Patents

Literature

349 results about "Cyclic test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cyclic test is a type of test in which a product, material, or object of interest is subjected to repeated testing, instead of a single test cycle.

Prediction method for life cycle of battery

InactiveCN103698710AExtend your lifeGood for determining performanceElectrical testingCyclic testTested time

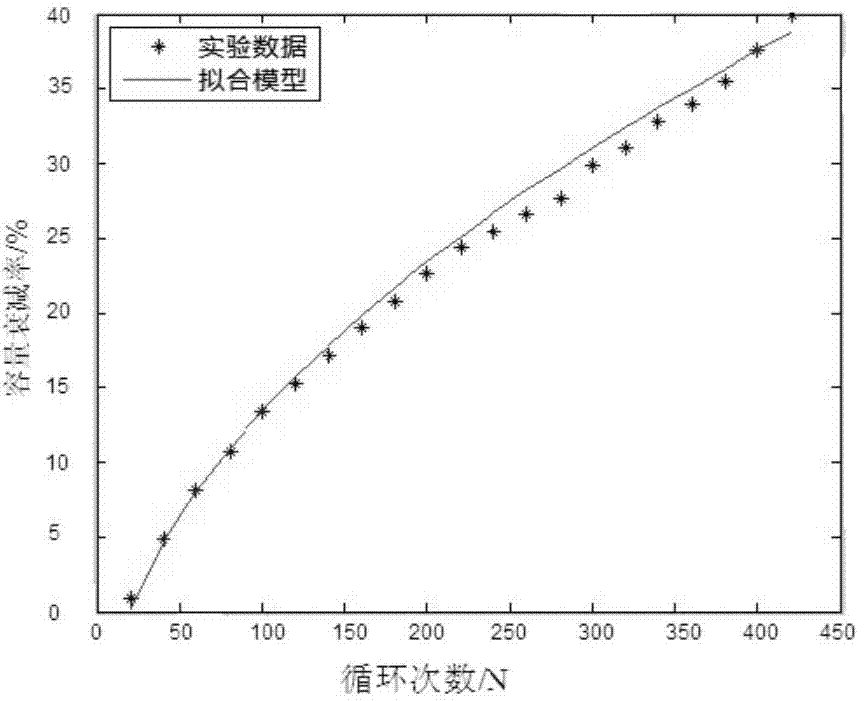

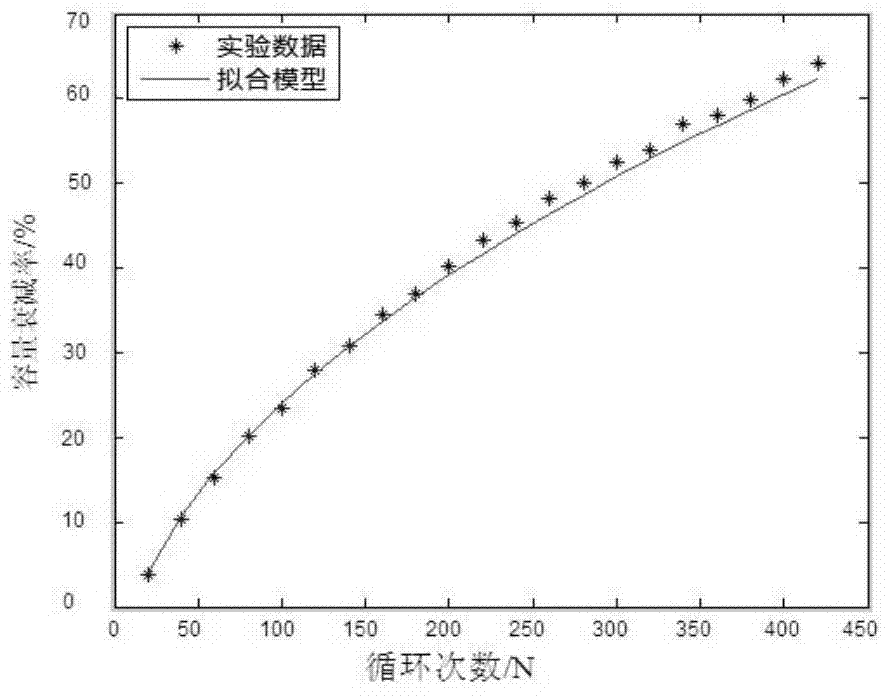

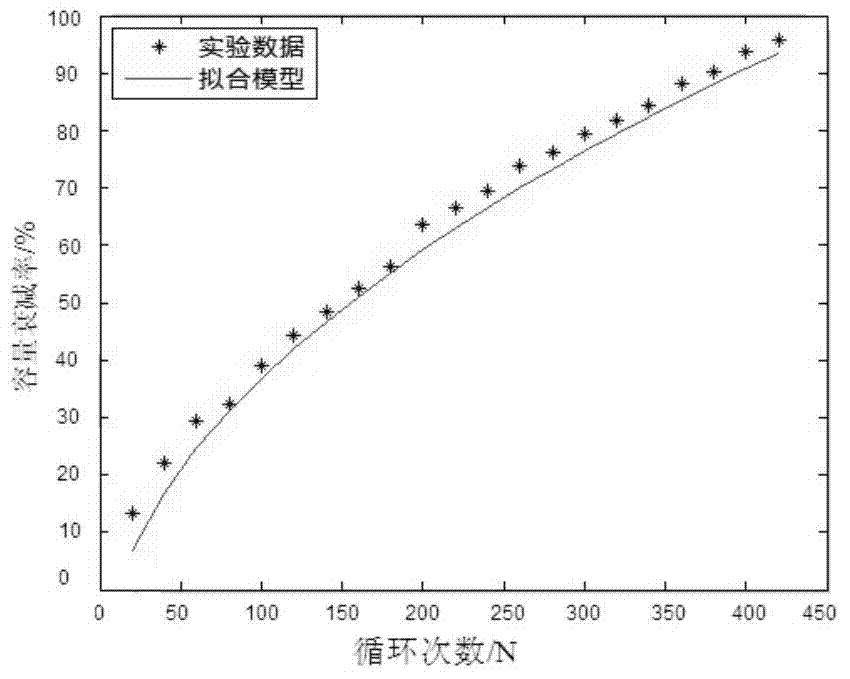

The invention discloses a prediction method for a life cycle of a battery. The prediction method comprises the following steps: drawing a curve of the number of discharge and capacity fading rate; determining a function model of the capacity fading rate Qloss of the battery and the number of discharge N of the battery; substituting data of a certain impact factor impacting the life of the battery into the function model, wherein Qloss is 50-80 percent of the nominal capacity of the battery; calculating to obtain the expected cycle period N of the battery. According to the prediction method disclosed by the invention, as long as little cyclic test is performed on the battery, the residual life of the battery can be judged, and therefore, the test time is greatly shortened and the test cost is greatly reduced; the objective condition of capacity fading during the actual use process of the battery can be truly and comprehensively described, the life and the residual life of the battery can be obtained, the performance of the battery can be helped to be determined, and the life of the battery is prolonged. As the established model is universal, the prediction method disclosed by the invention is suitable for establishing life fading models of various storage batteries.

Owner:CENT SOUTH UNIV +2

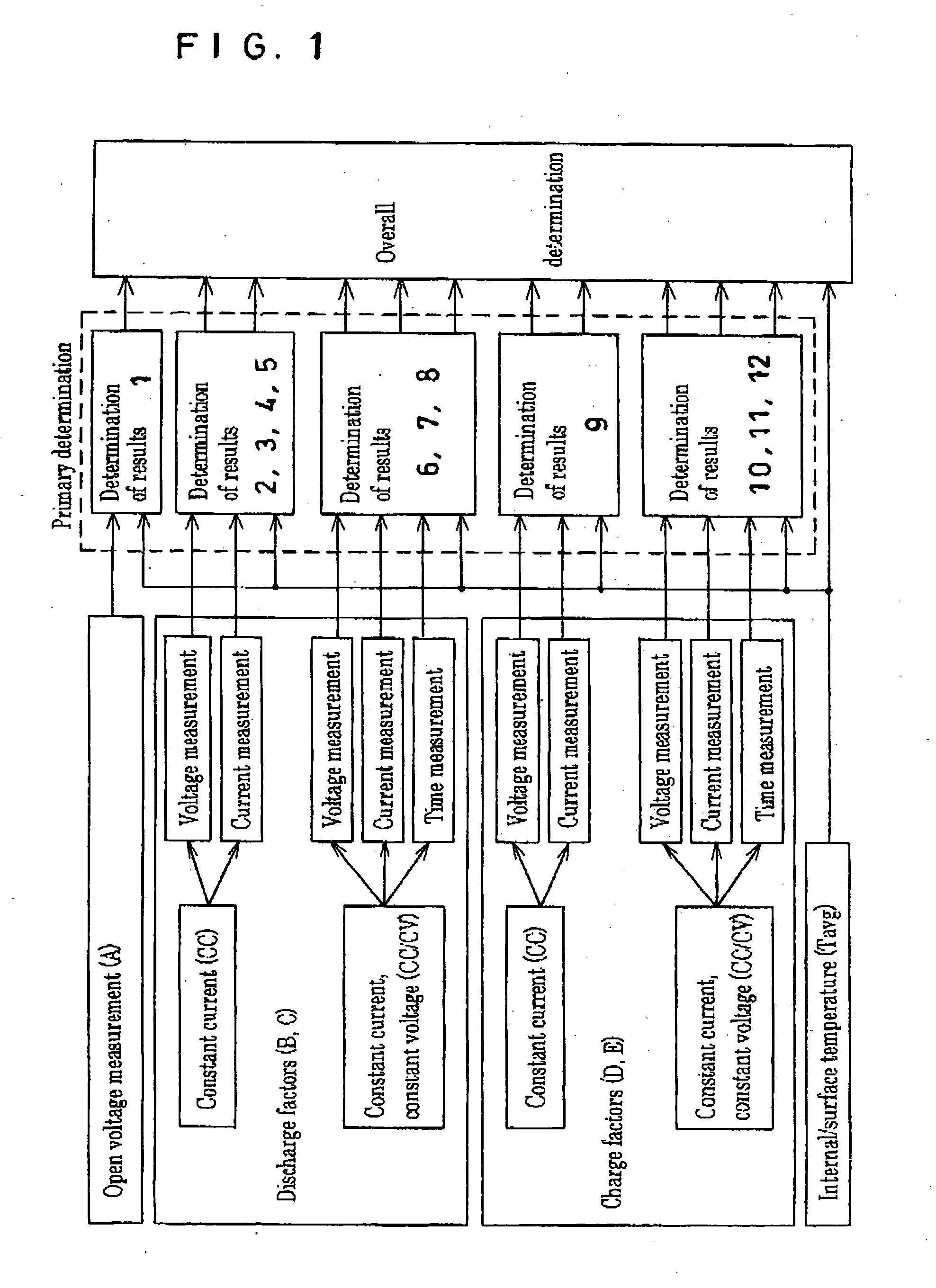

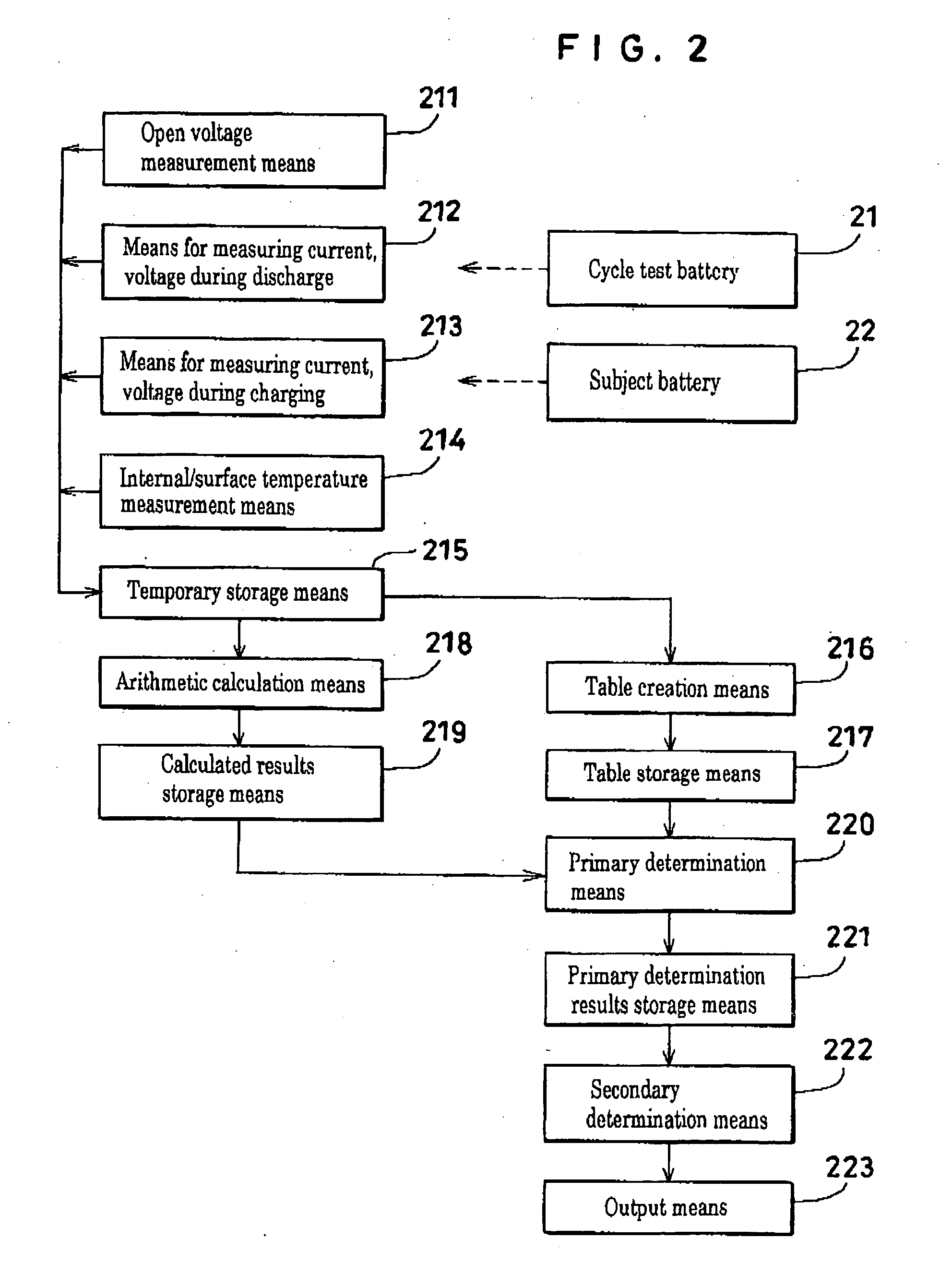

Method and apparatus for confirming the charge amount and degradation state of a battery, a storage medium, an information processing apparatus, and an electronic apparatus

ActiveUS20050110466A1The right amountDegradation of accuratelyBatteries circuit arrangementsMaterial analysis by electric/magnetic meansInformation processingTest battery

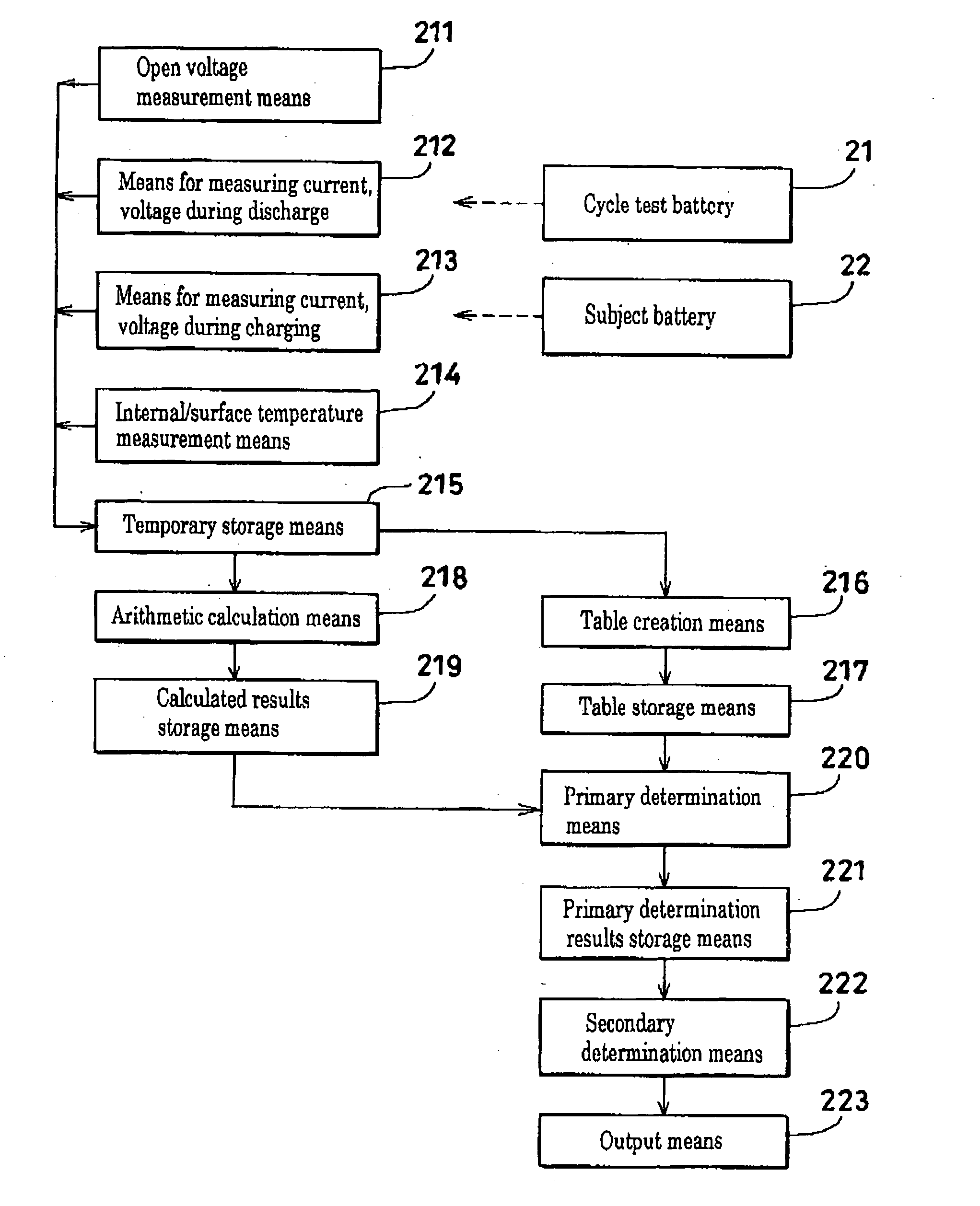

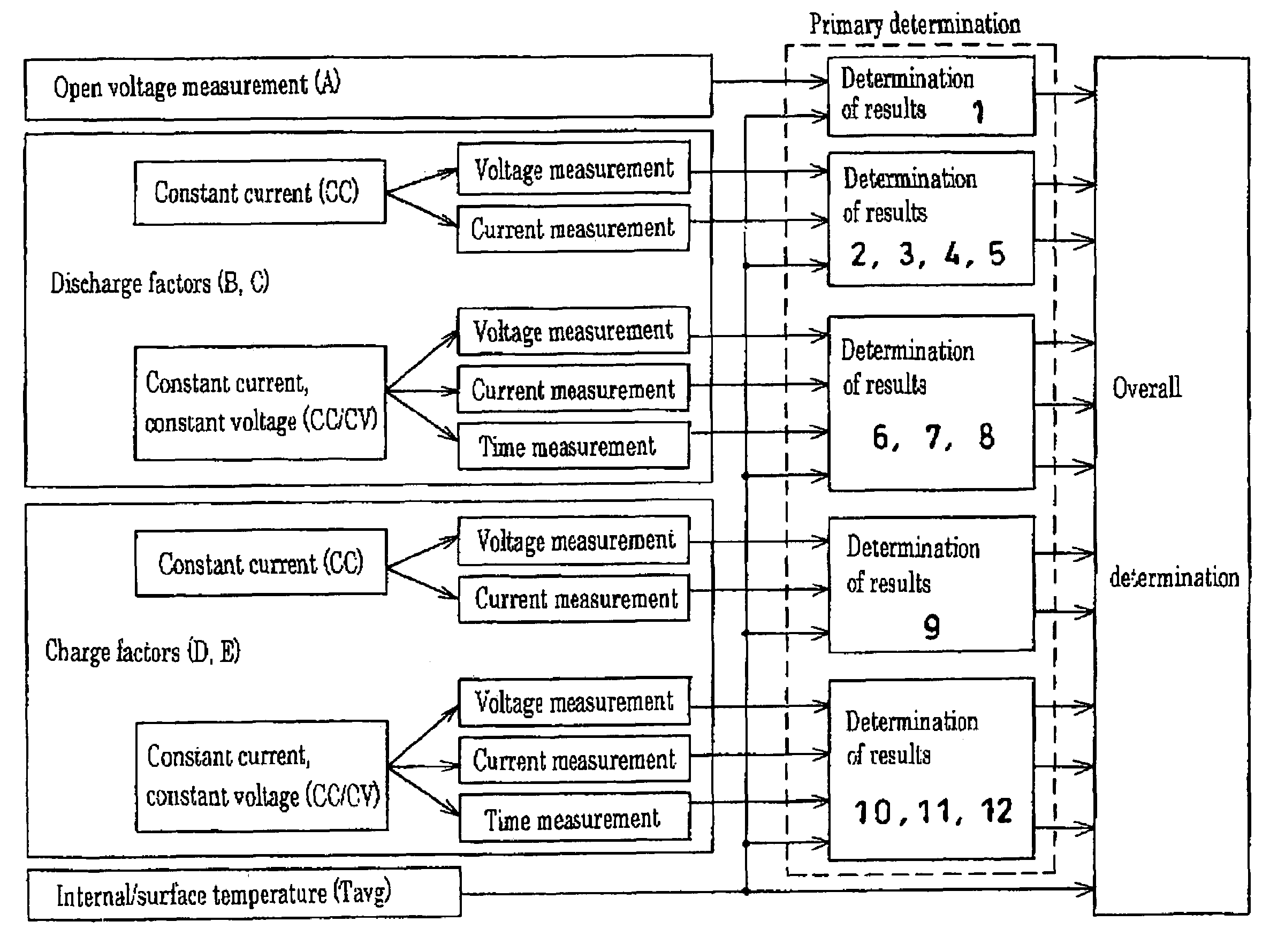

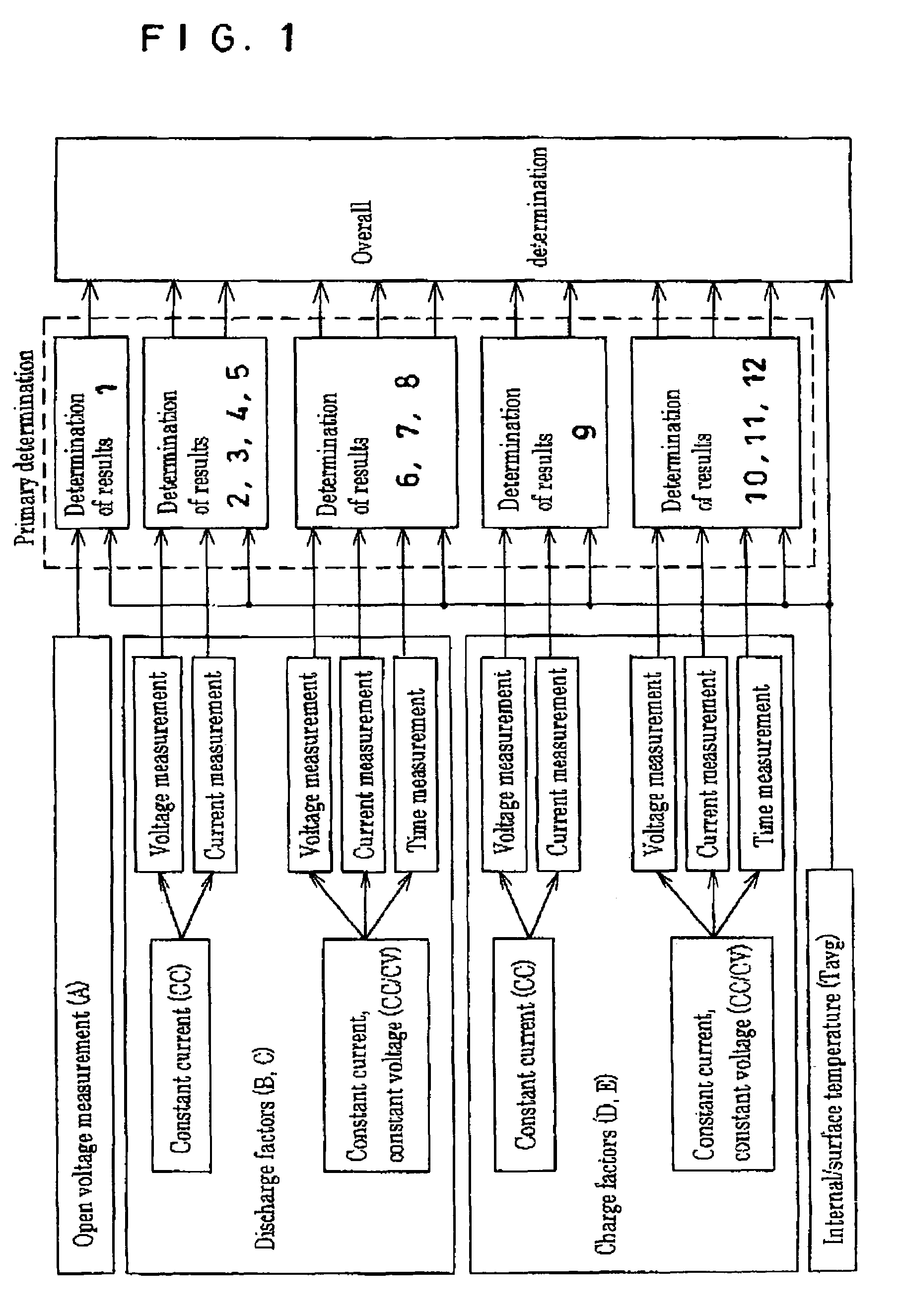

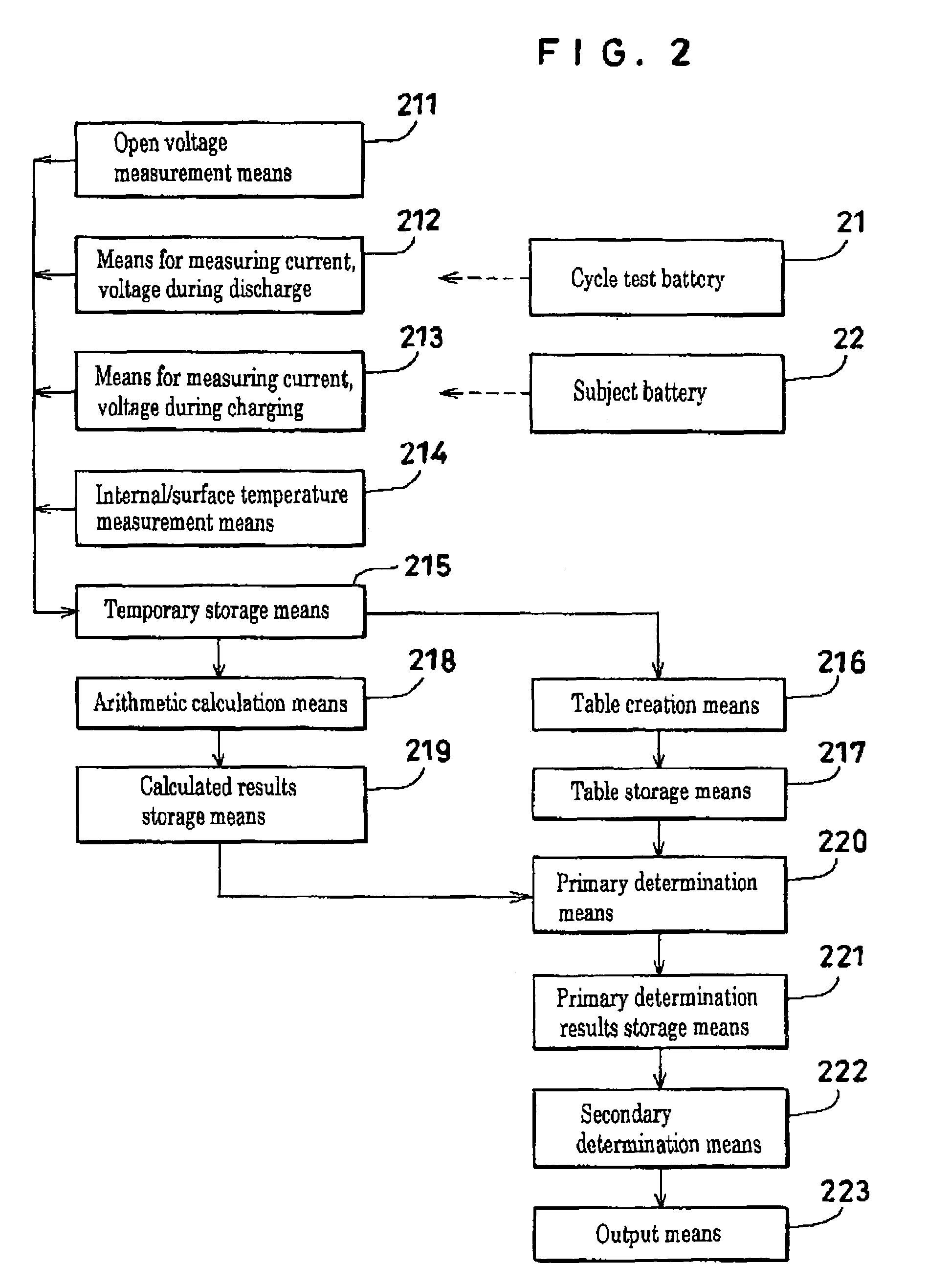

A method and apparatus is used to confirm the charge amount and degradation state of a battery. Various cycle test battery measurements are conducted at prescribed time intervals until the end of the battery life, and the measured values are used to generate a determination table or determination tables showing relationships between battery charge amount and degradation state. To establish the charge amount and degradation state of a subject battery, the subject battery is measured and the results compared with determination table values. The existing charge amount and the state of battery degradation are estimated in accordance with a determination table location of matching values.

Owner:TOYO SYSTEM CO LTD

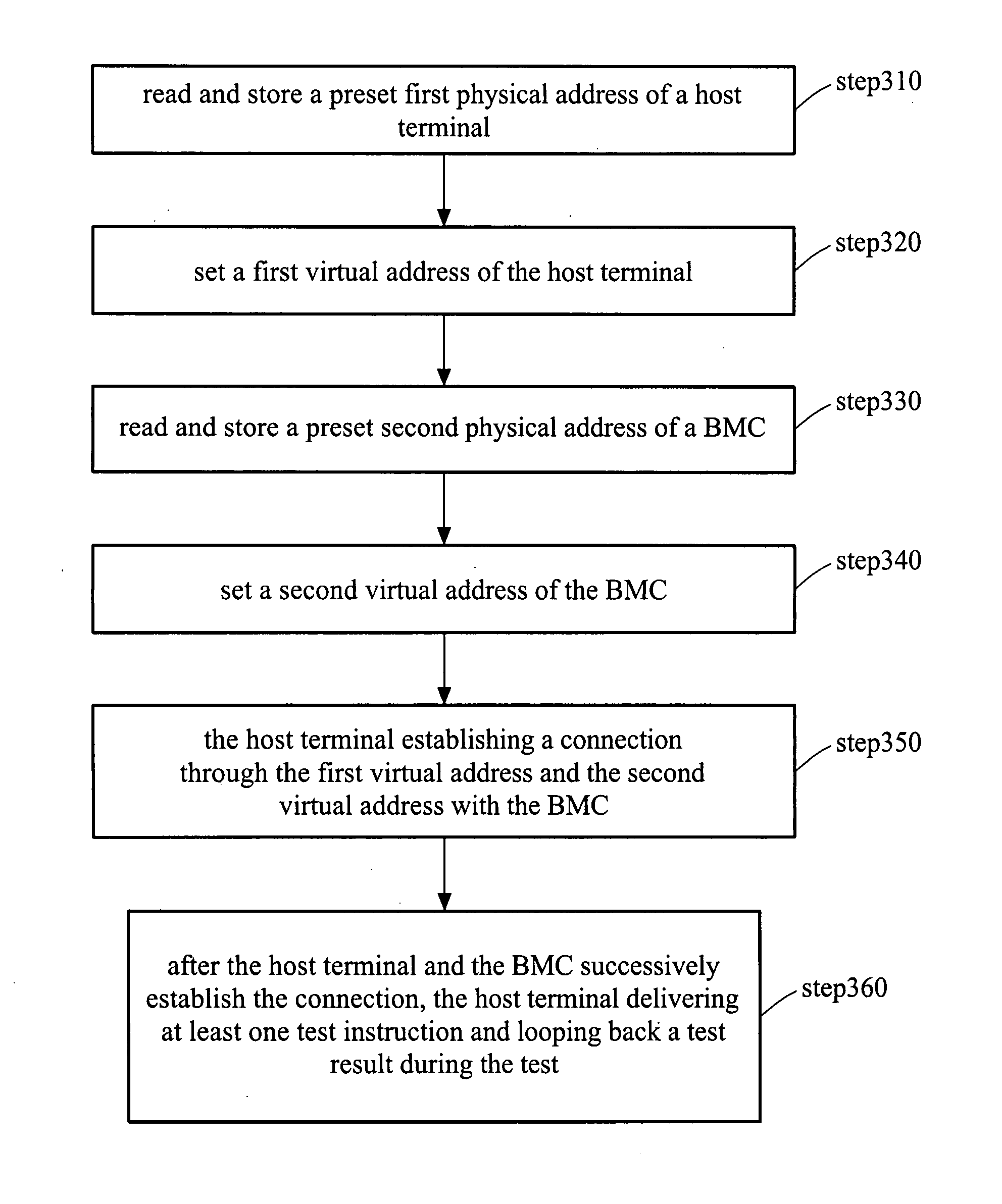

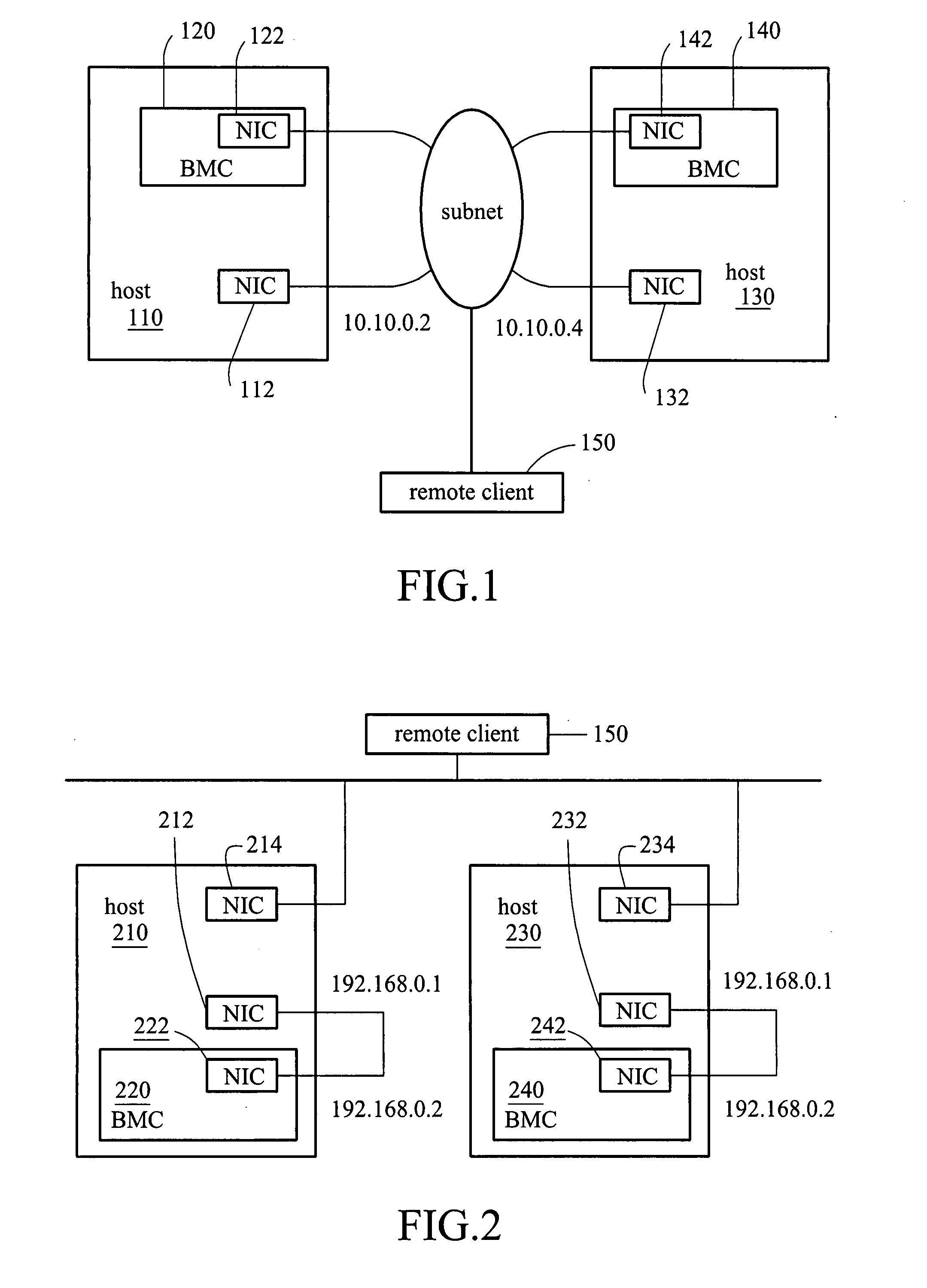

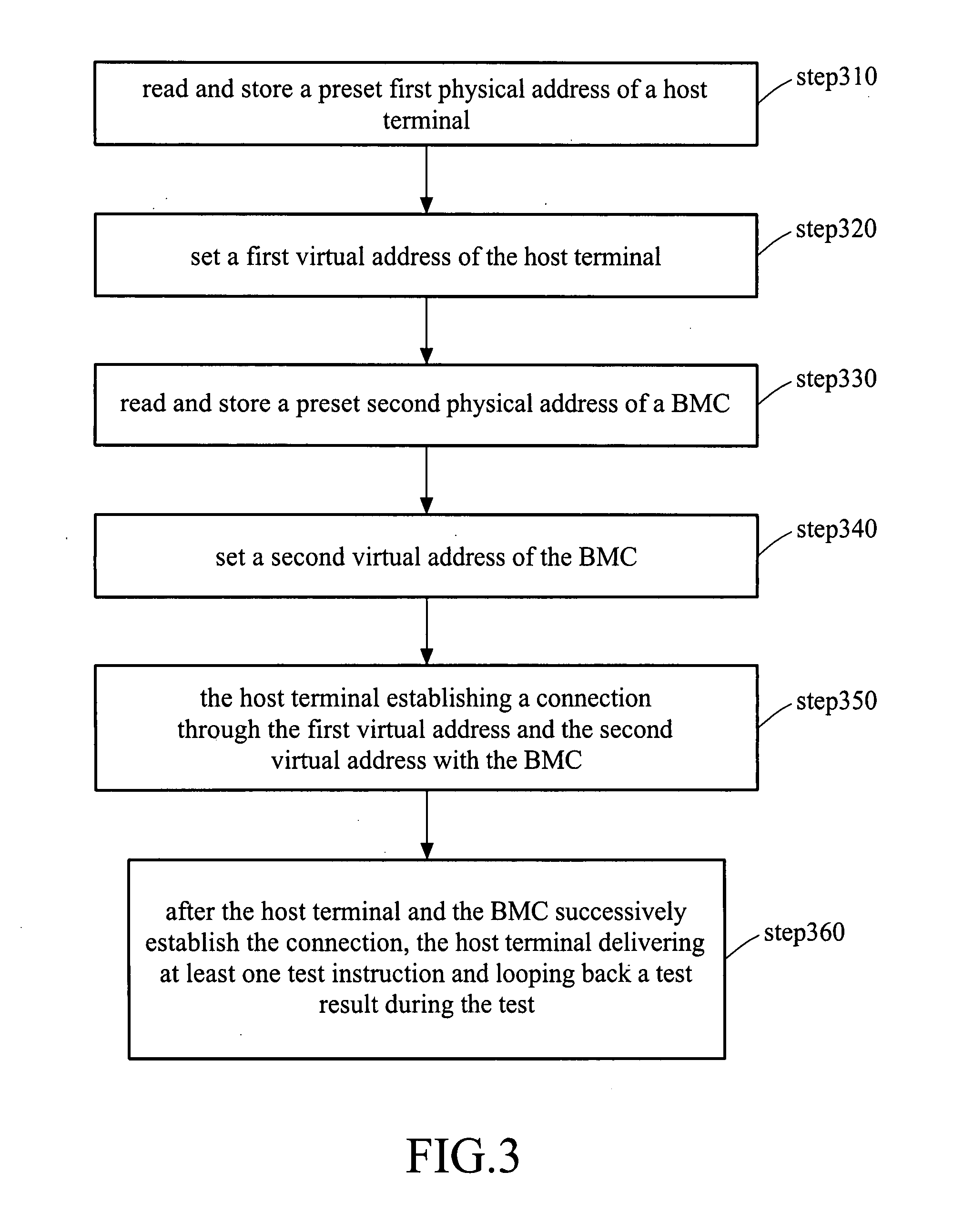

Test system using local loop to establish connection to baseboard management control and method therefor

InactiveUS20080205286A1Shorten the timeError prevention/detection by using return channelFrequency-division multiplex detailsCyclic testInner loop

A test system using a local loop to establish connection to baseboard management control is provided. The test system includes more than one host terminals having at least one network interface card (NIC) and at least one baseboard management controller (BMC) having one NIC. After establishing a connection for test between the host terminals and a remote subscriber, a connection for loop test is established with the BMC through a virtual address, so as to deliver a test instruction to the BMC for testing and to loop back a test result. The test system establishes the connection for loop test through the virtual address so as to perform a remote platform test similar to an inner loop test. Therefore, the test result will not be influenced by a network environment setting, and thus a batch test can be adopted to save the test time.

Owner:INVENTEC CORP

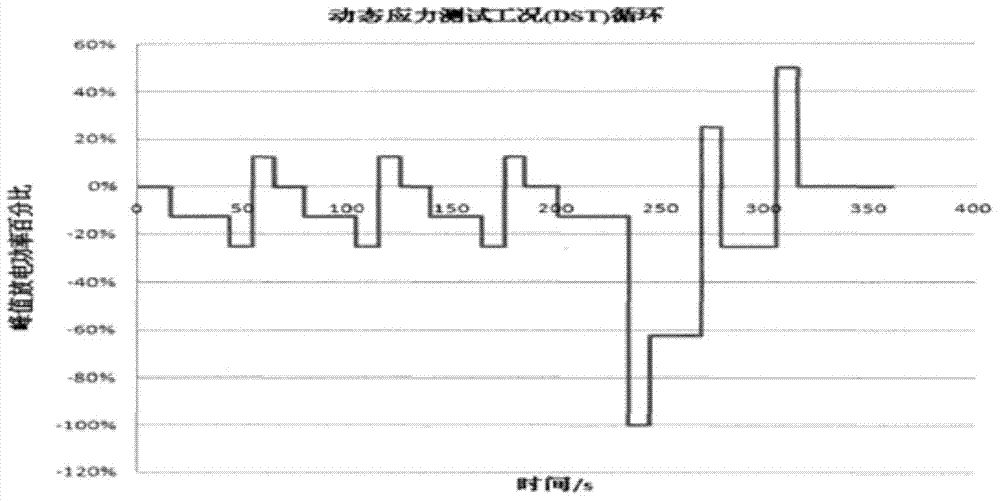

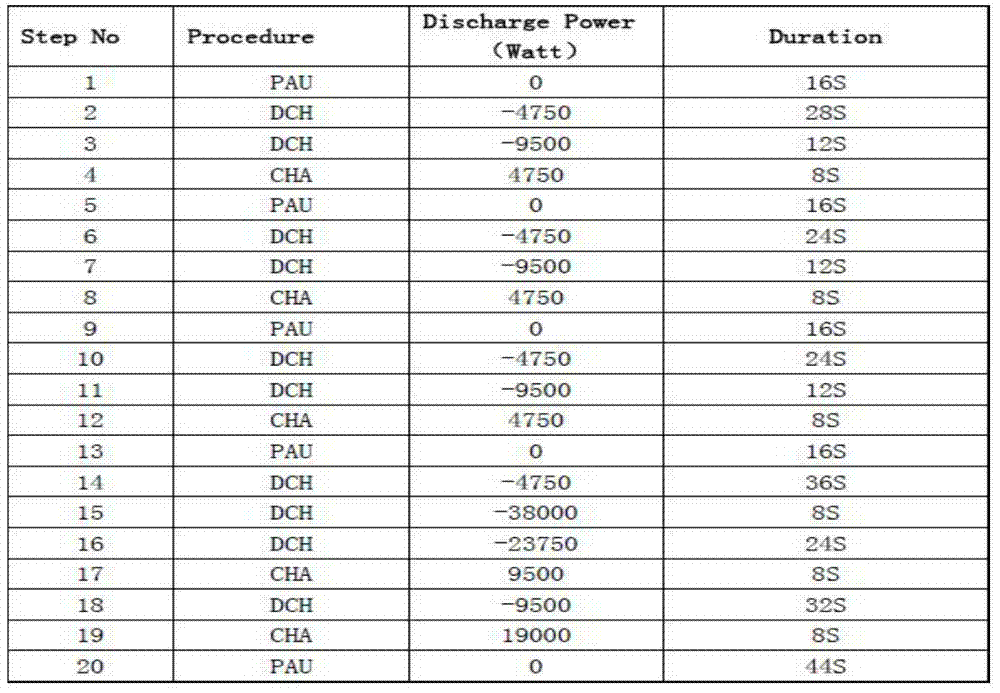

Method for predicting cycle life of battery pack for electric car

InactiveCN104714189AAccelerated agingEvaluate Cycle Life PerformanceElectrical testingCyclic testPredictive methods

The invention relates to a method for predicting the cycle life of a battery pack for an electric car. The method comprises the following steps: step I, carrying out standard capacity test on the battery pack at normal temperature, and recording a real standard capacity of the battery pack; step II, carrying out dynamic stress working condition circulating test on the battery pack, returning to the step I after multiple times of working condition circulating test is ended, recording the test times of the standard capacity, ending the circulating test at the temperature if the real capacity of the standard capacity test for continuous 4 to 6 times is less than 80 percent of the rated capacity, wherein the test times of the standard capacity indicate the cycle life of the battery pack; step III, repeating the step I and the step II, and testing the cycle life of the battery pack under multiple temperature points. According to the method, the battery pack cycle life data at the grouped time is collected, a fitted equation is obtained by virtue of data processing, and the cycle life of a lithium ion battery at present can be predicted.

Owner:CHERY AUTOMOBILE CO LTD

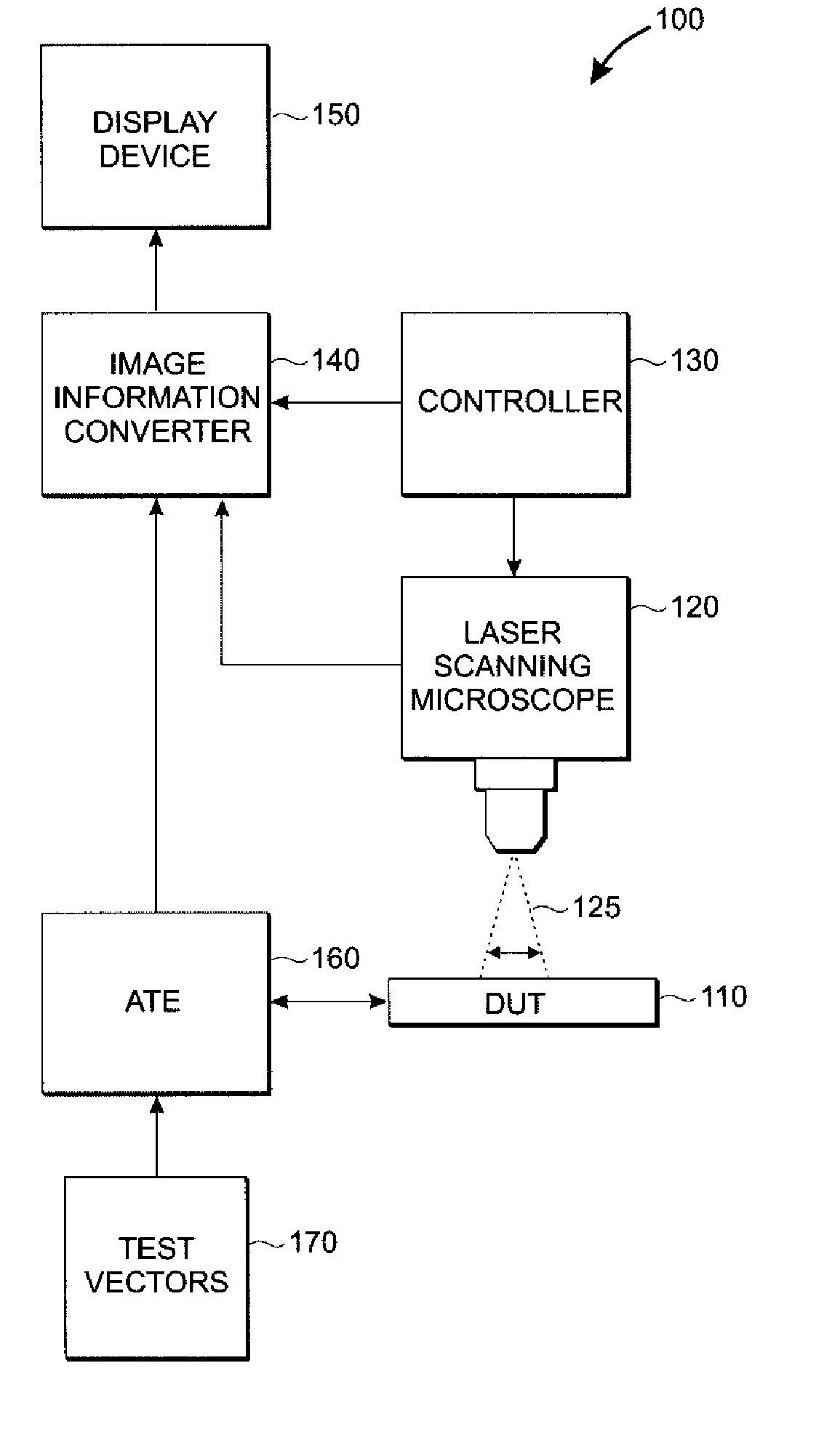

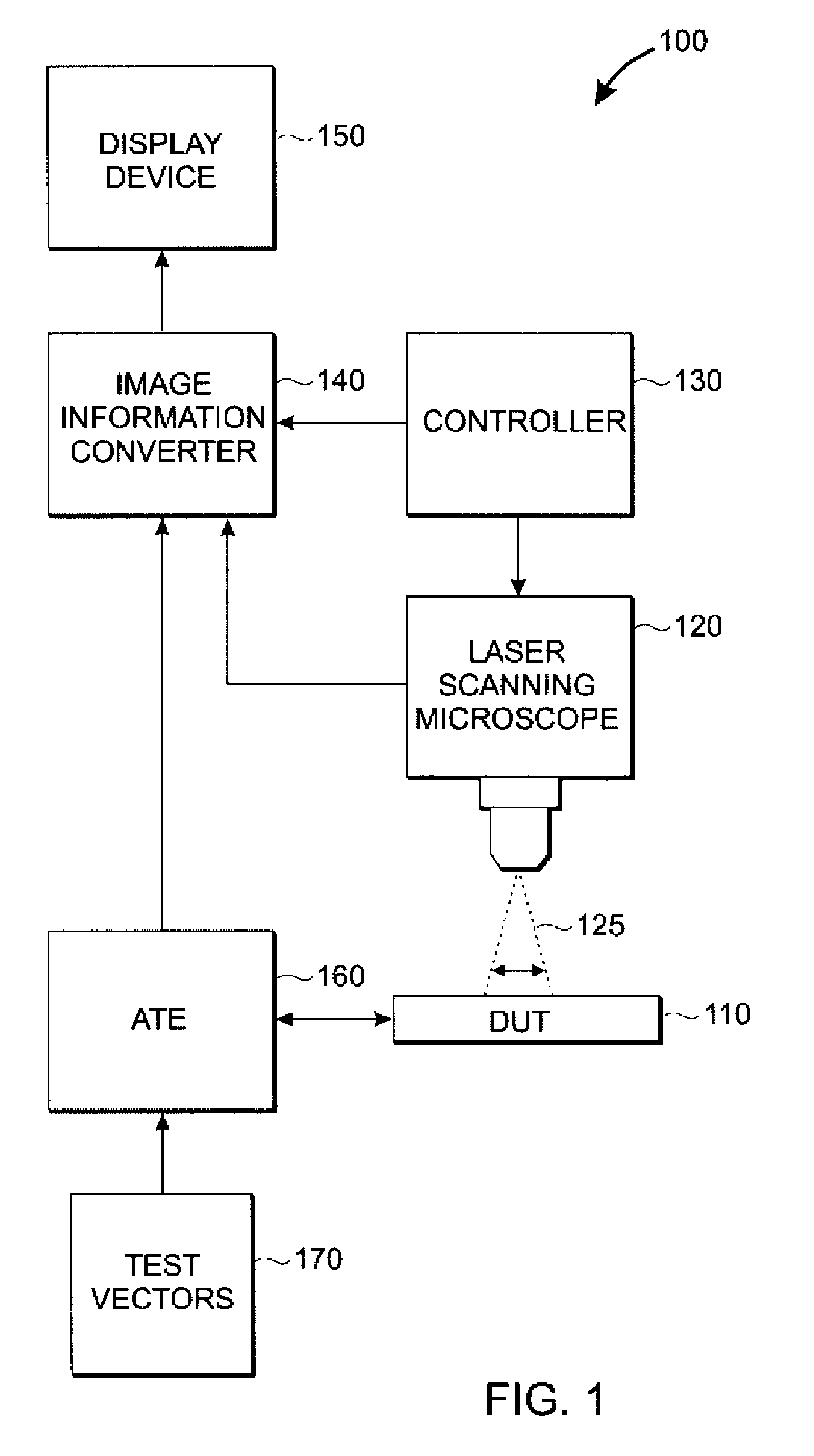

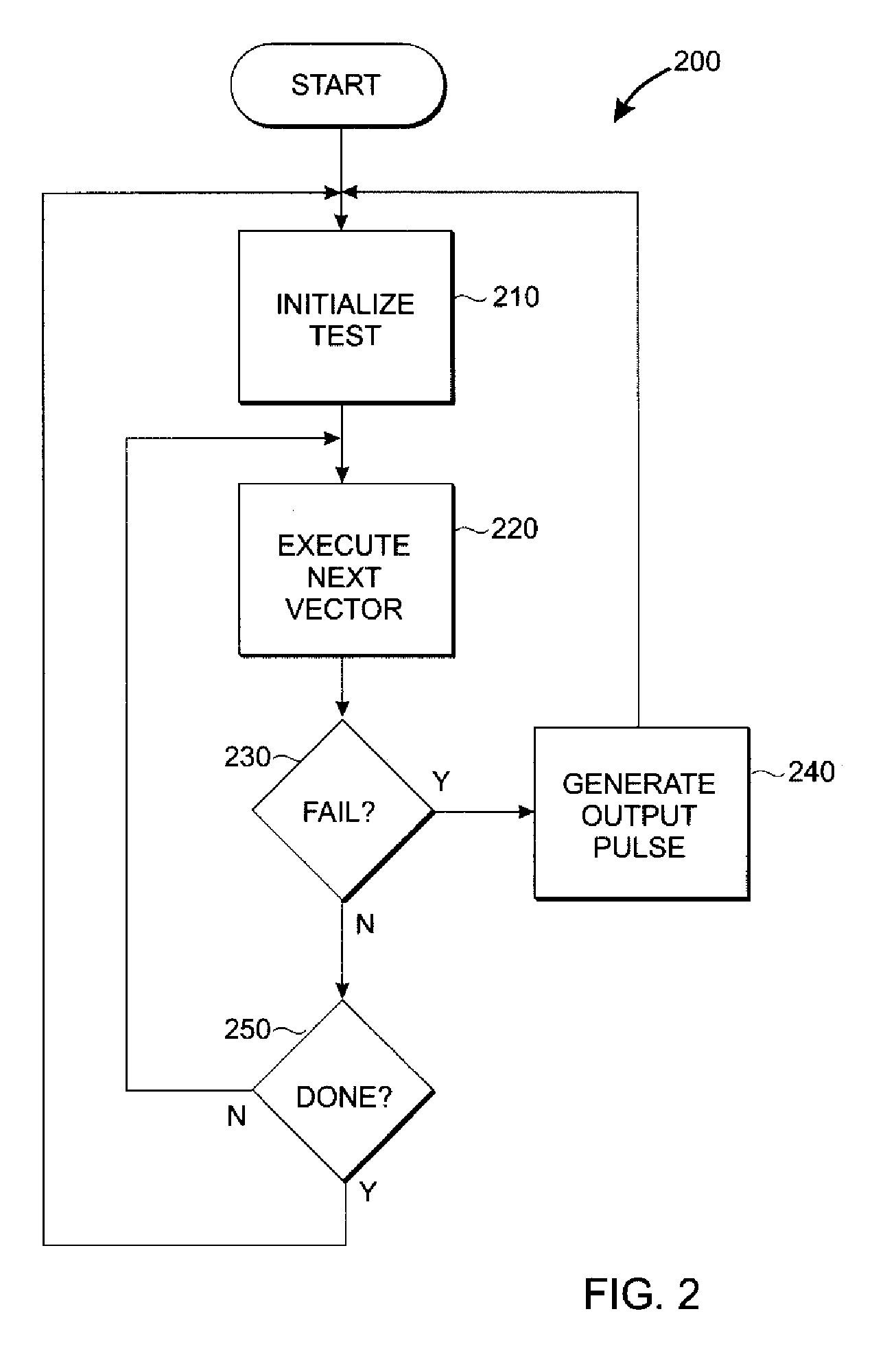

Laser-induced critical parameter analysis of CMOS devices

ActiveUS20060066325A1High resolutionShorten the test cycleCharacter and pattern recognitionIndividual semiconductor device testingLaser scanning microscopeLight energy

A technique is described for performing critical parameter analysis (CPA) of a semiconductor device (DUT) by combining the capabilities of conventional automated test equipment (ATE) with a focused optical beam scanning device such as a laser scanning microscope (LSM). The DUT is provided with a fixture such that it can be simultaneously scanned by the LSM or a similar device and exercised by the ATE. The ATE is used to determine pass / fail boundaries of operation of the DUT. Repeatable pass / fail limits (for timing, levels, etc.) are determined utilizing standard test patterns and methodologies. The ATE vector pattern(s) can then be programmed to “loop” the test under a known passing or failing state. When light energy from the LSM scanning beam sufficiently disturbs the DUT to produce a transition (i.e., to push the device outside of its critical parameter limits), this transition is indicated on the displayed image of the DUT, indicating to the user which elements of the DUT were implicated in the transition.

Owner:TWITTER INC

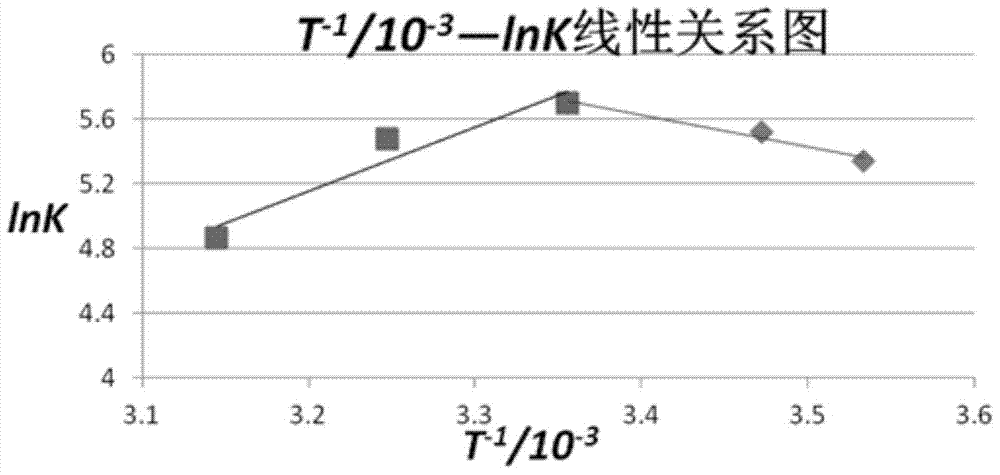

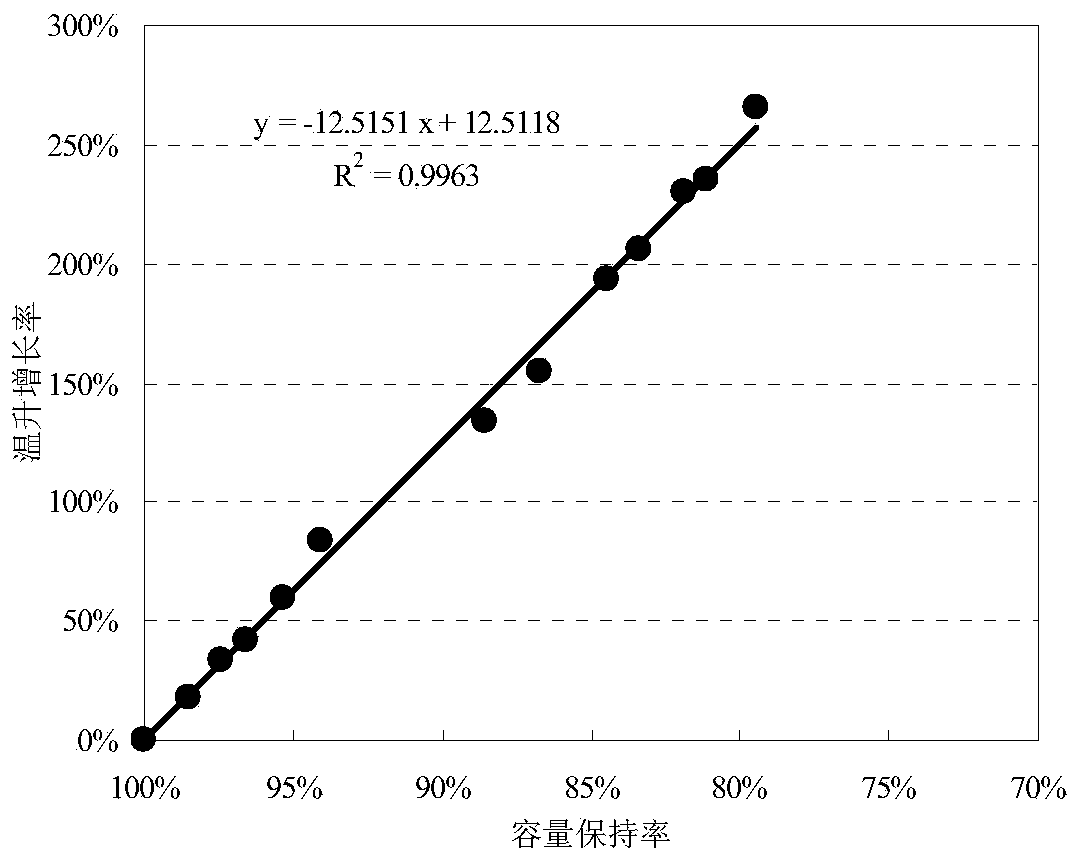

Method for predicating cycle life of lithium ion battery

ActiveCN103698712ACycle Life PredictionReduce time-consuming issues with performance evaluationElectrical testingCyclic testProcess engineering

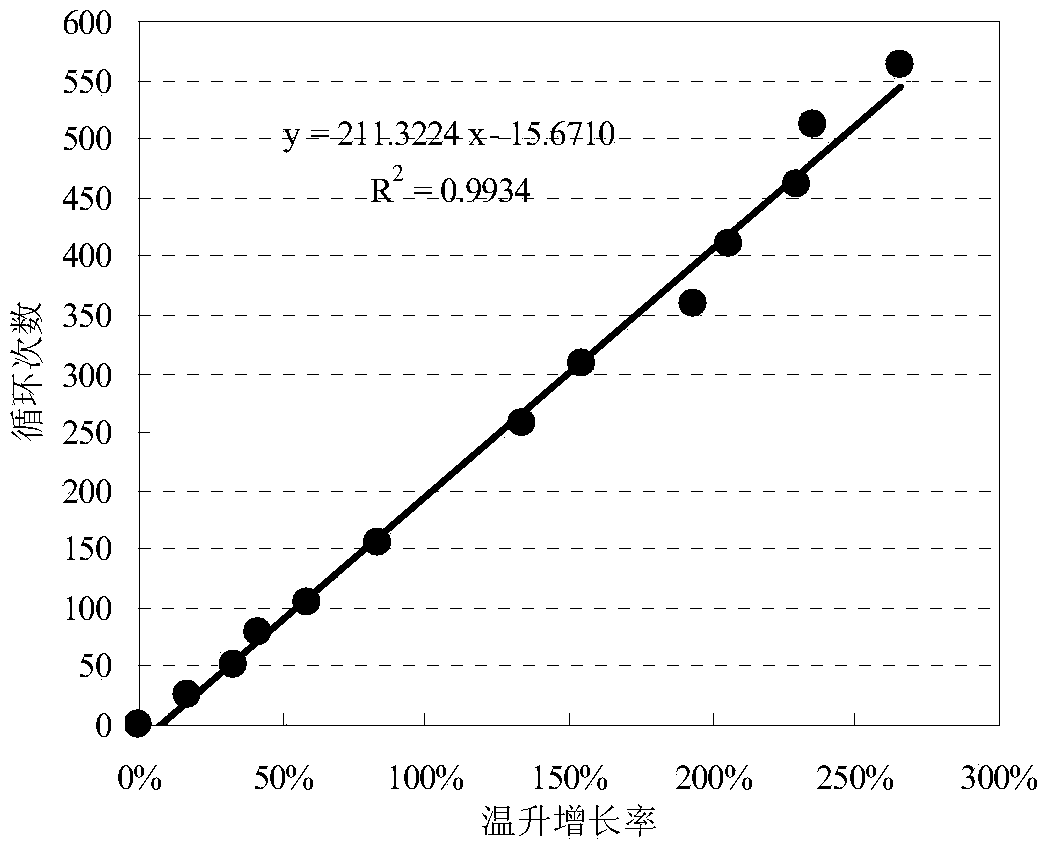

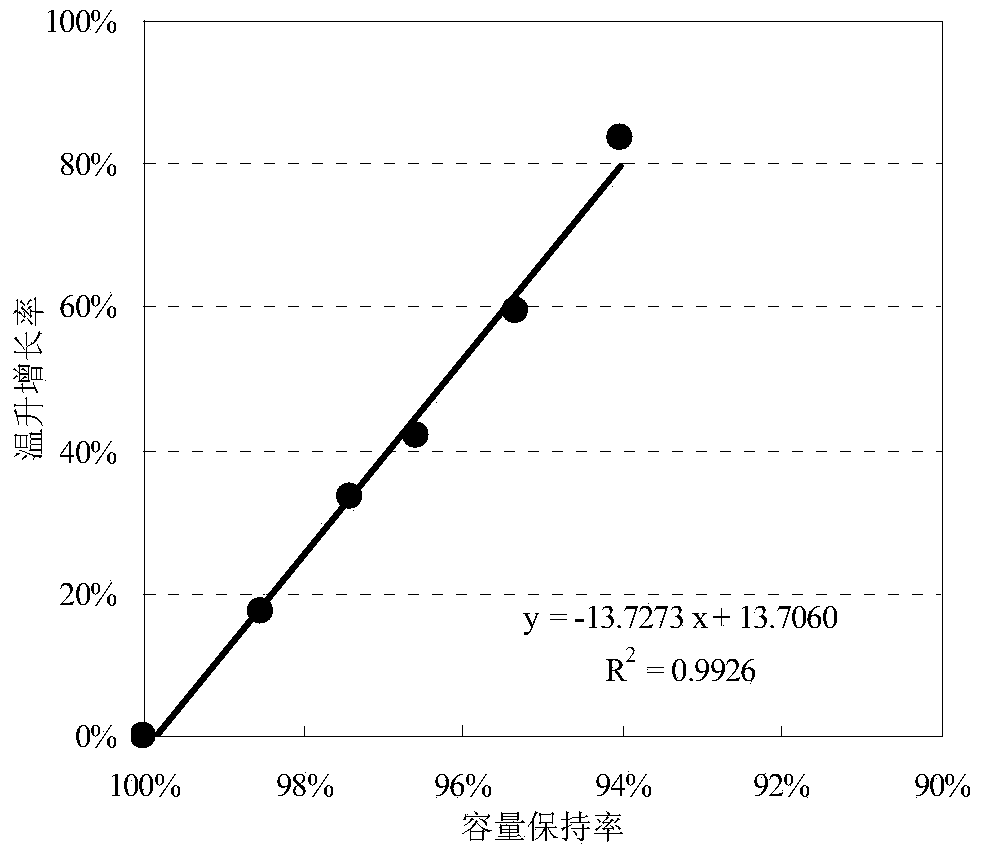

The invention relates to a method for predicating the cycle life of a lithium ion battery. The method comprises the following steps of performing batch-type cycle test on a to-be-evaluated battery in a to-be-evaluated cycle condition, and recording an accumulated cycle index and cycle volume conservation rate of the battery; transferring the battery not subjected to the batch-type cycle test and the battery subjected to the batch-type cycle test to an accelerating rate calorimeter, testing the thermal discharge in a charging process, recording temperature change data of the battery in the charging process, and calculating the temperature rise rate of the battery relative to an initial state; performing data fitting and calculation according to the accumulated cycle index and cycle volume conservation rate of the battery and predicating the cycle life of the battery. Compared with a conventional cycle test, the method provided by the invention has the advantages of greatly shortening the test period and avoiding energy consumption and resource waste generated by long-term test; in addition, data fitting is performed on the basis of short-term measured data, so that compared with pure-theory calculation and an empirical model, the method has the advantages of better universality and higher predicating accuracy.

Owner:TIANJIN LISHEN BATTERY +1

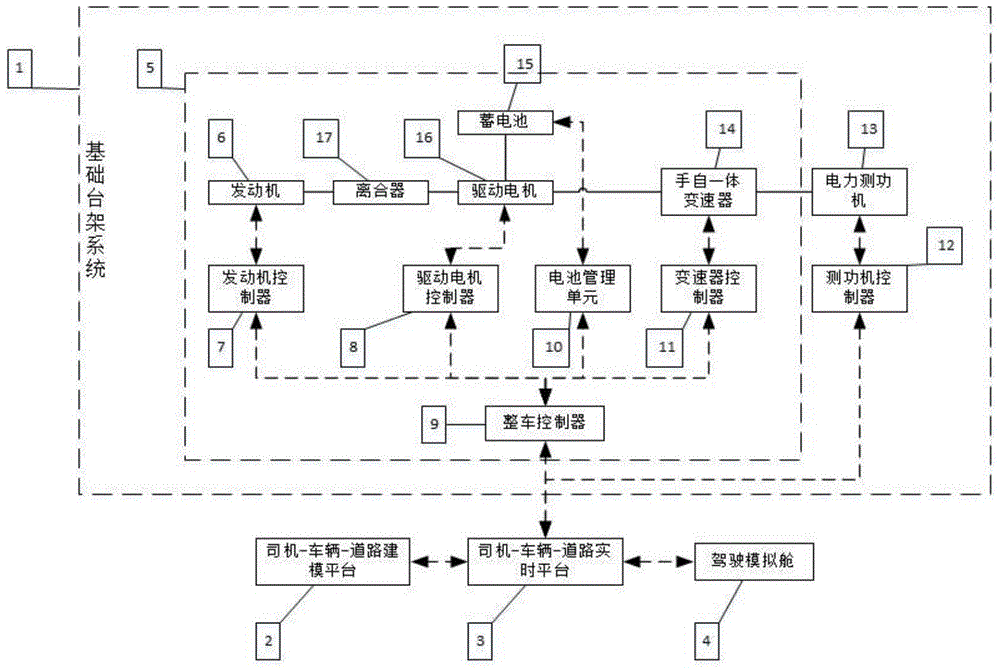

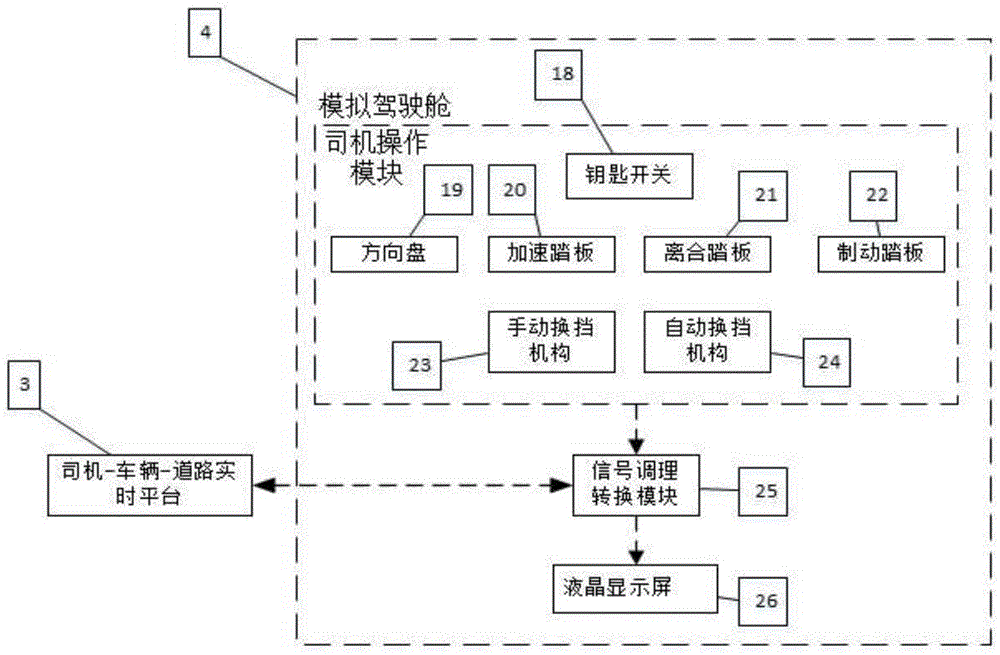

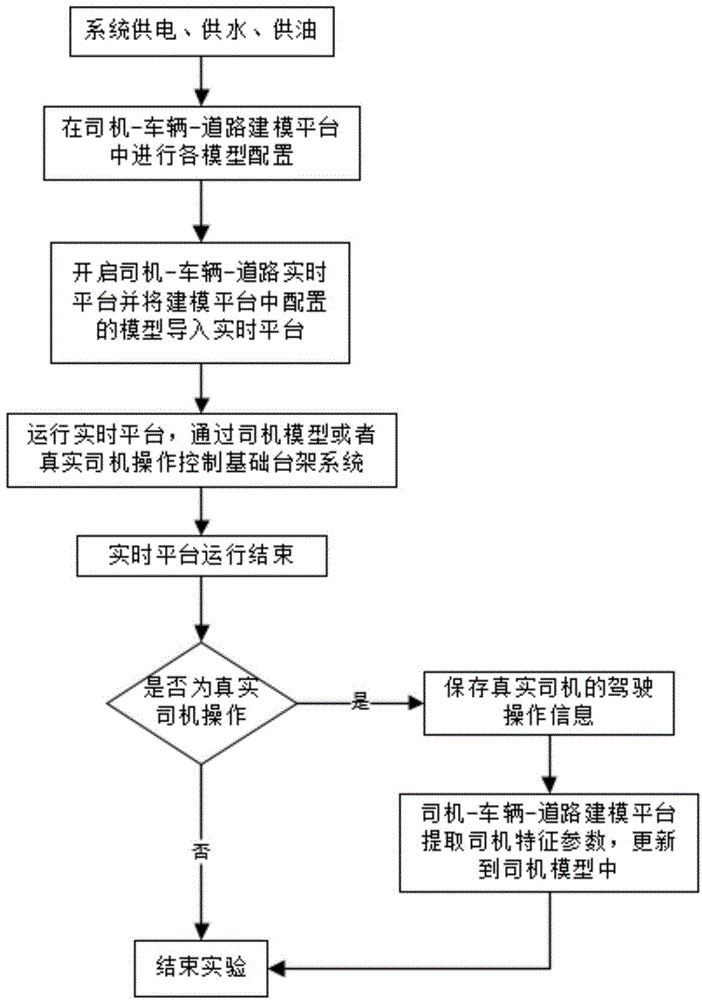

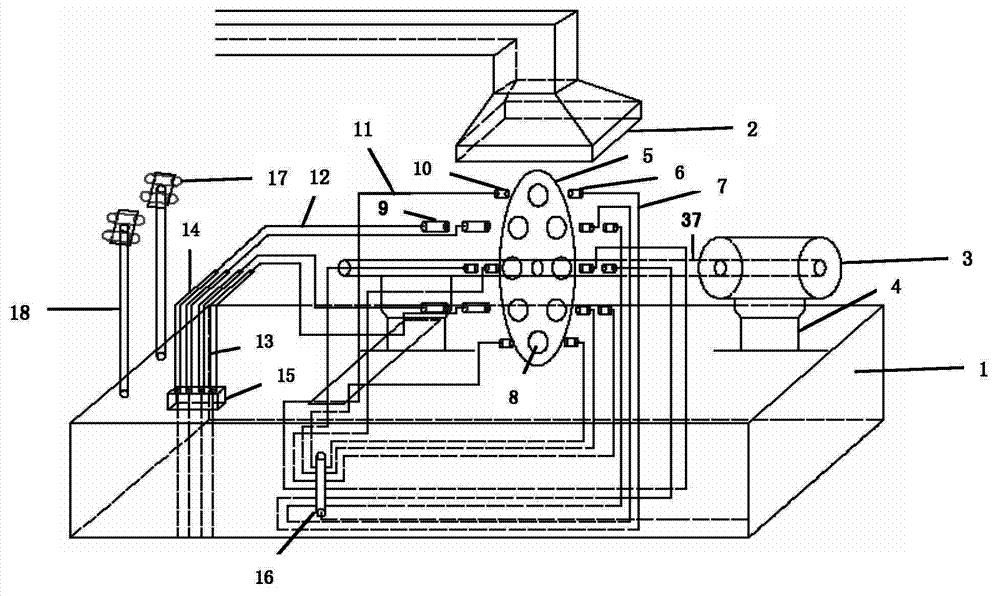

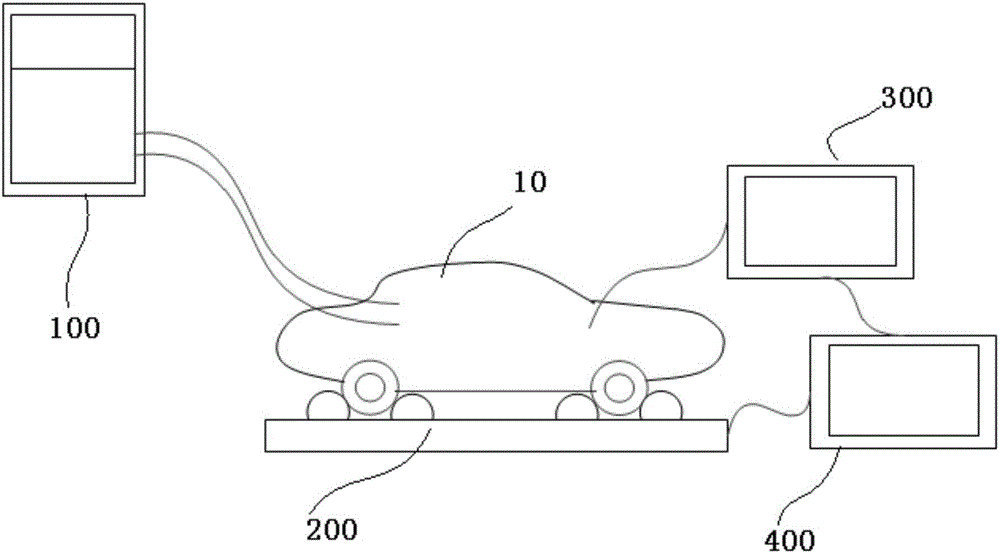

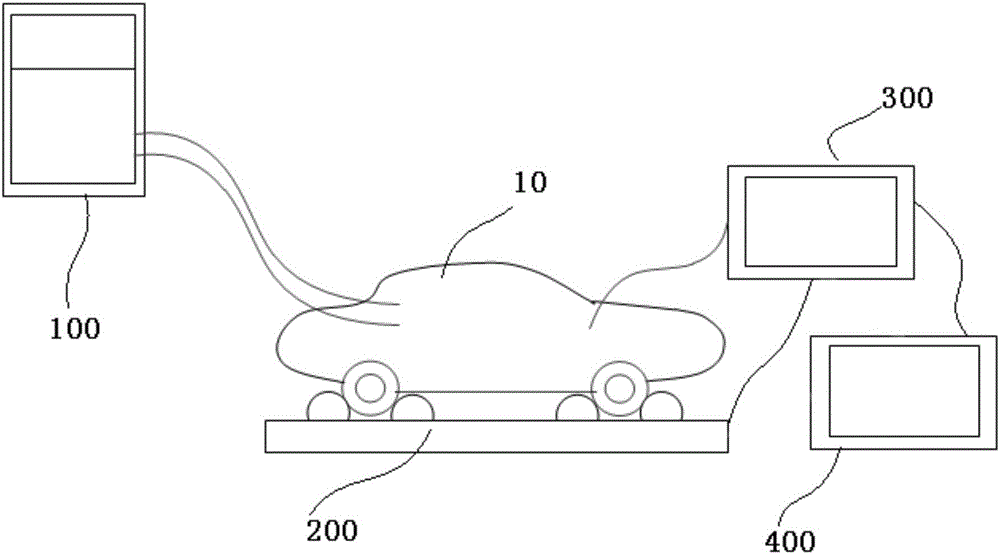

Virtual vehicle-based real driving cycle test device and method

The invention discloses a virtual vehicle-based real driving cycle test device and method. The method comprises the following steps: selecting a vehicle model, a road vehicle and a driver model in driver-vehicle-road modeling platform software to perform automatic driving or real driver driving; opening a driver-vehicle-road real-time platform and importing the driver model or the real driver operation, the vehicle model and the road model established in the driver-vehicle-road modeling platform into a real-time platform; operating the real-time operation platform; stopping the real-time platform after the driver model or the real driver drives under the selected road model and the vehicle model, and stopping a base frame system; saving operation information on a driver in a file of a specific format by the driver-vehicle-road modeling platform if the operation is the real driver operation, extracting a characteristic parameter of the driver and updating into the current driver model. According to the method, the calibration and the experiment of the entire vehicle are realized.

Owner:TIANJIN UNIV

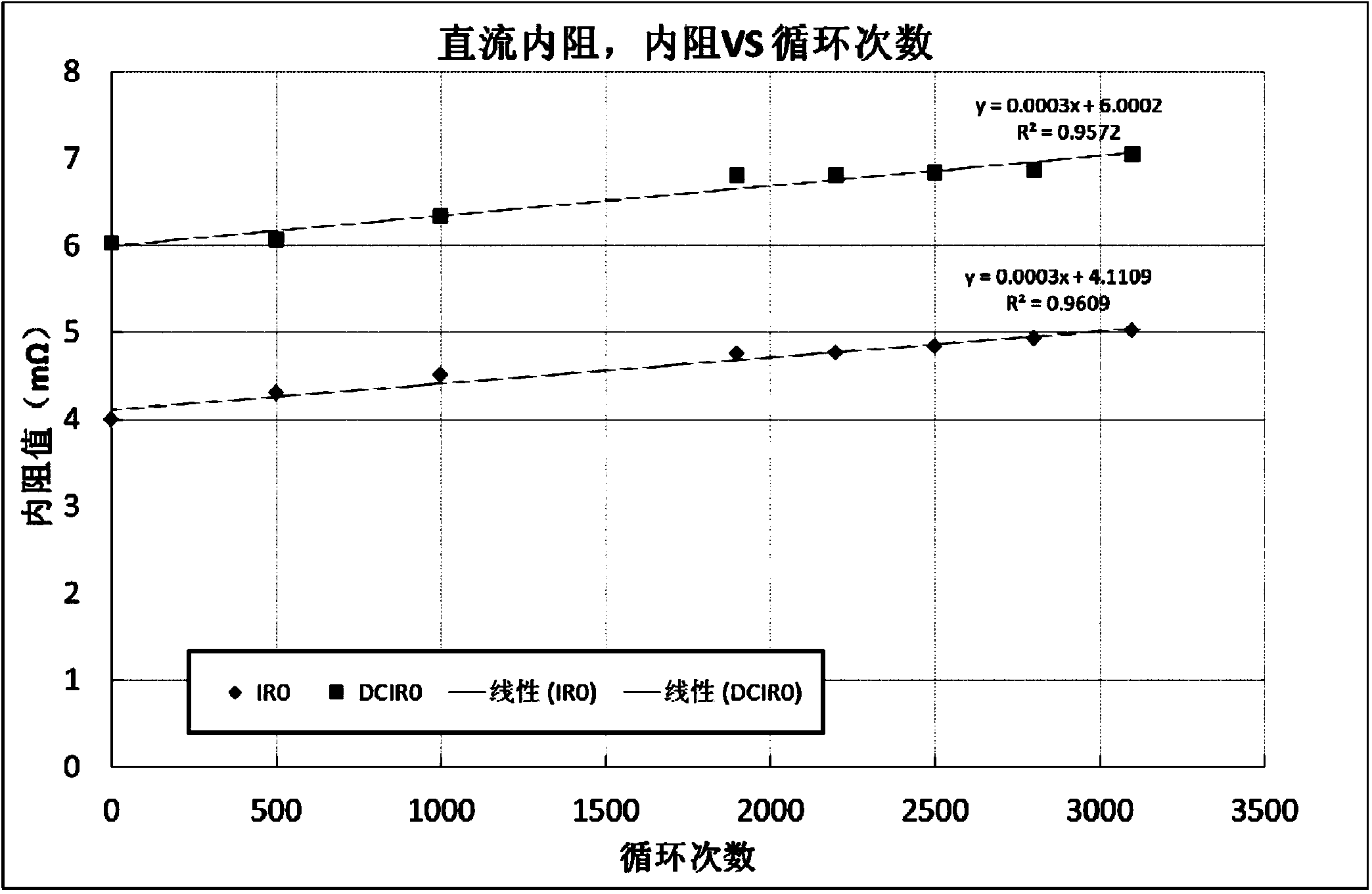

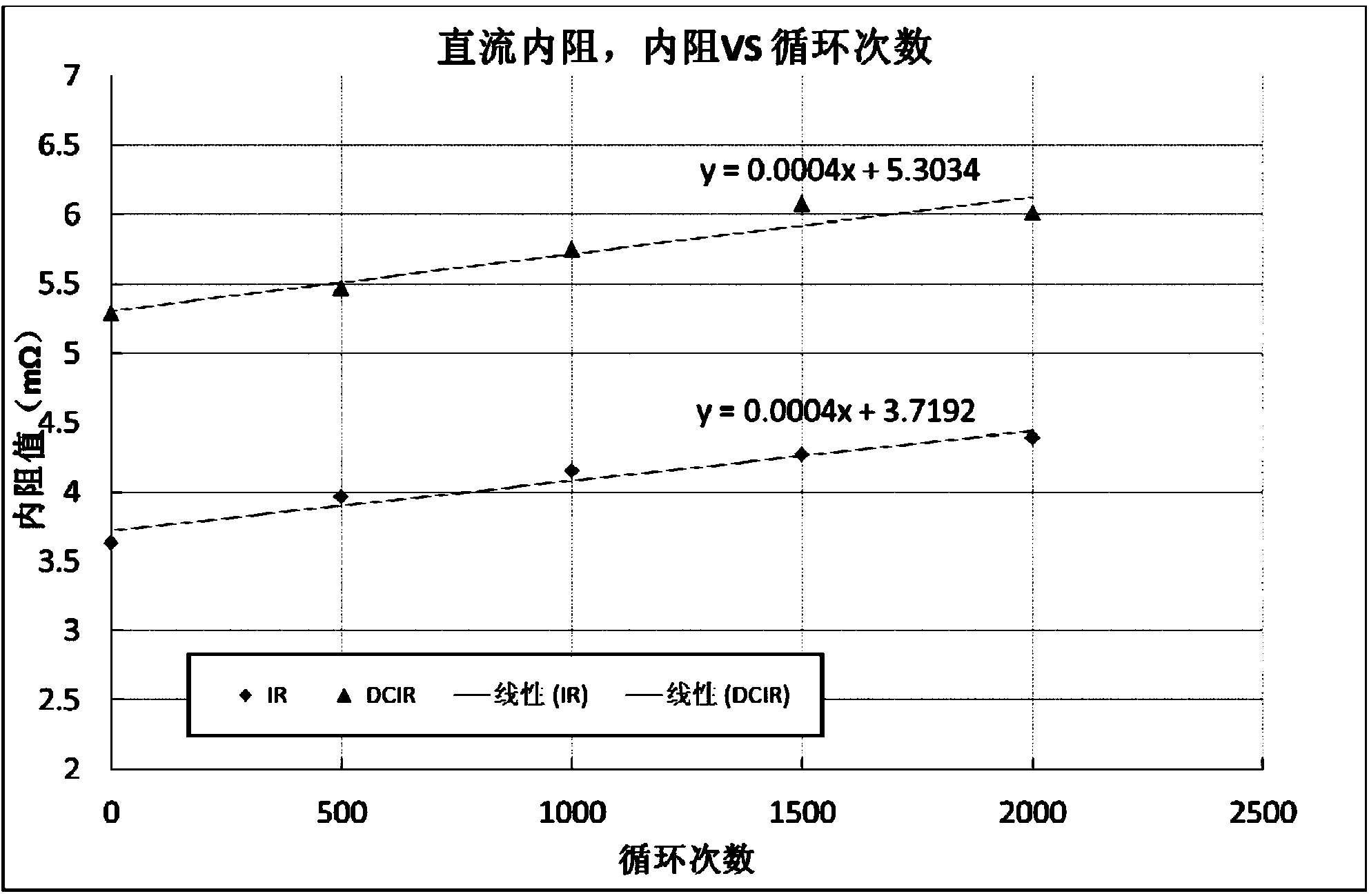

Method for inferring internal DC resistance of lithium ion battery

InactiveCN104330636AAvoid damageSave energyResistance/reactance/impedenceCyclic testInternal resistance

The invention discloses a method for inferring the internal DC resistance of a lithium ion battery. The method comprises the steps of performing cyclic tests on a sampled battery in the environment of a certain temperature and certain humidity, and testing the internal AC resistance IR0 and the internal DC resistance DCIR0 in a certain SOC state every certain cycles, establishing an IR-DCIR linear relation according to the internal AC resistance IR0 and the internal DC resistance DCIR0, when inferring the internal DC resistance of a battery in same model with the sampled battery, measuring the internal AC resistance IR of the battery to be tested at the same frequency according to the SOC state and the temperature and humidity conditions when the internal AC resistance of the sampled batter is measured, comparing the measured internal AC resistance IR with the established IR-DCIR linear relation, and performing ratiometric conversion on the internal AC resistance to obtain the internal DC resistance of the battery. The method for inferring the internal DC resistance of the lithium ion battery is capable of inferring the internal DC resistance according to the linear relation of the internal AC resistance and the internal DC resistance and avoiding the harm of multiple internal DC resistance tests by use of large current discharge to the battery, and also capable of obtaining higher detection speed and accuracy.

Owner:TIANJIN LISHEN BATTERY

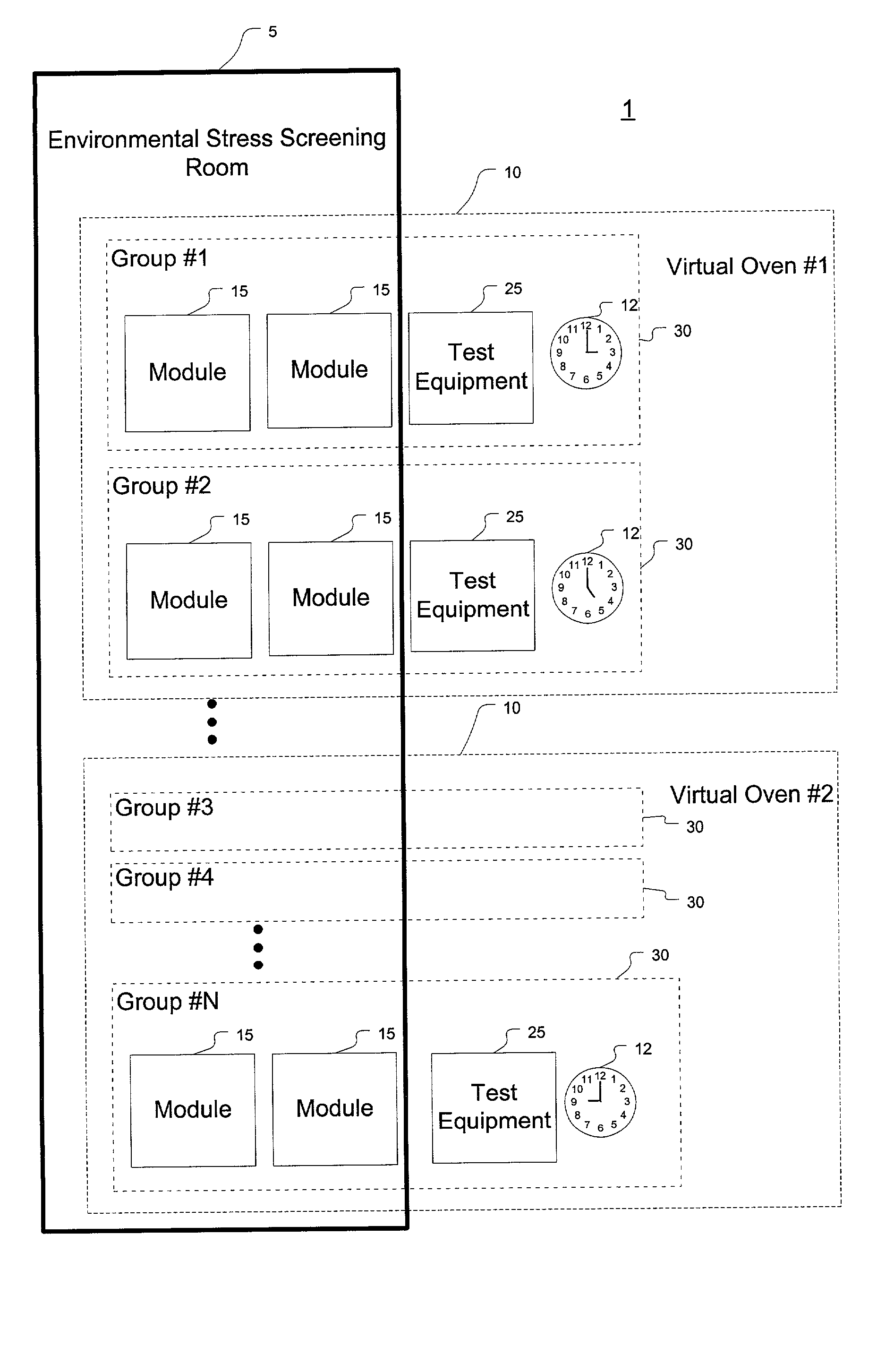

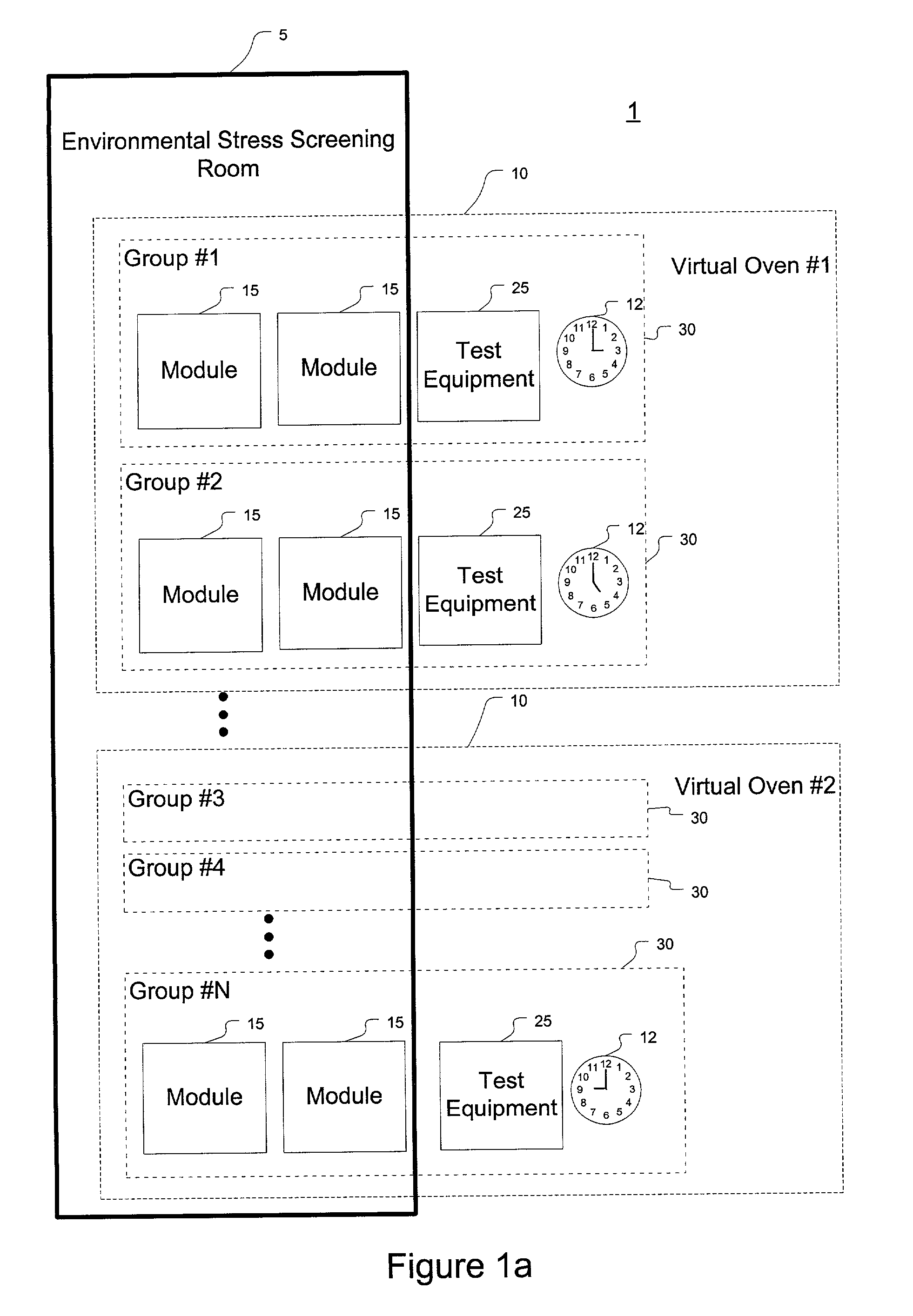

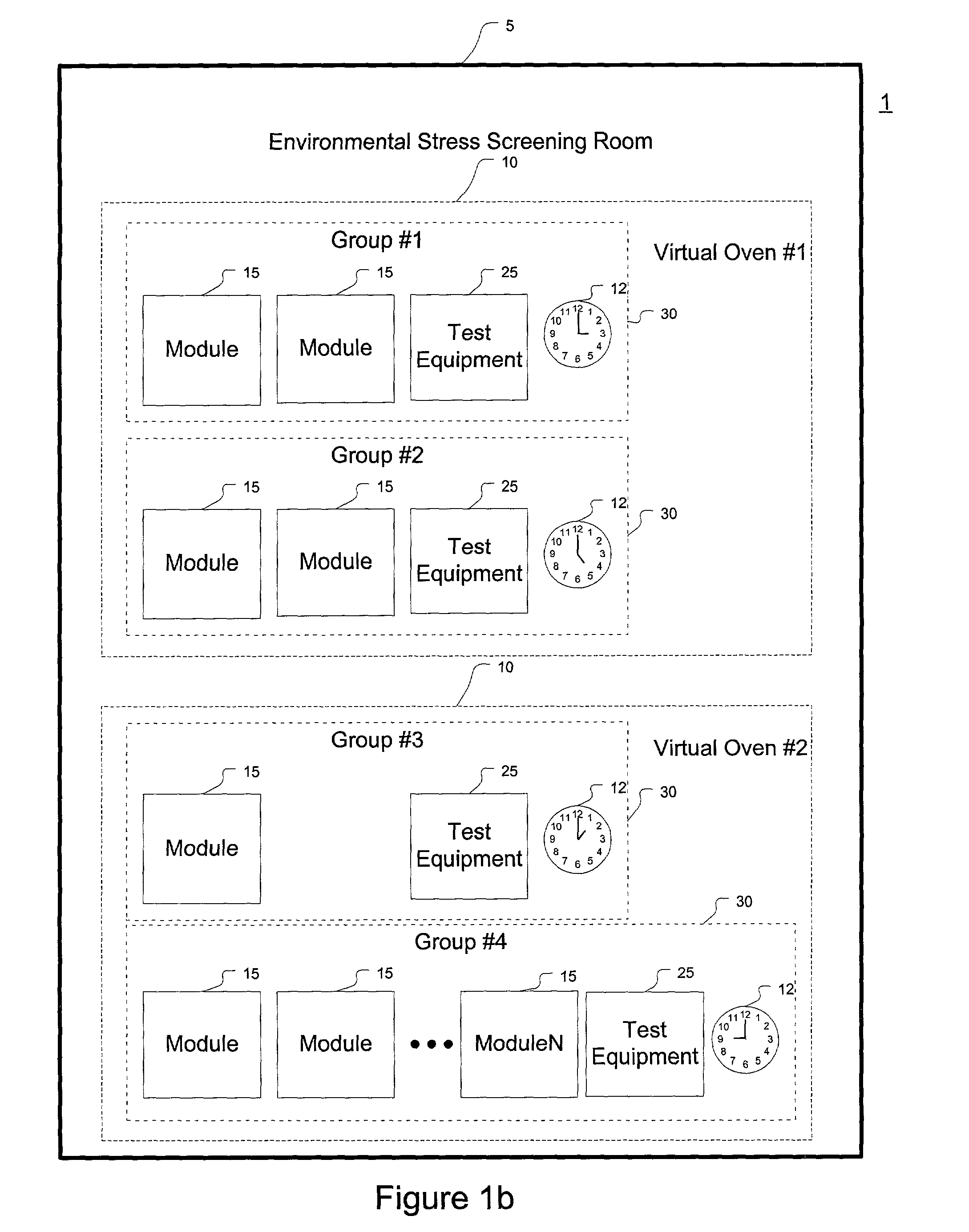

Automated monitoring system, virtual oven and method for stress testing logically grouped modules

InactiveUS20020105355A1Data processing applicationsResistance/reactance/impedenceComputer hardwareNetwork connection

A virtual oven efficiently conducts stress testing of large numbers of modules. The virtual oven includes a logical grouping of modules, a controller, test instruments and a database which are all connected via a network. The logical groupings of modules of several virtual ovens may be physically accommodated within a single environmental stress screening room. Switching between modules in a logical group permits a single test piece of test equipment to be time-shared among the modules in the logical group. The method of bum-in testing a logical group of modules rotates a test sequence, including passive and active test cycles, between the modules. A test signal is split and supplied to multiple modules. Passive testing may be performed by monitoring parameters of the module while the test signal is supplied to the module. Active testing may be a functional test of the module in which the test signal is supplied to, processed by, and output from the module. Such test signals output from the modules are switched to the test equipment on a time-share basis. In this way, the number or expensive test equipment set-ups may reduced. The controller for each virtual oven also generates displays so that a user can track the test progress of all modules within the virtual oven. The controller also builds a database of the active and passive tests for each module. A graphical user interface may be used to interact with the virtual oven, control the testing, and view the database.

Owner:CIENA

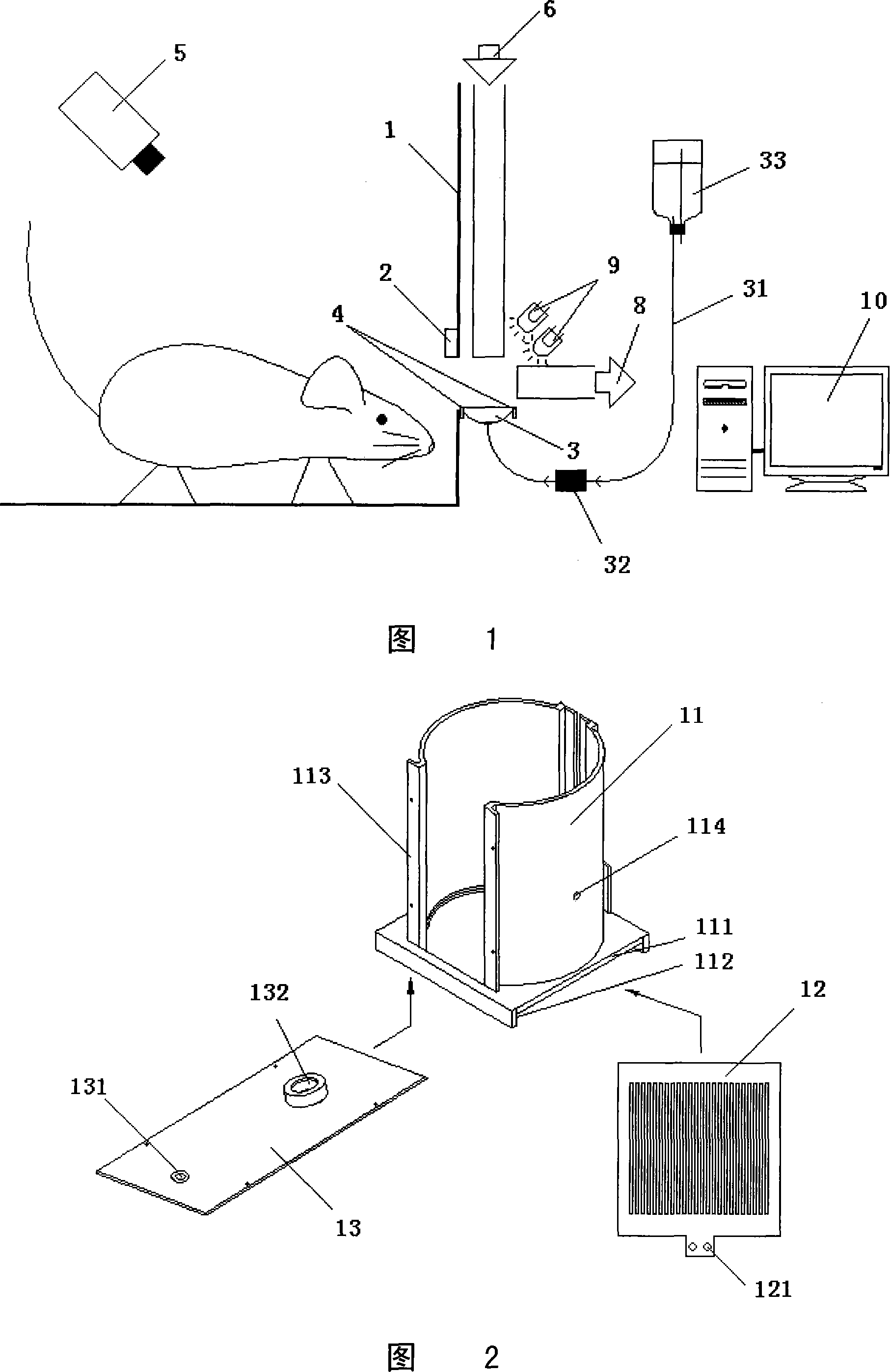

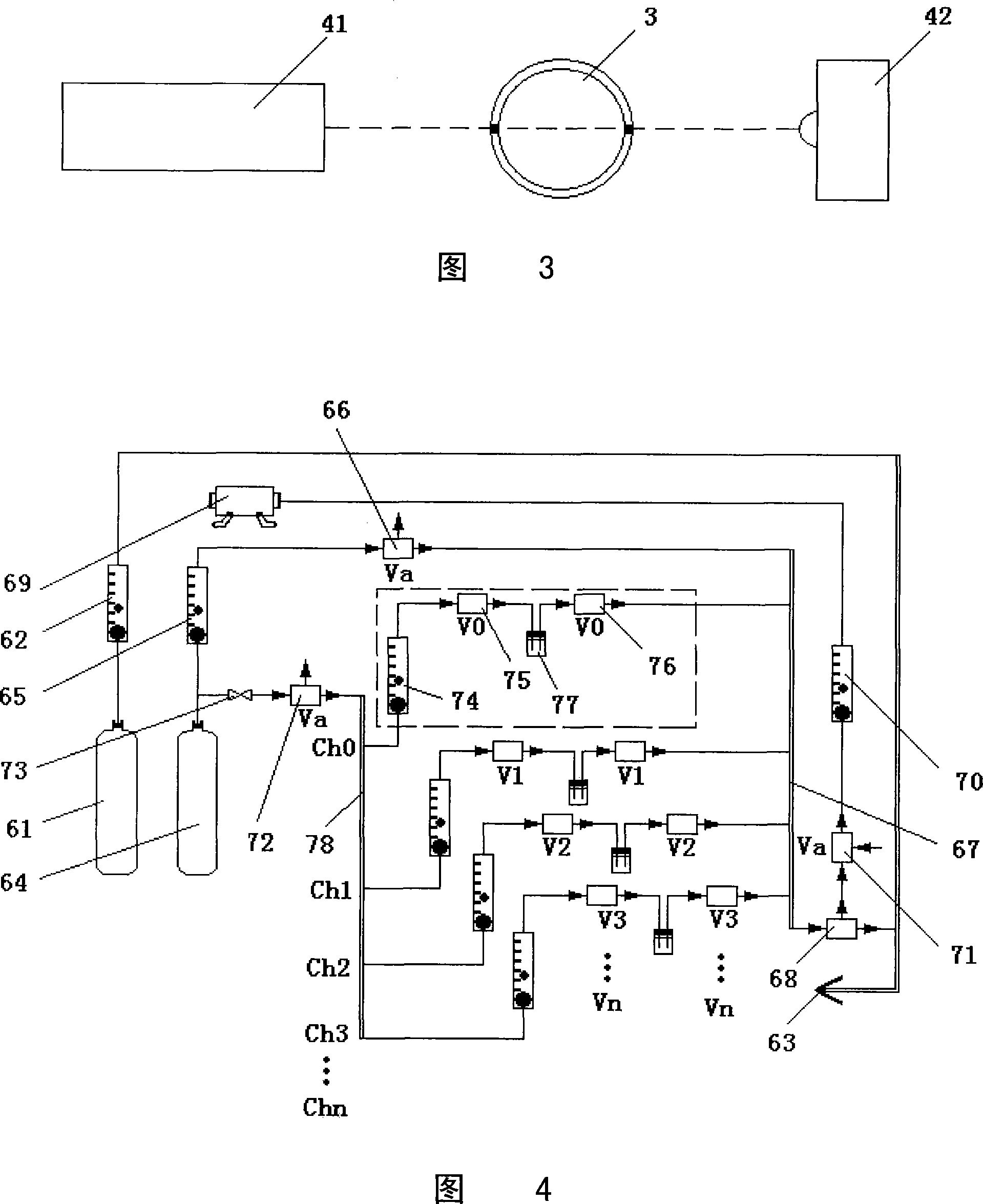

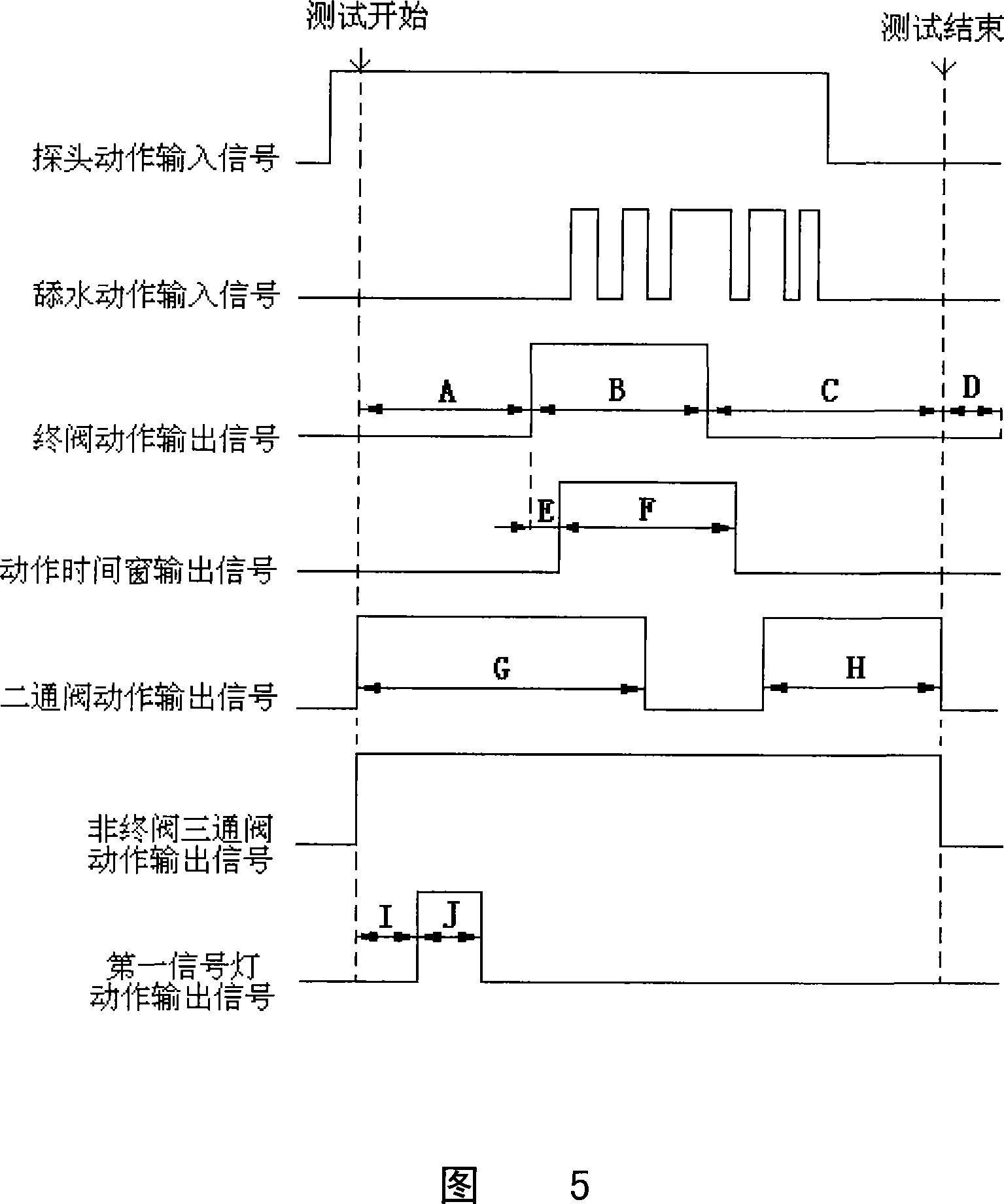

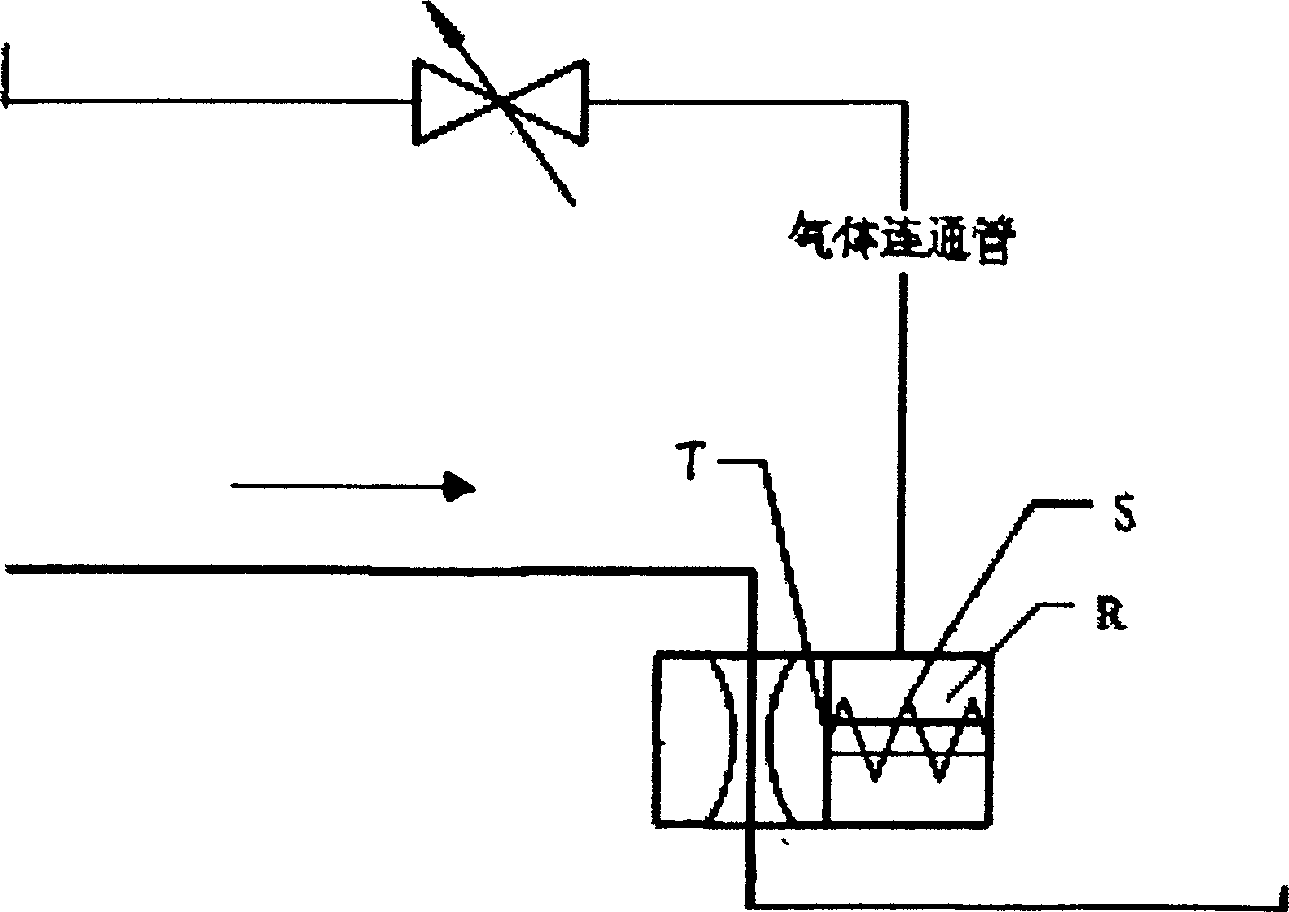

Animal olfaction study training method and system

InactiveCN101238798ADisplay and monitor behavior in real timePowerfulTaming and training devicesData acquisitionEngineering

The invention relates to an animal smell learning and training method and the system thereof, and the invention comprises the following steps: (1) before training animals, cut water supply for a long period of time, make animals have strong desire for finding water during training; (2) put animals into training ground, when training, supply the computer control system with two kinds of gas having various odors, then discharge them randomly in turn; (3) if under one kind of odor the animal licks water, it will be given some water as reward; while if under the other kind of odor the animal licks water, it will be given electric shocks as punishment; (4) test more than one hundred of times circularly like that, if animal can distinguish these two various odors, a correct operant conditioned reflex is created, according to the animal behaviour, whether the animal has the ability of distinguishing these two kinds of odors can be determined. The invention use multi-functional PCI data acquisition card, video capture card and control software in the system, so that it is able to control and record the experiment process automatically and analyze behaviors.

Owner:NAT INST OF BIOLOGICAL SCI BEIJING

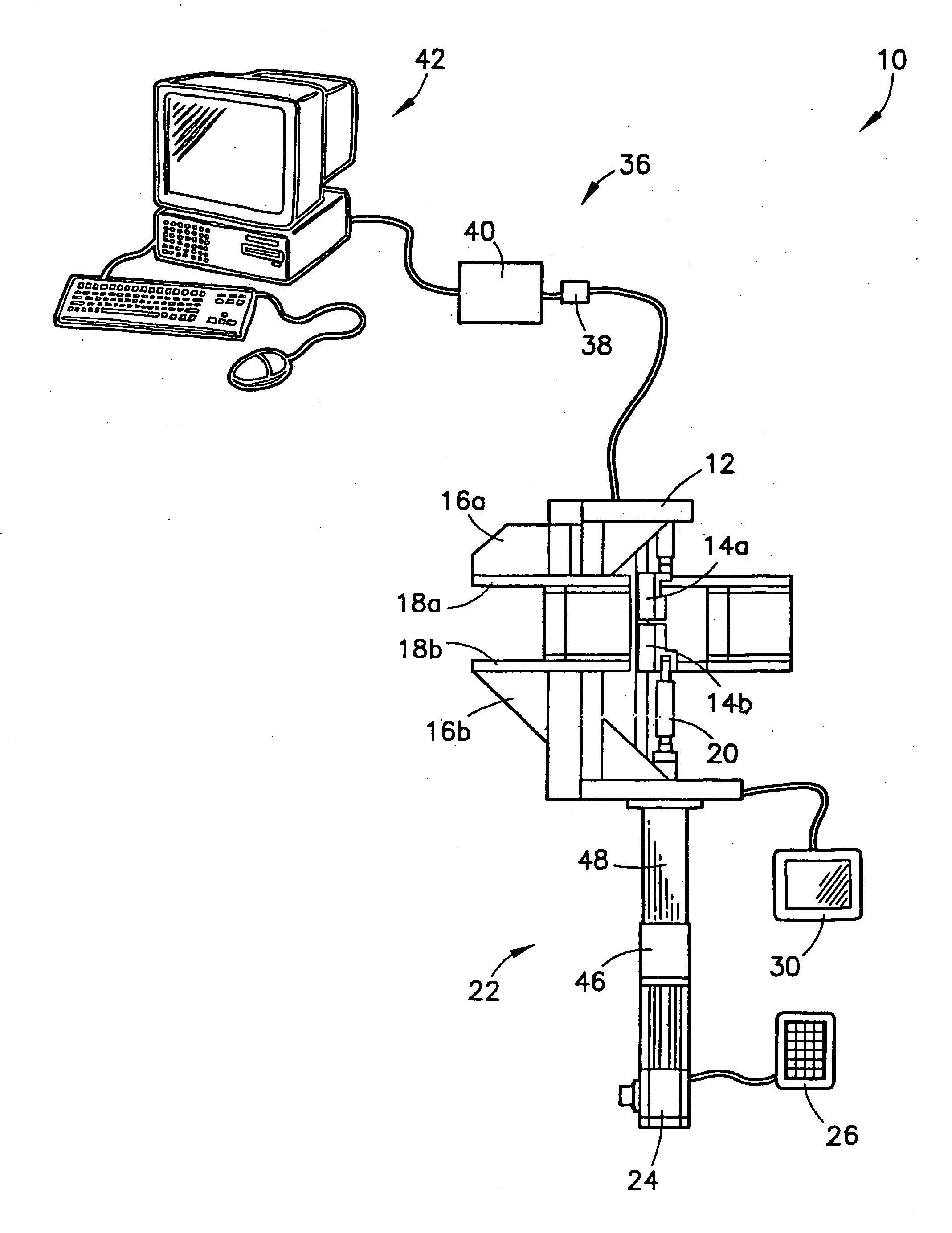

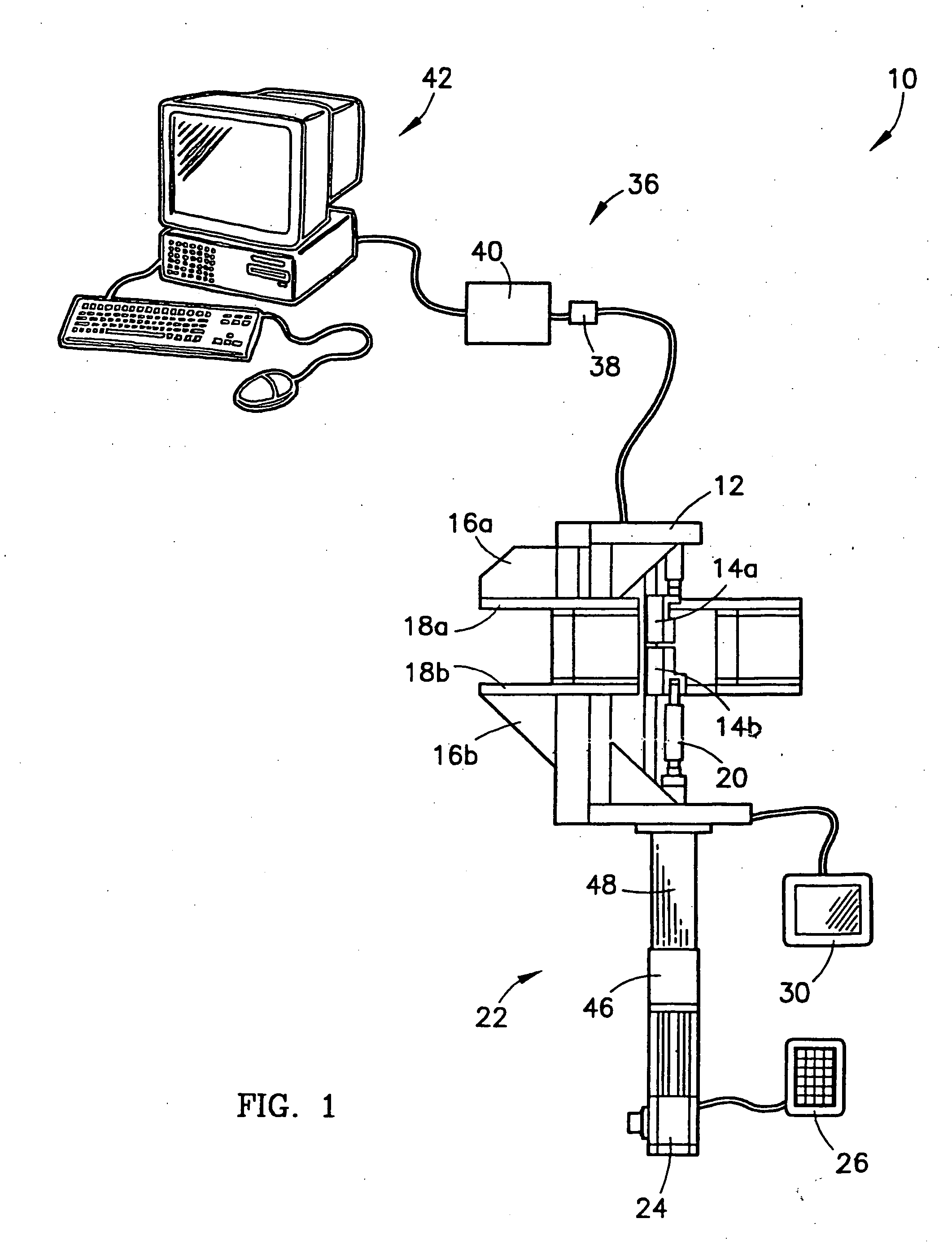

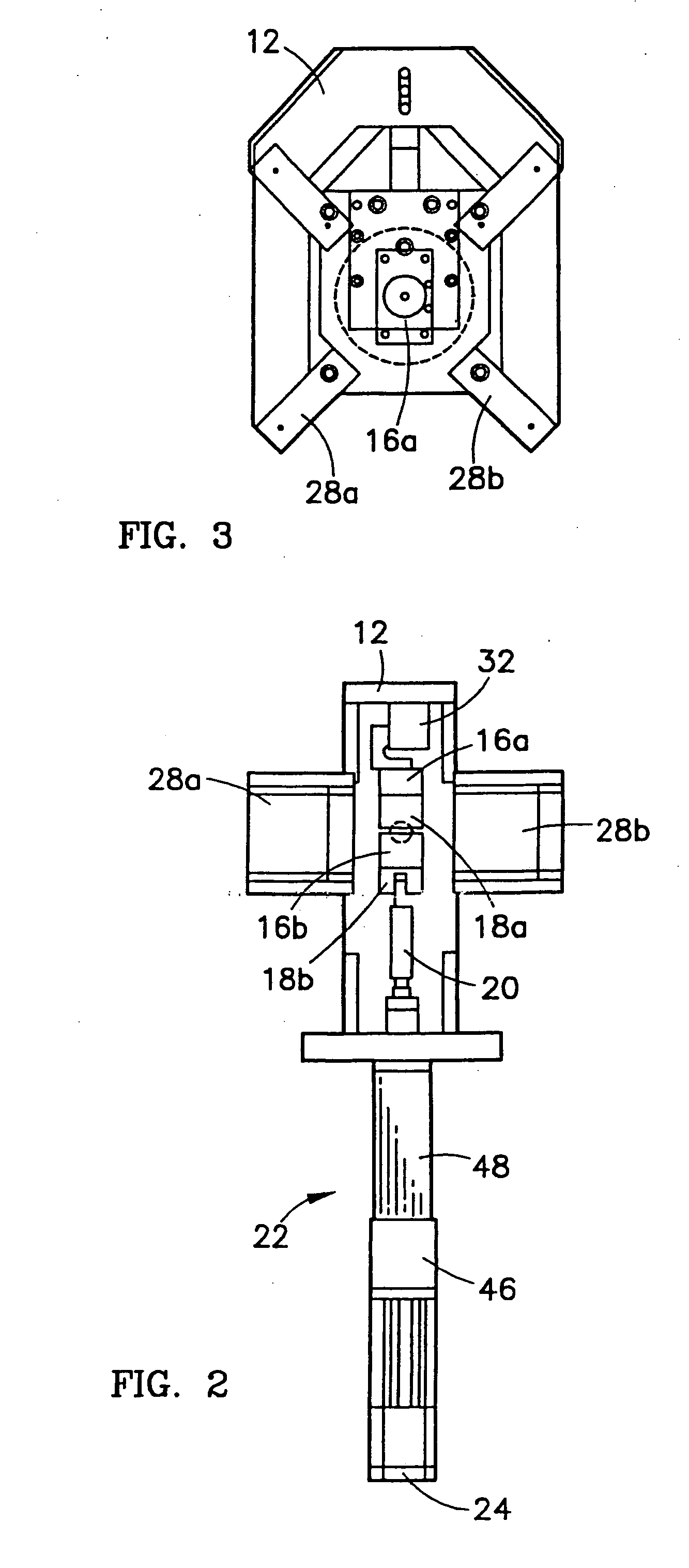

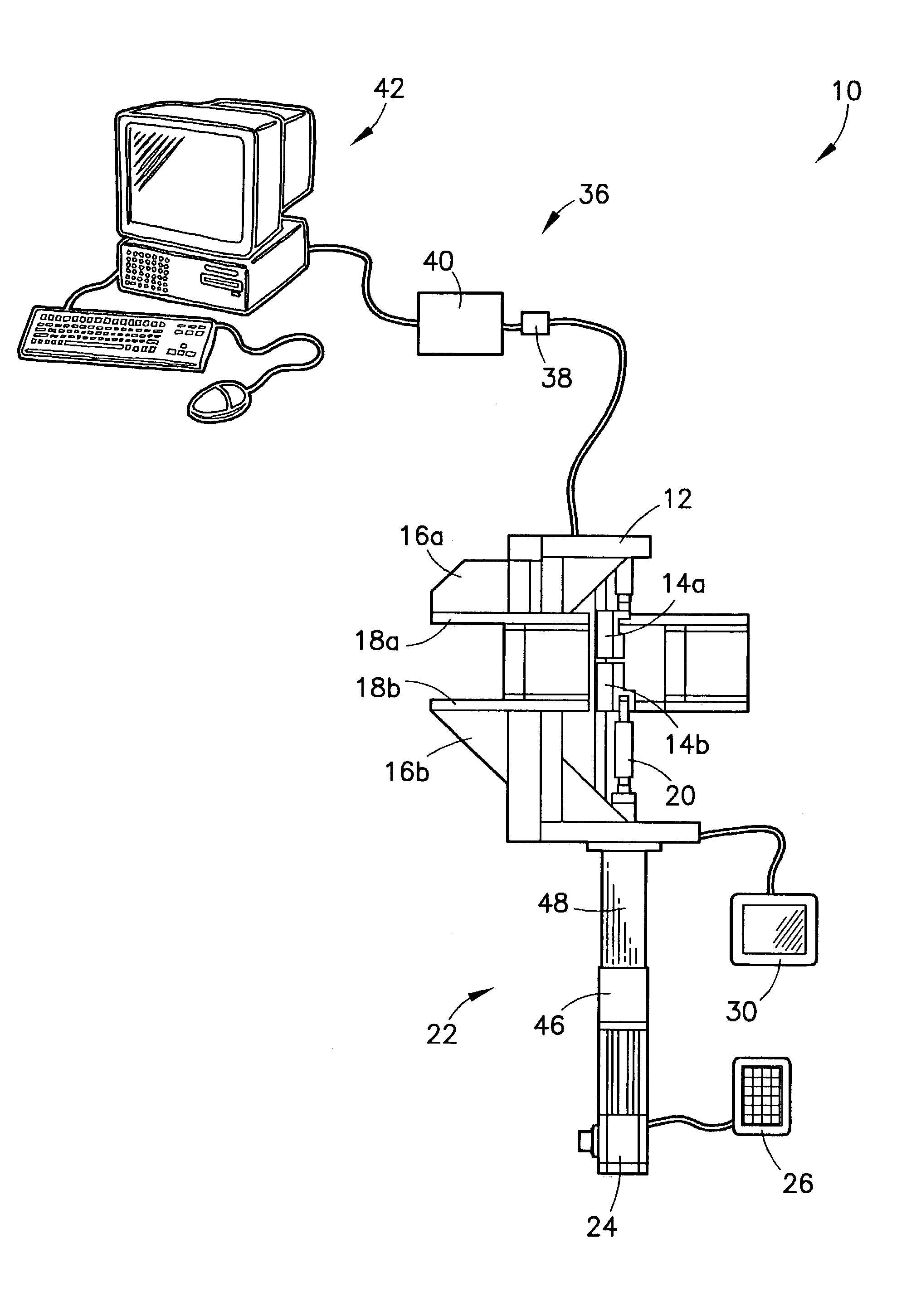

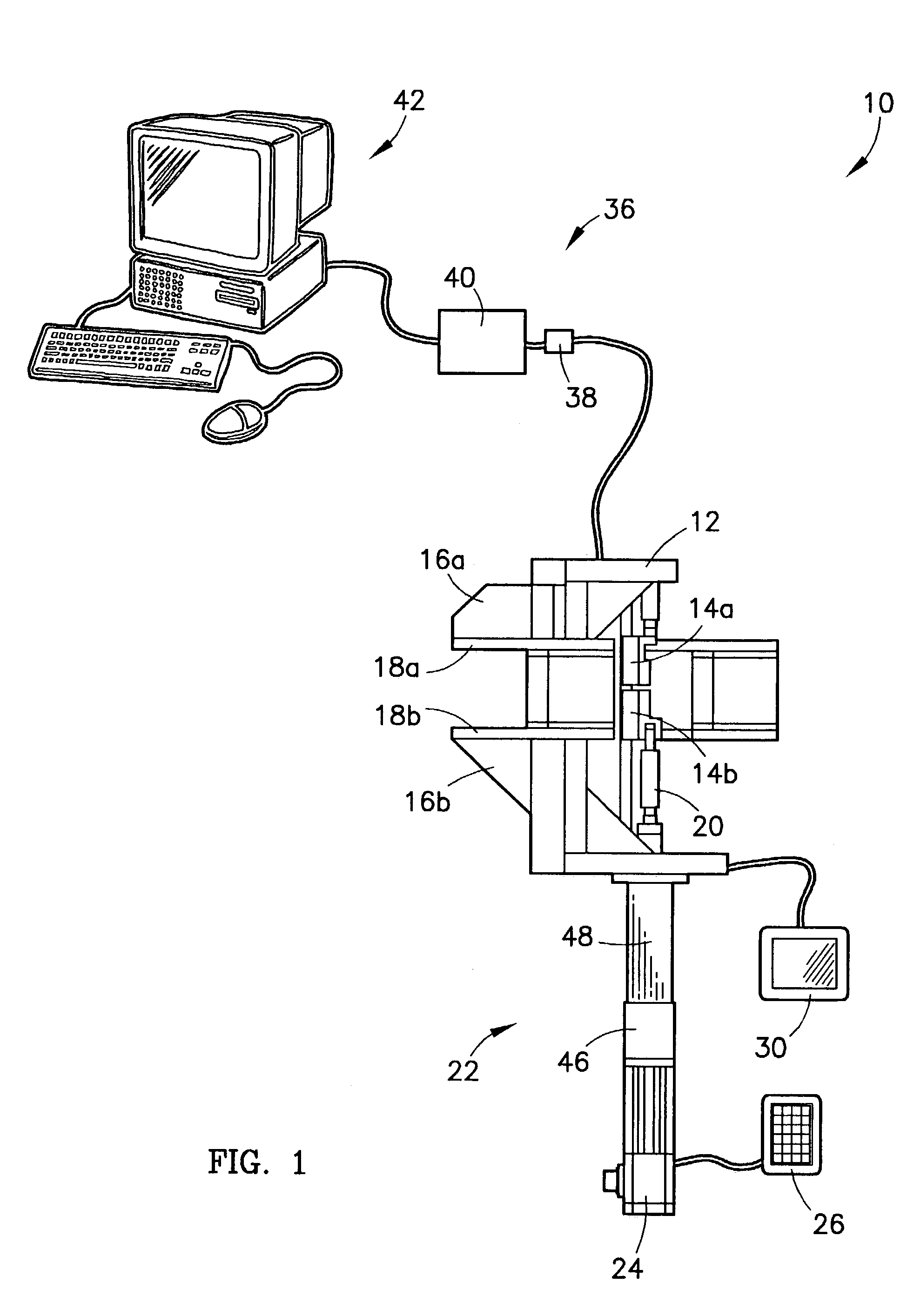

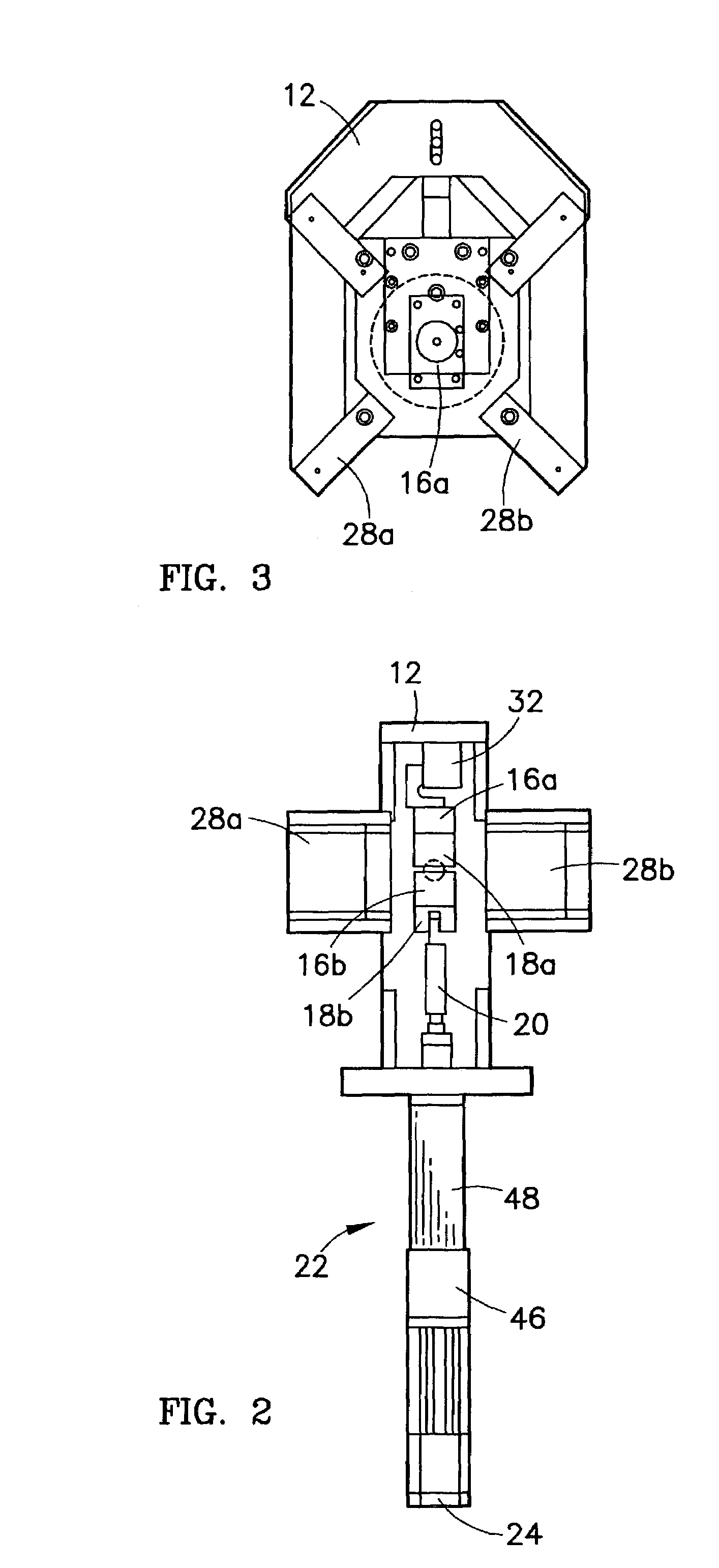

Micro-tensile testing system

InactiveUS20060096385A1Error minimizationMinimize measurement errorForce measurement by measuring optical property variationMaterial strength using tensile/compressive forcesCyclic testMicrometer

A micro-tensile testing system providing a stand-alone test platform for testing and reporting physical or engineering properties of test samples of materials having thicknesses of approximately between 0.002 inch and 0.030 inch, including, for example, LiGA engineered materials. The testing system is able to perform a variety of static, dynamic, and cyclic tests. The testing system includes a rigid frame and adjustable gripping supports to minimize measurement errors due to deflection or bending under load; serrated grips for securing the extremely small test sample; high-speed laser scan micrometers for obtaining accurate results; and test software for controlling the testing procedure and reporting results.

Owner:HONEYWELL FED MFG & TECHNOLOGI

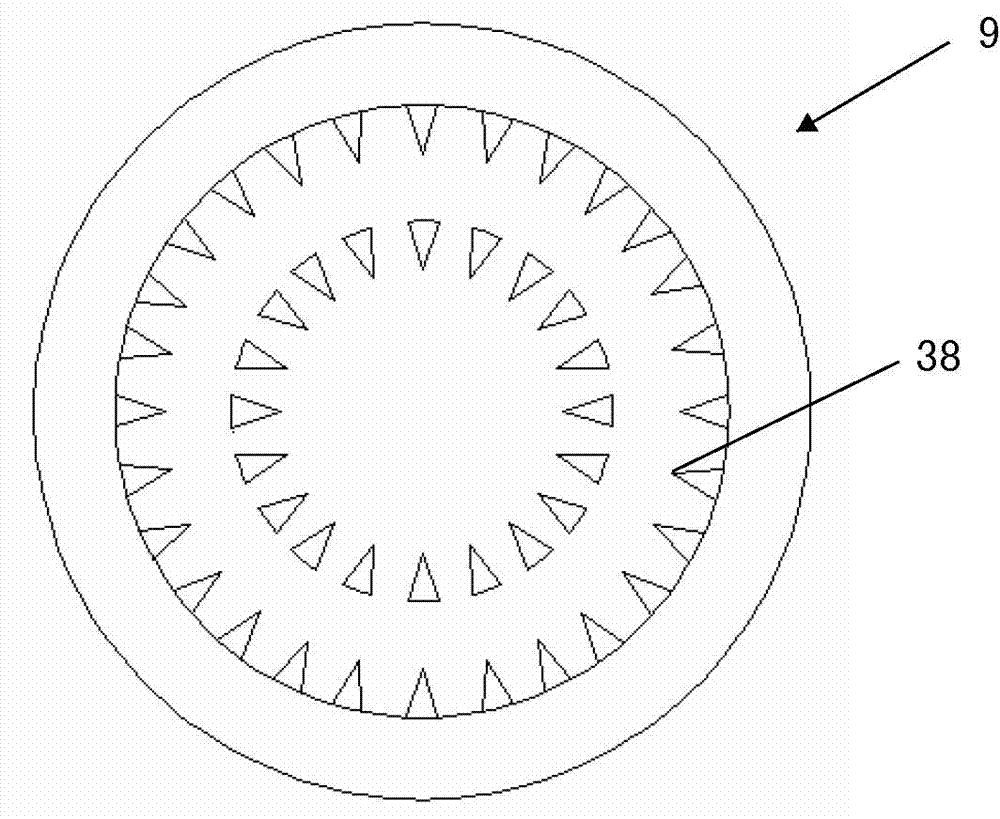

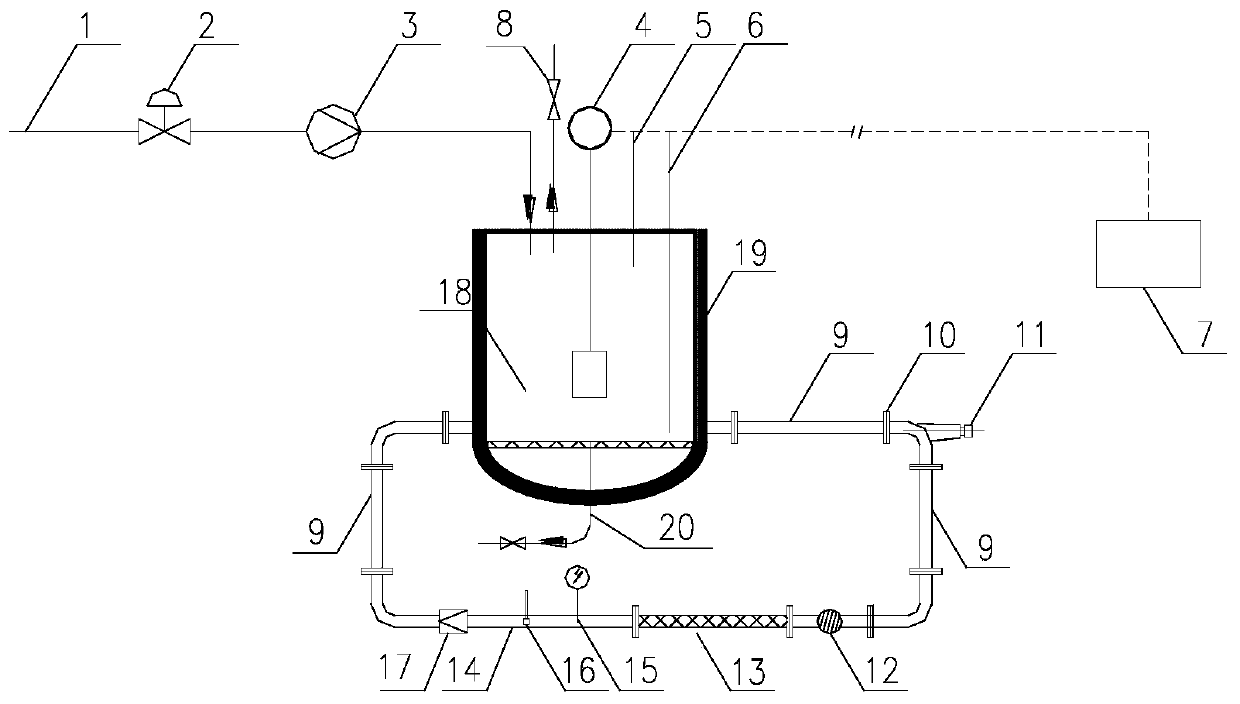

High-temperature flame flow device for dynamically and cyclically testing thermal shock resistance of thermal barrier coating

ActiveCN103487345AEffective thermal shock resistance for dynamic cycle testingEffective Dynamic Cycle TestStrength propertiesCyclic testEngineering

The invention relates to a high-temperature flame flow device for dynamically and cyclically testing thermal shock resistance of a thermal barrier coating. The high-temperature flame flow device comprises a rotatable sample mounting unit, a heating unit, a cooling unit and a control unit, wherein the sample mounting unit is used for mounting multiple samples; the heating unit is used for heating coated surfaces of the samples and is provided with at least one flame nozzle with multiple flame cores which are annularly arranged in a shape of a concentric circle; the cooling unit is used for cooling the samples; the control unit is configured to control rotation of the sample mounting unit, so that the multiple samples are alternately heated and cooled. According to the high-temperature flame flow device, a constant temperature field flame flow with a small radial temperature gradient can be formed, and the thermal shock resistance of the multiple samples can be dynamically and cyclically tested concurrently.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

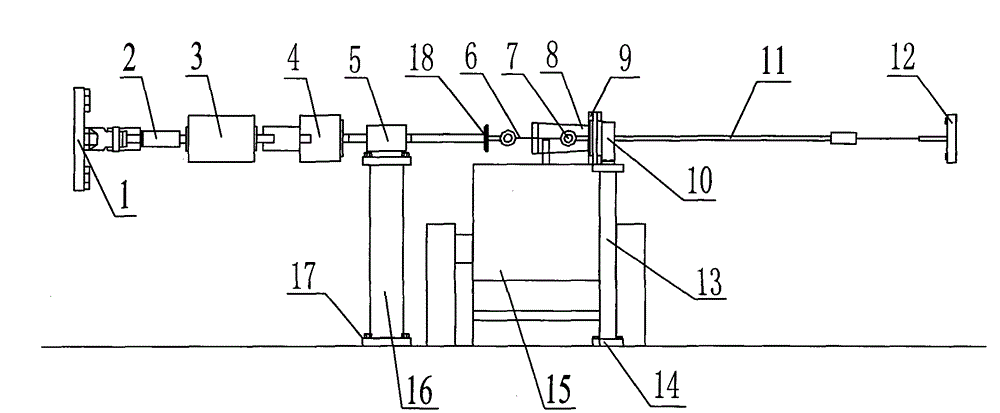

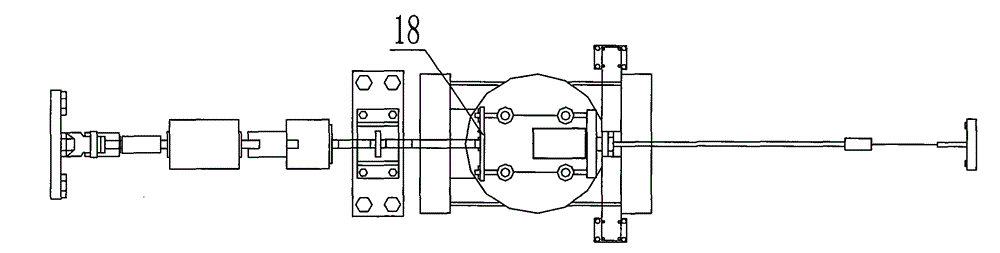

Cyclic test device for fatigue of aeroengine compressor blade

InactiveCN104062104ASimple structureEasy to operateMachine part testingVibration testingCyclic testEngineering

The invention relates to a cyclic test device for fatigue of an aeroengine compressor blade. The cyclic test device comprises a centrifugal force loading assembly for simulating cyclic loading of centrifugal force on the aeroengine compressor blade during working; the test device also comprises a high-frequency vibration loading assembly for simulating high-frequency loads on the aeroengine compressor blade during working; the high-frequency vibration loading assembly comprises vibrating table, a support A for fixing a compressor blade test piece and a support B for fixing the centrifugal force loading assembly, wherein the vibrating table is used for applying high-frequency vibration on the compressor blade test piece. The cyclic test device for the fatigue of the aeroengine compressor blade is simple in structure and convenient to operate; the cyclic test device is capable of simulating the low cyclic loading of the centrifugal force and the high-frequency loads on the aeroengine compressor blade during working so that the test state is completely consistent with the actual working state, and therefore, the centrifugal force loading test and the high-frequency load test of the compressor blade are realized, completely trustable predetermined safe cycle life is provided and then potential safety hazards in use can be avoided.

Owner:徐可君 +1

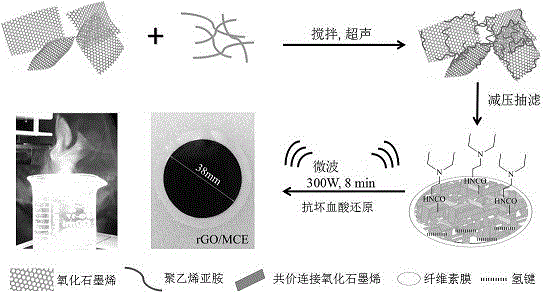

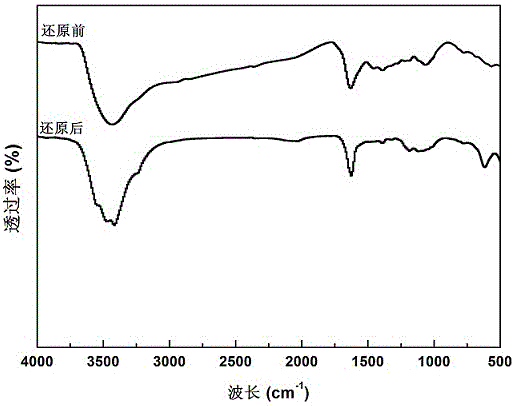

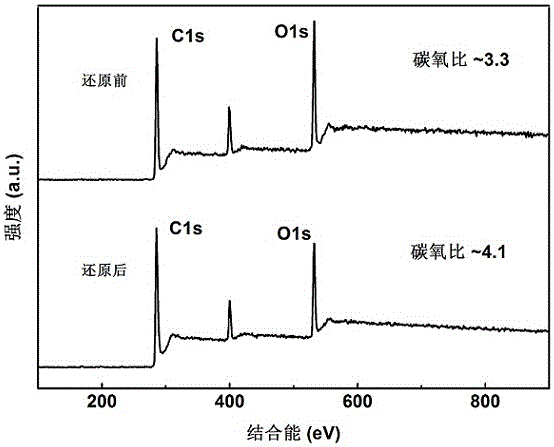

Reusable reduced graphene oxide-based photothermal conversion film and preparation method thereof

InactiveCN106744831AReduce usageEnhanced light absorptionSolar heating energySolar heat devicesCelluloseFiltration

The invention relates to a reusable reduced graphene oxide-based photothermal conversion film and a preparation method thereof. The method comprises the steps of firstly connecting a graphene oxide sheet by adopting a crosslinking agent under the action of agitation and ultrasound and then carrying out vacuum suction filtration on the mixed dispersion liquid to a mixed cellulose filter film; and quickly reducing the prepared graphene oxide / mixed cellulose film by using a reducing agent under a microwave assist to obtain the reduced graphene oxide-based double-layer photothermal conversion film. A steam performance test shows that the reduced graphene oxide-based double-layer photothermal conversion film achieves 60% of steam conversion efficiency under illumination of 1Kw / m<2>. A cyclic test result shows that the reduced graphene oxide-based double-layer photothermal conversion film still keeps the stable performance after repeated experiments for 30 times. The prepared photothermal conversion film is capable of directly converting solar energy into steam energy, is high in photothermal conversion efficiency, wide in application prospect, simple in preparation technology and low in cost, and has excellent mechanical stability and reusability.

Owner:HUBEI UNIV

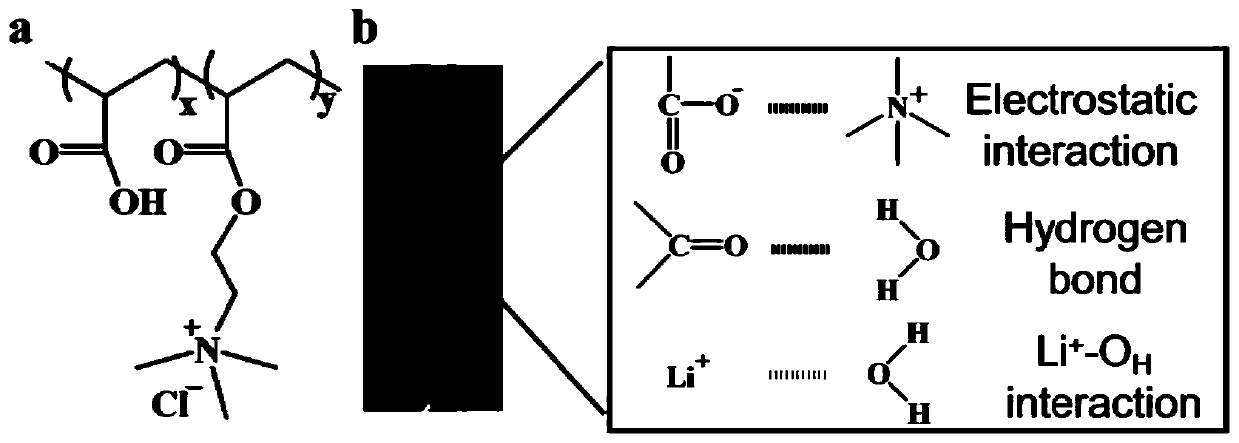

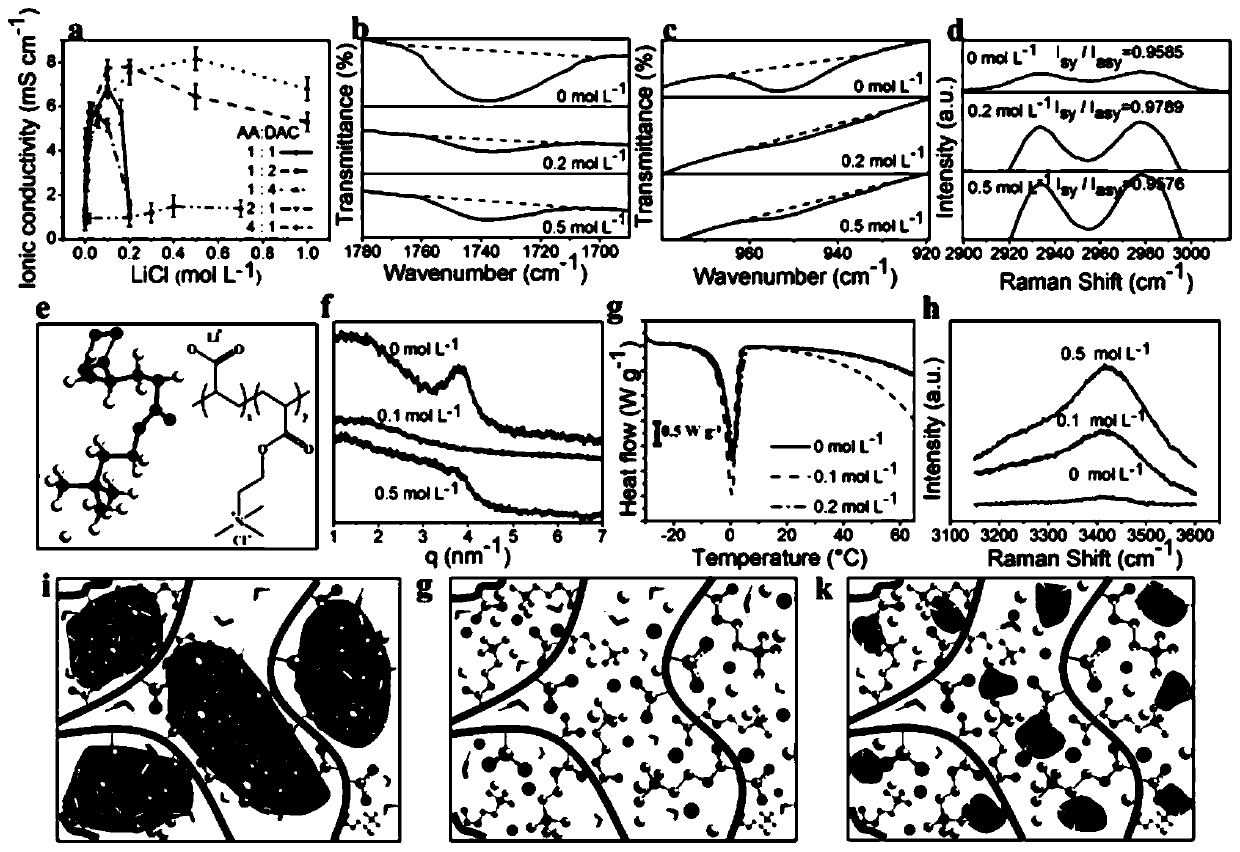

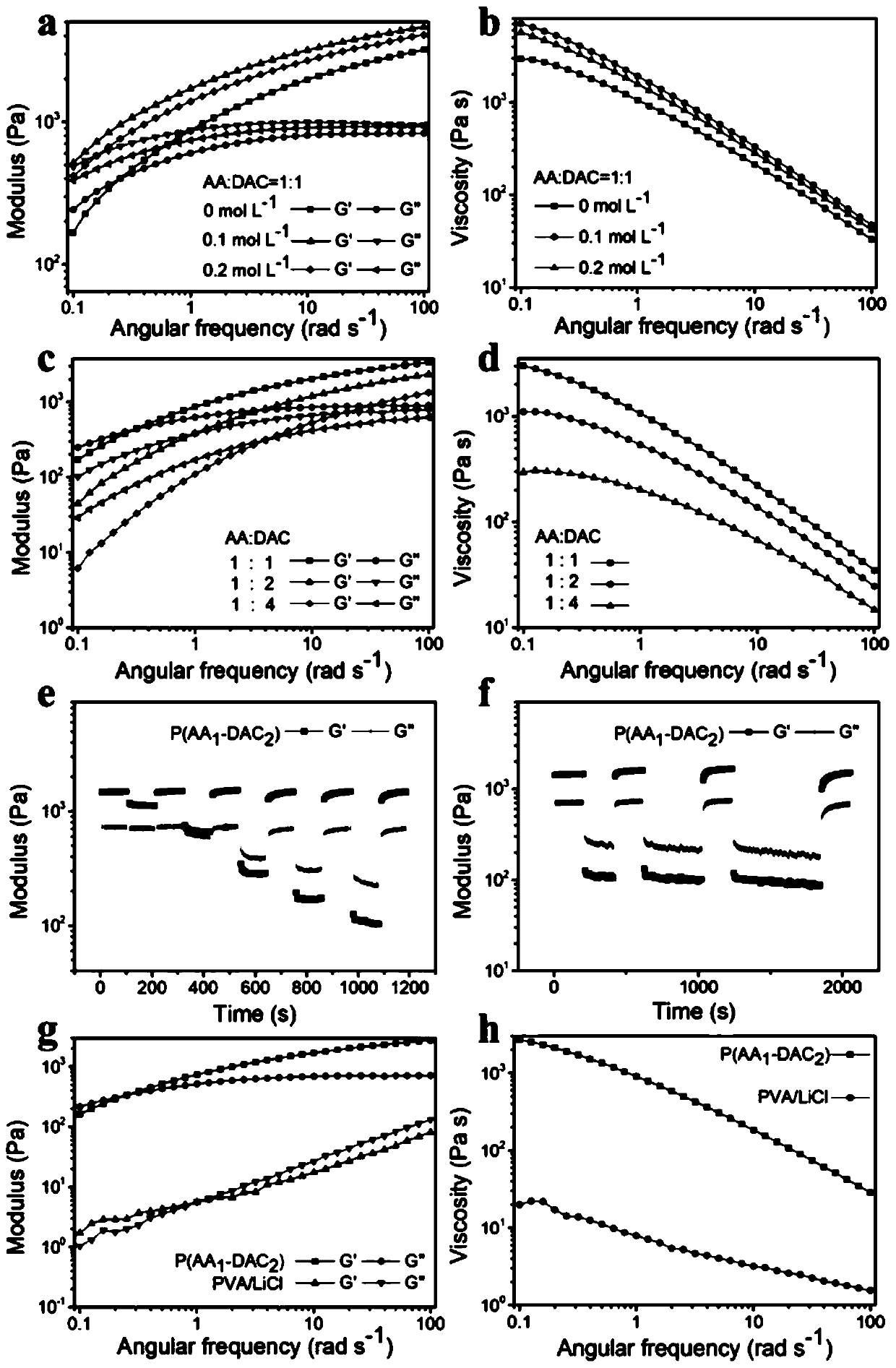

Amphoteric gel polymer electrolyte with good performance and preparation and application thereof

ActiveCN109935476AInhibit migrationReduce interface resistanceHybrid capacitor electrolytesHybrid/EDL manufactureCapacitancePolymer science

The invention relates to an amphoteric gel polymer electrolyte with good performance and preparation and application thereof. A series of zwitterionic gel electrolytes are prepared in the invention. An amphoteric gel electrolyte with high mechanical strength and a conductivity of 8.2 mScm-1 can be prepared by controlling the ratio of monomers and the concentration of lithium salt. The interfacialresistance between an electrode and the electrolyte is greatly reduced by immersing an AC electrode into a monomer solution for in-situ polymerization. The AC electrode with the in-situ polymerized electrolyte has a large area capacitance of 297mF cm-2 at a current density of 0.8 mA cm-2 and can remain 70% after 7000 cyclic tests. Remarkably, the combined solid capacitor not only have an area energy density up to 6.6 mWh cm-2 and a power density up to 2.4 W cm-2, but also have a good self-healing property. The work of the invention provides a new idea for the field of gel electrolytes, and obtains a zwitterionic gel electrolyte having great application potential in energy storage equipment.

Owner:QILU UNIV OF TECH

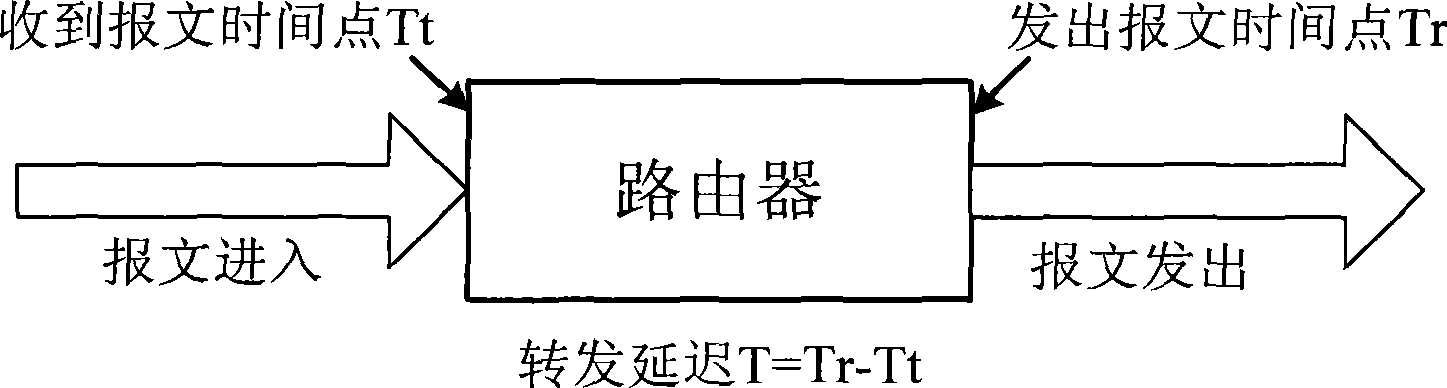

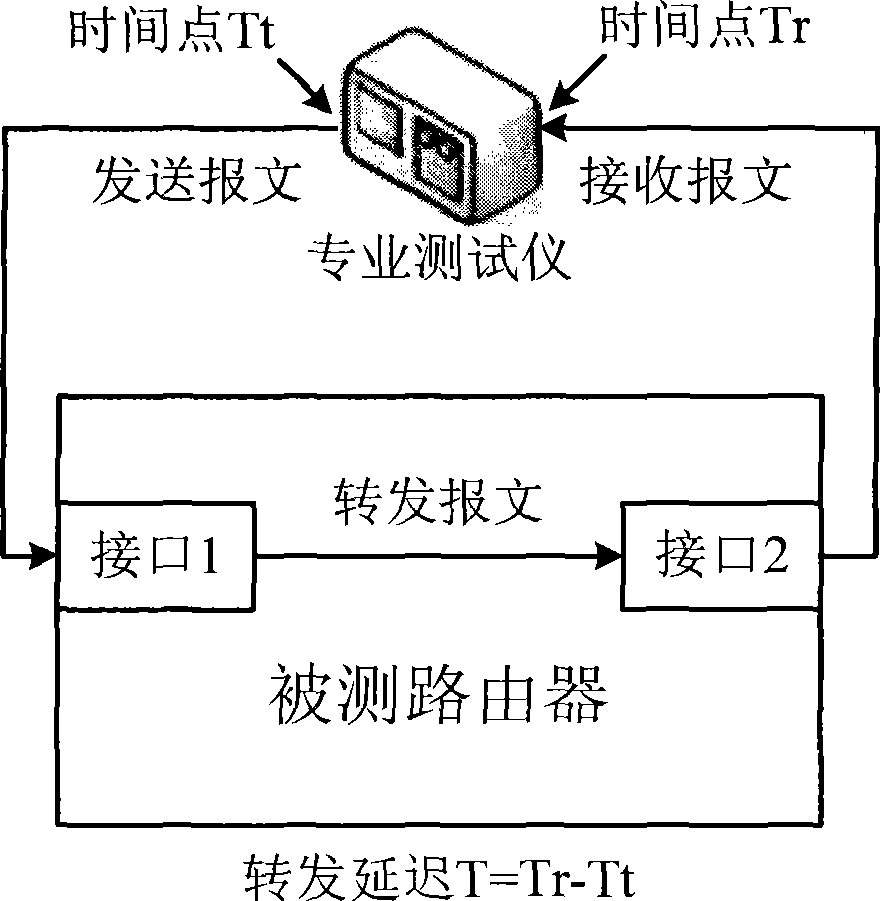

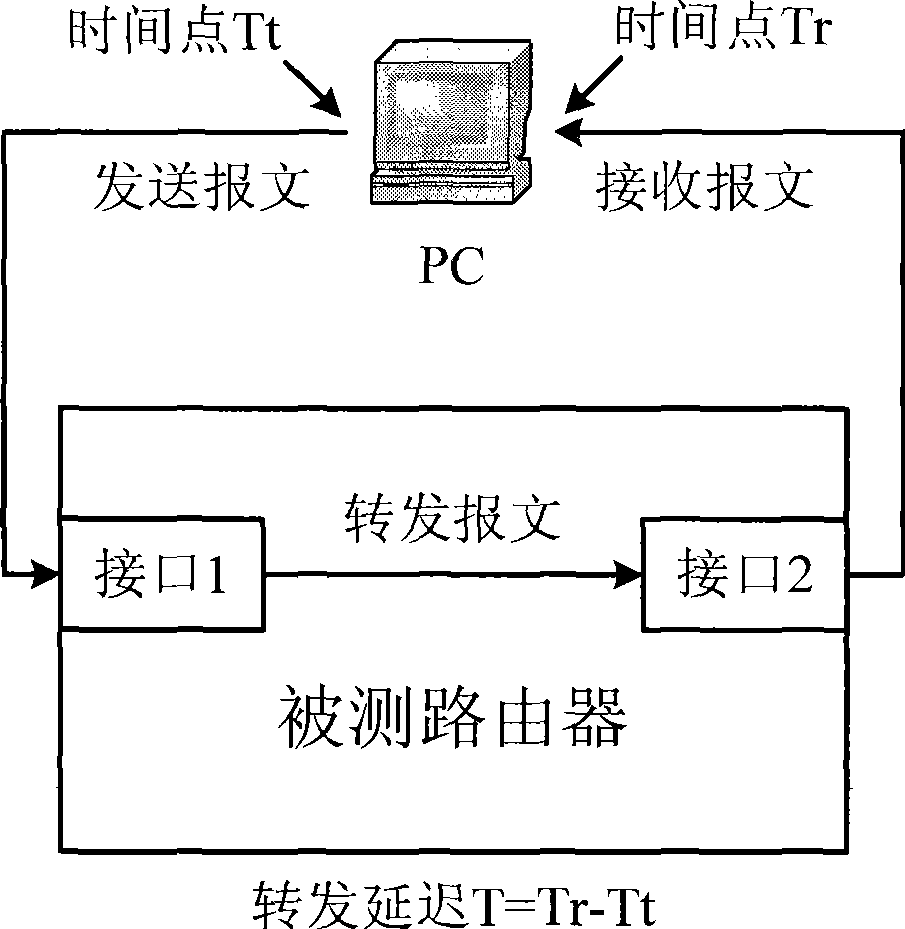

Method and system for testing forward delay

InactiveCN101547063AReduce testing costsReduce mistakesError preventionData switching networksCyclic testIp address

The invention provides a method and a system for testing forward delay, which are used for improving the accuracy of the forward delay test of common testing equipment. Through the configuration of a binding relation between a next hop IP address received by tested equipment and the port of the tested equipment on the tested equipment, the method enables a sent test message to perform circular test in the tested equipment. Therefore, the obtained result of the forward delay test has reduced errors caused by self time consumption in the forward delay test of a common testing instrument, so the high test cost caused by the use of a professional testing instrument is saved.

Owner:BEIJING XINWANG RUIJIE NETWORK TECH CO LTD

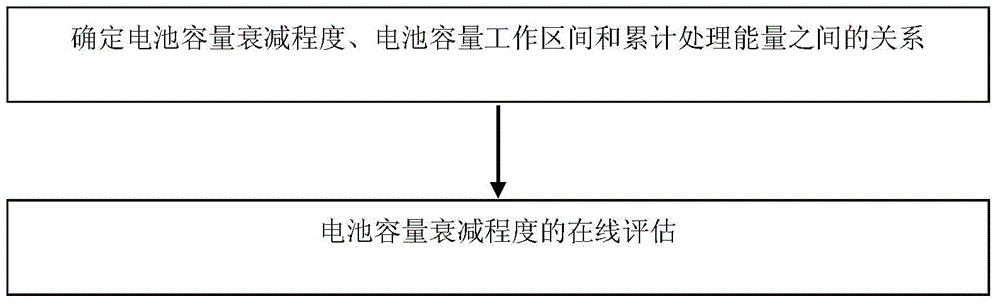

Method for evaluating capacity attenuation degree of lithium ion battery online

InactiveCN105738814AAssess the degree of capacity fadeSimple and fast operationElectrical testingUltrasound attenuationCyclic test

The invention relates to a method for evaluating the capacity attenuation degree of a lithium ion battery online. According to the method, the relationships of the capacity attenuation degree and accumulated processing energy of the battery under different charging and discharging depths are established through cyclic tests of the battery under the different charging and discharging depths, and the association relationships are applied to an energy storage monitoring system, and therefore, the on-line evaluation of the capacity attenuation degree of the lithium ion battery can be realized.

Owner:STATE GRID CORP OF CHINA +2

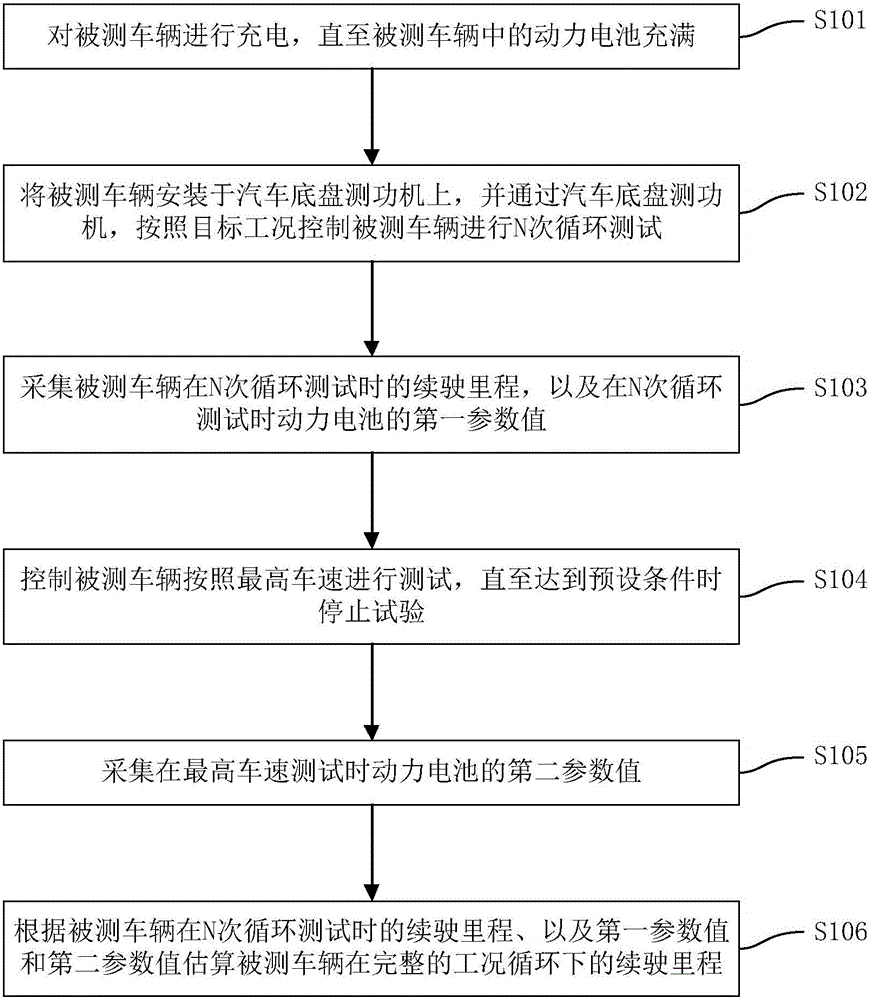

Test method and system of driving mileage of pure electric automobile

ActiveCN106226698AElectrical testingMeasurement of vehicle's tractive/propulsive powerCyclic testRepeatability

The invention discloses a test method and system of driving mileage of a pure electric automobile. The test method comprises steps of: charging a to-be-tested vehicle until the to-be-tested vehicle is fully charged; installing the to-be-tested vehicle on an automobile chassis dynamometer and carrying out cycle tests for N times on the to-be-tested vehicle according to a target test working condition; acquiring the driving mileage of the to-be-tested vehicle during the cycle tests for N times and a first parameter value of a power cell during the cycle tests for N times; controlling the to-be-tested vehicle to be subjected to the test according to the maximum speed and stopping the test until a preset condition is met; acquiring a second parameter value of the power cell during the test at the maximum speed; and estimating the driving mileage of the to-be-tested vehicle in the complete working condition cycle according to the driving mileage of the to-be-tested vehicle during the cycle test for N times, the first parameter value and the second parameter value. In this way, rapid test for the driving mileage is achieved and accurate test results can be ensured; and the repeatability rate is high and the operation is simple, so test periods and cost are reduced.

Owner:BEIJING ELECTRIC VEHICLE

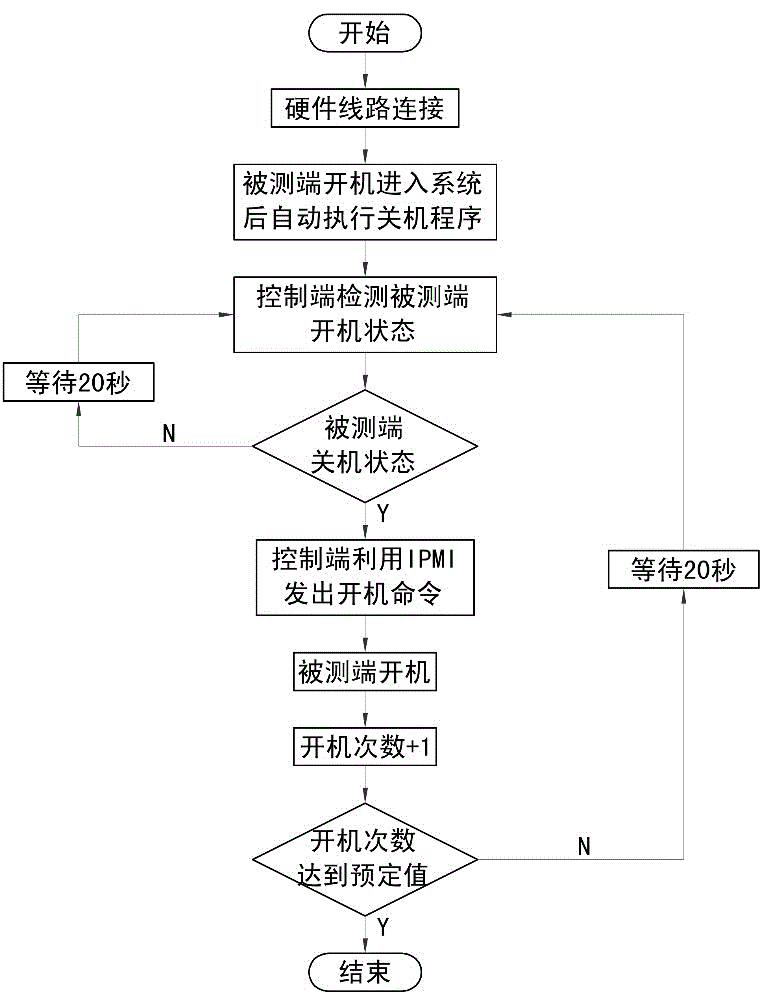

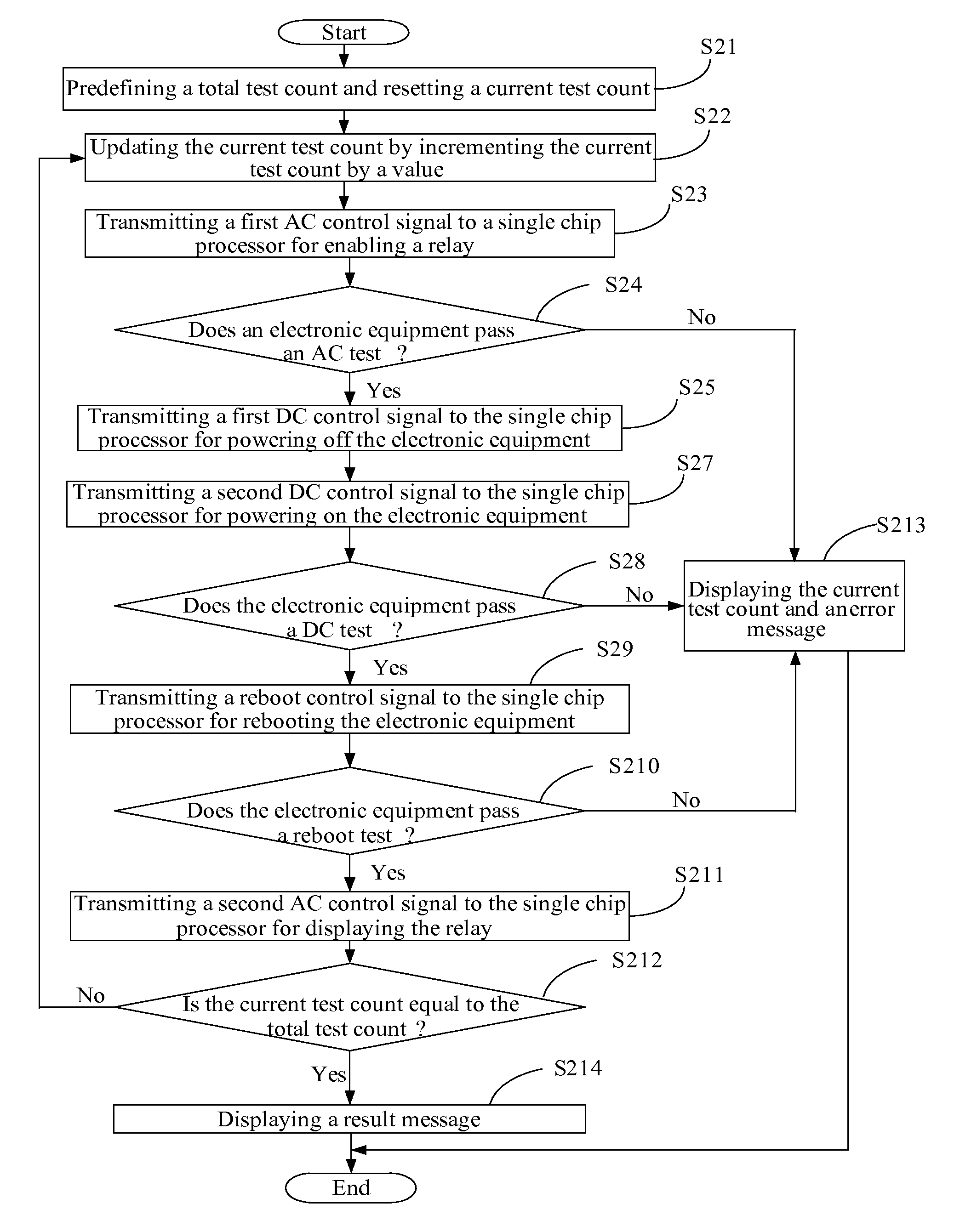

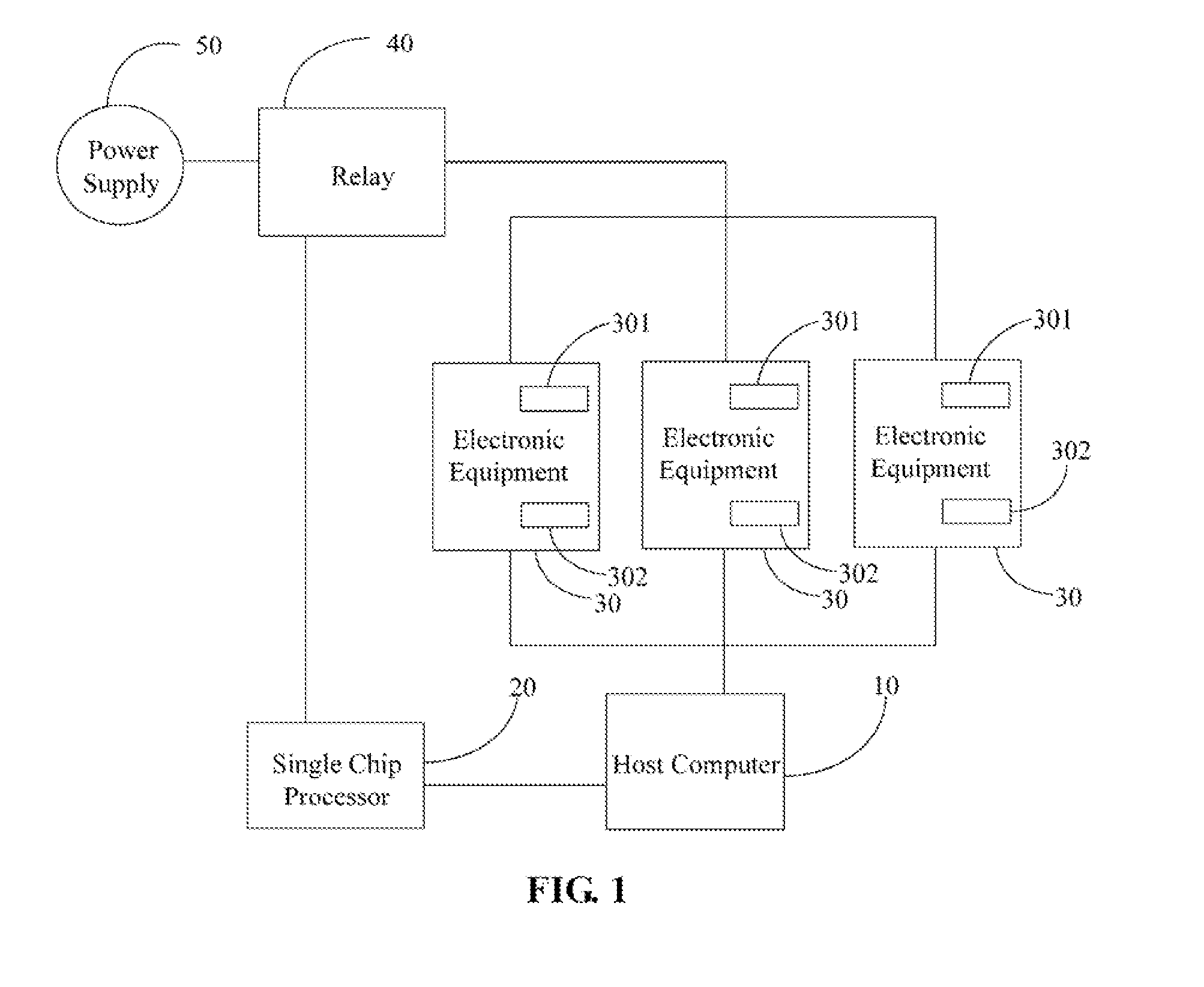

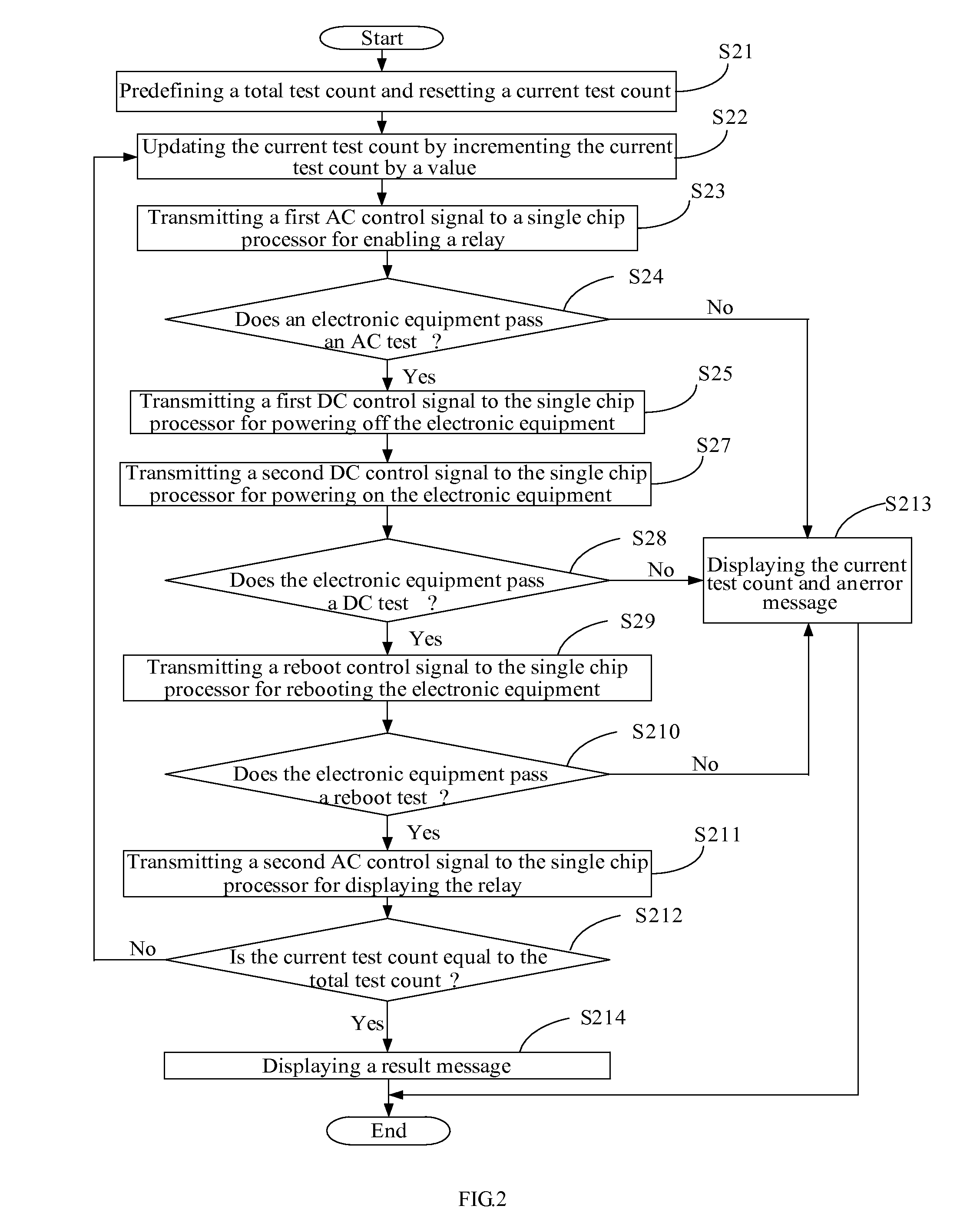

Server stability test method based on BMC startup and shutdown functions

PendingCN104899120AEasy to operateEfficient use ofDetecting faulty computer hardwareTest efficiencyCyclic test

The present invention particularly relates to a server stability test method based on BMC startup and shutdown functions. According to the server stability test method based on the BMC startup and shutdown functions, a linux system control end is connected with a network interface of a to-be-tested server of a tested end; a switch is further connected between the linux system control end and the to-be-tested server; the network interface of the to-be-tested server is a BMC port; and a test program is started up and automatically controls the power supply start-up action of the server so as to carry out unmanned cyclic test. The server stability test method based on the BMC startup and shutdown functions is simple to operate, does not need a special startup and shutdown device, has good usability, greatly saves the test time and improves the test efficiency; the server stability testing method based on the BMC startup and shutdown functions is suitable for all servers each with a BMC management function, basically has no requirements on an operating system, is excellent in the test process and can complete the test task very well.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

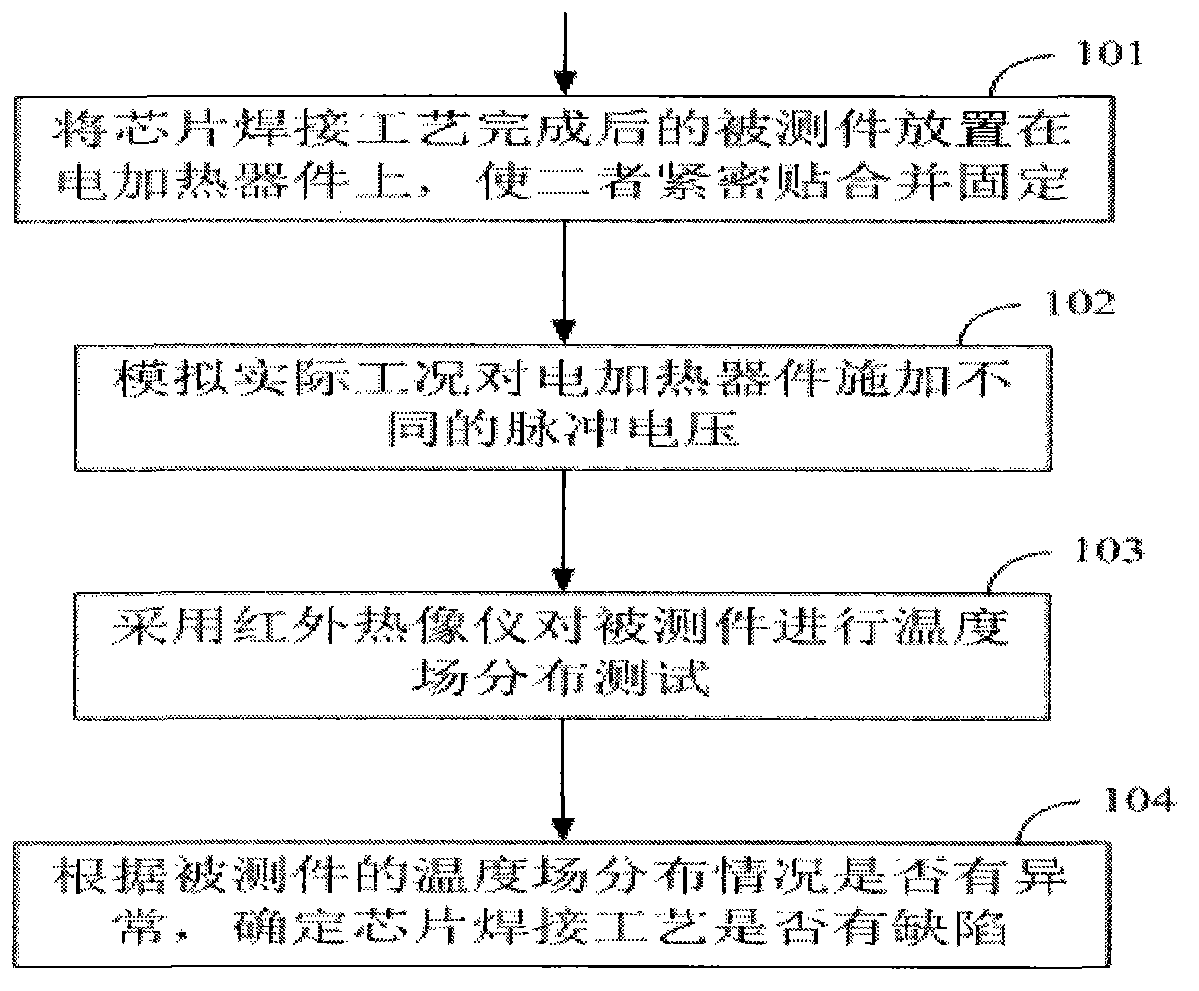

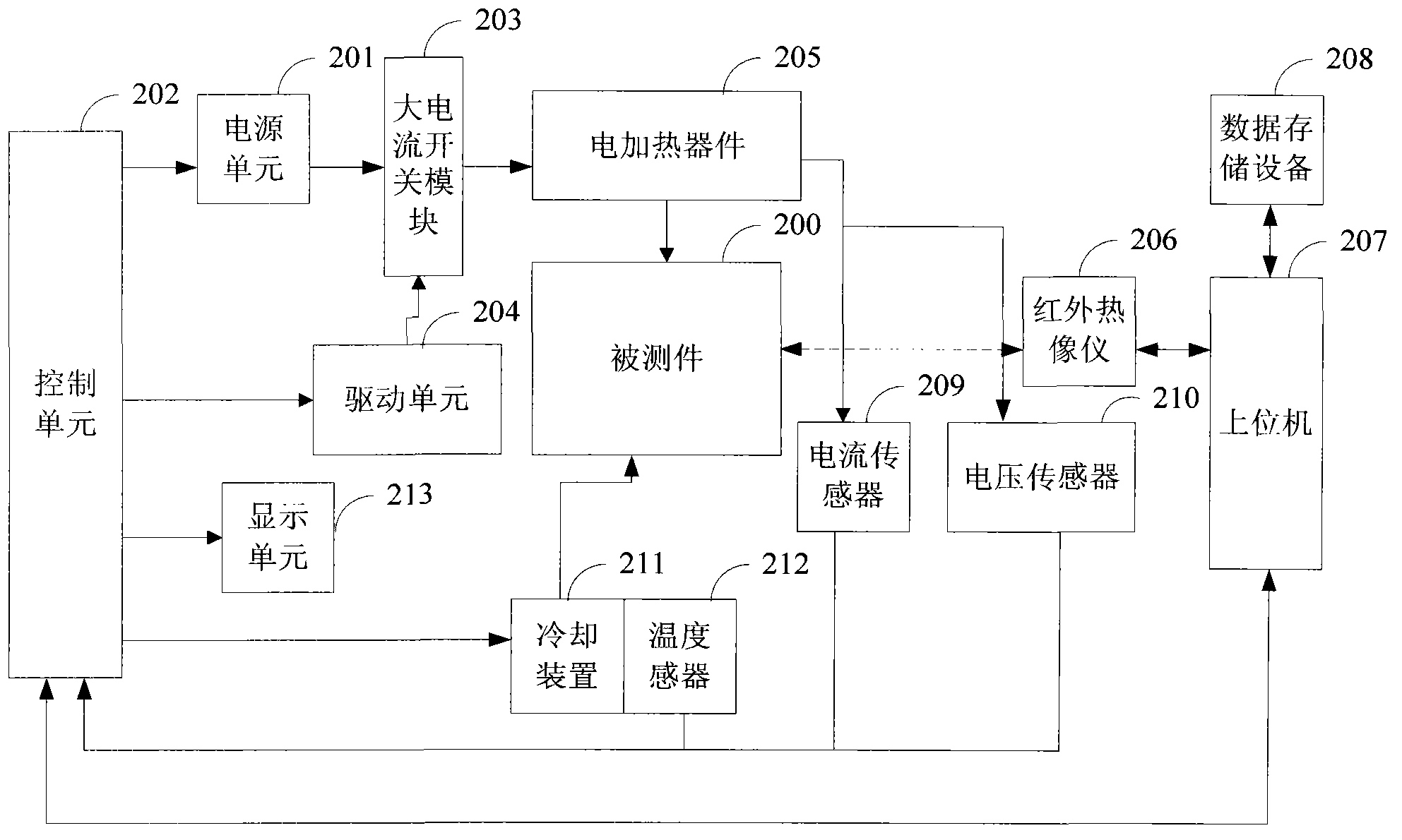

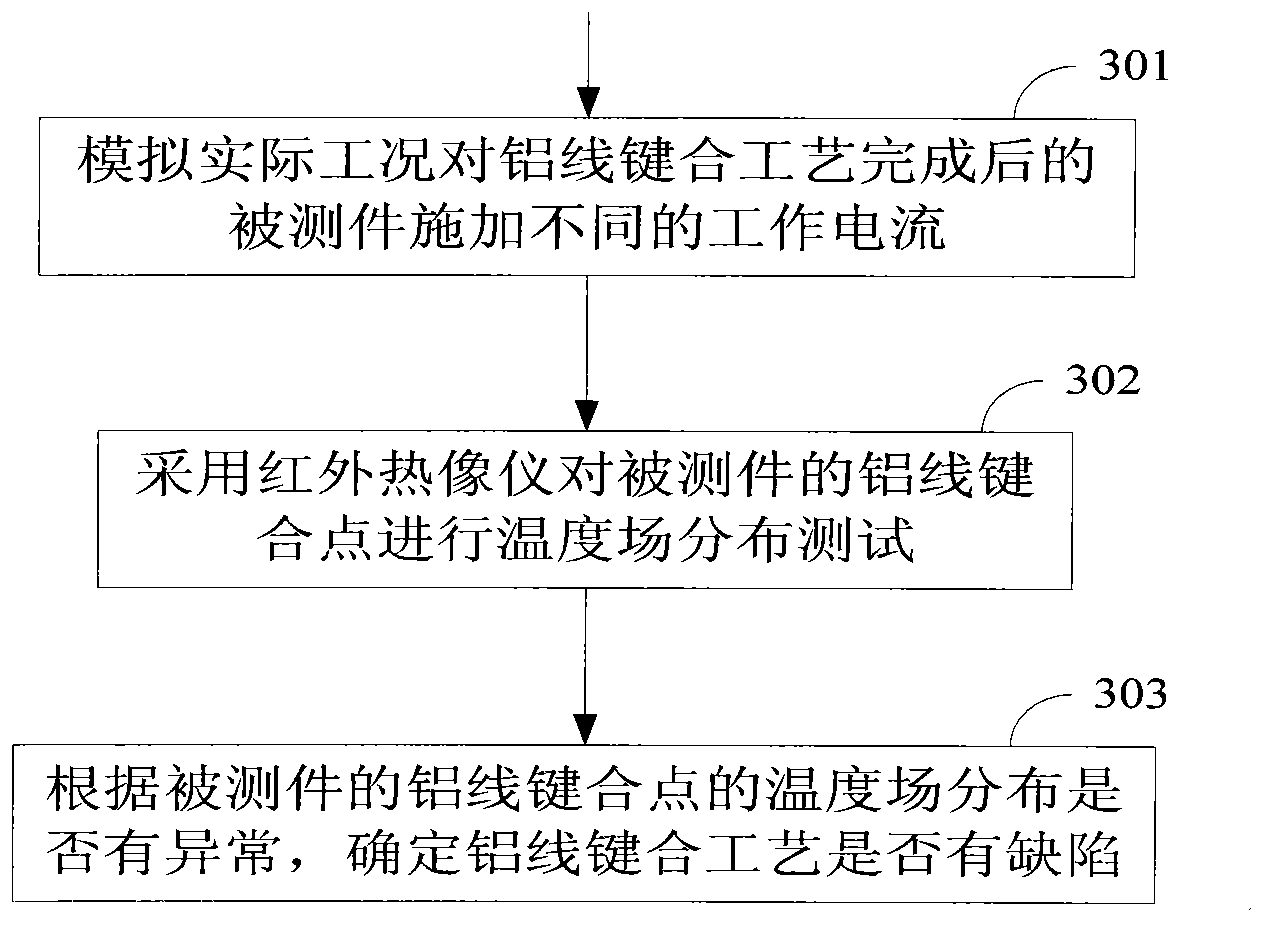

Method and system for testing power semiconductor module packaging technology

InactiveCN103579032AReduce testing costsRealize online monitoringSemiconductor/solid-state device testing/measurementSolid-state devicesTest powerCyclic test

The invention discloses a method and system for testing the power semiconductor module chip welding technology, a method and system for testing the power semiconductor module aluminum wire bonding technology, and a method and system for testing the packaging technology comprising the chip welding technology and the aluminum wire bonding technology. According to the method and system, an electric heating device is used for simulating working conditions, the impulse voltage / current is applied to the electric heating device, and / or the loop testing voltage / current is applied to heat a tested piece after chip welding, or the working voltage / current and / or the loop testing voltage / current are / is applied to a tested piece after aluminum wire bonding, and a heat infrared imager is adopted to conduct temperature field distribution testing on the tested piece. Whether the chip welding technology and / or the aluminum wire bonding technology have / has defects or not is determined according to the fact whether the temperature field distribution condition of the tested piece or an aluminum wire bonding point of the tested piece is abnormal or not. Dynamic monitoring on the chip welding technology and / or the aluminum wire bonding technology under actual working conditions is achieved, and the testing cost is reduced.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Power cycle test method for testing an electronic equipment

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

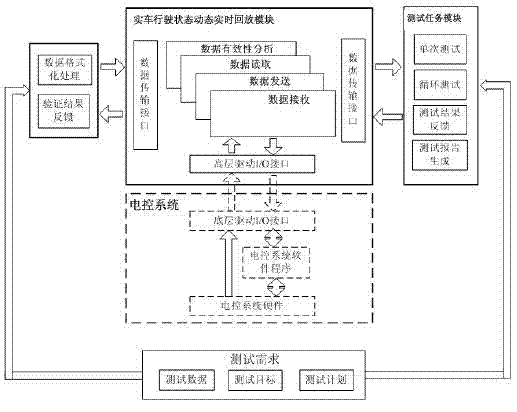

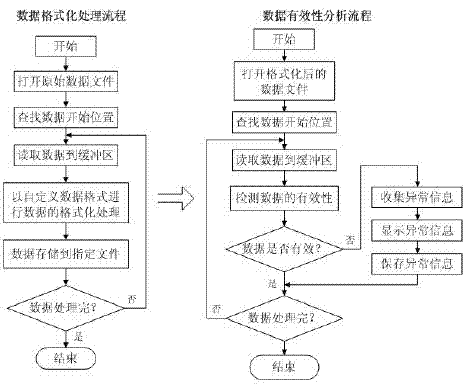

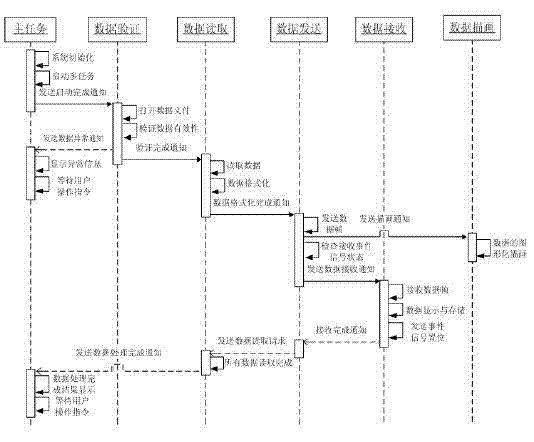

Method for testing vehicular electric control system based on real vehicle running state dynamic real-time playback

ActiveCN102231079AResolve dependenciesEasy wayElectric testing/monitoringE communicationElectric control

The invention discloses a method for testing a vehicular electric control system based on real vehicle running state dynamic real-time playback. The system comprises a data formatting processing module, a real vehicle running state dynamic real-time playback module, a testing task module and a high-level driving I / O (Input / Output) interface module communicating with the electric control system. The data formatting processing module is used for formatting vehicle road-test test data as an input and sending the formatted road-test test data to the real vehicle running state dynamic real-time playback module through a data transmission interface. The testing task module is set in a single test state or a cycle test state according to test requirements. The high-level driving I / O interface module is used for interacting real-time data with the vehicular electric control system based on a data communication interface card, transmitting the real vehicle running state data to a lower computer control system of the electric control system and building a true real vehicle running environment to the lower computer control system. According to the method disclosed by the invention, the real vehicle test number is effectively reduced; the cost is saved; and the development cycle of the electric control system is greatly shortened.

Owner:TONGJI UNIV

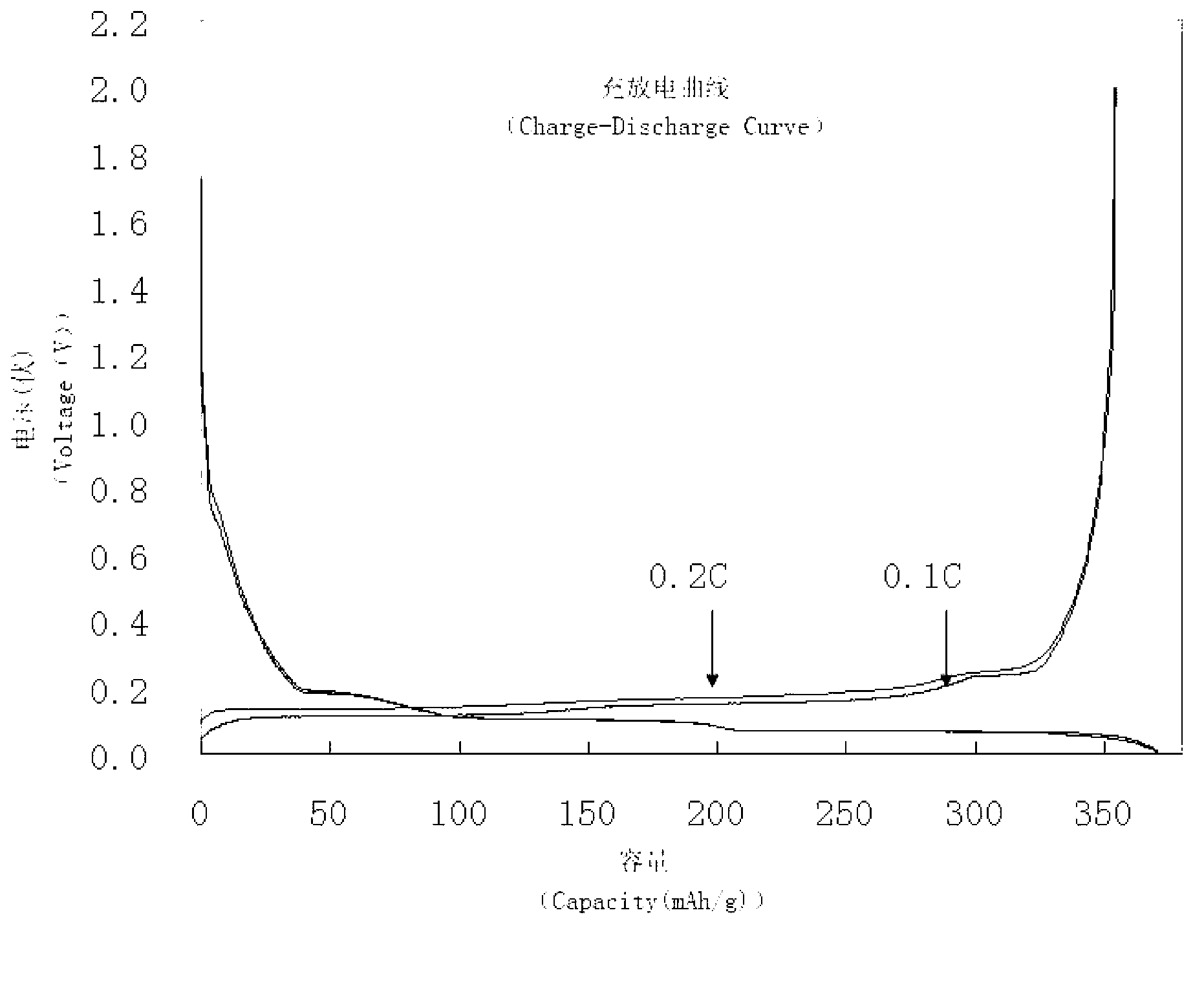

Method and apparatus for confirming the charge amount and degradation state of a battery, a storage medium, an information processing apparatus, and an electronic apparatus

ActiveUS7429849B2The right amountDegradation of accuratelyBatteries circuit arrangementsMaterial analysis by electric/magnetic meansInformation processingCyclic test

A method and apparatus is used to confirm the charge amount and degradation state of a battery. Various cycle test battery measurements are conducted at prescribed time intervals until the end of the battery life, and the measured values are used to generate a determination table or determination tables showing relationships between battery charge amount and degradation state. To establish the charge amount and degradation state of a subject battery, the subject battery is measured and the results compared with determination table values. The existing charge amount and the state of battery degradation are estimated in accordance with a determination table location of matching values.

Owner:TOYO SYSTEM CO LTD

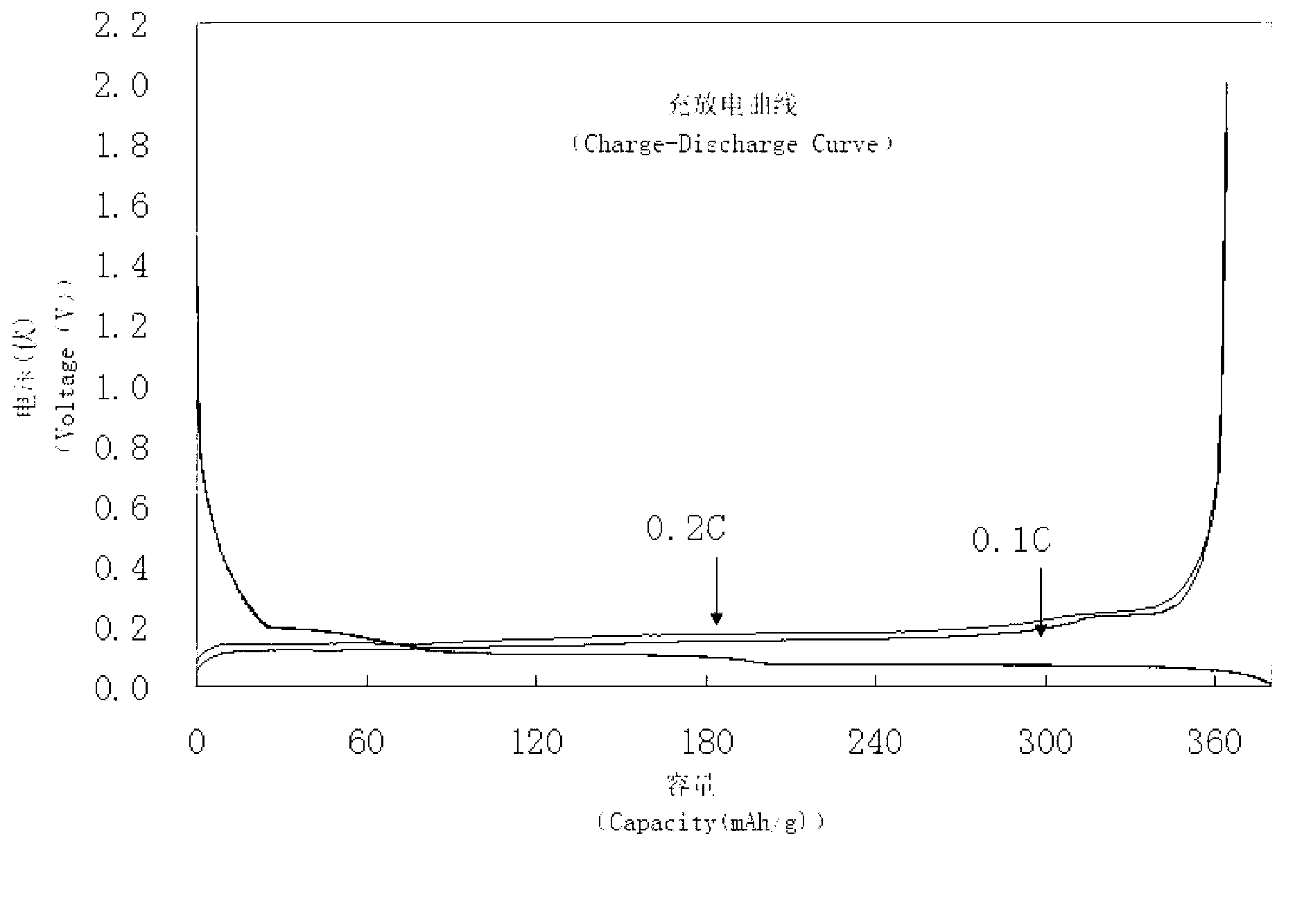

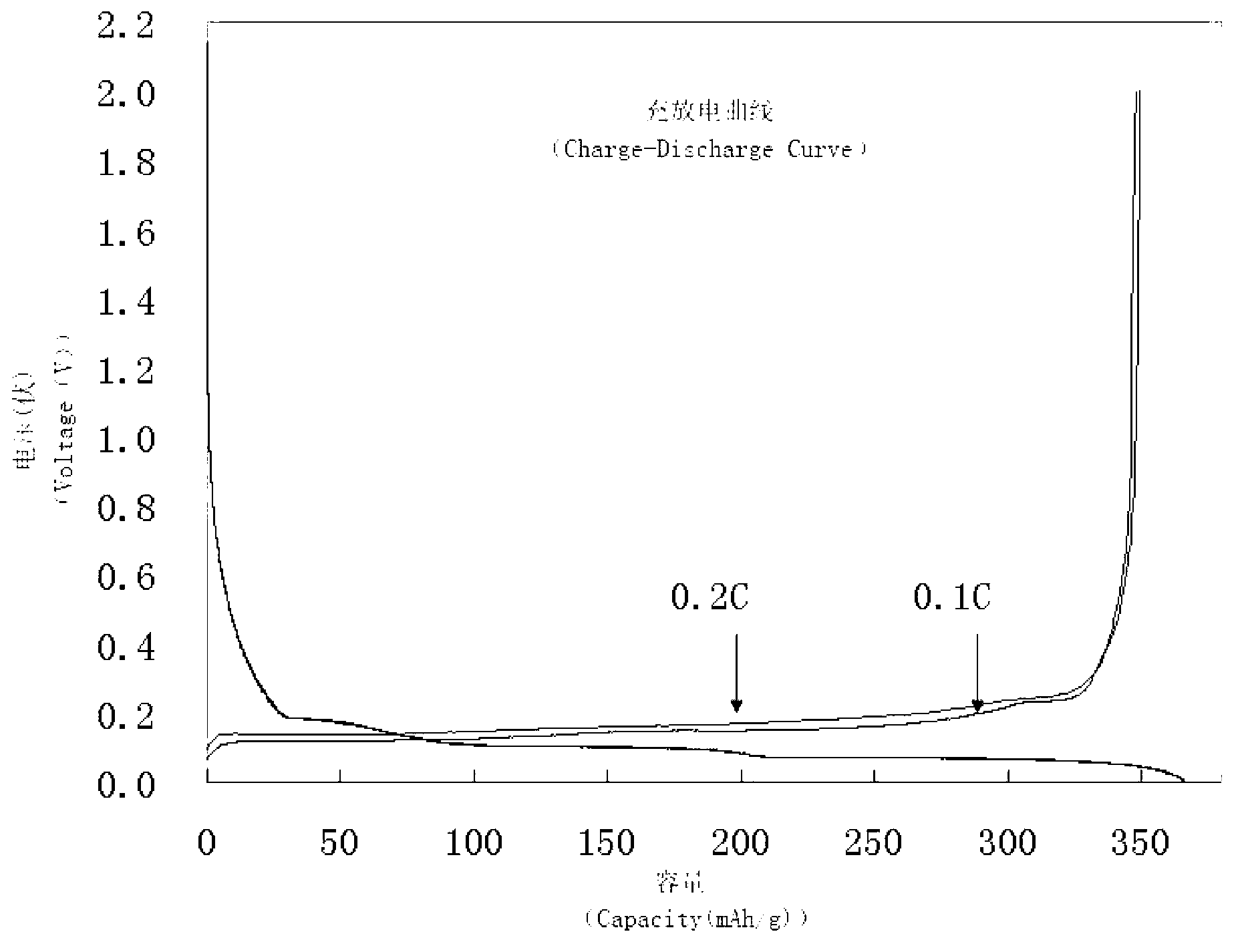

Quick test technique for electrochemical performances of carbon anode materials

ActiveCN103018301AEffective contactElectrochemical performance testing process is simpleMaterial electrochemical variablesElectrical batteryCopper foil

A quick test technique for electrochemical performances of carbon anode materials comprises the following steps: a, the carbon anode materials to be tested and electrode plate dressing are evenly coated on copper foils by the areal density of 0.6-1.0 g / dm<2>, and are dried to form electrode plates, wherein the electrode plate dressing is prepared by conductive agent, binding agent and thickening agent; b, the electrode plates are rolled by the compacting density of 1.1-1.5 g / cm<3> and are cut to electrode plates which are needed by half cells; c, half cell modules are assembled by the sequence of anode casings, electrode plates, diaphragms, lithium plates, washers and cathode covers, and are sealed under the pressure of 70-85 MPa to form the half cells; and d, the half cells are divided into a normal group and an experimental group for testing through a test cabinet, the test is implemented for one time or is circulated for a plurality of times, and judging whether the first charge-discharge gram specific capacity and the first charge-discharge efficiency of the carbon anode materials meet the requirements or not according to test results is carried out. The technique can easily, quickly and accurately test the electrochemical performances of the carbon anode materials, and can effectively reduce the test cost of the electrochemical performances of the carbon anode materials.

Owner:四川金汇能新材料股份有限公司 +2

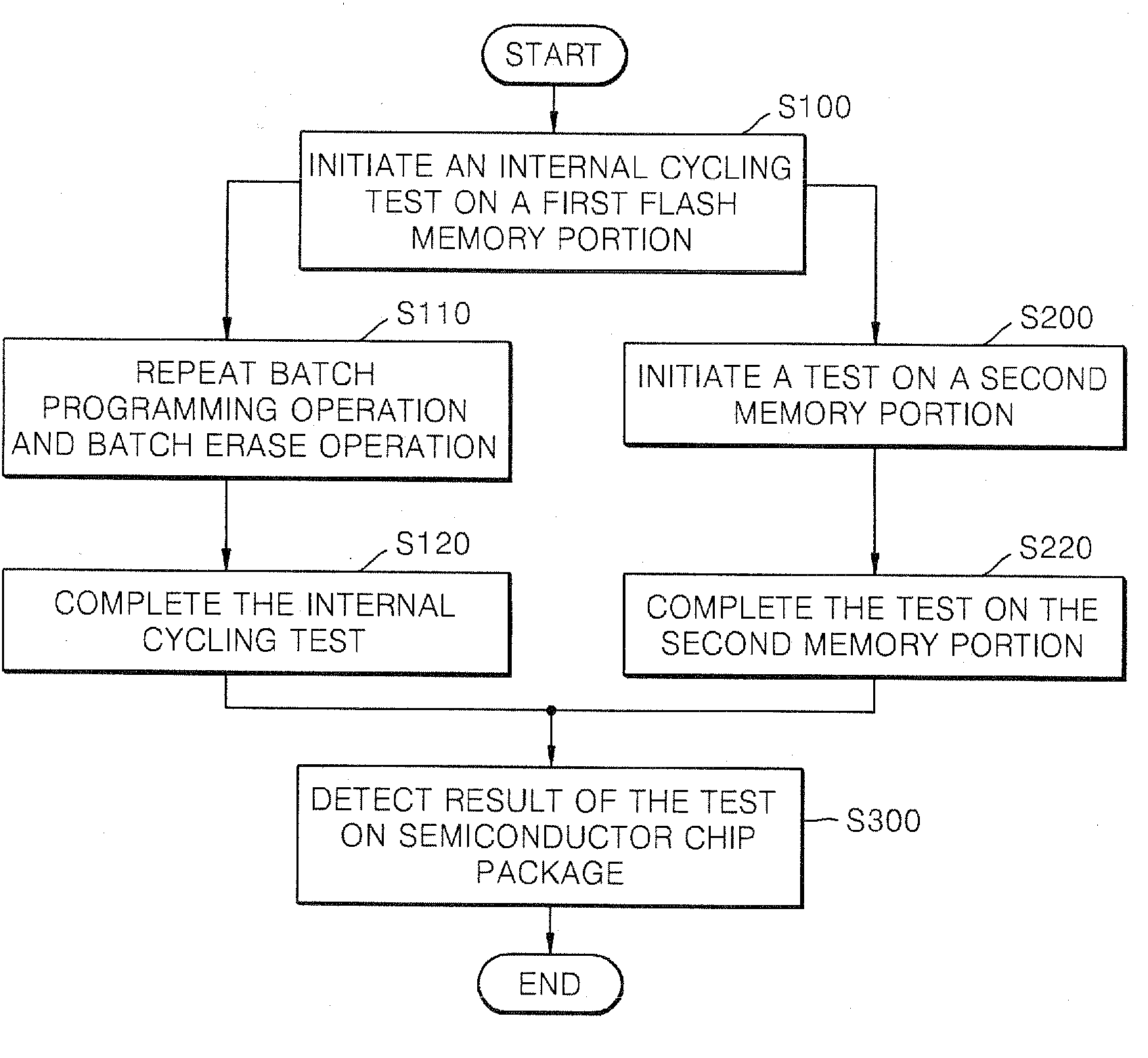

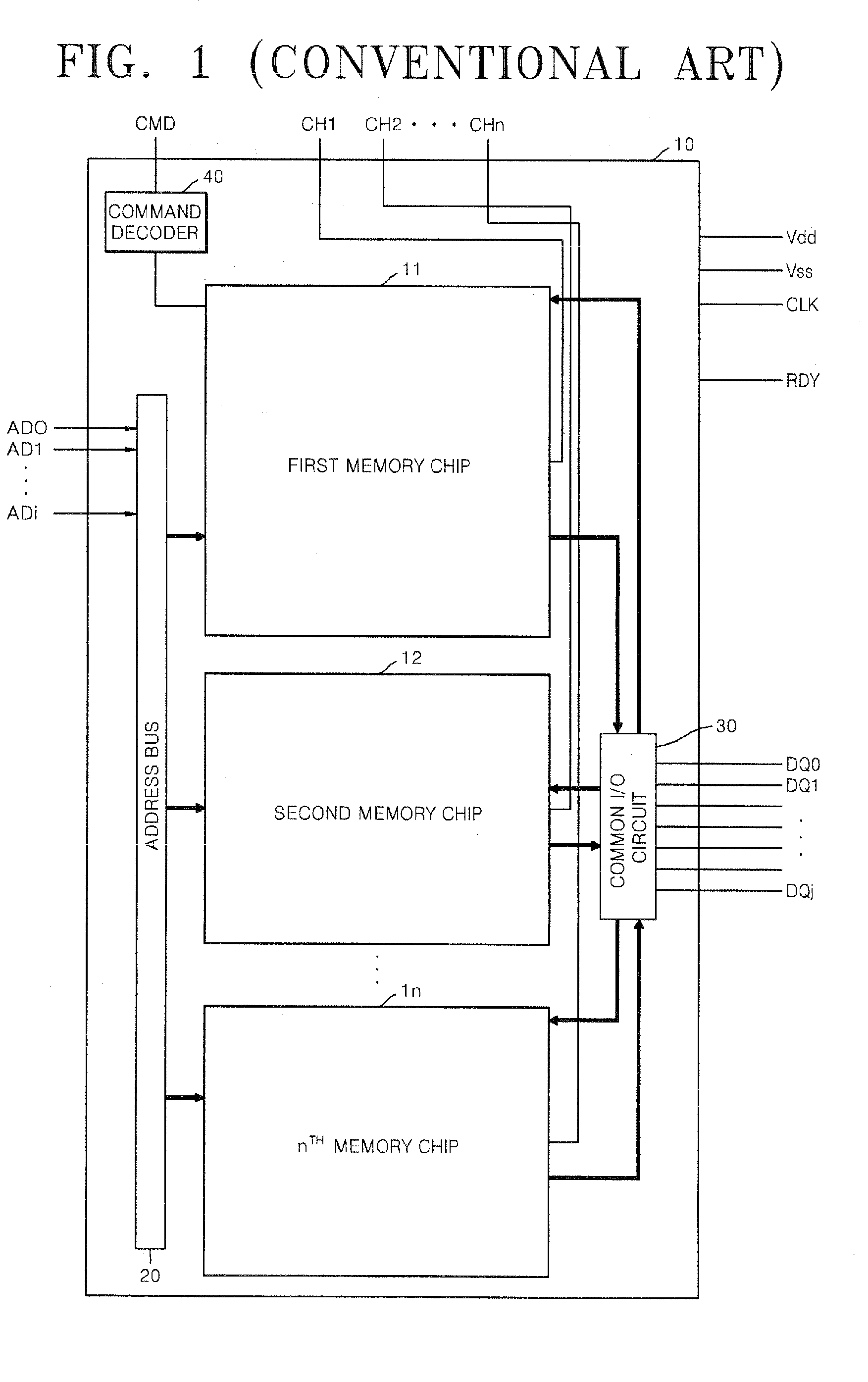

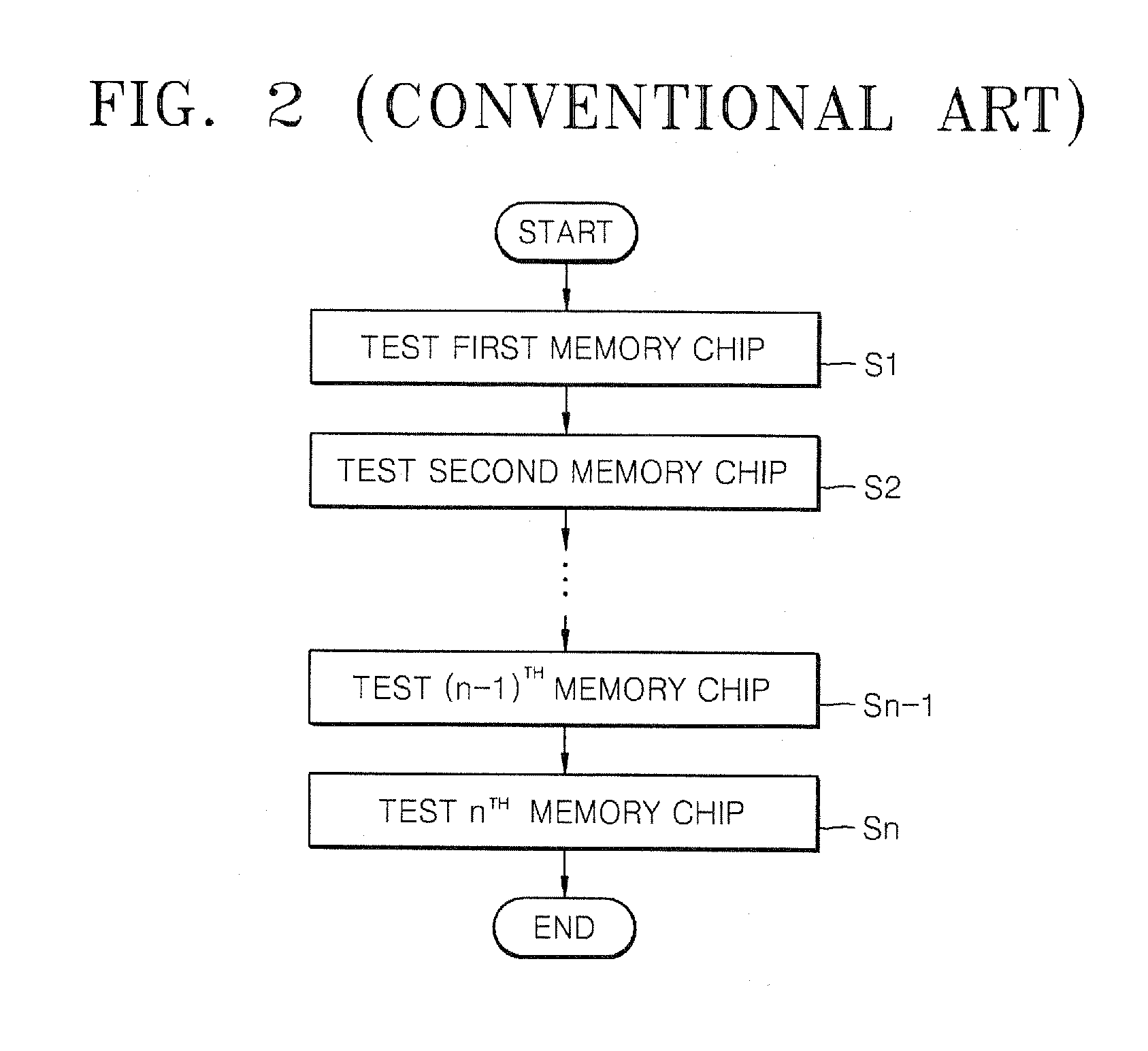

Semiconductor chip package and method and system for testing the same

InactiveUS20080106958A1Low costShort timeElectronic circuit testingDigital storageCyclic testInner loop

A semiconductor chip package with a flash memory portion and a method and system for testing the same are provided. After an internal cycling test is automatically and independently initiated on the flash memory chip, a test on other memory portions in the semiconductor chip package is performed. The semiconductor chip package includes a first flash memory portion, at least one second memory portions, and an internal cycling tester repetitively performing a batch programming operation and a batch erase operation on the first flash memory portion.

Owner:SAMSUNG ELECTRONICS CO LTD

Micro-tensile testing system

InactiveUS6983658B2Advantageously minimizing deflectionAdvantageously minimizing bendingForce measurement by measuring optical property variationStrength propertiesObservational errorCyclic test

Owner:HONEYWELL FED MFG & TECHNOLOGI

High temperature and high pressure gas, liquid and solid phase erosion corrosion test device and method

InactiveCN109856036ANo erosionFree combinationWeather/light/corrosion resistanceCirculator pumpMetallic materials

Owner:CHINA PETROLEUM ENG & CONSTR

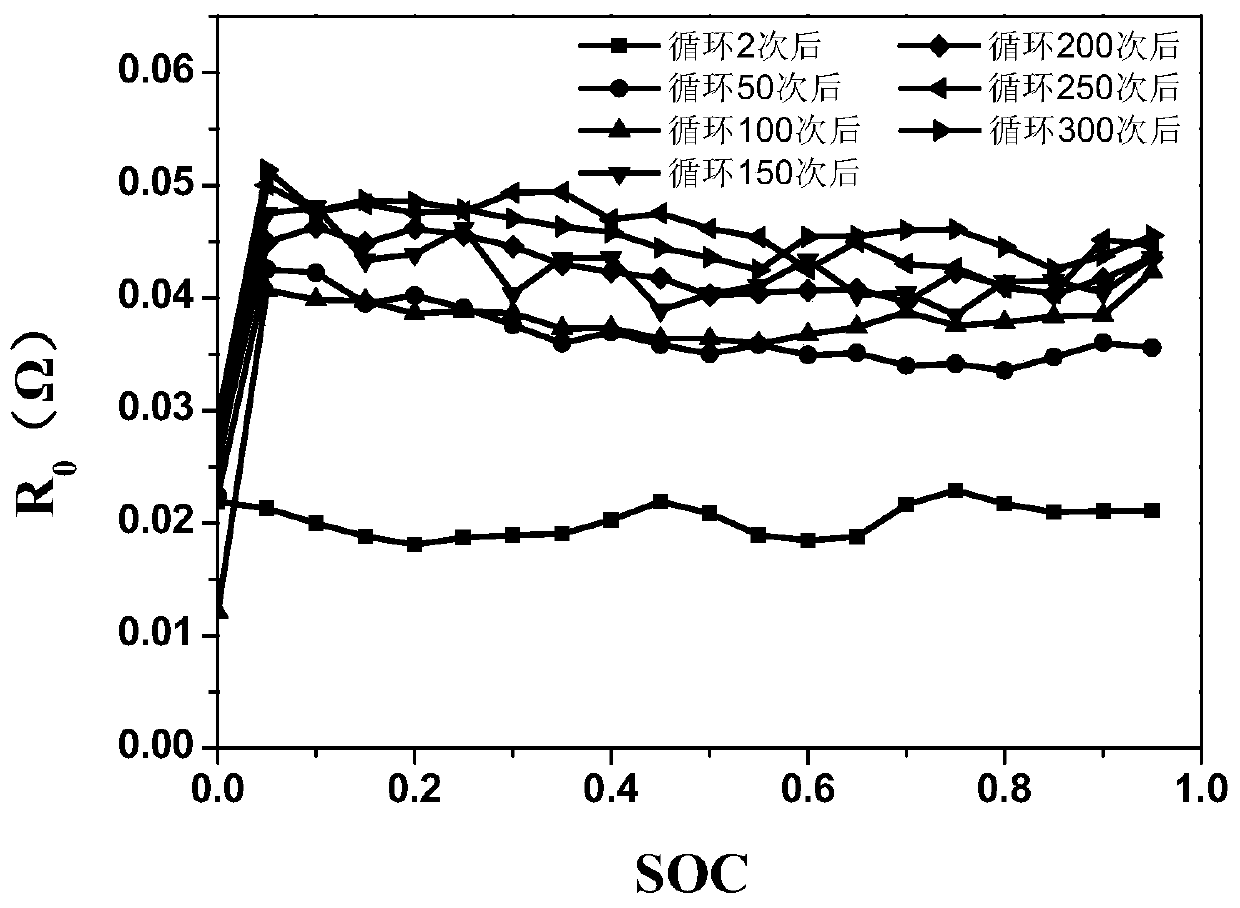

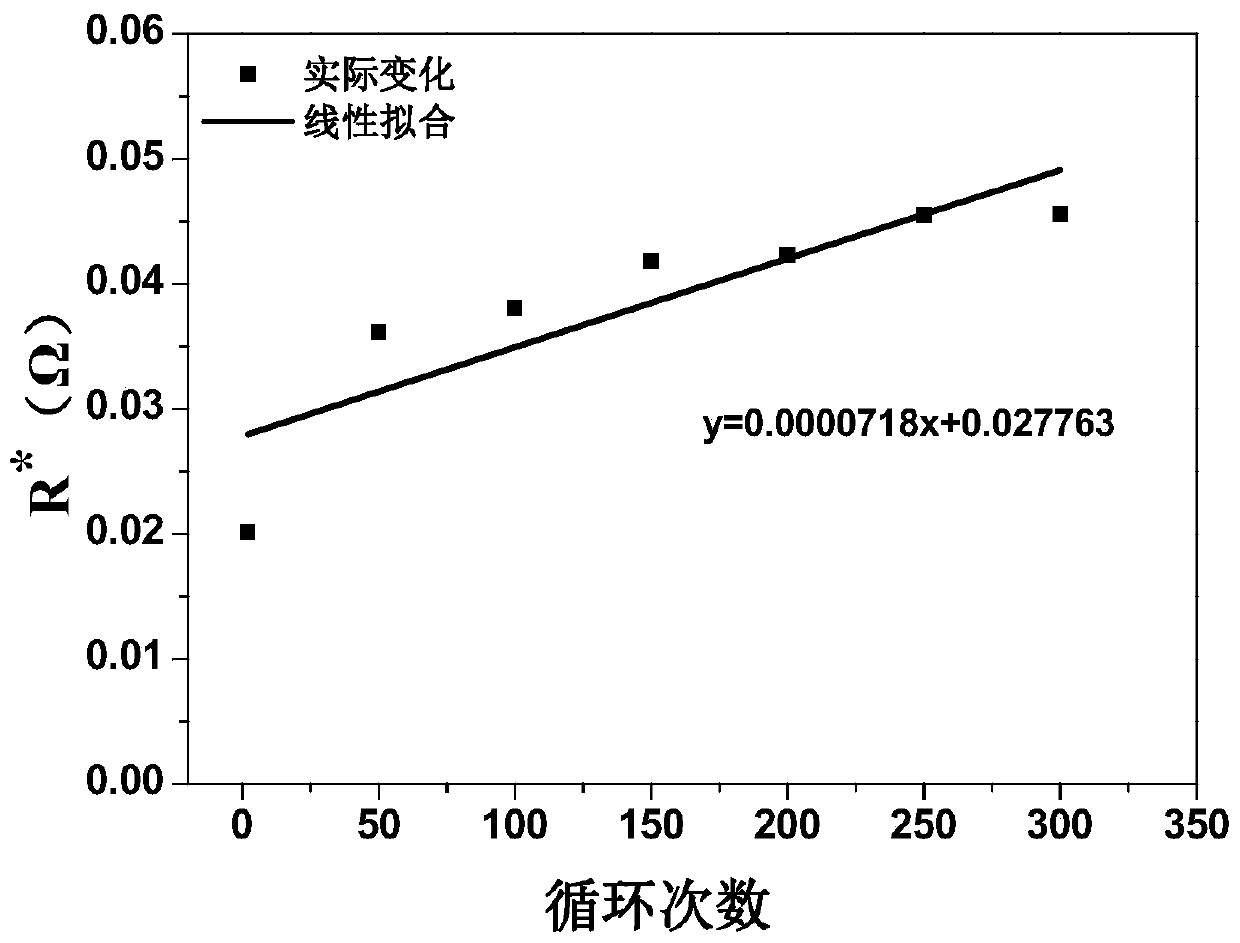

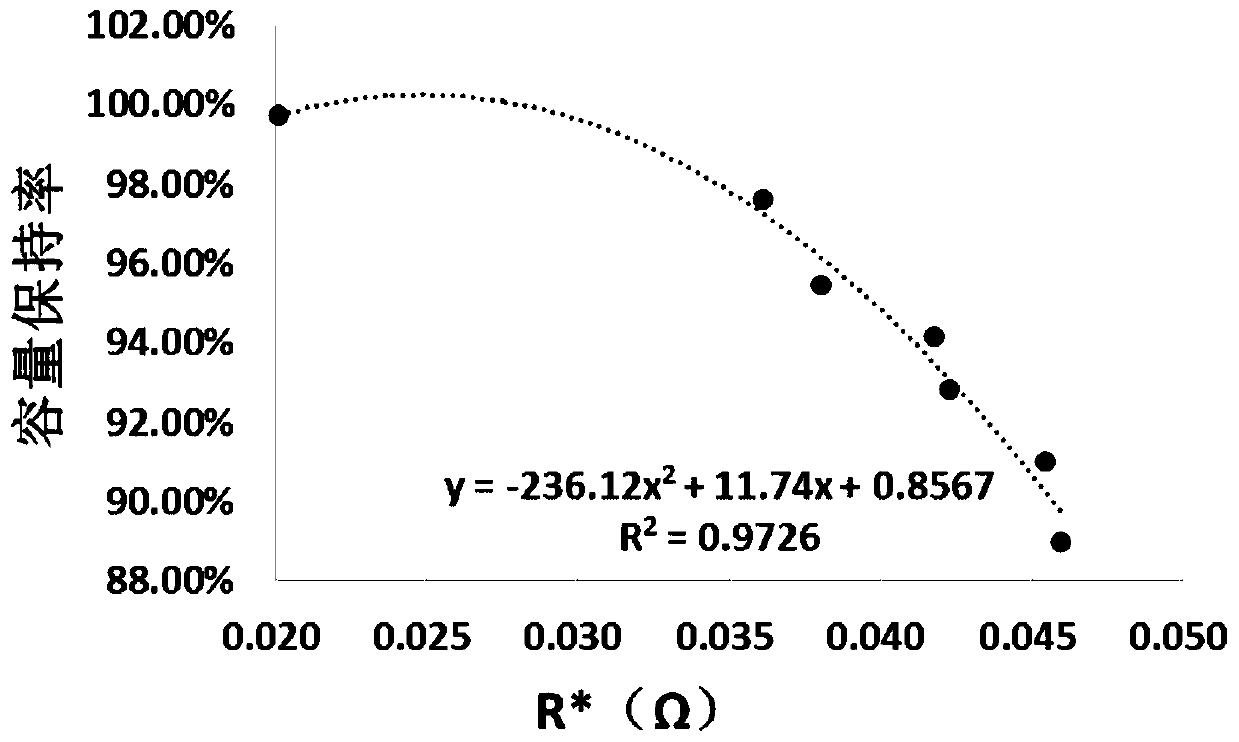

Method for predicting cycle life of lithium battery

ActiveCN109856559AShorten the timeReduce resource requirementsElectrical testingCyclic testInternal resistance

The invention provides a method for predicting the cycle life of a lithium battery. The lithium battery is subjected to different cycle numbers of charge and discharge performance tests and HPPC performance tests, and the voltage and capacity in the different cycle numbers of charge and discharge processes are recorded; according to change of the voltage of the lithium battery in HPPC test data, internal resistance in the charge and discharge directions under different SOC is calculated, and the average value, namely mean value internal resistance, fit under the different SOC and each cycle number is calculated; under the different cycle numbers, the mean value internal resistance is fitted with the SOC, and the corresponding law is found to obtain mean value internal resistance under thedifferent cycle numbers; and fit calculation is conducted according to test data of the mean value internal resistance and the cycle numbers, and the cycle life of the battery is predicted. The cyclelife of the battery can be quickly predicted through short-term cycle tests, and the time and resource waste generated by conventional tests are greatly lowered.

Owner:WUHAN UNIV OF TECH

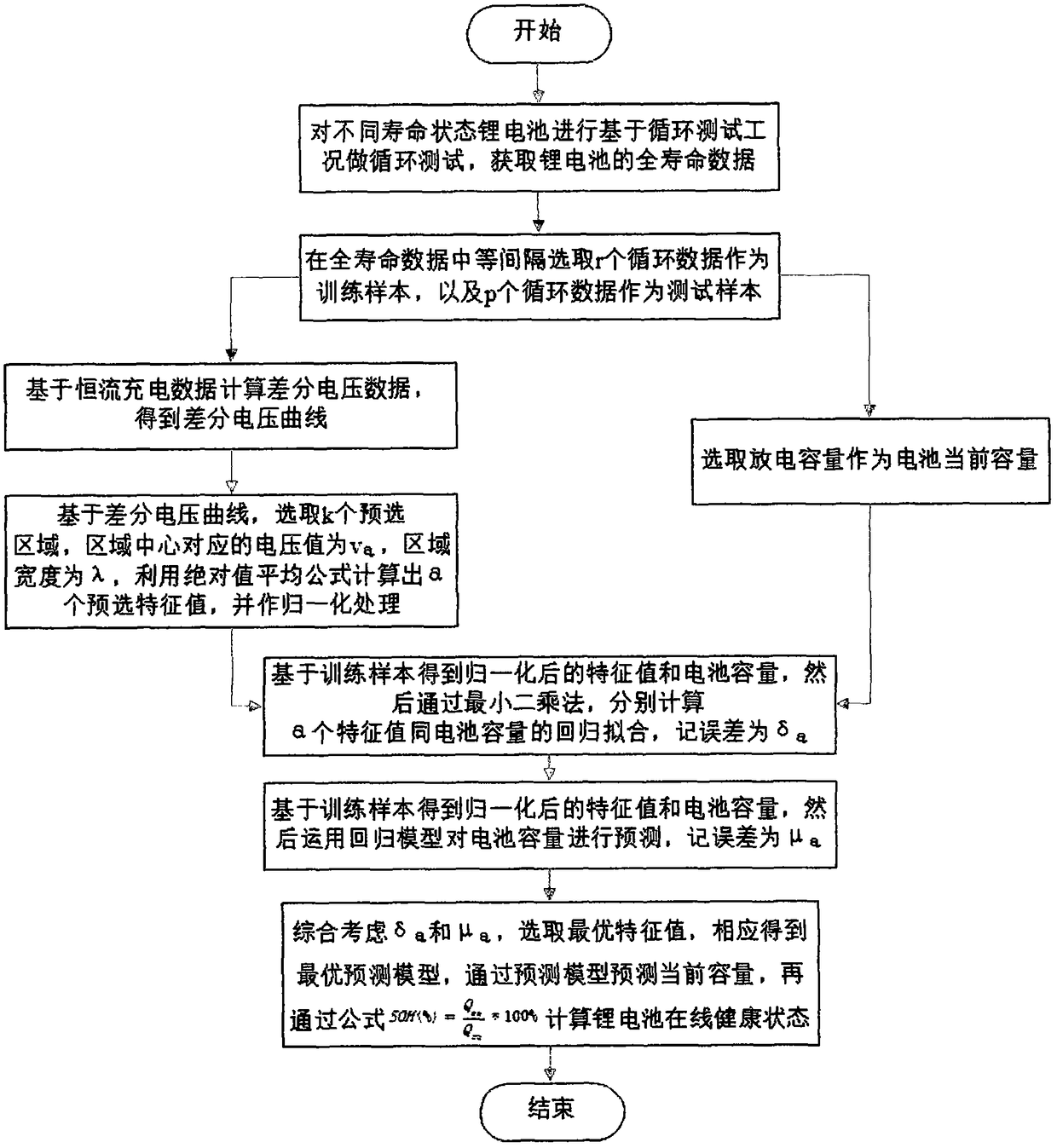

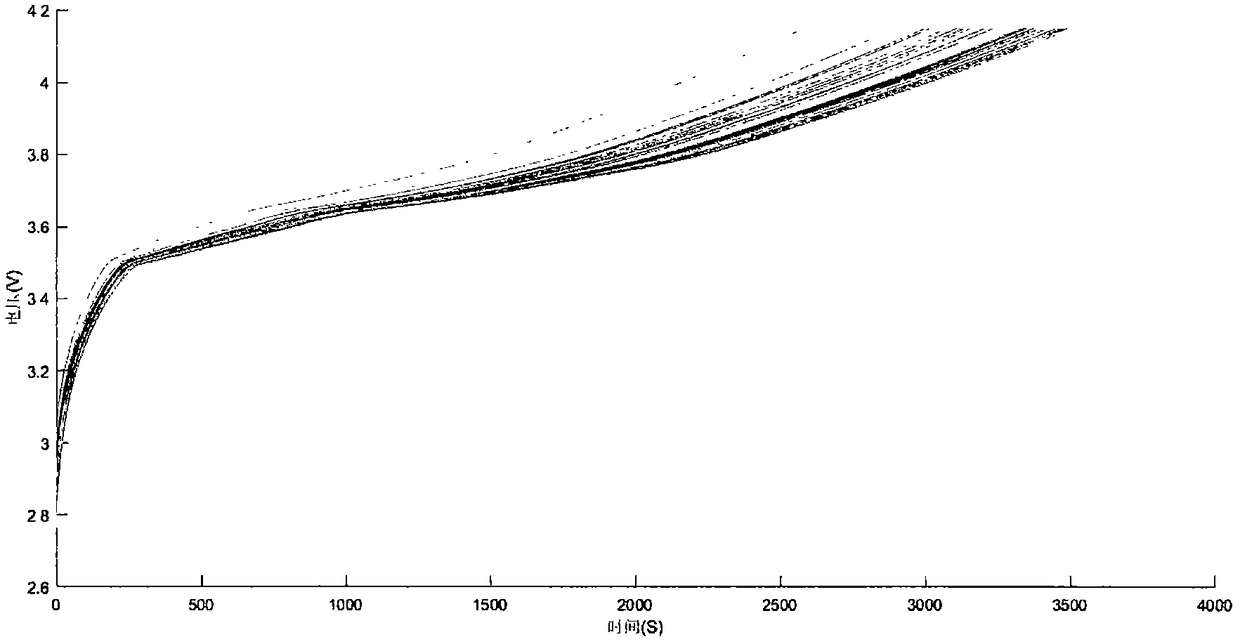

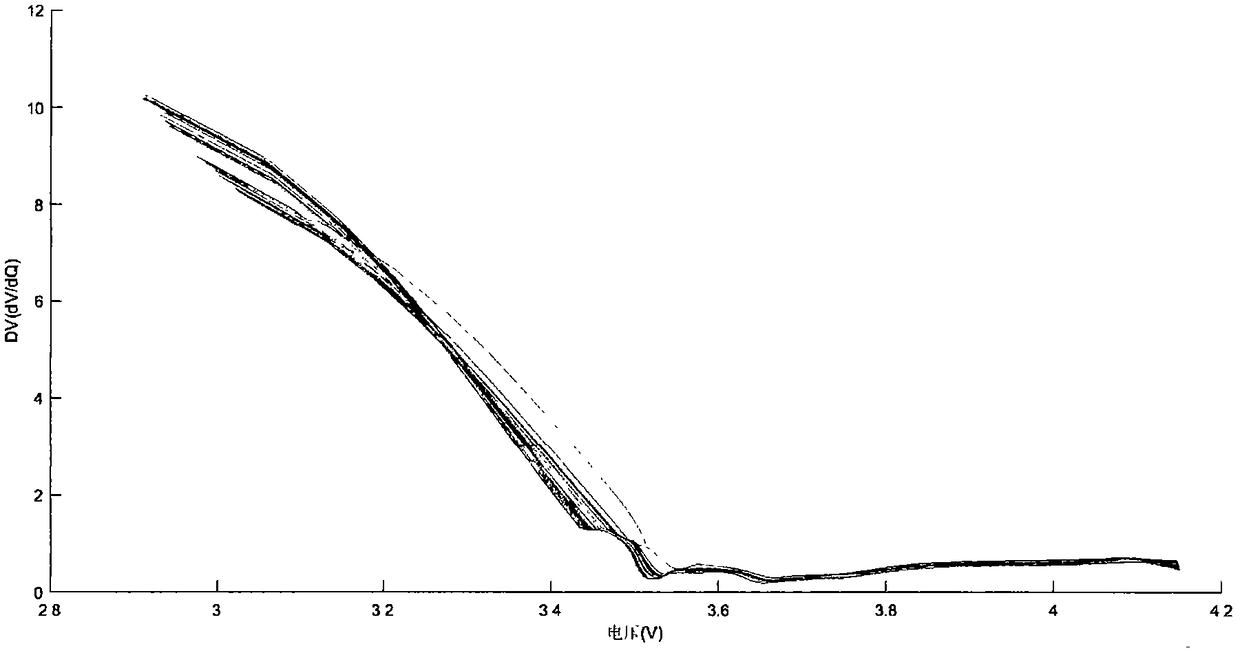

Lithium battery online health state fast prediction method based on voltage key characteristics

ActiveCN108549030AEasy to calculateImprove forecast accuracyElectrical testingCyclic testState prediction

In order to design a battery online health state prediction model, quickly calculate a health state of a battery at any life stage based on partial battery charging data and realize accurate functionjudgment on the battery, the invention provides a lithium battery online health state fast prediction method based on voltage key characteristics. The lithium battery online health state fast prediction method comprises the steps of: step (1), conducting cyclic tests on lithium batteries in different life state based on cyclic test working conditions, so as to obtain full-life data of the lithiumbatteries; step (2), acquiring battery capacities and calculating a differential voltage, and further pre-selecting key eigenvalues; step (3), and training and testing a prediction model based on thepre-selected eigenvalues, and finally selecting an optimal model to perform lithium battery online health state prediction. The lithium battery online health state fast prediction method realizes theeffect of calculating the battery health states online based on few data, judges the battery performance accurately, and improves the working efficiency.

Owner:罗斯德尔智能汽车(重庆)有限公司

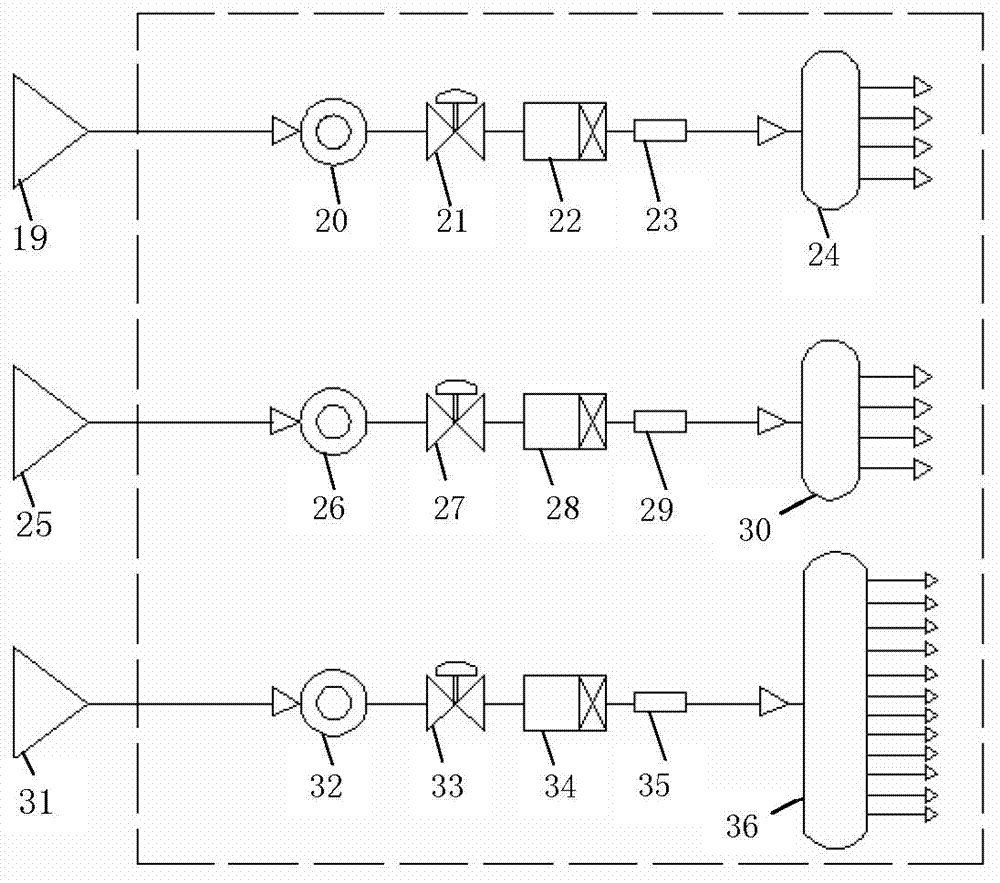

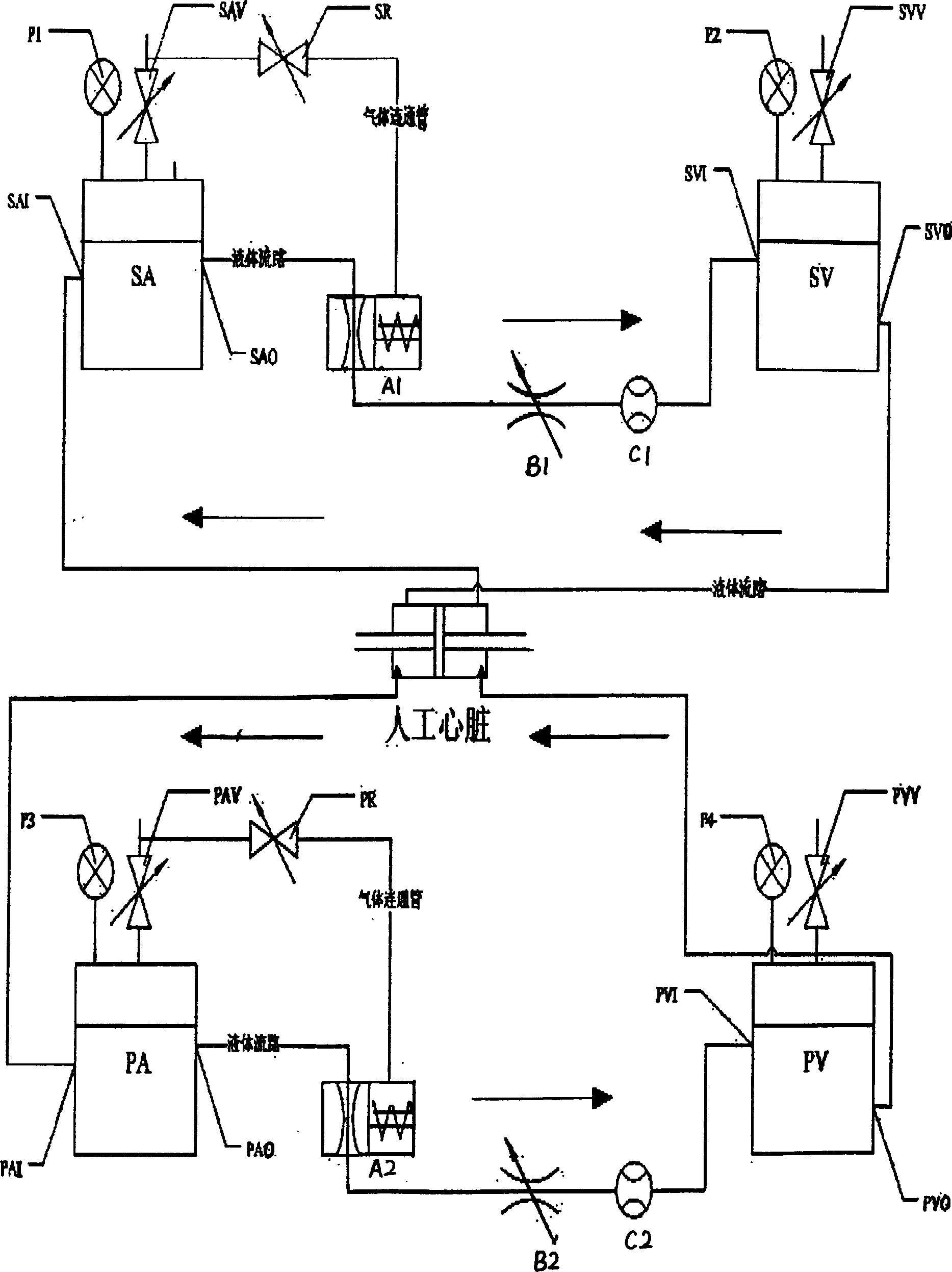

Simulated circulation test system for artificial heart

The present invention provides one kind of extracorporeal simulated circulation test system for artificial heart. The system consists of four test cavities and related connecting flow path, test equipment and flow path devices. By means of its adaptive damping valve and corresponding communication structure combined with cavity compliance and manual damping valve structure, the system characterizes the dynamic response characteristic of human body artery vessels for regulation based on initially selected physiological parameters to adapt the tested physiological environment. The system has manufacture uniformity, small integral size and variable damping, and is used for testing the power system of artificial heart.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com