Patents

Literature

36results about How to "Effective control of thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

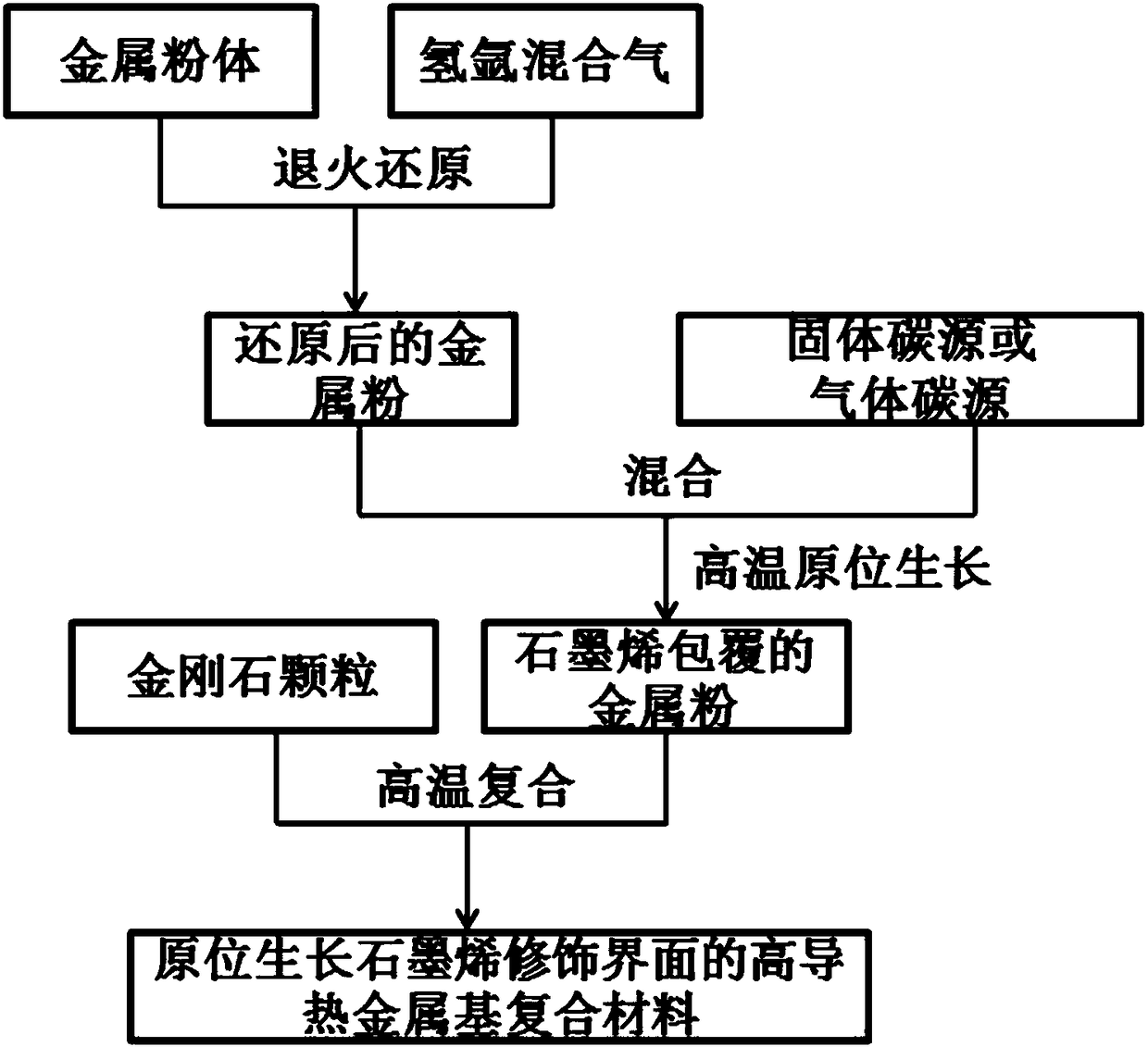

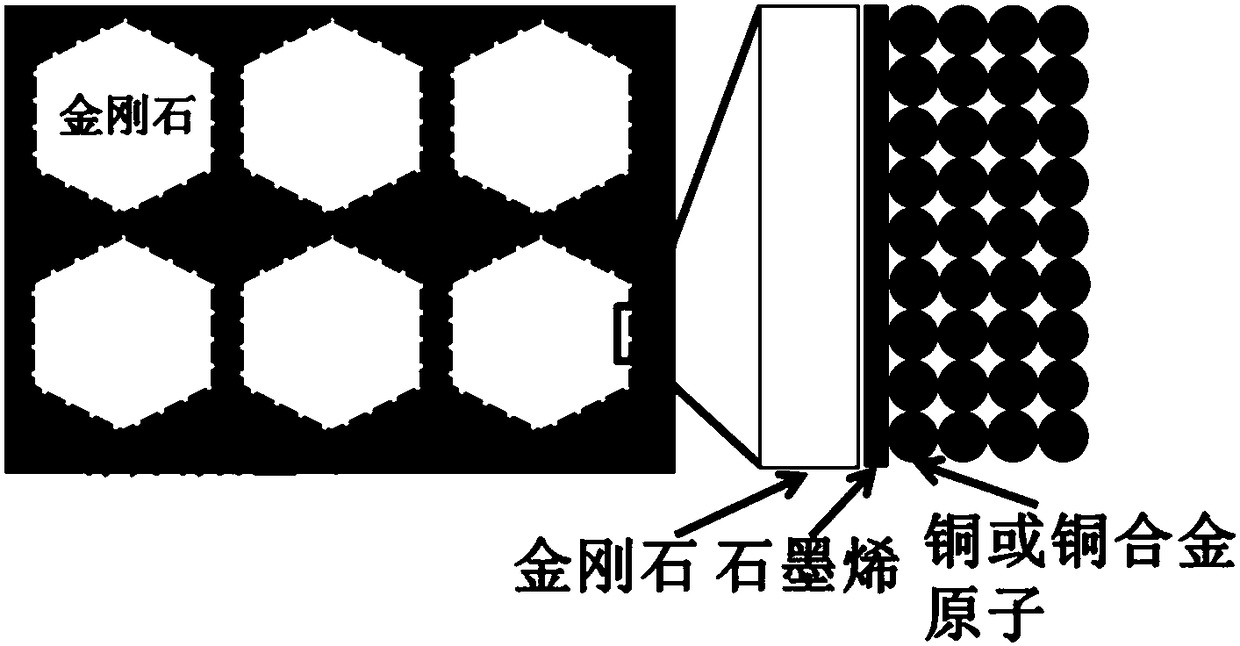

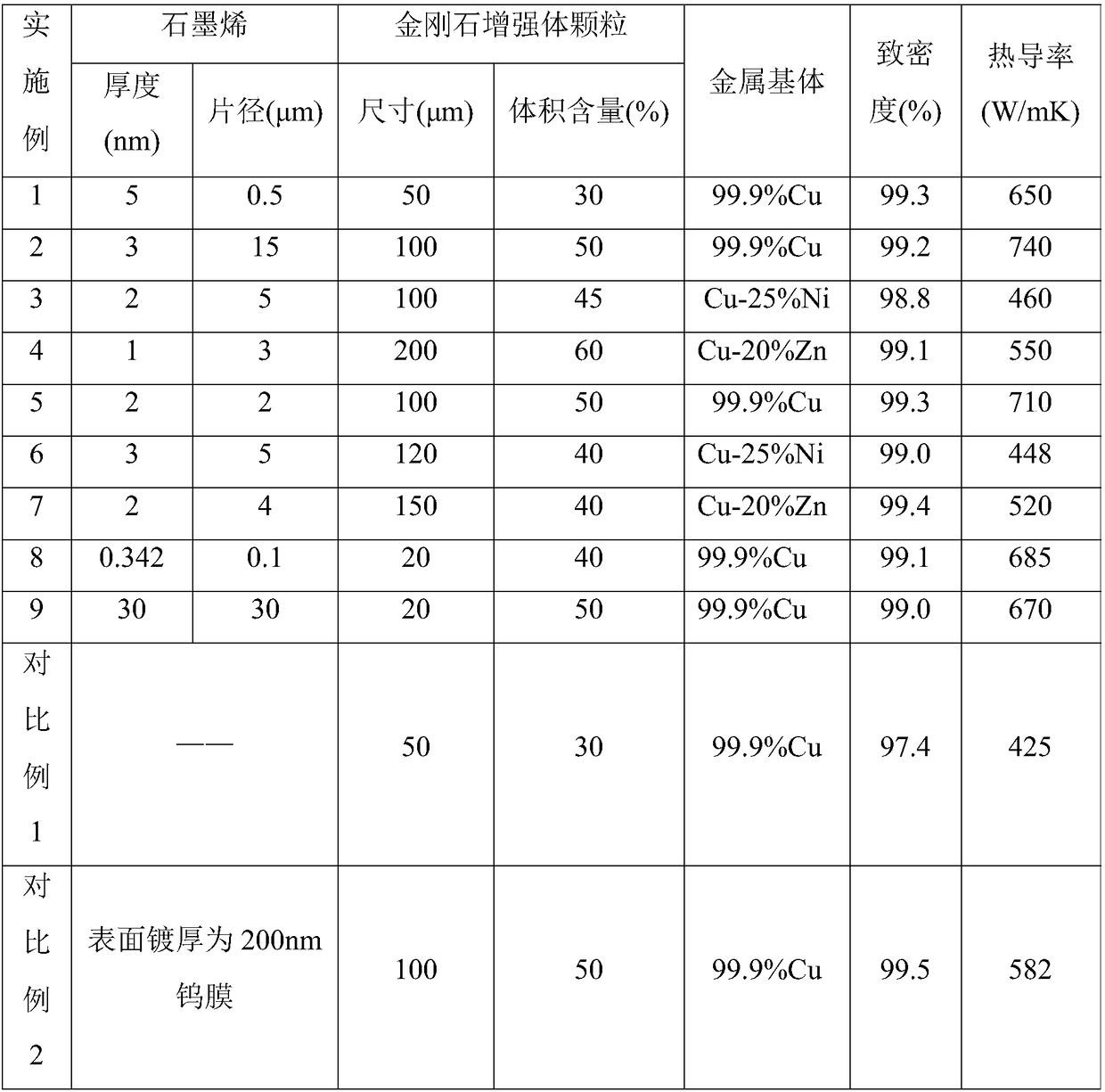

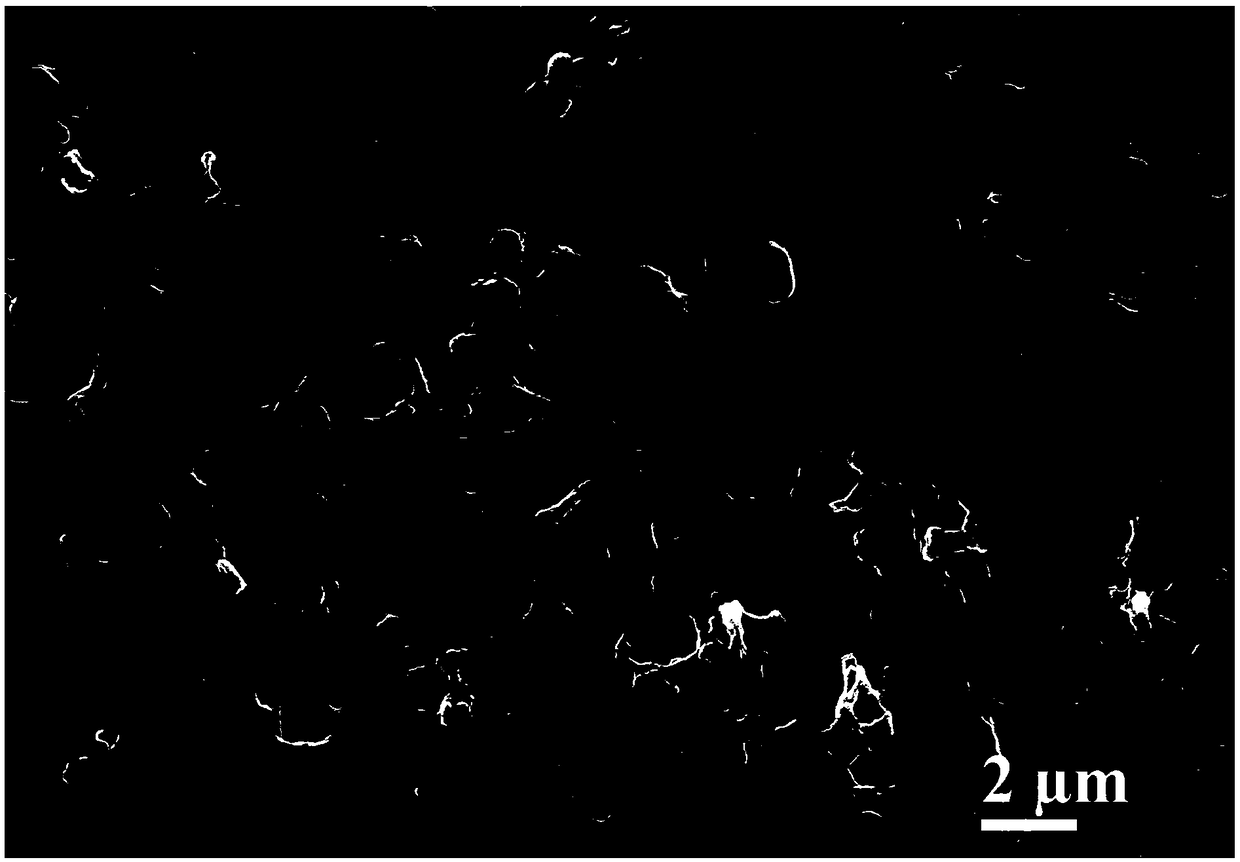

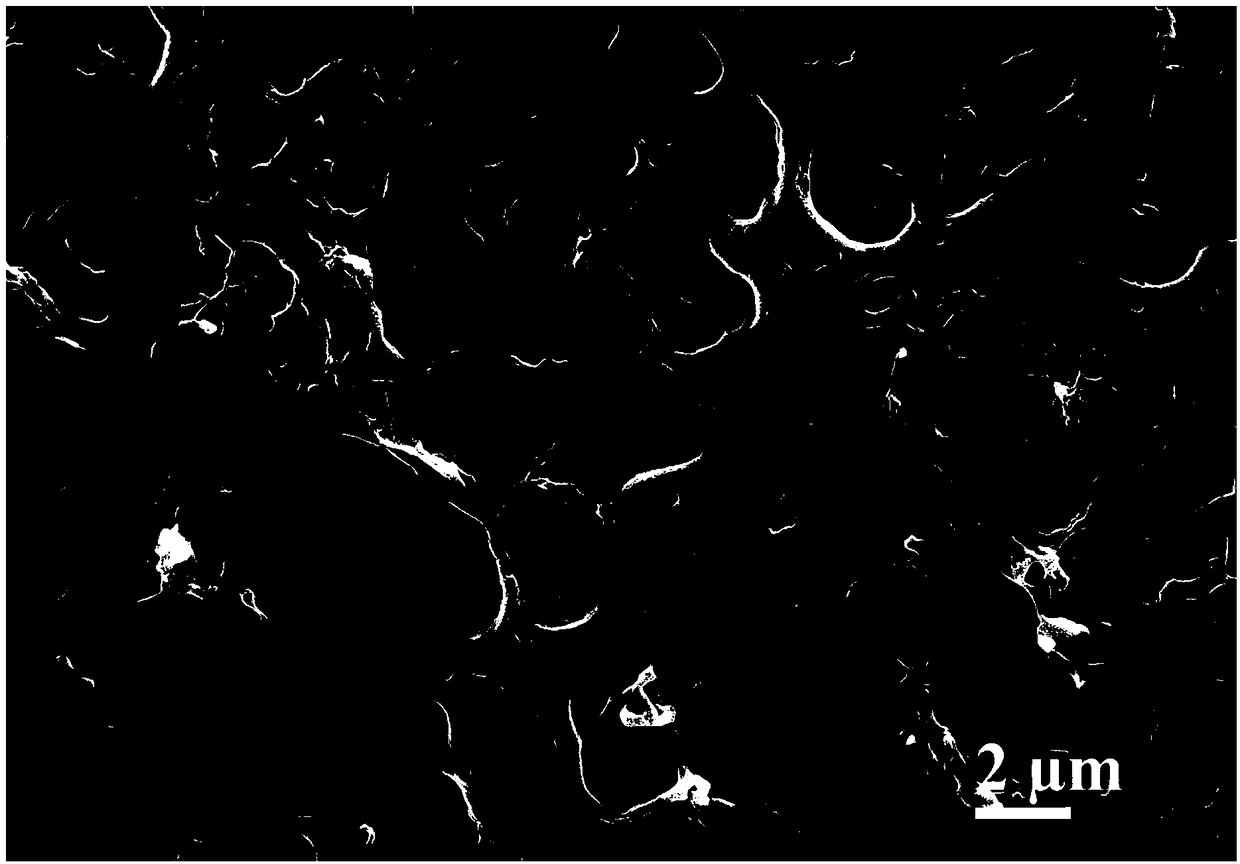

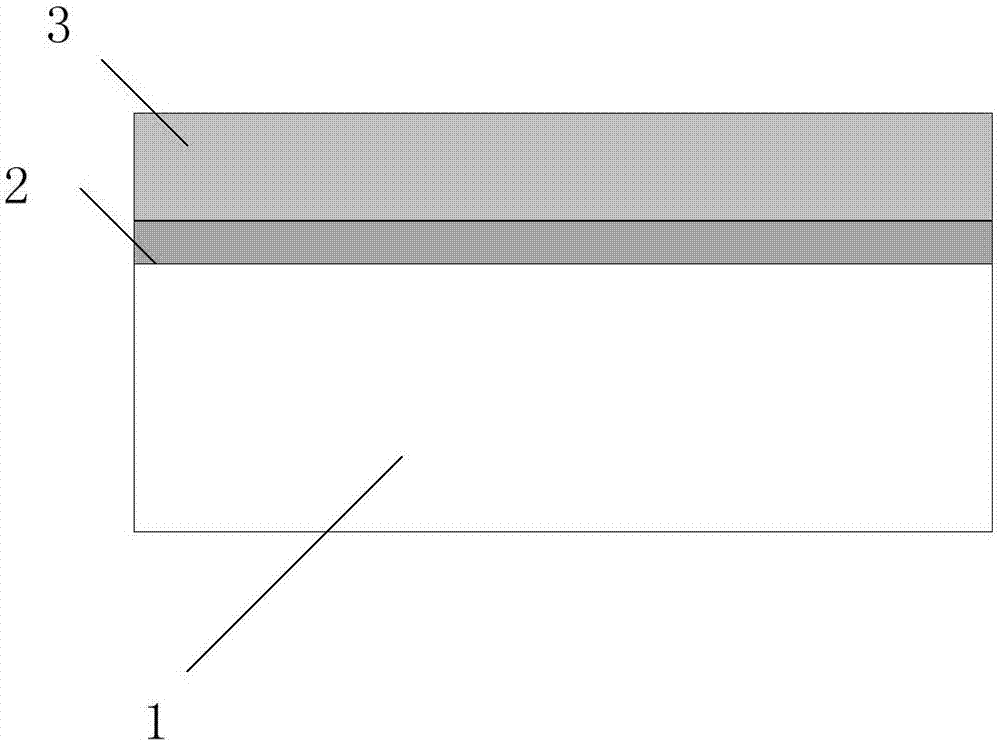

High-thermal-conductivity metal-based composite material with graphene-modified interface and preparation method thereof

InactiveCN108588529AImprove thermal conductivityThickness is easy to controlTransportation and packagingMetal-working apparatusSolid carbonHydrogen atmosphere

The invention provides a high-thermal-conductivity metal-based composite material with a graphene-modified interface and a preparation method of the high-thermal-conductivity metal-based composite material. The high-thermal-conductivity metal-based composite material with the graphene-modified interface comprises diamond and graphene-modified metal powder. The preparation method comprises the following steps that 1, annealing reduction is carried out on the metal powder so as to remove oxides on the surface; 2, the metal powder subjected to annealing reduction is coated with a solid carbon source or a gas carbon source, and high-temperature in-situ growth is carried out under the protection of hydrogen atmosphere to obtain graphene-coated metal powder; and 3, the graphene-coated metal powder is mixed with the diamond, and the high-thermal-conductivity metal-based composite material with the graphene-modified interface is prepared through hot-pressing sintering. According to the preparation method, the interface wettability between the metal matrix and the diamond particles is effectively improved, and the thermal resistance of the interface is reduced; and the high-thermal-conductivity graphene is introduced, so that the heat conductivity of the composite material is improved; and the high-thermal-conductivity metal-based composite material can be used as a material for the thermal management of a high-power-density device.

Owner:SHANGHAI JIAO TONG UNIV

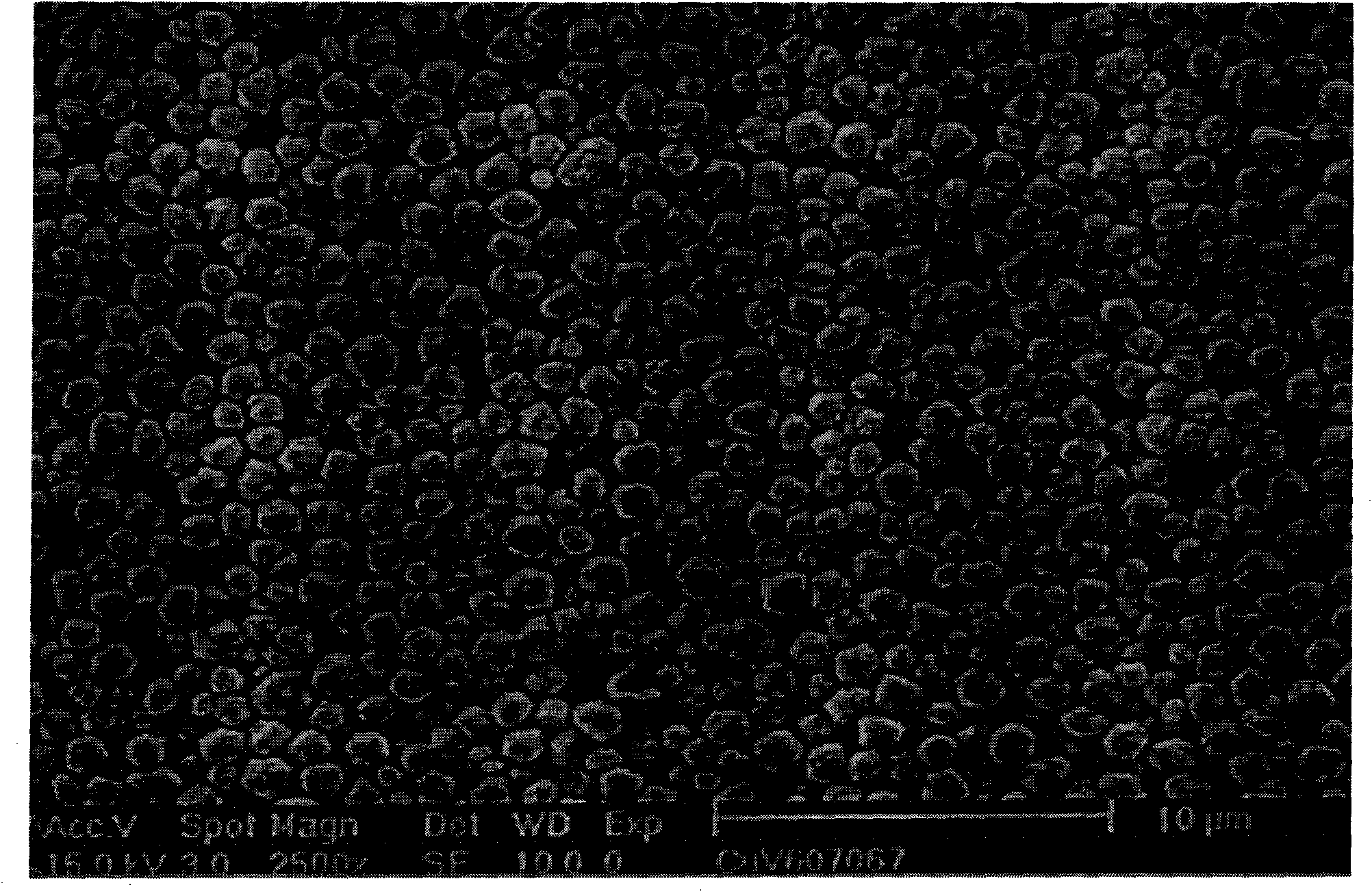

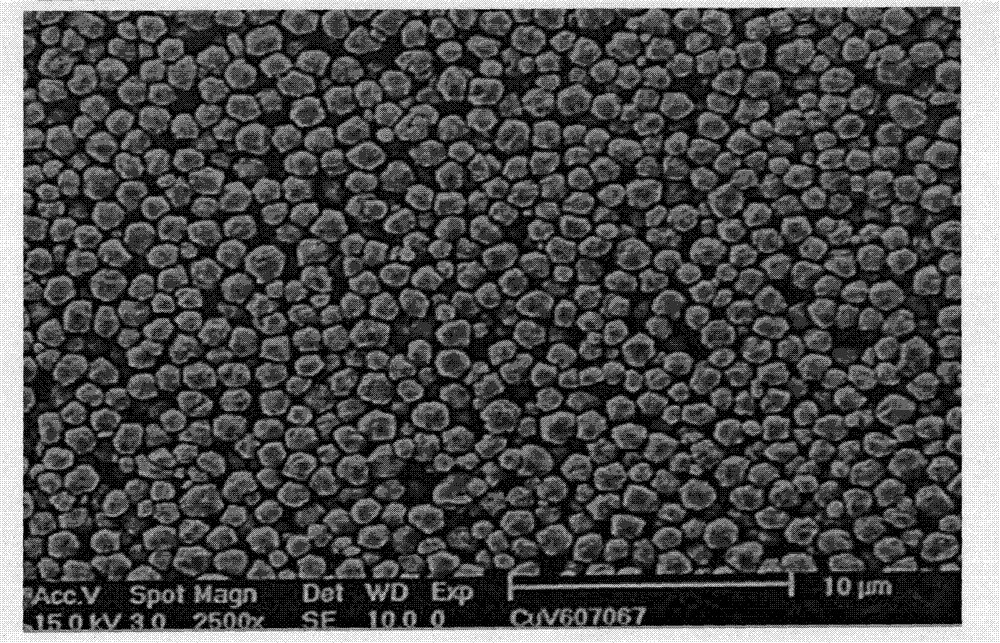

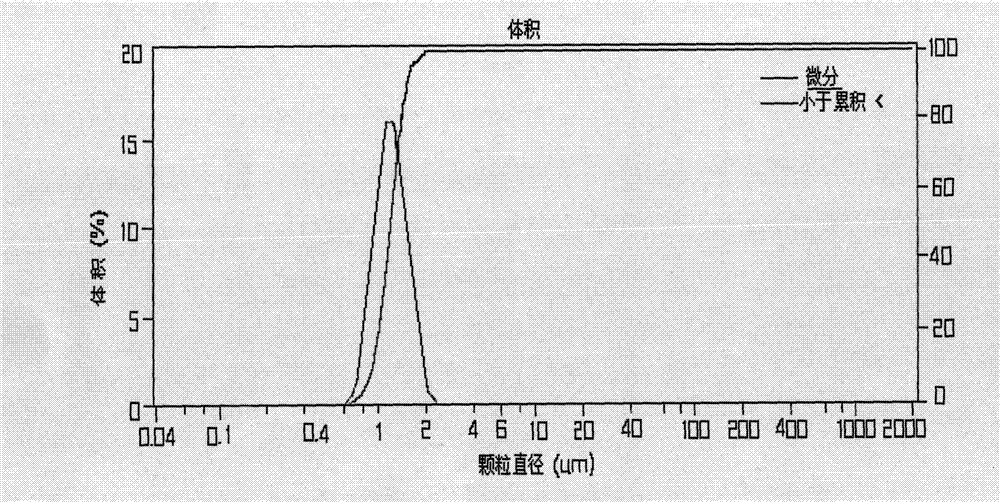

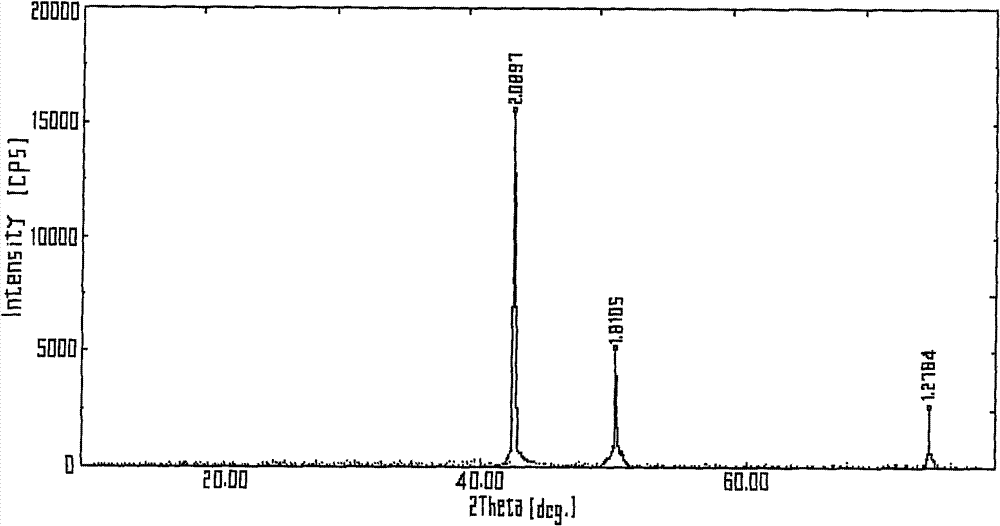

Method for preparing high-inoxidability sphere-like copper powder

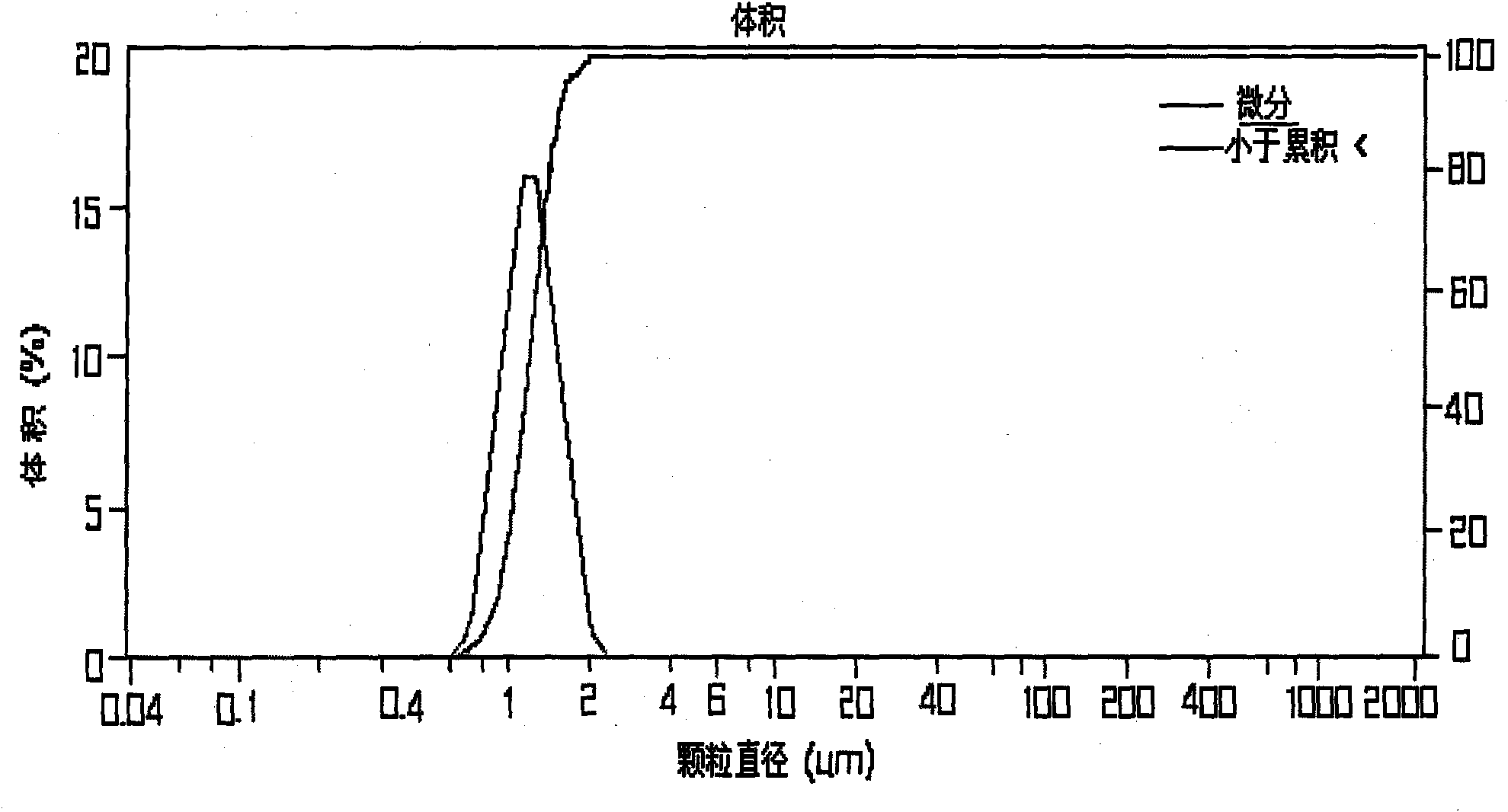

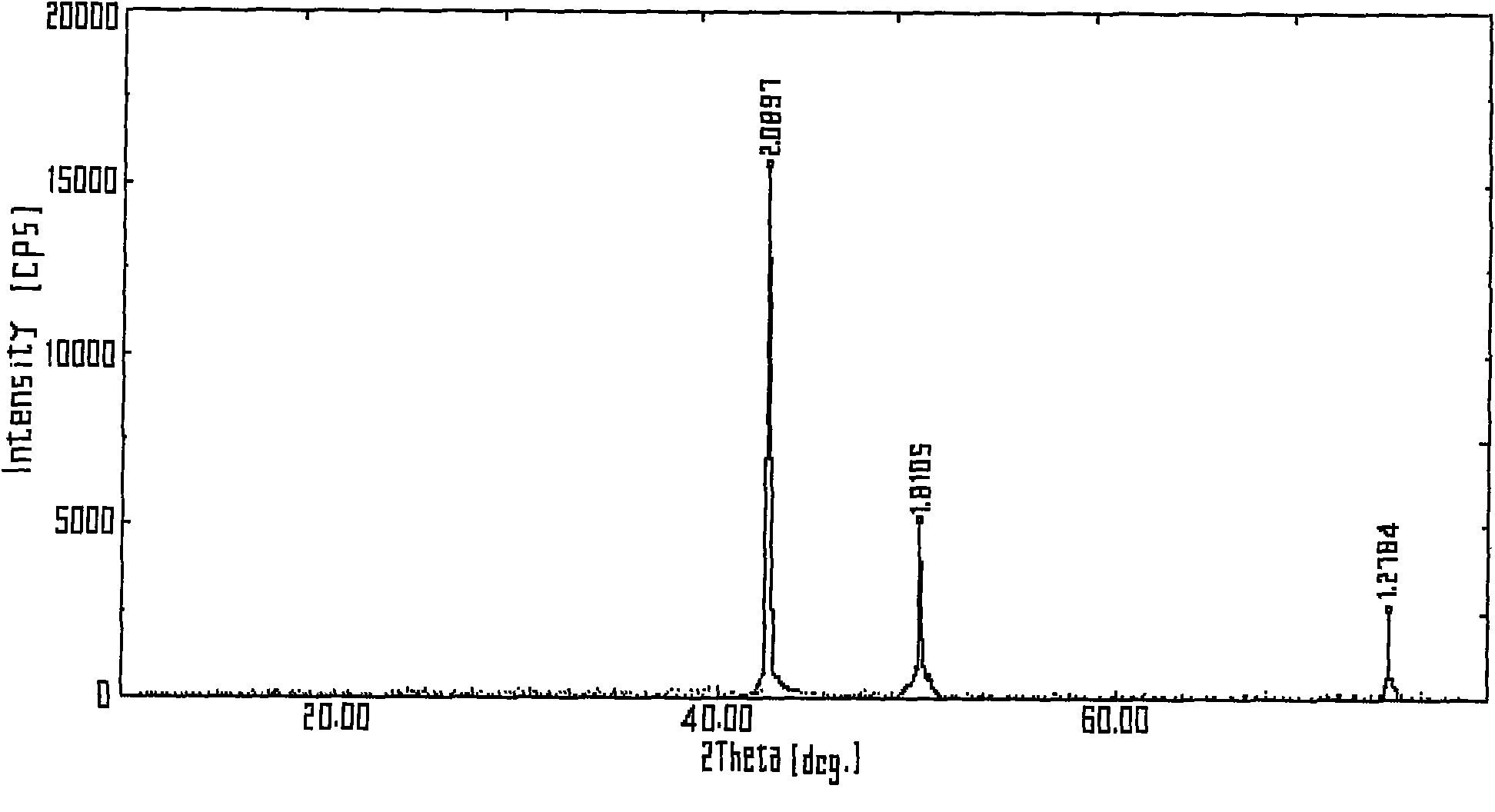

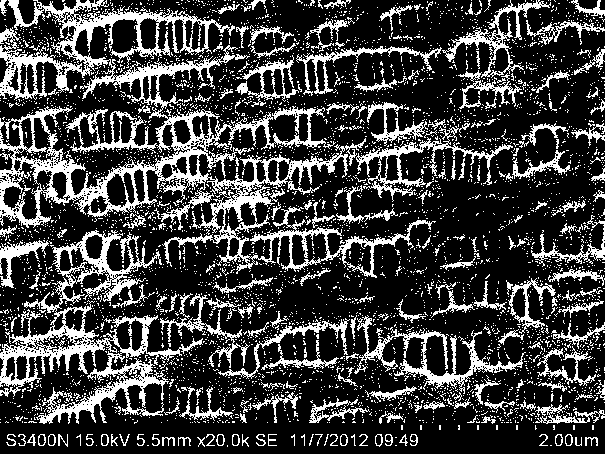

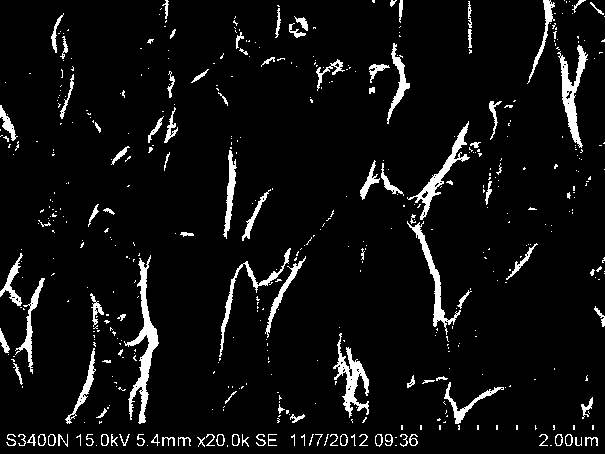

The invention discloses a method for preparing high-inoxidability sphere-like copper powder, which comprises the steps of reduction reaction, washing, surface chemical treatment and drying treatment, wherein the reduction reaction is to dissolve a reducing agent and a copperish initiator material into solvent and perform the reduction reaction under the action of an auxiliary agent, the reaction temperature is between 40 and 100 DEG C, and the reduction reaction time is between 2 and 5 hours. The reducing agent is vitamin C (C6H806, Vc,). The copperish initiator material is a substance which can be ionized into Cu2+ in aqueous solution and comprises one or several of hydrated copper sulfate, hydrated copper nitrate and hydrated copper chloride; the solvent is deionized water; and the auxiliary agent comprises an inorganic salt or an alkaline substance for adjusting the pH value and a water soluble polymer material for a surfactant. The obtained copper powder has the advantages of good dispersity, no agglomeration, small specific area, high tap density, controllable granule size, narrow grain size distribution range, and strong antioxygenic property.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

High-thermal conductivity eggshell type catalyst carrier and preparation method and application

ActiveCN104001556AHigh heat transfer efficiencySuitable for mass productionCatalyst carriersHydrocarbon from carbon oxidesThermal conductivityCorrosion

The invention relates to a high-thermal conductivity eggshell type catalyst carrier which is a metal ball, wherein the range of the average particle diameter of the metal ball is 1 to 5 mm, the specific surface area is 70 to 600 m<2> / g, the average pore diameter is 4 to 60 nm, the pore volume is 0.25 to 2.00 cm<3> / g, the thickness of a corrosion layer of the metal ball is 0.05 to 0.25 mm, and the corrosion layer is made of metal oxides. The high-thermal conductivity eggshell type catalyst carrier has the advantages of simplicity in preparation and controllable thickness of a shell layer and is suitable for large-scale industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

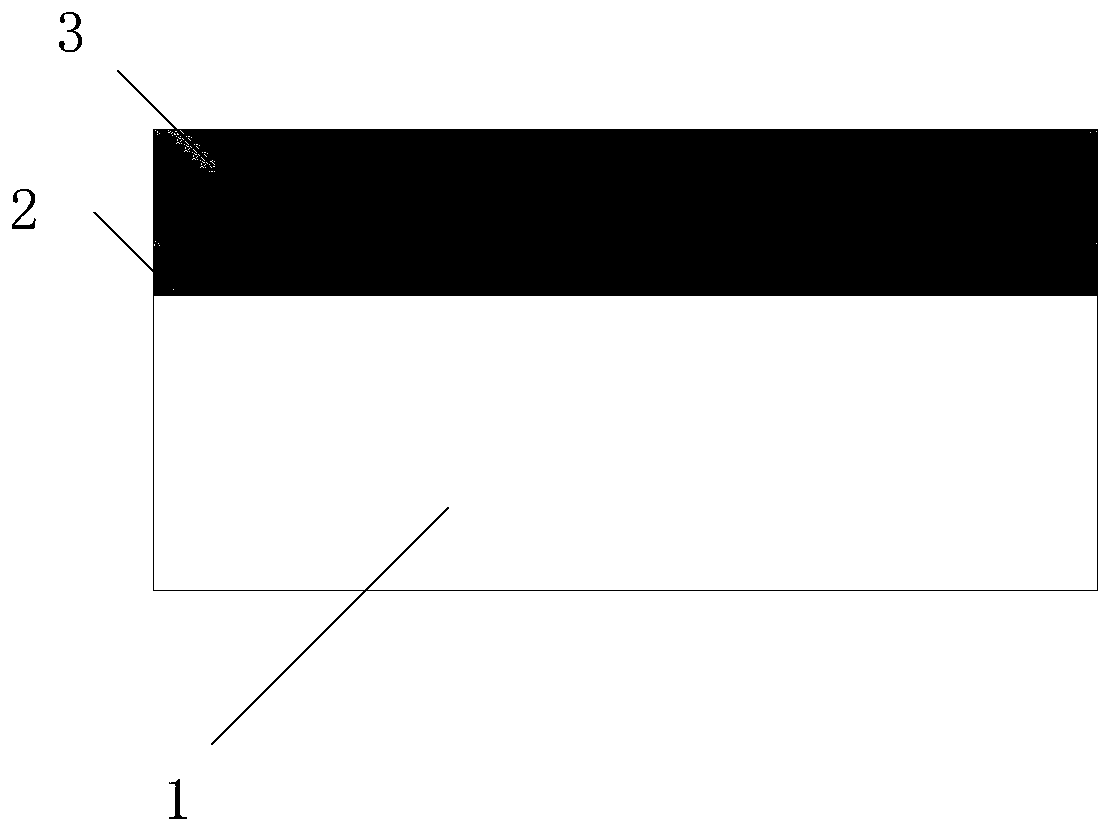

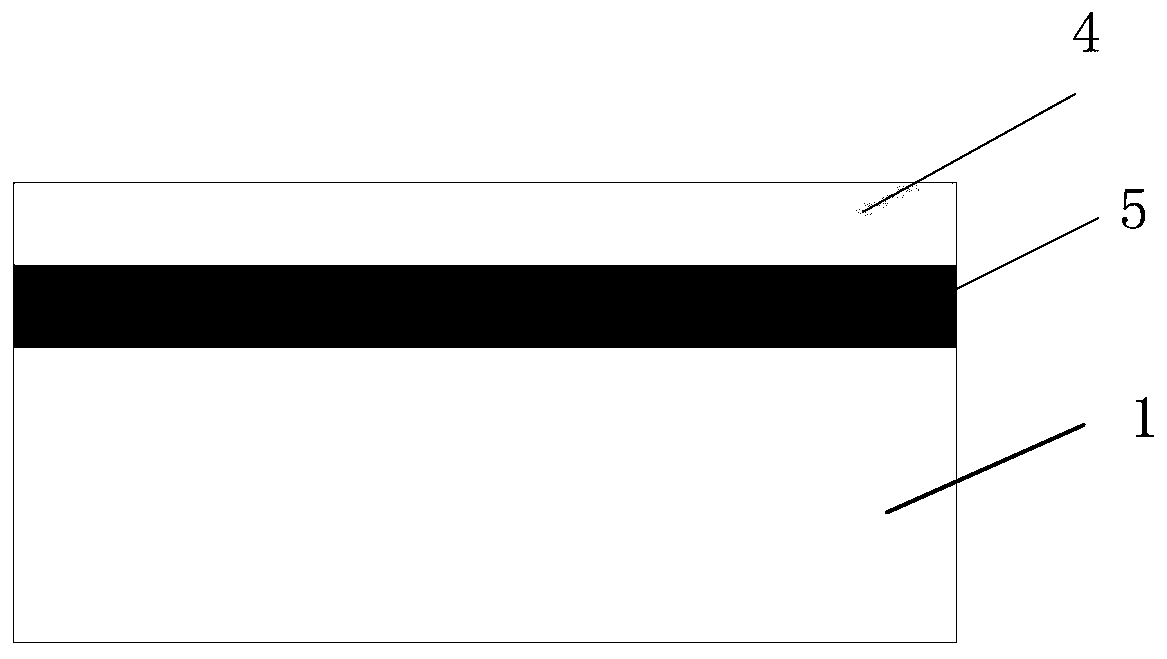

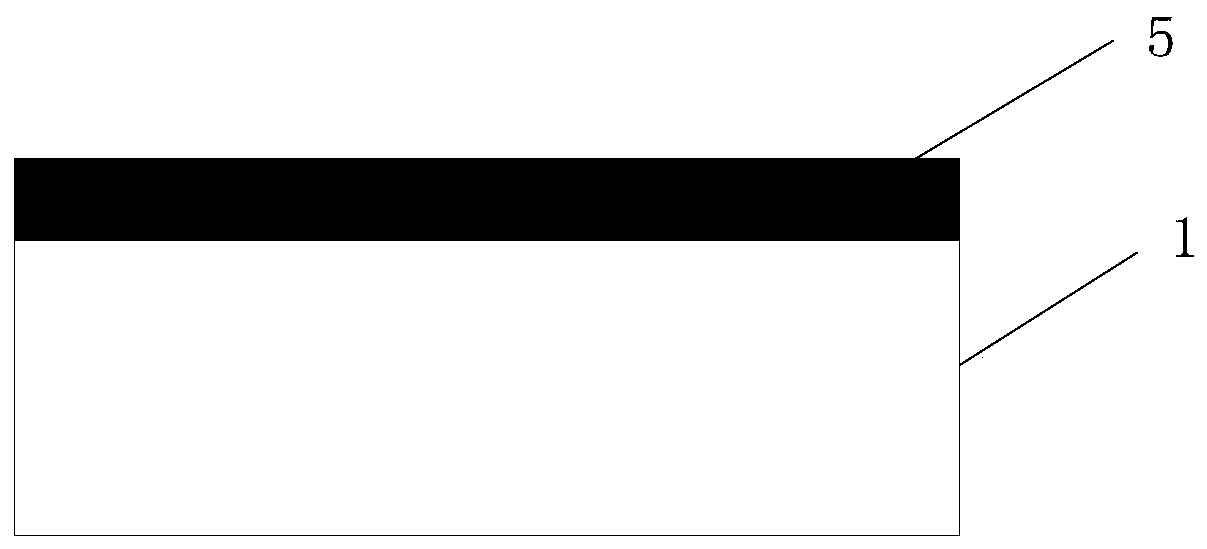

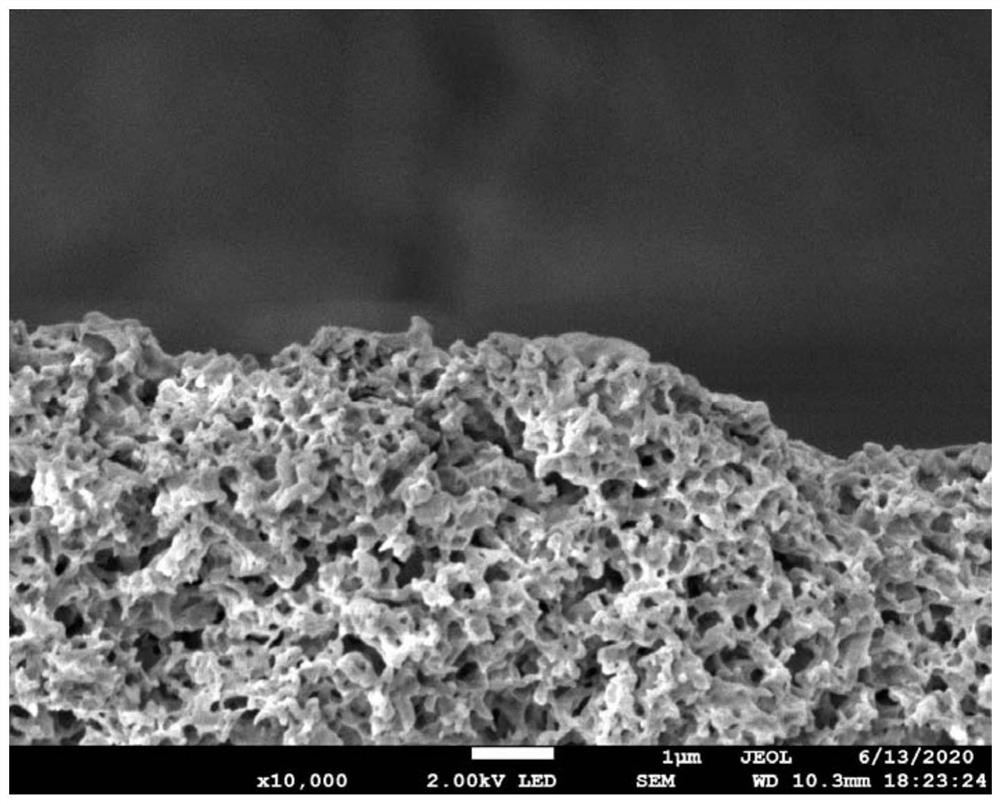

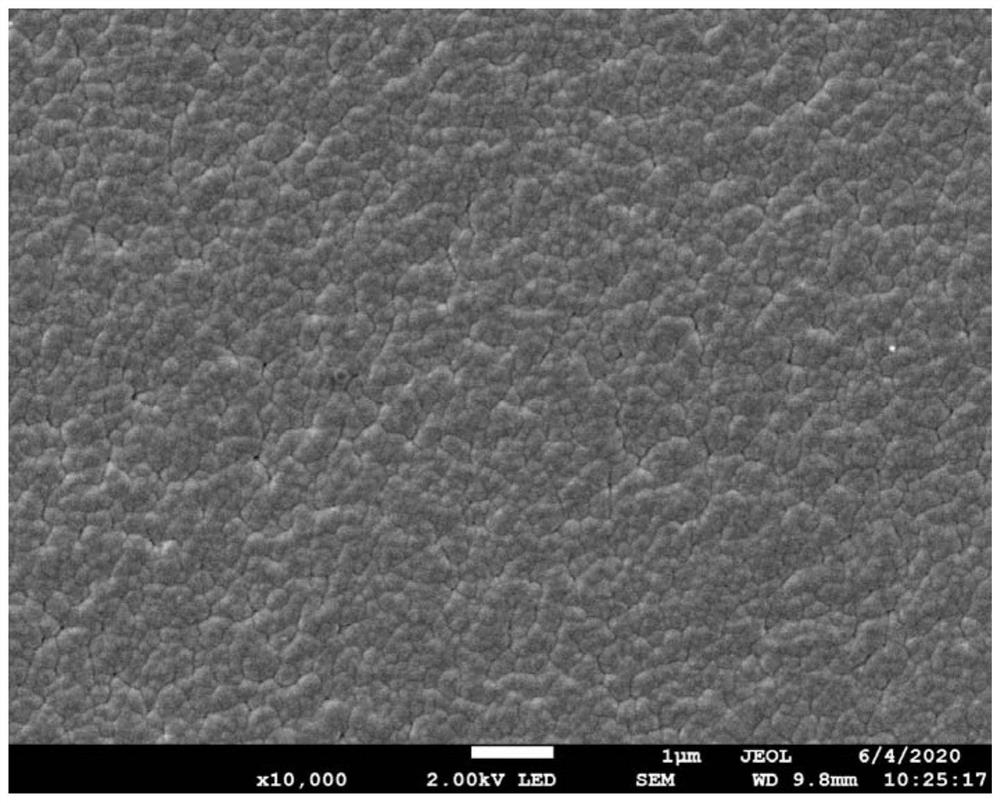

Preparation method for inorganic / organic multilayer composite separator

InactiveCN103066228AEffective control of thicknessGood electrophilic performanceVacuum evaporation coatingSputtering coatingOrganic solventPhysical chemistry

The invention discloses a preparation method for an inorganic / organic multilayer composite separator. The method comprises: soaking a separator in an organic solvent, cleaning surface of the separator by using ultrasonic vibration for 15 ~ 30min, drying in an oven, and then cutting the separator into a square separator; placing the above square separator and a target material into a RF (radio frequency) sputtering device; adjusting the air pressure of the RF sputtering device to be 0.1 ~ 1.0Pa, and then feeding in reactant gas, the sputtering power being 5 ~ 80W and the sputtering time being 5 ~ 100min; running the device, so target material plasma bombards gas molecules to form inorganic matter / organic matter which deposit on both sides of the separator to obtain an inorganic / organic multilayer composite separator. By uniformly sputtering one layer or a plurality of layers of inorganic matter / organic matter on the porous separator surface, the dimensional stability of ordinary separators is effectively improved, and the heat resistance of the separator is improved.

Owner:GUANGDONG UNIV OF TECH

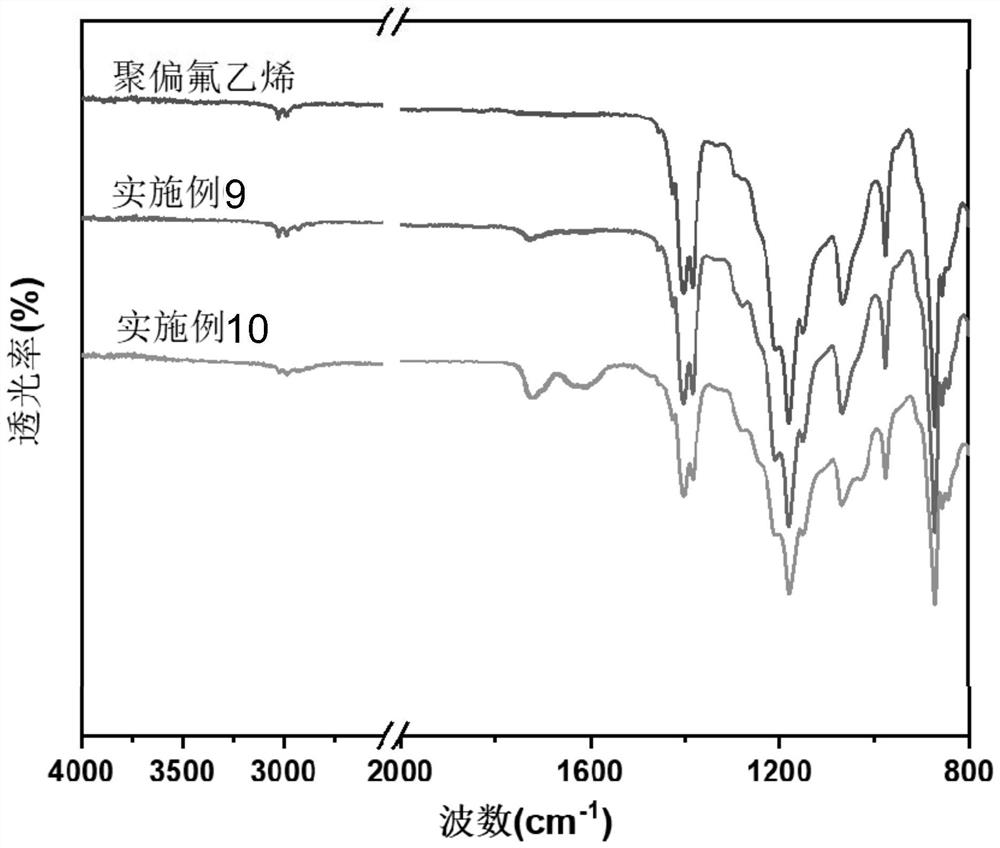

Oxide/fluorocarbon composite positive electrode material for primary lithium battery and preparation method thereof

PendingCN109888268AHigh discharge specific capacityIncrease discharge voltageCell electrodesElectrical batteryFluorocarbon

The invention relates to a composite positive electrode material for preparing a metal lithium primary battery with high discharge voltage and high specific capacity. The oxide coating technology is adopted to maintain the high discharge specific capacity of the fluorocarbon material while increasing the discharge voltage of the fluorocarbon material. Then the metal oxide / fluorocarbon composite positive electrode material with high specific energy is obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Construction method for proton exchange membrane with three-dimensional high specific surface area surface, and high performance membrane electrode based on proton exchange membrane

The invention discloses a construction method for a proton exchange membrane with a three-dimensional high specific surface area surface, and a high performance membrane electrode based on a proton exchange membrane. The method comprises the following steps: (1) preprocessing the proton exchange membrane; (2) mixing one or multiple types of pore-forming agent and perfluorinated sulfonic acid resinsolution which can be easily removed in water or low-boiling-point solvent, and carrying out ultrasound to form porous-layer slurry; (3) adopting a coating technology to coat one side of the proton exchange membrane layer with the porous-layer slurry to obtain a porous membrane precursor; (4) carrying out acid treatment on the porous membrane precursor, and washing with distilled water to obtainthe porous membrane used for a proton exchange membrane fuel battery. Compared with a commercial proton exchange membrane, the porous membrane prepared with the method has the advantages of regular three-dimensional porous structure and large specific surface area on a premise that membrane thickness is not obviously increased, and the performance of the final prepared membrane electrode of the proton exchange membrane fuel battery is improved.

Owner:SOUTH CHINA UNIV OF TECH

Silicon carbide coating and preparation method thereof

The invention relates to a silicon carbide coating and a preparation method thereof, and belongs to the technical field of inorganic functional coating materials. The preparation method of silicon carbide comprises the following steps: respectively preparing a first coating sizing agent and a second coating sizing agent, wherein the first coating sizing agent is prepared from phenolic resin, Si powder and SiC powder with a weight ratio of 3:(3 to 5):(0.5 to 1.5), and the second coating sizing agent is a silicified sizing agent; coating the surface of a carbon-containing material with the prepared first coating sizing agent, curing to obtain an inner coating layer, then coating the surface of the inner coating layer with the prepared silicified coating sizing agent, and curing to obtain an outer coating layer; performing high temperature vacuum sintering on the carbon-containing material on which the outer coating layer is formed, thus obtaining the silicon carbide coating. According to the silicon carbide coating provided by the embodiment of the invention, the inner coating layer and the outer coating layer can be formed by high temperature sintering for once, quick formation of the high-quality silicon carbide coating is realized, the preparation process is greatly simplified, and a preparation period is shortened by 50 percent or more; the method adapts to quick preparation of carbon-containing materials with different structures, different sizes and special shape and component coatings thereof.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

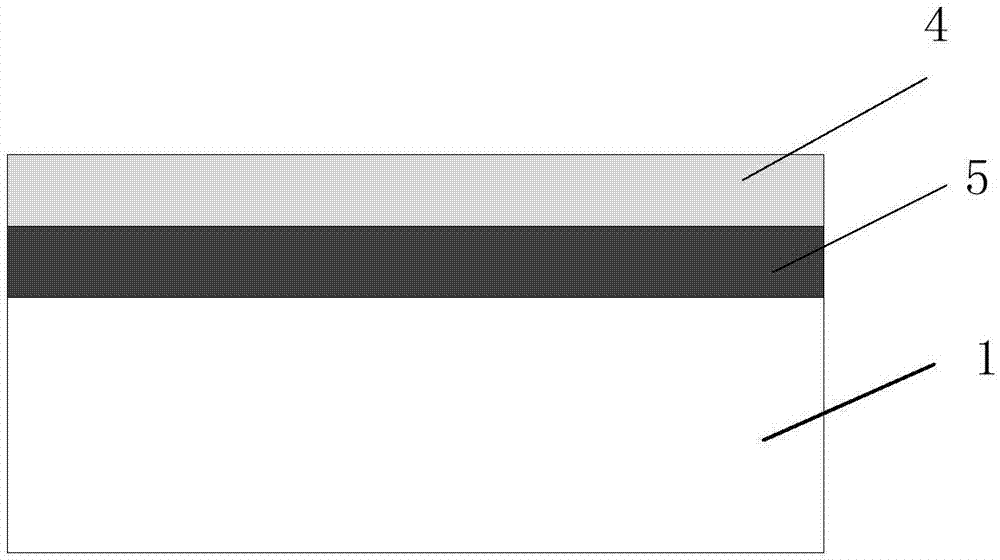

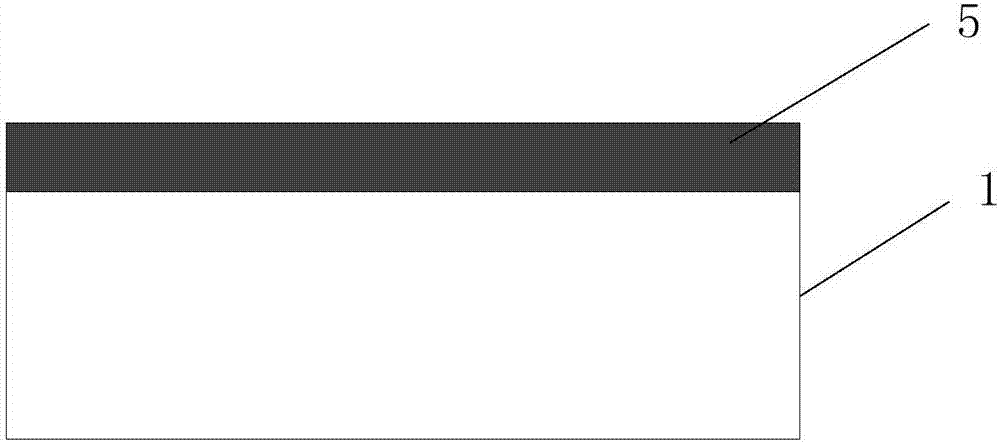

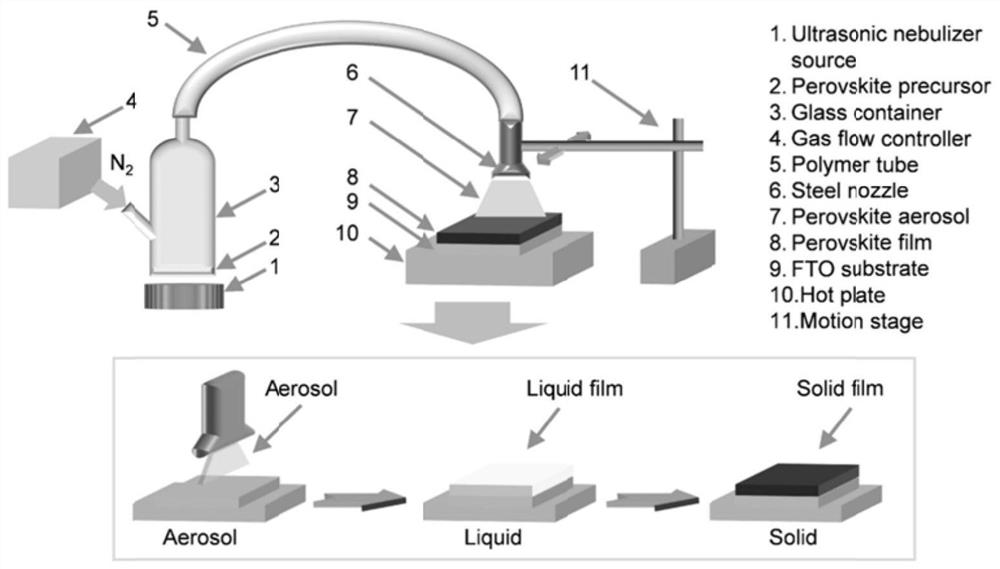

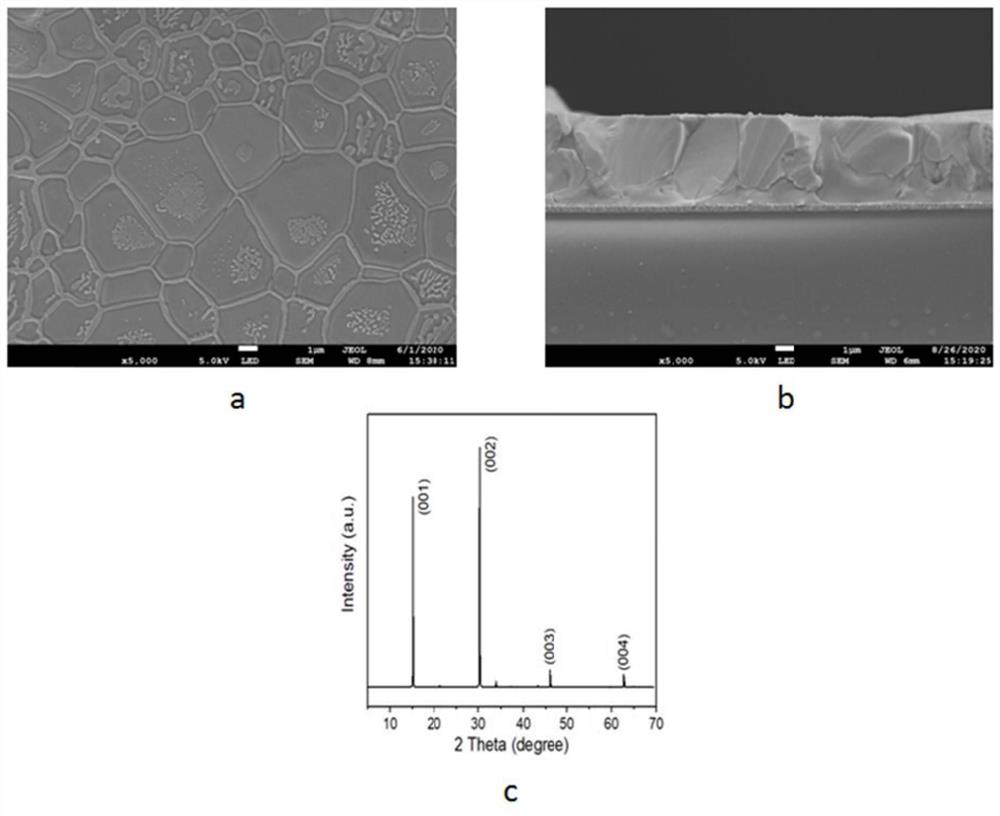

Perovskite double-band photoelectric detector and preparation method thereof

PendingCN112582554ARefine the grain sizeImprove film qualitySolid-state devicesSemiconductor/solid-state device manufacturingFreeze-dryingMaterials science

The invention relates to a perovskite thin film, a perovskite double-band photoelectric detector and a preparation method of the perovskite double-band photoelectric detector. The perovskite thin filmprepared according to the invention is uniform in surface and large in grain size, and is much stronger than a perovskite thin film prepared by a freeze drying method or a blade coating method. In addition, the perovskite thin film prepared by the method is controllable in thickness, has higher performance and stability, and meets the condition of double-band detection; meanwhile, the method is convenient to operate, is low in energy consumption, is simple and cheap and is beneficial to popularization. In addition, a dual-band photoelectric detector has a negative broadband detection mode anda positive narrowband detection mode in a short wavelength range and a sub-band gap wavelength range respectively, so that the dual-band photoelectric detector has very high wavelength selectivity. By regulating and controlling the band gap of perovskite, the wavelength range of negative broadband detection and the specific wavelength of positive narrowband detection of the detector can be adjusted. The detector does not need to change the working mode, and has very high application value and potential in the fields of mineral exploration, biological detection, artificial eyeballs, hyperspectral imaging and the like.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

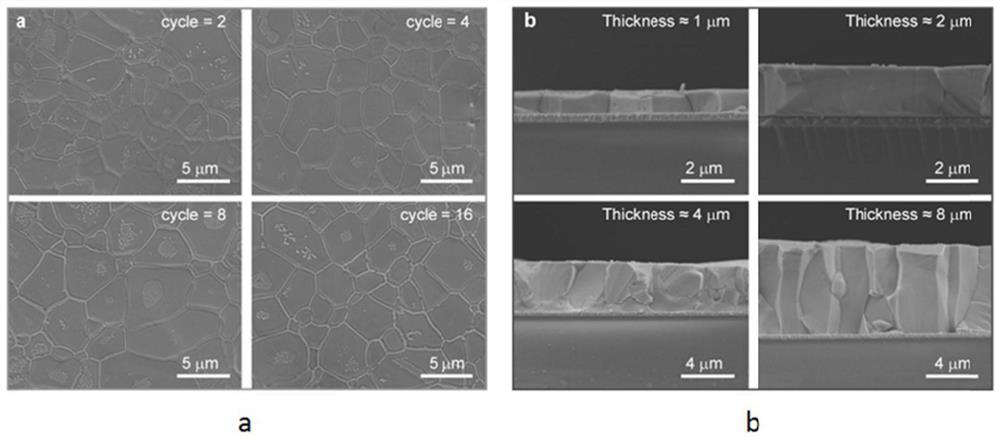

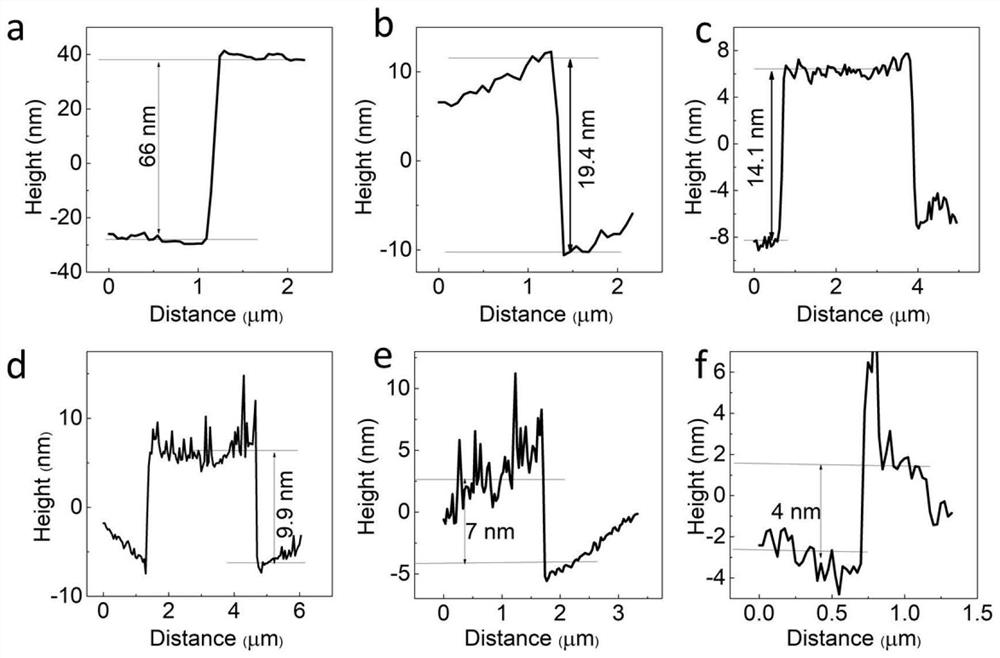

Method for inhibiting zinc dendritic crystal growth by using polydopamine film

PendingCN112349893AEffective control of thicknessPolymerization reaction conditions are easy to controlCell electrodesSecondary cells servicing/maintenanceMedicineDendrite (metal)

A method for inhibiting zinc dendritic crystal growth by using a polydopamine film comprises the steps: a zinc foil is soaked in a dopamine solution, and a polydopamine film layer is formed on the surface of zinc by adjusting the concentration of dopamine, the pH value of the solution, the polymerization time and the reaction temperature; the dopamine-modified zinc foil is used as the negative electrode of the secondary battery, and structural characterization after charge-discharge circulation shows that the surface of the electrode is smooth, and no obvious dendritic crystal is generated; and the polydopamine has strong metallophilicity, a stable protective layer is formed on the surface of the zinc foil, and the deposition of zinc is limited in a limited space, so that the growth of zinc dendrites is effectively inhibited, and the cycle life of the zinc negative electrode is prolonged. The method disclosed by the invention is simple in process, easy in reaction condition control, environment-friendly and beneficial to performance optimization and practical application of the zinc negative electrode.

Owner:XUZHOU NORMAL UNIVERSITY

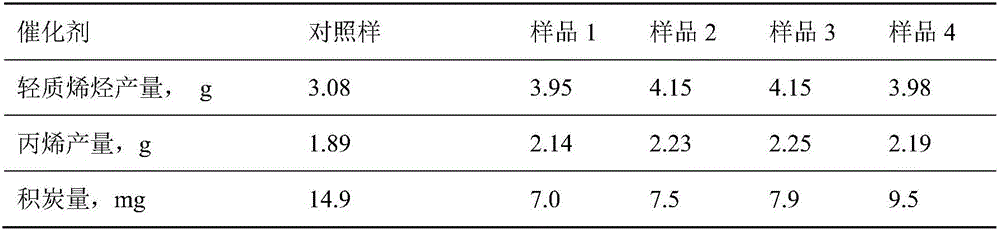

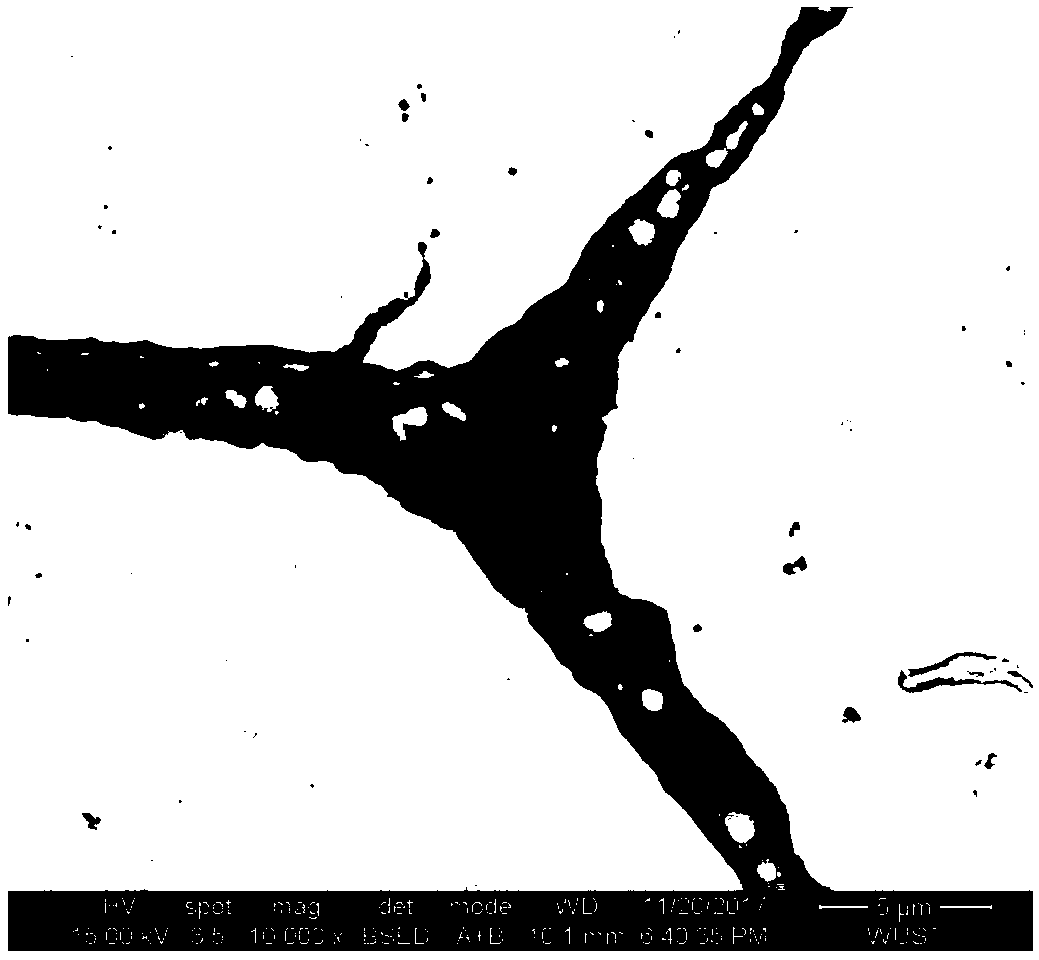

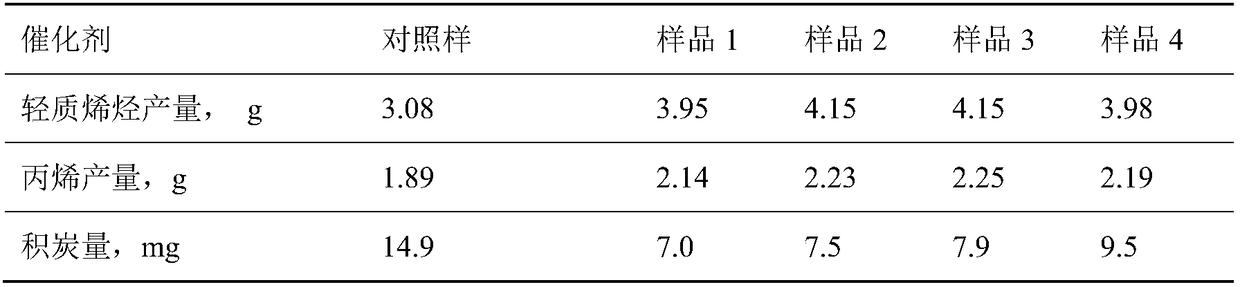

Superacid-coated HZSM-5 molecular sieve catalyst and preparation method and application thereof

ActiveCN106076401AEffective control of thicknessIncrease productionMolecular sieve catalystsMolecular sieve catalystMolecular sieveNaphtha

The invention belongs to the technical field of catalysts, and particularly discloses a superacid-coated HZSM-5 molecular sieve catalyst. The catalyst is prepared through the step that the surface of an HZSM-5 molecular sieve is coated with one of superacids including TiO2.H2SO4, ZrO2.H2SO4, TiO2.H2S2O8 and ZrO2.H2S2O8 or a composition of TiO2.H2SO4, ZrO2.H2SO4, TiO2.H2S2O8 and ZrO2.H2S2O8. The invention further discloses a preparation method of the superacid-coated HZSM-5 molecular sieve catalyst and application of the superacid-coated HZSM-5 molecular sieve catalyst in a technology for preparing low carbon olefin from naphtha through catalytic cracking.

Owner:TIANJIN UNIV

Fe3Si/Al2O3 composite magnetic powder core with core-shell structure and preparation method thereof

InactiveCN109994297AReduce lossReduce pollutionInorganic material magnetismInductances/transformers/magnets manufactureHigh resistivityUltimate tensile strength

The invention relates to a Fe3Si / Al2O3 composite magnetic powder core with a core-shell structure and a preparation method thereof. The technical scheme is as follows: Fe3O4 powder and FeSiAl powder are taken and mixed according to the mass ratio of (2-15):100, and the mixed powder is ball-milled for 4-12h at 100-300rpm to obtain FeSiAl / Fe3O4 core-shell particles; the FeSiAl / Fe3O4 core-shell particles are placed in a high-temperature sintering furnace, heated to 800-1300 DEG C under vacuum I or protective atmosphere I and sintered for 0.5-5h to obtain a sintered body; and the sintered body isplaced in a heat treatment furnace, heated to 500-1200 DEG C under vacuum II or protective atmosphere II and heat-treated for 0.5-5h to obtain a Fe3Si / Al2O3 composite magnetic powder core with a core-shell structure. The Fe3Si / Al2O3 composite magnetic powder core has the characteristics of less loss of raw materials, environment-friendliness, low production cost and simple preparation process. A product made of the Fe3Si / Al2O3 composite magnetic powder core has the advantages of uniform insulating layer, high resistivity, low magnetic loss, high saturation magnetization and low coercivity.

Owner:WUHAN UNIV OF SCI & TECH

Siliconized graphite and preparation method of siliconized graphite

The invention discloses siliconized graphite and a preparation method of the siliconized graphite; the inner part of the siliconized graphite is an ihrigizing graphite layer, and the surface of the siliconized graphite is a siliconizing layer. The siliconized graphite disclosed by the invention has the characteristics of high density, even texture, good electric and thermal conductivity, good heat resistance, good acid-base resistance, high oxidation stability, and good and stable mechanical property. The thickness of the siliconizing layer is 0.5 to 10 mm, and the thickness is controllable; the bonding strength of the siliconizing layer and the ihrigizing graphite layer is high. According to the siliconized graphite and the preparation method disclosed by the invention, siliconizing temperature and siliconizing time can be optimized, the thickness of the siliconizing layer and the ratio of alpha-sic (silicon carbide) and beta-sic can be effectively controlled, and the heat stability of the siliconized graphite is improved.

Owner:QINGDAO HUAJIE SILICON CARBON TECH CO LTD

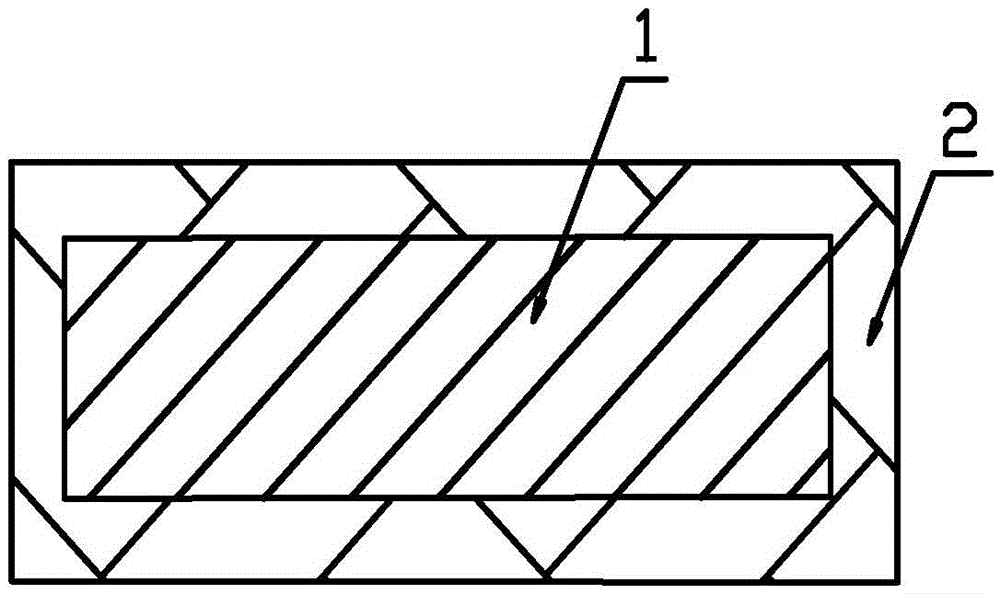

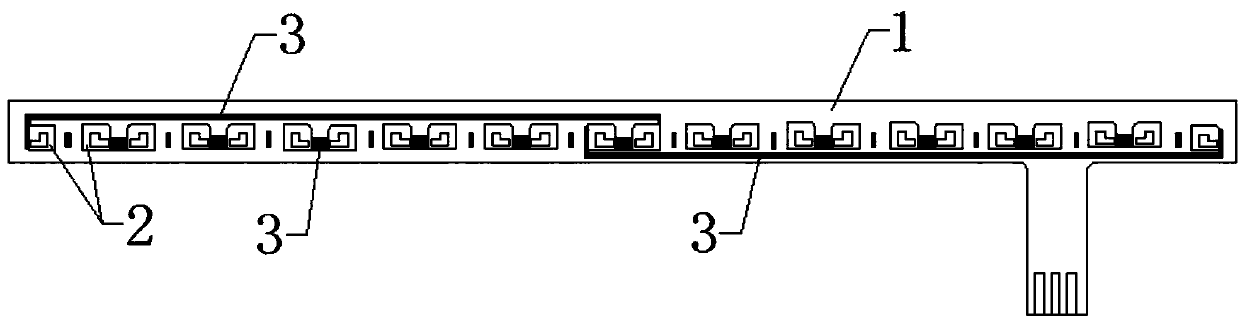

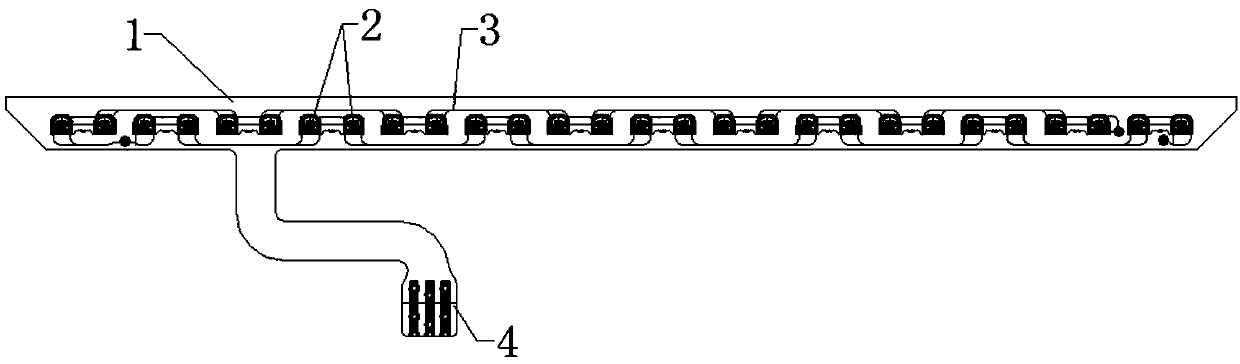

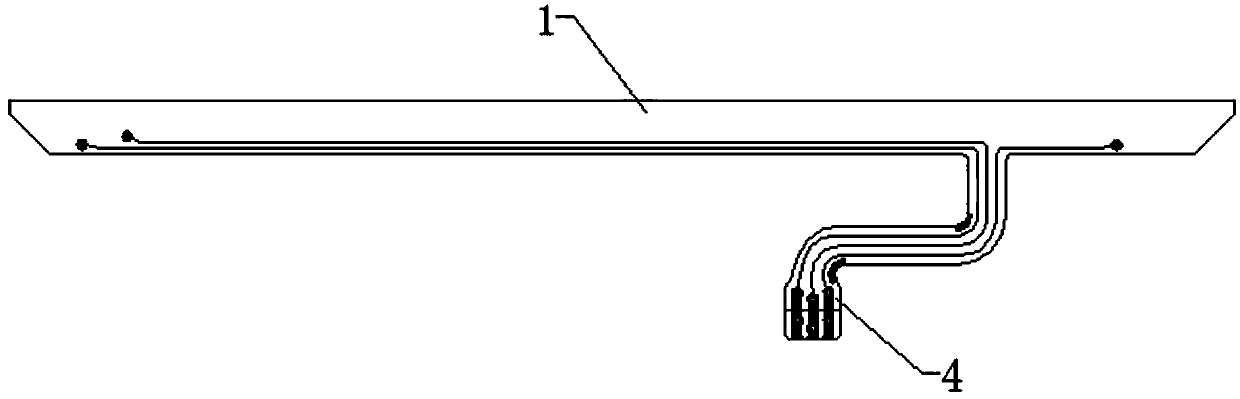

Backlight FPC board and backlight half-finished product

PendingCN108055770AReduce lossReduce lossesPrinted circuit aspectsElectrical connection printed elementsLine resistancePower flow

The invention discloses a backlight FPC board which includes an FPC board and multiple groups of pads arranged in an array along the length direction of the FPC board. The pads are bonded together through a jump wiring process. Each group of pads includes a pole A and a pole K. The jump wiring process is that the K pole of each pad jumps across an adjacent pad and is connected with the pole A of the next pad through a printed line. The invention further presents a backlight half-finished product which includes a light guide plate, an LED component and a backlight FPC board. The backlight FPC board is connected horizontally to the lower end of the light guide plate. The LED component is adhered to the back of the backlight FPC board through SMT. Solder paste is applied between the LED component and the backlight FPC board. The technical scheme can avoid the flash of backlight caused by the elevation of the LED component due to the fact that the lines absorb the solder paste. The loss ofbacklight brightness is reduced because of the high co-linearity, low line resistance and low current loss of LEDs. The thickness of the FPC board can be effectively controlled. The light effect andoptical brightness of the product can reach the best state.

Owner:JIANGXI HOLITECH TECH

A kind of silicon carbide coating and preparation method thereof

The invention relates to a silicon carbide coating and a preparation method thereof, and belongs to the technical field of inorganic functional coating materials. The preparation method of silicon carbide comprises the following steps: respectively preparing a first coating sizing agent and a second coating sizing agent, wherein the first coating sizing agent is prepared from phenolic resin, Si powder and SiC powder with a weight ratio of 3:(3 to 5):(0.5 to 1.5), and the second coating sizing agent is a silicified sizing agent; coating the surface of a carbon-containing material with the prepared first coating sizing agent, curing to obtain an inner coating layer, then coating the surface of the inner coating layer with the prepared silicified coating sizing agent, and curing to obtain an outer coating layer; performing high temperature vacuum sintering on the carbon-containing material on which the outer coating layer is formed, thus obtaining the silicon carbide coating. According to the silicon carbide coating provided by the embodiment of the invention, the inner coating layer and the outer coating layer can be formed by high temperature sintering for once, quick formation of the high-quality silicon carbide coating is realized, the preparation process is greatly simplified, and a preparation period is shortened by 50 percent or more; the method adapts to quick preparation of carbon-containing materials with different structures, different sizes and special shape and component coatings thereof.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Polyamide hollow fiber composite separation membrane and preparation method

ActiveCN112657342AEvenly dispersedEasy to separateSemi-permeable membranesHollow fibrePolymer science

The invention relates to a polyamide hollow fiber composite separation membrane and a preparation method thereof. The method comprises the following steps: a) mixing: uniformly mixing a high polymer, a diluent and an acyl chloride monomer to form a membrane casting solution; b) preparing a composite membrane: extruding the membrane casting solution by using an extruder to form a hollow fiber membrane shape, introducing the hollow fiber membrane shape into a cooling water bath in an amine monomer aqueous solution, carrying out interfacial polymerization on an acyl chloride monomer and an amine monomer to generate a polyamide layer while curing to form the membrane, and drying to obtain the composite membrane containing a polymer porous support layer and a polyamide separation layer; and c) post-treatment of the composite membrane: immersing the composite membrane obtained in the step b) into an extraction agent, and extracting the diluent in the membrane to obtain the polyamide hollow fiber composite separation membrane. The acyl chloride monomer is mixed in the support layer membrane casting solution, so that the acyl chloride monomer can be uniformly dispersed on the surface of the prepared support layer, and meanwhile, the acyl chloride monomer is pre-dispersed in the support layer, so that the binding force of the polyamide separation layer and the support layer can be effectively improved, and the structural stability of the prepared hollow fiber composite membrane is improved.

Owner:TSINGHUA UNIV

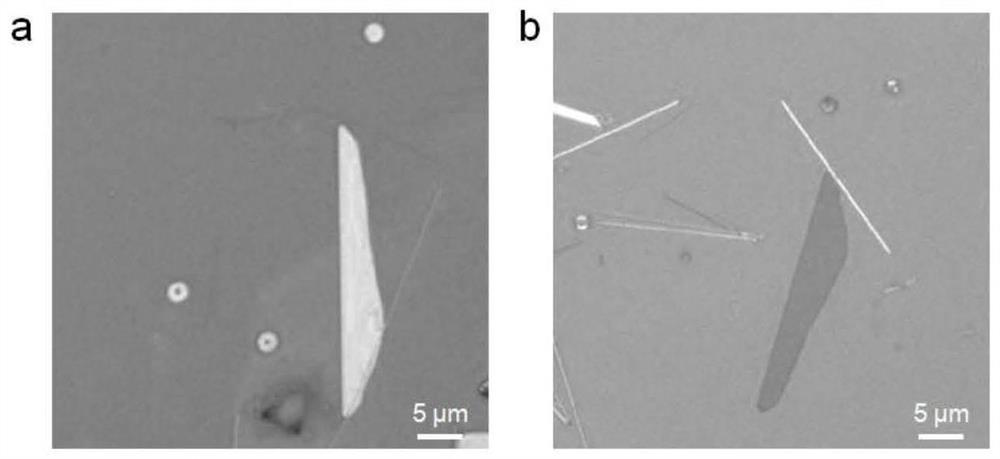

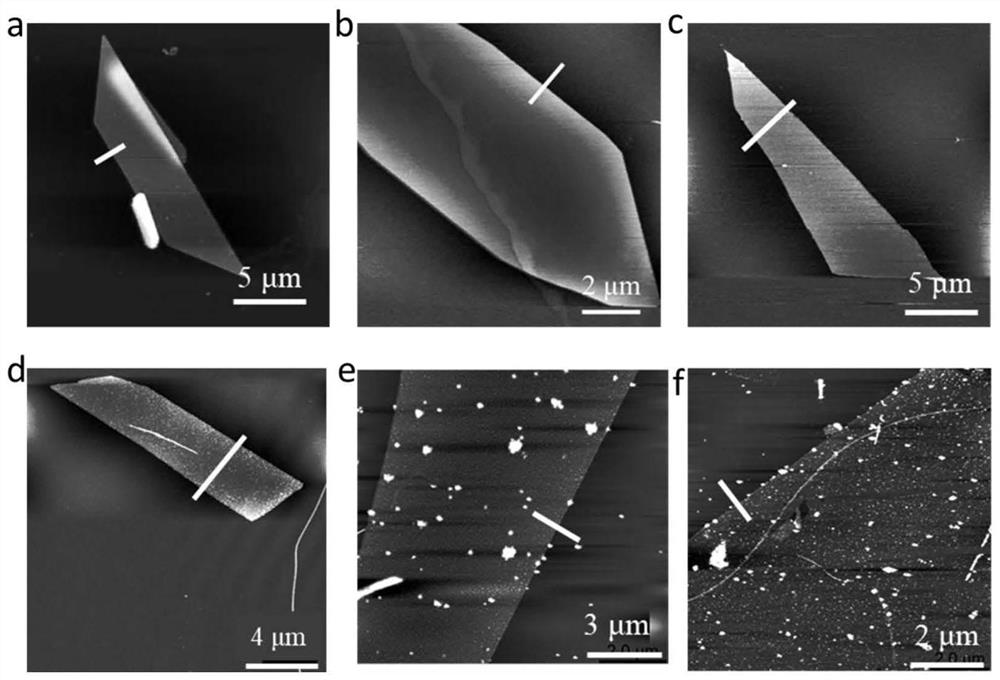

Method for reducing thickness of tellurium nanosheet

ActiveCN113401880APrecise thickness controlMeet material performance requirementsNanotechnologyElemental selenium/telluriumSemiconductor materialsField effect

The invention discloses a method for reducing the thickness of a tellurium nanosheet, and belongs to the technical field of nano materials, the method comprises the following steps: soaking the tellurium nanosheet in a weak oxidizing solution, taking out and drying to obtain the tellurium nanosheet with the reduced thickness, according to the method, the weak oxidizing solution and the surface of the tellurium nanosheet are subjected to mild oxidation reaction, the tellurium nanosheet is thinned, and accurate regulation and control of the thickness of the tellurium nanosheet can be achieved; according to the thin-layer tellurium nanosheet prepared by the method disclosed by the invention, the advantages of the p-type tellurium nanosheet can be fully played, the requirements of different devices on material performance are met, electronic and photoelectric devices based on the tellurium nanosheet can be constructed by utilizing electron beam exposure and vacuum evaporation of an electrode material, and the thin-layer tellurium nanosheet has good compatibility with a traditional semiconductor processing technology; according to the invention, multiple regulation and control of the thickness, the carrier concentration and the field effect switching ratio of the tellurium nanosheet can be realized, and support is provided for developing a two-dimensional p-type semiconductor material which is stable in performance and meets multi-scene requirements.

Owner:UNIV OF SCI & TECH BEIJING

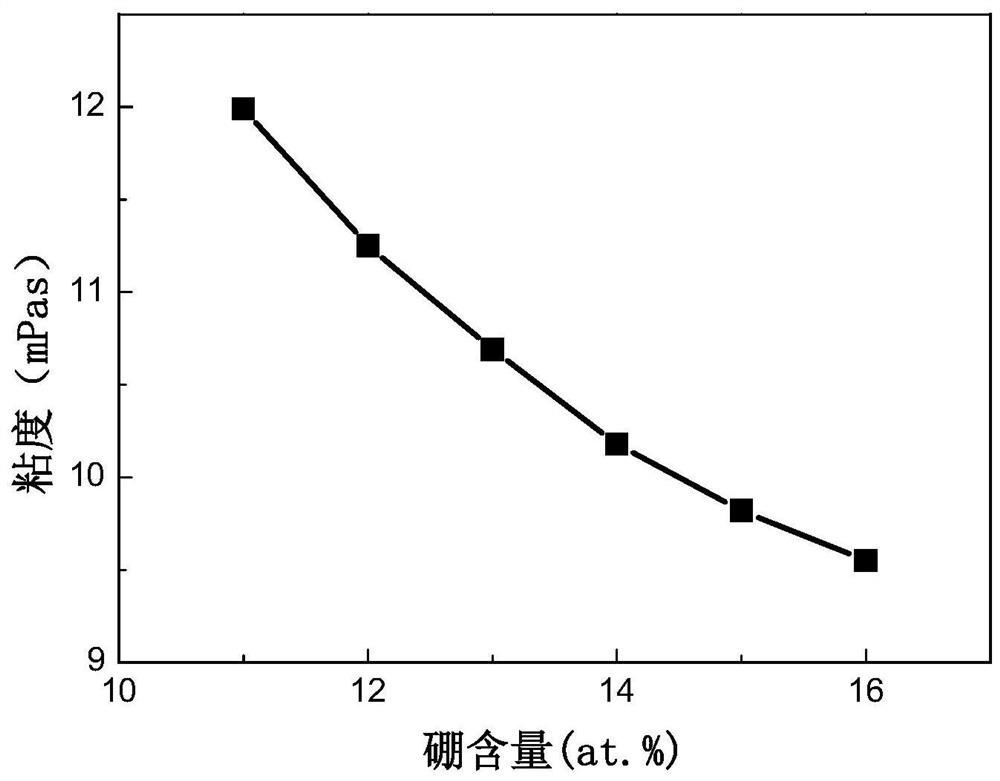

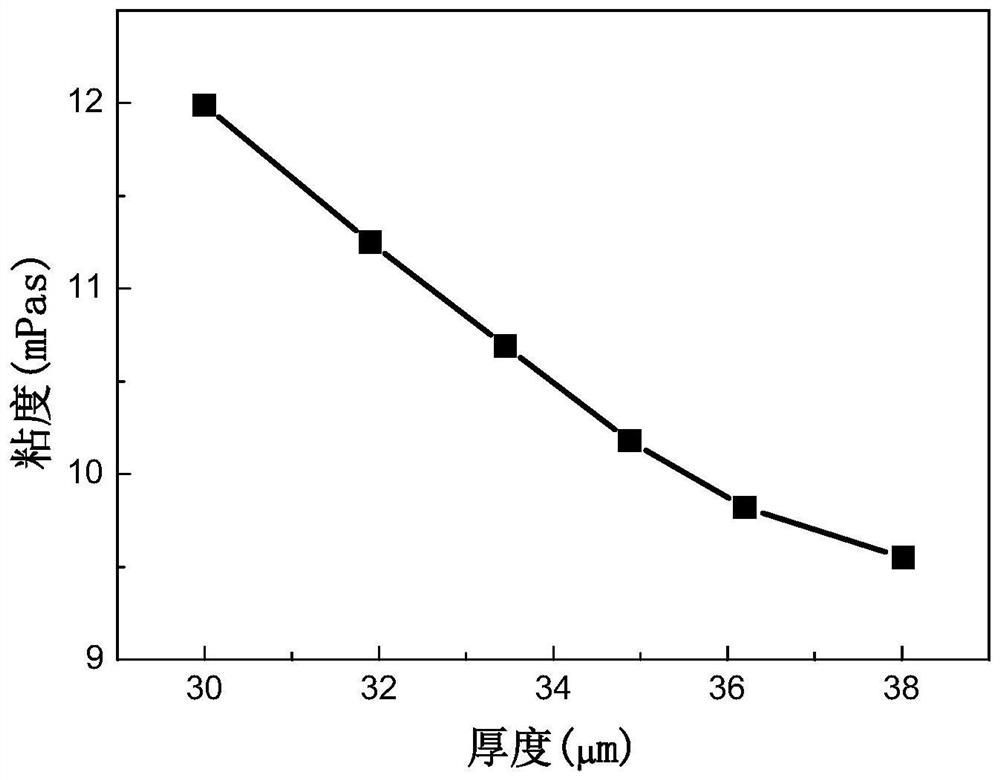

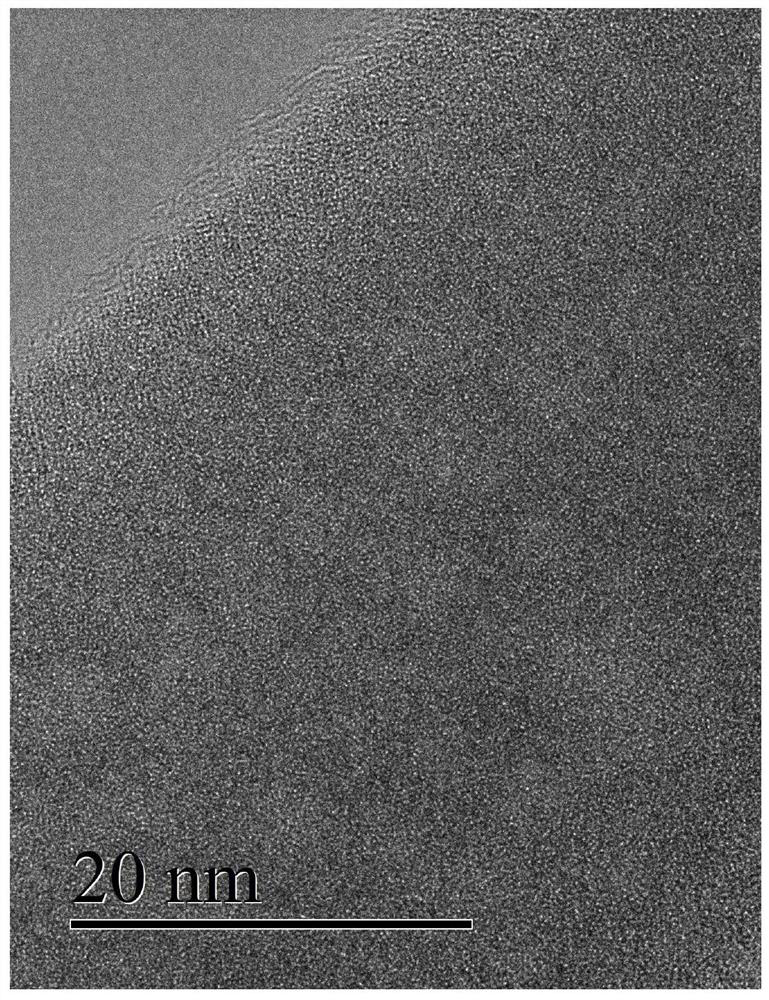

A process method for adjusting the thickness of iron-based amorphous alloy strip

The invention relates to a process method for regulating the thickness of iron-based amorphous alloy strips. The invention can control the iron-based amorphous alloy strip thickness by using the process method of iron-based alloy melt composition and heat treatment temperature without changing the rapid solidification process conditions. The thickness of the crystal alloy strip is reduced, and the difficulty of preparing the iron-based amorphous alloy thick strip is reduced. The invention has the characteristics of low implementation cost, high efficiency, strong controllability and repeatability, high technical reliability, etc., and is suitable for wide application in the technical field of metal functional material preparation.

Owner:江苏中科启航新材料工业研究院有限公司 +3

Three-shell iron-silicon-substrate soft magnet composite material and manufacturing method thereof

ActiveCN108788136AReduce lossNo pollution in the processTransportation and packagingMetal-working apparatusSilicon alloySoft magnet

The invention relates to a three-shell iron-silicon-substrate soft magnet composite material and a manufacturing method thereof. The technical scheme is characterized in that iron-silicon alloy powderis placed into water according to a iron-silicon alloy powder to water mass ratio of 1:(5-100); the mixture is stirred for 5-30 h at 30-80 DEG C; composite powder is obtained after solid-liquid separation; the composite powder is subjected to vacuum drying and placed in a mould; the powder is moulded through cold pressing under the condition of 300-1200 MPa to obtain a blank body; the blank bodyis placed in a high-temperature sintering furnace, is heated to 800-1300 DEG C at a vacuum condition or at a protection atmosphere condition, and is sintered for 0.5-5 h to obtain the sintered blank body; the sintered blank body is placed in a thermal treatment furnace, is heated to 500-1200 DEG C at the vacuum condition or the protection atmosphere condition and is subjected to thermal treatmentfor 0.5-5 h; and the blank body is furnace cooled to obtain the three-shell iron-silicon-substrate soft magnet composite material. The manufacturing method is simple in technique and low in productioncost; the manufactured product is not only uniform in isolation layer and extremely low in magnetic loss; and besides, the saturation flux density is high and constant magnetic permeability is high.

Owner:WUHAN UNIV OF SCI & TECH

A kind of hzsm-5 molecular sieve catalyst wrapped by superacid, its preparation method and application

ActiveCN106076401BEffective control of thicknessIncrease productionMolecular sieve catalystsBulk chemical productionMolecular sieveNaphtha

The invention belongs to the technical field of catalysts, and particularly discloses a superacid-coated HZSM-5 molecular sieve catalyst. The catalyst is prepared through the step that the surface of an HZSM-5 molecular sieve is coated with one of superacids including TiO2.H2SO4, ZrO2.H2SO4, TiO2.H2S2O8 and ZrO2.H2S2O8 or a composition of TiO2.H2SO4, ZrO2.H2SO4, TiO2.H2S2O8 and ZrO2.H2S2O8. The invention further discloses a preparation method of the superacid-coated HZSM-5 molecular sieve catalyst and application of the superacid-coated HZSM-5 molecular sieve catalyst in a technology for preparing low carbon olefin from naphtha through catalytic cracking.

Owner:TIANJIN UNIV

Method for preparing high-inoxidability sphere-like copper powder

The invention discloses a method for preparing high-inoxidability sphere-like copper powder, which comprises the steps of reduction reaction, washing, surface chemical treatment and drying treatment, wherein the reduction reaction is to dissolve a reducing agent and a copperish initiator material into solvent and perform the reduction reaction under the action of an auxiliary agent, the reaction temperature is between 40 and 100 DEG C, and the reduction reaction time is between 2 and 5 hours. The reducing agent is vitamin C (C6H806, Vc,). The copperish initiator material is a substance which can be ionized into Cu2+ in aqueous solution and comprises one or several of hydrated copper sulfate, hydrated copper nitrate and hydrated copper chloride; the solvent is deionized water; and the auxiliary agent comprises an inorganic salt or an alkaline substance for adjusting the pH value and a water soluble polymer material for a surfactant. The obtained copper powder has the advantages of gooddispersity, no agglomeration, small specific area, high tap density, controllable granule size, narrow grain size distribution range, and strong antioxygenic property.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

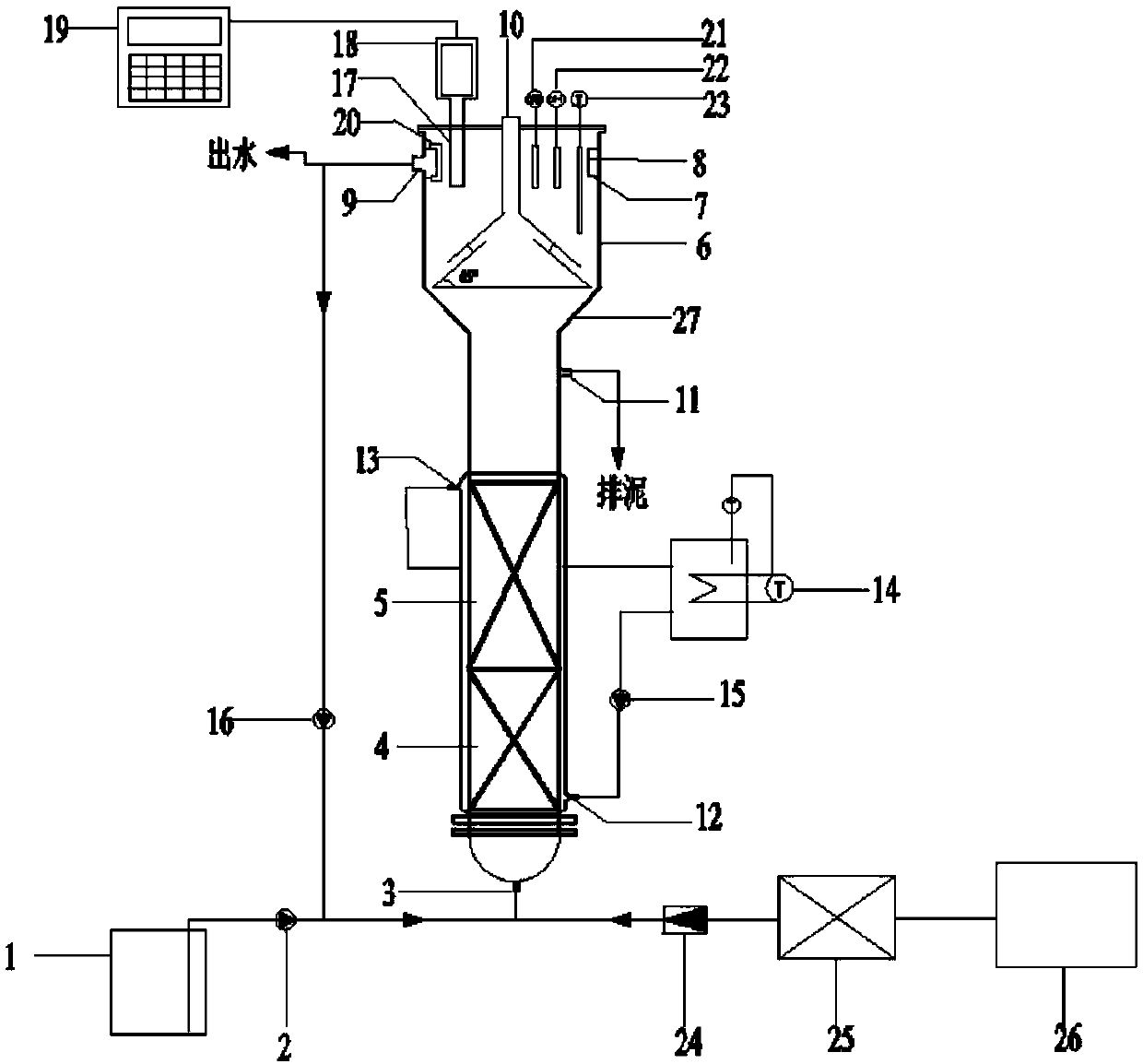

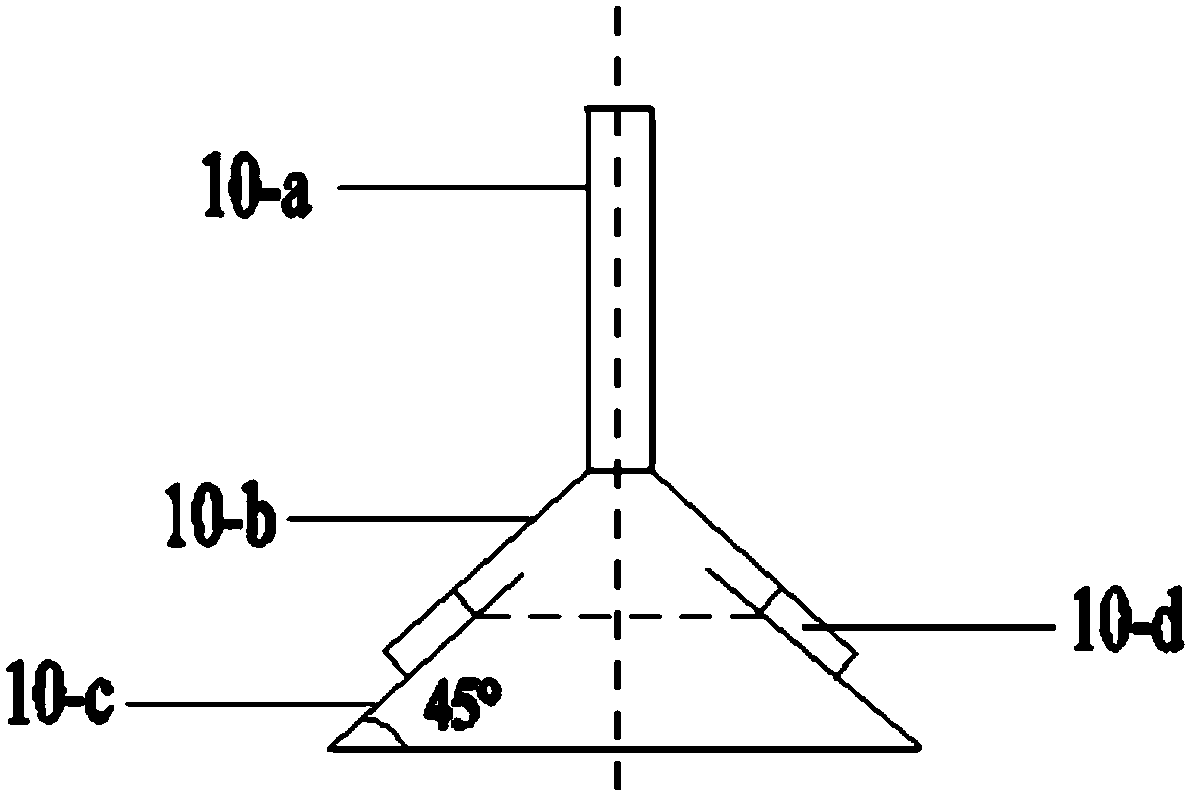

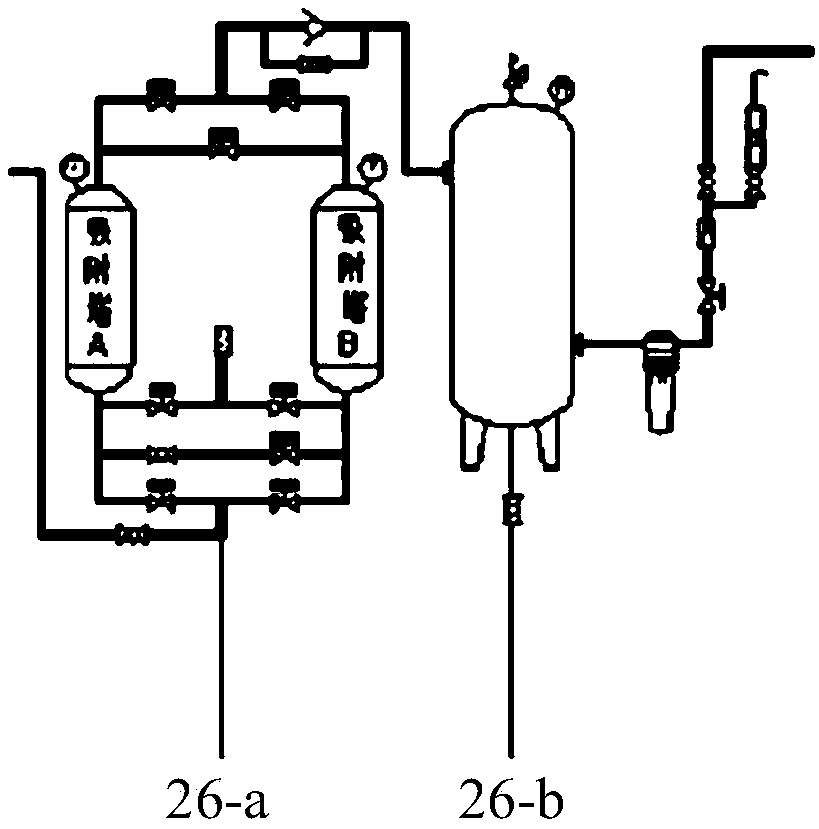

Method for treating high-concentration nitrate wastewater

InactiveCN110862186AAchieve regulationGuaranteed uptimeWater treatment compoundsWater contaminantsPre treatmentCarbon source

The invention discloses a method for treating high-concentration nitrate wastewater. The method includes the following steps: S1, adding a carbon source and nitrogen and phosphorus nutrients into thenitrate wastewater, and adjusting the pH of the wastewater to 2-4 to obtain pretreated wastewater; and S2, mixing the pretreated wastewater and circulating water, introducing the obtained mixed waterinto an anoxic expanded bed reactor to be in contact with a biological filler, and performing a denitrification reaction to obtain denitrified wastewater, wherein the circulating water is a product obtained by the denitrification reaction of the pretreated wastewater and the biological filler. The cost of treating the nitrate wastewater by using the method is lower, and the method can continuouslytreat the high-concentration nitrate (3000-35000 mg / L) wastewater, and has high treatment efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

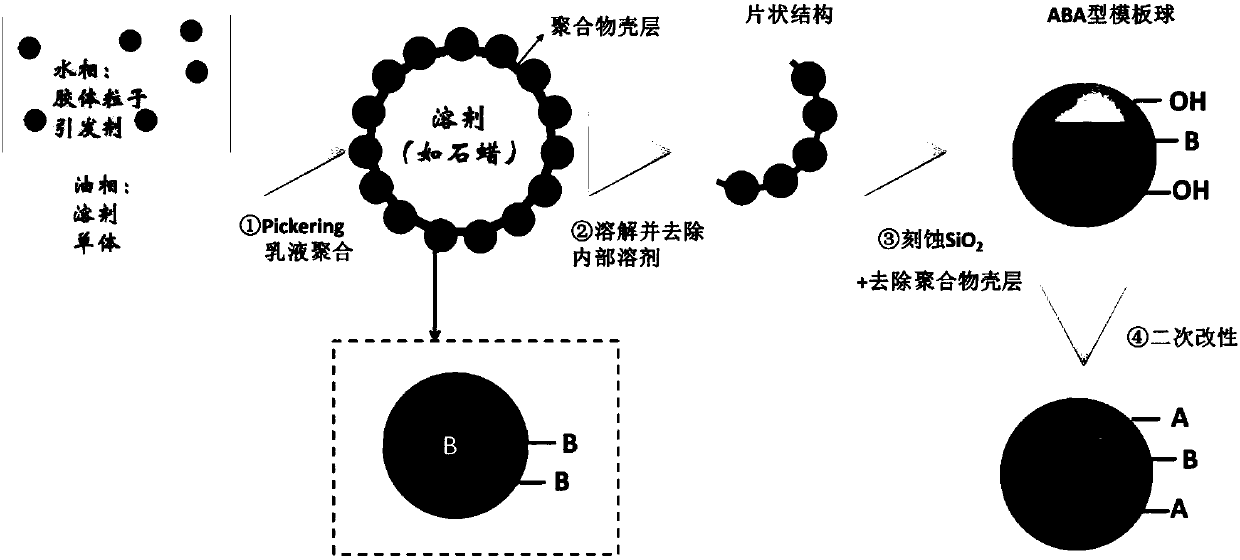

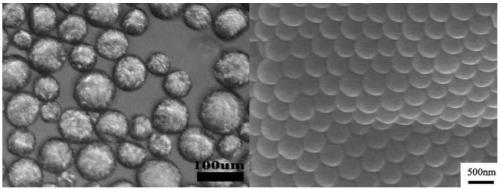

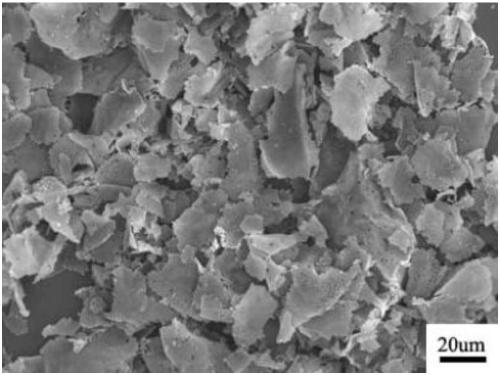

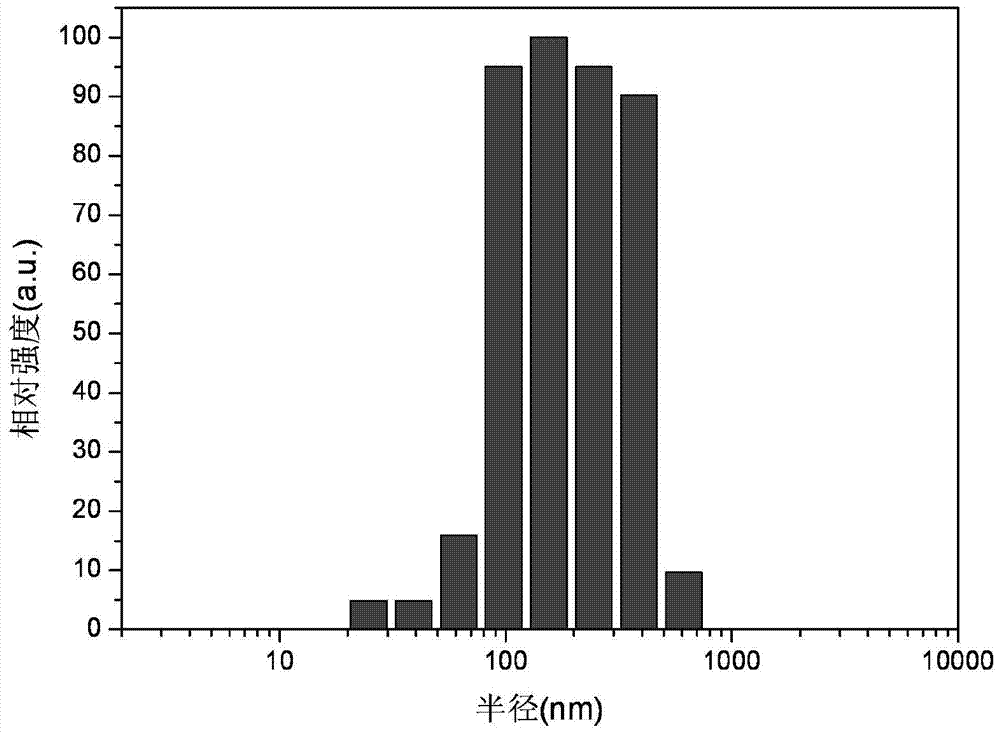

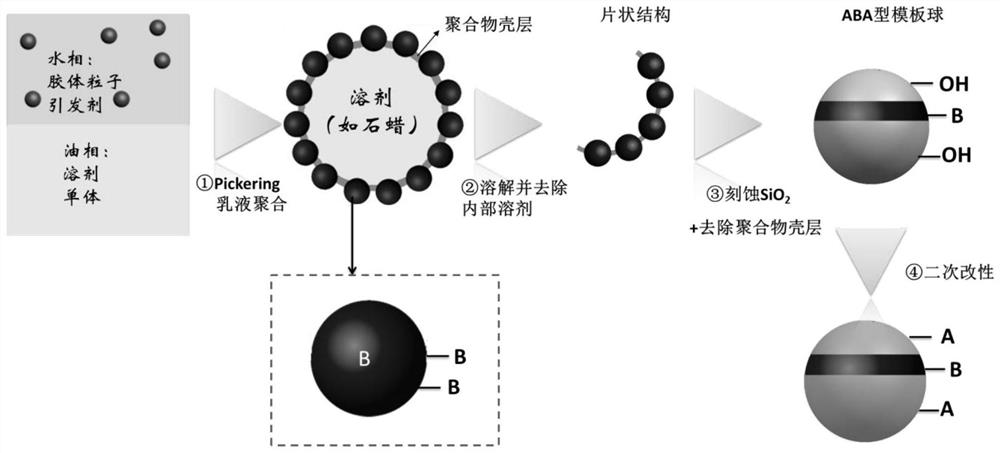

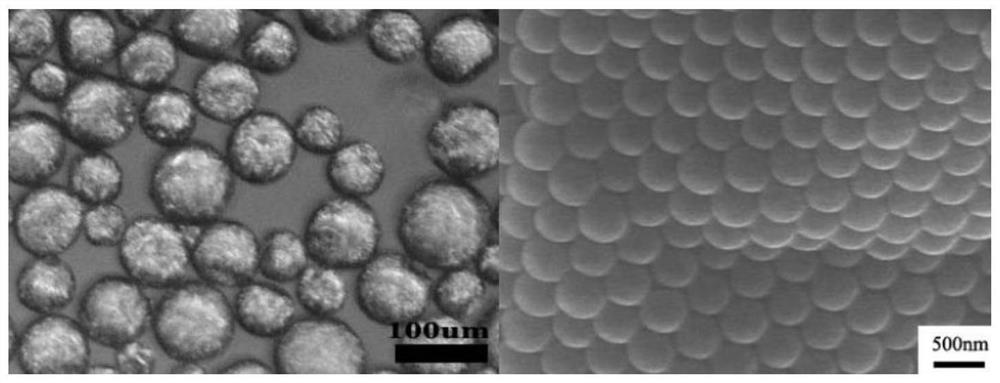

ABA-type colloidal particles having multiple properties on surface and preparation method of particles

InactiveCN109851698AMature production processGood control effectSilicaTitanium dioxideTectorial membraneEmulsion polymerization

The invention discloses ABA-type colloidal particles having multiple properties on the surface and a preparation method of the particles, and belongs to the technical field of preparation of submicron-scale materials. The method uses the colloidal particles as a particle emulsifying agent and a Pickering emulsion liquid water oil three-dimensional interface as a protective interface, in the Pickering emulsion liquid, a monomer is polymerized, phase separation occurs to the interface, a protective film is formed at the near equator-like position of the colloidal particles, the protective film is removed by selective modification or etching, and therefore the colloidal particles having a clear ABA-type partition on the surface and having a dimension of 100-1000 nm can be obtained. The methodprovided by the invention is based on emulsion polymerization, the mass production is easy to realize, the material has strong universality, and the prepared ABA-type colloidal particles have good application value on the aspects of photoelectromagnetic functional materials, medical materials and template materials.

Owner:TIANJIN CHENGJIAN UNIV

Fe3Si/Al2O3 composite powder with core-shell structure and preparation method thereof

InactiveCN109986084AReduce lossReduce pollutionTransportation and packagingMetal-working apparatusMagnetizationUltimate tensile strength

The invention relates to a Fe3Si / Al2O3 composite powder with core-shell structure and a preparation method thereof. According to the technical scheme, the method includes the steps of mixing Fe3O4 powder and FeSiAl powder according to the mass ratio, being 2-15 to 100, of the Fe3O4 powder to the FeSiAl powder, at 100 rpm to 300 rpm, carrying out ball milling on the mixed powder for 4 hours to 12 hours to obtain FeSiAl / Fe3O4 core-shell particles, putting the FeSiAl / Fe3O4 core-shell particles in a high-temperature tubular furnace, heating to 800 DEG C to 1300 DEG C under a vacuum condition or aprotective atmosphere condition, and carrying out heat treatment for 0.5 hour to 2 hours to obtain the Fe3Si / AL2O3 composite powder with the core-shell structure. The composite powder and the method have the advantages of less raw material loss, environmental friendliness, low preparation cost and simple process, and the prepared Fe3Si / Al2O3 composite powder with the core-shell structure is uniform in insulating layer, high in saturation magnetization intensity and low in coercive force.

Owner:WUHAN UNIV OF SCI & TECH

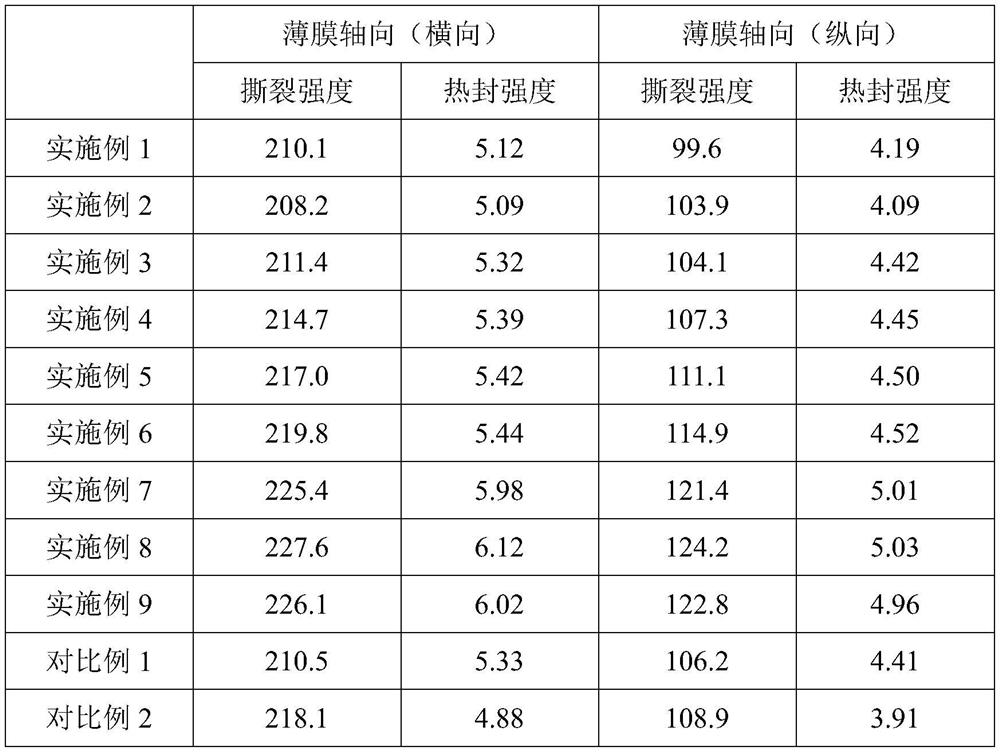

A fully biodegradable film with adjustable properties and its preparation method

ActiveCN109397810BPromote degradationExcellent physical and chemical propertiesSynthetic resin layered productsPolyesterPolymer science

The invention relates to the field of biodegradable high polymer materials and specifically relates to a fully biodegradable film with adjustable performances and a preparation method thereof. The preparation raw material of the fully biodegradable film includes polylactic acid and degradable polyester copolymer, wherein the molecular chain of degradable polyester copolymer contains an aliphatic polyester chain segment and an aromatic polyester chain segment.

Owner:XIAMEN AMESON NEW MATERIAL INC

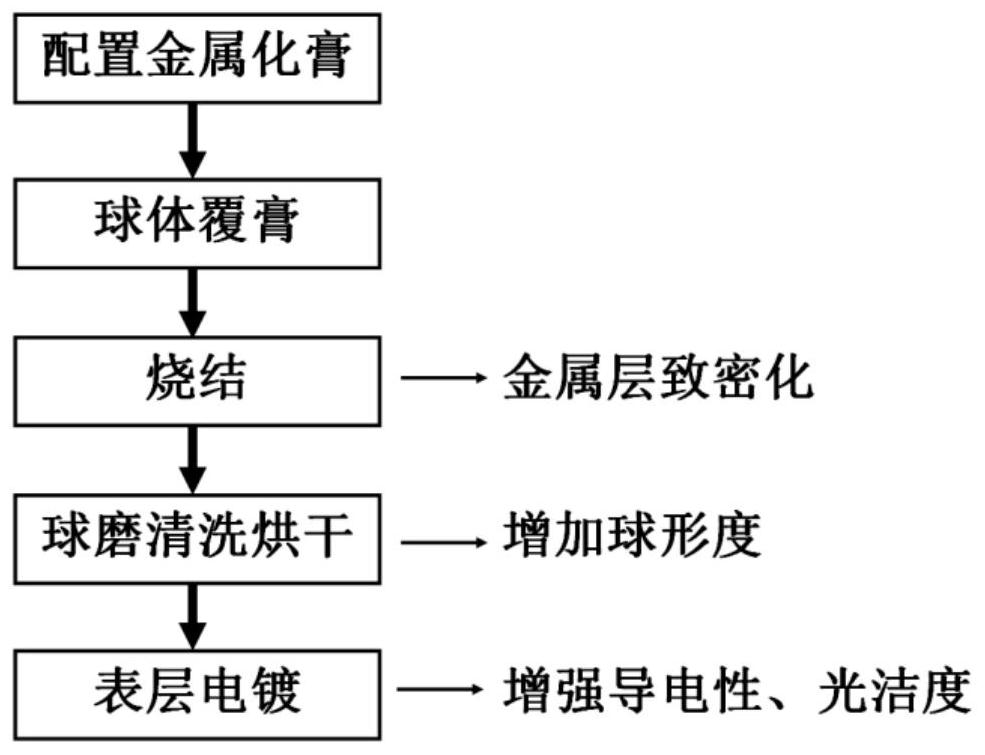

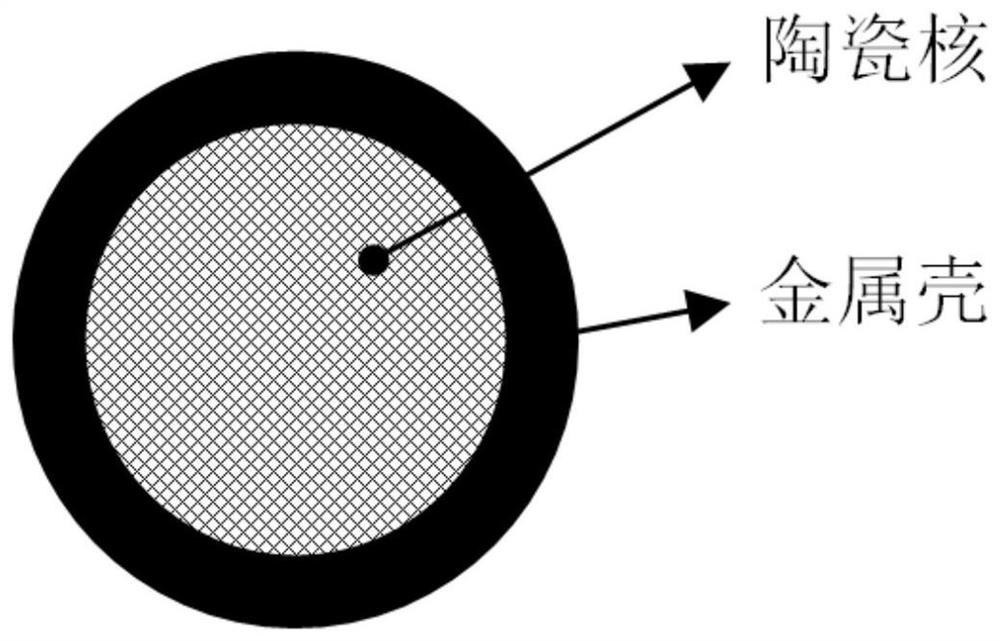

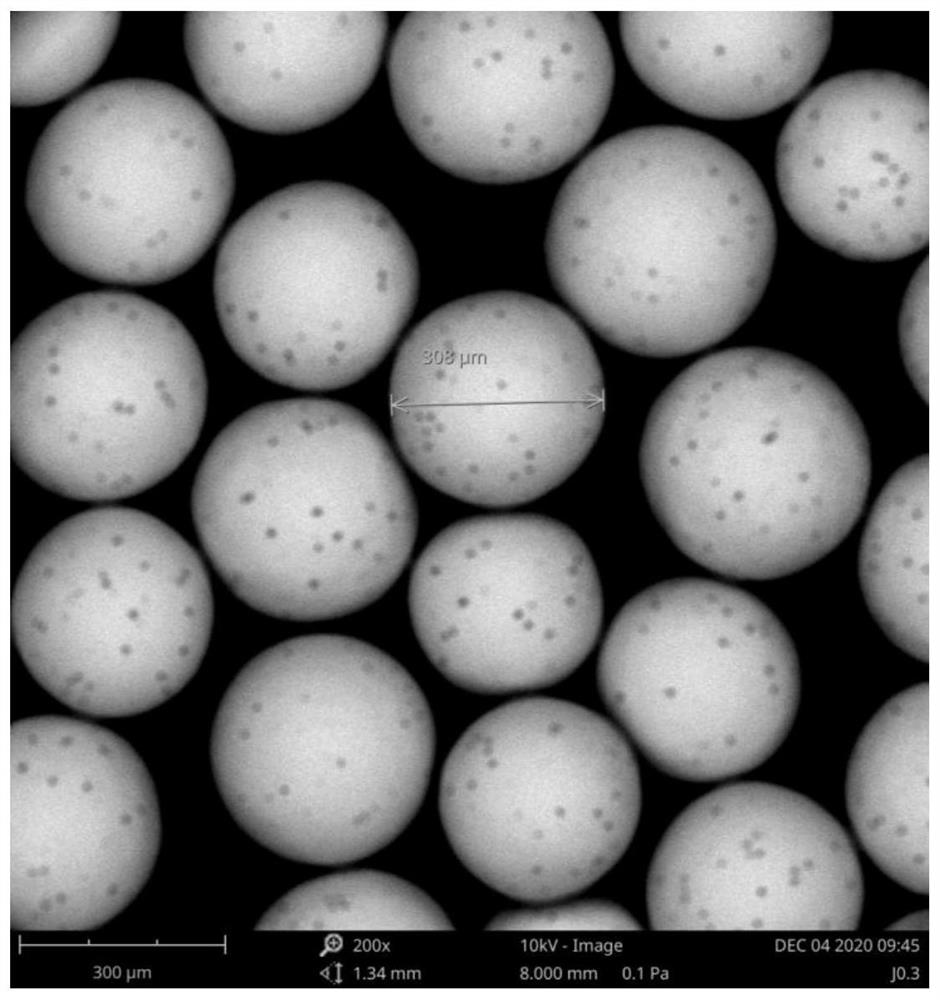

Core-shell structure conductive microsphere with adjustable specific gravity as well as preparation method and application of core-shell structure conductive microsphere

The invention discloses a core-shell structure conductive microsphere with adjustable specific gravity as well as a preparation method and application of the core-shell structure conductive microsphere. The conductive microsphere comprises a ceramic microsphere serving as a core and a metal shell layer coating the surface of the ceramic microsphere. The ceramic microsphere and metallized paste are used as raw materials, and the surface of the ceramic microsphere is coated with the metal shell layer with a certain thickness through a solid-phase sintering method. By adopting the metallization method disclosed by the invention, the bonding strength of the obtained metal shell layer and the surface of the ceramic microsphere core is high, the core-shell structure is compact, the metal shell layer is not easy to fall off, and the diameter of the obtained conductive microsphere with the core-shell structure is adjustable between 1-2000 [mu]m; meanwhile, the overall specific gravity of the core-shell structure microsphere can be adjusted by adjusting the diameter of the ceramic microsphere and the thickness of the coating metal shell layer, so that the conductive microsphere with different use requirements can be obtained; and further electroplating treatment can be carried out on the metal shell layer to improve the conductivity and smoothness of the metal shell layer, so that the application field of the conductive microsphere is widened.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

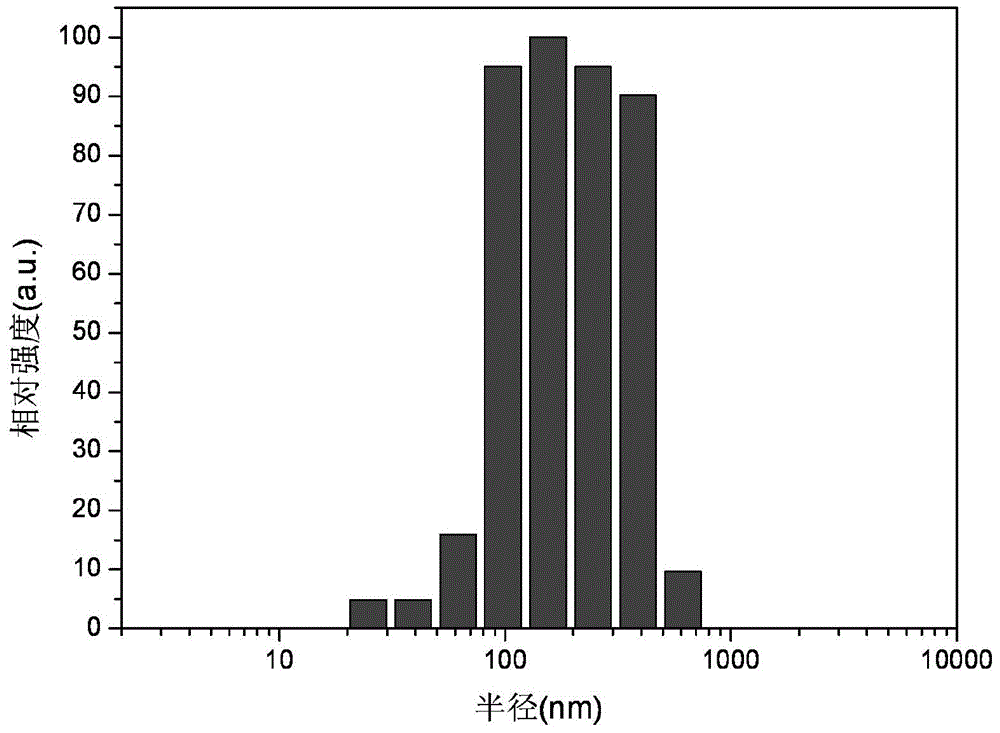

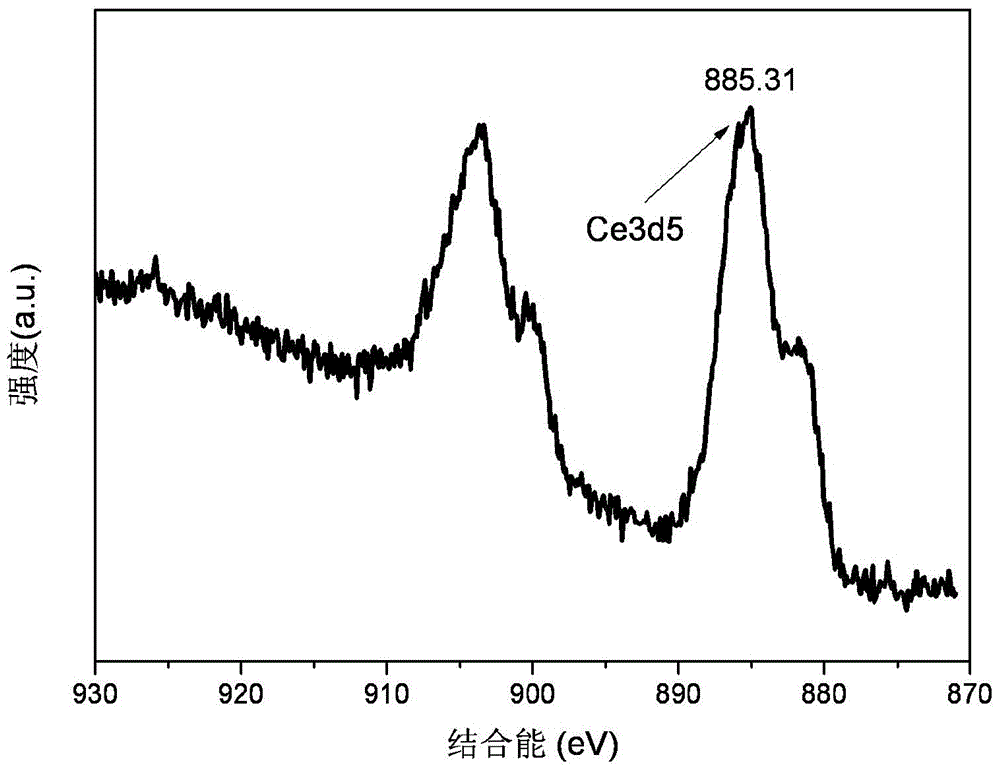

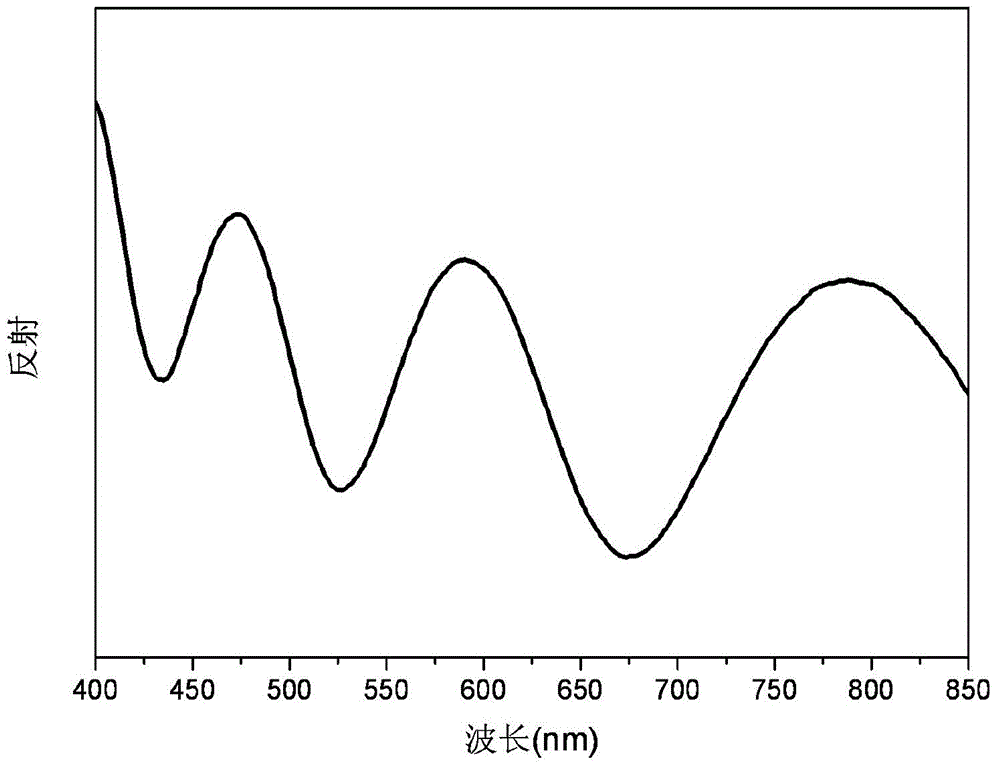

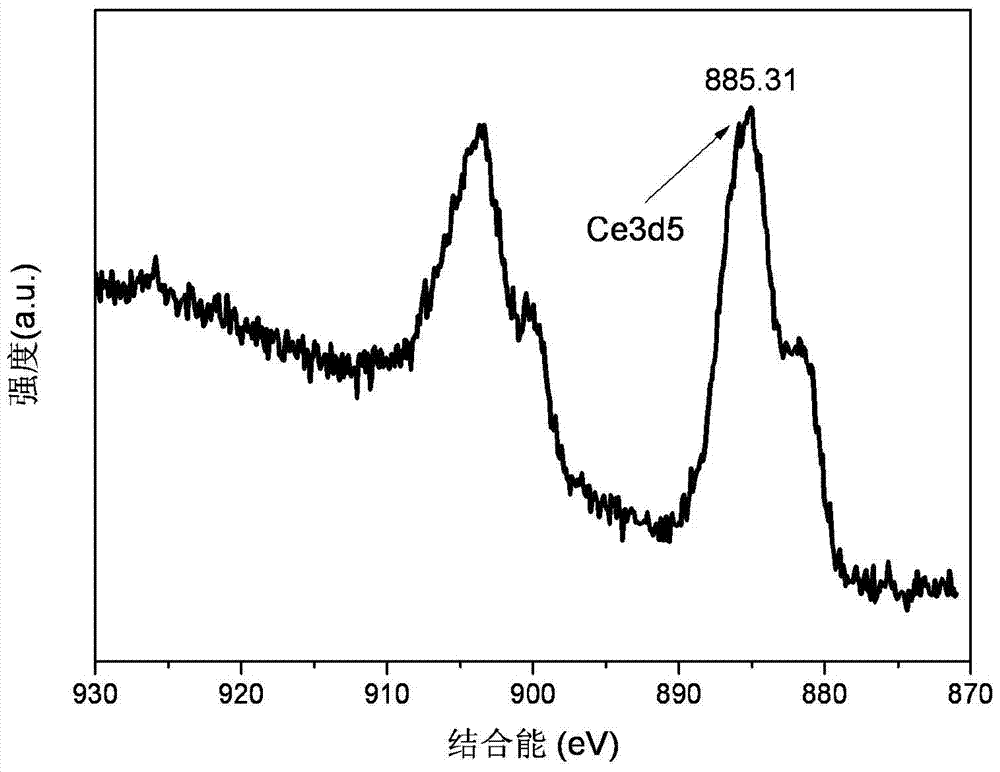

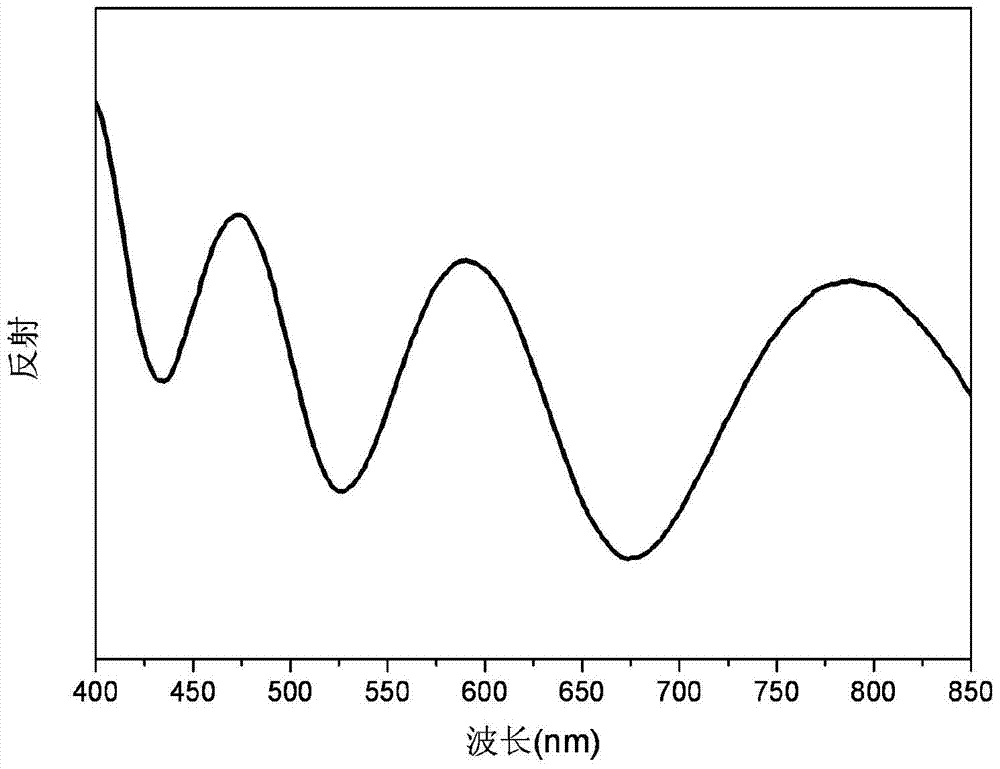

Preparation method of rare earth-containing high-molecular nanocomposite film

ActiveCN104445991AEffective regulation of fluorescenceEffective performance controlOptical propertyCationic polyelectrolytes

The invention relates to a preparation method of a rare earth-containing high-molecular nanocomposite film. The preparation method comprises the following steps of mixing an anionic polyelectrolyte liquid and a rare earth ionic salt liquid with the same volume and stirring for 12-24 hours to obtain a negatively charged high-molecular rare earth composite nanoparticle liquid; at 10-50 DEG C, placing a pretreated substrate into a cationic polyelectrolyte liquid, standing, cleaning and then placing the substrate into the negatively charged high-molecular rare earth composite nanoparticle liquid, standing, cleaning, circulating in such a manner to obtain the rare earth-containing high-molecular nanocomposite film. The preparation method is simple and is easy to operate and the prepared film has excellent optical property and broad application prospects.

Owner:DONGHUA UNIV

A kind of iron-silicon-based soft magnetic powder core with multiple insulating layers and preparation method thereof

ActiveCN108899152BOxidation process is simpleEasy to operateMagnetic materialsInsulation layerSilicon alloy

The invention discloses an iron-silicon based soft magnetic powder core with multiple insulation layers and a preparation method thereof. According to the technical scheme, iron-silicon alloy powder is stirred in a water vapor atmosphere at 100-260 DEG C for 0.5-3 hours to obtain composite powder; the composite powder is subjected to vacuum drying, placed in a mold and subjected to cold press molding at 300-1200 MPa to obtain a green body; the green body is placed in a high-temperature sintering furnace, heated to 800-1300 DEG C under the condition of vacuum or protective atmosphere and sintered for 0.5-5 hours to obtain a sintered green body; the sintered green body is placed in a heat treatment furnace, heated to 500-1200 DEG C under the condition of vacuum or protective atmosphere, subjected to heat treatment for 0.5-5 hours and cooled with the furnace to obtain the iron-silicon soft magnetic powder core with multiple insulation layers. The process is simple, the production cycle isshort, insulating coating layers of the prepared iron-silicon soft magnetic powder core with multiple insulation layers are uniform and thin, the eddy current loss is low, the saturation magnetic induction intensity is high, and the coercive force is low.

Owner:WUHAN UNIV OF SCI & TECH

A kind of preparation method of polymer nanocomposite film containing rare earth

ActiveCN104445991BUnique fluorescent propertiesEffective control of thicknessComposite filmOptical property

The invention relates to a preparation method of a rare earth-containing high-molecular nanocomposite film. The preparation method comprises the following steps of mixing an anionic polyelectrolyte liquid and a rare earth ionic salt liquid with the same volume and stirring for 12-24 hours to obtain a negatively charged high-molecular rare earth composite nanoparticle liquid; at 10-50 DEG C, placing a pretreated substrate into a cationic polyelectrolyte liquid, standing, cleaning and then placing the substrate into the negatively charged high-molecular rare earth composite nanoparticle liquid, standing, cleaning, circulating in such a manner to obtain the rare earth-containing high-molecular nanocomposite film. The preparation method is simple and is easy to operate and the prepared film has excellent optical property and broad application prospects.

Owner:DONGHUA UNIV

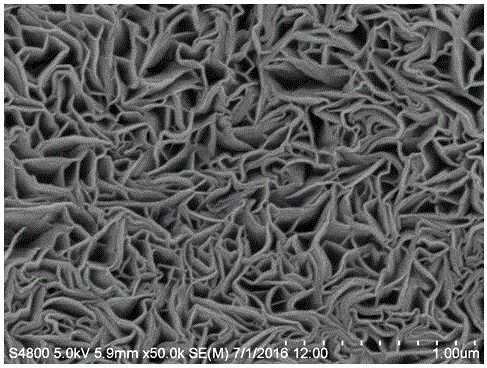

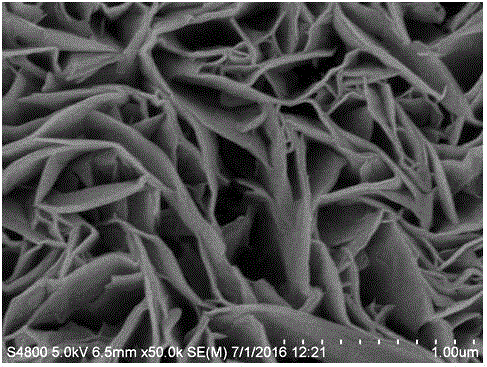

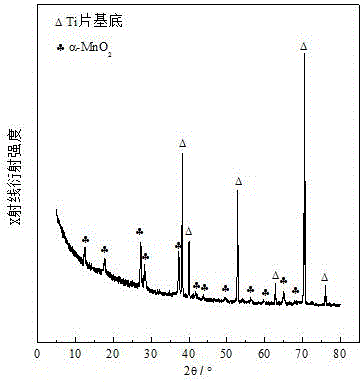

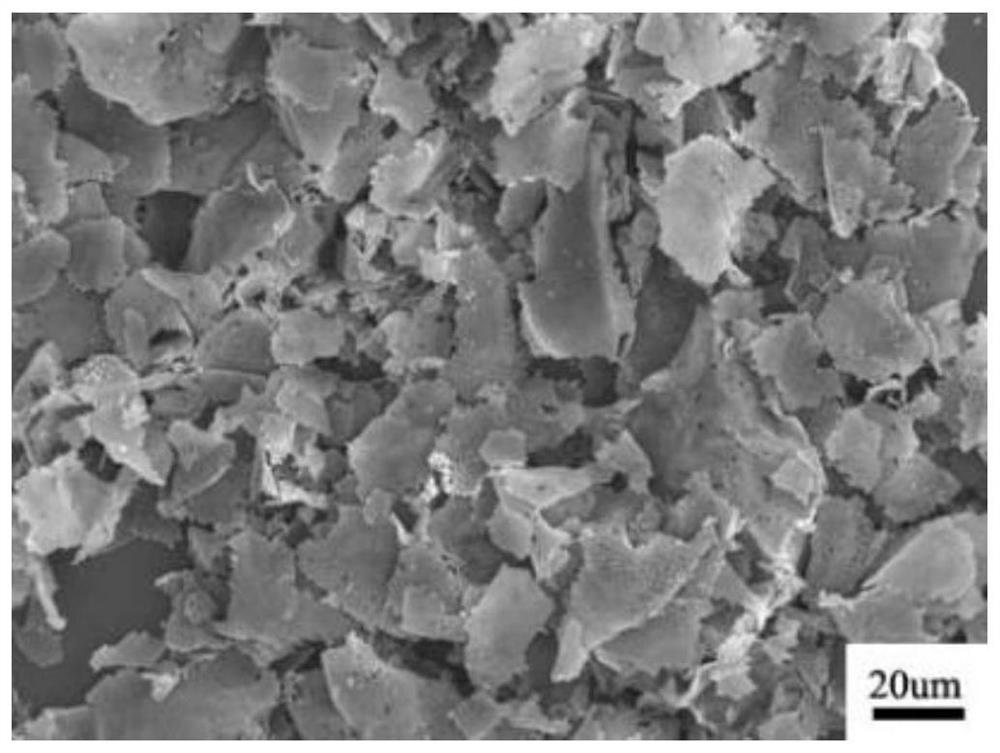

Method for growing manganese dioxide nano wall film on conductive substrate

ActiveCN106531473AEffective control of thicknessEffective control of gap widthHybrid capacitor electrodesNanotechnologySorbentAir purification

The invention discloses a method for growing a manganese dioxide nano wall film on a conductive substrate which comprises the step of immersing the conductive substrate with a clean surface in a reaction solution prepared from potassium permanganate solution and hydrochloric acid at a temperature of 40 to 100 degrees centigrade, after the reaction, cleaning and drying the product with deionized water. The method is simple, controllable in nano film morphology and dimension, low in cost and low in energy consumption, and the manganese dioxide nano wall supported on the conductive substrate has uniform size and strong adhesion. The prepared MnO2 nanowall film can be used directly as an electrode and is expected to be used in the fields of energy and environment such as catalyst or adsorbent carrier, separation material, magnetic material, oxidative degradation material, desulfurization or air purification material.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com