Prediction method for life cycle of battery

A battery life and prediction method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of life prediction complexity, affecting battery life, etc., and achieve the effect of saving test time and cost and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

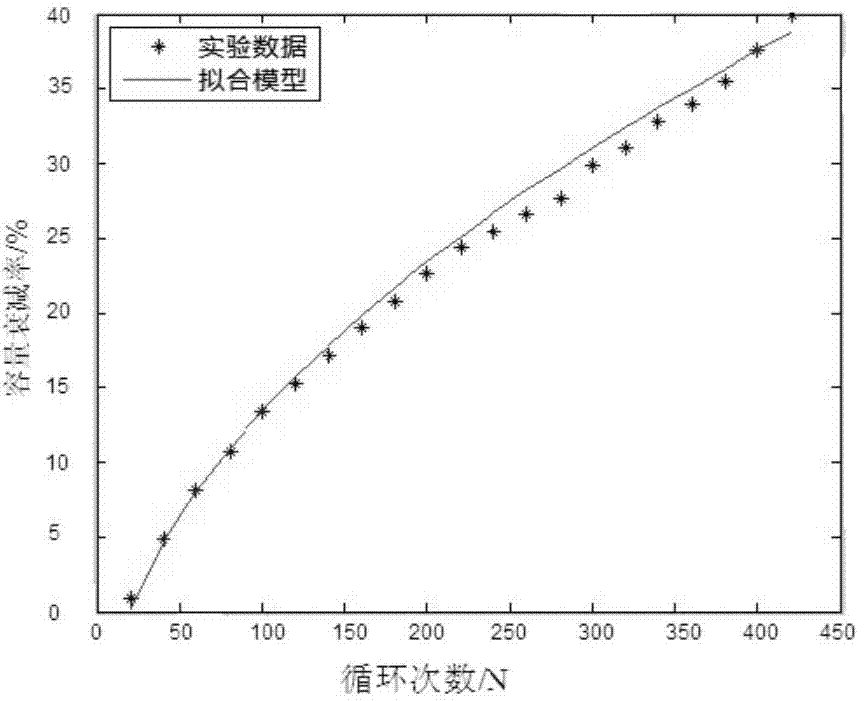

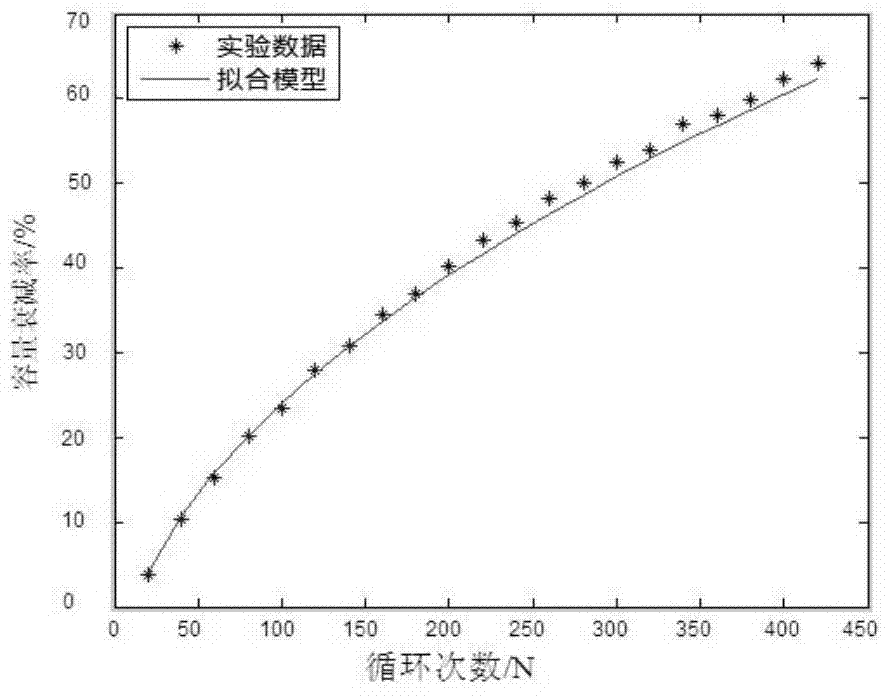

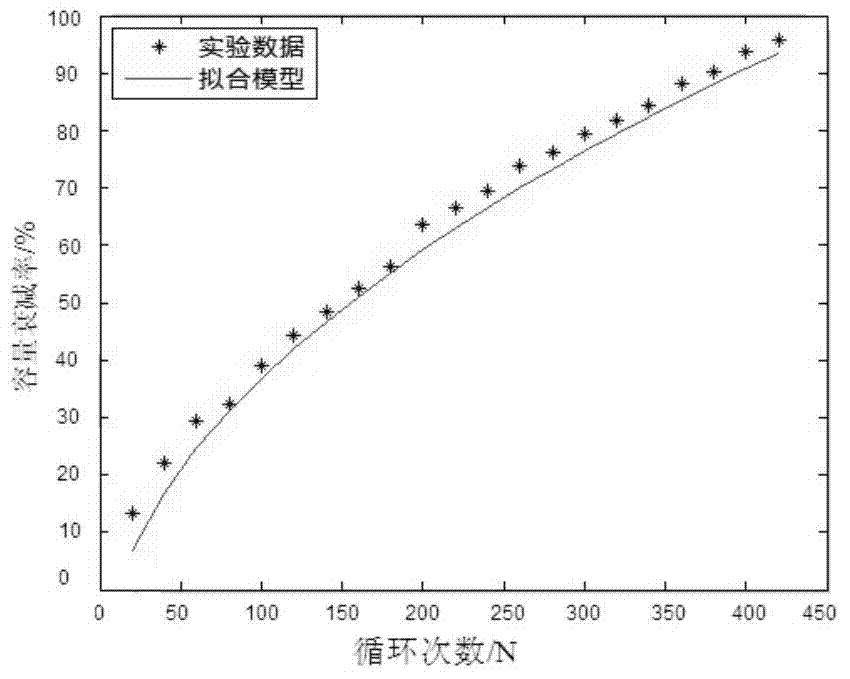

[0026] For 20Ah soft pack lithium power battery, at 25°C, use 0.25C constant current charge to 3.65V, then constant voltage 3.65V charge until the current is 0.05C cut-off (full charge), set aside for 30min. Then discharge the battery. Factors affecting battery life select temperature (T), discharge rate (C 放 ) and depth of discharge (D 放 ) and the number of discharge cycles (N). According to the battery discharge curve, the functional relationship between the battery capacity loss rate and each influencing factor is established Q loss = A N + B

[0027] The set discharge influence factors and levels are as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com