Patents

Literature

1259results about How to "Improve electrocatalytic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

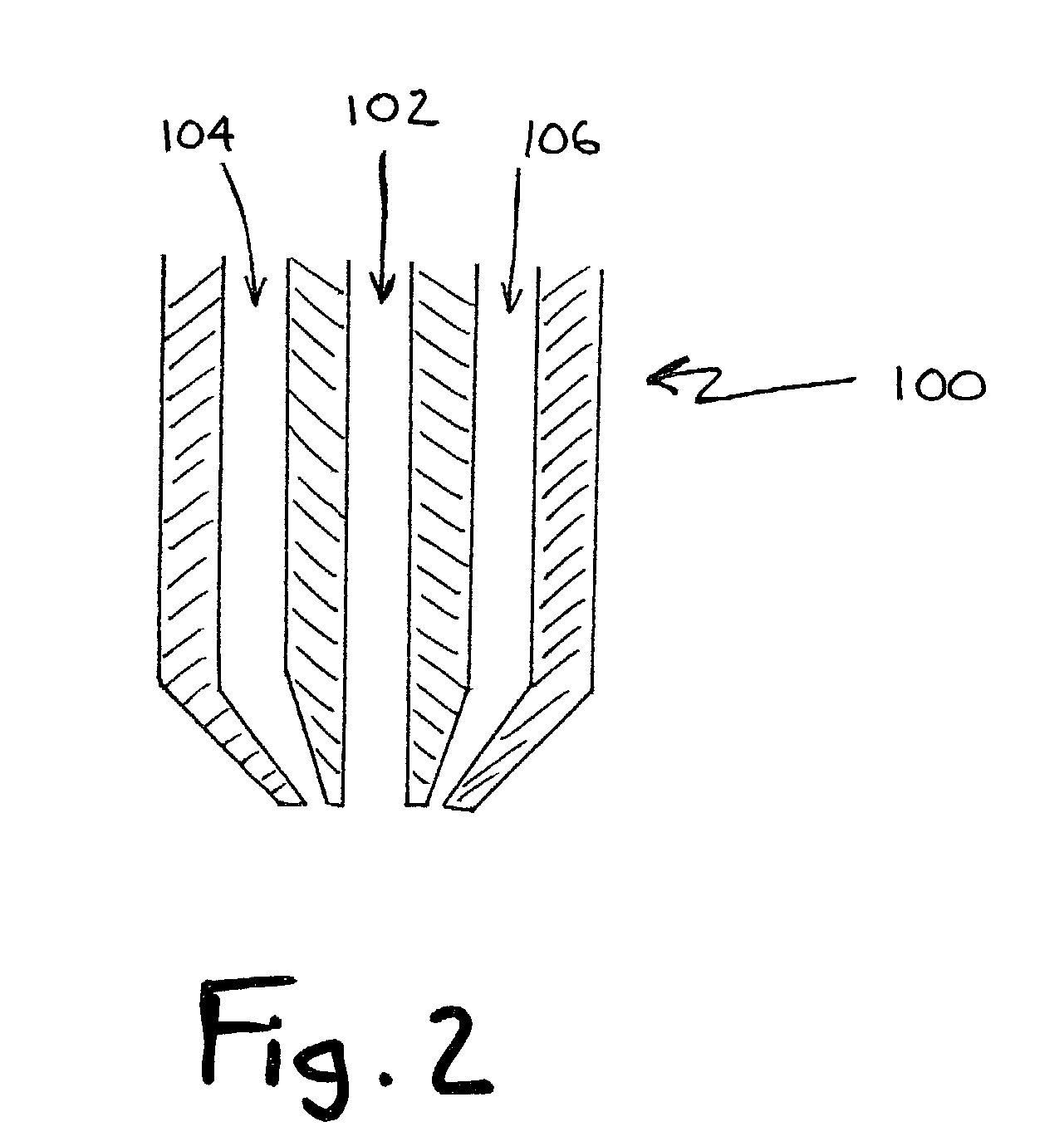

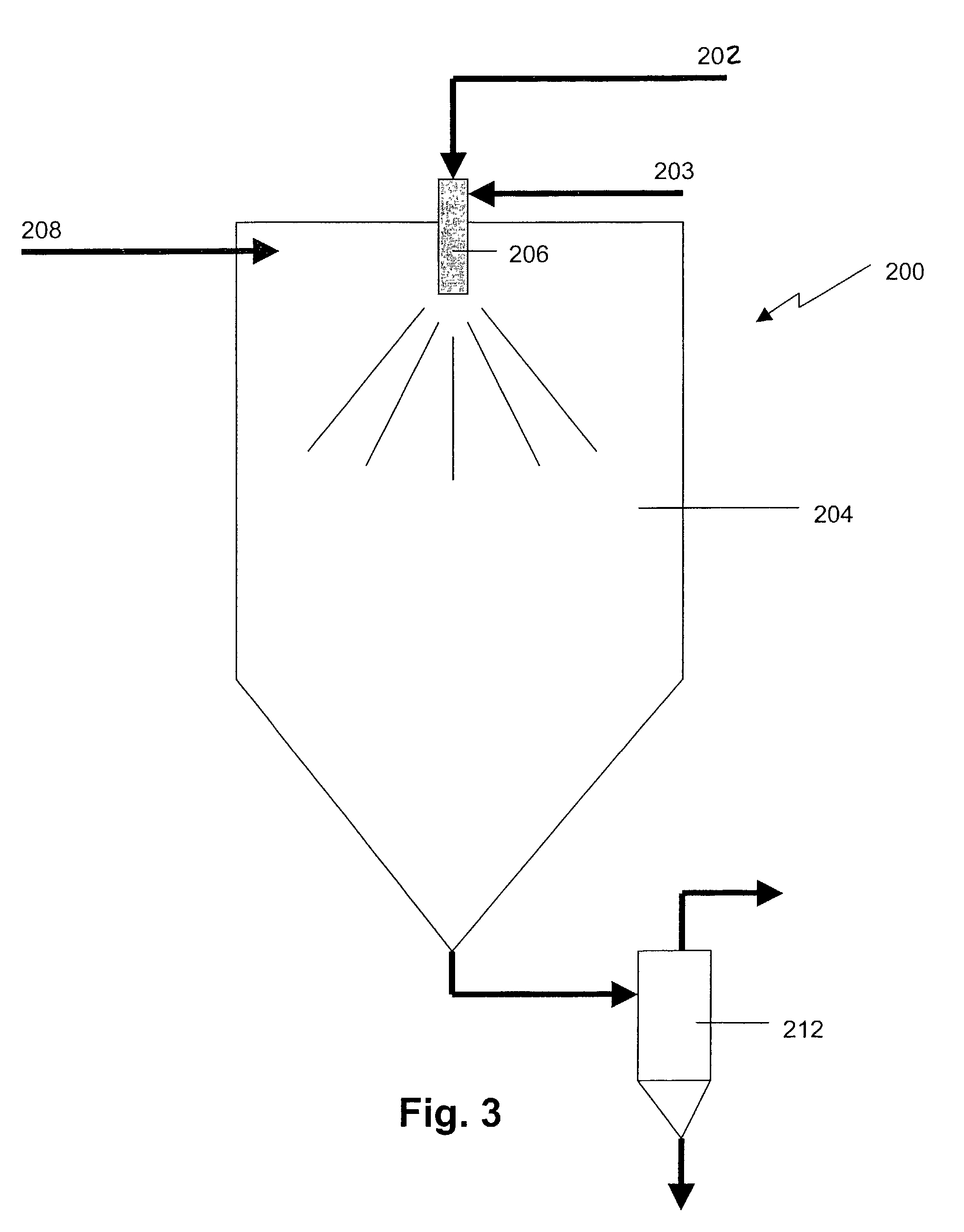

Electrocatalyst powders, methods for producing powders and devices fabricated from same

InactiveUS20020107140A1High purityImprove electrocatalytic activityMaterial granulation and coatingGranule coatingMicrostructureCarbon composites

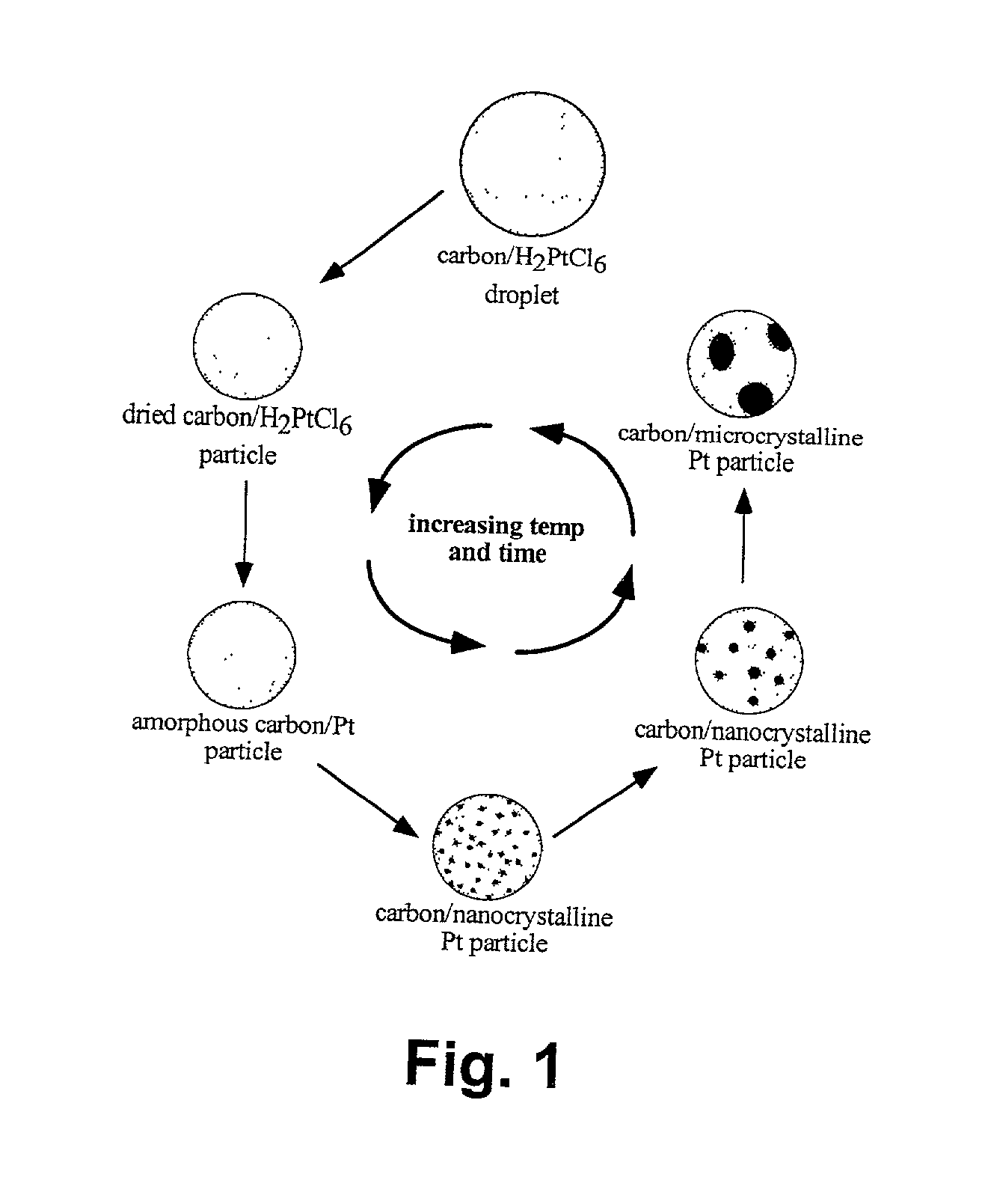

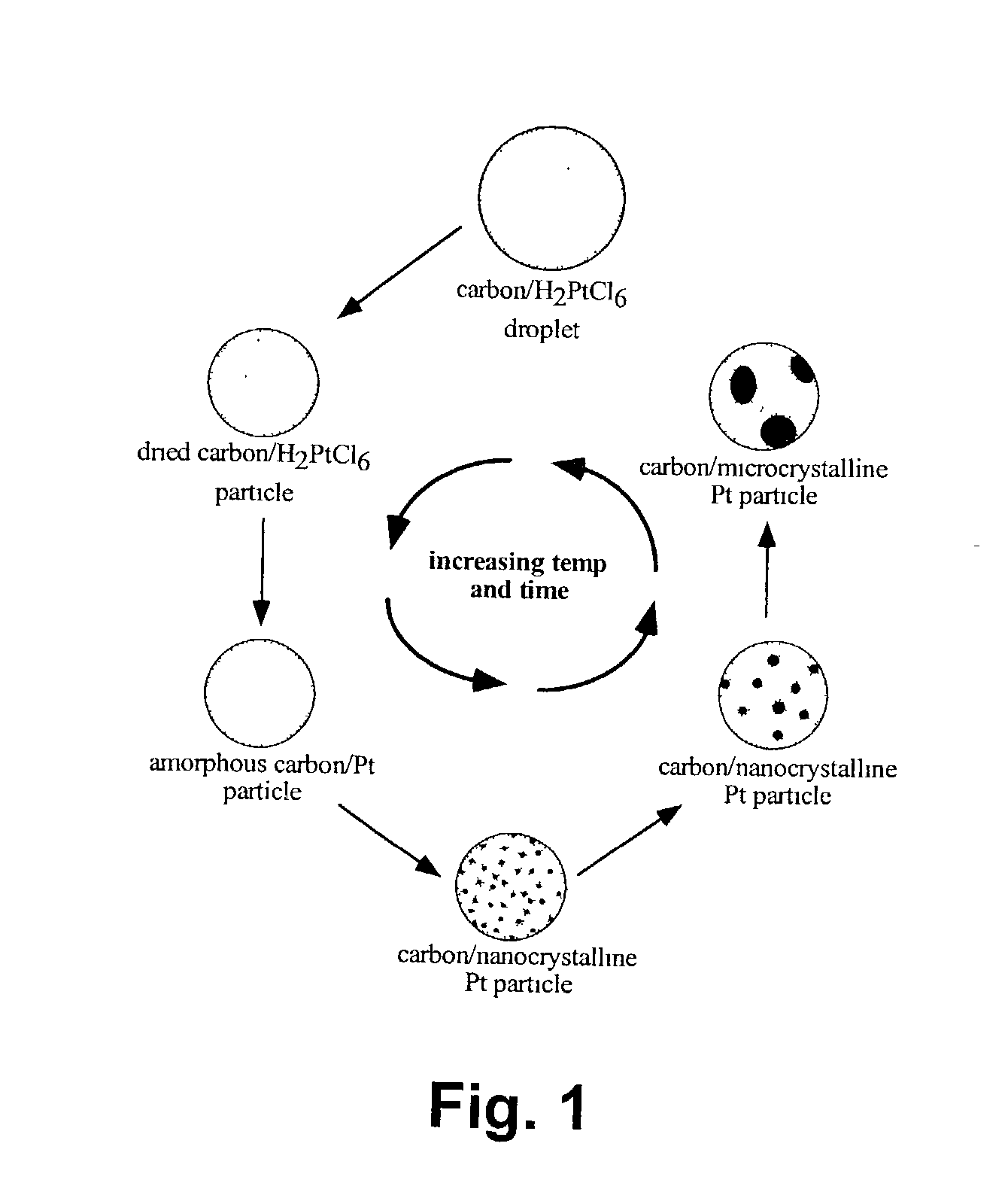

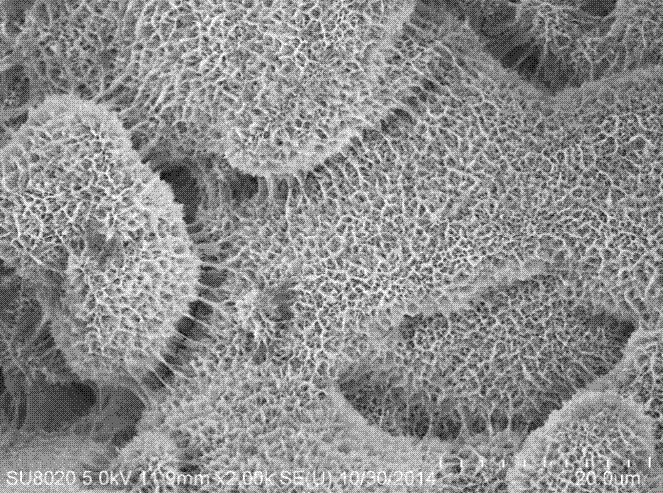

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

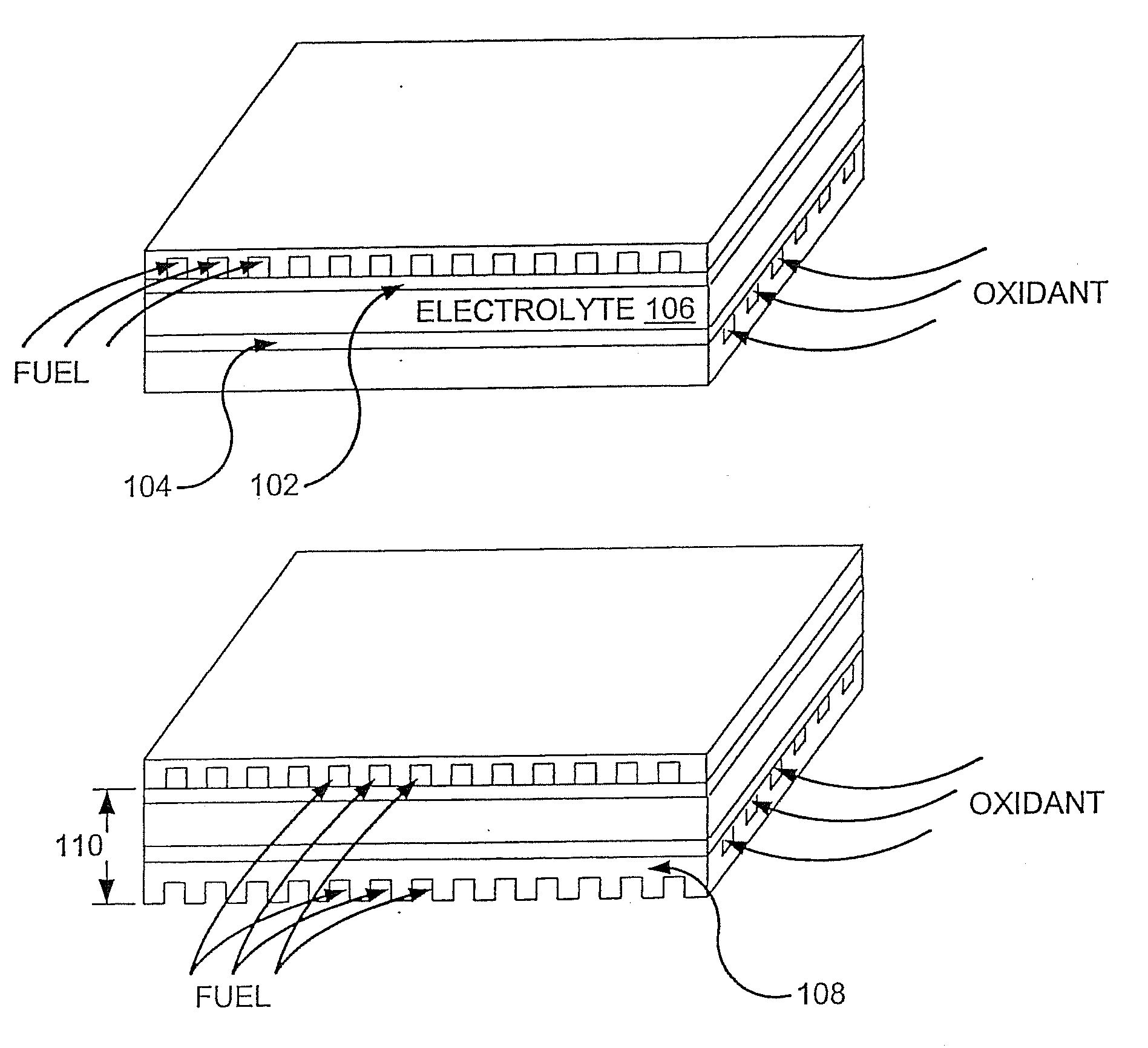

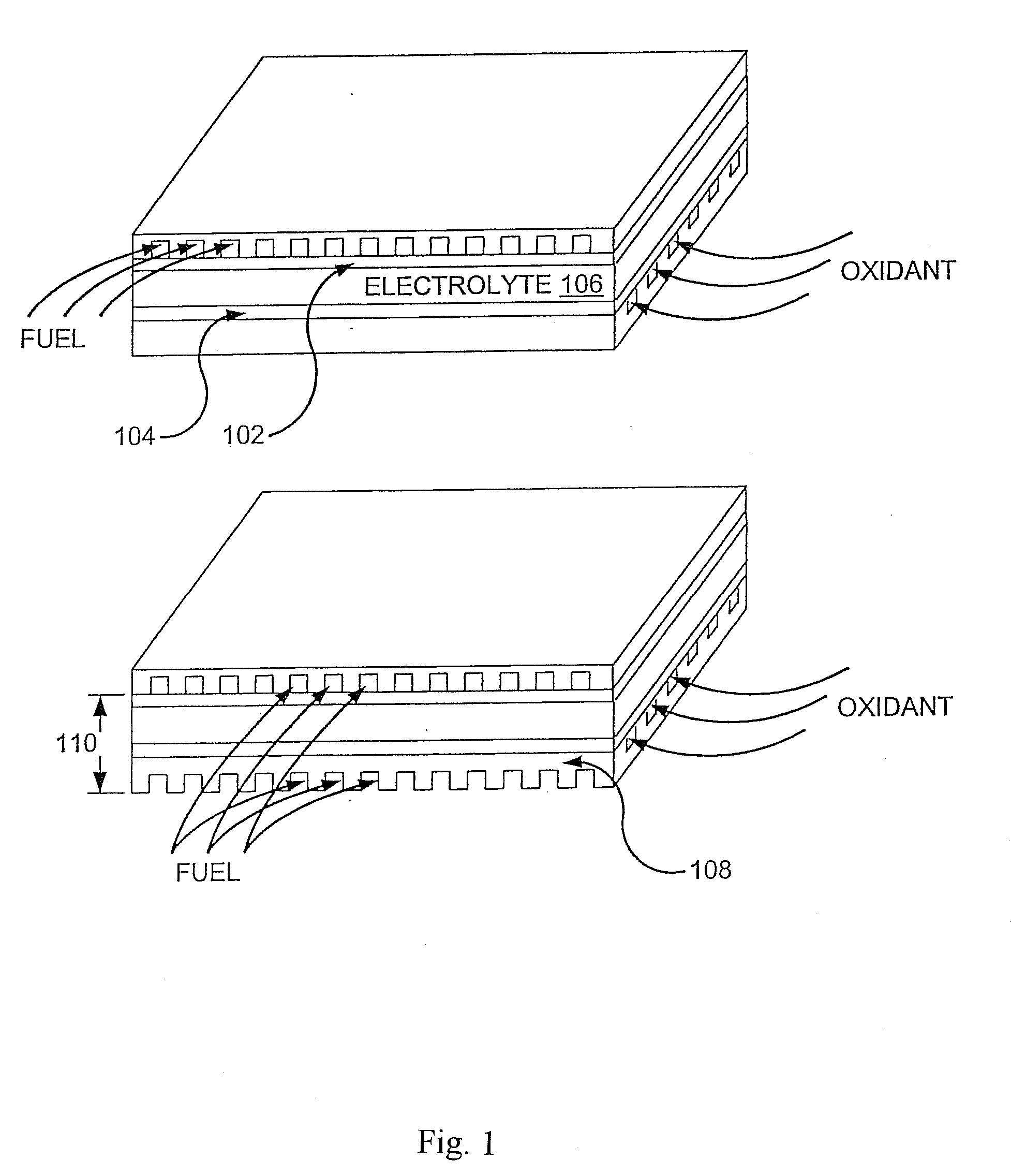

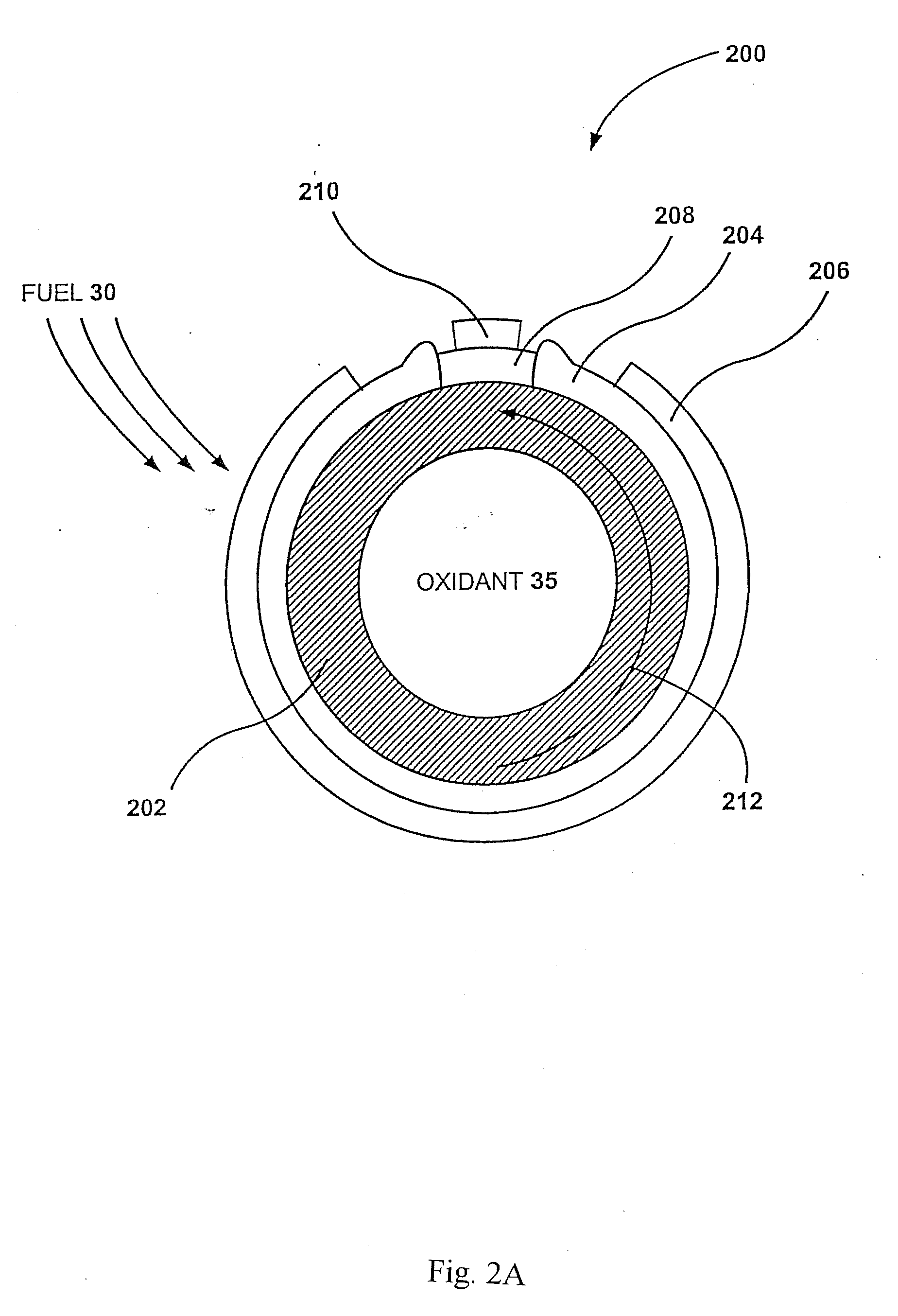

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

Structures for dense, crack free thin films

InactiveUS20070134532A1Reduce resistance lossHigh strengthFuel cells groupingFinal product manufactureHigh densityCrazing

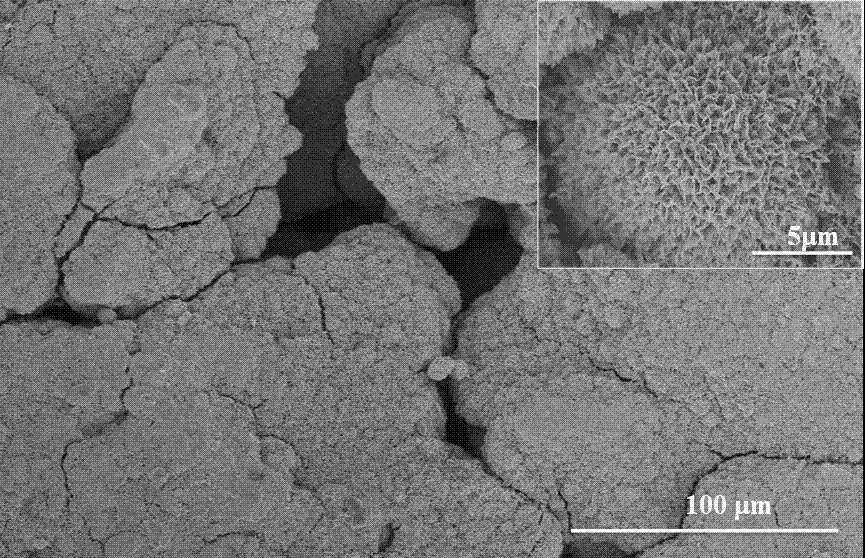

The process described herein provides a simple and cost effective method for making crack free, high density thin ceramic film. The steps involve depositing a layer of a ceramic material on a porous or dense substrate. The deposited layer is compacted and then the resultant laminate is sintered to achieve a higher density than would have been possible without the pre-firing compaction step.

Owner:RGT UNIV OF CALIFORNIA

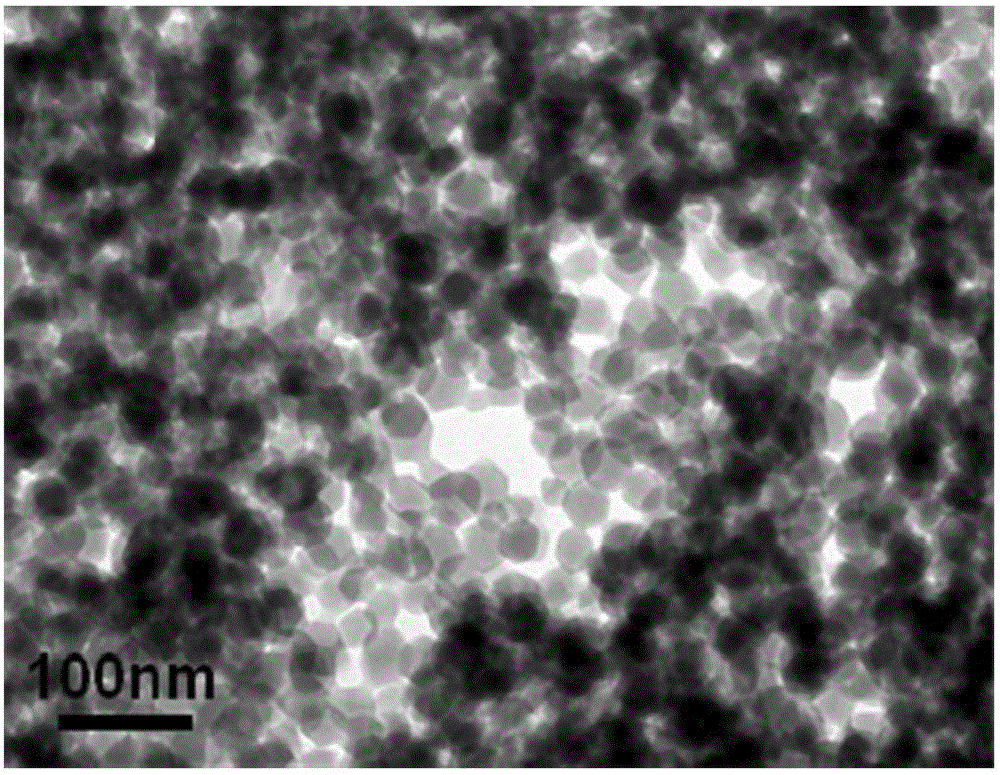

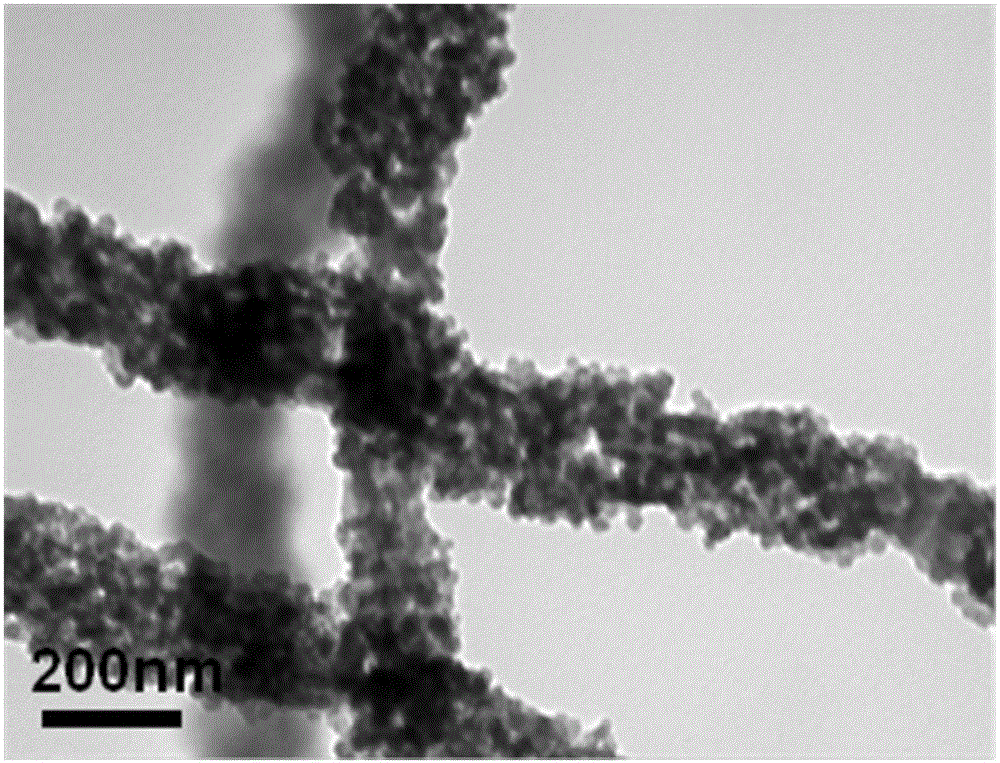

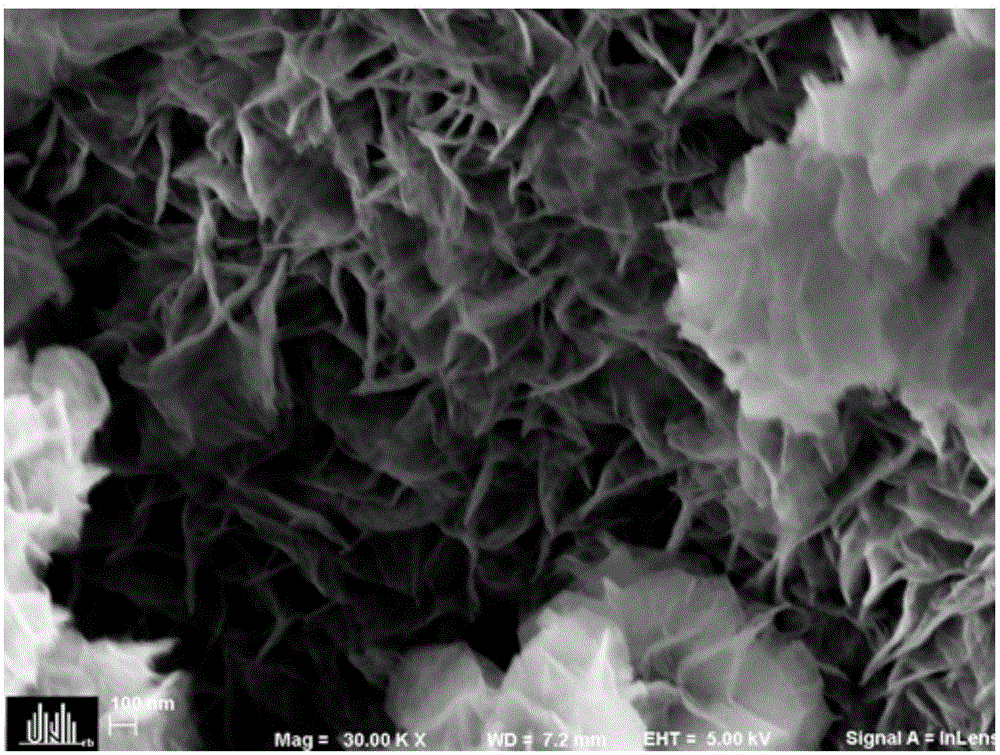

Preparation method of novel metal organic complex fibers and derivative porous carbon fibers thereof

ActiveCN105862174ASimple and fast operationHigh yieldMonocomponent synthetic polymer artificial filamentArtifical filament manufactureCarbon fibersNitrate

The invention discloses a preparation method of novel metal organic complex fibers and derivative porous carbon fibers thereof. The method comprises the following steps: respectively adding certain amounts of a precursor (zinc nitrate hexahydrate / cobalt nitrate hexahydrate) and dimethylimidazole to a methanol solution, and magnetically stirring above materials to obtain metal organic complex nano-particles; dispersing the metal organic complex nano-particles in an N,N-dimethyl formamide solution, and adding polyacrylonitrile to obtain an electrospinning solution; carrying out an electrospinning technology to obtain metal organic complex / polyacrylonitrile electrospinned fibers, collecting the metal organic complex / polyacrylonitrile electrospinned fibers with a copper mesh, and peeling to obtain a metal organic complex / polyacrylonitrile film; and calcining the film to obtain porous carbon fibers. The preparation method has the advantages of simple operation and high yield; and the derivative porous carbon fibers have high specific surface area and good electrocatalytic activity, and have very great application prospect in the fields of energy storage and conversion.

Owner:HEFEI UNIV OF TECH

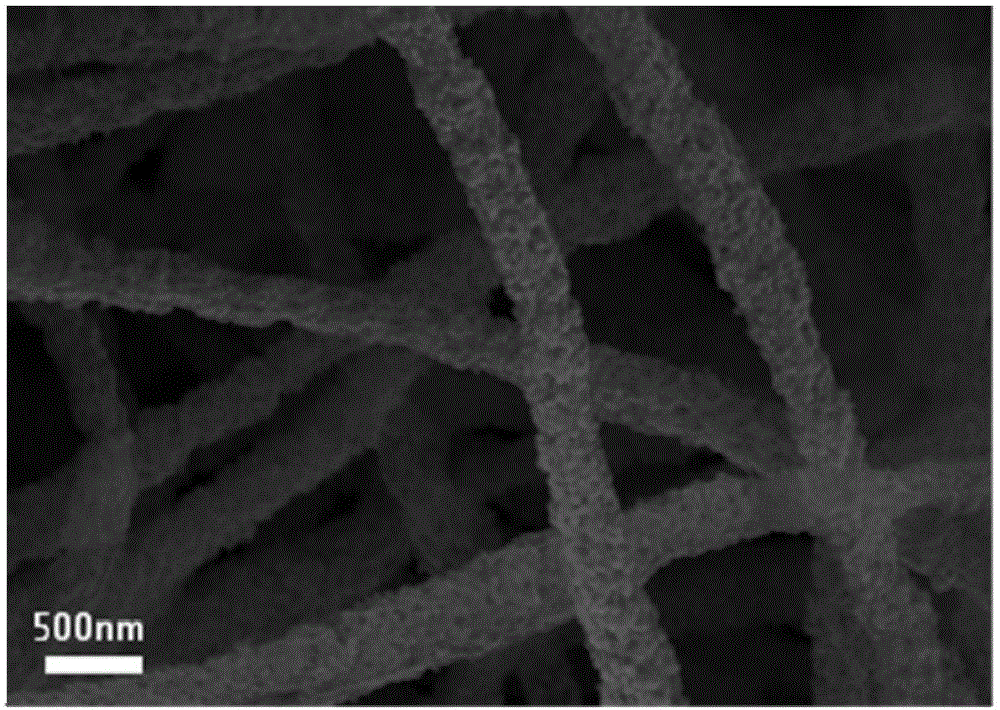

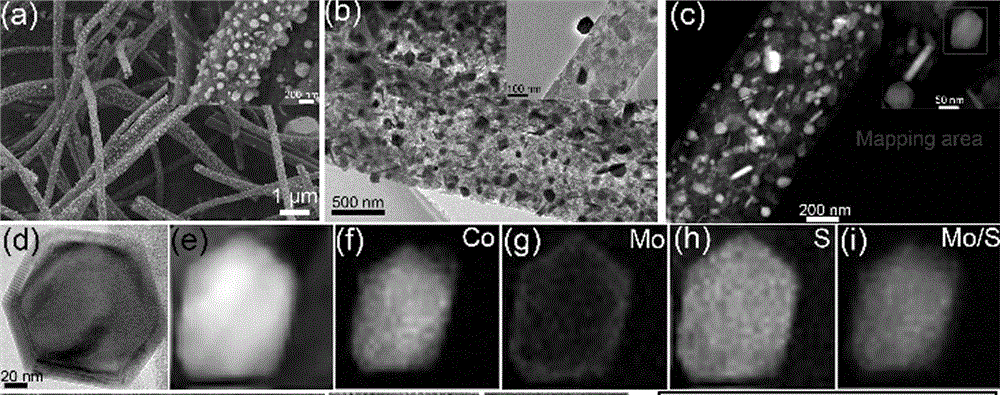

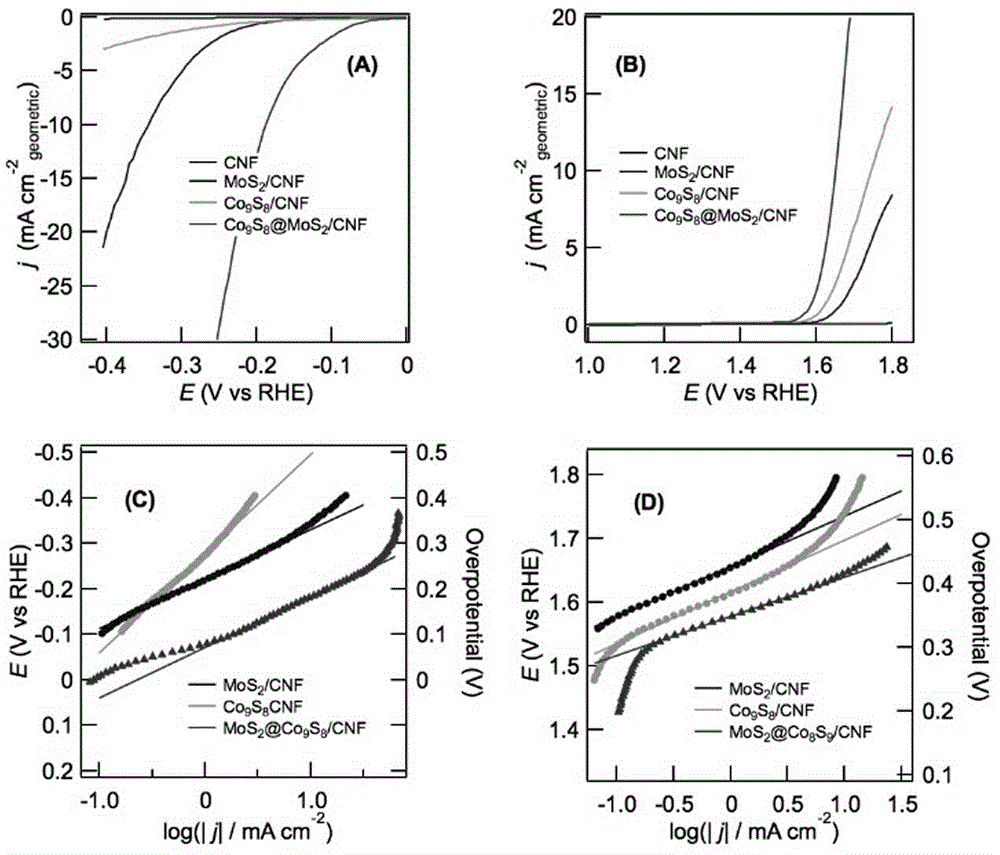

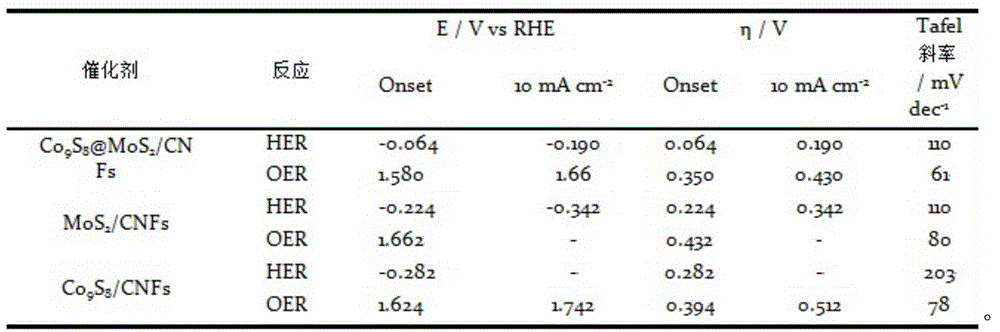

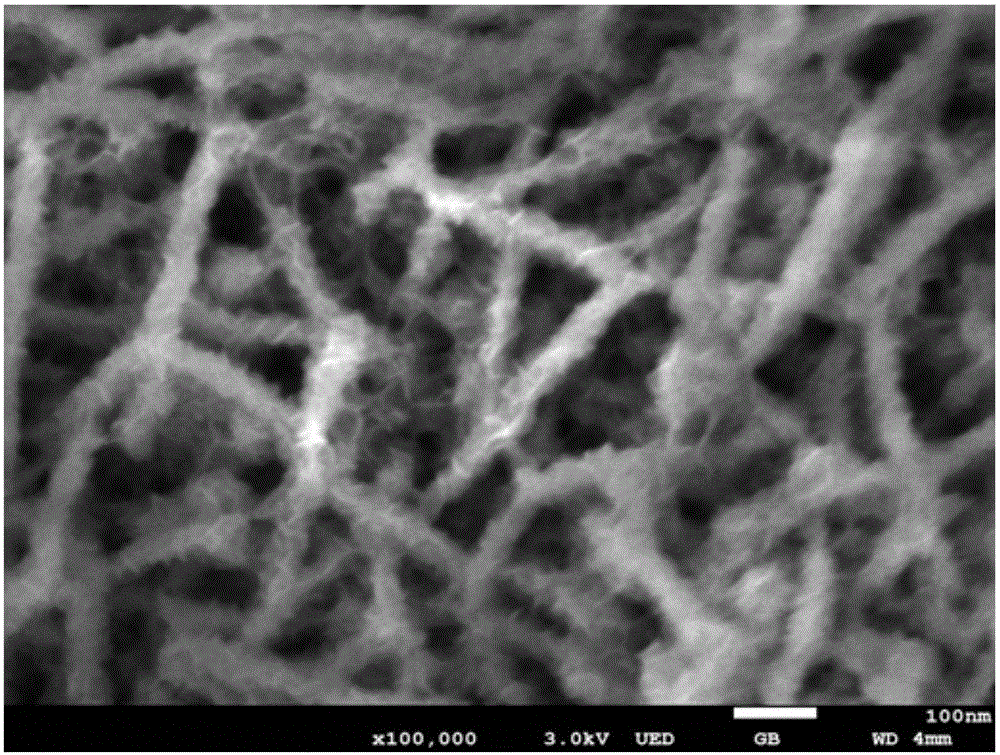

Electrolyzed-water catalytic material with nanometer core-shell structure of cobalt sulfide and molybdenum disulfide

ActiveCN104971744AIncrease the areaHigh porosityPhysical/chemical process catalystsElectrolysis componentsFiberPorosity

The invention discloses an electrolyzed-water catalytic material with a nanometer core-shell structure of cobalt sulfide and molybdenum disulfide. The electrolyzed-water catalytic material is composed of a catalytic active material and a carrier, wherein the catalytic active material is a material with the nanometer core-shell structure of cobalt sulfide and molybdenum disulfide; molybdenum disulfide is a shell; cobalt sulfide is a core; and the carrier is ultrafine carbon fiber. The electrolyzed-water catalytic material provided by the invention has high specific surface area and porosity, is favorable for diffusion and gas desorption of electrolyte, has the characteristics of dual functions of hydrogen evolution and oxygen evolution at the same time, and can be directly used as an electrode for electrocatalytic hydrogen preparation without the need of loading onto the electrode.

Owner:ZHEJIANG SCI-TECH UNIV

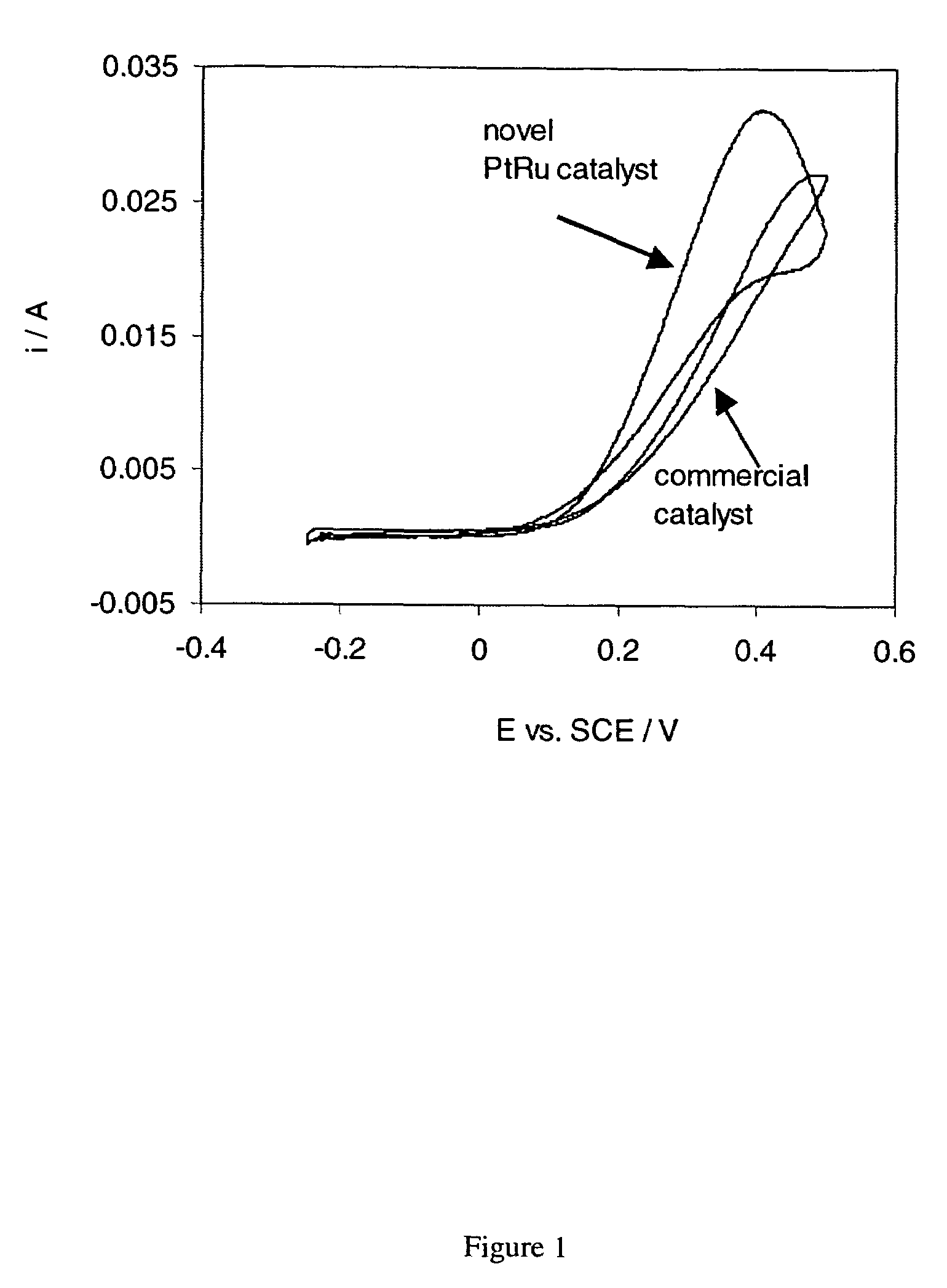

Platinum based nano-size catalysts

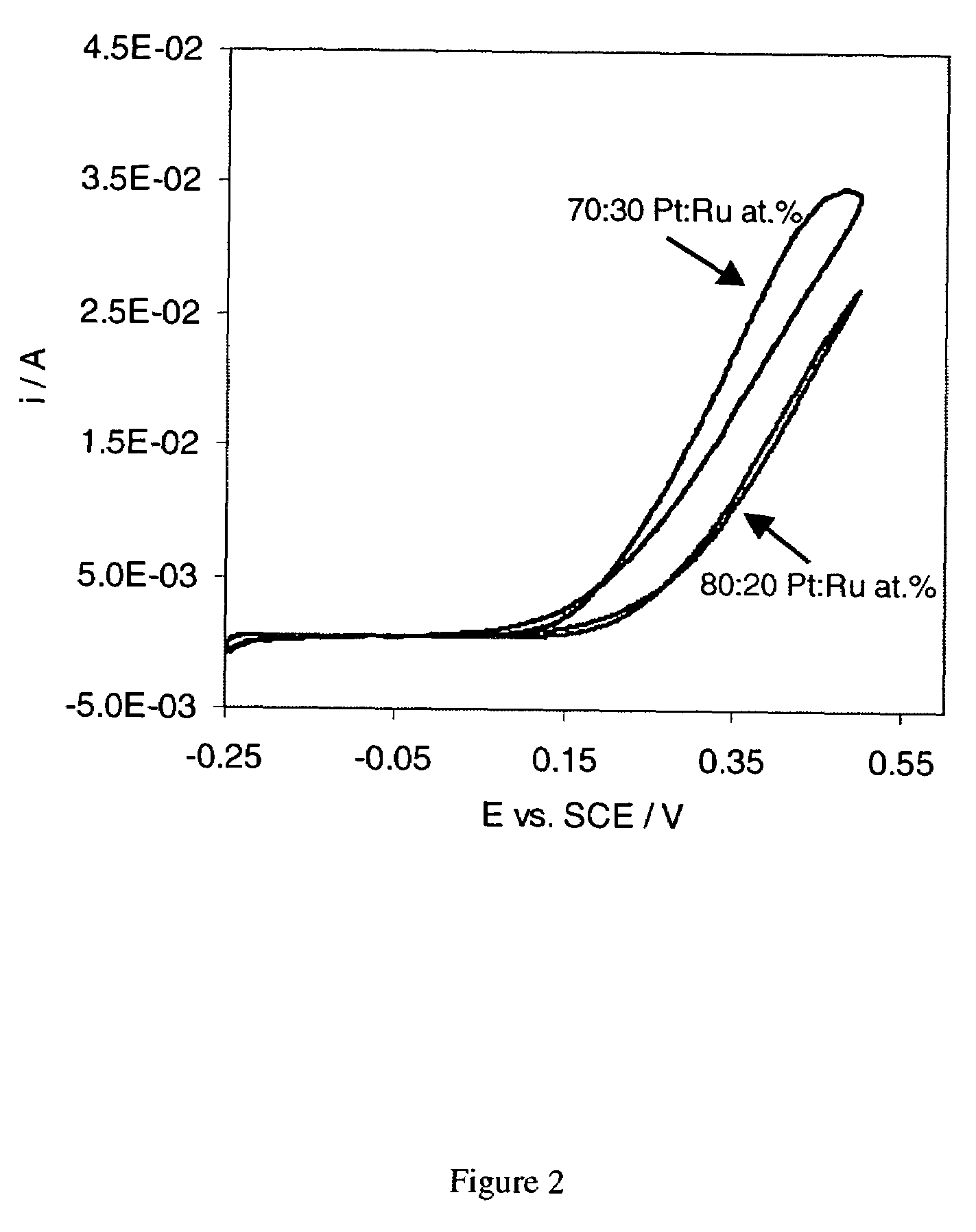

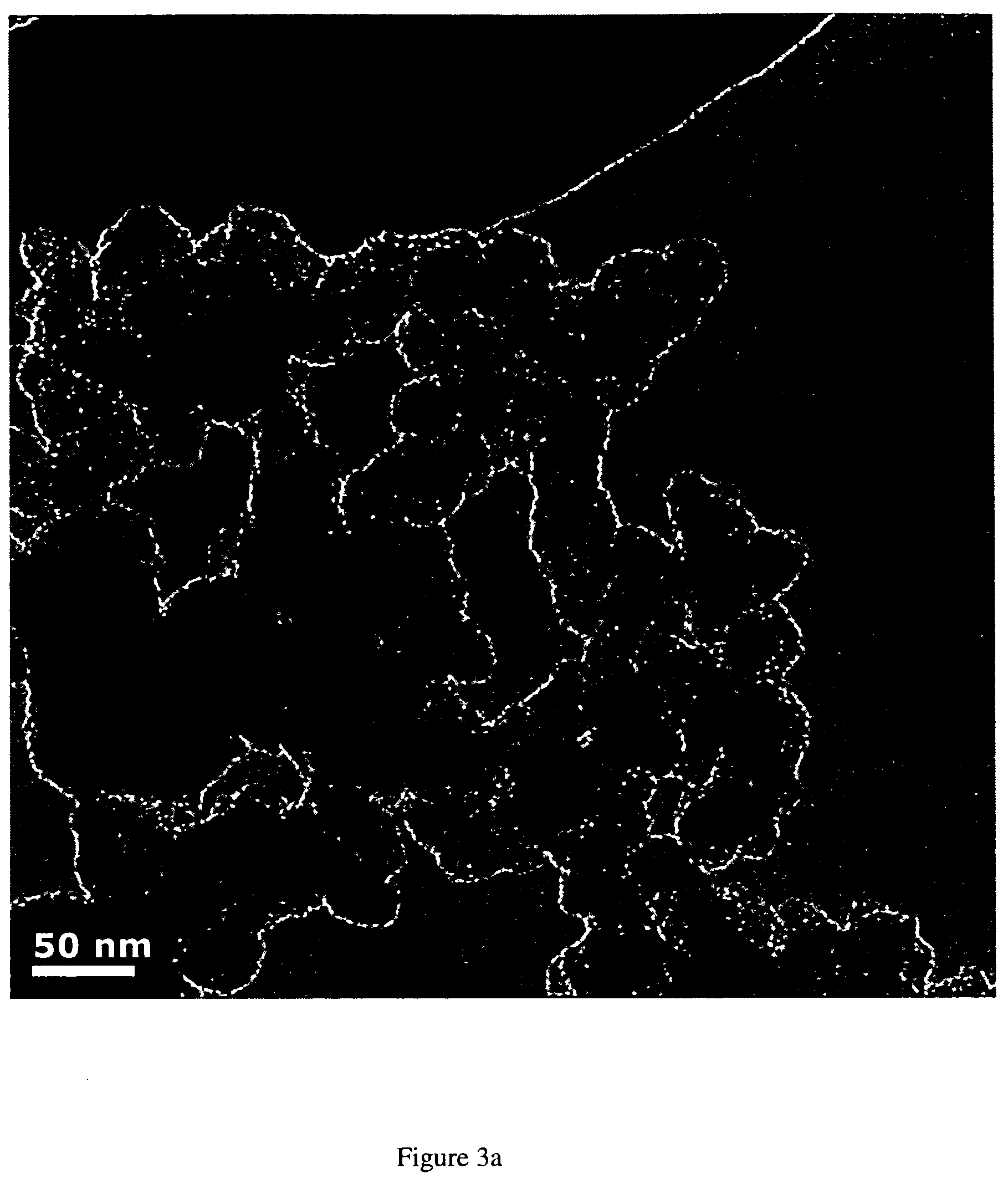

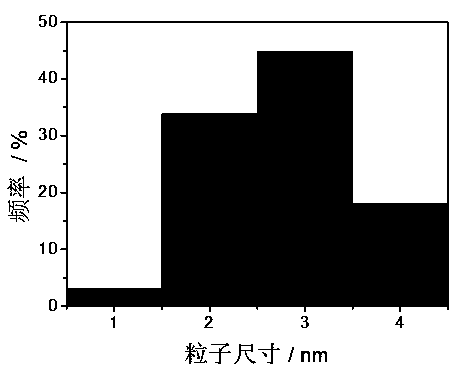

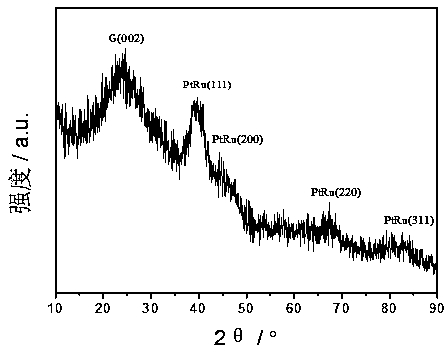

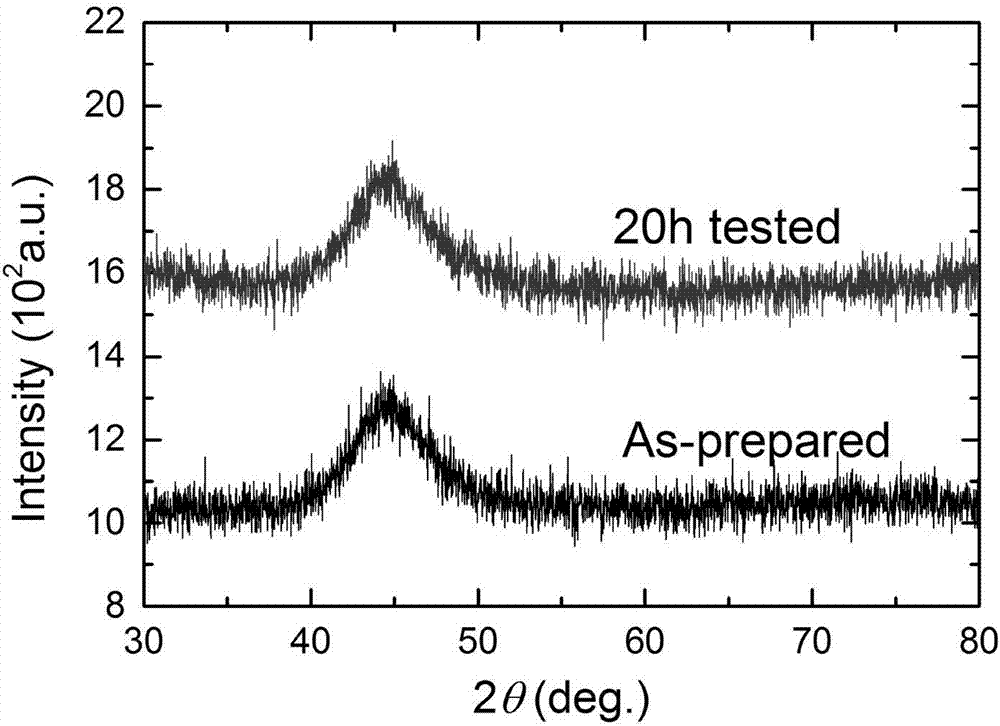

InactiveUS7566681B2Synthetic is simpleInvolvement between the nano-particle and the stabilizer, can be minimizedMaterial nanotechnologyCatalyst activation/preparationNano catalystCarbon black

The synthesis of Pt and PtRu and other Pt based nano-particles that catalyze the electrochemical oxidation of methanol, carbon monoxide and hydrogen, as well as oxygen reduction, is described. The Pt based catalysts are synthesized in solution forming particles of 0.8 to 10 nm size (forming a “colloidal” solution) and are subsequently applied to a desired substrate as e.g., carbon black, graphite, metals. The application of the nano-sized catalyst particles on the substrates involves electroless deposition at open-circuit, such as immersing the substrate into the colloidal solution or spraying the catalyst particles on the substrate. The Pt, PtRu and other Pt based catalyst can also be directly deposited on the substrate involving the simultaneous reduction and deposition of the Pt based catalysts onto the substrate surface and into its porous structure. The presently described synthesis and deposition of the resulting Pt based nano-particles on and into a variety of high surface area and preferably electronically conductive substrates results in electrodes of high surface areas, relates directly to the preparation and use of high surface area electrodes, (anodes and cathodes) which could be used in e.g., direct methanol, hydrogen and hydrogen containing carbon monoxide fuel cells.

Owner:RES COUNCIL OF CANADA

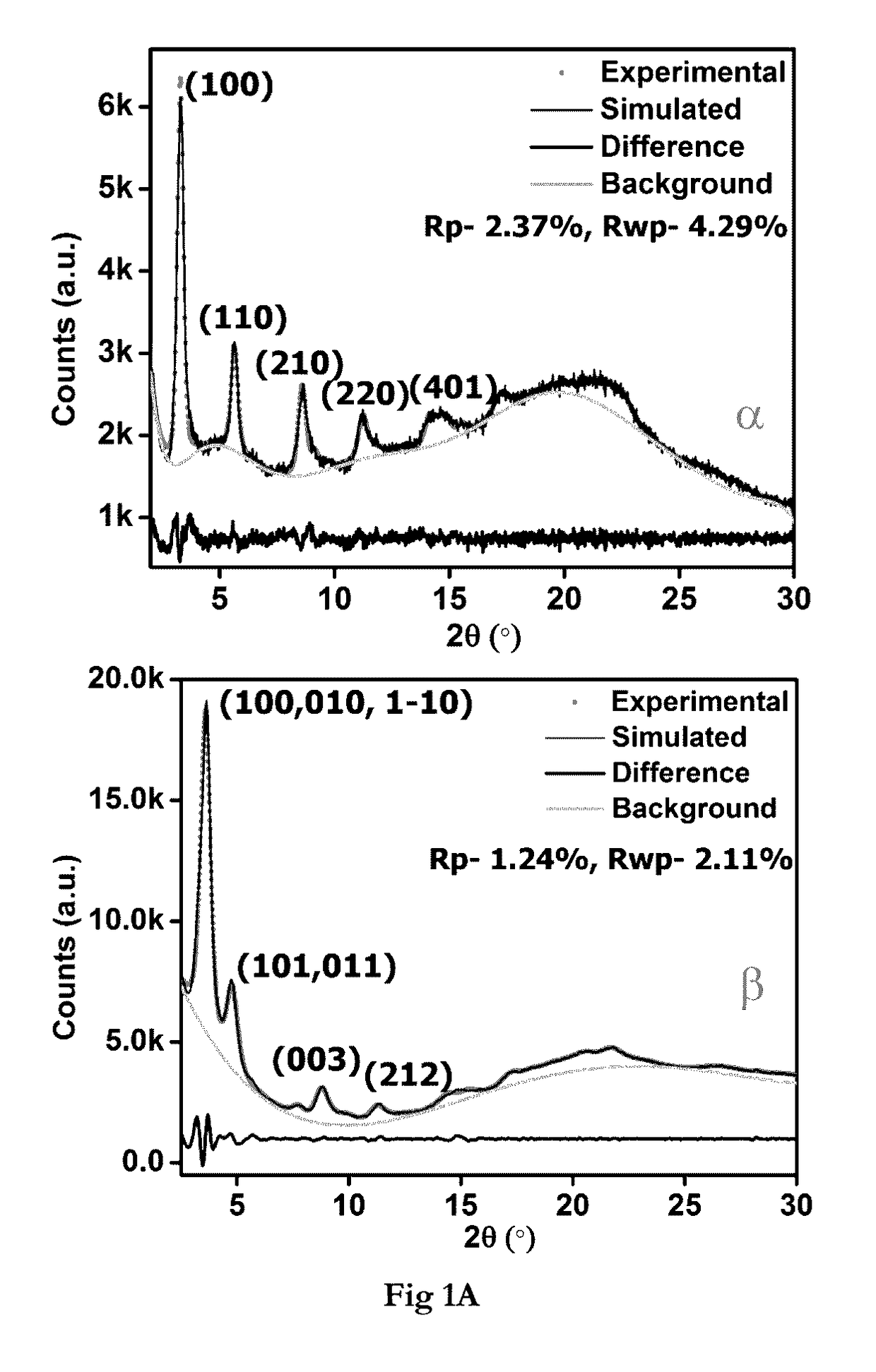

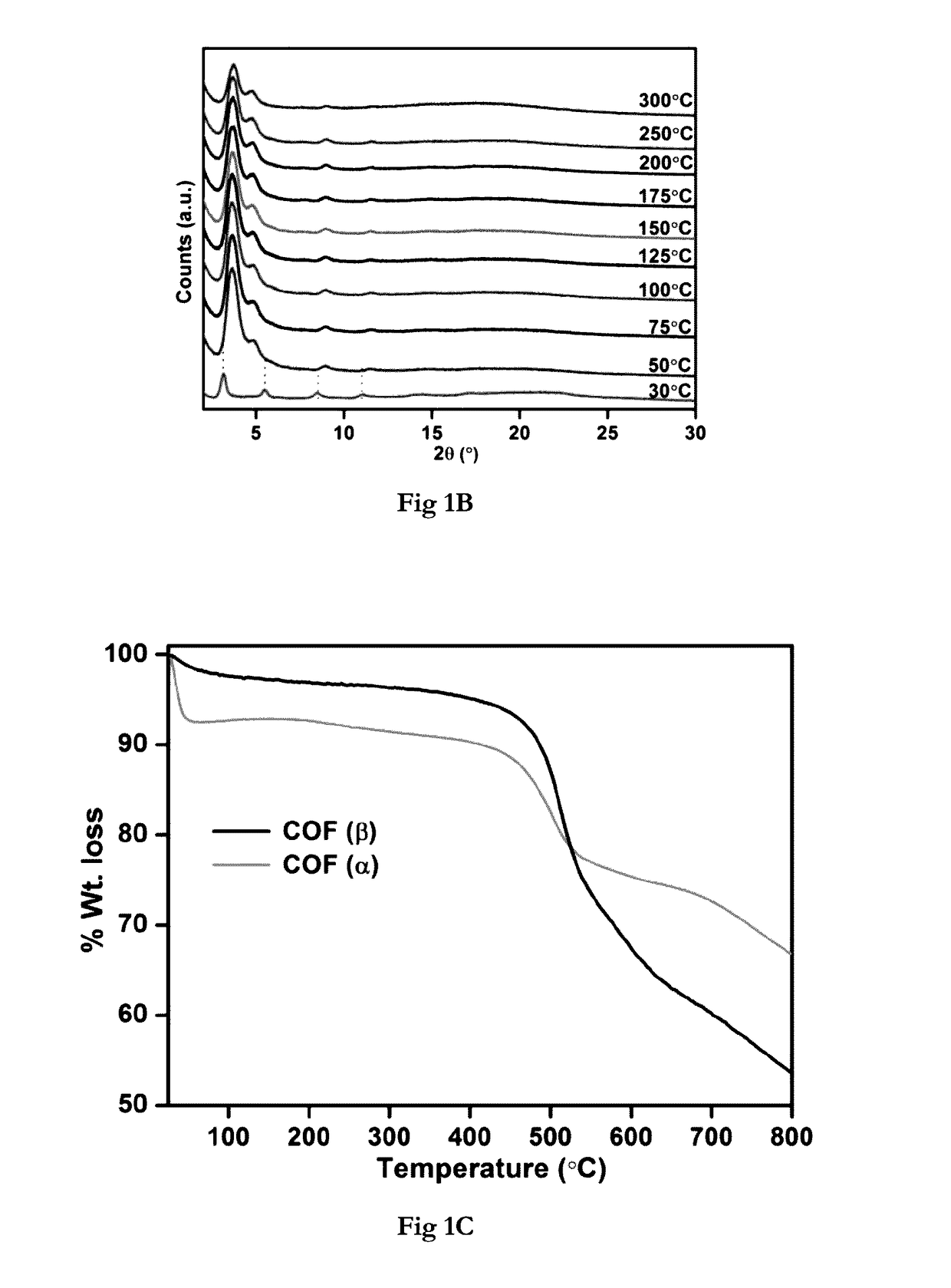

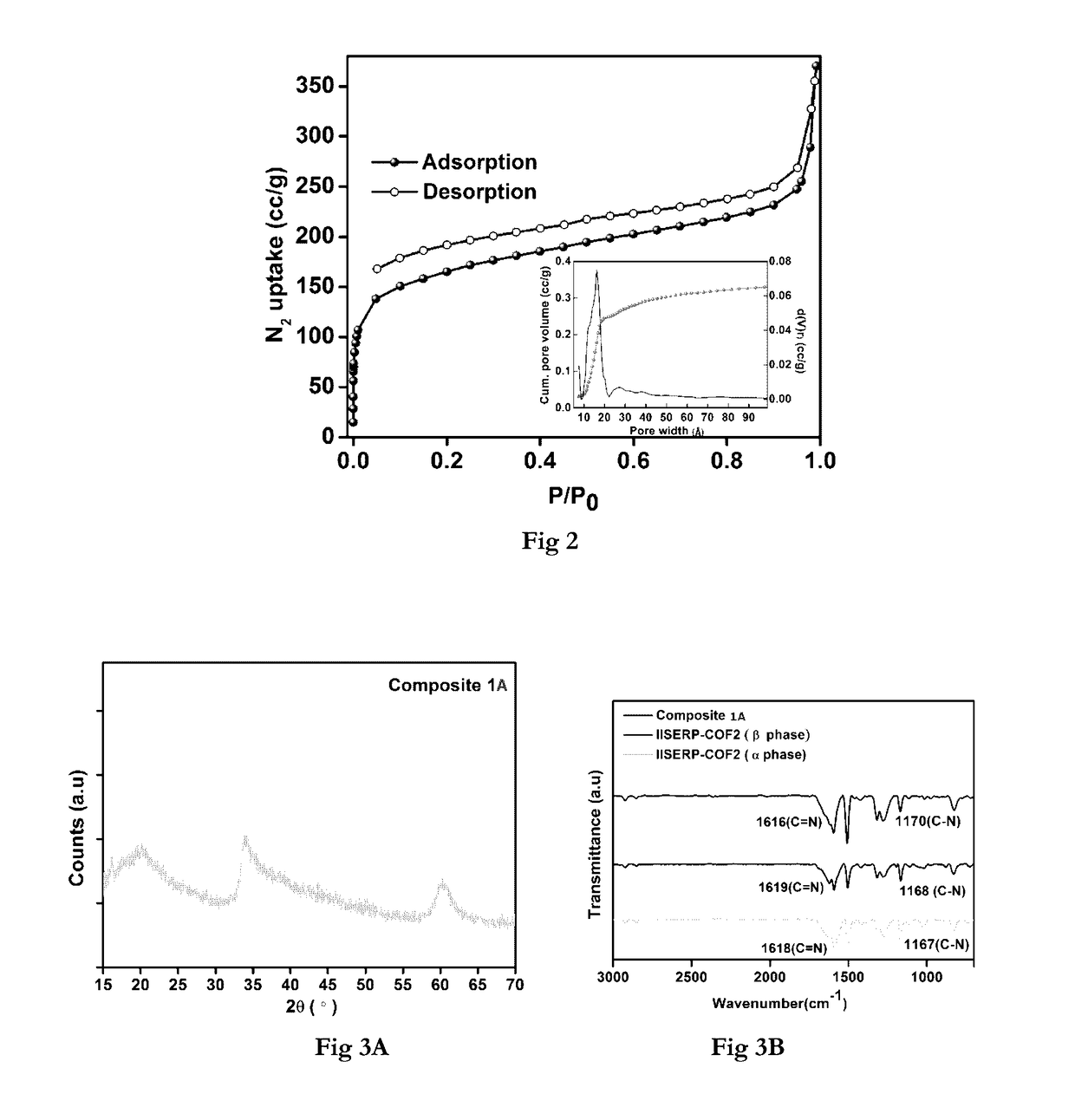

Covalent organic frameworks as porous supports for non-noble metal based water splitting electrocatalysts

ActiveUS20170130349A1Smooth connectionImprove performanceMultiple component coatingsElectrode with substrate and coatingMetal-organic frameworkManganese

The present invention discloses porous covalent organic frameworks (COF) supported noble metal-free nanoparticles which are useful as electrocatalysts for a water splitting system, and to the process for preparation of such electrocatalysts. The covalent organic frameworks (COF) supported noble metal-free nanoparticles have general formula (I):COF_AxBy(M)n (Formula I)wherein COF is selected from a Tris (4-formylphenyl)amine terephthaldehyde polymer or a benzimidazole-phloroglucinol polymer;‘A’ and ‘B’ each independently represent a transition metal selected from the group consisting of Ni, Co, Fe, Mn, Zn, and mixtures thereof; or ‘A’ and ‘B’ together represent a transition metal selected from the group consisting of Ni, Co, Fe, Mn, Zn, and mixtures thereof;‘M’ represents hydroxide or a nitride ion;‘x’ and ‘y’ represent the weight % of the metal loadings; or a ratio of x:y is between 0:1 and 1:0; and‘n’ is an integer 1 or 2 or 3.

Owner:INDIAN INST OF SCI EUDCATION & RES

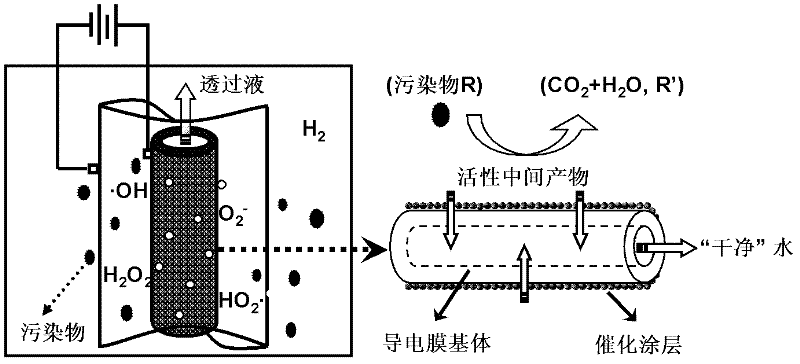

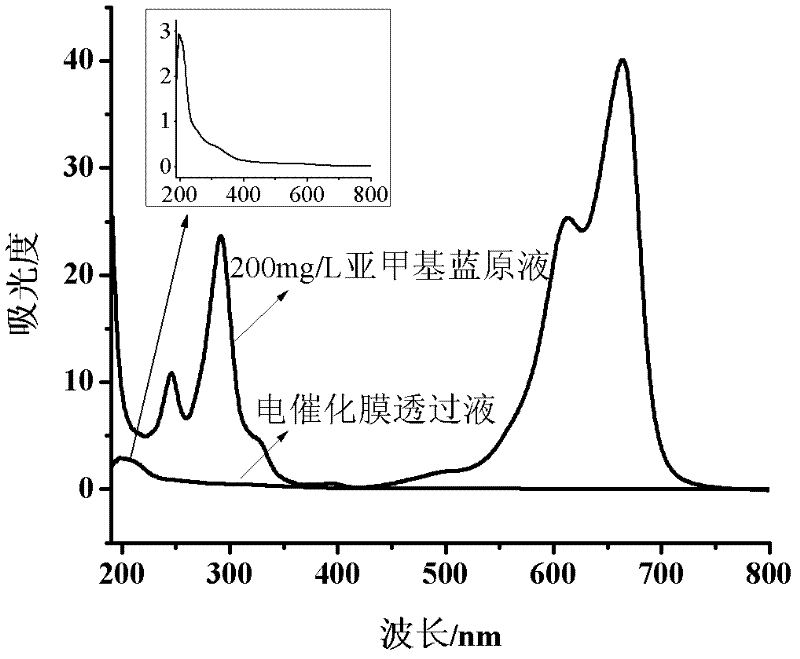

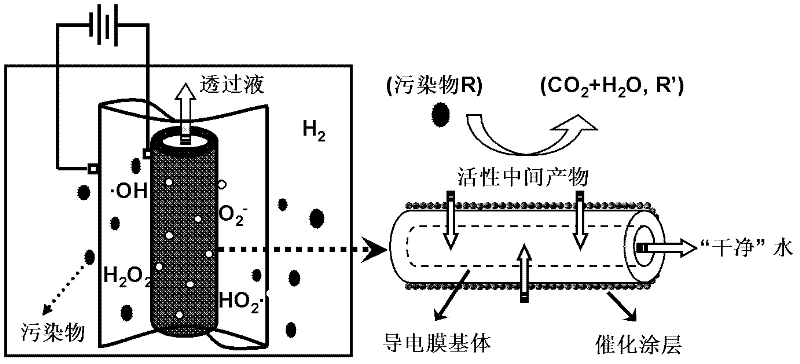

Nano loaded titanium-based electric catalytic film and preparation method thereof

InactiveCN102350228AImprove degradation efficiencyHigh electrode strengthSemi-permeable membranesDispersed particle separationAcid etchingCatalytic oxidation

The invention discloses a nano loaded titanium-based electric catalytic film comprising a conductive microporous separating titanium film matrix and a catalytic coating. Furthermore, the invention also discloses a preparation method of the nano loaded titanium-based electric catalytic film, which comprises the following steps of: (1) preprocessing the titanium film matrix by sand blasting, alkali washing, and acid etching: soaking the matrix after sand blasting in an NaOH solution for 0.5 to 2h, then processing for 1 to 2h in an oxalic acid solution with the mass percent concentration of 10 percent after washing to a neutral state, washing with water and drying at 100 to 120 DEG C; and (2) preparing and loading a catalytic coating: preparing the catalytic coating by adopting a sol-gel method, a thermal decomposition method, an electrodeposition method or a chemical vapor deposition method and loading at the surface of the titanium film matrix and in a hole. Furthermore, the invention also discloses a film reactor comprising the nano loaded titanium-based electric catalytic film. According to the nano loaded titanium-based electric catalytic film, the defects on material strength, range limitation of working voltage, catalytic oxidation efficacy and the like in the prior art are solved.

Owner:SHANGHAI CAS ADVANCED RES INST

Preparation method of layered ferronickel hydroxide electrode

ActiveCN106381506AComplete lamellar structureExcellent electrocatalytic activity and stabilityElectrodesUreaPlasma treatment

The invention discloses a preparation method of a layered ferronickel hydroxide electrode. The preparation method comprises the following steps: preparing a solution containing a ferric salt, a nickel salt and urea, wherein the concentration of the ferric salt is 1-100mmol / L, the concentration of the nickel salt is 1-100mmol / L and the concentration of the urea is 2-200mmol / L; and placing a substrate into the solution containing the ferric salt, the nickel salt and the urea, then placing the substrate in a hydrothermal reactor at the temperature of 60-180 DEG C, keeping the temperature for 1-20h, then washing and drying the substrate, and carrying out plasma treatment or high temperature calcination treatment in a protective atmosphere finally to obtain the layered ferronickel hydroxide electrode. The preparation method, is lower in reaction temperature, short in reaction time, simple in preparation process, strong in controllability and good in repeatability, improves the production efficiency, lowers the production cost, is green and environmental friendly and can effectively solve the problem of environmental pollution without participation of an organic solvent and a toxic chemical reagent in the reaction process.

Owner:XI AN JIAOTONG UNIV

Thick film conductor composition for use in biosensors

InactiveUS6599408B1Improve electrocatalytic activityStrong electrical signalImmobilised enzymesBioreactor/fermenter combinationsElectrical conductorCombined use

The invention is directed to polymer thick film conductor compositions comprising conductive metal particles selected from the group consisting of finely divided powders of platinum group metals and mixtures thereof or metallized graphite particles; in combination with a thermoplastic polymer and optionally, graphite conductive filler.

Owner:DUPONT ELECTRONICS INC

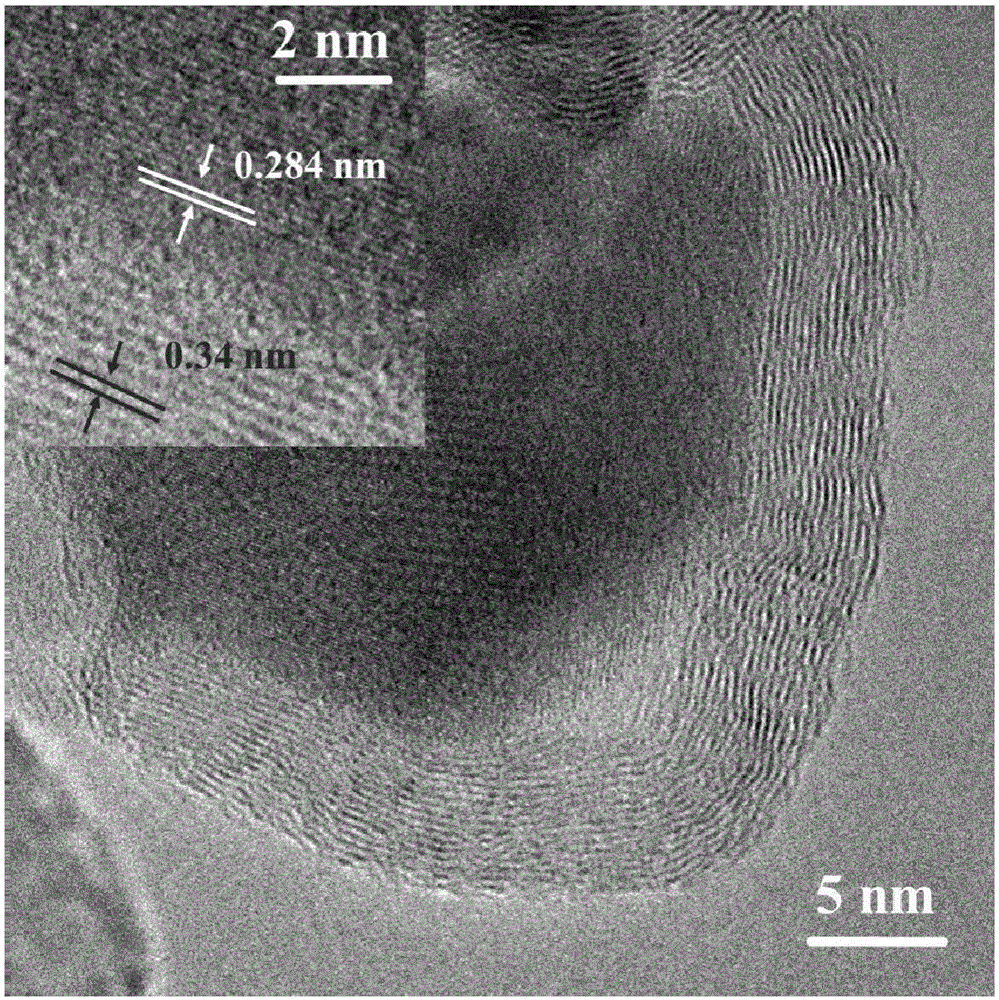

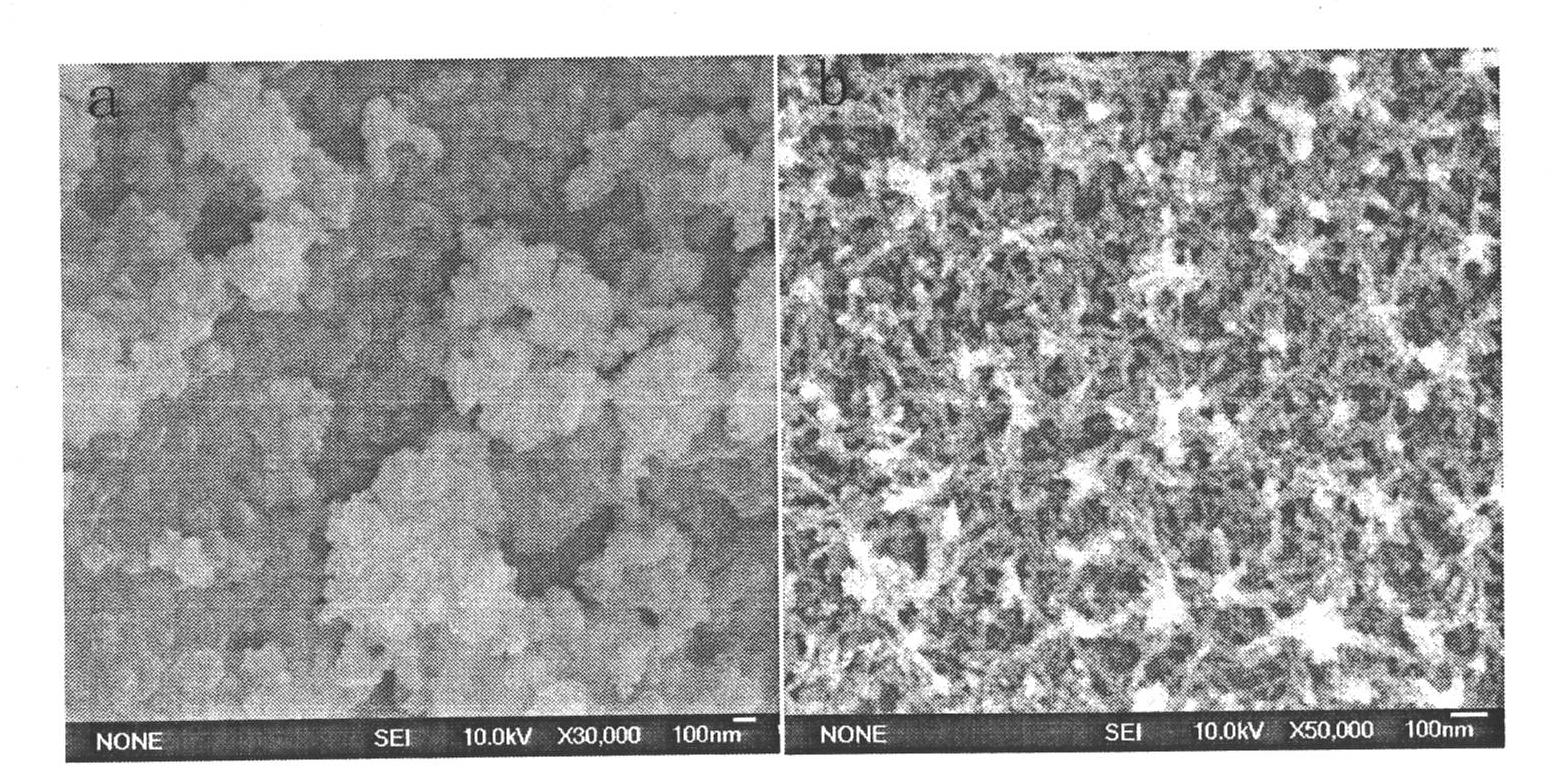

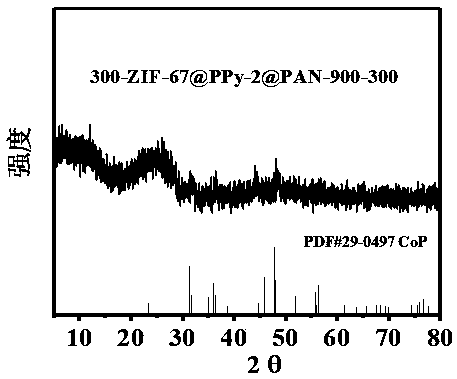

Preparation method of cobalt phosphide coated with carbon layers

InactiveCN106111171ACorrosion protectionHigh yieldPhysical/chemical process catalystsElectrodesCarbon layerHydrogen

The invention relates to a preparation method of cobalt phosphide coated with carbon layers. According to the method, cobalt salt and organic ligands are used as raw materials, a cobalt-containing metal-organic framework material is synthesized firstly and then subjected to high-temperature pyrolysis, air oxidation and low-temperature phosphating sequentially, and cobalt phosphide coated with the carbon layers is synthesized. Prepared cobalt phosphide is used as a hydrogen evolution catalyst under acidic and alkaline conditions and has high activity and high stability. The method is low in cost, mild in condition and suitable for industrial large-scale production, and products with relatively high purity can be obtained.

Owner:SUZHOU INSTITUE OF WUHAN UNIV

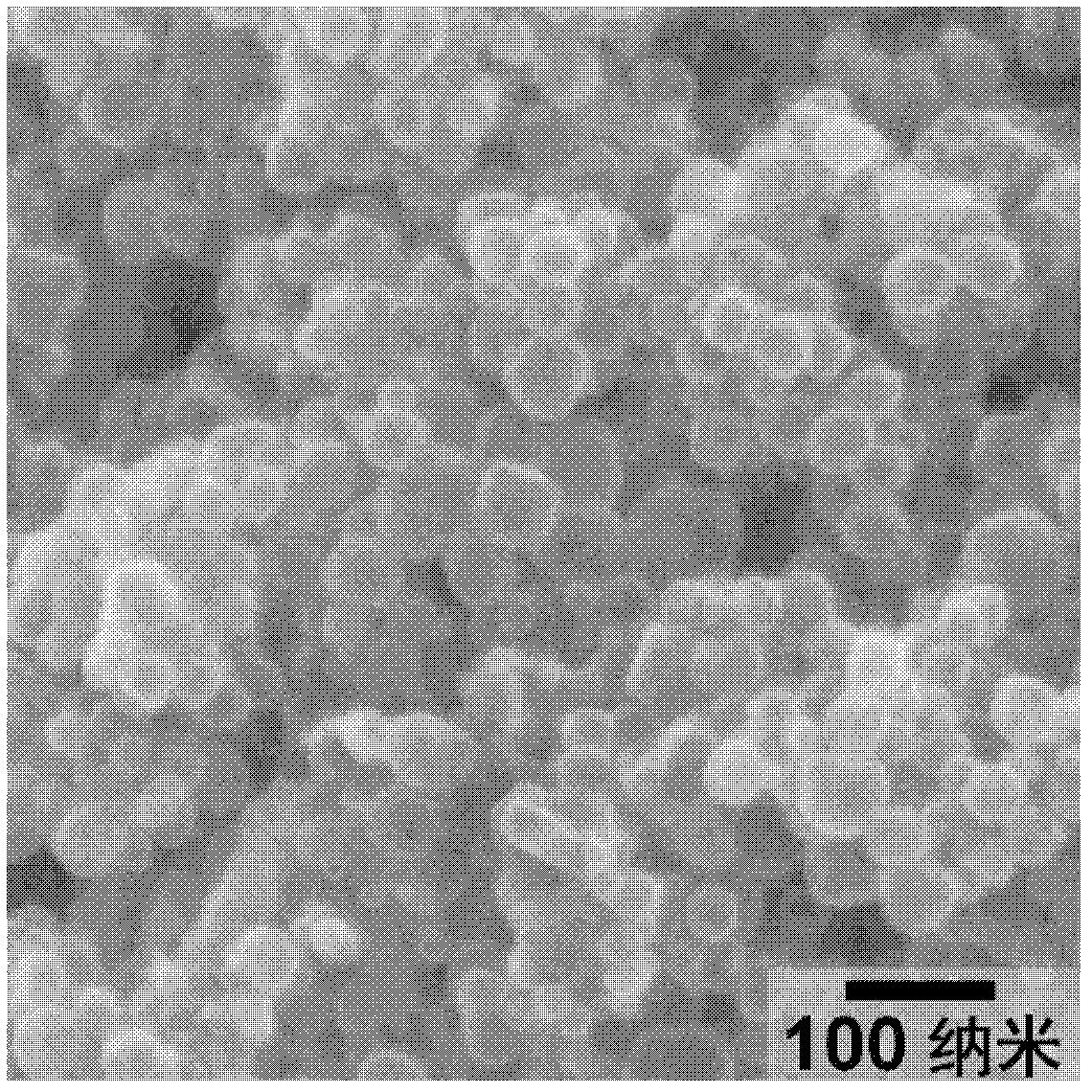

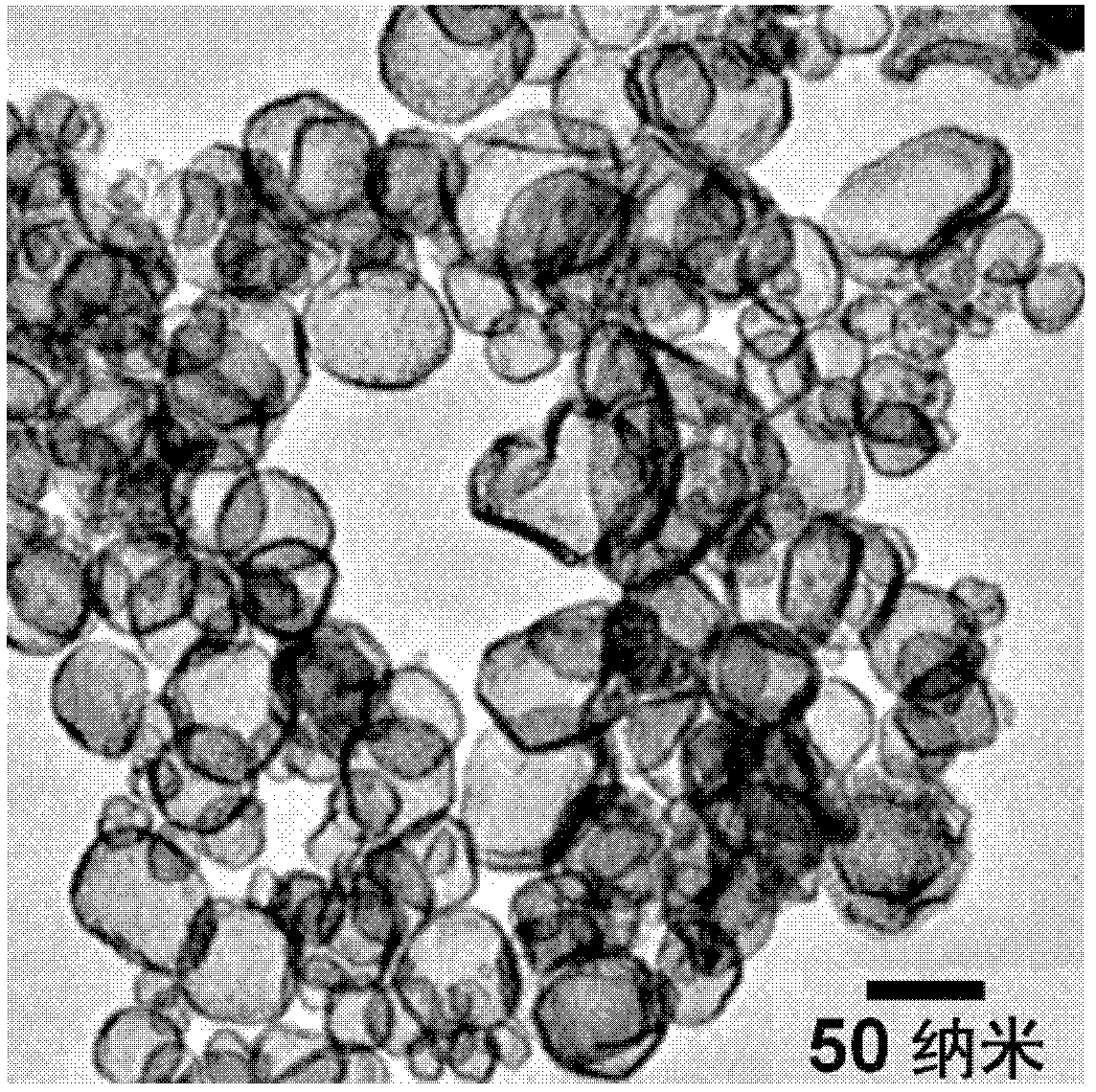

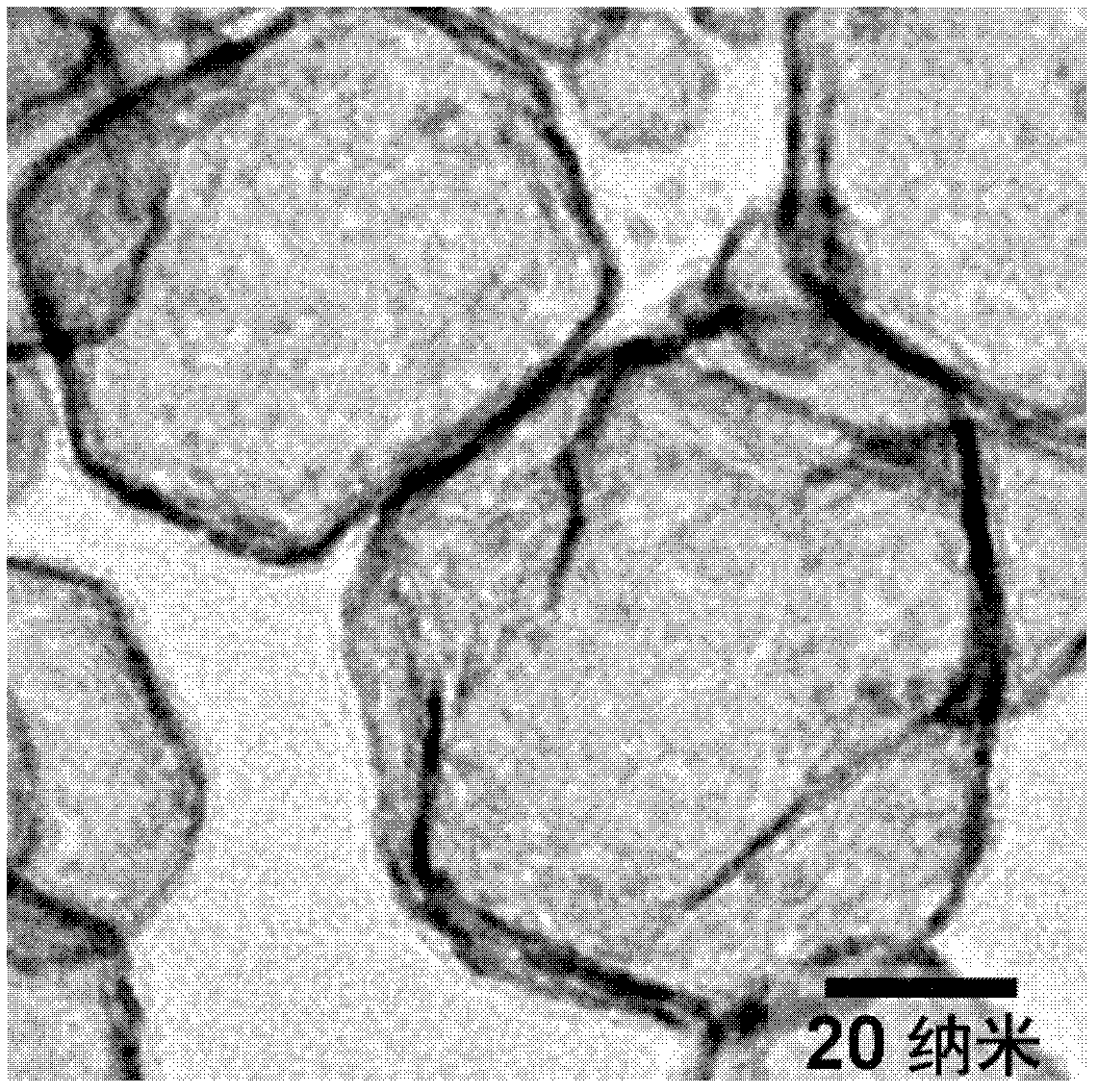

Hollow porous spherical platinum-silver alloy nano-material and preparation method for same

The invention relates to a hollow porous spherical platinum-silver alloy nano-material and a preparation method for the same. The nano-material is of a spherical structure with a porous shell and an internal cavity, the diameter of the spherical structure ranges from 5 nanometers to 500 nanometers, the inner diameter of the cavity ranges from 1 nanometer to 400 nanometers, the thickness of a porewall ranges from 1 nanometer to 50 nanometers, and the pore diameter ranges from 1 nanometer to 20 nanometers. Polyatomic alcohol, inorganic silver salt precursor, inorganic platinum salt precursor and polyvinylpyrrolidone are used as reaction raw materials, inorganic salt containing halogen ions and copper-containing inorganic salt are used as auxiliaries, and the hollow porous spherical platinum-silver alloy nano-material is synthesized by means of reaction. The preparation method is simple in process, convenient in operation, fine in repeatability and low in cost, and the obtained hollow porous spherical platinum-silver alloy nano-material can be used for the fields of chemical and electrochemical catalysis, chemical sensors, biomolecular sensors, information storage, fuel cells, solarcells and the like. Particularly, the hollow porous structure of the nano-material can be effectively applied to slow drug release and target-oriented drug delivery treatment.

Owner:SHANDONG UNIV

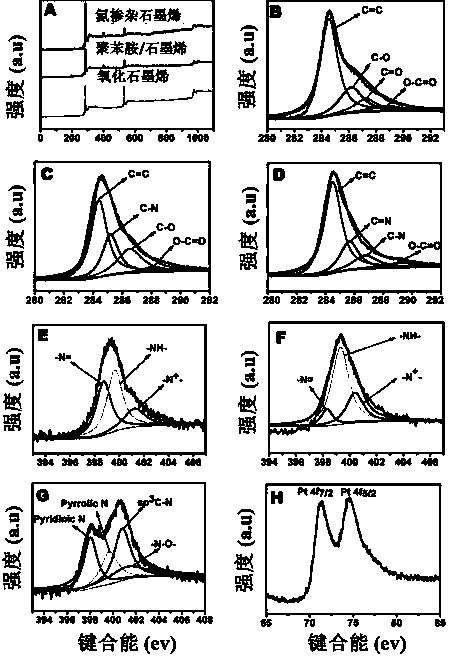

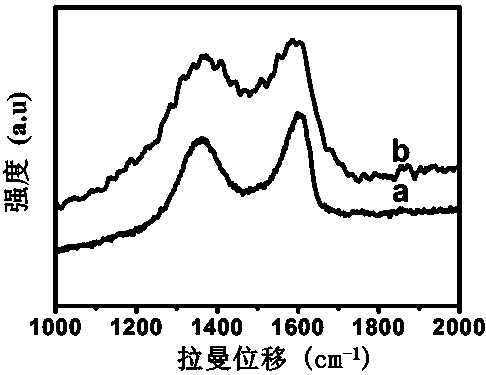

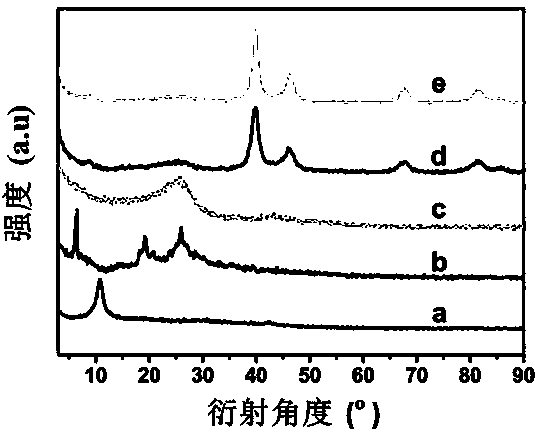

Preparation method of nitrogen-doped graphene loaded platinum nano-particle catalyst

InactiveCN103372428AAvoid uneven loadAvoid reunionMetal/metal-oxides/metal-hydroxide catalystsDoped graphenePtru catalyst

The invention discloses a preparation method of a nitrogen-doped graphene loaded platinum nano-particle catalyst. The preparation method comprises the following steps of: firstly, preparing graphene oxide (GO); secondly, preparing polyaniline / graphene oxide (PANI / GO) through a liquid-liquid interface polymerization method; thirdly, drying the PANI / GO, transferring the dried PANI / GO into a tubular furnace, and performing high-temperature treatment for 2 hours at 800 DEG C to prepare NGs (nitrogen-doped graphenes); and finally, ultrasonically dispersing the NGs into an aqueous solution, uniformly mixing the NGs with chloroplatinic acid according to a certain mass ratio, slowly adding sodium borohydride (NaBH4) into the mixed solution, and performing magnetic stirring for 8 hours to prepare the NGs loaded platinum nano-particle catalyst (Pt / NGs) which takes the NGs as a catalyst carrier to uniformly load platinum nano-particles to the surfaces of the NGs without any chemical modification. The nitrogen atoms which are doped into molecular structures of GNs not only provide a large amount of active sites for PtNPs loading, but also enhance the interaction between the PtNPs and an NGs carrier and improve the catalytic stability and catalytic activity of a nano composite material.

Owner:NANCHANG UNIV

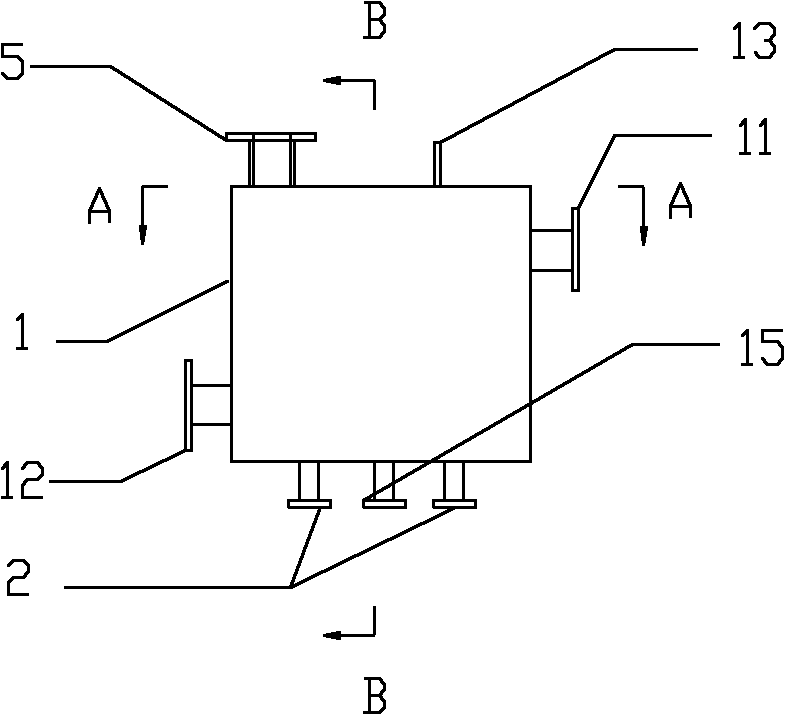

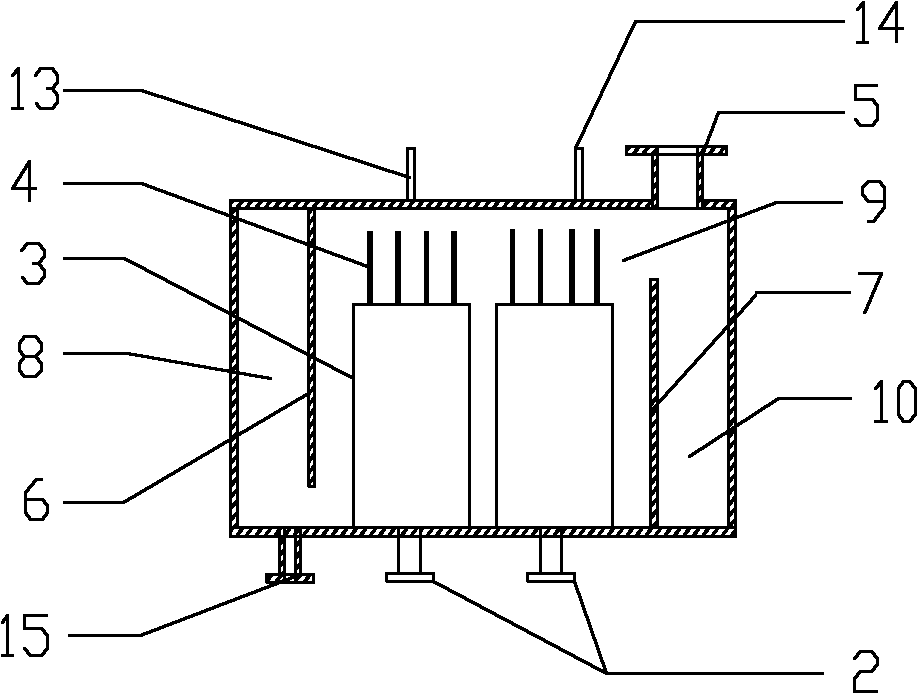

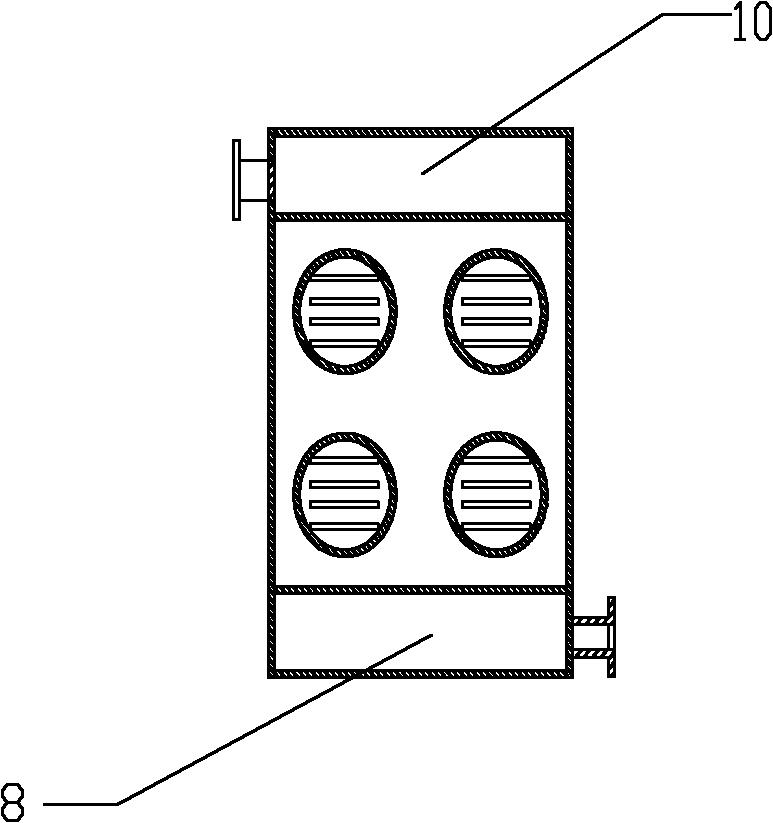

Nano catalytic electrolysis flocculation device

InactiveCN102010038APromote aggregation and sedimentationReduce dosageWater treatment compoundsSpecific water treatment objectivesFlocculationWater discharge

The invention discloses a nano catalytic electrolysis flocculation device, relating to an electrolysis flocculation device. The nano catalytic electrolysis flocculation device has the advantages of extremely low working voltage between two adjacent electrodes, large current density, small energy consumption, high electrical efficiency and no electrode consumption and electrolysis, and integrates solid-liquid separation function and gas-liquid separation function. The bottom of a shell is provided with a water inlet; the shell is internally provided with a scum baffle and a watertight shutter; the scum baffle and one inner side of the shell form a water discharging chamber; a gap is reserved between the bottom of the scum baffle and the bottom of the shell; the scum baffle and the other inner side of the shell form a slag discharging chamber; a gap is reserved between the top of the watertight shutter and the top of the shell; a hydrogen exhaust port is arranged on the top of the shell; an electrolyzer is arranged between the scum baffle and the watertight shutter; the top of the electrolyzer is open and the gap is reserved between the top of the electrolyzer and the top of the shell; electrodes are installed in the electrolyzer; a gas-liquid separation chamber is formed in the shell on the upper part of the electrolyzer; and a drain outlet is arranged at the bottom of the shell and us positioned between the watertight shutter and the adjacent electrolyzer.

Owner:BOYING XIAMEN SCI & TECH

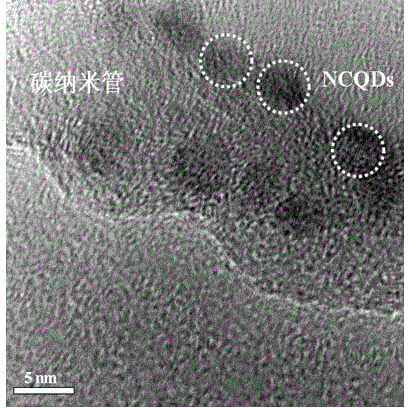

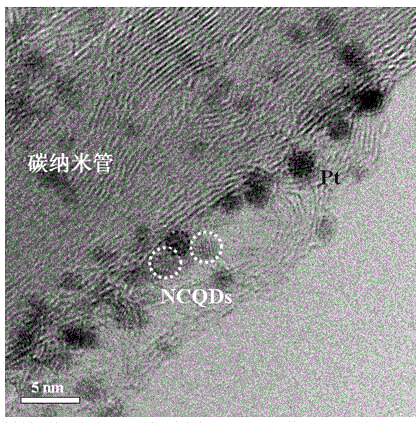

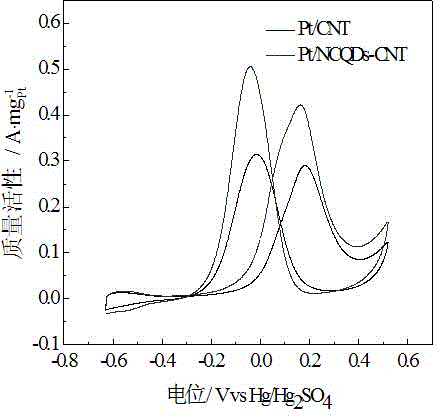

Preparation method of platinum based/nitrogen doped carbon quantum dot-carbon nanotube catalyst

ActiveCN104549407AGood dispersionFacilitate depositionMaterial nanotechnologyPhysical/chemical process catalystsDispersityCarbon nanotube supported catalyst

The invention discloses a preparation method of a platinum based / nitrogen doped carbon quantum dot-carbon nanotube catalyst. The preparation method comprises the following steps: 1, weighing a certain amount of a carbon source to mix with deionized water, and performing ultrasonic dispersion for 1-3 hours; 2, weighing a certain amount of carbon nanotubes to mix with a solution of the carbon source, thereby obtaining a mixture A; 3, putting the mixture A into a reaction kettle, heating at 140-180 DEG C for 1-12 hours, cooling, washing with deionized water, filtering, and performing vacuum drying to obtain a material B; and 4, preparing a platinum based catalyst by virtue of a microwave assisted ethylene glycol reduction method by taking the material B as a carrier, thereby obtaining the platinum based / nitrogen doped carbon quantum dot-carbon nanotube catalyst. According to the preparation method disclosed by the invention, nitrogen doped carbon quantum dots are used for modifying untreated carbon nanotubes and are compounded with the carbon nanotubes, so that the dispersity of platinum ions in the composite carrier is improved, and then the activity of the catalyst is promoted. The preparation method disclosed by the invention is simple and feasible, promotes the activity of the platinum based catalyst to a greater degree, and is hopeful for commercial application.

Owner:海卓健新能源材料(上海)有限公司

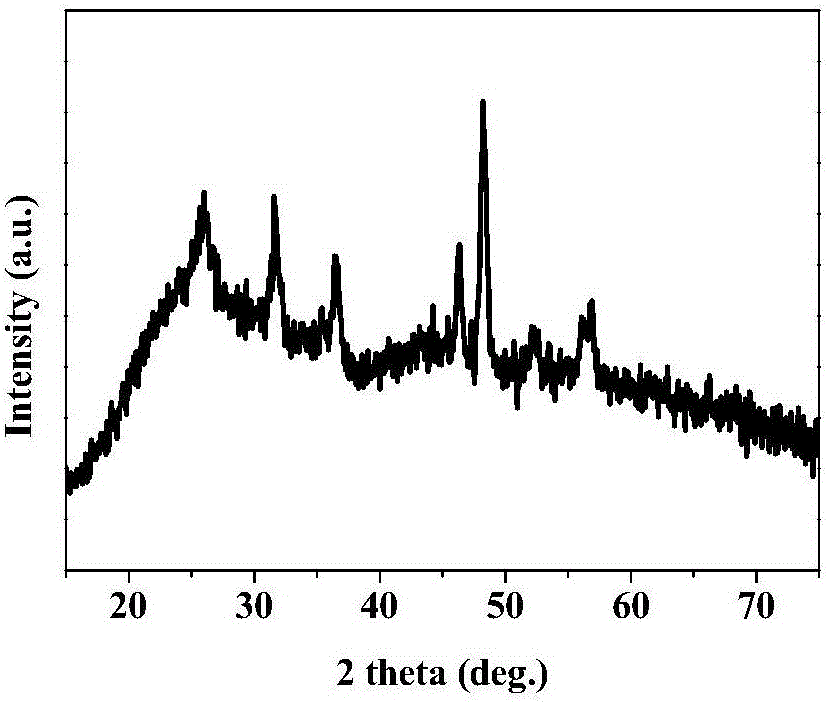

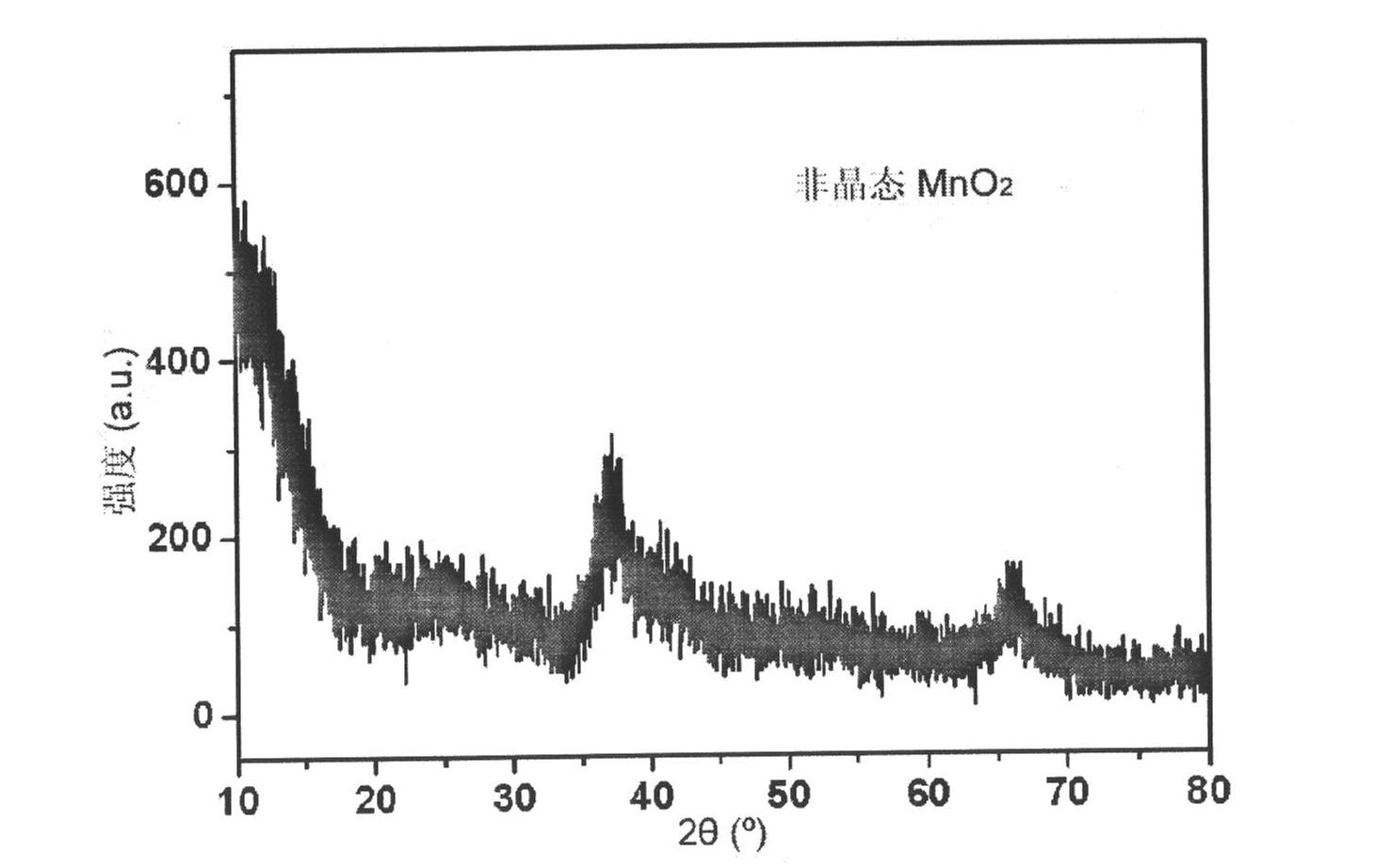

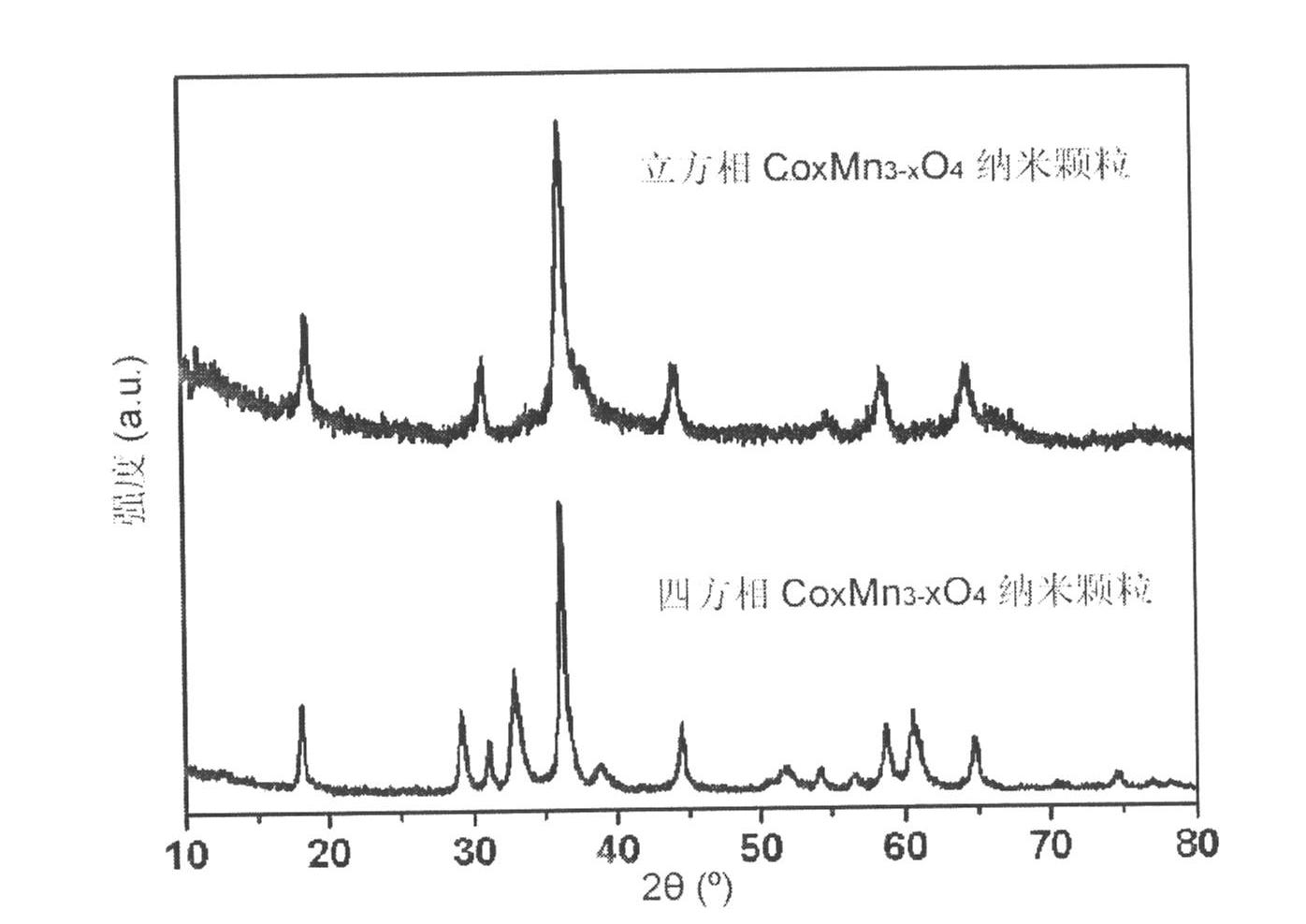

Manganese spinel nano material as well as preparation method and application of manganese spinel nano material

ActiveCN102082270AReduce consumptionShape is easy to controlNanomagnetismCell electrodesPotassiumManganese

The invention provides a manganese spinel nano material which comprises CoxMn(3-x)O4, MgMn2O4 and Mn3O4 nano particles as well as ZnMn2O4 hollow nano spheres, hollow micron spheres or nano pieces. The preparation method is as follows: MnO2 is reduced through a reducing agent at room temperature so as to prepare the manganese spinel nano material. The material can form a three-electrode system used for testing the redox property of the material, namely, in the three-electrode system, nano material is used as a working electrode, a Pt sheet is used as a counter electrode, saturated potassium chloride Ag / AgCl is used as a reference electrode and KOH solution is used as electrolyte. The invention has the advantages that the reaction process is carried out at room temperature, and energy source consumption is less; the nano material has a big specific surface area, and is capable of increasing the contact of active substance with oxygen and electrolyte; and the nano material as an electro-catalyst has high electro-catalysis efficiency, and has important value and actual significance in the fields of spinel oxide nano material preparation, electro-catalysis of metal air batteries and fuel cell and the like.

Owner:NANKAI UNIV

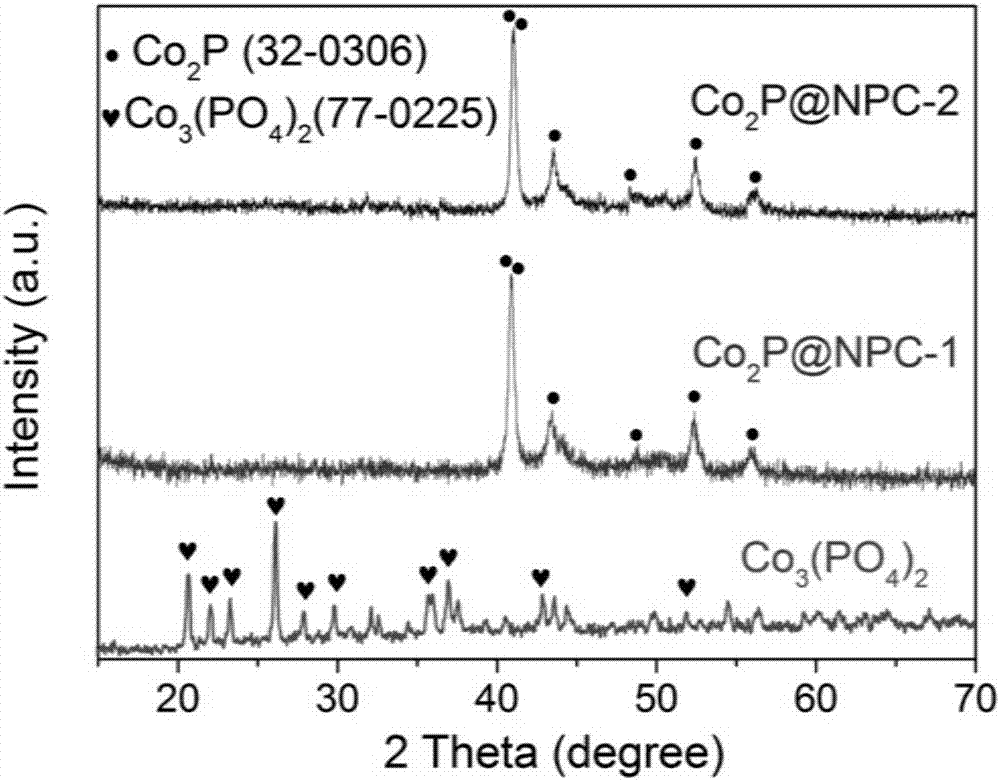

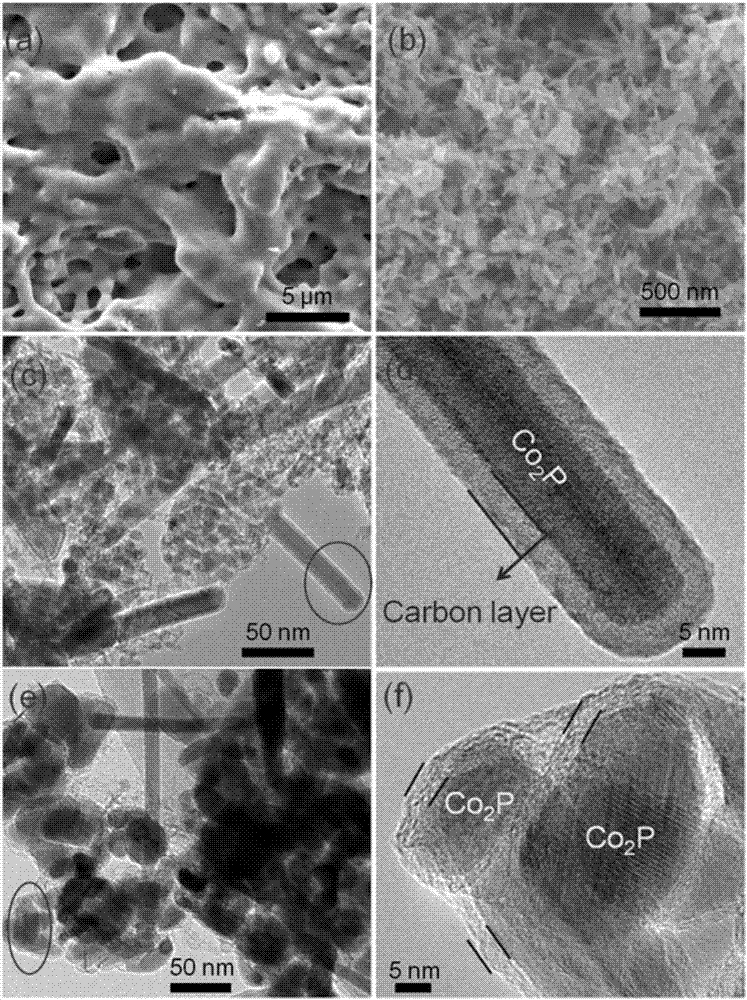

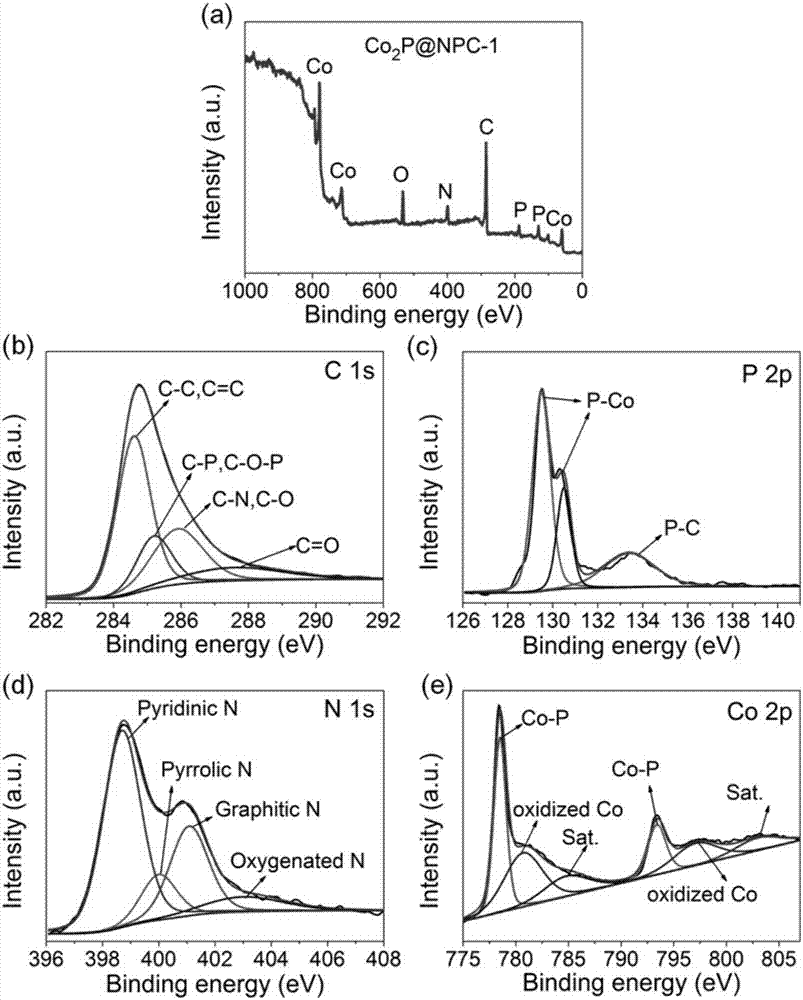

Oxygen reduction and oxygen evolution cobalt phosphide@NPC double-function compound catalyst and preparation method and application thereof

ActiveCN107051559AHigh catalytic activityImprove electrocatalytic performancePhysical/chemical process catalystsCell electrodesCarbon layerDecomposition

The invention discloses an oxygen reduction and oxygen evolution Co2P@NPC double-function compound catalyst and a preparation method and application thereof. The compound catalyst comprises N-P-codoped carbon layer coated Co2P nano rods and / or nano particles. The preparation method includes: evaporating and drying the solution of cobalt acetate, concentrated phosphoric acid and urea, and performing high-temperature treatment under protective atmosphere to obtain the compound catalyst. The preparation method has the advantages that the method is simple, low in cost and beneficial to industrial production; the prepared oxygen reduction and oxygen evolution Co2P@NPC double-function compound catalyst is applicable to fuel cell and water decomposition, high in activity and good in stability, the catalytic performance of the compound catalyst is close to that of a commercial precious metal 20wt% Pt / C and RuO2 catalyst, and the compound catalyst is promising in application prospect.

Owner:CENT SOUTH UNIV

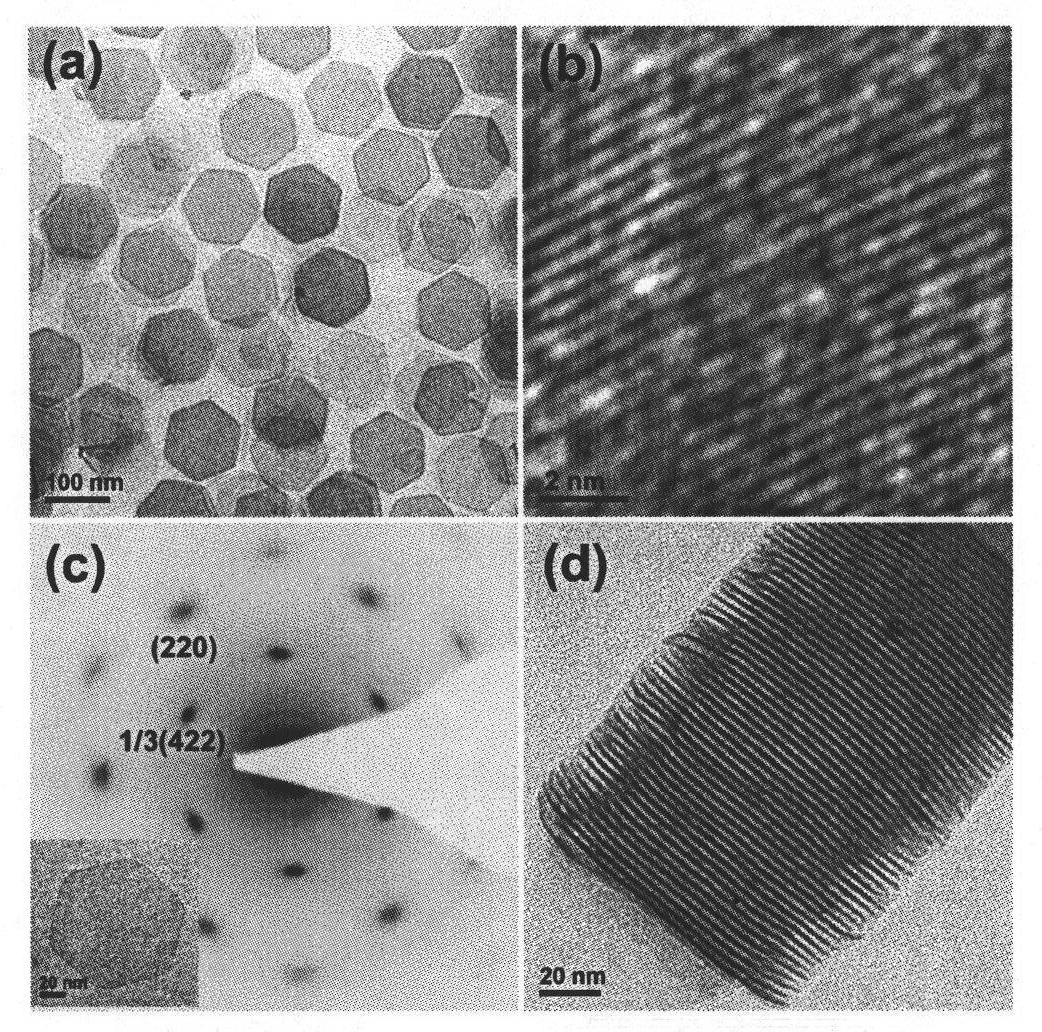

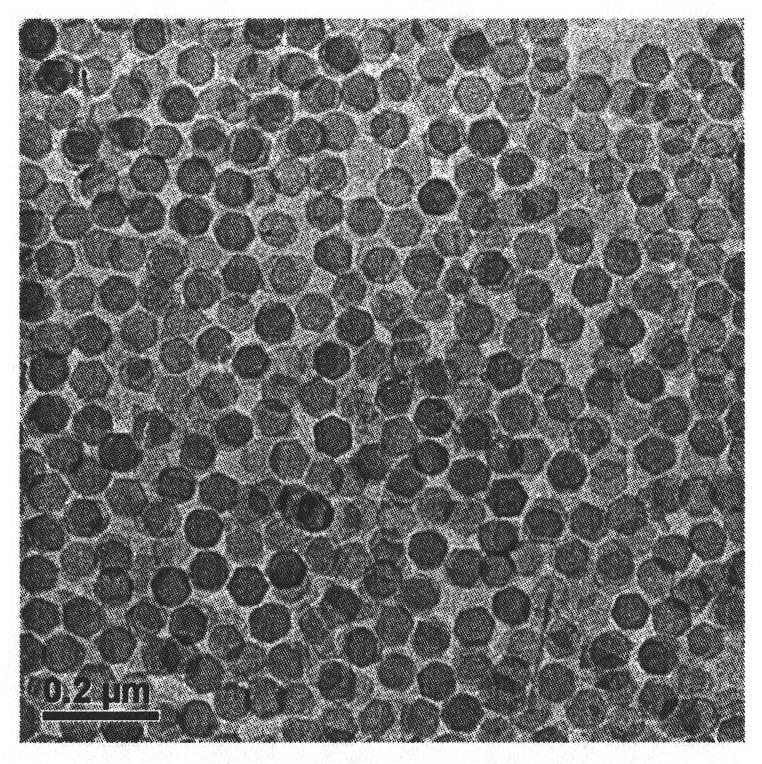

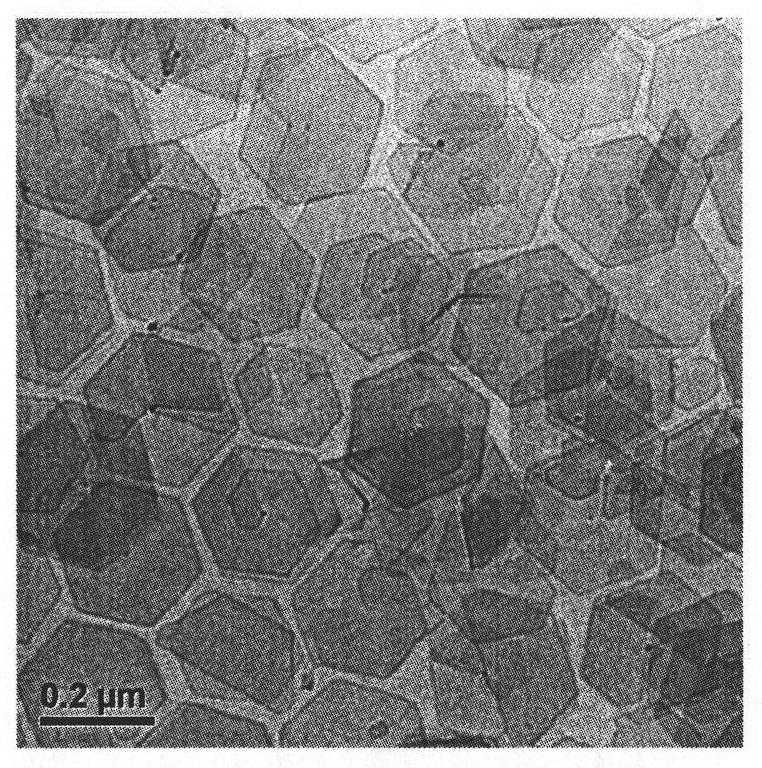

Synthesis method of palladium nano sheet

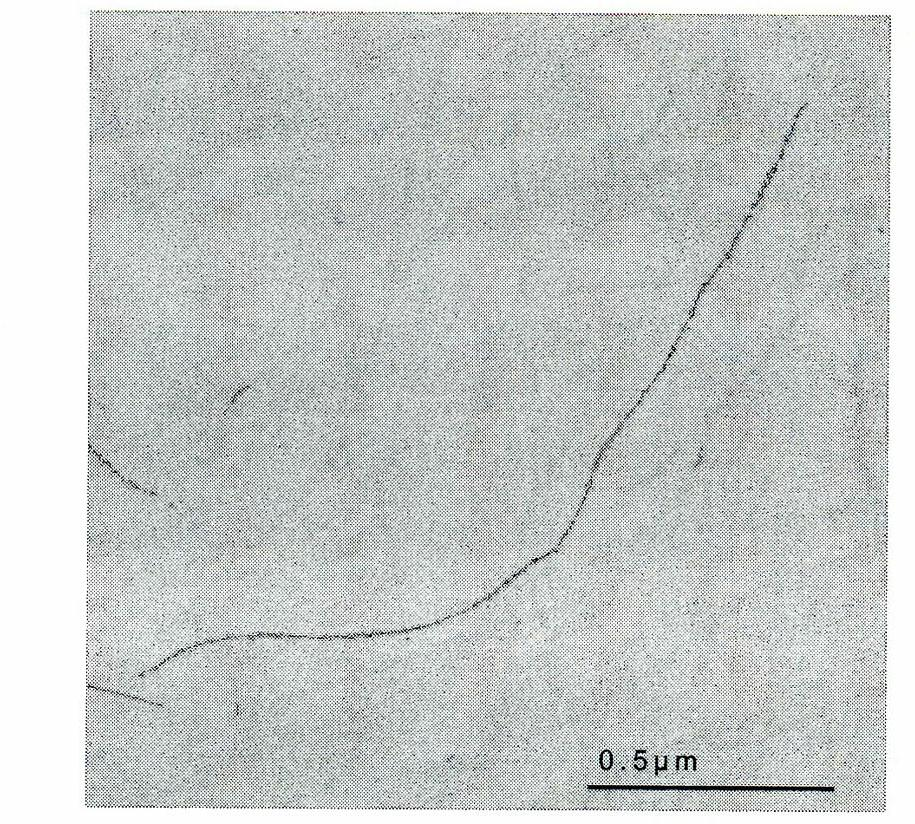

The invention provides a synthesis method of a palladium nano sheet, and relates to a palladium nano material. The method comprises the following steps: adding a palladium precursor, a surface protectant, and halogen ion-containing organic salt or halogen ion-containing inorganic salt to a solvent to obtain mixed liquor; placing the mixed liquor under a carbon monoxide atmosphere, and heating to 10-200 DEG C; and then cooling to room temperature, adding acetone, carrying out centrifugal purification, and cleaning to obtain the palladium nano sheet. The synthesized palladium nano sheet has the advantages of high yield greater than 80%, uniform particle diameter with the deviation smaller than 10%, ultrathin structure with the thickness about 1.8nm, larger specific area, high atom utilization ratio and favorable electro-catalytic activity. The size of the obtained palladium nano sheet can be well adjusted. The palladium nano sheet has good near-infrared spectrum absorption feature, has prodigious potential application in the biological thermal therapy, such as the application in the near-infrared thermal therapy for tumors; and the palladium nano sheet has favorable electro-catalytic performance.

Owner:XIAMEN UNIV

Titanium/graphene/oxide combined electrode

ActiveCN103526235APerfect quantum tunnelingImprove conductivityElectrodesCharge carrier mobilityTitanium

The invention relates to a titanium / graphene / oxide combined electrode, which belongs to the technical field of electroplating. The combined electrode is such structured that graphene and an oxide coating are successively coated on a matrix, wherein the oxide coating is an oxide of Mn, Pb or La, and the matrix is a titanium or titanium alloy plate or screen plate. A plurality of layers of graphene are coated on the matrix, each layer being 0.4 to 1.0 mm thick. The thickness of the oxide coating is 150 mu m to 700 mu m. The titanium or titanium alloy plate is 0.5 to 10 mm thick, and the mesh diameter of the screen plate is 0.1 to 5 mm. According to the invention, overall performance of the electrode is improved by using a stable lattice structure and high carrier mobility of graphene, advantages of each layer of graphene are performed, so the electrode has the advantages of high strength, good conductivity, high corrosion resistance, a long service life and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for surface pre-treatment of titanium electrode substrate

InactiveCN101565834AOptimal Preprocessing ParametersEnhanced electrocatalytic activity for oxygen evolutionElectrodesTitanium electrodeMetallic materials

The invention belongs to the field of metal material and relates to a method for surface treatment of a titanium electrode substrate. The service life and the electrocatalysis performance of the titanium electrode are greatly increased by the abrasive blasting pretreatment to the substrate. The abrasive blasting treatment is carried out on the titanium substrate; the nozzle pressure of an abrasive blasting machine is 0.3-0.5MPa; the Al2O3 grinding medium of 70-90 meshes is adopted; the blasting angle is 45-90 degrees; the distance from the nozzle to a workpiece is 1-2cm; the coarsening time is 15-30s; the titanium substrate is then pickled for pickling treatment in a 10wt.% of oxalic acid solution for 1.5-2.5 hours at the temperature of 90-95 DEG C; a Ti / IrO2.Ta2O5 oxide coating electrode is prepared on the obtained substrate by a thermal decomposition method, wherein the Ir is chloro-iridic acid, Ta is tantalum pentachloride and the molar ratio of Ir to Ta is 7:3; a coating solution is uniformly coated on the pre-treated titanium substrate by a soft hair brush; the titanium substrate is dried for 10min at the temperature of 120 DEG C, is subsequently arranged in a box-type resistance furnace and sintered for 10min at the temperature of 450 DEG C; the above operations of coating, drying and sintering are repeatedly carried out by 5-20 times; and the final sintering is carried out for 1h at the temperature of 450 DEG C. The method provides optimum pretreatment parameters, greatly prolongs the service life of the titanium electrode, effectively improves the electrocatalytic activity and greatly reduces the running and repairing cost for the electrode.

Owner:UNIV OF SCI & TECH BEIJING

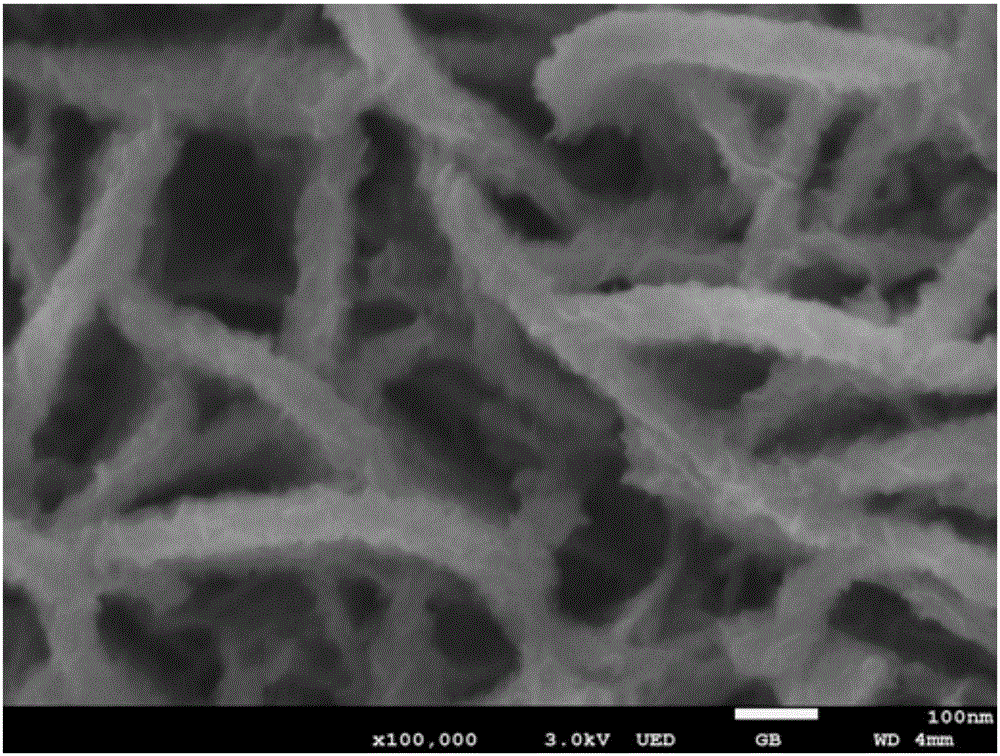

Preparation method of thermally-reduced graphene oxide/nano carbon fiber composite electrode for full-vanadium flow battery

InactiveCN104332640ALarge specific surface areaIncrease the reaction areaCell electrodesFiberCarbon fibers

The invention relates to the field of battery manufacturing and energy source storage and particularly provides a preparation method of a thermally-reduced graphene oxide / nano carbon fiber composite electrode for a full-vanadium flow battery. The preparation method comprises the following steps: firstly, preparing a spinning solution for an experiment; secondly, uniformly mixing graphite oxide powder and the spinning solution; stripping the graphite oxide powder into graphene oxide by using an ultrasonic manner; preparing a nano fiber membrane by adopting an electrostatic spinning method; and then pre-oxidizing the nano fiber membrane in the air and carbonizing in an inert atmosphere pipe type furnace to obtain the needed thermally-reduced graphene oxide / nano carbon fiber composite electrode. According to the full-vanadium flow battery composite electrode prepared by the method, the diameter of carbon fibers is a nano scale; and the carbon fibers are compounded with thermally-reduced graphene oxide and the roughness of the fibers is greatly increased, so that the specific surface area of the electrode is two orders of magnitudes higher than that of a traditionally-used electrode material. Meanwhile, the high-activity thermally-reduced graphene oxide is adopted so that the electrochemical activity of the electrode is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Oxygen reduction reaction catalyst

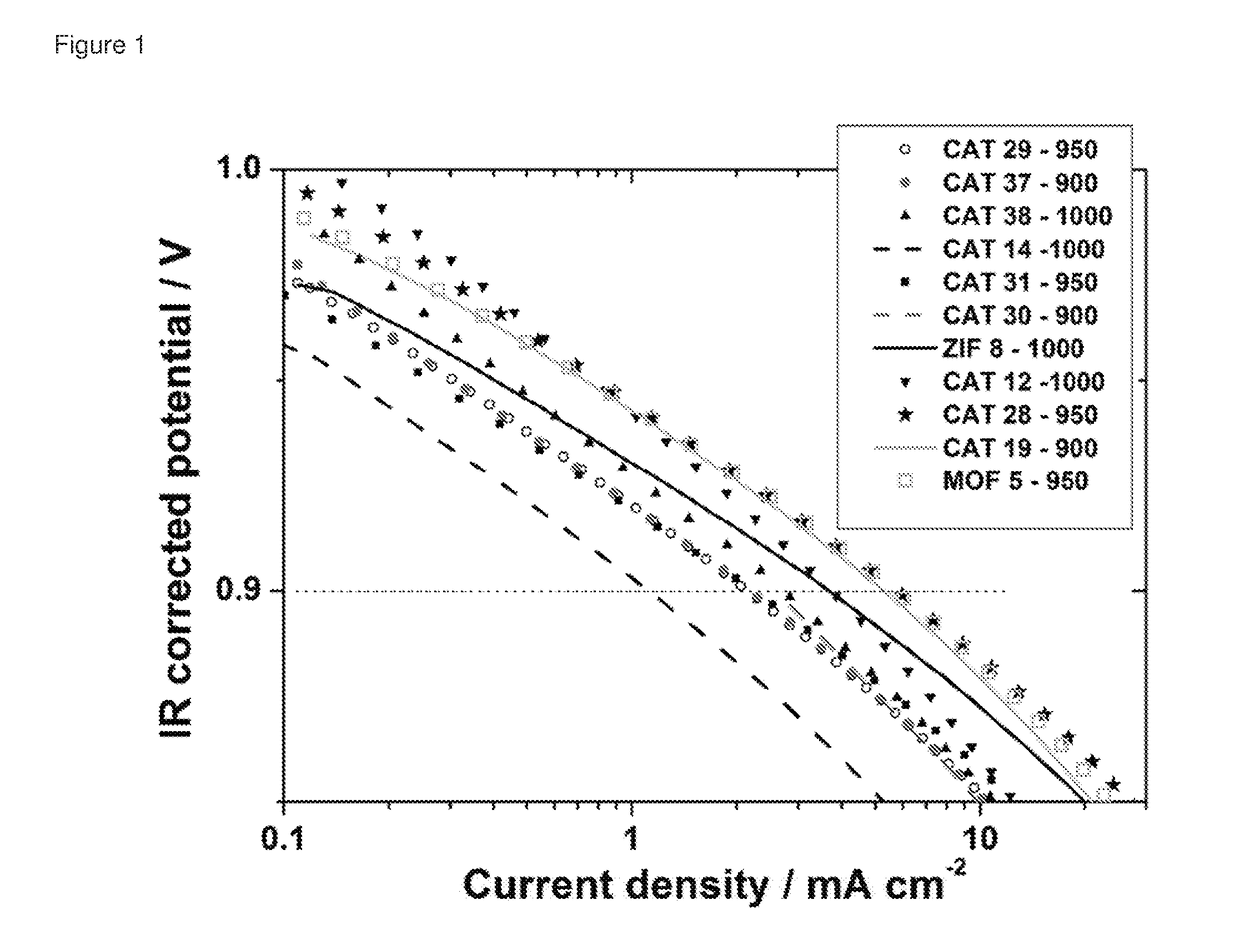

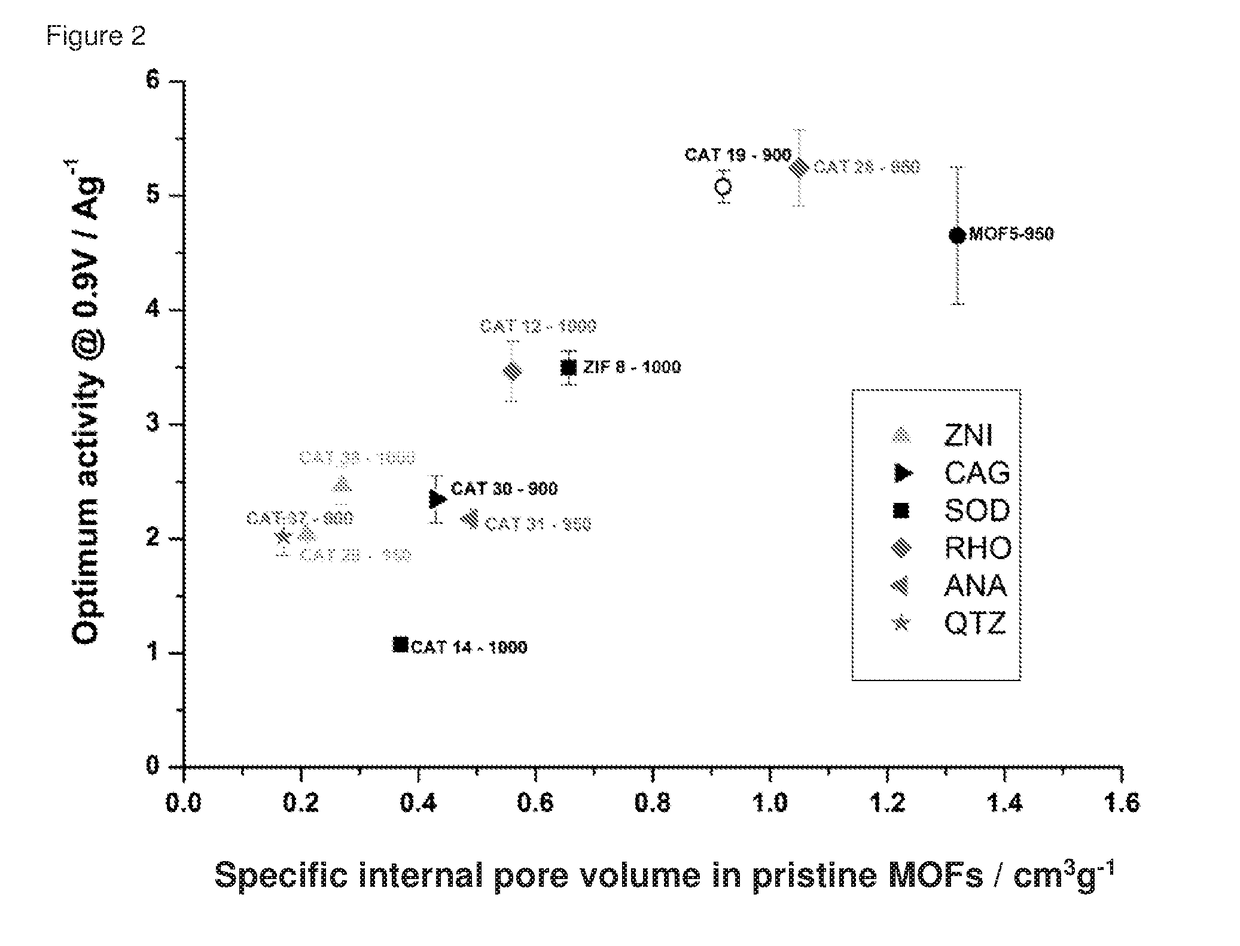

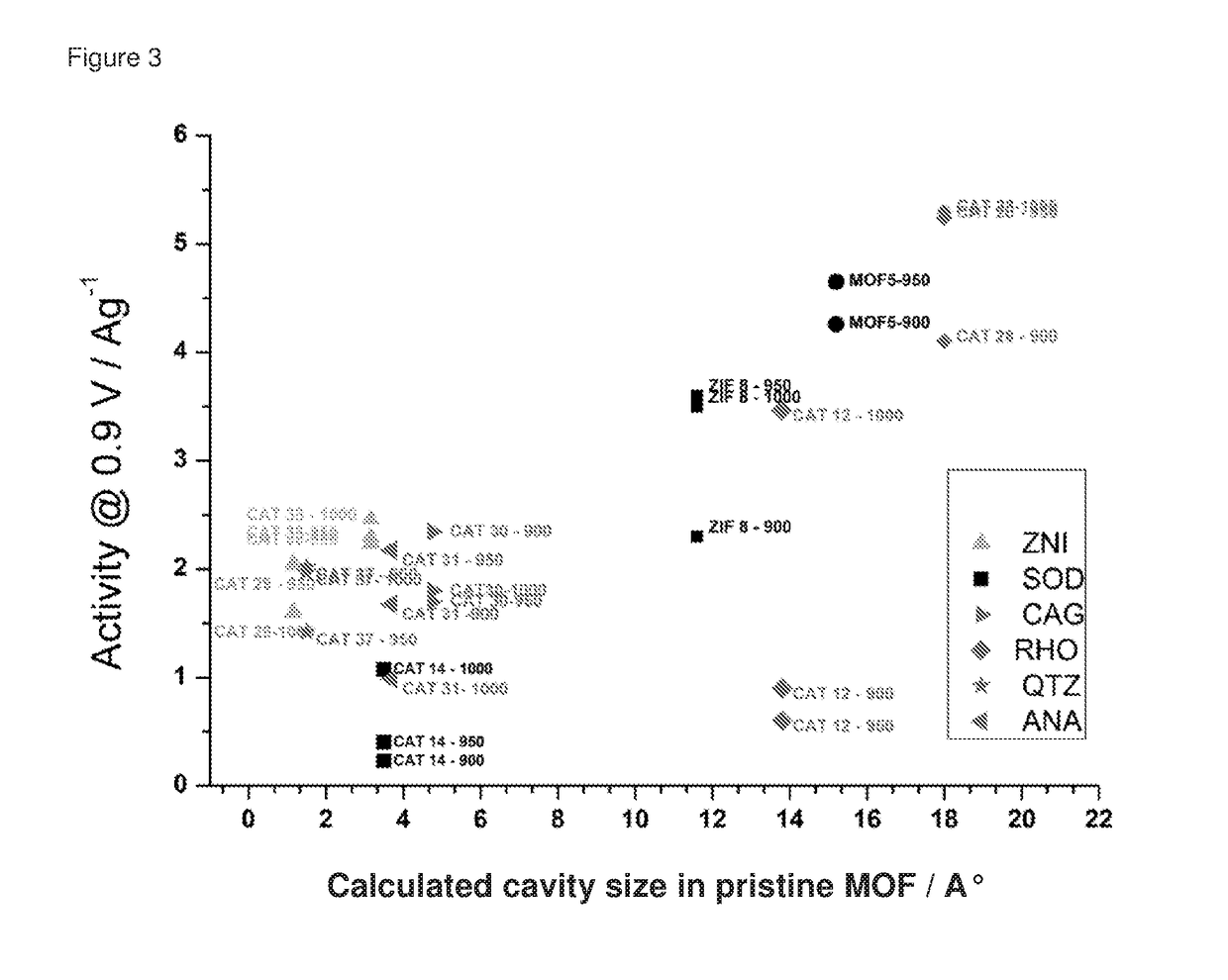

InactiveUS20180294485A1Improve electrocatalytic activityHigh catalytic activityMolecular sieve catalystsCell electrodesMetal-organic frameworkOxygen reduction reaction

A method for the manufacture of an oxygen reduction reaction (ORR) catalyst, the method comprising; providing a metal organic framework (MOF) material having a specific internal pore volume of 0.7 cm3g−1 or greater; providing a source of iron and / or cobalt; pyrolysing the MOF material together with the source of iron and / or cobalt to form the catalyst, wherein the MOF material comprises nitrogen and / or the MOF material is pyrolysed together with a source of nitrogen and the source of iron and / or cobalt is disclosed.

Owner:UNIV MONTPELLIER +2

Preparation method for combination electrode for all-vanadium redox flow battery

InactiveCN104241661AImprove electrochemical activityImprove energy efficiencySucessive textile treatmentsCell electrodesCarbon fibersCharge discharge

The invention relates to the field of battery manufacturing and energy storage, in particular to a preparation method of a bismuth-base catalyst / carbon nanofiber combination electrode for an all-vanadium redox flow battery. Firstly, spinning solution required for an experiment is prepared and then bismuth salt and the spinning solution are uniformly mixed. According to an electrostatic spinning method, a required nanofiber film is prepared and then the nanofiber film is pre-oxidized in the air and is carbonized in an inert atmosphere tube furnace so as to obtain the required bismuth-base electrocatalyst / carbon nanofiber combination electrode. After the obtained electrode material is cleaned and dried, testing of related electrochemical performance representation and charge-discharge properties can be carried out on the electrode material. The carbon fiber diameter, which is prepared according to the preparation method, is in the nano class; compared with a specific surface area of a conventionally used electrode material, the specific surface area of the bismuth-base catalyst / carbon nanofiber combination electrode is greatly increased. Moreover, the carbon nanofibers are compounded with a high-activity bismuth-base electrocatalyst, and thus, electrochemical activity of the electrode can be greatly improved, so that energy efficiency of the all-vanadium redox flow battery is greatly improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Nitrogen-doped graphene-loaded Pt-based alloy nanometre electrocatalyst and preparation method thereof

InactiveCN103413951AImprove electrocatalytic activityHigh catalytic activityMaterial nanotechnologyCell electrodesDoped graphenePtru catalyst

The invention relates to a nitrogen-doped graphene-loaded Pt-based alloy nanometre electrocatalyst and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: uniformly stirring graphene oxide, ethanediol and N-methylpyrrolidone in a mass ratio of (30 to 60): (1100 to 2800): (500 to 1600), and performing an ultrasonic dispersion treatment, so as to obtain a uniformly-dispersed suspension liquid; adding a metal salt solution and an H2PtCl6.6H2O solution in the uniformly-dispersed suspension liquid, uniformly stirring, and performing an ultrasonic dispersion treatment, so as to obtain a precursor; heating the precursor to 90-180 DEG C in an oil bath in a stirring condition, insulating heat, and performing condensation reflux for 1 to 5 hours, so as to obtain a black turbid liquid; performing vacuum suction filtration on the black turbid liquid, sequentially washing by acetone, distilled water and absolute ethyl alcohol, and performing vacuum drying at a room temperature to obtain the nitrogen-doped graphene-loaded Pt-based alloy nanometre electrocatalyst. The preparation method disclosed by the invention is simple in process and low in energy consumption; the prepared nitrogen-doped graphene-loaded Pt-based alloy nanometre electrocatalyst is high in catalytic activity, good in stability, uniform in the dispersion of nanometre particles, and controllable in the particle size of the nanometre particles.

Owner:WUHAN UNIV OF SCI & TECH

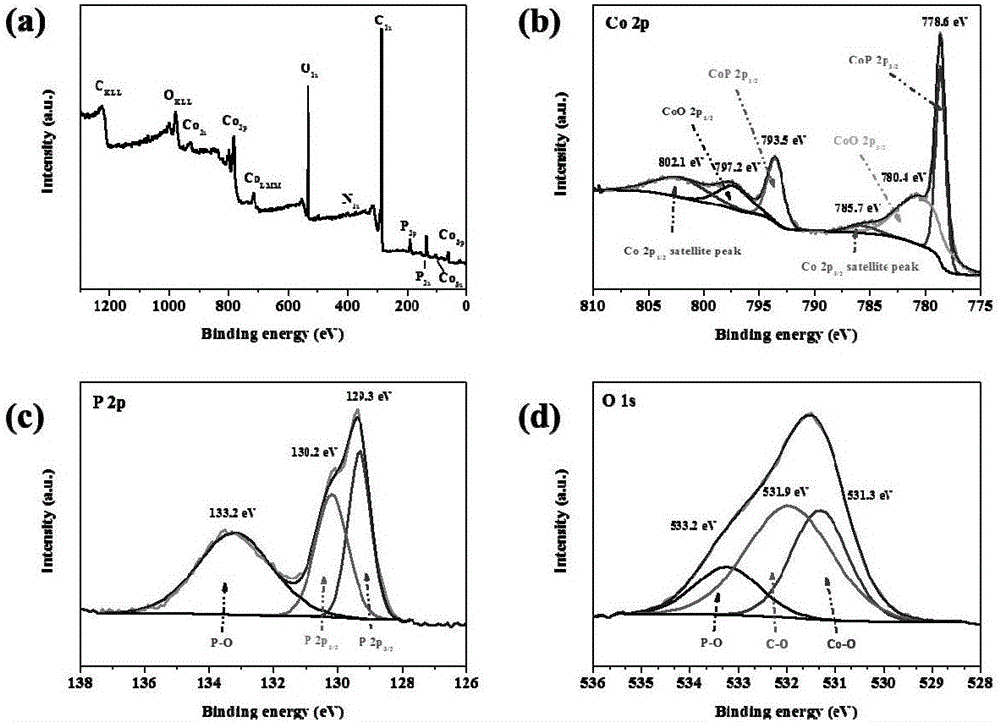

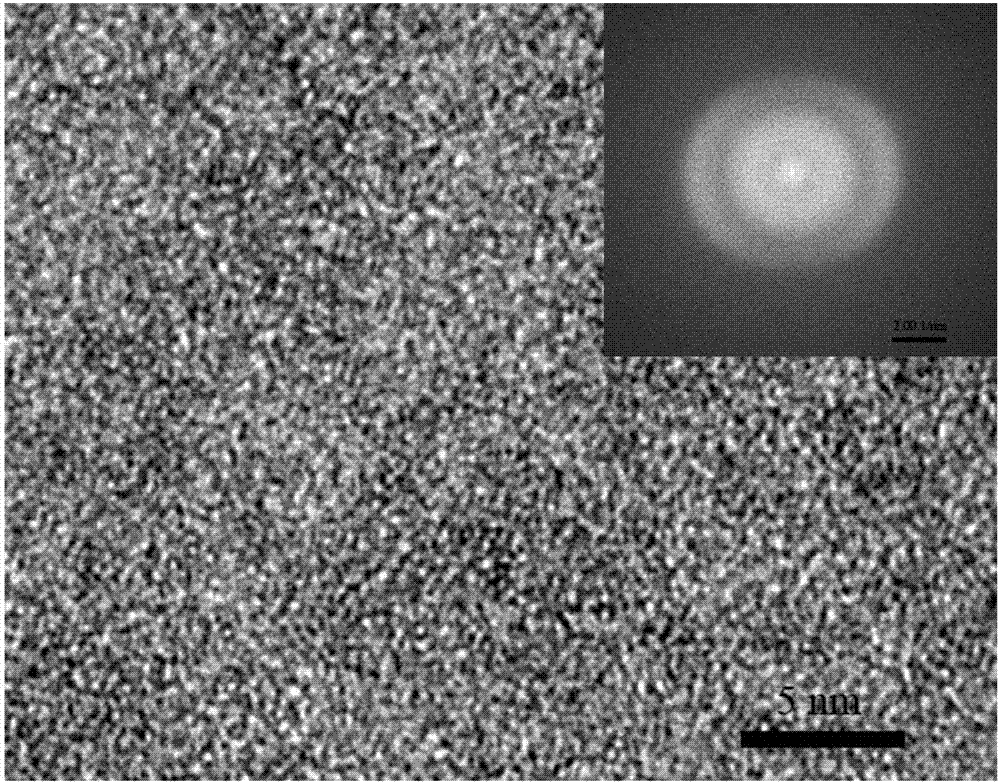

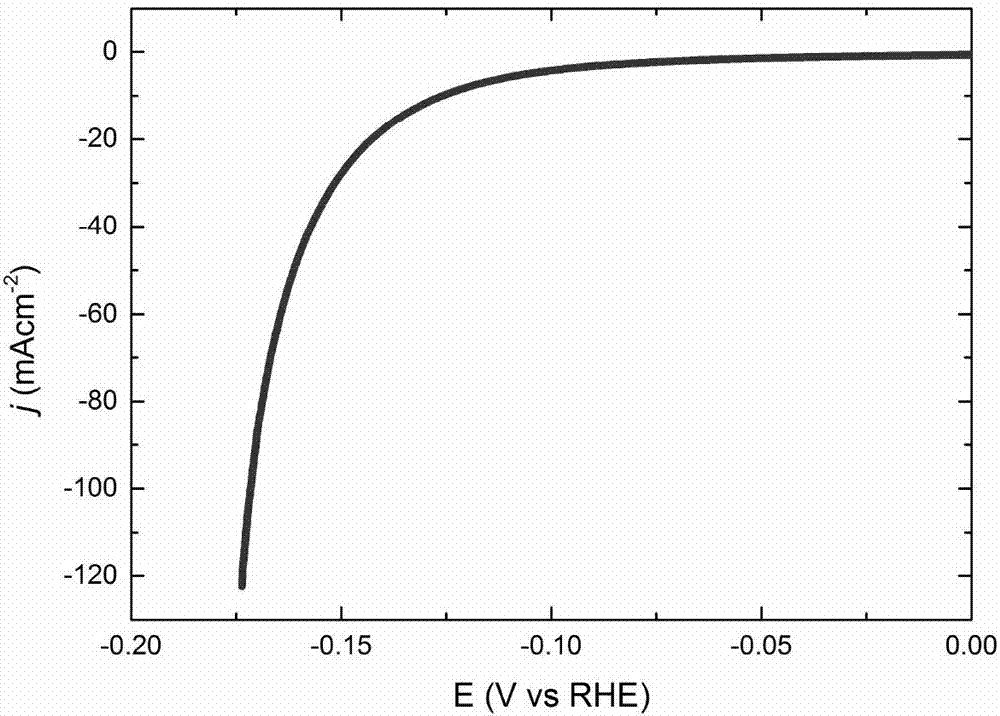

Fe-Co-P-C amorphous electro-catalyst for efficient hydrogen evolution reaction and preparation method thereof

ActiveCN107217219AExcellent vitrification abilityImprove electrocatalytic activityElectrodesElectricityHydrogen

The invention discloses a Fe-Co-P-C amorphous electro-catalyst for an efficient hydrogen evolution reaction and a preparation method thereof. The Fe-Co-P-C amorphous electro-catalyst for the efficient hydrogen evolution reaction is characterized in that the electro-catalyst is a Fe-Co-P-C amorphous alloy strip, components of the electro-catalyst are Fe(80-x)CoxP(20-y)Cy, 0<=x<=50, 0<=y<=15, and x and y are correspondingly the atomic percent of Co and the atomic percent of C in the Fe-Co-P-C amorphous alloy strip. The Fe-Co-P-C amorphous electro-catalyst is prepared by adopting a melt rotary quenching method, the preparation method is simple, easy to operate, low in cost and friendly to environment, the whole preparation process does not need special equipment, large-scale industrial production can be achieved, and the quality of the obtained alloy strip is high; and according to the prepared Fe-Co-P-C strip through the preparation method, the advantages of being good in conductivity, large in number of active sites, high in electro-catalytic performance and the like are achieved simultaneously, and the Fe-Co-P-C amorphous electro-catalyst is a hydrogen evolution electro-catalytic material which has the wide industrial application prospect.

Owner:HEFEI UNIV OF TECH

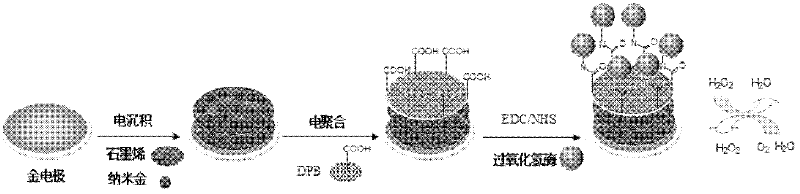

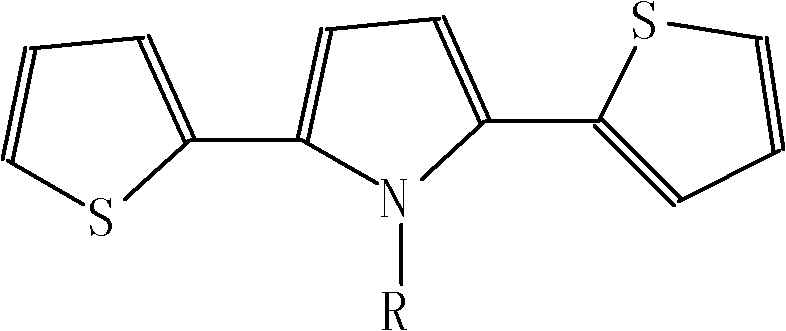

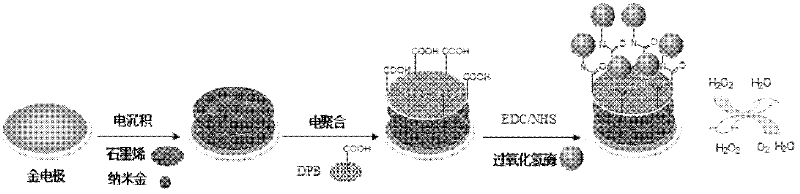

Method for preparing graphene biosensor

ActiveCN102520038ASensitive electrochemical responsePrecise size controlMaterial analysis by electric/magnetic meansSupporting electrolyteConductive polymer

The invention relates to a method for preparing a graphene biosensor, belonging to the technical field of electrochemistry. The method comprises the following steps of: immersing a processed gold electrode into graphene oxide and a sodium sulphate solution, electrically depositing the electrode through a control electric potential, taking out the electrode, washing the electrode by using water, after drying the electrode at room temperature, putting the electrode in a chloroauric acid solution, electrically depositing the electrode through the control electric potential, taking out the electrode, washing the electrode by using water, and drying the electrode at room temperature; putting a modified electrode in a conductive polymer monomer and a supporting electrolyte solution, polymerizing the electrode through the control electric potential by adopting a cyclic voltammetry, taking out the electrode, washing the electrode by using water, and drying the electrode at room temperature; and activating the modified electrode in an EDC / NHS (Dichloroethane / N-Hydroxysuccinimide) solution, and immersing the modified electrode in a vomiting toxin antibody. The method disclosed by the invention is used for fixing graphene, gold nanoparticles and conducting polymers through electro-deposition; therefore, the method is very green and environment-friendly; furthermore, the thickness of a coating and sizes and distribution densities of the gold nanoparticles can be precisely controlled, thus, the batch production repeatability of the modified electrode is good.

Owner:盐城福万家保温板有限公司

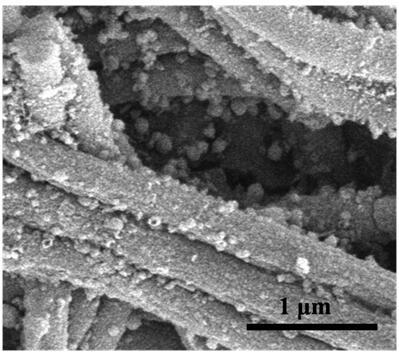

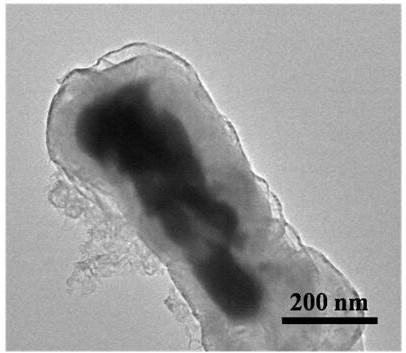

Preparation and application of transition metal phosphide/core-shell nitrogen-doped carbon nanofiber composite material

ActiveCN110052282AImprove conductivityImprove stabilityPhysical/chemical process catalystsElectrodesFiberElectrolysis

The invention provides a preparation method of a transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material. The preparation method includes preparing a carbon nanofiberaccording to an electrospinning technique by taking a carbon-containing high-molecular polymer as a carbon source, coating the carbon nanofiber with an electroconductive polymer through surface polymerization, loading an MOF material onto the surface of the carbon nanofiber coated with the electroconductive polymer according to an in-situ growth method to obtain a precursor, and subjecting the precursor to high-temperature carbonizing and phosphating to obtain the transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material. Activity test results show that the transition metal phosphide / core-shell nitrogen-doped carbon nanofiber composite material prepared by the preparation method has high electrocatalytic activity for total decomposition reaction of HER, OER and water and has high stability in acid-base media, thereby being a dual-functional catalyst that can replace precious metal and having a good development prospect in water electrolysis reaction.

Owner:NORTHWEST NORMAL UNIVERSITY

Electrocatalytic porous titanium filter membrane with micro nano structure and preparation method thereof

InactiveCN107020074AImprove electrocatalytic activityGood dispersionSemi-permeable membranesHeterogenous catalyst chemical elementsMicro nanoNanowire

An electrocatalytic porous titanium filter membrane with a micro nano structure and a preparation method thereof are disclosed, the electrocatalytic porous titanium filter membrane comprises a porous titanium film matrix, a TiO2 middle layer with the micro nano structure and an electrocatalytic active layer loaded on the TiO2 middle layer, the TiO2 middle layer with the micro nano structure is TiO2 nano flower, nanowire, nanorod or nanotube aggregates growing in situ on the porous titanium film matrix, and the electrocatalytic active layer is PbO2, SnO2, RuO2, IrO2, Sb2O5, Bi2O3 and other transition metal oxides or a composite comprising the various metal oxides. The method comprises three main steps: pretreatment of the porous titanium matrix, construction of the middle layer with the micro nano structure and loading of the active layer. The electrocatalytic porous titanium filter membrane has excellent mass transfer performance, high electrocatalytic activity, high pollutant removal efficiency, low energy consumption, and the like, thus having a good application prospect in the field of organic wastewater treatment.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Preparation method of ultrafine platinum nano-wire

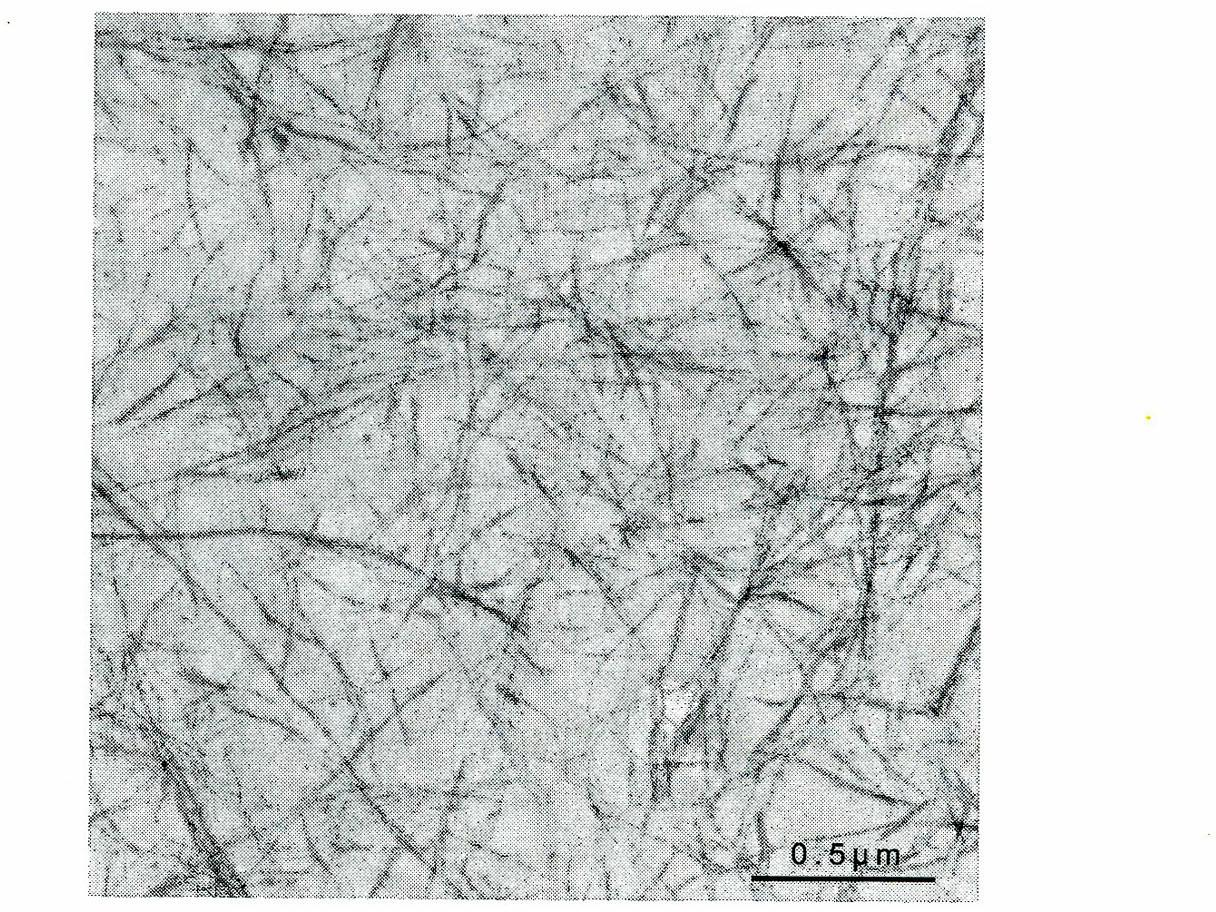

The invention relates to a preparation method of an ultrafine platinum nano-wire. The method mainly comprises that an insulin fiber suspension is obtained by dissolving bovine insulin powders into a hydrochloric acid solution with the concentration of 10-25 mM to prepare an insulin hydrochloric acid solution, blending the insulin hydrochloric acid solution with vortexes, and heating the blended insulin hydrochloric acid solution for 5-20 h in a constant-temperature metal bath at the temperature of 65-70 DEG C; and that the ultrafine platinum nano-wire is obtained by adding a chloroplatinic acid solution into the above insulin fiber suspension, fully blending the mixture, incubating the mixture for 10-20 h in a shaking table at the temperature of 4-10 DEG C and with the rotating speed of 50-100 r / min, dropwise adding a sodium borohydride reductant solution with a concentration of 5-10 mM into the mixture, and vibrating the mixture for 8-24 h in a shaking table at the temperature of 4-10 DEG C and with the rotating speed of 50-100 r / min to make the mixture fully reacted. The method of the invention has the advantages of a simple process, mild reaction conditions, and good repeatability, and is environment protective and highly efficient. With the method, appearance of the platinum nano-wire has no obvious changes while output of the nano-wire increases substantially. Thus, the nano-wire is provided with higher aspect ratio and simpler regulation and control method of output, thereby being easier to realize large-scale production.

Owner:YANSHAN UNIV

Method for performing electrochemical advanced treatment on landfill leachate based on ultraviolet reinforcement

InactiveCN101734750ALow costStable electrochemical reactionWater/sewage treatment by irradiationHigh concentrationReaction rate

The invention relates to a method for performing electromechanical advanced treatment on landfill leachate containing high-concentration chloride ions based on ultraviolet reinforcement, which belongs to the field of water treatment application. In the method, the biochemical effluent of the landfill leachate is taken as an advanced treatment object; an electrochemical indirect oxidation function (active chlorine produced from the high-concentration chloride ions in the leachate under an electrochemical function serves as a main oxidized group) is mainly utilized; and simultaneously, the active chlorine produced by performing in-situ electrochemistry is subjected to in-situ photodecomposition by introducing ultraviolet light, thereby producing a hydroxyl group, a chlorine free radical and the like with stronger oxidation capacity. The method has the advantages of accelerating reaction rate, simultaneously improving effect on the reduction of the chromaticity of the leachate and the removal of difficultly-degraded organic substances and ammonia nitrogen, so that the treated effluent can reach a set discharge standard.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com