Preparation method of cobalt phosphide coated with carbon layers

A technology of cobalt phosphide and encapsulation, which is applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of reduced energy conversion efficiency, lack of element abundance, and limited applications, etc., and meet the reaction conditions The effect of wide window, improved electrocatalytic activity, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Synthesis of MOF: weigh 2.5 mmol Co(NO 3 ) 2 ·6H 2 O and 5 mmol benzimidazole were mixed and dissolved completely with 60mL DMF, then transferred to the reactor and reacted at 130°C for 48 h. After the reaction was completed and cooled, pour off most of the clear liquid in the upper layer of the reactor , the purple crystals on the wall and bottom of the kettle were centrifuged, washed three times with EtOH, and the product was vacuum-dried in an oven at 60°C overnight, and the obtained purple crystal product was Co-MOF.

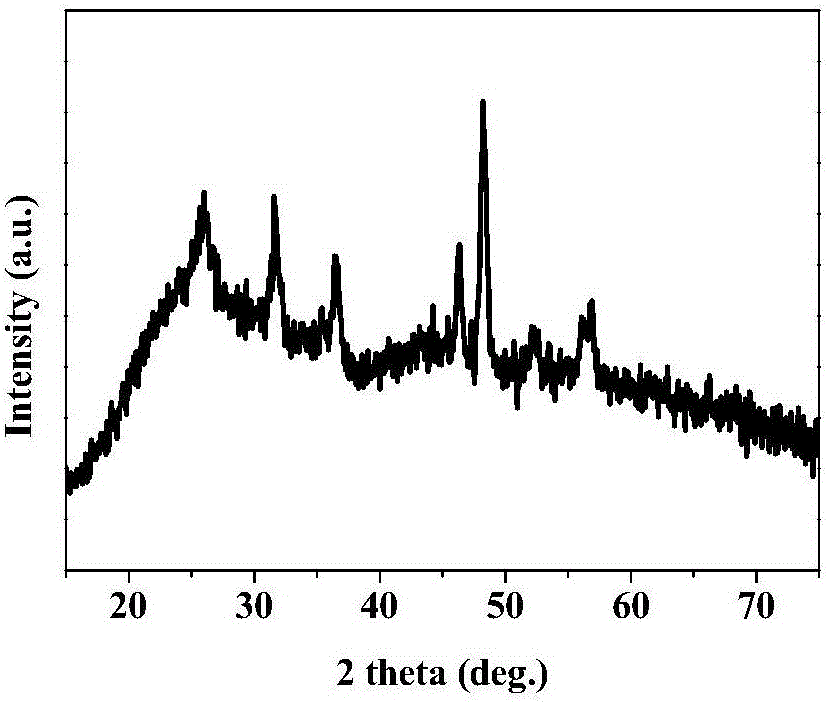

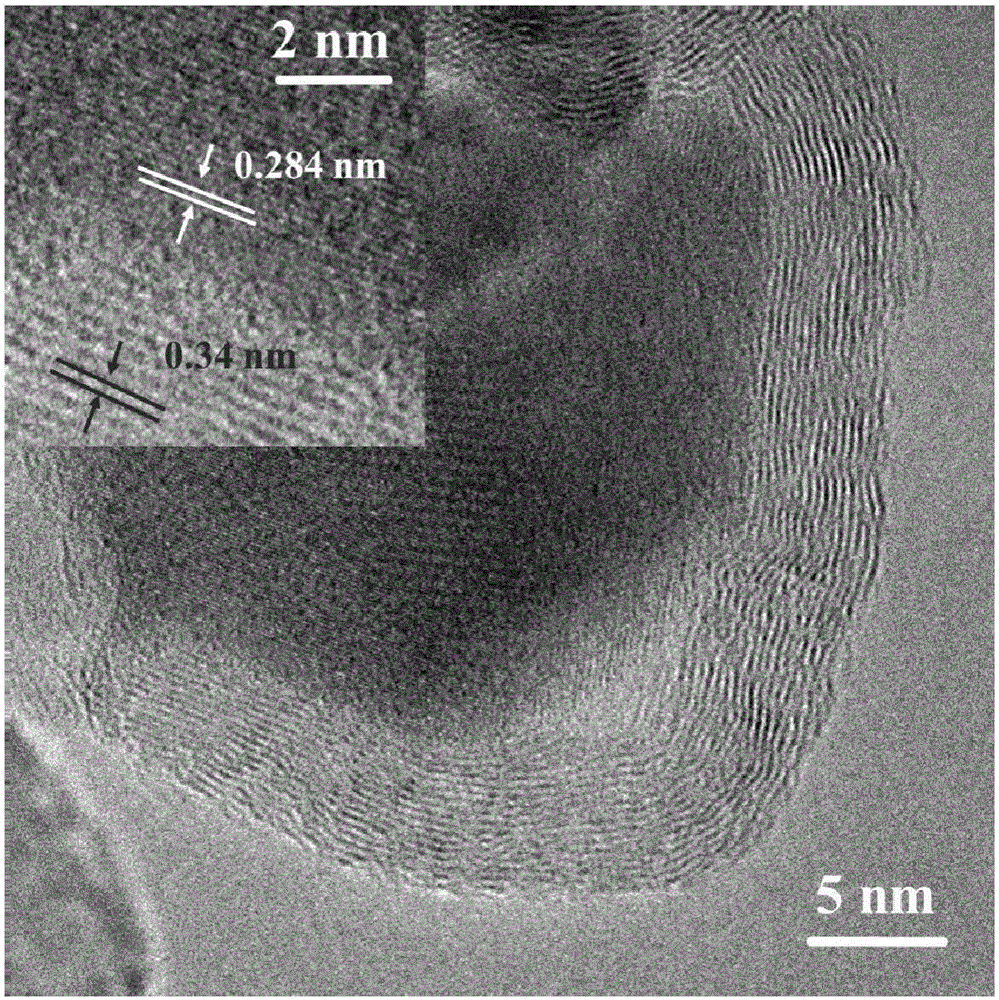

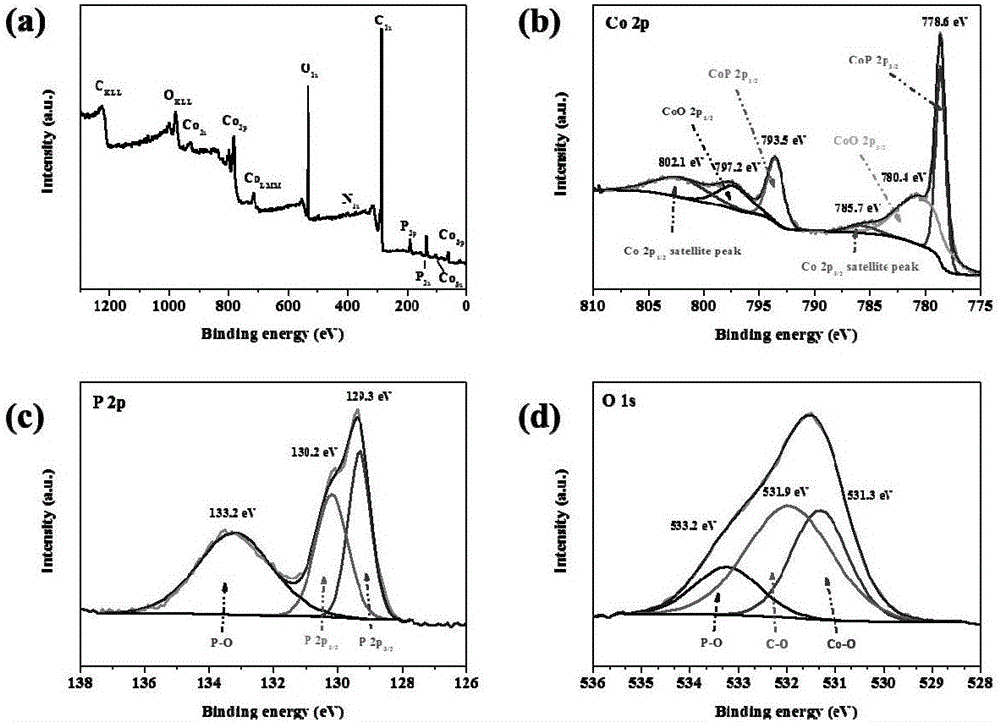

[0023] 2) Pyrolysis: put the Co-MOF obtained in the previous step in the magnetic boat of the tube furnace, and use N 2 As a protective gas, the temperature was raised to 900 °C at a heating rate of 5 °C / min and kept for 2 h. After natural cooling, the sample was taken out and it was Co-PC.

[0024] 3) Oxidation: Put the Co-PC obtained in the previous step in the magnetic boat of the tube furnace, raise the temperature to 250 °C in the air at a ...

Embodiment 2

[0030] 1) Synthesis of MOF: weigh 2.5 mmol Co(NO 3 ) 2 ·6H 2 O and 5 mmol benzimidazole were mixed and dissolved completely with 60mL DMF, then transferred to the reaction kettle and reacted at 130°C for 24 h respectively. After the reaction was completed and cooled, pour off most of the upper layer of the reaction kettle Clear the liquid, centrifuge the purple crystals on the wall and bottom of the kettle, wash with EtOH three times, and dry the product in a 60°C oven under vacuum overnight. The obtained purple crystal product is Co-MOF.

[0031] 2) Pyrolysis: put the Co-MOF obtained in the previous step in the magnetic boat of the tube furnace, and use N 2 As a protective gas, the temperature was raised to 900 °C at a heating rate of 5 °C / min and kept for 2 h. After natural cooling, the sample was taken out and it was Co-PC.

[0032] 3) Oxidation: Put the Co-PC obtained in the previous step in the magnetic boat of the tube furnace, raise the temperature to 250 °C in the a...

Embodiment 3

[0035] 1) Synthesis of MOF: weigh 2.5 mmol Co(NO 3 ) 2 ·6H 2 O and 5 mmol benzimidazole were mixed and dissolved completely with 60mL DMF, then transferred to the reaction kettle and reacted at 130°C for 24 h respectively. After the reaction was completed and cooled, pour off most of the upper layer of the reaction kettle Clear the liquid, centrifuge the purple crystals on the wall and bottom of the kettle, wash with EtOH three times, and dry the product in a 60°C oven under vacuum overnight. The obtained purple crystal product is Co-MOF.

[0036] 2) Pyrolysis: put the Co-MOF obtained in the previous step in the magnetic boat of the tube furnace, and use N 2 As a protective gas, the temperature was raised to 900 °C at a heating rate of 5 °C / min and kept for 2 h. After natural cooling, the sample was taken out and it was Co-PC.

[0037] 3) Oxidation: Put the Co-PC obtained in the previous step in the magnetic boat of the tube furnace, raise the temperature to 250 °C in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com