Method for preparing high-inoxidability sphere-like copper powder

An oxidizing, spherical-like technology, applied in the field of copper powder preparation, can solve the problems of poor reproducibility, huge equipment investment, and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 100g copper sulfate pentahydrate, add 500ml deionized water, stir and dissolve for later use, called A solution;

[0021] Weigh 25g of sodium hydroxide, add 200ml of deionized water, stir and dissolve for later use, called B solution;

[0022] Weigh 40g of Vc, add 300ml of deionized water, stir and dissolve for later use, called C solution;

[0023] Weigh 5g of PVA, add 100ml of deionized water, stir and dissolve for later use, called D solution

[0024] Weigh 0.25g of polymerized liquid resin, add 25ml of deionized water, stir at high speed and emulsify until it is in the form of an emulsion, which is called E solution.

[0025] Heat the four solutions of A, B, C, and D to 50°C respectively, and add the D, C, and B solutions to the A solution in turn under the condition of stirring (the adding time of each solution is ≤5 minutes). Stir one solution for 10 minutes, then add the latter solution until the addition is complete; stir and keep warm for 2 hours, raise...

Embodiment 2

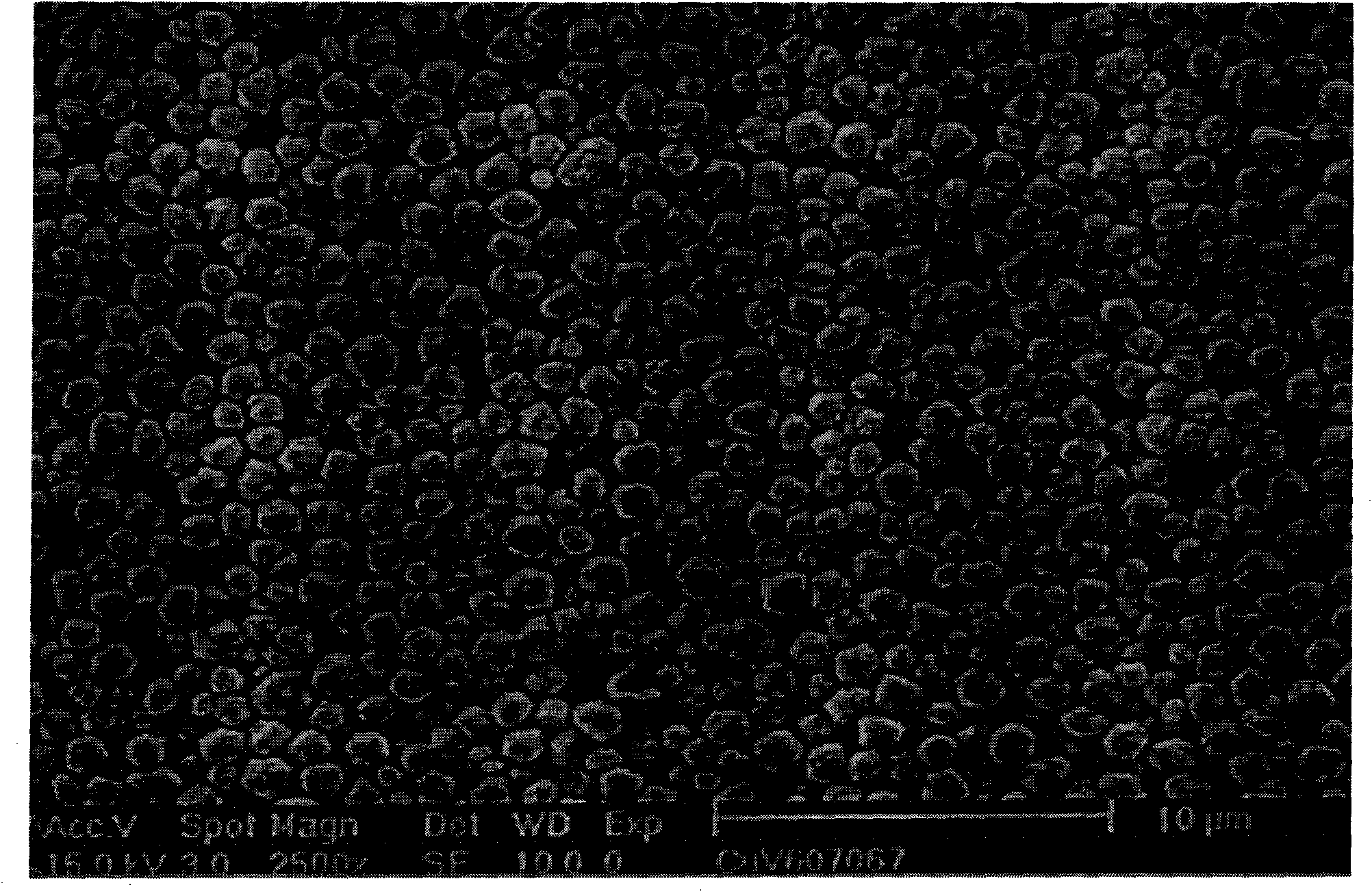

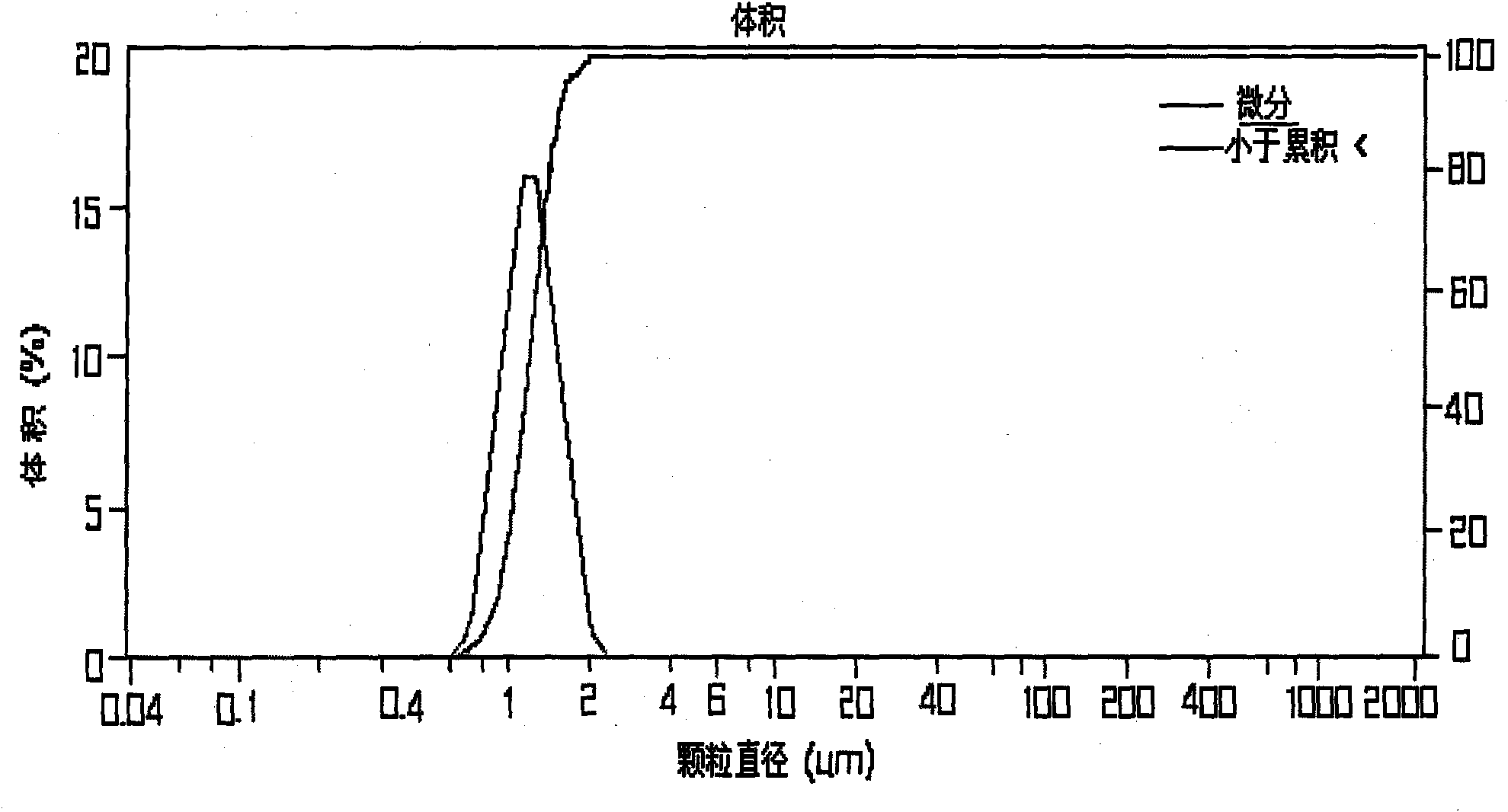

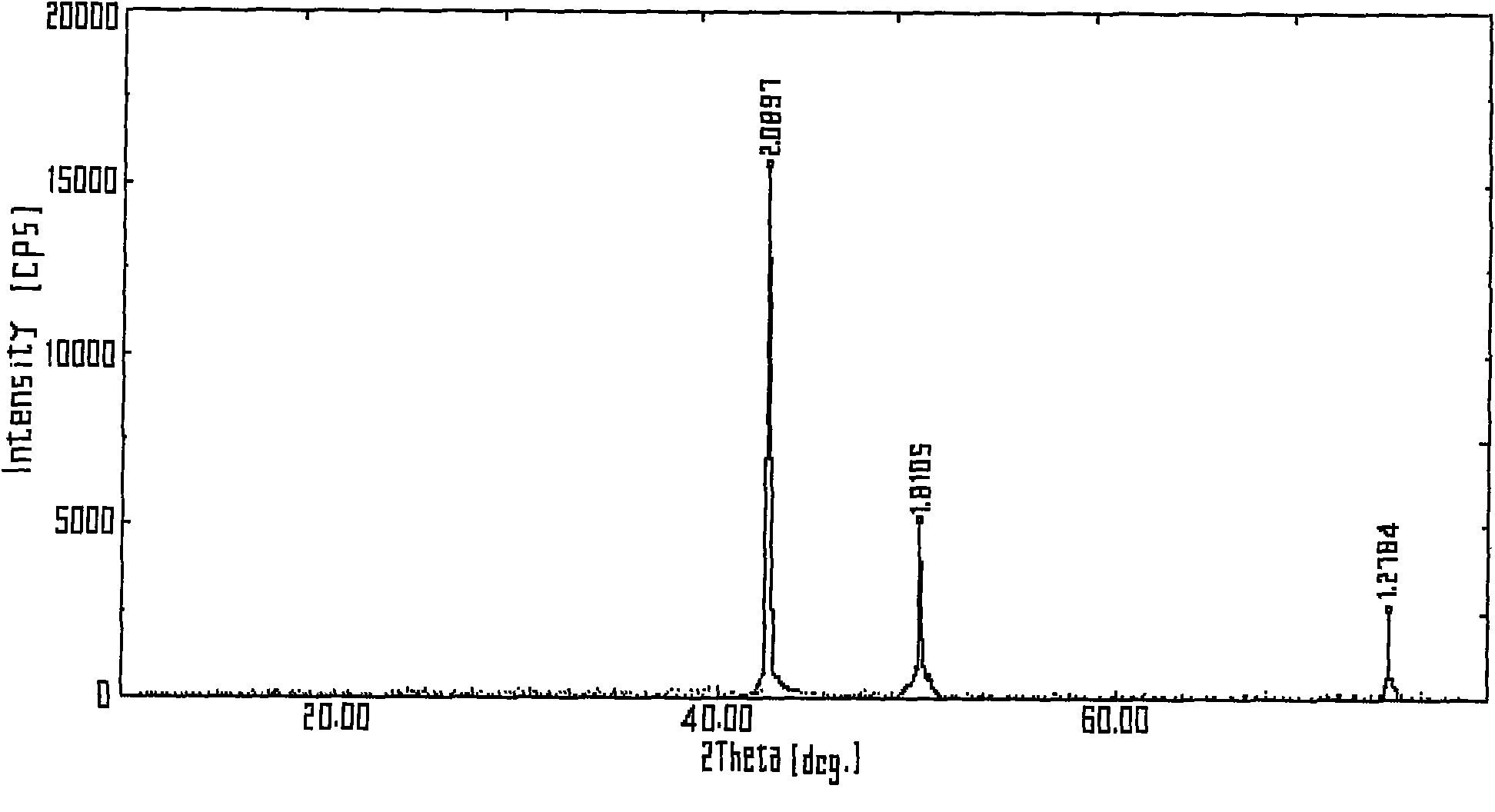

[0027] As in Example 1, the copper sulfate pentahydrate was changed to copper nitrate trihydrate, and the consumption was 97g, and the others were unchanged. The properties of the obtained copper powder are shown in Table 1. Electron microscope analysis SEM (2500 times) of quasi-spherical copper powder such as figure 1 Shown; the laser particle size distribution VPSD diagram of spherical copper powder is shown in figure 2 Shown; The X-ray diffraction analysis XRD of quasi-spherical copper powder is as image 3 Shown; thermal analysis STA diagram of spherical copper powder Figure 4 shown. These four test and analysis methods are commonly used particle analysis methods by those skilled in the art.

Embodiment 3

[0029] As in Example 1, copper sulfate pentahydrate was changed to copper chloride dihydrate, and the consumption was 68.5 g, and the others were unchanged. The properties of the obtained copper powder are shown in Table 1. Electron microscope analysis SEM (2500 times) of quasi-spherical copper powder such as figure 1 Shown; the laser particle size distribution VPSD diagram of spherical copper powder is shown in figure 2 Shown; The X-ray diffraction analysis XRD of quasi-spherical copper powder is as image 3 Shown; thermal analysis STA diagram of spherical copper powder Figure 4 shown. These four test and analysis methods are commonly used particle analysis methods by those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com