Patents

Literature

353 results about "Batch test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A batch test occurs when you run multiple scripts. It is typically done with automation. You program a batch test by placing the scripts in the order you wish to have them run and employing a tool that will execute the scripts in that specified order.

Test system using local loop to establish connection to baseboard management control and method therefor

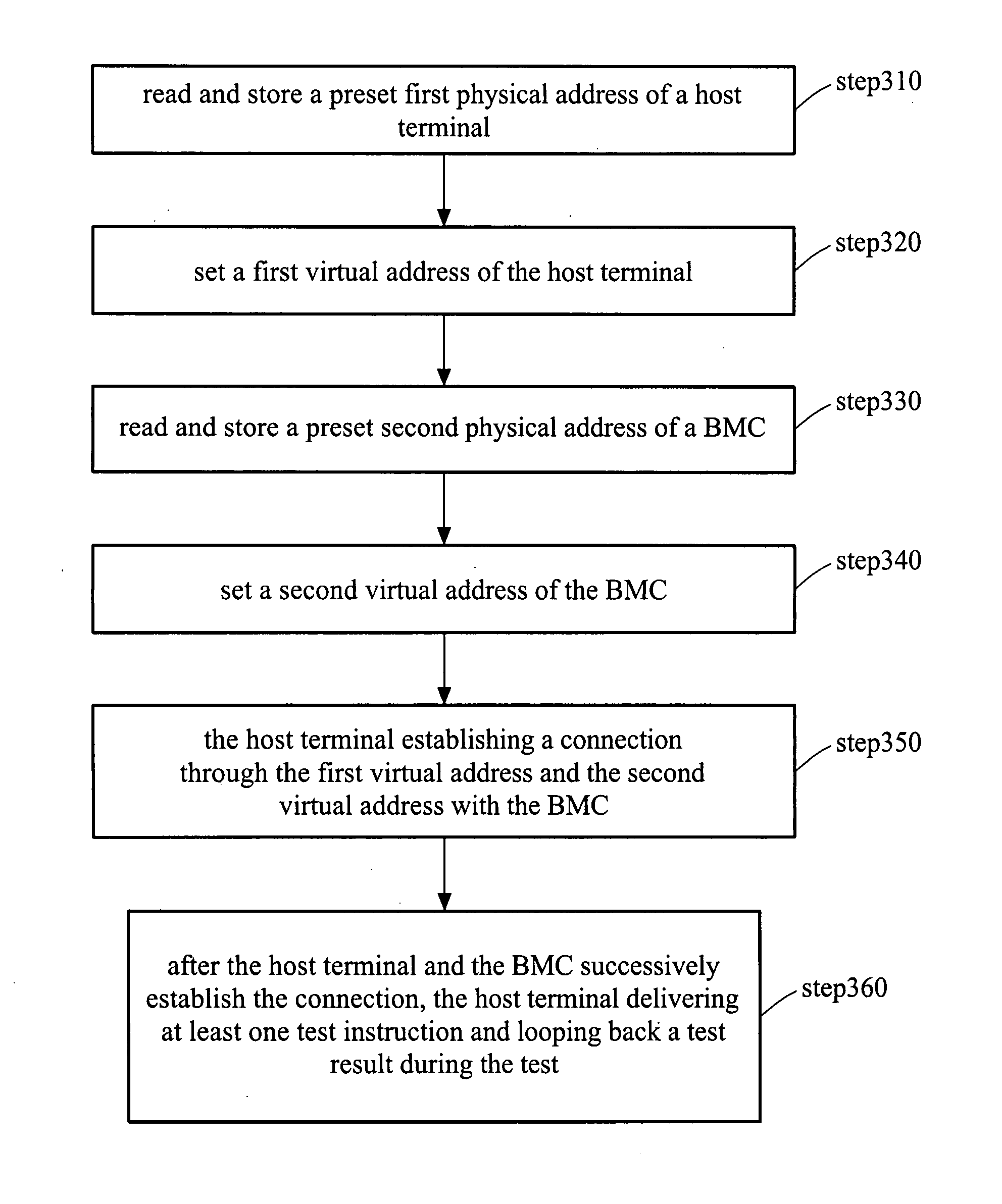

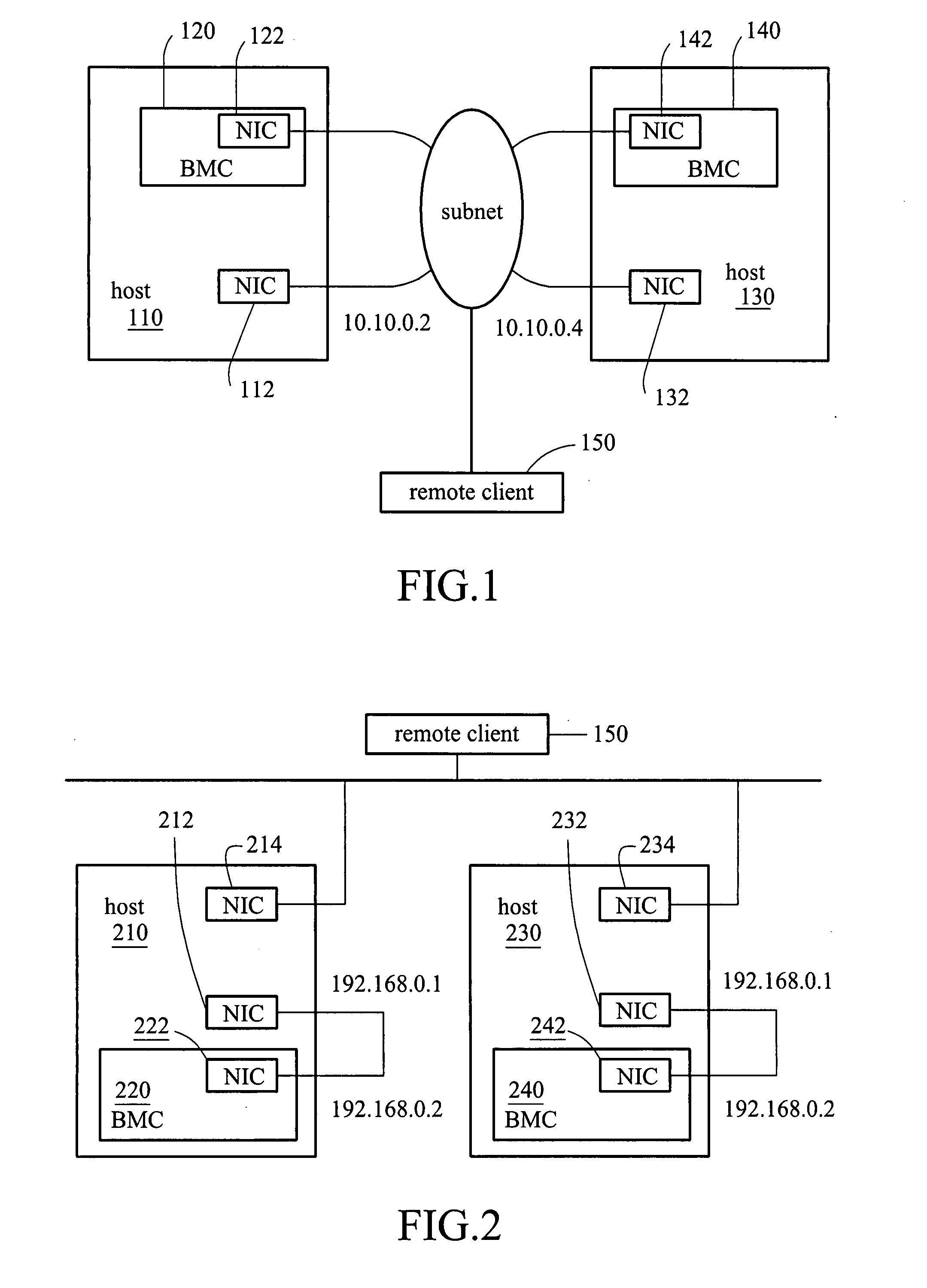

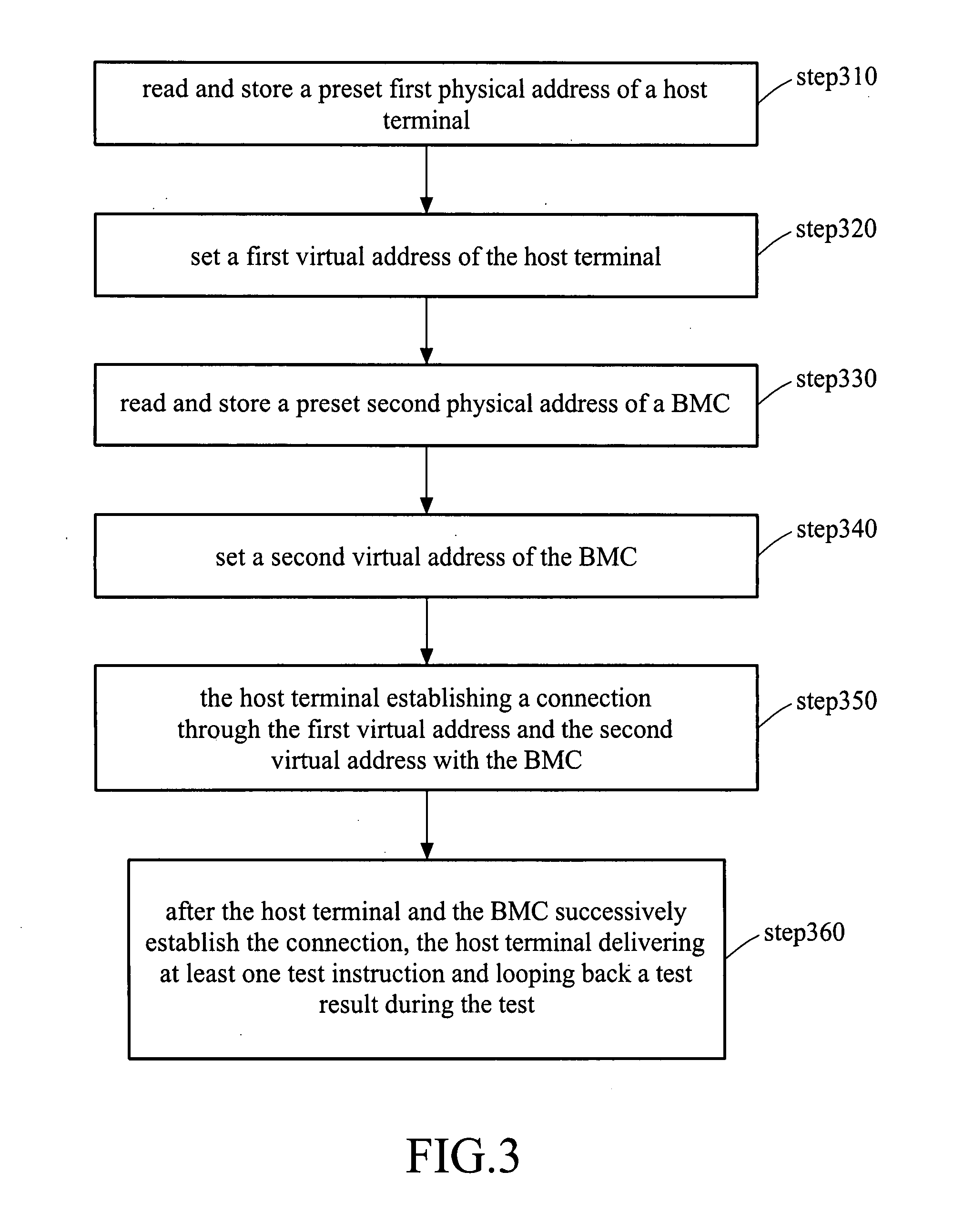

InactiveUS20080205286A1Shorten the timeError prevention/detection by using return channelFrequency-division multiplex detailsCyclic testInner loop

A test system using a local loop to establish connection to baseboard management control is provided. The test system includes more than one host terminals having at least one network interface card (NIC) and at least one baseboard management controller (BMC) having one NIC. After establishing a connection for test between the host terminals and a remote subscriber, a connection for loop test is established with the BMC through a virtual address, so as to deliver a test instruction to the BMC for testing and to loop back a test result. The test system establishes the connection for loop test through the virtual address so as to perform a remote platform test similar to an inner loop test. Therefore, the test result will not be influenced by a network environment setting, and thus a batch test can be adopted to save the test time.

Owner:INVENTEC CORP

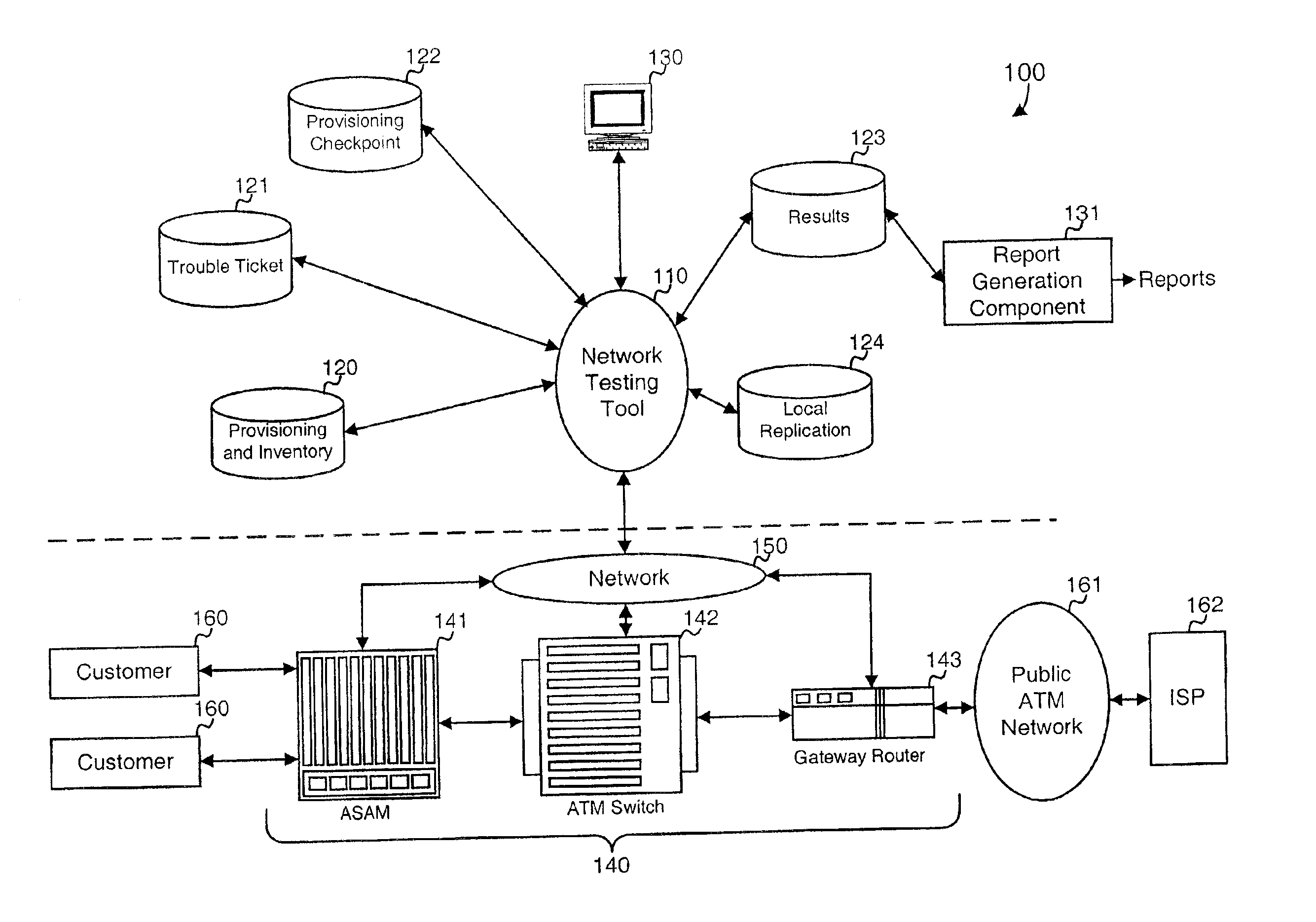

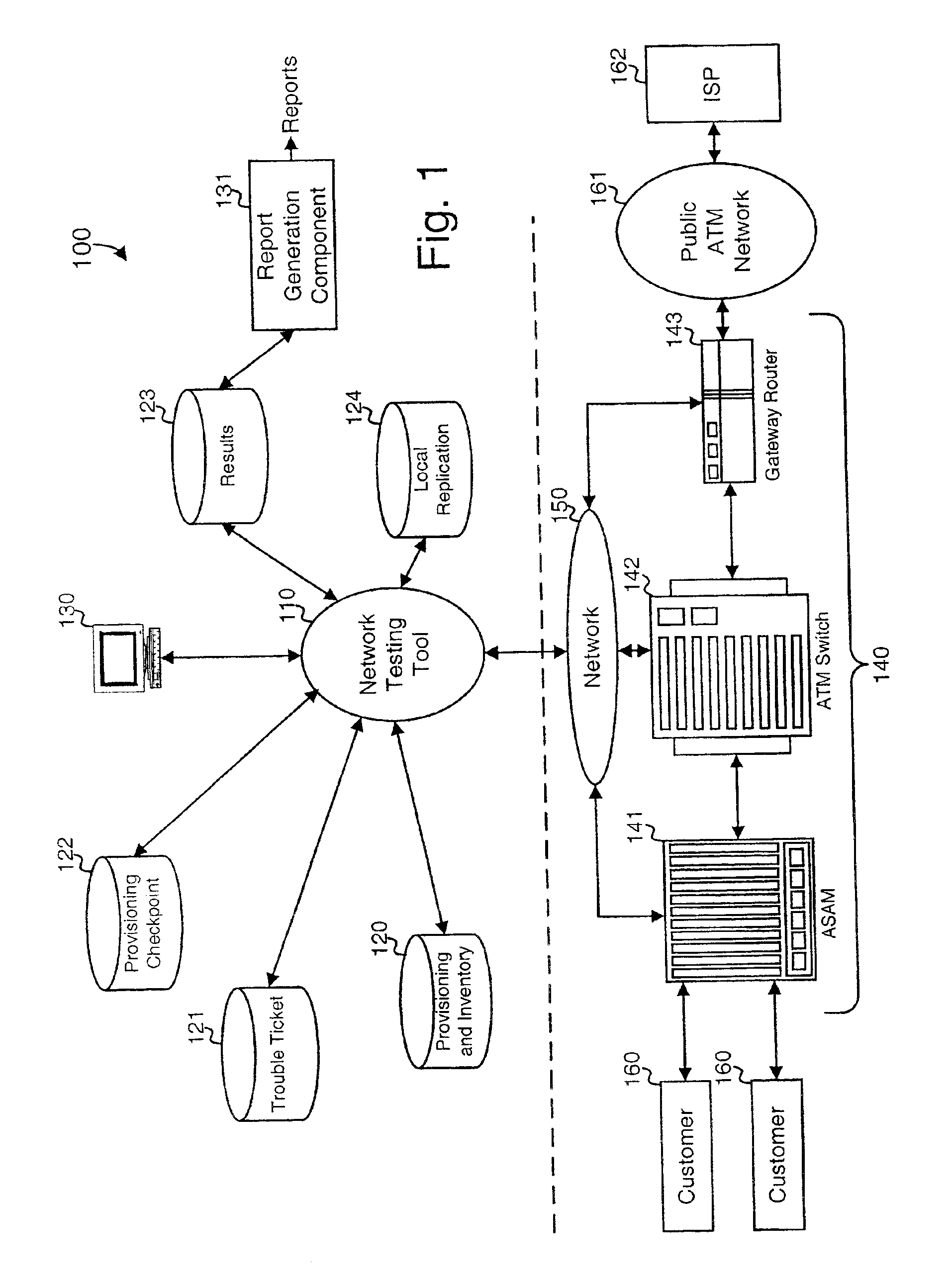

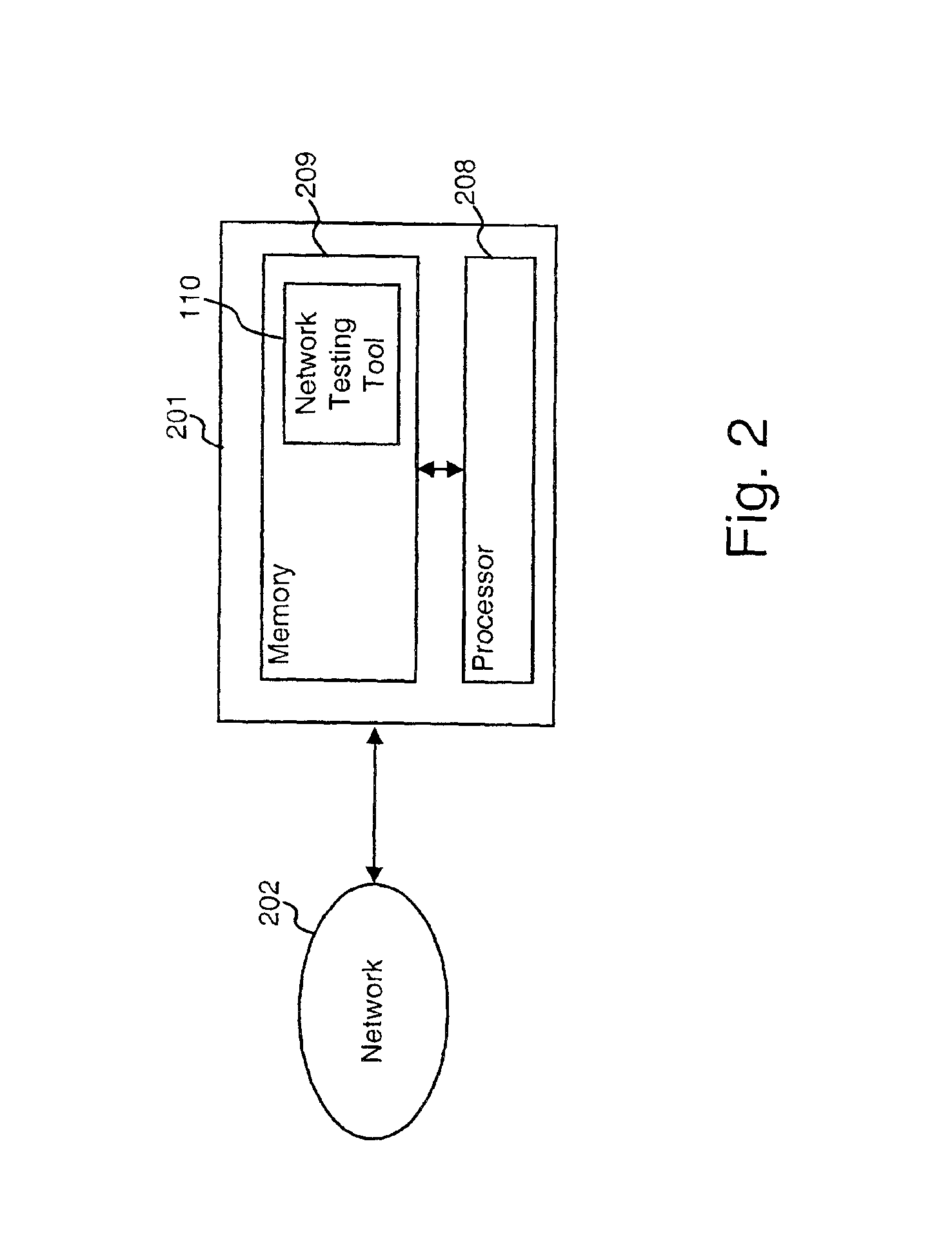

Automated DSL network testing software tool

InactiveUS6889339B1Error detection/correctionDigital computer detailsComputer hardwareNetwork testing

A DSL network testing tool (110) tests multiple elements (141, 143) in a DSL circuit. The testing tool may operate in either a single circuit test mode or a batch mode. In batch test mode, the network testing tool receives multiple DSL phone numbers and automatically tests the DSL circuit's elements corresponding to the phone numbers. The test information may be used when troubleshooting or provisioning DSL circuits.

Owner:VERIZON PATENT & LICENSING INC

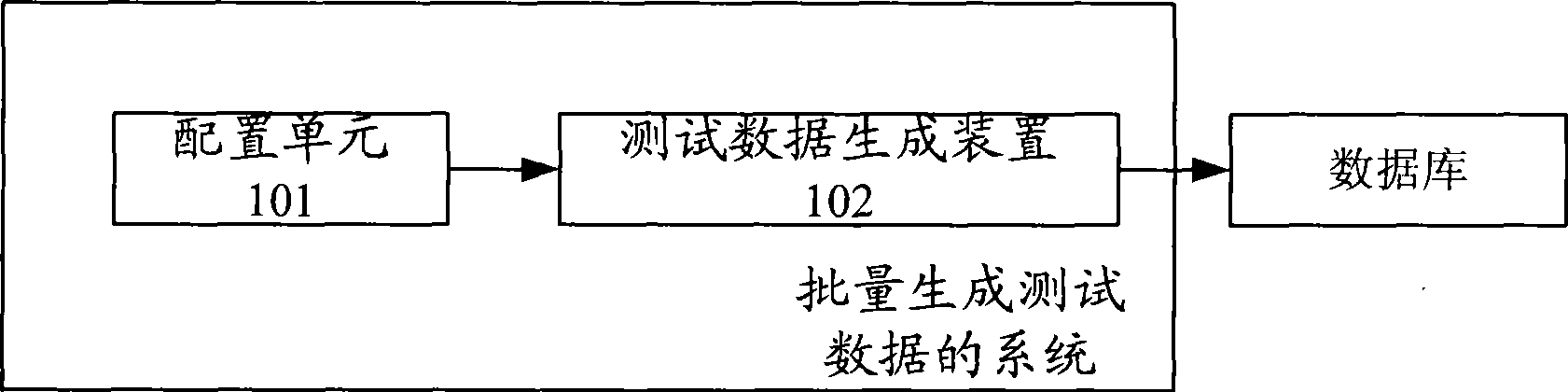

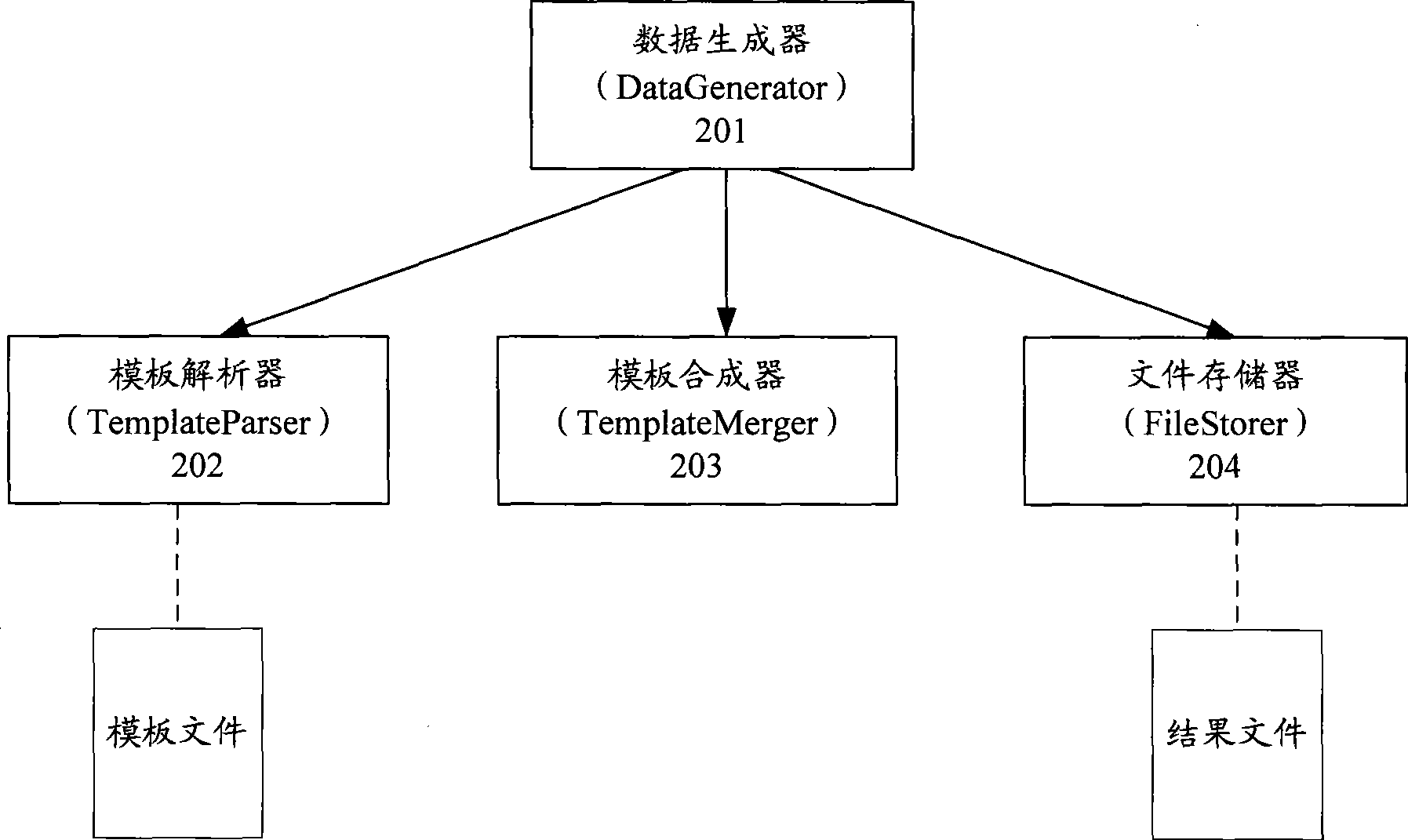

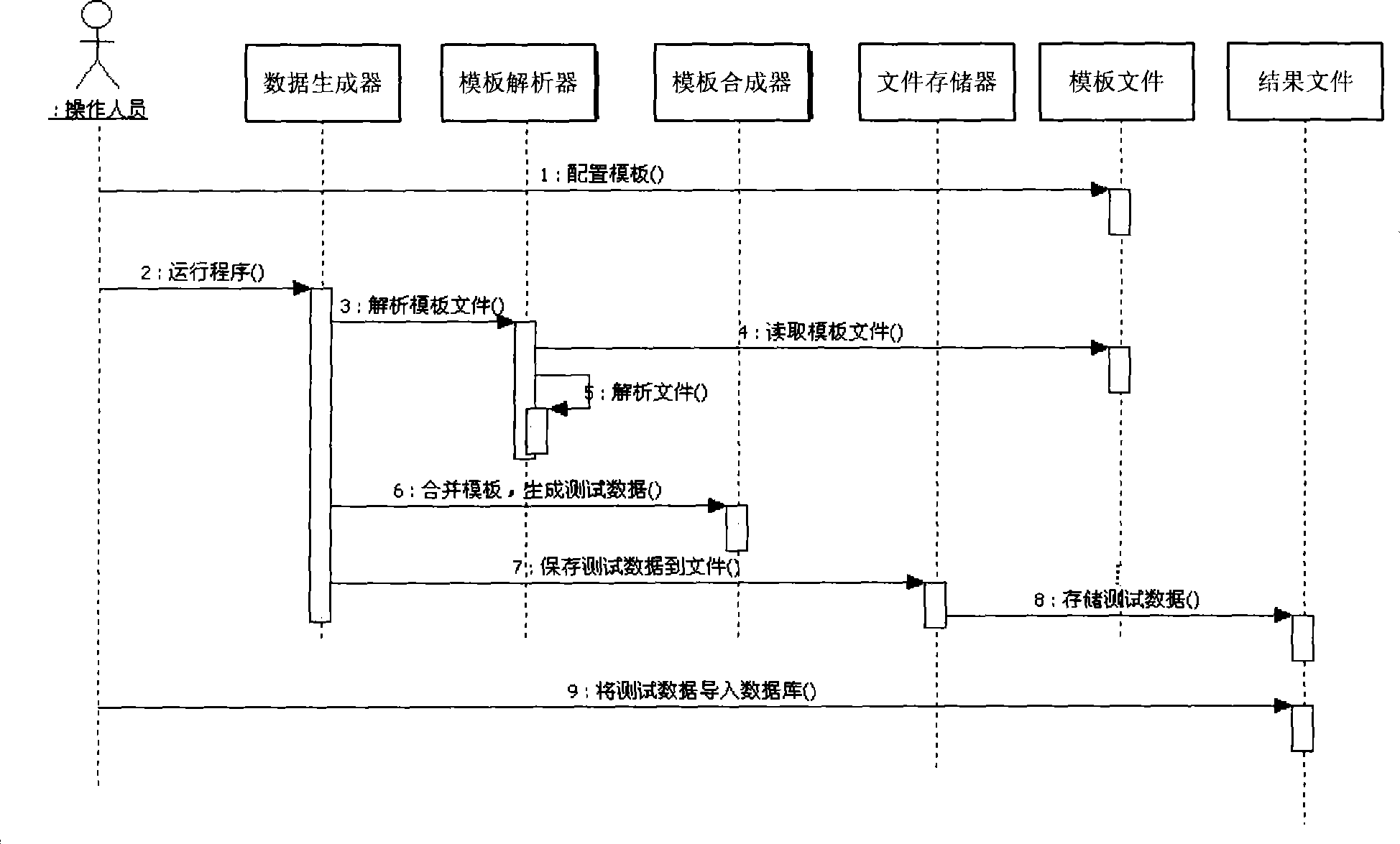

Method, system and apparatus for test data batch generation

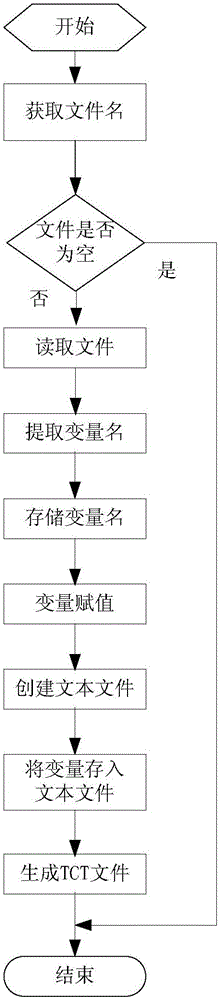

ActiveCN101430661AReduce the chance of errorAccurate processingSoftware testing/debuggingTest data generationBatch test

The invention discloses a batch test data generation method, a system and a device thereof. The method comprises a step of setting a template file which comprises an original statement of test data to be generated, the original statement comprises a dynamic change part of the test data which is represented as a variable and a fixed value part; the method further comprises the following steps: analyzing the template file, identifying the variable and the fixed value part in the template file; replacing the variable with true data according to the type and a generation mode of the variable, generating the dynamic part of the batch test data, and generating a static part of the batch test data according to the fixed value part; merging the dynamic part and the static part of the test data to generate the batch test data; and storing the batch test data in a destination file. The method, the system and the device can ensure that the generated data are correct, and can help accurately process multilist correlated data.

Owner:ADVANCED NEW TECH CO LTD

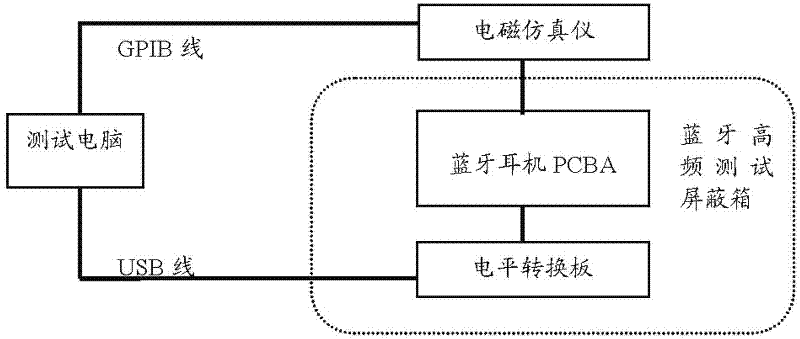

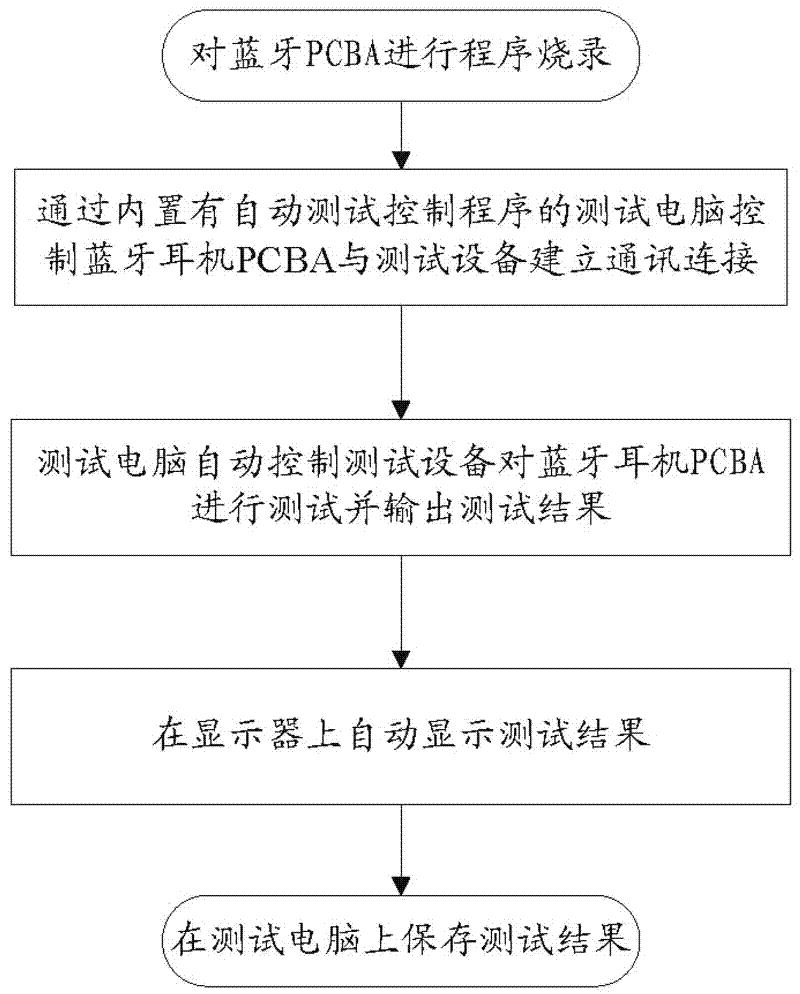

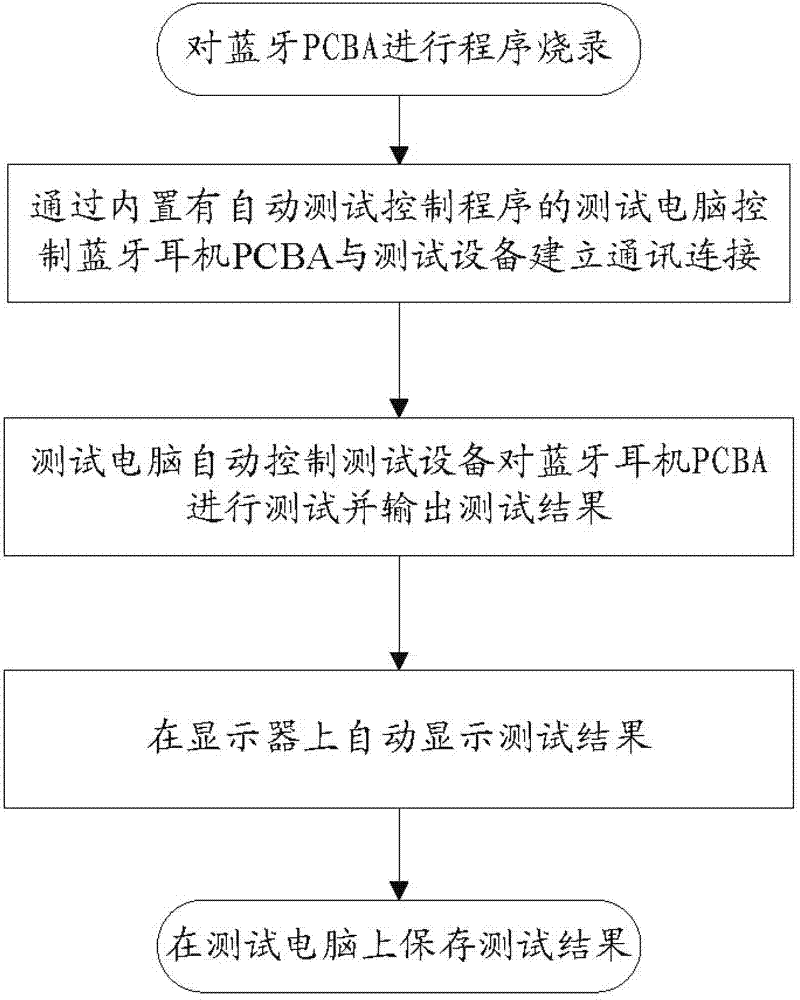

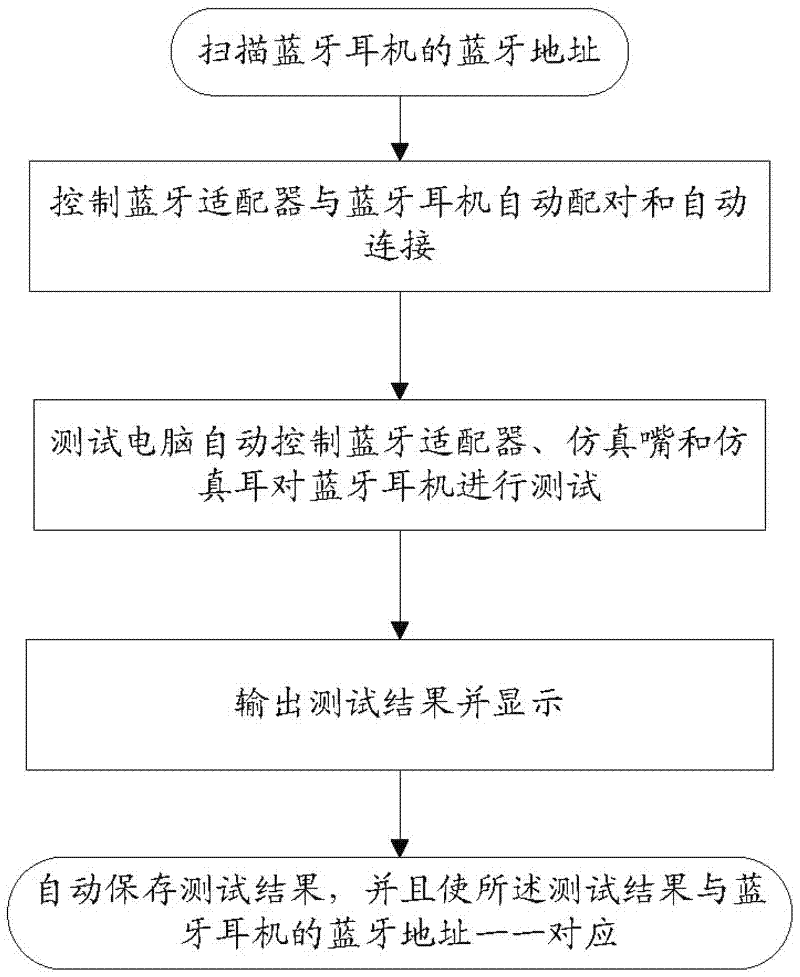

Batch test method and system for PCBA (Printed Circuit Board Assembly) of Bluetooth headset

InactiveCN102243281AImprove production test efficiencyElectrical testingTest efficiencyComputer hardware

The invention discloses a batch test method for a PCBA (Printed Circuit Board Assembly) of a Bluetooth headset, aiming at providing a batch test method of the PCBA of the Bluetooth headset, with high testing efficiency. The batch test method comprises the following steps of: controlling the PCBA of the Bluetooth headset and test equipment to establish a communication connection through a test computer internally provided with an automatic test control program; testing the PCBA of the Bluetooth headset by automatic control test equipment of the test computer and outputting a test result; and automatically displaying the test computer on a display. The invention also discloses a batch test system of the PCBA of the Bluetooth headset. The invention can be used for batch test of the PCBA of the Bluetooth headset.

Owner:GUANGZHOU LIWEI ELECTRONICS

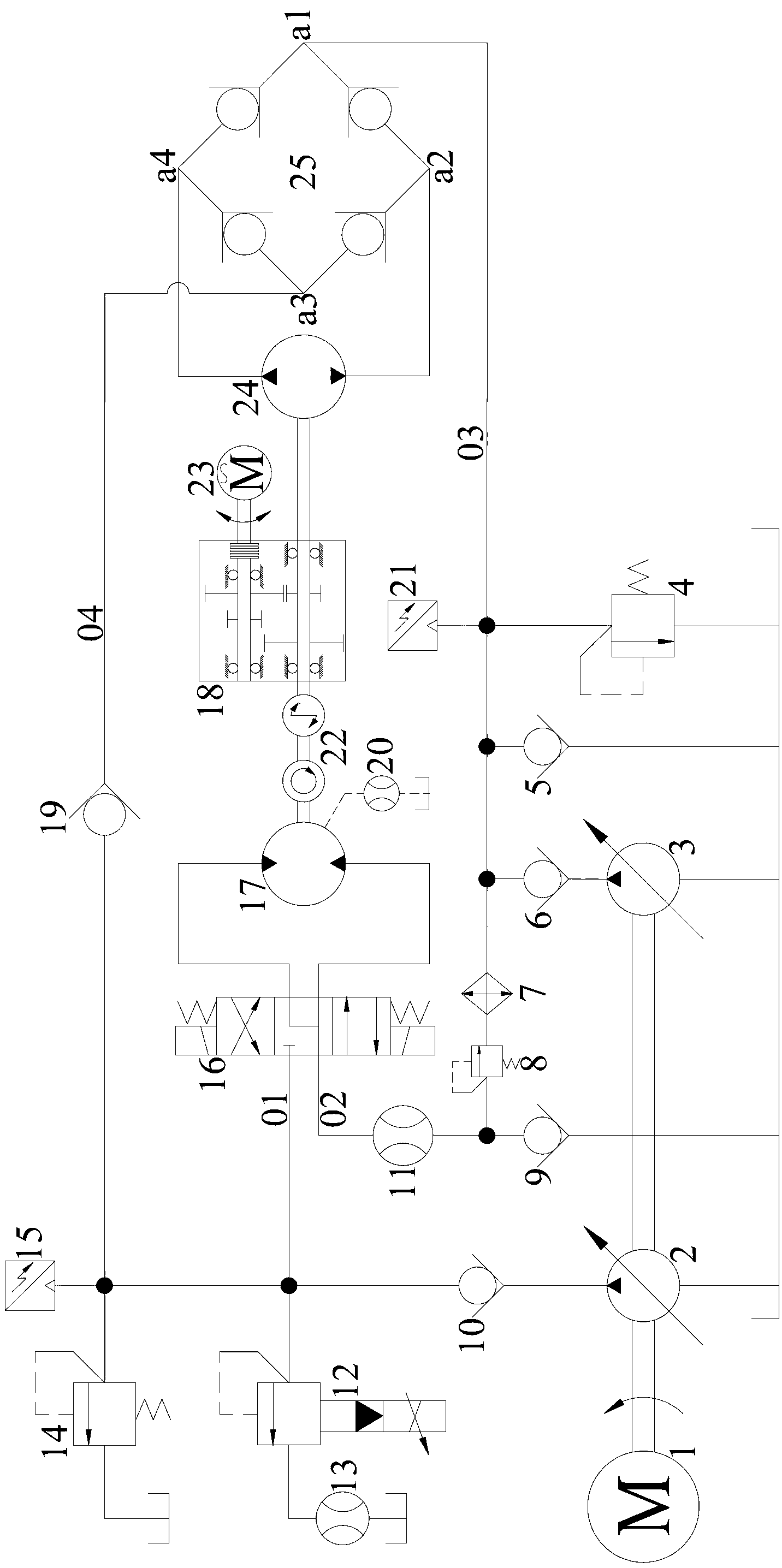

Testing system of hydraulic motor

InactiveCN102937125AImprove stabilityImprove recycling efficiencyFluid-pressure actuator testingHydraulic motorInlet channel

The invention relates to the technical field of motor tests and discloses a testing system of a hydraulic motor. The testing system of the hydraulic motor comprises a motor, a speed changing box, a tested motor, a loading motor, a first oil way, a second oil way, a feedback oil way and a compensation oil way. The speed changing box is provided with an acceleration gear and a deceleration gear, the input end of the speed changing box is in driving connection with the output end of the motor, the loading motor is butted with the tested motor through a power shaft, the output end of the speed changing box is in driving connection with the power shaft, the first oil way serves as an oil inlet channel of the tested motor, the second oil way serves as an oil return channel of the tested motor, the oil outlet end of the feedback oil way is communicated with the first oil way, and the oil outlet end of the feedback oil way selectively supplies oil for the oil inlet end of the feedback oil way or supplies oil for the oil inlet end of the feedback oil way through the loading motor. By means of the testing system, mechanical and hydraulic compensation power recovery modes or the hydraulic compensation power recovery mode can be selected according to needs, and testing requirements for power tests, service life tests, batch tests and the like on most majority of hydraulic motors can be met.

Owner:SANY AUTOMOBILE MFG CO LTD

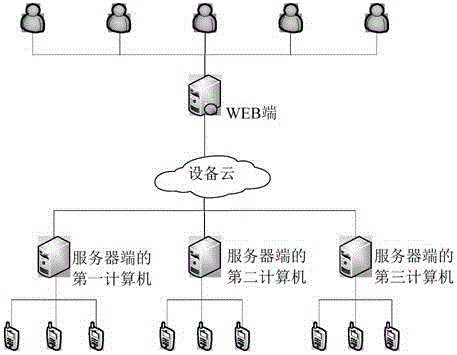

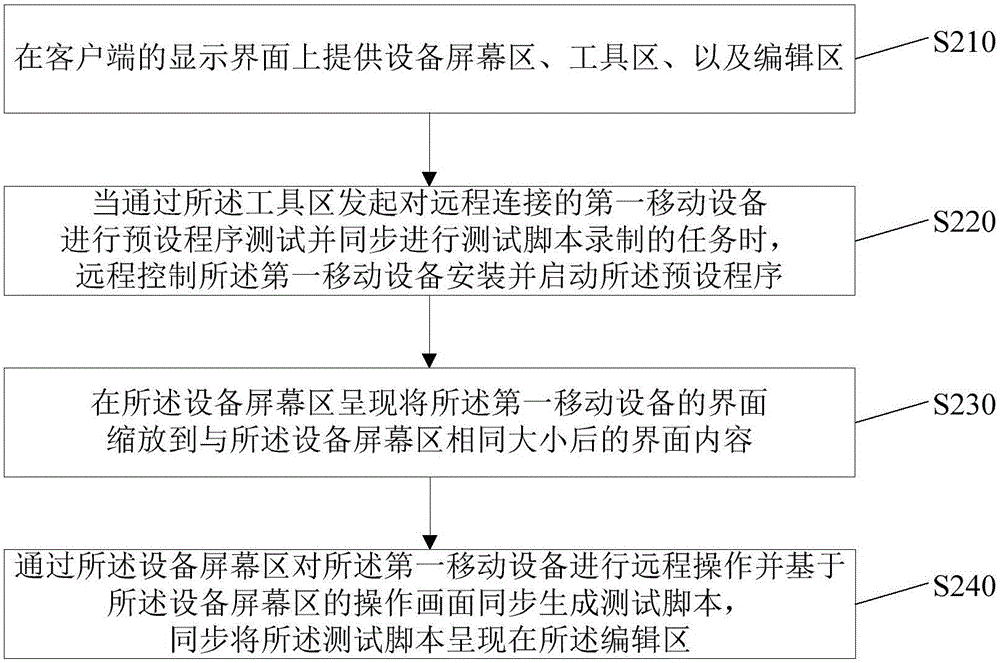

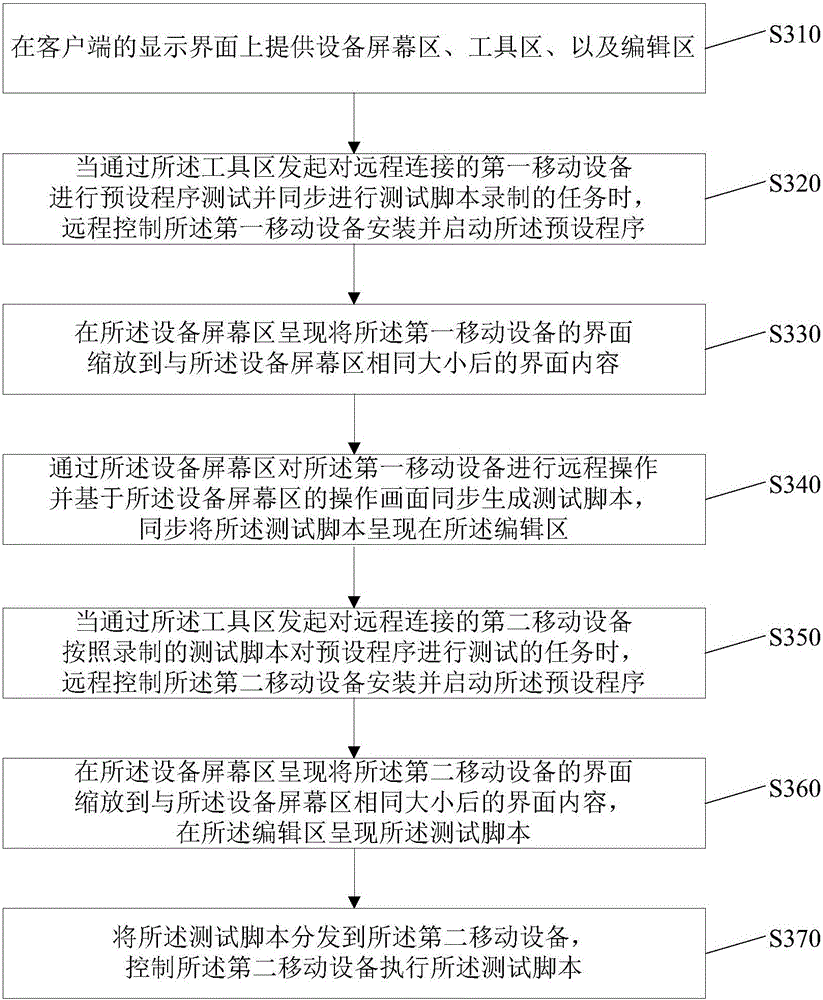

Cloud testing method and device

InactiveCN105740153AImprove compatibilityFacilitates automated testingSoftware testing/debuggingInput/output processes for data processingTest efficiencyTest script

The invention relates to a cloud testing method and device. The method comprises the steps of providing an equipment screen area, a tool area and an edit area on a display interface of a client; when a test script is recorded, presenting an interface content after the interface of first mobile equipment is scaled to the same size as the equipment screen area in the equipment screen area, remotely operating the first mobile equipment via the equipment screen area, synchronously generating a test script based on an operation picture of the equipment screen area, and synchronously presenting the test script in the edit area. According to the technical solution, script recording is performed on the basis of the display interface of the Web end, so that the method and the device can be applied to equipment with different resolutions, realize automatic test by playing back scripts in batch, can enhance the compatibility of the test script and can improve the testing efficiency during batch test.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

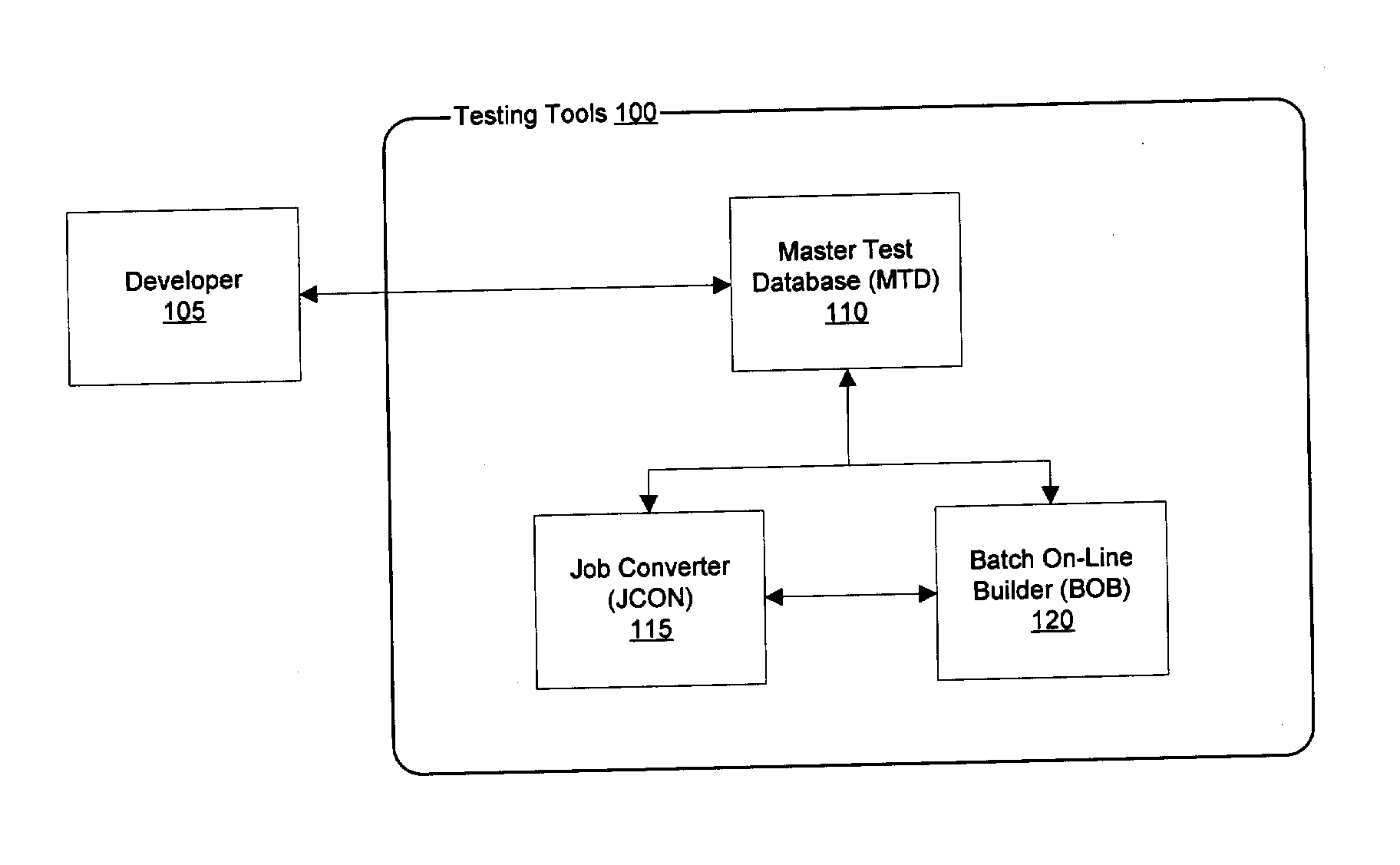

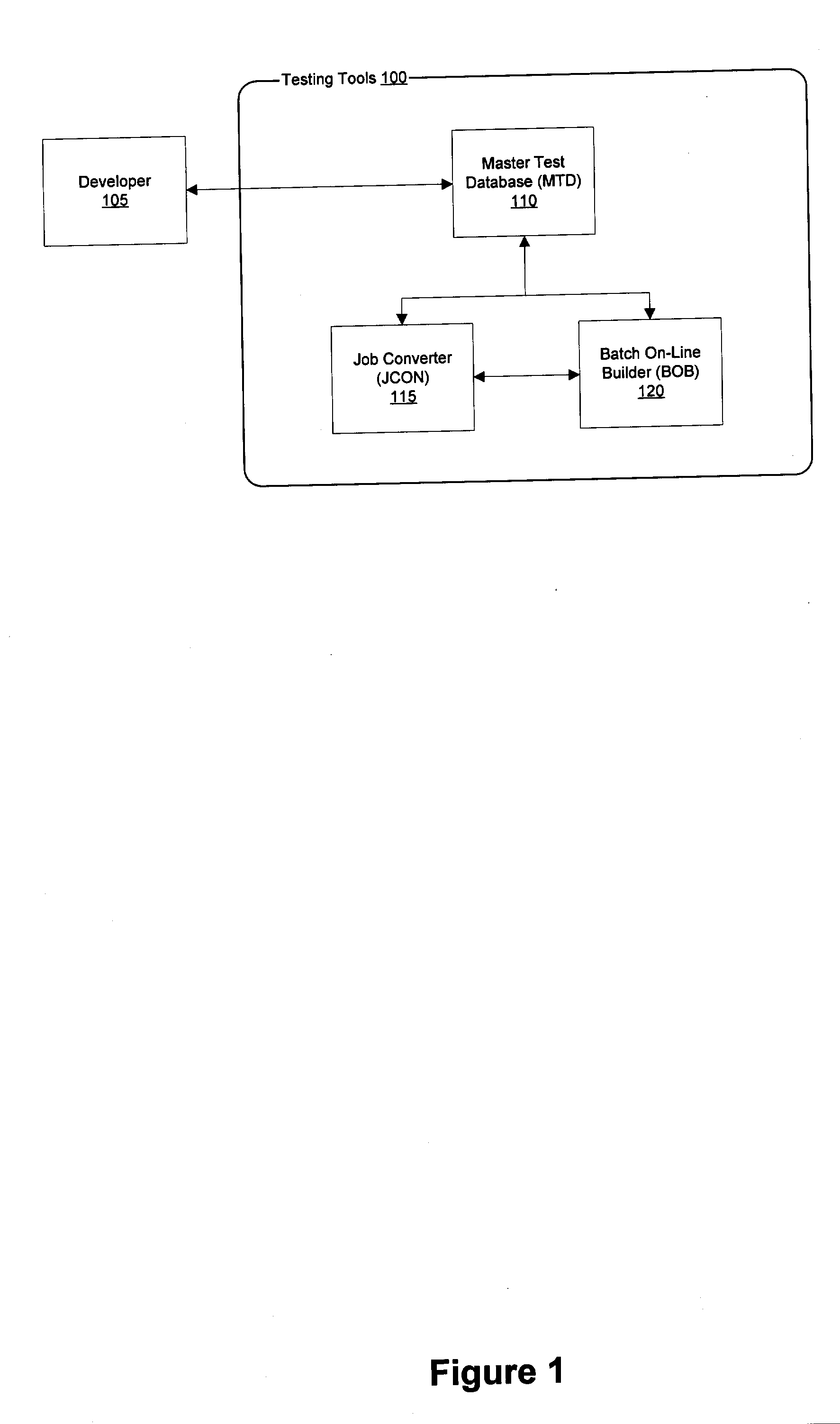

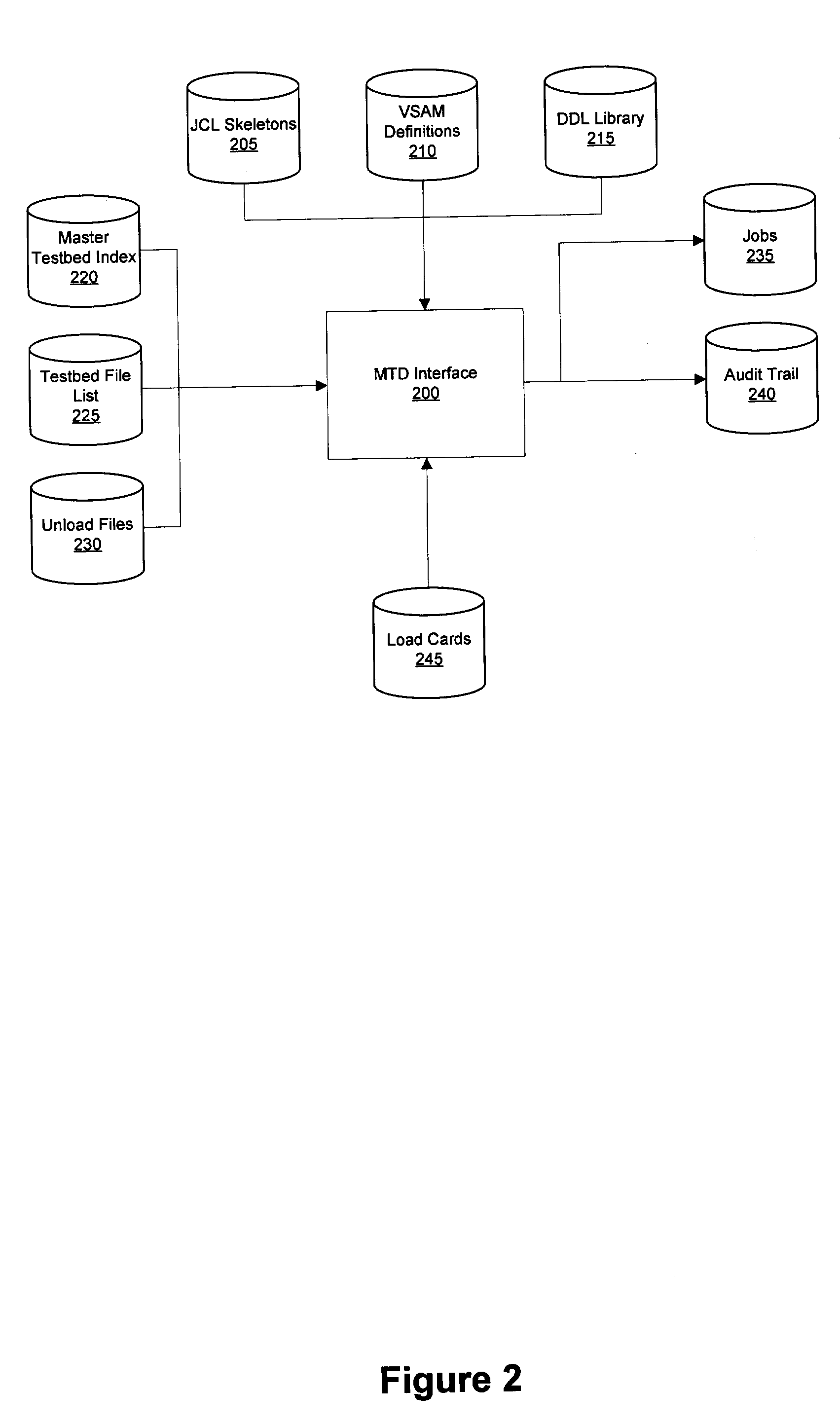

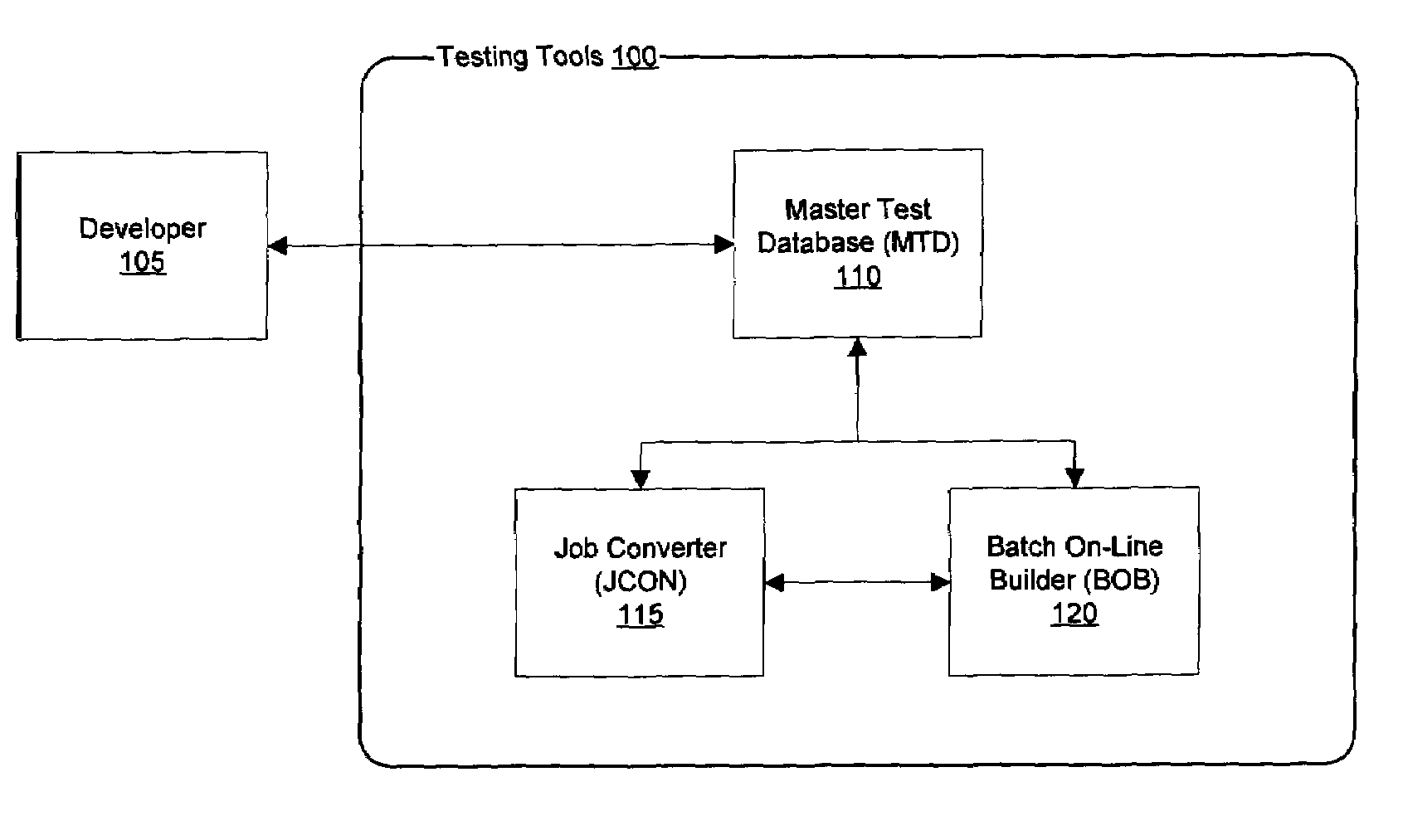

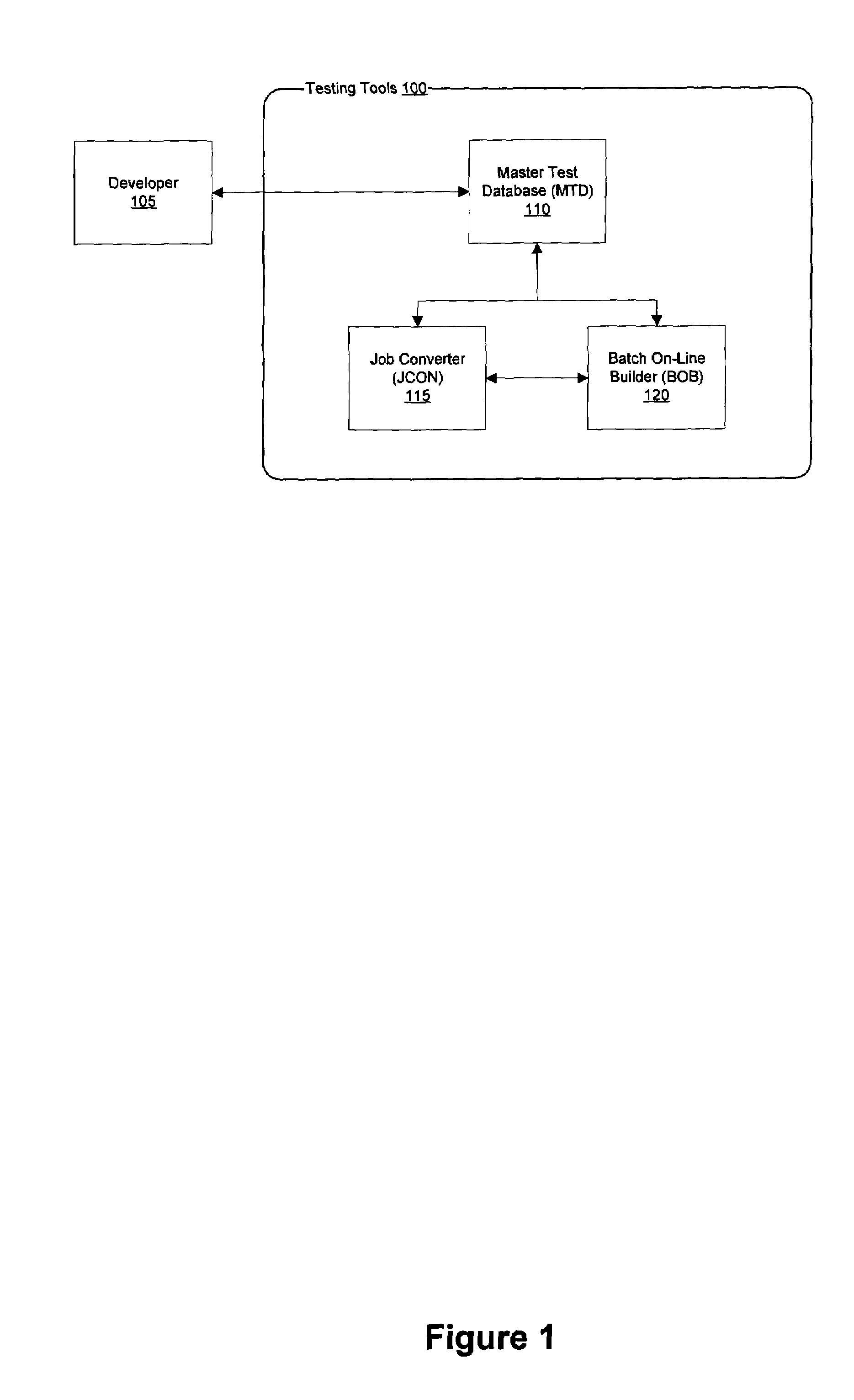

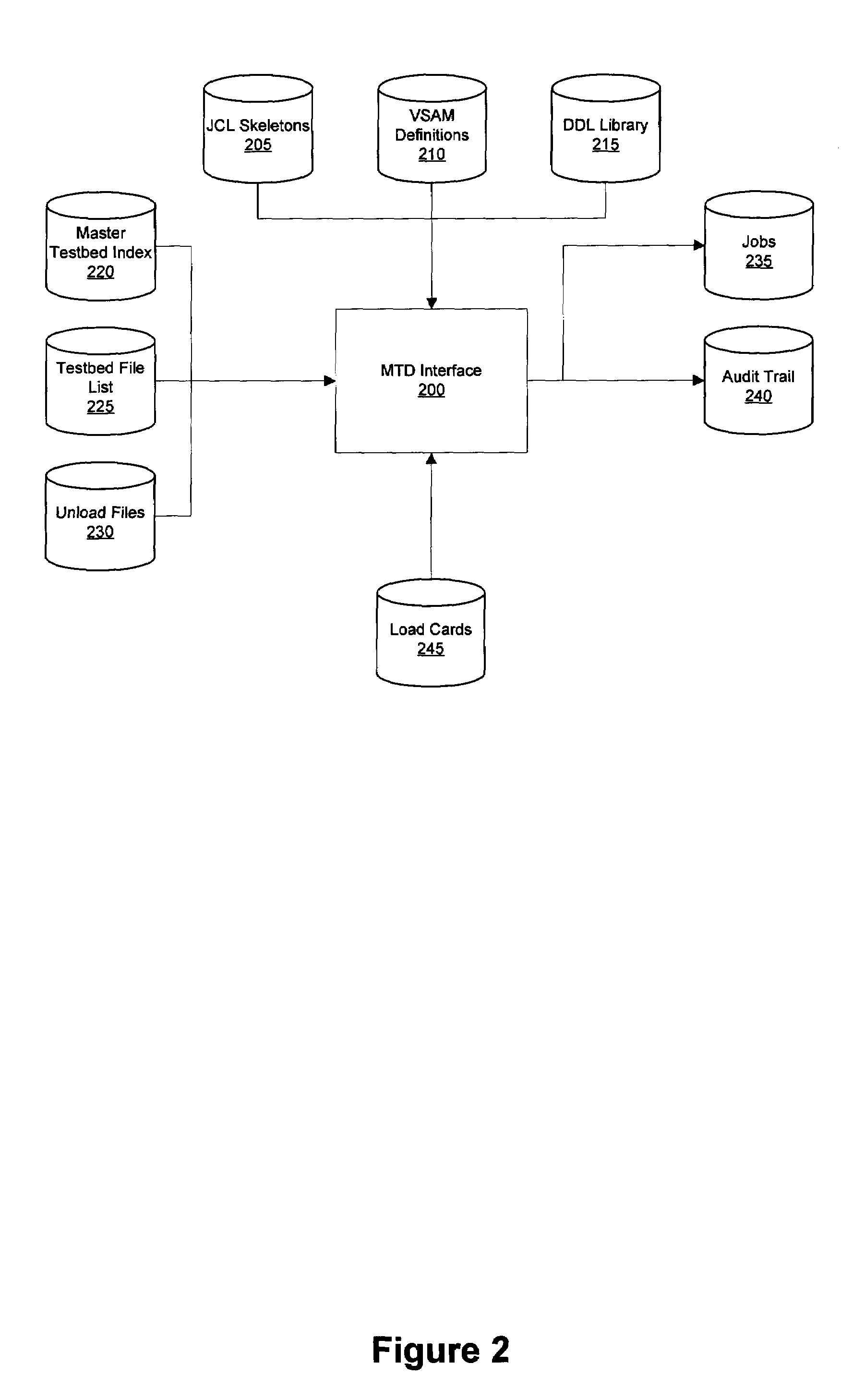

System and method for building full batch test environments

InactiveUS20050283667A1Easy loadingEnsure data integrityError detection/correctionSpecific program execution arrangementsComputer hardwarePersonalization

The invention includes an integrated toolset of software development aids for testing of software systems directed toward the production, access, management, and retrieval of stored data by providing a fast and efficient means for a developer to recreate production data within a testing environment. The toolset consists of components which, when combined, provide an interactive on-line system where a developer is provided with access to low volume, high-quality, depersonalized, and targeted data with referential integrity and is suitable for most testing needs.

Owner:LIBERTY PEAK VENTURES LLC

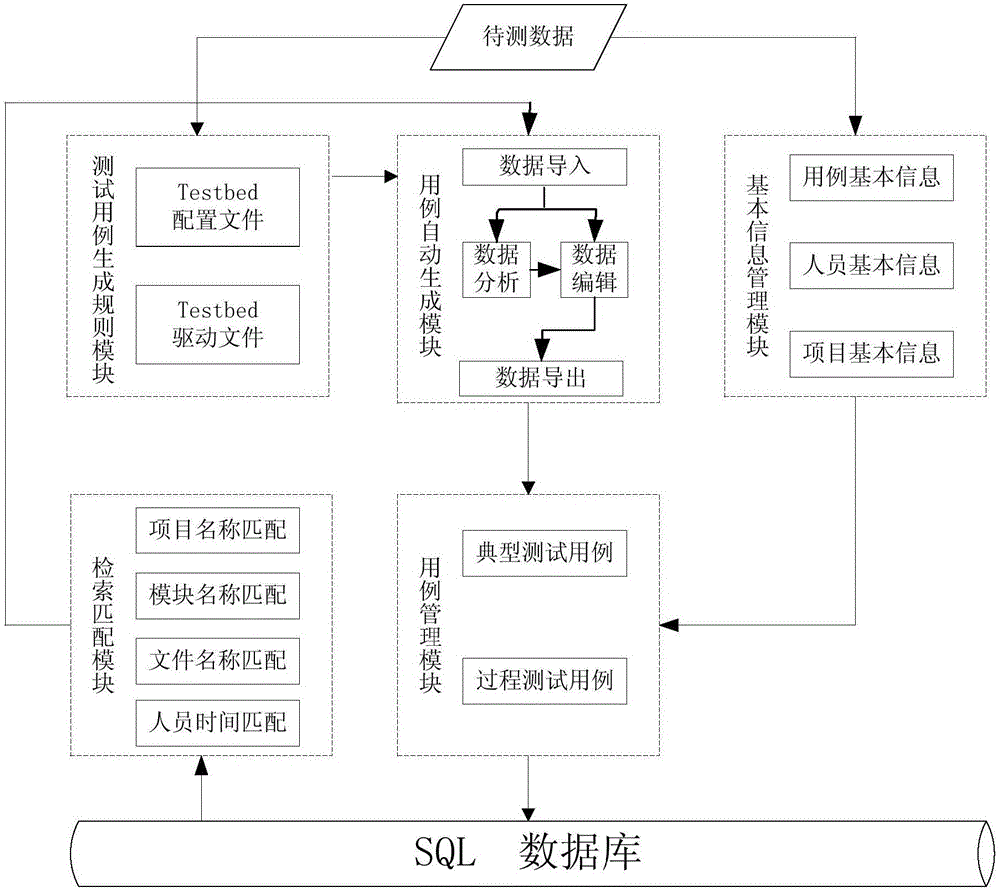

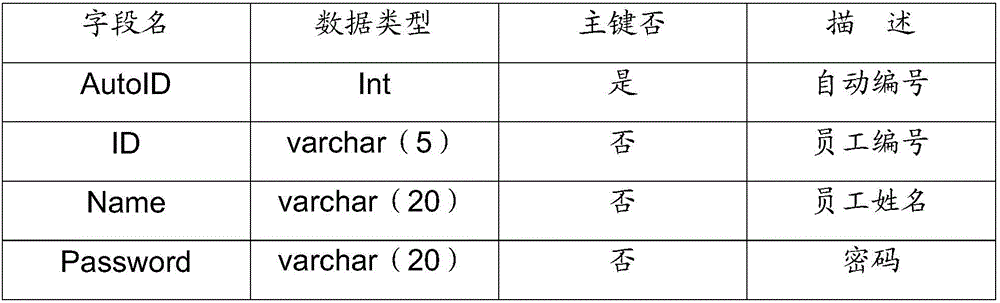

Software unit test case management system

ActiveCN106326122AImplement component managementImprove versatilitySoftware testing/debuggingTest qualityReuse rate

The invention discloses a software unit test case management system which comprises a case automatic generation module, a basic information management module, a retrieval match module and a case management module, wherein the case automatic generation module achieves the functions of data import, data analysis, data edition and data export, can generate a batch test case TCF file and import the file into a test tool to be executed automatically; the case management module can match test cases with basic information to form a process test case and a typical test case in the case management module, form a test case set, manage the test case set and facilitate the re-edition and reuse of the test cases; the retrieval match module can quickly and efficiently retrieve the finished test cases. For the characteristics that embedded servo software is large in code quantity and high in similarity, the software unit test case management system is high in automation degree and comprehensive and standard in test case, improves the unit test efficiency and the test quality, also improves the reuse rate of the test cases, and reduces the labor cost.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

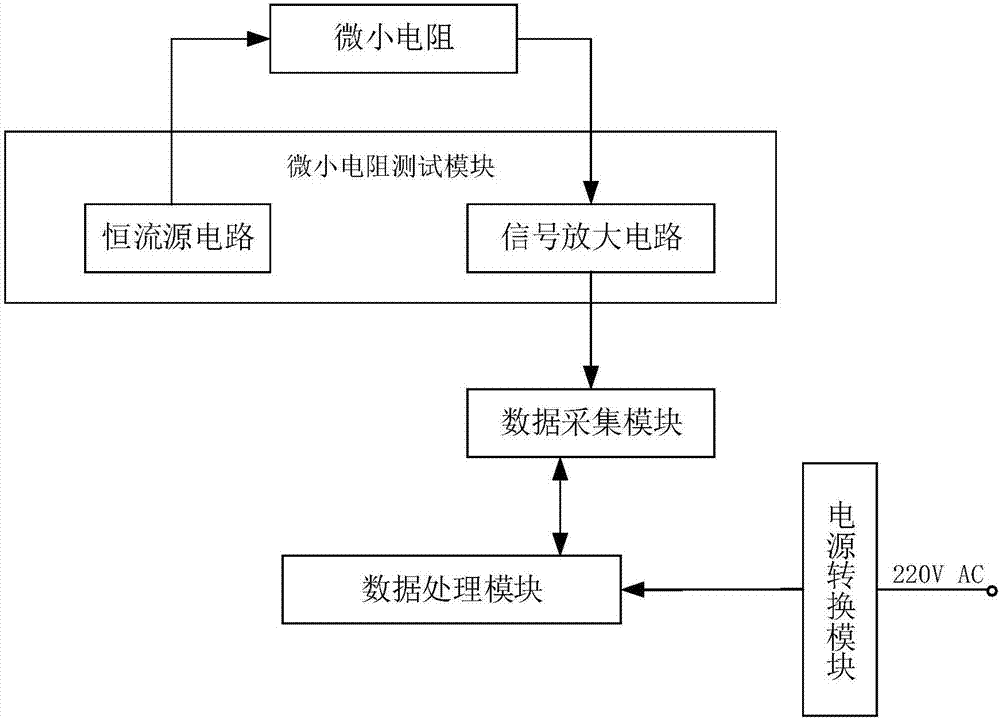

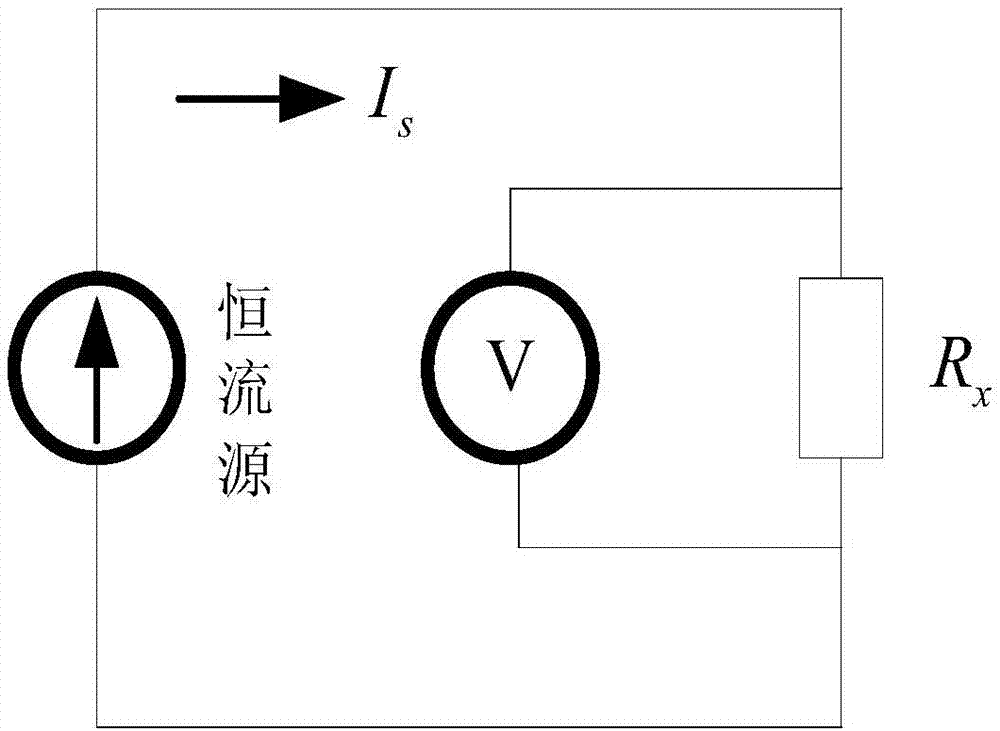

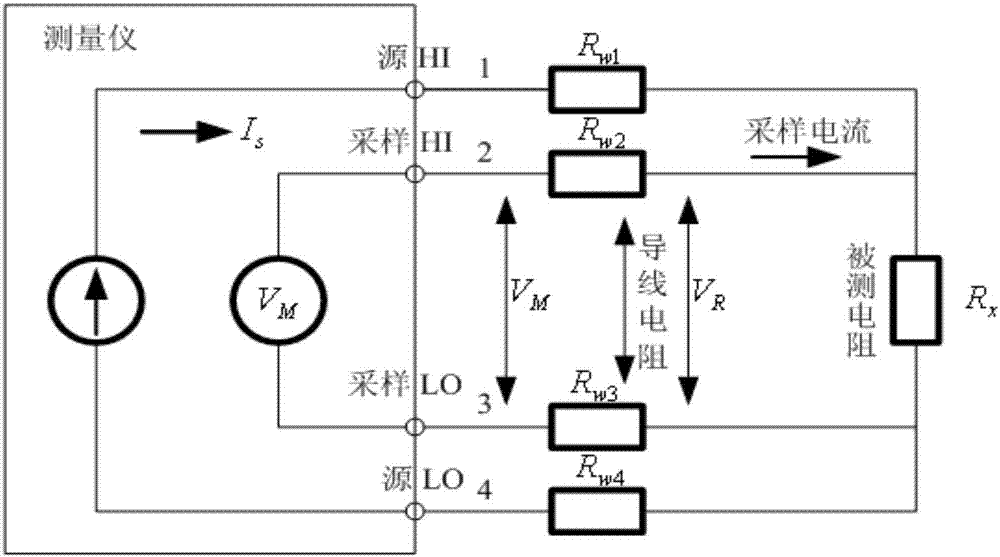

Precise tester for micro-resistor

InactiveCN108008191AReflect electrical propertiesRealize precise measurementResistance/reactance/impedenceObservational errorData acquisition

The invention discloses a precise tester for a micro-resistor. The precise tester comprises a data processing module, a data acquisition module and a micro-resistor test module. The micro-resistor test module comprises a constant current source circuit and a signal amplification circuit which are connected with the micro-resistor Rx to be tested. The constant current source circuit is used for applying constant current to the micro-resistor Rx to be tested. The data acquisition module acquires and processes the amplified voltage signal. The data processing module calculates the resistance value of the micro-resistor according to the constant current value and the acquired voltage value. The constant current source circuit comprises a constant current source Is and a clamp resistor Rc whichis connected in parallel with the micro-resistor Rx to be tested. The constant current source Is is used for applying constant current which is not greater than the current threshold to the micro-resistor Rx. The clamp resistor Rc clamps the voltage Ux of the micro-resistor Rx to be lower than the voltage threshold so that the measurement error caused by excessively high output voltage can be avoided. The precise tester for the micro-resistor has high test accuracy, multiple measurable channels, high degree of test automation and fast measurement speed so as to be particularly suitable for batch test of the micro-resistor.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

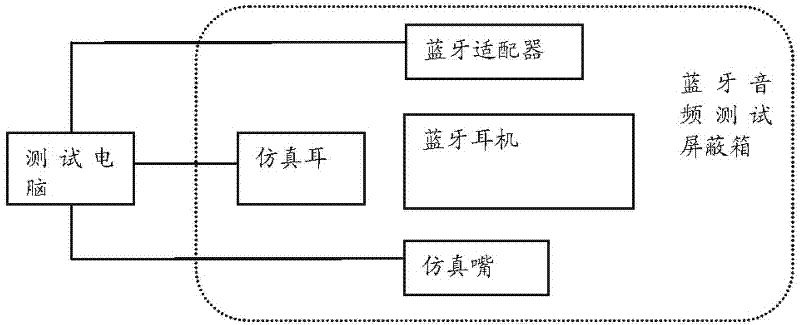

Batch testing method and system for bluetooth headset finished products

InactiveCN102291668AEase of mass productionReduce capital investmentElectrical apparatusTest efficiencyAutomatic control

The invention discloses a batch testing method for finished products of bluetooth earphones, aiming to provide a batch testing method for finished products of bluetooth earphones with high test efficiency and favorable for the batch production of bluetooth earphones. The computer controls the scanning device to scan the bluetooth address of the bluetooth headset, and controls the automatic pairing and automatic connection of the bluetooth adapter and the bluetooth headset according to the scanned bluetooth address; automatically controls the artificial mouth and the artificial ear to the speaker output frequency of the bluetooth headset through the test computer. Test the sound and echo sound; output the test result and display it. The invention also discloses a batch testing system for finished products of bluetooth earphones. The invention can be used for batch testing of finished products of bluetooth earphones.

Owner:GUANGZHOU LIWEI ELECTRONICS

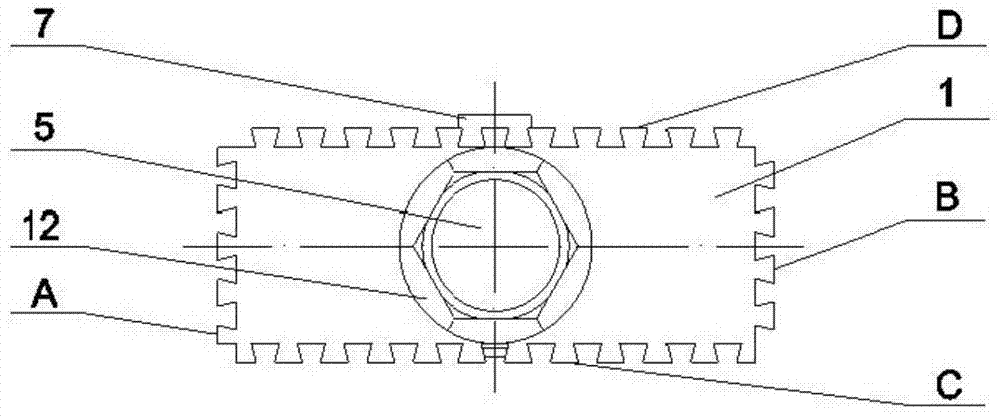

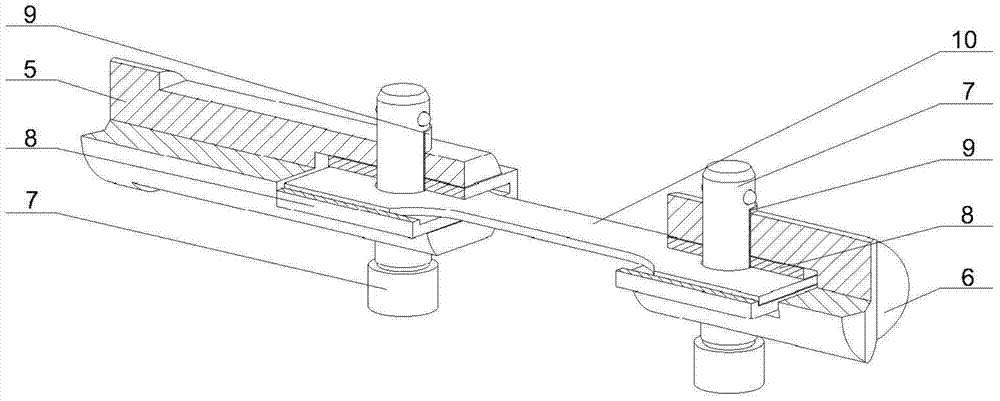

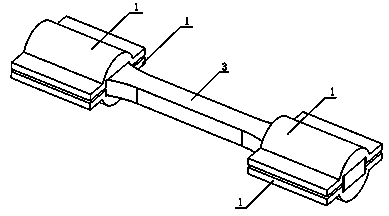

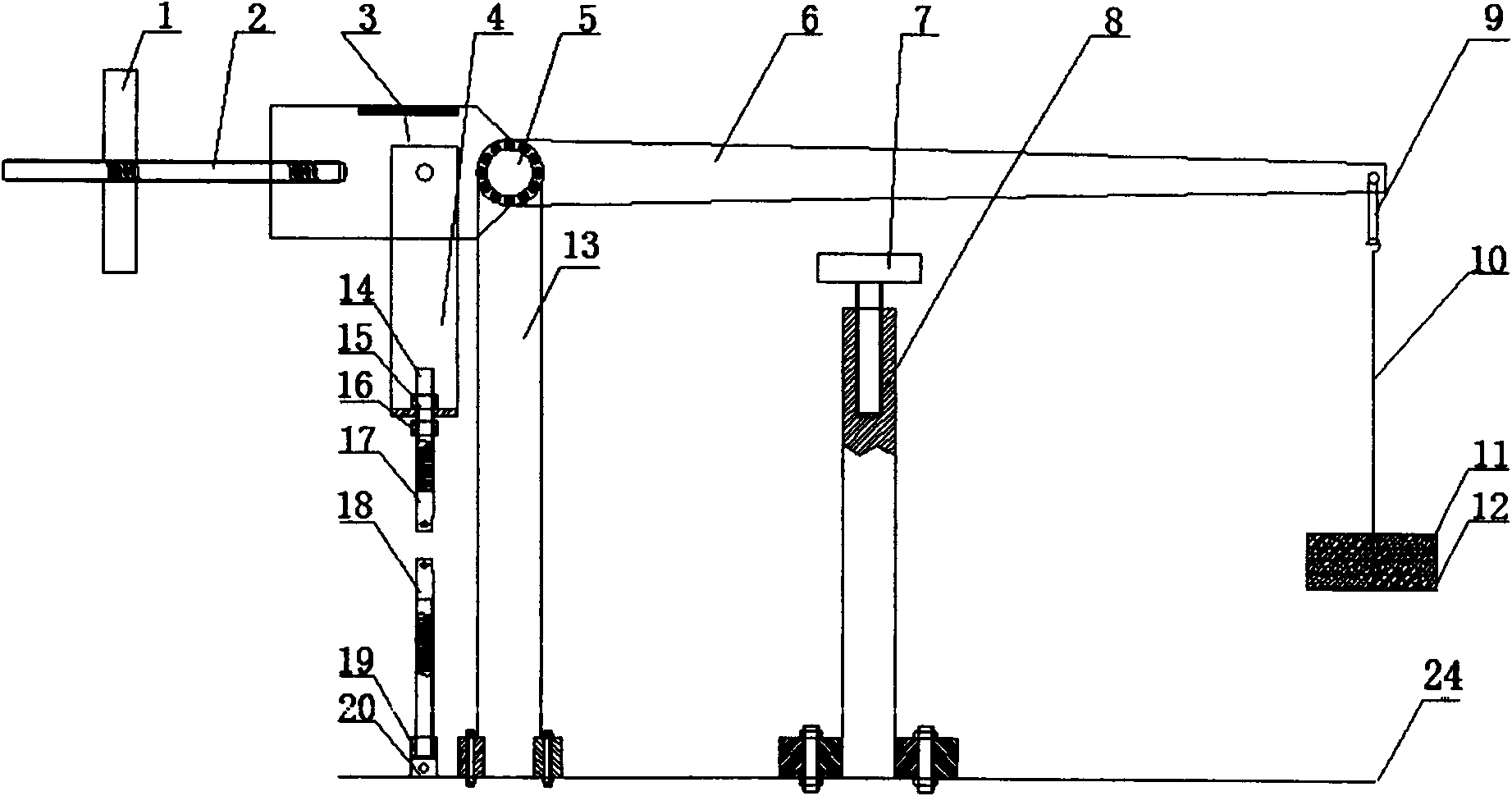

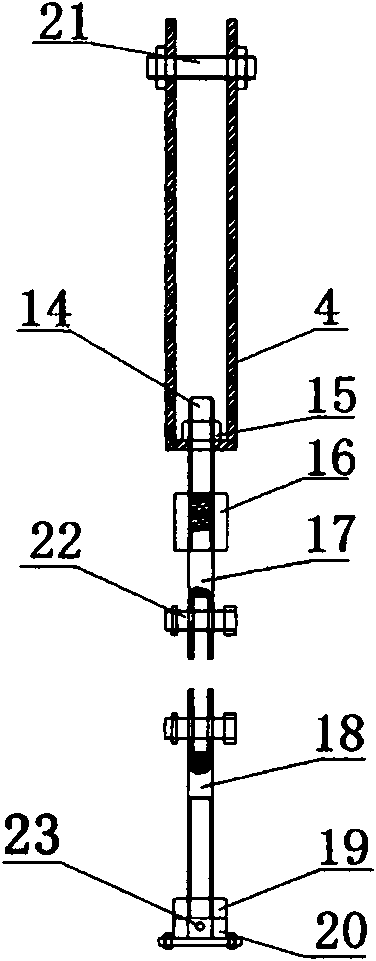

Constant-load tensile test device

ActiveCN104749029AEasy to carryEasy to assemble and disassembleMaterial strength using tensile/compressive forcesConstant loadMetallic materials

The invention belongs to the technical field of metal material test equipment and relates to a constant-load tensile test device. The constant-load tensile test device is characterized in that a rectangular cavity is formed in a force-bearing framework with A, B, C and D side surfaces, wherein circular-arc-shaped grooves capable of dispersing load on four right angles of the rectangular cavity are formed in four vertexes of the rectangular cavity; a sleeve type upper chuck is arranged on a perpendicular central axis at the inner side of an upper beam of the force-bearing framework; a threaded end of the upper chuck penetrates through the force-bearing framework and is provided with an insulating gasket, a loading spring and a loading nut in a sleeved mode; a lower chuck of a sleeve structure is arranged on a perpendicular central axis at the inner side of a lower beam of the force-bearing framework; a threaded end of the lower chuck is fixedly connected with the force-bearing framework; U-shaped slot structures are arranged at the clamping ends of the upper chuck and the lower chuck respectively; insulating gaskets are arranged in the centers at the two sides of each U-shaped slot structure. The constant-load tensile test device is small and light, easy to carry, assemble and fix, freely spliced to realize batch test of a tested part, safe and reliable, simple and convenient in a manual loading mode, and accurate and constant in loaded load.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

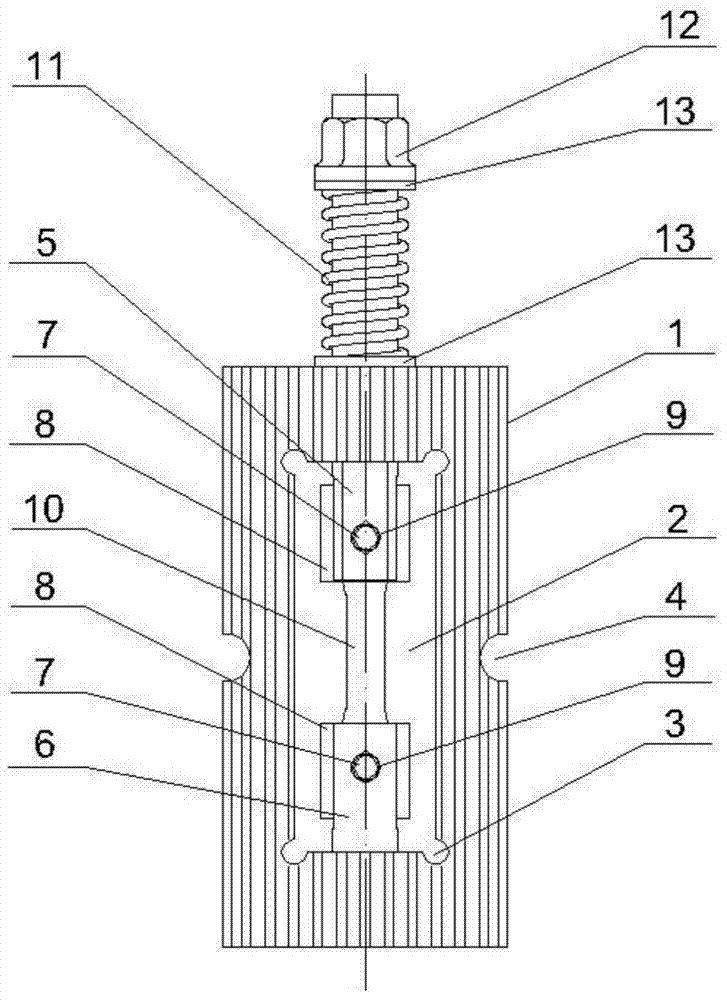

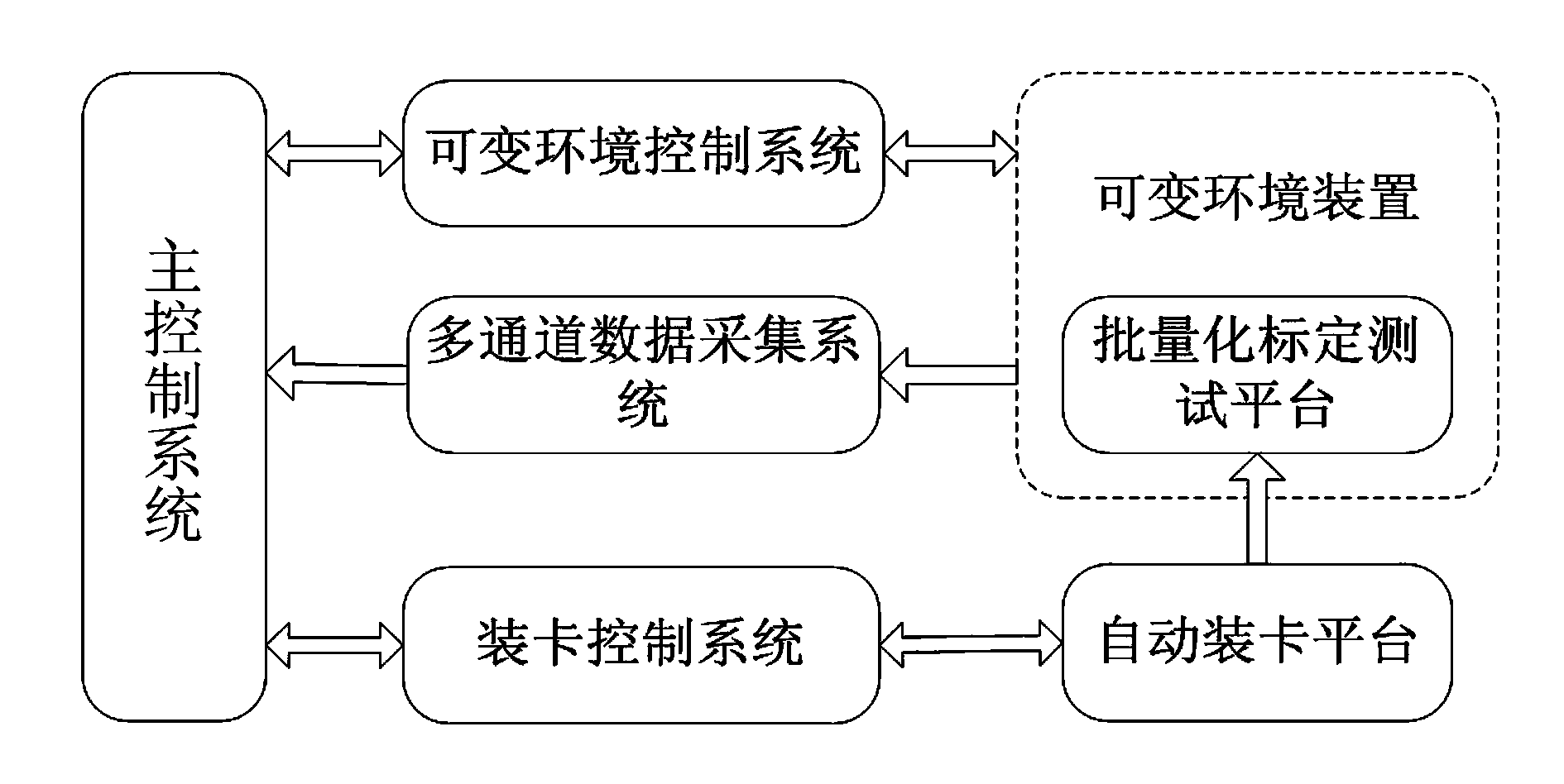

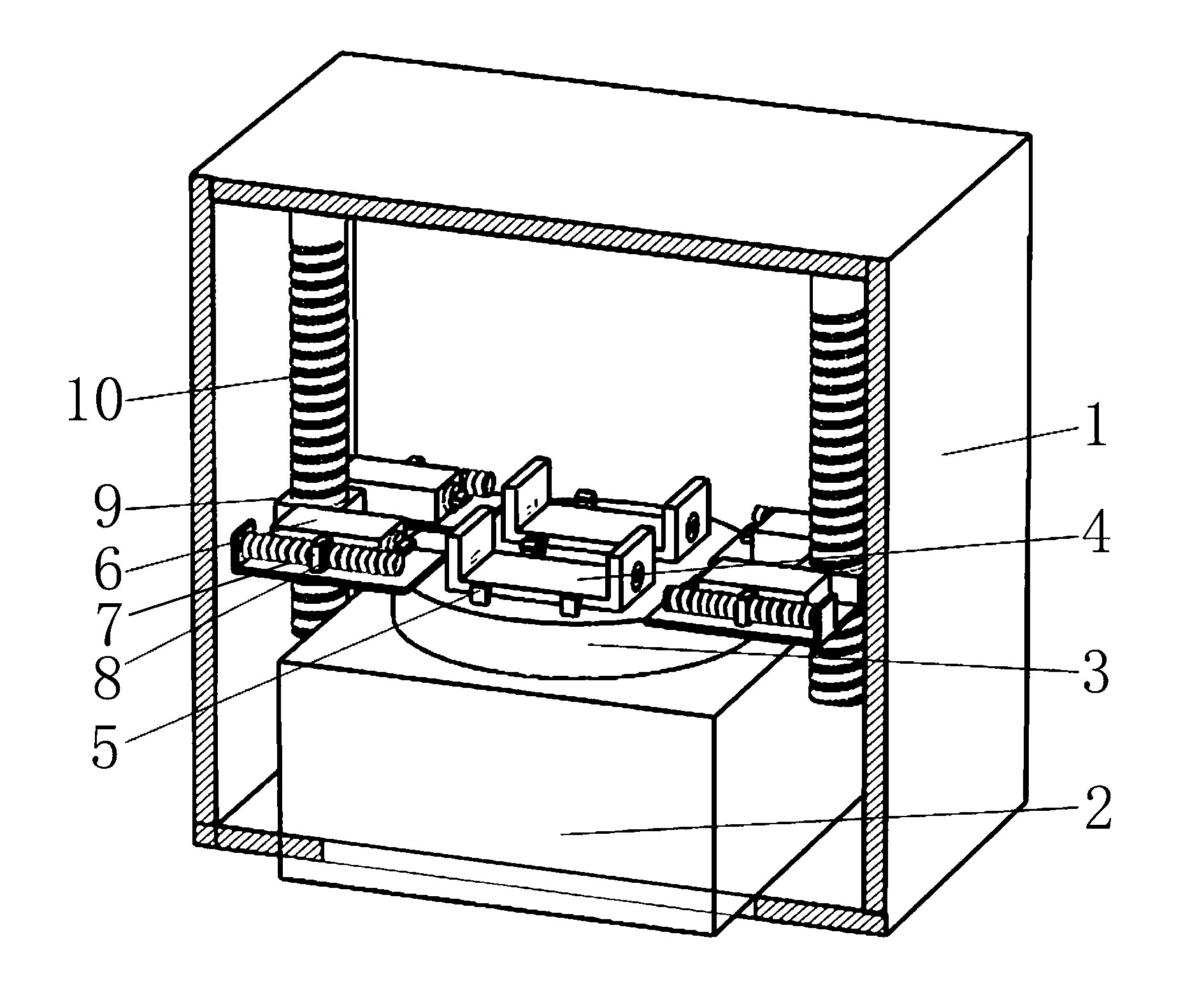

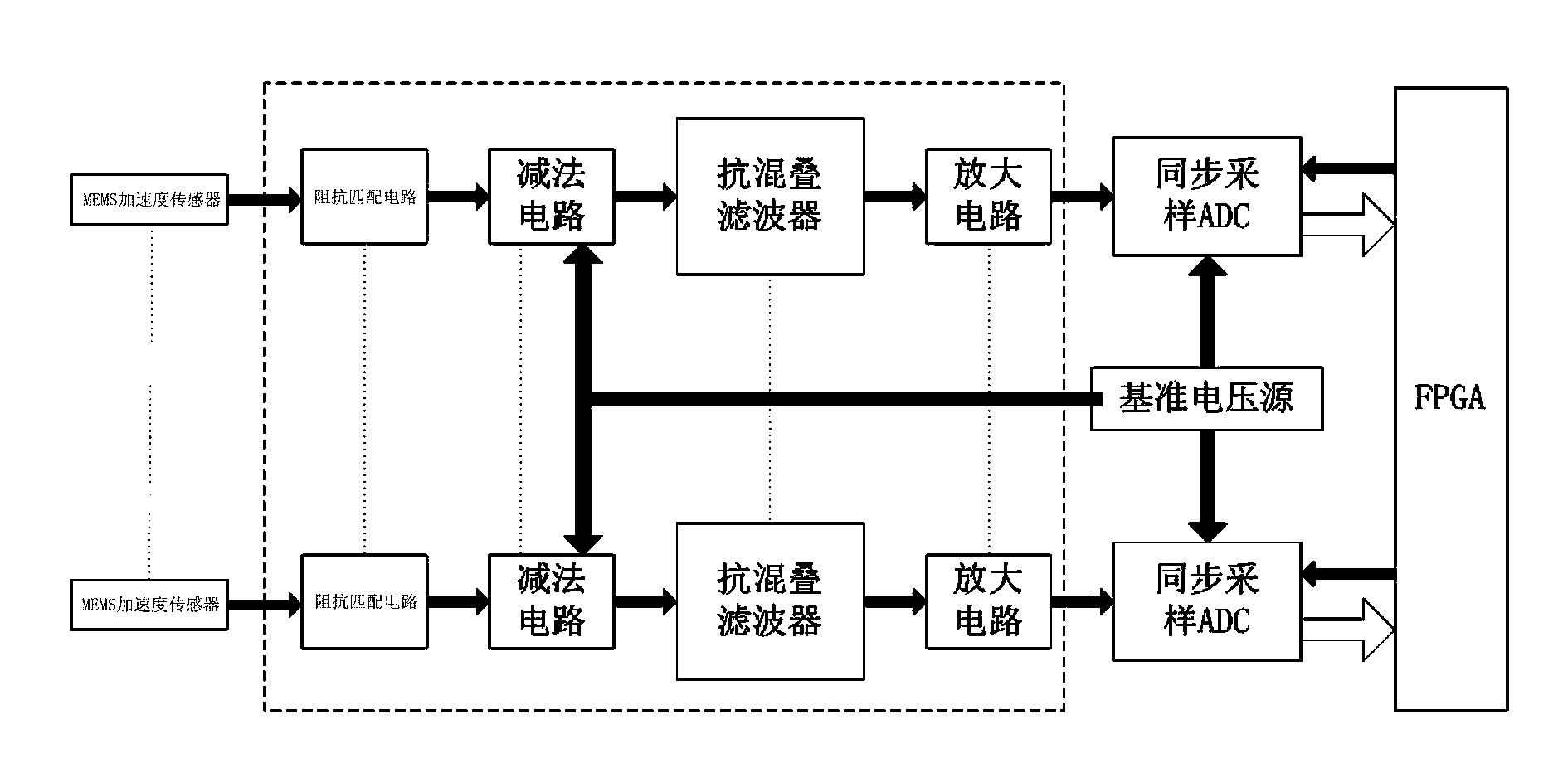

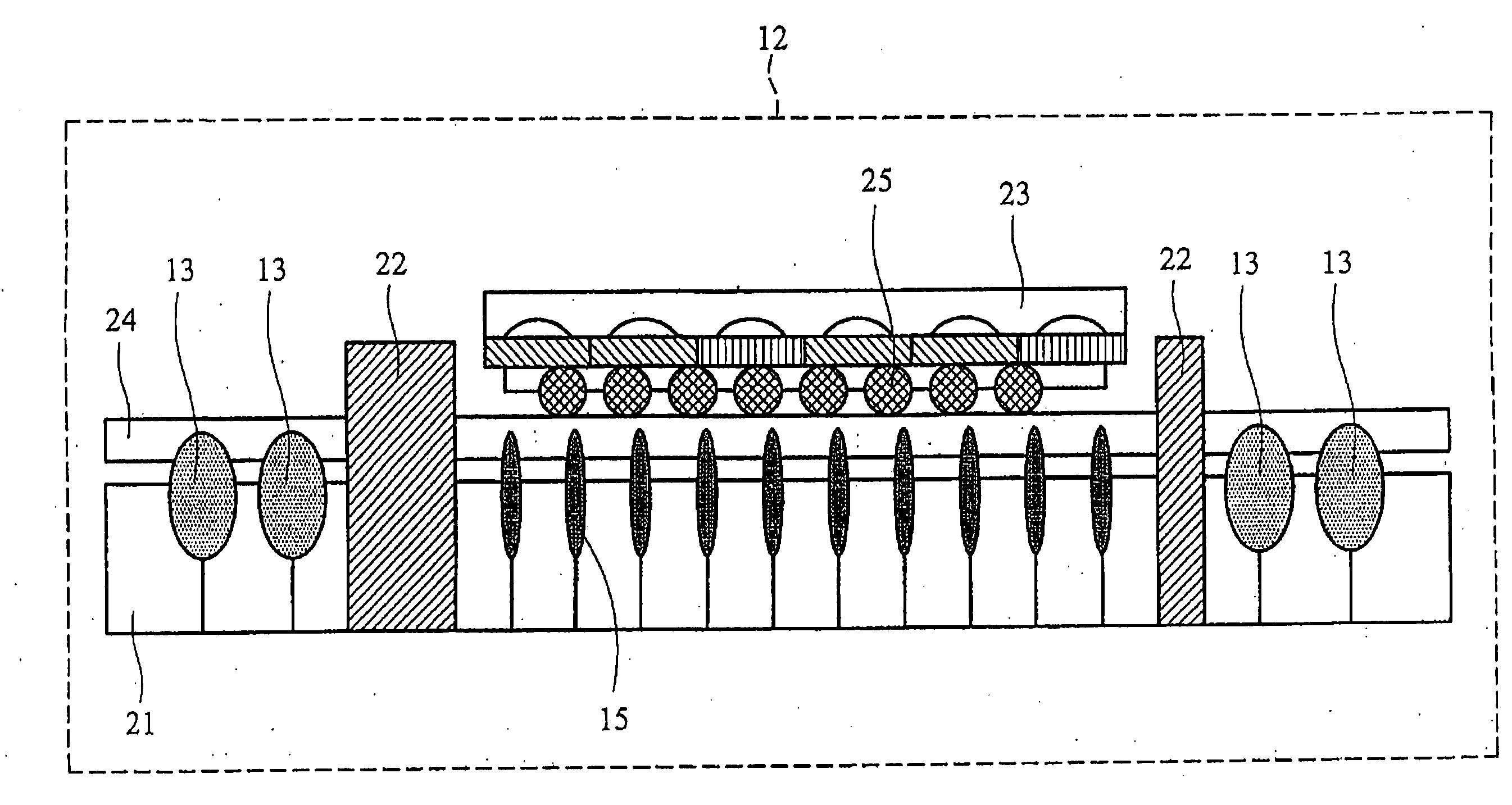

Multi-parameter batch test equipment of micro-electromechanical systems (MEMS) acceleration sensor

InactiveCN103063879AHigh calibration efficiencyCalibration calibration efficiency is lowTesting/calibration of speed/acceleration/shock measurement devicesControl systemData acquisition

The invention relates to standardization correction technology of a micro-electromechanical systems (MEMS) acceleration sensor, in particular to multi-parameter batch test equipment of the MEMS acceleration sensor. The multi-parameter batch test equipment of the MEMS acceleration sensor solves the problems that existing standardization correction technology is long in standardization correction time consumption, low in standardization correction efficiency, and limited in standardization correction ability, and can not achieve batch automatic standardization correction. The multi-parameter batch test equipment of the MEMS acceleration sensor comprises a changeable environment device, a batch standardization test platform, an automatic clamping and mounting platform, a multi-channel data collection system, a changeable environment control system, a clamping and mounting control system and a main control system. The batch standardization test platform, the automatic clamping and mounting platform and the changeable environment control system are arranged in a changeable environment device. A signal output end of the multi-channel data collection system is connected with a signal input end of the main control system. The invention is applied to standardization correction of the MEMS acceleration sensor.

Owner:苏州中盛纳米科技有限公司

System and method for building full batch test environments

InactiveUS7480898B2Facilitates of data of dataEasy extractionError detection/correctionSpecific program execution arrangementsSoftware systemSoftware engineering

The invention includes an integrated toolset of software development aids for testing of software systems directed toward the production, access, management, and retrieval of stored data by providing a fast and efficient means for a developer to recreate production data within a testing environment. The toolset consists of components which, when combined, provide an interactive on-line system where a developer is provided with access to low volume, high-quality, depersonalized, and targeted data with referential integrity and is suitable for most testing needs.

Owner:LIBERTY PEAK VENTURES LLC

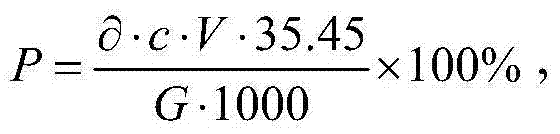

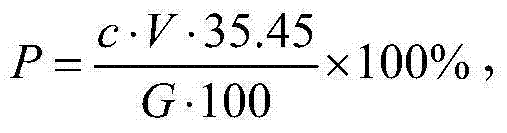

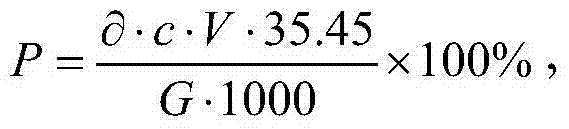

Improved method for determining free chlorine ions in cement paste or mortar

InactiveCN103926300ASuitable for mass testingImprove experimental precisionMaterial electrochemical variablesMaterials scienceIon

The invention provides an improved method for determining free chlorine ions in cement paste or mortar and belongs to the technical field of determination of building materials. The improved method comprises the following steps: preparing a sodium chloride standard solution and a silver nitrate solution with the concentration of c; grinding the mortar in concrete until all the mortar passes through a square hole sieve with the hole diameter of 0.63mm; drying the mortar at 105+ / -5 DEG C for 2 hours and recording the weight as G; adding de-ionized water; shaking and immersing; filtering and adding nitric acid into a filtering solution; inserting electrodes; connecting the two electrodes with a potentiometer; titrating by using the silver nitrate solution; recording potentials and readings of a corresponding burette; recording the volume V of silver nitrate corresponding to a titrating final point; calculating the content of the free chlorine ions in a cement slurry system according to a formula as shown in the specification; if the difference of titrating results of two times is less than 1%, finally obtaining an average value; if the difference of the titrating results of the two times is more than 1%, continuing to titrate until the difference of the titrating results of the two times is less than 1%. According to the method, the titrating final point is obvious and the accuracy is high; an experiment process is simple and convenient and is suitable for large-batch tests.

Owner:BEIJING UNIV OF TECH

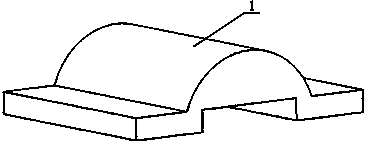

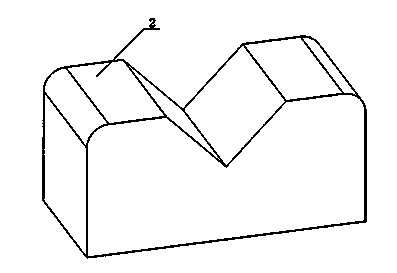

Centering device and method used for sheet-shaped material tensile test

ActiveCN104297053AReliable alignmentGuaranteed accuracyStrength propertiesTest sampleVisual inspection

The invention discloses a centering device and method used for a sheet-shaped material tensile test. The centering device comprises a centering reinforcing sheet and a sticking compaction device, wherein the sticking compaction device comprises a supporting frame and compaction blocks; the compaction blocks are mounted on the supporting frame in pairs; the compaction blocks in each pair are correspondingly arranged up and down; the compaction blocks are mounted on the supporting frame by slide blocks and guide rails; V-shaped grooves are formed in the surfaces of the compaction blocks; the V-shaped grooves of each pair of the compaction blocks are opposite; one face of the centering reinforcing sheet is provided with a semi-cylindrical bulge and the other face of the centering reinforcing sheet is provided with a groove as long as the semi-cylindrical bulge. The centering method comprises the following steps: applying glue, sticking, compacting and the like. According to the centering device and the centering method, manual visual inspection for adjusting a centering position is not needed, and a limiting mechanism for assisting centering is omitted; and the operation process is simple, the reliable centering of a test sample and a chuck is guaranteed and the efficiency of batch tests is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

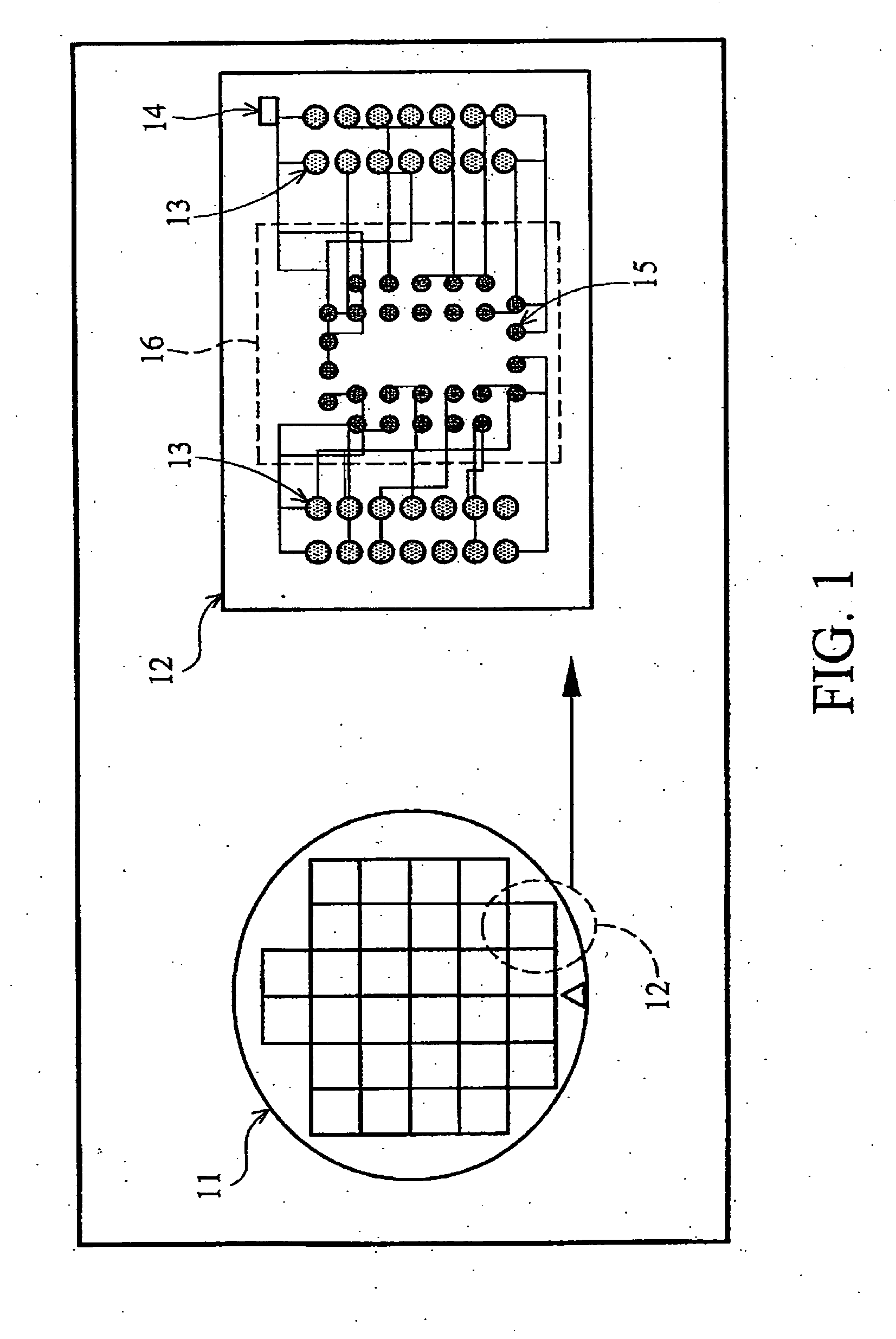

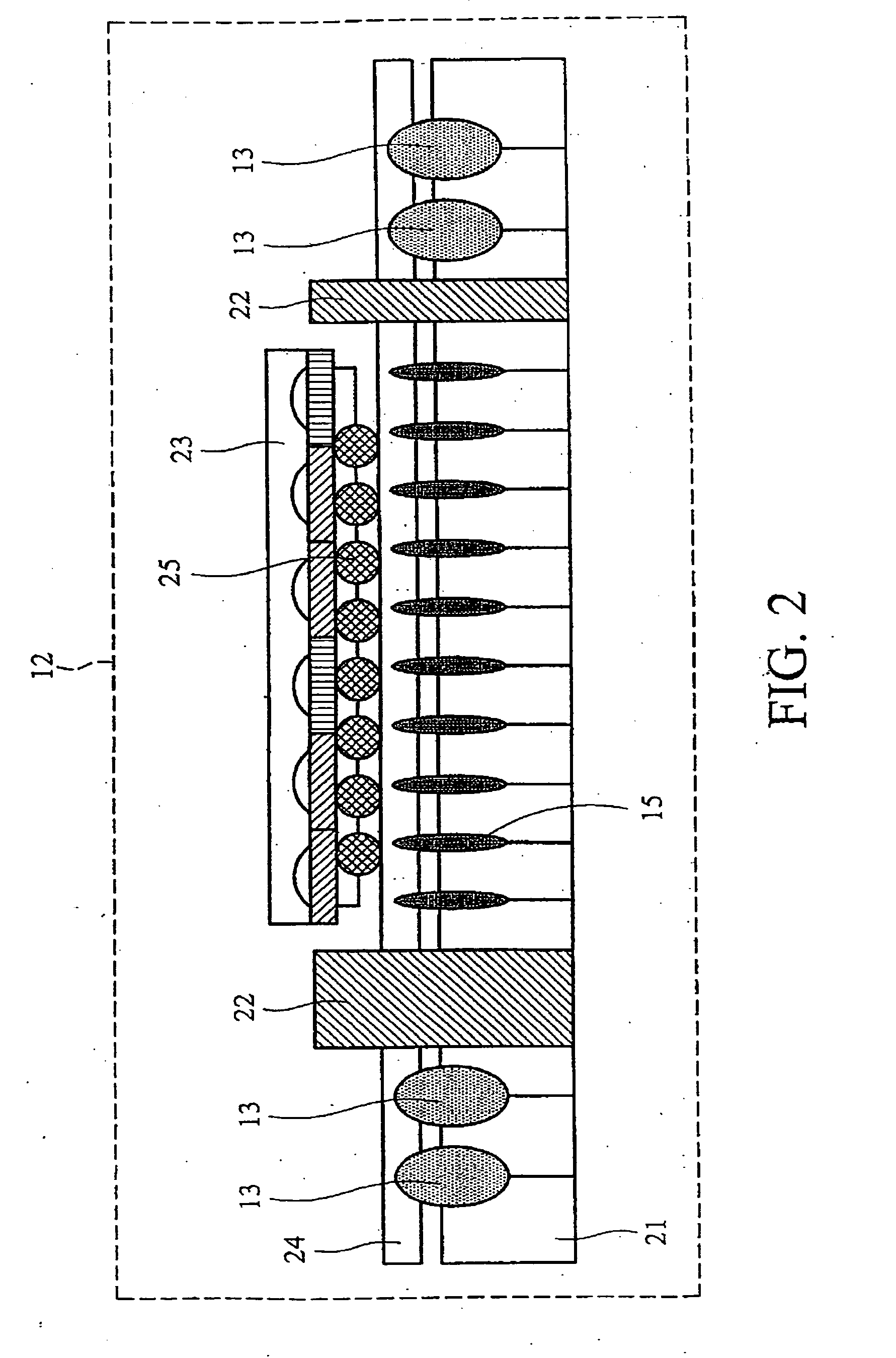

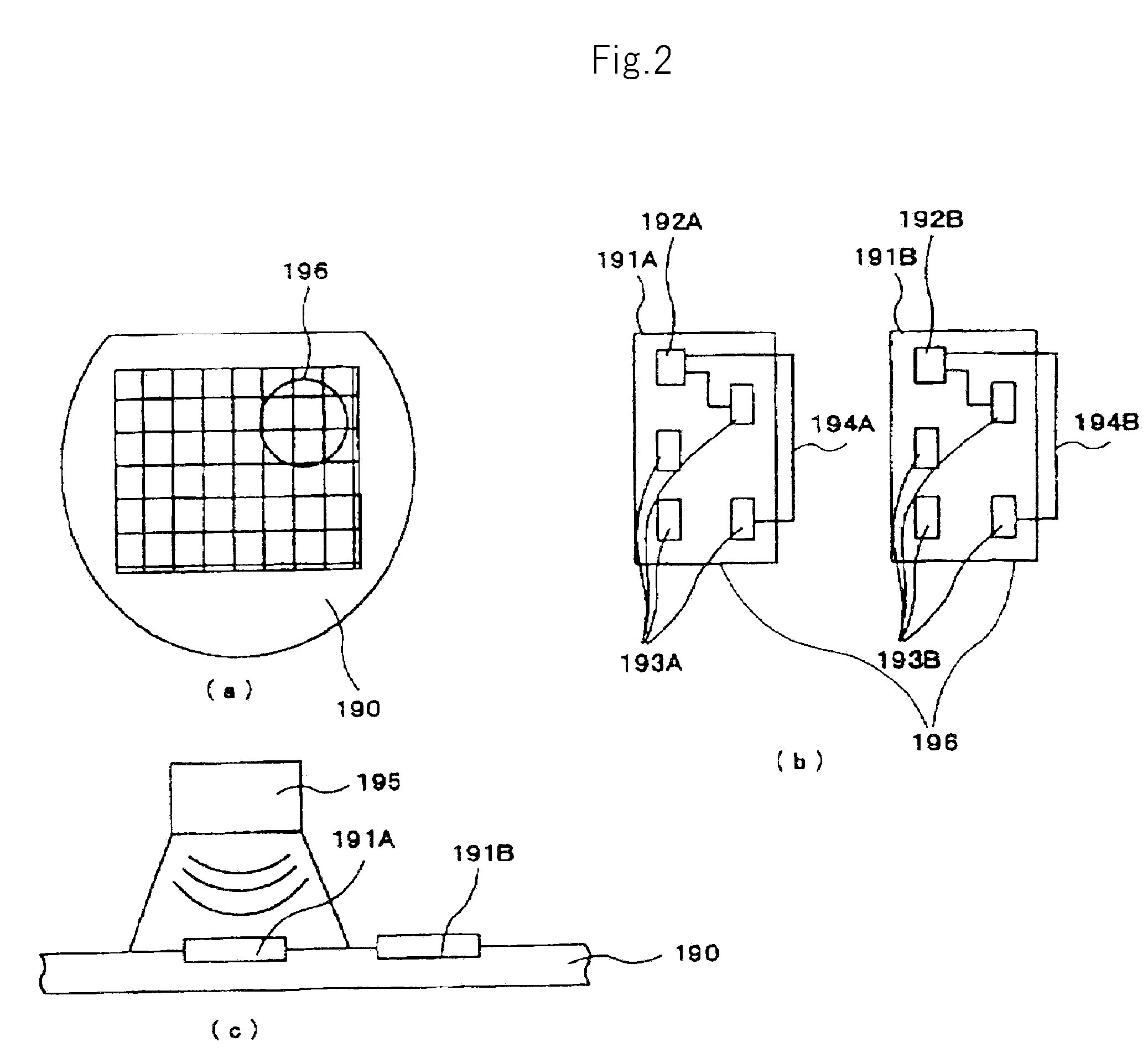

Batch-test system with a chip tray

ActiveUS20080169831A1Semiconductor/solid-state device testing/measurementSolid-state devicesProbe cardDirect feedback

A chip test system including a probe card, a chip tray and a cover plate fastened on the chip tray. The chip tray comprises a socket, a chip contact area, an extension contact area, and an alignment contact point. The socket loads the testing chip and is customized for the tested chip. The chip contact area has a plurality of chip contact points to electrically contact the chip. The extension contact area has a plurality of extension contact points corresponding to the chip contact points to direct test signals into the chip and direct feedback signals out of the chip. The alignment point provides an alignment location for the probe card during the chip test.

Owner:VISERA TECH CO LTD

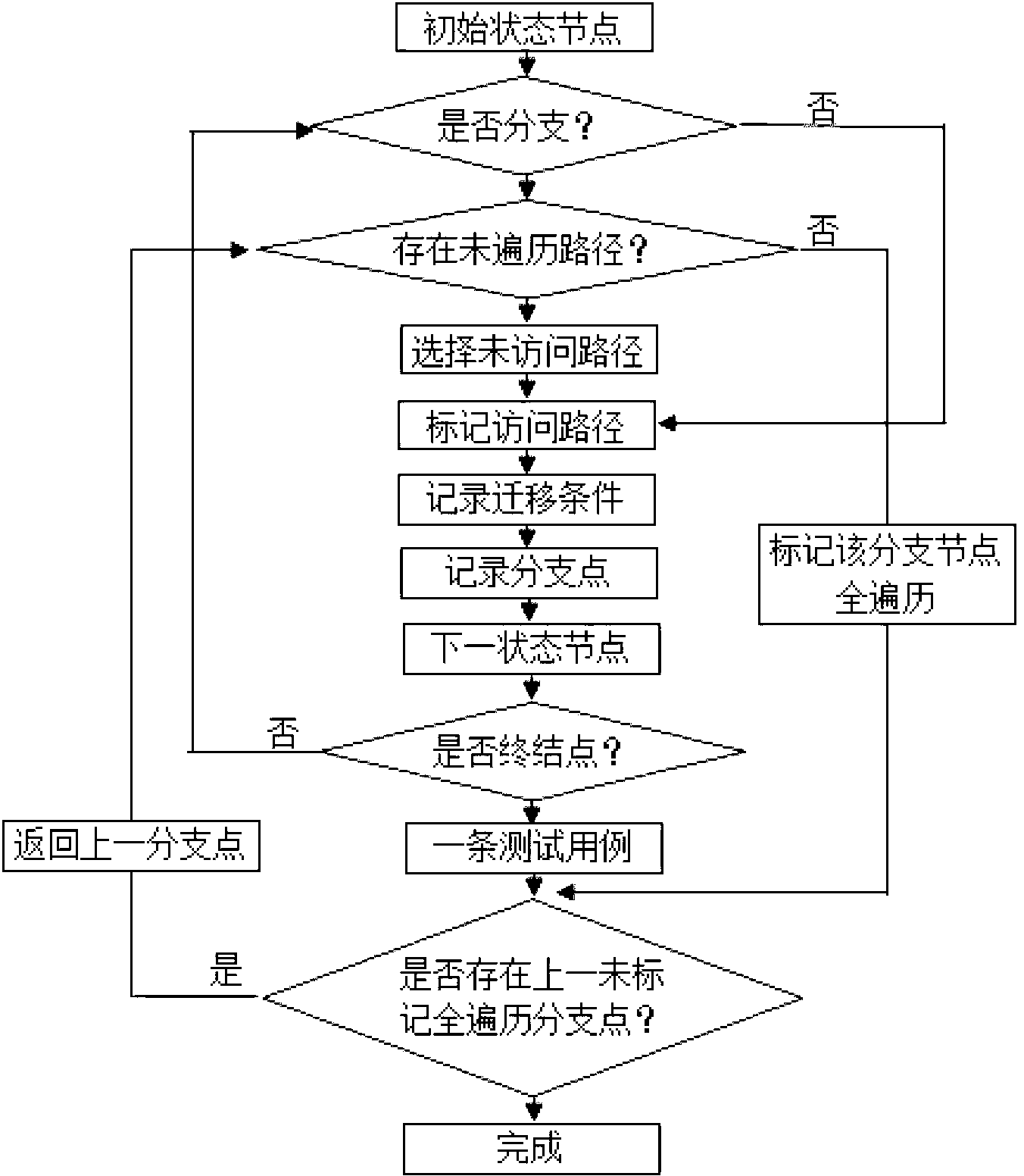

Function test system and test method of automobile body control module

InactiveCN102854877AEasy to implementEasy to findElectric testing/monitoringComputer moduleEngineering

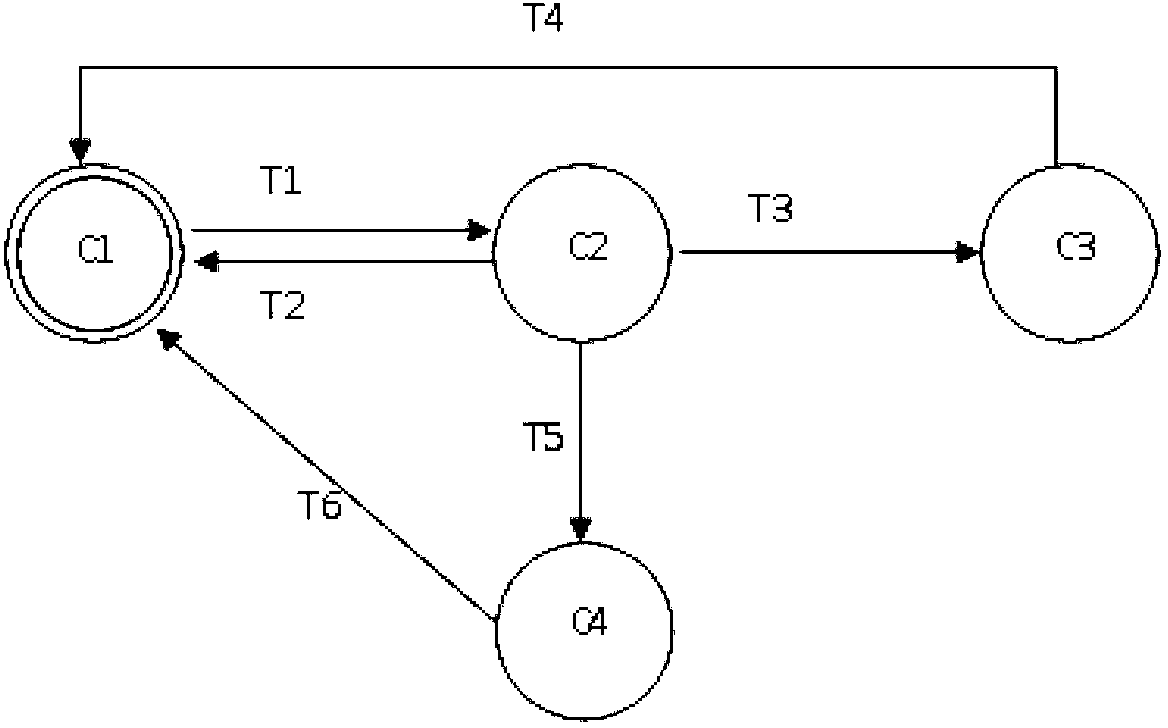

The invention discloses a function test system of an automobile body control module. The function test system comprises a junction box which is connected with an automobile function module to be tested, and the junction box is connected with a digital board card which is connected with an industrial personal computer. The invention also discloses a test method by utilizing the system. According to the function test system and the test method, on the aspect of hardware construction, the realization is convenient and rapid, under the premise of ensuring the precision, the cost is lowered, the system is expanded by loading different functions of board cards, and then can be conveniently connected with a device to be tested by the junction box, and on the aspect of test software, the system has the largest characteristics that a state diagram is utilized for generating a test case, the test purpose is realized by traversing the work state of a BCM (Body Control Module), the understanding is convenient, the operation is easy, the test effect is achieved, and when the test case is tested, the automatic batch test can be selected, the singly manual test is conducted, the function consistency can be automatically analyzed and designed in advance, the manual comparison can be conducted to implement sequential analysis, so that the problem can be found and checked conveniently.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

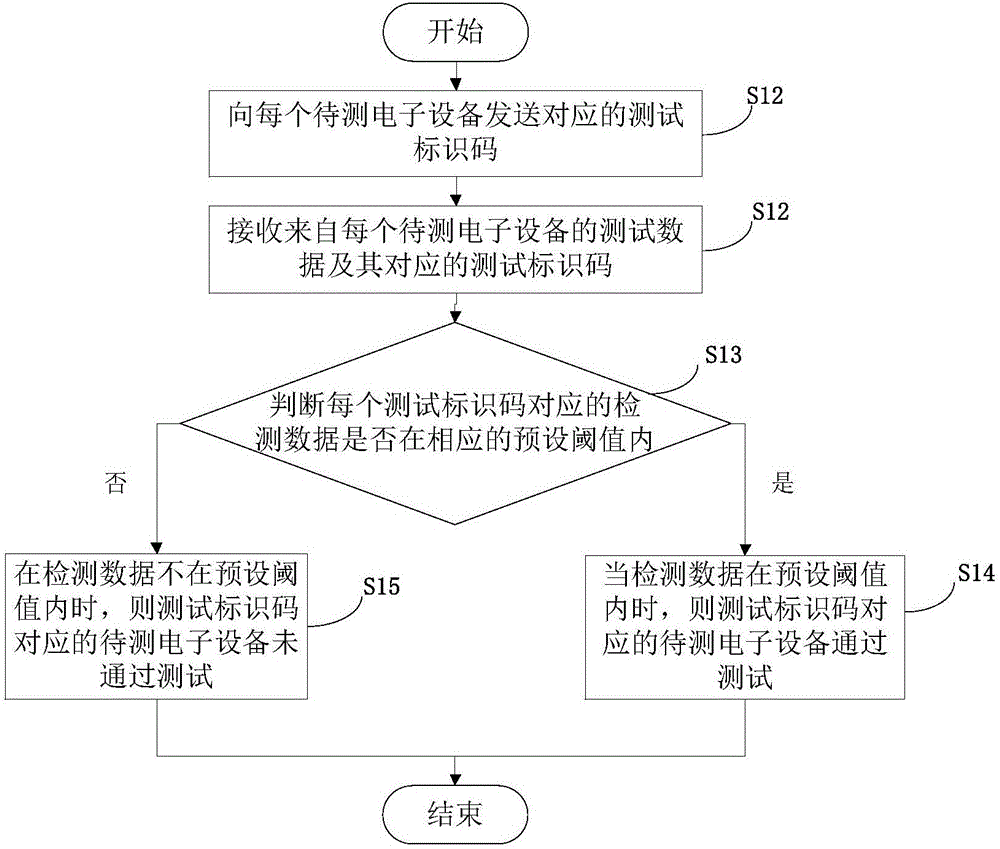

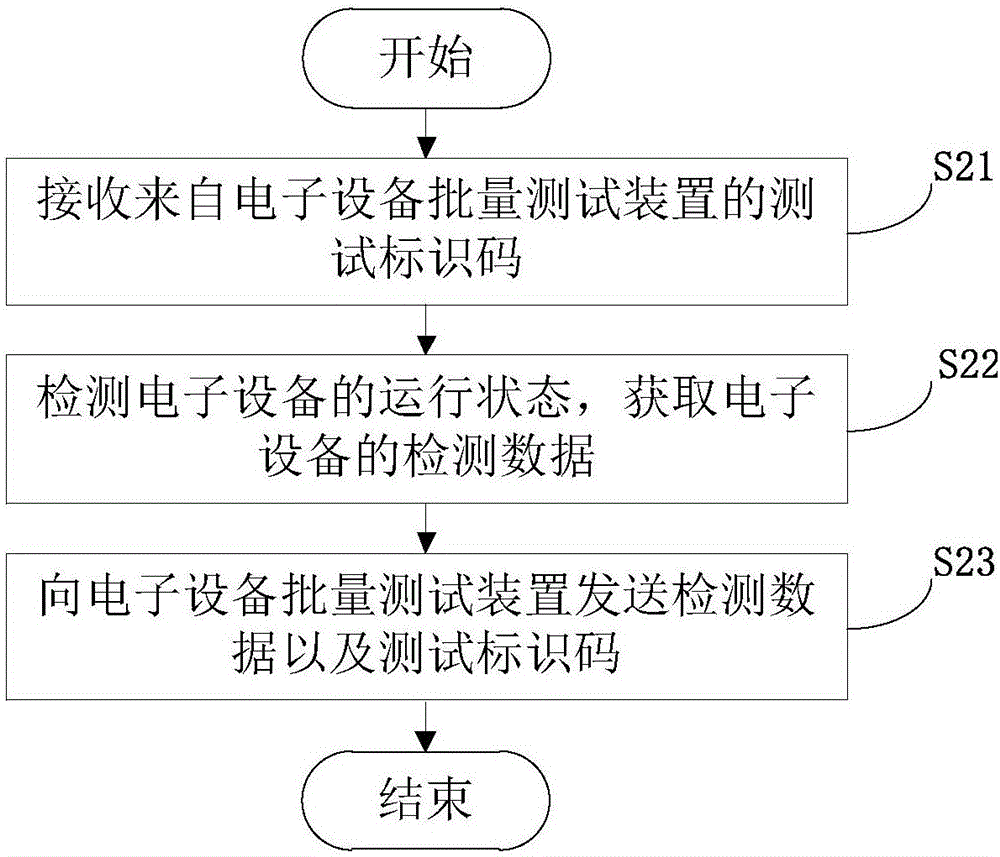

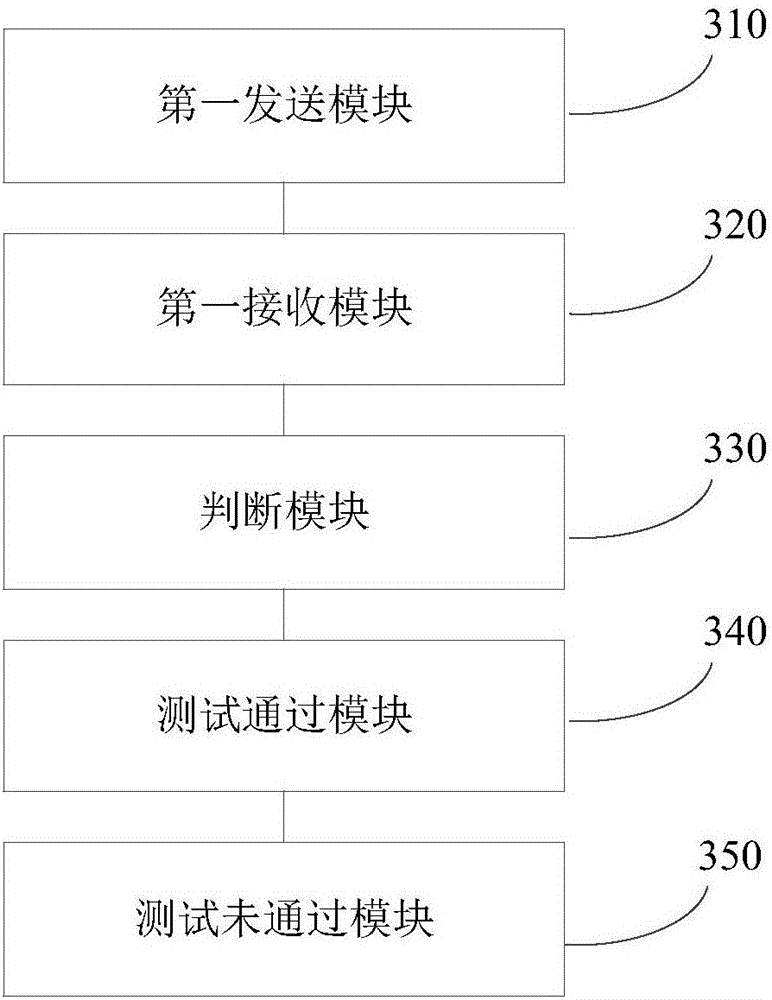

Electronic equipment batch test method, apparatus and electronic equipment thereof

InactiveCN106708007AImprove test efficiencyReduce testing costsElectric testing/monitoringTest efficiencyComputer hardware

The invention discloses an electronic equipment batch test method, an apparatus and electronic equipment thereof. The method comprises the following steps of sending a corresponding test identification code to each piece of electronic equipment to be tested; receiving test data and the corresponding test identification code from the each piece of electronic equipment to be tested; determining whether detection data corresponding to each test identification code is in a corresponding preset threshold; and when the detection data is in the preset threshold, indicating that the electronic equipment to be tested corresponding to the test identification code passes the test. In the scheme, through sending the test identification code to each piece of electronic equipment to be tested so as to carry out identity marking on the each piece of electronic equipment to be tested, according to the test identification code, received detection data is distinguished and is compared to the corresponding preset threshold so that batch test to the electronic equipment is realized; and test efficiency of the electronic equipment is increased and test cost is reduced.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

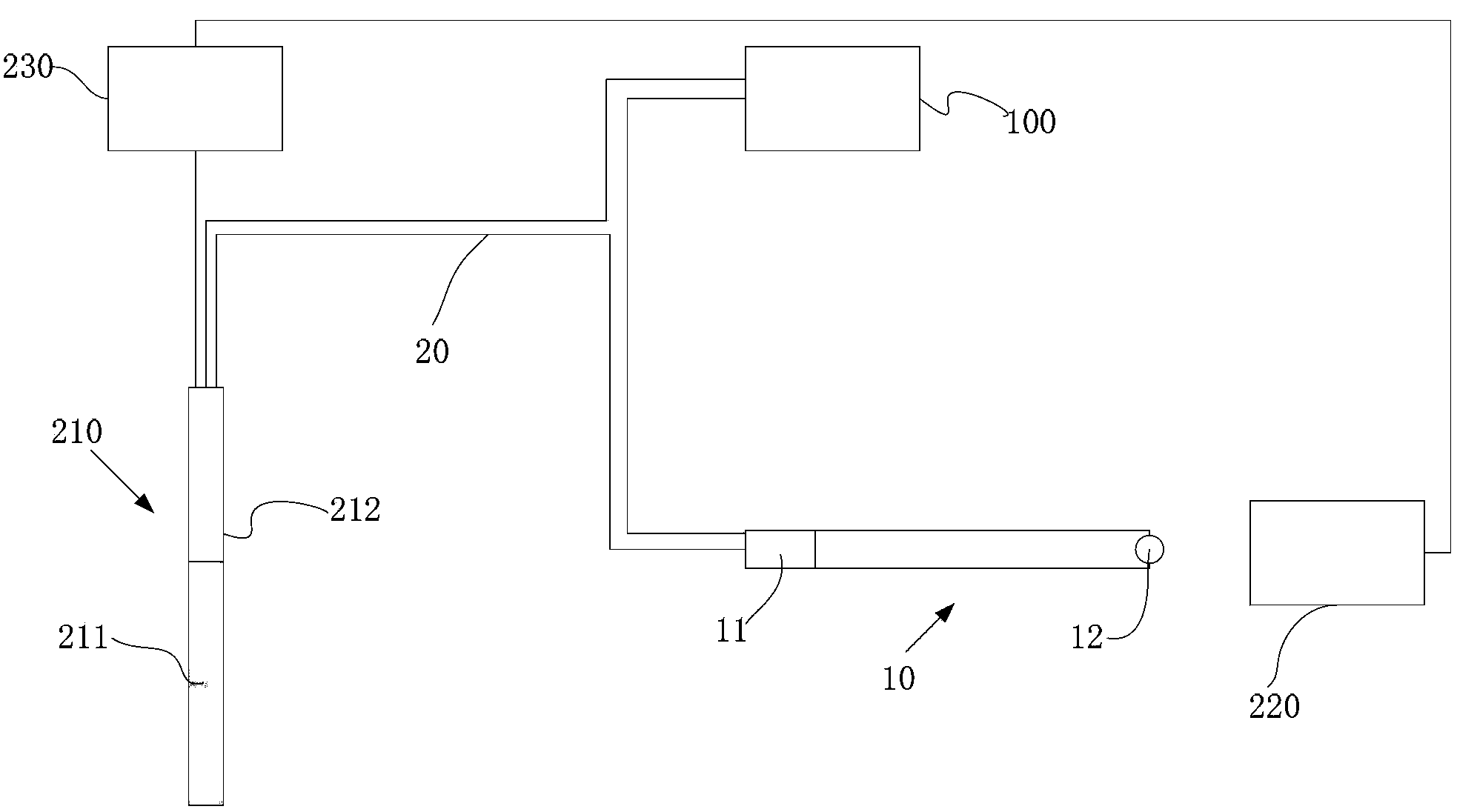

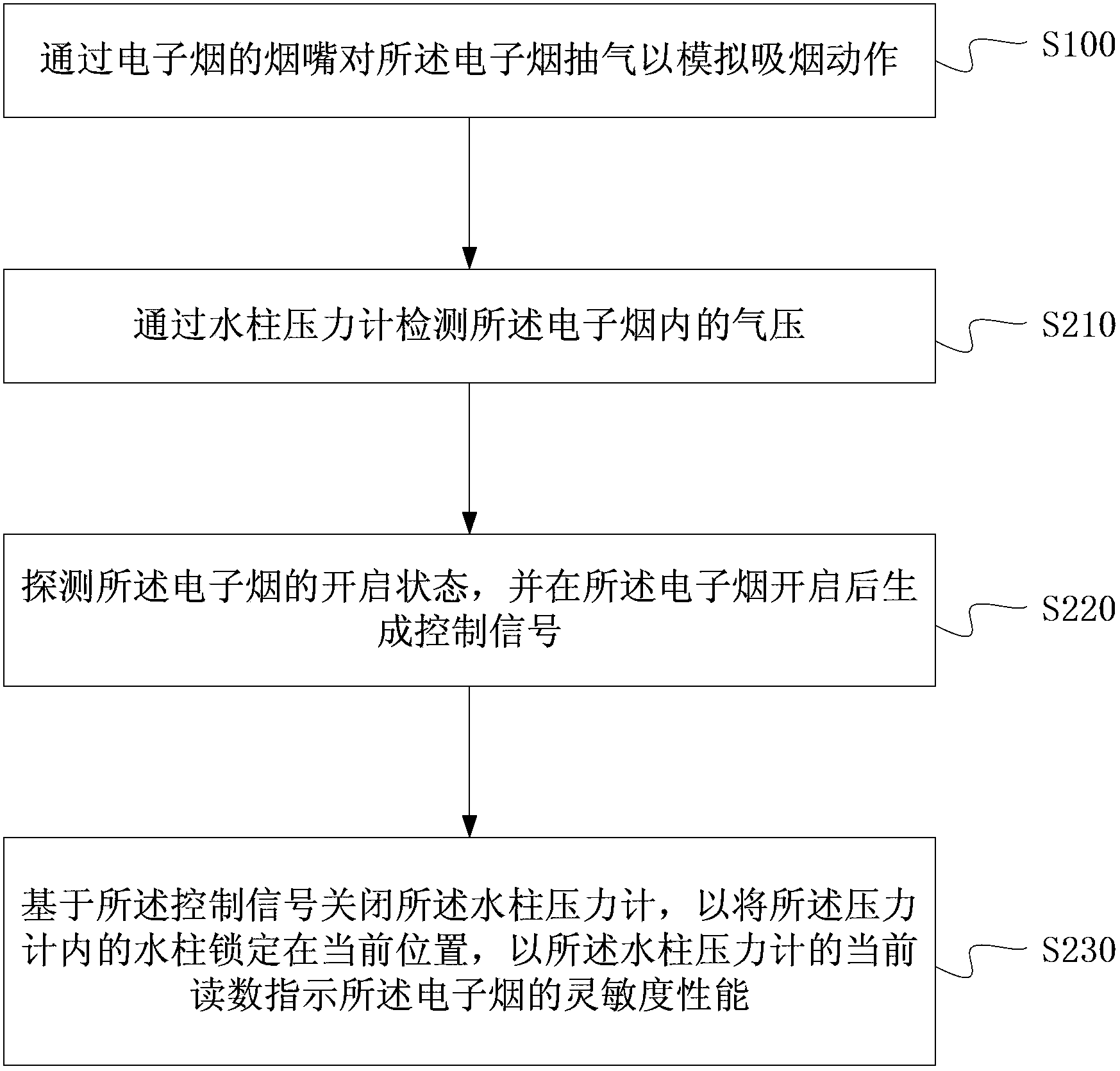

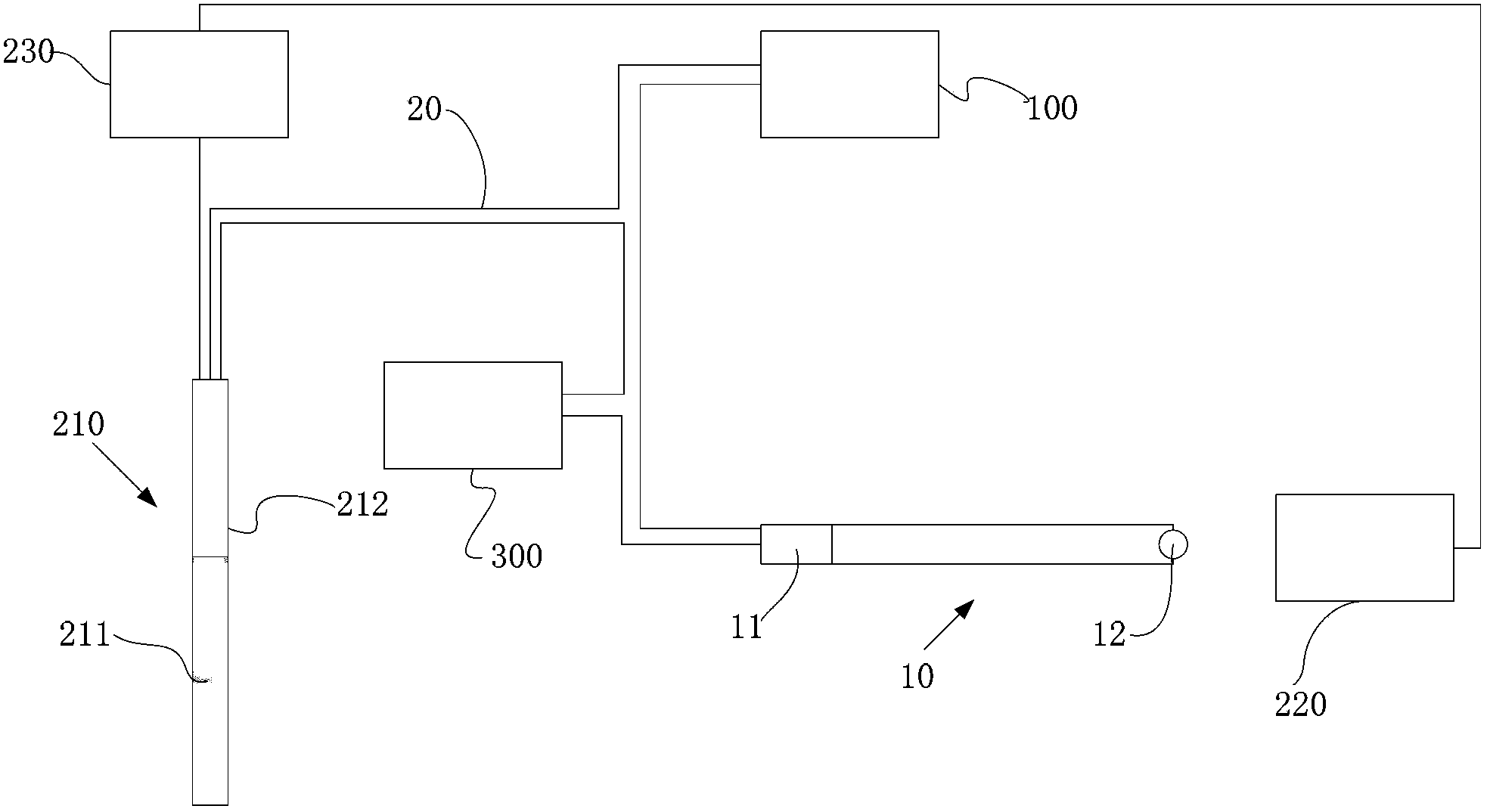

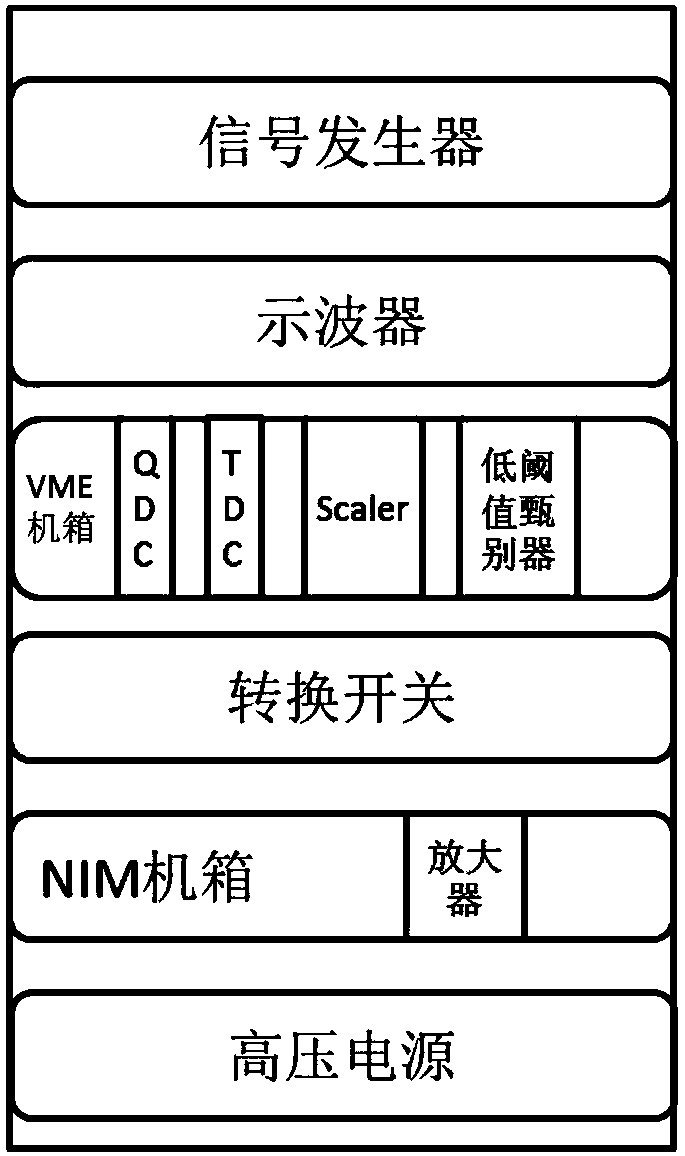

Electronic cigarette performance testing device and electronic cigarette performance testing method

InactiveCN103512827ATest results are accurate and unbiasedMaterial analysisControl signalElectronic cigarette

The invention discloses an electronic cigarette performance testing device and an electronic cigarette performance testing method. The electronic cigarette performance testing device comprises a sucking pump with an extract opening and a sensitivity detecting device, wherein the sucking pump with the extract opening is communicated with a cigarette holder of an electronic cigarette through a gas pipe and is used for extracting gas of the electronic cigarette so as to simulate smoking actions; the sensitivity detecting device is used for detecting the sensitivity performance of the electronic cigarette and further comprises a water column pressure meter, an electronic cigarette on-state detector and a pressure meter control module; the water column pressure meter is used for detecting air pressure in the electronic cigarette; the electronic cigarette on-state detector is used for detecting the on-state of the electronic cigarette and generating a control signal; the pressure meter control module is used for receiving the control signal, closing the water column pressure meter based on the control signal and locating a water column in the pressure meter at a current location; the current reading of the water column pressure meter is used for indicating the sensitivity performance of the electronic cigarette. According to the electronic cigarette performance testing device, experimental data is directly used for characterizing the sensitivity performance of the electronic cigarette, and therefore, testing results are accurate and fair; the electronic cigarette performance testing device and the electronic cigarette performance testing method have repeatability for all the electronic cigarettes, and therefore, the electronic cigarette performance testing device and the electronic cigarette performance testing method can be used for the batch test of the electronic cigarettes.

Owner:HUIZHOU KIMREE TECH

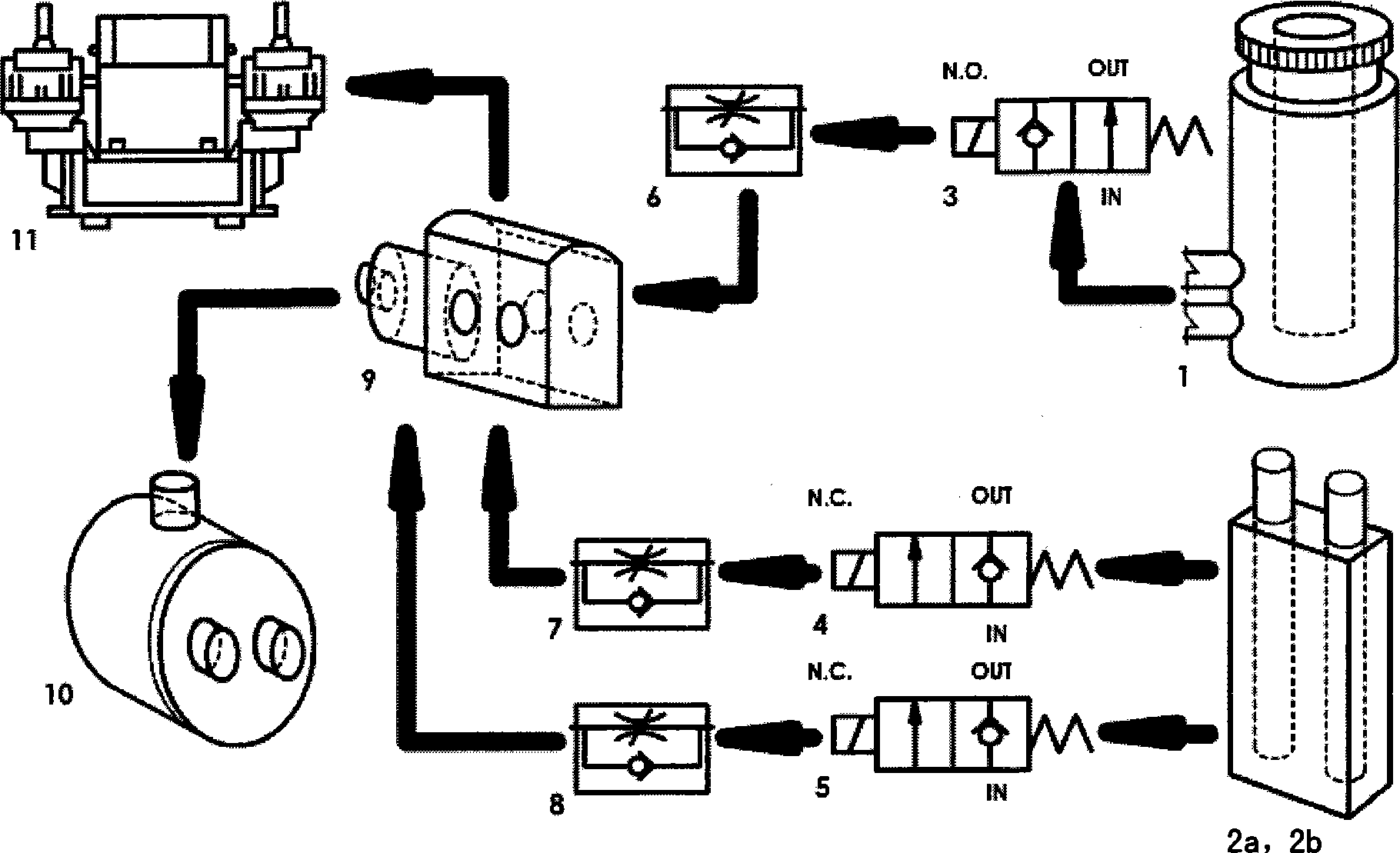

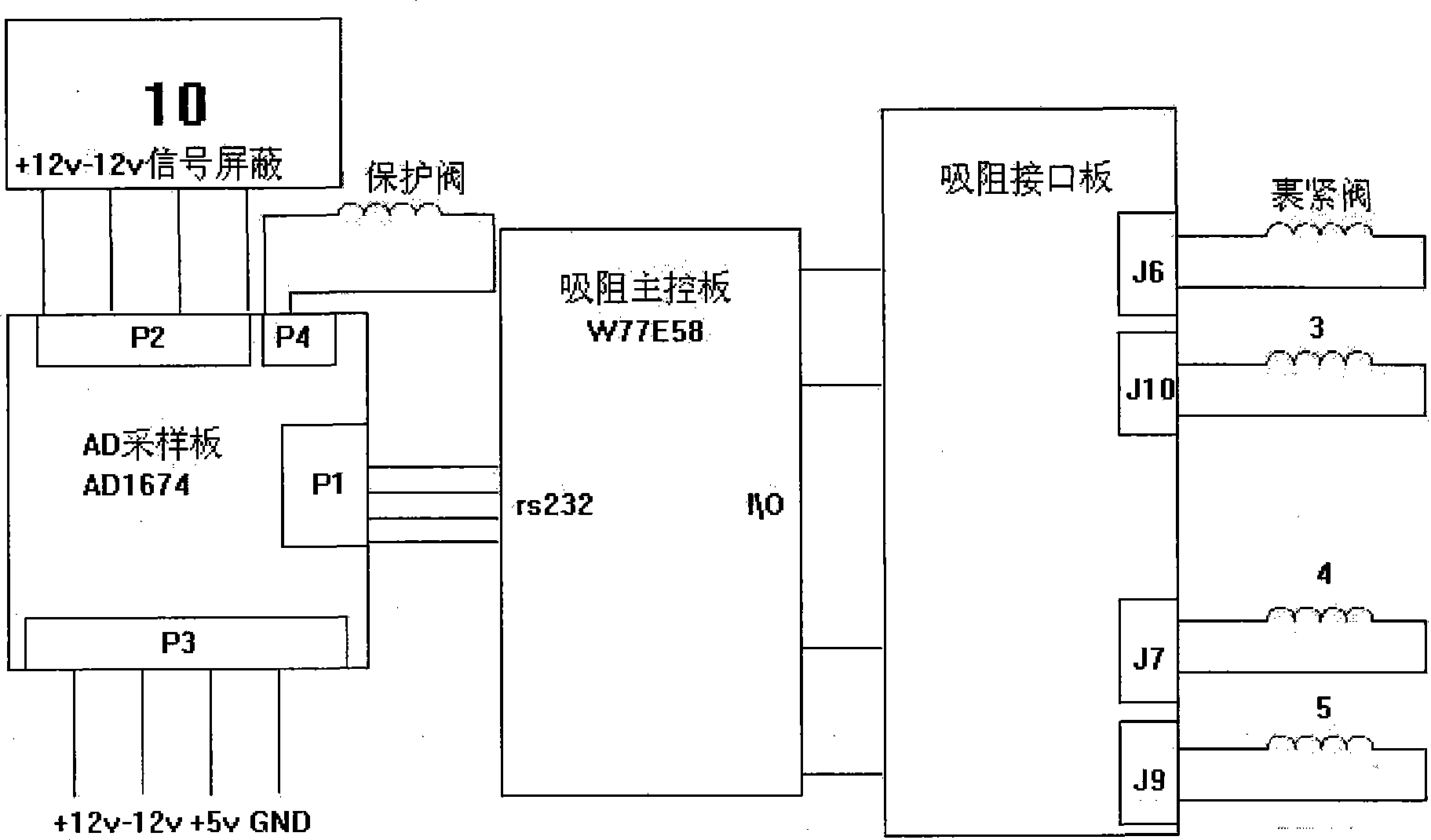

Automatic calibration system and method of resistance absorbing instrument

InactiveCN101413869AAvoid human interferenceReal-time calibrationPermeability/surface area analysisSample MeasureAutomatic control

The invention relates to an absorbing resistance instrument automatic calibration system, which is provided with a gas circuit device and an electric control gear. The gas circuit device comprises a calibration gas circuit and a measuring gas circuit. The calibration gas circuit is provided with two absorbing resistance rod gauge measuring heads. The measuring gas circuit is provided with a sample measuring head. The calibration gas circuit and the measuring gas circuit respectively pass through a motorized valve and a hand-operated valve, and then are connected with a negative pressure vacuum air pump by the same constant flow element and a surge chamber. The constant flow element and the surge chamber are internally provided with a gas differential pressure pickup. The electric control gear is provided with a drawing resistance main control panel, the output end of which is respectively connected with the motorized valve in each gas circuit by a drawing resistance interface board; a serial communication interface of the drawing resistance main control board is connected with a drawing resistance sensor by an AD sampling panel. The method is as follows: the negative pressure vacuum air pump is started; the benchmark pressure of the measuring gas circuit and the calibration gas circuit are regulated; a first drawing resistance rod gauge is calibrated; a second drawing resistance rod gauge is calibrated; the calibration cure parameter is calculated to obtain the rate of slope of the specification curve and the gain. The system avoids artificial interference, realizes automatically controlled real time calibration, and is suitable for batch test.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

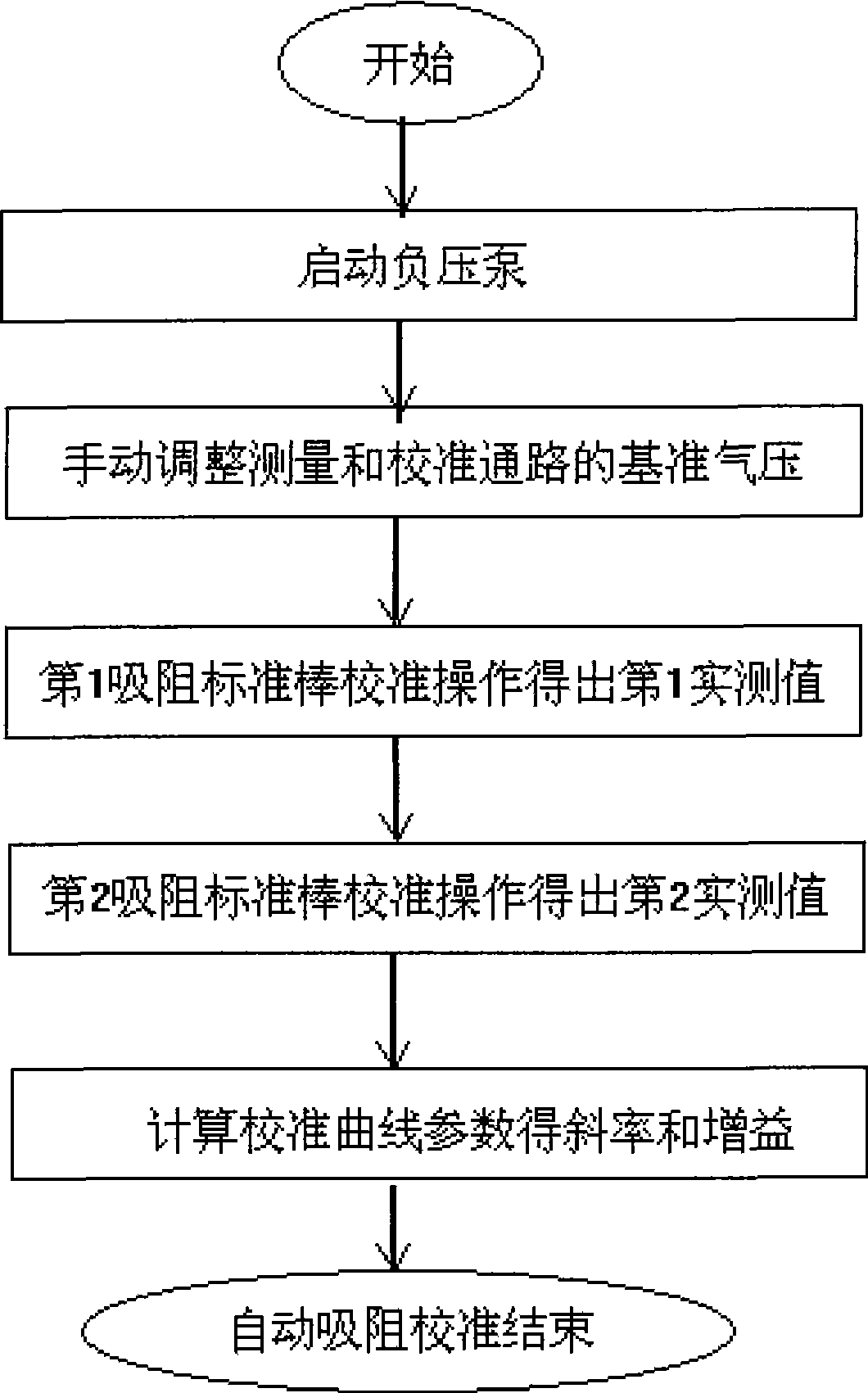

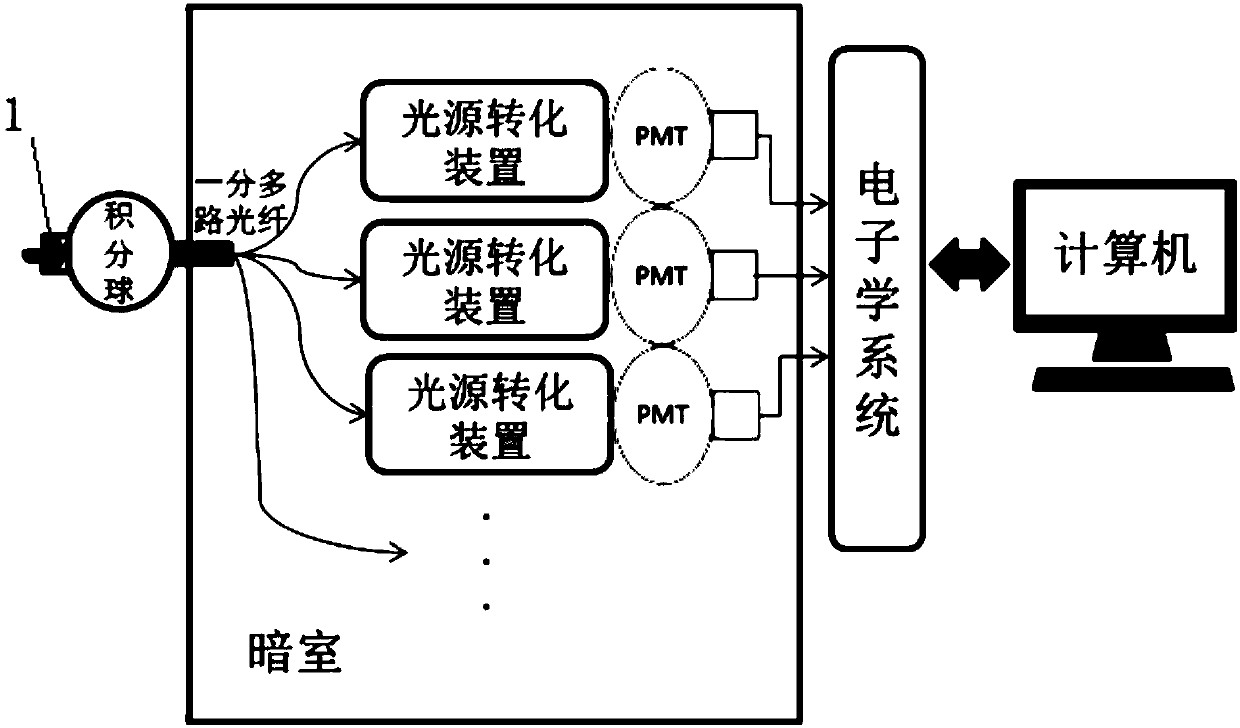

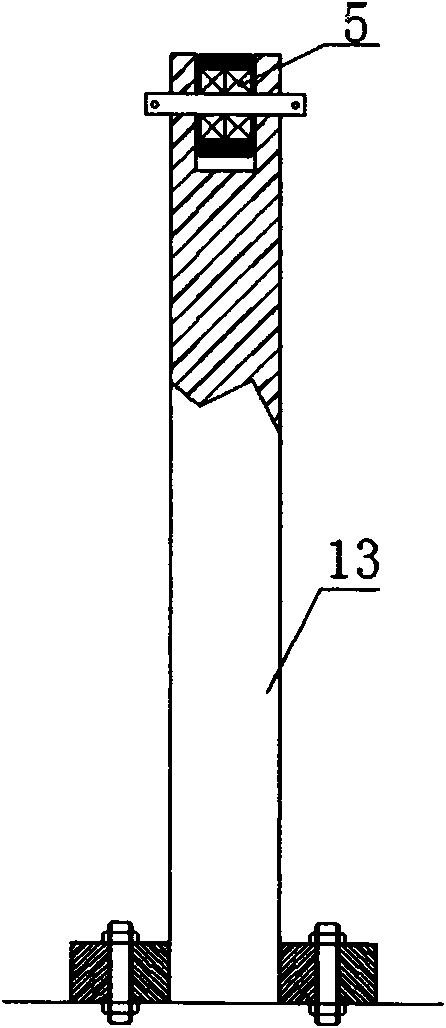

Large-area microchannel plate type photomultiplier test device

ActiveCN107560830AImplement batch testingTest accurateElectrical testingTesting optical propertiesOptoelectronicsPoint light source

The present invention provides a large-area microchannel plate type photomultiplier testing device. The device includes a light source system, an electronic system, a darkroom and a computer; the light source system uniformly transmits light emitted by a light source to a plurality of light source conversion devices through an integrating sphere and a one-to-many optical fiber; the light source conversion devices receive the point light source of the optical fiber and outputs uniform surface light sources; and each surface light source illuminates the total cathode surfaces of one large-size photomultiplier. According to the large-area microchannel plate type photomultiplier tube testing device of the invention, the overall performance of a plurality of large-area photomultipliers can be simultaneously tested on the basis of the electronic system and computer test software. With the large-area microchannel plate type photomultiplier testing device adopted, the batch test work of the overall performance of the large-size photomultipliers can be well completed, the compliance of the test environment and use environment of the large-size photomultipliers can be improved, the batch test efficiency of the large-size photomultipliers can be improved, the limitations of a point light source test system are eliminated, and the problem of low efficiency of a point-source scanning test system can be solved.

Owner:NORTH NIGHT VISION TECH +1

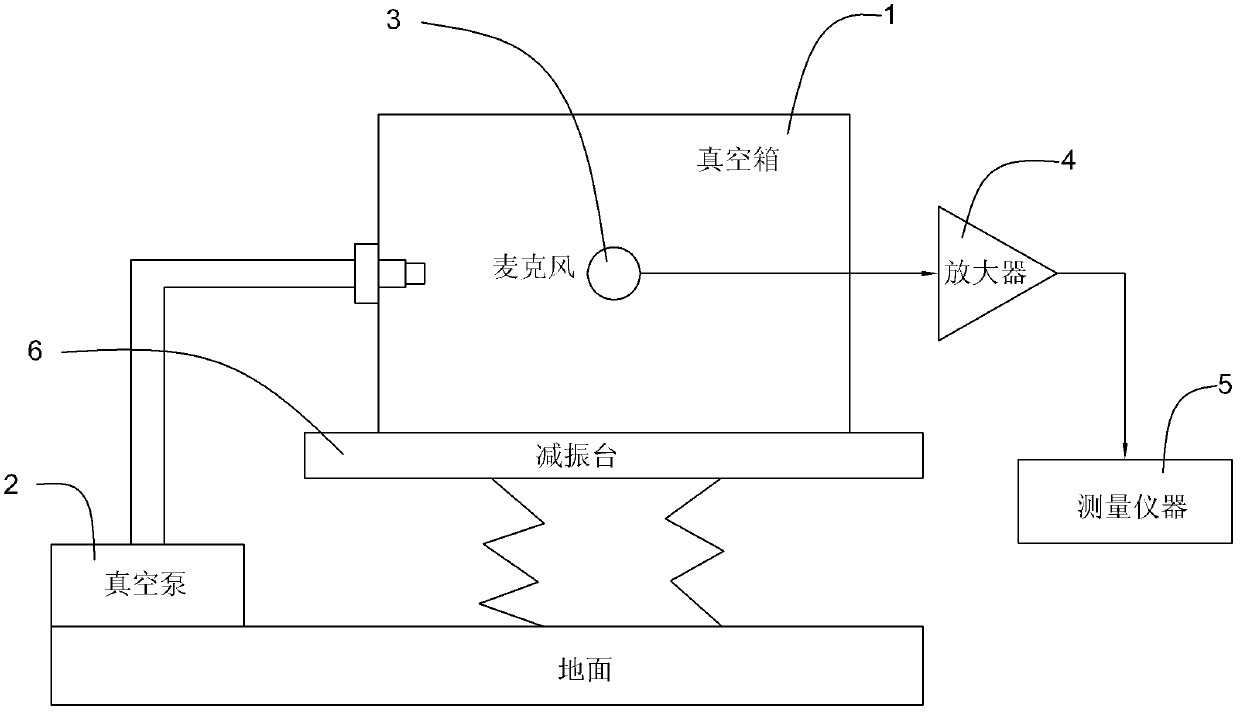

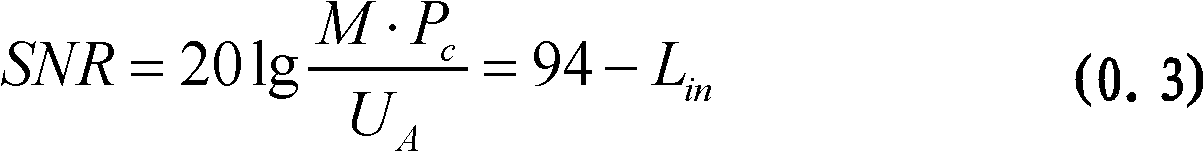

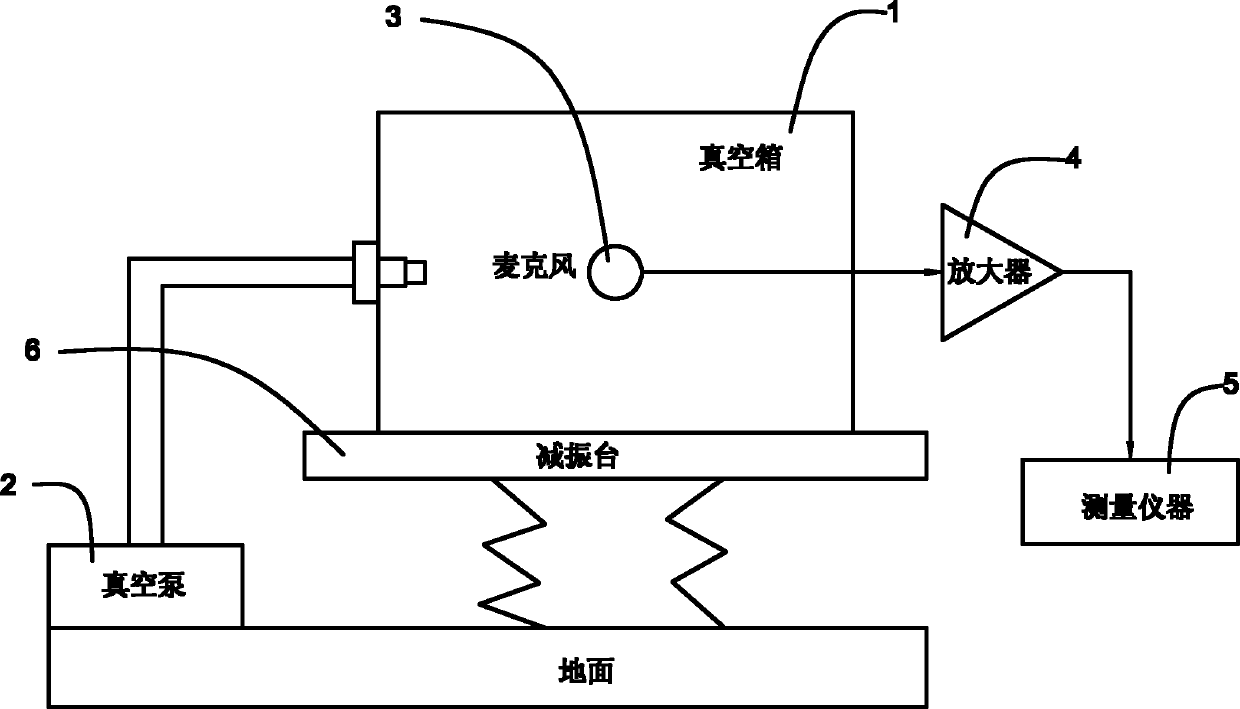

Testing method of intrinsic noise voltage of microphone and testing device of testing method

InactiveCN102711029ASmall sizeMeet the requirements of the test principleElectrical apparatusLow noiseMeasuring instrument

The invention provides a testing method of intrinsic noise voltage of a microphone and a testing device of the testing method. The method comprises the following steps of: providing the microphone and a vacuum box; placing the microphone into the vacuum box; then pumping air in the vacuum box by using a vacuum pump to form a vacuum environment; providing a low-noise amplifier and feeding an output signal of the microphone to the low-noise amplifier by utilizing a sealed cable; providing a measuring instrument, wherein the measuring instrument receives an electric signal of the low-noise amplifier; and then, measuring the intrinsic noise voltage of the microphone. The method utilizes the vacuum box so that low-noise testing requirements are easy to realize; testing principle requirements are met and the size of the vacuum box is not influenced by an acoustic structure; and the vacuum box is designed according to the size of the microphone and the size of a testing system is extremely reduced, so that the testing system is simple and is suitable for occasions such as a production line, in which the noise is large and large-batch tests are required.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +2

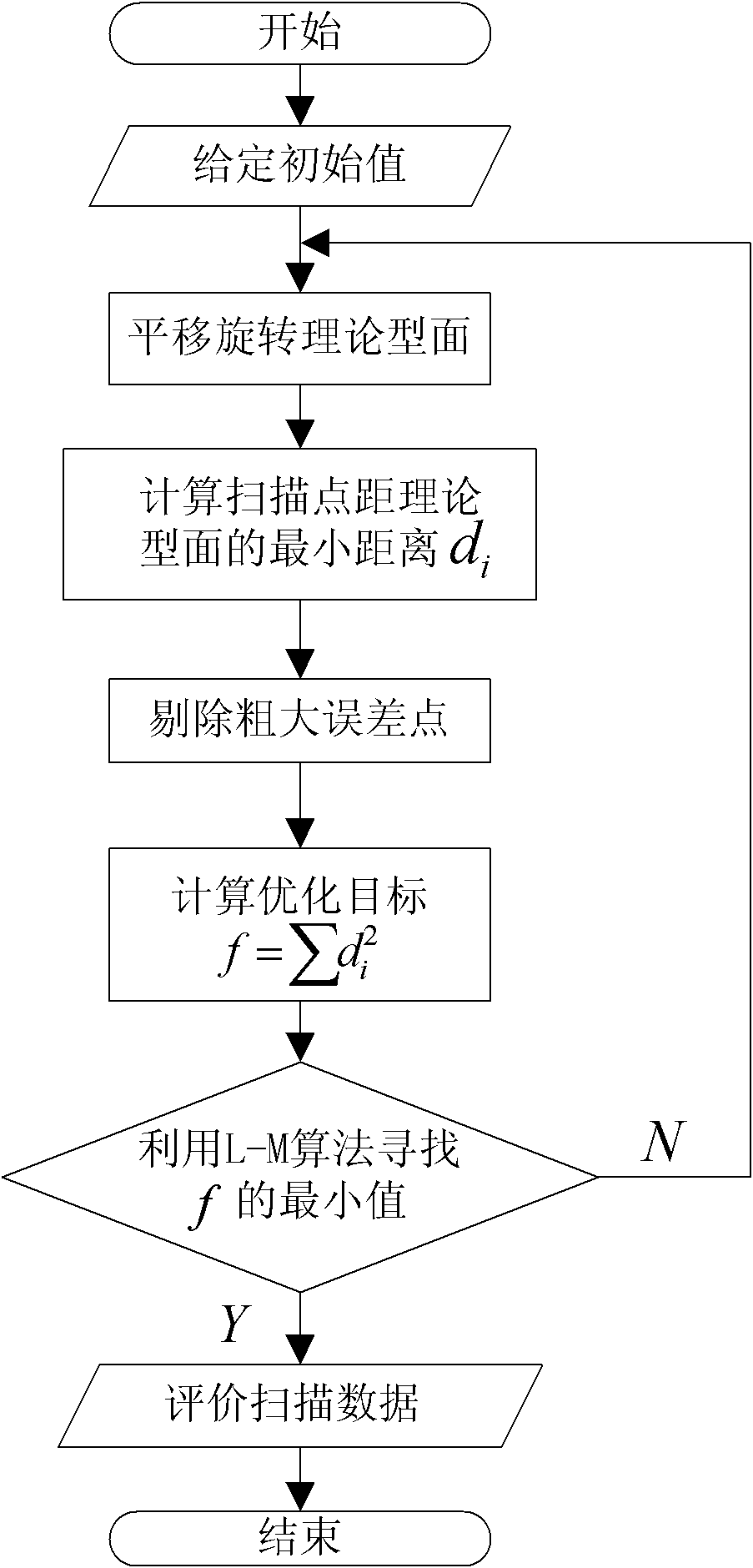

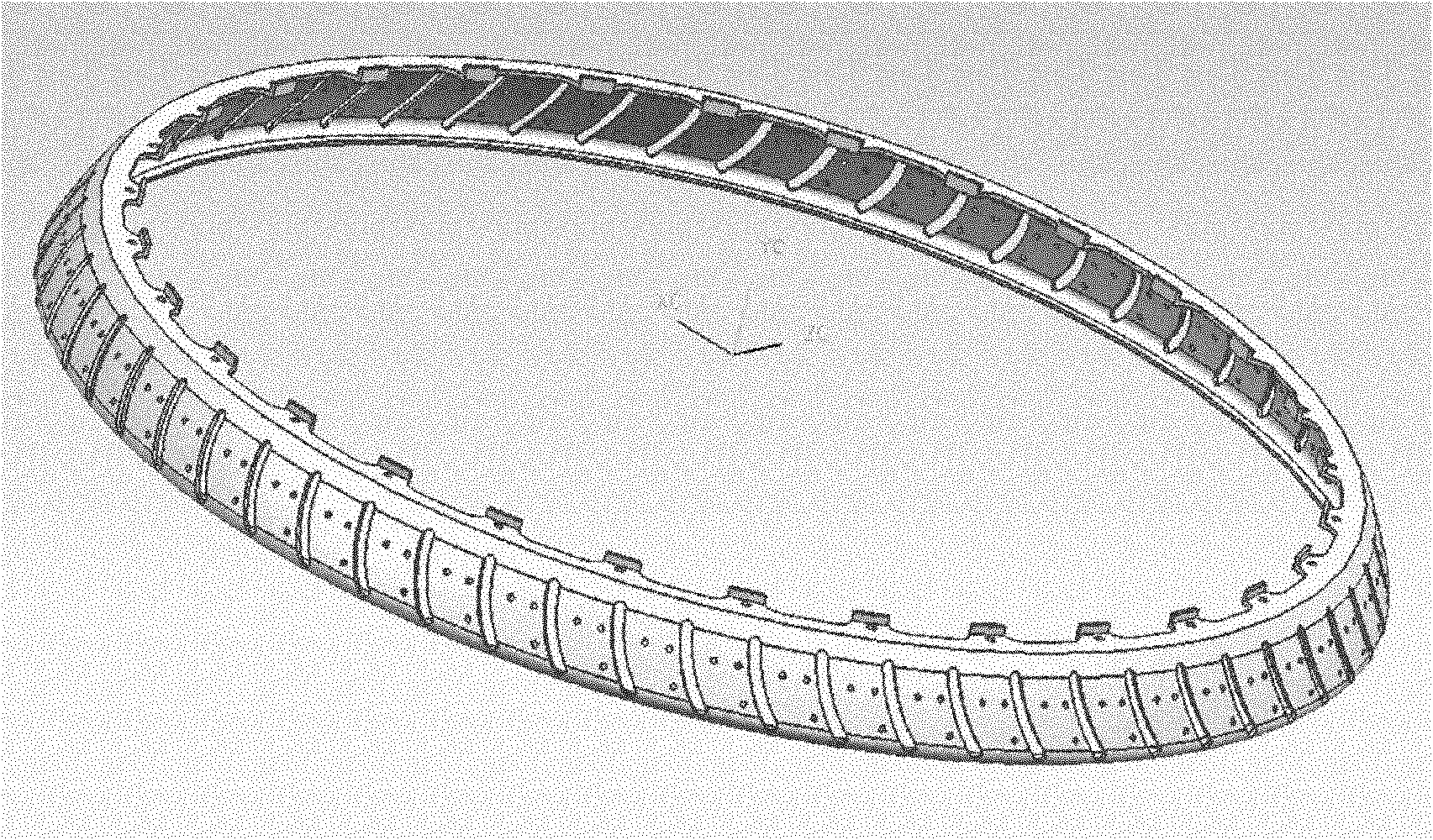

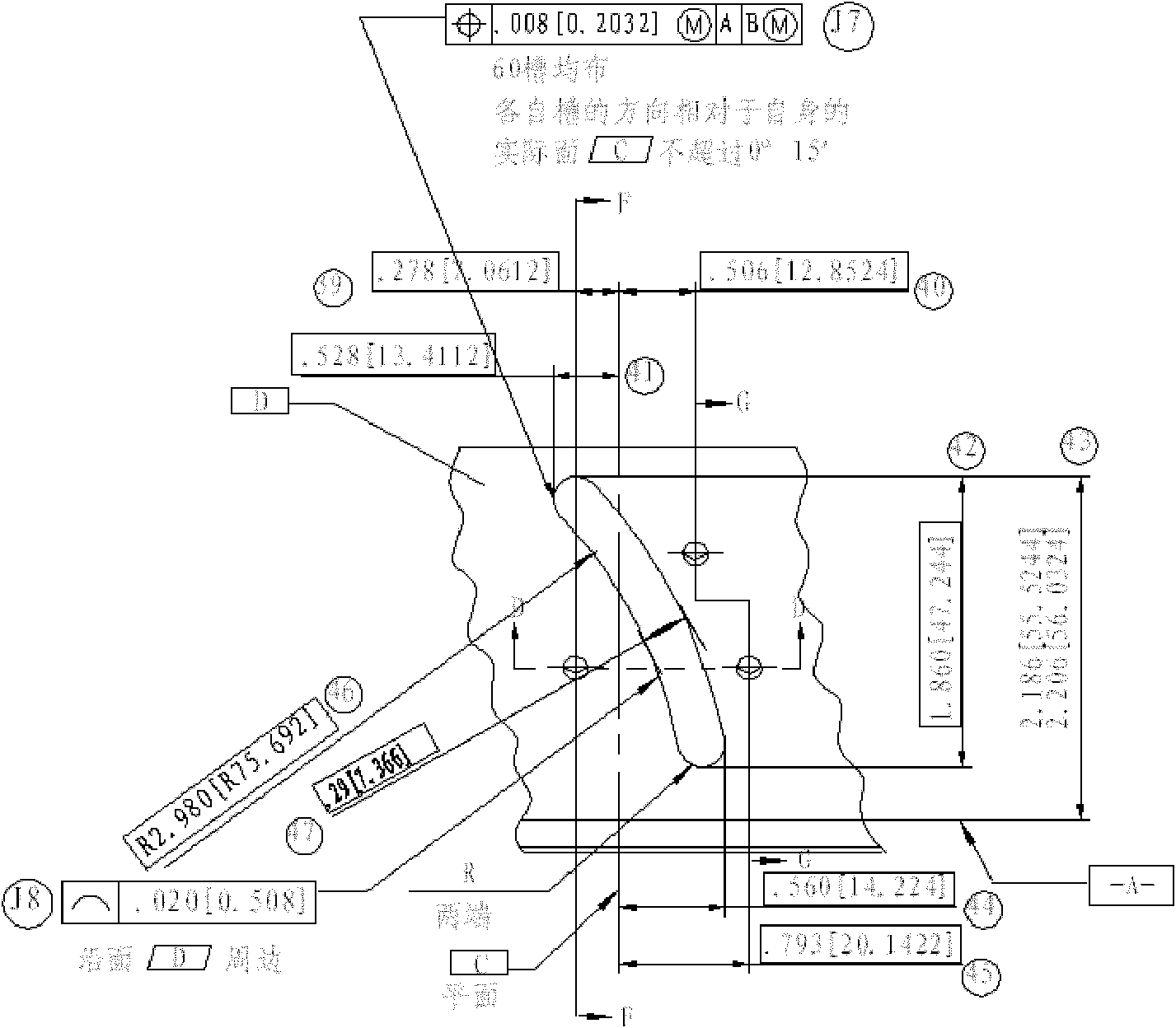

Measuring and calculating method of profile line part without datum

ActiveCN102486371AHigh precisionGood repeatabilityMeasurement devicesLevenberg–Marquardt algorithmAlgorithm

A measuring and calculating method of a profile line part without datum comprises the following steps: firstly, giving an initial translation value (Delta x, Delta y) and a rotation angle Delta theta of a scanning data point, defaulting an initial value to be zero, if the scanning data point has a large deviation with a theory type surface, manually giving the initial value; then, carrying out translation and rotation to the scanning data point and successively calculating a minimum distance di between the scanning data point and the theory type surface and rejecting a thick error point; secondly, using an improved Levenberg-Marquardt algorithm to perform an iterative solution to a least-squares fitting value of the theory type face to the scanning data point; finally, evaluating the scanning data and outputting an evaluation result. By using the measuring and calculating method of the profile line part without the datum disclosed in the invention, a concrete number can be given during evaluating the profile line, precision of the evaluation result is high and repeatability is good. A program writing mode is used to automatically realize calculation during calculating so as to improve batch test efficiency.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

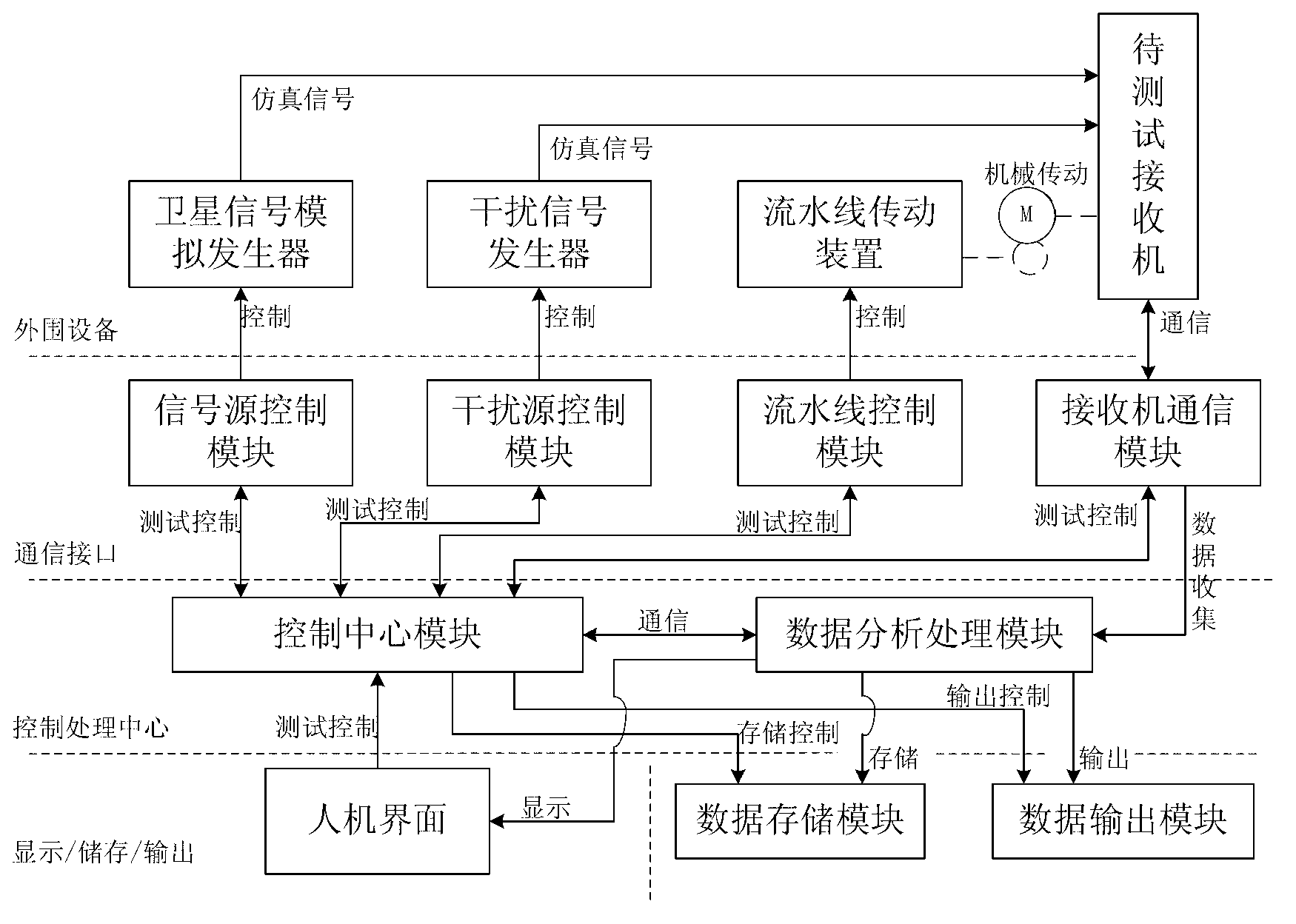

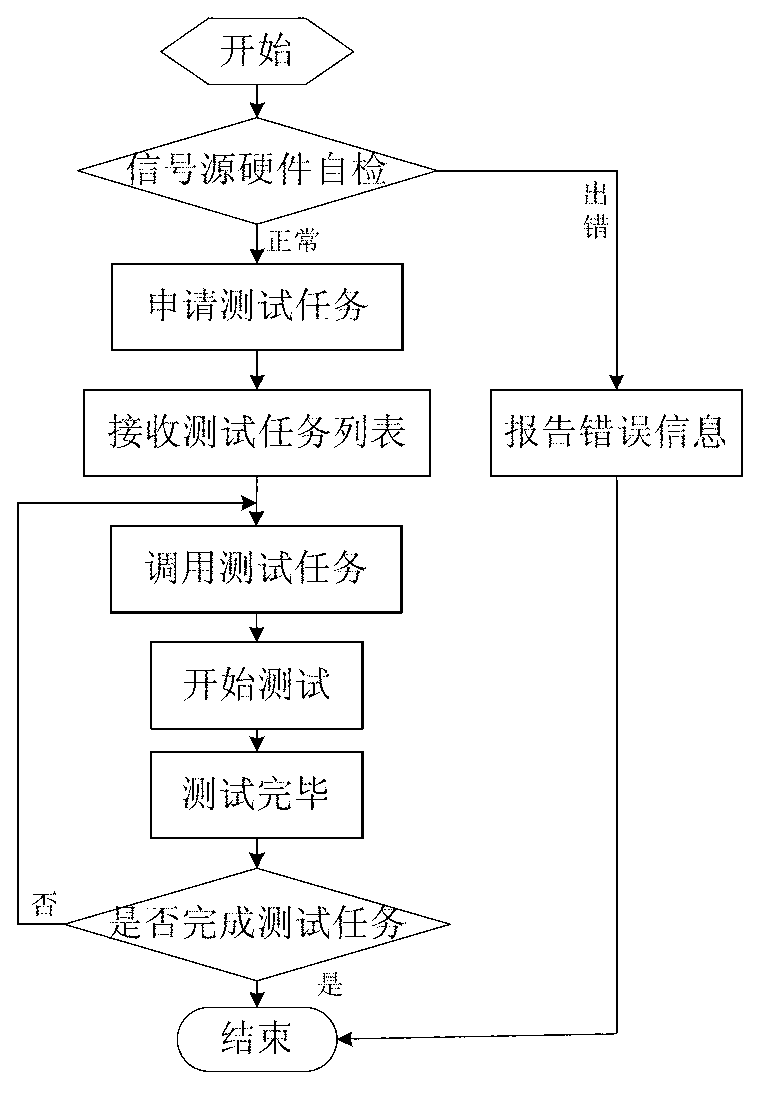

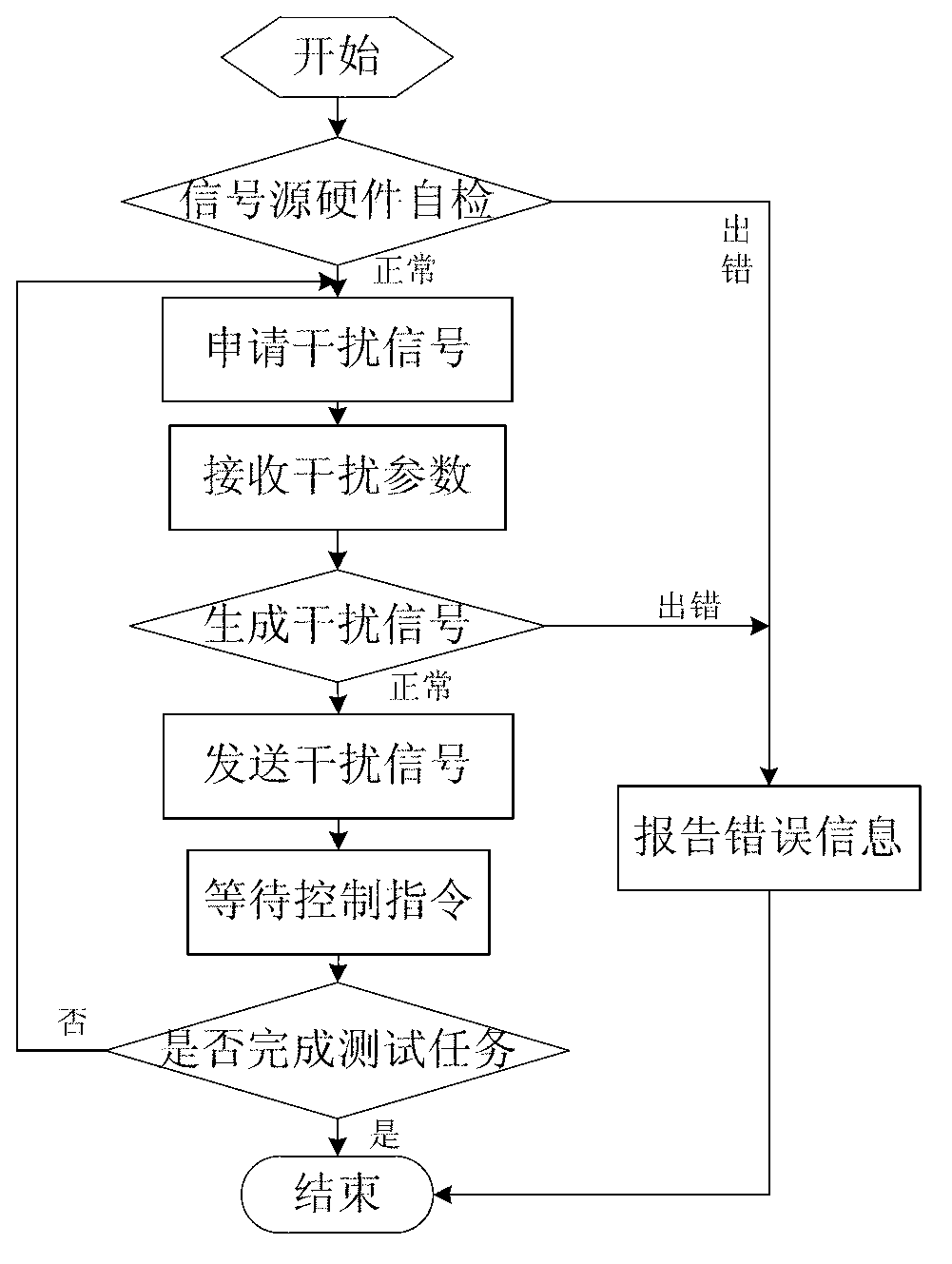

Batch automated testing method for navigation terminal receiver

ActiveCN103293536AShort working hoursOperational impactSatellite radio beaconingComputer terminalAssembly line

The invention relates to a batch automated testing method for a navigation terminal receiver. The batch automated testing method mainly aims at batch navigation receiver testing tasks and quick batch test for batch production of the navigation terminal receiver. Without involvement of an operator or many operators, the batch automated testing method has the advantages of high accuracy, consistency, efficiency and low cost and the like and is mainly applied to analog simulation generation technique of satellite navigation signals, bussing technique, assembly line based testing technique, sampling technique and database storage technique and automatic generation technique of test result report forms.

Owner:BEIHANG UNIV

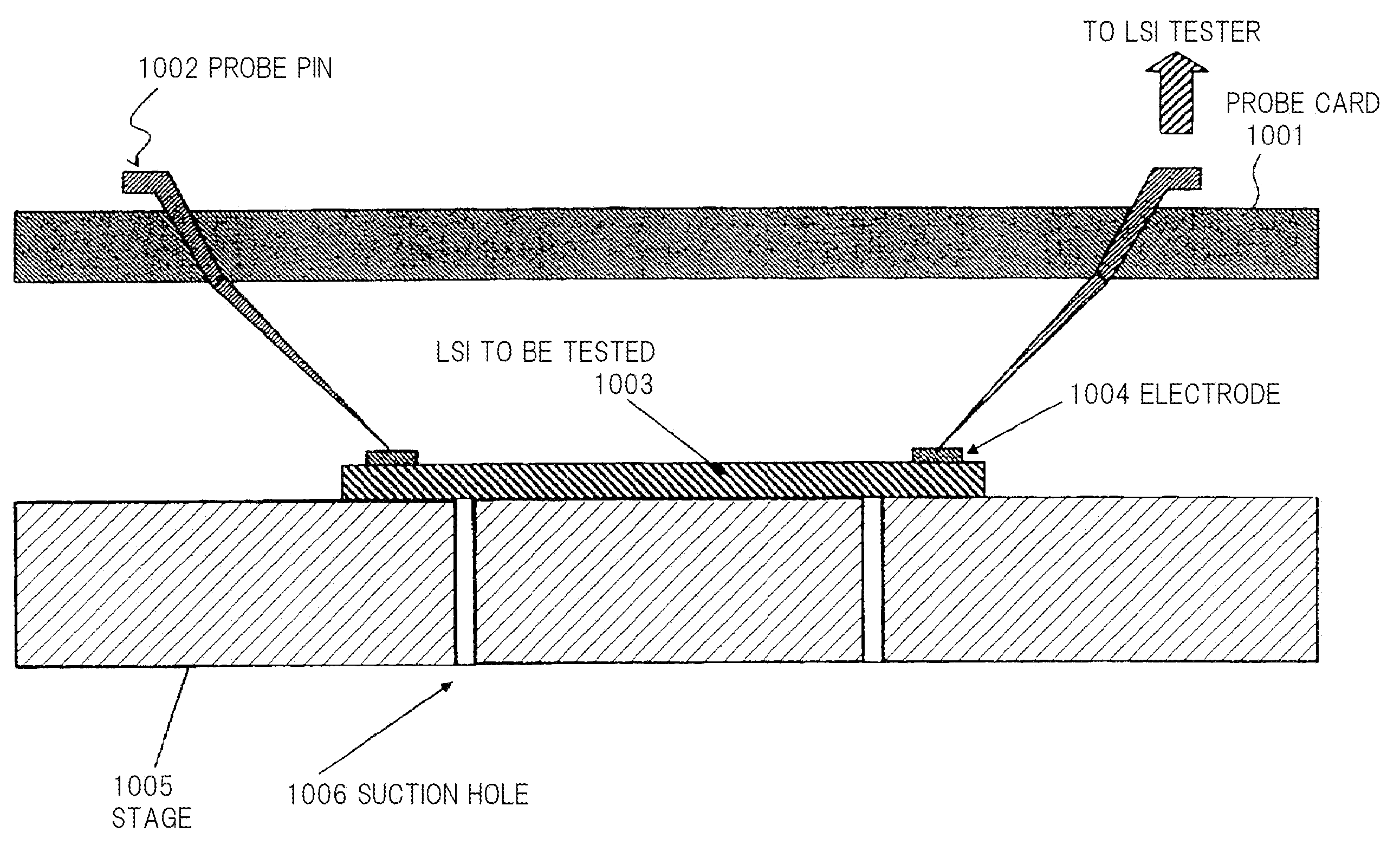

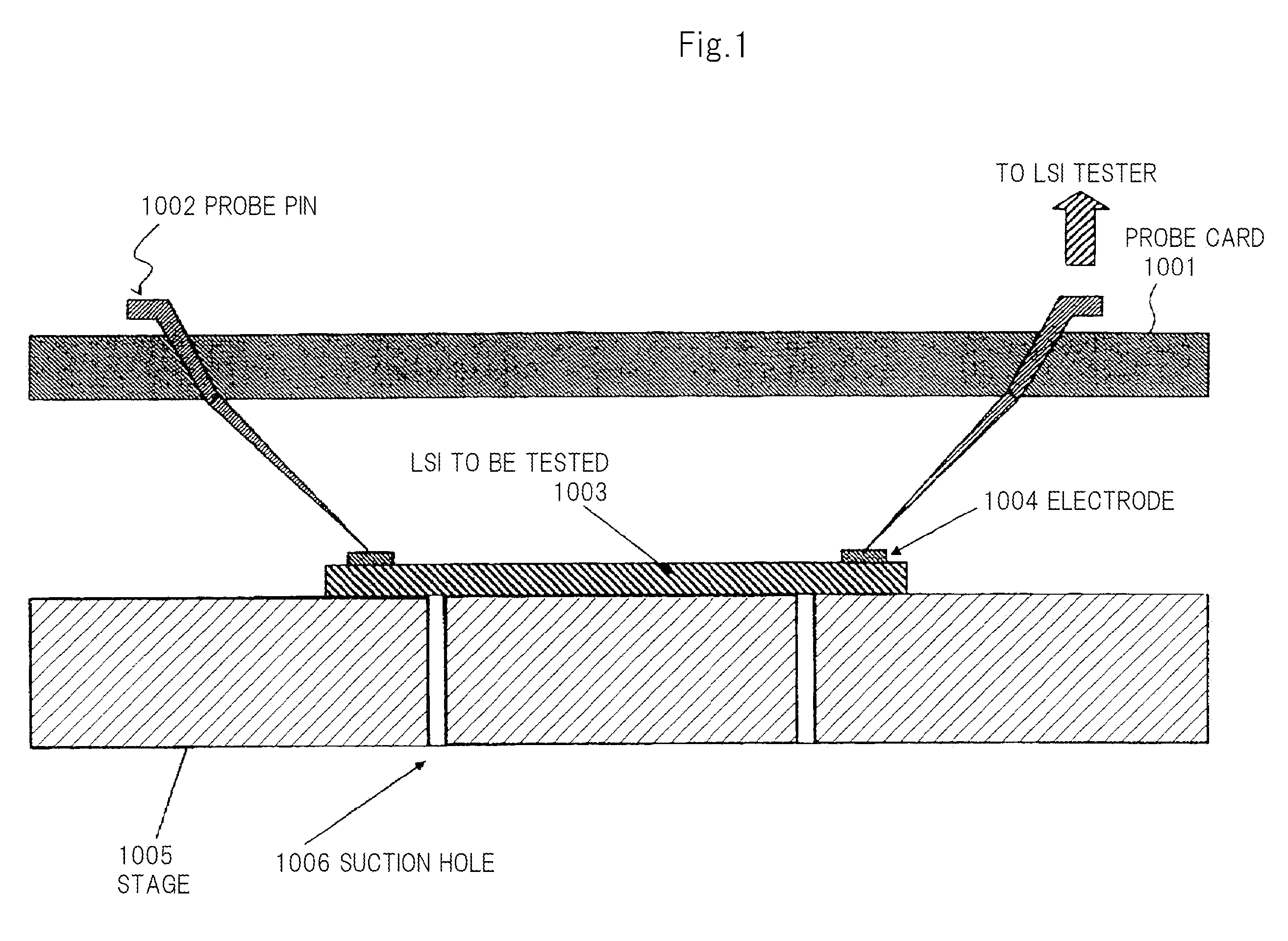

Apparatus and method for testing semiconductor and semiconductor device to be tested

InactiveUS20100194423A1Increase the number ofShorten test timeSemiconductor/solid-state device testing/measurementSolid-state devicesProbe cardContact type

Provided is a semiconductor testing apparatus which can perform batch test of semiconductor wafers. In the semiconductor testing apparatus, an LSI apparatus for conducting a test and which provided with a circuit and an electrode for transmitting noncontact signals, and a probe card to which a contact-type probe pin is attached are separately arranged. The semiconductor testing apparatus is provided with a recognition unit for precisely aligning the electrodes of the LSI apparatus for conducting a test, the LSI wafer to be tested and the probe card. The LSI apparatus for conducting a test and a probe pin of the probe card are mounted on a stage or a pressurizing head, and contact can be made to sandwich an LSI wafer to be tested, from both the front surface and the rear surface of the LSI wafer to be tested at the same time.

Owner:NEC CORP

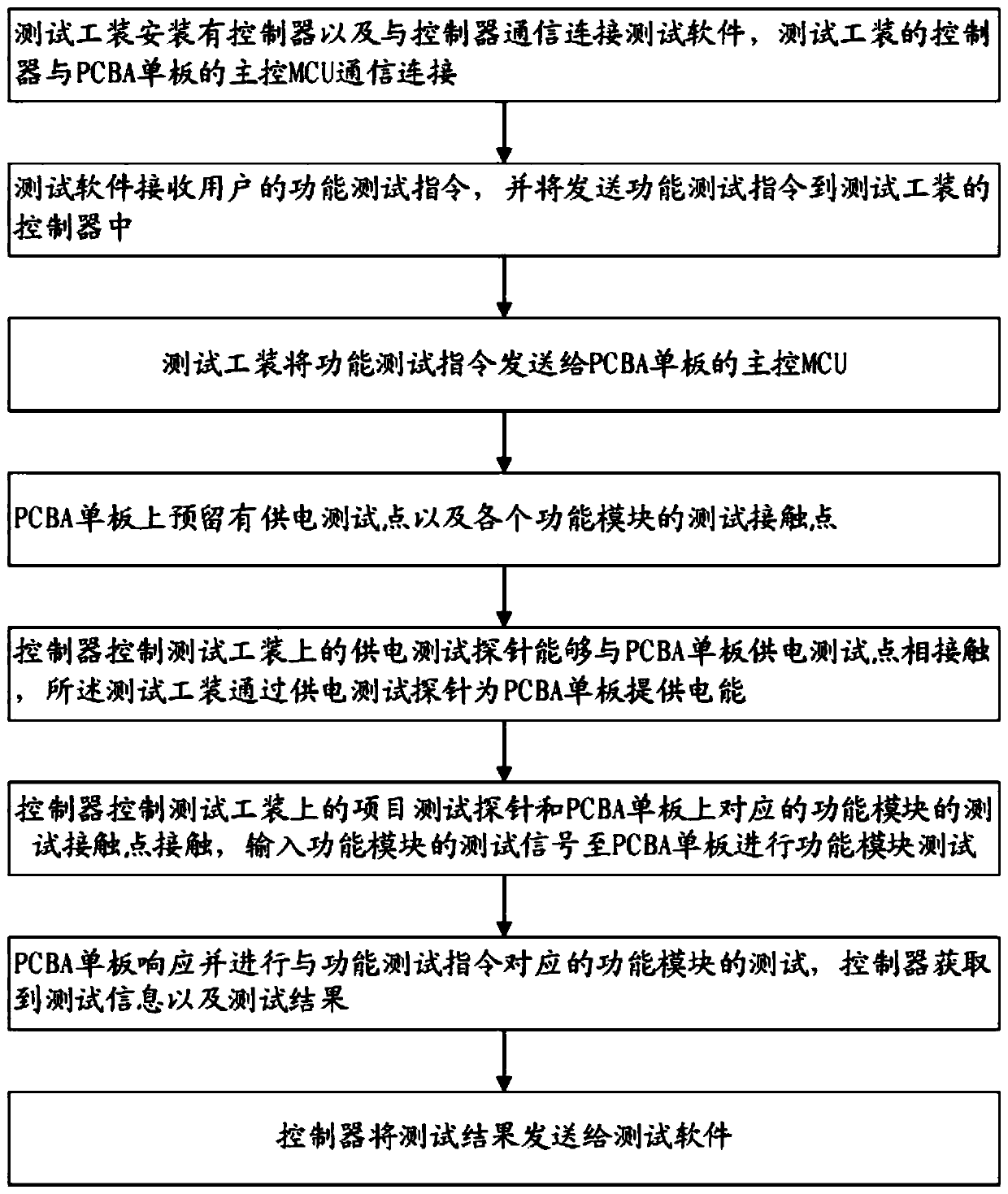

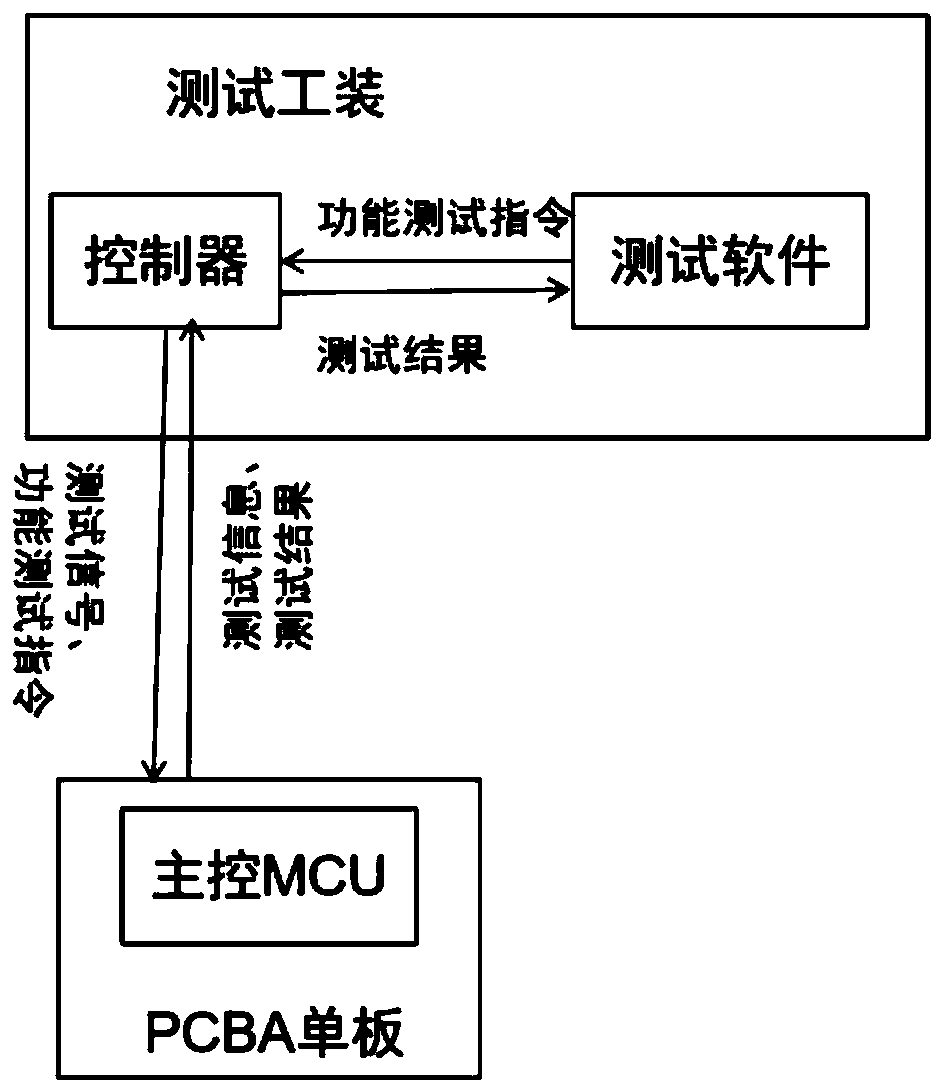

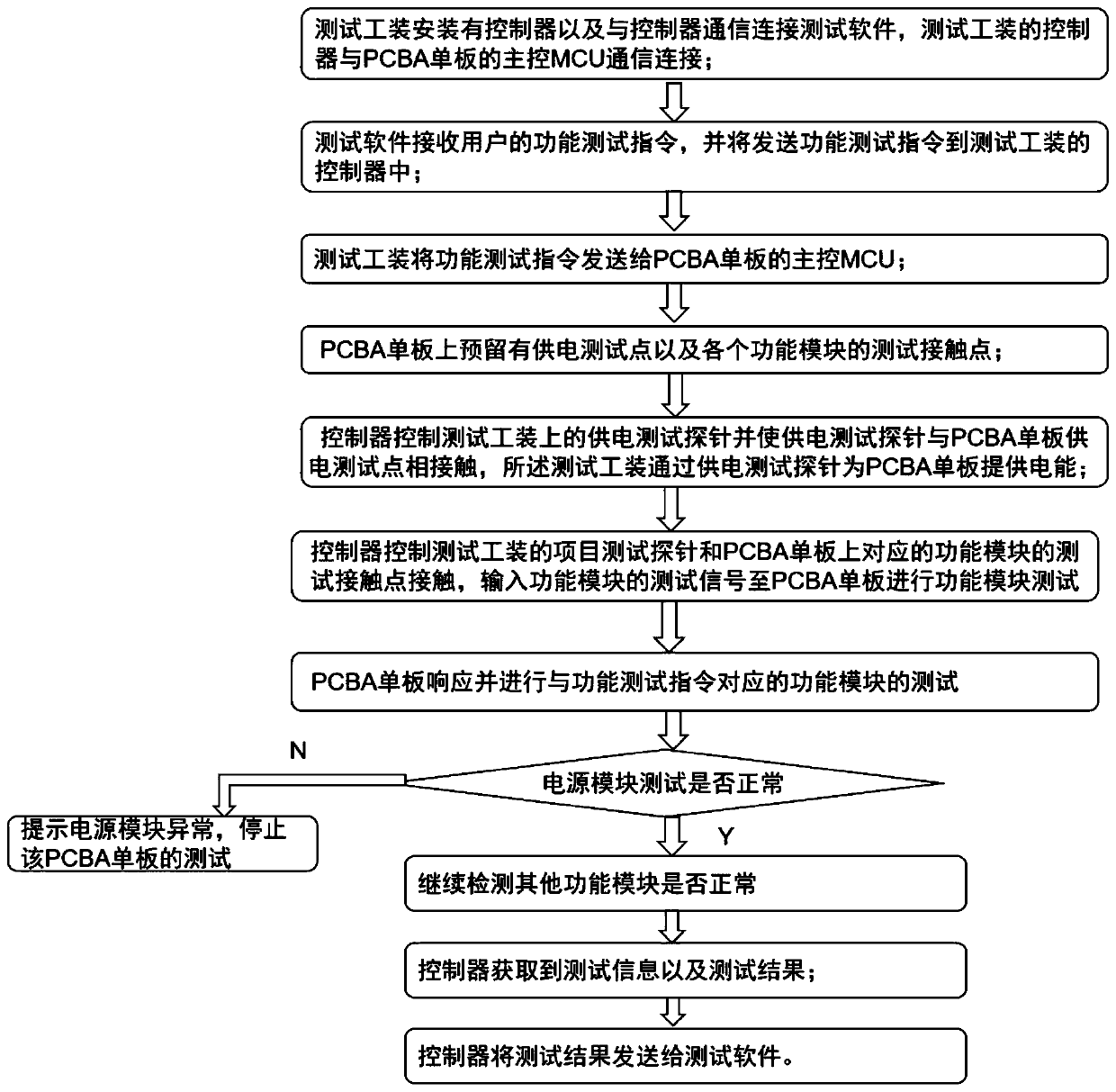

PCBA single board test method and system

ActiveCN110456259AImprove test efficiencyTest item refinementDigital circuit testingTest efficiencyComputer module

The invention provides a PCBA (Printed Circuit Board Assembly) single board test method. The method comprises the following steps that: test software receives a function test instruction of a user andsends the function test instruction to a controller of a test tool; the test tool sends the function test instruction to a main control MCU of a PCBA single board; a power supply test point and testcontact points of all the functional modules are reserved on the PCBA single board; the controller controls a power supply test probe on the test tool to provide electric energy for the PCBA single board; the controller controls the project test probe to be in contact with a test contact point of a corresponding function module on the PCBA single board to test the function modules; and the PCBA single board responds, and the controller obtains the function module test information and the test result of the PCBA single board. Through cooperation of the PCBA single board and the test tool, hardware full-function test is covered, test items are more refined, manual batch test can be replaced, the production hardware test efficiency is improved, it is guaranteed that factory product hardware is free of faults, and the production cost is greatly reduced.

Owner:SHENZHEN KINLONG HBS SMART TECH

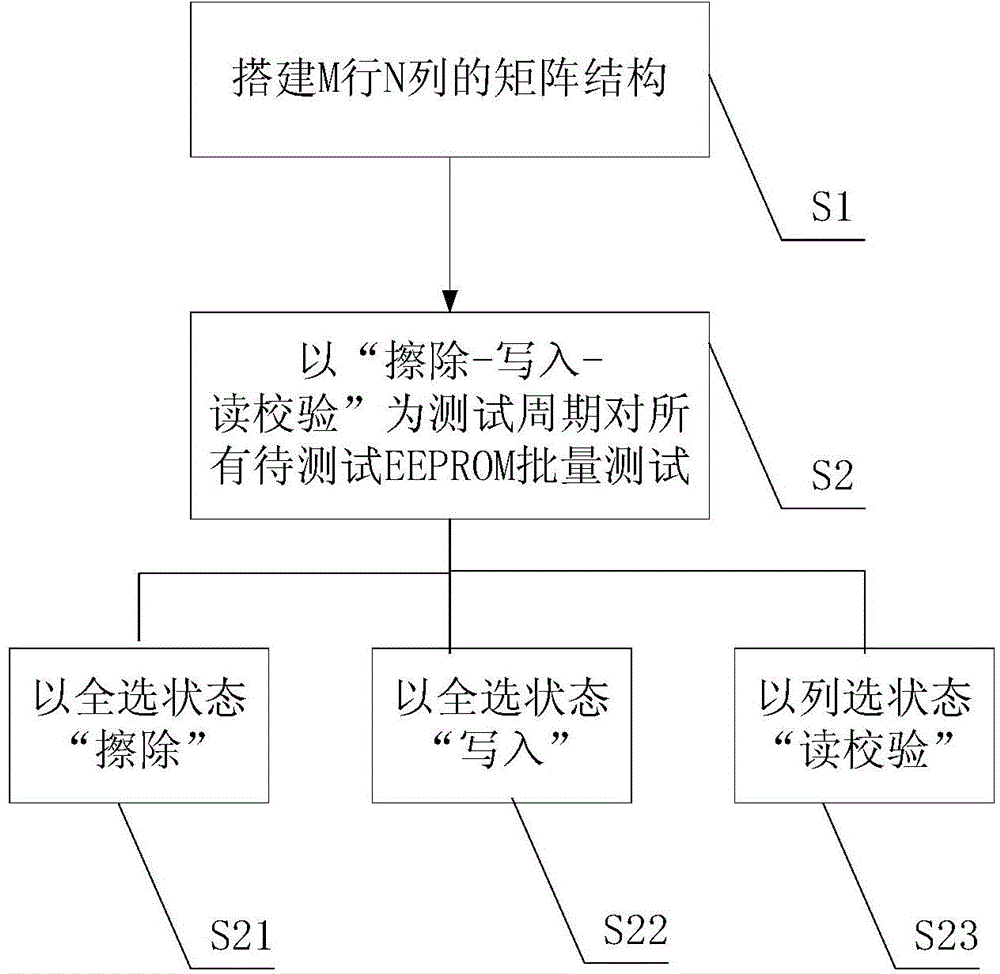

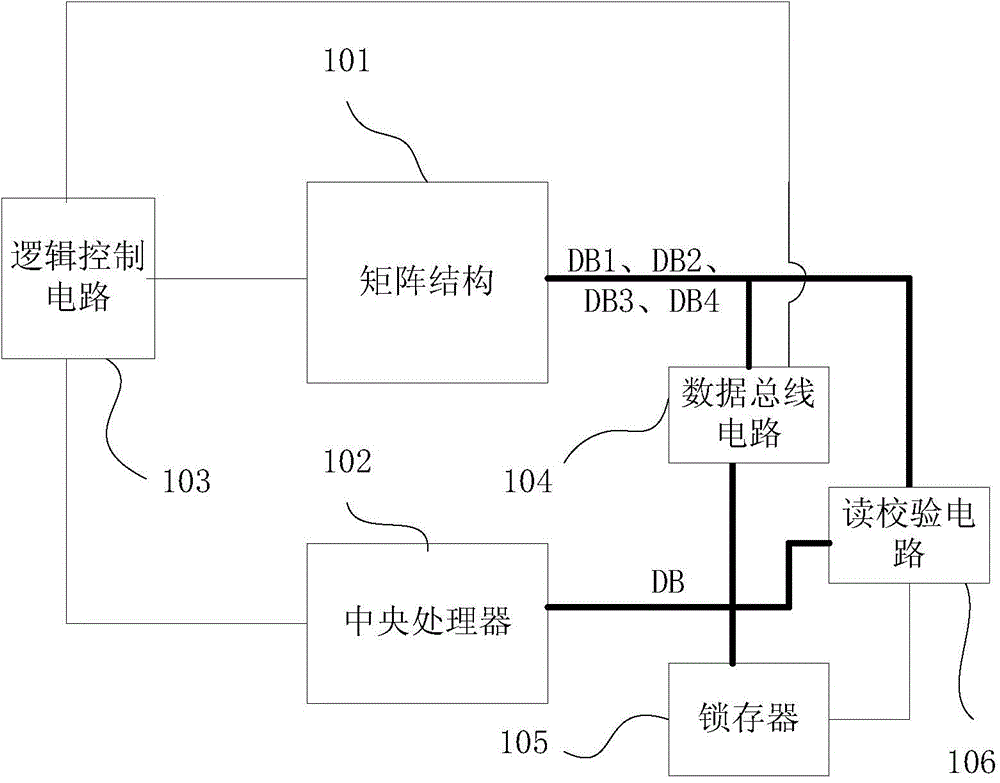

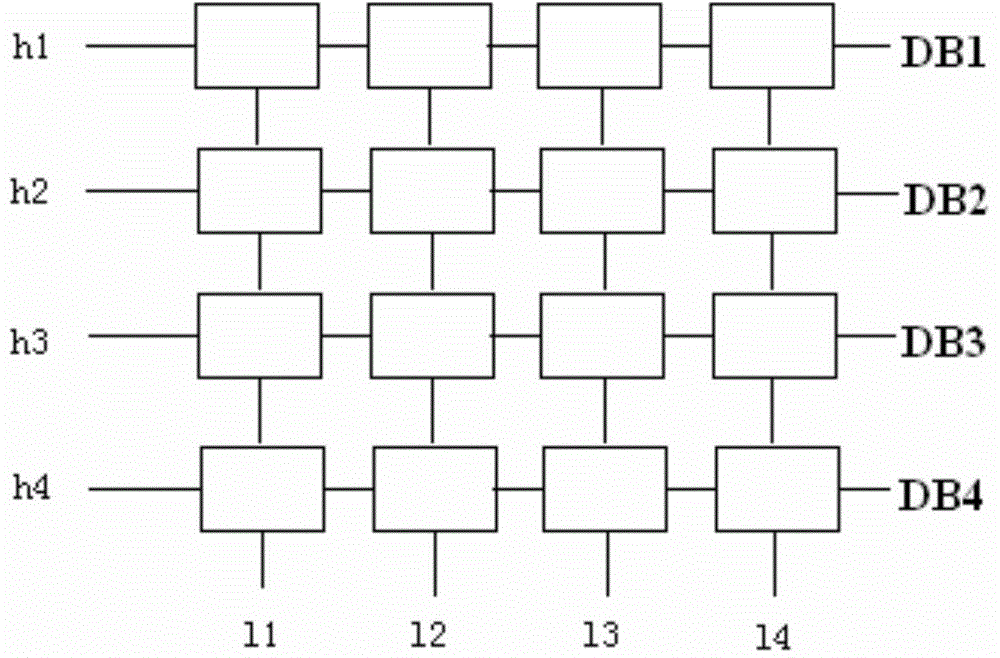

EEPROM durability test method and EEPROM durability test device

InactiveCN104658613AOmit the "check empty" stepImplement the select all operationStatic storageProgrammable read-only memoryComputer engineering

The invention discloses an EEPROM (Electrically Erasable Programmable Read-Only Memory) durability test method which comprises the steps of establishing a matrix structure, and performing batch tests on to-be-tested EEPROMs on all pipe positions by taking 'erase-write in-read check' as a test period in one round. The method is improved based on the existing EEPROM durability test process, the step of 'blank check' is omitted, and parallel operation is introduced, so that full selection operation is realized during 'erase' and 'write in', and a check result is directly produced through preprocessing during 'read check' to realize column selection operation. The invention further discloses an EEPROM durability test device which comprises a matrix structure, a central processing unit, a logic control circuit, a data bus circuit and a latch. The parallel operation is used as much as possible in each link of 'erase-write in-read check', so that the time is saved effectively and the efficiency is improved effectively.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

Dead load tensile device for tensile test

InactiveCN101655436AKeep constantSimple structureMaterial strength using tensile/compressive forcesFrame basedMetallic materials

The invention relates to a dead load tensile device for a tensile test, belongs to the technical field of the tensile test of a metal material. The device comprises a frame part and a bearing part, wherein the frame consists of a frame base, a stud and an anti-falling bracket, with the stud and the anti-falling bracket being fixed to the frame base and the stud being used for assembling the bearing part; the bearing part is connected with the stud via a rolling bearing, the balance of a bearing capacity arm is realized through a balance regulator and a level instrument on the top of the bearing capacity arm, a sample is assembled between the head of the bearing capacity arm and a chuck fixing base in an adjustably connecting way and is axially tensioned in a manner of weight loading in order to realize manual loading and the constancy of the loading. In combination with the advantages of traditional equipment, the experimental device overcomes own shortages, can realize manual loadingand batch test, and can guarantee the constancy of the loading.

Owner:UNIV OF SCI & TECH BEIJING

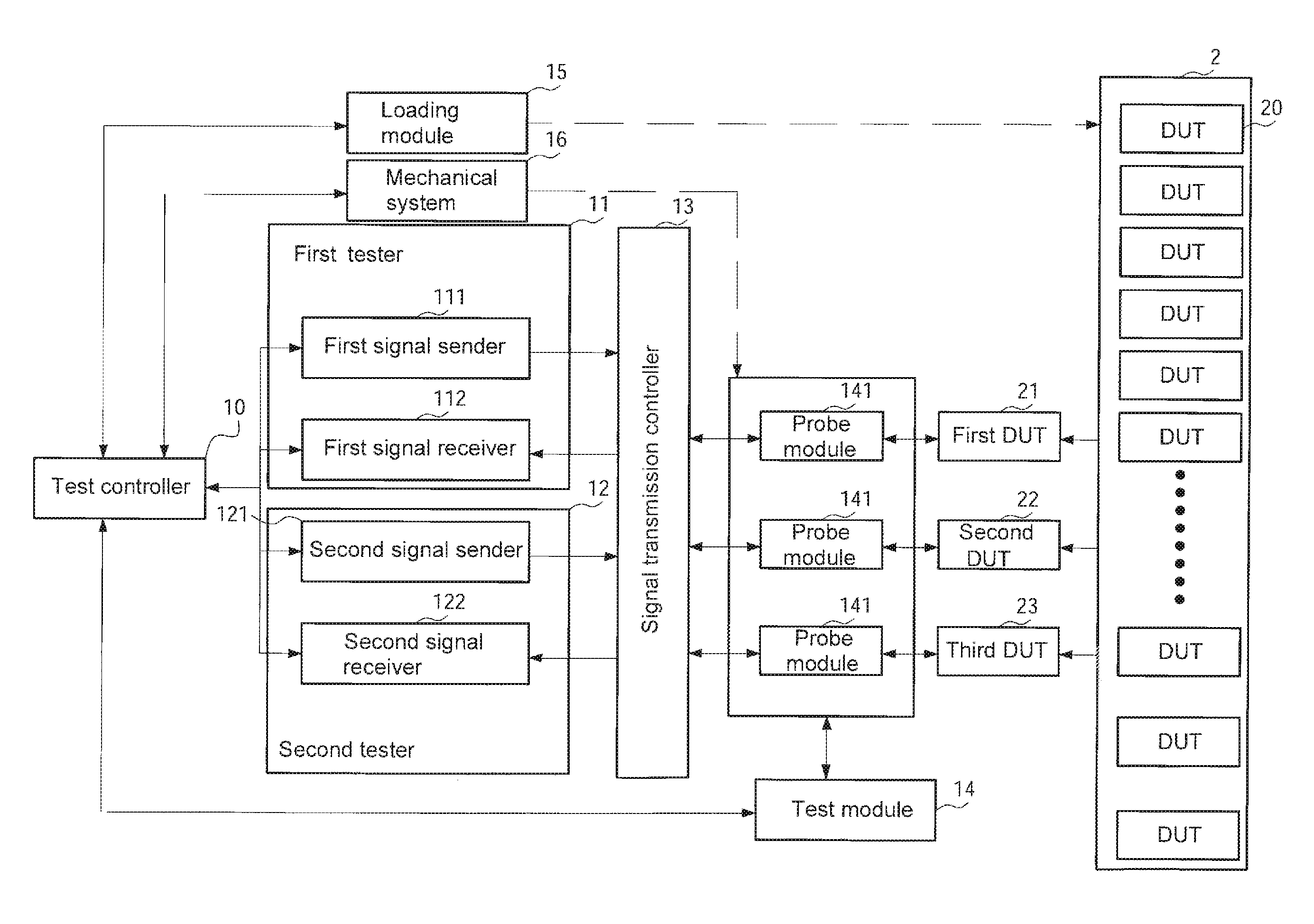

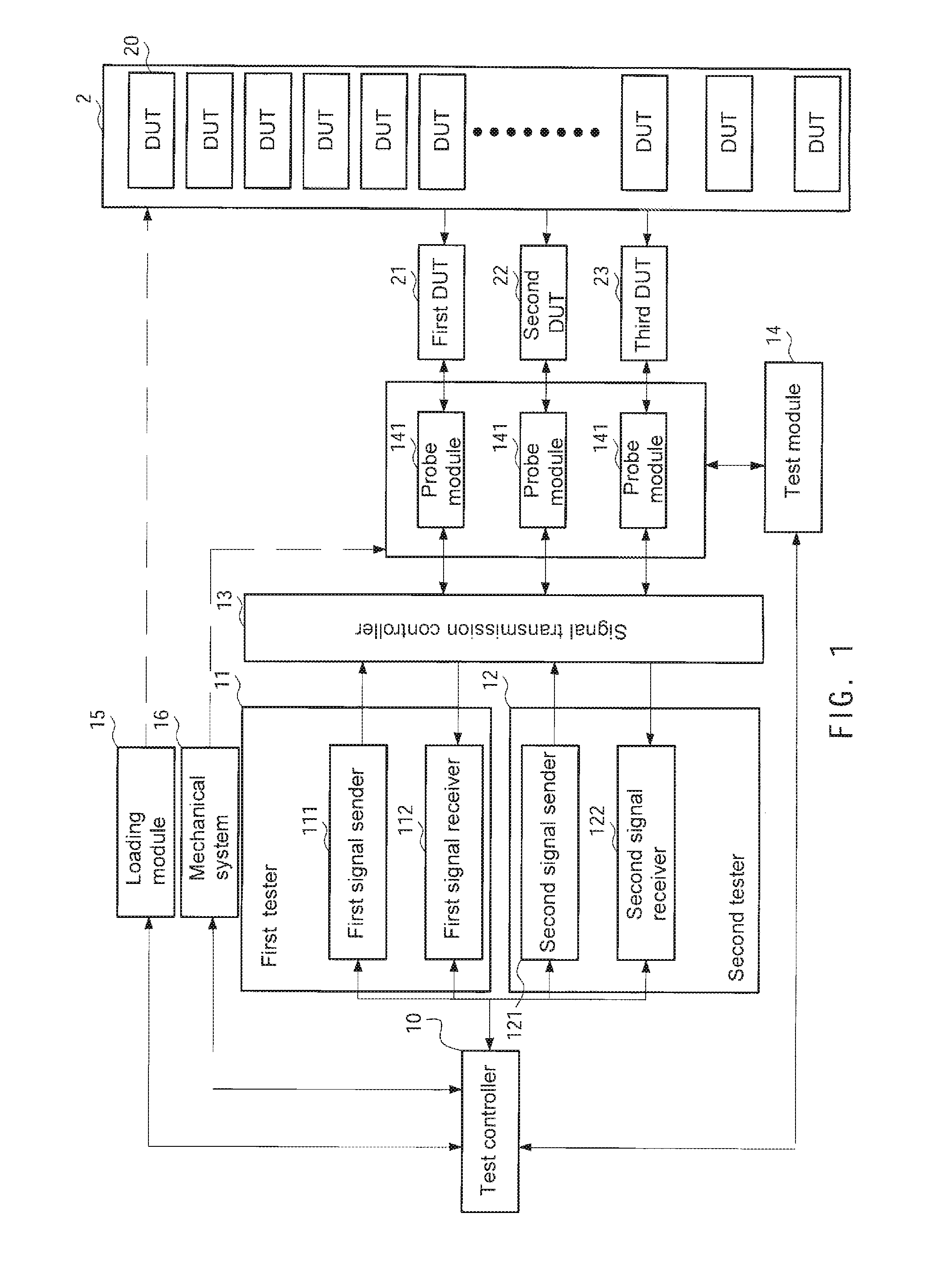

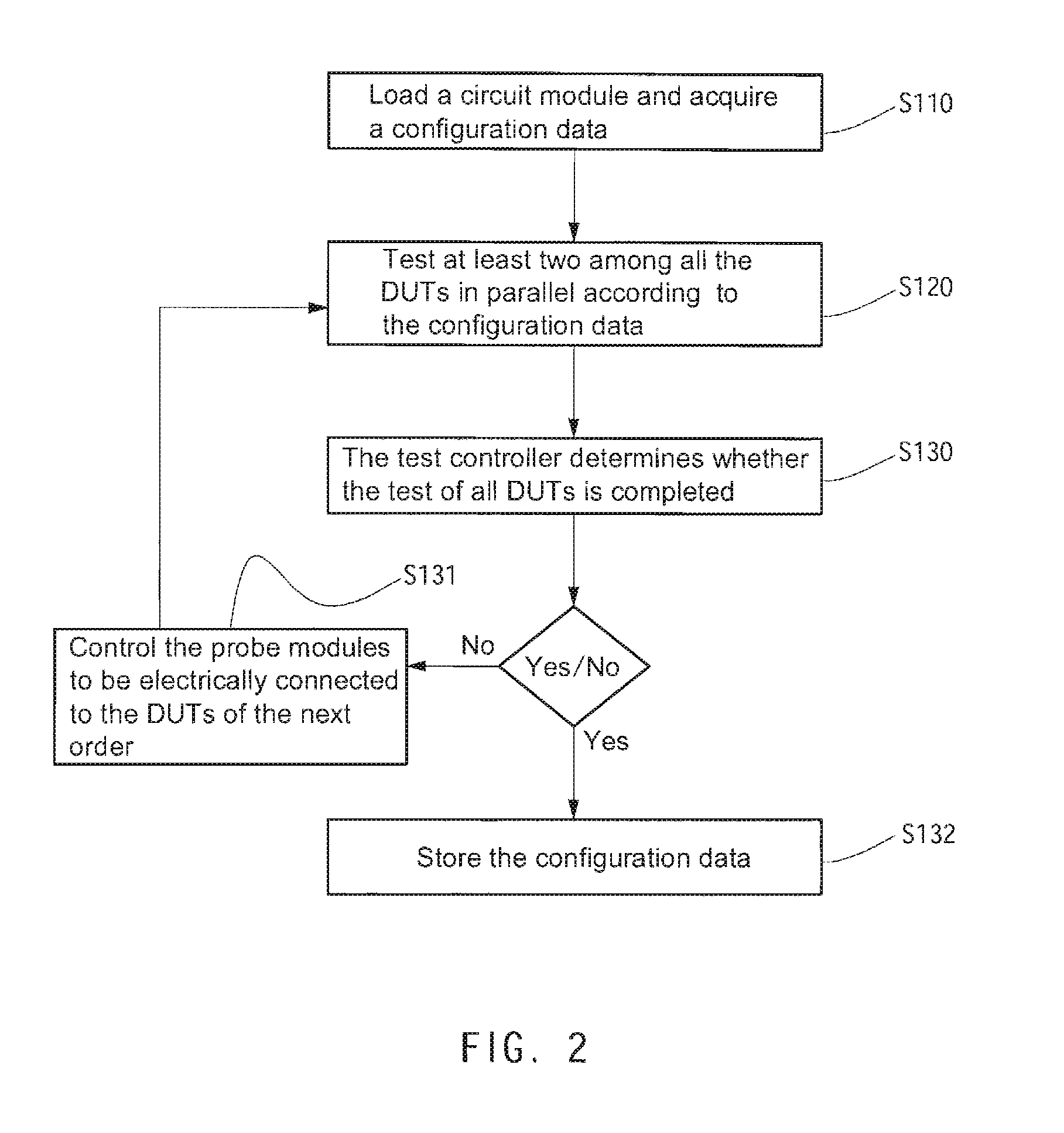

System in package batch test method and batch test system thereof

InactiveUS20100213950A1Shorten test timeUnnecessary loadAutomated test systemsElectricityControl signal

A system in package (SIP) batch test method and an SIP batch test system are applicable to an unpartitioned circuit module having a plurality of devices under test (DUTs). The circuit module is loaded in a loading module of the batch test system after probing test and molding operations. A test module of the batch test system is electrically coupled to at least two DUTs. At least two testers provide two different signal tests. A signal transmission controller controls signal transmission paths between the testers and the test module. A test controller controls the two testers and the test module to test the electrically coupled DUTs in parallel and record test results of the DUTs in configuration data. Finally, the circuit module is partitioned, so as to classify the DUTs according to the test results.

Owner:ACCTON TECHNOLOGY CORPORATION

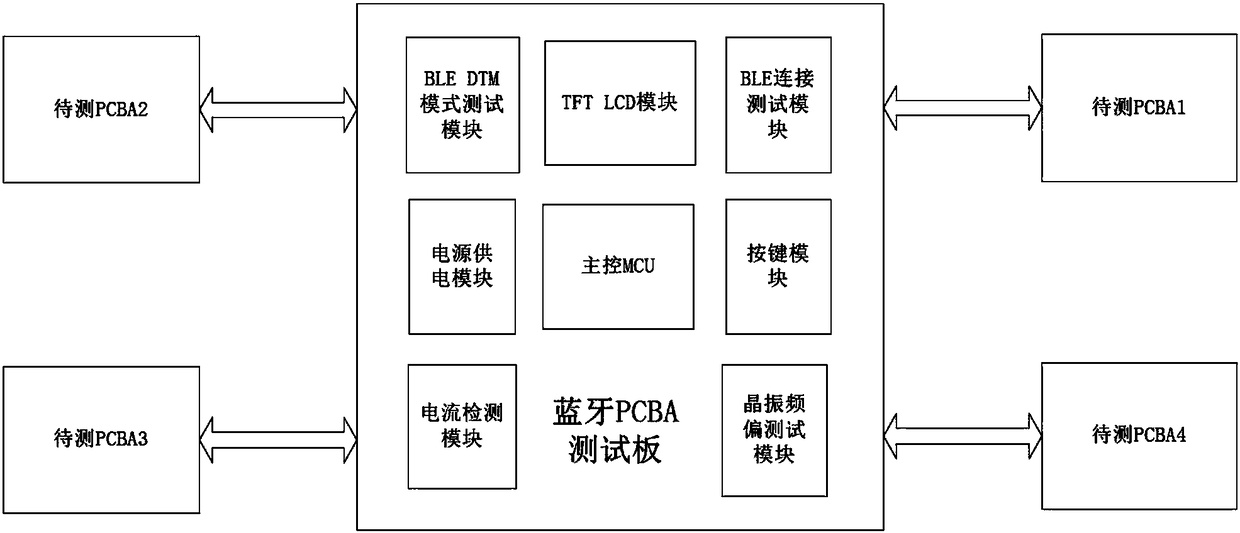

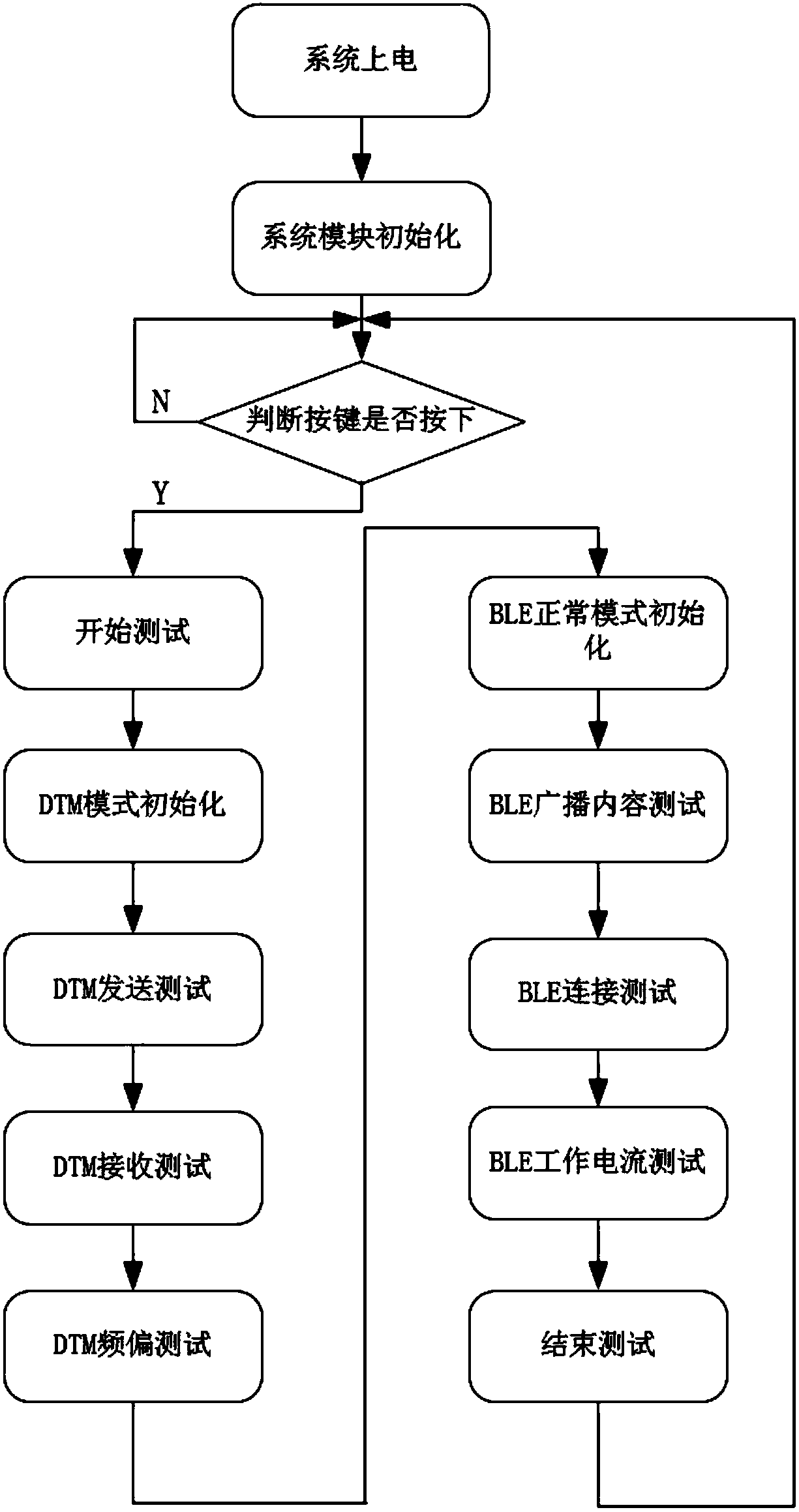

Bluetooth electronic scale PCBA batch test method and system

ActiveCN108089112AReduce stepsImprove test efficiencyElectronic circuit testingTest efficiencyEngineering

The invention discloses a bluetooth electronic scale PCBA batch test method and system. The system is composed of a bluetooth PCBA test board and four PCBAs to be tested, wherein the bluetooth PCBA test board comprises a BLE DTM mode test module, a BLE connection test module, a power supply module, a TFT LCD module, a key module, a current detection module, and a crystal vibration frequency deviation test module and a master control MCU. The four PCBAs to be tested can be tested at the same time, so that the testing efficiency is greatly improved compared with a traditional testing method.

Owner:CHIPSEA TECH SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com