one surface of the net-shaped copper foil through calendaring molding technology. The porosity of the net-shaped copper foil is 40-80%. The hole diameter is 0.002-2 mm. Compared with the prior art, the graphite copper foil composite heat radiating plate is advantageous in that the graphite film is formed on the net-shaped copper foil through calendaring molding technology; because no adhesive is used, interface thermal resistance is greatly reduced, and furthermore interlayer adhesive failure generated on the composite heat radiating plate is effectively prevented, thereby realizing excellent mechanical performance, high heat guiding performance and high heat radiating performance of the composite heat radiating plate, and greatly prolonging service life of the composite heat radiating plate. Furthermore, if porosity of the graphite copper foil composite heat radiating plate is overhigh, mechanical strength of the copper foil is reduced; and if porosity is overlow, combining strength between the copper foil and the graphite film is reduced. If the size of a mesh hole is overlarge, the graphite film cannot be closely combined with the copper foil; and if the size of the mesh hole is oversmall, insufficient combining force between the graphite film and the copper foil is caused.

Owner:DONGGUAN HONGYI THERMAL CONDUCTMTY MATERIAL CO LTD

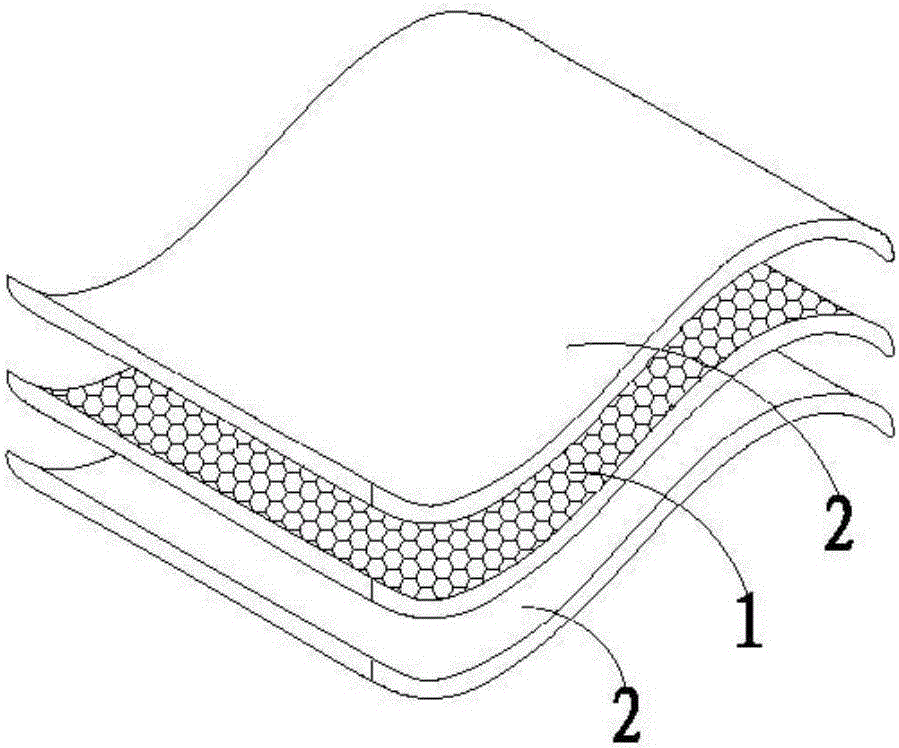

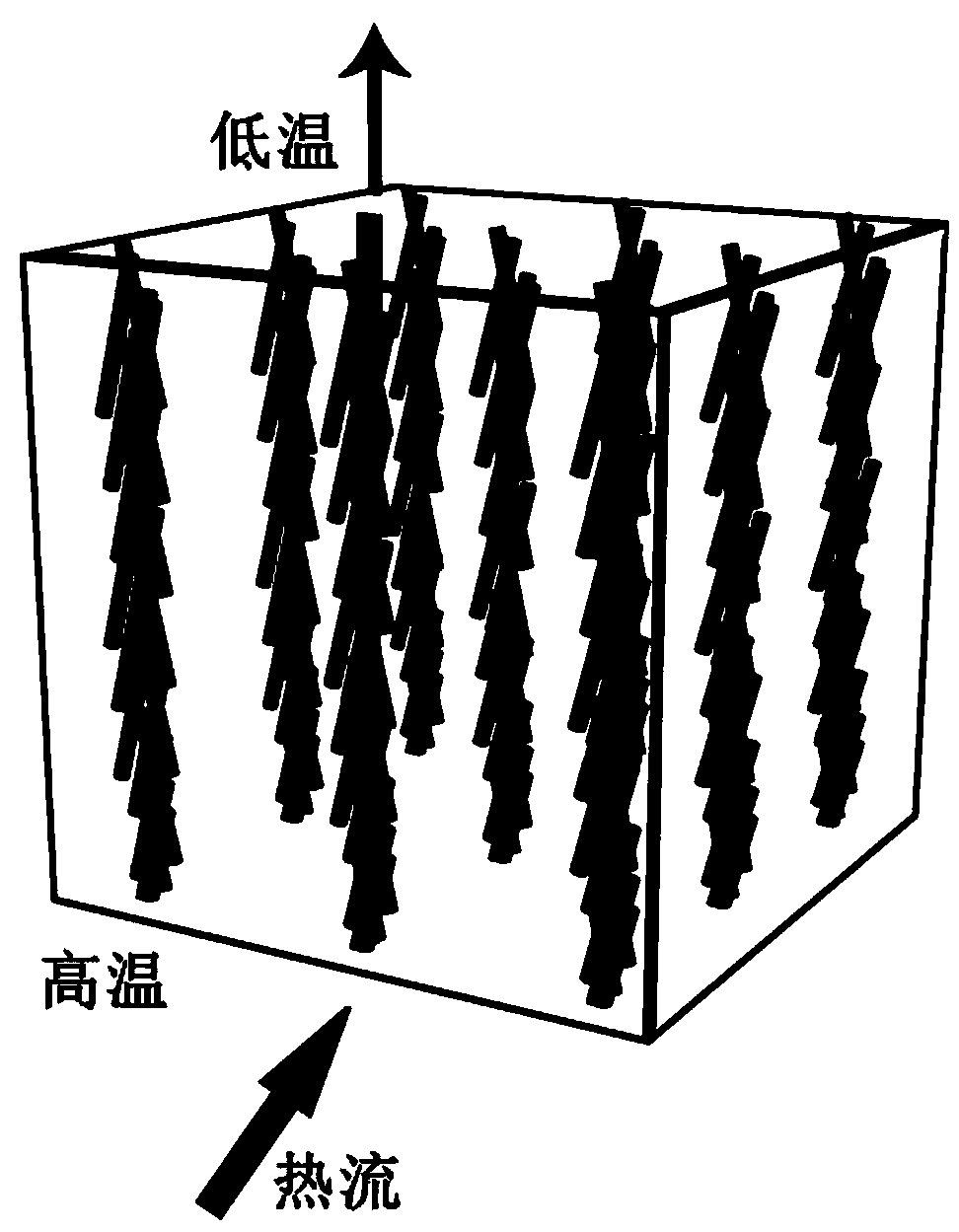

Thermal interface composite material, and preparation method and application thereof

ActiveCN110128792AImprove out-of-plane thermal conductivityHigh glass transition temperatureFiberCarbon fibers

The invention provides a thermal interface composite material, and a preparation method and an application thereof. The thermal interface composite material comprises a carbon fiber skeleton, and a polymer matrix for filling and coating the carbon fiber skeleton; and carbon fibers in the carbon fiber skeleton are arranged along a unidirectional manner. The directionally aligned carbon fibers establish a thermal conduction channel in the vertical direction of the thermal interface composite material, and the carbon fibers are mutually contacted and connected in the direction, so the overall interface thermal resistance of the material is reduced, and the out-of-plane thermal conductivity of the thermal interface composite material is greatly improved; and the carbon fiber skeleton and the polymer matrix cooperate with each other, so the thermal interface composite material has a high glass transition temperature and good mechanical properties such as strength and toughness. The thermalinterface composite material provided by the invention has excellent thermal conduction property and excellent mechanical properties, and the preparation method is simple, and is easy to operate, so the material is a novel thermal conduction material with a large-scale industrial production prospect.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Micro nanocomposite material with high thermal conductivity and preparation method thereof

InactiveCN103834127AImprove thermal conductivitySmall amount of thermally conductive fillerGraphiteMechanical property

The invention discloses a micro nanocomposite material with high thermal conductivity and a preparation method thereof. The preparation method comprises the following steps: dispersing graphite or expanded graphite into a surface modifier solution, stirring at a high speed for 30-60 minutes, then performing ultrasounic stripping on the obtained mixture for 0.5-10 hours, filtering and drying to obtain micro nano structure thermal conducting filler; mixing the micro nano structure thermal conducting filler with a thermal plasticity polymer by virtue of fusion or solution, so as to obtain a micro nanocomposite material, then placing the obtained micro nanocomposite material into a mould, and performing hot press molding at the temperature of 170-300 DEG C and the pressure of 10-18MPa, so that the micro nanocomposite material with high thermal conductivity is obtained, wherein quality content of the micro nanocomposite material in a composite material is 5-30%. The micro nanocomposite material with high thermal conductivity is prepared through ultrasonic stripping under action of surfactant while graphite or expanded graphite is taken as a raw material. The micro nancomposite material with high thermal conductivity has excellent thermal conductivity and good mechanical property and is simple to prepare and low in cost.

Owner:SOUTH CHINA UNIV OF TECH

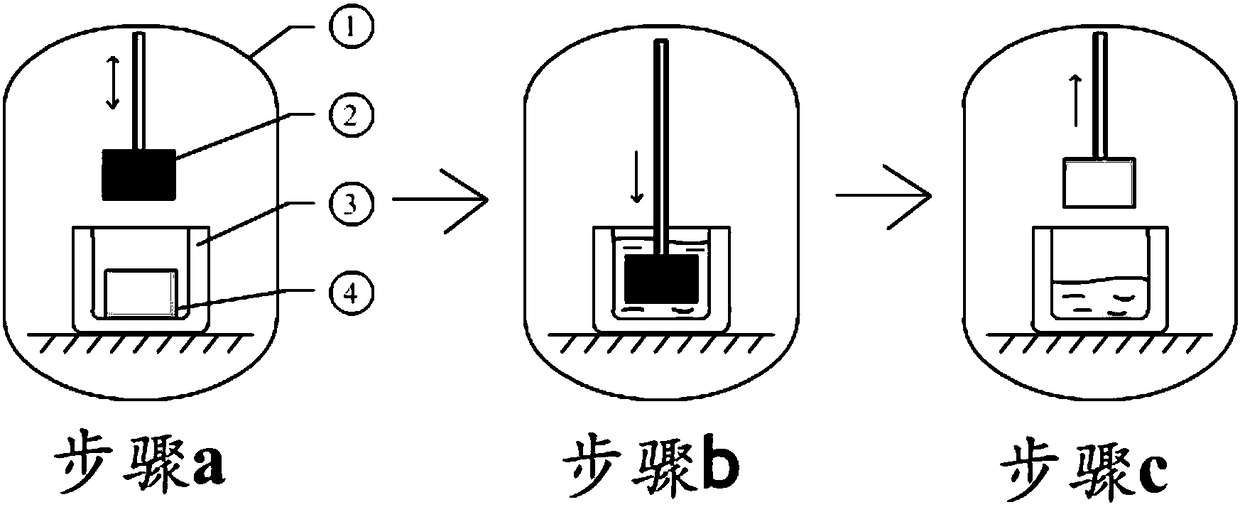

Preparation method of high-heat-conductivity diamond-copper composite

The invention discloses a preparation method of a high-heat-conductivity diamond-copper composite, and relates to a preparation method of a composite. The problems that an existing preparation methodof diamond-copper composite cannot achieve net shape forming, high quality and large batch preparation of large-size sheet samples is solved. The preparation method comprises the steps that diamond powder is placed into a die and compacted to form a precast body, the precast body is hoisted to the lower end of a lifting rod on the upper portion inside an air pressure infiltration furnace, and a crucible containing copper alloy is placed below the precast body in the furnace; vacuumizing is carried out, heating and copper melting are carried out under protection of inert gas, the lifting rod descends, pressurization infiltration is carried out, pressure is kept for cooling, pressure is released, and finally the die is removed. The preparation method has the beneficial effects that high-efficiency mass production can be achieved, the mechanical property is high, the rate of finished products is high, large-size sheet samples can be prepared, sample heat conductivity is improved, the preparation cost is low, the content of impurities is low, and the forming die and the crucible can be repeatedly used. The preparation method is applicable to preparing the high-heat-conductivity diamond-copper composite and component.

Owner:HARBIN INST OF TECH

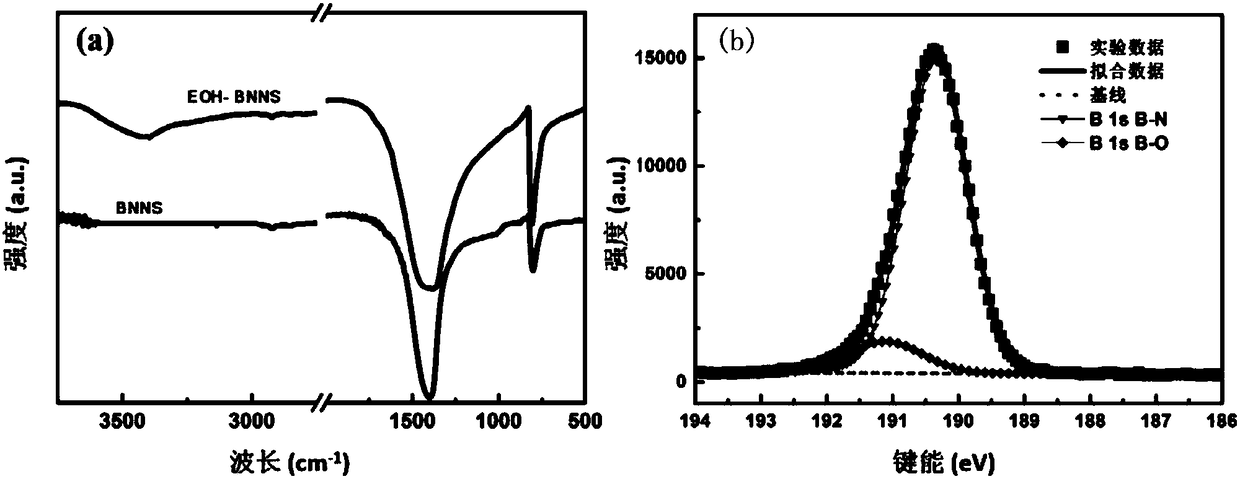

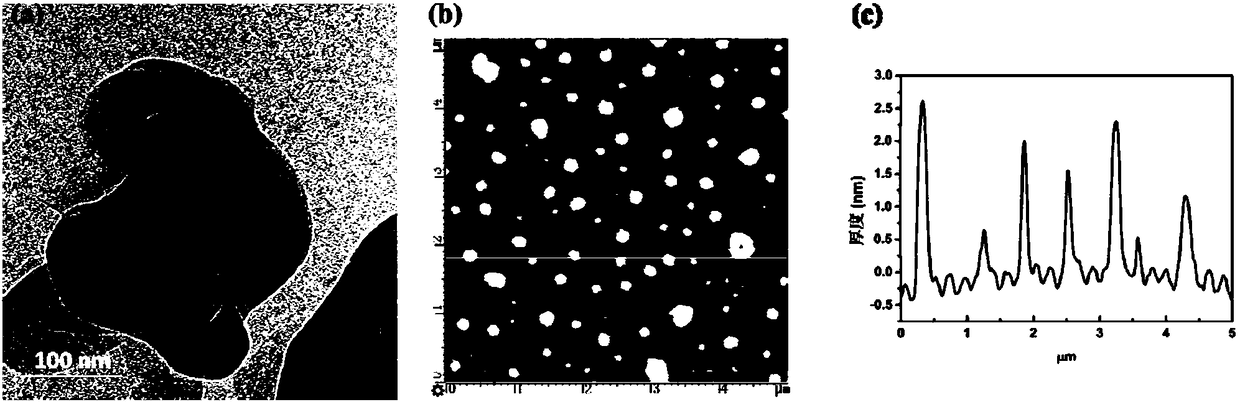

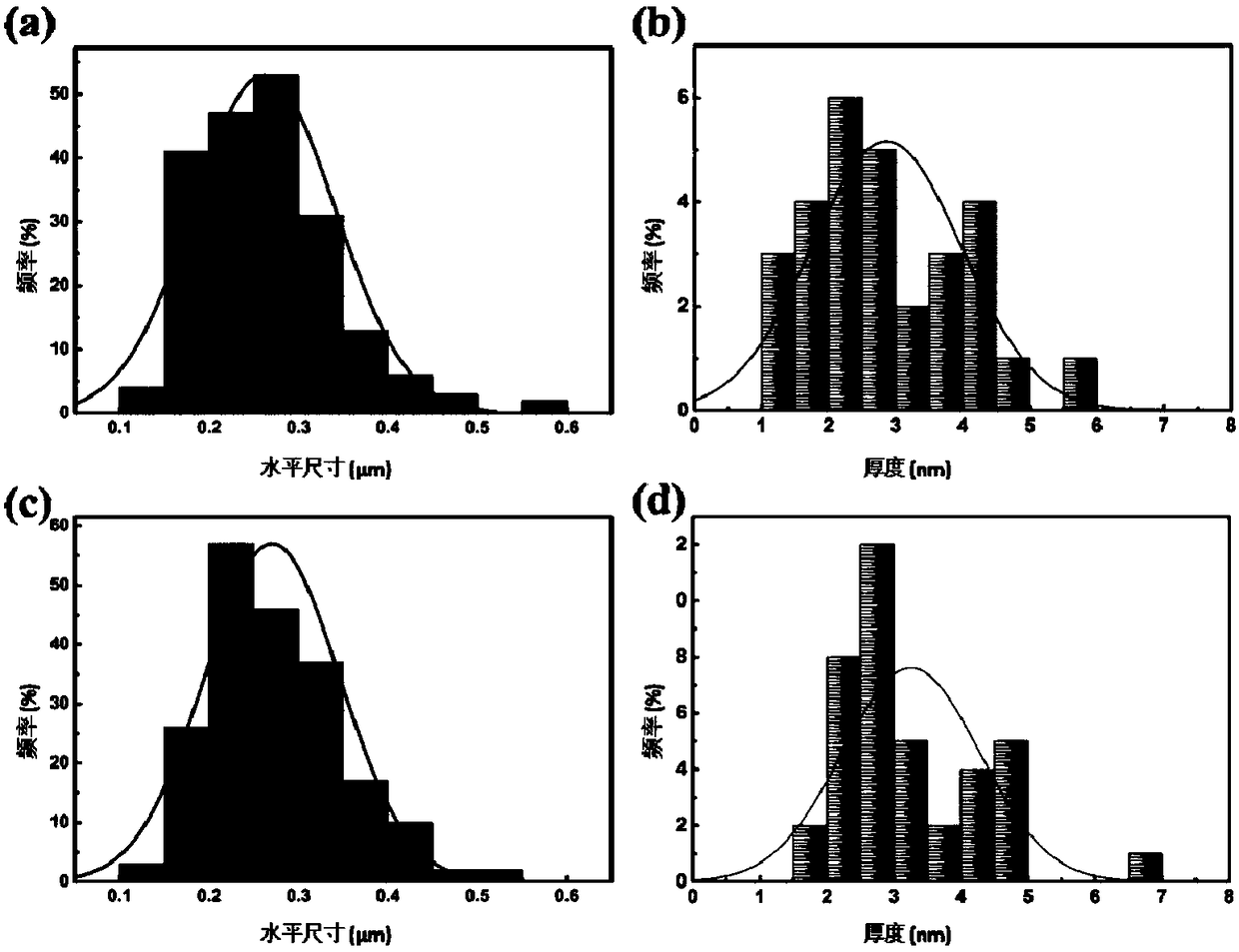

Edge hydroxylation modification method for hexagonal layered boron nitride

The invention belongs to the field of modification of boron nitride and relates to an edge hydroxylation modification method for hexagonal layered boron nitride. According to the edge hydroxylation modification method for the hexagonal layered boron nitride provided by the invention, the modification method comprises the following steps: adding urea and deionized water into hexagonal layered boronnitride to obtain a mixture; ball-milling at a room temperature until the mixture is uniformly dispersed, and enabling the hexagonal layered boron nitride to be completely hydroxylated; finally, removing the residual urea and impurities, and drying, thereby obtaining the edge hydroxylation modified hexagonal layered boron nitride, wherein a usage ratio of the hexagonal boron nitride to urea to deionized water is (500-20000 mg):(30-60 g):(12-24 mL). According to the method disclosed by the invention, the edge hydroxylation modified hexagonal layered boron nitride can be obtained, and the method is environmentally friendly, simple in preparation process, low in equipment requirements and applicable to expanded industrial production.

Owner:SICHUAN UNIV

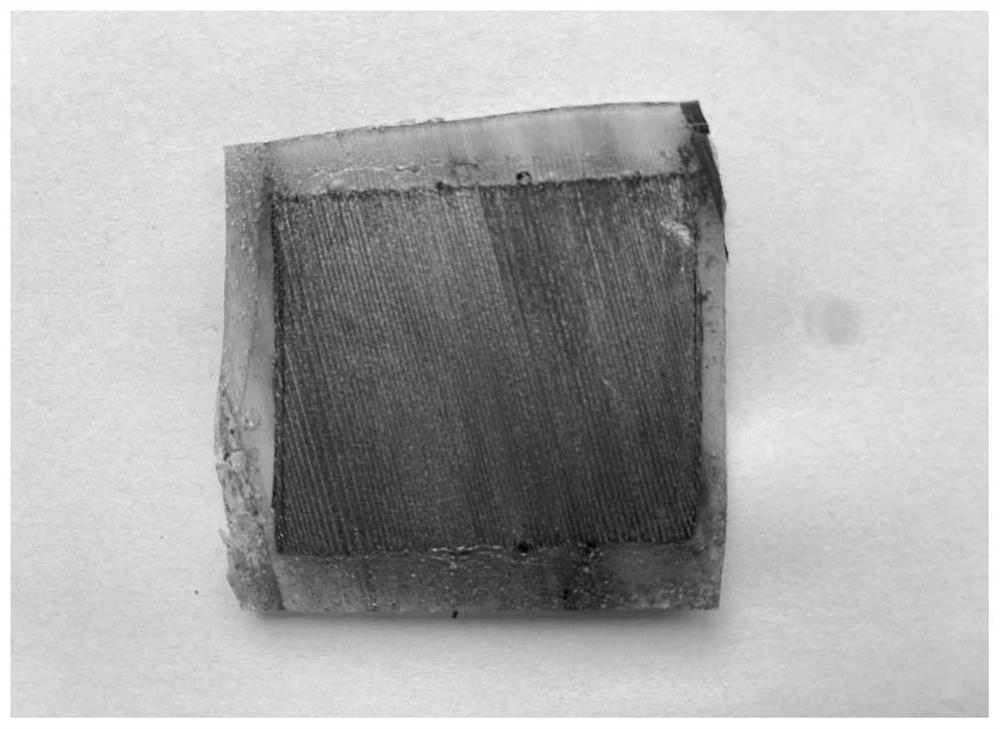

Graphene composite heat-conducting gasket and preparation method thereof

ActiveCN113510979AReduce gum contentImprove reliabilityLamination ancillary operationsLaminationPolymer scienceGraphite

The invention provides a graphene composite heat-conducting gasket which comprises a plurality of layers of graphene foam films arranged in the thickness direction and an adhesive, and the graphene foam films account for 50 wt.%-95 wt.%. The invention also provides a preparation method of the graphene composite heat-conducting gasket, wherein the preparation method comprises the steps: stacking the graphene foam films layer by layer and putting the graphene foam films into a mold, and applying pressure to tightly fit the films; uniformly coating the periphery of the graphene heat-conducting foam films subjected to pressure application with the adhesive, so as to completely coating a plurality of layers of graphene heat-conducting foam films into a block body; after the block body is cured and formed, cutting the block body into sheets along the stacking direction; dipping the cut sheets in dipping glue, taking out the sheets, and carrying out hot press molding on the taken-out sheets; and trimming the edge of the formed sheets, and removing an adhesive bonding area on the edge to obtain the graphene composite heat-conducting gasket. The heat-conducting gasket is low in density, high in heat conductivity in the thickness direction and low in heat resistance.

Owner:CHANGZHOU FUXI TECH CO LTD

High-heat-conduction diamond/copper composite material and manufacturing method of high-heat-conduction diamond/copper composite material

InactiveCN104625077ALower interface thermal resistanceImprove thermal conductivityVacuum evaporation coatingSputtering coatingHeat sinkChromium

The invention discloses a high-heat-conduction diamond / copper composite material and a manufacturing method of the high-heat-conduction diamond / copper composite material, and belongs to the field of heat sink materials. A base material of the composite material is metal copper, and a reinforcement material of the composite material is diamond particles wrapped by titanium or chrome. The manufacturing method of the composite material includes the steps that the surfaces of the diamond particles with different particle diameters are plated with the titanium or the chrome with a magnetron sputtering method, a metal copper sheet is placed on the diamond particles for assembling, and the assembly is loaded into a pyrophylite mold after vacuum heat treatment is carried out; ultrahigh-pressure infiltration sintering is carried out under different-sintering-technology condition, and the high-heat-conduction diamond / copper composite material is manufactured. By means of the high-heat-conduction diamond / copper composite material and the manufacturing method, the problem of graphitization of diamond under the high temperature condition is solved, the density of the manufactured composite material is higher than 99%, the heat conductivity of the composite material is 685 W / (m.K), and the composite material can be used as a heat sink material in the fields of electronic packaging and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Pump-driven two-phase circuit device for heat dissipation of high heat flux electronic device

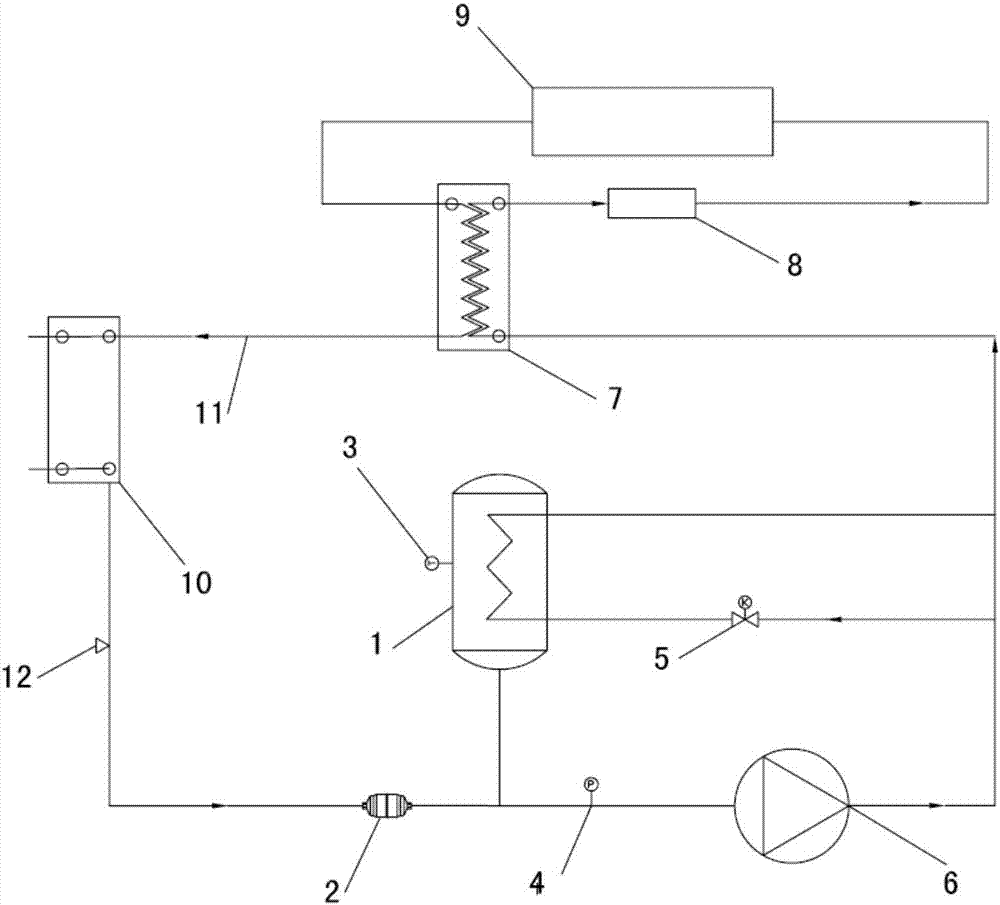

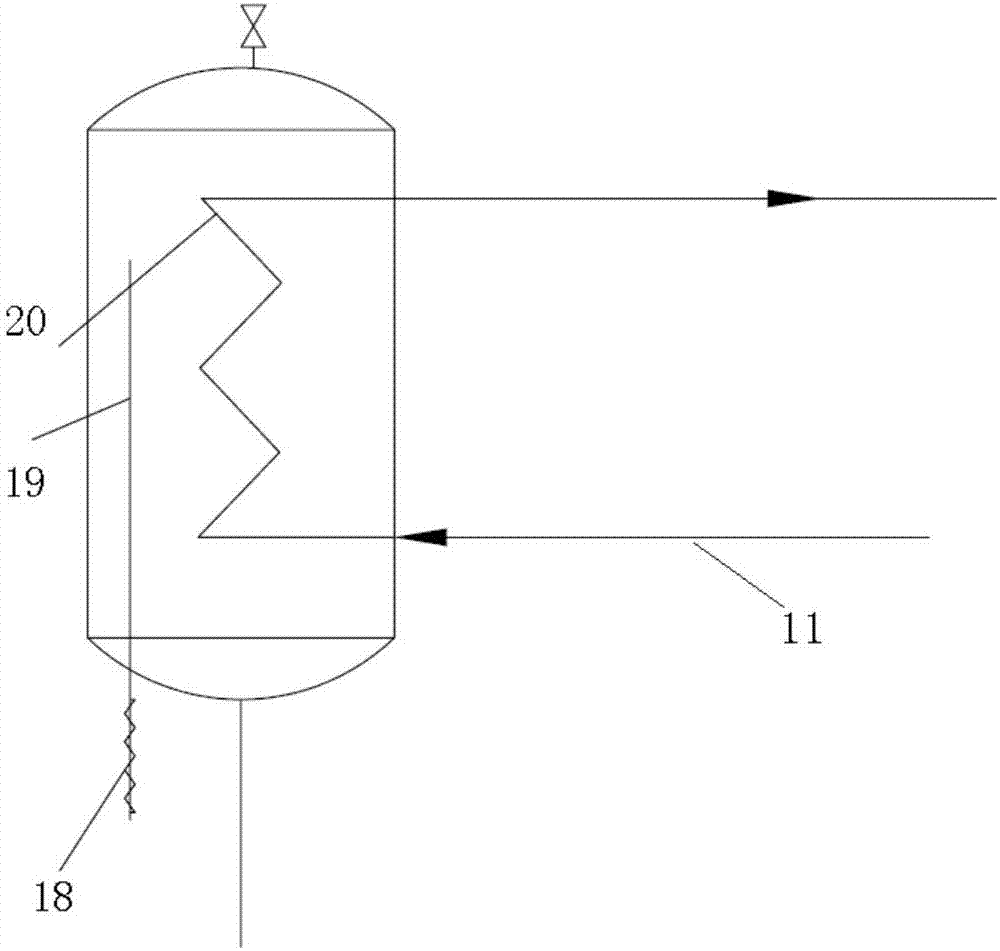

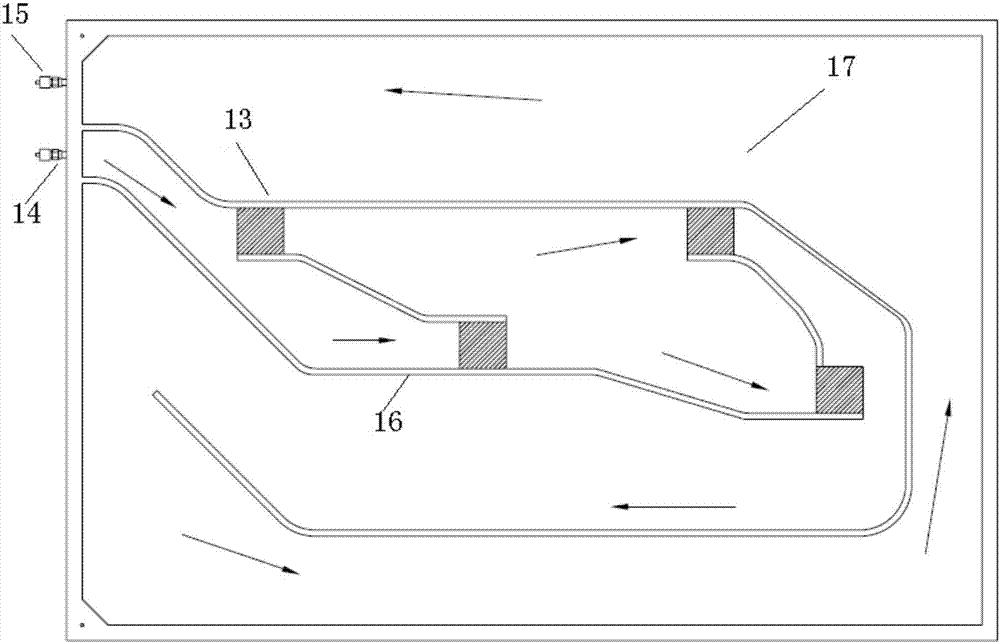

ActiveCN107454797AMeet job needsImprove cooling effectDigital data processing detailsCooling/ventilation/heating modificationsHeat fluxEvaporation

The invention provides a pump-driven two-phase circuit device for heat dissipation of a high heat flux electronic device. Heat is collected and transported by using an endothermic process in evaporation and an exothermic process in condensation during a circulation flow process of a working medium. An evaporator for the circuit device comprises micro-channels and fins. In an area of high heat flux, the micro-channels are used to dissipate heat and increase a heat transfer coefficient of a partial area, while in an area of low heat flux, the fins are used. Due to great area difference between the micro-channel area and the fin area in the evaporator, when the working medium in the micro-channels enters the fin area, volume quickly expands and temperature of the working medium reduces, so as to help heat dissipation of the device in the fin area. By using different structures and with little resources, heat dissipation problems of devices with different powers are solved. The pump-driven two-phase circuit device for heat dissipation of the high heat flux electronic device can adapt to heat dissipation of electronic devices with different heat flux densities and can satisfy working requirements of electronic devices with a heat flux density of 50 W / cm<2> or above.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

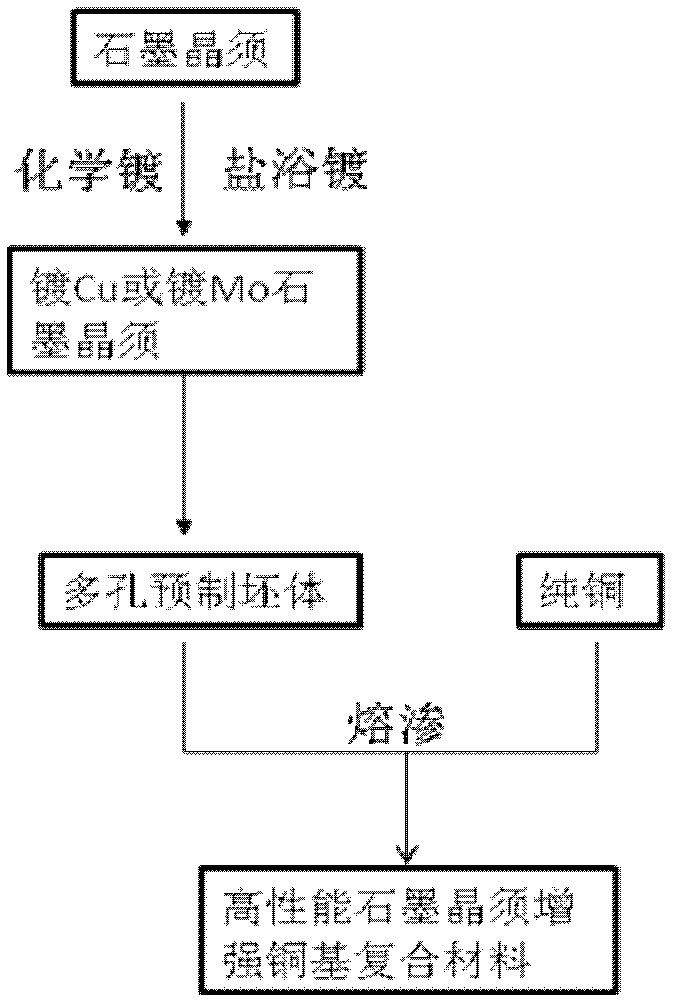

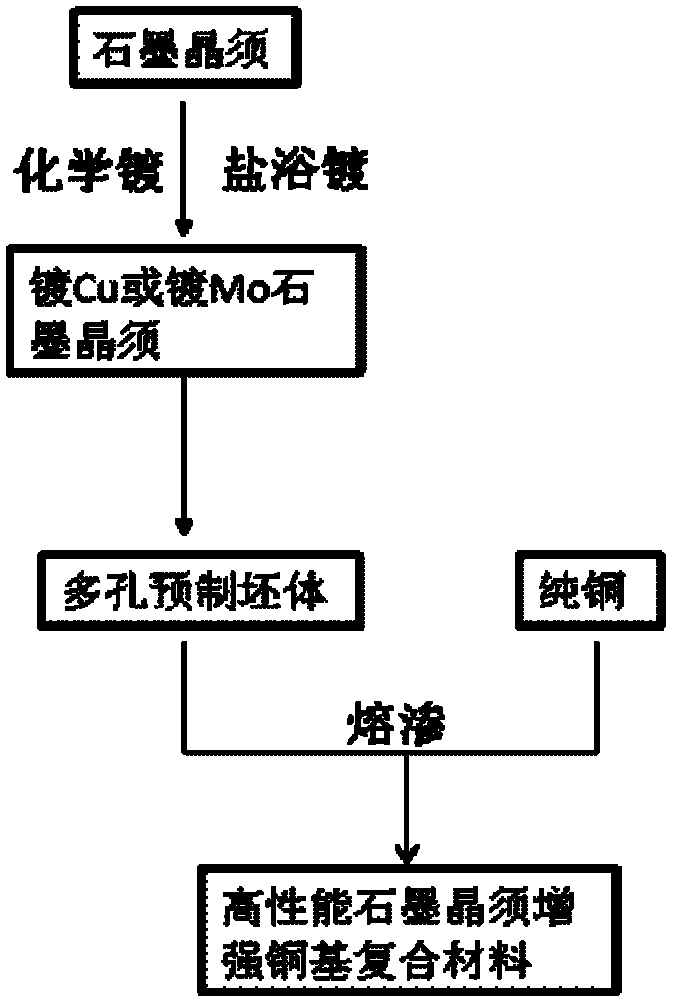

Preparation method of graphite whisker reinforced copper base composite material

InactiveCN102628149AHigh thermal conductivitySmall coefficient of thermal expansionCompression moldingChemical plating

The invention belongs to the research field of metal base composite material and relates to a high heat conductive graphite whisker reinforced copper base composite material and a preparation method thereof. The composite material comprises two parts of a matrix pure copper and a plated reinforcing phase high heat conductive graphite whiskers, wherein a volume fraction of the copper is 40%-65%, and a volume fraction of the plated graphite whisker is 35%-60%. A production process of the composite material comprises the steps of: first, plating copper or molybdenum on a surface of the graphite whisker by a chemical plating or salt bath plating method to form a 0.5-2 mum thick coating; adding a proper amount of binder into the graphite whisker treated with metal plating; carrying out compression molding; removing the binder through thermal debinding to form a porous preform; and finally stacking the preform and the pure copper and placing the two into an infiltration furnace to carry outvacuum pressure infiltration, so as to obtain the final graphite whisker reinforced copper base composite material part.

Owner:UNIV OF SCI & TECH BEIJING

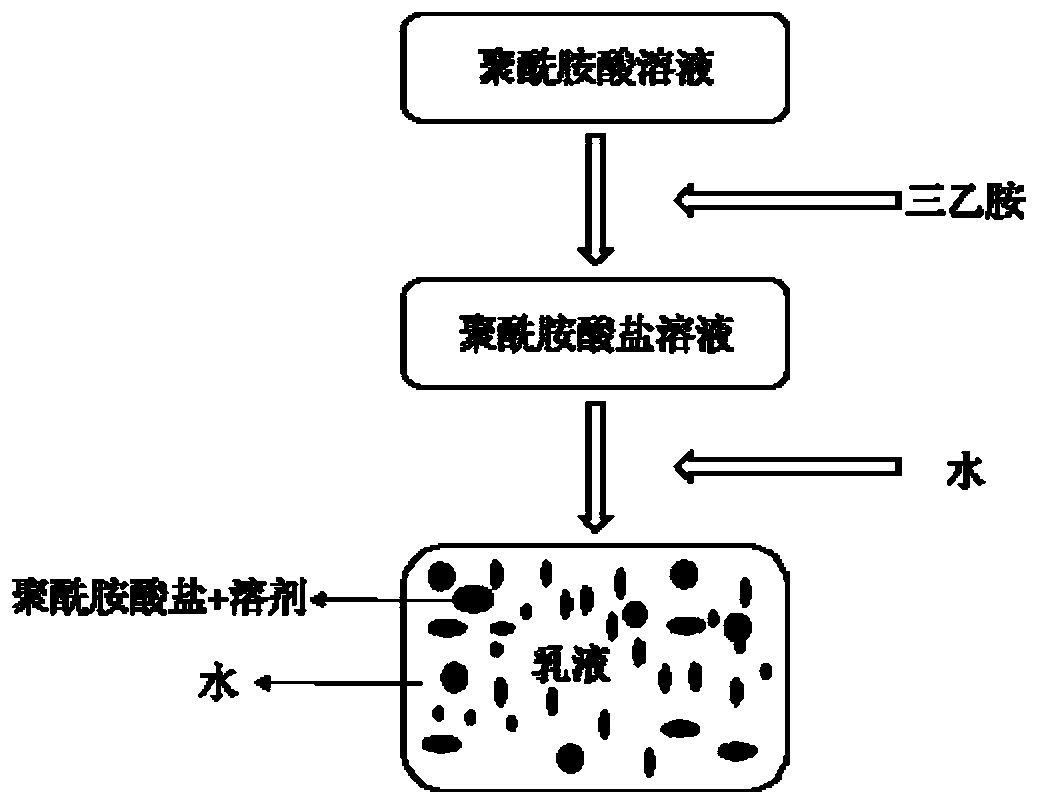

Graphene/polyimide heat-conduction film and preparation method thereof

InactiveCN111378191ASmall sizeLower interface thermal resistanceHeat-exchange elementsPolymer scienceHigh volume manufacturing

The embodiment of the invention provides a graphene / polyimide heat-conduction film and a preparation method thereof, which relate to the field of graphene. The preparation method of the graphene / polyimide heat conduction film mainly comprises the following steps: adding a polyamic acid nano-emulsion taking water as a medium into a graphene dispersion liquid taking water as a medium, and stirring to obtain graphene / polyamic acid composite slurry; and sequentially carrying out self-assembly film formation, imidization, carbonization and graphitization on the graphene / polyamic acid composite slurry. The preparation method is low in cost, environmentally friendly and suitable for mass production, the interface thermal resistance between graphene sheets in the heat conduction film can be reduced, and the heat conductivity is improved.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

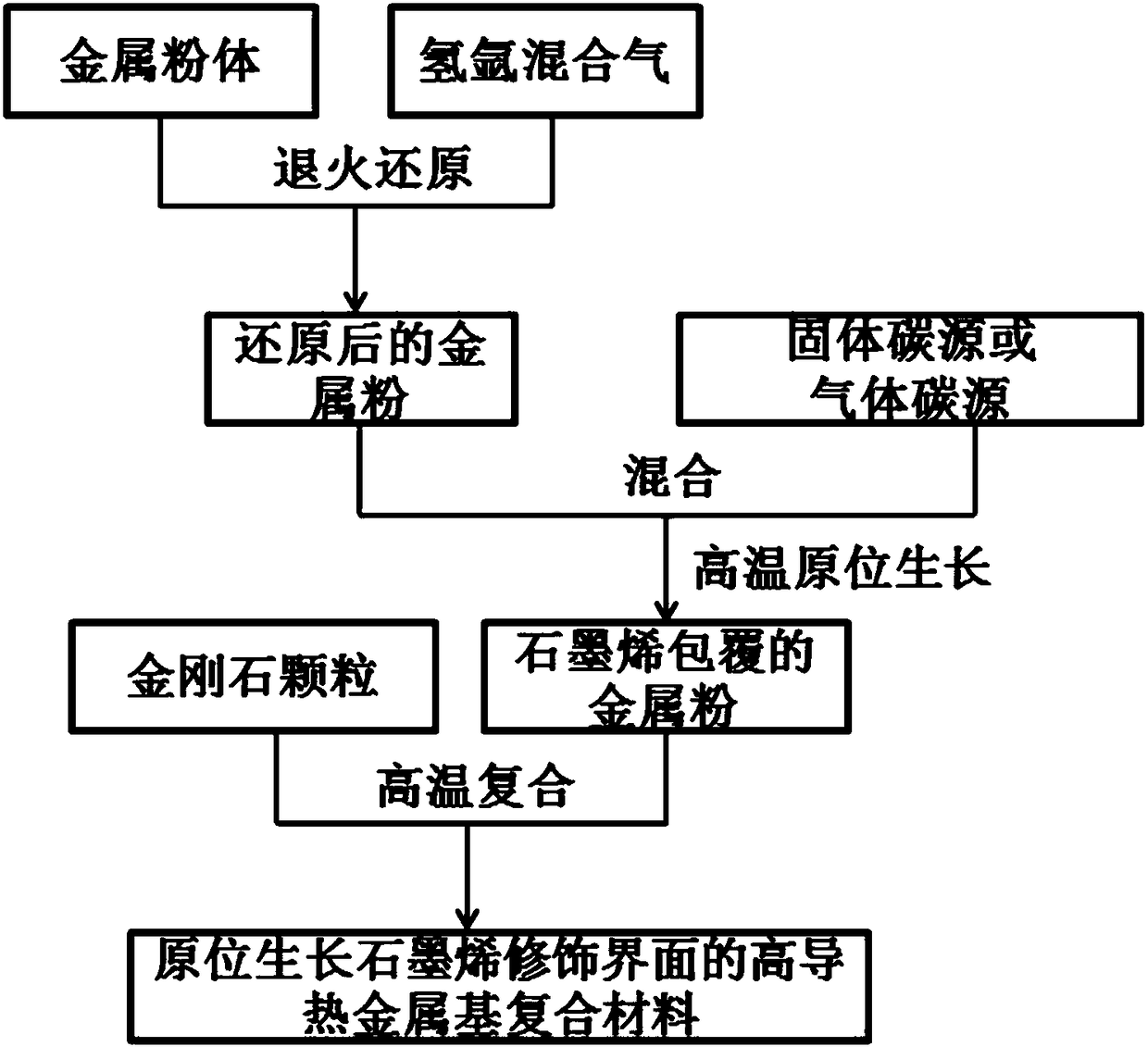

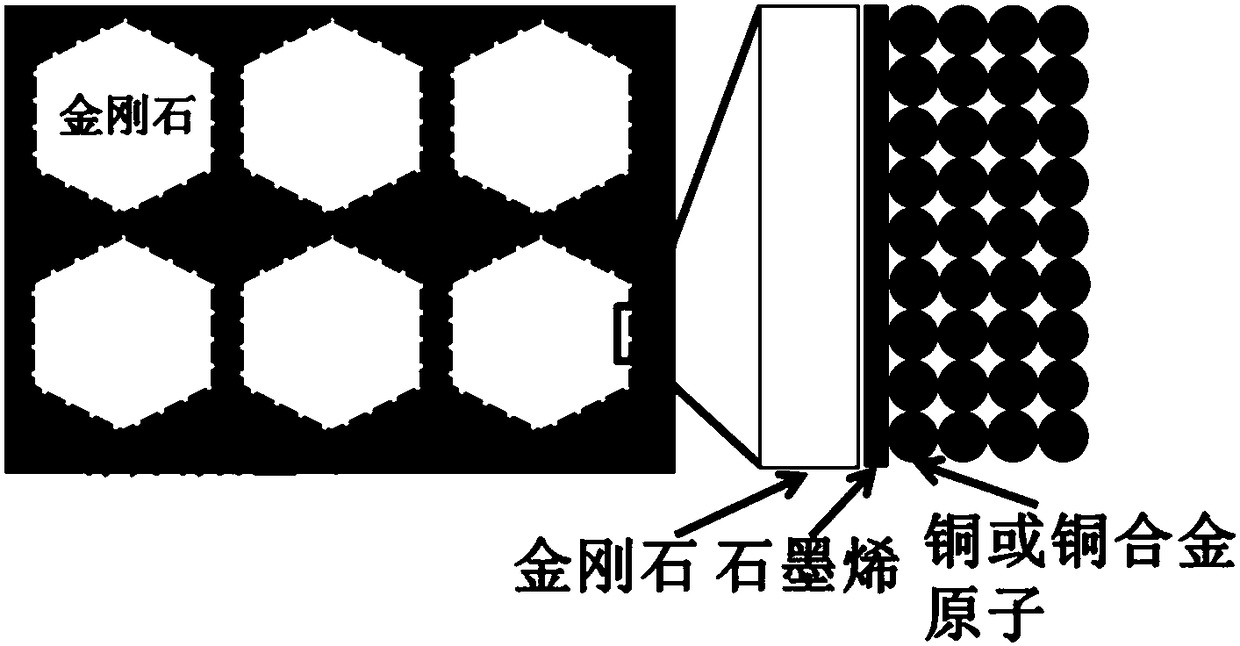

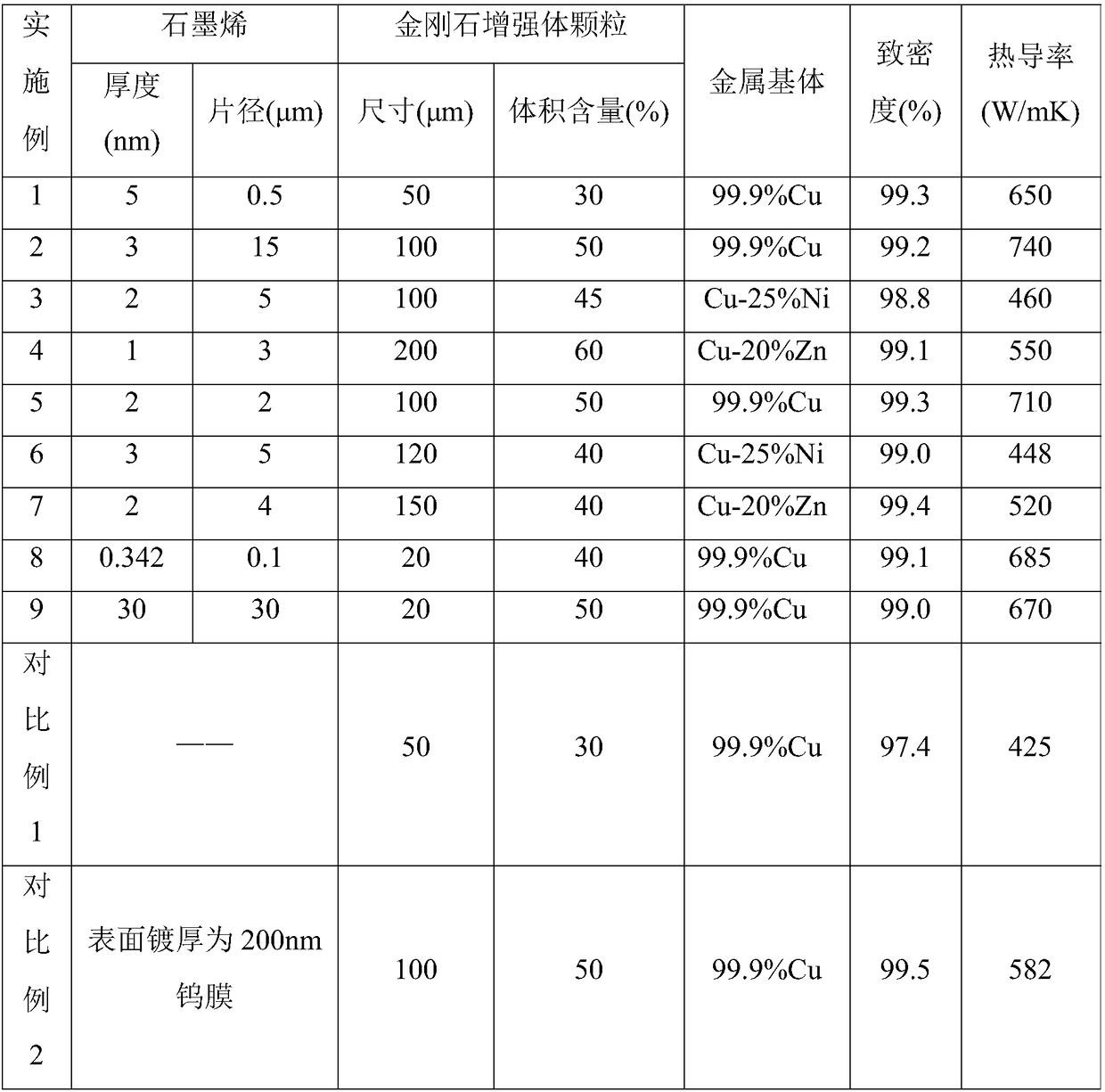

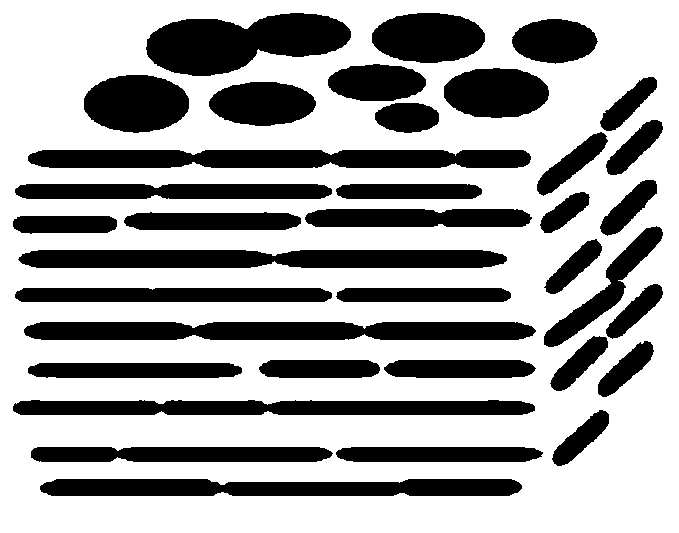

High-thermal-conductivity metal-based composite material with graphene-modified interface and preparation method thereof

InactiveCN108588529AImprove thermal conductivityThickness is easy to controlTransportation and packagingMetal-working apparatusSolid carbonHydrogen atmosphere

The invention provides a high-thermal-conductivity metal-based composite material with a graphene-modified interface and a preparation method of the high-thermal-conductivity metal-based composite material. The high-thermal-conductivity metal-based composite material with the graphene-modified interface comprises diamond and graphene-modified metal powder. The preparation method comprises the following steps that 1, annealing reduction is carried out on the metal powder so as to remove oxides on the surface; 2, the metal powder subjected to annealing reduction is coated with a solid carbon source or a gas carbon source, and high-temperature in-situ growth is carried out under the protection of hydrogen atmosphere to obtain graphene-coated metal powder; and 3, the graphene-coated metal powder is mixed with the diamond, and the high-thermal-conductivity metal-based composite material with the graphene-modified interface is prepared through hot-pressing sintering. According to the preparation method, the interface wettability between the metal matrix and the diamond particles is effectively improved, and the thermal resistance of the interface is reduced; and the high-thermal-conductivity graphene is introduced, so that the heat conductivity of the composite material is improved; and the high-thermal-conductivity metal-based composite material can be used as a material for the thermal management of a high-power-density device.

Owner:SHANGHAI JIAO TONG UNIV

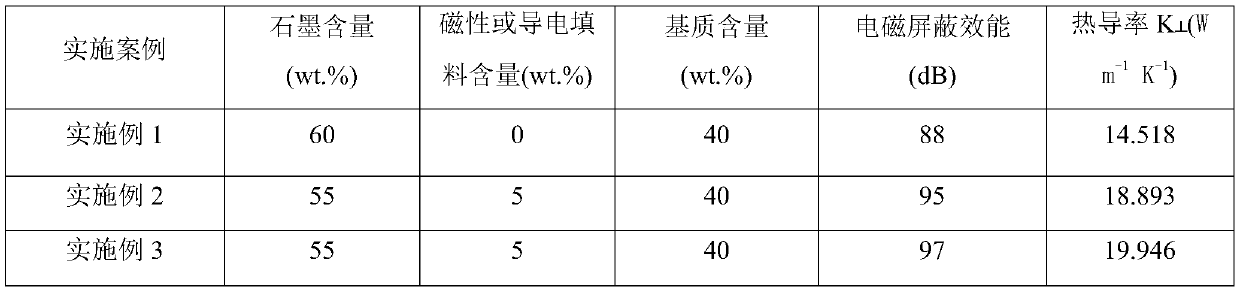

Heat-conducting electromagnetic shielding material with orientation structure and preparation method thereof

ActiveCN111267434AReduce contact resistanceEnhanced interactionMagnetic/electric field screeningSynthetic resin layered productsMagnetic shieldElectromagnetic wave interference

The invention relates to a heat-conducting electromagnetic shielding material with an orientation structure and a preparation method thereof, and particularly discloses a heat-conducting electromagnetic shielding material with a vertical orientation structure. The vertical orientation structure is a laminated sheet material, the sheet material takes a thermoplastic polymer as a matrix, and the matrix contains a filler; the filler is a combination of a heat-conducting filler and a conductive filler, a combination of the heat-conducting filler and a magnetic filler, or a combination of the heat-conducting filler, the conductive filler and the magnetic filler. Electromagnetic wave interference can be effectively reduced, the electromagnetic shielding performance of the material is remarkablyimproved, high anisotropic heat conductivity is achieved, and the purposes of high electric conductivity, high electromagnetic shielding efficiency and high heat conductivity of the composite materialare achieved.

Owner:SHENZHEN INST OF ADVANCED TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com