Patents

Literature

602 results about "Residual service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Life” has been defined as “service life remaining at certain period of consideration”. Residual service life prediction of building is an estimation of the remaining period of time during which a. building or its parts meet or exceed the performance requirements at any given time.

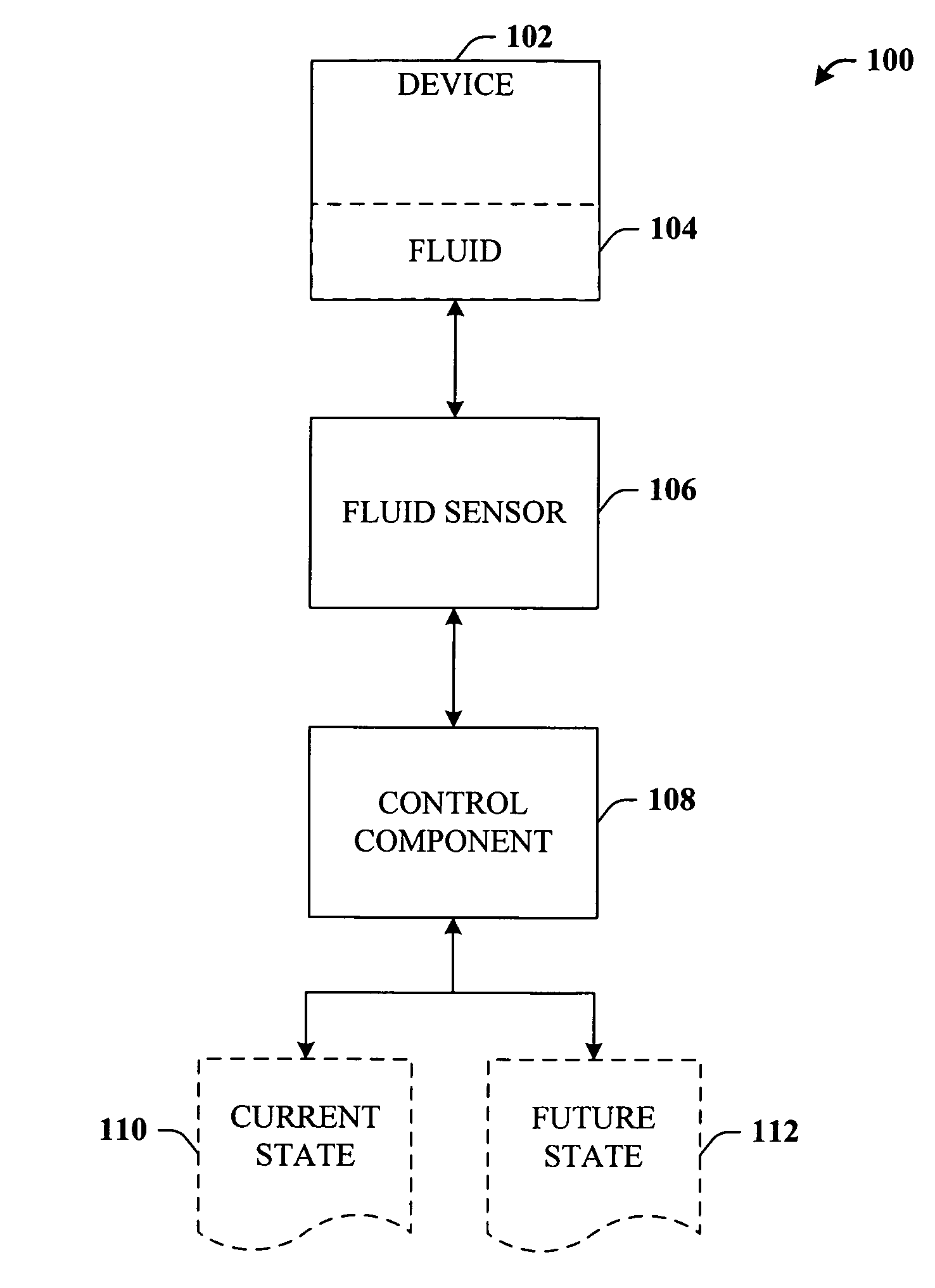

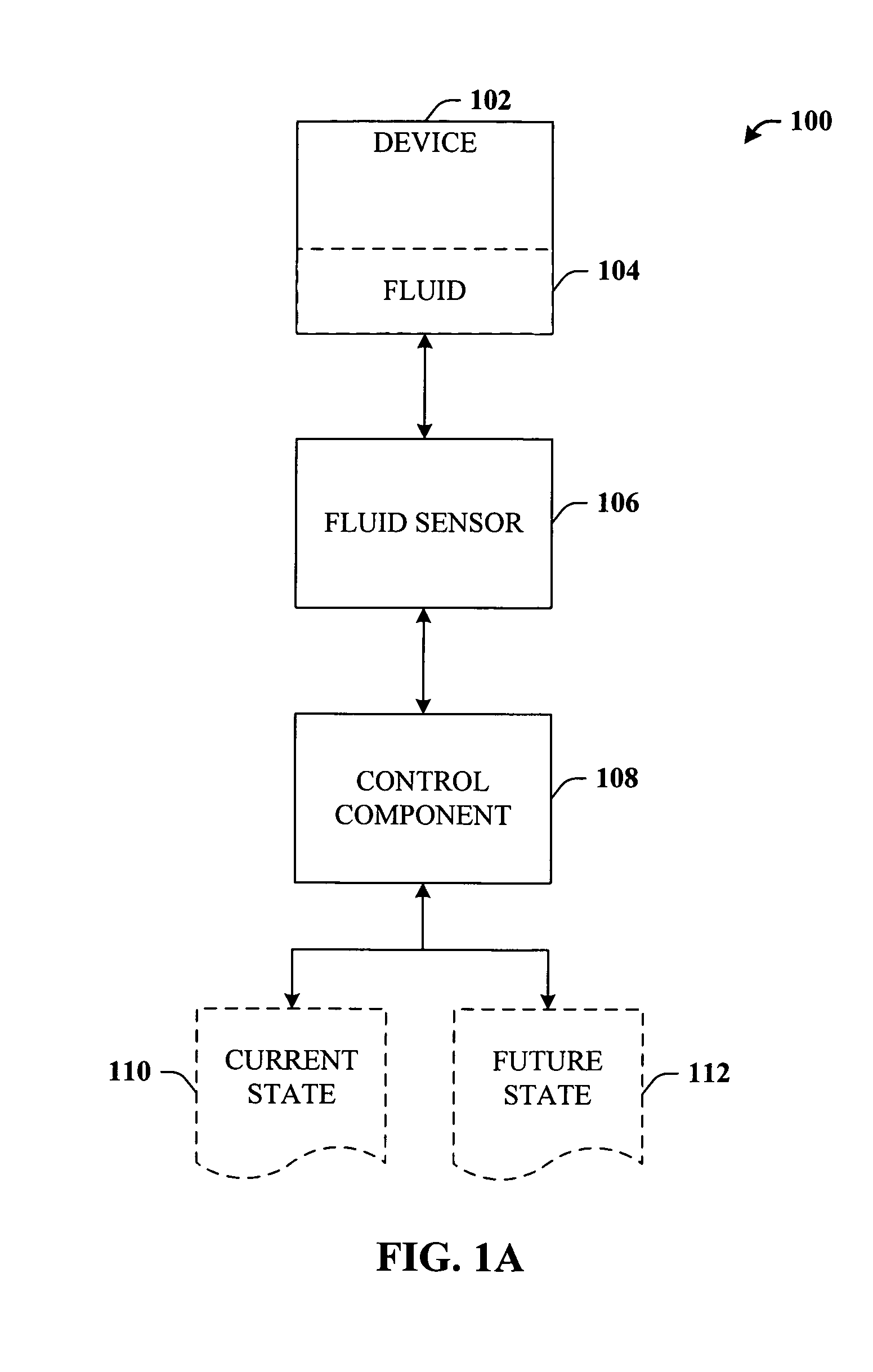

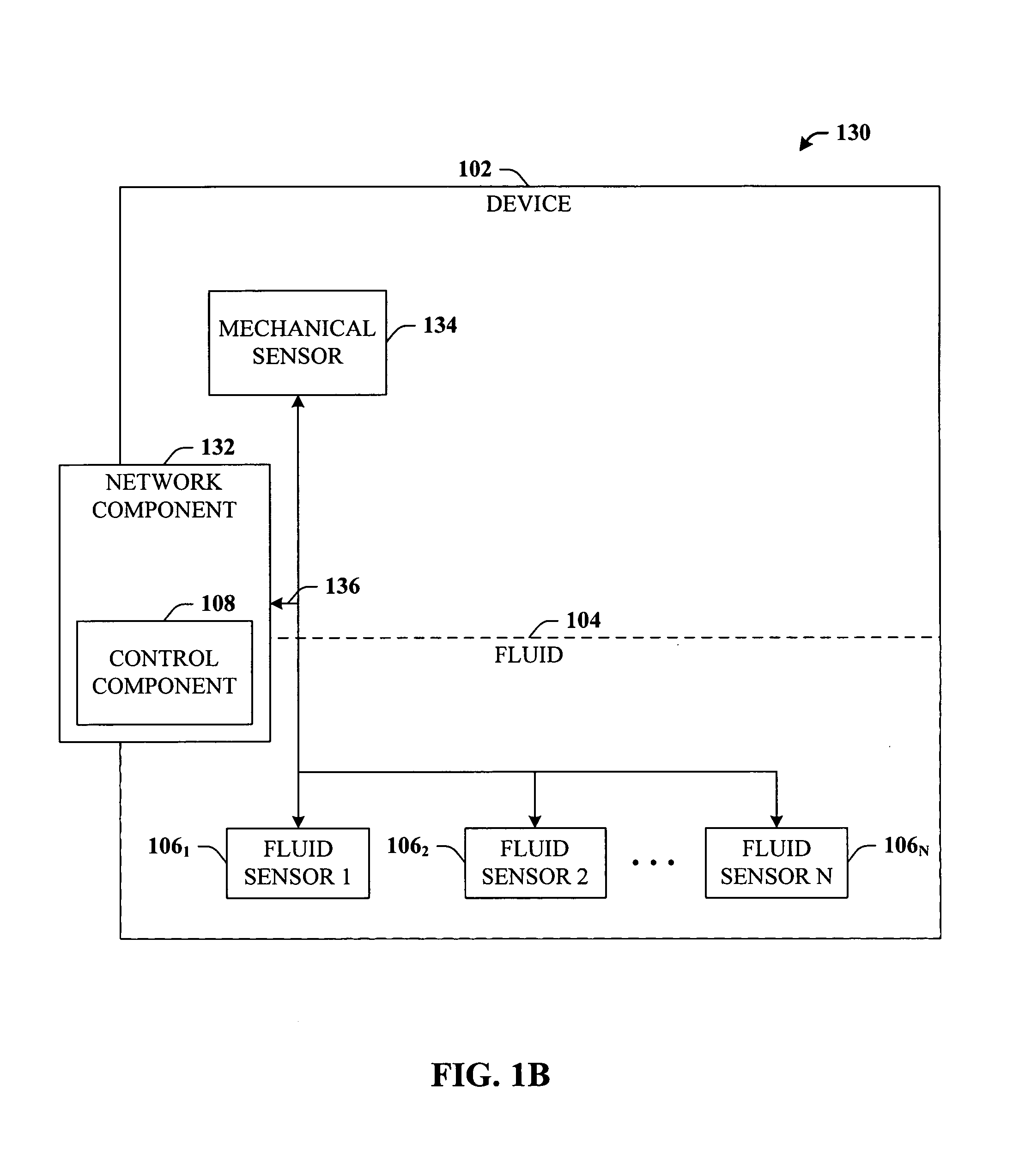

Intelligent fluid sensor for machinery diagnostics, prognostics, and control

ActiveUS7581434B1Minimizes bandwidth requirementImprove performanceFlow propertiesLubrication indication devicesControl systemEngineering

A system that facilitates device and / or machinery diagnostics, prognostics and control by way of condition sensing, such as sensing the condition of the device and / or a fluid of the device (e.g., fluid health indicators). The system can employ a plurality of sensors to determine a current state and estimate a future state of the fluid and / or device, as well as providing control of the device, e.g., in order to increase the remaining useful life of the fluid and / or operation of the device. The sensors can communicate wirelessly with each other, with the device, and / or with a central control system that provides, e.g., sensor fusion, prognostics and control integration. In addition, the sensors can be powered locally based upon the physical or chemical properties of the environment.

Owner:REXNORD IND LLC

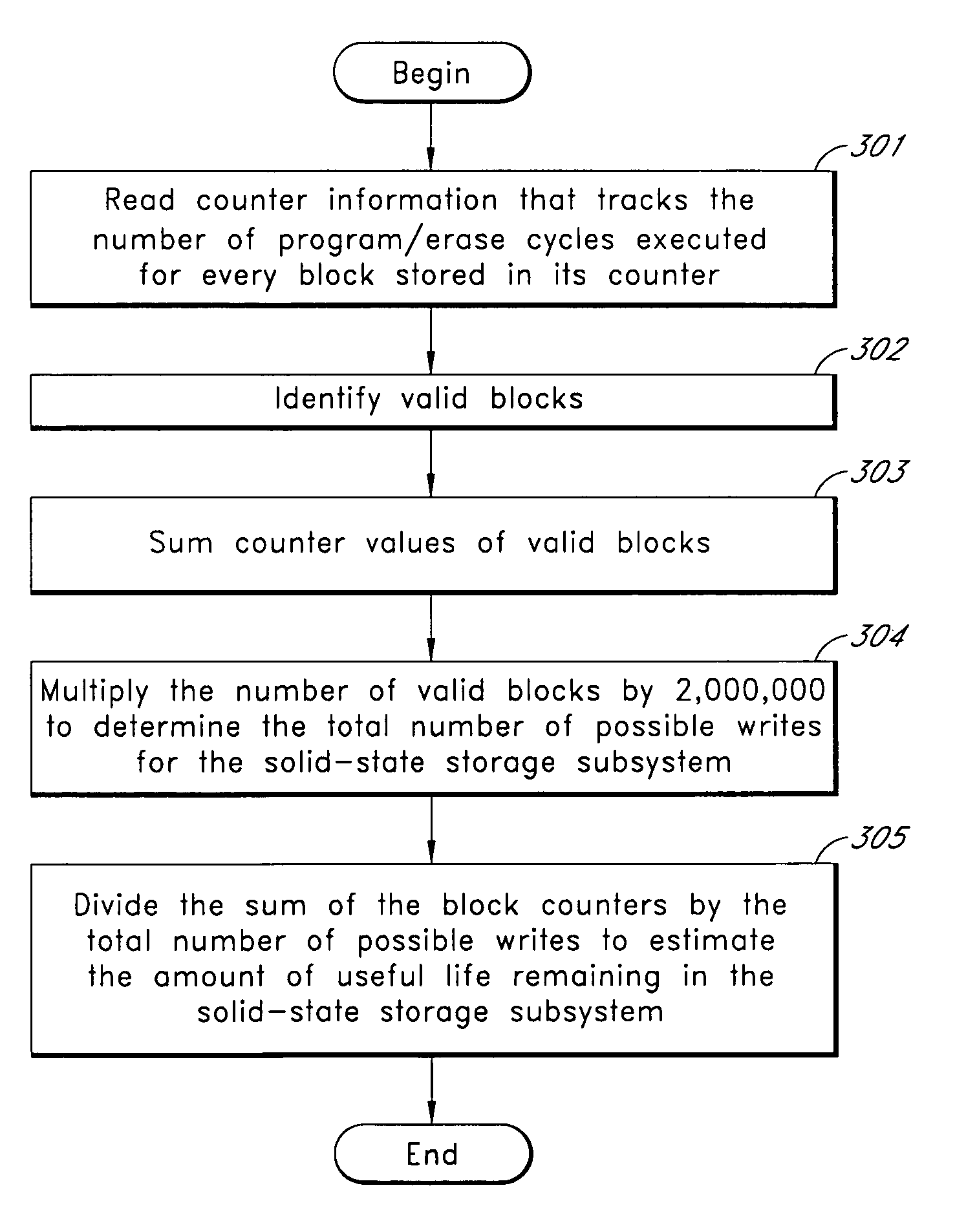

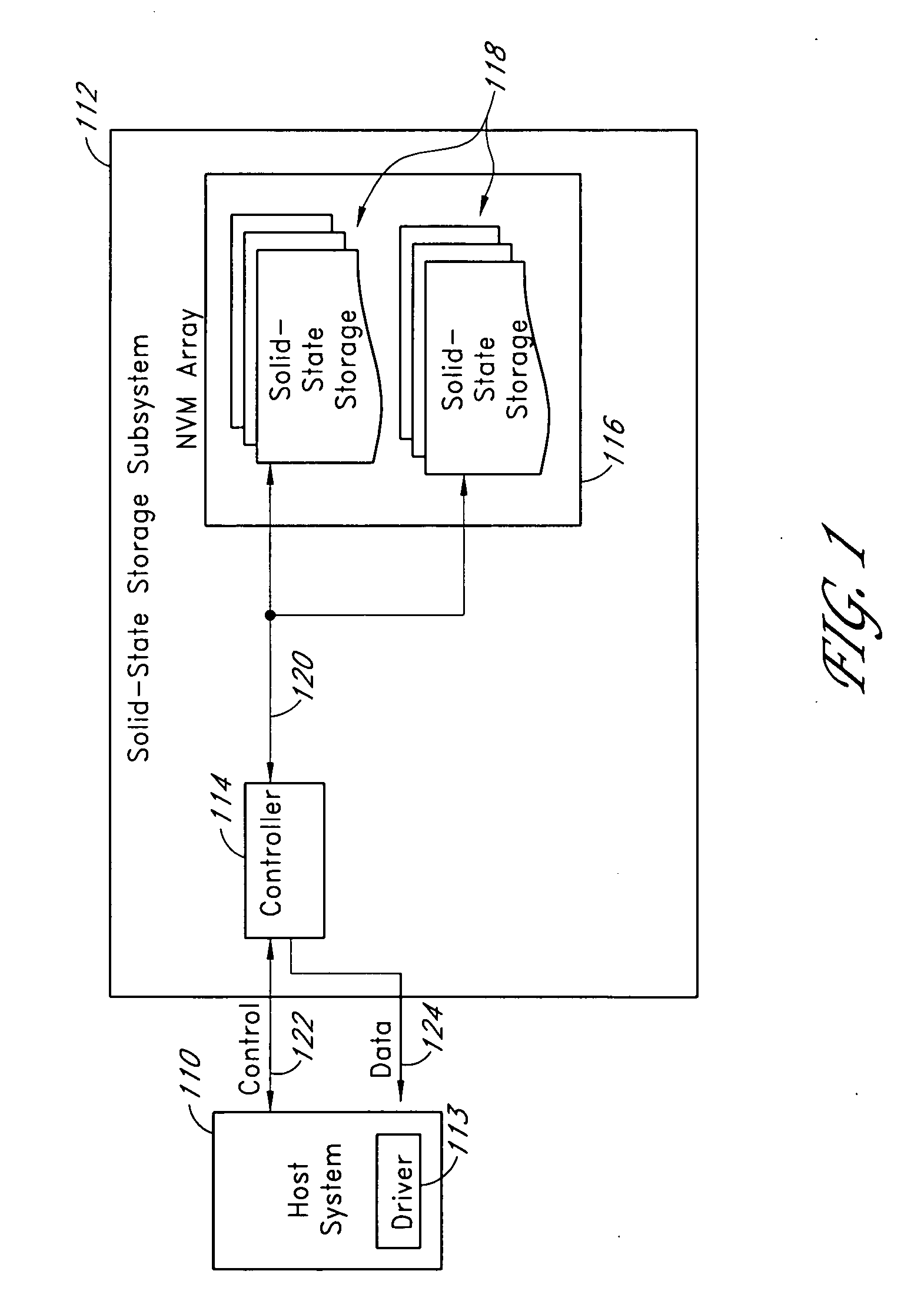

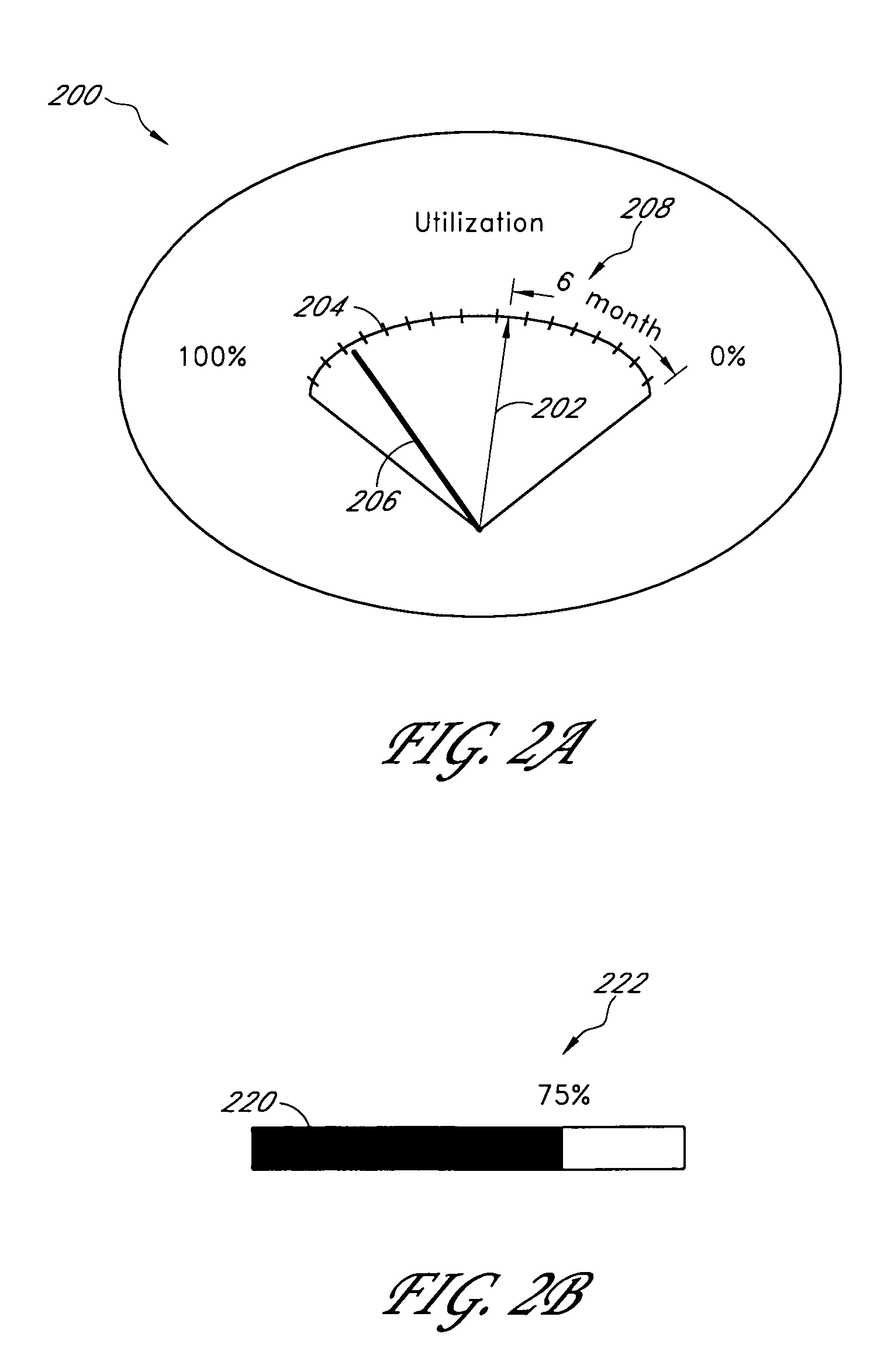

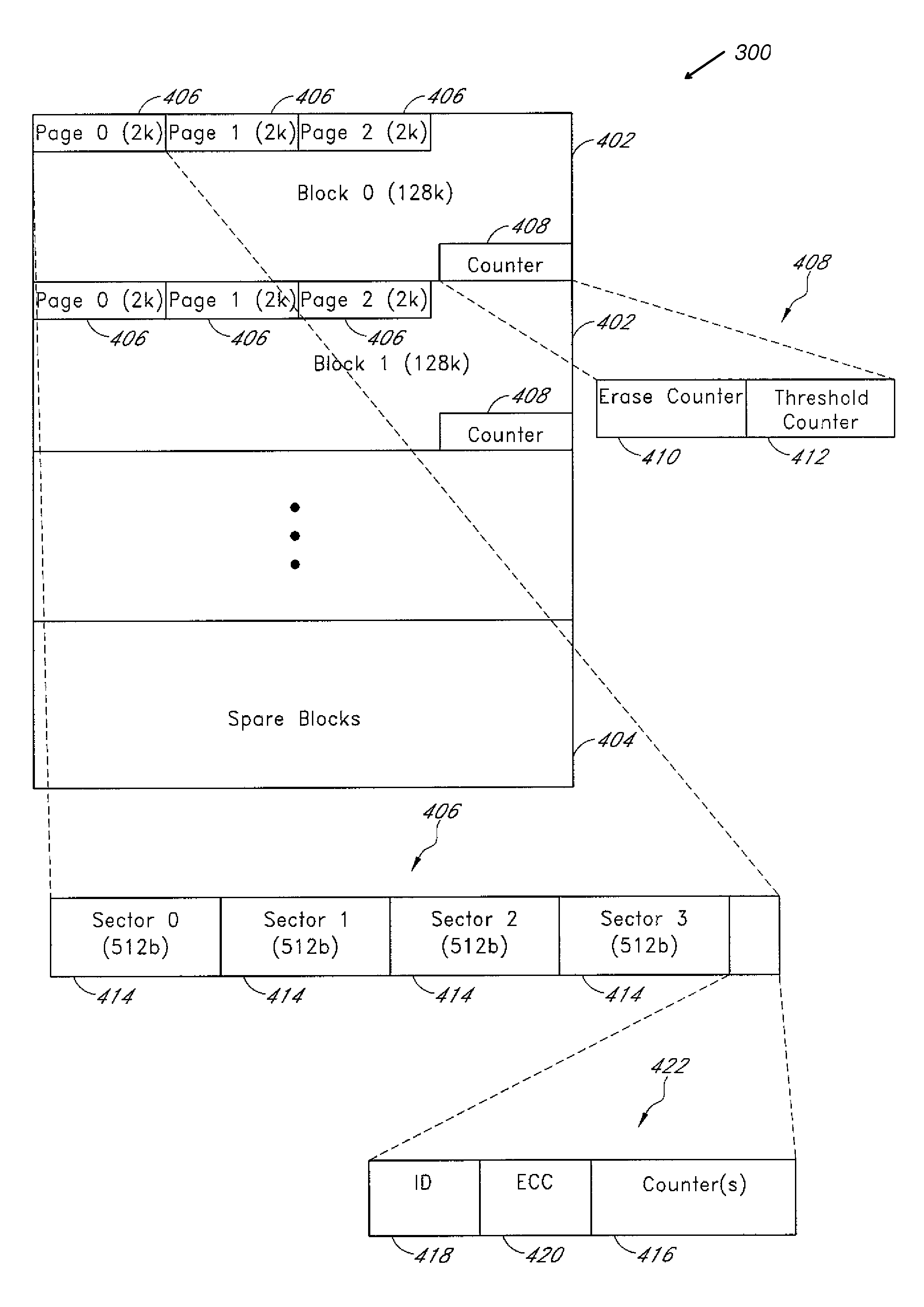

Systems and methods for measuring the useful life of solid-state storage devices

ActiveUS20070260811A1Memory architecture accessing/allocationRead-only memoriesSolid-state storageSystem maintenance

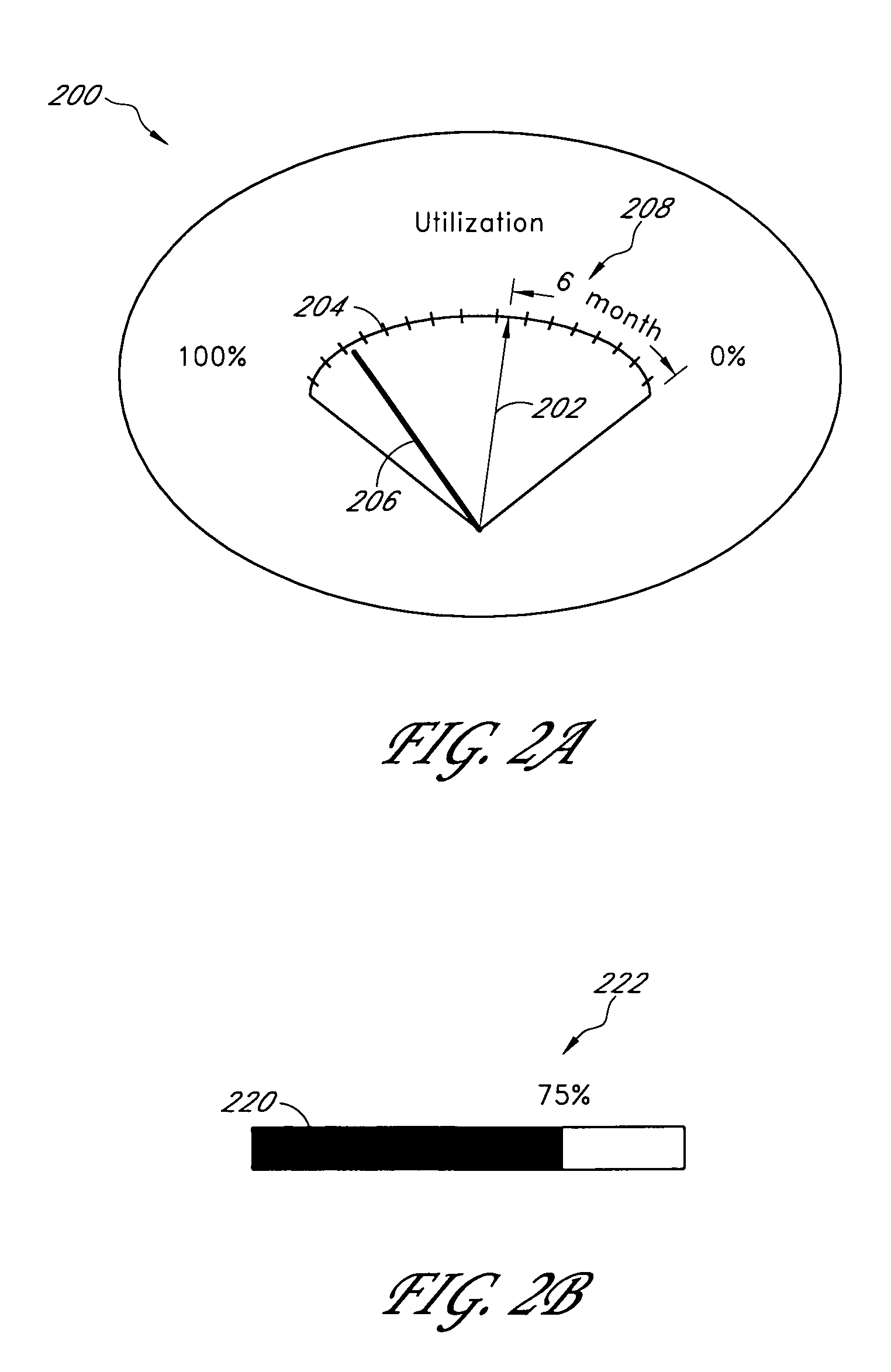

A non-volatile solid-state storage subsystem, such as a non-volatile memory device, maintains usage statistics reflective of the wear state, and thus the remaining useful life, of the subsystem's memory array. A host system reads the usage statistics information, or data derived therefrom, from the subsystem to evaluate the subsystem's remaining life expectancy. The host system may use this information for various purposes, such as to (a) display or report information regarding the remaining life of the subsystem; (b) adjust the frequency with which data is written to the subsystem; and / or (c) select the type(s) of data written to the subsystem.

Owner:WESTERN DIGITAL TECH INC

Systems and methods for measuring the useful life of solid-state storage devices

ActiveUS7653778B2Memory architecture accessing/allocationRead-only memoriesSolid-state storageLife time

A non-volatile solid-state storage subsystem, such as a non-volatile memory device, maintains usage statistics reflective of the wear state, and thus the remaining useful life, of the subsystem's memory array. A host system reads the usage statistics information, or data derived therefrom, from the subsystem to evaluate the subsystem's remaining life expectancy. The host system may use this information for various purposes, such as to (a) display or report information regarding the remaining life of the subsystem; (b) adjust the frequency with which data is written to the subsystem; and / or (c) select the type(s) of data written to the subsystem.

Owner:WESTERN DIGITAL TECH INC

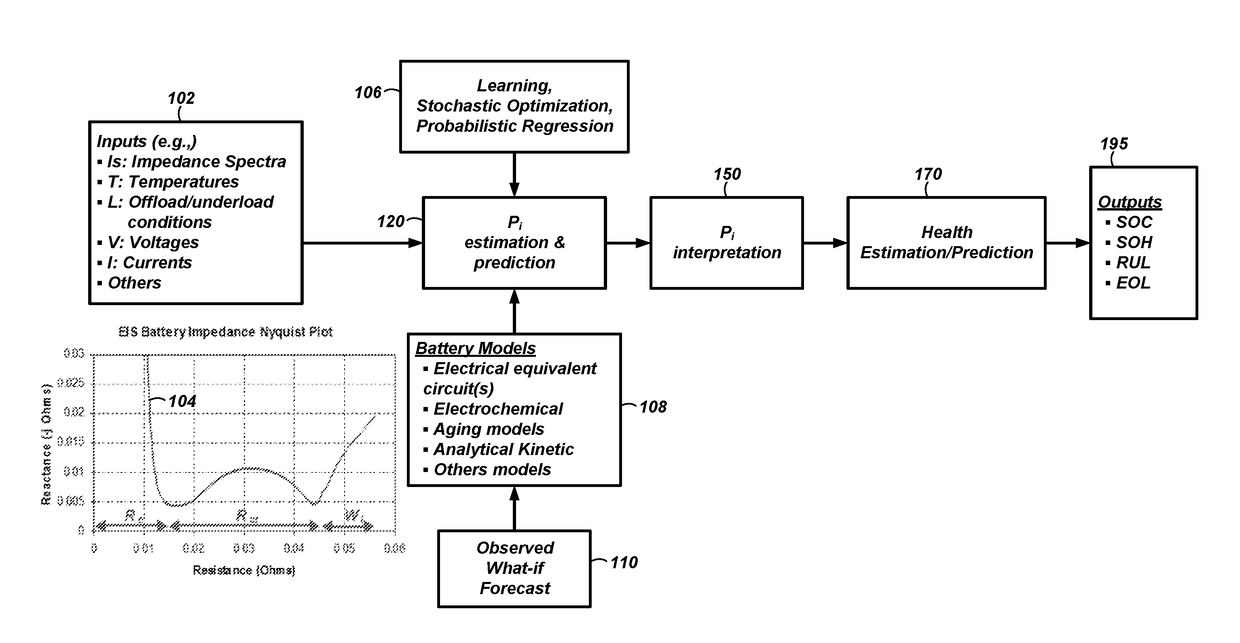

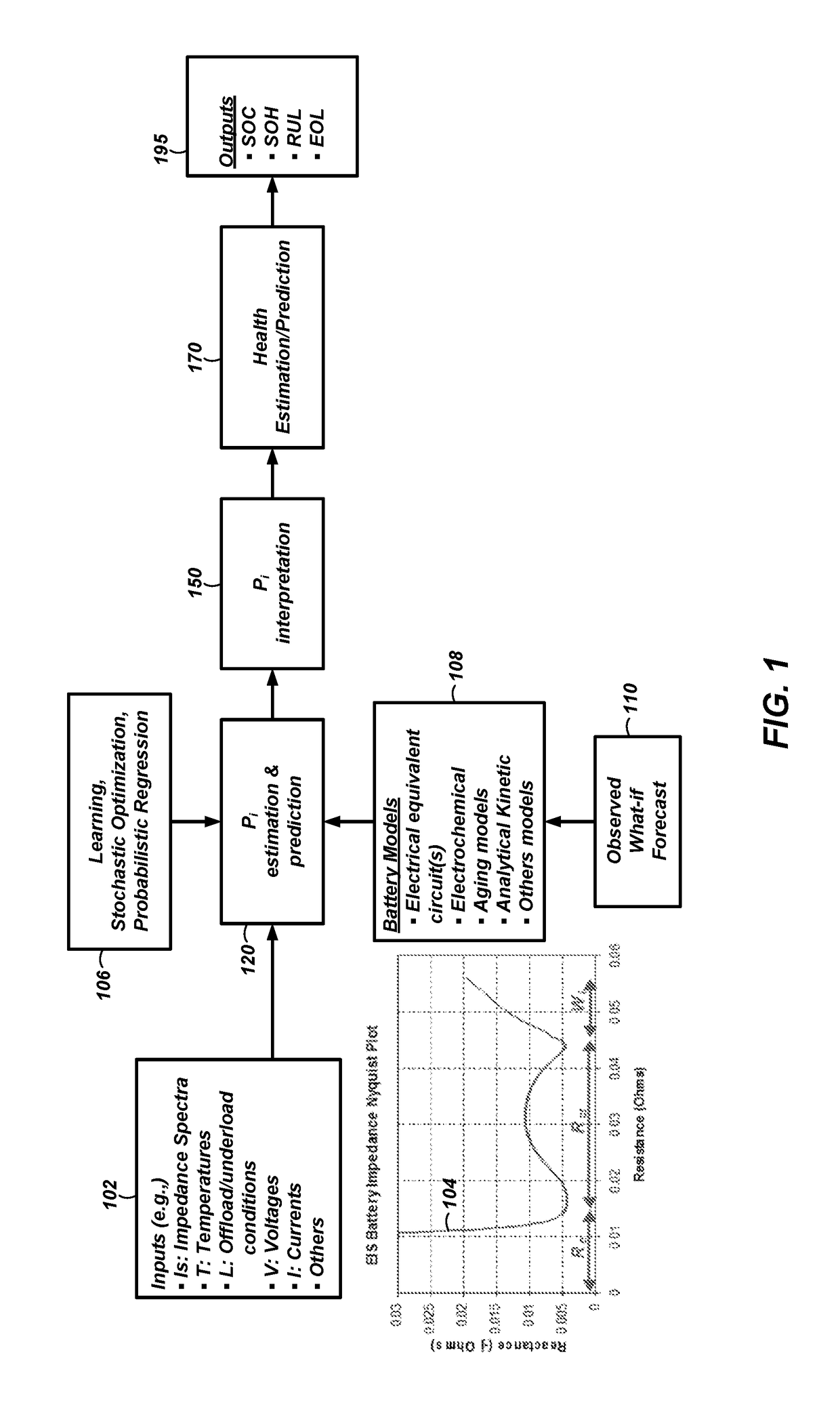

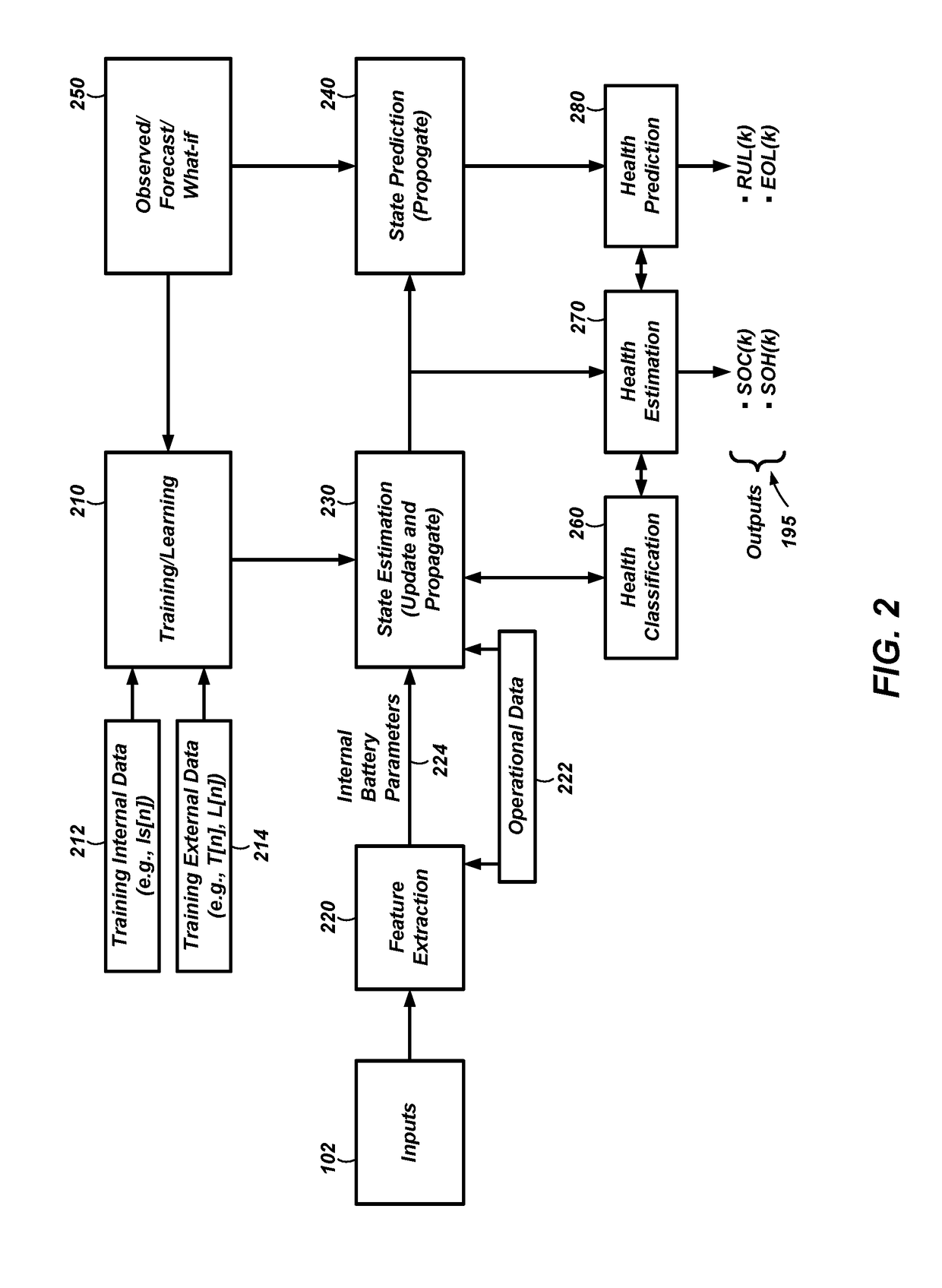

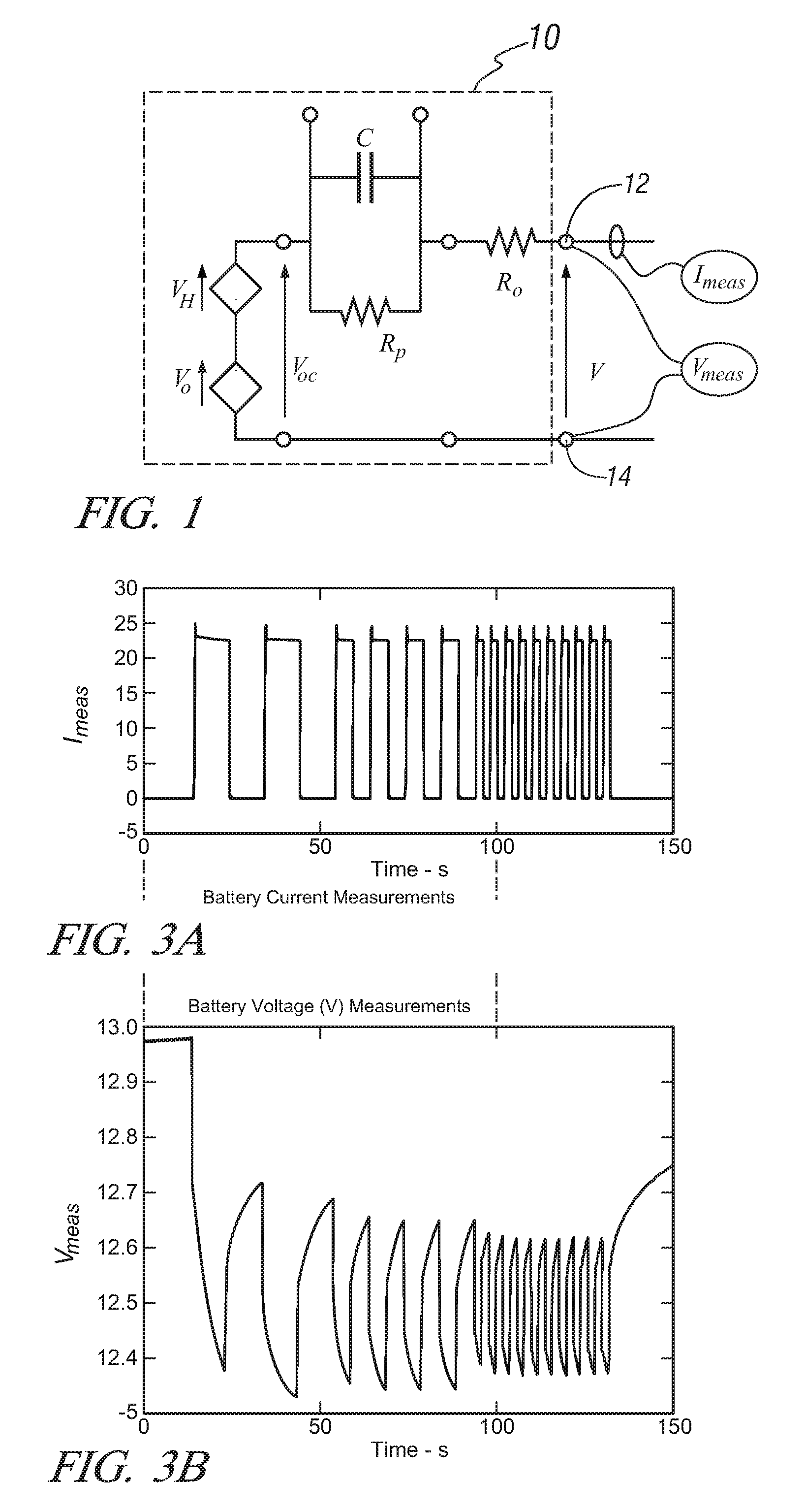

Systems and methods for estimation and prediction of battery health and performance

ActiveUS20180143257A1Testing/monitoring control systemsElectrical testingMoving averageState of health

Systems and computer-implemented methods are used for analyzing battery information. The battery information may be acquired from both passive data acquisition and active data acquisition. Active data may be used for feature extraction and parameter identification responsive to the input data relative to an electrical equivalent circuit model to develop geometric-based parameters and optimization-based parameters. These parameters can be combined with a decision fusion algorithm to develop internal battery parameters. Analysis processes including particle filter analysis, neural network analysis, and auto regressive moving average analysis can be used to analyze the internal battery parameters and develop battery health metrics. Additional decision fusion algorithms can be used to combine the internal battery parameters and the battery health metrics to develop state-of-health estimations, state-of-charge estimations, remaining-useful-life predictions, and end-of-life predictions for the battery.

Owner:BATTELLE ENERGY ALLIANCE LLC

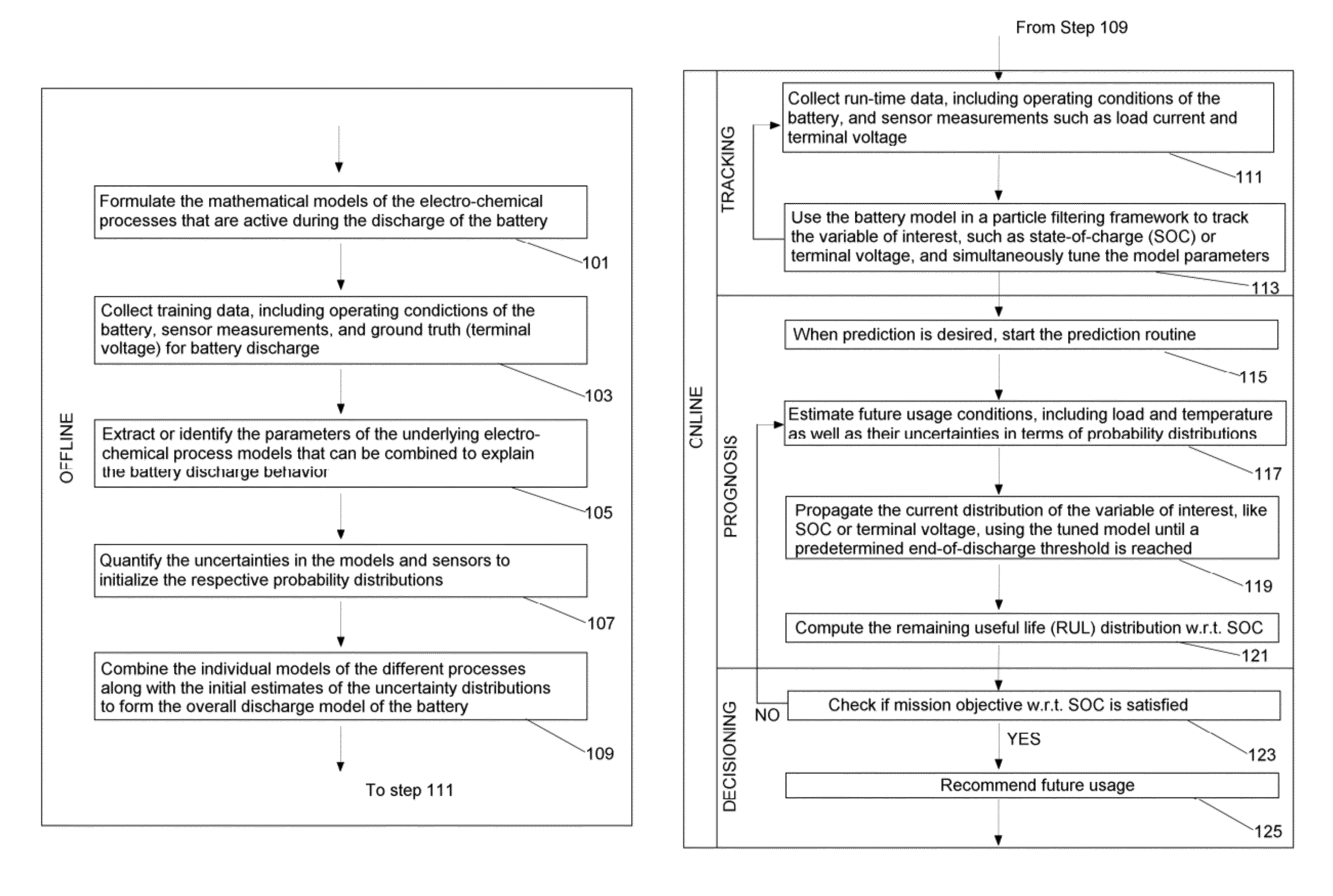

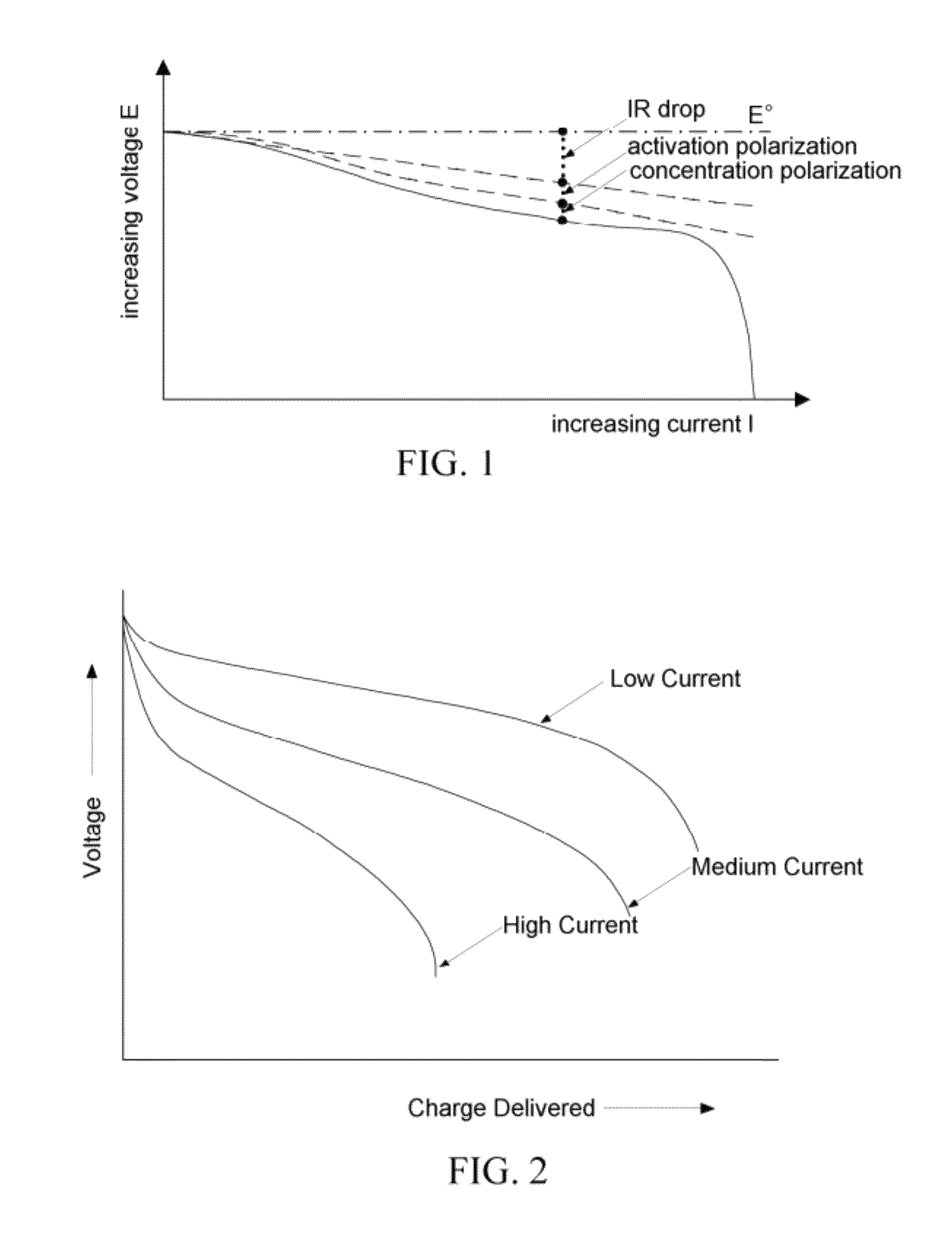

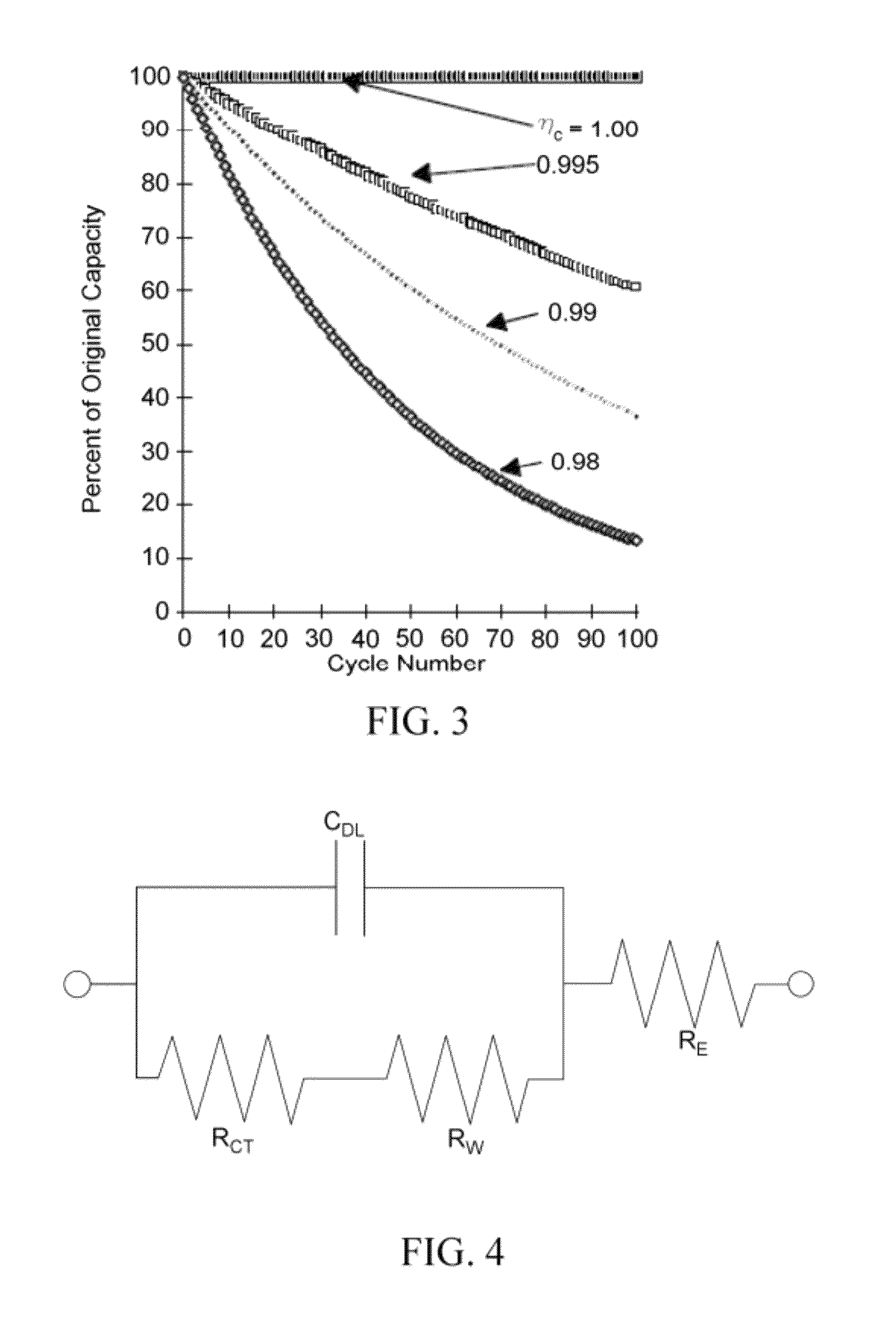

Model-based prognostics for batteries which estimates useful life and uses a probability density function

ActiveUS8332342B1Electrical testingSpecial data processing applicationsEngineeringResidual service life

This invention develops a mathematical model to describe battery behavior during individual discharge cycles as well as over its cycle life. The basis for the form of the model has been linked to the internal processes of the battery and validated using experimental data. Effects of temperature and load current have also been incorporated into the model. Subsequently, the model has been used in a Particle Filtering framework to make predictions of remaining useful life for individual discharge cycles as well as for cycle life. The prediction performance was found to be satisfactory as measured by performance metrics customized for prognostics for a sample case. The work presented here provides initial steps towards a comprehensive health management solution for energy storage devices.

Owner:NASA

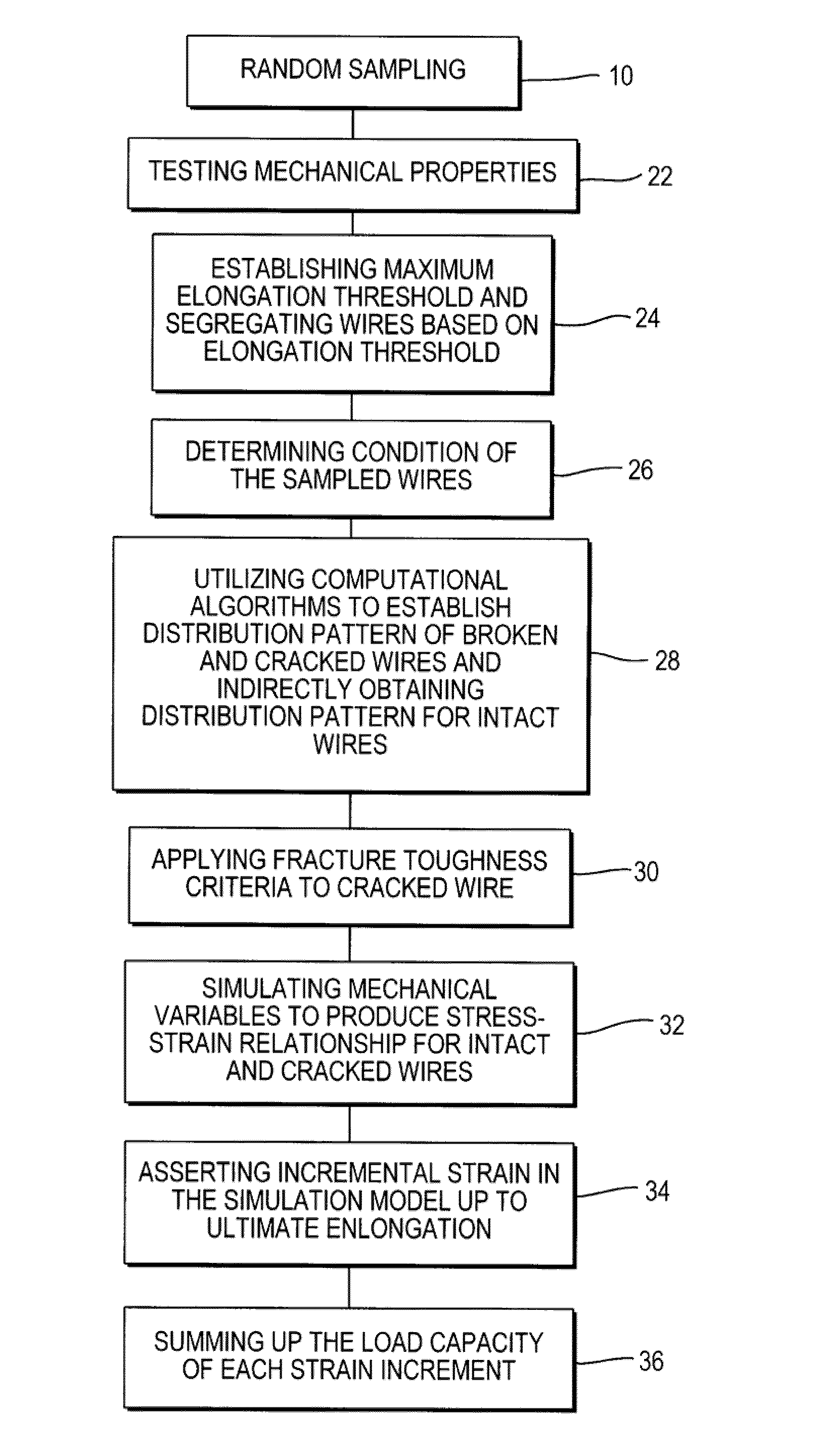

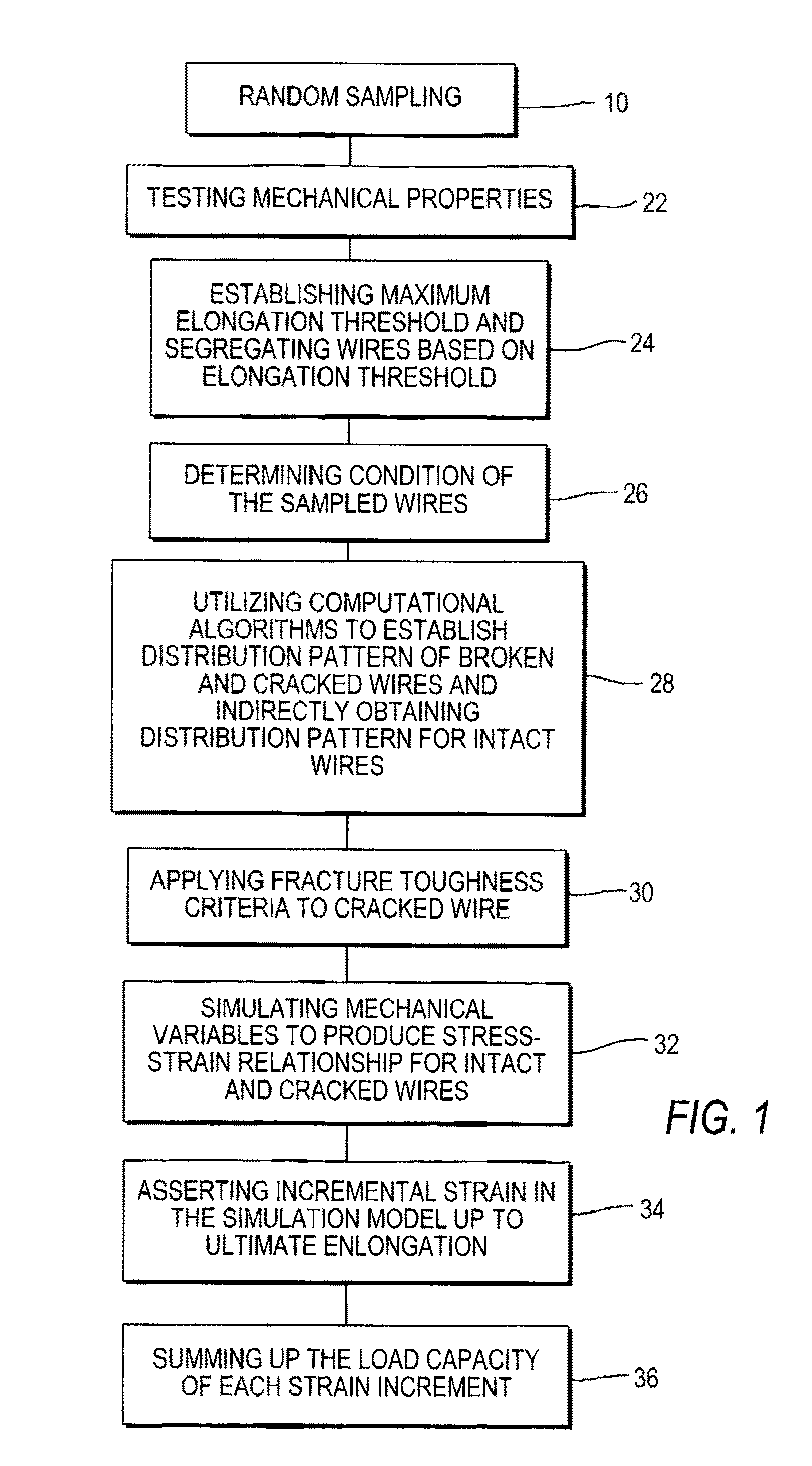

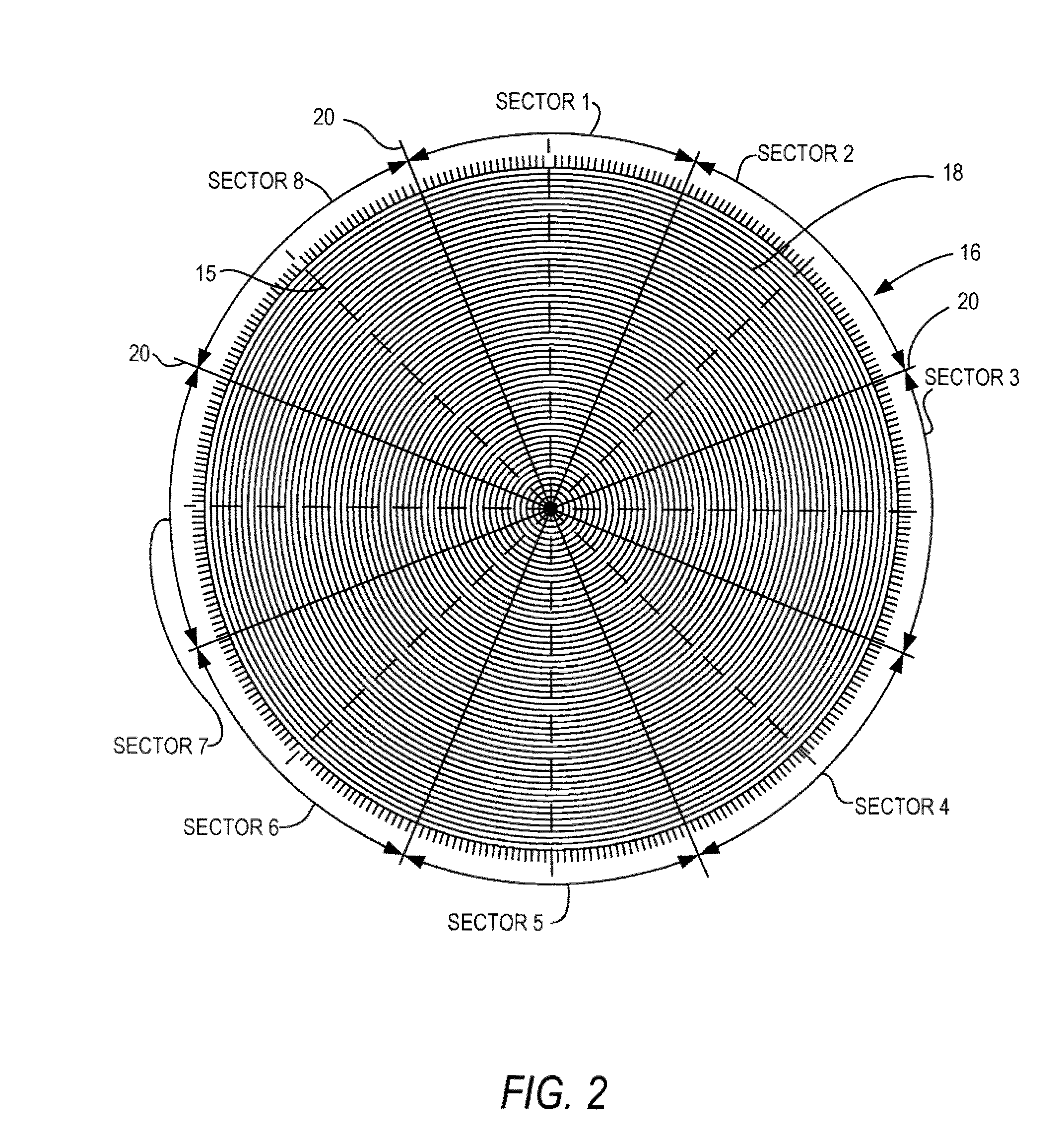

Method for assessment of cable strength and residual life

ActiveUS7992449B1Minimizes vulnerabilityMaterial strength using tensile/compressive forcesStress–strain curveEngineering

A method for determining the condition assessment and residual life span of bridge cables based on a parametric statistical model. The method includes random sampling of individual cable wires, mechanically testing the sampled wires, determining the probability of broken and cracked wires and the ultimate strength of cracked wires using fracture toughness and imputing the above data to simulate stress-strain curves for each wire in the cable, applying strain increments until reaching ultimate elongation. Assessing remaining service life of the cable by determining the rate of change of broken wires detected over a time frame, measuring the rate of change of fracture toughness over said time frame, and applying the rates of change to a time-dependent degradation prediction model.

Owner:MAHMOUD KHALED M

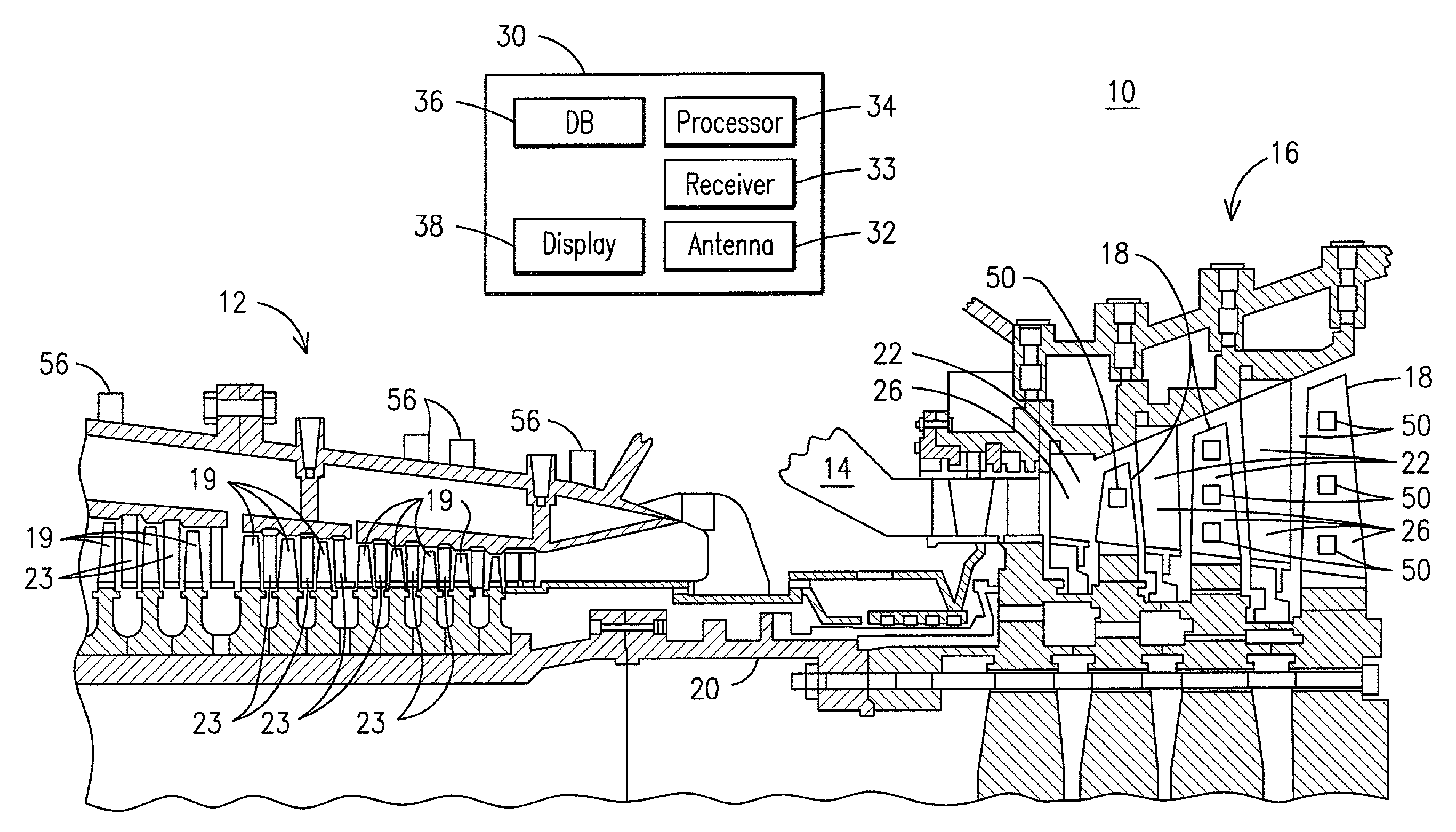

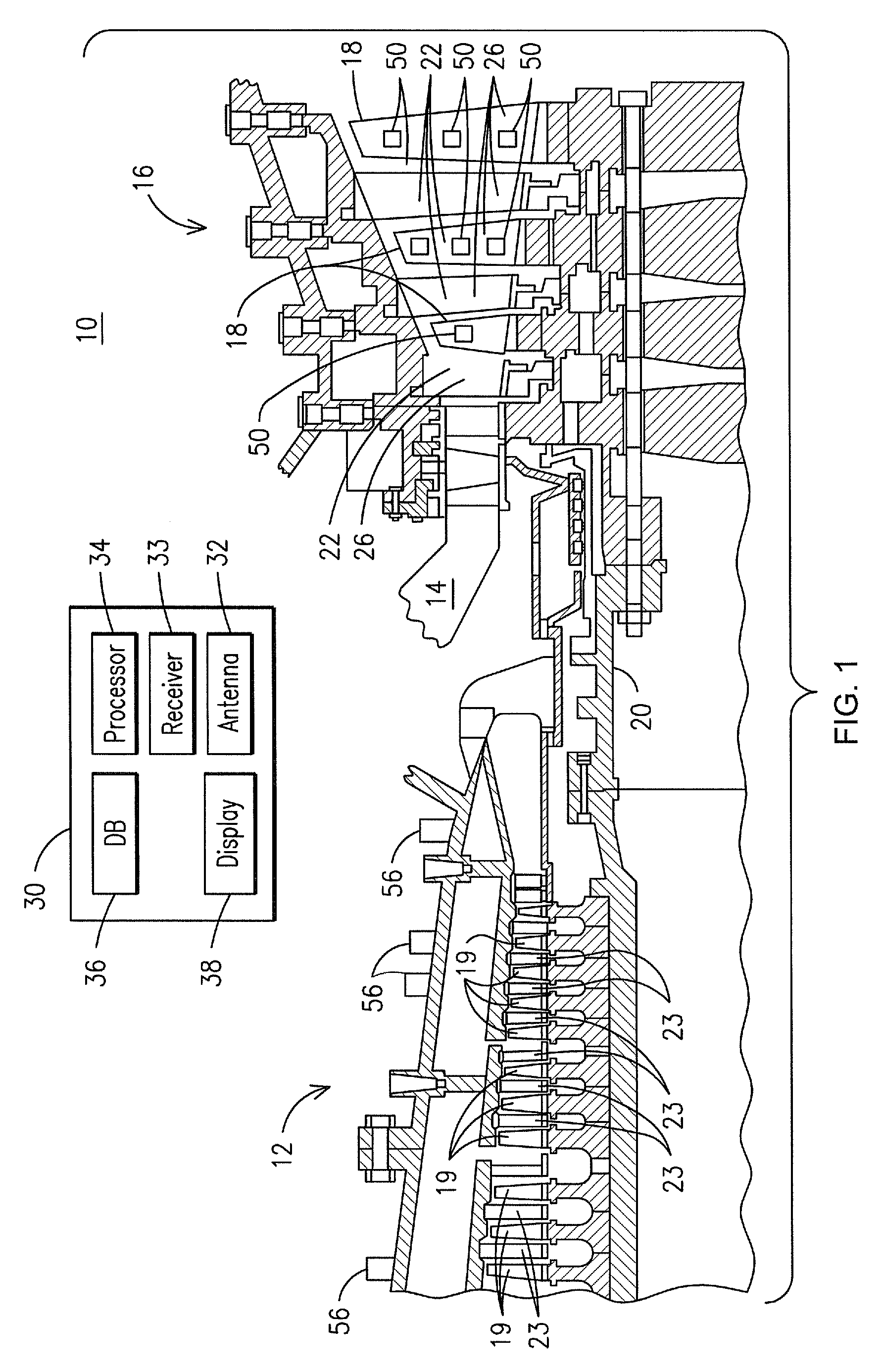

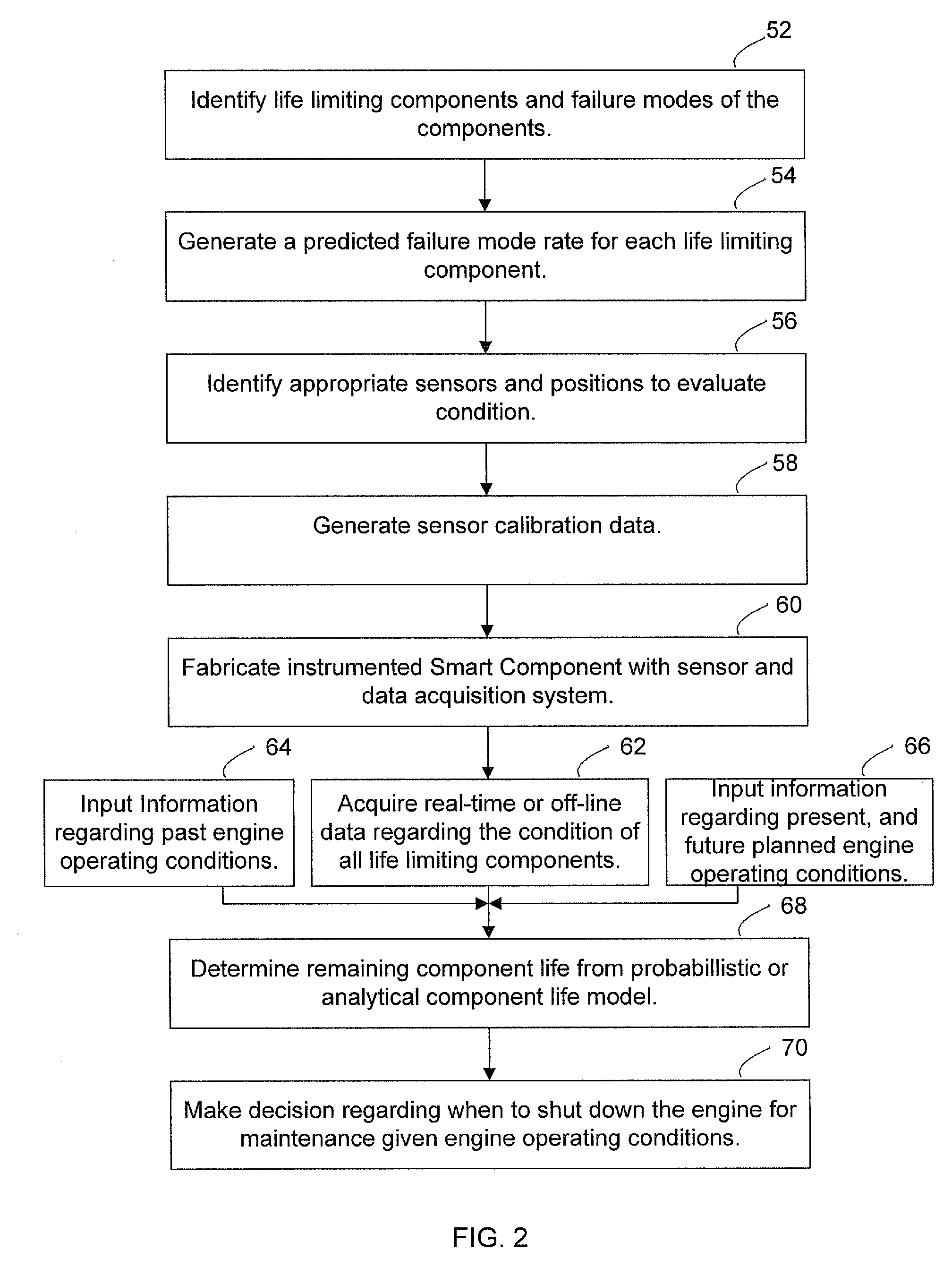

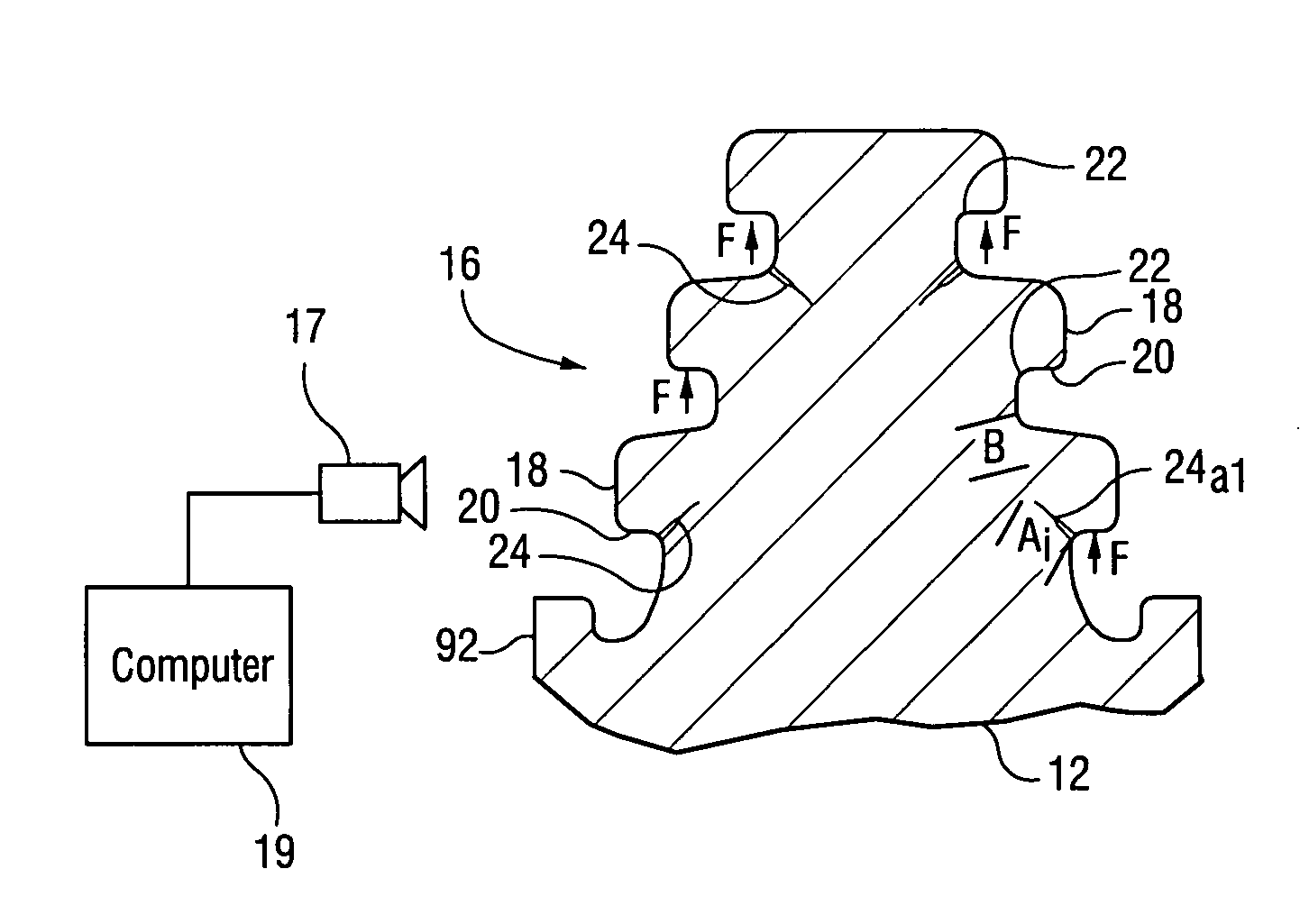

Method for predicting a remaining useful life of an engine and components thereof

A method for predicting the remaining useful life of an engine (10) having components (18, 19, 22, 23) that are instrumented with sensors (50) that generate electronic data signals indicative of an operating condition of the component comprises identifying (52) one or more components and at least one failure mode for each component that limit an operating life of the components and engine (10). The method further comprises acquiring (62) and storing data relative to current operating conditions of the components associated with the identified failure mode; and, then determining (68) a remaining useful life of the component based on the data relative to current operating condition of the components, the data relative to historical data of the operating condition associated with the failure mode and a predicted failure mode rate.

Owner:SIEMENS ENERGY INC

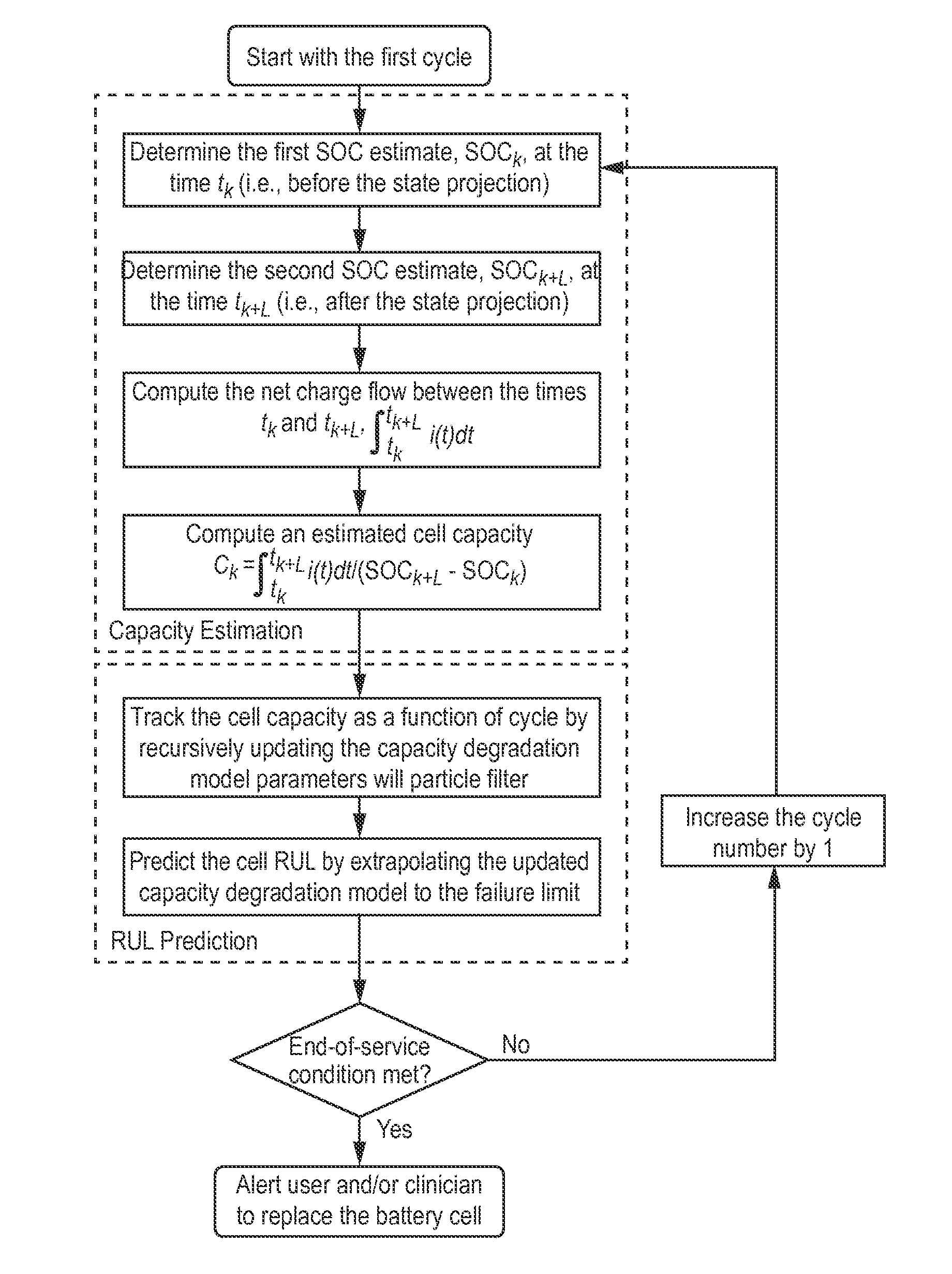

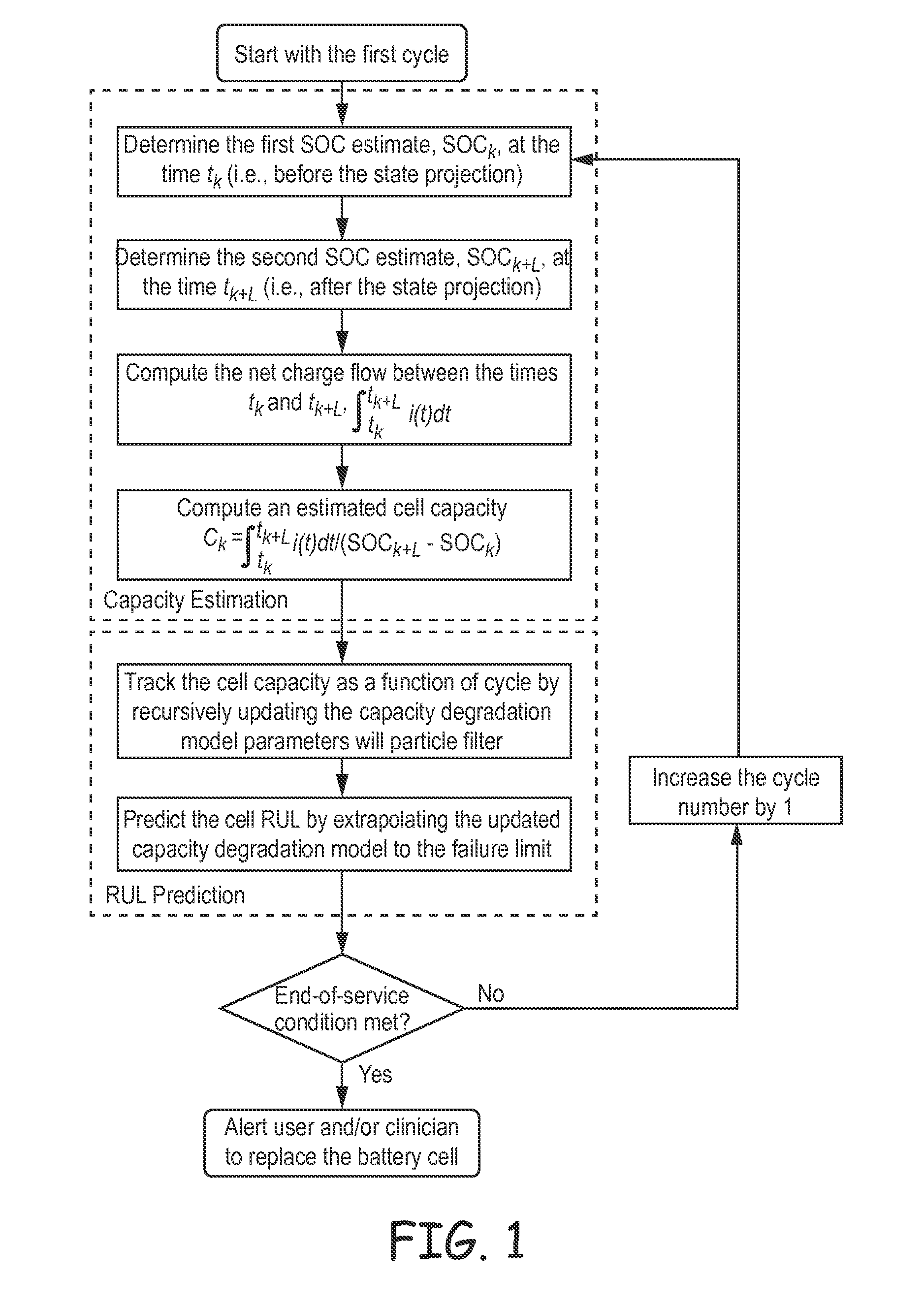

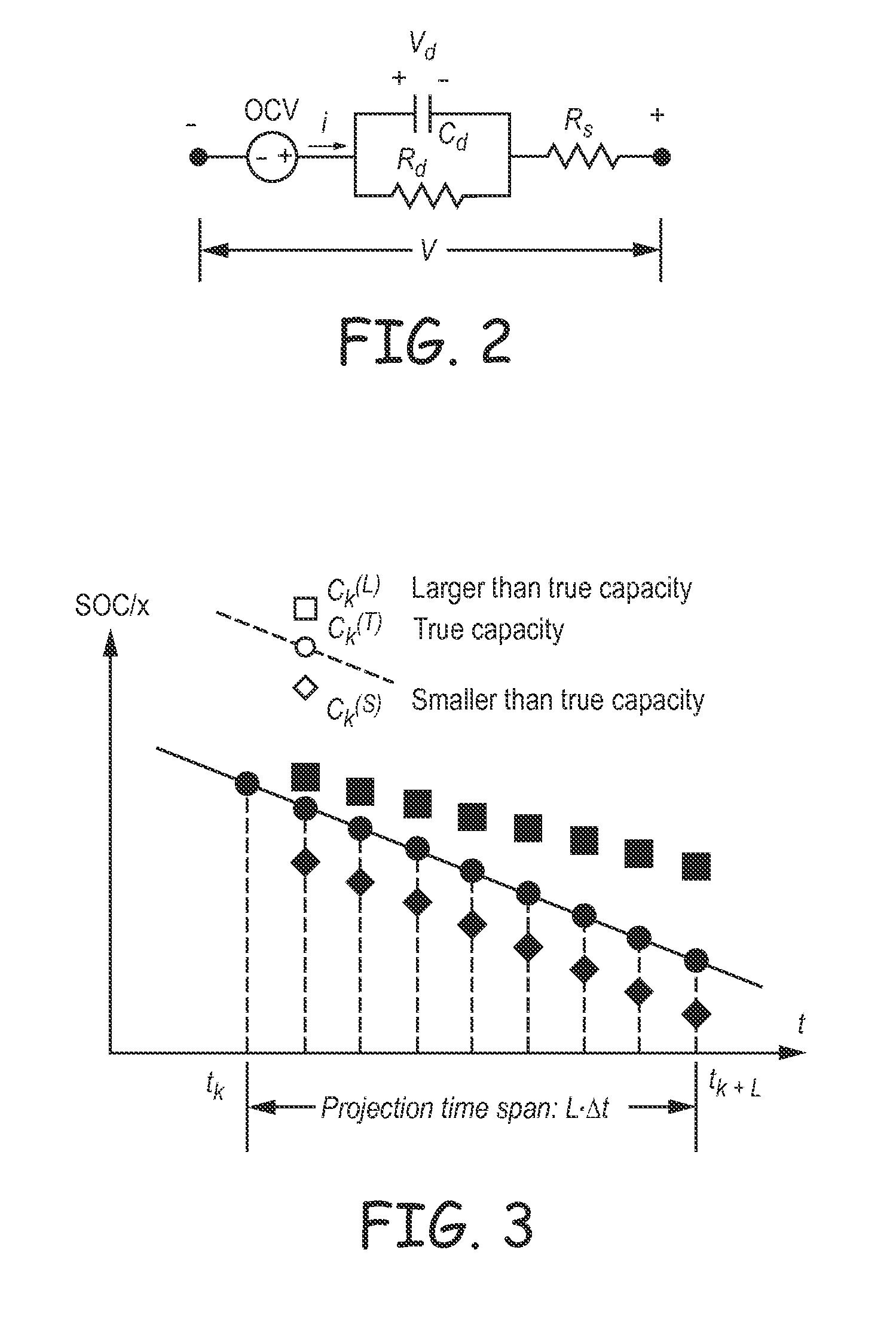

Method and System for Predicting Useful Life of a Rechargeable Battery

System and method for predicting the remaining useful life (RUL) of a rechargeable battery, such as a lithium-ion rechargeable battery. In a method, the capacity of the battery is determined based on at least changes of state of charge values estimated at a first and second time and a net charge flow of the battery and applying a particle filter to a capacity degradation formula using the determined capacity to form a capacity degradation model and determining the RUL using the capacity degradation model using a pre-defined end of service threshold. The system and method may be used to predict the RUL of a rechargeable battery in an implantable medical device.

Owner:MEDTRONIC INC

System and method for estimating remaining useful life

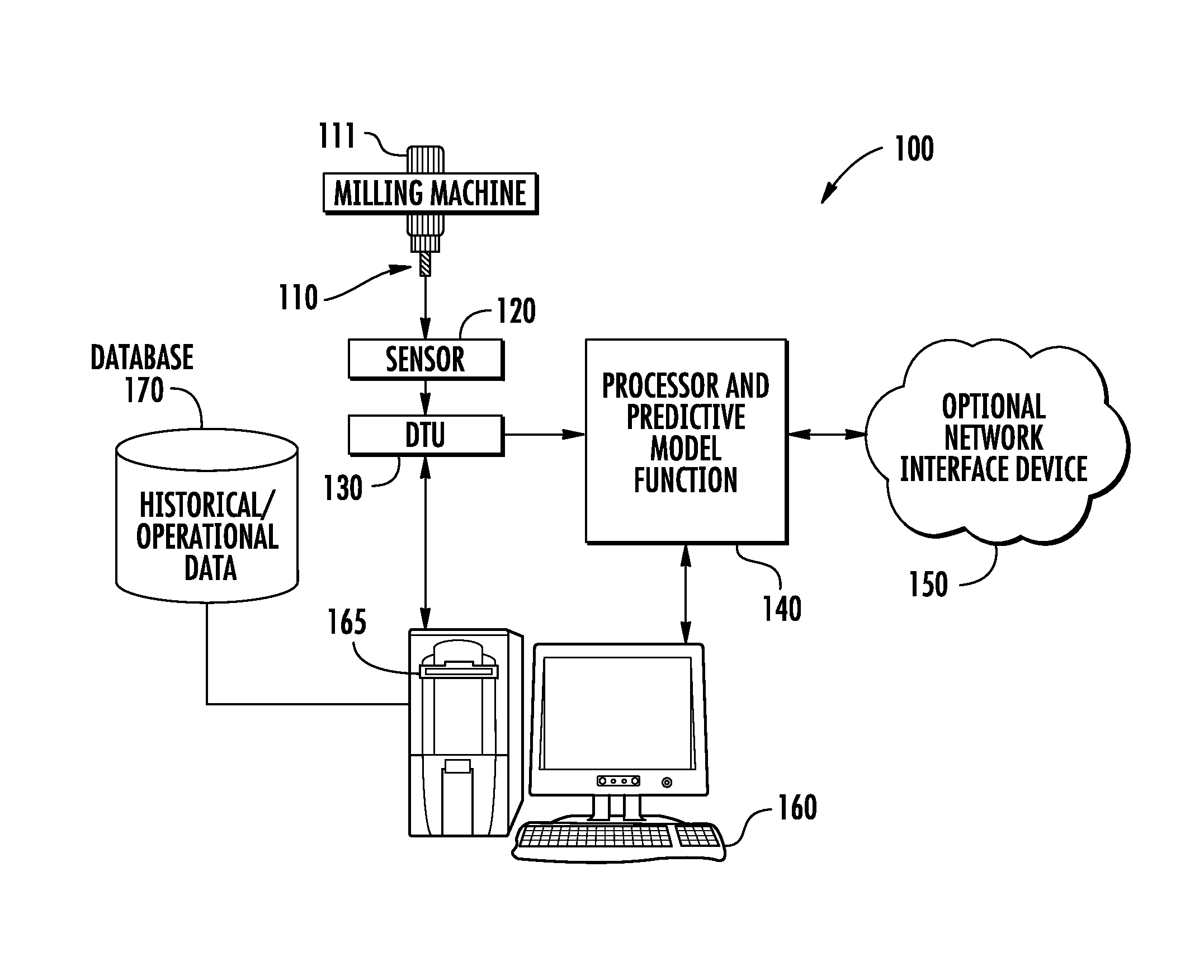

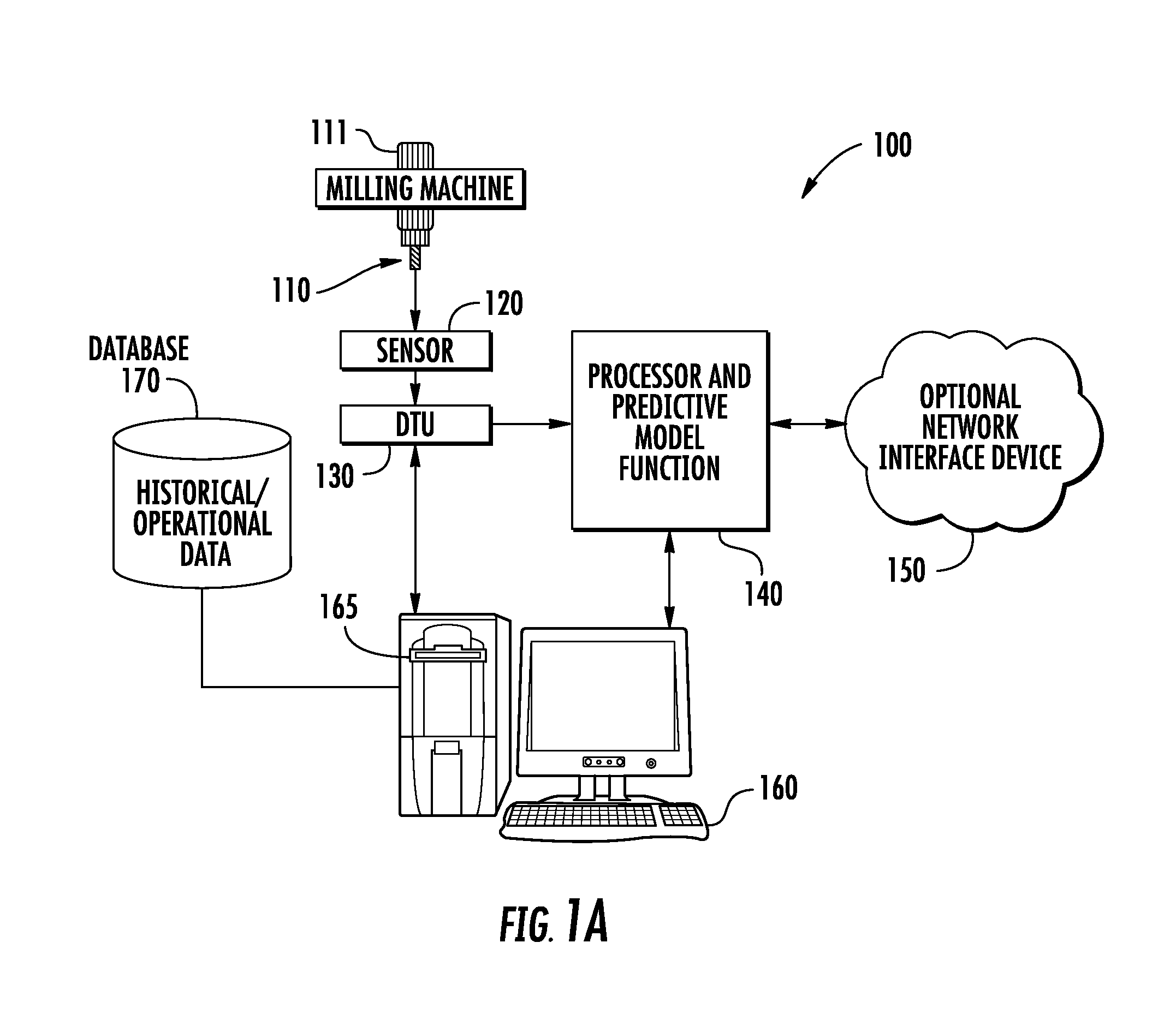

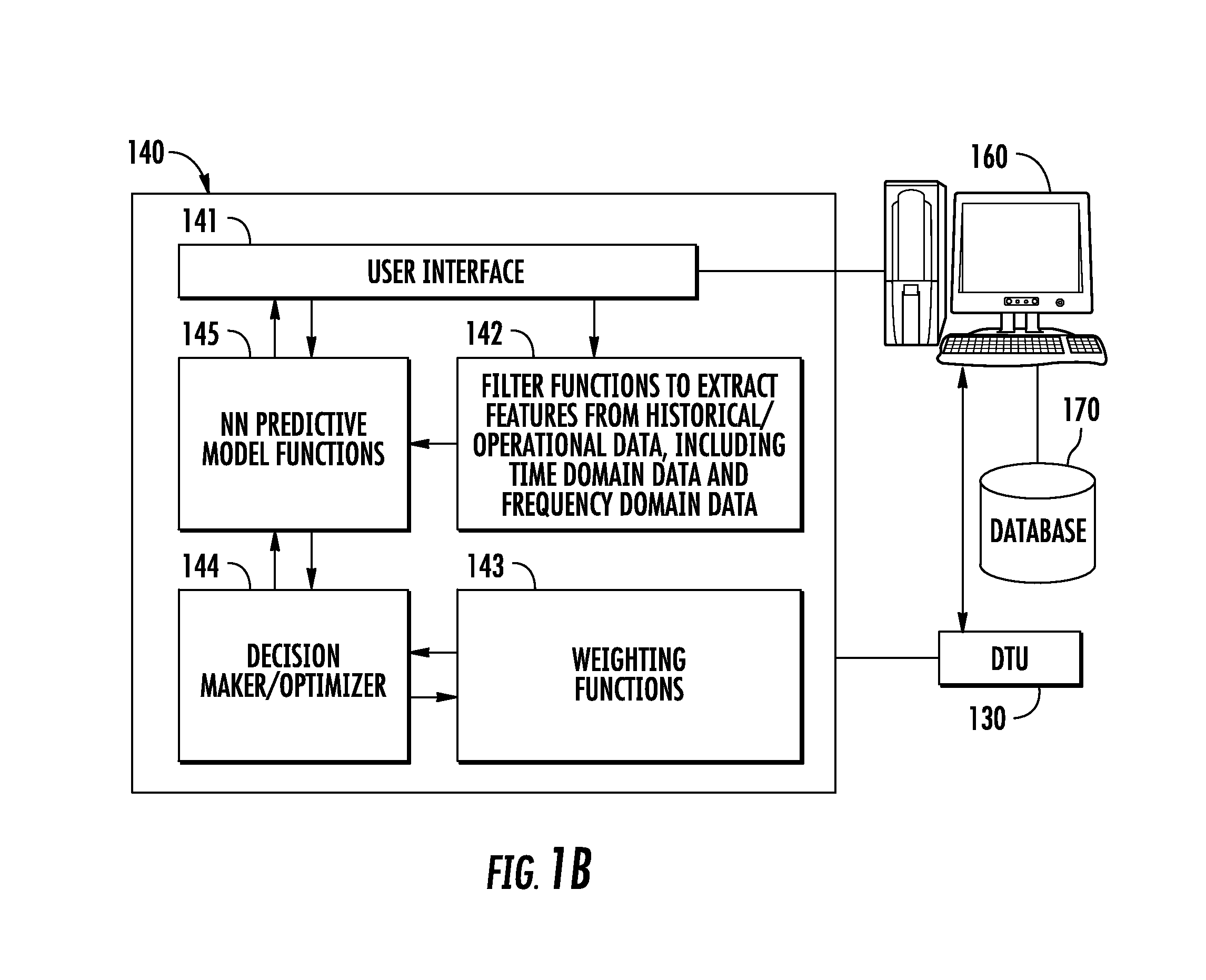

ActiveUS8781982B1Avoid failureTesting/monitoring control systemsDigital computer detailsFluteMachine learning

Mechanisms for predicting a remaining useful life of a cutter head of a milling machine that includes a plurality of flutes are disclosed. Features are extracted from reference data associated with a plurality of reference cutter heads. The reference data includes reference vibration data and reference wear data. At least two Neural Network predictive models are trained in parallel for predicting the remaining life of a new cutter head based upon the extracted features. Operational data associated with the new cutter head is obtained. The operational data includes operational vibration data and operational wear data. Features extracted from the operational data are input into an optimal predictive model of the at least two Neural Network predictive models. A remaining useful life of the new cutter head is estimated by the optimal predictive model.

Owner:LOCKHEED MARTIN CORP

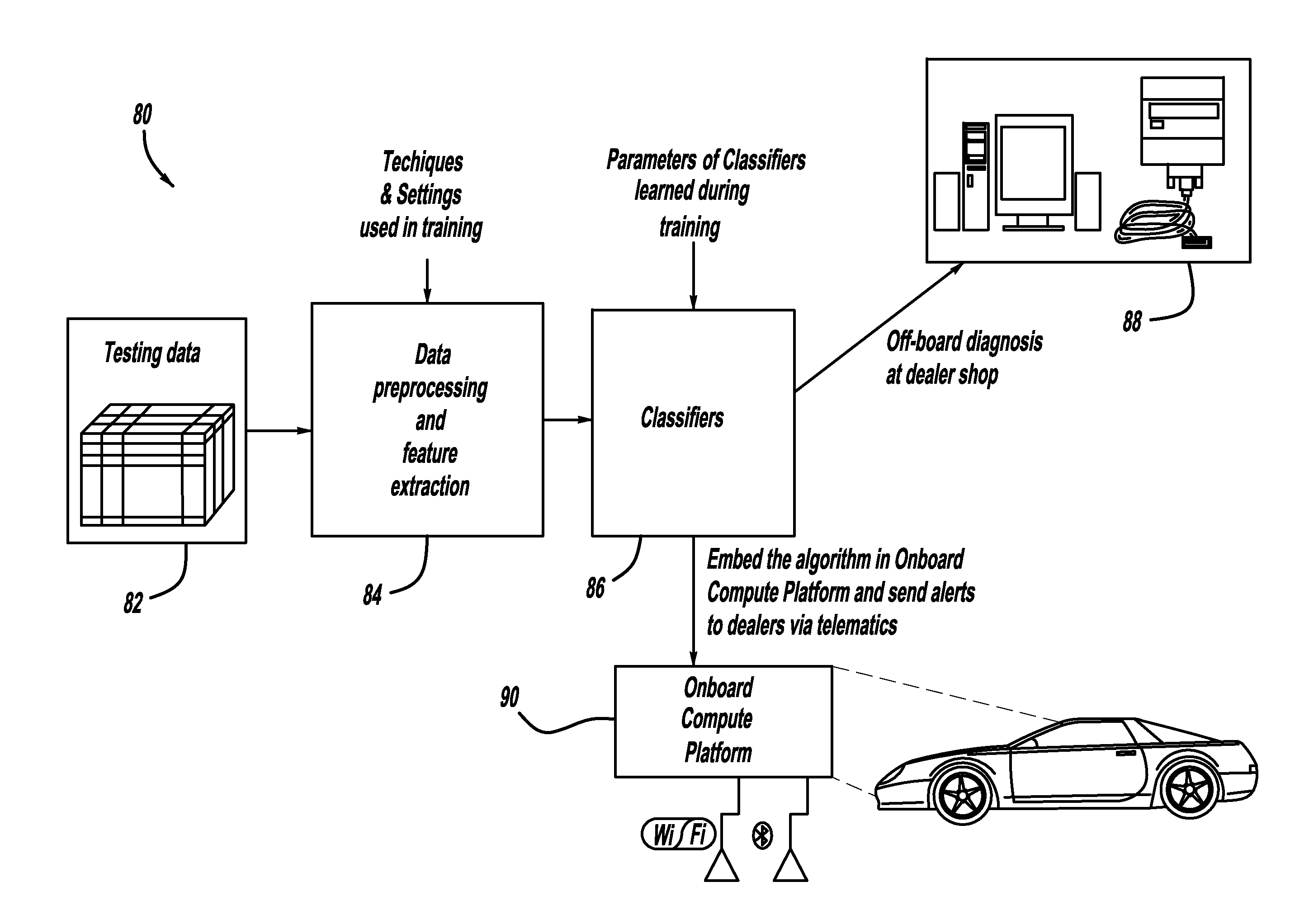

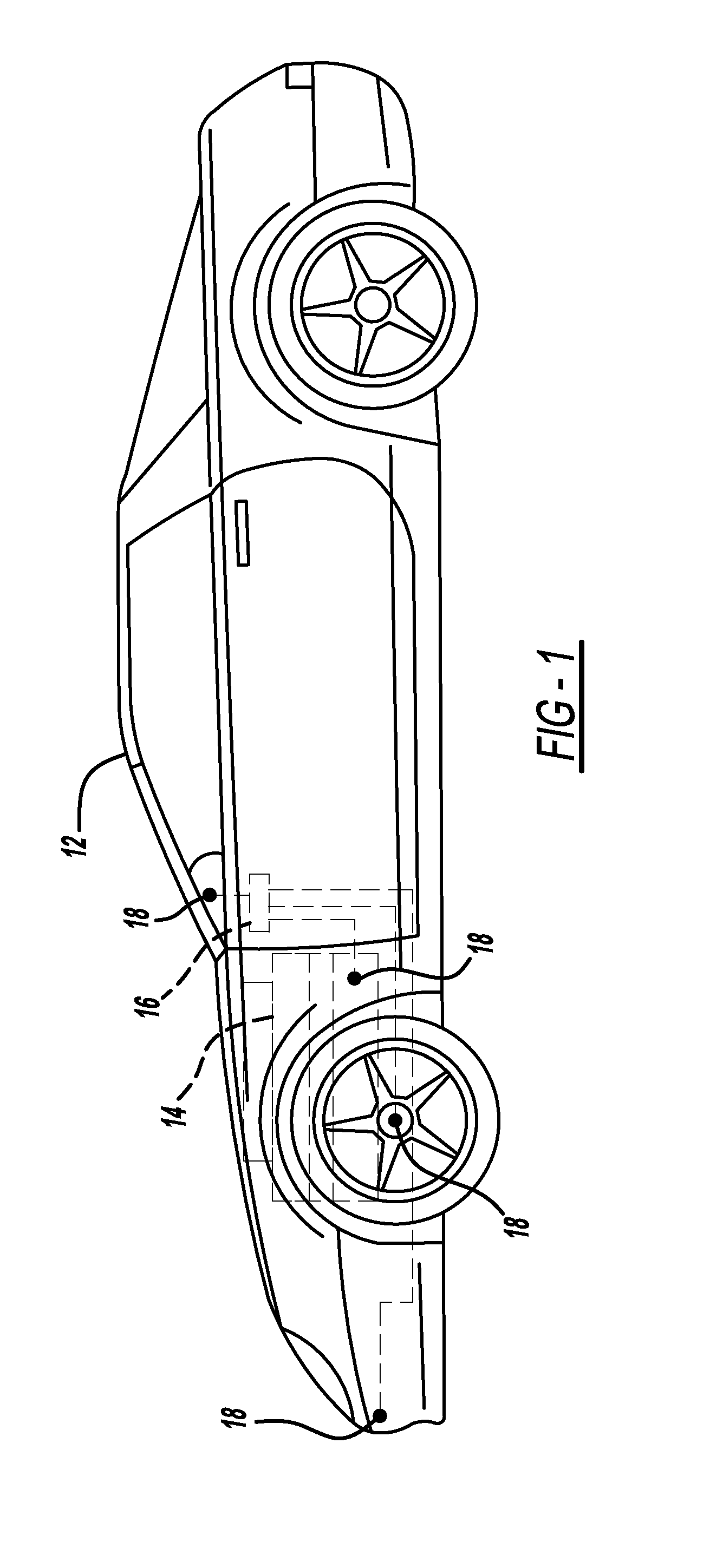

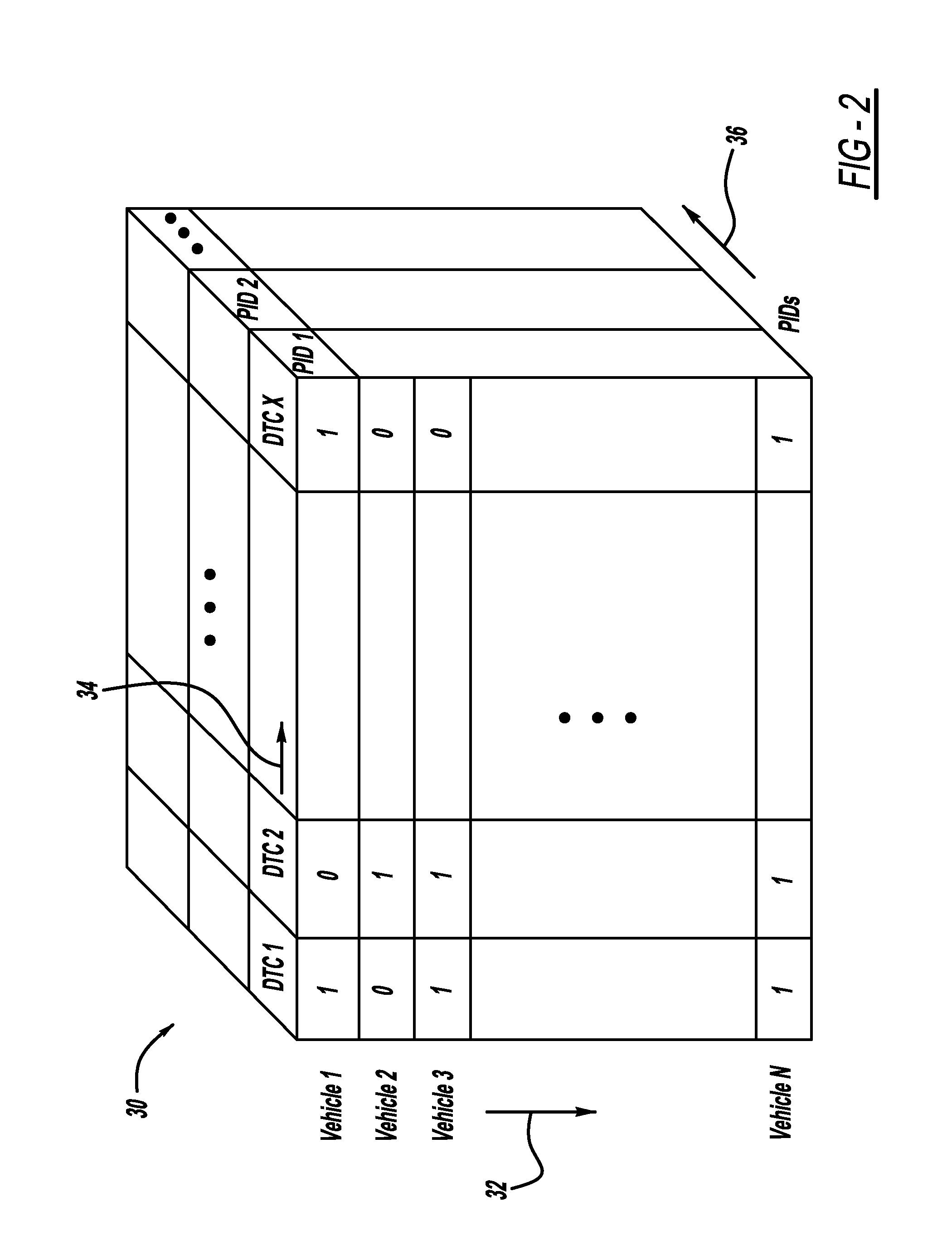

Event-driven fault diagnosis framework for automotive systems

ActiveUS20110238258A1Remaining useful lifeVehicle testingRegistering/indicating working of vehiclesAutomotive systemsWireless data

Systems and methods for capturing and analyzing significant parameter data from vehicle systems whenever a diagnostic trouble code (DTC) is triggered. A multi-dimensional matrix is constructed, with vehicles, DTCs, and parameter data comprising three dimensions of the matrix. The data matrix is populated with DTC and parameter data from many different vehicles, either when vehicles are taken to a dealer for service, or via wireless data download. Time can be added as a fourth dimension of the matrix, providing an indication of whether a particular system or component is temporally degrading. When sufficient data is accumulated, the data matrix is pre-processed, features are extracted from the data, and the features are classified, using a variety of mathematical techniques. Trained classifiers are then used to diagnose the root cause of any particular fault signal, and also to provide a prognosis of system health and remaining useful life.

Owner:GM GLOBAL TECH OPERATIONS LLC

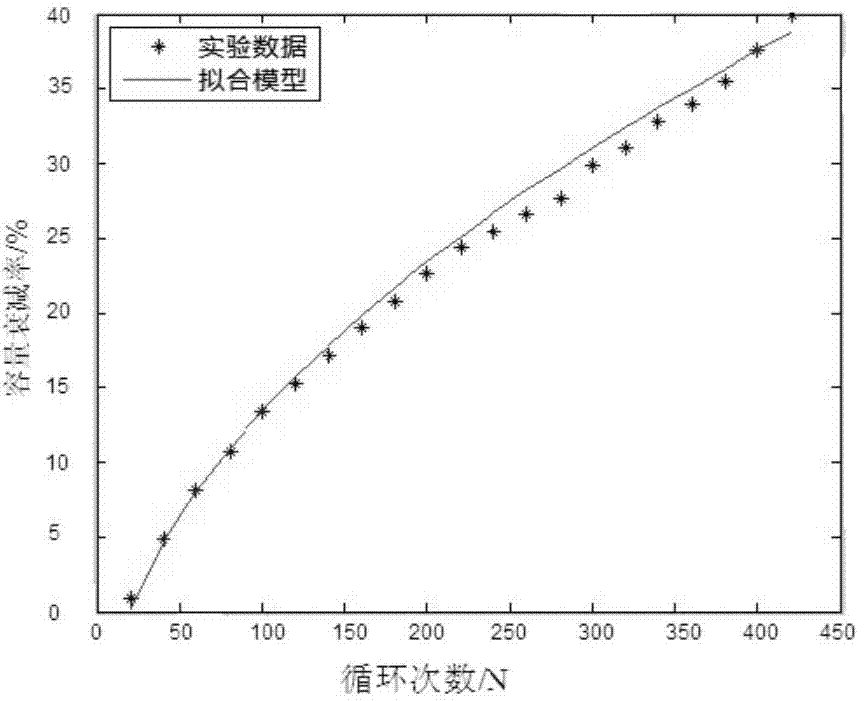

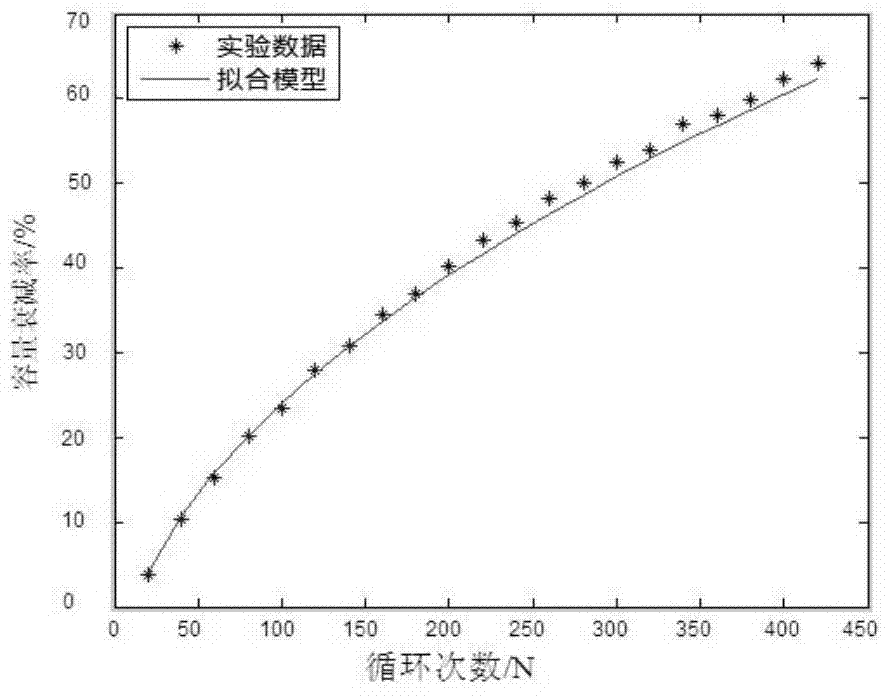

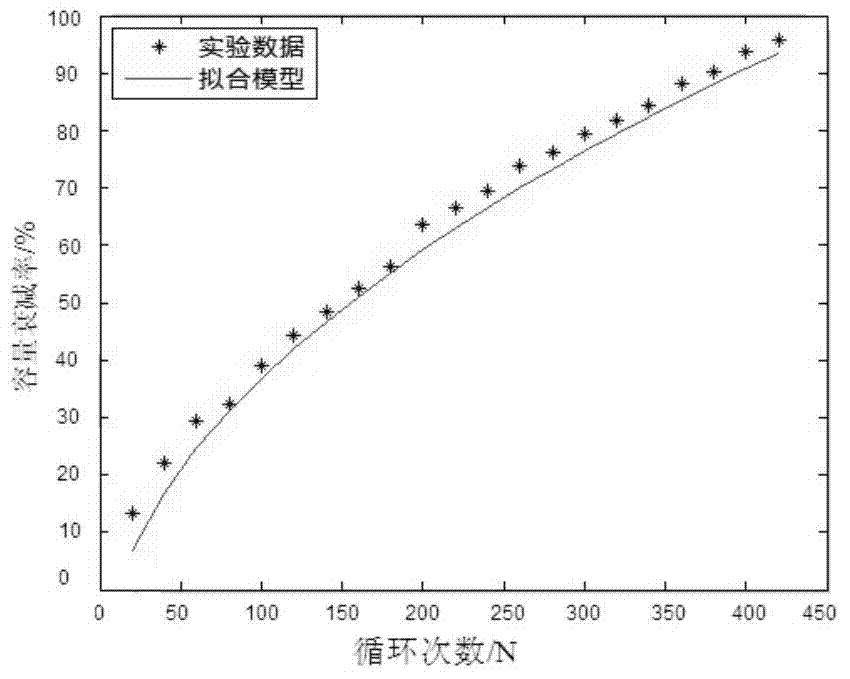

Prediction method for life cycle of battery

InactiveCN103698710AExtend your lifeGood for determining performanceElectrical testingCyclic testTested time

The invention discloses a prediction method for a life cycle of a battery. The prediction method comprises the following steps: drawing a curve of the number of discharge and capacity fading rate; determining a function model of the capacity fading rate Qloss of the battery and the number of discharge N of the battery; substituting data of a certain impact factor impacting the life of the battery into the function model, wherein Qloss is 50-80 percent of the nominal capacity of the battery; calculating to obtain the expected cycle period N of the battery. According to the prediction method disclosed by the invention, as long as little cyclic test is performed on the battery, the residual life of the battery can be judged, and therefore, the test time is greatly shortened and the test cost is greatly reduced; the objective condition of capacity fading during the actual use process of the battery can be truly and comprehensively described, the life and the residual life of the battery can be obtained, the performance of the battery can be helped to be determined, and the life of the battery is prolonged. As the established model is universal, the prediction method disclosed by the invention is suitable for establishing life fading models of various storage batteries.

Owner:CENT SOUTH UNIV +2

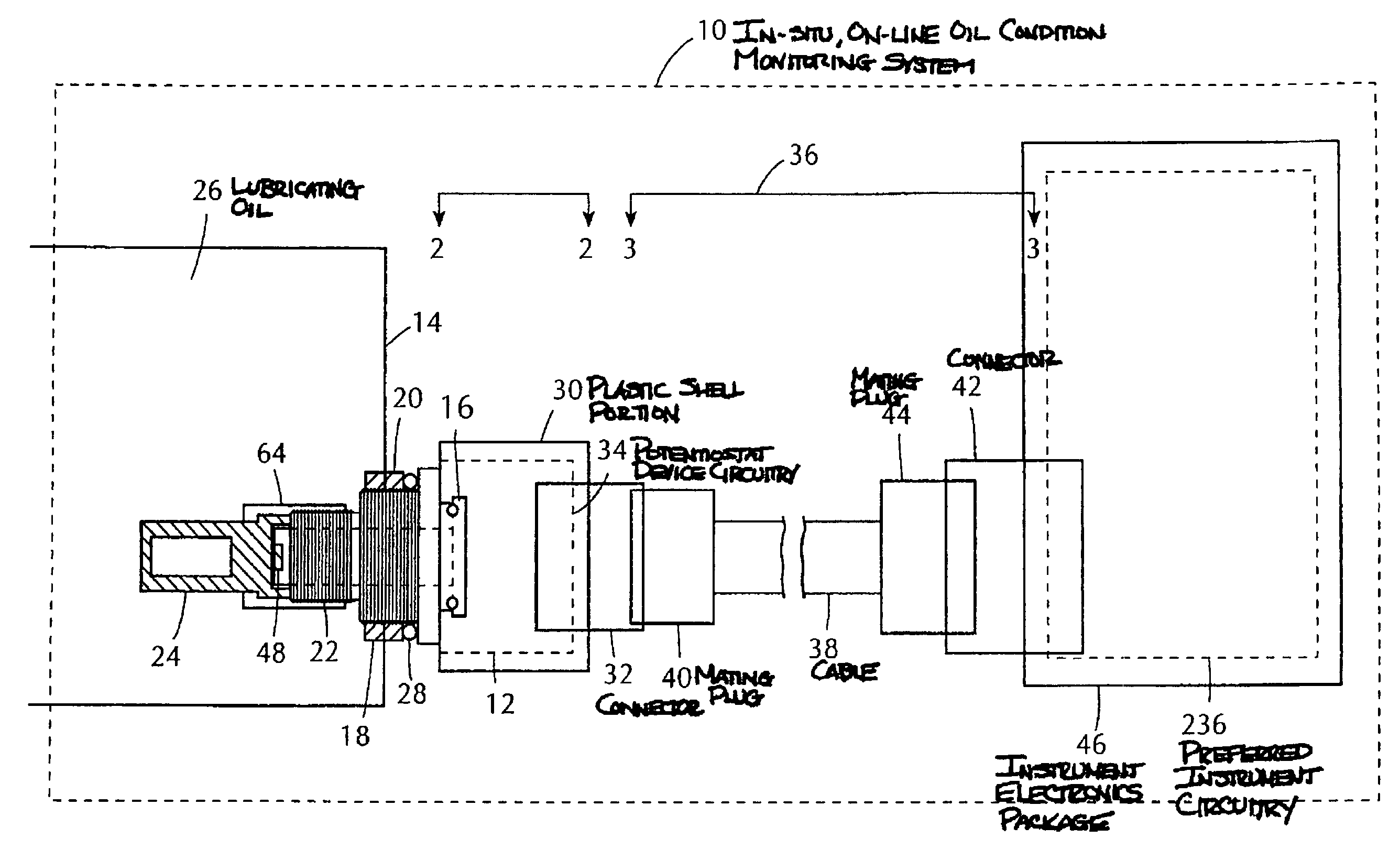

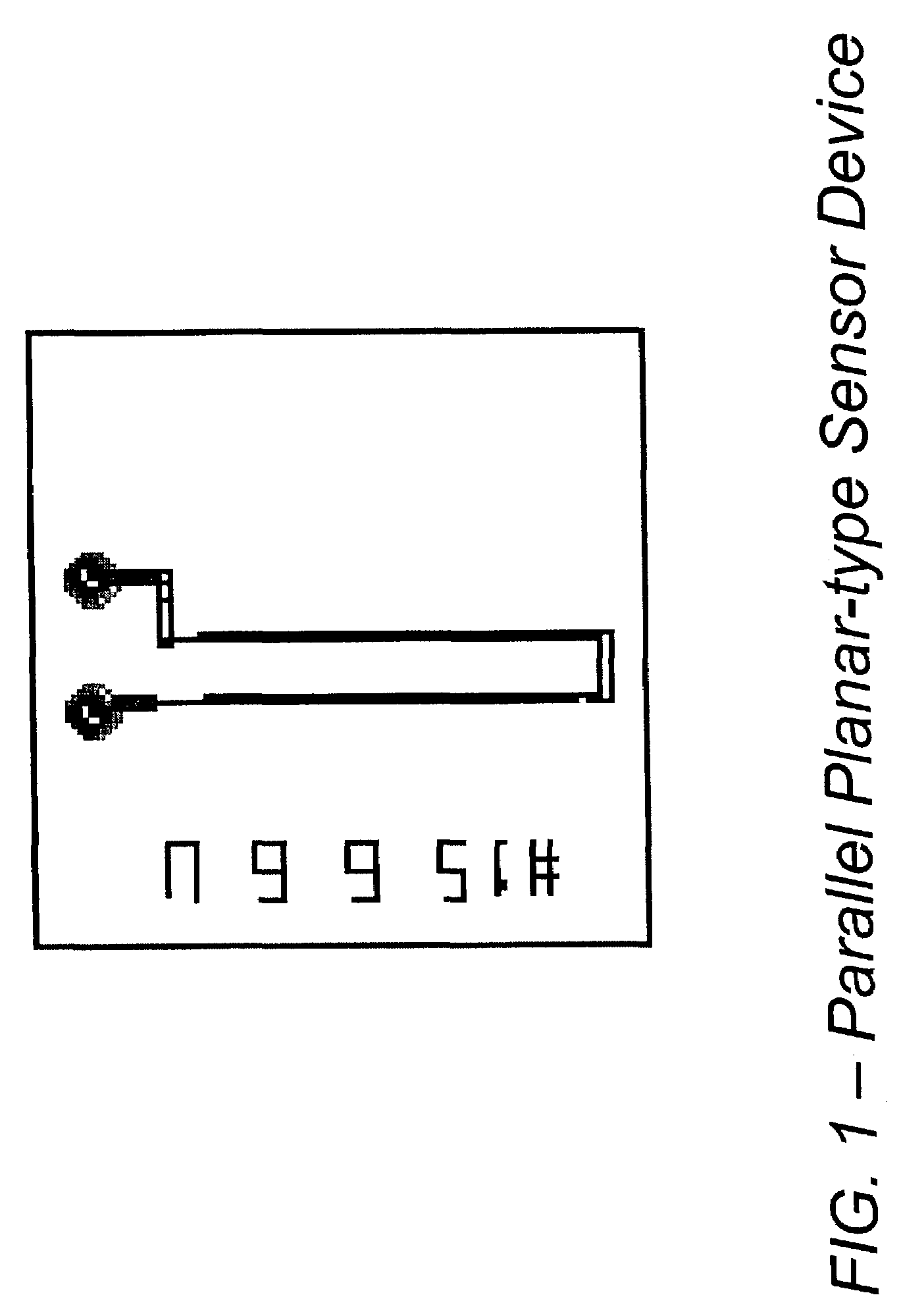

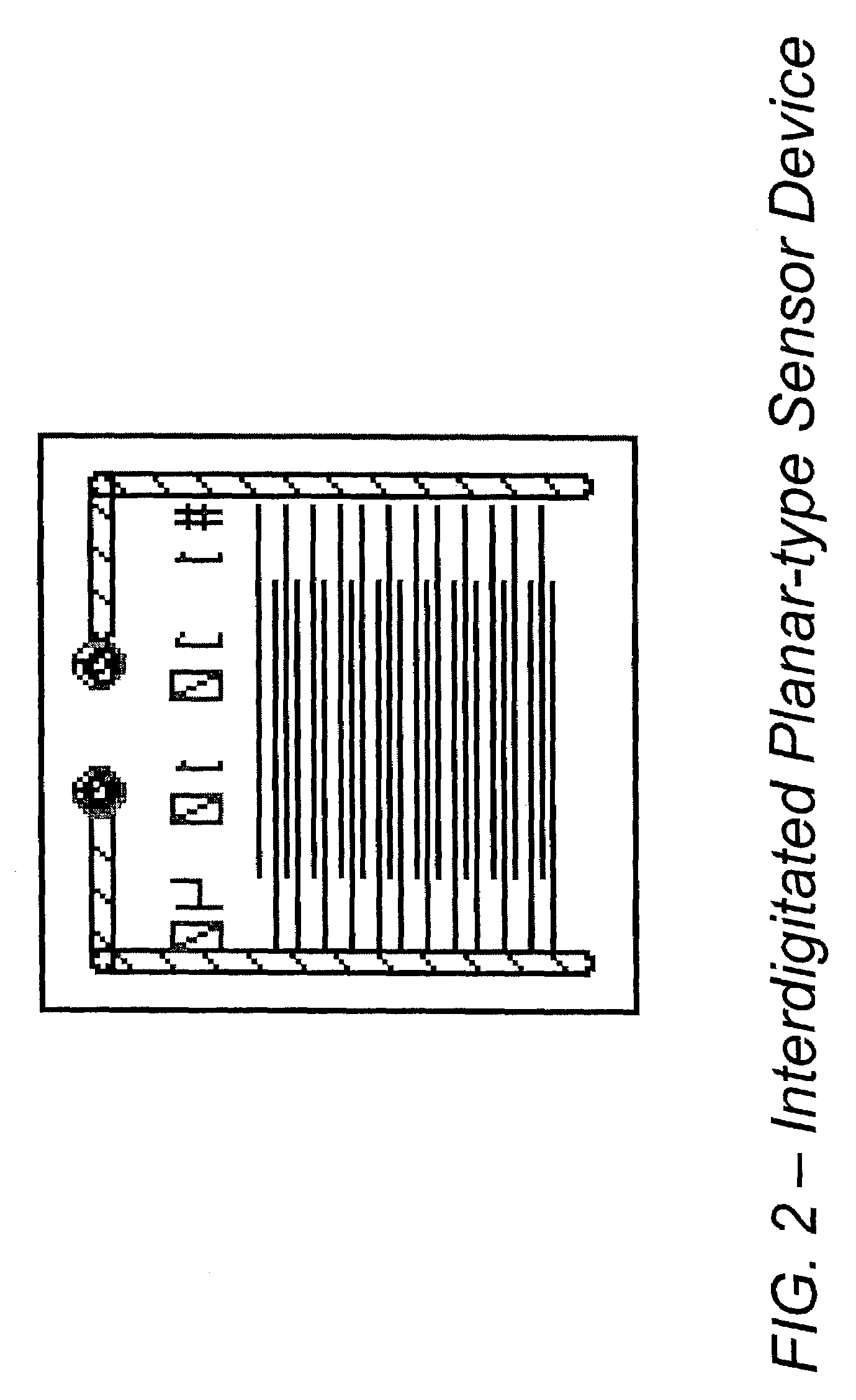

On-line oil condition sensor system for rotating and reciprocating machinery

InactiveUS7043402B2Improve performanceRepeatabilityFlow propertiesMachines/enginesElectrochemistryElectrode Contact

An on-line sensing system and method for monitoring in real-time thermal-oxidative breakdown, water contamination, and / or fuel dilution conditions in operational engine lubricating oils. The method of the invention includes an electrochemical impedance analysis technique specific to the particular oil to be monitored. Sensing devices having of at least two electrodes are configured for direct installation in an existing access port, or drain port, of a lubricating oil reservoir. An AC voltage waveform is applied to the sensing device (preferably less than 100 Hz) to produce voltage and current responses between the appropriate electrodes contacting the oil. The magnitude impedance |Z| and phase angle components of the complex impedance are used to characterize the quality and / or condition of the engine oil under test. The system also provides an electrical indication indicative of the percentage remaining useful life of the oil.

Owner:PHILLIPS INTPROP

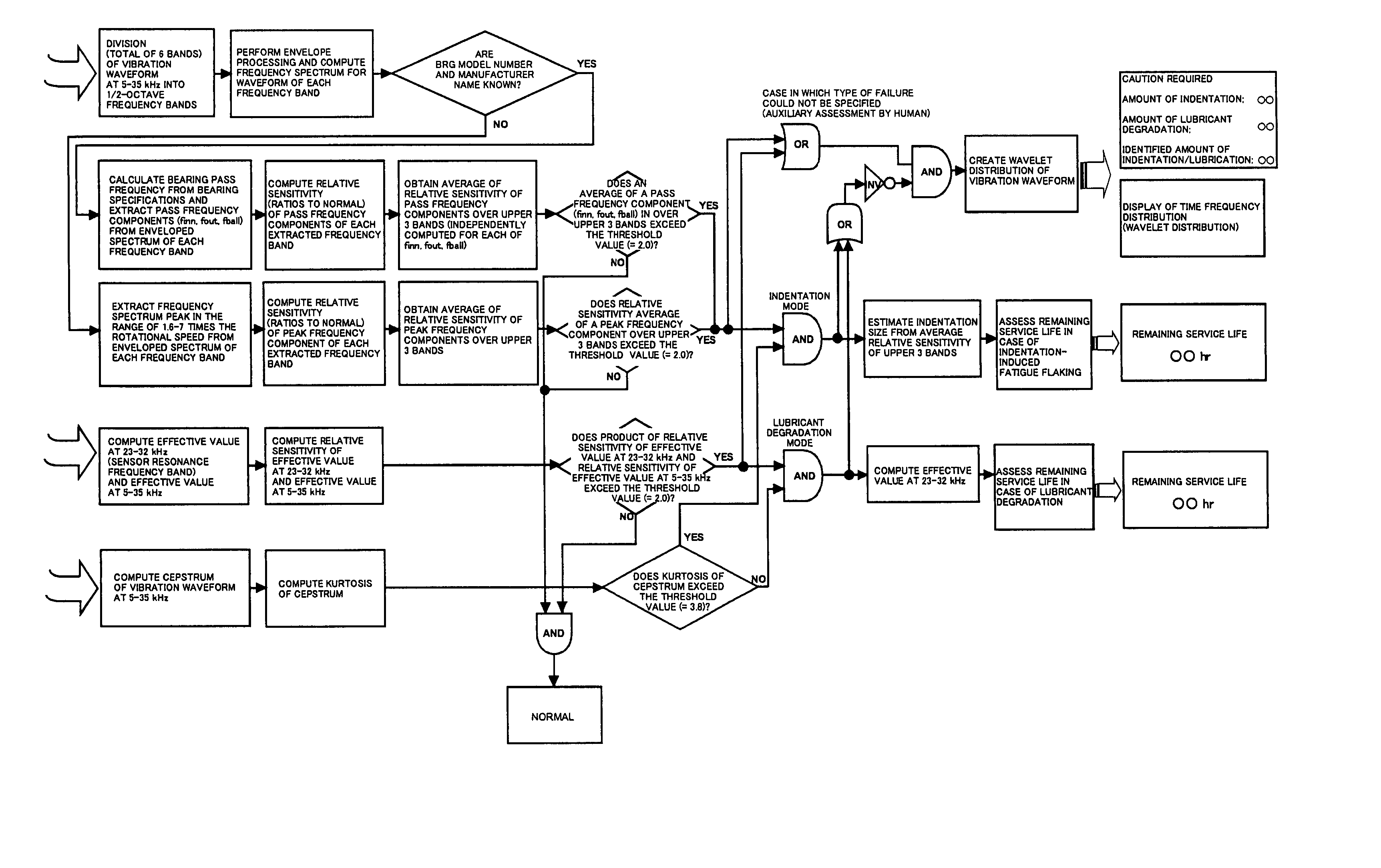

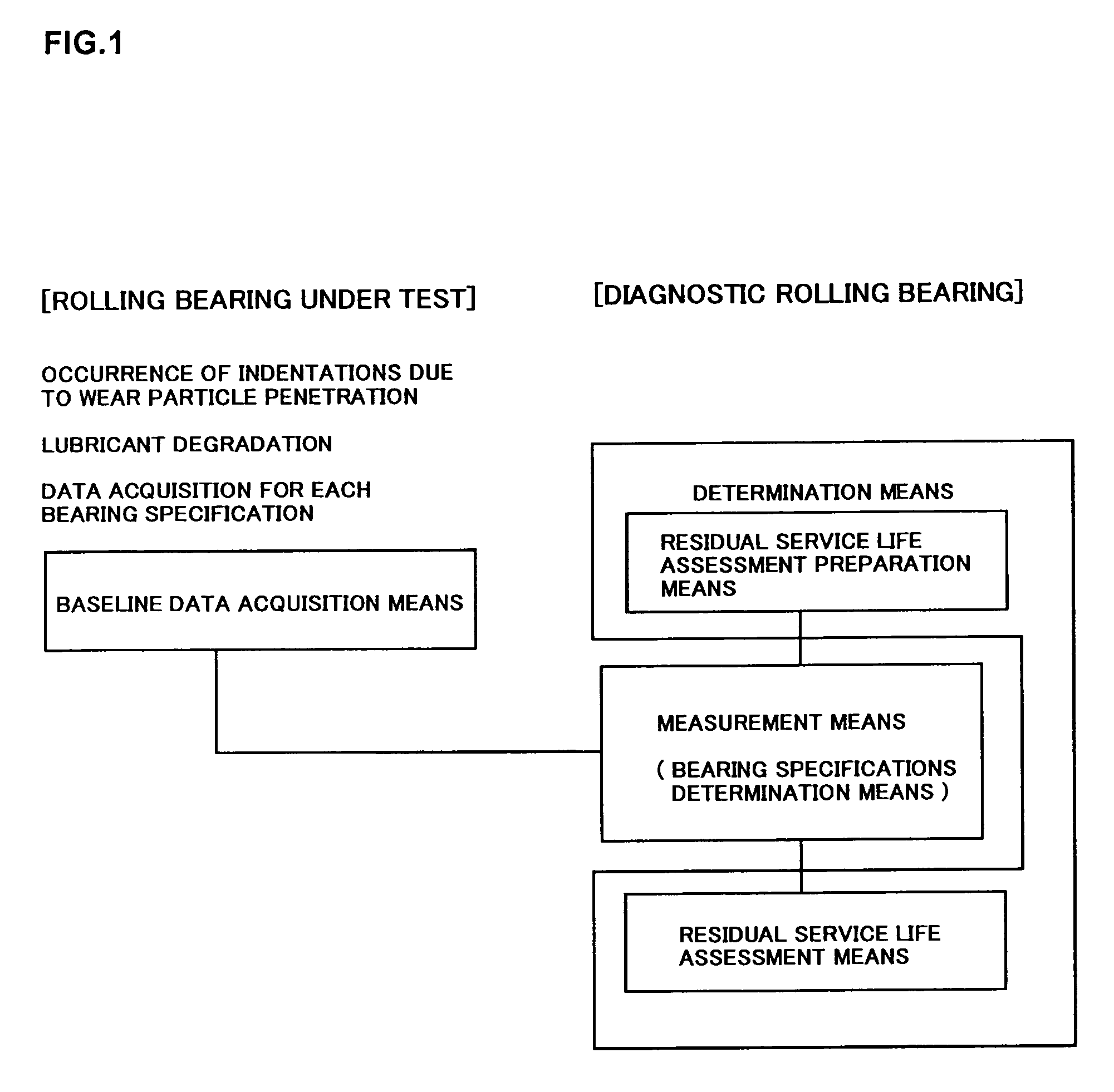

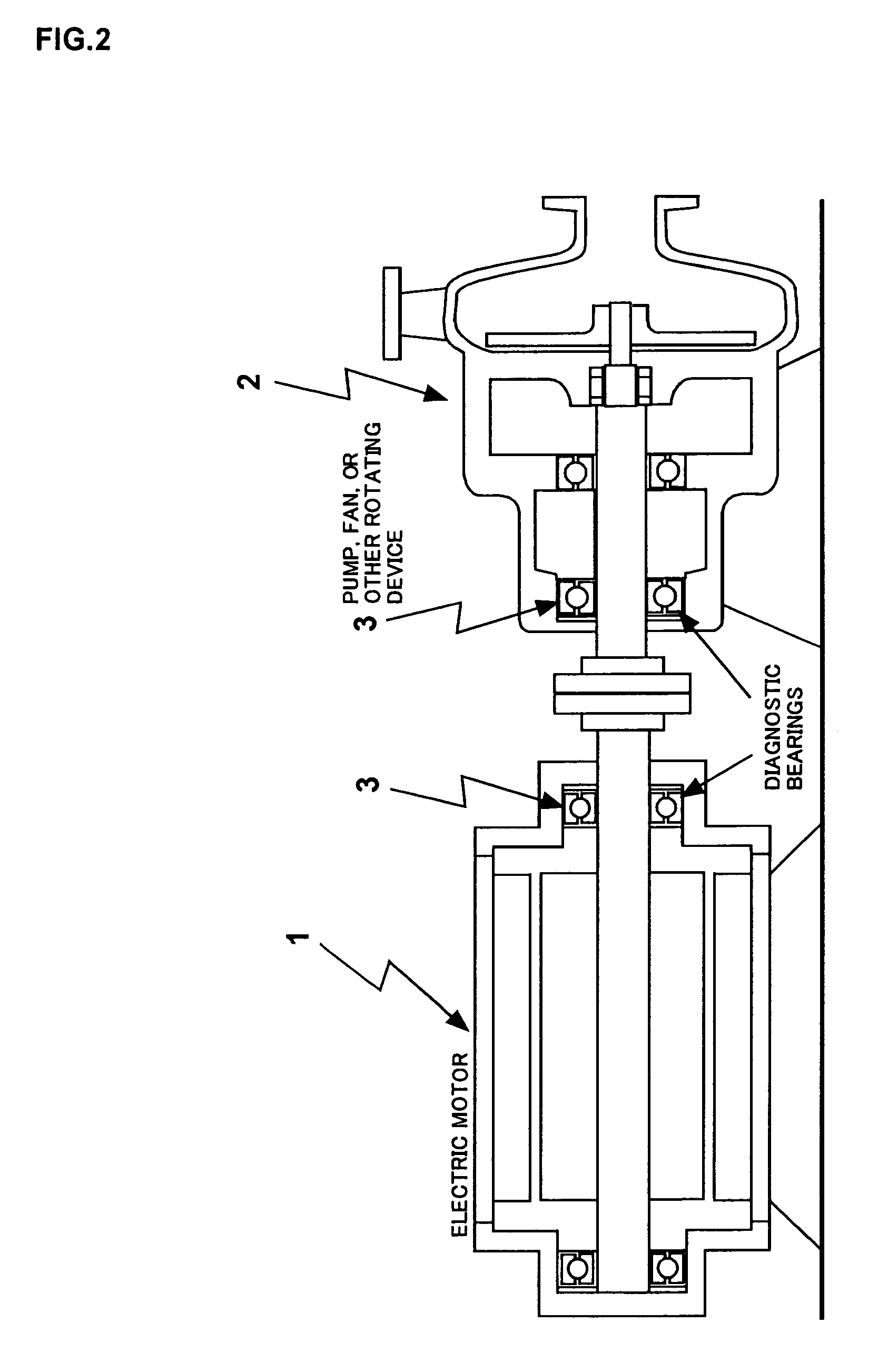

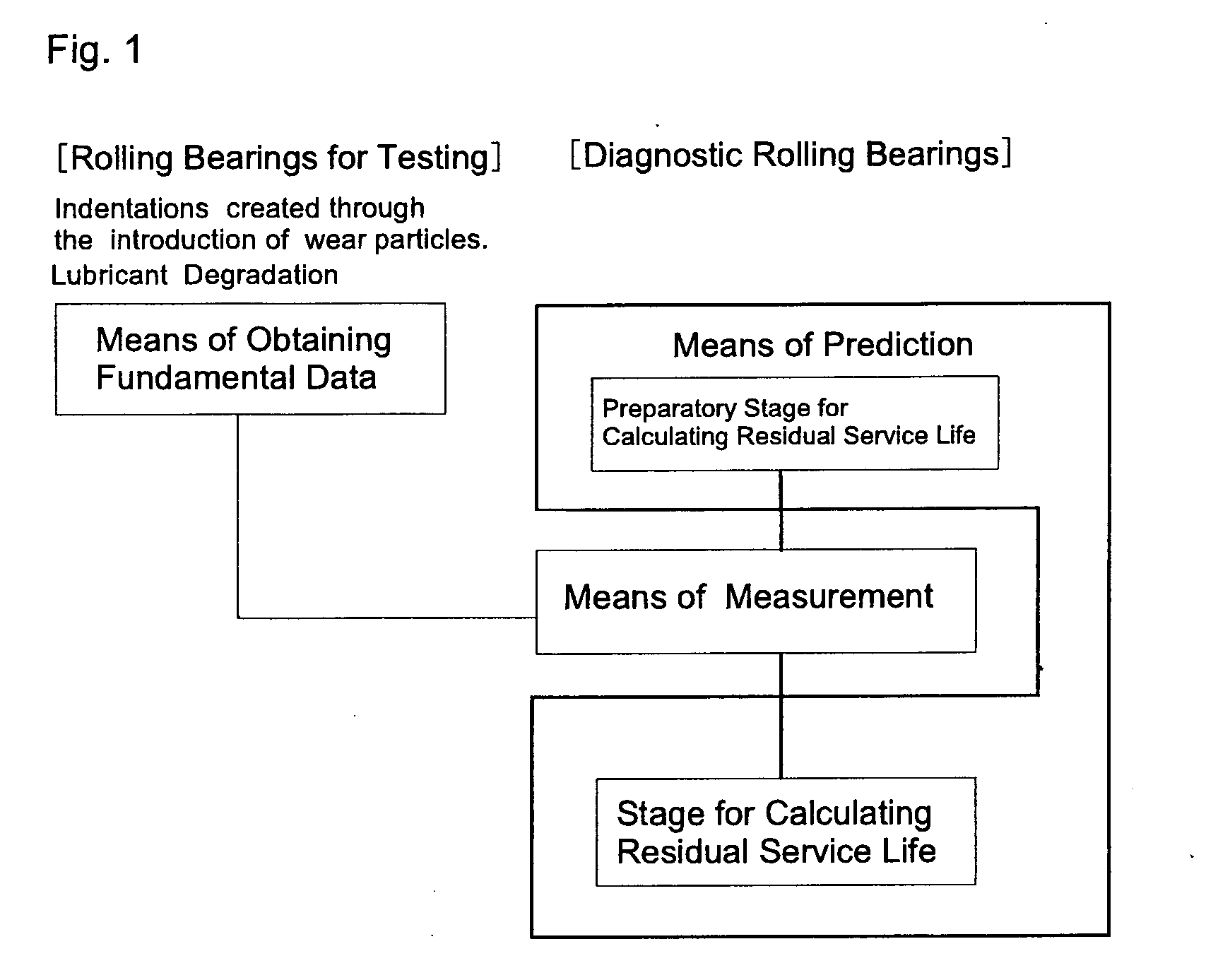

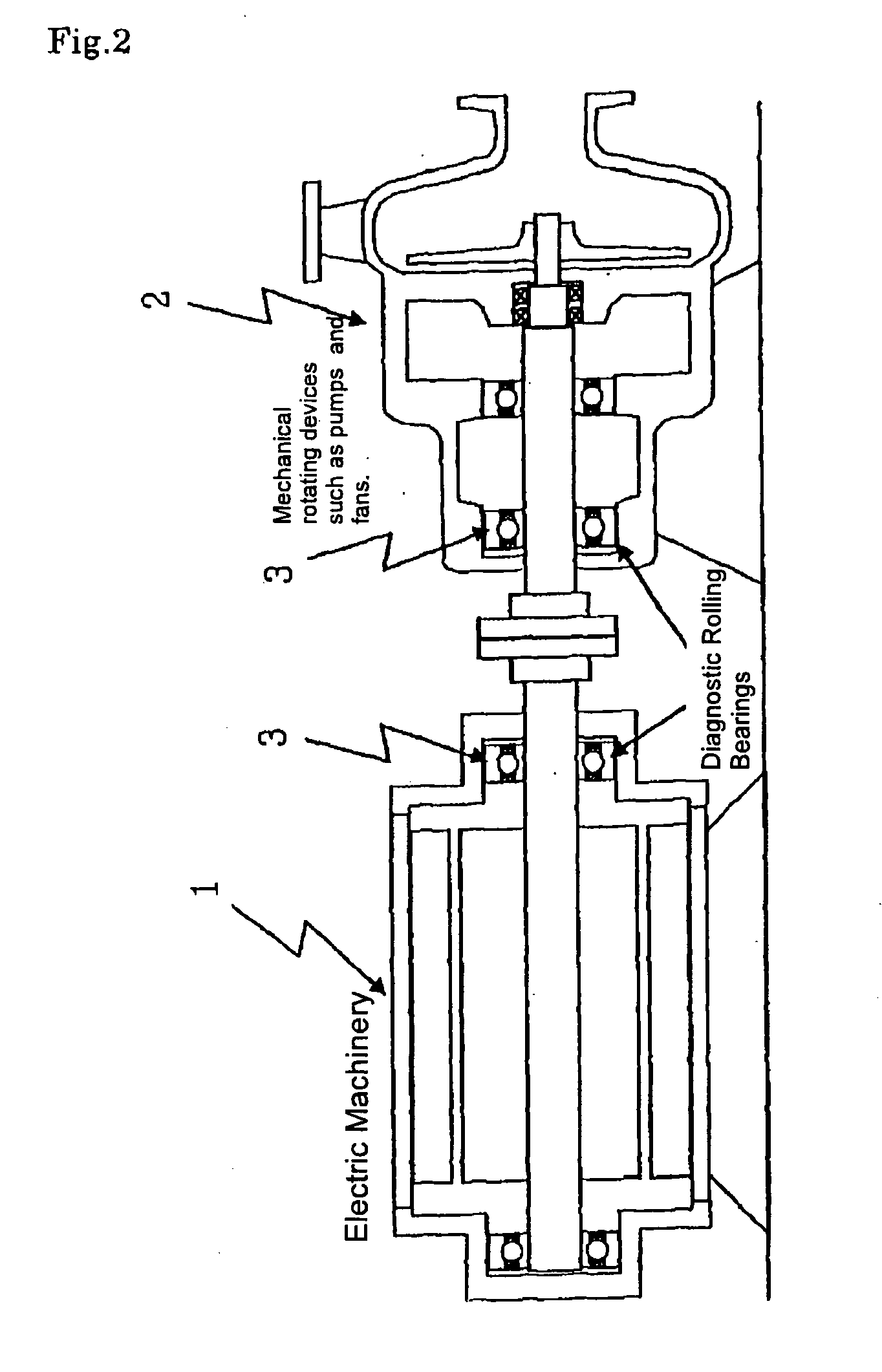

Method And Device For Assessing Residual Service Life Of Rolling Bearing

InactiveUS20070277613A1Improve accuracyVibration measurement in solidsMachine part testingBaseline dataAccelerometer

Degradation of the lubricant due to contamination of the lubricant with wear particles or moisture, which greatly affects the service life of rolling bearings, can be detected in a cost-effective manner through the use of a resonance frequency band signal or high-frequency signal of an accelerometer, and the service life of a rolling bearing can be estimated with high precision at an early stage on the basis of the detected state of the wear particles and lubricant. Provided is a method comprising baseline data acquisition means for obtaining vibration signals by using an accelerometer 4 and using a testing device to acquire resonance frequency band signals detectable at the highest sensitivity, for each specification such as model number, manufacturer name, and other specifications for a rolling bearing 3 as pertains to the relationship between the state of wear particle penetration in a rolling bearing 3 and the vibration / bearing service life, and to lubricant degradation and vibration / bearing service life; measurement means whereby an accelerometer 4 is used to obtain vibration signals for the rolling bearing 3 whose remaining service life is being assessed and which resides on a fan, a pump, or another rotating device 1, 2, for the purpose of measuring resonance frequency band signals detectable at the highest sensitivity; and determination means for estimating the state of wear particle penetration and the state of lubricant degradation of the diagnostic rolling bearing 3, and computing the remaining service life of the diagnostic rolling bearing 3 by using measurement values obtained by the measurement means, determination results of the bearing specification determination means, and data obtained by the baseline data acquisition means.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

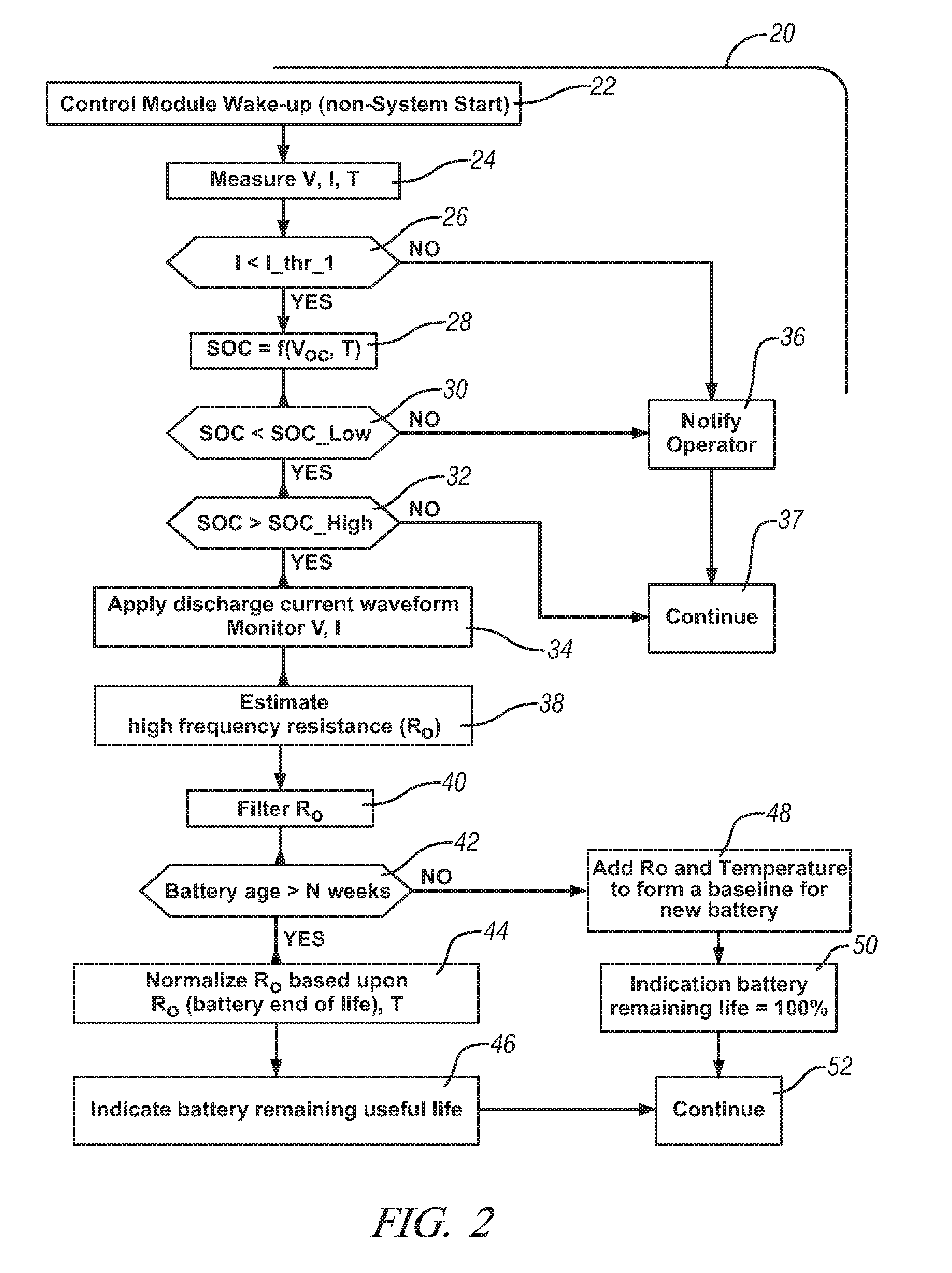

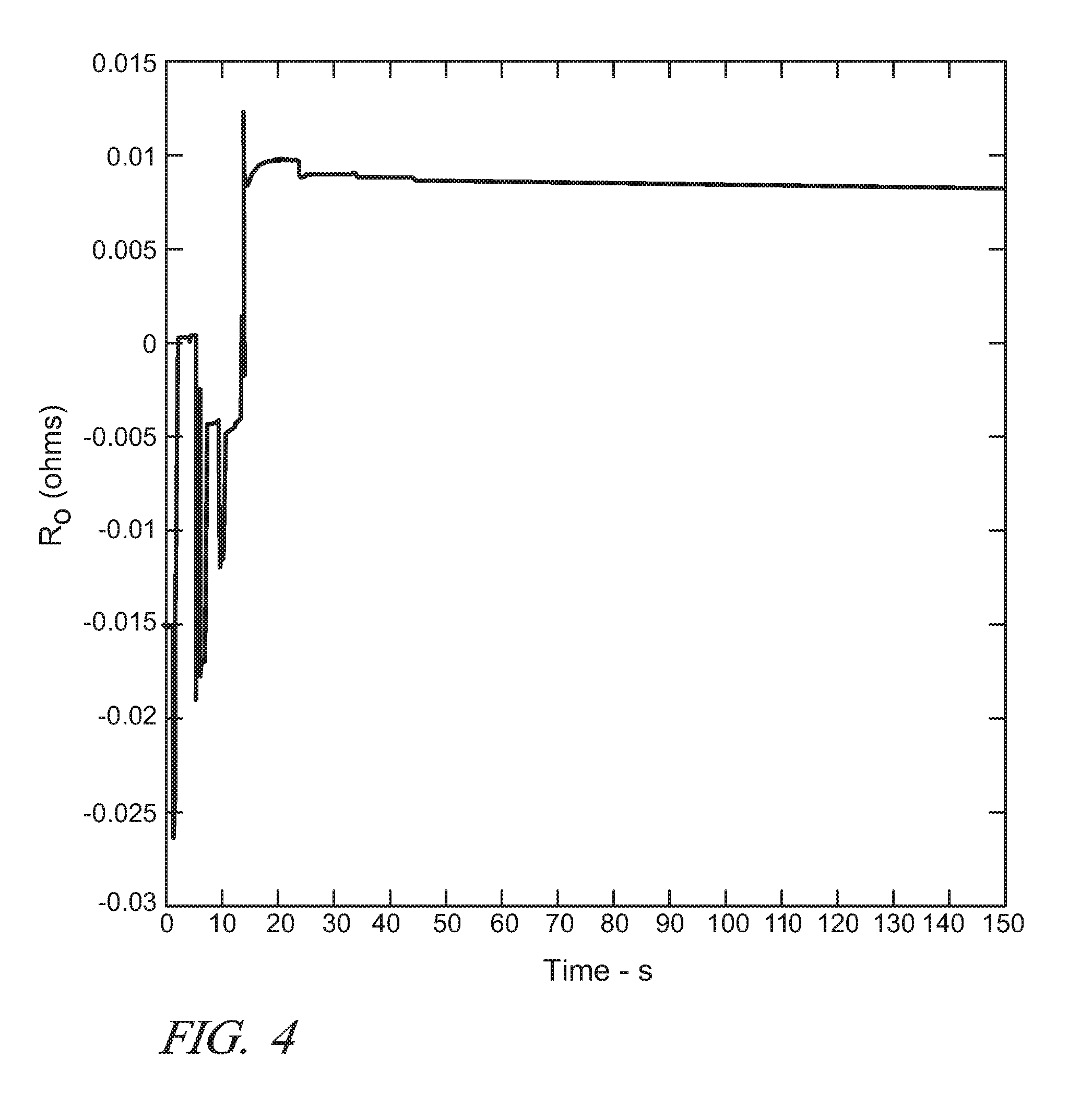

Method and article of manufacture for monitoring an electrical energy storage device

ActiveUS20070132456A1Material analysis by electric/magnetic meansTesting electric installations on transportElectrical resistance and conductanceElectricity

There is provided a method and article of manufacture for monitoring an electrical energy storage device for a system. The method comprises stabilizing the electrical energy storage device. Once the device is stabilized, a discrete electrical load is cyclically applied to the electrical energy storage device and state variables of the electrical energy storage device are monitored. A resistance of the electrical energy storage device is determined, and a remaining useful life parameter of the electrical energy storage device is determined based upon the determined resistance.

Owner:GM GLOBAL TECH OPERATIONS LLC

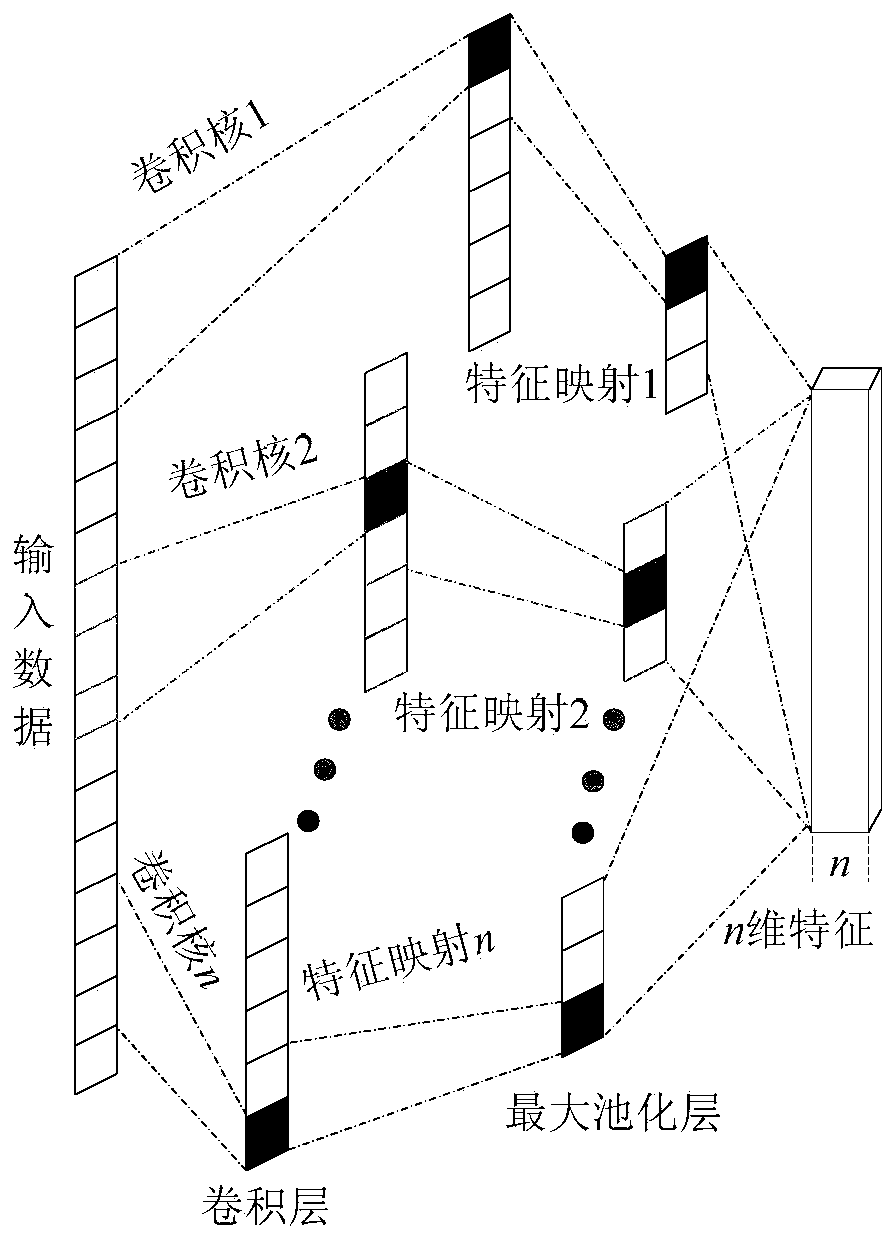

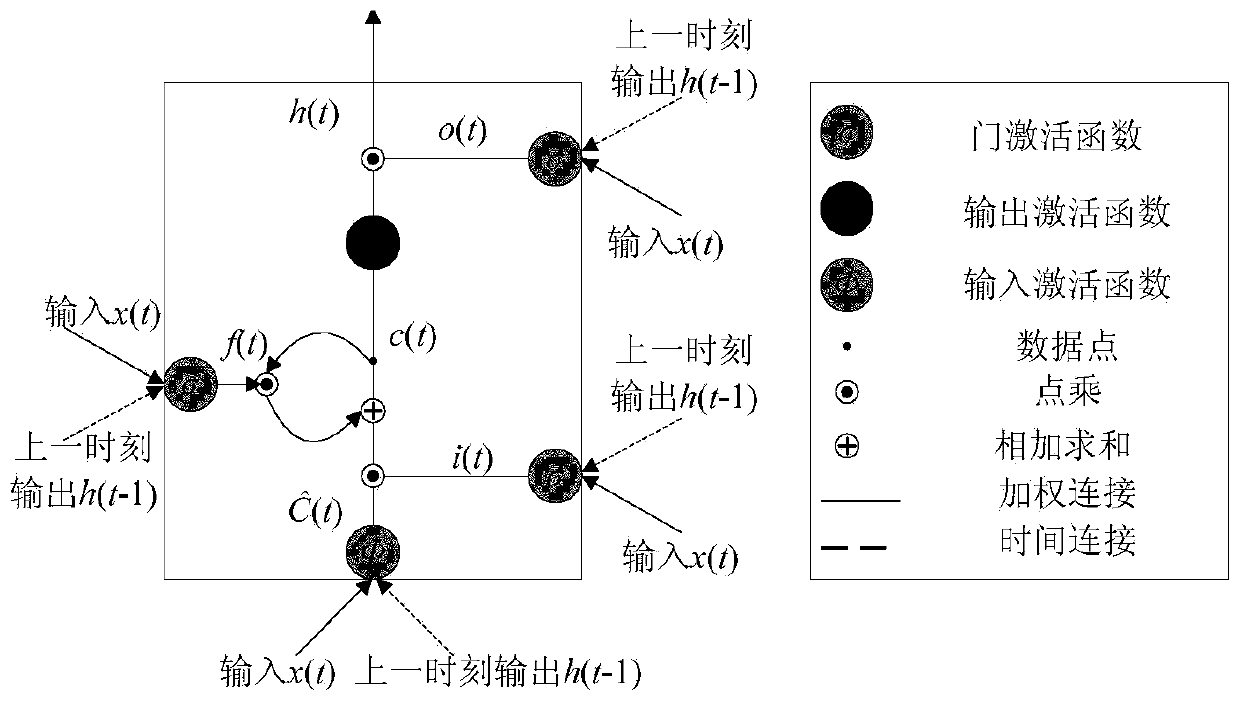

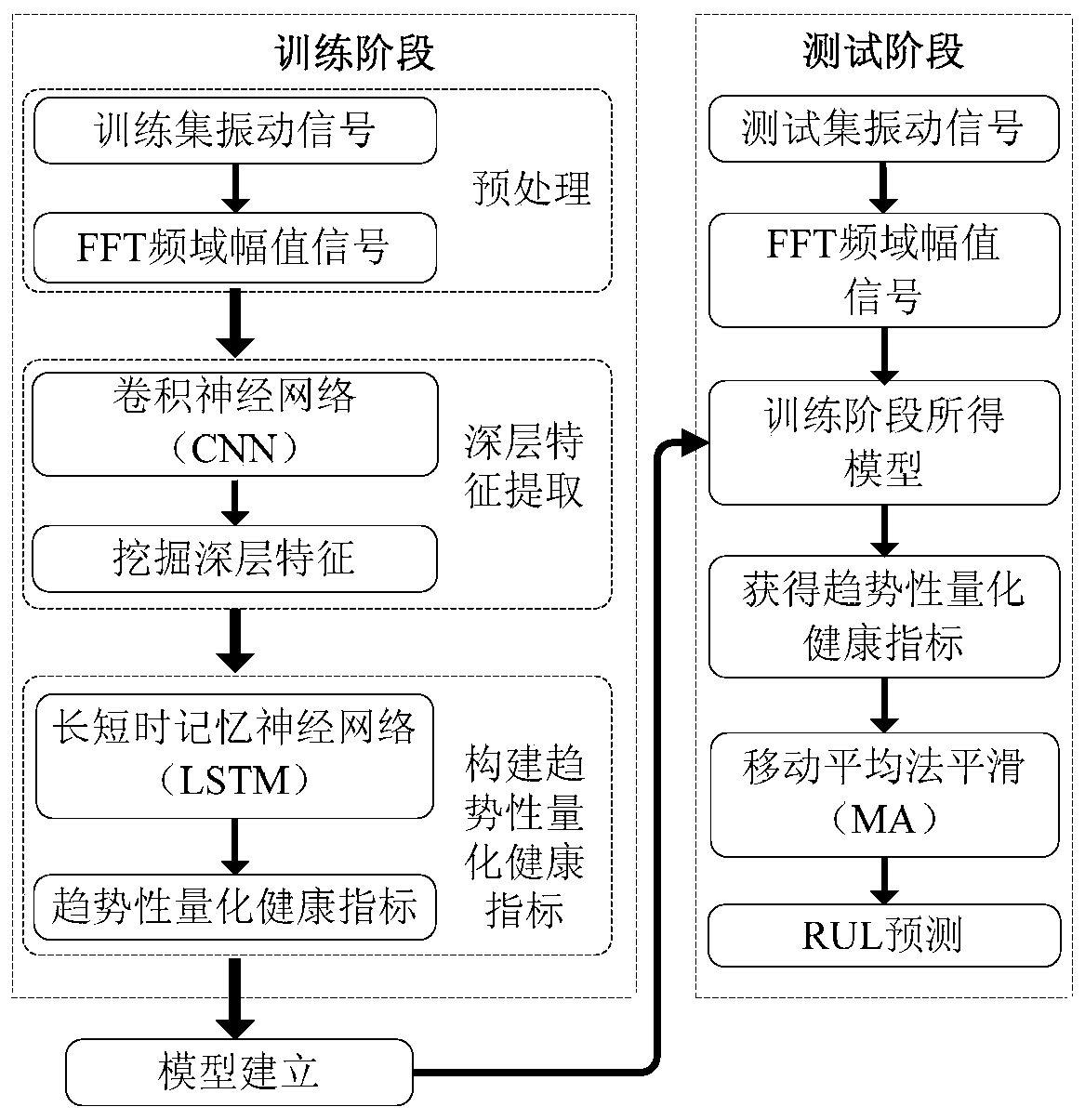

A CNN and LSTM-based rolling bearing residual service life prediction method

ActiveCN109726524AGood monotonic trendImprove approachMachine bearings testingCharacter and pattern recognitionMoving averageFast Fourier transform

The invention discloses a CNN and LSTM-based rolling bearing residual service life prediction method, and relates to the field of rolling bearing life prediction. The method aims to solve the problemthat residual service life (RUL) prediction of a rolling bearing is difficult in two modes of performance degradation gradual change faults and sudden faults. The method comprises the following stepsof: firstly, carrying out FFT (Fast Fourier Transform) on an original vibration signal of the rolling bearing, then carrying out normalization processing on a frequency domain amplitude signal obtained by preprocessing, and taking the frequency domain amplitude signal as the input of a CNN (Convolutional Neural Network); The CNN is used for automatically extracting data local abstract informationto mine deep features, and the problem that a traditional feature extraction method depends too much on expert experience is avoided. the deep features are input into an LSTM network, a trend quantitative health index is constructed, and a failure threshold value is determined at the same time; And finally, smoothing processing is carried out by using a moving average method, eliminating local oscillation, and a future failure moment is predicted by using polynomial curve fitting to realize rolling bearing RUL prediction. And the prediction result can be well close to the real life value.

Owner:HARBIN UNIV OF SCI & TECH

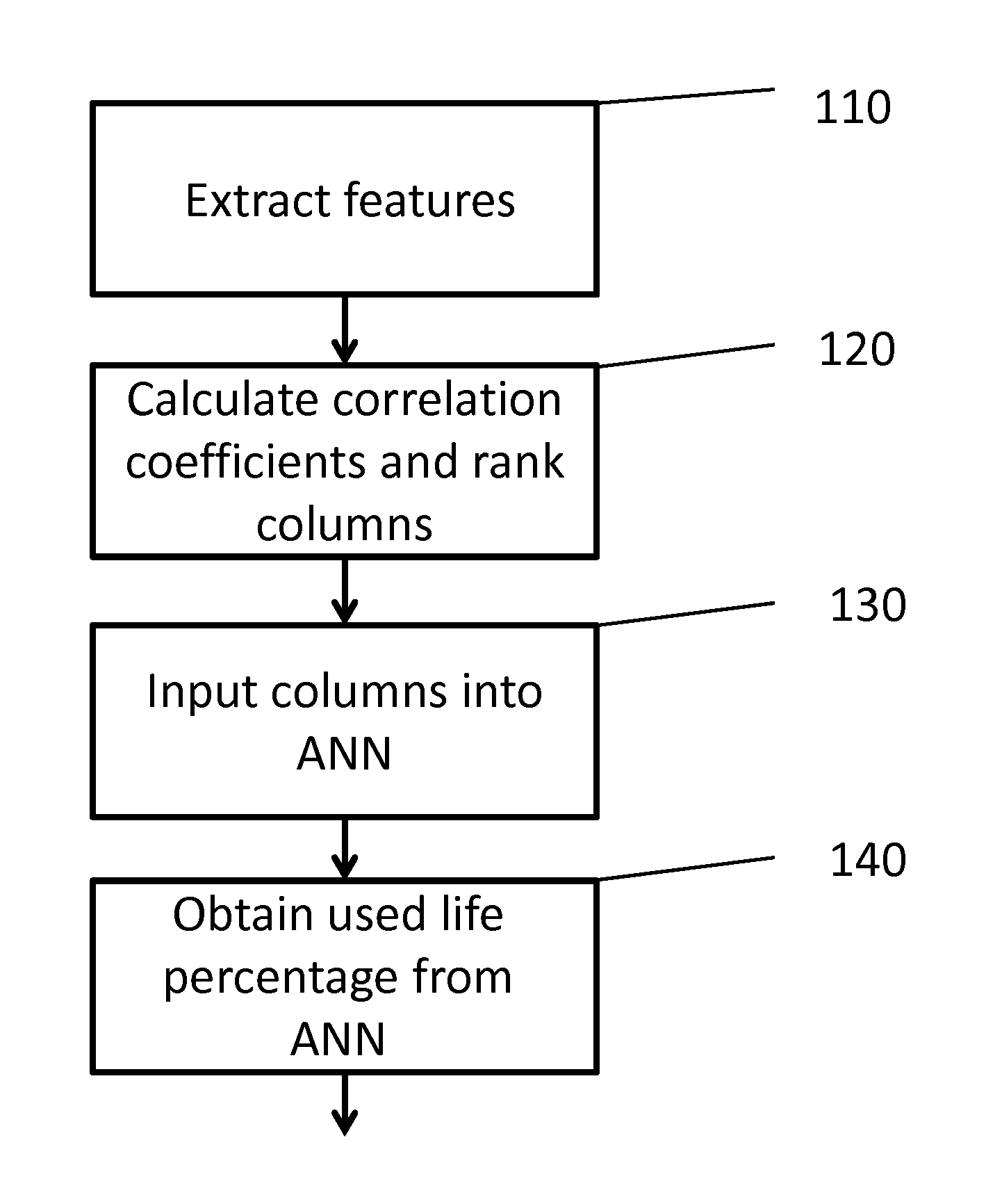

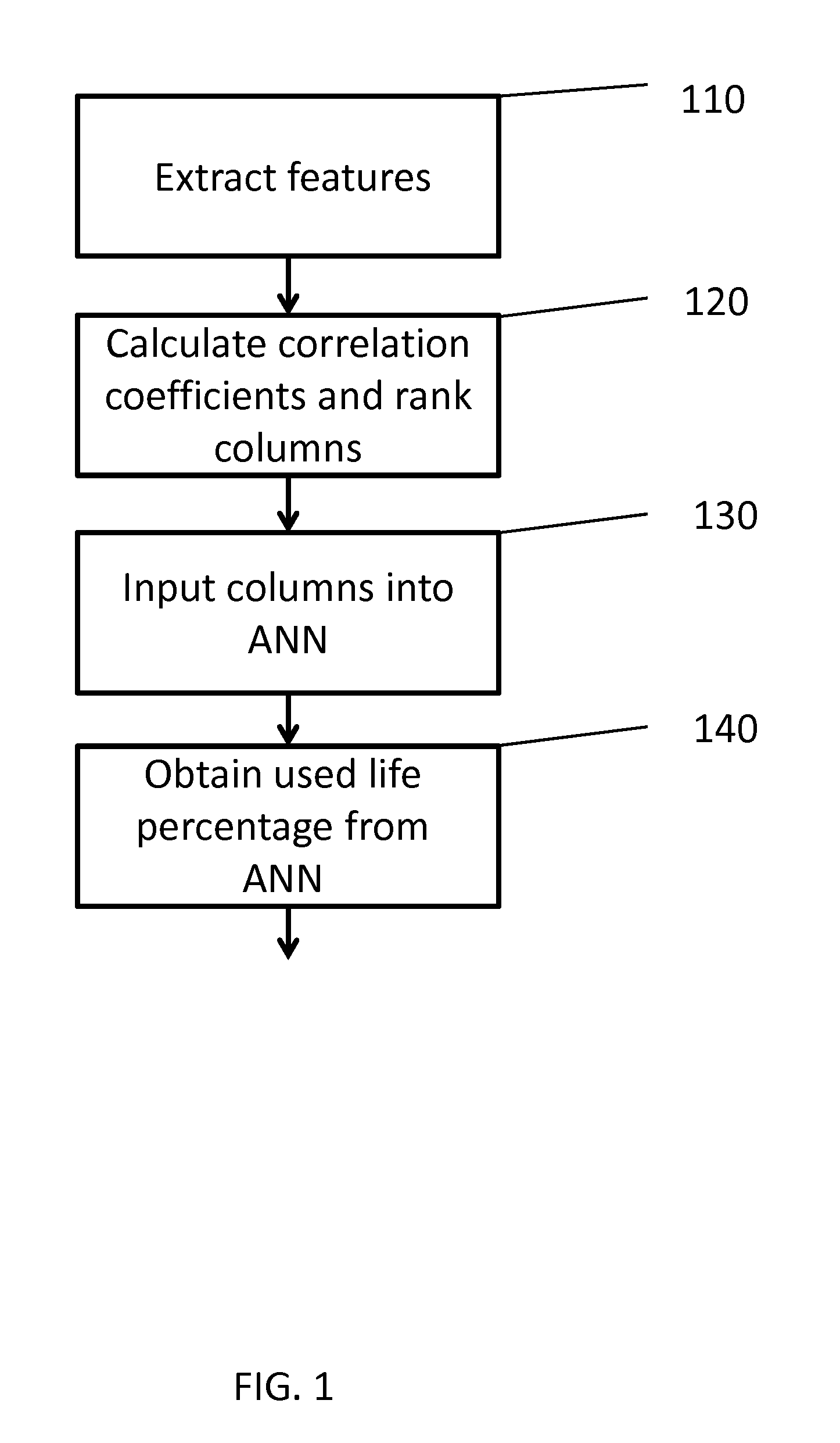

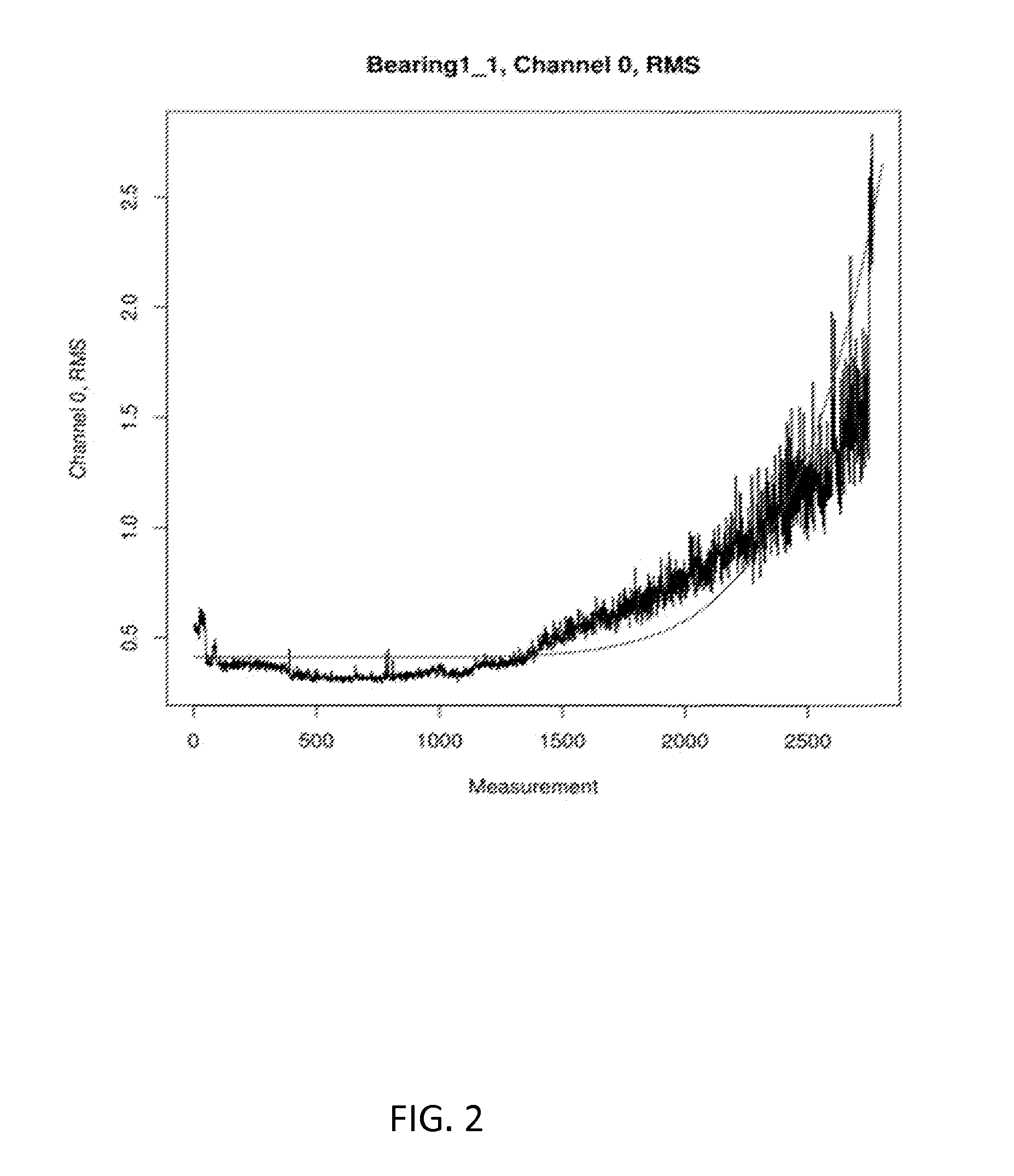

System and Method for Calculating Remaining Useful Time of Objects

ActiveUS20150262060A1Machine bearings testingDigital computer detailsMechanical componentsCondition monitoring

An aspect of the present invention is to provide a system and method for predicting the remaining useful time of mechanical components such as bearings. Another aspect of the present invention is to provide a system and method for predicting the remaining useful time of bearings based on available condition monitoring data. Another aspect of the present invention is to provide a system and method for automatically deciding which columns of input information are the most significant for predicting the remaining useful life of bearings. Another aspect of the present invention is to provide a system and method for performing an analysis of both test bearings and training bearings and determining which training bearings are most similar to a given test bearing. Another aspect of the present invention is to provide a system and method for training an artificial neural network.

Owner:SPARKCOGNITION INC

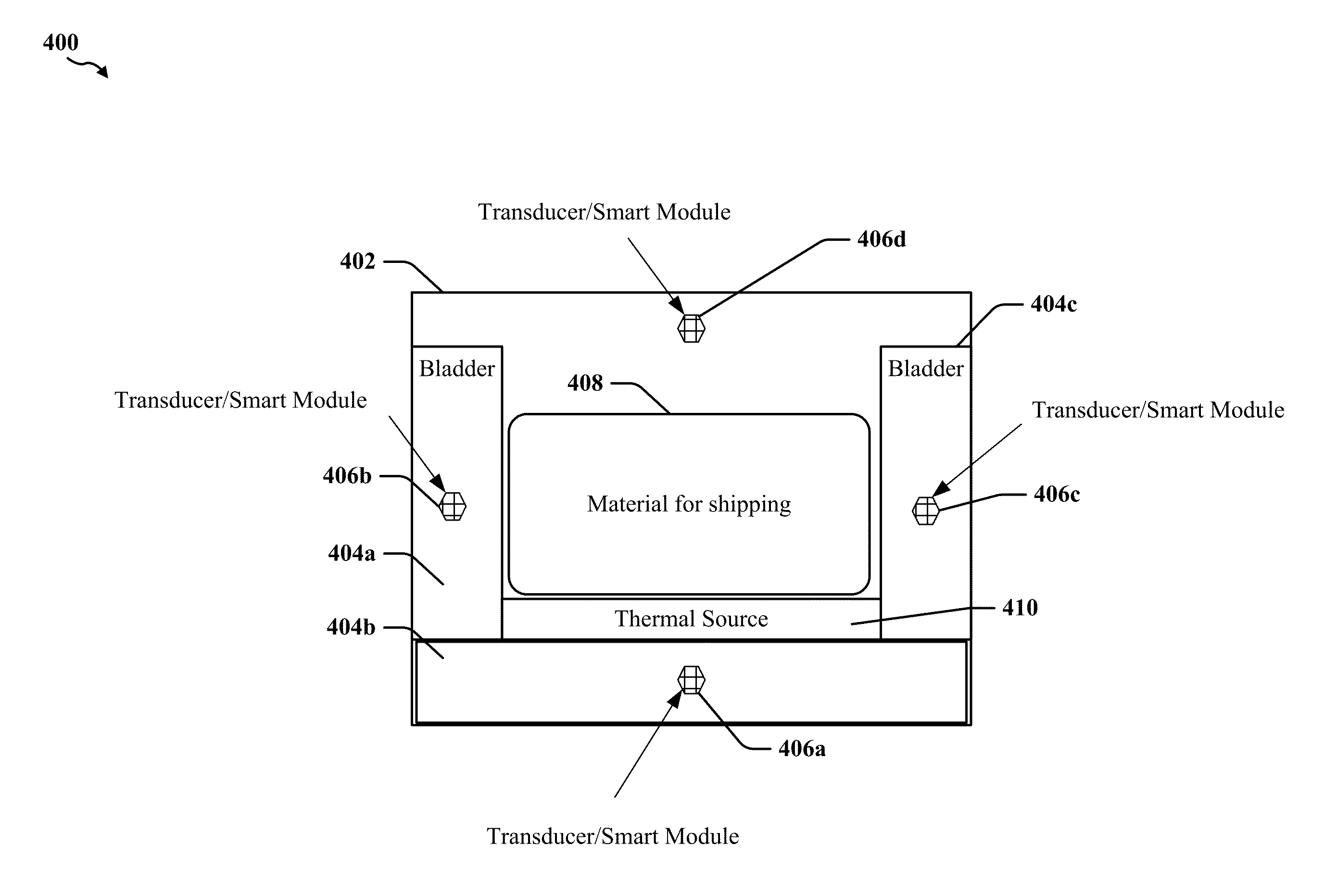

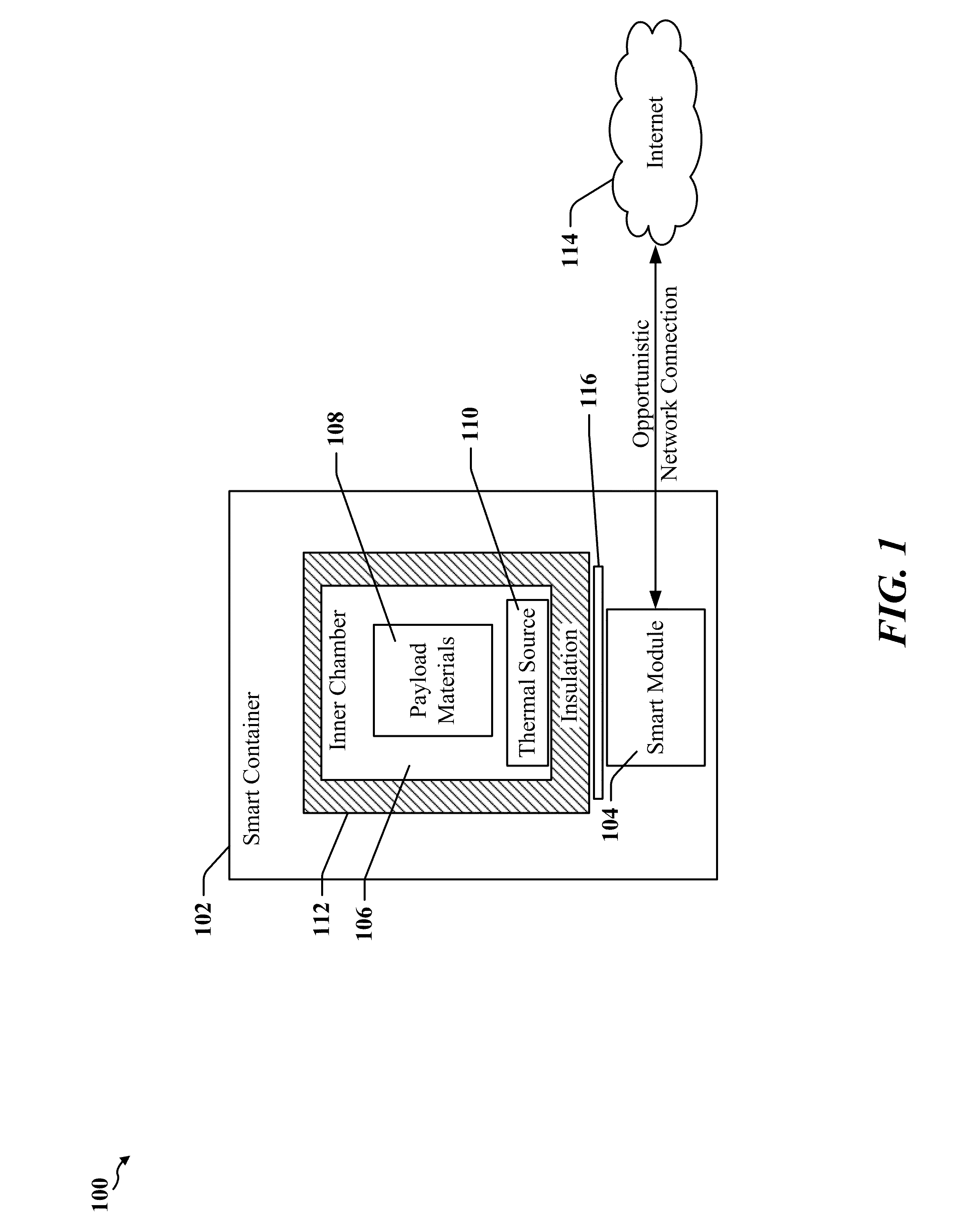

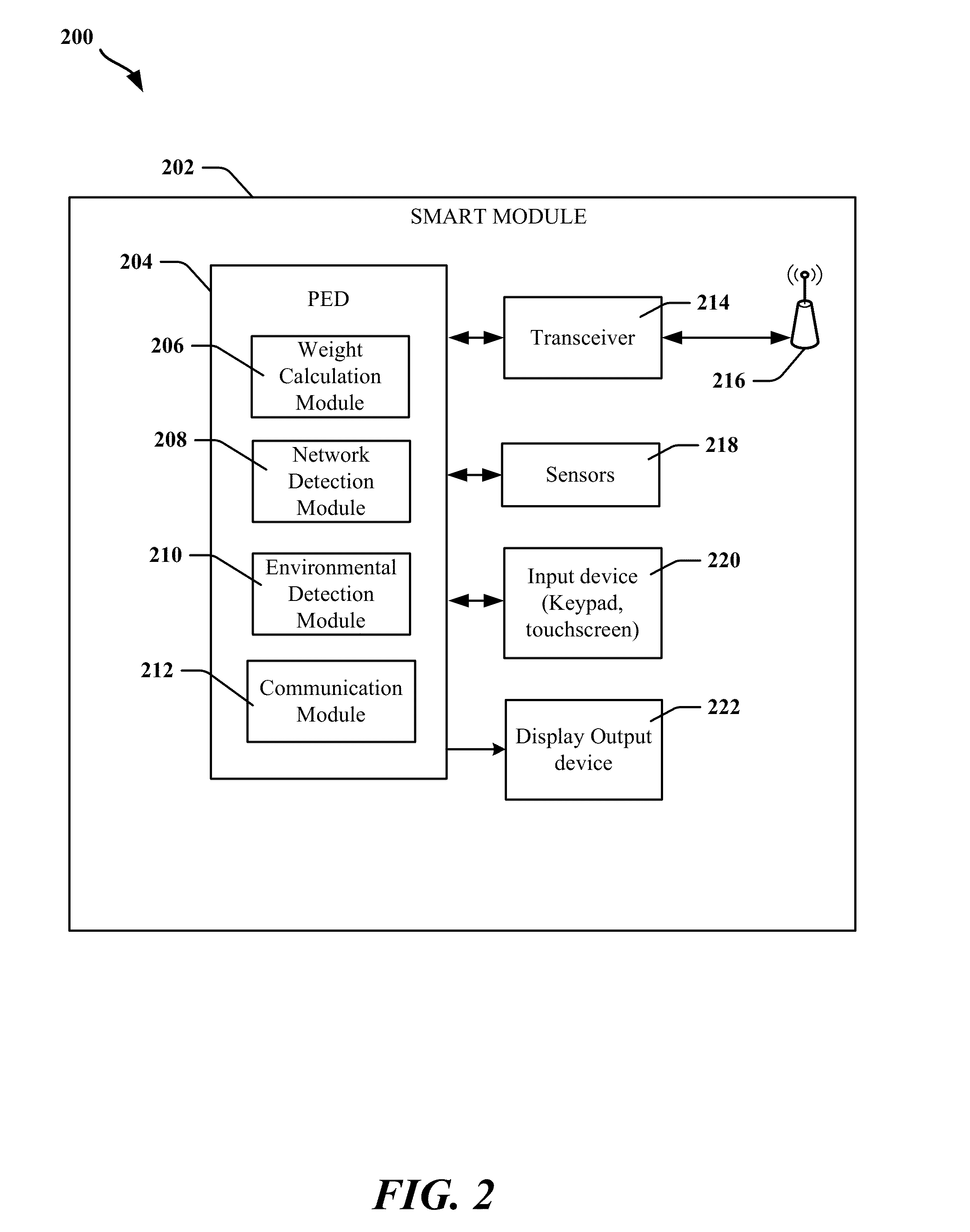

Method for determining the remaining life of a thermal mass in a shipping package while in transit

InactiveUS20130245991A1Data processing applicationsLighting and heating apparatusTemperature controlTransducer

A shipping container is described for use with methods for monitoring and controlling shipment of a temperature controlled material and determining the remaining useful life of a Thermal Source contained within the shipping container. The container comprises an inner enclosure adapted to carry one or more commodities during shipment, a bladder conformed to the inner surface of the inner chamber, or a plate upon which commodities are place, and instrumented with at least one transducer and at least one processing device configured to receive measurements from the at least one transducer. The processing device communicates the measurements to a networked device upon detecting the presence of a network. The networked device may transmit commands to the processing device that causes the processing device to adjust a configuration parameter.

Owner:KLATU NETWORKS

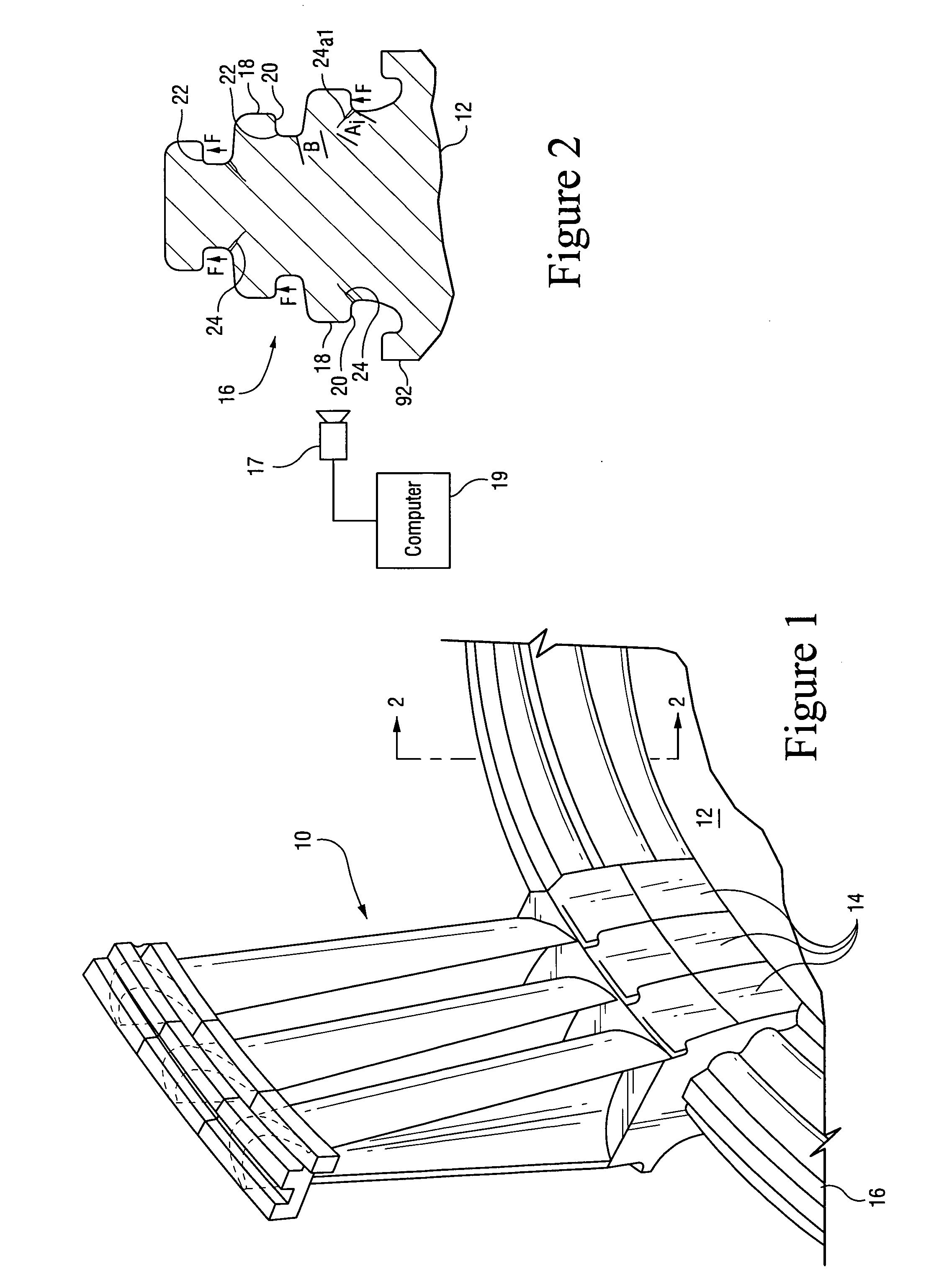

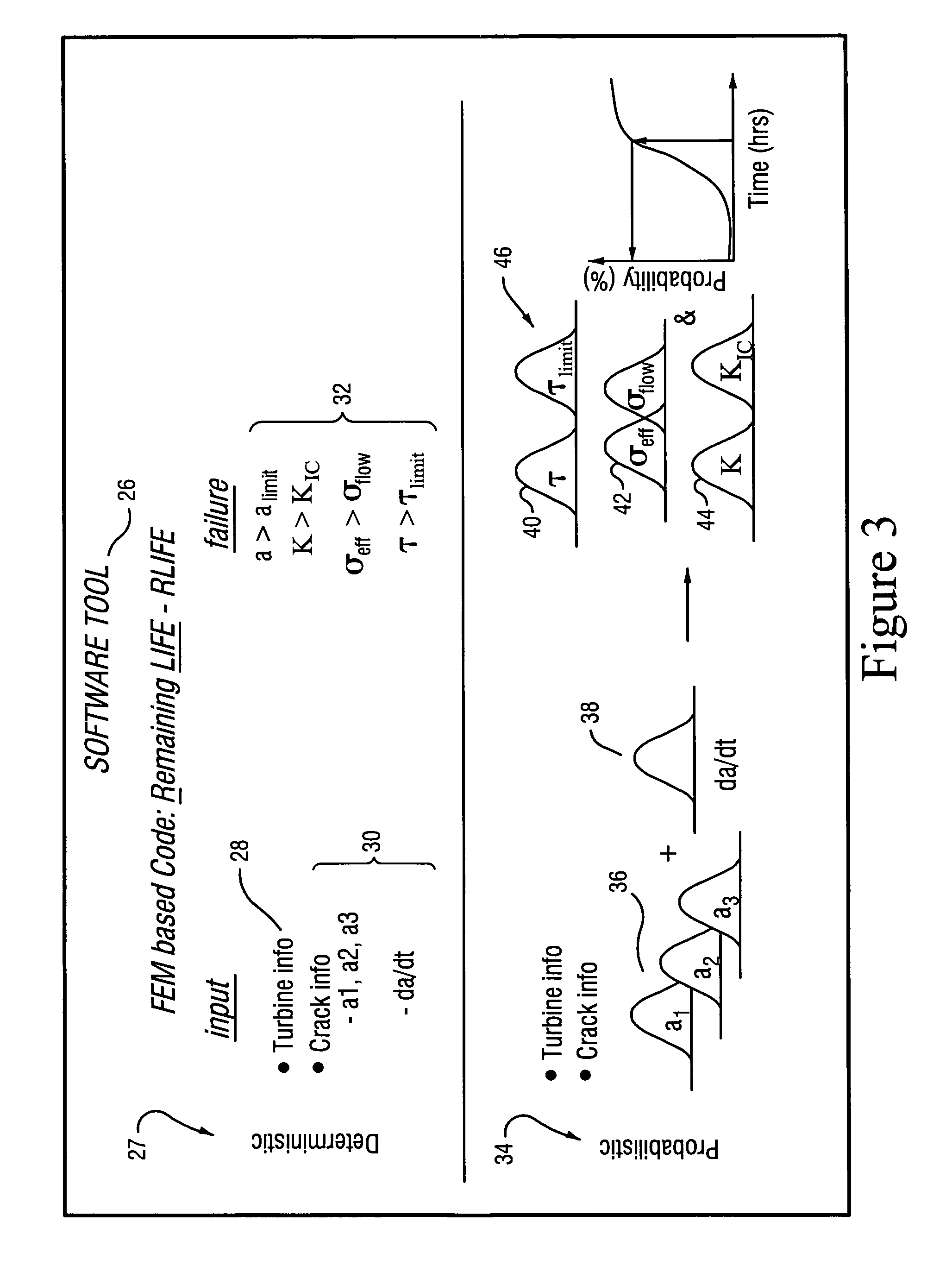

Method and system for assessing life of cracked dovetail in turbine

ActiveUS7162373B1Material analysis using sonic/ultrasonic/infrasonic wavesEngine fuctionsTurbineReliability engineering

A method has been developed for predicting a remaining operational life of a turbine component including: obtaining crack flaw data regarding current crack flaws in the turbine component; using the crack flaw data with data regarding the structure and operating conditions of the turbine component to determine force loads applied to the turbine component and generate crack propagation data; applying a probalistic analysis to the crack flaw data and the generated crack propagation data to generate a statistical distribution of crack data, and applying the statistical distribution of crack data to predict a time to failure of the component by iteratively determining the force loads for successive periods of time.

Owner:GENERAL ELECTRIC CO

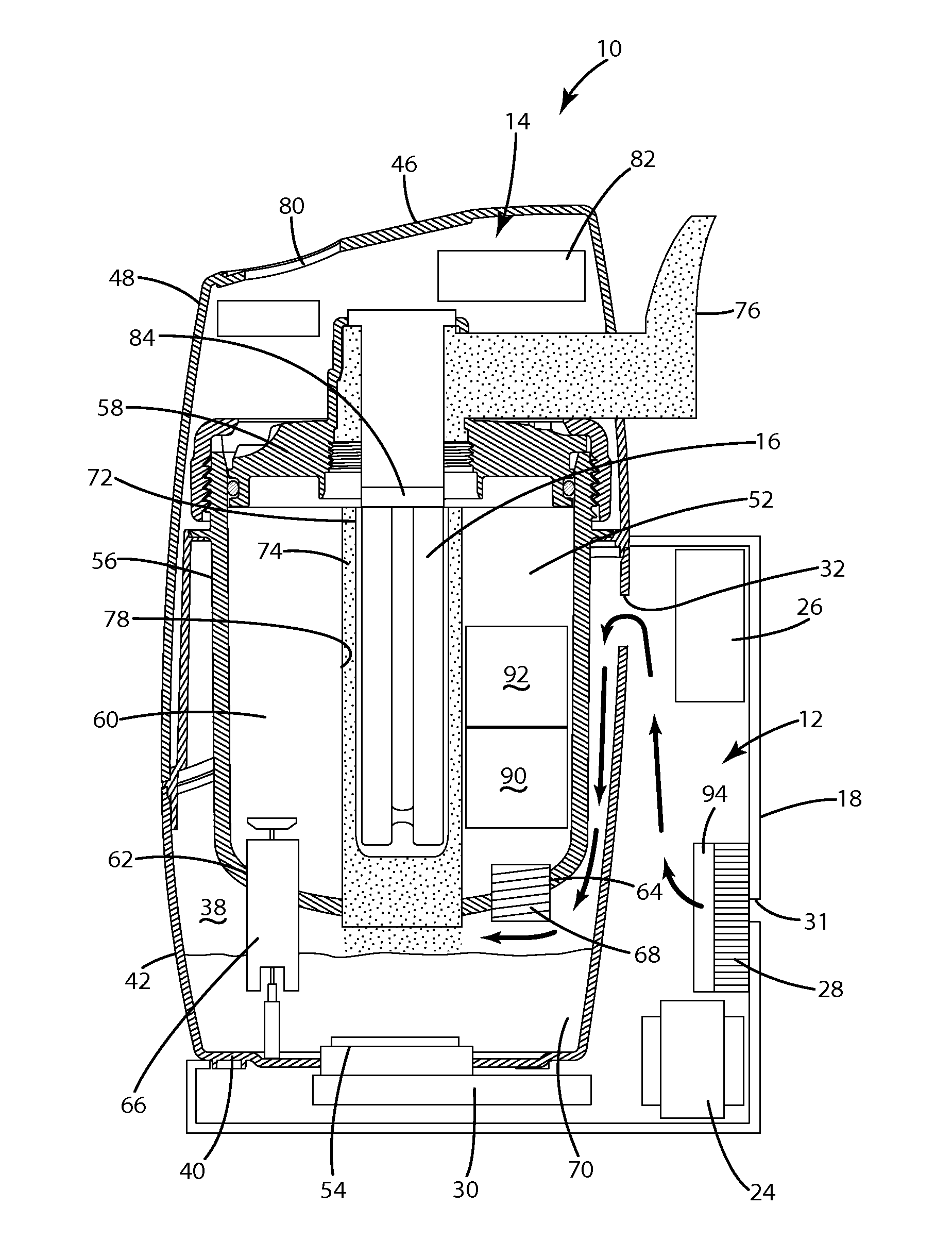

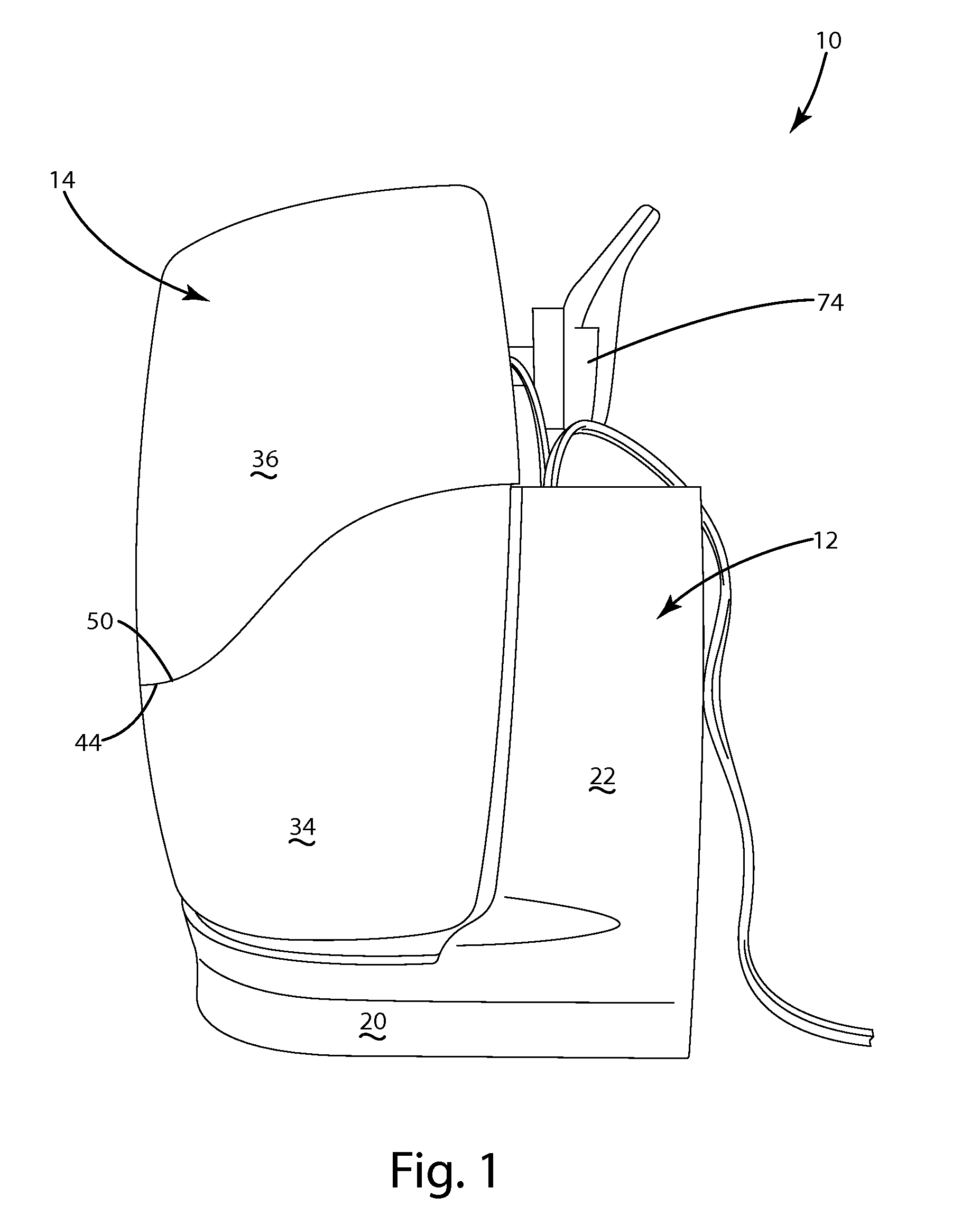

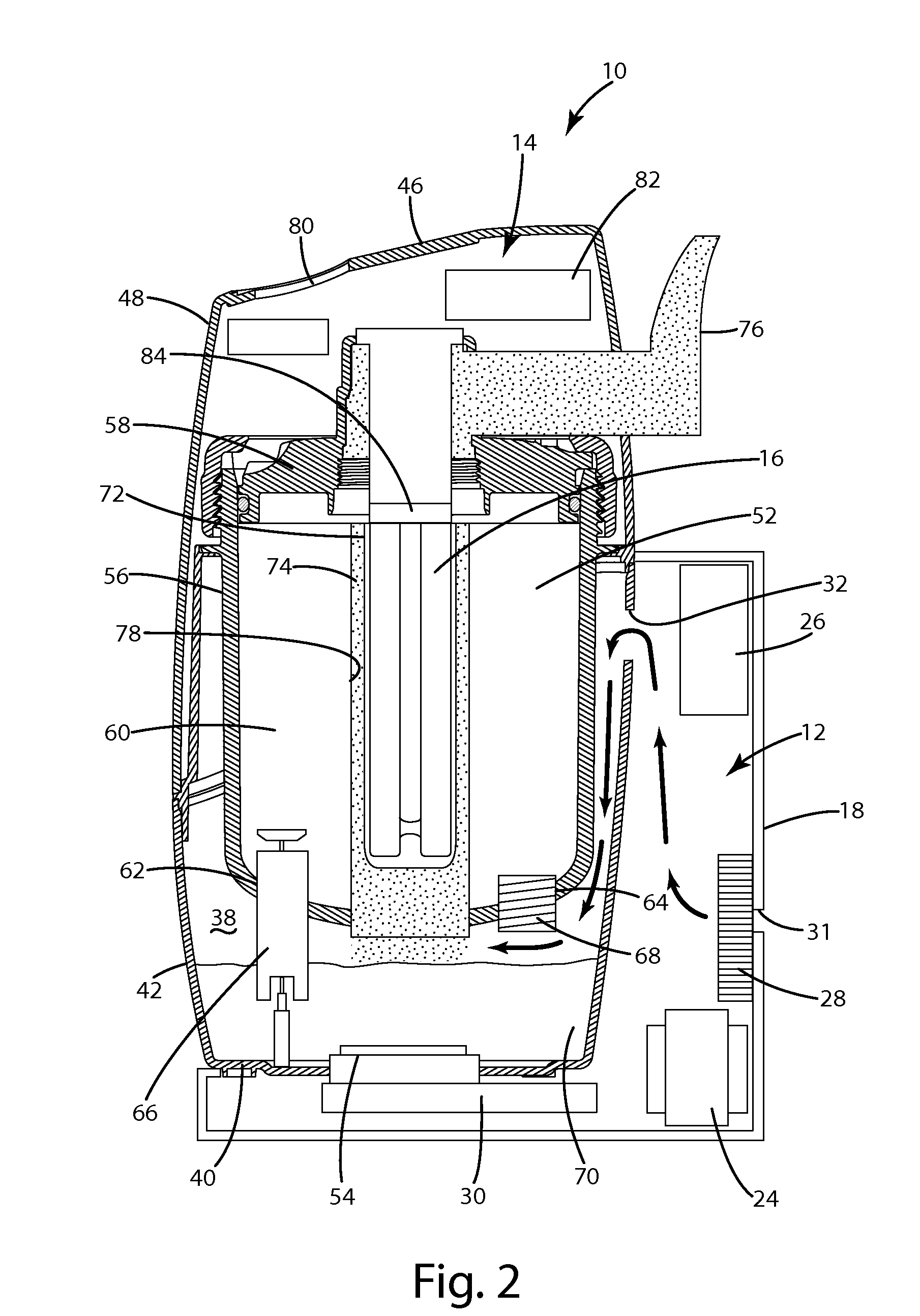

Humidifier with ultraviolet disinfection

ActiveUS20120234166A1Increase moisture contentAvoid effectivenessCombination devicesMechanical apparatusCylindrical channelUltraviolet lights

A humidifier for treating humidified air with germicidal light is provided. The humidifier includes a water reservoir, an atomizer to atomize a supply of water, and an ultraviolet light source to expose the atomized water to germicidal light. The ultraviolet light source extends vertically within a cylindrical channel to irradiate the atomized water dissipating upwardly from the atomizer. The water reservoir can include a carbon filter and a hardness-removing module for removing containments and metal oxides from the water supply. A control panel indicates the remaining useful life of the ultraviolet light source, the carbon filter and the hardness-removing module based on historical humidifier usage and water quality levels.

Owner:ACCESS BUSINESS GRP INT LLC

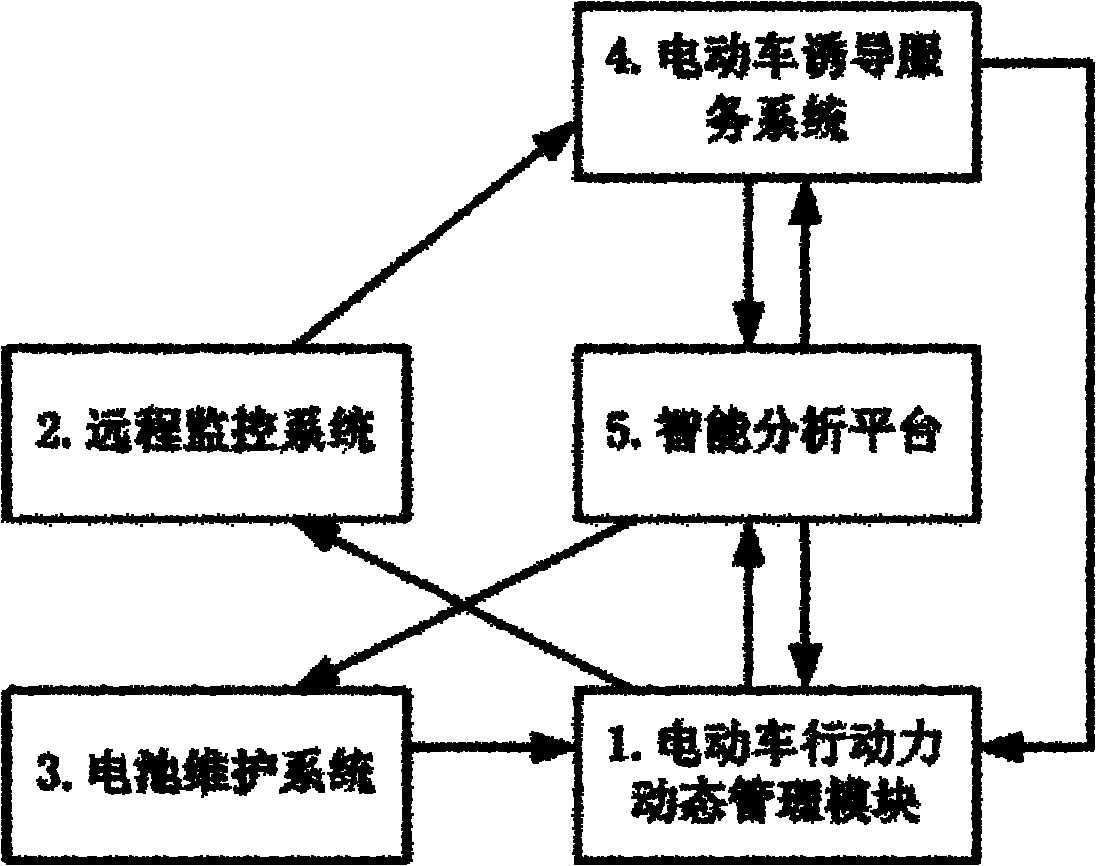

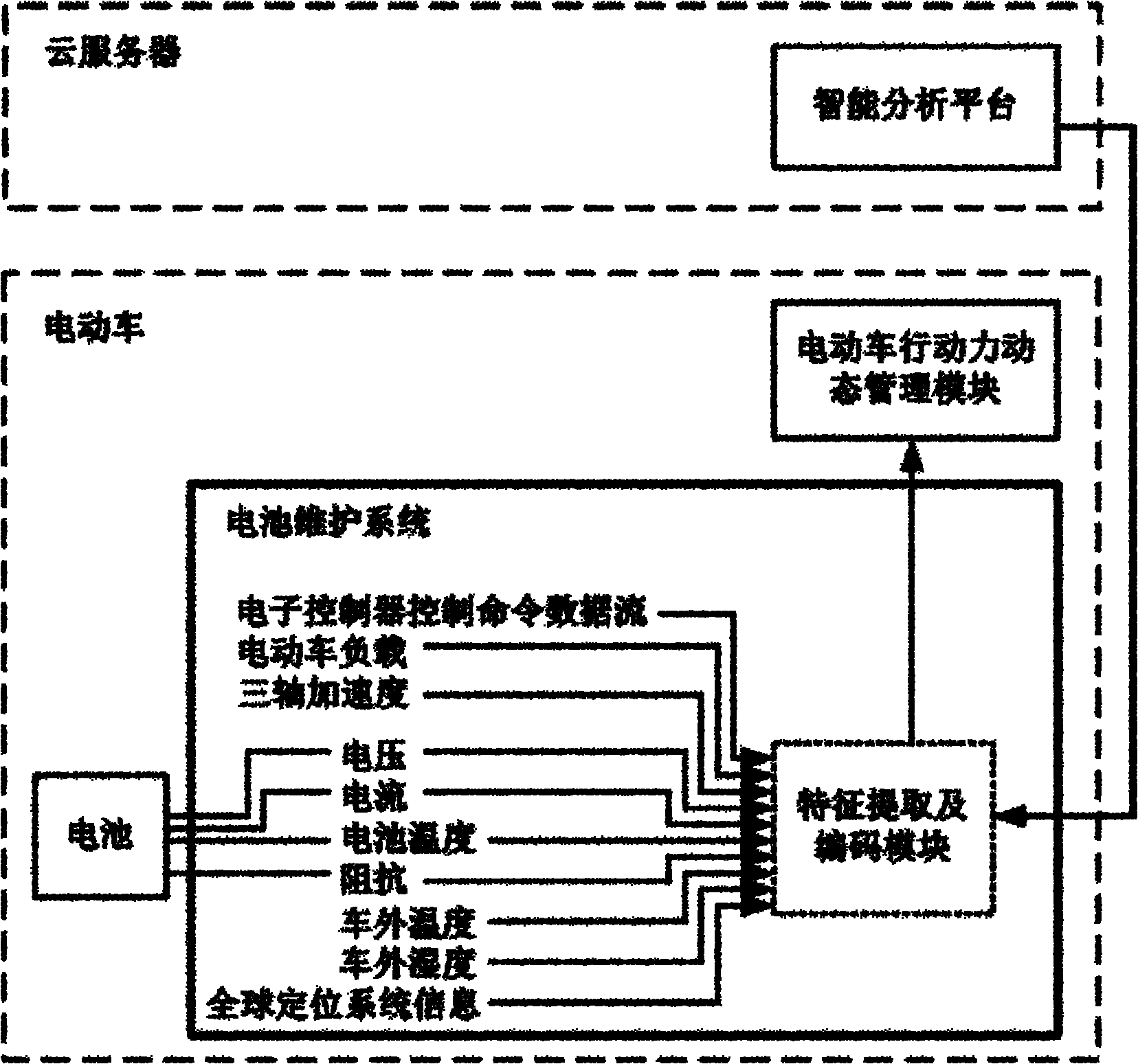

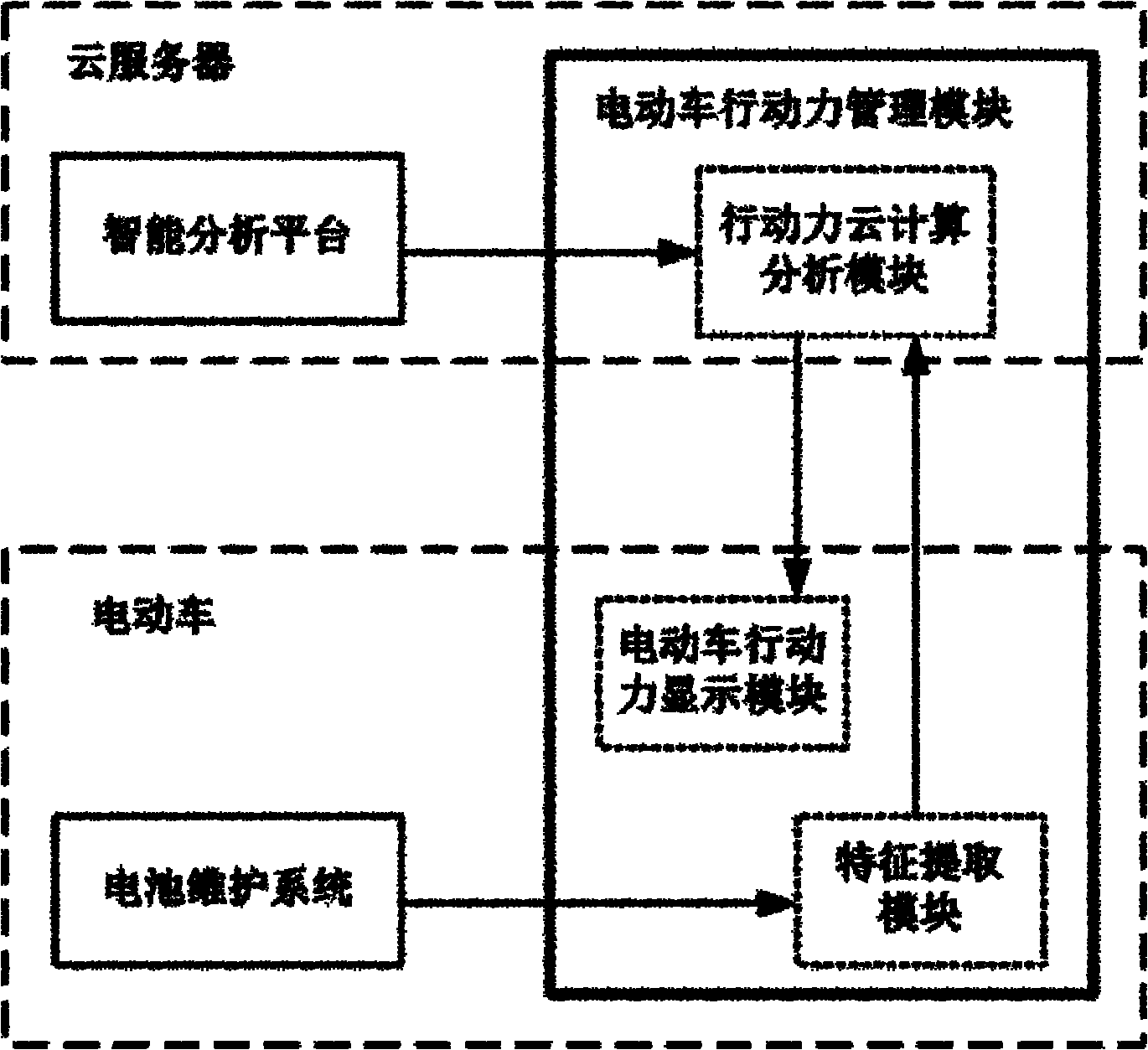

Electric car running power management system

ActiveCN102024999AReduce manufacturing costReduce design costData processing applicationsSecondary cells servicing/maintenanceData informationEngineering

The invention relates to an electric car power management and monitoring system in the technical field of electric cars. The system comprises an electric car running power dynamic management module, a battery maintenance system, a remote monitoring system, an electric car induction service system and an intelligent analysis platform, wherein the battery maintenance system is connected with various sensors on the electric car and used for acquiring data information and feature parameters; the electric car running power dynamic management module is connected with the battery maintenance system;the remote monitoring system is connected with the battery maintenance system to obtain positioning information from the battery maintenance system on the electric car; the intelligent analysis platform is connected with the electric car running power dynamic management module and used for transmitting model parameter information; and the electric car induction service system is connected with the intelligent service platform system and used for transmitting service queue information and service demand information shared in the network of electric car users. The invention can accurately forecast the residual service life of the battery of the electric car and realize the dynamic management of the running power condition of the electric car.

Owner:SHANGHAI JIAO TONG UNIV

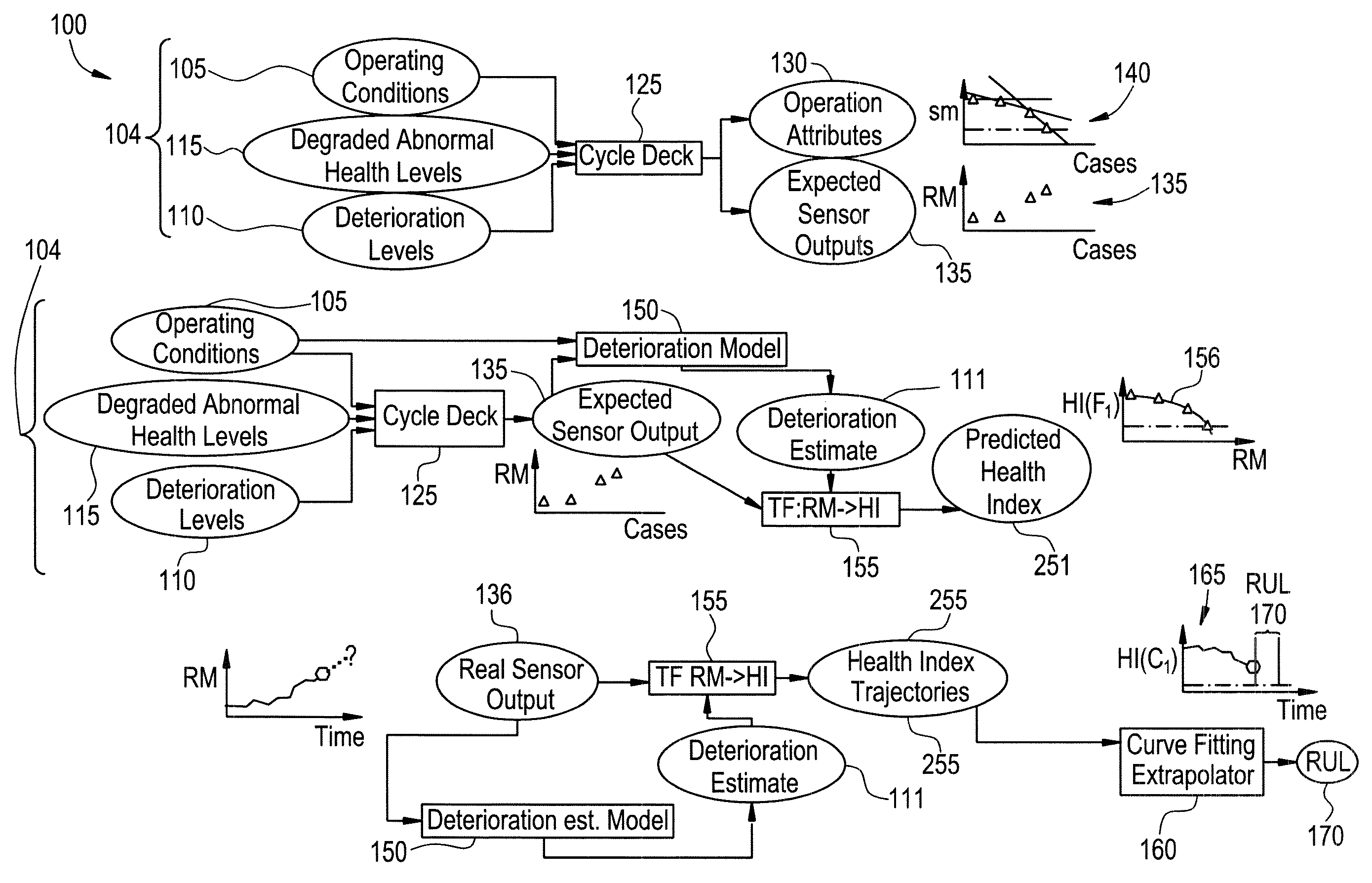

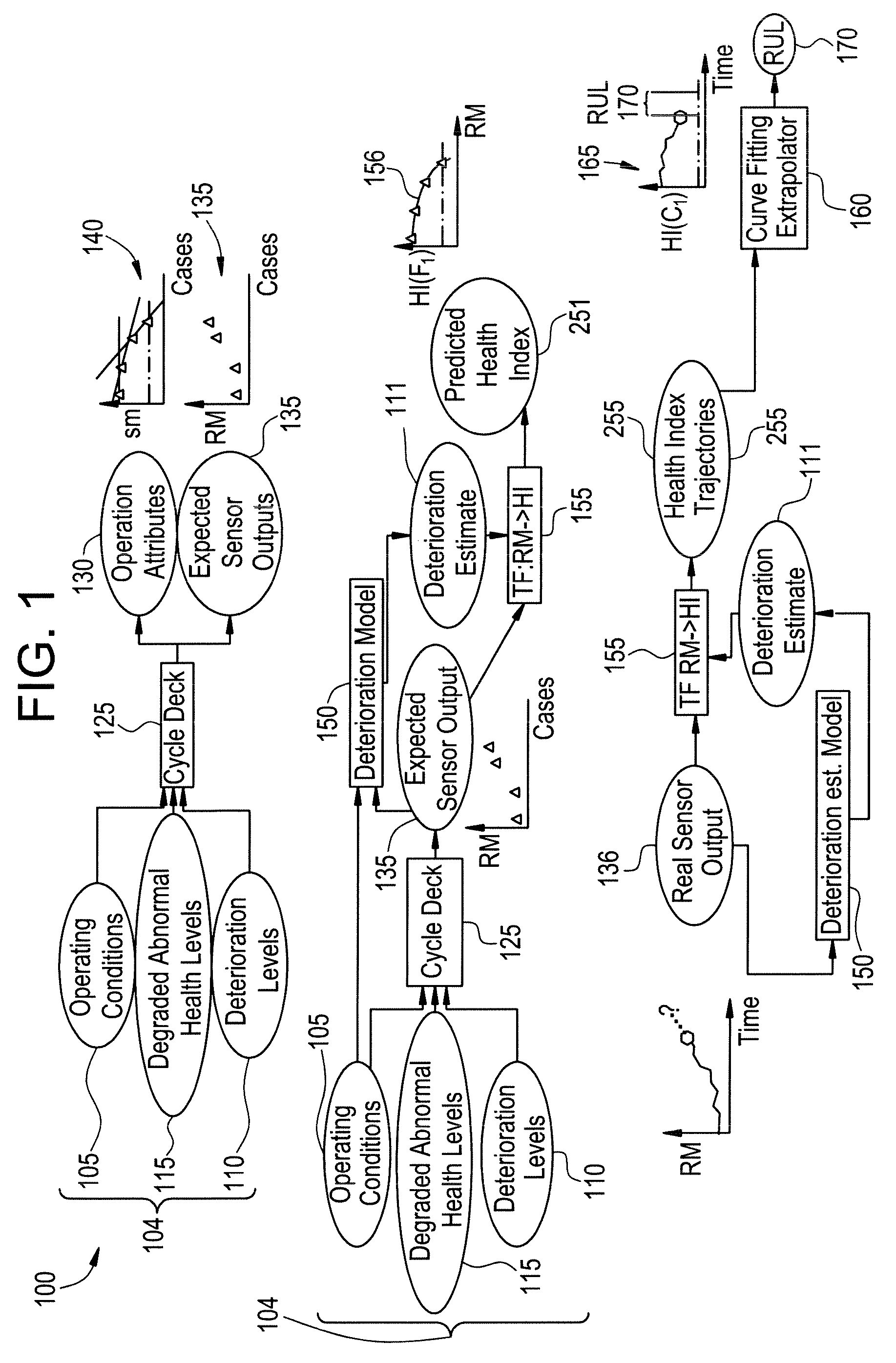

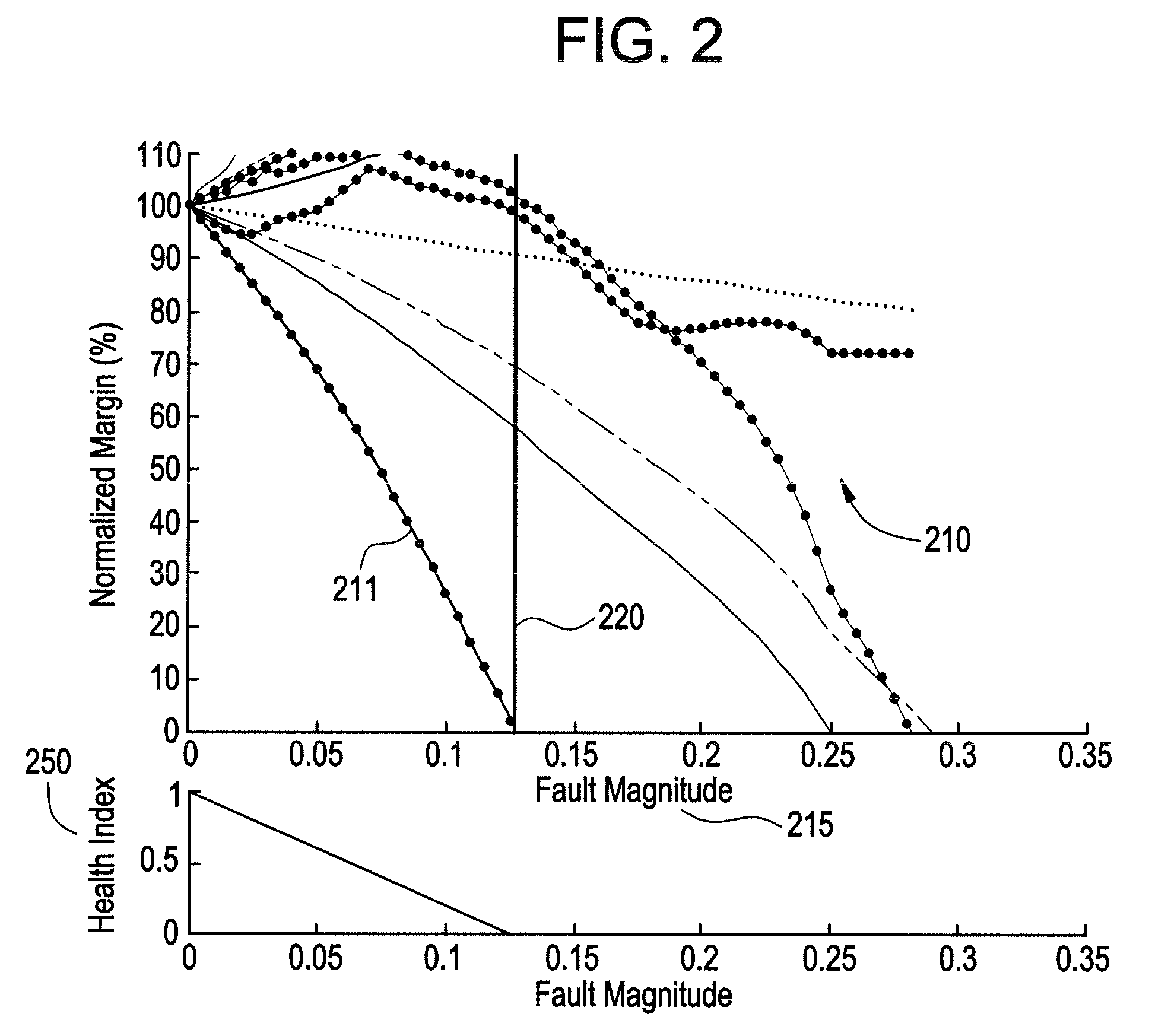

System and method for equipment life estimation

ActiveUS20080140352A1Programme controlDigital computer detailsSequence predictionReliability engineering

A method to predict equipment life is disclosed. The method includes making available a set of input parameters, and defining a model of a health of the equipment as a function of the set of input parameters. The method continues with receiving at least one signal representative of a respective one of an actual sensor output relating to an actual operation attribute margin of the equipment, predicting a remaining useful equipment life based upon a sequence of outputs of the model of the health of the equipment, and generating a signal corresponding to the remaining useful equipment life.

Owner:GENERAL ELECTRIC CO

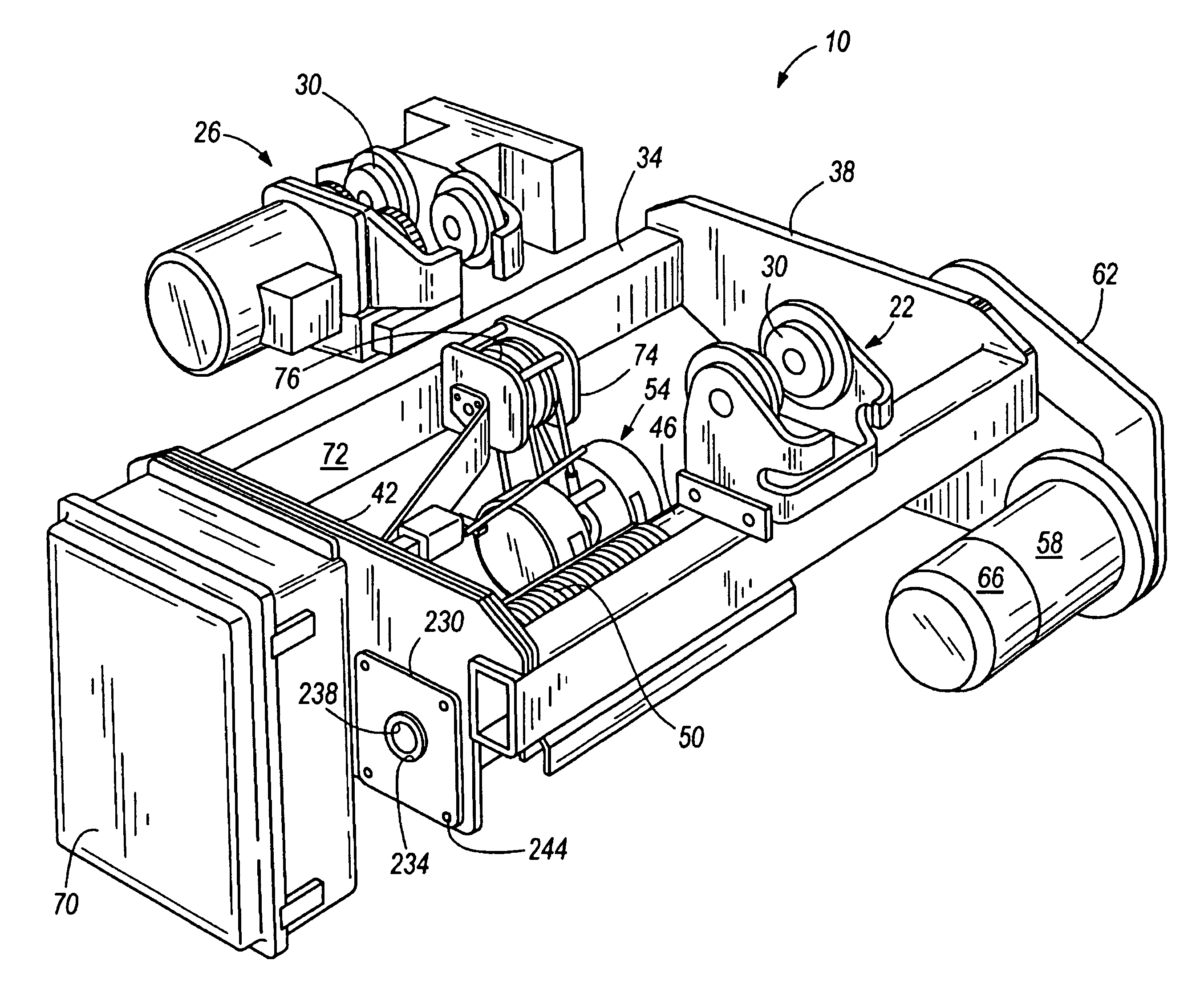

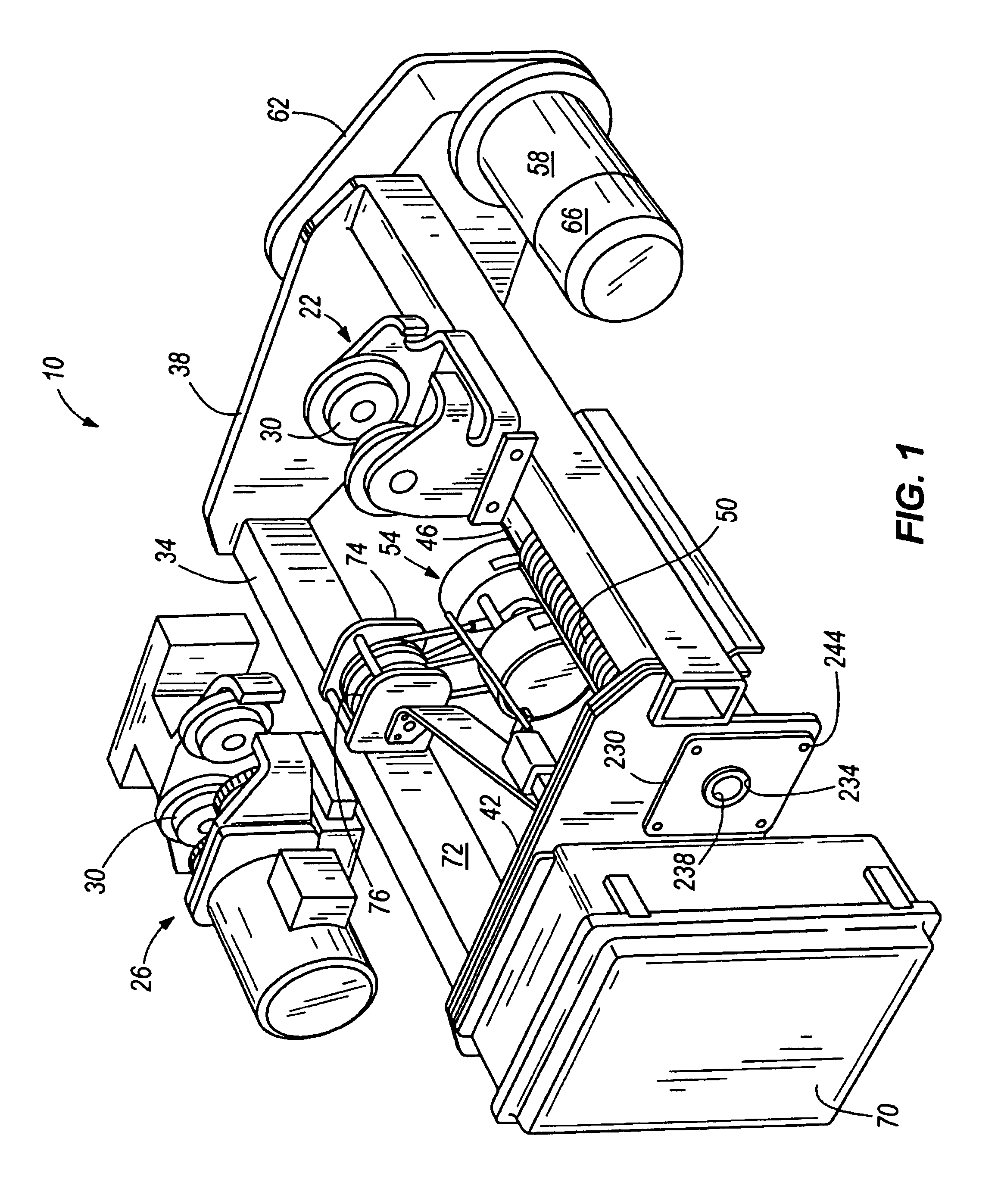

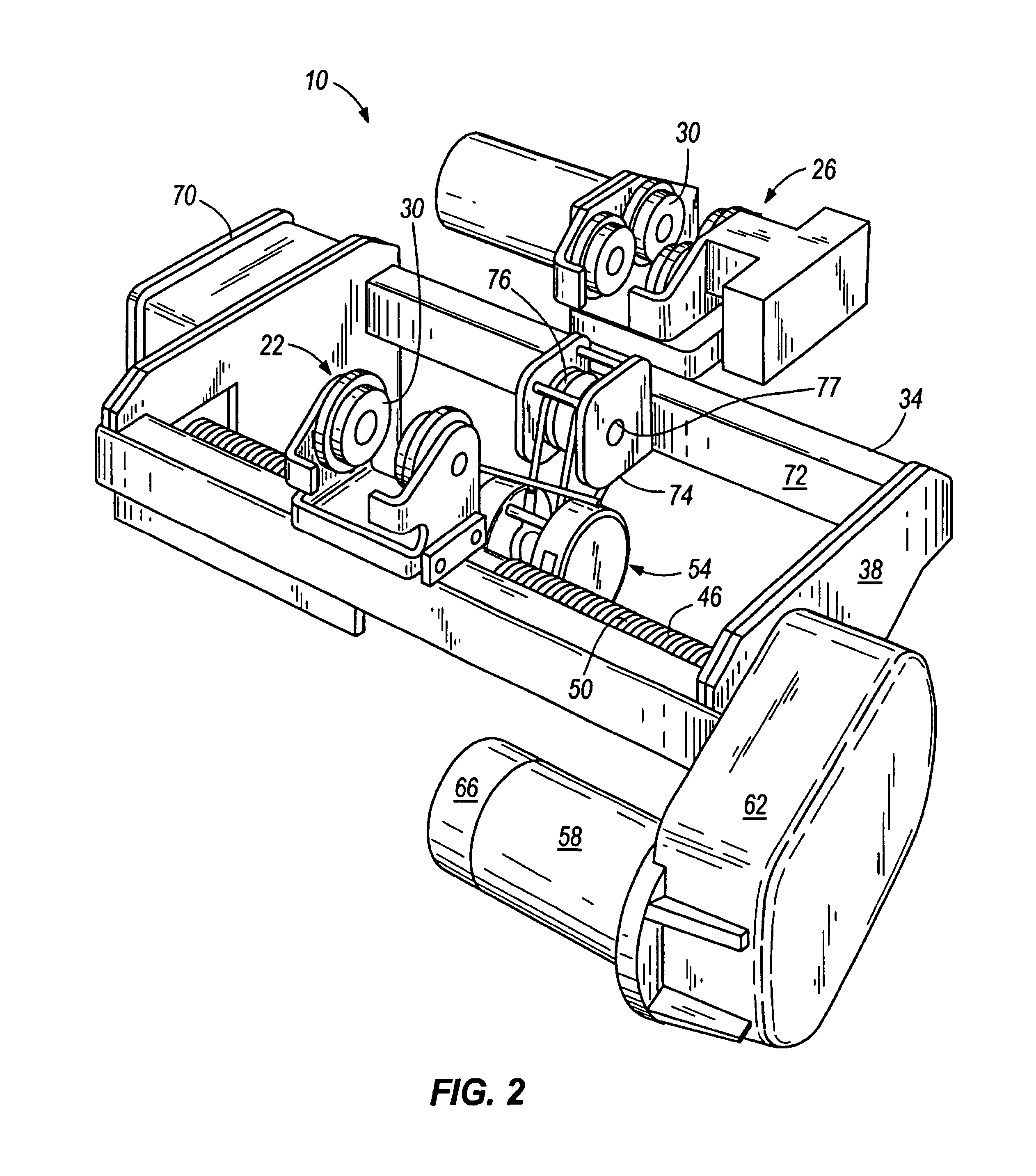

Hoist apparatus

The invention relates to a hoist apparatus including at least one of a three-part double reeved bottom block that has the same height profile as a two-part bottom block and the same lifting capacity as a three-part bottom block that includes an integral equalizer sheave nest, a device for limiting the rotation of a hoist drum beyond a desired position, a hybrid gear box adapted for use on two different categories and / or types of hoist apparatuses through the use of an adapter plate that permits coupling of the gearbox to the hoist drum of the hoist apparatus in a plurality of configurations and an external ring gear that results in a second output torque and speed of the gearbox, a self-lubricating load braking assembly having lubrication inlet holes and lubrication outlet holes for pumping lubrication into and out of the load brake assembly, a gearbox for use on the hoist apparatus including a two-stage high gear ratio gear set and a load brake assembly, a controller configured to acquire operational data representative of the hoist apparatus and generate an output indicative of a remaining useful life of the hoist apparatus, and an inverter controller configured to control verify load integrity and prevent possible load loss without the use of a load brake assembly and / or an encoder or similar feedback device.

Owner:U S BANK NAT ASSOC

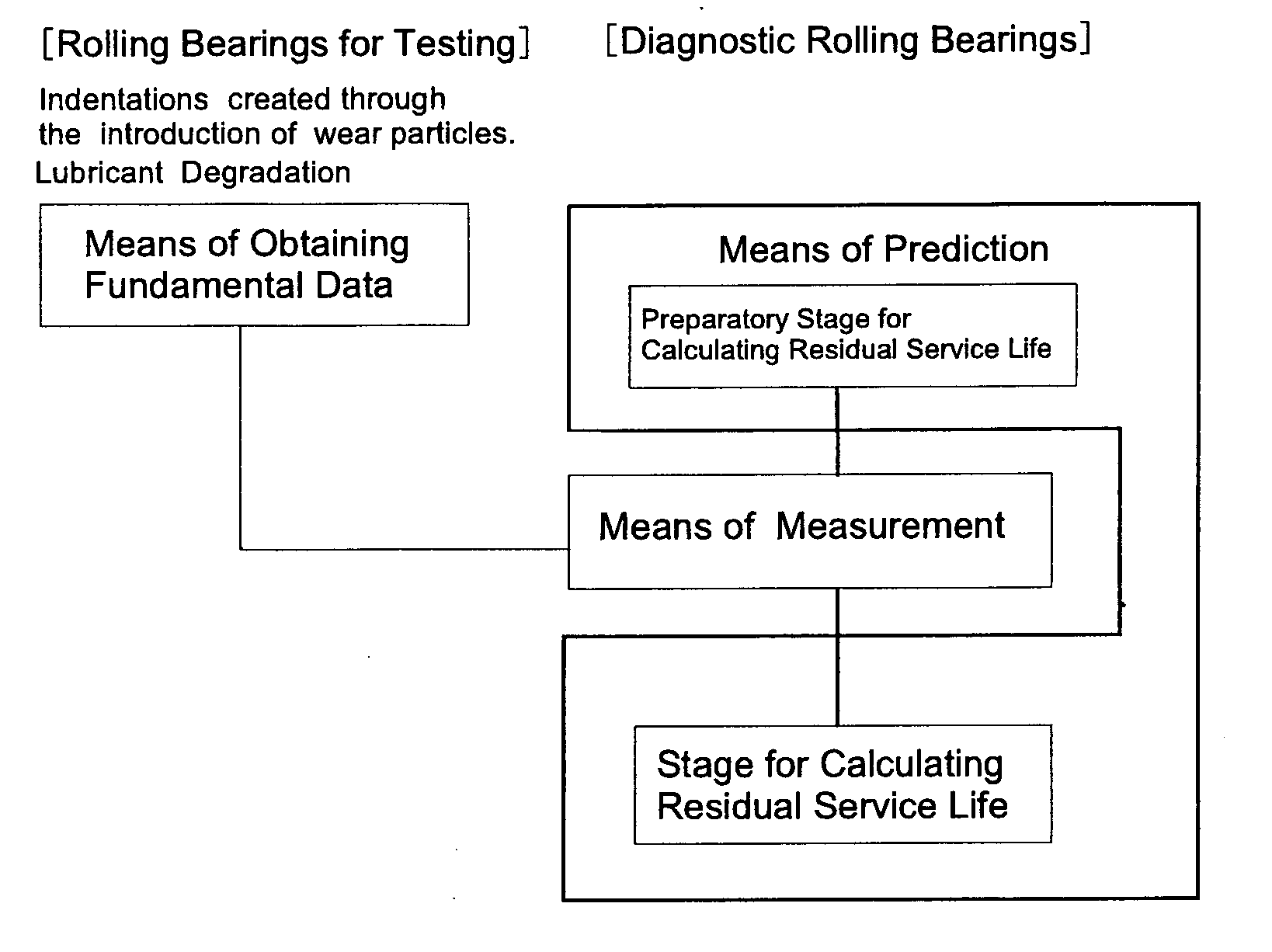

Method and apparatus for diagnosing residual life of rolling element bearing

InactiveUS20050246150A1Effective maintenanceEasy to implementVibration measurement in solidsPump componentsAccelerometerPredictive methods

An invention that utilizes signals from an accelerometer in resonant frequency bands or high frequency bands to, in a cost-effective manner, measure wear particle penetration of lubricant and lubricant degradation, both of which greatly affect prediction of residual service life; and, using as a basis these measurements of wear particle penetration and lubricant degradation, enables accurate estimation of residual service life for rolling bearings in the early stages. The invention is comprised of a means of obtaining fundamental data that uses a testing device to obtain data regarding the relationship, for rolling bearings (3), of wear particle penetration levels to vibration levels and service life, or to obtain data regarding the relationship, for rolling bearings (3), of lubricant degradation levels to vibration levels and service life; a means of measurement, where an accelerometer (4) is used to obtain vibration signals of diagnostic rolling bearings (3) residing on mechanical rotating devices (1, 2) for the purpose of measuring signals in resonant frequency bands only detectable at extremely high levels of sensitivity or signals in high frequency bands; and a means of prediction that uses readings obtained via said means of measurement and data obtained via said means of obtaining fundamental data to predict, for diagnostic rolling bearings (3), wear particle penetration levels and lubricant degradation levels, and to calculate residual service life for diagnostic rolling bearings (3).

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

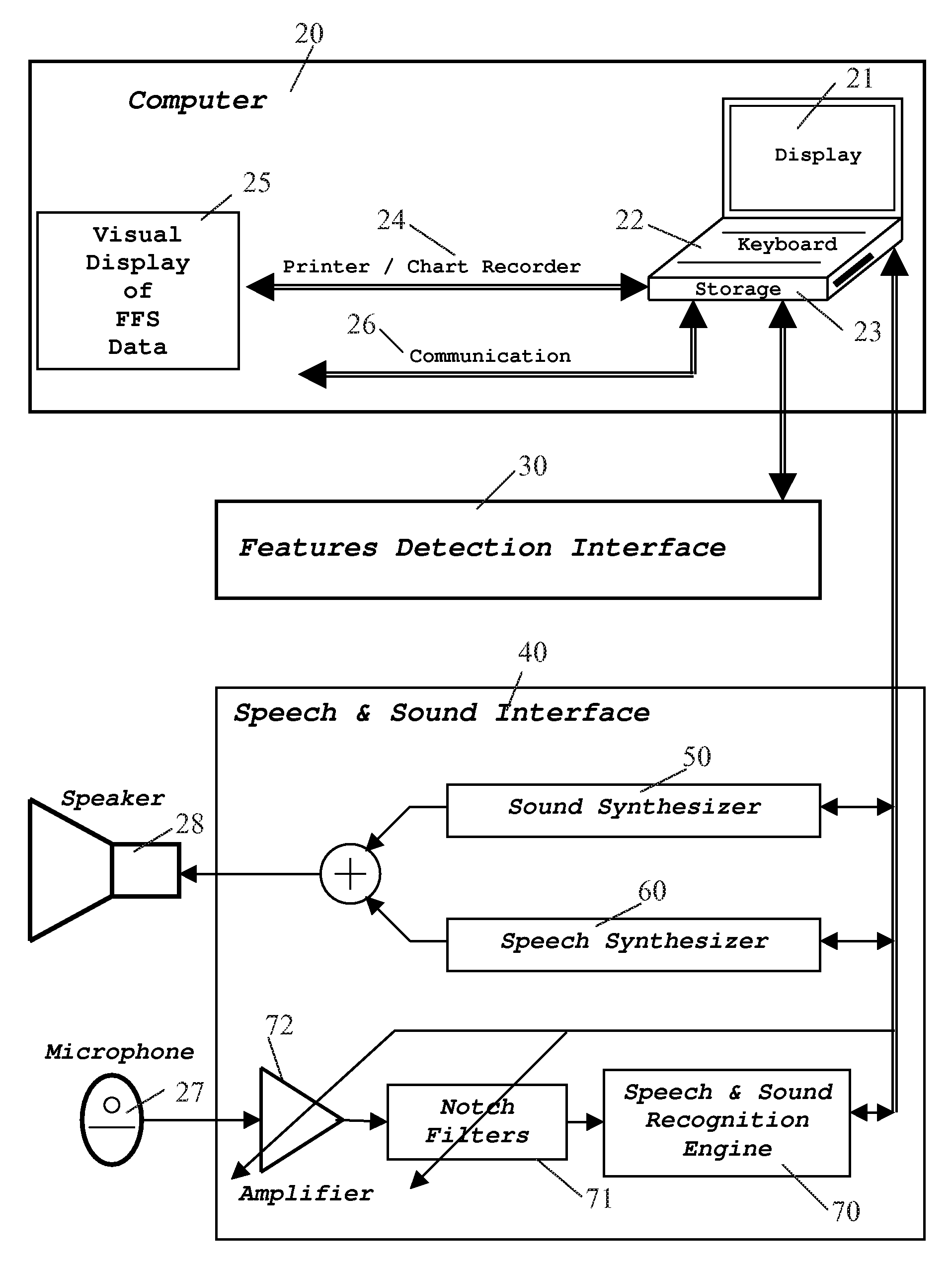

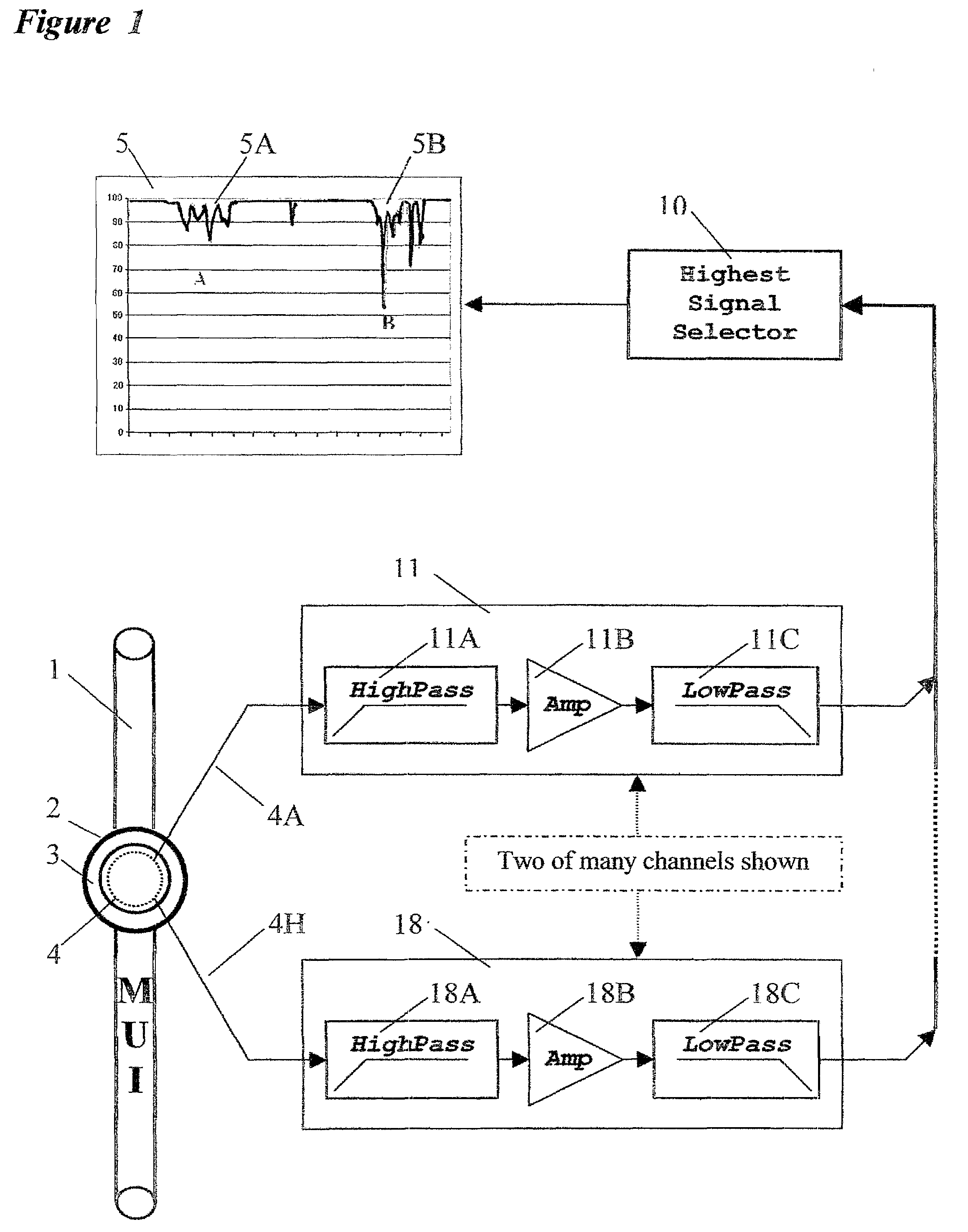

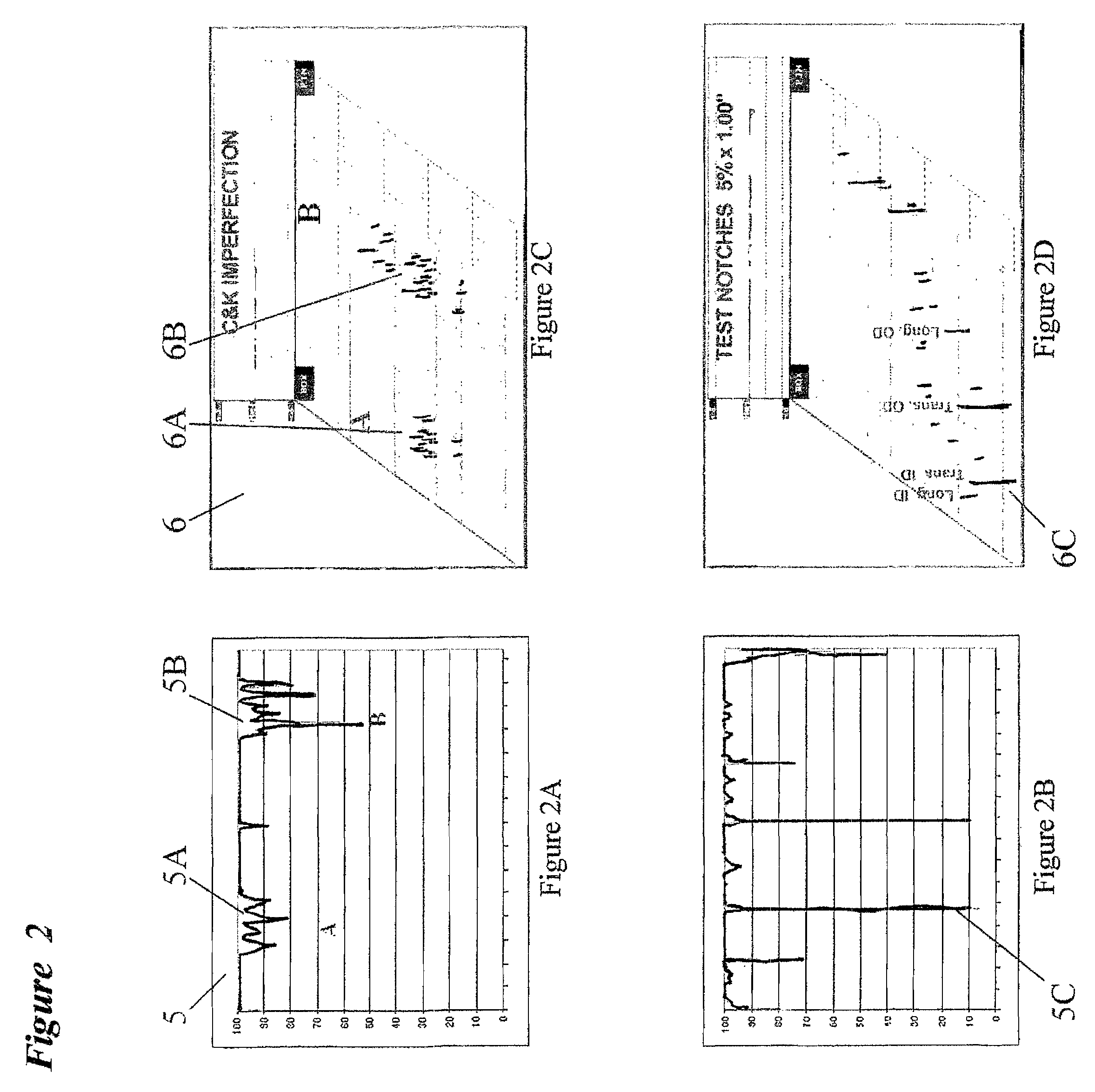

Autonomous Remaining Useful Life Estimation

ActiveUS20080004839A1Plug gaugesMaterial analysis by electric/magnetic meansFailure preventionFrequency spectrum

Autonomous remaining useful life estimation equipment interacts with the operator through natural speech, voice and sound and provides active failure prevention through automatic and / or continuous remaining useful life estimation of a material under evaluation. The equipment comprises at least one computer and a material features acquisition system operable to detect a plurality of material features. The features are then evaluated according to rules that capture the multidiscipline knowledge of experts and are already inputted into the computer. The computer iterations are processed until an acceptable conclusion is made regarding the condition of the material under evaluation, thus alleviating the need for multidiscipline experts to examine and analyze all the material data manually, a very slow and expensive process. Further, the natural speech and voice interaction preferably allows the operator to operate the equipment while wearing gloves or with dirty hands as he / she will not need to constantly physically manipulate the equipment. The remaining useful life estimation capability may also be retrofitted into conventional inspection systems by extracting pertinent features through spectral frequency analysis and sensor normalization and utilizing those features in the autonomous remaining useful life estimation system.

Owner:STYLWAN IP HLDG LLC

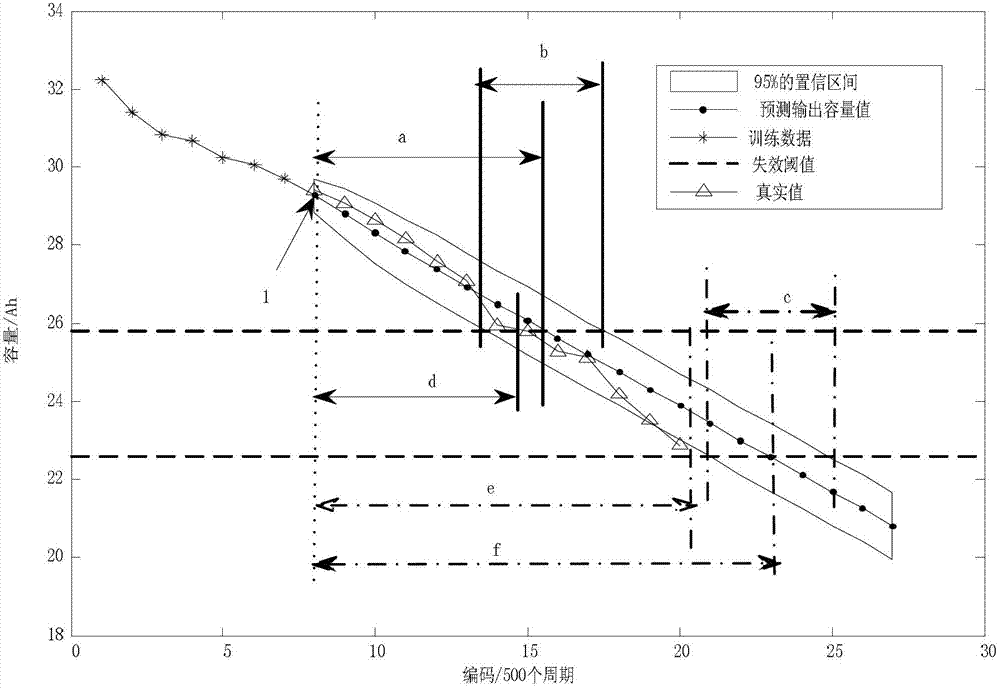

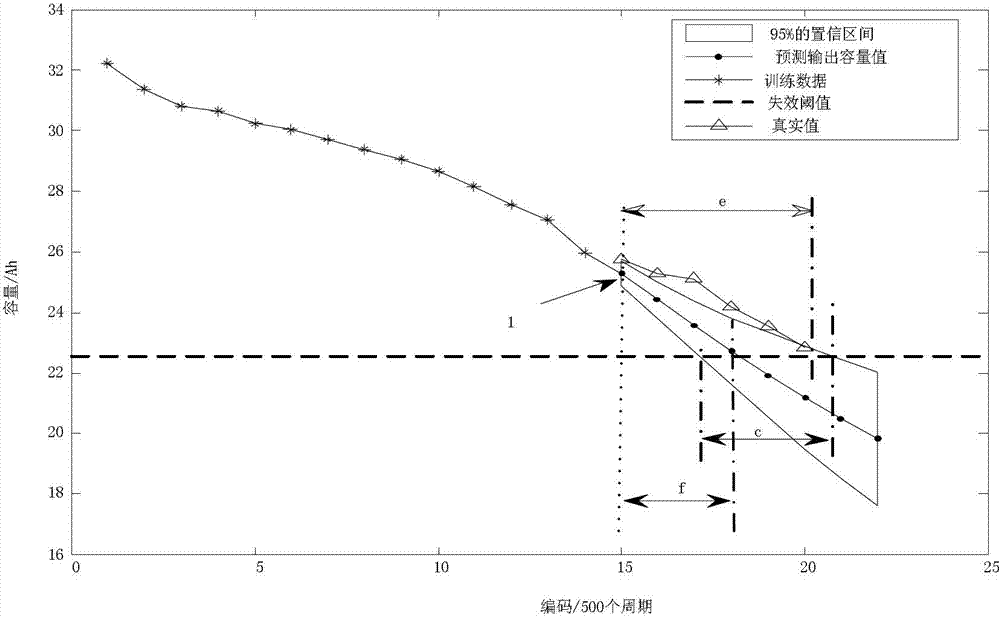

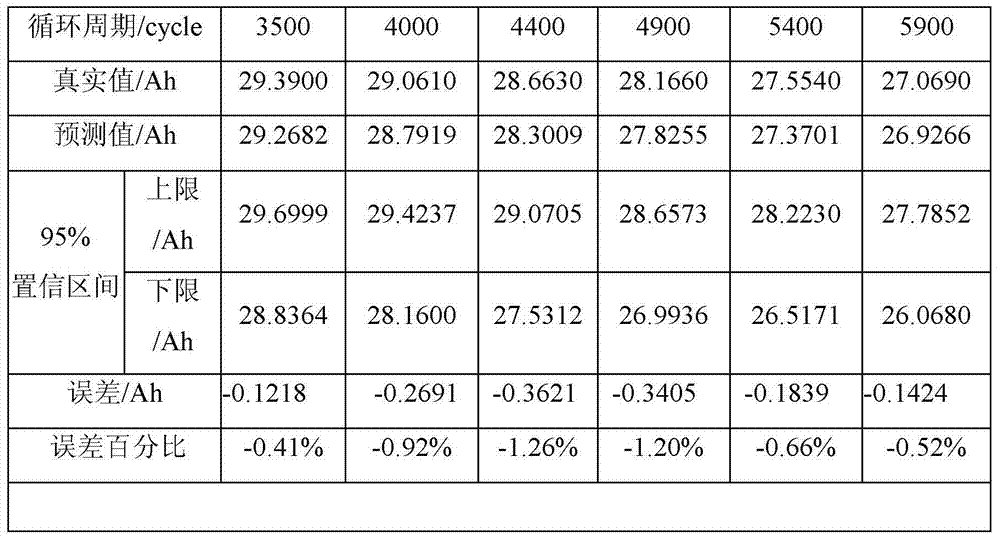

Lithium-ion battery capacity estimation and residual cycling life prediction method

The invention relates to a lithium-ion battery capacity estimation and residual cycling life prediction method, and relates to a method for estimating the capacity of a battery and predicting the service life of the battery, which solves the problem that the capacity of a lithium battery cannot be estimated, and the residual service life of the lithium battery cannot be predicted. a / n of the collected charging-discharging cycle times x, the discharging voltage of each charging-discharging cycle, the battery capacity, and the residual capacity data z of the battery after each time of charging and discharging cycle is used as the training data, and the residual data of the (n-a) / n is used as the test data, the training data is expanded by utilizing a segmented tertiary Hermite interpolation method, the training data of different interpolation points obtained after the expansion is used for modeling, a GPR (general purpose register) model with different parameters is used for carrying out the forecasting so as to predict the residual capacity of the battery after N times of charging and discharging cycles of the lithium battery, and the residual capacity of the battery after N times of charging and discharging cycles can be obtained; and the method is suitable for estimating the capacity of the battery and predicting the service life of the battery.

Owner:HARBIN INST OF TECH

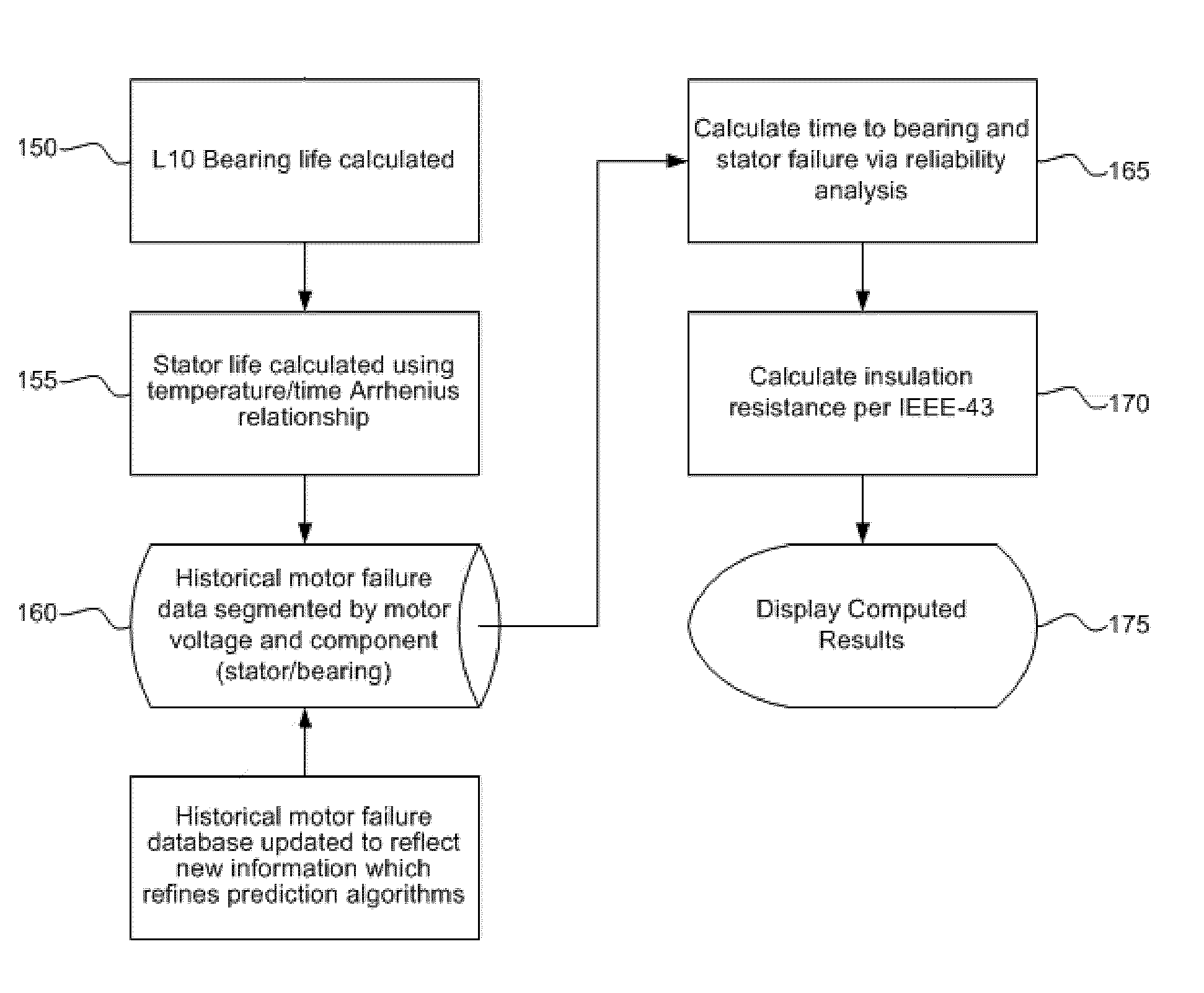

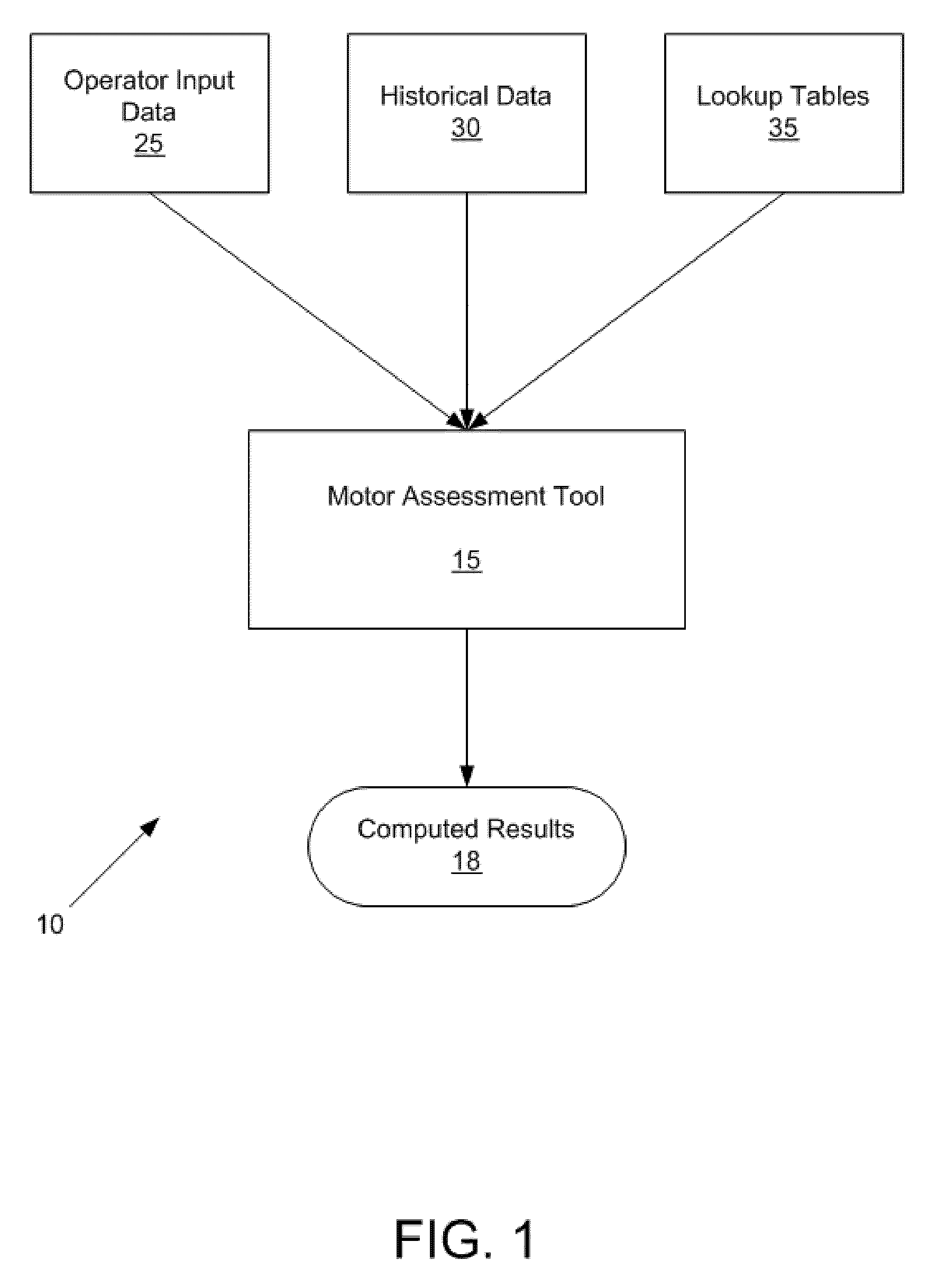

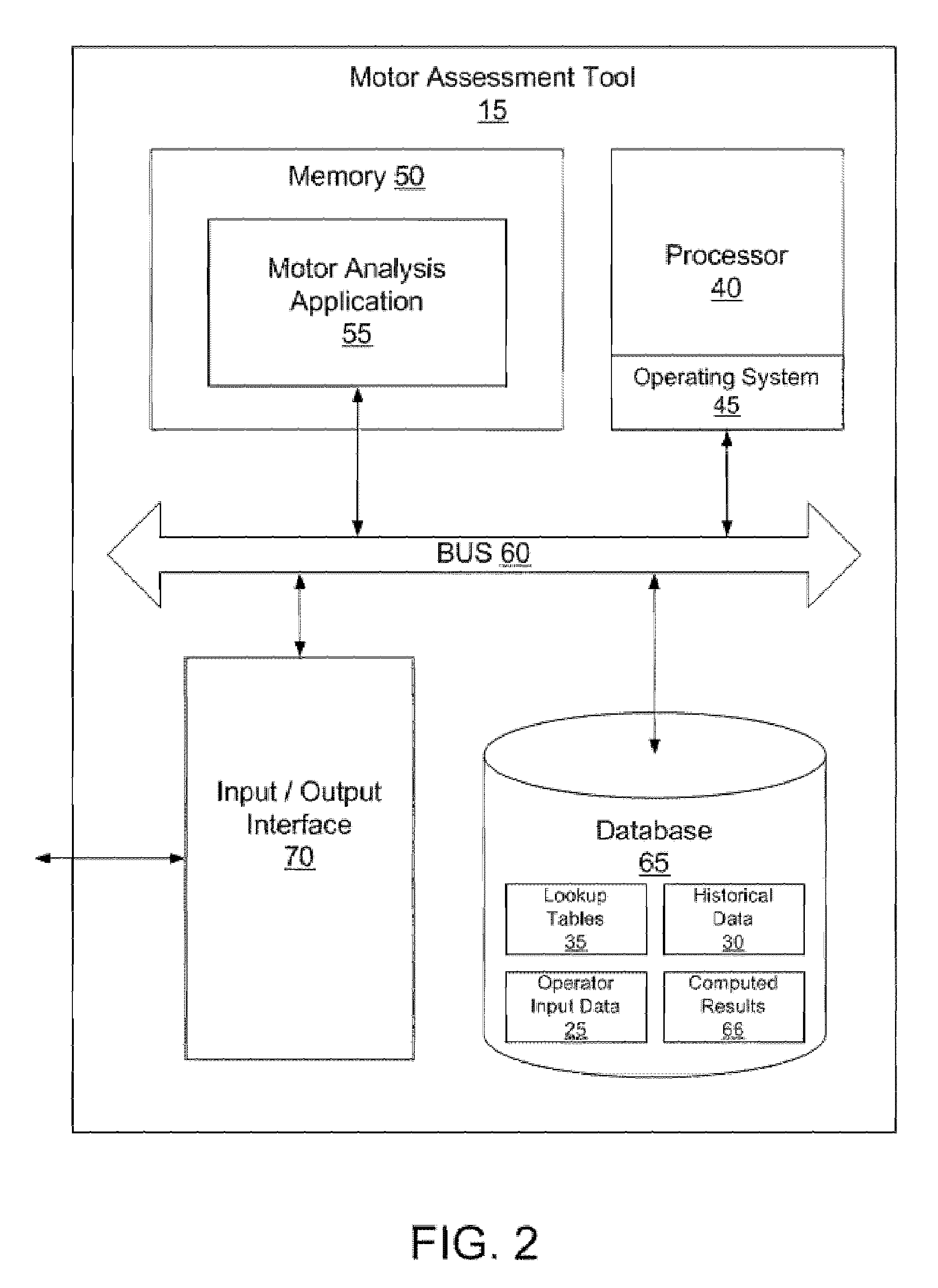

Systems, methods and computer program products for assessing the health of an electric motor

Systems, methods and computer program products calculate the life remaining in a machine, such as an electric motor, or the life remaining in individual components within a machine. Life remaining calculations are based on information collected from multiple sources, including operator input data, historical data, and lookup tables. Using this information the remaining useful life of the machine is calculated based on quantitative data, standard design life limits and on reliability analysis such that continuous historical parameter data is not required to analyze or assess the life of the machine.

Owner:GENERAL ELECTRIC CO

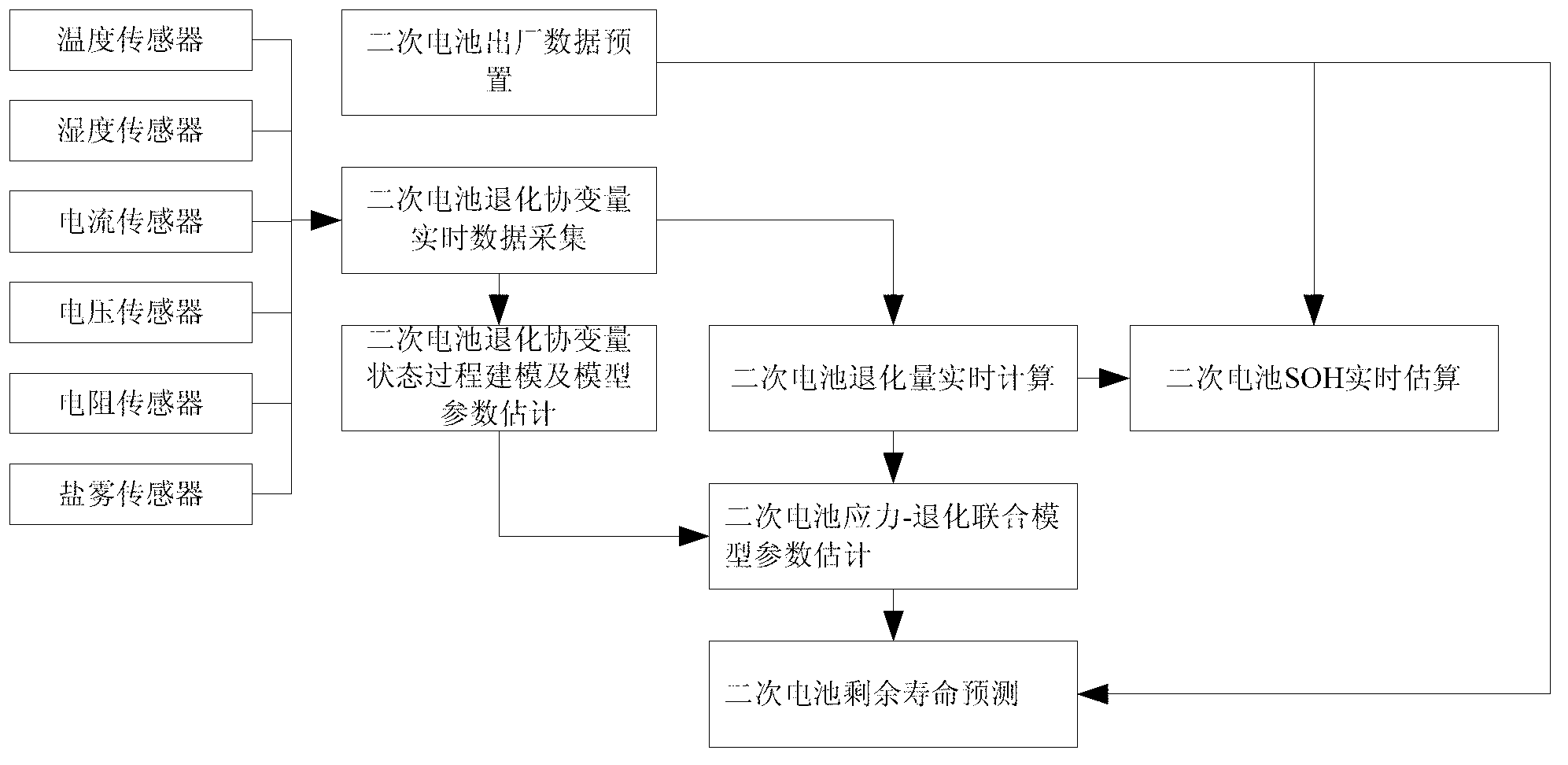

Method for estimating secondary cell SOH value and testing residual service life

InactiveCN103308864AOptimize usage efficiencyEase of maintenanceElectrical testingPredictive methodsModel parameters

The invention provides a method for estimating a secondary cell SOH value and testing the residual service life and relates to a method for predicting the residual service life of a secondary cell. The predicting method comprises the following steps of acquiring performance degradation concomitant variable data of the secondary cell in real time, establishing a secondary cell degradation concomitant variable state process model and estimating model parameters in real time, calculating a degradation quantity value of the secondary cell, calculating a result and cell ex-factory data in real time, estimating a current SOH value of the secondary cell in real time, establishing a secondary cell stress-degradation united model and estimating model parameters, and calculating the residual service life of the secondary cell under different using conditions according to preset using standards of the secondary cell in real time. By means of the method for estimating the secondary cell SOH value and testing the residual service life, the accuracy and the reliability of health status SOH estimation and residual service life prediction of the secondary cell can be improved, the using and maintenance efficiency of the cell is improved, and the service life of the cell is prolonged.

Owner:NAT UNIV OF DEFENSE TECH

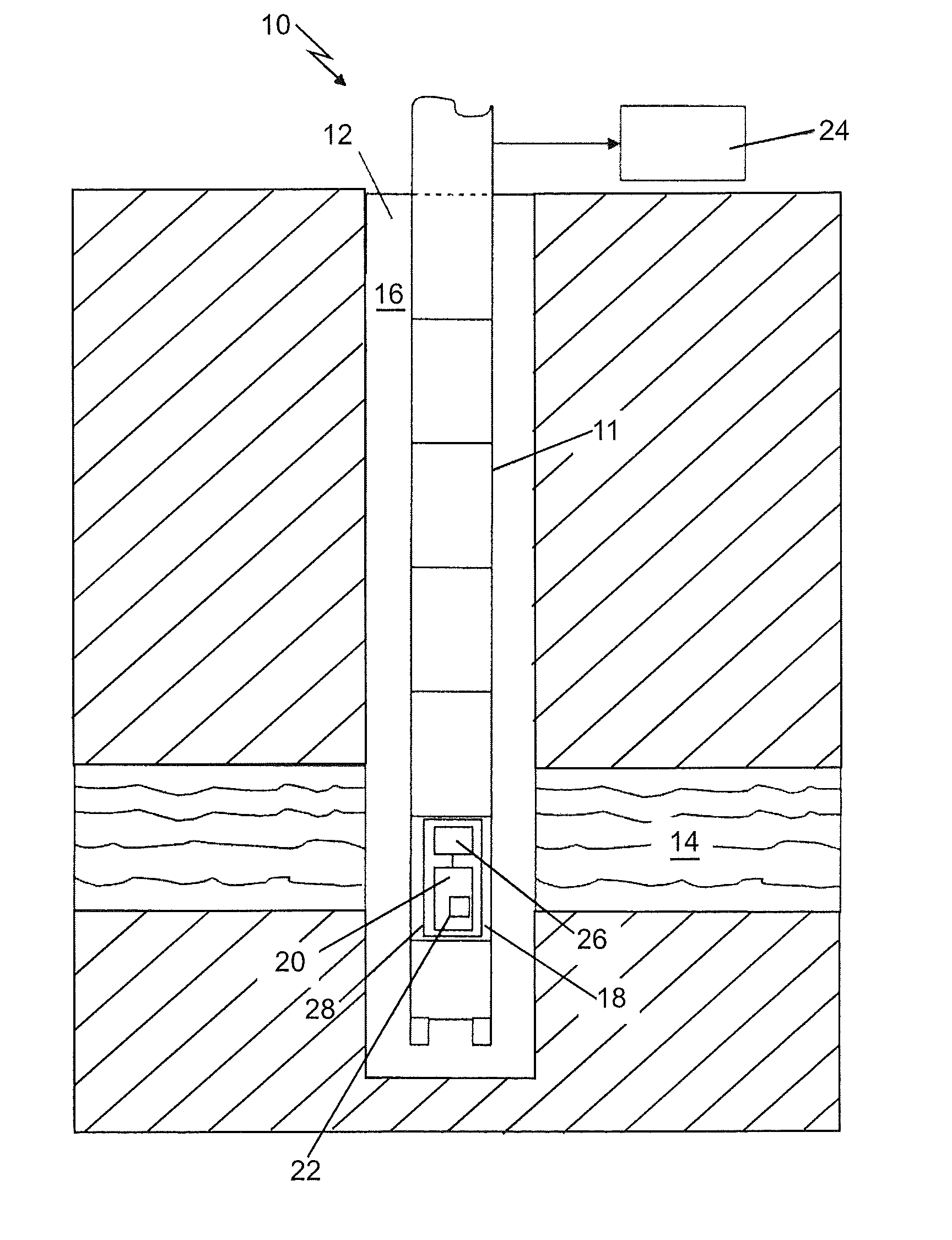

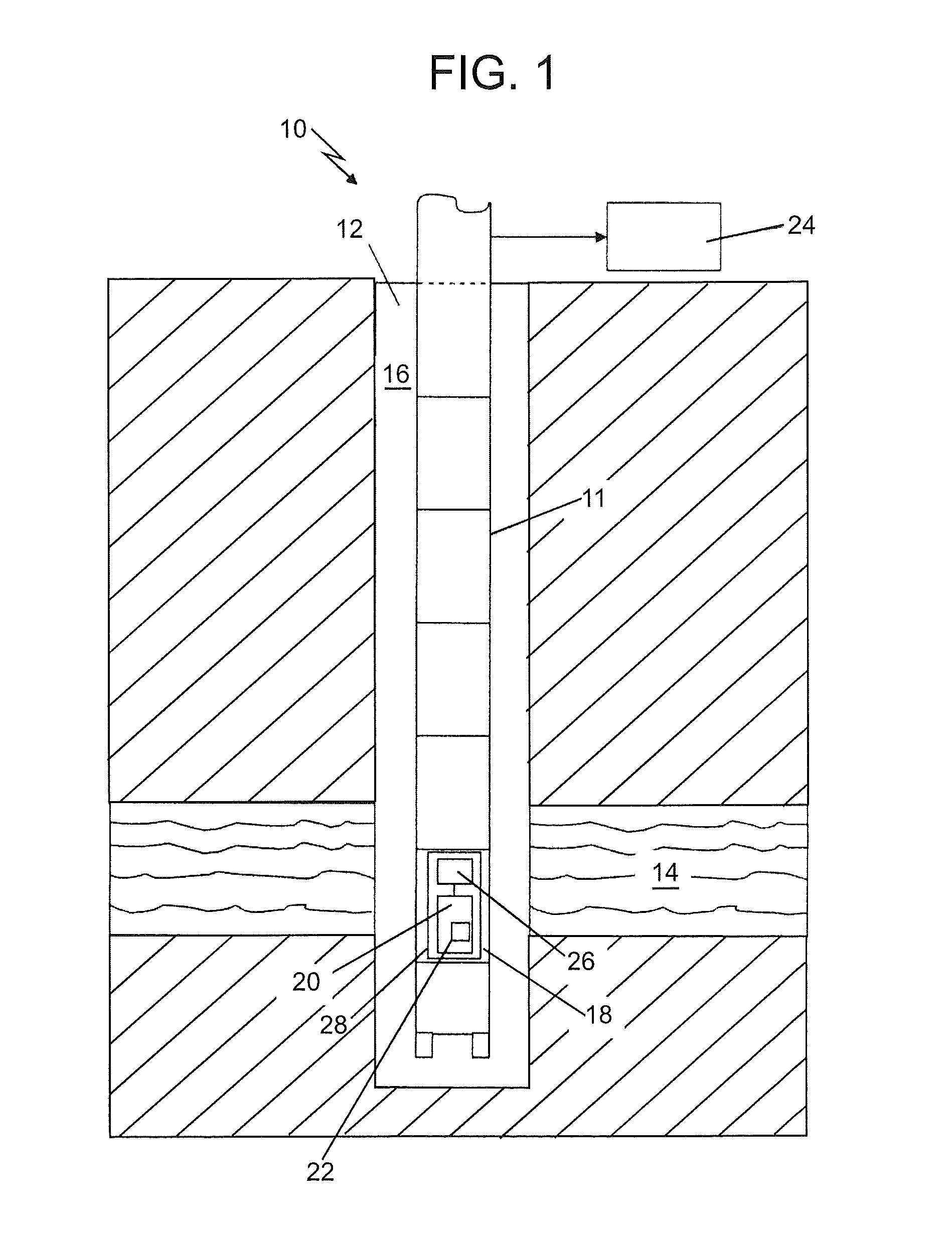

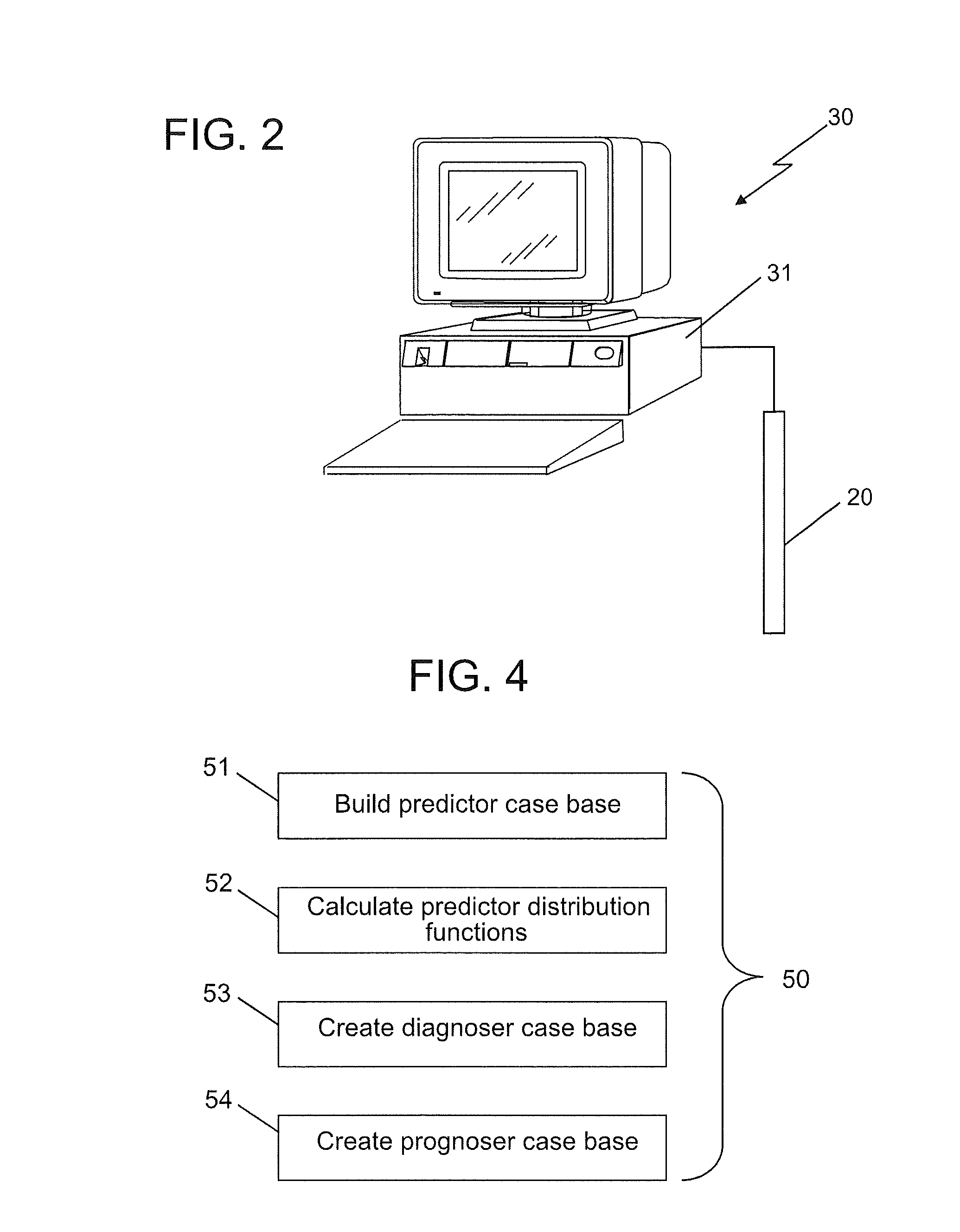

System and method for health assessment of downhole tools

A system for assessing the health of a mechanism includes a processor for receiving observation data from at least one sensor, the processor including: a detector receptive to the observation data and capable of identifying whether the mechanism is operating in a normal or degraded mode; a diagnoser to identify a type of fault from at least one symptom pattern; and a prognoser capable of calculating a remaining useful life (RUL) of the mechanism, wherein the prognoser includes a population prognoser for calculating the RUL based on a duration of use of the mechanism, a cause prognoser for calculating the RUL based on causal data, and an effect prognoser for calculating the RUL based on effect data generated from the fault. A method and computer program product for assessing the health of a downhole tool is also disclosed.

Owner:UNIV OF TENNESSEE RES FOUND +1

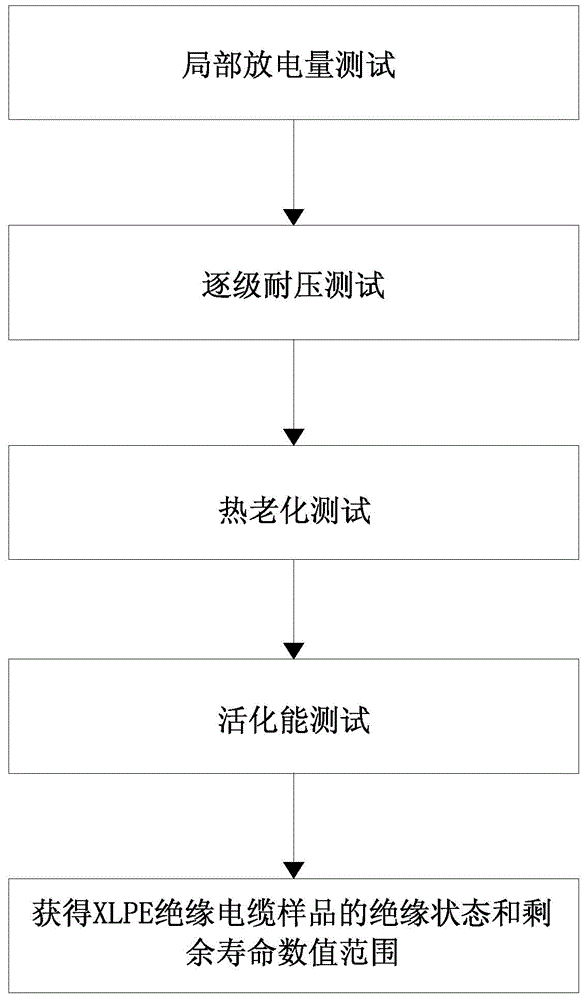

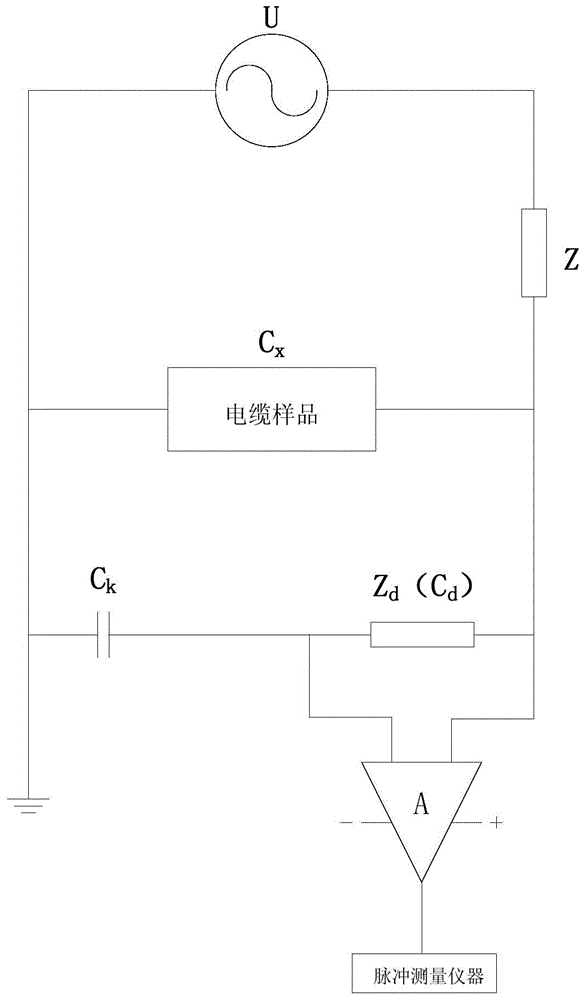

Insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties

The invention discloses an insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties. An insulating cable is an XLPE (Cross Linked Polyethylene) insulating cable. The method comprises a partial discharging amount test, a gradual layer voltage-resisting test, a thermal aging test and an activating energy test; an insulating state of an XLPE insulating cable sample is obtained according to a partial discharging amount calculated by he partial discharging amount test; a residual service life numerical value range of the XLPE insulating cable sample is obtained according to testing results of the gradual layer voltage-resisting test, the thermal aging test and the activating energy test. The method can integrate a plurality of indexes of cable aging evaluation, and combines macroscopic and microscopic change conditions, so that the residual service life data of the cable is completely analyzed in the three aspects of physical performances, chemical performances and electric performances, and the method has important guiding meanings on line modification and power grid planning.

Owner:SOUTH CHINA UNIV OF TECH

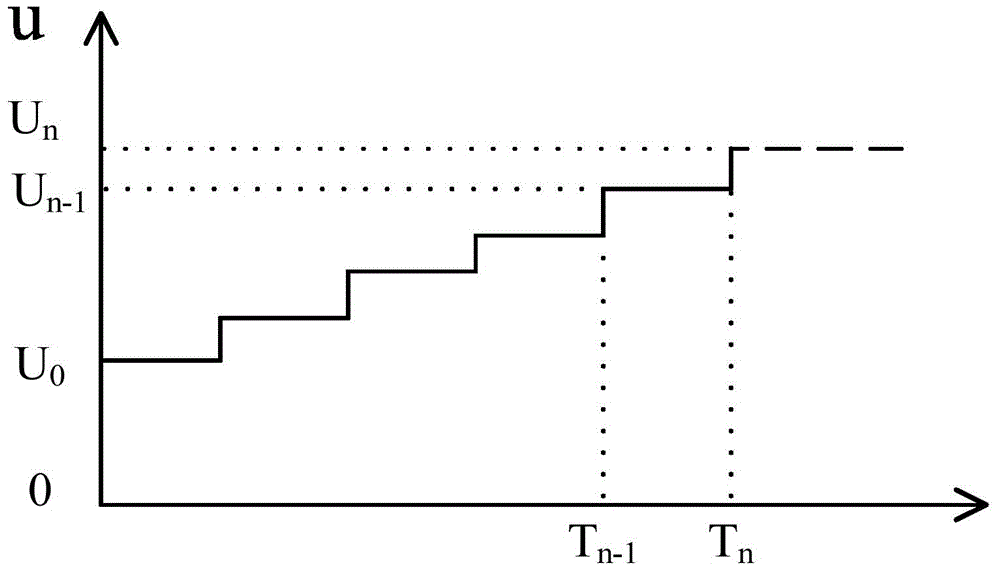

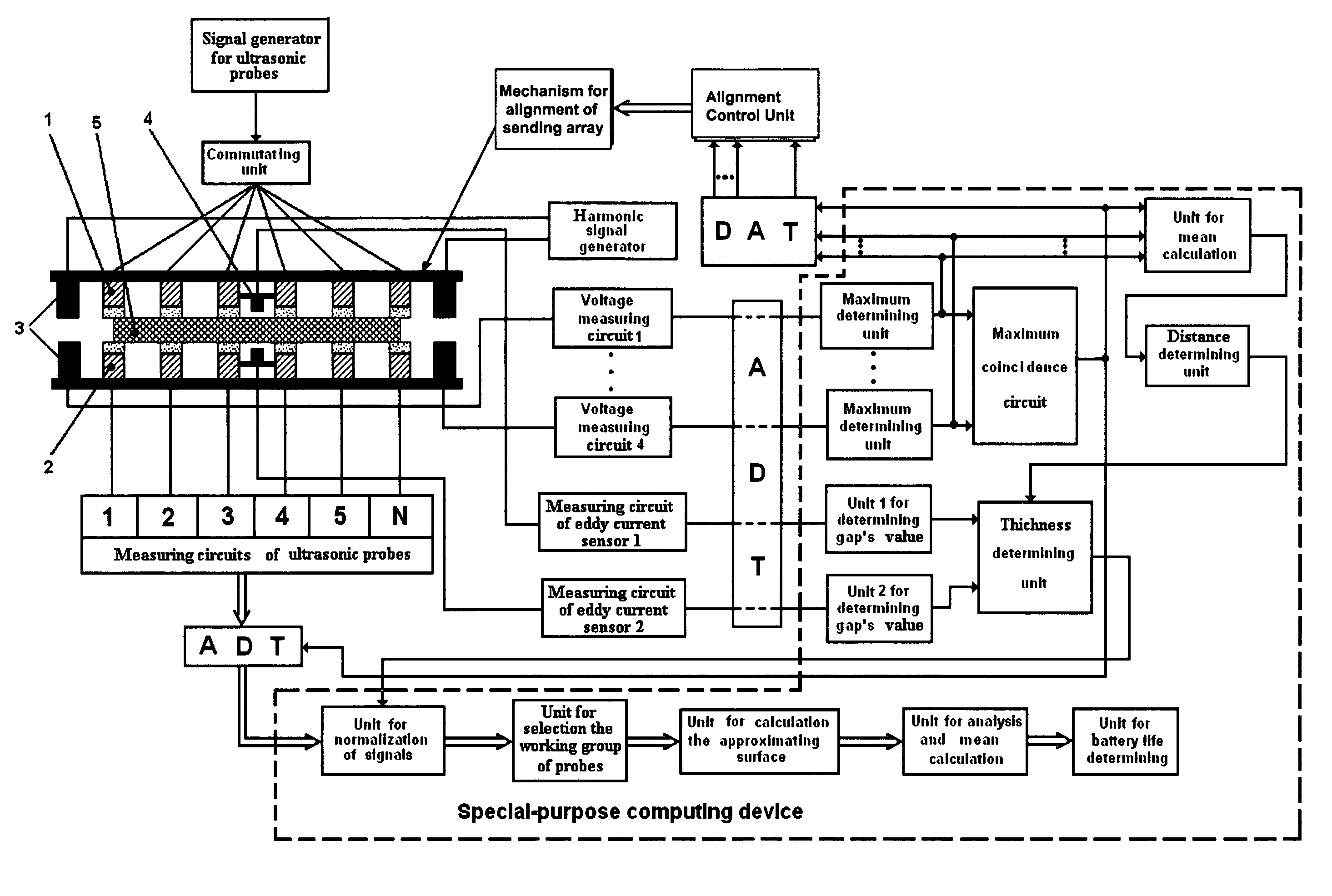

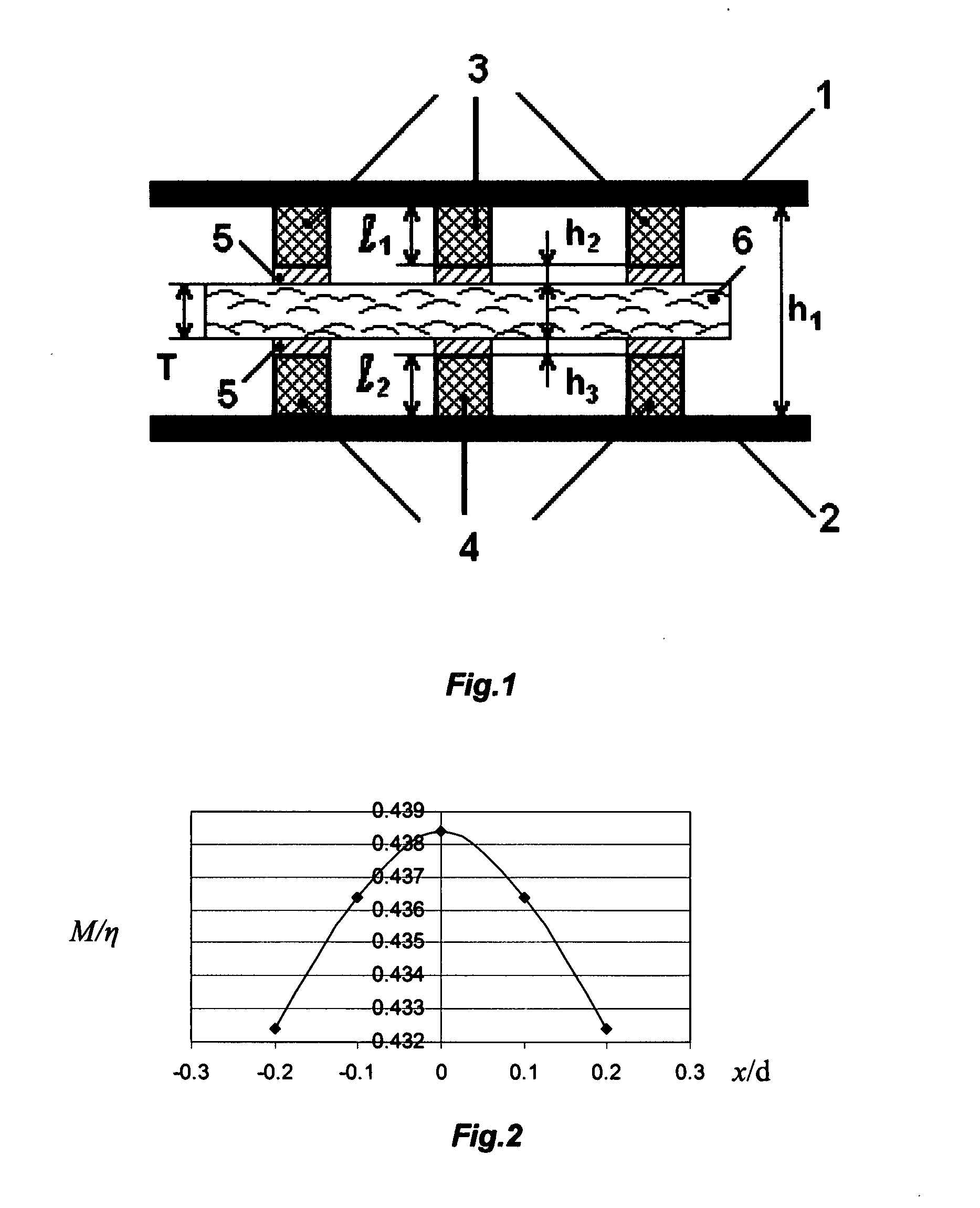

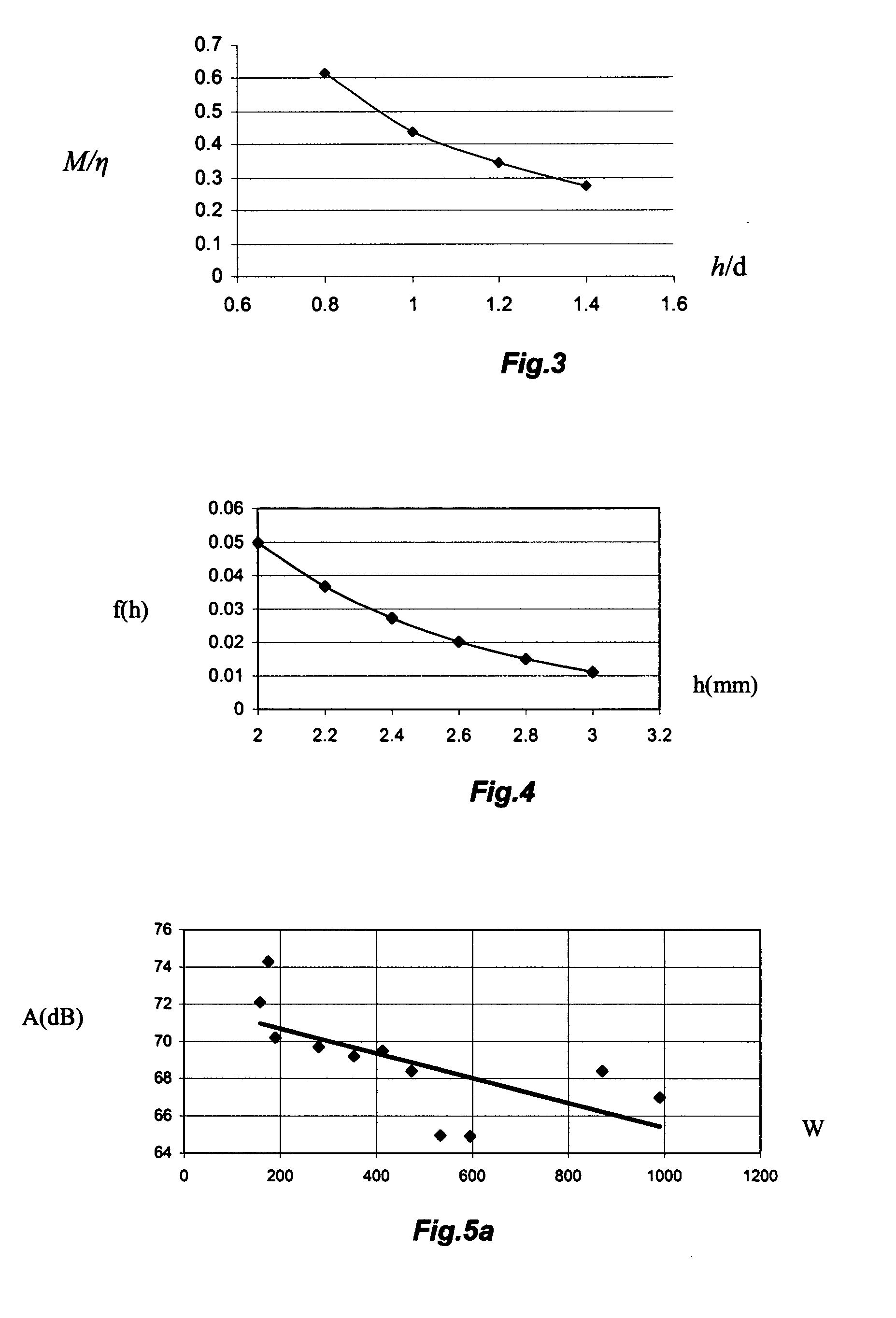

Apparatus and method for determining service life of electrochemical energy sources using combined ultrasonic and electromagnetic testing

InactiveUS20080028860A1Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMeasurement testSonification

The present invention is an apparatus and method for determining the remaining service life of electrochemical energy generation and storage device including batteries, supercapacitors, DSSC solar cells and fuel cell. Measurements are performed by passing ultrasonic oscillations through the test object. The apparatus of the present invention comprises two arrays of transmitting and receiving ultrasonic probes between which the object being tested is affixed. Polyurethane tips are used for matching the acoustic resistance of the probes with the test object body. The apparatus includes means for positioning the transmitting and the receiving probe arrays relative to each other. The apparatus includes an electromagnetic means for measuring the test object thickness. The calibration characteristic for determining the remaining service life of a the test object are established from the signal values from the ultrasonic probes related to the number of charge-discharge cycles obtained at various charge values. A three-dimensional approximating dependence surface is constructed using the normalized signals from the receiving probes. The average value of this surface is determined. The remaining service life of the test object is determined using a calibration curve based on the average level of the surface

Owner:ENERIZE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com