High-thermal-conductivity metal-based composite material with graphene-modified interface and preparation method thereof

A composite material and graphene technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of large interface thermal resistance, low interface layer thermal conductivity, and large difference in theoretical values, so as to improve thermal conductivity, The effect of adjusting the interface thickness and interfacial thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

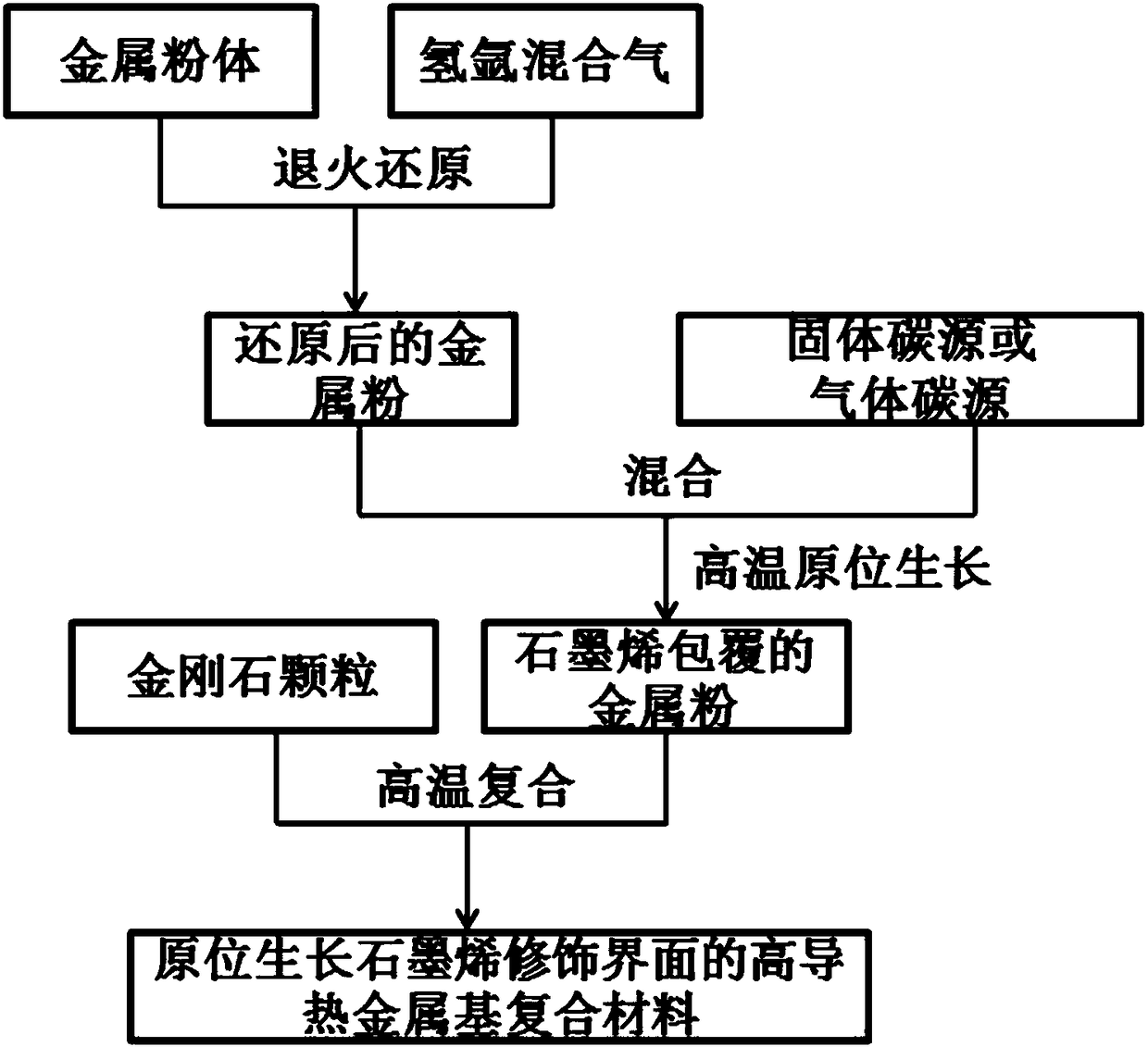

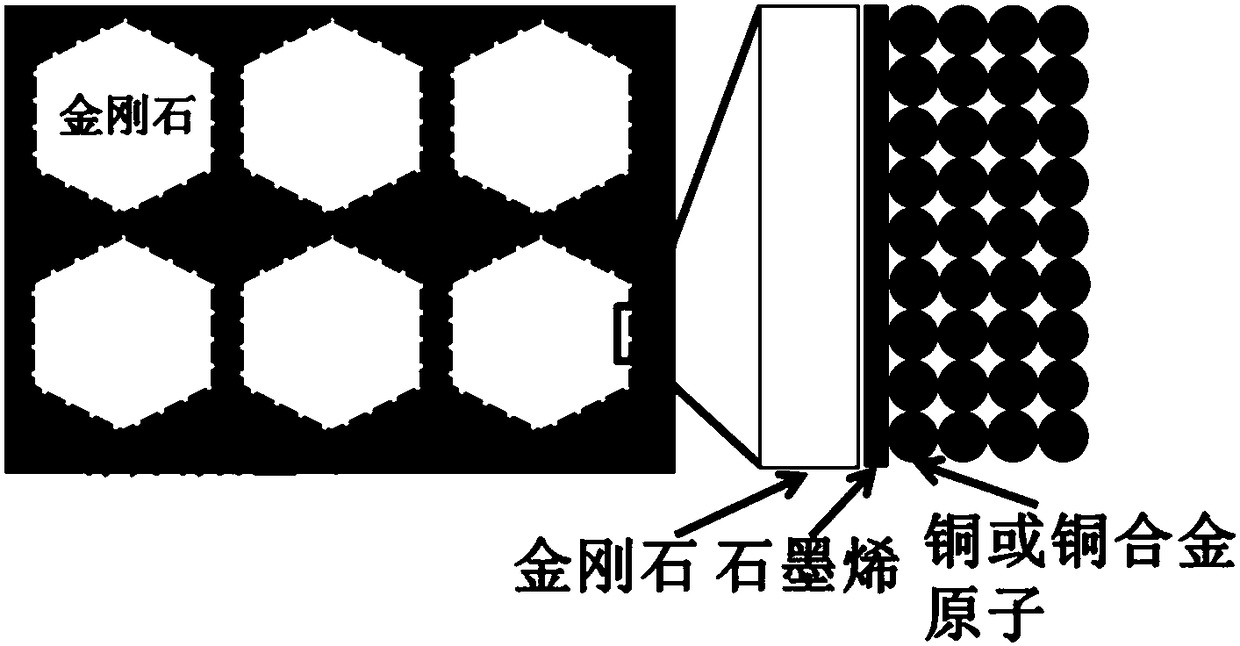

[0042] Such as figure 1 As shown, the preparation method of the high thermal conductivity metal matrix composite material of the graphene modified interface of the present invention specifically includes the following steps:

[0043] (1) First, the metal powder matrix is annealed and reduced to remove oxides on the surface;

[0044] (2) Coating the annealed and reduced metal powder with a solid carbon source or a gaseous carbon source, and growing in situ at a high temperature under the protection of a hydrogen atmosphere to obtain a graphene-coated metal powder;

[0045] (3) The graphene-coated and modified metal powder matrix is mixed with diamond, and sintered by hot pressing to prepare a high thermal conductivity metal matrix composite material with a graphene-modified interface.

[0046] The present invention is explained in detail by following embodiment:

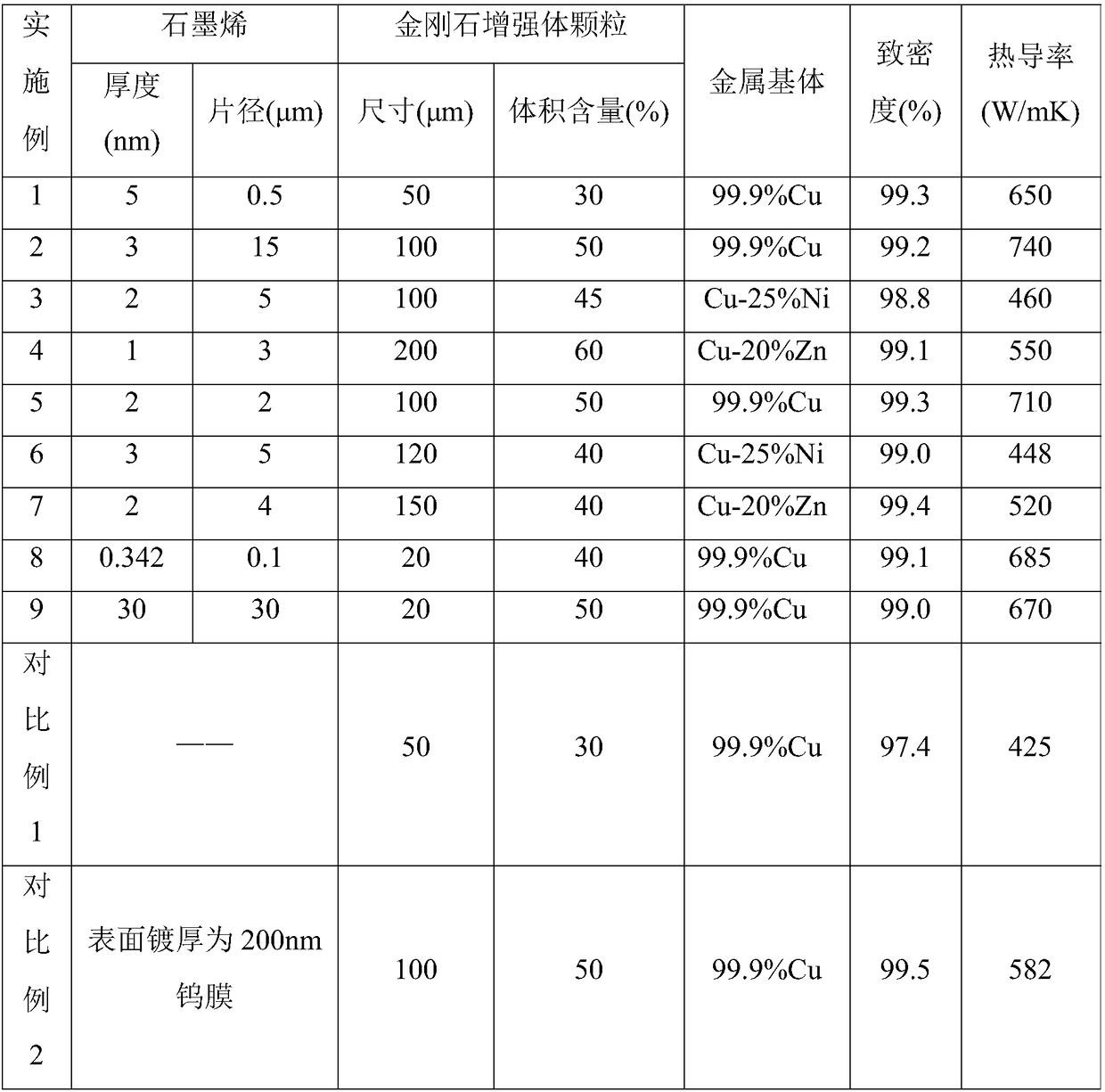

Embodiment 1

[0048] The pure copper powder with a particle size of 70 μm and a purity of 99.9% was annealed at 450 °C for 2 hours in a hydrogen-argon gas mixture, and 30 g of the annealed and reduced pure copper powder was added to a PMMA (1.25 g)-250 mL anisole (250 mL) solution , after mechanical stirring and mixing for 4 hours, centrifuge at 4000 rpm for 7 minutes, remove the lower layer of powder, dry at 80 ° C, put the coated copper powder in a crucible, and put it in a tube furnace Access to H 2 (200sccm) and Ar (300sccm) protective gas. The temperature in the furnace was raised to 900°C within 1.5 hours, held for 1 hour, and then rapidly cooled to room temperature in a hydrogen-argon mixture atmosphere to obtain in-situ grown graphene-modified copper powder; Particles (0.395 g) were mixed with graphene-modified copper powder (2.346 g). Hot press sintering, sintering at 900 ° C for 1 hour, the pressure is 50Mpa, the high thermal conductivity diamond-reinforced copper composite mate...

Embodiment 2

[0051] The pure copper powder with a particle size of 70 μm and a purity of 99.9% was annealed at 450°C for 2 hours in a hydrogen-argon gas mixture, and 30 g of the annealed and reduced pure copper powder was added to a PMMA (2.5 g)-250 mL anisole (250 mL) solution , after mechanical stirring and mixing for 4 hours, centrifuge at 4000 rpm for 7 minutes, remove the lower layer of powder, dry at 80 ° C, put the coated copper powder in a crucible, and put it in a tube furnace Access to H 2 (100sccm) and Ar (400sccm) protective gas. The temperature in the furnace was raised to 900°C within 1.5 hours, kept for 1 hour, and then rapidly cooled to room temperature in a hydrogen-argon mixture atmosphere to obtain in-situ grown graphene-modified copper powder; diamond particles with a particle size of 100 μm and a volume fraction of 50% (0.658g) mixed with graphene-modified copper powder (1.676g), hot-pressed and sintered, sintered at 920 ° C for 1 hour, and the pressure was 60 MPa to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com