Recycling and harmless treatment method for cyaniding tailing slurry

A technology for harmless treatment and cyanidation of tailings, applied in chemical instruments and methods, mining wastewater treatment, neutralized water/sewage treatment, etc. Surface water and other problems, to achieve the effect of speeding up the oxidation-reduction reaction speed, speeding up the acidification stripping speed, and speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: small batch test:

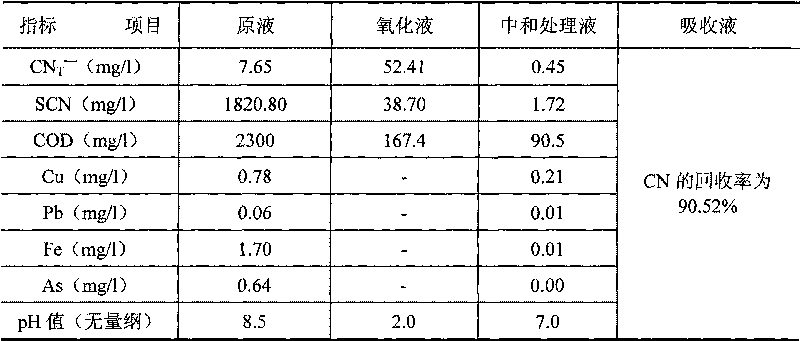

[0050] Take 2L cyanide tailings slurry, add hydrogen peroxide 17ml / L, the pH value is below 2, the reaction time is 2.5h, add the same amount of concentrated H at a constant temperature of 40°C with different gas-liquid ratios 2 SO 4 Carry out conversion and stripping, and absorb HCN with an absorption column equipped with 3L NaOH solution. After the lime is neutralized to a pH of 7, 2.5ml / L hydrogen peroxide is added to remove cyanide. The test results are shown in Table 1:

[0051] Table 1: Small-scale test results of recycling and harmless batch treatment of cyanide tailings slurry

[0052]

Embodiment 2

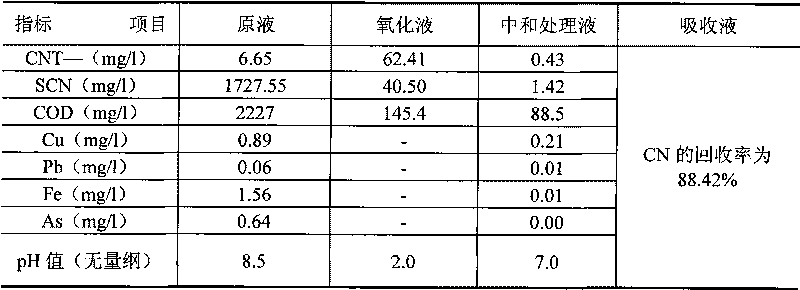

[0053] Example 2: Small continuous experiment:

[0054] According to the technical conditions obtained from the batch test, determine the following continuous test conditions:

[0055] (1), the processing capacity of tailings slurry: 2L / h;

[0056] (2), gas-liquid ratio: 400:1;

[0057] (3), temperature control: 40 ℃;

[0058] (4), agent flow rate: convert and blow off hydrogen peroxide 30ml / L, H 2 SO 4 6ml / L, CaO6g / L, cyanide removal hydrogen peroxide 2.5ml / L;

[0059] (5) Absorption solution: 15% NaOH 4L.

[0060] The test results are shown in Table 2:

[0061] Table 2: Small-scale continuous test results of cyanide tailings slurry recycling and harmless treatment

[0062]

Embodiment 3

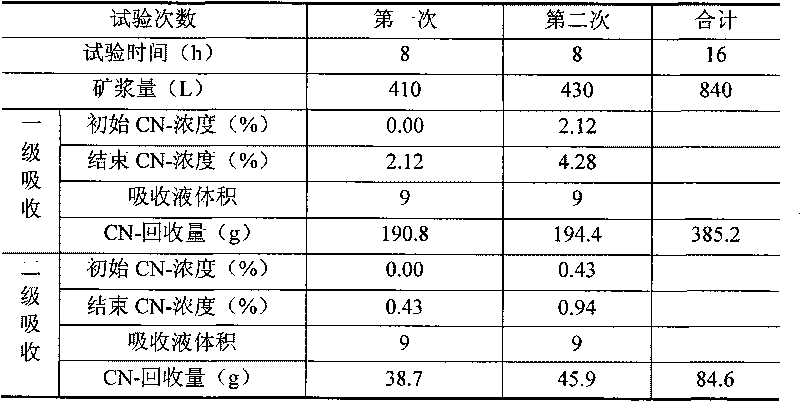

[0063] Embodiment 3: Pilot scale continuous treatment experiment:

[0064] This test adopts the 5 steps introduced by the present invention, the tailings slurry processing capacity is 50L / h, the hydrogen peroxide addition is 20mL / h, the sulfuric acid addition is 6mL / h, the slurry residence time is 1.5h, and the gas-liquid ratio is 300 : 1, the acidizing oxidation temperature is 40 ℃, carries out two experiments, each 8 hours, handles 840L of ore pulp altogether, and experimental result sees the following table 3:

[0065] Table 3: Small-scale continuous test results of cyanide tailings slurry recycling and harmless treatment

[0066]

[0067] Cumulative recovery of CN in the absorption solution - The amount is 469.8g; Theoretical SCN - Convert CN - The amount is 519.7g; the actual SCN - The conversion recovery rate was 90.14%. The experimental results are shown in Table 4:

[0068] Table 4: Results of continuous pilot test of cyanide tailings slurry recycling and harm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com