Patents

Literature

114results about How to "Improve production test efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

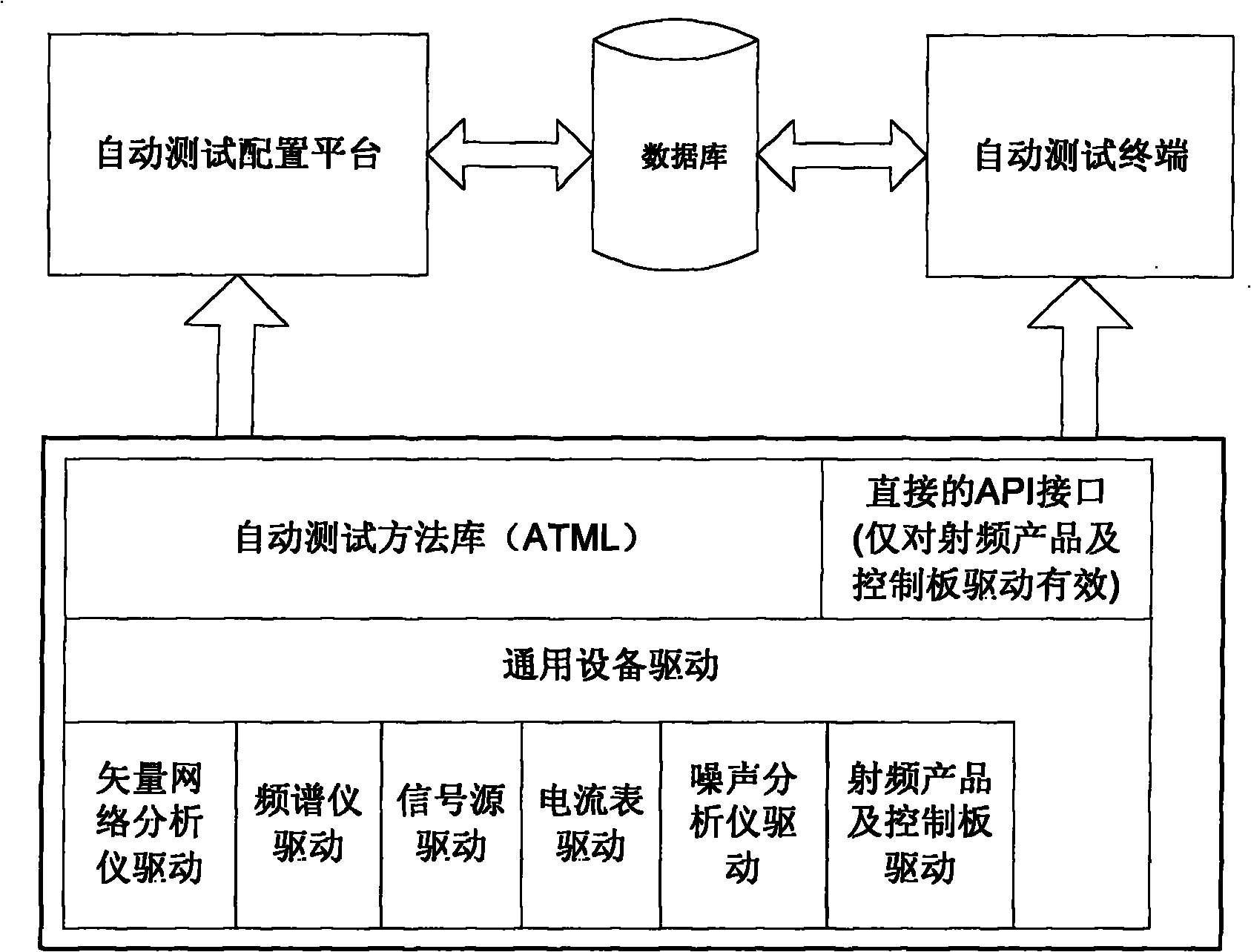

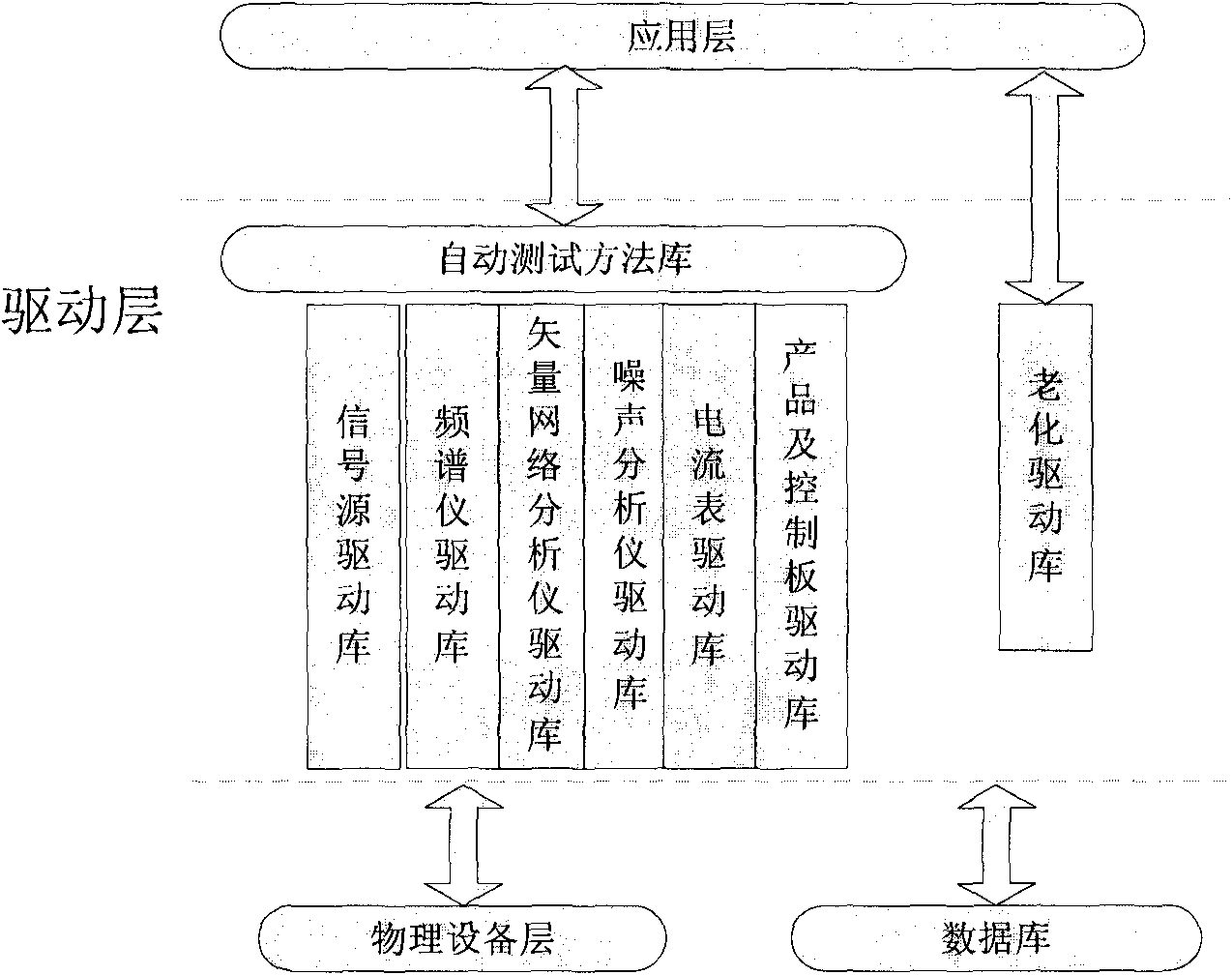

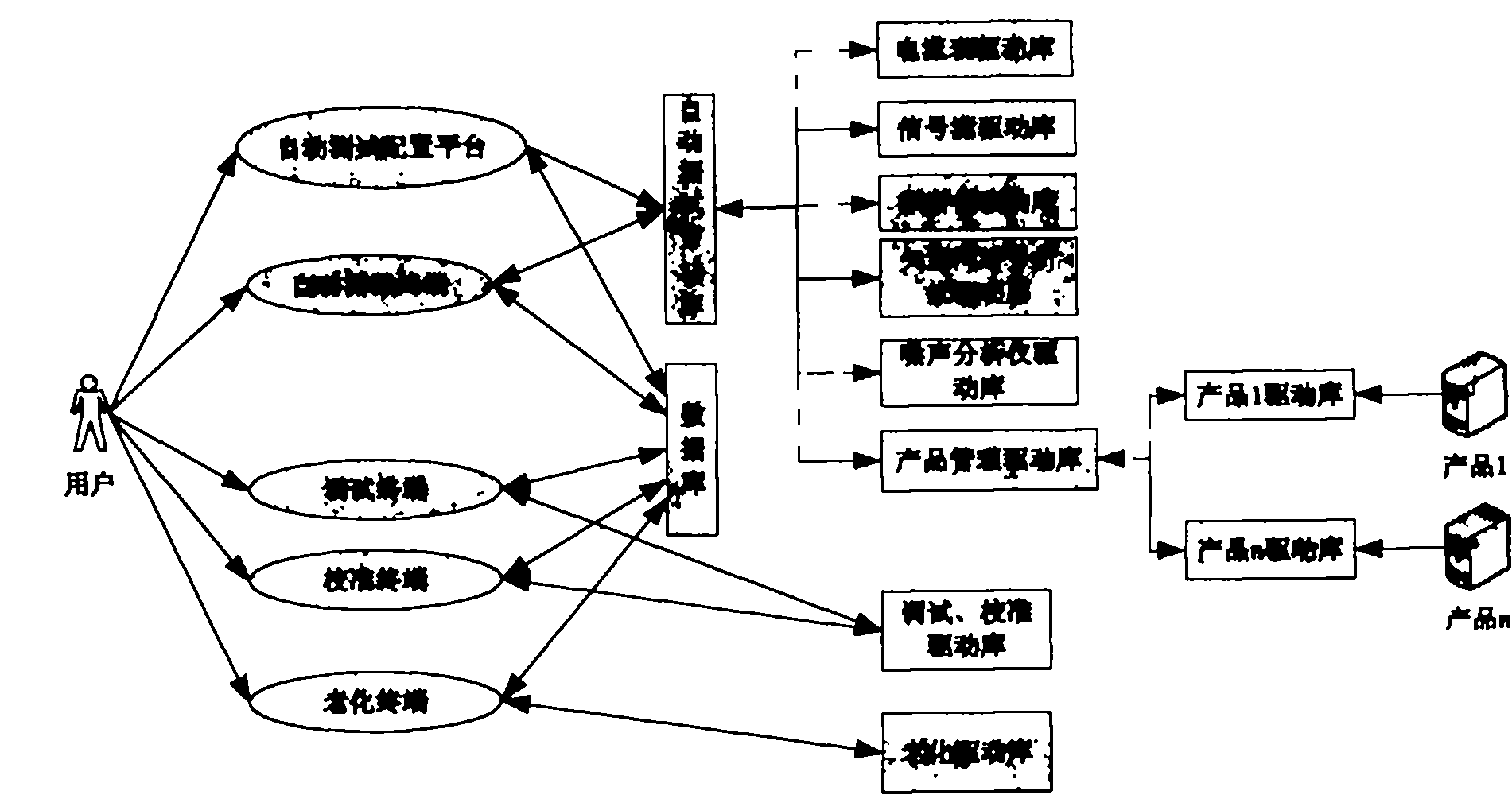

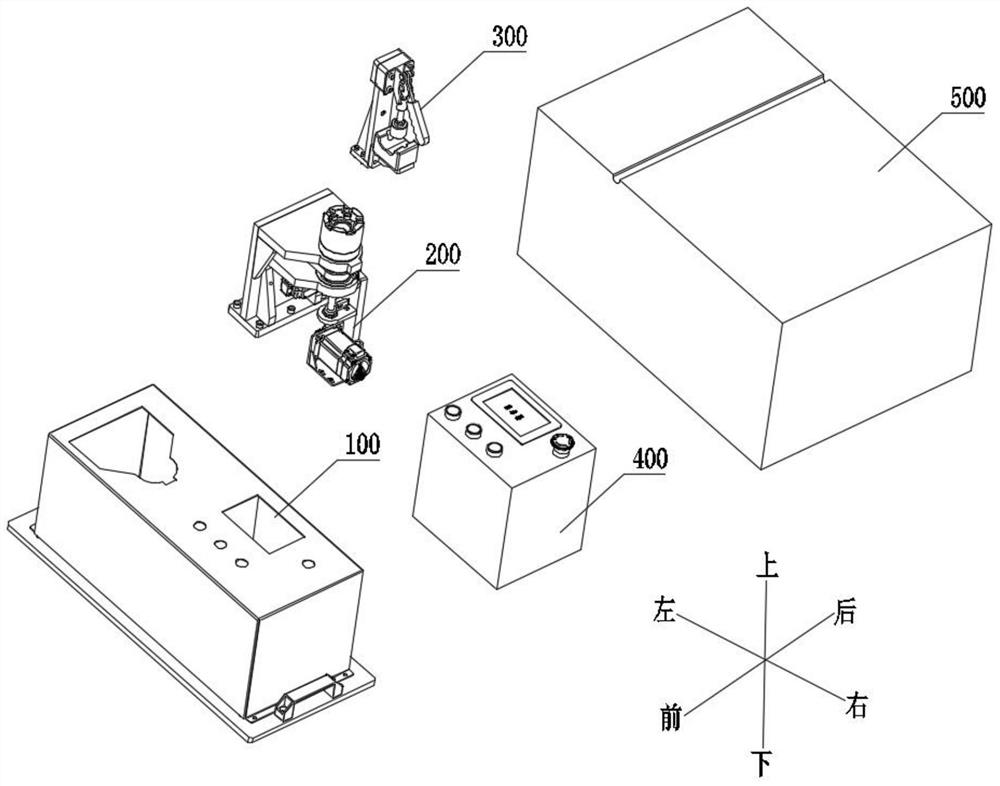

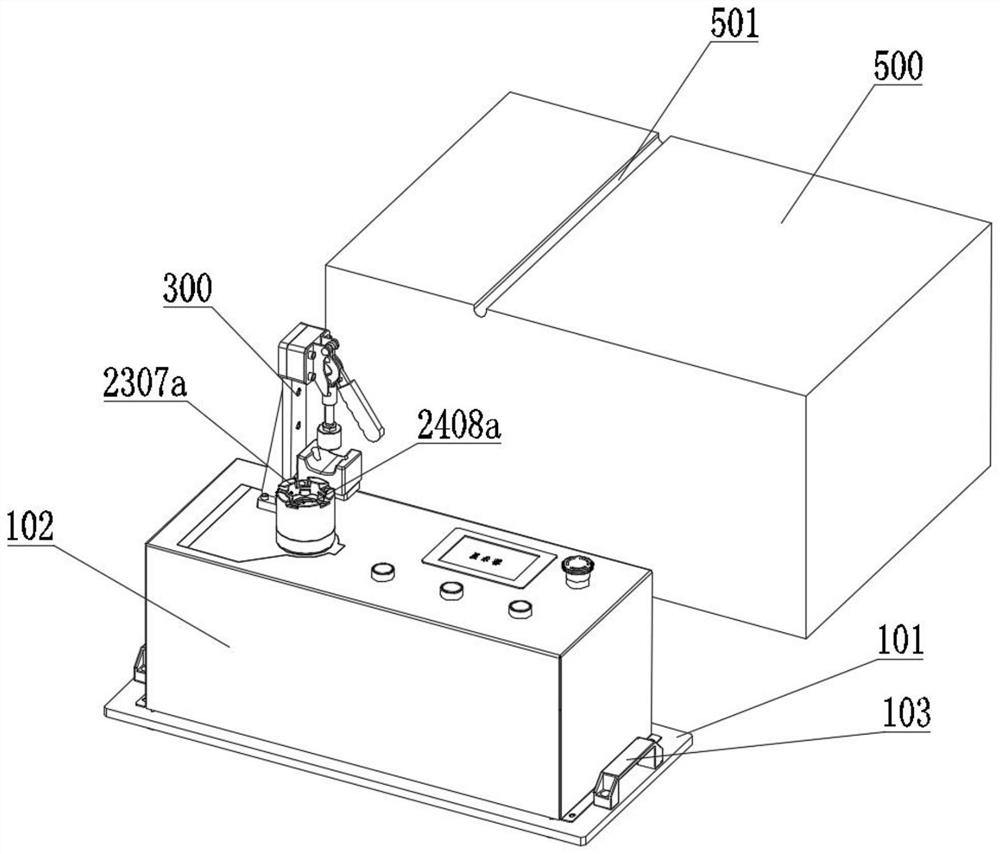

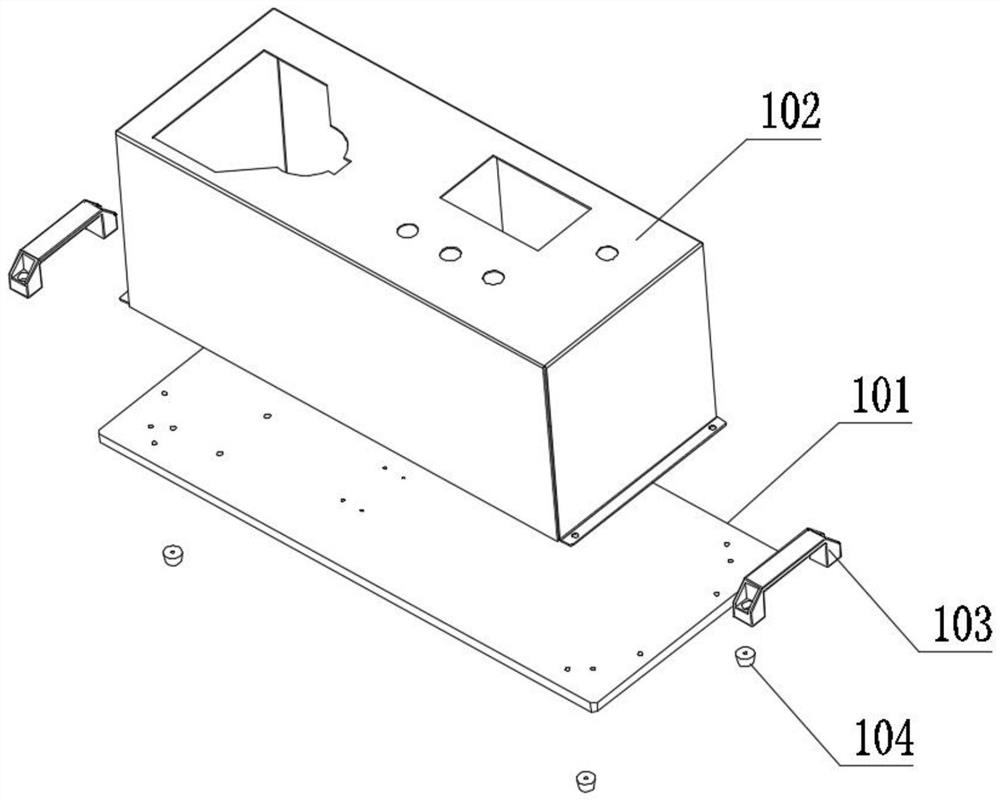

Flexibly-extendable automatic testing system platform suitable for testing radio frequency module product

ActiveCN101852832AImprove production test efficiencyEasy to useElectrical testingSoftware testing/debuggingRF moduleReusability

Owner:成都芯通软件有限公司

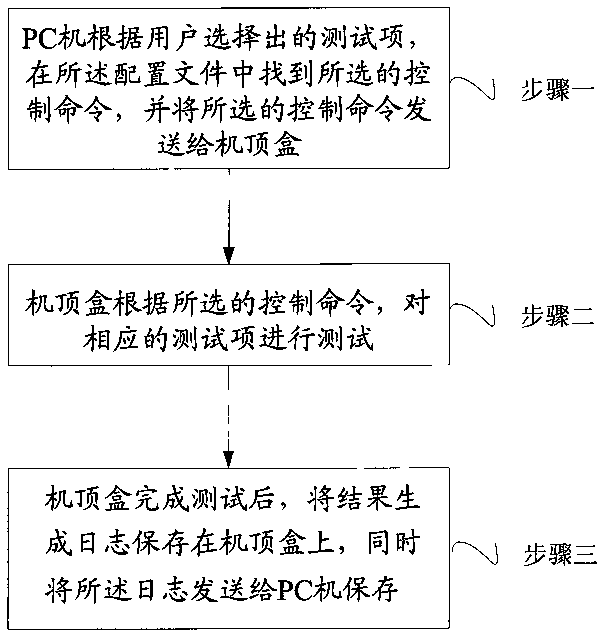

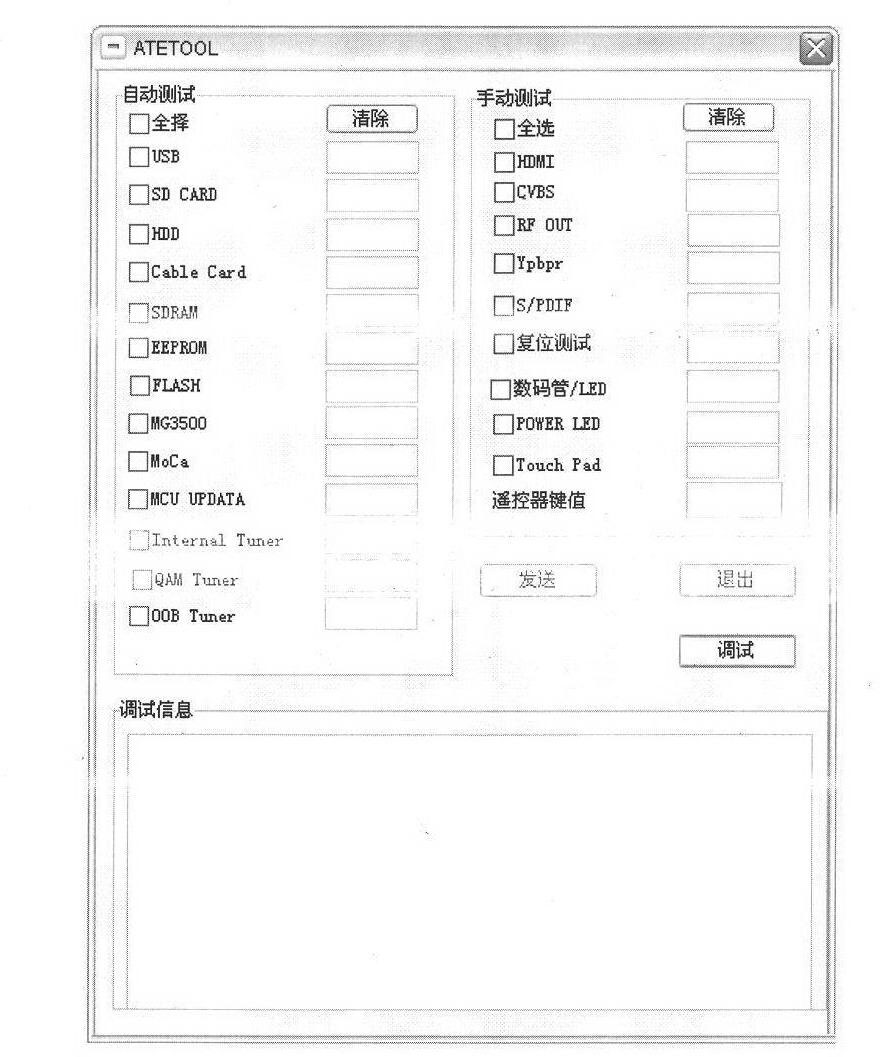

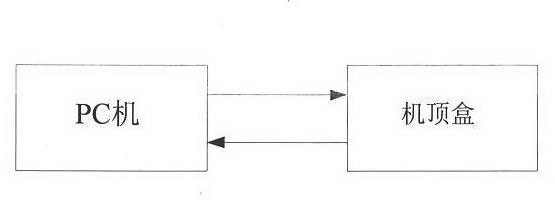

Test method of set-top box and test system thereof

InactiveCN102665094AEasy to operateSmall amount of software codeTelevision systemsTest executionSet top box

The invention relates to the set-top box field, especially to a test method of a set-top box and a test system thereof. The method comprises the following steps that: a configuration file is stored in a PC machine in advance, wherein the configuration file includes a plurality of control commands and each control command corresponds to one test item, and the PC machine generates a test interface including a plurality of test items; after a user selects a test item that needs to be tested on the test interface, the PC machine finds a selected control command in the configuration file according to the test item selected by the user and sends the selected control command to a set-top box; the set-top box tests a corresponding test item according to the selected control command; and after the test by the set-top box is completed, the result is generated into a log that is then stored in the set-top box; and meanwhile, the log is sent to the PC machine for storage. According to the invention, test interface software is developed on a PC machine and matched test execution software is developed on a set-top box; the software code scale is small; and besides, characteristics of simpleness, easiness of maintenance, easiness of operation and high portability are realized.

Owner:SHENZHEN JIUZHOU ELECTRIC

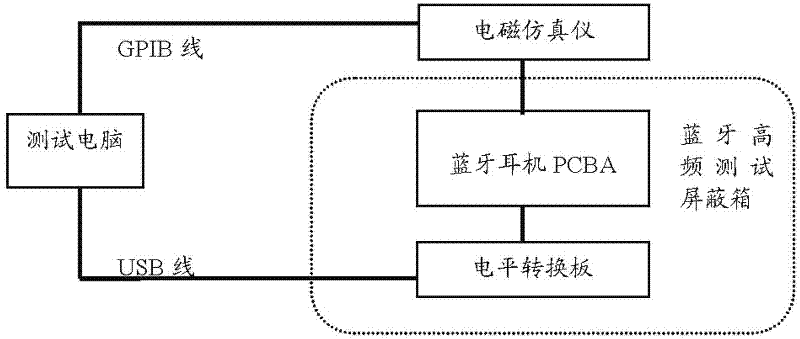

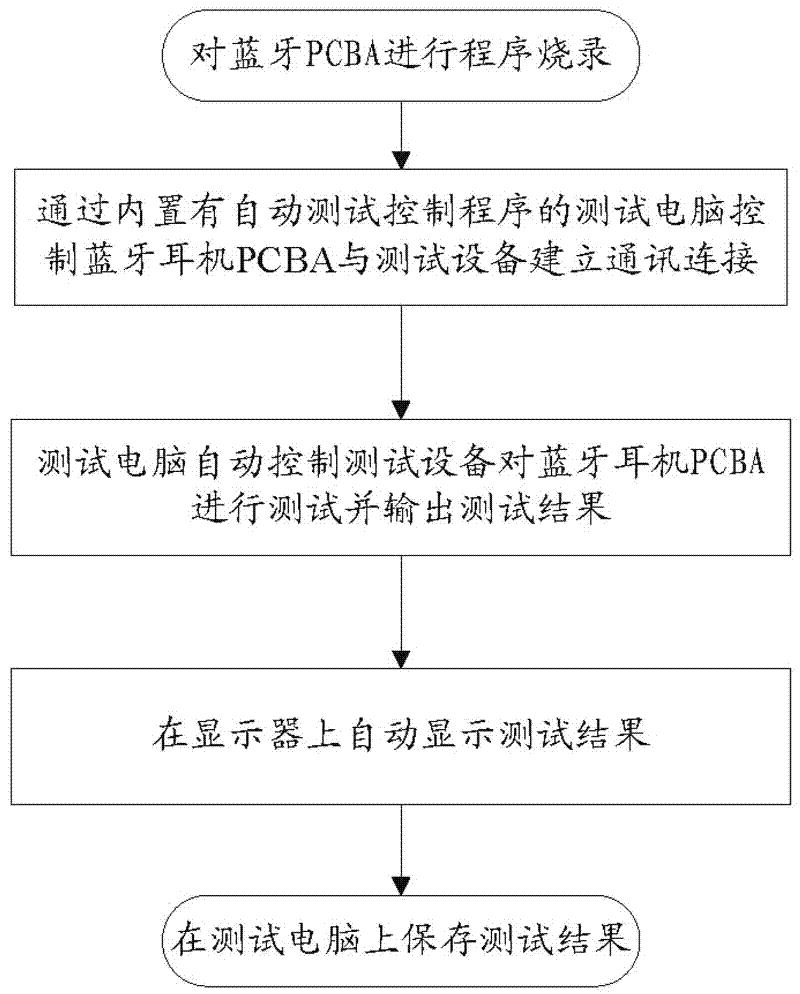

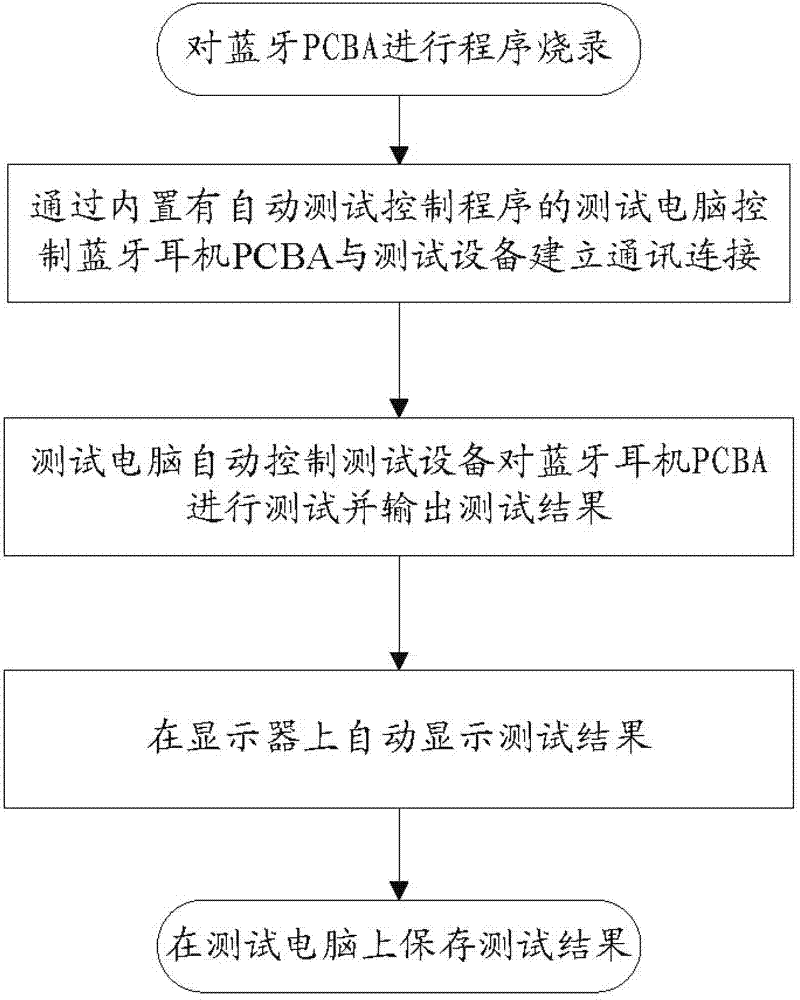

Batch test method and system for PCBA (Printed Circuit Board Assembly) of Bluetooth headset

InactiveCN102243281AImprove production test efficiencyElectrical testingTest efficiencyComputer hardware

The invention discloses a batch test method for a PCBA (Printed Circuit Board Assembly) of a Bluetooth headset, aiming at providing a batch test method of the PCBA of the Bluetooth headset, with high testing efficiency. The batch test method comprises the following steps of: controlling the PCBA of the Bluetooth headset and test equipment to establish a communication connection through a test computer internally provided with an automatic test control program; testing the PCBA of the Bluetooth headset by automatic control test equipment of the test computer and outputting a test result; and automatically displaying the test computer on a display. The invention also discloses a batch test system of the PCBA of the Bluetooth headset. The invention can be used for batch test of the PCBA of the Bluetooth headset.

Owner:GUANGZHOU LIWEI ELECTRONICS

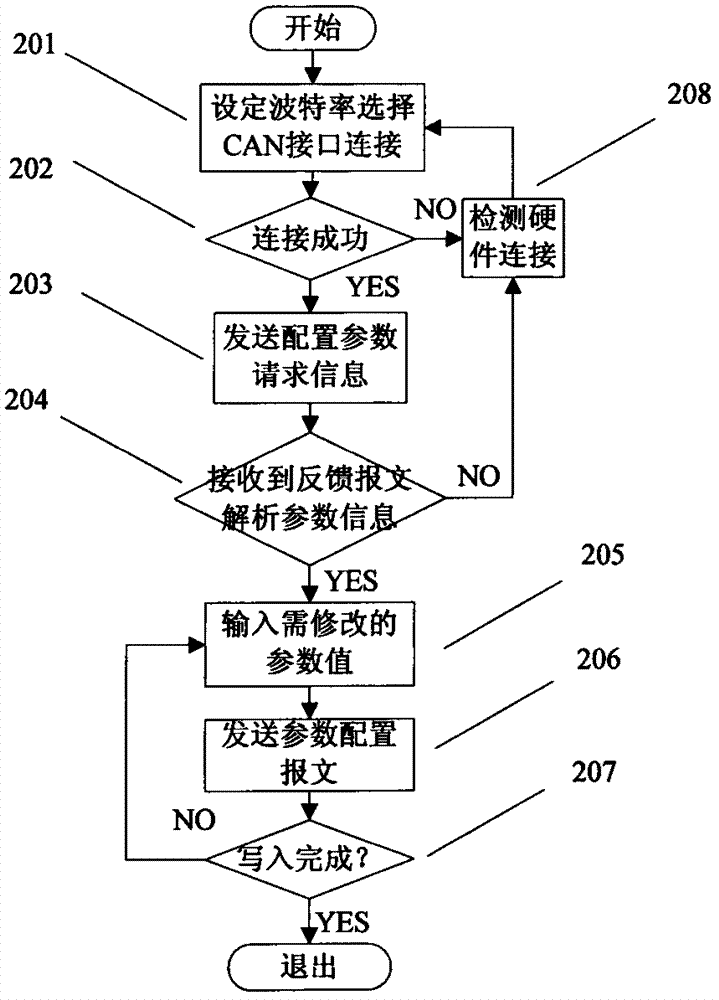

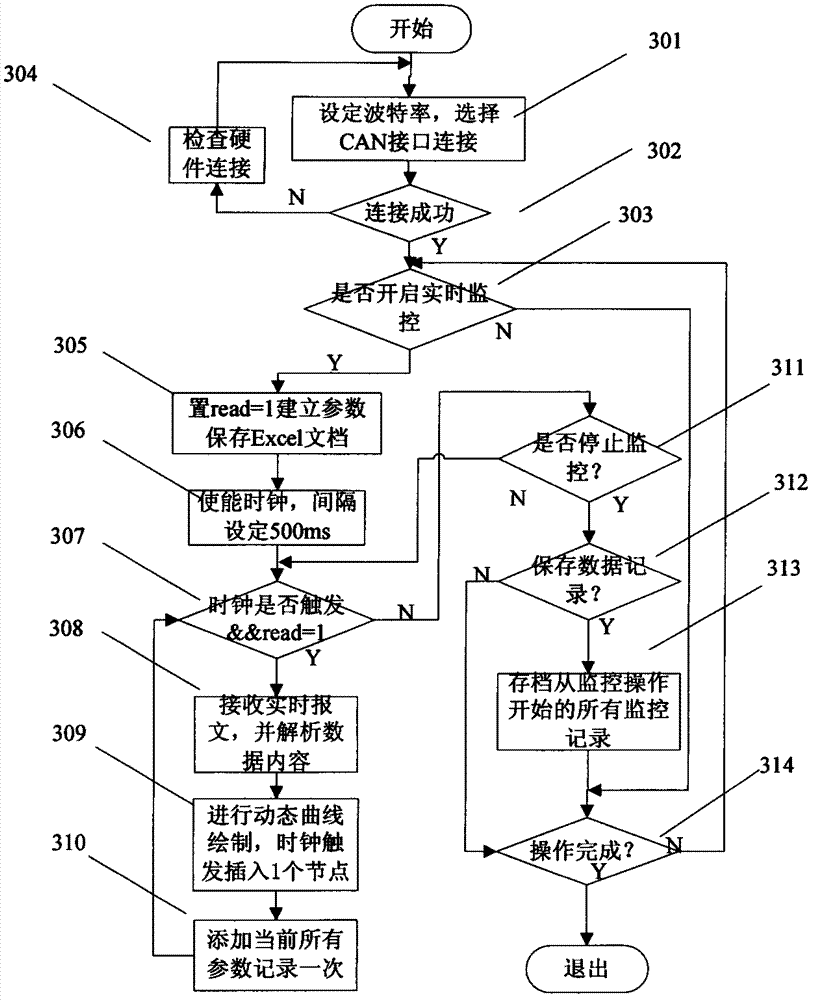

Real-time monitoring diagnostic system and diagnostic method for electromobile battery management system

ActiveCN103568863APreserve accuratelyShort intervalElectric vehicle charging technologyVehicular energy storageTime informationAutomotive battery

The invention discloses a real-time monitoring diagnostic system and diagnostic method for an electromobile battery management system. The real-time monitoring diagnostic system comprises an upper computer and a CAN communication data transmission module; the CAN communication data transmission module comprises a USB interface and a CAN wire interface, the USB interface is connected with the upper computer, and the CAN wire interface is connected with the CAN wire of a BMS. The diagnostic method comprises the steps that operation parameters and data displaying of a host machine and a slave machine of the BMS system are set; a monitoring system operates in real time and automatically stores real-time information; reliability and sensitivity of BMS protecting actions are verified, generation of voltages, currents, temperature signals and anomalous events can be simulated, so that reaction of the BMS to abnormal signals is captured and diagnosis is conducted on the BMS; control reliability of each relay of the BMS is detected. The real-time monitoring diagnostic system and diagnostic method for the electromobile battery management system meets detection application requirements during BMS batch production and improves production testing efficiency, can carry out real-time fault diagnosis on the BMS through the CAN, and provides an effective method for debugging and fault processing work.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

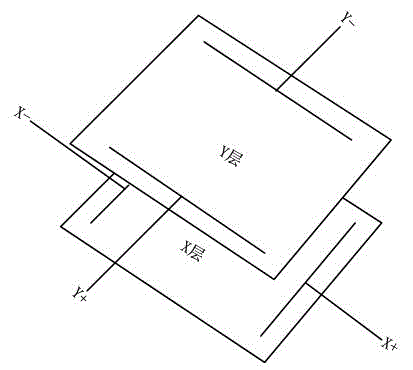

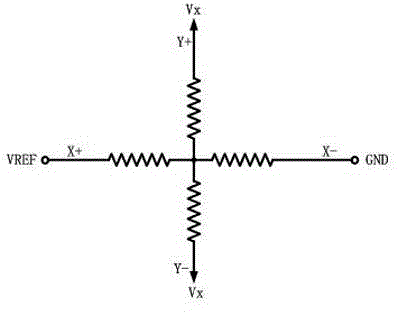

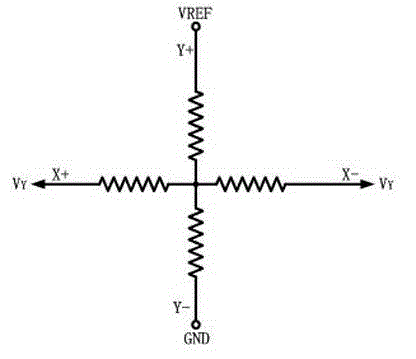

Touch screen detection method and electronic products

InactiveCN102722282AImprove detection efficiencyEasy to operateInput/output processes for data processingTouchscreenFault rate

The invention discloses a touch screen detection method and electronic products. The method is characterized by touching and sliding on a touch screen along the diagonal direction, receiving feedback coordinate values of the touch screen and judging the touch screen to be normal if all the X-axis and Y-axis numerical values are detected when detection is performed for the touch screen. Each sensing area of the touch screen is judged to be normal or not by simple diagonal sliding touch operation and by a method of detecting whether all the X-axis and Y-axis numerical values are traversed or not. Compared with a traditional scheme, the touch screen detection method is simple in operation, high in detection speed and high in accuracy rate of detection results. Production detecting efficiency of the electronic products can be remarkably improved while fault rate of manufactured products is decreased by applying the method to various electronic products needing to be assembled with touch screens.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

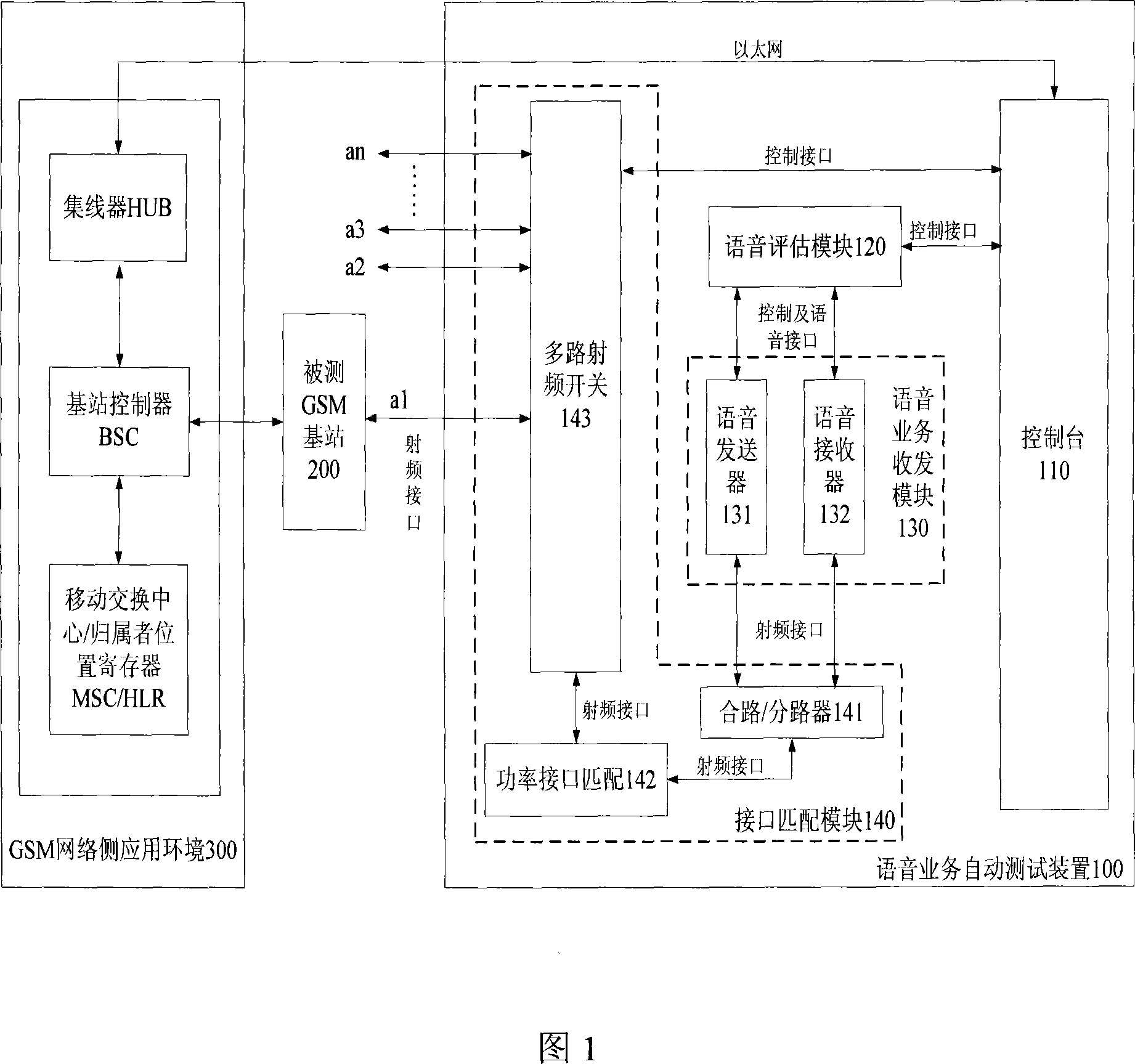

GSM base station voice service automatic testing equipment and method

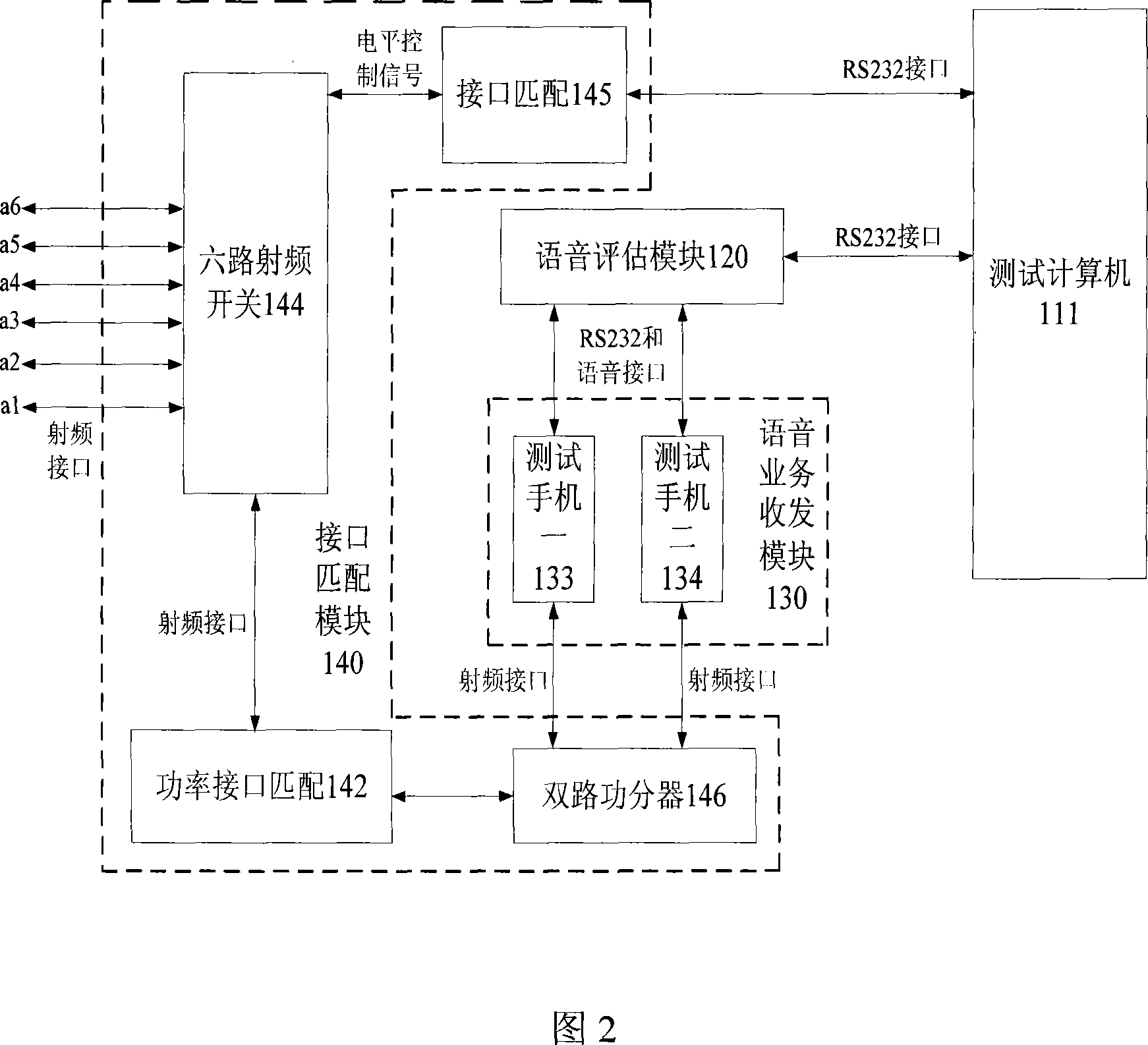

InactiveCN101137178AShield interferenceIncrease authenticitySupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsComputer hardwareRadio frequency

The invention relates to an automatic test device (100) of GSM base station voice service and method therefor, wherein, the device comprises a console (110), a voice evaluation module (120), a voice service receiving transmitting module (130) and an interface matching module (140); the method includes: a test base station is gated by the console (110) through software controlling a multi-channel radio frequency switch (143); a voice path connection is established by a script code which controls a voice sender (131) and a voice receiver (132); the voice evaluation module (120) sends voice test signals with specified sequence and contrast analyzes difference of sent voice and received voice, then sends analysis result to the console (110) for data processing and outputing test result. The device and method the disturbance of production test site environment to base station test is shielded by the device and method, an automatic operation for parallel test of a plurality of base stations is realized, the production test efficiency is improved.

Owner:ZTE CORP

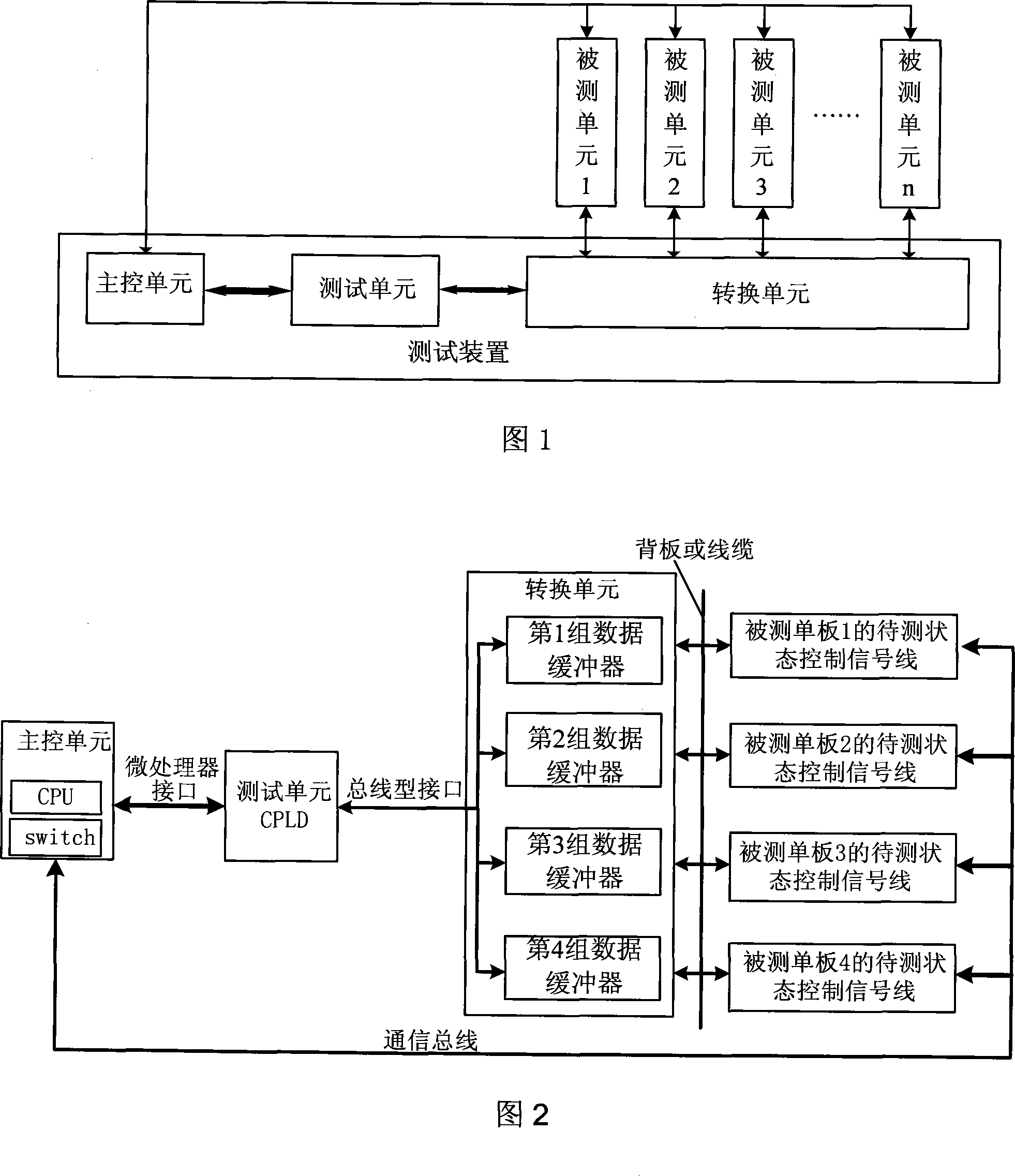

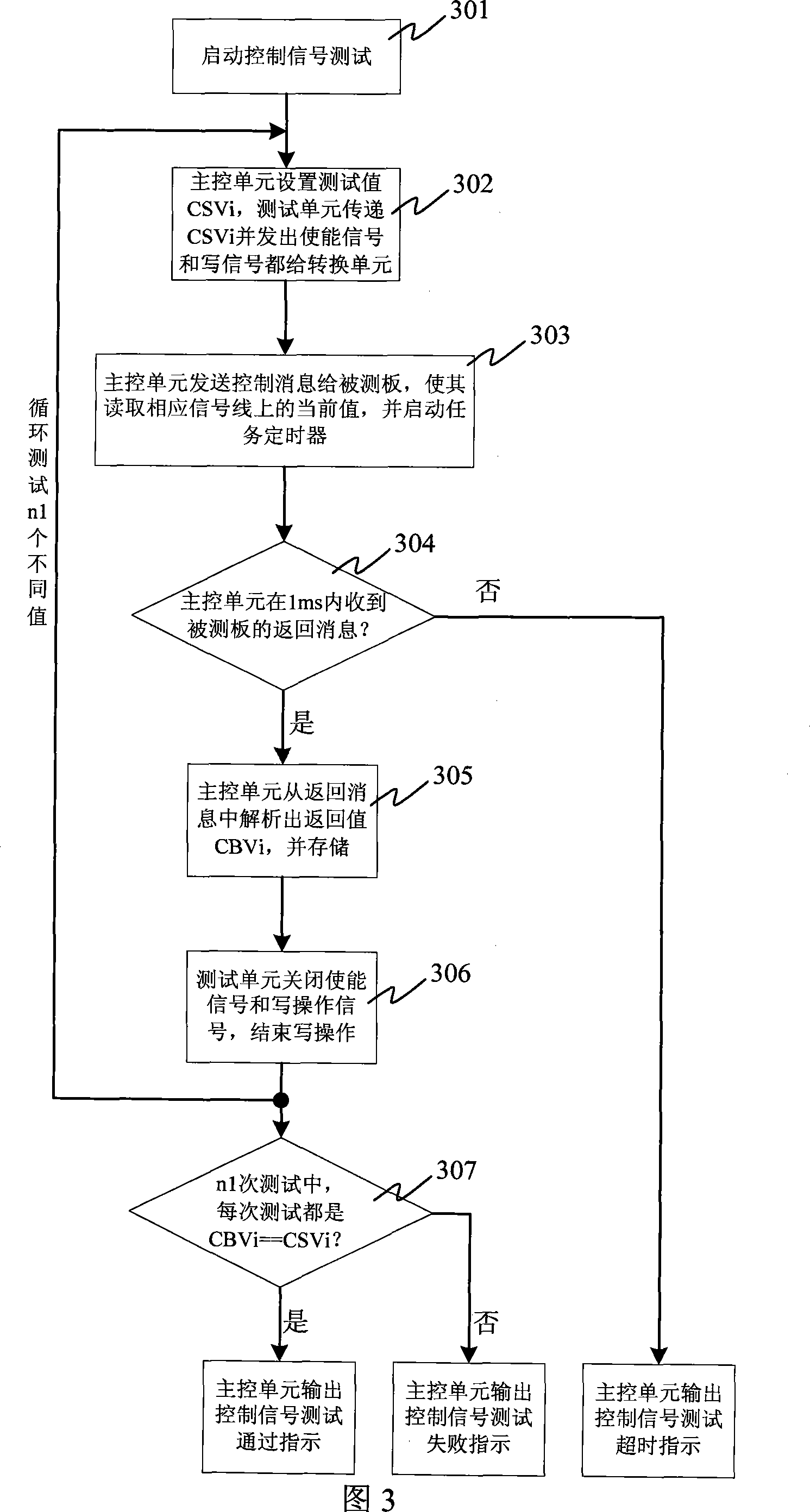

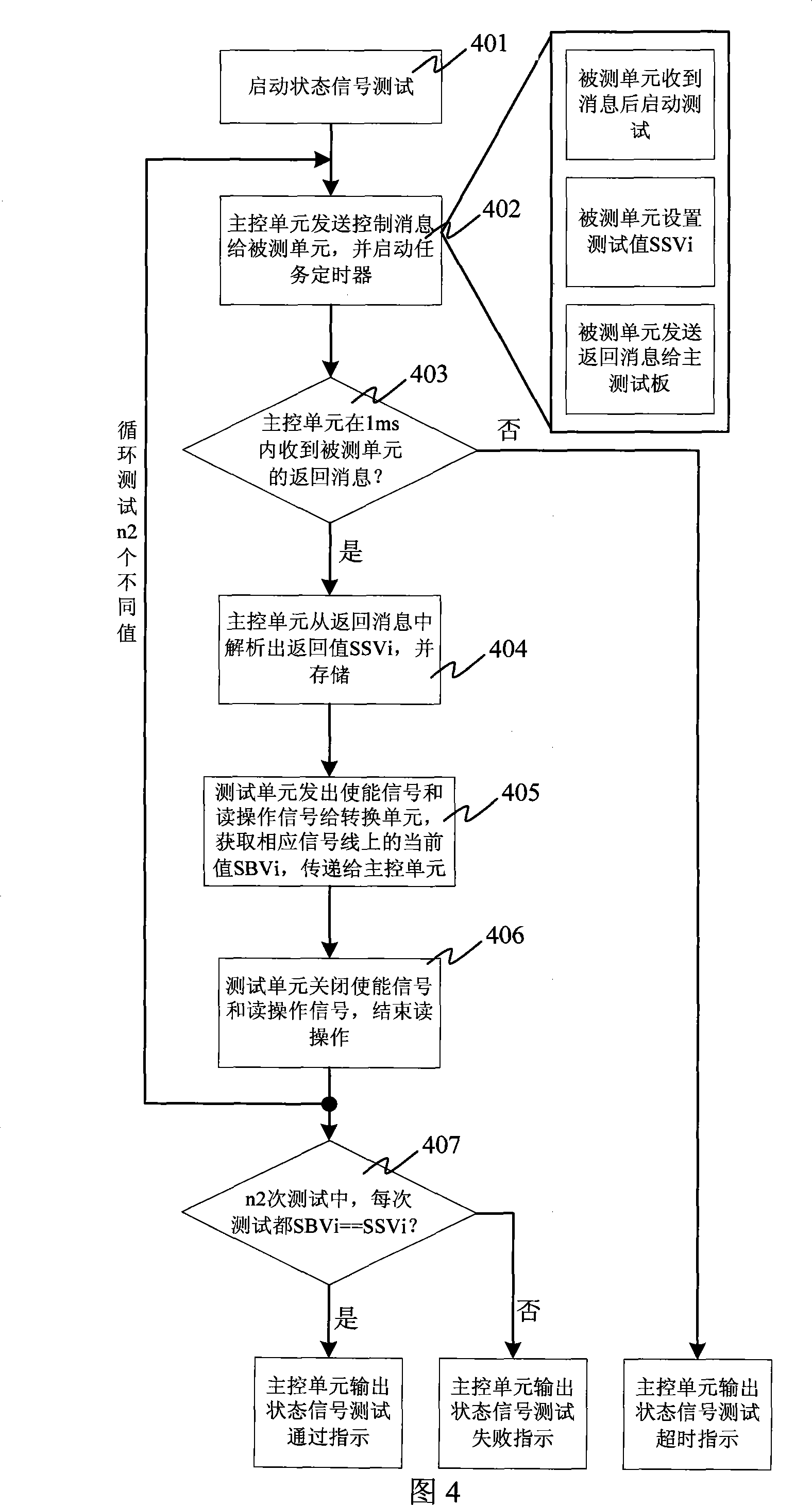

State control signal testing device

InactiveCN101222732AImplement functional testingIncrease the number of boardsSupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsValue setInformation transmission

The invention provides a status control signal testing device which is used for testing the status control signal function of a tested unit. The device comprises a main control unit, a testing unit and a conversion unit, wherein the main control unit is used for setting up a test value for the testing unit or obtaining the test value from the testing unit, comparing the set or obtained test value with the test value fed back by information transmission in the tested unit for consistency and further outputting a test result; the testing unit is used for controlling the working status of the conversion unit and relaying the test value set by the main control unit to the conversion unit or obtaining the test value from the conversion unit and storing the test value; the conversion unit is used for converting the control status signal line to be tested of the tested unit into a bus type interface signal line and receiving or sending out the test value of the tested unit. The testing device provided by the invention can make use of the pin resources of a programmable device effectively and improve production testing efficiency.

Owner:蒙路遥 +4

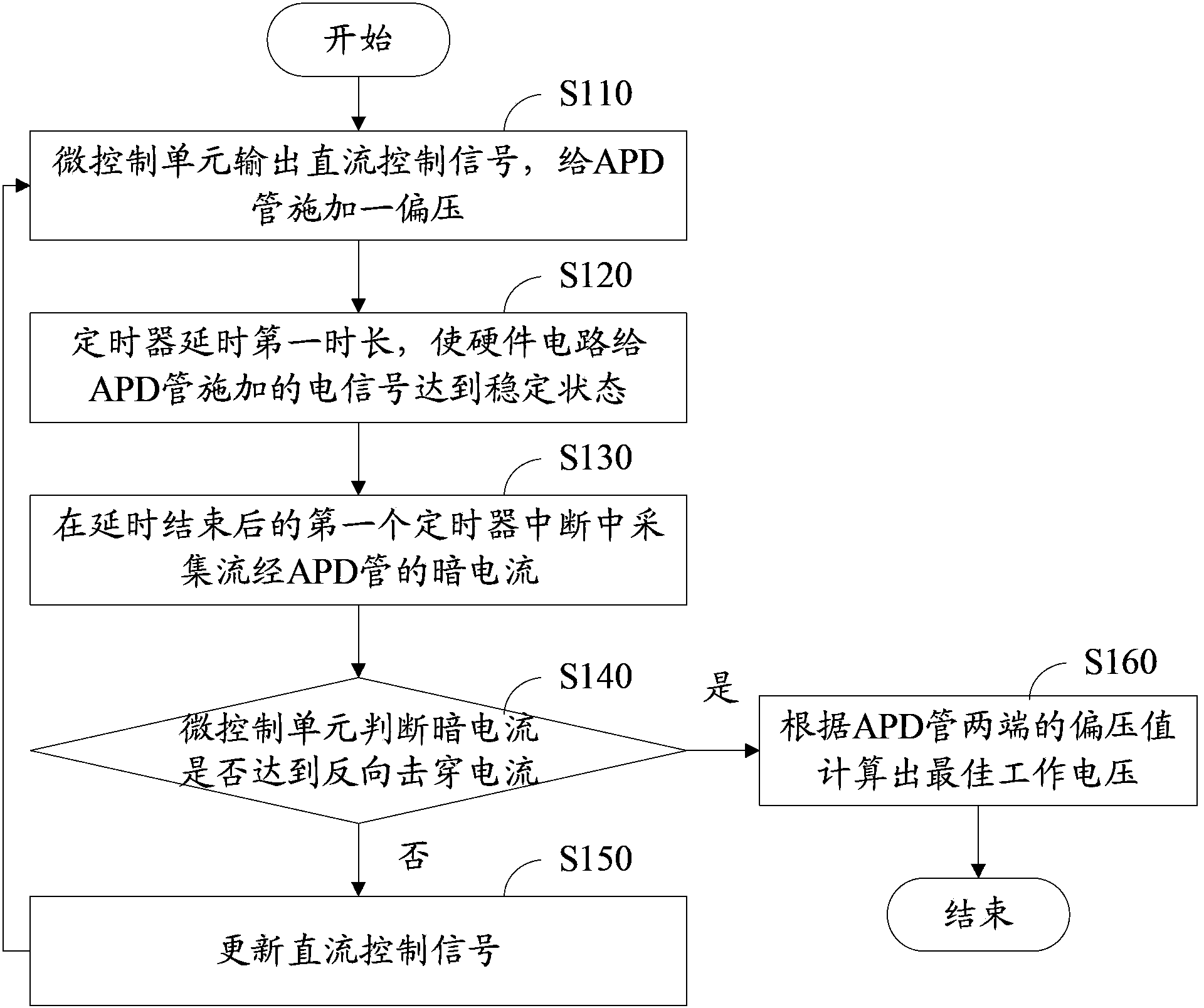

Optimum operating voltage test method of avalanche photodiode

ActiveCN104142460AImprove production test efficiencyIndividual semiconductor device testingTest efficiencyControl signal

The invention discloses an optimum operating voltage test method of an avalanche photodiode. The method includes the following steps that a micro-control unit outputs a direct current control signal; a bias voltage corresponding to the direct current control signal is applied to the avalanche photodiode; a timer achieves delaying by first preset duration; dark current flowing through the avalanche photodiode is collected within first timer interrupt after delaying is finished; the micro-control unit judges whether the dark current reaches reverse breakdown current or not; if the dark current reaches reverse the breakdown current, the optimum operating voltage of the avalanche photodiode is calculated out according to the value of the bias voltage; if the dark current does not reach the reverse breakdown current, the direct current control signal is updated, and the steps that the micro-control unit outputs a direct current control signal and a bias voltage corresponding to the direct current control signal is applied to the avalanche photodiode are carried out again. By means of a time slice rotation mode, in the delaying process of the timer, a main operating cycle of the micro-control unit can perform other operating tasks and other corresponding interruption work, and production test efficiency is improved.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

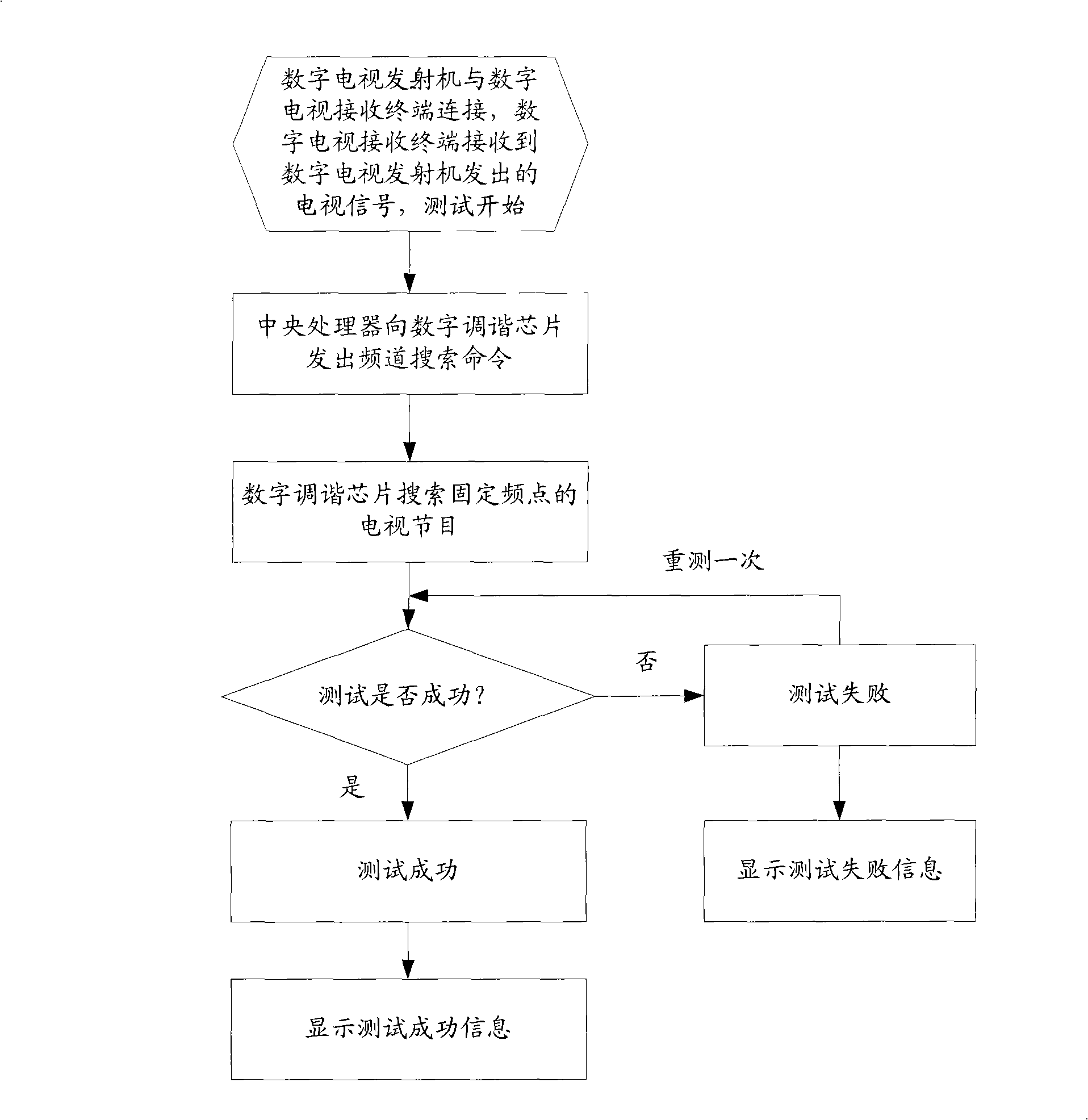

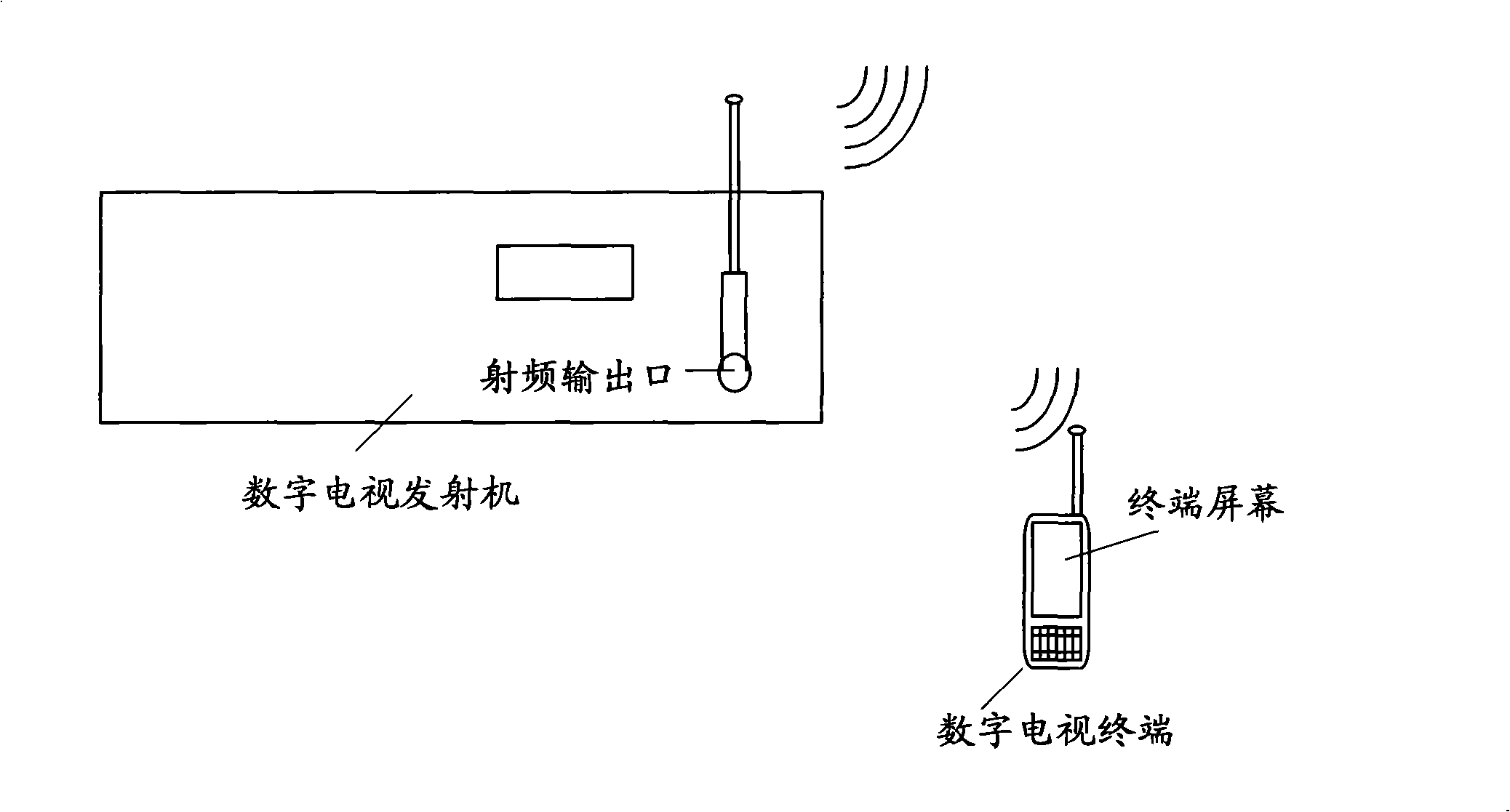

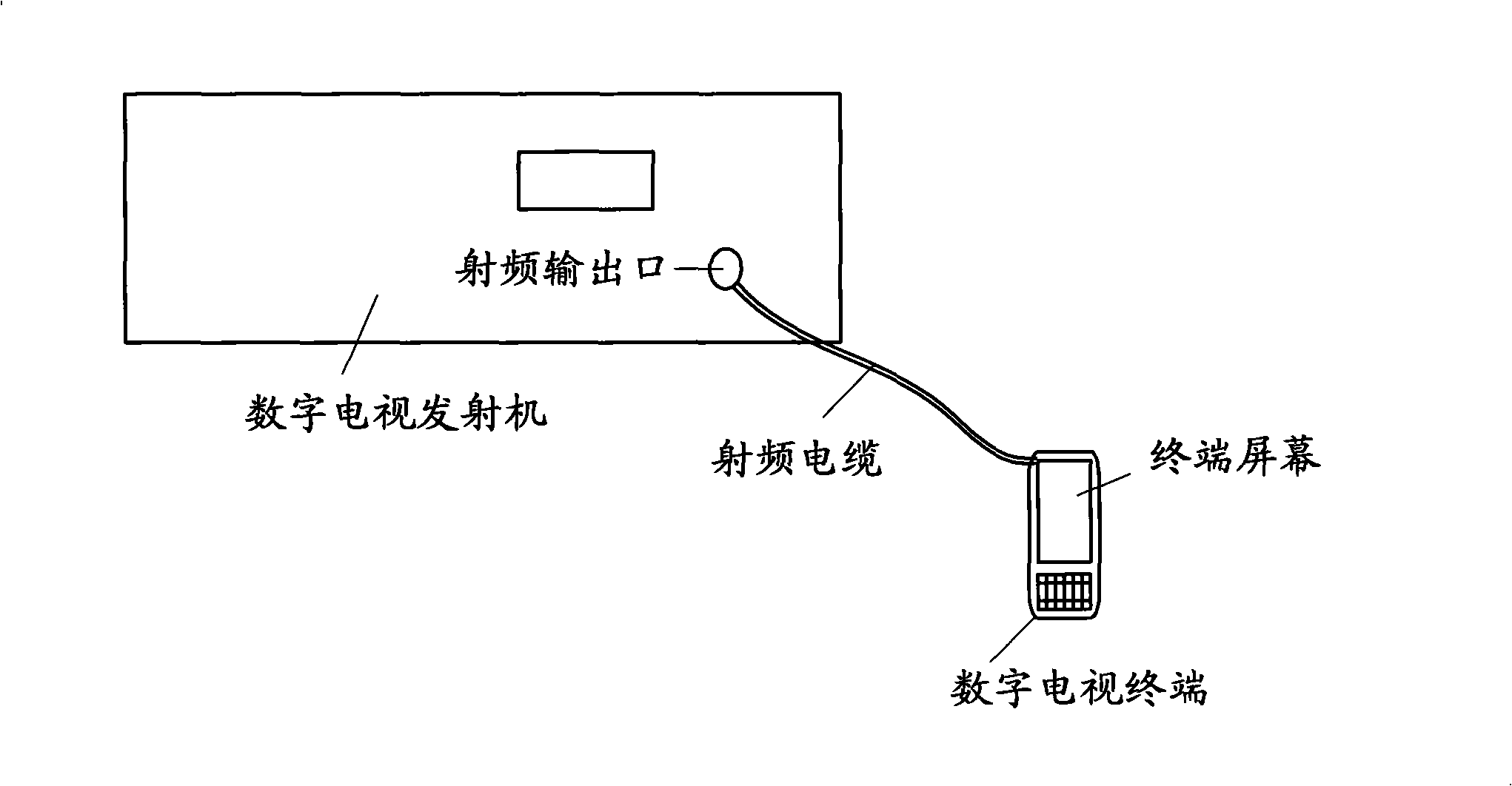

Method for testing receiving performance of digital television receiving terminal

InactiveCN101282494AShorten test timeImprove production test efficiencyTelevision system detailsColor television detailsFixed frequencyTelevision channel

The invention provides a method for testing receiving performance of a digital TV receiving terminal in the field of digital TV receiving terminal testing, comprising the following steps: connecting a digital TV transmitter to the digital TV receiving terminal, test starts after the digital TV receives terminal receiving TV signal from the digital TV transmitter; a central processor issues a channel searching command to the digital TV tuning chip; the digital TV tuning chip searches some TV channel with fixed-frequency; if channel searching is successful, the test pass, or else executes the next step; back to the former step, renewedly searching at least once, if channel searching is successful, the test pass, or else fails. The method of the invention realizes scan for a fixed frequency, thereby improving speed for testing TV receiving function of the digital TV receiving terminal, which further saves testing time and effectively improves testing efficiency.

Owner:ZTE CORP

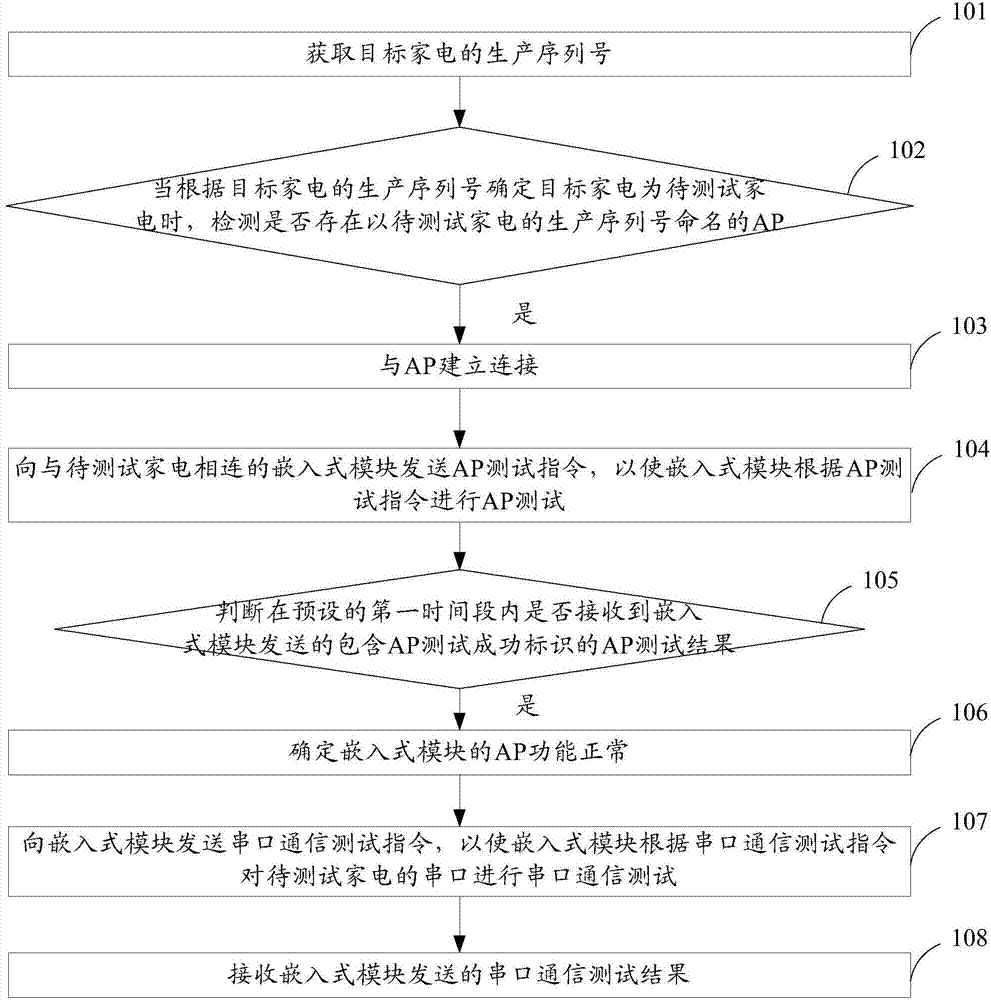

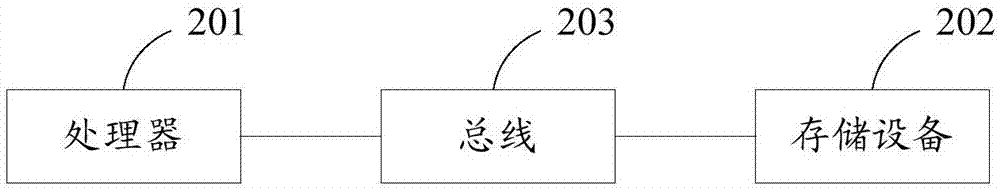

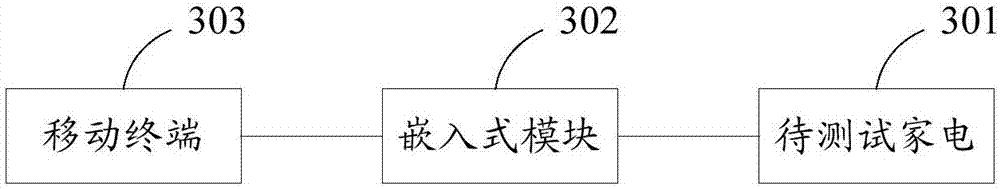

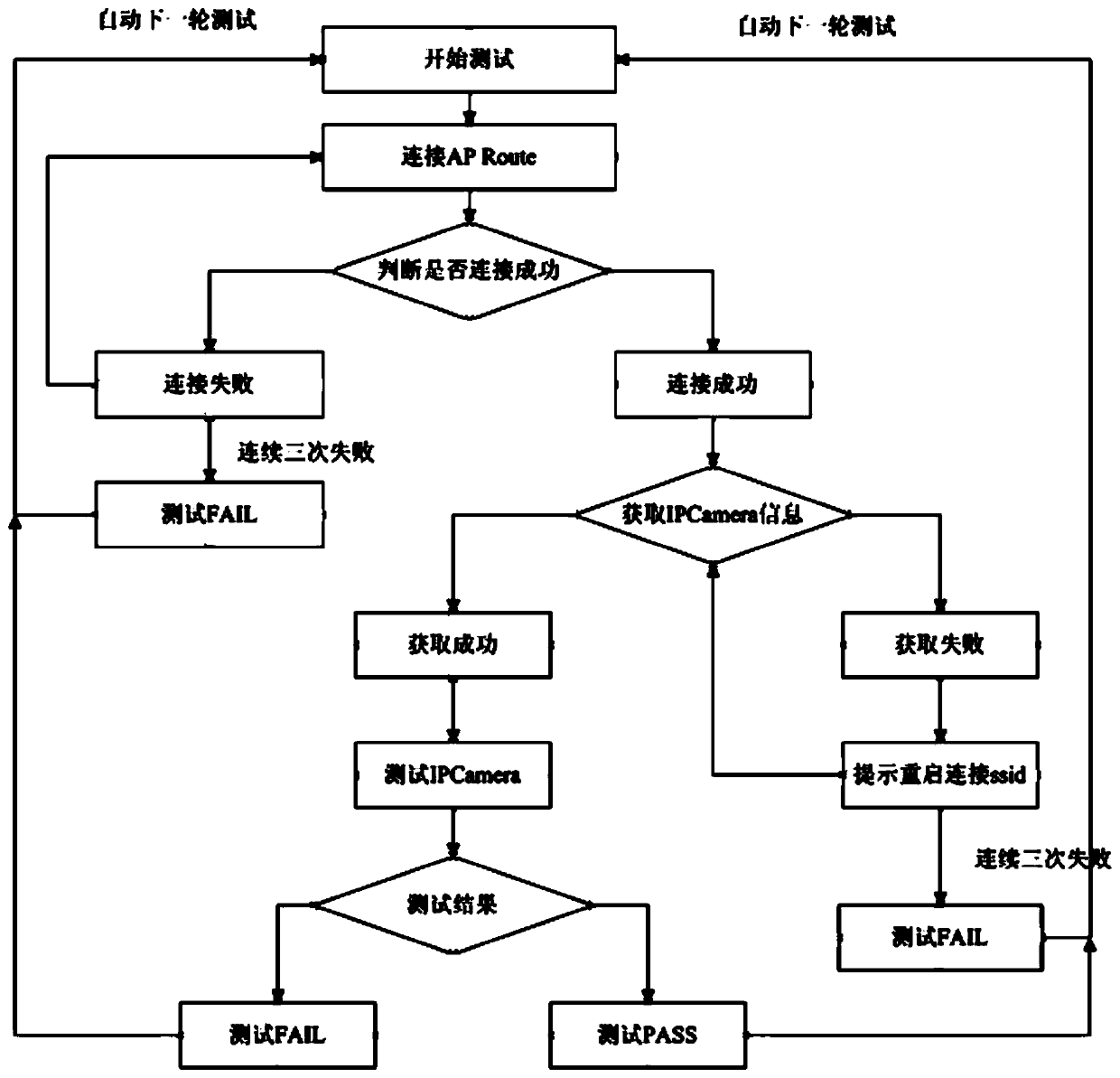

Production testing method and system for smart household appliance, storage device and mobile terminal

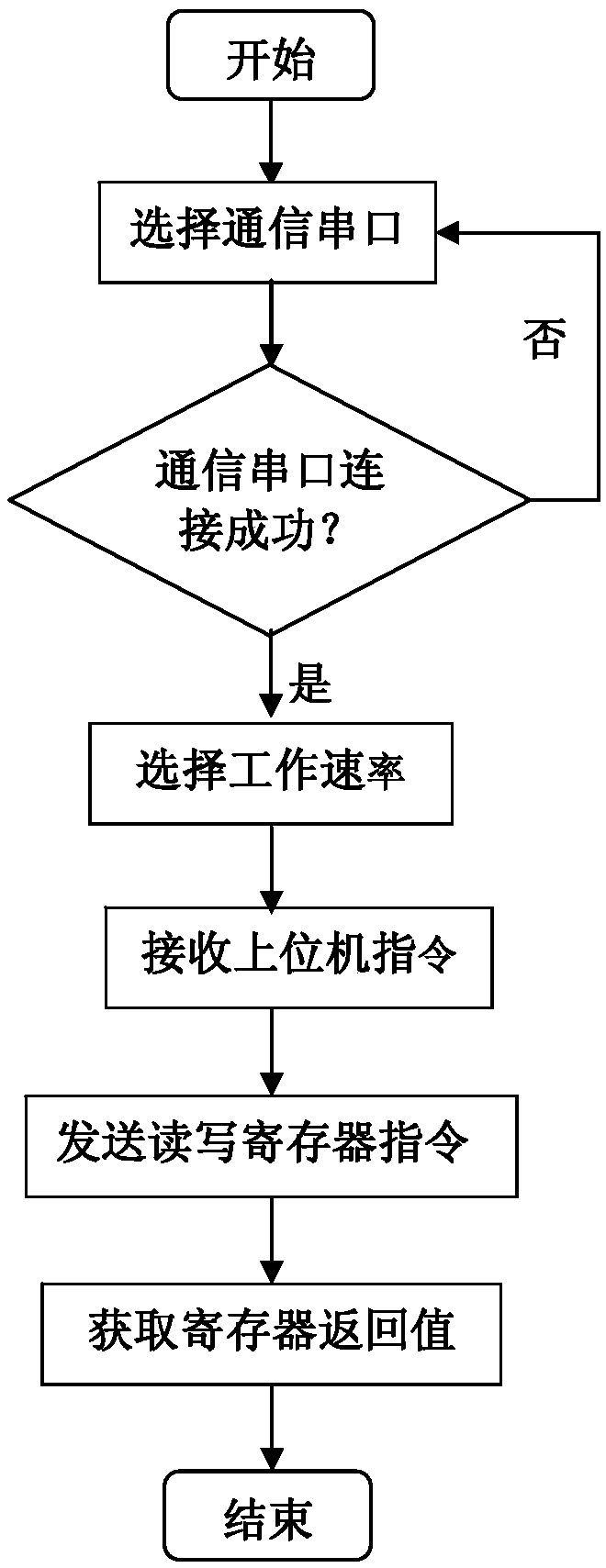

InactiveCN107204898AEasy to testImprove production test efficiencyDetecting faulty computer hardwareData switching networksSmart applianceSerial port

The invention provides a production testing method and system for a smart household appliance, a storage device and a mobile terminal. The method comprises steps as follows: acquiring a production serial number of a target household appliance; when the target household appliance is determined to be a to-be-tested household appliance according to the production serial number of the target household appliance, detecting whether an AP named after the production serial number of the to-be-tested household appliance exists, and if yes, establishing connection with the AP; sending an AP testing instruction to an embedded module connected with the to-be-tested household appliance so that the embedded module performs AP testing according to the AP testing instruction; determining the function of the AP of the embedded module to be normal when an AP testing result including an AP testing success identification sent by the embedded module is received in a preset time period; sending a serial port communication testing instruction to the embedded module so that the embedded module performs serial port communication testing on a serial port of the to-be-tested household appliance according to the serial port communication testing instruction; receiving a serial port communication testing result sent by the embedded module. With the adoption of the production testing method and system, the production testing process can be simplified.

Owner:合肥美菱物联科技有限公司

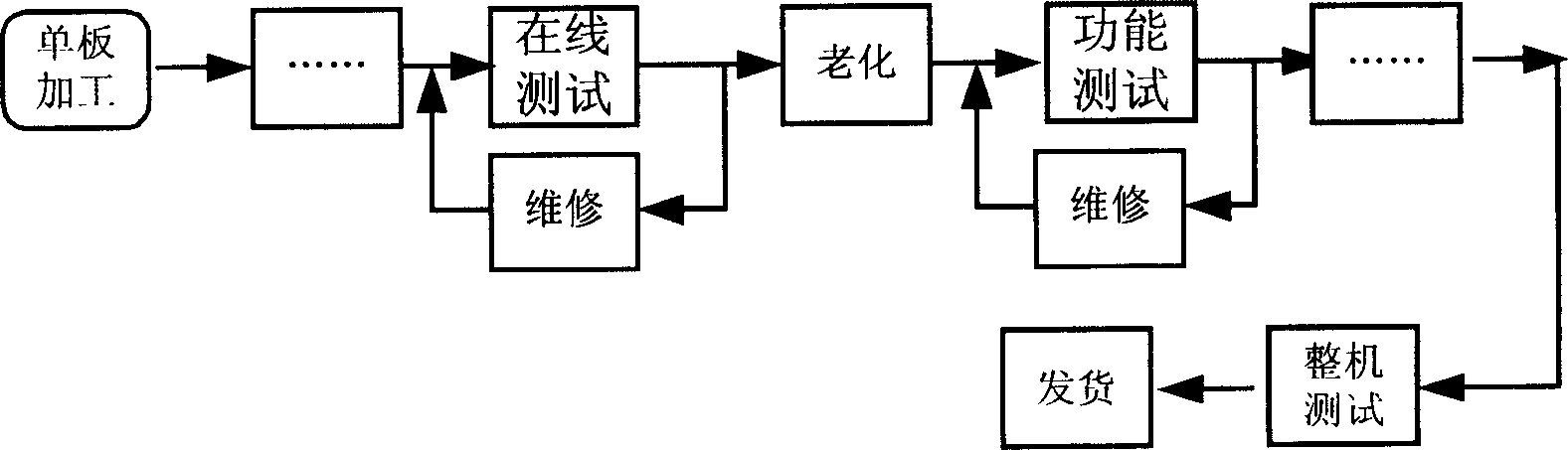

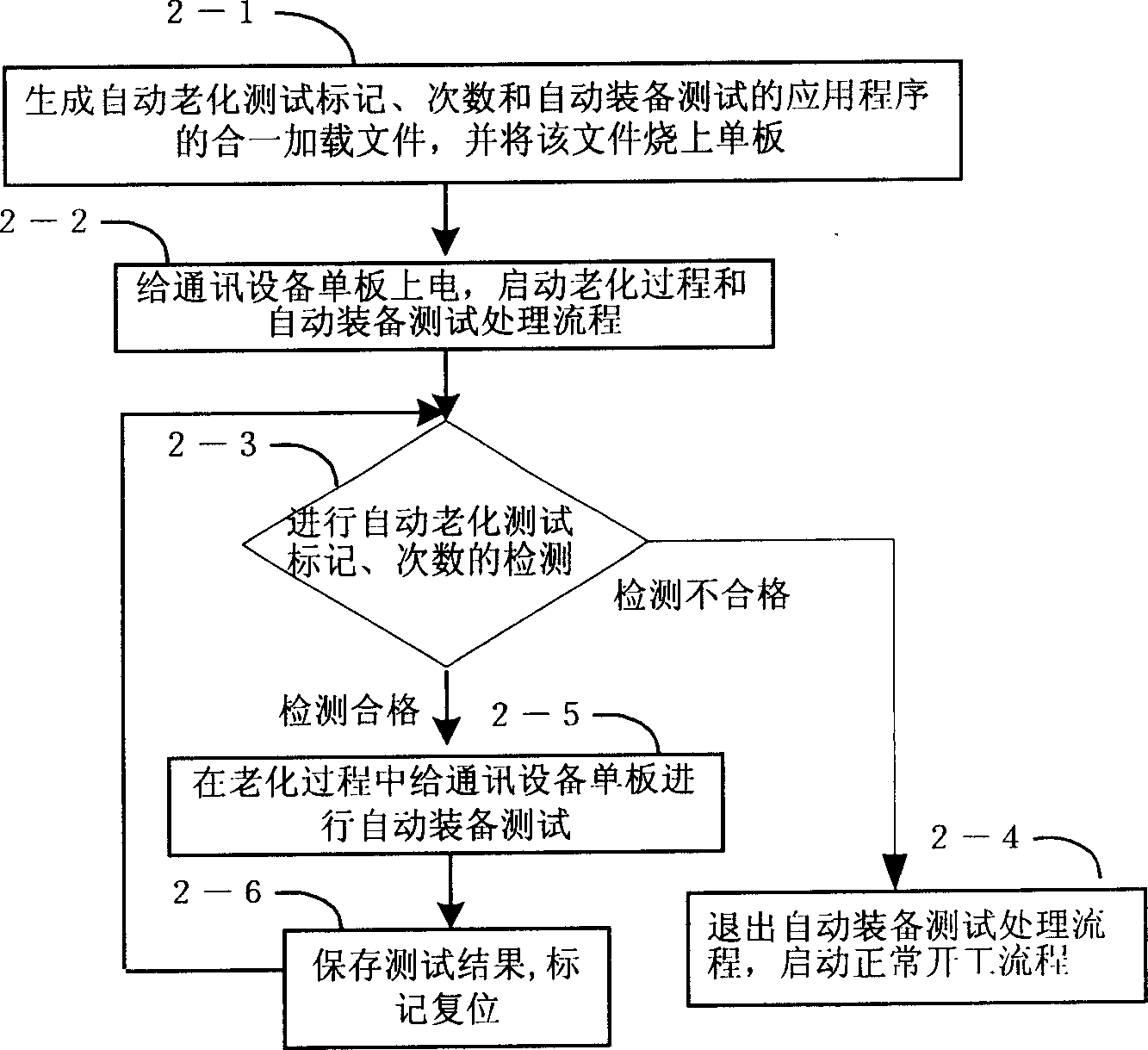

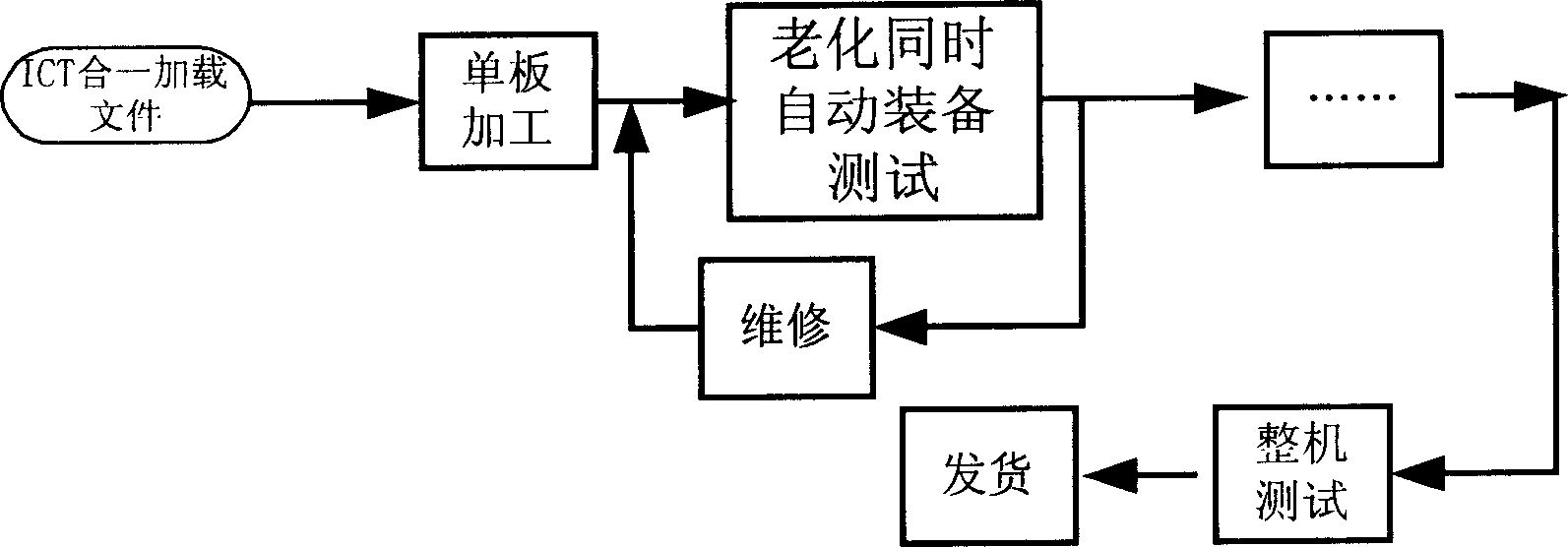

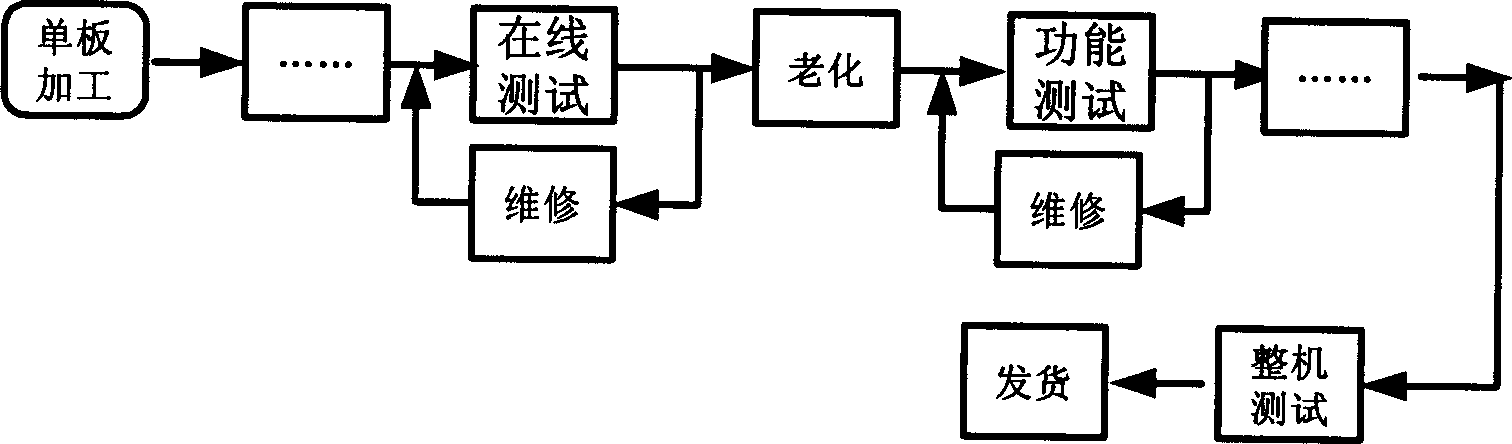

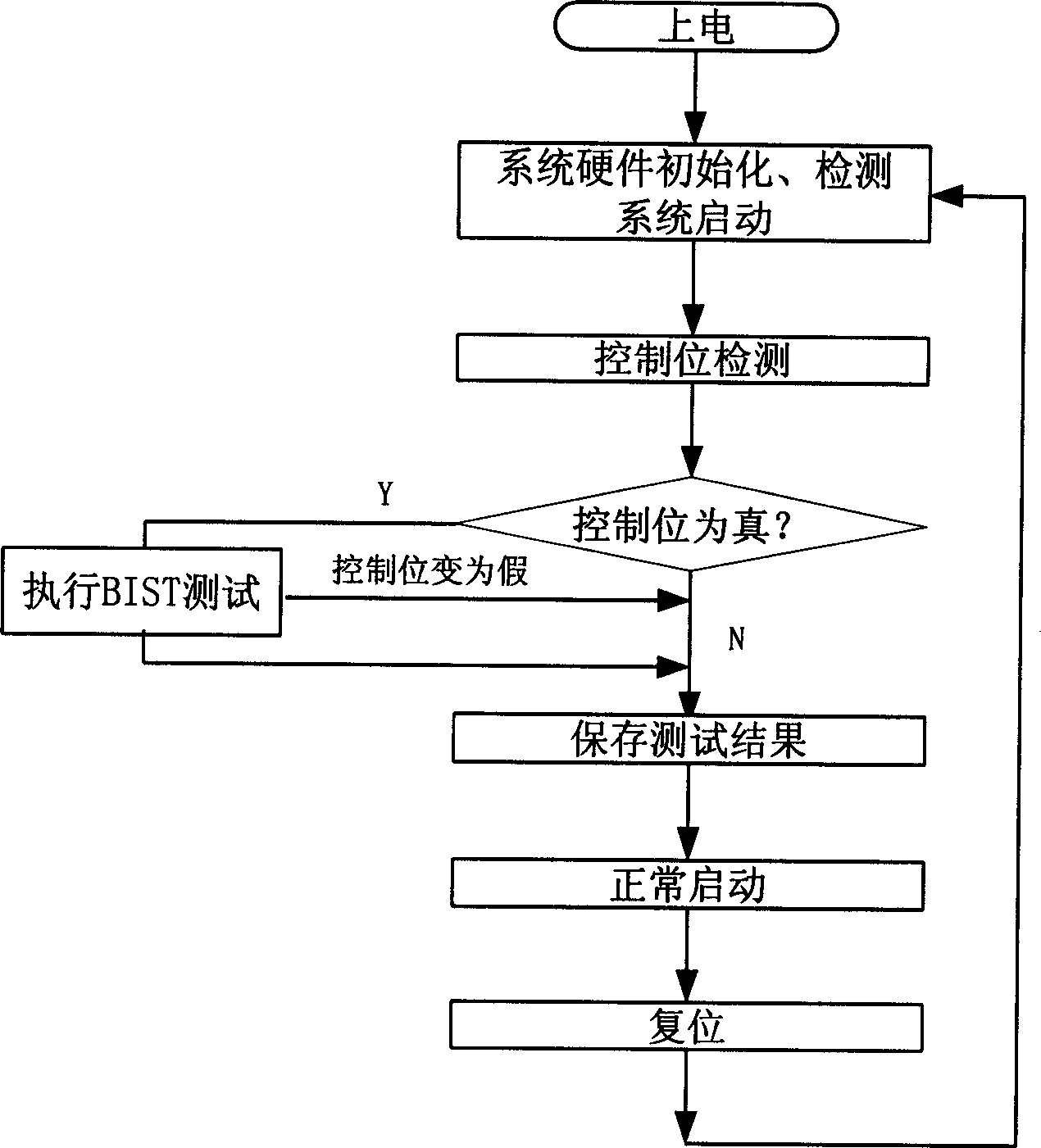

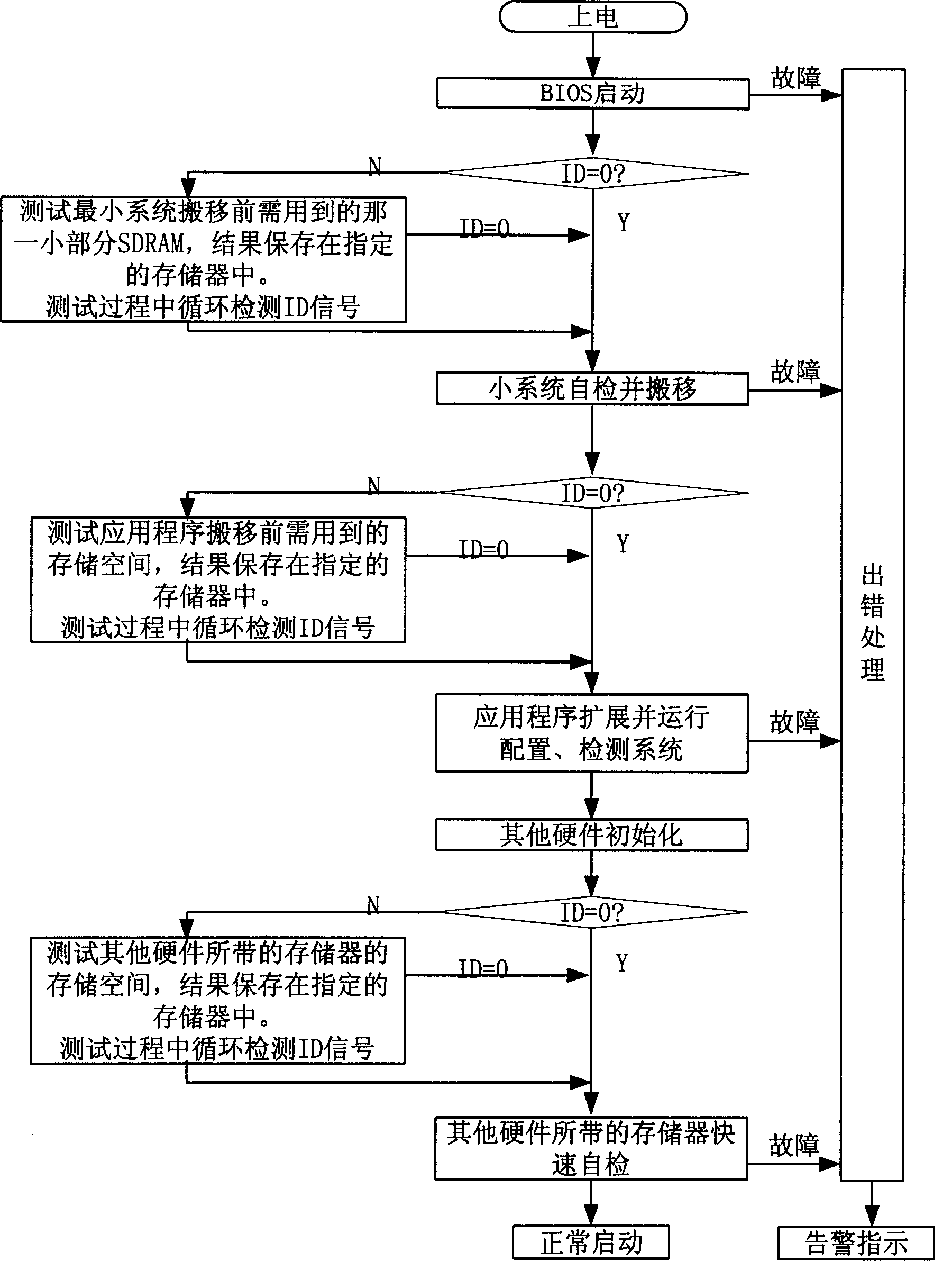

Production test method for communication equipment

InactiveCN1866040AExposure to aging failuresImprove production test efficiencyElectrical testingTransmission monitoringComputer moduleAutomatic testing

The disclosed testing method for communication device comprises: setting desired condition in device software; during device aging, when according to the condition, taking test. This invention can make full use of aging time to complete auto testing with high efficiency.

Owner:HUAWEI TECH CO LTD

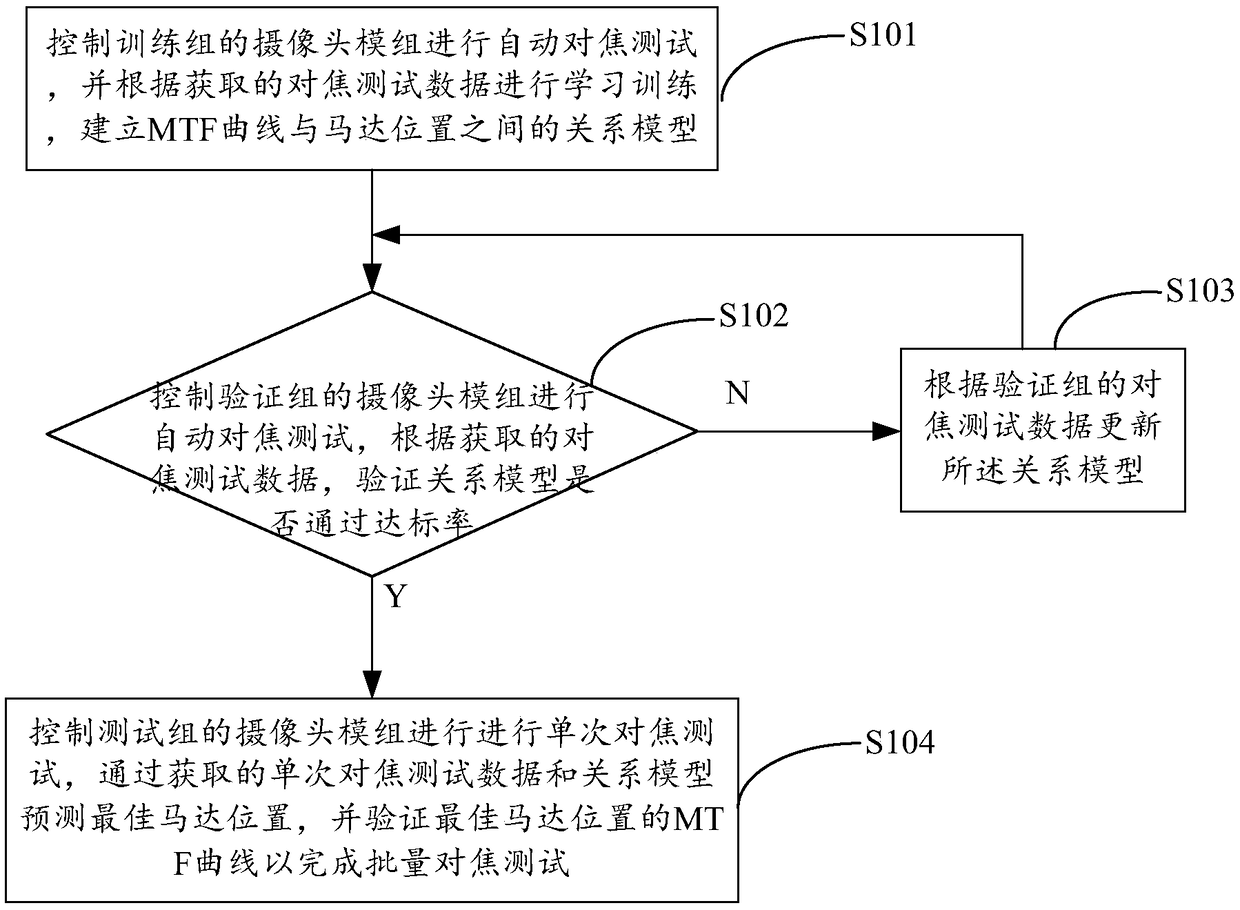

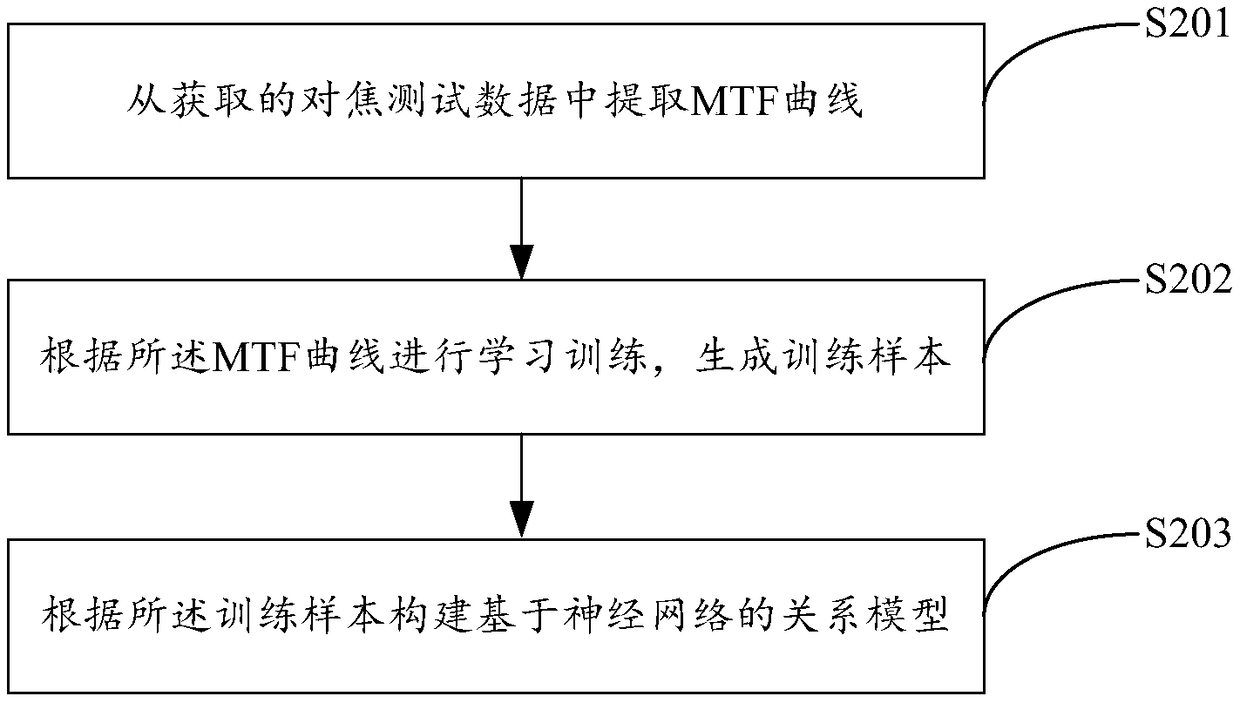

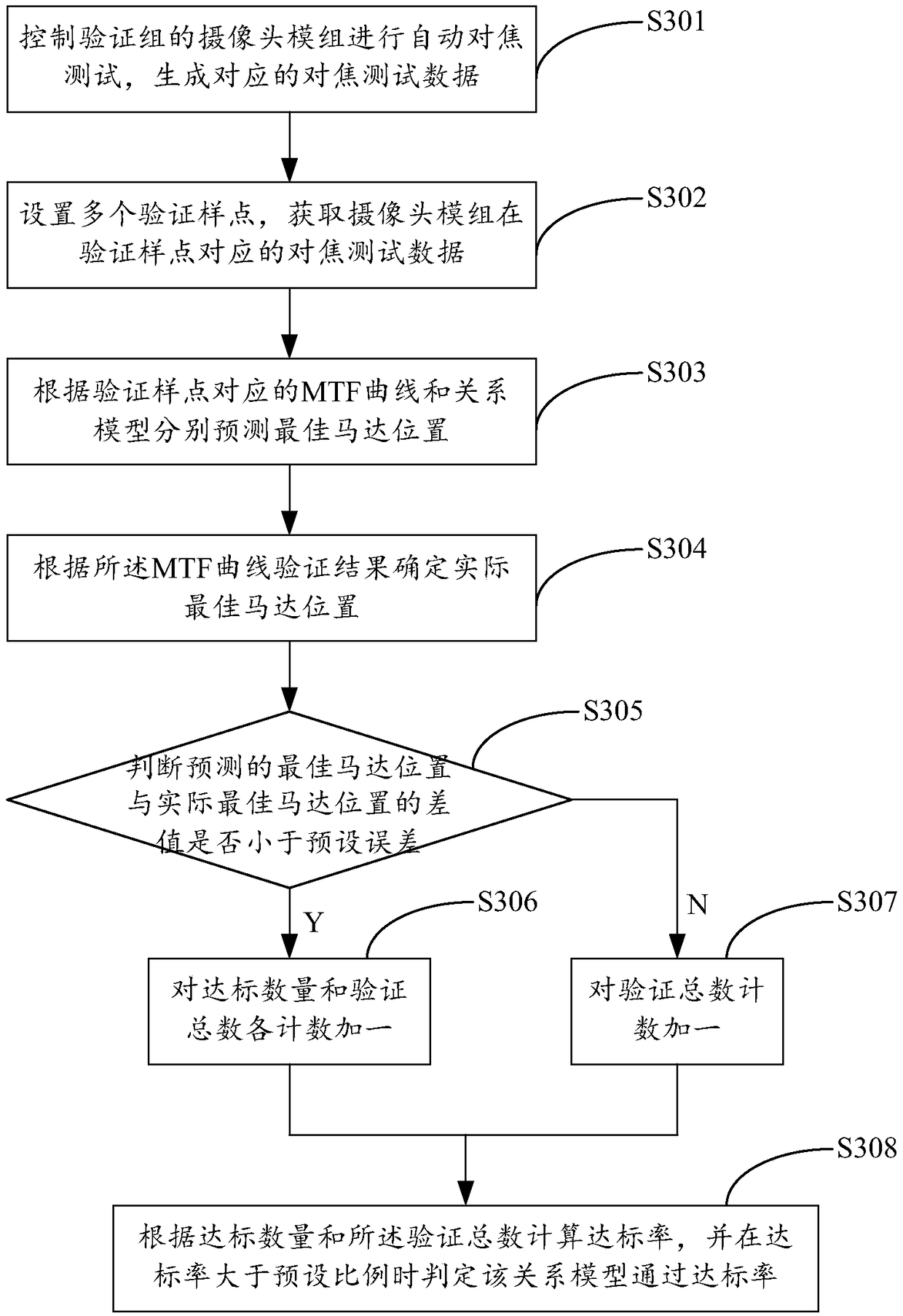

Method and system for testing batch focus of camera modules

ActiveCN109451304AReduce sampling test pointsReduce testing workloadTelevision systemsTest efficiencyRelational model

The invention is applicable to the field of optical imaging testing, and provides a method and system for testing batch focus of camera modules. The method comprises the following steps: controlling camera modules of a training group to perform an automatic focus test, performing learning training according to the focus test data, and establishing a relationship model between an MTF curve and themotor positions; controlling camera modules of a verification group to perform an automatic focus test to verify whether the relationship model passes the standard rate; if not, updating the relationship model according to the focus test data of the verification group; if so, controlling camera modules of a test group to perform a single focus test, predicting the optimal motor position by the single focus test data and the relationship model, and verifying the MTF curve of the optimal motor position. The method and system for testing batch focus of camera modules select a small amount of testdata in the early stage of the batch test to establish a relationship model through the neural network, and use the relationship model to predict the batch test of the optimal focus positions, whichgreatly reduces the sampling test points of the batch test and improves the test efficiency.

Owner:SHENZHEN CZTEK

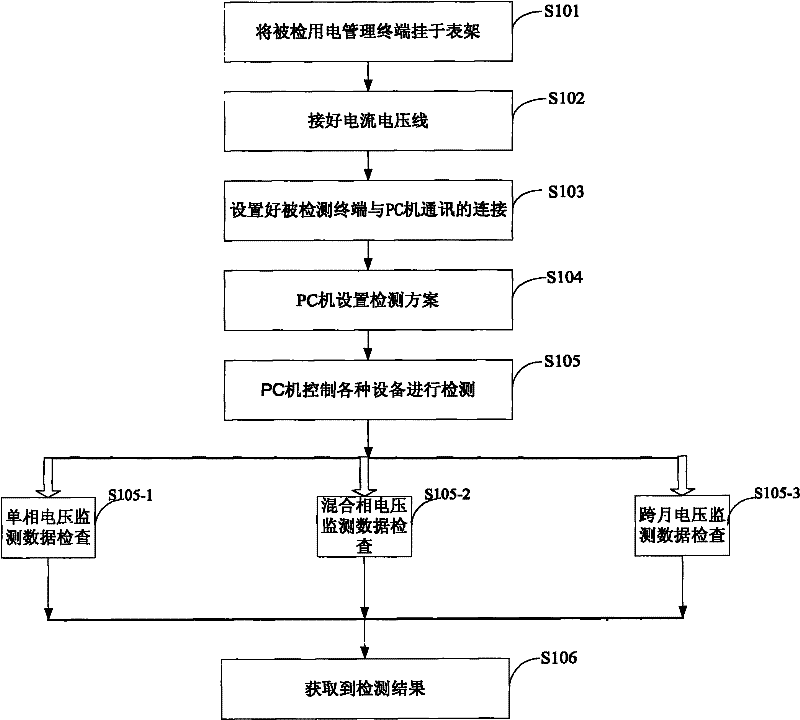

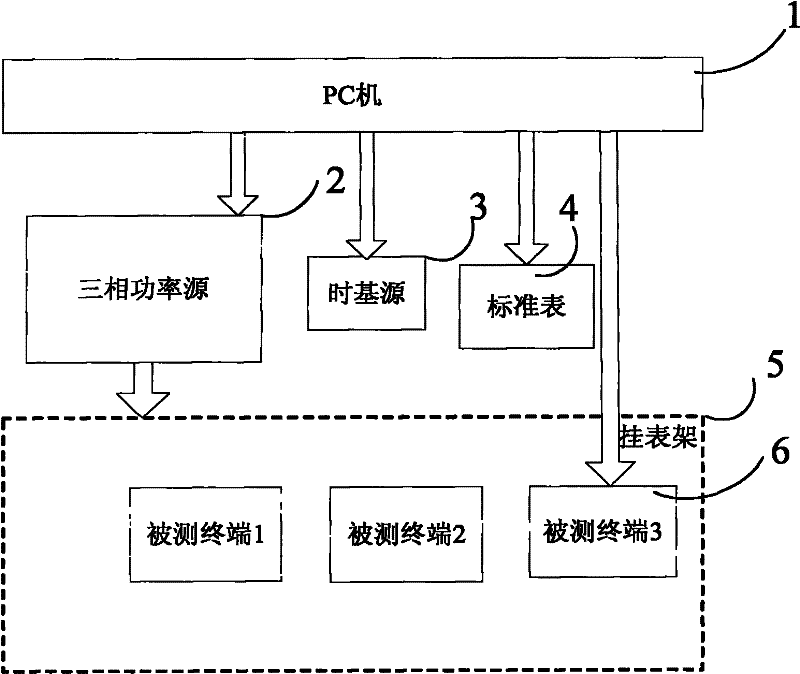

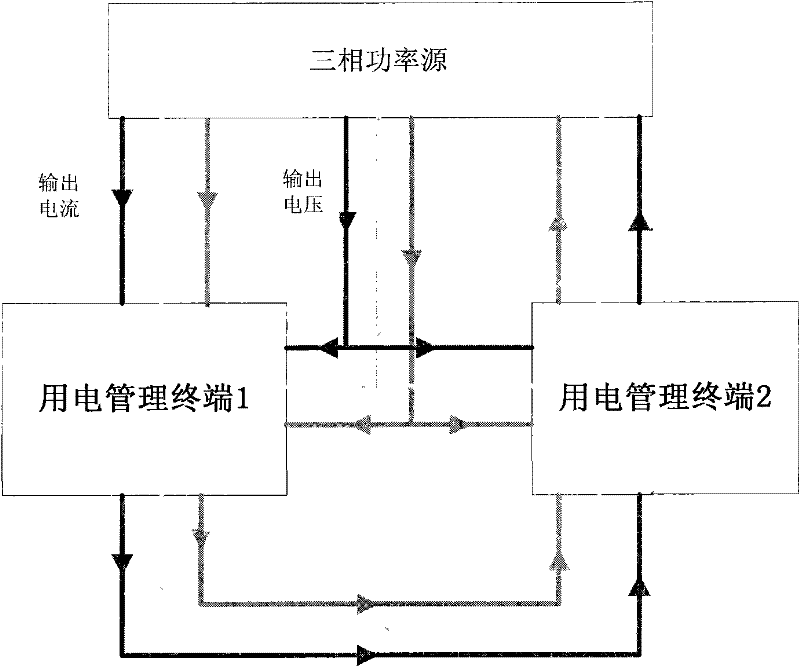

Method for detecting voltage monitoring function of electricity utilization management terminals in batches

ActiveCN102236046AImprove production test efficiencyReliable test resultsMeasurement using digital techniquesTerminal voltagePower usage

The invention relates to a method for detecting the voltage monitoring function of electricity utilization management terminals in batches, which comprises the following steps of: 1, connecting a plurality of terminals to be detected with voltage current wires and hanging on a meter hanging frame; 2, setting the communication connection of the terminals to be detected and a personal computer (PC); 3, setting the connection mode and voltage and current basic parameters of the terminals to be detected by using the PC; 4, setting or calling a prestored testing scheme by using PC software; 5, sending an instruction to the terminals to be detected and a source meter control cabinet by using the PC, outputting various voltage environments, and testing the terminals to be detected; and 6, reading the voltage current value of a standard meter through a serial port and calculating real voltage monitoring data in turn by using the PC, reading the voltage monitoring data of the terminals through a PC network, and comparing with the voltage monitoring value of the standard meter to obtain a conclusion. The method solves the problems that the indoor detection process is complicated, actual detection time is overlong, workload is high and the like in the conventional detection method, and has the advantages of high production testing efficiency, accurate and reliable testing result and the like.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Communication facility performance testing method

InactiveCN1490945AImprove production test efficiencyIncrease production capacityTransmitters monitoringReceivers monitoringCyclic testAging test

A test method for the performance of communication equipments, includes following steps: at the same time for aging test, makes building internal self-testing BIST, sets a control position in system to get the aging information. CPU tests whether or not the board is at the status of aging testing through the control position. According to the aging testing status controls the board to build internal self- testing BIST. Building internal self-testing BIST adopts loop testing, the result stores in relevant storage space; the saving of the results adopts double data backups marked with relevant sign position, the double data backup includes front two round results of loop testing, the sign position shows the relevant testing status at the time of getting this test result, takes effective testing result in a newest round as the criterion.

Owner:HUAWEI TECH CO LTD

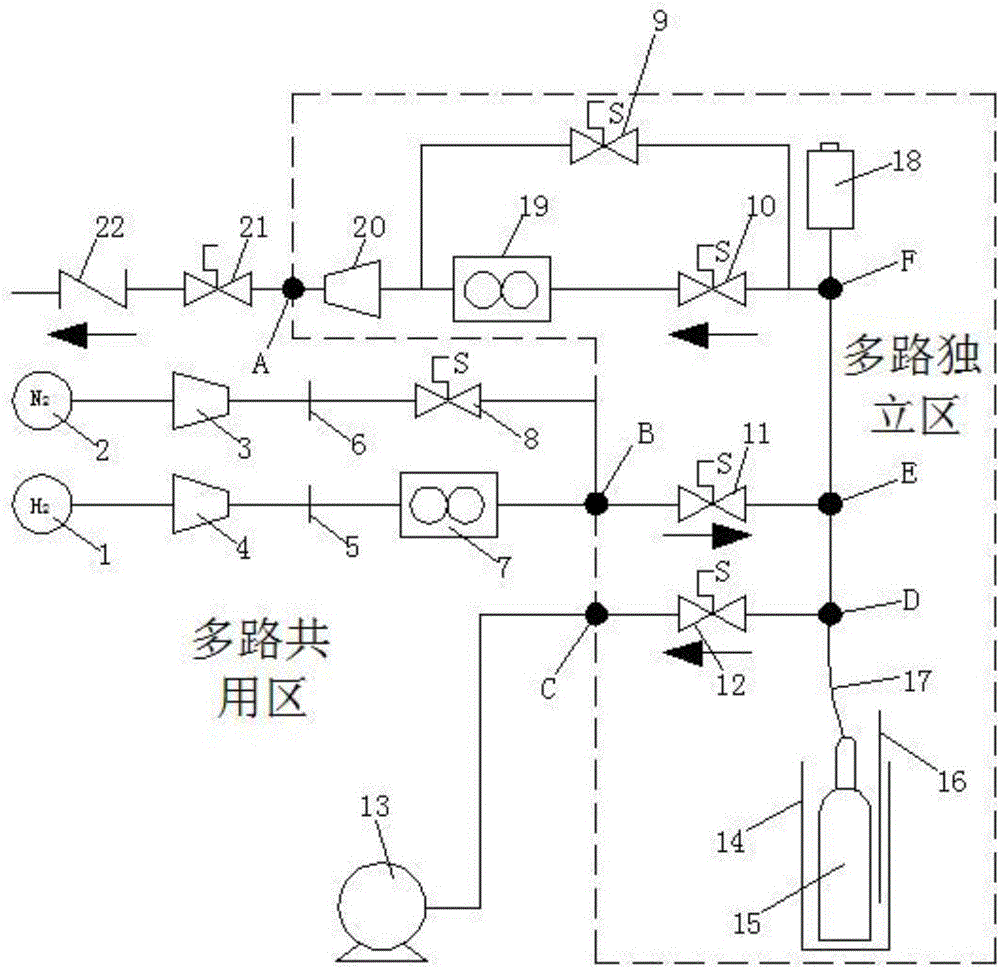

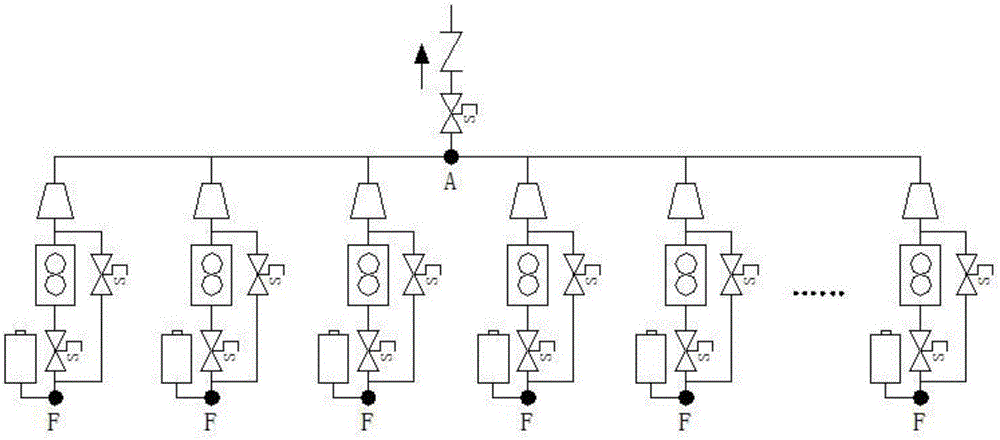

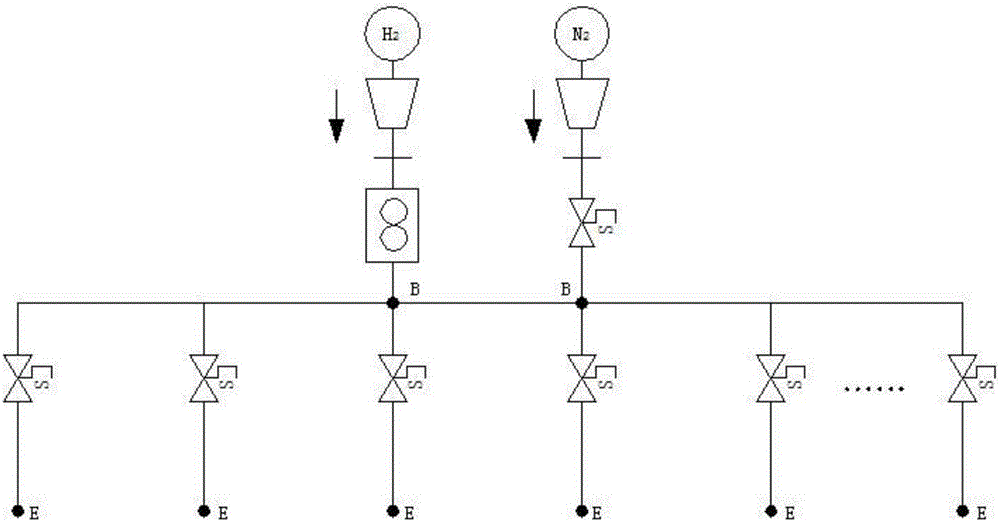

Multi-channel alloy type hydrogen storage tank activating, performance-testing and packaging integrated equipment and technical flow thereof

ActiveCN106838610AImprove production test efficiencyNovel structureProgramme controlMeasurement devicesSmall footprintNitrogen gas

The invention provides multi-channel alloy type hydrogen storage tank activating, performance-testing and packaging integrated equipment and a technical flow thereof, and belongs to the technical field of gas storage equipment and production testing. The equipment comprises an upper layer gas channel, an intermediate layer gas channel and a bottom layer gas channel, wherein the upper layer gas channel is formed by connecting a check valve, a two-way high-pressure electromagnetic valve, a pressure sensor and a first node; the intermediate layer gas channel is formed by connection of a hydrogen gas source, a nitrogen gas source, a reducing valve, a reducing valve, a filter, a mass flowmeter and a two-way high pressure electromagnetic valve; and the bottom layer gas channel is formed by connection of a mechanical vacuum pump, a third node, a two-way high pressure electromagnetic valve, a metal braid hose, an alloy type hydrogen storage tank and a temperature sensor. The multi-channel alloy type hydrogen storage tank activating, performance-testing and packaging integrated equipment has a novel structure, reasonable and compact layout, clear technical flow principle, high automatic degree and strong universality, covers small area, is easy and convenient to operate, and can be used for simultaneously operating alloy type hydrogen storage tanks with multiple specifications in multiple channels, so that the production testing efficiency of the alloy type hydrogen storage tanks can be greatly improved.

Owner:YANGZHOU UNIV

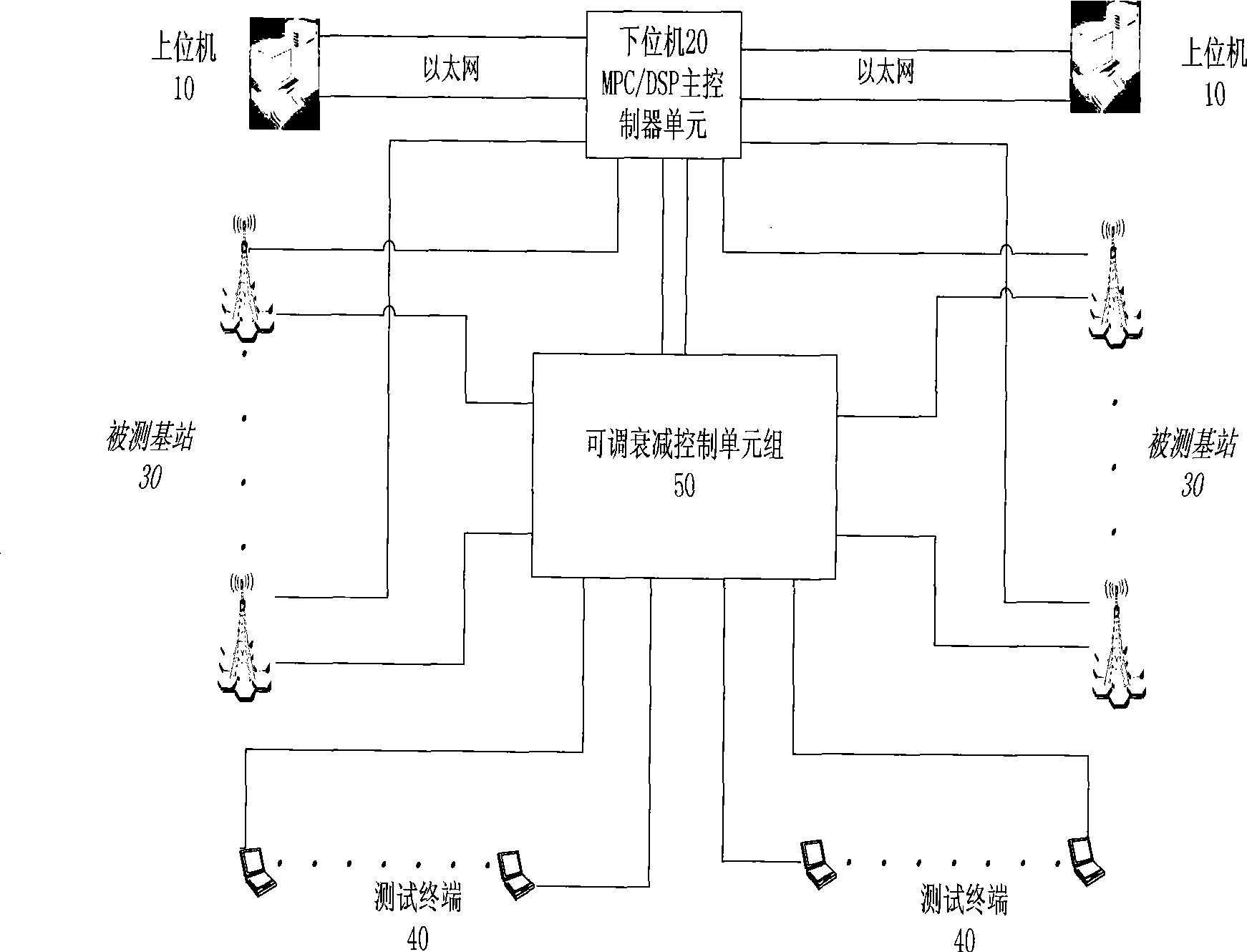

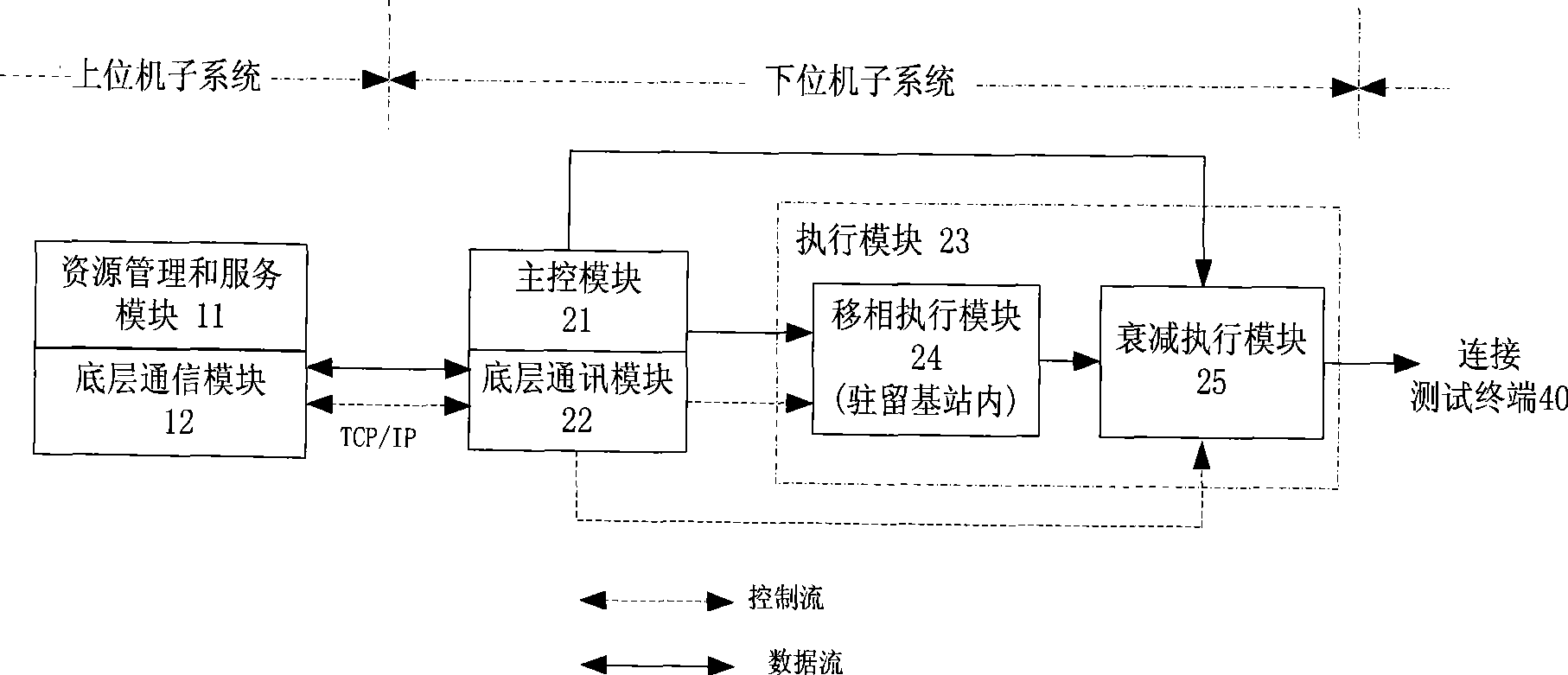

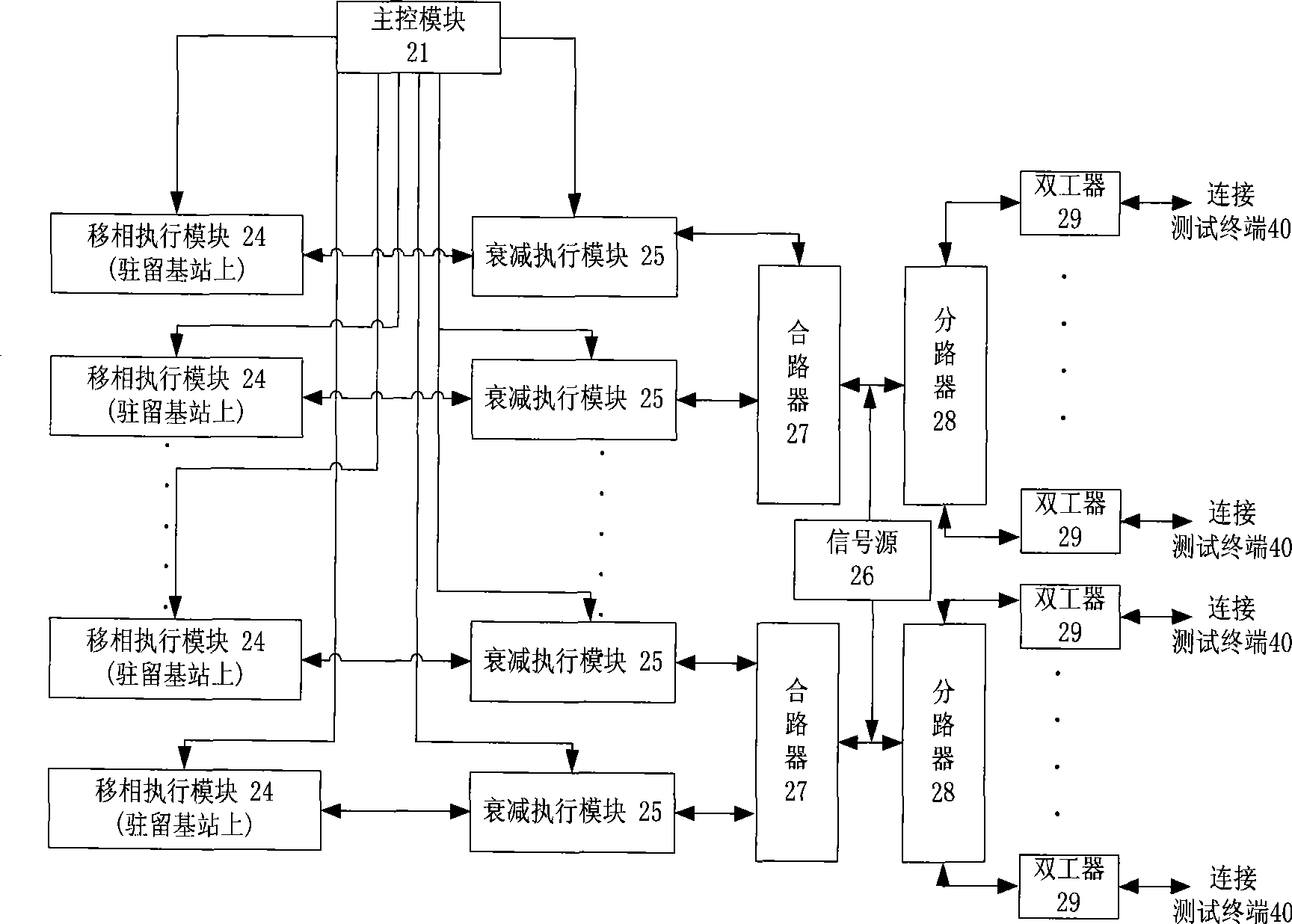

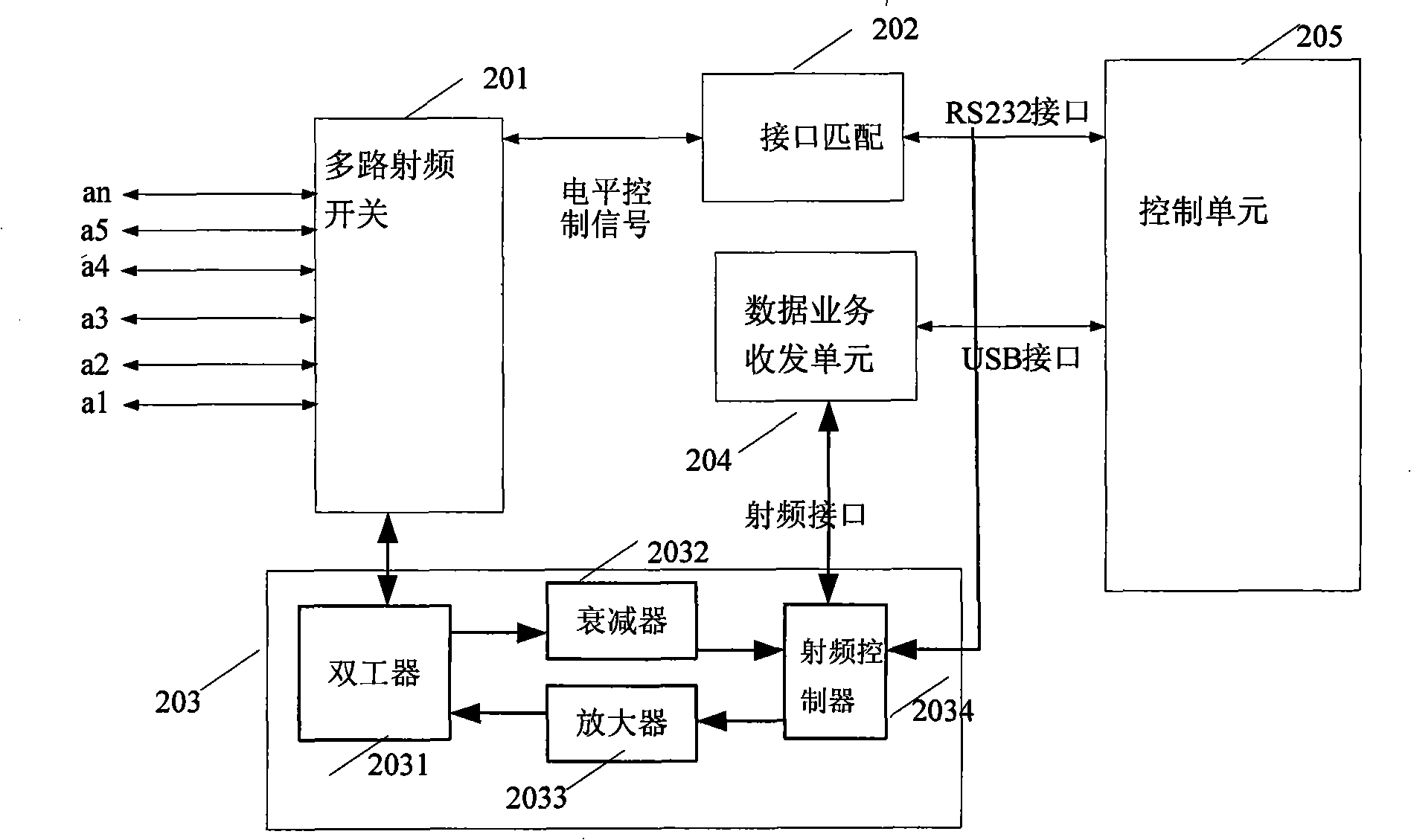

Test system and method for switching analog wireless channel

InactiveCN101415199AImprove reliabilityImprove production test efficiencyWireless communicationUltrasound attenuationTest script

The invention relates to a switching test system for simulating a wireless channel and a method thereof, wherein, the system comprises a resource management and service module (11), a low-level communication control module, a main control module (21) and an execution module (23); and the method comprises the following steps: the resource management and service module (11) forwards a test script to the main control module (21) by the low-level communication control module; and the main control module (21) controls the execution module (23) to perform phase-shifting and attenuation operations, and feeds back test results to the interface of an upper PC for real-time display. The method and the system can simultaneously realize the control over changes of amplitude and phase of wireless signals, and load different types of signal interferences by a signal source (26) to simulate external interferences of a real wireless scene, and more realistically simulate various wireless channel environments, thus improving the reliability of wired switching tests.

Owner:ZTE CORP

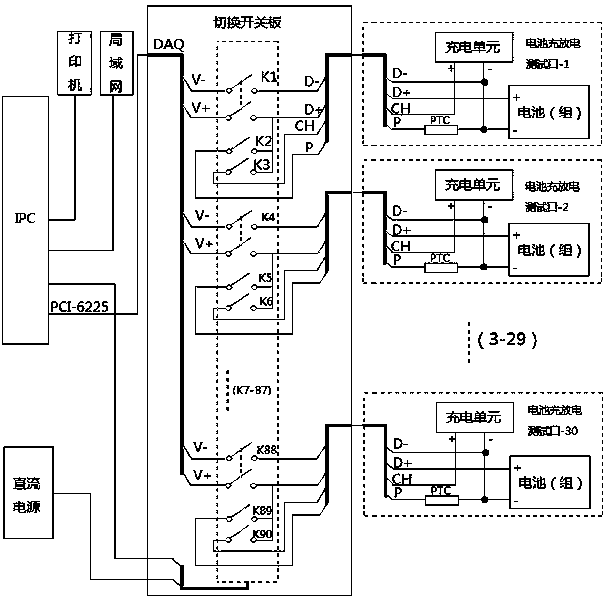

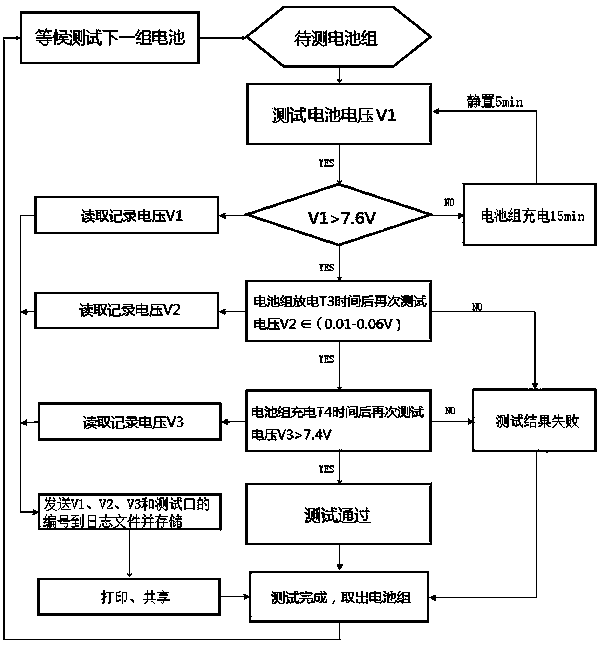

Battery testing station and testing method thereof

ActiveCN104035038AImprove production test efficiencyEasy for quality monitoringElectrical testingBattery chargeElectrical battery

The invention discloses a battery testing station and a testing method thereof. The battery testing station comprises a plurality of groups of battery charge and discharge testing ports, a switching switch group and a controller. Every group of battery charge and discharge testing port comprises a battery voltage testing port, a battery charging unit and a battery discharging unit; the switching switch comprises a plurality of groups of switching switches, every switching switch comprises switches K1, K2 and K3 which are connected to the battery voltage testing port, the battery discharging unit and the battery charging unit of the corresponding group of the battery charging and discharging port respectively; the controller is connected with the switching switch group through a PCI (peripheral component interconnect) bus to collect the voltage data of every battery voltage testing ports and controls the switching actions of every switch of the switching switch group through a serial bus. By means of a plurality of charge testing ports, the battery testing station can perform charge and discharge testing on multiple battery sets simultaneously, thereby improving the production testing efficiency; testing results can be automatically stored in the controller and uploaded to a local area network and accordingly facilitate quality monitoring.

Owner:BENCHMARK ELECTRONICS SUZHOU

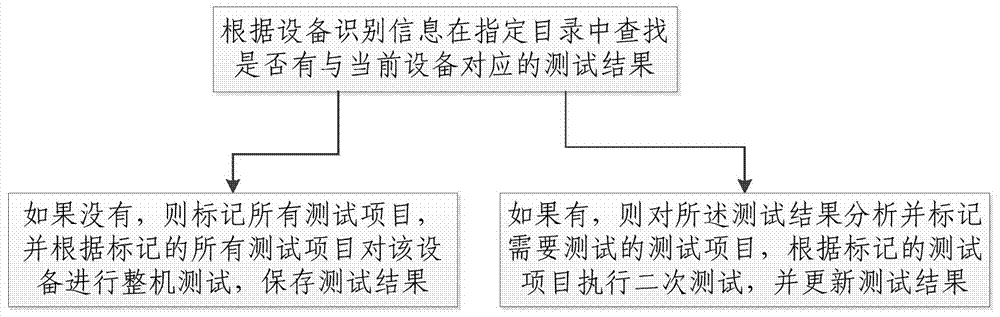

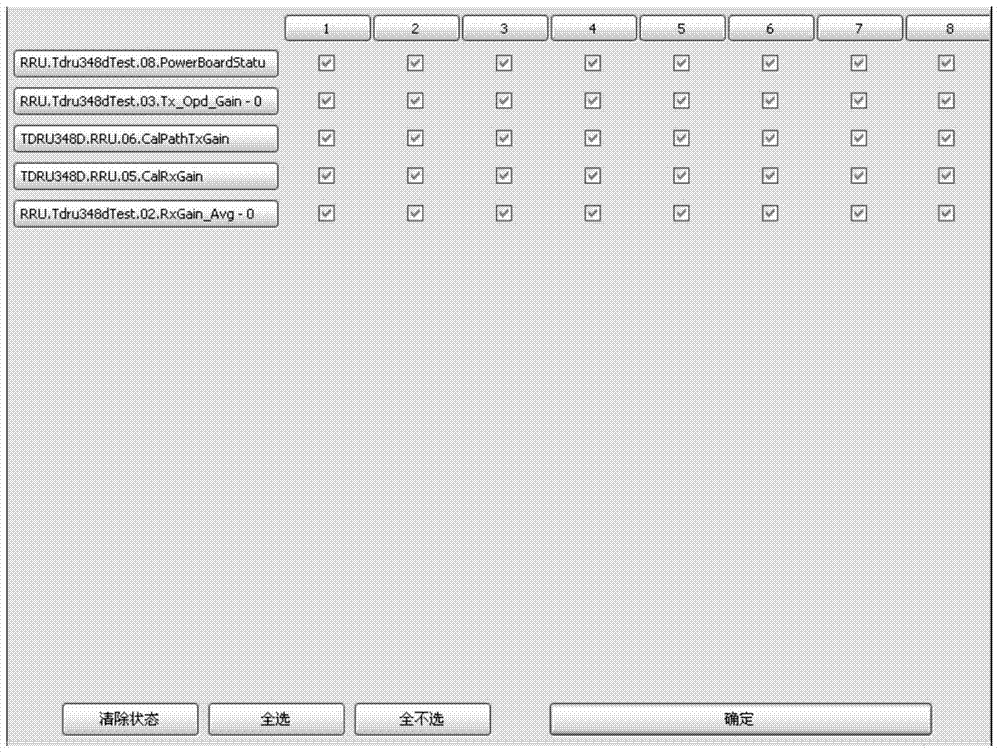

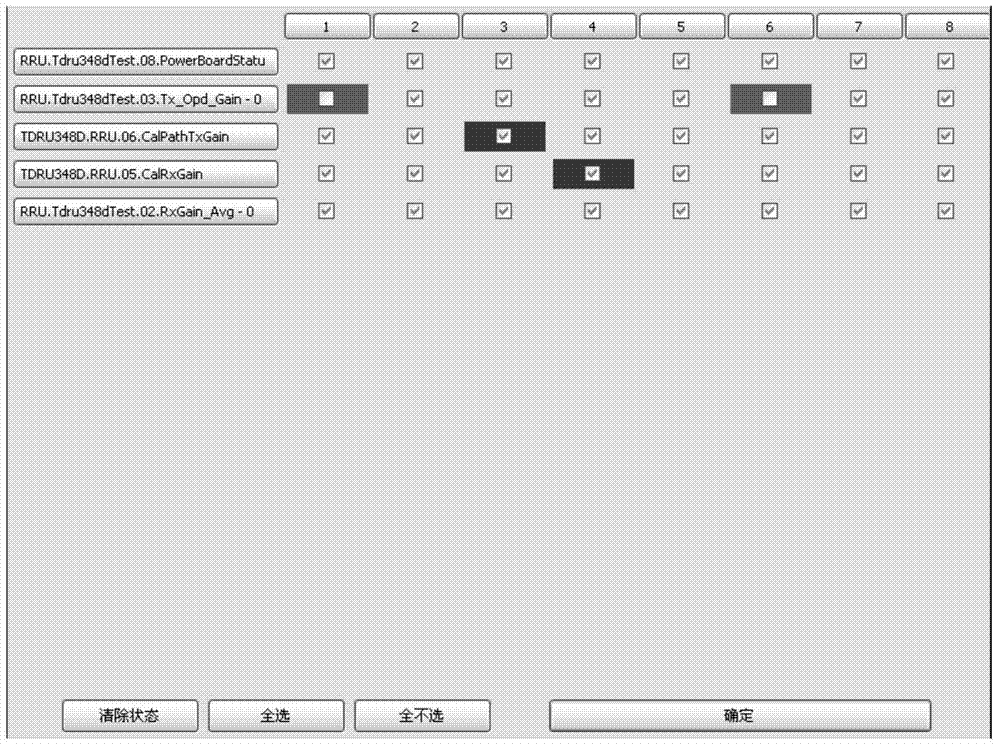

Multi-item test method for RRU (remote radio unit) base station

ActiveCN104244312AEasy to operateMeet testing needsWireless communicationProduction lineComputer science

The invention discloses a multi-item test method for an RRU (remote radio unit) base station. The method includes the steps of searching a specified catalogue for whether a test result corresponding to a current device exists or not according to identifier information of the device; if yes, analyzing the test result, marking a test item to be tested, executing a secondary test according to the marked test item, and updating the test result; if not, marking all of the test items, subjecting the device to overall test according to all of the marked test items, and storing the test result. The method has the advantages that the test items which fail to pass the test can be automatically and accurately marked, operations are facilitated for production line testers, and production testing efficiency is improved; the method is of certain universality, the demand for testing different types of devices can be met, labor and time of repeated development are decreased, and efficiency is improved.

Owner:SHANGHAI ULTIMATE POWER COMM TECH

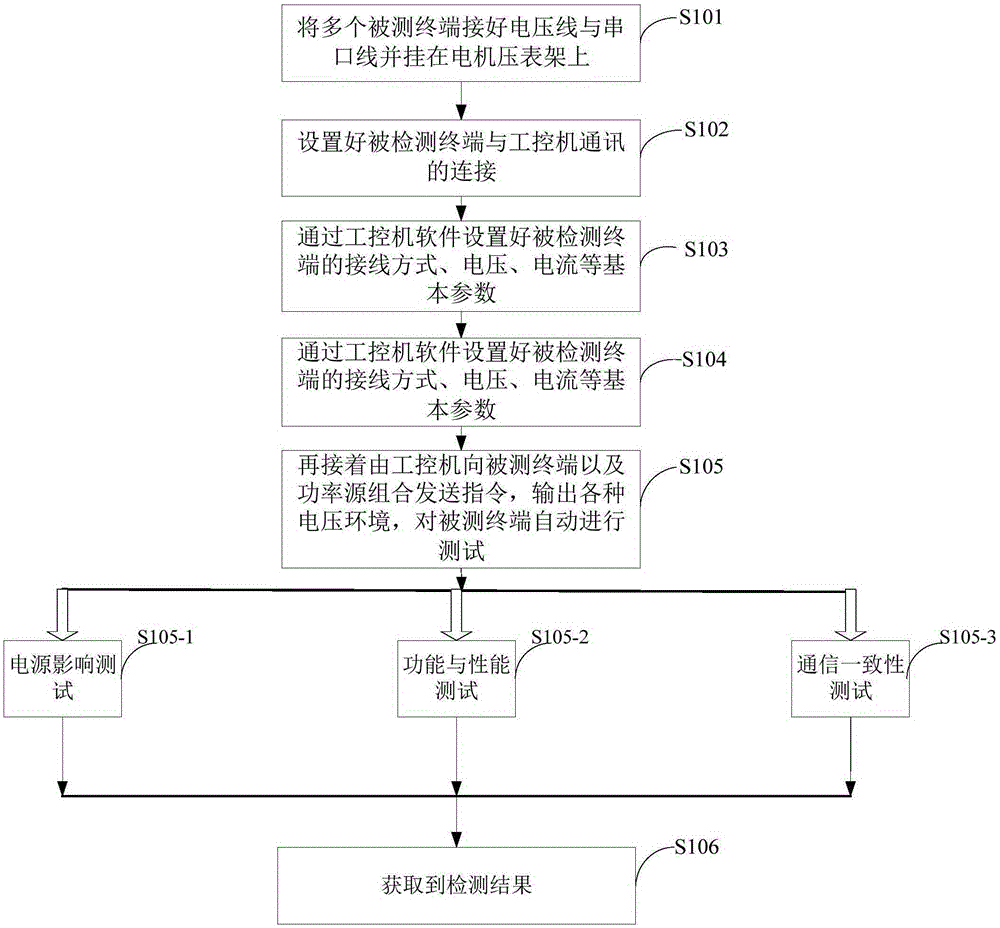

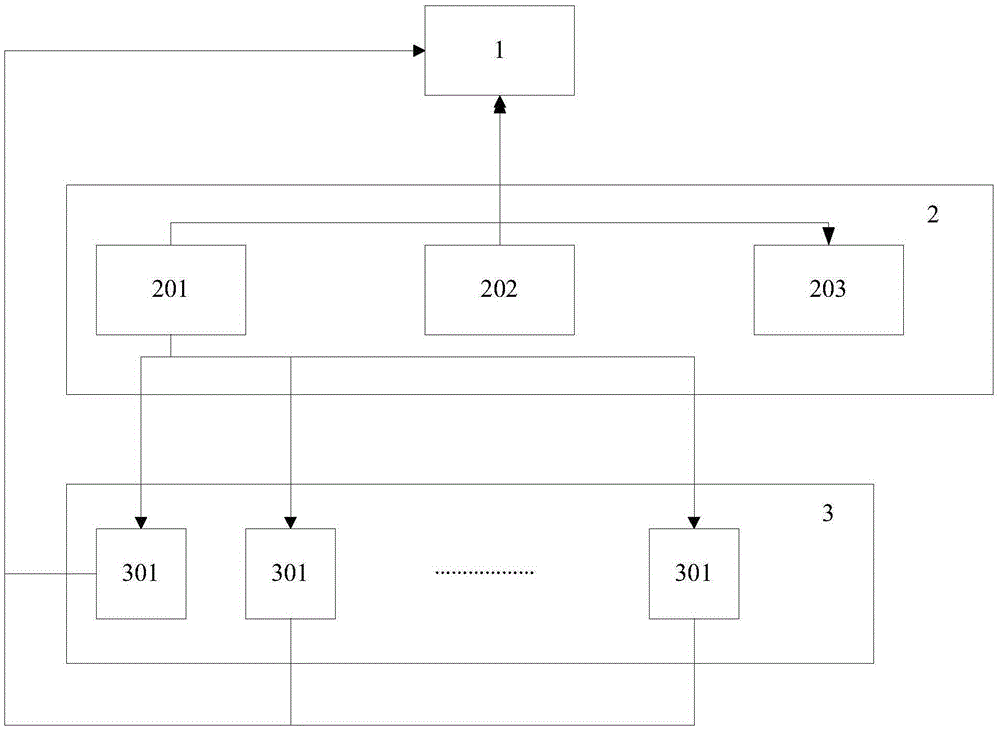

Method and system for automatic terminal detection

InactiveCN105301412AImprove production test efficiencyReliable test resultsElectrical testingPower flowComputer terminal

The invention relates to a method and a system for automatic terminal detection. The method comprises the steps that (1) a plurality of tested terminals are hung on a motor pressure meter frame and connected to an industrial personal computer by communications; (2) basic parameters of the tested terminals are set and a terminal detection testing manner is managed by the industrial personal computer; (3) the industrial personal computer sends instructions to the tested terminals and a power source combination, outputs various voltage and current environments and carries out automatic testing to the tested terminals, which comprises detection data checking of a power source influencing quantity, detection data checking of functions and performance and detection data checking of communication protocol conformance; and (4) various kinds of detection data of the tested terminals are called and read by the industrial personal computer and compared with detection data values of a standard table in order to obtain testing results of the tested terminals. In comparison with the prior art, the method and the system for the automatic terminal detection provided by the invention are advantageous in high efficiency, the accurate results, simple courses and the comprehensive data, etc.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Detection method, device and system for multi-tuner set top box

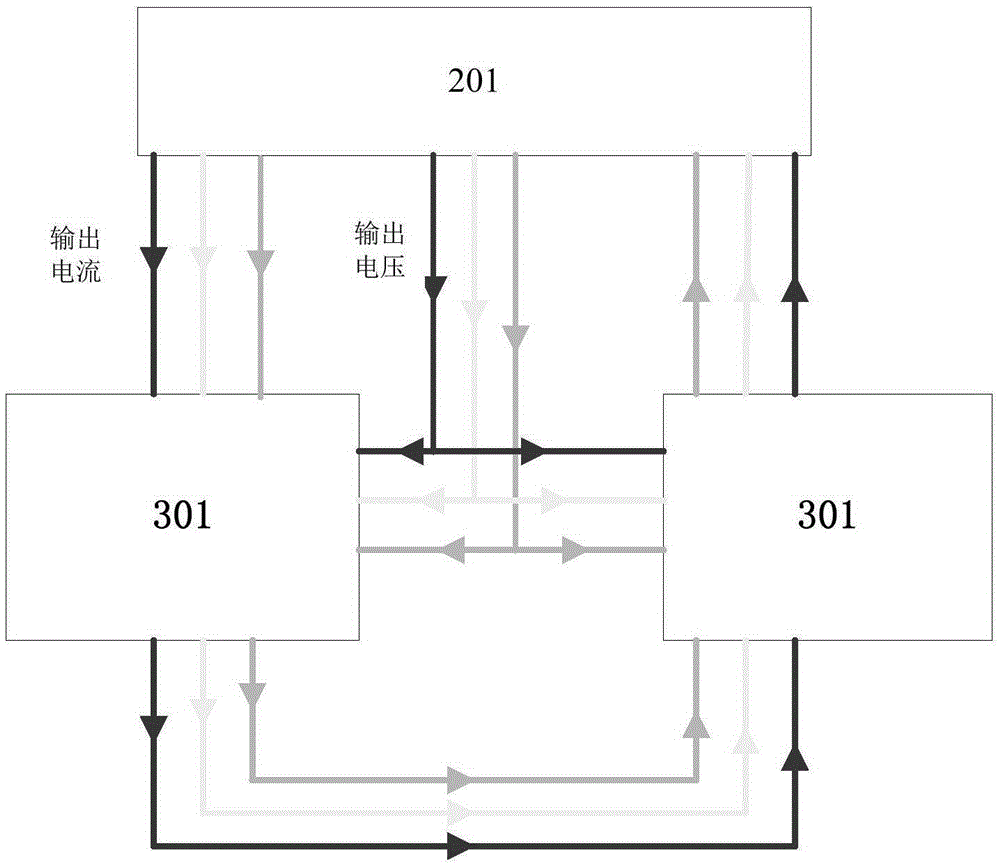

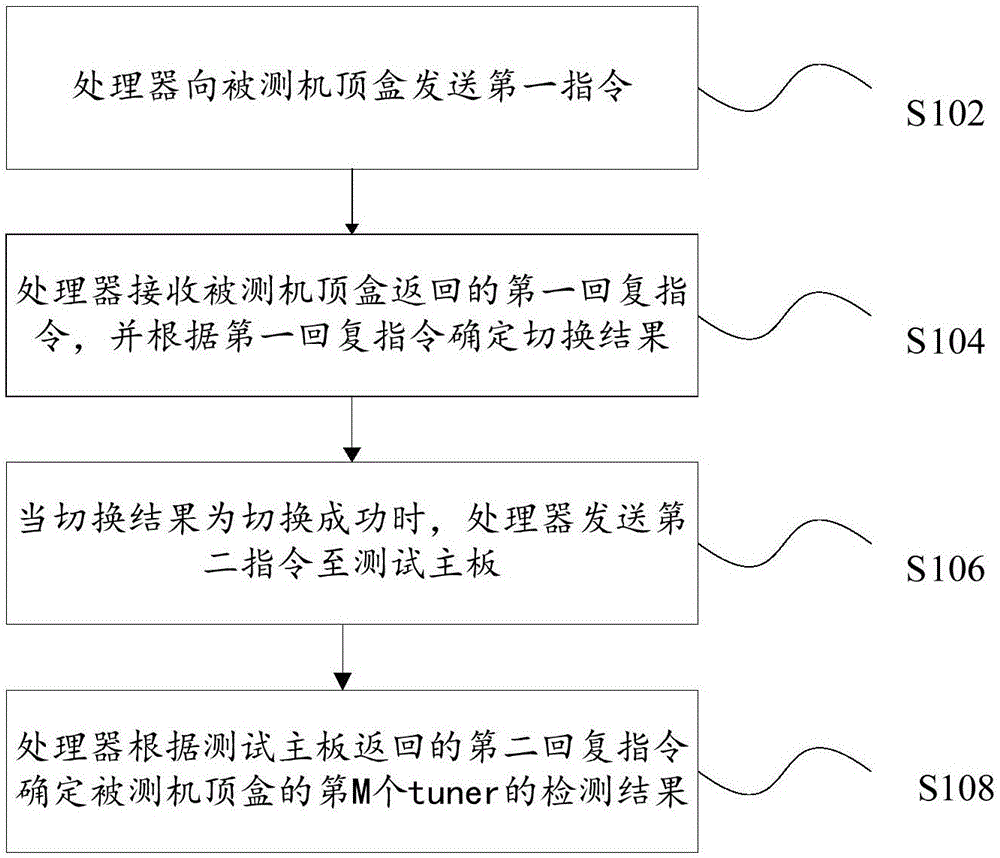

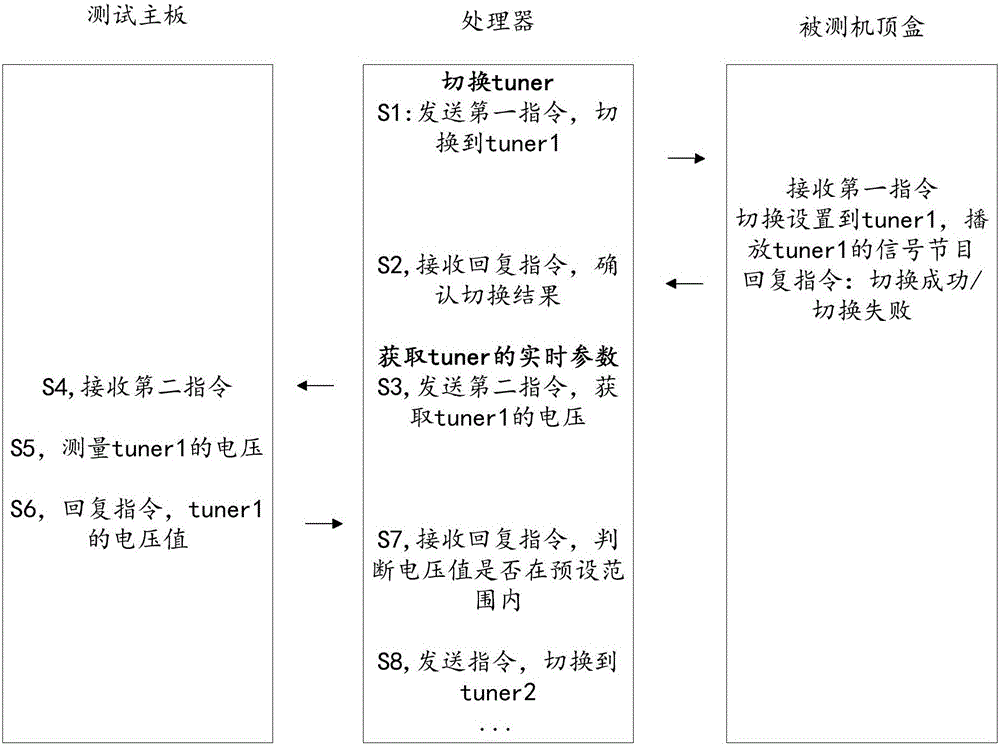

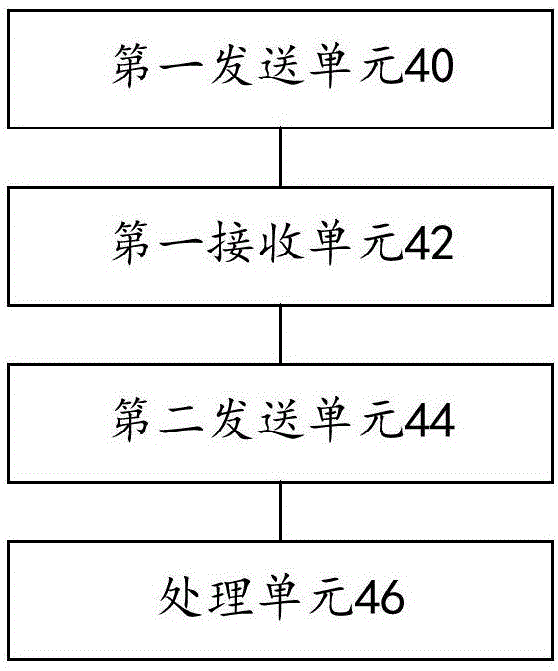

ActiveCN106803954AImprove production test efficiencyReduce manufacturing costTelevision systemsTest efficiencyTest set

The invention discloses a detection method, device and system for a multi-tuner set top box. The method includes the following steps: a processor sends a first instruction to a to-be-tested set top box, wherein the to-be-tested set top box includes N tuners, N is a natural number greater than or equal to 2, the first instruction is used for enabling the to-be-tested set top box to be switched to the M tuner and enabling the to-be-tested set top box to play signal programs of the M tuner, and M is a natural number smaller than or equal to N; the processor receives a first replay instruction returned by the to-be-tested set top box, and determines a switching result according to the first replay instruction; if the switching result shows that switching succeeds, the processor sends a second instruction to a test mainboard, wherein the second instruction is used for controlling the test mainboard to collect real-time parameters of the M tuner of the to-be-tested set top box; and the processor determines a detection result of the M tuner of the to-be-tested set top box according to a second replay instruction returned by the test mainboard. The detection method, device and system help to solve the technical problems of the prior art that the production test efficiency is low since only a single tuner interface can be tested during detection of a multi-tuner set top box.

Owner:ZHUHAI GOTECH INTELLIGENT TECH

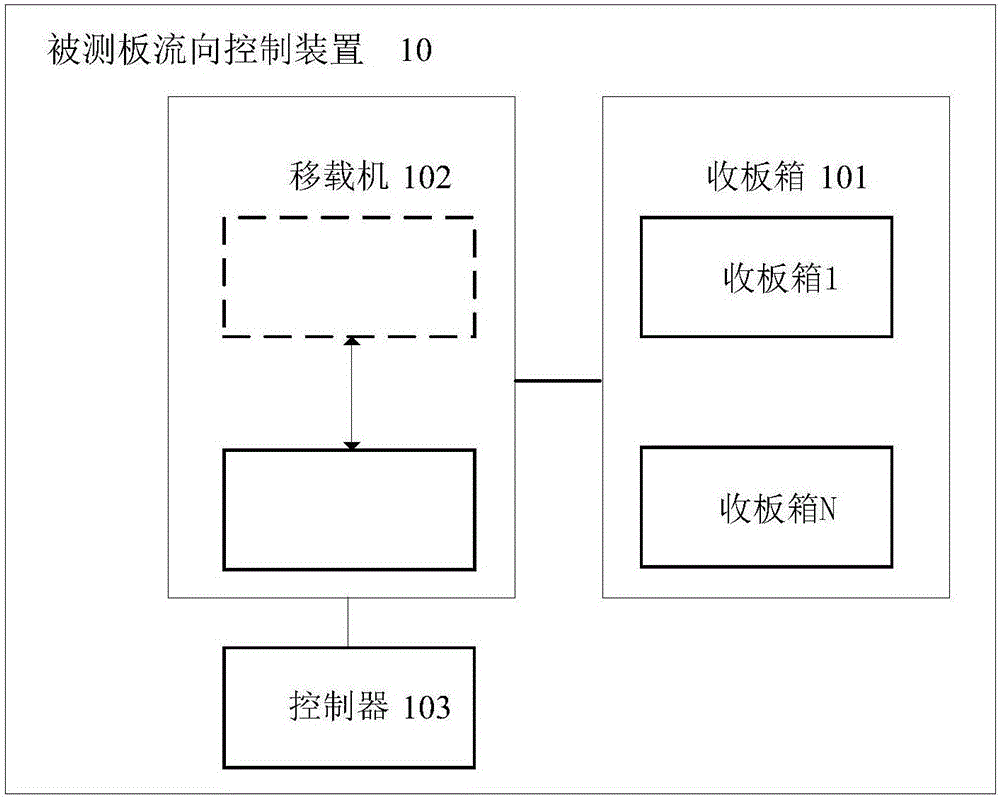

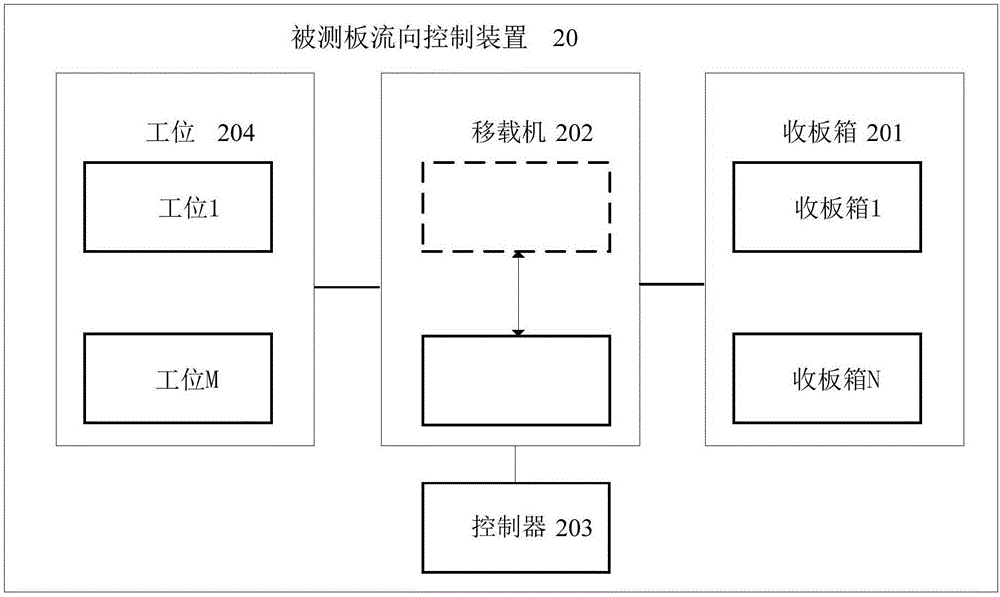

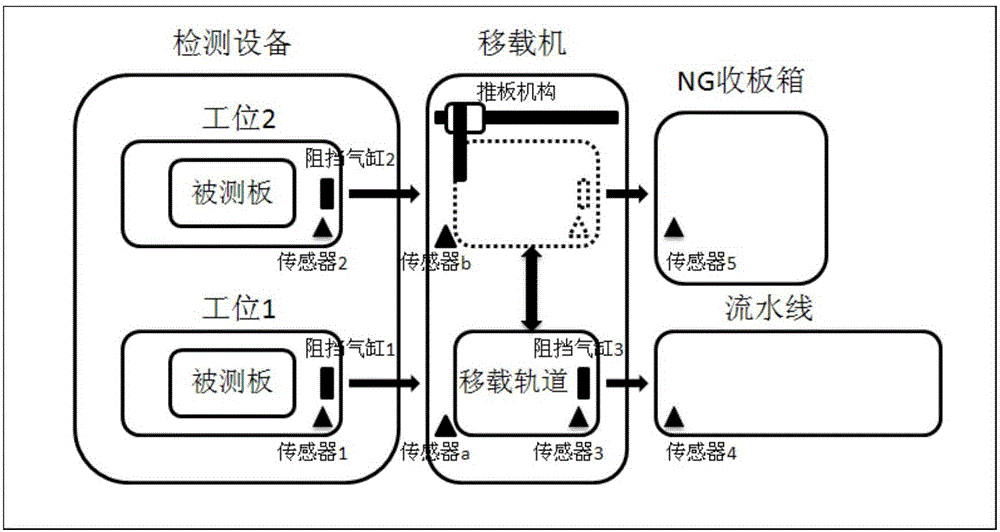

Tested plate flow direction control device and method, and visual inspection equipment

ActiveCN106583275AImplement automated test controlsImprove production test efficiencySortingVisual inspectionComputer engineering

The invention provides a tested plate flow direction control device, a tested plate flow direction control method and visual inspection equipment. The tested plate flow direction control device comprises at least two plate receiving boxes, a transfer machine and a controller, wherein each of the at least two plate receiving boxes corresponding to each of detection results and is used for receiving the tested plate corresponding to the detection result; and the controller is used for controlling the transfer machine to feed the tested plate which is detected to the plate receiving box corresponding to the test result according to the test result of the tested plate. According to the scheme provided by the invention, the tested plates with different test results can be automatically distinguished and processed by controlling the flow direction of the tested plates which are tested, so the production testing efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

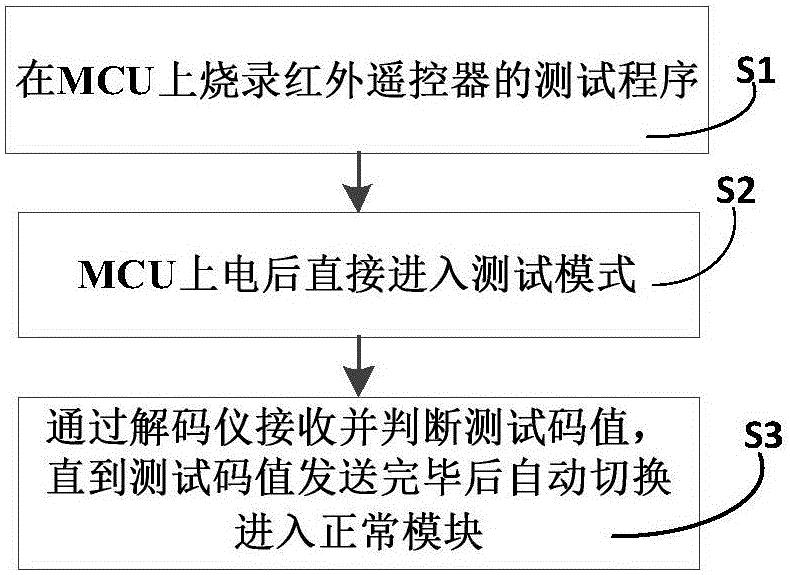

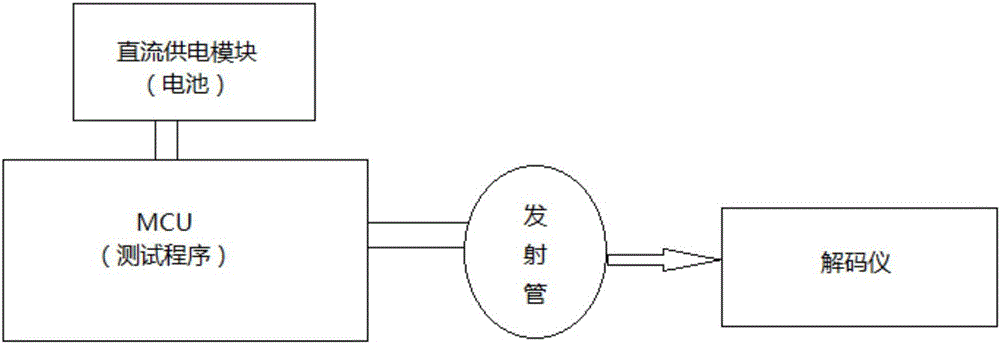

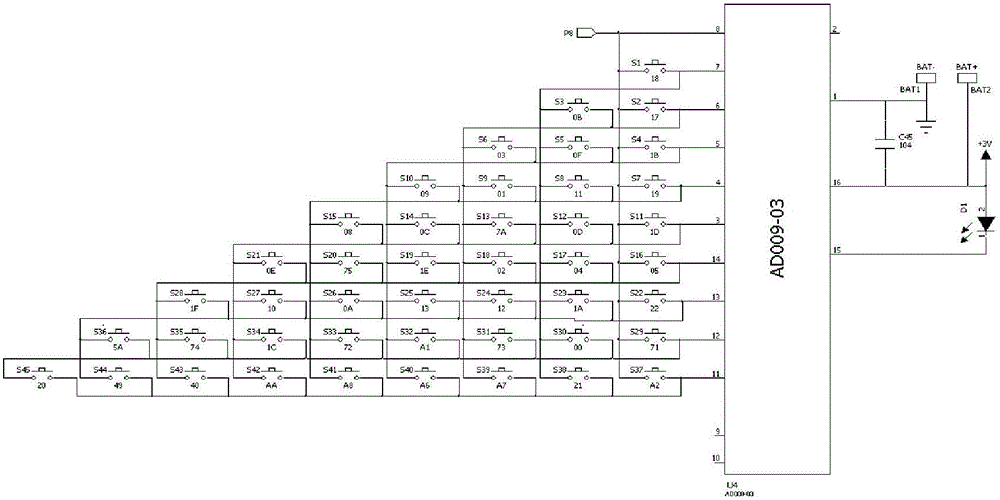

Method and system for testing infrared remote control

InactiveCN106097700ALower requirementImprove production test efficiencyNon-electrical signal transmission systemsElectricityRemote control

The invention provides a method and a system for testing an infrared remote control. The testing method comprises the following steps: S1, burning a test program of the infrared remote control on an MCU; S2, entering a test mode according to the test program after waiting until the MCU is directly electrified, wherein the MCU outputs a test code value; and S3, receiving and judging the test code value through a decoder, and entering a normal module through the MCU after the test code value is completely transmitted. According to the invention, after the infrared remote control is electrified, the MCU automatically enters the pre-burnt test program, then the test code value is immediately and automatically transmitted, and the MCU controls the infrared remote control to enter the normal mode after the test is completed; and therefore, a tester only needs to electrify and observe the test data in the test mode, and an operating mode of the infrared remote control does not need to be switched after test is completed. Therefore, the production testing efficiency can be greatly improved, and the cost is reduced.

Owner:SHENZHEN C&D ELECTRONICS

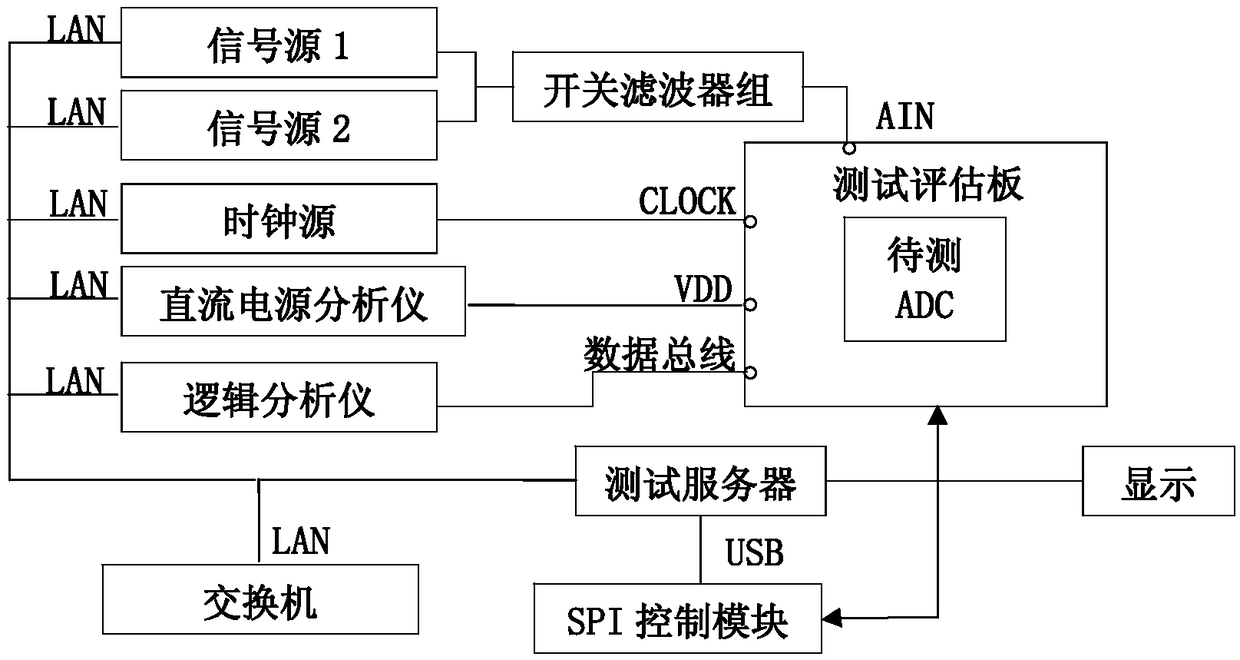

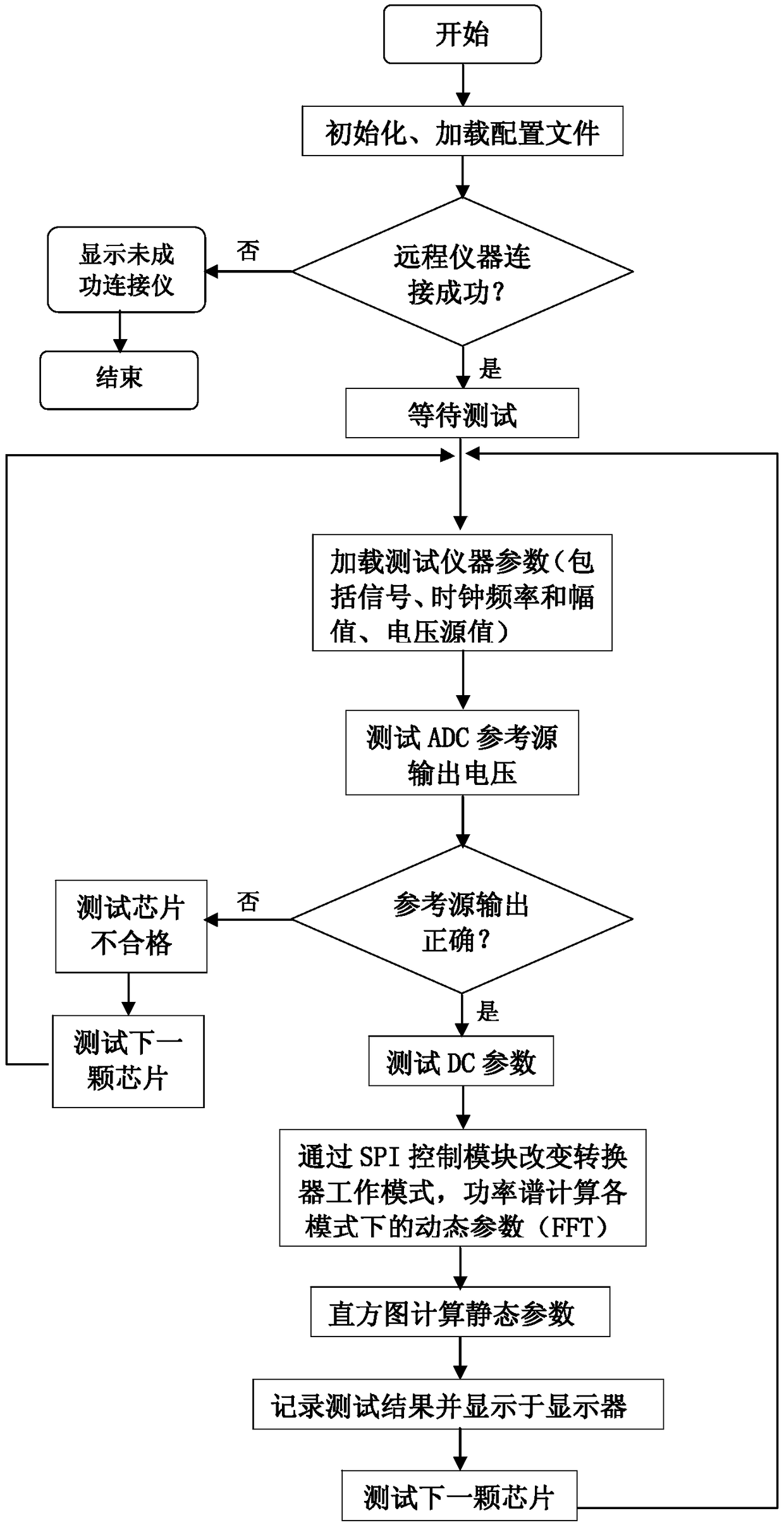

Automatic test system and method for GHz analog-to-digital converter

InactiveCN109120264AImprove production test efficiencyMeet mass production requirementsAnalogue/digital conversion calibration/testingDisplay deviceAnalog-to-digital converter

The invention provides an automatic test system and method for a GHz analog-to-digital converter. The automatic test system for a GHz analog-to-digital converter mainly includes a DC power supply analyzer, two signal sources, a clock source, a switching filter bank, a logic analyzers, an SPI control module, a test evaluation board, a switch, a test server, a display, and a cabinet, wherein the SPIcontrol module is connected to the test server through a USB cable, and each virtual instrument and the test server are arranged in the cabinet after being connected to the switch through an LAN bus;and based on TestStand and LabView, a host computer software is compiled to complete the control of the each virtual instrument and each module and evaluation of the full parameter characteristics ofthe converter, and then the test results are saved and displayed on the display, and the automatic test of the GHz analog-to-digital converter is finally realized. The automatic test system and method for a GHz analog-to-digital converter can simplify the testing process, can increase the number of measurable parameters of the GHz analog-to-digital converter, can improve the testing efficiency, and can reduce the maintenance cost of the test system software, and at the same time, the automatic test system has preferable compatibility and flexibility.

Owner:BEIJING MXTRONICS CORP +1

Method and device for determining performance of motor system as well as testing equipment

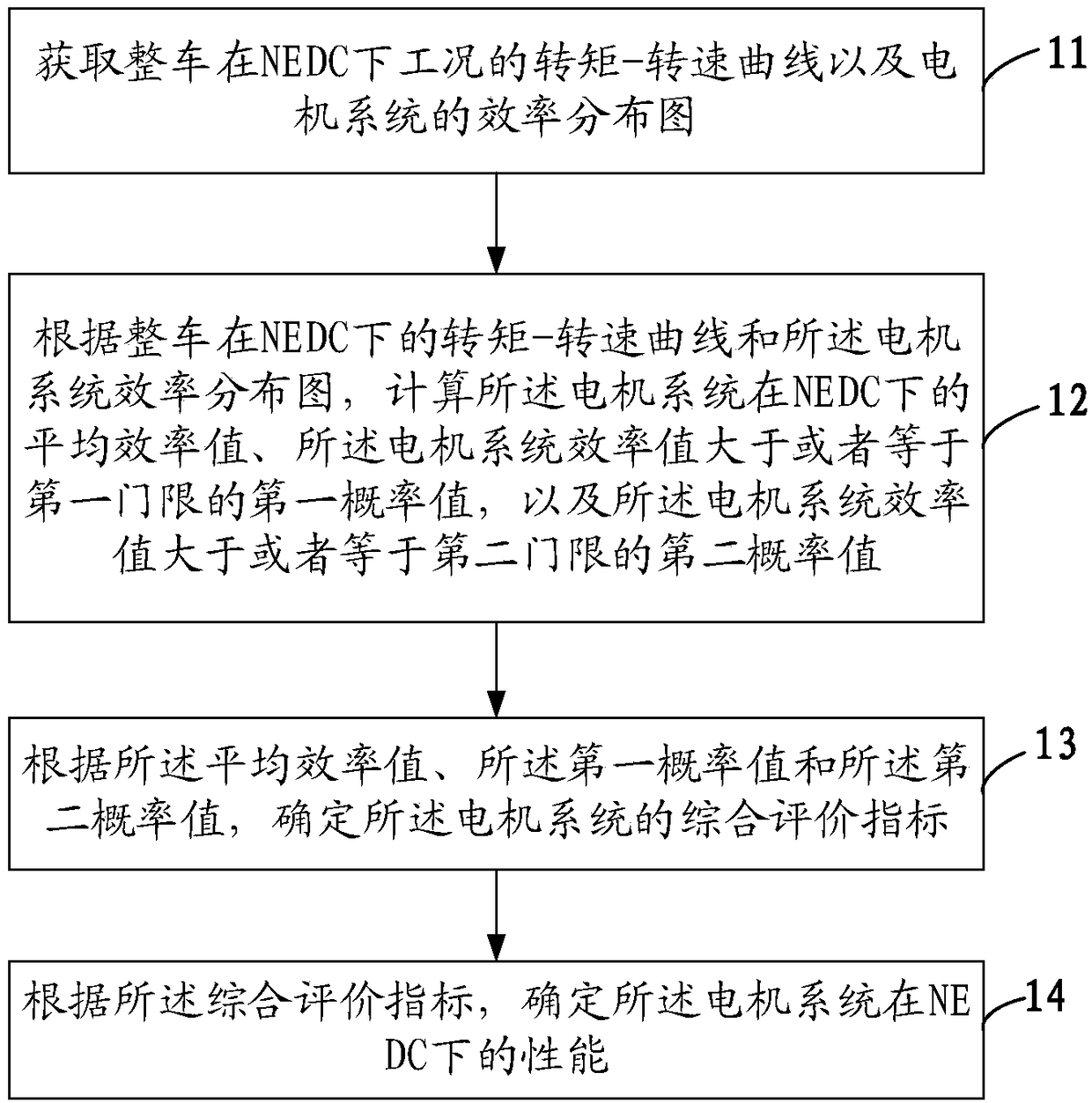

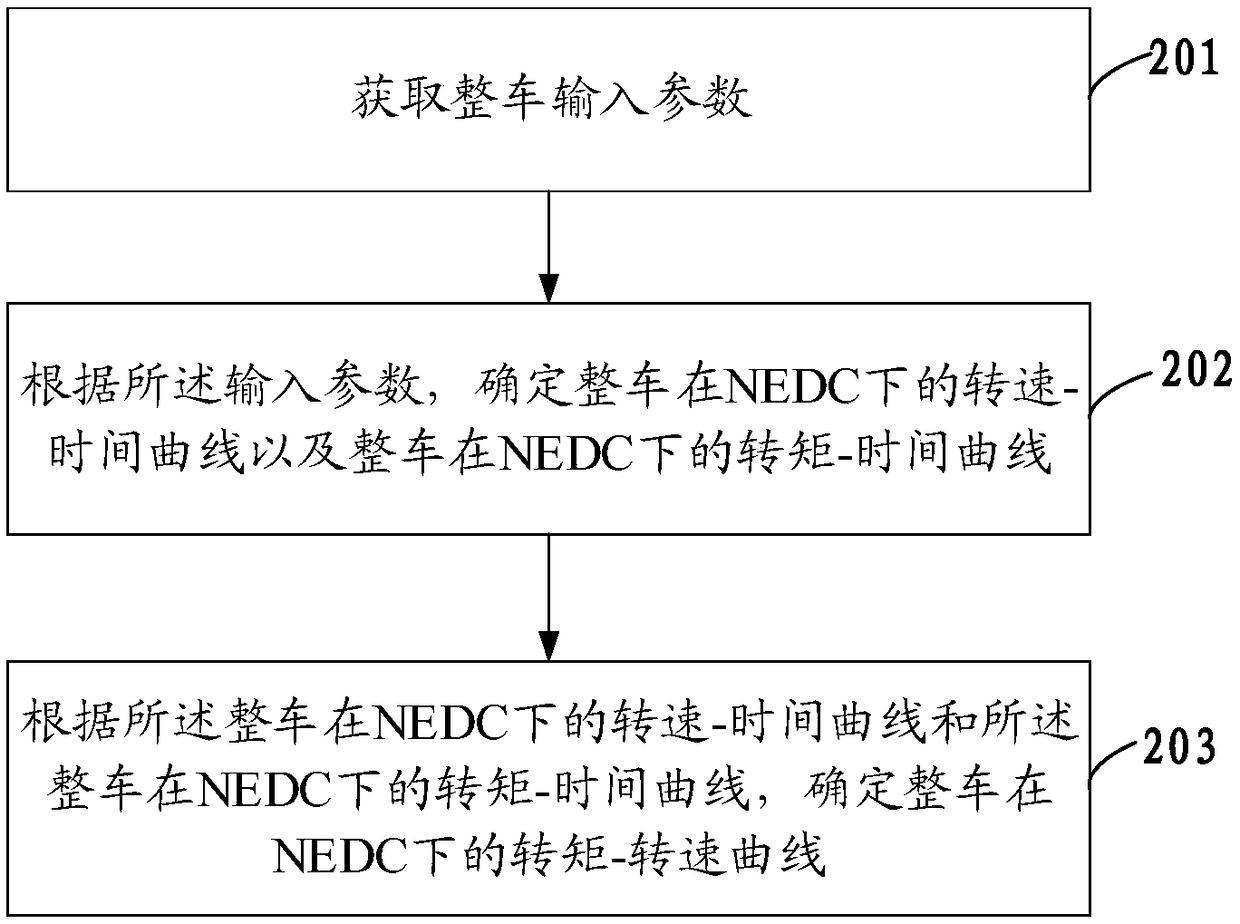

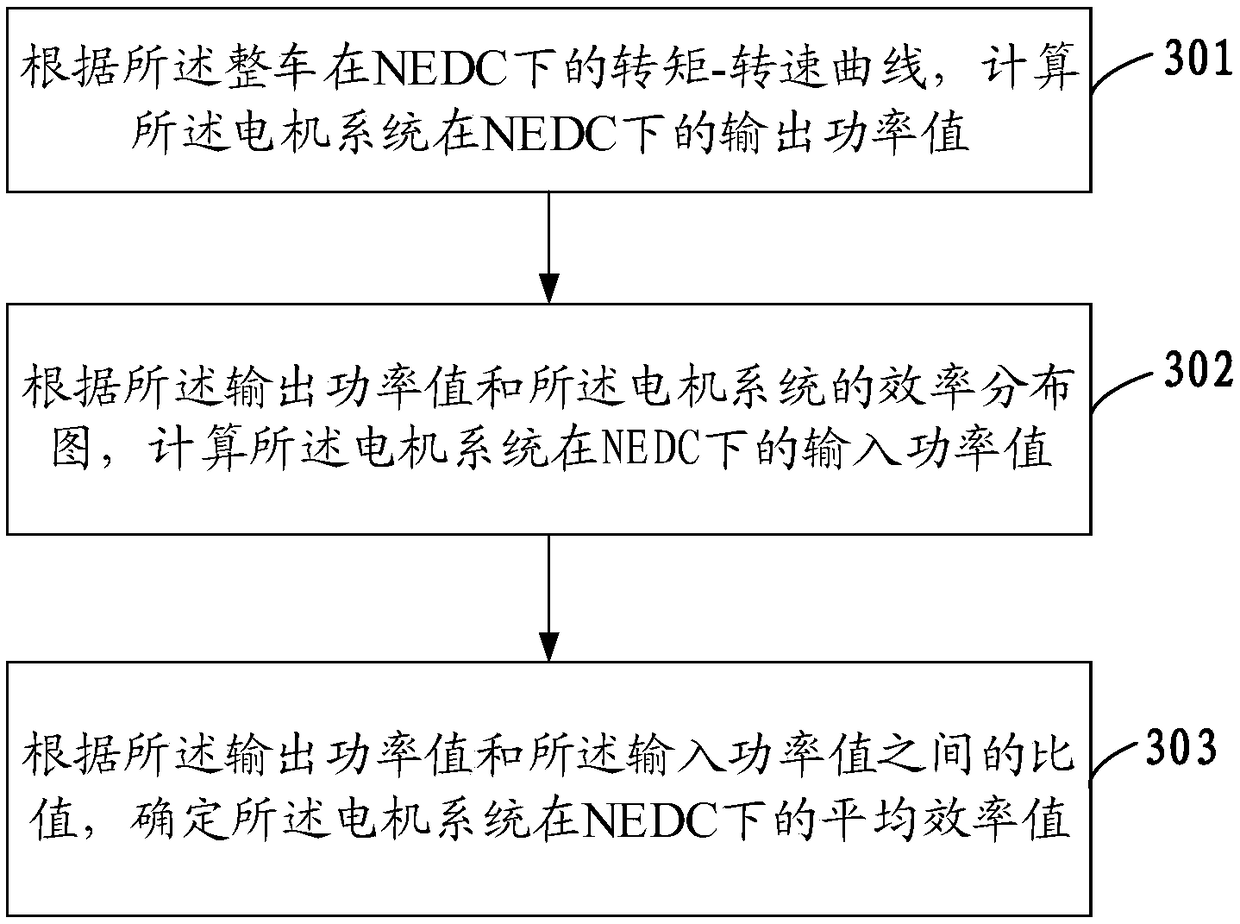

ActiveCN109100651ASimplify production testing processImprove production test efficiencyDynamo-electric machine testingDistribution diagramEnergy consumption

The invention discloses a method and a device for determining the performance of a motor system as well as testing equipment. The method comprises the following steps: acquiring a torque-speed curve of a whole vehicle under a NEDC (New European Driving Cycle) and an efficiency distribution diagram of the motor system; calculating the average efficiency value of the motor system under the NEDC according to the torque-speed curve of the whole vehicle under the NEDC and the efficiency distribution diagram of the motor system, a first probability value at which the efficiency value is greater thanor equal to a first threshold and a second probability value at which the efficiency value is greater than or equal to a second threshold; and determining the comprehensive evaluation index of the motor system according to the average efficiency value, the first probability value and the second probability value in order to determine the performance of the motor system under the NEDC. Through adoption of the method and the device, whether the performance of the motor system satisfies the requirement of the energy consumption index of the whole vehicle in an automobile production test can be evaluated; the evaluation of the motor system after the whole vehicle runs under the NEDC is avoided; the production test process is simplified; and the efficiency of the production test is improved.

Owner:BEIJING ELECTRIC VEHICLE

Hand wheel rotating mechanism and electronic endoscope bending part fatigue testing device

InactiveCN113267332AReduce the labor intensity of manual operation in bending fatigue testGuaranteed accuracyMachine part testingControl engineeringElectric machinery

The invention discloses a hand wheel rotating mechanism and an electronic endoscope bending part fatigue testing device. The hand wheel rotating mechanism comprises an upper and lower hand wheel motor module and a left and right hand wheel motor module, the upper and lower hand wheel motor module comprises an upper and lower hand wheel fixing piece, and the upper and lower hand wheel fixing piece is connected with a first driving mechanism through a first transmission assembly; the left and right hand wheel motor module comprises a left and right hand wheel fixing piece, and the left and right hand wheel fixing piece is connected with a second driving mechanism through a second transmission assembly; according to the invention, the bending fatigue test can be automatically carried out by the machine, the labor intensity of manual operation of the bending fatigue test of the operation part of the electronic endoscope is reduced, the production test efficiency is improved, and the accuracy of the bending angle in the fatigue test process is ensured through the automatic test system. Therefore, the tensile force of the steel wire in the endoscope body after testing is in a stable state, and the requirements of high-precision control of the operation part of the electronic endoscope and positioning of the bending angle of the bending part are met.

Owner:重庆金山医疗技术研究院有限公司

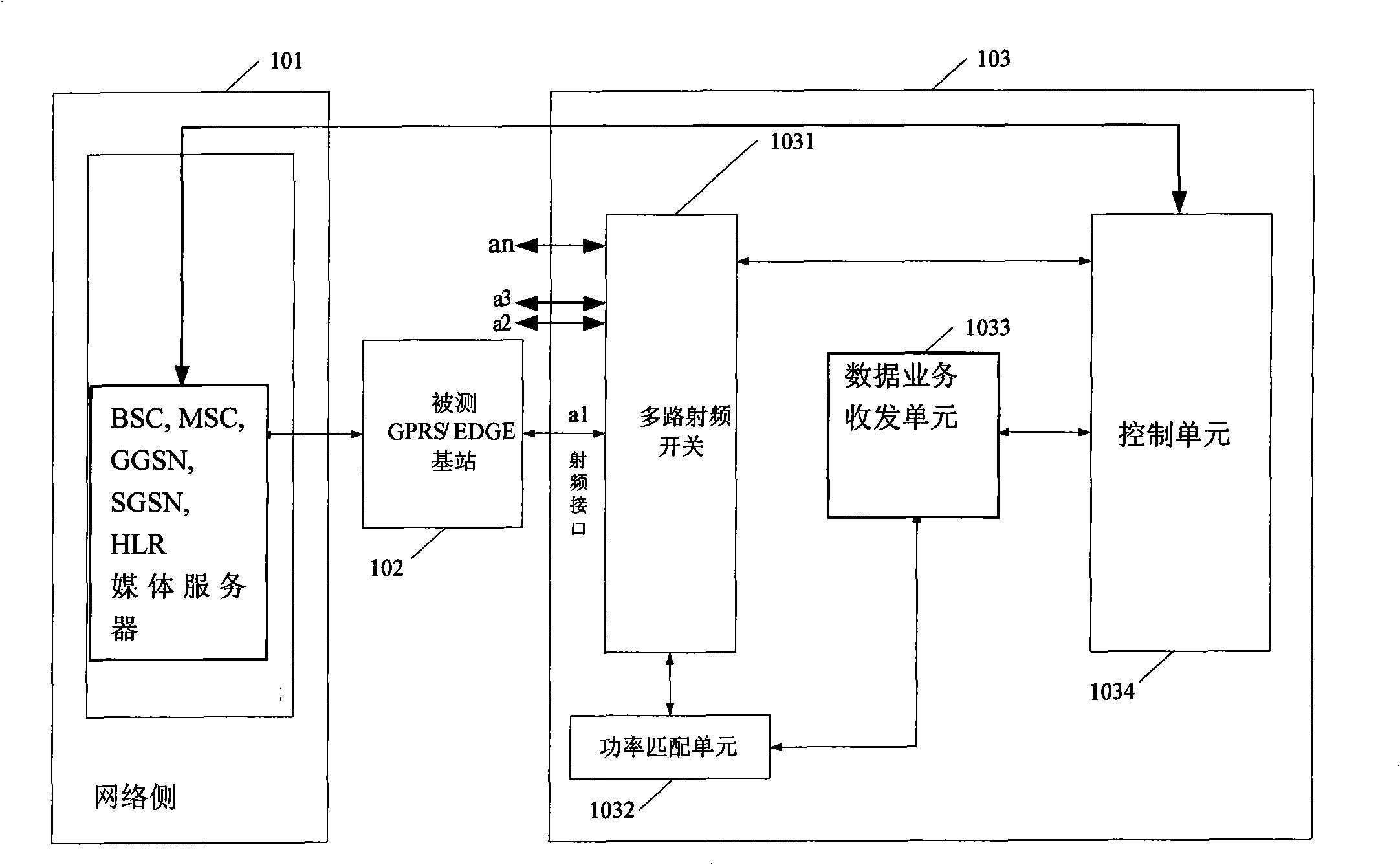

Device and method for testing base station

InactiveCN101330699AIncrease authenticityThe test result is accurateRadio/inductive link selection arrangementsCommunications systemEdge based

The invention provides a base station test device and a test method. The base station test device comprises an interface unit communicating with a base station to be tested in one or a plurality of wave bands; a data service receiving and sending unit which is connected with the interface unit, sends data to and receives data from the base station to be tested through the interface unit, and gets relevant transmission parameters of transmitted data; a control unit which is connected with the interface unit and the data service receiving and sending unit, used for controlling the data service receiving and sending unit to be accessed to the base station to be tested and to send data, and for reading and analyzing the transmission parameters of the data service receiving and sending unit. The base station test device and the test method solve the test problem of system joint debugging consistent to the actual operating environment of the base station, particularly, the base station of the mobile wireless communication systems of GPRS and EDGE based on GSM, and achieve the automatic operation of the test of the base station.

Owner:ZTE CORP

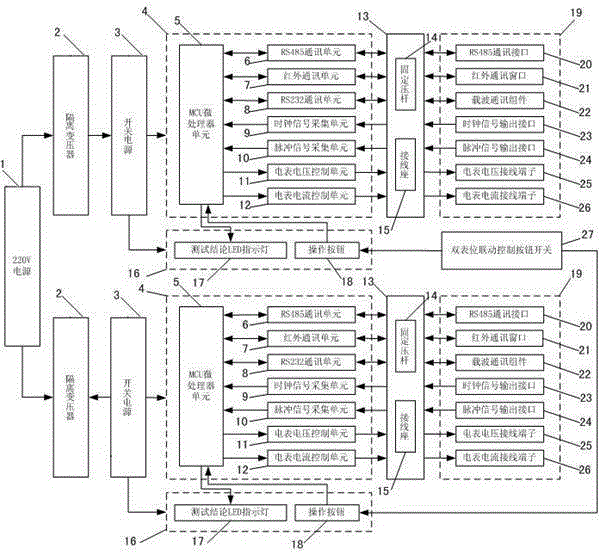

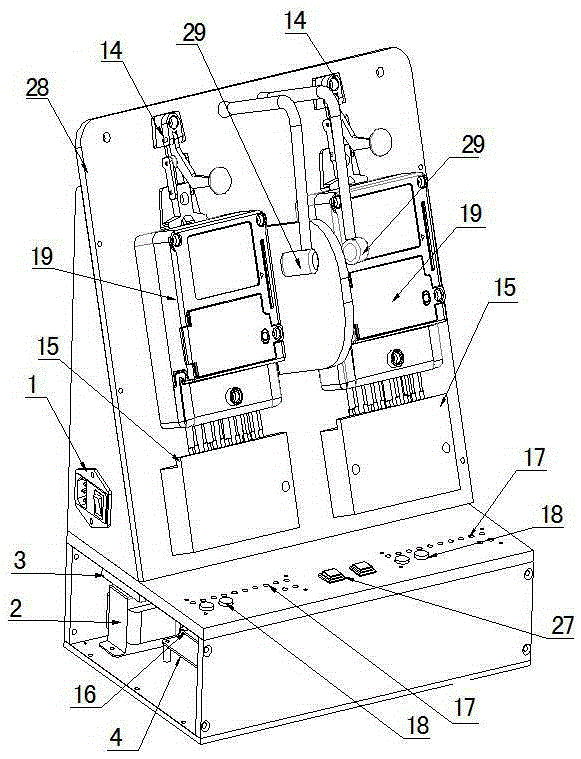

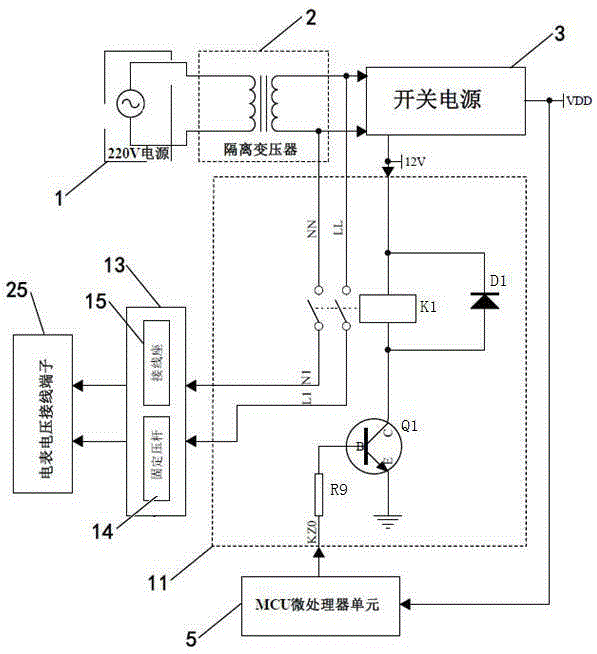

Electric energy meter function test tool

InactiveCN105807248AReduce production test costsLow operating skill requirementsElectrical measurementsEngineeringPush switch

The invention discloses an electric energy meter function test tool, and relates to an electric energy meter test apparatus. A 220V power source is successively connected with isolation transformers and switch power sources, the switch power sources are connected with test control units and test operation units, the test control units are connected with the test operation units, a dual-meter-position linkage control button switch is connected with the two test control units, MCU microprocessor units are in bidirectional connection with RS485 communication units, infrared communication units and RS232 communication units, clock signal acquisition units and pulse signal acquisition units are accessed to the MCU microprocessor units, the test control units are connected with detected electric energy meters through connection devices, and the detected electric energy meters are installed on connector bases of the connection devices and are compacted and fixed through fixation pressure bars. The operation is simple, the production test efficiency is high, the cost is low, the automation degree is high, the test accuracy is good, the requirement for operation skills of operators is low, and the stability and reliability are high.

Owner:JIANGSU SHENGDE ELECTRIC METER

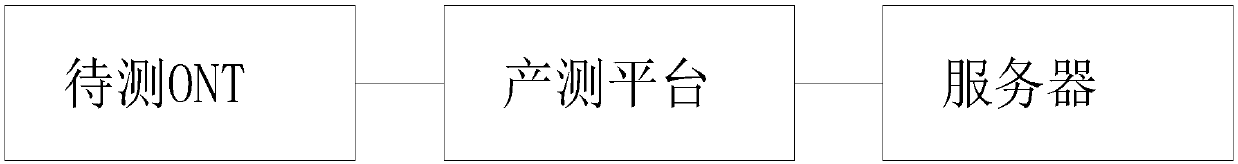

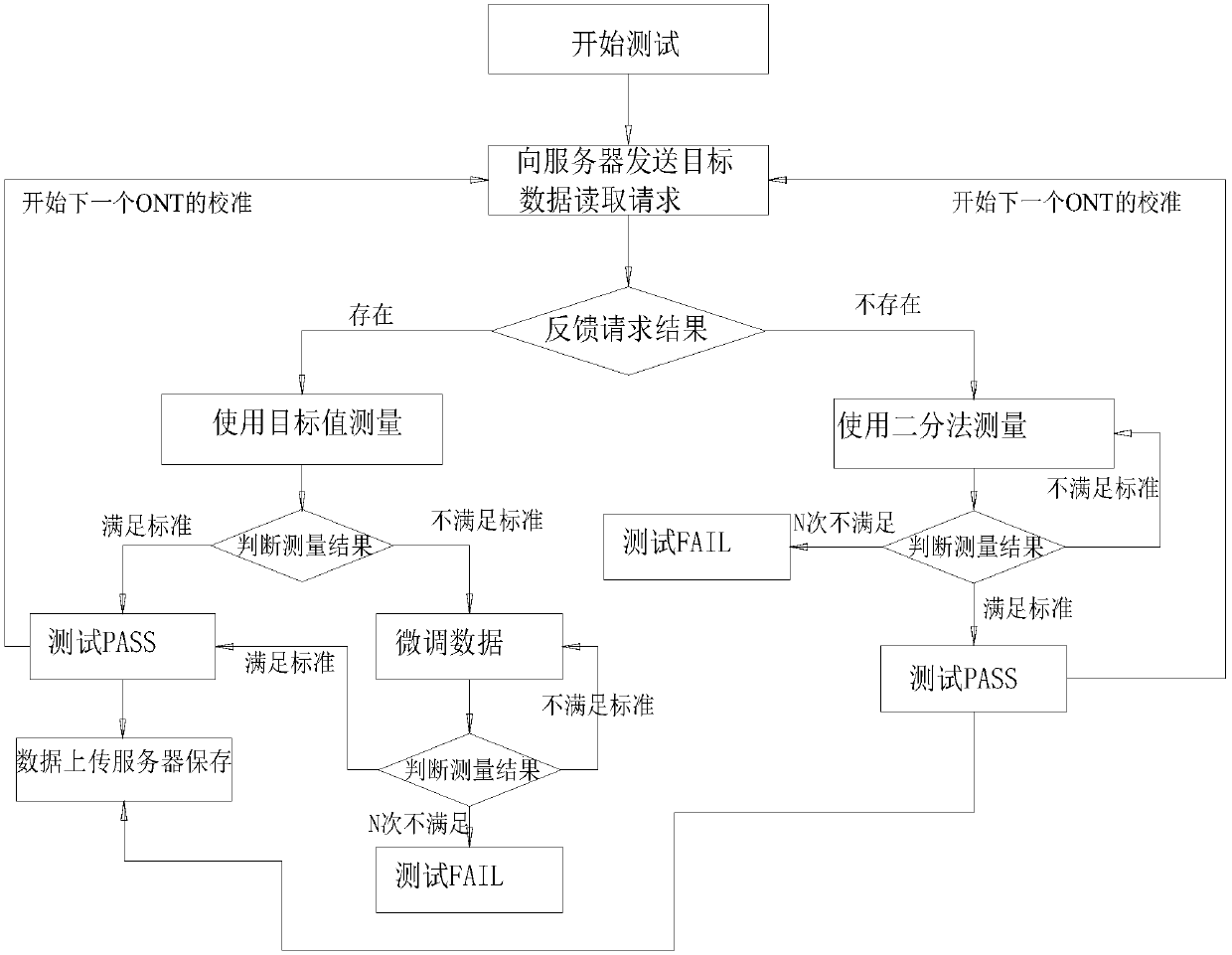

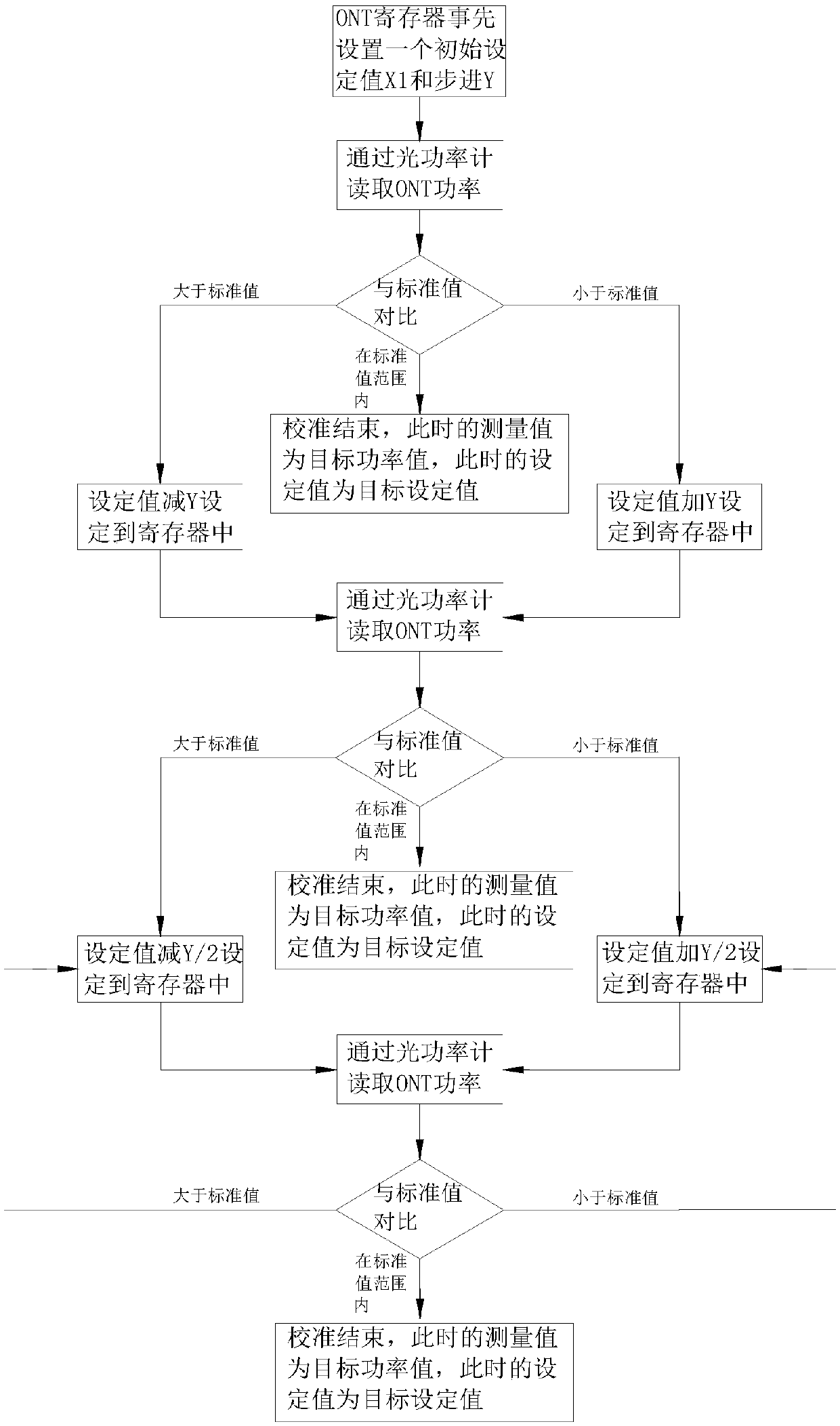

ONT power calibration method based on data analysis

ActiveCN107786264AImprove production test efficiencyReduce manufacturing costElectromagnetic network arrangementsTest platformData analysis

The invention discloses an ONT power calibration method based on data analysis. The method comprises the steps that an initial set value X1 and a stepping value Y are set in an ONT register in advance, and initial power P1 is obtained through a production test platform, wherein X1 and P1 form a data group R1, and the production test platform sends a target data reading request to a server according to the data group R1; the server receives the target data reading request and queries whether or not the data group R1 exists in a server database; if not, a dichotomy method is used for measurement; if yes, a target value is used for measurement. According to the method, the process of dichotomy calibration is mainly used for obtaining enough data samples at the beginning, when more and more data samples are obtained, testing is conducted basically according to the process of searching the samples for the target value, and at this moment, the efficiency can be greatly improved.

Owner:TAICANG T&W ELECTRONICS CO LTD

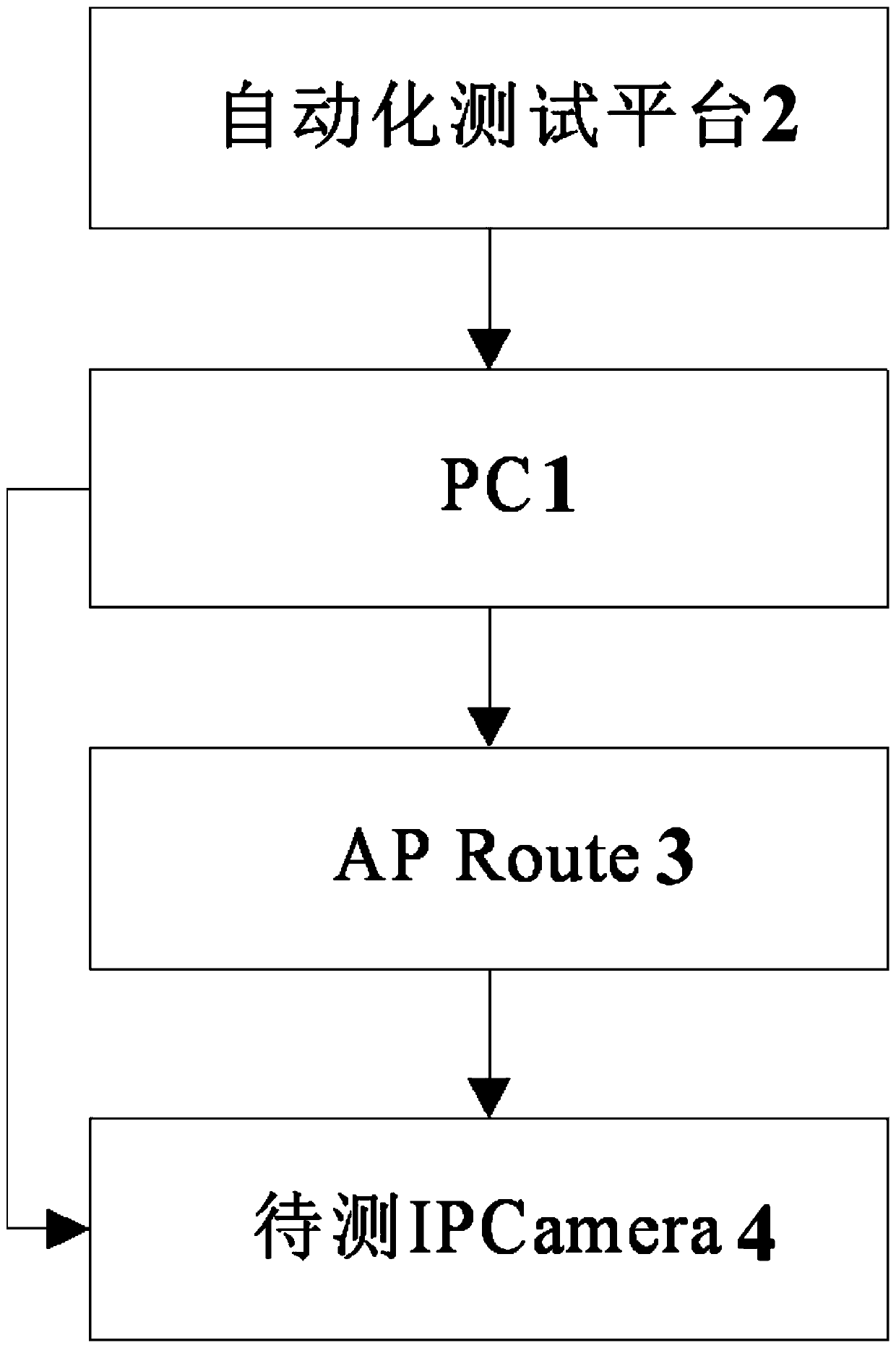

Network camera test system and method

InactiveCN111083471ANo need to worry about mutual interferenceResolve mutual interferenceTelevision systemsWireless routerHigh volume manufacturing

The invention discloses a network camera test system and method. The system comprises a pc, an automatic test platform which is arranged on the pc, a wireless router which is connected with the pc, aplurality of network cameras which are connected with the wireless router, the network cameras are further connected with the pc, a wifi module and an SD expansion port are arranged on each network camera, and an sd card is arranged in the SD expansion port. According to the invention, the IPCamera is set to be connected with different ssid and passwords through the SD extended function, the problem of mutual interference during mass production is solved, the cost investment is low, the universality is high, the stability is high, the production test efficiency is greatly improved, and the production test cost is reduced.

Owner:TAICANG T&W ELECTRONICS CO LTD

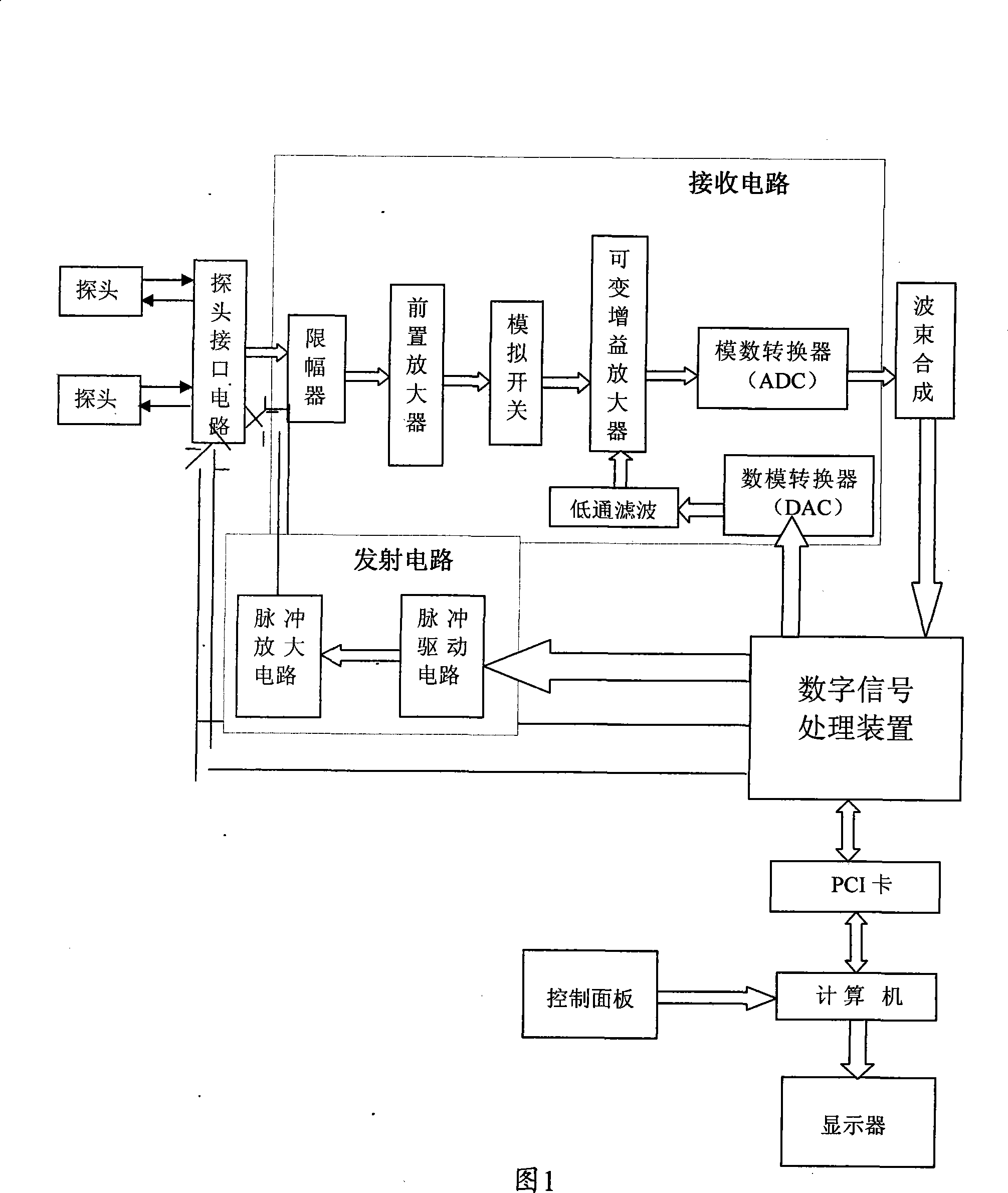

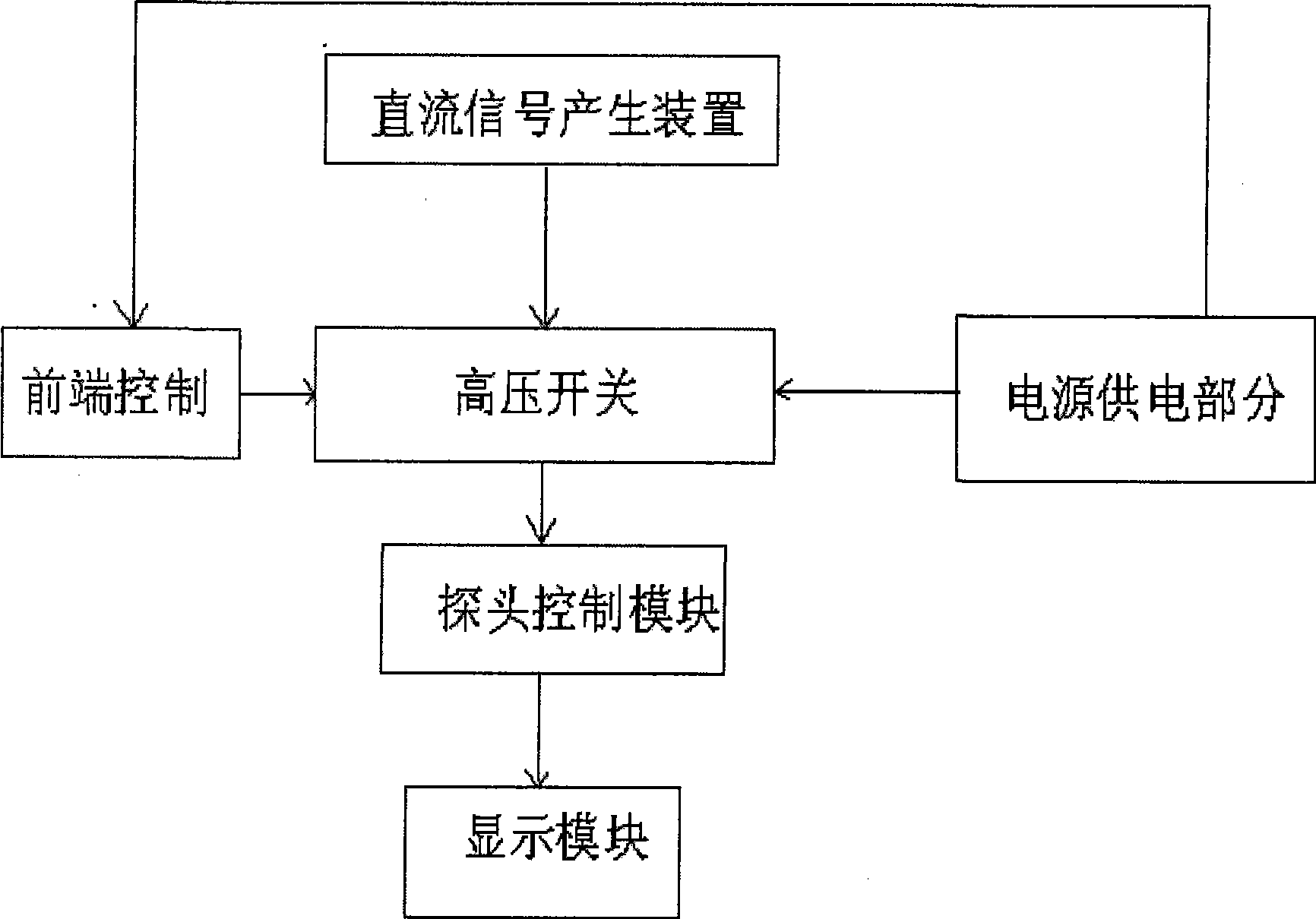

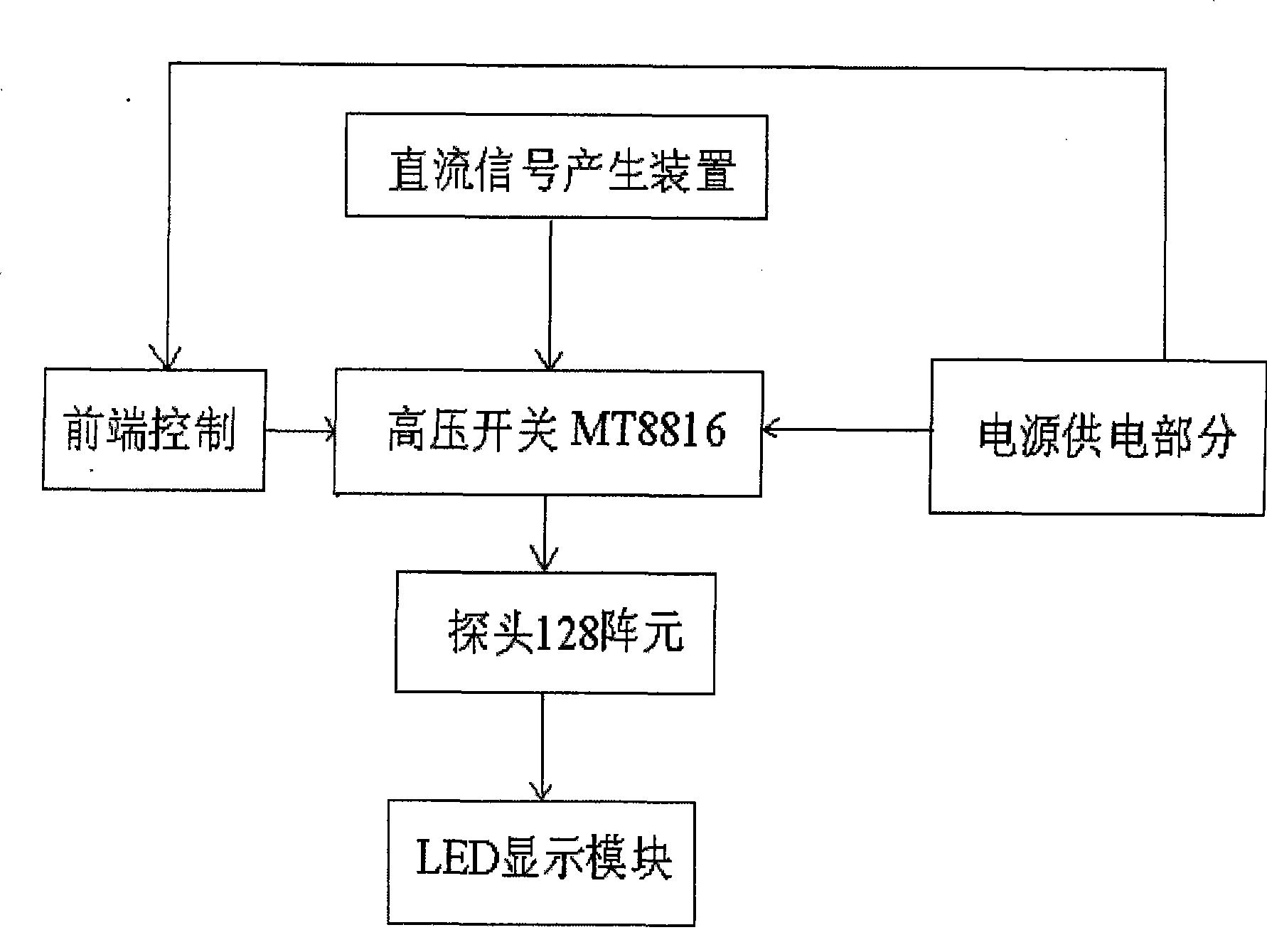

Channel connectivity diagnostic equipment of probe-head control module of ultrasonic diagnostic device

InactiveCN101396276AReduce test costImprove production test efficiencyUltrasonic/sonic/infrasonic diagnosticsElectrical testingDiagnostic equipmentsEngineering

A passage convexity diagnostic device of a probe control module of a diasonograph is characterized in that the device comprises a power supply source, a DC signal generation device, a high voltage switch, a front-end control module and a display module. The power supply source is respectively connected with the DC signal generation device, the high voltage switch, and the front-end control module. The DC signal generation device and the front-end control module are respectively connected with the high voltage switch connected with the input end of the probe control module which needs to be tested; the input end of the probe control module which needs to be tested is connected with the display module.

Owner:SHENZHEN LANDWIND IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com