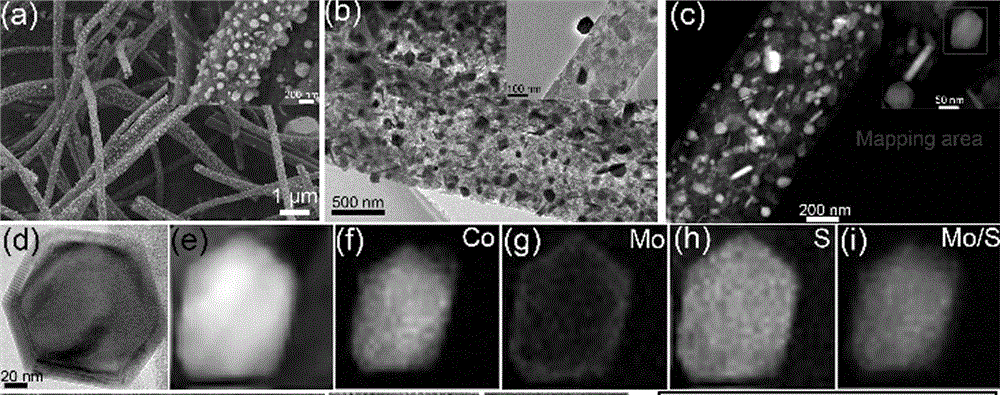

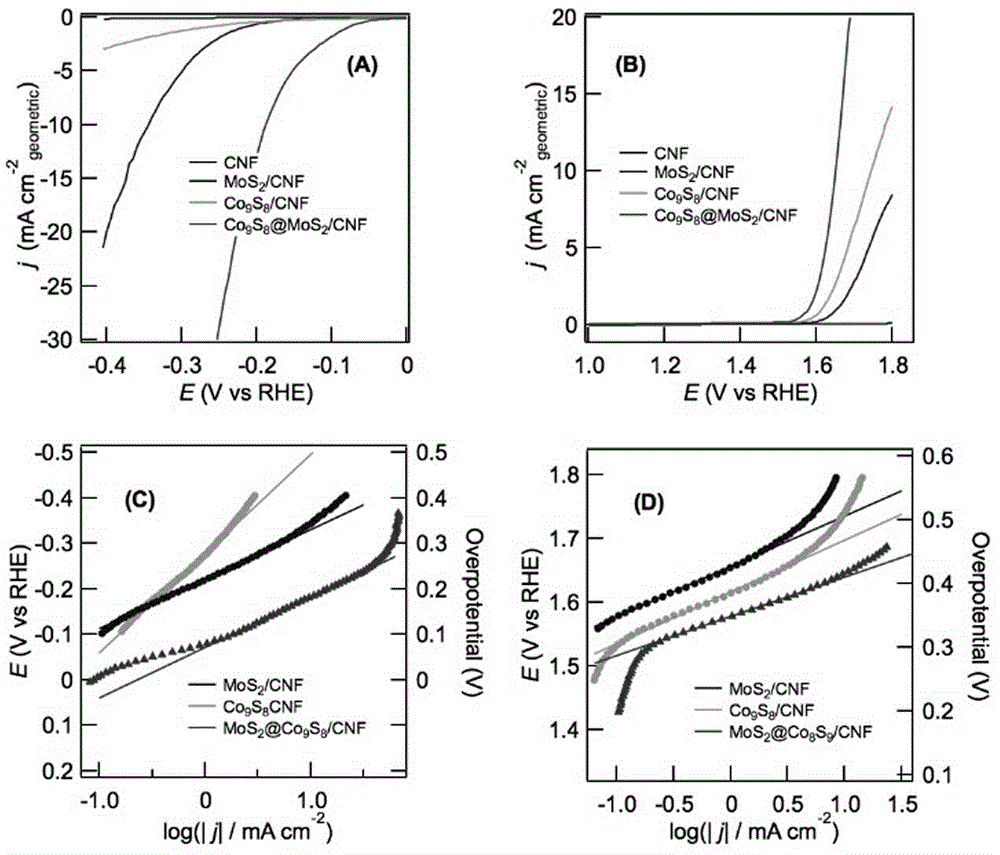

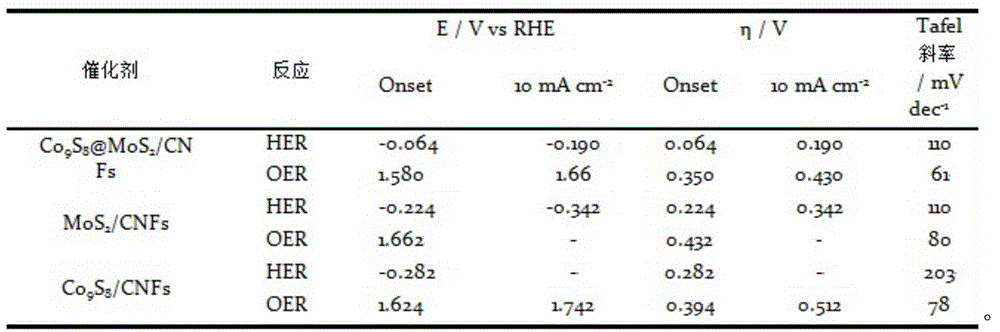

Electrolyzed-water catalytic material with nanometer core-shell structure of cobalt sulfide and molybdenum disulfide

A technology of molybdenum disulfide and catalytic materials, applied in the direction of physical/chemical process catalysts, electrolytic processes, electrolytic components, etc., can solve the bottleneck of catalytic activity of single-component materials, slow electron transfer rate, electrocatalytic electrode stability and poor cycle performance and other issues, to achieve the effect of facilitating diffusion and gas desorption, high porosity, good stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention comprises the steps of:

[0033] 1) The superfine fiber precursor is made into a spinning solution with a mass concentration of 5-15% with dimethylformamide, the precursor of molybdenum disulfide and the precursor of cobalt sulfide are dissolved in the spinning solution, and then The spinning solution is prepared by electrospinning to prepare superfine fibers; during electrospinning, the spinning voltage is controlled at 4-18kV, the distance from the receiving device to the spinning needle is 5-20cm, and the solution flow rate is 0.01mL / min. The superfine fiber precursor is one or more of polyacrylonitrile, polyethyleneimine, polyvinyl alcohol and cellulose. The precursor of cobalt sulfide is one or more of cobalt nitrate, cobalt phosphate, cobalt sulfate and cobalt carbonate. The precursor of molybdenum disulfide is one or more of ammonium tetrathiomolybdate, ammonium molybdate and ammonium heptamolybdate.

[0034] 2) A...

specific Embodiment

[0038] Get 0.15g cobalt nitrate and 0.2g ammonium tetrathiomolybdate and join in 30g polyacrylonitrile / dimethylformamide solution (wherein the mass concentration of polyacrylonitrile is 12%), adopt electrospinning method to this solution then Spinning is carried out, the spinning voltage is controlled to be 4kV, the distance from the receiving device to the spinning needle is 5cm (that is, the receiving distance is 5cm), and the solution flow rate is 0.01mL / min to obtain ultrafine fibers.

[0039] Add 0.5g ultra-fine fiber into the corundum boat, 1g sulfur powder into another corundum boat, both corundum boats are placed in the middle of the tube furnace, and the corundum boat with sulfur powder is at the upstream of the airflow; In air, the temperature was raised to 280°C at 5°C / min and maintained for 6 hours. Then the temperature was raised to 400°C, and the corundum boat containing the sulfur powder was heated to 300°C with a separate heating belt. After opening the argon g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com