Patents

Literature

4051 results about "Clear liquid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

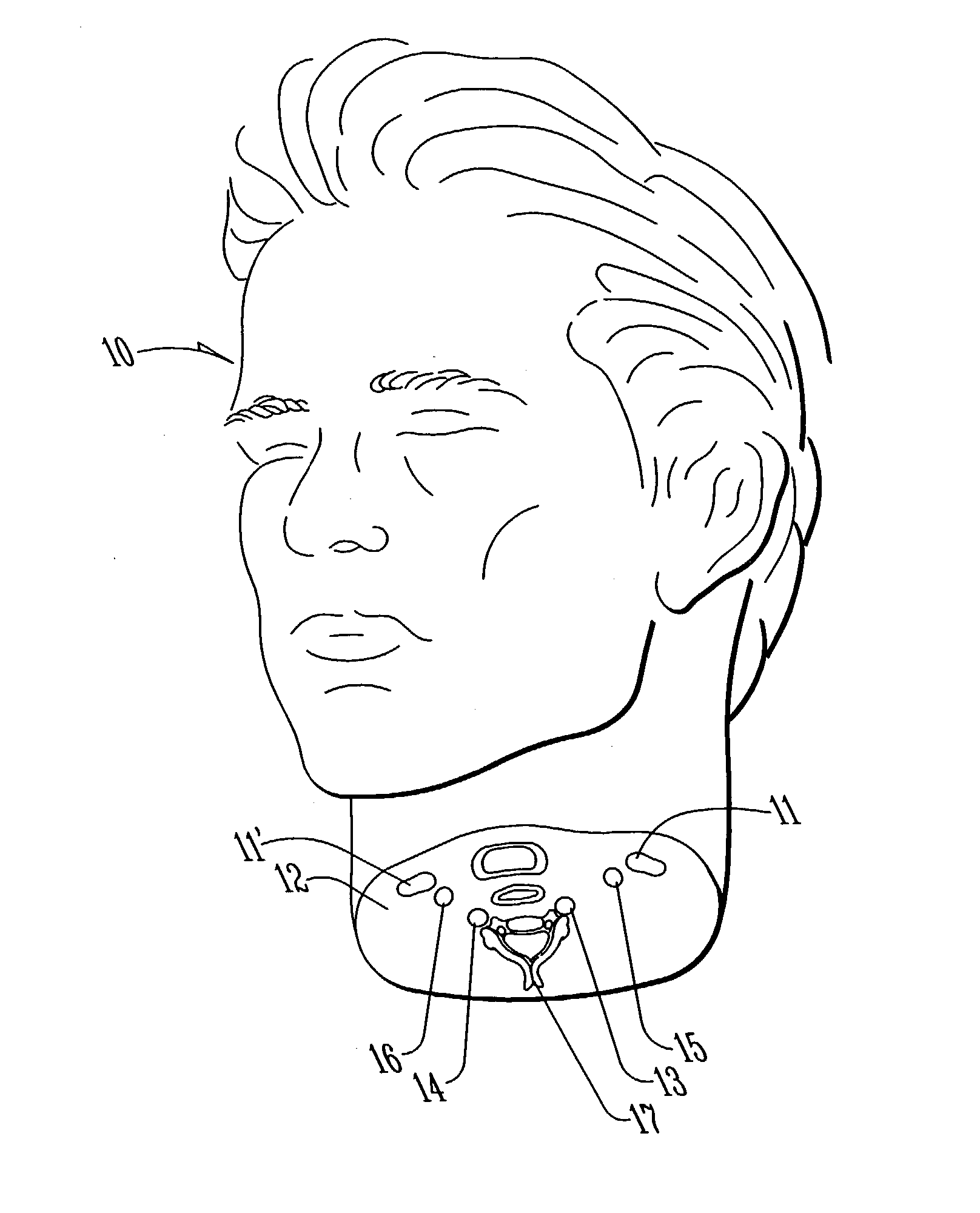

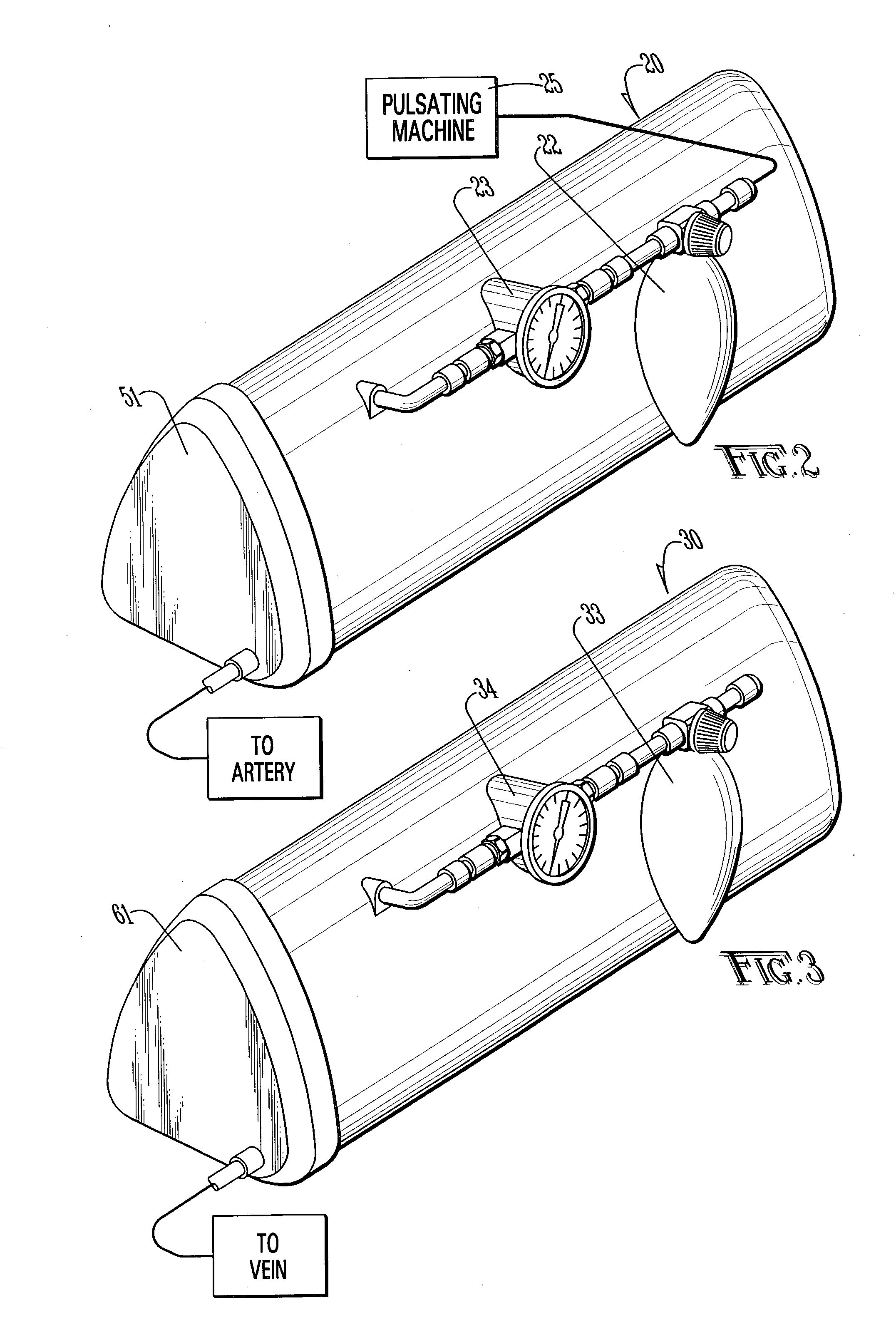

Method and apparatus for surgical training

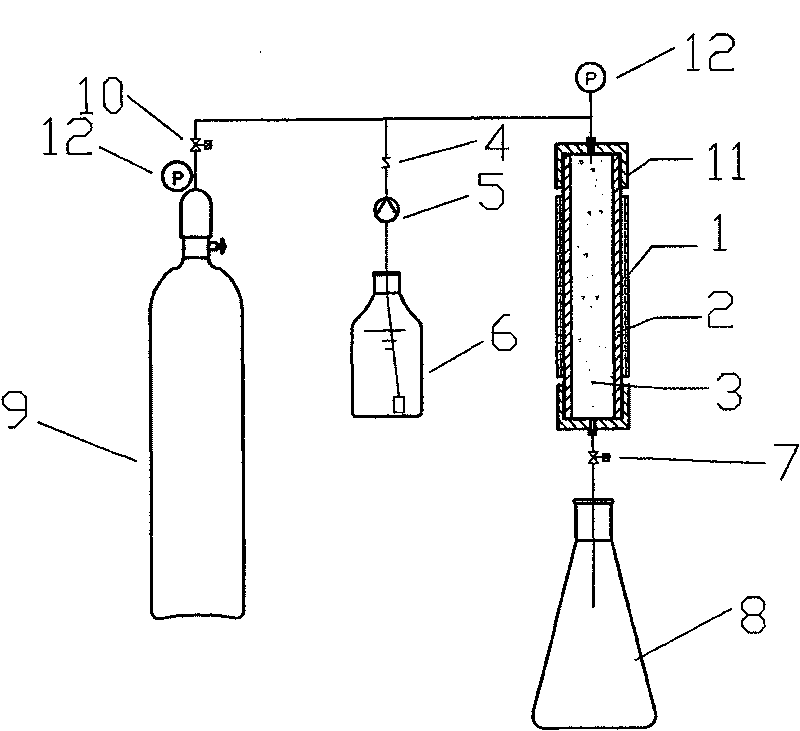

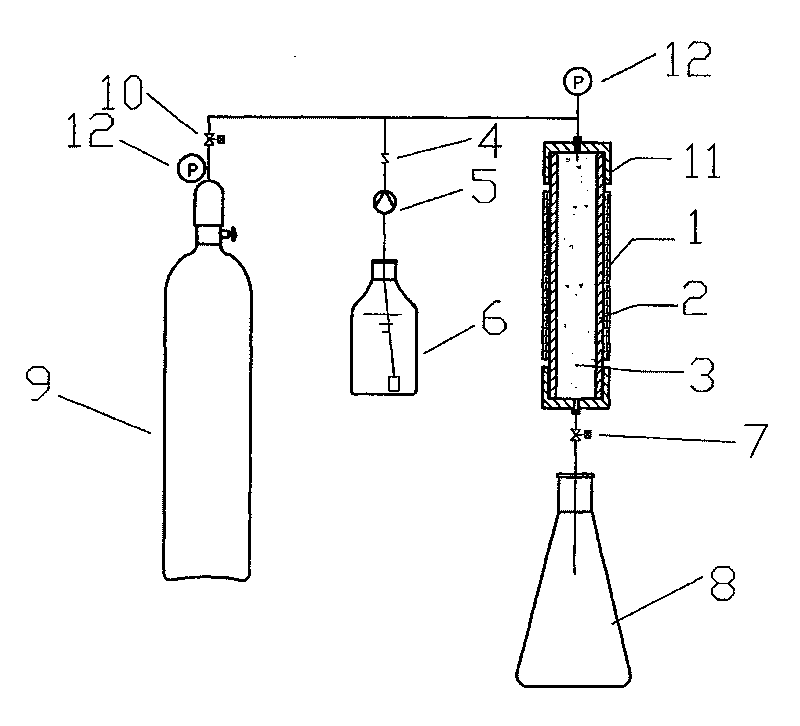

An apparatus and method for microsurgical training using cadaveric anatomy with filling of the vascular system by fluids under pressure to simulate the appearance and function of live surgery. One or more arteries on the specimen of cadaveric anatomy are cannulated and connected to an arterial reservoir having a flexible container holding an arterial fluid simulating the appearance of blood circulating in the arteries of the living organism from which the cadaveric anatomy is derived. Suitable static pressure simulating the arterial pressure appropriate to that of the living organism is applied to the air in an air-tight space surrounding the flexible container in the arterial reservoir. A pulsating machine provides air pulsations to the space surrounding the flexible fluid container to simulate the normal pulsations of the arterial system. One or more veins on the specimen are also cannulated and connected to a venous reservoir having a flexible container holding a venous fluid simulating the appearance of blood circulating in the veins of the living organism. Suitable static pressure simulating the venous pressure appropriate to that of the living organism is applied to the air in an air-tight space surrounding the flexible container in the venous reservoir. Optionally, if the specimen includes at least a portion of spinal canal, a clear fluid reservoir can be connected to the specimen through the spinal canal to simulate cerebrospinal fluid.

Owner:ABOUD GHAITH +1

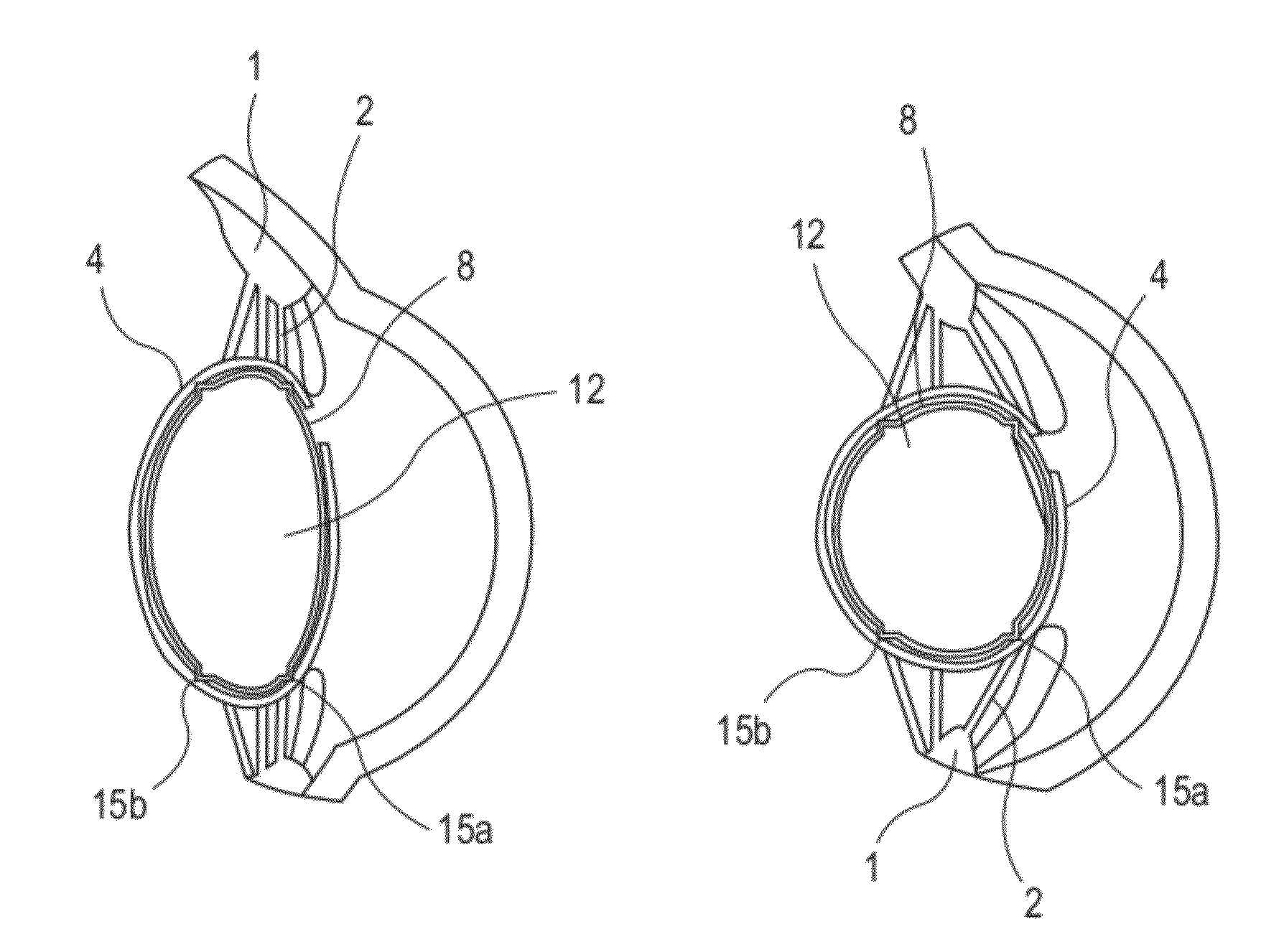

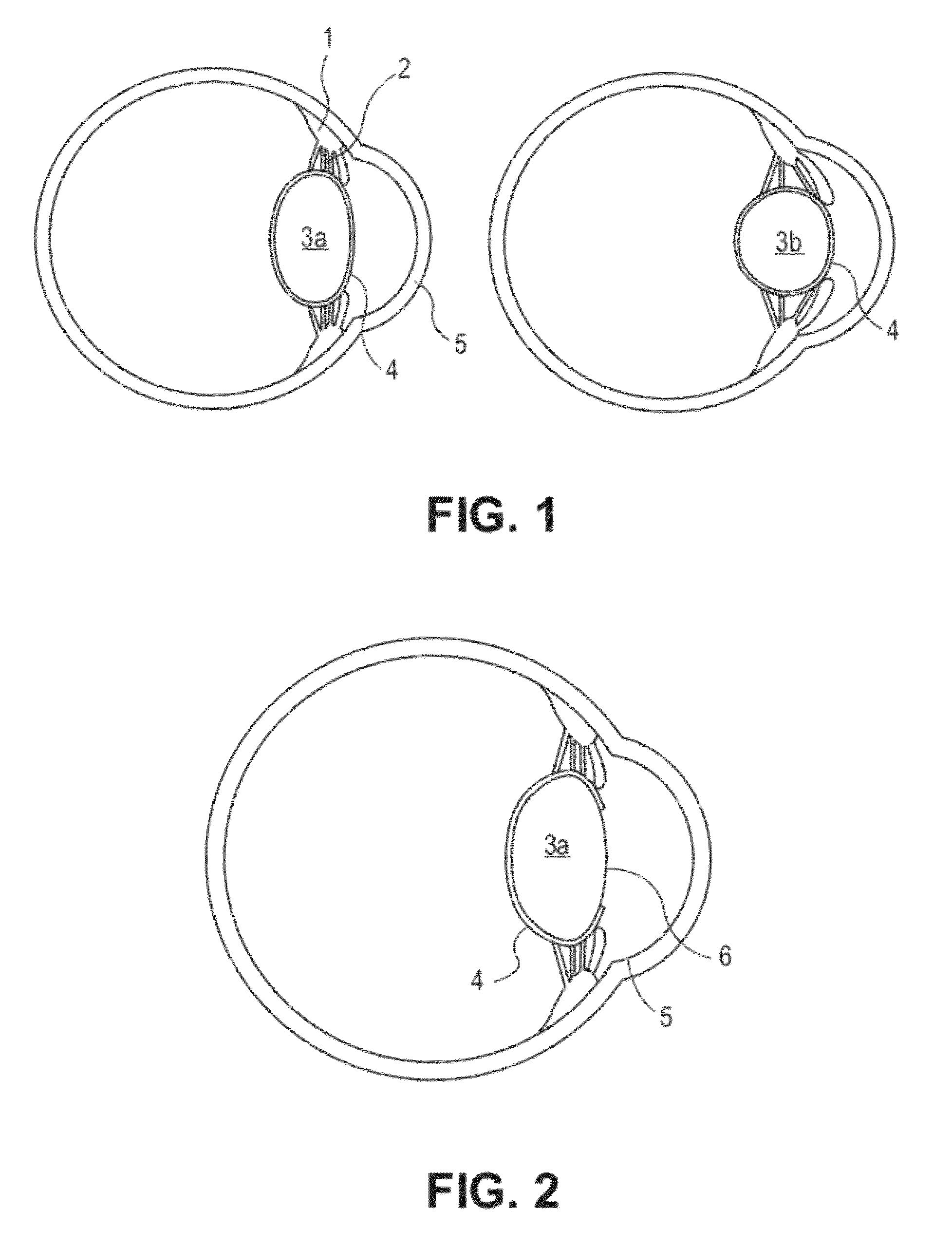

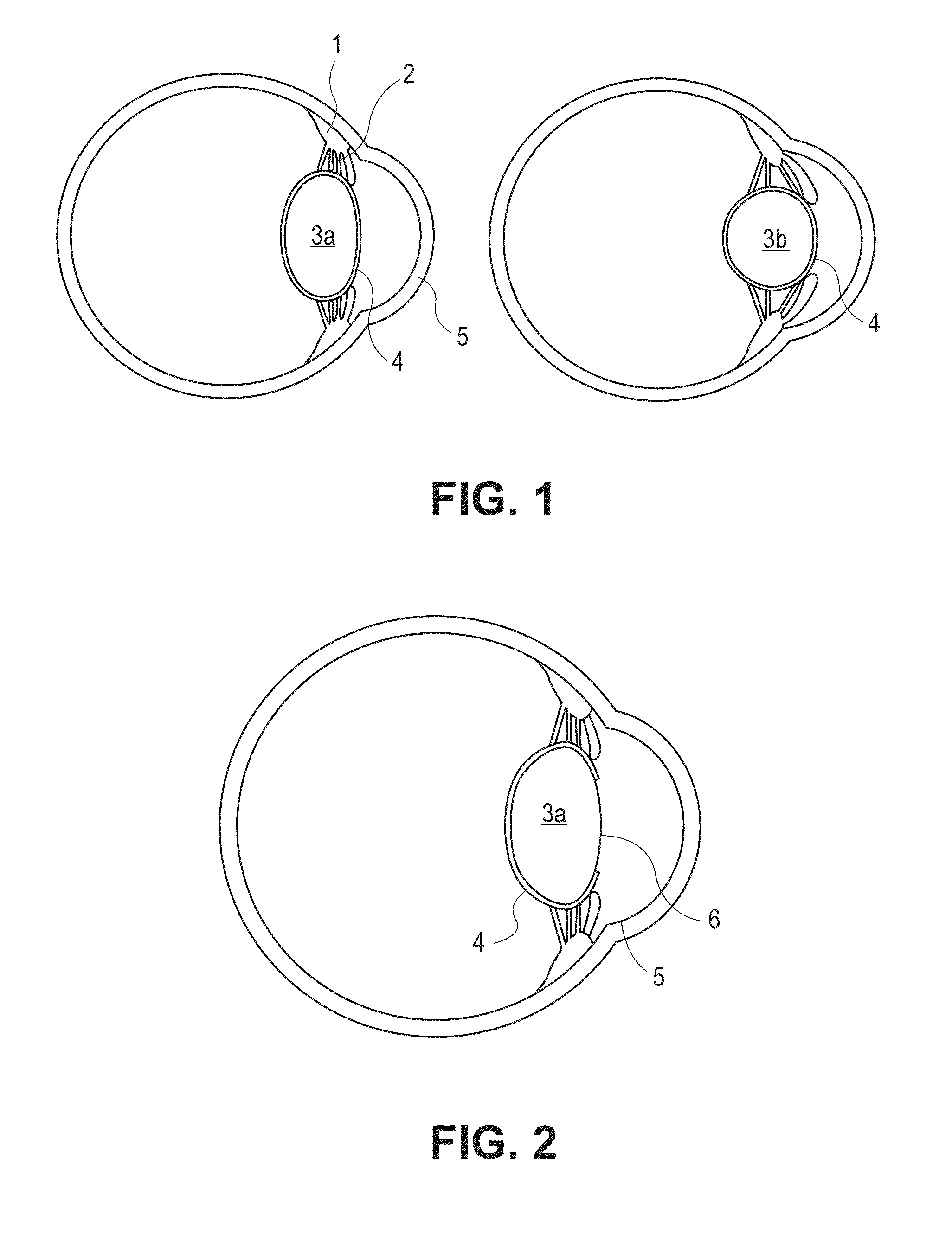

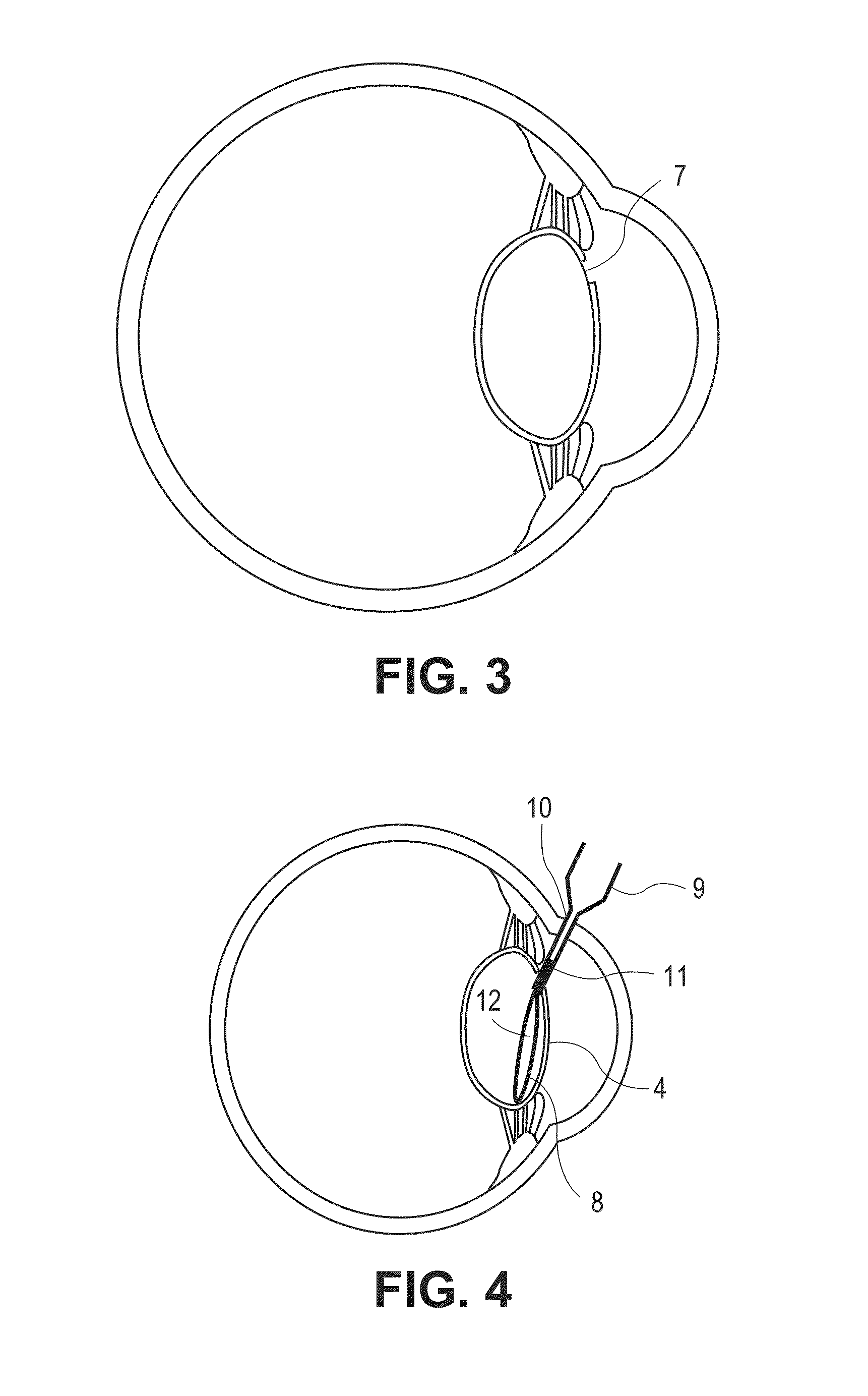

Accommodating intraocular lens

ActiveUS8771347B2Bright colorEasy to findEye surgeryTissue regenerationSurgical operationIntraocular lens

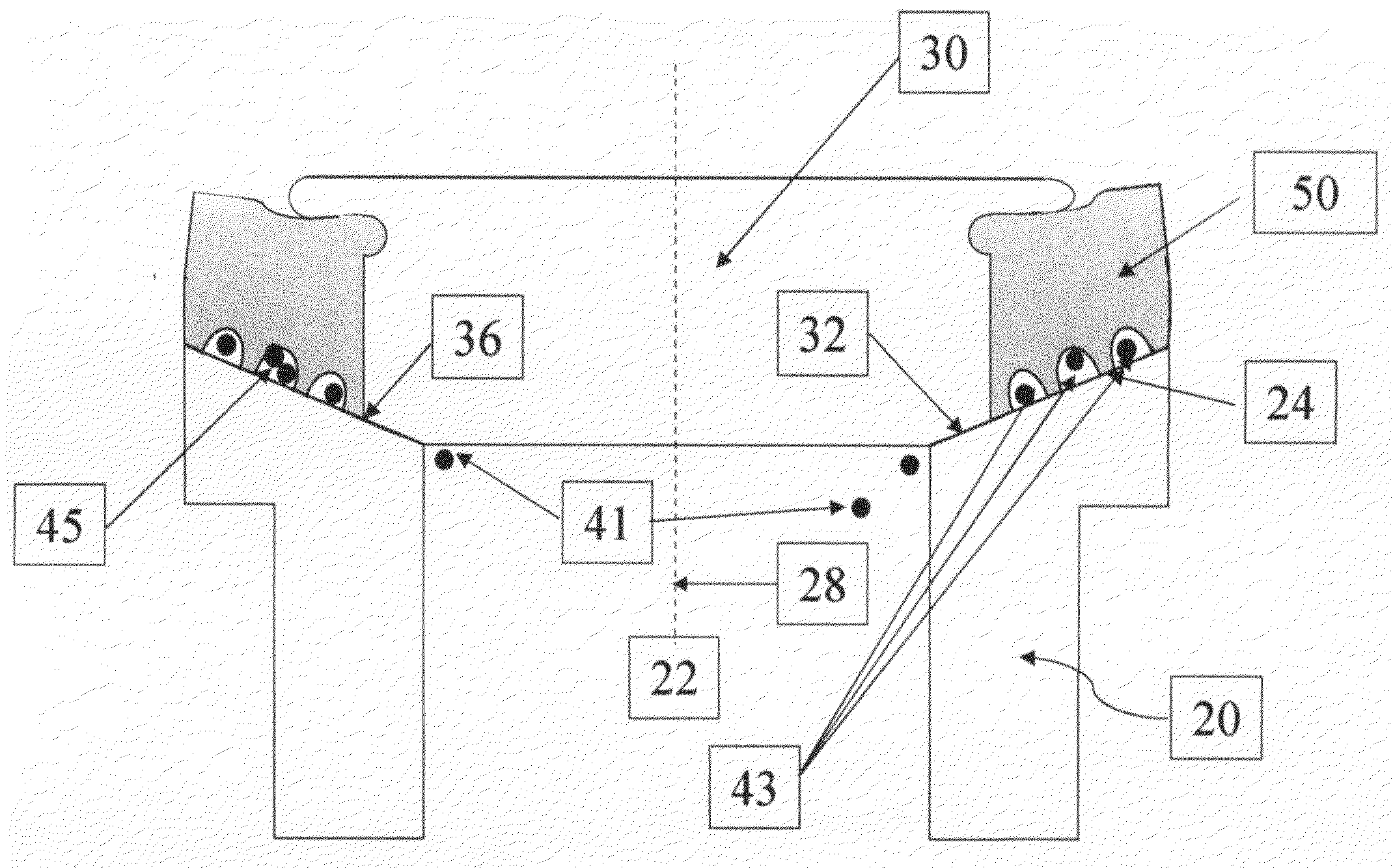

Systems, devices, and methods are presented for a prosthetic injectable intraocular lens. One or more silicone elastomeric patches located outside the optical path on the anterior side but away from the equator can be accessed by surgical needles in order to fill or adjust optically clear fluid within the lens. The fluid can be adjusted in order to set a base dioptric power of the lens and otherwise adjust a lens after its initial insertion. The elastomeric patches are sized so that they self-seal after a needle is withdrawn. A straight or stepped slit in the patch can allow a blunt needle to more easily access the interior of the lens.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

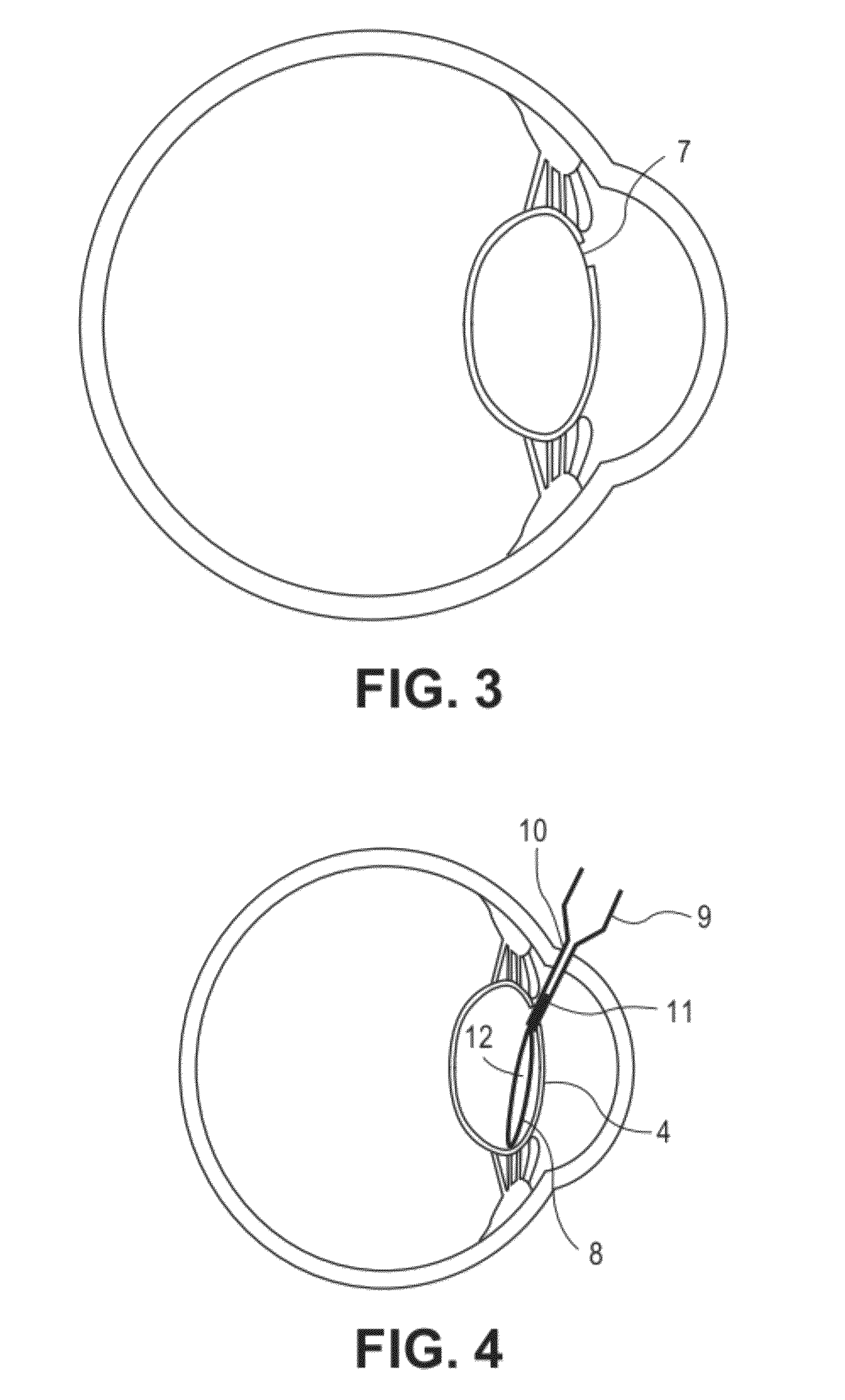

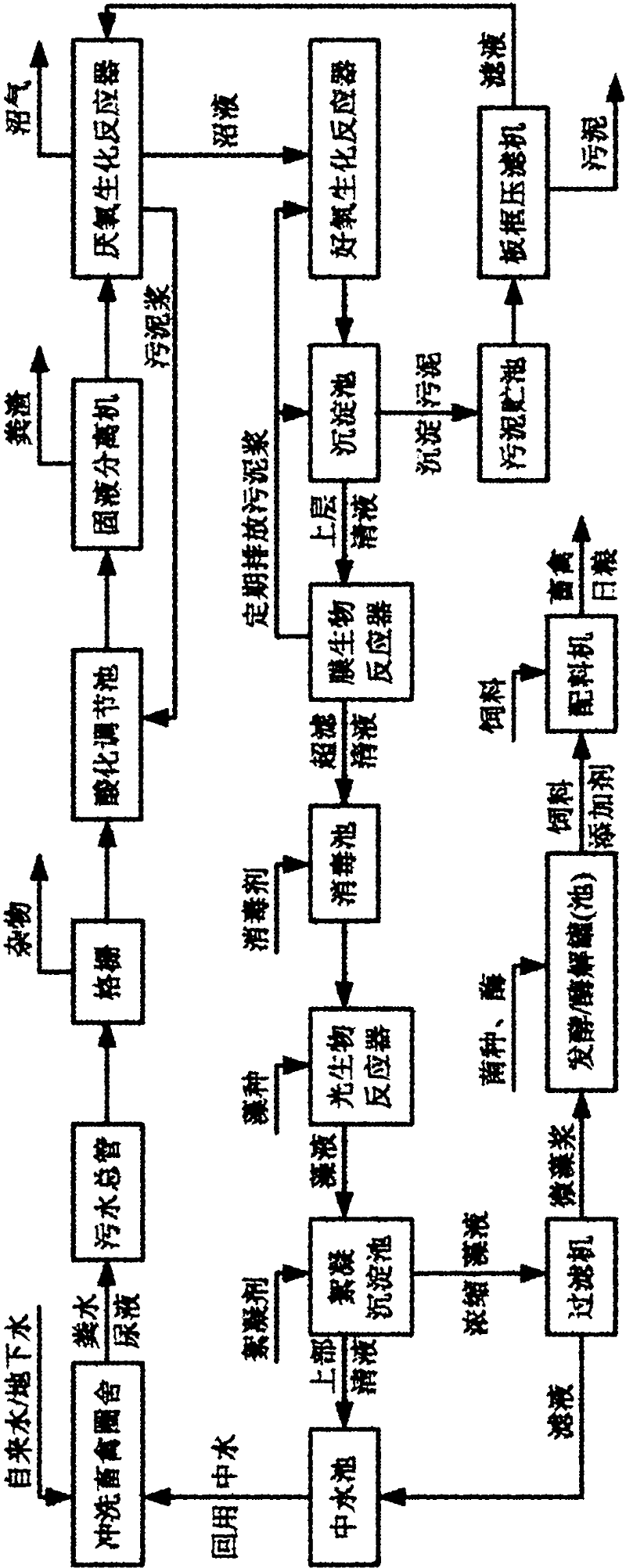

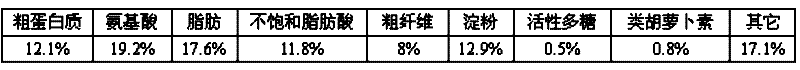

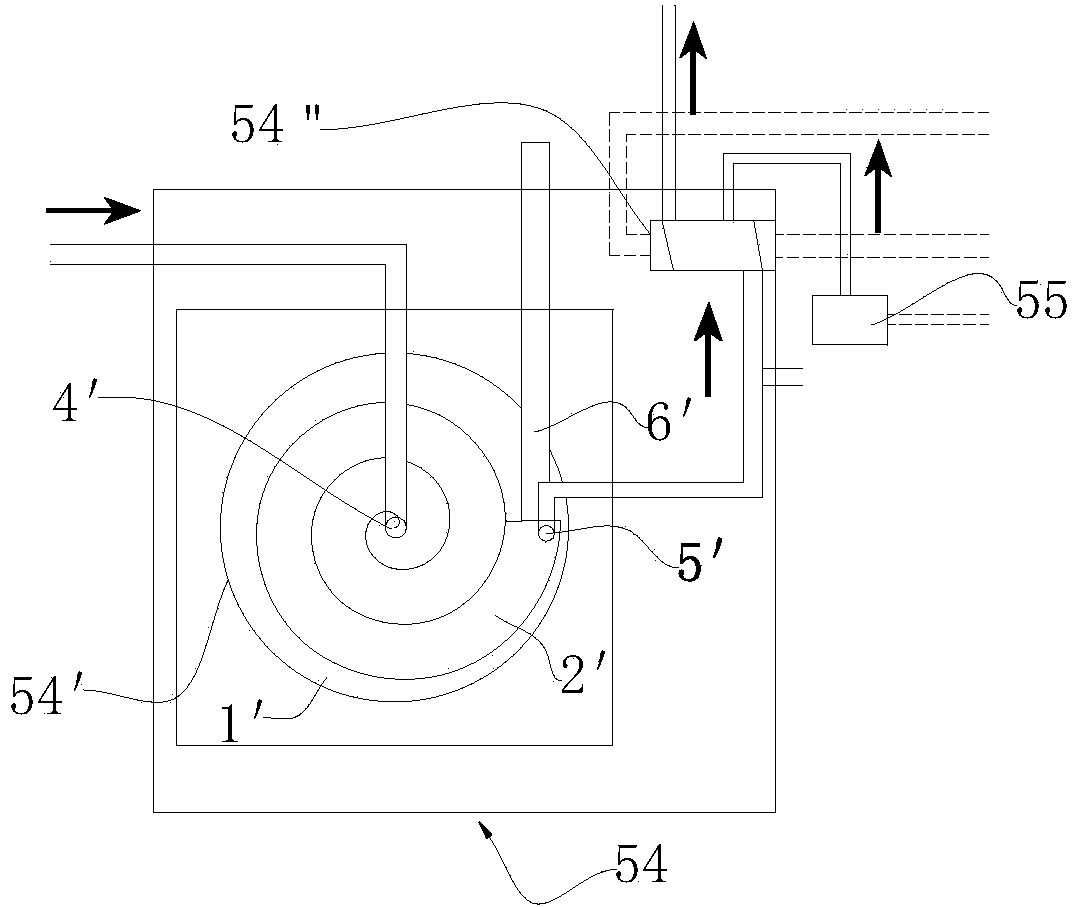

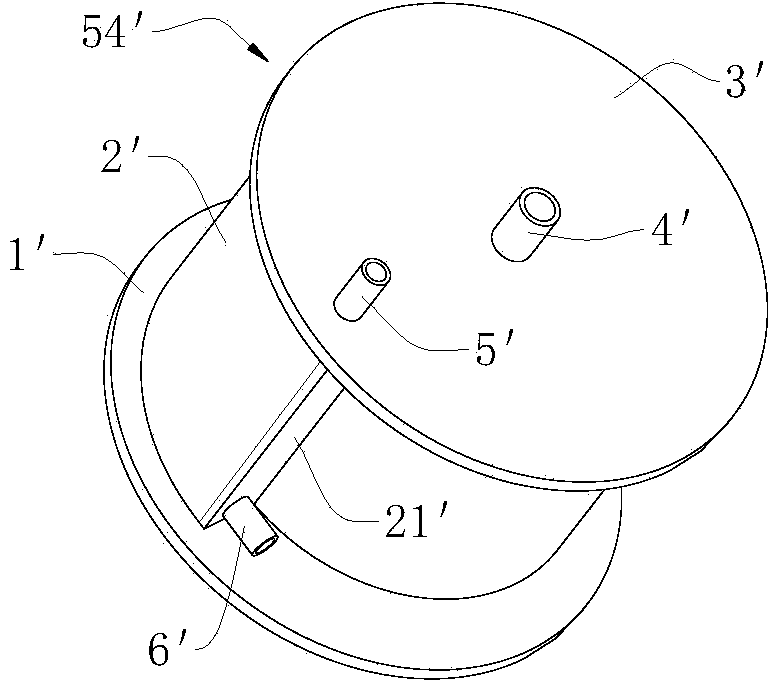

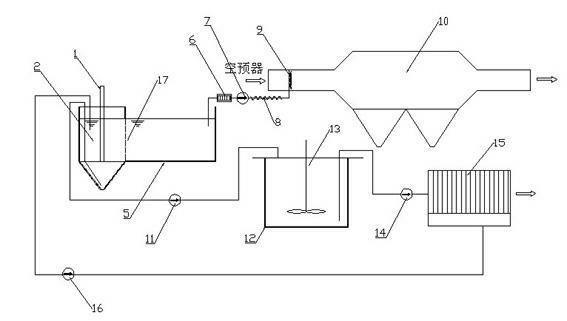

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

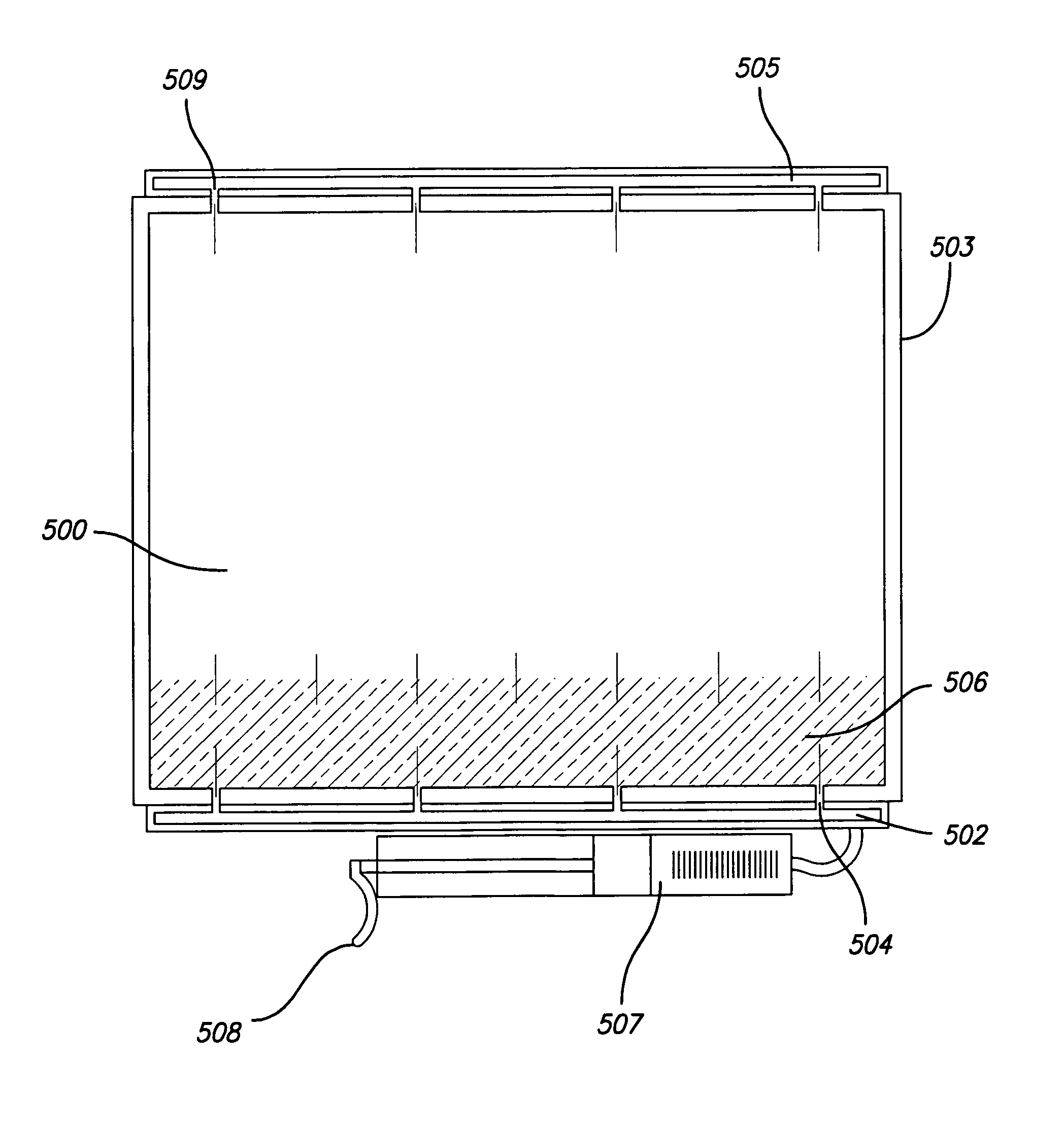

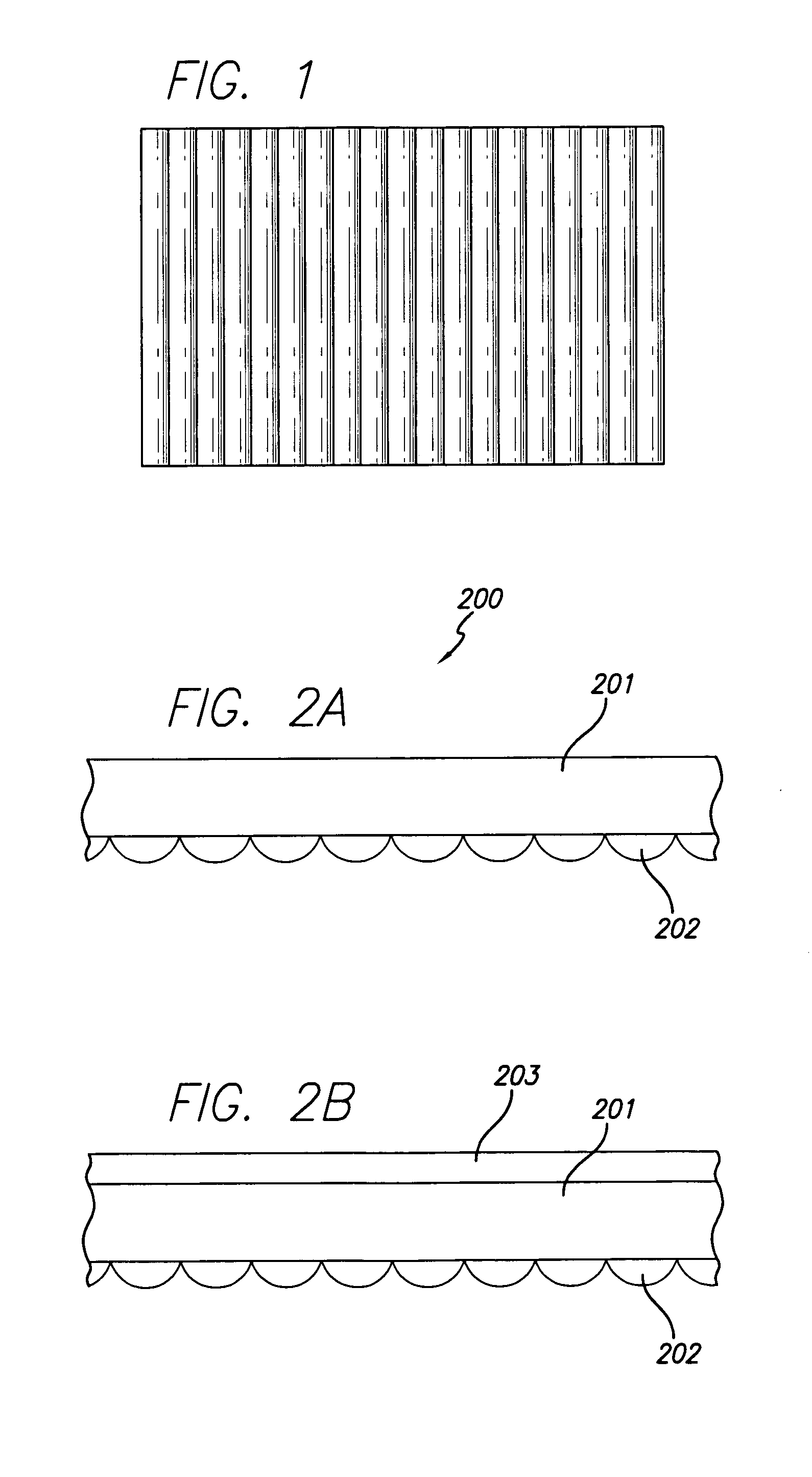

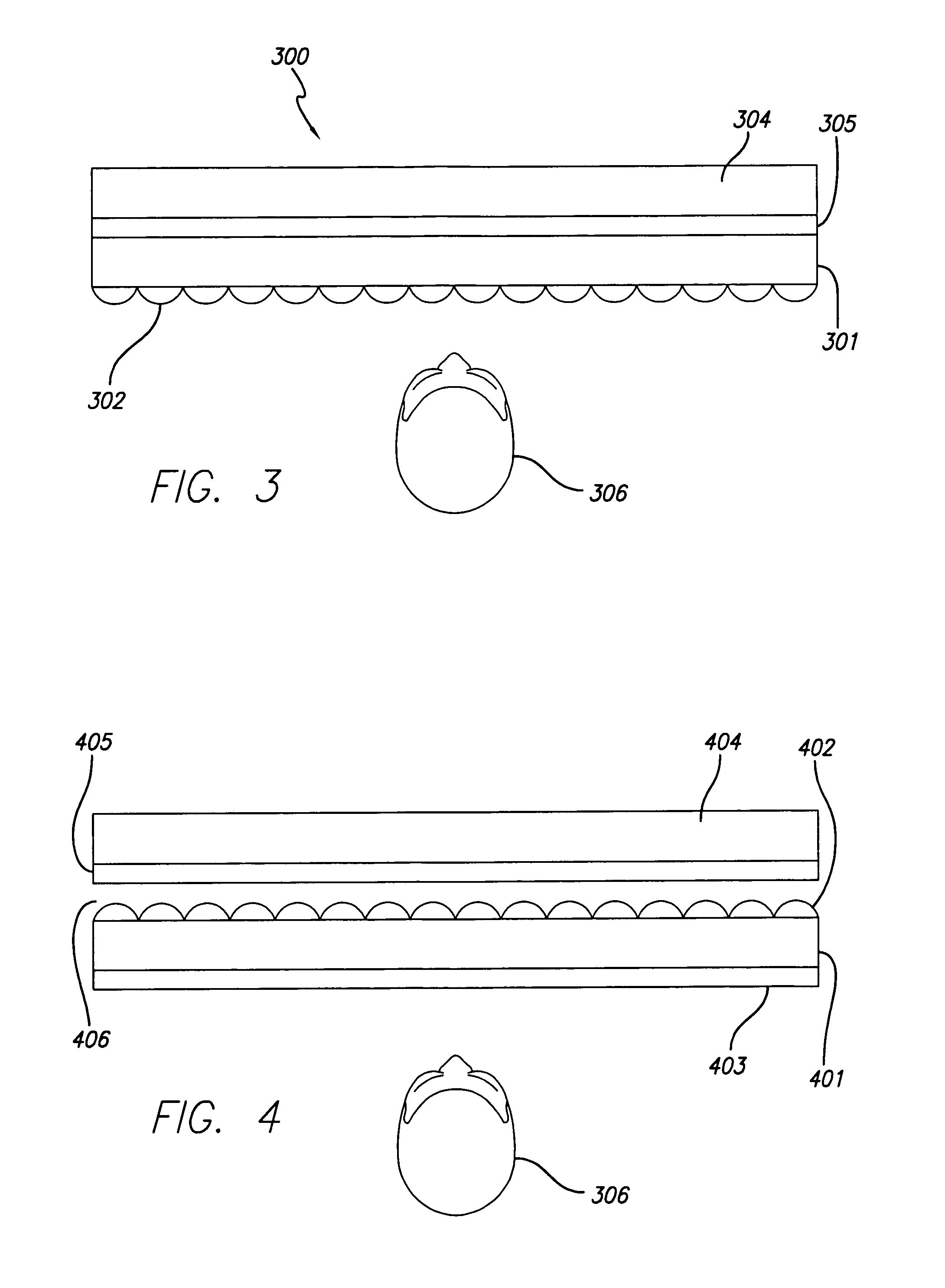

Autostereoscopic lenticular screen

An autostereoscopic lenticular screen has a lenticular screen held in juxtaposition with a display surface. The lenticular screen has lenticules disposed on one side thereof and a smooth surface on the other side thereof. In one aspect of the invention, a closed chamber is formed over the lenticules. In order to deactivate the refractive properties of the lenticular screen, and thereby view the display in a planar mode, an optically clear fluid, such as a fluoropolymer, is introduced into at least a portion of the closed chamber. In order to activate the refractive properties of the lenticular screen, and thereby view the display in a stereoscopic mode, the optically clear fluid is removed from the closed chamber. In a particularly preferred arrangement, the lenticular screen is oriented such that the lenticules face inwardly toward the display screen, and the smooth surface of the lenticular screen is coated with an antireflective material.

Owner:LEDOR LLC +1

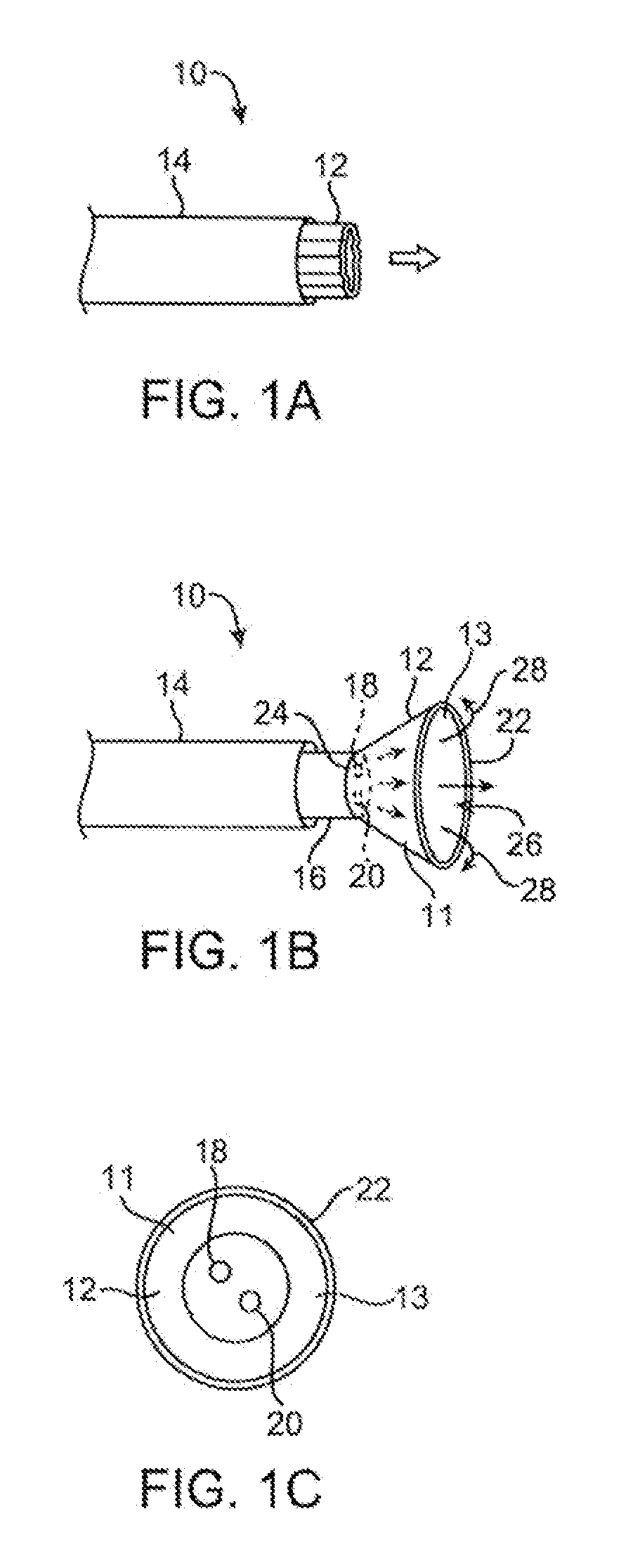

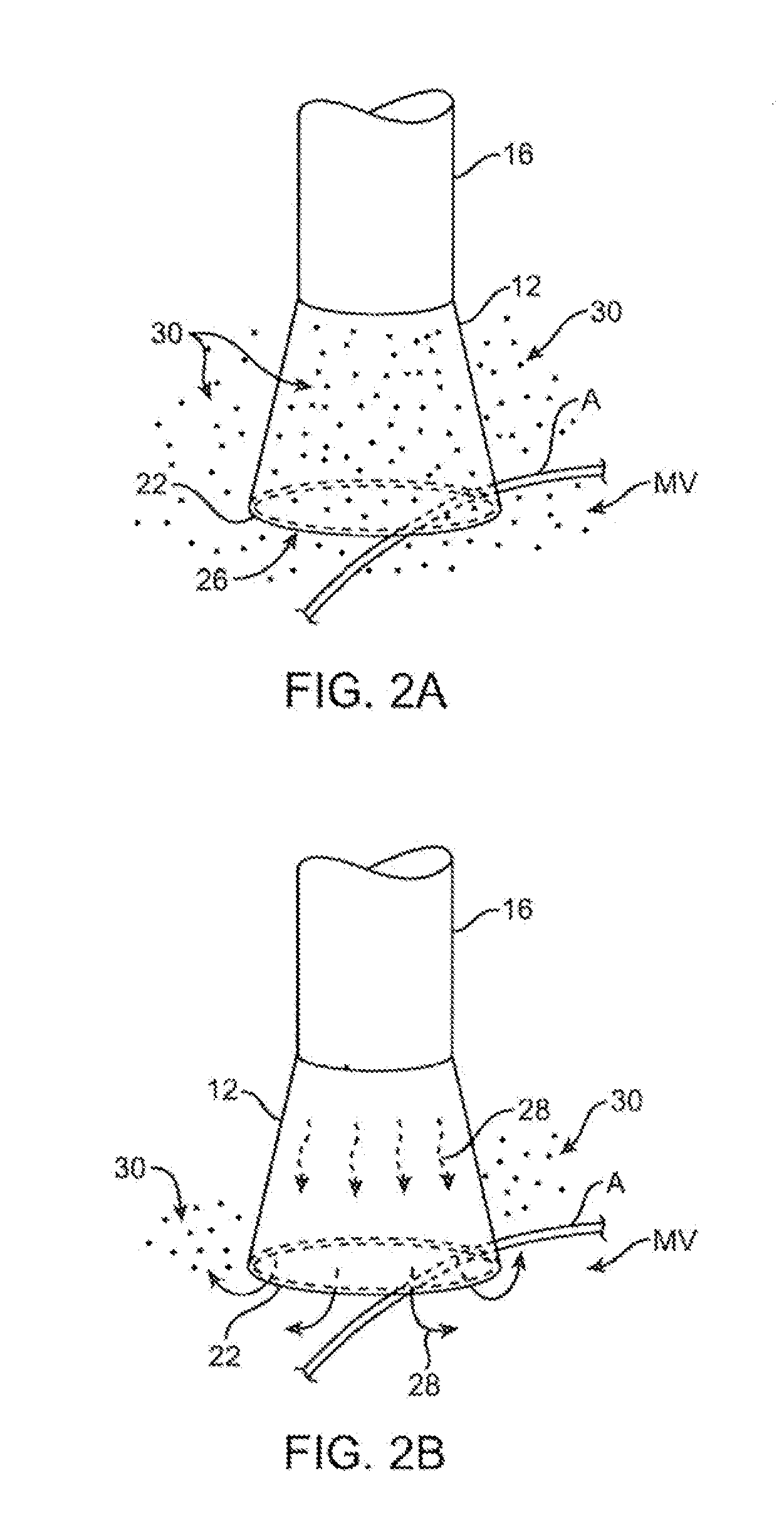

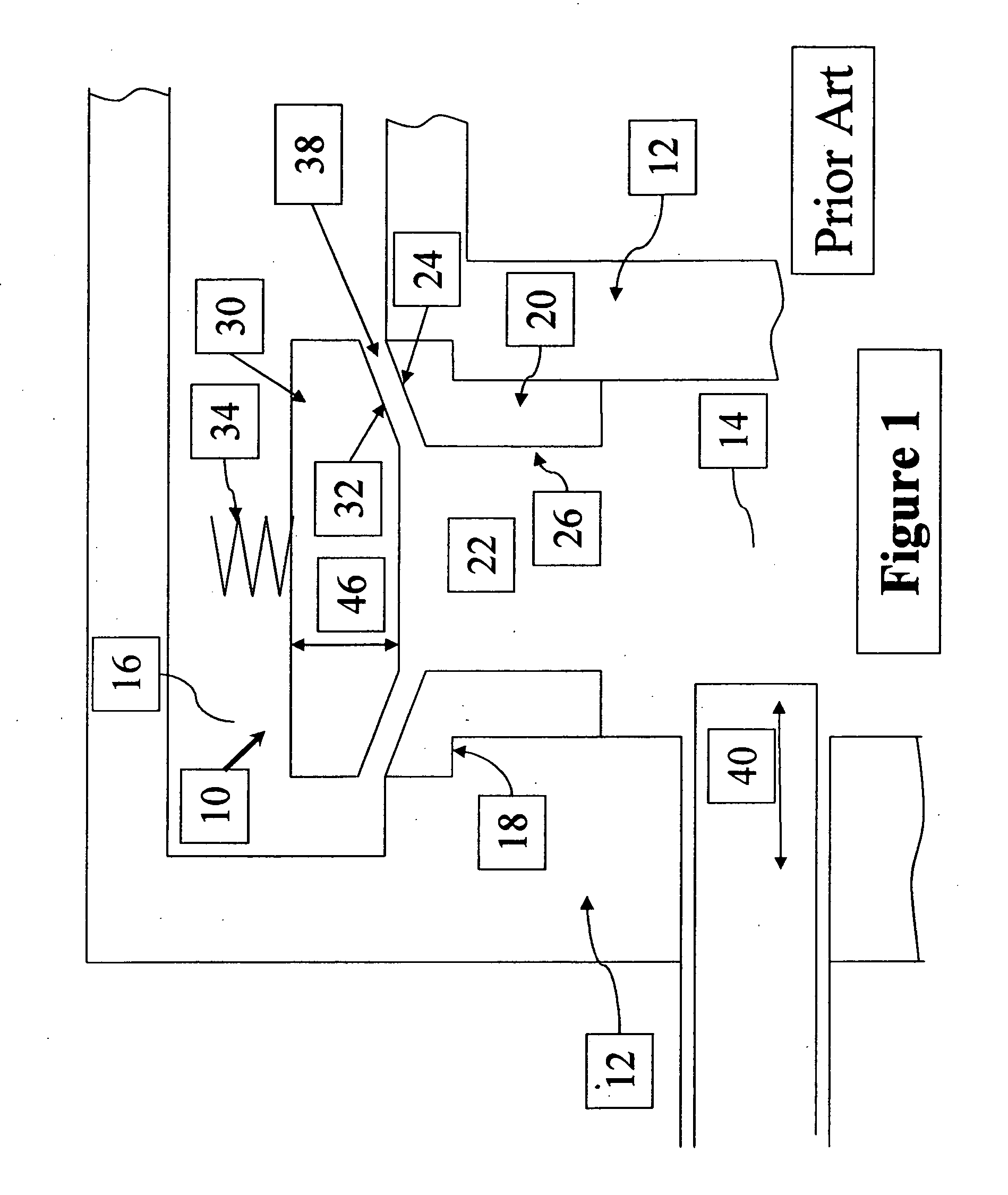

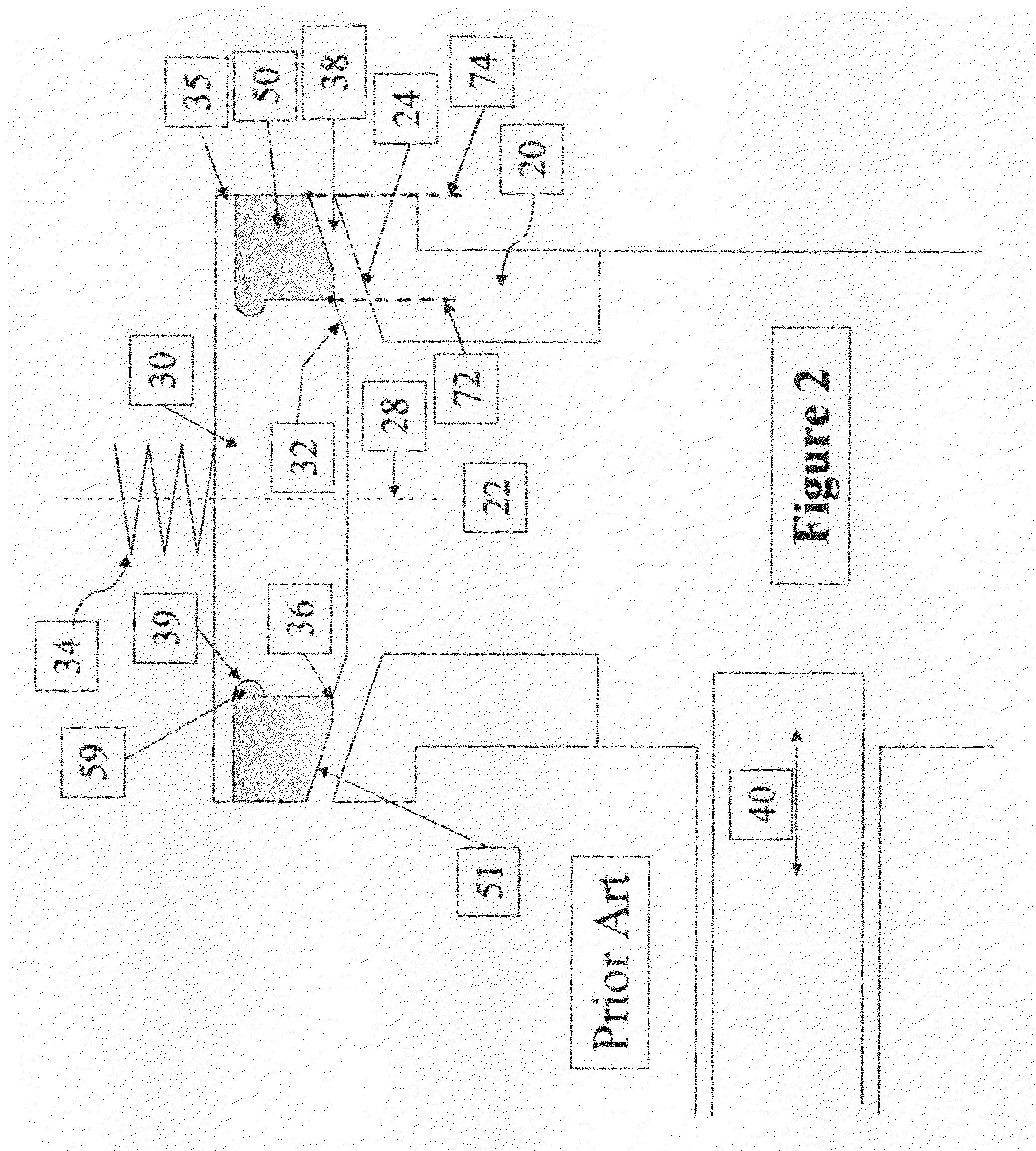

Methods and apparatus for efficient purging

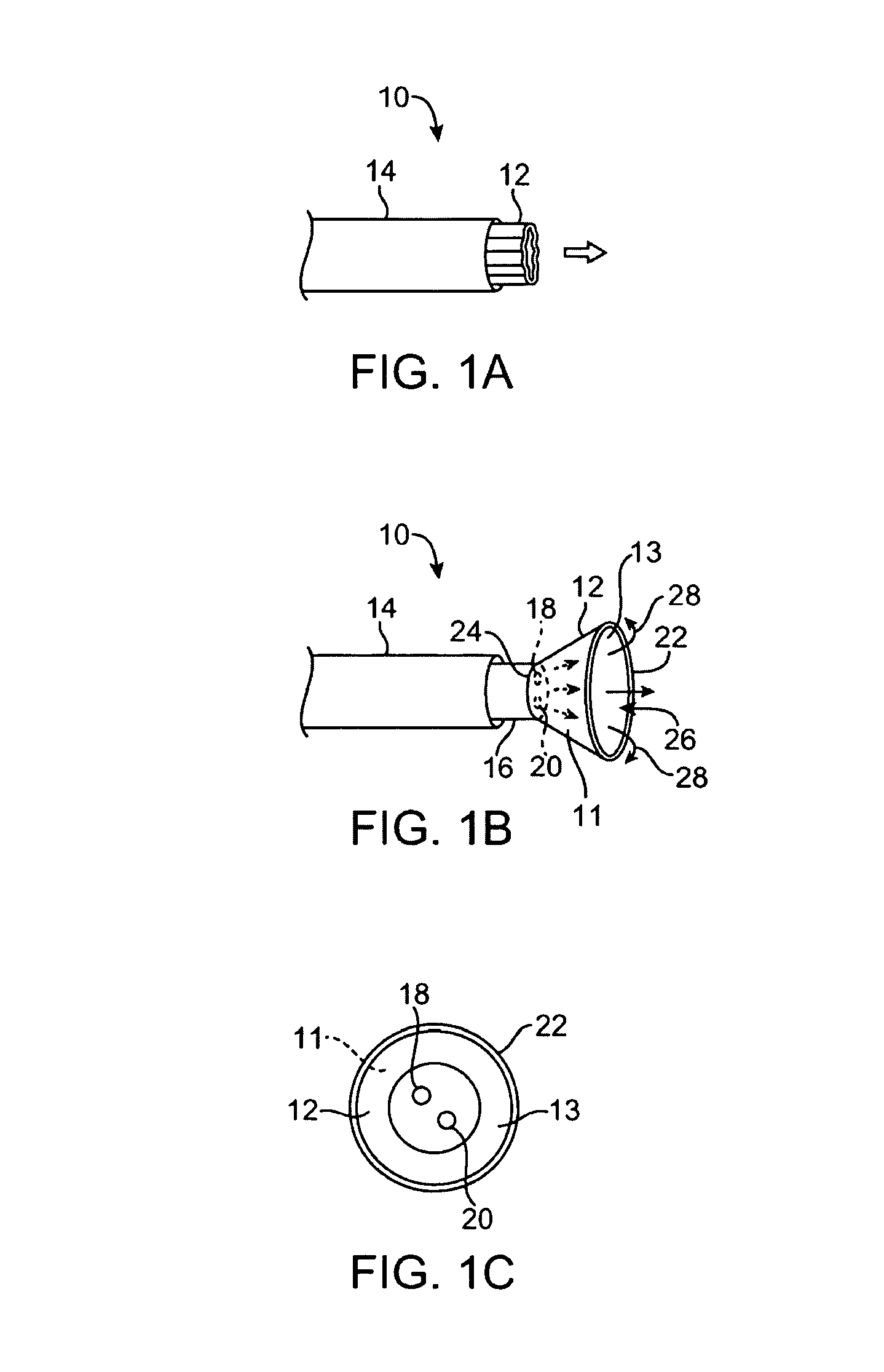

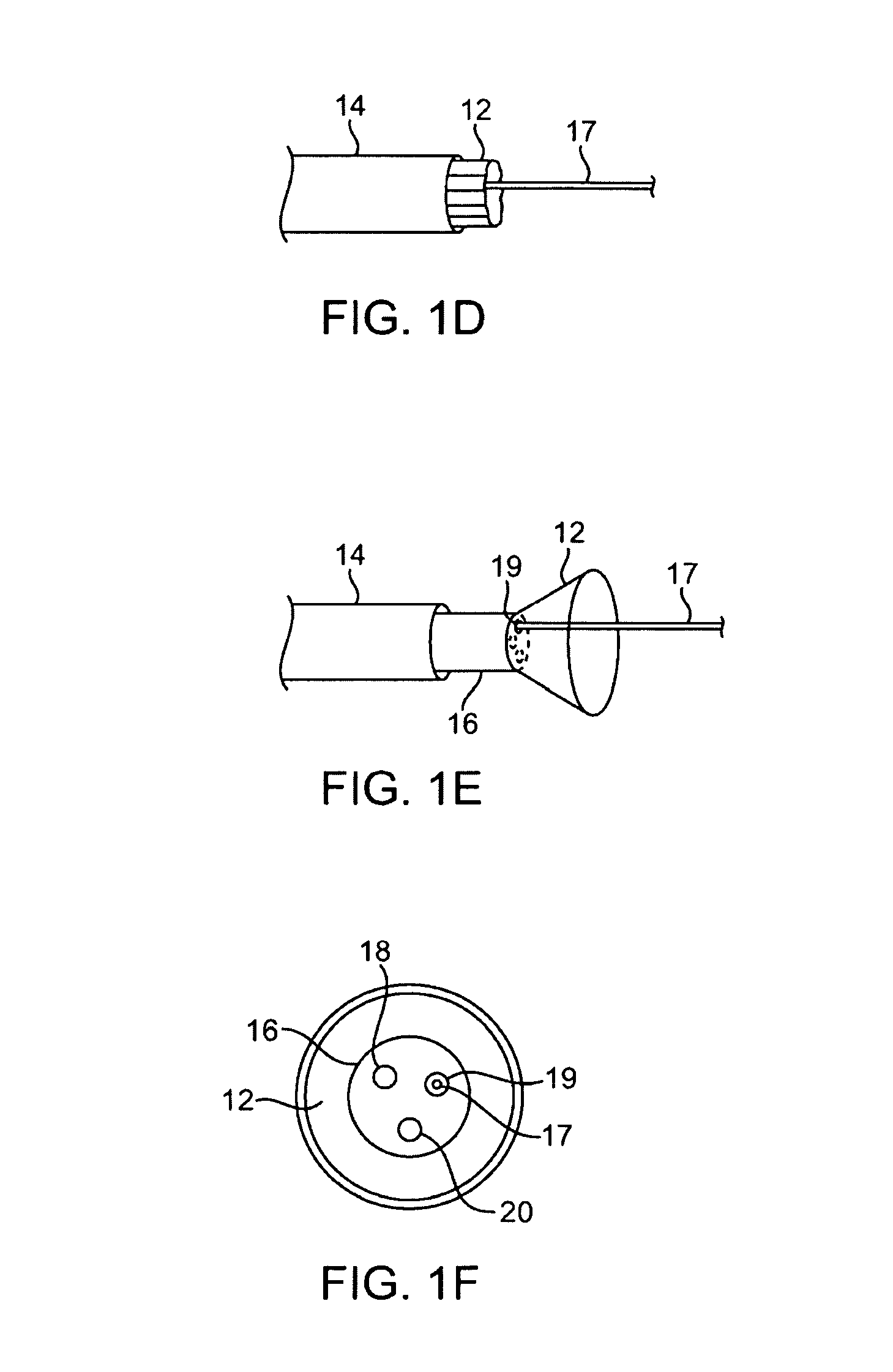

ActiveUS20100010311A1Increased riskMinimizing and controlling amountSurgeryEndoscopesBiomedical engineeringTissue imaging

Methods and apparatus for efficient purging from an imaging hood are described which facilitate the visualization of tissue regions through a clear fluid. Such a system may include an imaging hood having one or more layers covering the distal opening and defines one or more apertures which control the infusion and controlled retention of the clearing fluid into the hood. In this manner, the amount of clearing fluid may be limited and the clarity of the imaging of the underlying tissue through the fluid within the hood may be maintained for relatively longer periods of time by inhibiting, delaying, or preventing the infusion of surrounding blood into the viewing field. The aperture size may be controlled to decrease or increase through selective inflation of the membrane or other mechanisms.

Owner:INTUITIVE SURGICAL OPERATIONS INC

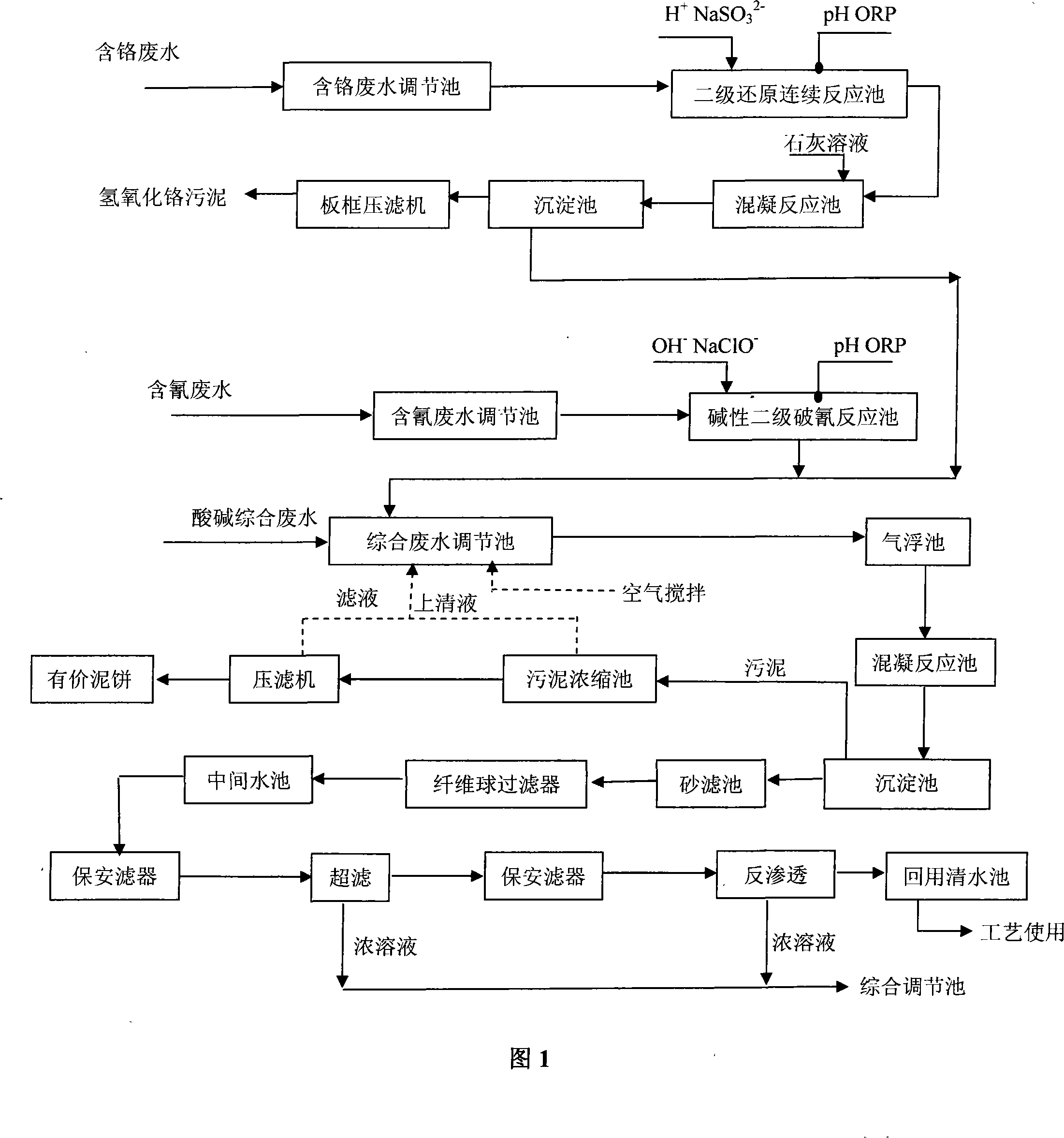

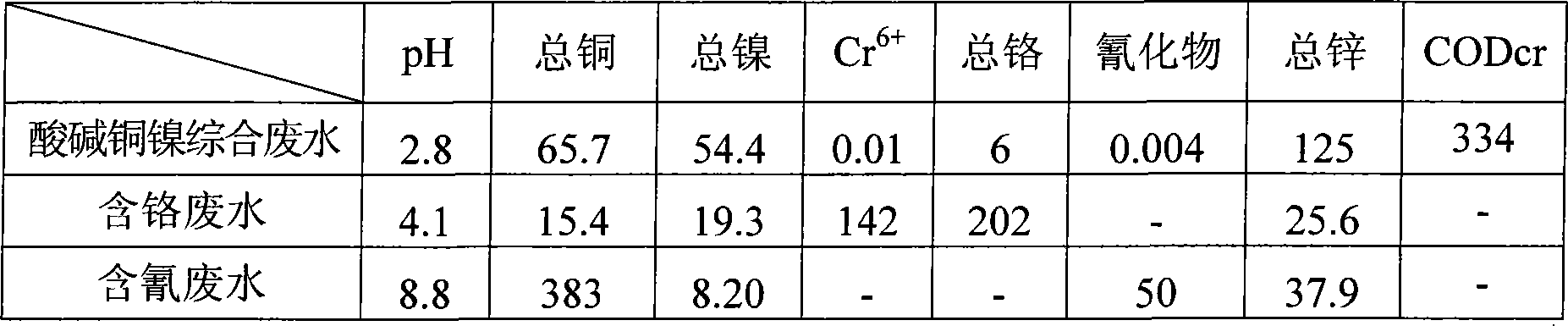

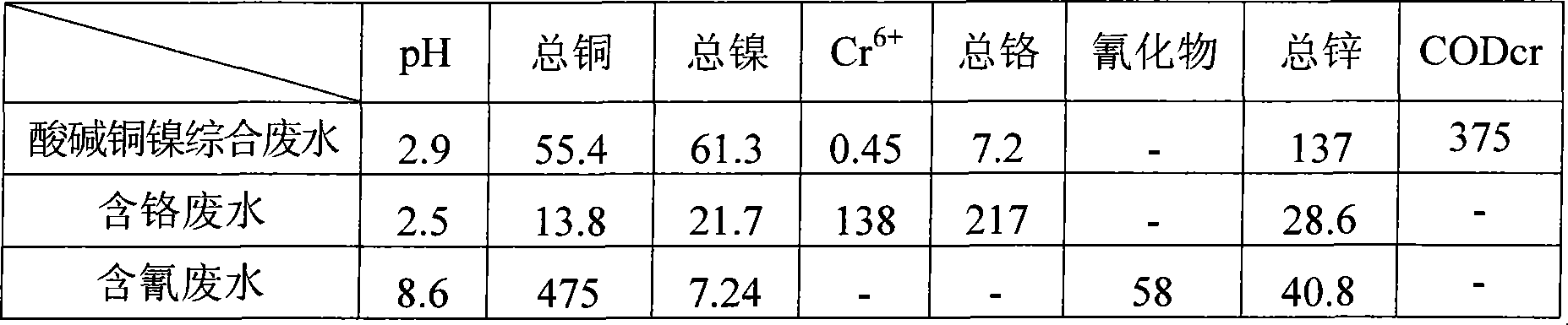

Integrated electroplating treatment method for waste water

InactiveCN101234828AReduce manufacturing costWater contaminantsWaste water treatment from metallurgical processWater productionWater quality

The invention relates to a method for treating comprehensive galvanization wastewater, particularly relating to a technique reclaiming resources of precious metal and recycly utilizing treated and comprehensively discharged galvanization wastewater. The method for treating the galvanization wastewater in the invention is characterized in that the following steps are included: (1) treating the wastewater containing chromium; (2) treating the wastewater containing cyanogen; (3) mixing and treating clear liquid obtained during treating the wastewater containing chromium in step (1) and the wastewater containing the cyanogen during treating the wastewater containing the cyanogen in step (2); (4) leading the clear liquid obtained during mixing and treating in step (3) into a reclaiming clean water pond; (5) leading the concentrated solution in step (4) into a comprehensive regulating pond of wastewater. Through treated by the technique of the method for treating comprehensive galvanization wastewater, each index of water quality of obtained water can reach or exceed the Drinking Water Sanitary Standard (GB5749-2006); the water can be reused in galvanization workshops; the water production rate of the reused water can reach over 80 percent; useful metal ions can be reclaimed; the target of environment protection can be met; benefits can be generated at the same time; the production cost can be reduced.

Owner:TIANJIN UNIV

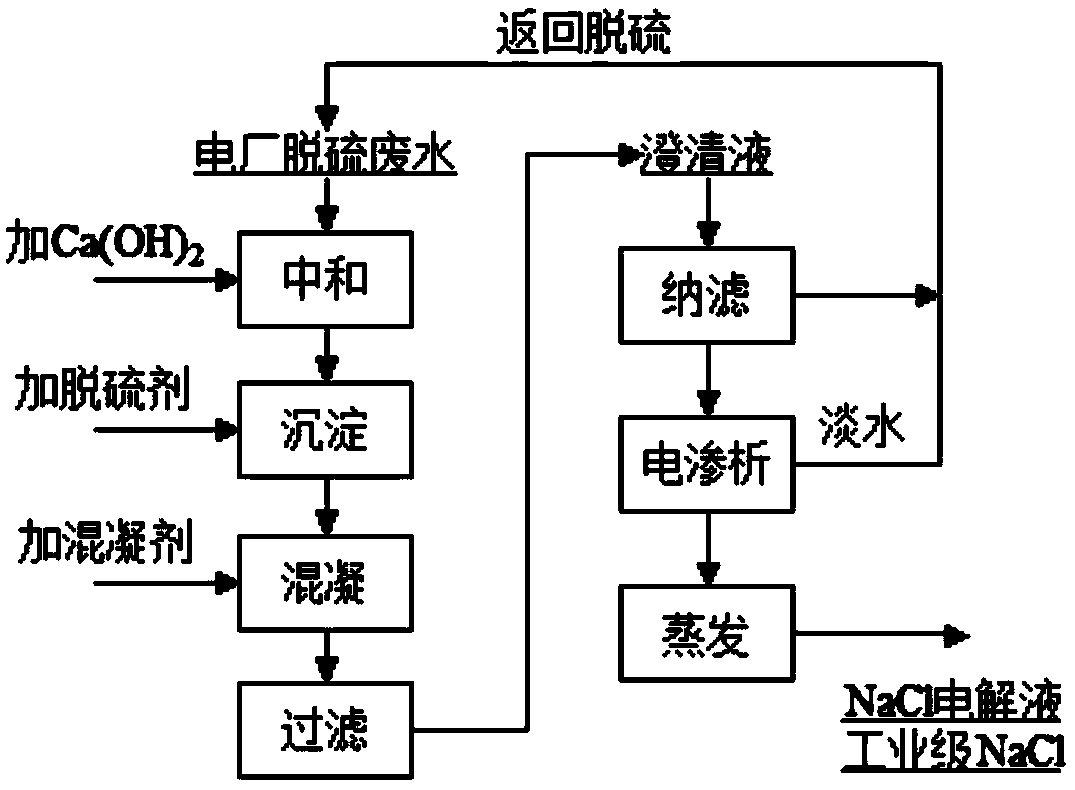

Method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting electrodialysis technology

ActiveCN104355473AMeet water requirementsImprove running stabilityGeneral water supply conservationDispersed particle separationChemical oxygen demandResource utilization

The invention relates to a method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting an electrodialysis technology. The method comprises the following steps: neutralizing, precipitating, coagulating and filtering the power plant desulphurization wastewater and removing CODs (Chemical Oxygen Demands), heavy metals, F-ions, gypsum, silicon dioxide, hydroxide of iron and aluminum and other insoluble particles in waste water; separating C1-ions and other monovalent ions in clear liquid from SO3<2->, SO4<2-> and other divalent ions through nanofiltration; desalinating and concentrating water produced by the nanofiltration by adopting a multistage countercurrent reverse electrodialysis method. The method has the advantages that the concentration of the Cl-ions in nanofiltration concentrated water and electrodialysis freshwater generated by the method is lower, and the nanofiltration concentrated water and the electrodialysis freshwater can be returned for flue gas desulfurization; the content of NaCl in a small amount of electrodialysis concentrated water produced reaches above 12 percent, the bivalent ions and other impurities are removed by nanofiltration, and the electrodialysis concentrated water is further evaporated and concentrated, so that chlorine-alkali industry electrolytes and NaCl salt can be obtained. Through the method, the zero-discharge treatment and the resource utilization of the desulfurization wastewater can be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

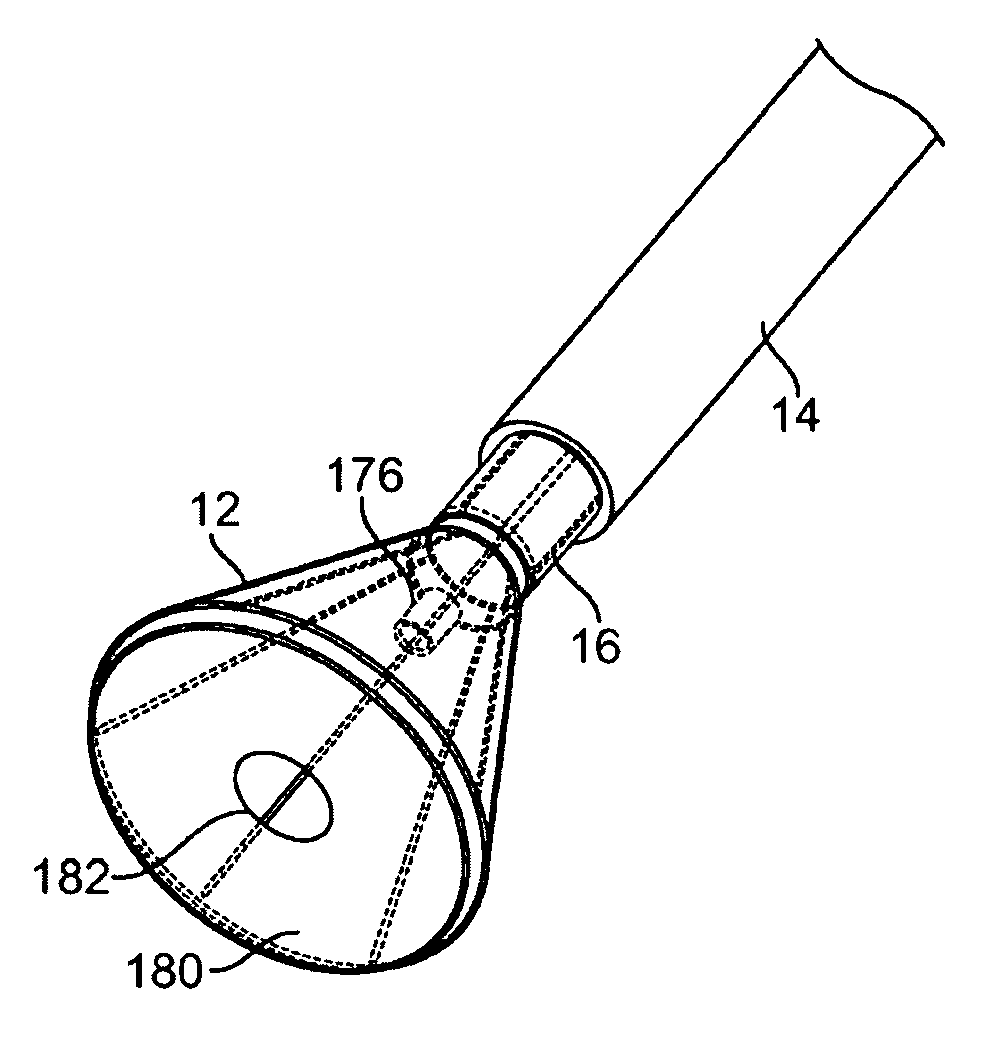

Flow reduction hood systems

ActiveUS8078266B2Minimize fluid leakageReduce eliminate deploymentEndoscopesLaproscopesCLARITYMedicine

Flow reduction hood systems are described which facilitate the visualization of tissue regions through a clear fluid. Such a system may include an imaging hood having one or more layers covering the distal opening and defines one or more apertures which control the infusion and controlled retention of the clearing fluid into the hood. In this manner, the amount of clearing fluid may be limited and the clarity of the imaging of the underlying tissue through the fluid within the hood may be maintained for relatively longer periods of time by inhibiting, delaying, or preventing the infusion of surrounding blood into the viewing field. The aperture size may be controlled to decrease or increase through selective inflation of the membrane or other mechanisms.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Detection box used for detecting light transmittance of printing and dyeing wastewater

ActiveCN104034702ALonger sedimentation distanceLengthen the timePreparing sample for investigationTransmissivity measurementsControl signalTransmittance

The invention relates to detection equipment used in a printing and dyeing wastewater physicochemical treatment system, in particular to a detection box used for detecting the light transmittance of printing and dyeing wastewater. The detection box comprises a box body, a sedimentation device and a light detecting device used for detecting the light transmittance of clear liquid on the printing and dyeing wastewater. The box body is provided with an input end used for being connected with a printing and dyeing wastewater sampling water inlet tube, a first output end used for being connected with a printing and dyeing wastewater sampling water outlet tube and a second output end used for discharging sediments. The sedimentation device and the light detecting device are all placed in the box body. The detection box can be used for conducting light transmittance capacity detection on the printing and dyeing water entering the inside of the detection box, measured light intensity signals are measured to be used as usable control signals, so that the clarity of the separated clear liquid is expressed, and human eyes are replaced to observe whether the printing and dyeing wastewater is fully flocculated or not.

Owner:林丽兵

Method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation

The invention provides a method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation, which comprises the following steps of: preparing four lactobacillus direct-throwing fermentation agents such as lactobacillus rhamnosus, pediococcus acidilactici, streptococcus thermophilus and lactobacillus brevis; then soaking brown rice for 10 hours at 30 DEG C, and germinating for 12 hours at 2 DEG C to prepare germinated brown rice; adding 3 times water into the germinated brown rice, grinding milk by adopting colloid, gelatinizing and saccharifying the milk, adding 150 grams of direct-throwing fermentation agents into each ton of liquid rice milk, and performing standing fermentation for 6 hours at the temperature of between 38 and 40 DEG C; and centrifuging the liquid rice milk at 5,000 revolutions per minute, removing residue, adding xylitol according to the clear liquid volume for blending, filtering the liquid by using a hollow fiber membrane, performing ultrahigh-temperature instantaneous sterilization for 2 seconds at 143 DEG C, and filling the liquid with pillow-type package or tetra package to obtain a finished product.

Owner:黑龙江大荒春酒业有限公司

Method and material for in situ corneal structural augmentation

InactiveUS20080139671A1Augmenting shape and thicknessSuitable as therapeuticBiocideLaser surgeryOptical propertyMedicine

A method and material for augmenting the shape and thickness of the cornea in situ includes applying a clear liquid collagen mixed with a customized crosslinker onto the augmentation surface or in a cavity (with or without a mold) and exposing the mixture to UVA radiation in vivo. Application of UVA at varying dosages demonstrate progressive optically clear gelation and biomechanical adherence properties, and in vitro optical properties (RI), mechanical suture strength and rheometric parameters are comparable to native corneal stromal tissue. Photochemical corneal collagen augmentation according to the invention makes it suitable to reconstruct and strengthen diseased and damaged eyes, ulcerated corneas, as well as provide a substrate for refractive onlay / inlay procedures and lamellar transplantation.

Owner:PRIAVISION

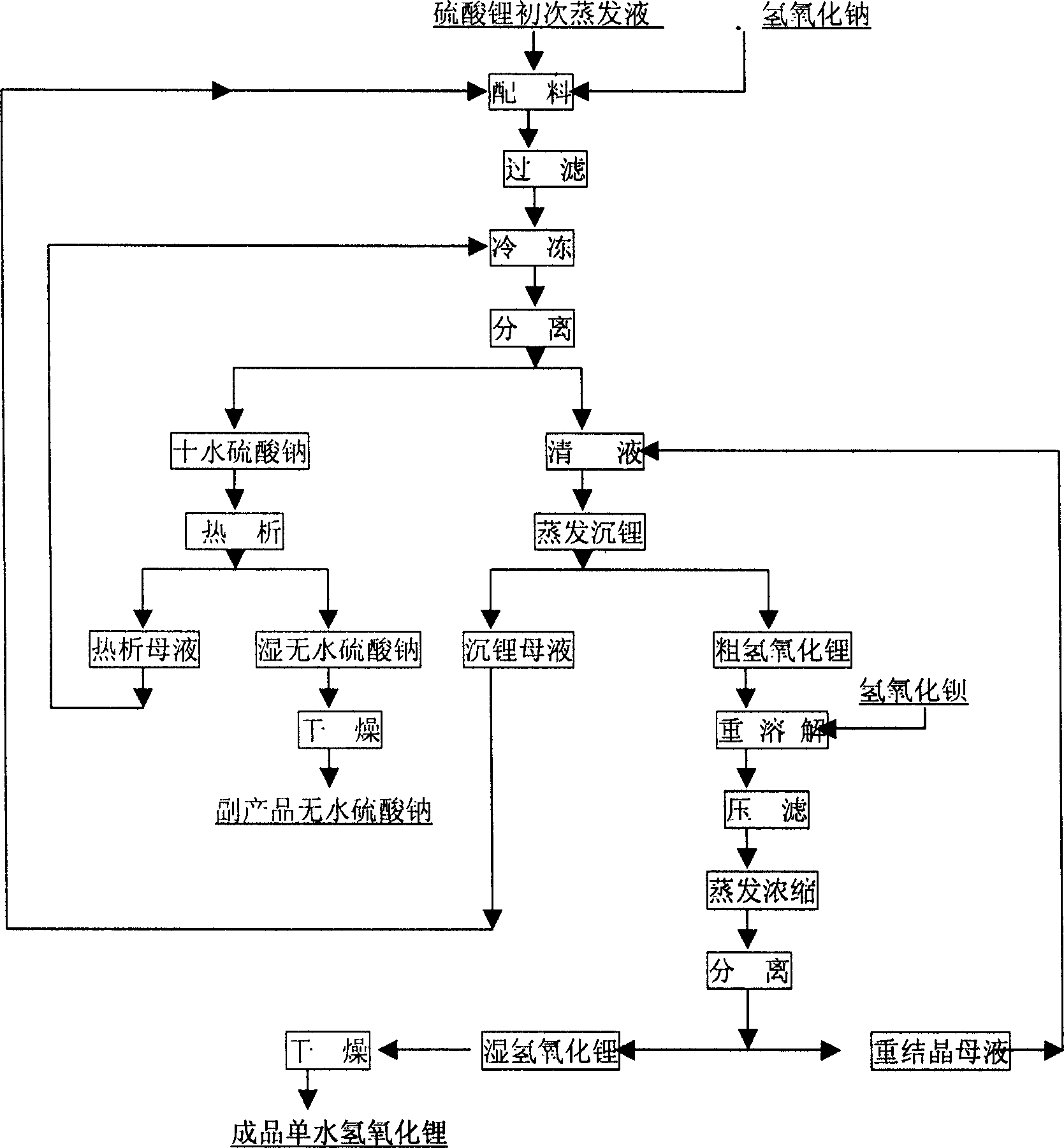

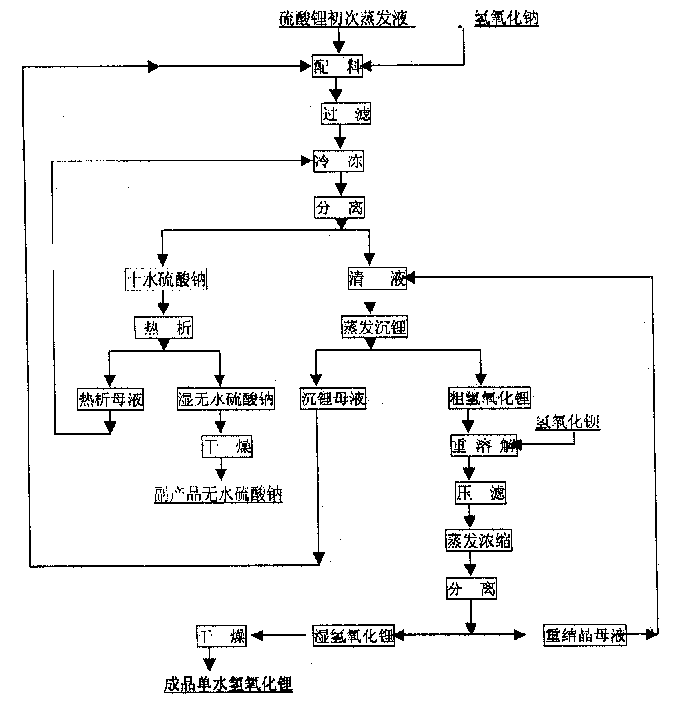

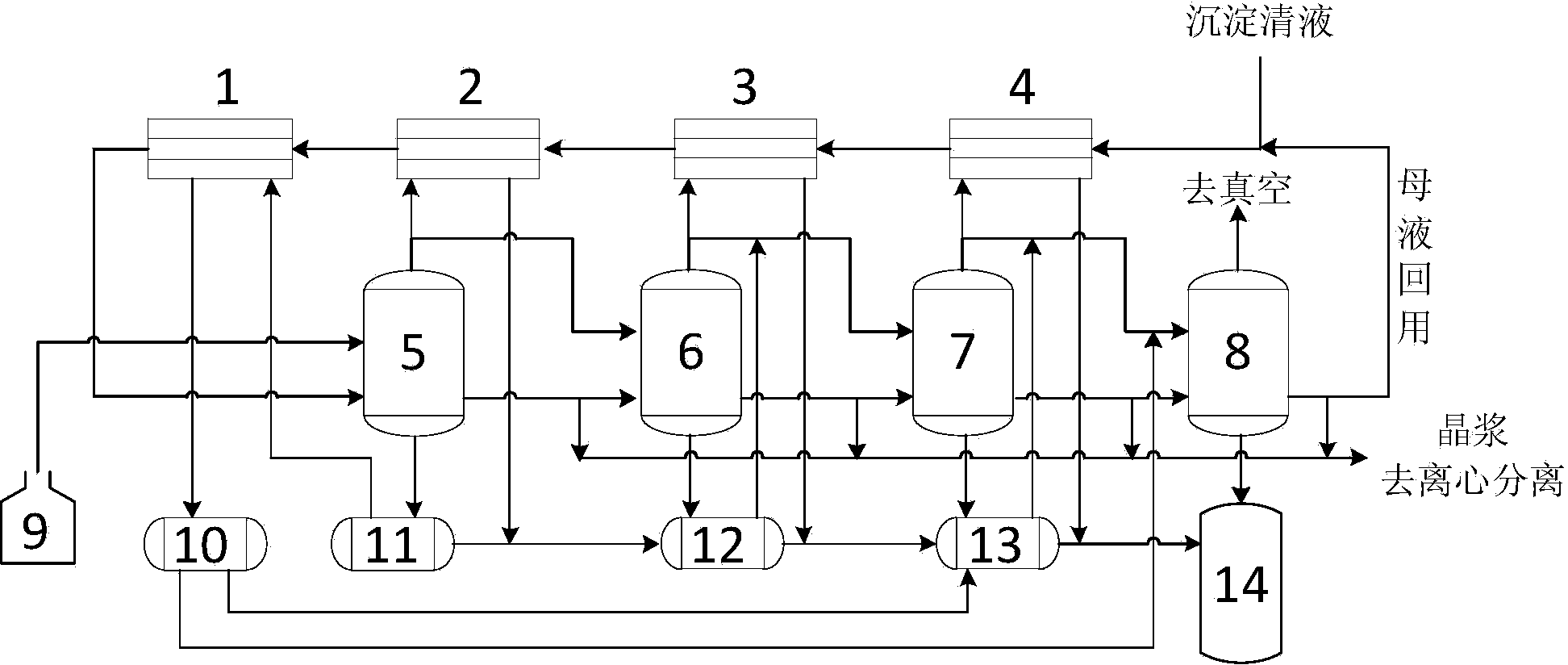

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

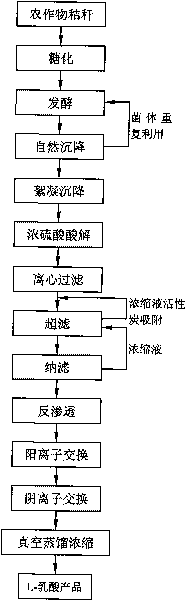

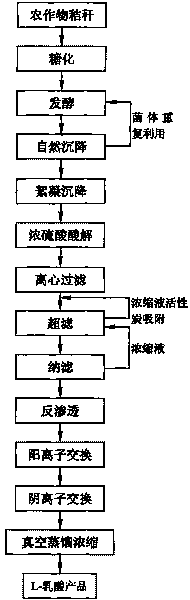

Method for producing L-lactic acid

InactiveCN101736042AReduce manufacturing costBroad industrial prospectsMicroorganism based processesFermentationUltrafiltrationReverse osmosis

The invention relates to a method for producing L-lactic acid. In the method, crop straw and Rhizopus oryzae serve as raw materials. The method particularly comprises the following operation steps: A. preparing straw saccharified liquid; B. adding auxiliary material to inoculate Rhizopus oryzae for fermentation; C repeatedly fermenting 25 batches; D. acidizing fermented clear liquid; E. ultrafiltration; F. nanofilteration; G. reverse osmosis; H. ion exchange; I. concentrating in vacuum to obtain the L-lactic acid product with the mass percentage concentration of 85%. The invention takes the straw hydrolysis saccharified liquid as the main raw material to prepare L-lactic acid, which obviously lowers the production cost of L-lactic acid; Rhizopus oryzae is adopted for once inoculation proliferation, thallus can be reused for several times to produce L-lactic acid, thus shortening L-lactic acid fermentation period, and obviously improving the fermentation strength of L-lactic acid; an advanced membrane separation and ion exchange integration technology is adopted to improve the lactic acid product quality; and the invention has simple process and strong continuity.

Owner:HEFEI UNIV OF TECH

Method for separating and recovering chromium from waste residue containing hexavalent chromium

ActiveCN101209873ASolve the problem of difficult leachingLow in chromiumSolid waste disposalWater/sewage treatmentSodium bicarbonateSocial benefits

The invention discloses a method for separating and recycling chromium from the waste residue containing hexavalent chromium. The waste residue containing hexavalent chromium which has fine particles and is difficult to subside is added with mineralizer and then is subject to hydrothermal method or heating treatment to generate the waste residue which can subside, the upper clear liquid is separated from the waste residue and then the waste residue is cleaned and dried. Sodium bicarbonate or salt-mixture of sodium carbonate and sodium bicarbonate is adopted as mineralizer. The invention has simple process, low cost, quick results, large throughput, complete detoxification and no secondary pollution and can make use of all the residue, thereby bringing comparatively high social benefit and economic benefit.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

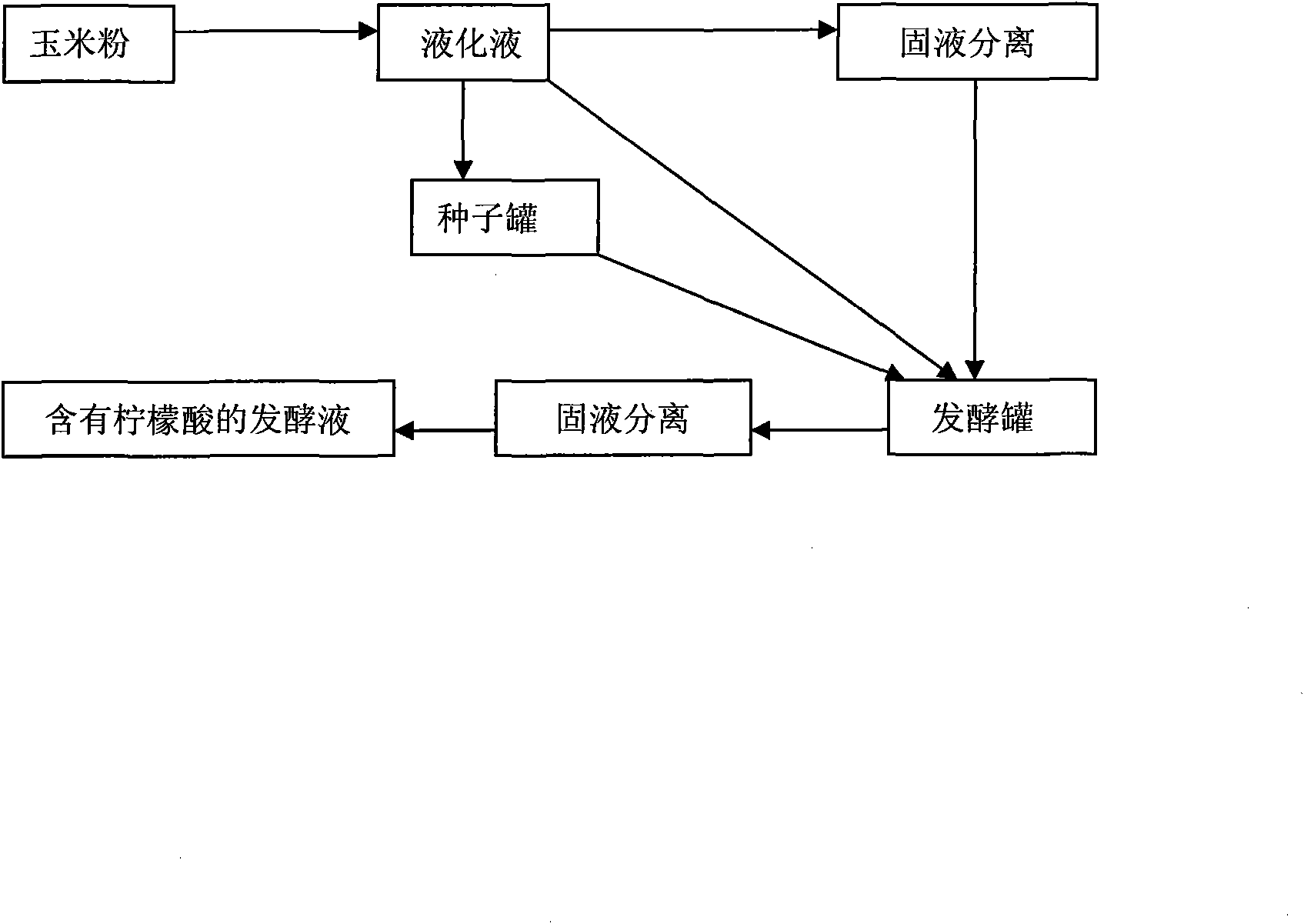

Preparation method of citric acid fermentation solution

ActiveCN101555497ASimple processReduce manufacturing costMicroorganism based processesFermentationNitrogen sourceCitric acid fermentation

The invention discloses a preparation method of a citric acid fermentation solution, which comprises the steps of: (1) mixing dry corn powder with water to form paste, adding amylase into the paste and then heating the paste, conducting spraying liquefaction by one time on the paste at the temperature ranging from 92 DEG C to 98 DEG C and then flash evaporation by one time, lowering the temperature to 88 DEG C to 90 DEG C and maintaining the liquefaction for 90min to 120min to obtain liquefied solution; (2) taking 5 percent to 15 percent of the liquefied solution obtained in the step (1), putting the liquefied solution into a seed tank, adding a nitrogen source, heating and sterilizing, maintaining for 20min to 30min, then lowering the temperature to 36 DEG C, and inoculating the obtained mixture into aspergillus niger strains for strain culture; (3) taking 5 percent to 15 percent of the liquefied solution obtained in the step (1), putting the liquefied solution into a fermenter; (4) taking the rest of the liquefied solution obtained in the step (1) for solid-liquid separation to obtain liquefaction clear liquid, putting the obtained liquefaction clear liquid into the fermenter, adding a nitrogen source, raising the temperature to 80 DEG C to 90 DEG C by heating, sterilizing, maintaining for 5min to 10min, lower the temperature to 38 DEG C, and leading the substances in the seed tank obtained in the step (2) into the fermenter; and (5) conducting solid-liquid separation to obtain the citric acid fermentation solution after ferment. The preparation method has the advantages of simple technique and low production cost.

Owner:COFCO BIOTECHNOLOGY CO LTD

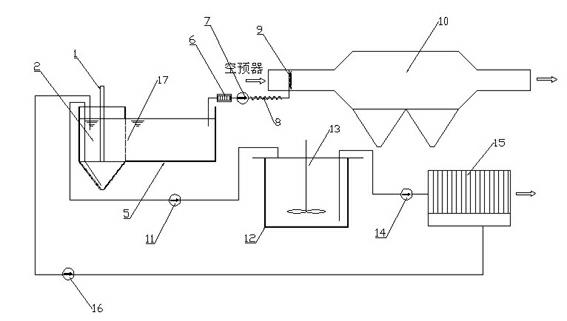

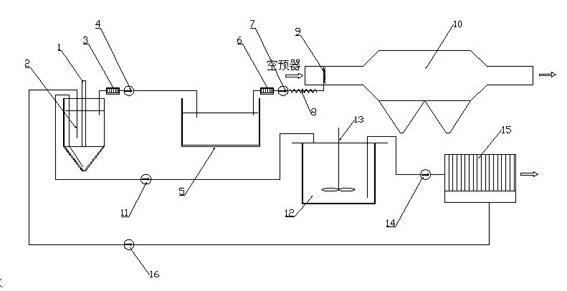

Method and system for zero emission treatment of desulfured waste water

ActiveCN102180549AConvenient zero-emission disposalSimple processWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSludgeWater filter

The invention discloses a method for zero emission treatment of desulfured waste water. The method comprises the following steps: 1) discharging the desulfured waste water obtained after desulfuration in a desulfuration tower into a preliminary sedimentation tank, carrying out primary separation in the preliminary sedimentation tank, and transporting an upper clear liquid separated out to a buffer pool through a slurry pump; 2) successively passing the desulfured waste water in the buffer pool through an atomization plant and a static dust catcher; 3) transporting the waste water which is from the lower part of the preliminary sedimentation tank and has large solid content to a filter press through an another sludge pump; and 4) feeding the waste water filtered back to the preliminary sedimentation tank through the slurry pump. Simultaneously, the invention also discloses a system for zero emission treatment of desulfured waste water. The zero emission treatment is conveniently carried out on the desulfured waste water through the method, the process is simple and labor is saved; and the system has a compact structure, the method is simple to implement, energy is saved, the quality of smoke at the inlet of the dust catcher is improved, the zero emission of the desulfured waste water can be really achieved, thus the system has the advantage of popularization value.

Owner:CHENGDU SHUKE TECH

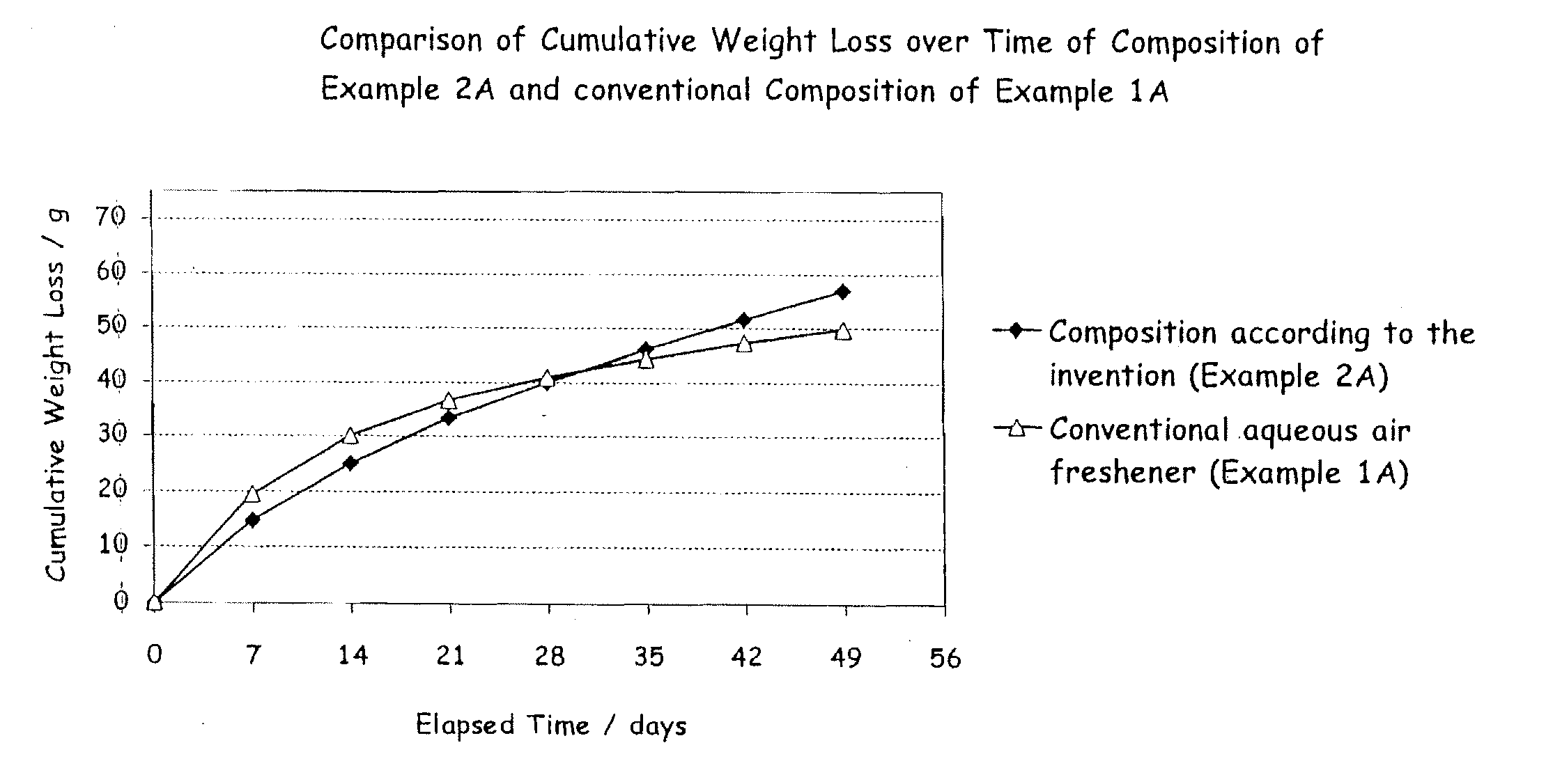

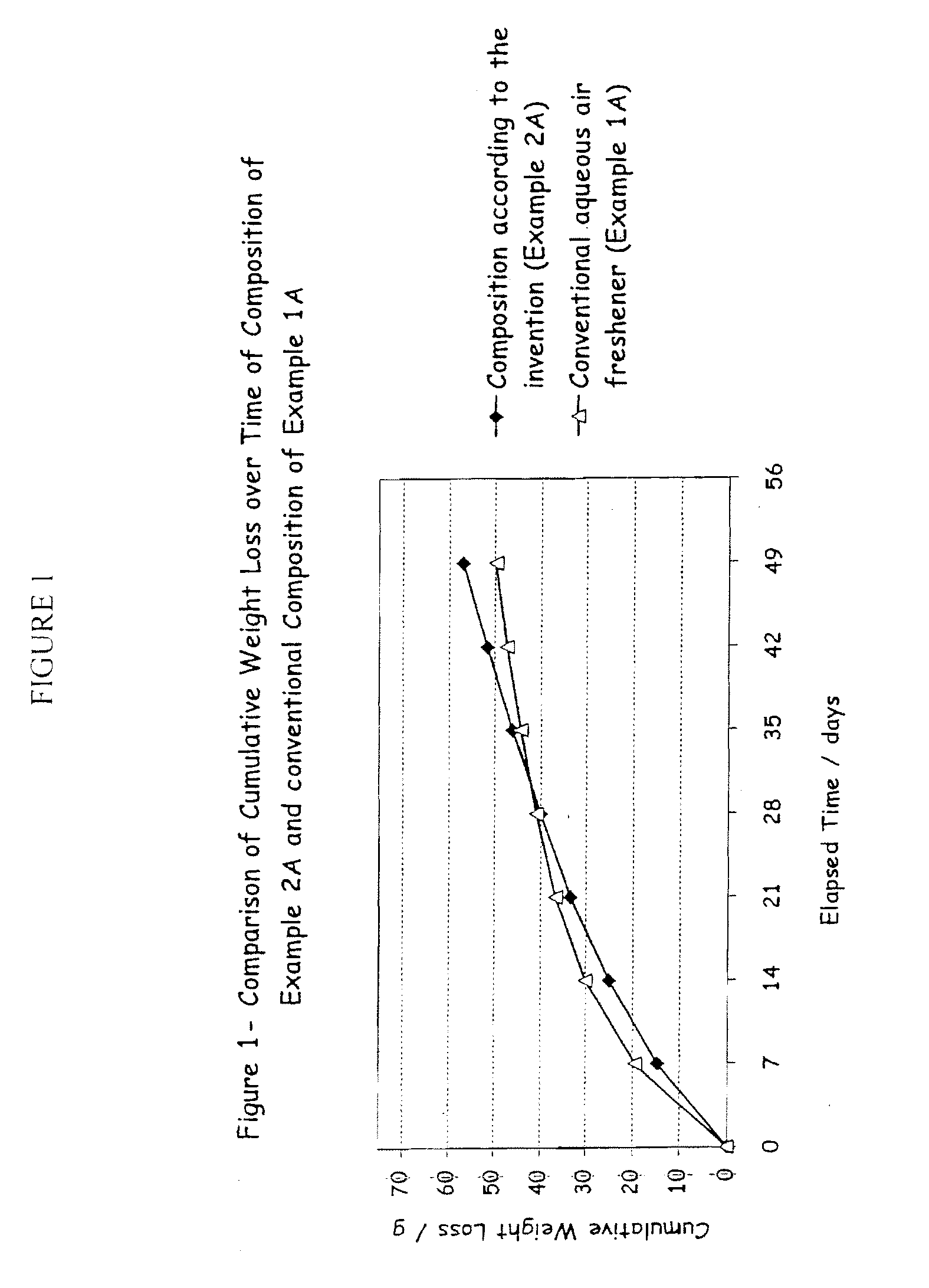

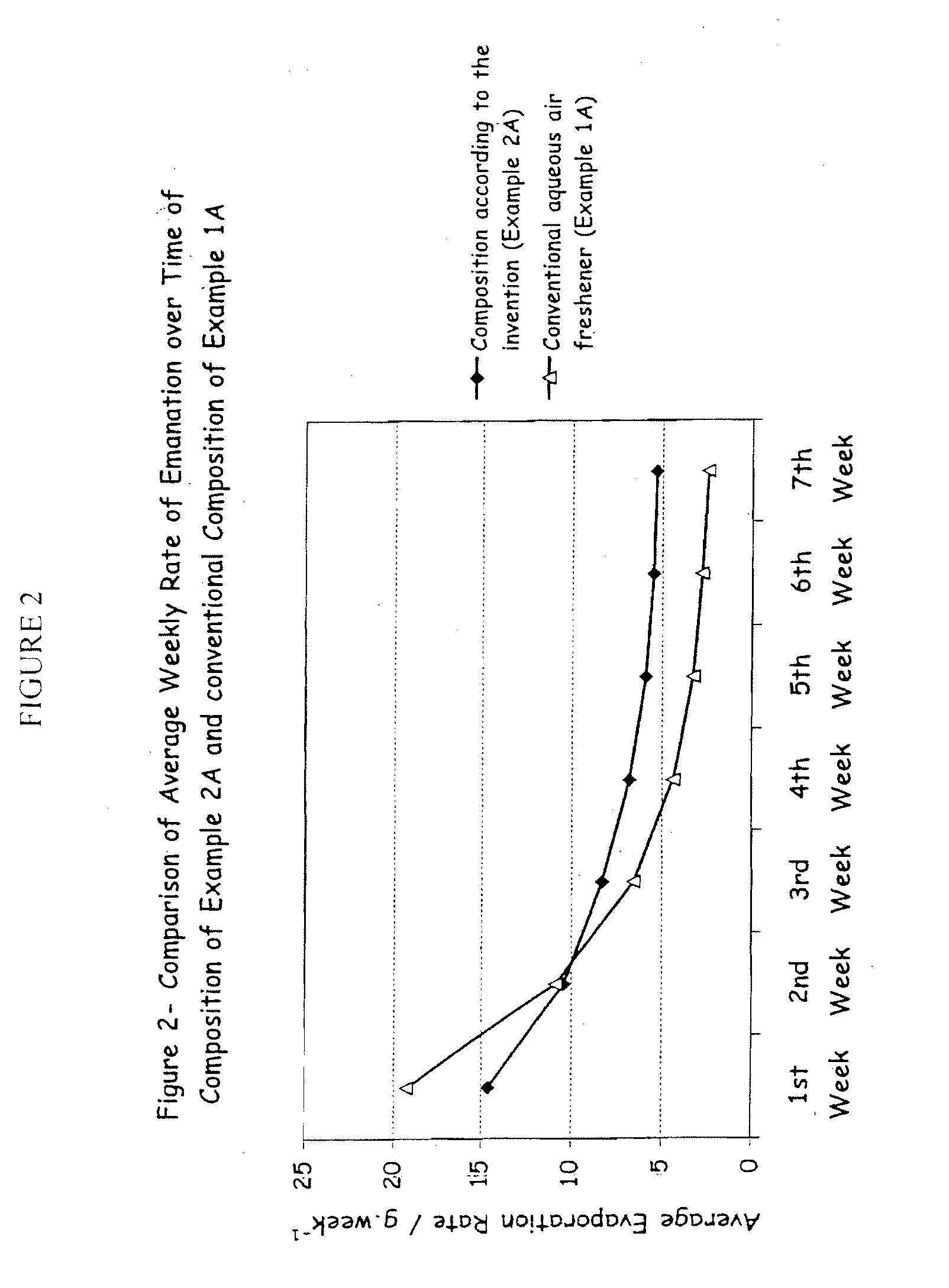

Air freshener device comprising a specific liquid composition

ActiveUS20080023569A1Confer and improve and modify and enhance odorCosmetic preparationsToilet preparationsWater basedAdditive ingredient

The present invention relates to air freshener devices comprising water-based liquid compositions, preferably clear liquids, that provide an improved rate of emanation of perfume ingredients from the air freshener emanating surface and allow the use of fragrance materials with a wide range of characteristics, namely a wide range of c log P values. The air fresheners contain liquid perfume compositions which comprise: i) 0.5 to 40% w / w of a perfume; ii) an oil-solubilising system containing one or more surfactants of the non-ionic, anionic, cationic, amphoteric type, or a mixture thereof; iii) a solubilizing-aid; and iv) at least 40% weight of water; weight percentages being relative to the total weight of liquid composition.

Owner:FIRMENICH SA

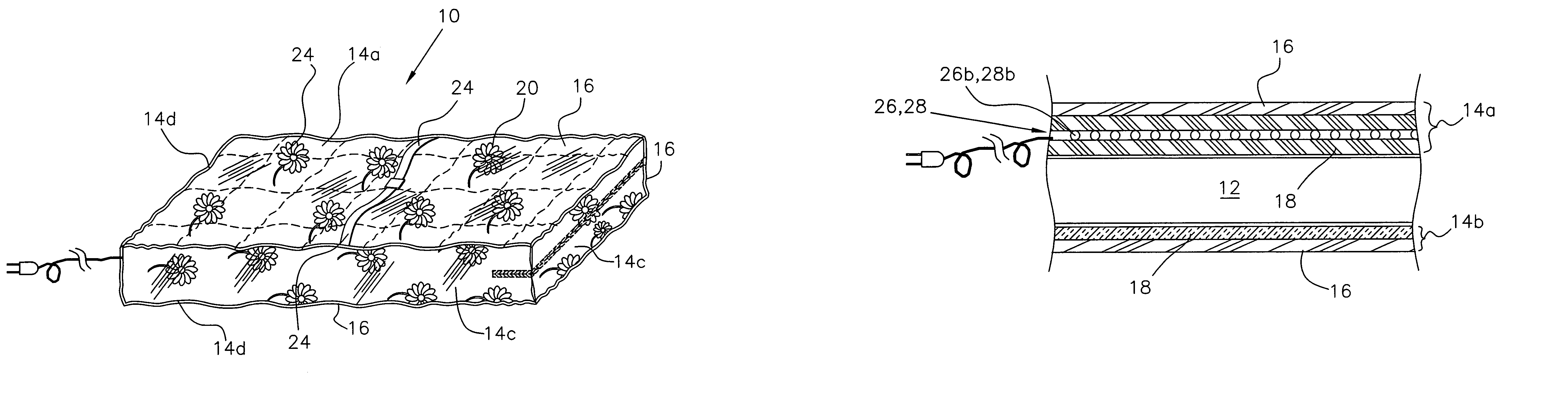

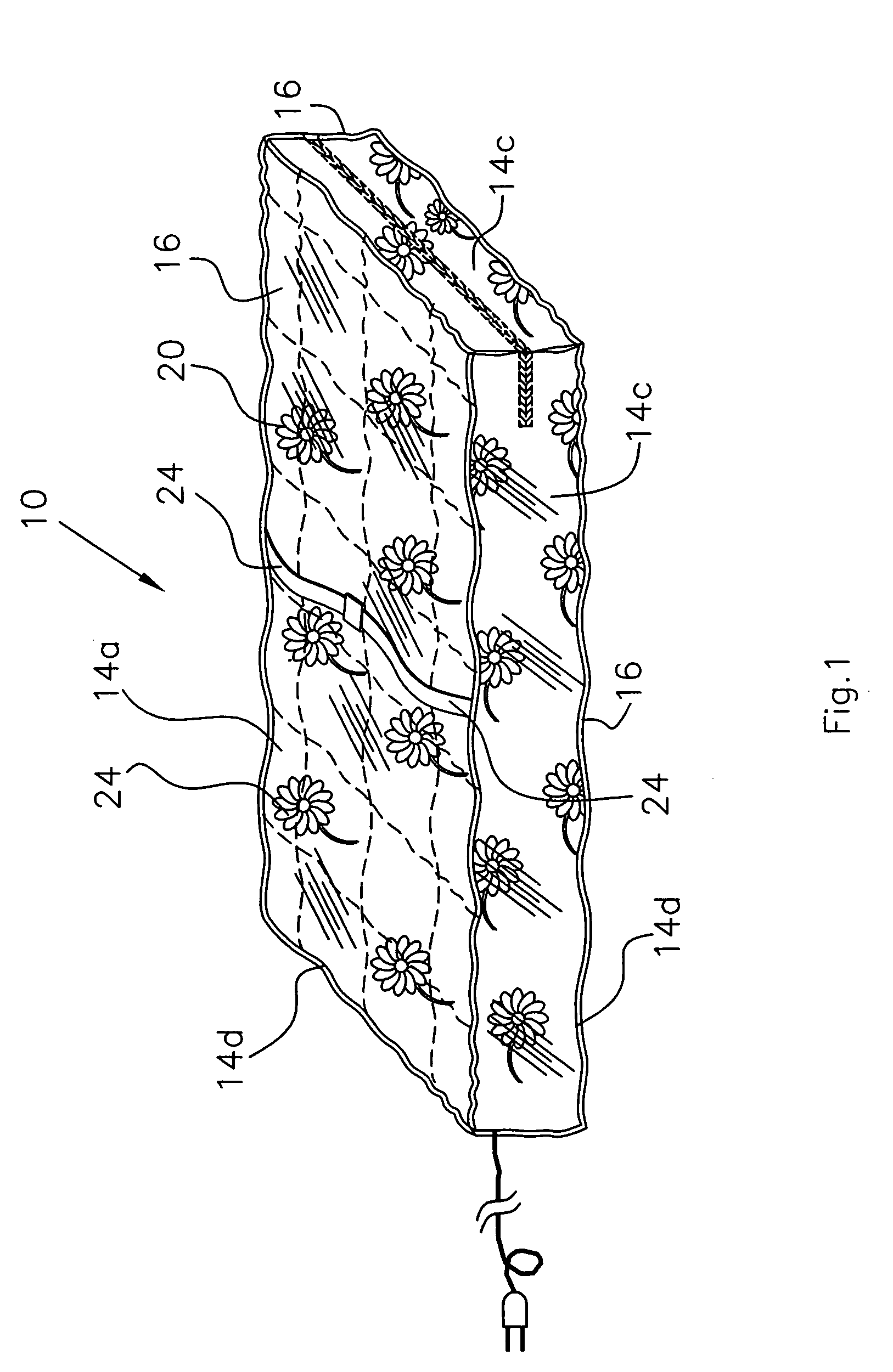

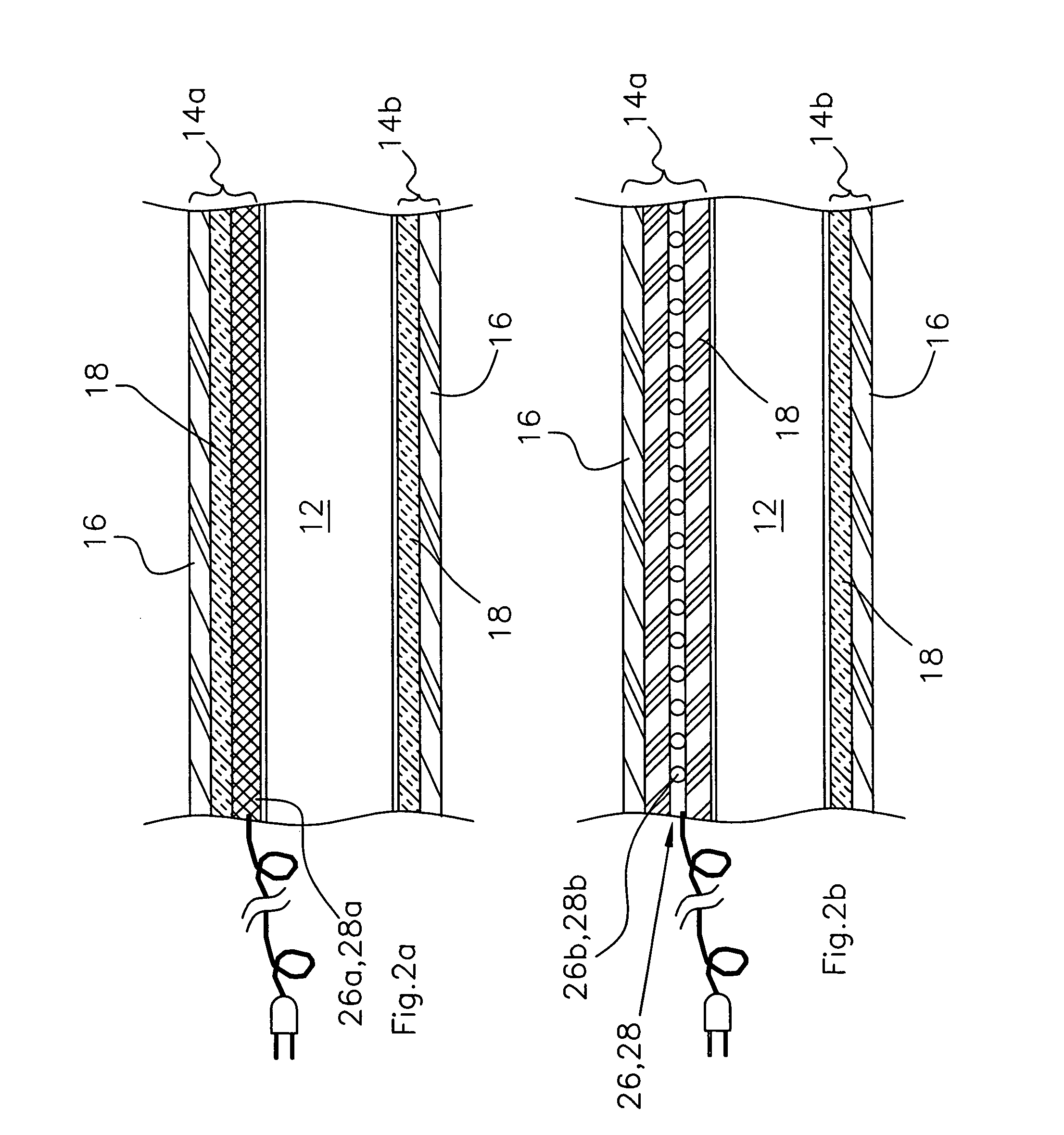

Changing pad cover

A changing pad cover having two generally parallel vinylized / fabric layers spaced-apart and four upright sides connecting each spaced-apart layer. One or both ends of the cover may have its raised sides contoured-shaped on its upper edge to allow for the upper layer of the cover to conform to the contoured upper surface shape of the pad. The cover is secured at one end with a closure device such as a hook and loop fastener. The vinylized layer comprises a clear liquid impermeable layer, which is superimposed in a face-to-face relationship with an underlying fabric material. The fabric material has decorative visual art indicia depicted on the fabric material. The cover may optionally include a heating pad and / or a vibrating pad in an underlying relationship to the fabric material of the upper portion of the cover or integral to the fabric material. An alternative embodiment includes the top and sides of the cover only.

Owner:WILSON MARY BESS

Method for preparing naringin or hesperidin

InactiveCN101704867AAdvancedQuick extractionSugar derivativesSugar derivatives preparationNaringinUltrasonic assisted

The invention relates to a method for preparing naringin or hesperidin, which comprises the following operating steps of: 1) drying and crushing fruits, fruit peels and fruit residues containing the naringin or the hesperidin, and respectively filling the crushed materials into an extraction kettle of a pressure solvent extraction device; 2) selecting an extraction solvent, setting an extraction pressure, an extraction temperature, an extraction static time and an extraction frequency, extracting with the pressure solvent extraction device, and collecting the extract liquor; and 3) concentrating the extract liquor in vacuum, centrifugating the extract liquor or filtering the extract liquor to remove insoluble substances, adjusting pH of the clear liquid, cooling the clear liquid to crystallize or precipitate, recrystallizing the coarse crystals, drying the coarse crystals, or re-dissolving the precipitate for re-precipitation, and obtaining a pure product of the naringin or the hesperidin. Compared with the conventional solvent extraction method, ultrasonic-assisted extraction method and microwave-assisted extraction method, the preparation method has the advantages of high speed, capability of repeatedly extracting, safety, high efficiency, and simple post treatment such as concentration and purification.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Valve apparatus

InactiveUS20090314979A1Reduces percentage deformationReduce distortionPositive displacement pump componentsCheck valvesSolid particleEngineering

A valve apparatus that has a longitudinal axis therethrough comprises a valve seat member, a valve closure member, a fluid flow path, and a resilient valve insert member. The valve seat member comprises a hollow bore and a first frustoconical contact surface that has an inner perimeter and an outer perimeter. The valve closure member comprises a valve body and a second frustoconical contact surface that is adapted to seal against the first frustoconical contact surface in a strike face area. The valve closure member is movable along the longitudinal axis of the valve apparatus. The fluid flow path extends through the bore of the valve seat member and between the valve seat member and the valve closure member. This fluid flow path is closed when the second frustoconical contact surface is sealed against the first frustoconical contact surface. The resilient insert member is attached to the valve closure member. It has an inner perimeter and an outer perimeter, the inner perimeter being adjacent to the strike face area on the second frustoconical surface. The resilient insert member is offset and adapted to contact the first frustoconical contact surface and form a hydraulic seal therewith at the inner perimeter of the insert member, before the first frustoconical contact surface comes in contact with the second frustoconical surface as the valve closes. The offset of the insert member is greater at its outer perimeter than at its inner perimeter, and is greater at its outer perimeter than the diameter of the largest particle in any fluid to be pumped. The insert is deformable but substantially non-compressible and comprises a particle retaining means to accommodate solid particles that are trapped between the insert and the valve seat member when the valve closes. The particle retaining means has at least one cavity (void space) that is in fluid contact with the flow path for fluids between the valve seat member and valve closure member when the valve is open. The cavity has an opening in fluid contact with the flow path for fluids when the valve is open and is large enough to accommodate one or more solid particles within the interior of the cavity. The volume of the cavity contracts as the valve closes, whereby solid particles are screened from the fluid and retained within the cavity, and whereby clear fluid is forced out of the cavity into the flow path and directed inwardly toward the bore of the valve seat member through the gap between the first and second frustoconical contact surfaces.

Owner:MCINTIRE WILLIAM RAY

Method and equipment for treating oil stain and flue dust through flue gas desulfurization system

ActiveCN103463949AImprove purification effectQuality improvementUsing liquid separation agentHigh densityFlue gas

The invention relates to a method for treating oil stain and flue dust through a flue gas desulfurization system. The method comprises that: 1) raw flue gas containing oil stain and / or flue dust enters an absorption tower, oil stain and flue dust are scrubbed and enter an absorption liquid, and the purified flue gas is discharged from the absorption tower top; 2) the absorption liquid containing the oil stain and the flue dust is discharged into a maintenance pool; 3) the absorption liquid containing the oil stain and the flue dust is conveyed to an oil dust separator through a maintenance pump to carry out oil dust separation, and then is conveyed to a filtration system, wherein the absorption liquid directly enters the filtration system when the absorption liquid only contains the flue dust, and the absorption liquid is firstly conveyed to the oil dust separator when the absorption liquid contains the oil stain; 4) the absorption liquid is subjected to oil stain and flue dust separation in the oil dust separator, wherein the oil stain has a low density so as to float on the surface, the oil stain residue is collected into an oil stain pool through an oil decanter on the oil dust separator, and the flue dust has a high density so as to sink on the bottom of the oil dust separator; and 5) the high flue dust content absorption liquid on the bottom of the oil dust separator is conveyed to the filtration system through a filtration feeding pump, the clear liquid returns to the absorption tower after filtration to be subjected to desulfurization absorption, and the filtration residue is collected in a flue dust residue pool.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

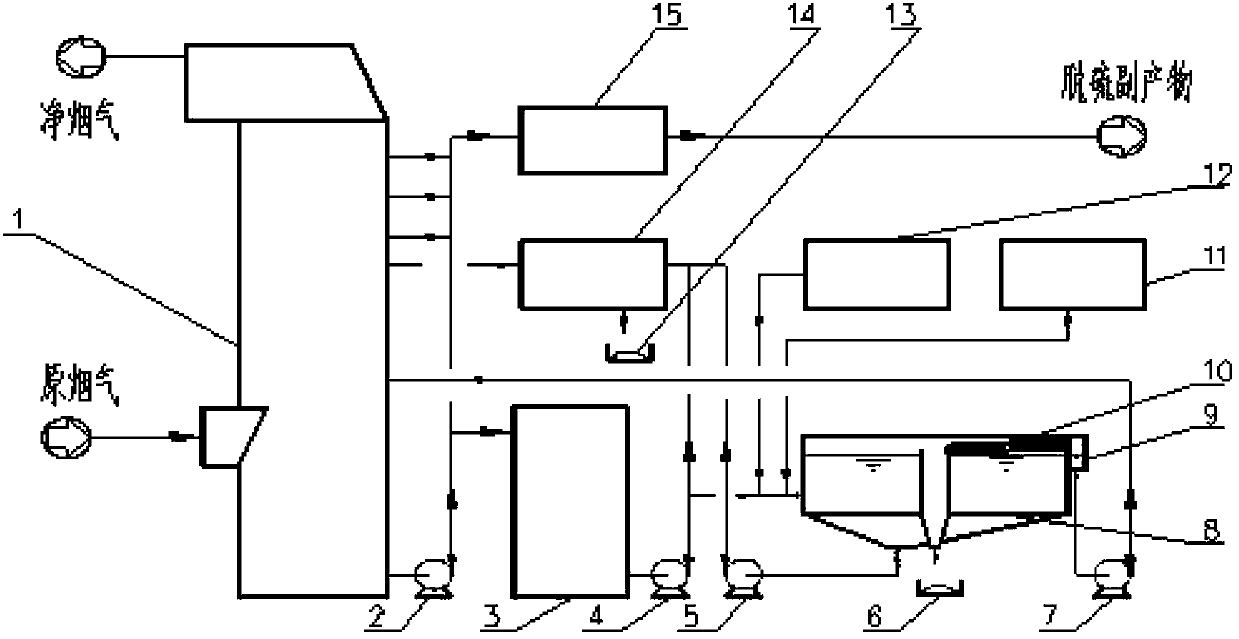

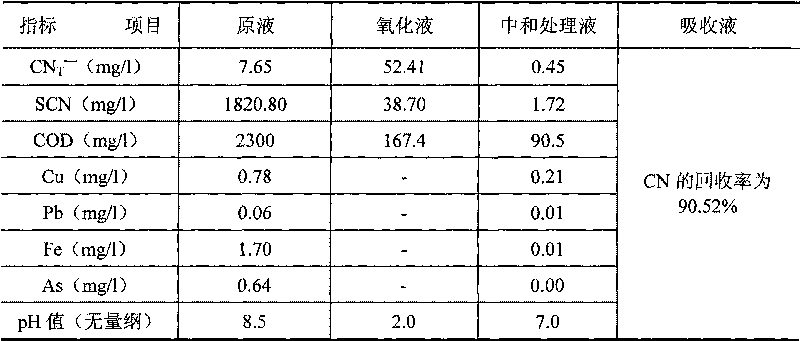

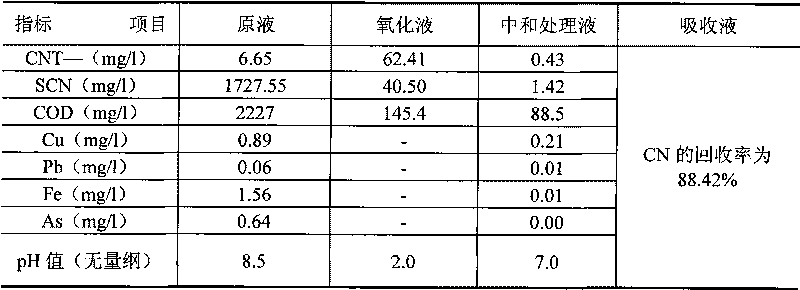

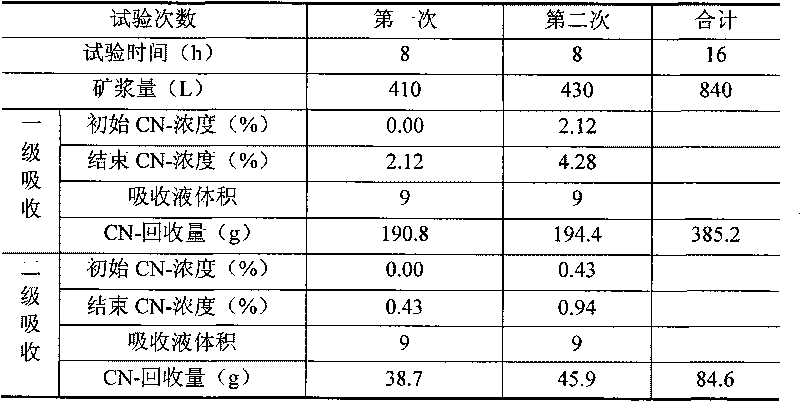

Recycling and harmless treatment method for cyaniding tailing slurry

ActiveCN101759274AIncrease contact areaToxicWaste water treatment from quariesWater contaminantsSlagGas phase

The invention discloses a recycling and harmless treatment method for cyaniding tailing slurry. In the method, the cyaniding tailing slurry containing cyanogen, thiocyanate, heavy metal and arsenic and liquid containing hydrogen peroxide are subjected to direct mixing treatment; the method utilizes high specific surface area of micro-fine granular ore to add the contact opportunity between the thiocyanate and the hydrogen peroxide and the contact area between gas phase and liquid phase through surface adsorption to accelerate a speed of oxidation-reduction reaction and an acidifying and stripping speed, utilizes metallic substances contained in slag to accelerate the reaction rate of the oxidation-reduction reaction without the addition of catalyst, and can reduce cost; meanwhile, in neutralization, Fe3+ in the slag is utilized to meet the requirement of arsenic precipitation without the addition of an arsenic precipitation reagent; when residual cyanides is removed from the hydrogen peroxide liquid, the hydrogen peroxide liquid and cyano complexes which are difficult to remove through the oxidation-reduction reaction form sediment so that the residual thiocyanate is further removed; the method can make the conversion rate of the thiocyanate in the ore slurry more than or equal to 88 percent; and compared with the treatment of filter pressing clear liquid of homogeneous ore slurry, the total reclaiming rate can be increased by over 20 percent.

Owner:CHANGCHUN GOLD RES INST +1

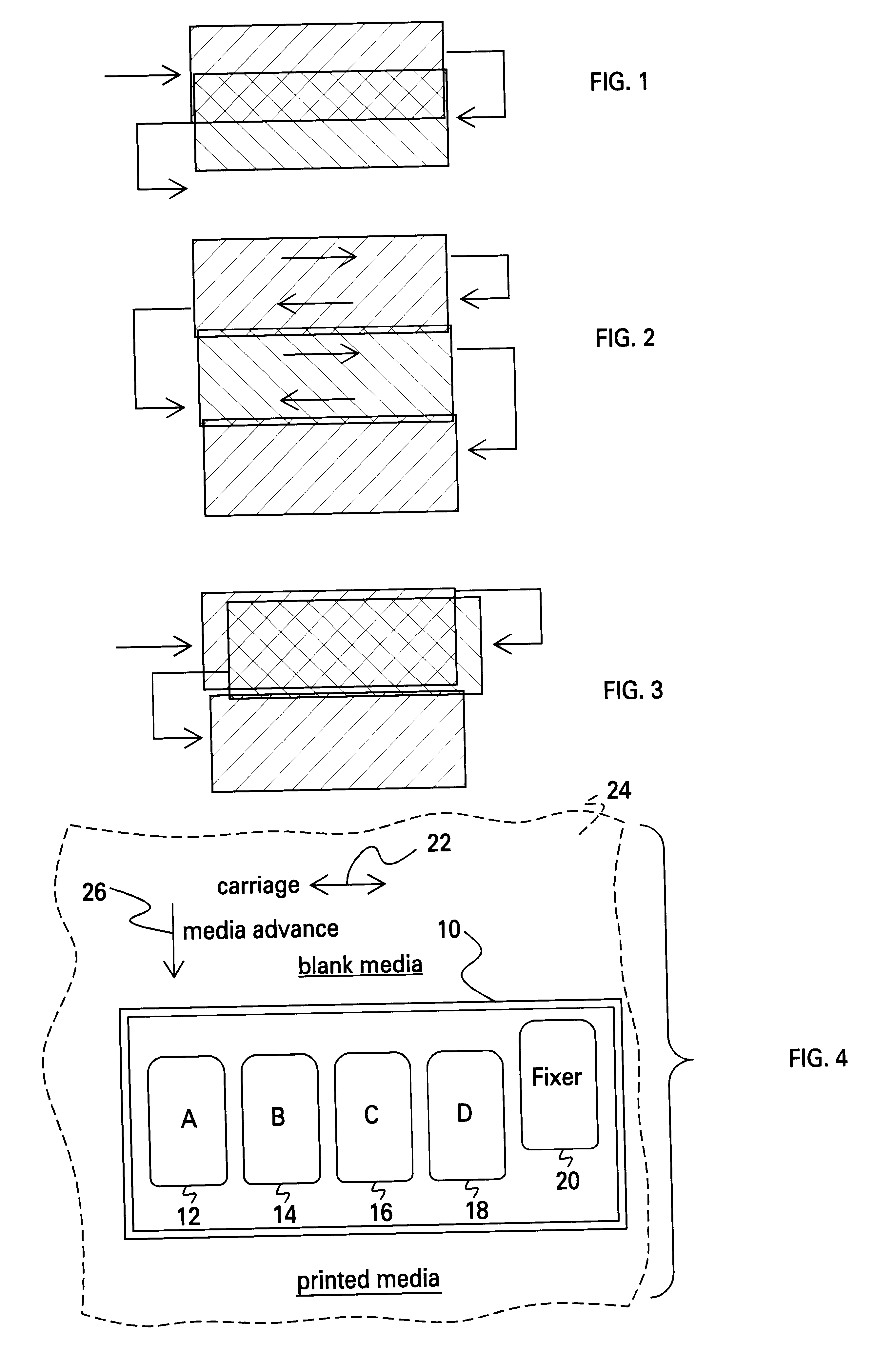

Enhancement of ink jet image waterfastness with overprinting

InactiveUS6503978B1Increased durabilityWet waterfastnessDuplicating/marking methodsInksOrganic acidEngineering

In a four pen ink jet printer comprising cyan, yellow, magenta, and black inks, a clear liquid is applied to printed ink on a print medium via a fifth pen, thereby fixing. the colorants, which in turn improves the durability of the printed ink. The clear fixer fluid comprises at least one organic acid and, optionally, a salt of at least one polymeric acid.

Owner:HEWLETT PACKARD DEV CO LP

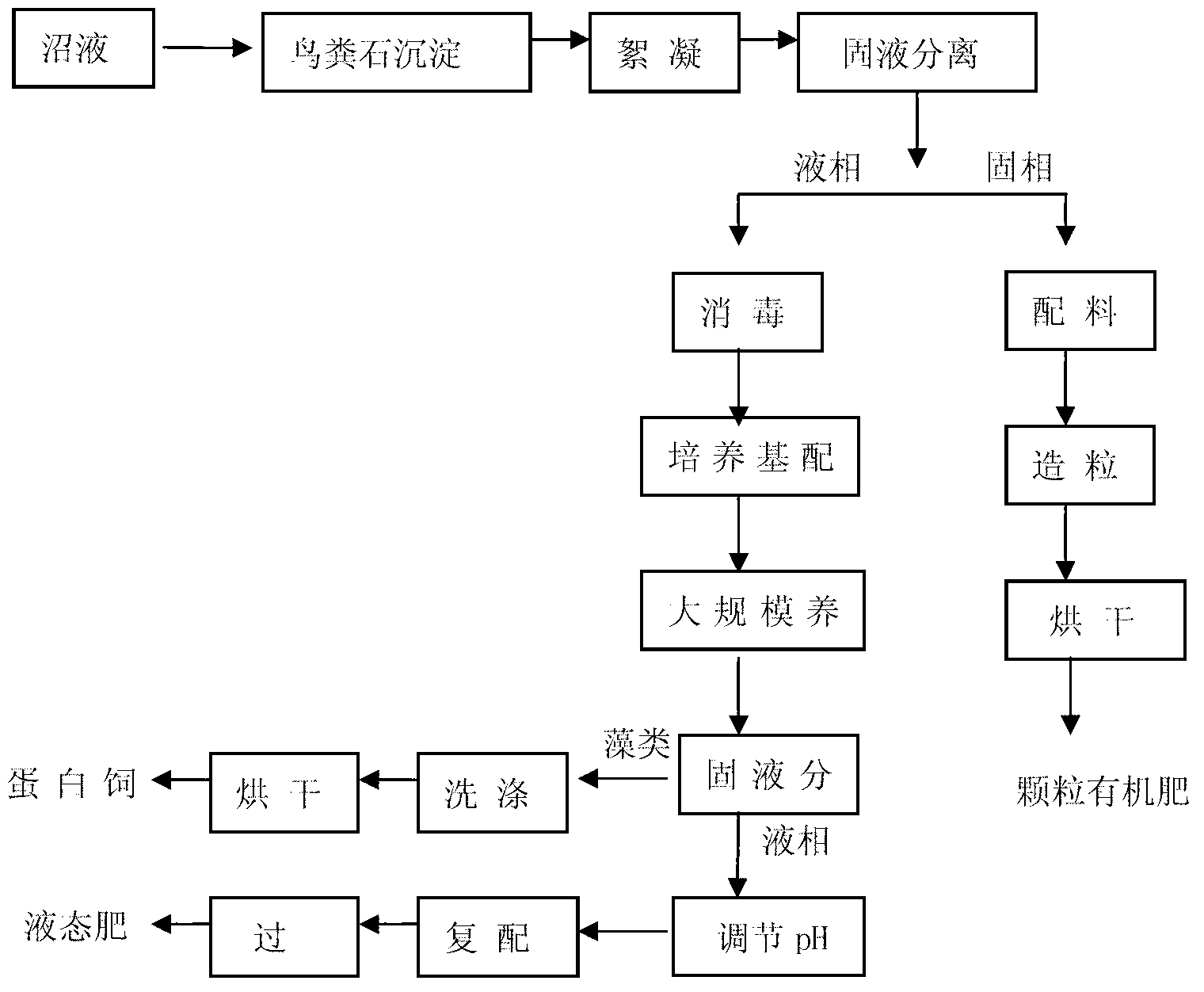

Method for whole-process recycling of multiple biogas slurry components

InactiveCN102795725ASolving Biotoxicity IssuesIncrease nitrogen and phosphorus contentUnicellular algaeClimate change adaptationUltrafiltrationSlurry

The invention discloses a method for whole-process recycling of multiple biogas slurry components and belongs to the technical field of environmental protection. The method comprises the following steps of pre-treating biogas slurry by struvite precipitation and flocculation, carrying out solid-liquid separation to obtain biogas residues, carrying out blending, granulation and drying of the biogas residues to obtain organic fertilizer particles satisfying the NY525-2012 ''organic fertilizer'' standard, disinfecting a clear liquid obtained by solid-liquid separation, adding nutrients into the disinfected clear liquid to obtain an alga medium, separating out cultured algae, carrying out washing, drying and crushing of the cultured algae to obtain protein feed satisfying a feed hygiene standard, adding nutrients into the remaining liquid as a liquid fertilizer production mother liquor obtained by alga separation, adjusting a pH value of the mixed liquid, and carrying out ultrafiltration to obtain a liquid fertilizer product satisfying the GB / T17419-1998 ''foliar microelement fertilizer'' standard. The method provided by the invention realizes comprehensive, efficient and integrated utilization of biogas slurry components. Through marketing or utilization, organic fertilizer particles, foliar fertilizer and protein feed prepared by the method further improve the income and a return rate of biogas engineering.

Owner:中国科学院生态环境研究中心鄂尔多斯固体废弃物资源化工程技术研究所

Preparation method of highland barley grain drink

The invention discloses a preparation method of a highland barley grain drink. The method comprises the following steps: baking; crushing; adding water and gelatinizing; adding amylase and liquefying; adding glucoamylase and saccharifying; separating slurry and residue; taking clear liquid and adding sugar, citric acid, emulsifier and thickener to mix; homogenizing; filling; and sterilizing. Due to the adoption of the method of the invention, the problem of precipitation and layering is solved, and the highland barley grain drink prepared by the method retains the unique nutrition, color and flavor of highland barley and refreshing taste.

Owner:QINGHAI UNIVERSITY

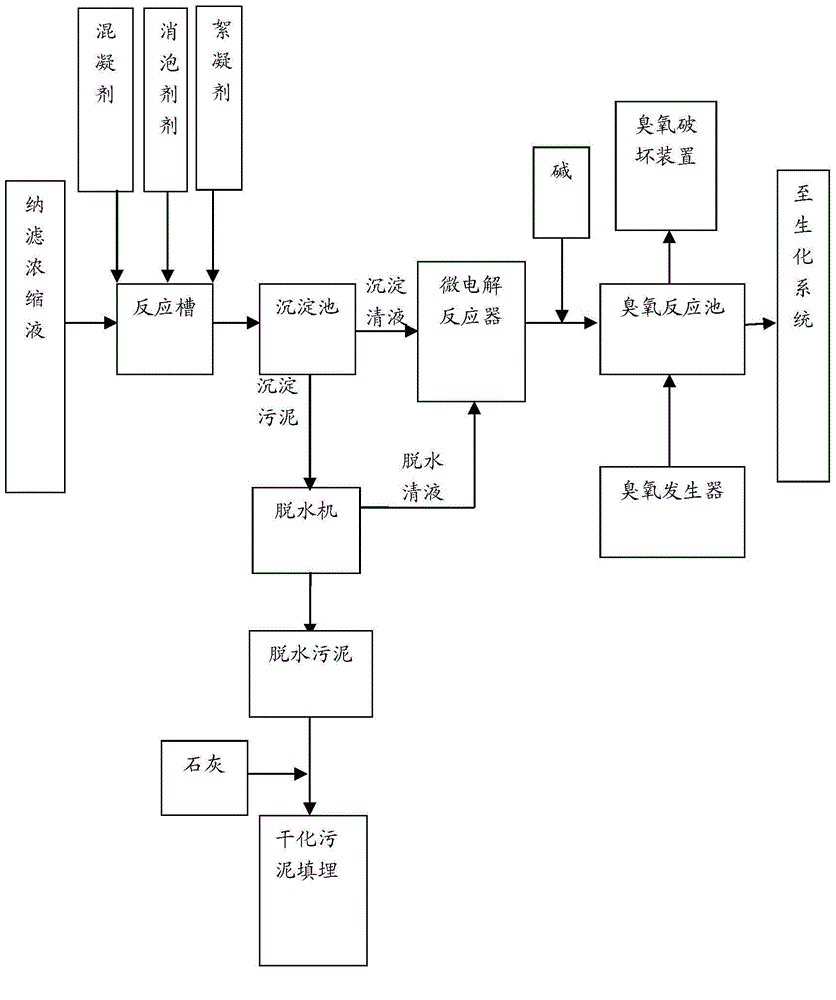

Landfill leachate nanofiltration concentrate treatment method

ActiveCN104478157AHigh removal rateImprove economyWater contaminantsMultistage water/sewage treatmentOzone generatorChemical reaction

The invention provides a landfill leachate nanofiltration concentrate treatment method. The method comprises the following steps: pumping a landfill leachate nanofiltration concentrate into a reaction tank, adding a coagulant, an antifoaming agent and a flocculating agent into the reaction tank, and reacting; allowing the obtained concentrate to go through a pipeline and flow into a precipitation pool, and carrying out solid-liquid separation to obtain precipitated sludge and a precipitated clear liquid; pumping the precipitated sludge into a dehydrator for separation, sending the generated dehydrated clear liquid and the precipitated clear liquid to a microelectrolysis reactor, and oxidizing; adding an alkali to oxidized water to adjust the pH value to 7-9, sending the obtained water to an ozone reaction tank for further oxidation, and introducing ozone generated by an ozone generator into an ozone reaction tank for aeration; and returning the treated nanofiltration concentrate to a biochemical system. The method ingeniously combining a physical and chemical reaction with a biochemical technology has the advantages of stable running, easy operation and maintenance, low running cost and high treatment efficiency, and partially solves the carbon source insufficiency problem of landfill leachate.

Owner:GARDEN ENVIRONMENTAL PROTECTION

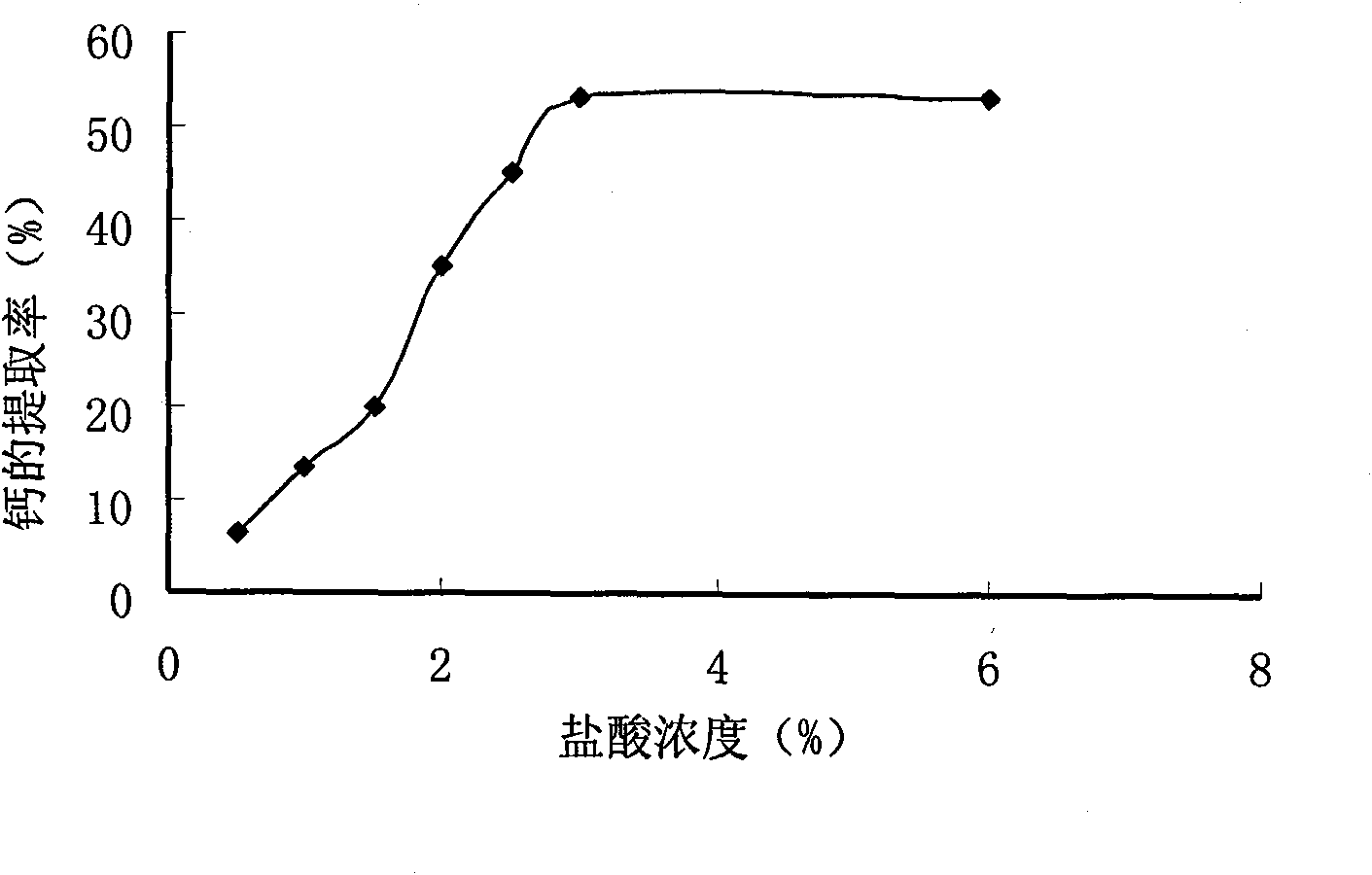

Method for preparing compound amino acid chelate calcium from low-value freshwater fish bones

InactiveCN101648884ATake advantage ofIncrease added valueOrganic compound preparationAmino-carboxyl compound preparationCalcium borogluconateSodium hydroxide

The invention relates to a method for preparing compound amino acid chelate calcium from low-value freshwater fish bones. The method comprises the following steps: washing and steaming fish bones andthen soaking the fish bones in sodium hydroxide; then washing the fish bones to be neutral; drying and pulverizing the fish bones; extracting calcium in fish bone powder by an acidolysis method; chelating calcium ions in the fish bone powder by using compound amino acid; carrying out centrifugation to obtain clear liquid; washing an obtained product twice by absolute alcohol and then carrying outcentrifugation to obtain precipitates; and drying and pulverizing the precipitates to obtain a calcium acid chelate capsule product. The invention firstly adopts the fish bones which are by-products of processing low-value freshwater fishes to prepare the compound amino acid chelate calcium, thereby greatly improving the additional value of the by-products of the freshwater fishes. Proved by an animal experiment, the compound amino acid chelate calcium has thighbones calcium content of a rat of 32.81-43.41 and thighbones calcium retention rate of 5.30-16.30. If the compound amino acid chelatecalcium is matched with VD3, the bioavailability can be increased more and the effect of calcium supplement is improved. The calcium supplement effect of the compound amino acid chelate calcium is equivalent to the calcium supplement effect of calcium gluconate and higher than the calcium supplement effect of calcium carbonate, but the calcium retention rate of the compound amino acid chelate calcium is obviously higher than that of the calcium gluconate group and the calcium carbonate group.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

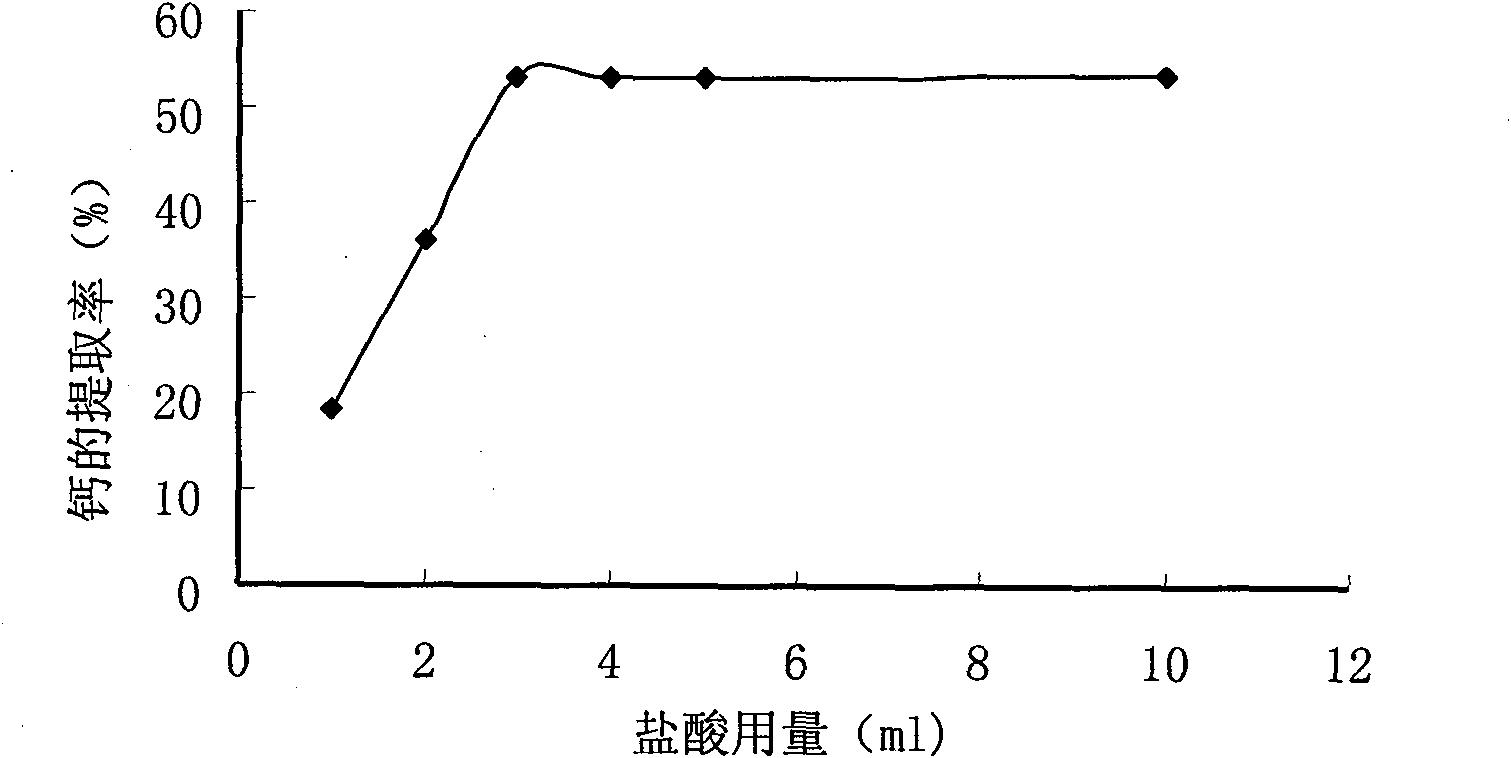

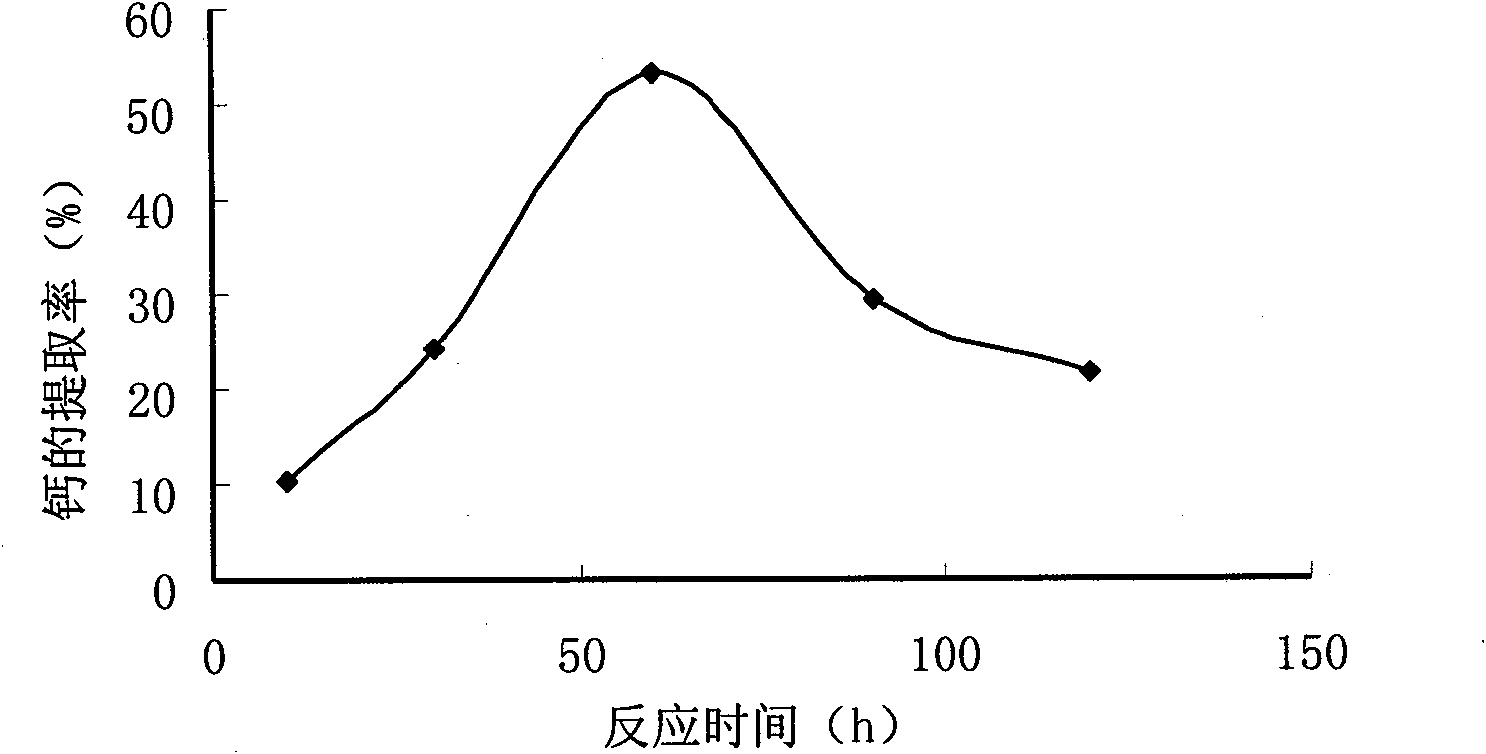

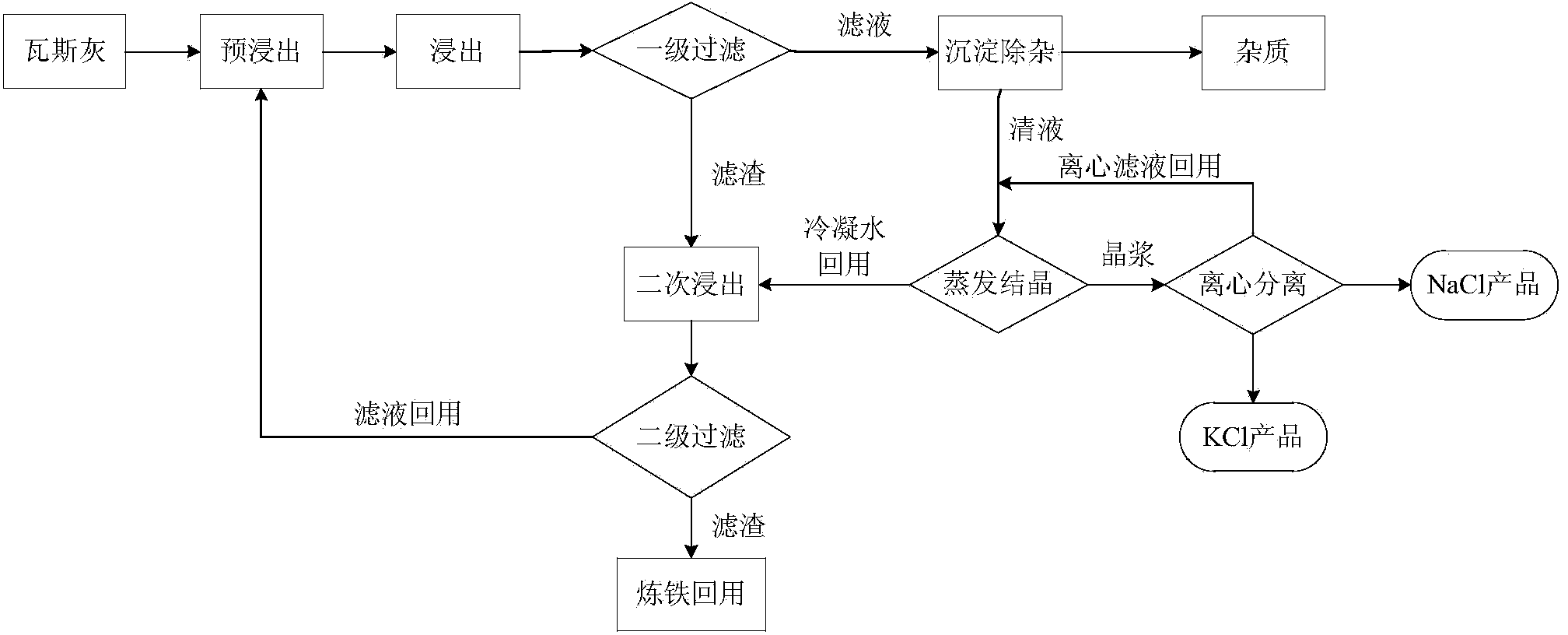

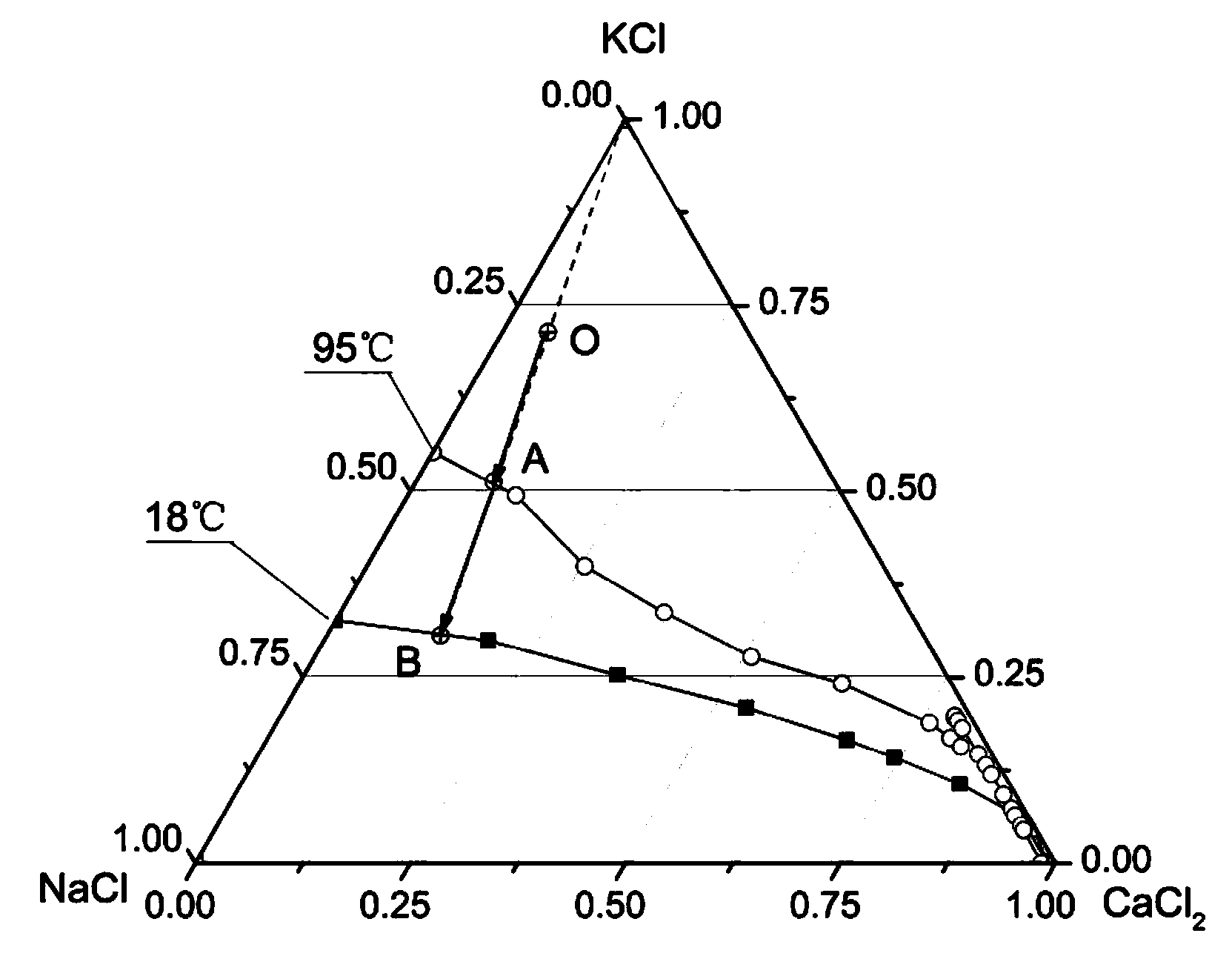

Method for producing potassium chloride by using blast furnace dust of iron and steel enterprises

ActiveCN103435073AHarm reductionQuality improvementAlkali metal chloridesProcess engineeringEnvironmental engineering

The invention discloses a method for producing potassium chloride by using blast furnace dust of iron and steel enterprises. The method comprises the following steps: mixing the blast furnace dust with running water according to a certain ratio in a pre-leaching process; at the end of the mixing, stirring and leaching the mixed solution in a leaching process; filtering the mixed solution in a primary filtering procedure; removing impurities out of primary filtrate in a precipitating and impurity removing procedure; leaching the primary filter residue for the second time in a secondary leaching procedure; adding a precipitator to the primary filtrate in the precipitating procedure for precipitate and removing impurities; standing still for layering or filtering after completely precipitating; carry out multi-effect crystallization on clear liquid in an evaporation crystallization process to produce potassium chloride and sodium chloride products; filtering the mixed solution to secondary filtering equipment after the secondary leaching procedure reaches the filter condition; and recycling secondary filter residue for making iron, and returning the secondary filtrate to the pre-leaching process to be used again. By adopting the method, the high potassium feature in the blast furnace dust is fully utilized, waste materials are changed into valuable resources, the damage of emission of waste to the environment is reduced, and a high-quality potassium chloride product is also produced.

Owner:UNIV OF SCI & TECH BEIJING

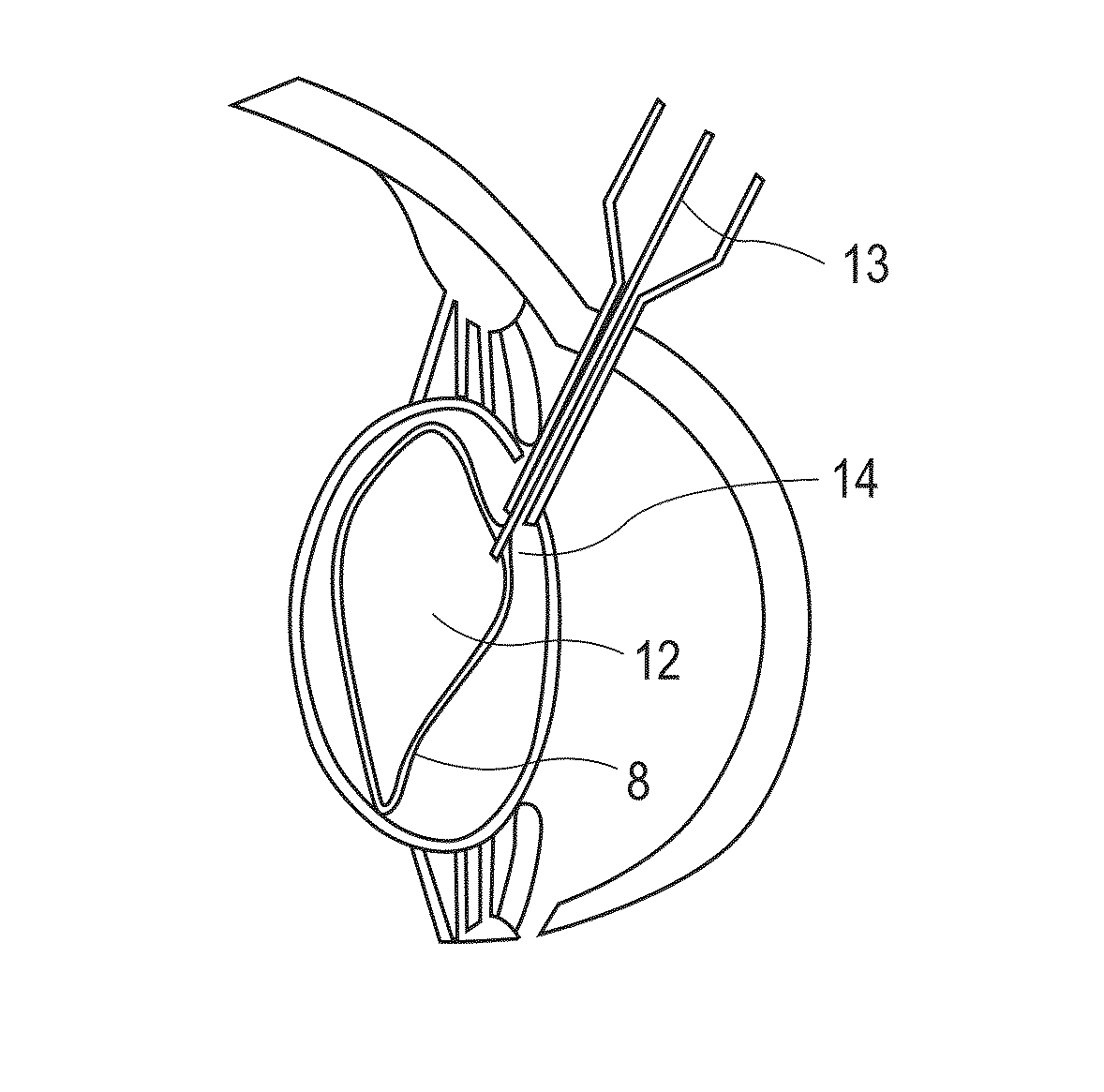

Accommodating intraocular lens

InactiveUS20140227437A1Bright colorEasy to findOptical articlesTissue regenerationElastomerIntraocular lens

Systems, devices, and methods are presented for a prosthetic injectable intraocular lens. The lenses can be made from silicone, fluorosilicone, and phenyl substituted silicone and be semipermeable to air. One or more silicone elastomeric patches located outside the optical path on the anterior side but away from the equator can be accessed by surgical needles in order to fill or adjust optically clear fluid within the lens. The fluid can be adjusted in order to set a base dioptric power of the lens and otherwise adjust a lens after its initial insertion. The elastomeric patches are sized so that they self-seal after a needle is withdrawn. A straight or stepped slit in the patch can allow a blunt needle to more easily access the interior of the lens.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

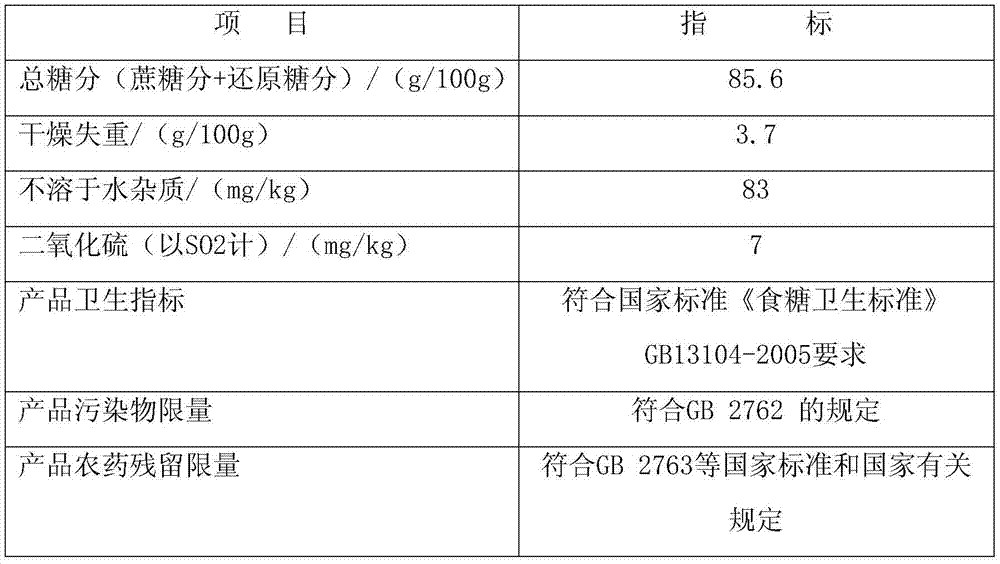

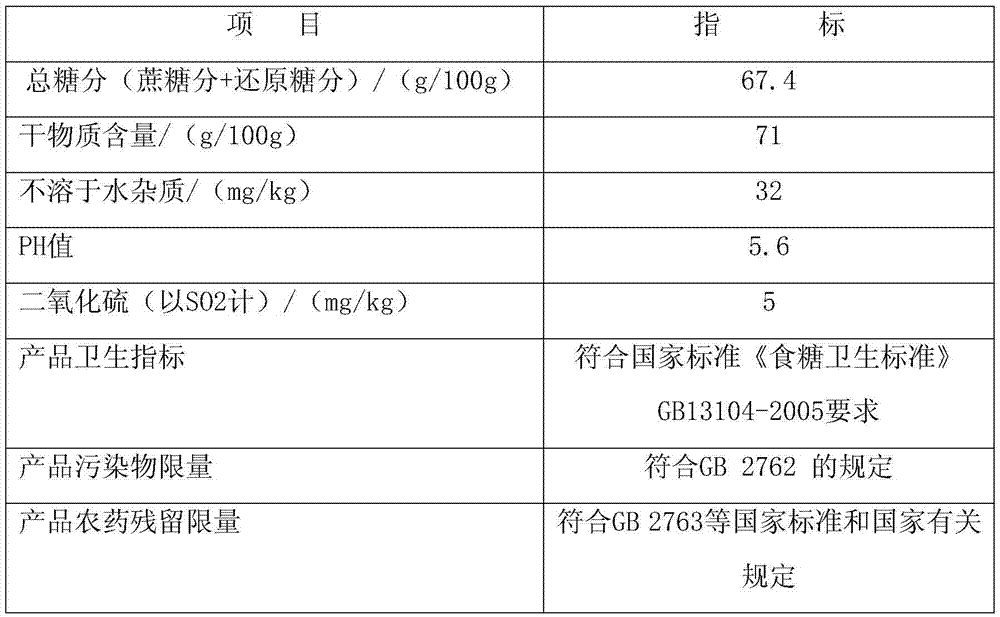

Method for producing raw juice brown sugar

The invention relates to a method for producing raw juice brown sugar and belongs to the technical field of food processing. The invention aims at solving the technical problem of providing a method for producing raw juice brown sugar with higher quality. The method for producing the raw juice brown sugar comprises the following steps: a, juicing sugarcane, and sieving, so as to obtain raw juice after sieving and screening residue; b, heating the raw juice after sieving, eliminating formed floating condensation products, so as to obtain clear juice, and filtering, so as to obtain filtrate I; c, standing the filtrate I for 2-3 hours, and removing fine silt impurities at the bottom layer, so as to obtain sugar juice clear liquid; d, evaporating and concentrating the sugar juice clear liquid obtained in the step c into syrup with the brix of 85-90 degree Bx, then carrying out sugar boiling to obtain massecuite, sanding, and moulding, so as to obtain lump sugar; or evaporating and concentrating the sugar juice clear liquid obtained in the step c into clear syrup with the brix of 55-60 degree Bx, and then carrying out sugar boiling at normal pressure, so that liquid brown sugar with the concentration of 68-78 degree Bx is obtained.

Owner:MIYI HUASENTY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com